Page 1

Operating Instructions

for

Disk-type tool turret

0.5.473.520 107 468

110 660

111 092

111 432

112 862

115 702

BA 892 e

2007-03-27

125 365

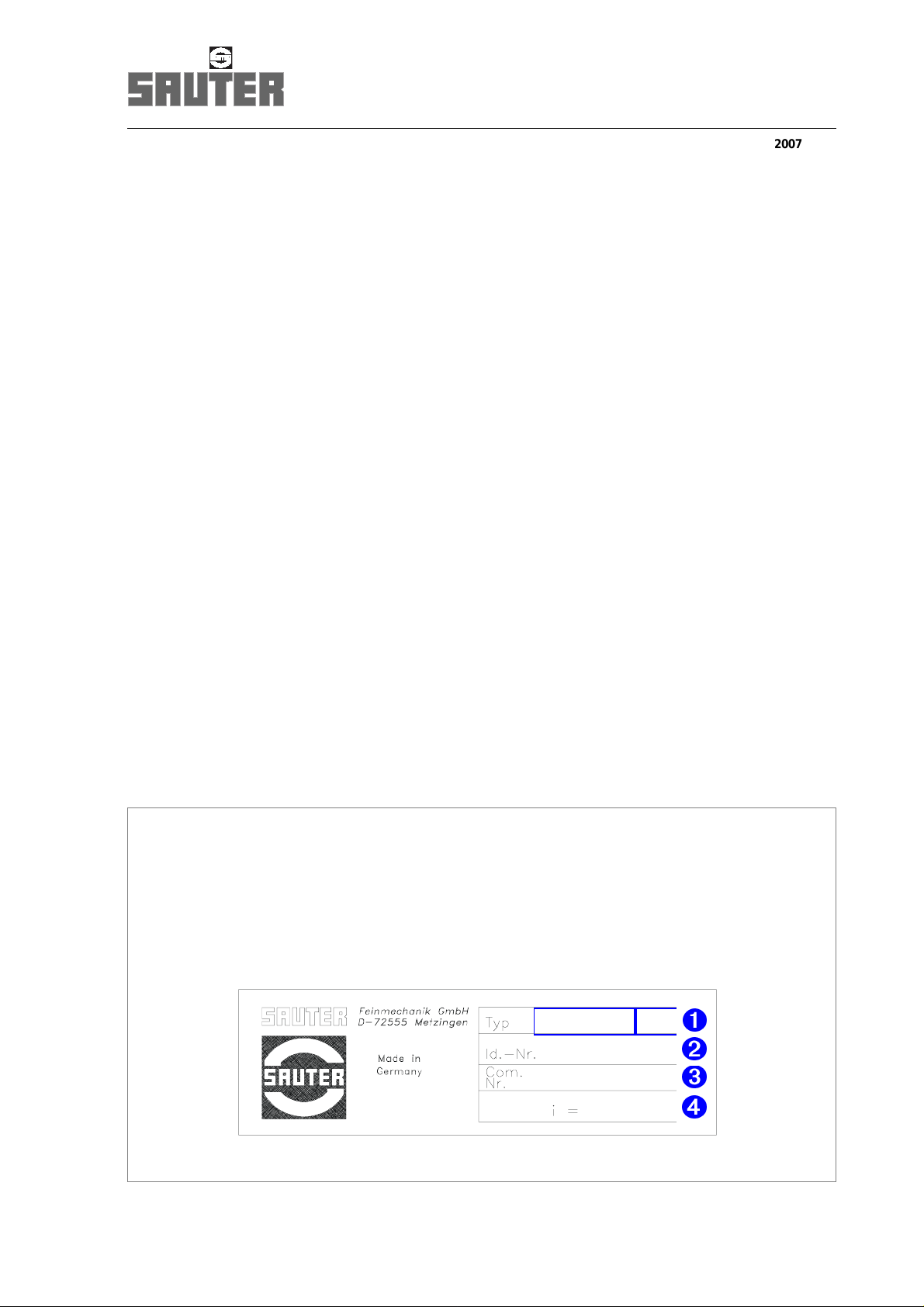

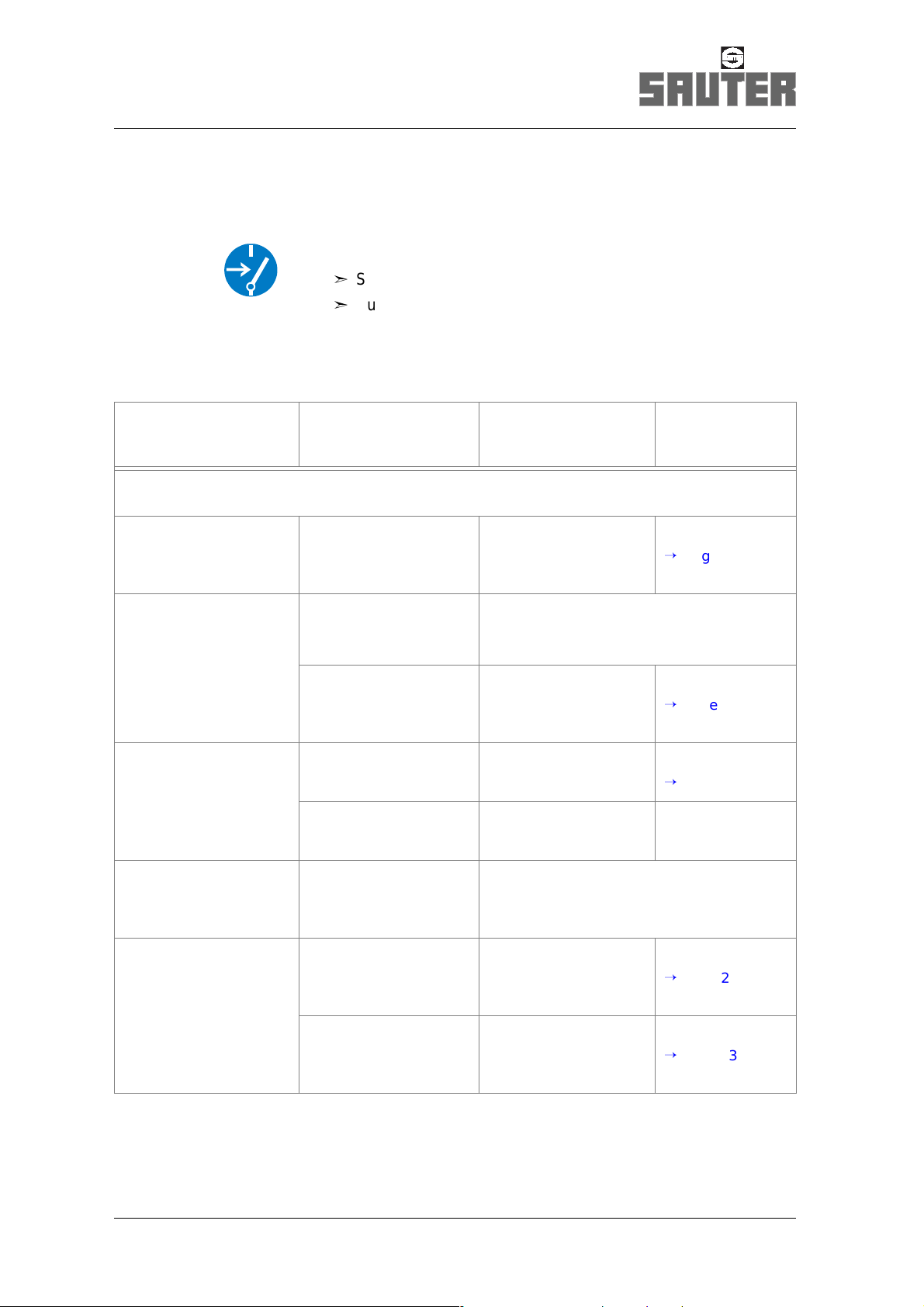

Product data as per nameplate on the housing

1. Classification number (series, size)

2. Identification number

3. Order number

4. Gear ratio

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\DB_Rev_BA-892.fm

x.x.xxx.x xx

xxx xxx

xx-xxx-xx-xx

xxx

Basis-BA: 06-10-23 Manual translation

Page 2

The present manual is part of the product.

°

The manual should be kept in an easily accessible place during the product’s lifetime.

°

The manual should be passed on to the next owner/user of the product.

°

Make sure that any possible supplement received is duly added to the manual.

Page 3

Table of contents

Interpretation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Use within specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Required skills. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Notes on product-specific risks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5 Liability and warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Product description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Designation of parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Manual mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Service intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3 Maintenance work. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4 Repairs after fault conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.5 Aligning the tool disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.6 Replacing the cooling lubricant valve . . . . . . . . . . . . . . . . . . . . . . . 26

4.7 Adjusting the angular encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.8 Replacing the angular encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.9 Proximity switch S7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.10 Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5 Replacement parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Replacement parts for turrets (without tool drive)

Replacement parts tool drive for turret

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\BA_473520_ölIVZ.fm

Survey: Disk-type tool turret 0.5.480.5..

3

Page 4

Table of contents

Appendix

Diagram of functions: Disk-type tool turret . . . . . . . . . . . . . . . . . . . . . . . . . SK - 919

Diagram of functions: Disk-type tool turret . . . . . . . . . . . . . . . . . . . . . . . . . SK - 920

Wiring diagram: Disk-type tool turret . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . EP - 870

Diagram of functions: Tool drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SK - 940

Wiring diagram: Tool drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . EP - 855

Contact/Order information

4

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\BA_473520_ölIVZ.fm

Page 5

Interpretatio n o f symbols

Interpretation of symbols

Warning notes

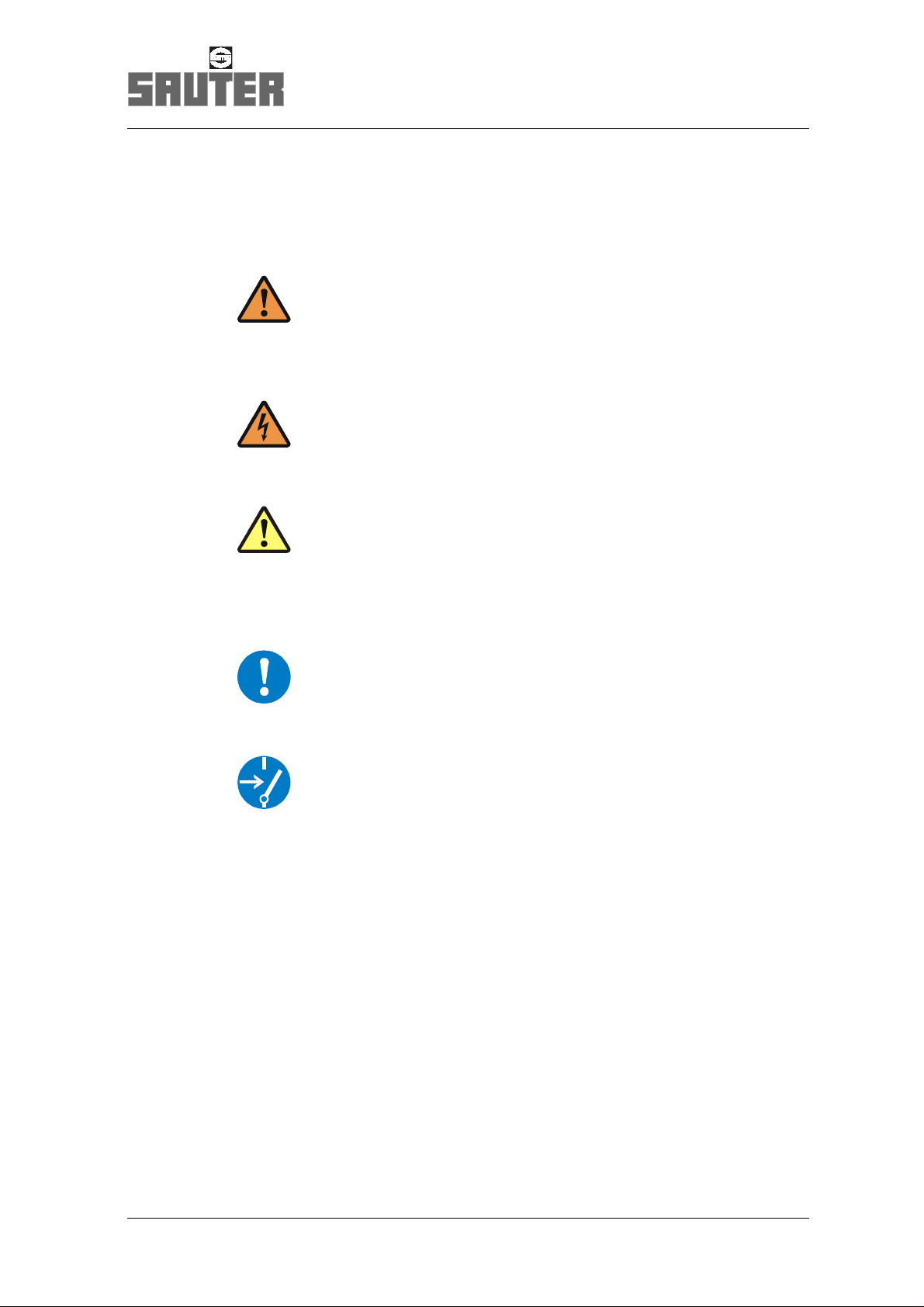

WARNING

1)

This warning de sig n ate s a potentially hazardous sit ua tio n

which may lead to serious injuries, or even death.

WARNING

1)

Risk of electric shock due to high voltages!

CAUTION

1)

This caution designates a potentially hazardous situation in

which the produ ct or p rop erty in its environment could be

damaged.

IMPORTANT

For application notes and other useful information.

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\Konventionen_BA.fm

Clearing

Clear machine before carrying out any further work!

1) Classification of signal wo rd s acc. to ANSI Z535.4

5

Page 6

Interpretation of symbols

Symbols for action instructions

°

Designates an a cti on in stru c tion

·

Designates the result of an action

¢

Designates a c ro ss -ref ere nc e

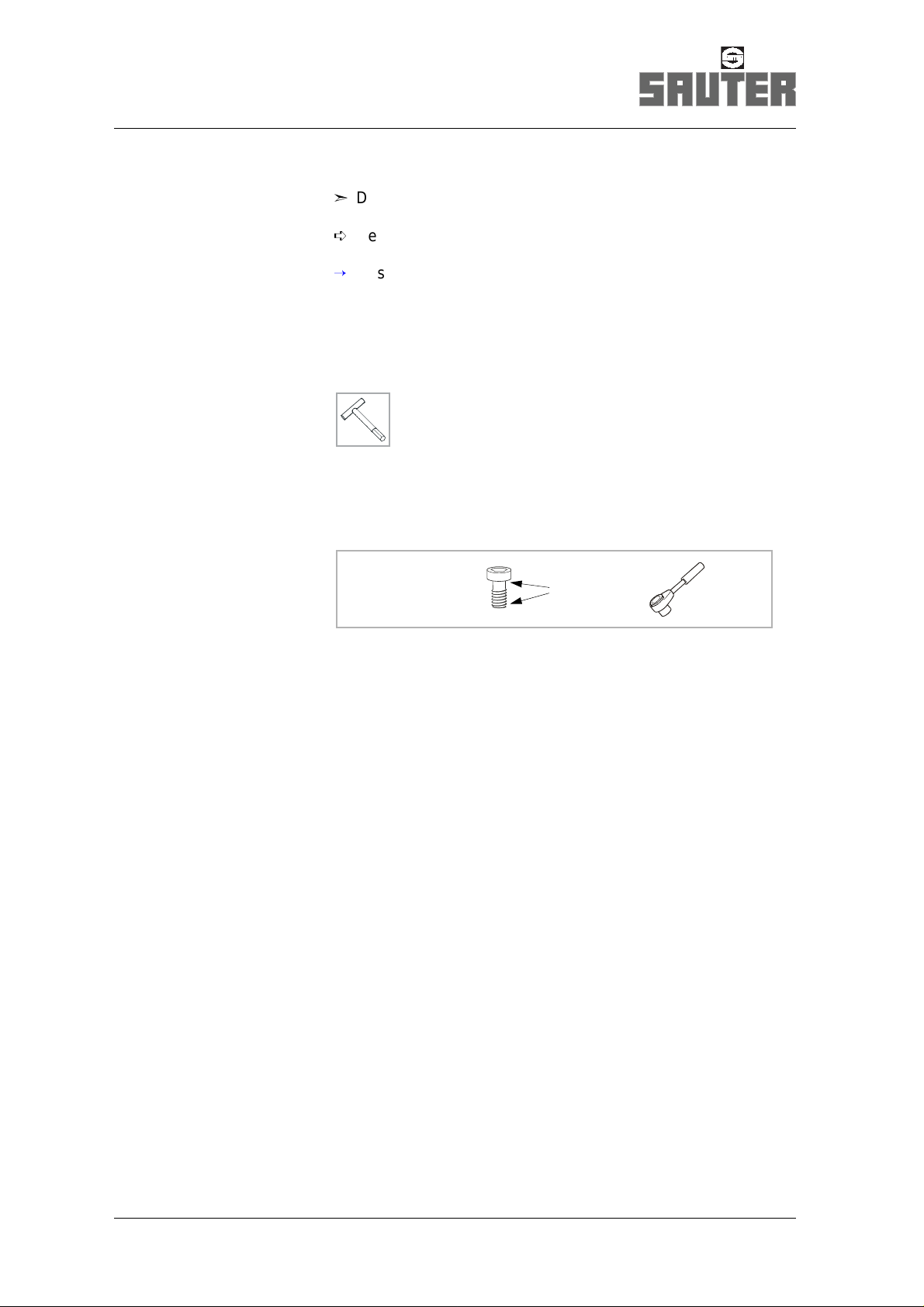

Tools required: here, hexagonal pin wrench complete with

Tgrip

Use M10 bolts, qua lity 1 2. 9; u s e M o S

marked, tightening torq ue 7 0 Nm.

M10 - 12.9 MoS

2

Abbreviations

max. maximum

perm. permissible

Fig. figure

if nec. if necessary

approx. approximately

acc. according (to)

incl. inclusive (of)

to lubricate th e po ints

2

70 Nm

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\Konventionen_BA.fm

6

Page 7

1 Safety notes

The turret correspon d s t o th e sta te of the art and the

recognized tech nic a l s afe ty rul es. Ne ve rth el ess h a za rds a nd

risks can occur.

1.1 Use within specifications

°

Install and op era te turre t o nl y i n m a ch ines complying with

the relevant regulation s for worksp ace pro tecti on.

°

Operate turret only in perfect condition and in compliance

with the Operating Instructions.

1.2 Required skills

Safety note s

• Work may only be pe rfo r me d on the tu rret by qualified staff.

These are person s w ho are a ble to id en tif y ri sk s an d t o

prevent possibl e h az ard s on th e b as is o f th ei r sp ec ia l

training and their experience (IEC 60 201-1).

• All work on the electrical system is to be carried out by a

qualified electrical engineer only.

• Only trained and competent personnel may work on the

turret; this personn el m us t h av e be en instructed in

accordance with the Operating Instructions and directly on

the turret.

1.3 Notes on product-specific risks

Setting tasks require a 24V D C power sup ply.

Clearing required prior to any work:

°

Switch the machine off.

°

Push the motor pro te cti on switch for the turret into the

OFF po s itio n.

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\Sicherheit_allgem_480-473.fm

7

Page 8

Safety note s

WARNING

In the event of a fau lt or a collision, unexpected rota tio n of t he

tool disk is pos si ble.

Injury hazard.

CAUTION

Do not attempt any further switching operations, if the turret is

damaged, as otherwise considerable conseq uential damage

may be cause d.

°

Call SAUTER Service.

CAUTION

Functional fau lts m ay b e c a us ed by a n ing r es s of ch ip s and

contamination.

°

Close open too l l oc ations and cooling lubrica nt bo res by

means of suitable closing plugs.

For manual operation, turn the motor sha ft with the help of a

hexagonal pin wrench, complete with T-grip.

WARNING

A reversal of the m om e nt of the m oto r re su lts in th e

acceleration of the mot or shaft . The hexag onal pin wr ench may

thus be unexpectedly accelerated.

Therefore, in order to avoid the ejection of the hexagonal pin

wrench and resu lti ng in ju ries , firmly grip the hexagonal pin

wrench.

1.4 Disposal

°

Comply with all national and regional disposal regulations

and laws.

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\Sicherheit_allgem_480-473.fm

8

Page 9

1.5 Liability and warranty

The information contained in these Operating Instructions is in

conformity with the k no wledge at the point of printing .

Subject to modifica tio ns wh ich o cc ur with in the fra m ewo rk of

continuous further development.

All liability an d w a rran ty sh a ll be excluded if

• the notes and instructions contained in these Operating

Instructions are not complied with,

• the product is not used as directed,

¢

Use within specific at ion s, pa ge 7

• the product including accessories is in correctly operated,

• the product including accessories is in competently repaired

and maintained,

• conversions and f unctional cha nges are imp lemented witho ut

approval by the manufacturer,

• no suitabl e sp in d le uni t s are us e d as st ipulated in SAUTER

Product Informat io n PI 14.2, for examp le ,

• no suitable tool disks and tool holders are used,

• no original replacement parts are used.

Liability and warra nt y

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\Gewährleistung.fm

9

Page 10

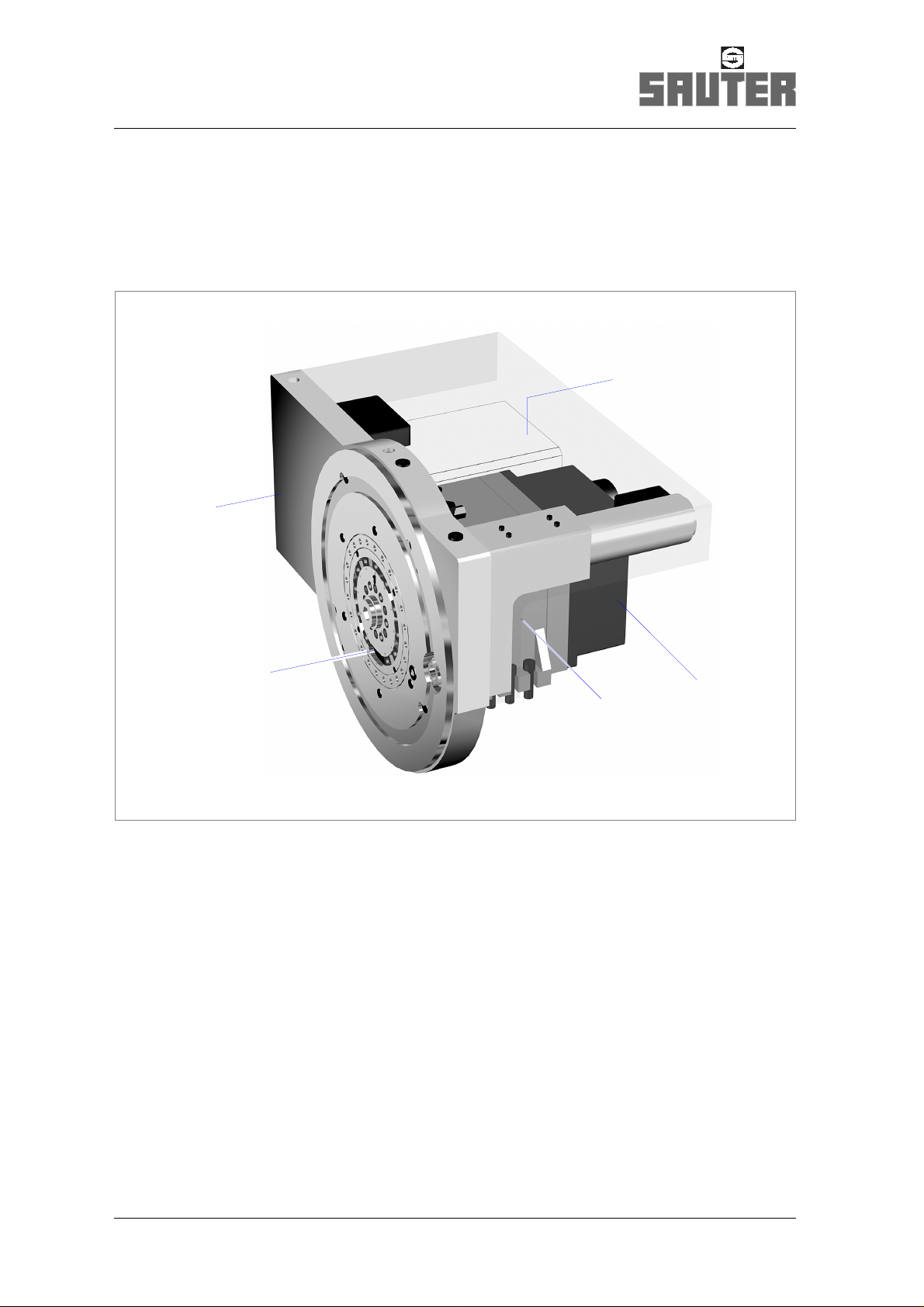

Product description

Designation of parts

2 Product description

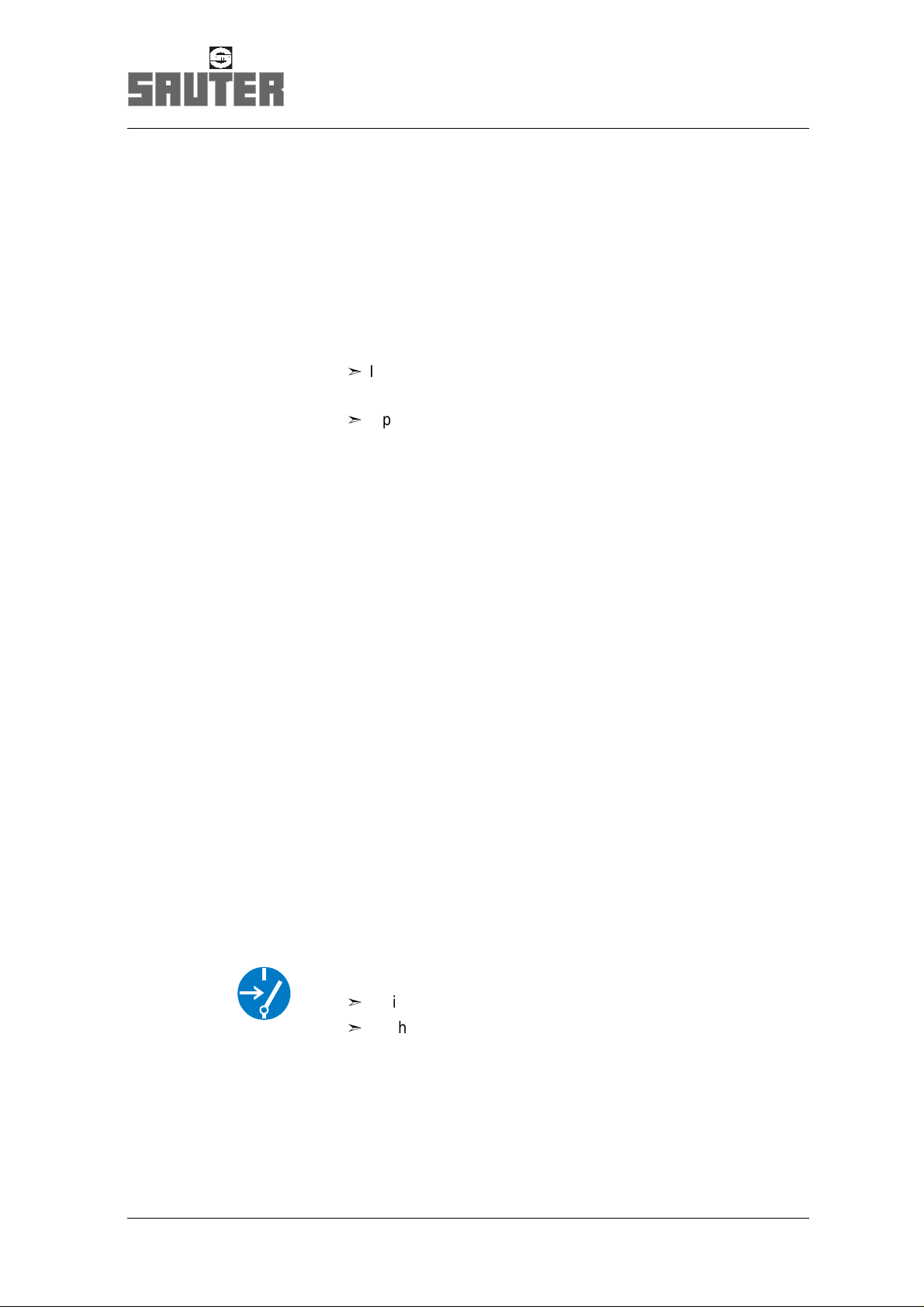

2.1 Designation of parts

2

3

1

4

5

1 Locating disk

2 Tool drive unit: gear housing

3 Tool drive motor

1)

4 Covering hood for electric components

5 Turret housing

10

1) not included in scope of delivery

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\PB_473520-25.fm

Page 11

Product description

Designation of parts

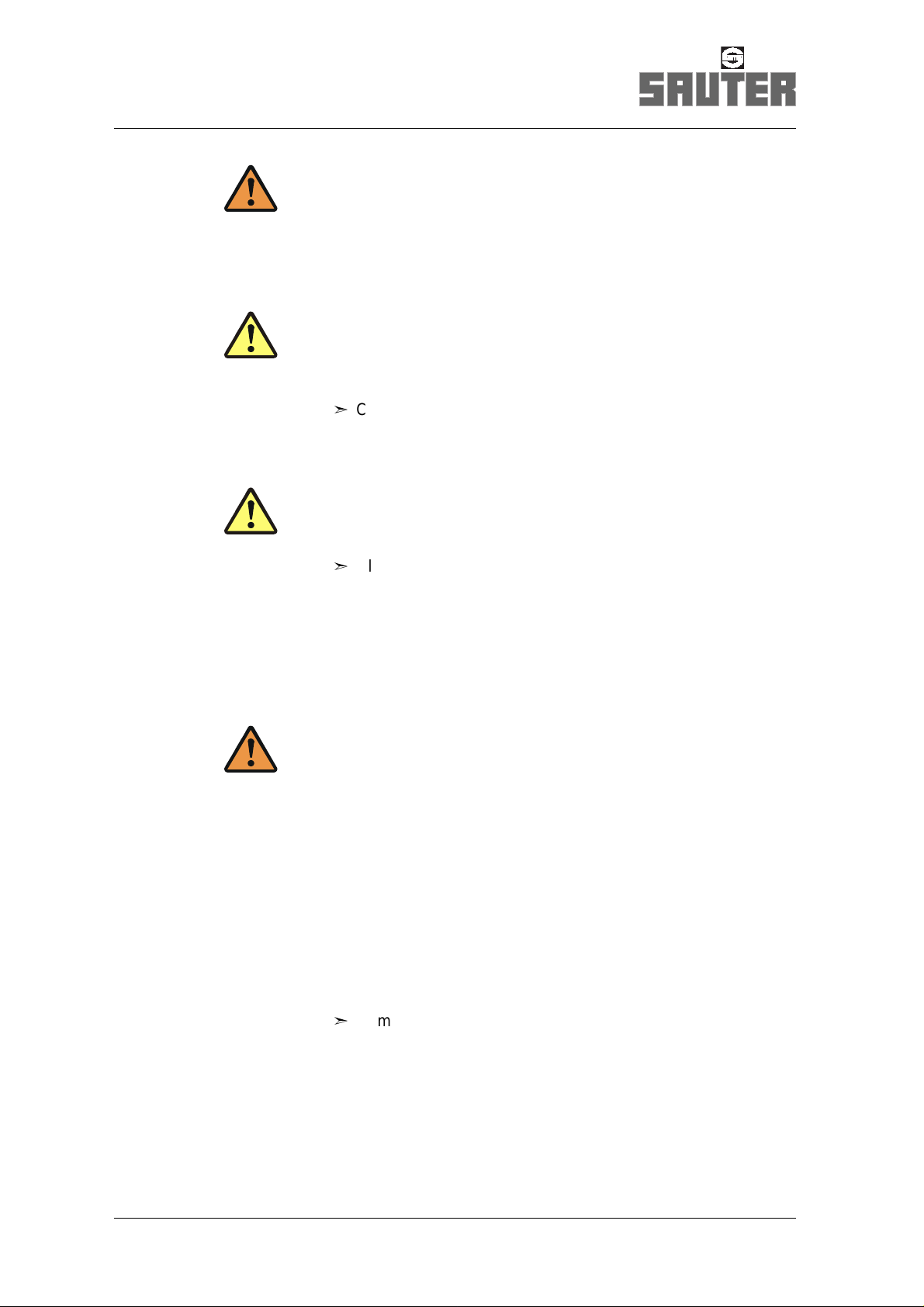

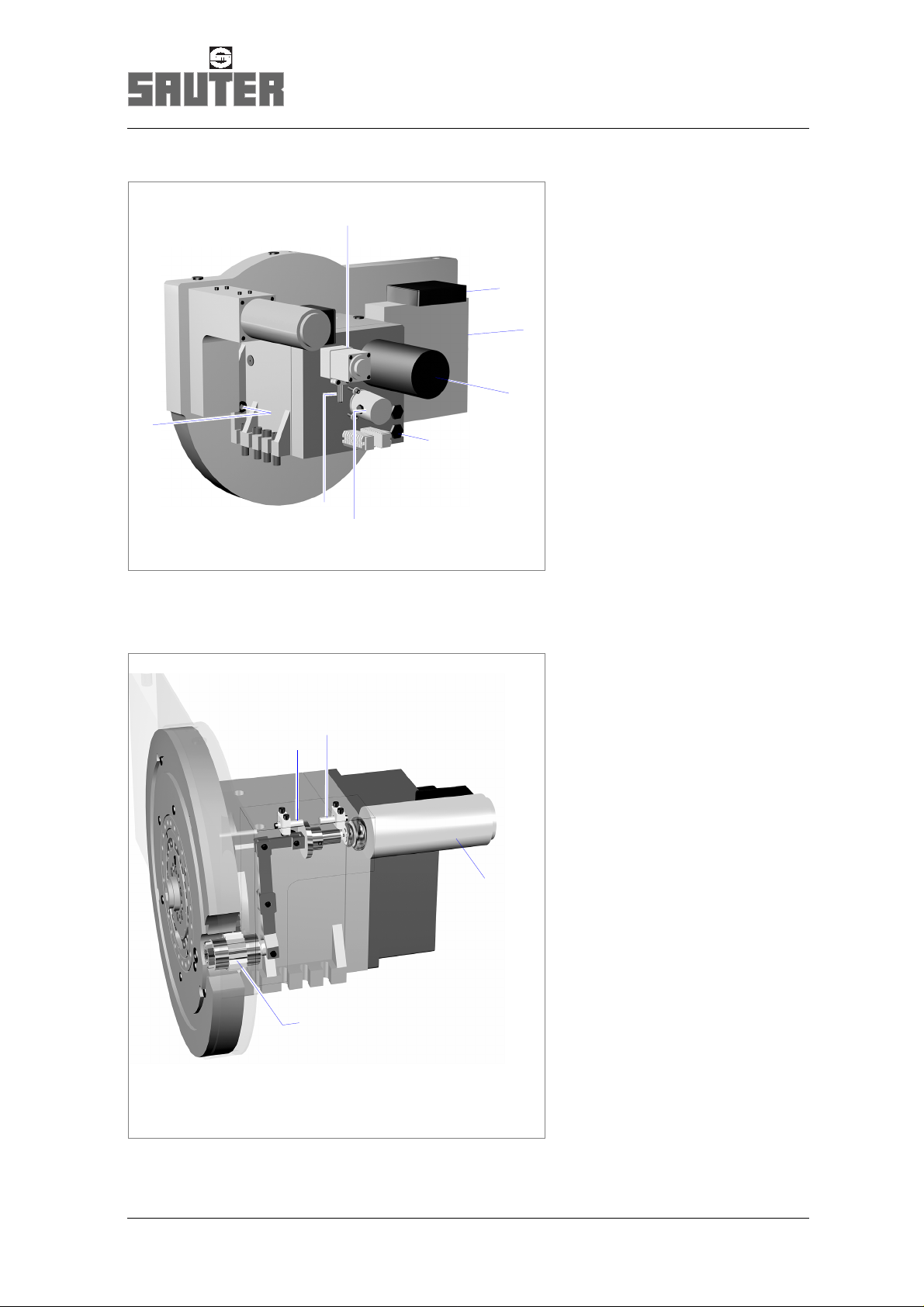

13

12

6

11

10

6 Solenoid

7 Terminal box:

tool drive motor

7

8

8 Flange plate:

tool drive motor

9 Turret motor

10 Electric connection:

turret

9

11 Angular encoder

12 Proximity switch S7

“Check pre-indexation”

13 Cooling lubricant

cartridge

14

14 Proximity switch S11

“Tool drive

disengaged”

15

15 Proximity switch S10

“Tool drive engaged”

16 Solenoid

17 Tool drive coupling

16

17

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\PB_473520-25.fm

11

Page 12

Product description

Technical data 0.5.473.520

2.2 Technical data

Number of indexing positions 8 or 12 or 16

Perm. tangential torque

1)

Nm 3,000

(turret locked)

at calculated safety

Perm. mass moment of inertia of tool disk,

kgm

2

1.3

1.8 – 7.5

2)

tool holders, and tools

Perm. unbalance (load moment) caused

Nm 63

by tool holders and tools

Indexing times

Theoretical cycle time

2)

41 α+

i

s

----------------× 017,× 01,+

n

.

.

(unlock/turn/lock)

at rotating angle α [degrees]

Gear ratio i see turret type plate

Motor speed n rpm see motor rating plate

Perm. indexing frequency min

-1

10 – 5.5

2)

Operating voltage/mains frequency see motor rating plate

Degree of protection IP 65

Turret mass

kg approx. 70

(without tool disk)

Perm. ambient temperature range °C

°F

Operating pressure for cooling lubricant

3)

Cooling lubricant valve – standard version

constant supply

externally switched suppl y

Medium pressure valve (option)

1) The perm. loads refer to processing without load shocks. Whenever processing is

subject to intermittent cuts, shocks or impacts, a significantly reduction in the values

needs to be taken into account.

2) Depending on gear ratio and mains frequency

3) In order to achieve an extended service life of the cooling lubricant valve, it is advisable

to filter the cooling lubricant by ≤ 100µm. Post-connected loads (spindle units with

internal cooling lubricant guide a.o.) may require a higher degree of filter fineness. Note

and comply with the manufacturer’s instructions!

bar

bar

bar

+10 ... +40

+50 ... + 104

7

14

25

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\Td_473520.fm

12

Page 13

Product description

Technical data 0.5.473.520

Tool drive

Mass (without any motor) kg approx. 40

1)

Gear ratio i 41/41 41/31 41/27 41/21

2)

Perm. speed

on tool drive coupling n

Max. perm. torque

2) 3)

perm

M

perm

rpm 4000

Nm 32

on tool drive coupling

Transferable power

2)

P

perm

kW 10

Suitable for spindle units

coupling profile 17 × 14 DIN 5482

1) The data stated here may differ on special versions.

2) M

3) The permissible torque can be utilized for non-pulse machining operations.

is the permissible peak load for the gears.

perm

The torque must be limited on the motor frequency converter to the value

indicated, while adhering to the gear ratio involved!

The useful power data depend on the performance characteristic curve of the motor type

used.

For strongly pulsed machining operations - e.g. inserted tooth milling cutters and others only a significantly reduced drive torque should be applied to protect the gears against

any overloads.

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\Td_473520.fm

13

Page 14

Manual mode

3 Manual mode

In manual mode, the me chanical functions of the disk-type tool

turret will be checked:

• following initial assembly to the machine

• during troubleshooting

• after a renewed setup following fault conditions

Clearing required prior to any work:

°

Switch the machine off.

°

Push the motor prote cti on s witc h f or t he tu rret i nto th e

OFF p os ition.

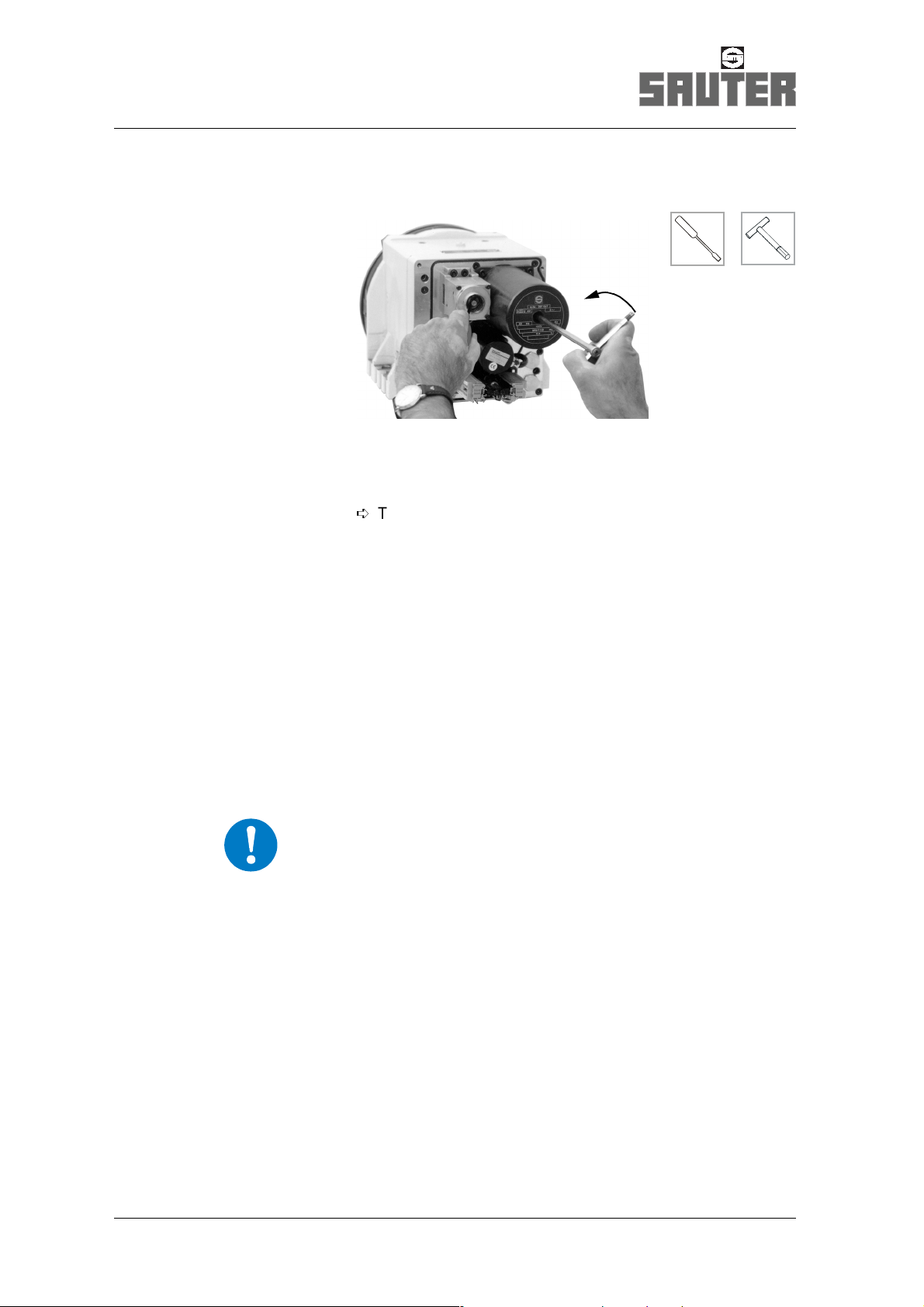

1. Undo fixing screws of covering hood,

withdraw covering hood to rear.

If necessary, use push-off screw.

2. Remove screw plug on motor housing.

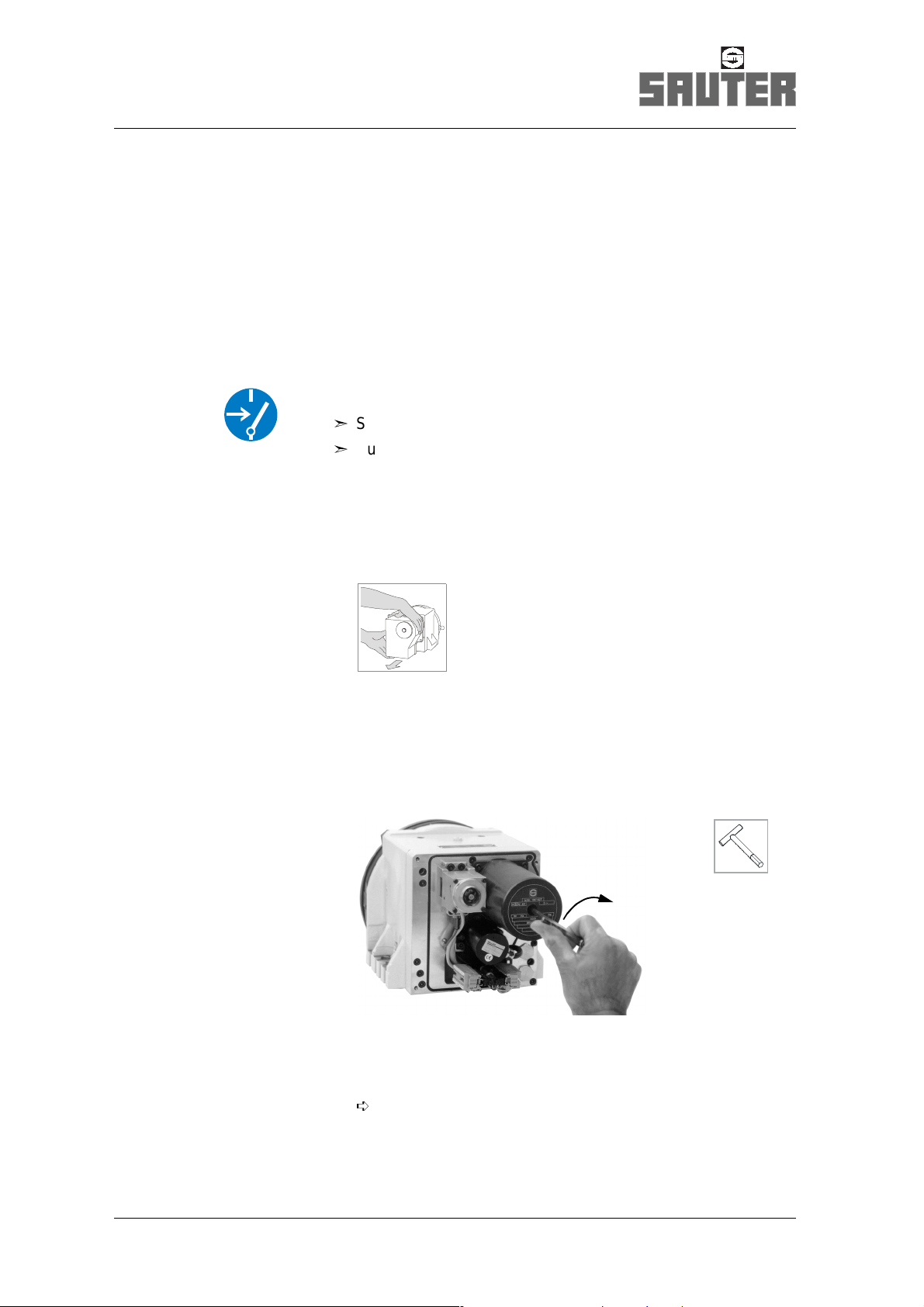

Unlock turret

3. Use a hexagonal pin wrench, complete with T-grip, to rotate

the motor shaft.

·

If the disk-type tool turret is locked, the locating disk (or

tool disk) does no t co-rotat e; the centre position of t he lock

can be felt.

14

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\HB_480.fm

Page 15

Manual mode

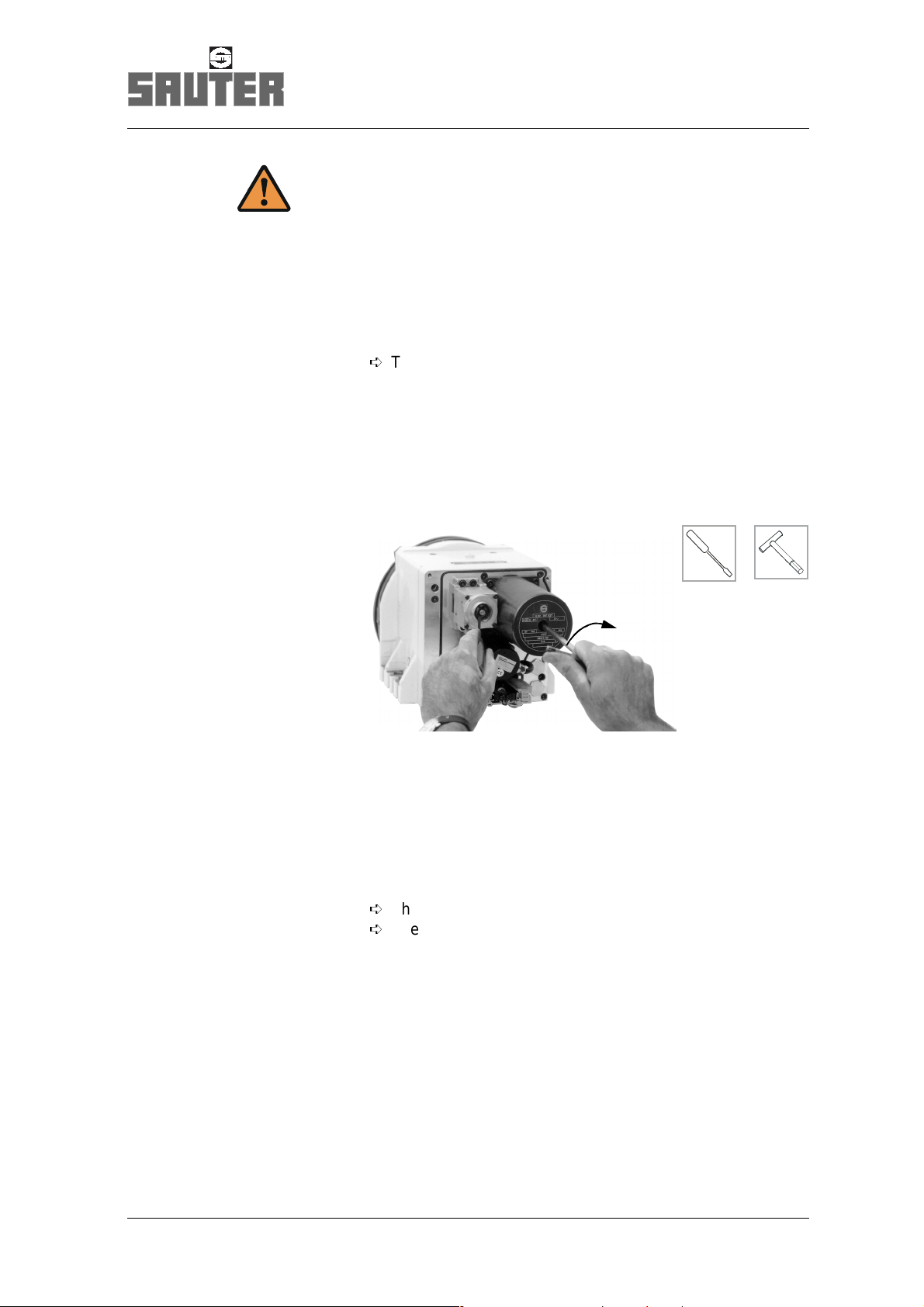

WARNING

A reversal of the m ome nt o f t he m oto r re su lts in th e

acceleration of the motor shaft. The hexagonal pin wrench may

thus be unexpectedly accelerated.

Therefore, in order to avoid the ejection of the hexagonal pin

wrench and resu lti ng in juri es , fi rm ly grip the hexagonal pin

wrench.

4. Keep the same direction of rotation, continue to rotate.

·

The disk-type tool tur ret unlo cks; a r eversal o f the mo ment

on the motor shaft can be felt.

Rotate tool di sk

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\HB_480.fm

5. Keep direction of rotation, continue to rotate disk until

locating disk (or tool disk) starts to turn as well.

6. Keep direction of rotation, continue to rotate disk until

locating disk (or tool disk) has reached the position r equired,

then press in the keeper by means of a screwdriver.

·

The preindexing bolt engages into a hole.

·

The tool disk cannot be rotated any further.

15

Page 16

Manual mode

Lock turret

7. Reverse direction of rotation on the motor shaft whilst

simultaneously pressing in keeper.

·

The disk-type tool turret locks.

The lock resistance can be felt when rotation is continued.

The locking process ends, if t he centr e pos ition o f the lock

can be felt.

On completion of setup or maintenance work:

8. Screw in plug and fit covering hood.

Note position of cables in order to avoid any pinching of the

same.

Lock turret in position 1

IMPORTANT

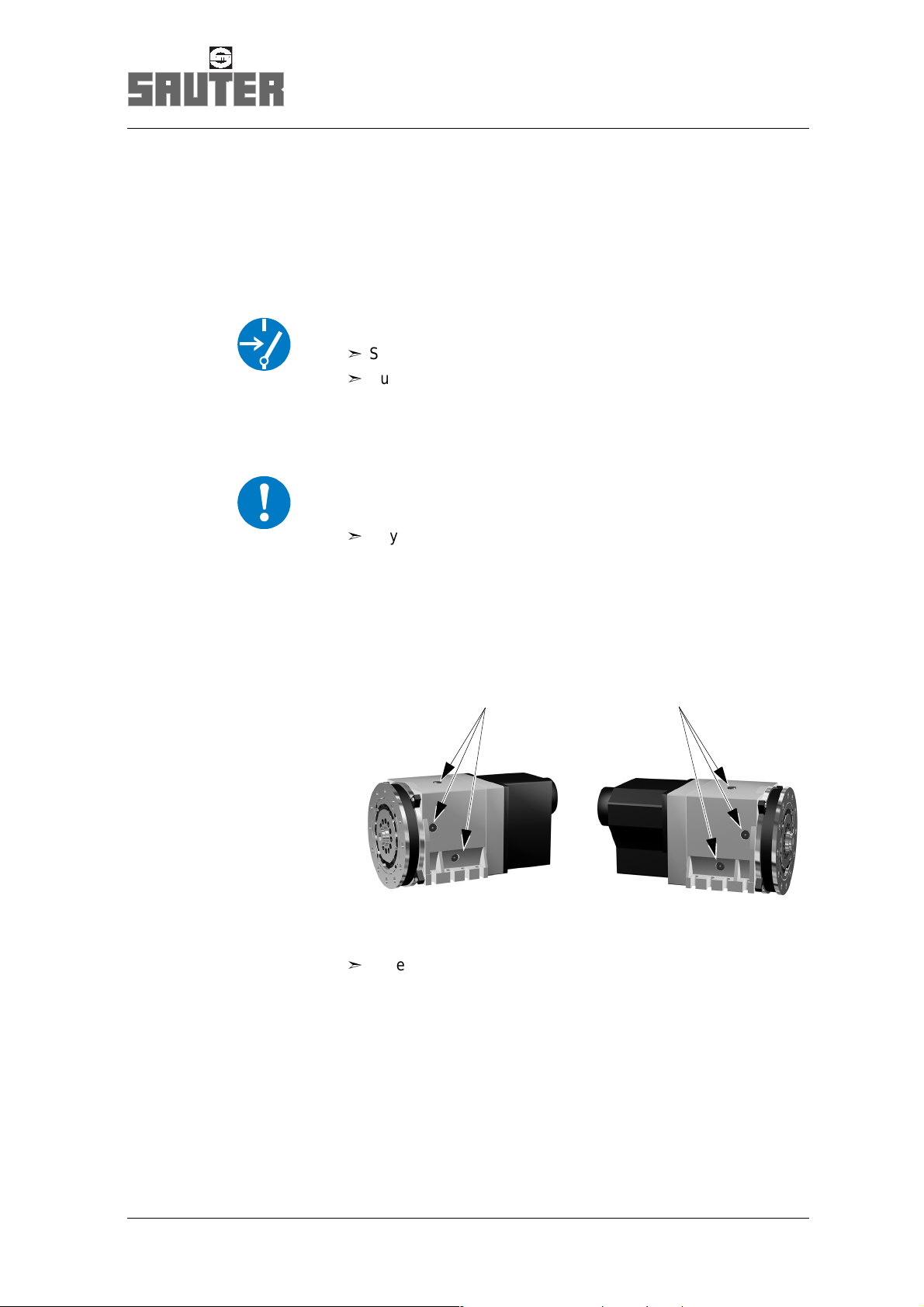

For some setup and mai nte nanc e work th e disk -type tool tu rret

has to be locked in position 1.

Precondition

• Numeral 1 of the locating disk has reached its 12 o’clock

position relative to the turret base area.

or

• Position 1 of the tool disk is in working position .

16

1. Use a hexagonal pin wrench, complete with T-grip, and

rotate the motor shaft until position 1 has been reached.

2. Press in the keeper by means of a screwdriver and rotate the

motor shaft until the disk-type tool turret locks (see above).

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\HB_480.fm

Page 17

4 Maintenance

Turret maintenance compri ses the followin g tasks:

• Cleaning,

• Checking,

• Setting and

• Repair.

The service life of the turret is approx. 2–3 million switchings

or approx. 5 years.

The service life of the tool drive unit is

approx. 8000 operating hours.

These values appl y to

• collision-free operation,

Maintenance

Safety note s

• compliance with the specified operating conditions and the

permissible loa ds ,

¢

Technical data, page 12

4.1 Safety notes

¢

Page 7

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_SI_Zeit_480-473.fm

17

Page 18

Maintenance

Service intervals

4.2 Service intervals

Plan your tasks car efully in order to provide fo r troublefree o peration an d

reduce necessar y downtimes to a minimum.

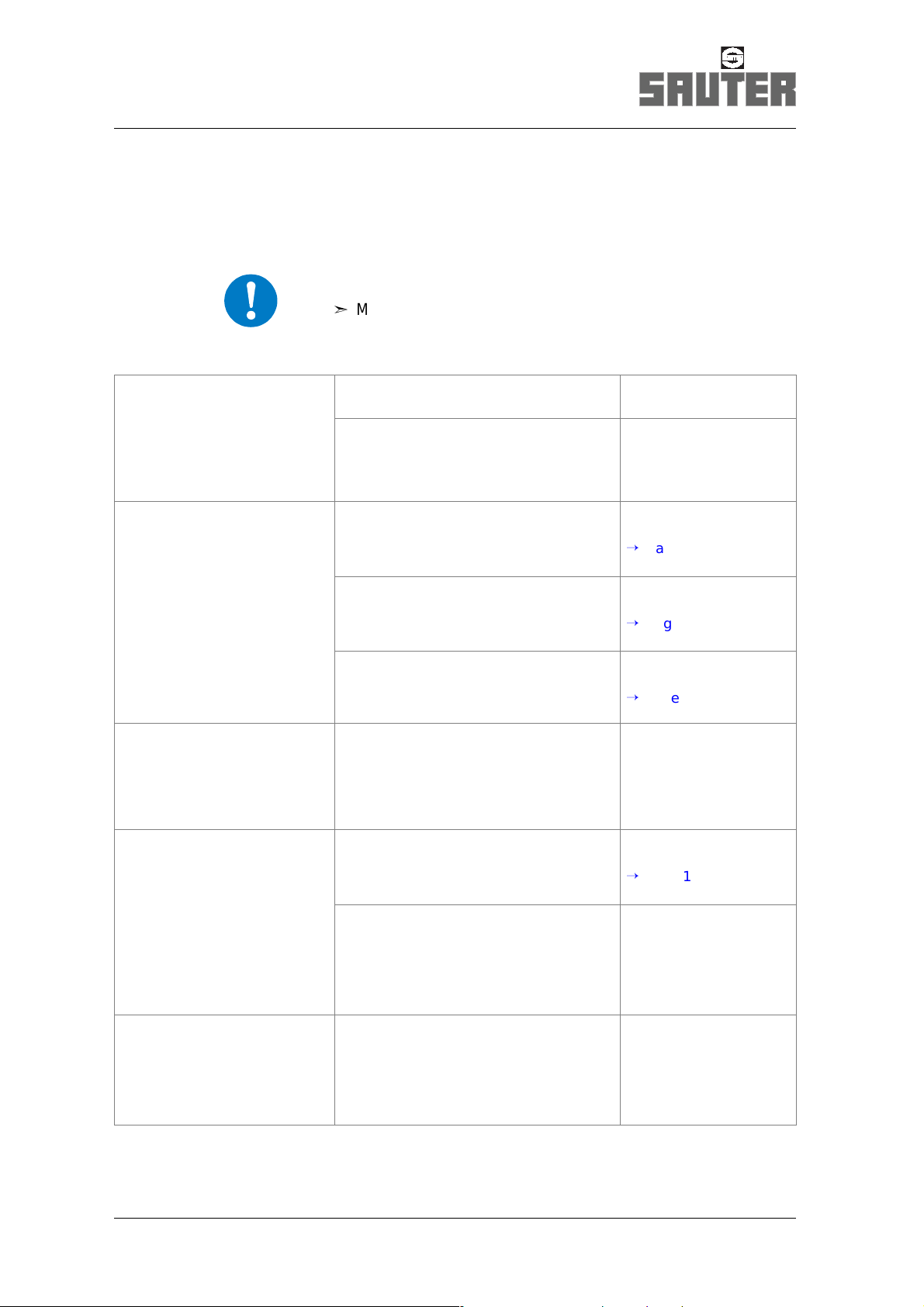

IMPORTANT

°

Maintenance intervals must be adapted

to the operating conditions involved.

if required

after 4000 operatin g hours

of the machine

respectively

after 2½ years

respectively

after 8000 operating hours

of the machine

respectively

Clean tool drive coupling. User

Check tool drive coupling for d amage,

User

replace if necessary.

SAUTER Service

Check cooling lubricant valve for wear

and leakage.

Replace any defective parts.

Check oil of the turret gearbox

User

¢

Page 26

User

chamber;

¢

if necessary, replenish oil.

Check grease condition of tool drive

unit; if necessary, replenish grease.

Check all electrical lines and

Page 19

User

¢

Page 21

User

connections for mechanical damage as

well as embrittlement.

Replace any defective parts.

Change the oil of the turret gearbox

Specialist electrical

engineer

User

chamber.

¢

Page 19

1)

after approx. 2–3 million

indexing operations

respectively

18

The service life of the tool drive unit

SAUTER Service

may possibly be reach ed, depend ing

on the operating conditions involv ed.

A general overhaul is recommende d

for further trouble-free operation.

The service life of the turret may

SAUTER Service

possibly be reached, depending on the

operating conditions involved.

A general overhaul is recommende d

for further trouble-free operation.

1) These are persons who are able to identify risks and to prevent possible hazards

on the basis of their special training and their experience

(IEC 60 201-1).

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_SI_Zeit_480-473.fm

Page 19

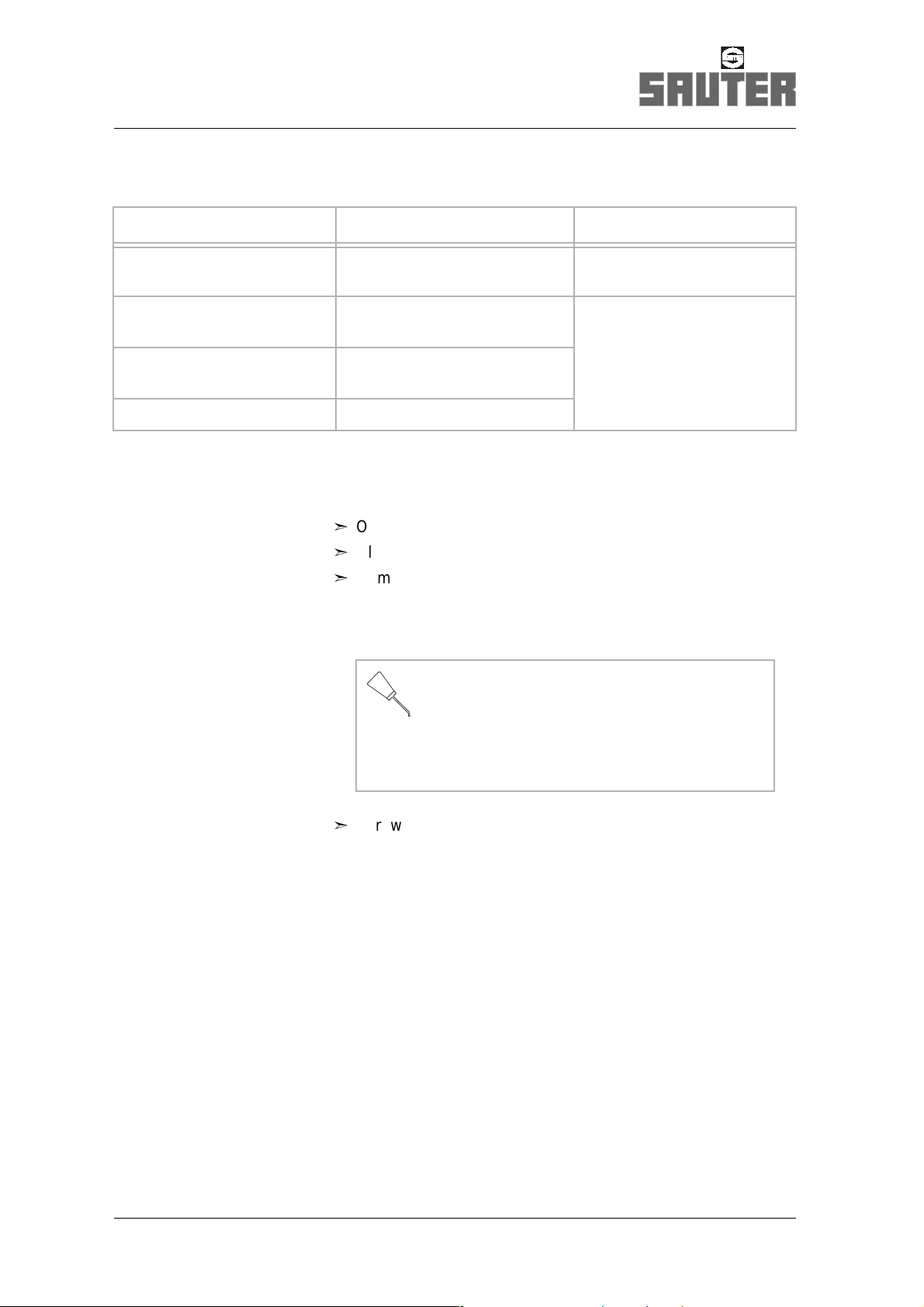

4.3 Maintenance work

Turret gearbox chamber

The turret gearbox chamber ha s to be service d after 4,00 0 operating hou rs.

Clearing required prior to any work:

°

Switch the machine off.

°

Push the motor pro te cti on switch for the turret into the

OFF po s itio n.

IMPORTANT

Improperly disposed used oil is a danger for our environment.

°

Pay attention to the le ga l re gu lat ion s for the waste disposal

of used oil.

Maintenance work

Turret gearbox chamber

In line with the setup position of the disk-type tool tur ret, the

following apertures (1) for draining or replenishing oil are

provided:

11

Checking the oil

°

Carefully unsc rew o il dra in plu g and drain the oil

(max. 10 cm

3

) into a suitable co ntainer.

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_Oel_Rev_480516-20-25.fm

19

Page 20

Maintenance work

Turret gearbox chamber

Assess oil condition

Condition Cause Action

Oil black or brow n, w ith ou t

metallic abrasi on

Oil black or brown, with

metallic abrasi on

Oil white, mixed with cooling

lubricant

Natural consum p tion –

Internal parts of turret are

damaged

Turret sealings are damage d

None oil left Turret sealings are damaged

Changing the oil

°

Open oil drai n p lu g, drain waste oil.

°

Close oil drain plug.

°

Remove screw plug from oil charging hole.

Fill oil

300cm

3

Request SAUTER Service!

lubricating oil C acc. to ISO 6743/ 6

viscosity ISO VG 46 acc. to DIN 51562

°

Screw in screw plug.

20

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_Oel_Rev_480516-20-25.fm

Page 21

Maintenance work

Tool drive

The tool drive is lubricated with grease.

The grease needs t o be checked a fter 4,000 h ours of opera tion

of the tool drive.

Clearing required prior to any work:

°

Switch the machine off.

°

Push the motor pro te cti on switch for the turret into the

OFF po s itio n.

Preparation

°

Provide access to the ap e rtu re (1) on the tool drive.

Tool drive

1

Checking the grease condit ion

°

Unscrew screw plug on aperture (1).

°

Rotate gear and assess grease condition:

Condition Cause Measure

No grease visible on gear Natural consumption Replenish grease.

Grease: blac k or b r own ,

without metallic a bra s ion

Grease: blac k or b r own ,

with metallic abra si on

cooling lubrican t

Traces of natural wear –

Internal parts of turret are

damaged

Turret sealings are damag ed

Request SAUTER Service!Grease: whi te, mixed with

Grease mixe d wi th oil Turret sealings are d am ag ed

Replenishing the grease

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_Fett_WZA_473.fm

3

°

Close aperture (1) by means of screw plug.

ISOFLEX NBU 15max. 20cm

(KLÜBER)

21

Page 22

Repairs after fault conditions

Possible faults and remedies

4.4 Repairs after fault conditions

Clearing required prior to any work:

°

Switch the machine off.

°

Push the motor prote cti on sw itc h f or t he tu rret i nto th e

OFF p os ition.

Fault Cause Remedy Who carries out

this task?

Turret

Incorrect center height,

tool disk offset relative

to locating disk

Tool disk does not

rotate

Turret is difficult to

operate

(Thermo protection

device has responded)

Turret no longer locks

or the pre-indexing bolt

gets caught

Tool disk does not stop

in the selected position

Collision when turret is

locked

Gearwheels are

defective

Proximity switch S11

does not switch

Insufficient oil in the

gearbox chamber

Contactor is defective Check motor drive

Collision during

pivoting

Angular encoder is not

correctly adjusted or

defective

Turn back tool disk in

the annular groove and

align

SAUTER

Service

Check proximity switch

S11; if necessary, set

or replace

Check oil

SAUTER

Service

Check angular

encoder, set or replace

if necessary

User

¢

Page 25

User

¢

Page 37

User

¢

Page 19

User

User

¢

Page 27,

page 29

22

Proximity switch S7

does not switch

Check proximity switch

S7, set or replace if

necessary

User

¢

Page 33

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_Stör_480-473.fm

Page 23

Repairs afte r fault conditions

Possible fa u lts and remedies

Fault Cause Remedy Who carries out

this task?

Tool disk stops in

between two positions

Chips between tool

disk and turret

Remove tool disk,

remove chips

Leakage oil escapes Seals are defective SAUTER

Service

Cooling lubricant is not

being transferred

Cooling lubricant

escapes between tool

Cooling lubricant valve

is defective

Cooling lubricant valve/

line is blocked

Cooling lubricant valve

is defective

Replace cooling

lubricant valve

Blow cooling lubricant

valve/line clear

Replace cooling

lubricant valve

disk and turret

Tangential play of tool

disk when turret is

Collision while turret is

locked

SAUTER

Service

locked

Wear due to lack of oil

User

User

¢

Page 26

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_Stör_480-473.fm

23

Page 24

Repairs after fault conditions

Possible faults and remedies

Fault Cause Remedy Who carries out

this task?

Tool drive

Tool drive does not

Tool disk is displaced Align tool disk

engage

Tool drive coupling is

defective

Pinion shaft is

defective

Solenoid is defective Replace solenoid and

Tool is not driven Gearwheels are

defective

Tool drive motor is

defective

Proximity switch S10

does not switch

SAUTER

Service

Replace defective

part,

adjust solenoid

adjust

SAUTER

Service

Replace tool drive

motor

Check proximity switch

S10, set or replace if

necessary

User

¢

Page 25

User

¢

Page 36

User

User

¢

Page 37

24

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_Stör_480-473.fm

Page 25

4.5 Aligning the tool disk

Preparation

Clearing required prior to any work:

°

Switch the machine off.

°

Push the motor pro te cti on switch for the turret into the

OFF po s itio n.

°

Lock turret.

¢

Manual mode, page 14

Aligning

Repairs a fte r fa u lt conditions

Aligning the tool disk

1

1

°

If necessary, undo screws (1).

°

Align the locating hole to center height of the machine;

use a plug gaug e (2 ) if required.

°

Tighten screws (1).

M10 - 12.9 77 Nm

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_Ausr_WS_480-473.fm

MoS

2

25

Page 26

Repairs after fault conditions

Replacing the cooling lubricant valve

4.6 Replacing the cooling lubricant valve

The cooling lubri cant valve is a wearing pa rt and has to be serviced after

4,000 hours of opera tion.

Clearing required prior to any work:

°

Switch the machine off.

°

Push the motor prote cti on s witc h f or t he tu rret i nto th e

OFF p os ition.

Checking

Check whethe r c oo lin g lub ric ant emerges between tool dis k

and turret.

°

If necessary, replace defective parts or the entire cooling

lubricant valve.

1)

1

2

3

Replacing

°

Undo screw plug (3).

°

Withdraw coolin g l ub ric ant cartridge complete with

screw plug (3).

°

Check cooling lubricant cartridge; if necessary, replace

bushing (1) and O-ring seal (2).

°

Refit cooling lubricant cartridge complete with screw plug.

26

1) Customized versions may also differ from the present version.

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_KSS_WZA.fm

Page 27

Repairs a fte r fa u lt conditions

Adjusting the angular encoder

4.7 Adjusting the angular encoder

IMPORTANT

Setting tasks require a 24V D C power sup ply.

Preparation

°

Lock disk-type tool turret in position 1.

¢

Manual mode, page14

°

Undo claws by means of a hexagonal pin wrench.

Adjusting

°

Rotate angular encoder out of position until illuminated diode

lights up.

°

Clamp in angular encoder by means of the claws.

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_Einstell_WPG_4805xx.fm

27

Page 28

Repairs after fault conditions

Adjusting the angular encoder

Checking the setup for symmetr y

1. Use hexagonal pin wrench with T-grip for rotating the motor

2. Rotate motor shaft until illuminated diode on the angu lar

shaft.

encoder or the indication “Position 1” on the machine are

extinguished.

3. Note the T-grip position.

WARNING

A reversal of the m om e nt of the m oto r re su lts in th e

acceleration of the mot or shaft . The hexag onal pin wr ench may

thus be unexpectedly accelerated.

Therefore, in order to avoid the ejection of the hexagonal pin

wrench and resu lti ng in ju ries , firmly grip the hexagonal pin

wrench.

4. Carefully continue to rotate until a moment reversal can be

felt on the motor shaft.

5. Note the T-grip position.

The distance between the two grip positions characterizes the

angle range.

6. Repeat steps 1 to 5 with reverse direction of rotation. The

α must be the same for both directions of rotation!

angle

28

By turning the angular encoder out of position, any

dissymmetry can be removed.

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_Einstell_WPG_4805xx.fm

Page 29

Repairs a fte r fa u lt conditions

Replacing the angular encoder

4.8 Replacing the angular encoder

The location of the a ngular encoder depends on t he disk-typ e tool turret

version (without /with flui d rotary fee dthrough).

IMPORTANT

Setting tasks require a 24V D C power sup ply.

Angular encoder, centrally positioned

Preparation

°

Lock disk-type tool turret in position 1.

¢

Manual mode, page 14

1

2

3

°

Note the position of the c ab le ou tle t (2 ) on th e

angular encoder (1), remove attachment.

°

Undo cables (3) on te rm ina l s tri p (n ote wh ere th ey a r e

connected).

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_Ausw_WPG_480520-25.fm

°

Undo claws by means of a hexagonal pin wrench.

29

Page 30

Repairs after fault conditions

Replacing the angular encoder

Replacing

°

°

°

Undo setscrew.

Carefully withdraw angular encoder.

Connect new angular encoder electrically.

¢

Wiring diagram: D is k -t ype too l tu rr et EP - 87 0

in the appendix to these Operating Instructions.

°

Rotate shaft of the angular encoder until the illumination of

the LED on the angular encoder indicates the “Position 1”

setting.

This indication must remain whilst the following steps are

carried out.

IMPORTANT

The LED is used o nly to in d ica te po sition 1 during the

adjustment work. It is no position indicator during operation.

°

Ensure that the cable outlet is in its correct position.

30

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_Ausw_WPG_480520-25.fm

Page 31

Repairs a fte r fa u lt conditions

Replacing the angular encoder

°

Insert the shaft o f th e a ng ul ar enc o de r in to the bore of the

flexible shaft an d introduce carefully until the an gu la r

encoder is in contact with the plate. Ensure that the claws

are in their correct position!

°

Use setscrew to attach the angular encoder to the shaft.

°

If necessary, check the adjustment of the angular encoder.

¢

Page 28

°

Use claws to secure the angular encoder.

°

Fit covering hood. Note position of cables in order to avoid

any pinching of the same.

Angular encoder, in side position

Preparation

°

Lock disk-type tool turret in position 1.

¢

Manual mode, page 14

1

23

°

Note the position of the cable outlet (2) on the angular

encoder (3), remove attachment.

°

Undo cables (1) on te rm ina l s tri p (n ote wh ere th ey a r e

connected).

Replacing

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_Ausw_WPG_480520-25.fm

°

Undo claws by means of a hexagonal pin wrench.

31

Page 32

Repairs after fault conditions

Replacing the angular encoder

°

°

°

Carefully withdraw angular encoder.

On the shaft of the angul ar encoder, a disk is locate d which is

fixed in position by means of a setscrew.

Undo setscrew and remove disk.

Connect new angular encoder electrically.

¢

Wiring diagram: D is k -t ype too l tu rr et EP - 87 0

in the appendix to these Operating Instructions.

°

Rotate shaft of the angular encoder until the illumination of

the LED on the angular encoder indicates the “Position 1”

setting.

This indication must remain whilst the following steps are

carried out.

°

Fit disk in its correct position.

°

Ensure that the cable outlet is in its correct position.

°

Insert the angula r en c od er i nto th e op en ing o f th e p la te,

note the position of the claws!

°

If necessary, check the adjustment of the angular encoder.

¢

Page 28

32

°

Use claws to secure the angular encoder.

°

Fit covering hood. Note position of cables in order to avoid

any pinching of the same.

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_Ausw_WPG_480520-25.fm

Page 33

4.9 Proximi ty s w it ch S7

IMPORTANT

Setting tasks require a 24V D C power sup ply.

Clearing required prior to any work:

°

Switch the machine off.

°

Push the motor pro te cti on switch for the turret into the

OFF po s itio n.

°

Undo fixing screws of covering hood, withdraw covering

hood to rear. If necessary, use push-off screw.

Repairs a fte r fa u lt conditions

Proximity s wit ch S 7

Replacing

2

1

°

Undo clip (3) and withdraw proximity switch (1) from

3

eccentric bushing (2).

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_S7_4805xx.fm

33

Page 34

Repairs after fault conditions

Proximity s wit ch S 7

Checking

.

°

°

Adjusting

°

+

brown

11

8

V

24 V

black

blue

−

H-Signal ≥ 90% of rated voltage

Apply a voltage of 24 V DC to the proximity sw itc h (1).

The proximity switch is energized when the LED lights up.

Insert tested/new proximity switch (1).

Unlock disk-type to ol tu rret.

¢

Manual mode, page14

°

Move disk-type tool turret into a location between two

positions.

If the keeper (M) is operated, the preindexing bolt (4) can be

pressed in pa rtia lly o nl y.

a

5

4

M

°

Set switching distance x = 0.3 – 0.5 mm.

°

Determine dimension a.

x

2

3

1

34

a = stroke of the preindexing bolt (4) up to the damping

ring (5) when the so le no id is op erated manually

(corresponds to the press-in depth of the keeper (M)).

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_S7_4805xx.fm

Page 35

Repairs a fte r fa u lt conditions

Proximity s wit ch S 7

°

Adjust proximity switch (1) on eccentric bushing (2) such that

its signal begins to drop after a + 2

+0.5

mm immersion depth

of the preindexing bolt.

Any greater immers io n de pth m ay cau se th e mo to r to be

blocked.

°

Tighten clip (3).

°

Fit covering hood. Note position of cables in order to avoid

any pinching of the same.

Function test

°

Switch on turret.

°

Check switch in g process repeatedly.

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_S7_4805xx.fm

35

Page 36

Repairs after fault conditions

Solenoid

4.10 Solenoid

The solenoid deter mines the engagemen t path. The co upling end p ositions

are controlled b y mean s of t he prox imity s witches S 10 “Tool drive engaged”

and S11 “Tool drive disengaged”.

Clearing required prior to any work:

°

°

Preparation

°

If a tool disk is f itte d, th e tool holder location must be

accessible in working position:

°

Switch the machine off.

Push the motor prote cti on s witc h f or t he tu rret i nto th e

OFF p os ition.

If necessary, remove the covering hood on the tool drive unit.

If necessary, disassemble tool ho ld er.

1

3

5

Replacing

°

Remove screws (1) on the flange plate of the soleno id (2).

°

Undo setscrew (5).

°

Replace the solenoid(2) c omplete with adjusting nut(3) and

4

2

bushing (4).

°

Tighten screws (1).

36

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_Mag_WZA073.fm

Page 37

~1mm

Repairs a fte r fa u lt conditions

Solenoid

Checking

Is the clearance from t he pinion shaft (10) to the edge of the

spindle unit coupling (11) 1mm when the keeper is drawn out?

°

If necessary, adjust final coupling position.

67 8 9

0.3-0.5mm

53

1011

Adjusting the final coupling position

°

Undo setscre w (5).

°

Undo adjusting nut (3) and rotate keeper.

°

Adjust clearan ce.

°

Tighten setscrew (5).

Adjusting the proximity switches

°

Undo screws (8) of clip (7).

°

Adjust proximity switch S11 (6) to a clearanc e of 0. 3 - 0.5 mm

relative to its switching area.

°

Tighten screws (8) of clip(7 ).

°

Adjust proximit y s w itc h S10 (9) in the same wa y.

F:\Sauter\FRAME-AR\TD\0-5-473-\eng\Ba892\IH_Mag_WZA073.fm

37

Page 38

Replacement parts

5 Replacement parts

IMPORTANT

Only use the order form if you wish to order

any replacement parts!

A

B

38

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_Übersicht_473520_BA-892.fm

Page 39

Replacement parts

A Replacement parts for turrets (without tool drive)

¢

Indexing, page 40

¢

Clamping and angular encoder, page 41

¢

Gear, drive, pre-indexation, page 4 2

B Replacement parts tool drive for turret

¢

0.5.473.520 - 107 468

- 110 660

0.5.473.520 - 111 092

- 111 432

- 112 862

0.5.473.520 - 115 702

Page 44 - 45

¢

Page 46 - 47

¢

Page 48 - 49

¢

Page 50 - 51

¢

Page 52 - 53

¢

Page 54 - 55

- 125 365

-

¢

Page 56 - 57

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_Übersicht_473520_BA-892.fm

39

Page 40

Replacement parts

Indexing

Indexing

1

2

Setscrew is only applied

and secured (LOCTITE 221)

No. Ident No. Designation Qty.

1 058 073

2 102 048

O-ring seal

Replacements parts group Indexing

1

3

40

IMPORTANT Request assembly guideline MR 02.025!

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_480520.fm

Page 41

Clamping and angular encoder

Clamping and angular encoder

Replacement parts

1

2

3

4

No. Ident No. Designation Qty.

1 067586 Disk (for tuning) 1

2 063 358

3

O-ring seal

Replacements parts group Clamping

1

1

IMPORTANT Request assembly guideline M R 02.025!

4 105 500

Angular encoder

1

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_480520.fm

41

Page 42

Replacement parts

Gear, drive, pre-indexation

Gear, drive, pre-indexation

12 5364

42

7

89 10

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_480520.fm

Page 43

Replacement parts

Gear, drive, pre-indexation

No. Ident No. Designation Qty.

1 071 904

2 078 218

3 069 340

4 063 365

5 065 718

6Motor

7 004 157

8 070 460

9 067 659

10 064 813

Sealing ring

O-ring seal

O-ring seal

O-ring seal

O-ring seal

1) 2)

Proximity switch

Sealing ring

Compression spring

Solenoid

1

1

1

1

1

1

1

1

1

1

1) will be supplied complete with housing and bearing

2) data according to motor’s nameplate

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_480520.fm

43

Page 44

Replacement parts Tool Drive

for turret 0.5.473.520 - 107 468

for turret 0.5.473.520 - 107 468

6

7

8

5

4

3

2

9

Setscrew is only applied and

secured

(LOCTITE 221)

A

10

B

11

12

44

1

13

14

15

16

(16)

(14)

(15)

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_473520-107468.fm

Page 45

Replacement parts Tool Drive

for turret 0.5.473.520 - 107 468

0.5.473.520 - 107 468

No. Ident No. Designation Qty.

1036 588

2063 365

3069 657

4068 017

5000 706

Spaghetti hose

O-ring seal

Wire race ball bearing

O-ring seal

Deep groove ball bearing

6 058 548 O-ring seal

058 521 O-ring seal

063 461 O-ring seal

065 993 O-ring seal

7076 749

8118 182

Proximity switch

Solenoid

9 058 495 O-ring seal

059 932 O-ring seal

1) 2) 3) 4)

5)

6)

7)

1) 2) 3) 4) 6) 7)

5)

0.636m

1

1

1

1

1

1

1

1

2

1

1

1

10 034 592

11 058 506

12 A 075 508

12 B 101 121

13 103 530

14 065 138

15 038 494

16 060 663

1) for motor SIEMENS 1FT5 072

2) for motor SIEMENS 1FT5 076

3) for motor SIEMENS 1FT6 084

4) for motor FAGOR FXM 55

5) for motor FANUC alpha 22

6) for motor SIEMENS 1FT5 066

7) for motor FANUC 6S

8) standard version

9) version for medium pressure

FU groove ring

O-ring seal

Cooling lubricant valve, complete

Cooling lubricant valve, complete

Pinion shaft, complete

Radial seal for rotating shaft

Deep groove ball bearing

O-ring seal

1

1

8)

9)

1

1

1

2

2

2

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_473520-107468.fm

45

Page 46

Replacement parts Tool Drive

for turret 0.5.473.520 - 110 660

for turret 0.5.473.520 - 110 660

6

7

8

5

4

3

2

9

Setscrew is only applied and

secured

(LOCTITE 221)

A

10

B

11

12

46

1

13

14

15

16

(16)

(14)

(15)

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_473520-110660.fm

Page 47

Replacement parts Tool Drive

for turret 0.5.473.520 - 110 660

0.5.473.520 - 110 660

No. Ident No. Designation Qty.

1036 588

2067 810

3068 207

4064 594

5000 706

Spaghetti hose

O-ring seal

Wire race ball bearing

O-ring seal

Deep groove ball bearing

6 058 075 O-ring seal

058 548 O-ring seal

058 521 O-ring seal

065 993 O-ring seal

7076 749

8118 182

Proximity switch

Solenoid

9 058 521 O-ring seal

065 993 O-ring seal

1)

2)

3)

4) 5) 6)

3) 6)

1) 2) 4) 5)

0.636m

1

1

1

1

1

1

1

1

2

1

1

1

10 034 592

11 058 506

12 A 075 508

12 B 101 121

13 103 778

14 065 138

15 038 494

16 060 663

1) for motor FANUC 2S

2) for motor SIEMENS 1FT5 072

3) for motor FANUC alpha M12

4) for motor SIEMENS 1FT6 064

5) for motor INDRAMAT MDD 93A

6) for motor FANUC alpha M12/4000HVi

7) standard version

8) version for medium pressure

FU groove ring

O-ring seal

Cooling lubricant valve, complete

Cooling lubricant valve, complete

Pinion shaft, complete

Radial seal for rotating shaft

Deep groove ball bearing

O-ring seal

1

1

7)

8)

1

1

1

2

2

2

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_473520-110660.fm

47

Page 48

Replacement parts Tool Drive

for turret 0.5.473.520 - 111 092

for turret 0.5.473.520 - 111 092

6

7

8

5

4

3

2

9

Setscrew is only applied and

secured

(LOCTITE 221)

A

10

B

11

12

48

1

13

14

15

16

(16)

(14)

(15)

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_473520-111092.fm

Page 49

Replacement parts Tool Drive

for turret 0.5.473.520 - 111 092

0.5.473.520 - 111 092

No. Ident No. Designation Qty.

1036 588

2063 365

3069 657

4068 017

5000 706

Spaghetti hose

O-ring seal

Wire race ball bearing

O-ring seal

Deep groove ball bearing

6 058 075 O-ring seal

058 548 O-ring seal

065 993 O-ring seal

7076 749

8118 182

Proximity switch

Solenoid

1)

2)

3)

0.636m

9 059 932 O-ring seal 1

10 034 592

11 058 506

FU groove ring

O-ring seal

1

1

1

1

1

1

1

2

1

1

1

12 A 075 508

12 B 101 121

13 104 127

14 065 138

15 038 494

16 060 663

1) for motor FANUC alpha 3

2) for motor SIEMENS 1FT6 082

3) for motor FANUC alpha 1,5

4) standard version

5) version for medium pressure

Cooling lubricant valve, complete

Cooling lubricant valve, complete

Pinion shaft, complete

Radial seal for rotating shaft

Deep groove ball bearing

O-ring seal

4)

5)

1

1

1

2

2

2

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_473520-111092.fm

49

Page 50

Replacement parts Tool Drive

for turret 0.5.473.520 - 111 432

for turret 0.5.473.520 - 111 432

6

7

8

5

4

3

2

9

Setscrew is only applied and

secured

(LOCTITE 221)

A

10

B

11

12

50

1

13

14

15

16

(16)

(14)

(15)

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_473520-111432.fm

Page 51

Replacement parts Tool Drive

for turret 0.5.473.520 - 111 432

0.5.473.520 - 111 432

No. Ident No. Designation Qty.

1036 588

2063 365

3069 657

4068 017

5000 706

Spaghetti hose

O-ring seal

Wire race ball bearing

O-ring seal

Deep groove ball bearing

6 058 548 O-ring seal

058 521 O-ring seal

063 461 O-ring seal

065 993 O-ring seal

7076 749

8118 182

Proximity switch

Solenoid

9 058 495 O-ring seal

059 932 O-ring seal

1) 2) 3)

4)

5)

6)

1) 2) 3) 5) 6)

4)

0.636m

1

1

1

1

1

1

1

1

2

1

1

1

10 034 592

11 058 506

12 A 075 508

12 B 101 121

13 103 530

14 065 138

15 038 494

16 060 663

1) for motor SIEMENS 1FT5 072

2) for motor SIEMENS 1FT5 076

3) for motor SIEMENS 1FT6 084

4) for motor FANUC alpha 22

5) for motor SIEMENS 1FT5 066

6) for motor FANUC 6S

7) standard version

8) version for medium pressure

FU groove ring

O-ring seal

Cooling lubricant valve, complete

Cooling lubricant valve, complete

Pinion shaft, complete

Radial seal for rotating shaft

Deep groove ball bearing

O-ring seal

1

1

7)

8)

1

1

1

2

2

2

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_473520-111432.fm

51

Page 52

Replacement parts Tool Drive

for turret 0.5.473.520 - 112 862

for turret 0.5.473.520 - 112 862

6

7

8

5

4

3

2

9

Setscrew is only applied and

secured

(LOCTITE 221)

A

10

B

11

12

52

1

13

14

15

16

(16)

(14)

(15)

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_473520-112862.fm

Page 53

Replacement parts Tool Drive

for turret 0.5.473.520 - 112 862

0.5.473.520 - 112 862

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2063 365

3069 657

4068 017

5000 706

6 058 075 O-ring seal

058 548 O-ring seal

065 993 O-ring seal

7076 749

8118 182

O-ring seal

Wire race ball bearing

O-ring seal

Deep groove ball bearing

1)

2)

3)

Proximity switch

Solenoid

9 059 932 O-ring seal 1

10 034 592

11 058 506

12 A 075 508

FU groove ring

O-ring seal

Cooling lubricant valve, complete

4)

1

1

1

1

1

1

1

2

1

1

1

1

12 B 101 121

13 104 127

14 065 138

15 038 494

16 060 663

1) for motor FANUC alpha 3

2) for motor SIEMENS 1FT6 082

3) for motor FANUC alpha 1,5

4) standard version

5) version for medium pressure

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_473520-112862.fm

Cooling lubricant valve, complete

Pinion shaft, complete

Radial seal for rotating shaft

Deep groove ball bearing

O-ring seal

5)

1

1

2

2

2

53

Page 54

Replacement parts Tool Drive

for turret 0.5.473.520 - 115 702

for turret 0.5.473.520 - 115 702

6

7

8

5

4

3

2

9

Setscrew is only applied and

secured

(LOCTITE 221)

A

10

B

11

12

54

1

13

14

15

16

(16)

(14)

(15)

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_473520-115702.fm

Page 55

Replacement parts Tool Drive

for turret 0.5.473.520 - 115 702

0.5.473.520 - 115 702

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2063 365

3069 657

4068 017

5000 706

O-ring seal

Wire race ball bearing

O-ring seal

Deep groove ball bearing

6 058 548 O-ring seal

058 521 O-ring seal

063 461 O-ring seal

065 993 O-ring seal

7076 749

8118 182

Proximity switch

Solenoid

9 058 495 O-ring seal

059 932 O-ring seal

10 034 592

FU groove ring

1) 2) 3)

4)

5)

6)

1) 2) 3) 5) 6)

4)

1

1

1

1

1

1

1

1

2

1

1

1

1

11 058 506

12 A 075 508

12 B 101 121

13 103 530

14 065 138

15 038 494

16 060 663

1) for motor SIEMENS 1FT5 072

2) for motor SIEMENS 1FT5 076

3) for motor SIEMENS 1FT6 084

4) for motor FANUC alpha 22

5) for motor SIEMENS 1FT5 066

6) for motor FANUC 6S

7) standard version

8) version for medium pressure

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_473520-115702.fm

O-ring seal

Cooling lubricant valve, complete

Cooling lubricant valve, complete

Pinion shaft, complete

Radial seal for rotating shaft

Deep groove ball bearing

O-ring seal

1

7)

8)

1

1

1

2

2

2

55

Page 56

Replacement parts Tool Drive

for turret 0.5.473.520 - 125 365

for turret 0.5.473.520 - 125 365

6

7

8

5

4

3

2

9

Setscrew is only applied and

secured

(LOCTITE 221)

A

10

B

11

12

56

1

13

14

15

16

(16)

(14)

(15)

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_473520-125365.fm

Page 57

Replacement parts Tool Drive

for turret 0.5.473.520 - 125 365

0.5.473.520 - 125 365

No. Ident No. Designation Qty.

1036 588

2067 810

3068 207

4064 594

5000 706

Spaghetti hose

O-ring seal

Wire race ball bearing

O-ring seal

Deep groove ball bearing

6 058 075 O-ring seal

068 208 O-ring seal

7076 749

8118 182

Proximity switch

Solenoid

9 058 521 O-ring seal

059 308 O-ring seal

10 034 592

11 058 506

FU groove ring

O-ring seal

1) 2)

3)

1) 2)

3)

0.636m

1

1

1

1

1

1

2

1

1

1

1

1

12 A 075 508

12 B 101 121

13 103 778

14 065 138

15 038 494

16 060 663

1) for motor FANUC 2S

2) for motor FANUC 3S

3) for motor SIEMENS 1FT6 084

4) standard version

5) version for medium pressure

Cooling lubricant valve, complete

Cooling lubricant valve, complete

Pinion shaft, complete

Radial seal for rotating shaft

Deep groove ball bearing

O-ring seal

4)

5)

1

1

1

2

2

2

F:\Sauter\FRAME-AR\TD\0-5-473-\ger\Ba892\E_473520-125365.fm

57

Page 58

Page 59

82

81

13

2

5

4

6

7

8910

11

13

12 1614

15

17

181920

21

22

23

24 25 26

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

27

28

29

30

31

32

33

34

35

36

37

*

64

* Winkelpositionsgeber: Anbau variabel

61

6263

60

Survey: Disk-type tool turre t 0.5.480.5..

51535759 4955

47

46

485052545658

45

44

43

42

41

40

39

38

Angular encoder: variable ins tal la tion

Capteur de position angulaire: Montage variable

0.5. 480.5..

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Page 70

Page 71

Order information

FAX

Service

SAUTER Feinmechanik GmbH

Postfach 1551

D-72545 Metzingen

Germany

++49 (0) 7123–926– 0

++49 (0) 7123–926– 193

Contact

#

IMPORTANT

Please indicate in your orders:

Product data as per nameplate on the housing

1. Classification number (series, size)

2. Identification number

3. Order number

Ordering data as per replacement-parts drawing and

table

4. Identification number and quantity of the spare part

requested.

Client

5. Company

6. Client’s name and phone number.

service@sauter-feinmechanik.com

x.x.xxx.x xx

xxx xxx

xx-xxx-xx-xx

xxx

➊

➋

➌

Loading...

Loading...