Page 1

2012-01-24

Operating Instructions

BA 1130 en

Disc-Type Tool Turret

0.5.473.520

The present manual is part of the product.

• The manual should be kept in an easily accessible place during the product’s lifetime.

• The manual should be passed on to the next owner /user of the product.

• Make sure that any possible supplement received is duly added to the manual.

Manual Translation

Page 2

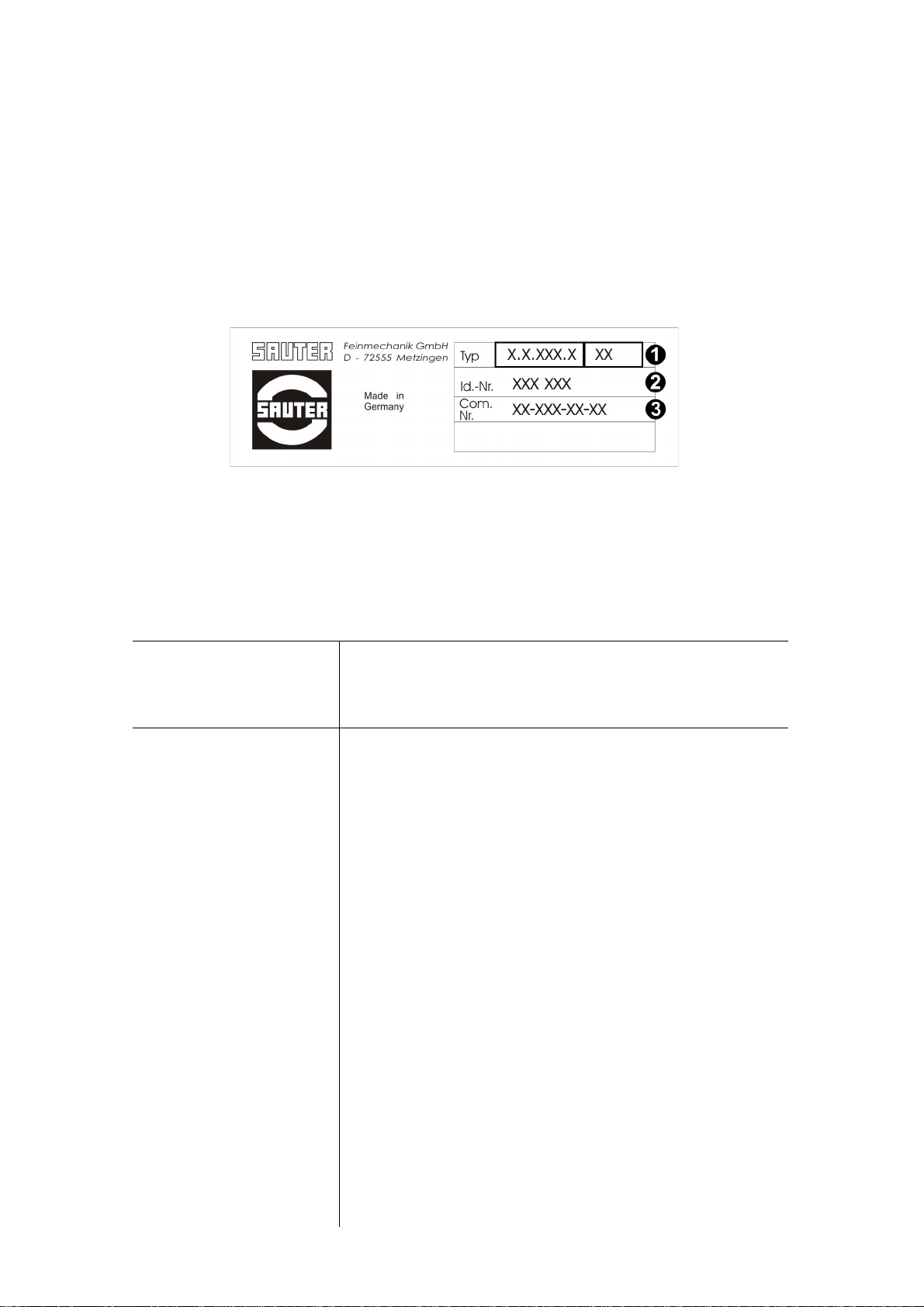

Type plate on turret housing

1 Classification number (series, size)

2 Identification number

3 Order number

BA 1130 en

Classification number

Identification number

(series, size)

0.5.473.520

089 632 115 785

103 012 120 362

103 292 125 365

106 302 125 544

107 198 128 037

107 468 129 602

109 332 134 263

110 660 134 969

111 092 138 083

111 272 138 420

112 722 142 499

112 862 143 182

113 290 143 370

114 703

115 702

Page 3

Table of contents

1 Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Use within specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Required skills. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Notes on product-specific risks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Product description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

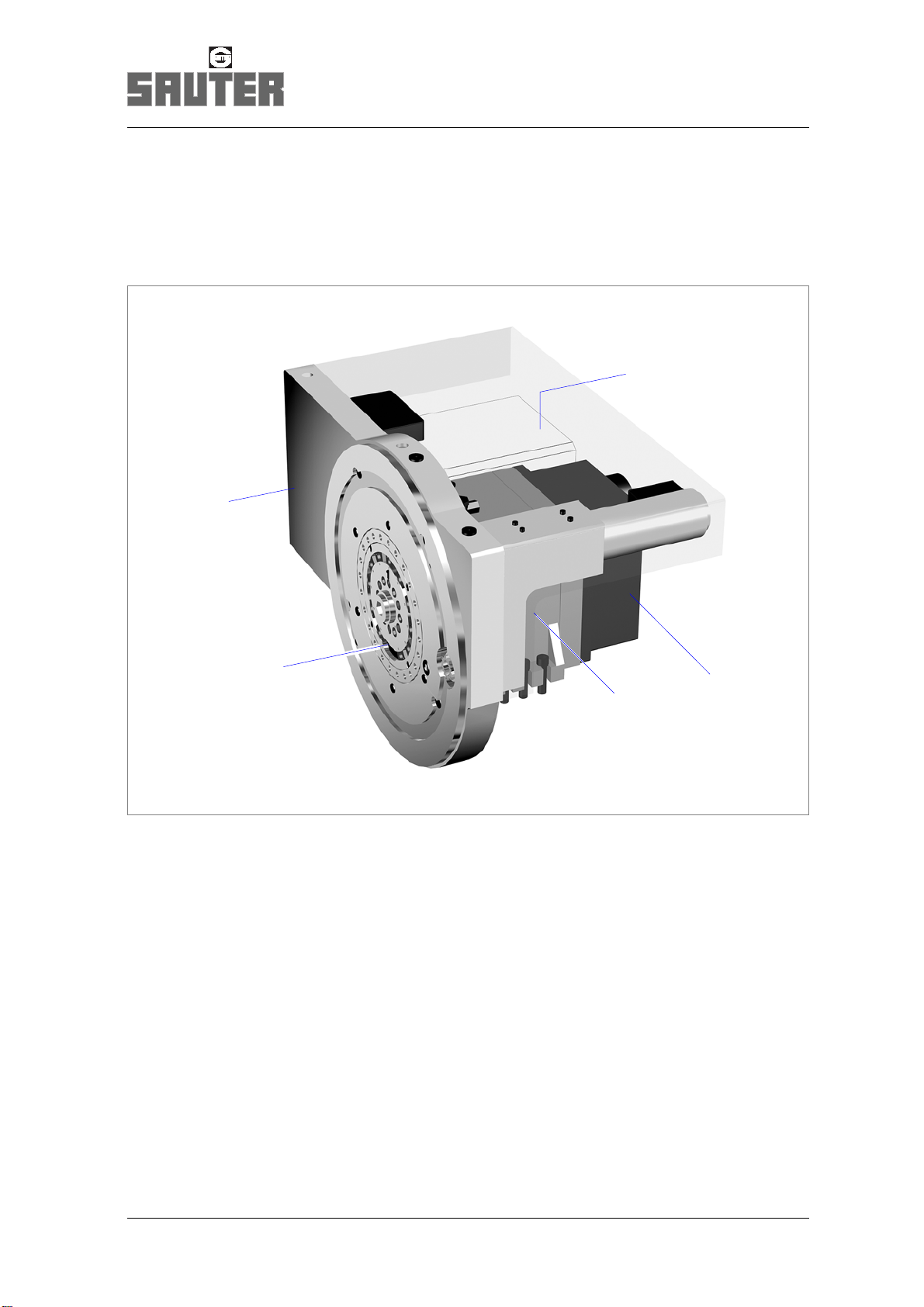

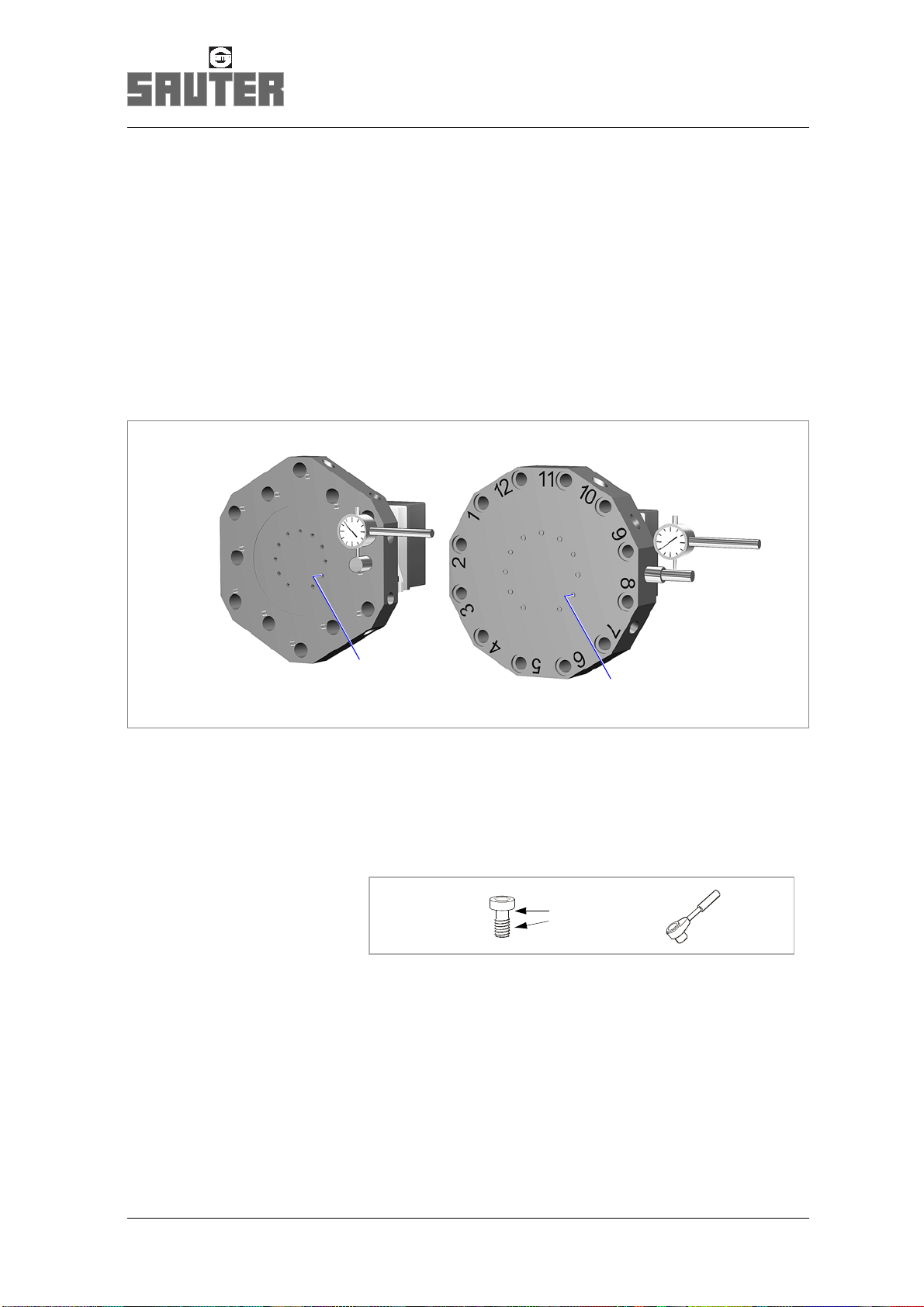

2.1 Designation of parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Manual mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 Survey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

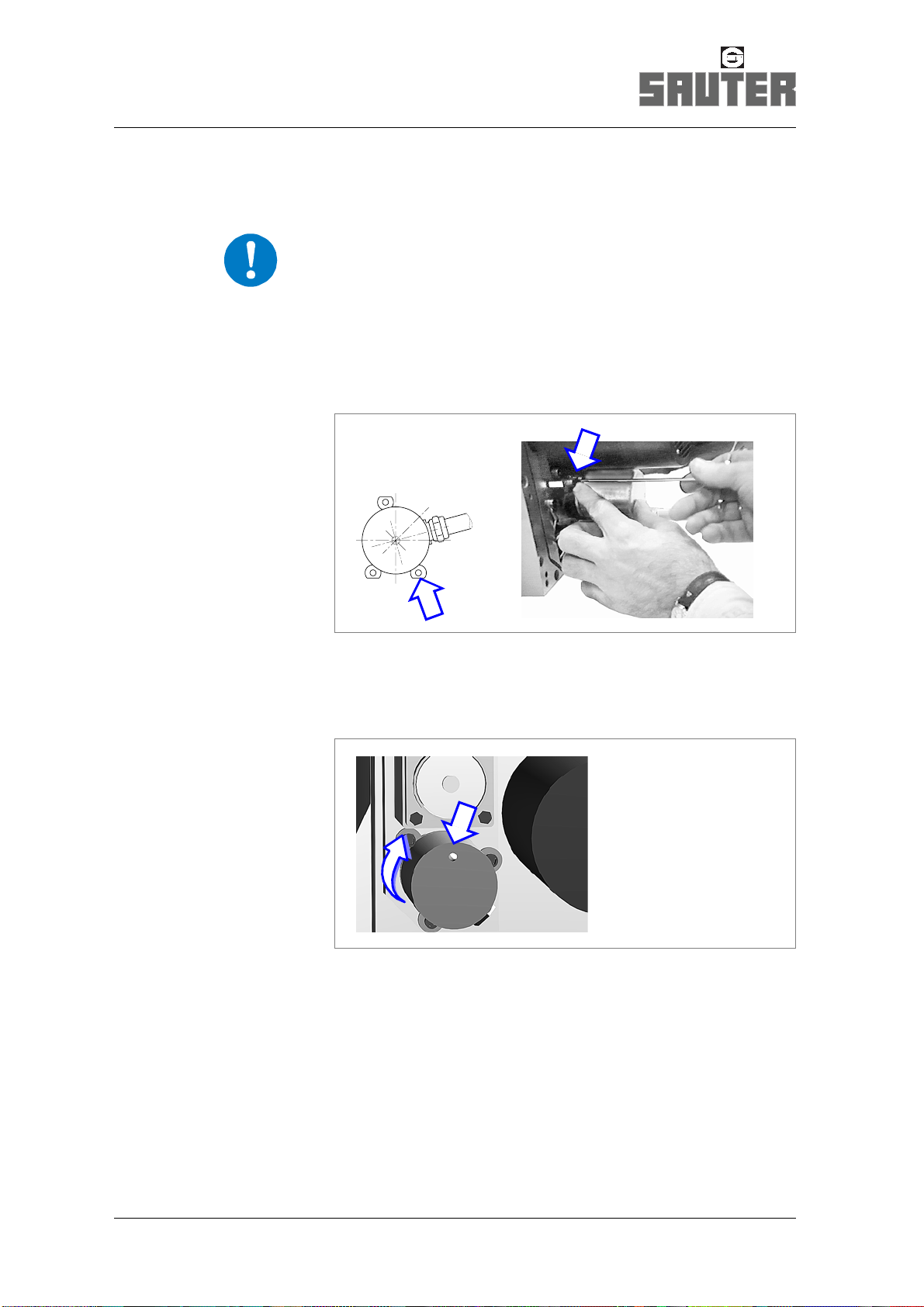

4.2 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Possible faults and remedies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 Survey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Service life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3 Service intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.4 Maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.5 Aligning the tool disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.6 Adjusting the angular encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.7 Replacing the angular encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.8 Proximity switch S7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.9 Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.10 Cooling lubricant valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6 Replacement parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Basis-BA 2012-01-19

BA 1130 3

Page 4

Table of contents

Appendix

EP-870

Wiring diagram

Disk-type tool turret

EP-855

Wiring diagram

Tool drive

SK-919

Diagram of functions

Disk-type tool turret

SK-920

Diagram of functions

Disk-type tool turret

SK-940

Diagram of functions

Tool drive

Contact/Order information

4 BA 1130

Page 5

1 Safety notes

The turret corresponds to the state of the art and the

recognized technical safety rules. Nevertheless hazards and

risks can occur.

1.1 Use within specifications

➣ Install and operate turret only in machines complying with

the relevant regulations for workspace protection.

➣ Operate turret only in perfect condition and in compliance

with the Operating Instructions.

1.2 Required skills

Safe ty n o tes

• Work may only be performed on the turret by qualified staff.

These are persons who are able to identify risks and to

prevent possible hazards on the basis of their special

training and their experience (IEC 60 201-1).

• All work on the electrical system is to be carried out by a

qualified electrical engineer only.

• Only trained and competent personnel may work on the

turret; this personnel must have been instructed in

accordance with the Operating Instructions and directly on

the tu rr e t.

1.3 Notes on product-specific risks

Setting tasks require a 24V DC power supply.

Clearing required prior to any work:

➣ Switch the machine off.

➣ Depressurize turret.

BA 1130 5

Page 6

Safe ty note s

WARNING

In the event of a fault or a collision, unexpected rotation of the

tool disk is possible.

Injury hazard.

CAUTION

Do not attempt any further switching operati ons, if the turret is

damaged, as otherwise considerable consequential damage

may be caused.

➣ Call SAUTER Service.

CAUTION

Functional faults may be caused by an ingress of chips and

contamination.

➣ Close open tool locations and cooling lubricant bores by

means of suitable closing plugs.

For manual operation, turn the motor shaft with the help of a

hexagonal pin wrench, complete with T-grip.

WARNING

A reversal of the moment of the motor results in the

accelerat io n of the moto r sh aft . The he x ago nal pin wr e nc h may

thus be unexpectedly accelerated.

Therefore, in order to avoid the ejection of the hex agonal pin

wrench and resulting injuries, firmly grip the hexagonal pin

wrench.

1.4 Disposal

➣ Comply with all national and regional disposal regulations

and laws.

6 BA 1130

Page 7

2 Product description

2.1 Designation of parts

2

Product de s cr ipt ion

Design ation of parts

3

1

4

5

1 Locating disk

2 Tool drive: gear housing

3 Tool drive motor

1)

4 Covering hood for electric components

5 Turret housing

1) not included in scope of delivery

BA 1130 7

Page 8

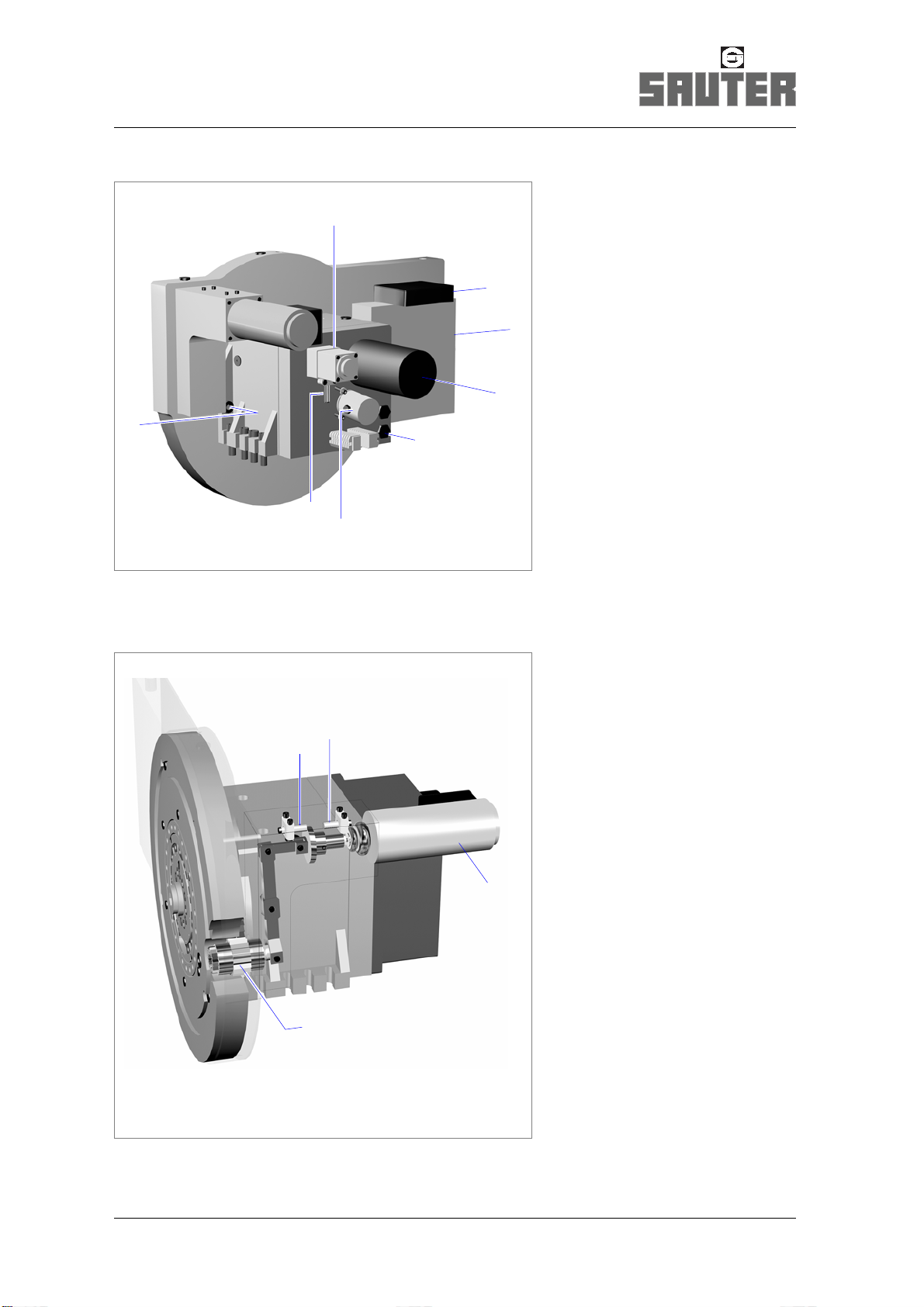

Product de s cr ipt ion

Designation of parts

13

12

6

11

10

6 Solenoid

7 Terminal box

(tool drive motor)

7

8

8 Flange plate

(tool drive motor)

9 Turret motor

10 Electric supply for turret

11 Angular encoder

9

12 Proximity switch S7

“Check pre-indexation”

13 Cooling lubricant

cartridge

14

17

15

14 Proximity switch S11

“Tool drive disengaged”

15 Proximity switch S10

“Tool drive engaged”

16 Solenoid

17 Tool drive coupling

16

8 BA 1130

Page 9

Product de s cr ipt ion

Technical data 0.5.473.520

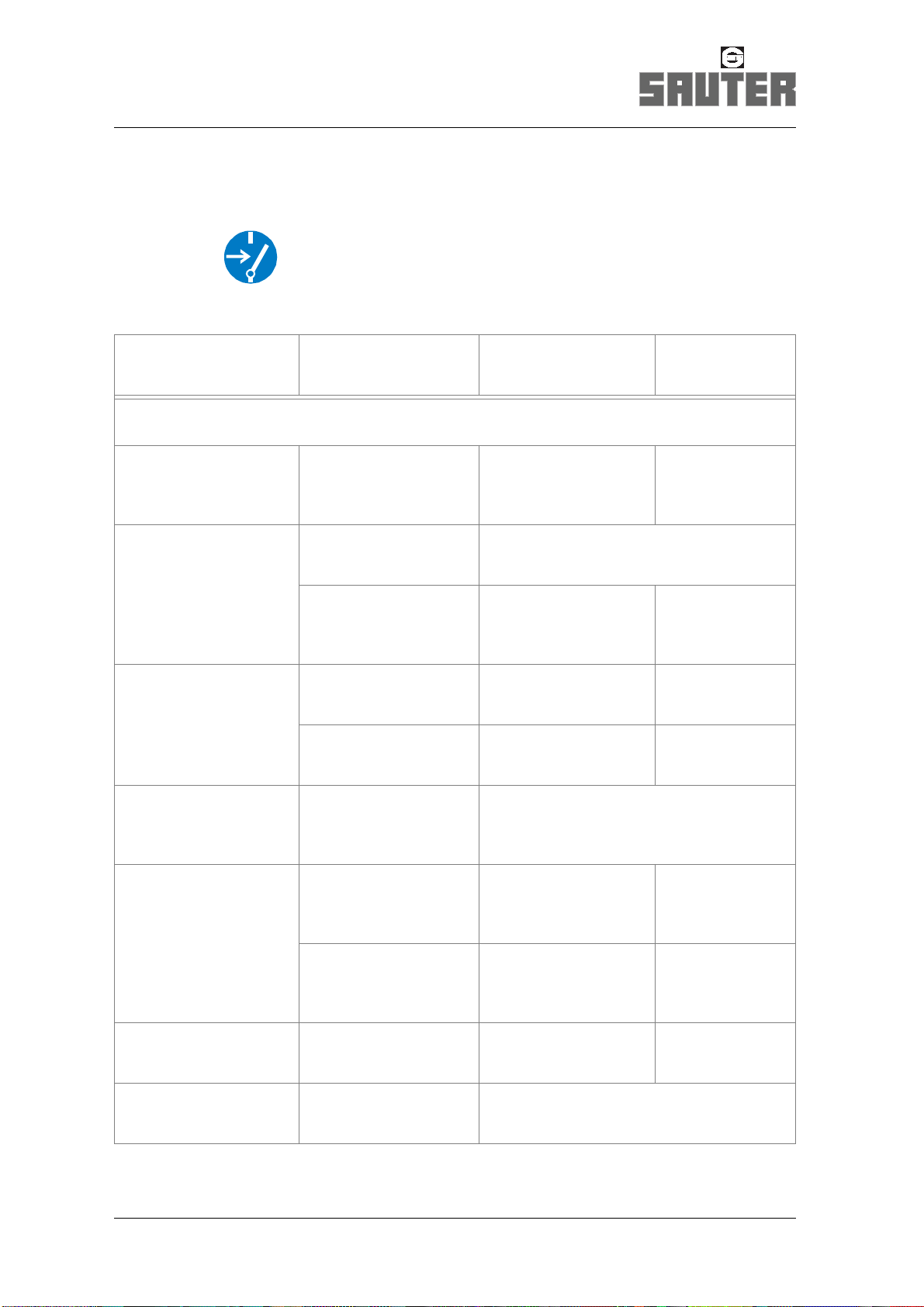

2.2 Technical data

Number of indexing positions 8 or 12 or 16

Perm. tangential torque

1)

Nm 3,000

(turret locked)

at calculated safety

Perm. mass moment of inertia of tool disk,

kgm

2

1.3

1.8 – 7.5

2)

tool holders, and tools

Perm. unbalance (load moment)

Nm 63

caused by tool holders and tools

Indexing times

Theoretical cycle time

(unlock/turn/lock)

2)

s

41 α+

----------------

× 017,× 01,+

i

n

.

.

at rotating angle α [degrees]

Gear ratio i see turret type plate

Motor speed n rpm see motor rating plate

Perm. indexing frequency min

-1

10 – 5.5

2)

Operating voltage/m ains frequ ency see motor rating plate

Degree of protection IP 65

Turret mass

kg approx. 70

(wit h o ut tool di s k)

Perm. ambient temperature range °C

°F

Operating pressure for cooling lubricant

3)

+10 ... +40

+50 ... + 104

Cooling lubricant valve – standard version

constant supply

externally switched supply

Medium pressure valve (option)

1) The perm. loads refer to processing without load shocks. Whenever processing is subject

to intermittent cuts , shocks or impacts, a significa ntly reduction in the values needs to be

taken into account.

2) De pending on gea r rat io an d ma in s f re qu e n cy

3) In order to achieve an extended service life of the cooling lubricant valve, it is advisable to

filter the cooling lubricant by ≤ 100µm. Post-connected loads (spindle units with internal

coolin g lubricant guide a.o.) may require a higher degree of filter fineness. Note and

comply with the manufacturer’s instructions!

bar

bar

bar

7

14

25

BA 1130 9

Page 10

Product de s cr ipt ion

Technical data 0.5.473.520

Tool drive

Mass (without any motor) kg

Gear ratio

Perm. speed

Max. perm. torque

1)

2)

on tool drive coupling n

2) 3)

M

i

perm

perm

approx. 40

41/ 41 41/ 31 41 /27 41/21

rpm 4000

Nm 32

on tool drive coupling

Transferable power

2)

P

perm

kW

10

Suitable for spindle units

coupling profile 17 × 14 DIN 5482

1) Th e da t a st ate d he re may dif fer on sp ec ia l versions.

2) M

3) The permissible torque can be utilized for non-pulse machining operations.

is the pe rmissible peak load for the gears.

perm

The torque must be limited on the motor freque ncy converter to the va lue

indicated, while adhering to the gear ratio involved!

The us eful power data depend on the performa nce characteristic curve of the motor type

used.

For strongly pulsed machining operations - e.g. inserted tooth milling cutters and others only a significantly reduce d drive torque should be applied to protect the gears again s t

any overloads.

10 BA 1130

Page 11

3 Manual mode

In manual mode, the mechanical functions of the disk-type tool

turret will be checked:

• following initial assembly to the machine

• during troubleshooting

• after a renewed setup following fault conditions

Clearing required prior to any work:

➣ Switch the machine off.

➣ Depressurize turret.

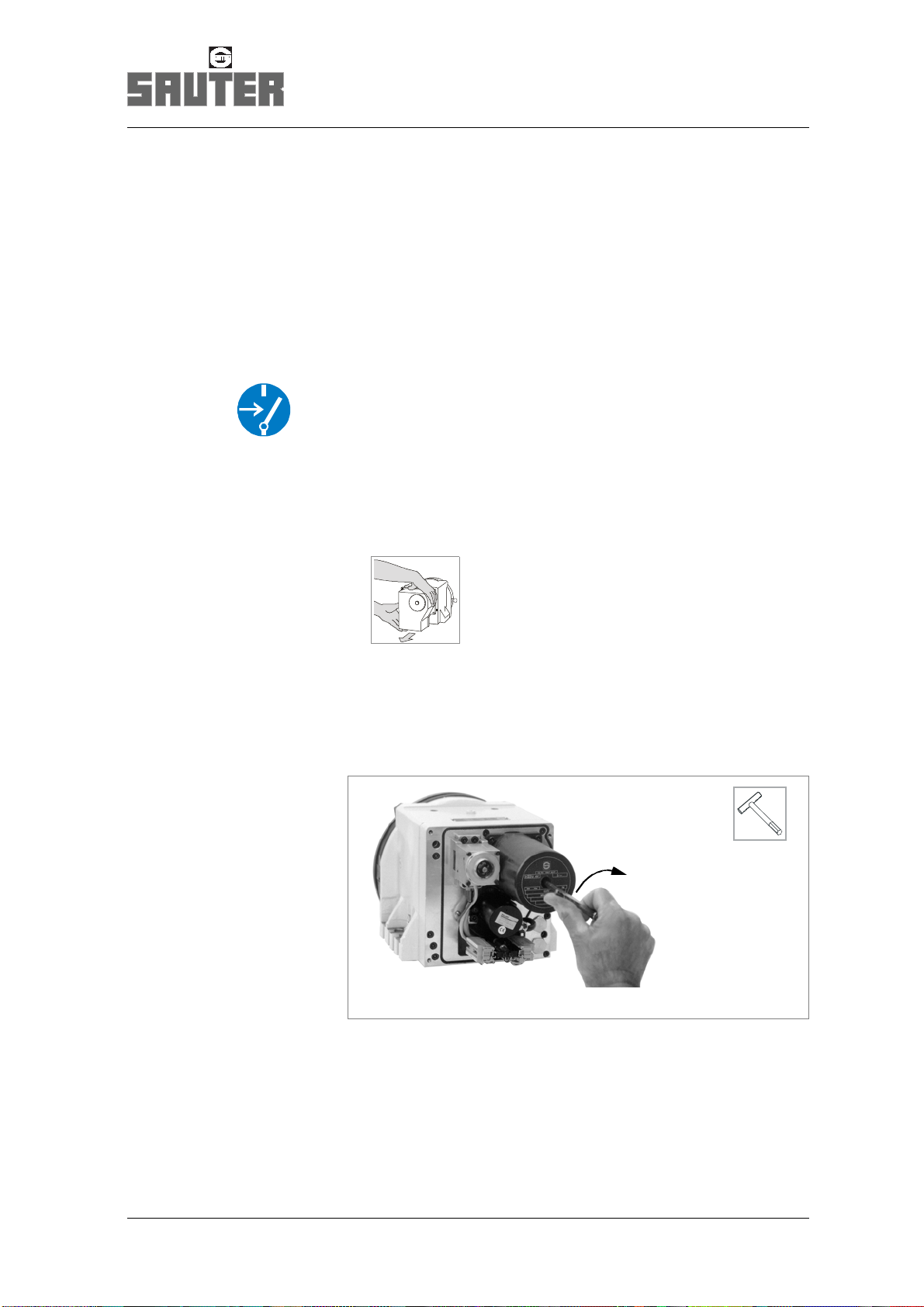

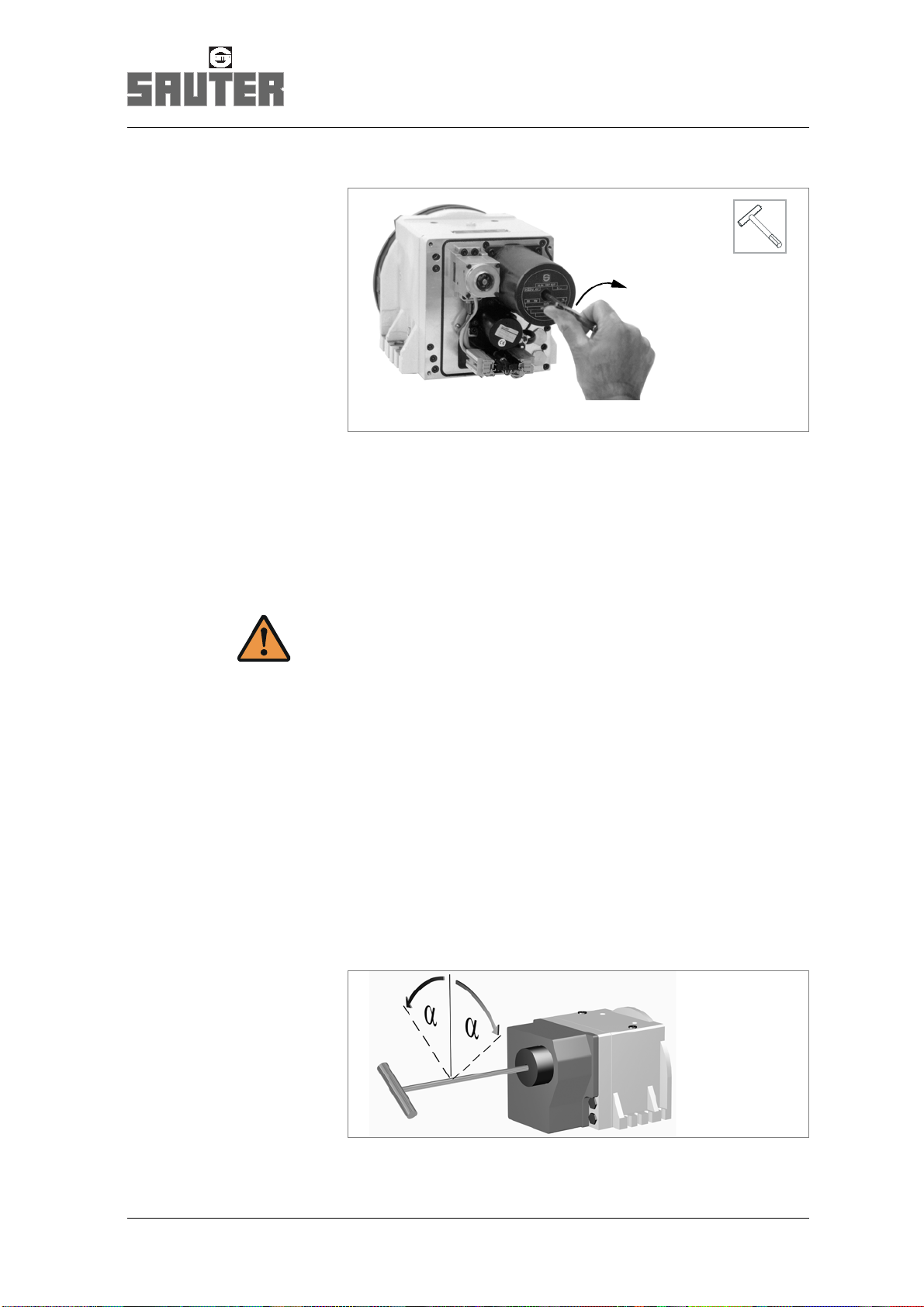

1. Undo fixing screws of covering hood,

withdraw covering hood to rear.

If necessary, use push-off screw.

Manual mode

2. Remove screw plug on motor housing.

Unlock turret

3. Use a hexagonal pin wrench, complete wi t h T-gr ip, to rotate

the moto r sh af t.

➪ If the disk-type tool turret is locked, the locating disk (or

tool disk) does not co-rotate; the centre position of the lock

can be felt.

BA 1130 11

Page 12

Manual mode

WARNING

A reversal of the moment of the motor results in the

accelerat io n of the moto r sh aft . The he x ago nal pin wr e nc h may

thus be unexpectedly accelerated.

Therefore, in order to avoid the ejection of the hex agonal pin

wrench and resulting injuries, firmly grip the hexagonal pin

wrench.

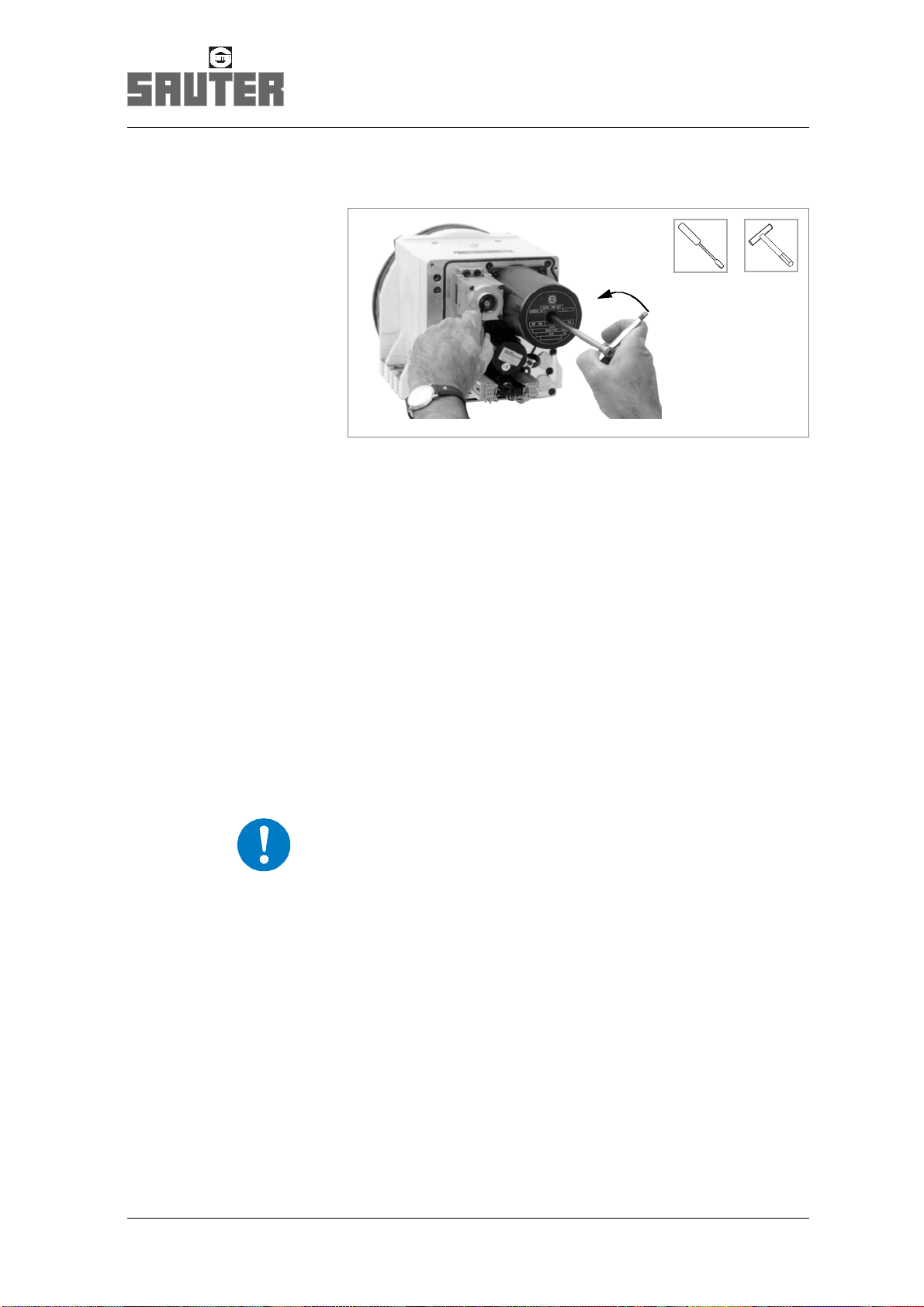

4. Keep the same direction of rotation, continue to rotate.

➪ The disk-type tool turret unlocks; a reversal of the moment

on the motor shaft can be felt.

Rotate tool disk

5. Keep direction of rotation, continue to rotate disk until

loca ting dis k (o r tool dis k) starts to tur n as we ll.

6. Keep direction of rotation, continue to rotate disk until

locati n g dis k (o r tool disk ) has re ac h ed th e po s iti o n re qu i r ed ,

then pre s s in the keep er by mean s of a scr ewd ri ver.

➪ The preindexing bolt engages into a hole.

➪ The tool disk c annot be rotated any further.

12 BA 1130

Page 13

Manual mode

Lock turret

7. Reverse direction of rotation on the motor shaft whilst

simultaneously pressing in keeper.

➪ The disk-type tool turret locks.

The lock resis tance can be felt when rotation is conti nued.

The locking process ends, if the centre position of the lock

can be felt.

On completion of setup or maintenance work:

8. Screw in plug an d fit c over ing hoo d.

Note po siti o n of cables in order to avoid any pinc hin g of the

same.

Lock turret in position 1

IMPORTANT

For some setup and maintenance work the disk-type tool turret

has to be locked in position 1.

Precondition

• Numeral 1 of the locating disk has reached its 12 o’clock

position relative to the turret base area.

or

• Position 1 of the tool disk is in working position.

1. Use a hexagon al pin wre n ch, comp let e with T-grip, and

rotate the motor shaft until position 1 has been reached.

2. Press i n the k eeper b y means of a scr ewd rive r an d rotat e th e

motor shaft until the disk-type tool turret locks (see above).

BA 1130 13

Page 14

Page 15

4 Operation

4.1 Survey

Changing

Tools

Clearing faults

4.2 Tools

→

Page 15

→

Page 16

Operation

Survey

CAUTION

Risk of machine damage due to changing a driven tool

incorrectly:

Impacts on the tool holding fixture can damage

the turre t drive train.

Therefore, always change driven tools as follows:

➣ When loosening/clamping the tool holding fixture, always

support it with a second spanner.

or

➣ Remove spindle unit, change tool and refit spindle unit.

BA 1130 15

Page 16

Operation

Possible faults a nd remedies

4.3 Possible faults and remedies

Clearing required prior to any work:

➣ Switch the machine off.

➣ Depressur ize turret .

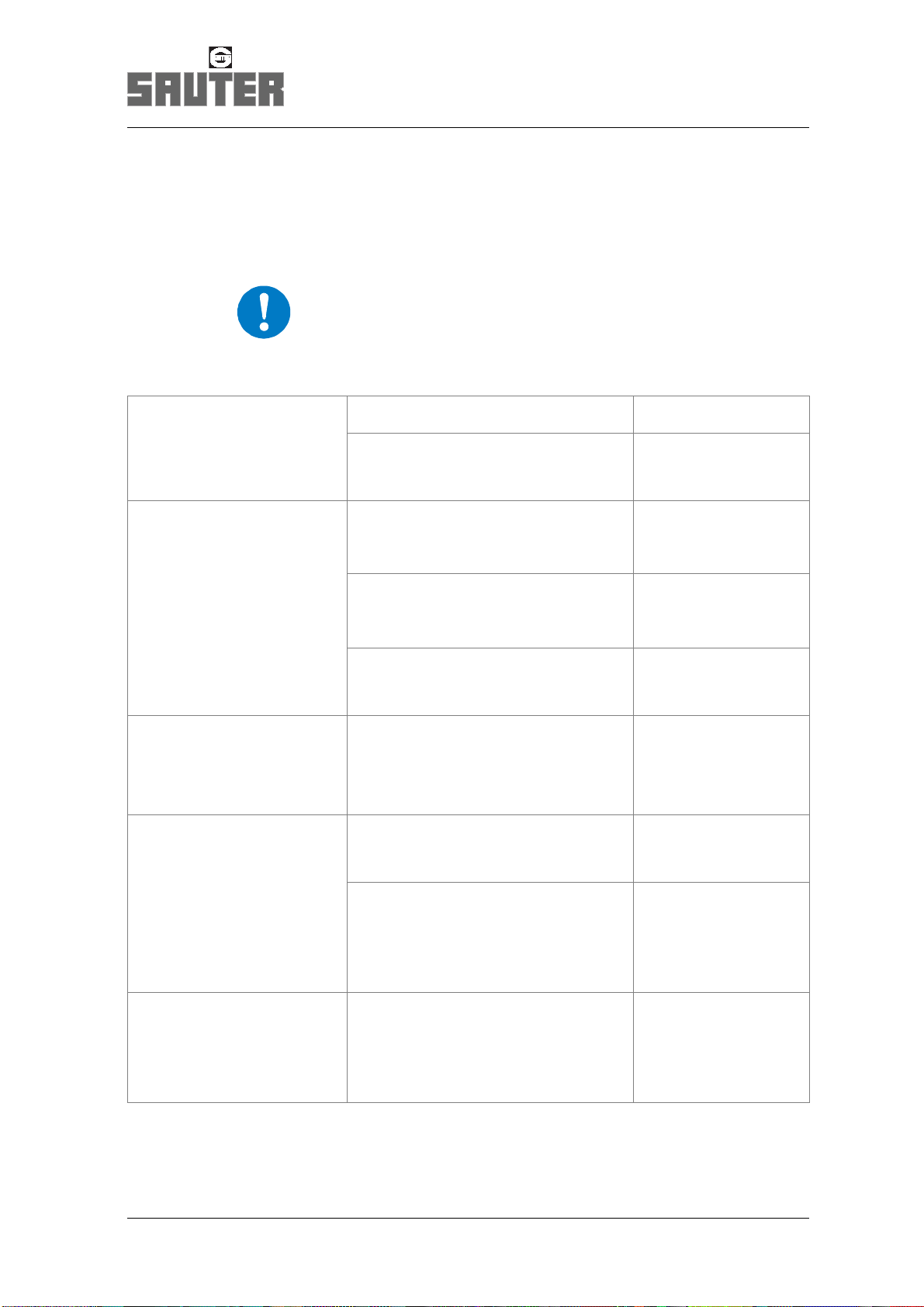

Fault Cause Remedy Who carries out

this task?

Turret

Incorrect center heigh t,

tool disk offset relative

to locating disk

Tool disk does not

rotate

Tur ret is diffic ult to

operate

(Thermo protection

device has respon de d)

Turret no lo nger l ocks or

the pre-indexing bolt

gets caught

Tool disk does not stop

in the selected po s i t io n

Collision when turret is

locked

Gearwheels are

defective

Proximity switch S11

does not switch

Insufficient oil in the

gearbox chamber

Contactor is defective Check motor drive

Collision during

pivoting

Angular encoder is not

correctly adjusted or

defective

Turn back tool disk in

the annular groove and

align

SAUTER

Service

Check pro ximity s witch

S11; if necessary, set

or replace

Check oil

SAUTER

Service

Check angular

encoder , set or replac e

if necessar y

User

→

Page 23

User

→

Page 35

User

→

Page 20

User

User

→

Page 24 ,

page 26

Proximity switch S7

does not switch

Too l di sk s top s i n

between two positions

Leakage oil escapes Seals are defective SAUTER

Chips between tool

disk an d turret

Check pro ximity s witch

S7, se t or replace if

necessary

Remove tool disk,

remove chips

Service

User

→

Page 31

User

16 BA 1130

Page 17

Operation

Possible faults and remedies

Fault Cause Remedy Who car ries out

this task?

Cooling lubricant is not

being transferred

Cool in g l ubricant

escapes between tool

disk and turret

Tange ntial play of tool

disk when turret i s

locked

Tool drive

Tool drive does not

engage

Cooling lubricant valve

is defective

Cool in g l ubricant va lve/

line is blocked

Cooling lubricant valve

is defective

Collision while turret is

locked

Wear due to lack of oil

To ol d is k is disp lace d Align tool disk

Tool drive coupling is

defective

Replace cooling

lubricant valve

Blow cooling lubricant

valve/lin e clear

Replace cooling

lubricant valve

SAUTER

Service

SAUTER

Service

User

→

User

→

Page 37

Page 23

Pinion sh aft i s def ec ti v e Repla ce def ect iv e

Solenoid is defective Replace solenoid and

Tool is not driven Gear wh eels are

defective

Tool drive motor is

defective

Proximity switch S10

does not switch

part,

adjust solenoid

adjust

SAUTER

Service

Replac e tool drive

motor

Check proximity switch

S10, se t or replace if

necessary

User

→

User

User

→

Page 34

Page 35

BA 1130 17

Page 18

Maintena nce

Survey

5 Maintenance

Safety notes

→

Page 5

5.1 Survey

Planne d preventive maintenance

Repairs a f ter fault conditio ns

→

Page 19

→

Page 16

5.2 Se rvi ce life

The service life of the turret is approx. 8 million switchings or

approx. 5 years.

The service life of the tool drive unit is

approx. 8000 operating hours.

These values apply to

• collisio n-f ree op er ation ,

• compliance with the specified operating conditions and the

permissible loads,

→

Technical data, page 12

18 BA 1130

Page 19

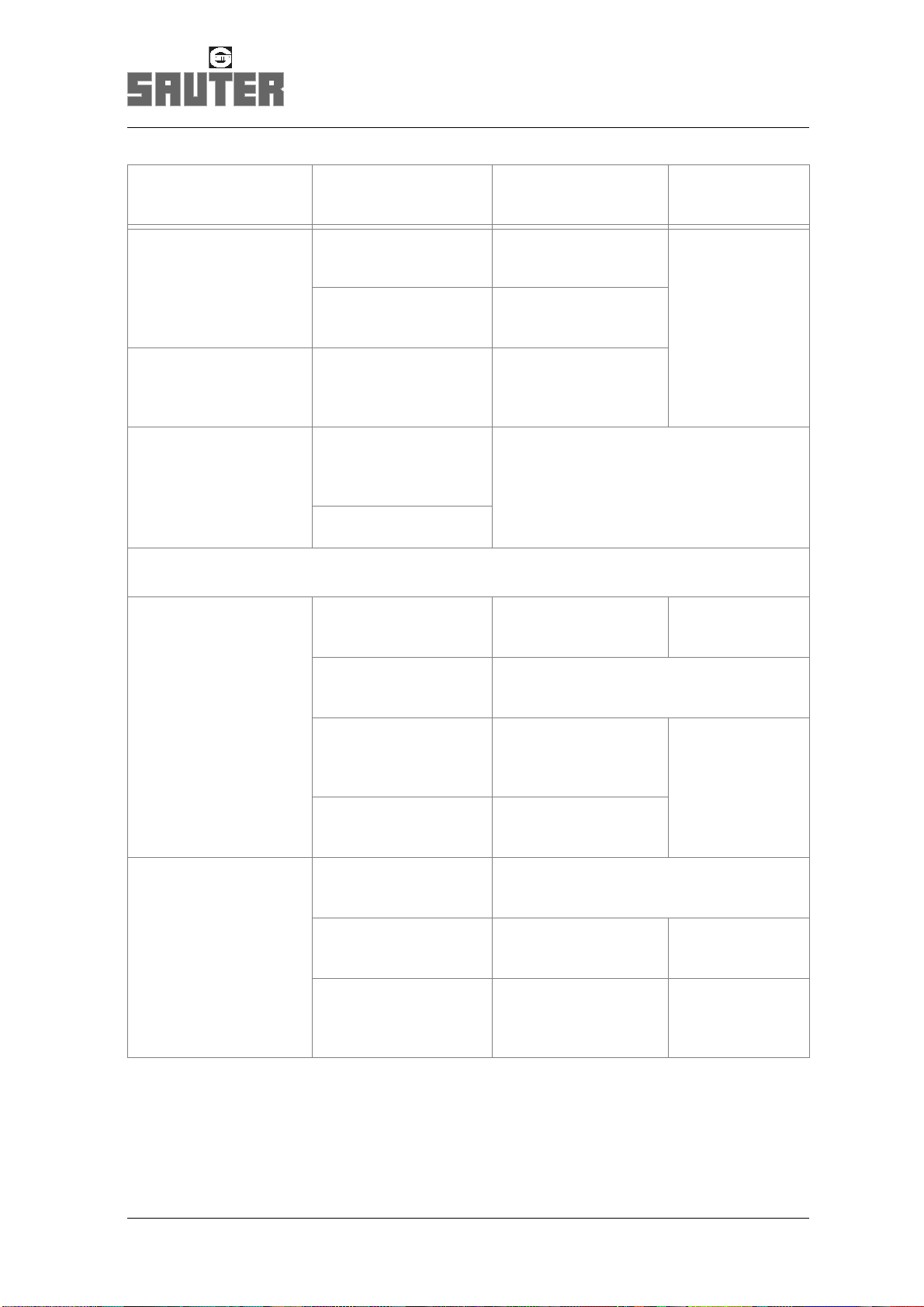

5.3 Service intervals

Plan your tasks careful ly in order t o provide for troublefree ope ration and

reduce necessar y d owntimes to a m inimum.

IMPORTANT

➣ Maintenance intervals must be adapted

to the operating conditions involved.

if required Clean to o l d rive coupling. User

Maintena nc e

Service intervals

Check tool drive coupling for damage,

replace if necessary.

after 4 0 00 operating hours

of the machine respectively

Check cooling lubr i ca nt valve for wear

and leak a ge.

Replace any defective parts.

Check oil of the turret g ea rbox

chamber;

if necessary, replenish oi l.

Check grease condition of tool drive

unit; if necess a ry, replenish grease.

after 2½ years respectively Check all elect r ical lines an d

connec ti ons for mechanical d ama ge a s

well as embrittlement.

Replace any defective parts.

after 8 0 00 operating hours

of the machine respectively

Change the oil of the turret gearbox

chamber.

The service life of the tool drive unit

may possibly be reached, depending

on the operating conditions involved.

A general overhaul is recommended

for furt her trouble-free operatio n.

User

SAUTER Service

User

→

Page 37

User

→

Page 20

User

→

Page 22

User

Specialist electrical

engineer

1)

User

→

Page 20

SAUTER Service

after a p prox. 2 –3 mil lion

indexing operations

respectively

The service life of the turret may

possibly be reached, depending on the

operating conditions involved.

SAUTER Service

A general overhaul is recommended

for furt her trouble-free operatio n.

1) These ar e pe rso ns w ho ar e ab le t o id en tif y ri sk s and t o pr e v en t pos sib le ha zard s

on the basis of their special training and their experience

(IEC 60 201-1).

BA 1130 19

Page 20

Maintena nc e w ork

Tu rret gearbox chamber

5.4 Maintenance work

Turret gear b ox ch amber

The turret gear box chamber has to be ser viced after 4, 000 operating hour s.

Clearing required prior to any work:

➣ Switch the machine off.

➣ Depressur ize turret .

IMPORTAN T

Improperly disposed used oil is a danger for our environment.

➣ Pay attention to the legal regulations for the waste disposal

of used oil.

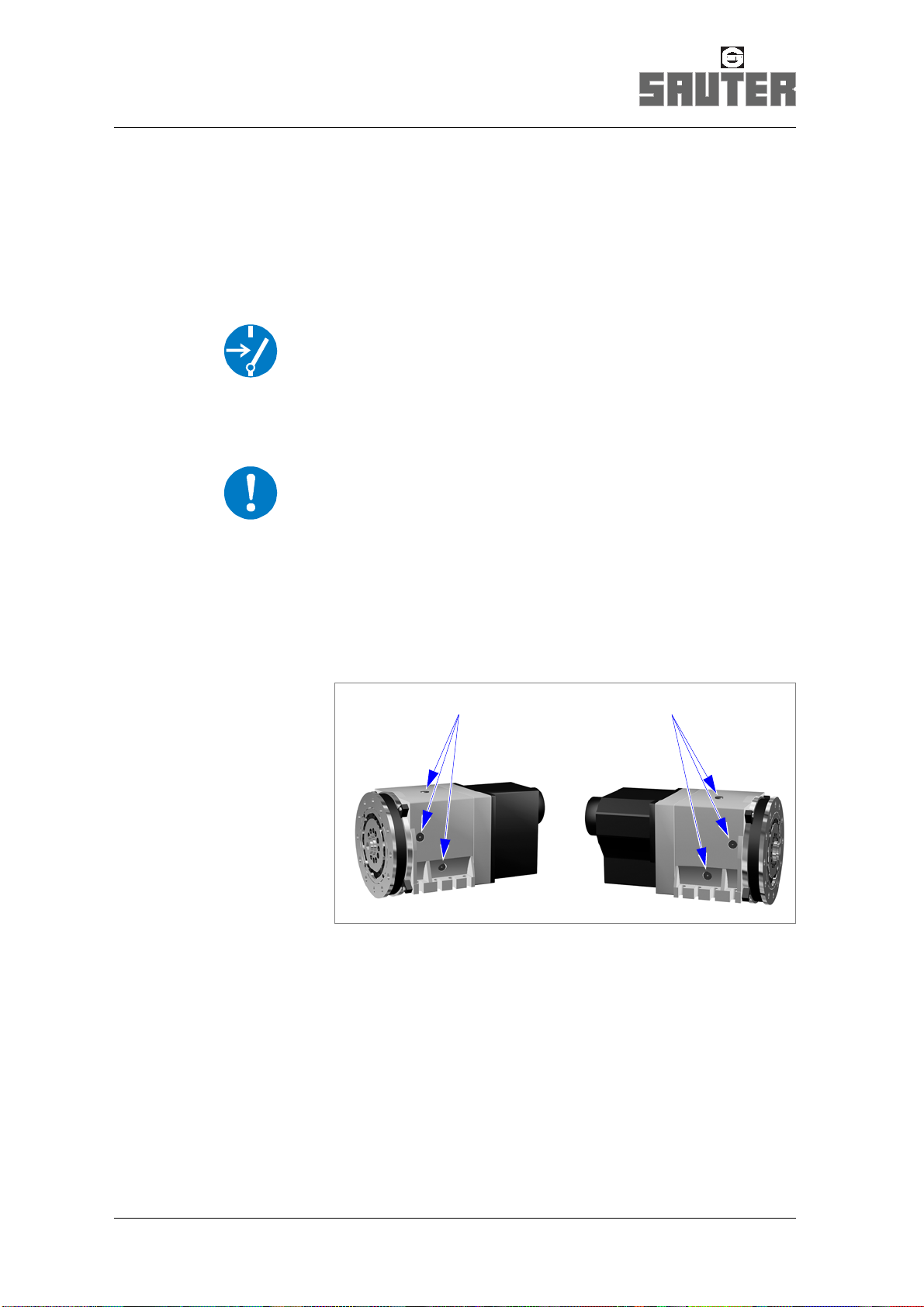

In line w ith the setup position of the disk-type tool turret, the

following apertures (1) for draining or replenishing oil are

provided:

11

Checking the oil

➣ Carefully unscrew oil drain plug and drain the oil

(max. 10 cm

3

) into a suitable container.

20 BA 1130

Page 21

Tu rret gearbox chamber

Assess oil c ondit ion

Condition Cause Action

Maintena nc e wo rk

Oil black or brown, without

metallic abrasio n

Oil black or brown, with

metallic abrasio n

Oil white, mixed with cooling

lubricant

Natural consumption –

Internal parts of turret are

damaged

Turret sealings are damaged

None oil left Turret sealings are damaged

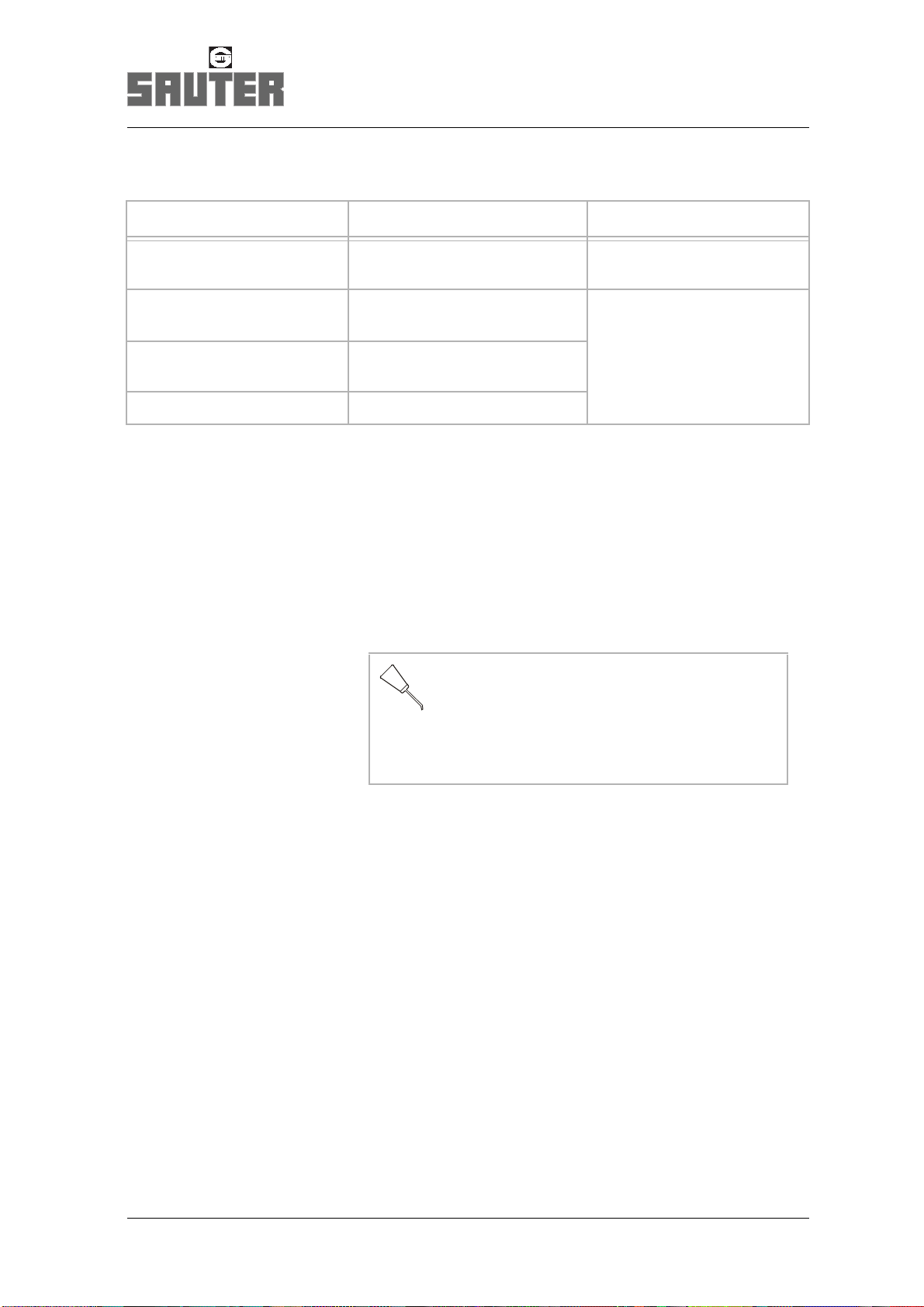

Changing the oil

➣ Open oil drain plug, drain waste oil.

➣ Close oil drain plug.

➣ Remove screw plug from oil charging hole.

Fill oil

300cm

3

Request SAUTER Service!

lubricating oil C acc. to ISO 6743/6

viscosity ISO VG 46 acc. to DIN 51562

➣ Screw in screw plug.

BA 1130 21

Page 22

Maintena nc e w ork

Tool dr iv e

Tool drive

• The product is lubricated with grease.

Lubricant used:

CENTOPLEX CX4/375 (KLÜBER)

• Lubrication must be checked after 4,000 operating hours

respectively.

Clearing required prior to any work:

➣ Switch the machine off.

➣ Depressur ize turret .

➣ Clear access to opening on tool drive.

➣ Remove screw plug off opening.

➣ Rotate gear and assess grease condition:

Condition Cause Measure

Grease: black or brown,

without metallic abrasion

No grease visible on gear Natural consumption

Grease: black or brown,

with metallic abr a si o n

Grease: white, mixed with

cooling lubricant

Grease mixed with oil

Trace of natural wear –

Internal parts of turret

are damaged

Turret sealings

are damaged

➣ Replenish grease.

approx. 1 05 c m

CENTOPLEX CX4/375

➣ Request SAUTER Service!

➣ Re-insert screw plug.

3

22 BA 1130

Page 23

5.5 Aligning the tool disk

Preparation

➣ Lock turre t .

→

Manual mode, page 11

Aligni ng

Repairs after fault conditions

Aligning the tool disk

1

1

➣ If necessary, undo screws (1).

➣ Align the locating hole to center height of the machine;

use a plug gauge (2) if required.

➣ Tighte n sc rews (1 ).

M10 - 12.9 77 Nm

MoS

2

BA 1130 23

Page 24

Repairs aft e r f a ult c onditions

Adjusting the angular encoder

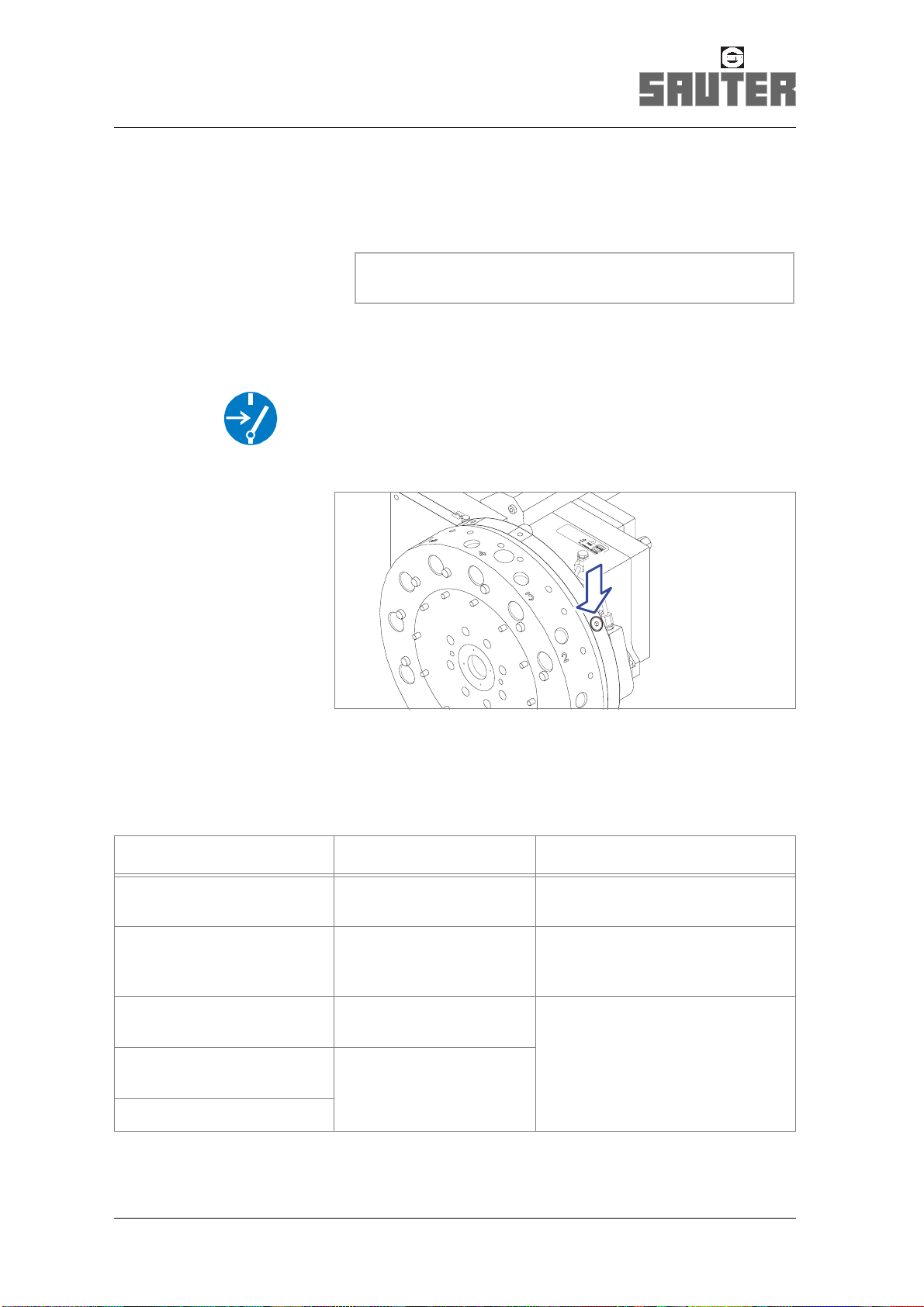

5.6 Adjusting the angula r encoder

IMPORTAN T

Setting tasks require a 24V DC power supply.

Preparation

➣ Lock disk-type tool turret in position 1.

Manual mode, page11

→

➣ Undo claws by means of a hexagonal pin wrench.

Adjustin g

➣ Rotate a ngular enc ode r out of pos itio n unt il il lumi nat ed di ode

lights up.

➣ Clamp in angular encoder by means of the claws.

24 BA 1130

Page 25

Repairs after fault conditions

Adjusting the angular encoder

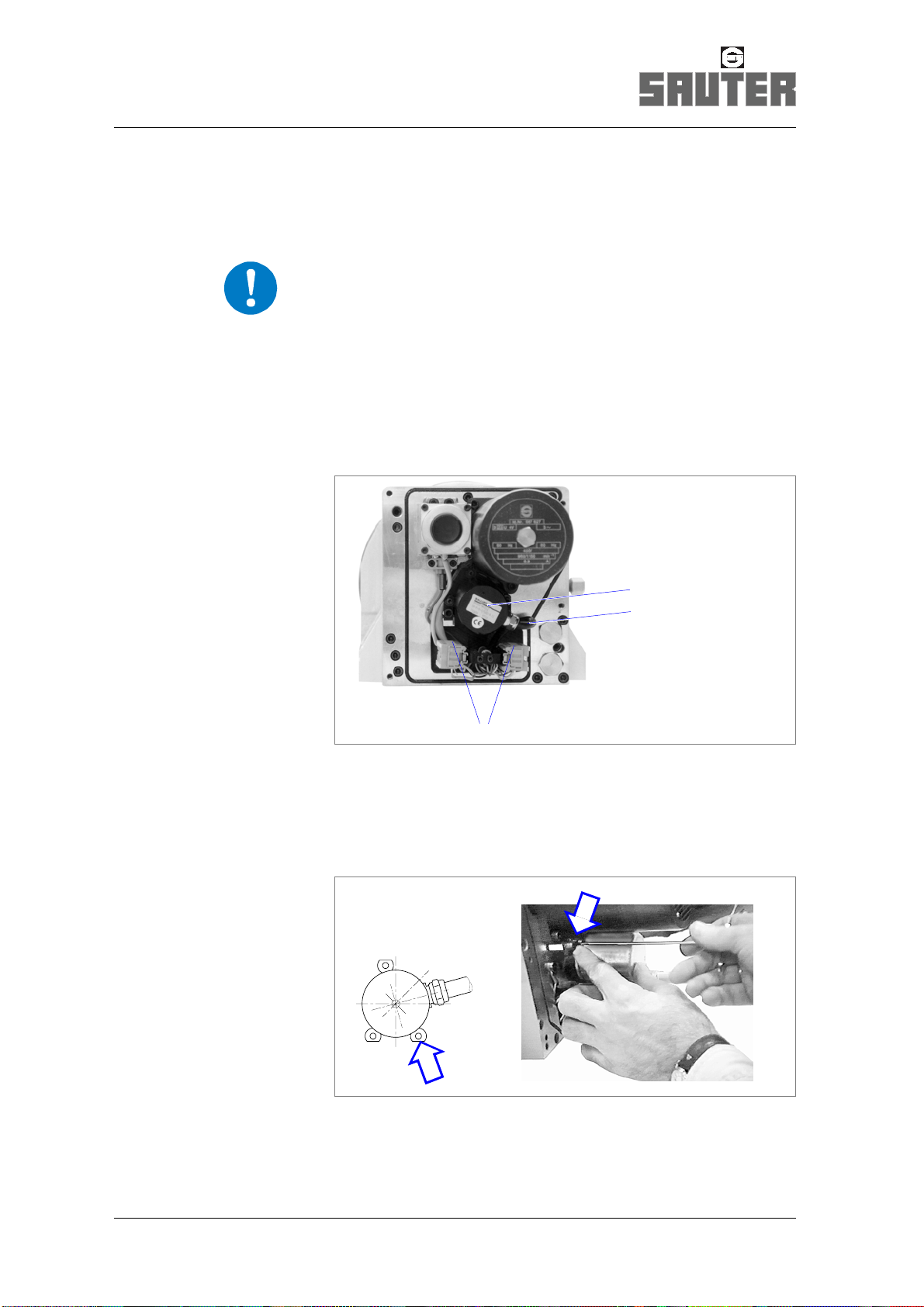

Checking the setup for symmetry

1. Use hexagonal pin wrench with T-grip for rotating the motor

shaft.

2. Rotate motor shaft until illuminated diode on the angular

encoder or the ind ic ati on “Positio n 1” on th e ma c hin e are

extinguished.

3. Note the T-grip position.

WARNING

A reversal of the moment of the motor results in the

acceler ati on of t he mo tor s haf t. The hexagonal pin wrench ma y

thus be unexpectedly accelerated.

Therefore, in order to avoid the ejection of the hexagonal pin

wrench and resulting injuries, firmly grip the hexagonal pin

wrench.

4. Carefully continue to rotate until a moment reversal can be

felt on the moto r sha ft .

5. Note the T-grip position.

The distance between the two grip positions characterizes the

angle range.

6. R ep ea t ste ps 1 to 5 w i th reverse dire ctio n of rot at ion . The

α must be the same for both directions of rotation!

angle

By turning the angular encoder out of position, any

dissymmetry can be removed.

BA 1130 25

Page 26

Repairs aft e r f a ult c onditions

Replacing the angular encoder

5.7 Repl acing the angular encoder

The location of t he angular enc oder depe nds on the disk -type tool turr et

version (without/with fluid rotary feedthrough).

IMPORTAN T

Setting tasks require a 24V DC power supply.

Angular encoder, centrally positioned

Preparation

➣ Lock disk-type tool turret in position 1.

→

Manual mode, page11

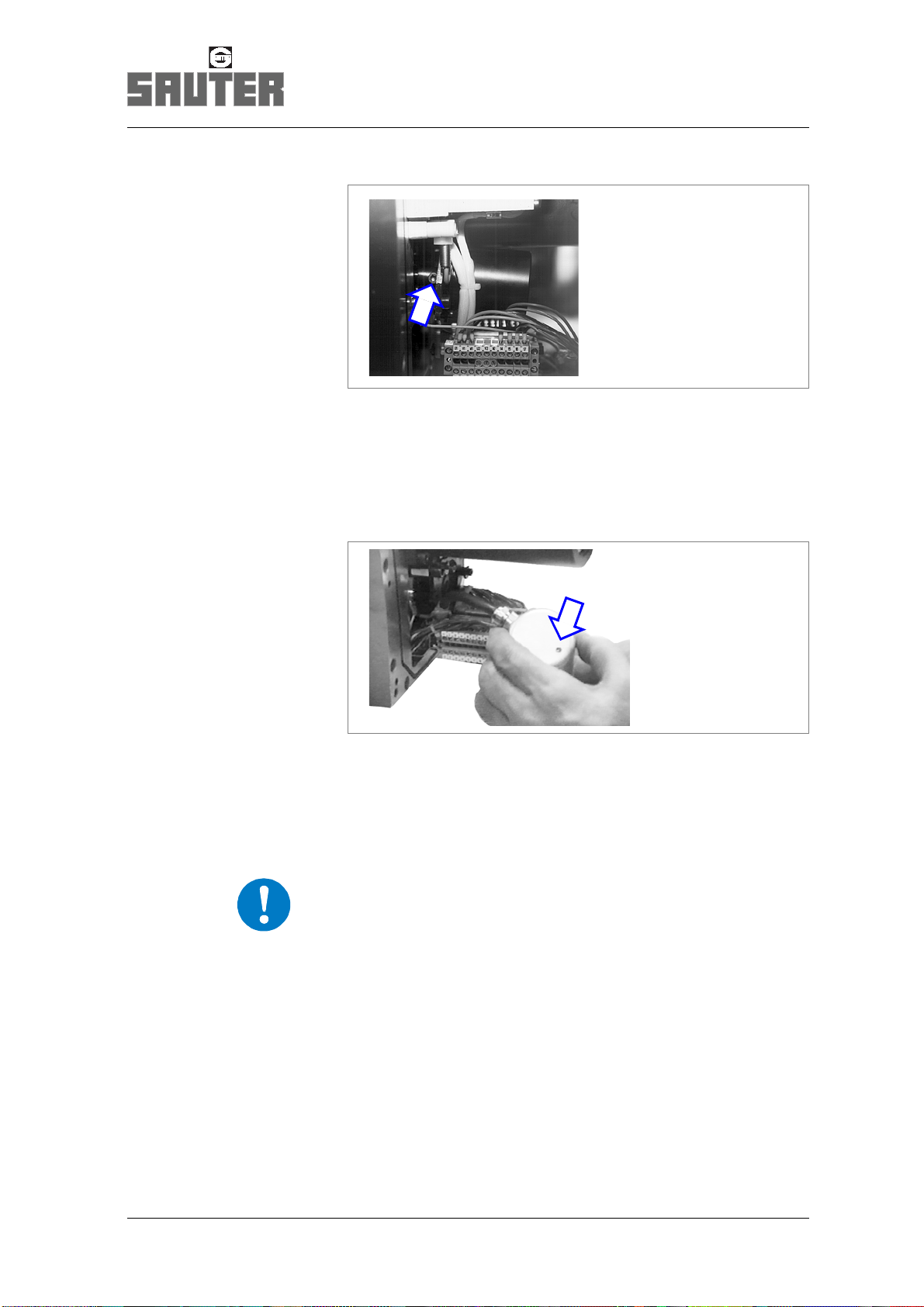

1

2

3

➣ Note the position of the cable outlet (2) on the

angular encoder (1), remove attachment.

➣ Undo cables (3) on terminal strip (note where they are

connected).

➣ Undo claws by means of a hexagonal pin wrench.

26 BA 1130

Page 27

Repairs after fault conditions

Replacing the angular encoder

Replacing

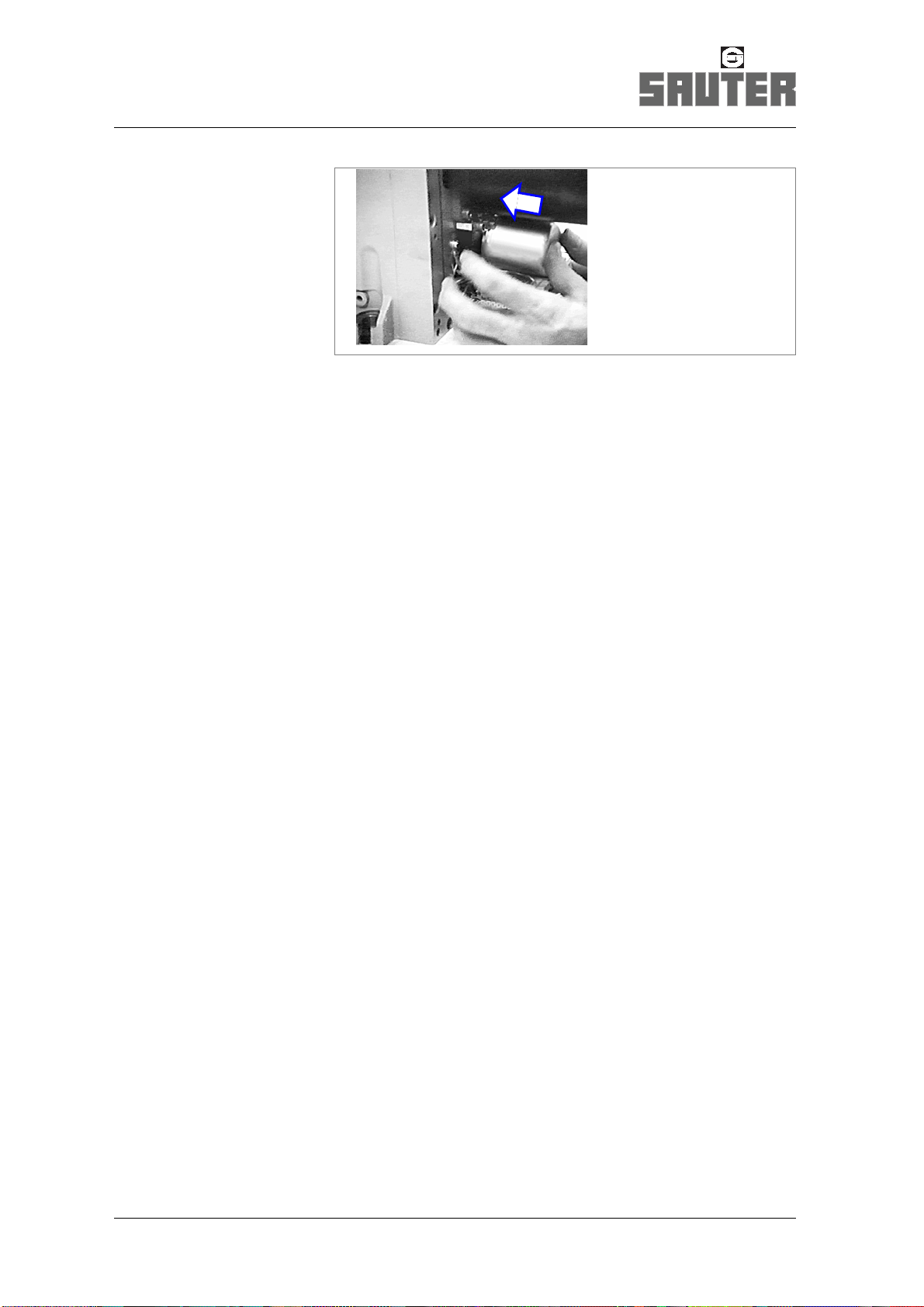

➣ Undo setscrew.

➣ Carefully withdraw angular encoder.

➣ Connect new angular encoder electrically.

Wiring diagram EP-870 in the appendix to these

→

Operating Instructions

➣ Rotate shaft of the angular encoder until the illumin ation of

the LED on the angular encoder indicates the “Position 1”

setting.

This indication must remain w hilst the following steps are

carried out.

IMPORTANT

The LED is used only to indicate position 1 during the

adjustment work. It is no position indicator during operation.

BA 1130 27

Page 28

Repairs aft e r f a ult c onditions

Replacing the angular encoder

➣ Ensur e th at the cabl e outle t is in its cor r ect posi t ion .

➣ Insert the shaft of the angular encoder into the bore of the

➣ Use setscrew to attach the angular encoder to the shaft.

➣ If necessary, check the adjustment of the angular encoder.

flexible shaft and introduce carefully until the angular

encoder is in contact with the plate. Ensure that the claws

are in their correct position!

Page 25

→

➣ Use claws to secure the angular encoder.

➣ Fit covering hood. Note position of cables in order to avoid

any pinching of the same.

28 BA 1130

Page 29

Repairs after fault conditions

Replacing the angular encoder

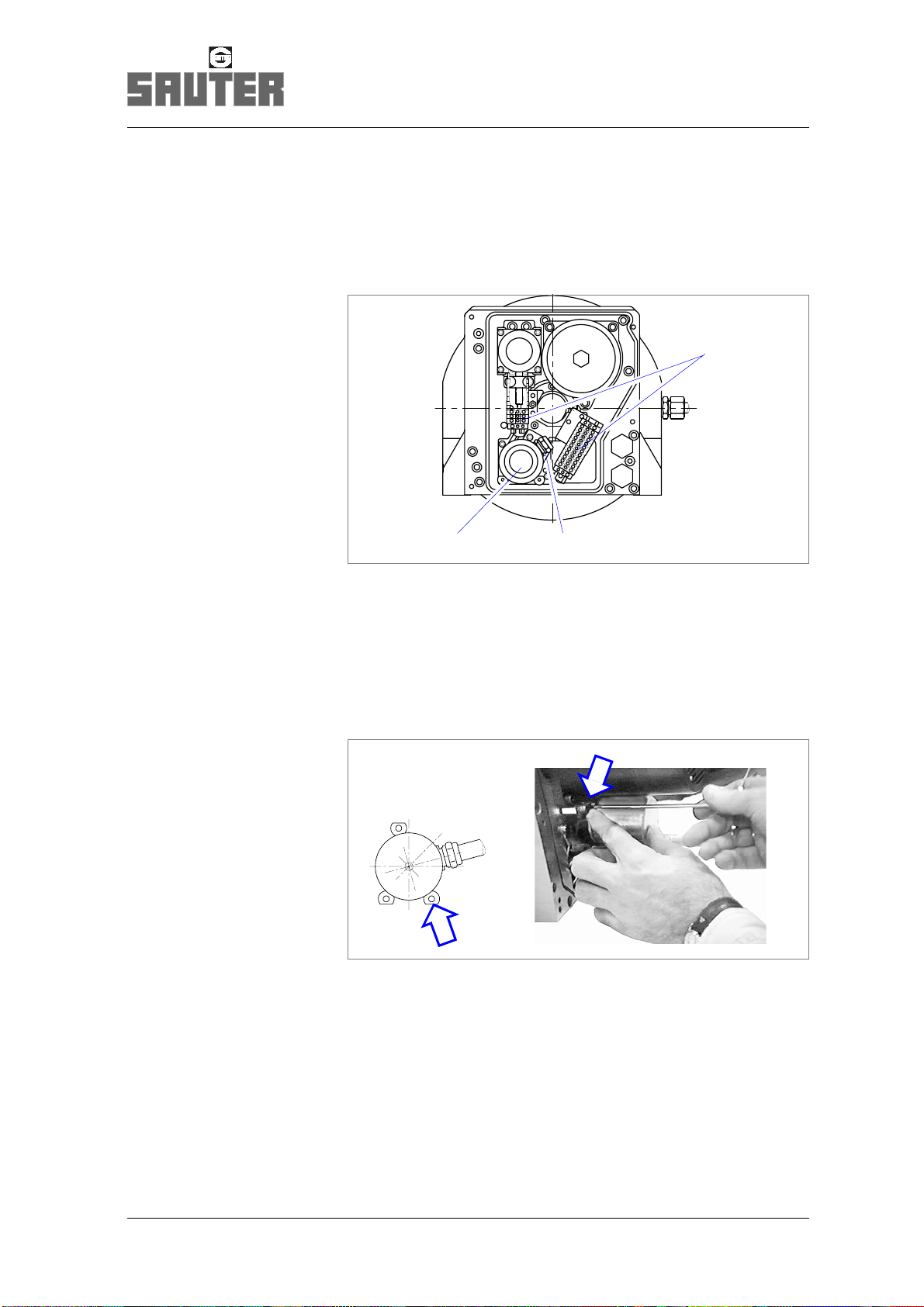

Angular e ncoder, in side positio n

Preparation

➣ Lock disk-type tool turret in position 1.

→

Manual mode, page 11

1

23

➣ Note the position of the cable outlet (2) on the angular

encoder (3), remove attachment.

➣ Undo cables (1) on terminal strip (note where they are

connected).

Replacing

➣ Undo claws by mea ns of a hex ag on al pin wr en ch .

➣ Carefully withdraw angular encoder.

On the shaft of the angular encoder, a disk is located which is

fixed in position by means of a setscrew.

➣ Undo setscrew and remove disk.

➣ Connect new angular encoder electrically.

Wiring diagram EP-870 in the appendix to these

→

Operating Instructions

BA 1130 29

Page 30

Repairs aft e r f a ult c onditions

Replacing the angular encoder

➣ Rotate shaft of the angular encoder until the illumination of

➣ Fit disk in its correct posi tion.

the LED on the angular encoder indicates the “Position 1”

setting.

This indication must remain whilst the following steps are

carried out.

➣ Ensur e th at the cabl e outle t is in its cor r ect posi t ion .

➣ Insert the angular encoder into the opening of the plate,

note the position of the claws!

➣ If necessary, check the adjustment of the angular encoder.

Page 25

→

➣ Use claws to secure the angular encoder.

➣ Fit covering hood. Note position of cables in order to avoid

any pinching of the same.

30 BA 1130

Page 31

5.8 Proximity switch S7

IMPORTANT

Setting tasks require a 24V DC power supply.

Clearing required prior to any work:

➣ Switch the machine off.

➣ Depressurize turret.

➣ Undo fixing screws of covering hood, withdraw covering

hood to rear. If necessary, use push-off screw.

Repairs after fault conditions

Proximity switch S 7

Replacing

2

1

➣ Undo clip (3 ) a nd withdraw proximity switch (1 ) from

eccentric bushing (2).

3

BA 1130 31

Page 32

Repairs aft e r f a ult c onditions

Proximity switch S 7

Checking

.

+

brown

black

blue

8

11

V

24 V

−

H-Signal ≥ 90% of rated voltage

➣ Apply a voltage of 24 V DC to the proximity switch (1).

The proximity switch is energized when the LED lights up.

➣ Insert tested/new proximity switch (1).

Adjusting

➣ Unlock disk-type tool turret.

→

Manual mode, page 11

➣ Move disk-type tool turret into a location between two

positions.

If the k eepe r (M) is oper ate d, t he p r ei ndexing bolt ( 4) c an b e

pres se d in pa rtial l y on ly.

a

5

4

M

x

3

2

1

➣ Set switching distance x = 0.3 – 0.5 mm.

➣ Determine dimension a.

a = stroke of the preindexing bolt (4) up to the damping

ring (5) when the solenoid is operated manually

(corresponds to the press-in depth of the keeper (M)).

32 BA 1130

Page 33

Repairs after fault conditions

Proximity switch S 7

➣ Adjust proximity s witch (1) on eccentric bu shing (2) such that

its signal begins to drop after a+ 2

+0.5

mm immersion depth

of the preindexing bolt.

Any greater immersion depth may cause the motor to be

blocked.

➣ Tighten clip (3).

➣ Fit covering hood. Note position of cables in order to avoid

any pinchin g of the same.

Function test

➣ Switch on turret.

➣ Check switching process repeatedly.

BA 1130 33

Page 34

Repairs aft e r f a ult c onditions

Solenoid

5.9 Solenoid

The solenoid dete rm ines the engage ment pat h. The coupling e nd positions

are controlled by means of the proximity switch es S10 “Tool drive engaged”

and S11 “Tool drive disengaged”.

Clearing required prior to any work:

➣ Switch the machine off.

➣ Depressur ize turret .

Preparation

➣ If necessary, remove the covering hood on the tool drive unit.

If a tool disk is fitted, the tool holder location must be

accessible in working position:

➣ If necessary, disassemble tool holder.

1

2

5

Replacing

3

4

➣ Remove screws (1) on the flange plate of the solenoid (2).

➣ Undo setscrew (5).

➣ Replace the solenoid (2) complete with adjusting nut (3) and

bushing (4).

➣ Tighten screws (1).

34 BA 1130

Page 35

~1mm

Repairs after fault conditions

Solenoi d

Checking

Is the clearance from the pinion shaft (10) to the edge of the

spindle unit coupling (11) 1mm when the keeper is drawn out?

➣ If necessary, adjust final coupling position.

67 8 9

0.3-0.5mm

53

1011

Adjusting the final coupling position

➣ Undo setscrew (5).

➣ Undo adjusting nut (3) and rotate keeper.

➣ Adjust clearance.

➣ Tighten setscrew (5).

Adjusting the proximity switches

➣ Undo screws (8) of clip(7).

➣ Adju st pro xi mi ty sw itc h S11 (6) to a c l ear anc e of 0. 3 - 0. 5 mm

rel at i ve to it s switchin g a re a .

➣ Tighten screws (8) of clip (7).

➣ Adjust proximity switch S10 (9) in the same way.

BA 1130 35

Page 36

Page 37

5.10 Cooling lubr icant valve

• Cooling lubricant valves for SAUTER Disk-type tool turrets

are executed depending on the order involved.

The cooling lubricant connection may be situated on the

valve.

• Cooling lubricant valves are wearing parts and must

therefore be inspected after 4,000 operating hours of the

machine resp ecti vely.

• For ordering replacement parts, the identification number of

the cooling lubricant valve can be indicated, if engraved.

Otherwise, the order number (i.e. Comm. No. on the turret

nameplate) must be given.

• Operating pressure and filter fineness for cooling lubricant:

Technical data

→

Repairs after fault conditions

Cooling lub ricant valve

Clearing required prior to any work:

➣ Switch the machine off.

➣ Depressurize turret.

➣ Turn off cooling lubricant supply unit.

Replacing

1

3

2

➣ Unscrew screw p lug (2).

➣ Withdraw cooling lubricant cartridge complete with

screw plu g (2).

➣ Check cooling lubricant cartridge; if necessary, replace

bushing (3) and O-ring seal (1).

➣ Refit cooling lubricant cartridge complete with screw plug.

BA 1130 37

Page 38

Replacement parts

6 Replacement par ts

IMPORTANT

➣ Please contact SAUTER Services.

➣ Please follow the ordering instructions.

Information at the end of the present manual

→

A

B

A Replacement parts for turrets (without tool drive)

Indexing, page 40

→

→

Clamping and angular encoder, page 41

→

Gear, drive, pre-indexation, page 42

IMPORTANT

Request assembly guideline MR 02.025!

38 BA 1130

Page 39

B Replacement parts tool drive for turret

0.5.473.520 - 089 632

- 103 012

→

→

Replacement parts

Page 44

Page 46

-

103 292

- 106 302

- 107 198

- 107 468

-

109 332

- 110 660

- 111 092

- 111 272

- 112 722

- 112 862

- 113 290

- 114 703

-

115 702

- 115 785

- 120 362

→

Page 48

→

Page 50

→

Page 52

→

Page 54

→

Page 56

→

Page 58

→

Page 60

→

Page 62

→

Page 64

→

Page 66

→

Page 68

→

Page 70

→

Page 72

→

Page 74

→

Page 76

- 125 365

- 125 544

- 128 037

- 129 602

- 134 263

- 134 969

- 138 083

- 138 420

- 142 499

- 143 182

-

143 370

→

→

→

→

→

→

→

→

→

→

→

Page 78

Page 80

Page 82

Page 84

Page 86

Page 88

Page 90

Page 92

Page 94

Page 96

Page 98

BA 1130 39

Page 40

Replacement parts

Indexing

Indexing

1

2

Setscrew is only applied

and secured (LOCTITE 221)

No. Ident No. Designation Qty.

1 058 073 O-ring seal 1

2 102 048

Replacements parts group

Indexing

3

40 BA 1130

Page 41

Clamping and angular encoder

Clamping and angular encoder

Replacement parts

1

2

3

4

No. Ident No. Designation Qty.

1 067 586 Disk (for tuning) 1

2 063 358

3

4 105 500

O-ring seal

Replacements parts group

Angular encoder

Clamping

1

1

1

BA 1130 41

Page 42

Replacement parts

Gear, drive, pre-indexation

Gear, drive, pre-indexation

12 5364

7

89 10

42 BA 1130

Page 43

Replacement parts

Gear, drive, pre -in dexa t ion

No. Ident No. Designation Qty.

1 071 904

2 078 218

3 069 340

4 063 365

5 065 718

Sealing ring

O-ring seal

O-ring seal

O-ring seal

O-ring seal

6 Motor

7 004 157

8 070 460

9 067 659

10 064 813

Proximity switch

Sealing ring

Compression spring

Solenoid

1) will be supplied complete with housing and bearing

2) data according to motor’s nameplate

1) 2)

1

1

1

1

1

1

1

1

1

1

BA 1130 43

Page 44

Replacement parts To ol Drive

for tur re t 0.5.47 3.52 0 - 089 6 32

for turret 0.5.473.520 - 089 632

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

44 BA 1130

Page 45

Replacement parts Tool D rive

for turret 0.5.473.520 - 089 632

0.5.473.520 - 089 632

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 068 017

O-ring seal

3 066 935 Wire race ball bearing 1

4 058 543

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

065 993 O-ring seal

7 060 801 O-ring seal

058 495 O-ring seal

8 076 749

Proximity switch

1) 2)

3)

1) 3)

2)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 103 778 Pinion shaft, complete 1

1

1

1

1

1

1

2

1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor SIEMENS 1FT6 086

2) for motor SIEMENS 1FK7 083

3) for motor FANUC alpha 30 /3000

2

BA 1130 45

Page 46

Replacement parts To ol Drive

for turret 0.5.473.520 - 103 012

for turret 0.5.473.520 - 103 012

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

46 BA 1130

Page 47

Replacement parts Tool D rive

for turret 0.5.473.520 - 103 012

0.5.473.520 - 103 012

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 068 017

O-ring seal

3 066 935 Wire race ball bearing 1

4 058 543

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

058 075 O-ring seal

065 993 O-ring seal

1) 2)

3)

4) 5) 6)

7 058 495 O-ring seal 1

8 076 749

Proximity switch

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 103 530 Pinion shaft, complete 1

1

1

1

1

1

2

1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor SIEMENS 1FT5 076

2) for motor SIEMENS 1FT6 084

3) for motor FANUC 2S

4) for motor SIEMENS 1FT6 064

5) for motor INDRAMAT MAC 93

6) for motor MITSUBISHI HA 203

2

BA 1130 47

Page 48

Replacement parts To ol Drive

for turret 0.5.473.520 - 103 292

for turret 0.5.473.520 - 103 292

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

48 BA 1130

Page 49

Replacement parts Tool D rive

for turret 0.5.473.520 - 103 292

0.5.473.520 - 103 292

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 063 365

O-ring seal

3 069 657 Wire race ball bearing 1

4 058 494

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

7 059 932 O-ring seal

058 548 O-ring seal

8 076 749

Proximity switch

1) 2)

1)

2)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 130 633 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

1

1

1

1

1

2

1

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor SIEMENS 1FT6 082 i=1

2) for motor SIEMENS 1FT6 082 i=1.32

2

BA 1130 49

Page 50

Replacement parts To ol Drive

for turret 0.5.473.520 - 106 302

for turret 0.5.473.520 - 106 302

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

50 BA 1130

Page 51

Replacement parts Tool D rive

for turret 0.5.473.520 - 106 302

0.5.473.520 - 106 302

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 068 017

O-ring seal

3 066 935 Wire race ball bearing 1

4 058 555

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

060 117 O-ring seal

065 993 O-ring seal

7 058 495 O-ring seal

058 521 O-ring seal

059 304 O-ring seal

8 076 749

Proximity switch

1) 2) 3)

4)

5)

1) 2) 4)

5)

3)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

1

1

1

1

1

1

1

1

2

11 058 506

O-ring seal

12 103 530 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor SIEMENS 1FT5 076

2) for motor SIEMENS 1FT6 084

3) for motor SIEMENS 1FT6 066

4) for motor FANUC 20 S

5) for motor FANUC alpha 30

1

2

BA 1130 51

Page 52

Replacement parts To ol Drive

for turret 0.5.473.520 - 107 198

for turret 0.5.473.520 - 107 198

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

52 BA 1130

Page 53

Replacement parts Tool D rive

for turret 0.5.473.520 - 107 198

0.5.473.520 - 107 198

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 063 365

O-ring seal

3 069 657 Wire race ball bearing 1

4 068 017

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

058 521 O-ring seal

058 075 O-ring seal

7 058 495 O-ring seal

059 303 O-ring seal

8 076 749

Proximity switch

1) 2) 3)

4) 5)

6)

1) 2) 3)

4) 5) 6)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

1

1

1

1

1

1

1

2

1

12 103 778 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor SIEMENS 1FT5 07x

2) for motor SIEMENS 1FT6 08x

3) for motor HEIDENHAIN QS4 155 C ECODIN

4) for motor FANUC alpha 12 /4000 HVis

5) for motor FANUC alpha 22 /4000 HVis

6) for motor FANUC alpha 2

2

BA 1130 53

Page 54

Replacement parts To ol Drive

for turret 0.5.473.520 - 107 468

for turret 0.5.473.520 - 107 468

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

54 BA 1130

Page 55

Replacement parts Tool D rive

for turret 0.5.473.520 - 107 468

0.5.473.520 - 107 468

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 063 365

O-ring seal

3 069 657 Wire race ball bearing 1

4 068 017

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

058 521 O-ring seal

063 461 O-ring seal

065 993 O-ring seal

7 058 495 O-ring seal

059 932 O-ring seal

8 076 749

Proximity switch

1) 2) 3) 4)

5)

6)

7)

1) 2) 3) 4) 6) 7)

5)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

1

1

1

1

1

1

1

1

2

11 058 506

O-ring seal

12 103 530 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor SIEMENS 1FT5 072

2) for motor SIEMENS 1FT5 076

3) for motor SIEMENS 1FT6 084

4) for motor FAGOR FXM 55

5) for motor FANUC alpha 22

6) for motor SIEMENS 1FT5 066

7) for motor FANUC 6S

1

2

BA 1130 55

Page 56

Replacement parts To ol Drive

for turret 0.5.473.520 - 109 332

for turret 0.5.473.520 - 109 332

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

56 BA 1130

Page 57

Replacement parts Tool D rive

for turret 0.5.473.520 - 109 332

0.5.473.520 - 109 332

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 068 017

O-ring seal

3 066 935 Wire race ball bearing 1

4 058 543

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

065 993 O-ring seal

7 060 801 O-ring seal

058 495 O-ring seal

8 076 749

Proximity switch

1) 2)

3)

1) 3)

2)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 103 778 Pinion shaft, complete 1

1

1

1

1

1

1

2

1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor SIEMENS 1FT6 086

2) for motor SIEMENS 1FK7 083

3) for motor FANUC alpha 30 /3000

2

BA 1130 57

Page 58

Replacement parts To ol Drive

for turret 0.5.473.520 - 110 660

for turret 0.5.473.520 - 110 660

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

58 BA 1130

Page 59

Replacement parts Tool D rive

for turret 0.5.473.520 - 110 660

0.5.473.520 - 110 660

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 067 810

O-ring seal

3 068 207 Wire race ball bearing 1

4 064 594

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 075 O-ring seal

058 548 O-ring seal

058 521 O-ring seal

065 993 O-ring seal

7 058 521 O-ring seal

065 993 O-ring seal

8 076 749

Proximity switch

1)

2)

3)

4) 5) 6)

3) 6)

1) 2) 4) 5)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

1

1

1

1

1

1

1

1

2

11 058 506

O-ring seal

12 103 778 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor FANUC 2S

2) for motor SIEMENS 1FT5 072

3) for motor FANUC alpha M 12

4) for motor SIEMENS 1FT6 064

5) for motor INDRAMAT MDD 93A

6) for motor FANUC alpha M 12/4 000 HVi

1

2

BA 1130 59

Page 60

Replacement parts To ol Drive

for turret 0.5.473.520 - 111 092

for turret 0.5.473.520 - 111 092

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

60 BA 1130

Page 61

Replacement parts Tool D rive

for turret 0.5.473.520 - 111 092

0.5.473.520 - 111 092

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 063 365

O-ring seal

3 069 657 Wire race ball bearing 1

4 068 017

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 075 O-ring seal

058 548 O-ring seal

065 993 O-ring seal

7 059 932 O-ring seal

8 076 749

Proximity switch

1)

2)

3)

1) 2) 3)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 104 127 Pinion shaft, complete 1

1

1

1

1

1

1

2

1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor FANUC alpha 3

2) for motor SIEMENS 1FT6 082

3) for motor FANUC alpha 1,5

2

BA 1130 61

Page 62

Replacement parts To ol Drive

for turret 0.5.473.520 - 111 272

for turret 0.5.473.520 - 111 272

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

62 BA 1130

Page 63

Replacement parts Tool D rive

for turret 0.5.473.520 - 111 272

0.5.473.520 - 111 272

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 068 017

O-ring seal

3 066 935 Wire race ball bearing 1

4 062 797

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

058 075 O-ring seal

058 665 O-ring seal

7 058 521 O-ring seal

58 548 O-ring seal

8 076 749

Proximity switch

1) 2) 3)

4)

5)

1) 2) 5)

3) 4)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

1

1

1

1

1

1

1

2

1

12 103 530 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor SIEMENS 1FT5 074

2) for motor SIEMENS 1FT6 084

3) for motor INDRAMAT MHD 93B

4) for motor FANUC alpha 2

5) for motor FANUC 2S

2

BA 1130 63

Page 64

Replacement parts To ol Drive

for turret 0.5.473.520 - 112 722

for turret 0.5.473.520 - 112 722

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

64 BA 1130

Page 65

Replacement parts Tool D rive

for turret 0.5.473.520 - 112 722

0.5.473.520 - 112 722

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 063 365

O-ring seal

3 069 657 Wire race ball bearing 1

4 058 494

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

065 993 O-ring seal

7 059 932 O-ring seal

8 076 749

Proximity switch

1)

2) 3)

1) 2) 3)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 130 734 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

1

1

1

1

1

2

1

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor SIEMENS 1FT6 082

2) for motor FANUC alpha 1,5

3) for motor FANUC alpha 12 /4000is

2

BA 1130 65

Page 66

Replacement parts To ol Drive

for turret 0.5.473.520 - 112 862

for turret 0.5.473.520 - 112 862

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

66 BA 1130

Page 67

Replacement parts Tool D rive

for turret 0.5.473.520 - 112 862

0.5.473.520 - 112 862

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 063 365

O-ring seal

3 069 657 Wire race ball bearing 1

4 068 017

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 075 O-ring seal

058 548 O-ring seal

065 993 O-ring seal

7 059 932 O-ring seal

8 076 749

Proximity switch

1)

2)

3)

1) 2) 3)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 104 127 Pinion shaft, complete 1

1

1

1

1

1

1

2

1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor FANUC alpha 3

2) for motor SIEMENS 1FT6 082

3) for motor FANUC alpha 1,5

2

BA 1130 67

Page 68

Replacement parts To ol Drive

for turret 0.5.473.520 - 113 290

for turret 0.5.473.520 - 113 290

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

68 BA 1130

Page 69

Replacement parts Tool D rive

for turret 0.5.473.520 - 113 290

0.5.473.520 - 113 290

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 063 365

O-ring seal

3 069 657 Wire race ball bearing 1

4 068 017

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

058 521 O-ring seal

7 058 495 O-ring seal

059 303 O-ring seal

8 076 749

Proximity switch

1) 2)

3) 4)

1) 2)

3) 4)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 101 926 Pinion shaft, complete 1

1

1

1

1

1

1

2

1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor SIEMENS 1FT5 07x

2) for motor SIEMENS 1FT6 08x

3) for motor FANUC alpha 12 /4000 HVis

4) for motor FANUC alpha 22 /4000 HVis

2

BA 1130 69

Page 70

Replacement parts To ol Drive

for turret 0.5.473.520 - 114 703

for turret 0.5.473.520 - 114 703

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

70 BA 1130

Page 71

Replacement parts Tool D rive

for turret 0.5.473.520 - 114 703

0.5.473.520 - 114 703

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 063 365

O-ring seal

3 069 657 Wire race ball bearing 1

4 058 494

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

7 059 932 O-ring seal

058 548 O-ring seal

8 076 749

Proximity switch

1) 2)

1)

2)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 130 633 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

1

1

1

1

1

2

1

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor SIEMENS 1FT6 082 i=1

2) for motor SIEMENS 1FT6 082 i=1.32

2

BA 1130 71

Page 72

Replacement parts To ol Drive

for turret 0.5.473.520 - 115 702

for turret 0.5.473.520 - 115 702

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

72 BA 1130

Page 73

Replacement parts Tool D rive

for turret 0.5.473.520 - 115 702

0.5.473.520 - 115 702

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 063 365

O-ring seal

3 069 657 Wire race ball bearing 1

4 068 017

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

058 521 O-ring seal

063 461 O-ring seal

065 993 O-ring seal

7 058 495 O-ring seal

059 932 O-ring seal

8 076 749

Proximity switch

1) 2) 3)

4)

5)

6)

1) 2) 3) 5) 6)

4)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

1

1

1

1

1

1

1

1

2

11 058 506

O-ring seal

12 103 530 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor SIEMENS 1FT5 072

2) for motor SIEMENS 1FT5 076

3) for motor SIEMENS 1FT6 0084

4) for motor FANUC alpha 22

5) for motor SIEMENS 1FT5 066

6) for motor FANUC 6S

1

2

BA 1130 73

Page 74

Replacement parts To ol Drive

for turret 0.5.473.520 - 115 785

for turret 0.5.473.520 - 115 785

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

74 BA 1130

Page 75

Replacement parts Tool D rive

for turret 0.5.473.520 - 115 785

0.5.473.520 - 115 785

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 063 365

O-ring seal

3 069 657 Wire race ball bearing 1

4 068 017

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

058 521 O-ring seal

058 075 O-ring seal

7 058 495 O-ring seal

059 303 O-ring seal

8 076 749

Proximity switch

1) 2) 3)

4) 5)

6)

1) 2) 3)

4) 5) 6)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

1

1

1

1

1

1

1

2

1

12 103 778 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor SIEMENS 1FT5 07x

2) for motor SIEMENS 1FT6 08x

3) for motor HEIDENHAIN QS4 155 C ECODIN

4) for motor FANUC alpha 12 /4000 HVis

5) for motor FANUC alpha 22 /4000 HVis

6) for motor FANUC alpha 2

2

BA 1130 75

Page 76

Replacement parts To ol Drive

for turret 0.5.473.520 - 120 362

for turret 0.5.473.520 - 120 362

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

76 BA 1130

Page 77

Replacement parts Tool D rive

for turret 0.5.473.520 - 120 362

0.5.473.520 - 120 362

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 063 365

O-ring seal

3 069 657 Wire race ball bearing 1

4 058 494

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

112 272 O-ring seal

7 059 932 O-ring seal

8 076 749

Proximity switch

1)

2)

1) 2)

1

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 130 633 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

1

1

1

1

2

1

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor SIEMENS 1FT6 082

2) for motor FANUC alpha 3

2

BA 1130 77

Page 78

Replacement parts To ol Drive

for turret 0.5.473.520 - 125 365

for turret 0.5.473.520 - 125 365

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

78 BA 1130

Page 79

Replacement parts Tool D rive

for turret 0.5.473.520 - 125 365

0.5.473.520 - 125 365

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 067 810

O-ring seal

3 068 207 Wire race ball bearing 1

4 064 594

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 075 O-ring seal

068 208 O-ring seal

7 058 521 O-ring seal

059 308 O-ring seal

8 076 749

Proximity switch

1) 2)

3)

1) 2)

3)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 103 778 Pinion shaft, complete 1

1

1

1

1

1

1

2

1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor FANUC 2S

2) for motor FANUC 3S

3) for motor SIEMENS 1FT6 084

2

BA 1130 79

Page 80

Replacement parts To ol Drive

for turret 0.5.473.520 - 125 544

for turret 0.5.473.520 - 125 544

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

80 BA 1130

Page 81

Replacement parts Tool D rive

for turret 0.5.473.520 - 125 544

0.5.473.520- 089632

0.5.473.520 - 125 544

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 068 017

O-ring seal

3 066 935 Wire race ball bearing 1

4 058 543

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

065 993 O-ring seal

7 060 801 O-ring seal

058 495 O-ring seal

8 076 749

Proximity switch

1) 2)

3)

1) 3)

2)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 103 778 Pinion shaft, complete 1

1

1

1

1

1

1

2

1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor SIEMENS 1FT6 086

2) for motor SIEMENS 1FK7 083

3) for motor FANUC alpha 30 /3000

2

BA 1130 81

Page 82

Replacement parts To ol Drive

for turret 0.5.473.520 - 128 037

for turret 0.5.473.520 - 128 037

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

82 BA 1130

Page 83

Replacement parts Tool D rive

for turret 0.5.473.520 - 128 037

0.5.473.520 - 128 037

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 068 017

O-ring seal

3 066 935 Wire race ball bearing 1

4 058 543

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

7 058 495 O-ring seal

8 076 749

Proximity switch

1) 2)

1) 2)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 103 530 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

1

1

1

1

2

1

15 060 663

O-ring seal

1) for motor SIEMENS 1FT5 076

2) for motor SIEMENS 1FK7 083

2

BA 1130 83

Page 84

Replacement parts To ol Drive

for turret 0.5.473.520 - 129 602

for turret 0.5.473.520 - 129 602

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

84 BA 1130

Page 85

Replacement parts Tool D rive

for turret 0.5.473.520 - 129 602

0.5.473.520 - 129 602

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 068 017

O-ring seal

3 066 935 Wire race ball bearing 1

4 058 543

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

7 058 495 O-ring seal

8 076 749

Proximity switch

1) 2)

1) 2)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 103 530 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

1

1

1

1

2

1

15 060 663

O-ring seal

1) for motor SIEMENS 1FT5 076

2) for motor SIEMENS 1FK7 083

2

BA 1130 85

Page 86

Replacement parts To ol Drive

for turret 0.5.473.520 - 134 263

for turret 0.5.473.520 - 134 263

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

86 BA 1130

Page 87

Replacement parts Tool D rive

for turret 0.5.473.520 - 134 263

0.5.473.520 - 134 263

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 063 365

O-ring seal

3 068 017 Wire race ball bearing 1

4 058 494

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 521 O-ring seal

7 127 636 O-ring seal

8 076 749

Proximity switch

1)

1)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 130 633 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

1

1

1

1

2

1

15 060 663

O-ring seal

1) for motor FANUC alpha 22 /6000

2

BA 1130 87

Page 88

Replacement parts To ol Drive

for turret 0.5.473.520 - 134 969

for turret 0.5.473.520 - 134 969

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

88 BA 1130

Page 89

Replacement parts Tool D rive

for turret 0.5.473.520 - 134 969

0.5.473.520 - 134 969

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 063 365

O-ring seal

3 069 657 Wire race ball bearing 1

4 068 017

O-ring seal

5 000 706 Deep groove ball bearing 1

6 072 763 O-ring seal

7 060 801 O-ring seal

8 076 749

Proximity switch

1)

1)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 103 778 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

1

1

1

1

2

1

15 060 663

O-ring seal

1) for motor FAGOR FM7 A055-1

2

BA 1130 89

Page 90

Replacement parts To ol Drive

for turret 0.5.473.520 - 138 083

for turret 0.5.473.520 - 138 083

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

90 BA 1130

Page 91

Replacement parts Tool D rive

for turret 0.5.473.520 - 138 083

0.5.473.520 - 138 083

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 063 365

O-ring seal

3 069 657 Wire race ball bearing 1

4 068 017

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

7 059 932 O-ring seal

8 076 749

Proximity switch

1)

1)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 104 127 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

1

1

1

1

2

1

15 060 663

O-ring seal

1) for motor SIEMENS 1FT6 082

2

BA 1130 91

Page 92

Replacement parts To ol Drive

for turret 0.5.473.520 - 138 420

for turret 0.5.473.520 - 138 420

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

92 BA 1130

Page 93

Replacement parts Tool D rive

for turret 0.5.473.520 - 138 420

0.5.473.520 - 138 420

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 068 017

O-ring seal

3 066 935 Wire race ball bearing 1

4 058 555

O-ring seal

5 000 706 Deep groove ball bearing 1

6 065 993 O-ring seal

7 058 495 O-ring seal

8 076 749

Proximity switch

1)

1)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 130 633 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

1

1

1

1

2

1

15 060 663

O-ring seal

1) for motor INDRAMAT MAC 93

2

BA 1130 93

Page 94

Replacement parts To ol Drive

for turret 0.5.473.520 - 142 499

for turret 0.5.473.520 - 142 499

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

94 BA 1130

Page 95

Replacement parts Tool D rive

for turret 0.5.473.520 - 142 499

0.5.473.520 - 142 499

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 068 017

O-ring seal

3 066 935 Wire race ball bearing 1

4 058 555

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

060 117 O-ring seal

7 058 495 O-ring seal

059 304 O-ring seal

8 076 749

Proximity switch

1) 2)

3)

1) 3)

2)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 103 530 Pinion shaft, complete 1

1

1

1

1

1

1

2

1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor SIEMENS 1FT6 084

2) for motor SIEMENS 1FT6 066

3) for motor FANUC 20 S

2

BA 1130 95

Page 96

Replacement parts To ol Drive

for turret 0.5.473.520 - 143 182

for turret 0.5.473.520 - 143 182

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

96 BA 1130

Page 97

Replacement parts Tool D rive

for turret 0.5.473.520 - 143 182

0.5.473.520 - 143 182

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 063 365

O-ring seal

3 069 657 Wire race ball bearing 1

4 068 017

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

7 058 665 O-ring seal

8 076 749

Proximity switch

1)

1)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 103 778 Pinion shaft, complete 1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

1

1

1

1

2

1

15 060 663

O-ring seal

1) for motor SIEMENS 1FT6 08x

2

BA 1130 97

Page 98

Replacement parts To ol Drive

for turret 0.5.473.520 - 143 370

for turret 0.5.473.520 - 143 370

6

5

4

3

Setscrew is only applied and

secured

(LOCTITE 221)

2

1

7

10

11

13

12

14

8

15

9

(15)

(13)

(14)

98 BA 1130

Page 99

Replacement parts Tool D rive

for turret 0.5.473.520 - 143 370

0.5.473.520- 089632

0.5.473.520 - 143 370

No. Ident No. Designation Qty.

1 036 588 Spaghetti hose 0.636 m

2 068 017

O-ring seal

3 066 935 Wire race ball bearing 1

4 058 543

O-ring seal

5 000 706 Deep groove ball bearing 1

6 058 548 O-ring seal

065 993 O-ring seal

7 060 801 O-ring seal

058 495 O-ring seal

8 076 749

Proximity switch

1) 2)

3)

1) 3)

2)

9 065 815 Solenoid 1

10 034 592 FU groove ring 1

11 058 506

O-ring seal

12 103 778 Pinion shaft, complete 1

1

1

1

1

1

1

2

1

13 074 861 Radial seal for rotating shaft 2

14 038 494 Deep groove ball bearing 2

15 060 663

O-ring seal

1) for motor SIEMENS 1FT6 086

2) for motor SIEMENS 1FK7 083

3) for motor FANUC alpha 30 /3000

2

BA 1130 99

Page 100

Loading...

Loading...