sauter AXM 117SSeries,AXM 117S F202,AXM 117S F302,AXM 117S F402 User Manual

55.011

Y07552

M

100 %

0 V Output signal y 10 V

B07650

0 %

Direction

of operation 2

Direction

of operation 1

Type

Direction of

operation1)

Running

time

Stroke

Thrust

Power

Weight

s

mm N

kg

AXM 117S F202

1

60 4 120 2)

24 V~

0,15

AXM 117S F302

2

60 4 120 2)

24 V~

0,15

AXM 117S F402

1 or 2 3)

60 4 120 2)

24 V~

0,15

Power supply 24 V~

± 15%, 50...60 Hz

Ambient temperature

–0...50 °C

Power consumption on

starting

5 VA

Ambient humidity

< 75% rh

Type of protection

IP 40 (EN 60529)

Control voltage

0...10 V; Ri = 20 kΩ

Protection class

III (IEC 60730)

Control voltage F402 3)

0...10 V; 5,2...10 V; 0...4,8 V

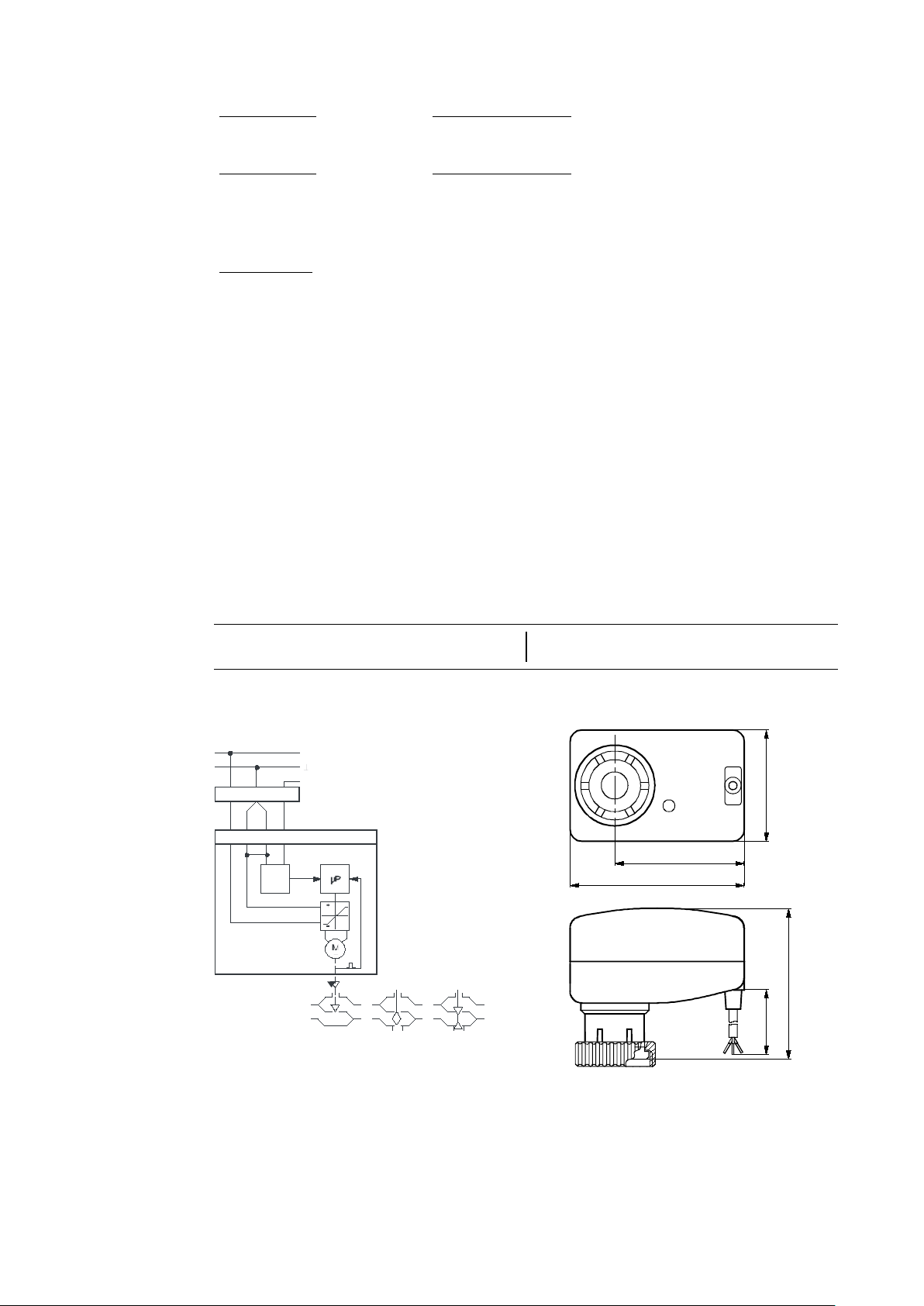

Wiring diagram

A06147

Control current

max. 0,5 mA

Dimension drawing

M06146

Max. operating temperature

100 °C at valve

Fitting instructions

MV 505456

Accessories

0371235 001

Adaptor for fitting to Oventrop valves (M30 × 1)

0550393 001

Adaptor Danfoss RA2000, 22 mm

0371356 001

Adaptor for fitting to Beulco or Tobler underfloor-heating distribution stations (M30 × 1)

0550393 002

Adaptor Danfoss RAVL, 26 mm

0550393 003

Adaptor Danfoss RAV, 34 mm

0371361 001

Adaptor for fitting to Herz valves, type Herz-TS’90 (M28 × 1,5)

0371363 001

Adaptor for fitting to Tour & Andersson valves, type TA/RVT (M28 × 1,5)

1)

Direction of operation 2: rising 0…10V = drive extends (VXL, VUL, BUL closes, BXL control passage opens).

2)

Pushing force: min. 100 N, max. 150 N

3)

The direction of operation and the setting of the control voltage can be set using jumpers

7155011003 07

AXM 117S: Motorised drive (with positioner) for unit valves

How energy efficiency is improved

Automatic valve adjustment and intelligent cut-out enable maximum energy efficiency.

Areas of application

Actuation of through and three-way unit valves in the VUL, BUL, VXL and BXL series. For controllers

with continuous output in combination with intelligent unitary control systems.

Features

• Pushing force 120 N

• Fits onto valve with M30 × 1.5 thread

• Stepping motor with control and electronic cut-off

• Version with control action A or B or adjustable

• Maintenance-free gearbox

• Suitable for retrofitting existing installations using an appropriate adaptor

• Operating status control using integrated LED display

Technical description

• Two-part plastic housing, light grey (RAL7035)

• Nickel-plated brass nut

• Connecting cable, light grey 1.50 m long, 3 × 0.25 mm²

• Running time for 4 mm stroke: 60 s

• Installation position: vertical to horizontal, but not upside down

Direction of operation 1: rising 0…10V = drive retracts (VXL, VUL, BUL opens, BXL control passage closes).

Operation

During commissioning (with valve fitted), the actuator moves to the two end positions and memorises

the number of steps taken to do so. The 0...10 V control signal is then linearly assigned to this effective stroke. The motor activates the valve and switches off as soon as the stroke position concurs with

the controller signal. In the end positions or in the event of an overload, the motor is switched off within 2 minutes. If the control voltage has not changed for 2 hours (in the range 0...0,5 V), the motor –

after approx. 2 hours – runs briefly to the end positions and, if necessary, corrects its position

memory. A complete cycle is performed every 24 hours on the AXM117SF202 and F302 in order to

prevent the plug from jamming. The LED lights up when power is applied to the drive, and flashes

when the motor is running.

Sauter Components

55.011 AXM 117S

Stroke

max. 4,5 mm

Running time

15 s/mm

7155011003 07

74

55

47

L=1,5m

62,5

M06146a

B10 094a

24 V~

VUL / VXL

2

1a 1 b

3

21 3

0...10V

A/D

BXL

BUL

1b

blau

bleu

blue

azzu ro

azul

bl å

blauw

2

rot

rouge

red

ross o

rojo

röd

rood

1a

sc hw arz

noir

black

n ero

negro

svart

zwa rt

3

weiss

blanc

white

bianco

blanco

vit

w it

AXM117SF202 or AXM117SF402, direction of operation 1

As the control signal rises, the drive spindle retracts and the VUL, VXL through valves and the BUL

three-way valve (control passage) open. On the BXL three-way valve, the control passage closes.

AXM117SF302 or AXM117SF402, direction of operation 2

As the control signal rises, the drive spindle extends and the VUL, VXL through valves and the BUL

three-way valve (control passage) close. On the BXL three-way valve, the control passage opens.

The black earth lead 1a (24 V~) and the blue earth lead 1b (control voltage) should be connected

together to a common earth lead.

AXM117SF402

After removing the cap on the lid, you can make the following settings using jumpers:-

– Auto reset ‘on’ or ‘off’. In the ‘on’ (active) position, the drive re-adjusts itself every 24 hours by

moving to the end position or to the internal stop. In the ‘off’ (inactive) position, this readjustment does not occur.

– The input signal can be set to either 0...10 V or 5,2...10 V or 0...4,8 V.

– Direction of operation 1 or 2 can be selected; factory setting is direction of operation 2.

Replace the cap after you have finished making the setting.

Engineering and fitting notes

No tools should be used to fit the drive onto the valve. In the event of a power failure, the valve can be

opened by removing the drive. When connecting or transposing the power cable, power must be

switched off.

The drive must only be fitted on the valve when the drive spindle is notextended 100%. Status when

delivered: 50% of stroke.

Fitting outdoors. If the devices are fitted outdoors, we recommend that additional measures be taken

to protect them against the effects of the weather.

Standards and regulations

The drive conforms to the relevant EU standards.

EMC Directive: CE as per EN 61000-6-3 and EN 61000-6-1

Additional technical details

Wiring diagram Dimension drawing

Sauter Components

Loading...

Loading...