sauter AVM Series,AVM 104S F132,AVM 105S F132,AVM 114S F132,AVM 115S F132 Instructions Manual

AVM 104S…115S: Valve drive with Sauter Universal Technology SUT

For controllers with continuous output (0...10V) or switched output (2- or 3-point control). To operate

through valves or three-way valves in series VXN/BXN, VUD/BUD, VUE/BUE. Choice of characteristic

(linear/equal-percentage) can be set on the actuator.

Two-part housing of fire-retardant plastic, lower part in black, upper part in yellow. With stepping motor,

SUT electronic control unit and maintenance-free gears. Fixing bracket of plastic and cap nut of brass

for fitting the valve. Assembly with the valve is practically automatic. Direction of operation can be

changed at the cable. Electronic, torque-based cut-out via stops on either the actuator or the valve;

automatic adaptation to the valve’s stroke. Coding switches for selecting characteristic and running

time. Disengageable gears for positioning the valve by hand (Allen key enclosed with product). Power

cable 1,2 m long, 5× 0,5 mm². Fitting position: anywhere from vertical to horizontal, but not upside dow n.

mm

Stroke

mm

5)

Pushing force

Pushing force

3)

; MV 505795

3)

Power Weight

N

2)

2)

0

0 or 10V

Switching range Xsh 200 mV

1)

200 ms

Wiring diagram A09673

Power Weight

N

; MV 505795

kg

0,7

0,7

kg

Type Running timesStroke

For valves with linear characteristic, can be switched over to equal-percentage

AVM 104S F132

AVM 114S F132

35/65/130 7,5 250 24 V~/=

60/120 7,5 500 24 V~/=

For valves with equal-percentage characteristic, can be switched over to linear

AVM 105S F132

AVM 115S F132

Positioner

Control signal 0...10V, Ri > 100 kΩ Starting point U

Positional feedback signal 0...10V, load > 10 kΩ Control span ΔU 10V

Power supply 24V∼± 20%, 50...60 Hz Protection (horizontal) IP 54 as per EN 60529

Power consumption

AVM 105S F132 4,8 W 8,5 VA Response time

AVM 115S F132 4,9 W 8,7 VA

Max. m e d i a t e m p e r a t u r e 100 °C Dimension drawing M09743

Permissible amb. temp. –10...55 °C Fitting instructions 1 . 4S MV 505790

Ambient humidity 5…95 %rh Fitting instructions 1 . 5S MV 506065

1)

35/60/120 8,0 250 24 V~/= 0,7

60/120 8,0 500 24 V~/= 0,7

24V= 2)+ 20% / - 10% Protection class III as per IEC 60730

without condensation Declaration on materials MD 51.362

For control valve type KTM512 / TA-Regulator DN 15…50

Type Running time

s

AVM 115S F901

80/160 10,0 500 24 V~ 0,7

Deviation from standard type: inverse scale therefore inverse direction of operation. Adaptor for

control valve available on the valve or from TA-Regulator, stating reference no. 52 757 003.

Accessories

0313529 001* Split-range unit for setting sequences; to be fitted in separate distribution box as

per MV 505671

0372145 001* Single auxiliary change-over contacts

0372145 002* Double auxiliary change-over contacts

0372249 001* Intermediate piece required for media temperature >100 °C

(recommended for temperature < 10 °C); MV 505932

0372273 001* Adaptor for Siemens VVG / VXG 44 and 48 valves; MV 505848

0372286 001 Potentiometer

0372286 002 Potentiometer

0372286 003 Potentiometer

0372462 001 CASE Drives PC Tool for configuration of actuators per computer; MV 506101

*) Dimension drawing or wiring diagram are available under the same number

1) Also for 2-point or 3-point. depending on type of connection

2) 24V = for input signal of 0...10V only on AVM 1 . 4; on AVM 1 . 5S for all functions.

3) Fully variable from 0...100%; max. loading 5 (2) A. 24....230V

4) Only one potentiometer or one set of auxiliary contacts can be fitted to each drive!

5) Maximum stroke of drive = 10,0 mm

4)

130 Ω; MV 505795

4)

1000 Ω; MV 505795

4)

5000 Ω; MV 505795

51.362/1

M

Y07552

100 %

D

ir

of

ecti

o

pe

on

r

a

tio

n

2

o

0 %

0 V Output signal y 10 V

ion

1

ct

n

tio

Dire

a

er

p

f o

B07650

Sauter Components

7151362003 03

51.362/2 AVM 104S...115S

Operation

Depending on how it is connected (see wiring diagram). the actuator can be used as a continuous

0...10V. as a 2-point (open/close) or as a 3-point drive (open/stop/close) with intermediate position.

The running time can be matched to requirements using switches S1 and S2 (AVM 105, S1 only). The

characteristic (equal-percentage or linear) can be selected with switch S3. The AVM 104/114 is combined with valves that have a linear basic characteristic such as the VXN and BXN valves. The

AVM 105/115 is combined with valves that have an equal-percentage basic characteristic such as the

VUD. BUD. VUE and BUE valves. The AVM 115 can be fitted on a valve with a linear characteristic (e.g.

VUE 050F200). but you must pay attention to the position of the coding switches. With the AVM 105. it is

not possible to create an equal-percentage characteristic for a valve with a linear characteristic.

Manual adjustment is performed by disengaging the gears (sliding switch next to the power cable) and

simultaneously turning. using an Allen key in the insert on the upper part of the drive. Eight mm of

stroke is attained with 1½ turns.

N.B.: After manual adjustment. re-set the sliding switch (engage the gears).

Connected as a 2-point actuator

Open/close activation can be effected via two wires. Power is applied to the drive via the blue and the

brown wires. On connecting power to the black wire. the valve’s control passage opens. When power

is switched off. the drive goes to the opposite end position and closes the valve.

The unused red and grey wires should not be connected. nor should they come into contact with other

wires. We recommend that you insulate them.

Connected as a 3-point control unit

By connecting power to the wires (brown or black). the valve can be moved to any position. The coupling rod extends and opens the valve if power is applied to the black wire. It retracts and closes the

valve if power is applied to the blue and the brown wires.

In the end positions (on hitting a stop in the valve or reaching the maximum stroke) or in the event of

an overload. the electronic motor cut-off responds (no end switches). The direction of the stroke can be

changed by swapping the power-supply w ires over (BN/BK). The unused red and grey w ires should not

be connected. nor should they come into contact with other wires. We recommend that you insulate

them.

Connections for control voltage 0...10V

The integrated positioner controls the drive as a function of the controller’s positioning signal y.

Direction of operation 1 (mains power on brown wire): the coupling rod extends and opens the valve

(control passage) as the positioning signal rises.

Direction of operation 2 (mains power on black wire): the coupling rod retracts and closes the valve

(control passage) as the positioning signal rises.

The starting point and the control span are both permanently set. There is a split-range unit available

(as an accessory) for setting partial ranges.

After manual adjustment or in the event of a power failure for longer than 5 minutes, the drive readjusts itself automatically, always with a running time of:

AVM 104 65 s

AVM 114 60 s

AVM 105 35 s

AVM 115 60 s

After power has been applied. the stepping motor moves to the lower stop. connects to the valve spindle and moves to the upper stop in the valve. thereby determining the closed position. Depending on

the control voltage. any stroke between 0 and 8 mm can then be obtained. Thanks to the electronics

unit. no steps can be lost. and the drive needs no periodical re-adjustment. Parallel operation of more

than one drive of the same type is guaranteed.

The feedback signal y0 = 0...10V corresponds to the effective stroke of 0 to 8 mm.

If the control signal (0...10V) is interrupted and direction of operation 1 is connected. the valve closes

fully (0% position).

The valve’s characteristic can be selected using the coding switch. The characteristics can be generated only if the drive is used as a continuous drive. Other switches enable the running times to be set.

These can be applied irrespective of whether the 2-point. 3-point or the continuous function has been

chosen.

Sauter Components

7151362003 03

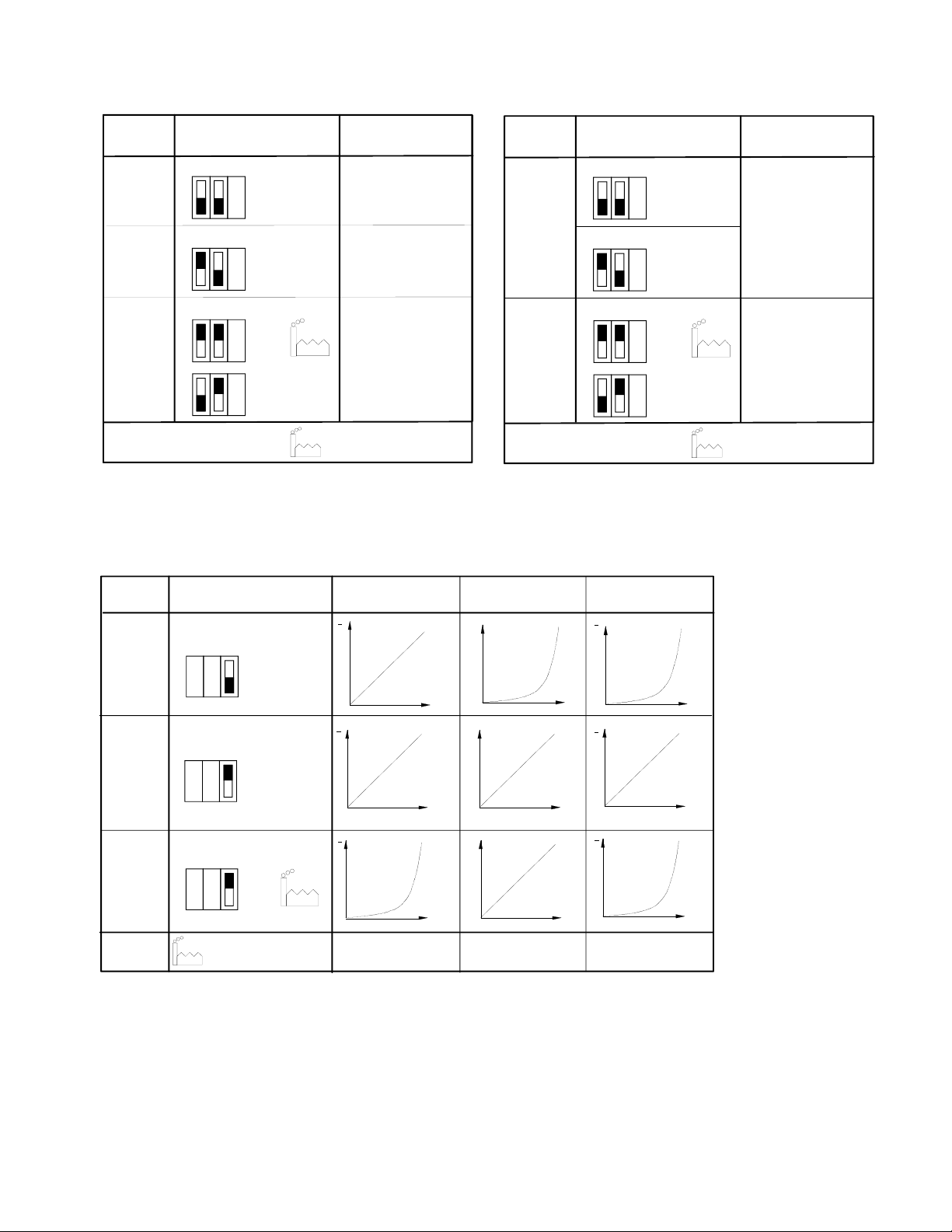

Coding switch for running time selection

AVM 104 S

Run time

per mm

4,375 s

8,125 s

Switch coding

1 2 3

On

Off

1 2 3

On

Off

Run time for

8 mm stroke

35 s ± 1

65 s ± 2

AVM 114S

Run time

per mm

7,5 s

Switch coding

1 2 3

1 2 3

AVM 104S...115S 51.362/3

Run time for

8 mm stroke

On

Off

60 s ± 2

On

Off

1 2 3

On

Off

16,25 s

On

Off

= factory setting

Coding switch for characteristics selection

AVM 104S , AVM 114S

Desired

character.

curve

Switch coding

Characteristic

curve for valve

v

1 2 3

On

Equal

percentage

Off

v

1 2 3

Linear

On

Off

v

1 2 3

On

Off

Equal

percentage

= factory setting

130 s ± 4

Stroke

Stroke

Stroke

B10699

Stroke

Stroke

Stroke

15 s

Characteristic

curve for drive

Signal

Signal

Signal

1 2 3

On

Off

On

Off

Effective on valve

v

= %

Signal

v

lin

Signal

v

= %

Signal

B10701

120 s ± 4

= factory setting

B10700

Sauter Components

7151362003 03

Loading...

Loading...