Satake RMGS 844, RMGS 284 Manual

INSTRUCTION MANUAL

OPTICAL SORTER 4#

RMGS 284 564 844 1404AMS/BM/DMS/AIS/BI/DIS

Type: RMGS1404

0901-27A

Introduction

This machine is a Optical Sorter of the chute system which adopts a highly-sensitive camera and can sort out an accepted grain and a rejected grain with the delicate difference of hue and tone with sufficient accuracy.In order to fully demonstrate the function and performance of this machine, and also in order to use regularly for a long time, read this instruction manual throughly. The outline about this instruction manual is explained below.

For Safety |

P.1 |

Make sure to read this instruction manual prior to operation, maintenance and inspection.

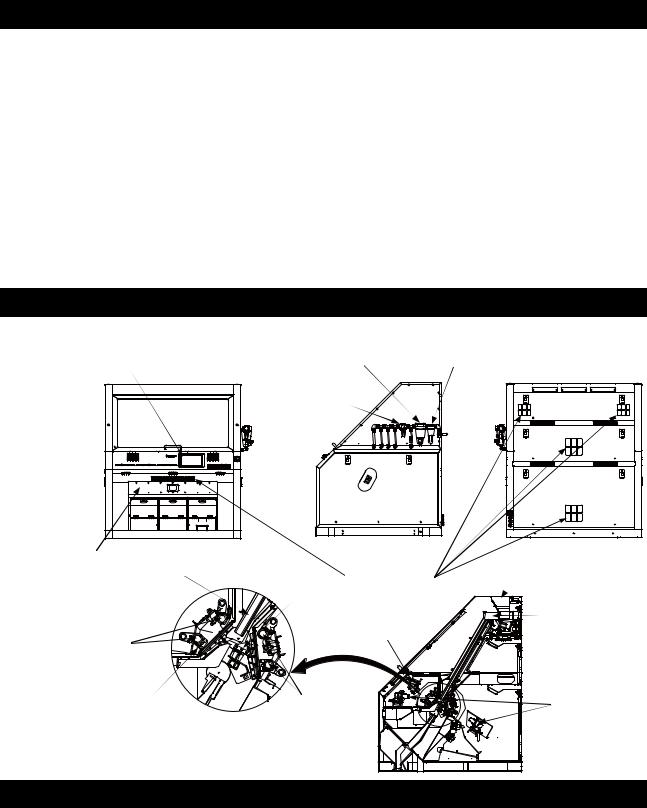

Name and Function of Each Part |

P.5 |

Understand the name and function of each part well and operate them.

Touch screen |

|

Micro mist separator |

Air filter |

||

|

|

|

|

|

|

Regulator

Dust-collecting |

|

|

equipment |

|

|

Chute |

Suction filter |

Material tank |

|

Wiper |

Feeder |

|

NIR camera |

|

Fluorescent lamp |

|

|

|

|

|

Halogen lamp |

Fluorescent |

CCD camera |

|

lamp |

Mechanism of Machine

The materials thrown in from the material tank are sent out with a feeder, and are supplied to a chute. The materials which the flow was stabilized with the chute were given up by the optical section are checked with the upper and lower cameras, and what was distinguished from rejected grains is flown by the air from an air nozzle at a reject outlet. Adoption of a highly-sensitive camera and a stabilized supply realize high-precision sorting.

Explanation of Operating Method and Work Procedure |

P.74 |

Full explanation of procedure and order of operating methods.

Main menu

Operation Monitor Screen |

Sub menu |

•Touch “OPERATION/STOP” and the operation starts with selected setting.

•When loading another setting, touch “Variety” of main menu.

•When adjusting each setting, select each icons of main menu. (Main menu has each sub menu.)

•When setting details, access the higher user level on the main menu. (A password is required to access the higher level.)

•When turning off the power, touch “Stand by” of main menu.

Maintenance and Inspection |

P.85 |

In order to demonstrate the function and performance of this machine enough, carry out daily check and a scheduled inspection certainly, and prevent a trouble

|

|

|

Air filters |

|

Covers |

|

|

|

Dust-collecting |

|

|

|

|

Covers |

|

|

equipment |

|

|

|

|

|

|

|

|

Chute |

Suction filter |

|

|

||

|

|

|

|

|

|||

|

|

|

|

Wiper |

Feeder |

|

|

|

Fluoresecnt lamp |

|

|

|

|||

|

|

|

|

|

|

||

|

Optical section |

Fluorescent lamp |

|

|

|||

No. |

Action |

Frequency |

Ref. |

No. |

Action |

Frequency |

Ref. |

|

Check dirt in detecting |

Once a week |

See P.85 |

|

Check covers |

Once a week |

|

|

section |

|

|

|

|

|

|

|

Check dust-collecting |

Once a week |

|

Check and clean wiper |

Once a week |

See P.85 |

|

|

equipment |

|

|

|

|

|

|

|

Check fluorescent lamp |

Once a week |

See P.87 |

|

Check chute |

Once a week |

See P.90 |

|

Check and clean feeder |

Once a week |

See P.90 |

|

Check and clean |

Once a week |

See P.91 |

|

|

|

|

|

suction filters |

|

|

|

Check air filter |

Once a week |

See P.92 |

|

Daily check |

Once a day |

|

IMPORTANT NOTICE

Specifications and/or machine appearance may change for improvement without notice.

1. For Safety Use:

!WARNING

(1)Follow this manual when operating, inspecting, or maintaining this machine.

If you have any questions on this machine, contact your local Satake branch office for answers before operations.

(2)All operating hazards cannot be anticipated regarding this machine. The instructions and warnings as stipulated in this manual and the warning labels attached on the machine are not all assumed as hazards. Take special consideration to maintain safe operation. Follow the instructions and warnings as stipulated in this manual, and heed the warning labels affixed to this machine.

(3)Do not operate this appliance for any use outside of original design. Operating this machine outside original parameters can cause accidents to personnel and damage to the machine.

Do not modify the inspection or maintenance schedules.

(4)Operators shall work with managers and superintendents to follow safety procedures and run the machine in a safe manner.

2.For Instruction Manual:

!CAUTION

(1)Keep this manual at hand if you have questions about the machine. Contact the local Satake representative if this manual is lost. Satake would be happy to send a replacement manual.

(2)Illustrations and displays as stipulated in this manual may differ from the actual ones because they are simplified for easy viewing and understanding by exaggeration or abbreviation.

(3)If you have any questions or errors in this manual, contact the local Satake office.

(4)If this manual is assembled or collated incorrectly, contact the local Satake office to ask for a correct one. Be sure to inform them of the machine name and model at that time.

(5)If this machine is transferred, or sold to a new owner, make sure this manual stays with the machine.

i

WARRANTY AND AFTER-SALES SERVICE

1.Limitation of Warranty

<Warranty Clause>

Our equipment is manufactured and supplied under the strict quality control and inspection guidelines. We warrant that supplied equipment will be free from defects in material and workmanship for the period of either a) one (1) year from the date of initial start-up operation, or

b)eighteen (18) months from the date of shipment from our shipping port (on the basis of the Bill of Lading date), whichever is earlier. If any parts or equipment fail to meet the above stated warranty, we shall supply replacement parts and machines at our own expense provided that any such failure is clearly proven by the client. The client shall notify us in writing within thirty (30) days from the date of any such failure. Consumable parts and replacement costs are always

borne by the client, even if the warranty period has not elapsed.

<Limitation Clause>

1.We shall be entirely free from any responsibility and/or liability if product failure is caused by any of the following:

(1)Misoperation, maintenance and inspection, or negligent treatment of the equipment by the client and/or user

(2)Any modifications to the design and/or construction, in whole or in part, of the equipment or any parts therein by the client and/or user

(3)Use outside of normal application and/or abnormal use under overcapacity

(4)Usage of non-genuine parts

(5)Relocation and/or transfer of equipment from the place where initially assembled, erected constructed and/or installed by the client and/or user

(6)Acts of God, climate, war, warlike hostilities, civil commotion, riots, strikes, fire, lockouts, plague, or other epidemics, and any other similar circumstances beyond our control

(7)Any loss or damage to equipment which occurs after shipment of equipment from our delivery port

2.If this machine is transferred or sold to a new owner, contact the local Satake office.

If Satake is not contacted, Satake will be unable to determine the status of the machine (maintenance record, installation status) or confirm the existence or non-existence of the accompanying documents. As a result, the safety and performance of this machine may not be guaranteed.

2.After-Sales Service

<Limitation of Supply of Spare Parts>

(1)The limitation on the supply of spare parts for the machine is 12 years after production of the machine is discontinued, though some special parts may be unavailable even if the limitation period has not elapsed.

(2)The supply of spare parts for this machine will principally finish according to the above limitation of supply. However, if, after the limitation time has elapsed, the client wishes to purchase spare parts, Satake may be able to submit a price quotation for the parts desired.

ii

CONTENTS

IMPORTANT NOTICE ............................................................................................. |

i |

|

WARRANTY AND AFTER-SALES SERVICE......................................................... |

ii |

|

1 FOR SAFETY........................................................................................................... |

1 |

|

1.1 |

Safety Requirements and Caution Warnings................................................. |

1 |

|

1.1.1 Safety Requirements............................................................................ |

1 |

|

1.1.2 Prohibition Clause ................................................................................ |

1 |

1.2 |

Hazards ......................................................................................................... |

2 |

1.3 |

Hazard Labels................................................................................................ |

2 |

1.4 |

Position of Hazard Labels.............................................................................. |

3 |

2 SPECIFICATIONS, DIMENSIONS, AND EXPLANATION OF EACH PART ........... |

5 |

|

2.1 |

Specifications................................................................................................. |

5 |

2.2 |

Dimensions .................................................................................................... |

7 |

|

2.2.1 RMGS 284 ........................................................................................... |

7 |

|

2.2.2 RMGS 564 ........................................................................................... |

8 |

|

2.2.3 RMGS 844 ........................................................................................... |

9 |

|

2.2.4 RMGS 1404 ....................................................................................... |

10 |

2.3 |

Function of Each Model ............................................................................... |

11 |

2.4 |

Name and Function of Each Part................................................................. |

12 |

3 ASSEMBLY AND INSTALLATION......................................................................... |

13 |

|

3.1 |

Caution of Installation .................................................................................. |

13 |

3.2 |

Dimensions of Inlet, Outlet and Dust-collecting Duct................................... |

14 |

|

3.2.1 RMGS 284AMS/AIS (Flat 90×2 : U Channel 90×1) ........................... |

14 |

|

3.2.2 RMGS 284BM/BI (Flat 90×3 : 0) ........................................................ |

15 |

|

3.2.3 RMGS 564AMS/AIS (Flat 280×1, Flat 90×1 : U Channel 90×2) ........ |

16 |

|

3.2.4 RMGS 564AMS/AIS (Flat 280×1, Flat 90×2 : U Channel 90×1) ........ |

17 |

|

3.2.5 GS 564BM/BI (Flat 280×2 : 0)............................................................ |

18 |

|

3.2.6 RMGS 844AMS/AIS (Flat 280×2 : U Channel 90×3) ......................... |

19 |

|

3.2.7 RMGS 844AMS/AIS (Flat 280×2, Flat 90×1 : U Channel 90×2) ........ |

20 |

|

3.2.8 RMGS 844BM/BI (Flat 280×3 : 0) ...................................................... |

21 |

|

3.2.9 RMGS 1404 AMS/AIS (Flat 280×3 : U Channel 90×6) ...................... |

22 |

|

3.2.10 RMGS 1404 AMS/AIS (Flat 280×4 : U Channel 90×3) .................... |

23 |

|

3.2.11 RMGS 1404 DIS (Flat 280×3 : Flat 280×1, Flat 90×1 : U Channel 90×2). 24 |

|

|

3.2.12 RMGS 1404 BM/BI (Flat 280×5 : 0) ................................................. |

25 |

3.3 |

Space around the Machine.......................................................................... |

26 |

|

SAFETY FOR |

|

|

EXPLANATION AND |

SPECIFICATION, |

|

|

|

|

||

|

|

||

PART EACH OF |

DIMENSIONS |

|

|

|

|

||

AND ASSEMBLY |

|

|

|

INSTALLATION |

|

|

|

PANEL TOUCH |

OF EXPLANATION |

|

|

|

|

||

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

OPERATION |

|

|

|

|

|

|

|

|

|

|

INSPECTION |

AND MAINTENANCE |

|

|

|

|

|

|

|

TROUBLESHOOTINGCIRCUITS ELECTRICAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.4 |

Welding Guidelines...................................................................................... |

26 |

|

3.5 |

Transportation Guidelines............................................................................ |

26 |

|

3.6 |

Main Body Installation.................................................................................. |

27 |

|

3.7 |

Material Tank and Sample Outlet Installation .............................................. |

27 |

|

3.8 |

Air Piping Installation ................................................................................... |

28 |

|

3.9 |

Connecting a Power Supply ........................................................................ |

32 |

|

3.10 |

Dust Suction Piping Installation ................................................................. |

32 |

|

3.11 |

Connecting an External Level Meter Alarm ............................................... |

32 |

|

3.12 |

Removing Fixing Brackets Installing the Feeder ....................................... |

33 |

|

4 EXPLANATION OF TOUCH PANEL ..................................................................... |

34 |

||

4.1 |

Title Screen.................................................................................................. |

34 |

|

4.2 |

Operation Monitor Screen............................................................................ |

35 |

|

4.3 |

Flow Rate Adjustment Screen ..................................................................... |

37 |

|

4.4 |

Flow Rate Adjustment (Detail) Screen (User Level 2 and 3) ....................... |

38 |

|

4.5 |

Sensitivity Adjustment Screen ..................................................................... |

39 |

|

4.6 |

Sensitivity Adjustment (Detail) Screen (User Level 2 and 3) ....................... |

40 |

|

4.7 |

Similation Screen (User Level 2 and 3) ....................................................... |

42 |

|

|

4.7.1 Capturing the Simulation Image......................................................... |

44 |

|

|

4.7.2 Saving the File ................................................................................... |

47 |

|

|

4.7.3 Loading the File.................................................................................. |

47 |

|

4.8 |

Variety Setting Screen ................................................................................. |

48 |

|

4.9 |

Variety List Screen....................................................................................... |

49 |

|

|

4.9.1 Saving Present Setting....................................................................... |

49 |

|

|

4.9.2 Changing a Saved Variety Name....................................................... |

51 |

|

4.10 |

Alarm Monitor Screen (User Level 1) ........................................................ |

52 |

|

4.11 |

Alarm Monitor Screen (User Level 2 and 3) .............................................. |

52 |

|

4.12 |

Operation Log Screen (User Level 2 and 3) .............................................. |

53 |

|

4.13 |

Alarm Log Screen (User Level 2 and 3) .................................................... |

53 |

|

4.14 |

Remaining Time, Date/Time Screen (User Level 2 and 3) ........................ |

54 |

|

4.15 |

Ejector Remaining Time Screen (User Level 2 and 3) .............................. |

55 |

|

4.16 |

Ejector Test Screen (User Level 2 and 3).................................................. |

56 |

|

4.17 |

Sorting Mode Screen (User Level 2 and 3) ............................................... |

57 |

|

4.18 |

Background Setting Screen (User Level 2 and 3) ..................................... |

59 |

|

4.19 |

Auto Flow Setting (by Level) Screen (User Level 2 and 3)........................ |

60 |

|

4.20 |

External Communication Screen (User Level 2 and 3).............................. |

61 |

|

4.21 |

Signal Processor Setting Screen (User Level 3) ....................................... |

62 |

|

4.22 |

Software Update Screen (User Level 2 and 3) .......................................... |

64 |

4.23 |

Auto Flow Setting (by Ejector) Screen (User Level 3) ............................... |

65 |

4.24 |

Timer Setting Screen (User Level 3) ......................................................... |

67 |

4.25 |

Camera Position Screen (User Level 3) .................................................... |

68 |

4.26 |

Language Screen ...................................................................................... |

69 |

4.27 |

Model Selection Screen (User Level 3) ..................................................... |

70 |

4.28 |

Product Setting 1 Screen (User Level 3) ................................................... |

71 |

4.29 |

User Level Screen ..................................................................................... |

72 |

5 OPERATION .......................................................................................................... |

74 |

|

5.1 Operation Adjustment .................................................................................. |

74 |

|

5.2 Operation Correction ................................................................................... |

77 |

|

5.2.1 Flow of Rice Grains............................................................................ |

77 |

|

5.2.2 Adjusting Method of Flow Rate .......................................................... |

77 |

|

5.2.3 Wiper.................................................................................................. |

78 |

|

5.2.4 Alarm Monitor..................................................................................... |

79 |

|

5.2.5 Alarm Cancel...................................................................................... |

80 |

|

5.2.6 Tank Sensor....................................................................................... |

81 |

|

5.2.7 Delay and Dwell of Ejector ................................................................. |

83 |

|

5.2.8 Heater for cold latitudes (Standard kit for brown rice; only in Japan). 84 |

||

6 MAINTENANCE AND INSPECTION ..................................................................... |

85 |

|

6.1 Maintenance and Inspection List ................................................................. |

85 |

|

6.1.1 Replacement of Fluorescent Lamp and Halogen Lamp..................... |

87 |

|

6.1.2 Connection of Air Piping..................................................................... |

88 |

|

6.1.3 Ejector Replacement and Disassembly ............................................. |

89 |

|

6.1.4 Cleaning of Feeder Trough ................................................................ |

90 |

|

6.1.5 Chute.................................................................................................. |

90 |

|

6.1.6 Replacement of Cooling Fan Filter..................................................... |

91 |

|

6.1.7 Replacement of Filter Element for Micro-Mist Separator ................... |

92 |

|

RMGS 284, 564, 844 .......................................................................... |

92 |

|

6.1.8 Replacement of Air-Filter Element ..................................................... |

93 |

|

RMGS 284, 564, 844 .......................................................................... |

93 |

|

6.1.9 Replacement of Filter Element of Air Filter and Core-Lessing Filter .. |

94 |

|

RMGS 1404 ......................................................................................... |

94 |

|

<Procedure of Replacement of Filter Element> .......................................... |

94 |

|

6.2 Consumable Parts List................................................................................. |

95 |

|

6.3 Main Parts List............................................................................................. |

97 |

|

6.3.1 RMGS 284 ......................................................................................... |

97 |

|

6.3.2 RMGS 564 ....................................................................................... |

100 |

|

6.3.3 RMGS 844 ....................................................................................... |

103 |

6.3.4 RMGS 1404 ..................................................................................... |

106 |

7 ELECTRICAL CIRCUITS ..................................................................................... |

109 |

7.1 Wiring Diagram (RMGS 284)..................................................................... |

109 |

7.1.1 Transformer Section......................................................................... |

109 |

7.1.2 Power Supply Unit (Control Circuit) ................................................. |

110 |

7.1.3 Power Supply Unit (Control Power Curcuit 1) .................................. |

111 |

7.1.4 Power Supply Unit (Control Power Curcuit 2) .................................. |

112 |

7.1.5 Signal Processing and Computer..................................................... |

113 |

7.1.6 Fluorescent Lamp ............................................................................ |

114 |

7.1.7 Right Section of the Main body (Feeder Board)............................... |

115 |

7.1.8 Power Supply Unit (Alarm Board) .................................................... |

116 |

7.1.9 Valve Board 1................................................................................... |

117 |

7.2 Wiring Diagram (RMGS 564)..................................................................... |

118 |

7.2.1 Transformer/Breaker Unit................................................................. |

118 |

7.2.2 Power Supply Unit (Control Circuit) ................................................. |

119 |

7.2.3 Power Supply Unit (Valve Power Supply Circuit)............................. |

120 |

7.2.4 Power Supply Unit (Control Power Supply Circuit 1) ....................... |

121 |

7.2.5 Power Supply Unit (Control Power Supply Circuit 2) ....................... |

122 |

7.2.6 Signal Processing and Computer..................................................... |

123 |

7.2.7 Fluorescent Lamp ............................................................................ |

124 |

7.2.8 Right Section of the Main Body........................................................ |

125 |

7.2.9 Power Supply Unit (Alarm Board) .................................................... |

126 |

7.2.10 Valve Board 1, 2, 3......................................................................... |

127 |

7.2.11 Valve Board 4, 5, 6......................................................................... |

128 |

7.3 Wiring Diagram (RMGS 844)..................................................................... |

129 |

7.3.1 Transformer/Breaker Unit................................................................. |

129 |

7.3.2 Power Supply Unit (Control Circuit) ................................................. |

130 |

7.3.3 Power Supply Unit (Valve Power Circuit)......................................... |

131 |

7.3.4 Power Supply Unit (Control Power Curcuit 1) .................................. |

132 |

7.3.5 Power Supply Unit (Control Power Curcuit 2) .................................. |

133 |

7.3.6 Signal Processing and Computer..................................................... |

134 |

7.3.7 Fluorescent Lamp ............................................................................ |

135 |

7.3.8 Main Body Right Section (Feeder Board) ........................................ |

136 |

7.3.9 Power Supply Unit (Alarm Board) .................................................... |

137 |

7.3.10 Valve Board 1, 2, 3......................................................................... |

138 |

7.3.11 Valve Board 4, 5, 6......................................................................... |

139 |

7.3.12 Valve Board 7, 8, 9......................................................................... |

140 |

7.4 Wiring Diagram (RMGS 1404)................................................................... |

141 |

7.4.1 Transformer/Breaker Unit A, Transformer Unit B............................. |

141 |

7.4.2 Power Supply Unit (Control Circuit) ................................................. |

142 |

7.4.3 Power Supply Unit (Valve Power Circuit)......................................... |

143 |

7.4.4 Power Suppy Unit (Control Power Circuit 1) .................................... |

144 |

7.4.5 Power Suppy Unit (Control Power Circuit 2) .................................... |

145 |

7.4.6 Signal Processing and Computer..................................................... |

146 |

7.4.7 Fluorescent Lamp ............................................................................ |

147 |

7.4.8 Right Section of the Main Body (Feeder Board) .............................. |

148 |

7.4.9 Power Supply Unit (Alarm Board) .................................................... |

149 |

7.4.10 Valve Baord 1, 2, 3......................................................................... |

150 |

7.4.11 Valve Board 4, 5, 6......................................................................... |

151 |

7.4.12 Valve Board 7, 8, 9......................................................................... |

152 |

7.4.13 Valve Board 10, 11, 12................................................................... |

153 |

7.4.14 Valve Board 13, 14, 15................................................................... |

154 |

7.5 Transformer and Power Supply Unit (RMGS 284) .................................... |

155 |

7.5.1 Configuration.................................................................................... |

155 |

7.5.2 Transformer and Power Supply Unit Parts....................................... |

156 |

7.6 Transformer and Power Supply Unit (RMGS 564) .................................... |

157 |

7.6.1 Configuration.................................................................................... |

157 |

7.6.2 Transformer and Power Supply Unit Parts....................................... |

158 |

7.7 Transformer and Power Supply Unit (RMGS 844) .................................... |

159 |

7.7.1 Configuration.................................................................................... |

159 |

7.7.2 Transformer and Power Supply Unit Parts....................................... |

160 |

7.8 Transformer and Power Supply Unit (RMGS 1404) .................................. |

161 |

7.8.1 Configuration.................................................................................... |

161 |

7.8.2 Transformer and Power Supply Unit Parts....................................... |

162 |

7.9 Feeder PCB 1, 2 ........................................................................................ |

164 |

7.10 Single Board Computer (SBC)................................................................. |

166 |

7.11 CPU PCB................................................................................................. |

167 |

7.12 Signal Processing PCB............................................................................ |

169 |

7.13 Alarm PCB 1, 2 ........................................................................................ |

171 |

7.14 LED PCB (013P307)................................................................................ |

174 |

7.15 Valve Drive PCB ...................................................................................... |

175 |

7.16 Inverter..................................................................................................... |

176 |

8 TROUBLESHOOTING ......................................................................................... |

177 |

8.1 Troubleshooting List .................................................................................. |

177 |

1 FOR SAFETY

This chapter presents a list of safety guidelines to prevent a fatal or serious injury to the operator.

1.1Safety Requirements and Caution Warnings

The safety guidelines are divided into two sections: requirements for use to ensure operator safety and caution warnings to prevent accidents.

1.1.1Safety Requirements

(1)Operator must have hair cut short and wear clothes and shoes that are free of stray or loose fabric in order to protect from advertent contact with machinery. Always wear a helmet and safety shoes when carring out any inspection or maintenance.

(2)Ensure that passages around the machine, as well as surrounding areas, are kept clean at all times.

(3)Always properly ground the machine in order to protect personnel from fires or electric accidents caused by current leaks.

(4)Always inspect the machine before starting operation.

When carrying out any inspection work, always power off and clearly indicate that the machine is under inspection or maintenance both in the control room and on the control panel.

(5)Always power off before inspection and maintenance and affix an “Under Inspection” sign over the power switch. After the inspection, be sure all tools are picked up.

(6)Check all bolts, nuts, and belts for any looseness or damage. Be sure to replace all covers after completing this check.

(7)Check for any cuts or damage to power cord, wiring, and cables. Ensure all connectors and plugs are seated properly.

(8)Always stop the machine when greasing the driving part of the machine.

(9)You should get familiarized yourself with the power off procedure for a case of emergency.

(10)When two or more persons operate the machine, each person must confirm readiness to the others before starting the machine.

1.1.2Prohibition Clause

(1)Keep water and other liquids away from the machine. Contact with water or other liquids can short electric circuits, subsequently causing the machine to break down.

(2)Do not touch any live parts while the machine is powered on.

(3)Do not permit any person other than the individual in charge of machine operation to operate the machine.

(4)Keep the operating area clear of any people other than those permitted by the operator. Never let children near the machine.

(5)Operate the machine with all covers in place.

Do not attempt to remove any cover while the machine is running.

(6)Do not touch any moving parts while the machine is operating.

(7)Do not put flammable items near the machine.

(8)Wear a dustproof mask and goggles when operating the machine in a dusty place.

1

SAFETY FOR

SAFETY FOR

1.2Hazards

In order to protect workers and prevent damage to processing material, the following two methods are used to call attention to possible dangers while operating.

(1)A printed warning in this instruction manual

(2)A warning label affixed to the machine

Printed warning and hazard labels are classified into following three levels depending on the degree of risk or accident at the time of work.

Study these warning signs and always follow the stated instructions.

Warning Word |

Definition |

!WARNING This shows potential hazard. Failure to follow this warning

increases the possibility of fatal or serious injury.

This shows a potential hazard. Failure to follow this warning

!CAUTION increase the possibility of middle or minor class injury,

damage to equipment or machinery, or trouble with the material or product.

NOTE |

This warning calls attention to, and places emphasis on, |

|

certain special information. |

||

|

1.3Hazard Labels

Hazard labels are used to indicate the machine areas/parts requiring special attention.

Be sure to fully understand the content of danger prevention warnings, including the exact positions and dangers involved.

NOTE

Handling of Hazard Label

•Be sure all hazard labels can be easily seen and read. Clean or replace the label if legibile.

•Use cloth, water and detergent to remove the dirt from a hazard label. Never use organic solvents or gasoline.

•Replace damaged, missing, or unreadable hazard labels with new ones.

2

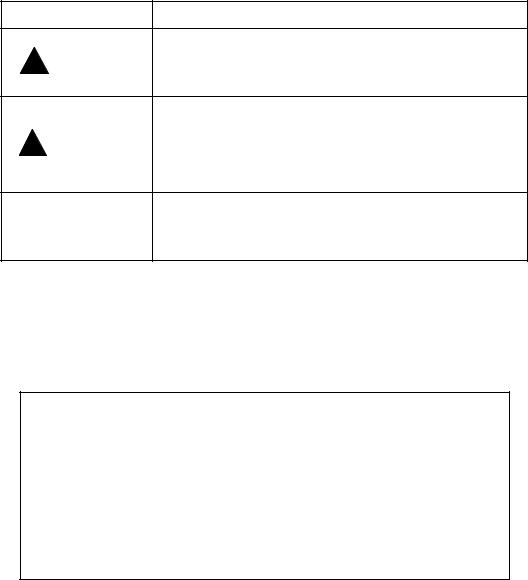

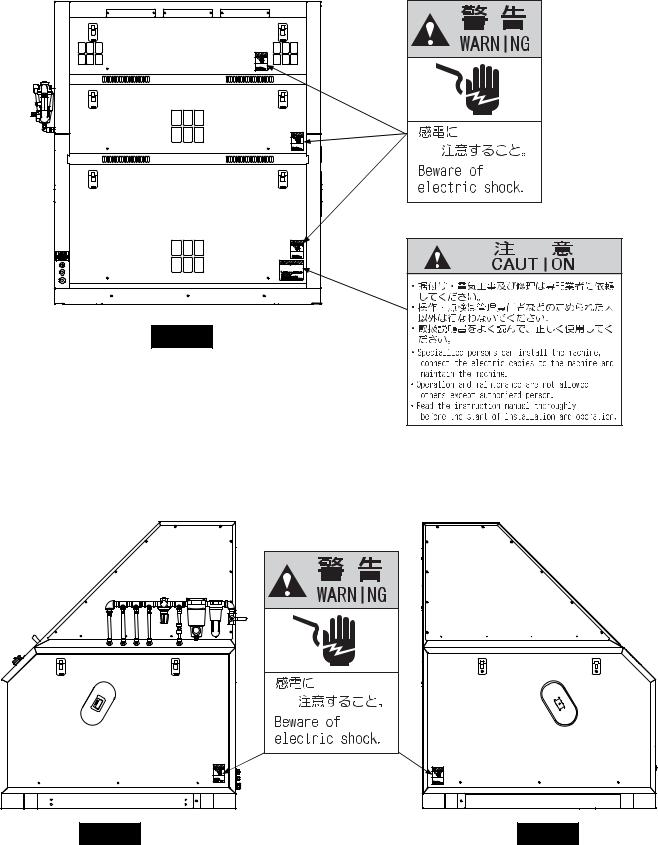

1.4Position of Hazard Labels

Positions of the following hazzard labels are shown below.

299001511

SAFETY FOR

SAFETY FOR

Front

299001575

299001509

Fig. 1-1 Position of Hazard Labels (1)

3

299001509

Rear

299001535

|

299001509 |

Right |

Left |

|

Fig. 1-2 Position of Hazard Labels (2) |

4

2 SPECIFICATIONS, DIMENSIONS, AND EXPLANATION OF EACH PART

2.1 Specifications

Table 2-1 Specifications List (RMGS 284)

|

Model |

|

AMS |

|

AIS |

|

|

BM |

|

BI |

|||

|

Number of |

|

|

Primary |

|

Flat 90×2 |

|

|

|

|

Flat 280×1 |

||

|

|

|

sorting |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

chute |

|

Secondary |

U channel 90×1 |

|

|

|

|

|

||||

|

|

|

|

sorting |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Capacity |

|

White rice |

0.3 ~ 3.6 |

|

|

|

|

0.45 ~ 5.4 |

||||

|

|

|

Brown rice |

0.3 ~ 1.8 |

|

|

|

|

0.45 ~ 2.7 |

||||

|

(t/h) |

|

|

|

|

|

|

||||||

|

|

|

Wheat/Barley |

|

0.3 ~ 1.8 |

|

|

|

|

0.45 ~ 2.7 |

|||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

Sorting discolored grain in milled rice and |

brown rice. |

|

|

||||

|

|

|

|

|

|

Sorting chalky grain in milled rice and brown rice. |

|

|

|||||

|

Major applications |

|

Sorting discolored and chalky grain in milled rice. |

|

|

|

|||||||

|

|

Sorting discolored grain in wheat and barley. |

|

|

|

||||||||

|

|

|

|

|

|||||||||

|

|

|

|

|

|

Sorting inorganic substances (glass, white stone,etc.) in the above-mentioned materials. |

|||||||

|

|

|

|

|

|

is for only AMS and BM. |

|

|

|

||||

|

Power supply (V) |

|

|

|

Single phase 200 |

|

|

|

|||||

|

Required |

|

|

Normal |

|

|

1.2 |

|

|

|

|||

|

power (kW) |

|

Maximum |

|

|

1.7 |

|

|

|

||||

|

Required air volume |

|

|

|

200 ~ 500 NL/min |

|

|

||||||

Dust collector (Optional) |

|

|

7 3/min |

|

|

|

|||||||

|

Compressor (kW) |

|

|

|

2.2 ~ 5.5 |

|

|

|

|||||

|

Net weight (kg) |

|

|

|

520 |

|

|

|

|||||

|

Dimensions (mm) |

|

|

949×1550×1900 |

|

|

|||||||

|

[Width×Length×Height] |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|||||

Table 2-2 Specifications List (RMGS 564)

|

Model |

AMS |

|

AIS |

Flat 280×1, |

BM |

|

BI |

|||||||

|

Number of |

|

|

Primary |

Flat 280×1, |

|

Flat 280×1, |

|

Flat 280×1, |

|

Flat 280×2 |

||||

|

|

|

sorting |

Flat 90×2 |

|

Flat 90×1 |

|

Flat 90×2 |

|

Flat 90×1 |

|||||

|

|

|

|

|

|

|

|

|

|||||||

|

chute |

|

Secondary |

U channel |

|

U channel |

|

U channel |

|

U channel |

|

|

|||

|

|

|

|

sorting |

90×1 |

|

90×2 |

|

90×1 |

|

90×2 |

|

|||

|

|

|

|

|

|

|

|

|

|

||||||

|

Capacity |

|

White rice |

0.75 ~ 9.0 |

|

0.6 ~ 7.2 |

|

0.75 ~ 9.0 |

|

0.6 ~ 7.2 |

1.35 ~ 16.2 |

||||

|

|

|

Brown rice |

|

|

|

0.6 ~ 3.6 |

|

|

|

0.6 ~ 3.6 |

1.35 ~ 8.1 |

|||

|

(t/h) |

|

|

|

|

|

|

||||||||

|

|

|

Wheat/Barley |

|

|

|

0.6 ~ 3.6 |

|

|

|

0.6 ~ 3.6 |

1.35 ~ 8.1 |

|||

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

Sorting discolored grain in milled |

rice and brown rice. |

|

|

|

|||||

|

|

|

|

|

|

Sorting chalky grain in milled rice and brown rice. |

|

|

|

|

|||||

|

Major applications |

|

Sorting discolored and chalky grain in milled rice. |

|

|

|

|

||||||||

|

|

Sorting discolored grain in wheat and barley. |

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

Sorting inorganic substances (glass, white stone,etc.) in the above-mentioned materials. |

|||||||||

|

|

|

|

|

|

is for only AMS and BM. |

|

|

|

|

|

|

|

||

|

Power supply (V) |

|

|

|

Single phase 200 |

|

|

|

|

||||||

|

Required |

|

|

Normal |

|

|

|

|

2.0 |

|

|

|

|

|

|

|

power (kW) |

|

Maximum |

|

3.0 |

|

2.7 |

|

3.0 |

|

2.7 |

||||

|

Required air volume |

|

|

|

400 ~ 1000 NL/min |

|

|

|

|

||||||

Dust collector (Optional) |

|

|

|

|

7 3/min |

|

|

|

|

||||||

|

Compressor (kW) |

|

|

|

|

3.7 ~ 7.5 |

|

|

|

|

|

||||

|

Net weight (kg) |

|

|

|

700 |

|

|

|

|

|

|||||

|

Dimensions (mm) |

|

|

|

|

1309×1550×1900 |

|

|

|

|

|||||

|

[Width×Length×Height] |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

5

EXPLANATION AND |

SPECIFICATIONS, |

|

|

||

PART EACH OF |

DIMENSIONS |

|

|

Table 2-3 Specifications List (RMGS 844)

|

Model |

AMS |

|

|

AIS |

|

BM |

|

BI |

||||||

|

|

|

|

Primary |

Flat 280×2, |

|

Flat 280×2 |

|

Flat 280×2, |

|

Flat 280×2 |

Flat 280×3 |

|||

|

Number of |

|

|

sorting |

Flat 90×1 |

|

|

Flat 90×1 |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

chute |

|

Secondary |

U channel |

|

U channel |

|

U channel |

|

U channel |

|

|

|||

|

|

|

|

sorting |

90×2 |

|

90×3 |

|

90×2 |

|

90×3 |

|

|||

|

|

|

|

|

|

|

|

|

|

||||||

|

Capacity |

|

|

White rice |

1.05 ~ 12.6 |

|

0.9 ~ 10.8 |

|

1.05 ~ 12.6 |

|

0.9 ~ 10.8 |

1.35 ~ 16.2 |

|||

|

|

|

Brown rice |

|

|

0.9 ~ 5.4 |

|

|

|

0.9 ~ 5.4 |

1.35 ~ 8.1 |

||||

|

(t/h) |

|

|

|

|

|

|||||||||

|

|

Wheat/Barley |

|

|

0.9 ~ 5.4 |

|

|

|

0.9 ~ 5.4 |

1.35 ~ 8.1 |

|||||

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

Sorting discolored grain in milled |

rice and brown rice. |

|

|

|

|||||

|

|

|

|

|

|

Sorting chalky grain in milled rice and brown rice. |

|

|

|

|

|||||

|

Major applications |

|

Sorting discolored and chalky grain in milled rice. |

|

|

|

|

||||||||

|

|

Sorting discolored grain in wheat and barley. |

|

|

|

|

|||||||||

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

Sorting inorganic substances (glass, white stone,etc.) in the above-mentioned materials. |

|||||||||

|

|

|

|

|

|

is for only AMS and BM. |

|

|

|

|

|

|

|

||

|

Power supply (V) |

|

|

|

Single phase 200 |

|

|

|

|

||||||

|

Required |

|

|

Normal |

|

|

|

2.4 |

|

|

|

|

|

||

|

power (kW) |

|

|

Maximum |

3.9 |

|

|

3.3 |

|

3.9 |

|

3.3 |

|||

|

Required air volume |

|

|

|

600 ~ 1500 NL/min |

|

|

|

|

||||||

Dust collector (Optional) |

|

|

|

|

12 3/min |

|

|

|

|

||||||

|

Compressor (kW) |

|

|

|

|

5.5 ~ 11.0 |

|

|

|

|

|

||||

|

Net weight (kg) |

|

|

|

920 |

|

|

|

|

|

|||||

|

Dimensions (mm) |

|

|

|

1669×1550×1900 |

|

|

|

|

||||||

|

[Width×Length×Height] |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|||||

Table 2-4 Specifications List (RMGS 1404)

|

Model |

AMS |

AIS |

|

BM |

|

BI |

DMS |

DIS |

|||||||

|

|

|

|

Primary |

Flat |

|

Flat |

Flat |

Flat |

|

Flat 280×5 |

Flat 280×3 |

||||

|

|

|

|

sorting |

280×4 |

|

280×3 |

280×4 |

280×3 |

|

||||||

|

Number of |

|

|

|

|

|

|

|

|

|

||||||

|

|

Secondary |

U channel |

|

U channel |

U channel |

U channel |

|

|

|

Flat 280×1, |

|||||

|

chute |

|

|

sorting |

90×3 |

|

90×6 |

90×3 |

90×6 |

|

|

Flat 90×1 |

||||

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

Tertiary |

|

|

|

|

|

|

|

|

U channel |

|||

|

|

|

|

sorting |

|

|

|

90×2 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Capacity |

|

White rice |

1.8 ~ 21.6 |

|

1.35 ~ 16.2 |

1.8 ~ 21.6 |

1.35 ~ 16.2 |

|

2.25 ~ 27.0 |

1.35 ~ 16.2 |

|||||

|

|

|

Brown rice |

1.8 ~ 10.8 |

|

1.35 ~ 8.1 |

1.8 ~ 10.8 |

1.35 ~ 8.1 |

|

2.25 ~ 13.5 |

1.35 ~ 8.1 |

|||||

|

(t/h) |

|

|

|

|

|||||||||||

|

|

|

Wheat/Barley |

|

1.8 ~ 10.8 |

|

1.35 ~ 8.1 |

1.8 ~ 10.8 |

1.35 ~ 8.1 |

|

2.25 ~ 13.5 |

1.35 ~ 8.1 |

||||

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

Sorting discolored grain |

in milled rice and brown rice. |

|

|

|

|

|||||

|

|

|

|

|

|

Sorting chalky grain in milled rice and brown rice. |

|

|

|

|

|

|||||

|

Major applications |

|

Sorting discolored and chalky grain in milled rice. |

|

|

|

|

|

||||||||

|

|

Sorting discolored grain in wheat and barley. |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

Sorting inorganic substances (glass, white stone,etc.) in the above-mentioned materials. |

||||||||||

|

|

|

|

|

|

is for only AMS, BM and DMS. |

|

|

|

|

|

|

|

|||

|

Power supply (V) |

|

|

|

Single phase 200 |

|

|

|

|

|

||||||

|

Required |

|

|

Normal |

|

|

|

|

|

4.0 |

|

|

|

|

|

|

|

power (kW) |

|

Maximum |

|

6.0 |

5.4 |

|

6.0 |

|

5.4 |

6.0 |

5.4 |

||||

|

Required air volume |

|

|

|

1000 ~ 2000 NL/min |

|

|

|

|

|

||||||

Dust collector (Optional) |

|

|

|

15 3/min |

|

|

|

|

|

|||||||

|

Compressor (kW) |

|

|

|

7.5 ~ 15.0 |

|

|

|

|

|

|

|||||

|

Net weight (kg) |

|

|

|

|

1300 |

|

|

|

|

|

|

||||

|

Dimensions (mm) |

|

|

|

|

2250×1550×1900 |

|

|

|

|

|

|

||||

|

[Width×Length×Height] |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

*Inorganic substances are noncarbon compounds, including stones and glass.

*Capacity depends on material variety and mixing rate of contaminants.

*When processing materials of very high mixture rates of contamination, large volume of compressed air is required. Be careful of your compressor capacity.

*This machine is without conveyors. The user shall prepare conveyers. (Available as an option.)

*Use the U channel chute if primary sorting volume is 0.45t/h or less.

6

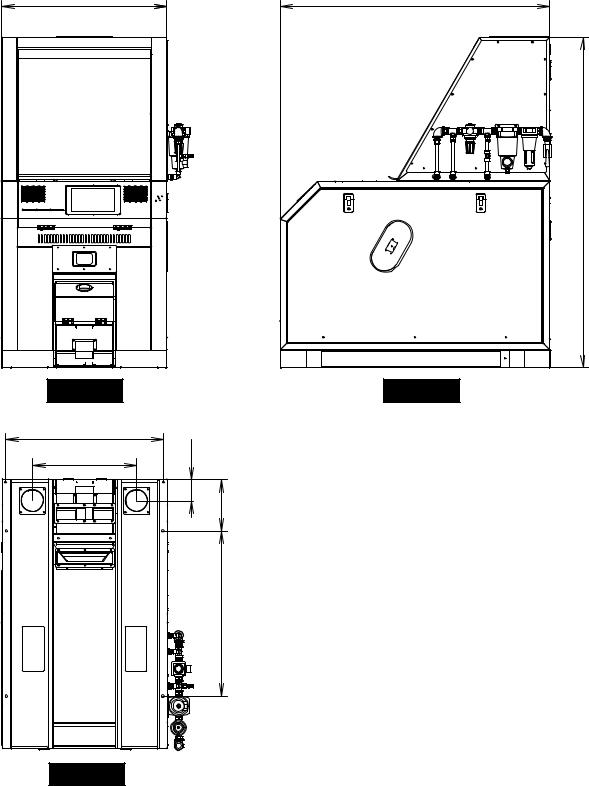

2.2Dimensions

2.2.1RMGS 284

Unit: mm

949 |

1550 |

EXPLANATION AND |

SPECIFICATIONS, |

|

|

||

PART EACH OF |

DIMENSIONS |

|

|

1900

Front

908

599

Right

126

300

950

Bottom

Fig. 2-1 Dimensions (RMGS 284)

7

2.2.2 RMGS 564

Unit: mm

1309 |

1550 |

|

1900

Front

1258

959

Right

126 300

950

Bottom

Fig. 2-2 Dimensions (RMGS 564)

8

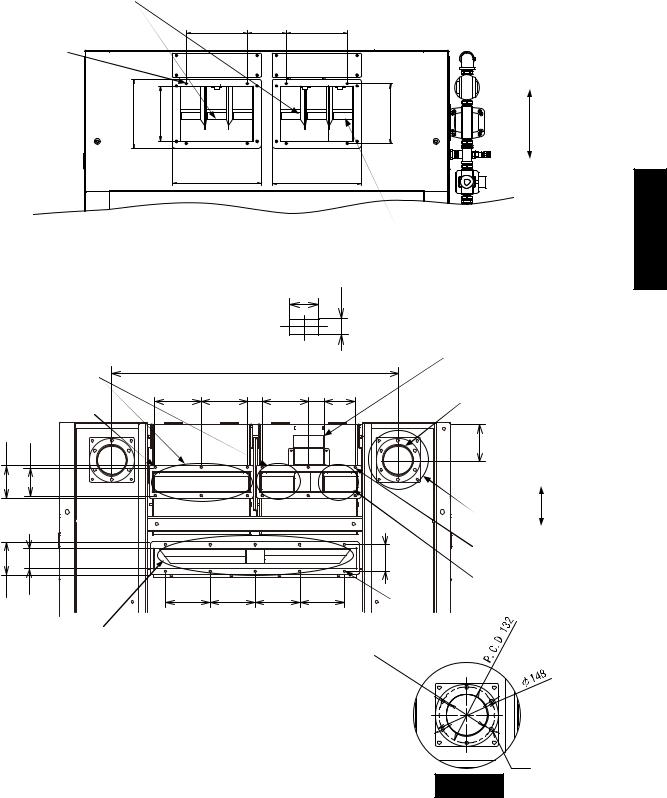

2.2.3 RMGS 844

1669

Front

1618

1319

Unit: mm |

|

|

1550 |

|

|

|

EXPLANATION AND |

SPECIFICATIONS, |

1900 |

PART EACH OF |

DIMENSIONS |

Right

126 300

950

Bottom

Fig. 2-3 Dimensions (RMGS 844)

9

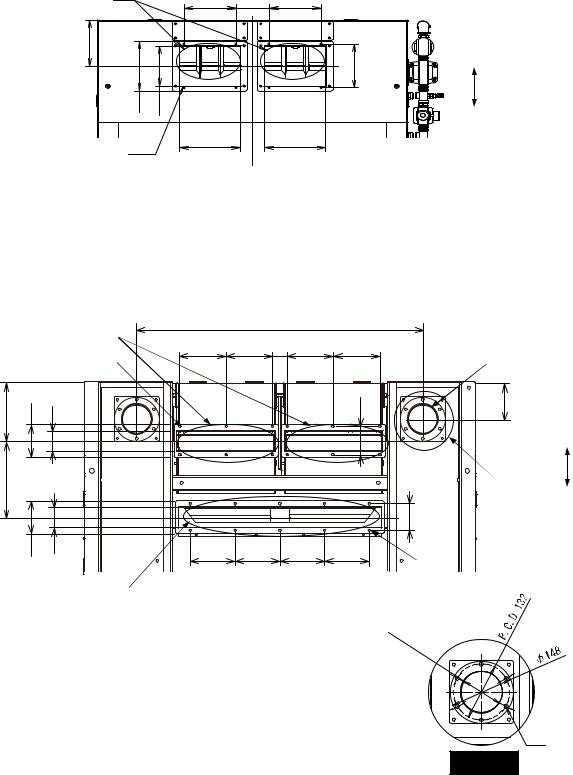

2.2.4 RMGS 1404 |

|

1900 |

|

1920 |

|

Front |

|

1890 |

|

1670 |

148 |

300

950

Unit: mm

1550

1900 |

Right

Bottom

Fig. 2-4 Dimensions (RMGS 1404)

10

2.3 Function of Each Model

Table 2-5 Function of Each Model

|

Model |

|

Sorting of Glass |

Primary/Secondary |

|

Primary/Secondary/Tertiary |

|

|

and Stone |

Sorting |

|

Sorting |

|

|

|

|

|

|||

|

AMS |

○ |

○ |

× |

||

|

AIS |

× |

○ |

× |

||

|

BM |

○ |

× (Only primary sorting) |

× |

||

|

BI |

× |

× (Only primary sorting) |

× |

||

|

DMS |

○ |

× |

|

○ |

|

|

DIS |

× |

× |

|

○ |

|

<AMS/AIS> |

<BM/BI> |

<DMS/DIS> |

Material |

Material |

Material |

EXPLANATION AND |

SPECIFICATIONS, |

|

|

||

PART EACH OF |

DIMENSIONS |

|

|

Primary |

Secondary |

Primary sorting |

Primary |

Secondary Tertiary |

|

sorting |

sorting sorting |

||||

sorting |

sorting |

|

|||

|

|

|

|||

Primary reject |

|

|

Secondary reject |

||

Final reject |

Primary reject Tertiary accept |

||||

|

Secondary accept |

||||

|

|

Secondary accept |

|||

|

|

|

|

||

Product |

Final reject |

Product |

Product |

Final reject |

|

|

|

||||

Fig. 2-5 Function of Each Model

11

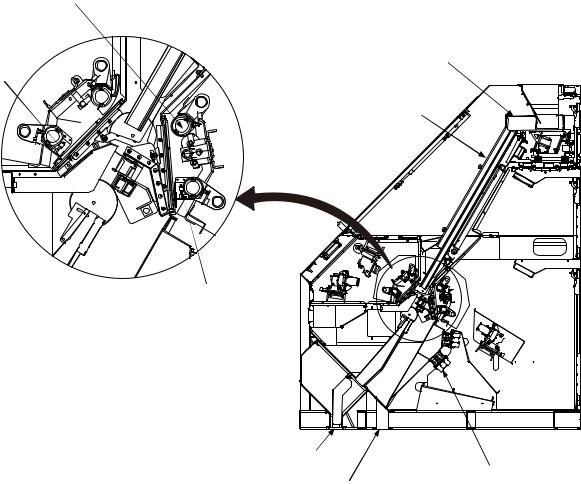

2.4 Name and Function of Each Part

Fluorescent lamp

Feeder

Wiper

Chute

Halogen lamp |

Accept outlet |

Ejector valve

Reject outlet

Fig. 2-6 Structure (Side Surface)

Material is continuously supplied through the intake hopper and feeder, and the flow is rectified by the chute.

The rectified flow of rice grains enters the optical section at a constant rate.

The optical section is illuminated by four fluorescent lamps and halogen lamps placed on the front and rear sides. The fluorescent lamp is the light source to sort any discolored and chalky grains and the halogen lamp is the light source to sort glass, stone and plastics in the grain.

Rice passing through the optical section is observed from both front and rear sides.

When any discolored grains, chalky grain, glass, stone and plastic materials (rejects) are detected by the reflected or passed light.

They are blown off by the air jet from the ejector to the outside of the accept outlet (reject outlet). The wiper is provided to keep the anti-dust glass screen clean for the consistent sorting function.

12

3 ASSEMBLY AND INSTALLATION

|

|

! |

WARNING |

|

|

|

|

|

|

||

|

|

• Wrong choice of the location for installation may cause injuries. |

|

||

|

|

|

|

||

3.1 Caution of Installation |

|

|

|||

(1) |

Place the machine horizontally. |

|

|

||

|

The machine should be installed on the level surface. |

ANDSSEMBLYA INSTALLATION |

|||

(2) |

Install the machine at a vibration-free place. |

||||

|

|||||

When installing the machine on a common base together with other machines, special attention should be paid to the strength of the base. And when mounting a large hopper tank on top of the machine, avoid attaching it directly to the machine itself to prevent adverse effects by the vibration caused by the down flow of materials. Strong vibrations will cause the down flow of materials through the feeder while the machine is not operation, or cause poor contact in the electrical connections.

(3) Avoid the influences of sunlight and illumination.

If strong lights directly enter the optical section by the passage of time, the brightness in the optical section will fluctuate which may induce failures in sorting operation. When installing the machine near the windows facing south, a proper measure should be taken to avoid the fluctuation of brightness. In addition, pay attention not to allow light from fluorescent lamps or mercury lamps to enter the detecting section because it may cause malfunction.

(4) On ambient temperature, humidity, dust and other environmental factors.

Operating ambient temperature range is 0 to 40 . Avoid to install the machine on the location where it is humid, hot, or dusty. Install a heater for cold district of option when the ambient temperature becomes below 10 . In case that the ambient temperature arounf the machine exceeds the specified range, install the air conditioner.

(5) Avoid to install the sorter on the process next following the rice milling.

It must be installed on the process coming just after grain size selection.The chute is likely to collect bran immediately after the rice milling, or in winter. Ideally, it should be placed after the cooling process. If the bran still adheres to the chute, turn on the heater switch. In case of brown rice sorting, keep temperature difference between brown rice and outside less than 5 . If brown rice stored in low temperature is sorted directly, condensation on the surface of brown rice causes bran adhesion in brown rice tank and on chute, there is a possibility of having a bad influence on sorting performance. In this case, use chute heater unit for brown rice of option.If the sorter is installed after the process of removing the broken grain or bran, it will not only minimize failures but improve efficiency. Rotary sifter and white rice grading machine should be installed in the process preceding to the new color sorter.

13

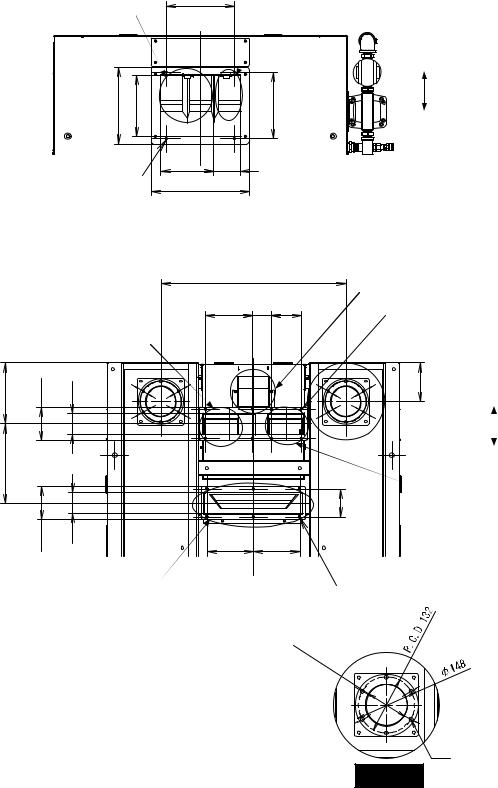

3.2Dimensions of Inlet, Outlet and Dust-collecting Duct

3.2.1RMGS 284AMS/AIS (Flat 90×2 : U Channel 90×1)

Unit: mm

220

Primary sorting inlet |

Secondary sorting inlet |

Rear

250 |

198 |

216 |

Front

4-M6

171 88

320

Fig. 3-1 Dimensions of Inlets

Primary accept outlet

199 |

110 |

67 |

255.5 |

|

|

|

110 |

67 |

Primary reject outlet

599

153 59 98

Secondary reject outlet |

|

8-M6 |

|

A |

|

12 |

Front |

|

|

Rear

|

Secondary |

|

90 |

accept |

|

outlet |

||

|

150 150

|

|

|

6-M6 |

φ |

|

|

|

9 |

|

|

|

6 |

|

|

|

|

( |

|

|

|

|

I |

|

|

|

n |

|

|

|

n |

|

|

|

e |

|

|

|

r |

d |

|

|

|

i |

|

|

|

a |

|

|

|

. |

|

|

|

) |

6φ9 hole

Detail A

Dust-collecting duct

Fig. 3-2 Dimensions of Outlets and Dust-Collecting Duct

14

3.2.2 RMGS 284BM/BI (Flat 90×3 : 0)

Unit: mm

Inlet 220

Rear

250 |

198 |

Front

4-M6 |

259 |

320 |

Fig. 3-3 Dimensions of Inlets

|

|

|

599 |

|

|

|

|

6-M6 |

|

|

|

155 |

155 |

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

199 |

110 |

67 |

|

|

|

|

|

126 |

|

|

|

|

|

|

|

|

|

|

Front |

255.5 |

|

|

|

|

|

|

|

Accept |

Rear |

|

|

|

|

|

|

|

|

outlet |

|

|

|

|

|

|

|

|

|

|

|

|

110 |

67 |

|

|

|

|

|

|

|

|

|

Reject outlet |

|

|

|

6-M6 |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

φ |

|

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

( |

|

|

|

|

|

|

|

|

|

|

I |

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

e |

|

|

|

|

|

|

|

|

|

r |

d |

|

|

|

|

|

|

|

|

|

i |

|

|

|

|

|

|

|

|

|

a |

|

|

|

|

|

|

|

|

|

|

. |

|

|

|

|

|

|

|

|

|

) |

|

AND SSEMBLYA INSTALLATION

6φ9 hole

Detail A

Dust-collecting duct

Fig. 3-4 Dimensions of Outlets and Dust-Collecting Duct

15

3.2.3 RMGS 564AMS/AIS (Flat 280×1, Flat 90×1 : U Channel 90×2)

Unit: mm

Primary sorting inlet

227

250 |

198 |

4×2-M6

220 |

140 |

220 |

Secondary sorting inlet |

|

|

|

|||

|

|

|

216 |

Rear |

|

|

|

|

|

255/259 |

|

255/259 |

|

Front |

320 |

|

320 |

|

|

|

|

|

||

Fig. 3-5 Dimensions of Inlets

103

58

|

|

|

|

|

959 |

|

|

Secondary |

|

|

Primary accept outlet |

|

|

|

|

reject outlet |

|

||||

|

|

|

|

|

|

|

||||

155 |

155 |

50 |

98 |

59 |

155 |

|

|

|||

|

|

6-M6 |

2-5” dust-collecting |

|||||||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

duct |

199 |

110 |

67 |

|

|

|

|

|

94 |

126 |

Front |

|

|

|

|

|

|

|

|

|

|

|

255.5 |

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

8-M6 |

Rear |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

90 |

|

|

110 |

67 |

150 |

150 |

|

150 |

150 |

Secondary |

||

|

|

accept outlet |

||||||||

|

Primary reject outlet |

|

|

|

|

|

|

10-M6 |

|

|

|

|

|

|

|

|

|

|

|

||

φ |

|

|

|

9 |

|

|

|

6 |

|

|

|

|

( |

|

|

|

|

I |

|

|

|

n |

|

|

|

n |

|

|

|

e |

|

|

|

r |

d |

|

|

|

i |

|

|

|

a |

|

|

|

. |

|

|

|

) |

6φ9 hole

Detail A

Dust-collecting duct (Serial No.41730015 and higher)

Fig. 3-6 Dimensions of Outlets and Dust-Collecting Duct

16

3.2.4 RMGS 564AMS/AIS (Flat 280×1, Flat 90×2 : U Channel 90×1)

Unit: mm

Primary sorting inlet |

|

|

|

|

|

220 |

140 |

220 |

|

2×4-M6 |

|

|

|

|

|

|

|

|

Rear |

250 |

198 |

|

|

216 |

|

320 |

|

320 |

Front |

|

|

|

|

Secondary sorting inlet |

Fig. 3-7 Dimensions of Inlets

Primary accept outlet

6-M6

110 |

94 |

110 |

67 |

Primary reject outlet

103 |

58 |

|

959

155 155 50 153 59 150

|

|

|

|

90 |

|

|

150 |

150 |

150 |

150 |

|

10-M6 |

|

|

|

|

|

|

||

|

|

|

φ |

|

|

|

|

|

|

9 |

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

( |

|

|

|

|

|

|

|

I |

|

|

|

|

|

|

n |

|

|

|

|

|

|

n |

|

|

|

|

|

|

e |

|

|

|

|

|

|

r |

d |

|

|

|

|

|

|

i |

|

|

|

|

|

|

a |

|

|

|

|

|

|

. |

|

|

|

|

|

|

) |

Secondary reject outlet

2-5” dust-collecting duct

126

Front

A

8-M6 Rear

Secondary accept outlet

AND SSEMBLYA INSTALLATION

6φ9 hole

Detail A

Dust-collecting duct (Serial No.41730015 and higher)

Fig. 3-8 Dimensions of Outlets and Dust-Collecting Duct

17

3.2.5 GS 564BM/BI (Flat 280×2 : 0)

Inlet |

220 140 220 |

227 216

250 |

198 |

255/259 255/259

4×2-M6

Unit: mm

Rear

Front

Fig. 3-9 Dimensions of Inlets

|

|

Accept outlet |

|

|

959 |

|

|

|

|

155 |

155 |

50 |

155 |

155 |

|

|

|

6×2-M6 |

|||||

|

|

|

|

|

|

|

|

199 |

110 |

67 |

|

|

|

|

94 |

255.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

90 |

|

110 |

67 |

150 |

150 |

150 |

150 |

|

|

|

Reject outlet |

|

|

|

|

10-M6 |

|

|

|

|

|

|

|

|

φ |

|

|

|

9 |

|

|

|

6 |

|

|

|

|

( |

|

|

|

|

I |

|

|

|

n |

|

|

|

n |

|

|

|

e |

|

|

|

r |

d |

|

|

|

i |

|

|

|

a |

|

|

|

. |

|

|

|

) |

2-5” dust-collecting duct

126

Front

A

Rear

6φ9 hole

Detail A

Dust-collecting duct (Serial No.41730015 and higher)

Fig. 3-10 Dimensions of Outlets and Dust-Collecting Duct

18

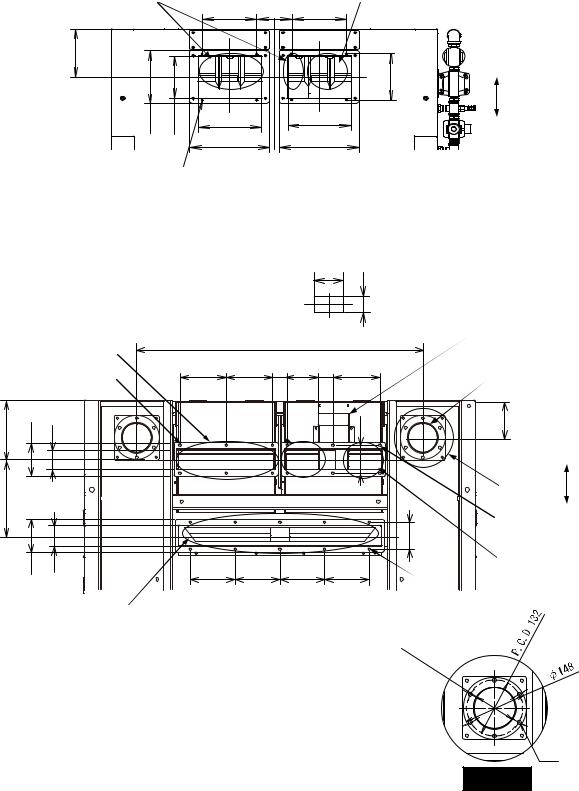

3.2.6 RMGS 844AMS/AIS (Flat 280×2 : U Channel 90×3)

Unit: mm

Primary sorting inlet

227

250 |

198 |

4×3-M6

220 140 220 140 220 |

Secondary sorting inlet |

|

|

|

Rear |

259 |

259 |

259 |

|

320 |

320 |

320 |

Front |

|

Fig. 3-11 Dimensions of Inlets

103 |

58 |

|

AND SSEMBLYA

INSTALLATION

|

|

|

|

Secondary |

Primary |

1319 |

|

reject outlet |

|

accept outlet |

155 50 155 |

155 50 155 |

155 |

|

155 |

2-5” dust-collecting |

|||

|

|

|

|

|

duct

199 |

110 |

67 |

|

|

|

|

|

94 |

255.5 |

|

|

|

|

|

|

|

|

|

110 |

67 |

150 |

150 |

150 |

150 |

150 |

150 |

|

|

|

||||||

Primary reject outlet |

|

|

1037 |

|

|

|||

|

|

|

|

|

|

|||

|

126 |

Front |

|

A |

|

|

3×6-M6 |

Rear |

90 |

Secondary |

|

|

|

|

|

accept outlet |

|

14-M6

φ |

|

|

|

9 |

|

|

|

6 |

|

|

|

|

( |

|

|

|

|

I |

|

|

|

n |

|

|

|

n |

|

|

|

e |

|

|

|

r |

d |

|

|

|

i |

|

|

|

a |

|

|

|

. |

|

|

|

) |

6φ9 hole

Detail A

Dust-collecting duct

Fig. 3-12 Dimensions of Outlets and Dust-Collecting Duct

19

3.2.7 RMGS 844AMS/AIS (Flat 280×2, Flat 90×1 : U Channel 90×2)

Unit: mm

3×4-M6 |

220 |

140 |

|

|

|

250 |

200 |

|

|

320 |

|

220 140 |

220 |

Secondary sorting inlet |

|

|

Rear |

|

|

216 |

320 |

320 |

Front |

|

|

Prymary sprting inlet

Fig. 3-13 Dimensions of Inlets

103

Primary accept outlet

110 |

|

110 |

67 |

Primary reject outlet

|

|

|

|

|

|

|

|

|

58 |

|

|

|

|

|

|

1319 |

|

|

|

|

|

|

|

Secondary reject outlet |

|

|

|

|

|

|

|

|

|

|

|

|

||

155 |

155 |

50 |

155 |

155 |

50 98 |

59 |

153 |

|

|

|

|

Secondary accept outlet |

|

|

|

|

2-5” dust-colelcting duct |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

126 |

|

|

|

|

|

|

|

|

|

|

|

|

Front |

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

90 |

Rear |

|

|

|

|

|

|

|

|

|

|

|

|

||

150 |

150 |

150 |

150 |

150 |

150 |

|

|

|

|

|

||

|

|

|

1037 |

|

|

|

|

|

|

14-M6 |

||

|

|

|

|

|

|

|

φ |

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

( |

|

|

|

|

|

|

|

|

|

|

|

|

|

I |

|

|

|

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

e |

|

|

|

|

|

|

|

|

|

|

|

|

r |

d |

|

|

|

|

|

|

|

|

|

|

|

|

i |

|

|

|

|

|

|

|

|

|

|

|

|

a |

|

|

|

|

|

|

|

|

|

|

|

|

. |

|

|

|

|

|

|

|

|

|

|

|

|

) |

|

6φ9 hole

Detail A

Dust-collecting duct

Fig. 3-14 Dimensions of Outlets and Dust-Collecting Duct

20

Loading...

Loading...