Operating Instructions | Betriebsanleitung

Sterisart® Universal Pump 16419

Sterisart

®

Universal-Pumpe 16419

1000072189

English .............................................Page 3

Deutsch ............................................Seite 21

Contents

1 General Safety Information ......................................4

®

2 Intended Use of the Sterisart

3 Important Notes on the Safe and Proper Usage of the Sterisart

Universal Pump ...............................................5

4 Unpacking the Pump and Checking the Equipment Supplied.............6

5 Description of the Sterisart

6 Startup......................................................9

7 Application..................................................10

8 Operating the Sterisart

9 Cleaning and Sanitization ......................................12

10 Installation in an Isolator.......................................13

11 Important Notes Concerning the Warranty .........................13

Universal Pump .......................5

®

®

Universal Pump.........................7

®

Universal Pump 16419 .....................11

12 Troubleshooting ..............................................14

13 Technical Specifications........................................15

®

14 Ordering Information for the Sterisart

Universal Pump ...............16

15 Ordering Information for Consumables ...........................17

16 Literature...................................................18

17 Storage and Shipping..........................................18

17.1 Storage .........................................................18

17.2 Returning Devices and Parts........................................18

18 Disposal ....................................................19

18.1 Information on Decontamination ...................................19

18.2 Disposing of Device and Parts ......................................19

18.2.1 Information on Disposal ....................................19

18.2.2 Disposal ..................................................19

19 Conformity..................................................20

20 Legal information about licenses and trademarks ...................20

20.1 Millipore™.......................................................20

Contents 3

1 General Safety Information

Explanation of Safety Symbols Used

These operating instructions contain important information which is visibly marked.

This information must be observed in order to avoid hazards to users as well as to

avoid damage and|or malfunctions to the device.

Symbols in the operating instructions:

Important Note! Important information

Danger! General danger with risk of injury

Laser warning

General information and|or help

Symbols on the manufacturer‘s ID label

AC voltage

Return and disposal

Observe instructions for use

Manufacturer

4 General Safety Information

2 Intended Use of the

®

Sterisart

The new Sterisart® Universal pump is a peristaltic pump equipped with appropriate

devices for attaching a closed sterility test system and a sample container.

The pump draws liquid from the sample container into the specially designed double

tubing, distributing the liquid equally to both sample containers of the sterility test

system. The sample is rinsed in a similar way. After the nutrient media is added, the

sample containers are incubated for a prescribed time and evaluated.

Universal Pump

3 Important Notes on the Safe

®

and Proper Usage of the Sterisart

Universal Pump

– The Sterisart® Universal pump must be switched off before any electrical

connections are made or broken (e.g. when plugging in or unplugging the power

cable or foot switch).

– The Sterisart® Universal pump must only be used with the original current-carrying

parts supplied with it (power cable with ferrite core, D-Sub connecting cable and

foot switch). The D-Sub protective cap supplied must cover the port when the

D-Sub connecting cable is not connected.

– The Sterisart® Universal pump is designed for use with Sterisart® NF filtration

systems. The suitability of any other tubing must be approved by Sartorius.

– Only plastic and glass bottles with a filling volume of 500 ml or less are permitted

to be placed in the delivered bottle holder.

– Only authorized Sartorius service technicians are allowed to open the pump

housing.

– Do not expose the Sterisart® Universal pump to extreme temperatures.

– Improper use or handling will invalidate the manufacturer‘s guarantee.

– Sterisart® Universal pump may only be used with a grounded, readily accessible and

fuse-protected electrical outlet that complies with national standards.

Intended Use of the Sterisart® Universal Pump 5

4 Unpacking the Pump and Checking

the Equipment Supplied

When unpacking the Sterisart® Universal pump 16419 make sure not to leave

any parts in the packaging. The equipment supplied includes the following accessories

(one of each):

– Sterisart® Universal pump 16419

– Power cable (depends on country rating)

– Container for draining

– Pump cover for container for draining (Sterisart® units)

– Drain tubing

– Fastening arm

– Bottle holder

– Support rod

– Bow

– Clamping lever with sleeve

– Operating instructions German | English

6 Unpacking the Pump and Checking the Equipment Supplied

5 Description of the Sterisart®

Universal Pump

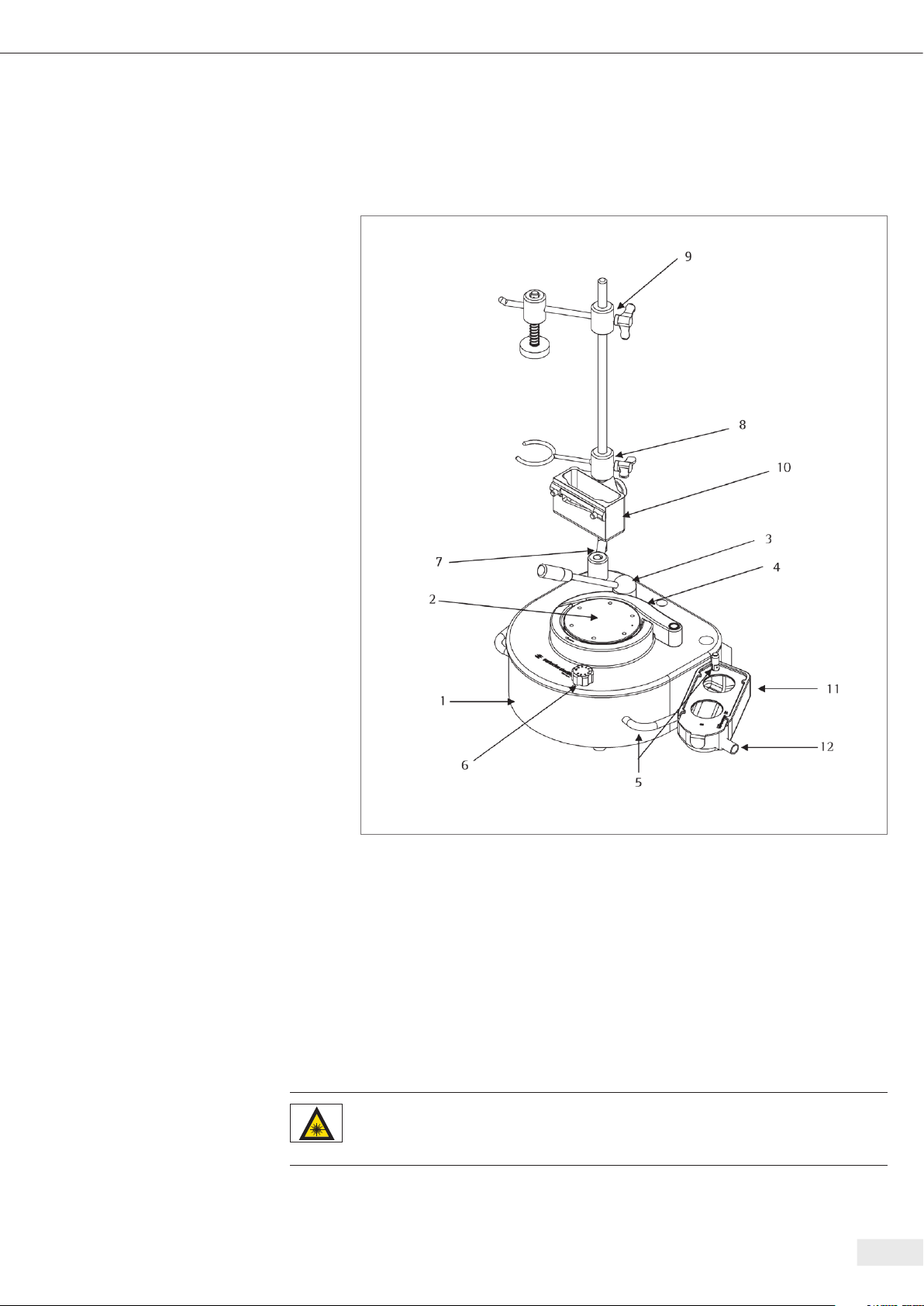

Fig. 1

The Sterisart® Universal pump 16419 (see Fig. 1) consists of pump housing (1) with pump

head (2), lever (3), bow (4) and handles (5). On the right handle, there is also a bolt with

a tilting lock for the container for draining (11). The selecting knob (6) is at the front on

the right. The stand (7) with the holding ring for bottles (8) and fastening arm (9) and the

optional ampoule breaker (10) is located on the left side of the pump.

The container for draining (Fig. 1; 11) for the sterility test containers is located on the

right side of the pump. The drain tubing can be attached to the appropriate connector

(barb) on the container for draining (Fig. 1; 12).

Laser warning

The internal barcode scanner emits a laser beam.

Do not look directly into the beam.

Description of the Sterisart® Universal Pump 7

1 2 3 4 5 6

Fig. 2

Located on the rear panel (see Figure 2): a laser warning label (1), On|Off switch (2),

AC power socket (3), socket for the foot switch (4), an RS-232 interface port for

connecting a PC/MMC card reader (5) and the manufacturer’s ID label (6).

8 Description of the Sterisart® Universal Pump

6 Startup

Set up the Sterisart® universal pump ergonomically in a suitable area (cleanroom,

laminar flow work bench, isolator).

Before initial start-up, the accessories supplied must be assembled on the Sterisart®

Universal pump. Please proceed in the following order:

– At the back left, push the support rod (Fig.1, 7) onto the pin of the upper part of the

pump until it is firmly in place. The holes in the foot of the support rod allow the

positioning of the support rod to be altered.

– Fasten the bottle holder (Fig. 1, 8) and the fastening arm (Fig. 1, 9) to the support

rod. If necessary, attach the ampoule breaker (Fig. 1, 10) beforehand.

– Insert the bow (Fig. 1, 4) and the clamping lever (Fig. 1, 3) on the corresponding

bolts on the top of the pump. The lever is jacketed in a plastic sleeve, which can be

removed for cleaning. If signs of wear appear on this sleeve after it has been in use

for some time, it can be re-ordered as a spare part (see chapter “Ordering informa-

tion for the Sterisart® Universal Pump”).

– After connecting the drain tubing to the barb (Fig. 1, 12) of the container for drain-

ing (Fig. 1, 11); attach the container for draining to the appropriate bolts on the

right handle (Fig. 1, 5). The container for draining and the cover plate are attached

by moving the tilting lock.

– Fasten the end of the drain tubing to the appropriate drain.

Very Important Note!

Always make sure that there is a sufficient liquid level differential (> 5 cm) between the container for draining and the drain. This makes safe drainage possible

and prevents backflow into the container for draining. Make sure that the drain

tubing is kept lower than the pump to prevent the drain pan from overflowing.

Treat the waste as a biohazard. Only dispose of it in accordance with current

regulations.

– Plug the foot switch into the designated socket located on the rear panel (see Fig. 2,

4). Fasten the plug to the socket by turning it clockwise.

– Plug the power cable into the male power socket on the back of the Sterisart®

Universal pump and into a grounded electrical outlet (Fig. 2, 3).

– Use the On|Off switch (Fig. 2, 2) at the rear side of the Sterisart® Universal pump to

turn it on.

Startup 9

7 Application

Caution!

General danger with risk of injury

Do not operate the Sterisart® Universal pump until the tubing has been properly

installed. The pump may only be operated with the tubing inserted and only by

one person at a time. Never pump any flammable, corrosive or explosive fluids.

Users should always wear tight-fitting clothing (no ties, etc.).

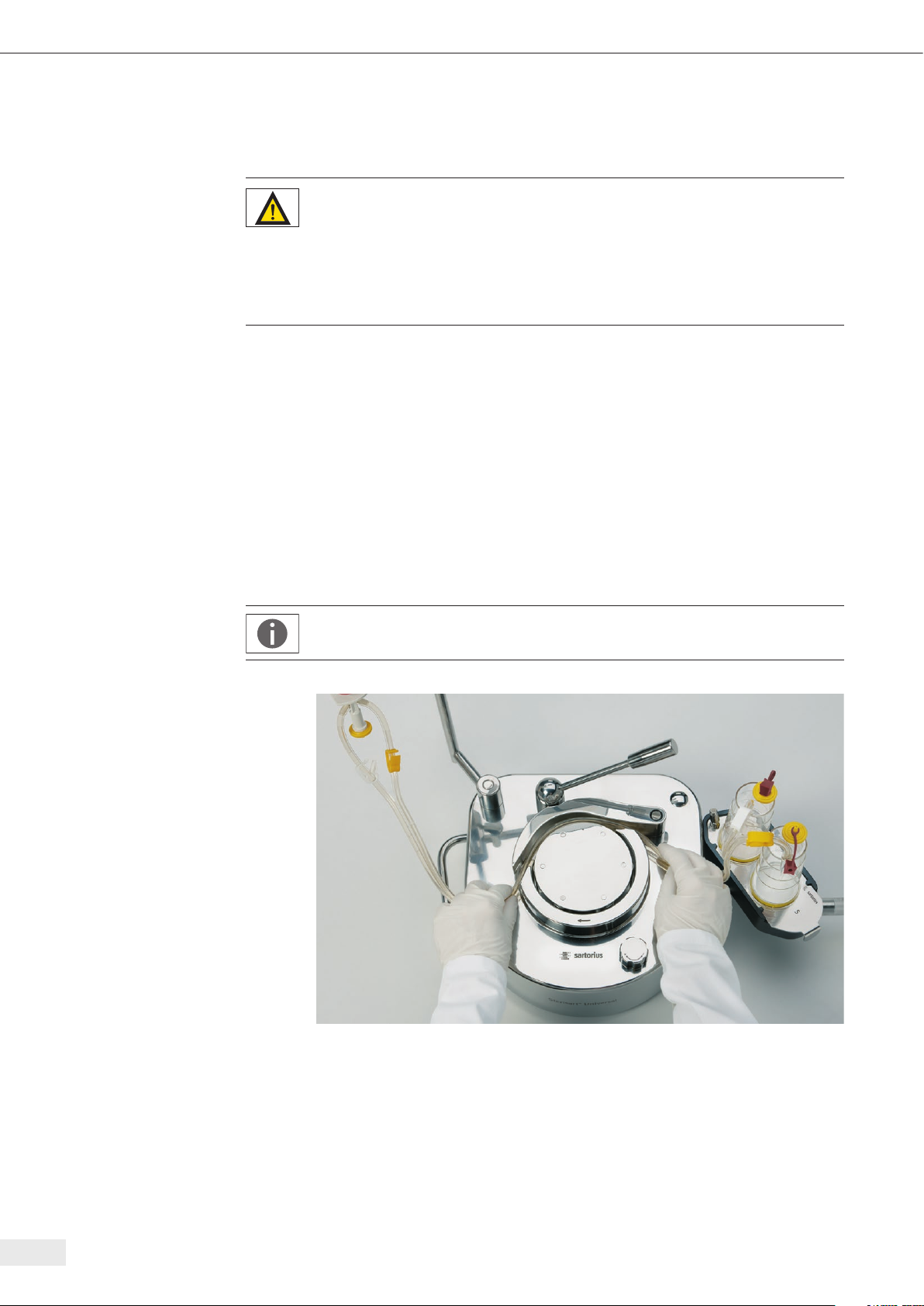

To be able to operate the pump, Sterisart® sterility test systems must be installed

beforehand. To do this, follow the steps given below:

Remove the sterility test systems from their respective packaging and place the sterility test sample containers in the container for draining on the right side of the pump.

– Now open the lever and the bow.

– Keep the tubing around the rotor of the pump (the arrow on the fixed part sur-

rounding the pump head indicates the subsequent direction of rotation), so that no

kinks occur and the tubing is not under tension (Fig. 3). The tubing is attached by

simply inserting it (with it lying on the ground) and fastening the lever (Fig. 4). In

this way, the tubing is automatically correctly positioned.

Important Note!

When threading the tubing, make sure that it is not kinked or twisted.

Fig. 3

10 Application

– To start the pumping process, the tubing must be fully inserted and the lever

must be engaged. A safety function ensures that the pump does not start if the

lever or the bow are open.

– After threading the tubing and closing the lever, insert the removal spike/needle of

the Sterisart® NF system as described in the instructions for the Sterisart® NF steril-

ity test system. Then attach the test liquid container (e.g., bag or bottle) by hanging

it on the support rod (bag) or by placing it in the holding ring on the support rod

(bottle). The holding ring accepts bottles of various sizes. The holder must be turned

so that the sterility test system tubing is not under tension after the spike | needle

has been inserted and so that the spike | needle cannot slip out of the container.

For testing ampoules, an ampoule breaker is also attached to the support rod.

Use the integrated knife to scratch the neck of the ampoule, then snap off the top.

The broken-off top of the ampoule falls into the collection container (which can be

emptied later).

– For the following pumping process, make sure that the Sterisart® NF sample

containers are correctly positioned in the intended holders, and that the tubing

has been inserted without tension or kinking.

Important Note!

When the lever is opened, the Sterisart® Universal pump is turned off

immediately by a safety function. In this event, the Sterisart® Universal pump

can be restarted after adequately closing all components.

8 Operating the Sterisart® Universal

Pump 16419

The Sterisart® Universal Pump 16419 can be started up either by pressing the selec-

ting knob or by activating the optional foot switch. The speed can be smoothly adjusted using the selecting knob. The pump is switched off by again pressing the selecting knob or by releasing the foot switch.

Fig. 4

Operating the Sterisart® Universal Pump 16419 11

9 Cleaning and Sanitization

Caution!

Ports on the back panel are not tight.

The Sterisart® Universal pump is not suited for sanitization (gaseous or atomized)

with peracetic acid, hydrogen peroxide, or other decontamination procedures

commonly used in isolators, unless it is built into an isolator countertop. These

types of disinfectant can be used when the pump has been professionally

installed in the isolator.

– Before cleaning the pump rotor, turn off the main power switch and unplug the

power cable.

The following parts of the pump have to be removed for cleaning:

– Bow, lever, support rod and container for draining

– Disconnect the pump head:

– The rotor must be turned by hand until the marking on the upper side (black dot)

is pointing backwards.

– The marking indicates the position of the fastening screw that is located in the

rotor mid-section.

– Loosen this screw with a 4-mm Allen wrench. Do not turn the screw out

completely.

– Pull the rotor upwards.

– Pull the speed-selecting knob upwards.

Comply with the IP protection rating! No liquid may enter the Sterisart®

Universal pump. Disconnect the pump from line voltage before any cleaning,

maintenance, or repair work.

Cleaning stainless steel surfaces:

The stainless steel housing can be cleaned at regular intervals. Clean stainless steel

parts with a wet cloth. Customary cleaning agents suitable for stainless steel can be

used without risk. For surface sanitization, use commercially available disinfectants

that are suitable for stainless steel.

Do not use any cleaning agents on the stainless steel housing that contain sodium

hydroxide or acetic, sulfuric or citric acid. The use of steel wool cleaning sponges is

prohibited.

All stainless steel surfaces can be cleaned by wiping with a moist cloth and with the

following products:

– Peracetic acid, H2O2 and acetic acid (2.5%)

– Quaternary ammonium

– Formaldehyde and glutaraldehyde

– Isopropyl alcohol

– Ethanol 70%

Autoclavable at 121°C for 20 min. are bow, lever, speed selecting knob, support rod,

bottle holder, counter-bottle holder and container for draining (complete).

12 Cleaning and Sanitization

Never autoclave the pump rotor and never submerge it into any liquid.

Only use a slightly moistened cloth | tissue for cleaning | desinfecting.

After cleaning, all parts should be secured as described in Chapter “6 Startup,”

page 9. The rotor is assembled as follows:

– The rotor shaft has a groove on the side turned towards the back.

– Push the rotor upwards onto the shaft.

– Turn the marking on the rotor towards the back, so that the groove on the rotor

shaft aligns with the marking on the rotor

– Tighten the screw in the rotor to guarantee that the rotor is firmly seated.

10 Installation in an Isolator

The installation must be carried out by the isolator manufacturer.

To install the Sterisart® Universal pump in an isolator, it must be opened up first.

Make sure to unplug it from AC current (mains supply) before opening it!

During assembly, please follow the installation instructions precisely (part of the

installation kit for isolators, order number 1ZE---0050). The instructions are available

separately from the manufacturer.

11 Important Notes Concerning the

Warranty

The correct functioning and safe use of the Sterisart® Universal pump is only guaranteed when it is operated according to the information given in these instructions.

The equipment manufacturer is responsible only for effects on safety, dependability

and performance of the instrument if assembly, extensions, new settings, changes or

repairs are carried out by persons authorized by him to do so, if the electrical installation in the room is in conformance with IEC requirements and if the equipment is

used in accordance with these operating instructions.

Any changes made to the Sterisart® Universal pump will invalidate the manufacturer‘s

warranty unless they are previously agreed to by authorized Sartorius Service staff, or

carried out by them.

Installation in an Isolator 13

12 Troubleshooting

This section lists a few problems that could arise in connection with the Sterisart®

pump. Several solutions are given for each problem. The first solution given is usually

the most likely one. If this does not solve the problem, go down the list of suggestions

until the problem has been solved.

Important Note!

The pump must be switched off before electrical connections are unplugged

or plugged in!

Should it not be possible to locate and solve the problem in this way, contact the

appropriate service center (see the back cover of this manual).

Problem Solution

No function; no display The pump is not switched on, or is not correctly connected to the electric supply.

Plug the power cable into the electric outlet correctly and to the Sterisart

pump. Switch on the on-off switch.

Check the electric supply; switch on multiple outlet sockets; check the wiring.

If these possibilities are not feasible, the primary fuse in the main line filter may be

defective.

Changing this, with the power cable unplugged, must only be performed by

authorized personnel!

The pump rotor does not rotate. The locking lever is open or the foot switch is not properly connected.

The bow has been removed from the pump.

Check the connection of the foot switch to the pump.

®

Universal

14 Troubleshooting

13 Technical Specifications

Dimensions pump in mm (W × D × H) approx. 336 × 260 × 210 (with lever)

Dimensions pump with holding

ring for bottles, container for

draining in mm

Weight: Basic model 16419 Approx. 13.5 kg

Maximum operating temperature 40°C

Further data IP41 in accordance to IEC 60529/EN 60529

Electrical connection

Voltage 100 – 240 VAC ± 10%

Frequency 50 – 60 Hz

Power consumption 100 VA

Pump

Pump flow rate 70 – 650 ml/min (depending on the tubing)

Tubing

Correct functioning of the Sterisart

with tubing that has been approved by Sartorius.

Materials

Base plate, lever, bow, rotor Stainless steel 316L (1.4435)

Housing, connection port,

support rod, bottle holder

Connecting cable PVC

Container for draining, plastic

sleeve for lever, hydrodynamic

bearing for bow

Hydrodynamic bearing for lever Iglidur X

Seals, gaskets, drain tubing Silicone

(W × D × H) 440 × 365 × 485

®

Universal pump is only guaranteed when used

Stainless steel 316 (1.4401)

PET

Technical Specifications 15

14 Ordering Information for the

®

Sterisart

Order No. Description

16419 Sterisart

16973 Ampoule tongs

1ZG---0009 Bottle holder

1ZF---0004 Fastening arm

1ZA---0002 Drain tubing

1ZW---0002 Ampoule breaker

1ZE---0033 Foot switch

1ZF---0013 Stand

1ZG---0028 Container for draining

1ZB---0001 Plastic sleeve for lever

1ZF---0007 Wing nut

1ZS---0005 Bow

1ZS---0002 Lever

Universal Pump

®

Universal pump, basic model

1ZL---0003 Rotor

®

1ZG---0023 Cover for container for draining (Sterisart

1ZG---0024 Cover for container for draining (Millipore™ sterility test units)

®

1ZG---0014 Adaptor for Sterisart

a Millipore™ Equinox pump

1ZG---0039 Transport trolley

1ZE---0041 Installation kit isolators

Additional accessories are available on request.

container for draining for use with

sterility test units)

16 Ordering Information for the Sterisart® Universal Pump

15 Ordering Information for

Consumables

Recommended disposable sterility test units for use with pump.

Order No. Description

®

16466-ACD Sterisart

(box of 10, individually sterilized with ETO; single-packed).

16467-ACD Sterisart

(box of 10, individually sterilized with ETO; single-packed)

16468-ACD Sterisart

connectors (box of 10, individually sterilized with ETO; singlepacked)

16466-GBD Sterisart

(box of 10, individually gamma sterilized, double-packed).

Optimal for use in isolators.

16467-GBD Sterisart

(box of 10, individually gamma sterilized, double-packed).

Optimal for use in isolators.

16468-GBD Sterisart

lock connectors (box of 10, individually gamma sterilized, doublepacked). Optimal for use in isolators.

16469-GBD Sterisart

(box of 10, individually gamma sterilized, double-packed).

Optimal for use in isolators.

16470-GBD Sterisart

unvented vials (box of 10, individually gamma sterilized, doublepacked). Optimal for use in isolators.

16475-GBD Sterisart

powders in unvented vials (box of 10, individually gamma sterilized, double-packed). Optimal for use in isolators.

16476-GBD Sterisart

closed containers (box of 10, individually gamma sterilized,

double-packed). Optimal for use in isolators.

16477-GBD Sterisart

(box of 10, individually gamma sterilized, double-packed). Optimal

for use in isolators.

16478-GBD Sterisart

male connectors (box of 10, individually gamma sterilized, doublepacked). Optimal for use in isolators.

Additional Sterisart

NF alpha, dual-needle metal spike for closed containers

®

NF alpha, 6-cm metal needle for open containers

®

NF alpha, system for medical devices with Luer lock

®

NF gamma, dual-needle metal spike for closed containers

®

NF gamma, 6-cm metal needle for open containers

®

NF gamma, system for medical devices with Luer or Luer

®

NF gamma, system with adapter for prefilled syringes

®

NF gamma, system for slightly soluble powders in

®

NF gamma, system for lyophilized or freely soluble

®

NF gamma, system with short dual-needle metal spike for

®

NF gamma, system for liquids in plastic containers

®

NF gamma, system for medical containers with Luer lock

®

units are available on request.

Ordering Information for Consumables 17

16 Literature

Data sheet Sterisart® Universal Pump English

Publ. No.: SLD2010-e Order No.: 85030-531-17

®

Brochure Sterisart

Publ. No.: SLD1003-e Order No.: 85030-531-14

Universal Pump English

17 Storage and Shipping

17.1 Storage

Procedure

t If the device is in operation:

t Decommission the device.

t Clean the device.

t Store the device according to the ambient conditions (see Chapter “13 Technical

Specifications,” page 15).

17.2 Returning Devices and Parts

Defective devices or parts can be sent back to Sartorius. Returned devices must be

clean, decontaminated, and properly packed.

Transport damage as well as measures for subsequent cleaning and disinfection of

the device or parts by Sartorius shall be charged to sender.

WARNING

Risk of injury due to contaminated devices!

Devices contaminated with hazardous materials [nuclear, biological or chemical

(NBC)] will not be accepted for repair or disposal.

t Observe the information on decontamination (see Chapter “13 Technical Specifi-

cations,” page 15).

Procedure

t Decommission the device.

t Contact Sartorius Service for instructions on how to return equipment or parts

(please refer to our website at www.sartorius.com for return instructions).

t Pack the device and the parts in an un-used original packaging.

The original packaging can be ordered (contact Sartorius Service).

18 Literature

18 Disposal

18.1 Information on Decontamination

The device does not contain any hazardous materials that would necessitate special

disposal actions. The media (e.g. acids, bases) used during the process are potentially

hazardous materials that could cause biological or chemical hazards.

According to the EU Directive on Hazardous Substances, the owners of devices that

come into contact with hazardous substances are responsible for properly disposing

of these devices and for declaring such devices when transporting them.

WARNING

Risk of injury due to contaminated devices!

Devices contaminated with hazardous materials [nuclear, biological or chemical

(NBC)] will not be accepted for repair or disposal.

18.2 Disposing of Device and Parts

18.2.1 Information on Disposal

The device and the device accessories must be disposed of properly by disposal

facilities.

A lithium cell battery is installed inside the device. Batteries must be disposed of

properly by disposal facilities.

The packaging is made of environmentally friendly materials that can be used as

secondary raw materials.

18.2.2 Disposal

Requirements

The device has been decontaminated.

Procedure

t Dispose of the device. Follow the disposal instructions on our website

(www.sartorius.com). Inform the disposal facility that there is a lithium cell

battery installed inside the device.

t Dispose of the packaging in accordance with local government regulations.

t Dispose of the consumables in accordance with local government regulations.

Disposal 19

19 Conformity

The attached documents confirm compliance of the device with the directives or

standards cited.

20 Legal information about licenses

and trademarks

20.1 Millipore™

Millipore™ is a registered trademark of Merck KGaA, Darmstadt, Germany or its

affiliates.

Inhalt

1 Allgemeine Sicherheitshinweise ..................................22

®

2 Verwendung der Sterisart

Universal-Pumpe ........................23

3 Wichtige Hinweise für den sicheren und korrekten Gebrauch

der Sterisart

®

Universal-Pumpe ..................................23

4 Auspacken des Gerätes und Überprüfung des Lieferumfanges...........24

®

5 Beschreibung der Sterisart

Universal-Pumpe .......................25

6 Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7 Anwendung .................................................28

®

8 Betrieb der Sterisart

Universal-Pumpe 16419 ......................29

9 Reinigung, Desinfektion........................................30

10 Montage in einem Isolator......................................31

11 Wichtige Hinweise zur Gewährleistung ............................31

12 Hilfe bei Problemen ...........................................32

13 Technische Daten.............................................33

®

14 Bestellinformationen für die Sterisart

Universal-Pumpe 16419.........34

15 Bestellinformationen Verbrauchsartikel ...........................35

16 Dokumentation ..............................................36

17 Lagerung und Versand .........................................36

17.1 Lagern ..........................................................36

17.2 Geräte und Teile zurücksenden .....................................36

18 Entsorgung..................................................37

18.1 Hinweise zur Dekontamination .....................................37

18.2 Gerät und Teile entsorgen..........................................37

18.2.1 Hinweise zur Entsorgung....................................37

18.2.2 Entsorgen ................................................37

19 Konformität.................................................38

20 Lizenzrechtliche oder markenrechtliche Informationen ................38

20.1 Millipore™.......................................................38

21

1 Allgemeine Sicherheitshinweise

Erklärung der verwendeten Sicherheitssymbole

In dieser Bedienungsanleitung sind wichtige Hinweise visuell gekennzeichnet.

Diese Hinweise sind Voraussetzung für den Ausschluss von Gefährdungen

für den Anwender, sowie für die Vermeidung von Beschädigungen bzw. Funktionsstörungen am Gerät.

Symbole in der Bedienungsanleitung:

Achtung! Wichtiger Hinweis

Gefahr! Allgemeine Gefahr mit Verletzungsrisiko

Laserwarnhinweis

Allgemeiner Hinweis bzw. Hilfe

Symbole auf dem Typenschild:

Wechselspannung

Rücknahme und Entsorgung

Gebrauchsanweisung beachten

Hersteller

22 Allgemeine Sicherheitshinweise

2 Verwendung der Sterisart®

Universal-Pumpe

Bei der neuen Sterisart® Universal-Pumpe handelt es sich um eine peristaltische

Schlauchpumpe aus Edelstahl für den Sterilitätstest, die mit den entsprechenden Vorrichtungen zur Befestigung des Sartorius Sterilitätstestsystems und des zu testenden

Probegefäßes ausgerüstet ist.

Die Pumpe zieht die zu testende Flüssigkeit aus dem Probenbehälter durch das dafür

speziell konzipierte Doppelschlauchsystem und pumpt sie in die beiden Testbehälter

des Sterilitätstestsystems. Das Spülen der Probe erfolgt in analoger Weise. Nach Zugabe der Nährmedien werden die Sterilitätstestbehälter für einen vorgeschriebenen

Zeit raum inkubiert und ausgewertet.

3 Wichtige Hinweise für den sicheren

und korrekten Gebrauch der

®

Sterisart

Universal-Pumpe

– Die Steckverbindungen an der Sterisart® Universal-Pumpe (Netzschalter, Fuß-

schalter) dürfen nur bei ausgeschaltetem Gerät gezogen bzw. eingesteckt werden.

– Es dürfen nur die mitgelieferten spannungsführenden Originalteile (Netzkabel mit

Ferritkern, Verbindungskabel sowie Fußschalter) eingesetzt werden. Bei nicht

angeschlossenem D-Sub Kabel ist die mitgelieferte montierte D-Sub Schutzkappe

zu tragen.

– Die Sterisart® Universal-Pumpe ist für den Einsatz mit Sterisart® NF Filtrationssystemen

konzipiert worden. Die Eignung anderer Schlauchsysteme muss durch Sartorius

überprüft werden.

– In den mitgelieferten Flaschenhalter dürfen ausschließlich Kunststoff- oder Glas-

flaschen mit einem maximalen Füllvolumen von 500 ml eingestellt werden.

– Nur von Sartorius autorisierten Technikern ist es erlaubt das Pumpengehäuse zu

öffnen.

– Das Gerät keinen extremen Temperaturen aussetzen.

– Unsachgemäße Nutzung kann zum Erlöschen der Gewährleistung führen.

– Das Gerät darf nur an geerdeter, gut zugänglicher und dem Nationalen Standard

entsprechender, abgesicherter Steckdose verwendet werden.

Verwendung der Sterisart® Universal-Pumpe 23

4 Auspacken des Gerätes und

Überprüfung des Lieferumfanges

Beim Auspacken der Sterisart® Universal-Pumpe 16419 achten Sie bitte darauf, dass

keine Teile in der Verpackung verbleiben. Zum Lieferumfang gehören die folgenden

Zubehörteile (je 1 Stück):

– Sterisart® Universal-Pumpe 16419

– Netzkabel (länderspezifisch)

– Ablaufbehälter

– Abdeckung Ablaufbehälter (Sterisart® Einheiten)

– Ablaufschlauch

– Haltearm

– Flaschenhalter

– Stativ

– Bügel

– Klemmhebel mit Hülse

– Bedienungsanleitung Deutsch | Englisch

24 Auspacken des Gerätes und Überprüfung des Lieferumfanges

5 Beschreibung der Sterisart®

Universal-Pumpe

Abb. 1

Die Sterisart® Universalpumpe 16419 (siehe Abb. 1) besteht aus Pumpengehäuse (1)

mit Pumpenkopf (2), Hebel (3), Bügel (4) und Griffen (5). Auf dem rechten Griff sitzt

weiterhin ein Bolzen mit Kippfixierung für den Abblaufbehälter (11). Vorne rechts

sitzt der Wählknopf (6). Auf der linken Seite der Pumpe befindet sich das Stativ (7)

mit Flaschenhalter (8) und Haltearm (9) sowie der optionale Ampullenbrecher (10).

An der rechten Seite der Pumpe ist der Ablaufbehälter (Abb. 1; 11) für die Sterilitätstestbehälter angebracht. An ihm kann ein Ablaufschlauch an dem dafür vorgesehenem Anschlussstutzen (Abb. 1; 12) angeschlossen werden.

Laserwarnhinweis!

Der interne Barcodescanner emittiert Laserstrahlung.

Nicht in den Strahl blicken.

Beschreibung der Sterisart® Universal-Pumpe 25

1 2 3 4 5 6

Abb. 2

An der Rückseite (siehe Abb. 3) befinden sich ein Laser-Warnhinweisschild (1),

der Ein|Ausschalter (2), Netzanschluss (3), Anschluss für den Fußschalter (4), RS-232

PC-Anbindung/MMC Kartenlesegerät (5) sowie das Typenschild (6).

26 Beschreibung der Sterisart® Universal-Pumpe

6 Inbetriebnahme

Die Sterisart® Universal-Pumpe sollte in einem geeigneten Raum (Reinraum |

LAF-Werkbank, Isolator) ergonomisch aufgestellt werden.

Bei der erstmaligen Inbetriebnahme müssen Sie das mitgelieferte Zubehör an die

Sterisart® Universal-Pumpe montieren. Gehen Sie dazu bitte in der angegebenen

Reihenfolge vor:

– Stecken Sie das Stativ (Abb.1, 7) hinten links auf die Stifte des Pumpenoberteiles

bis es fest sitzt. Die Bohrungen im Fuß des Statives erlauben unterschiedliche

Positionierungen des Statives.

– An dem Stativ befestigen Sie zuerst den Flaschenhalter (Abb. 1, 8), danach den

Haltearm (Abb. 1, 9). Bei Bedarf bringen Sie vorher den Ampullenbrecher (Abb.1, 10)

an.

– Stecken Sie den Bügel (Abb. 1, 4) und den Klemmhebel (Abb. 1, 3) auf die ent-

sprechenden Bolzen auf der Oberseite der Pumpe. Der Hebel ist mit einer Kunst-

stoffhülse ummantelt, die zu Reinigungs zwecken entfernt werden kann. Sollte im

Laufe der Benutzung diese Hülse Verschleißerscheinungen aufweisen, kann diese als

Ersatzteil nachbestellt werden (siehe Kapitel Bestellinformationen).

– Nach Anbringung des Ablaufschlauches an den Anschlussstutzen (Abb. 1, 12) des

Ablaufbehälters (Abb. 1, 11) bringen Sie diesen an dem dafür vorgesehenen Bolzen

auf dem rechten Griff (Abb. 1, 5) an. Der Ablaufbehälter sowie die Abdeckplatte

werden durch Umlegen der Kippfixierung befestigt.

– Das Ende des Ablaufschlauches bitte an einen vorhanden Abfluss montieren.

Hinweis!

Achten Sie darauf, dass ein ausreichender Höhenunterschied (> 5 cm) zwischen

Ablaufbehälter und Abfluss vorhanden ist, der ein gesichertes Abfließen

ermöglicht, sowie einen Rückfluss in den Ablaufbehälter verhindert. Hierbei ist

darauf zu achten, dass der Schlauch immer tiefer liegt als die Pumpe, da sonst

ein Überlaufen der Ablaufwanne eintritt.

Achtung! Wichtiger Hinweis!

Behandeln Sie den Abfall als Biohazard. Beseitigen Sie diesen nur gemäß der

geltenden Vorschriften.

– Schließen sie den Fußschalter an der Rückseite an die vorgesehene Buchse an

(Abb. 2; 4). Verschrauben Sie den Stecker mit der Buchse im Uhrzeigersinn.

– Stecken Sie das Netzkabel auf der Rückseite der Sterisart® Universal-Pumpe in

die Netzanschlussbuchse (Abb. 2; 3) und in eine Steckdose mit angeschlossenem

Schutzleiter.

– Schalten Sie die Sterisart® Universal-Pumpe über den Netzschalter (Abb. 2; 2) auf

der Geräterückseite ein.

Inbetriebnahme 27

7 Anwendung

Gefahr!

Allgemeine Gefahr mit Verletzungsrisiko

Pumpe darf nur mit eingelegtem Schlauch und von einer Person gleichzeitig

betrieben werden. Es dürfen keine entflammbaren, ätzenden und explosiven

Flüssigkeiten gefördert werden. Es ist darauf zu achten enganliegende Kleidung

zu tragen (keine Krawatte o.ä.).

Zum Betrieb der Pumpe muss diese zuerst mit Sterisart® Sterilitätstest systemen

bestückt werden. Hierfür sind folgende Schritte notwendig:

Nehmen Sie die Sterilitätstest systeme aus der Verpackung und stellen Sie die Sterilitätstestbehälter in den Ablaufbehälter auf der rechten Geräteseite der Pumpe.

– Öffnen Sie nun den Hebel und den Bügel der Pumpe.

– Halten Sie den Schlauch so um den Rotor der Pumpe (der Pfeil auf dem unbeweg-

lichen Teil, welcher den Pumpenkopf umgibt, gibt die spätere Drehrichtung an), dass

keine Knicke entstehen und der Schlauch nicht gespannt ist (Abb. 3). Die Fixierung

des Schlauches erfolgt durch einfaches Einlegen des Schlauches (auf dem Boden

auf liegend) und Befestigen des Hebels (Abb. 4). Hierdurch wird der Schlauch automatisch richtig positioniert.

Hinweis! Beim Einlegen des Schlauches ist auf jeden Fall darauf zu achten, dass

der Schlauch sauber geführt wird.

Abb. 3

28 Anwendung

– Zum Starten des Pumpvorganges muss der Schlauch komplett eingelegt und der

Hebel eingerastet sein. Eine Sicherheitsfunktion sorgt dafür, dass bei geöffnetem

Hebel oder Bügel die Pumpe nicht startet.

– Nach dem vollständigen Einlegen des Schlauches wird der Entnahmespike | die

Nadel des Sterisart® NF Systems, wie in der Bedienungsanleitung für das Sterisart®

NF Sterilitätstestsystem beschrieben, in die Entnahmestelle des Probengefäßes

eingestochen. Anschließend wird das Probengefäß (z.B. Beutel oder Flasche), durch

Aufhängen (Beutel) oder Hineinstellen (Flasche) in den Flaschenhalter an dem Stativ

angebracht. Der Flaschenhalter dient zur Aufnahme verschiedener Flaschengrößen.

Der Flaschenhalter muss so ausgerichtet sein, dass nach Einstechen des Entnahme-

spikes | der Nadel, der Schlauch des Sterilitätstestsystemes nicht gespannt ist und

ein Herausrutschen des Entnahmespikes | der Nadel aus dem Probengefäß ausge-

schlossen ist.

Für die Prüfung von Ampullen befindet sich ein Ampullenbrecher ebenfalls an dem

Stativ. Die Ampullen können an dem integrierten Messer angeritzt und anschließend

gebrochen werden. Die abgebrochenen Ampullenspitzen werden in dem Auffangbehälter aufgefangen (dieser Behälter kann dann zu einem späteren Zeitpunkt geleert

werden).

– Für den folgenden Pumpvorgang achten Sie darauf, dass die Sterisart® NF Testbe-

hälter in den vorgesehenen Aufnahmen stehen, und der Schlauch ohne Spannung

und Knicke eingelegt ist.

Achtung! Wichtiger Hinweis!

Beim Öffnen des Hebels wird die Sterisart® Universal-Pumpe durch eine Sicherheitsfunktion sofort abgeschaltet. In diesem Falle ist die Sterisart® UniversalPumpe nach ordnungsgemäßem Schließen aller Bauteile neu zu starten.

8 Betrieb der Sterisart® Universal-

Pumpe 16419

Die Sterisart® Universal-Pumpe 16419 kann entweder durch Drücken des Wähl-

knopfes in Gang gesetzt werden oder durch Betätigen des optionalen Fußschalters.

Hierbei kann die Geschwindigkeit stufenlos am Wählknopf eingestellt werden. Das

Ausschalten erfolgt durch erneutes Drücken des Wählknopfes oder Loslassen des Fußschalters.

.

Abb. 4

Betrieb der Sterisart® Universal-Pumpe 16419 29

9 Reinigung, Desinfektion

Achtung!

Anschlüsse hinten sind nicht dicht.

Die Sterisart® Universal-Pumpe ist, sofern sie nicht in eine Isolator arbeitsplatte

dicht eingebaut ist, nicht für die Desinfektion (gasförmig oder vernebelt) mit

Peressigsäure, H2O2 oder andere im Isolator gebräuchliche Dekontaminationverfahren geeignet. Im fachgerecht eingebauten Zustand im Isolator können

diese Desinfektionsmittel eingesetzt werden.

– Vor der Reinigung des Pumpen rotors schalten Sie die Pumpe am Netzschalter aus

und entfernen Sie das Netzkabel.

Zur Reinigung müssen folgende Teile von der Pumpe abgenommen werden:

– Bügel, Exzenterhebel, Stativ und Ablaufbehälter

– Entfernen des Pumpenkopfs:

– Der Rotor muss per Hand so gedreht werden, dass die Markierung auf der Ober-

seite (schwarzer Punkt) nach hinten weist.

– Die Markierung kennzeichnet die Position der Befestigungsschraube, die sich im

Rotormittelteil befindet.

– Lösen Sie diese Schraube mit einem 4 mm Inbusschlüssel. Drehen Sie die Schrau-

be nicht ganz heraus.

– Ziehen Sie den Rotor nach oben ab.

– Ziehen Sie den Geschwindigkeitswählknopf nach oben ab.

IP-Schutz einhalten! Es darf keine Flüssigkeit in die Sterisart® Universal-Pumpe

gelangen. Vor der Reinigung, Wartung oder Reparatur das Gerät von der

Betriebsspannung trennen.

Reinigung der Edelstahloberflächen:

Das Edelstahlgehäuse kann in regelmäßigen Abständen gereinigt werden. Edelstahlteile mit einem angefeuchteten Tuch reinigen. Handelsübliche Reiniger, die für Edelstahl geeignet sind, können gefahrlos eingesetzt werden. Zur Oberflächendesinfektion

handelsübliche Desinfektionsmittel, die für Edelstahl geeignet sind, einsetzen.

Keine Reinigungsmittel für das Edelstahlgehäuse verwenden, die Natronlauge, Essig-,

Schwefel- oder Zitronensäure enthalten. Die Verwendung von Putzschwämmen aus

Stahlwolle ist verboten.

Alle Edelstahloberflächen können mit folgenden Produkten wischend feucht gereinigt

werden:

– Peressigsäure, H2O2 und Essigsäure (2,5%)

– Quartäres Ammonium

– Formaldehyd und Glutaraldehyd

– Isopropylalkohol

– Ethanol 70%

30 Reinigung, Desinfektion

Autoklavierbar bei 121°C und 20 Minuten sind: Bügel, Exzenterhebel, Wählknopf,

Stativ, Flaschenhalter, Flaschengegenhalter und Ablaufbehälter (komplett).

Niemals den Pumpenrotor autoklavieren oder in Flüssigkeit tauchen.

Zur Reinigung | Desinfektion nur ein leicht angefeuchtetes Tuch verwenden.

Nach Reinigung werden alle Teile wie im Kapitel „Inbetriebnahme“ auf Seite 27

beschrieben befestigt. Der Rotor wird folgendermaßen montiert:

– Die Rotorwelle besitzt auf der nach hinten gewandten Seite eine Einkerbung.

– Schieben sie den Rotor von oben auf die Welle.

– Drehen sie die Markierung auf dem Rotor nach hinten, so dass die Einkerbung auf

der Rotorwelle und die Markierung auf dem Rotor fluchten.

– Drehen Sie die Schraube im Rotormittelteil fest, sodass ein fester Sitz des Rotors

gewährleistet ist.

10 Montage in einem Isolator

Die Montage der Pumpe in einem Isolator darf nur durch den

Isolatorhersteller erfolgen.

Zur Montage der Sterisart® Universal-Pumpe in einem Isolator muss das Gerät auf

jeden Fall geöffnet werden. Hierzu muss auf jeden Fall der Netzstecker gezogen sein.

Für die Montage beachten Sie bitte genau die Einbauvorschrift (Bestandteil des

Einbaukits für Isolatoren, Bestellnummer 1ZE---0050) die separat vom Hersteller

erhältlich ist.

11 Wichtige Hinweise zur

Gewährleistung

Die Funktion und die Sicherheit der Sterisart® Universal Pumpe wird nur nach den

Informationen in dieser Anleitung gewährleistet.

Der Hersteller des Gerätes betrachtet sich nur dann für die Auswirkungen auf

die Sicherheit, Zuverlässigkeit und Leistung des Geräts als verantwortlich,

wenn Montage, Erweiterungen, Neueinstellung, Änderung oder Reparaturen durch

von ihm ermächtigte Personen ausgeführt werden, die elektrische Installation

des Raumes den Anforderungen von IEC-Festlegungen entspricht und das Gerät in

Übereinstimmung mit der Bedienungsanleitung verwendet wird.

Veränderungen an der Sterisart® Universal-Pumpe, die nicht nach Absprache oder

durch autorisiertes Sartorius Servicepersonal vorgenommen wurden, befreien den

Hersteller von jeglicher Gewährleistung.

Montage in einem Isolator 31

12 Hilfe bei Problemen

In diesem Kapitel werden einige Probleme aufgezeigt, die in Zusammenhang mit

der Sterisart®pumpe auftreten können. Für jedes Problem sind mehrere Lösungsmöglichkeiten aufgeführt. Der erste Vorschlag ist in der Regel der naheliegendste.

Wird das Problem dadurch nicht gelöst, sollten Sie die Vorschläge in der aufgeführten

Reihenfolge durchführen, bis der Fehler behoben ist.

Bei dem Lösen oder Verbinden von Steckverbindungen muss das Gerät ausgeschaltet sein!

Sollte sich der Fehler auf diese Weise nicht beheben lassen, wenden Sie sich bitte an

Ihre zuständige Service-Stelle.

Problem Lösung

Keine Funktion, Display geht nicht an Die Pumpe ist nicht eingeschaltet oder nicht richtig an die Stromversorgung

angeschlossen.

Netzkabel richtig in die Steckdose und in die Sterisart

Netzschalter einschalten.

Die Stromzuführung überprüfen, Mehrfachsteckdosen evtl. einschalten, Zuleitungen

überprüfen.

Sollten diese Möglichkeiten ausgeschlossen sein, könnte auch die Primärsicherung im

Netzfilter defekt sein.

Ein Auswechseln bei gezogenem Netzstecker darf nur durch Fachpersonal erfolgen!

Die Pumpe dreht sich nicht. Der Verschlusshebel ist geöffnet oder der Fußschalter ist nicht richtig angeschlossen.

Der Bügel ist von der Pumpe entnommen.

Den Anschluss des Fußschalters an der Pumpe überprüfen.

®

Universal-Pumpe einstecken,

32 Hilfe bei Problemen

13 Technische Daten

Abmessungen Pumpe in mm

(B × T × H)

Abmessungen Pumpe mit

Flaschenhalter und Ablaufbehälter in

mm (B × T × H)

Gewicht ca 13.5 kg

Maximale Betriebstemperatur 40°C

Weitere Daten IP41 gemäß IEC 60529/EN 60529

Elektrischer Anschluss

Spannung 100 – 240 V ± 10%

Frequenz 50 – 60 Hz

Leistung 100 VA

Pumpe

Förderleistung 70 – 650 ml/min (systemabhängig)

Schlauchsysteme

Die einwandfreie Funktion der Sterisart

von Sartorius freigegebenen Schlauchsystemen gewährleistet.

Materialien

Basisplatte, Hebel, Bügel, Rotor Edelstahl 1.4435 (316L)

Gehäuse, Steckereinschub,

Stativ, Flaschenhalterung

Ablaufbehälter, Hebelum-

mantelung, Bügelgleitlager

Gleitlager Hebel Iglidur X

Dichtungen, Kleber, Ablaufschlauch Silikon

336 × 260 × 210 (mit Hebel)

440 × 365 × 485

®

Universal-Pumpe wird nur bei Verwendung

Edelstahl 1.4401 (316)

PET

Technische Daten 33

14 Bestellinformationen für die

®

Sterisart

Bestellnummern Beschreibung

16419 Sterisart

16973 Ampullenzange

1ZG---0009 Flaschenhalter

1ZF---0004 Haltearm

1ZA---0002 Ablaufschlauch

1ZW---0002 Ampullenbrecher

1ZE---0033 Fußschalter

1ZF---0013 Stativ

1ZG---0028 Ablaufbehälter

1ZB---0001 Kunststoffhülse Klemmhebel

1ZF---0007 Flügelschraube

1ZS---0005 Klemmbügel

1ZS---0002 Hebel

Universal-Pumpe 16419

®

Universal-Pumpe, Grundversion

1ZL---0003 Rotor

®

1ZG---0023 Abdeckung Ablaufbehälter für Sterisart

1ZG---0024 Abdeckung Ablaufbehälter für Millipore™ Sterilitätstesteinheiten

®

1ZG---0014 Adapter für Sterisart

Equinox Pumpe

1ZE---0039 Transport Trolley

1ZE---0041 Einbaukit Isolatoren

Weiteres Zubehör auf Anfrage!

Ablaufbehälter zum Gebrauch an Millipore™

Sterilitätstesteinheiten

34 Bestellinformationen für die Sterisart® Universal-Pumpe 16419

15 Bestellinformationen

Verbrauchsartikel

Empfohlene Einweg-Sterilitätstesteinheiten zum Einsatz mit der Pumpe:

Bestellnummern Beschreibung

®

16466-ACD Sterisart

Behälter (10 Stück, einzeln steril verpackt, ETO-sterilisiert)

16467-ACD Sterisart

(10 Stück, einzeln steril verpackt, ETO-sterilisiert)

16468-ACD Sterisart

Luer|Luer-Lock-Anschluss (10 Stück, einzeln steril verpackt,

ETO-sterilisiert)

16466-GBD Sterisart

Behälter (steril, doppelt verpackt, Verpackungsgröße 10 Einheiten).

Optimal für den Einsatz in Isolatoren

16467-GBD Sterisart

(steril, doppelt verpackt, Verpackungsgröße 10 Einheiten).

Optimal für den Einsatz in Isolatoren

16468-GBD Sterisart

Luer oder Luer Lock Anschluss (steril, doppelt verpackt, Verpackungsgröße 10 Einheiten). Optimal für den Einsatz in Isolatoren

16469-GBD Sterisart

verpackt, Verpackungsgröße 10 Einheiten).

Optimal für den Einsatz in Isolatoren

16470-GBD Sterisart

geschlossenen Behältern (steril, doppelt verpackt, Verpackungsgröße 10 Einheiten). Optimal für den Einsatz in Isolatoren

16475-GBD Sterisart

doppelt verpackt, Verpackungsgröße 10 Einheiten).

Optimal für den Einsatz in Isolatoren

16476-GBD Sterisart

geschlossene Behälter (10 Stück, steril, doppelt verpackt).

Optimal für den Einsatz in Isolatoren)

16477-GBD Sterisart

hältern (10 Stück, steril, doppelt verpackt).

Optimal für den Einsatz in Isolatoren

16478-GBD Sterisart

mit Luer Lock männlich Anschluss (steril, doppelt verpackt,

Verpackungsgröße 10 Einheiten).

Optimal für den Einsatz in Isolatoren

Weitere Sterisart

®

Einheiten erhalten Sie auf Anfrage.

NF alpha, Metall-Doppelnadel für geschlossene

®

NF alpha, 6 cm Metallnadel für offene Behälter

®

NF alpha, Adapter für medizinische Behältnisse mit

®

NF gamma, Metall-Doppelnadel für geschlossene

®

NF gamma, 6 cm Metallnadel für offene Behälter

®

NF gamma, Adapter für medizinische Behältnisse mit

®

NF gamma, System für Fertigspritzen (steril, doppelt

®

NF gamma, System für schwerlösliche Pulver in

®

NF gamma, System für leichtlösliche Pulver (steril,

®

NF gamma, System mit kurzer Metall-Doppelnadel für

®

NF gamma, System für Flüssigkeiten in Kunststoffbe-

®

NF gamma, Adapter für medizinische Behältnisse

Bestellinformationen Verbrauchsartikel 35

16 Dokumentation

Datenblatt Sterisart® Universal-Pumpe Deutsch

Publ. Nr.: SLD2010-d Bestellnummer: 85030-531-18

®

Datenblatt Sterisart

Publ. Nr.: SLD2010-e Bestellnummer: 85030-531-17

Broschüre Sterisart

Publ. Nr.: SLD1003-d Bestellnummer: 85030-531-15

Broschüre Sterisart

Publ. Nr.: SLD1003-e Bestellnummer: 85030-531-14

Universal-Pumpe Englisch

®

Universal-Pumpe Deutsch

®

Universal-Pumpe Englisch

17 Lagerung und Versand

17.1 Lagern

Vorgehen

t Wenn das Gerät in Betrieb ist:

t Das Gerät außer Betrieb nehmen.

t Das Gerät reinigen.

t Das Gerät gemäß den Umgebungsbedingungen lagern (siehe Kapitel „13 Techni-

sche Daten“ auf Seite 33).

17.2 Geräte und Teile zurücksenden

Defekte Geräte oder Teile können an Sartorius zurückgesendet werden. Zurückgesandte Geräte müssen sauber, dekontaminiert und sachgerecht verpackt sein.

Transportschäden sowie Maßnahmen zur nachträglichen Reinigung und Desinfektion

des Geräts oder der Teile durch Sartorius gehen zu Lasten des Absenders.

WARNUNG

Verletzungsgefahr durch kontaminierte Geräte!

Mit gefährlichen Stoffen kontaminierte Geräte (ABC-Kontamination) werden nicht

zur Reparatur und Entsorgung zurückgenommen.

t Die Hinweise zur Dekontamination beachten (siehe Kapitel „13 Technische Daten“

auf Seite 33).

Vorgehen

t Das Gerät außer Betrieb nehmen.

t Den Sartorius Service kontaktieren, um Hinweise zur Rücksendung von Geräten

oder Teilen zu erhalten (Hinweise zur Rücksendung siehe auf unserer Internetseite www.sartorius.com).

t Das Gerät und die Teile in einer ungenutzten Original-Verpackung oder in einem

Transportkoffer für den Versand verpacken. Die Original-Verpackung kann

bestellt werden (den Sartorius Service kontaktieren).

36 Dokumentation

18 Entsorgung

18.1 Hinweise zur Dekontamination

Das Gerät enthält keine gefährlichen Betriebsstoffe, deren Beseitigung besondere

Maßnahmen erfordert. Potentielle Gefahrstoffe, von denen biologische oder chemische Gefahren ausgehen können, sind die im Prozess verwendeten Medien (z. B.

Säuren, Laugen).

Gemäß EU-Richtlinien zur Europäischen Gefahrstoffverordnung ist der Eigentümer

von Geräten, die mit Gefahrstoffen in Berührung gekommen sind, für die sachgerechte Entsorgung und Deklaration bei deren Transport verantwortlich.

WARNUNG

Verletzungsgefahr durch kontaminierte Geräte!

Mit gefährlichen Stoffen kontaminierte Geräte (ABC-Kontamination) werden nicht

zur Reparatur und Entsorgung zurückgenommen.

18.2 Gerät und Teile entsorgen

18.2.1 Hinweise zur Entsorgung

Das Gerät und das Zubehör zum Gerät müssen fachgerecht durch Entsorgungseinrichtungen entsorgt werden.

Im Inneren des Geräts ist eine Lithium-Knopfzelle verbaut. Batterien müssen fachgerecht durch Entsorgungseinrichtungen entsorgt werden.

Die Verpackung besteht aus umweltfreundlichen Materialien, die als Sekundärrohstoffe dienen können.

18.2.2 Entsorgen

Voraussetzungen

Das Gerät ist dekontaminiert.

Vorgehen

t Das Gerät entsorgen. Dazu die Entsorgungshinweise auf unserer Internetseite

(www.sartorius.com) beachten. Die Entsorgungseinrichtung darüber informieren,

dass im Inneren des Geräts eine Lithium-Knopfzelle verbaut ist.

t Die Verpackung gemäß den landesrechtlichen Bestimmungen entsorgen.

t Das Verbrauchsmaterial gemäß den landesrechtlichen Bestimmungen entsorgen.

Entsorgung 37

19 Konformität

Mit den beigefügten Dokumenten wird die Übereinstimmung des Geräts mit den

benannten Richtlinien oder Normen erklärt.

20 Lizenzrechtliche oder

markenrechtliche Informationen

20.1 Millipore™

Millipore™ ist eine eingetragene Marke der Merck KGaA, Darmstadt, Deutschland,

oder ihrer Tochtergesellschaften.

38 Konformität

Certificate:

80003373

Master Contract:

167555

Project:

80003373

Date Issued:

2019-07-24

Issued To:

Sartorius Lab Instruments GmbH & Co. KG

Otto-Brenner-Strasse 20

Goettingen, Niedersachsen, 37079

Germany

The products listed below are eligible to bear the CSA Mark shown with

indicator 'US' for US only or without either indicator for Canada only.

CLASS - C872106 - ELECTRICAL LABORATORY EQUIPMENT

CLASS - C872186 - ELECTRICAL LABORATORY EQUIPMENT Certified to US Standards

Certificate of Compliance

adjacent indicators 'C' and 'US' for Canada and US or with adjacent

PRODUCTS

Peristaltic pumps, table top, portable, AC powered, Class I (grounded), models and rating as follow;

16419 and 16420, each rated: 100-240 V~, 50-60 Hz, 100 VA

Notes:

1. The above model is cord connected, Equipment Class I, Pollution Degree 2 and Overvoltage category II.

2. Mode of operation: Continuous

3. Environmental Conditions: +10 to +40 °C, 2000 m. max, 80% rH max.

Issued by:

Eric Fortier

Eric Fortier

DQD 507 Rev. 2019-04-30 © 2018 CSA Group. All rights reserved. Page 1

Certificate: 80003373

Master Contract: 167555

Project: 80003373

Date Issued: 2019-07-24

CONDITIONS OF ACCEPTABILITY

(1) If at any time there is a conflict between the system safety provisions and any relevant local (national or

regional) requirements, the local requirements always take precedence.

(2) For use in dry locations and indoor only.

(3) No user replaceable battery. Internal non rechargeable lithium cell can only be replaced by Service

personnel.

(4) Appliance coupler on power cord is considered as a disconnect device, it must remain accessible.

(5) Professional laboratory equipment; only trained personal is allowed to operate the unit.

(6) Pump is only allowed to be operated once the tubing has been properly installed into the unit.

APPLICABLE REQUIREMENTS

CAN/CSA-C22.2 No. 61010-1-12 - Safety Requirements for Electrical Equipment for Measurement,

+ UPD1:15 + UPD2:16 + AMD1:2018 Control, and Laboratory Use, Part 1: General Requirements

ANSI/UL 61010-1-2012 +AMD1:2018 - Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use - Part 1: General Requirements

DQD 507 Rev. 2019-04-30 © 2018 CSA Group. All rights reserved. Page 2

Certificate: 80003373

Master Contract: 167555

Project

Date

Description

80003373

2019-07-24

CSA c/us certification of a sterelization pump, model Sterisart based on CB

Supplement to Certificate of Compliance

The products listed, including the latest revision described below,

are eligible to be marked in accordance with the referenced Certificate.

Product Certification History

report from SIQ

DQD 507 Rev. 2019-04-30 © 2018 CSA Group. All rights reserved. Page 1

Last updated:

The information and figures contained in these

instructions correspond to the version date

specified below.

Sartorius reserves the right to make changes

to the technology, features, specifications and

design of the equipment without notice.

Masculine or feminine forms are used to

facilitate legibility in these instructions and

always simultaneously denote the other

gender as well.

Copyright notice:

This instruction manual, including all of its

components, is protected by copyright.

Any use beyond the limits of the copyright law

is not permitted without our approval.

This applies in particular to reprinting,

translation and editing irrespective of the type

of media used.

© Sartorius Germany

Sartorius Lab Instruments GmbH & Co. KG

Otto-Brenner-Strasse 20

37079 Goettingen, Germany

Phone: +49.551.308.0

www.sartorius.com

06 | 2019

Printed in the EU on paper bleached

without chlorine. | HB

Publication No.: SLD6028-a190608

Loading...

Loading...