Page 1

INSTALLATION INSTRUCTIONS

– W-3WAY ECO-i System Air Conditioner –

for Refrigerant R410A

This air conditioner uses the new refrigerant R410A.

NOTE

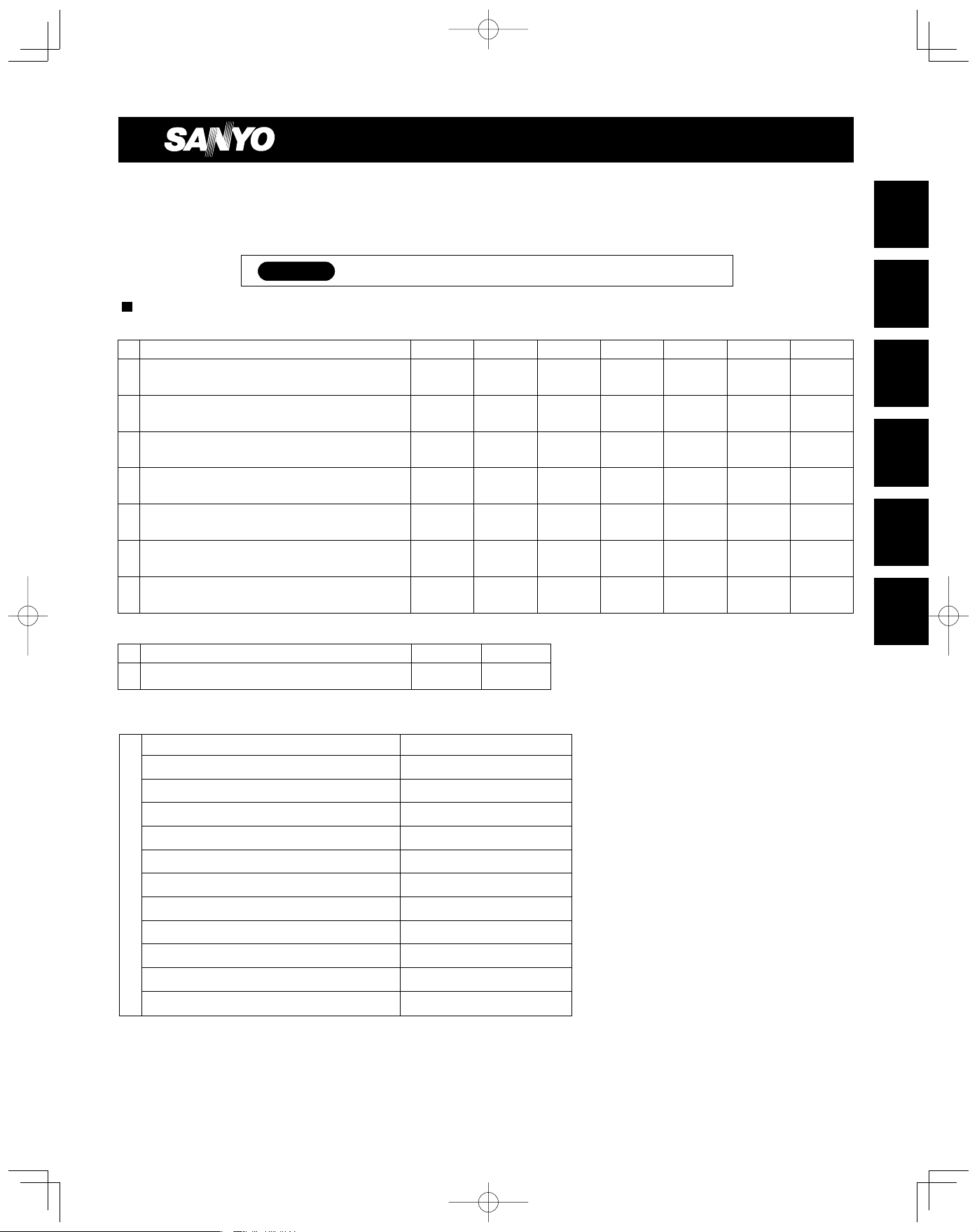

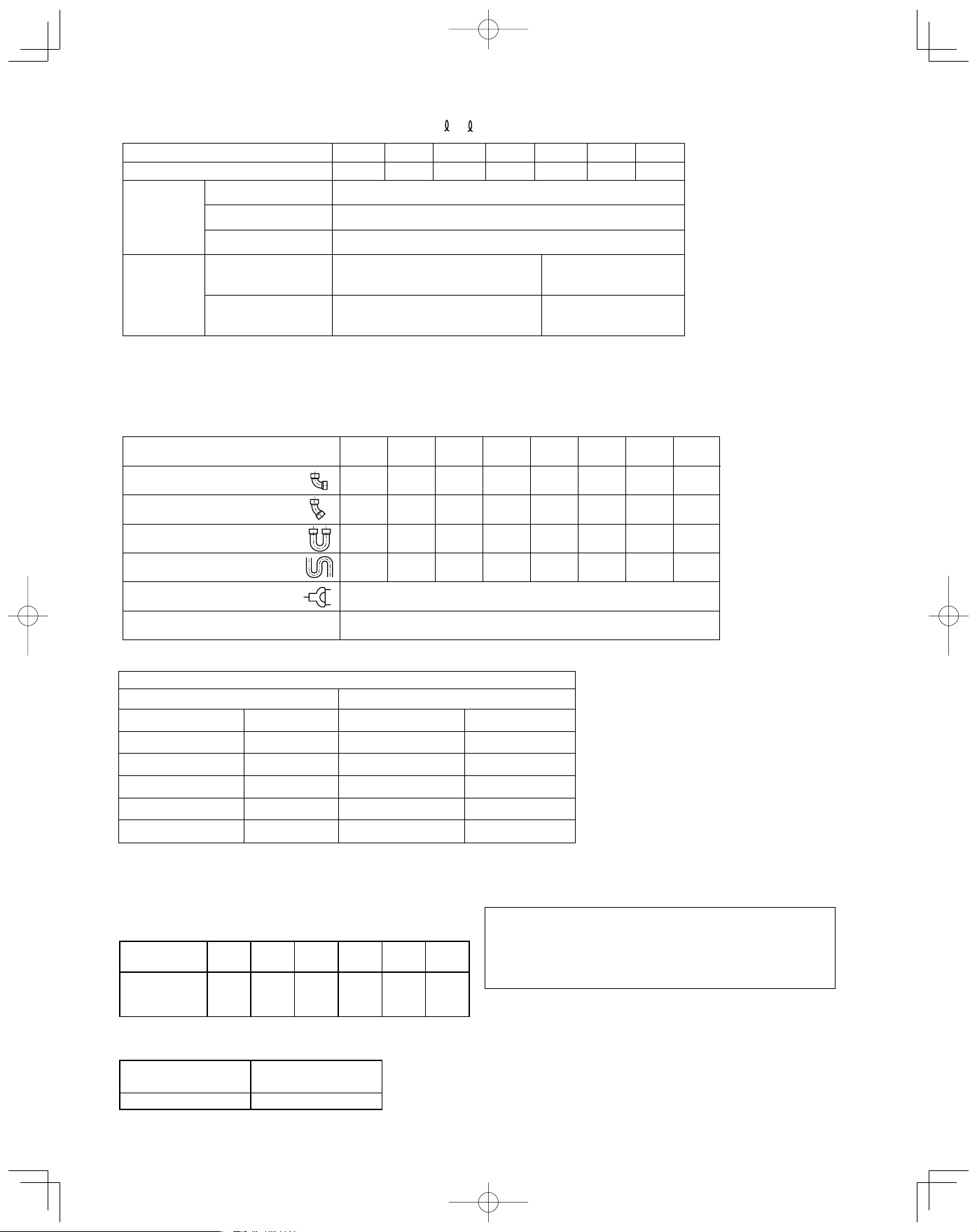

R410A Models

Indoor Units

Class 9 12 18 24 36 48

X 4-Way Air Discharge Semi-Concealed Type XHX1252 XHX1852 XHX2452 XHX3652

XM 4-Way Air Discharge Semi-Concealed Type XMHX1252 XMHX1852

A 1-Way Air Discharge Semi-Concealed Type AHX0752 AHX0952 AHX1252

U Concealed Duct Type UHX0752 UHX1252 UHX1852 UHX2452 UHX3652

D DHX3652 DHX4852

T Ceiling-Mounted Type THX1252 THX1852 THX2452

K Wall-Mounted Type KHX0752 KHX0952 KHX1252 KHX1852 KHX2452

Concealed Duct

High-Static Pressure Type

Outdoor Units

Class 90 140

CECO-i W-3WAY

* Refrigerant R410A is used in the outdoor units.

Optional Controllers

Timer Wired Remote Controller RCS-TM80BG

Wireless Remote Controller (For U, D Types) RCS-BH80AAB.WL

Wireless Remote Controller (For X Type) RCS-SH80AAB.WL

Wireless Remote Controller (For XM Type) RCS-XM18AAB.WL

Wireless Remote Controller (For A, T Types) RCS-TRP80AAB.WL

RC Wireless Remote Controller (For K Type) RCS-SH1AAB

Simplified Remote Controller RCS-KR1AGB

System Controller SHA-KC64UG

Intelligent Controller SHA-KT256BA

Communication Adaptor SHA-KA128AAB

Remote Sensor ART-K45AGB

LonWorks Interface SHA-LN16UAB

External diameter of service port R410A: 5/16"

7

CHDZ09053 CHDZ14053

CHDZR09053 CHDZR14053

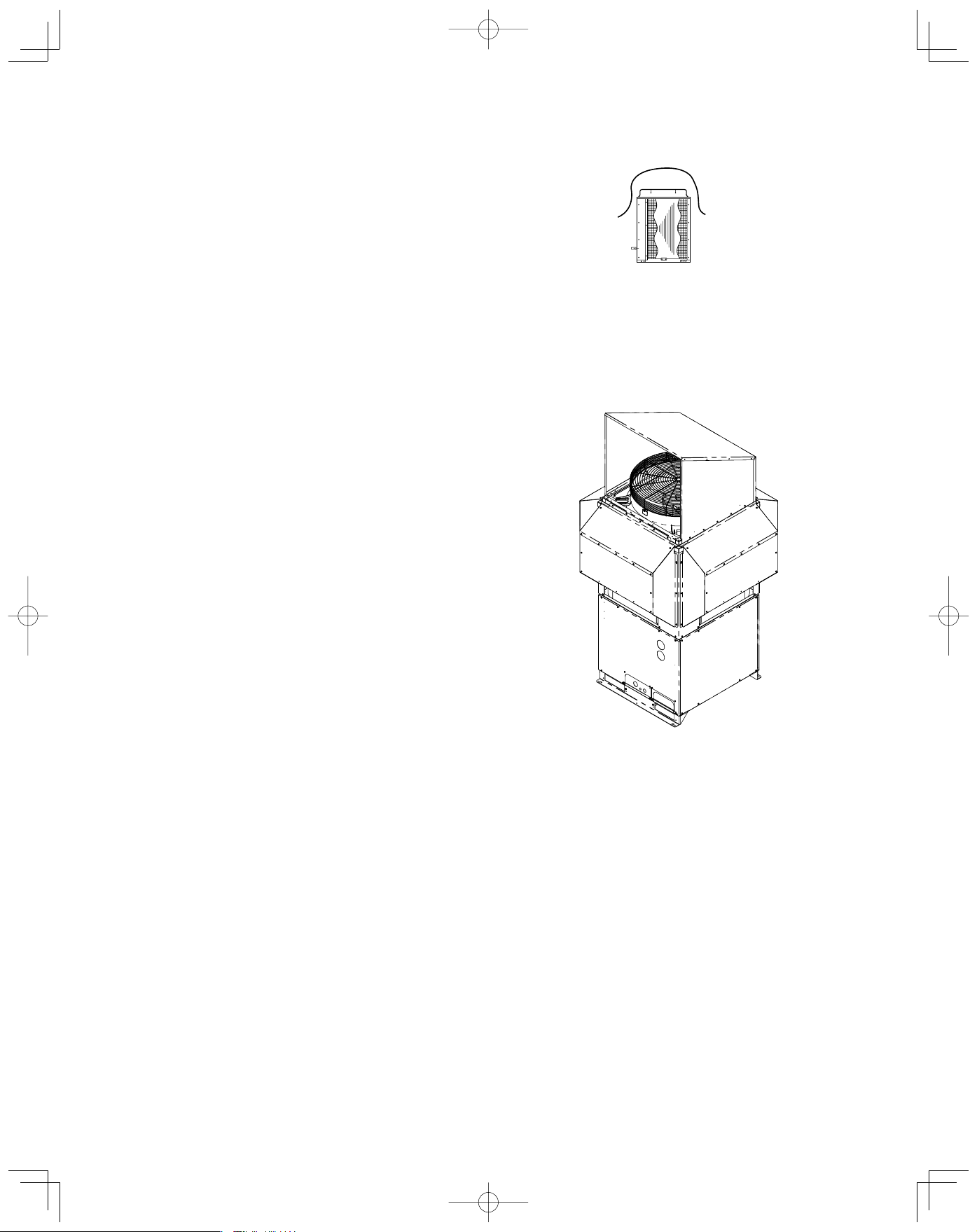

X

XM

A

U

D

T

K

SANYO Commercial Solutions In Canada

A division of SANYO North America Corporation SANYO Canada Inc.

Cornerstone Business Park 1-300 Applewood Crescent

1062 Thorndale Avenue Concord, Ontario

85464369098000 ©SANYO 2008

W-3WAYECO-iUS.inddaW-3WAYECO-iUS.indda 2008/02/0710:55:342008/02/0710:55:34

Bensenville, IL 60106, U.S.A. L4K 5C7, Canada

a

Page 2

IMPORTANT!

Please Read Before Starting

This air conditioning system meets strict safety and operating standards. As the installer or service person, it is an

important part of your job to install or service the system so

it operates safely and efficiently.

For safe installation and trouble-free operation, you must:

●

Carefully read this instruction booklet before beginning.

●

Follow each installation or repair step exactly as shown.

●

Observe all local, state, and national electrical codes.

●

Pay close attention to all warning and caution notices

given in this manual.

This symbol refers to a hazard or

WARNING

CAUTION

unsafe practice which can result

in severe personal injury or death.

This symbol refers to a hazard or

unsafe practice which can result

in personal injury or product or

property damage.

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help for a

special problem, contact our sales/service outlet or your

certified dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for

improper installation or maintenance service, including failure to follow the instructions in this document.

SPECIAL PRECAUTIONS

WARNING

When Wiring

When Installing…

…In a Room

Properly insulate any tubing run inside a room to prevent

“sweating” that can cause dripping and water damage to

walls and floors.

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide

a solid, level foundation for the outdoor unit. This prevents

water damage and abnormal vibration.

…In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a

metal frame. Provide a suitable air baffle.

…In a Snowy Area (for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is higher

than drifting snow. Provide snow vents.

When Connecting Refrigerant Tubing

• Ventilate the room well, in the event that is refrigerant

gas leaks during the installation. Be careful not to allow

contact of the refrigerant gas with a flame as this will

cause the generation of poisonous gas.

• Keep all tubing runs as short as possible.

• Use the flare method for connecting tubing.

• Apply refrigerant lubricant to the matching surfaces of

the flare and union tubes before connecting them, then

tighten the nut with a torque wrench for a leak-free connection.

• Check carefully for leaks before starting the test run.

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

ONLY A QUALIFIED, EXPERIENCED

ELECTRICIAN SHOULD ATTEMPT TO

WIRE THIS SYSTEM.

• Do not supply power to the unit until all wiring and tubing

are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this

system. Carefully refer to the wiring diagram and these

instructions when wiring. Improper connections and inadequate grounding can cause accidental injury or death.

• Ground the unit following local electrical codes.

• Connect all wiring tightly. Loose wiring may cause overheating at connection points and a possible fire hazard.

When Transporting

Be careful when picking up and moving the indoor and outdoor

units. Get a partner to help, and bend your knees when lifting

to reduce strain on your back. Sharp edges or thin aluminum

fins on the air conditioner can cut your fingers.

When Servicing

• Turn the power OFF at the main power box (mains)

before opening the unit to check or repair electrical parts

and wiring.

• Keep your fingers and clothing away from any moving

parts.

• Clean up the site after you finish, remembering to check

that no metal scraps or bits of wiring have been left

inside the unit being serviced.

CAUTION

• Ventilate any enclosed areas when installing or testing

the refrigeration system. Escaped refrigerant gas, on

contact with fire or heat, can produce dangerously toxic

gas.

• Confirm after installation that no refrigerant gas is leaking. If the gas comes in contact with a burning stove, gas

water heater, electric room heater or other heat source,

it can cause the generation of poisonous gas.

2

W-3WAYECO-iUS.indd2W-3WAYECO-iUS.indd2 2008/02/0710:55:362008/02/0710:55:36

Page 3

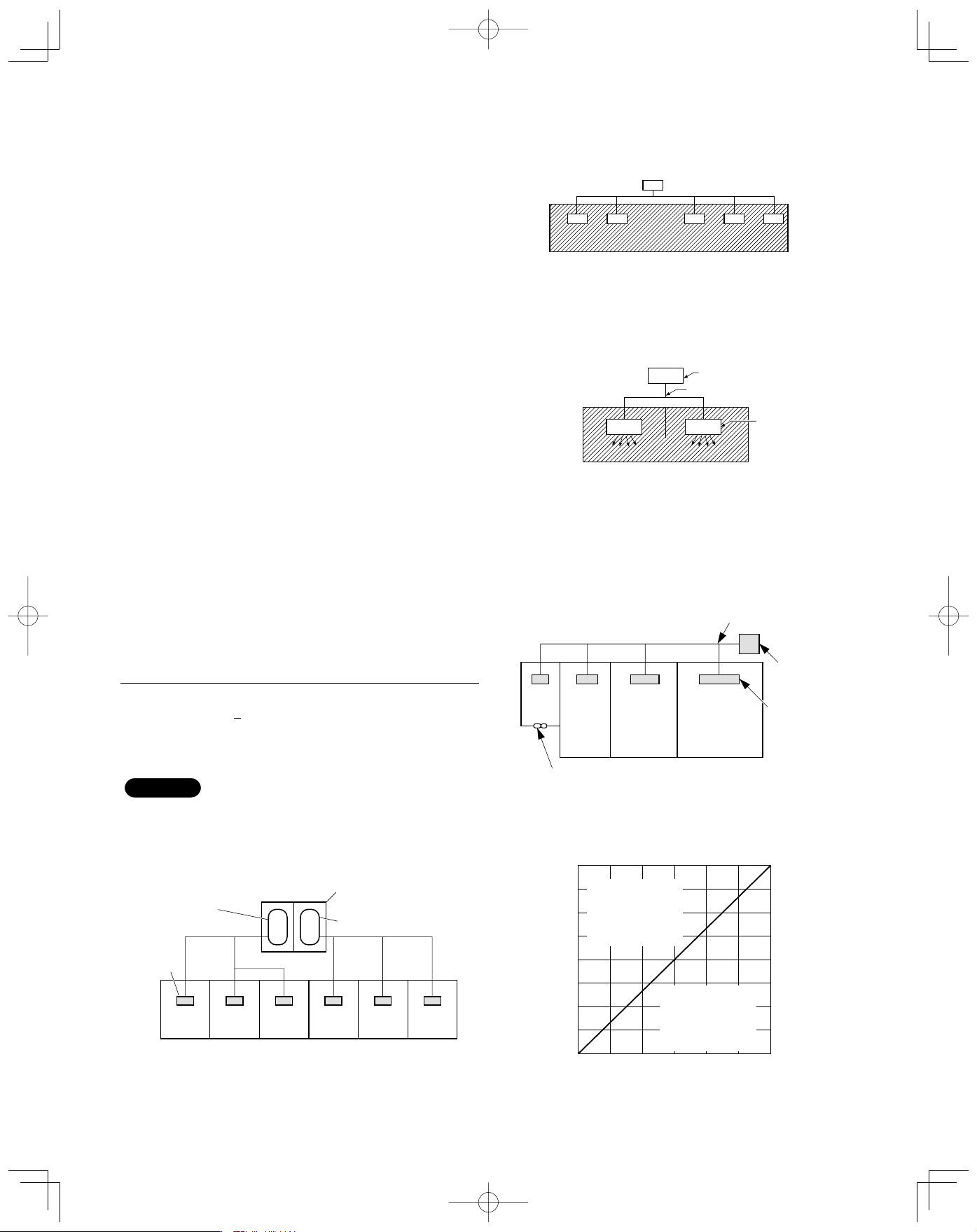

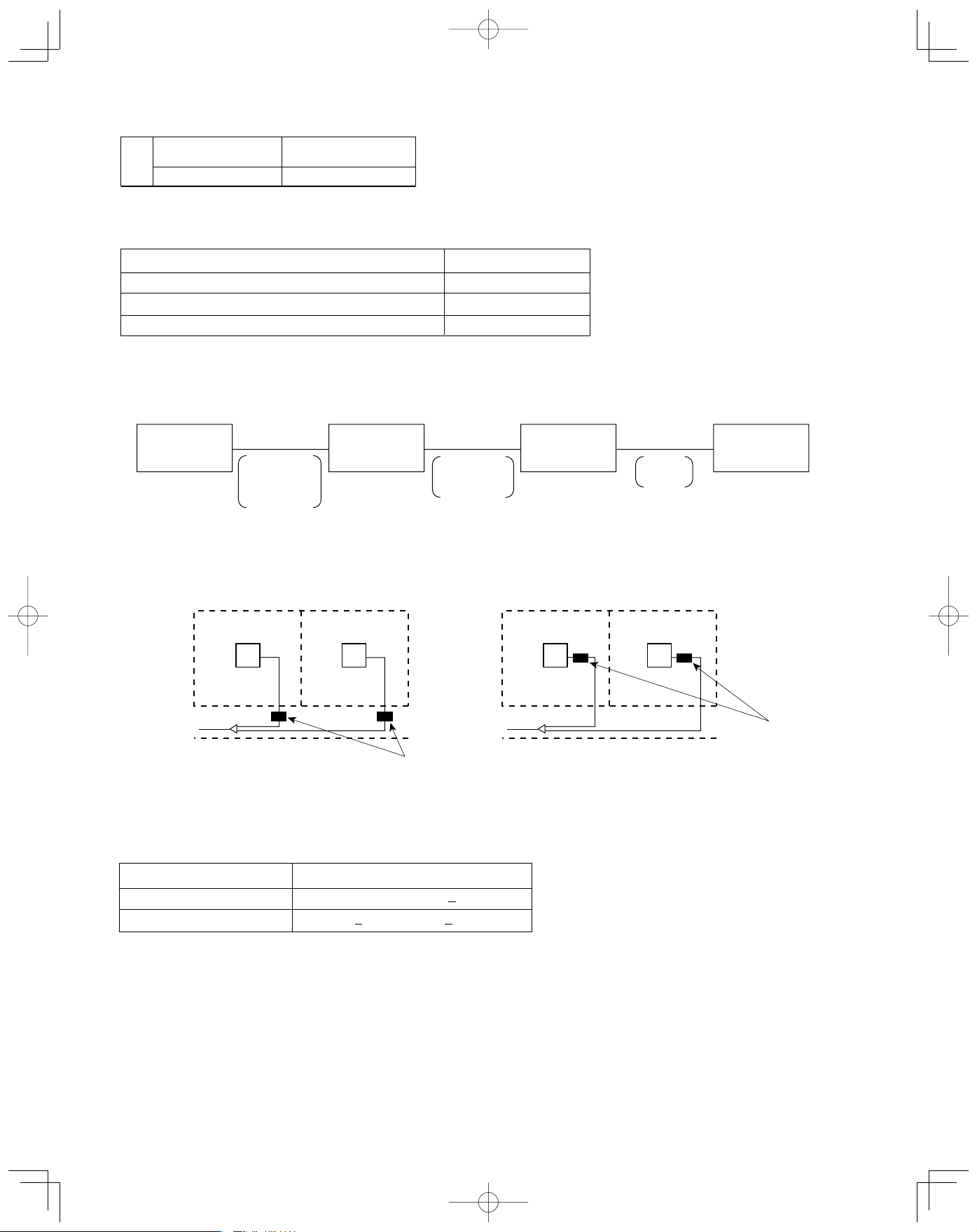

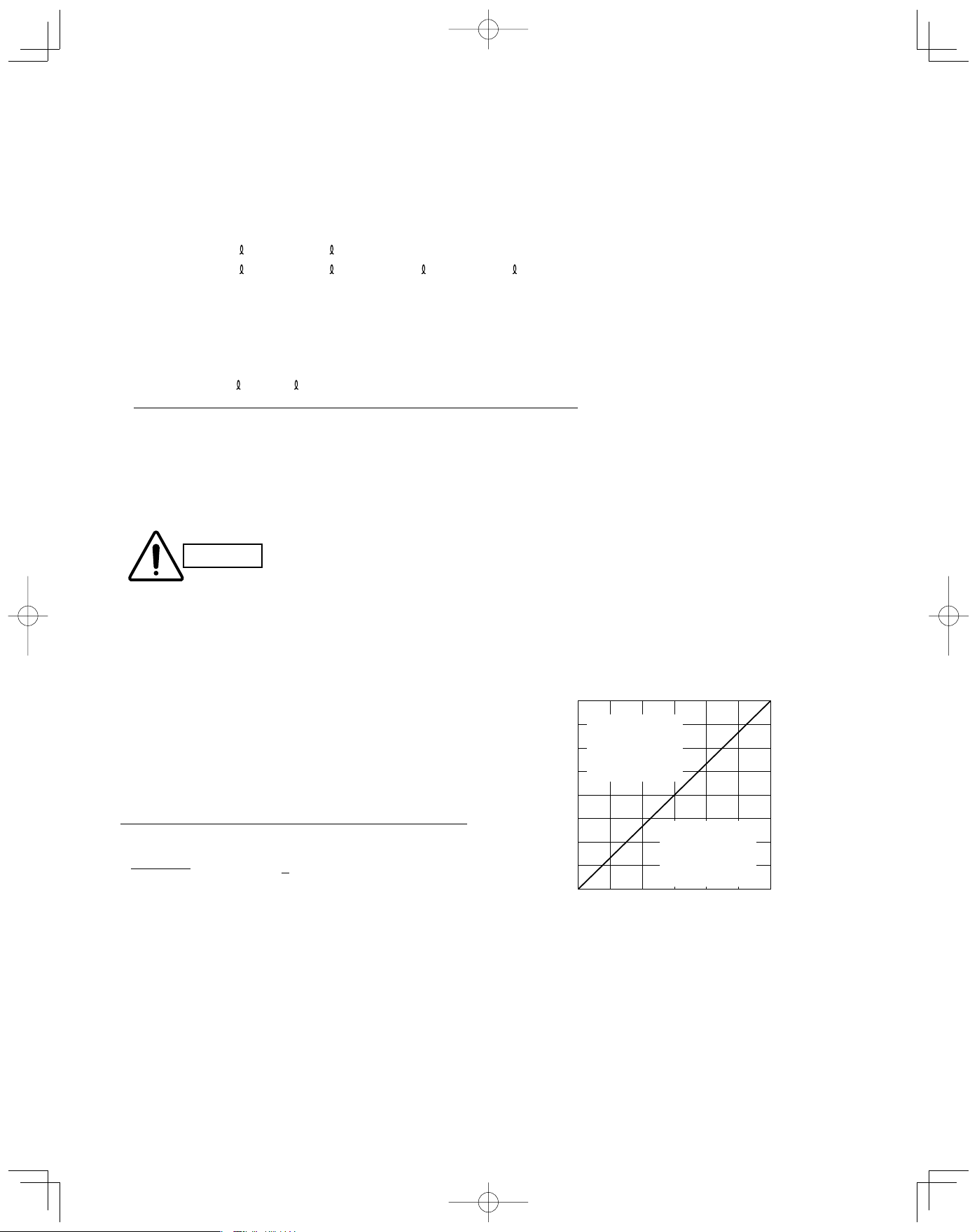

Check of Density Limit

2. The standards for minimum room volume are as follows.

The room in which the air conditioner is to be

installed requires a design that in the event of refrigerant gas leaking out, its density will not exceed a set

limit.

The refrigerant (R410A), which is used in the air conditioner, is safe, without the toxicity or combustibility of ammonia,

and is not restricted by laws imposed to protect the ozone

layer. However, since it contains more than air, it poses

the risk of suffocation if its density should rise excessively.

Suffocation from leakage of refrigerant is almost non-existent. With the recent increase in the number of high density

buildings, however, the installation of multi air conditioner

systems is on the increase because of the need for effective use of floor space, individual control, energy conservation by curtailing heat and carrying power, etc.

Most importantly, the multi air conditioner system is able

to replenish a large amount of refrigerant compared to

conventional individual air conditioners. If a single unit

of the multi air conditioner system is to be installed in a

small room, select a suitable model and installation procedure so that if the refrigerant accidentally leaks out,

its density does not reach the limit (and in the event of

an emergency, measures can be made before injury can

occur).

In a room where the density may exceed the limit, create

an opening with adjacent rooms, or install mechanical

ventilation combined with a gas leak detection device.

The density is as given below.

Total amount of refrigerant (lbs)

3

Min. volume of the indoor unit installed room (ft.

<

Density limit (oz/ft.

3

)

)

The density limit of refrigerant which is used in multi air conditioners is 0.3 oz/ft.

3

(ISO 5149).

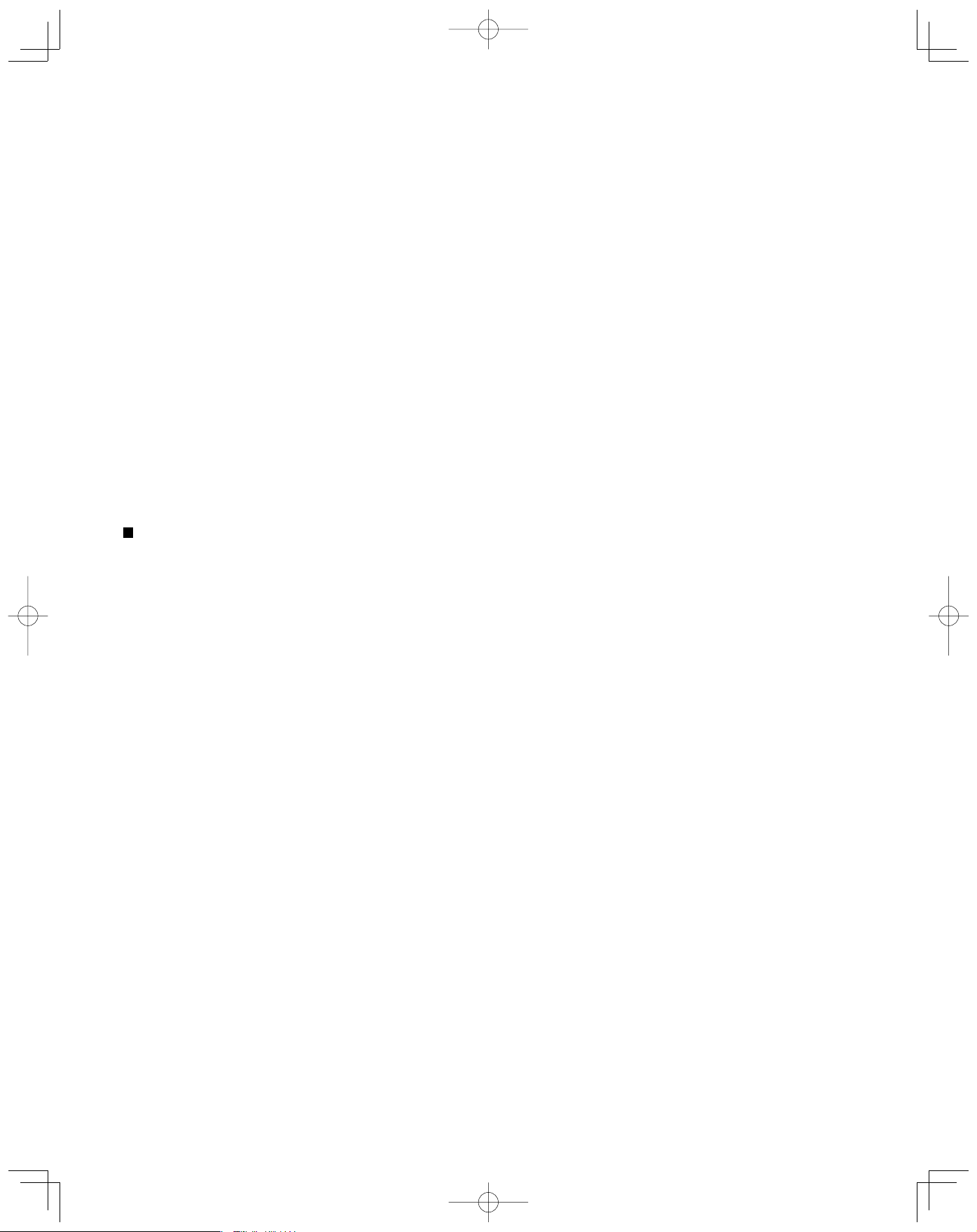

NOTE

1. If there are 2 or more refrigerating systems in a single

refrigerating device, the amount of refrigerant should be

as charged in each independent device.

For the amount of charge in this example:

Outdoor unit

e.g., charged

amount (353 oz)

Indoor unit

Room A Room B Room C Room D Room E Room F

The possible amount of leaked refrigerant gas in rooms A, B

and C is 353 oz.

The possible amount of leaked refrigerant gas in rooms D, E

and F is 529 oz.

e.g., charged

amount (529 oz)

(1) No partition (shaded portion)

(2) When there is an effective opening with the adjacent

room for ventilation of leaking refrigerant gas (opening without a door, or an opening 0.15% or larger than

the respective floor spaces at the top or bottom of the

door).

Outdoor unit

Refrigerant tubing

Indoor unit

(3) If an indoor unit is installed in each partitioned room

and the refrigerant tubing is interconnected, the smallest room of course becomes the object. But when

mechanical ventilation is installed interlocked with a

gas leakage detector in the smallest room where the

density limit is exceeded, the volume of the next smallest room becomes the object.

Refrigerant tubing

Outdoor unit

Ver y

small

room

Small

room

Mechanical ventilation device – Gas leak detector

Medium

room

Large room

Indoor unit

3. The minimum indoor floor space compared with the

amount of refrigerant is roughly as follows: (When the

ceiling is 8.8 ft. high)

3

ft.

4000

3500

3000

2500

2000

1500

Min. indoor volume

1000

Range below

the density limit of

0.3 oz/ft.

(countermeasures

not needed)

500

00

0

3

Range above

the density limit of

0.3 oz/ft.

(countermeasures

needed)

400200 600 800 1000 1200

Total amount of refrigerant

3

3

454

398

341

284

227

170

114

57

oz

2

ft.

Min. indoor floor area

(when the ceiling is 8.8 ft. high)

W-3WAYECO-iUS.indd3W-3WAYECO-iUS.indd3 2008/02/0710:55:362008/02/0710:55:36

Page 4

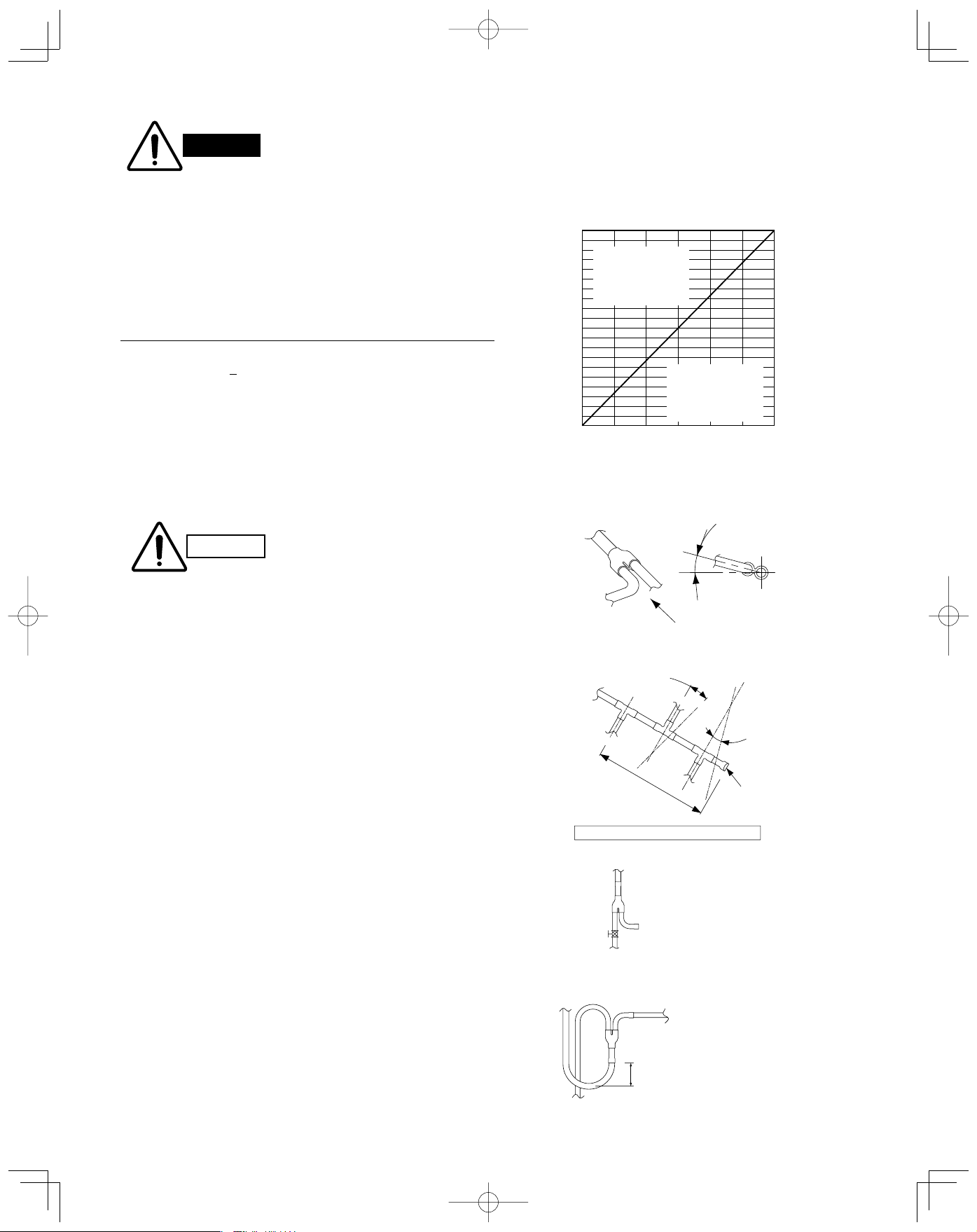

Precautions for Installation Using New Refrigerant

1. Care regarding tubing

1-1. Process tubing

●

Material: Use C1220 phosphorous deoxidized copper specified in JIS H3300 “Copper and Copper Alloy Seamless

Pipes and Tubes.”

For tubes of ø7/8" (ø22.22 mm) or larger, use C1220 T-1/2H material or H material, and do not bend the tubes.

●

Tubing size: Be sure to use the sizes indicated in the table below.

●

Use a tube cutter when cutting the tubing, and be sure to remove any flash. This also applies to distribution joints

(optional).

●

When bending tubing, use a bending radius that is 4 times the outer diameter of the tubing or larger.

Use sufficient care in handling the tubing. Seal the tubing ends with caps or tape to

CAUTION

Copper tube

Wall thickness 1/32 (0.8) 1/32 (0.8) 1/32 (0.8) 5/128 (1.0)

Copper tube

Wall thickness 5/128 (1.0) 5/128 (1.0) 5/128 (1.0) 3/64 (1.1)

Material O

Outer diameter 1/4 (6.35) 3/8 (9.52) 1/2 (12.7) 5/8 (15.88) 3/4 (19.05)

Material 1/ 2 H, H

Outer diameter 7/8 (22.22) 1 (25.4) 1-1/8 (28.58) 1-1/4 (31.75) 1-1/2 (38.1) 1-5/8 (41.28)

prevent dirt, moisture, or other foreign substances from entering. These substances

can result in system malfunction.

Unit: in. (mm)

over 5/128 (1.0)

over 3/64 (1.15)

over

Unit: in. (mm)

3/64 (1.20)

1-2. Prevent impurities including water, dust and oxide from entering the tubing. Impurities can cause R410A refriger-

ant deterioration and compressor defects. Due to the features of the refrigerant and refrigerating machine oil, the

prevention of water and other impurities becomes more important than ever.

2. Be sure to recharge the refrigerant only in liquid form.

2-1. Since R410A is a non-azeotrope, recharging the refrigerant in gas form can lower performance and cause defects

in the unit.

2-2. Since refrigerant composition changes and performance decreases when gas leaks, collect the remaining refriger-

ant and recharge the required total amount of new refrigerant after fixing the leak.

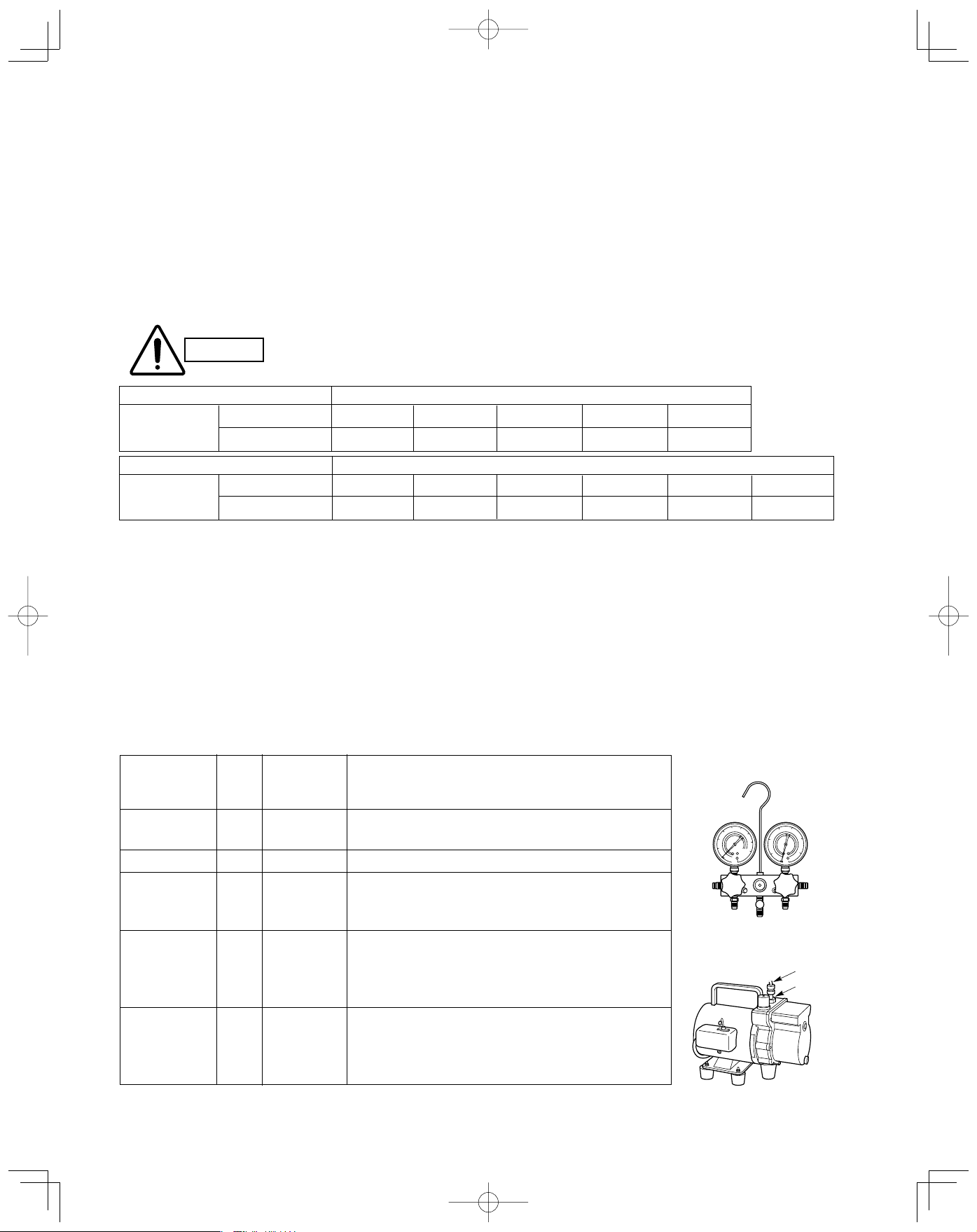

3. Different tools required

3-1. Tool specifications have been changed due to the characteristics of R410A.

Some tools for R22- and R407C-type refrigerant systems cannot be used.

Item compatible Remarks

with R410A?

Manifold gauge Yes No Types of refrigerant, refrigerating machine

oil, and pressure gauge are different.

Charge hose Yes No To resist higher pressure, material must be changed.

Vacuum pump Yes Yes Use a conventional vacuum pump if it is equipped

with a check valve. If it has no check valve,

purchase and attach a vacuum pump adapter.

Leak detector Yes No Leak detectors for CFC and HCFC that

react to chlorine do not function because

R410A contains no chlorine. Leak detector

for HFC134a can be used for R410A.

Flaring oil Yes No For systems that use R22, apply mineral oil (Suniso oil)

to the flare nuts on the tubing to prevent refrigerant

leakage. For machines that use R407C or R410A, apply

synthetic oil (ether oil) to the flare nuts.

New

tool?

R407C tools

Manifold gauge

Vacuum pump

Outlet

Inlet

* Using tools for R22 and R407C and new tools for R410A together can cause defects.

4

W-3WAYECO-iUS.indd4W-3WAYECO-iUS.indd4 2008/02/0710:55:372008/02/0710:55:37

Page 5

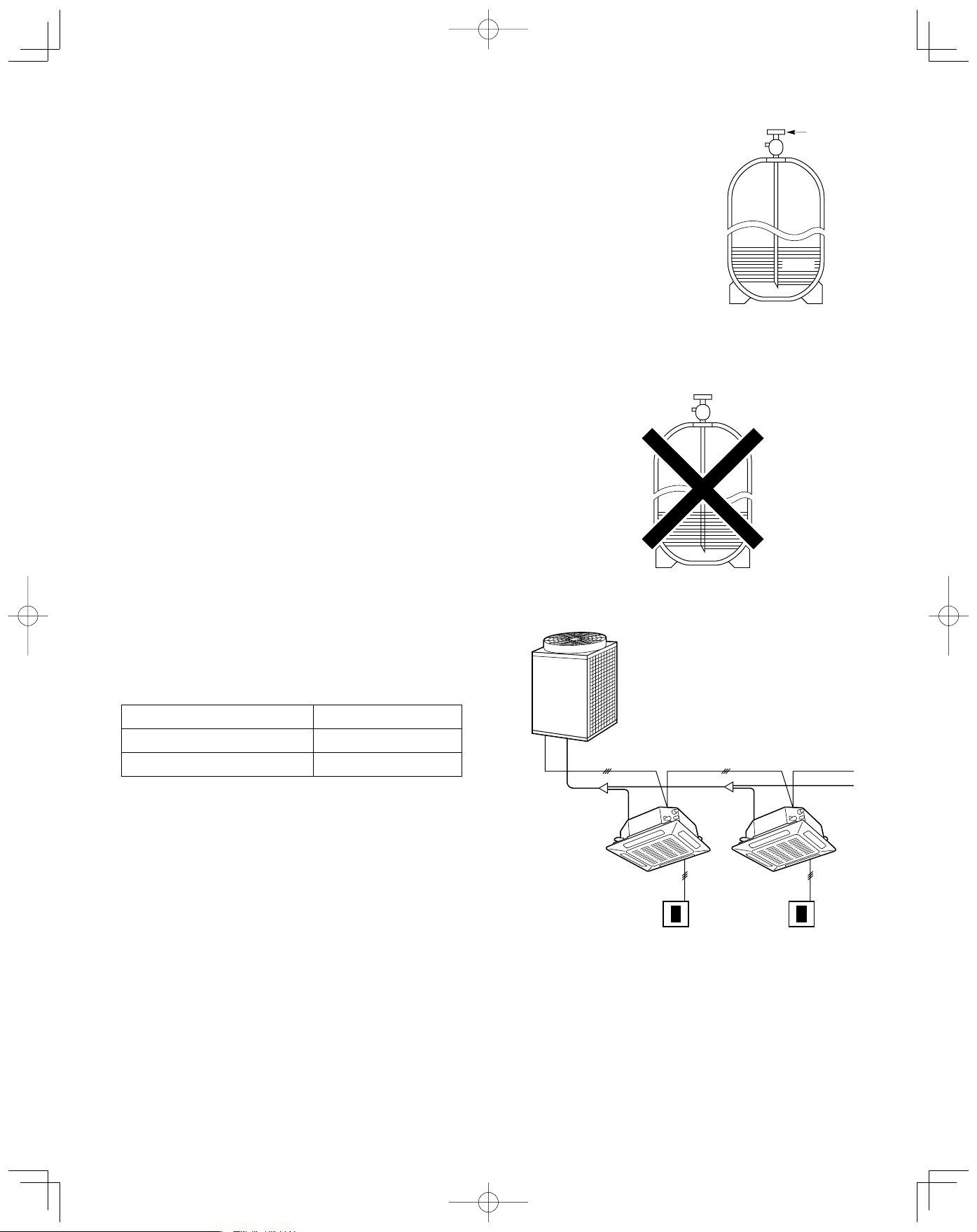

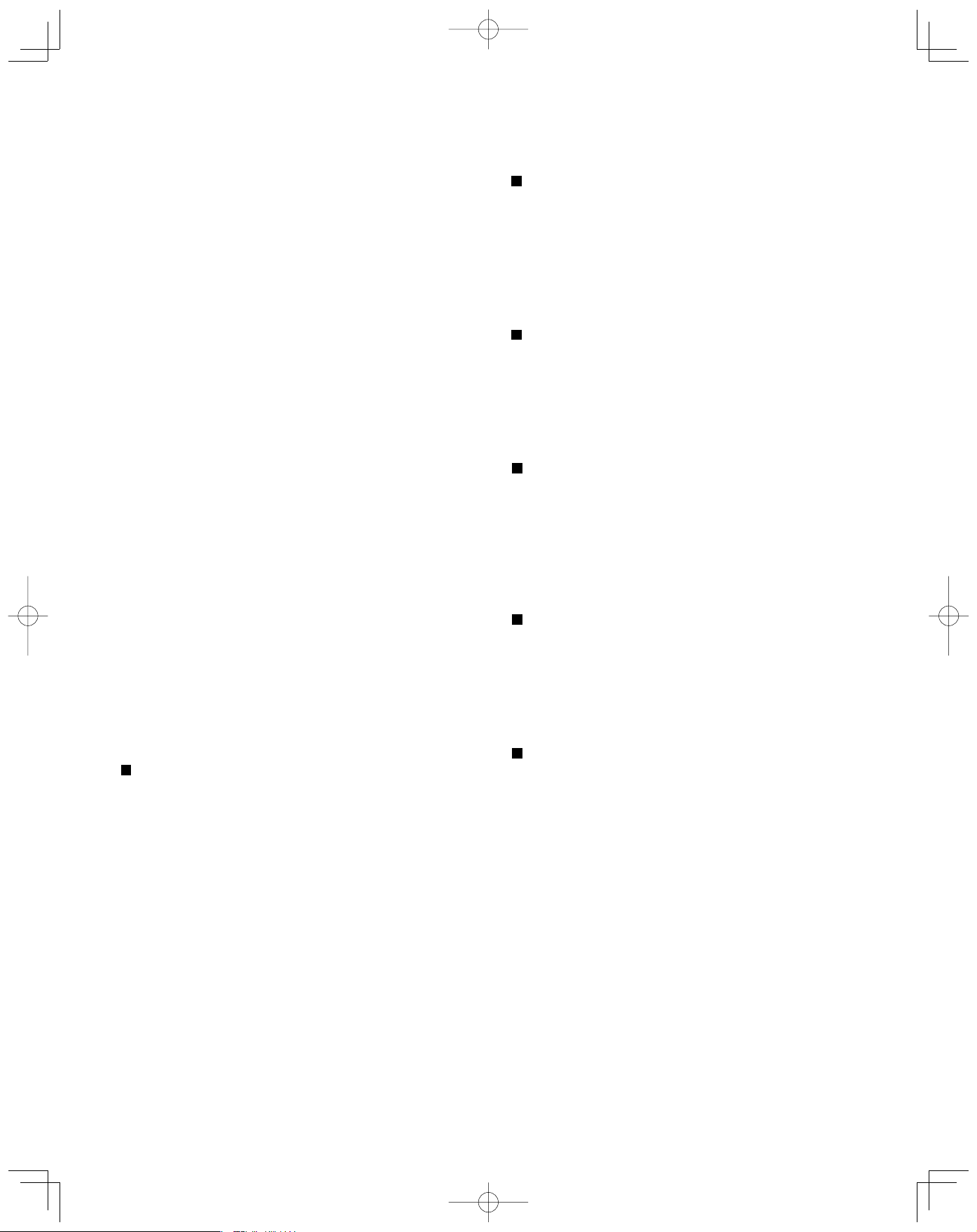

3-2. Use R410A exclusive cylinder only.

New refrigerant R410A cannot be used for

earlier models

1. Compressor specifications are different.

If recharging a R22 or R407C compressor with R410A,

durability will significantly decrease since some of the

materials used for compressor parts are different.

2. Existing tubing cannot be used (especially R22).

Completely cleaning out residual refrigerating

machine oil is impossible, even by flushing.

Valve

Single-outlet valve

(with siphon tube)

Liquid refrigerant should be recharged

with the cylinder standing on end as

shown.

Liquid

3. Refrigerating machine oil differs (R22).

Since R22 refrigerating machine oil is mineral oil, it

does not dissolve in R410A. Therefore, refrigerating

machine oil discharged from the compressor can cause

compressor damage.

R22 refrigerating machine oil Mineral oil (Suniso oil)

R407C refrigerating machine oil Synthetic fluid (ether oil)

R410A refrigerating machine oil Synthetic fluid (ether oil)

R410A

5

W-3WAYECO-iUS.indd5W-3WAYECO-iUS.indd5 2008/02/0710:55:372008/02/0710:55:37

Page 6

CONTENTS

Page Page

IMPORTANT! . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Please Read Before Starting

Check of Density Limit

Precautions for Installation Using New Refrigerant

New refrigerant R410A cannot be used for earlier models

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1-1. Tools Required for Installation (not supplied)

1-2. Accessories Supplied

1-3. Type of Copper Tube and Insulation Material

1-4. Additional Materials Required for Installation

1-5. Tubing Length

1-6. Tubing Size

1-7. Straight Equivalent Length of Joints

1-8. Additional Refrigerant Charge

1-9. System Limitations

1-10. Installation Standards

1-11. Check of Limit Density

1-12. Installing Distribution Joint

1-13. Optional Distribution Joint Kits

Optional Distribution Joint Kits

1-14. Optional Solenoid Valve Kit

Example of Tubing Size Selection and

1-15.

Refrigerant Charge Amount

2. SELECTING THE INSTALLATION SITE . . . . 23

2-1. Indoor Unit

2-2. Outdoor Unit

2-3. Precautions When Installing in Heavy Snow

Areas

2-4. Dimensions of Wind Ducting

2-5. Dimensions of Snow Ducting

3. HOW TO INSTALL THE INDOOR UNIT . . . . . 28

4-Way Air Discharge Semi-Concealed Type

(X Type)

3-1. Preparation for Suspending

3-2. Suspending the Indoor Unit

3-3. Placing the Unit Inside the Ceiling

3-4. Installing the Drain Piping

3-5. Checking the Drainage

3-6. How to Install the Ceiling Panel

3-7. Special Remarks

(XM Type)

3-8. Preparation for Suspending

3-9. Suspending the Indoor Unit

3-10. Placing the Unit Inside the Ceiling

3-11. Installing the Drain Piping

3-12. Checking the Drainage

3-13. How to Install the Ceiling Panel

1-Way Air Discharge Semi-Concealed Type

(A Type)

3-14. Suspending the Indoor Unit

3-15. Placing the Unit Inside the Ceiling

3-16. Installing the Drain Piping

3-17. Checking the Drainage

3-18. Electrical Power Wiring

3-19. How to Install the Ceiling Panel

Concealed Duct Type (U Type)

3-20. Required Minimum Space for Installation and

Service

3-21. Suspending the Indoor Unit

3-22. Installing the Drain Piping

3-23. Checking the Drainage

3-24. Increasing the Fan Speed

Concealed Duct High-Static Pressure Type

(D Type)

3-25. Required Minimum Space for Installation and

Service

3-26. Suspending the Indoor Unit

3-27. Installing the Drain Piping

3-28. Caution for Ducting Work

3-29. Indoor Fan Performance

Ceiling-Mounted Type (T Type)

3-30. Required Minimum Space for Installation and

Service

3-31. Suspending the Indoor Unit

3-32. Duct for Fresh Air

3-33. Shaping the Tubing

3-34. Installing the Drain Piping

Wall-Mounted Type (K Type)

3-35. Removing the Rear Panel from the Unit

3-36. Selecting and Making a Hole

3-37. Installing the Rear Panel onto the Wall

3-38. Removing the Grille to Install the Indoor Unit

3-39. Preparing the Tubing

3-40. Shaping the Tubing

3-41. Installing the Drain Hose

3-42. When Using Wireless Remote Controller

Instead of Wired Remote Controller

4. HOW TO INSTALL THE OUTDOOR UNIT . . . 64

4-1. Transporting

4-2. Installing the Outdoor Unit

4-3. Remove the Brackets Used for Transport

4-4. Routing the Tubing

4-5. Prepare the Tubing

4-6. Connect the Tubing

6

W-3WAYECO-iUS.indd6W-3WAYECO-iUS.indd6 2008/02/0710:55:372008/02/0710:55:37

Page 7

Page

5. ELECTRICAL WIRING . . . . . . . . . . . . . . . . . . 68

5-1. General Precautions on Wiring

5-2. Recommended Wire Length and Wire

Diameter for Power Supply System

5-3. Wiring System Diagram

5-4. Important Note When Wiring for

Common Type

5-5. Important Note When Wiring for

XM Type

6.

HOW TO PROCESS TUBING . . . . . . . . . . . . 76

6-1. Connecting the Refrigerant Tubing

6-2. Connecting Tubing Between Indoor and

Outdoor Units

6-3. Insulating the Refrigerant Tubing

6-4. Taping the Tubes

6-5. Finishing the Installation

7. AIR PURGING . . . . . . . . . . . . . . . . . . . . . . . . . 80

Air Purging with a Vacuum Pump (for Test Run)

Preparation

8. TEST RUN . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8-1. Preparing for Test Run

8-2. Test Run Procedure

8-3. Main Outdoor Unit PCB Setting

8-4. Auto Address Setting

8-5. Remote Controller Test Run Settings

8-6. Caution for Pump Down

8-7. Meaning of Alarm Messages

9. APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

9-1. 4-Way Air Discharge Semi-Concealed Type

(X, XM Types)

9-2. 1-Way Air Discharge Semi-Concealed Type

(A Type)

9-3. Concealed Duct (High-Static Pressure) Type

(U, D Types)

9-4. Ceiling-Mounted Type (T Type)

9-5. Wall-Mounted Type (K Type)

7

W-3WAYECO-iUS.indd7W-3WAYECO-iUS.indd7 2008/02/0710:55:372008/02/0710:55:37

Page 8

1. GENERAL

This booklet briefly outlines where and how to install the air conditioning system. Please read over the entire set of instructions for

the outdoor unit and make sure all accessory parts listed are with the system before beginning.

1-1. Tools Required for Installation (not supplied)

1. Flathead screwdriver

2. Phillips head screwdriver

3. Knife or wire stripper

4. Tape measure

5. Carpenter’s level

6. Sabre saw or key hole saw

7. Hacksaw

8. Core bits

9. Hammer

10. Drill

11. Tube cutter

12. Tube flaring tool

13. Torque wrench

14. Adjustable wrench

15. Reamer (for deburring)

1-2. Accessories Supplied

See Tables 1-1 – 1-8.

1-3. Type of Copper Tube and Insulation Material

If you wish to purchase these materials separately from a

local source, you will need:

1. Deoxidized annealed copper tube for refrigerant tubing.

2. Foamed polyethylene insulation for copper tubes as

required to precise length of tubing. Wall thickness of the

insulation should be not less than 5/16 in.

3. Use insulated copper wire for field wiring. Wire size varies

with the total length of wiring.

“

Refer to

5. ELECTRICAL WIRING” for details.

Check local electrical codes and

CAUTION

regulations before obtaining

wire. Also, check any specified

instructions or limitations.

1-4. Additional Materials Required for Installation

1. Refrigeration (armored) tape

2. Insulated staples or clamps for connecting wire

(See your local codes.)

3. Putty

4. Refrigeration tubing lubricant

5. Clamps or saddles to secure refrigerant tubing

6. Scale for weighing

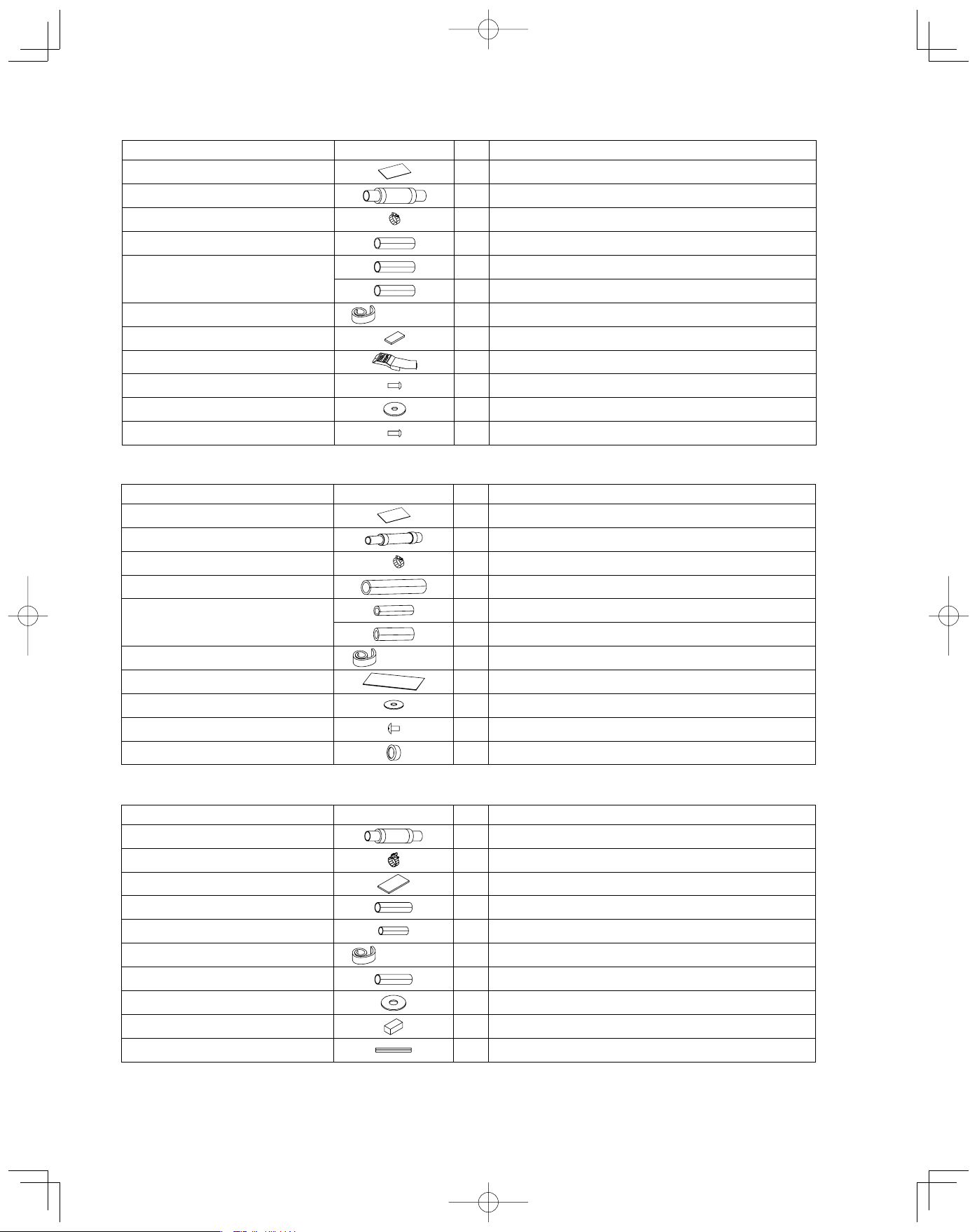

Table 1-1 Outdoor Unit

Part name

Connection tubing

Outer

diameter

ø1-1/8"

Outer

diameter

ø7/8"

Figure

Instruction manual paper

Inner

diameter

ø1"

Inner

diameter

ø3/4"

Q’ty

09053 Model

(10 hp)

0

14053 Model

(16 hp)

1

10

11

(hp = horse power)

8

W-3WAYECO-iUS.indd8W-3WAYECO-iUS.indd8 2008/02/0710:55:382008/02/0710:55:38

Page 9

Table 1-2 (4-Way Air Discharge Semi-Concealed) (X-Type)

Part Name Figure

Full-scale installation diagram

Drain hose

Hose band

Drain insulator

Flare insulator

Insulating tape

Packing

Wiring cover

Screw

Washer

Screw

White

(heat-resisting)

Q’ty

Printed on container box

1

For securing drain hose

1

For securing drain hose

1

For drain joint

1

For liquid tube

1

For gas tube

1

For gas tube joint

2

For drain joint

1

For covering electrical wiring

1

For full-scale installation diagram

4

For suspending indoor unit from ceiling

8

For fixing the wiring cover

1

Table 1-3 (1-Way Air Discharge Semi-Concealed)

Part Name Figure

Full-scale installation diagram Printed on container box

Drain hose

Hose band

Drain insulator

Flare insulator

Insulating tape

Washer

Screw

Bushing

White

(heat-resisting)

Q’ty

1

1

For securing drain hose

1

For securing drain hose

1

For drain joint

1

For liquid tube

1

For gas tube

For gas tube joint

2

For drain joint

1Packing

8

For suspending indoor unit from ceiling

4

For full-scale installation diagram

1

For electrical junction box

Remarks

Remarks

Table 1-4 (Concealed Duct)

Part Name Figure

Drain hose

Hose band 1

Packing 1

Drain insulator 1

Flare insulator 1

Insulating tape 2

Flare insulator 1

Washer 8

Sealing putty 1

Vinyl clamp 8

●

Use M10 or 3/8" for suspending bolts.

●

Field supply for suspending bolts and nuts.

White

(heat-resisting)

Q’ty

For securing drain hose

1

For securing drain hose

For drain joint

For drain joint

For liquid tube

For gas and liquid tubes flare nuts

For gas tube

For suspending indoor unit from ceiling

For sealing recessed portion of power supply

For flare and drain insulators

Remarks

9

W-3WAYECO-iUS.indd9W-3WAYECO-iUS.indd9 2008/02/0710:55:382008/02/0710:55:38

Page 10

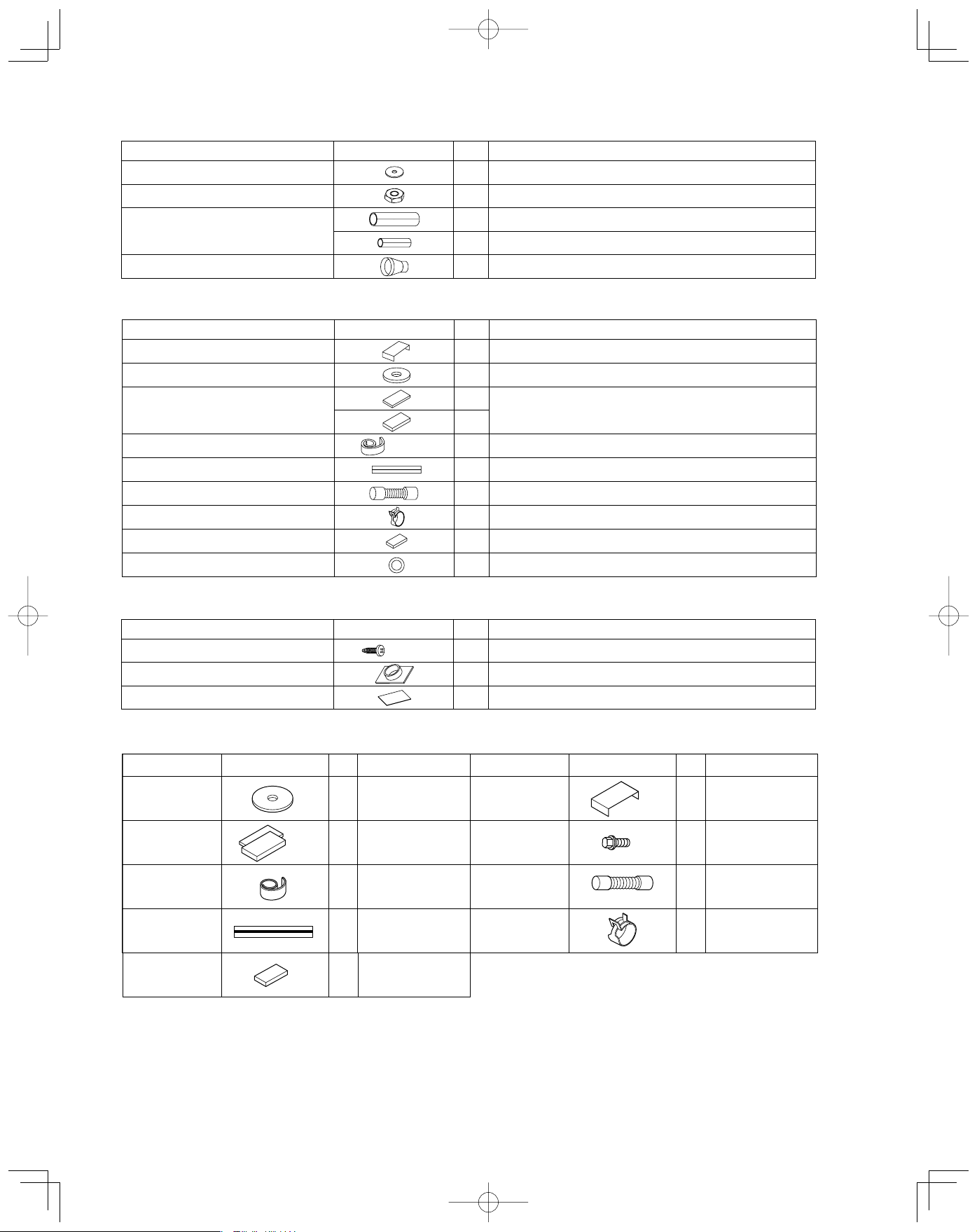

Table 1-5 (Concealed Duct High-Static Pressure)

Part Name Figure

Flare insulator

Q’ty

8 For suspending indoor unit from ceiling Washer

8 For suspending indoor unit from ceiling Nut

1 For gas tube

1 For liquid tube

1 For drain pipe connection Drain socket

Remarks

Table 1-6 (Ceiling-Mounted)

Part Name Figure

Full-scale installation diagram 1 Printed on container box

Washer 4 For temporarily suspending indoor unit from ceiling

T1/8"

T3/16"

Insulating tape 2 For gas and liquid tubes flare nuts

White

(heat-resisting)

Vinyl clamp 8 For flare and drain insulators

Drain hose 1 For main unit and PVC pipe joints

Hose band 2 For drain hose connection

Drain insulator 1 For drain hose joint

Gum eyelet 2 For power supply inlet and 3 way wiring

L5-1/2"

Q’ty

2

2

Remarks

For gas and liquid tube joints Flare insulator

inlet

Table 1-7 (Wall-Mounted)

Part Name Figure

5/32" s 1"

Q’ty

10 For fixing the rear panel Tapping screw

1 For improved tubing appearance Plastic cover

1 For insulating flare nut (2452 type only) Insulator

Table 1-8 (4-Way Air Discharge Semi-Concealed) (XM Type)

Parts Name Figure RemarksQ'ty

T3

T5

8

2

set

2

8

1

Washer

Flare

insulation

Insulation tie

Vinyl tie

Drain hose

insulation

●

Use M10 or 3/8" for suspending bolts.

●

Field supply for suspending bolts and nuts.

T10

For temporarily

suspending indoor

unit from ceiling

For gas /

liquid tube

connection

For gas /

liquid tube / flare

nut connection

For flare / drain

insulating

connection

For drain tube

connection

Parts Name Figure RemarksQ'ty

Full-scale

installation

diagram

Washer head

screw

Drain hose

Hose band

Remarks

L140

Printed on

1

container box

For full-scale

installation

4

diagram

For unit & PVC

1

tube connection

For drain hose

2

connection

10

W-3WAYECO-iUS.indd10W-3WAYECO-iUS.indd10 2008/02/2116:33:302008/02/2116:33:30

Page 11

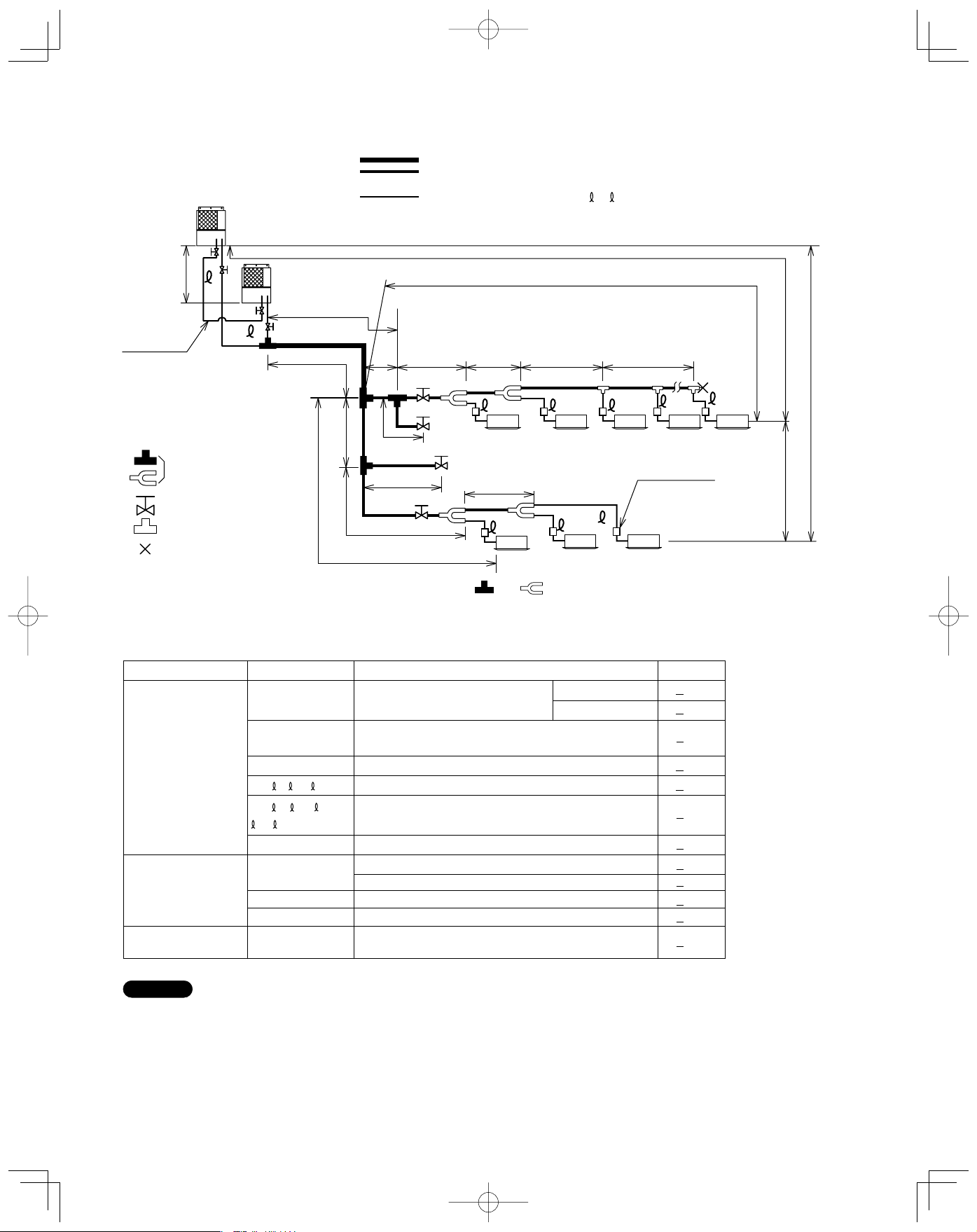

1-5. Tubing Length

Select the installation location so that the length and size of refrigerant tubing are within the allowable range shown

in the figure below.

1. Main tubing length LM = LA + LB … b 262 ft.

2. Main distribution tubes LC – LH are selected according to the capacity after the

3. Sizes of indoor unit connection tubing 1 – 40 are determined by the connection tubing

distribution joint.

sizes on the indoor units.

H3

Balance tubing

(ø9.52)

C

LM

B

LB LC

LD

L2

L1

T-joint tubing

(header joint system)

LE L3

LA

H1

H2

Explanation of symbols

Distribution joint

(APR: purchased separately)

LF

Max. 1.3 ft.

Max. 1.3 ft.

For

extension

For

extension

4

5 6

LH

Ball valve (field supply)

T-joint (field supply)

Solidly welded shut

(pinch weld)

Note: Do not use commercially available T-joints for the liquid tubing and parts.

* Be sure to use special R410A distribution joints (APR: purchased separately) for outdoor

unit connections and tubing branches.

L4

LG

1

2

7

Solenoid valve kit

40

3

R410A distribution joint

APR-CHRZP900BAB (for outdoor unit)

APR-RZP224BAB (for indoor unit)

APR-RZP680BAB (for indoor unit)

APR-RZP1350BAB (for indoor unit)

Table 1-9 Ranges that Apply to Refrigerant Tubing Lengths and to Differences in Installation Heights

Item Mark Contents Length (ft.)

Actual length 492

Equivalent length 574

Allowable tubing

length

Allowable elevation

difference

L1 Max. tubing length

$L (L2 – L4)

Difference between max. length and min.

length from the No. 1 distribution joint

LM Max. length of main tubing (at max. diameter) 262

40

,2...

1

2

+

L1+

A

...

1

B

+

+LF+LG+LH each distribution tube (only liquid tubing)

L5

H1

H2

Max. length of each distribution tube 98

39

+

Total max. tubing length including length of

Distance between outdoor units

When outdoor unit is installed higher than indoor unit 164

When outdoor unit is installed lower than indoor unit 131

Max. difference between indoor units

H3 Max. difference between outdoor units

Allowable length of

joint tubing

L = Length, H = Height

L3

T-joint tubing (field-supply); Max. tubing length between

the first T-joint and solidly welded-shut end point

NOTE

1: If the longest tubing length (L1) exceeds 295 ft. (equivalent length), increase the sizes of the main tubes (LM) by 1 rank for

the discharge tubes, suction tubes, and liquid tubes. (Use a field supply reducer.)

2: If the longest main tube length (LM) exceeds 164 ft., increase the main tube size at the portion before 164 ft. by 1 rank for

the suction tubes and discharge tubes. (Use a field supply reducer.)

(For the portion that exceeds 164 ft., set based on the main tube sizes (LA) listed in the table on the following page.)

>

>

>

>

>

>

>

>

>

>

>

>

131

*2

984

32

49

13

6.6

11

W-3WAYECO-iUS.indd11W-3WAYECO-iUS.indd11 2008/02/0710:55:392008/02/0710:55:39

Page 12

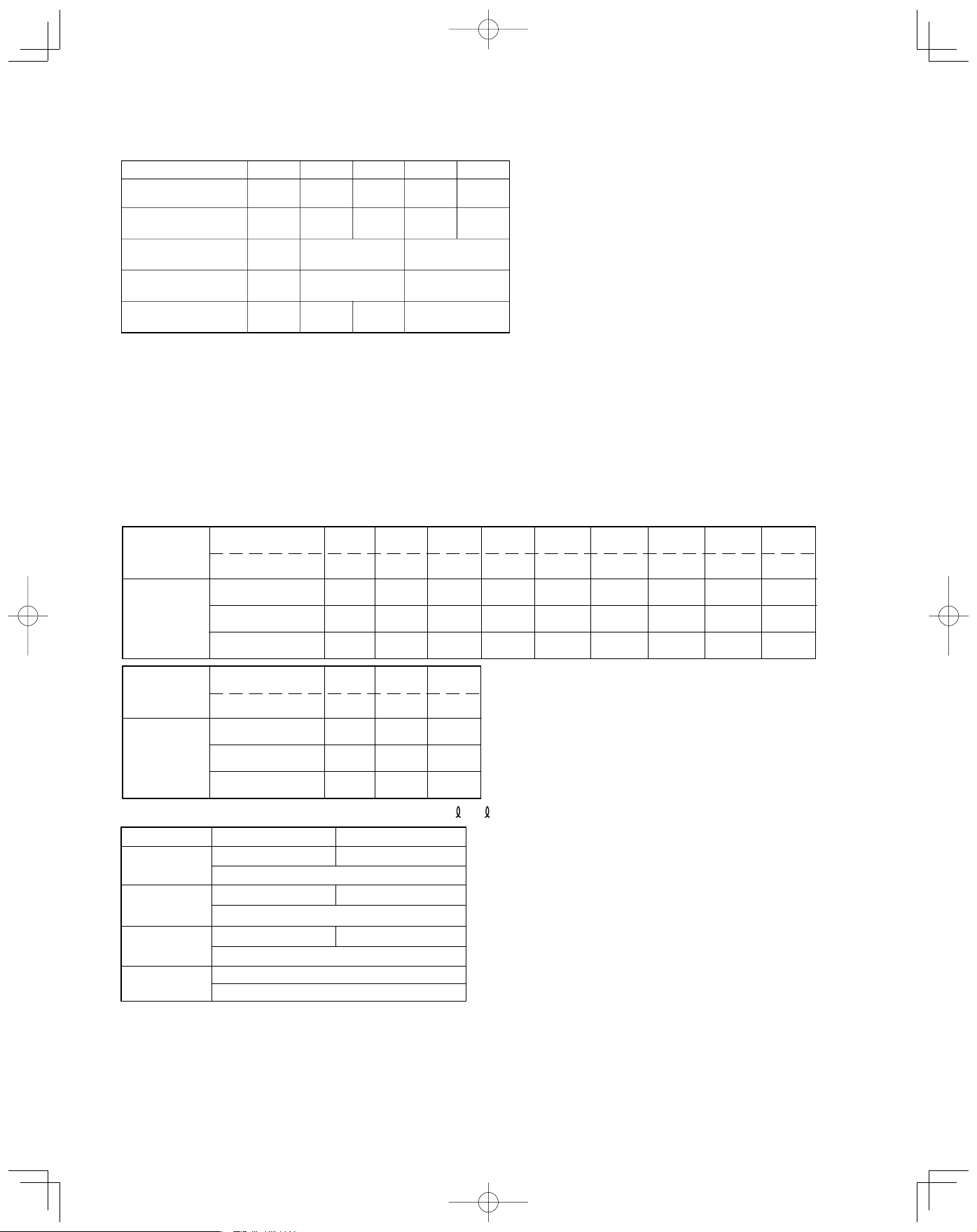

1-6. Tubing Size

Table 1-10 Main Tubing Size (LA)

Unit: in. (mm)

26

16

10

ø1-3/8"

(ø34.92)

ø1-1/8"

(ø28.58)

(ø19.05)

307.100

32

16

16

ø3/4"

BTU/h

Total system

horsepower

Combined

outdoor units

Suction tubing

Discharge tubing

Liquid tubing

95.500

10

10

ø7/8"

(ø22.22)

ø3/4"

(ø19.05)

ø3/8"

(ø9.52)

153.600

16

16

ø1-1/8"

(ø28.58)

(ø22.22)

ø1/2"

(ø12.70)

ø7/8"

191.000

20

10

10

ø5/8"

(ø15.88)

249.100

*1: If future extension is planned, select the tubing diameter based on the total horsepower after extension.

However extension is not possible if the resulting tubing size is two ranks higher.

*2: The balance tube (outdoor unit tube) diameter is ø3/8" (ø9.52).

*3: Type 1 tubing should be used for the refrigerant tubes.

*4: If the length of the longest tube (L1) exceeds 295 ft. (equivalent length), increase the main tube (LM) size by 1 rank for the

suction, discharge, and liquid tubes. (Use field-supply reducers.) (Select from Table 1-10 and Table 1-15.)

*5: If the longest main tube length (LM) exceeds 164 ft., increase the main tube size at the portion before 164 ft. by 1 rank for

the suction tubes and discharge tubes.

(For the portion that exceeds 164 ft., set based on the main tube sizes (LA) listed in the table above.)

Table 1-11 Main Tubing Size After Distribution (LB, LC...)

Total capacity

after distribution

Tubing size

Total capacity

after distribution

Tubing size

Below BTU/h

Over BTU/h

Suction tubing

Discharge tubing

Liquid tubing

Below BTU/h

Over BTU/h

Suction tubing

Discharge tubing

Liquid tubing

24.200

(2.5 hp)

–

ø5/8"

(ø15.88)

ø1/2"

(ø12.70)

ø3/8"

(ø9.52)

258.000

(27 hp)

238.900

(25 hp)

ø1-3/8"

(ø34.93)

ø1-1/8"

(ø28.58)

ø3/4"

(ø19.05)

54.600

(6 hp)

24.200

(2.5 hp)

ø3/4"

(ø19.05)

ø5/8"

(ø15.88)

ø3/8"

(ø9.52)

334.400

(35 hp)

258.000

(27 hp)

ø1-3/8"

(ø34.93)

ø1-1/8"

(ø28.58)

ø3/4"

(ø19.05)

85.300

(9 hp)

54.600

(6 hp)

ø3/4"

(ø19.05)

ø5/8"

(ø15.88)

ø3/8"

(ø9.52)

–

334.400

(35 hp)

ø1-1/2"

(ø38.10)

ø1-1/8"

(ø28.58)

ø3/4"

(ø19.05)

102.400

(11 hp)

85.300

(9 hp)

ø7/8"

(ø22.22)

ø3/4"

(ø19.05)

ø3/8"

(ø9.52)

124.200

(13 hp)

102.400

(11 hp)

ø1-1/8"

(ø28.58)

ø3/4"

(ø19.05)

ø1/2"

(ø12.70)

143.300

(15 hp)

124.200

(13 hp)

ø1-1/8"

(ø28.58)

ø7/8"

(ø22.22)

ø1/2"

(ø12.70)

162.400

(17 hp)

143.300

(15 hp)

ø1-1/8"

(ø28.58)

ø7/8"

(ø22.22)

ø1/2"

(ø12.70)

*1: If the total capacity of the indoor units con-

nected to the tube ends is different from the

total capacity of the outdoor units, then the

main tube size is selected based on the total

capacity of the outdoor units.

(For LA, LB, and LF in particular)

Unit: in. (mm)

hp = horsepower

200.600

(21 hp)

162.400

(17 hp)

ø1-1/8"

(ø28.58)

ø7/8"

(ø22.22)

ø5/8"

(ø15.88)

238.900

(25 hp)

200.600

(21 hp)

ø1-1/8"

(ø28.58)

ø1-1/8"

(ø28.58)

ø5/8"

(ø15.88)

Table 1-12 Outdoor Unit Tubing Connection Size ( A – D)

BTU/h

Suction tubing

95.500 153.600

ø7/8"(ø22.22)

ø1-1/8"(ø28.58)

Brazing connection

Discharge

tubing

Liquid tubing

Balance tubing

ø3/4"(ø19.05)

Brazing connection

ø3/8"(ø9.52)

Brazing connection

ø3/8"(ø9.52)

Flare connection

ø7/8"(ø22.22)

ø1/2"(ø12.7)

Unit: in. (mm)

12

W-3WAYECO-iUS.indd12W-3WAYECO-iUS.indd12 2008/02/0710:55:392008/02/0710:55:39

Page 13

Table 1-13 Indoor Unit Tubing Connection Size ( 1 – 40)

Indoor unit type

Total system horsepower

Distribution

joint –

solenoid valve

kit tubing

Solenoid valve

kit – Indoor

Suction tubing

Discharge tubing

Liquid tubing

Gas tubing

unit tubing

connection

Liquid tubing

7

0.8

912

1

1.3

ø1/2"

(ø12.70)

ø1/4"

(ø6.35)

18 24

2345

ø5/8"

(ø15.88)

ø1/2"

(ø12.70)

ø3/8"

(ø9.52)

ø5/8"

(ø15.88)

ø3/8"

(ø9.52)

36

in. (mm)

48

*1: For the solenoid valve kits, use type 160 with parallel specifications. Branch the tubing before and after the solenoid valve kits.

1-7. Straight Equivalent Length of Joints

Design the tubing system by referring to the following table for the straight equivalent length of joints.

Table 1-14 Straight Equivalent Length of Joints

Gas tubing size (in.(mm))

90o elbow

45o elbow

U-shape tube bent

(R2–23/64–3–15/16 in.)

T r ap bend

1/2"

(12.7)

1 ft.

(0.30 m)

0.8 ft.

(0.23 m)

3 ft.

(0.90 m)

7.5 ft.

(2.30 m)

5/8"

(15.88)

1.1 ft.

(0.35 m)

0.9 ft.

(0.26 m)

3.4 ft.

(1.05 m)

9.2 ft.

(2.80 m)

3/4"

(19.05)

1.4 ft.

(0.42 m)

1 ft.

(0.32 m)

4.1 ft.

(1.26 m)

10.5 ft.

(3.20 m)

7/8"

(22.22)1"(25.4)

1.6 ft.

(0.48 m)

1.2 ft.

(0.36 m)

4.7 ft.

(1.44 m)

12.5 ft.

(3.80 m)

1.7 ft.

(0.52 m)

1.3 ft.

(0.39 m)

5.1 ft.

(1.56 m)

14.1 ft.

(4.30 m)

1-1/8"

(28.58)

1.9 ft.

(0.57 m)

1.4 ft.

(0.43 m)

5.6 ft.

(1.71 m)

15.4 ft.

(4.70 m)

1-1/4"

(31.8)

2.3 ft.

(0.70m)

1.7 ft.

(0.53 m)

6.9 ft.

(2.10 m)

16.4 ft.

(5.00 m)

1-1/2"

(38.1)

2.6 ft.

(0.79 m)

1.9 ft.

(0.59 m)

7.8 ft.

(2.37 m)

14.0 ft.

(5.80 m)

Y-branch distr ibution joint Equivalent length con version not needed.

Ball v alve f or ser vice Equivalent length con version not needed.

Table 1-15 Refrigerant tubing (Existing tubing can be used.)

Material O Material 1/2H • H

ø1/4" (ø6.35) t1/32 (t0.8)

ø3/8" (ø9.52) t1/32 (t0.8) ø1-1/8" (ø28.58) t5/128 (t1.0)

ø1/2" (ø12.7) t1/32 (t0.8) ø1-1/4" (ø31.75) t3/64 (t1.1)

ø5/8" (ø15.88) t5/128 (t1.0) ø1-1/2" (ø38.10) over t3/64 (t1.15)

ø3/4" (ø19.05)

ø7/8" (ø22.22) t5/128 (t1.0)

Tubing size (in. (mm))

over t5/128 (t1.0)

* When bending the tubes, use a bending

radius that is at least 4 times the outer

diameter of the tubes.

In addition, take sufficient care to avoid

crushing or damaging the tubes when

bending them.

ø1-5/8" (ø41.28) over t3/64 (t1.20)

1-8. Additional Refrigerant Charge

Additional refrigerant charge amount is calculated from the liquid tubing total length as follows.

Table 1-16-1 Amount of Refrigerant Charge Per ft.,

According to Liquid Tubing Size

Liquid tubing

size

Amount of

refrigerant

charge (oz/ft.)

ø1/4"

(ø6.35)

ø3/8"

(ø9.52)

ø1/2"

(ø12.7)

ø5/8"

(ø15.88)

ø3/4"

(ø19.05)

ø7/8"

(ø22.22)

0.279 0.602 1.38 1.99 2.78 3.93

Required amount of charge = Necessary Amount of

Refrigerant Charge Per Unit (14053 Type) + (Amount

of refrigerant charge per ft. of each size of liquid tube

its tube length) + (...) + (...)

×

* Always charge accurately using a scale for weighing.

Table 1-16-2 Necessary Amount of Refrigerant

Charge Per Unit

CHDZ09053

CHDZR09053

— 113 oz/unit

W-3WAYECO-iUS.indd13W-3WAYECO-iUS.indd13 2008/02/1512:29:032008/02/1512:29:03

CHDZ14053

CHDZR14053

13

Page 14

Table 1-17 Refrigerant Charge Amount at Shipment (for outdoor unit)

CHDZ09053 CHDZ14053

DC

CHDZR09053 CHDZR14053

(oz)

416 416

1-9. System Limitations

Table 1-18 System Limitations

Max. No. allowable connected outdoor units 2

Max. capacity allowable connected outdoor units

Max. connectable indoor units 40

307,100 BTU/h (32 hp, 90 kw)

*1

Max. allowable indoor/outdoor capacity ratio 50 – 130 %

*1: In the case of 20 hp (type 191.100 BTU/h) or smaller units, the number is limited by the total capacity of the connected indoor units.

1-10. Installation Standards

Relationship between A/C units and refrigerant tubing

Outdoor unit Outdoor unit Indoor unit

●

Install the solenoid valve kit 98 ft. or less from the indoor unit.

●

In quiet locations such as hospitals, libraries, and hotel rooms, the refrigerant noise may be somewhat notice-

4-tube layout 3-tube layout 2-tube layout

Suction tube

Discharge tube

Liquid tube

Balance tube

Suction tube

Discharge tube

Liquid tube

Solenoid

valve kit

Gas tube

Liquid

tube

able. It is recommended that the solenoid valve kit be installed inside the corridor ceiling, at a location outside

the room.

Room

Indoor unit

Room

Indoor unit

NO

Room

Indoor unit

Room

Indoor unit

YES

Hallway

Solenoid

valve kit

Hallway

Solenoid

valve kit

Common solenoid valve kit

●

Multiple indoor units under group control can utilize a solenoid valve kit in common.

●

Categories of connected indoor unit capacities are determined by the solenoid valve kit.

Type of solenoid valve kit Total capacity of indoor units (BTU/h)

160 19.000

56 7.500

●

If the capacity range is exceeded, use 2 solenoid valves connected in parallel.

<

Total capacity < 54.600

<

Total capacity < 19.000

14

W-3WAYECO-iUS.indd14W-3WAYECO-iUS.indd14 2008/02/0710:55:402008/02/0710:55:40

Page 15

Always check the gas density

WARNING

limit for the room in which the

unit is installed.

1-11. Check of Limit Density

When installing an air conditioner in a room, it is necessary

to ensure that even if the refrigerant gas accidentally leaks

out, its density does not exceed the limit level for that room.

If the density could exceed the limit level, it is necessary to

provide an opening between the unit and the adjacent room,

or to install mechanical ventilation which is interlocked with

a leak detector.

(Total refrigerant charged amount: oz)

(Min. indoor volume where the indoor unit is installed: ft.3)

<

Limit density 0.3 (oz/ft.

3

)

The limit density of refrigerant which is used in this unit is

0.3 oz/ft.3 (ISO 5149).

The shipped outdoor unit comes charged with the amount of

refrigerant fixed for each type, so add it to the amount that

is charged in the field. (For the refrigerant charge amount at

shipment, refer to the unit’s nameplate.)

tubing to the malfunctioning unit will accumulate

and may damage the compressor.)

Minimum indoor volume & floor area as against the

amount of refrigerant is roughly as given in the following table.

3

ft.

10000

9500

9000

Range below

8500

the density limit of

8000

7500

7000

6500

6000

5500

5000

4500

4000

3500

Min. indoor volume

3000

2500

2000

1500

1000

500

00

0

3

0.3 oz/ft.

(countermeasures

not needed)

Range above

the density limit of

0.3 oz/ft.

(countermeasures

needed)

1000500 1500 2000 2500 3000

Total amount of refrigerant

3

Tube branching methods (horizontal use)

2

ft.

1136

1079

1022

966

909

852

795

738

682

625

568

511

454

398

Min. indoor floor area

341

284

227

170

114

57

oz

(when the ceiling is 8.8 ft. high)

1-12. Installing Distribution Joint

Pay special attention to any

CAUTION

location, such as a basement,

etc., where leaking refrigerant

can accumulate, since refrigerant gas is heavier than air.

(1) Refer to “HOW TO ATTACH DISTRIBUTION JOINT”

enclosed with the optional distribution joint kit

(APR-CHRZP900BAB, RZP224BAB, RZP680BAB,

RZP1350BAB).

(2) When creating a branch using a commercially available

T-joint (header joint system), orient the main tubing so

that it is either horizontal (level) or vertical. In order to

prevent accumulation of refrigerant oil in stopped units,

if the main tubing is horizontal then each branch tubing

length should be at an angle that is greater than horizontal. If the main tubing is vertical, provide a raised starting

portion for each branch.

[Header joint system]

●

Be sure to solidly weld shut the T-joint end (marked

by “X” in the figure). In addition, pay attention to the

insertion depth of each connected tube so that the

flow of refrigerant within the T-joint is not impeded.

●

When using the header joint system, do not make fur-

ther branches in the tubing.

●

Do not use the header joint system on the outdoor

unit side.

(3) If there are height differences between indoor units or if

branch tubing that follows a distribution joint is connected to only 1 unit, a trap or ball valve must be added to

that distribution joint. (When adding the ball valve, locate

it within 15 - 3/4" of the distribution joint.)

If a trap or ball valve is not added, do not operate

the system before repairs to a malfunctioning unit

are completed. (The refrigerant oil sent through the

15

B

Header joint system (Indoor)

Outdoor

Indoor

Horizontal

line

L3 6.56 ft.

Types of vertical trap specifications

(When using ball valve)

Main tubing

Ball valve

(BV: purchased

separately)

Indoor unit (1)

(When not using ball valve)

Main tubing

Indoor unit is directed downward

Indoor unit (more than 2 units)

(If only 1 unit is connected, a ball valve

is also needed on this side.)

Branch tubing is

directed upward.

More than

7–7/8"

A

Arrow view

Install at a

positive angle

Indoor

Indoor

Horizontal

line

Horizontal

Indoor unit

15 to 30

B

Horizontal

line

View as seen

from arrow

Install at a

positive angle

(15 – 30°)

Solidly welded

shut (X)

(Each unit is connected

to tubing that is either

level or is directed

downward.)

A

W-3WAYECO-iUS.indd15W-3WAYECO-iUS.indd15 2008/02/0710:55:402008/02/0710:55:40

Page 16

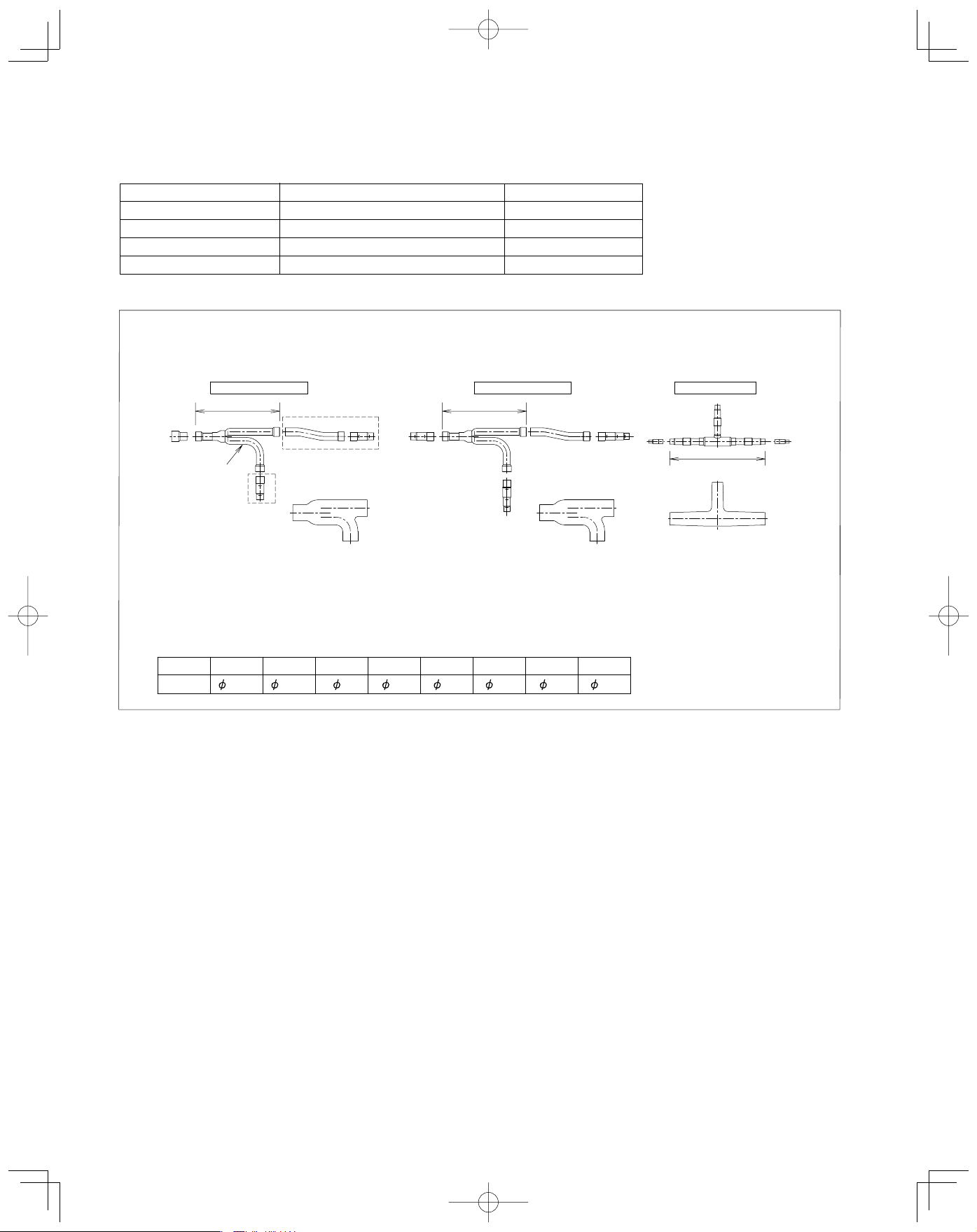

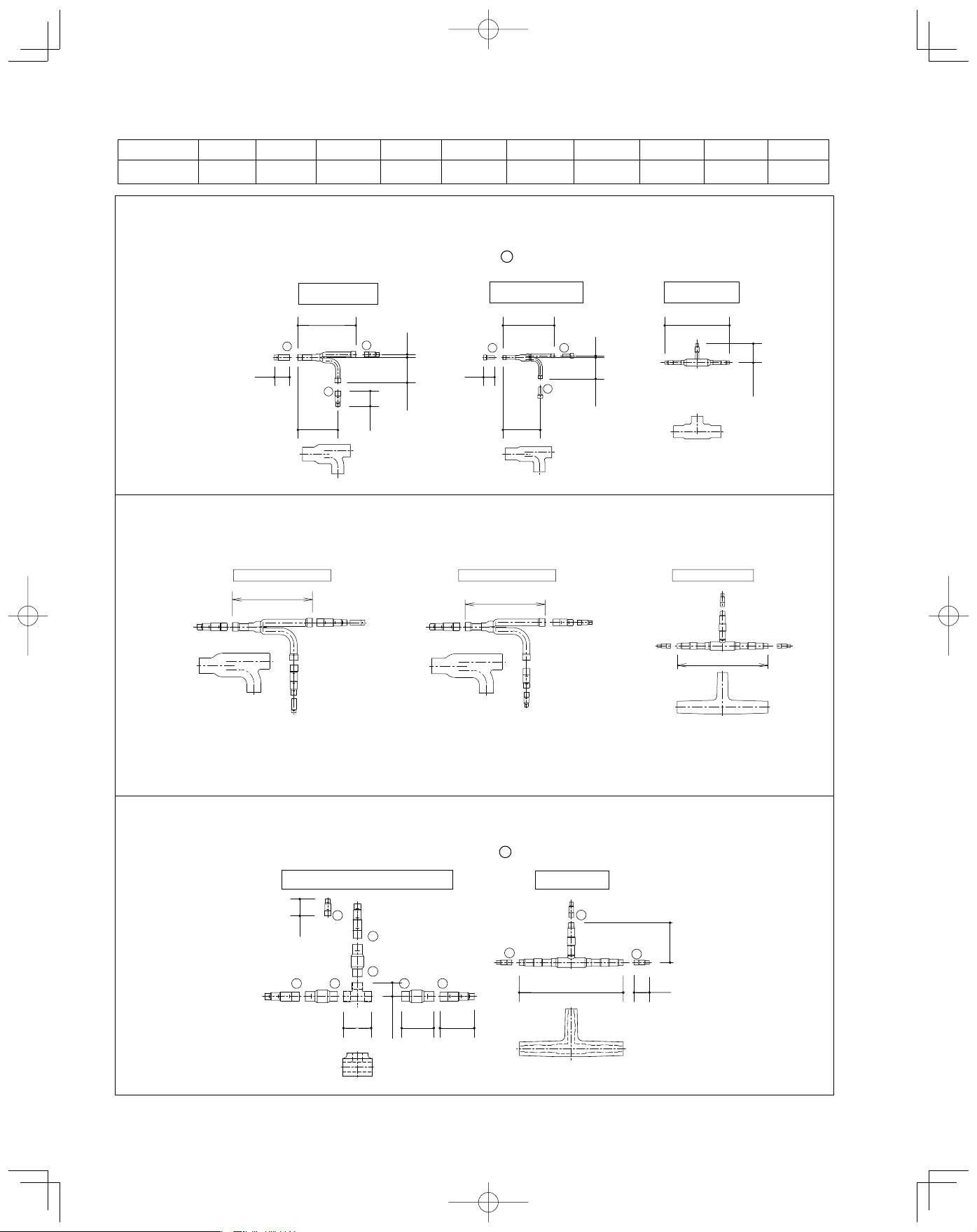

1-13. Optional Distribution Joint Kits

See the installation instructions packaged with the distribution joint kit for the installation procedure.

Table 1-19

Model name Cooling capacity after distribution Remarks

1. APR-CHRZP900BAB 307.100 BTU/h or less For outdoor unit

2. APR-RZP224BAB 76.400 BTU/h or less For indoor unit

3. APR-RZP680BAB 232.000 BTU/h or less For indoor unit

4. APR-RZP1350BAB 460.700 BTU/h or less For indoor unit

Tubing size (with thermal insulation)

■

1. APR-CHRZP900BAB

For outdoor unit (Capacity after distribution joint is 307.100 BTU/h or less.)

Note that the dimension marked with every alphabetical letter in the diagram shows the inner diameter.

Suction Tube

B

Distribution

Joint

11- 13/ 16 11- 13/ 16

C

#C

#C

D

E

C

D

E

DE

Insulation

*Insulators for both the Suction tube and the Discharge tube are the same.

C

Discharge Tube

#C

#C

D

E

F

Liquid Tube

G

F

EDF

C

F

G

H

I

E

E

13-25/64

EFG

HI

InsulationInsulation

Unit: in.

*Suction tube and Discharge tube are similar in sizes and both the tube entrances have the same diameter. So the both

Distribution joints can fit into different tubes. Since the diameter of the tube ends for both Suction and Discharge tube are

different, take care not to connect the distribution joint different. See the " # " marks on the above figures.

Table 1-20 Dimensions for connections of each part

Size

Inch

Part B Part C Part D Part E Part F Part G Part H Part I

7/81-1/4

3/41-1/8 3/85/8 1/21

16

W-3WAYECO-iUS.indd16W-3WAYECO-iUS.indd16 2008/02/0710:55:402008/02/0710:55:40

Page 17

Table 1-21 Dimensions for connections of each part

Unit: in.

Position A B C D E F G H I J

Dimension ø1-1/2" ø1-1/4" ø1-1/8" ø1" ø7/8" ø3/4" ø5/8" ø1/2" ø3/8" –

2. APR-RZP224BAB

Use: For indoor unit (Capacity after distribution joint is 76.400 BTU/h or less.)

Example: (F below indicates inner diameter. below indicates outer diameter.)

F

Liquid tubing

9–1/4

I

H

HIIH

2–23/32

2–11/64

F

G

F

Suction tubing

8–17/64

F

F

F

G

H

5–45/64

F

GH

2–11/64

3–5/8 15/32

1–37/64

Discharge tubing

7–21/64

H

G

5–23/64

H

G

HH

H

H

G

3–1/32 9/32

Thermal insulation

Thermal insulation

Thermal insulation

Unit: in.

3. APR-RZP680BAB

Use: For indoor unit (Capacity after distribution joint is greater than 76.400 BTU/h and no more than 232.000 BTU/h.)

Note that the dimension marked with every alphabetical letter in the diagram shows the inner diameter.

Suction Tube

11- 13/ 16

#C

EFD

C

D

EF

G

#C

D

E

Insulation

F

G

*Insulators for both the Suction tube and the Discharge tube are the same.

*Suction tube and Discharge tube are similar in sizes and both the tube entrances have the same diameter. So the both

Distribution joints can fit into different tubes. Since the diameter of the tube ends for both Suction and Discharge tube are

different, take care not to connect the distribution joint different. See the " # " marks on the above figures.

FED

Insulation

Discharge Tube

11-13/16

C

#D

E

F

G

H

#D

Liquid Tube

I

H

FE

HG

GF E

H

I

G

F

E

EFG

13-25/64

Insulation

Unit: in.

IH

4. APR-RZP1350BAB

Use: For indoor unit (Capacity after distribution joint is greater than 232.000 BTU/h and no more than 460.700 BTU/h.)

Example: (B below indicates inner diameter. below indicates outer diameter.)

Suction tubing • Discharge tubing

H

G

2–11/64

C

Thermal insulation

W-3WAYECO-iUS.indd17W-3WAYECO-iUS.indd17 2008/02/0710:55:402008/02/0710:55:40

F

BB

3–35/64

F

E

D

C

C

A

B

B

BB

4–9/64 4–13/32

1–49/64

C

B

Liquid tubing

I

H

G

G

F

E

E

13–25/64

G

E

F

G

G

F

I

H

ECDAFFADCE

Thermal insulation

G

5–1/8

HI

1–31/32

Unit: in.

17

Page 18

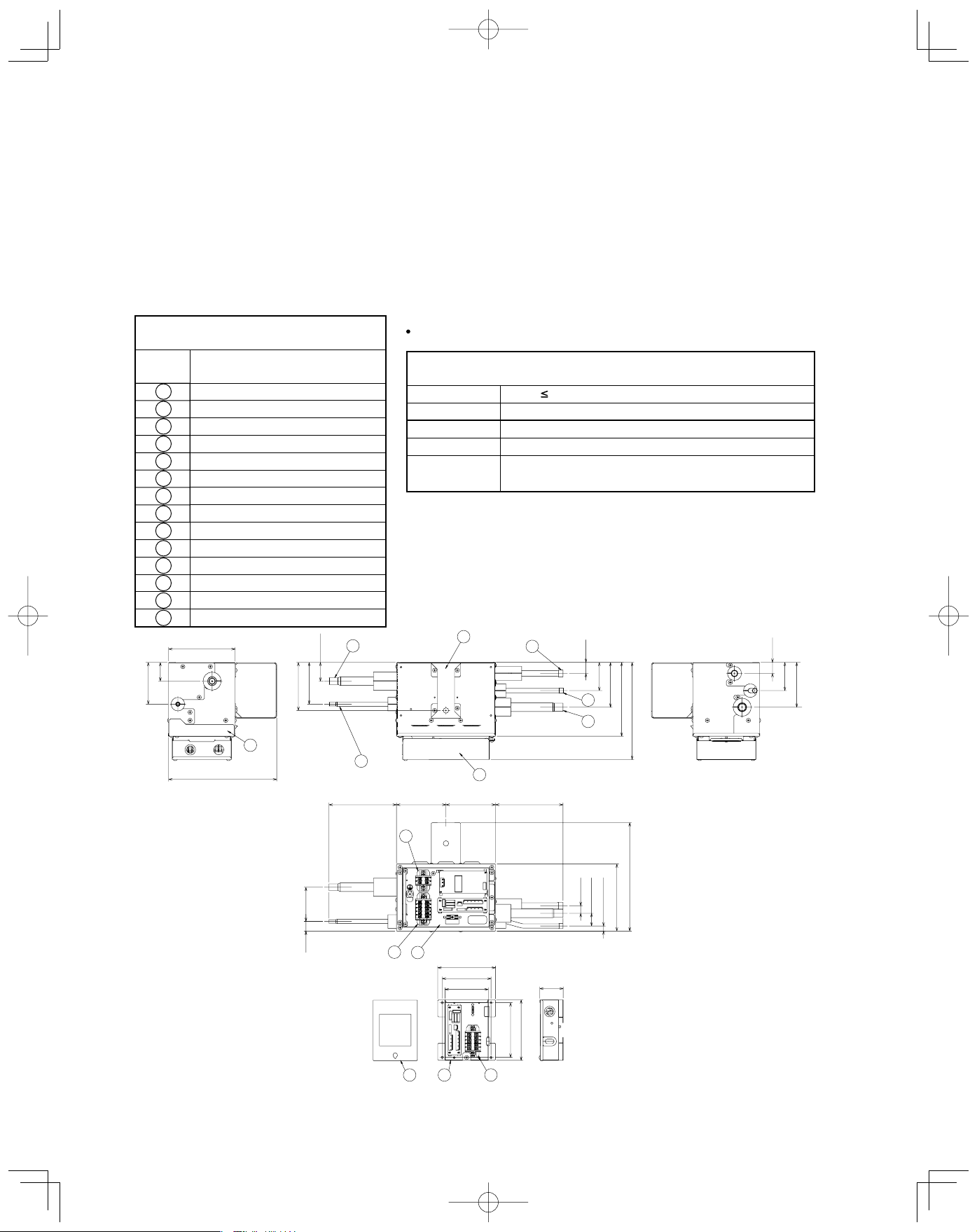

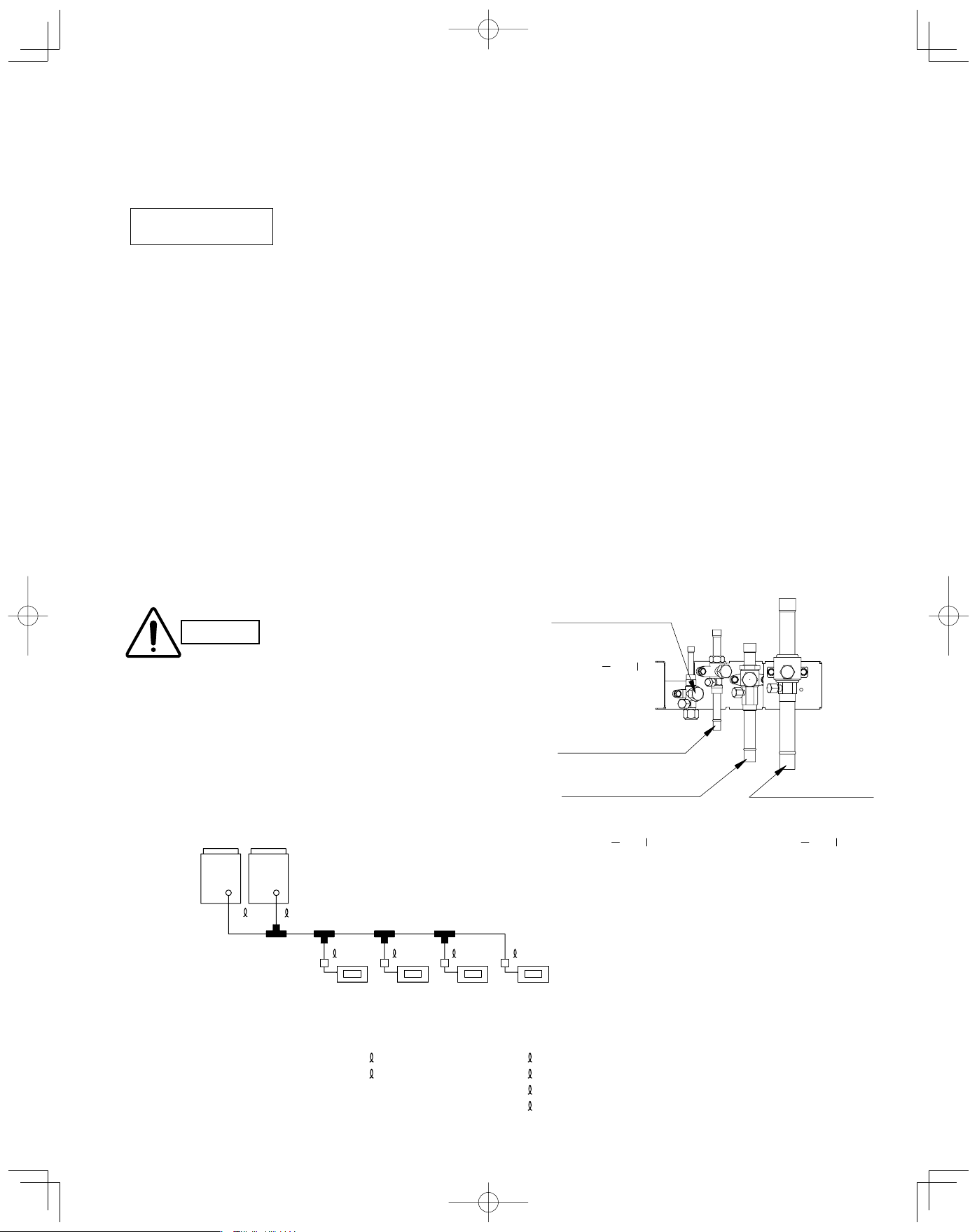

1-14. Optional Solenoid Valve Kit

Precautions on Installation of Solenoid Valve Kit

(1) Clean base metals thoroughly.

(2) Use proper ventilation to carry fumes away from the work area.

(3) Use a high quality silver based solder of at least 15 % silver.

(4) Heat the base materials broadly and uniformly.

(5) Take precautions not to overheat the device which could damage sensitive internal components.

(6) Insure compliance with all local codes!

Part

Number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1-21/32

3-21/32

ATK-RZP56BAWB

Types and specifications of

tubing connections

Gas tube: ID1/2"

Liquid tube : ID1/4"

Suspension hook

Liquid tube : ID3/8"

Suction tube: ID5/8"

Discharge tube: ID1/2"

Service panel

Base of control box

Terminal for power line

Terminal for communication line

Earth (M5 with washer)

Cover of control box

Relay kit

Cover of relay kit

5-25/32

1-21/32

3-21/32

4-7/32

Specifications

ATK-RZP56BAWB

Compatibility

Power source

Power input

Net weight

Accessories

7.500 Total capacity of indoor units (BTU/h) < 19.000

Single-phase 200V 50/60Hz (supplied by indoor unit)

20 W

151.7 oz.

Washer x 2

Insulating tape

1

3

6

63/64

4

5

2-31/64

3-15/16

6-29/64

8-15/32

63/64

2-31/64

3-15/16

9-13/32

7

53/64 2-63/64

2

5-55/64

4-21/64 4-21/64

9

11

8

5-3/64

4-1/4

3-25/32

12

5-55/64

9-29/64

7/16

43/64

1-7/64

5-55/64

2-3/64

5-9/32

4-49/64

Unit: in.

1314

10

18

W-3WAYECO-iUS.indd18W-3WAYECO-iUS.indd18 2008/02/0710:55:412008/02/0710:55:41

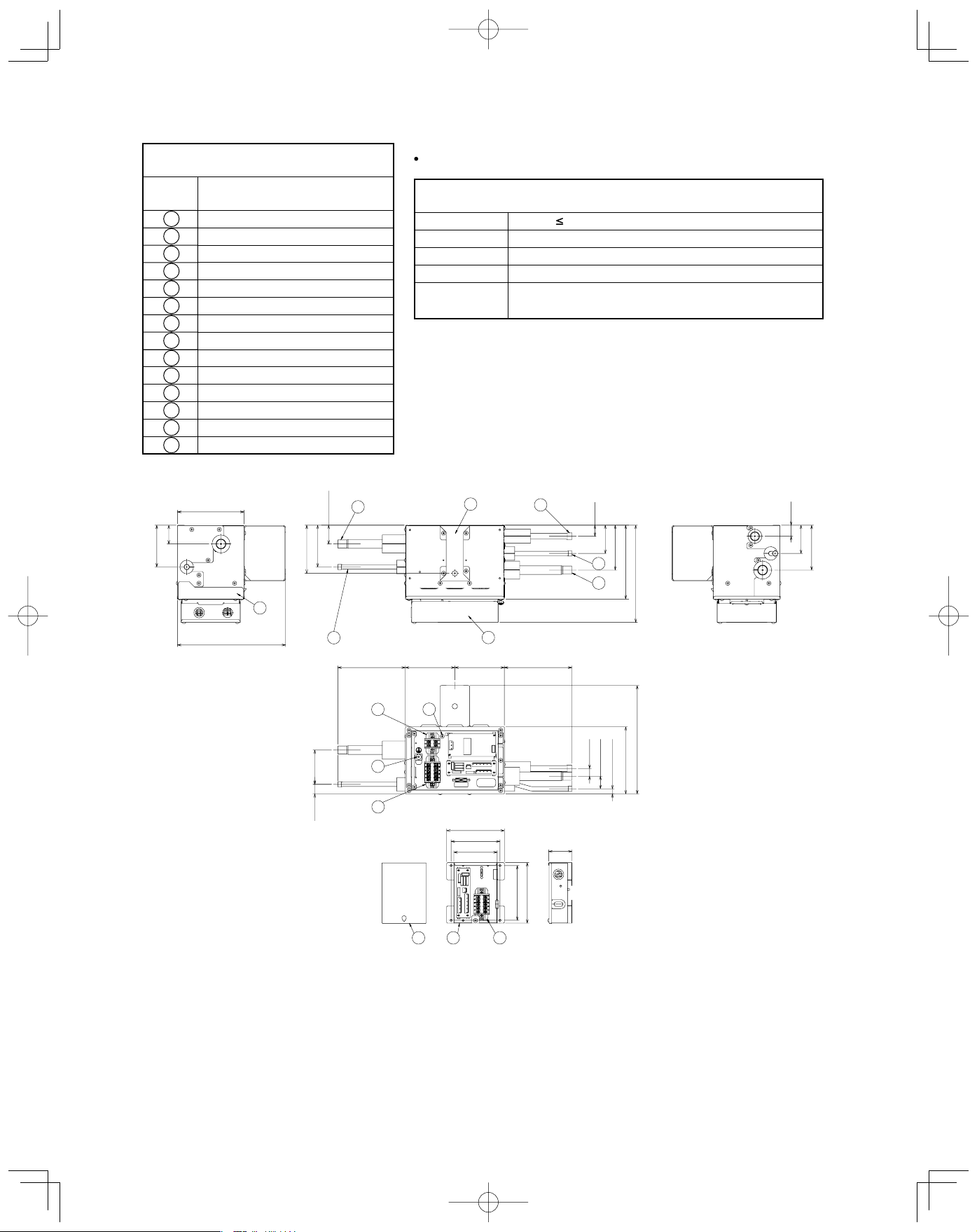

Page 19

ATK-RZP160BAWB

Specifications

Part

Number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1-21/32

3-21/32

Types and specifications of

tubing connections

Gas tube: ID5/8"

Liquid tube : ID3/8"

Suspension hook

Liquid tube : ID3/8"

Suction tube: ID5/8"

Discharge tube: ID1/2"

Service panel

Base of control box

Terminal for power line

Terminal for communication line

Earth (M5 with washer)

Cover of control box

Relay kit

Cover of relay kit

5-25/32

4-7/32

3-21/32

1-21/32

ATK-RZP160BAWB

Compatibility

Power source

Power input

Net weight

Accessories

19.000 Total capacity of indoor units (BTU/h) < 54.600

Single-phase 200V 50/60Hz (supplied by indoor unit)

25 W

165.8 oz.

Washer x 2

Insulating tape

1

3

6

63/64

4

5

2-31/64

3-15/16

6-29/64

8-15/32

63/64

2-31/64

3-15/16

9-13/32

7

53/64 2-63/64

2

5-55/64 5-55/64

11

10

9

4-21/64 4-21/64

8

5-3/64

4-1/4

3-25/32

12

9-29/64

7/16

43/64

1-7/64

5-55/64

2-3/64

5-9/32

4-49/64

Unit: in.

1314

10

19

W-3WAYECO-iUS.indd19W-3WAYECO-iUS.indd19 2008/02/0710:55:412008/02/0710:55:41

Page 20

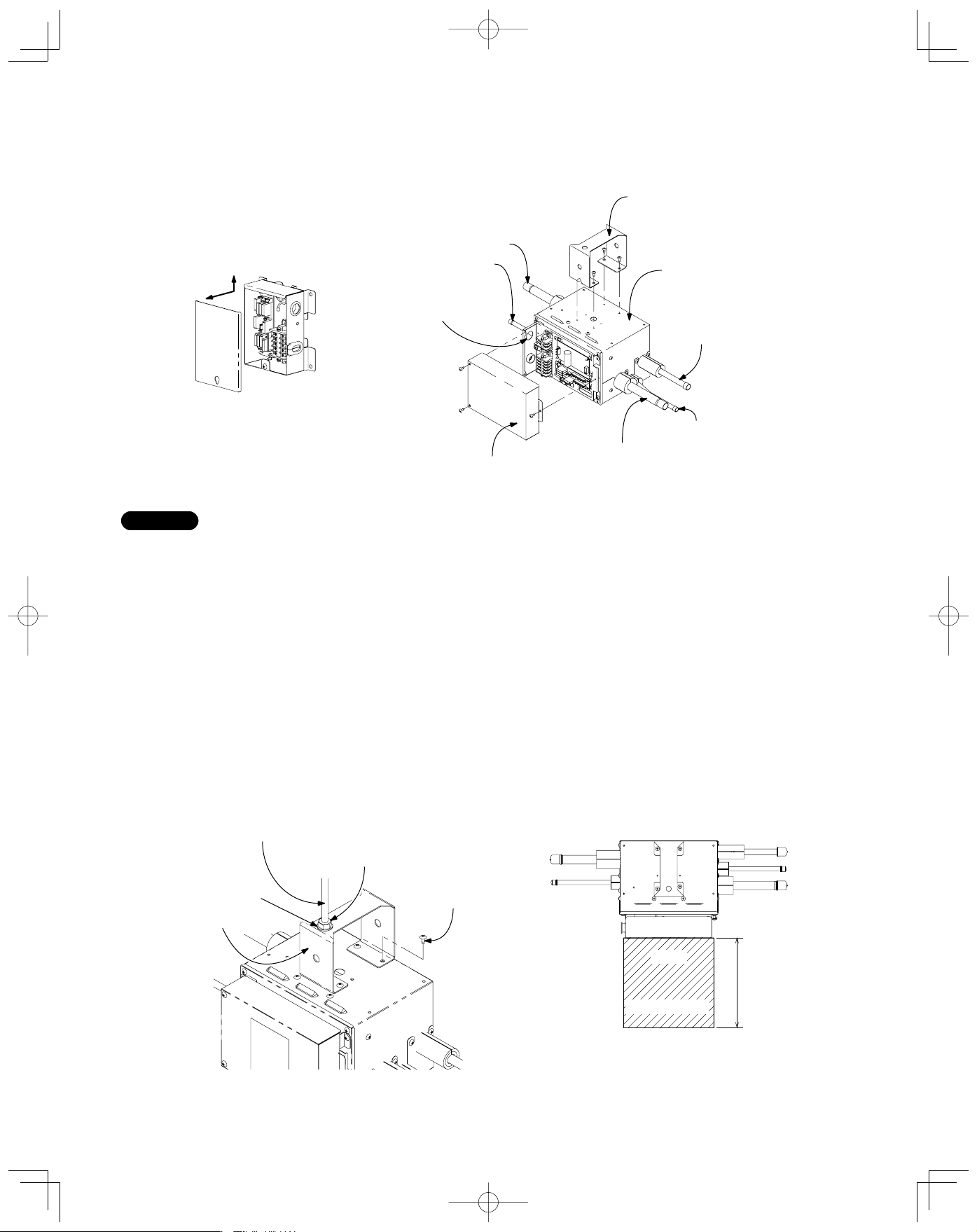

Installation of Solenoid Valve Kit

1. Install the relay kit into the indoor unit.

Refer to the Installation Manual for the solenoid valve kit.

2. Connect the solenoid valve kit and the relay kit in the field.

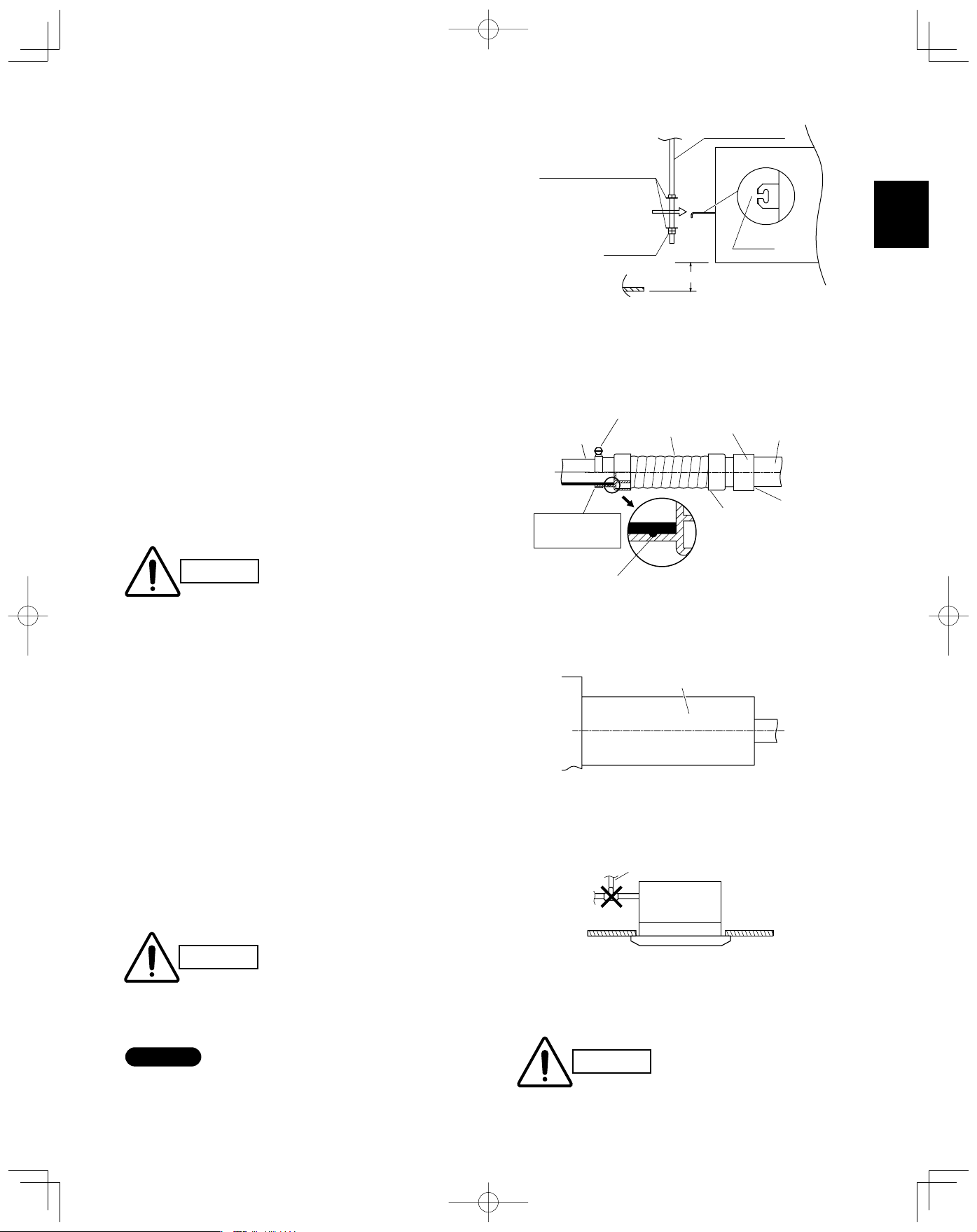

Gas tube

Liquid tube

Connect with

conduit for

power supply

Suspension hook

Top surface

Discharge tube

Relay kit

Front

Liquid tube

Suction tube

Cover of control box

NOTE

Notes on Installation

• Be sure to secure the valve body by using its structure with the suspension bolt, etc.

• Install the valve body within a distance of 98 ft. from the indoor unit.

Some refrigerant noise will be produced. Therefore in hospitals, libraries, hotel guest rooms, and other quiet

locations, it is recommended that the solenoid valve kit be installed on the ceiling reverse side of a hallway or

another location separated from the room.

• When installing the valve body, install with the top surface facing up. Secure 7-7/8" or more of space to the front

so that the front service panel can be removed.

• If the supplied suspension hook will not be used, and other fastening devices will be attached in the field, use

the 4 screw holes on the top surface. DO NOT use any long screws other than the supplied screws. Use of other

screws may puncture the internal tubing, resulting in refrigerant leakage.

• Do not block the air holes.

Suspension bolt (3/8" or M10) (field supplied)

Nut (field supplied) (3/8" or M10)

Washer

M4 screws

(12 pcs.)

Suspension hook

Front

Service space

20

W-3WAYECO-iUS.indd20W-3WAYECO-iUS.indd20 2008/02/0710:55:412008/02/0710:55:41

7-7/8" or more

Page 21

1-15. Example of Tubing Size Selection and Refrigerant Charge Amount

Additional refrigerant charging

Based on the values in Tables 1-10, 11, 12, 15 and 16-2 use the liquid tubing size and length, and calculate the amount of additional

refrigerant charge using the formula below.

Required additional

refrigerant charge (oz)

(a) : Liquid tubing Total length of ø7/8" (ft.) (d) : Liquid tubing Total length of ø1/2" (ft.)

(b) : Liquid tubing Total length of ø3/4" (ft.) (e) : Liquid tubing Total length of ø3/8" (ft.)

(c) : Liquid tubing Total length of ø5/8" (ft.) (f ) : Liquid tubing Total length of ø1/4" (ft.)

Charging procedure

●

Be sure to charge with R410A refrigerant in liquid form.

1. After performing a vacuum, charge with refrigerant from the liquid tubing side. At this time, all valves must be in the “fully

closed” position.

2. If it was not possible to charge the designated amount, operate the system in Cooling mode while charging with refrigerant

from the gas tubing side. (This is performed at the time of the test run. For this, all valves must be in the “fully open” position.

However if only one outdoor unit is installed, a balance tube is not used. Therefore, leave the valves fully closed.)

Charge with R410A refrigerant in liquid form.

With R410A refrigerant, charge while adjusting the amount being fed a little at a time in order to prevent liquid refrigerant from

backing up.

After charging is completed, turn all valves to the “fully open” position.

●

Replace the tubing covers as they were before.

●

CAUTION

Example:

Outdoor unit

09053

model

Necessary Amount of Refrigerant Charge Per Unit + 3.93 × (a) + 2.78 × (b) + 1.99 × (c) + 1.38 × (d) +

=

0.602 × (e) + 0.279 × (f)

1. R410A additional charging absolutely must

be done through liquid charging.

2. The R410A refrigerant cylinder has a gray

base color, and the top part is pink.

Balance tube

Use a flathead screwdriver

and open by turning the part

with the screw groove to the

right, from " " to " "

3. The R410A refrigerant cylinder includes a

siphon tube. Check that the siphon tube is

present. (This is indicated on the label at

the top of the cylinder.)

4. Due to differences in the refrigerant, pressure, and refrigerant oil involved in installation, it is not possible in some cases to

use the same tools for R22 and for R410A.

09053

model

Liquid tube

Use a hex wrench (width 5/32 inch)

and turn to the left to open.

Discharge tube

Use a flathead screwdriver

and open by turning the part

with the screw groove to the

right, from " " to " "

Use a flathead screwdriver

and open by turning the part

with the screw groove to the

right, from " " to " "

Suction tube

A

B

Example of each tubing length

●

LB

LA

1 2 3 4

48 model 48 model 48 model 36 model

LC

Main tubing Distribution joint tubing

LA = 131 ft. Outdoor side Indoor side

LB = 16 ft.

LC = 16 ft.

A = 7 ft. 1 = 98 ft.

B = 7 ft. 2 = 16 ft.

3 = 16 ft.

4 = 65 ft.

21

W-3WAYECO-iUS.indd21W-3WAYECO-iUS.indd21 2008/02/1513:01:022008/02/1513:01:02

Page 22

Obtain liquid tubing size from Tables 1-10, 11, 12 and 15.

●

Main tubing

LA = ø5/8 (ft.) (Total capacity of indoor unit is 179,400 BTU/h) The longest tubing length in this example

LB = ø1/2 (ft.) (Total capacity of indoor unit is 131,600 BTU/h) (LA = 131 ft.)

LC = ø3/8 (ft.) (Total capacity of indoor unit is 83,800 BTU/h)

Distribution joint tubing

Outdoor side

Indoor side

Obtain charge amount for each tubing size

●

A: ø3/8 (ft.) B: ø3/8 (ft.) (from outdoor unit connection tubing)

1: ø3/8 (ft.) 2: ø3/8 (ft.) 3: ø3/8 (ft.) 4: ø3/8 (ft.) (from indoor unit connection tubing)

Note that the charge amounts per 1 meter are different for each liquid tubing size.

ø5/8 (ft.) → LA : 131 ft. × 1.99 oz/ft. = 261 oz

ø1/2 (ft.) → LB : 16 ft. × 1.38 oz/ft. = 22 oz

ø3/8 (ft.) → LC +

A – B + 1 – 4 : 225 ft. × 0.602 oz/ft. = 135 oz

Total 418 oz

Additional refrigerant charge amount is 418 oz.

Remark:

When operating only one model CHDZ (R) 14053 or jointing with one more model, be sure to include the values in Table 1-16-2

Necessary Amount of Refrigerant Charge Per Unit.

CAUTION

Be sure to check the limit density for

the room in which the indoor unit is

installed.

Checking of limit density

Density limit is determined on the basis of the size of a room

using an indoor unit of minimum capacity. For instance, when

2

an indoor unit is used in a room (floor area 161 ft.

3

ing height 8.8 ft. = room volume 1417 ft.

), the graph at right

shows that the minimum room volume should be 2455 ft.

2

(floor area 279 ft.

) for refrigerant of 418 oz.

× ceil-

3

<Determination by calculation>

Overall refrigerant charge amount for the air conditioner: oz

(Minimum room volume for indoor unit: ft.3)

418 (oz)

=

1417 (ft.

= 0.29 (oz/ft.

3

)

3

) < 0.3 (oz/ft.3)

Therefore, openings such as louvers are not required for this

room.

3

ft.

4000

3500

3000

2500

2000

1500

Min. indoor volume

1000

Range below

the density limit of

0.3 oz/ft.

(countermeasures

not needed)

500

00

0

3

Range above

the density limit of

0.3 oz/ft.

(countermeasures

needed)

400200 600 800 1000 1200

Total amount of refrigerant

3

2

ft.

454

398

341

284

227

170

114

Min. indoor floor area

57

oz

(when the ceiling is 8.8 ft. high)

22

W-3WAYECO-iUS.indd22W-3WAYECO-iUS.indd22 2008/02/0710:55:422008/02/0710:55:42

Page 23

2. SELECTING THE INSTALLATION SITE

2-1. Indoor Unit

Ceiling-Mounted T ype

Ceiling

AVOID:

areas where leakage of flammable gas may be expected.

●

places where large amounts of oil mist exist.

●

direct sunlight.

●

locations near heat sources which may affect the

●

performance of the unit.

locations where external air may enter the room directly.

●

This may cause “sweating” on the air discharge ports,

causing them to spray or drip.

locations where the remote controller will be splashed with

●

water or affected by dampness or humidity.

installing the remote controller behind curtains or furniture.

●

locations where high-frequency emissions are generated.

●

DO:

select an appropriate position from which every corner of

●

the room can be uniformly cooled.

select a location where the ceiling is strong enough to

●

support the weight of the unit.

select a location where tubing and drain pipe have the

●

shortest run to the outdoor unit.

allow room for operation and maintenance as well as

●

unrestricted air flow around the unit.

install the unit within the maximum elevation difference

●

above or below the outdoor unit and within a total tubing

length (L) from the outdoor unit as detailed in Table 1-9.

allow room for mounting the remote controller about 3 ft.

●

off the floor, in an area that is not in direct sunlight nor in

the flow of cool air from the indoor unit.

NOTE

Air delivery will be degraded if the distance from the floor to

the ceiling is greater than 10 ft.

Wall

Min. 10 in.

Front view

Min. 10 in.

NOTE

The rear of the indoor unit can be installed flush

against the wall.

Air

discharge

Min. 2 ft.

Side vie w

Air intake

Max. 10 in.

Obstacle

Fig. 2-1

Concealed Duct (High-Static Pressure) Type

4-Way Air Discharge Semi-Concealed Type

3 ft.

3 ft.

3 ft.

3 ft.

3 ft.

Fig. 2-2

1-Way Air Discharge Semi-Concealed Type

Ceiling

Min. 2 in.

Air

discharge

Min. 3 ft.

Obstacle

Air

intake

Min. 2 in.

Wall

Wall

Side view

Fig. 2-3

Wall-Mounted T ype

Min.

6 in.

23

W-3WAYECO-iUS.indd23W-3WAYECO-iUS.indd23 2008/02/0710:55:422008/02/0710:55:42

Min.6 in.

Front View

Fig. 2-4

Min.

6 in.

Page 24

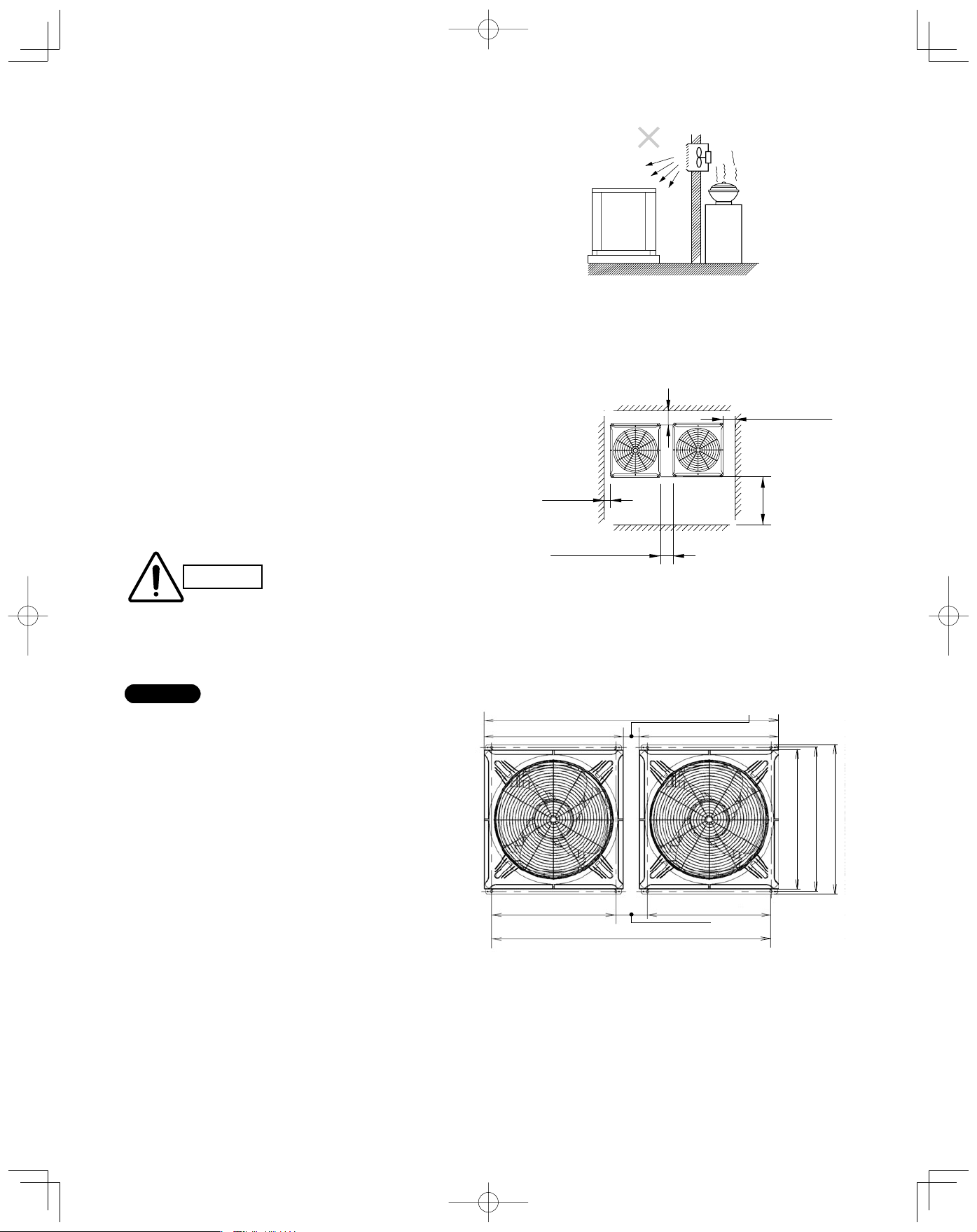

2-2. Outdoor Unit

AVOID:

heat sources, exhaust fans, etc.

●

damp, humid or uneven locations

●

indoors (no-ventilation location)

●

DO:

choose a place as cool as possible.

●

choose a place that is well ventilated.

●

allow enough room around the unit for air intake/

●

exhaust and possible maintenance.

Installation Space

Install the outdoor unit where there is enough space for ven-

tilation. Otherwise the unit may not operate properly. Fig. 2-6

shows the minimum space requirement around the outdoor

units when 3 sides are open and only 1 side is shuttered,

with open space above the unit. The mounting base should

be concrete or a similar material that allows for adequate

drainage. Make provisions for anchor bolts, platform height,

and other site-specific installation requirements.

Leave space open above the

●

CAUTION

unit.

Construct louvers or other

●

openings in the wall, if necessary, to ensure adequate

ventilation.

Exhaust fan

Hot air

Heat

Outdoor

unit

source

Fig. 2-5

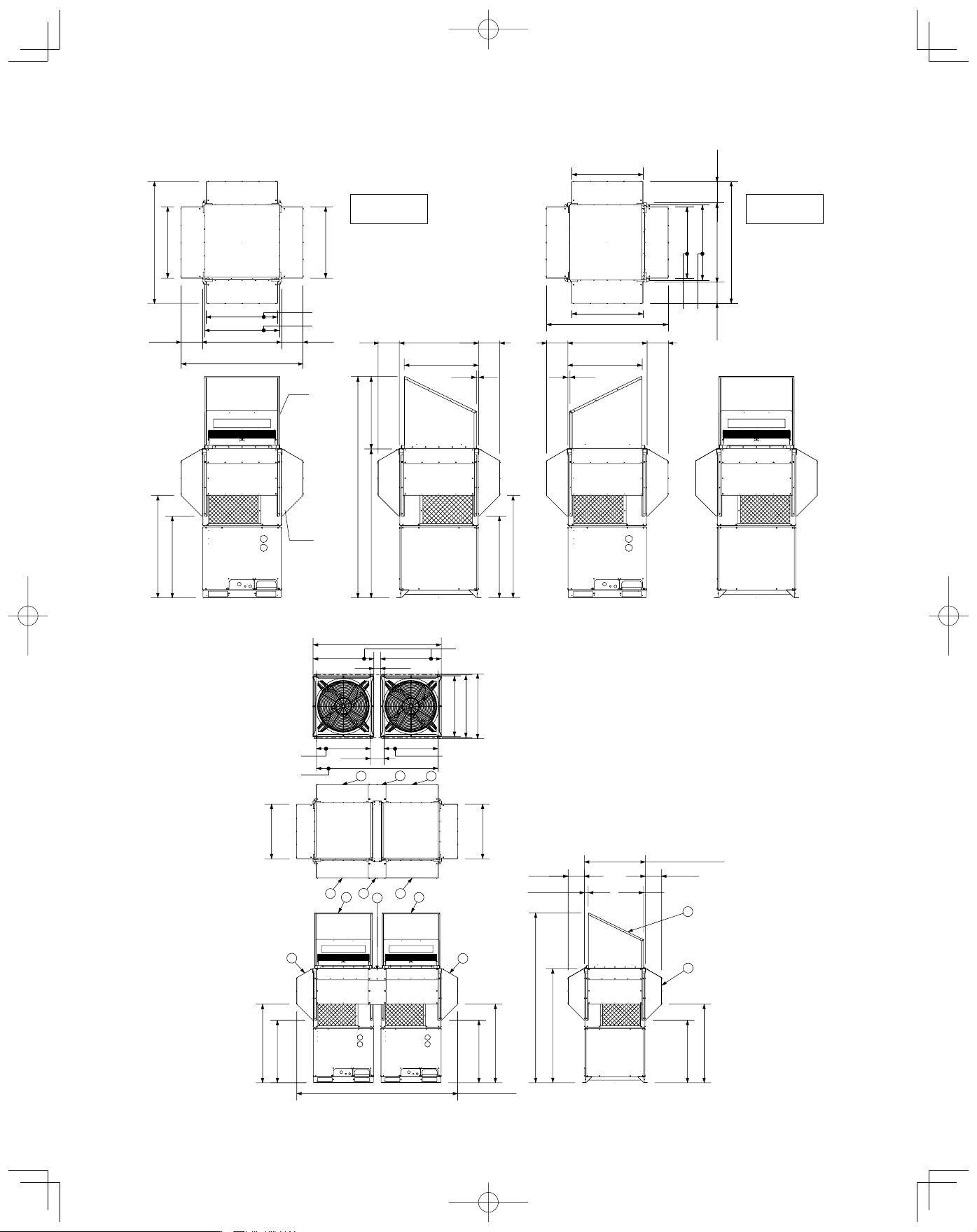

Example of installation of 2 units

(When wall height is below 6 ft.)

* More than 4 in.

* More than 4 in.

More than

2 in.

* More than 4 in.

* However, be sure to ensure a space of 1 ft. or more at

either the right side or the rear of the unit.

More than

1.7 ft.

Fig. 2-6

NOTE

Do not do any wiring or tubing within 1 ft. of the front

●

panel, because this space is needed as a servicing

space for the compressor.

Ensure a base height of 4 in. or more to ensure that

●

drainage water does not accumulate and freeze

around the bottom of the unit.

If installing a drain pan, install the drain pan prior to

●

installing the outdoor unit.

* Make sure there is at least 6 in. between the outdoor

unit and the ground.

Also, the direction of the tubing and electrical wiring

should be from the front of the outdoor unit.

74-1/64 (Ceiling panel dimensions)

35-3/64 (Ceiling panel dimensions) 35-3/64 (Ceiling panel dimensions)

31-7/64 (Installation hole pitch) 31-7/64 (Installation hole pitch)

70-5/64 (Installation hole pitch)

3-15/16

7-7/8

Top view

Fig. 2-7

36-7/32 (Installation hole pitch)

35-3/64 (Ceiling panel dimensions)

37-13/32 (Maximum dimensions)

Unit: in.

24

W-3WAYECO-iUS.indd24W-3WAYECO-iUS.indd24 2008/02/0710:55:432008/02/0710:55:43

Page 25

2-3. Precautions When Installing in Heavy Snow

Areas

a) The platform should be higher than the maximum snow

depth. (Fig. 2-8)

b) The 2 anchoring feet of the outdoor unit should be used

for the platform, and the platform should be installed

beneath the air-intake side of the outdoor unit.

c) The platform foundation must be solid and the unit must

be secured with anchor bolts.

d) When installing on a roof subject to strong wind, coun-

termeasures must be taken to prevent the unit from

being overturned.

AVOID

Without snowproof ducting

(Without platform)

Fig. 2-8

25

Fig. 2-9

W-3WAYECO-iUS.indd25W-3WAYECO-iUS.indd25 2008/02/0710:55:432008/02/0710:55:43

Page 26

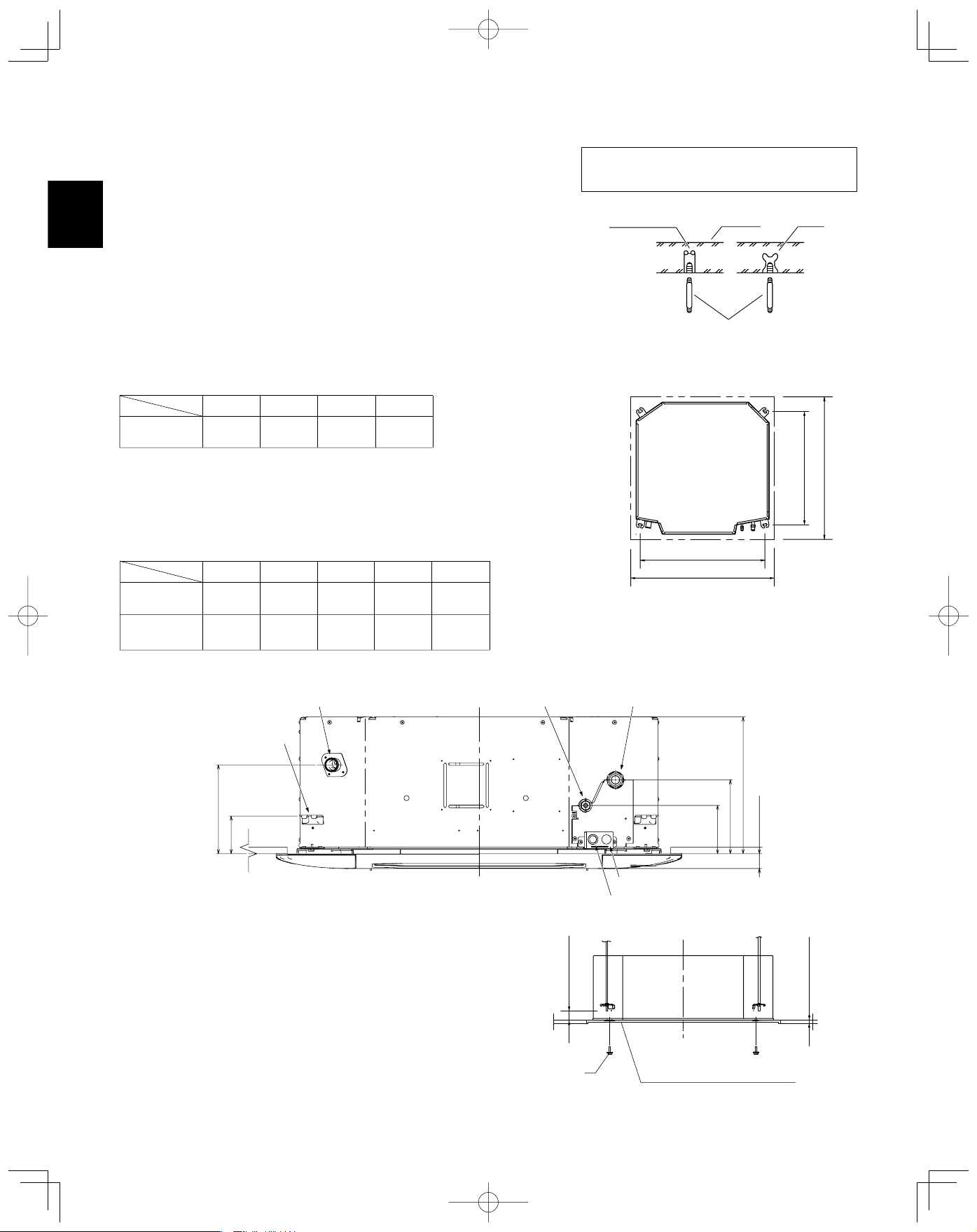

2-4. Dimensions of Wind Ducting

Reference diagram for air-discharge chamber (field supply)

unit: in.

Ceiling panel

33-3/16

35-3/64

(Ceiling panel dimensions)

35-15/64

(Maximum bracket dimensions)

33-3/16

35-3/64

Air direction: Front direction Air direction: Right direction

35-3/64

(Ceiling panel dimensions)

2-11/64 15/16

97-29/32

65-53/64 (32-5/64)

35-3/64

(Ceiling panel dimensions)

2-11/6415/16

97-29/32

65-53/64 (32-5/64)

Ceiling panel

35-15/64

(Ceiling panel dimensions)

(Maximum bracket dimensions)

Front view Front view Right side view Right side view

Note: Can be installed so that the air direction is to the front, right, left or rear direction.

2-unit installation

(2-unit installation: maximum dimensions)

74-7/32

33-3/16

31-7/64

5-25/32

(Installation hole pitch)

7-7/8

33-3/16

31-7/64

Top view

36-7/32

(Installation hole pitch)

2-11/64 15/16

97-29/32

unit: in.

35-3/64

(Ceiling panel dimensions)

65-53/64 (32-5/64)

Front view Right side view

26

W-3WAYECO-iUS.indd26W-3WAYECO-iUS.indd26 2008/02/0710:55:452008/02/0710:55:45

Page 27

2-5. Dimensions of Snow Ducting

Reference diagram for snow-proof ducting (field supply)

31-17/32

53-55/64

31-17/32

9-13/32

45-5/16

(Ceiling panel dimensions)

36-7/64

2-unit installation

Air direction:

Front direction

Ceiling panel

31-17/32

31-17/32 (Air intake duct)

35-3/64

53-55/64

33-3/16 (Air outlet duct)

9-13/32

1 pc.

4 pc.

9-13/32

(32-5/64)

97-29/32

65-53/64

35-3/64

(Ceiling panel dimensions)

32-7/8 32-7/8

Front view Right side view

Note: Can be installed so that the air direction is to the front, right, left or rear direction.

74-1/64 (Ceiling panel dimensions)

35-3/64

35-3/64

3-15/16

Ceiling panel dimensions

9-13/32

15/16 15/16

36-7/64

9-13/32

45-5/16

Air direction:

Right direction

Ceiling panel

35-3/64

53-55/64

31-17/32

53-55/64

35-3/64

(Ceiling panel dimensions)

9-13/32

9-13/32 9-13/32

unit: in.

33-3/16 (Air outlet duct)

31-17/32 (Air intake duct)

Front view Right side view

Installation hole pitch

31-17/32

45-5/16

36-7/64

Top (Before installation of snowfall protection duct)

35-3/64

36-7/32

37-13/32

31-7/64

7-7/8

223

31-7/64

70-5/64

Installation hole pitchInstallation hole pitch

unit: in.

31-17/32

Ceiling panel

2

1

2

3

3

92-53/64

2

1

2

36-7/64

9-29/64 9-29/64

97-29/32

65-53/64

45-5/16

35-3/64

(Ceiling panel dimensions)

7/82-11/64

1

2

36-7/64

45-5/16

Front view Right side view

27

W-3WAYECO-iUS.indd27W-3WAYECO-iUS.indd27 2008/02/0710:55:462008/02/0710:55:46

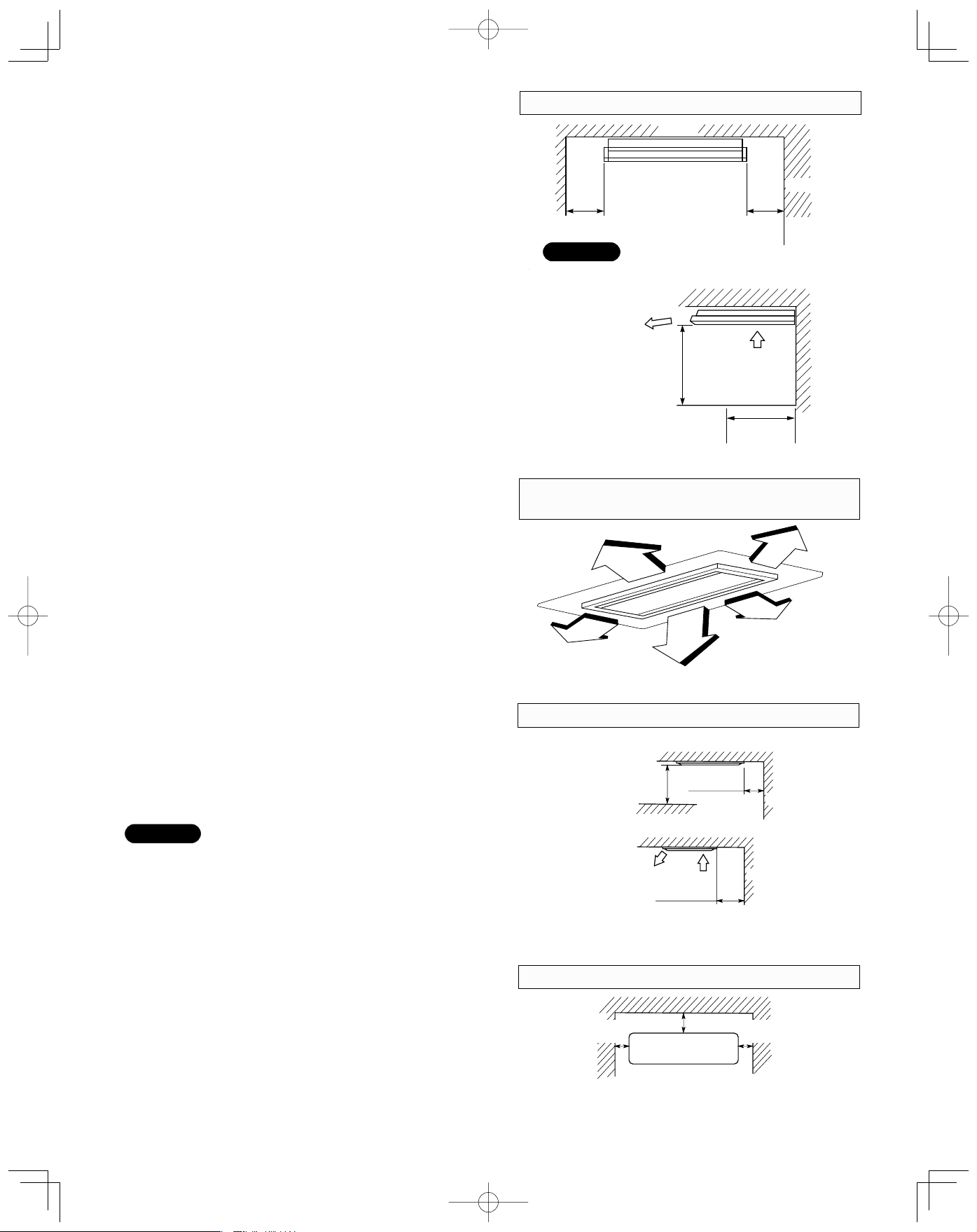

Page 28

X

3. HOW TO INSTALL THE INDOOR UNIT

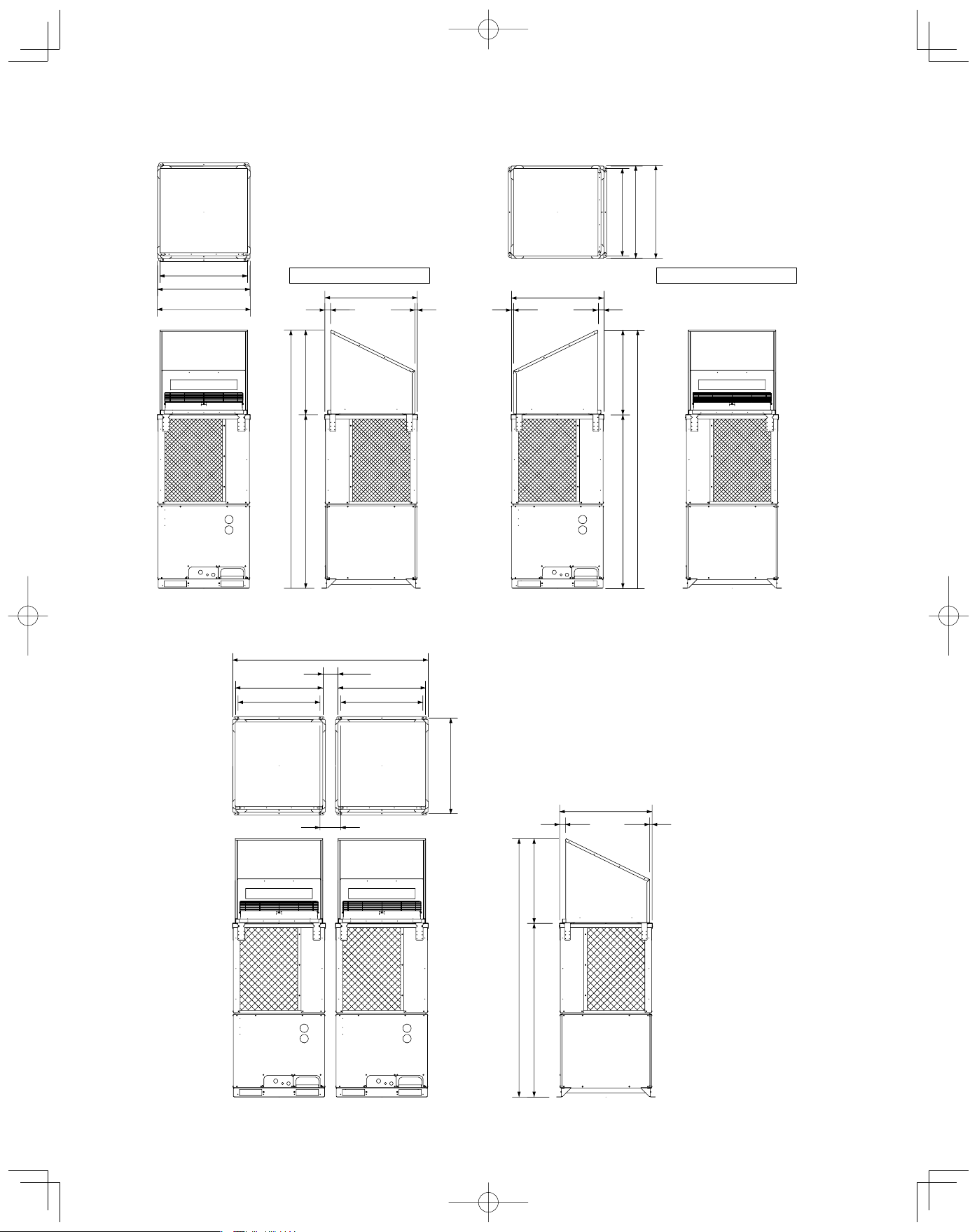

4-Way Air Discharge Semi-Concealed Type (X Type)

■

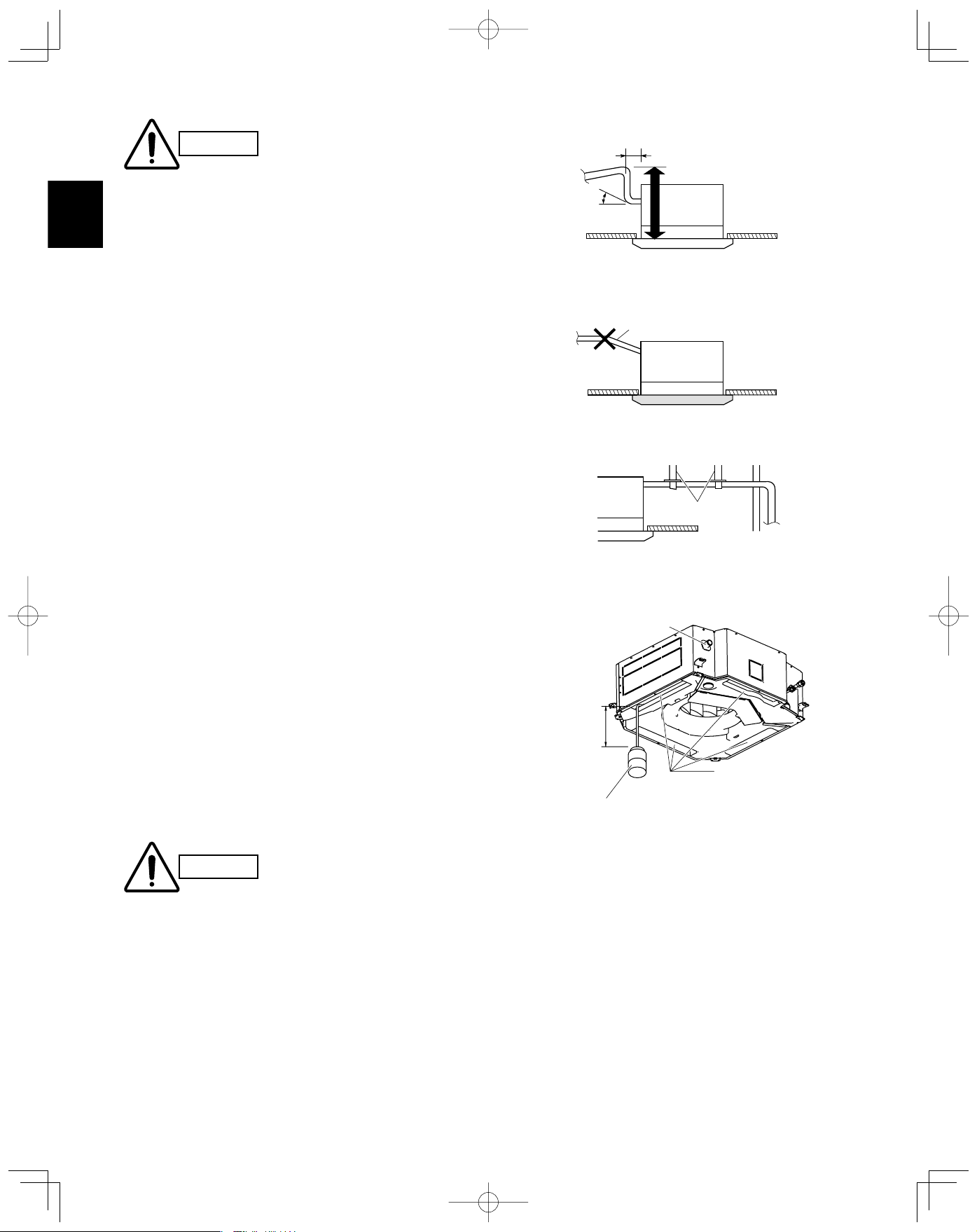

3-1. Preparation for Suspending

This unit uses a drain pump. Use a carpenter’s level to check that the

unit is level.

3-2. Suspending the Indoor Unit

(1) Fix the suspension bolts securely in the ceiling using the method

shown in the diagrams (Figs. 3-1 and 3-2), by attaching them to

the ceiling support structure, or by any other method that ensures

that the unit will be securely and safely suspended.

(2) Follow Fig. 3-2 and Table 3-1 to make the holes in the ceiling.

34-27/32

(885)

Unit: in. (mm)

34-27/32

(885)

Table 3-1

Type

Length

12, 18, 24, 36

ABCD

31-1/32

(788)

28-15/32

(723)

(3) Determine the pitch of the suspension bolts using the supplied

full-scale installation diagram. The diagram and table (Fig. 3-3 and

Table 3-2) show the relationship between the positions of the suspension fitting, unit, and panel.

8-17/64

(210)

8-17/64

(210)

Unit: in. (mm)

E

3-15/32

(88)

3-15/32

(88)

Table 3-2

Type

Length

12, 18, 24

36

ABCD

4-29/64

(113)

4-29/64

(113)

6-13/16

(173)

6-13/16

(173)

10-5/64

(256)

12-9/16

(319)

Note: For DC Fan Tap Change Procedure

for 4-Way Cassette, see page 34.

Hole-in-anchor

Hole-in-plug

Concrete Insert

Suspension bolt (M10 or 3/8")

(field supply)

Fig. 3-1

B (suspension bolt pitch)

D (ceiling opening dimension)

A (suspension bolt pitch)

C (ceiling opening dimension)

Fig. 3-2

Drain outlet(other side)

(VP25)

Suspension lug

D

E

Refregerant tubing joint(liquid side) Refregerant tubing joint(gas side)

3-3. Placing the Unit Inside the Ceiling

(1) When placing the unit inside the ceiling, determine

the pitch of the suspension bolts using the supplied

full-scale installation diagram. (Fig. 3-4)

Tubing and wiring must be laid inside the ceiling

when suspending the unit. If the ceiling is already

constructed, lay the tubing and wiring into position

for connection to the unit before placing the unit

inside the ceiling.

Fig. 3-3

Over 19/32 (15)

Supplied bolt

A

Power supply outlet

Inter-unit control wiring

Full-scale installation diagram

(printed on top of container box)

Fig. 3-4

C

B

1-3/8 (35)

Unit: in. (mm)

15/32 – 43/64

(12 – 17)

Unit: in. (mm)

28

W-3WAYECO-iUS.indd28W-3WAYECO-iUS.indd28 2008/02/0710:55:472008/02/0710:55:47

Page 29

(2) The length of suspension bolts must be appropriate

for a distance between the bottom of the bolt and the

bottom of the unit of more than 19/32 in. as shown in

Fig. 3-5.

Nuts and washers

(use for upper and lower)

Suspension bolt

Suspension lug

(3) Thread the 3 hexagonal nuts and 2 washers (field

supply) onto each of the 4 suspension bolts as shown

in Fig. 3-5. Use 1 nut and 1 washer for the upper side,

and 2 nuts and 1 washer for the lower side, so that the

unit will not fall off the suspension lugs.

(4) Adjust so that the distance between the unit and the

ceiling bottom is 15/32 to 43/64 in. Tighten the nuts on

the upper side and lower side of the suspension lug.

(5) Remove the protective polyethylene used to protect

the fan parts during transport.

3-4. Installing the Drain Piping

(1) Prepare a standard hard PVC pipe (O.D. 1-1/4 in.) for

the drain and use the supplied drain hose and hose

band to prevent water leaks.

The PVC pipe must be purchased separately. The

unit’s transparent drain port allows you to check drainage. (Fig. 3-6)

CAUTION

●