SANYO VPC-E6U, VPC-E6GXW, VPC-E6GX, VPC-E6EXW, VPC-E6EX WARNING

...

WARNING

Do not use solder containing lead.

This product has been manufactured using lead-free solder in

order to help preserve the environment.

Because of this, be sure to use lead-free solder when carrying

out repair work, and never use solder containing lead.

Lead-free solder has a melting point that is 30 - 40°C (86 104°F) higher than solder containing lead, and moreover it does

not contain lead which attaches easily to other metals. As a

result, it does not melt as easily as solder containing lead, and

soldering will be more difficult even if the temperature of the

soldering iron is increased.

The extra difficulty in soldering means that soldering time will

increase and damage to the components or the circuit board

may easily occur.

Because of this, you should use a soldering iron and solder

that satisfy the following conditions when carrying out repair

work.

Soldering iron

Use a soldering iron which is 70 W or equivalent, and which

lets you adjust the tip temperature up to 450°C (842°F). It

should also have as good temperature recovery characteristics as possible.

Set the temperature to 350°C (662°F) or less for chip components, to 380°C (716°F) for lead wires and similar, and to 420°C

(788°F) when installing and removing shield plates.

The tip of the soldering iron should have a C-cut shape or a

driver shape so that it can contact the circuit board as flat or in

a line as much as possible.

Note:

If replacing existing solder containing lead with lead-free solder in the soldered parts of products that have been manufactured up until now, remove all of the existing solder at those

parts before applying the lead-free solder.

Solder

Use solder with the metal content and composition ratio by

weight given in the table below. Do not use solders which do

not meet these conditions.

Metal content

Composition

ratio by weight

Lead-free solder is available for purchase as a service tool.

Use the following part number when ordering:

Part name: Lead-free solder with resin (0.5 mm dia., 500 g)

Part number: VJ8-0270

Tin (Sn) Silver (Ag)

96.5 %

3.0 %

Copper (Cu)

0.5 %

– 2 –

1. OUTLINE OF CIRCUIT DESCRIPTION

1-1. CCD CIRCUIT DESCRIPTION

1. IC Configuration

The CCD peripheral circuit block basically consists of the following ICs.

IC903 (MN39830PLJ-A) CCD imager

IC901 (AN20112A) V driver

IC905 (AD9996BBCZ) CDS, AGC, A/D converter,

H driver, vertical TG

Pin 1

5

V

6

12

Pin 13

H

58

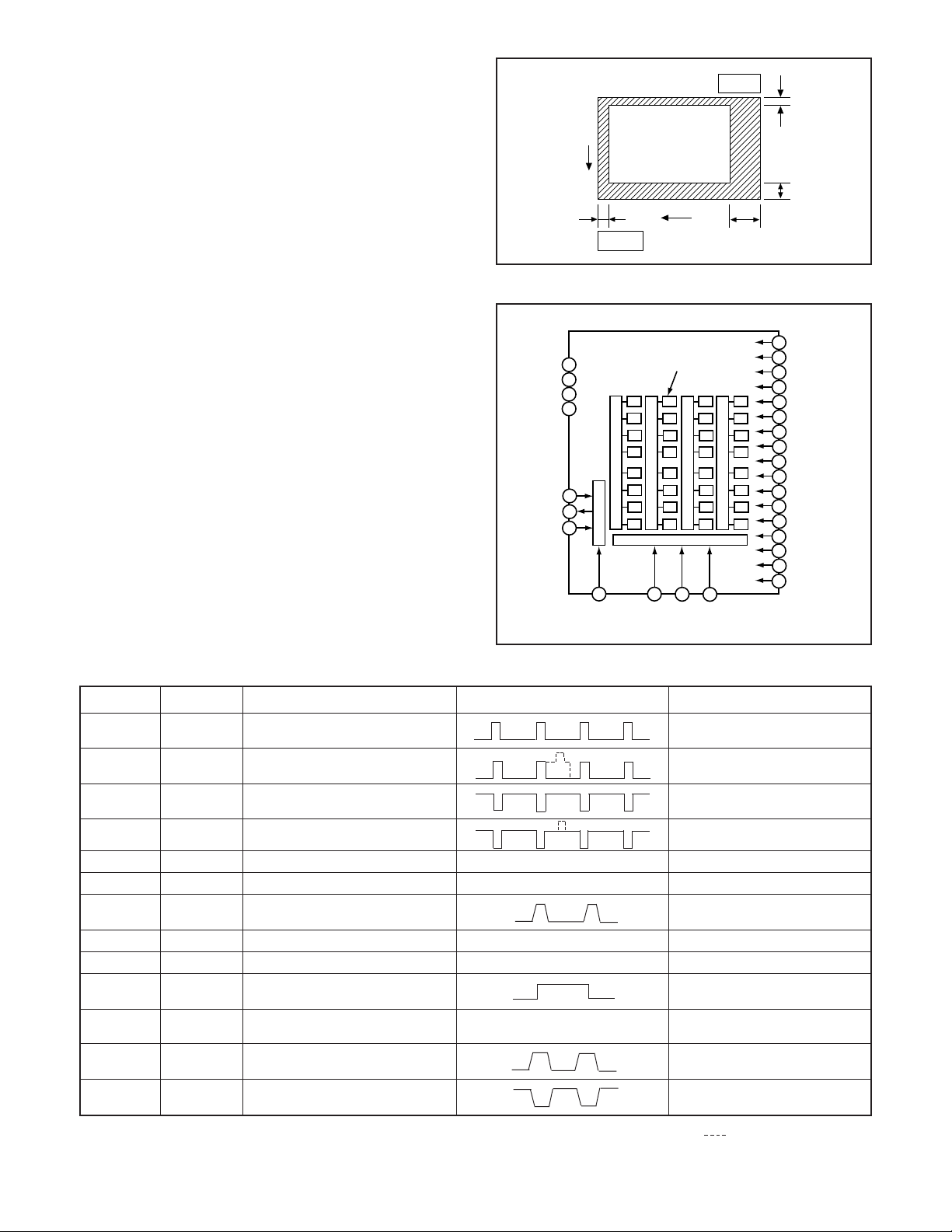

2. IC903 (CCD)

[Structure]

Interline type CCD image sensor

Optical size 1/2.5 type format

Effective pixels 2864 (H) X 2160 (V)

Pixels in total 2934 (H) X 2171 (V)

Optical black

Horizontal (H) direction: Front 12 pixels, Rear 58 pixels

Vertical (V) direction: Front 6 pixels, Rear 5 pixels

Dummy bit number Horizontal : 28 Vertical :7

Pin No.

Symbol Pin Description

Fig. 1-1.Optical Black Location (Top View)

NC

NC

NC

NC

VDD

VO

GND

13

14

27

28

15

16

17

18

Photo diode

Vertical shift register

Output part

Horizontal shift register

22

RG

ø

HL

ø

10

11

12

25

26

19

20

23

24

H2

H1

ø

ø

21

Fig. 1-2. CCD Block Diagram

Waveform

Voltag e

ø

1

ø

2

ø

3

ø

4

ø

5

ø

6

ø

7

ø

8

9

ø

ø

ø

GND

ø

ø

PT

SUBSW

ø

V6

V5B

V5A

V4

V3B

V3A

V3L

V3R

V2

V1

V1S

V5R

V5L

Vsub

1, 25, 26

2, 3

4, 7, 8, 9, 11

5, 6, 10

16

15

18

12, 17

19

20

21

22, 23

24

5L, V5R, V6

V

5A, V5B Vertical register transfer clock

V

V1S, V2, V3L,

V3R, V4

V

1, V3A, V3B

VO

VDD

ØRG

GND

PT

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

Signal output

Circuit power DC 12 V

Reset gate clock

GND

Protection transister bias

Substrate controlSUB SW

SUB

L, H1

H

H

Substrate clock

Horizontal register transfer clock

Horizontal register transfer clock

2

Table 1-1. CCD Pin Description

-6.0 V, 0 V

-6.0 V, 0 V, 12 V

-6.0 V, 0 V

-6.0 V, 0 V, 12 V

DC

Aprox. 12 V

4.5 V, 7.8 V

GND 0 V

DC

-6.0 V

0, 3.3 V (When importing all

picture element: 3.3 V)

DC

Aprox. 6 V

(Different from every CCD)

0 V, 3.3 V

0 V, 3.3 V

When sensor read-out

– 3 –

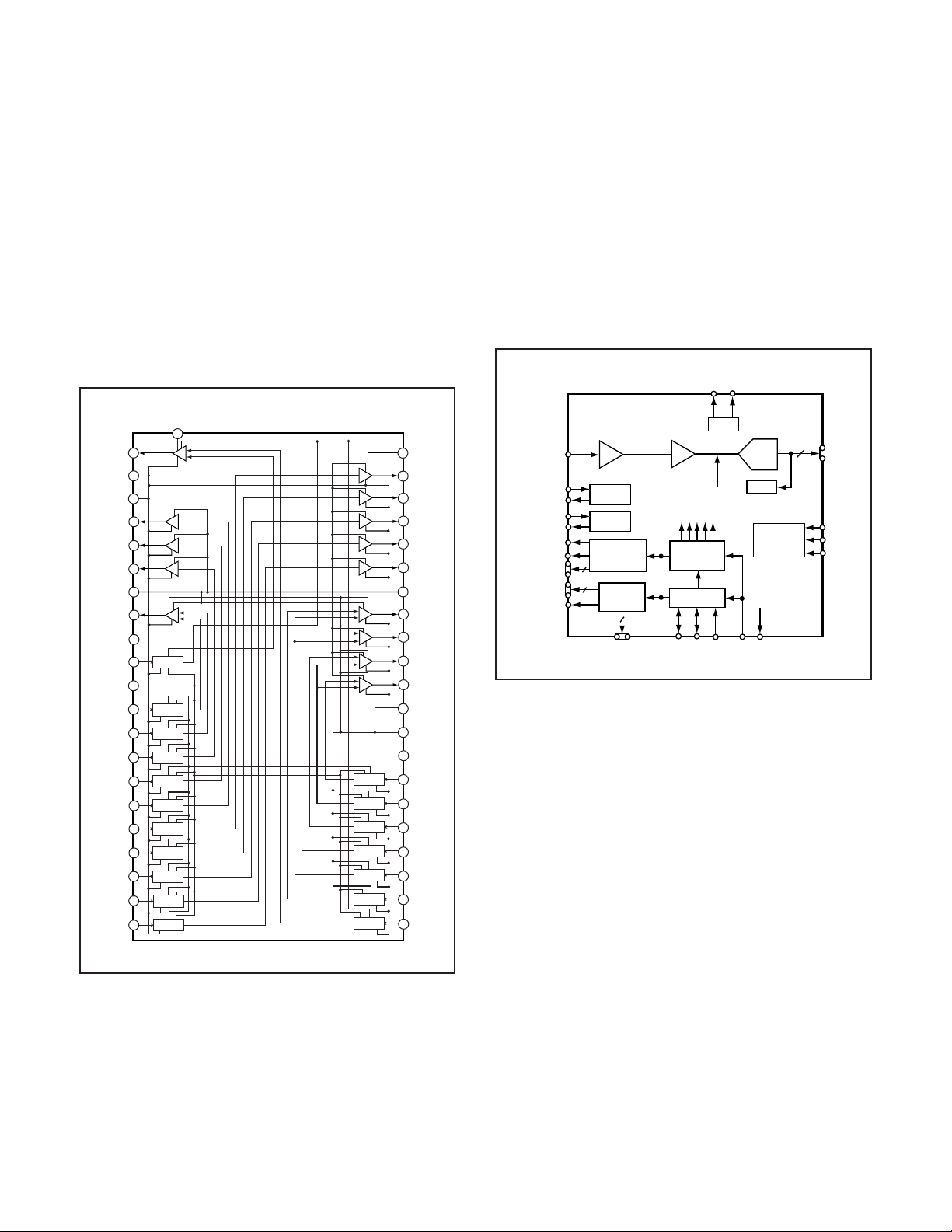

3. Part of IC905 (generation of vertical transfer clock,

H Driver) and IC901 (V Driver)

An H driver (part of IC905) and V driver (IC901) are necessary in order to generate the clocks (vertical transfer clock,

horizontal transfer clock and electronic shutter clock) which

driver the CCD.

IC905 has the generation of horizontal transfer clock and the

function of H driver, and is an inverter IC which drives the

horizontal CCDs (H1 and H2). It carries out generating vertical transfer clock, and output to IC901.

In addition the XV1-XV6 signals which are output from IC905

are vertical transfer clocks, and the XSG signal is superimposed onto XV1, XV3 and XV5 at IC901 in order to generate

a ternary pulse. In addition, the XSUB signal which is output

from IC101 is used as the sweep pulse for the electronic shutter, and the RG signal which is output from IC905 is the reset

gate clock.

4. IC905 (H Driver, CDS, AGC and A/D converter)

IC905 contains the functions of H driver, CDS, AGC and A/D

converter. As horizontal clock driver for CCD image sensor,

HØ1 (A and B) and HØ2 (A and B) are generated inside, and

output to CCD.

The video signal which is output from the CCD is input to pin

(A6) of IC905. There are sampling hold blocks generated from

the SHP and SHD pulses, and it is here that CDS (correlated

double sampling) is carried out.

After passing through the CDS circuit, the signal passes

through the AGC amplifier (VGA: Variable Gain Amplifier). It

is A/D converted internally into a 14-bit signal, and is then

input to ASIC (IC101). The gain of the VGA amplifier is controlled by pin (A2), (B3) and (C4) serial signal which is output

from ASIC (IC101).

REFB

REFT

OSUB

VM

OV1

RESET

SUBCNT

VDC

CH1

V5R

V5L

V3R

V3L

V1S

CLI

AD9996

14-BIT

ADC

CLAMP

INTERNAL

REGISTERS

CLO

14

DOUT

SL

SCK

SDI

VMSUB

9

3-level

10

VL

5

VL

27

2-level

24OV2

2-level

23OV4

2-level

21OV6

8

3-level

20

28

Level

1

conversion

3

Level

32

conversion

Level

V1

33

conversion

Level

31

V6

conversion

Level

V4

30

conversion

Level

29

V2

conversion

Level

37

conversion

Level

38

conversion

Level

35

conversion

Level

36

conversion

Level

34

conversion

2-level

2-level

2-level

2-level

2-level

3-level

3-level

3-level

3-level

Level

conversion

Level

conversion

Level

conversion

Level

conversion

Level

conversion

Level

conversion

Level

conversion

7

VHH

16

OV5R

15

OV5L

18

OV3R

17

OV3L

19

OV1S

25

VM

12

OV5A

11

OV5B

14

OV3A

13

OV3B

6

VH

26

VH

4

GND

41

CH2

40

V3

39

CH4

44

CH3

43

V5

42

CH5

2

SUB

CCDIN

3V INPUT

1.8V OUTPUT

1.8V INPUT

3V OUTPUT

H1 TO H8

XV1 TO XV24

XSUBCK

RG

HL

CDS

-3dB, 0dB, +3dB

LDO

REG

CHARGE

PUMP

HORIZONTAL

DRIVERS

8

24

VERTICAL

TIMING

CONTROL

8

GP01 TO GP08

Fig. 1-4. IC905 Block Diagram

6~42 dB

VGA

INTERNAL

CLOCKS

PRECISION

TIMING

GENERATOR

SYNC

GENERATOR

VD

HD

SYNC

VREF

Fig. 1-3. IC901 Block Diagram

– 4 –

Loading...

Loading...