Sanyo VMC-L2617P Service Manual

SERVICE MANUAL

FILE NO.

Color LCD monitor

CONTENTS

SPECIFICATIONS.....................................4

1. DISASSEMBL Y .....................................5

2. ADJUSTMENT ......................................6

3. PARTS LIST .........................................8

CIRCUIT DIAGRAMS &

PRINTED WIRING BOARDS ................. C1

VMC-L2617P

(Product Code : 114 956 08)

(Europe, U.K., PAL General)

VMC-L2617

(Product Code : 114 956 10)

(U.S.A., Canada, NTSC General)

RoHS

This product does not contain any hazardous substances prohibited by the RoHS Directive.

WARNING

You are requested to use RoHS compliant parts for maintenance or repair.

You are requested to use lead-free solder.

(This product has been manufactured using lead-free solder. Be sure to follow the warning given on page 3 when carrying

out repair work.)

NOTE: 1. Parts order must contain model number, part number, and description.

2. Substitute parts may be supplied as the service parts.

3. N.S.P. : Not available as service parts.

Design and specifications are subject to change without notice.

L8MAQ/XE, US (R)

REFERENCE No.SM5310787

SAFETY PRECAUTIONS

WARNING:

Service should not be attempted by anyone unfamiliar with the necessary precautions for this recording or playback

equipment. The following precautions are necessary during servicing:

1. Many electrical and mechanical parts in this recorder have

special safety-related characteristics for providing protection against shock, fire and other hazards. These characteristics often go unnoticed in a visual inspection, and the

protection afforded by them cannot necessarily be obtained by using replacement components with higher

ratings (voltage, wattage, etc.).

2. Replacement parts having special safety-related characteristics are identified in this manual, and in the schematic

diagrams, by the symbol

. These components have

values that are of special significance to product safety.

Should any component (identified by the symbol

) need

to be replaced, use only the part designated in the parts

List. Do not deviate from the specified resistance, wattage,

and voltage ratings.

AC VOLTMETER

(5000 ohms per volt or more sensitivity)

Reading should not exceed 300 mVrms

3. Before returning the set to the customer, always perform

an AC leakage current check on the exposed metallic parts

of the cabinet, such as terminals, screwheads, metal

overlays, etc. to be sure that the set is safe to operate

without the danger of electrical shock, Plug the AC line

cord directly into a 120 V AC outlet. (Do not use a line

isolation transformer during this check.) Use an AC voltmeter

with a sensitivity of 5000 ohms per volt (or more) as follows:

Connect a 1500 ohms, 10 watt resistor, paralleled by a 0.15

mfd, 150 VAC capacitor, between a known good earth

ground (water pipe, conduit, etc.) and the exposed metallic

parts, one at a time. Measure the AC voltage across the

1500 ohms resistor and 0.15 mfd capacitor combination.

Reverse the AC plug at the AC outlet and repeat the AC

voltage measurements for each exposed metallic part.

The measured voltage must not exceed 300 mVrms. This

corresponds to 200 µA AC. Any value exceeding this limit

constitutes a potential shock hazard and must be corrected

immediately.

4. Fuse symbol marks.

For CANADA

AC OUTLET

Color LCD

monitor

1500 Ohm

10 Watt

0.15uF 150 VAC

Place this probe on each

exposed metallic part

Voltmeter Hook-up for Leakage Current Check

Good earth ground such as

a water pipe,conduit etc.

For U.S.A.

Fuse rating is marked at

adjacent fuse.

UNDERWRITERS LABORATORIES Standard

CAUTION "Risk of fire-replace fuse as marked"

- 2 -

WARNING

Do not use solder containing lead.

This product has been manufactured using lead-free

solder in order to help preserve the environment.

Because of this, be sure to use lead-free solder when

carrying out repair work, and never use solder

containing lead.

Lead-free solder has a melting point that is 30 - 40°C (86 104°F) higher than solder containing lead, and moreover it

does not contain lead which attaches easily to other metals.

As a result, it does not melt as easily as solder containing

lead, and soldering will be more difficult even if the

temperature of the soldering iron is increased.

The extra difficulty in soldering means that soldering time

will increase and damage to the components or the circuit

board may easily occur.

Because of this, you should use a soldering iron and

solder that satisfy the following conditions when carrying out

repair work.

Note:

If replacing existing solder containing lead with lead-free

solder in the soldered parts of products that have been

manufactured up until now, remove all of the existing solder

at those parts before applying the lead-free solder.

Soldering iron

Use a soldering iron which is 70 W or equivalent, and

which lets you adjust the tip temperature up to 450°C

(842°F). It should also have as good temperature recovery

characteristics as possible.

Set the temperature to 350°C (662°F) or less for chip

components, to 380°C (716°F) for lead wires and similar,

and to 420°C (788°F) when installing and removing shield

plates.

The tip of the soldering iron should have a C-cut shape or

a driver shape so that it can contact the circuit board as flat

or in a line as much as possible.

Solder

Use solder with the metal content and composition ratio by

weight given in the table below. Do not use solders which

do not meet these conditions.

Metal content Tin (Sn) Silver (Ag) Copper (Cu)

Composition

ratio by weight

96.5% 3.0% 0.5%

Lead-free solder is available for purchase as a service tool.

Use the following part number when ordering:

Part name: Lead-free solder with resin (0.5 mm dia., 500 g)

Part number: VJ8-0270

- 3 -

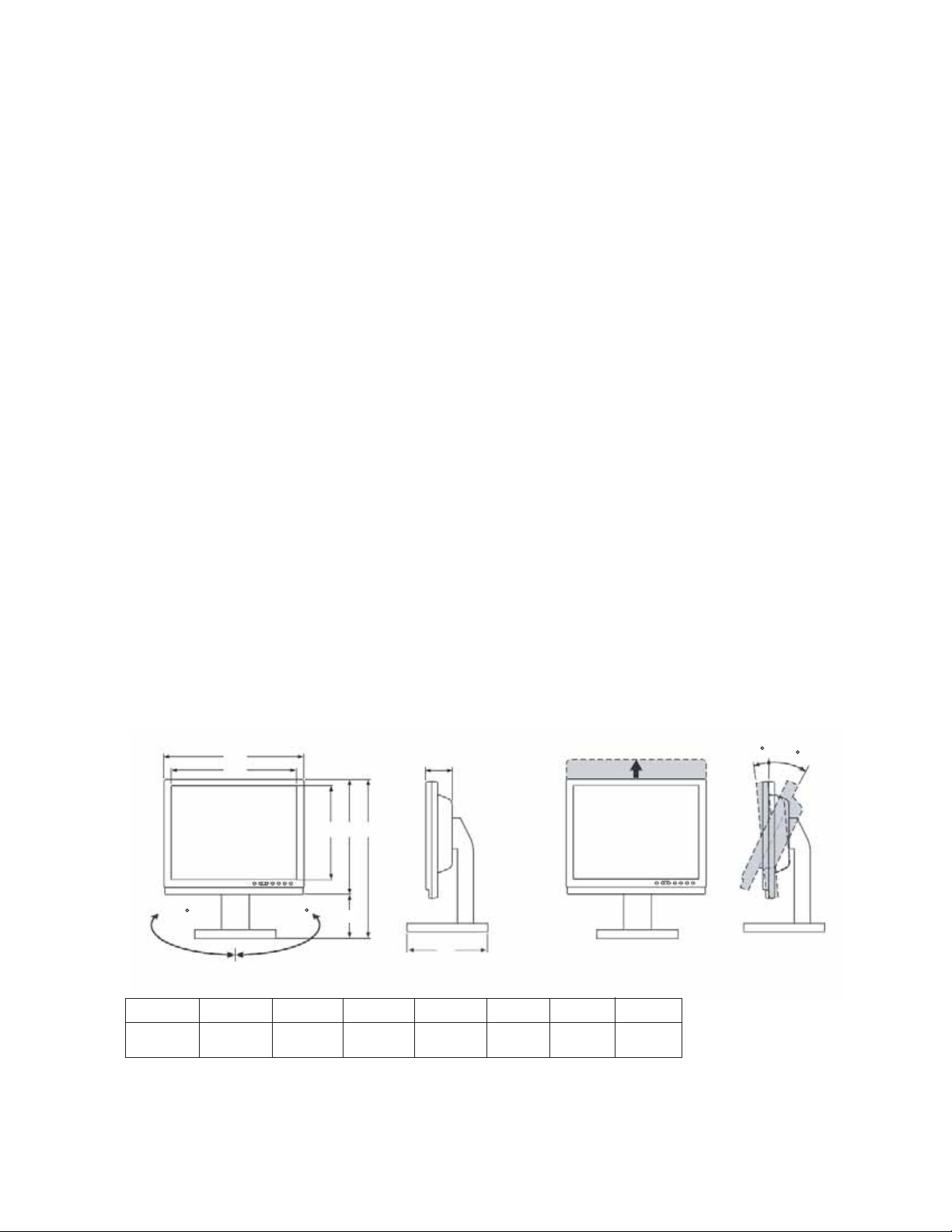

SPECIFICATIONS

Display type : SXGA a-Si TFT LCD

Color system : PAL/NTSC (Automatic detection)

LCD display : 17” active matrix TFT LCD panel

Viewable size (H x V) : 338 x 270 mm/13.3 x 10.6 in. (4:3)

Pixel pitch (H x V) : 0.264 x 0.264 mm/0.01 x 0.01 in.

Horizontal resolution : 1280 x 1024, PAL: 620 NTSC: 600 TV lines (Y/C input mode)

Viewing angle degree : Left/Right/Up/Down: 80°

Scanning frequency : Horizontal 30k - 81kHz, Vertical 56 - 75 Hz

Contrast ratio : 1000:1

Brightness : 300 cd/m / 359 cd/yd

2

Response time Tr/Tf : 1.3/3.7 ms

Display color : 16.7 M

Display monitor timing : VESA compatible (VGA mode)

Display mode : Video A, Video B, S-Video, VGA

Input connector

Video signal (BNC IN) : Composite sync signal, 1.0 Vp-p, 75 ohms BNC connector x 2

S-Video signal (Y/C IN) : Separate Y/C signal, mini-DIN connector

Y signal : 1.0 Vp-p, 75 ohms negative sync

C signal : 0.286 Vp-p, 75 ohms negative sync

Audio signal (AUDIO IN) : -6.0 dBs (400 mVrms), 2W (1W + 1W) stereo, RCA pin x 2

VGA signal (VGA IN) : VGA monitor connector (15-pin)

Red signal, Green signal, Blue signal : 0.7 Vp-p, 75 ohms positive sync

Output connector

Video signal (BNC OUT) : Composite sync signal, 1.0 Vp-p, 75 ohms BNC connector x 2

S-Video signal (Y/C OUT) : Separate Y/C signal, mini-DIN connector

Y signal : 1.0 Vp-p, 75 ohms negative sync

C signal : 0.286 Vp-p, 75 ohms negative sync

Menu language : English/ French/ German/ Spanish/ Italian/ Portuguese/ Dutch/ Swedish/ Russian/ Korean/ Japanese

Power input : AC 100 V - 240 V

Operating condition : Temperature : 0°C - +40°C/32°F - 104°F

Humidity : 10 - 90 % (non-condensation)

Storage condition : Temperature : -20°C - +45°C/-4°F - +113°F

Humidity : 5 - 95 %

Power consumption : Approx. 42 W (0.7 A)

Weight : Approx. 6.0 kg/13.2 lbs.

Dimensions :

2

165

A

B

(Swivel)

165

C D E

F

G

H

100 (3.9)

(Lift)

A B C D E F G H

371 (14.6) 339 (13.4) 272 (10.7) 331 (13.0) 368 (14.5) 37 (1.5) 67 (2.6) 220 (8.7)

Note

Unit: mm (inch)

When adjusting the screen tilt, please make sure not to damage the screen.

After adjusting the tilt, check the cables to ensure the monitor is not pulled over.

- 4 -

25

5

(Tilt)

1. DISASSEMBLY

1-1. DISASSEMBLY

1. Remove the two screws 4 x 10.

2. Remove the ass’y stand P.

1

3. Remove the three screws 3 x 10.

4. Remove the ass’y cover P-rear.

4

5. Release the two hooks.

6. Remove the cover jack.

7. Release the two hooks.

8. Remove the shield-lamp.

9. Remove the ass’y chassis shield.

13. Remove the screw 3 x 8.

14. Remove the ass’y IR board.

2

15. Remove the ass’y FUNCTION board.

16. Cover front.

16

15

13

14

17. Remove the two screws.

18. Remove the four screws 3 x 8.

19. Remove the screw 4 x 8.

20. Remove the IP board.

21. Remove the MAIN board.

3

17

21

20

19

19

18

9

7

8

10. Remove the LCD panel.

11. Remove the glass protection.

12. Ass’y cover front.

6

5

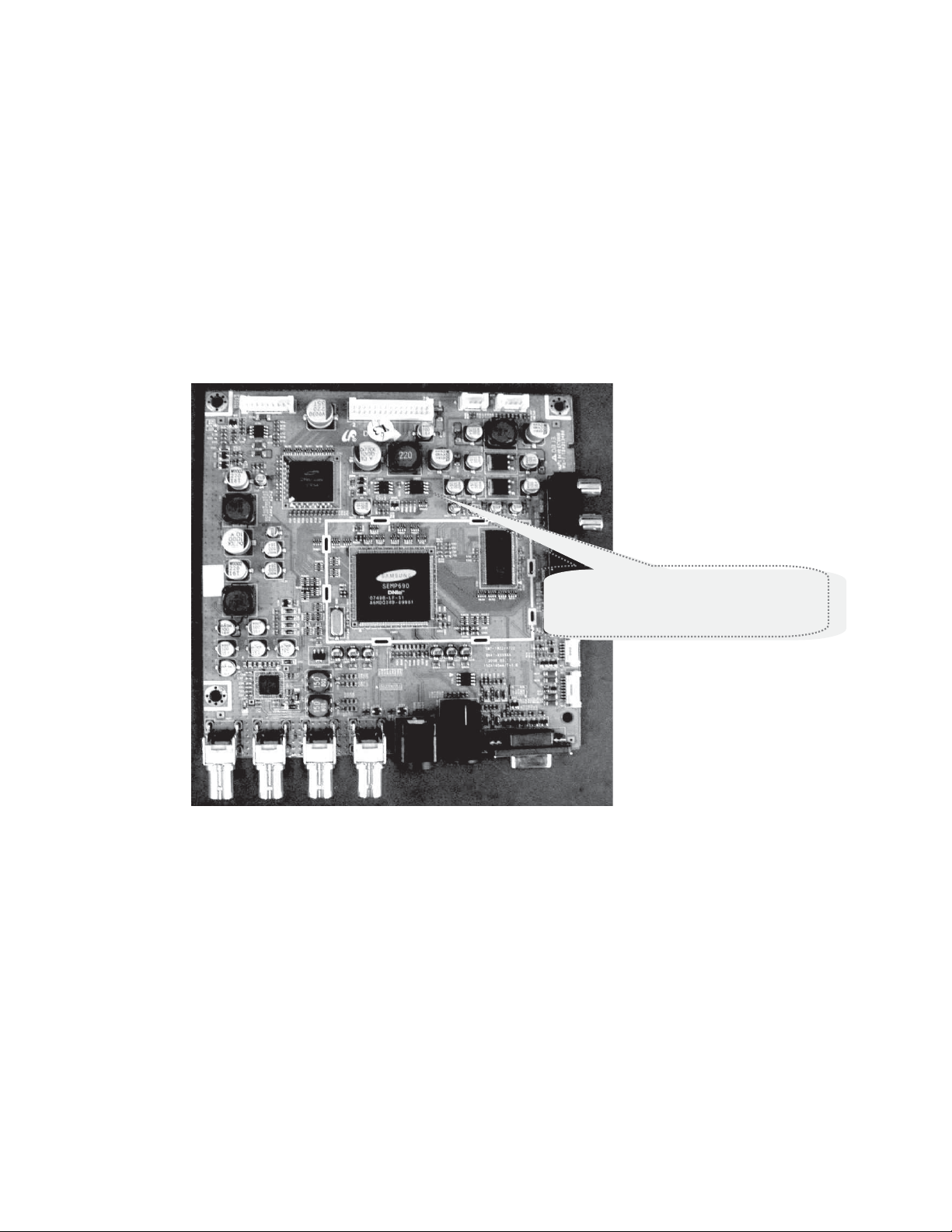

1-2. BOARD LOCA TION

MAIN board

LCD panel

IP board

10

11

12

IR board

FUNCTION board

- 5 -

2. ADJUSTMENT

This section describes to adjust LCD monitor after replacing FLASH, Main board or Panel.

2-1. Program Upgrade

Change MICOM

If the similer happenings occur, FLASH can be changed

EX1) When screen appears but remote control and function key aren’t working

EX2) When LED is on but the screen doesn’t appear

EX3) After mass production, when the micom program version is up-graded

*FLASH replacement can be done when Service Bulletin issue is in practice.

The process of working need to be prepare on Service Bulletin.

Upgraded

After disassembling the set (refer to SET disassemble), remove the FLASH in the exist IC6003 and replace new FLASH.

-Use appropriate JIG or any sharp tool and place in the both corners to assist in removing.

(Be aware! If the socket cause any damage after replacement the monitor will not function properly.)

-When inserting, attend to IC direction and press with suitable amount of strength.

-After replacement, in case of EEPROM Clear, enter to Factory mode and perform into action.

FLASH

- 6 -

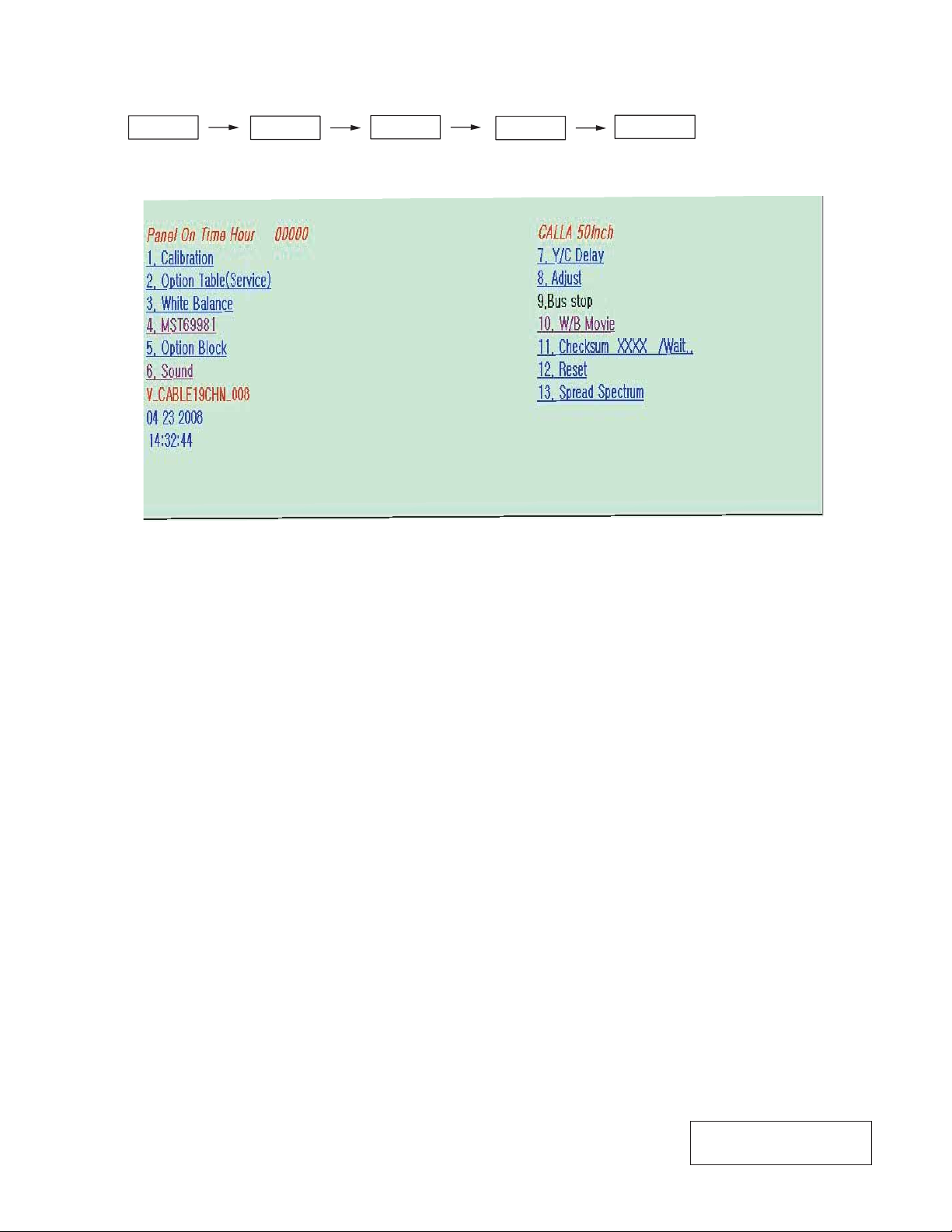

2-2. Factory Mode Adjustments

2-2-1. Factory Mode Admission

MUTE

2-2-2. Service Mode Menu

Calibration

1. AV calibration

2. COMP calibration

3. PC calibration

4. HDMI calibration

White Balance

1. Sub-briteness

2. R-offset

3. G-offset

4. B-offset

5. Sub-contrast

6. R-gain

7. G-gain

8. B-gain

1

Option Table (Service)

1. Ready

2. Inch option

3. Panel vender

4. Panel type

5. Model option

6. Anynet +

7. Auto power

8. Nordic

9. LNA menu

10. TTX on/off

11. TTX list

12. Carrier mute

13. High deviation

14. Volume curve

15. HDMI hotplug

16. HDMI hotplugclkcontrol

17. HDMI hotplugdelay

18. Hotel option

19. Shop mode

20. Color space

21. PC ident

22. Language

23. Ch. table

24. TTX group

25. iDTV country

8

2

Adjust

1. V Mute time

2. Dynamic contrast

3. Dynamic dimming

4. Dynamic CE

5. LNA plus

6. Magazine LNA

7. Pixelshift test

8. Debug

9. ACR

10. D-watchdog

11. UART select

12. FBE select

13. Tuner

14. Tuner TOP semco

15. Tuner TOP alp s

16. D.Gamma

17. M.Gamma

Power on

W/B Movie

1. WB movie

2. Color mode

3. Color tone

4. Msub bright

5. Msub contr

6. W1 R gain

7. W1 B gain

8. W1 R offset

9. W1 B offset

10. W2 R gain

11. W2 B gain

12. W2 R offset

13. W2 B offset

14. NO R gain

15. NO B gain

16. NO R offset

17. NO B offset

18. C2 R gain

19. C2 B gain

20. C2 R offset

21. C2 B offset

22. Movie contrast

23. Movie brightness

24. Movie color

25. Movie sharpness

26. Movie color tone

W1 Warm1 W2 Warm2

NO Normal C2 Cool2

- 7 -

Loading...

Loading...