Page 1

X

K

T

U

C

RC

(WD)

RC

(WL)

TRC

SC

85464359863005 ©SANYO 2007

– Split System Heat Pump Air Conditioner –

INSTALLATION INSTRUCTIONS

Model Combinations

Combine indoor and outdoor units only as listed below.

Indoor Units and Outdoor Units

* When air discharge chamber is installed.

OPERATING LIMITS

Maximum Conditions Cooling / Heating

Outdoor temperature : 109°F DB / 65°F WB

Room temperature : 71°F WB / 80°F DB

Minimum Conditions

Outdoor temperature : 0°F* DB / 5°F WB

Room temperature : 57°F WB / 59°F DB

Units should be installed by licensed contractor according to

local code requirements.

Indoor Unit Type 26 30 36 42 Remarks

X

4-Way Air Discharge

XH2672R XH3672R XH4272R Optional remote controller

Semi-Concealed

XHW2672R XHW3672R XHW4272R with Wired Remote Controller: RCS-TM80BG

KH2672R KH3072R KH3672R Optional remote controller

K Wall-Mounted

KHS2672R KHS3072R KHS3672R with Wireless Remote Controller: RCS-SH1UA

KHH2672R Optional remote controller

KHHS2672R

with Wireless Remote Controller: RCS-SH1UA

TH2672R TH3672R TH4272R Optional remote controller

THW2672R THW3672R THW4272R with Wired Remote Controller: RCS-TM80BG

T Ceiling-Mounted THH2672R THH3672R Unit with Back-up heater

THHW2672R THHW3672R

Unit with Back-up heater

with Wired Remote Controller: RCS-TM80BG

U Concealed-Duct

UH2672R UH3672R Optional remote controller

UHW2672R UHW3672R with Wired Remote Controller: RCS-TM80BG

C Outdoor Units

CH2672R CH3072R CH3672R CH4272R H/P

C2672R C3072R C3672R C4272R S/C

RC

Wired Remote

RCS-SH80UG (Optional part)

(WD)

Controller

RC Wireless Remote

Built-in type: RCS-SH80UA.WL (Optional part) for X and T type Indoor units

(WL)

Controller

External type: RCS-BH80UA.WL (Optional part) for U type Indoor units

Built-in type: RCS-SH80UA (Accessory part / Optional part) for K type Indoor units

Timer Remote

for X, T and U type Indoor units.

TRC

Controller

RCS-TM80BG* (Accessory part / Optional part)

* Timer Remote Controller comes with

Owner’s Manual and Installation Instructions.

SC System Controller SHA-KC64UG (Optional part)

SANYO Commercial Solutions In Canada

A division of SANYO North America Corporation SANYO Canada Inc.

Cornerstone Business Park 1-300 Applewood Crescent

1062 Thorndale Avenue Concord, Ontario

Bensenville, IL 60106, U.S.A. L4K 5C7, Canada

07-115 SSHP_II 5/7/07 3:59 PM Page a

Page 2

2

IMPORTANT!

Please Read Before Starting

This air conditioning system meets strict safety and operating

standards. As the installer or service person, it is an important part of your job to install or service the system so it operates safely and efficiently.

For safe installation and trouble-free operation, you must:

Carefully read this instruction booklet before beginning.

Follow each installation or repair step exactly as shown.

Observe all local, state, and national electrical codes.

Pay close attention to all warning and caution notices

given in this manual.

This symbol refers to a hazard or

unsafe practice which can result

in severe personal injury or death.

This symbol refers to a hazard or

unsafe practice which can result

in personal injury or product or

property damage.

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help for a

special problem, contact our sales/service outlet or your

certified dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for

improper installation or maintenance service, including failure to follow the instructions in this document.

SPECIAL PRECAUTIONS

When Wiring

ELECTRICAL SHOCK CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH. ONLY A

QUALIFIED, EXPERIENCED ELECTRICIAN

SHOULD ATTEMPT TO WIRE THIS SYSTEM.

• Do not supply power to the unit until all wiring and tubing

are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this system. Carefully refer to the wiring diagram and these

instructions when wiring. Improper connections and inadequate grounding can cause accidental injury or death.

• Ground the unit following local electrical codes.

• Connect all wiring tightly. Loose wiring may cause overheating at connection points and a possible fire hazard.

When Transporting

Be careful when picking up and moving the indoor and outdoor

units. Get a partner to help, and bend your knees when lifting to

reduce strain on your back. Sharp edges or thin aluminum fins

on the air conditioner can cut your fingers.

When Installing…

…In a Room

Properly insulate any tubing run inside a room to prevent

“sweating” that can cause dripping and water damage to

walls and floors.

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide a

solid, level foundation for the outdoor unit. This prevents

water damage and abnormal vibration.

…In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a

metal frame. Provide a suitable air baffle.

…In a Snowy Area (for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is higher

than drifting snow. Provide snow vents.

When Connecting Refrigerant Tubing

• Ventilate the room well, in the event that is refrigerant

gas leaks during the installation. Be careful not to allow

contact of the refrigerant gas with a flame as this will

cause the generation of poisonous gas.

• Keep all tubing runs as short as possible.

• Use the flare method for connecting tubing.

• Apply refrigerant lubricant to the matching surfaces of

the flare and union tubes before connecting them, then

tighten the nut with a torque wrench for a leak-free connection.

• Check carefully for leaks before starting the test run.

When Servicing

• Turn the power OFF at the main power box (mains)

before opening the unit to check or repair electrical parts

and wiring.

• Keep your fingers and clothing away from any moving

parts.

• Clean up the site after you finish, remembering to check

that no metal scraps or bits of wiring have been left

inside the unit being serviced.

• Ventilate any enclosed areas when installing or testing

the refrigeration system. Escaped refrigerant gas, on

contact with fire or heat, can produce dangerously toxic

gas.

• Confirm after installation that no refrigerant gas is leaking. If the gas comes in contact with a burning stove, gas

water heater, electric room heater or other heat source,

it can cause the generation of poisonous gas.

07-115 SSHP_II 5/7/07 3:59 PM Page 2

WARNING

CAUTION

WARNING

CAUTION

Page 3

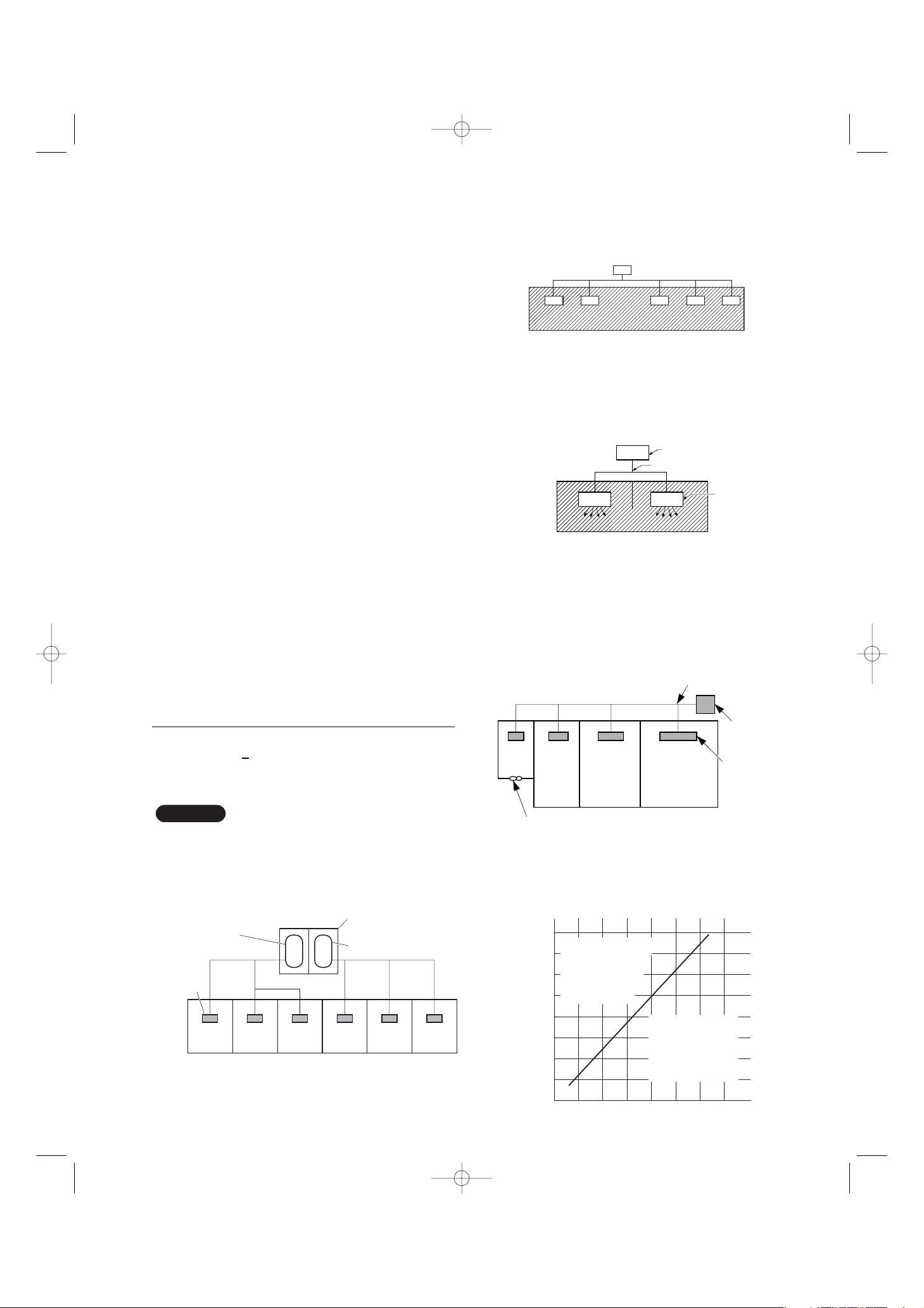

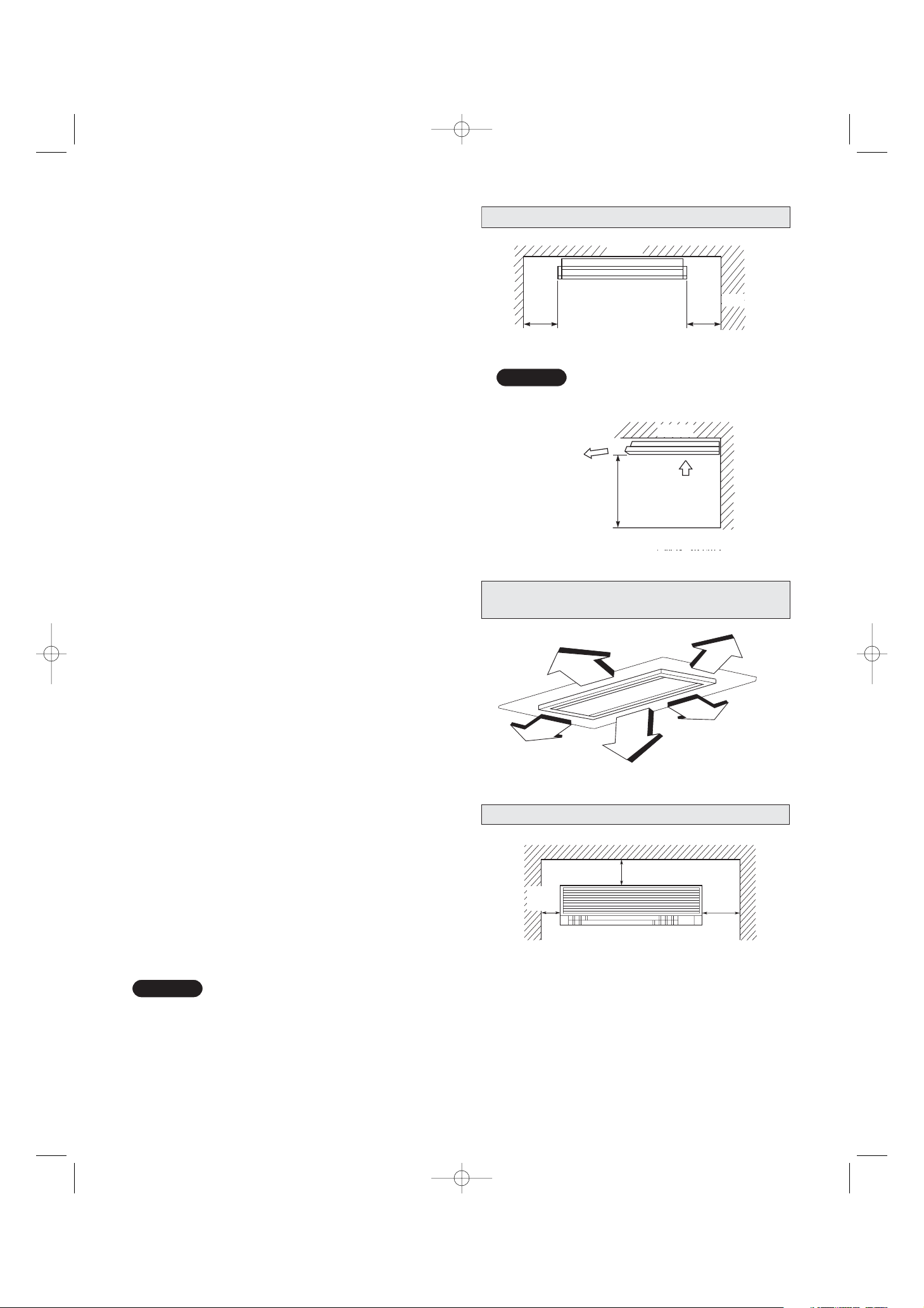

2. The standards for minimum room volume are as

follows.

(1) No partition (shaded portion)

(2) When there is an effective opening with the adja-

cent room for ventilation of leaking refrigerant gas

(opening without a door, or an opening 0.15% or

larger than the respective floor spaces at the top

or bottom of the door).

(3) If an indoor unit is installed in each partitioned

room and the refrigerant tubing is interconnected,

the smallest room of course becomes the object.

But when mechanical ventilation is installed interlocked with a gas leakage detector in the smallest

room where the density limit is exceeded, the volume of the next smallest room becomes the object.

3. The minimum indoor floor space compared with the

amount of refrigerant is roughly as follows (when

the ceiling is 9 ft. high):

Check of Density Limit

The room in which the air conditioner is to be

installed requires a design that in the event of

refrigerant gas leaking out, its density will not

exceed a set limit.

The refrigerant (R410A), which is used in the air conditioner, is safe, without the toxicity or combustibility of

ammonia, and is not restricted by laws imposed to protect the ozone layer. However, since it contains more

than air, it poses the risk of suffocation if its density

should rise excessively. Suffocation from leakage of

refrigerant is almost non-existent. With the recent

increase in the number of high density buildings, however, the installation of multi air conditioner systems is

on the increase because of the need for effective use

of floor space, individual control, energy conservation

by curtailing heat and carrying power, etc.

Most importantly, the multi air conditioner system is

able to replenish a large amount of refrigerant compared to conventional individual air conditioners. If a

single unit of the multi air conditioner system is to be

installed in a small room, select a suitable model and

installation procedure so that if the refrigerant accidentally leaks out, its density does not reach the limit

(and in the event of an emergency, measures can be

made before injury can occur).

In a room where the density may exceed the limit,

create an opening with adjacent rooms, or install

mechanical ventilation combined with a gas leak

detection device. The density is as given below.

Total amount of refrigerant (oz.)

Min. volume of the indoor unit installed room (ft.3)

< Density limit (oz./ft.

3

)

The density limit of refrigerant which is used in multi air conditioners is 0.3 oz./ft.

3

(ISO 5149).

1. If there are 2 or more refrigerating systems in a single refrigerating device, the amount of refrigerant

should be as charged in each independent device.

For the amount of charge in this example:

The possible amount of leaked refrigerant gas in rooms

A, B and C is 22 lbs.

The possible amount of leaked refrigerant gas in rooms

D, E and F is 33 lbs.

3

07-115 SSHP_II 5/7/07 3:59 PM Page 3

NOTE

Outdoor unit

Refrigerant tubing

Refrigerant tubing

Very

small

room

Small

room

Mechanical ventilation device – Gas leak detector

Medium

room

Large room

Indoor unit

Outdoor unit

Indoor unit

e.g., charged

amount (22 lbs.)

Indoor unit

Outdoor unit

e.g., charged

amount (33 lbs.)

Room A Room B Room C Room D Room E Room F

3

ft.

430

Range below the

376

density limit

of 0.3 oz./ft.

323

(countermeasures

not needed)

269

215

161

108

Min. indoor floor space

54

0

3

Range above

the density limit

of 0.3 oz./ft.

(countermeasures

needed)

22 44 66

Total amount of refrigerant

3

lbs.

Page 4

4

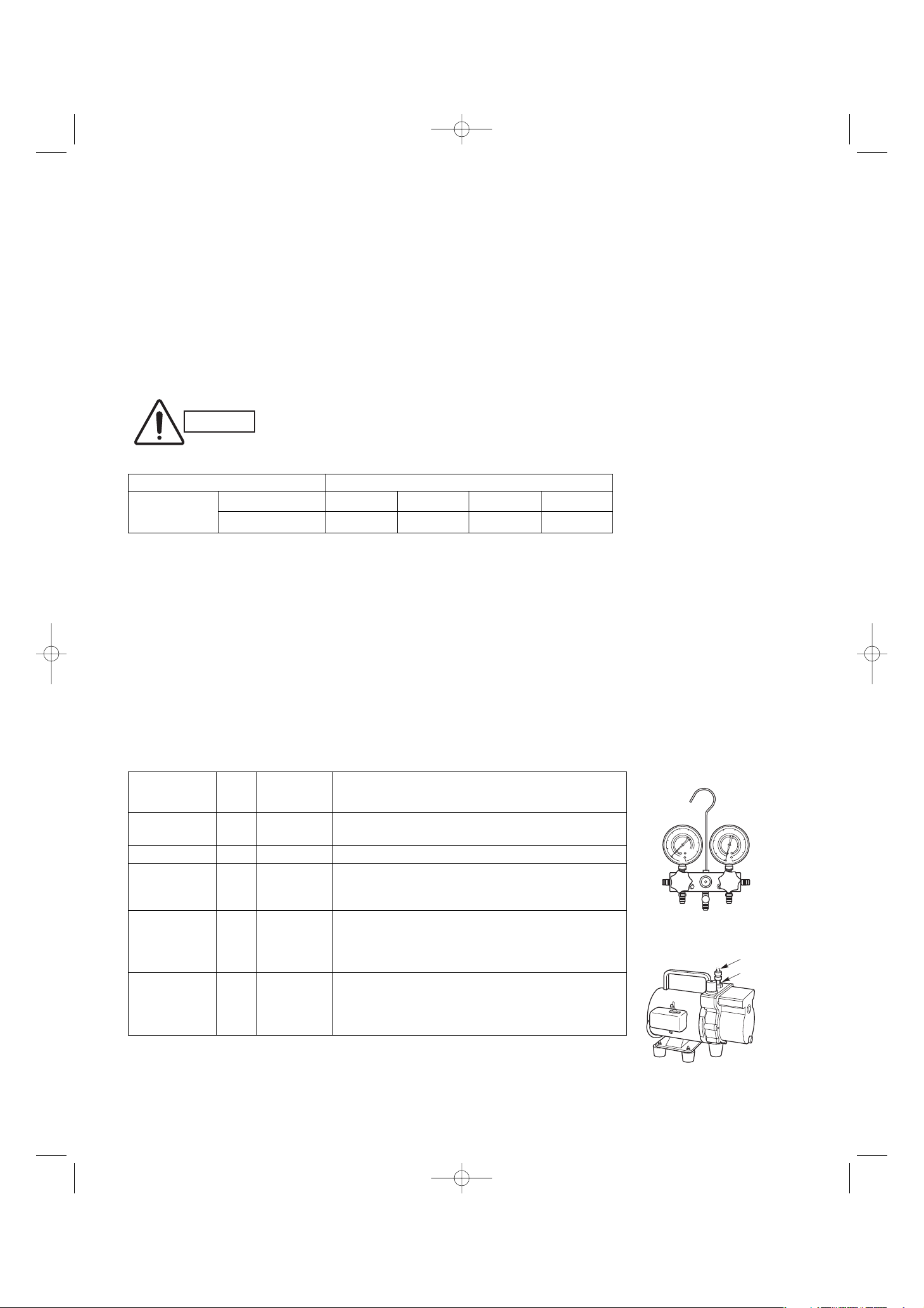

R407C tools

Item compatible Remarks

with R410A?

Manifold gauge Yes No Types of refrigerant, refrigerating machine oil, and

pressure gauge are different.

Charge hose Yes No To resist higher pressure, material must be changed.

Vacuum pump Yes Yes Use a conventional vacuum pump if it is equipped

with a check valve. If it has no check valve,

purchase and attach a vacuum pump adapter.

Leak detector Yes No Leak detectors for CFC and HCFC that

react to chlorine do not function because

R410A contains no chlorine. Leak detector

for HFC134a can be used for R410A.

Flaring oil Yes No For systems that use R22, apply mineral oil (Suniso oil)

to the flare nuts on the tubing to prevent refrigerant

leakage. For machines that use R407C or R410A, apply

synthetic oil (ether oil) to the flare nuts.

1-2. Prevent impurities including water, dust and oxide from entering the tubing. Impurities can cause R410A

refrigerant deterioration and compressor defects. Due to the features of the refrigerant and refrigerating

machine oil, the prevention of water and other impurities becomes more important than ever.

2. Be sure to recharge the refrigerant only in liquid form.

2-1. Since R410A is a non-azeotrope, recharging the refrigerant in gas form can lower performance and cause

defects of the unit.

2-2. Since refrigerant composition changes and performance decreases when gas leaks, collect the remaining

refrigerant and recharge the required total amount of new refrigerant after fixing the leak.

3. Different tools required

3-1. Tool specifications have been changed due to the characteristics of R410A.

Some tools for R22- and R407C-type refrigerant systems cannot be used.

Unit: inch

Material O

Copper tube

Outer diameter 1/4 3/8 1/2 5/8

Wall thickness 1/32 1/32 1/32 5/128

Precautions for Installation Using New Refrigerant

1. Care regarding tubing

1-1. Process tubing

Material: Use C1220 phosphorous deoxidized copper specified in JIS H3300 “Copper and Copper Alloy Seam-

less Pipes and Tubes.”

Tubing size: Be sure to use the sizes indicated in the table below.

Use a tube cutter when cutting the tubing, and be sure to remove any flash. This also applies to distribution

joints (optional).

When bending tubing ø5/8" or smaller, use a bending radius that is 4 times the outer diameter of the tubing or larger.

* Using tools for R22 and R407C and new tools for R410A together can cause defects.

Use sufficient care in handling the tubing. Seal the tubing ends with

caps or tape to prevent dirt, moisture, or other foreign substances

from entering. These substances can result in system malfunction.

New

tool?

07-115 SSHP_II 5/7/07 3:59 PM Page 4

CAUTION

Manifold gauge

Vacuum pump

Outlet

Inlet

Page 5

5

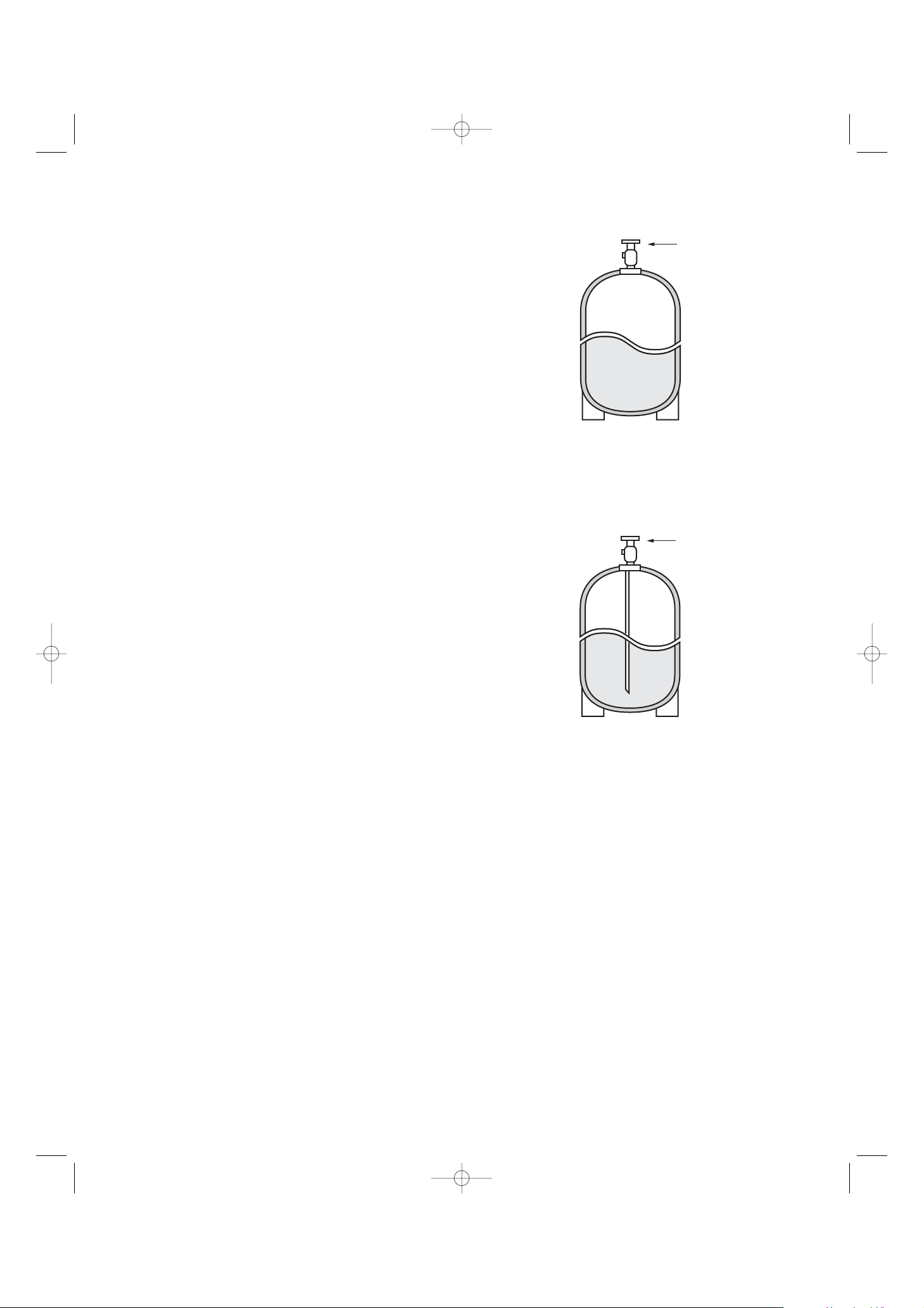

3-2. Use R410A exclusive cylinder only.

When charging with a refrigerant cylinder, use an

electronic scale for charging refrigerant. In this

case, if the volume of refrigerant in the cylinder

becomes less than 20% of the fully-charged

amount, the composition of the refrigerant starts

to change. Thus, do not use the refrigerant if the

amount in the charging cylinder is less than 20%.

Also, charge the minimum necessary amount to

the charging cylinder before using it to charge the

air conditioning unit.

07-115 SSHP_II 5/7/07 3:59 PM Page 5

Configuration and characteristics of cylinders

Valve

Liquid

Single valve

Charge liquid refrigerant with

cylinder in up-side-down position.

Fig. 1

Valve

Liquid

Single valve (with siphon tube)

Charge with cylinder in normal position.

Fig. 2

Page 6

6

Concealed-Duct Type (U Type) . . . . . . . . . . . . . . 51

3-22. Required Minimum Space for Installation and

Service

3-23. Suspending the Indoor Unit

3-24. Installing the Drain Piping

3-25. Checking the Drainage

3-26. Increasing the Fan Speed

4.

HOW TO INSTALL THE OUTDOOR UNIT

. . . . . 56

4-1. Installing the Outdoor Unit

4-2. Drainage Work

4-3. Routing the Tubing and Wiring

5. ELECTRICAL WIRING . . . . . . . . . . . . . . . . . . . . 57

5-1. General Precautions on Wiring

5-2. Recommended Wire Length and Wire

Diameter for Power Supply System

5-3. Wiring System Diagrams

5-4. How to Connect Wiring to the Terminal

6. HOW TO INSTALL THE WIRED REMOTE

CONTROLLER (OPTIONAL PART) . . . . . . . . . . 60

6-1. Installation Site Selection

6-2. Wired Remote Controller Installation

6-3. Basic Wiring Diagram

6-4. Wiring System Diagram for Group Control

6-5. Wiring System Diagram for Multiple Remote

Controllers

6-6. How to Switch the Indoor Temperature Sensor

6-7. Trouble Diagnostics

7. HOW TO INSTALL THE WIRELESS REMOTE

CONTROLLER

(ACCESSORY PART / OPTIONAL PART) . . . . . 68

7-1. Wireless Remote Controller Installation

7-2. Room Temperature Sensor Setting

7-3. Address Switches

7-4. Setting the Model Code

<RCS-SH80UA.WL>

4-Way Air Discharge Semi-Concealed Type

(X Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7-5. Indicator Section Installation

7-6. Operating Controller Installation

Ceiling-Mounted Type (T Type) . . . . . . . . . . . . . . 71

7-7. Indicator Section Installation

7-8. Operating Controller Installation

7-9. Electrical Wiring

7-10. Test Run Switch

7-11. Misoperation Alarm Indicators

Page

IMPORTANT! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Please Read Before Starting

Check of Density Limit

Precautions for Installation Using New Refrigerant

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-1. Tools Required for Installation (not supplied)

1-2. Accessories Supplied with Outdoor Unit

1-3. Type of Copper Tube and Insulation Material

1-4. Additional Materials Required for Installation

1-5. Tubing Size

2. SELECTING THE INSTALLATION SITE . . . . . . 16

2-1. Indoor Unit

2-2. Outdoor Unit

2-3. Air-Discharge Chamber for Top Discharge

2-4. Installing the Unit in Heavy Snow Areas

2-5. Precautions for Installation in Heavy Snow

Areas

2-6. Dimensions of Wind Ducting

2-7. Dimensions of Snow Ducting

3. HOW TO INSTALL THE INDOOR UNIT . . . . . . . 26

4-Way Air Discharge Semi-Concealed Type

(X Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3-1. Suspending the Indoor Unit

3-2. Preparation for Suspending

3-3. Placing the Unit Inside the Ceiling

3-4. Installing the Drain Piping

3-5. Checking the Drainage

3-6. Before Installing the Ceiling Panel

3-7. Installing the Ceiling Panel

3-8. When Removing the Ceiling Panel

for Servicing

3-9. Duct for Fresh Air

Wall-Mounted Type (K Type) . . . . . . . . . . . . . . . . 34

3-10. Removing the Wall Fixture from the Unit

3-11. Selecting and Making a Hole

3-12. Installing the Rear Panel on the Wall

3-13. Removing the Grille to Install the Indoor Unit

3-14. Preparing the Indoor Side Tubing

3-15. Wiring Instructions

3-16. Wiring Instructions for Inter-Unit Connections

3-17. Shaping the Tubing

3-18. Installing the Drain Hose

Ceiling-Mounted Type (T Type) . . . . . . . . . . . . . . 47

3-19. Suspending the Indoor Unit

3-20. Duct for Fresh Air

3-21. Installing the Drain Piping

CONTENTS

Page

07-115 SSHP_II 5/7/07 3:59 PM Page 6

Page 7

7

<RCS-BH80UA.WL>

7-12. Separate Type Signal Receiving Unit Installation

7-13. Electrical Wiring

7-14. Test Run Switch

7-15. Misoperation Alarm Indicators

7-16. Basic Wiring Diagram

7-17. Wiring System Diagram for Group Control

7-18. Wiring System Diagram for Multiple Remote Controllers

<RCS-SH1UA>

7-19. Test Run Procedure

7-20. Check Items Before the Test Run

7-21. Preparing for the Test Run

7-22. Precautions

7-23. When Setting Indoor Unit Control PCB Switch for

Wall-Mounted Indoor Unit

8. HOW TO INSTALL THE SYSTEM CONTROLLER

(OPTIONAL PART) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8-1. System Controller Installation

8-2. Electrical Wiring

8-3. Address Switch Setting

8-4. Mode Setting

8-5. How to Perform Zone Registration

8-6. Connection with Other Equipment

8-7. Memory Back Up Switch

8-8. Test Run

9. HOW TO PROCESS TUBING . . . . . . . . . . . . . . . . . . . . . . . . . 97

9-1. Connecting the Refrigerant Tubing

9-2. Connecting Tubing between Indoor and

Outdoor Units

9-3. Insulating the Refrigerant Tubing

9-4. Taping the Tubes

9-5. Finishing the Installation

10. LEAK TEST, EVACUATION AND ADDITIONAL

REFRIGERANT CHARGE . . . . . . . . . . . . . . . . . . . . . . . . . 101

10-1. Leak Test

10-2. Evacuation

10-3. Charging Additional Refrigerant

10-4. Finishing the Job

11. TEST RUN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

11-1. Preparing for Test Run

11-2. Caution

11-3. Test Run Procedure

11-4. Items to Check Before the Test Run

11-5. Test Run Using the Remote Controller

11-6. Precautions

11-7. Table of Self-Diagnostic Functions and Corrections

(X, T, U, K Type)

11-8. Examples of Wiring Diagrams

Page

07-115 SSHP_II 5/7/07 3:59 PM Page 7

Page 8

8

1. GENERAL

This booklet briefly outlines where and how to install

the air conditioning system. Please read over the

entire set of instructions for the indoor and outdoor

units and make sure all accessory parts listed are

with the system before beginning.

1-1. Tools Required for Installation (not supplied)

1. Standard screwdriver

2. Phillips head screwdriver

3. Knife or wire stripper

4. Tape measure

5. Level

6. Sabre saw or key hole saw

7. Hacksaw

8. Core bits

9. Hammer

10. Drill

11. Tube cutter

12. Tube flaring tool

13. Torque wrench

14. Adjustable wrench

15. Reamer (for deburring)

1-2. Accessories Supplied with Outdoor Unit

See Tables 1-1 to 1-9.

1-3. Type of Copper Tube and Insulation Material

Copper tubing for connecting the outdoor unit to the

indoor unit is available in kits which contain the liquid

and gas tubing, fittings and insulation. Consult your

nearest sales outlet or A/C workshop.

If you wish to purchase these materials separately

from a local source, you will need:

1. Deoxidized annealed copper tube for refrigerant

tubing.

2. Foamed polyethylene insulation for copper tubes

as required to precise length of tubing.

Wall thickness of the insulation should be not less

than 5/16 in.

3. Use insulated copper wire for field wiring. Wire size

varies with the total length of wiring. Refer to

Section 5. “Electrical Wiring” for details.

1-4. Additional Materials Required for Installation

1. Refrigeration (armored) tape

2. Insulated staples or clamps for connecting wire

(See your local codes.)

3. Putty

4. Refrigeration tubing lubricant

5. Clamps or saddles to secure refrigerant tubing

6. Scale for weighing

Check local electrical codes

and regulations before

obtaining wire. Also, check

any specified instructions

or limitations.

Table Type

1-1 4-Way Air Discharge Semi-Concealed

1-2 Wall-Mounted

1-3 Ceiling-Mounted

1-4 Concealed-Duct

1-5 Outdoor Unit

1-6 Wired Remote Controller

1-7 Wireless Remote Controller

1-8 Timer Remote Controller

1-9 System Controller

07-115 SSHP_II 5/7/07 3:59 PM Page 8

CAUTION

Page 9

9

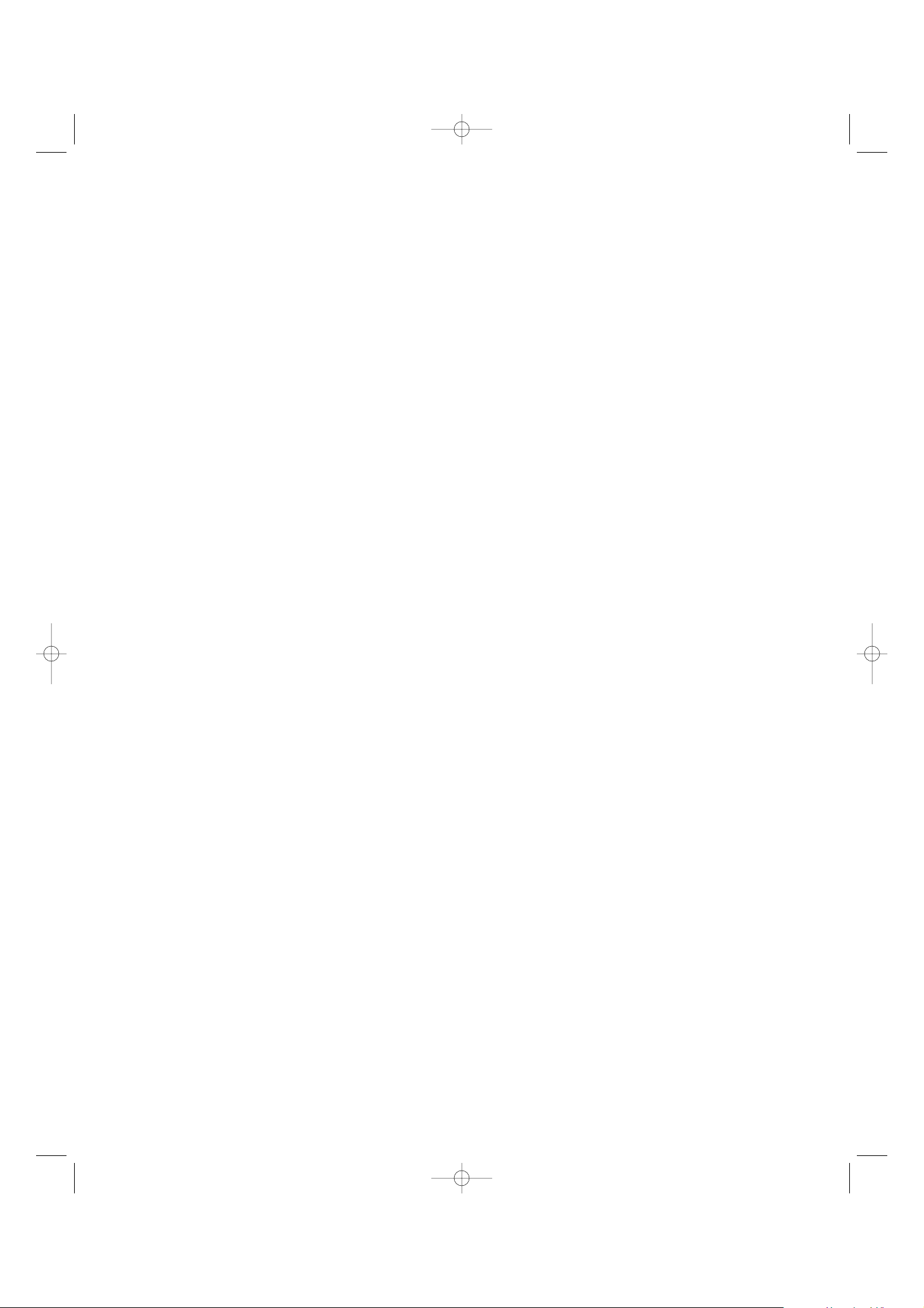

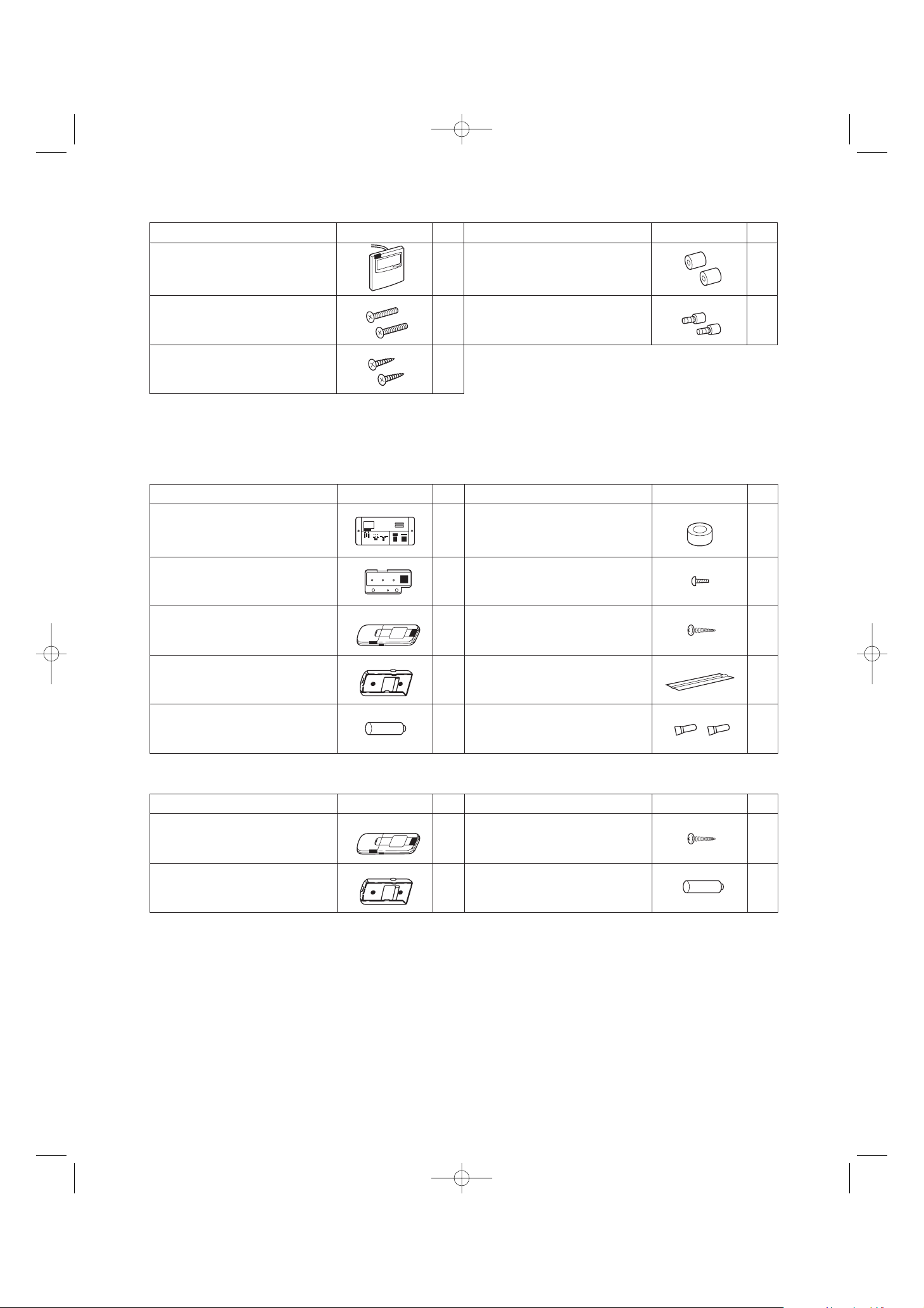

Table 1-2 KH / KHS (Wall-Mounted)

Table 1-1 XH / XHW (4-Way Air Discharge Semi-Concealed)

07-115 SSHP_II 5/7/07 3:59 PM Page 9

Part Name Figure

Full-scale installation diagram 1

Flare insulator 2

Washer 8

Insulating tape 1

(White)

Hose band2

Packing 1

Drain insulator 1

Drain hose1

Drain hose adaptor 1

Sealing putty 1

Tube connector 1

Wired remote controller

(comes with 7-7/8 in. wire)

Wood screws 2

Wire joints

Owner’s Manual 1

Installation Instructions 1

Q’ty

For determining suspension bolt pitch

For gas and liquid tubes

For suspending indoor unit from ceiling

For gas tube flare nuts

For securing drain hose

For drain joint

For drain joint

For drain outlet

For sealing recessed portion of power supply

For sizing up of liquid tube from 1/4 in. to 3

(only for 26 type)

1

For XHW type

For XHW type

For XHW type

2

For XHW type

For XHW type

Remarks

/8 in.

Part Name Figure Remarks

Wall fixture

Insulator

Mounting plate

Tapping screw

*1

*1

*1

*1

Truss-head

Phillips

4 × 1 in.

Full-scale diagram

Wall fixture

Rawl plug

Cover

Tapping screw

Insulator

Tube connector

L shape tube connector

*2

*2

*2

*2

*2

Truss-head

Phillips

4× 5/8 in.

‘Q’ty

For supporting indoor unit

1

1

For insulation of tubing of the indoor unit

For securing indoor unit

1

For attaching wall fixture

20

For determining location where indoor unit is

1

installed

1

For supporting indoor unit

10

For attaching wall fixture

1

For improved tubing appearance

10

For attaching wall fixture

1

For insulation of tubing of indoor unit

For sizing up of liquid t

1

(only for 26 type)

Simplifies on-site tubing work

1

ube from 1/4 in. to 3/8 in.

Wireless remote controller 1

Wireless remote controller

mounting cradle

Tr uss-head tapping screws

4 × 5/8 in.

Batteries

*1

KH(S)3672R

*2

KH(S)3072R

KH(S)3672R

For KHS type

For KHS type

1

2

For KHS type

2

For KHS type

Page 10

10

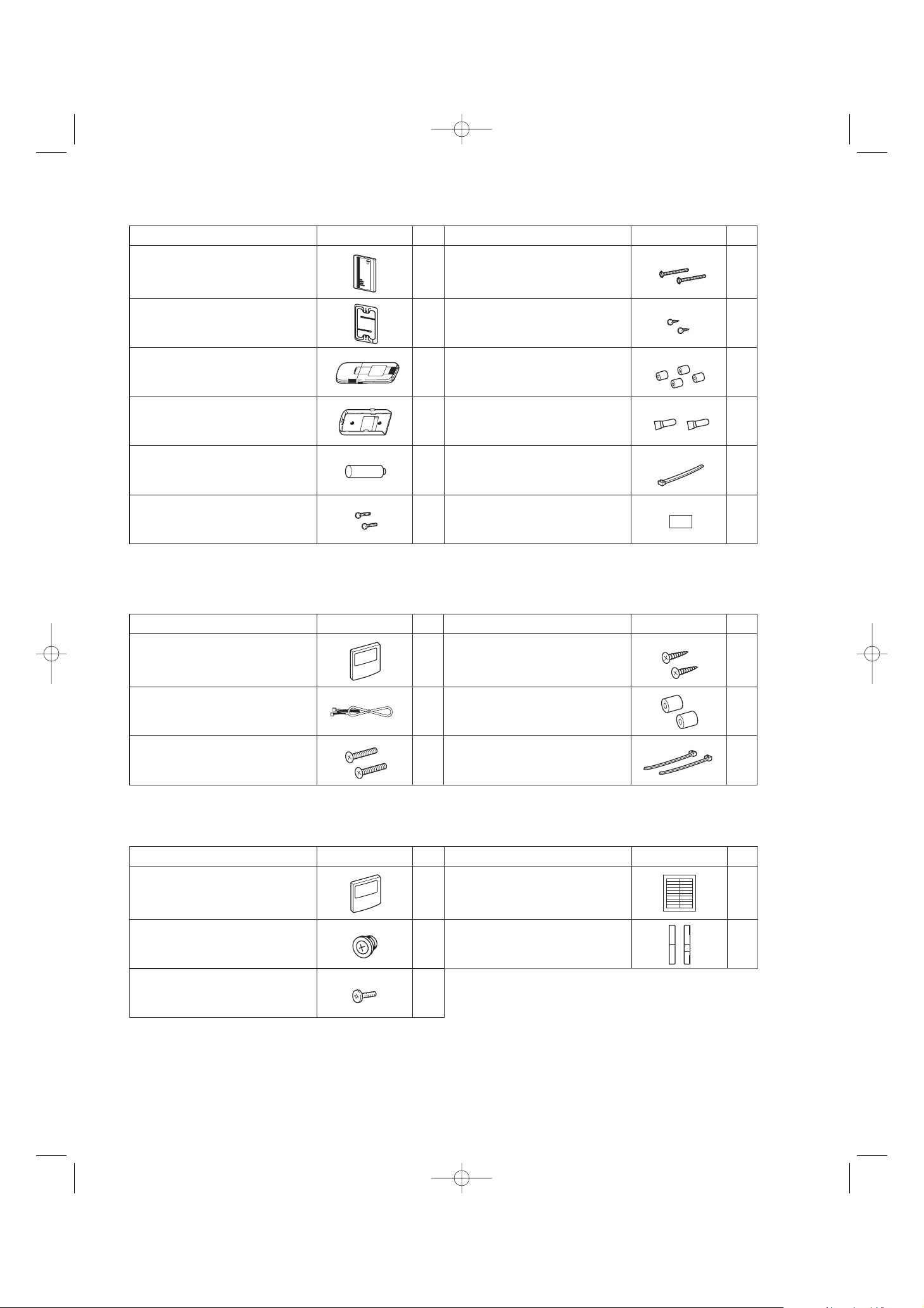

Table1-4 UH / UHW (Concealed-Duct)

Table 1-3 TH / THW (Ceiling-Mounted)

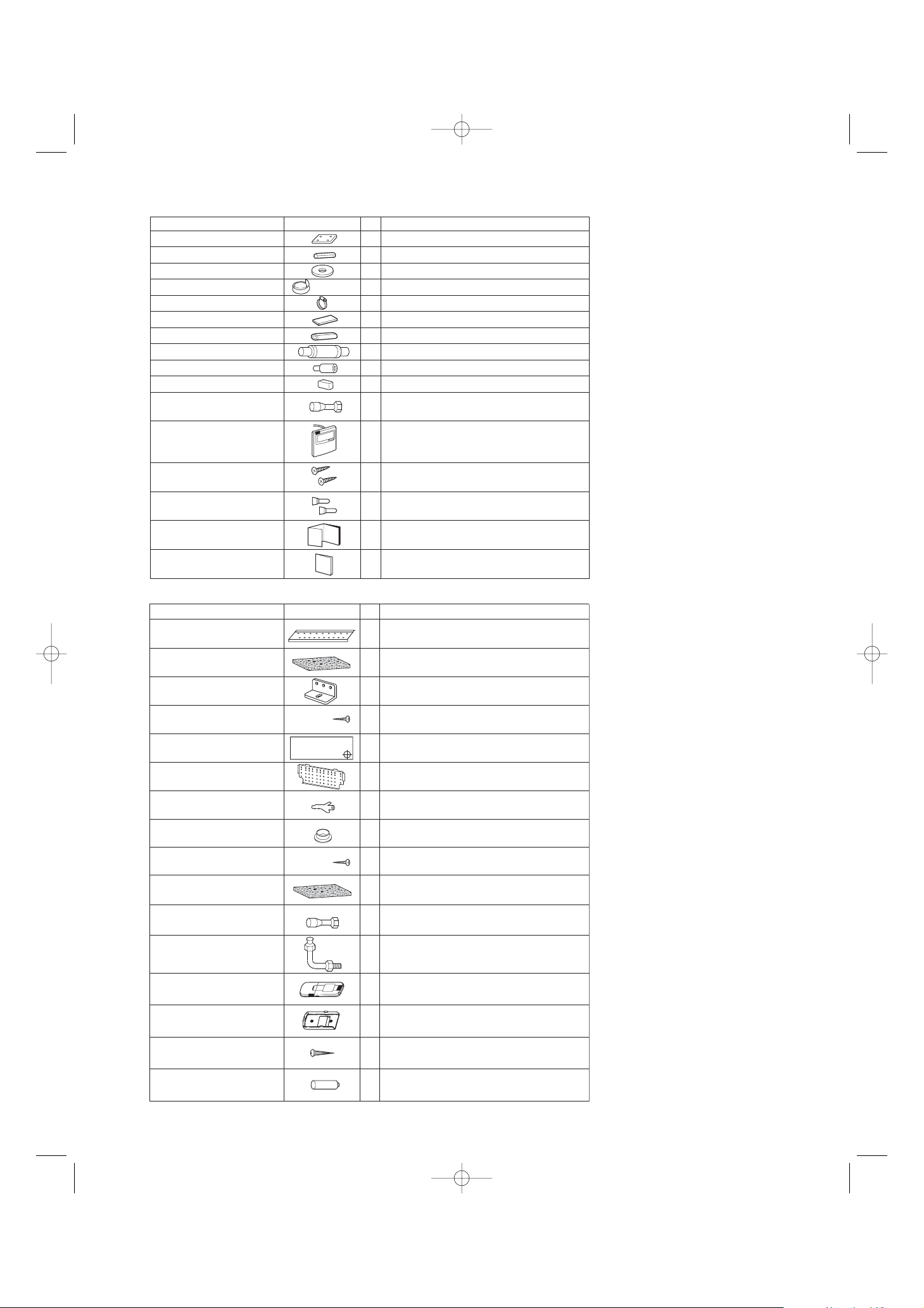

07-115 SSHP_II 5/7/07 3:59 PM Page 10

Part Name Figure Remarks

Special washer

Drain insulator 1

Flare insulator

T5

Drain hose adaptor 1

Drain hose clamp 4

Insulating tape

Vinyl clamp 2

Full-scale installation

diagram

Sealing putty 1

Drain hose1

Tube connector 1

Wired remote controller

(comes with 7-7/8 in. wire)

Wood screws 2

Wire joints

Owner’s Manual 1

Black

White

(heat-resisting)

‘Q’ty

For temporarily suspending indoor unit

4

from ceiling

For drain hose joint

T3

1 Set

For gas tube joints

For gas tube and drain hose joint

2

For gas flare joints

1

For ends of flare insulator

For determining suspension bolt pitch

1

For sealing recessed portion of power supply

For sizing up of liquid tube from 1/4 in. to 3/8 in.

(only for 26 type)

1

For THW type

For THW type

For THW type

2

For THW type

Installation Instructions 1

Part Name Figure

Flare insulator 2

Insulating tape

Tapping screw TOTA4-10

Jumper cable* 1

Hose band1

Packing 1

Sealing putty 1

Drain insulator 1

Drain hose1

Drain hose adaptor 1

Clamp 9

Tube connector 1

Wired remote controller

(comes with 7-7/8 in. wire)

Wood screws 2

(Black)

(White)

For THW type

‘Q’ty

2

2

14 or 20 or 24

1

Remarks

For gas and liquid tubes

For gas and liquid tubes

For gas and liquid tube flare nuts

For air intake duct connection

For increasing fan speed

For securing

drain hose

For drain joint

For sealing recessed portion of power supply

For drain joint

For securing drain hose & refrigerant tubing

For sizing up of liquid tube from 1/4 in. to 3/8 in.

(only for 26 type)

For UHW type

For UHW type

Wire joints

2

Owner’s Manual 1

Installation Instructions 1

* Jumper cable is housed inside the electrical component box.

For UHW type

For UHW type

For UHW type

Page 11

11

07-115 SSHP_II 5/7/07 3:59 PM Page 11

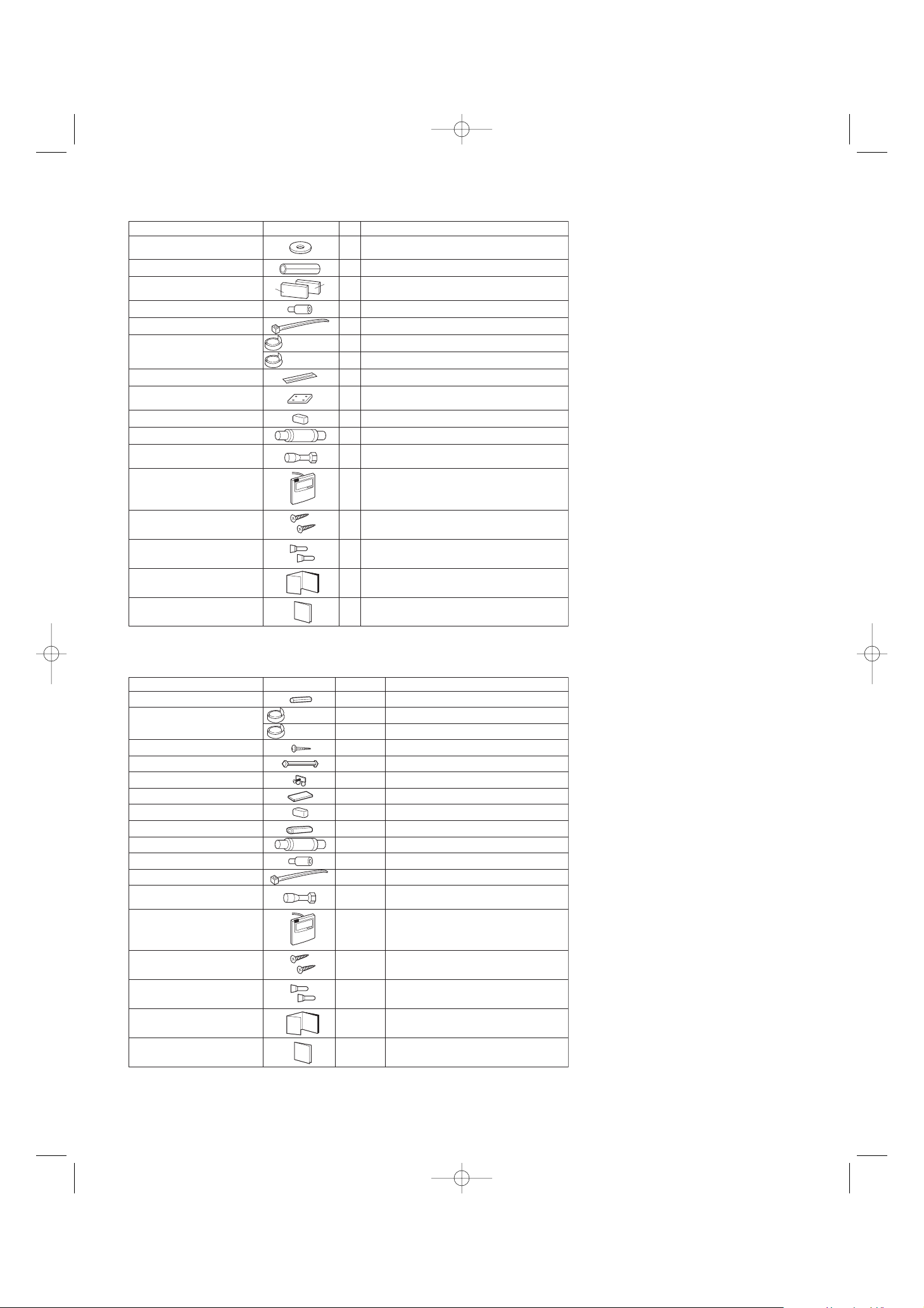

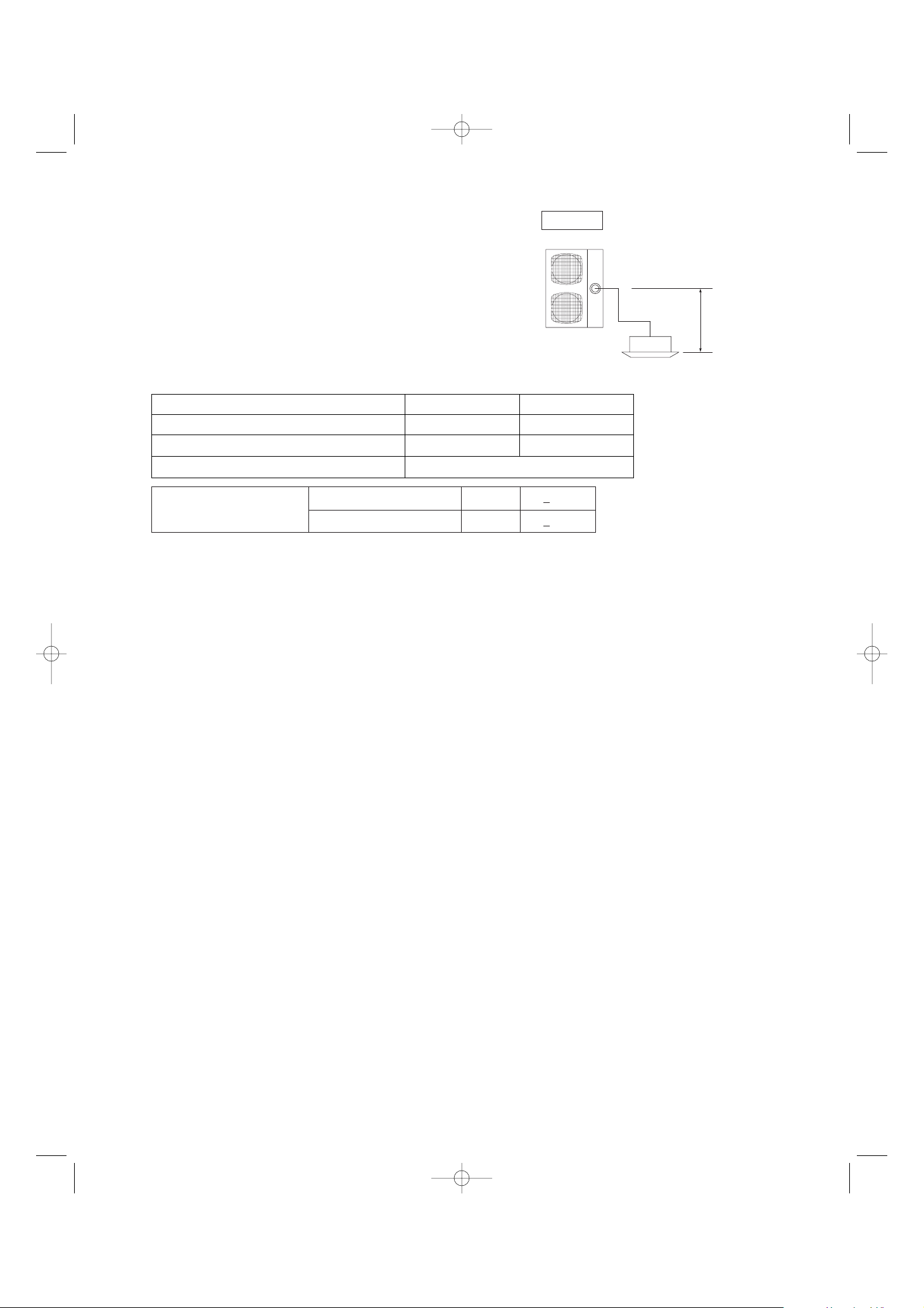

Table 1-5 (Accessories for the Wired Remote Controller)

Part Name Figure

Wired remote controller

(comes with 7-7/8 in. wire)

Machine screws

M4 × 1 in.

‘Q’ty

1 Spacers 2

2 Wire joints 4

Part Name Figure

‘Q’ty

Wood screws 2

Table 1-6 (Accessories for the Wireless Remote Controller)

<RCS-SH80UA.WL>

Part Name Figure

‘Q’ty

Part Name Figure

‘Q’ty

Operation controller 1 Spacers 2

Run Timer

Indicator section 14

Heating preparations

Pan-head tapping screws

4× 13/32 in.

Wireless remote controller 1 2

Wireless remote controller

mounting cradle

Tr uss-head tapping screws

4 × 5/8 in.

Vinyl clamps

1 3

L 5-29/32

Batteries 2 Wire joints 4

<RCS-SH1UA>

Part Name Figure Part Name Figure

Wireless remote controller 1 2

Wireless remote controller

‘Q’ty ‘Q’ty

Tr uss-head tapping screws

4 × 5/8 in.

12

Batteries

mounting cradle

Page 12

12

07-115 SSHP_II 5/7/07 3:59 PM Page 12

<RCS-BH80UA.WL>

Part Name Figure

Separate type signal receiving unit

(comes with 7-7/8 in. wire)

‘Q’ty

Small screws

12

M4 × 1-9/16 in.

Part Name Figure

Carrier for ceiling installation 1Wood screws 2

Wireless remote controller 1 Spacers 4

Wireless remote controller

1 Wire joints 4

mounting cradle

Batteries 2 Clamp

Machine screws

M4 × 1 in.

Ceiling installation paper pattern

21

(

3-3/4 × 2-1/32 in.

)

Table 1-7 (Accessories for the Timer Remote Controller)

‘Q’ty

1

Part Name Figure

Timer Remote Controller

Connecting wiring

length 4 ft.

Machine screws

‘Q’ty

Part Name Figure

1Wood screws

1 Spacers 2

2 Clamps

M4 × 1 in.

Table 1-8 (Accessories for the System Controller)

Part Name Figure

System controller 1 1

Rubber bushing

(7/8 in.)

Screws for fixture

(1-3/16 in.)

‘Q’ty

Label

(Identification label)

Label

41

(Terminal base label)

Part Name Figure

SYSTEM CONTROLLER IDENTIFICATION LABEL

ALL Central Control ALL RCU.

ZONE1 Central Control

ZONE1 RCU.

ZONE2 RCU.

ZONE2 Central Control

ZONE3 Central Control

ZONE3 RCU.

ZONE4 Central Control

ZONE4 RCU.

*Please attach this label on surface of the lid after cleaning.

*If need to write down some detail, use magic marker.

ALL ON

U1

INPUT

Interunit

control

wiring

ALL OFF

U2

INPUT

COMMON

U2 Aux.

INPUT

OPERATION

STATE

UNUSED

OUTPUT

ALARM

OUTPUT

DC12V

FROM

INDOOR

UNIT PCB.

COMMON

OUTPUT

2

‘Q’ty

2

2

‘Q’ty

Page 13

13

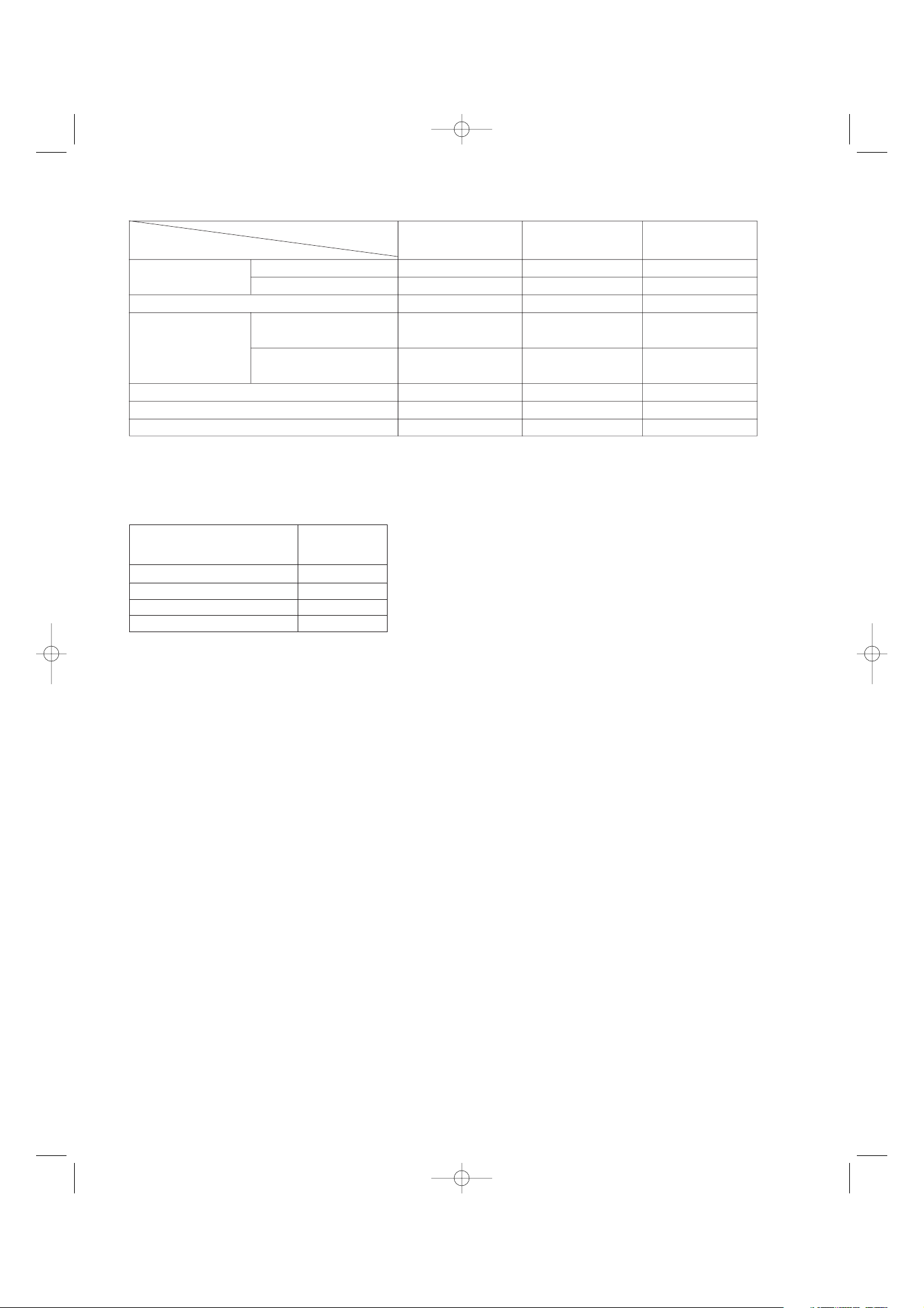

1-5. Tubing Size

Single type

Refrigerant tubing between the indoor and outdoor units

should be kept as short as possible.

The length of the refrigerant tubes between the indoor

and outdoor units are limited by the elevation difference

between the 2 units. During tubing work, try to make both

the tubing length (L) and the difference in elevation (H1)

as short as possible. Refer to Table 1-10.

Table 1-9

Indoor unit type 26, 30, 36 types 42 type

Maximum length 165 ft. 165 ft.

Charge-less tubing length (actual length) 10 – 100 ft. 15 – 100 ft.

Additional charge per 1 ft. 0.43 oz.

07-115 SSHP_II 5/7/07 3:59 PM Page 13

Single

Maximum indoor-outdoor

height difference

If outdoor unit is higher

If outdoor unit is lower

H1

H1

< 100

< 50

Main tubing L

H1

Page 14

14

Table 1-10 Tubing Data for Models

Table 1-11 List of Connection Tube Sizes

07-115 SSHP_II 5/7/07 3:59 PM Page 14

Tubing Data

Tubing size

outer diameter

Liquid tube in. (mm) 3/8 (9.52) 3/8 (9.52) 3/8 (9.52)

Gas tube in. (mm) 5/8 (15.88) 5/8 (15.88) 5/8 (15.88)

Limit of tubing length (ft.)

Limit of elevation

difference between

the 2 units

Outdoor unit is placed

higher (ft.)

Outdoor unit is placed

lower (ft.)

Max. allowable tubing length at shipment (ft.)

Required additional refrigerant *

Refrigerant charged at shipment (lbs.) 4.2 6.2 7.9

No additional charge of compressor oil is necessary.

1

*

If total tubing length becomes 100 to 165 ft., charge additional refrigerant by 0.43 oz./ft.

Type capacity of indoor units

Gas tube

Liquid tube

Amount of additional charge per 1 ft.

Models

1

Main tubing (L)

(oz./ft.)

26 – 42

ø5/8"

ø3/8"

0.43 oz.

C(H)2672R

C(H)3072R

C(H)3672R

C(H)4272R

165 165 165

100 100 100

50 50 50

10 – 100 10 – 100 10 – 100

a) 0.43 b) 0.43 b) 0.43

Page 15

15

1. This unit requires no additional refrigerant charge up to 100 ft. tubing length.

In case of more than 100 ft., additional

refrigerant charge is required. Refer to

Table 1-11.

2. In case of multi type installation,

indoor units should be installed within

the same room. If multi type indoor

units are installed in different rooms,

temperature control may develop problems because thermostat operation

must follow the thermostat condition of

1 indoor unit only (the main unit).

Always check the gas density

for the room in which the unit is

installed.

Pay special attention to any

location, such as a basement

or recessed area, etc. where

leaked refrigerant can collect,

since refrigerant gas is heavier than air.

Check of limit density

When installing an air conditioner in a room, it is necessary to ensure that even if the refrigerant gas accidentally escapes, its density does not exceed the limit level.

If the density might exceed the limit level, it is necessary to set up an opening between it and the adjacent

room, or to install mechanical ventilation which is interlocked with the leak detector.

(Total refrigerant charged amount: oz.)

(Min indoor volume where the indoor unit is installed: ft.3)

<

Limit density 0.3 (oz./ft.3)

The limit density of refrigerant which is used in this unit

is 0.3 oz./ft.

3

(ISO 5149).

The shipped outdoor unit comes charged with the

amount of refrigerant fixed for each type; so add it to

the amount that is charged at the field. (For the refrigerant charge amount at shipment, refer to the unit’s

nameplate.)

Minimum indoor volume & floor area relative to

the amount of refrigerant is roughly as given in

the following table.

07-115 SSHP_II 5/7/07 3:59 PM Page 15

CAUTION

WARNING

2

ft.

538

484

430

376

323

269

215

161

Min. indoor floor area

(when the ceiling is 9 ft. high)

108

54

3

ft.

4,842

4,356

3,870

3,384

2,907

2,421

1,935

1,449

Min. indoor volume

Range below the

density limit of

0.3 oz./ft.

(Countermeasures

not needed)

972

486

22

Total amount of refrigerant

3

44 66 88 lbs.

CAUTION

Range above the

density limit of

0.3 oz./ft.

(Countermeasures

needed)

3

Page 16

16

2. SELECTING THE INSTALLATION SITE

2-1. Indoor Unit

AVOID:

areas where leakage of flammable gas may be

expected.

places where large amounts of oil mist exist.

direct sunlight.

locations near inverter lamps which may affect the

performance of the unit.

locations near heat sources which may affect the

performance of the unit.

locations where external air may enter the room

directly. This may cause “sweating” on the air discharge ports, causing them to spray or drip.

locations where the remote controller will be splashed

with water or affected by dampness or humidity.

installing the remote controller behind curtains or

furniture.

locations where the receiver in the indoor unit is

exposed to the inverter lamp light. Faulty operation of

the unit occurs.

DO:

select an appropriate position from which every

corner of the room can be uniformly cooled.

select a location where the ceiling is strong enough

to support the weight of the unit.

select a location where tubing and drain pipe have

the shortest run to the outdoor unit.

allow room for operation and maintenance as well as

unrestricted air flow around the unit.

install the unit within the maximum elevation

difference above or below the outdoor unit and within

a total tubing length (L) from the outdoor unit as

detailed in Table 1-11.

allow room for mounting the remote controller about

3 ft. off the floor, in an area that is not in direct

sunlight nor in the flow of cool air from the indoor

unit.

Air delivery will be degraded if the distance from the

floor to the ceiling is greater than 10 ft.

07-115 SSHP_II 5/7/07 3:59 PM Page 16

Ceiling-Mounted Type

Ceiling

Wall

Min. 10 inch

Front view

Min. 10 inch

NOTE

The rear of the indoor unit can be installed flush

against the wall.

Air

discharge

Min. 2 ft.

Ceiling

Air intake

Side view

4-Way Air Discharge Type

Concealed-Duct Type

3 ft.

3 ft.

3 ft.

3 ft.

3 ft.

NOTE

Min.

6 inch

Wall-Mounted Type

Min.

6 inch

Min.

12 inch

Page 17

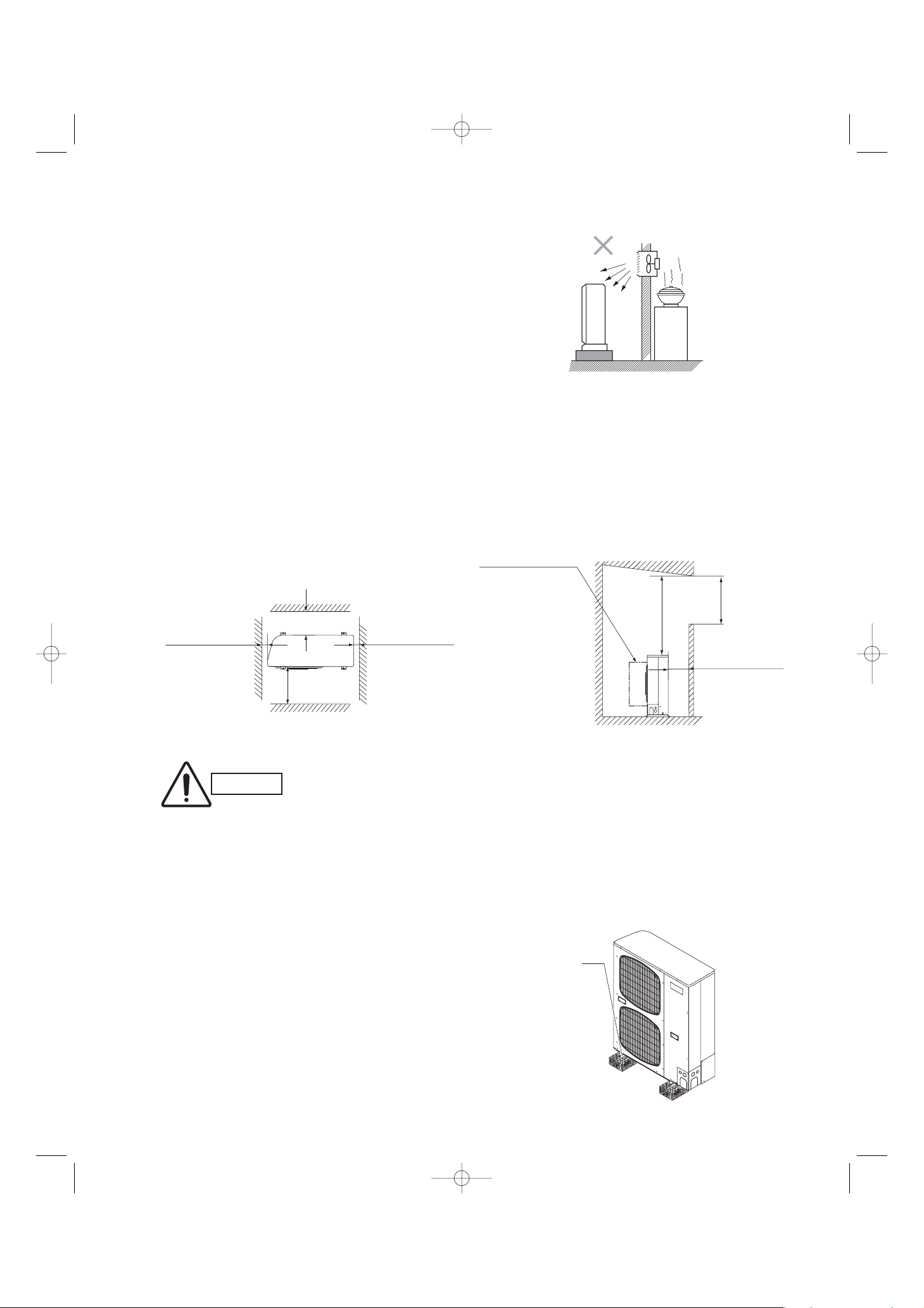

2-2. Outdoor Unit

AVOID:

heat sources, exhaust fans, etc. (Fig. 2-1)

damp, humid or uneven locations

DO:

choose a place as cool as possible.

choose a place that is well ventilated and outside

air temperature does not exceed maximum 115°F

constantly.

allow enough room around the unit for air intake/

exhaust and possible maintenance. (Fig. 2-2)

use lug bolts or equal to bolt down unit, reducing

vibration and noise.

if cooling operation is to be used when the outdoor

air temperature is 23°F or below, install a duct on

the outdoor unit.

Installation space

Distance between obstructions and the unit air inlet

and outlet must be as shown below.

Fig. 2-1

Fig. 2-3

Fig. 2-4

Installation requirements

provide a solid base (concrete block, 4" × 16"

beams or equal), a minimum of 6" above ground

level to reduce humidity and protect the unit against

possible water damage and decreased service life.

(Fig. 2-4)

use lug bolts or equal to bolt down unit, reducing

vibration and noise.

Concerning inlet-side distance “C” (Fig. 2-2)

The minimum for distance “C” is 6" if there are no obstructions on the outlet side

(wall *1 side) and *2 or *4 is not present. In all other cases, the minimum for distance

“C” is 8".

If the unit is installed with the outlet side facing wall *1, then there must be no obstruc-

tions on 2 of the remaining 3 sides: *2, *3, *4.

If wall *1 is on the outlet side (Fig. 2-2), or if obstructions are present on all 3 sides *2,

*3, and *4 (Fig. 2-2), then the minimum distance for “A” and “B” is 80" (Fig. 2-3). Even

if there is no wall on the outlet side, a minimum of 3.3 ft. is required.

Fig. 2-2

17

07-115 SSHP_II 5/7/07 3:59 PM Page 17

More than 25/64"

*3

Inlet side C

Outlet side

More than

3.3 ft.

*1

More than 25/64"

*4*2

Hot air

Air direction chamber

(field supply)

Exhaust fan

Outdoor

unit

(Obstruction above unit)

*1

Heat source

B

A

Inlet side

More than 8"

(Obstruction on

inlet side)

(Ground)

CAUTION

Anchor bolts

(4 pieces)

Page 18

18

Fig. 2-5

Fig. 2-6

Fig. 2-7

2-3. Air-Discharge Chamber for Top Discharge

Be sure to install an air discharge chamber in the

field when:

it is difficult to keep a space of min. 20" between

the air discharge outlet and an obstacle.

the air discharge outlet is facing a sidewalk and

discharged hot air may bother passers-by.

Refer to Fig. 2-5.

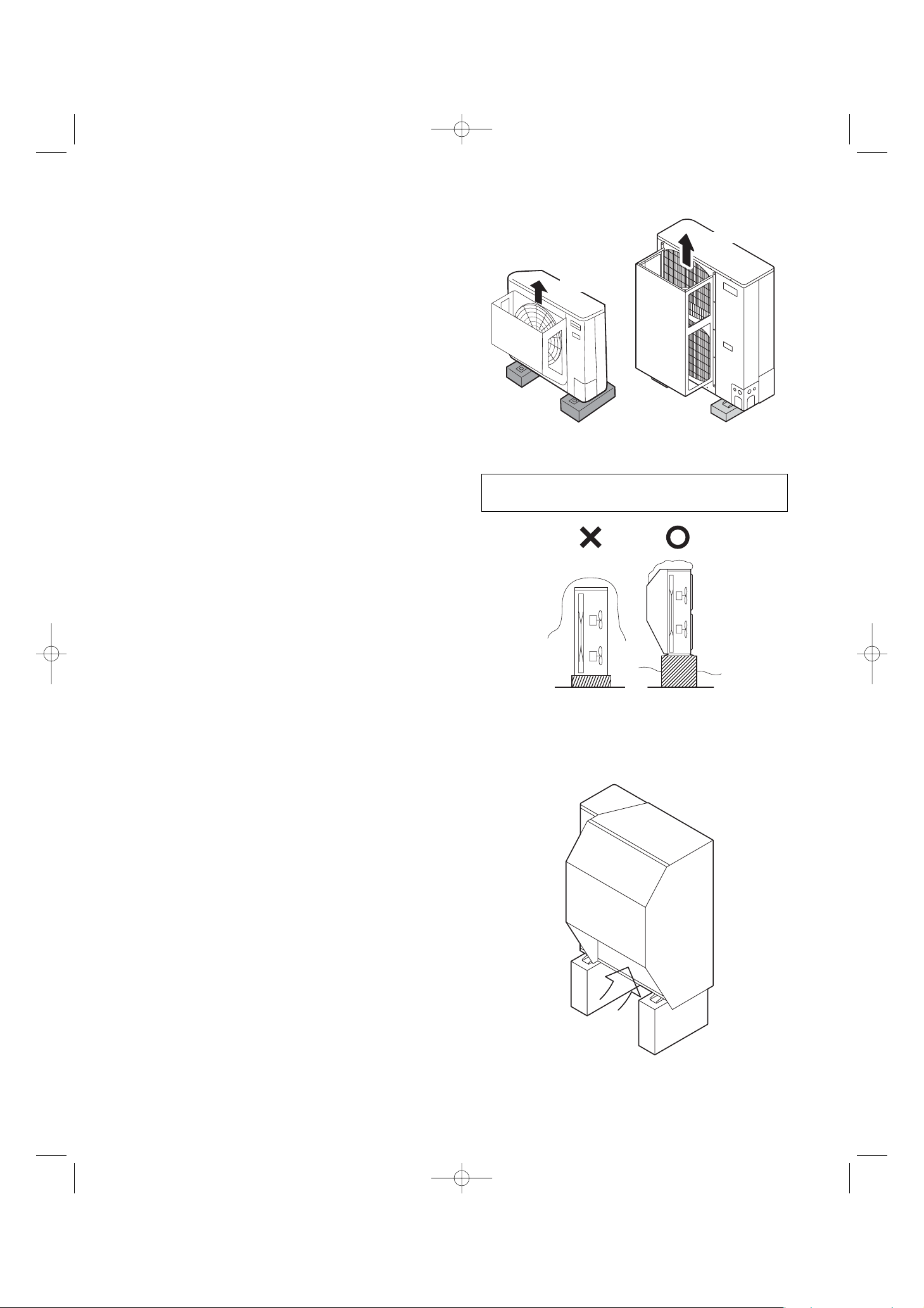

2-4. Installing the Unit in Heavy Snow Areas

In locations with strong wind, snow-proof ducting

should be fitted and direct exposure to the wind

should be avoided as much as possible.

Countermeasures against snow and wind

In regions with snow and strong wind, the following

problems may occur when the outdoor unit is not provided with a platform and snow-proof ducting:

a) The outdoor fan may not run and damage to the

unit may occur.

b) There may be no air flow.

c) The tubing may freeze and burst.

d) The condenser pressure may drop because of

strong wind, and the indoor unit may freeze.

2-5. Precautions for Installation in Heavy Snow

Areas

(1) The platform should be higher than the max. snow

depth. (Fig. 2-6)

(2) The 2 anchoring feet of the outdoor unit should be

used for the platform, and the platform should be

installed beneath the air intake side of outdoor

unit.

(3) The platform foundation must be firm and the unit

must be secured with anchor bolts.

(4) In case of installation on a roof subject to strong

wind, countermeasures must be taken to prevent

the unit from being blown over.

In regions with significant snowfall, the outdoor unit should

be provided with a platform and snow-proof duct.

07-115 SSHP_II 5/7/07 3:59 PM Page 18

Air discharge

Air discharge

Without snowproof ducting

(Low platform)

Outdoor

Unit

Duct

With snowproof ducting

(High platform)

Air

Intake

Page 19

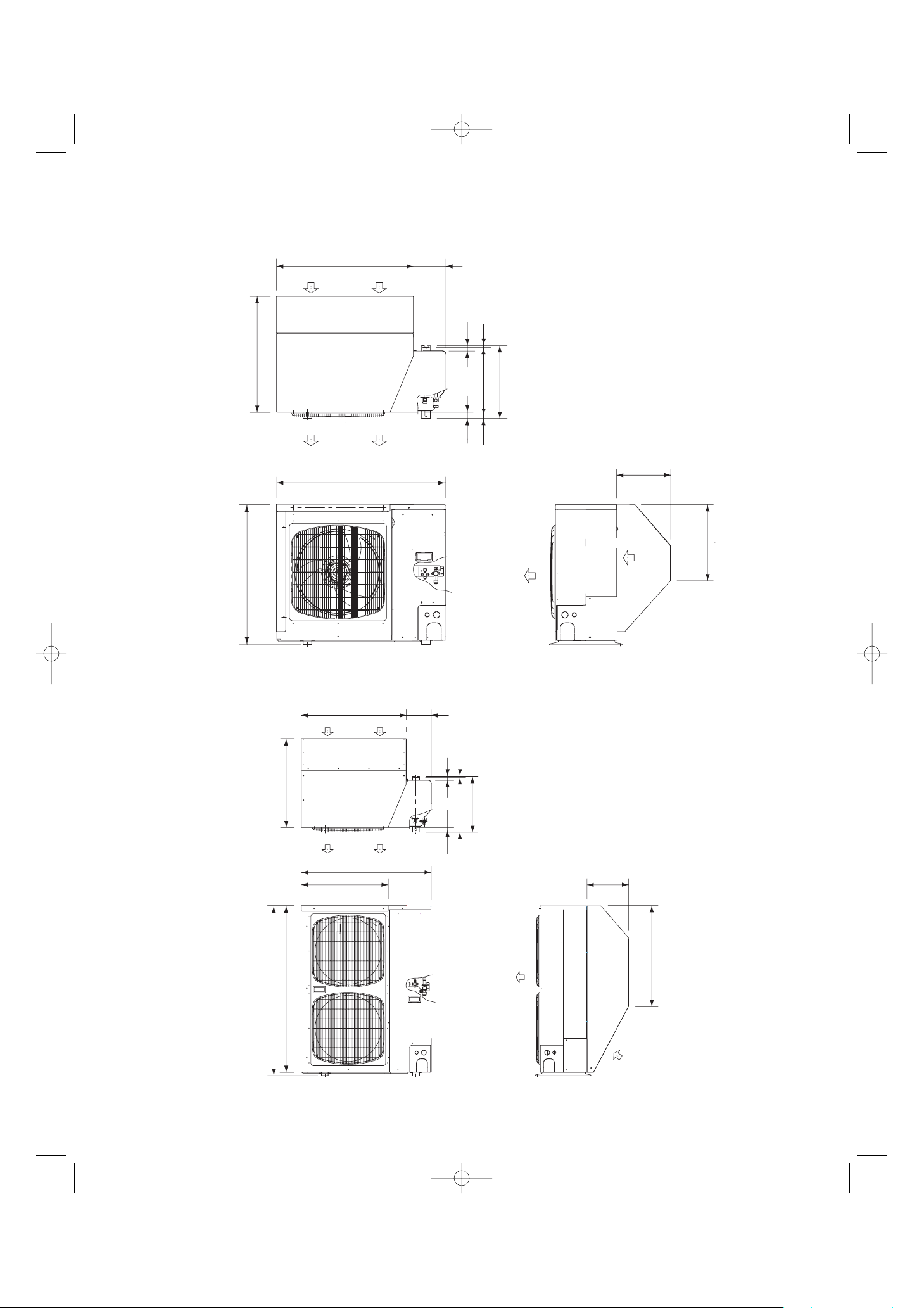

2-6. Dimensions of Wind Ducting

Reference diagram for air-discharge chamber (field supply)

STK–DRV80U for 2672R / 3072R / 3672R unit

STK-DRE140A for 4272R unit

Unit: inch

Note: In snowy regions, if there is concern that snow may enter the air discharge

chamber, remove the base of the chamber (10 screws) before using.

Unit: inch

19

07-115 SSHP_II 5/7/07 3:59 PM Page 19

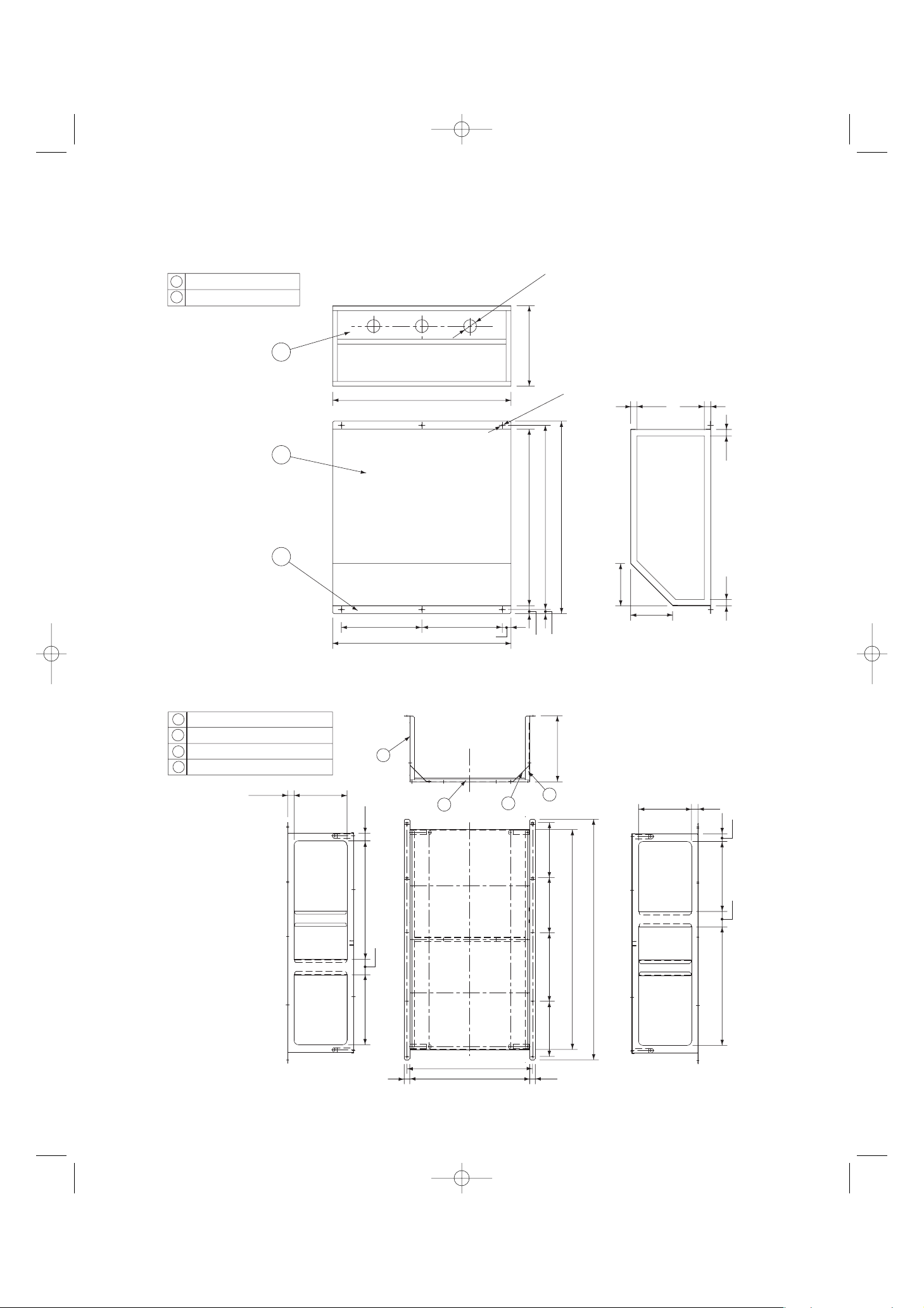

1 Air discharge chamber

2 Air discharge chamber (base)

3-ø5/32 hole

2

1

2

21-13/16

21-13/16

9-27/32

(25/32)

6-ø15/64 hole

22-7/16

23-15/32

21-39/64

9-27/329-27/32

1-1/16

15/16 17/32

(25/32)

Rectangular hole

(both sides)

5-3/16

5-5/32

(25/32)(25/32)

1 Unit front, air discharge chamber

2 Unit left side, air discharge chamber

3 Unit light side, air discharge chamber

4 Reinforcement brackets, 4 locations

2

9-7/161-1/8

1

Rectangular

hole

Rectangular

hole

1-3/821-5/3212-15/32

2-3/4

22-13/32

21-13/3211

4

11-13/16

3

9-27/32

9-27/32

12-7/329-27/32

39-1/4

42-29/32

9-7/16

Rectangular

hole

Rectangular

hole

1-1/8

1-3/8

12-15/3221-5/32

2-3/4

Page 20

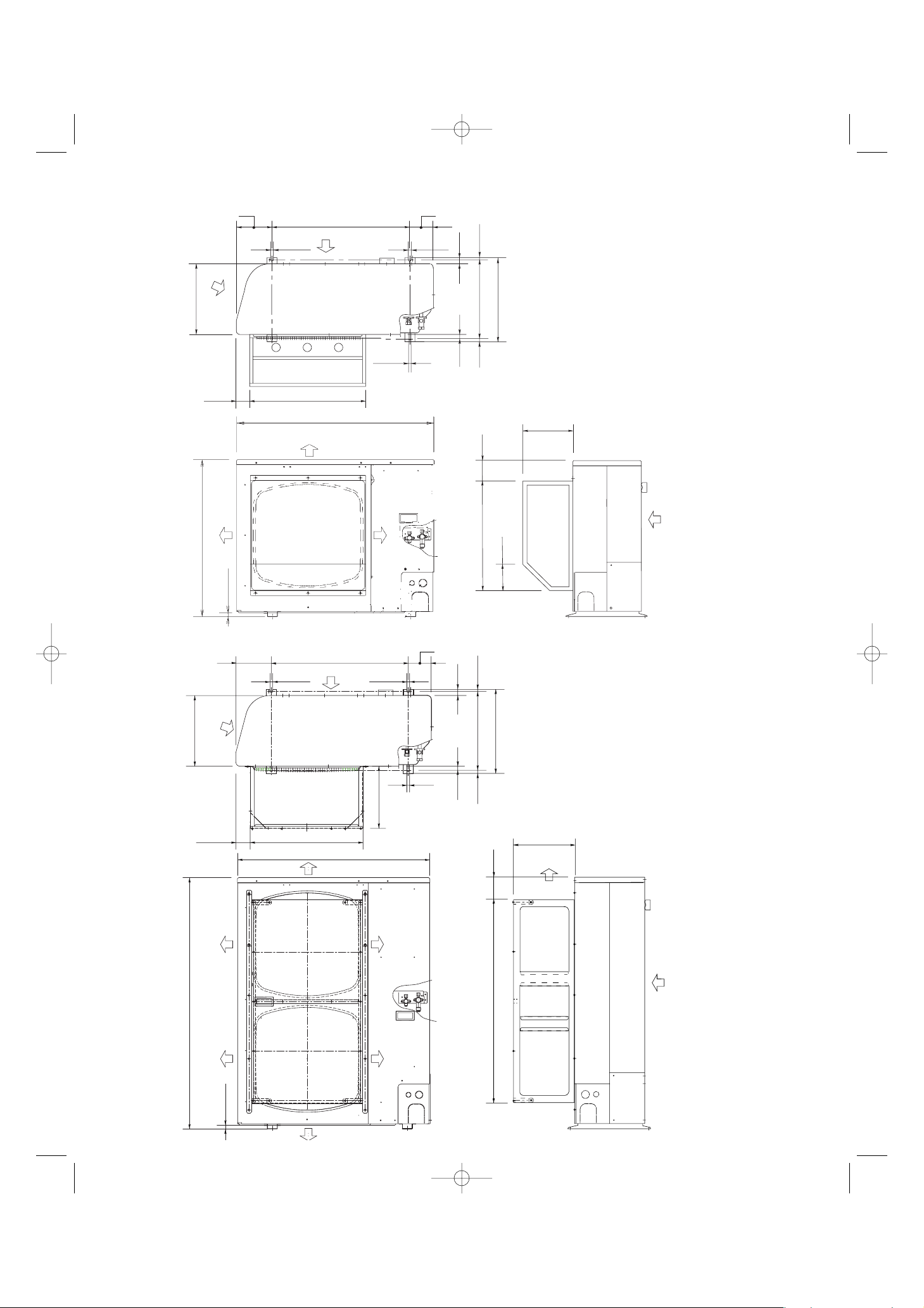

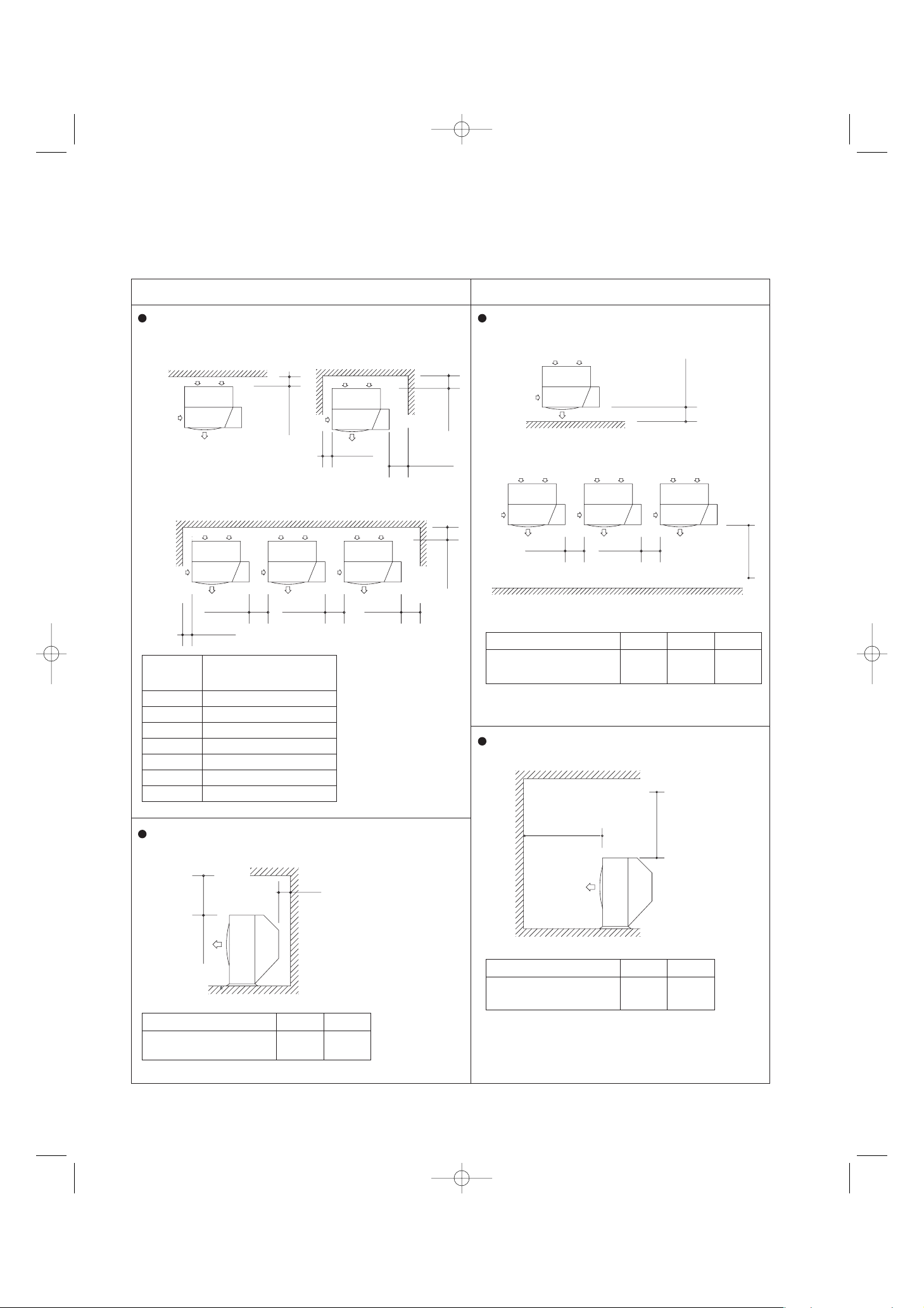

Dimensions of Outdoor Unit with air-discharge chamber (field supply)

2672R / 3072R / 3672R unit with STK-DRV80U

4272R unit with STK-DRE140A

Unit: inch

Unit: inch

20

07-115 SSHP_II 5/7/07 3:59 PM Page 20

4-5/16

Wind

direction

13-3/8

6-11/16

25-31/32

1/2 1/2

Wind direction

2-17/32

30-23/32

Wind direction

1/2

21-13/16

37

Wind direction

Wind direction

25/32 25/32

13/32

14-31/32

15-15/16

19/32

21-5/8 4-1/16

9-27/32

Wind direction

5-3/16

23/32

Wind

direction

13-3/8

2-11/36 21-13/32

Wind

direction

25-31/326-11/16

Wind direction

1/2 1/2

37

11-13/16

Wind

direction

1/2

4-5/16

25/3225/32

14-31/32 13/3219/32

15-15/16

4-1/439-1/4

11- 13/ 16

Wind direction

Wind direction

48-7/16

Wind

direction

23/32

Wind

direction

Page 21

21

Reference diagram for air-discharge chamber (field supply)

C(H)2672R / 3072R / 3672R / 4272R with STK-DRV80U & DRE140A

Required space around outdoor unit

If the air discharge chamber is used, the space shown below must be secured around the outdoor unit.

If the unit is used without the required space, a protective device may activate, preventing the unit from operating.

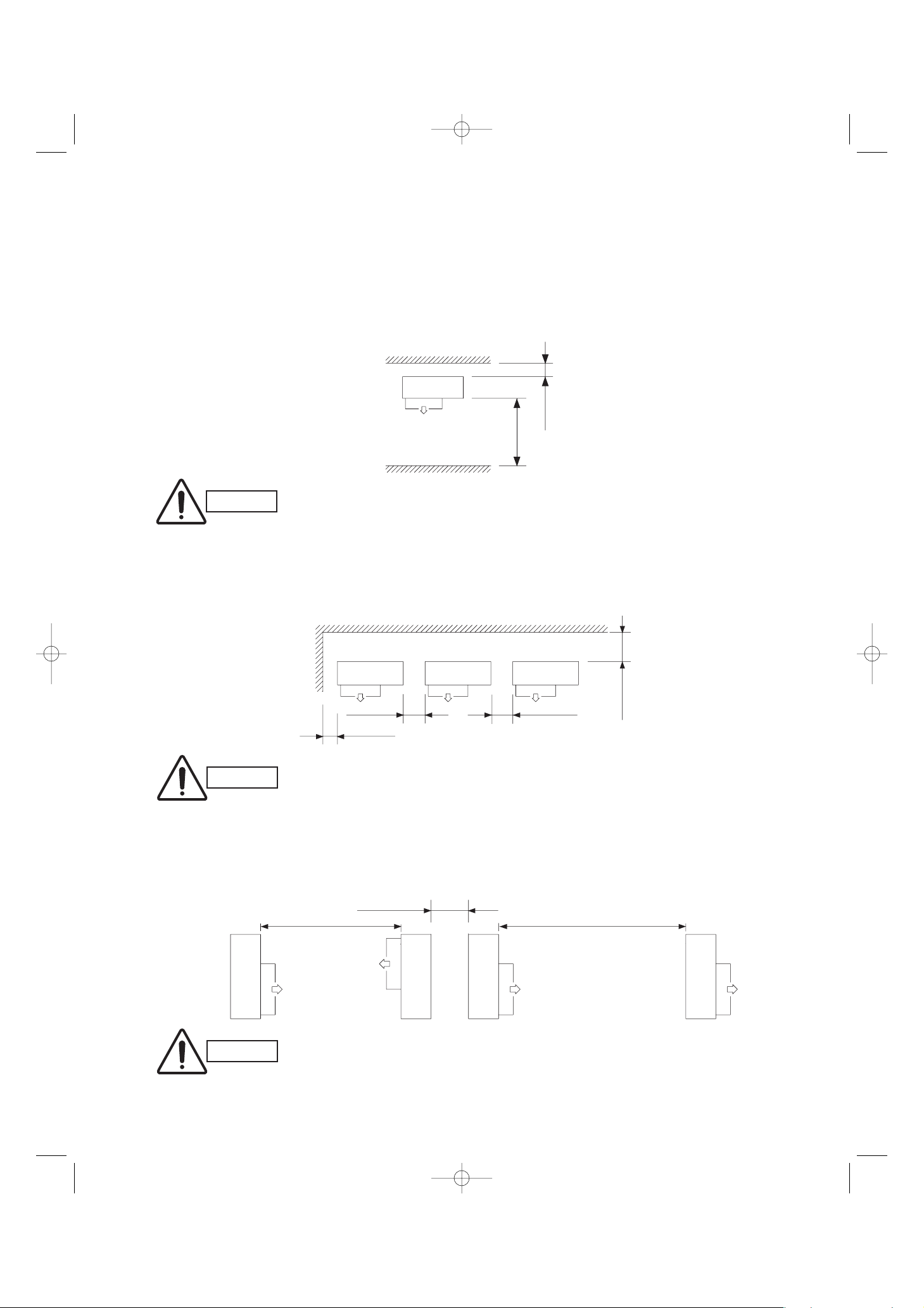

(1) Single-unit installation

The top and both sides must remain open. If there are obstacles to the front and rear of

the outdoor unit, the obstacle at either the front or rear must be no taller than the height of

the outdoor unit.

(2) Multiple-unit installation

Installation in lateral rows

The front and top must remain open.

The obstacles must be no taller than the height of the outdoor unit.

The front and both sides must remain open.

Installation in front-rear rows

Installation with intakes facing outlets Installation with intakes facing

intakes or outlets facing outlets

More than 15-3/4

More than 11-13/16 More than 11-13/16

More than 7-7/8

Unit: inch

Unit: inch

Unit: inch

07-115 SSHP_II 5/7/07 3:59 PM Page 21

Min. 7-7/8

Min. 39-3/8

CAUTION

CAUTION

More than 59-1/16

More than 15-3/4

More than 78-3/4

CAUTION

Page 22

22

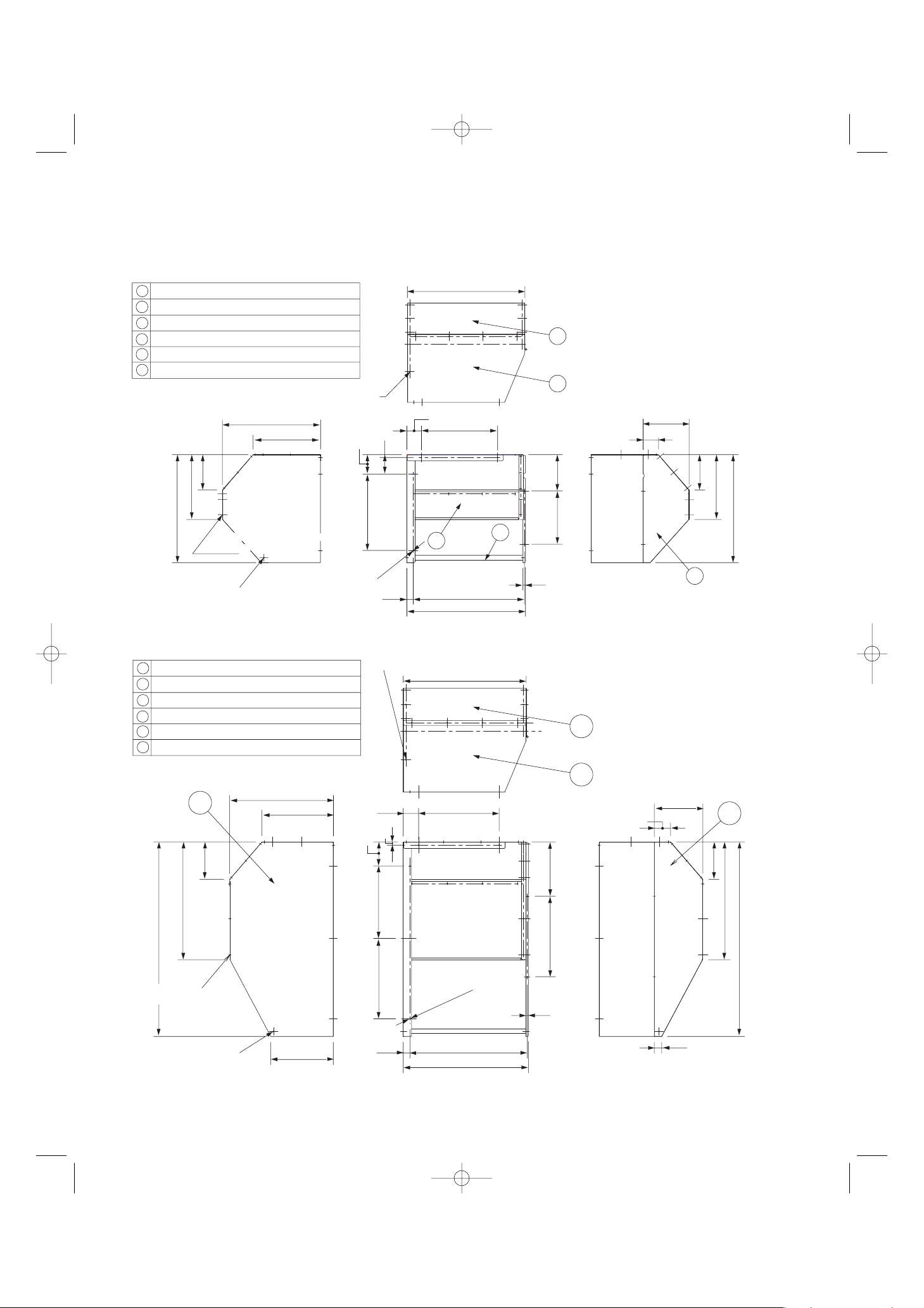

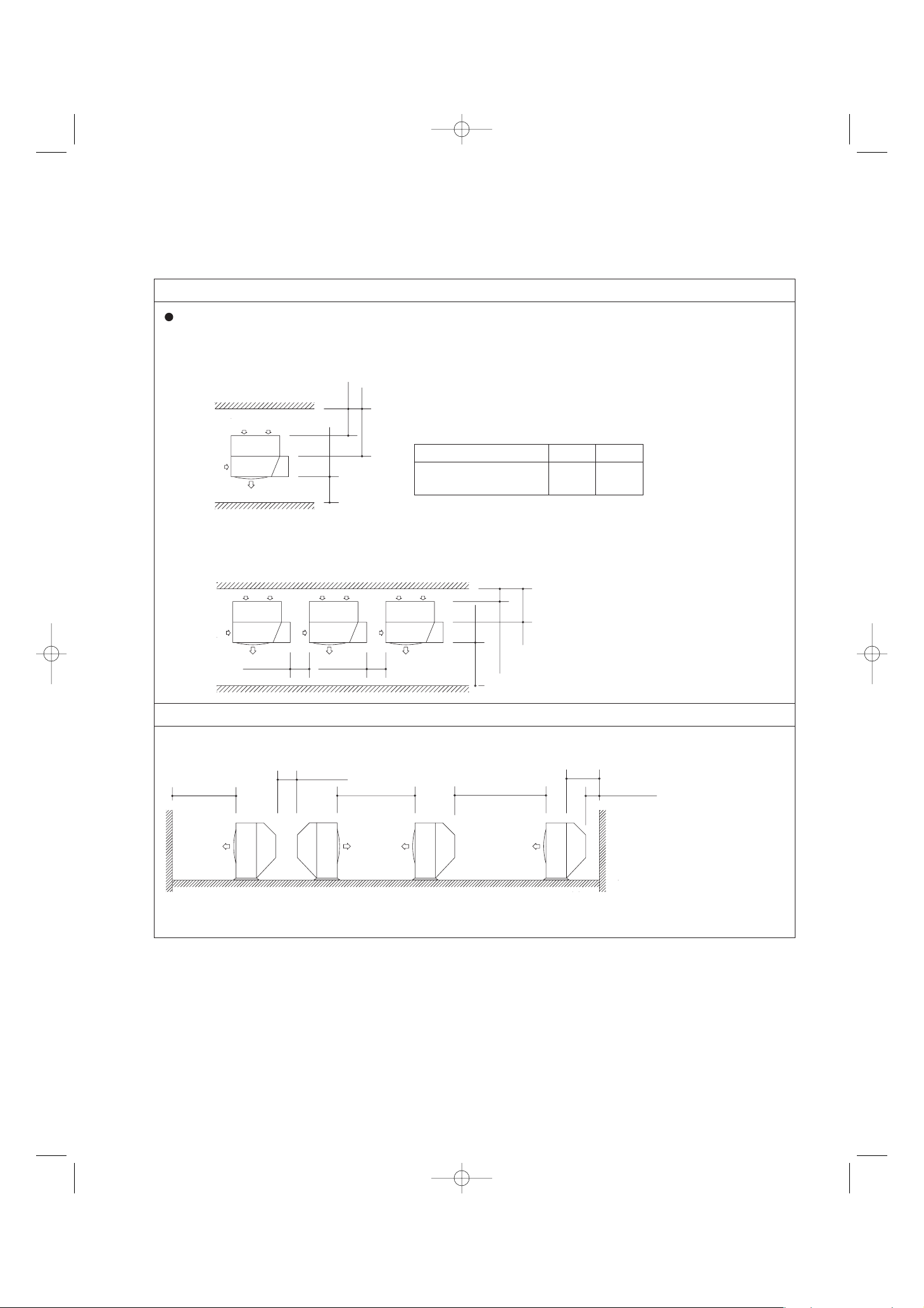

2-7. Dimensions of Snow Ducting

Reference diagram for snow-proof vents (field supply)

STK-BDRE80A for 2672R / 3072R / 3672R unit

STK-BDR140U for 4272R unit

Unit: inch

Unit: inch

07-115 SSHP_II 5/7/07 3:59 PM Page 22

1 Unit top, snow-proof vent

2 Unit left side

3 Unit right side

4 Unit reverse side

5 Unit reverse side

6 Unit sides, reinforcement brackets for snow-proof vent

Fastened by screws at 13 locations

25-13/32

17-15/32

9-3/16

16-25/32

27-29/32

Fastened by screws at 3 locations

(also on reverse side)

Unit anchor hole

Fastened by screw at 1

location (also on reverse side)

(6 – ø7 hole)

5-3/32

19-11/16

1-21/32

25/32

3-3/4

5

30-3/32

19-11/16

28-3/4

30-11/16

4

1

11-29/32

3-31/32

9-3/8

6

13-25/32

5/8

9-3/16

16-25/32

27-29/32

2

1 Unit top, snow-proof vent

2 Unit left side

3 Unit right side

4 Unit reverse side

5 Unit reverse side

6 Unit sides, reinforcement brackets for snow-proof vent

3

9-3/16

28-13/16

47-19/32

Fastened by screws at

3 locations (also on reverse side)

25-13/32

17-15/32

Fastened by screws at 13 locations

3-3/4 19-11/16

25-32

5-29/32

17-23/3219-11/16

30-3/32

Unit anchor hole

(7 – ø7 hole)

13-5/1619-11/16

5/8

4

1

11-7/8

3-31/32

2

9-3/16

28-13/16

47-19/32

Fastened by screw at

1 location (also on reverse side)

15-9/32

1-5/8 28-3/4

30-5/8

1-13/16

Page 23

23

2672R / 3072R / 3672R unit with STK-BDRE80A

Dimensions of outdoor unit with snow-proof vents (field supply)

4272R unit with STK-BDR140U

Unit: inch

Unit: inch

07-115 SSHP_II 5/7/07 3:59 PM Page 23

Wind direction

30-3/32

Wind direction

7-1/16

25-13/32

Wind direction Wind direction

37

30-23/32

25/32

14-31/32 13/3219/32

3/4

Wind direction

15-15/16

11-29/32

Wind direction

16-3/4

25-13/32

48-7/16

47-19/37

Wind direction

Wind direction

24-7/8

30-3/32

Wind direction

37

7-1/16

Wind direction

25/3225/32

14-31/32 13/3219/32

15-15/16

Wind direction

11-29/32

28-13/16

Wind direction

Page 24

Reference diagram for snow-proof vents – 1

Space requirements for setting – (1)

C(H)2672R / 3072R / 3672R / 4272R with STK-BDRE80A & STK-BDR140U

Unit: inch

24

07-115 SSHP_II 5/7/07 3:59 PM Page 24

[Obstacle to the rear of unit]

[Obstacle to the front of unit]

Top is open: Top is open:

(1) Single-unit installation

(2) Obstacles on both sides

(1) Single-unit installation

Min. A

Min. B

Min. C

Min. D

(2) Multiple-unit installation (2 or more units)

(3) Multiple-unit installation (2 or more units)

Min. G

Min. E Min. E

Note:

In cases 2 and 3 the

height of the obstacle

must be no taller than

the height of the

outdoor unit.

Outdoor unit

A

B

C

D

E

F

G

Min. E

Min. F

C(H)2672R / 3072R /

3672R / 4872R

5-29/32

5-29/32

11-13/16

7-7/8

11-13/16

5-29/32

7-7/8

Min. I Min. I

Outdoor unit

C(H)2672R / 3072R /

3672R / 4272R

H

19-11/16

Top is blocked by an obstacle:

Min. H

Min. J

I

11-13/16J39-3/8

Top is blocked by an obstacle:

Min. K

Outdoor unit

C(H)2672R / 3072R /

3672R / 4272R

L

19-11/16

Min. L

K

5-29/32

Min. M

Outdoor unit

C(H)2672R / 3072R /

3672R / 4272R

M

39-3/8

Min. N

N

39-3/8

Page 25

25

Reference diagram for snow-proof vents – 2

Space requirements for setting – (2)

C(H)2672R / 3072R / 3672R / 4272R with STK-BDRE80A & STK-BDR140U

Unit: inch

07-115 SSHP_II 5/7/07 3:59 PM Page 25

[Obstacles to the front and rear of unit]

The top and both sides must remain open. Either the obstacle to the front or

the obstacle to the rear must be no taller than the height of the outdoor unit.

(1) Single-unit installation

Q

Min. P

Dimension Q

If a snow protection duct is attached after the unit is

installed, verify that dimension Q is 19-11/16 in. or more.

Min. O

Outdoor unit

C(H)2672R / 3072R /

3672R / 4272R

O

39-3/8

P

5-29/32

(2) Obstacles on both sides

Q

Min. 11-13/36

Min. 11-13/16

Min. 7-7/8

Min. 39-3/8

[Installation in front-rear rows]

• The top and both sides must remain open. Either the obstacle to the front or the obstacle

to the rear must be no taller than the height of the outdoor unit.

Min. 11-13/16

Min. 39-3/8 Min. 7-7/8

Min. 59-1/16 Min. 78-3/4

0

Dimension Q

If a snow protection duct is

attached after the unit is

installed, verify that dimension

Q is 19-11/16 in. or more.

Page 26

X

26

3. HOW TO INSTALL THE INDOOR UNIT

4-Way Air Discharge Semi-Concealed Type

(X Type)

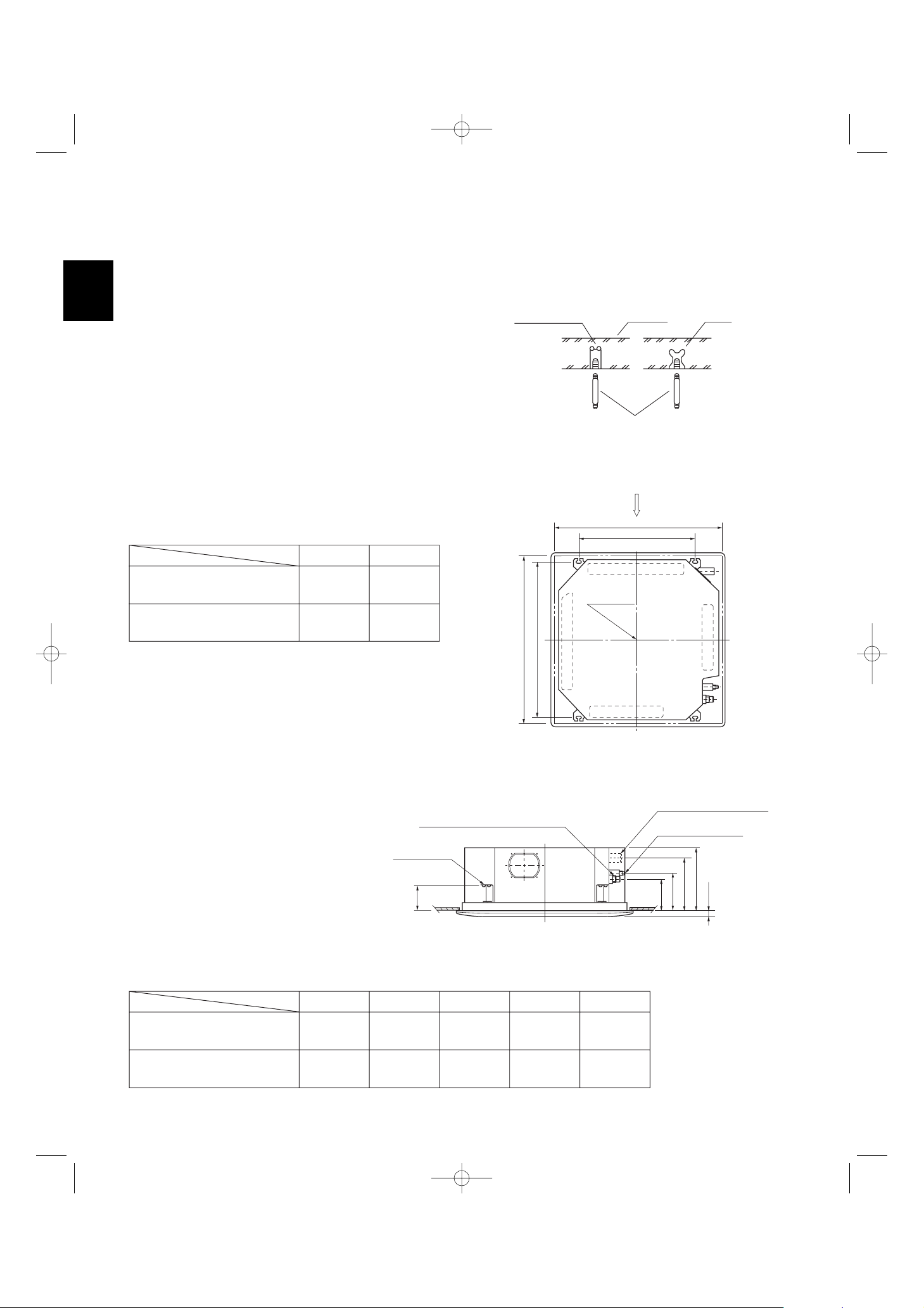

3-1. Suspending the Indoor Unit

This unit uses a drain pump. Use a carpenter’s level to

check that the unit is level.

3-2. Preparation for Suspending

(1) Fix the suspension bolts securely in the ceiling

using the method shown in the diagrams (Figs. 3-1

and 3-2), by attaching them to the ceiling support

structure, or by any other method that ensures that

the unit will be securely and safely suspended.

(2) Follow Fig. 3-2 and Table 3-1 to make the holes in

the ceiling.

(3) Determine the pitch of the suspension bolts using

the supplied full-scale installation diagram. The

diagram and table (Fig. 3-3 and Table 3-2) show

the relationship between the positions of the suspension fitting, the unit, and the panel.

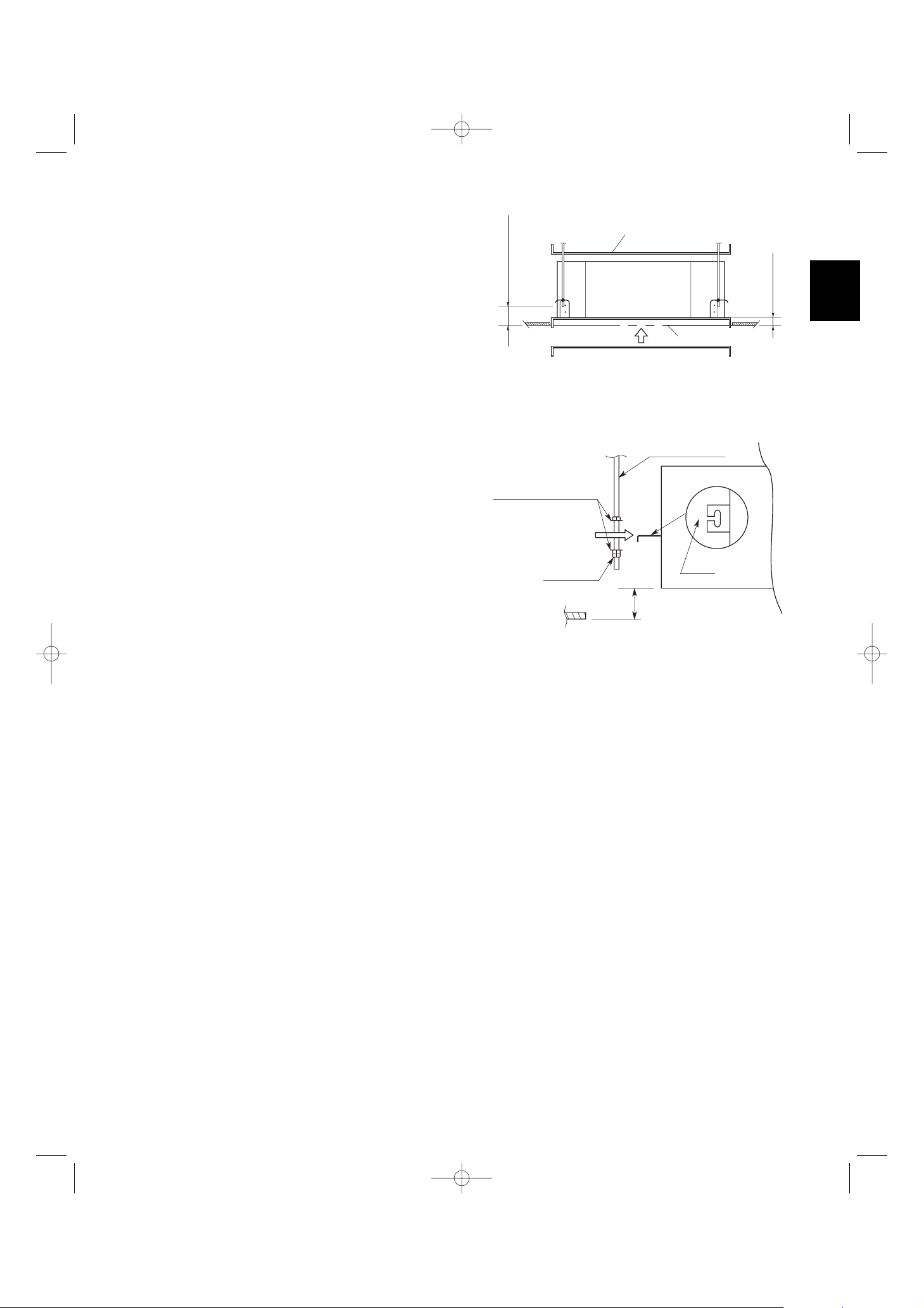

Fig. 3-1

Fig. 3-2

Unit: inch

Fig. 3-3

Unit: inch

07-115 SSHP_II 5/7/07 3:59 PM Page 26

Hole-in-anchor

Hole-in-plug

Concrete Insert

Suspension bolt (M10 or 3/8")

(field supply)

Table 3-1

Type

XH(W)2672R

(PNR-XH2442)

XH(W)3672R, XH(W)4272R

(PNR-XH3642)

Length

A

32-9/32

(820)

43-11/16

(1,110)

Unit: inch (mm)

B

22-9/32

(566)

33-11/16

(856)

)gninepo gnilieC( 23/9-23

nsion bolt pitch)epsuS( 61/31-92

A (Ceiling opening)

(Suspension bolt pitch)

Grille center

X

B

Drain hose

side

Refrigerant

tubing side

Table 3-2

Type

Length

XH(W)2672R

(PNR-XH2442)

XH(W)3672R, XH(W)4272R

(PNR-XH3632)

A

6-3/16

(157)

6-3/16

(157)

Refrigerant tubing joint (gas tube side)

Suspension lug

E

7-5/32

(182)

7-5/32

(182)

10-9/32

(261)

11-15/32

(291)

13-1/16

D EB C

12-1/8

(308)

(338)

Unit: inch (mm)

4-7/8

(124)

4-7/8

(124)

Drain connection (other side)

(VP25)

Refrigerant tubing joint

(liquid tube side)

D

61/3

C

B

A

1

Page 27

27

X

3-3. Placing the Unit Inside the Ceiling

(1) When placing the unit inside the ceiling, determine

the pitch of the suspension bolts using the

supplied full-scale installation diagram. (Fig. 3-4)

The size of the opening for the indoor unit can be

confirmed by attaching the full-scale installation

diagram beneath the unit. (Fig. 3-4)

Tubing and wiring must be laid inside the ceiling

when suspending the unit. If the ceiling is already

constructed, lay the tubing and wiring into position

for connection to the unit before placing the unit

inside the ceiling.

(2) The length of each suspension bolt must be

appropriate for a distance between the bottom of

the bolt and the bottom of the ceiling of 19/32 in.

or more as shown in Fig. 3-4.

(3) Thread the 2 hexagonal nuts (field supply) and

washers onto the 4 suspension bolts as shown in

Fig. 3-5.

Use 2 sets of nuts and washers (upper and lower),

so that the unit will not fall off the suspension lugs.

(4) Remove the protective cardboard used to protect

the fan parts during transport.

(5) Adjust the distance between the unit and surface

of the ceiling. (1-7/8 in.) (Fig. 3-4)

Fig. 3-4

Fig. 3-5

07-115 SSHP_II 5/7/07 3:59 PM Page 27

erom ro hcni 23/91

Nuts and washers

(Use above and below)

Full-scale installation diagram

(printed on a cardboard packing)

Double nuts

Suspension bolt

Upper

Lower

1-7/8 inch

Full-scale installation

diagram

Suspension lug

Notch

hc

n

i

8/7-

1

Page 28

X

28

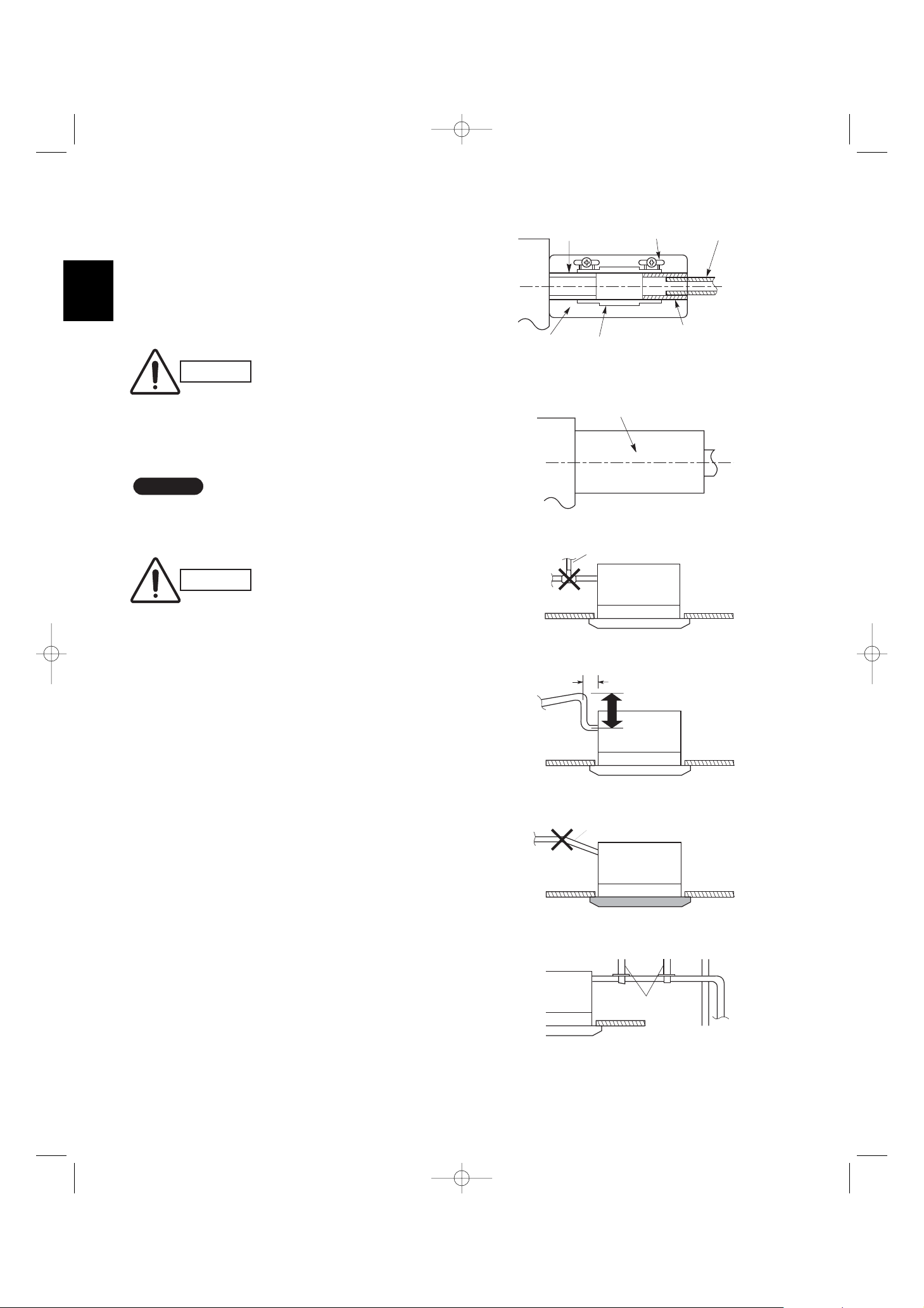

3-4. Installing the Drain Piping

(1) Prepare standard hard PVC pipe for the drain and

use the supplied drain hose and hose band to prevent water leaks.

The PVC pipe must be purchased separately. The

transparent part allows you to check drainage.

(Fig. 3-6)

(2) After checking the drainage, wrap the supplied

packing and drain pipe insulator around the pipe.

(Fig. 3-7)

Ensure the drain pipe has a downward gradient (1/100

or more) and that there are no water traps.

Tighten the hose clamps so

their locking nuts face upward.

(Fig. 3-6)

Do not install an air bleeder tube, as this may cause

water to spray from the drain tube outlet. (Fig. 3-8)

If it is necessary to increase the height of the drain

pipe, the section directly after the connection port

can be raised a maximum of 19-11/16 in. Do not

raise it any higher than 19-11/16 in., as this could

result in water leaks. (Fig. 3-9)

Do not install the pipe with an upward gradient from

the connection port. This will cause drain water to

flow backwards and leak when the unit is stopped.

(Fig. 3-10)

Do not apply force to the piping on the unit side

when connecting the drain pipe. The pipe should

not be allowed to hang unsupported from its

connection to the unit. Fasten the pipe to a wall,

frame, or other support as close to the unit as

possible. (Fig. 3-11)

Provide insulation for any drain pipe that is run

indoors.

Fig. 3-6

Fig. 3-7

Fig. 3-8

Fig. 3-9

Fig. 3-10

Fig. 3-11

07-115 SSHP_II 5/7/07 3:59 PM Page 28

Hard PVC pipe

(not supplied)

Drain hose

adapter

(supplied)

CAUTION

Transparent part for

checking drainage

Packing

(supplied)

Drain hose

(supplied)

Hose band

(supplied)

Drain insulator (supplied)

NOTE

Air bleeder

CAUTION

11-3/4 in. or less (as short as possible)

19-11/16 in. or less

Upward gradient

Support

pieces

Page 29

29

X

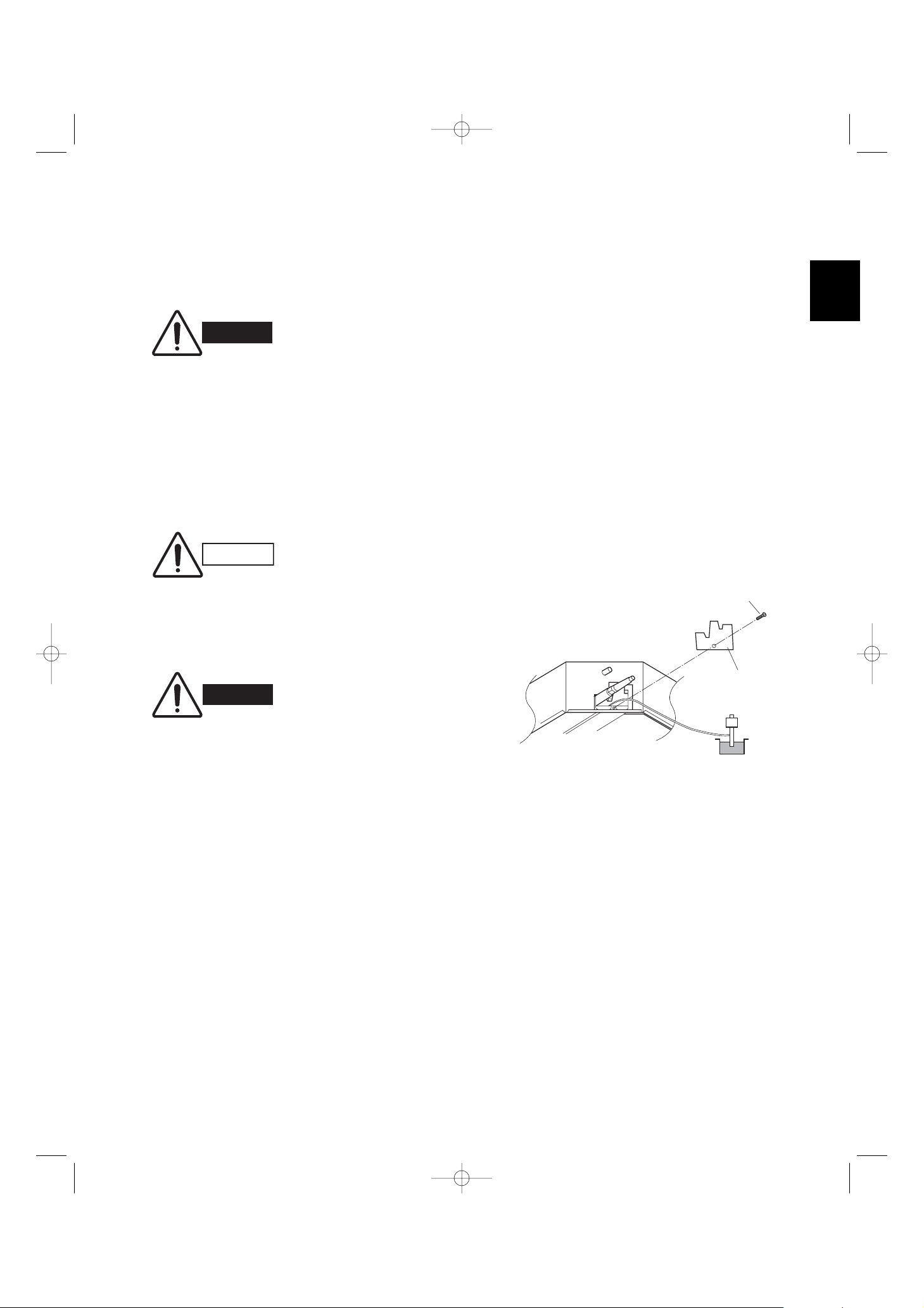

3-5. Checking the Drainage

After wiring and piping are completed, use the following procedure to check that the water will drain smoothly. For this, prepare a bucket and wiping cloth to catch

and wipe up spilled water.

(1) Take off the tube cover and through the opening,

slowly pour about 43 oz. of water into the drain pan

to check drainage.

(2) Do Test Run to check the drainage after complet-

ing installation. When performing Test Run, be

sure to observe the Test Run procedure.

Refer to page 105.

(3) After drain checking is finished, return the Opera-

tion Selector switch to the RUN position (ON position ) and remount the tube cover.

Do not supply power to the

unit until the tubing and

wiring to the outdoor unit are

completed.

Be careful since the fan will

start turning when checking

the drainage.

To mount the tube cover, use

5/16" (4

××

8 mm) tapping

screws. Do not use long

screws as they may puncture

the drain pan and cause water

leakage.

Fig. 3-12

07-115 SSHP_II 5/7/07 3:59 PM Page 29

WARNING

CAUTION

WARNING

5/16"(4 × 8 mm)

tapping screw

Tube cover

Siphon

Page 30

X

30

Ceiling Panel

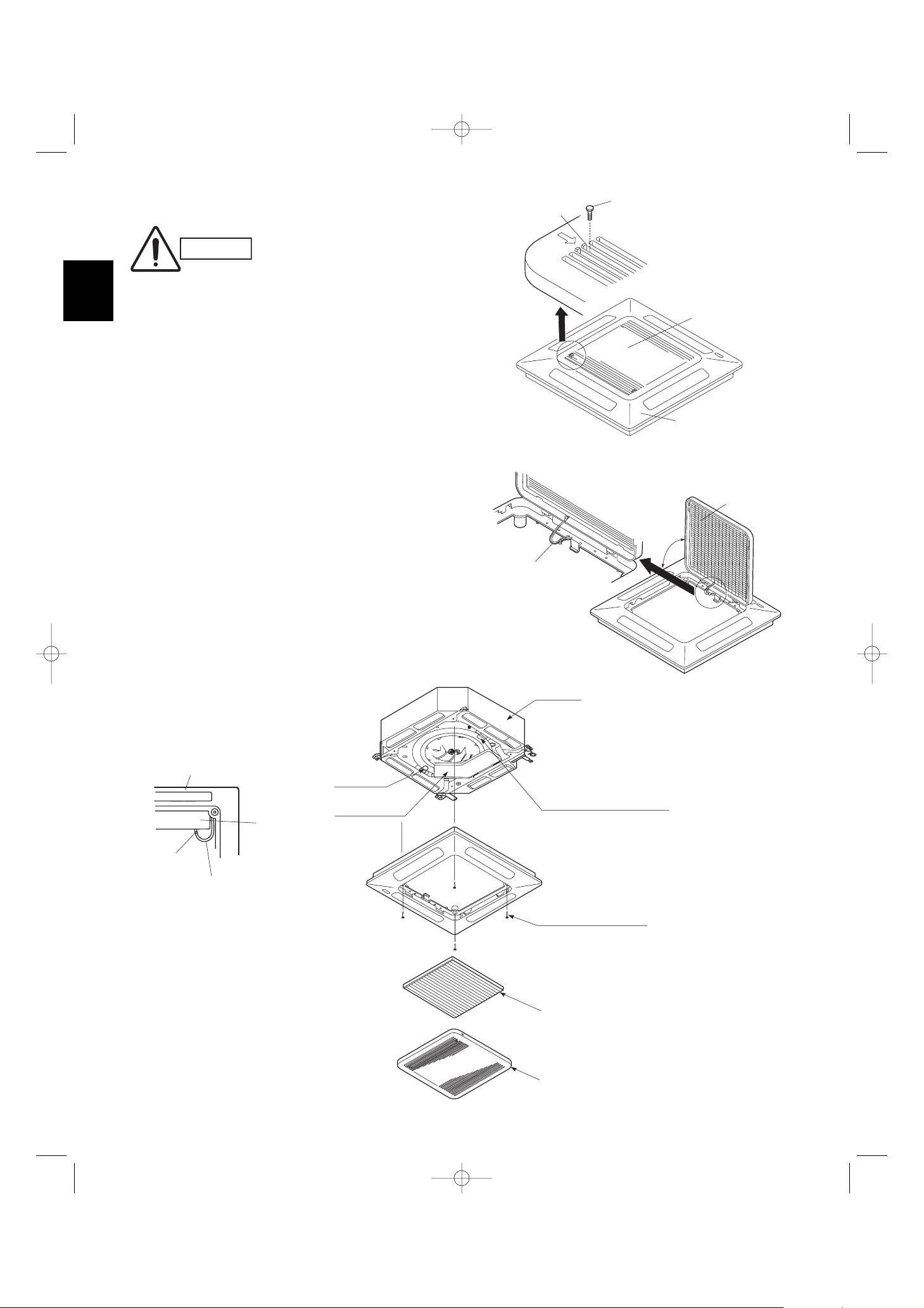

3-6. Before Installing the Ceiling Panel

(1) Remove the air-intake grille and air filter from the

ceiling panel. (Figs. 3-13 and 3-14)

(a) Remove the 2 screws on the latch of the air-

intake grille. (Fig. 3-13)

(b) Press on the 2 latches of the air-intake grille

with your thumbs in the direction of the arrow

to open the grille. (Fig. 3-13)

(c) With the air-intake grille open about 45°,

remove the safety cord (hook on the grille

side). (Fig. 3-14)

(d) Pull the air-intake grille towards you to remove

it from the ceiling panel.

(2) Pull down the two panel catches on the body of

the indoor unit body. (Fig. 3-15)

Never touch or attempt to

move the air direction louver

by hand or you may damage

the unit. Instead, use the

remote control unit if you want

to change the direction or air

flow.

Fig. 3-13

Fig. 3-14

Fig. 3-15

07-115 SSHP_II 5/7/07 3:59 PM Page 30

Latch

CAUTION

Screw

Air-intake grille

Ceiling panel

Air filter

Safety cord

45°

Ceiling panel

Panel catch

Electrical

component box

Electrical

component box

Clamp

Ceiling panel wiring

connector

Unit body

Panel catch

(arrange facing downwards)

(2 locations)

Screws M5 with washer

(supplied)

Air filter

Air-intake grille

Page 31

31

X

3-7. Installing the Ceiling Panel

(1) Lift the ceiling panel and position it to align the

panel hook with the panel catch of the indoor unit.

The ceiling panel must be mounted in the correct direction. Note that the 2 catches of the panel differ in size.

Confirm that the catches are correctly matched

between the ceiling panel and the indoor unit body.

(2) Next, check to see that the ceiling panel is prop-

erly aligned with the seamline of the ceiling. If it is

not, remove the ceiling panel and slightly readjust

the indoor unit body to the proper suspension

point.

(3) When the ceiling panel has been properly aligned,

use the supplied 4 mounting screws (M5) with

washers to permanently fasten the ceiling panel.

(4) Install the wiring connector from the ceiling panel

to the connector in the electrical component box of

the indoor unit. After installing the connector, use

the clamp on the body of the indoor unit to secure

the wiring.

(5) Install the air filter and air-intake grille by perform-

ing the steps in section 3-6 in reverse.

Rehook the safety cord before closing the air-intake

grille.

3-8. When Removing the Ceiling Panel

for Servicing

When removing the ceiling panel for servicing, remove

the air-intake grille and air filter, disconnect the wiring

connector inside the electrical component box, and then

remove the 4 mounting screws.

07-115 SSHP_II 5/7/07 3:59 PM Page 31

NOTE

NOTE

Page 32

X

32

3-9. Duct for Fresh Air

There is a duct connection part on side of the indoor

unit. (Fig. 3-16)

An optional air-intake plenum (including duct connection

box and flange) can be attached to the indoor unit.

(1) Accessories

Check that the following parts are in the box when

unpacking.

(2) Installation

Installation steps (a) to (d) are the same for both the

CMB-GSJ80U and the CMB-GSJ140U. The figure

illustrates installation of air-intake plenum to the

indoor unit. (Fig. 3-17)

(a) Installing the air-intake plenum

Set the air-intake plenum to the indoor unit taking care

not to set it in the wrong direction. (Fig. 3-17)

Fasten the air-intake plenum with the accessory screws.

(M5 × L5 in., 4 pcs) (Fig. 3-17)

(b) Installing the duct connection box

Fasten the duct connection flange to the duct connection box with the accessory screws.

(M4 × L1/2 in., 4 pcs) (Fig. 3-18)

Put the duct connection box into the rectangular hole of

the air-intake plenum and fasten it to both sides of the

indoor unit and plenum with the accessory screws.

(M4 × L1/2 in., 3 pcs) (Fig. 3-18)

(c) Installing the indoor unit

Install the indoor unit to the ceiling. (Install the indoor

unit according to items 3-1 to 3-6.)

When installing in a preexisting location, install the

indoor unit before installing

the duct connection box.

Fig. 3-16

Fig. 3-17

Unit: inch

07-115 SSHP_II 5/7/07 3:59 PM Page 32

For fresh air intake

e

l

o

h

8

/

Air-intake plenum Type

CMB-GSJ80U

CMB-GSJ140U

(XH(W)3672R, XH(W)4272R)

PNR-XH2442

(XH(W)2672R)

PNR-XH3642

8/3-2

2-5/32

Detail of fresh air intake

1

ø-

4

/31-4ø

23

Name RemarksʻQʼty

Cord with socket

(9P) intaking fresh air.

Connecting line. Not necessary for

1

Screw

(M5 × L5 in.) (for fastening)

4

Screw

(M4 × L1/2 in.) (for fastening)

Duct connection box 1 (for fresh air)

7

Duct connection flange1

CAUTION

Air-intake filter

Duct connection flange / box

(for connecting fresh air duct

Installation

screws

Air-intake

plenum

Indoor unit

)

Socket cover

Panel lead wire (8P)

Clamper

8P socket (red)

(electrical

component box)

8P socket (red)

(ceiling panel side)

Page 33

33

X

(d) Installing the ceiling panel

Attach the ceiling panel to the chamber. Drawing the

panel downwards sets the panel in position temporarily

with the panel catch (at 2 locations).

Remove the socket cover of the air-intake plenum and

pass the 8P sockets through it. (Fix the panel lead wire

with the chamber side clamp.) (Fig. 3-17)

Connect the 8P socket (electrical component box side)

to the 8P socket (ceiling panel side) of the indoor unit

electrical component box.

Reattach the socket cover.

Fig. 3-18

07-115 SSHP_II 5/7/07 3:59 PM Page 33

Duct

connection

flange

Installation screws

(M4 × 1/2 in.)

Panel catch

Ceiling panel

Duct connection box

Page 34

34

K

Wall-Mounted Type (K Type)

3-10. Removing the Wall Fixture from the Unit

Remove and discard the set screws and take off the

rear panel. (Fig. 3-19)

Tubing can be extended in 3 directions as shown in

Fig. 3-20. Select the direction that provides the shortest

run to the outside unit.

3-11. Selecting and Making a Hole

(1) Remove the rear panel from the indoor unit and

place it on the wall at the location selected. Make

sure the unit is horizontal using a carpenter’s level

or tape measure to measure down from the ceiling.

(2) Determine which side of the unit you should make

the hole. (Fig. 3-21)

(3) Before making a hole, check carefully that no studs

or pipes are directly run behind the spot to be cut.

KH(S)2672R

KH(S)2672R

Also avoid areas where electrical wiring or conduits are

located.

The above precautions are also applicable if tubing

goes through the wall in any other location.

(4) Using a sabre saw, key hole saw or hole-cutting

drill attachment, cut a hole in the wall. See Table

3-3 and Fig. 3-22.

Table 3-3

(5) Measure the thickness of the wall from the inside

edge to the outside edge and cut PVC pipe at a

slight angle 1/4" shorter than the thickness of the

wall. (Fig. 3-23)

(6) Place the plastic cover over the end of the pipe (for

indoor side only) and insert in the wall.

(Fig. 3-24)

Hole Dia. (inch)

3-3/16"

Fig. 3-19

Fig. 3-20

Fig. 3-21

Fig. 3-22

Fig. 3-23

Fig. 3-24

Hole should be made at a slight downward slant to

the outdoor side.

07-115 SSHP_II 5/7/07 3:59 PM Page 34

NOTE

Set screws for transportation only

Left-rear tubling

Right-rear

tubing

(recommended)

Right tubing

In case of left-rear or right-rear tubing

CAUTION

NOTE

Center of

left-rear

tubing hole

Center of

right-rear

tubing hole

PVC pipe (locally purchased)

Indoor

side

Outdoor

side

INSIDE

Wall

Plastic cover

(Field supply)

OUTSIDE

Cut at slight angle

PVC pipe

Slight

angle

Page 35

35

K

One hole is required for the air conditioner tubing, and

may be either on the left or right side. (Also see section

3-14. Preparing the Indoor Side Tubing.)

(1) Tape the full-scale installation diagram on the wall

at the location selected. Make sure the unit is

horizontal using a level or tape measure to

measure down from the ceiling. (Fig. 3-25)

(2) Determine if the hole is to be drilled at the left or

right hole location.

(3) Before drilling a hole, check that there are no

studs or pipes behind the determined location.

KH(S)3072R, KH(S)3672R

Avoid any area where electrical

wiring or conduit is located.

Also take this precaution if the

tubing goes through a wall at

any other location.

(4) Using a sabre saw, key hole saw or 3-5/32 in.

hole-cutting drill attachment, make a hole in the

wall. The required minimum hole diameter for

these models is 3-3/16 in. (Fig. 3-26)

(5) Measure the thickness of the wall from the inside

edge to the outside edge and cut PVC pipe at a

slight angle 1/4 in. shorter than the thickness of

the wall. (Fig. 3-27)

(6) Place the plastic cover over the end of the pipe,

(for indoor side only) and insert in the wall.

(Fig. 3-28)

Fig. 3-25

Fig. 3-26

Fig. 3-27

Fig. 3-28

Hole should be made at a slight downward slant to

the outdoor side.

07-115 SSHP_II 5/7/07 3:59 PM Page 35

CAUTION

NOTE

Tape

Full-scale

installation diagram

Indoor

side

Outdoor

side

PVC pipe (locally purchased)

Cut at slight angle

INSIDE

Plastic

cover

Wall

OUTSIDE

PVC pipe

Slight

angle

Page 36

36

K

Remove and discard the set screws and take off the

wall fixture. (Fig. 3-29)

(1) Tape the full-scale installation diagram on the wall

at the location selected. Make sure the unit is horizontal using a level or tape measure to measure

down from the ceiling. (Fig. 3-30)

(2) Before drilling a hole, check that there are no studs

or pipes behind the determined location.

KHH(S)2672R

KHH(S)2672R

Avoid any area where electrical

wiring or conduit is located.

Also take this precaution if the

tubing goes through a wall at

any other location.

Fig. 3-29

Fig. 3-30

(3) Using a sabre saw, key hole saw or 3-5/32 in.

hole-cutting drill attachment, make a hole in the

wall. The required minimum hole diameter for

these models is 3-3/16 in. (Fig. 3-31)

(4) Measure the thickness of the wall from the inside

edge to the outside edge and cut PVC pipe at a

slight angle 1/4 in. shorter than the thickness of

the wall. (Fig. 3-32)

(5) Place the plastic cover over the end of the pipe,

(for indoor side only) and insert in the wall.

(Fig. 3-33)

Fig. 3-31

Fig. 3-32

Fig. 3-33

Hole should be made at a slight dowward slant to the

outdoor side.

07-115 SSHP_II 5/7/07 3:59 PM Page 36

Wall fixture

Set screws only for transportation

lacs-lluF

Tape

noitallatsni e

margaid

CAUTION

NOTE

Indoor

side

Outdoor

side

PVC pipe (locally purchased)

INSIDE

Plastic

cover

Cut at slight angle

Wall

OUTSIDE

PVC pipe

Slight

angle

Page 37

37

K

3-12. Installing the Rear Panel on the Wall

Be sure to confirm that the wall is strong enough to suspend

the unit.

See either Item a) or b) below depending on the wall type.

a) If Wooden Wall

(1) Attach the rear panel to the wall with the 10 screws provid-

ed. (Fig. 3-34)

If you are not able to line up the holes in the rear panel

with the beam locations marked on the wall, use toggle

bolts to go through the holes on the panel or drill 3/16 in.

dia. holes in the panel over the stud locations and then

mount the rear panel.

(2) Double-check with a ruler or carpenter’s level that the

panel is level. This is important to install the unit properly.

(Fig. 3-35)

(3) Make sure the panel is flush against the wall. Any space

between the wall and unit will cause noise and vibration.

b) If Block, Brick, Concrete or Similar Type Wall

Make 3/16" dia. holes in the wall. Insert rawl plugs for appropriate mounting screws. (Fig. 3-36)

Confirm that the wall is strong enough to support the unit.

a) If Wooden Wall

(1) Attach the wall fixture to the wall with the 12 screws pro-

vided. (Fig. 3-37) If you are not able to line up the holes in

the wall fixture with the beam locations marked on the

wall, use rawl plugs or toggle bolts to go through the holes

on the panel or drill 3/16 in. dia. holes in the wall fixture

over the stud locations.

(2) Check with a tape measure or carpenter’s level that the

wall fixture is level. This is important so that the unit is correctly installed.

(3) Make sure the wall fixture is flush against the wall. Any

space between the wall and unit will cause noise and

vibration.

b) If Block, Brick, Concrete or Similar Type Wall

Make 3/16 in. dia. holes in the wall. Insert rawl plugs for

appropriate mounting screws. (Fig. 3-36)

KH(S)2672R

Fig. 3-36

Fig. 3-37

KH(S)3072R, KH(S)3672R

Fig. 3-35

Fig. 3-34

07-115 SSHP_II 5/7/07 3:59 PM Page 37

1-3/16

3/16

dia. hole

Rawl plug

(Field supply)

Wall fixture

"

or more

"

Page 38

38

K

Confirm that the wall is strong enough to support the

unit.

a) If Wooden Wall

(1) Attach the wall fixture to the wall with the 9 screws

provided. (Fig. 3-38)

If you are not able to line up the holes in the wall

fixture with the beam locations marked on the wall,

use rawl plugs or toggle bolts to go through the

holes on the panel or drill 13/64 in. dia. holes in the

panel over the stud locations and then mount the

wall fixture.

(2) Check with a tape measure or carpenter’s level

that the wall fixture is level. This is important so

that the unit is correctly installed.

(3) Make sure the wall fixture is flush against the wall.

Any space between the wall and unit will cause

noise and vibration.

b) If the Wall is Brick, Concrete or Similar

Drill 3/16 in. dia. holes in the wall. Insert rawl plugs for

appropriate mounting screws. (Fig. 3-39)

KHH(S)2672R

Fig. 3-38

Fig. 3-39

07-115 SSHP_II 5/7/07 3:59 PM Page 38

wall fixture

3/16 in.

dia. hole

Rawl plug

Page 39

39

K

3-13. Remove the Grille to Install the Indoor Unit

Basically, these models can be installed and wired

without removing the grille. If access to any internal

part is needed, follow the steps given below:

How to remove the grille

(1) Set the 2 flaps in the horizontal position.

(2) Unscrew the 3 screws. (Fig. 3-40a)

(3) Remove the grille.

(a) Hold both corners of the air intake grille, then

pull out and up to open. (Fig. 3-40b)

(b) Use a standard screwdriver to push up the 3

tabs to remove the grille. (Fig. 3-40b)

(c) Pull the lower part of the grille toward you to

remove. (Fig. 3-40a)

How to replace the grille

(1) Close the flaps.

(2) Reinstall the grille into the lower part while aligning

its tabs on the upper part. (Fig. 3-41a) Insert the

tabs in the slots and push the lower part of the

grille back into position.

(3) Press at each of the 5 tabs to completely close the

grille. Make sure that the grille and frame are firmly

fitted together. (Fig. 3-41b)

KH(S)2672R

Fig. 3-40a

Fig. 3-40b

Fig. 3-41a

Fig. 3-41b

07-115 SSHP_II 5/7/07 3:59 PM Page 39

Grille

Air-intake grille

Air-intake grille

Page 40

40

K

How to Remove the Grille

(1) Remove the plastic cover. (Fig. 3-42)

(2) Remove the clamp for the wiring connector.

(Fig. 3-43)

(3) Disconnect the 2 wiring connectors. (Fig. 3-44)

(4) Set the flap in the horizontal position. (Fig. 3-45)

(5) Remove the 3 screws. (Fig. 3-45)

(6) Remove the grille. (Fig. 3-45)