Page 1

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

NOTICES

1. The contents stated in this document and the product may be subject to

change without prior notice.

When you kindly study to use this product, please ask our distributor or us

for the latest information.

2. This product is developed and produced for usage onto normal electronic

products (office automation equipments, communication peripherals, electric

appliance products, game machines, etc.) and is not suitable for applications

which need extremely high reliability or extreme safety (aero- or space-use

machines, control equipments for nuclear power, life keeping equipments,

etc.).

3. This document shall not grant or guarantee any right to adapt intellectual

property or any other patents of third party.

4. Please use this product correctly according to operating conditions and

precautions for use stated in this document.

Please install safety proof in your designing to avoid human accident, fire

accident and social damage, which may be resulted from malfunction of this

product.

www.panelook.com

5. This product is not designed to withstand against radiant rays.

6. It is strictly prohibited to copy or publish a part or whole of this document

without our prior written approval.

REVISION HISTORY

DATE REVISION

NO.

Jul.8,04 Ver. 1 - Initial Release

Oct.22,04 Ver. 2

Mar.29,04 Ver. 3

SANYO EPSON IMAGING DEVICES

CORPORATION

PAGE DESCRIPTIONS

Weight:TBD->690 TYP. 2

Power Supply current:TBD->250

3 Color of CIE coordinate Rx,y;Gx,y;Bx,y:TBD->(xxx)

4

8 DCLK f

2,3,4,9,11 (xxx)->xxx

8

9 Eliminate the Duty,tSI,tHP,tSD,tHD: (xxx)->xxx

11

BACKLIGHT CHARACTERISTIC:TBD->xxx

:(41)->(50.8),DE fH(40)->(48.1),DE fV:(62)->(75)

CLK

Add the INTERFACE (LVDS) SIGNAL TIMING PARAMETERS

POWER ON/OFF SEQUENCE REQUIREMENT

Add the VCM

Change the character: VIH -> VTH

Change the character: V

TM121SVA01

IL -> VTL

Ver. 3

Page

1/16

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

MECHANICAL CHARACTERISTICS

ITEM SPECIFICATION UNIT

Module size 280.0(W) x 218.0(H) x 11.5 Typ.(t) mm

Resolution

Sub pixel pitch 0.1025(W) x 0.3075(H) mm

Pixel pitch 0.3075(W) x 0.3075(H) mm

Active viewing area 246.0(W) x 184.5(H) mm

Bezel opening area 249.0(W) x 187.5(H) mm

Weight 690 TYP. g

ELECTRICAL ABSOLUTE MAXIMUM RATINGS

ITEM SYMBOL MIN MAX UNIT NOTE

Power supply voltage VDD-VSS 0 4.0 V

Input voltage VI Vss-0.3 VDD+0.3 V

Lamp current IL - 8 mA

Lamp supply voltage

www.panelook.com

Ta=25 degC

800 x R㨯G㨯B(W) x 600(H)

Ta=25 degC

VHV - 2000 Vrms

V

LGND - 100 Vrms

pixel

ENVIRONMENTAL ABSOLUTE MAXIMUM RATINGS

ITEM SYMBOL CONDITIONS MIN MAX UNIT NOTE

TST Storage -20 60 Ambient

temperature

Humidity - Ta=40 degC max. - 85 %RH No condensation

Vibration - Storage - 1.5 G Note 3

Shock - Storage - 50 G XYZ 11ms/direction

OP Operation 0 50

T

degC Note 1

Note 2

[Note 1] Care should be taken so that the LCD module may not be subjected to the

temperature beyond this specification.

[Note 2] Ta>40 degC : Absolute humidity shall be less than that of 85%RH/40 degC.

[Note 3] 10-200Hz, 30min/cycle, X/Y/Z each one cycle and except for resonant frequency.

Ta=25 degC

ELECTRICAL CHARACTERISTICS

V

ITEM SYMBOL CONDITIONS MIN TYP MAX UNIT NOTE

Power supply voltage VDD-VSS 3.0 3.3 3.6 V

LVDS input

Threshold voltage

Common mode

voltage of LVDS input

LVDS input

Termination resistor

Power Supply current IDD Note 1 - 250 - mA

VTH High level - - +100

V

TL Low level -100 - -

CM 1.125 1.25 1.375 V

V

T - 100 - ohms Internal

R

DD=3.3V, fCLK=40MHz ,fH=38kHz, fV=60Hz, Ta=25 degC

mV V

CM=1.25V

[Note 1] Under the following display image :

Typical Value: Display pattern is 64 gray scale bar.

[Note 2] V

SANYO EPSON IMAGING DEVICES

CM : Common mode voltage of LVDS input

CORPORATION

TM121SVA0 1 Ver. 3

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Page

2/16

www.panelook.com

Page 4

Ǿ

Ǭ

Ǿ

Ǿ

ǰ

ǰ

ǰ

Ǿ

ǰ

Ǿ

Ǿ

r

㱢

㱔

㱔

㱔

㱔

㱔

㱢

㱔

㱐

㱐

Global LCD Panel Exchange Center

OPTICAL CHARACTERISTICS

ITEM

Brightness B

Brightness uniformity

Contrast ratio CR

Viewing angle range

Rise tr - 30 - Response

time

Color of

CIE

coordinate

Fall tf

Red

Green

Blue

White

www.panelook.com

Ta=25 degC, VDD=3.3V, fCLK=40MHz, fH=38kHz, fV=60Hz

SYMBOL

B

CONDITIONS MIN TYP

=0 deg.

=0 deg.

=0 deg.

= 0 deg.

CR>10

=0 deg.

= 90 deg.

=180 deg.

=270 deg.

- 340 -

- - 1.45 -

- 300 - -

- 40 -

- 50 -

- 20 -

- 50 -

- 20 x - 0.60 y - 0.35 x - 0.32 y - 0.56 x - 0.15 -

=0 deg.

y - 0.13 x 0.31 0.34 0.37

y

0.32 0.35 0.38

MAX

UNIT NOTE

cd/m

deg.

ms.

Note

2

5,7,8

Note

6,7,8

Note

2,4,8

Note 1,2,

4,8

Note

3,4,8

- Note 4,8

=180deg.

=270deg.

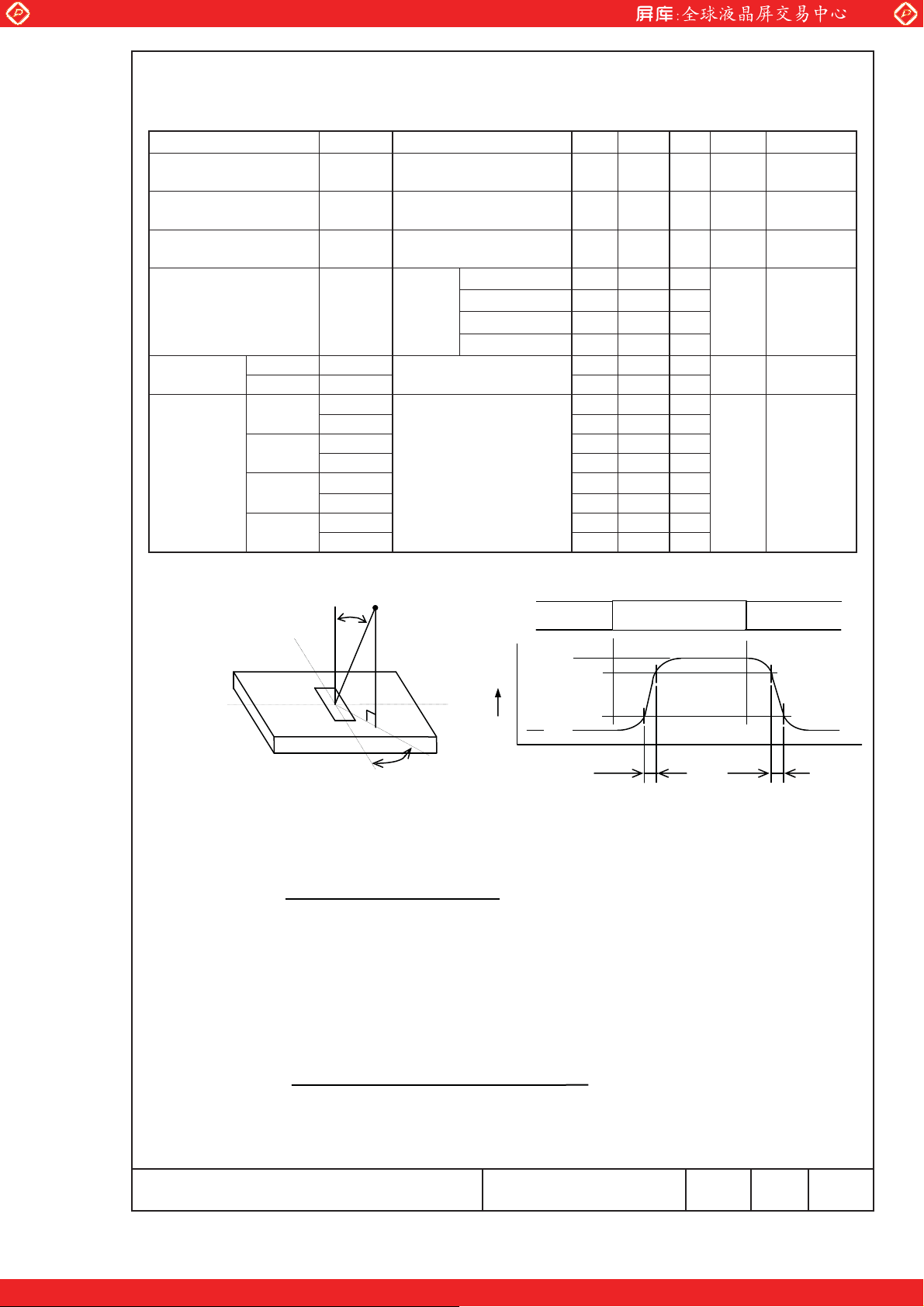

[Note 1] and [Note 3] Response time

=0deg.

=90deg.

B

Black Black

100%

90%

10%

0%

t

[Note 2] Contrast ratio "CR" is defined as :

Brightness at White

CR =

Brightness at Black

[Note 4] This shall be measured at center (point No.3 shown in Note 7).

[Note 5] The brightness shall be the average of five points.

[Note 6] The brightness uniformity "

B" is defined as :

Maximum brightness of five points

B =

Minimum brightness of five points

White DATA

tf

SANYO EPSON IMAGING DEVICES

CORPORATION

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

TM121SVA01

Ver. 3

Page

3/16

www.panelook.com

Page 5

Global LCD Panel Exchange Center

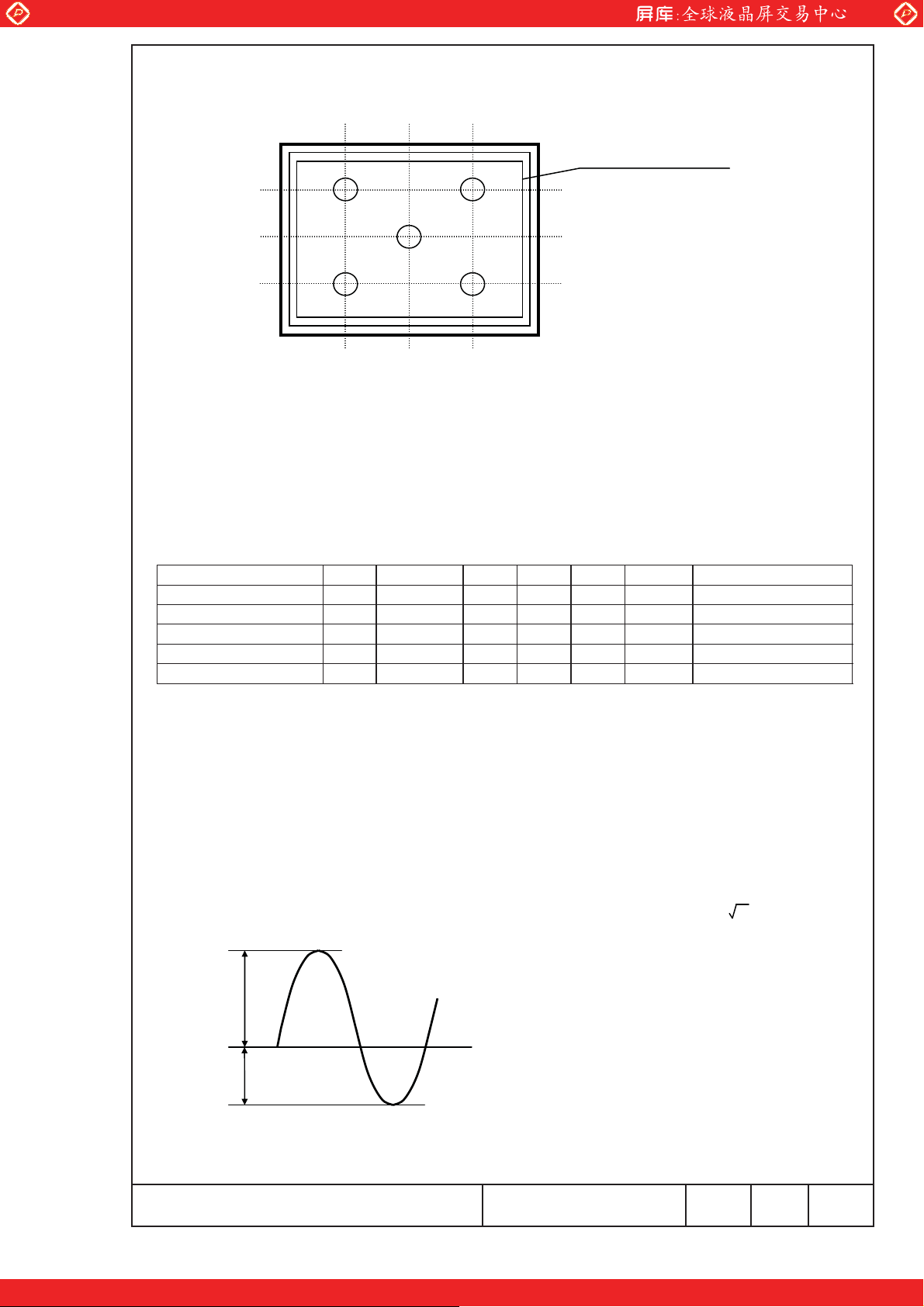

[Note 7] Measurement points

1/6Vp

www.panelook.com

5/6Hp1/2Hp1/6Hp

Active area

1 2

1/2Vp

5/6Vp

4

3

5

Vp: Total Number of Vertical pixel

Hp: Total Number of horizontal pixel

[Note 8] Measurement condition

(1) Measurement equipment: BM-5A (TOPCON Corp.), Field=2 degree

(2) Ambient temperature Ta: 25 +/- 2 degC

(3) LCD: All pixels are WHITE, V

DD=3.3V, fCLK=40MHz, fH=38kHz, fV=60Hz

(4) Measure after 30 minutes of CFL warm up.

(5) I

L=6.0mArms with the CFL inverter CXA-P1212-VJL (TDK).

BACKLIGHT CHARACTERISTICS

ITEM SYM. CONDITIOS MIN TYP MAX UNIT NOTE

Lamp voltage VL - 510 - Vrms at IL=6.0mArms

Lamp current IL 3 - 8 mArms

Operating frequency fL 40 - 65 kHz

Start up voltage VS - - 1300 Vrms at Ta=0 degC

Lamp life

tOL

Ta=25 degC

Recommended value

Recommended value

50000

- - Hours at IL=6.0 mArms

[Note 1] Backlight driving conditions (operating frequency fL especially) may interfere

with horizontal frequency f

Therefore the operating frequency f

horizontal frequency f

H, causing the beat or flicker on the display.

L shall be adjusted in relation to

H to avoid interference.

[Note 2] The inverter open voltage should be larger than start up voltage, otherwise backlight

may blinking for a moment after turns on or not be turned on. And this voltage

should be applied to lamp for more than 1 second to start up, otherwise backlight

may not be turned on.

[Note 3] If driving current waveform is asymmetrical, mercury deviation inside of CFL will

incline to one side and consequently abnormal lighting may occur.

To prevent such unfavorable lighting, driving current waveform is asked to have

unbalance rate of less than 10% and wave-height rate of less than 2 +/- 10%.

And this driving waveform shall be confirmed in your system.

Unbalance rate = | Ip - I-p | / IL x 100 (%)

Ip

I-p

Current waveform

Wave-height rate = I

I

p : High peak value

-p : Low peak value

I

I

L : Effective value

p (or I-p) / IL

[Note 4] The inverter of ground reference type should be used. The inverter of ground floating

type should not be used.

SANYO EPSON IMAGING DEVICES

CORPORATION

TM121SVA0 1 Ve r.3

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Page

4/16

www.panelook.com

Page 6

r

Global LCD Panel Exchange Center

www.panelook.com

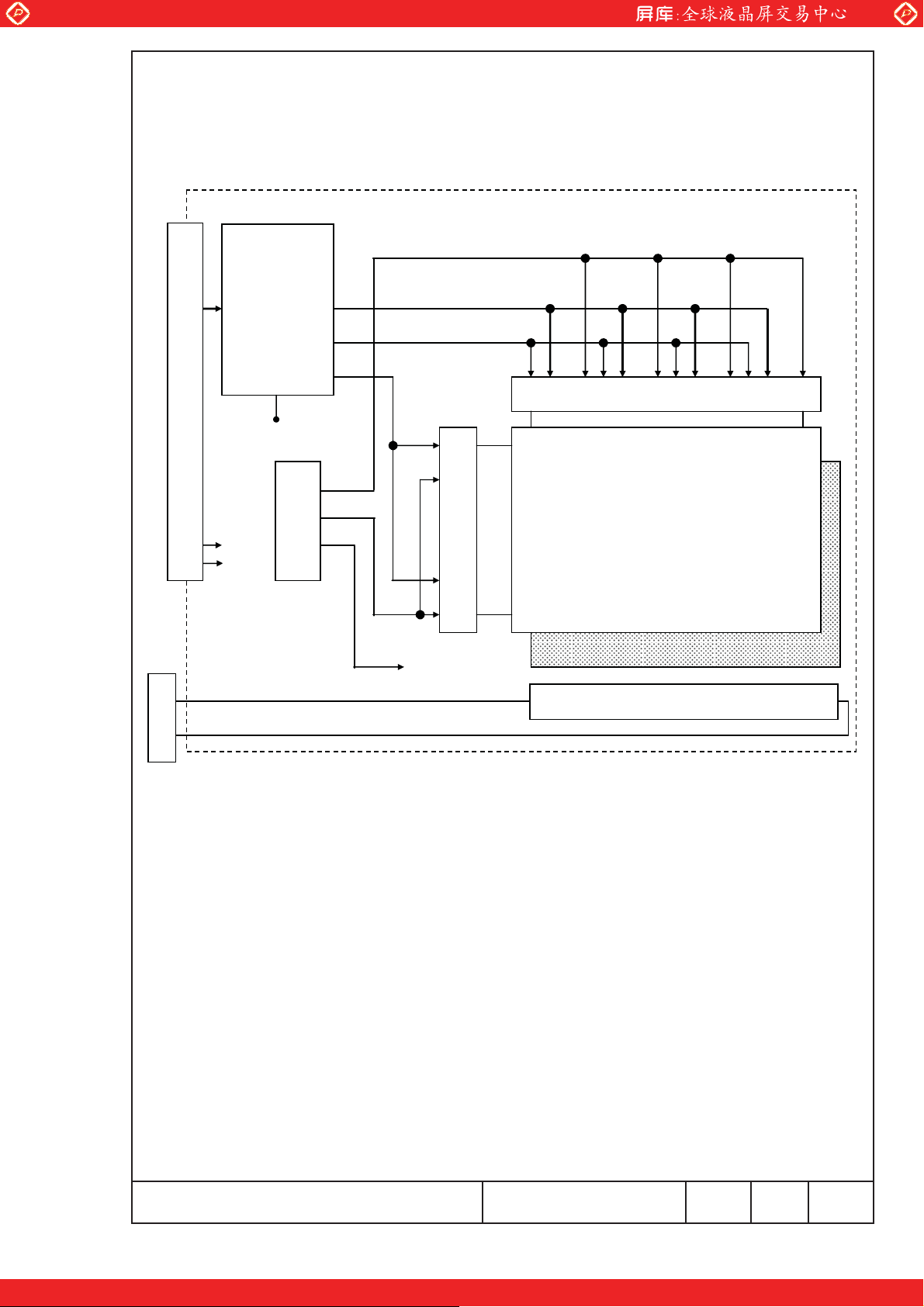

BLOCK DIAGRAM

ASIC

TFT

Timing

Generator

CN1

DE

VDD

VSS

DC/DC

(LVDS-Receiver)

Converter

DATA

Gate Drive

600

Source Driver

800(RGB)

TFT Panel

FLCN1,2

Back Light

Vcom

2CFL

SANYO EPSON IMAGING DEVICES

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

CORPORATION

TM121SVA01

Ver. 3

Page

5/16

www.panelook.com

Page 7

Global LCD Panel Exchange Center

INTERFACE PIN CONNECTIONS

LCM : CN1

PIN NO. SYMBOL FUNCTION

1 VDD Power Supply ( 3.3V normal)

2 VDD Power Supply ( 3.3V normal)

3 VSS Ground

4 VSS Ground

5 Rin0- Receiver Signal(-)

6 Rin0+ Receiver Signal(+)

7 VSS Ground

8 Rin1- Receiver Signal(-)

9 Rin1+ Receiver Signal(+)

10 VSS Ground

11 Rin2- Receiver Signal(-)

12 Rin2+ Receiver Signal(+)

13 VSS Ground

14 RCLK- Clock Signal(-)

15 RCLK+ Clock Signal(+)

16 VSS Ground

17 NC No Connection(Should be open during operation)

18 NC No Connection(Should be open during operation)

19 VSS Ground

20 NC No Connection(Should be open during operation)

www.panelook.com

CN1 : FI-SEB20P-HF10 (JAE)

Suitable mating connector: FI-S20S/FI-SE20M/FI-SE20MR(JAE)

[Note 1] Internal termination resistors of LVDS input lines are 100 ohms.

[Note 2] Valid synchronous signals are DCLK and DE. HSYNC and VSYNC are not used

Back Light : FLCN1,2

PIN NO. SYMBOL FUNCTION

1 H.V High voltage for CFL

2 N.C. No connection

3 LGND Low voltage for CFL

FLCN1,2 : BHR-03VS-1 (JST)

Suitable mating connector: SM02(8.0)B-BHS-1 (JST)

SANYO EPSON IMAGING DEVICES

CORPORATION

TM121SVA0 1 Ve r.3

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Page

6/16

www.panelook.com

Page 8

(

)

(

)

(

)

Global LCD Panel Exchange Center

INTERFACE (LVDS) DATA ASSIGNMENT

Rin0 +/-

Rin1 +/-

Rin2 +/-

RCLK +/-

Rxout 6

GO(LSB)

Rxout13

Rxout20 DERxout19

www.panelook.com

Rxout 5

R5

MSB

Rxout12

VSYNC

Rxout 4

R4

Rxout11

Rxout18

HSYNC

Rxout 3

R3

Rxout10

Rxout17

B5

MSB

Rxout 2

R2

Rxout 9

Rxout16

B4

Rxout 1

R1

Rxout 8

Rxout15 B3Rxout14

Rxout 0

R0

LSB

Rxout 7

B2

INTERFACE SIGNALS

SYMBOL FUNCTION

DCLK Data Clock

HSYNC Horizontal Sync - This signal initiates a new line (negative).

VSYNC Vertical Sync - This signal initiates a new frame (negative).

DE Data Enable (positive)

R0 Red Data (LSB)

R1 Red Data

R2 Red Data

R3 Red Data

R4 Red Data

R5 Red Data (MSB)

G0 Green Data (LSB)

G1 Green Data

G2 Green Data

G3 Green Data

G4 Green Data

G5 Green Data (MSB)

B0 Blue Data (LSB)

B1 Blue Data

B2 Blue Data

B3 Blue Data

B4 Blue Data

B5 Blue Data (MSB)

[Note 1] The valid synchronous signals are DCLK and DE. HSYNC and VSYNC are invalid.

[Note 2] INTERFACE SIGNALS are loaded from LVDS-transmitter to TFT Timing generator

with LVDS sequence. (See BLOCK DIAGRAM.)

SANYO EPSON IMAGING DEVICES

CORPORATION

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

TM121SV-A01 Ver.3

Page

7/16

www.panelook.com

Page 9

㩷

㩷

p

Global LCD Panel Exchange Center

INTERFACE (LVDS) SIGNAL TIMING PARAMETERS

LVDS INPUT TIMING Ta=25 degC, VDD=3.3V, fCLK=40MHz

PARAMETER SYMBOL

Input Data Position 0 tRIP1 tCLK=25.0ns -0.9 0.0 0.9 ns

Input Data Position 1 tRIP0 tCLK=25.0ns tCLK/7-0.9 tCLK/7 tCLK /7+0.9 ns

Input Data Position 2 tRIP6 tCLK=25.0ns 2tCLK/7-0.9 2tCLK/7 2tCLK /7+0.9 ns

Input Data Position 3 tRIP5 tCLK=25.0ns 3tCLK/7-0.9 3tCLK/7 3tCLK /7+0.9 ns

Input Data Position 4 tRIP4 tCLK=25.0ns 4tCLK/7-0.9 4tCLK/7 4tCLK /7+0.9 ns

Input Data Position 5 tRIP3 tCLK=25.0ns 5tCLK/7-0.9 5tCLK/7 5tCLK /7+0.9 ns

Input Data Position 6 tRIP2 tCLK=25.0ns 6tCLK/7-0.9 6tCLK/7 6tCLK /7+0.9 ns

㩷

tRIP2

tRIP3

tRIP4

tRIP5

tRIP6

tRIP0

tRIP1

www.panelook.com

CONDITION MIN TYP MAX UNIT

Rin x +/-

LVDS In

ut Data

RX1

RX0RX2 RX6 RX5

RX4 RX3 RX2 RX1

RX0

RCLK +/-

LVDS Input Clock

Figure 1 LVDS data-input-timing waveform diagram

tCLK

JITTER TOLERANCE Ta=25 degC, VDD=3.3V, fCLK=40MHz

PARAMETER SYMBOL MIN TYP MAX UNIT

Simple cycle jitter tcj1 - - 300 ps

Clock-period change rate tcj2 - - 25 ps/cycle

㩷 㩷

*This is the value when tRIP0-6 is the typical value written in the LVDS INPUT TIMING.

The simple cycle jitter is ordinary cycle jitter.

Assuming that the period of a given clock cycle

n is represented by tCLK , for example , the

period of cycle n +1 may be tolerated up to

tCLK ±300[ps]. However , if period fluctuations

continue , the limit to that change rate , rather

than this tolerable range , constitutes the

”clock-period change rate.”

In Figure 2, the lowest clock period during this

interval is 24.9 ns, and the highest clock period

is 25.3 ns. Therefore, the clock-period change

rate during this interval is calculated from the

equation shown below.

25.3-24.9=0.4[ns]

0.4 / 5(cycles)=0.08[ns]

Because a period fluctuation of 80 ps per cycle exists here, the rated ”clock-period change

rate” in the above table is not achieved.

25.4

25.3

25.2

25.1

period (ns)

25.0

24.9

24.8

0 50 100 150

Figure 2 Example of impermissible cycle jitter

cycle

SANYO EPSON IMAGING DEVICES

CORPORATION

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

TM121SVA01

Ver. 3

Page

8/16

www.panelook.com

Page 10

Global LCD Panel Exchange Center

INTERFACE SIGNAL TIMING PARAMETERS (DE_MODE)

PARAMETER SYMBOL MIN TYP MAX UNIT NOTE

DCLK Frequency fCLK 38 40 50.8 MHz tCLK=1/fCLK

Horiz. Period tHP 950 1056 1100 tCLK

Horiz. DE tHDE 800 800 800 tCLK

DE

[Note 1] These signal timing parameters are specified at the digital inputs of LVDS

[Note 2] The values in this table only show the normal operating conditions of internal logic

Horiz. Freq. fH 35 38 48.1 KHz fH=1/tHP

Vert. Period tVP 609 628 800 tHP fV=60Hz typical

Vert. DE nVDE 600 600 600 n

Vert. Freq. f

transmitter. With respect to setup time and hold time for DE and DATA signals,

please refer to input signal specification of LVDS transmitter.

Recommended LVDS transmitter : SN75LVDS84 (TI)

circuit, and it does not assure the conditions for appearance and display quality.

The conditions for appearance and display quality are shown in the inspection

standard separately.

www.panelook.com

V 57 60 75 Hz fV=1/tVP

INTERFACE SIGNAL TIMING DIAGRAM ( DE_MODE )

DE

DE

SANYO EPSON IMAGING DEVICES

Shrink

CORPORATION

tHDE

tHP

tVP

-----

TM121SV-A01 Ver.3

-

Page

9/16

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

RELATIONSHIP BETWEEN INPUT DATA AND DISPLAY COLOR

www.panelook.com

DISPLAY

COLOR

BASIC

COLOR

RED

GREEN

BLUE

INPUT DATA

R DATA G DATA B DATA

MSB LSB MSB LSB MSB LSB

R5 R4 R3 R2 R1 R0 G5 G4 G3 G2 G1 G0 B5 B4 B3 B2 B1 B0

BLACK L L L L L L L L L L L L L L L L L L

RED(63) H H H H H H L L L L L L L L L L L L

GREEN(63) L L L L L L H H H H H H L L L L L L

BLUE(63) L L L L L L L L L L L L H H H H H H

CYAN L L L L L L H H H H H H H H H H H H

MAGENTA H H H H H H L L L L L L H H H H H H

YELLOW H H H H H H H H H H H H L L L L L L

WHITE H H H H H H H H H H H H H H H H H H

BLACK L L L L L L L L L L L L L L L L L L

RED(1) L L L L L H L L L L L L L L L L L L

RED(2) L L L L H L L L L L L L L L L L L L

: : : :

: : : :

RED(61) H H H H L H L L L L L L L L L L L L

RED(62) H H H H H L L L L L L L L L L L L L

RED(63) H H H H H H L L L L L L L L L L L L

BLACK L L L L L L L L L L L L L L L L L L

GREEN(1) L L L L L L L L L L L H L L L L L L

GREEN(2) L L L L L L L L L L H L L L L L L L

: : : :

: : : :

GREEN(61) L L L L L L H H H H L H L L L L L L

GREEN(62) L L L L L L H H H H H L L L L L L L

GREEN(63) L L L L L L H H H H H H L L L L L L

BLACK L L L L L L L L L L L L L L L L L L

BLUE(1) L L L L L L L L L L L L L L L L L H

BLUE(2) L L L L L L L L L L L L L L L L H L

: : : :

: : : :

BLUE(61) L L L L L L L L L L L L H H H H L H

BLUE(62) L L L L L L L L L L L L H H H H H L

BLUE(63) L L L L L L L L L L L L H H H H H H

[Note 1] Color(n) --- 'n' indicates gray scale step.

RELATIONSHIP BETWEEN INPUT DATA AND DISPLAY POSITION

1㨯1 1㨯2 1㨯3

2㨯1 2㨯22㨯800

3㨯1

.

.

.

.

599㨯1 599㨯800

600㨯1 600㨯2

. . . . . . . . . .

SANYO EPSON IMAGING DEVICES

CORPORATION

. . . . . . . .

VpHp

RGB

TM121SVA01

1㨯799 1㨯800

600㨯799 600㨯800

Ver. 3

.

.

.

.

Page

10/16

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

POWER ON/OFF SEQUENCE REQUIREMENT

www.panelook.com

VDD

Logic input

CFL

Recommend

10%

0V

0< t1< 10ms

2< 40ms

0 < t

0V

100ms < t3

ON

OFF

Power-on

90%

15ms < t6< 200ms

0 < t5 < 20ms

VALID DATA

Power-off

90%

VTH

VTL

0ms < t4

10%

VCM

VDD=3.3V

1sec < t7

When the power is off, logic input must be kept at either low level or high impedance.

Power sequence for CFL (backlight) is not specified especially, however it is

recommended to consider some timing difference between logic input as shown above.

If backlight lights on before LCD starts function, or if backlight is kept on after LCD

stopped function, screen may look white for a moment or abnormal image may be

displayed.

This is caused by variation in output signal from timing generator at logic input on or

off. It does not cause damage to liquid crystal molecule and driving circuit.

SANYO EPSON IMAGING DEVICES

CORPORATION

TM121SVA01

Ver. 3

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Page

11/16

www.panelook.com

Page 13

Global LCD Panel Exchange Center

PRECAUTIONS (INSTRUCTIONS FOR SAFE AND PROPER USE)

1. Instructions for safety

(1) Please do not disassemble or modify LCD module to avoid the possibility of

electric shock, damage of electronic components, scratch at display surface and

invasion of foreign particles. In addition, such activity may result in fire accident

due to burning of electronic component.

LCD module disassembled or modified by customer is out of warranty.

(2) Please be careful in handling of LCD module with broken glass.

When the display glass breaks, please pay attention not to injure your fingers. The

display surface has the plastic film attached, which prevents dispersion of glass

pieces, however touching broken edge will injure your fingers. Also CFL (Cold

Cathode Fluorescent Lamp) is made of glass, therefore please pay attention in

the same way.

(3) Please do not touch the fluid flown out of broken display glass.

If the fluid should stick to hand or clothes, wipe off with soap or alcohol

immediately and then wash it with water. If the fluid should get in eyes, wash eyes

immediately with pure water for more than 15 minutes and then consult the doctor.

www.panelook.com

(4) Please make secure connection of CFL connector.

Please make sure that CFL connector from LCD module is connected with output

connector on inverter circuit securely. Poor connection may cause smoke or fire

accident due to high voltage in circuit. If connection may not be secure, please

switch off the power supply for LCD module and CFL and then make secure

connection.

Please do not make connection with another connector than recommended

mating connector.

(5) CFL contains mercury inside. Please follow regulations or rules established by

local autonomy at its disposal.

(6) Please be careful to electric shock.

Before handling LCD module, please switch off the power supply.

Since high voltage is applied to CFL terminal, cable, connector and inverter circuit

in operation mode, touching them will cause electric shock.

2. Instructions for designing

(1) Mounting of LCD

Please fix LCD module at all mounting flanges / holes shown in this specification

for installation onto system. The used screws should have proper dimensions.

Furthermore, designing of mounting parts should be adequate so that LCD

module is not warped or twisted, to achieve good display quality.

(2) Polarity of power supply for CFL

Please give careful consideration in designing so that each polar of cable should

be connected correctly at assembling (i.e. high voltage side is connected to high

voltage side and low voltage side is connected to low voltage side). Since longer

CFL cable may cause insatiable start-up of CFL and reduction of brightness,

please make cable short as much as possible.

SANYO EPSON IMAGING DEVICES

CORPORATION

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

TM121SVA01

Ver. 3

Page

12/16

www.panelook.com

Page 14

Global LCD Panel Exchange Center

(3) Power supply for CFL

Please design the circuit so that high voltage output can be kept for more than 1

second. The shorter time may not start up CFL. The driving inverter circuit is

recommended to be the type which CFL current can be controlled.

The type which voltage is controlled is not recommended, because it may cause

big current under high temperature and insatiable start-up of CFL under low

temperature.

If LCD display turned into reddish screen or remarkable brightness decreases by

the end of CFL life, please make a consideration of design that the backlight is

turned off immediately.

(4) Heat radiation

CFL generates heat at lighting and causes temperature rise inside system.

Therefore, designing to radiate heat like radiation slits at cabinet is recommended

to meet the specified operating temperature range for LCD module.

(5) Noise on power line

Spike noise contained in power line causes abnormal operation of driving circuit

and abnormal display. To avoid it, spike noise should be suppressed below VDD

+/- 200mVp-p. (In any case, absolute maximum rating should be kept.)

www.panelook.com

(6) Power sequence

Before LCD module is switched on, please make sure that power supply and input

signals of system, testing equipment, etc. meet the recommended power

sequence.

(7) Absolute maximum rating

Absolute maximum rating specified in this specification has to be kept in any case.

It shows the maximum that cannot be exceeded.

Exceeding it may cause burning or non-recoverable break of electronic

components in circuit. Please make system design so that absolute maximum

rating is not exceeded even if ambient temperature, input signal and components

are varied.

(8) Protection for power supply

Please study to adapt protection for power supply against trouble of LCD module,

depending on usage condition of system. Fuse installed on LCD module should

be never modified. Any modification to make the function of fuse ineffective may

cause burning or break of printed wiring board or other components at circuit

trouble.

(9) Protection against electric shock

High voltage is applied to CFL connector, inverter circuit and CFL at lighting.

Please make design not to expose or be accessible to such high voltage parts to

avoid electric shock.

(10) Protection cover and cut-off filter for ultraviolet rays

When LCD module is used under severe condition like outdoor, it is

recommended to use transparent protection cover over display surface to avoid

scratches and invasion of dust and water. In addition, when LCD module is

exposed to direct sun light for long time, use of cut-off filter for ultraviolet rays is

also recommended. Please be careful not to get condensation.

3. Instructions for use and handling

(1) Protection against Static electricity

C-MOS LSI and semiconductors are easily damaged by static discharge. LCD

module should be handled on conductive mat by person grounded with wrist strap

etc. to avoid getting static electricity. Please be careful not to generate static

electricity during operation.

SANYO EPSON IMAGING DEVICES

CORPORATION

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

TM121SVA01

Ver. 3

Page

13/16

www.panelook.com

Page 15

Global LCD Panel Exchange Center

(2) Protection against dust and stain

LCD module should be handled in circumstance as clean as possible.

It is recommended to wear fingerstalls or ductless and soft gloves before handling

to avoid getting dust or stain on display surface.

(3) Protection film for display surface

It is recommended to remove protection film at nearly final process of assembling

to avoid getting scratch or dust. To remove film, please pick up its edge with

dull-head tweezers or cellophane tape at first and then remove film gradually

taking more than 3 seconds. If film is removed quickly, static electricity may be

generated and may damage semiconductors or electronic components.

(4) Contamination of display surface

When display surface of LCD module is contaminated, please wipe the surface

softly with cotton swab or clean cloth. If it is not enough, please take it away with

cellophane tape or wipe the surface with cotton swab or clean cloth containing

benzine. In this case, please be careful so that benzine does not get in inside of

LCD module, because it may be damaged.

(5) Water drop on LCD surface

Please do not leave LCD module with water drop. When the display surface gets

water drop, please wipe it off with cotton swab or soft cloth immediately, otherwise

display surface will be deteriorated.

If water gets in inside of LCD module, circuit may be damaged.

www.panelook.com

(6) Please make sure that LCD module is not warped or twisted at installation into

system. Even temporary warp or twist may be the cause for failure.

(7) Mechanical stress

Please be careful not to apply strong mechanical stress like drop or shock to LCD

module. Such stress may cause break of display glass and CFL or may be the

cause for failure.

(8) Pressure to display surface

Please be careful not to apply strong pressure to display surface. Such pressure

may cause scratches at surface or may be the cause of failure.

(9) Protection against scratch

Please be careful not to hit, press or rub the display surface with hard material like

tools. In addition, please do not put heavy or hard material on display surface, and

do not stack LCD modules. Polarizer at front surface can be easily scratched.

(10) Plugging in of connector

Please be careful not to apply strong stress to connector part of LCD module at

plugging in or out, because strong stress may damage the inside connection. At

plugging in connector, place LCD module on the flat surface and hold the

backside of connector on LCD module. Please make sure that connector is

plugged in correctly. Insecure connection may be the cause for failure during

operation.

In addition, please be careful not to put the connecting cable between cabinet of

system and LCD module at installing LCD module into system.

(11) Handling of CFL cable and FPC (Flexible Printed Circuit)

Please be careful not to pull or scratch CFL cable, because CFL or soldered part

of cable may be damaged consequently.

Also FPC should not be pulled or scratched.

(12) Switching off before plugging in connector

Please make sure that power is switched off before plugging in connector.

If power is on at plugging in or out, circuit of LCD module may be damaged.

When LCD is switched on for test or inspection, please make sure that power

supply and input signals of driving system meet the specified power sequence.

SANYO EPSON IMAGING DEVICES

CORPORATION

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

TM121SVA01

Ver. 3

Page

14/16

www.panelook.com

Page 16

Global LCD Panel Exchange Center

(13) Temperature dependence of LCD display

Response speed (optical response) of LCD display is dependent on temperature.

Under low temperature, response speed is slower.

Also brightness and chromaticity change slightly depending on temperature.

(14) Slow light-up of CFL under low temperature

Under low temperature, start-up of CFL gets difficult. (The time from switch-on to

stable lighting becomes longer.)

As characteristic of CFL, operation under low temperature makes the life time

shorter. To avoid this, it is recommended to operate under normal temperature.

(15) Condensation

LCD module may get condensation on its display surface and inside in the

circumstance where temperature changes much in short time.

Condensation can cause deterioration or failure. Therefore, please be careful not

to get condensation.

(16) Remaining of image

Displaying the same pattern for long time may cause remaining of image even

after changing the pattern. This is not failure but will disappear with time.

www.panelook.com

4. Instructions for storage and transportation

(1) Storage

Please store LCD module in the dark place of room temperature and low humidity

in original packing condition, to avoid condensation that may cause failure.

Since sudden temperature change may cause condensation, please store in

circumstance of stable temperature.

(2) Stacking number

Since excessive weight causes deformation and damage of carton box, please

stack only up to the number stated on carton box for storage and transportation.

(3) Handling

Since LCD module consists of glass and precise electronic components, it will be

damaged by excessive shock and drop. Therefore, please handle the carton box

carefully to minimize shock at loading, reloading and transportation.

SANYO EPSON IMAGING DEVICES

CORPORATION

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

TM121SVA01

Ver. 3

Page

15/16

www.panelook.com

Page 17

Global LCD Panel Exchange Center

www.panelook.com

16/16

Page

Ver. 3

A01

TM121SV

CORPORATION

SANYO EPSON IMAGING DEVICES

Outer Dimensions

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Note : All dimensional tolerance +/- 0.5mm unless otherwise

FLCN1,2 :BHR-03VS-1(JST)

CNI :F1-SEB20P-HF10(JAE)

www.panelook.com

Loading...

Loading...