Sanyo STK6105 Specifications

Overview

The STK6105 is a hybrid IC incorporating a 3-phase

brushless motor controller and driver into a single

package, on the Sanyo IMST (Insulated Metal Substrate

Technology) substrate. Revolution speed is controlled

through the DC voltage level (Vref1) external input and

PWM control of motor phase winding current. The

driver is MOSFET to minimize circuit loss and handle

high-output current (rush current) demands.

Applications

• PPC and LBP drum motors

• Air conditioner fan motors

Features

• The output driver transistor is MOSFET for low power

loss (half that of a bipolar transistor) and reliable

handling of high-output current (rush current).

• Variation in Vref1level causes the driver transistor to

switch to PWM drive for high-efficiency motor speed

variation.

• Normal and reverse revolution select function.

• Start/stop and brake functions.

• Current limiter function.

52595TH (OT) / 12793YO No. 4345-1/11

Specifications

Maximum Ratings at Ta=25°C

Allowable Operating Ranges at Ta=25°C

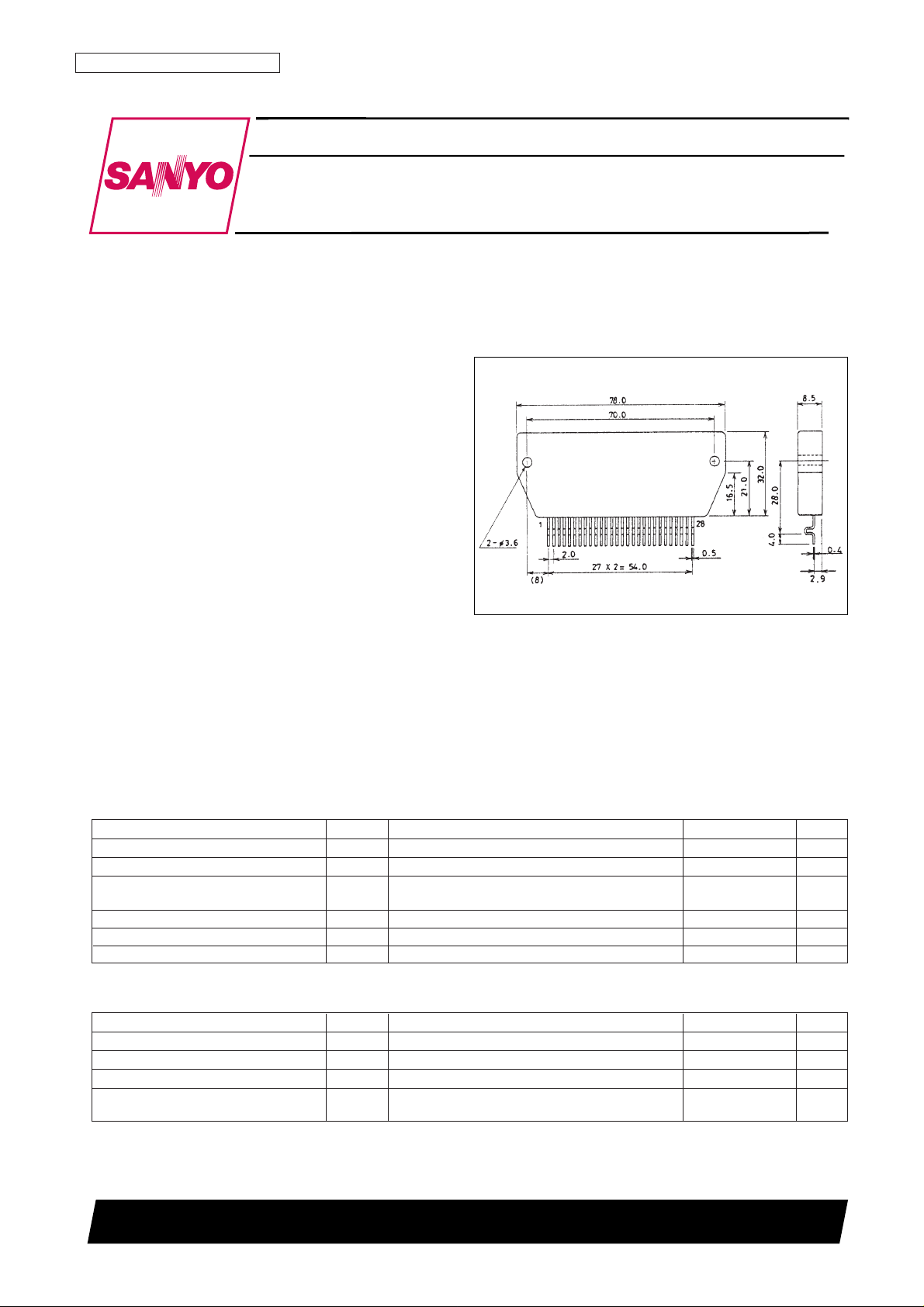

Package Dimensions

unit: mm

4130

[STK6105]

Thick Film Hybrid IC

Ordering number : EN4345A

STK6105

SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquarters

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

DC 3-phase Brushless Motor Driver

(Output Current 5A)

Parameter Symbol Conditions Ratings Unit

Maximum supply voltage 1 V

CC

1 max No input signal 50 V

Maximum supply voltage 2 V

CC

2 max No input signal 7 V

Maximum output current Io max

Position detect input signal cycle = 30 ms,

8A

PWM duty = 50%, operation time 1s

Operating substrate temperature Tc max 105 °C

Junction temperature Tj max 150 °C

Storage temperature Tstg -40 to +125 °C

Parameter Symbol Conditions Ratings Unit

Supply voltage 1 V

CC

1 With input signal 16 to 42 V

Output current Io ave DC phases present 5 A

Supply voltage 2 V

CC

2 With input signal 4.75 to 6.00 V

Brake current I

OB

80 Hz full sine waves (all phases).

11 A

Operating time 0.1 s, duty = 5% (see Note 1).

Electrical Characteristics at Tc=25°C, VCC1 = 24V, VCC2 = 5.0V

Parameter Symbol Conditions

Ratings

min typ max

Unit

Supply current 1 (pin 13) I

CCO

1 CW revolution 12 20 mA

Supply current 2 (pin 13) I

CCO

2 Braking 26 38 mA

Output saturation voltage 1 Vst1 V

CC

1 sideTR, Io = 5A 0.70 0.91 V

Output saturation voltage 2 Vst2 GND sideTR, Io = 5A 0.85 1.11 V

Internal MOSFET diode forward

V

F

IF= 5A 1.0 1.5 V

voltage

PWM oscillation frequency f

C

20 25 30 kHz

Current limiter reference voltage Vref2 0.78 0.83 0.88 V

Position detect input sensitivity V

H

20 500 mV

Position detect common mode range CMRH 2.0 4.5 V

Input “L” current 1 (pins 2,3) I

IL1

V

IL1

= GND 130 200 µA

Input “L” voltage 1 (pins 2,3) V

IL1

1.0 V

Input “L” current 2 (pin 4) I

IL2

V

IL2

= GND 570 910 µA

Input “L” voltage 2 (pin 4) V

IL2

1.0 V

Vref

1

“H” voltage Vref

1H

GND side transistor not in PWM 2.82 3.20 V

Vref1“L” voltage Vref

1L

GND side transistor off 0.15 0.35 V

Zener voltage V

Z

5.7 6.2 6.7 V

FG output current I

FGH

VFG= 1.6V 80 µA

FG output “L” voltage V

FGL

IFG= 0.3mA 0.4 V

FG output pulse width t

FG

CF= 0.1µF, RF= 10kΩ 0.9 1.0 1.1 ms

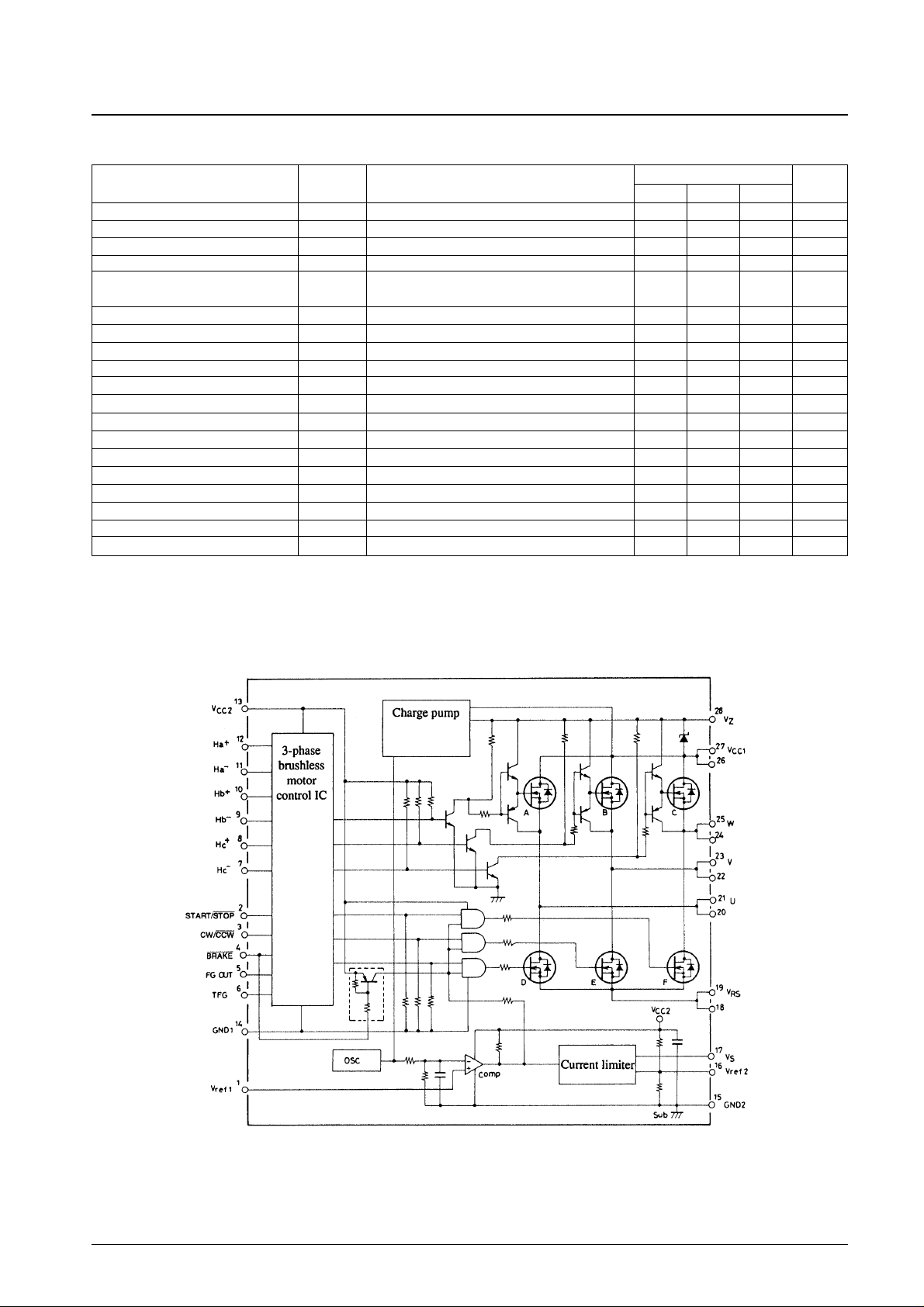

Equivalent Circuit

STK6105

No. 4345--2/11

Pin Functions

Pin No. Symbol Function

1 Vref

1

GND-side driver transistor PWM control pin; range 0.15 to 3.2V

2 START/STOP “H” = start, “L” = stop (all transistors off)

3 CW/CCW “H” = CW, “L” = CCW

4 BRAKE “H” = rotate, “L” = Only GND-side transistor on

5 FG OUT Position detect signal: output 6 pulses per cycle

6 TFG For setting FG OUT “L” level pulse width. R

F

and CFpins.

7 H

C–

Motor position detect signal input pin (to Hall device)

8 H

C+

Motor position detect signal input pin (to Hall device)

9 H

b–

Motor position detect signal input pin (to Hall device)

10 H

b+

Motor position detect signal input pin (to Hall device)

11 H

a–

Motor position detect signal input pin (to Hall device)

12 H

a+

Motor position detect signal input pin (to Hall device)

13 VCC2 Motor controller supply voltage pin

14 GND1 Motor controller IC GND pin; signal gnd (SG)

15 GND2 External R

S

GND-side connection pin; power gnd (PG)

16 Vref

2

Current limiter set pin; 0.167VCC2 when open.

17 V

S

External RScurrent limiter detect pin

18, 19 V

RS

External RSconnect pin

20, 21 U Output pin (to motor winding)

22, 23 V Output pin (to motor winding)

24, 25 W Output pin (to motor winding)

26, 27 V

CC

1 Supply voltage pin (to motor)

28 V

Z

Zener voltage (6.2V typ) for VCC1 driver transistor date source supply

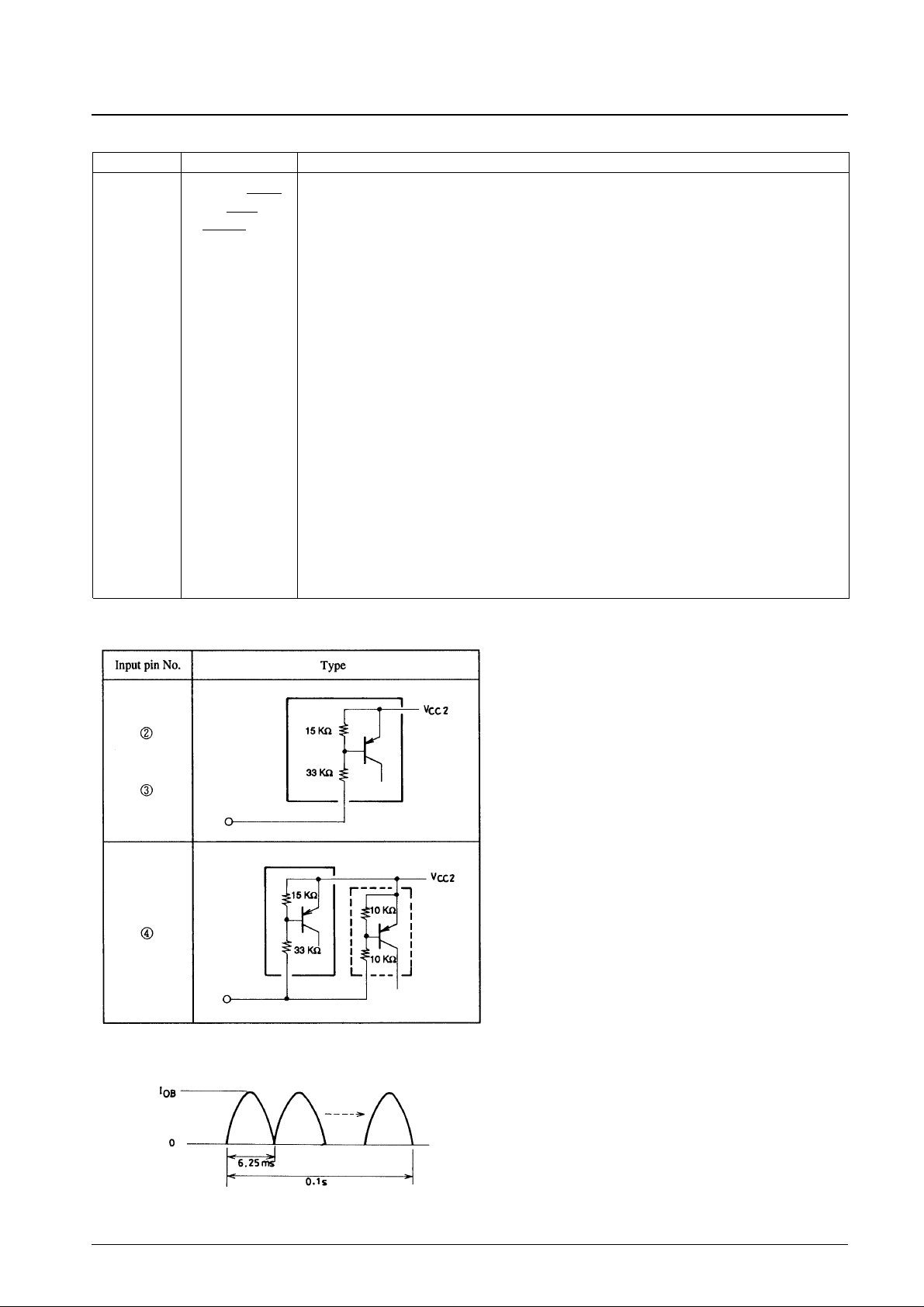

Input Type

Note 1: IOBindicates the operating current waveform peak as shown below.

STK6105

No. 4345--3/11

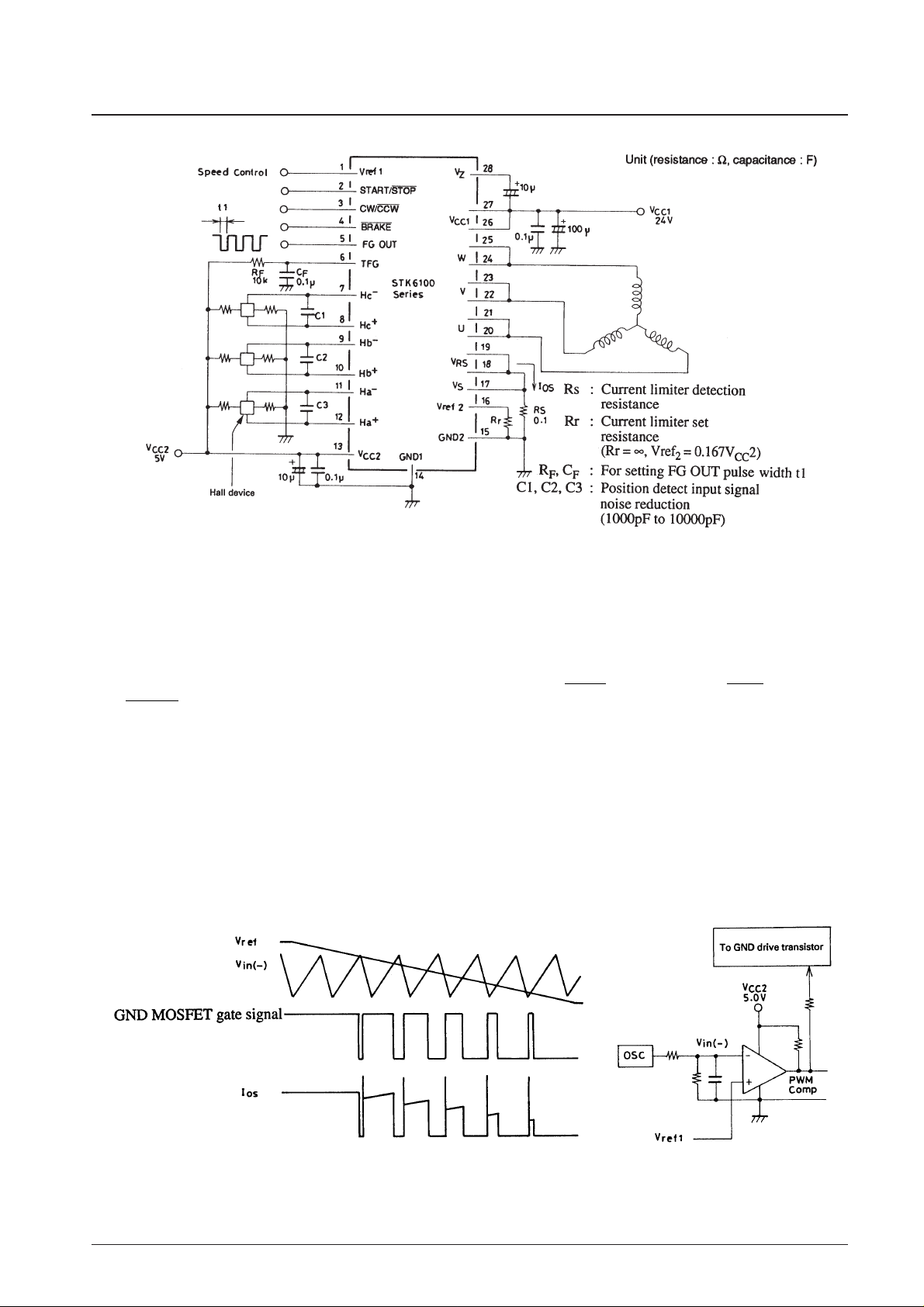

Sample Application Circuit

Description of Operation

The DC 3-phase brushless motor generally uses a permanent magnet for the rotor and places the stator coil around it.

When the rotor and stator coil are excited, magnetic force is generated between the poles, which is used for revolution

torque. For efficient revolution it is necessary to know precisely where the rotor pole is in relation to the stator pole. In

the brushless motor Hall devices and Hall ICs are widely used for this purpose, by detecting the electric power generated

along the lines of magnetic force.

(1) Motor rotating force

The block diagram for this HIC is given in Fig. 2.

The conditions before input of VCC1, with VCC2 on, are START/STOP pin H level, CW/CCW pin H level,

BRAKE pin H level and Vref1pin (speed control input) H level. The position detect signal at this time, due to the

effect of the rotor magnetic field, will be output signals from 1 or 2 devices (of the 3) so that HX+>HX–is input to

HIC pins 7-12. The signals input to pins 7-12 are input to the motor controller and converted into signals

compatible with 3-phase brushless motor revolution. When VCC1 is supplied the charge pump circuit activates,

generating VCC1 MOSFET gate voltage VZ. This outputs excitation current to the motor phase windings as

indicated in the timing chart (Fig. 3), and rotating the motor.

For revolution speed control, the Vref1pin voltage is converted and used for PWM drive to increase GND

transistor efficiency, controlling the conduction of motor current Io (Fig. 1). Control of Io means control of power

supplied to the motor, which controls motor rpm. In general motor rpm N is proportional to the PWM on duty

(when motor load is constant). The PWM on duty is proportional to the size of Vref1(see Fig. 13), and the relation

of N is as outlined below.

Ν ∝ PWM ON Duty ∝ Vref

1

Fig.1 PWM Drive Principle

STK6105

No. 4345--4/11

Loading...

Loading...