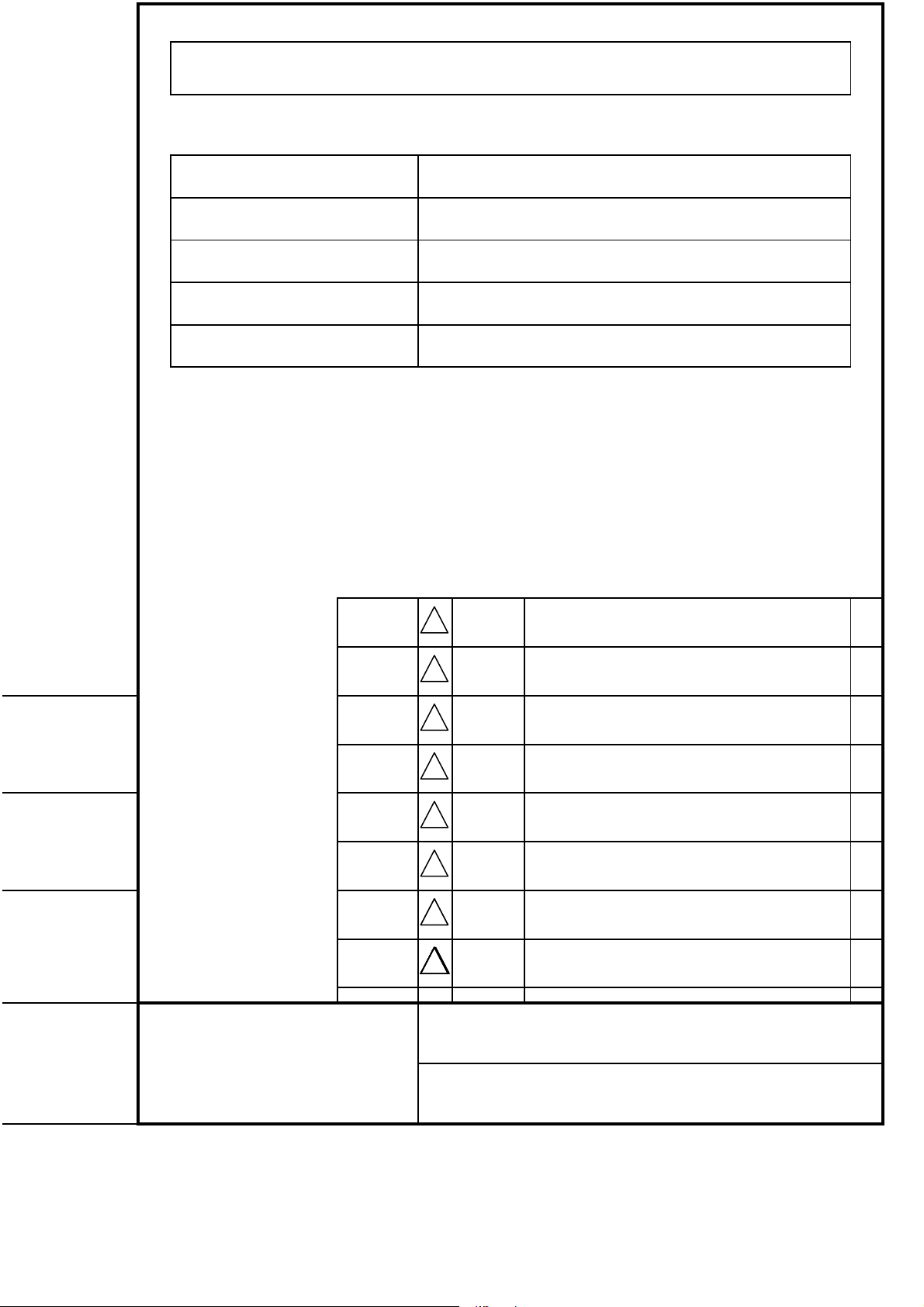

Page 1

INSTRUCTION MANUAL

FIRST MADE FOR SAP-KC9,12,18,25,30AP

MATERIAL OR MODEL *PAPER-JO

DIMENSION OR MAKER WOODFREE 80gm

COLOR BLACK Print

EZIS4AETON

APPROVALS

N.Yamazaki

2010/Feb/1

CHECK

Tai C.S

2010/Feb/1

DESIGN

Tai C S

2010/Feb/1

DRAWN

REMARKS:

SAMS ONLY

1

ON.RSNOISIVERETADSLAVORPPA

PART CODE

85S-6-4181-007-00-0

PART NAME

EXPLANATORY BOOKLET

Page 2

INSTRUCTION MANUAL

Split System Air Conditioner

INDOOOR UNIT OUTDOOR UNIT

COOL / DRY MODEL

SAP-K9AP

SAP-C9AP

SAP-K12AP SAP-C12AP

SAP-K18AP SAP-C18AP

SAP-K25AP SAP-C25AP

SAP-K30AP SAP-C30AP

HA1-PHA21K-PAS

Save These Instructions!

Pub. OI-85S64181007000 © SANYO 2010

SANYO Electric Co., Ltd.

Page 3

Instruction Manual

Features

Features

This air conditioner is equipped with cooling and drying functions. Details on these functions are

provided below; refer to these descriptions when using the air conditioner.

24-hour Clock with ON/OFF

Program Timer

The remote control unit allows you

to set a wide variety of timer-based

operations including automatic

ON/OFF with timer setting, sametime ON/OFF every day, ON timer,

OFF timer and Combination timer.

Mild Dry

By coupling the compressor and

fan operation, intermittent drying

can be precisely controlled

according to room temperature so

that air is efficiently dehumidified.

Auto Clean

Fan operates when the unit is

stopped to prevent the generation

of mould and odors within the

indoor unit.

Automatic Fan Operation

Convenient microprocessor control

automatically adjusts fan speed to

High, Medium or Low, according to

room temperature to maintain a

comfortable airflow throughout the

room.

Air Sweep Control

The air sweep function moves the

flap up and down in the air outlet,

directing air in a sweeping motion

around the room and providing

comfort to every corner.

Automatic Restart Function for

Power Failure

Even when power failure occurs.

Preset programmed operation is

Reactivated once power resumes.

Humanized Sleep Function

Temperature gently rises or falls

automatically to maintain

comfortable room temperature and

saves energy.

Rapid Cooling

The high-efficient system makes

Cooling fast but still remains high

EER/COP.

Super Quiet

Specially-designed air vent

efficiently reduce noise.

Turbo

Cools the room intensely.

Self Diagnosis

Error code is displayed for fast and

easy maintenance, should a

problem occurs.

Low Voltage Startup (Min.198V)

The unit starts safely even when

the voltage is below the rated

voltage.

Child Lock

Remote controller keys are

lockable to prevent misoperation.

Blue Fin

Anti-corrosion blue fin is more

effective than a common coil.

1

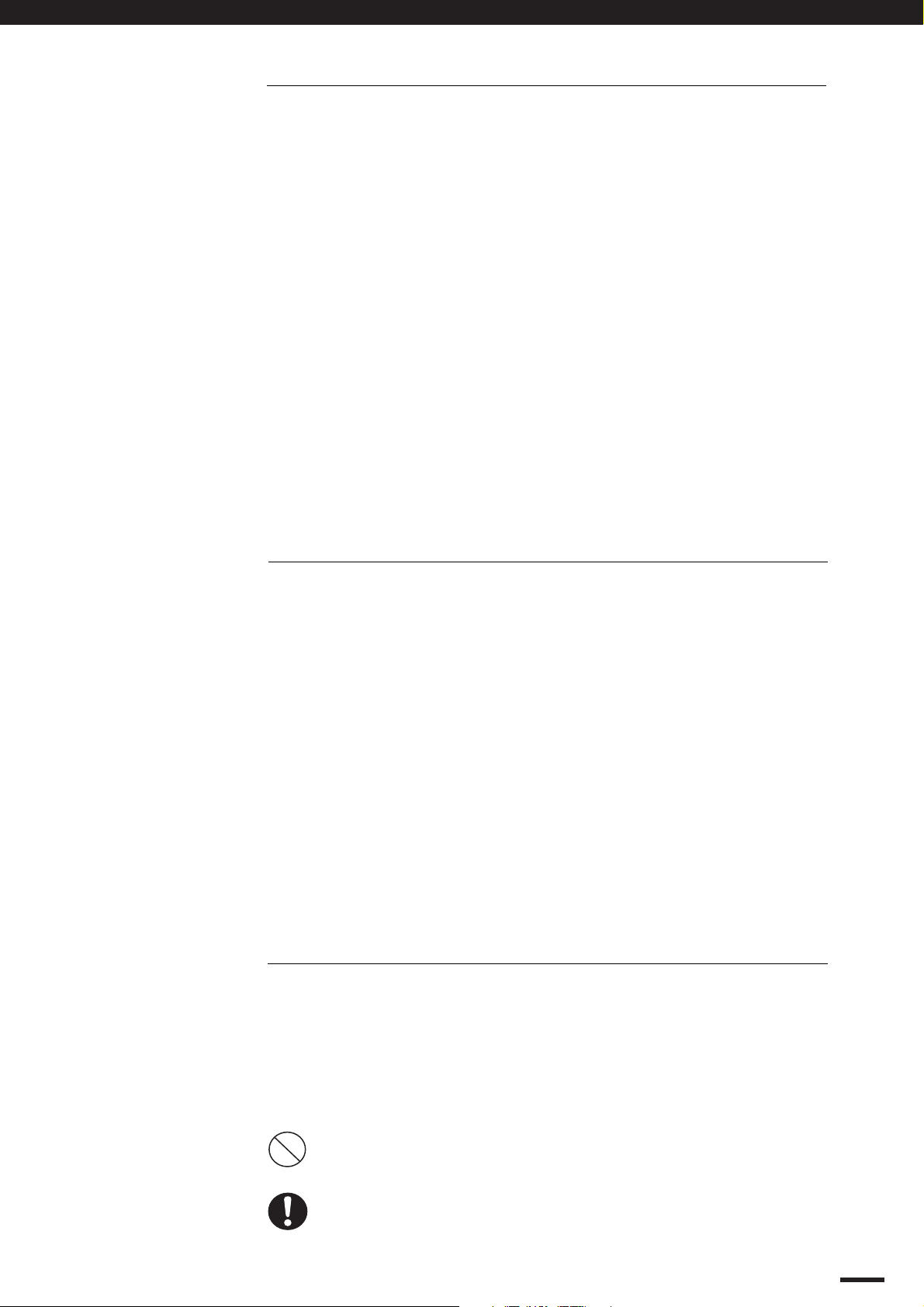

Page 4

Instruction Manual

Contents

Instruction Manual

Page

Features

...............................................

................................. 1

Operation and Maintenance

1. Notices for operation .............................................................

2. Notices for user .................................................................

3. Names and functions of each part .....................................

4. Operation of wireless remote control unit ..........................

5. Clean and care .................................................................

6. Troubleshooting ................................................................

Installation Service

7. Notices for installation ...........................................................

8. Installation dimension diagram . ........................................

9. Install indoor unit ..............................................................

10. Install outdoor unit ............................................................

11. Pump down .......................................................................

12. Check after installation and Test operation ......................

13. Self diagnosis function .....................................................

3

5

6

7

15

17

19

21

22

26

32

33

34

Product Information

If you have problems or questions concerning your Air Conditioner,

you will need the following information. Model and serial numbers

are on the nameplate on the bottom of the cabinet.

Model No. _______________Serial No. _____________________

Date of purchase _______________________________________

Dealer’s addres _______________________________________

Phone number_________________

Thank you for choosing SANYO air conditioner, please read

this instruction manual carefully before operating the unit

and keep it carefully for consultation.

Alert Symbols

The following symbols used in this manual, alert you to

potentially dangerous conditions to users, service personnel

or the appliance:

This symbol stands for the items should be forbidden.

This symbol stands for the items should be followed.

2

Page 5

Operation and Maintenance

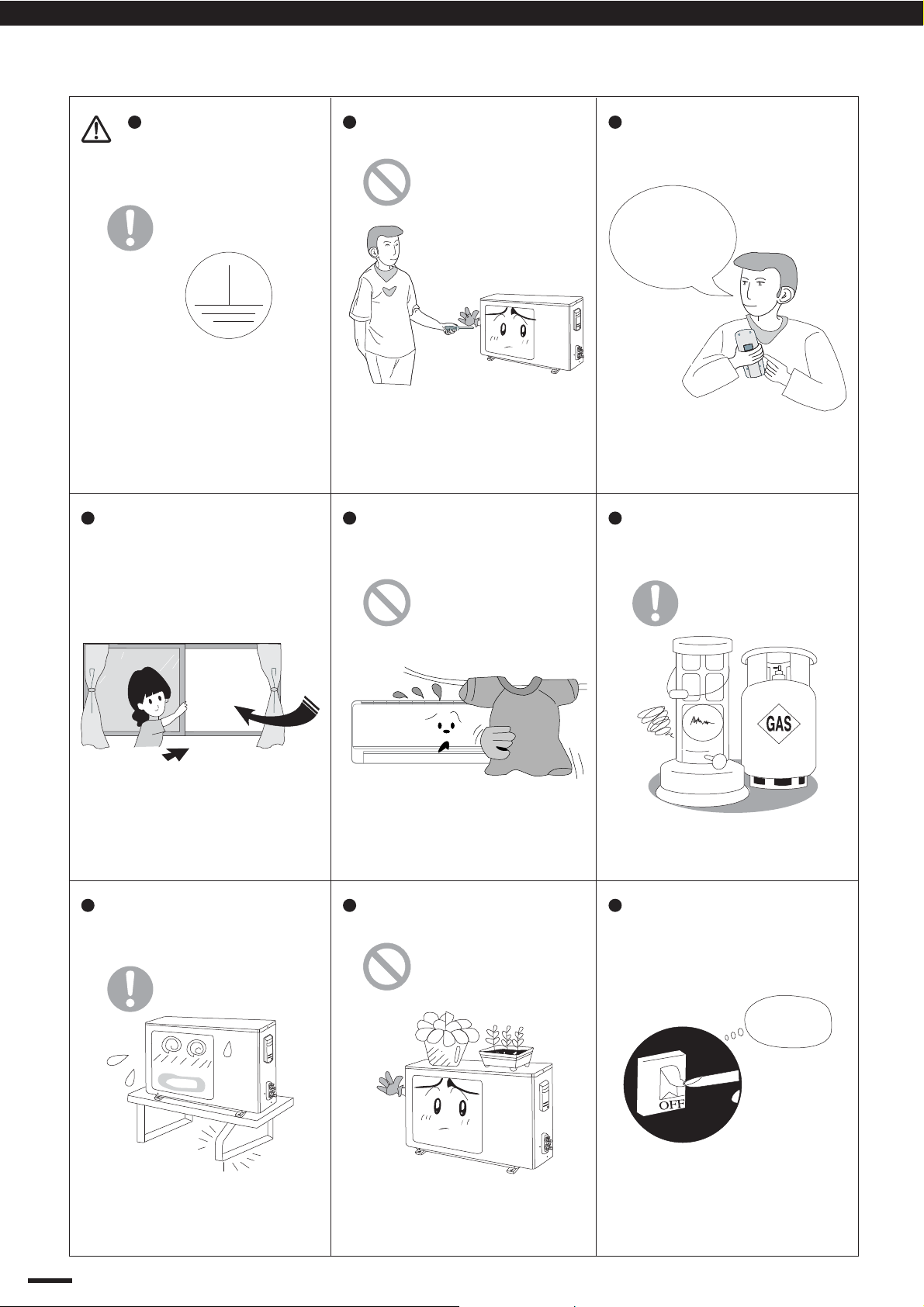

1. NOTICES FOR OPERATION

Each unit must be

properly grounded with a

ground (or earth) wire or

through the supply wiring.

If not, please ask the qualified

personnel to install.

Furthermore, do not connect

each wire to the gas pipe,water

pipe, drainage pipe or any other

improper places.

Don't leave windows and doors

open for a long time while operating

the air conditioner.

Don't attempt to repair the air

conditioner by yourself.

The wrong repair will lead to an

electric shock or fire, so you

should contact the SANYO

service center for repair.

Don't block the air intake or outlet

vents of both the outdoor and indoor

units.

Select the most appropriate

temperature.

Keep room

cooler than

outside about

o

5 C.

It can help to preclude the

electricity wasted.

Never use or store gasoline or

other flammable vapor or liquid

near the air conditioner.

It can decrease the air

conditioning capacity.

Please make sure whether

the installed stand is firm

enough or not.

If it is damaged, it may lead to

the fall of the unit and cause the

injury.

It can decrease the air conditioning

capacity or cause a malfunction.

Do not step on the top of the

outdoor unit or place things on it.

As falling off the outdoor unit can

be dangerous.

It is very dangerous and it may

cause a fire or explosion.

If abnormal phenomenon (like

burning odor, etc) occur, turn off

power supply and contact

SANYO service center.

Cut Off

Power

If abnormal phenomenon

Icontinues, the unit may be

damaged and cause electric

shock or fire.

3

Page 6

Operation and Maintenance

1. NOTICES FOR OPERATION

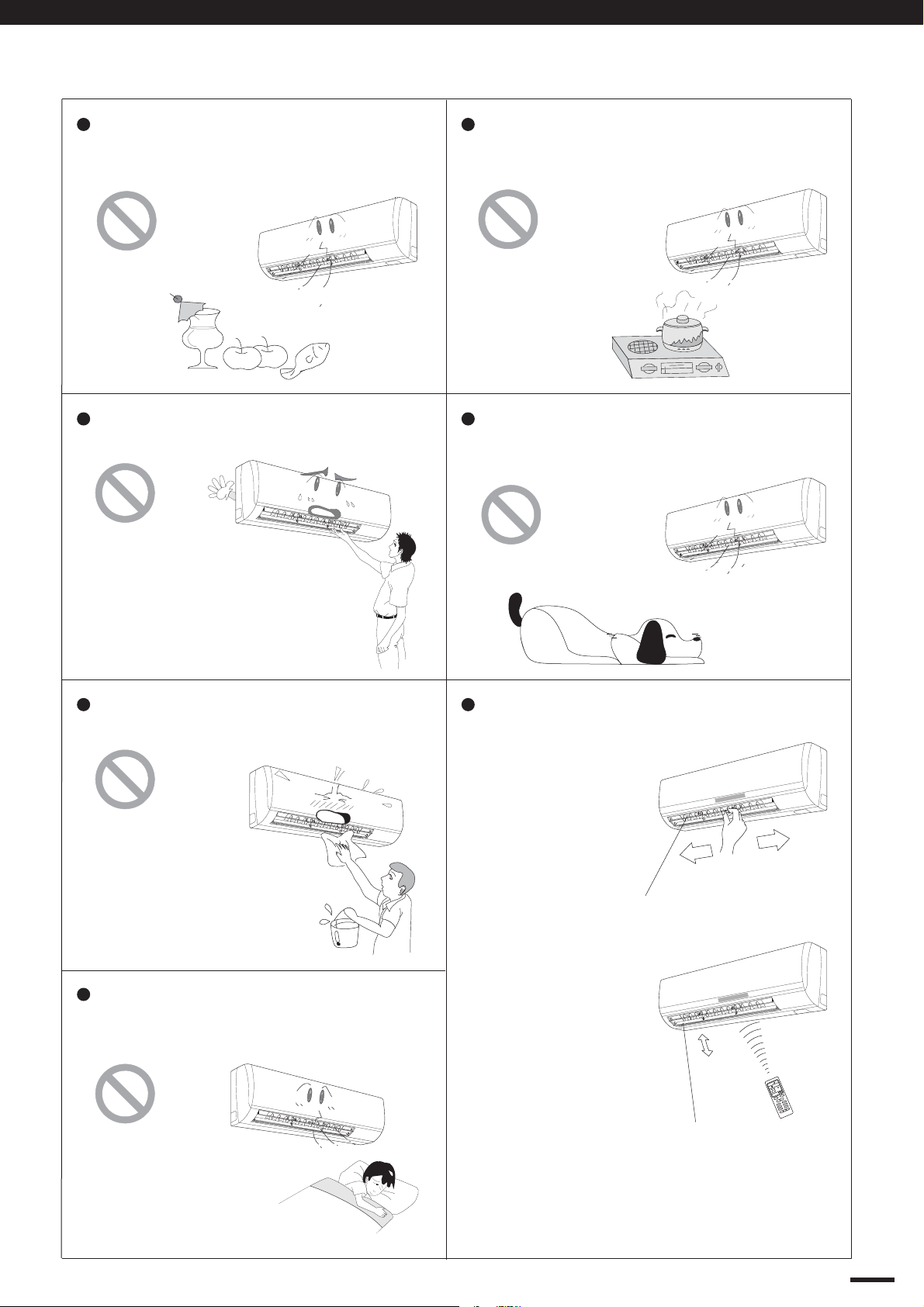

Do not use the air conditioner for other

purposes,such as drying clothes,

preserving foods, etc.

Do not insert your hands or stick into

the air intake or outlet vents.

Do not place a space heater near the air

conditioner. CO toxicosis may occur as

a result of imcomplete burning.

Do not blow the wind to animals and

plants directly. It can cause a bad

influence to them.

Splashing water on the air conditioner

can cause electric shock or malfunction.

Do not apply the cold wind to the body

for a long time. It can cause the health

problems.

Adjusting the airflow direction correctly.

a) Horizontal:

The horizontal

airflow can be

adjusted by

moving the

louver with

your hand

to the left

or right.

Louver of left /

right direction.

b) Vertical:

The vetical air

flow can be

adjusted by

moving the flap

OPER

FAN

with the remote

control unit.

Use the SWING

button to set

Flap of upward /

downward position.

C

SWING

AM

ON

E

D

O

M

F

F

O

/

N

+

O

P

M

E

T

P

M

E

T

G

N

I

W

S

K

N

C

A

O

L

F

C

F

P

F

E

E

O

-

L

T

S

+

N

O

E

-

M

I

T

T

L

E

C

N

A

C

E

M

I

T

either the auto

sweep or set to the

recommended position.

4

Page 7

2. NOTICES FOR USER

Operation and Maintenance

2.1 Working Principle &

Special Functions

for Cooling

2.2 Working Temperature Range

Temperature Indoor air temperature Outdoor air temperature

Max.

COOLING

Min.

Principle:

Air conditioner absorbs heat in the room and transmit to

outdoor and discharged, so that indoor ambient

temperature decreased. It's cooling capacity will decrease

by the increase of outdoor ambient temperature.

Anti-freezing Function:

If the units is running in COOL mode and in low

temperature, there will be frost formed on the heat

exchanger, when indoor heat exchanger temperature

decreased below 0 C, the indoor unit micro-computer will

stop compressor running and protect the unit.

32 °C DB / 23 °C WB

21 °C DB / 15 °C WB

o

52 °C DB / ---

21 °C DB / ---

The operating temperature range (outdoor temperature) for cooling unit is 21 °C ~ 52 °C.

2.3 The Conditions of Unit Can't Operate Normally.

In the following temp. range, the protection device may act, this may cause unit stop running.

Outdoor temperature

above

“COOL” running

“DRY” running

Under the relative humidity is above 80% ( doors and windows are opened) when cooling or

dehumidifying for a long time, there may have dew drip off near the air vent.

52°C 32°C

52°C

Outdoor temperature

below

21°C

18°C 32°C

Indoor temperature

above

5

Page 8

S/n

)

cable

)

e c

l

)

)

er

)

)

dica

Cool

Dry

Fa

Ru

S

)

Wall Pipe

d T

)

e

)

e

Operation and Maintenance

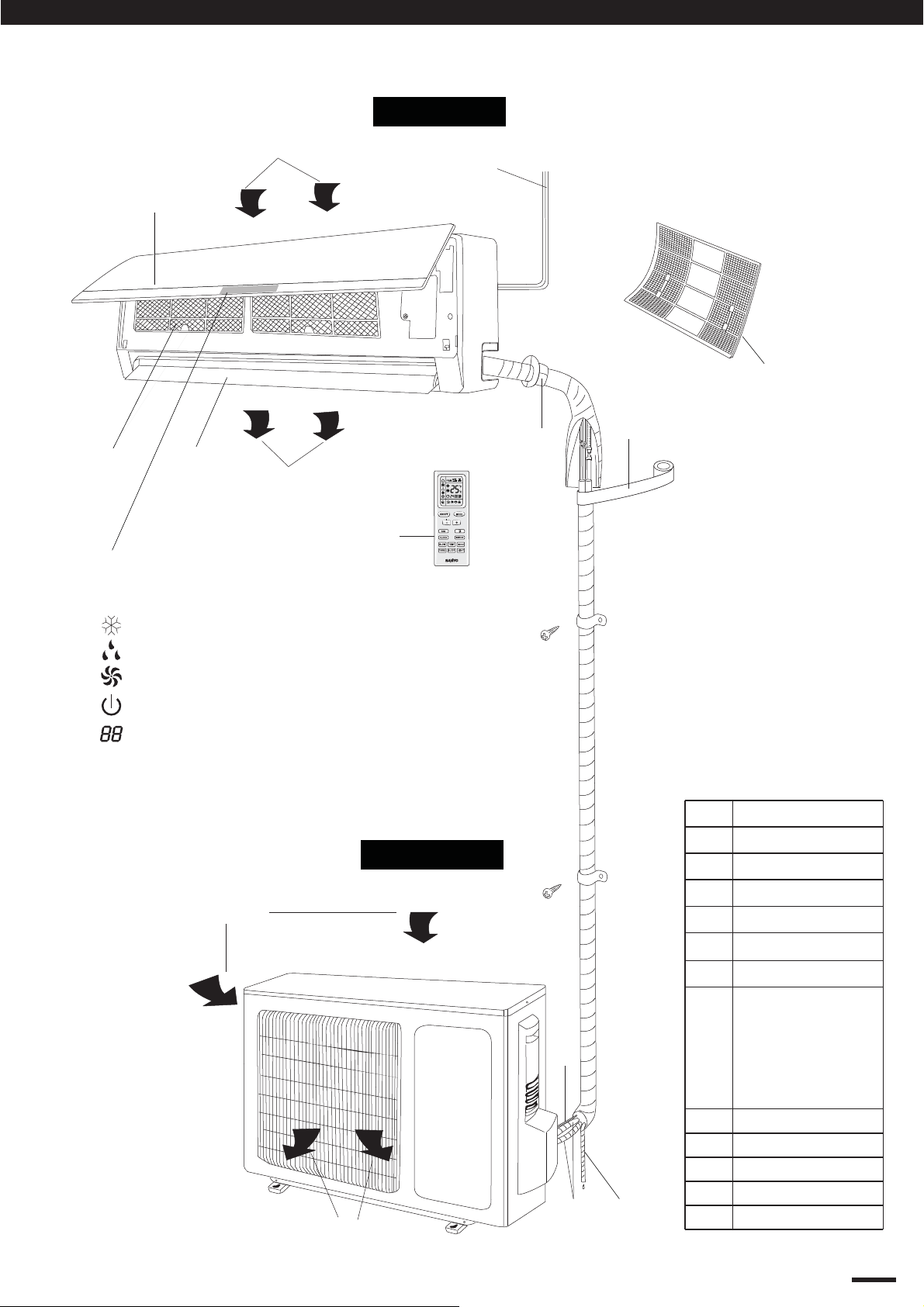

3. NAMES AND FUCTIONS OF EACH PART

Indoor Unit

Air intake

(1)

(3)

(8)

(4)

(5)

Air outlet

Back side

of part (4)

(9)

(6) (7)

The pattern in displayer:

:Cool

:Dry

:Fan

:Run

:Set temp.

Air inlet

(2)

Wireless

remote control

Outdoor Unit

art Name

1

2

(3

4

5

6)Receiver

7

ower

mot

ront Panel

t

uide Louver

n

tor

ontro

(10)

n

n

et Temp.

8

9)

10

11

(12)

Air outlet

(11)

12)

n

ape

onnection Wir

Drainage Pipe

onnection Pip

6

Page 9

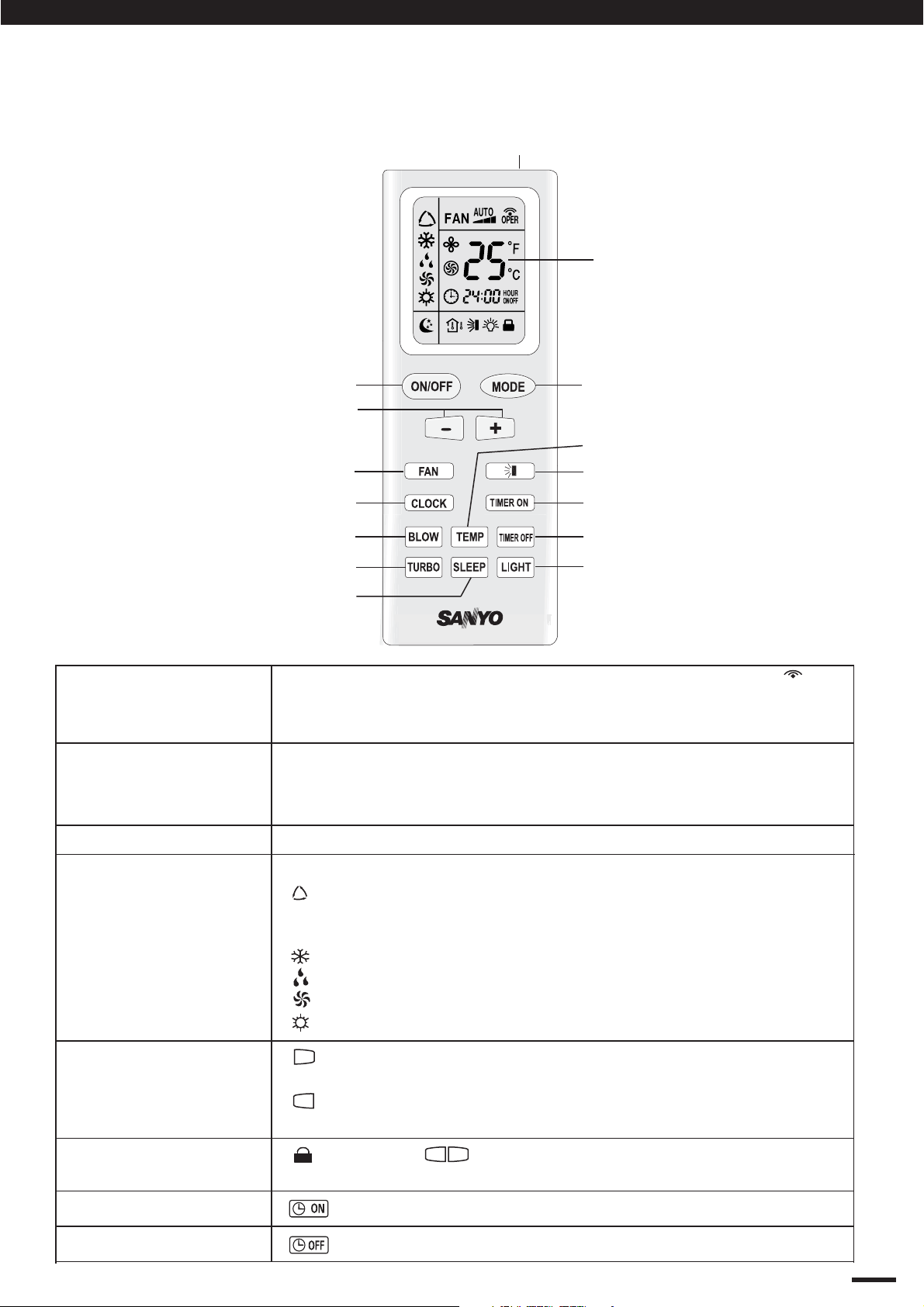

Operation and Maintenance

4. OPERATION OF WIRELESS REMOTE CONTROL UNIT

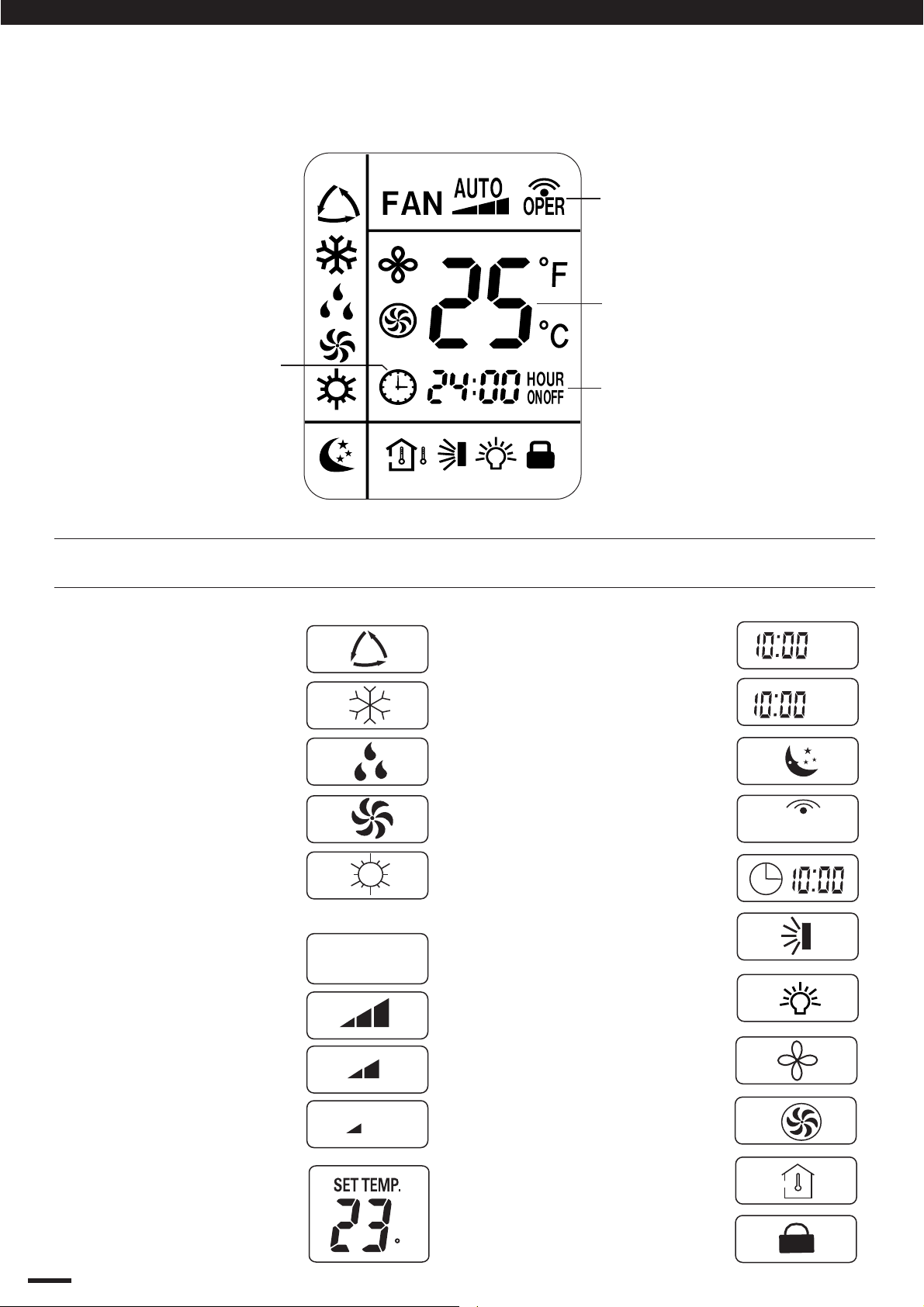

4.1 Remote Control Unit (Display)

Displayed when

transmitting data

Displayed when setting

temperature

Displayed the clock

(1) Operation mode

AUTO ..........................

COOL ..........................

DRY.......... ....................

FAN .............................

Symbols

(4) Timer

(5) Sleep ..............................

(6) Confirmation of ..............

transmission

Displayed when setting

timer

24-hour ON Timer .........

ON

24hour OFF Timer .........

OFF

OPER

HEAT ............................

(Not for cooling only model)

(2) Fan speed

Automatic operation .....

HIGH ............................

MID...............................

LOW ............................

(3) Set temperature

16 – 30 °C

When set to 23 °C ...

7

AUTO

C

(7) Clock indication ............

(8) Sweep indication ............

(9) Light .............................

(10) Blow .............................

(11) Turbo ...........................

(12) TEMP ...........................

(13) Lock ............................

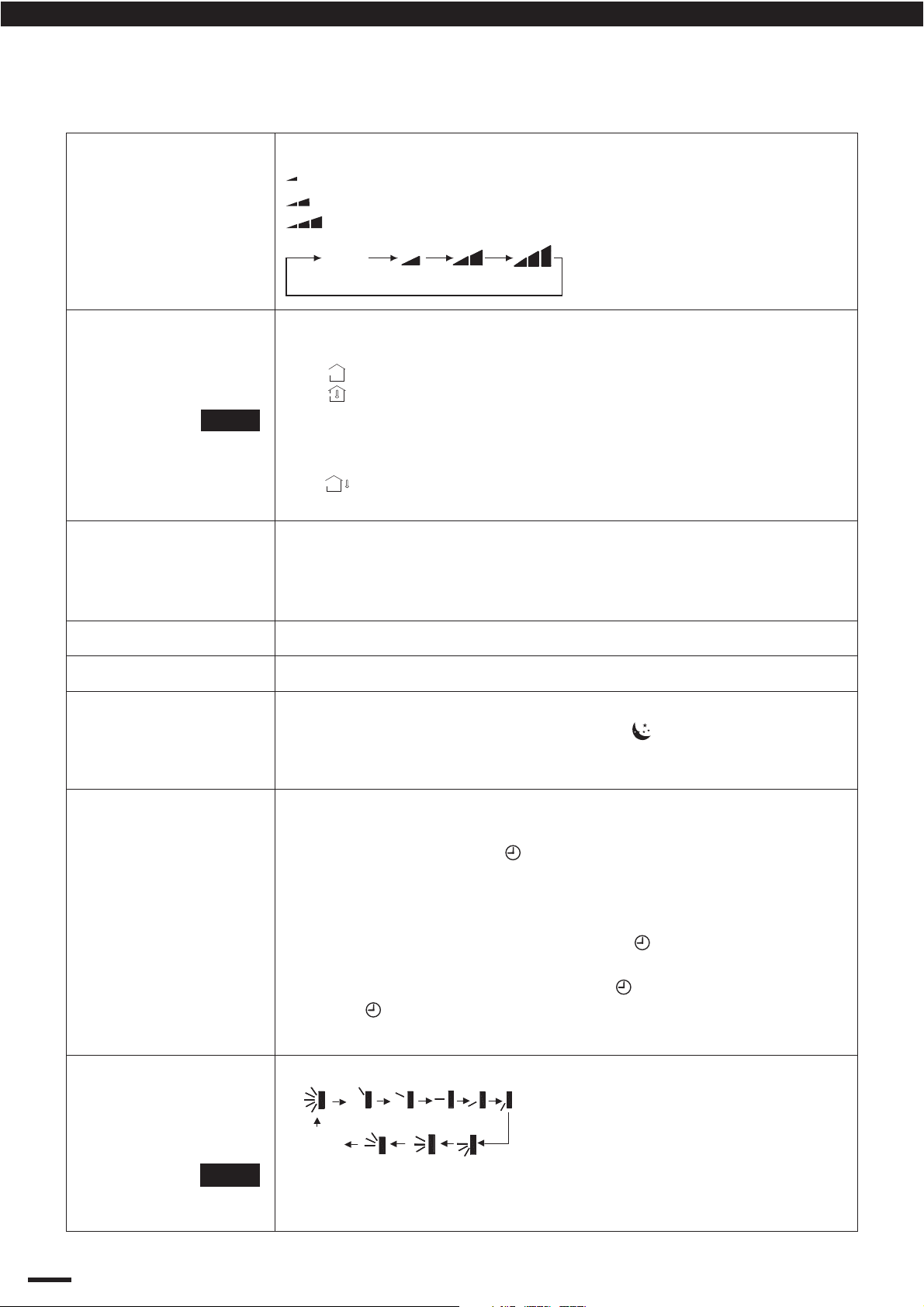

Page 10

Operation and Maintenance

4. OPERATION OF WIRELESS REMOTE CONTROL UNIT

4.2 Remote Control Unit (Functions)

Signal Transmitter

Display

ON/OFF operation button

TEMP. setting button

FAN SPEED Selector button

CLOCK button

BLOW button

TURBO button

SLEEP button

Transmitter

Display

When you press the buttons on the remote control unit, the

mark appears in the display to transmit the setting changes to

the receiver in the air conditioner.

Information on the operating conditions is displayed while the

remote control unit is switched on. If the unit is turned off, only

CLOCK and TEMP was displayed.

MODE operation button

TEMP button

SWING button

TIMER ON button

TIMER OFF button

LIGHT button

OPER

ON/OFF operation

MODE selector button

(+) / (-) setting

buttons

LOCK / UNLOCK

button

TIMER ON button

TIMER OFF button

(AUTO)

(COOL)

(DRY)

(FAN)

(HEAT)

This button is for turning the air conditioner ON and OFF.

To select “AUTO” “COOL”, “DRY” or “FAN” mode.

: When choosed this setting, the air conditioner calculates

the difference between the thermostat setting and the room

temperature and to select suitable running method.

: The air conditioner makes the room cooler.

: The air conditioner reduces the humidity in the room.

: The air conditioner run the indoor fan only.

: NOT function for cooling only model.

+

: Press the (+) button to increase set temperature, continue

press 2 seconds for fast increasing set temperature.

-

: Press the (-) button to reduce set temperature, continue

press 2 seconds for fast reducing set temperature.

-

: Press the button at the same time to lock or unlock

wireless remote controller.

: The air conditioner starts at the set time.

: The air conditioner stops at the set time.

+

8

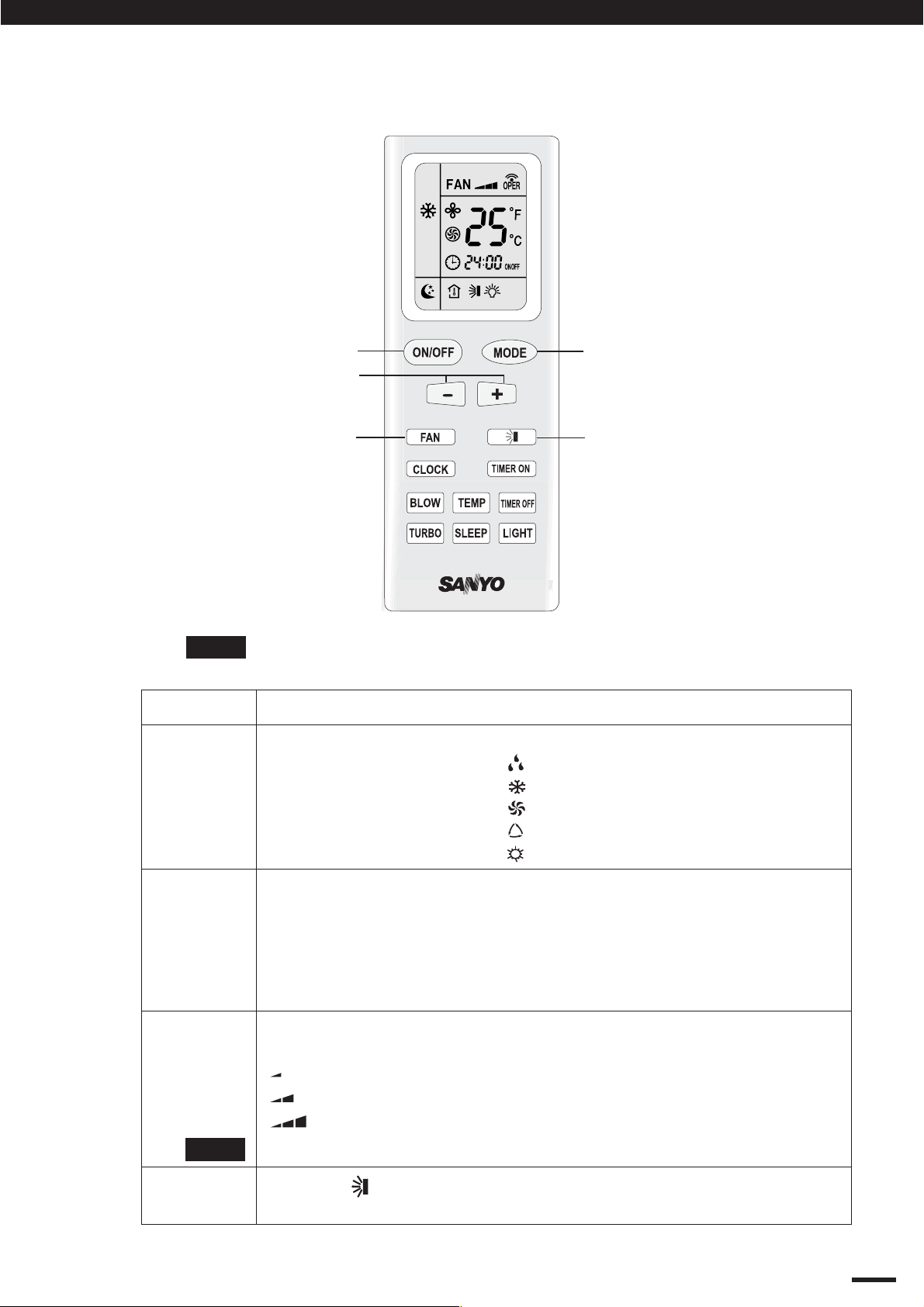

Page 11

Operation and Maintenance

4. OPERATION OF WIRELESS REMOTE CONTROL UNIT

4.2 Remote Control Unit Functions (Continued)

FAN SPEED selector

button

TEMP button

NOTE

BLOW button

AUTO

: The air conditioner automatically decides the fan speeds.

: Low fan speed.

: Medium fan speed.

: High fan speed.

AUTO

Press to see set temperature or indoor temperature which show on

the indicator lamp according to customer requirement.

: Display the presetting temperature.

: Display the indoor ambient temperature (5 seconds)

It will display the ambient temperature for 5 seconds,

After 5s later, then will back to display the presetting

temperature.

: Current displaying status will not be changed.

No Icon : Default to display the pesetting temperature.

Press to begin or stop indoor fan from blowing indoor components

to dry. This function applicable to “COOL” & “DRY” mode only. In

“AUTO” & “FAN”, “BLOW” function can not be set up and there is

no “BLOW” displaying.

LIGHT button

TURBO button

SLEEP button

CLOCK Button

SWING Button

Press this button will turn ON / OFF the display of indicator light.

Press to quickly cool or heat the room with intense cool or hot air.

For details, see “SLEEP MODE” (P.g 12). When you press this

button in the“DRY” or “COOL” mode, the mark appears in the

display, and the remote control unit will automatically adjust the set

temperature to save energy.

Use this button to set the clock.

How it Works?

Press clock button, signal blink and display. Within 5 seconds,

the value can be adjusted by pressing “+” or “-” button, if press this

button continuously for 2 seconds and above, in every 0.5 seconds,

the value on ten place of Minute will be increased 1. During

blinking, repress the Clock button, signal will be constantly

displayed and it denotes the setting succeeded. After powered on,

12:00 is defaulted to display and signal will be displayed. If there

is signal be displayed that denotes the current time value is

Clock value, otherwise it is a Timer value.

To set the air swing direction which circurlarly change as:

OFF

NOTE

9

When the guide louver start to swing up and down, if turn off

the Swing, the air guide louver will stop at the current

position. (refer P.g 13 for more detail)

Page 12

Operation and Maintenance

4. OPERATION OF WIRELESS REMOTE CONTROL UNIT

4.3 Using the General Operation

NOTE

STEP 1

STEP 2

STEP 1

STEP 3

STEP 4

Press the setting buttons as described below and change the settings

as desired.

To start the air conditioner, press the ON/OFF operation button.

Press the MODE selector button and select the desired mode.

For DRY operation

For COOLING operation

For FAN only operation

For AUTO operation

For HEATING operation

→

→

→

→

→

(Not function for cooling only model)

STEP 2

STEP 5

STEP 3

STEP 4

NOTE

STEP 5

Press the TEMP. setting buttons to change the temperature setting

to the desired temperature.

Adjustable temperature range:

30 °C (86 °F) max.—16 °C (61 °F) min.

Under “AUTO” operation, the temperature can not be adjust.

Under other operation, the initial value is 25 °C (77 °F).

Set the FAN SPEED selector button to the setting you want.

AUTO

Under Dry mode, the fan speed is automatically set to LOW.

Press the

automatically

To STOP the air conditioner, press the ON/OFF operation button again.

: Auto fan speed.

: Low fan speed.

: Middle fan speed.

: High fan speed.

button and set the air blow direction as desired or

.

10

Page 13

Operation and Maintenance

4. OPERATION OF WIRELESS REMOTE CONTROL UNIT

4.4 Using the 24-Hour “ON” or “OFF” Timer

4.4.1TIMER ON mode

(Example)

ON

After the length of time set for TIMER ON elapses, the unit

begins operating.

The display depicted at left indicates that the air conditioner will

begin operating in 10 hours.

Setting procedure:

STEP 1

Press the “ON/OFF” button and press “MODE”

button to set the desired operation mode. (See

“Operation with the Remote Control Unit”, Pg10).

Again, press the “ON/OFF” button to “OFF” the unit.

STEP 2

STEP 3

Press the “TIMER-ON” button.

Press the “T-ON” button (which advances the clock

displayed) to set the time at which you want

operation to begin.

The time can be set for 1 min. intervals for 24 hrs.

Hold pressing (+) / (-) button, it quickly change the

time value.

Press the “T-ON” button again to confirm the set

time is 10 A.M.

4.4.2 TIMER OFF mode

(Example)

OFF

The display changes immediately to CLOCK, but the

indication remains.

To check the status of the timer while it is counting down,

press the “TIMER-ON” button.

Cancellation Procedure : Press the “TIMER ON” button again

to cancel.

After the length of time set for TIMER OFF elapses, the unit

stops operating.

The display depicted at left indicates that the air conditioner will

stop operating in 10 A.M.

Setting procedure:

STEP 1

STEP 2

Press the TIMER OFF button.

Press the “T-OFF” button (which advances the clock

displayed) to set the time at which you want

operation to stop.

The time can be set for 1 min. intervals for 24 hrs.

Hold pressing (+) / (-) button, it quickly change the

time value.

Press the “T-OFF” button again to confirm the off

time is 10 A.M.

11

The display changes immediately to CLOCK, but the

indication remains.

To check the status of the timer while it is counting down,

press the “T-OFF” button.

Cancellation Procedure : Press the “TIMER OFF” button once

again.

Page 14

Operation and Maintenance

4. OPERATION OF WIRELESS REMOTE CONTROL UNIT

4.5 Using the SLEEP Operation

In Cooling and DRY

Mode : ( and )

SLEEP Mode is used for saving energy.

Press the SLEEP button while operation.

The mark appears in the display.

To release the SLEEP function, press the SLEEP button

again.

When the SLEEP mode is selected, the air conditioner

automatically rases the temperature setting 1 °C when 60

minutes have passed after the selection was made, and

then another 1 °C after another 60 minutes have passed,

regardless of the indoor temperature when SLEEP was

selected. Afterwards, the unit will remain this temperature.

This enables you to save energy without sacrificing comfort.

This function is convenient when gentle cooling is needed.

Setting

temperature

1 °C

1 °C

4.6 Using of the “Special”

Features

“DRY”

Operation

How it works?

“AUTO”

Operation

How it works?

Press the

SLEEP button

60 min.

Time60 min.

• While DRY operation, fan speed is automatically set to LOW.

• If the room temp. is 2 °C higher than the Set Temperature,

the unit will run in COOL mode.

• Once the room temp. reaches ± 2 °C of the level that was set,

the unit repeats the cycle of compressor turning “ON” 6 mins

and turning “OFF” 4 mins automatically.

• When AUTO mode is selected, the default temperature will be

displayed on the LCD, the unit will be in accordance with the

room temperature automatically to select the suitable running

method and to adjust ambient comfortable.

“BLOW”

Operation

How it works?

This function indicates that moisture on evaporator of indoor

unit will be blowed after the unit is stopped to avoid mould.

Once blow function is on, while the unit is off by pressing the

ON/OFF button, the indoor fan will continue running for about

10 min. at low speed. In this period, press “BLOW” button

again can stop indoor fan directly.

12

Page 15

Operation and Maintenance

4. OPERATION OF WIRELESS REMOTE CONTROL UNIT

4.6 Using of the “Special”

Features (Continued)

“TURBO”

How it works?

When setting the light function, the mark will display on the

remote controller screen by pressing this button. In which case,

the displayer indicator light will be on if the AC receives this

signal.

Operation

How it works?

“LIGHT”

Operation

How it works?

“LOCK”

Operation

How it works?

During “COOL” mode, if start this function, the unit will run at

super-high fan speed to cool quickly so that the ambient temp.

approachs the preset temp. as soon as possible.

It's a special selective button for the users , who are not

accustomed to the light at sleeping.

Setting “ON” the displayer indicator light

Setting “OFF ” the displayer indicator light

To cancel the light function, the mark will disapper on the

remote controller screen. In which case, the displayer indicator

light will be off if the unit receives this signal.

Press “+” and “-” buttons simultaneously to Lock / Unlock the

keyboard. If the remote controller is locked, the will be

displayed on it, inwhich case, press any button, the mark will

flicker for three times. If the keyboard is unlocked, the mark

will disappear.

“SWING”

Operation

How it works?

“ °F ” / “ °C ”

Operation

How it works?

About Swing Up and Down

1. Press swing up and down button continuously more than 2s,

the main unit will swing back and forth from up to down, and

then loosen the button, the unit will stop swinging and

present position of guide louver will be kept immediately.

2. Under swing up and down mode, when the status is

switched from off to , if press this button again 2s later,

status will switch to off status directly; if press this button

again within 2s,the change of swing status will depend on

the circulation sequence stated below:

OFF

About switch between Fahrenheit and Centigrade.

Under status of unit off, press “MODE” and “-” buttons

simultaneously and release both button immediately will switch

in °C and °F.

13

Power Failure

During Operation

How it works?

In the event of power failure, the unit will stop. When the power

is resumed, the unit will restart automatically after 3 minutes.

Page 16

Operation and Maintenance

4. OPERATION OF WIRELESS REMOTE CONTROL UNIT

4.7 How to Install Batteries

1. Slightly to press the place with , along the

arrowhead direction to push the back cover of

wireless remote control. (Fig. 1)

2. Take out the old batteries. (Fig. 1)

3. Insert two new AAA1.5V dry batteries, and pay

attention to the polarity. (Fig. 2)

4. Attach the back cover. (Fig. 2, procedure 4)

NOTE

• The batteries last about six months. Replace the

batteries when the remote control unit’s display

fails to light, or when the remote control cannot be

used to change the air conditioner’s settings.

• When changing the batteries, do not use the old

or different batteries, Use two fresh leak-proof type

-AAA alkaline batteries, otherwise, it can cause the

malfunction of the wireless remote control.

• If the wireless remote control will not be used for

more than one month, please take them out, and

don't let the leakage liquid damage the wireless

remote control.

• It should be placed at where is 1m away from the

TV set or stereo sound sets. If the wireless remote

control can not operate normally, please take

them out, after 30s later and reinsert, if they can’t

normally run, please change them.

• The remote control signal can be received at a

distance of up to about 4meter.

2

1

Fig. 1

3

4

Sketch map for

changing batteries

Fig. 2

(Indoor unit)

Air conditioner

4.8 Using the Remote Control Unit

When using the remote control unit, always point the

unit’s transmitter head directly at the air conditioner’s

receiver. (Fig. 3)

4.9 Emergency Operation

If the wireless remote control is lost or broken, please

use the manual switch button. At this time, the unit

will run at the “AUTO” mode, but the temperature and

fan speed cannot be changed. (Fig. 4)

To open the panel, the manual switch is located on

the displayer box. The operation was shown as below:

• Turn “ON” the Unit:

At unit turned off, press the button, the unit will run

at Auto mode immediately. The microcomputer will

accord to the indoor temperature to select (Cooling,

Heating or Fan) and obtain the comfortable effect.

• Turn “OFF” the Unit:

At unit turned on, press the button, the unit will stop

working.

Receiver

FAN

OPER

C

ON

SWING

AM

O

N

/

O

F

F

T

EM

M

P

-

F

T

A

EM

N

P

+

S

L

E

E

P

S

W

T

I

N

O

G

N

C

L

O

T

C

I

M

K

E

-

T

O

C

A

F

N

C

F

E

L

T

I

M

E

+

(Transmitter head)

O

D

E

Remote control unit

Fig. 3

Manual switch

Fig. 4

o

14

Page 17

Operation and Maintenance

5. CLEAN AND CARE

CAUTION

1. For safety, be sure to turn the air conditioner off

and also disconnect the power before cleaning.

Or it may cause electric shock.

2. Never sprinkle water on the indoor unit and the

outdoor unit for cleaning because it can cause an

electric shock.

3. Volatile liquid (e.g. thinner or gasoline) will

damage the air conditioner. (So wipe the units

with a dry soft cloth, or a cloth slightly moistened

with water or cleanser.)

5.1 Clean the Front Panel

(Make sure to take it off before cleaning)

Fig. 4a

1. Take off the front panel

Push in both ends of grooves to the shown position

beside at the same time by the arrow direction.

(Fig. 4a, 4b)

2. Washing

Clean with a soft brush, water and neutral detergent,

and then to dry it with a clean soft cloth. (Fig. 5)

NOTE

3. Put on front panel

Insert the supports on both ends of panel into groove,

and put the mid rotating shaft in groove, cover the

panel cover according to arrow direction and cover

well. (Fig. 6a,6b)

Do not use hot water which temperature

above 45°C to prevent fade or

deformation.

5.2 Cleaning the Air Filters

(Recommended once every 3 months)

NOTE

1. There are microcomputer components

and circuit diagram on the LCD of front

panel.

2. After taking off the filter, some metal

edges and the fins are sharp and may

cause injury if handled improperly; be

especially careful when you clean these

parts.

3. If dust is much more around the air

conditioner, the air filters should be

cleaned more often.

4. The internal coil and other components

of the outdoor unit must be cleaned

every year. Consult your dealer or

service center.

Fig. 4b

Fig. 5

Fig. 6a

Fig. 6b

15

Page 18

Operation and Maintenance

5. CLEAN AND CARE

5.2 Cleaning the Air Filters (Continued)

1. Take Down the Air Filters

Pull out the panel to an angle at botttom grooves on

panel. And, pull the air filter upward then downward

to take it off. (Fig. 7).

2. Cleaning

To clean the dust adhering to the filters, you can

either use a vacuum cleaner, or wash them with

warm water (the water with the neutral detergent

should below 45 C) when the filters are very dirty

(such asoil stain), and dry it in the shade. (Fig.8)

NOTE

3. Put back the filter

Put back the filter, then cover the surface panel well.

(Fig. 9)

Don't use hot water which temperature

is above 45°C to prevent fade or

deformation.

Don't dry it on fire for filter, it would

catch a fire or deformation.

o

5.3 Check Before You Use

1. Be sure that nothing obstructs the air outlet and

intake vents. (Fig.10)

2. Check that whether ground wire is properly

connected or not.

3. Check that whether the batteries of air conditioner

are changed or not.

4. Check that whether installation stand of the outdoor

unit is damaged or not. If damaged, please contact

the dealer.

Fig.7

air filter

Fig.8

Fig.9

5.4 Maintain After Use

1. Turn main power off.

2. Clean the filter, indoor and outdoor units' bodies.

3. Clear dust and obstructions from the outdoor unit.

4. Repaint the rubiginous place on the outdoor unit to

prevent it from spreading.

Fig.10

16

Page 19

Operation and Maintenance

6. TROUBLESHOOTING

CAUTION

Don't attempt to repair the air conditioner by yourself, it can cause an electric shock or fire.

Please check the following items before asking for repair, it can save your time and money.

gnitoohselbuorTnonemonehP

Dot not operate immediately when the air

conditioner is restarted.

Waiting

There's unusual smell blowing from the outlet

after operation is started.

Sound of water flow can be heard during

operation.

Once the air conditioner be restarted

immediately after turned off, overload

protect switch would make it will run after a 3

delay of minutes.

The unit has no peculiar smell by itself. If

happened, this is the smell accumulated in the

ambient.

Solution : Clean the air filters (see Pg.15).

If the problem still has, the unit required

servicing. Hence, please contact with SANYO

authorized maintenance center.

Sometimes there is swoosh, or gurgle while

the air conditioner is started, stopped or when

the compressor started or stopped running,

the sound is due to refrigerant flowing. They

are not malfunctions.

Creaking noise can be heard when start or

stop the unit.

,rehgih era ytidimuh dna .pmet roodni nehW.dettime si tsim ehT

sometimes this phenomenon will happen.

This is caused by the room air is swiftly cooled

down. After run for a while, indoor temp. and

humidity will fall down, the mist will die away.

This is caused by the deformation of plastic

due to the change of temperature.

17

Page 20

6. TROUBLESHOOTING

Operation and Maintenance

gnitoohselbuorTnonemonehP

The unit can not operate.

Breaking off

Cooling(Heating) efficiency is not good.

Remote control is not available.

• Has the power been shut down?

• Is the power plug loosed?

• Is voltage too high or too low?

(tested by professional)

•

Has the TIMER ON function been well

operated?

•

Is temperature setting suitable?

• Does inlet or outlet vents obstructed?

• Is filter dirty?

• Are the windows and doors closed?

• Did fan speed set at low speed?

• Is there any heat sources in the room?

• The unit is interfered by abnormal

interference or changing function too

frequently, wireless remote control can not

control occationally. Plug out power plug

and re-insert well could resume normal

operation.

• Is the control in the receiving area? Or is

there obstruction.

• Check if the voltage batteries in the control

is enough, if not, change batteries.

.

If water leakage in indoor unit.

If water leakage in outdoor unit.

Noise from indoor unit emitted.

Indoor unit can't deliver air.

Moisture on air outlet vent.

• The air humidity is on the high side.

• Condensing water over flowed.

• The indoor unit drainage pipe connection

loosed.

• When the unit is running in COOL mode,

the connection of pipe and pipe joint will

be condensed due to the water cooled

down.

• Fan or compressor relay switching

(On/OFF) sound.

•

In DRY “ ” mode, indoor fan sometimes

will stop, in order to avoid condensing

water be vaporized again, restrain

temperature raising

• If unit is running under the high humidity for

a long time, the moisture will be condensed

on the air outlet grill and drip off.

18

Page 21

Installation Service

7. NOTICES FOR INSTALLATION

Important Notices

7.1 Basic Requirements

for Installation

Position

1. The unit installation work must be done by qualified

personnel according to the local rules and this manual.

2. Before install, please contact with local authorized

maintenance center. If the unit is not installed by the

authorized maintenance center, the malfunction may

not solved, due to discommodious contacts.

3. When removing the unit to the other place, please

firstly contact with the authorized SANYO Maintenance

Center in the local area.

Install in the following place may cause malfunction. If it

is unavoidable contact with service center please:

1. Place where strong heat sources, vapors, flammable gas or

volatile object are emitted.

2. Place where high-frequency waves are generated by radio

equipment, welders and medical equipment.

3. Place where a lot of salinities such as coast exists.

4. Place where a sulfured gas such as the hot spring zones is

generate.

5. Place where the oil (machine oil) is contained in the air.

6. Other place with special circumstance.

7.2 Indoor Unit

Installation Position

Selection

7.3 Outdoor Unit

Installation

Position Selection

1. The air inlet and outlet vent should be far from the

obstruction, make sure that the air can be blown through

the whole room.

2. Select a position where the condensing water can be easily

drained out, and the places easily connected for outdoor

unit.

3. Select a location where the children can not reach.

4. Can select the place where is strong enough to withstand

the full weight and vibration of the unit. And will not increase

the noise.

5. Be sure to leave enough space to allow access for routine

maintenance. The height of installed location should be

200cm or more from the floor.6. Select a place about 1m or

more away from TVset or any other electric appliances.

7. Select a place where the filter can be easily taken out.

8. Make sure that the indoor unit installation should accord

with installation dimension diagram requirements. (Pg.24)

1. Select a location from which noise and outflow air emitted

by unit will not inconvenience neighbours, animals, plants.

2. Select a location with sufficient ventilation.

3. Select a location where there should be no obstructions

cover the inlet and outlet vent.

4. The location should be able to withstand the full weight and

vibration of the outdoor unit and permit safe installation.

5. Select a dry place, but do not expose under the direct

sunlight or strong wind.

19

Page 22

Installation Service

7. NOTICES FOR INSTALLATION

7.3 Outdoor Unit

Installation Position

Selection

(Continued)

7.4 Safety Requirements

for Electric

Appliances

6. Make sure that the outdoor unit installation dimension

should accord with installation dimension diagram,

convenient for maintenance, repair. ( See Pg.21)

7. The height difference of connecting the tubing & the max.

length of connecting tubing refer to Pg.31, Table 4.

8. Select a place where it is not reachable for the children.

9. Select a place where will not block the passage and do

not influence the city appearance.

1. The power supply should be used the rated voltage and

AC exclusive circuit, the power cable diameter should be

satisfied.

2. Voltage applying range: the normal running range is rated

voltage 198V - 264V.

3. Don't drag the power cable emphatically.

4. It should be reliable earthed and it should be connected to

the special earth device, the installation work should be

operated by the professional.

• The creepage protect switch and air switch with enough

capacity must be installed in the fixing circuit.

• Air switch (thermal-magnetic breaker) can protect the short

circuit and overload.

5. The min. distance from the unit and combustive surface is

1.5m.

7.5 Earthing

Requirements

7.6 Others

NOTE

1. Air conditioner is type 1 electric appliance, thus please do

conduct reliable earthing measure.

2. The yellow-green two-color wire in air conditioner is

earthing wire and cannot be used for other purpose. It

cannot be cut off and be fix it by screw, otherwise it would

cause electric shock.

3. The user power must offer the reliable earthing terminal.

DO NOT connect the earthing wire with the bellow places:

- Gas pipe

- Tap water pipe

- Contamination pipe

- Other places that the professional personnel consider

them unreliable.

1. The connection method of unit and power cable as well as

the interconnection method of each isolated component

should refer to the circuit diagram stick on the unit.

2. The model of the blown fuse and rated value should refer

to the silk-screen on the controller or fuse sleeve.

3. The outside static pressure is 0MPa when the unit is

testing.

• The power supply position should be

correctly connected, and that should be

reliably connected, no internal short circuit.

•

Wrong connection, may cause fire.

20

Page 23

Installation Service

8. INSTALLATION DIENSION DIAGRAM

Space to the ceiling

15cm

Above

Space to the wall

15cm Above

Space to the wall

300cm

Above

250

cm

Above

Air outlet side

Space to the floor

•

The dimensions of the space necessary for correct

installation of the appliance including the minimum

permissible distances to adjacent structures.

15cm Above

Models

Space to the obstruction

30cm Above

Space to the wall

200cm Above

Air outlet side

A

Outdoor Unit Installation Dimension (mm)

50cm Above

B

Air inlet side

30cm Above

Space to the wall

50cm Above

BA

682044PA9C-PAS

682045PA21C-PAS

243055PA81C-PAS

183065PA52C-PAS

378275PA03C-PAS

21

Page 24

9. INSTALL INDOOR UNIT

Installation Service

9.1 Install the Rear Panel

1. Always mount the rear panel horizontally.

Due to the water tray of indoor unit has been

been adopted the both-way drainage design,

the outlet of water tray should be adjusted

slightly down when installing, that is taking the

outlet of the water tray as the center of a circle,

the included angle between the evaporator and

level should be 0 or more, that is good for

condensing water drainage.

2. Fix the rear panel on the wall with screws.

(Where is pre-covered with plastic granula)

3. Be sure that the rear panel has been fixed

firmly enough to support the weight of an adult

of 60kg, further more, the weight should be

evenly shared by each screw.

9.2 Install the Piping Hole

1. Determine which side of the unit you should

make the hole for tubing and wiring.

(Fig.11,12)

2. Make the piping hole (Ф55 or Ф70) in the wall

at a slight downward slant to the outdoor side.

(Fig.13)

NOTE

3. Insert the piping-hole sleeve into the hole to

prevent the connection piping and wiring from

from being damaged when passing through

the hole.

• Before making the hole, check

carefully that no studs or pipes

are directly run behind the spot

to be cut.

• Also avoid areas where electrical

wiring or conduits are located.

Model: K30AP

Wall

Space

to the

wall

150mm

above

Left

φ70mm (Rear piping hole)

Mark on the

middle of it

180mm

Wall-Mounting Plate

Models: K18AP / K25AP

Wall

Space

to the

wall

150mm

above

Left

φ55/70mm (Rear piping hole)

Mark on the

middle of it

138mm

Models: K12AP

Wall

φ

55mm

Space

to the

wall

150mm

above

Mark on the

middle of it

130mm

Left

(Rear piping hole)

Models: K9AP

Wall

φ

55mm

Mark on the

middle of it

Space

to the

wall

35mm

150mm

above

Left

(Rear piping hole)

(Rear piping hole)

Fig.11

Left

tubing

Gradienter

251mm

50mm

90mm

(Rear piping hole) φ70mm

Gradienter

Space

184mm

to the

wall

150mm

above

50mm

60mm

(Rear piping hole) φ 55/70m

Gradienter

173mm

50mm

90mm

(Rear piping hole)

Gradienter

150mm

40mm

90mm

Space

to the

wall

150mm

above

φ

Space

to the

wall

150mm

above

Right

φ

55mm

Right

Wall

Right

55mm

Wall

Right-rear

tubing

(recommended)

Wall

Space

to the

wall

150mm

above

Right

Wall

9.3 Install the Water Drainage Pipe

1. Drainage hose must be placed at downward

slant downward slant for smooth drainage.

2. Do not wrench, bend or heave the drainage

hose or flood its end by water. (Fig.14)

3. The prolonged drainage hose should be

covered by heat insulation material when

through indoor.

Wrenched

Fig.14

Bent

Flooded

Left-rear

tubing

Fig.12

Indoor

Wall pipe

Hole Dia.

( K9AP, K12AP K18AP )

Ø 55mm

Fig.13

Right tubing

Outdoor

Seal pad

Ø55 / Ø70

Protection

sleeve pipe

Hole Dia.

( K25AP, K30AP )

Ø 70mm

22

Page 25

Installation Service

9. INSTALL INDOOR UNIT

9.4 Connect Indoor and Outdoor Electric Wire

1. The power wire and power connection wire are

supplied in factory in a fixed length. (Fig.15,16,17)

WARNING

To avoid the risk of fire hazard, do

consult your local dealer if additional

wire length is required.

2. Open the surface panel and remove the wiring

cover. (Fig.15,16,17)

3. Route the power connection wire from the back of

the indoor unit and pull it toward the front through

the wiring hole for connection.

4. Connect the interconnection cord to the terminal

block, and then fix the cord with wire clamp.

5. Re-assemble the clamp and wiring cover.

6. Re-cover the surface panel.

Power Supply Wire

(Fixed in unit 1.6m)

Wiring Cover

2

N(1)

Blue

Black

Power connection wire

to outdoor unit

Yellow-Green

(Factory supplied 5m)

Fig.15 (K9AP, K12AP)

WARNING

Since one end of power connector wire has

been connected in the unit, when testing unit

with electrified, the other end of the power

connect wire may carry electricity. Please note

to prepare well insulation to prevent short

circuit or electricity shock.

9.4.1 Wiring Instructions

NOTE General Precautions on Wirings

1. Before wiring, confirm the rated voltage of

the unit as shown in nameplate, then carry

out the wiring closely follow the wiring

diagram.

2. Provide a power outlet to be used exclusively

for each unit, with a power supply disconnect

and circuit breaker for overcurrent protection

provided in the exclusive line.

3. To prevent possible hazard due to insulation

failure, the unit must be grounded.

4. Each wiring connection must be done tightly

and in accordance with the wiring system

diagram. Wrong wiring may cause the unit to

misoperate or become damaged.

5. Do not allowed wiring to touch the refrigerant

tubing, compressor, or any moving parts of

the fan.

6. Unauthorised changes in the internal wiring

can be very dangerous.The manufacturer will

accept no responsibility for any damage or

misoperation that occurs as a result of such

unauthorised changes.

Power Supply Wire

(Fixed in unit 1.8m)

Wiring Cover

2

Black

3

Brown

Power connection wire

to outdoor unit

Yellow-Green

(Factory supplied 5m)

N(1)

Blue

Fig.16 (K18AP, K25AP)

Wiring Cover

2

Black

3

Brown

Power connection wire

to outdoor unit

Yellow-Green

(Factory supplied 5.5m)

N(1)

Blue

Fig.17 (K30AP)

23

Page 26

Installation Service

9. INSTALL INDOOR UNIT

9.4.2 Wire Length and Diameter

Regulations on wiring diameter differ from locality. For field wiring requirements, please refer to

local electrical codes. Carefully observe these regulations when carrrying out the installation.

Table 1 lists the recommended and max. allowable wire lengths and diameters for the power

supply system. Please refer to the wiring system diagram (Fig.18 & 19) for the meaning of “A”, “B”

in Table 1a,b,c,d.

Table 1a

Cross-sectional

area (mm2)

Model 1.0x (3)

KC9AP

Recommended

*(A)

1.6m 17m 10A

*(B)

1.0x (3) 1.0

5.0m

Max. allowed

(A) + (B)

Fuse or circuit

breaker capacity

Table 1b

Cross-sectional

area (mm2)

Model 1.5 x (3)

KC12AP

Recommended

*(A)

1.6m 22m 10A

*(B)

1.5 x (3) 1.5

5.0m

Max. allowed

(A) + (B)

Fuse or circuit

breaker capacity

Table 1c

Cross-sectional

area (mm2)

Model 2.5 x (3)

KC18AP 1.8m

KC25AP 1.8m

Recommended

*(A)

*(B)

2.5 x (4) 2.5

5.0m

Max. allowed

(A) + (B)

32m

32m

Fuse or Circuit

breaker capacity

20A

30A5.0m

Table 1d

Cross-sectional

area (mm2)

Model

KC30AP

*(A) Power supply wiring length (m) ; *(B) Power connection wire length (m)

Recommended

*(A)

4.0 x (3)

6.0m

1.0 x (4) 4.0

*(B)

5.5m

Max. allowed

(A)

*(B)

1.0 x (4)

20m 30A

32m

Fuse or circuit

breaker capacity

CAUTION

• Be sure to connect the power supply line to the

indoor unit as shown in the wiring diagram.

(a) Fig.18 (KC9AP, KC12AP, KC18AP, KC25AP)

The outdoor unit draws its power from the

indoor unit.

(b) Fig.19 (KC30AP)

The indoor unit draws its power from the

outdoor unit.

WARNING

• Be sure to comply with local codes on running

the wire from the indoor unit to the outdoor

unit (size of wire and wiring method, etc.).

• Each wire must be firmly connected.

• No wire should be allowed to touch refrigerant

tubing, the compressor, or any moving part.

WARNING

WIRING SYSTEM DIAGRAM

Models: KC9AP, KC12AP

OUTDOOR

UNIT

Terminal

N(1)

2

Blue

Black

Yellow-Green

(Grounding Line)

Power Supply

Single Phase

230VAC 60HZ

L

N

Grounding Line

Models: KC18AP, KC25AP

OUTDOOR

UNIT

Terminal

N(1)

2

Blue

Black

Brown

Yellow-Green

(Grounding Line)

Power Supply

Single Phase

230VAC 60HZ

L

N

Grounding Line

Fig. 18 Outdoor unit draws its power

from indoor unit.

INDOOR

UNIT

Terminal

N(1)

2

Model: KC30AP

Blue

Black

Brown

Yellow-Green

(Grounding Line)

Power Supply

Single Phase

230VAC 60HZ

N

L

Grounding Line

(B)

(A)

BN (BK)

BU (WH)

(B)

(A)

BN

BU

OUTDOOR

(B)

(A)

BU

BN

INDOOR

UNIT

Terminal

N(1)

2

L

N

P.C.B

INDOOR

UNIT

Terminal

N(1)

2

33

L

N

P.C.B

UNIT

Terminal

N(1)

2

33

N(4)

5

To avoid the risk of electric shock, each air

conditioner unit must be grounded.

Fig. 19 Indoor unit draws its power

from outdoor unit.

24

Page 27

9. INSTALL INDOOR UNIT

9.5 How to Install the Indoor Unit

For tubing, choose either the left side or right

side direction.

1. When routing the piping and wiring from the

left or right side of indoor unit, cut off the

tailing from the chassis in necessary.

(As shown in Fig 20)

•

Cut off the tailings 1 when routing the

wiring only.

•

Cut of the tailings 1 and tailings 2 when

routing both the wiring and piping.

2. Take out the piping from body case, wrap

the piping, electric wire, water pipe with

tape and push them through the piping hole.

(As show in Fig.21)

3. Hang the mounting slots of the indoor unit

on the upper tabs of the rear panel and

check if it is securely seated on the rear

panel. (As show in Fig.22)

Installation Service

Gas side piping

Gas side piping

insulation

Finally wrap

it with tape

Tailing 2

Tailing 1

Fig.20

External connection

electric wire

Liquid side piping

Liquid side piping

insulation

Water drainage

pipe

4. Carefully bend the tubing (if necesasry) to

run along the wall in the direction of outdoor

unit and then tape as far as the fittings.

(Refer 9.3 on Pg. 22). The drain hose should

come staright down the wall to a point where

water run off won't stain the wall.

5. Connect the refrigerant tubing to the outdoor

unit. (After performing a leak test on the

connecting part, insulate it with the tubing

insulation. (Fig.21) Also, refer to Pg 28,

(connecting tubing between indoor and

outdoor unit).

NOTE

For stable operation of the air

conditioner, do not install wallmounted type indoor units less than

2.5m from the floor level. (Fig.23)

CAUTION

Do not supply power to

unit or operate it until

all tubing and wiring to

the outside unit are

completed.

Risk of Electric Shock

Right

右后

Right rear

Fig.21

Fixing hook

Mounting

board

Fig. 22

Indoor unit

Minimum height

from floor level

2.5m

Left

Left rear

Mounting board

Wall

25

Floor level

Fig.23

Page 28

Installation Service

10. INSTALL OUTDOOR UNIT

10.1 Wiring Instructions for the Outdoor

Unit

Regulations on wire size differ from locality.

For field wiring requirements, please refer to

your local electrical codes. Make sure that

the installation fully complies with all local

and national regulations.

1. C9AP, C12AP, C18AP, C25AP

Disassemble the handle on the outdoor

unit right side plate. (Screw x 1pc)

C30AP

Disassemble the front side plate on the

outdoor front side. (Screw x 3pcs)

2. Take off wire clamp, connect and fix

power connect cord to terminal of line

bank. Connect the inter-unit wiring

and power line according to the

drawing on the handle (C9,12,18,25AP)

or front side plate (C30AP).

NOTE

Use the wire clamp to fix the

signal control wire, then

connect to the corresponding

connector.

Handle

Handle

Blue

Wire clamp

Black

Power

1.

Connection

Wire

2.

Yellow-green

Fig. 24a (C9AP,C12AP)

3

Blue

Black

Yellow-green

Brown

3. Fix the power connection cable with wire

clamp. (Fig. 24)

4. Be sure to size each wire allowing approx.

10 cm longer than the required length for

wiring, Store excess wiring inside the

cabinet.

5. When connections are completed, check

that all connections are correct as shown

in the wiring system diagram on the

handle / front side plate.

6. Be sure to ground the unit according to

your local codes.

7. Install back the handle / front side plate.

Front side

plate

WARNING

Loose wiring may cause the terminal to

overheat or result in unit malfunction.

A fire hazard may also exist. Therefore,

be sure all wiring is tightly connected.

Power

Connection

Wire clamp

1.

Wire

2.

Fig. 24b (C18AP, C25AP)

N(1)

Blue

Black

Power

Connection

Wire

3

N(4)

5

Blue

Brown

Wire clamp

Brown

Power

Supply

Wire

( Factory

supplied

6m )

Fig. 24c (C30AP)

Yellow-Green

26

Page 29

Installation Service

10. INSTALL OUTDOOR UNIT

10.2 Refrigerant Tubing

10.2.1 Use of The Flaring Method

Many of the conventional split system air

conditioners employ the flaring method to

connect refrigerant tubes which run between

indoor and outdoor units. In this method, the

copper tubes are flared at each end and

connected with flares nuts.

10.2.2 Flaring Procedure With A Flare Tool

•

Cut the copper tube to the required length

with a tube cutter. It is recommended to

cut approx. 30 - 50 cm longer than the

tubing length you estimate.

•

Remove burrs at the end of the copper

tube with a reamer or file. This procedure

is important and should be done carefully

to make a good flare. (Fig.25)

NOTE

When reaming, hold the tube end

downward and be sure that no

copper scraps fall into the tube.

(Fig.26)

Before

Deburring

After

Fig.25

Copper

tubing

Reamer

Fig.26

•

Remove the flare nut from the unit and be

sure to mount it on the copper tube.

•

Make a flare at the end of copper tube with

a flare tool.* (Fig.27)

(*Use "GRID" or equivalent.)

NOTE

10.2.3 Caution Before Connecting Tubes Tightly

•

Be sure to apply a sealing cap or water-

proof tape to prevent dust or water from

getting into the tubes before they are used.

•

Be sure to apply refrigerant lubricant to the

matching surfaces of the flare and union

before connecting them together. This is

effective for reducing gas leaks. (Fig.28)

•

For proper connection, align the union tube

and flare tube straight with each other, then

screw in the flare nut lightly at first to obtain

a smooth match. (Fig.29)

A good flare should have the

following charactcteristics:

- inside surface is glossy and

smooth.

- edge is smooth.

- tapered sides are of uniform

length.

Flare nut

Copper

Flare tool

Fig.27

Apply refrigerant

Iubricant here and here

Fig.28

Union

Fig.29

tubing

Flare nut

27

Page 30

Installation Service

10. INSTALL OUTDOOR UNIT

10.2.4 Connecting Tubing between Indoor and

Outdoor Units

•

Tightly connect the indoor side refrigerant

tubing extended from the wall with the outdoor

side tubing. (Fig. 30)

•

To fasten the flare nuts, apply specified torque

as table 2:

Table 2

Tube Dia. Tightening Torque

6.35 mm

9.52 mm

12.7 mm

15.88 mm

10.2.5 Insulation of Refrigerant Tubing

IMPORTANT

To prevent heat loss and wet floors due to

drippingof condensation, both tubes must be

well insulated with proper insulation material.

The thickness of the insulation should be a min.

8mm. (Fig. 31, 32)

CAUTION

Approx. 15 - 20 N.m (1.5 - 2.0 kg.m)

Approx. 35 - 40 N.m (3.5 - 4.0 kg.m)

Approx. 50 - 55 N.m (5.0 - 5.5 kg.m)

Approx. 68 - 82 N.m (6.8 - 8.2 kg.m)

Min.

8 mm

Indoor unit

Torque wrench

Spanner

Outdoor unit

Fig.30

Insulation

Fig.31

Insulation

Thickness:

min. 8 mm

After a tube has been insulated, never try to bend

it into a narrow curve, as this may cause to break

or crack.

10.2.6 Taping the Tubes

•

At this time, the 2 refrigerant tubes (and

electrical wire if codes permit) should be taped

together with armoring tape. The drain hose

may also be taped together as 1 bundle with

the tubing.

•

Wrap the armoring tape from the bottom of the

outdoor to the top of tubing where it enters the

wall. As you wrap the tubing, overlap half of

each previous tape turn. (Fig. 33)

Clamp tubing bundle to wall, using 1 clamp

•

approx. every 120cm.

NOTE

Do not wind the armoring tape too

tightly, since this will decrease the

heat insulation effect. Also, be sure

the condensation drain hose splits

away from the bundle and drips

clear of the unit and the tubing.

Fig.32

Clamp

Insulated tubes

Fig.33

Apply putty here

10.2.7 Finish the Installation

After finishing insulating and taping over the

tubing, use sealing putty to seal off the hole in

the wall to prevent rain and draft from entering.

(Fig. 34) shows refrigerant tubing taped

separately from the drain hose.

Tubing

Fig.34

28

Page 31

Installation Service

10. INSTALL OUTDOOR UNIT

10.3 Air Purging

Air and moisture remaining in the refrigerant

system have undersirable effects as indicated

below. Therefore, they must be purged

completely.

• Pressure in the system rises

• Operating current rises

• Cooling (or heating) efficiency drops

• Moisture in the air may freeze and block

capillary tubing.

• Water may lead to corrosion of parts in the

refrigerant system.

AIR PURGING WITH A VACUUM PUMP

(FOR TEST RUN)

1. Check that each tube (both narrow and wide

tubes) between the indoor and outdoor units

have been properly connected and all wiring

for the test run has been completed. Noted

that both narrow and wide tube service valves

on the outdoor unit are kept closed at this

stage.

Indoor unit

Outdoor unit

Manifold valve

2. Using a adjustable wrench or box wrench,

remove the valve caps from the service on

both narrow and wide tubes.

3. Connect a vacuum pump and a manifold

valve (with pressure gauges) to the service

port on the wide tube service valve. (Fig.35)

CAUTION

Be sure to use a manifold valve for air

purging. If it is not available, use a stop valve

for this pupose. The "Hi" knob of the

manifold valve must always be kept closed.

4. With the "Lo" knob of the manifold valve open,

run the vacuum pump. The operation time for

the vacuum pump varies with tubing length

and the capacity of the pump. The following

table shows the amount of time for evacuation:

Table 3

Required time for evacuation when

capacity of 100 liter/h vacuum pump is used

If tubing length is

less than 7 m

10 min. or more

If tubing length is

more than 7 m

15 min.or more

Pressure

gauge

NOTE

Lo

Hi

Vacuum pump

Fig.35

The require time in the table

3 is calculated based on the

assumption that the ideal

(or target) vacuum condition

is around 10 mmHg abs.

29

Page 32

Installation Service

10. INSTALL OUTDOOR UNIT

10.3 Air Purging - (Continued)

5. With the vacuum pump still running, close

the "Low" knob of the manifold valve. Then

stop the vacuum pump.

6. With the accessory hex wrench, turn the

valve stem on the narrow tube service valve

counter-clockwise by 90 degrees (1/4 turn)

for 10 seconds, and then turn the stem

clockwise to close it again. (Fig.36)

CAUTION

Be sure completely insert the hex

wrench before attempting to turn

the valve.

7. Leak test all joints at tubing (both indoor and

outdoor) with liquid soap. Bubbles indicate a

leak. Be sure to wipe off the soap with a

clean cloth.

8. WIth the hex wrench, turn the wide tube

service valve stem counter-clockwise to fully

open the valve.

o

90 (1/4 turn)

Valve Cap

Vacuum hose to manifold valve

Fig. 36

Narrow tube

Hex wrench

Wide tube

9. Turn the narrow tube service valve stem

counter- clockwise to fully open the valve.

10. Loosen the vacuum hose connected to the

wide tube service port slightly to release the

pressure. Then, remove the hose.

CAUTION

This may cause the refrigerant gas

to leak. In order to avoid this, take

off the hose quickly.

11. Fasten the valve cap on the wide tube

service port securely with an adjustable

wrench or box wrench. Next, mount the

valve cap on the service valve and

tightened it to 200 kg-cm with a torque

wrench. This process is very important to

prevent gas leaking from the system.

12. Test run the air conditioner. (See page 33)

15. Wipe off the soap on the tubing.

13. While the air conditioner is running, apply

liquid soap to check for any gas leaks

around the service valves or caps.

14. If there is no leakage, stop the air

conditioner.

This completes air purging with a

vacuum pump and the air conditioner is

ready for actual operation.

30

Page 33

Installation Service

10. INSTALL OUTDOOR UNIT

10.4 Tubing Length

Install unit within the maximum elevation

different (H) above or below the outdoor

unit and within a tatal tubing length (L)

from the outdoor unit as detailed showed

in Table 4 and Fig.37.

Table 4

Model

Max. Allowable Tubing

Length at Shipment

1

(m)*

Limit of Tubing

C9AP 5.0

C12AP 5.0

C18AP 5.0

C25AP 5.0

Length (L)

(m)

15

20

25

30

INDOOR

UNIT

Elevation

difference (H)

Limit of Elevation

Different (H)

(m)

5

5

7

7

Tubing length (L)

OUTDOOR

UNIT

Fig. 37

Required Amount of

Additional Refrigerant

(g/m)*

20

20

30

30

2

C30AP 5.0

*1 Standard tubing length is 5.0m.

*2 If total tubing length becomes 5.0m to 20 or 25 or 30m, charge additional refrigerant (R22) according

to table 4 above. No additional charge of compressor oil is necessary.

10.5 Accessories

Table 5 listed the accessories supplied with the unit.

Table 5

Parts Figure

Power

Connection

Wire

Tapping

Screw

Model:

K9AP,K12AP

4.2 x 25 mm

Models:

K18AP, K25AP, K30AP

30

Q’ty

1

5

10

15

50

Parts Figure Q’ty

AAA alkaline

battery

Flare Nut

Remote

Control Unit

*(K9AP, K12AP only)

OPER

FAN

0

C

ONOFF

TIMER OFF

MODE

TIMER ON

SLEEP LIGHT

- +

FAN

CLOCK

ON/OFF

BLOW TEMP

TURBO

2

1

1

31

Ins. Tube

Power

Supply

Wire

*(K30AP only)

1

Putty

1

Remote Control

1

Holder

1

(Optional)

*Only for specified model.

Page 34

11. PUMP DOWN

11.1 What is Pump Down?

Pump down means collecting all refrigerant gas

in system back into the outdoor unit without

losing any of gas. Pump down is used when the

unit is to be moved or before serving the

refrigerant circuit.

11.2 Pump Down Procedure

Installation Service

Indoor unit

NOTE

1. Connect the Lo side charging hose of the

manifold valve to the service port on the wide

tube service valve. (Fig 39)

2. Using a hex wrench, turn the narrow tube

service valve clockwise all the way to close

the service valve (Fig 40). (Be sure to confirm

that the wide tube service valve is fully open.)

3. Press the ON / OFF button and start cooling

operation.

4. When the low pressure gauge reading falls

from 1 to 0.5 kg/cm

tube valve stem (Fig 41). Then quickly stop

the unit.

5. Disconnect all gauges and hoses, and

replace the valve caps as they were before.

Be sure to carry out pump down

with the unit in cooling mode.

2

, fully close the wide

Manifold valve

Pressure

gauge

Lo

Outdoor unit

Hi

Narrow tube

Hex wrench

Wide tube

Valve Cap

Vacuum hose to manifold valve

Fig. 41

Fig. 39

Narrow tube

Hex wrench

Wide tube

Valve Cap

Vacuum hose to manifold valve

Fig. 40

32

Page 35

Installation Service

12. CHECK AFTER INSTALLATION AND TEST RUN

12.1 Check After Installation

Check the items listed in below table after installation of air conditioner.

Items to be checked Possible malfunction

• Has it been fixed firmly? • The unit may drop, shake or emit noise.

• Have you done the refrigerant leakage

test?

• Is heat insulation sufficient?

• Is the voltage in accordance with the rated

voltage marked on the nameplate?

• Is the electric wiring and piping connection

installed correctly and securely?

• Has the unit been connected to a secure

earth connection?

• Is the power cord specified?

• Is the inlet and outlet been covered?

• It may cause insufficient of cooling

capacity.

• It may cause condensation and dripping.

• It may cause condensation and dripping• Is water drainage well?

• It may cause electric malfunction or

damage the part.

• It may cause electrical leakage.

• It may cause electric malfunction or

damage the part

• It may cause electric malfunction or

damage the part

• It may cause of insufficient cooling

capacity.

• Has the length of connection pipes and

refrigerant capacity been recorded?

• The refrigerant capacity is not accurate.

12.2 Test Operation

12.2.1 Before Test Operation

• Do not switch on power before installation is finished completely

• Electric wiring must be connected correctly and securely.

• Cut-off valves of the connection pipes should be opened.

• All the impurities such as scraps and thrums must be cleared from the unit.

12.2.2 Test Operation Method

• Switch on power, press "ON / OFF" button on the wireless remote controller to start the

operation.

• Press MODE button, to select the “COOL”, “FAN” mode to check whether the operation is

normal or not.

33

Page 36

Installation Service

Error Code

(Indoor)

Diagnostics Item

Diagnostics contents

Models

F1

Indoor room

temperature sensor.

F2

Indoor heat exchanger

coil sensor.

• Sensor opens circuit or short circuit.

• Contact failure at connector.

• Indoor P.C.B failure.

C5

OTP data

(Jumper Cap).

• Jumper Cap on P.C.B failure.

• Indoor P.C.B failure.

K12AP,

K18AP,

K25AP,

K30AP.

H6

Indoor fan motor lock

current.

• Indoor fan motor failure.

If motor running speed is too slow /

stop for 1 min., in order to prevent

motor self-protection activated, it will

stop running and display lock.

• Contact failure at connector.

K12AP,

K18AP,

K25AP.

E5

Overload current

protection.

• Indoor P.C.B overload current

protector activated.

K18AP,

K25AP.

F3

Outdoor temperature

sensor.

• Outdoor dummy Sensor (R1) failure.

• Indoor / outdoor P.C.B failure.

K30AP

only

F4

Outdoor heat

exchanger sensor.

• Outdoor dummy Sensor (R 2) failure.

• Indoor / outdoor P.C.B failure.

K30AP

only

Table 6b. – ONLY for KC30AP.

Error Code

(Indoor)

Diagnostics Item

LED

(Outdoor)

Diagnostics Contents

E1

High pressure

protection.

Outdoor P.C.B

LED 1 blinking.

• High-pressure switch sensor

activated / failure.

E5

Overload current

protection.

Outdoor P.C.B

LED 2 blinking.

• Outdoor P.C.B overload current

protector activated.

E6

Communication signal

between indoor &

outdoor unit failure.

Outdoor P.C.B

LED 1, 2, 3

blinking.

• Indoor / Outdoor P.C.B failure.

• Wrong wirings connection.

• Wirings contact failure.

-

Communications signal

between Indoor &

outdoor unit normal.

Outdoor P.C.B

LED 4, 5 blink

alternately.

• It shows that the communication

signal is correctly under this

condition.

13. SELF DIAGNOSIS FUNCTION

13.1 What is self diagnosis function?

When the problem detected in the air conditioner, the operation stops and LED indicator lamps

on the indoor unit will display the error code (Fig. 42).

Kindly refer Table 6a,b for the meanings of error code and indications for each models.

Fig. 42

Table 6a

K9AP,

K9AP,

34

Page 37

SANYO Electric Co.,Ltd

Loading...

Loading...