Sanyo PLC-XU75,PLC-XU78 Service Manual

FILE NO.

SERVICE MANUAL

Multimedia Projector

Model No. PLC-XU78

PLC-XU75

U.S.A, Canada,

Europe, U.K, Asia

Original Version

PRODUCT CODE

PLC-XU78 PLC-XU75

1 122 390 00 (KH3AC) 1 122 416 00 (KZ3AC)

1 122 391 00 (LH3AC) 1 122 417 00 (LZ3AC)

1 122 391 02 (LH3CC) 1 122 417 02 (LZ3CC)

Chassis No. KH3-XU7800

KZ3-XU7500

Match the Chassis No. on the unit's back cover with the

Chassis No. in the Service Manual.

If the Original Version Service Manual Chassis No. does

not match the unit’s, additional Service Literature is required. You must refer to “Notices” to the Original Service

Manual prior to servicing the unit.

REFERENCE NO. SM5110874-00

Contents

SERVICE MANUAL ....................................................... 1

Contents ........................................................................ 2

Safety Instructions ......................................................... 3

Safety Precautions ..................................................... 3

Product Safety Notice ................................................. 3

Service Personnel Warning ........................................ 3

Specifications ................................................................4

Circuit Protections .........................................................5

Thermal switch ........................................................... 5

Lamp cover switch ...................................................... 5

Fuse ............................................................................ 5

Warning temperature and power failure protection .... 6

Air filter care and cleaning .......................................... 6

Security Function Notice ................................................ 7

Lamp Replacement .......................................................8

Lamp replacement ...................................................... 8

How to reset Lamp Replace Counter ......................... 8

How to check Lamp Used Time .................................. 8

Mechanical Disassembly ............................................... 9

Optical Parts Disassembly ........................................... 15

Adjustments ................................................................. 21

Adjustments after Parts Replacement ...................... 21

Optical Adjustments ..................................................... 22

Contrast adjustment ................................................. 22

Integrator lens adjustment ........................................ 23

Relay lens-Out adjustment ....................................... 24

Electrical Adjustments ................................................. 25

Service Adjustment Menu Operation ........................ 25

Memory IC (IC1371) Replacement ........................... 25

Circuit Adjustments ................................................... 26

Test Points and Locations ........................................ 30

Service Adjustment Data Table ................................ 31

Chassis Block Diagrams .............................................. 49

Chassis over view ..................................................... 49

System control .......................................................... 50

Power supply & protection circuit ............................. 51

Fan control circuit ..................................................... 52

Troubleshooting ........................................................... 53

Indicators and Projector Condition ........................... 53

No Power .................................................................. 54

No Picture ................................................................. 55

No Sound .................................................................. 56

System Control & I/O Port Functions (IC301) ........... 57

Waveform .................................................................... 58

Cleaning ......................................................................59

IC Block Diagrams ....................................................... 60

Electrical Parts List ...................................................... 64

Electrical Parts Location ........................................... 65

Electrical Parts List ................................................... 66

Mechanical Parts List ..................................................84

Cabinet Parts Location ............................................. 84

Optical Parts Location .............................................. 85

Mechanical Parts List ............................................... 89

Diagrams & Drawings ..................................................A1

Parts description and reading in schematic diagram ...A2

Schematic Diagrams ...................................................A3

Printed Wiring Board Diagrams ...................................A9

Pin description of diode, transistor and IC .................A13

Note on Soldering ......................................................A14

-2-

Safety Instructions

Safety Precautions

WARNING:

The chassis of this projector is isolated (COLD) from AC line by using the converter transformer. Primary side

of the converter and lamp power supply unit circuit is connected to the AC line and it is hot, which hot circuit is

identified with the line ( ) in the schematic diagram. For continued product safety and protection of personnel injury, servicing should be made with qualified personnel.

The following precautions must be observed.

ment covers or shields, barriers, etc.

1: An isolation transformer should be connected in

the power line between the projector and the AC

line before any service is performed on the projector.

DO NOT OPERATE THIS PROJECTOR WITHOUT

THE PROTECTIVE SHIELD IN POSITION AND PR

OPERLY SECURED.

2: Comply with all caution and safety-related notes

provided on the cabinet back, cabinet bottom, inside

the cabinet or on the chassis.

3: When replacing a chassis in the cabinet, always

be certain that all the protective devices are

installed properly, such as, control knobs, adjust-

4: Before replacing the cabinet cover, thoroughly

inspect the inside of the cabinet to see that no stray

parts or tools have been left inside.

Before returning any projector to the customer, the

service personnel must be sure it is completely safe

to operate without danger of electric shock.

Product Safety Notice

Product safety should be considered when a component replacement is made in any area of the projector.

Components indicated by mark ! in the parts list and the schematic diagram designate components in which

safety can be of special significance. It is, therefore, particularly recommended that the replacement of there

parts must be made by exactly the same parts.

Eye damage may result from directly viewing the light produced by the Lamp used in this equipment. Always

turn off Lamp before opening cover. The Ultraviolet radiation eye protection required during this servicing.

Never turn the power on without the lamp to avoid electric-shock or damage of the devices since the stabilizer

generates high voltages (15kV - 25kV) at its starts.

Since the lamp is very high temperature during units operation replacement of the lamp should be done at least

45 minutes after the power has been turned off, to allow the lamp cool-off.

Service Personnel Warning

-3-

Specifications

Mechanical Information

Projector Type Multi-media Projector

Dimensions (W x H x D) 13.19" x 3.14" x 9.39" (335 mm x 79.7 mm x 238.4 mm) (Not including adjustable feet)

Net Weight 6.83 lbs (3.1 kgs)

Feet Adjustment 0˚ to 10.0˚

Panel Resolution

LCD Panel System 0.6" TFT Active Matrix type, 3 panels

Panel Resolution 1,024 x 768 dots

Number of Pixels 2,359,296 (1,024 x 768 x 3 panels)

Signal Compatibility

Color System

High Definition TV Signal 480i, 480p, 575i, 575p, 720p, 1035i, and 1080i

Scanning Frequency H-sync. 15 ~ 100 kHz, V-sync. 50 ~ 100 Hz

PAL, SECAM, NTSC, NTSC4.43, PAL-M, PAL-N

Optical Information

Projection Image Size (Diagonal) Adjustable from 40" to 300"

Projection Lens F 1.65 ~ 1.81 lens with f 22.5 ~ 27 mm with manual zoom and focus

Throw Distance 4.6 - 41.3’ (1.4 m - 12.6 m)

Projection Lamp PLC-XU75: 200W

PLC-XU78: 220W

Interface

Video Input Jack RCA Type x 1

S-Videdo Input Jack Mini DIN 4 pin x 1

Audio Input Jacks RCA Type x 2

Computer Input 1/Component Input Terminal Anlaog RGB (Mini D-sub 15 pin) Terminal x 1

Computer Input 2/Monitor Output Terminal

Computer/ Component Audio Input Jack

Service Port Connector Mini DIN 8 pin x 1

Audio Output Jack Mini Jack (stereo) x 1 (Variable)

Anlaog RGB (Mini D-sub 15 pin) Terminal x 1 (In/Out switchable)

Mini Jack (stereo) x 1

Audio

Internal Audio Amp 1.0W RMS

Built-in Speaker 1 speaker, ø1.1" (28mm)

Power

Voltage and Power Consumption AC 100 ~ 120 V (3.2A Max. Ampere), 50 / 60 Hz (The U.S.A and Canada)

AC 200 ~ 240 V (1.6A Max. Ampere), 50 / 60 Hz (Continental Europe and The U.K.)

Operating Environment

Operating Temperature 41 ˚F ~ 95 ˚F (5 ˚C ~ 35 ˚C)

Storage Temperature 14 ˚F ~ 140 ˚F (-10˚C ~ 60 ˚C)

Remote Control

Battery AA or LR6 1.5V ALKALINE TYPE x 2

Operating Range 16.4’ (5m) / ±30˚

Dimensions 1.9”(W) x 0.87”(H) x 5.7”(D) (49mm x 22mm x 145.3mm)

Net Weight 3.53 oz (100 g) (including batteries)

● The specifications are subject to change without notice.

● LCD panels are manufactured to the highest possible standards. Even though 99.99% of the pixels are effective, a tiny fraction of the pixels (0.01% or

less) may be ineffective by the characteristics of the LCD panels.

This symbol on the nameplate means the product is Listed by Underwriters

Laboratories Inc. It is designed and manufactured to meet rigid U.L. safety standards against risk of fire, casualty and electrical hazards.

-4-

Circuit Protections

This projector provides the following circuit protections to operate in safety. If the abnormality occurs inside the projector, it will automatically turn off by operating one of the following protection circuits.

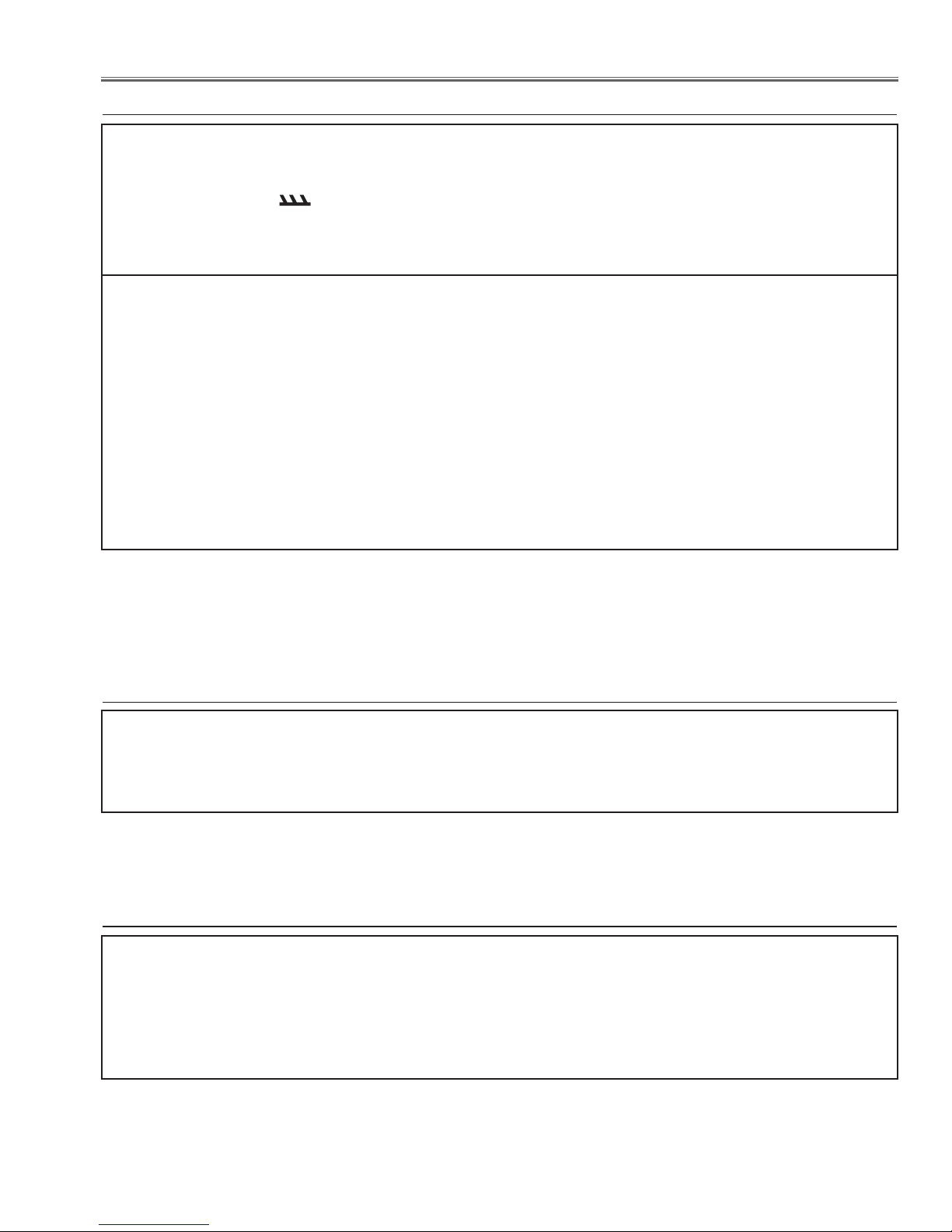

Thermal switch

There is the thermal switch (SW902) inside of the projector to detect

the internal temperature rising abnormally. When the internal temperature reaches near 100˚C, the thermal switch opens to stop the

operation of the power supply circuit.

The thermal switch cannot be reset itself automatically even if the

internal temperature becomes normal. Reset the thermal switch

following to the below procedure.

How to reset the thermal switch

1. Remove the cabinet top.

2. Press the reset button on the thermal switch.

CAUTION:

Before press the reset button, make sure that the AC cord must be

disconnected from the AC outlet.

Thermal switch (SW902)

Lamp cover switch

The lamp cover switch (SW901) cuts off the drive signal to the lamp

circuit when the lamp cover is removed or not closed completely.

After opening the lamp cover for replacing the lamp ass’y, place the

lamp cover correctly otherwise the projector can not turn on.

Fuse

A fuse is located inside of the projector. When the POWER indicator

is not lightning, the fuse may be opened. Check the fuse as following steps.

The fuse should be used with the following type;

Fuse Part No.: 323 021 7804

TYPE T6.3AH 250V FUSE

LITTLE FUSE INC. TYPE 21506.3

Fuse

How to replace the fuse

1. The fuse is placed on the filter board. Remove the cabinet top

following to the Cabinet Disassembly.

2. Take the fuse off, and replace the new one with the specified type.

-5-

Circuit Protections

Warning temperature and power failure protection

The projector will be automatically turned off when the internal temperature of the projector is abnormally high, or the

cooling fans stop spinning, or the power supplies in the projector are failed.

- If the WARNING indicator is flashing, it may detect the abnormal temperature inside the projector. Check the following possible causes and wait until the WARNING indicator stops flashing, and then try to turn on the projector.

- If the WARNING indicator lights red, it may defect the cooling fans or power supply circuits. Check fans operation

and power supply lines referring to the chapter “Power supply & protection circuit” in the Chassis Block Diagram

section.

Possible causes

- Air filters are clogged with dust particles. Remove dust from the air filters by following instructions in the “Air filter

care and cleaning” below.

- Ventilation slots of the projector are blocked. In such an event, reposition the projector so that ventilation slots are

not obstructed.

- Check if projector is used at higher temperature place (Normal operating temperature is 5 to 35 ˚C or 41 to 95˚F)

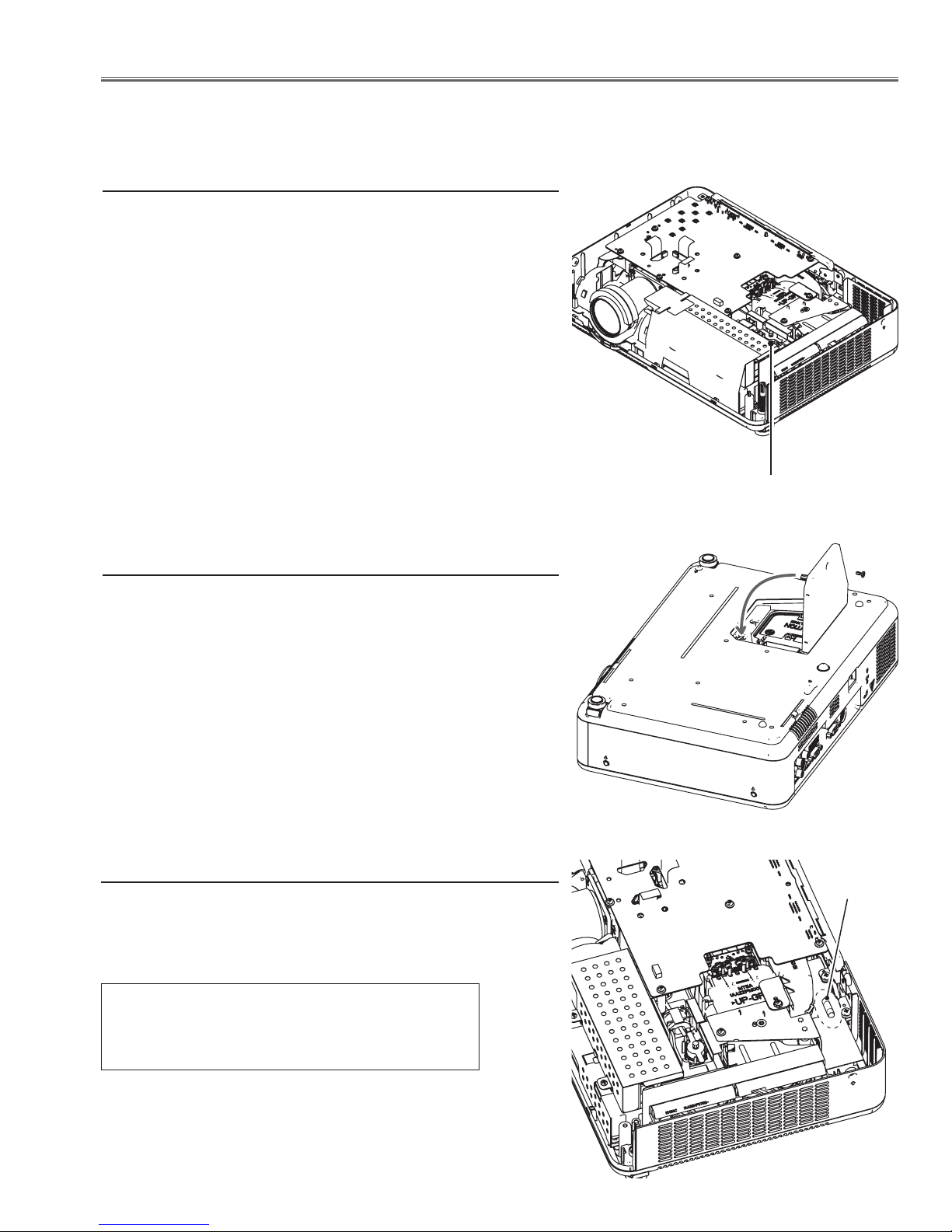

Air filter care and cleaning

Air filters prevent dust from accumulating on the optical elements inside the projector. Should the air filters become

clogged with dust particles, it will reduce cooling fans’ effectiveness and may result in internal heat build up and adversely affect the life of the projector. Clean the air filters following the steps below.

1. Turn off the projector, and disconnect the AC power cord

from the AC outlet.

2. Turn over the projector and remove the air filters by pull-

ing the latches upward.

3. Clean the air filters with a brush or rinse them softly.

4. When cleaning the air filters by rinsing, dry them well. Re-

place the air filters properly. Make sure that the air filters

are fully inserted.

CAUTION:

Do not operate the projector with the air filters removed.

Dust may accumulate on the LCD panel and the projection

mirror degrading picture quality.

Do not put small parts into the air intake vents. It may result

in malfunction of the projector.

RECOMMENDATION:

We recommend avoiding dusty/smoky environments

when operating the projector. Usage in these

environments may cause poor image quality.

When using the projector under dusty or smoky conditions, dust may accumulate on a lens, LCD panels, or optical

elements inside the projector. This condition may degrade the quality of a projected image.

When the symptoms above are noticed, contact your authorized dealer or service station for proper cleaning.

Air filters

-6-

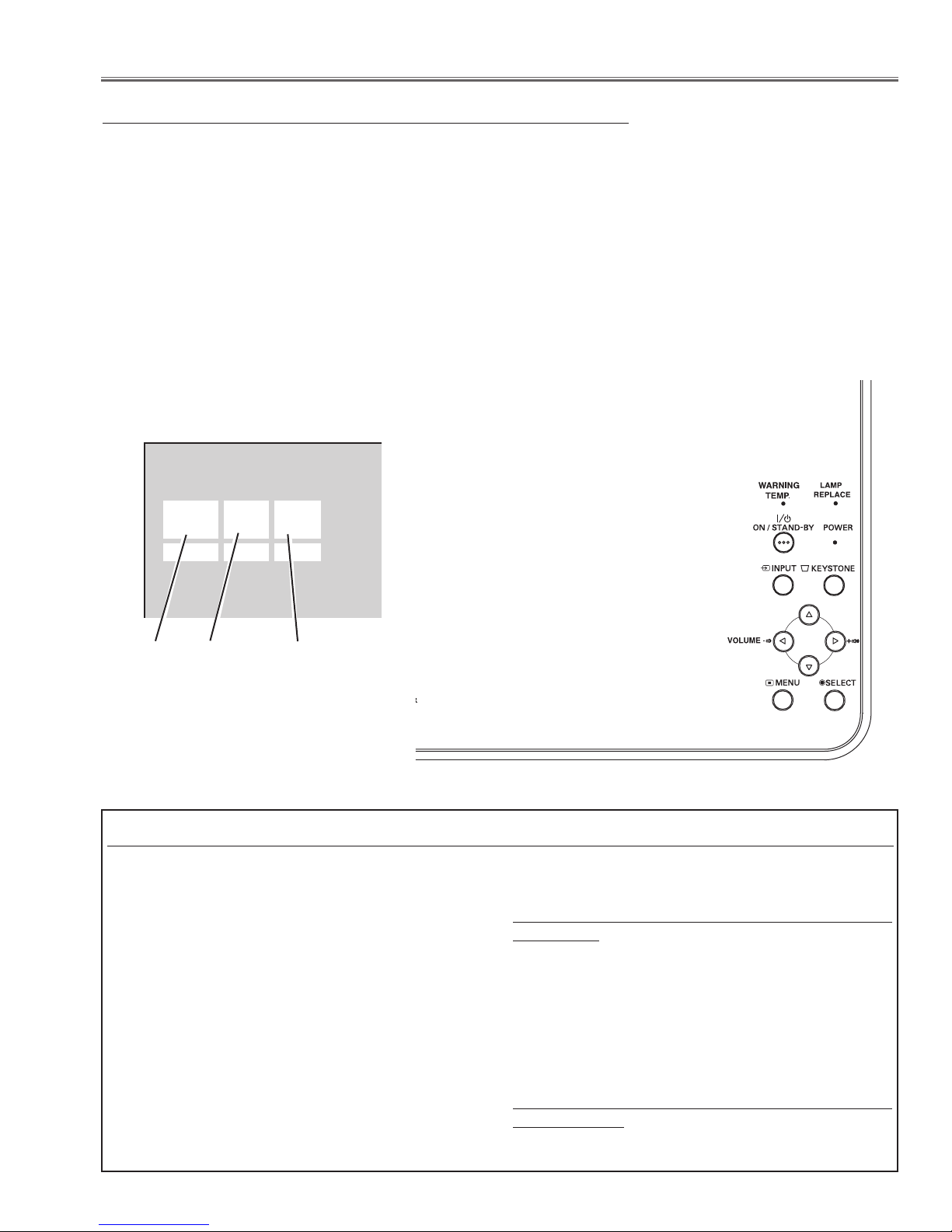

Security Function Notice

This projector provides security functions such as "Key lock", "PIN code lock" and "Logo PIN code lock". When the projector has set these security function on, you are required to enter correct PIN code to use the projector. If you do not

know the correct PIN code to the projector, the projector can no longer be operated or started. In this case, you must

reset those function first according to the resetting procedure described below and then check up on the projector.

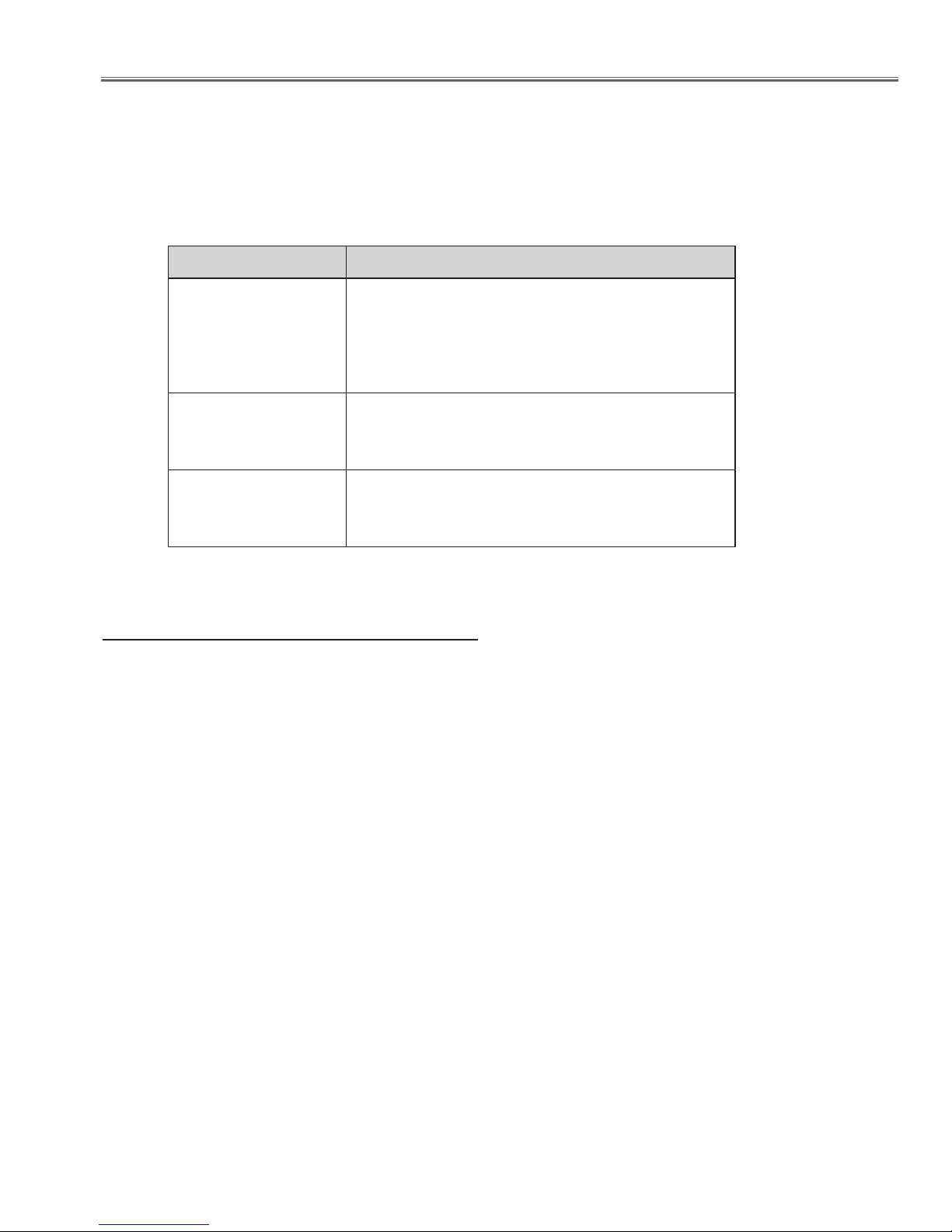

Function Description

Locks operation of the top control or the remote control.

Key lock

PIN code lock

Logo PIN code lock

If the Key lock is enabled with top control lock, the projector can no longer be started.

Initial setting: Key lock function is disabled

Prevents the projector from being operated by an unauthorized person.

Initial code: “1234”

Prevents an unauthorized person for changing the

start-up logo on the screen.

Initial code: “4321”

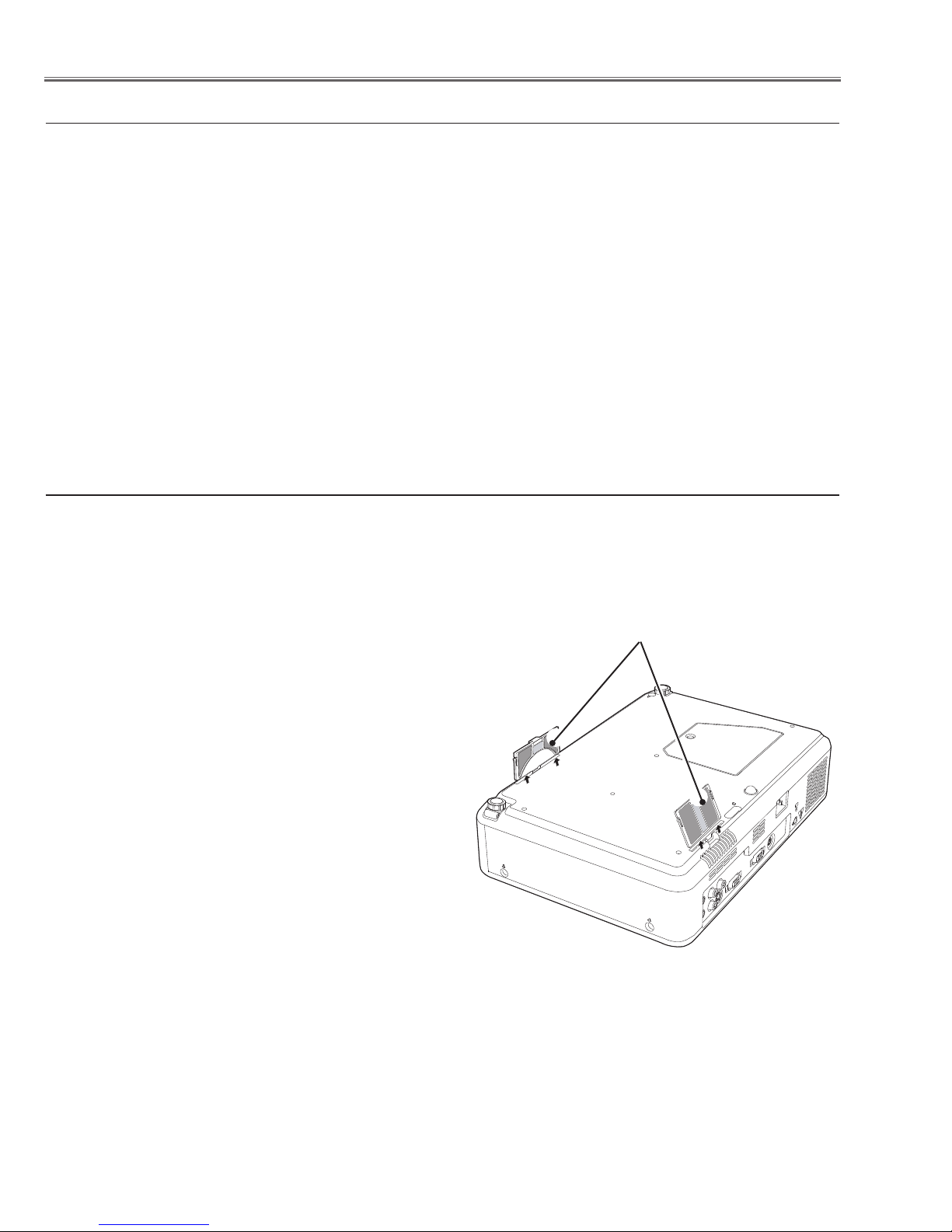

Resetting procedure

1 Disconnect the AC power cord from the AC outlet.

2 As pressing the SELECT button on the projector, connect the AC power cord into an AC outlet again. Keep

pressing the SELECT button until the POWER indicator lights continuously.

This is complete the resetting of the security function. The PIN code lock and Logo PIN code lock are reset

as the initial PIN code at the factory and the Key lock function is disabled.

Please refer to the owner's manual for further information of the security functions.

-7-

Lamp Replacement

Counter

Projector 525H

Lamp

Normal 150H

Eco 375H

Corresponding value 675H

Lamp replacement

WARNING:

- For continued safety, replace with a lamp assembly of the same type.

- Allow the projector to cool for at least 45 minutes before you open the

lamp cover. The inside of the projector can become very hot.

- Do not drop the lamp module or touch the glass bulb! The glass can

shatter and cause injury.

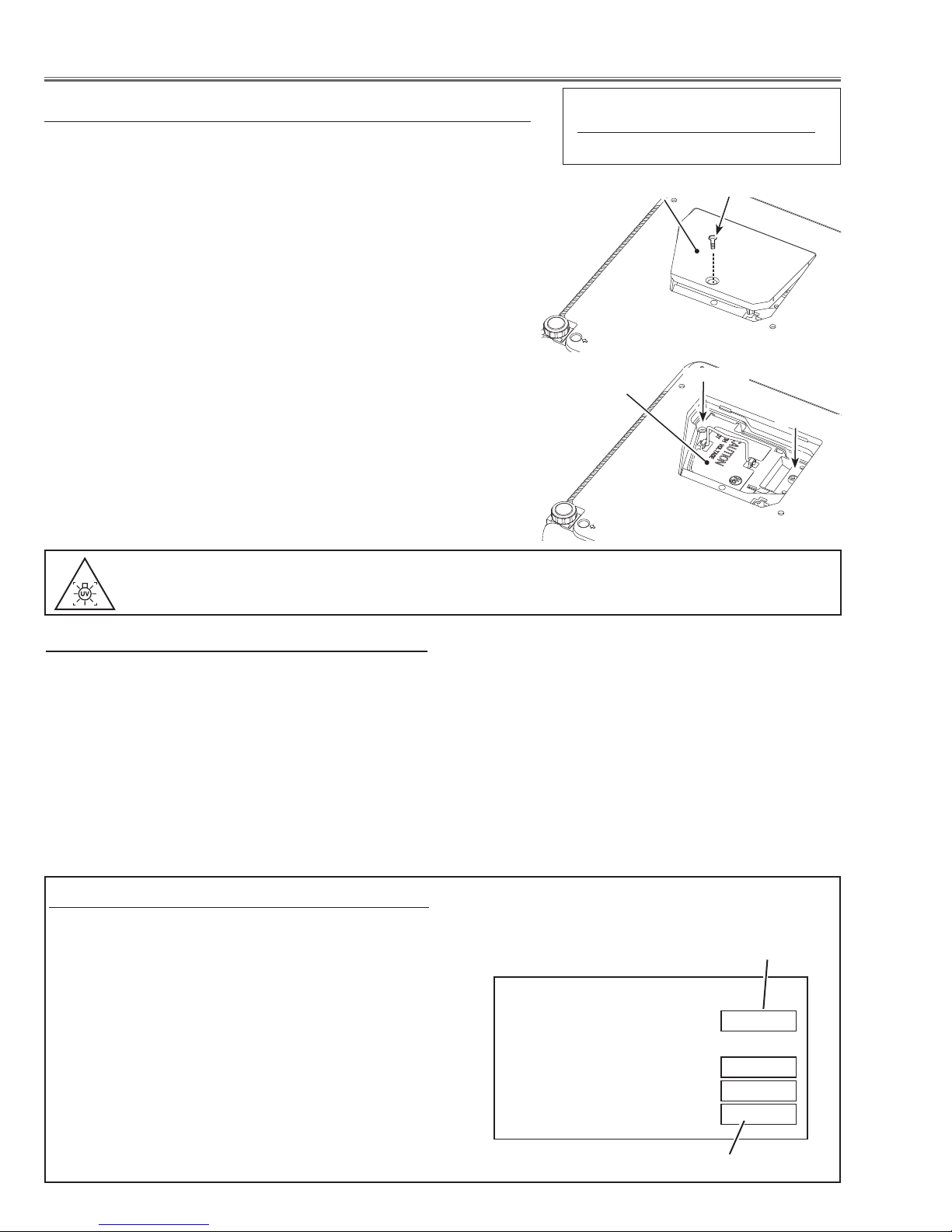

Procedure

1 Turn off the projector and disconnect the AC cord.

2 Loosen 1 screw with a screwdriver and remove the lamp cover.

3

Loosen w screws and pull out the lamp assembly by grasping the ledges.

4 Replace the lamp with a new one and tighten the 2 screws back into

position. Make sure that the lamp is set properly. Replace the lamp

cover and tighten the screw.

5 Connect the AC cord to the projector and turn on.

6 Reset the lamp replacement counter, see below explanation.

Note

- The projector cannot be turned-on with lamp cover removed, because

when the lamp cover is removed, the lamp cover switch is also released to switch off the lamp circuit.

ORDER REPLACEMENT LAMP

Type No. Parts No.

POA-LMP115 610 334 9565

Lamp Cover

Lamp

Screw

Screw

Screw

WARNING : TURN OFF THE UV LAMP BEFORE OPENING THE LAMP COVER.

USE UV RADIATION EYE AND SKIN PROTECTION DURING SERVICEING.

How to reset Lamp Replace Counter

1 Turn the projector on, press the MENU button and the

On-Screen Menu will appear. Press the 7 or 8 but-

ton to move the red frame pointer to the Setting Menu

icon.

2 Press the d button to move the red frame pointer to

the Lamp counter reset item and then press the SELECT button. Select "Reset" and press the SELECT

button. The message "Lamp replace counter Reset?"

is displayed. Move the pointer to [Yes] and then press

the SELECT button.

* Refer to owner's manual for further information.

How to check Lamp Used Time

The LAMP REPLACE indicator will light yellow when

the total lamp used time (Corresponding value) reaches

3,000 hours. This is to indicate that lamp replacement is

required.

The total lamp used time is calculated by using the below expression,

Total lamp used time = Teco + Tnormal x 2

Recommendation

Should the air filter become clogged with dust particles,

it will reduce the cooling fan’s effectiveness and may result in internal heat build up and short lamp life. We recommend cleaning the air filter after the projection lamp

is replaced.

Refer to “Air Filter Cleaning”.

2 The projector used time and lamp used time will be

displayed on the screen briefly as follows.

Projector used time

Teco: used time in the Eco mode

Tnormal : used time in the Normal mode

You can check the lamp used time following to the below

procedure.

1 Press and hold the ON/STAND-BY button on the pro-

jector for more than 20 seconds.

Total lamp used time

-8-

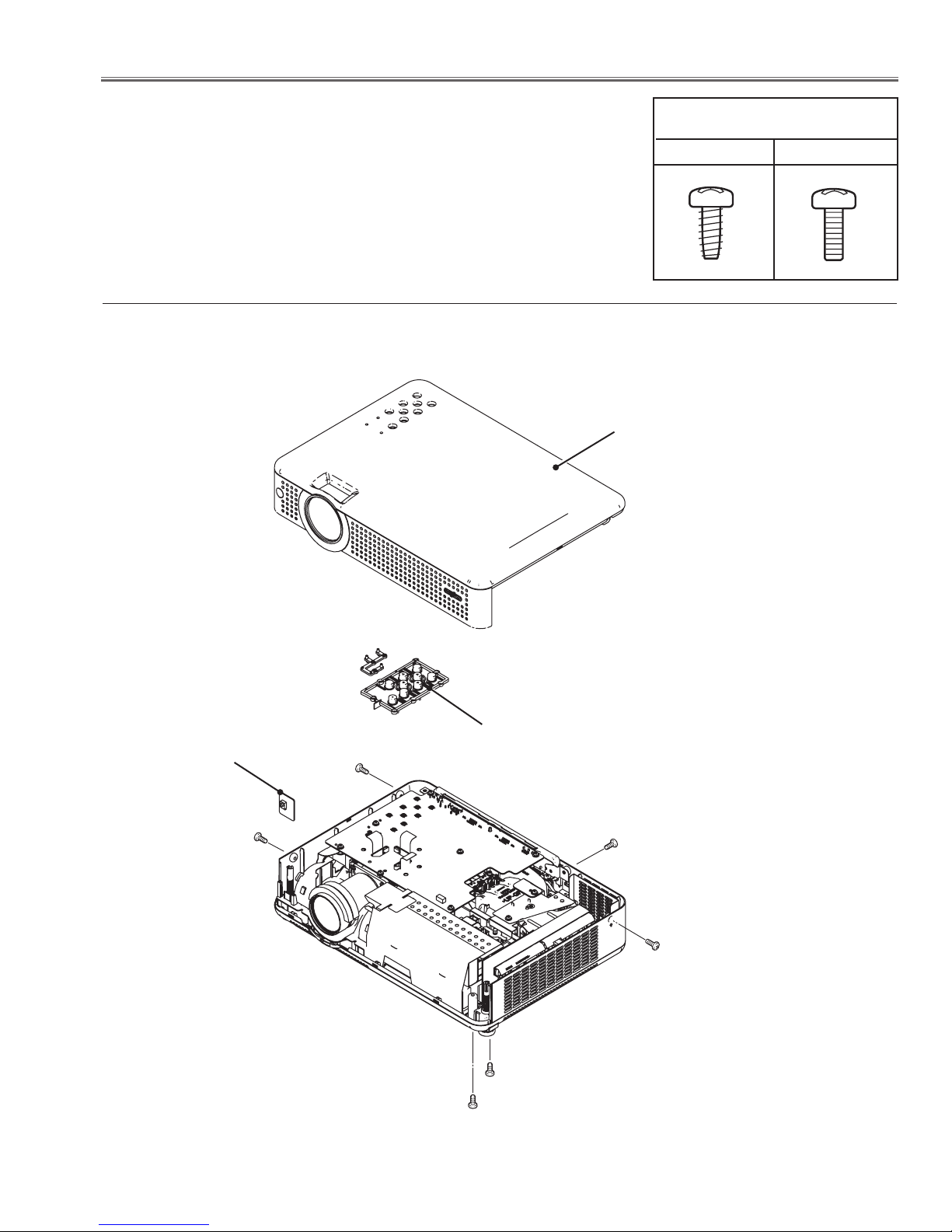

Mechanical Disassembly

Mechanical disassembly should be made following procedures in numerical order.

Following steps show the basic procedures, therefore unnecessary step may

be ignored.

Caution:

The parts and screws should be placed exactly the same position as the original

otherwise it may cause loss of performance and product safety.

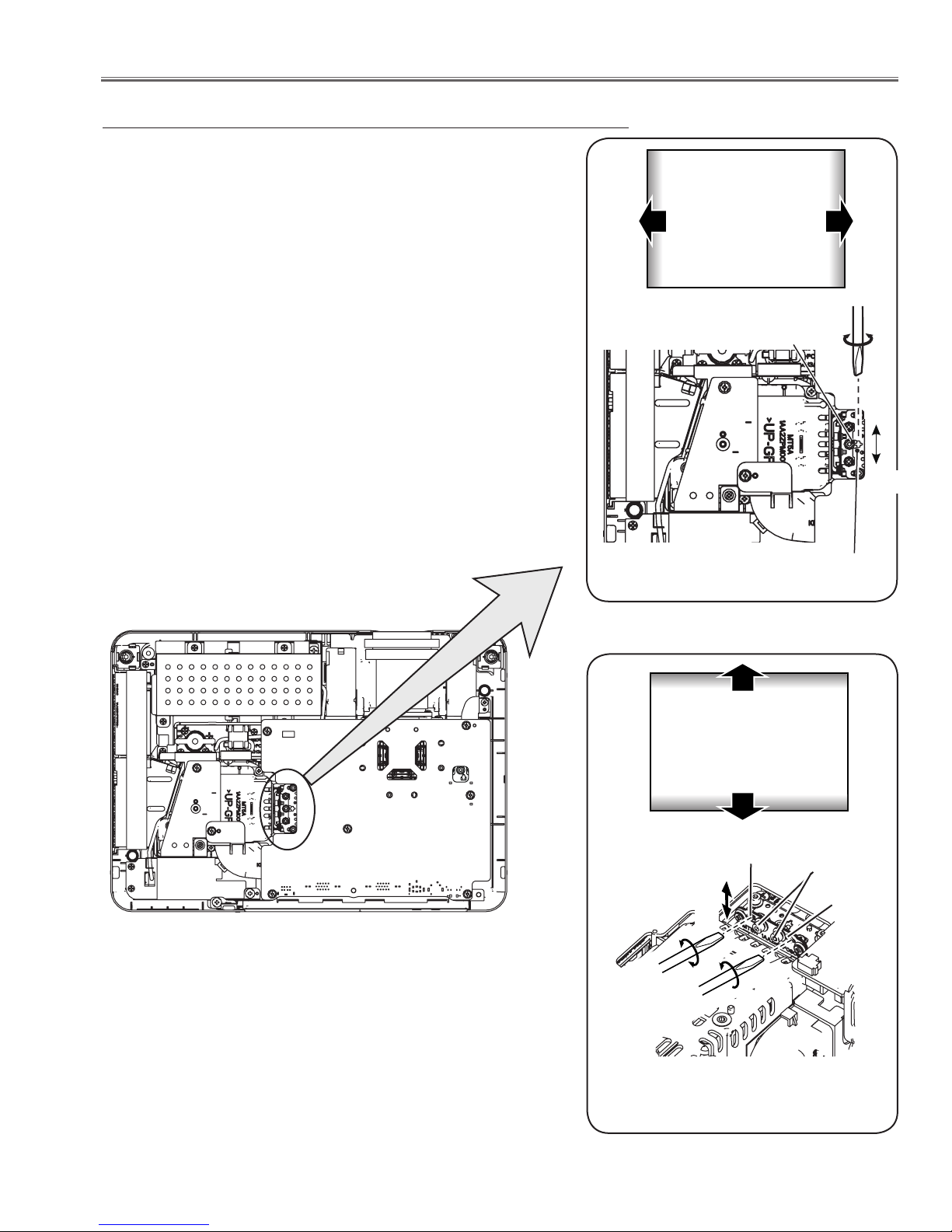

z Cabinet Top & R/C Board removal

Cabinet Top

Screws Expression

(Type Diameter x Length) mm

T type M Type

R/C Board

Control

Buttons

(M3x8)x6

Fig.1

-9-

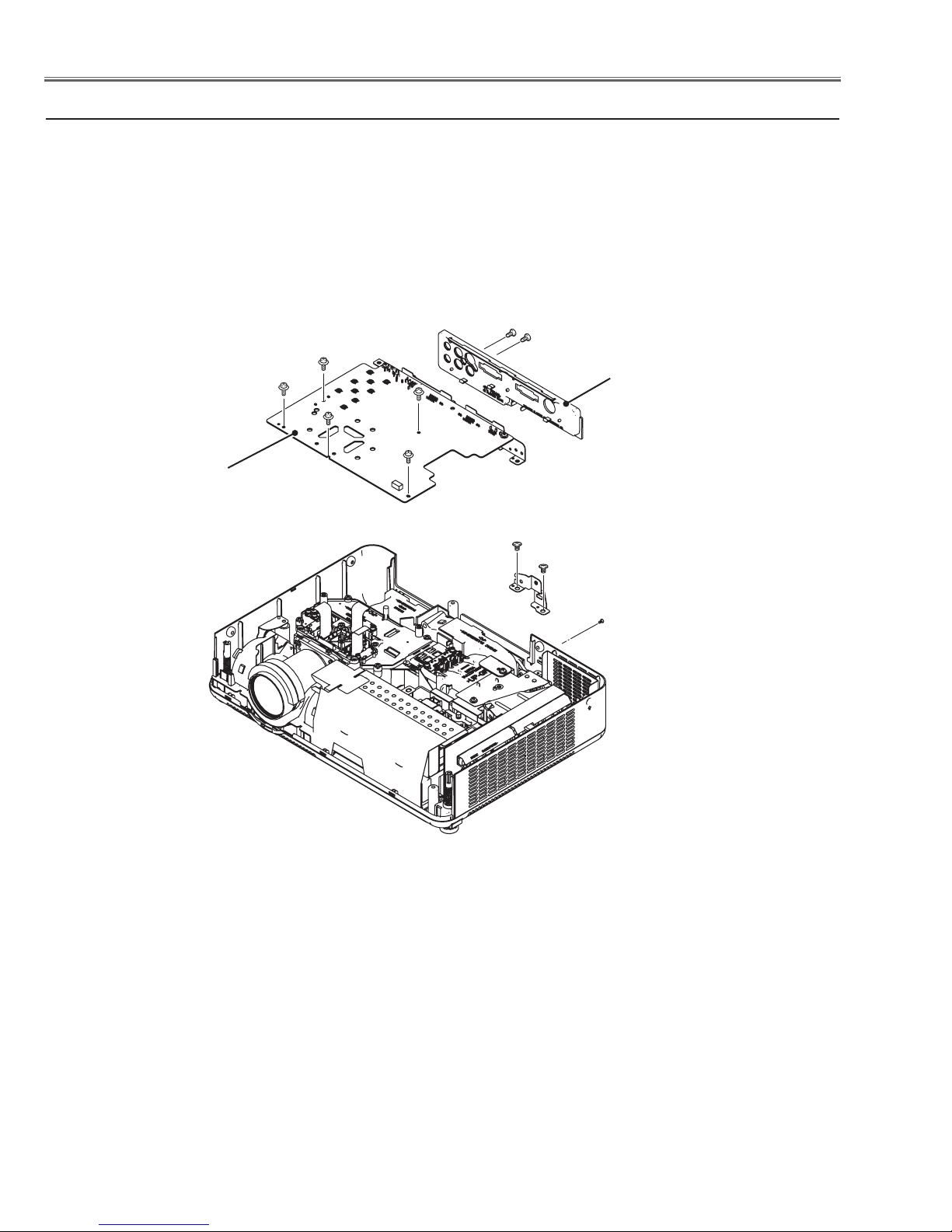

Mechanical Disassembly

x Main Board, Filter Board removal

(M2.5x8)x5

Main board

(T3x6)x2

AV Panel

(M3x6)x2

(M2x4)

Fig.2

-10-

Mechanical Disassembly

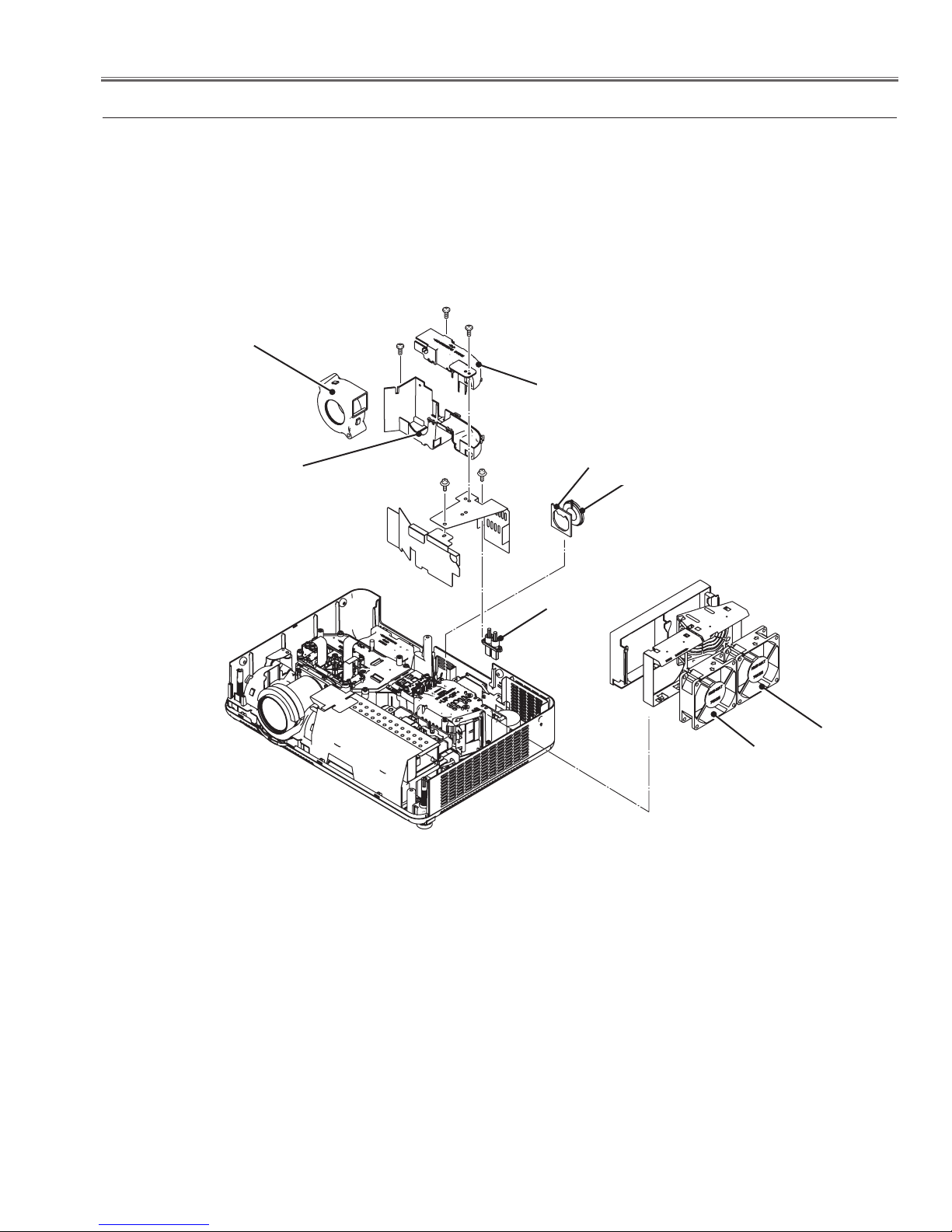

c Fan (FN901, FN902, FN906) removal

(T3x8)x2

FN906

Lamp Duct

Bottom

(M2.5x8)

(M2.5x6)

(M3x7.5)

Lamp Duct

Top

Spacer

Speaker

Ballast

socket

FN902

FN901

Fig.3

-11-

Mechanical Disassembly

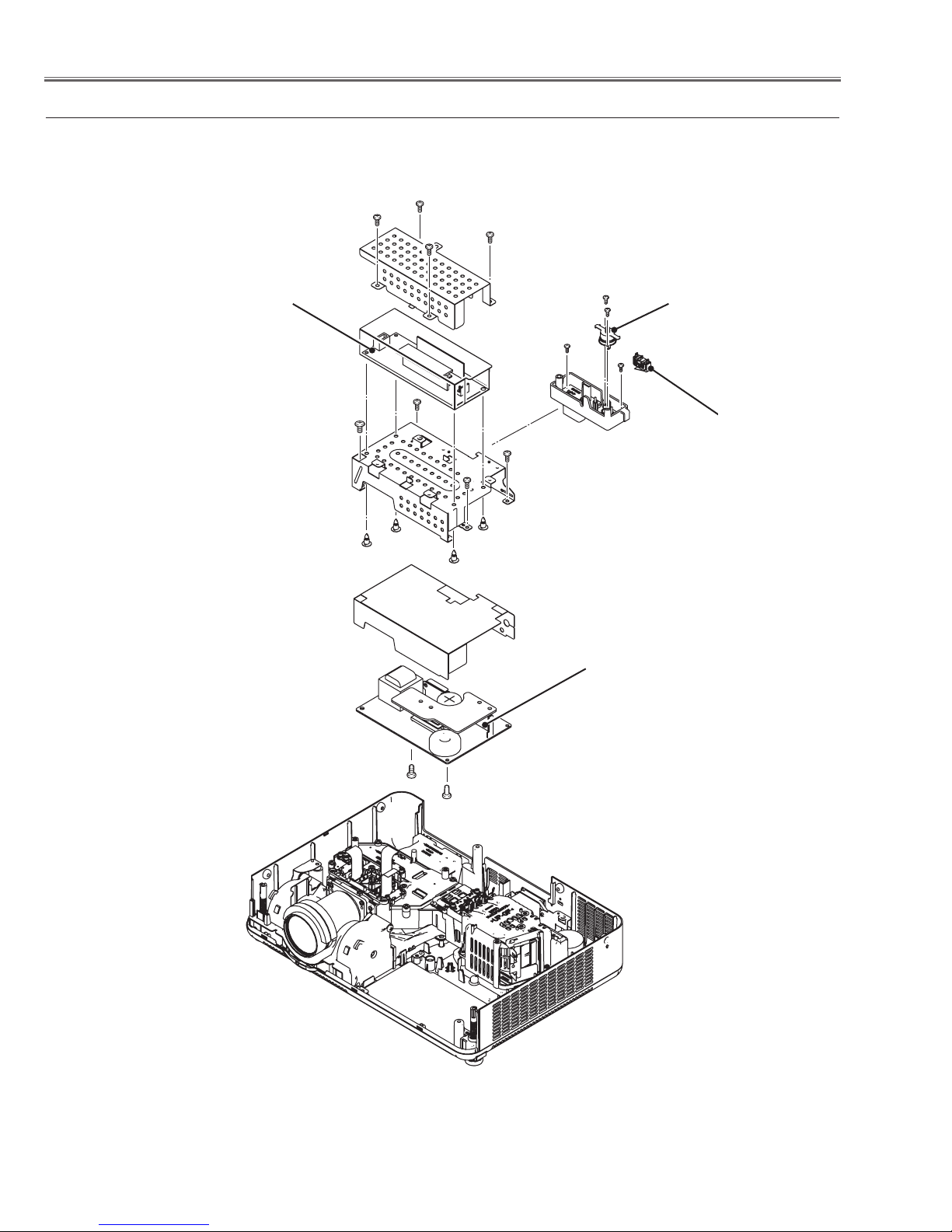

v Ballast, Power Board, SW901, SW902 removal

(M4x8)

Ballast Board

(M4x8)

(T3x6)x3

(T3x6)x2

Thermal Switch

(SW902)

(T3x6)x2

Lamp Cover

Switch (SW901)

(T3x6)x2

(T3x6)

Power Board

Fig.4

-12-

Mechanical Disassembly

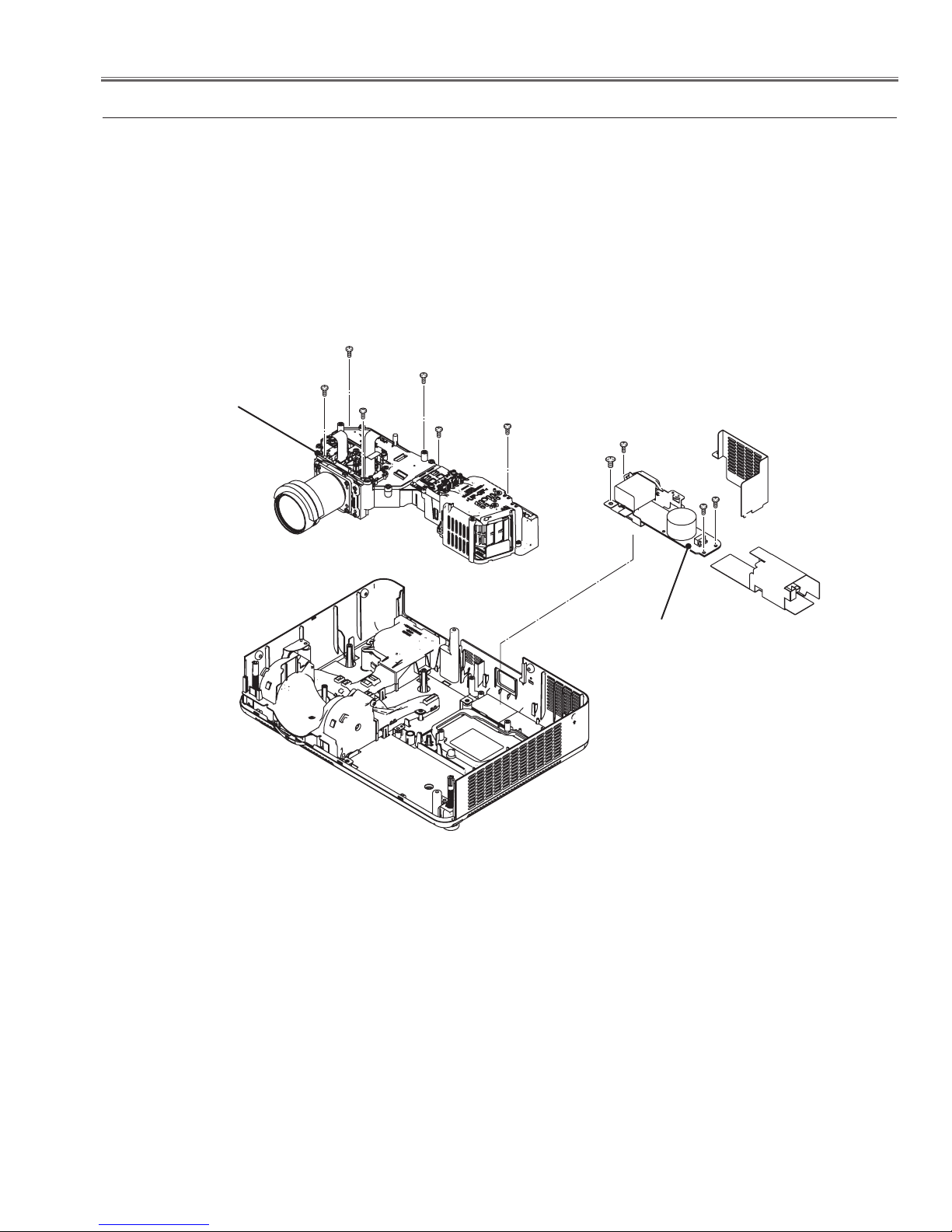

b Filter Board, Optical Unit removal

(T3x8)x6

Optical Unit

(T3x8)x2

(M4x8)

(M3x7.5)

Filter

Board

Fig.5

-13-

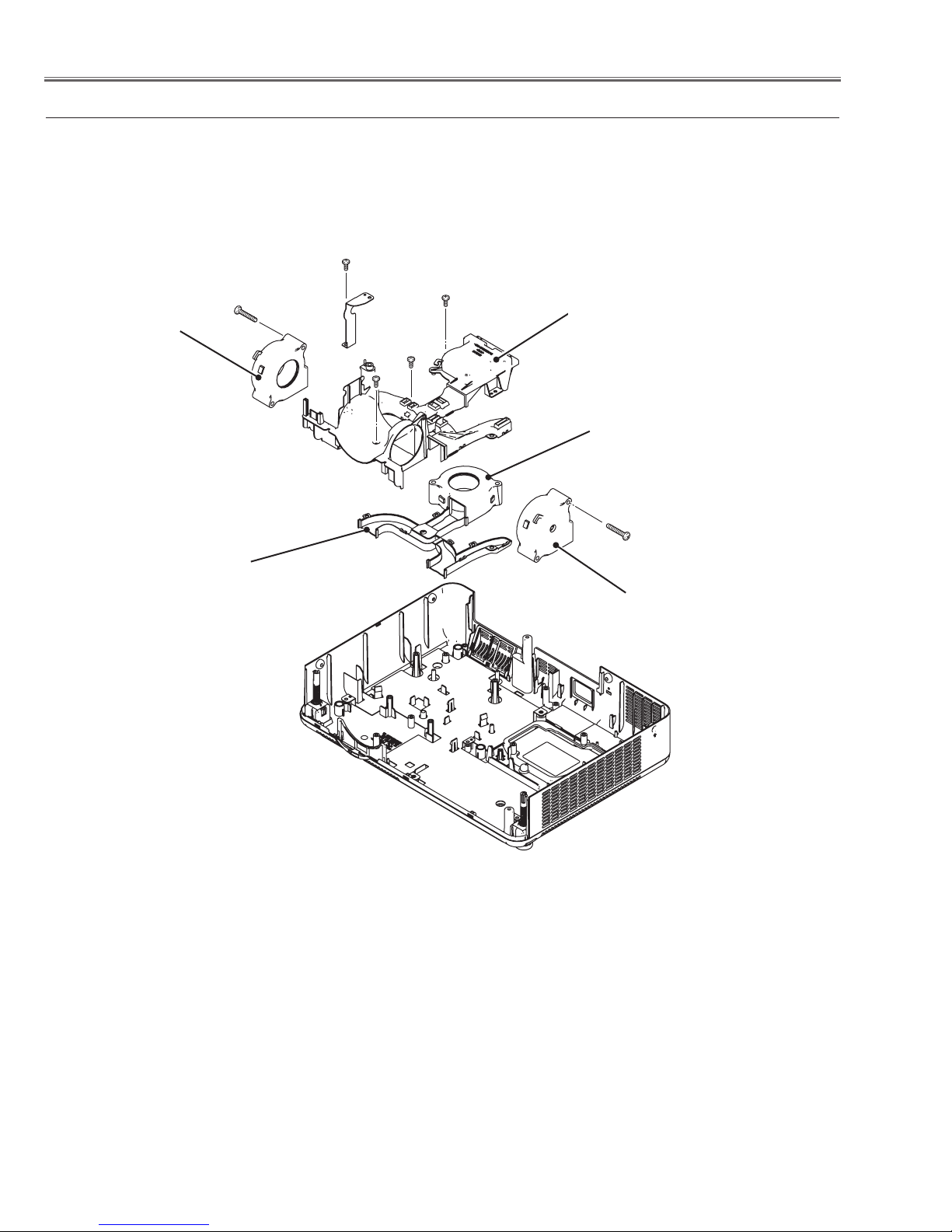

n Fan (FN903, FN904, FN905) removal

(T3x8)

FN905

Panel Duct

(T3x30)

Bottom

(T3x8)x3

Panel

Duct Top

FN904

(T3x30)

FN903

Fig.6

-14-

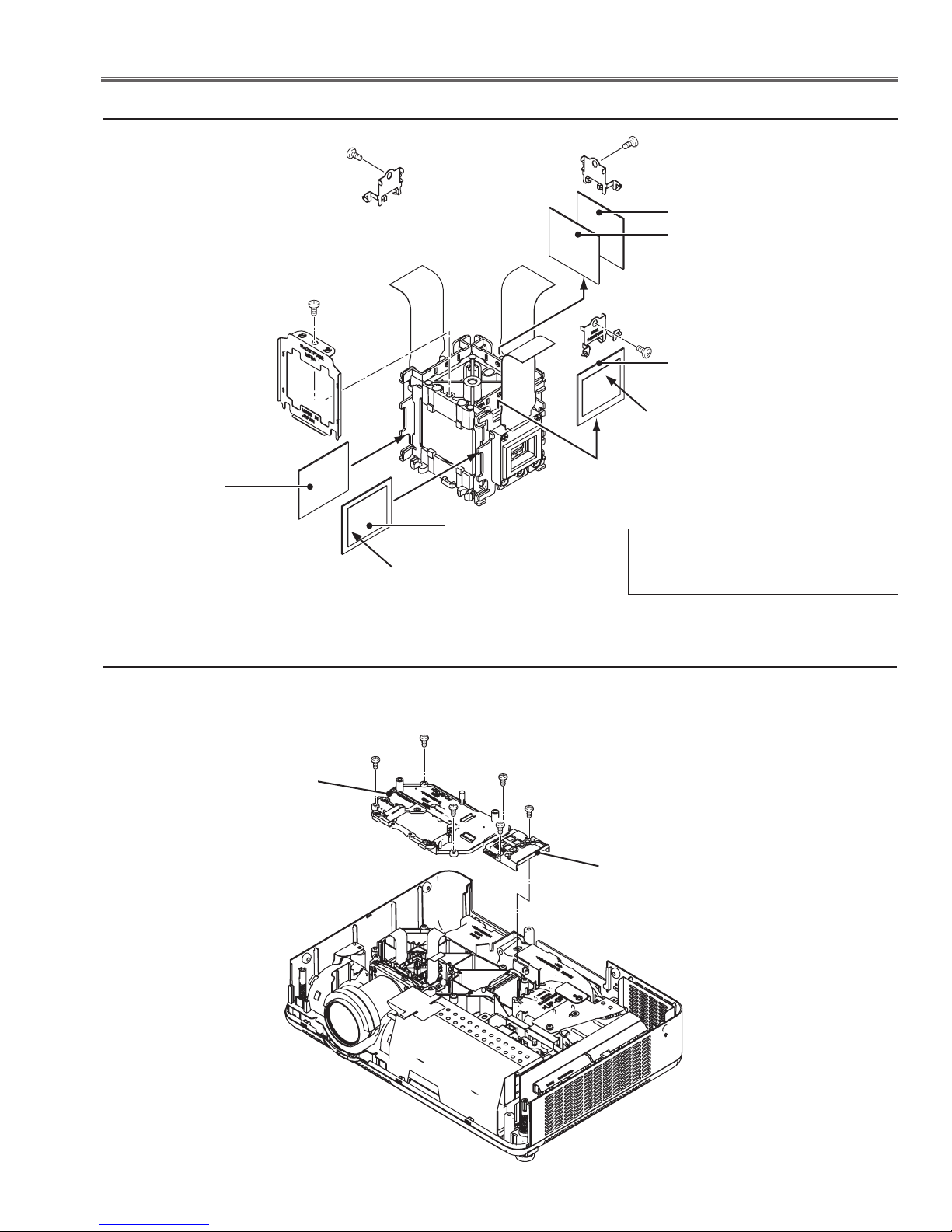

Optical Parts Disassembly

Before taking this procedure, remove Cabinet Top , Cabinet Front and Main Board following to the “Mechanical Disassembly”.

Disassembly requires a 2.0mm hex wrench.

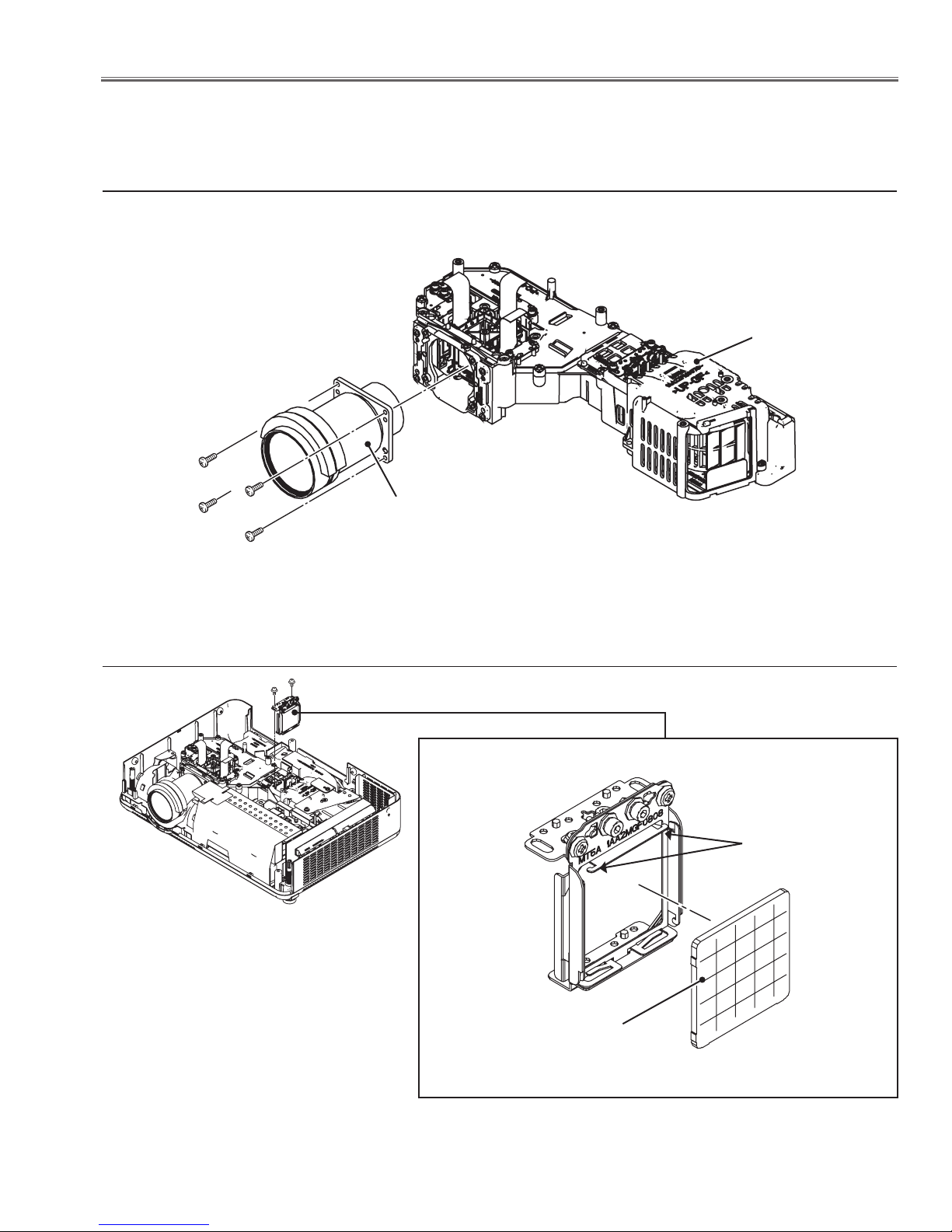

z Projection lens removal

Note: When removing the projection lens, remove the optical unit from the cabinet bottom first.

Optical Unit

(M2.5x8)x4

Projection Lens

Fig.1

z Integrator lens-in disassembly

(M2.5x5)x2

Integrator Lens-In Ass'y

Fig.2

Hooks

Integrator lens-in

* Rugged surface

(Behind)

-15-

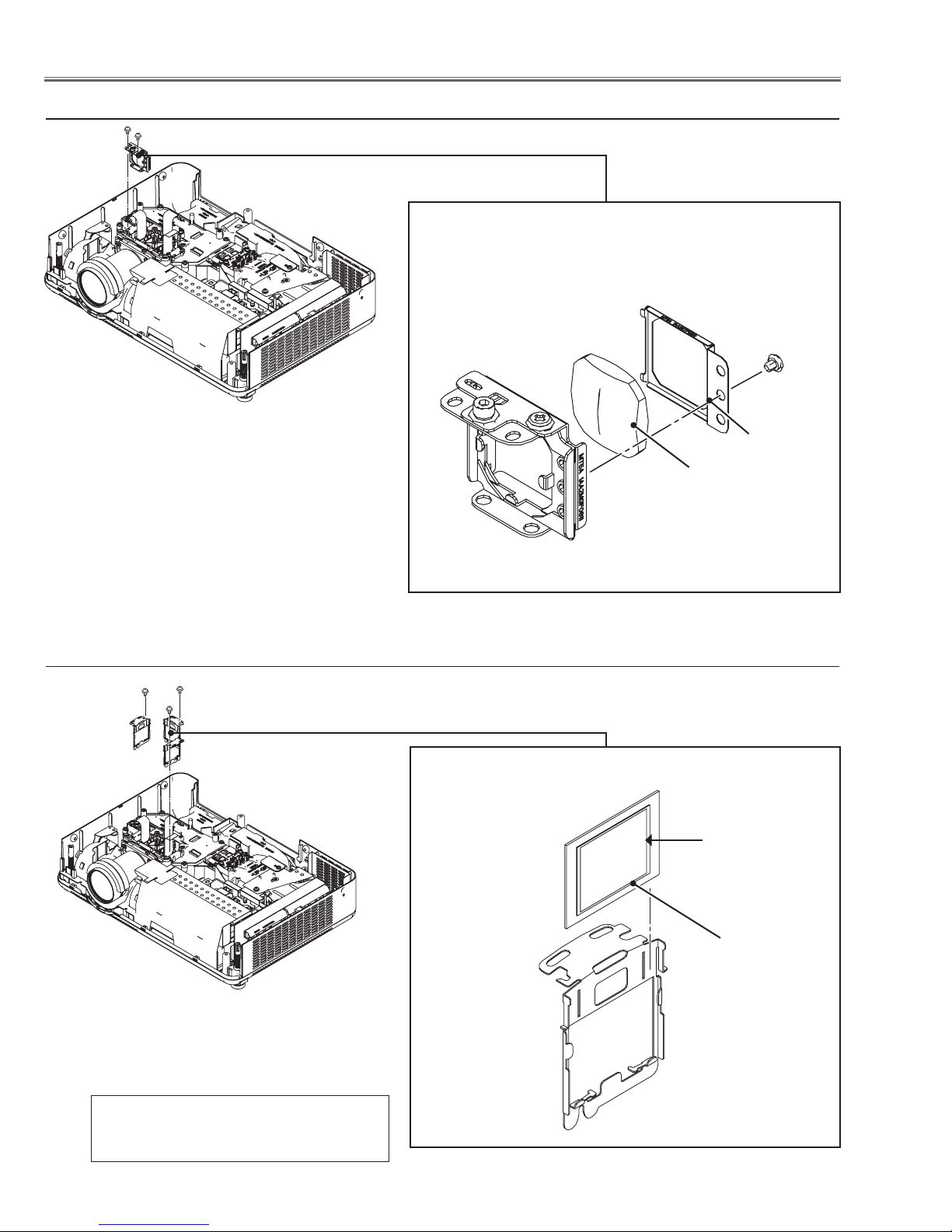

c Relay lens disassembly

(M2.5x5)x2

Relay lens Ass'y

Spring

Relay lens

Fig.3

v Polarized glass-in disassembly

(M2.5x5)x1

Polarized glass-in Ass'y

Film side

Polarized glass

* Mount the polarized glasses as the film

attached side comes to the prism side.

Fig.4

-16-

Optical Pats Disassembly

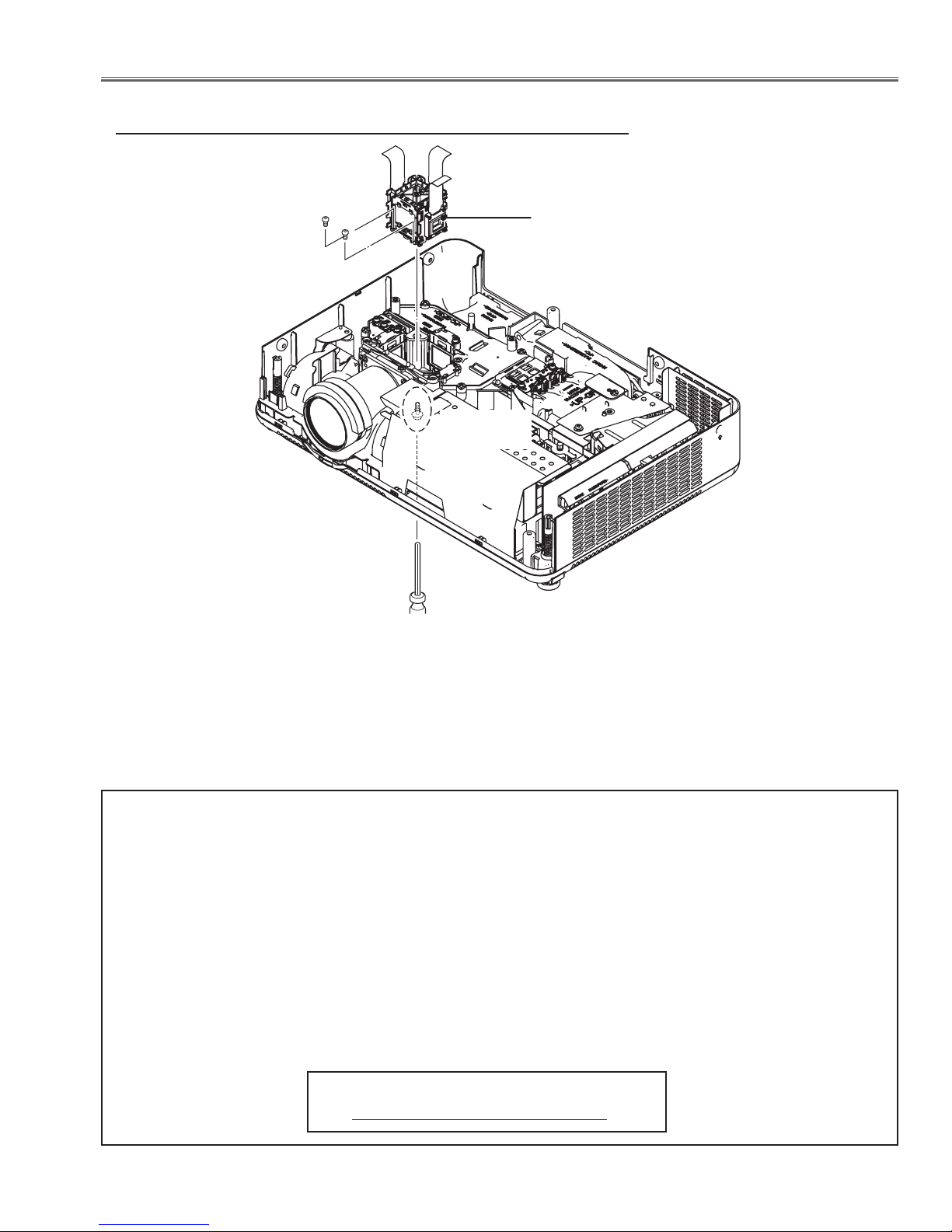

b LCD Panel/Prism Ass’y removal

(M2.5x4)x2

(M3x10)

(Bottom side)

LCD Panel/

Prism Ass’y

Fig.5-1

IMPORTANT NOTICE on LCD Panel/Prism Ass'y Replacement

LCD panels used for this model can not be replaced separately. Do not disassemble the LCD Panel/Prism Ass’y.

These LCD panels are installed with precision at the factory. When replacing the LCD panel, should be replaced

whole of the LCD panels and prism ass’y at once.

After replacing LCD Panel/Prism ass’y, please check the following points.

- Check that there is no color shading at the top, bottom, left or right of the screen. If there is, try to remove the

shading following to the chapter “Optical Adjustment”.

- Check the white balance. If it needs the adjustment, adjust the white balance following to the “White Balance

Adjustment” , “Gamma Adjustment” and “Common Centre Adjustment” in the chapter “Electrical Adjustment”.

- Check the white uniformity on the screen.

If you find the color shading at the some part of the screen, it needs to take the color shading adjustment. This

adjustment should be performed by a computer and it also requires a special software “Color Shading Correction”.

The software will be supplied separately and can be ordered as follows;

COLOR SHADING CORRECTION Ver. 4.00

Service Parts No. 645 075 9611

-17-

L3P06X-85G00

1-B-1234A1

-85G00

L3P06X-86G00

1-B-1234A1

-86G00

L3P06X-65G00

1-B-1234A1

-65G00

L3P06X-66G00

1-B-1234A1

-66G00

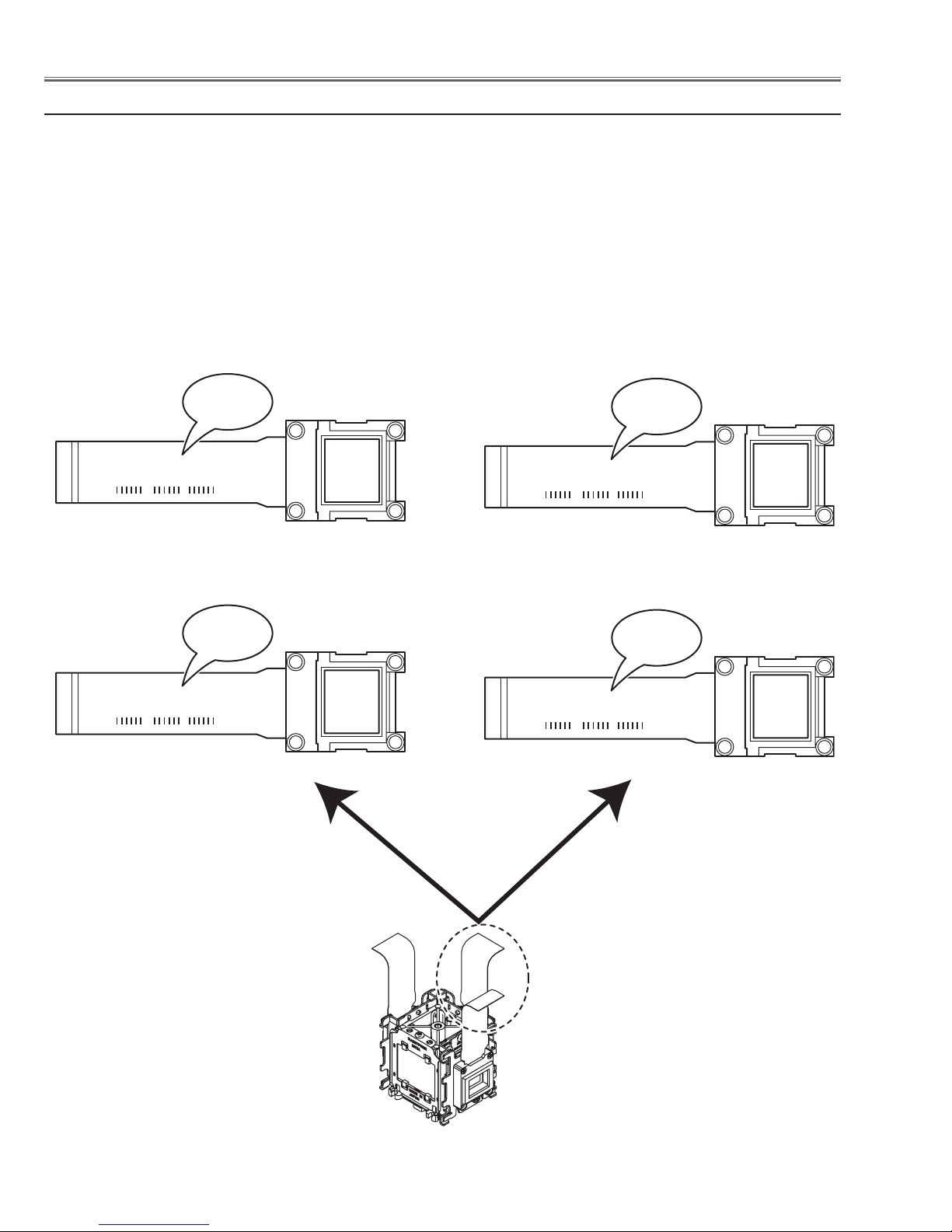

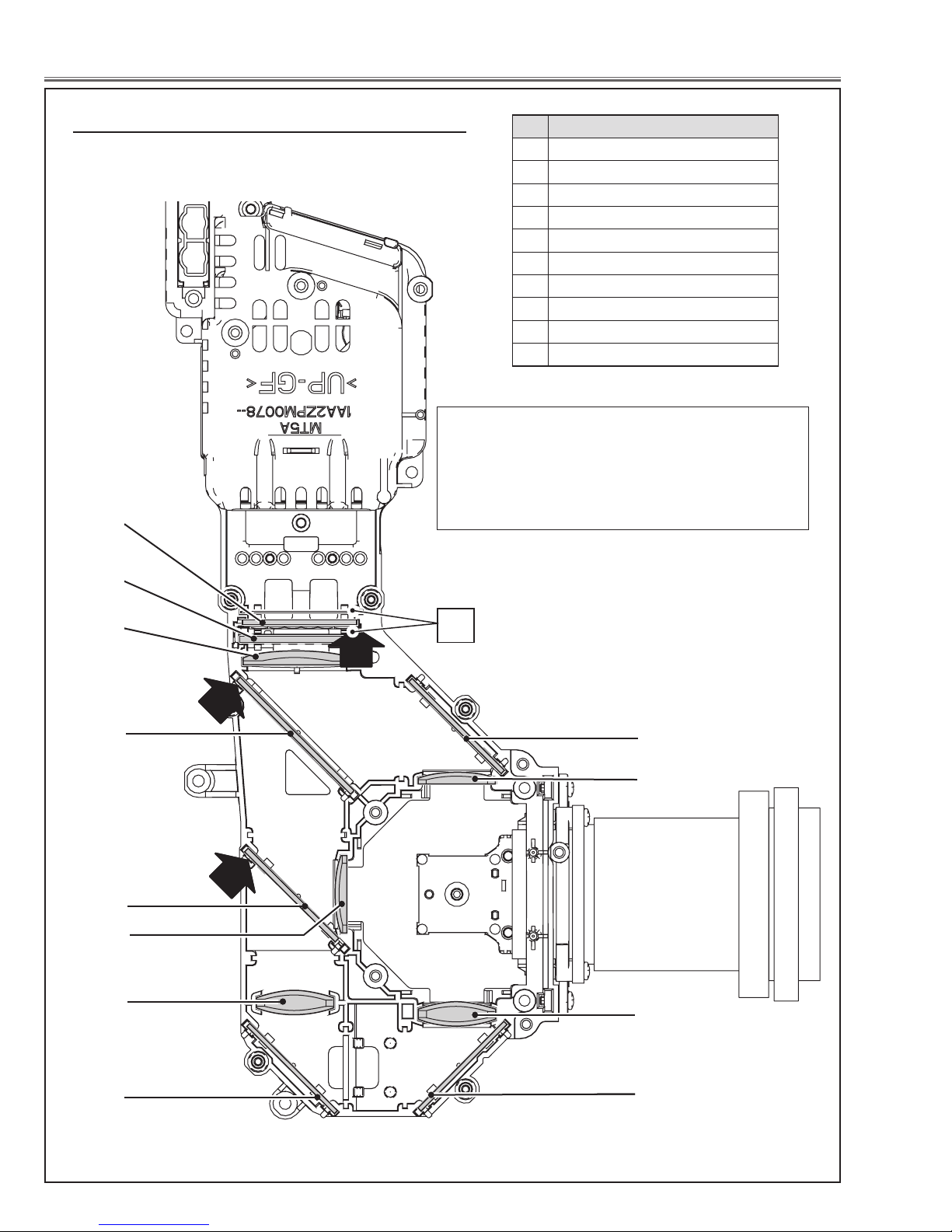

Optical Parts Disassembly

Panel Type Check

There are 2 types of LCD Panel/Prism Ass'y for this model. Either L-Type or R-Type LCD Panel/Prism Ass'y is used

on the projector. Check which type of LCD Panel/Prism Ass'y is used with the figure below.

When replacing the LCD Panel/Prism Ass'y, you need to take "Panel Type Check and Setting" on the Electrical Adjustment for the replaced LCD Panel/Prism Ass'y.

The gamma-characteristics is different between L-Type and R-Type LCD Panel/Prism Ass'y.

How to check the type of LCDPanel/Prism Ass'y

Check the printed number on the flat cable of the G-LCD Panel.

L-Type LCD Panel/Prism Ass'y R-Type LCD Panel/Prism Ass'y

Model PLC-XU78

Model PLC-XU75

G-LCD PANEL

Fig.5-2

-18-

Optical Pats Disassembly

n Polarized glass-out, Pre-polarized glass removal

Polarized Glass(B)

(Red)

(M2x4)

(M2x2)

Film

Polarized Glass(B)

(M2x2)

(Green)

Pre-Polarized Glass(G)

Polarized Glass(G)

(M2x2)

Pre-Polarized Glass(B)

Film

(Blue)

Fig.6

* Mount the polarized glasses as the

film attached side comes to the LCD

panel side.

n Optical Unit Top removal

Optical Unit Top-B

(M3x8)x4

(M3x8)x2

Optical Unit Top-A

Fig.7

-19-

Optical Parts Disassembly

, Locations and Directions

When mounting or assembling the optical parts in the optical unit, the parts must be mounted in the specified location and direction as shown in figure below.

The arrows in the figure indicate the mount direction

of the part for the replacement. Check the number

on the arrows and mount each part according to its

note;

A: The printed part no. comes to this side.

1

1

B: Rugged surface comes to this side.

No. Parts Name

1 Integrator lens (OUT)

2 Prism beam splitter (PBS)

3 Condenser lens (OUT)

4 Dichroic mirror (B)

5 Dichroic mirror (G)

6 Condenser lens (G)

7 Mirror (R)

8 Condenser lens (R)

9 Condenser lens (B)

10 Mirror (B)

2

2

3

3

B

B

A

A

4

4

A

A

5

5

6

6

8

8

Slit

10

10

9

9

8

8

7

7

-20-

7

7

Fig.8

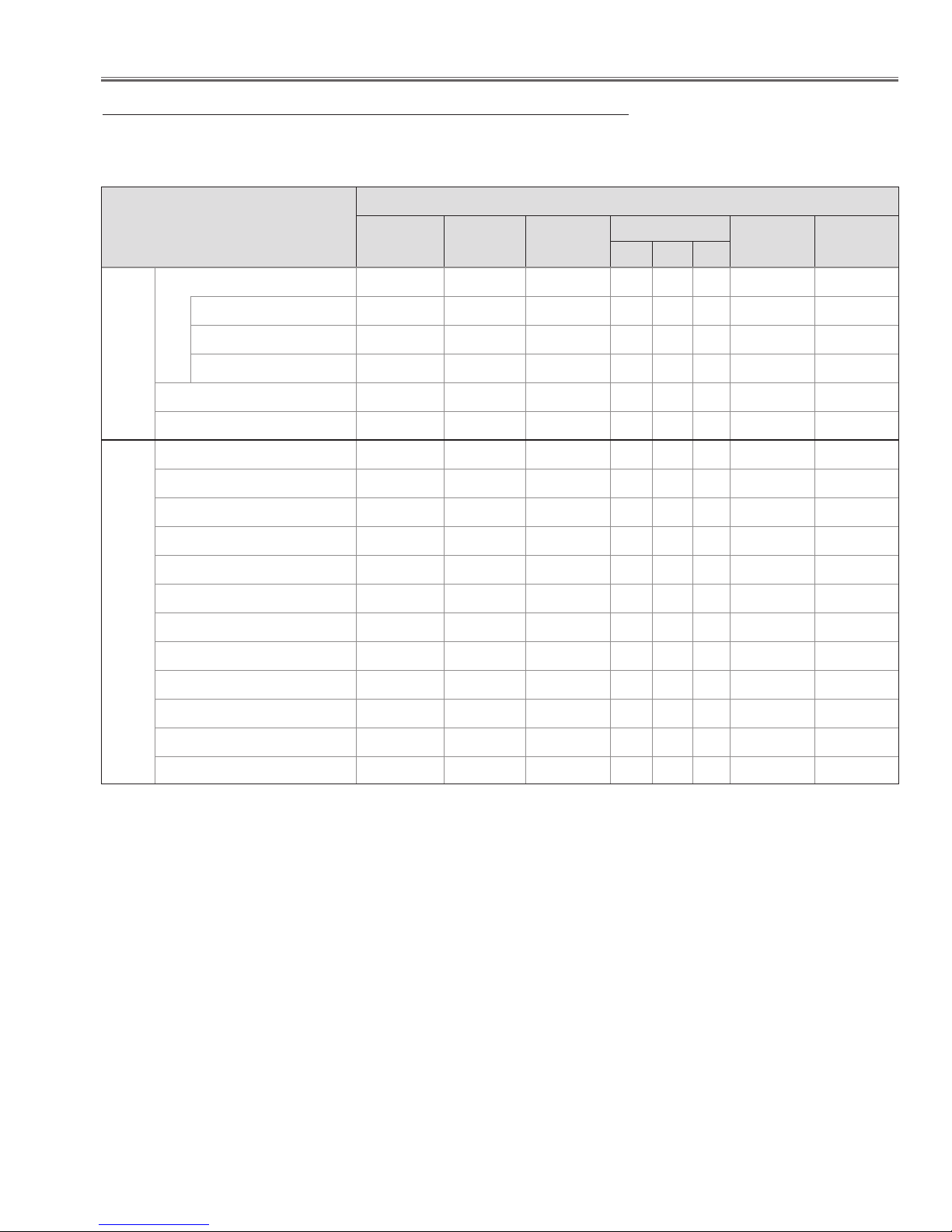

Adjustments

Adjustments after Parts Replacement

LCD/

Prism Ass’y

Optical Adjustments

Contrast Adjustment

● : Adjustment necessary ❍ : Check necessary

Disassembly / Replaced Parts

Integrator

Lens (OUT)

Relay

Lens (OUT)

Polarized Glass

Power Board Main Board

R G B

R-Contrast adjustment

G-Contrast adjustment

B-Contrast adjustment

Integrator lens adjustment

Relay lens-out adjustment

Panel type check and setting

Fan control adjustment

Auto-calibration [PC]

Electrical Adjustments

Auto-calibration [Component]

Auto-calibration [Video]

Common center adjustment

50% white adjustment [PC]

White balance adjustment [PC]

50% white adjustment [Video]

White balance adjustment [Video]

White uniformity adjustment

●

●

●

❍ ●

❍ ●

● ●

● ●

●

●

●

● ●

● ●

❍ ❍

● ●

❍ ❍

❍ ❍

-21-

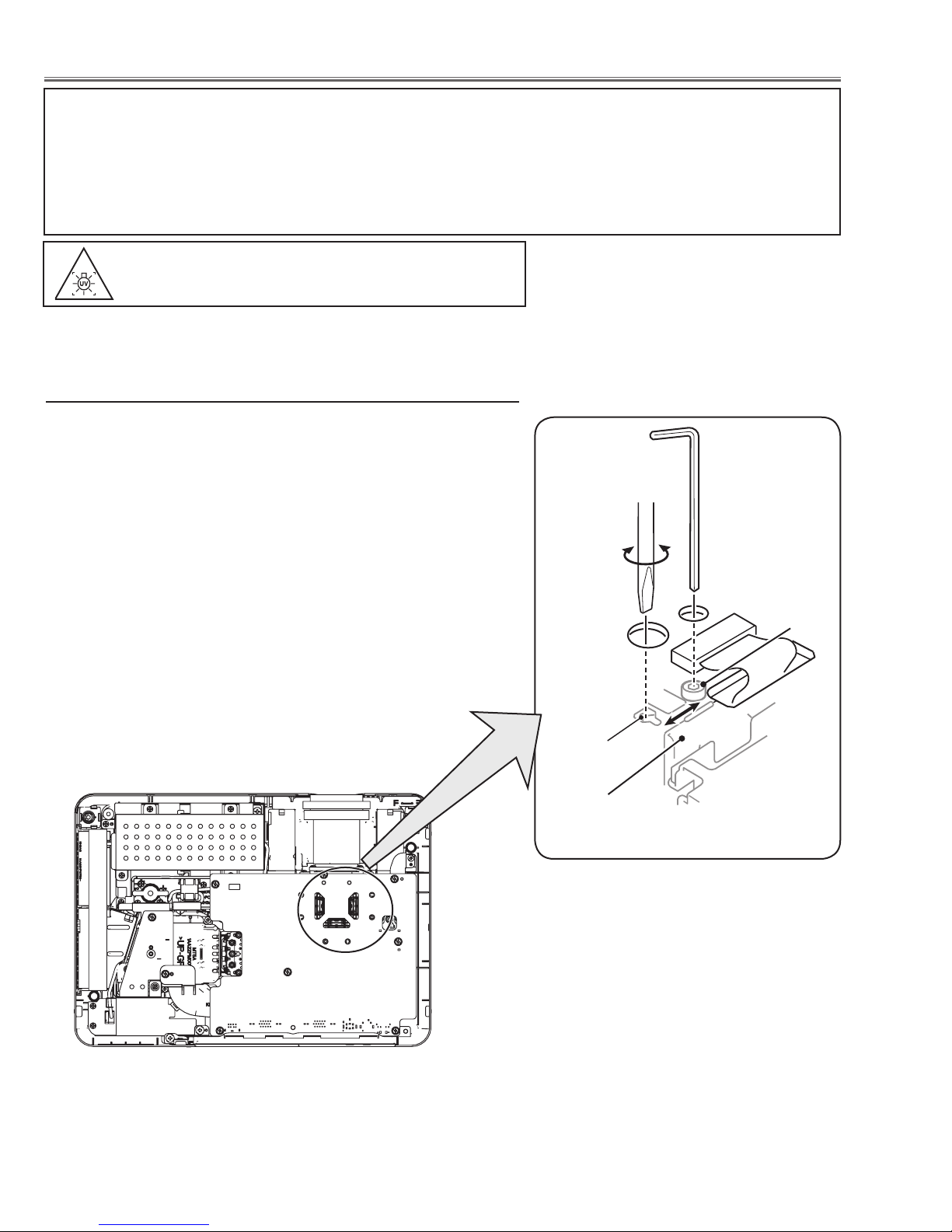

Optical Adjustments

Before taking optical adjustments below, remove the Cabinet Top following to the “Mechanical Disassembly”.

Adjustments require a 2.0mm hex wrench and a slot screwdriver. When you adjust Integrator lens or Relay lens

adjustment, you need to disconnect FPC cables of LCD panels on the main board.

Optical adjustment requires a 2.0mm hex wrench and a slot screwdriver.

Note: Do not disconnect connectors on the main board, because the projector cannot turn on due to operate the

power failure protection.

WARNING : USE UV RADIATION EYE AND SKIN PRO-

TECTION DURING SERVICEING

CAUTION: To prevent suffer of UV radiation, those adjustment must be

completed within 25 minutes.

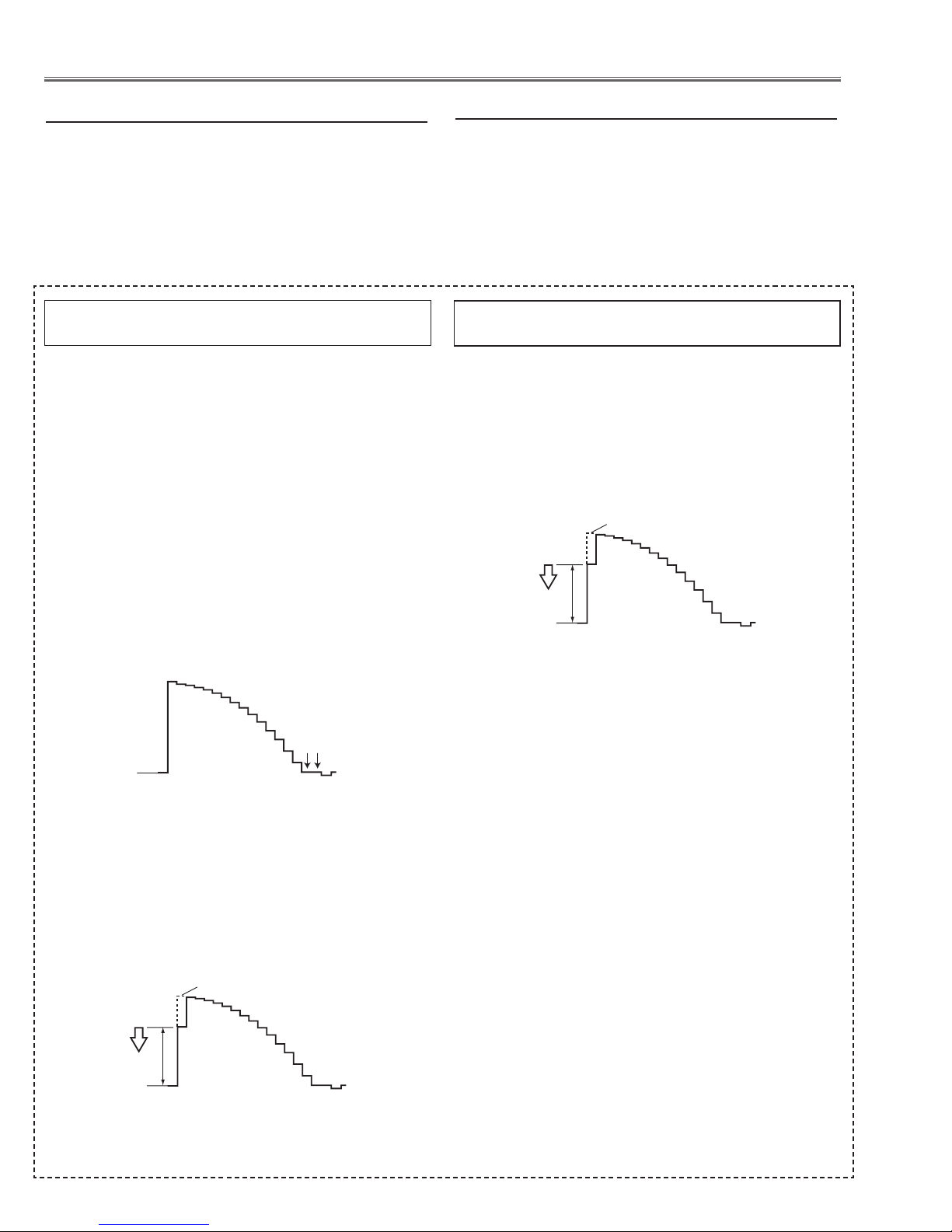

Contrast adjustment

[Before Adjustment]

- Input a 100% of black raster signal.

1 Loosen a screw A (Fig.1) on the polarized glass mounting base

which you intend to adjust.

2 Adjust the slot B to obtain the darkest brightness on the screen by

using a slot screwdriver.

3 Tighten the screw A to fix the polarized glass mounting base.

Repeat steps 1 to 3 for remaining polarized glasses.

Slot B

Polarized glass

mounting base

A

Fig.1

-22-

Optical Adjustments

Integrator lens adjustment

1 Turn the projector on by a state of without FPC cables.

2 Project all of lights on the screen.

3 Adjust the adjustment base of integrator lens assy to make color

uniformity in white.

1) If the shading appears on the left or right of the screen as shown

in Fig.2-1, loosen 1 screw A , and adjust the slot B to make

color uniformity in white by using a slot screwdriver.

2) If the shading appears on the top or bottom of the screen as

shown in Fig.2-2, loosen 2 screws C, and adjust the slots D to

make color uniformity in white by using a slot screwdriver

4 Tighten screws A and C to fix the Integrator lens unit.

Note:

The relay lens adjustment must be carried out after completing this

adjustment.

a

White

b

A

a

b

Fig.2-1

Moving of slot B

x

y

Slot B

x

White

y

Slot D

C

Slot D

Fig.2-2

Moving of Slot D

-23-

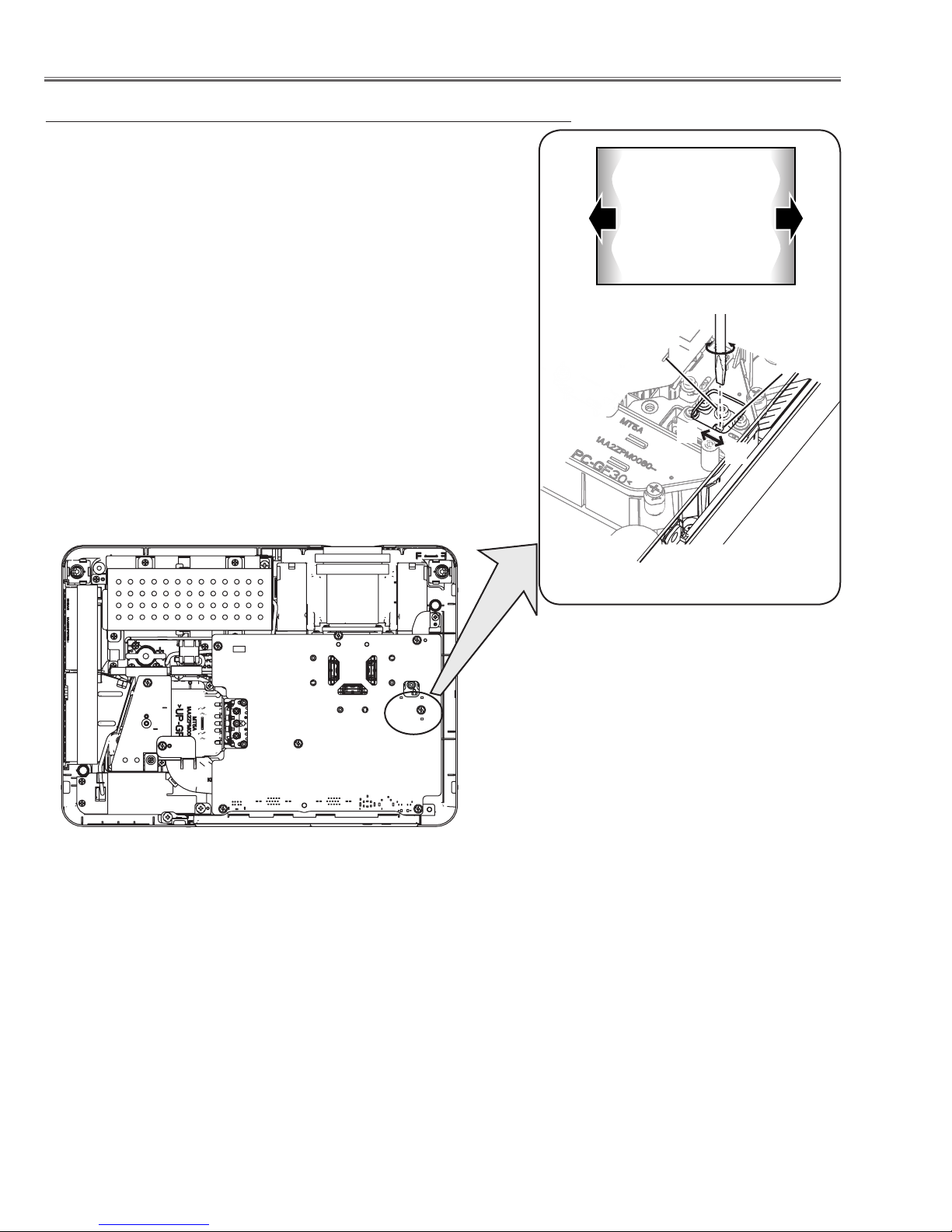

Optical Adjustments

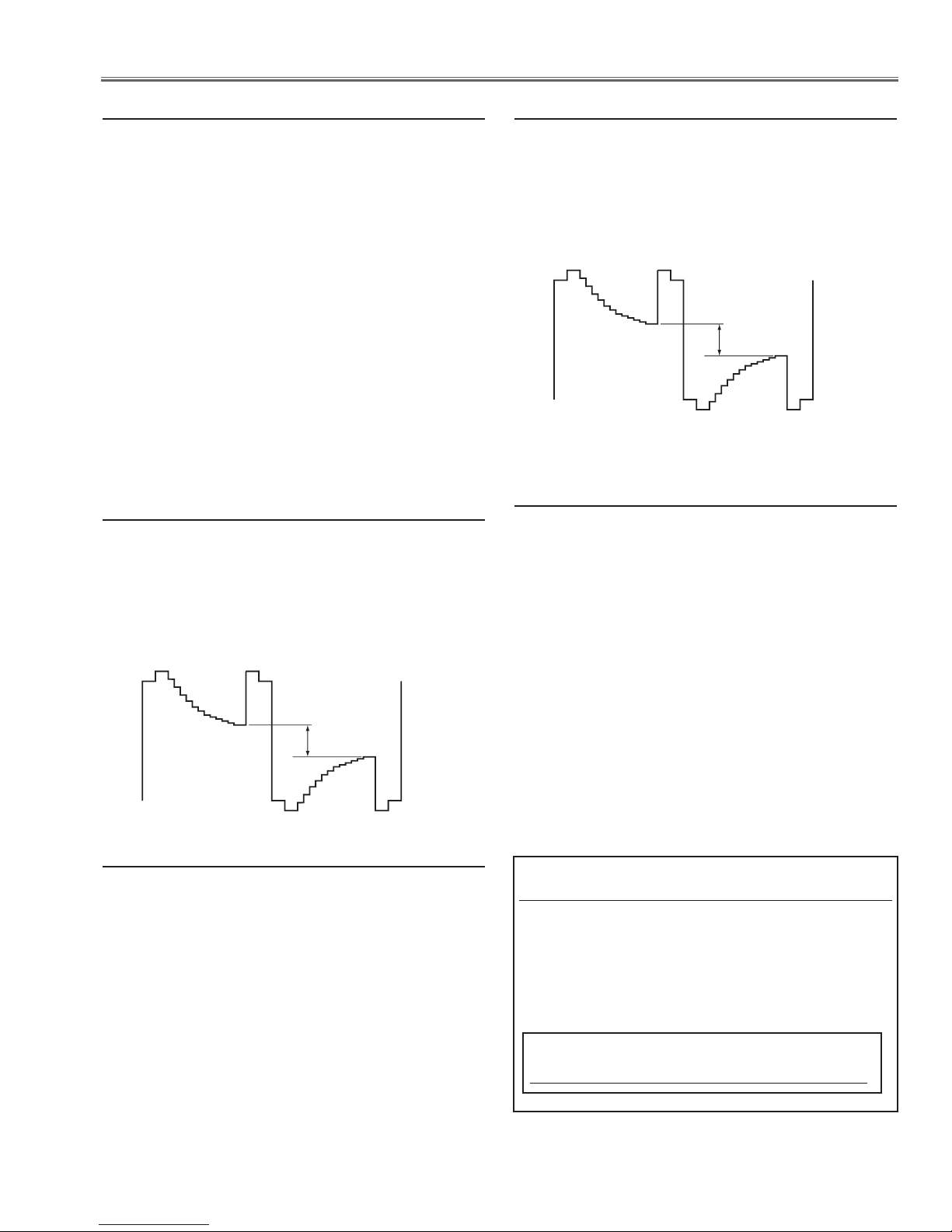

Relay lens-Out adjustment

1 Turn the projector on by a state of without FPC cables.

2 Project all of lights on the screen.

3 Adjust the adjustment base of relay lens assy to make color unifor-

mity in white.

If the shading appears on the left or right of the screen as shown in

Fig.3, loosen 1 screw A, and adjust the slot B to make color unifor-

mity in white by using a slot screwdriver.

4 Tighten the screws A to fix the relay lens unit.

b

White

a

Fig.3

Slot B

A

a

b

-24-

Service Mode

Input Video

Group No. Data

0 0 32

Ver. 1 .00

Electrical Adjustments

Service Adjustment Menu Operation

To enter the service mode

To enter the “Service Mode”, press and hold the MENU and SELECT button for more than 3 seconds. The service

menu appears on the screen as follows.

To adjust service data

Select the adjustment group no. by pressing the MENU button (increase) or SELECT button (decrease), and

select the adjustment item no. by pressing the pointer e or d button, and change the data value by pressing the

7 or 8 button. Refer to the “Service Adjustment Data Table” for further description of adjustment group no., item

no. and data value.

To exit the service mode

To exit the service mode, press the ON/STAND-BY button.

Group No.

Item No.

Data value

Memory IC (IC1371) Replacement

Memory IC on the main board stores the data for the

service adjustments, and should not be replaced except

for the case of defective device.

If replaced, the re-adjustments are required following to

the “Electrical Adjustments”.

The data of lamp replacement counter is stored in the

Memory IC.

Please note that the lamp replace counter will be reset

when the memory IC is replaced.

(Lamp replace counter cannot be set to the previous

value.)

● Caution to memory IC replacement

When memory IC is replaced with new one, the CPU

writes down the default data of the service adjustments

to the replaced IC as the mentioned on the service adjustment table. As these data are not the same data as

factory shipped data, it should be required to perform

the re-adjustments following to the “Electrical Adjustments”.

Please note that in this case the lamp replace counter

will be reset.

● Caution of Main Board replacement (in the case

memory IC is not defective)

When the main board is replaced, memory IC should

be replaced with the one on previous main board. After

replacement, it should be required to perform the re-adjustments following to the “Electrical Adjustments”.

In this case, the lamp replace counter can be kept the

value as before.

-25-

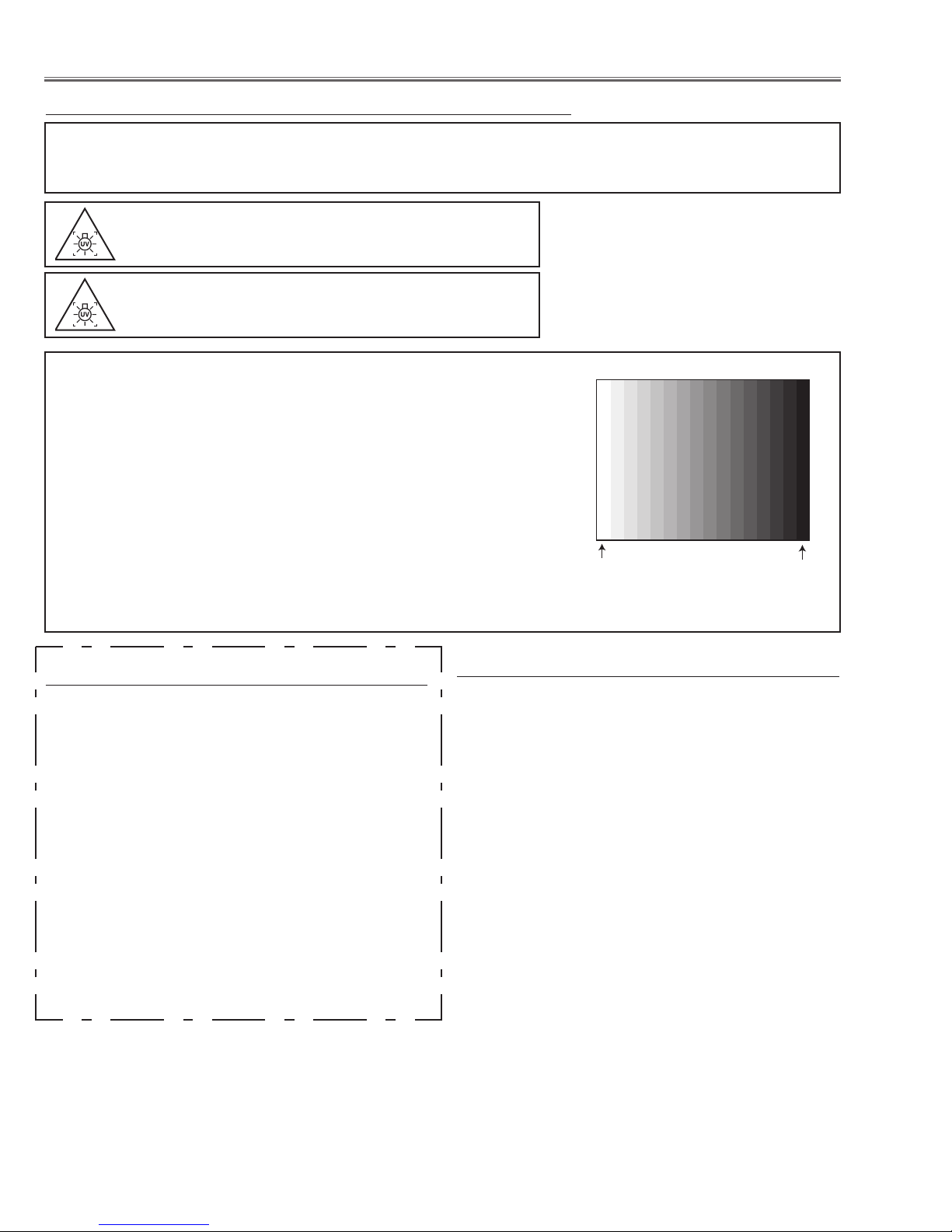

White 100%

Black 100%

Electrical Adjustments

Circuit Adjustments

CAUTION: The each circuit has been made by the fine adjustment at factory. Do not attempt to adjust the following

adjustments except requiring the readjustments in servicing otherwise it may cause loss of performance

and product safety.

WARNING : USE UV RADIATION EYE AND SKIN

PROTECTION DURING SERVICING.

CAUTION:

To prevent suffer of UV radiation, those adjustments

must be completed within 25 minutes.

[Adjustment Condition]

● Input signal

Video signal .......................

Computer signal ................... 0.7Vp-p/75W terminated, 16 steps gray scale

Component Video signal ...... 0.7Vp-p/75W terminated, 16 steps gray scale

● Picture control mode ........ “STANDARD” mode unless otherwise not-

Note:

* Please refer to “Service Adjustment Menu Operation” for entering the service mode and adjusting the service data.

Output Voltage adjustment

After replacing the Power Board readjust the Output voltage adjustment as follows.

1. Connect a digital voltmeter to pins 1 (+) and 3 (-) of

K6D.

2. Adjust the voltage by using VR611 as following.

AC Input Reading

230V 370V ±2V

Caution:

Be sure to connect the lamp when taking this adjustment.

* This adjustment is not required even if the power board

is replaced because this adjustment is carried out before parts shipment.

1.0Vp-p/75W terminated, 16 steps gray scale

(Composite video signal)

pattern

(Component video signal with 480p, 575p,

720p or 1080i format)

ed.

z Panel Type Check and Setting

* Before setting, you need to check which type of LCD pan-

el is placed on the projector according to the item "LCD

Panel/Prism Ass'y removal" in the chapter "Optical Parts

Disassembly".

1. Enter the service mode.

2. Panel Type Check

Select group no. “290”, item no. “0”. Check the data

value as follows;

Data value: 0 For L-Type of LCD Panel

Data value: 20 For R-Type of LCD panel

3. Panel Type Setting

Select group no. “290”, item no. “1” and change data

value from 10 to 0 or 20 depending on your LCD Panel

type. When the data value reaches 0 or 20, it returns

to 10 quickly. The gamma-characteristics changes ac-

cording to your selection.

16 steps gray scale pattern

Note:

Be careful to take this adjustment. The value of gamma

adjustment data will be reset and cannot be restored if

you change the mode of LCD panel type.

-26-

Electrical Adjustments

Pedestal Lebel

Black Lebel

(a)

White Level

x Fan Control adjustment

1. Enter the service mode.

2. Connect a digital voltmeter to test point “TPFANA” (+)

and chassis ground (-). Select group no. “250”, item

no. “0” and change data value to adjust voltage to be

5.0 ±0.1V.

3. Connect a digital voltmeter to test point “TPFANB” (+)

and chassis ground (-). Select item no. “2” and change

data value to adjust voltage to be 5.0 ±0.1V.

4. Connect a digital voltmeter to test point “TPFANA”

(+) and chassis ground (-). Select item no. “94”

and change data value to adjust voltage to be 13.5

±0.1V.

5. Connect a digital voltmeter to test point “TPFANB”

(+) and chassis ground (-). Select item no. “96”

and change data value to adjust voltage to be 13.5

±0.1V.

Below adjustments are performed when the above auto

calibration is failed.

Pedestal adjustment [PC]

1. Enter the service mode.

2. Receive the 16-step grey scale computer signal with

Computer1 [RGB] mode.

3. Connect an oscilloscope to test point “TP_G1” (+)

and chassis ground (-).

4. Select group no. “0”, item no. “0” and change data

value to adjust the pedestal level and black level to be

the same level.

5. Connect an oscilloscope to test point “TP_R1” (+) and

chassis ground (-).

6. Select item no. “1” and change data value to adjust the

pedestal level and black level to be the same level.

7. Connect an oscilloscope to test point “TP_B1” (+) and

chassis ground (-).

8. Select item no. “2” and change data value to adjust the

pedestal level and black level to be the same level.

c Auto Calibration adjustment [PC]

1. Enter the service mode.

2. Receive the 16-step grey scale computer signal with

Computer1 [RGB] mode.

3. To start the auto-calibration for PC adjustment, select

group no. “260”, item no. “0” and then change data

value from “0” to “1”. After the auto-calibration completed, "OK" will appear on the screen.

Gain adjustment [PC]

1. Enter the service mode.

2. Receive the 16-step grey scale computer signal with

Computer1 [RGB] mode.

3. Connect an oscilloscope to test point “TP35G” (+)

and chassis ground (-).

4. Select group no. “0”, item no. “3” and adjust the amplitude “a” to be minimum by changing the Data value.

5. Connect an oscilloscope to test point “TP35R” (+) and

chassis ground (-).

6. Select group no. “0”, item no. “4” and adjust the amplitude “a” to be minimum by changing the Data value.

7. Connect an oscilloscope to test point “TP35B” (+) and

chassis ground (-).

8. Select group no. “0”, item no. “5” and adjust the amplitude “a” to be minimum by changing the Data value.

-27-

Electrical Adjustments

(a)

White Level

(a)

White Level

Pedestal Lebel

Black Lebel

v Auto Calibration adjustment [Component]

1. Enter the service mode.

2. Receive the 16-step grey scale 480i-component sig-

nal with Computer1 [Component] mode.

3. To start the auto-calibration for Component adjust-

ment, select group no. “260”, item no. “0” and then

change data value from “0” to “1”. After the auto-calibration completed, "OK" will appear on the screen.

Below adjustments are performed when the above auto

calibration is failed.

Pedestal adjustment [Component]

1. Enter the service mode.

2. Receive the 16-step grey scale 480i-component signal

with Computer1 [Component] mode.

3. Connect an oscilloscope to test point “TP_G1” (+)

and chassis ground (-).

4. Select group no. “0”, item no. “0” and change data

value to adjust the pedestal level and black level to be

the same level.

5. Connect an oscilloscope to test point “TP_R1” (+) and

chassis ground (-).

6. Select item no. “1” and change data value to adjust the

pedestal level and black level to be the same level.

7. Connect an oscilloscope to test point “TP_B1” (+) and

chassis ground (-).

8. Select item no. “2” and change data value to adjust the

pedestal level and black level to be the same level.

b Auto Calibration adjustment [Video]

1. Enter the service mode.

2. Receive the 16-step grey scale composite video sig-

nal with Video [Video] mode.

3. To start the auto-calibration for Component adjust-

ment, select group no. “260”, item no. “0” and then

change data value from “0” to “1”. After the auto-calibration completed, "OK" will appear on the screen.

below adjustment is performed when the above auto

calibration is failed.

Gain adjustment [Video]

1. Enter the service mode.

2. Receive the 16-step grey scale composite video signal

with Video [Video] mode.

3. Connect an oscilloscope to test point “TP_G1” (+) and

chassis ground (-).

4. Select group no. “20”, item no. “0” and adjust the amplitude “a” to be minimum by changing the Data value.

Gain adjustment [Component]

1. Enter the service mode.

2. Receive the 16-step grey scale 480i-component signal

with Computer1 [Component] mode.

3. Connect an oscilloscope to test point “TP_G1” (+) and

chassis ground (-).

4. Select group no. “0”, item no. “3” and adjust the amplitude “a” to be minimum by changing the Data value.

-28-

(a)

white level

white level

(a)

white level

white level

n Common Center adjustment

1. Enter the service mode.

2. Receive the 50%-Whole Gray computer signal with

Computer1 [RGB] mode.

3. Select group no. “100”, item no. “92” and change

data value to “2” to reduce the panel frequency.

4. Project only green light component to the screen.

5. Select group no. “101”, item no. “1” and change

data value to obtain the minimum flicker on the

screen.

6. Project only red light component to the screen.

7. Select item no. “0” and change data value to obtain

the minimum flicker on the screen.

8. Project only blue light component to the screen.

9. Select item no. “2 and change data value to obtain

the minimum flicker on the screen.

10. Select group no. “100”, item no. “92” and change

data value to “0” to reset the panel frequency.

. 50% White adjustment [Video]

1. Receive the 16-step grey scale composite video sig-

nal with Video mode.

2. Enter the service mode.

3. Connect an oscilloscope to test point “TP_G1” (+)

and chassis ground (-).

4. Select group no. “100”, item no. “6” and change data

value to adjust amplitude “a” to be 2.2 ±0.1V.

m 50% White adjustment [PC]

1. Enter the service mode.

2. Receive the 16-step grey scale computer signal with

Computer1 [RGB] mode.

3. Connect an oscilloscope to test point “TP_G1” (+)

and chassis ground (-).

4. Select group no. “100”, item no. “6” and change data

value to adjust amplitude “a” to be 1.6 ±0.1V.

, White Balance adjustment [PC]

1. Enter the service mode,

2. Receive the 16-step gray scale computer signal with

Computer1 [RGB] mode.

3. Select group no. “100” item no. “7” (Red) or “8” (Blue),

and change Data values respectively to make a proper white balance.

⁄0 White Balance adjustment [Video]

1. Receive the 16-step grey scale composite video sig-

nal with Video mode.

2. Enter the service mode, select group no. “100” item

no. “7” (Red) or “8” (Blue), and change Data values

respectively to make a proper white balance.

Confirm that the same white balance is obtained in video

and computer input.

Note On White Uniformity Adjustment

If you find the color shading on the screen, please adjust the white uniformity by using the proper computer

and “Color Shading Correction” software supplied separately.

Confirm that the same white balance is obtained in video

and computer input.

The software can be ordered as follows;

COLOR SHADING CORRECTION Ver. 4.00

Service Parts No. 645 075 9611

-29-

K10A

K10B

K30B

K8R

K20A

K20B

K40B

K801

IC561

K5B

K5G

K5R

K6B

K6J

K6K

K6N

K6R

K8D

K8F

K8H

K8S

K406

IC501

IC531

TP_G1

TP_R1

TP_B1

TPFANA

TPFANB

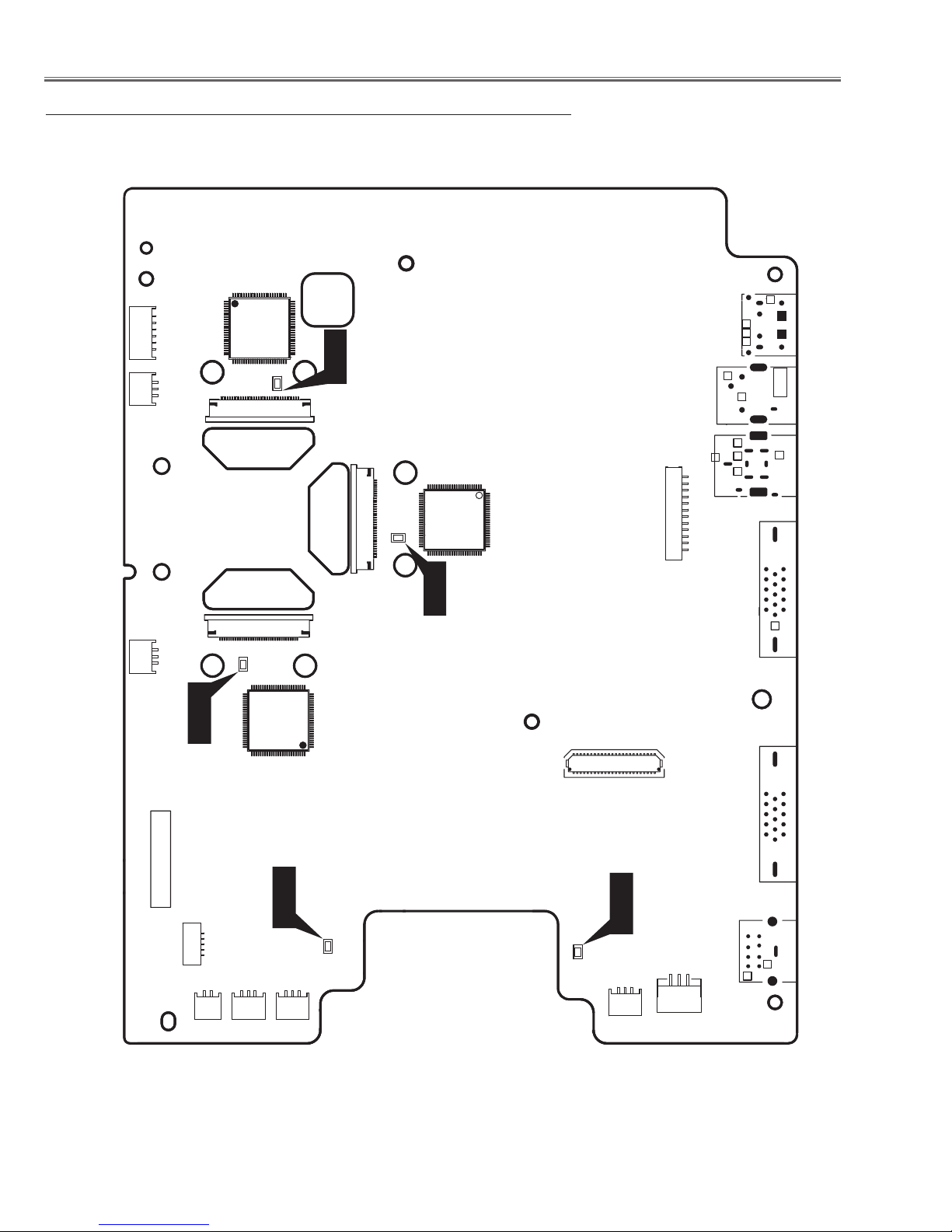

Electrical Adjustments

Test Points and Locations

MAIN BOARD

-30-

Loading...

Loading...