Sanyo PLC-XP21N,PLC-XP21E,PLC-XP21B Service

Notice

n

CORRECTION

[B

PRODUCTION

CHANGE

EJ

SERVICE

FLASH

El!

ADD

INFORMATION

Please

add

this

notice

to

the

Service

Manuals

listed

below.

Revision

1

Category

:

Model

No.:

Destination:

Multimedia

projector

PLC-XP21N

PLC-XP21E

PLC-XP21B

U.S.A-.

Canada

Europe.

Asia.

Africa,

M.E.

U.K.

(PLC-XP2tN)

(PLC-XP21E)

(PLC-XP21B)

Date:

Effective

from

Chassis

No.

Ref.

No.:

Mar./2001

MF&.XP21N01

PLC-XP21E01

PLC-XP21B01

SM5H0202

Give

complete

"CHASSIS

NO."

for

parts

order

or

servicing,

it

is

shown

on

the

rating

sheet

on

the

cabinet

of

the

Projector.

NOTE:

This

service

manual

is

production

change

notice,

but

not

dif-

ference

service

information

and

New

version

from

chassis

no.

MF6-XP21N01,

PLC-XP21E01

and

PLC-XP21BOL

W

CONTENTS

Specifications

DtsassemMies

and

Reptacement

Procedures

Machanicai

disassemblies

Opttcat

untt

disassembles

LCD

pane!

replacement

Assy

!amp

t'eptacetDent

Safety

fnstructiorts

Cfrcurt

Protections

TrouMeshooting

Wa^/e^rms

Atignmont

Procedures

Service

adjustments

BectJicai

adjustment

Focus

adjustments

Convergence

adjustment

2

3-17

3-8

9-14

15

16-17

18

19

20-27

28-29

30-43

31-32

33-37

38-39

40

integrator

iens

adjustment

Reiay

tens

adjustment

Polarized

glass

adjustment

CPU

input/output

port

functions

Maintenance

Notes

on

scnemaSc

diagram

Parts

Ust

Cabinet,

Chassis

and

Optical

parts

itst

Eiectnca)

parts

iist

Parts

location

and

PWB

pattern

diagrams

Btock

diagram

and

Low

power

dtstrtbution

Schematic

diagrams

41

42

43

44-47

48-49

50-51

52-79

54-58

59-79

P1-P3

61

S1-S8

PRODUCT

CODE

112207370:(MF6AA)

112207470:(PF6AA)

112207472:(PF6CA)

REFERENCE

NO.

SM5110202-01

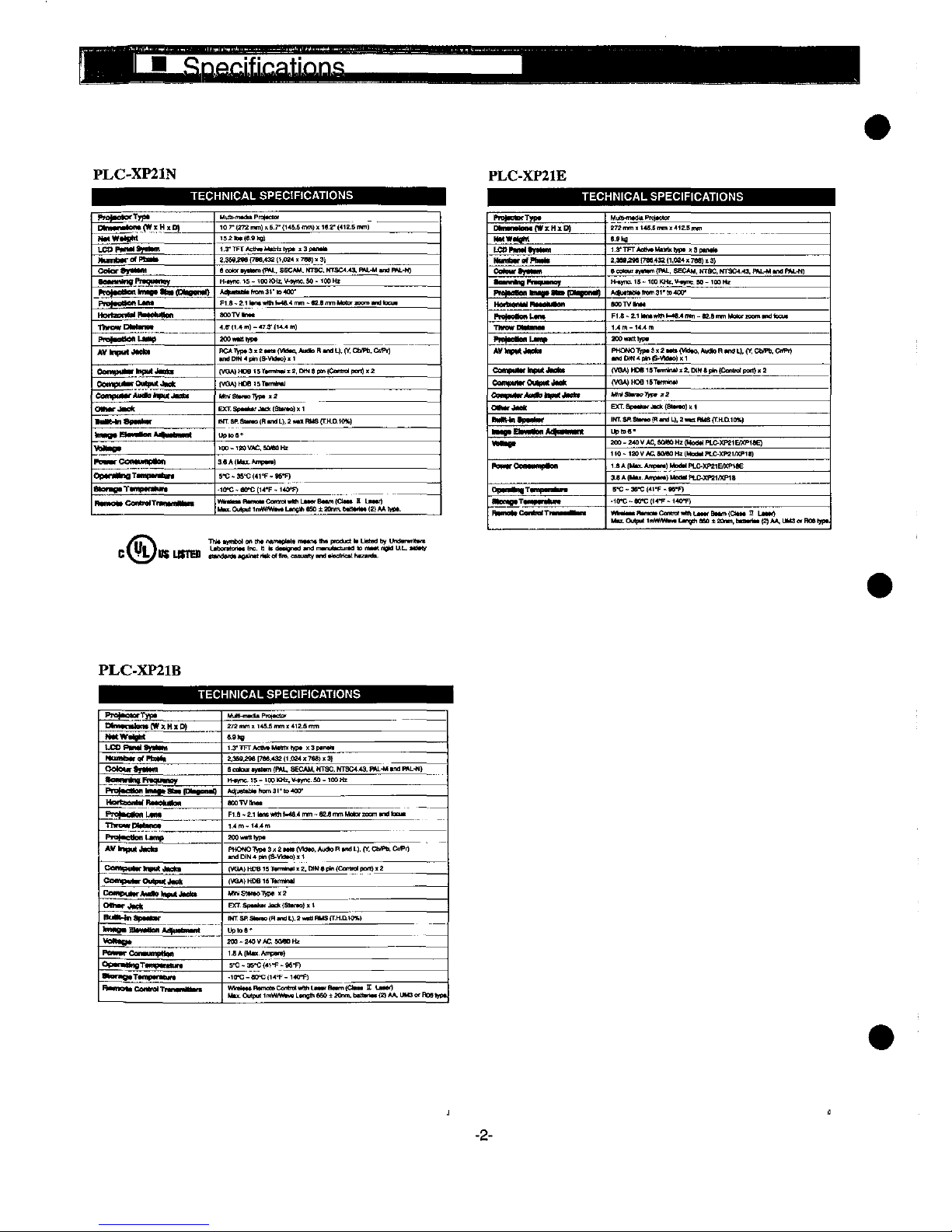

PLC-XP21N

PLC-XP21E

TECHN)CAL

SPECtF)CAT)ONS

TECHN)CAL

SPEC)F)CAT)ONS

Pmt-otofTypt

M)tMf-tcn<(W]tH:tt))

HMWttNM

LCOt^MOf^m

tttmtXtrofPHttt

Cater

OMfM

aefn)n(tf^qu<MCt

n

ot^M^nn

how

*'^

CfH^o"^

Prf)ftottML*M

m<n^t<m

ttM^'<)M

nwowDM——

PrB)<o<tML)X^

AVtnput^^

Omtt)tt<tf

ttput

JMc*

ee<Mpm-rOtX^tJt)et

CempHMf*Mao!nputJ^*

OWMfJ-*

fMnapt^m^

ttO«(t<HB-^aoM(t-h))-nt

WXt^tt

)^^rCc^-^t-.

Opt^t^T-Hp^^,

atom^TtmptMMw

^^.C^.T^^-.

M^-mttM

Pmt*oo'

10

7-

<272

tnm) ^ 6.?-

(145^

'w)'

K.2*

(4I2.S

mm)

mx^e.ete!

t.3-T)^T'tc'h^M^htyp*

tSptnttt

!.35<^M

f7M.43Z

ft.fa'H

7M).

3)

6

cotOf

t^tm

tPM-.

SECAM.

MTSC.

MTSC<.<^

PM--M

tntt

R^.-W)

H-^ne.

'S - 100

KHt

V-wv:. M '

'CO

m

*<tt-ttHth<im3''<t)400-

F1.a-:.1'*^'!Wt-4e.*'nm-M.e'nm'*<!).

mnuMdticu.

aooTVtntt

<.^t'.<m)-47.T<K.4m)

MOM<tWt

^D^^^^^^^^^

fVaA)HDe':T^m!^^:.DM<pM(Camfo)peft)^2

fVOA^HOatST^m^

Mh.S'^o1^p..S

E)cr.sp*^*fJ*^fatMo)ti

)HT. M S^m)

jR

md

L),:

f^)

RM9

{T.H.D.10%)

UfKot'

^-IMVAC.SMNHz

3.AfM^.An^.)

S'C - M'C

f4t°F - M*F)

-1[fC-efrCft<'F-t*0°F)

MM.Omp^tmWW^t^nt*'esO±Mnm.MmtnttMAAWt.

PntftottfTypt

D)mtnOam<(W^Mta)

MMWj^t

[.Ctt!^^t)f'ttM

tt')mHtfatPh<tf

Catexftjtm))

t^t^fn^no^

rrm)tnt<on

tn'm

Mm

(!H*))nn^)

ThM^Btt^nat

f^ftNteoUM^

jM'))))^J«ft^

ComtMMfH)tMtJ))(*t

C<^t)M-(MtMtA^

Cc''w"<"*M!h!HtM*Mt*

OtMfjMt

'^Untp^'r

^Mt^

fJMfrMMM^Xtno

QtM^T-nptt^iM

m^tT^jomxF)

tt^C^MT

MuM-'ntdtPffttCtor

!72nm"4S.!mn'):<tZ.5nm

6.9ka

1.3'TPTAO)ttMt)^tH)t

!.3pt!nt^

2.3M^<

;7M,43:

(1.0M

jt

7M)

13)

e

eo'OM

t^tm

(P)U..

SECAM.

MTSC,

NT9C4.^.

HU--^

md

PM.-N)

tKt^'S'1MK^.V<v^:M-HCMf

A«mttMttrem3t'to^OO'

MOTV^ntt

F)^-X1)tntfM"^t.4mm-M.emmMot«toon'tm<tMtt

1.4m-t*.*m

200M)tt)H-

PHONO'!^i)t2tttttVX)to.*))OH(Htn<fU.(Y.CM^.C^P^

tVaA)MOet9T.mtnt)tt.DtHt)i)r.<Cmtm)pomjt:

(V(M^HDet5Ttnn'nM

M^St^)-^..^

EXT.

Spt^ttJte^fStt^o)).)

!Mr.SP.S'Me)RtndL).2tMiRMafT.H.[l1M.)

Uttoe'

200-MOVAC,MMOH!(Mo<MPLC-XM1E/XPteE)

t'O - tZOV ^ MM m f'*)d*tPt.&.XM''XPH)

l.t A fMtt.

Amptft)

Mod*)

PLC-XKI&XPttE

MA(Mt..AmpM)MeOttt^MMt/)(Pia

S-C-3!(-Cf<1-F-M-F)

.ttrc-M^fM'F-t^O^

)M^ttt'ttmottCmM')tmL*tttBttm(attt n Lttt^

tHt t ..M..,.

L^Xmttt^tfM!. t tdtt'anMf*n.)n^nut^±j^ammMf'eMtiL.ttttt/

G ^ ^/

HS

mttB

mmf)eWo*'ntt'Wo"^cmuo^t-^*^e'ne^h-z-t^

PLC-XP21B

TECHNtCAL

SPEOFtCATfONS

P'<^ctefTyp<

Dtt««n)t)ont(W);H!<[^

MMW^^tt

LCD

P)MM<

0)^-0

MtMNbtrofMMtt

Qete^tj!M)!')

<<Mmntn))R<qu<nef

t^f^OtOM

!mt))t

NtM

(Dftten^

MatteonMM^tXMttM

P'^tM^nL*^

TttftxofM'tMC*

PTnf^onD)mp

AWtHpMJ^f

Campt<t<r)n^)tJ^t.t

CB'Mt<tt)trOmpMJ))e)t

Cot))pt^rA<x^!ot«Jt^*

Othtf^ett

Bm^tnapottf

fnma*

ritftHnn

*^«t«<^«

Wa'Mto'

Po-M-ConttMpMM'

Optf*MneT<mp*MtuM

^ofO<T*mp*^tun'

B*mqtt

CMtmi

Tt^tt^ttM

MtjHUn^PmttCto.

!7:

n<t) j I4S.S

mm . 4)2.5

mn

e.9^

t.3'TFr<MMMt<tftK)t

):3ptnet

Z,3M^M

[TM.43^

ft

.OM

)t

7M) < 3)

a

t^om

t^tttm

(P^

SECAM.

'<TaC.

MTSM.O.

PM.-M

md

PM.-M)

tt<ync.'5-'MmHz.V^ne.M-IM)m

Af!jDtMtmim3^'to<00-

aootvnMt

F1.a-2.1Mxm'-M.*"m-M.emmM[<ormmtnt)tM

1.<m-'<.<m

200w*tttH)t

PHONO'^ptS^ZMM

(VMM.

Attdk)Rt^L).fY.CM^.CnPr)

(VaA)HOB1STtm^i.?.D)Mtp^<CtMm'pon)<Z

(VQA)HOB15TtmMi

MntSMtoTtpt

)!2

EfT.Sp**)-.JM.fS!^)).t

fMT

Sf

S<Mt)

(H

tnd

L).:

^^tt

HMS

F.H.n'M.)

UpM6'

ZOO'MOVAC.M^OMt

t.NAfM-t.Ampm)

S°C-3S'C(4^°F^96f)

-t(t-C-eO-C(K'F-'40f)

M^OuqM1mW^^tLtne)h6Ml2()nm.btttMtt(2t**.UM<i'Hoe)te*

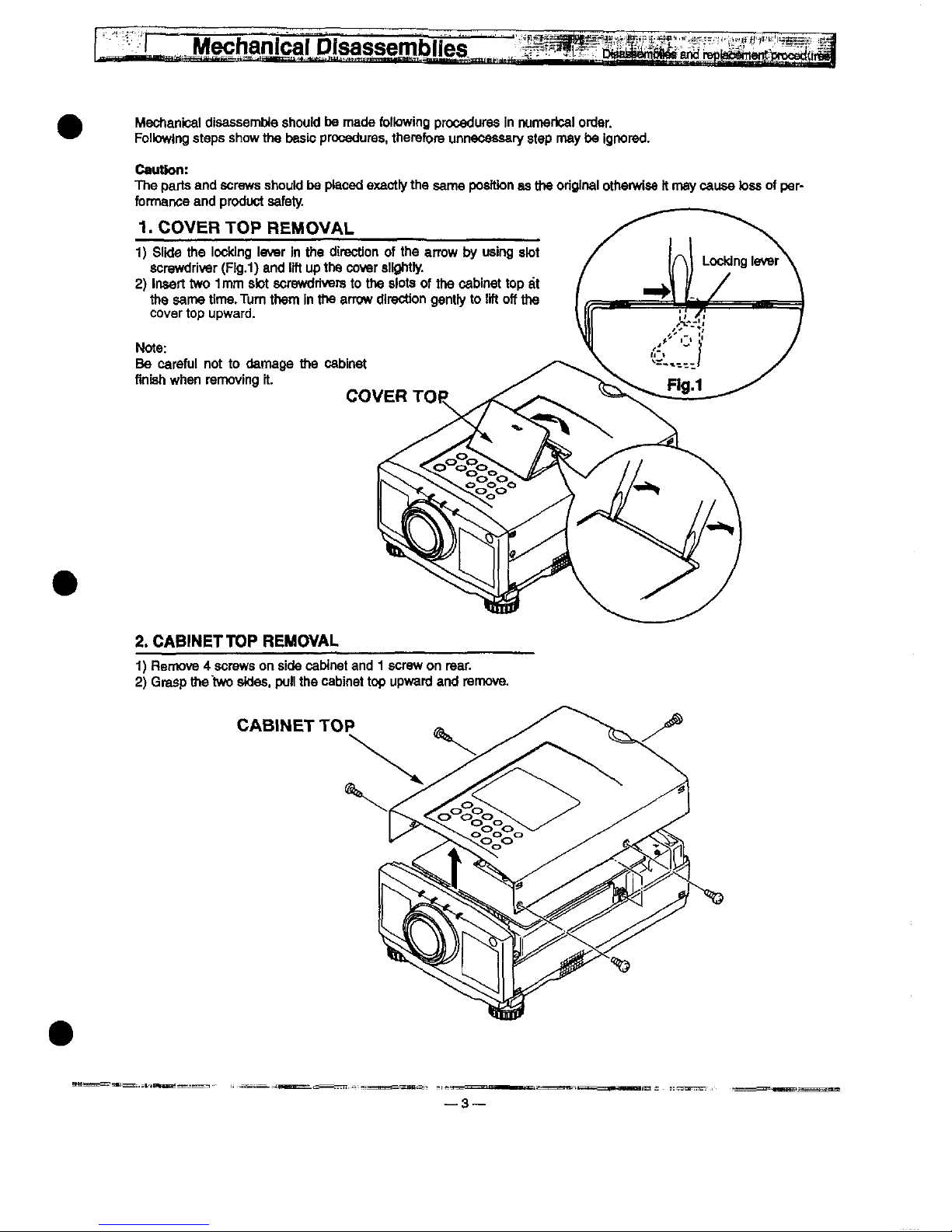

Mechanica)

disassemble

shoutd

be

made

foUowing

procedures

in

numertcai

order.

Foitowtng

steps

show

the

basic

procedures,

therefore

unnecessary

step

may

be

ignored.

Cautton:

The

parts

and

screws

shoutd

be

placed

exactty

the

same

posftton

as

the

origina)

otherwise H may

cause

toss

of

per-

formance

and

product

safety

1.

COVER

TOP

REMOVAL

1)

S)kte

the

)ocking

)evsr

in

the

direction

of

the

arrow

by

using

slot

screwdriver

(Fig.1)

and

tift

up

the

cover

sttghtty.

2)

tnseft

two

1mm

s!ot

screwdrivers

to

the

siots

of

the

cabinet

top

at

the

same

time.

Turn

them

in

the

arrow

direction

gontty

to

!tft

off

the

cover

top

upward.

Note:

Be

carefui

not

to

damage

the

cabinet

finish

when

removing

M.

COVER

TOR

2.

CABINET

TOP

REMOVAL

1)

Remove 4 screws

on

side

cabinet

and 1 screw

on

rear.

2)

Grasp

the

two

stdes.

pu)i

the

cabinet

top

upward

and

remove.

CABLET

TOP

^

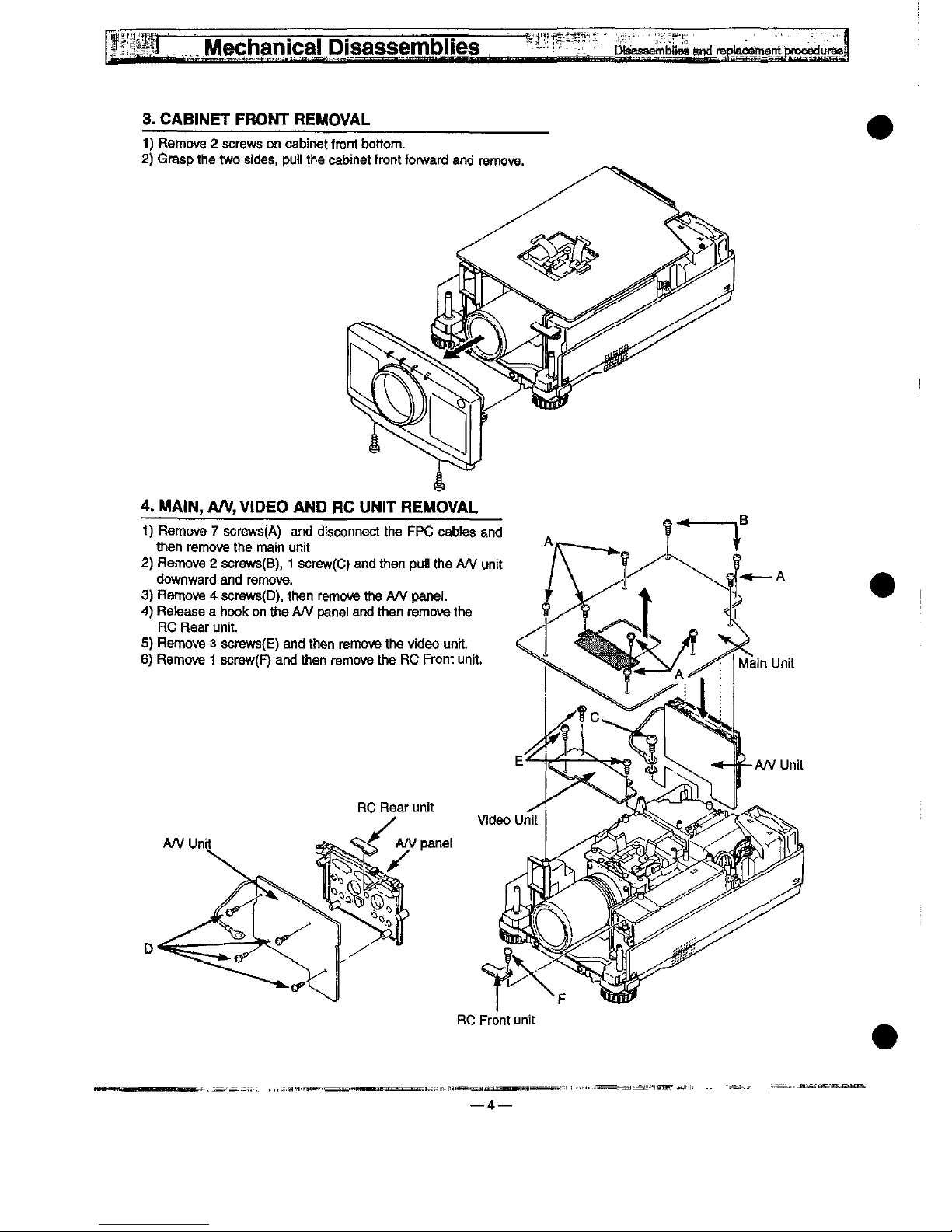

3.

CAB)NET

FRONT

REMOVAL

1)

Remove 2 screws

on

cabinet

front

bottom.

2)

Grasp

the

two

sfdes,

putt

the

cabinet

front

forward

and

remove.

RC

Front

unit

—4

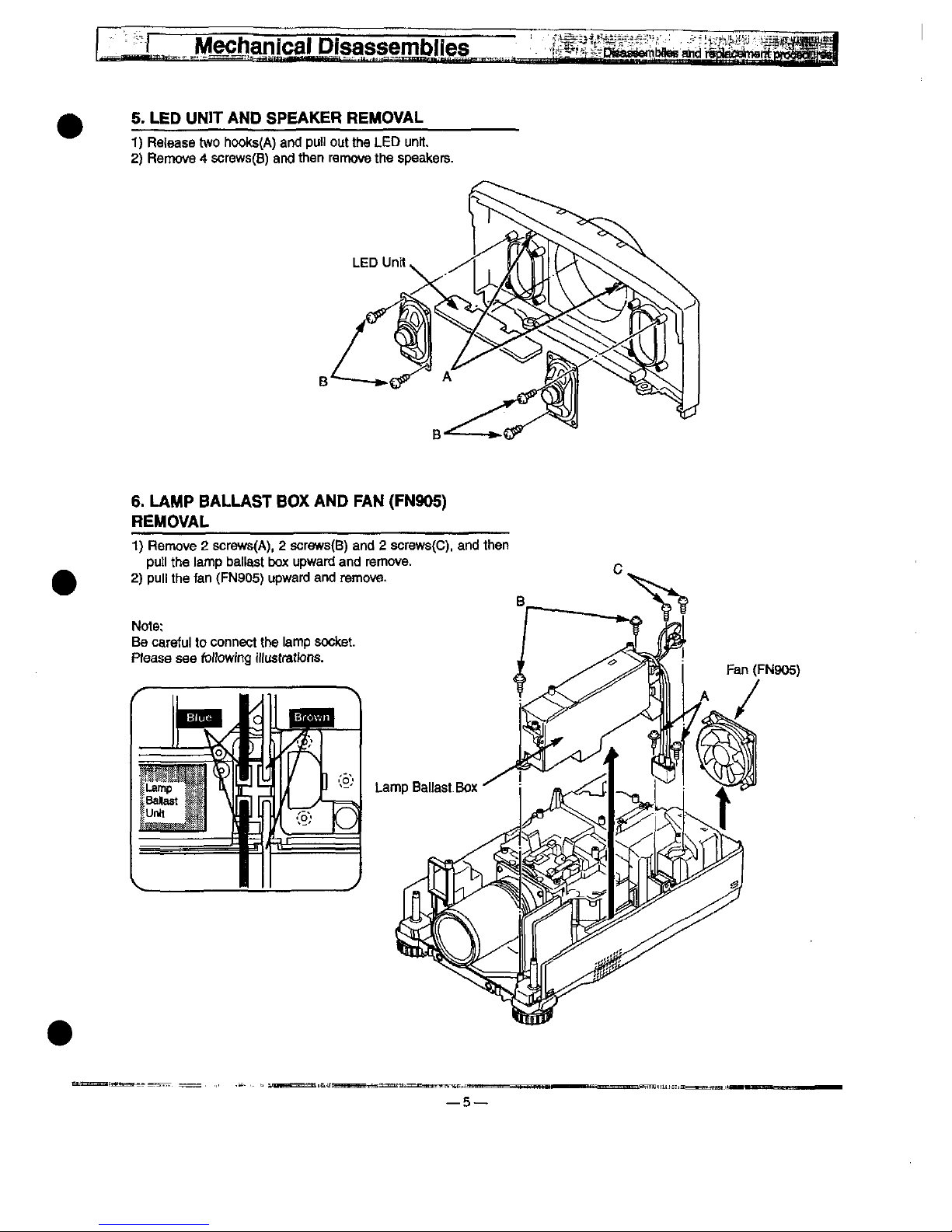

5.

LED

UNIT

AND

SPEAKER

REMOVAL

1)

Refease

two

hooks(A)

and

put)

out

the

LED

unrt.

2)

Remove 4 screws(B)

arnj

then

remove

the

speakers.

6.

LAMP

BALLAST

BOX

AND

FAN

(FN905)

REMOVAL

1)

Remove 2 screws(A),

2

screws(B)

and 2 screws(C).

and

then

put)

the

iamp

bat(ast

box

upward

and

remove.

2)

pu)!

the

fan

(FN905)

upward

and

remove.

Note:

Be

carefu)

to

connect

the

tamp

socket.

Ptease

see

fottowing

i))ustrattons.

Lamp

—5—

Fan

(FN905)

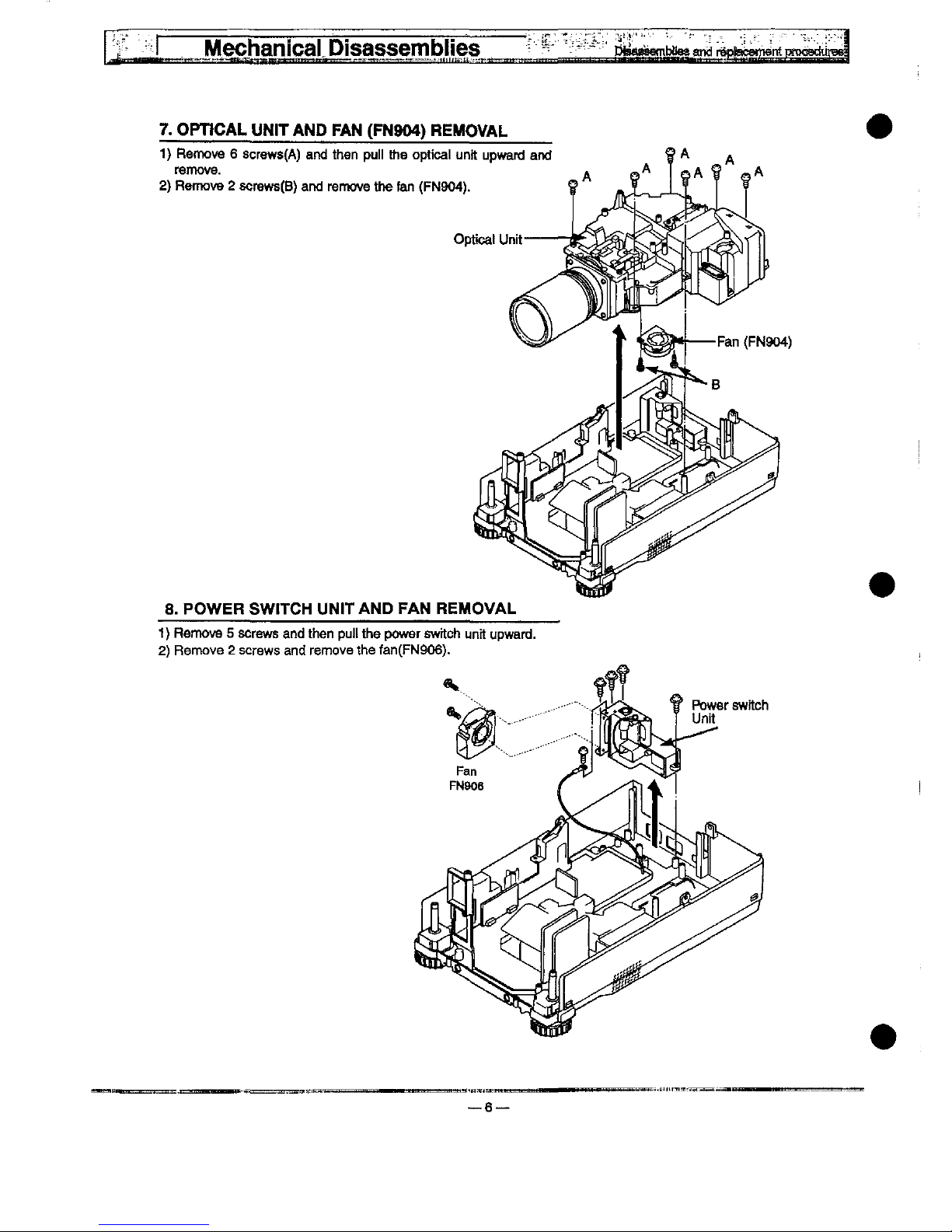

7.

OPDCAL

UN)T

AND

FAN

(PN904)

REMOVAL

1)

Remove 6 screws(A)

and

then

pu!)

the

optica)

unit

upward

and

femove.

2)

Remove 2 screws(B)

and

remove

the

fan

(FN904).

8.

POWER

SWrrCH

UN)TAND

FAN

REMOVAL

1)

Remove 5 screws

and

then

puf)

the

power

swrtch

unit

upward.

2)

Remove 2 screws

and

remove

the

fan(FN906).

Mechanica)

Dtsassembties

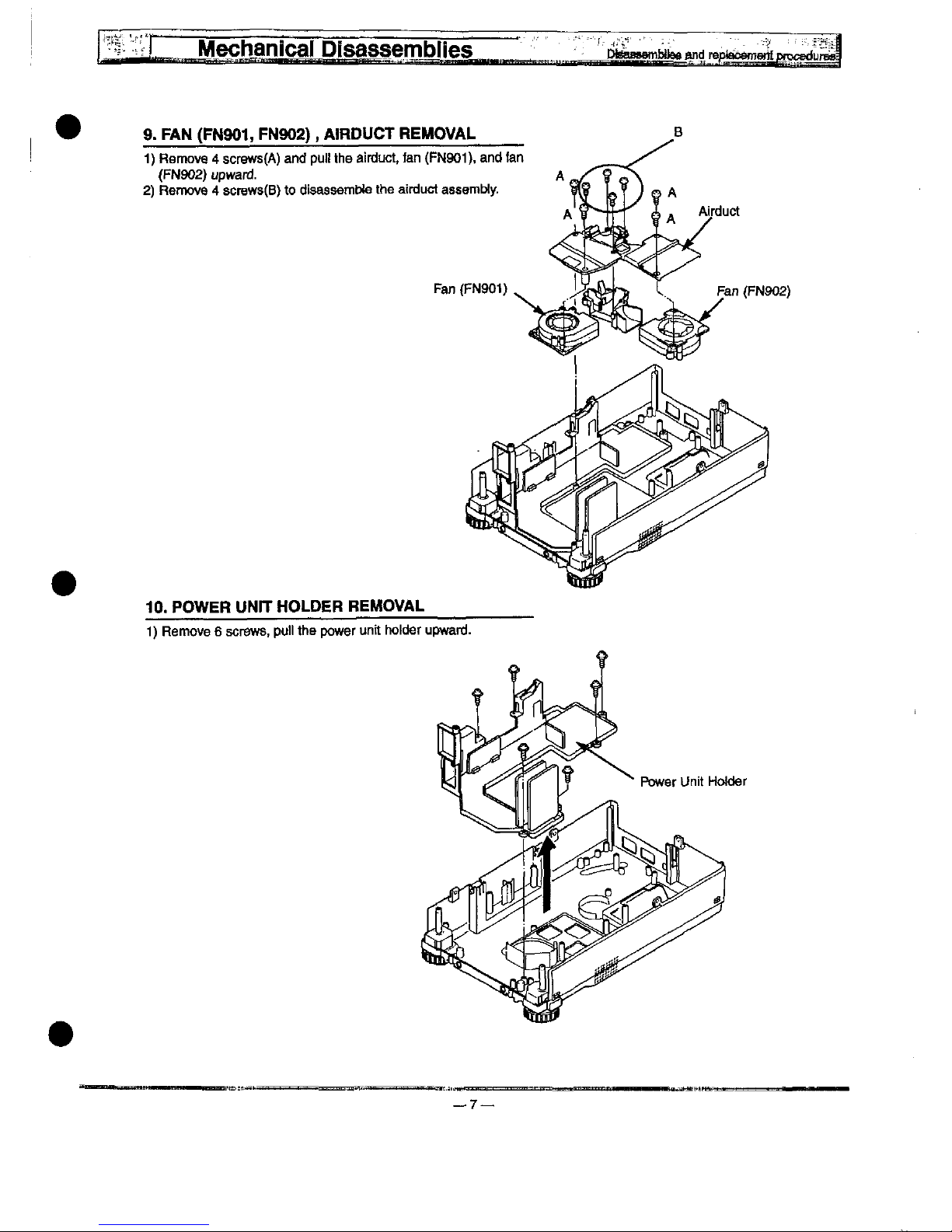

9.

FAN

(PNM^

FN902),

A!RDUCT

REMOVAL

1)

Remove 4 screws(A)

and

pu)!

the

airduct,

fan

(FN901).

and

fan

(FN902)

upward.

2)

Remove 4 screws(B)

to

disassembte

the

airduct

assembty.

Fan

(FN901)

Fan

(FN902)

10.

POWER

UNrr

HOLDER

REMOVAL

1)

Remove 6 screws,

pu))

the

power

unit

hokter

upward.

Power

Unit

Hofder

Mechanica)

Disassembles

^^MnMtee

and

'^a<^^

M^^^

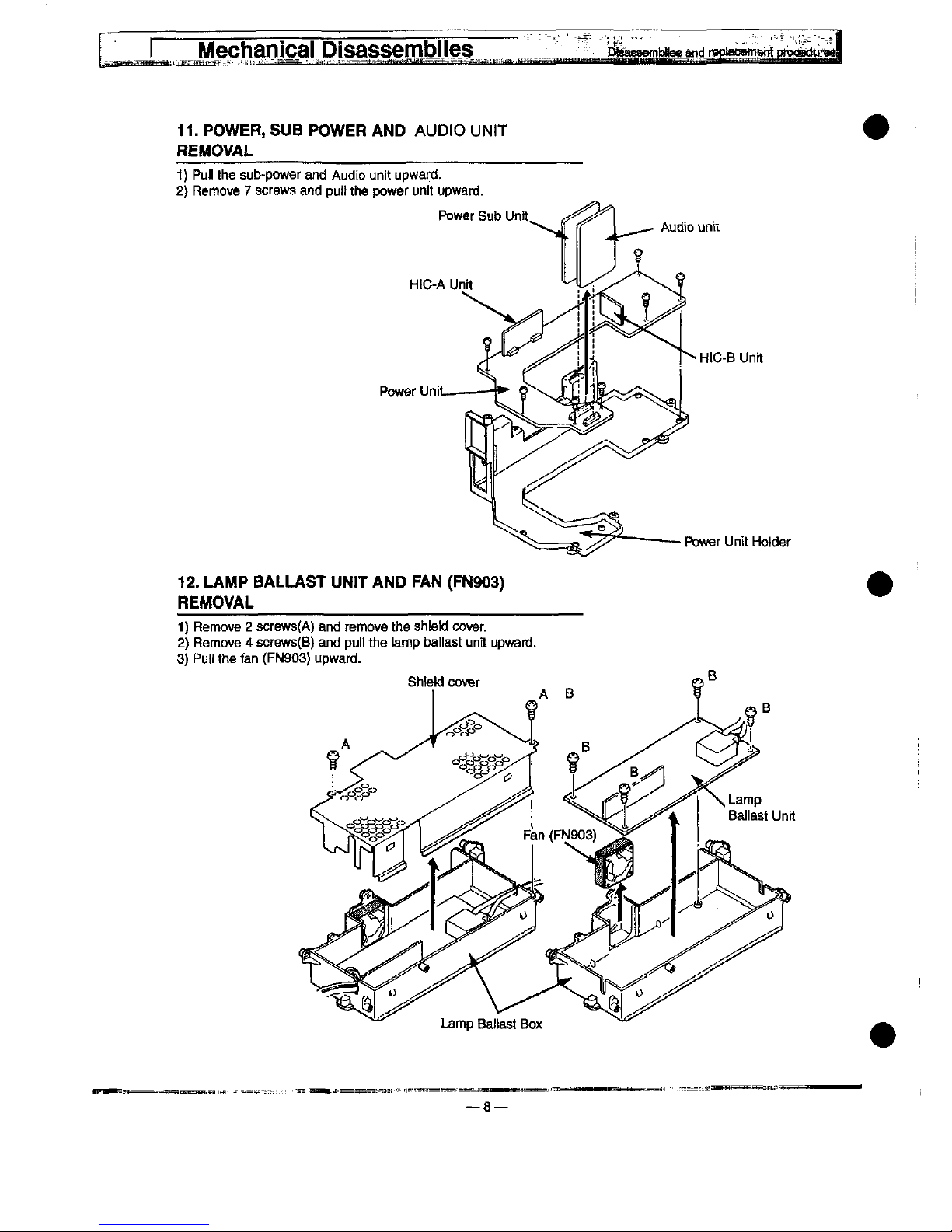

11.

POWER,

SUB

POWER

AND

AUD)0

UN)T

REMOVAL

1)

Pufi

the

sub-power

and

Audio

unit

upward.

2}

Remove 7 screws

and

pu)!

the

power

unit

upward.

HtC-A

Unit

Power

Uni

Audio

unit

HiC-B

Unrt

Power

Unit

Hotder

12.

LAMP

BALLAST

UN!T

AND

FAN

(FN903)

REMOVAL

1)

Remove 2 screws(A)

and

remove

the

shie)d

cover.

2)

Remove 4 screws(B)

and

puit

the

tamp

batiast

unit

upward.

3)

Pu)i

the

fan

(FN903)

upward.

Lamp

Baftast

Box

—8—

DtMMOfnbHes

and

repta&Mnent

prc^dur

Remove

the

cabinet,

cabinet

front,

main,

video

and

A/V

unit

fottow-

ing

to

steps 2 to 4 of

"Mechanicat

Disassembles".

1.

LENS

ASSY

REMOVAL

1)

Remove 4 screws

and

remove

the

tens

assy.

Fig.1

2.

RELAY

LENS

AND

INTEGRATOR

LENS

AND

POLARtZED

GLASS-)N

R,

G, B REMOVAL

1)

Remove 2 screws(A)

and

then

putt

the

retay

tens

upward.

2)

Remove 2 screws(B)

and

then

putt

the

integrator

tens

upward.

3)

Remove

each

screw(C)

and

then

putt

the

polarized

giass-in

R,

G,

B

upward.

Polarized

Gtass-tN

(G)

Pofarized

Gtass-)N

(R)

Pofarized

Gtass-tN

(B)

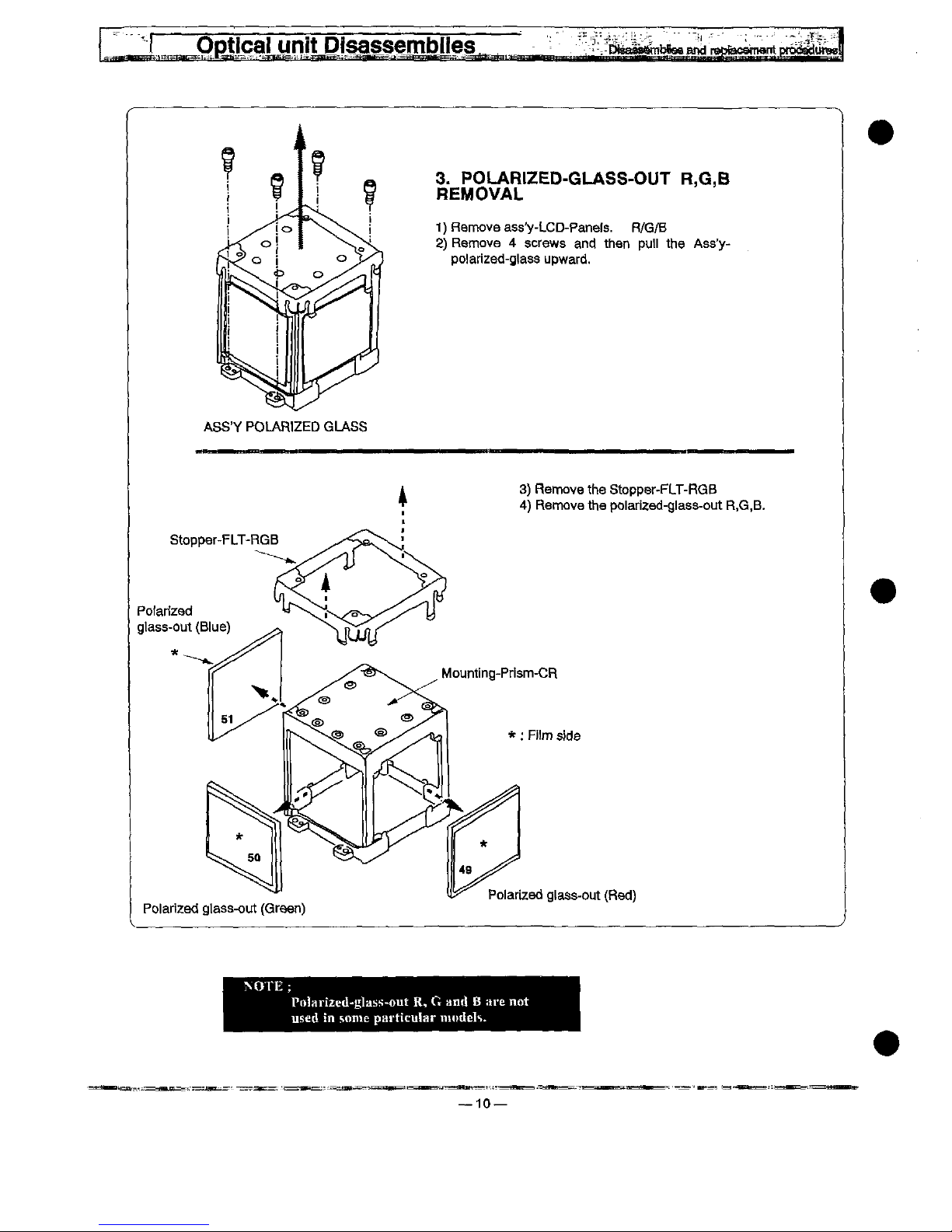

3.

POLARtZED-GLASS-OUT

R,G,B

REMOVAL

1)

Remove

ass'y-LCD-Panefs.

R/G/B

2)

Remove 4 screws

and

then

pu))

the

Ass'y-

po)arized-g)ass

upward.

ASS'Y

POLAR)ZED

GLASS

3)

Remove

the

Stoppor-FLT-RGB

4)

Remove

the

po)arized-g)ass-out

R.G.B.

Pofarfzad

gtass-out

(B!ue)

Mounting-Prism-CR

*:

Fi!m

stde

Po)arized

gtass-out

(Green)

Po)arized

gtass-out

(Red)

?<OTE;

Pn!arized-gt.i^-out

R, G and B are

not

used

in

some

particufar

models.

10—

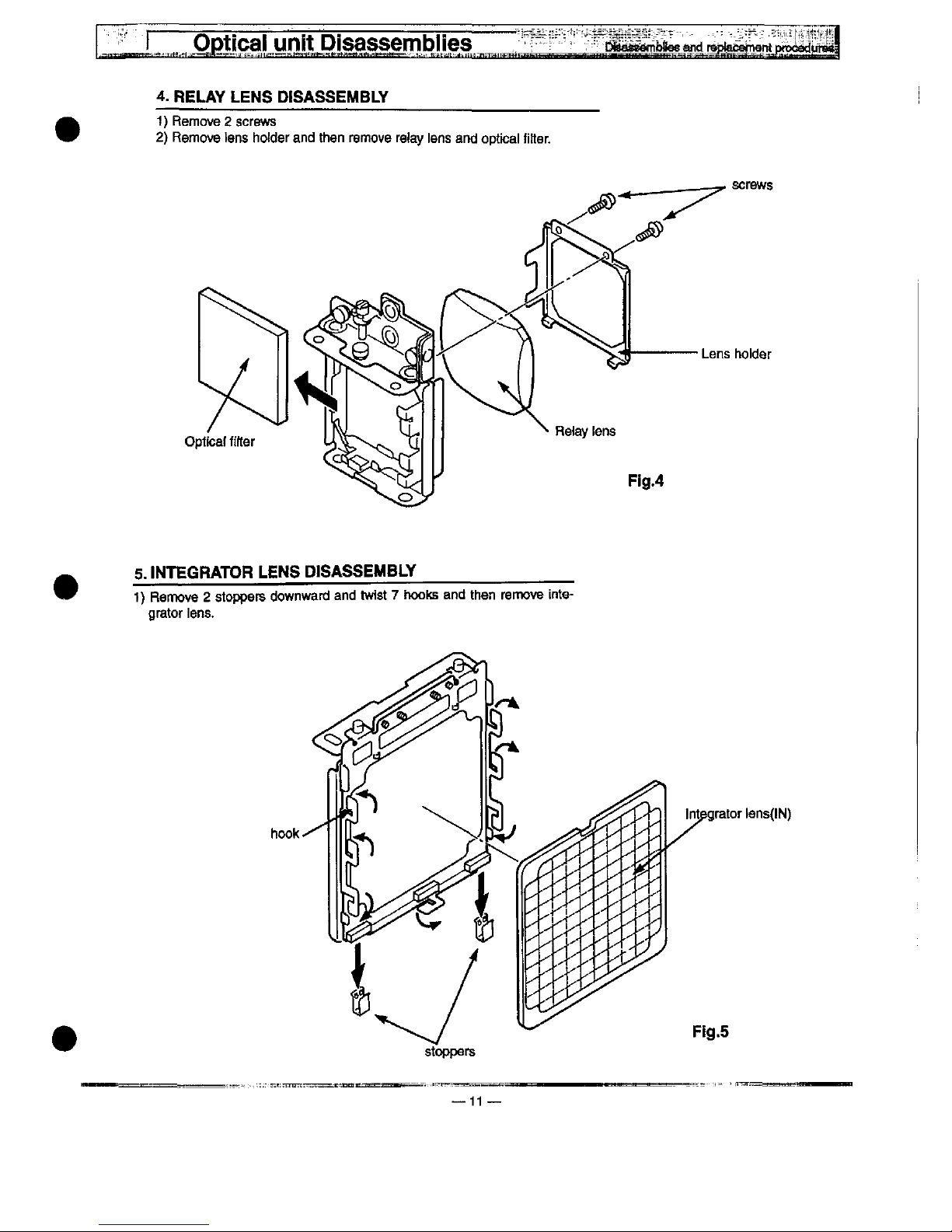

4.

RELAY

LENS

DISASSEMBLY

1)

Remove 2 screws

2)

Remove

tens

hofder

and

then

remove

retay

tens

and

optica)

fitter.

screws

Lens

hohjer

5.

tNTEGRATOR

LENS

D)SASSEMBLY

1)

Remove 2 stoppers

downward

and

twist 7 hooks

and

then

remove

inte-

grator

iens.

hook

Integrator

(ens(!N)

Fig.5

stoppers

11

6.

OPTICAL

BASE

TOP

REMOVAL

Remove 9 screws

and

then

puf)

the

optica)

baae

top

upwafd.

Optical

base

top

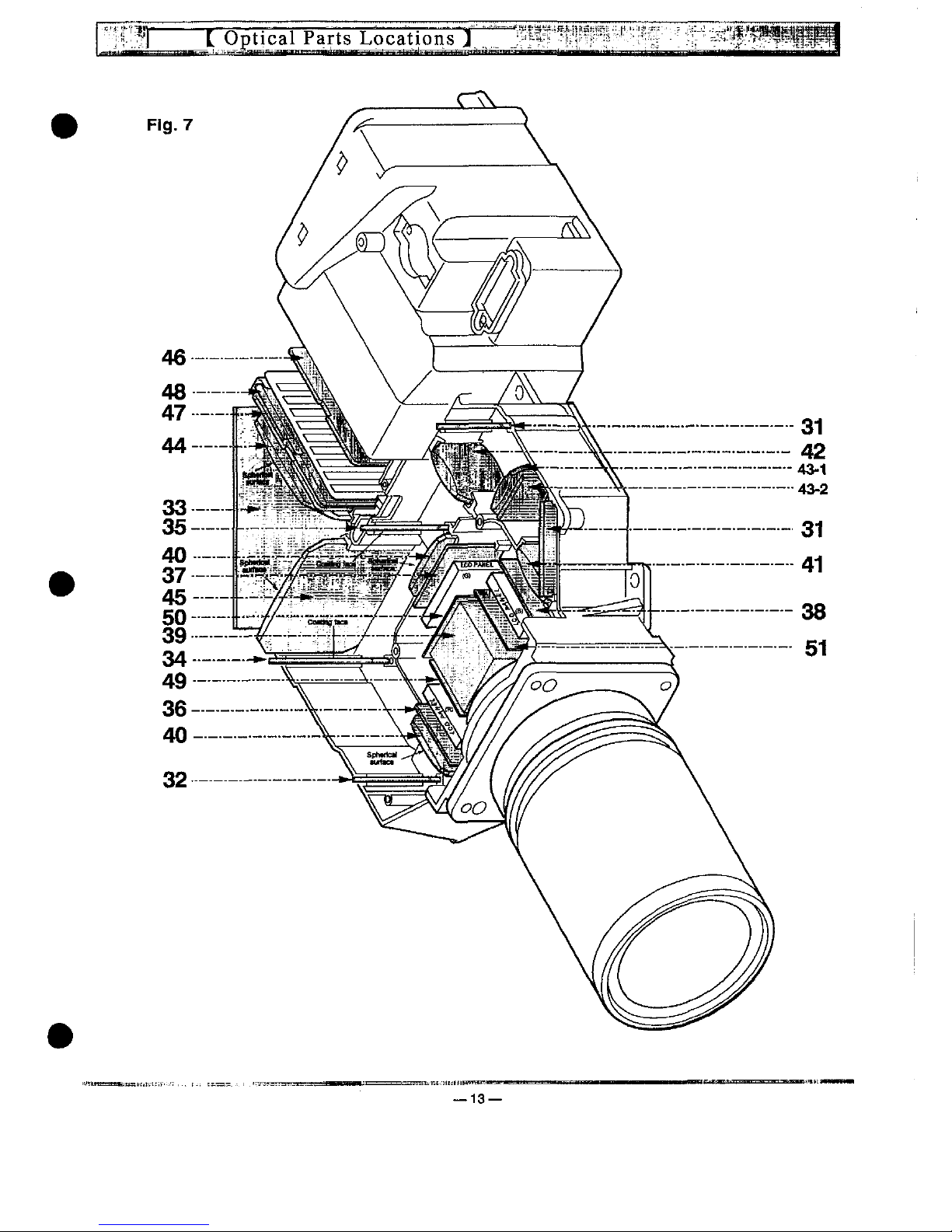

OPTICAL

31

32

33

34

35

36

37

38

39

40

41

PARTS

LOCATES

MIRROR(B)

MIRROR(R)

MIRROR(W)

DICHROIC

MIRROR

(R)

DICHROIC

MIRROR

(G)

POLARIZED

GLASS-IN(R)

POLARIZED

GLASS-IN(G)

POLARIZED

GLASS-IN(B)

ASSY,PRISM

LENS,

COmSER

LENS.CONDENSER(B)

Refer

to

.next

page

42

LENS.RELAY(IN)

43-1

LENS.RELAY(OUT)

43-2

OPTICAL

FILTER(UV

CUT)

44

LENS.CONDENSER(IN)

45

LENS,

CONDE^ER(OUT)

46

LENS.

ItTTEGRATORdN)

47

ASSY.LENS,INT.(OUT)

48

PRISM(P.B.S.)

(Polarized

Beam

Splitter)

49

POLARIZED

GLASS-OUT(R)

50

POLARIZED

GLASS-OUT(G)

51

POLARIZED

GLASS-0[fT(B)

NOTE;

Key

MO.

49,

50

and

SKpotartxed-glass-out

R,

G

and

B)

are

not

used

in

some

particular

models.

12—

-13—

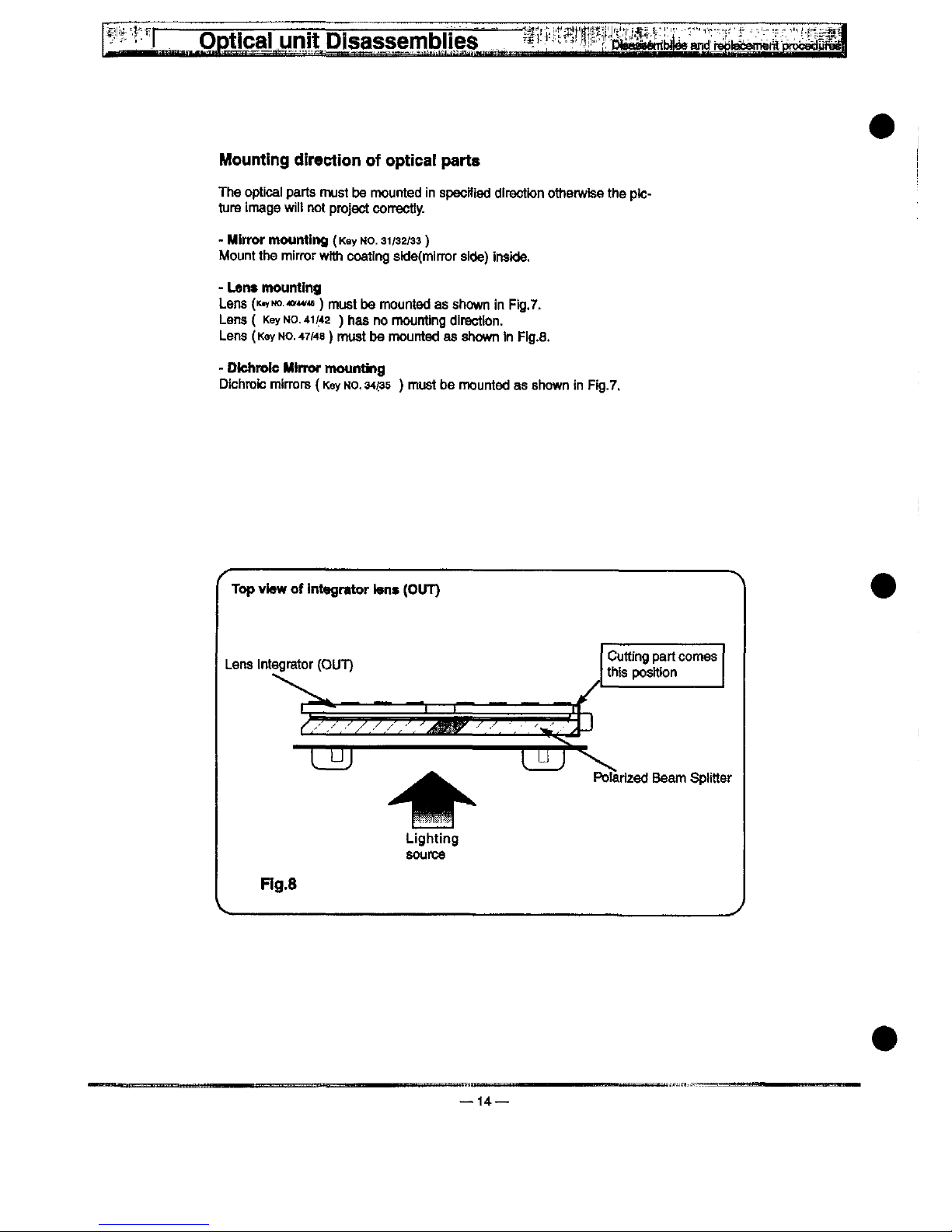

Mounting

direction

of

optica!

parts

The

optical

parts

must

be

mounted

in

specified

direction

otherwise

the

ptc-

ture

image

wiit

not

project

correctiy.

-

Mirror

mounting

(Key

Mo.

31/32/33)

Mount

the

mirror

wHh

coatfng

sidefmirror

side)

inside.

-

Lent

mounttng

Lens

(K^Mo.<of^<e)

must

be

mounted

as

shown

in

Fig.7.

Lens(

Key

No.

41/42

)hasno

mounting

directton.

Lens

(Key

MO.

47/48)

must

be

mounted

as

shown

tn

FJg.a.

-

Dtchrotc

Mtnw

mounting

Dichroic

mtrrors

(Key

NO.

34/35

)

must

be

mounted

as

shown

in

Fig.7.

/^\

Top

view

of

integrator

ten*

(OUT)

Cuttfng

part

comes

this

position

1^—————[^T^

Pofartzect

Beam

Sptitter

Lighting

source

Fig.8

14

!!.^.!'F^

'.,.

'E^^^-^^J^^

^-:{.V^D&^

f.

Remove

the

FPC

cabfe

on

the

main

board.

2.

Remove 4 screws

(A=B)ue,

B=Green,

C=Red)

for

the

assy

LCD

Pane).

3.

Pu)!

out

the

ass'y

LCD

Pane).

Remove 3 screws,

^en

remove

the

LCD

Pane)

and

replace

it.

LCD

pane!

mounting

ptate

Green

Panet

unit

—15

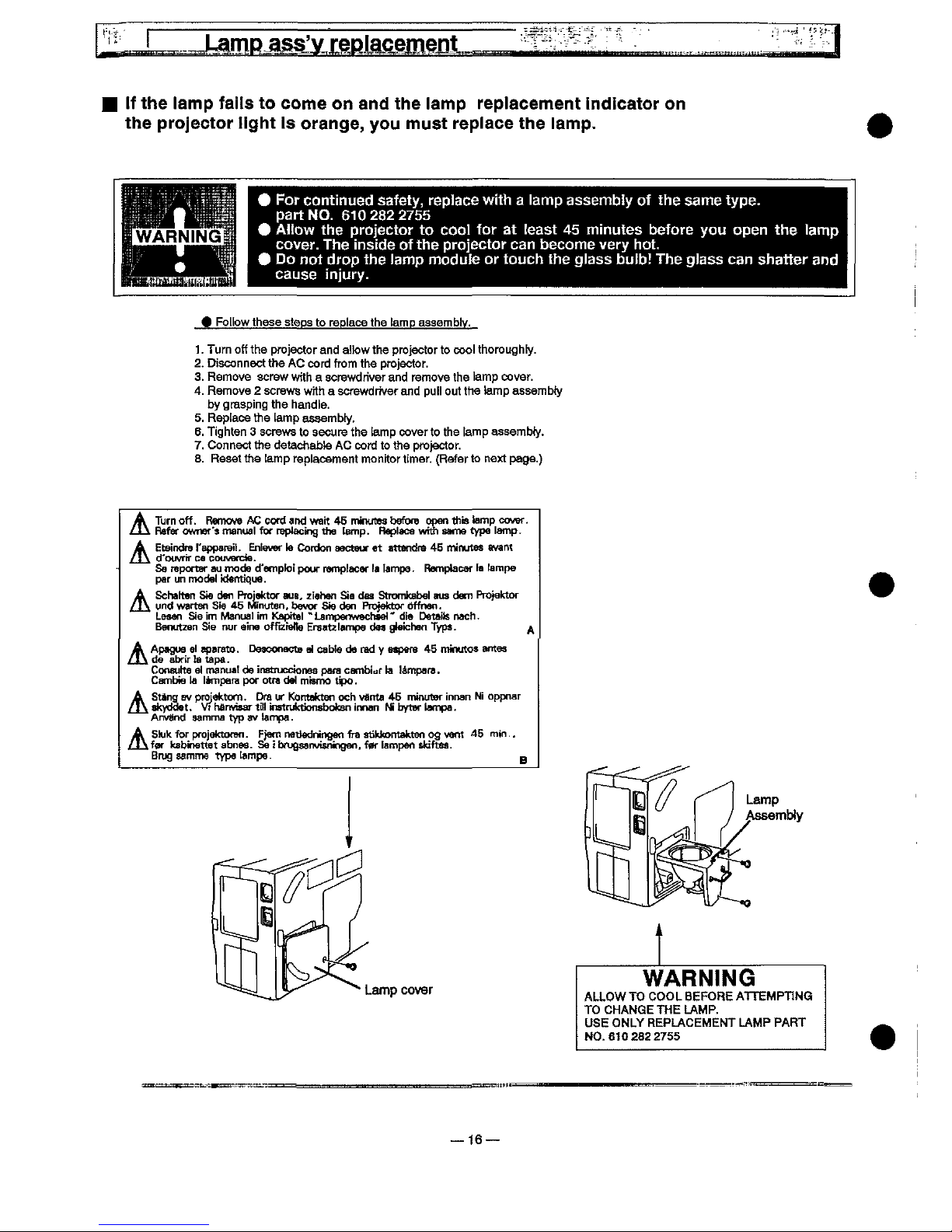

tf

the

tamp

fai!s

to

come

on

and

the

tamp

replacement

indicator

on

the

projector

!ight

is

orange,

you

must

replace

the

!amp.

^

For

continued

safety,

replace

with a lamp

assembly

of

the

same

type.

part

NO.

6102822755

^

AHow

the

projector

to

coo)

for

at

teast

45

minutes

before

you

open

the

tamp

cover.

The

inside

of

the

projector

can

become

very

hot.

^

Do

not

drop

the

iamp

modu!e

or

touch

the

glass

buib!

The

giass

can

shatter

and

cause

injury.

^FoUQW

those

steps

to

replace

the

tamp

assembly.

1.

Turn

off

the

projector

and

a))ow

the

projector

to

coo)

thoroughfy.

2.

Disconnect

the

AC

cord

from

the

projector.

3.

Remove

screw

with a screwdriver

and

remove

the

tamp

cover.

4.

Remove 2 screws

with a screwdriver

and

putt

out

the

tamp

assembfy

by

grasping

the

handle.

5.

Replace

the

[amp

assambty.

6.

Tighten 3 screws

to

secure

the

tamp

cover

to

the

tamp

assembty.

7.

Connect

the

detachabte

AC

cord

to

the

projector.

8.

Reset

the

[amp

replacement

monitor

timer.

(Refer

to

next

page.)

Turn

off.

Remove

AC

cord

and

wait

46

mitKftes

bofofe

open

this

tamp

cover.

Refer

owner'?

manuat

for

reptacing

the

tamp-

Reptace

whh

same

type

tamp.

Eteindre

f'apparait.

Entever

)a

Cordon

aectauf

et

attendra

46

minutes

avant

d'owrir

ce

couvercte.

Se

ntportar

au

mode

d'empfoi

pour

remp!acer

t<

tampe.

RetDpbcar

fa

tampe

par

un

mode)

ktentique.

Schatten

Sie

den

Projektor

aus.

z!ehen

Sia

dss

Stromkabet

aus

dam

Projektor

und

warten

Sie

45

Mnuten.

bevor

Sie

den

Pn3}ektof

offnen.

LeMn

Sie

im

Manua)

im

Kapite! ' LampenwechM)"

die

Dataits

nacfi.

Benutzen

Sie

nur

cine

offiziette

Ersatz

!ampe

dM

gfeichon

Typt.

^

Apagua

e)

aparato.

Desconocte

a)

cabte

da

rad y aapera

45

minutoe

antes

t

de

abrir

ta

tapa.

Consuho

o!

manuat

de

instnjccionss

para

cambiof

ta

tampafa.

Cambte

ta

!ampam

per

otra

de)

mismo

t^M.

Stang

sv

projektom.

Dra

ur

Kontattteti

och

vanta

46

neuter

innan

Ni

oppnar

^skydoet.

VtharMsartititnstruk^onsbotcBninnan

MbylBrtampa.

Anvand

aamma

typ

av

tampa.

Sk'ttforpfojetctorBn.

^jemnettedningenfras^hkontaktenogvent

45

rnif)..

tfar

kabinettetabnes-

Seibnjgsanvisningen.ferfampenshiftM.

Brug

samme

type

tampe.

n

Lamp

cover

Lamp

AssemMy

WARNtNG

ALLOW

TO

COOL

BEFORE

ATTEMPTtNG

TO

CHANGE

THE

LAMP.

USE

ONLY

REPLACEMENT

LAMP

PART

N0.6102822755

16

Lamp

ass'yMplacement

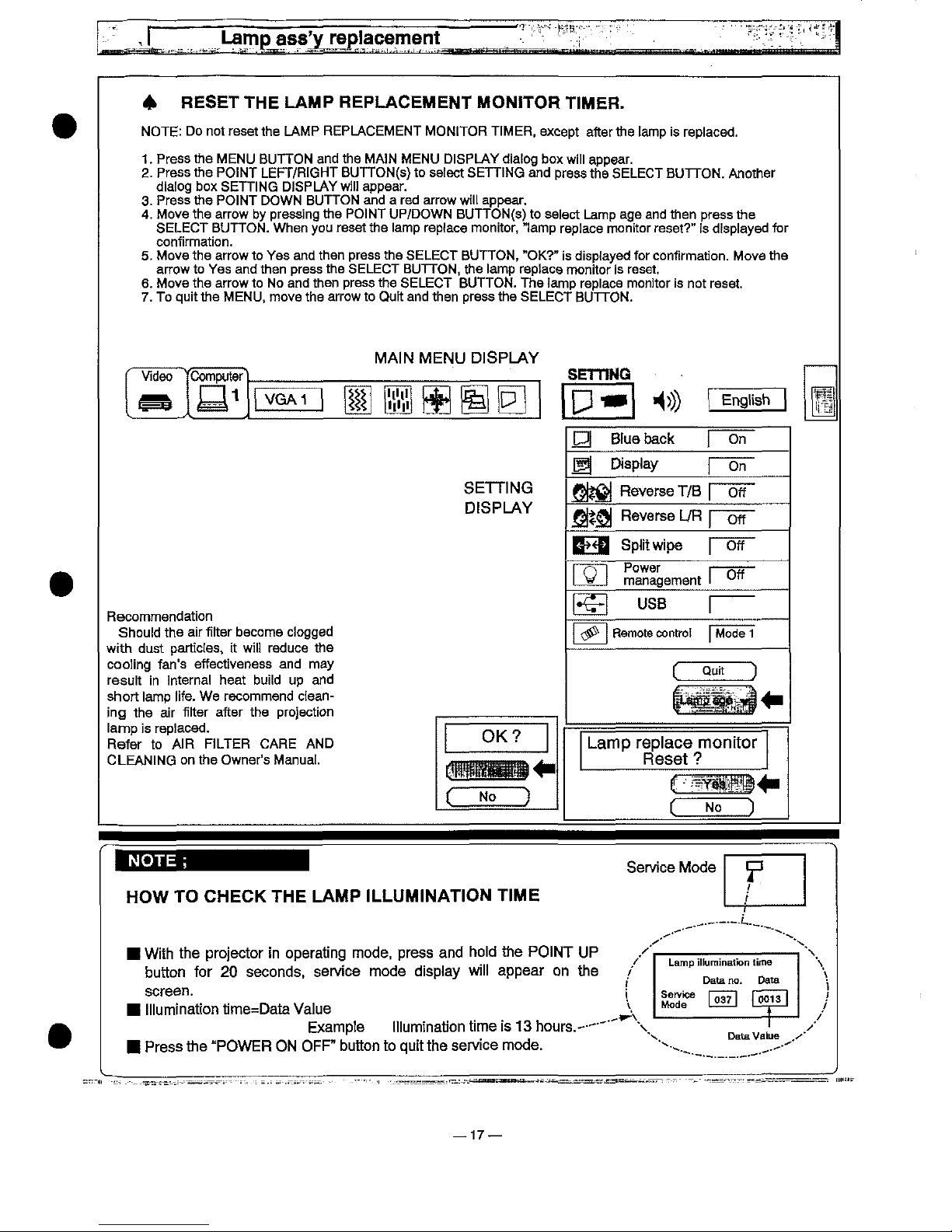

^

RESET

THE

LAMP

REPLACEMENT

MON!TOR

T)MER.

NOTE:

Do

not

reset

the

LAMP

REPLACEMENT

MONtTOR

TtMER,

except

after

the

[amp

is

rep)aced.

1.

Press

the

MENU

BUTTON

and

the

MA)N

MENU

D)SPLAY

diabg

box

wiii

appear.

2.

Press

the

POiNT

LEFT/RtGHT

BUTTON(s)

to

seiect

SETTiNG

and

press

the

SELECT

BUTTON.

Another

diafog

box

SETDNG

DJSPLAYwiii

appear.

3.

Press

the

POiNT

DOWN

BUTTON

and a red

arrow

wiii

appear.

4.

Move

the

arrow

by

pressing

the

PO)NT

UP/DOWN

BUTTON(s)

to

se)ect

Lamp

age

and

then

press

the

SELECT

BUTTON.

When

you

reset

the

tamp

repface

monitor,

"tamp

repiace

monitor

reset?"

is

displayed

for

confirmation.

5.

Move

the

arrow

to

Yes

and

then

press

the

SELECT

BUTTON,

"OK?"

is

disptayed

for

confirmation.

Move

the

arrow

to

Yes

and

then

press

the

SELECT

BUTTON,

the

iamp

roptace

monitor

is

reset.

6.

Move

the

arrow

to

No

and

then

press

the

SELECT

BUTTON.

The

famp

replace

monitor

is

not

reset.

7.

To

quit

the

MENU,

move

the

arrow

to

Quit

and

then

press

the

SELECT

BUTTON.

MAIN

MENU

DISPLAY

't't'

'!')'

Engtish

Btue

back

Disptay

SETDNG

DfSPLAY

Reverse

T/B

Reverse

L/R

B^<B

Sp)itwipe

Power

management

Recommendation

Should

the

air

fitter

become

ciogged

with

dust

partlctes,

[t

wiH

reduce

the

cooling

fan's

effectiveness

and

may

resuit

in

internal

heat

buiid

up

and

short

iamp

iife.

We

recommend

clean-

ing

the

air

fitter

after

the

projection

tamp

is

reptaced.

Refer

to

AIR

FtLTER

CARE

AND

CLEANING

on

the

Owner's

Manual.

US8

Remote

controi

Mode

1

Quit

Lamp

rep)ace

monitor

Reset

?

No

NOTE

;

HOW

TO

CHECK

THE

LAMP

)LLUM)NAT)ON

T)ME

F

/

With

the

projector

in

operating

mode,

press

and

hotd

the

PO!NT

UP

button

tor

20

seconds,

service

mode

disptay

witt

appear

on

the

screen.

tttumination

time=Data

Vaiue

Exampte

titumination

time

is

13

hours.'--"

Press

the

"POWER

ON

OFF"

button

to

quit

the

service

mode.

Lamp

iHumination

time

Data

no.

Data

',

^^

[1^

f^]

A

!————————}—

Data

Va!ue

.^'

—17

SAFETY

tNSTRUCTtONS

r

SAFETY

PRECAUT^ONS^

WARNING:

The

chassis

of

this

projector

is

isolated

(COLD)

from

AC

fine

by

using

the

converter

transformer.

Pr)mary

s!de

of

the

converter

transformer

and

tamp

power

suppty

unit

circuit

is

connected

to

the

AC

line

and

tt

ia

hot,

which

hot

circuit

is

identified

with

the

iino

in

the

schematic

diagram.

For

continued

product

safety

and

protection

of

personnet

injury,

servicing

should

be

made

wtth

quali-

fied

personnel.

The

following

precautions

must

be

observed:

1.

An

isolation

transformer

shouid

be

connected

in

the

power

iine

between

the

projector

and

the

AC

itne

before

any

service

is

performed

on

the

projector.

2.Comp)y

with

aii

caution

and

safety-

related

notes

provided

on

the

cabinet

back,

cabinet

bottom,

inside

the

cabinet

or

on

the

chassis.

3-

When

reptadng a chassis

in

the

cabinet,

aiways

be

certain

that

atf

the

protective

devices

are

instated

property,

such

as

control

knobs,

adjustment

covers

of

sh!e)ds

and

barriers.

DO

MOT

OPERATE

THIS

PROJECTOR

W!TH-

OUT

THE

PROTECTIVE

SHIELD

iM

POSmON

AMD

PROPERLY

SECURED.

4.

Before

repfacing

the

cabinet

cover,

thorough!/

inspect

the

insfde

of

the

cabinet

to

see

that

no

stray

parts

or

too)s

have

been

left

inside.

Before

returning

any

projector

to

the

customer,

the

service

personnel

must

perform

the

following

safety

checks

and

be

sure

that

it

is

compieteiy

safe

to

operate

without

danger

of

electrical

shock.

r

PRODUCT

SAFETY

NOTiCE

]

Product

safety

shouid

be

considered

when a component

repfacement

is

made

in

any

area

of

the

projector.

Components

indicated

by a mark

(^)

in

the

parts

iist

and

the

schematic

diagram

designate

components

in

which

safety

can

be

of

special

significance,

it

is,

therefore,

particularly

recommended

that

the

reptace-

ment

of

these

parts

must

be

made

by

exactly

the

same

parts.

^

SERVICE

PERSONNEL

WARNING

j

Eye

damage

may

result

from

directiy

viewing

the

fight

produced

by

the

Lamp

used

tn

this

equipment.

Atways

turn

off

Lamp

before

opening

cover.

uttravioiet

radiation

eye

protection

required

during

this

servicing.

Never

turn

the

power

on

without

the

tamp

to

avoid

efectric-

shoctt

or

damage

of

the

devices

since

the

stabilizer

generates

high

voitages(

=

25kV)

at

its

start.

Since

the

!amp

is

very

high

temperature

during

units

operation.

Replacement

of

the

tamp

shouid

be

done

at

least

one

hour

after

the

power

has

been

turned

off,

to

aiiow

the

iamp

cooi - off.

(

DO

NOT

ATTEMPT

TO

SERVING

THE

REMOTE

CONTROL

UNIT.

^

Laser

Beam

may

be

leaked

out

when

in

disassemble

the

Unit.

As

the

Laser

Beam

used

in

this

Remote

control

unit

is

harmful

to

the

eyes.

t

CAUTfON

^

^ j ,

LASER

RADU.DOW-

^^^

DO

MOT

STARE

!MTO

BEAU

^^MAX.tXfnvr;)mW

WAVE

^EWaTW:

eso ± ZOnm

f^ASS

!t

U^SM

PRODUCT

TM<pnMmN"co^)tMw)th2t

CFR

p^HMO-M

00

HOT

STARE

'MTO

SEAM

CLASS 2 tASEH

PROOUCT

LASER

STRAHUHQ

MCM'

tM

DEW

STRA^t-

BUCKEM

LASER

KLASSE:

^--f&HP-^Z

^-'^Ba

tr-Ata^^.:t^^^t

tEC6092S-t^m.t

tat7

MAX.OUTP'jrj&^tf^):'"W

WAVELEMOrm<t^):aso±20Mn

18

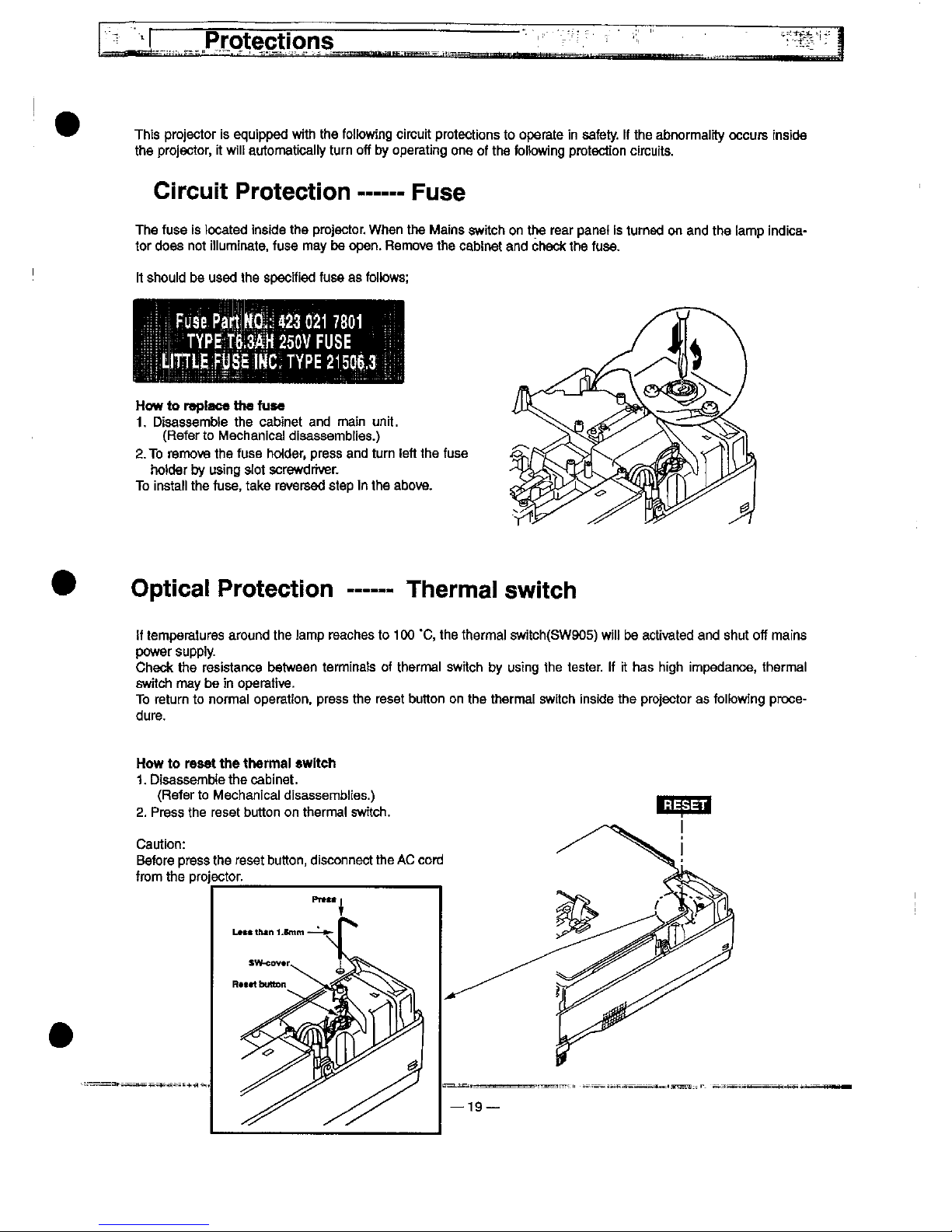

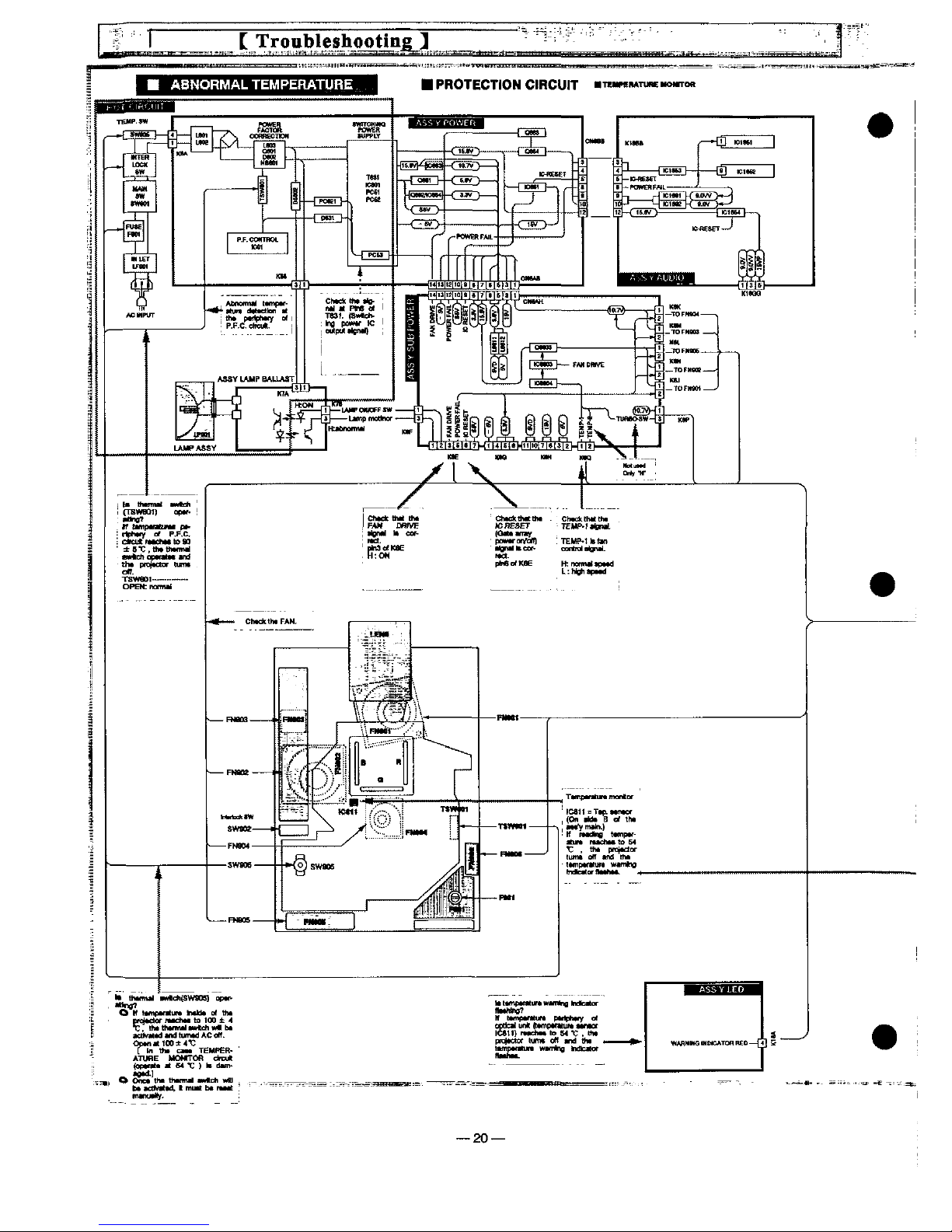

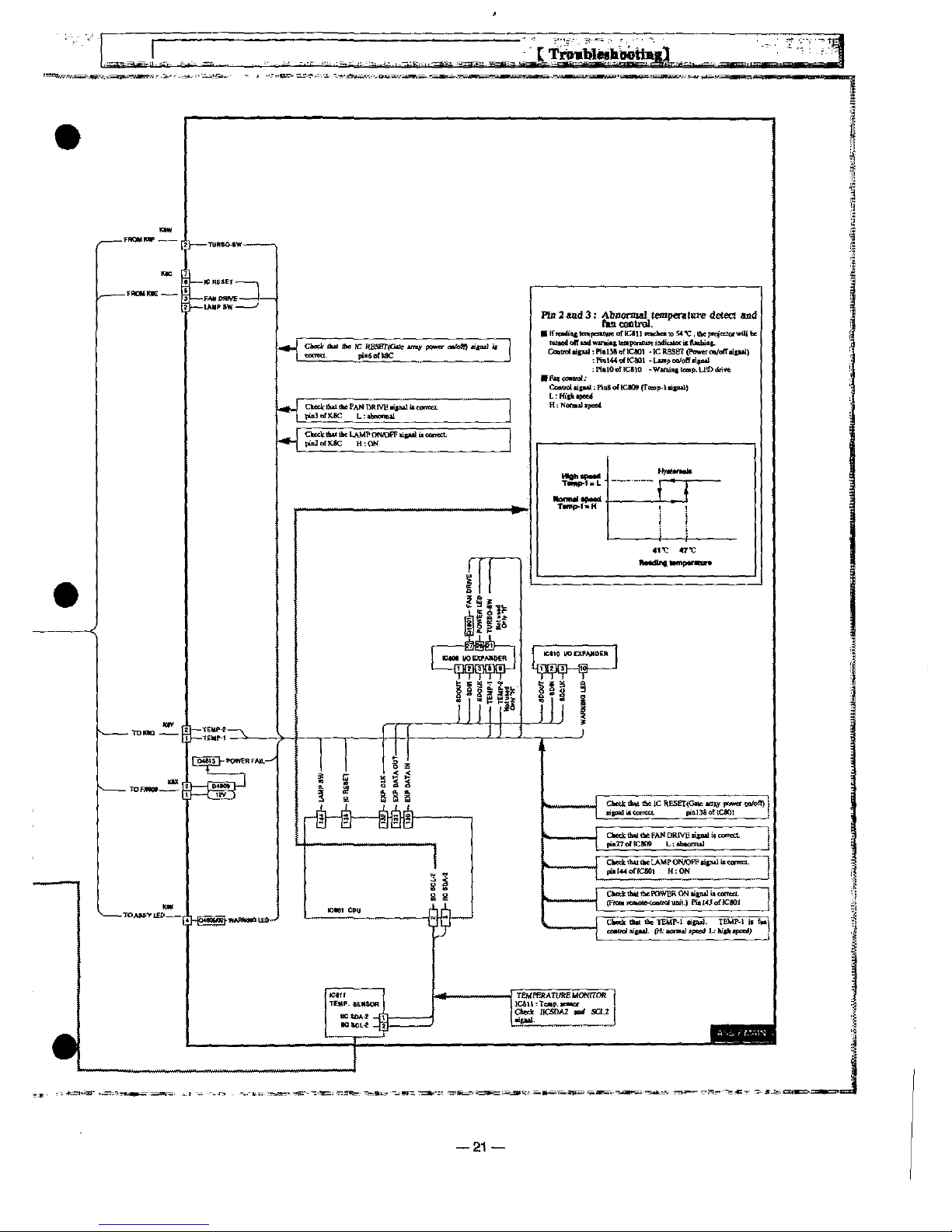

This

projector

is

equipped

with

the

foitowing

circuit

protections

to

operate

in

safety.

if

the

abnormaifty

occurs

inside

the

projector,

it

wii!

automatically

turn

off

by

operating

one

of

the

foHowing

protection

circuits.

Circuit

Protection

Fuse

The

fuse

is

located

inside

the

projector.

When

the

Mains

switch

on

the

rear

panef

is

turned

on

and

the

tamp

indica-

tor

does

not

itiuminate.

fuse

may

be

open.

Remove

the

cabinet

and

check

the

fuse.

tt

shouid

bo

used

the

specified

fuse

as

foitows:

FuaePa'tt^^230217801

TYPE

T$:3AH

250V

FUSE

How

to

reptace

the

fuae

1.

Disassembte

the

cabinet

and

main

unit.

(Refer

to

Mechanica!

disassemblies.)

2.

To

remove

the

fuse

ho<der,

press

and

turn

feft

the

fuse

hotder

by

using

stot

screwdriver.

To

instati

the

fuse,

take

reversed

step

in

the

above.

Optical

Protection

Therma!

switch

!f

temperatures

around

the

famp

reaches

to

100

'C,

the

thermat

switch(SW905)

w!it

be

activated

and

shut

off

mains

power

supp)y.

Check

the

resistartce

between

terminats

of

therma!

switch

by

using

the

tester,

tf

it

has

high

impedance,

thermal

switch

may

be

in

operative.

To

return

to

normai

operation,

press

the

reset

button

on

the

thermal

switch

inside

the

projector

as

foifowing

proce-

dure-

How

to

reset

the

therma)

twitch

1.

Disassembte

the

cabinet.

(Refer

to

Mechanfcai

disassemblies.)

2.

Press

the

reset

button

on

therma)

switch.

Caution:

Before

press

the

reset

button,

disconnect

the

AC

cord

from

the

projector.

tt

One*

tt*

thtnntt

tt^ch

wB

et^fN^ttd.

tmutt

&t

ftttt

21—

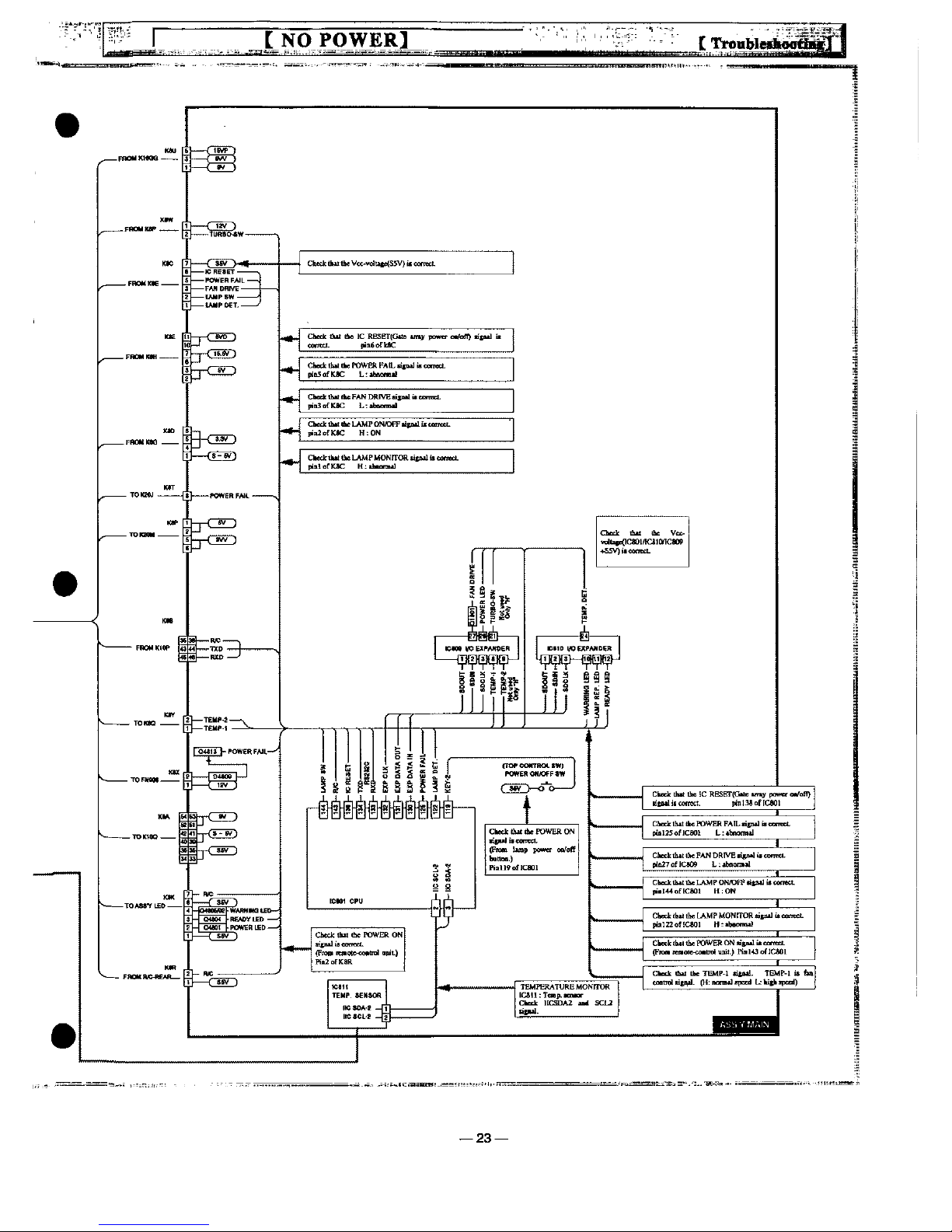

C

NO

POWERS

--23—

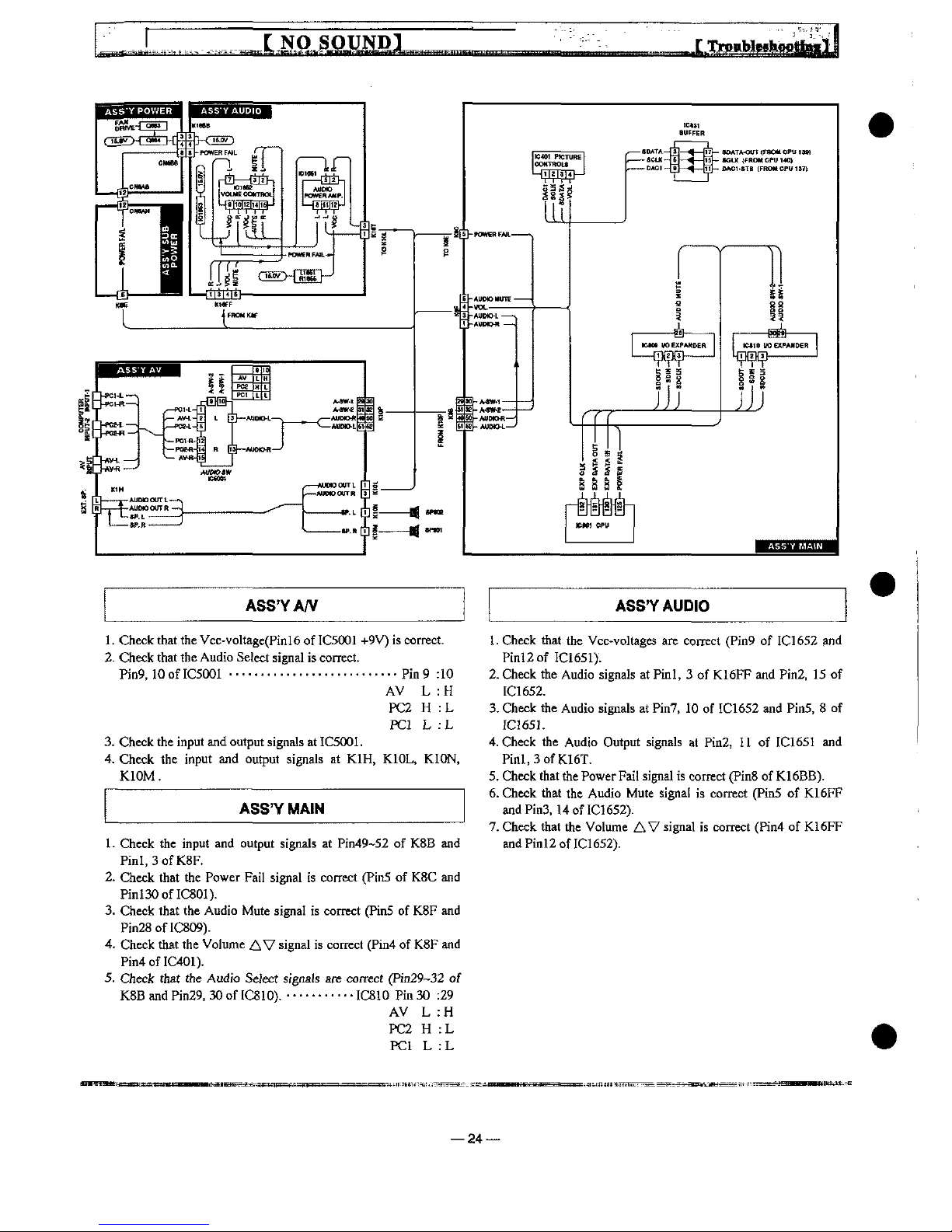

ASS'YA/V

ASS'YAUD)0

1.

Check

that

the

Vcc-voItage(Pinl6

of

IC5001

+9V)

is

correct.

2.

Check

that

the

Audio

Setect

signal

is

correct.

Pin9,10ofIC5001

.....................----..p;n9

:10

AV L :H

PC2 H :L

PC1 L ;

L

3.

Check

the

input

and

output

signals

at

IC5001.

4.

Check

the

input

and

output

signals

at

K1H,

K10L,

K10N,

K10M.

ASS'YMA)N

1 - Check

the

input

and

output

signals

at

Pin49-52

of

K8B

and

Pinl.3ofK.8F.

2-

Check

that

the

Power

Fait

signal

is

correct

(Pin5

of

K8C

and

Pinl30ofIC80I).

3.

Check

that

the

Audio

Mute

signal

is

correct

(Pin5

of

K8F

and

Pin28ofIC809).

4.

Check

that

the

Vo)ume

AV

signa!

is

correct

(Pin4

of

K8F

and

Pin4of!C401).

5.

Check

that

the

Audio

Select

signats

afc

correct

(Pin29-32

of

K8B

and

Pin29,

30

of

IC8IO).

...........

IC8IO

Pin

30

:29

AV L :H

PC2 H :L

PC1 L :L

1.

Check

that

the

Vcc-voltages

are

correct

(Pin9

of

IC1652

and

P:nl2of

IC1651).

2-

Check

the

Audio

signals

at

Pint, 3 of

K16FF

and

Pin2,

15

of

IC1652.

3-

Check

the

Audio

signals

at

Pin7,

10

of

IC1652

and

Pin5, 8 of

JC165J.

4.

Check

the

Audio

Output

signals

at

Pin2,

11

of

tC1651

and

Pml,3ofK16T.

5.

Check

that

the

Power

Fait

signa!

is

cornet

(Pm8

of

K16BB).

6.

Check

that

the

Audio

Mute

signa!

is

correct

(Pin5

of

K16FF

and

Pin3.14

of

IC1652).

7.

Check

that

the

Vohme

AV

signal

is

correct

(Pin4

of

K16FF

and

Pinl2

of

IC1652).

—24

Loading...

Loading...