Sanyo PLC-XP21N, PLC-XP21E, PLC-XP21B Service Manual

SERV)CE

MANUAL

Mutti-media

Projector

S4^0

F/L^

NO.

MODEL

NO.

PLC-XP21

N

(U.5.A.

,Canada)

PLC-XP21

E

(Europe,

Asia,

Africa,

M.E.)

PLC-XP21

B

(U.K.)

ORiGtNALVERSiON

Chassis

No.

MF6-XP21NOO

PLC-XP21

EOO

PLC-XP21BOO

NOTE:Match

the

Chassis

No.

on

the

unit's

back

cover

with

the

Chassis

No.

in

the

Service

Manuai.

if

the

Ortginai

Version

Service

Manua)

Chassis

No.

does

not

match

the

unit's,

additiona)

Service

Literature

is

required.

You

must

refer

to

"Notices"

to

the

Origina)

Service

Manuat

prior

to

servicing

the

unit.

Give

complete

"Chassis

NO."

for

parts

order

or

servicing,

[t

is

shown

on

the

rating

sheet

on

the

cabinet

of

the

Projector.

CC

Specifications

....--------

Disassemblies

and

Replacemen

Mechanical

disassemblies

Optical

unit

disassemblies

LCD

pane)

replacement

-

Assy

lamp

replacement

-'

Safety

Instructions

---------

Circuit

Protections

.....----

Troubleshooting

......-.-.

Waveforms

..------"--"

Alignment

Procedures

------

Service

adjustments - -

- - -

Focus

adjustments - -

" "

Convergence

adjustment

Product

Code

: 1 122

073

60

: 1 12207460

: 1 122

074

62

INTENTS

..............................

^

tt

Procedures

.-------......

3-17

...........................

9^14

.............................

15

.............................

19

..........................

20-27

..........................

38-39

.............................

^0

PLC-XP21N

MF6AF

PLC-XP21E

PF6AF

PLC-XP21B

PF6CF

Integrator

lens

adjustment

.......................

Polarized

glass

adjustment

.---.---.....----..---

CPU

input/output

port

functions

.---..--.---.-.------

Maintenance......................................

Notes

on

schematic

diagram

..-.-.--------...-------

Cabinet,

Chassis

and

Optical

parts

list

--....-..----.

Parts

location

and

PWB

pattern

diagrams

.----..-.....

Block

diagram

and

Low

power

distribution

---......-..

Schematic

diagrams

.-.--.--...--..-------..---..-

REFERENCE

NO.

......

41

------

42

------

43

- - - 44-47

..-

48-49

- - - 50-51

- - - 52-79

- - -

54"-58

- - -

59-79

SM5110202

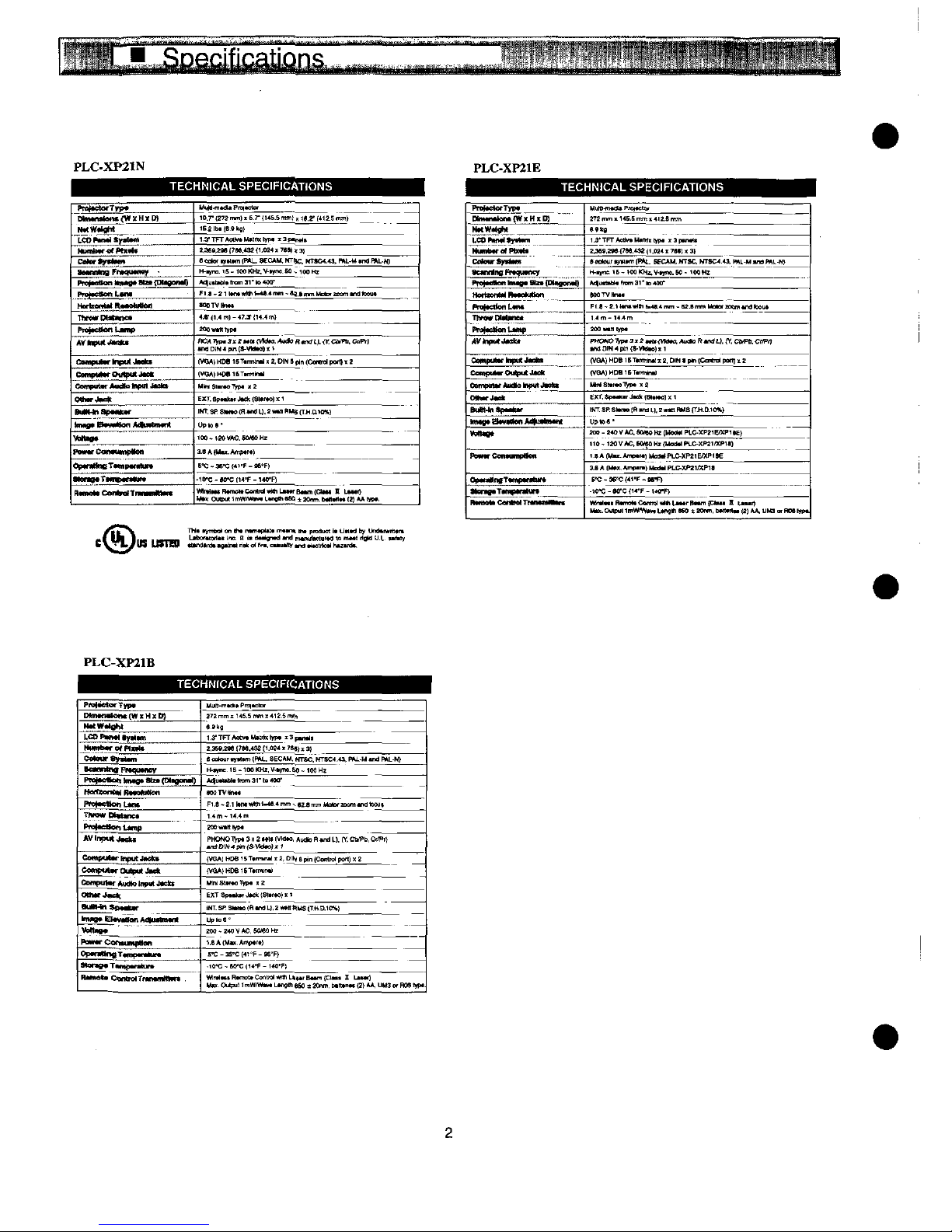

PLC-XP21N

PLC-XP21E

TECHN)CAL

SPEOFiCATfONS

TECHN)CAL

SPEOFJCATtONS

pr^tctofTn^

Dtt)«n*tent(W!fHtD)

tMWtfoM

LCO^«ty*tM!'

Mmnt^«Pt]t'tt

Ce)et<^**M

ac<mtr)Q

rrxrn""^

fMtMttonitf*a*atzt[Dtte''"'')

^^^U^!

HoftmnMtttt^BMton

Ttx^wOM-ne*

fM^tettent^mp

^ttttUt^M**

c<w<)pmtrtt^mj«t*

CetxpMttf

Output-fct

Cmmptt*r*Hdh'f^<HJ*attt

Othtr^ett

MtHtap-'tfMf

)-MWBM*Men*t<n«ttMnt

^Mt*o*

P<^rC<^Mmp<KM

Op<MHM()Tt«)p<ntt)tt<

attt^*T*<nptm<tUt<

ft^.C^^T^^-.

MMM-mtdH

P^'ctc'

10.7-

(272mm)

.6.7-

f)4S.Smm),

K.2-

(tt2 5 mmt

t6.:!bt<6.eta)

1.3'TFrAMvtMMtt'^p*

'3f-n^*

M6t,Me

!7M.o:

f'.m< ' Tet) t a)

e

M)e.

^.Mm

(P*L.

MCAM.

tT^c.

MTMM.O.

ML-M

tmt

^L-N)

H-^ne.tS-)MKm.VtYM.M.)0))Ht

*qtitH<!tt'r<m3I''o4M'

FI.<-2TtntwW!t-«.<nm-^.tmmMm.tcam^d'o!M

MtTVXntt

4.t'<].4m)-<7.J<14.4m)

MOwMttp.

^D^4^^^'^""^"^''^'^'^'

(WA)HMtST.nnMJ.2.D)Nt^<C<nM)ponf2

(WMtt^ettT^minti

M^St^el^.j.2

EXT.8pt*ttfJtti((3t*ftO)''

^MT.3P6)n*e<H*^L).!wMHUsjT.H.CHO^)

UpMt'

'M^MVAC.KWHz

3.eA(M^.A^^

6'C'3e'Cf4''F-t6'F)

-IO-c-M-Cn4'F-14<fF)

M*<Ouaiut"^M^.L*n^hMftt:om.6t<ttnttf!)**Wt.

PmftctctTtp*

DfM^MtfWxHKO]

HOW't^t

).eOP*M<)'yfm

MmnXwrofPOf^t

CC'e')rS^*)M

acxnntnct^qu^e^

PtCt*e''ottttHtjttSht(Dt))jn)n.t<)

Hot^MiM<B«eMton

f^ttt)'onf-*n*

Tt^wDM*net

PMf<eNcnt.Mtp

^V)f)ttt<J«af

eeMpm*r)nt<m*M'm

Ceotpo^OutMtJ'cft

Cefnt)UMfJhtdfo'Hpu)J^)tt

tMtMfJ'Mt

Boemttp't'r

)m<(tt&m«tMtMtU^MM

^<M(X

fe^Contumpttcn

Opm(tne-r*mptn<m*

)ttM(t*Tt«)<xn)tUM

tt^t.C^^Tt—nOt^

Muttt-mtanPrc^Ma.

272

mm . 145.5

mm , 4^.6

mm

ett^

t^'TFrAf^tMtmttypt

t3ptn^t

2,3fe.Mt

(TM.'M

(t

.M41

TM) < 3}

6

tKo^'

t^ttm

fP*L

SECAM.

NTSC.

MTSC4.43.

Mj..M

*na

fW.-N)

H-^n:.

'6 - )<M

«Ht.

^t^nc. K '

'«

H!

*^UtfU''mm3I'<o40t)-

MOTVhn..

F^.< - 2.'

ttnt^f

t^.4

mn. - M.Bmm

Mo<ot

mtrntrdtom^

t.<m-t4.4m

M(!-M<M)t

^^^^^^'^'"^"'^'^°'^

{VGA)

HDB

^Ttmitntt

12.

CMN < pm

tCa*d

pat) ^ 2

(VO*)HM^T.mt^

M^SM^TYp*);!

E)tT.!.p^^J-^t8t.^o)JH

^.SP.S'M.!RML).:-*ttRMar^D.IO%)

UpMt'

!00 - MO^

AC.

MMO

Ht

(MeCf

PLC-XP2'&XPHE)

"0-

1MV*C.

M^O

Hi

(Modf

PLC-)tP2"XPIt)

'^AfMt.*mp*'*)Me<MPLC-XM'E/Xf<E

3.6*[UM.*mp^.)MnMPLC.XM1MPH

M - 3FC

{41-^ - M-F)

-1f^C-M°C('<'F-t^M

^S^^^^L^^^m^^^.^^

PLC-XP21B

TECHNfCAL

SPECfPfCATfONS

Pto)*ctor-rvpt

Nm*tMion<[WxH]tD]

M*tWtt))ht

[.CD^MftYtttm

M^^^^^

e<t^)f<Mt*m

BatnntnaPttqmncy

PK')M<Mttt)n)()*atz*fD<t<)OM<)

Haf'iMnt'ttRtteMten

PrefeNonLtn*

Th'<^Cttt)M)Ct

PMf^t^Dmp

AV)npt)t4^t

CM<^tfMf)f^utJ<tCKt

C<Mnpm<rO^<<pt)(J)te):

CBmpt<t*fAtKttotn^^ekt

Oth^Joet!

MMnNt)^^

'M)^*Ef<M''tanAdtu*tnMnt

W)<^^*

'^MfCofMtmtp)ton

Op*n<tn(tTtmp*rttuf<

Mof*B'TM)ptr*h^t

'^^M*

ControtTfttto^tM*

Mttt-m^t.

P^^to.

:7Smm.nS.Smmt412.5m^

e.ft)

t^'TFrAM^MMm:^pt

'3p^^t

2.3M.2ee

(TM.4M

ft.OM

176t)

13)

e

tBtou'

ty«tm

{PM..

SEC*M.

m-sc.

MTSC4.43.

R^-.M

tnd

PM.-^

H-^nc.^-IOOMhz.^-^no.So-tMH!

At<utttt))t'mm3''tn400-

MOTV^.t

FI.t-:.t)tHt

wMX-M.4mm.-M.emn.

Motif

mm

tnd

bout

1.4m-'4.4m

^WtttfHX

^^^^^"'^^'''^'^'''^"

(VGA)

HDB

UTtnn^ . S.

D!H 6 pjn

(CcM^

po^) X :

(vaA)HDeiSTtmm^

M^S'^.T^p..2

EXTSptt)tfJttk!SMtO)x'

jNT.SRS<Mtt!(RtnaL!.2**t"tUS{THmO%)

Lfptoa'

2M-240VM.M^OHr

1.6A(U^.Amptft)

:-C-3S-C(4T'F-M'F)

-'0-C-M°C(H-F-140'F.

^^.*^^'L^^

^^^..^^

U^ . ^

W.

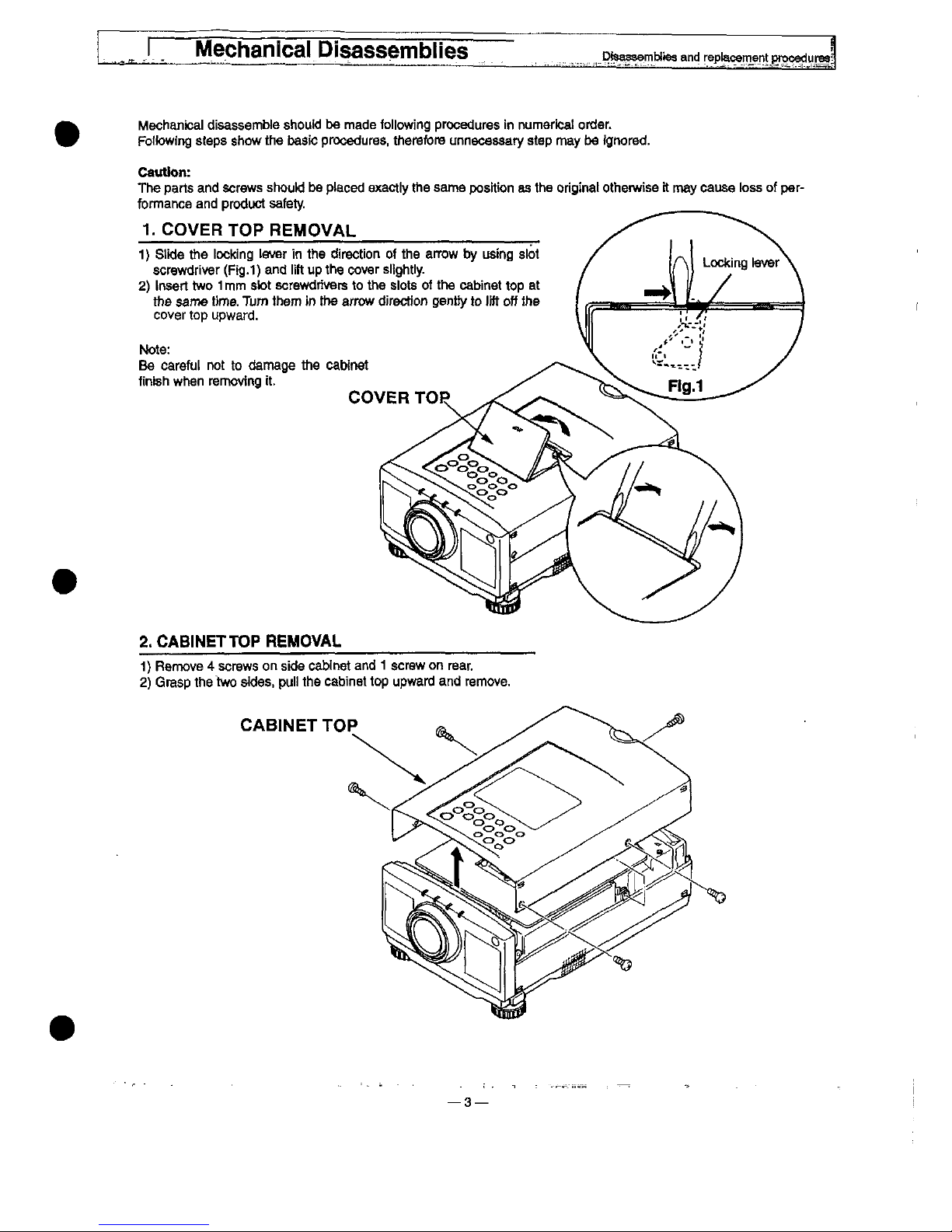

Mechanical

disassemble

shoufd

be

made

following

procedures

in

numerica!

order.

Fottowing

steps

show

the

basic

procedures,

therefore

unnecessary

step

may

be

ignored.

Caution:

The

parts

and

screws

shoutd

be

placed

exactly

the

same

position

as

the

origina)

otherwise

it

may

cause

toss

of

per-

formance

and

product

safety.

1.

COVER

TOP

REMOVAL

1)

Sttde

the

locking

iever

in

the

direction

of

the

arrow

by

using

slot

screwdriver

(Fig.1)

and

iift

up

the

cover

sitghtiy.

2)

hsert

two 1 mm

stot

screwdrivers

to

the

siots

of

the

cabinet

top

at

the

same

t)me.

Turn

them

in

the

arrow

direction

gentty

to

iift

off

the

cover

top

upward.

Note:

Be

carefut

not

to

damage

the

cabinet

finish

when

removing

it.

COVER

TOP

2.

CABtNETTOP

REMOVAL

1)

Remove 4 screws

on

side

cabinet

and 1 screw

on

rear.

2)

Grasp

the

two

sides,

pui!

the

cabinet

top

upward

and

remove.

CABtNET

TOP

—3—

Mechanica)

Disassembles

Disa^embttes

and

reptacemant

pfoceduresj

..tr-r^f-^^

-r_^_^^,-

,-_=)

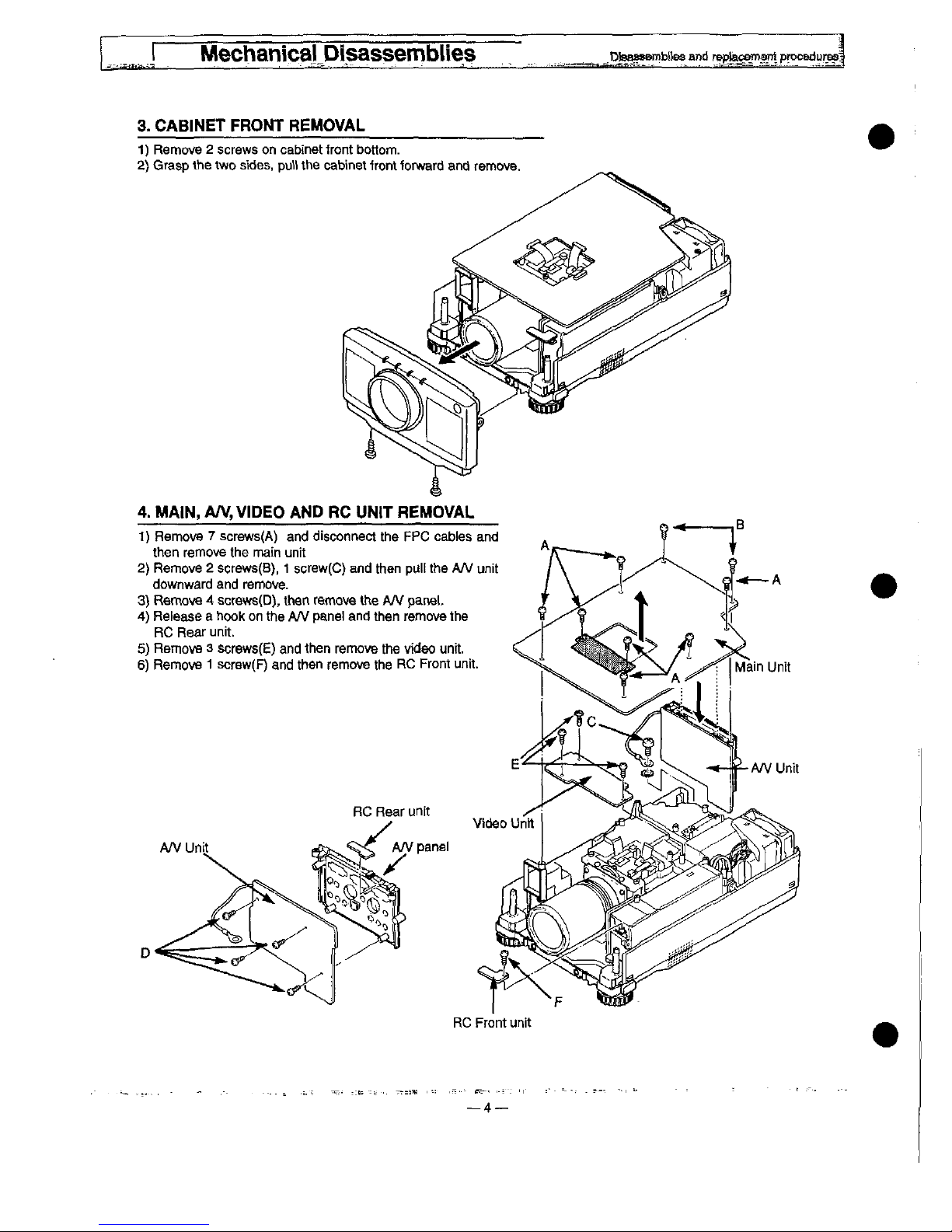

3.

CAB)NET

FRONT

REMOVAL

1)

Remove 2 screws

on

cabinet

tront

bottom.

2)

Grasp

the

two

sides,

put)

the

cabinet

front

forward

and

remove.

RC

Front

unit

—4

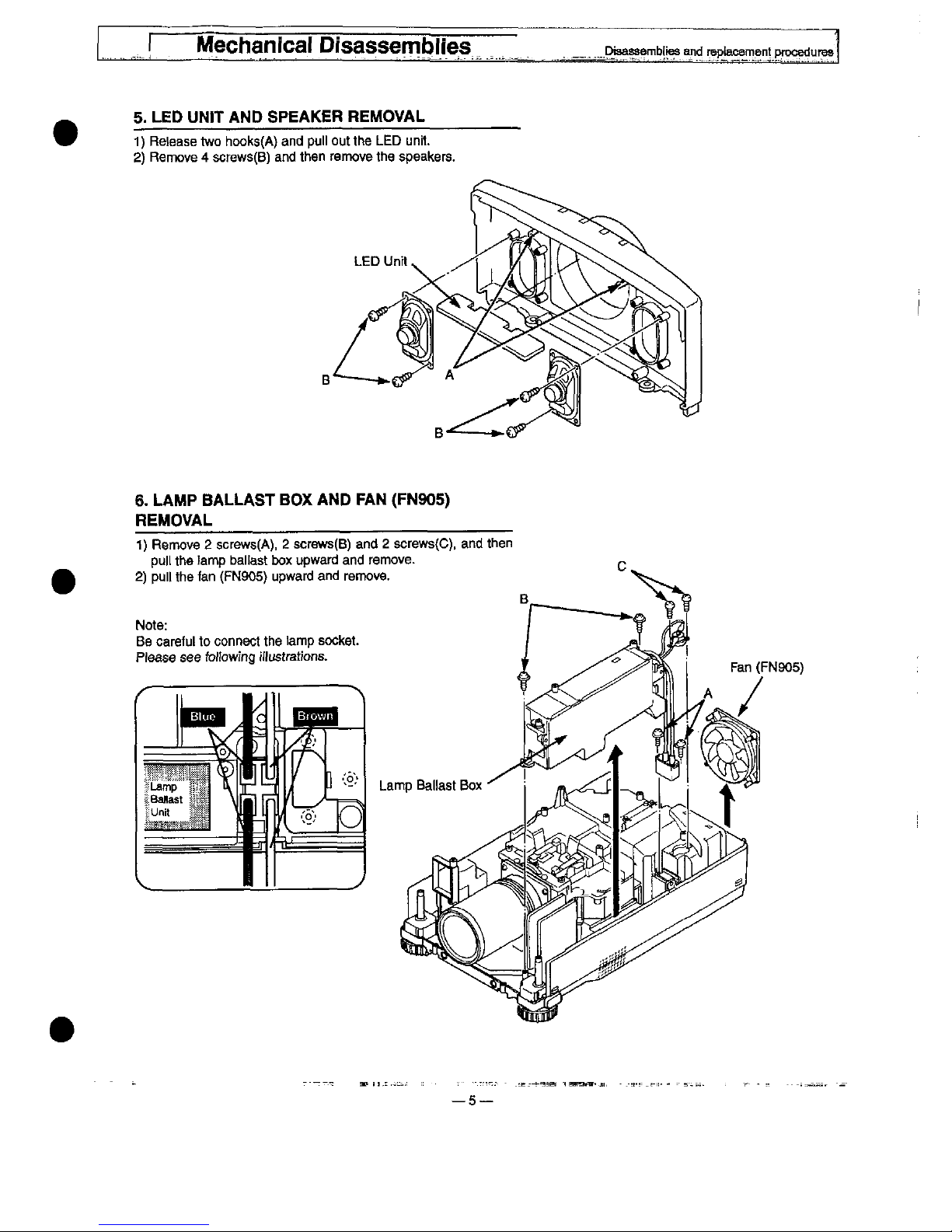

5.

LED

UN!T

AND

SPEAKER

REMOVAL

1)

Retease

two

hooks(A)

and

pu!)

out

the

LED

unH.

2)

Remove 4 screws(B)

and

then

remove

the

speakers.

6.

LAMP

BALLAST

BOX

AND

PAN

(FN905)

REMOVAL

1)

Remove 2 screws(A),

2

screws(B)

and 2 screws(C).

and

then

putt

the

!amp

ba)[ast

box

upward

and

remove.

2)

pu)[

the

fan

(FN905)

upward

and

remove.

Note:

Be

carefut

to

connect

the

tamp

socket.

Ptease

see

fo)towing

frustrations.

—5

Mechanics)

Disassembles

Dtsassembttea

and

reptacement

procedures

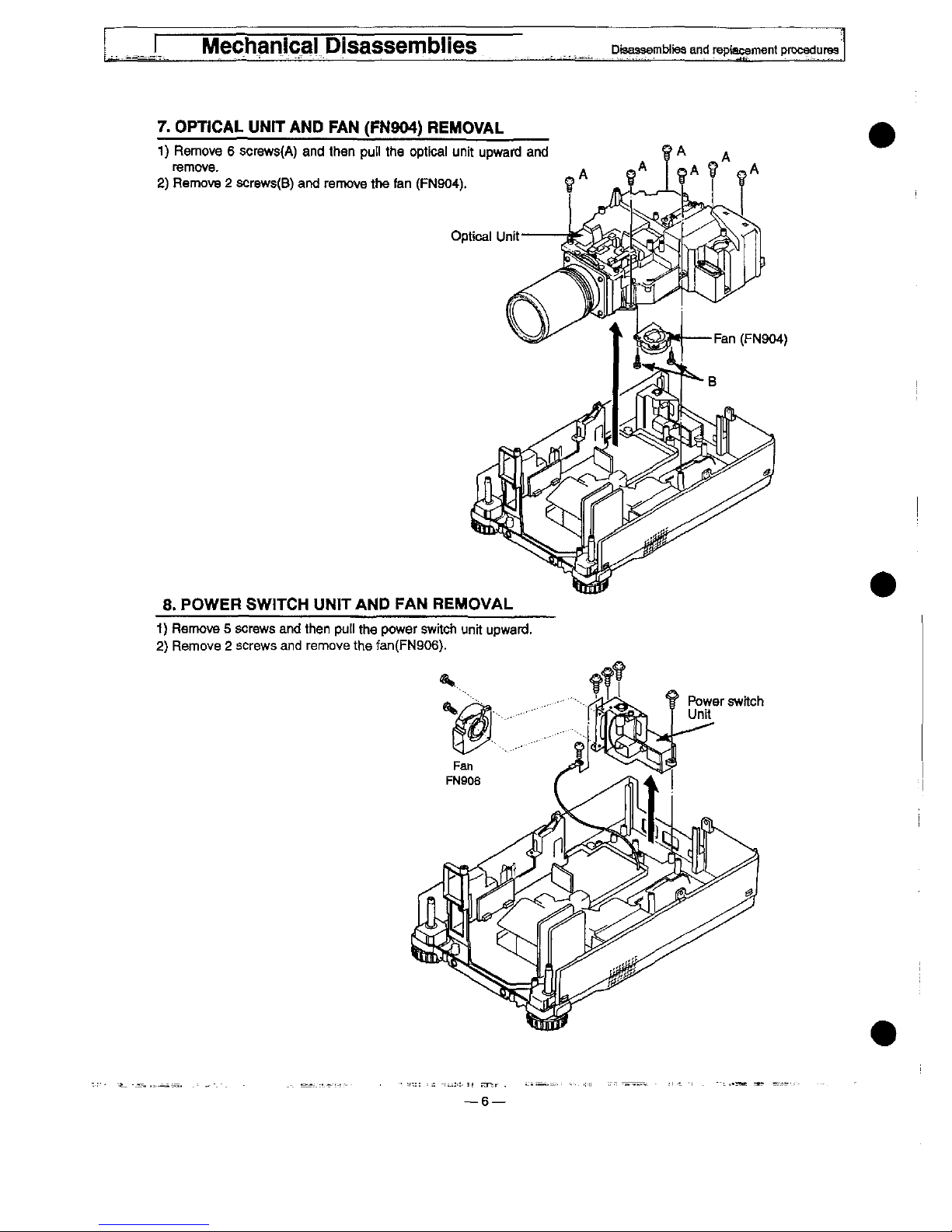

7.

OPTICAL

UNtT

AND

FAN

(FN904)

REMOVAL

1)

Remove 6 screws(A)

and

then

put)

the

optica)

unit

upward

and

remove.

2)

Remove 2 screws(B)

and

remove

the

fan

(FN904).

8.

POWER

SW!TCH

UNiTAND

FAN

REMOVAL

1)

Remove 5 screws

and

then

put)

the

power

switch

unit

upward.

2)

Remove 2 screws

and

remove

the

fan(FN906).

Mechanica)

Disassembles

Dtsaasembties

and

rep)acement

procedures

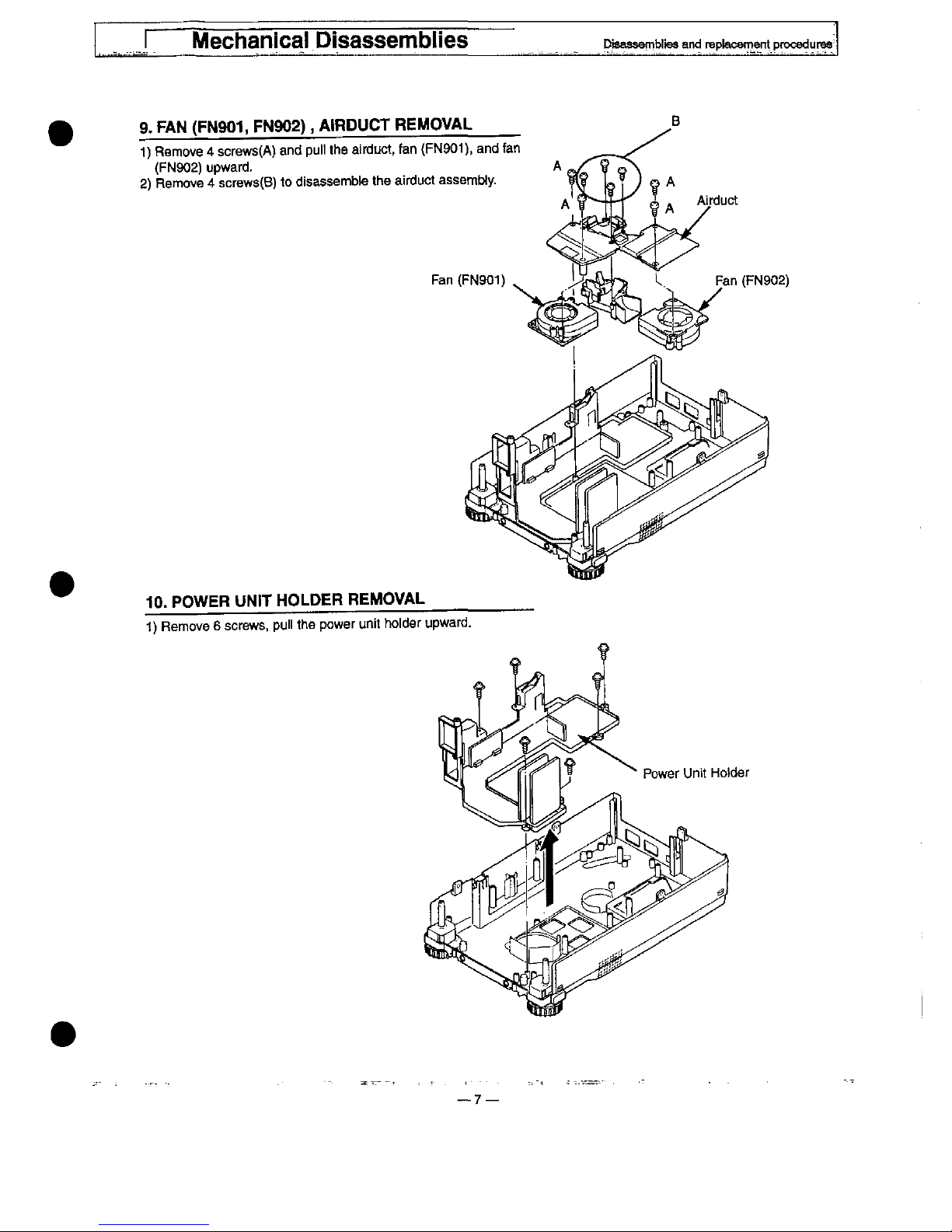

9.

FAN

(FN901,

FN902),

MRDUCT

REMOVAL

1)

Remove 4 screws(A)

and

pu!)

the

airduct,

fan

(FN901).

and

fan

(FN902)

upward.

2)

Remove 4 screws(B)

to

disassembte

the

airduct

assembty.

Fan

(FN901)

10.

POWER

UN)T

HOLDER

REMOVAL

1)

Remove 6 screws,

pu!)

the

power

unit

ho)der

upward.

7—

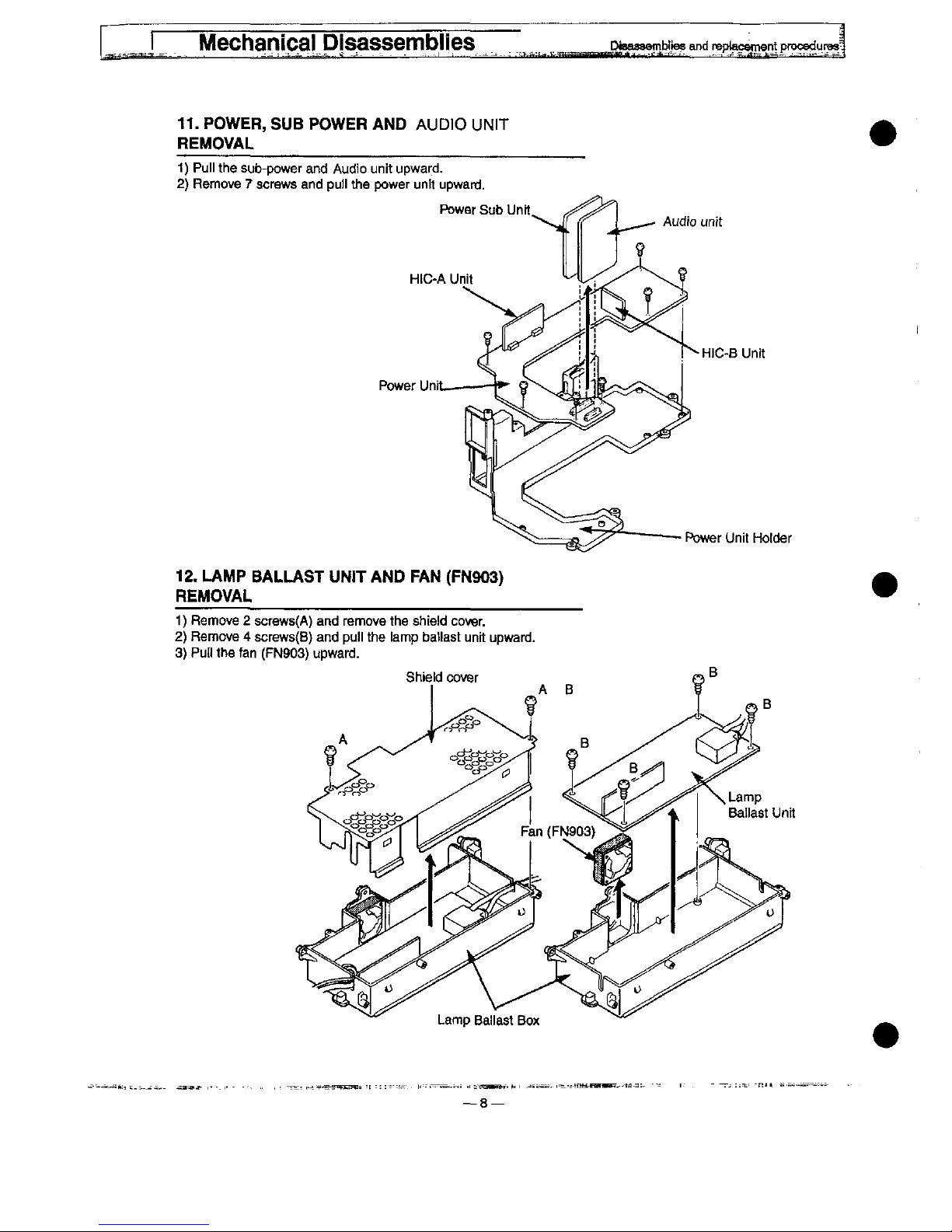

11.

POWER,

SUB

POWER

AND

AUDIO

UN)T

REMOVAL

1)

Pu!)

the

sub-power

and

Audio

unit

upward.

2)

Remove 7 screws

and

pu))

the

power

untt

upward.

Audio

ufift

HtC-A

Unit

Power

Uni

HJC-B

Unit

flower

Unit

Hotder

12.

LAMP

BALLAST

UNn-

AND

FAN

(FN903)

REMOVAL

1)

Remove 2 screws(A)

and

remove

the

shield

cover.

2)

Remove 4 screws(B)

and

puii

the

iamp

batiast

unit

upward.

3)

Put)

the

fan

(FN903)

upward.

Optical

unit

Disassemblies

Dst^semb^ias

and

raptaceme^pfpcedurMJ

Remove

the

cabinet,

cabinet

front,

main,

video

and

A/V

unit

foitow-

ing

to

stops 2 to 4 of

"Mechanical

Disassembles".

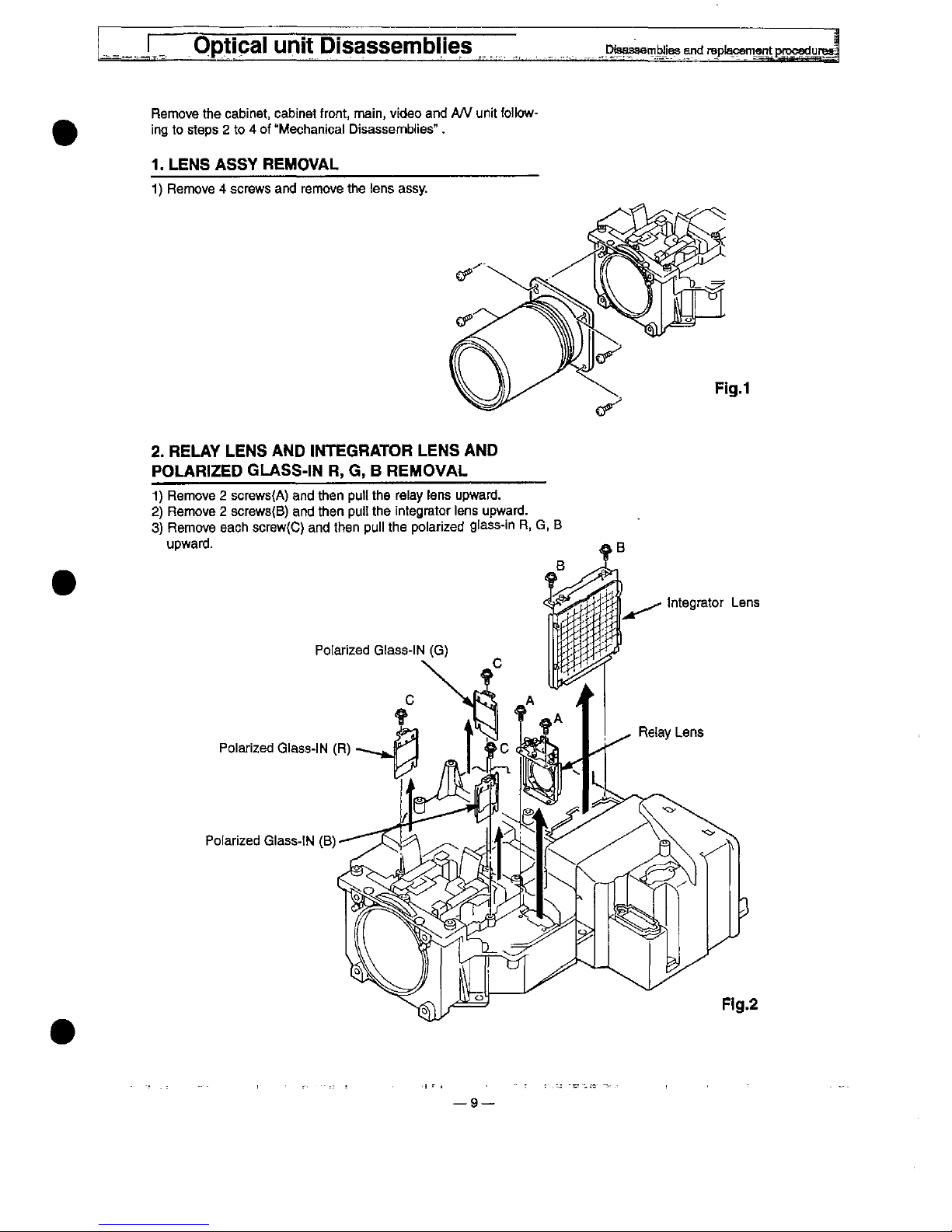

1.

LENS

ASSY

REMOVAL

1)

Remove 4 screws

and

remove

the

tens

assy.

Fig.1

2.

RELAY

LENS

AND

tNTEGRATOR

LENS

AND

POLAR)ZED

GLASS-)N

R,

G, B REMOVAL

1)

Remove 2 screws(A)

and

then

putt

the

re!ay

tens

upward.

2)

Remove 2 screws(B)

and

then

put!

the

integrator

!ens

upward.

3)

Remove

each

screw(C)

and

then

pu!!

the

po)arized

gfass-in

R,

G,

B

upward.

Pofarized

G!ass-)N

(G)

Po)arized

G)ass-!N

(R)

Polarized

G'ass-tN

(B)

—9

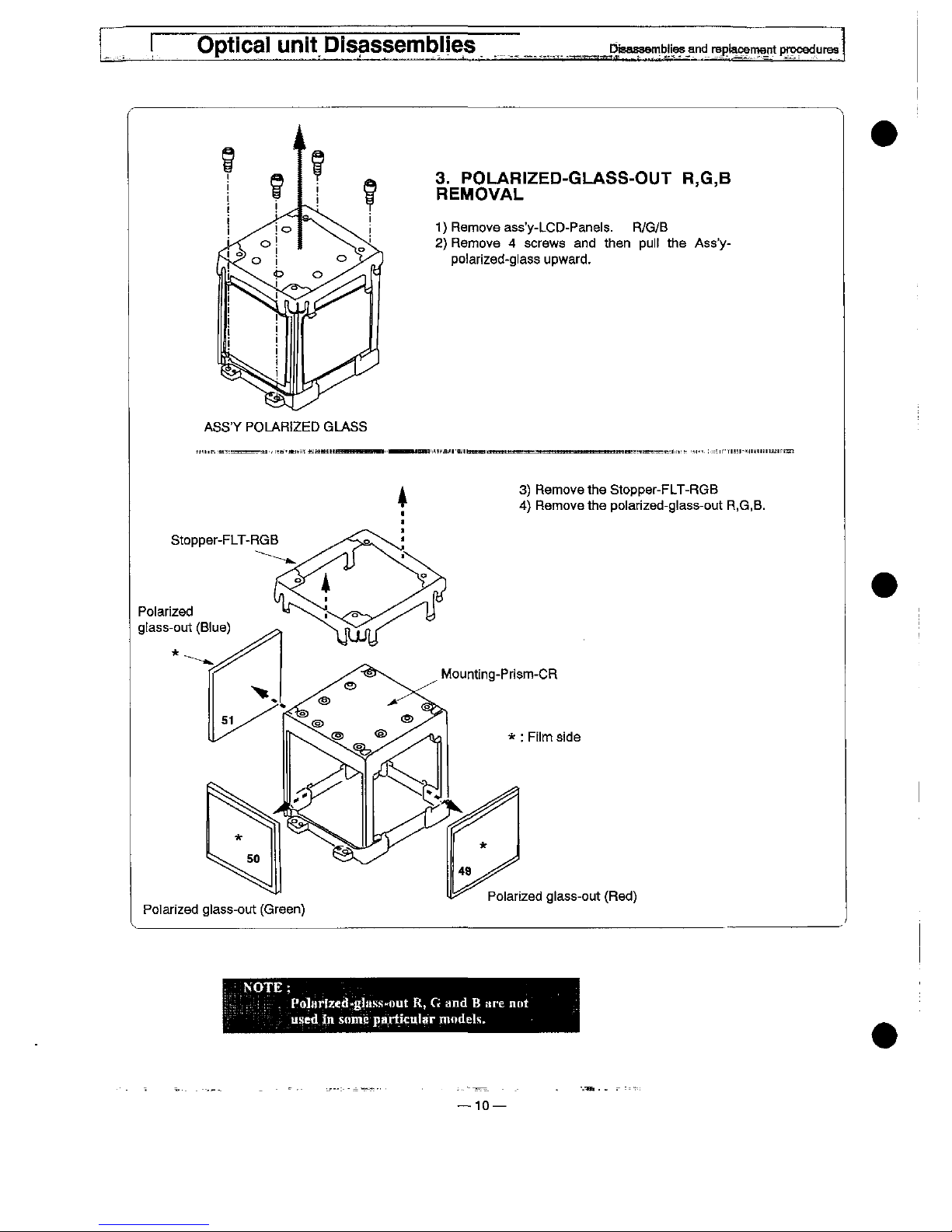

3.

POLAR!ZED-GLASS-OUT

R,G,B

REMOVAL

1)

Remove

ass'y-LCD-Panets.

R/G/B

2)

Remove 4 screws

and

then

pu!!

the

Ass'y-

po!arized-g!ass

upward.

ASS'Y

POLARfZED

GLASS

3)

Remove

the

Stopper-FLT-RGB

4)

Remove

the

po)arized-g)ass-out

R,G,B.

Po)arized

g

[ass-cut

(B)ue)

Mounting-Prism-CR

*

:

F[)m

side

Po)ar!zed

g)ass-out

(Green)

Po)arized

g)ass-out

(Red)

Po!H^iMd-g!it';s-out

R, G and B are

not

used

in

some

parMcutar

modet'i.

10—

Optica)

unit

DisassembHes

Diaasaerr)b)fes

and

repi^en^nt

procedurM

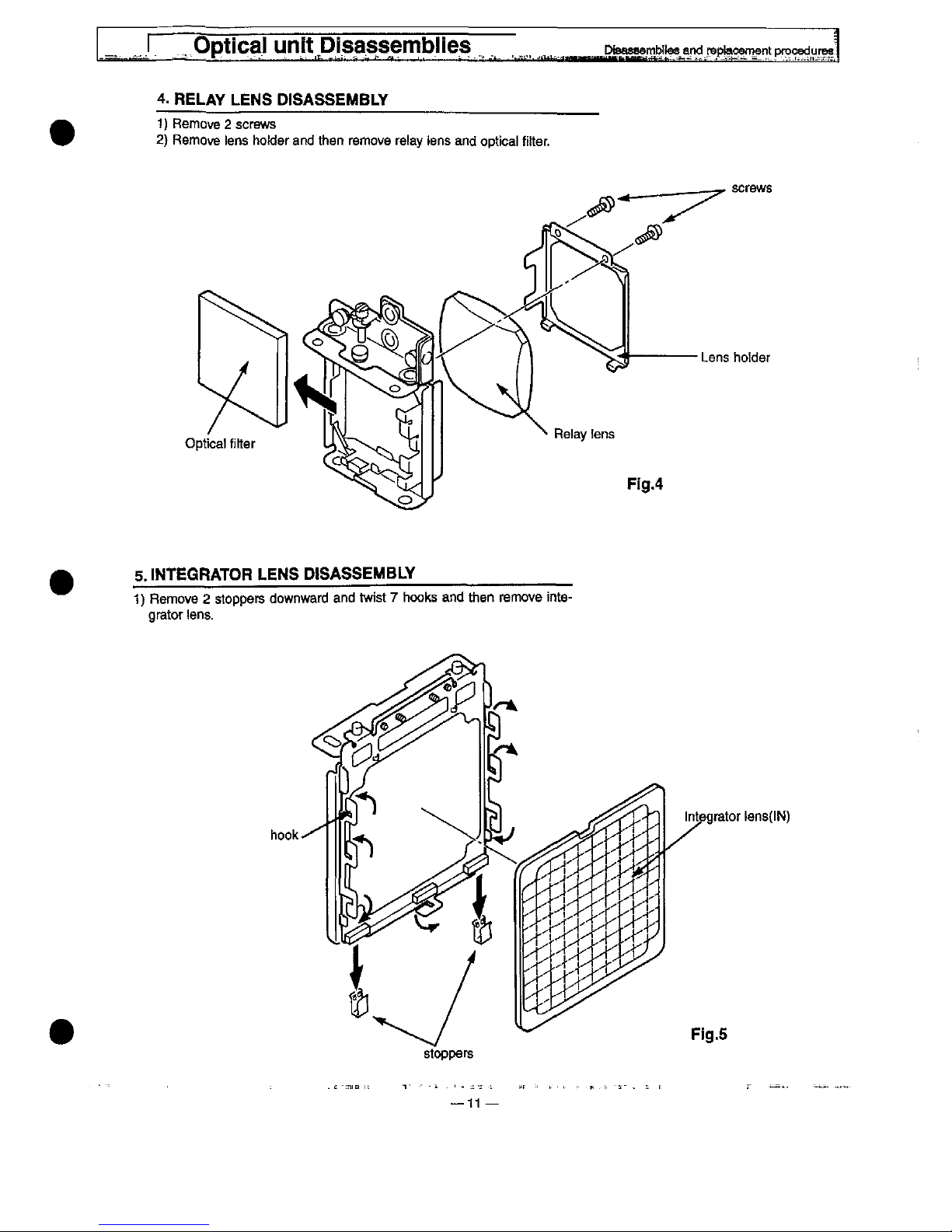

4.

RELAY

LENS

D)SASSEMBLV

1)

Remove 2 screws

2)

Remove

tens

ho!der

and

then

remove

re!ay

tens

and

optica)

fitter.

screws

Lens

hotder

5.

)NTEGRATOR

LENS

DtSASSEMBLY

1)

Remove 2 stoppers

downward

and

twist 7 hooks

and

then

remove

inte-

grator

iens.

hook

integrator

iens(iN)

Fig.5

stoppers

11

Opticat

unit

Disassemblies

DsassembEies

and

reptacement

procedures

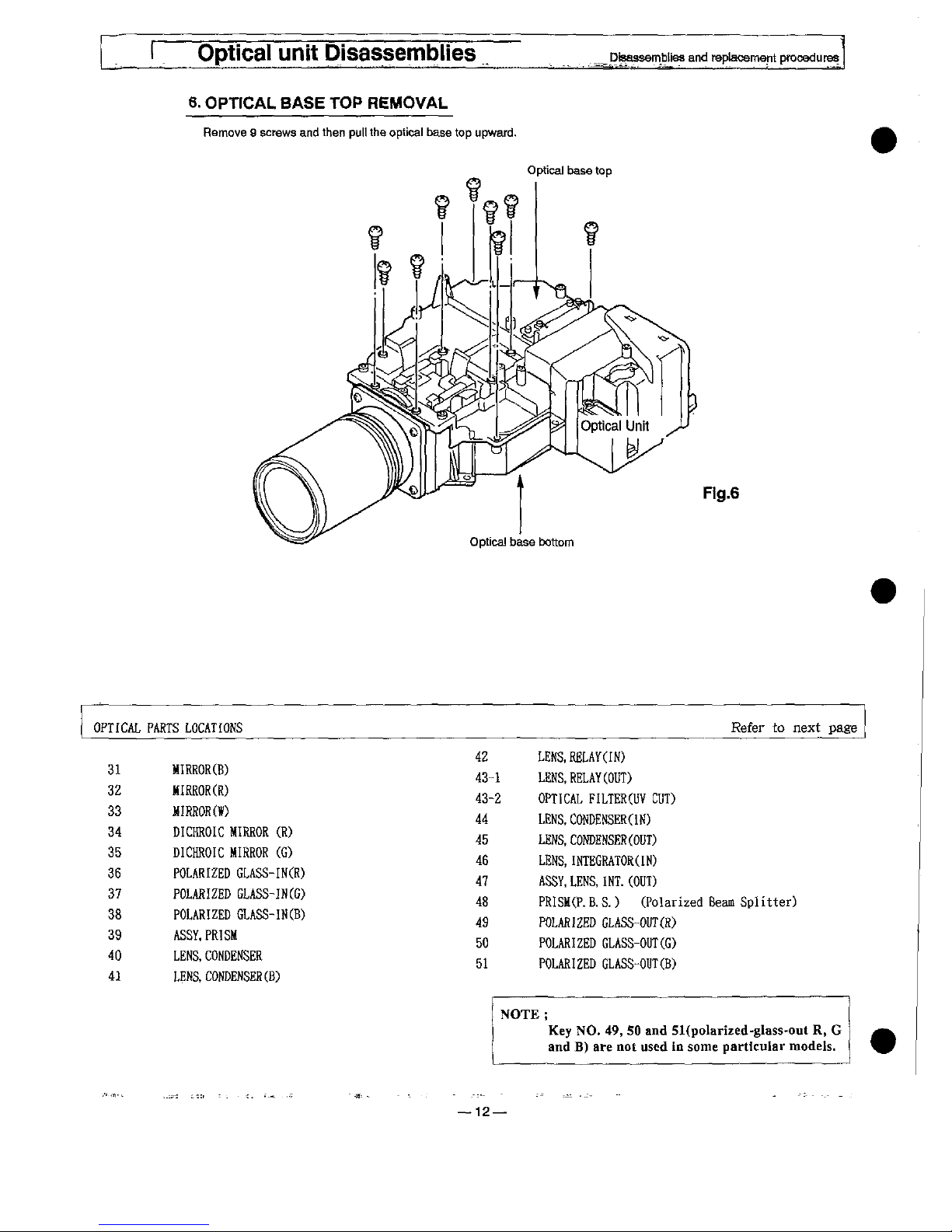

6.

OPTtCAL

BASE

TOP

REMOVAL

Remove 9 screws

and

then

pu!!

the

optica)

base

top

upward.

Optica)

base

top

Fig.6

OPrfCAL

31

32

33

34

35

36

37

38

39

40

41

PARTS

LOCATES

MIRROR(B)

MIRROR(R)

MIRROR(W)

DICHROIC

MIRROR

(R)

DICHROIC

MIRROR

(G)

POLARIZED

GLASS-IN(R)

POLARIZED

GLASS-IN(G)

POLARIZED

GLASS-IN(B)

ASSY.PRISM

LENS.CONDENSER

LEKS.CONDENSER(B)

42

43-1

43-2

44

45

46

47

48

49

50

51

Refer

to

next.

page

LE^.

RELAY(IN)

LENS.RELAY(OUT)

OPTICAL

FILTER(UV

CUT)

LENS.CONDENSER(IN)

LENS.CONDENSER(OUT)

LENS,INTEGRATOR(IN)

ASSY.LENS.INT.(OUT)

PRISM(P.B.S.)

(Polarized

Beam

Splitter)

POLARIZED

GLASS-OUT(R)

POLARIZED

GLASS-OUT(G)

POLARIZED

GLASS-OUT(B)

NOTE;

Key

NO.

49,

50

and

51(polarixed-g!ass-out

R,

G

and

B)

are

not

used

in

some

particular

modets.

12—

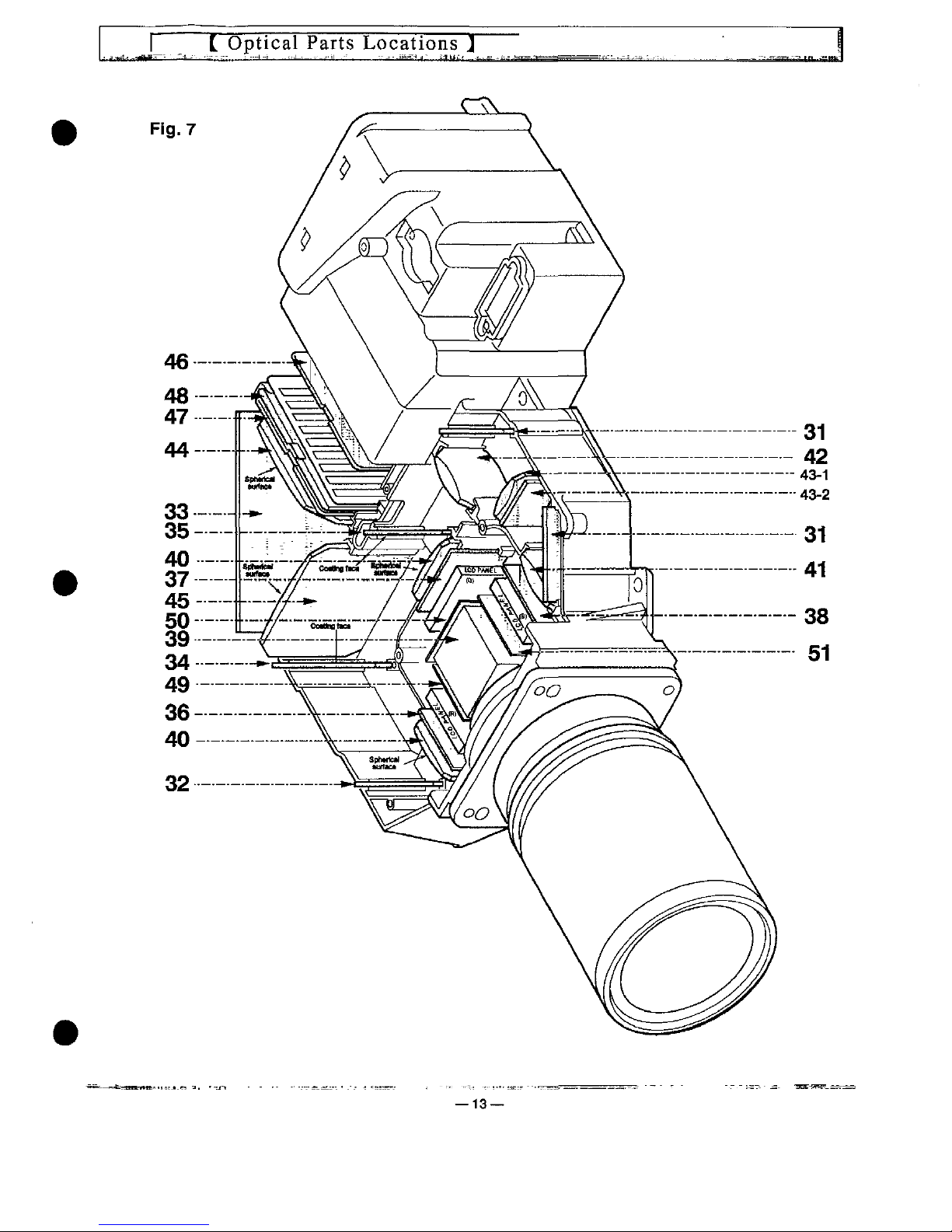

L

Optical

Parts

Locations

J

—13

Optical

unit

Disassembles

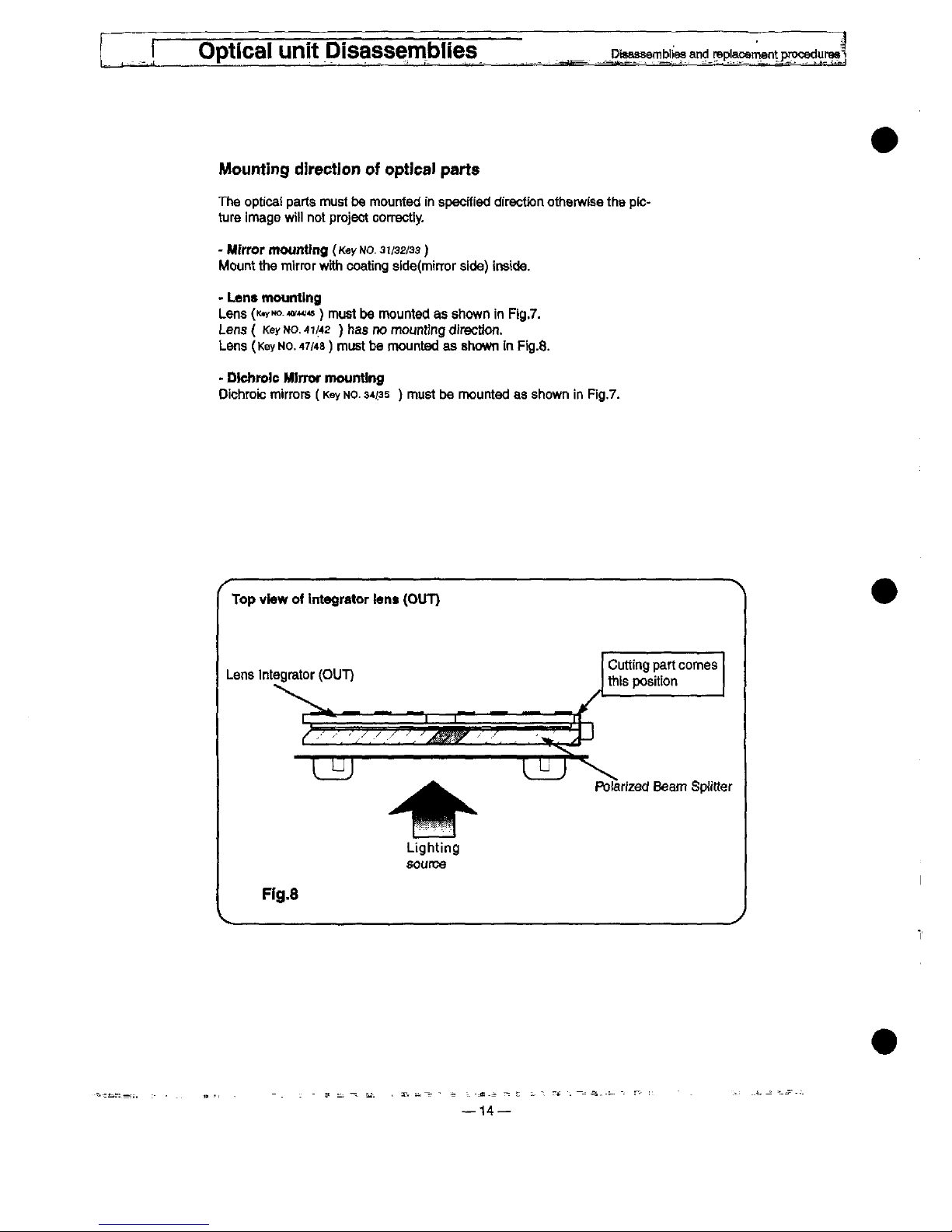

Mounting

direction

of

optical

parts

The

optica!

parts

must

be

mounted

in

specified

direction

otherwise

the

pic-

ture

image

wii)

not

project

correctty.

-

Mhror

mounttna

('<ey

No. 3 j/sz/ss)

Mount

the

mirror

wtth

coating

side(mtrror

side)

inside.

-

Lent

mounttng

Lens

('<^Mo.w^<s)

must

be

mounted

as

shown

in

Fig.7.

Lens(

Kef

Mo.-4^42

)

has

no

mounting

direction.

Lens

(Key

No.

47/49)

must

be

mounted

as

shown

in

Fig.8.

-

Dtchrotc

Mtnw

mounting

Dichrok:

mirrors

(Key

wo.

34^35

)

must

be

mounted

as

shown

in

Fig.7.

Top

view

of

integrator

tena

(OUT)

Lens

integrator

(OUT)

^

/

.^

.

^

Cutting

part

comes

this

position

Potarfzed

Beam

Spiftter

Lighting

source

Fig.8

14—

LCD

PANEL

REPLACEMENT

^s^

-^:

-

*-

Disassembfies

and

roptacemefTt

procadures

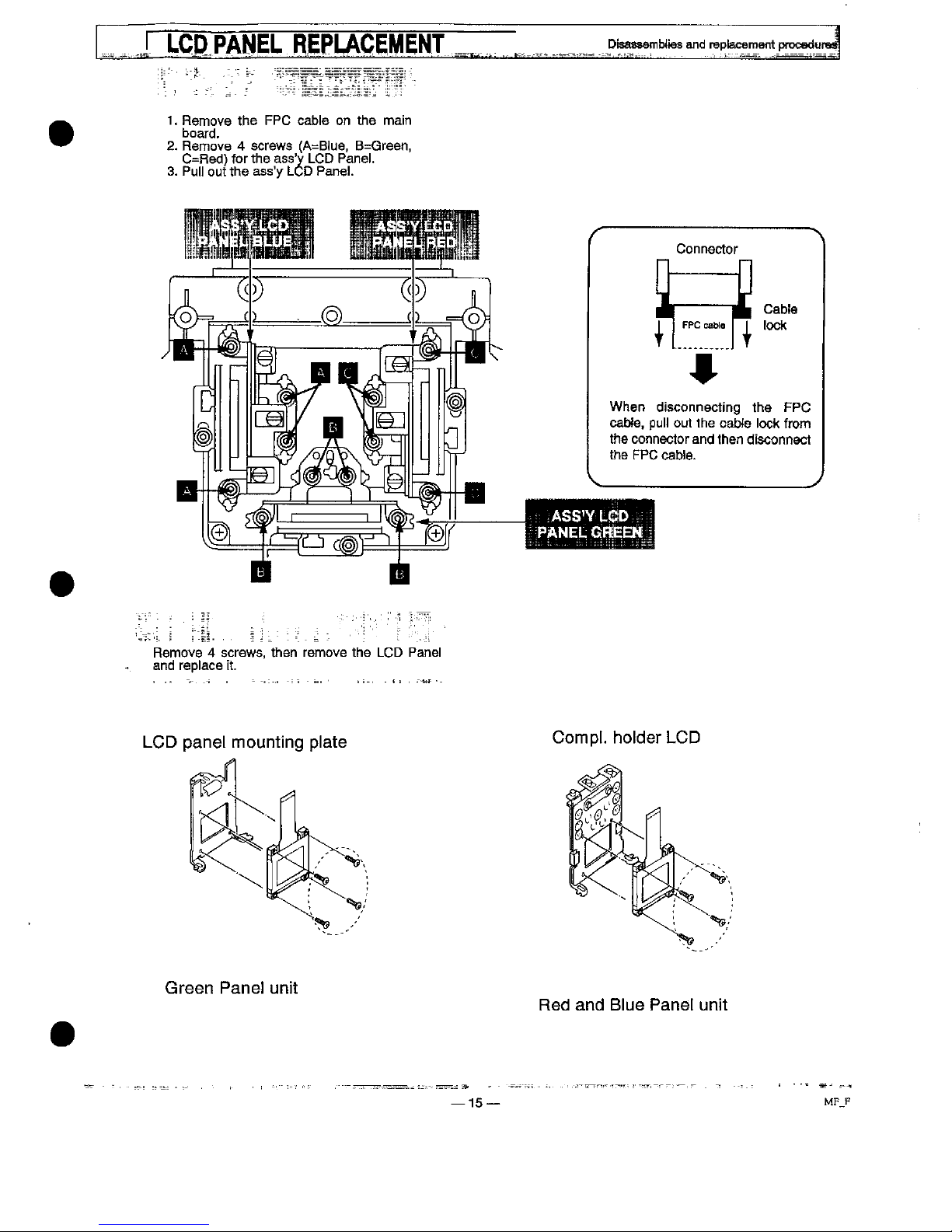

1.

Remove

the

FPC

cab)e

on

the

main

board.

2.

Remove 4 screws

(A=B)ue,

B=Green,

C=Red)

for

the

ass'y

LCD

Pane).

3.

Pu)i

out

the

ass'y

LCD

Pane!.

Remove 4 screws,

then

remove

the

LCD

Pane)

and

rep)ace

it.

LCD

pane)

mounting

p!ate

^

Green

Pane)

unit

CompL

hotder

LCD

Red

and

B)ue

Pane!

unit

15

MF

F

Lamp

assly

reRJacement

tf

the

tamp

fa!)s

to

come

on

and

the

tamp

reptacement

indicator

on

the

projector

tight

)s

orange,

you

must

rep)ace

the

tamp.

^

For

continued

safety,

rep!ace

with a tamp

assembly

of

the

same

type.

part

NO.

6102822755

^

Aiiow

the

projector

to

coo!

for

at

!east

45

minutes

before

you

open

the

tamp

cover.

The

inside

of

the

projector

can

become

very

hot.

^

Do

not

drop

the

iamp

module

or

touch

the

g!ass

buib!

The

giass

can

shatter

and

cause

injury.

<t

FoJ!ow

these

steps

to

roptace

the

iampassombtv.

1.

Turn

off

the

projector

and

a!)ow

the

projector

to

coo)

thoroughty.

2.

Disconnect

the

AC

cord

from

the

projector.

3.

Remove

screw

with a screwdriver

and

remove

the

tamp

cover.

4.

Remove 2 screws

with a screwdriver

and

pu)!

out

the

[amp

assembly

by

grasping

the

handle.

5.

Roptace

the

)amp

assemb)y-

6-

Tighten 3 screws

to

secure

the

)amp

cover

to

the

tamp

assemb)y.

7.

Connect

the

detachable

AC

cord

to

the

projector.

8.

Reset

the

)amp

rep!acement

monitor

timer.

(Refer

to

next

page.)

Turn

off.

Remove

AC

cord

and

wait

46

minutea

before

open

this

tamp

cover.

^

Refer

owner's

manua!

for

reptacing

the

tamp.

Reptace

with

same

type

tamp.

Etsindra

)'apparei).

Entew

te

Cordon

secteuf

et

attandfe

46

mtrnrtes

avant

^

d'ouvrir

ce

couvercte.

Se

raportBr

au

moda

d'amptoi

pour

ramptacer

[a

)ampe.

Remp)acar

ta

)ampe

par

un

mode)

identiqua.

Schahen

Sie

den

Projektof

aua.

z!ehen

Sie

das

Stromkabe!

aus

dem

Projektor

^

und

warten

Sio

46

Minuten.

bevof

Sfe

den

Projektor

offnen.

LeMn

Sie

im

Manuat

im

Kapite!

'Lampenwechsef'

die

Detaifs

nach.

Benutxen

Sie

nur

eine

offizt9)[e

Ersamampe

des

gteichon

typs-

^

Apague

e!

sparato.

Deeconecte

et

caMa

da

fad y a^pera

45

minutos

antes

t

de

abrir

)a

tapa.

Consutia

e!

manuat

de

inairuccioDaa

para

cambiof

ta

)ampara.

Csmbie

ta

)amparH

por

otra

de)

nnsfno

tipo.

Stang

av

projektom.

Dra

ur

Kontatcten

oeh

vanta

46

minutar

innan

Ni

oppnar

^skydoet.

VthanviMft^instruk^on^bokeninnan

Mbyterfampa.

Anvand

sammatypaviampa.

Shik

for

projaktoran.

Fjam

natfedningen

frB

stikkontaktan

og

vent

45

fntn

tfar

kabinettet

abnes-

Se i brugsanvisningen,

f0f

tampen

skiftes.

Brngsamme

type)ampe.

0

Lamp

Assembty

Lamp

cover

WARN)NG

ALLOW

TO

COOL

BEFORE

ATTEMPTING

TO

CHANGE

THE

LAMP.

USE

ONLY

REPLACEMENT

LAMP

PART

N0.6102822755

—16—

Lamp

ass'y

replacement

^

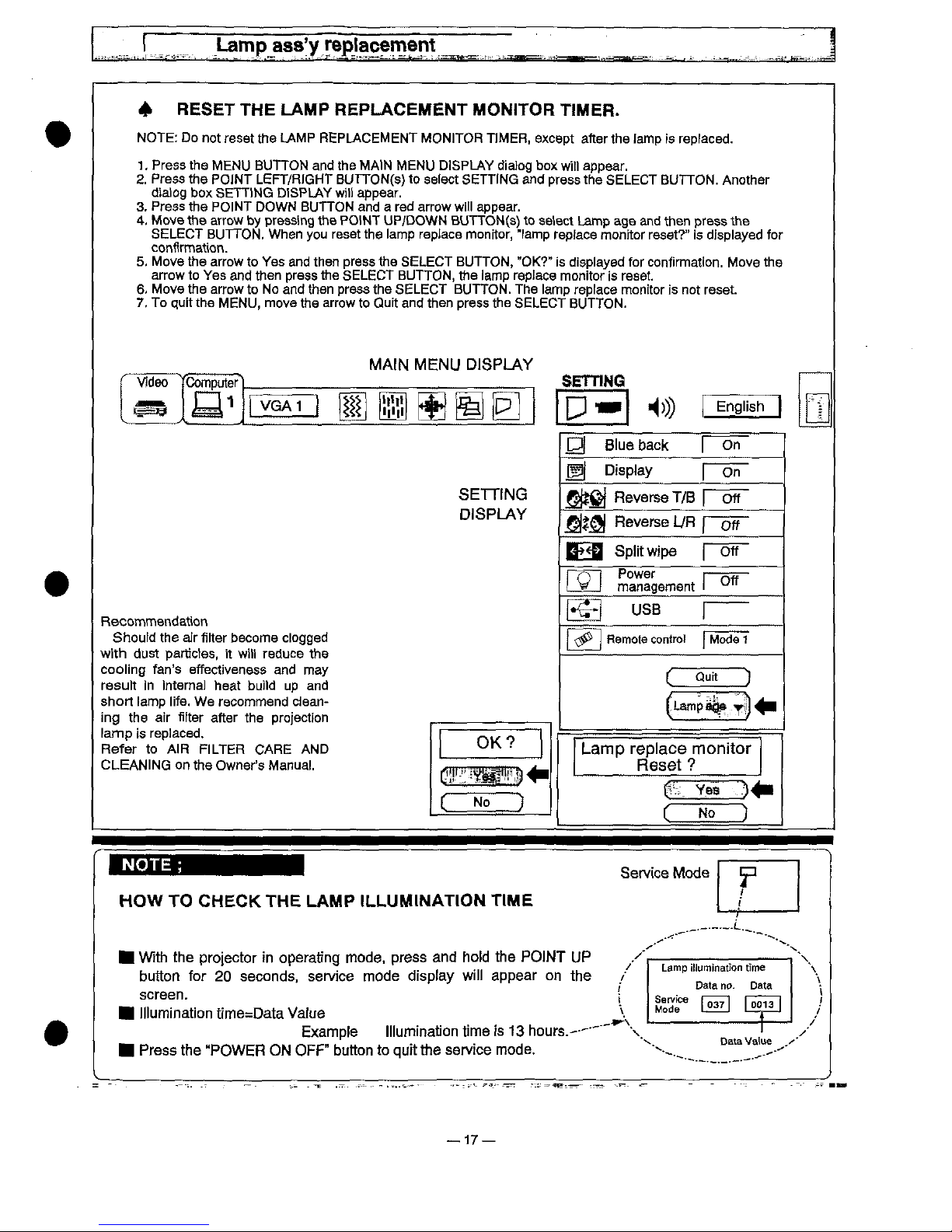

RESET

THE

LAMP

REPLACEMENT

MON)TOR

T!MER.

NOTE:

Do

not

reset

the

LAMP

REPLACEMENT

MONITOR

T)MER,

except

after

the

tamp

is

replaced.

1.

Press

the

MENU

BUTTON

and

the

MA)N

MENU

DISPLAY

dia)og

box

wit)

appear.

2.

Press

the

POINT

LEFT/RiGHT

BUTTON(s)

to

select

SETT)NG

and

press

the

SELECT

BUTTON.

Another

alaiog

box

SETTtNG

DiSPLAY

witi

appear.

3.

Press

the

PO)NT

DOWN

BUTTON

and a red

arrow

wi!i

appear.

4.

Move

the

arrow

by

pressing

the

FONT

UP/DOWN

BUTTON(s)

to

setect

Lamp

age

and

then

press

the

SELECT

BUTTON.

When

you

reset

the

tamp

roptace

monitor,

"lamp

repface

monitor

reset?"

is

displayed

for

confirmation.

5.

Move

the

arrow

to

Yes

and

then

press

the

SELECT

BUTTON,

"OK?"

is

displayed

for

confirmation.

Move

the

arrow

to

Yes

and

then

press

the

SELECT

BUTTON,

the

lamp

repface

monitor

is

reset.

6.

Move

the

arrow

to

No

and

then

press

the

SELECT

BUTTON.

The

iamp

repface

monitor

is

not

reset.

7.

To

quit

the

MENU,

move

the

arrow

to

Quit

and

then

press

the

SELECT

BUTTON.

MAtN

MENU

D)SPLAY

5ETDNG

English

[Dj

B)ue

back

Display

SETTING

DISPLAY

Reverse

T/B

j^<^

Reverse

L/R

p-ofT

B^

Split

wipe

Power

management

Recommendation

Should

the

aJr

fitter

become

dogged

with

dust

partictes.

it

wiH

reduce

the

cooiing

fan's

effectiveness

and

may

resu)t

in

internal

heat

bui)d

up

and

short

tamp

iife.

We

recommend

dean-

ing

the

air

fitter

after

the

projection

tamp

is

repiaced.

Refer

to

AtR

FILTER

CARE

AND

CLEANING

on

the

Owner's

Manual.

OK?

L'^-

i

^

^^.^^

No

)

US8

Hemote

contro!

Mode

1

(Quit

)

Lamp

rep!ace

monitor

Reset

?

No

NOTE:

HOW

TO

CHECK

THE

LAMP

)LLUMtNATtON

TtME

F

t

With

the

protector

in

operating

mode.

press

and

hotd

the

POINT

UP

button

for

20

seconds,

service

mode

disptay

wiii

appear

on

the

screen.

iiiumination

time=Data

Vatue

Exampte

)iiumination

time

is

13

hours.--"

Press

the

"POWER

ON

OFF"

button

to

quit

the

service

mode.

/

Lamp

itfumination

time

\

;'

Data

no.

Data

',

^r

u^]

u^)

^^

t————-^-j

/

Data

Vatue

.^'

17—

SAFETY

)NSTRUCT)ONS

^

SAFETY

PRECAUTIONS]

WARN)NG:

The

chassis

of

this

projector

is

isolated

(COLD)

from

AC

)'ne

by

using

the

converter

transformer.

Primary

side

of

the

converter

transformer

and

tamp

power

supply

unit

circuit

is

connected

to

the

AC

line

and

it

is

hot,

which

hot

circuit

is

identified

with

the

iine

in

the

schematic

diagram.

For

continued

product

safety

and

protection

of

personne!

injury,

servicing

shouid

be

made

with

quati-

fied

personnel.

The

foitowing

precautions

must

be

observed:

1.

An

isolation

transformer

shouid

be

connected

in

the

power

iine

between

the

projector

and

the

AC

iine

before

any

service

is

performed

on

the

projector.

2.

Compty

with

a!i

caution

and

safety-

rotated

notes

provided

on

the

cabinet

back,

cabinet

bottom,

inside

the

cabinet

or

on

the

chassis.

3.

When

replacing a chassis

in

the

cabinet,

always

be

certain

that

aii

the

protective

devices

are

instated

property,

such

as

control

knobs,

adjustment

covers

or

shiejds

and

barriers.

DO

NOT

OPERATE

TH)S

PROJECTOR

WtTH-

OUT

THE

PROTECT!VE

SHIELD

)N

POSmON

AND

PROPERLY

SECURED.

4.

Before

replacing

the

cabinet

cover,

thoroughiy

inspect

the

inside

of

the

cabinet

to

see

that

no

stray

parts

or

toots

have

been

iett

inside.

Before

returning

any

projector

to

the

customer,

the

service

personnel

must

perform

the

following

safety

checks

and

be

sure

that

it

is

compieteiy

safe

to

operate

without

danger

of

etectricai

shock.

[PRODUCT

SAFETY

NOT)CE

]

Product

safety

should

be

considered

when a component

replacement

is

made

in

any

area

of

the

projector.

Components

indicated

by a mark

(A)

in

the

parts

iist

and

the

schematic

diagram

designate

components

in

which

safety

can

be

of

speciai

significance,

it

is,

therefore,

particularly

recommended

that

the

replace-

ment

of

these

parts

must

be

made

by

exactly

the

same

parts.

t

SERVICE

PERSONNEL

WARNING

]

Eye

damage

may

resutt

from

direct)y

viewing

the

iight

produced

by

the

Lamp

used

in

this

equipment.

Always

turn

off

Lamp

before

opening

cover.

uttraviotet

radiation

eye

protection

required

during

this

servicing.

Never

turn

the

power

on

without

the

iamp

to

avoid

etectrfc-

shock

or

damage

of

the

devices

since

the

stabilizer

generates

high

voitages(

=

25kV)

at

its

start.

Since

the

iamp

is

very

high

temperature

during

units

operation.

Replacement

of

the

!amp

should

be

done

at

ioast

one

hour

after

the

power

has

been

turned

off,

to

atiow

the

lamp

coo)

off.

r

DO

NOT

ATTEMPT

TO

SERV!CiNG

THE

REMOTE

CONTROL

UNtT.

]

Laser

Beam

may

be

[eaked

out

when

in

disassemble

the

Unit.

As

the

Laser

Beam

used

in

this

Remote

control

unit

is

harmful

to

the

eyes.

j

CAUTtON

t

'.!/

LASER

RADfATION-

-^^

00

NOT

STARE

'MTO

BEAM

^^

'

'

MAX.

OUTPUT:

tmW

WAVE

tBMQTH:

MOt

BOnm

CLASS H LASER

PRODUCT

ptfttfMOJO

DO

MOT

STARE

!MTO

BEAM

CLASS 2 LASER

PRODUCT

LASERSTRAHUMQ

MCHT

)M

DEM

STRAHL

6UCKEM

LASER

KLASSE

2

L—V&tt?7^2

L.--'^.

)i-^%f^^^t<[t.^^

)ECeoe2E-t.Am.t

)9B7

MAX.

OUTPUT^A^JJ):

'mW

WAVE

LEMQTmKS

t:

6SO ± 20nm

18—

Protections

This

projector

is

equipped

with

the

following

circuit

protections

to

operate

in

safety,

if

the

abnormatity

occurs

inside

the

projector,

it

wiii

automatical

turn

off

by

operating

one

of

the

foHowing

protection

circuits.

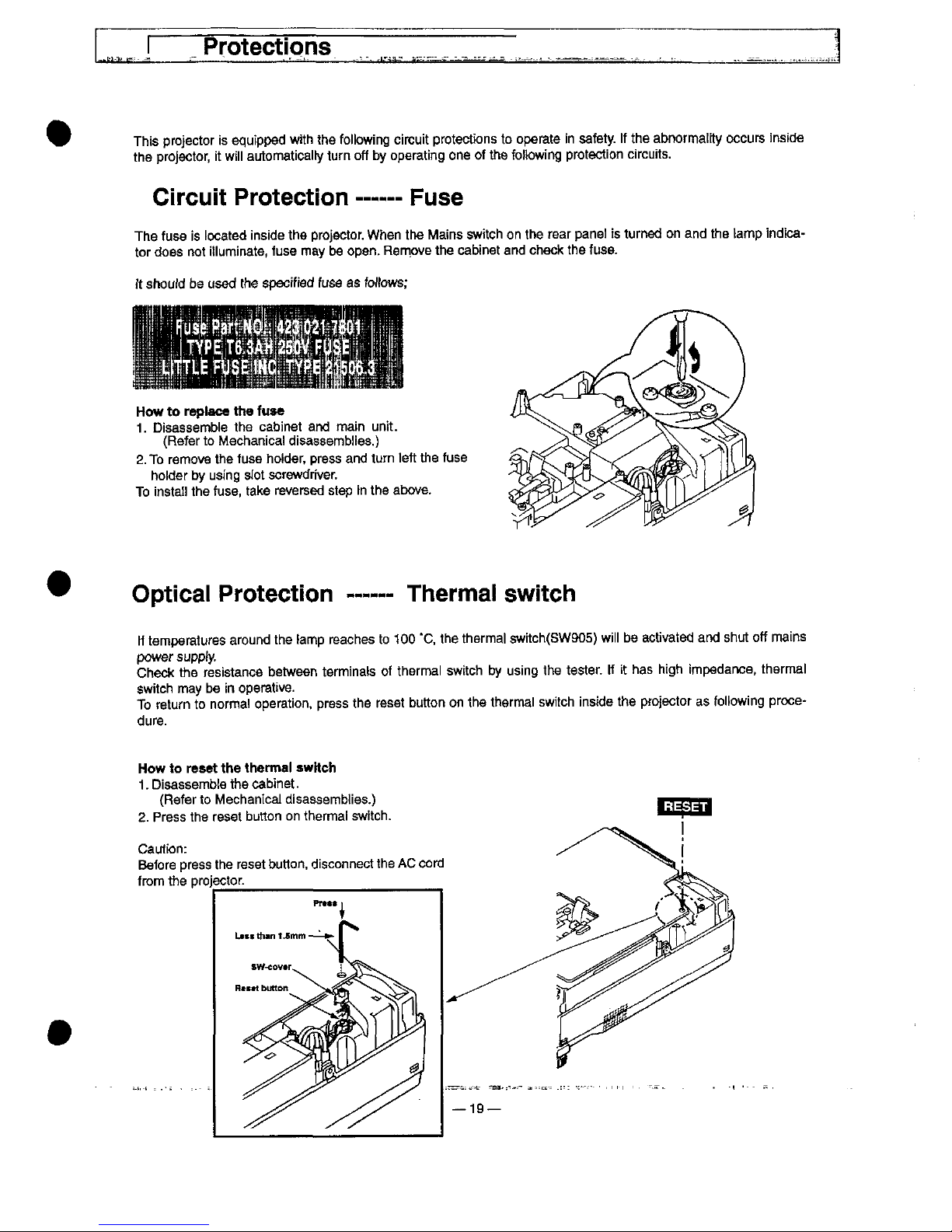

Circuit

Protection

Fuse

The

fuse

is

located

inside

the

projector.

When

the

Mains

switch

on

the

rear

pane)

is

turned

on

and

the

tamp

indica-

tor

does

not

itiuminate.

fuse

may

be

open.

Remove

the

cabinet

and

check

the

fuse.

it

shouid

be

used

the

specified

fuse

as

foftows;

How

to

reptace

the

fuae

1.

Disassemble

the

cabinet

and

main

unit.

(Refer

to

Mechanica)

disassembles.)

2.

To

remove

the

fuse

hotder,

press

and

turn

ieft

the

fuse

hoider

by

using

slot

screwdriver.

To

insta!!

the

fuse.

take

reversed

step

in

the

above.

Optica)

Protection

Thermai

switch

if

temperatures

around

the

tamp

reaches

to

100

'C.

the

thermal

switch(SW905)

wiii

be

activated

and

shut

off

mains

power

suppfy.

Check

the

resistance

between

terminais

of

thermal

switch

by

using

the

tester,

if

it

has

high

impedance,

thermal

switch

may

be

in

operative.

To

return

to

norma)

operation,

press

the

reset

button

on

the

thermal

switch

inside

the

projector

as

following

proce-

dure.

How

to

reset

the

therma)

awttch

1.

Disassembte

the

cabinet.

(Refer

to

Mechanical

disassembles.)

2.

Press

the

reset

button

on

thermal

switch.

Caution;

Before

press

the

reset

button,

disconnect

the

AC

cord

from

the

projector_____

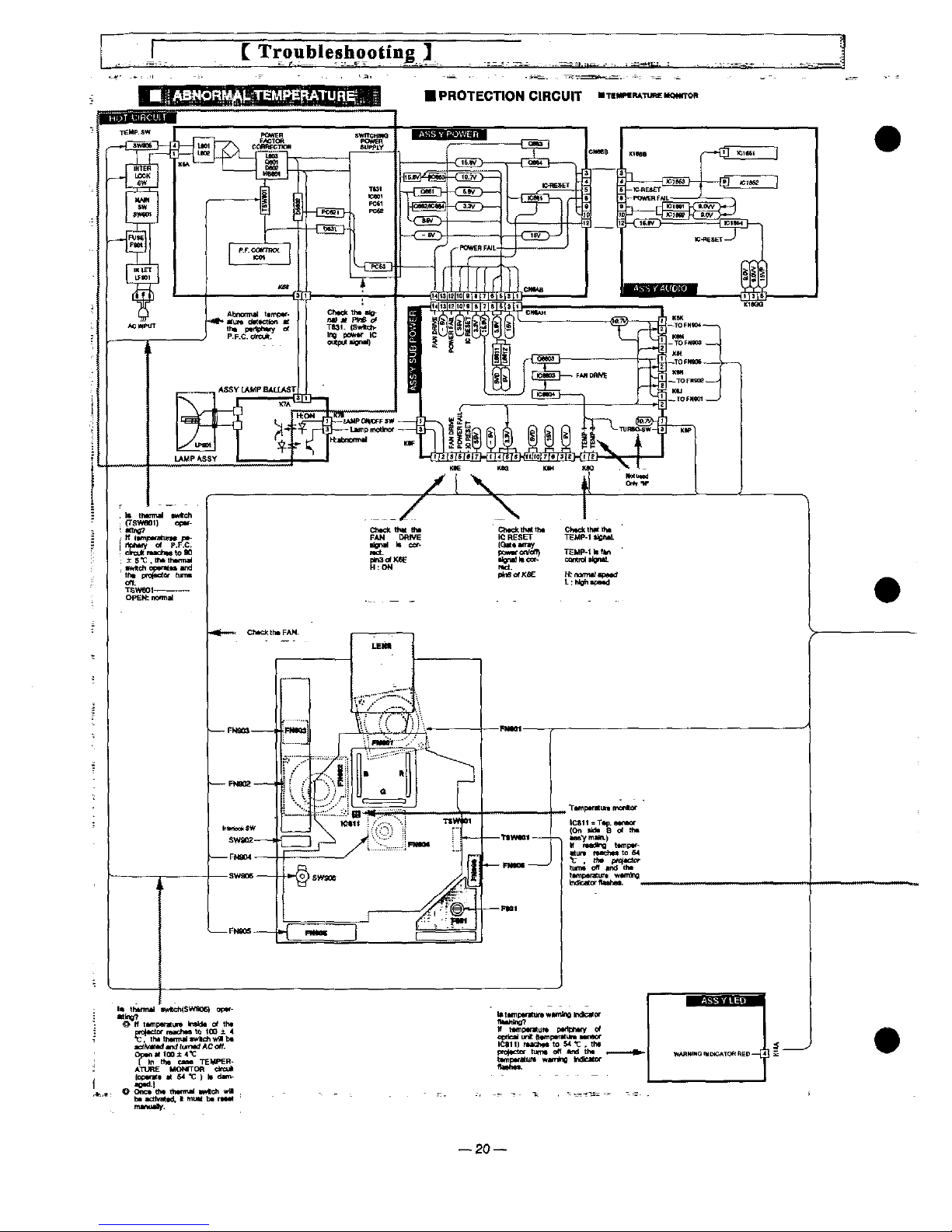

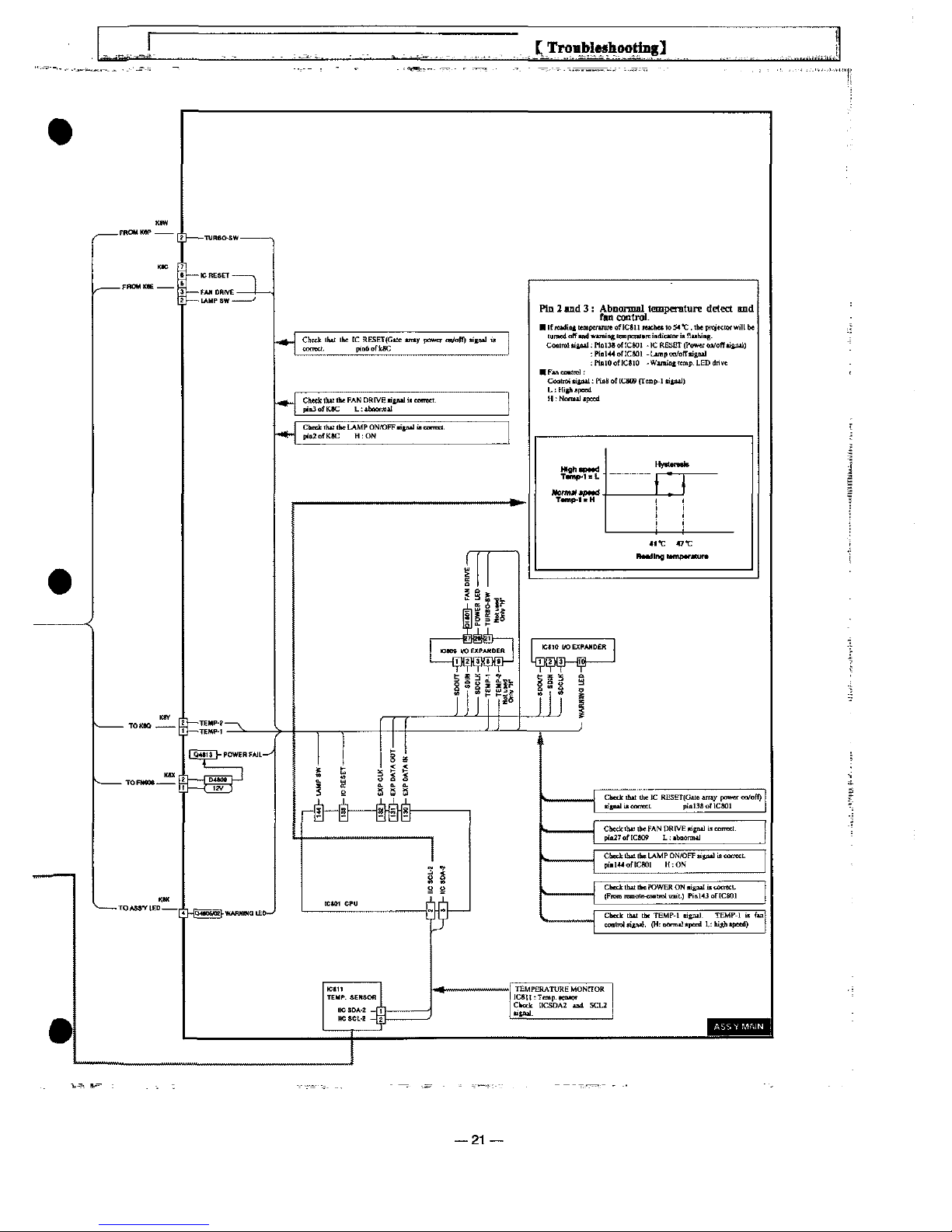

______

*C,

thtthenn*i<w!M^wMb*

*ct^)Md

^)d

funttd

AC

off.

Optn*t)00±<^

[in

tht

MM

TEMPCR-

ATUREMOMTORdfcu)'

t«xt^t « M

'C ) h

d^^

t0<d.j

One*

tM

ttxnntf

Mttc^

wO

bt

tOhmttd. f muM

b*

m*t

21

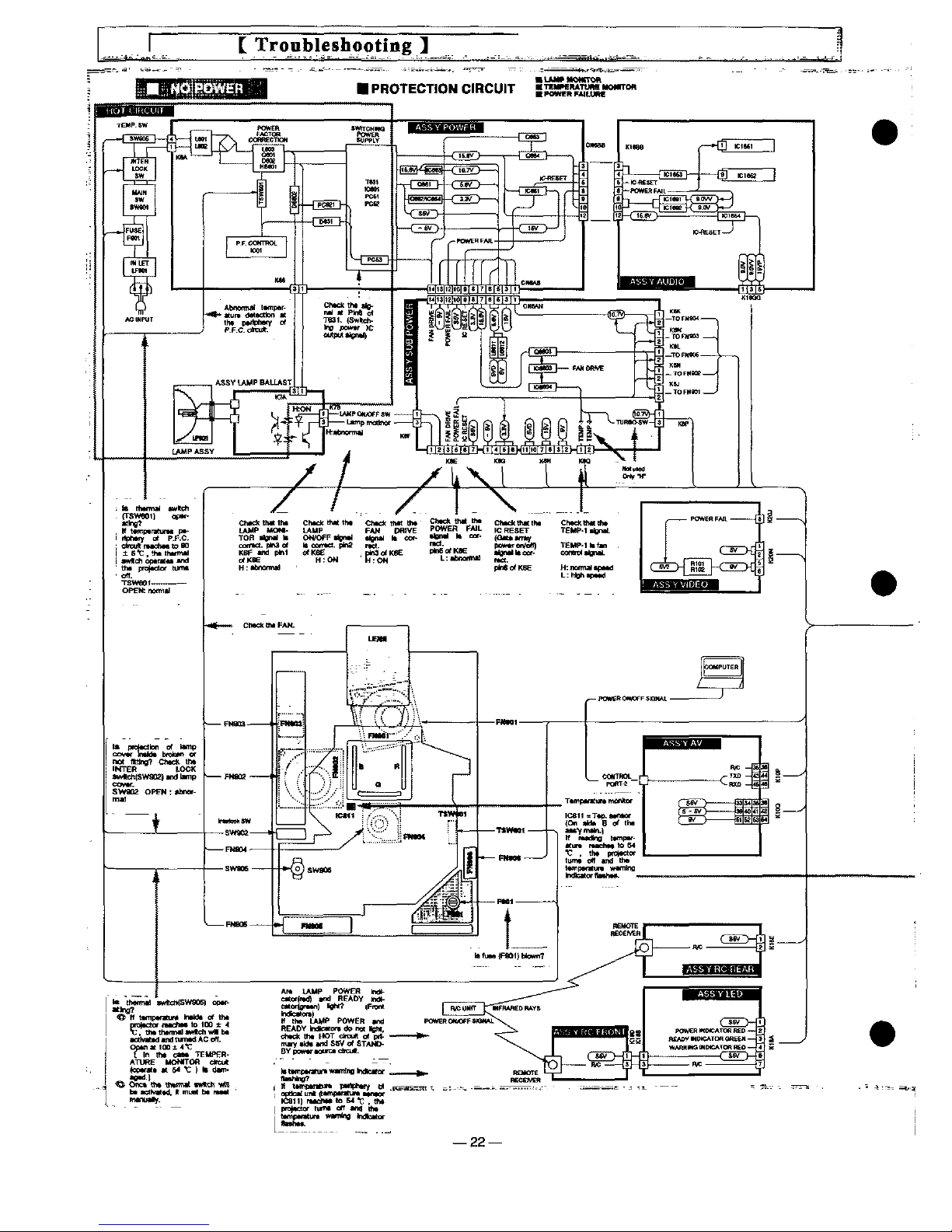

--22—

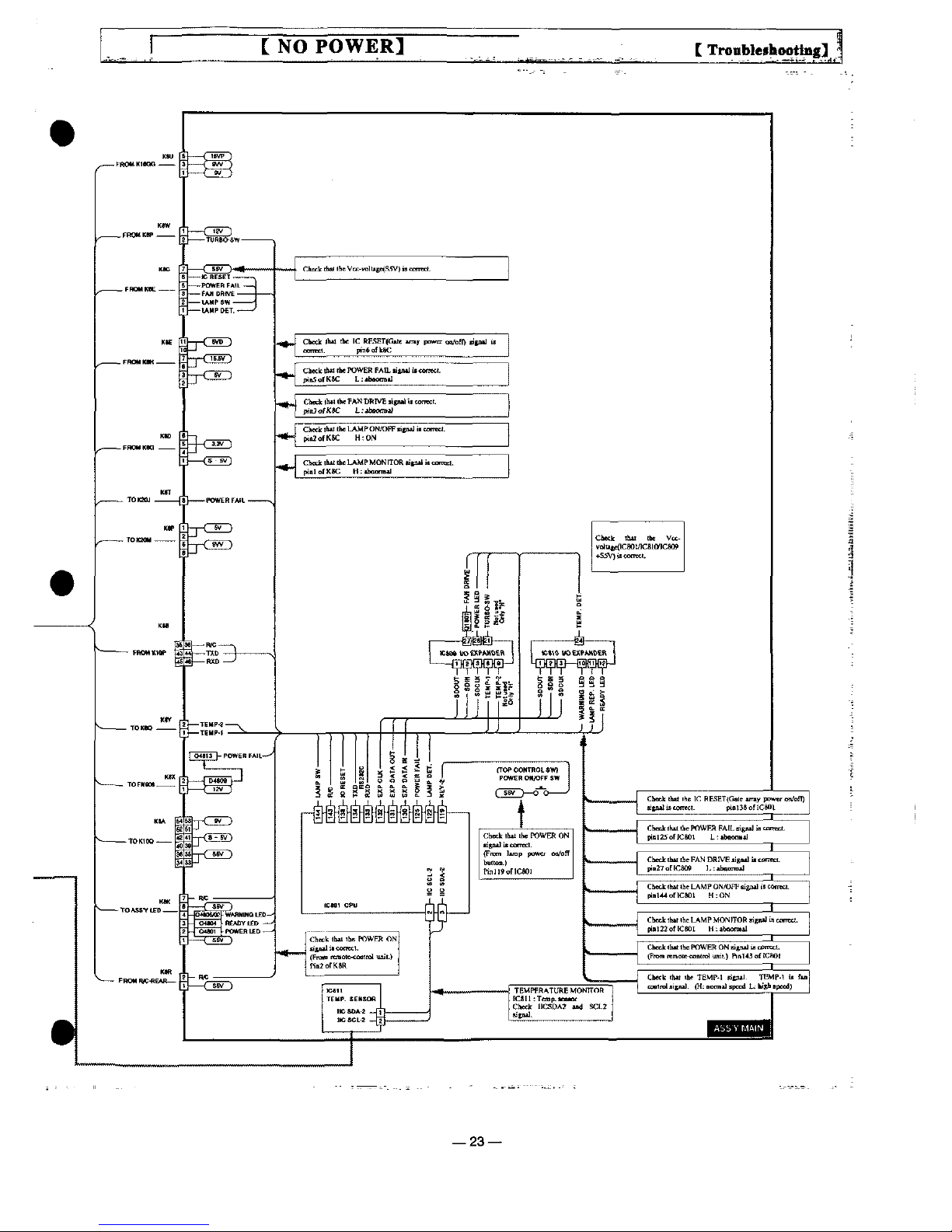

^

NO

POWER]

--23—

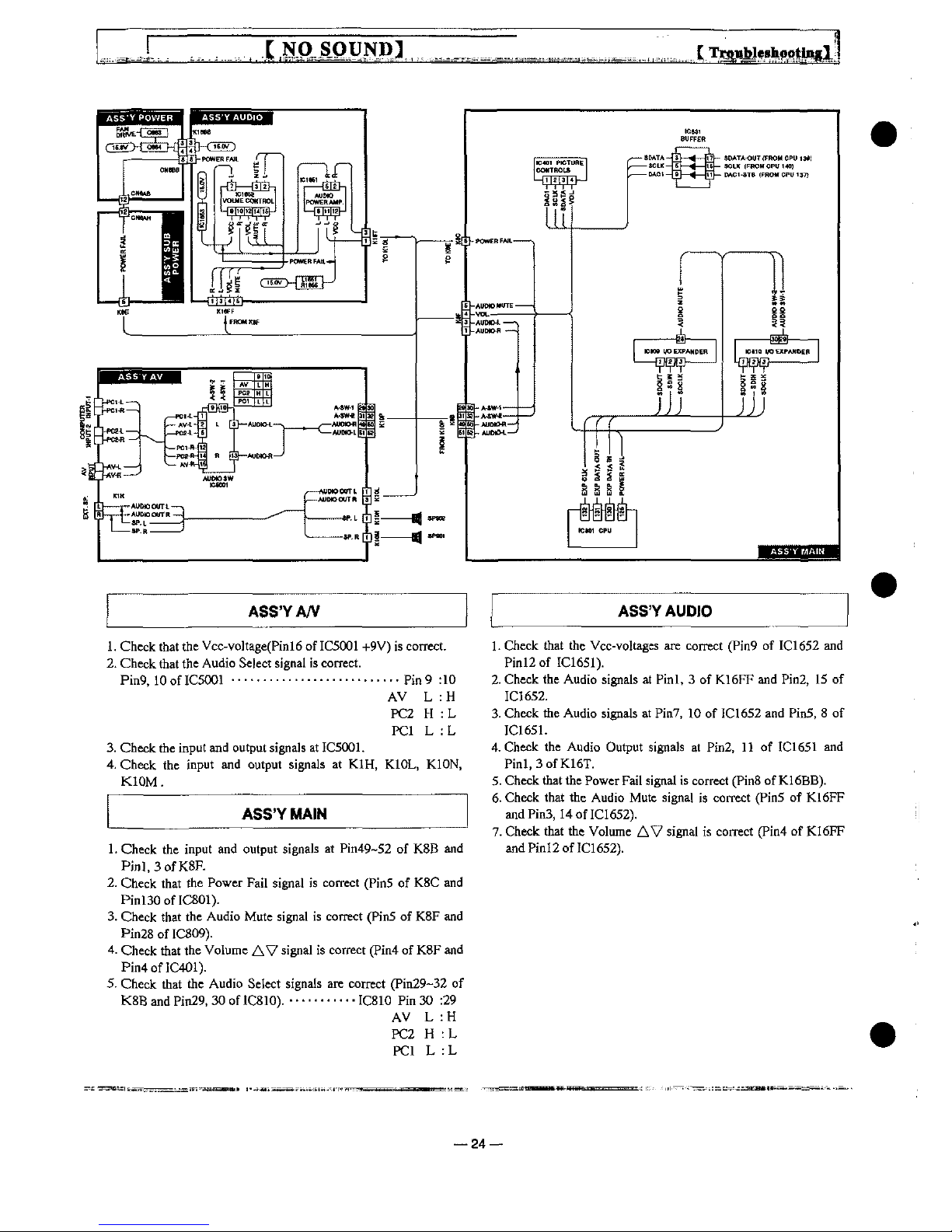

[NO

SOUND]

ASS'YA/V

ASS'YAUDiO

1.

Check

that

the

Vcc-vo)tage(Pinl6

of

IC5001

+9V)

is

correct.

2.

Check

that

the

Audio

Seject

signat

is

correct.

Pin9,10

of

IC5001

...........................

pin 9 :10

AV L :H

PC2 H :L

PC1 L :L

3.

Check

the

input

and

output

signals

at

IC5001.

4.

Check

the

input

and

output

signats

at

K1H,

K.10L,

K10N.

K10M.

ASS'YMAtN

1.

Check

the

input

and

output

signals

at

Pin49-52

of

K8B

and

PinI.3ofK8R

2.

Check

that

the

Power

Fail

signal

is

correct

(Pin5

of

K8C

and

Pinl30

of

IC801).

3.

Check

that

the

Audio

Mute

signal

is

correct

(Pin5

of

K8F

and

Pin28ofIC809).

4.

Cheek

that

the

Volume

AV

signal

is

correct

(Pin4

of

K8F

and

Pin4ofIC401).

5.

Check

that

the

Audio

Setect

signals

are

correct

(Pin29-32

of

K8B

and

Pin29,

30

ofICSlO).

...........

IC810

Pin

30

:29

AV L :H

PC2 H :L

PC1 L :L

1.

Check

that

the

Vcc-voltages

are

correct

(Pin9

of

IC1652

and

Pinl2

of

IC1651).

2.

Check

the

Audio

signals

at

Pinl. 3 of

K16FF

and

Pin2.

15

of

IC1652.

3.

Check

the

Audio

signals

at

Pin7,

10

of

IC1652

and

Pin5. 8 of

IC1651.

4.

Check

the

Audio

Output

signals

at

Pin2,

11

of

IC1651

and

Pinl,3ofK16T.

5.

Check

that

the

Power

Fail

signat

is

correct

(Pin8

of

K16BB).

6.

Check

that

the

Audio

Mute

signal

is

correct

(Pin5

of

K16FF

and

Pin3,14

of

IC1652).

7.

Check

that

the

Volume

AV

signal

is

correct

(Pin4

of

K16FF

and

Pinl2

of

IC1652).

24

Loading...

Loading...