Sanyo PLC-XP18N,PLC-XP18E,PLC-XP18B Service Manual

SERViCE

MANUAL

Mu^-med!a

Projector

S4^o

F/^

MO.

MODEL

NO.

PLC-XP18N

(U.S.A.

.Canada)

PLC-XP18E

(Europe,

Asia,

Africa,

M.E.)

PLC-XP18B

(U.K.)

ORIGINAL

VERSION

Chassis

No.

MH6-XP18NOO

PLC-XP18EOO

PLC-XP18BOO

NOTE:Match

the

Chassis

No.

on

the

unit's

back

cover

with

the

Chassis

No.

in

the

Service

Manuaf.

tf

the

Ortgfnai

Version

Service

Manua!

Chassis

No.

does

not

match

the

unit's,

additional

Service

Literature

is

required.

You

must

refer

to

"Notices"

to

the

Original

Service

Manual

prior

to

servicing

the

unit.

Give

complete

"Chassis

NO."

for

parts

order

or

servicing,

ft

!s

shown

on

the

rating

sheet

on

the

cabinet

of

the

Projector.

Specifications

Disassemblies

Mechanica

Optical

urn

LCD

pane)

Assy

tamp

Safety

Instruc

Circuit

Protec

Troubleshooti

Waveforms

-

Alignment

Prc

Service

ad

Electrical

a

Focus

adju.

Convcrgen

Product

Code

CONTENTS

and

Replacement

Procedures

disassemblies

--....-.-...--

t

disassemblies

-.........-.--

replacement

.........

replacement

..----.....-..--

ions

""..-..

ions............--.-....."

ng

........................

ustments

.......-..--.

djustments

.."--......-""

stments

--.-..""........"

ce

adjustment

."--......."

1

12207740

:

PLC-XP18N

1

12207840

:

PLC-XP18E

1

12207842

:

PLC-XP18P

................

^

.............

3^17

.............

9^14

...............

15

............^6-^7

...............

^g

...............

19

............

20-27

............

30-43

............

31"-32

...............

^o

MH6AA

PH6AA

PH6CA

mtegratoT

lens

adjustment

---..-.----.......

Relay

lens

adjustment

-..----......""..---

Polarized

glass

adjustment

.--.....--.-..---.

CPU

input/output

port

functions

---...-.........

Maintenance

- - -

---..-..--........."----....-

Notes

on

schematic

diagram

........"---.....-

Parts

-List

..................................

Cabinet,

Chassis

and

Optical

patts

!ist...----..

Electrical

parts

list

...".......----..---....

Parts

location

and

PWB

pattern

diagrams

---....-

Block

diagram

and

Low

power

distribution " "

- -

-

Schematic

diagrams

..........................

REFERENCE

----------

41

..........

43

.......

48-49

.......

5^51

.......

52-79

.......

59-79

..........B1

WO.SM5110206

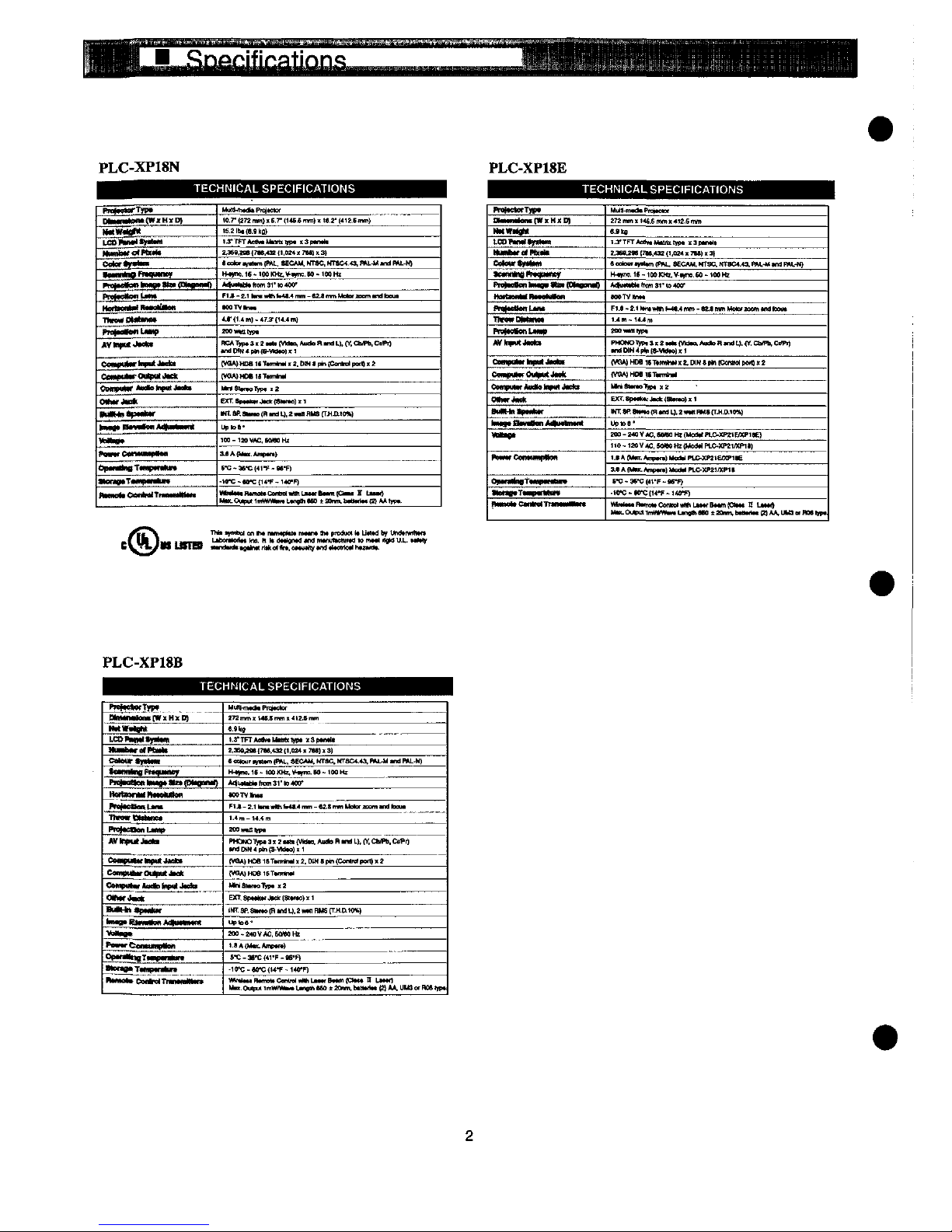

PLC-XP18N

PLC-XP18E

TECHN)CAL

SPEC)F)CAT)ONS

TECHN)CAL

SPEC!F)CAT!ONS

PmtteMfTyp*

NM—tM^tW'MtD)

tMWtt^t

LO)^'*")MtM'

MM^Xfc<M)Mt<

C«)u<)t)"MM

tut)t)t)eR^^*f

^Mtte^Mtt^Btt'fDhtM*))

f^^tan'J^'

Hoftt.XtM

mottttMett

Tttfo^Mtttme*

Pt^at^LtXt^

jtV)nt^tJ**t

CMXtMtM-'nptttJtdtt

Cetxpt^ftMpM^A

CMnp^Me'nf^.'-*'

0)htf*tatt

XXttMatpt-tM'

tnx.t*

HH^ttfto

jM)tt.t«.!)t

^Mt^'

t^)ttC«titM))t«M

Op-^wTtMf^tXM

^tefOtttTttf'HtM

n—ofCemMTuMmM't'

MuM^ttttPn^eMt

'a.7't:7tnm)'E.7'(t*6.6mm)tte.:'f<'!.Emm)

'6.:^tn«.9k^

'^'TtTAettMMtMtM)*

!t3))tn*H

MM^e(7M^Mt'.OM'7M)t3}

t<!o)o't^ttmjPAL.MC*M.MTaC.MTMM.O.)'^L-MtndML-N)

^m<.

16 - 'M

KH^^t^t:. M -

'<M

H!

*t'^Ntfem31')o<M'

F'^-^.Htn.wthh-M.4nm-M.t'm'MofccmMttoem

tMT\t^t

4.t-(t.^)-47^<14.4m)

MOwMttyp.

aC*^pt3.:ttt.(VMt^Autft.atnau.(^.ChM).Ct^)

[Va*)HDattTtm'n*)'a.mmf*'(OonMpo[a'!'

(VOA)MOt'eT*m*^

MntNt^oT^p.

j.t

Exr.atM-^jM'fa^*ti)ti

'MT.MSMm)(R-mj.2tMt)RMSfT^mo%)

Up

tea'

IM-1MWC.MMH.

MAft^.A^f.)

t-C^-C(4t-F-M-F)

-'<^-M-C{K'F-t<C'F)

i^^^^L^^^X^^

t^)*etefT)^

D)t)MtXfon*[W]tH^D)

MtW*^t

t.eo^ttmtfmttn

HMXttfefPOMX

CetCM't^ffM

OMM)t<t)t^()Mney

flatten

)'H<N*«MfC<«Ban^

Mat^MttttM^aMfon

f^tt«M)^f

ThMwDtttMM

Pt^teWenL'ttxt)

^)^J^.

OMttpaMftntM

*)(*);

CemfHt^OtttMtJtttft

C<Mpt)t*rMe)^Jt<<(t

0)h^*«*

MHxtpt-Mr

)-^n-^-.*<)""m"<

<Mt^.

MM^CeM<)Mt^M

Op'!t)'^T*<MMMtHt*

tten)BtTto^n)H«

it^^.CMMT......^

.

MuM-nttttt^t^M

272

mm < '<t.6

mm < 412-6

mm

M^

t.yTFTAetttf^MtM)*

*3fM^*

2.9M.Met7W.<3!(t.aM'7M)!'^

tcoUxft^ttmfP^L.iECAM.'^SC.

NTaC4.43.ML-MtttjRH.-H)

^t)me.'e-tMKHt.V.on).M-")OHz

MhttttNtttm3t'M40^

tMTV!htt

Fl.t-n'Mt^t-M.tmm-tMmmHeMtMmtMtM^

'.4m-t*.4^

MOMMttfp.

tMMH*p't)t^-MOte))ft

{VQA)HDenTtm)tif!tt.D<mt^tCcn)M)pe^)t:

(VaA)

HM

)t1tnntn'

MMSXtto^i;^

EX^.Sp^t^J^fStmom

tm;we^«)(Htt^L),2'MNHMafr^.D.'e%)

upMe*

MO-MOV*c.NMaHtfMaa.fPUmM'EM'i)E)

ne-1ZCVtC.MMm{ModOPLC-XM1^tP1t)

t.tA[Mtn.A^M)Mt^)'^&^<M'EM't)e

MA<MM.)^p^.)Mc<MPLC-)(P2I/)(''^

M:-3t^:f<t'P-t6^)

-)e^-te^:tt4'F-)<e^)

Wt*)tttntmottC<M)M<)*hLtttfBt^!C't<t n Ltttt)

LttOfttodtt

hM. t X

dtOentd

tnd

mtnu^oWtd M m*t<

t^f

u.L.

t*M^

PLC-XP18B

TECHN)CAL

SPECtF)CATfONS

PKt*ttcrTtP*

NMtM^n)f[W!<H)tp)

H^W*t^

[^&httMH^^

^«''t!fOtP6ttt<t

CoteMT^tttOt

tM)mi)f^)fMo)t«M]'

thr^nf)!-*'

^'^

)MM

fOMttaOtf)

HMtMnMtt*M)t)t)en

PM^MMattLMt

Tt^wOtttMe*

'^*eeanU)tntt

^tt^UtJtCttt

CM«))Mttf)t)pumc'Ct

CamptttMOt^mmf*

CM^ot^Jht^topotJ^*

OtfMf^ct

ButttttapM**t

'^9''a.tX«t<HM)MMMtnt

^Mt^t

'^MfeenMmptfon

OptfOt^Tt-ptf^uf*

TMfr'9*

T<«^tr*tjrt

'^^.^MT^^,

HtJM^nttttPn^tetor

27ZmmtMMmn't<'Mmm

M^

'.a'TPTAMhthXmtttn)*

Of^ttt

e.3ae^M{7M.<^m.OM)t7M)0)

ea!tmr.^ttm(f^MO*M.MTac.MTaC<.4a.ML-UtndP)U.-M)

H^nc.t6-'(mKHz.V^^M-'0(!Ht

*<ttt)^tthcm:1'M*M'

*MTVh.tt

F'.t-:.''^.^M.4mm-eM^Hota.mom.ndb=u.

'.<m-)4.<m

aHwMW

PWOn01^)t3!?t*ttftM*o.A))*)R'ndL}.tY.Ch<Pt).CKPf)

<nJD)M4ph(S-VM*<H!tt

(MA}HCei6Ttm<n^t:.MMt[4n(C<ntMtMn))t:

fWA}HDe'6TwmM

MMB<tftoT^)ti;:

EXT.

St^tHttJttf

(attMO) x t

'HT.

9P.

8)t<*e

(R

Md

U.:

x«)

RMS

(T^.[11(<%)

up'c.e'

MO.MovAC,6n<em

1.tA(Mt)LAmpttt)

t-c-M'c(4i'F-es'H

-tO^-M^^-F-KO-F)

^^T^^^^^^^^u

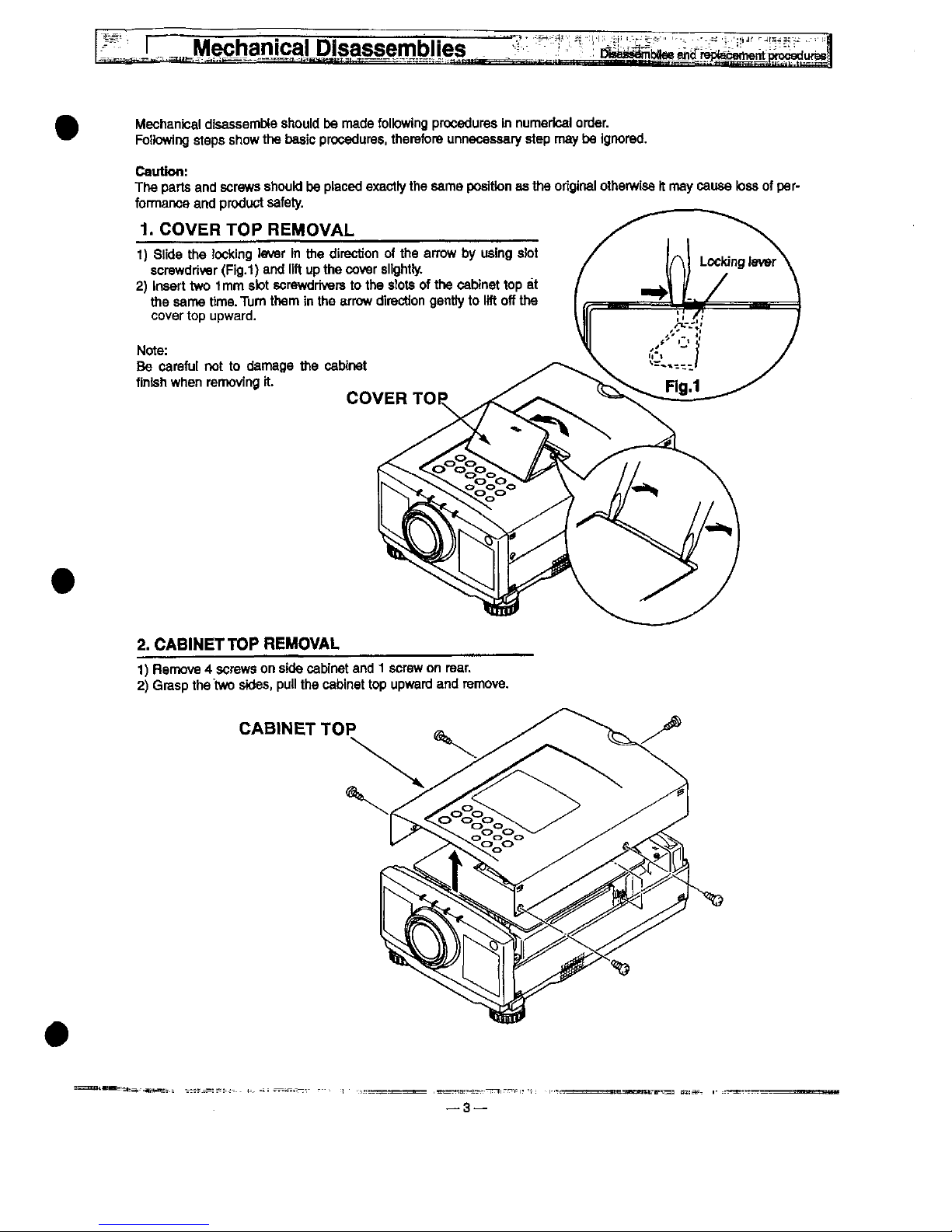

Mechanjca)

D!sassemb)ies

Mechantca)

disassembte

shouid

be

made

following

procedures

in

numencai

order.

Fo!!owing

steps

show

the

basic

procedures,

therefore

unnecessary

step

may

be

ignored.

Cautton:

The

parts

and

screws

shouk)

be

piaced

exactiy

the

same

position

as

the

ongina)

otherwise

)t

may

cause

toss

of

per-

formance

and

product

safety.

1.

COVER

TOP

REMOVAL

1)

Siide

the

tocking

iever

in

the

direction

of

the

arrow

by

using

s!ot

screwdriver

(Fig.t)

and

ifft

up

the

cover

siight!y-

2)

insert

two

'tmm

stot

screwdrivers

to

the

stots

of

the

cabinet

top

at

the

same

time.

Thm

them

in

the

arrow

direction

gentty

to

lift

off

the

cover

top

upward.

Note:

Be

carefui

not

to

damage

the

cabinet

finish

when

removing

it.

COVER

TOP

2.

CAB!NETTOP

REMOVAL

1)

Remove 4 screws

on

side

cabinet

and 1 screw

on

rear.

2)

Grasp

the

two

stdes,

puii

the

cabinet

top

upward

and

remove.

CABINET

TOP

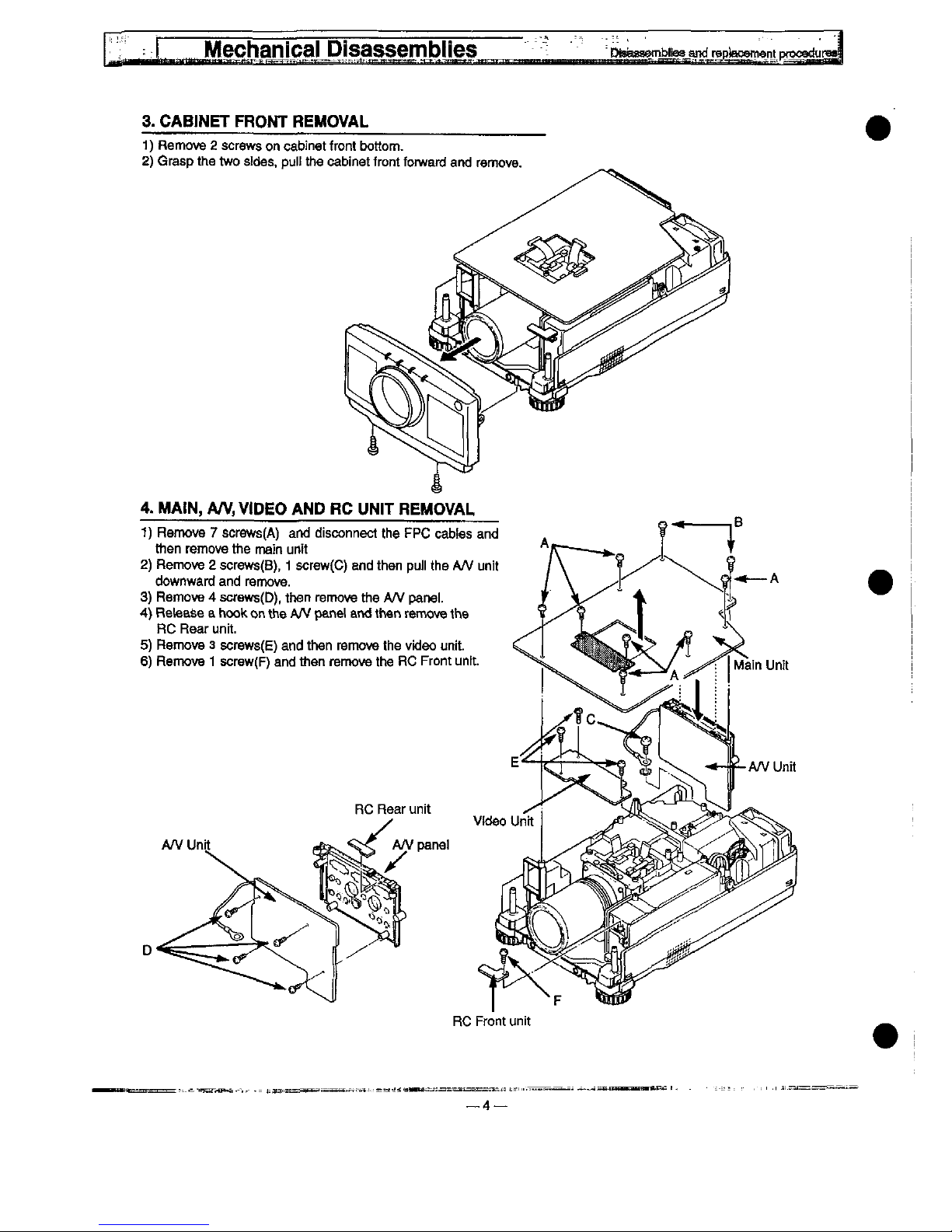

3.

CABINET

FRONT

REMOVAL

1)

Remove 2 screws

on

cabinet

front

bottom.

2)

Grasp

the

two

stdes.

putt

the

cabinet

front

forward

and

remove.

RC

Front

unit

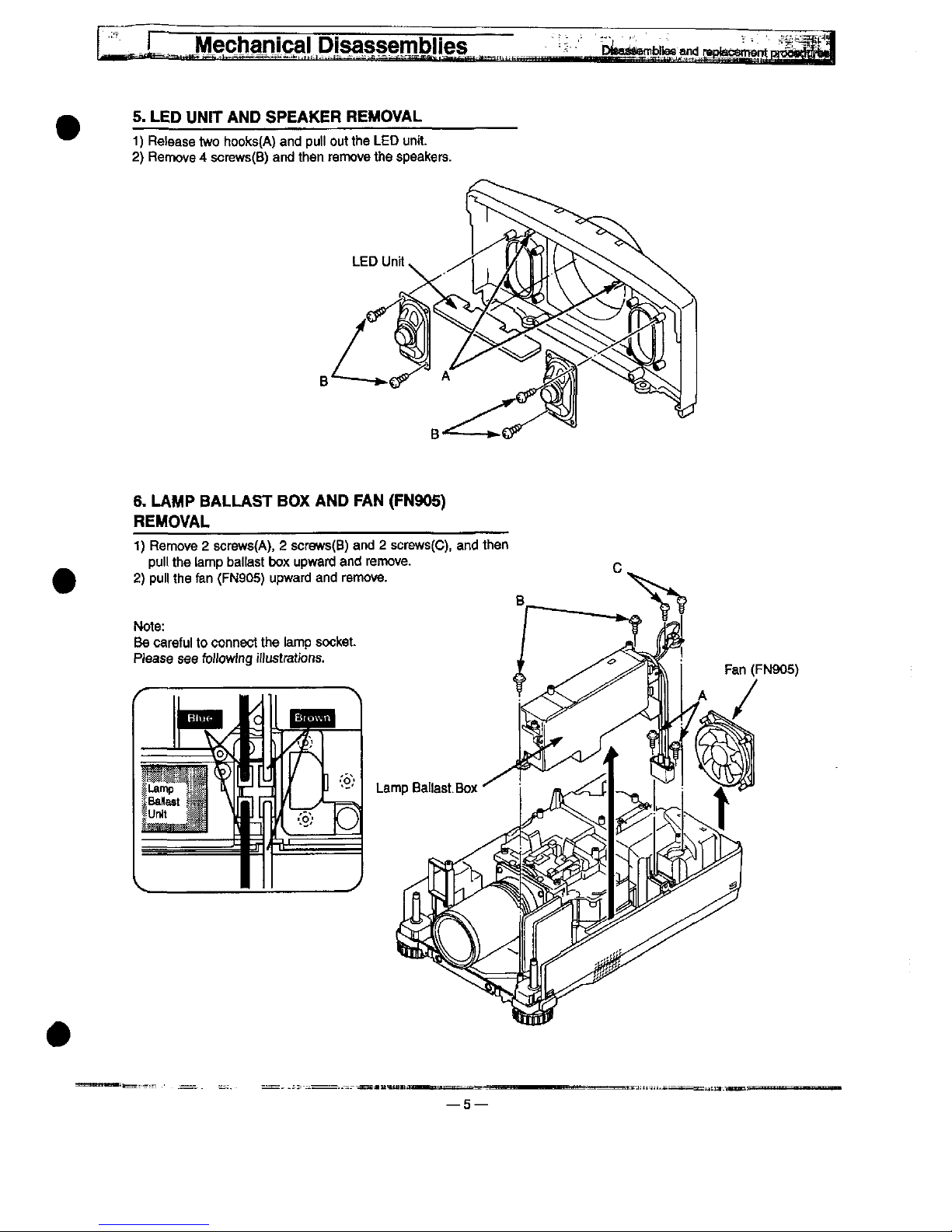

5.

LED

UN!T

AND

SPEAKER

REMOVAL

1)

Retease

two

hooks(A)

and

pu))

out

the

LED

unit.

2)

Remove 4 screws(B)

and

then

remove

the

speakers.

6.

LAMP

BALLAST

BOX

AND

FAN

(FN905)

REMOVAL

1)

Remove 2 screws(A), 2 screws(B)

and 2 screws(C),

and

then

pu)!

the

tamp

ba)!ast

box

upward

and

remove.

2)

pu))

the

fan

(FN905)

upward

and

remove.

—5—

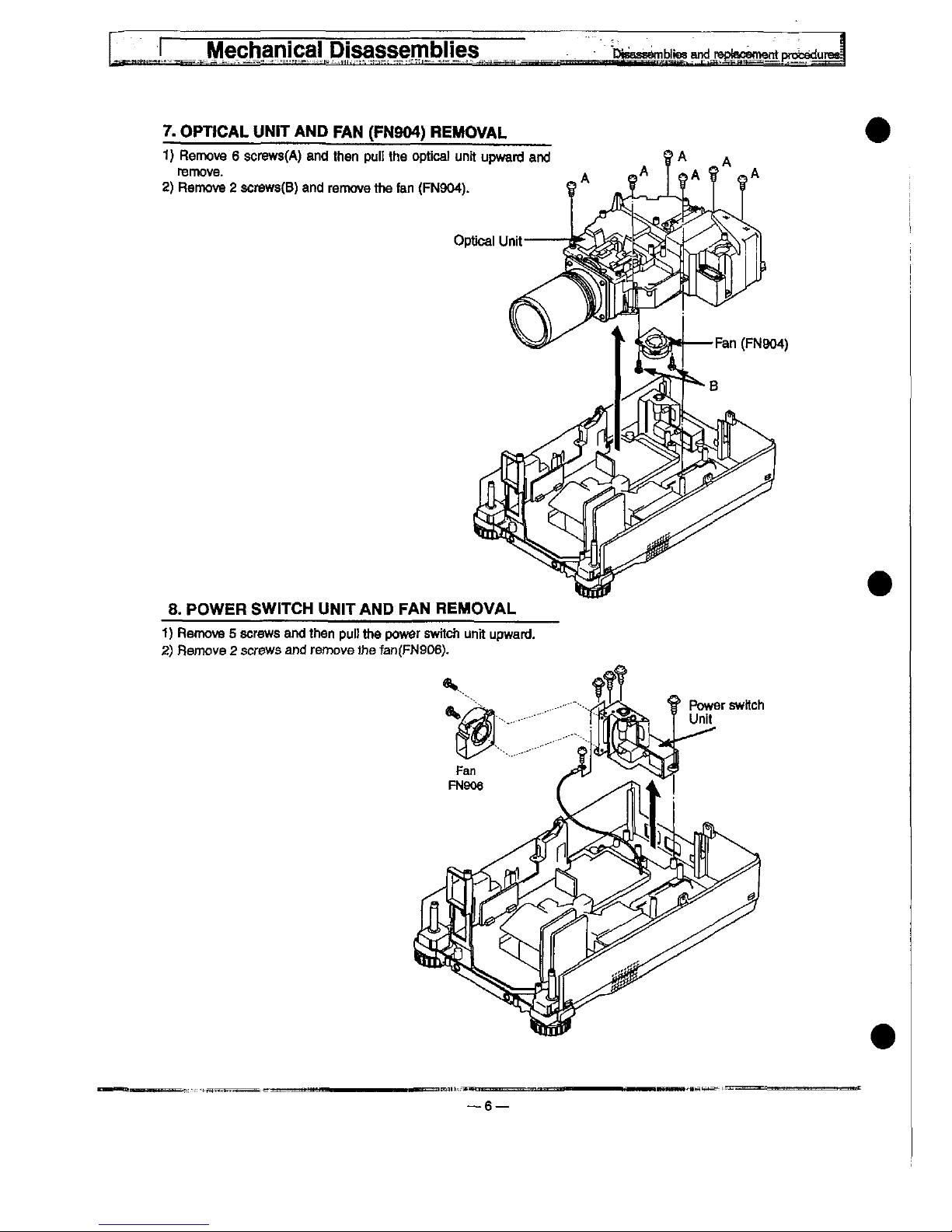

7.

OPDCAL

UN!T

AND

FAN

(FN904)

REMOVAL

f)

Remove 6 screws(A)

and

then

pu!!

the

optica)

unit

upward

and

remove.

2)

Remove 2 screws(B)

and

remove

the

fan

(FN904).

8.

POWER

SW!TCH

UN)TAND

FAN

REMOVAL

1)

Remove 5 screws

and

then

pu)!

the

power

switch

unit

upward.

2)

Remove 2 screws

and

remove

the

fan(FN906).

6—

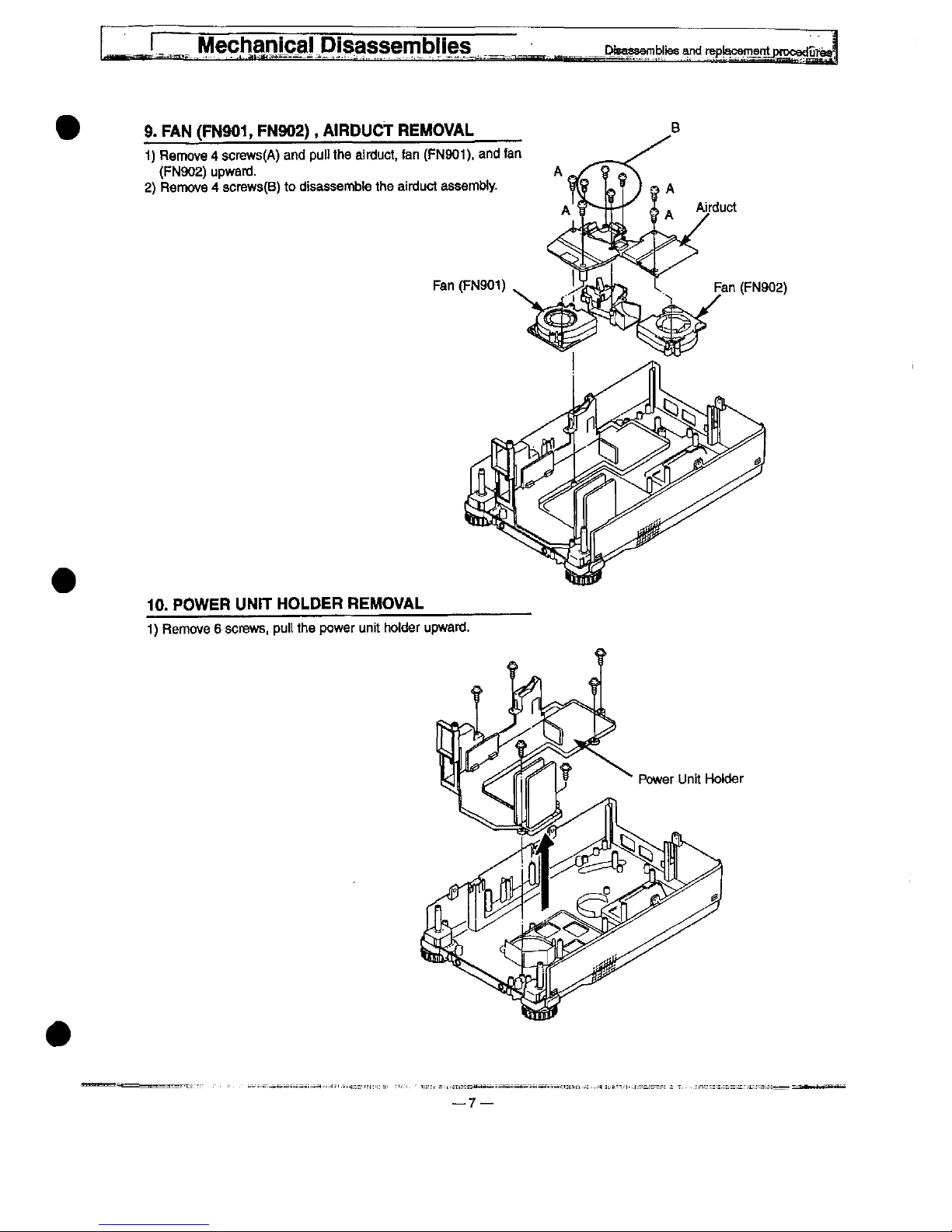

9.

FAN

(FN901,

PN902),

A!RDUCT

REMOVAL

-))

Remove 4 screws(A)

and

pu)t

the

airduct,

fan

(FN901).

and

fan

(FN902)

upward.

2)

Remove 4 screws(B)

to

dtsassembte

the

airduct

assemMy.

Fan

(FN901)

10.

POWER

UN!T

HOLDER

REMOVAL

1)

Remove 6 screws,

pu)[

the

power

unit

hofder

upward-

Power

Unit

Hokier

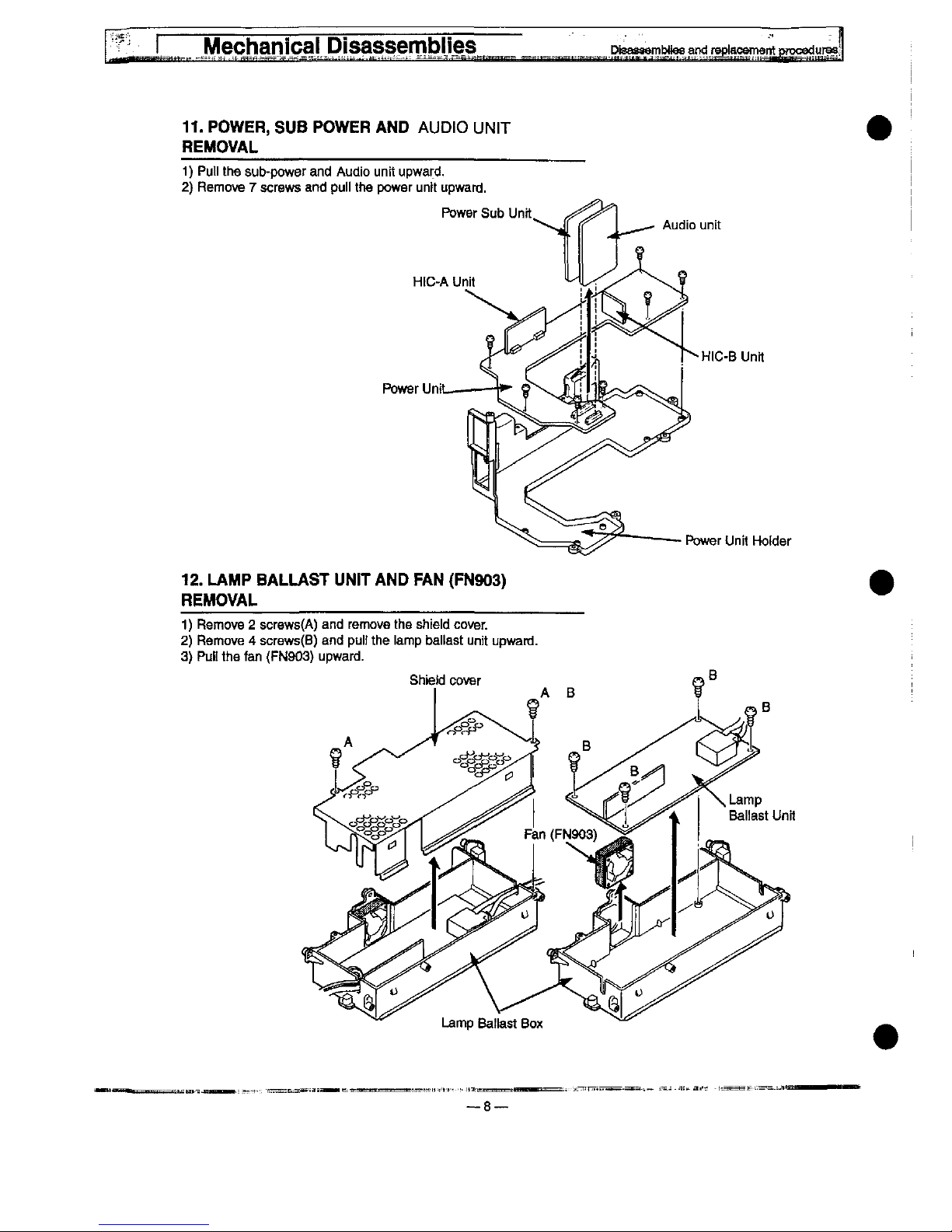

11.

POWER,

SUB

POWER

AND

AUDtO

UN)T

REMOVAL

1)

Put)

the

sub-power

and

Audio

unit

upward.

2)

Remove 7 screws

and

pu!!

the

power

unit

upward.

Audio

unit

HtC-A

Unit

Power

Uni

H!C-B

Unit

Power

Unit

Hotder

12.

LAMP

BALLAST

UN!T

AND

FAN

(FN903)

REMOVAL

1)

Remove 2 screws(A)

and

remove

the

shieid

cover.

2)

Remove 4 screws(B)

and

puif

the

iamp

baitast

unit

upward.

3)

Put!

the

fan

(FN903)

upward.

Lamp

Battast

Box

Remove

the

cabinet,

cabinet

front,

main,

video

and

A/V

unit

fo!kw-

ing

to

steps 2 to 4 of

"Mechanical

Disassembles".

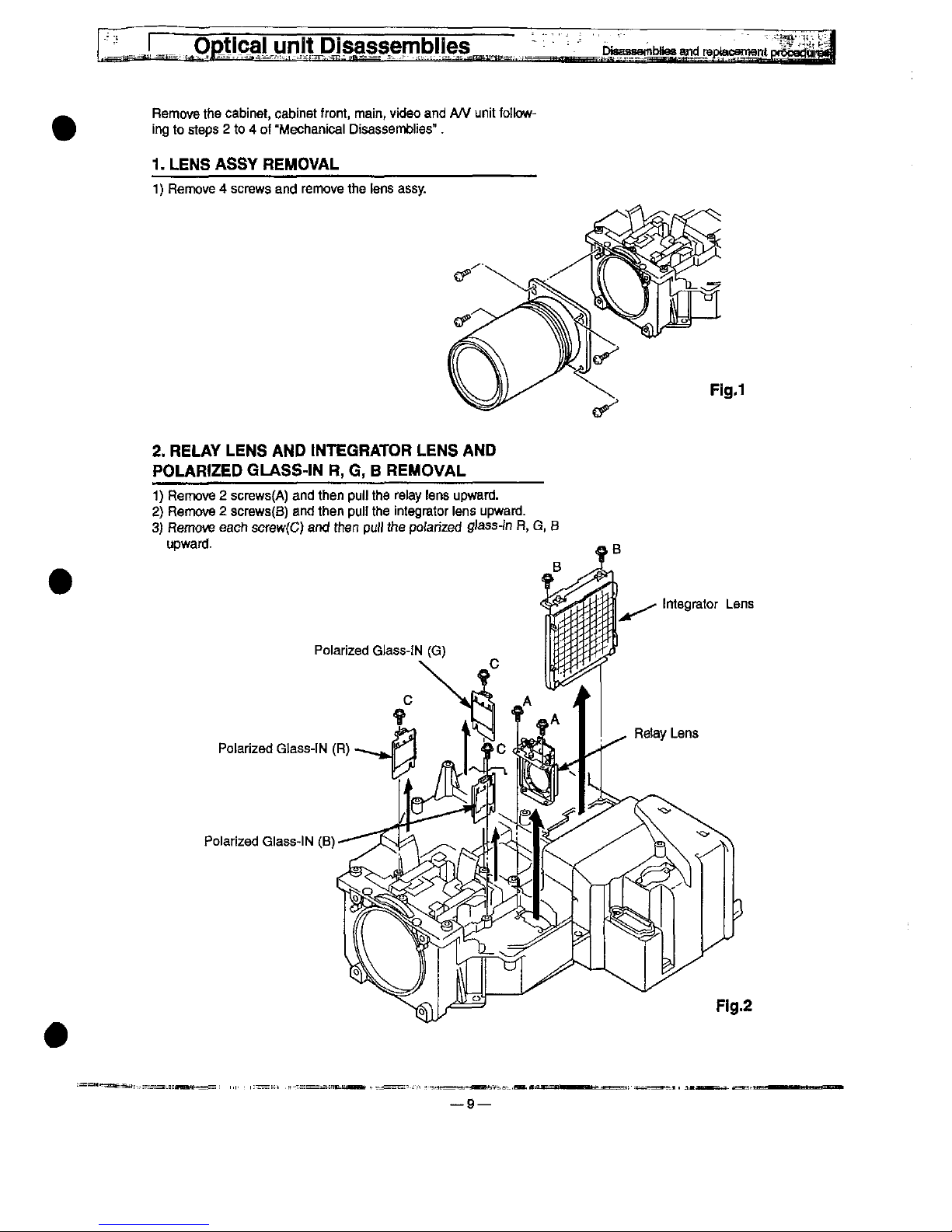

1.

LENS

ASSY

REMOVAL

1)

Remove 4 screws

and

remove

the

tens

assy.

F!g.1

2.

RELAY

LENS

AND

tNTEGRATOR

LENS

AND

POLARIZED

GLASS-)N

R,

G, B REMOVAL

1)

Remove 2 screws(A)

and

then

pufi

the

relay

tens

upward.

2)

Remove 2 screws(B)

and

then

puf!

the

integrator

iens

upward.

3)

Remove

each

screw(C)

and

then

pu!!

the

pofahzed

giass-in

R,

G,

B

upward.

Polarized

Gtass-!N

(G)

Potarized

Gtass-)N

(R)

Poiarized

Giass-iN

(B)

9—

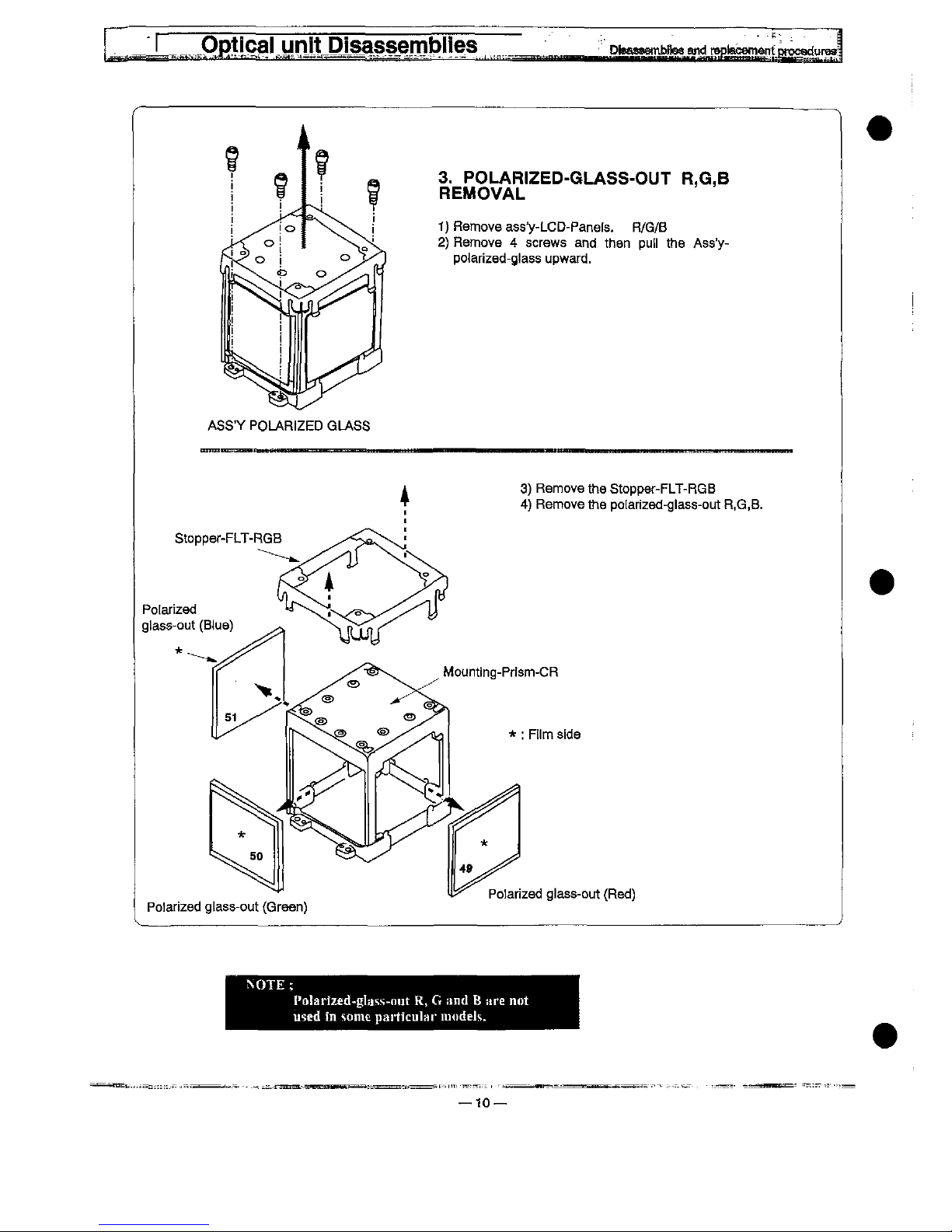

3.

POLAR)ZED-GLASS-OUT

R,G,B

REMOVAL

1)

Remove

ass'y-LCD-Panefs.

R/G/B

2)

Remove 4 screws

and

then

put)

the

Ass'y-

po)arized-g!ass

upward.

ASS'Y

POLAR)ZED

GLASS

3)

Remove

the

Stopper-FLT-RGB

4)

Remove

the

po[arized-g)ass-out

R,G,B.

Potarized

gtass-out

(B)ue)

Mounting-Prfsm-CR

*

:

F!)m

side

Poiarized

g^ass-out

(Green)

Po)arized

g)ass-out

(Red)

Poiarfzed-gt.iss-nut

R, G !tnd B Hre

not

med m 'i!)me

pat'ticutar

inodet',.

10

Qptica)

unJtDJsassembHes

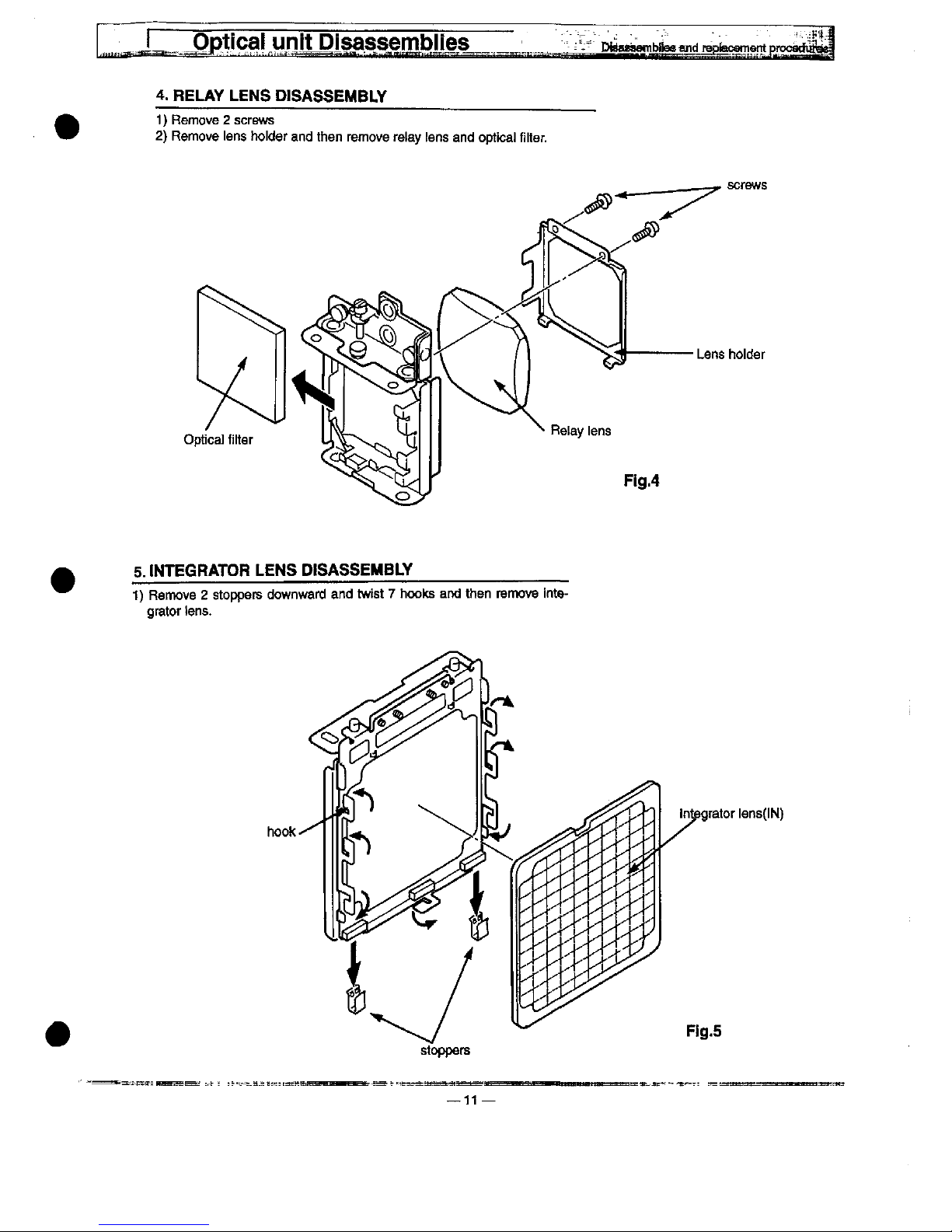

4.

RELAY

LENS

D!SASSEMBLY

1)

Remove 2 screws

2)

Remove

tens

ho)der

and

then

remove

retay

tens

and

optica)

fitter.

screws

Lens

ho)der

5.

tMTEGRATOR

LENS

DISASSEMBLY

1)

Remove 2 stoppers

downward

and

twist 7 hooks

and

then

rerrtovo

inte-

grator

tens.

stoppers

11

integrator

iens(iN)

Pig.5

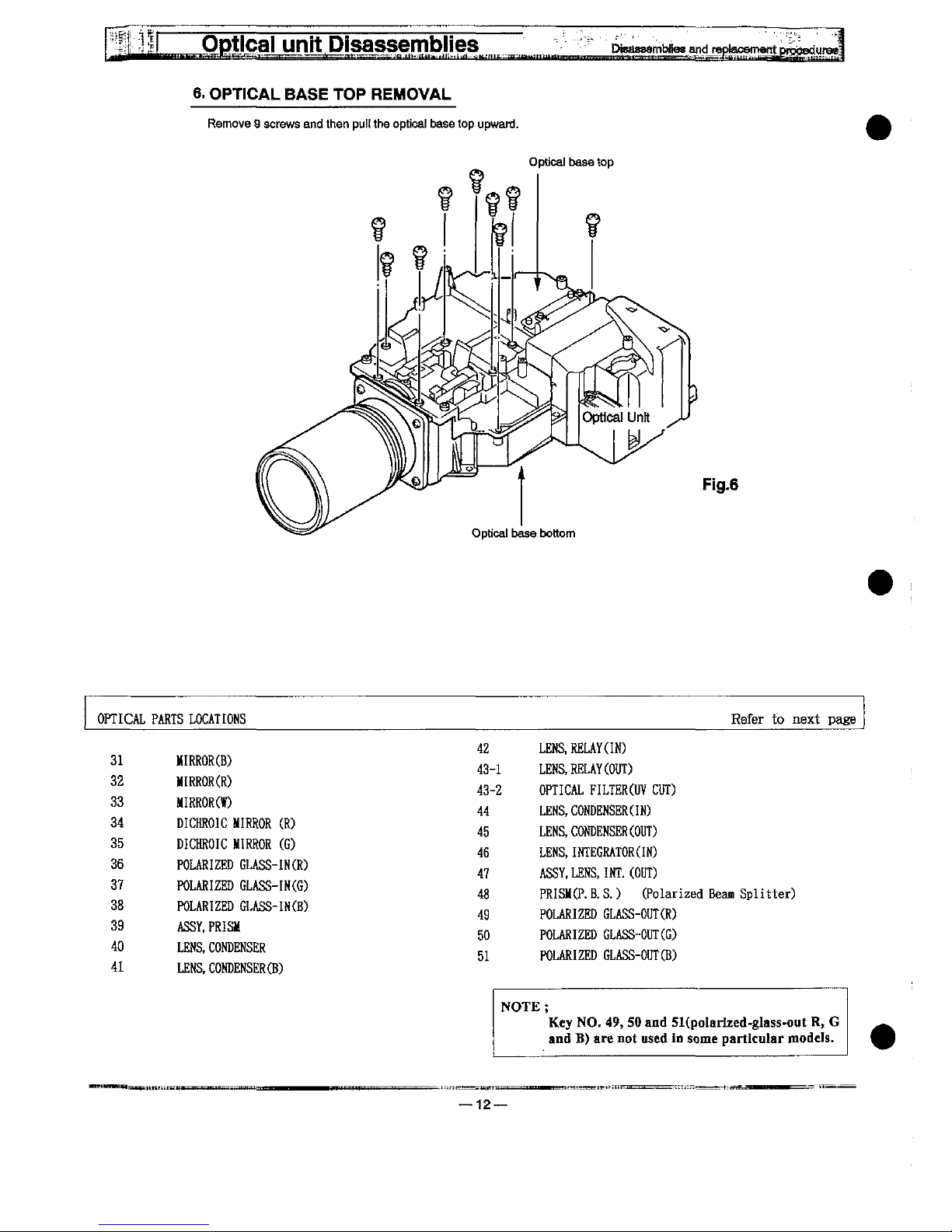

6.

OPT)CAL

BASE

TOP

REMOVAL

Remove 9 screws

and

then

pu^f

the

optica)

base

top

upward.

Optica)

base

top

Fig.6

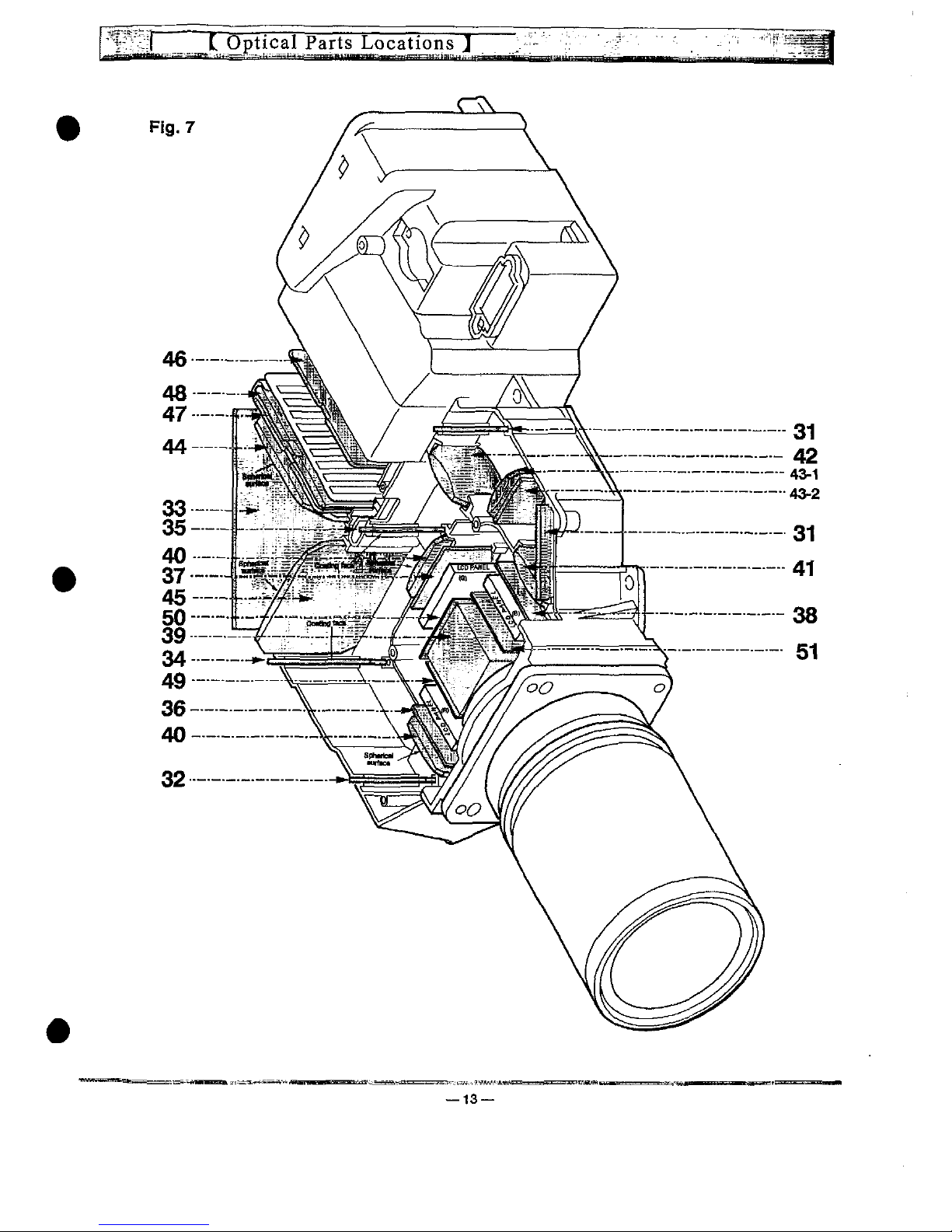

OPTICAL

31

32

33

34

35

36

37

38

39

40

41

PARTS

LOCATIONS

MIRROR(B)

MIRROR(R)

MIRROR(W)

DICHROIC

MIRROR

(R)

DICHROIC

MIRROR

(G)

POLARIZED

GLASS-IN(R)

POLARIZED

GLASS-IN(G)

POLARIZED

GLASS-IN(B)

ASSY.PRISM

LENS,CONDENSER

LENS,CONDENSER(B)

42

43-1

43-2

44

45

46

47

48

49

50

51

Refer

to

next

page

LENS.RELAY(IN)

LENS,RELAY(OUT)

OPTICAL

FILTERS

CUT)

LENS,CONDENSER(IN)

LENS.CONDENSER(OUT)

LENS,

INTEGRATORS)

ASSY,LENS.INT.(OUT)

PRISM(P.B.S.)

(Polarized

Beam

Splitter)

POLARIZED

GLASS-CUT(R)

POLARIZED

GLASS-OUT(G)

POLARIZED

GLASS-OUT(B)

NOTE;

Key

NO.

49,

50

and

5Kpo!arixed-gtass-ont

R,

G

and

B)

are

not

used

in

some

particular

models.

12

13

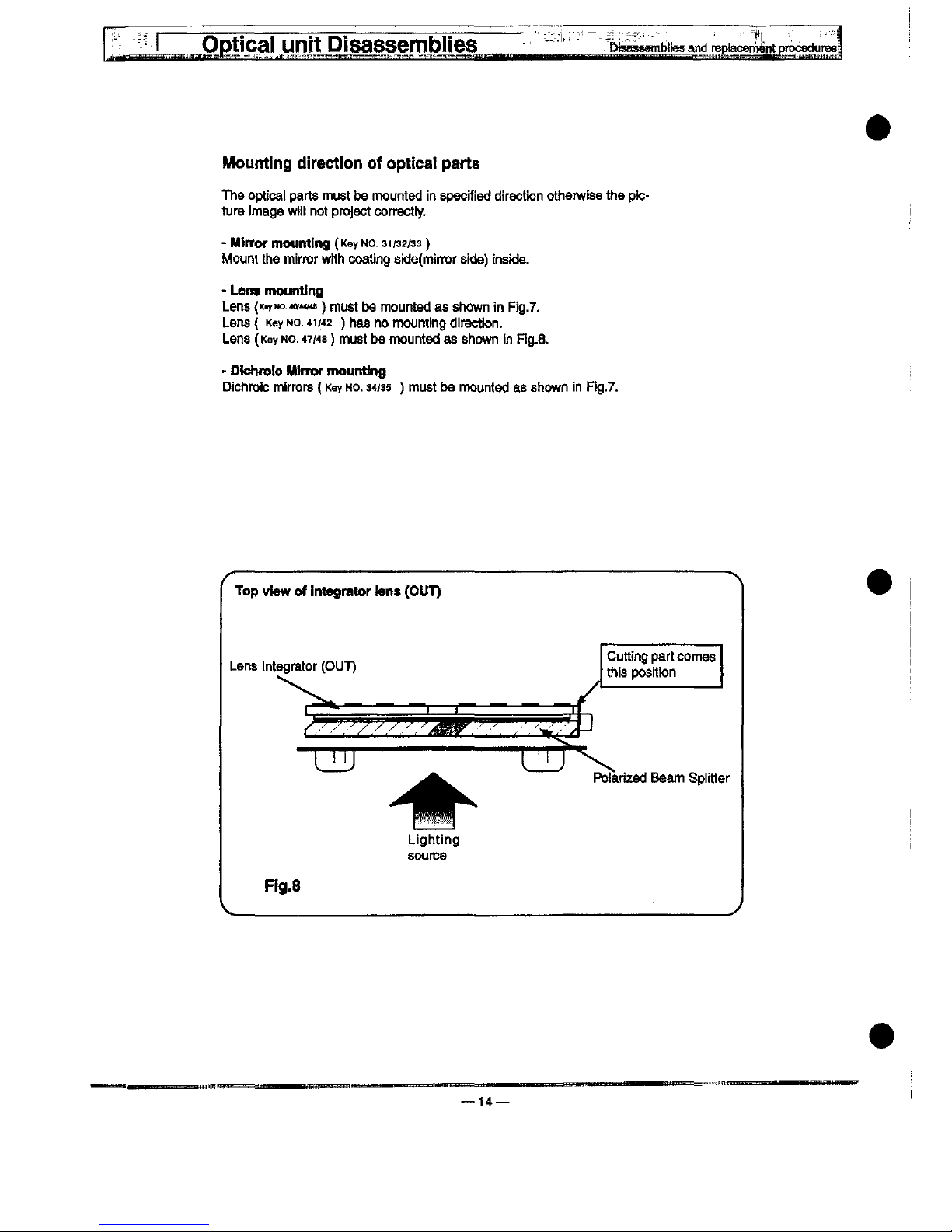

Mounting

direction

of

optica!

parts

The

optica)

parts

must

be

mounted

in

specified

direction

otherwise

the

pic-

ture

imago

wift

not

project

correctiy.

-

Minor

mounting

(Key

No

31/32/33)

Mount

the

mirror

wtth

coating

sid8(mirror

sitte)

inside.

-

Lent

mounting

Lens

(fyMo

w<^)

mu$t

be

mounted

as

shown

in

Ffg.7.

Lens { Key

Mo.

41/42

)

has

no

mounting

direction.

Lens

(Key

no.

47/48)

must

be

mounted

as

shown

in

Fig.8.

-

Dtchro!c

Mtrrof

mounting

Dichroic

mirrors

(Key

no.

34/35

)

must

bo

mounted

as

shown

in

Fig.7.

^^

Top

view

of

integrator

teM

(OUT)

Cutting

part

comes

this

position

Potanzed

Beam

Spittter

Lighting

source

Ftg.8

14—

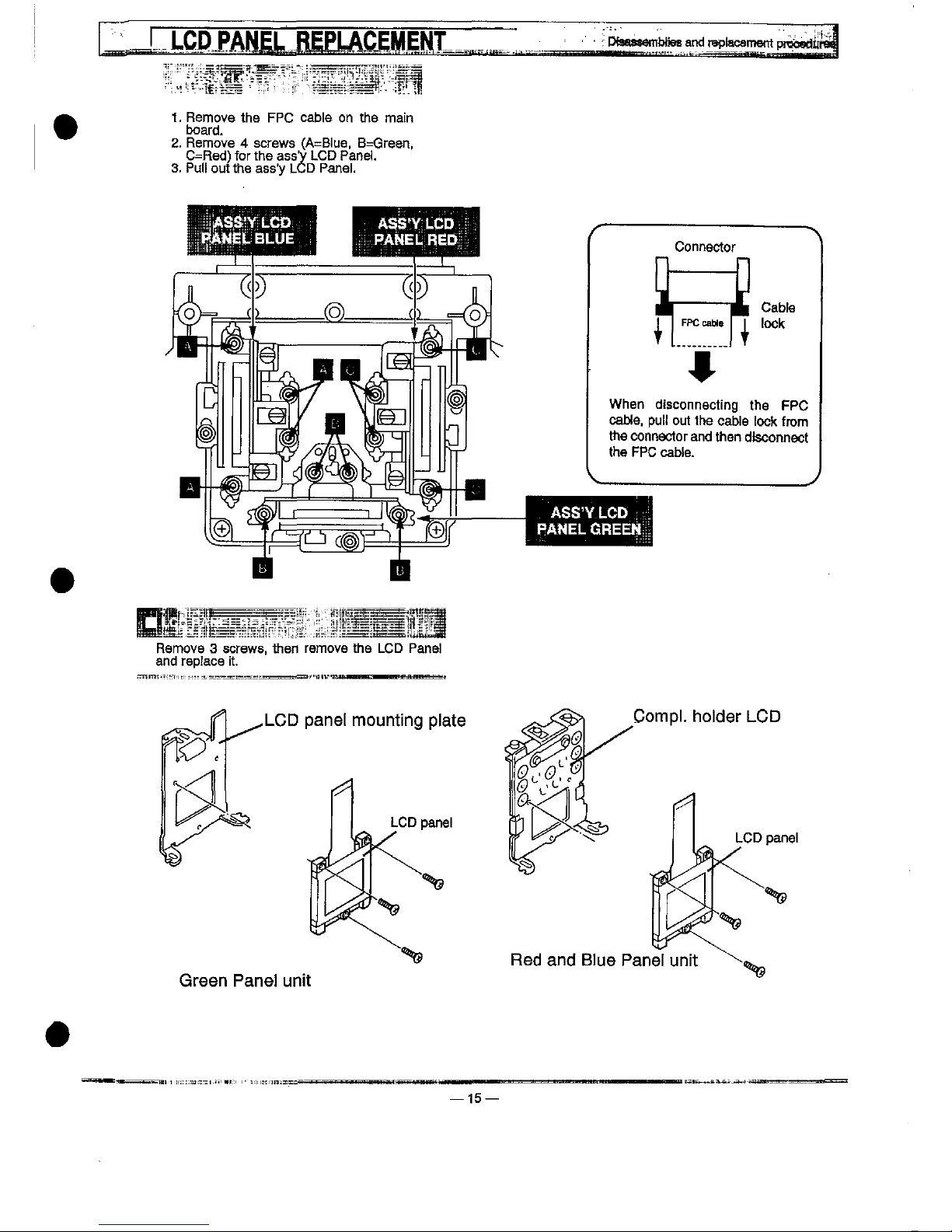

LCD

J'ANE.PLACEMENT

1.

Remove

^e

FPC

cabte

on

the

ma!n

board.

2.

Remove 4 screws

(A=B!ue,

B=Green,

C=Red)

for

the

ass'y

LCD

Pane).

3.

Pu)!

out

the

ass'y

LCD

Pane).

Remove 3 screws,

then

remove

the

LCD

Pane!

and

repfaco

it.

LCD

pane!

mounting

p)ate

Green

Pane)

unit

15—

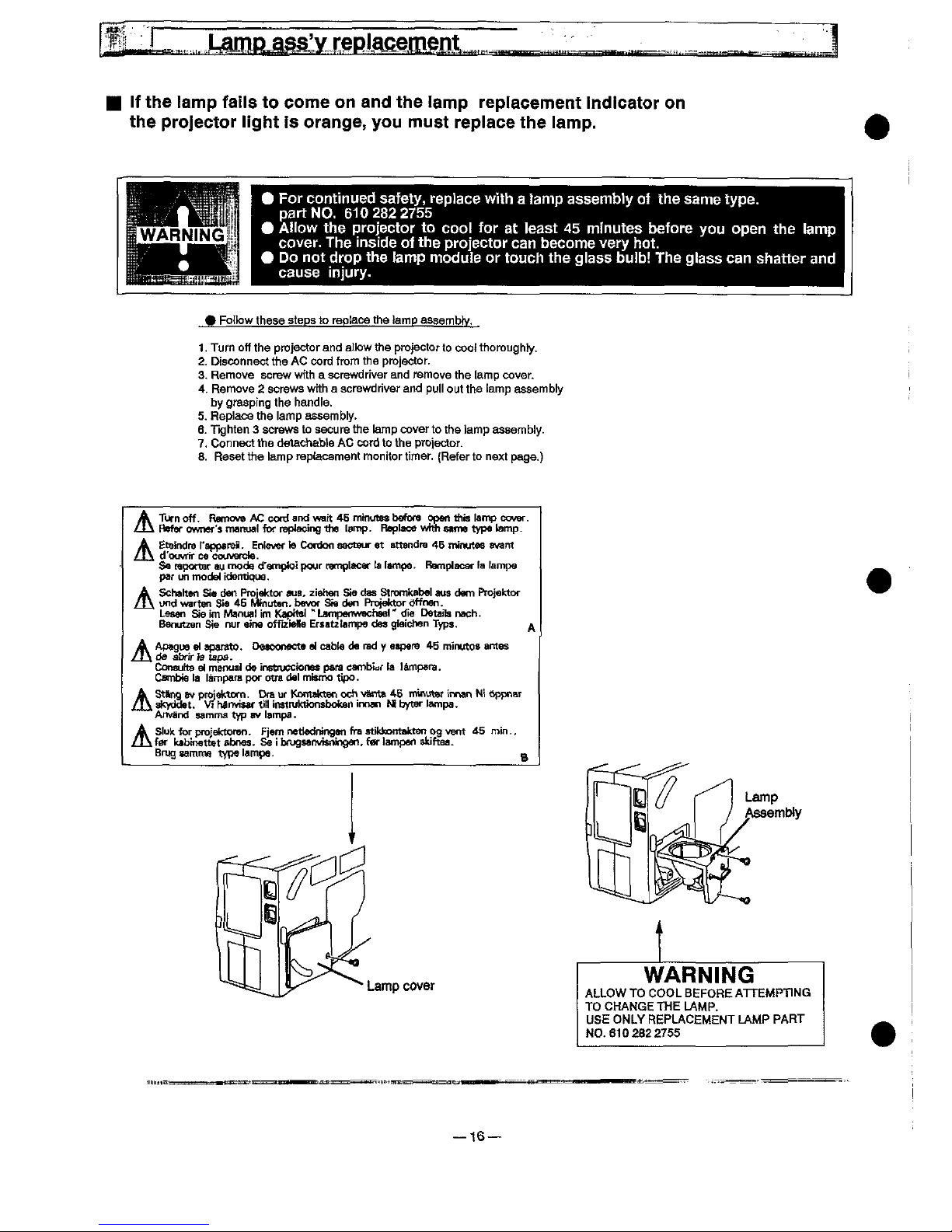

)f

the

tamp

faHs

to

come

on

and

the

tamp

reptacement

indicator

on

the

projector

tight

is

orange,

you

must

replace

the

lamp.

^

For

continued

safety,

rep)ace

with a !amp

assembly

of

the

same

type.

part

NO.

6102822755

^

AHow

the

projector

to

coo!

for

at

ieast

45

minutes

before

you

open

the

tamp

cover.

The

inside

of

the

projector

can

become

very

hot.

^

Do

not

drop

the

tamp

modute

or

touch

the

giass

bu)b!

The

glass

can

shatter

and

cause

injury.

^

Fotbw

these

steps

to

roptace

the

tamp

assembty.

1.

Turn

off

the

projector

and

at)ow

the

projector

to

coof

thoroughty.

2.

Disconnect

the

AC

cord

from

the

projector.

3-

Remove

screw

with a screwdriver

and

remove

the

tamp

cover.

4.

Remove 2 screws

wrth a screwdriver

and

pu!)

out

the

tamp

assemb)y

by

grasping

the

handte.

5.

Repiace

the

)atDp

assemb)y.

6.

Tighten 3 screws

to

secure

the

tamp

cover

to

the

tamp

assemb)y.

7.

Connect

the

detachaMe

AC

cord

to

the

projector.

8.

Reset

the

tamp

repfacement

monitor

timer.

(Refer

to

next

page.)

^

Turn

off.

Remova

AC

cord

and

watt

46

minutes

before

open

this

tamp

cover.

"^

Refer

owner'a

manua)

for

replacing

the

tamp.

Rep)ace

wnh

Mme

type

tamp.

A

EtaindreFapparoi).

Entente

Cordon

aacteur

at

sttandra

46

minutes

avant

/^\

d'ouvrtr

ce

couvefcte.

Sa

mportar

au

fnodg

d'amptoi

pour

ramptacer

ta

ttmpa.

Remptacar

ta

fampe

par

un

modef

identique.

A

Schahen

Se

den

Projaktor

aus,

ziehen

Sie

dss

Stromkabe)

aus

dem

Projektor

/!\

und

warten

Sie

46

Mfnuten.

bavor

Sta

den

Protetctor

<trfner).

LeMn

Sie

im

Manua)

im

KapiM)

"Lampertwachse)''

die

Detaits

nach.

Banutzen

Sie

nur

aine

offiziette

Ersatztampe

dea

giaichen

Typs.

^

A

Apague

wt

aparato.

DMConecte

a)

cabta

da

rad y aapera

45

mintftos

amos

/t\

da

abrirfa

tapa-

Consuha

e)

manuat

do

instfucctonM

para

cambiar

ta

tampara.

Csmbie

)a

)ampafa

por

otra

da)

misfno

tipo.

A

St^ng

BV

projektom.

Dra

ur

Kiontdtten

och

va)m

46

minu^r

innan

Mi

6ppnar

/J\

aftyddet.

Vt

MnvJMf

tit)

!nMtu)c6onsbottan

innan M bytar

)ampa.

Anvand

samma

typ

av

)ampa-

A

S<uk

^r

projektoren.

Fjam

nettedningen

fra

sdkkontakten

og

vent

^5

rrMn..

/!\

far

ktbinettet

abnes-

Se i bnjga'nvisninoen,

far

)ampan

skiftaa.

BfugzatDmetypetampe.

n

Lamp

Assembty

Lamp

cover

WARNtNG

ALLOW

TO

COOL

BEFORE

ATTEMPTING

TO

CHANGE

THE

LAMP.

USE

ONLY

REPLACEMENT

LAMP

PART

N0-6102822755

t6

Lamp

ass'yrep)acement

^

RESET

THE

LAMP

REPLACEMENT

MONITOR

TtMER.

NOTE:

Do

not

reset

the

LAMP

REPLACEMENT

MON)TOR

T)MER,

except

after

the

tamp

is

rep)aced.

1.

Press

the

MENU

BUTTON

and

the

MA!N

MENU

D)SPLAY

diaiog

box

wit)

appear.

2.

Press

the

PO)NT

LEFT/RIGHT

BUTTON(s)

to

se)ect

SETTING

and

press

the

SELECT

BUTTON.

Another

diatog

box

SETDNG

D)SPLAY

wiit

appear.

3.

Press

the

PO)NT

DOWN

BUTTON

and a red

arrow

wit)

appear.

4.

Move

the

arrow

by

pressing

the

PO)NT

UP/DOWN

BUTTOM(s)

to

setoct

Lamp

age

and

then

press

the

SELECT

BUTTON.

When

you

reset

the

tamp

rep!ace

monitor,

lamp

reptace

monitor

reset?"

is

displayed

for

confirmation.

5.

Move

the

arrow

to

Yes

and

then

press

the

SELECT

BUTTON,

"OK?"

is

displayed

for

confirmation.

Move

the

arrow

to

Yes

and

then

press

the

SELECT

BUTTON,

the

tamp

replace

monitor

is

reset.

6.

Move

the

arrow

to

No

and

then

press

the

SELECT

BUTTON.

The

iamp

repface

monitor

is

not

reset.

7.

To

quit

the

MENU,

move

the

arrow

to

Quit

and

then

press

the

SELECT

BUTTON.

MAtN

MENU

DtSPLAY

D)

B)ue

back

Dtsptay

Eng)ish

SETDNG

DISPLAY

Reverse

T/B

Reverse

L/R

)^<B

Spiitwipe

Recommendation

Should

the

air

fitter

become

ctogged

with

dust

particles,

it

wiii

reduce

the

cooiing

fan's

effectiveness

and

may

resuft

in

internal

heat

buiid

up

and

short

iamp

iife.

We

recommend

dean-

ing

the

air

fitter

after

the

projection

iamp

is

replaced.

Refer

to

AiR

FILTER

CARE

AND

CLEANING

on

the

Owner's

Manuai.

OK?

S

^

M

No

)

B^

Power

management

USB

^

Remote

contro!

Mode

1

(

Quit

)

Lamp

rep!ace

monitor

Reset

?

No

NOTE:

Service

Mode

HOW

TO

CHECK

THE

LAMP

tLLUM)NAT!ON

T)ME

P—,

/

!

With

the

projector

in

operating

mode.

press

and

ho!d

the

POINT

UP

button

for

20

seconds,

service

mode

disptay

wit!

appear

on

the

screen.

!

tiiumination

time^Data

Va!ue

Examp)e

)iiumination

time

is

13

hours.--""

!

Press

the

"POWER

ON

OFF"

button

to

qu!tthe

service

mode.

\

Lamp

JXuminatton

titne

Data

no.

Data

^

[0^]

[^

Data

Va)ue

.^'

17

SAFETY

!NSTRUCT)ONS

^

SAFETY

PRECAUT!ONS]

WARNING:

The

chassis

of

this

projector

is

isolated

(COLD)

from

AC

line

by

using

the

converter

transformer.

Primary

side

of

the

converter

transformer

and

iamp

power

supply

unit

circuit

is

connected

to

the

AC

iine

and

it

is

hot,

which

hot

circuit

is

identified

with

the

iine

in

the

schematic

diagram.

For

continued

product

safety

and

protection

of

personnel

injury,

servicing

shouid

be

made

with

qua)i-

fied

personnel

The

foiiowing

precautions

must

bo

observed:

1.

An

isotatfon

transformer

shoutd

be

connected

in

the

power

iine

between

the

projector

and

the

AC

iine

before

any

service

is

performed

on

the

projector.

2.

Comp)y

with

ai)

caution

and

safety-

rotated

notes

provided

on

the

cabinet

back,

cabinet

bottom,

inside

the

cabinet

or

on

the

chassis.

3.

When

rep)acing a chassis

in

the

cabinet,

atways

be

certain

that

aii

the

protective

devices

are

installed

properiy,

such

as

control

knobs,

adjustment

covers

or

shields

and

barriers.

DO

NOT

OPERATE

TH)S

PROJECTOR

WtTH-

OUT

THE

PROTECTtVE

SHIELD

)N

POS)T)ON

AND

PROPERLY

SECURED.

4.

Before

replacing

the

cabinet

cover,

thoroughiy

inspect

the

inside

of

the

cabinet

to

see

that

no

stray

parts

or

toois

have

been

ieft

inside.

Before

returning

any

projector

to

the

customer,

the

service

personne)

must

perform

the

following

safety

checks

and

be

sure

that

it

is

compfeteiy

safe

to

operate

without

danger

of

eioctricai

shock.

[PRODUCT

SAFETY

NOT)CE

J

Product

safety

shou)d

be

considered

when a component

replacement

is

made

in

any

area

of

the

projector.

Components

indicated

by a mark

(A)

in

the

parts

list

and

the

schematic

diagram

designate

components

in

which

safety

can

be

of

speciai

significance,

tt

is,

therefore,

particularly

recommended

that

the

replace-

ment

of

these

parts

must

be

made

by

exactly

the

same

parts.

[

SERV)CE

PERSONNEL

WARN!NG

^

Eye

damage

may

resutt

from

directty

viewing

the

tight

produced

by

the

Lamp

used

in

this

equipment.

Atways

turn

off

Lamp

before

opening

cover.

uttravioiet

radiation

eye

protection

required

during

this

servicing.

Never

turn

the

power

on

without

the

tamp

to

avoid

etectric

shock

or

damage

of

the

devices

since

the

stabilizer

generates

high

voitages(

==

25kV)

at

its

start.

Since

the

iamp

is

very

high

temperature

during

units

operation.

Replacement

of

the

lamp

shou!d

be

done

at

teast

one

hour

after

the

power

has

been

turned

off,

to

a!iow

the

tamp

coot - off.

[

DO

NOT

ATTEMPT

TO

SERViONG

THE

REMOTE

CONTROL

UN)T.

^

Laser

Beam

may

be

ieaked

out

when

in

disassemble

the

Unit.

As

the

Laser

Beam

used

in

this

Remote

control

unit

is

harmful

to

the

eyes.

t

CAUTiON

t

, j ,

LASER

RAMATtOM

-

^^^ M HOT

STARE

'MTO

BEAU

^^

'

! ' MAX.

OUTPUT:

tmW

WAVE

UEMQTH:

BSO ± BCrm

CLASS E LASER

PRODUCT

Thttproduttf

compos

wtthEt

CFR

pMtMO.M

M

MOT

STARE

'MTO

BEAM

CLASS : LASER

PROOUCT

LASER-STRAHUMQ

MtCHT

!N

DCN

STHAHL

BUCKEN

LASER

KLASSE

:

t--^&M^?x2

^-fMa

^-AtO^^t^';^

'ECe0626-<.Am.t

<aa7

MAX.OUTPUTj<bA:fi{Jn:'mW

WAVE

LENQTmtt^) ^ 660 ± ZOMn

18

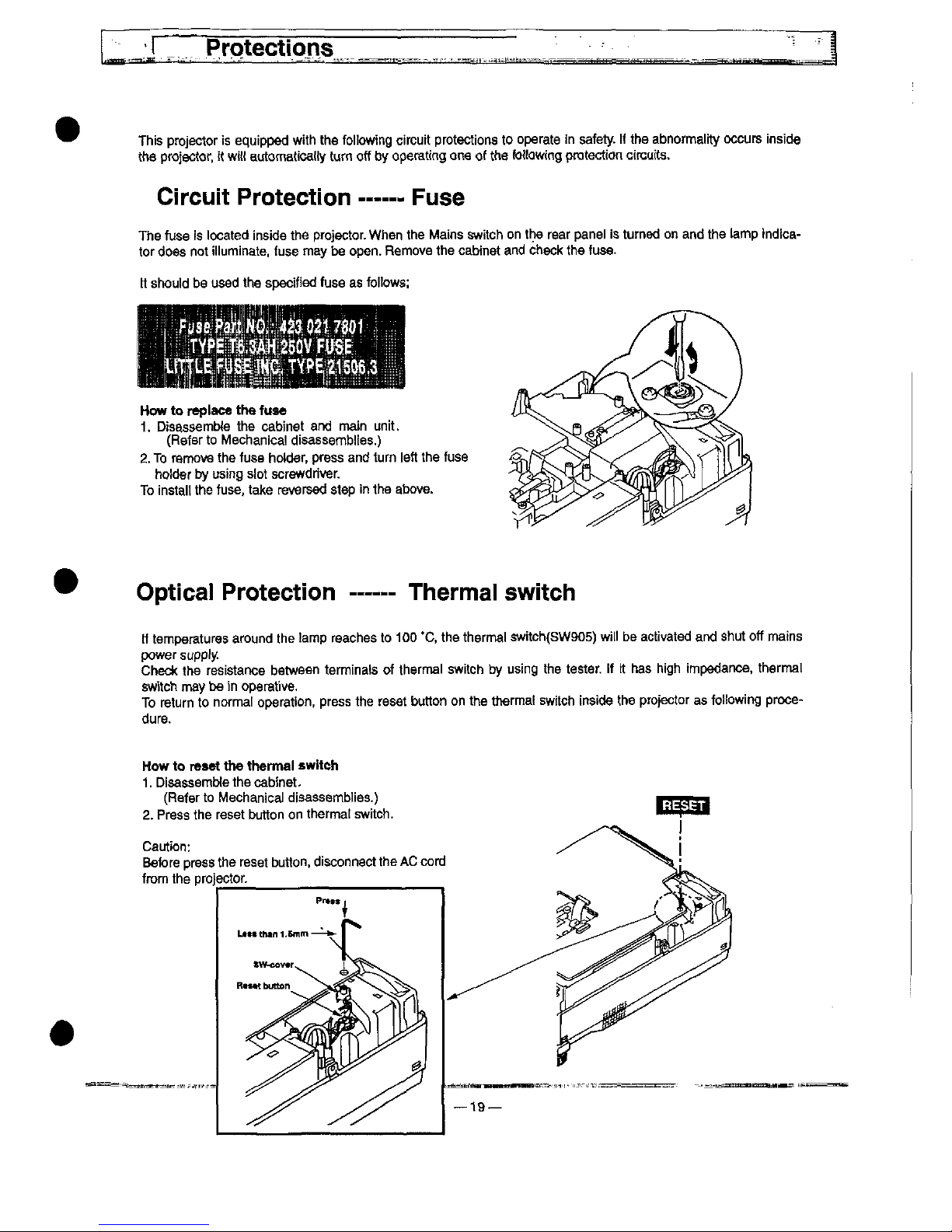

Protections

This

projector

is

equipped

with

the

following

circuit

protections

to

operate

in

safety. H the

abnormality

occurs

inside

the

projector,

tt

wiff

automatical

turn

off

by

operating

one

of

the

lowing

protection

circufts.

Circuit

Protection

Fuse

The

fuse

!s

located

inside

the

projector.

When

the

Mains

switch

on

the

rear

panei

is

turned

on

and

the

tamp

tndica-

tor

does

not

iiiuminate,

fuse

may

be

open.

Remove

the

cabinet

and

check

the

fuse.

tt

shouid

be

used

the

specified

fuse

as

foiiows:

How

to

reptace

the

fuse

1.

Disassembfe

the

cabinet

and

main

unit.

(Refer

to

Mechanica)

disassembles.)

2.

To

remove

the

fuse

hotder,

press

and

turn

ieft

the

fuse

holder

by

using

siot

screwdriver

To

instait

the

fuse,

take

reversed

step

in

the

above.

Optica!

Protection

Thermal

switch

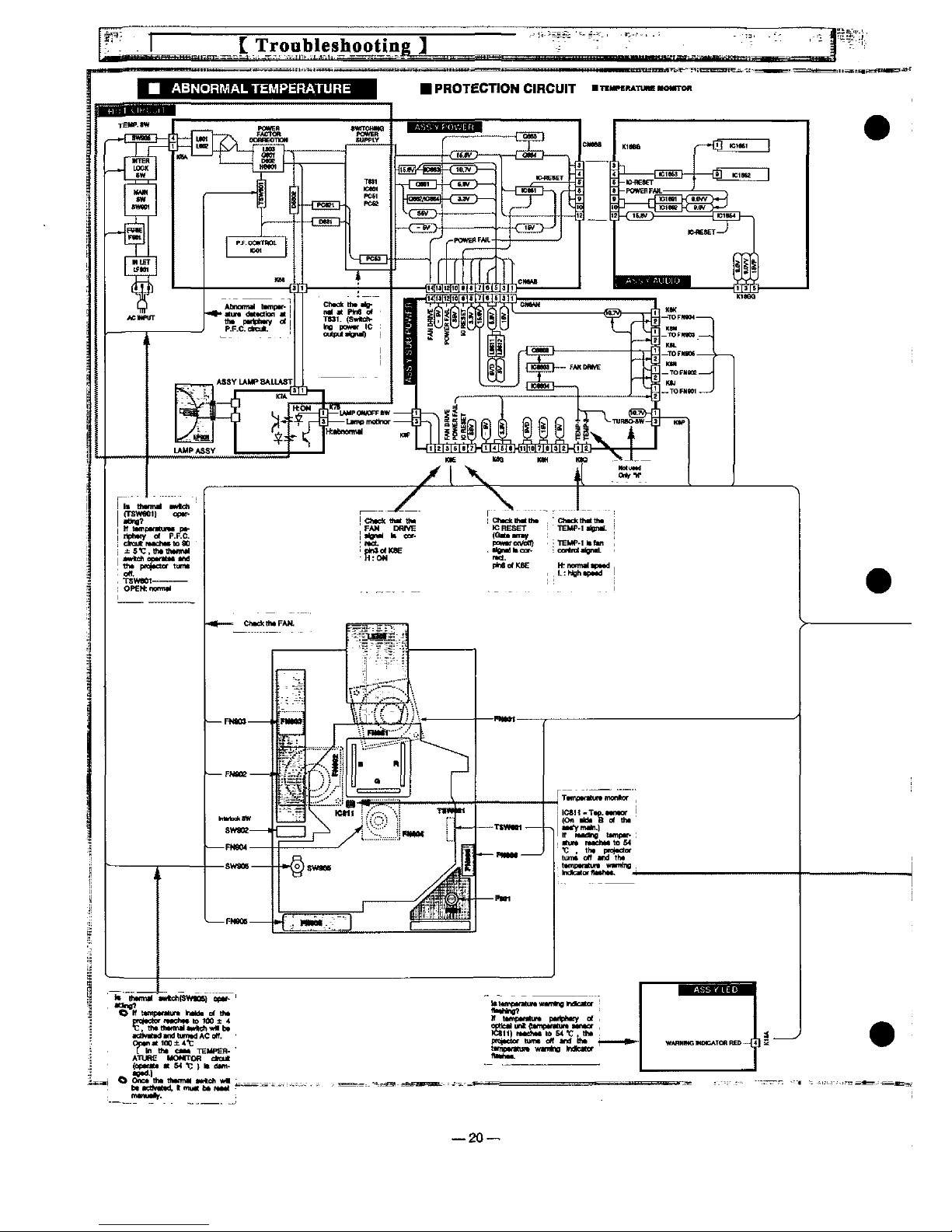

tf

temperatures

around

the

tamp

reaches

to

100

*C.

the

thermal

switch(SW905)

wii)

be

activated

and

shut

off

mains

power

supply

Check

the

resistartce

between

terminats

of

thermal

switch

by

using

the

tester,

ft

tt

has

high

impedance,

thermal

switch

may

be

in

operative.

To

return

to

normal

operation,

press

the

reset

button

on

the

thermat

switch

inside

the

projector

as

fo)!owing

proce-

dure.

How

to

re&et

the

therma)

swttch

1.

DisassemMe

the

cabinet.

(Refer

to

Mechanical

disassemblies.)

2.

Press

the

reset

button

on

thermat

switch.

Caution:

Before

press

the

reset

button,

disconnect

the

AC

cord

from

the

projector

____

ATUREHOMfTOR

ctcu*

(e^MM

ft M T ) "

d*m.

<e*^)

0

One*

th*

thtfmtt

t<f0e^

w*

)MMtMHd.<'"uttb<tfttt<

—21

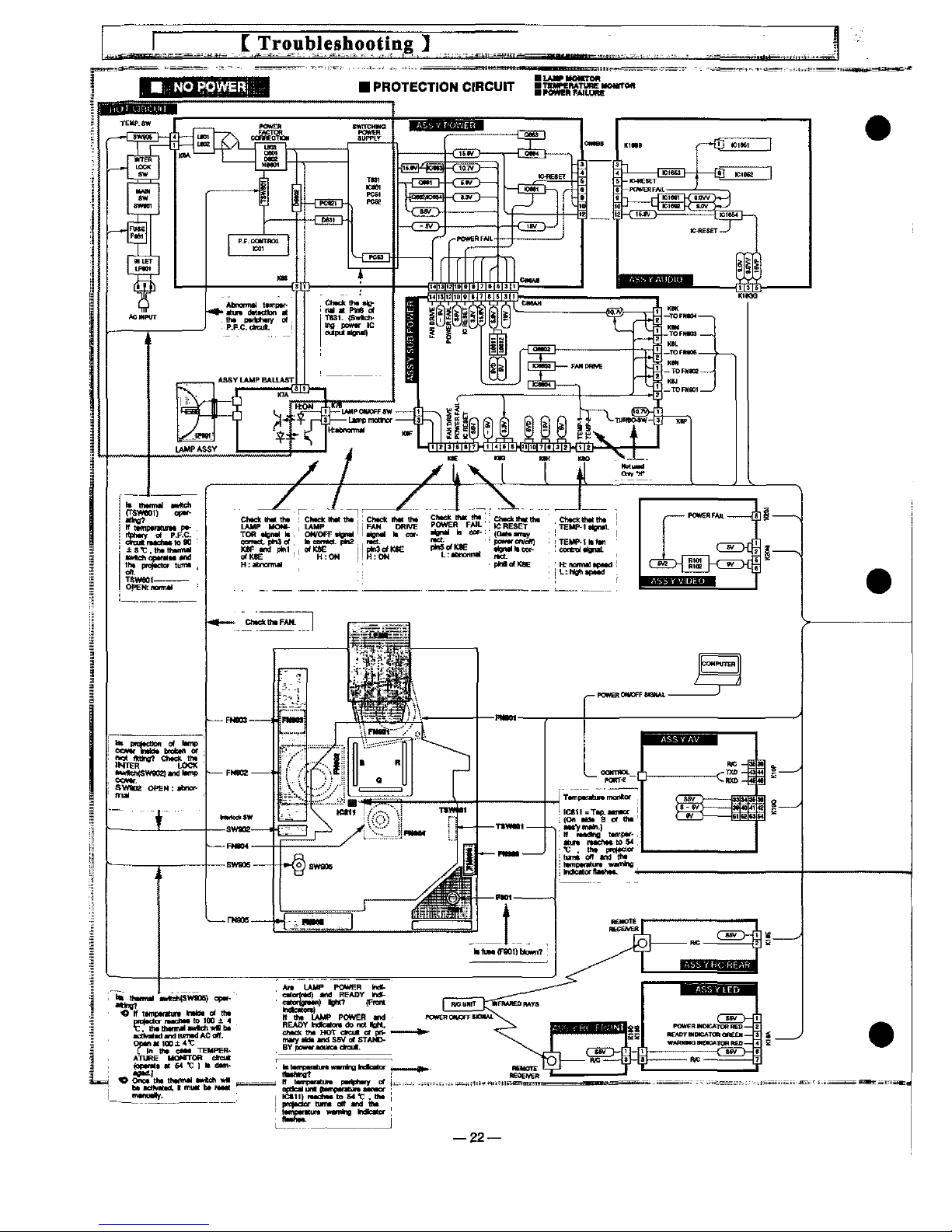

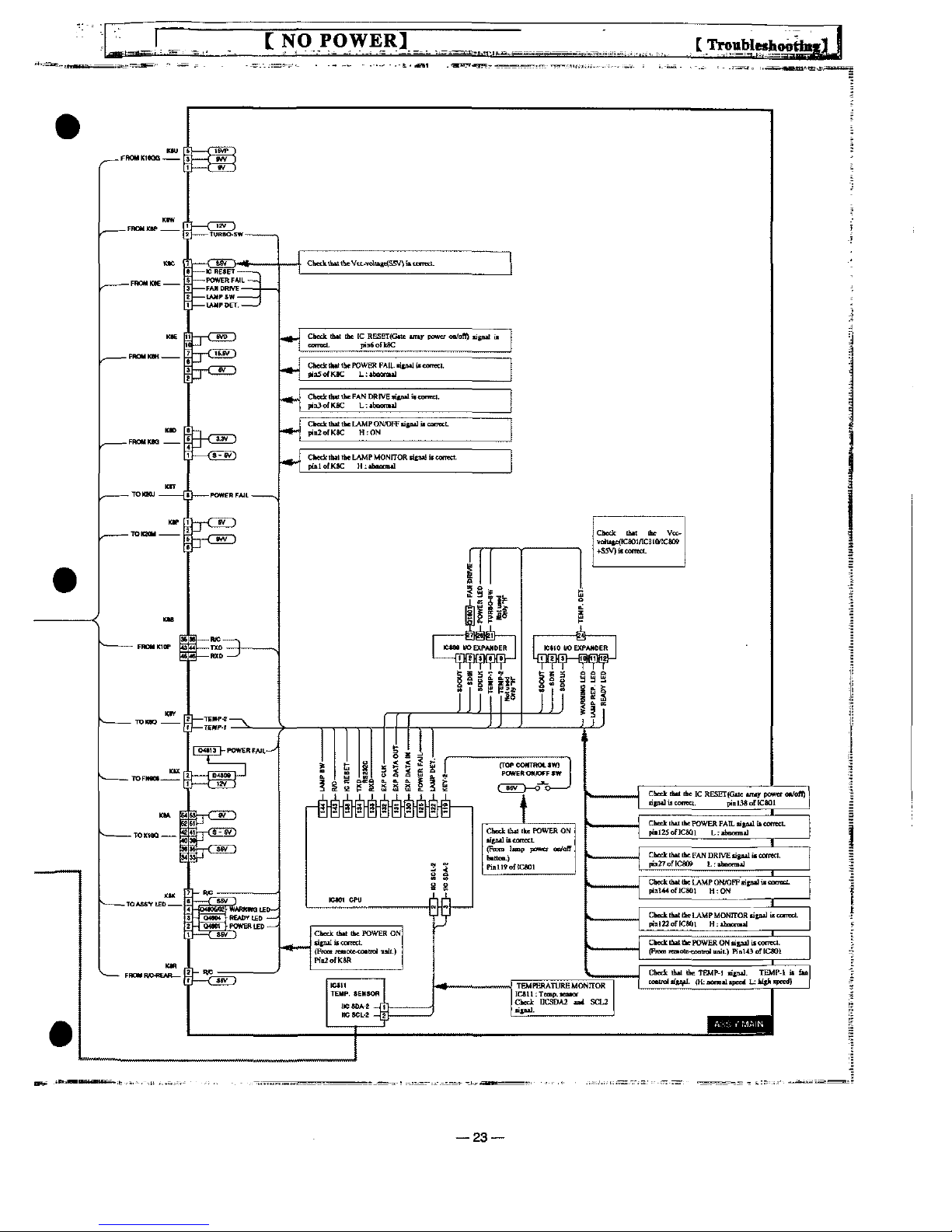

[

NO

POWERJ

23

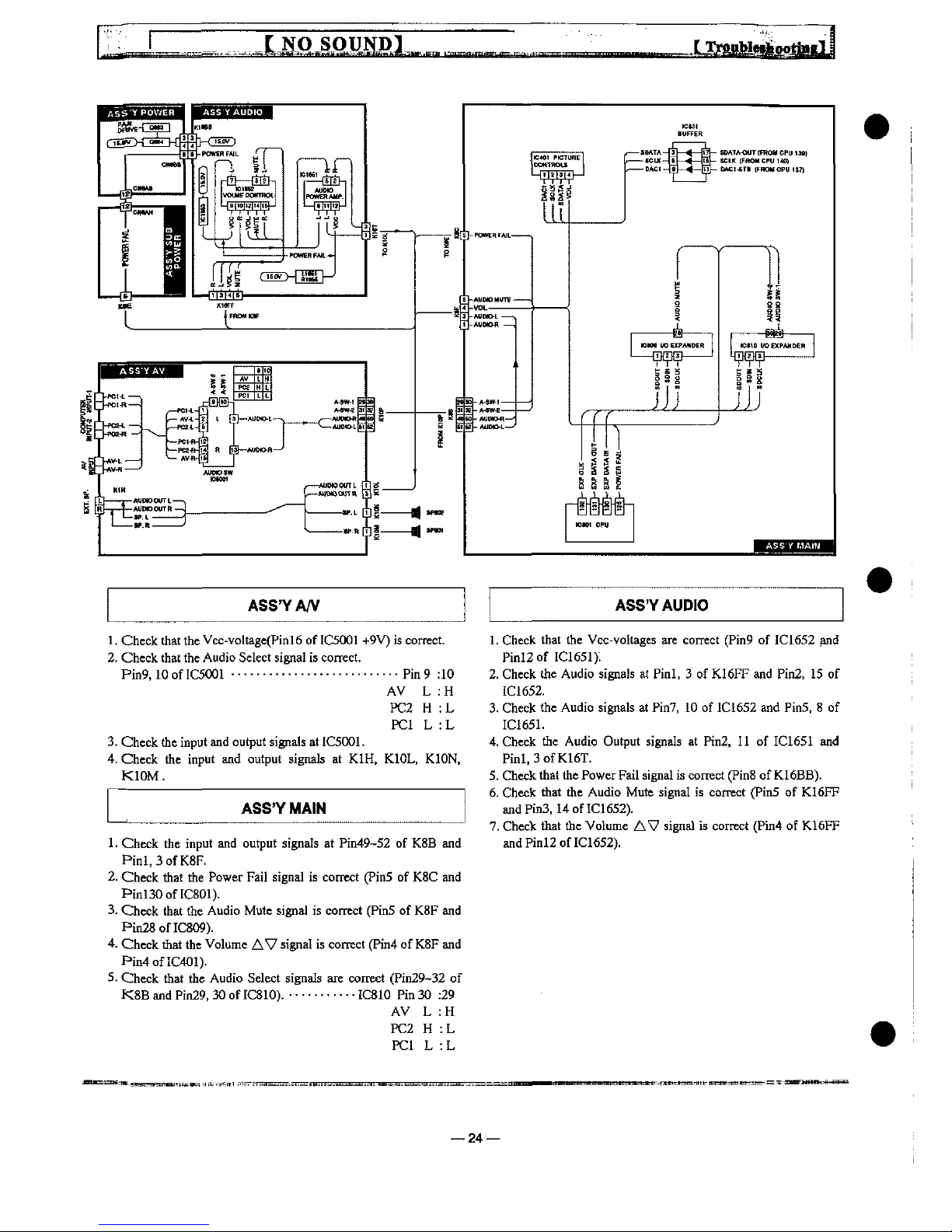

ASS'YA/V

ASS'YAUD!0

1.

Check

that

the

Vcc-vo)tage(Pinl6

of

IC5001

+9V)

is

comet.

2.

Check

that

the

Audio

Select

signal

is

correct.

Pin9.10

ofIC5001---------------------------Pin9:10

AV

L:H

PC2H:L

PC1

L:L

3.

Check

the

input

and

output

signals

at

IC5001.

4.

Check

the

input

and

output

signals

at

KIH.

K10L,

K10N.

K10M.

1.

Check

the

input

and

output

signals

at

Pin49-52

of

K88

and

Pinl,3ofK8F.

2.

Check

that

the

Power

Fai)

signa)

is

correct

(Pin5

of

K8C

and

Pinl30ofIC801).

3-

Check

that

the

Audio

Mute

signa)

is

correct

(Pin5

of

K8F

and

Pm28ofIC809).

4.

Check

that

the

Volume

AV

signal

is

correct

(Pin4

of

K8F

and

F'in4ofIC401).

5.

Check

that

the

Audio

Select

signals

are

correct

(Pin29-32

of

K8B

and

Pin29.

30

of

IC810).

.-.......--

IC810

Pin

30

:29

AV

L:H

PC2H:L

PC1

L:L

1.

Check

that

the

Vcc-voftages

are

correct

(Pin9

of

IC1652

and

Pinl2of

IC1651).

2.

Check

the

Audio

signa!s

at

Pinl. 3 of

K16FF

and

Pin2.

15

of

IC1652.

3.

Check

the

Audio

signals

at

Pin7.

10

of

IC1652

and

Pin5, 8 of

IC1651.

4.

Check

the

Audio

Output

signals

at

Pin2,

11

of

IC1651

and

Pinl,3ofK16T.

5.

Check

that

the

Power

Fait

signal

is

correct

(Pin8

of

K16BB).

6.

Check

that

the

Audio

Mute

signal

is

correct

(Pin5

of

K16FF

andPinS,

14

of

IC1652).

7.

Check

that

the

Volume

AV

signa)

is

correct

(Pin4

of

K16FF

and

Pinl2of

IC1652).

24—

Loading...

Loading...