Page 1

Multimedia Projector

SERVICE MANUAL

PRODUCT CODE

1 122 223 00 (MP3A)

1 122 226 00 (PP3A)

1 122 226 02 (PP3C)

Original Version

REFERENCE NO. SM5110522

FILE NO.

Model No. PLC-SW30

U.S.A., Canada,

Europe, Asia, Africa

Chassis No. MP3-SW3000

NOTE: Match the Chassis No. on the unit’s

back cover with the Chassis No. in the

Service Manual.

If the Original Version Service

Manual Chassis No. does not match

the unit’s, additional Service

Literature is required.You must refer to

“Notices” to the Original Service

Manual prior to servicing the unit.

Page 2

2

■ Contents

■ Safety instructions ________________________________________________3

■ Specifications __________________________________________________ 4

■ Circuit protections ______________________________________________ 5-6

● Fuse ____________________________________________________ 5

● Thermal switch ____________________________________________ 5

● Lamp cover switch __________________________________________ 5

● Warning temperature and power failure protection ________________ 6

■ Lamp replacement ______________________________________________ 7

■ Mechanical disassemblies ______________________________________ 8-13

■ Optical parts disassemblies ____________________________________ 14-16

■ LCD panel/prism ass’y replacement ________________________________ 17

■ Adjustments after parts replacement ________________________________ 18

■ Optical adjustments __________________________________________ 19-21

● Contrast adjustment ________________________________________ 19

● Condenser lens adjustment __________________________________ 20

● Relay lens adjustment ______________________________________ 21

■ Electric adjustments __________________________________________ 22-30

● Service adjustment menu operation ____________________________ 22

● Circuit adjustments ______________________________________ 23-25

● Service adjustment data table ______________________________ 26-29

● Test points and locations ____________________________________ 30

■ Circuit block diagrams ________________________________________ 31-33

■ Power supply lines ______________________________________________ 34

■ Troubleshooting ______________________________________________ 35-38

● Indicators and Projector Condition ____________________________ 35

● No power ________________________________________________ 36

● No picture ________________________________________________ 37

● No sound ________________________________________________ 38

■ Waveforms ____________________________________________________ 39

■ Control port functions ________________________________________ 40-43

■ Cleaning ______________________________________________________ 44

■ IC block diagrams ____________________________________________ 45-48

■ Service parts lists ____________________________________________ 49-67

● Electrical parts list ______________________________________ 49-63

● Mechanical parts list ____________________________________ 64-65

● Optical parts list ________________________________________ 66-67

Drawings & Diagrams ________________________________________ A1-A9

■ Parts description and reading in schematic diagram____________________ A2

■ Schematic diagrams __________________________________________ A3-A6

■ Printed wiring board diagrams __________________________________ A7-A8

■ Pins description of ICs, transistors, diodes __________________________ A9

Page 3

3

■ Safety Instructions

WARNING:

The chassis of this projector is isolated (COLD) from AC line by using the converter transformer. Primary side of

the converter and lamp power supply unit circuit is connected to the AC line and it is hot, which hot circuit is identified with the line ( ) in the schematic diagram. For continued product safety and protection of personnel

injury, servicing should be made with qualified personnel.

The following precautions must be observed.

SAFETY PRECAUTIONS

1: An isolation transformer should be connected in the

power line between the projector and the AC line

before any service is performed on the projector.

2: Comply with all caution and safety-related notes pro-

vided on the cabinet back, cabinet bottom, inside the

cabinet or on the chassis.

3: When replacing a chassis in the cabinet, always be

certain that all the protective devices are installed

properly, such as, control knobs, adjustment covers

or shields, barriers, etc.

DO NOT OPERATE THIS PROJECTOR WITHOUT

THE PROTECTIVE SHIELD IN POSITION AND

PROPERLY SECURED.

4: Before replacing the cabinet cover, thoroughly

inspect the inside of the cabinet to see that no stray

parts or tools have been left inside.

Before returning any projector to the customer, the

service personnel must be sure it is completely safe to

operate without danger of electric shock.

SERVICE PERSONNEL WARNING

Eye damage may result from directly viewing the light produced by the Lamp used in this equipment. Always turn

off Lamp before opening cover. The Ultraviolet radiation eye protection required during this servicing.

Never turn the power on without the lamp to avoid electric-shock or damage of the devices since the stabilizer

generates high voltages(15kV - 20kV) at its starts.

Since the lamp is very high temperature during units operation replacement of the lamp should be done at least

45 minutes after the power has been turned off, to allow the lamp cool-off.

PRODUCT SAFETY NOTICE

Product safety should be considered when a component replacement is made in any area of the projector.

Components indicated by mark in the parts list and the schematic diagram designate components in which

safety can be of special significance. It is, therefore, particularly recommended that the replacement of there parts

must be made by exactly the same parts.

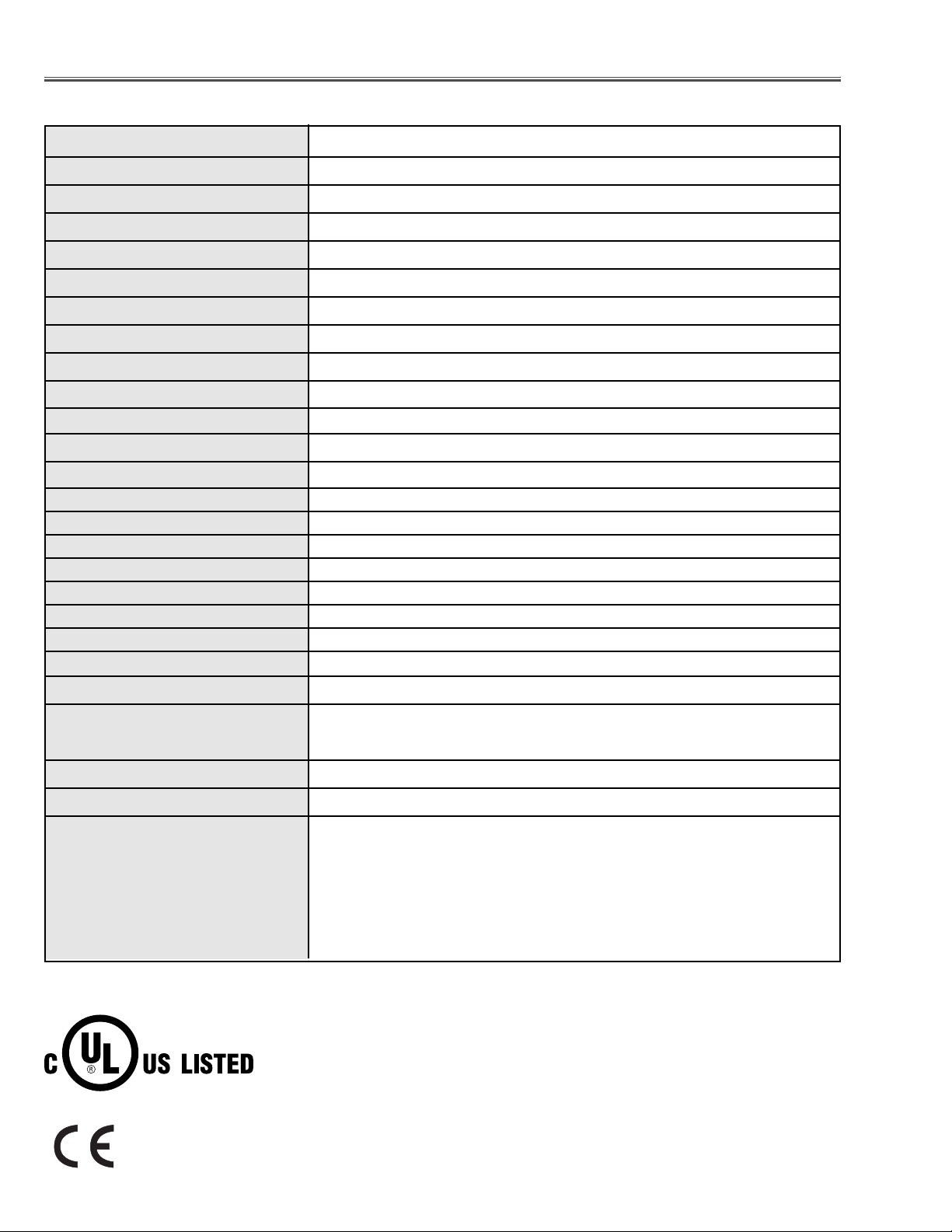

Page 4

4

■ Specifications

● The specifications are subject to change without notice.

This symbol on the nameplate means the product is Listed by Underwriters

Laboratories Inc. It is designed and manufactured to meet rigid U.L. safety standards against risk of fire, casualty and electrical hazards.

Projector Type Multi-media Projector

Dimensions (W x H x D) 10.63” x 3.07” x 7.48” (270mm x 78mm x 190mm) (not including Adjustable Feet)

Net Weight 4.6 lbs (2.1 kg)

LCD Panel System 0.5” TFT Active Matrix type, 3 panels

Panel Resolution 800 x 600 dots

Number of Pixels 1,440,000 (800 x 600 x 3 panels)

Color System PAL, SECAM, NTSC, NTSC4.43, PAL-M and PAL-N

High Definition TV SIgnal 480i, 480p, 575i, 575p, 720p, 1035i and 1080i

Scanning Frequency H-sync. 15 ~ 80 kHz, V-sync. 50 ~ 100 Hz

Projection Image Size (Diagonal) Adjustable from 34” to 200”

Projection Lens F 1.6 ~ 1.8 lens with f 18.3 mm ~ 21.9 mm with manual zoom and focus

Throw Distance 4.3’ ~ 21.2’ (1.3 m ~ 6.5 m)

Projection Lamp 160 W

Video Input Jack RCA Type x 1 (Video) and and Mini DIN 4 pin x 1 (S-Video)

AV Audio Input Jack Mini Jack (stereo) x 1

Computer Input Terminal (VGA) HDB 15 Terminal x 1

Computer Audio Input Jack Mini Jack (stereo) x 1

Control Port Connector Mini DIN 8 pin x 1

USB Connector USB Series B receptacle x 1

Internal Audio Amp 0.8 W RMS

Build-in Speaker 1 speaker, ø1.3" (32 mm)

Feet Adjustment 0˚ to 8.0˚

Voltage and AC 100 ~ 120V (2.4A Max. Ampere), 50/60Hz (The U.S.A and Canada)

Power Consumption AC 200 ~ 240V (1.2A Max. Ampere), 50/60Hz (Continental Europe and The U.K.)

Operating Temperature 41 ˚F ~ 95 ˚F (5˚C ~ 35˚C)

Storage Temperature 14 ˚F ~ 140 ˚F (-10˚C ~ 60˚C)

Remote Control Unit Wireless Remote Control, batteries AAA, SUM-04 or R03 type x 2

Presentation Remote Control, batteries AAA, SUM-04 or R03 type x 2

Presentation Remote Receiver

The CE Mark is a Directive conformity mark of the European Community (EC).

Page 5

-5-

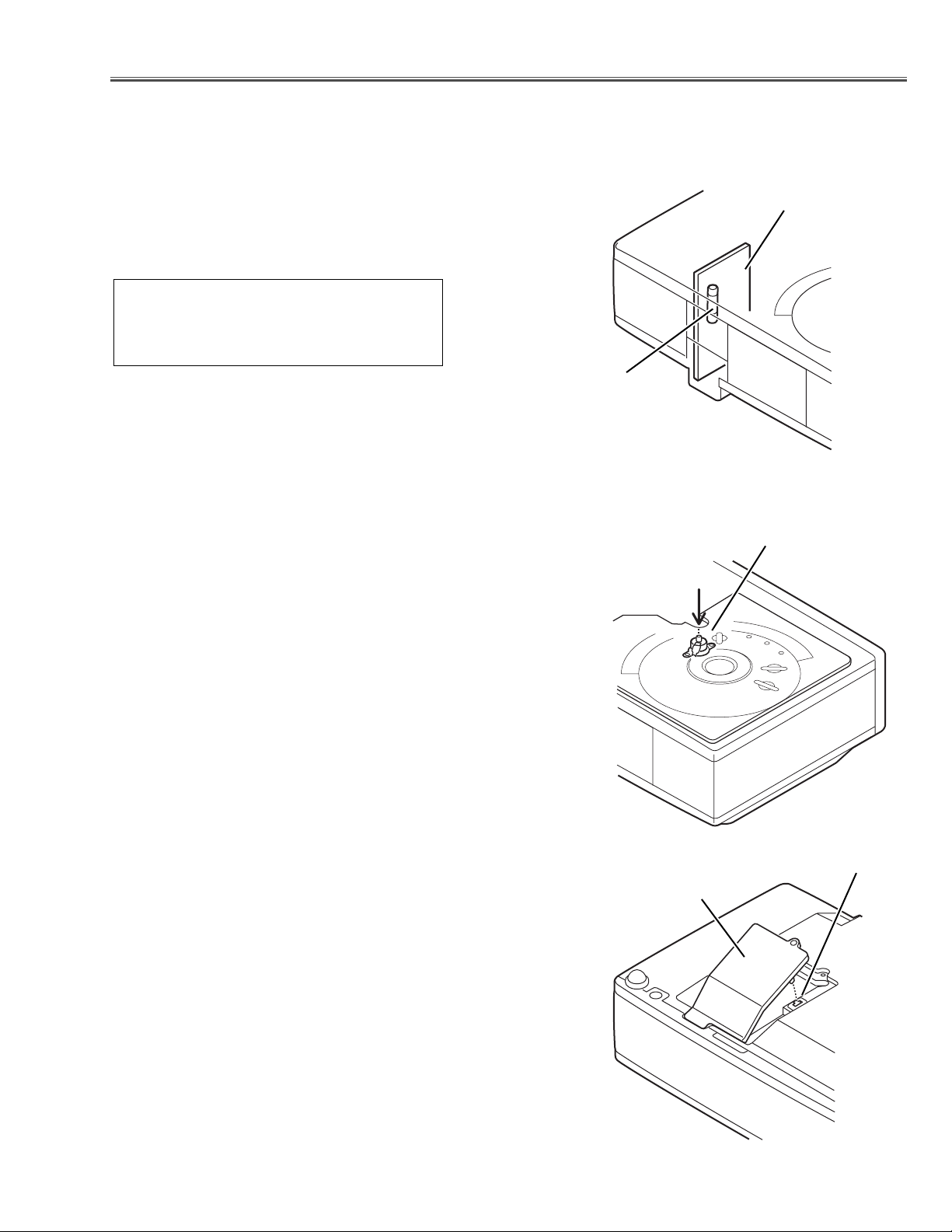

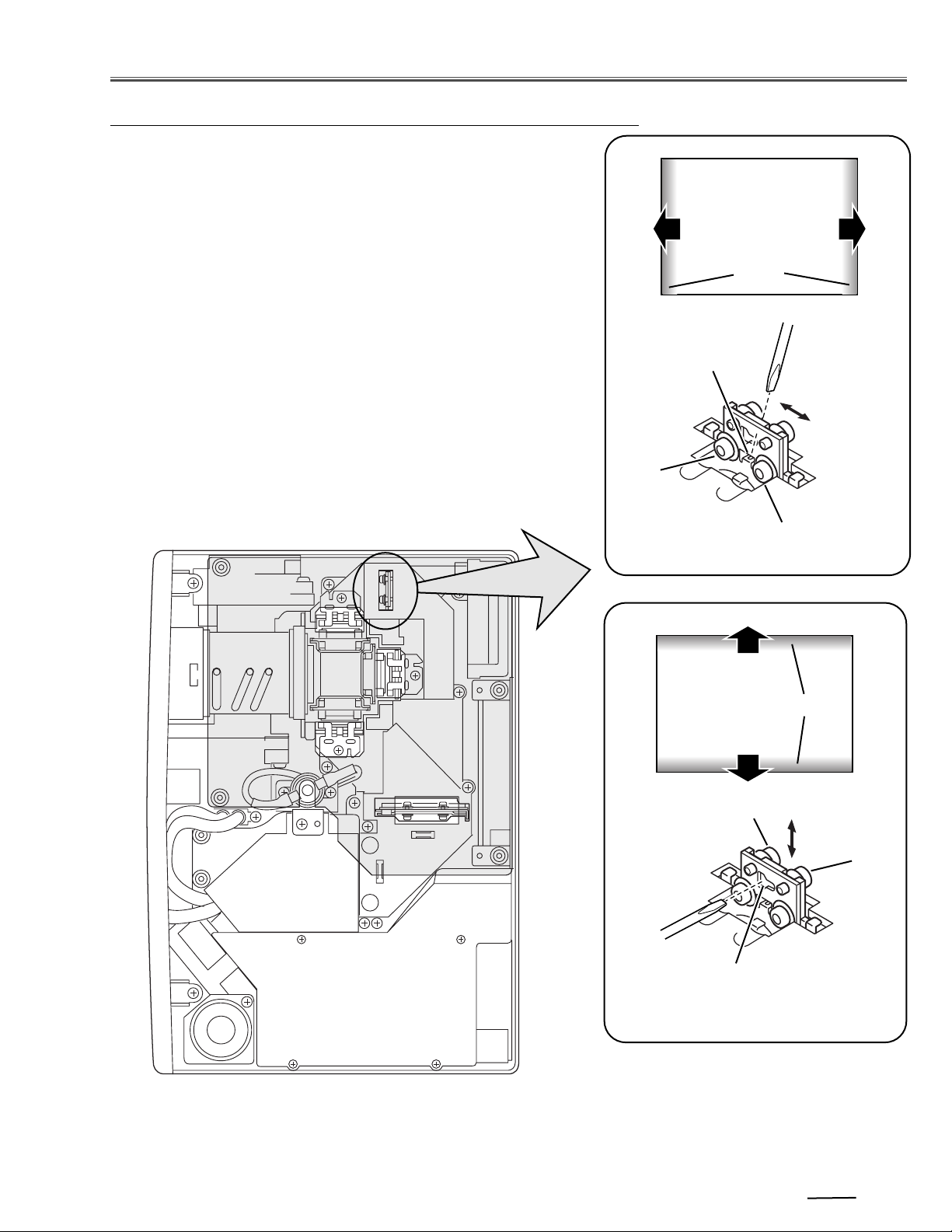

● Lamp cover switch

The lamp cover switch (SW8801) cuts off the drive signal to the

lamp circuit when the lamp cover is removed or no close completely. After opening the lamp cover for replacing the lamp ass’y,

place the lamp cover correctly otherwise the projector can not

turn on.

● Thermal switch

There is the thermal switch (SW902) inside of the projector to

prevent the internal temperature rising abnormally. When the

internal temperature reaches near 100˚C, turn off the AC main

power supply automatically.

The thermal switch is not reset to normal automatically even if the

internal temperature becomes normal. Reset the thermal switch

following procedure.

Check the resistance between terminals of thermal switch by

using the tester. If it has high impedance, thermal switch may be

in operative.

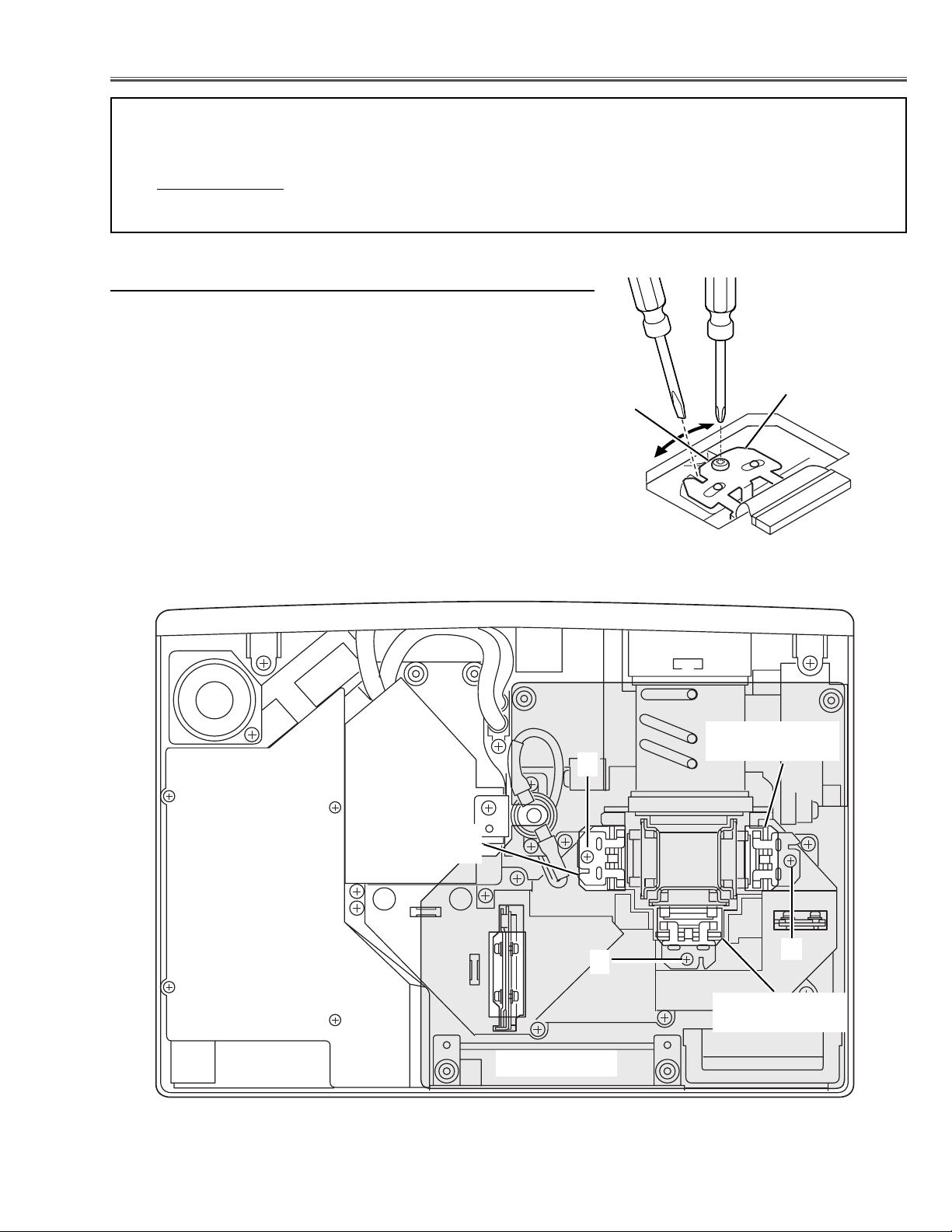

How to reset the thermal switch

1.

Remove the cabinet top following to “Mechanical

Disassemblies”.

2. Press the reset button on the thermal switch with a sharp-

pointed tool.

CAUTION:

Before press the reset button, make sure that the AC cord must

be disconnected from the AC outlet.

■ Circuit Protections

This projector provides the following circuit protections to operate in safety. If the abnormality occurs inside the projector, it will automatically turn off by operating one of the following protection circuits.

● Fuse

A fuse is located inside of the projector. When the POWER indicator is not lightning, the fuse may be opened. Check the fuse as following steps.

The fuse should be used with the following type;

How to replace the fuse

1. Remove the cabinet top following to “Mechanical

Disassemblies”.

2. Remove the cover on the Filter Board.

3. Remove fuse from fuse holder.

To install the fuse, take reversed step in the above.

Fuse Part No.: 423 022 2102

TYPE T4.0AH 250V FUSE

LITTEL FUSE INC. TYPE 215004

Fuse

Filter Board

Thermal Switch

Lamp Cover

Lamp Cover Switch

Page 6

-6-

Circuit Protections

● Warning temperature and power failure protection

The WARNING indicator flashes red and the projector will automatically turn off when the internal temperature of

the projector exceeds the normal temperature or when stopping cooling fans or when the internal power supply

lines are failed.

Check the following possible causes and wait until stopping the WARNING indicator flashing.

Possible causes

- Air filter is clogged with dust particles. Remove dust from the air filter by following instructions in the “Air filter

care and cleaning” below.

- Ventilation slots of the projector are blocked. In such an event, reposition the projector so that ventilation slots are

not obstructed.

- Check if projector is used at higher temperature place (Normal operating temperature is 5 to 35 ˚C or 41 to 95˚F)

If the WARNING indicator still continues to flash, there may be defects on cooling fans or power supply circuits.

Please check fan operation and power supply lines referring to the “Power Supply Lines Chart”.

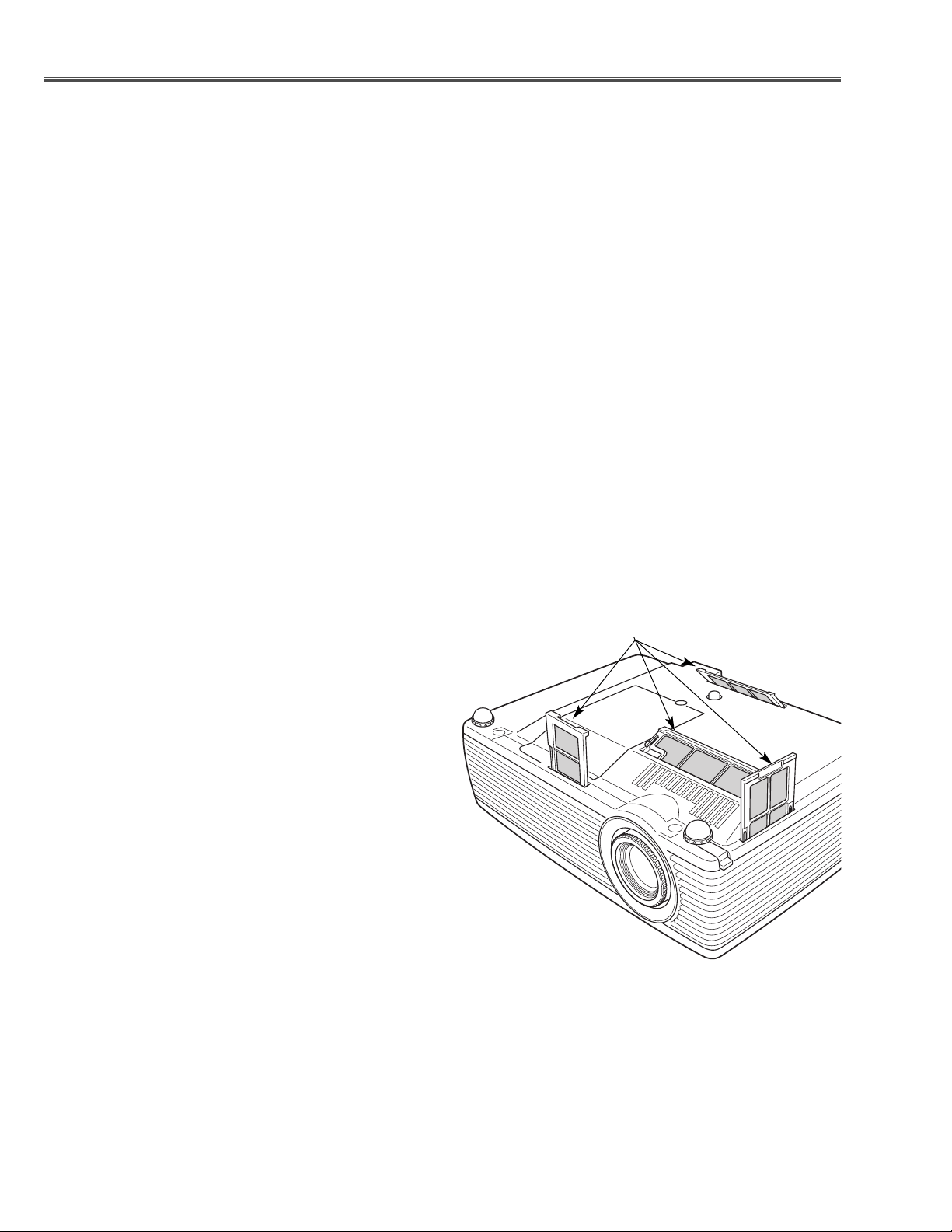

Air filter care and cleaning

The removable air filter prevents dust from accumulation on the surface of the projection lens and projection mirror.

Should the air filters become clogged with dust particles, it will reduce the cooling fan’s effectiveness and may

result in internal heat build up and adversely affect the life of the projector.

To clean up the air filters, follow the cleaning procedure

below:

1. Tu rn the projector off, and disconnect the AC power

cord from the AC outlet.

2. Tu rn the projector upside down and remove the air fil-

ters by pulling the latches upward.

3. Clean the air filters with a brush or wash out dust and

particles.

4. Replace each air filter properly. Make sure that the air

filters are fully inserted.

CAUTION:

Do not operate the projector with the air filters removed.

Dust may accumulate on the LCD panel and the mirror,

and it may spoil the fine picture image.

Do not put the small parts into the air intake vents. It may

result in the malfunction of the projector. The air filter is

small parts. Take care that children don’t eat or swallow it.

RECOMMENDATION

We recommend avoiding dusty, smoky environments when operating the projector. Usage in these environments

may cause poor image quality.

When using under dusty or smoky conditions, dust may accumulate on optical elements inside the projector. The

condition may degrade the quality of a projected image.

When the above symptoms are noticed, please clean up the LCD panel and lens following to the “Cleaning

Method”.

Air filters

Page 7

-7-

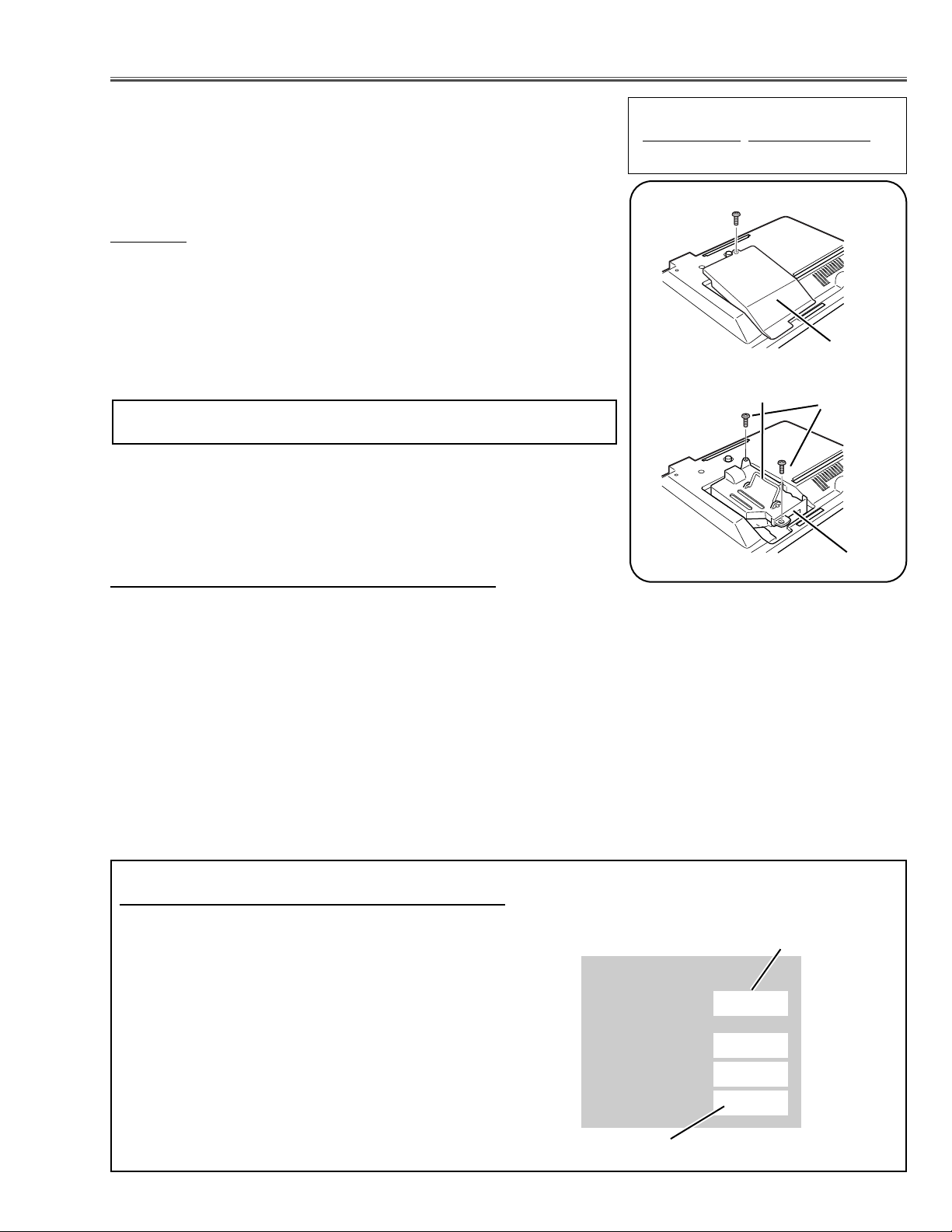

WARNING:

- Allow a projector to cool, for at least 45 minutes before you open Lamp

Cover. The inside of a projector can become very hot.

- For continued safety, replace with a lamp assembly of the same type.

- Do not drop a lamp assembly or touch a glass bulb! The glass can

shatter and may cause injury.

Procedure

1 Tu rn off the projector and disconnect the AC plug. Allow the projector to

cool at least for 45 minutes.

2 Remove 1 screw and remove the lamp cover.

3 Remove 2 screws and pull out the lamp assembly by grasping the han-

dle.

4 Replace the lamp assembly securely and tighten 2 screws.

5 Close the lamp cover and tighten 1 screw.

6 Connect the AC Power Cord to the projector and turn on the projector.

Note:

- Do not reset the Lamp Replace Counter, except after lamp is replaced.

- The projector can not be turned-on with lamp cover removed, because

when the lamp cover is removed, the lamp cover switch is also released

to switch off the mains power for safety.

7 Reset the Lamp Replace Counter, see below explanation.

■ Lamp Replacement

1 Tu rn the projector on, and press the MENU button

and the on-screen menu will appear. Press the

POINT LEFT/RIGHT buttons to move the red frame

pointer to the Setting Menu icon.

2 Press the POINT DOWN button to move the red

frame pointer to “Lamp counter reset” and then press

the SELECT button. The message “Lamp replace

counter reset?” is displayed. Move the pointer to [Yes]

and then press the SELECT button.

3 Another confirmation dialog box appears and select

[Yes] to reset Lamp Replace Counter .

Please refer to the owners manual for further information.

Recommendation

Should the air filter become clogged with dust particles,

it will reduce the cooling fan’s effectiveness and may

result in internal heat build up and short lamp life. We

recommend cleaning the air filter after the projection

lamp is replaced.

Refer to “Air Filter Cleaning”.

The LAMP REPLACE indicator will light yellow when

the total lamp used time reaches 2000 hours. This is

to indicate that lamp replacement is required.

The total lamp used time is calculated by using the

below expression;

Total lamp used time = Teco + Tnomal (1+1/4)

Teco : used time in the Eco mode

Tnormal : used time in the Normal and Auto mode

You can check the lamp replace counter following to

below procedure.

1 Press and hold the POWER ON-OFF button on the

projector or the remote control unit for more than 20

seconds.

2 The projector used time and lamp used time will be

displayed on the screen briefly.

Lamp cover

Total lamp used time

ORDER REPLACEMENT LAMP

T

ype No.

Service Parts No.

POA-LMP57 610 308 3117

How to reset Lamp Replace Counter

How to check Lamp used time

Screws

Handle

Lamp Assembly

Screw

Projector used time

Counter

Projector

Lamp

Normal

Eco

130H

24H

100H

Total

130H

Page 8

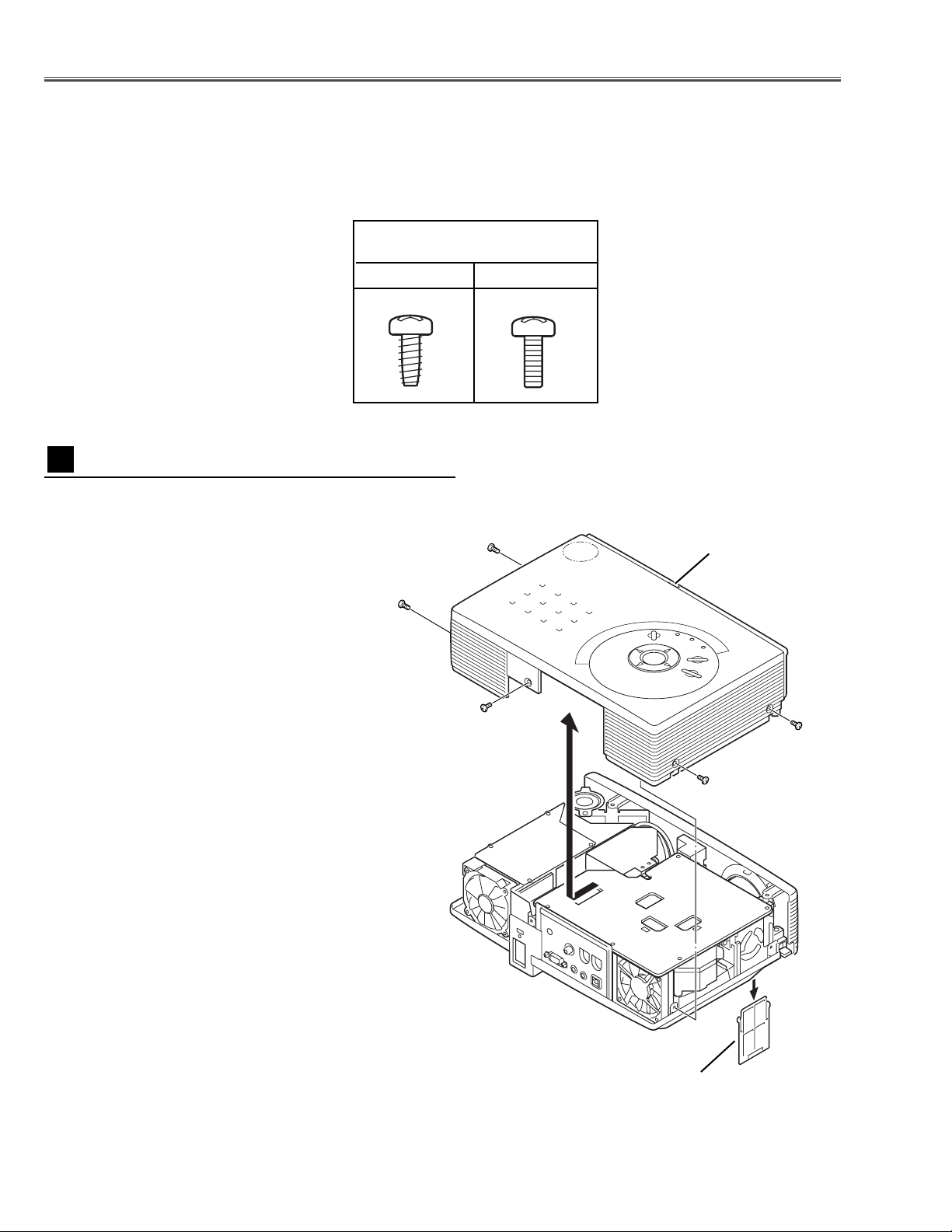

-8-

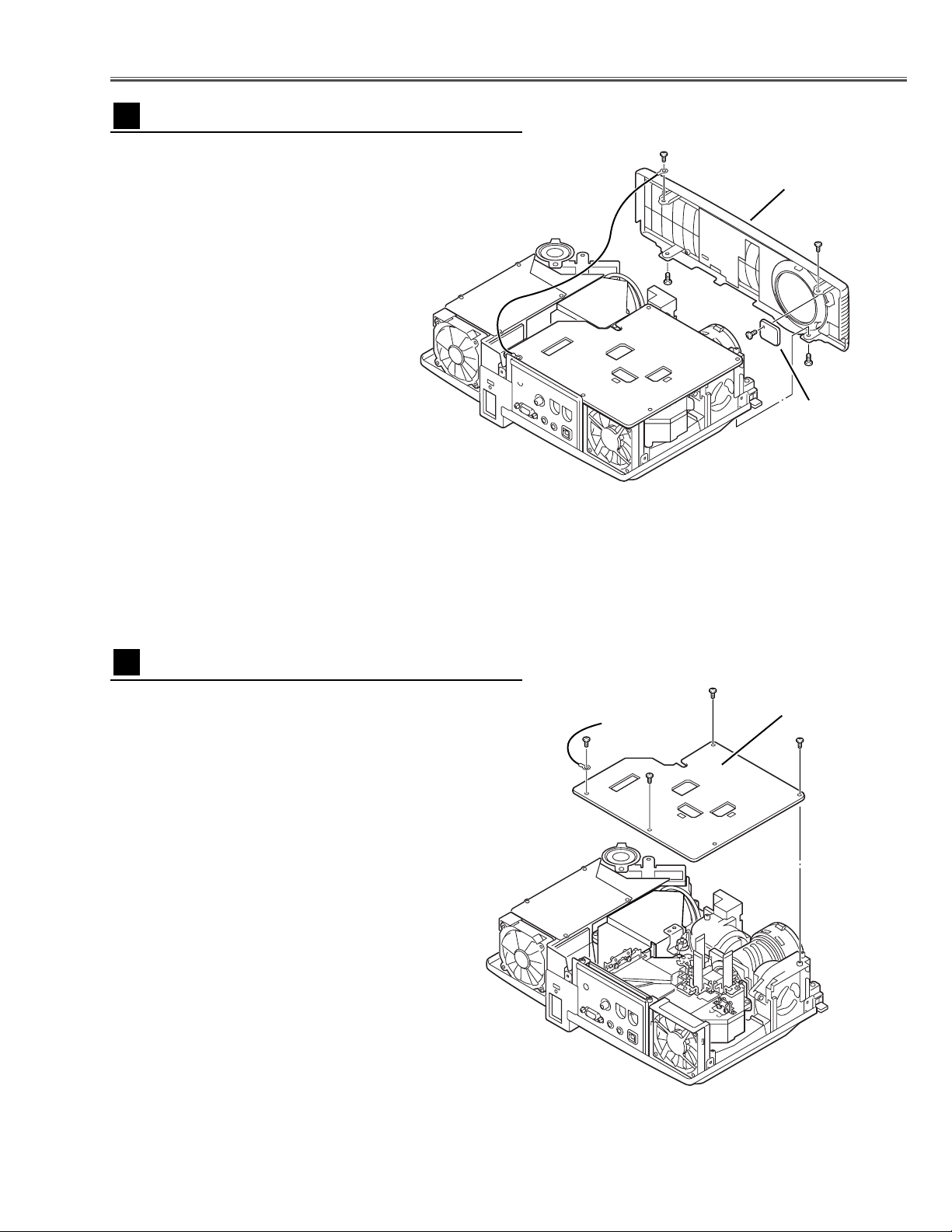

1 Remove the Air Filter in the side of the set at first.

(If not, the filter would be broken.)

2 Remove 4 screws A (M3x6) and 1 screw B (M3x8),

and then take the Cabinet Top upward off.

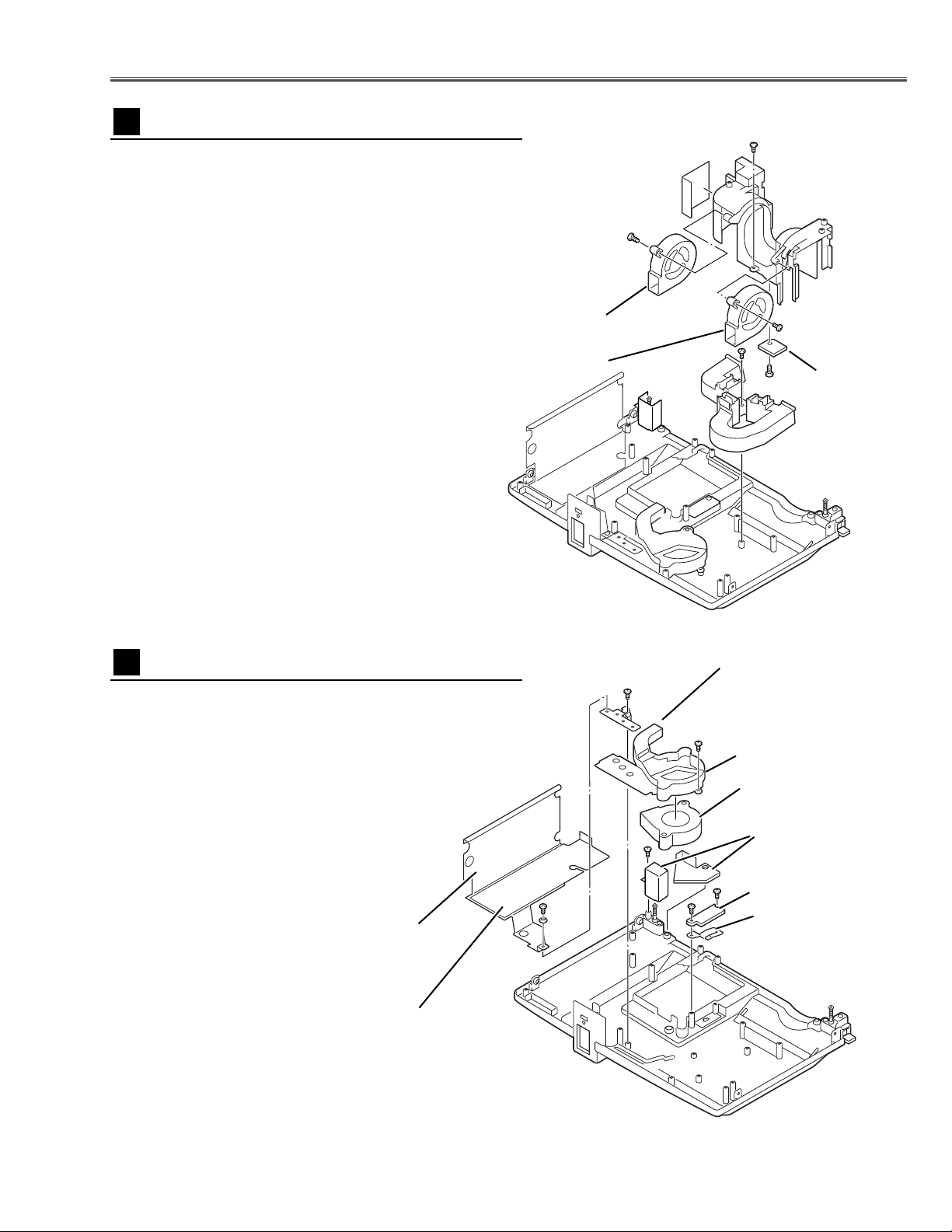

■ Mechanical Disassemblies

Mechanical disassemble should be made following procedures in numerical order.

Following steps show the basic procedures, therefore unnecessary step may be ignored.

Caution:

The parts and screws should be placed exactly the same position as the original otherwise it may cause loss of

performance and product safety.

Fig.1

Cabinet Top removal

1

Screws Expression

(Type Diameter x Length

) mm

T type M Type

A

A

A

B

A

Air filter (Panel net_side)

Cabinet Top

Page 9

-9-

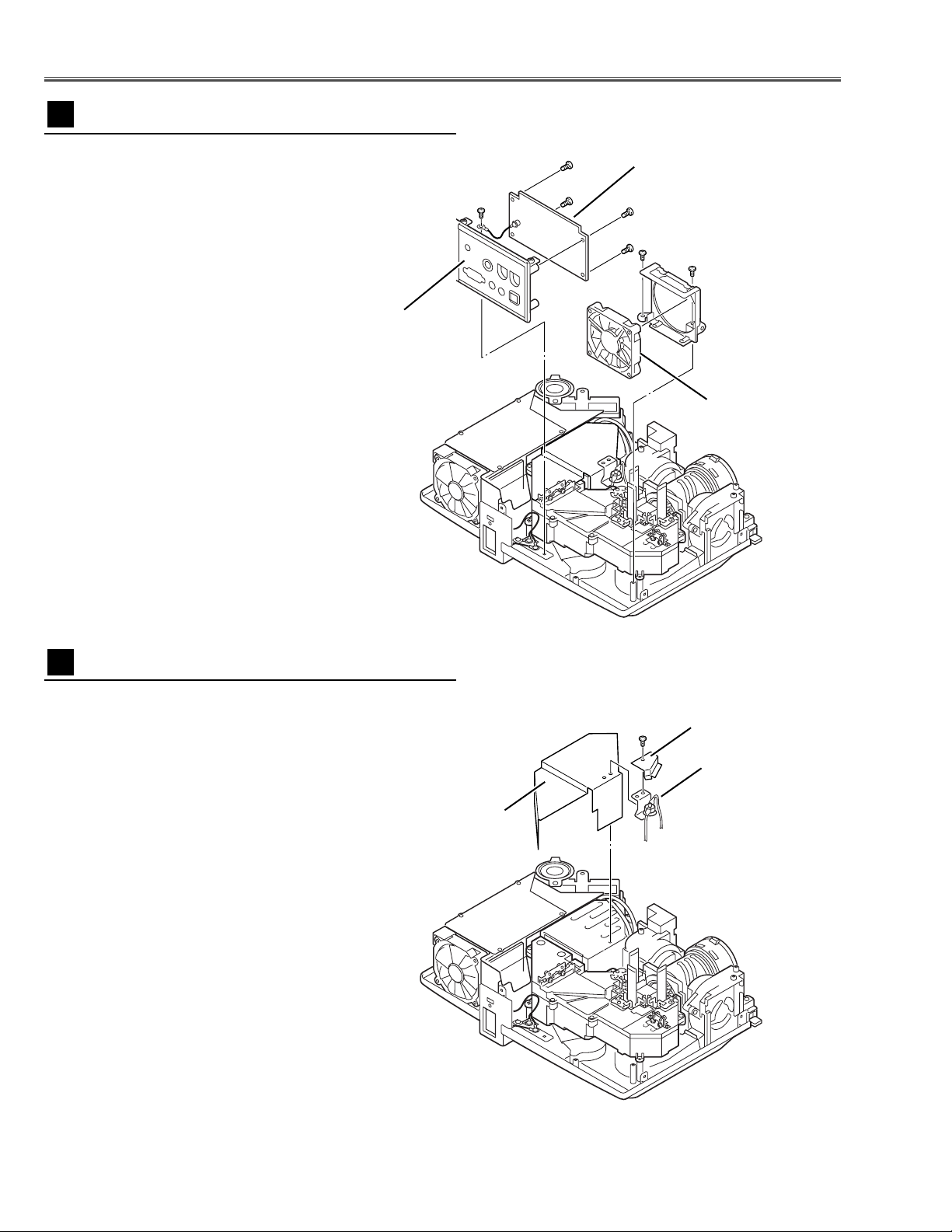

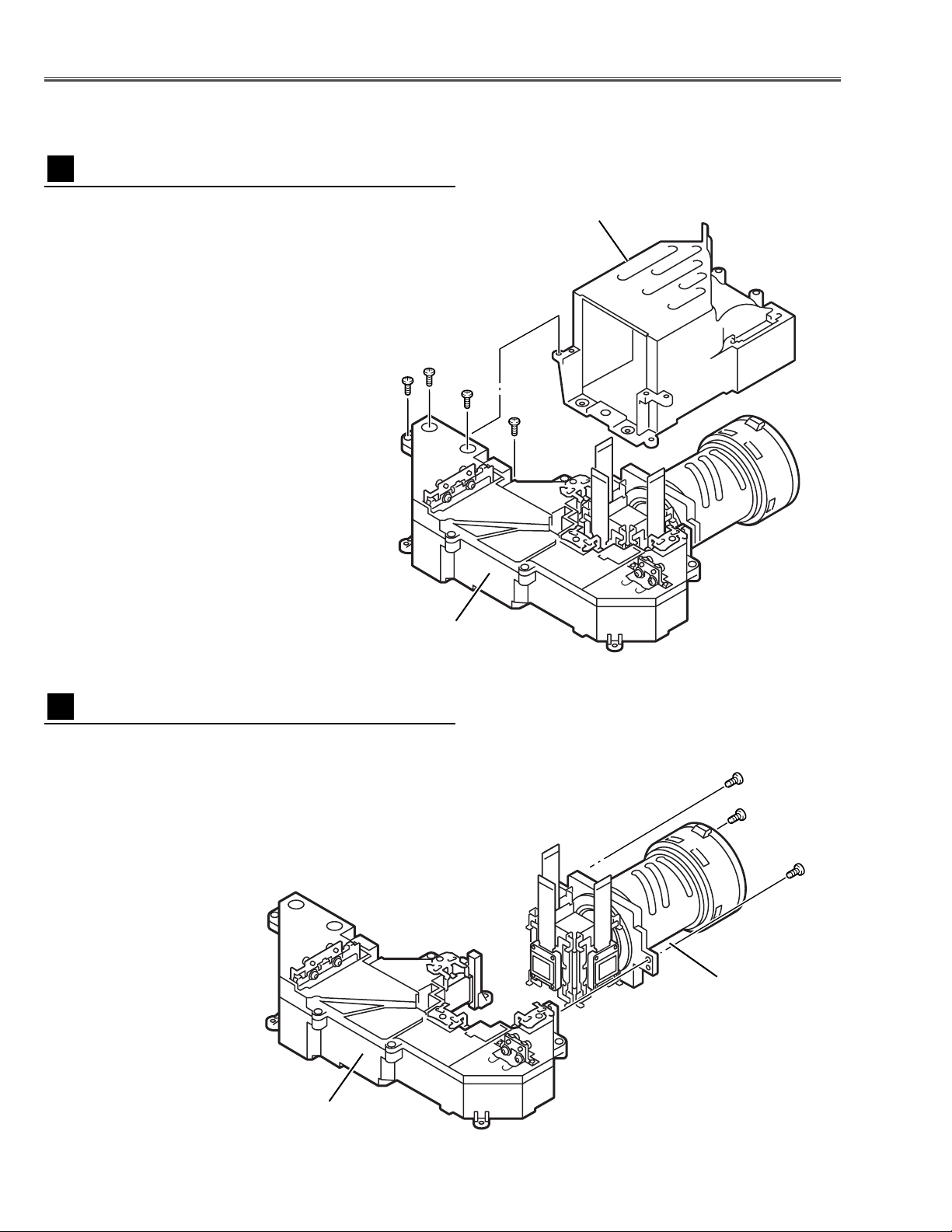

Mechanical Disassemblies

1 Remove 4 screws (M3x6) to take the Main Board upward.

Fig.3

Main Board removal

3

Main Board

1 Remove 2 screws A (M3x6) and 2 screws B (M3x6

black) to take the Cabinet Front off.

2 Remove 1 screw C (T3x6) to the R/C Board on the

Cabinet Front.

Fig.2

Cabinet Front and R/C Board removal

2

C

A

A

B

B

R/C Board

Cabinet Front

Page 10

-10-

Mechanical Disassemblies

1 Remove 1 screw (M3x6) to take the Thermal Switch

(SW902) and the Cover Spacer off.

Fig.5

Thermal SW removal

5

Thermal SW

Lamp Cover Spacer

Fig.4

1 Remove 1 screw A (M4x4) and take the Rear Panel

ass’y upward off.

2 Remove 2 screws B (T3x8) to take the fan (FN903) off.

3 Remove 4 screws C (T3x6) and take AV Board from the

Rear Panel ass’y off.

Rear Panel, AV Board and FN903 removal

4

A

B

C

B

C

C

C

AV Board

Rear Panel

FN903

Thermal SW Cover

Page 11

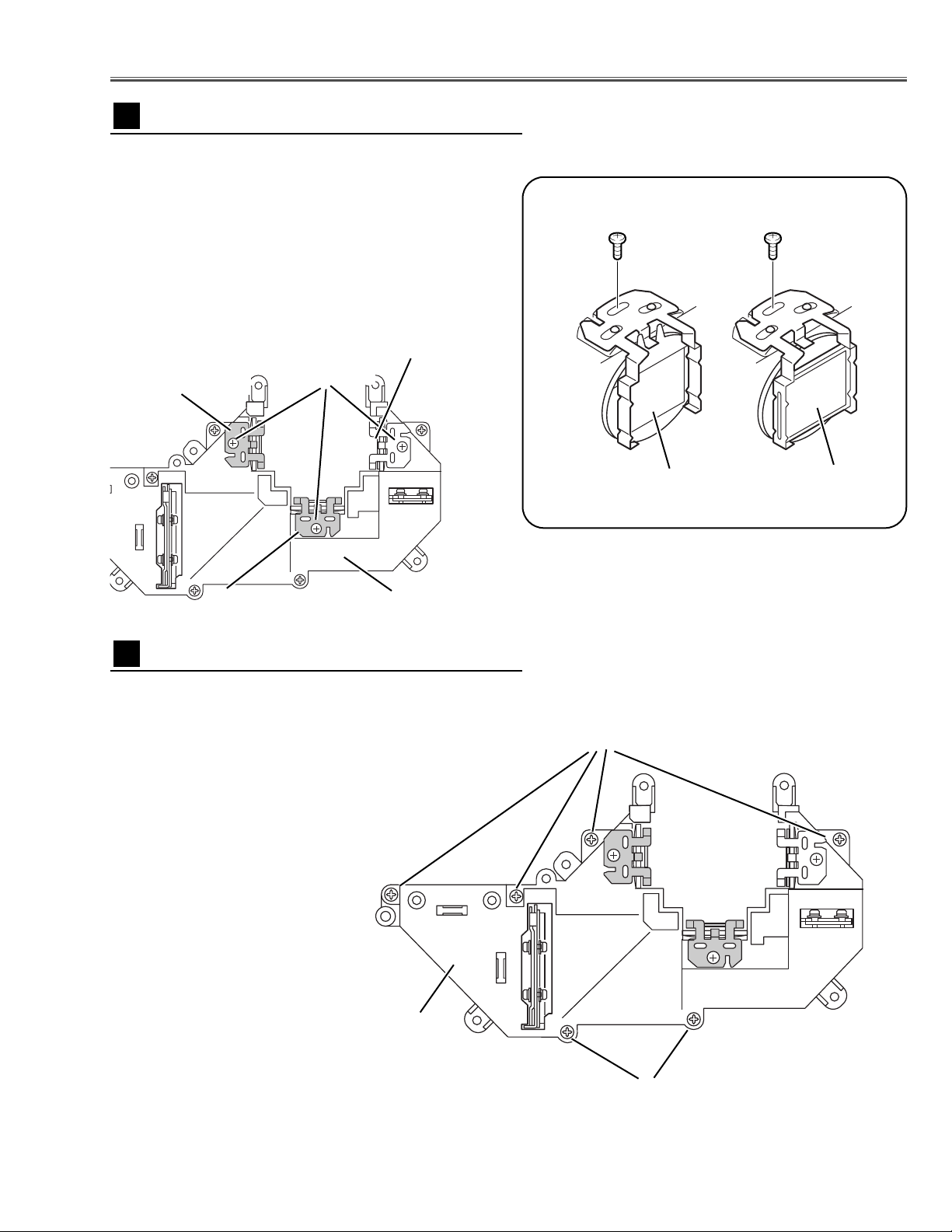

-11-

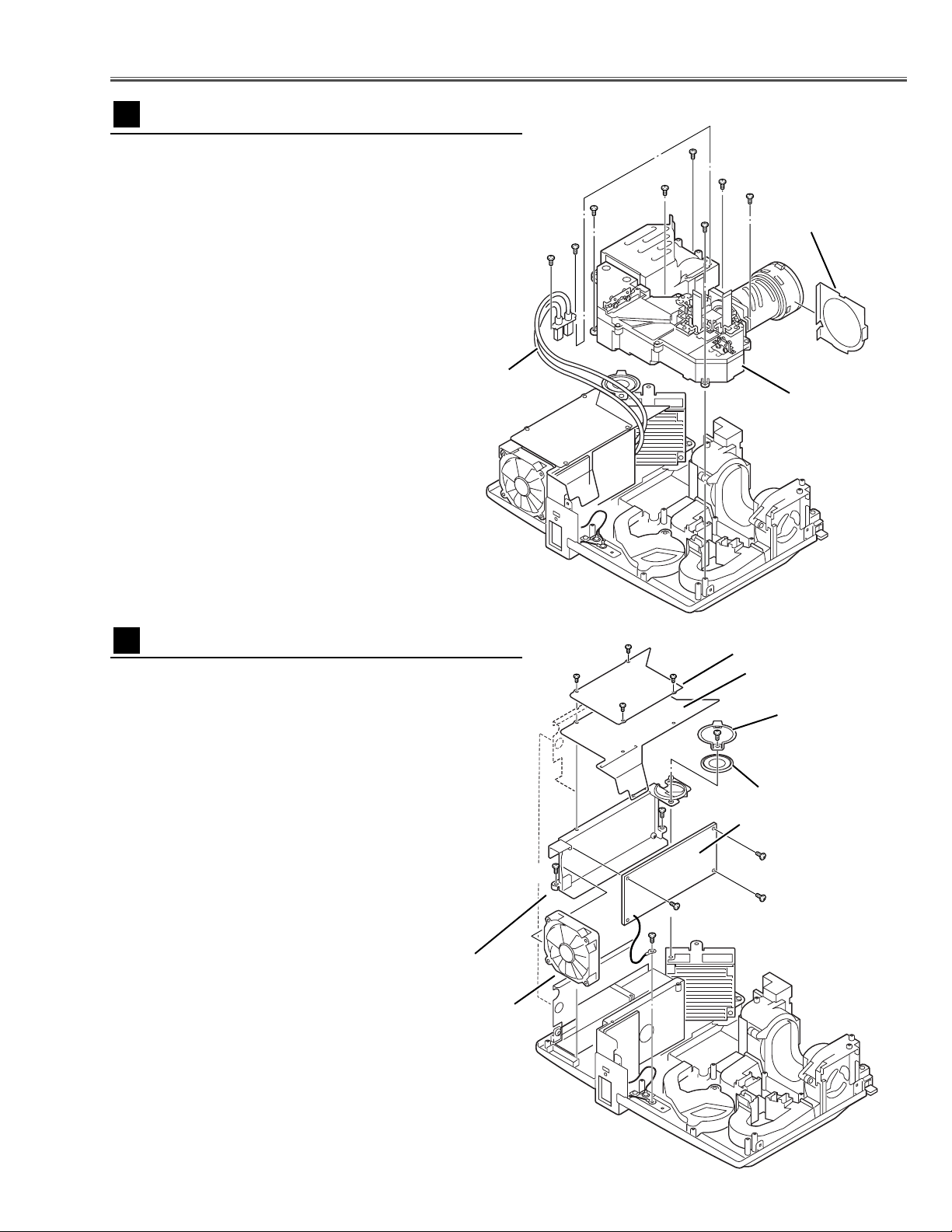

Mechanical Disassemblies

1 Remove 4 screws A (T2x4) to take off the spacer sheet

and the shield plate on the Power Board.

2 Remove 1 screw B (M3x8) to take the Speaker(SP901)

off.

3 Remove 2 screws C (T3x8) and 1 screw D (M4x4) to take

the Power Unit and the Fan(FN906) off.

4 Ta ke the Fan(FN906) from the Holder by pulling it.

5 Remove 3 screws E (T3x6) to take the Power Unit off.

Notes:

You can remove the connectors on the Power Unit

after the Lamp Ballast Unit removal.

Fig.7

Power Unit, Speaker and FN906 removal

7

A

A

A

A

B

E

E

E

D

C

Spacer Sheet

Speaker Holder

Speaker (SP901)

Power Board

FN906

Holder

Fig.6

1 Remove 2 screws A (M3x8) and take the Lamp Cable

off.

2 Remove 6 screws B (T3x10) and take the Optical Unit

upward off.

Optical Unit removal

6

A

A

B

B

B

B

B

B

Optical Unit

Lamp Cable

Shield Plate

C

Cover lens sheet

Page 12

-12-

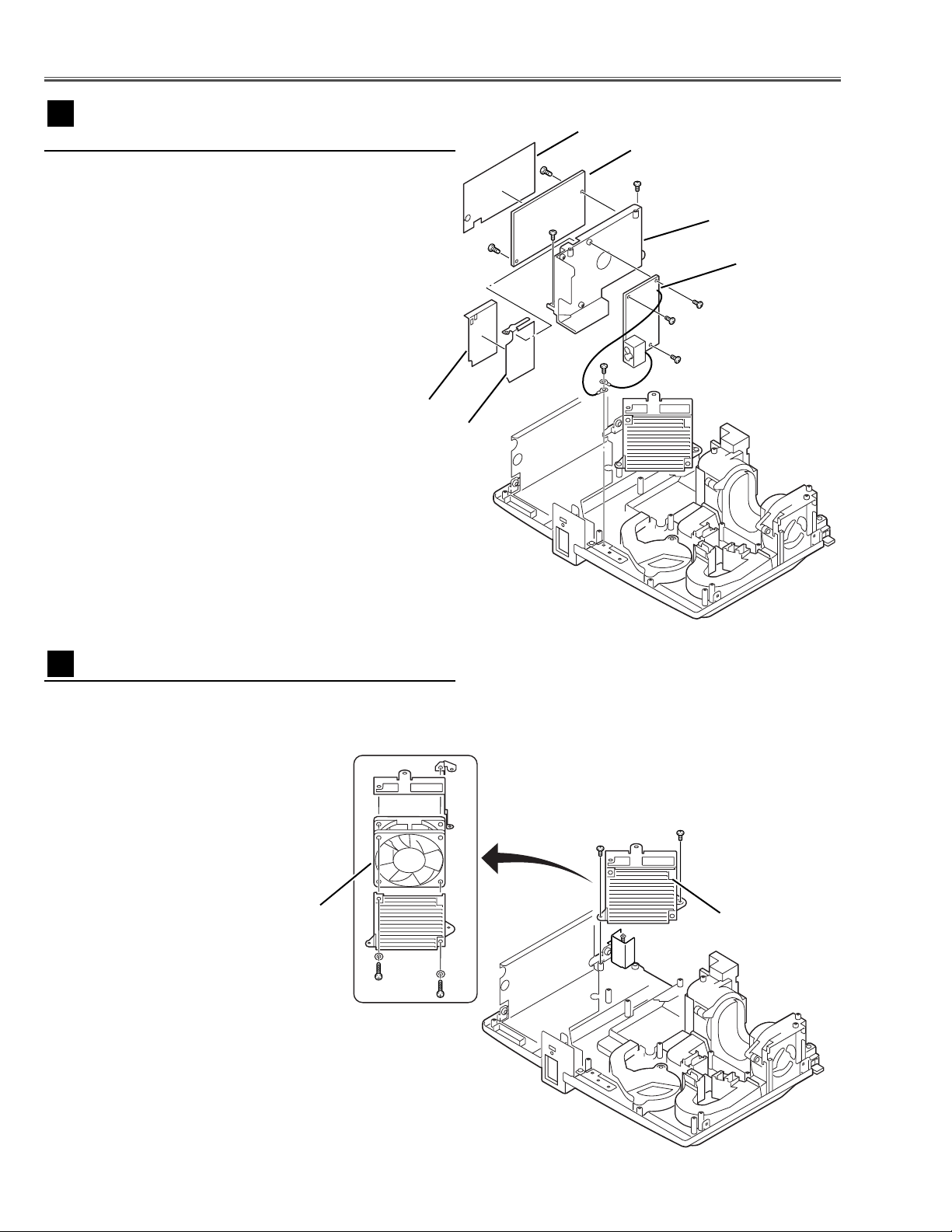

Mechanical Disassemblies

1 Remove 2 screws A (T3x8) to take the Fan (FN904)

ass'y off.

2 Remove 2 screws B (M3x30) to take the Fan (FN904)

off from the Fan mounting base.

Fig.9

FN904 removal

9

A

A

B

B

FN904 Ass'y

FN904

Fig.8

1 Remove 1 screw A (M4x4) to take the Earth cable off.

2 Remove 2 screws B (T3x8) to take the Lamp Ballast

Unit and the Filter Board off.

3 Remove 2 screws C (T3x6) to take the Lamp Ballast

Unit off.

4 Remove 3 screws D (T3x6) to take the Filter Board off.

Lamp Ballast Unit and Filter Board

removal

8

A

B

B

C

C

D

D

D

Lamp ballast Board

Holder

Filter Board

Spacer Sheet

Spacer Sheet

Shield Plate

Page 13

-13-

1 Remove 1 screws A (T4x4) to take the shield plate off.

2 Remove 2 screws B (T3x8) to take the Fan (FN901) and

the duct off.

3 Remove 2 screws C (T3x8) to take the SW Board and

the spring off.

Mechanical Disassemblies

Fig.11

FN901 and Lamp Cover SW removal

11

FN901

SW Board

Spring

Earth Plate

Duct

B

B

C

C

1 Remove 1 screw A (T3x8) to take the Duct under the

Panel.

2 Remove 1 screw B (T3x8) to take the Holder with the

Fans(FN902 and FN905) off.

3 Remove 2 screws C (T3x10) to take the Fans (FN902

and FN905) off.

4 Remove 1 screw D (T3x6) to take the Sensor Board off.

Fig.10

FN902, FN905 and Sensor Board removal

10

A

B

C

C

D

Sensor Board

FN902

FN905

Shield Plate

A

Spacer sheet

Spacer

Page 14

■ Optical Parts Disassemblies

Before taking this procedure, remove Cabinet Top, Main Board and Optical Unit following to the “Mechanical

Disassemblies”.

Fig.2

-14-

Fig.1

1

Remove 4 screws to take the Lamp Holder off.

Lamp Holder removal

1

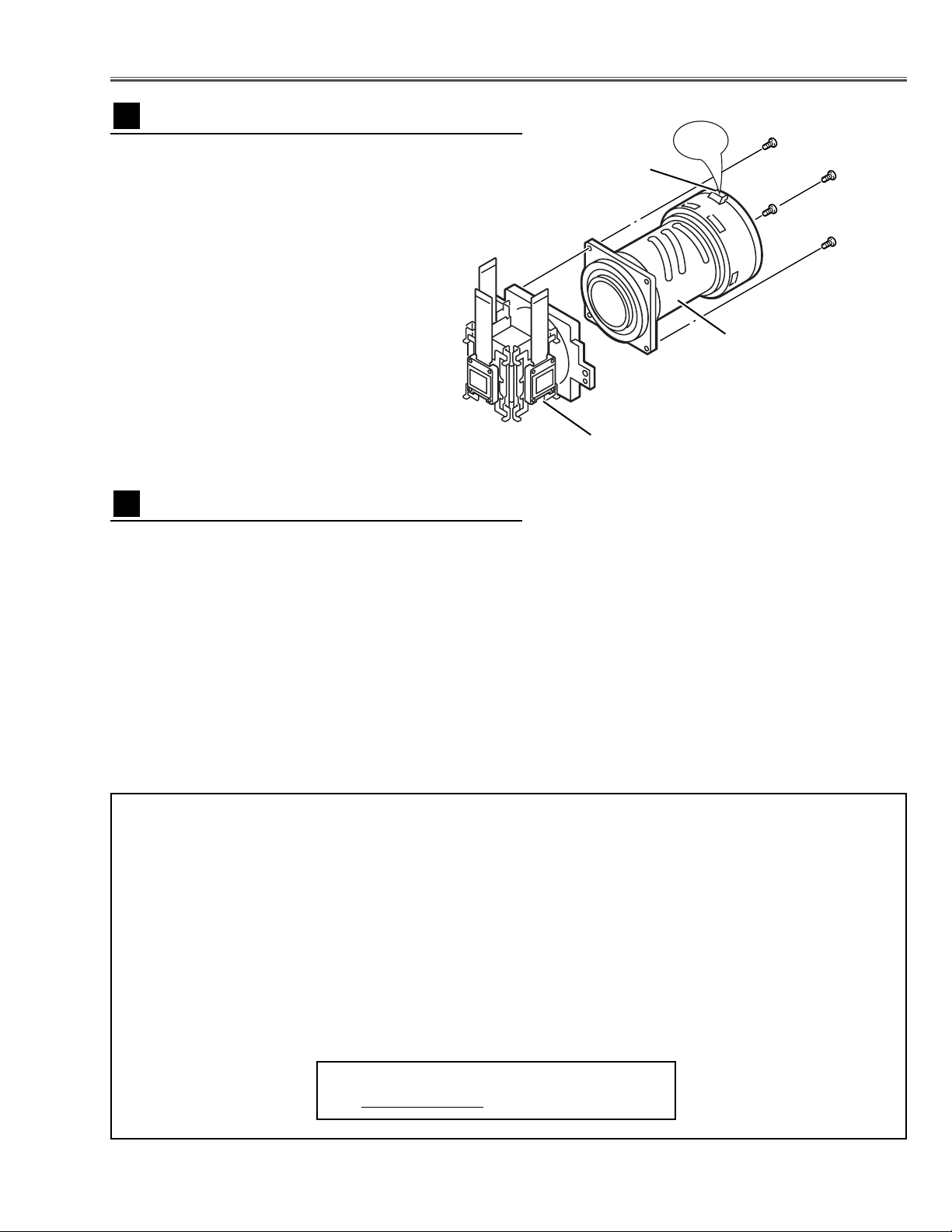

1 Remove 3 screws to take the Projection Lens ass'y off.

Projection Lens Ass'y removal

2

Optical Unit Box

Lamp Holder

Optical Unit Box

Projection Lens

and Panel/Prism Ass'y

Page 15

-15-

Fig.4

Fig.3-1

1 Remove each screw to take the polarized glass-in R/G/B

off.

Note:

The polarized glass-in_red is sticked on the condenser

lens_red. So, it cannot be removed separately.

Polarized Glass-In removal

3

1 Remove 6 screws to take the Optical unit top off.

Optical Unit Top removal

4

Optical Unit Box

Optical Unit Base

Polarized glass_Red Polarized glass

_Green and Blue

Polarized glass sticked

on Condenser lens(R)

Polarized glass with

mounting holder

Fig.3-

2

RB

G

Screw

Polarized glass_Red

Polarized glass_Blue

Polarized glass_Green

Screw

Screw

Optical Parts Disassemblies

Page 16

-16-

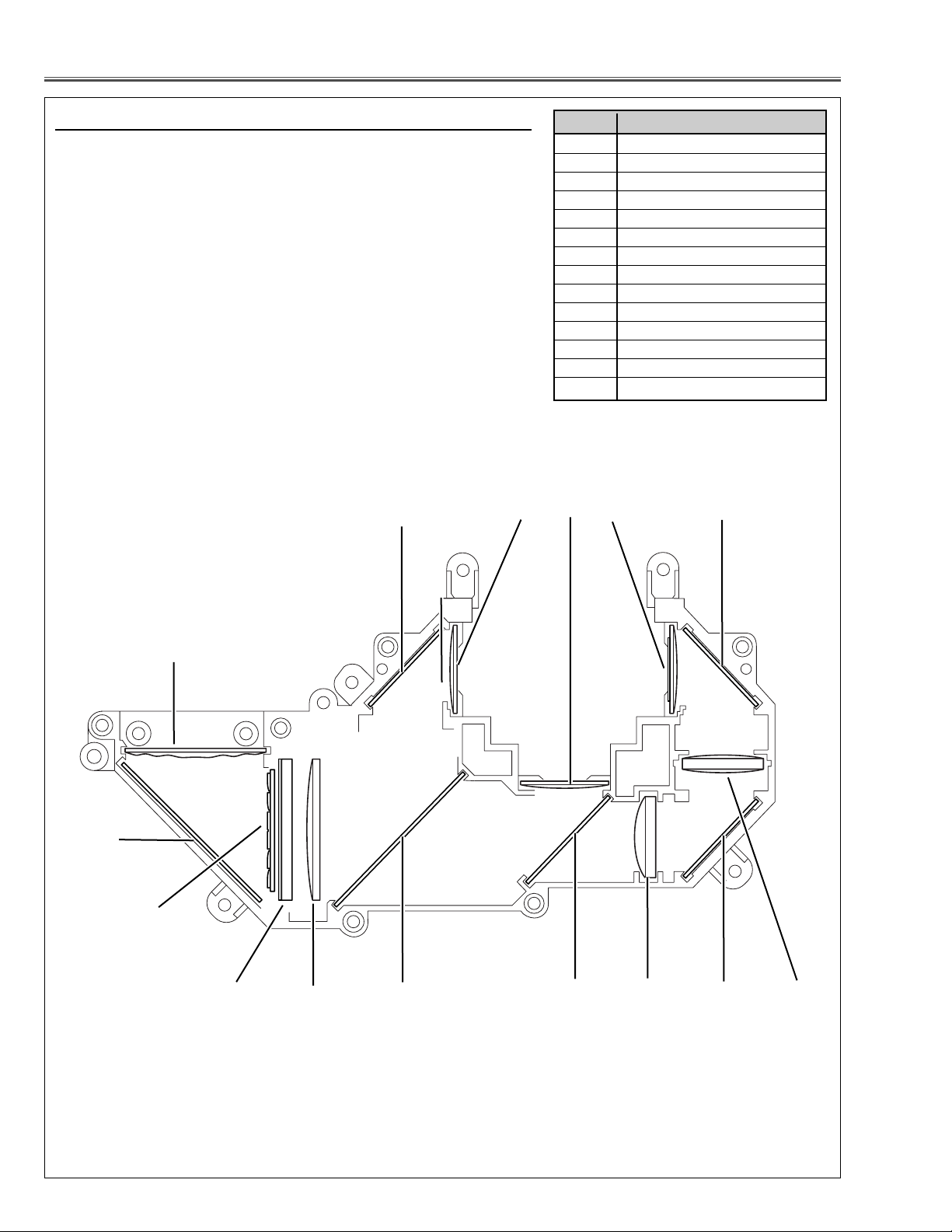

Optical Parts Disassemblies

When the optical parts in the optical unit mounting or assembling, the

parts must be mounted in the specified location and direction as

shown in figure below.

14

12

Fig.5

3

1

2

4

9

Locations and Directions

13

6

1 Integrator lens (IN)

2 Mirror (W)

3 Integrator lens (OUT)

4 PBS (polarizing beam splitter)

5 Condenser lens (IN)

6 Dichroic mirror (B)

7 Dichroic mirror (G)

8Relay lens (IN)

9 Mirror (R)

10 Relay lens (OUT)

11 Condenser lens (R)

12 Condenser lens (G)

13 Condenser lens (B)

14 Mirror (B)

Key No. Description

10

11

5

7 8 9

Page 17

-17-

■ LCD Panel/Prism Ass’y Replacement

IMPORTANT NOTICE on LCD Panel/Prism Ass'y Replacement

LCD panels used for this model can not be replaced separately. Do not disassemble the LCD Panel/Prism Ass’y.

These LCD panels are installed with precision at the factory. When replacing the LCD panel, should be replaced

whole of the LCD panels and prism ass’y at once.

After replacing LCD Panel/Prism ass’y, please check the following adjustments.

- Check the “Condenser Lens Adjustment” and “Relay Lens Adjustment” following to chapter “Optical

Adjustment”.

- Check the “White Balance Adjustment” and “Common Centre Adjustment” following to chapter

“Electrical Adjustment”.

- Check the white uniformity on the screen.

If you find the color shading, please adjust the white uniformity by using the proper computer and

“Color Shading Correction” software supplied separately. The software can be ordered as follows;

COLOR SHADING CORRECTION Ver. 3.0

Service Parts No. 645 056 6288

1 Remove 4 screws to take the Projection Lens off.

LCD Panel/Prism Ass'y removal

1

Projection Lens

Panel/Prism Ass'y

Fig.1

1

Tighten 4 screws to fix the Projection Lens securely,

making sure that the zoom lever is upside.

Note:

Do not replace the LCD panel separately otherwise it can

not obtain proper picture.

Do not touch the prism, the LCD panel and the electrode

of flexible cable.

LCD Panel/Prism Ass'y attachment

2

Zoom Lever

UP

Page 18

-18-

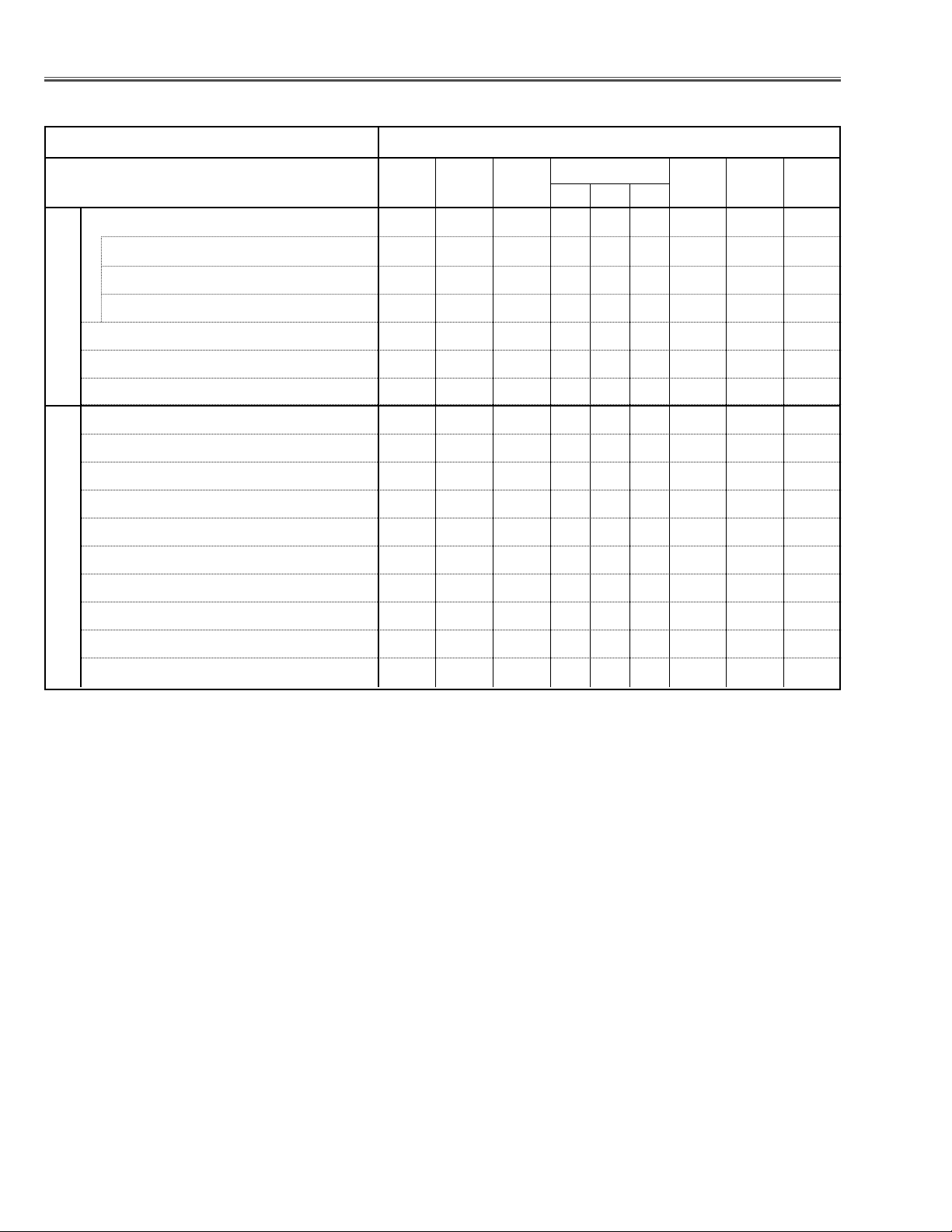

● : Adjustment necessary ❍ : Check necessary

■ Adjustments after Parts Replacement

Contrast Adjustment

R-Contrast adjustment ❍●

G-Contrast Adjustment ❍●

B-Contrast adjustment ❍●

Condenser lens adjustment ❍❍

Relay lens adjustment ❍❍

PC pedestal adjustment ●

PC gain adjustment ●

Video gain adjustment ●

480p pedestal adjustment ●

480p gain adjustment ●

480i gain adjustment ●

Gamma adjustment (PC and AV) ●

Common center adjustment ●●

White balance adjustment (PC and AV) ❍❍

Disassembly / Replaced Parts

LCD/

Prism

Ass’y

Optical

Unit

Polarized glass

R(✽ ) GB

Optical Adjustments

Electrical Adjustments

Powe r

Board

Main

Board

Note(✽ ): The polarized glass(R) is sticked on the condenser lens(R).

Page 19

-19-

G-Polarized Glass

Mounting Base

R-Polarized Glass

Mounting Base

B-Polarized Glass

Mounting Base

A

A

A

Fig.1-2

■ Optical Adjustments

Main Board

Before taking optical adjustments below, remove the Cabinet Top and Main Board following to the “Mechanical

Disassemblies”

Adjustments require a plus screwdriver, 2.0mm hex wrench and a slot screwdriver.

Note: Do not disconnect connectors K8A, K8B, K8H, K48K, K48L, K66A, K66B, K66C, K66D, K66E and K66F

on the main board, because the projector can not turn on due to operate the power failure protection.

Fig.1-1

Polarized

glass

mounting base

A

[Before Adjustment]

- Input a 100% of black raster signal.

[R/G/B-CONTRAST ADJUSTMENT]

1 Loosen a screw A (Fig.1-1/1-2) on the polarized glass mounting

base which you intend to adjust.

2 Tu rn the polarized glass mounting base as shown in Fig.1-1 to

obtain the darkest brightness on the screen.

3 Tighten the screw A to fix the polarized glass mounting base.

Repeat steps 1 to 3 for remaining polarized glasses.

Contrast adjustment

Page 20

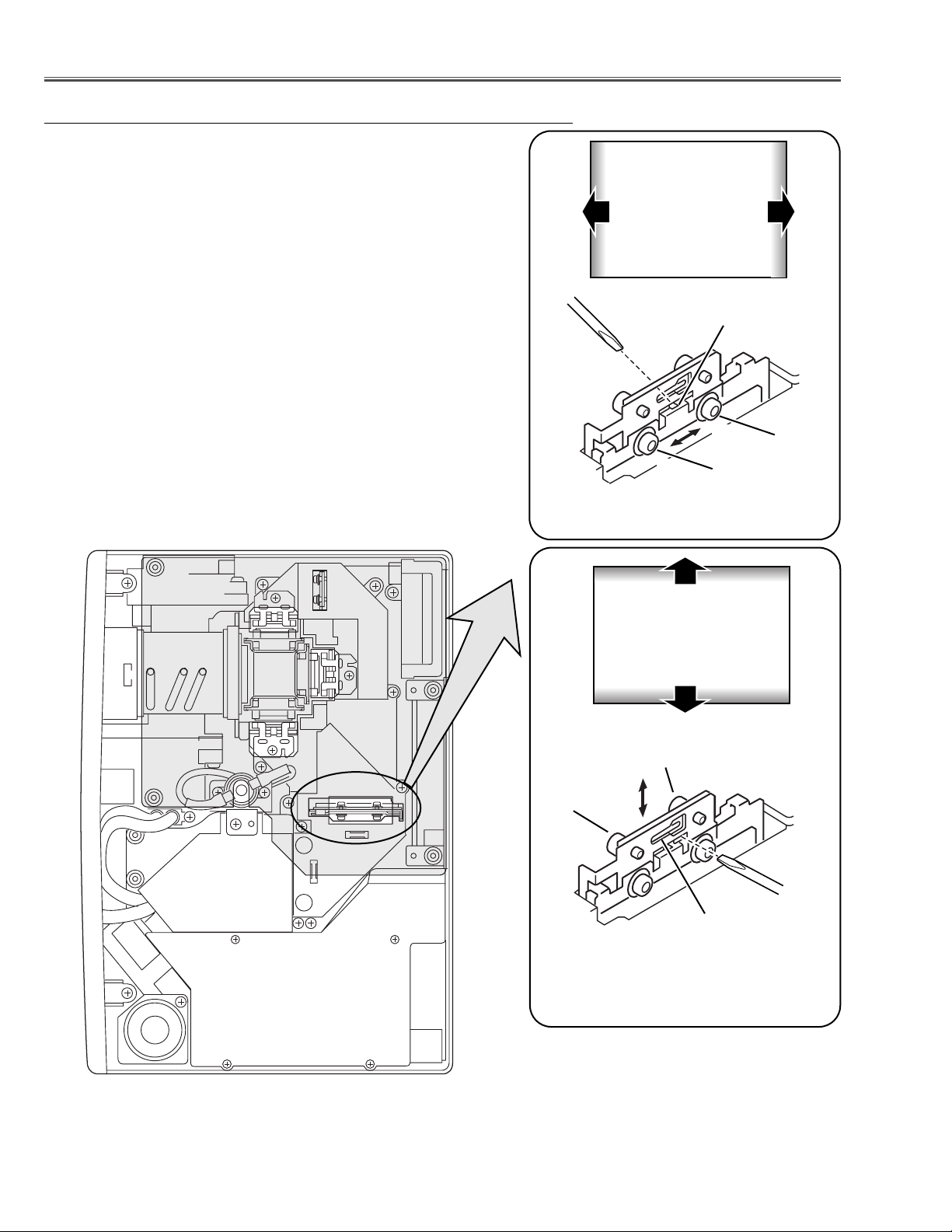

-20-

Optical Adjustments

Fig.2-2

1 Tu rn the projector on by a state of without FPC cables.

2 Adjust the adjustment base of condenser lens ass’y to make color

uniformity in white.

1) If the shading appears on the left or right of the screen as

shown in Fig.2-1, loosen 2 screws A with the 2.0mm hex driver, and adjust the slot B to make color uniformity in green by

using a slot screwdriver.

2) If the shading appears on the top or bottom of the screen as

shown in Fig.2-2, loosen 2 screws C with the 2.0mm hex driver, and adjust the slot D to make color uniformity in green by

using a slot screwdriver

3 Tighten screws A and C to fix the Condenser lens unit.

Note:

The relay lens adjustment must be carried out after completing this

adjustment.

y

x

Moving of Slot D

Slot D

a

b

b

a

Moving of slot B

Fig.2-1

Slot B

A

C

x

y

White

White

Condenser Lens adjustment

A

C

Page 21

-21-

1 Tu rn the projector on by a state of without FPC cables.

2 Adjust the adjustment base of relay lens ass’y to make color unifor-

mity in white.

1) If the cyan bar appears on the left or right of the screen as shown

in Fig.4-1, loosen 2 screws A with the 2.0mm hex driver, and

adjust the slot B to make color uniformity in white by using a slot

screwdriver.

2) If the cyan bar appears on the top or bottom of the screen as

shown in Fig.4-2, loosen 2 screws C with the 2.0mm hex driver,

and adjust the slot D to make color uniformity in white by using

a slot screwdriver.

3 Tighten the screws A and C to fix the relay lens unit.

Fig.4-1

A

Slot B

b

a

a

Moving of slot B

b

White

Fig.4-2

Slot D

Moving of slot D

y

x

C

Optical Adjustments

x

y

Relay lens-Out adjustment

White

C

Cyan

Cyan

A

Page 22

-22-

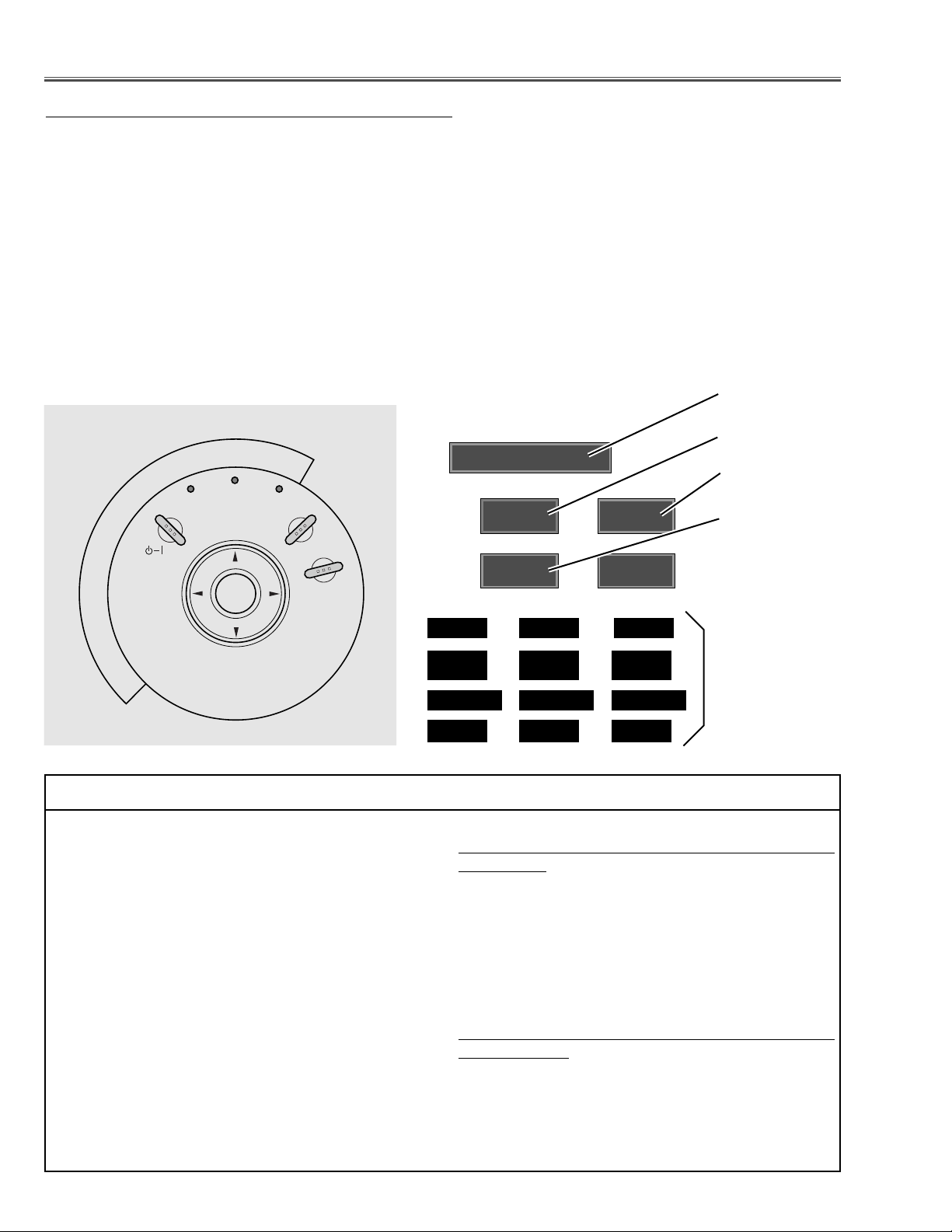

■ Electrical Adjustments

To enter the service mode

To enter the “Service Mode”, press and hold the MENU and INPUT button on the projector at the same time for

more than 3 seconds, or press and hold the MENU button on the remote control unit for more than 20 seconds.

The service menu appears on the screen as follows.

To adjust service data

Select the adjustment item no. by pressing the pointer UP or DOWN button, and change the data value by pressing the VOLUME – or VOLUME + button. Refer to the “Service Adjustment Data Table” for further description of

adjustment item no. and data value.

To exit the service mode

To exit the service mode, press the POWER ON-OFF button on the projector or the remote control unit.

● Service Adjustment Menu Operation

IC1841 on the main board stores the data for the service adjustments, and should not be replaced except for

the case of defective device.

If replaced, it should be performed the re-adjustments

following to the “Electrical Adjustments”.

The data of lamp replacement monitor timer is stored

in the IC1841.

Please note that the lamp replace counter is reset

when the memory IC (IC1841) is replaced.

(Lamp replace counter can not be set to the previous

value.)

● Caution to memory IC replacement

When IC1841 is replaced with new one, the CPU

writes down the default data of the service adjustments

to the replaced IC, refer to the service adjustment

table. As these data are not the same data as factory

shipped data, it should be required to perform the re-

adjustments following to the “Electrical Adjustments”.

Please note that in this case the lamp replace counter

will be reset.

● Caution of Main Board replacement (in the case

IC1841 is not defective)

When the main board is replaced, IC1841 should be

replaced with the one on previous main board. After

replacement, it should be required to perform the readjustments following to the “Electrical Adjustments”.

In this case, the lamp replace counter can be kept the

v

alue as before.

● Memory IC Replacement

Data value

Item No.

Input Mode

Version No.

Note :

This part of display is available

at the service

mode No.60 - 83.

ON- OFF

POWER

WARNING

–

E

M

U

L

O

V

SELECT

LAMP

REPLACE

V

O

L

U

M

E

+

INPUT

MENU

Service Mode

Computer

70

35

100

TempA TempB TempC

32.10

43.21 45.67

Fan1Speed Fan2Speed Fan3Speed

97 105 79

Page 23

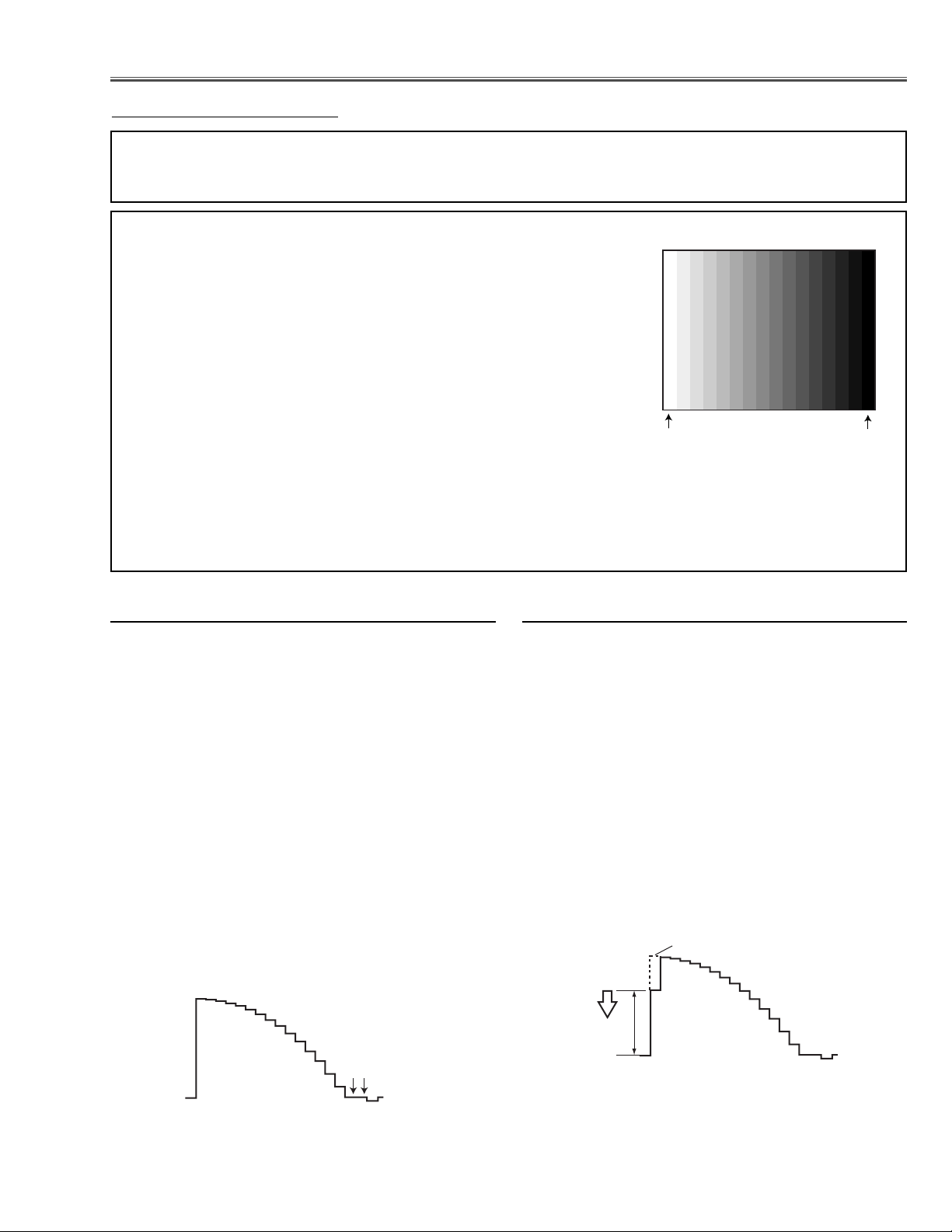

1. Receive the 16-step gray scale computer signal with

COMPUTER IN [RGB] mode.

2. Enter the service mode.

3. Connect an oscilloscope to test point “TPR1” (+) and

chassis ground (-).

4. Select item no. “7” and change data value to adjust

waveform “a” to be minimum amplitude.

5. Connect an oscilloscope to test point “TPG1” (+) and

chassis ground (-).

6. Select item no. “8” and change data value to adjust

waveform “a” to be minimum amplitude.

7. Connect an oscilloscope to test point “TPB1” (+) and

chassis ground (-).

8. Select item no. “9” and change data value to adjust

waveform “a” to be minimum amplitude.

-23-

● Circuit Adjustments

CAUTION: The each circuit has been made by the fine adjustment at factory. Do not attempt to adjust the follow-

ing adjustments except requiring the readjustments in servicing otherwise it may cause loss of performance and product safety.

Electrical Adjustments

[Adjustment Condition]

● Input signal

Video signal .......................... 1.0Vp-p/75Ω terminated, 16 steps gray

scale, white 100% and white 50% pattern (Composite video signal)

Computer signal .................... 0.7Vp-p/75Ω terminated, 16 steps gray

scale pattern (SVGA)

Component Video signal ........ 0.7Vp-p/75Ω terminated, 16 steps gray

scale, white 100% and black 0% pattern (480i format and 480p format)

● Picture control mode ................ “STANDARD” mode unless otherwise

noted.

Note:

* Please refer to “Service Adjustment Menu Operation” for entering to the service mode and adjusting the service

data.

x PC Gain adjustment

16 steps gray scale pattern

1. Receive the 16-step gray scale computer signal with

COMPUTER IN [RGB] mode.

2. Enter the service mode.

3. Connect an oscilloscope to test point “TPR1” (+) and

chassis ground (-).

4. Select item no. “275” and change data value to adjust

the pedestal level and black level to be the same

level.

5. Connect an oscilloscope to test point “TPG1” (+) and

chassis ground (-).

6. Select item no. “276” and change data value to adjust

the pedestal level and black level to be the same

level.

7. Connect an oscilloscope to test point “TPB1” (+) and

chassis ground (-).

8. Select item no. “277” and change data value to adjust

the pedestal level and black level to be the same

level.

z PC Pedestal adjustment

White 100%

Black 100%

White Level

Black Lebel

Pedestal Lebel

(a)

Page 24

-24-

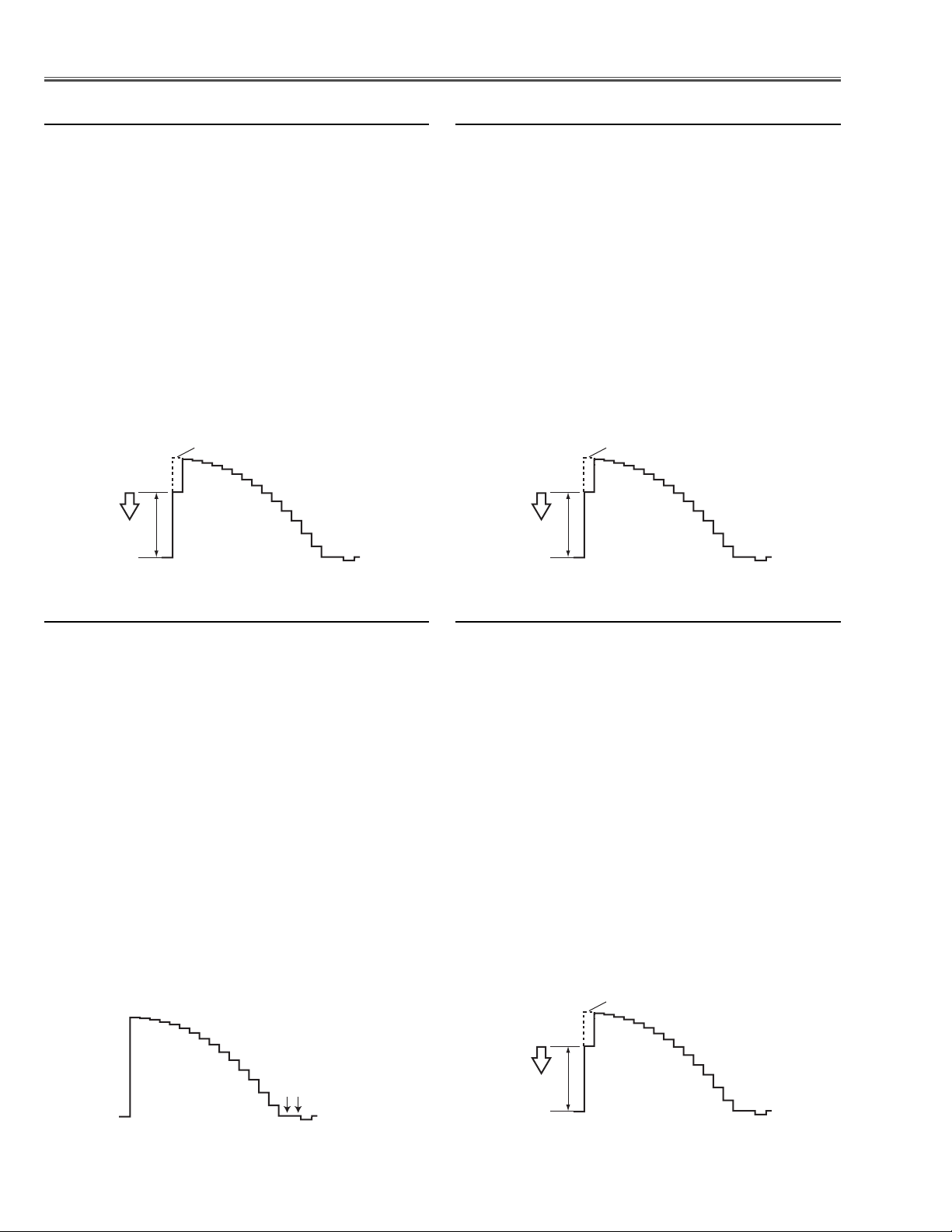

1. Receive the 16-step gray scale component signal

(480i format) with COMPUTER IN [COMPONENT]

mode.

2. Enter the service mode.

3. Connect an oscilloscope to test point “TPR1”(+) and

chassis ground (-).

4. Select item no. “7” and change data value to adjust

waveform “a” to be minimum amplitude.

5. Connect an oscilloscope to test point “TPG1” (+) and

chassis ground (-).

6. Select item no. “8” and change data value to adjust

waveform “a” to be minimum amplitude.

7. Connect an oscilloscope to test point “TPB1”(+) and

chassis ground (-).

8. Select item no. “9” and change data value to adjust

waveform “a” to be minimum amplitude.

1. Receive the 16-step gray scale component signal

(480p format) with COMPUTER IN [COMPONENT]

mode.

2. Enter the service mode.

3. Connect an oscilloscope to test point “TPR1”(+) and

chassis ground (-).

4. Select item no. “7” and change data value to adjust

waveform “a” to be minimum amplitude.

5. Connect an oscilloscope to test point “TPG1” (+) and

chassis ground (-).

6. Select item no. “8” and change data value to adjust

waveform “a” to be minimum amplitude.

7. Connect an oscilloscope to test point “TPB1”(+) and

chassis ground (-).

8. Select item no. “9” and change data value to adjust

waveform “a” to be minimum amplitude.

1. Receive the 16-step gray scale composite video signal with Video [Video] mode.

2. Enter the service mode.

3. Connect an oscilloscope to test point “TPR1” (+) and

chassis ground (-).

4. Select item no. “7” and change data value to adjust

waveform “a” to be minimum amplitude.

5. Connect an oscilloscope to test point “TPG1” (+) and

chassis ground (-).

6. Select item no. “8” and change data value to adjust

waveform “a” to be minimum amplitude.

7. Connect an oscilloscope to test point “TPB1” (+) and

chassis ground (-).

8. Select item no. “9” and change data value to adjust

waveform “a” to be minimum amplitude.

c Video Gain adjustment

Electrical Adjustments

b 480p Gain adjustment

n 480i Gain adjustment

1. Receive the 16-step gray scale component signal

(480p format) with COMPUTER IN [COMPONENT]

mode.

2. Enter the service mode.

3. Connect an oscilloscope to test point “TPR1” (+) and

chassis ground (-).

4. Select item no. “275” and change data value to adjust

the pedestal level and black level to be the same

level.

5. Connect an oscilloscope to test point “TPG1” (+) and

chassis ground (-).

6. Select item no. “276” and change data value to adjust

the pedestal level and black level to be the same

level.

7. Connect an oscilloscope to test point “TPB1” (+) and

chassis ground (-).

8. Select item no. “277” and change data value to adjust

the pedestal level and black level to be the same

level.

v 480p Pedestal adjustment

White Level

(a)

White Level

(a)

White Level

Black Lebel

Pedestal Lebel

(a)

Page 25

-25-

1. Receive the 16-step gray scale computer signal with

COMPUTER IN [RGB] mode.

2. Enter the service mode.

3. Project only red light component to the screen.

4. Select item no. “15” and change data value to obtain

the minimum flicker on the screen.

5. Project only green light component to the screen.

6. Select item no. “14” and change data value to obtain

the minimum flicker on the screen.

7. Project only blue light component to the screen.

8. Select item no. “13” and change data value to obtain

the minimum flicker on the screen.

, Common Center adjustment

[PC-GAMMA ADJUSTMENT]

1. Receive the 100% whole-white computer signal with

COMPUTER IN [RGB] mode.

2. Enter the service mode.

3. Measure luminance on the screen with the luminance

meter. It is A for the reading of luminance meter.

4. Change the signal source to the 50% whole-white

computer signal with COMPUTER IN [RGB] mode.

5. Select item no. “16” and change data value to make

the reading of luminance meter to be Ax23%.

[AV-GAMMA ADJUSTMENT]

1. Receive the 100% whole-white composite video signal with Video [Video] mode.

2. Enter the service mode.

3. Measure luminance on the screen with the luminance

meter. It is B for the reading of luminance meter.

4. Change the signal source to the 50% whole-white

computer signal with Video [Video] mode.

5. Select item no. “16” and change data value to make

the reading of luminance meter to be Bx22%.

m Gamma adjustment

Electrical Adjustments

[PC WHITE BALANCE ADJUSTMENT]

1. Receive the 16-step gray scale computer signal with

COMPUTER IN [RGB] mode.

2. Enter the service mode, select item no. “17” (Red) or

“18” (Blue), and change data values respectively to

make a proper white balance.

[AV WHITE BALANCE ADJUSTMENT]

3. Receive the 16-step gray scale video signal with

Video [Video] mode.

4. Enter the service mode, select item no. “17” (Red) or

“18” (Blue), and change data values respectively to

make a proper white balance.

Confirm that the same white balance is obtained in

video and computer input.

. White Balance adjustment

If you find the color shading on the screen, please

adjust the white uniformity by using the proper computer and “Color Shading Correction” software supplied

separately. The software can be ordered as follows;

COLOR SHADING CORRECTION ver.. 3.0

Service Parts No. 645 056 6288

NOTE ON WHITE UNIFORMITY

ADJUSTMENT

Page 26

-26-

1 R-VIDEOCNT M62392FP 143

2G-VIDEOCNT M62392FP 143 Video Center Adjustment ( = R/G/B-V1)

3B-VIDEOCNT M62392FP 143

4 R-Sub-Bright L3E7070K0A 0

5 G-Sub-Bright L3E7070K0A 0 Sub-Bright Adjustment

6 B-Sub-Bright L3E7070K0A 0

7 R-Sub-Gain L3E7070K0A 550 560 540 530 ✻ Gain Adjustment [R]

8 G-Sub-Gain L3E7070K0A 550 560 540 530 ✻ Gain Adjustment [G]

9 B-Sub-Gain L3E7070K0A 530 550 540 530 ✻ Gain Adjustment [B]

10 REF-R M62392FP 190

11 REF-G M62392FP 190

12 REF-B M62392FP 190

13 BVCOM L3E6100D0A 130

14 GVCOM L3E6100D0A 130 ✻ Common Center Adjustment

15 RVCOM L3E6100D0A 130

16 G-Gamma-Shift L3E7070K0A 512 512 512 512 ✻ Gamma Adjustment

17 R-Gamma-Shift L3E7070K0A 512 512 512 512 ✻ White Balance Adjustment [R]

18 B-Gamma-Shift L3E7070K0A 512 512 512 512 ✻ White Balance Adjustment [B]

19 NRS-B M62393FP 153 NRS Adjustment (up side)

20 NRS-A M62392FP 35 NRS Adjustment (down side)

21 R-V2 M62392FP 163

22 G-V2 M62392FP 163 Video Center Adjustment (Link to Item No.1-3)

23 B-V2 M62392FP 163

24 SubBright PW168 128 128 128 128

25 SubColor PW168 85 85 85 N/A

26 SubTint PW168 128 128 128 N/A

27 - 0

28 SubBright (Video) VPC3230 N/A Note 1 N/A 128 127 Note 1: 575i = the same as PAL

29 SubCont (Video) VPC3230 N/A Note 1 N/A 50 49

30 SubColor (Video) VPC3230 N/A Note 1 N/A 2070 2070

31 SubTint (Video) VPC3230 N/A Note 1 N/A 512 512

32 SubBright (480i,575i) VPC3230 N/A 199 N/A 196 197

33 SubCont (480i,575i) VPC3230 N/A 25 N/A 25 26

34 SubColor (480i,575i) VPC3230 N/A 31 N/A 23 23 Note 2: 480i = the same as NTSC

35 SubColor (480i,575i) VPC3230 N/A Note 2 N/A 29 29 575i = the same as PAL

36 - 0

37 V-Line Color Shading Correction Setting (R1) L3E7070K0A 2 Vertical Line Color Shading Correction

38 V-Line Color Shading Correction Setting (R2) L3E7070K0A 1

39 V-Line Color Shading Correction Setting (R3) L3E7070K0A 254

40 V-Line Color Shading Correction Setting (G1) L3E7070K0A 2

41 V-Line Color Shading Correction Setting (G2) L3E7070K0A 1

42 V-Line Color Shading Correction Setting (G3) L3E7070K0A 254

43 V-Line Color Shading Correction Setting (B1) L3E7070K0A 2

44 V-Line Color Shading Correction Setting (B2) L3E7070K0A 1

45 V-Line Color Shading Correction Setting (B3) L3E7070K0A 254

46 R-Reference voltage (H) L3E7070K0A 0

47 R-Reference voltage (L) L3E7070K0A 0

48 G-Reference voltage (H) L3E7070K0A 0

49 G-Reference voltage (L) L3E7070K0A 0

50 B-Reference voltage (H) L3E7070K0A 0

51 B-Reference voltage (L) L3E7070K0A 0

52 Color Shading Correction ON/OFF L3E7070K0A 1

53 Lamp Life Time 0 Read only

54 Baud Rate 10:9600 / 1: 19200 / 2: 38400

55 Shoot Out Mode 0 0: Normal / 1: Shoot out 1

56 Forced NOBRAND 0 0: Normal / 1: NOBRAND

FAN CONTROL Range

60 Fan Control SW 0 0-1 0: Auto / 1: manual

61 Fan Min. control (Fan 1) 97 70-210

62 Fan Min. control (Fan 2) 118 70-210

Initial

ItemNo. Name Device PC YCbCr Video Detail

480i(+) 480p(+) NTSC PAL Note: 480i(+) = 480i & 575i, 480p(+) = 480p & HDTV

● Service Adjustment Data Table

These initial values are the reference data written from the CPU

ROM to memory IC when replaced new memory IC. The adjustment items indicated with “✻” are required to readjust following

to the “Electrical adjustments”. Other items should be used with

the initial data value.

Electrical Adjustments

Page 27

-27-

Electrical Adjustments

Range

63 Fan Min. control (Fan 3) 79 70-210

65 Fan Max. control (Fan 1) 205 70-210

66 Fan Max. control (Fan 2) 147 70-210

67 Fan Max. control (Fan 3) 205 70-210

69 Temp. Low ( Sensor 1) 28 10-100

70 Temp High (Sensor 1) 34 30-100

71 Temp. Error (Sensor 1) 40 30-100

72 Temp. Low ( Sensor 2) 43 10-100

73 Fan 2 Low Speed Cooling Time at the first half period 0 0-20 0: 20sec / 1: 22sec / ... / 20: 60sec

74 Fan 2 Low Speed Cooling Voltage at the first half period 62 70-210

75 Temp. High (Sensor 2) 41 30-100

76 Temp. Error (Sensor 2) 51 30-100

77 Temp. Error (Sensor 1-3) 30 10-100

78 Temp. Error Cooling TIme 3 0-15 0: always ON / 1: 30s / 2: 60s / ... / 15: 450s

79 Cooling Time 3 1-15 1: 30sec / 2: 60sec / ... / 15: 450sec

80 HighLand Mode 0 0-3 0: Auto / 1: ON Low / 2: ON Mid / 3: ON High

81 Fan1 Speed 205 Fan Speed at Manual Setting

82 Fan2 Speed 147

83 Fan3 Speed 205

84 Min. Temp. (Sensor 2) at temp. error (Sensor 1-2) 45 30-100

85 Normal Fan Mode 0 0-2 0: Auto / 1: manual / 2: HighLand Mode

86 Cooling Fan Mode 0

87 Service Fan Mode 0

VPC3230

90 Notch Filter Select VPC3230 N/A Note 1 N/A 3 3 Note 1: 480i = the same as NTSC

91 Diagonal Dot Reduction VPC3230 N/A Note 1 N/A 1 1 575i = the same as PAL

92 Horizontal Differential Gain VPC3230 N/A Note 1 N/A 3 3

93 Vertical Differential Gain VPC3230 N/A Note 1 N/A 0 0

94 Vertical Peaking Gain VPC3230 N/A Note 1 N/A 7 7

95 AFC other1 VPC3230 N/A Note 1 N/A 540 540

96 AFC other2 VPC3230 N/A Note 1 N/A 536 536

97 Horizontal Peaking Filter VPC3230 N/A Note 1 N/A 1 1

98 Peaking Gain VPC3230 N/A Note 1 N/A 2 2

99 Peaking Filter Coring Enable VPC3230 N/A Note 1 N/A 0 0

101 Horizontal Lowpass Filter VPC3230 N/A Note 1 N/A 1 1

102 Horizontal Lowpass Filter Chroma VPC3230 N/A Note 1 N/A 0 0

103 DOR VPC3230 N/A Note 1 N/A 0 0

104 COR VPC3230 N/A Note 1 N/A 0 0

105 SGAIN VPC3230 N/A Note 1 N/A 15 15

106 YC Delay VPC3230 N/A Note 1 N/A 62 62

ADC

272 REDGAIN AD9883 70 N/A 70 N/A N/A

273 GRNGAIN AD9883 70 N/A 70 N/A N/A

274 BLUGAIN AD9883 70 N/A 70 N/A N/A

275 REDOFST AD9883 60 N/A 60 N/A N/A ✻ Pedestal Adjustment [R]

276 GRNOFST AD9883 60 N/A 65 N/A N/A ✻ Pedestal Adjustment [G]

277 BLUOFST AD9883 65 N/A 65 N/A N/A ✻ Pedestal Adjustment [B]

278 Clamp Duration AD9883 N/A N/A

279 Clamp Placement AD9883 N/A N/A

281 RACLP M62399FP 0

282 GACLP M62399FP 0

283 BACLP M62399FP 0

FAN CONTROL 2

288 Eco Fan Max. Control (Fan 1) 170

289 Eco Fan Max. Control (Fan 2) 71

290 Eco Fan Max. Control (Fan 3) 130

291 DLY3.3V_ON 100

292 DLY5V_ON 100

293 Eco Fan Min. Control (Fan 1) 79

294 Eco Fan Min. Control (Fan 2) 62

295 Eco Fan Min. Control (Fan 3) 71

OverScan

297 Expand Ratio (Vertical) 60Hz PIXEL N/A 1 N/A Video and S-Video mode only.

298 Expand Ratio (Horizontal) 60Hz PIXEL N/A 17 N/A Progressive OFF

299 Position (Horizontal) 60Hz PIXEL N/A 513 N/A

Initial

ItemNo. Name Device PC YCbCr Video Detail

480i(+) 480p(+) NTSC PAL Note: 480i(+) = 480i & 575i, 480p(+) = 480p & HDTV

Page 28

-28-

300 Position (Vertical) 60Hz PIXEL N/A 384 N/A

301 Expand Ratio (Vertical) 50Hz PIXEL N/A 5 Video and S-Video mode only

302 Expand Ratio (Horizontal) 50Hz PIXEL N/A 24 Progressive OFF

303 Position (Horizontal) 50Hz PIXEL N/A 519

304 Position (Vertical) 50Hz PIXEL N/A 383

305 Expand Ratio (Vertical) 480i PIXEL N/A 1 N/A For Component 480i mode

306 Expand Ratio (Horizontal) 480i PIXEL N/A 17 N/A Progressive OFF

307 Position (Horizontal) 480i PIXEL N/A 513 N/A

308 Position (Vertical) 480i PIXEL N/A 384 N/A

309 Expand Ratio (Vertical) 575i PIXEL N/A 5 N/A For Component 575i mode

310 Expand Ratio (Horizontal) 575i PIXEL N/A 24 N/A Progressive OFF

311 Position (Horizontal) 575i PIXEL N/A 519 N/A

312 Position (Vertical) 575i PIXEL N/A 383 N/A

313 Expand Ratio (Vertical) 480p PIXEL N/A 10 N/A For Component 480p mode

314 Expand Ratio (Horizontal) 480p PIXEL N/A 32 N/A

315 Position (Horizontal) 480p PIXEL N/A 517 N/A

316 Position (Vertical) 480p PIXEL N/A 382 N/A

317 Expand Ratio (Vertical) 575p PIXEL N/A 18 N/A For Component 575p mode

318 Expand Ratio (Horizontal) 575p PIXEL N/A 29 N/A

319 Position (Horizontal) 575p PIXEL N/A 517 N/A

320 Position (Vertical) 575p PIXEL N/A 393 N/A

321 Expand Ratio (Vertical) 720p PIXEL 9 N/A 10 N/A For Component and RGB 720p mode

322 Expand Ratio (Horizontal) 720p PIXEL 15 N/A 14 N/A

323 Position (Horizontal) 720p PIXEL 513 N/A 525 N/A

324 Position (Vertical) 720p PIXEL 385 N/A 385 N/A

325 Expand Ratio (Vertical) 1035i PIXEL 5 N/A 5 N/A For Component mode and RGB HDTV 1035i

326 Expand Ratio (Horizontal) 1035i PIXEL 23 N/A 23 N/A

327 Position (Horizontal) 1035i PIXEL 510 N/A 519 N/A

328 Position (Vertical) 1035i PIXEL 382 N/A 382 N/A

329 Expand Ratio (Vertical) 1080i PIXEL 7 N/A 7 N/A For Component mode and RGB HDTV 1080i

330 Expand Ratio (Horizontal) 1080i PIXEL 22 N/A 23 N/A

331 Position (Horizontal) 1080i PIXEL 508 N/A 517 N/A

332 Position (Vertical) 1080i PIXEL 382 N/A 383 N/A

333 Expand Ratio (Vertical) 60Hz PIXEL 7 N/A For RGB NTSC 480i

334 Expand Ratio (Horizontal) 60Hz PIXEL 36 N/A

335 Position (Horizontal) 60Hz PIXEL 517 N/A

336 Position (Vertical) 60Hz PIXEL 383 N/A

337 Expand Ratio (Vertical) 50Hz PIXEL 20 N/A For RGB PAL 575i

338 Expand Ratio (Horizontal) 50Hz PIXEL 40 N/A

339 Position (Horizontal) 50Hz PIXEL 515 N/A

340 Position (Vertical) 50Hz PIXEL 384 N/A

341 Expand Ratio (Vertical) 50Hz PIXEL 7 N/A 7 N/A For 1080i_50Hz and RGB HDTV 1080i_50Hz

342 Expand Ratio (Horizontal) 50Hz PIXEL 14 N/A 14 N/A

343 Position (Horizontal) 50Hz PIXEL 517 N/A 522 N/A

344 Position (Vertical) 50Hz PIXEL 384 N/A 384 N/A

345 Expand Ratio (Vertical) SCART PIXEL 5 N/A For RGB SCART

346 Expand Ratio (Horizontal) SCART PIXEL 23 N/A Progressive OFF

347 Position (Horizontal) SCART PIXEL 518 N/A

348 Position (Vertical) SCART PIXEL 383 N/A

349 Expand Ratio (Vertical) 60Hz PIXEL N/A 2 N/A For Video and S-Video only

350 Expand Ratio (Horizontal) 60Hz PIXEL N/A 17 N/A Progressive ON

351 Position (Horizontal) 60Hz PIXEL N/A 513 N/A

352 Position (Vertical) 50Hz PIXEL N/A 383 N/A

353 Expand Ratio (Vertical) 50Hz PIXEL N/A 5

354 Expand Ratio (Horizontal) 50Hz PIXEL N/A 23

355 Position (Horizontal) 50Hz PIXEL N/A 519

356 Position (Vertical) 50Hz PIXEL N/A 383

357 Expand ratio (Vertical) 480i PIXEL N/A 2 N/A For Component 480i mode

358 Expand Ratio (Horizontal) 480i PIXEL N/A 17 N/A Progressive ON

359 Position (Horizontal) 480i PIXEL N/A 513 N/A

360 Position (Vertical) 480i PIXEL N/A 383 N/A

361 Expand ratio (Vertical) 575i PIXEL N/A 5 N/A For Component 575i mode

362 Expand Ratio (Horizontal) 575i PIXEL N/A 24 N/A Progressive ON

363 Position (Horizontal) 575i PIXEL N/A 519 N/A

364 Position (Vertical) 575i PIXEL N/A 383 N/A

365 Expand ratio (Vertical) SCART PIXEL 5 N/A For RGB SCART

Electrical Adjustments

Initial

ItemNo. Name Device PC YCbCr Video Detail

480i(+) 480p(+) NTSC PAL Note: 480i(+) = 480i & 575i, 480p(+) = 480p & HDTV

Page 29

-29-

Electrical Adjustments

366 Expand Ratio (Horizontal) SCART PIXEL 23 N/A For RGB SCART

367 Position (Horizontal) SCART PIXEL 518 N/A Progressive ON

368 Position (Vertical) SCART PIXEL 383 N/A

369 Expand ratio (Vertical) 60Hz PIXEL 10 N/A For RGB 480p

370 Expand Ratio (Horizontal) 60Hz PIXEL 33 N/A

371 Position (Horizontal) 60Hz PIXEL 508 N/A

372 Position (Vertical) 60Hz PIXEL 375 N/A

373 Expand ratio (Vertical) 50Hz PIXEL 21 N/A For RGB 575p

374 Expand Ratio (Horizontal) 50Hz PIXEL 30 N/A

375 Position (Horizontal) 50Hz PIXEL 512 N/A

376 Position (Vertical) 50Hz PIXEL 385 N/A

400 Gamma Shift Combination ON/OFF 1 0: each source separate / 1: PC source only separate

401 PC Frame Lock OFF 0 0: ON for all source / 1: OFF at PC

402 Auto Grayscale black control start point 31

403 Auto Grayscale black control limit point 16

404 Auto Grayscale black control target point 0

405 Auto Grayscale white control start point 33

406 Auto Grayscale white control limit point 56

407 Auto Grayscale white control target point 0

Initial

ItemNo. Name Device PC YCbCr Video Detail

480i(+) 480p(+) NTSC PAL Note: 480i(+) = 480i & 575i, 480p(+) = 480p & HDTV

Page 30

-30-

Electrical Adjustments

● MAIN BOARD

Test Points and Locations

K8E

K66A K66B

K8H

K8A

K66C

K66E

K8F

TPGVS

TPGHS

IC3561

IC3551

IC8201

TP6202B

TP6202G

TP6202R

TE101

IC3571

IC501

TPB1

TEGFBK

TPB1

TP103

IC101

K25B

IC401

TPVHS

IC531

TPVVS

K25G

TEGND2

TPG1

TPG1

IC561

K25R

TE301

TPR1

IC9401

IC3501

TPR1

TP2561

TPDVS

TPDHS

IC301

TP2531

TPRESET

K48K

IC5302

PART SIDE

1AA4B10C3650A

K8W

K8G

K8V

Page 31

-31-

■ Chassis Block Diagrams

● Chassis Overview

SPEAKER

B-LCD PANEL G-LCD PANEL R-LCD PANEL

Audio

controlled IC.

-

Remark :

This mark means IIC

IC5003

IC5002

VOLUME

+

IC5001

IC501

AUDIO-AMP.

CONTROL

AUDIO-SW

DRIVER

B-PANEL

IC801

FLASH ROM

IC531

B

RXD/TXD

IC9801

RS-232C

DRIVER

G-PANEL

IC401

COLOR

CORRECTION

IC9401

TURBO

DIGITAL

SYSTEM BUS

USB

IC9861

DRIVER/RECEIVER

G

SYSTEM BUS

IC301

CONTROLLER

IC561

DRIVER

R-PANEL

IC401

IC1802

EXPANDER

OSD,

MAIN CPU,

De-INTERLACE

RGB

RGB

A/D

IC8201

RGB / Y,Cb,Cr

RGB/Component

IC3501

R

NRS_SW

KEY

LED

IC1801

EXPANDER

Y,Cb,Cr

IC101

RGB(SCART)

Y,Cb,Cr (480i, 575i)

KEY

OPTION

BUFFER

IC1811/14

YUV

VIDEO

DECODER

Y/C

VIDEO

LCD

DRIVER

DAC

IC3571

H/V

H/V

IC5301

H / V /

G_SYNC

LCD

DRIVER

FA N

DAC

IC3561

H/V

IC5303

SYNC_SW

H/V

IC5302

YUV_SYNC

RGB_SYNC

IC1841

EEPROM

AUDIO

VIDEO

DAC

IC3551

G_SYNC

IC8801

IIC BUS

POWER

IC1871

POWER

SUPPLY

IC1882

SUB CPU

IC1881

INVERTER

TEMP.

SENSOR

FAIL

COMPARATOR

IC8802

P. F.

UNIT_POWER

TEMP.

SENSOR

IC1861

INVERTER

CONTROLLER

IC8821

KEY SWR/C PRE AMP

FA N

CONTROL

POWER

SWITCHING

BRIDGE

TEMP.

SENSOR

LED

SUPPLY

DIODE

CONT BOARD SENSOR BOARD

R/C BOARD

FANS

AV BOARD MAIN BOARD

L/R

L/R

COMPUTER/

COMPONENT

AUDIO

A V

PORT

CONTROL

RESET SW

USB

RGB

IC5201

SELECTOR

D-SUB_15

COMPUTER/

COMPONENT

Y/C

Video

RGB/Component

Y/C

VIDEO

S-VIDEO

SW BOARD

LAMP COVER SW

LAMP

BALLAST

LINE

FUSE

UNIT_LAMP BALLAST

AC

LAMP

FILTER

FILTER BOARD

SW

THERMAL

100~240V

Page 32

-32-

● Video signal processing circuit and LCD panel driving circuit

Chassis Block Diagrams

B-LCD

PANEL

G-LCD

PANEL

R-LCD

PANEL

K25RK25GK25B

+

<4053>

NRSA/NRSB

18,19

DAC

IC3561

<M62398>

IIC_1

TP2561

NRS

IC3531

BUFFER

<LT1206>

TP2531

+

IC3531

R/G/B_V1/V2

19

14

DAC

IC3571

<M62398>

IIC_2

NRS_SW

RO

TPR1

IC561

R-LCD

CBAL_SW

DRIVER

<L3E06100>

5

15

DAC

IC3551

IIC_2

NRS

IC3521

BUFFER

FPRR,FPRG

14

<M62393>

<LM7171>

TPB1

B-LCD

IC501

SCLK/SDATA

DRIVER

<L3E06100>

BO

ROUT

TPG1

IC531

GO

IC401

COLOR

BOUT

GOUT

IC9401

G-LCD

DRIVER

<L3E06100>

SHADING

<L3E07070>

CORRECTION

TURBO

DIGITAL

<LC24085>

SCLK/SDATA

MAIN BOARDAV BOARD

GR

GG

GVS

GREF,GCOAST,GCLK,GFBK,CLAMP

IC8201

TP6202B

TP6202R

TP6202G

K50A

K10D

IC5201

Other sources

480p,575p only

DR

DG

IC301

GB

A/D

<AD9883A>

RGB

YUV

<AN5870>

RGB SW /

SYNC SEP.

H/V

DB

CPU

OSD

FRC, CRC,

IIC_2

IIC_1

RGB(SCART)

YUV(480i, 575i)

G_SYNC

<PW168A>

De-INTERLACE

IC101

DIGITAL

CV_S

GVSGHS

TPVHS

VY

VUV

DECODER

<VPC3230>

Y/C

H

DHS,DVS,DCLK

SYSTEM_BUS

TPGVS

TPGHS

6

5

TPVVS

VIDEO

13

2,5

H/V

VHS,VVS,VPEN,VFIELD,VCLK,VHDREN

FILT_480p/575p

S_SW

Y/C

8

V

H

9

11

IC5301

<BA7078>

RGB_SYNC

3

G_SYNC

IC1881

BUFFER

<74LCX541>

3

11

H

2

12

16

28

IC5302

YUV_SYNC

26

IC5303

V

<TA1370>

K50B

K10E

VIDEO

S_SW

PC/AV_SW

IIC_2

FILT_480p/575p

116 715,1420,19,18 13,12,11 4,6 29

COMPUTER IN /

COMPONENT IN

VIDEOS_VIDEO

Page 33

-33-

Chassis Block Diagrams

● System Controls

SW

USB

RESET

-

USB+/USB

CPU_RESET

TEMP.

IC8821

SENSOR

P_SCL1/SDA1

SENSOR BOARD

POWER BOARDCN202K8A

FA N

CONTROL

POW_ON

LAMP BALLAST

LAMP_DET

DIMMER

CN300K48K

3,5 1 15-141917-18 7

3452

154

ON/OFF

SW BOARD

SW8801

ERROR : Open

1-2 3-4

LAMP COVER SW

K8811K48L

AV BOARD

IC5201

FILT_480P

K10DK50A

SELECTOR

PORT

CONTROL

RXD1/TXD1

K8H K88A

USB

IC9861

FAN_SW

Power-ON : H

19

IC1802

OUTPUT

EXPANDER

NRSA/B

18-19

4-6

REF_RGB

FAN_CONT1

15

14

IC3561

DAC

10

FAN_CONT2

FAN_CONT3

16

CBAL_SW

15

IC5001

AUD_SW

AUD_PC/AV

12

IC3551

DAC

IC5002

VOLUME

2

VOL

PC/AV_SW

14

13

IC5303

SYNC_SW

FILT_480P

5

ERROR : H

Lamp Dimmer Control

L = Low beam. H = High Beam

TXL

RXL

SCEL

Lamp-ON : L

IC501,

IC531,

IC561

S&H

IC401

COLOR

IC9801

DRIVER

RS232C

RECEIVER

CORRECT

S-VIDEO

K10E

K50B

CONTROL

TURBO_ST

13

14-16

S_SW

ON_3.3V IC5631

R/G/B_ST

12

KEY

K8G K68B

SWITTCH

WARNING

red

17-19

LAMP_REP

yellow

green

LED-On: H

KEY01-03

WARNING

LAMP_REP

15

14

16

IC1801

OUTPUT

EXPANDER

POWER

red

POWER

13

CONTROL BOARD

AMP

IC5003

4

MUTE

READY

12

R/C

Mute-ON : H

RECEIVER

R/C BOARD

K68C

K8E

IC8802

TEMP.

SENSOR

IC8801

TEMP.

SENSOR

MAIN BOARD

IC101

VIDEO

DECODER

IC1841

EEPROM

P_SCL1/SDA1

Always Available

Q1841

Q1842

3.3V to 5V

M_SCL1/SDA1

Always Available

44,116

P_SCL2/SDA2

Q1843

M_SCL2/SDA2

45,46

Q1844

B_V1/V2

18-19

16-17

IC3571

DAC

IC5302

YUV_SYNC

Standby off Standby off

3.3V to 5V

IC8201

A/D

R_V1/V2

G_V1/V2

14-15

1

IC1881

INVERTER

2

7

4

IC1882

SUB CPU

5

IC4801

LAMP_PWM

140 1

178

6

9

3

6

4

NAND

2

LAMP_POW

Lamp-ON : H

4

11

ERROR : L

FAN_ERR

TURBO

IC9401

SCLK/SDATA

IC1821

BUFFER

SCLK/SDATA_PW

117,180

IC301

MAIN CPU

RXD/TXD

47,181

1

IC351

6

5

IC361

3

NMI

173

BUFFER

OR GATE

WR/RD

56,127

ERROR : H

LAMP_ERR

8

IC1811

BUFFER

OPTION

RESISTORS

A1 - A21

S_SW

9

675

OPTION2

OPTION1

IC801

KEY11-13

2-4

OPTION3

FLASH

From the power fail

detection diodes.

2

IC1871

COMPARATOR

D0 - D15

3

174

P_FAIL

1

IC1861

INVERTER

12

ERROR : L

R_C

182

Page 34

-34-

■ Power Supply Lines

● Power supply circuit, Protection circuit and Fan control circuit

AV BOARD

12V

246

K50B K10E

5V

MAIN BOARD

D5641

D2511

15VP

L2511

15VL

Q2501

Stand-by : L

ON_15V

D491,D492

9V

1.8V

IC491

IC5642

12V

3.3V

IC5641

IC5631

5V

16V

5V_AU

834-5 10 32 74859 5143

834-5 10 32 74859

5V

-

D5631

5V

-

1.5V_PW

3.3V_PW

Q372

Q371

IC371

5VA

5V_PW

L370

Q3582

LCD

BLUE

PANEL

K25B K25G K25R

15VP

Power Fail: L

2.5V_PW

D101

Power Fail: L

174

IC392

74 72

Stand-by : L

3.3V_M

5V_SW

IC1802

19

IC102

FAN_SW

Power-On: H

FAN3

FAN2

FAN1

LCD

PANEL

GREEN

2

IC1871

COMPARATOR

3

IC301

SYSTEM

CONTROL

DAC

IC3561

EXPANDER

161514

FAN_CONT1

FAN_CONT2

LCD

RED

Lamp-On: H

140

178

IC1811

BUFFER

LAMP_ERR

FAN_CONT3

PANEL

P_SCLK1/SDA1

LAMP_POW

LAMP_PWM

PWM

NAND

IC4801

4

6

5

IC1882

SUB CPU

4

783

Lamp Error: H

5V

K48K

TEMP.

IC8801

Fan Error : L

FAN_ERR

9

2

IC1881

INVERTER

614

RXL

Lamp Error: H

5143

TEMP.

IC8802

SENSOR

5V

D5624

FAN3

D5619

FAN2

D5612

FAN1

11

Lamp-On: L

SCEL

TXL

SENSOR

D5622

Q5611

Fan Lock : H

K8H

12

12

12

12 12

12

K48L

K88A

K66F

K66E

K66D

K66C

K66B

K66A

K8811

TEMP.

IC8821

SENSOR

FN906

FN903

FN904

FN901

FN905

FN902

SW8801

LAMP COVER SW

SENSOR BOARD

SW BOARD

PRIMARY

CIRCUIT

CN201 K8B

16V

5V_AU

T101

CONVERTER

5V

TRANS.

5V

-

PC301

IC301

MC201

FAN CONTROL

PC302

OSC.

POWER

MC202

PC303

FAN CONTROL

MC203

FAN CONTROL

P. F .

BRIDGE

CN202 K8A

CONTROL

DIODE

UNIT_POWER

CN101 CN102

THERMAL SW

CN300

CN100

375V

15VB

K6A

PC303

PC501

PC300

FILTER BOARD

IGNITOR

FUSE

UNIT_LAMP

BALLAST

K601

AC INPUT

Page 35

-35-

■ Troubleshooting

Check the indicators for projector condition.

• • • lights green. • • • lights red.

• • •

off

• • • flashes green.

✽ When the life of the projection lamp draws to an end, the LAMP REPLACE indicator lights yellow. When this indicator lights yellow,

replace the projection lamp with a new one promptly. Reset the Lamp replace counter after replacement of the lamp.

The projector is OFF. (The AC power cord is unplugged.)

The projector is preparing for stand-by or the projection lamp is being cooled

down. The projector cannot be turned on until cooling is completed.

The temperature inside the projector is abnormally high. The projector cannot be turned on. When the projector is cooled down enough and the temperature returns to normal, the POWER indicator lights red and the projector can be turned on. (The WARNING . indicator keeps flashing.) Check and

clean the Air filter.

Projector Condition

The projector is ready to be turned on with the POWER ON-OFF button.

POWER

red/green

Indicators

LAMP

REPLACE

yellow

WARNING

red

The projector detects an abnormal condition and cannot be turned on.

Unplug the AC power cord and plug it again to turn on the projector. If the

projector is turned off again, disconnect the AC power cord and contact the

dealer or the service center for service and checkup. Do not leave the projector on. It may cause electric shock or a fire hazard.

✽

✽

✽

✽

✽

The projector is operating normally.

The projector is in the Power management mode.

✽

✽

The projector has been cooled down enough and the temperature returns to

normal. When turning on the projector, the WARNING indicator stops flashing. Check and clean the air filters.

• • • flashes red.

Indicators and Projector Condition

Page 36

-36-

Troubleshooting

● No Power

- When all the LED indicators are not lighting, the symptom indicates that the primary power supply circuit

does not operate properly. Check the power primary circuit and parts as follow;

AC cord

F601 (Fuse)

Power board

SW902 (Thermal sw.) ......short in normal

SW902 opens when the surrounding temperature of the switch exceeds 100°C.

This projector provides a function which can be specified a defective area simply by indicating the LEDs on the control panel. Connect the AC cord and press the Power button once and then check the LED indication.

- When the WARNING (red) indicator lights, the symptom indicates that the projector detected an abnormality

in the cooling fan operation or in the power supply secondary circuits. Check fan operation and power supply

lines, and the driving signal status.

An abnormality occurs on the secondary power supply lines.

Power failure detection diodes detect abnormal voltage on the power supply circuits.

POWER_FAIL (Error:L) signals are sent to pin 174 of IC301(System Controller) via IC1871(Comparator).

Check the shortage of secondary circuits, ICs, condensers, etc.

Check power supply lines, 15VP, 9V, 3.3V and 1.8V on the Main Board.

An abnormality occurs on the fan control circuits.

Power failure detection diodes detect the fan operation stop. Check FN901, FN902, FN903, FN904, FN905,

FN906 and peripheral circuit.

Check fan's power supply lines and detection diodes D5612, D5619 and D5624.

Check fan lock signal(Lock:H) and Q5611, D5622 and peripheral circuit.

An abnormality occurs on power starter signals (FAN_SW, 5V_SW, ON_15V).

FAN_SW signal (Power-on:H) is output from pin 19 of IC1802 and applied to the Power Board. It drives

the power oscillation circuit and power supply for the cooling fans in Power Board.

5V_SW signal(Power-on:H) is output from pin 74 of IC301 and sent to Q3582, then 5VA line is supplied.

ON_15V signal(Power-on:H) is output from pin 72 of IC301 and sent to Q2501, then 15VL line is supplied.

An abnormality occurs on Lamp drive signal (LAMP_POW, LAMP_ERR).

- LAMP_POW signal(Power-on:H) is output from pin 140 of IC301 and sent to IC1882 via IC4801.

SCEL signal(Lamp-on:L) is output from pin 4 of IC4801 via IC1881 and sent to Lamp Ballast Unit through

SW8801(Lamp Cover SW).

- TXL signal is output from pin 3 of IC1882 and sent to Lamp ballast Unit via IC1881.

(TXL signal is applied for lamp power control. Lo: Low power, Hi: High power)

- RXL signal(Lamp status signal) is output from Lamp Ballast Unit and sent to pin 4 of IC1882 via IC1881,

then LAMP_ERR signal is output from pin 7 of IC1882 and sent to IC301 via IC1811.

If an abnormality occurred on the lamp ballast unit, RXL signal and LAMP_ERR signal become "H" and

then IC301 shuts down the power supply circuit.

- When the WARNING(red) and POWER(red) indicators are flashing, the symptom indicates that the projector detected an abnormal temperature risen inside the projector. Check the air filters and remove the object

near the intake and exhaust fan openings, and wait until the POWER indicator stops flashing, and then try to

turn on the projector.

The internal temperature is monitored by sensor ICs, IC8821 on Sensor Board, IC8801 and IC8802 on Main Board.

Reset switch

The microprocessor inside the

projector may occasionally malfunction and does not allow any

controls. In this case, press the

reset switch on the rear panel

with a sharp tool to restart the

projector.

Lamp cover switch

Make sure that the lamp cover

is mounted correctly. If not or

the lamp cover removed, the

lamp does not light on for the

safety. Check the lamp cover

and lamp cover switch

(SW8801).

Page 37

-37-

Troubleshooting

● No Picture

No picture with all of

input sources

Check signal processing stage and LCD driving stage;

Check RGB S&H signals at test points TPR1, TPG1, TPB1.

Check NRS signals at test points TP2531 and TP2561.

Check power supply circuit 15VP and peripheral circuit.

Check ICs IC501, IC531, IC561, IC3531, IC401, IC9401, IC301 and

peripheral circuit.

No picture with Computer

RGB input source

Check PC source selecting stage;

Check IC5201 and peripheral circuit on the AV board.

RGB signals are selected at RIN1/GIN1/BIN1 of IC5201 and sent to

IC8201, A/D converter IC.

Check RGB signals at test points TP6202R/G/B.

H/V sync signal is output from IC5201 and sent to IC301 through

IC5301 and IC5303.

GSYNC signal of the source without H/V sync signals is output from

IC5201, and sent to IC5301 and IC5302, then sync separated signals

are sent to IC301 through IC5303.

PC/AV_SW signal is applied on IC5303, output from pin 14 of IC3551

for selecting sync signals.

Check H/V_SYNC signal at test points TPGHS/TPGVS.

No picture with Computer

RGB(Scart) input source

Ye s

Ye s

Ye s

No

No

No

Check following steps.

Check AV source selecting stage;

Check composite video signal (Video) on the AV and Main board.

Check IC101, Video decoder, and peripheral circuit.

No picture with video

input source

Ye s

Check PC source selecting stage;

RGB(Scart) signals are sent to IC101, Video decoder IC.

Check RGB signals at pin 3, 2 and 1 of IC101.

CV_SCART signal for sync is sent to pin 72 of IC101.

Check CV_SCART signal and test points TPVHS/TPVVS.

Check AV source selecting stage;

Check S-video signal (Y/C) on the AV and Main board.

Check IC101, Video decoder, and peripheral circuit.

S_SW signal (S-Video cable is connected:L) is applied on pin 9 of

IC1811.

No picture with S-VIDEO

input source

Check AV/PC source selecting stage;

Check component signal (Y/Cr,Pr/Cb,Pb) on the AV and Main board.

Component signals (480i/575i format) are sent to IC101 directly.

Component signals (480p/575p format) are selected at

RIN2/GIN2/BIN2 of IC5201 and other HDTV format signals are selected at RIN1/GIN1/BIN1 of IC5201, and then sent to IC8201.

Check IC5201, IC8201, IC101 and peripheral circuit.

Sync signals of 480i/575i format signal are output from IC101.

Sync signals of other format signals are output from IC5302.

Check H/V_sync signal at test points TPGHS/TPGVS/TPVHS/TPVVS.

No picture with

Component input source

No

Ye s

Ye s

No

Page 38

-38-

Troubleshooting

● Audio signal processing circuit

● No Sound

Check AUD_PC/AV switching circuit.

Check IC5001, audio-sw IC, and peripheral circuit.

AUD_PC/AV_SW (PC:H) signal is applied on pin 10 of IC5001

through Q5003, sent from pin 12 of IC3551.

Is the audio signal

observed at pins 3 and

13 of IC5001?

Check Audio amp.and control circuit.

Check IC5003, audio-amp IC, and peripheral circuit.

MUTE signal (Mute:L) is applied on pin 4 of IC5003, sent from

pin 12 of IC1801.

VOLUME signal is applied on pin 2 of IC5002., sent from pin 13 of

IC3551.

Check 5V_AUD power supply line.

Is the audio signal

observed at pins 5 and

8 of IC5003?

Check audio output circuit.

Check speaker, connection of the terminal “K8F”.

Ye s

No

Ye s

No

Check following steps.

PC

AUDIO-IN

AV

AUDIO-IN

AV

BOARD

L

R

L

R

8

9

10

11

K10E

K50B

IC5001

AUDIO-SW

<4052>

12

14

1

5

Q5001

13

L

R

3

Q5002

10

IC5002

VOLUME

<BA7655A>

1

Q5003

AUD_PC/AV_SW

IC301

SYSTEM

CONTROL

<PW168A>

P_SCLK2

P_SCDA2

DATA BU S

IC3551

D/A

CONVERTER

<M62393>

AUDIO-SW Switching Logic

PC AV

AUD_PC/AV_SW at IC3551 H L

AUD_PC/AV_SW at IC5001 L H

MAIN BOARD

IC5003

AMP.

<LM4865M>

3

+ 2 +

Q5004

2

VOLUME

Mute: L

Mute: H

IC1801

OUTPUT

EXPANDER

<74LCX574>

4

Q5006

MUTE

121312

SP901

1

3

K8F

+

-

5

8

Page 39

-39-

■ Waveforms

VIDEO-IN <TP103, IC101-75> Analog H-SYNC <TPGHS>

Analog V-SYNC <TPGVS>

Digital H-SYNC <TPDHS> Digital V-SYNC <TPDVS>

NRS <TP2531,TP2561>

R-S&H OUT <TPR1> G-S&H OUT <TPG1>

B-S&H OUT <TPB1>

Page 40

-40-

● System Control & I/O Port Table (IC301)

■ Control Port Functions

178Port A7 LAMP_PWM PWM Output to Sub-CPU PWM O

115Port A6 MUPO_ON I

44 Port A5 M_SCL1 I/O

116Port A4 M_SDA1 O

45 Port A3 M_SCL2 I/O

46 Port A2 M_SDA2 O

117Port A1 SCLK 3 Line Serial Bus Clock O

180Port A0 SDATA 3 Line Serial Bus Data O

173Port B7 NMI Reset SW Input I

111 P ort B6 IRM_STB 3 Line Serial Bus Strobe O

40 Port B5 3L_EN 3 Line Serial Bus Enable O

174Port B4 POWER_FAIL Power Fail Detection Error = L I

41 Port B3 A23 Address Bus 23

175Port B2 A22 Address Bus 22

112Port B1 A21 Address Bus 21

229 Port B0 A20 Address Bus 20

71 Port E7 5V_SW Standby 5V OFF Standby = L O

139Port E6 DCLK_SW O

200 Port E5 VHDPEN IC101 Video Decoder Enable O

140Port E4 LAMP_POW Lamp ON to Sub-CPU Lamp-ON = H O

201 Port E3 USB_VBUS USB Connector Detection Not used I

141Port E2 USB_RST USB Device Reset Output O

72 Port E1 ON_15V Standby 15V OFF Standby = L O

142Port E0 USB_EN USB Device Enable Output O

119Port F7 IRRCVR1 IR Receiver Input 1 Not used I

182Port F6 IRRCVR0 IR Receiver Input 0 I

47 Port F5 RXD I

182Port F4 TXD O

189Port F3 CS0 I/O Expander Chip Select (Output) O

55 Port F2 CS1 I/O Expander Chip Select (Input) O