Page 1

PLASMA MONITORSERVICE MANUAL

FILE NO.

Model No. PDP-42WV1

PDP-42WV1S

(EUROPE, ASIA)

PDP42WV1A

PDP-42WV1AS

(U.S.A.)

ORIGINAL VERSION

PRODUCT CODE

1 110 017 00 PDP-42WV1, J3TF

1 110 023 00 PDP-42WV1A, J3TFA

1 110 043 00 PDP-42WV1S, J3TG

1 110 044 00 PDP-42WV1AS, J3TGA

REFERENCE NO. SM5110505-00

Chassis No. PDP-42WV1-00

(PDP-42WV1)

NOTE: Match the Chassis No. on the

unit’s back cover with the Chassis

No. in the Service Manual.

If the Original Version Service

Manual Chassis No. does not

match the unit’s, additional

Service Literature is required. You

must refer to “Notices” to the

Original Service Manual prior to

servicing the unit.

CONTENTS

Pages

SAFETY INSTRUCTIONS --------------------------------------------------------------------- 2

TECHNICAL SPECIFICATIONS ------------------------------------------------------------- 3

DIMENSIONS AND OPTIONS---------------------------------------------------------------- 3

BATTERY REPLACEMENT------------------------------------------------------------------- 4

MECHANICAL DISASSEMBLIES ------------------------------------------------------- 5 - 8

ADJUSTMENT------------------------------------------------------------------------------ 9 - 16

CIRCUIT BLOCK DIAGRAM----------------------------------------------------------------- 17

POWER SUPPLY LINES--------------------------------------------------------------------- 18

POWER FAIL CIRCUIT----------------------------------------------------------------- 19 - 21

TROUBLESHOOTING ------------------------------------------------------------------------ 22

CONTROL PORT FUNCTIONS ------------------------------------------------------ 23 - 24

PIN DESCRIPTION OF DIODE, TRANSISTOR AND IC----------------------------- 25

PARTS LIST ------------------------------------------------------------------------------- 26 - 43

PARTS DESCRIPTION AND READING IN SCHEMATIC DIAGRAM ------------ 44

SCHEMATIC DIAGRAMS---------------------------------------------------------- A-1 - A-15

PRINTED WIRING BOARD DIAGRAMS-------------------------------------A-16 - A-24

Chassis No. PDP-42WV1S-00

(PDP-42WV1S)

Chassis No. J3T -42WV1A00

(PDP-42WV1A)

Chassis No. J3T -42WV1AS00

(PDP-42WV1AS)

Page 2

-2-

■ Safety Instructions

Product safety should be considered when a component replacement is made in any area of the monitor.

Components indicated by mark in the parts list and the schematic diagram designate components in

which safety can be of special significance. It is, therefore, particularly recommended that the replacement of

there parts must be made by exactly the same parts.

PRODUCT SAFETY NOTICE

SAFETY PRECAUTIONS

WARNING : TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS APPLIANCE TO

RAIN OR MOISTURE.

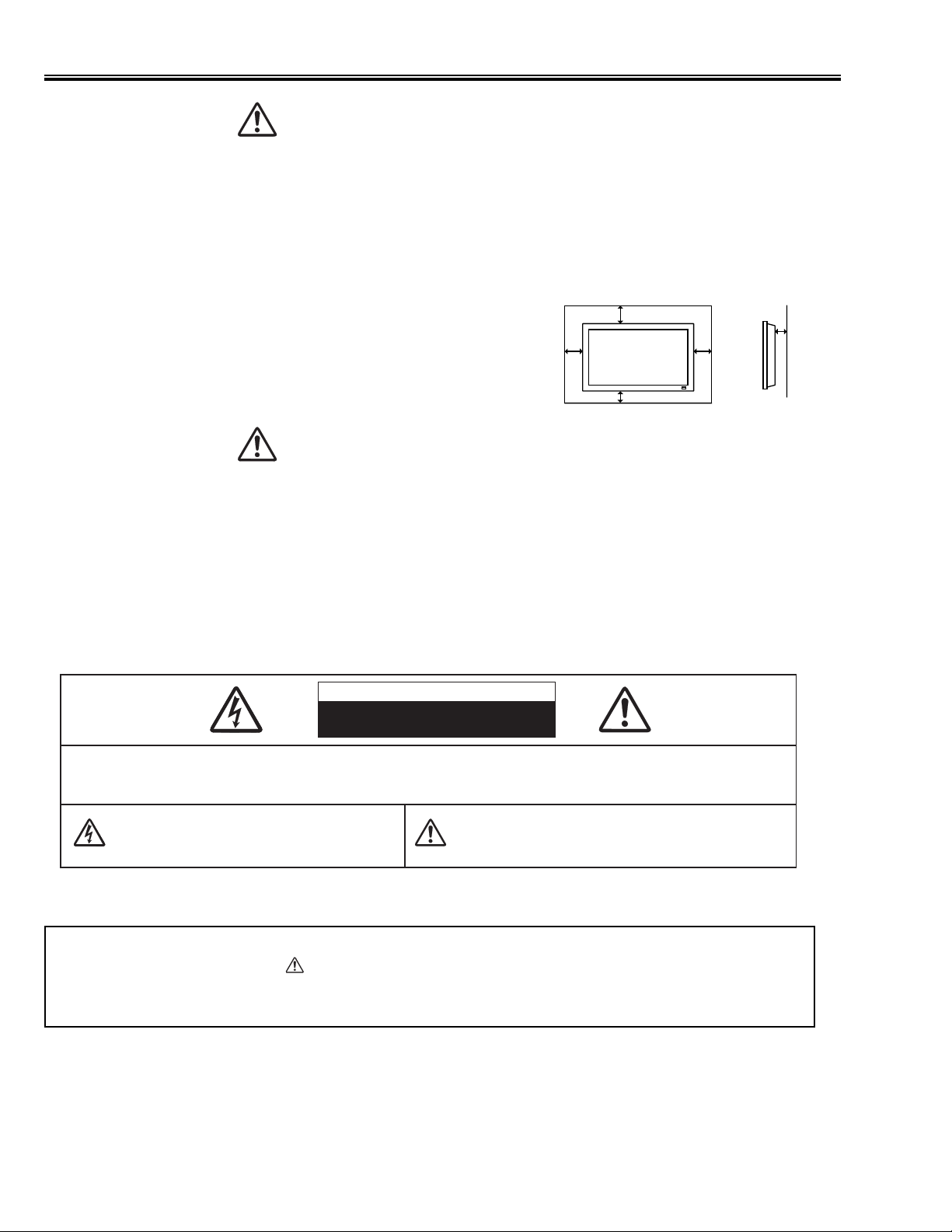

● This Plasma Monitor should be set in the way indicated. If not, it may result in a fire hazard.

● Take appropriate space on the top, sides and rear of the Plasma Monitor cabinet for allowing air circulation and

cooling the Plasma Monitor. Minimum clearance must be maintained. If the Plasma Monitor is to be built into

a compartment or similarly enclosed, the minimum distances must

be maintained. Do not cover the ventilation slot on the Plasma

Monitor. Heat build-up can reduce the life of your Plasma

Monitor, and can also be dangerous.

● If the Plasma Monitor is not to be used for an extended time,

unplug the Plasma Monitor from the power outlet.

READ AND KEEP THIS OWNER'S MANUAL FOR LATER USE.

CAUTION IN INSTALLING

SIDE, TOP and BOTTOM

10 cm

10 cm

6 cm

REAR

3 cm

10 cm

Handle the

●

Locate set away from heat, excessive dust, and direct sunlight.

●

For correct installation and mounting it is strongly recommended to use a trained, authorized dealer. Failure to

●

follow correct mounting procedures could result in damage to the equipment or injury to the installer.

Plasma

Monitor carefully when installing it and do not drop.

NOTE :

When Plasma Monitor is not used for a long period of time, unlighting dots may be observed. This is caused by

characteristic of the Plasma Monitor. If this occurs, turn the Plasma Monitor on and leave it on about 1 hour. These

dots will gradually disappear.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION : TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE COVER (OR BACK). NO USER-

SERVICEABLE PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

THIS SYMBOL INDICATES THAT DANGEROUS

VOLTAGE CONSTITUTING A RISK OF ELECTRIC

SHOCK IS PRESENT WITHIN THIS UNIT.

THIS SYMBOL INDICATES THAT THERE ARE IMPORTANT

OPERATING AND MAINTENANCE INSTRUCTIONS IN THE

OWNER'S MANUAL WITH THIS UNIT.

Page 3

-3-

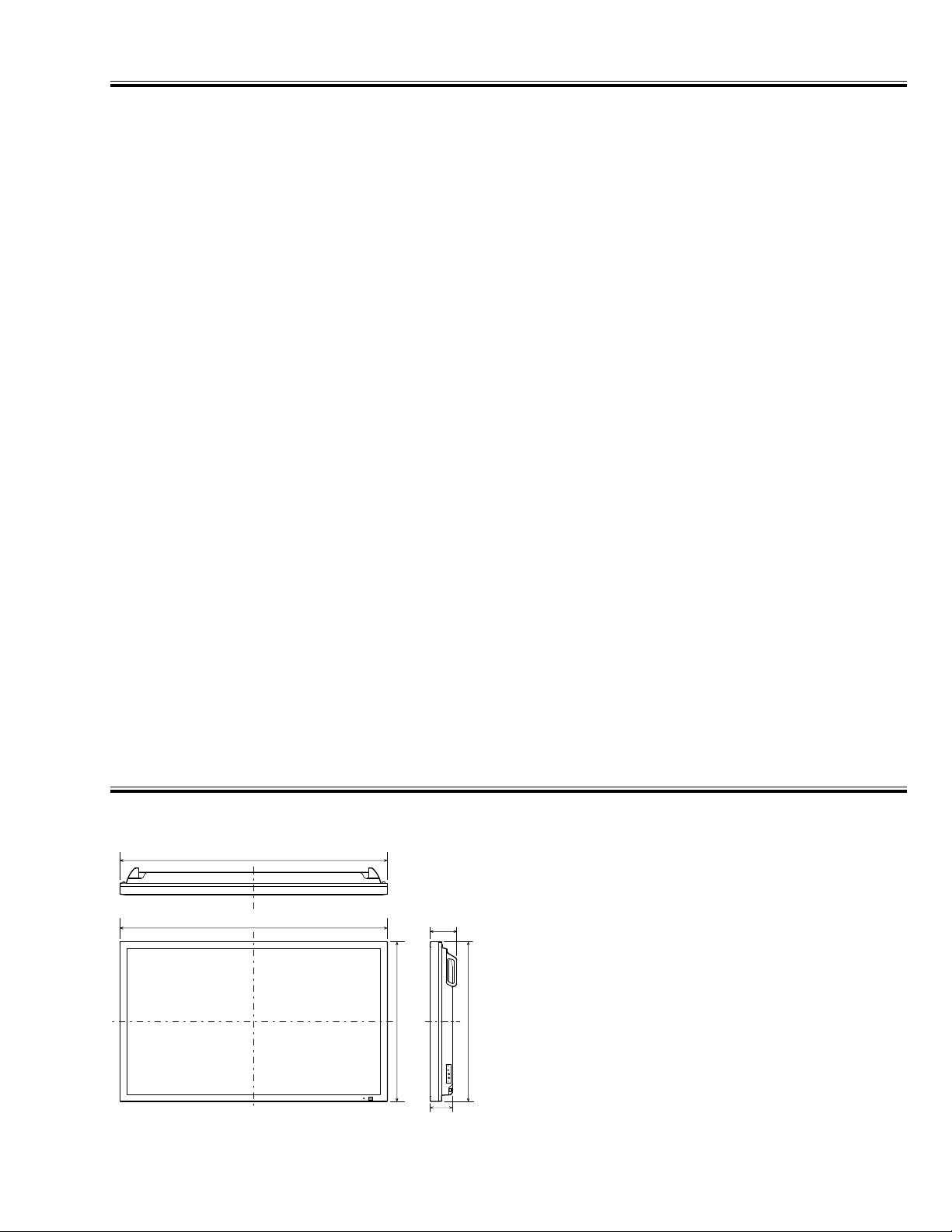

■ Dimensions and Options

MEASUREMENT OPTIONS

Size in mm (inch)

The products listed below are optionally supplied.

When ordering these products, give name and Type No. to

sales dealer.

Speaker unit KA-SX-42V (R and L)

(Color: Black)

KA-SX-42VS (R and L)

(Color: Silver)

Table top stand KA-TD-42V

Tilt mount unit KA-TI-42V

Wall mount unit KA-WA-42V

Contact the sales dealer for other available options.

■ Technical Specifications

Screen Diagonal

42V

Product name

Multimedia Plasma Monitor

Panel type

Plasma Display Panel (16 x 9)

Display area

920 mm (W) x 518 mm (H)

Resolution / Color

852 x 480 pixels

PC Interface

RGB

Capability

Up to SXGA

Plug & Play

VESA DDC2B

Power Management

VESA DPMS

Audio Amp

10W + 10W (8 )

Terminals

PC IN

RGB (D-SUB 15pin)

AUDIO R / L (Stereo Mini jack)

WIRED RC IN / OUT

Mini Jack

EXT. SP OUT

R and L, 10W (8 ), Push type

POWER SUPPLY

AC 200 - 240V 50/60 Hz (PDP-42WV1/PDP-42WV1S)

AC 100 - 120V 50/60 Hz (PDP-42WV1A/PDP-42WV1AS)

DIMENSION (W x H x D)

1022 x 610 x 85 mm

(

402.4" x 240.2" x 33.5" )

(not including handles)

WEIGHT (NET)

29.8 kg

(

65.7 lbs )

(Plasma Monitor only)

Regulations

FCC CLASS-A, UL (PDP-42WV1A/PDP-42WV1S), CE (PDP-42WV1/PDP-42WV1S)

Environmental Considerations

Operating Temperature

0˚C ~ 40˚C (32˚F ~ 104˚F )

Humidity

20 ~ 80%

Storage Temperature

-10˚C ~ 50˚C (14˚F ~ 122˚F)

Humidity

20 ~ 80 %

Accessories

Owner’s Manual

AC Power Cord

Wired/Wireless Remote Control Transmitter and Batteries

Remote Control Cable

Ferrite Cores (x2)

1022

(40.2)

1022

(40.2)

610

(24.0)

(3.4)

102

(4.0)

85

610

(24.0)

Page 4

-4-

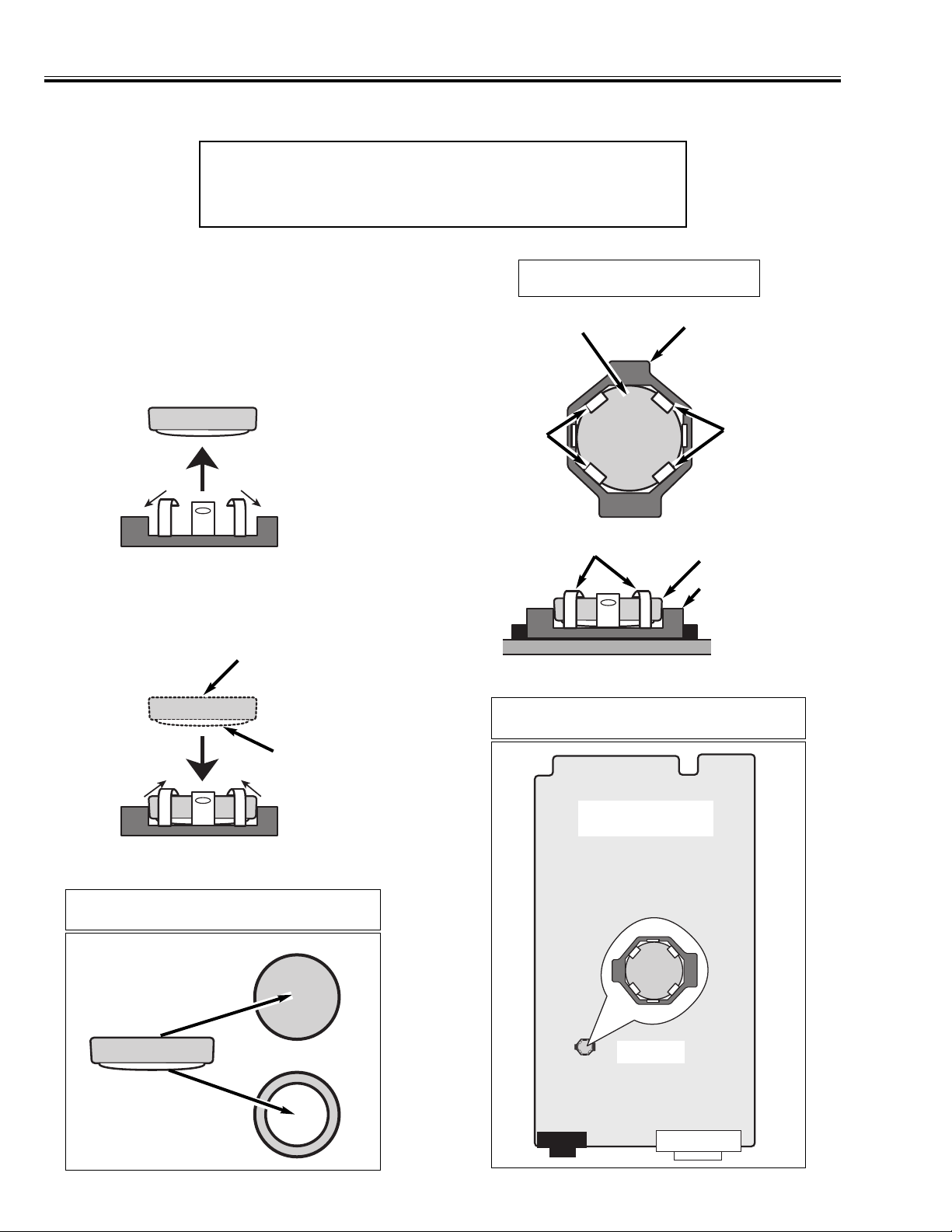

■ Battery Replacement

This Plasma Monitor is used a battery for Clock Function.

■ Battery Replacement

The battery is fixed to Main Board with Battery

Holder.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

Battery Holder

Battery

Hook

Hook

Battery

Battery Holder

Hook

Main Board

Location of Battery

(+) Side

(-) Side

(1) Remove the battery from battery holder to bent

hooks slightly.

(2) Mount a new battery by correct polarity and

bent hooks back.

Polarity of Battery

(+) Side

(-) Side

Main Board

Battery

Parts No.: 645 059 8302

Page 5

C

-5-

■ Mechanical Disassemblies

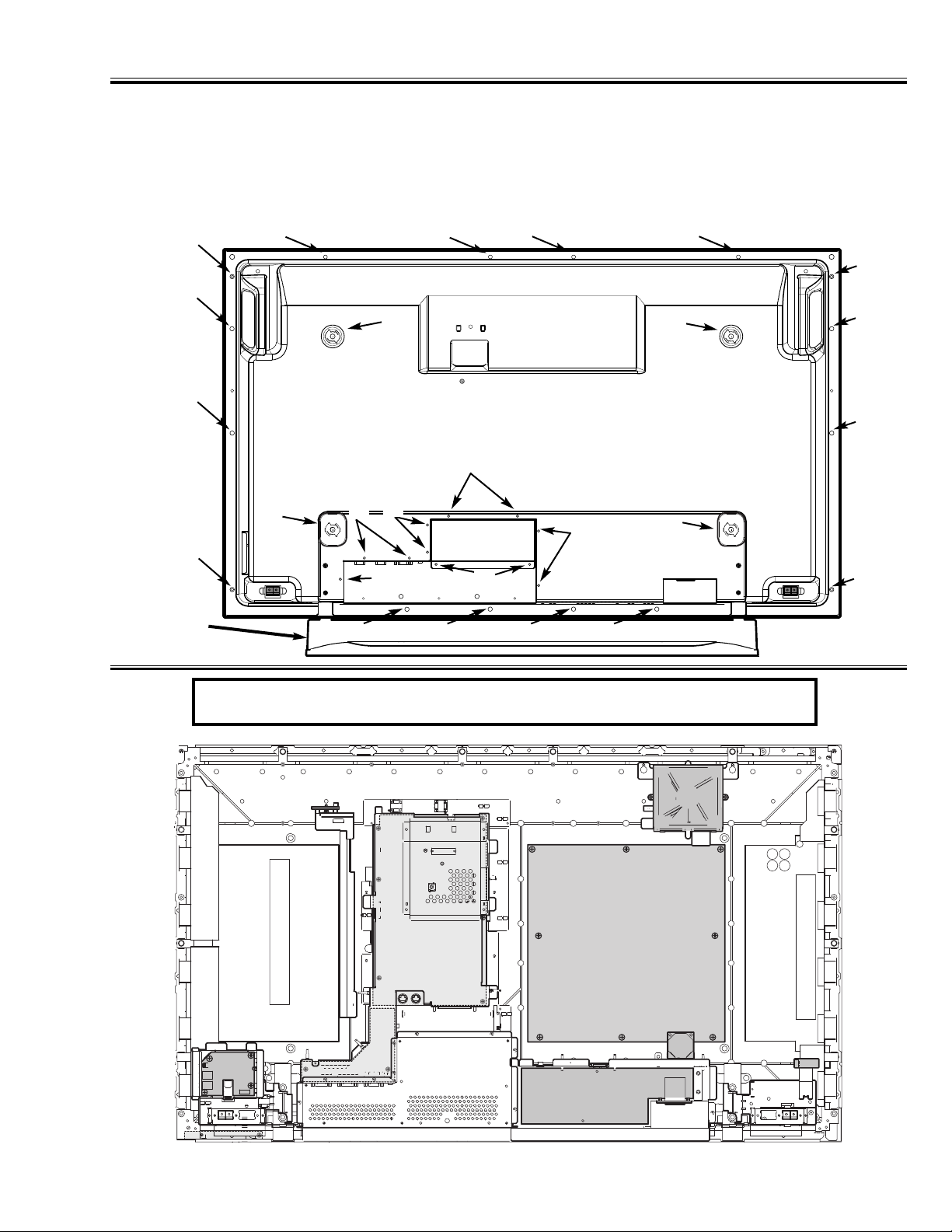

1. Cabinet Back Removal (Fig. 1)

Remove screws (A, B, C) and remove Cabinet Back as Fig. 1.

Note: For removal Option Slot Cocer, remove screws (D) and slide down.

A (4pcs: 8X20), B (9pcs: 3X6), C (16pcs: Special Screw), D (2pcs: 3X6)

Fig. 1

A

A

A

A

B

B

B

B

B

C

C

C

C

C

C C

C

C

C

C

C

C C C

Option

Stand

D

Option

Slot Cover

Location of Circuit Board and Electric Parts

Page 6

-6-

Mechanical Disassemblies

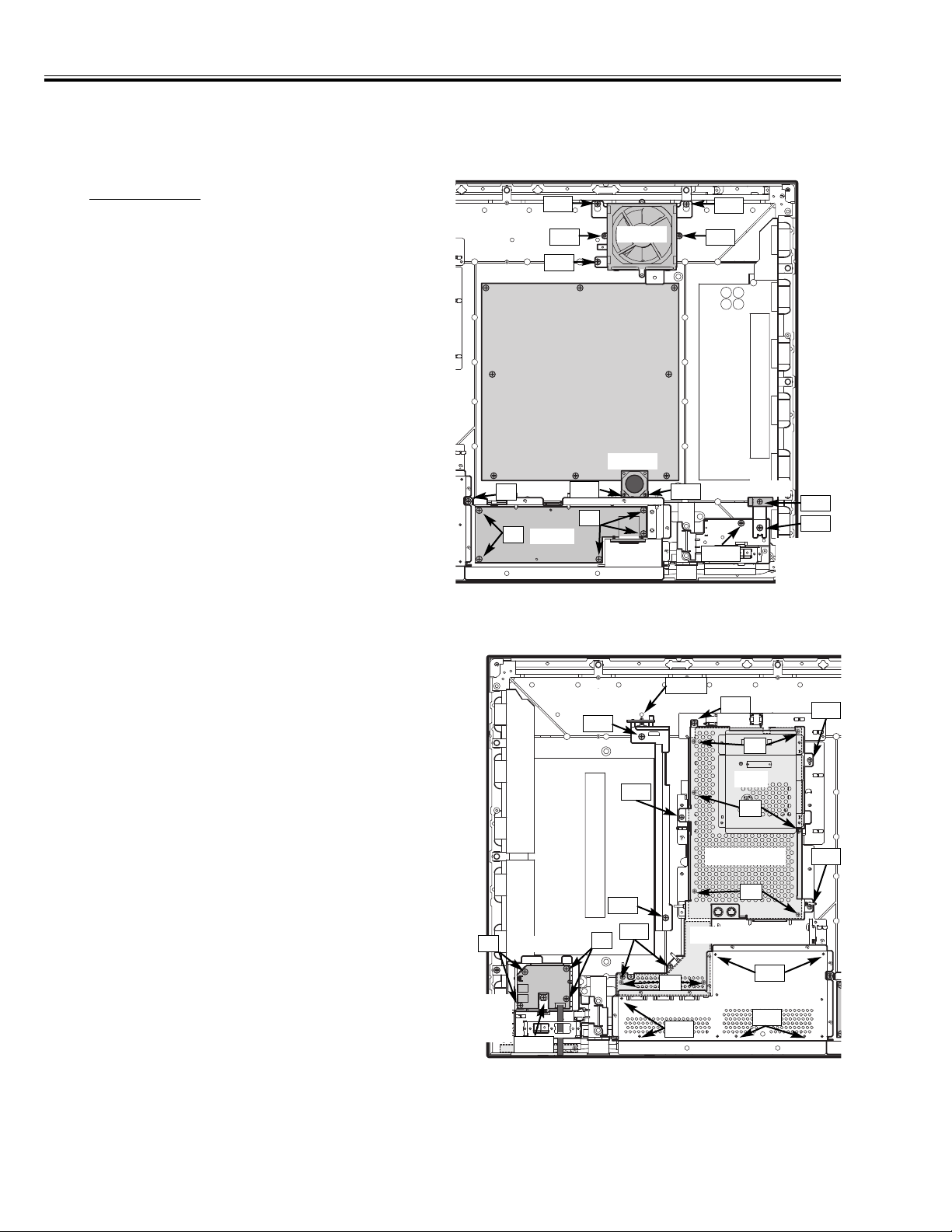

2. Chassis Removal

[ATTENTION]

This PDP monitor is used the different kind of screw.

Using correct screw is needed to avoid the damage.

2-1 Fans Removal (Fig. 3)

FN1901

1) Remove screws (FN1: 3pcs) and take Fan (FN1901)

with the holder off.

2) Remove screws (FN2: 2pcs) and take Fan from the

holder.

FN1903

1) Remove screws (FN3: 2pcs) and take Fan (FN1903)

with the holder off.

2-2 Power Board Removal (Fig. 3)

1) Remove screws (P1: 5pcs) and take Power Board

off.

✽ Remove screw (P2: 1pc) and take Power Board with

the holder off.

2-3 Sensor-A Board Removal (Fig. 3)

1) Remove screw (SA1: 1pc) and take Sensor-A Board

off.

✽ Remove screw (SA2: 1pc) and take Sensor-A Board

with the plate off.

✽✽ Remove screw (STB1: 1pc) and take Speaker

Terminal Base (R) with the Sensor-A Board and

holder off.

2-4 Sensor-B Board Removal (Fig. 4)

1) Remove Sensor-B Board from the Hook.

✽ Remove screws (SB1: 2pcs) and take Sensor-B

Board with the plate off.

2-5 Jack-B Board Removal (Fig. 4)

1) Remove screw (B1: 4pcs) and take Jack-B Board

with the holder off.

✽ Remove screw (STB2: 1pc) and take Speaker

Terminal Base (R) with the Jack-B Board and holder

off.

2-6 Main and Jack-A Boards Removal (Fig. 4)

1) Remove screws (SP1: 6pcs) and take Shield Plate

(for Main and Jack-A board) off.

2) Remove screws (M1: 6pcs) and take Main board off.

3) Remove screws (TP1: 6pcs) and nut-screws of the

terminals on Jack-A board (6pcs), and take Terminal

Plate off.

4) Remove screws (A1: 2pcs) and take Jack-A board

off.

Note: If the cable is fixed by ferrite core or CV band

(fixer), remove it as the need arises. After servicing, it is necessary to be fixed again to previous

position.

Power

Sensor-A

FN1901

FN1903

Speaker

Terminal

Base(R)

SA1

SA2

STB1

FN2

FN2

FN1

FN1

FN1

FN3

FN3

P2

P1

P1

Fig. 3

Fig. 4

Sensor-B

SB1

Hook

Speaker

Terminal

Base(L)

STB2

Jack-B

B1

B1

SB1

Jack-A

Main

Shield Plate

Terminal Plate

SP1

SP1

SP1

SP1

SP1

A1

M1

M1

M1

TP1

TP1

TP1

Page 7

-7-

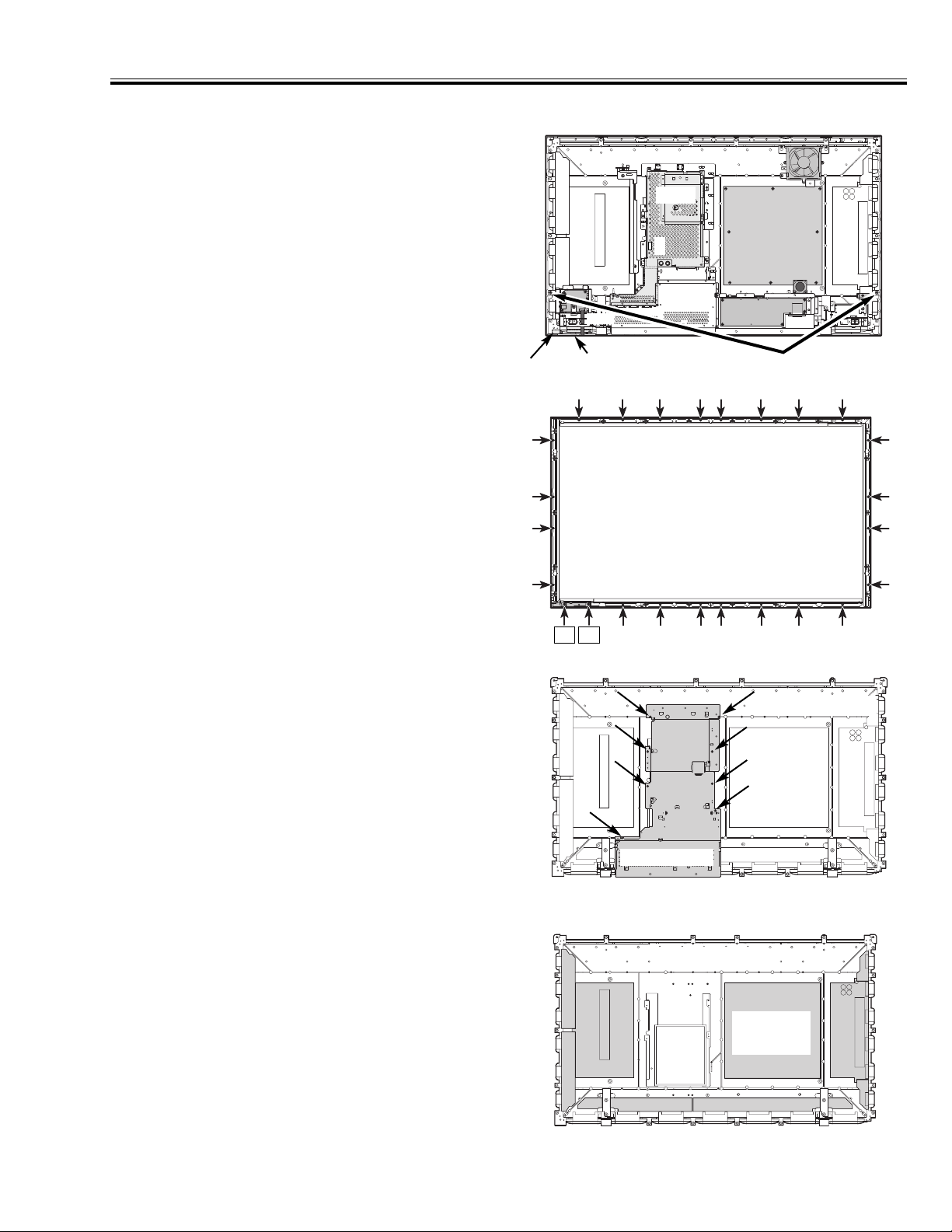

3. Cabinet Front and Optical Filter Removal

4. Panel Module Removal

Fig. 6

1) Proceed 1 to 3 to remove Cabinet Back,

Chassis and Cabinet Front.

2) Remove screws (8pcs) of Chassis Base and take it

from Panel Module.

(Fig. 7)

Note: Units of Fig.8 are included with Panel for PDP

Module. Do not remove them from Panel. For

removal of Panel, it is necessary to change

these all units together. Main Power Module is

included with Panel Module too. Do not

remove Main Power Module from Panel Module.

Mechanical Disassemblies

Fig. 5

Mounting Filter Plate-U

Mounting Filter Plate-D

Mounting Filter Plate-L

Mounting Filter Plate-R

C1

C1

Cabinet Front includes Optical Filter to protect the damage of Panel, improve picture quality, or prevent exposure of interference.

Note: The Optical Filter is easy to be damaged. Do not

touch directly by hand. If there is the dust,

remove it by watery neutral detergent.

3-1 Cabinet Front Removal (Fig. 5)

1) Remove the lead wire of Control board from Main

Board (K8J).

2) Remove the lead wire of Membrane Switch from

Jack-B board (K1104).

✽ Membrane Switch is fixed on the Cabinet Front by

two-sided tape.

3) Remove screws (2pcs) of Fig.5 and take Cabinet

Front off.

3-2 Control Board and Optical Filter Removal

(Fig. 6)

1) Remove screws (C1: 2pcs, Others: 7pcs) of

Mounting Filter Plate-D and take Mounting Filter

Plate-D and Control Board off.

2) Remove screws (16pcs) of Mounting Filter Plate-A,

B and C and take Mounting Filter Plate-A, B and C

and Optical Filter off.

Control

Membrane

Switch

Main

K8J

K1104

Fig. 7

Chassis Base

PDP Module

Fig. 8

PDP Module

Main Power

Module

Page 8

-8-

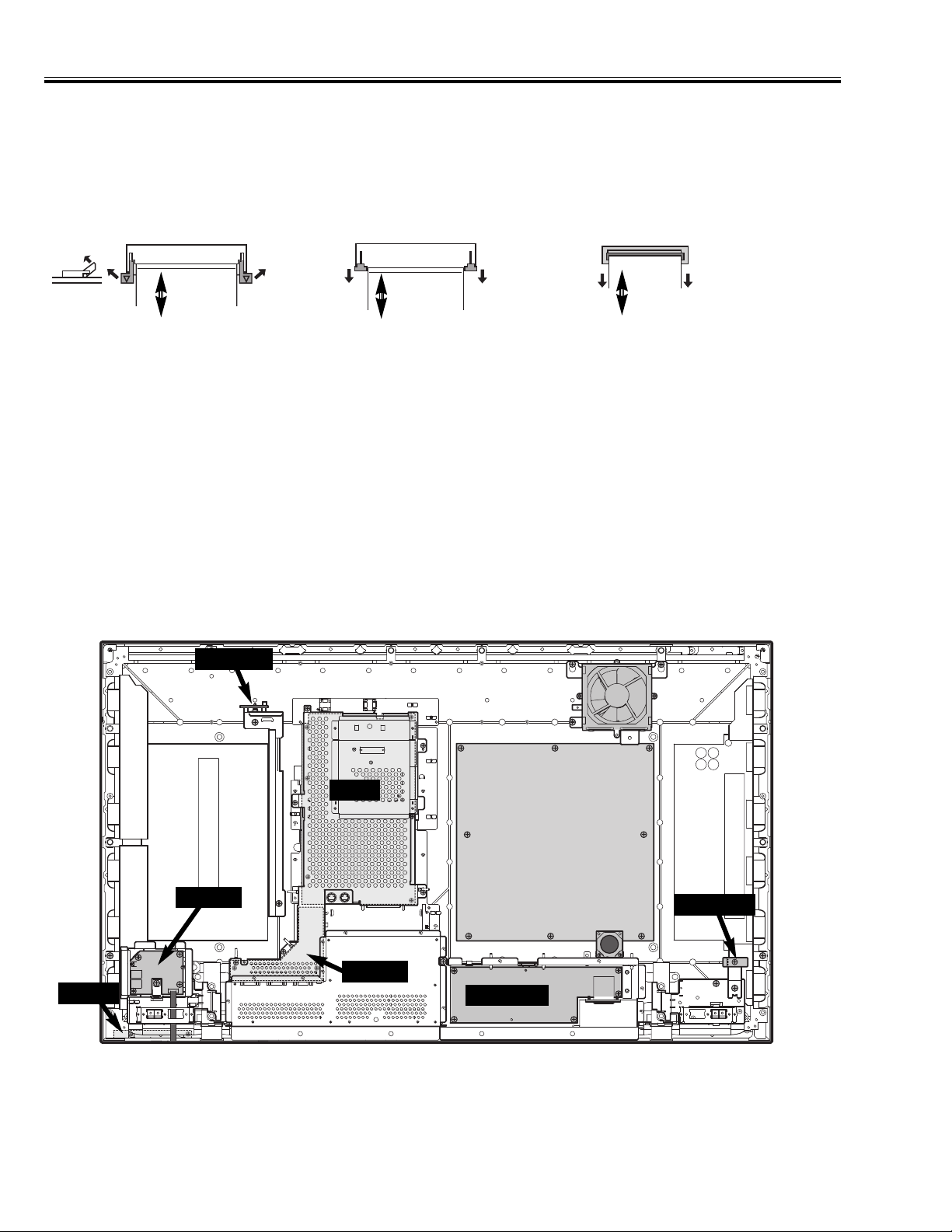

■ Flat Cable Removal

This set is used 3 kinds of connector for flat cable. For removal of cable, refer as below not to damage.

■ For Gasket

The gasket is provided to prevent exposure of interference for other radio and television receptions.

The gasket should be

replaced on previous positions after servicing.

For removal of flat cable, slide hook of

both sides.

For insert and fixing, slide hook to previous position after inserting the flat

cable.

Type A Type B Type C

For removal of flat cable, lift up hook of

both sides.

For insert and fixing, hold down hook

after inserting the flat cable.

For removal of flat cable, pull off only.

For fixing , insert into socket.

Cable

Cable

Cable

Mechanical Disassemblies

■ Notice for service of Board

In below boards, can be repaired inside parts or unit itself. Order service parts for repair.

Main

Power

Jack-A

Jack-B

Sensor-A

Sensor-B

Control

Note: Control Board and Membrane Switch are fixed at Cabinet Front.

Page 9

-9-

■ Adjustment

Before Adjustment

This adjustment is done to enter Service Mode by Remote

Control Unit.

■ To enter Service Mode

Quick operation is needed to enter Service Mode.

(1) Turn the monitor on.

(2) Press and hold the MENU button on the monitor.

(3) Keep item (2) and press the STATUS button and

release the both buttons.

(4) Within 2 seconds after item (3), press the MUTE

button to appear the Service Mode Display.

■ Service Mode Display

■ To return to the Normal Mode

Once turn the Monitor off by pressing “POWER” button on the monitor or remote control unit and turn it on again.

MENU Button

➡

7/ 8

Data Setting

(-) / (+)

To enter

Service Mode

STATUS

e

To select :

Adjustment

Item

d

To select :

Adjustment

Item

Sub-Image

Sub-Cont

0

PC

Main

42WV1

CAUTION

The each circuit has been made by the fine adjustment at factory. Do not attempt to adjust

the following adjustments except requiring the readjustments in servicing otherwise it may

cause loss of performance and product safety.

To enter

Service Mode

MUTE

1ah(26)

215

Model 215(WV1)

Sub 138

Temp1 27

Temp2 10

PDP Time 10h

OK

INPUTMENU

VOLUME

PICTURE

INPUT

E

M

U

L

O

V

MUTE

ON-OFF

BACK

V

O

L

U

M

E

MENU

OK

LOCAT 2-Win SIZE

STATUS

F

WIDE ON-OFF

PIP

Page 10

-10-

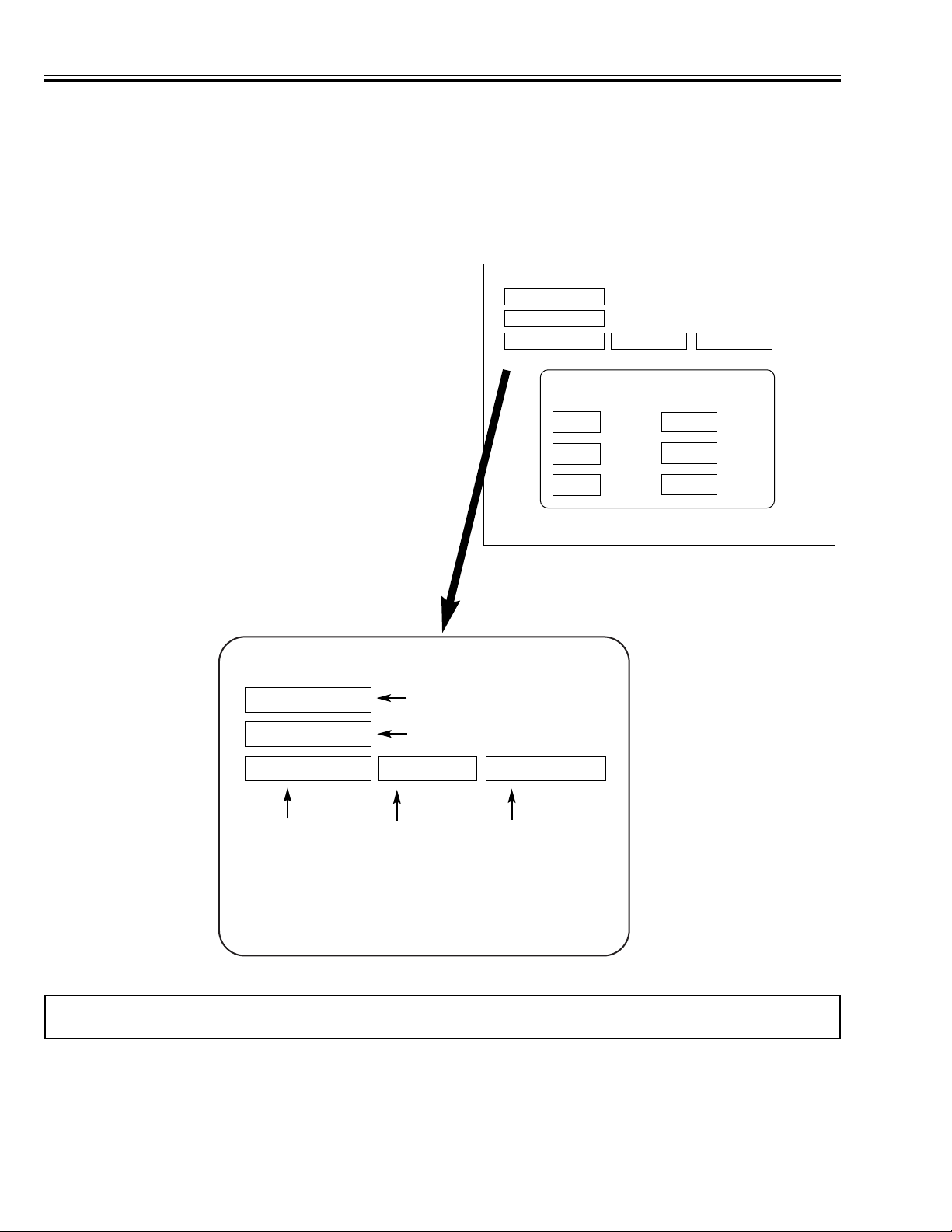

■ To adjust

The next 5 pages show Data for adjustment.

To select adjustment item, press eor dbutton on the remote control unit.

To adjust data, press 7or 8button on the remote control unit.

The all data adjusted in service mode memorizes into non-volatile memory IC.

Note: In the explanation all buttons are indicated for remote control unit without any notice.

Service Mode Display

Sub-Image

1) Select adjustment item by ebut-

ton.

Adjustment item is displayed in order. To

reverse adjustment item, press

d

button.

Selected byeordButton Adjusted by

7

or8Button.

3) To exit the Service Mode.

To exit the service mode, press POWER ON-

OFF button on the monitor or remote control

unit.

2) Adjust the data by 7or 8button.

Sub-Cont PC 1ah(26)

Adjustment Item Adjustment Data

Number

Adjustment

Sub-Image

Sub-Cont

0

PC

Main

42WV1

1ah(26)

215

Model 215(WV1)

Sub 138

Temp1

27

Temp2 23

PDP Time 10h

0

Adjustment Mode

Adjustment Name

✽ This menu is for factory data,

not used for servicing.

✽

Page 11

-11-

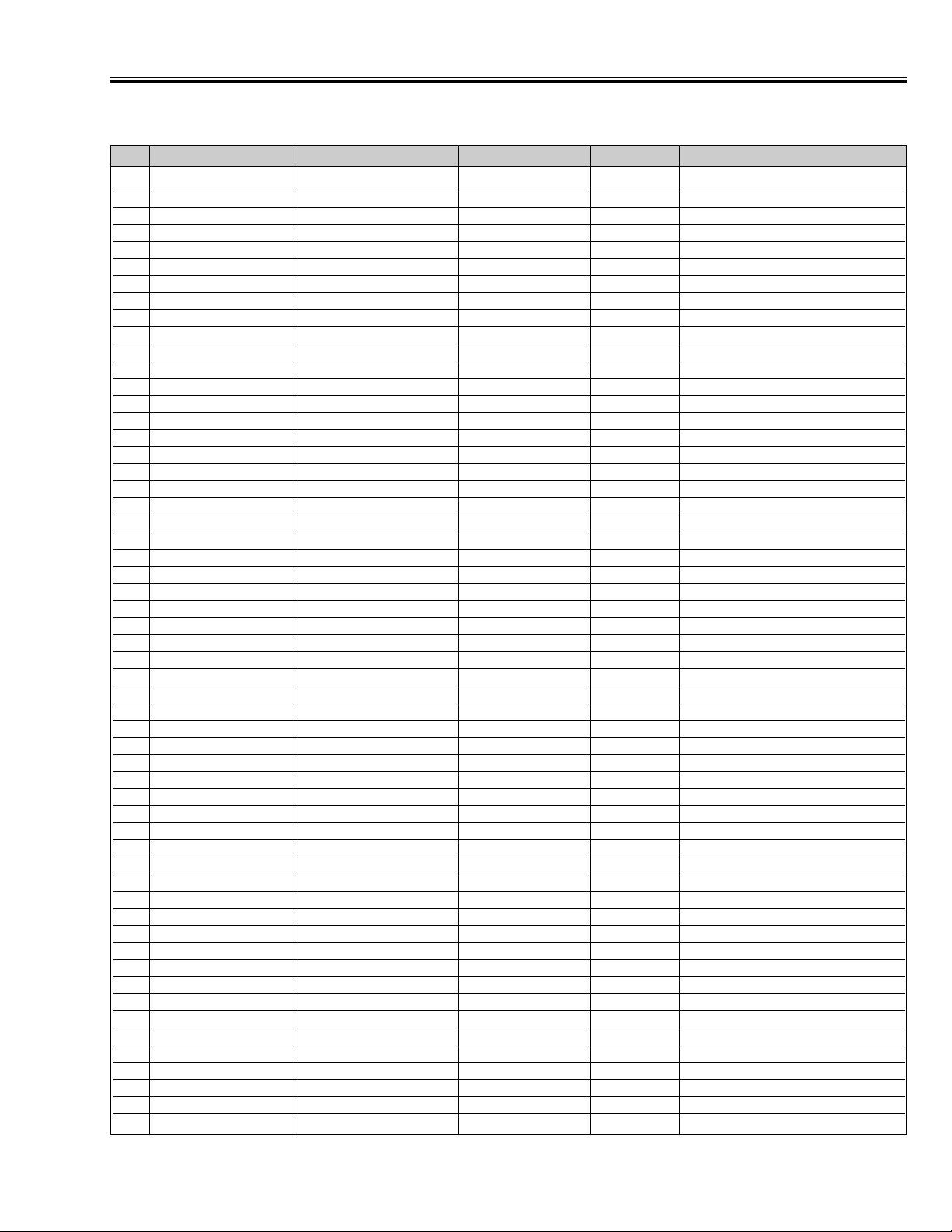

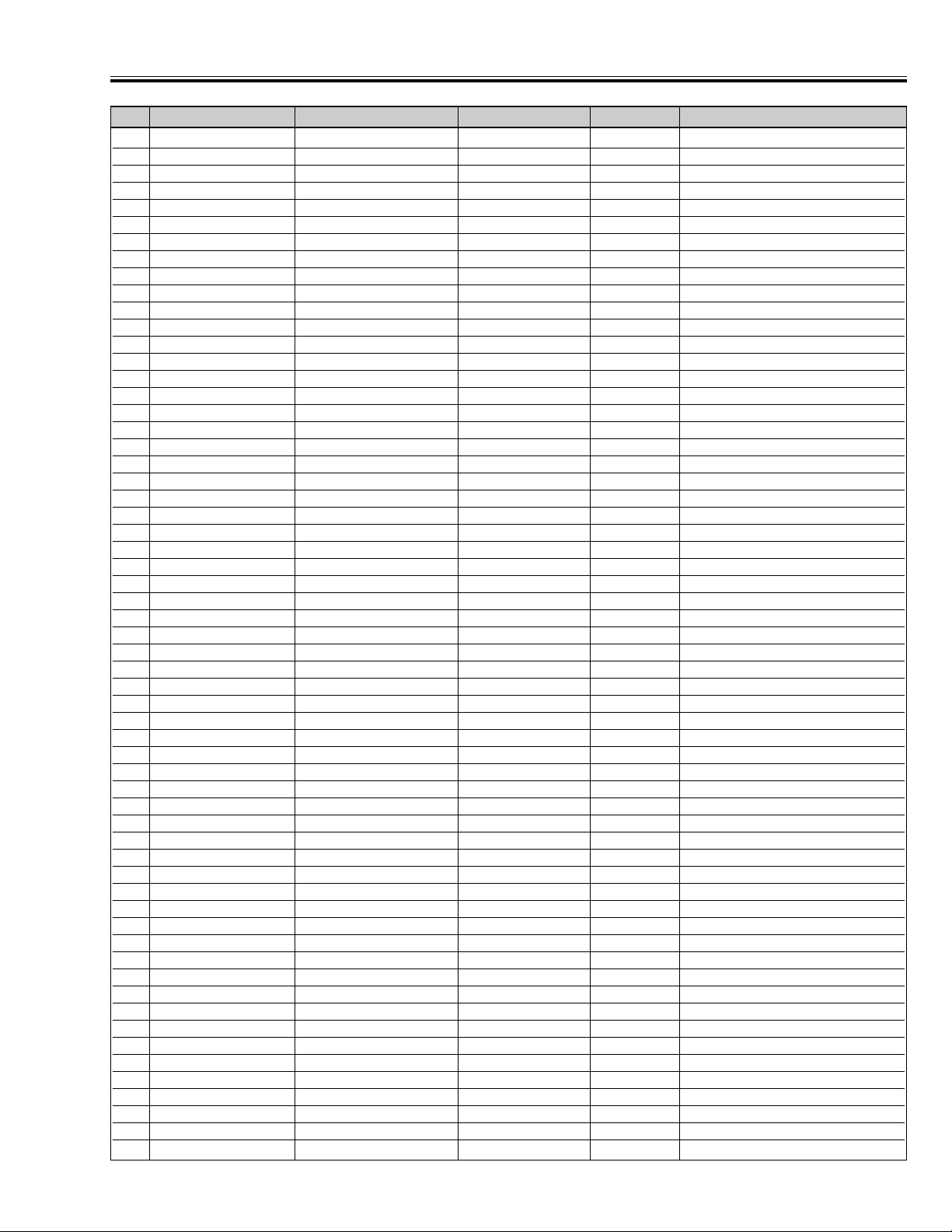

■ Service Adjustment Data Table

Adjustment

• All data except in gray box area is fixed. Do not change for correct operating.

• Data in gray box area is initial. Can be set according to adjustment information.

0 Sub Image PC Sub-Cont 1ah(26)

1 Sub-Bright 80h(128)

2 Sub-Color 23h(35)

3 Sub-Tint 80h(128)

4 Component Sub-Cont 1ch(28)

5 Sub-Bright 26h(38)

6 Sub-Color 1ch(28)

7 Sub-Tint 80h(128)

8 NTSC Sub-Cont 1ch(28)

9 Sub-Bright 80h(128)

10 Sub-Color 1fh(31)

11 Sub-Tint 80h(128)

12 PAL Sub-Cont 1bh(27)

13 Sub-Bright 80h(128)

14 Sub-Color 1fh(31)

15 Sub-Tint 80h(128)

16 SECAM Sub-Cont 1bh(27)

17 Sub-Bright 80h(128)

18 Sub-Color 1fh(31)

19 Sub-Tint 80h(128)

20 D PC Sub-Cont 15h(21)

21 Sub-Bright 80h(128)

22 Sub-Color 23h(35)

23 Sub-Tint 80h(128)

24 TEL TEXT Sub-Cont 1ch(28)

25 Sub-Bright 80h(128)

26 Sub-Color 20h(32)

27 Sub-Tint 80h(128)

28 HDCP Sub-Cont 15h(21)

29 Sub-Bright 80h(128)

30 Sub-Color 23h(35)

31 Sub-Tint 80h(128)

32 PC Sub-Sharp 09h(9)

33 Component D1 Sub-Sharp 15h(21)

34 Component D2 Sub-Sharp 15h(21)

35 Component D3 Sub-Sharp 15h(21)

36 Component D4 Sub-Sharp 15h(21)

37 NTSC YC Sub-Sharp 0ch(12)

38 PAL YC Sub-Sharp 0ch(12)

39 SECAM YC Sub-Sharp 0ch(12)

40 NTSC VBS Sub-Sharp 0dh(13)

41 PAL VBS Sub-Sharp 0dh(13)

42 SECAM VBS Sub-Sharp 0dh(13)

43 SCART Sub-Sharp 00h(0)

44 TEL TEXT Sub-Sharp 0ch(12)

45 Image Menu Standard AV Contrast 34h(52)

46 Bright 1fh(31)

47 Color 1fh(31)

48 Tint 00h(0)

49 Sharp 08h(8)

50 Gamma 03h(3)

51 Dynamic AV Contrast 3fh(63)

52 Bright 1fh(31)

53 Color 23h(35)

54 Tint 00h(0)

55 Sharp 08h(8)

NO. Name Mode Item Initial Data Note

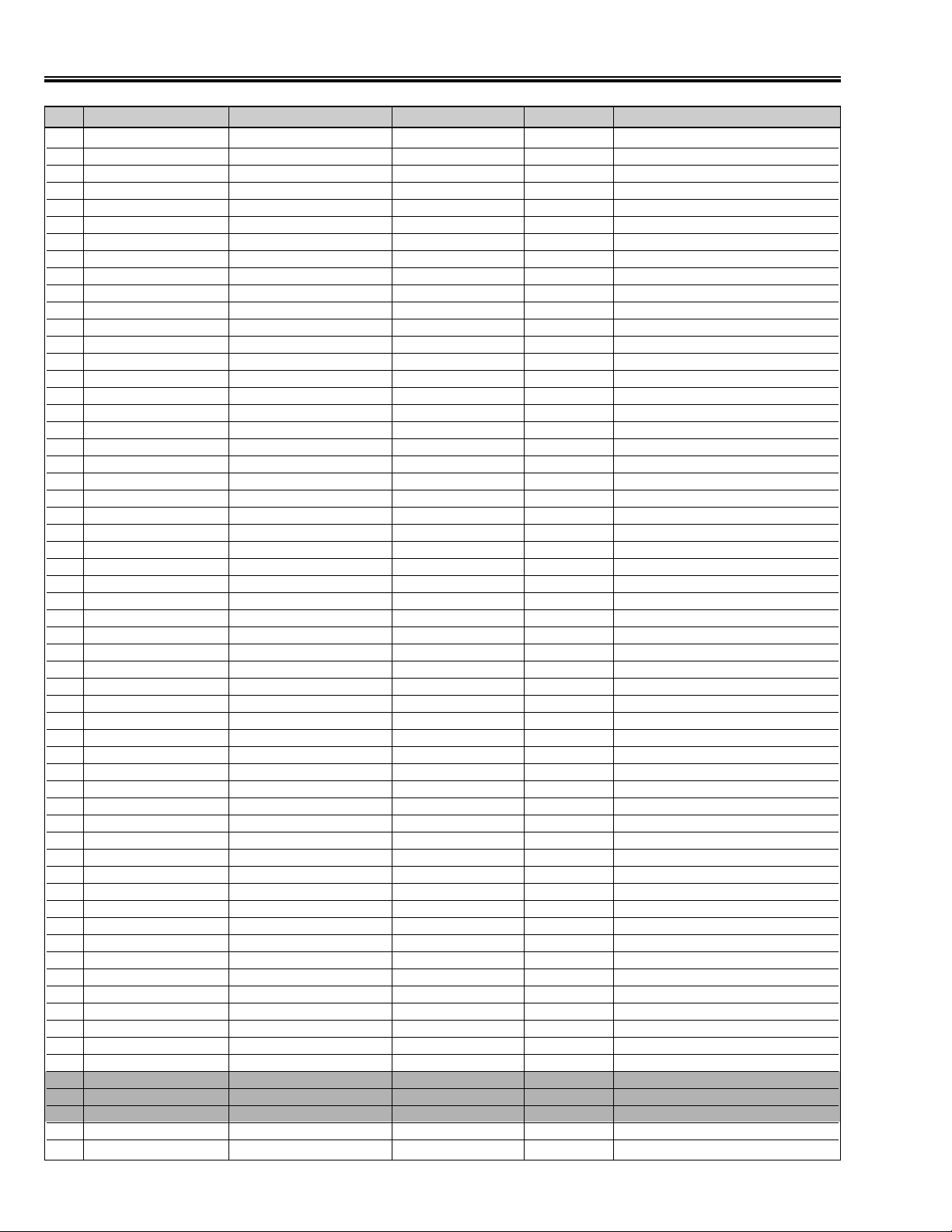

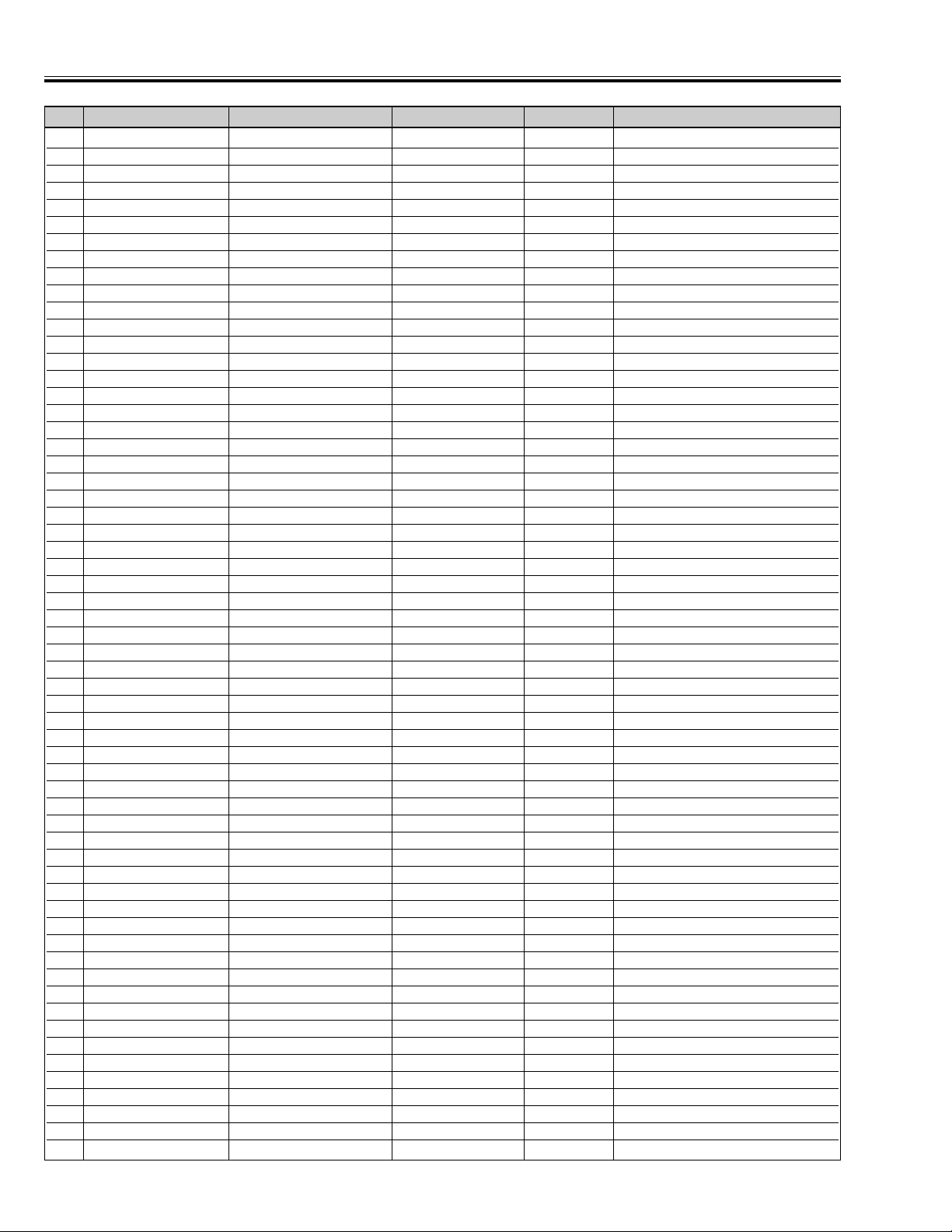

Page 12

-12-

Adjustment

56 Gamma 05h(5)

57 Cinema AV Contrast 1fh(31)

58 Bright 1fh(31)

59 Color 1bh(27)

60 Tint 00h(0)

61 Sharp 08h(8)

62 Gamma 00h(0)

63 Standard PC Contrast 2fh(47)

64 Bright 1fh(31)

65 Color 1fh(31)

66 Tint 00h(0)

67 Sharp 08h(8)

68 Gamma 03h(3)

69 Graphics PC Contrast 3fh(63)

70 Bright 1fh(31)

71 Color 23h(35)

72 Tint 00h(0)

73 Sharp 0ch(12)

74 Gamma 05h(5)

75 Text PC Contrast 28h(40)

76 Bright 1fh(31)

77 Color 19h(25)

78 Tint 00h(0)

79 Sharp 07h(7)

80 Gamma 07h(7)

81 VPC3230D AV AB Low Byte 1ch(28)

82 AB High Byte 02h(2)

83 AC Low Byte 1ch(28)

84 AC High Byte 02h(2)

85 BE 06h(6)

86 PLL 02h(2)

87 AD9884 540p Phase 10h(16)

88 540p(50) Phase 10h(16)

89 525i Phase 12h(18)

90 625i Phase 12h(18)

91 525p Phase 10h(16)

92 625p Phase 10h(16)

93 1035i / 1080i Phase 10h(16)

94 1080i(50) Phase 10h(16)

95 720p Phase 16h(22)

96 720p(50) Phase 10h(16)

97 Out 525i On/Off 01h(1)

98 Out 625i On/Off 01h(1)

99 Color Balance White:VBS/YC Red 80h(128)

100 Green 80h(128)

101 Blue 80h(128)

102 Black:VBS/YC Red 00h(0)

103 Green 00h(0)

104 Blue 00h(0)

105 White:Component Red 80h(128)

106 Green 80h(128)

107 Blue 80h(128)

108 Black:Component Red 00h(0)

109 Green 00h(0)

110 Blue 00h(0)

111 White:PC Red 75h(117)

112 Green 80h(128)

113 Blue 75h(117)

114 Black:PC Red 00h(0)

115 Green 00h(0)

NO. Name Mode Item Initial Data Note

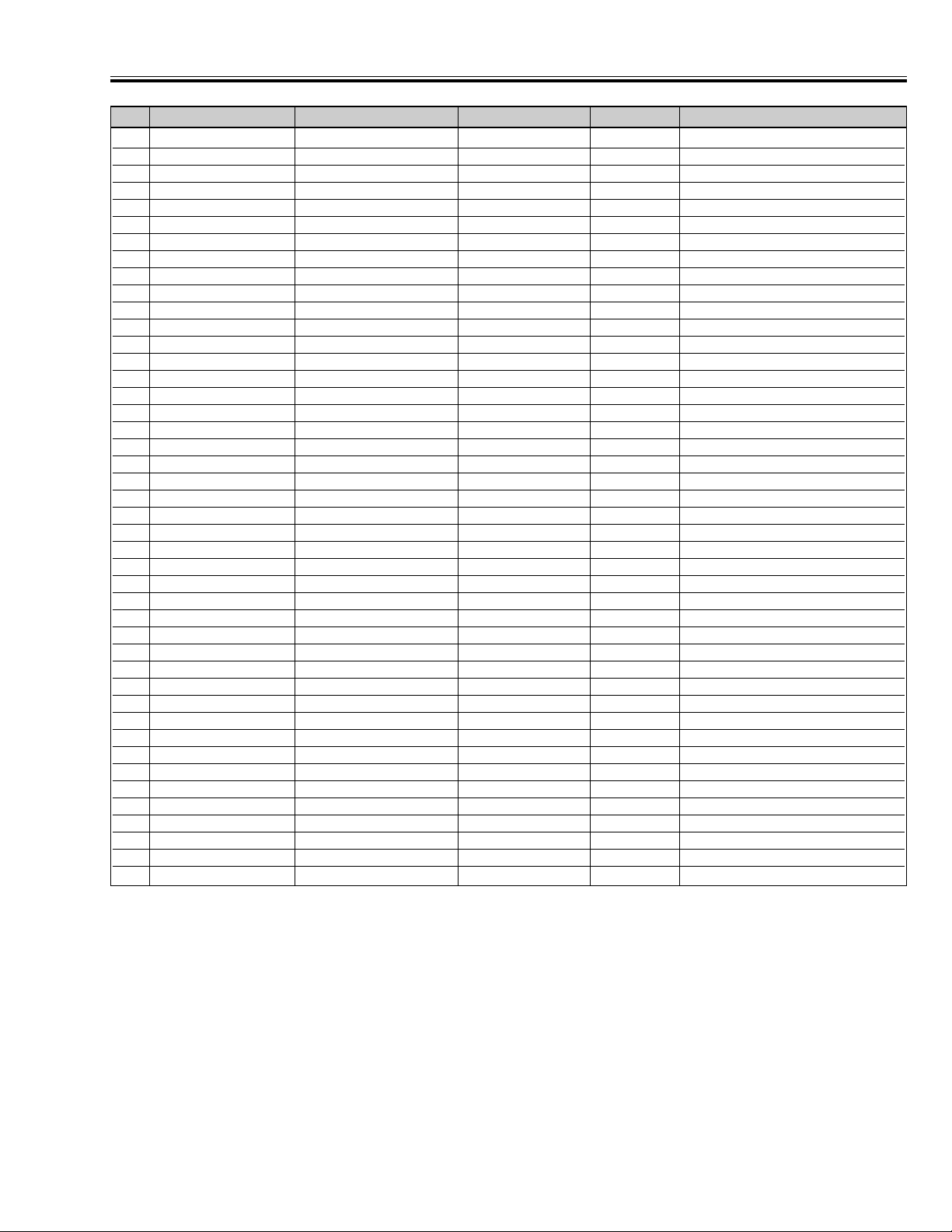

Page 13

-13-

Adjustment

116 Blue 00h(0)

117 White:DVI/HDCP Red 80h(128)

118 Green 80h(128)

119 Blue 80h(128)

120 Black:DVI/HDCP Red 00h(0)

121 Green 00h(0)

122 Blue 00h(0)

123 Color Temp AV High Red 76h(118)

124 Green 7ah(122)

125 Blue 80h(128)

126 AV Mid Red 80h(128)

127 Green 80h(128)

128 Blue 80h(128)

129 AV Low Red 80h(128)

130 Green 7eh(126)

131 Blue 73h(115)

132 PC High Red 76h(118)

133 Green 7ah(122)

134 Blue 80h(128)

135 PC Mid Red 80h(128)

136 Green 80h(128)

137 Blue 80h(128)

138 PC Low Red 80h(128)

139 Green 7eh(126)

140 Blue 73h(115)

141 Sound Device Sound AGC On/Off 00h(0)

142 Level 01h(1)

143 Sound BCSB/Bass Sub-Set 01h(1)

144 Sound BCST/Treb Sub-Set 01h(1)

145 Wide Pc Just Width +/- Flag 00h(0)

146 Data High 00h(0)

147 Data Low 00h(0)

148 Video Just Width +/- Flag 00h(0)

149 Data High 27h(39)

150 Data Low 00h(0)

151 PDP Error Diffusion On/Off SW 02h(2)

152 H Start Pos 1 Data 20h(32)

153 H Start Width 1 Data bah(186)

154 H Start Pos 2 Data 96h(150)

155 H Start Width 2 Data 40h(64)

156 Threshold PC MPD 01h(1)

157 AV MPD 01h(1)

158 50Hz / 50Hz - 100 F SW 04h(4)

159 ABL Level Hi Data 23h(35)

160 ABL Level Lo Data 19h(25)

161 H Start Width Top 1 Bit 01h(1)

162 H Start Width Top 2 Bit 01h(1)

163 Side Bar Off Border Color Type 1 Red 00h(0)

164 Green 00h(0)

165 Blue 00h(0)

166 Side Bar On Border Color Type 2 Red 40h(64)

167 Green 40h(64)

168 Blue 40h(64)

169 Over Scan 525i VBS H Start + 1fh(31)

170 V Start + 09h(9)

171 Width + 09h(9)

172 Height + 07h(7)

173 525i YC H Start + 1fh(31)

174 V Start + 09h(9)

175 Width + 09h(9)

NO. Name Mode Item Initial Data Note

Page 14

-14-

Adjustment

176 Height + 07h(7)

177 525i Component H Start + 19h(25)

178 V Start + 0fh(15)

179 Width + 07h(7)

180 Height + 05h(5)

181 525p Component H Start + 1dh(29)

182 V Start + 0ah(10)

183 Width + 07h(7)

184 Height + 05h(5)

185 625i VBS H Start + 14h(20)

186 V Start + 1fh(31)

187 Width + 0ah(10)

188 Height + 07h(7)

189 625i YC H Start + 14h(20)

190 V Start + 1fh(31)

191 Width + 0ah(10)

192 Height + 07h(7)

193 625i Component H Start + 2fh(47)

194 V Start + 14h(20)

195 Width + 08h(8)

196 Height + 06h(6)

197 625p Component H Start + 2fh(47)

198 V Start + 14h(20)

199 Width + 08h(8)

200 Height + 08h(8)

201 1080i Component H Start + 2ch(44)

202 V Start + 20h(32)

203 Width + 05h(5)

204 Height + 05h(5)

205 1080i(50) Component H Start + 2dh(45)

206 V Start + 18h(24)

207 Width + 05h(5)

208 Height + 04h(4)

209 720p Component H Start + 1dh(29)

210 V Start + 12h(18)

211 Width + 05h(5)

212 Height + 05h(5)

213 720p(50) Component H Start + 2ch(44)

214 V Start + 13h(19)

215 Width + 05h(5)

216 Height + 05h(5)

217 540p Component H Start + 2ch(44)

218 V Start + 10h(16)

219 Width + 05h(5)

220 Height + 06h(6)

221 540p(50) Component H Start + 2dh(45)

222 V Start + 0eh(14)

223 Width + 05h(5)

224 Height + 06h(6)

225 Image AGC VPC Start Value 27h(39)

226 Limit Value 3fh(63)

227 Step Size 01h(1)

228 Stop Range 08h(8)

229 AD9884 Start Value a7h(167)

230 Limit Value 6ah(106)

231 Step Size 04h(4)

232 Stop Range 08h(8)

233 Max Peak PC Peak e6h(230)

234 TV/VBS/YC d7h(215)

235 D2 - D4 Peak d7h(215)

NO. Name Mode Item Initial Data Note

Page 15

-15-

Adjustment

236 Min Ratio —- 00h(0)

237 Avail Ratio —- 0fh(15)

238 AGC On/Off Active 01h(1)

239 AGCD1 On/Off Active 01h(1)

240 Main Ver Main Ver No. d1h(209)

241 Power State Power Fail State 00h(0)

242 Power PDP Fail State 00h(0)

243 Fan Control Mode Command 01h(1)

244 Field Control Condition - 1 Field Begin 00h(0)

245 Field End 01h(1)

246 Condition - 2 Field Begin 00h(0)

247 Field End 02h(2)

248 Condition - 3 Field Begin 00h(0)

249 Field End 03h(3)

250 Condition - 4 Field Begin 00h(0)

251 Field End 04h(4)

252 Condition - 5 Field Begin 00h(0)

253 Field End 05h(5)

254 Condition - 6 Field Begin 00h(0)

255 Field End 06h(6)

256 Color Filter Control PC Red 1 1fh(31)

257 Red 2 1fh(31)

258 Green 1 1fh(31)

259 Green 2 1fh(31)

260 Blue 1 1fh(31)

261 Blue 2 1fh(31)

262 DVI Red 1 1fh(31)

263 Red 2 1fh(31)

264 Green 1 1fh(31)

265 Green 2 1fh(31)

266 Blue 1 1fh(31)

267 Blue 2 1fh(31)

268 Component Red 1 1fh(31)

269 Red 2 1fh(31)

270 Green 1 1fh(31)

271 Green 2 1fh(31)

272 Blue 1 1fh(31)

273 Blue 2 1fh(31)

274 VBS/YC Red 1 1fh(31)

275 Red 2 1fh(31)

276 Green 1 1fh(31)

277 Green 2 1fh(31)

278 Blue 1 1fh(31)

279 Blue 2 1fh(31)

NO. Name Mode Item Initial Data Note

Page 16

-16-

■ Setting the fixed data

(1) Receive the good quality signal.

(2) Enter the Service Mode

(3) Confirm fixed data to be same as data table. If it is different, change to

correct data.

(4) Return to the Normal Mode

This adjustment is controlled by the Sub CPU (IC801) thorough the IIC Data Bus Line in the chassis, and

those adjustment data are memorized into the memory IC (IC804). Therefore, SUB CPU Board or the

memory IC (IC808) is replaced, data of those will be disappeared. Readjustment should be made. Initial

data is provided in the CPU ROM ,when memory IC (IC804) is replaced with new one, CPU ROM data is

loaded into the memory. (Data list will be shown in previous 5 pages.) Initial data is provided to operating

the monitor basically. For operating the monitor quality performance, further adjustment required following

chassis electrical adjustment.

■ White Balance Adjustment

Pattern : White Pattern

Condition : Screen Size : FULL, Picture Image Level : STANDARD

Adjustment : Enter the service mode, select item No. 111 [ Red ], 112 [ Green ] or 113 [ Blue ]

(White:PC), and adjust a proper white balance.

Note : After adjustment, confirm white balance again by normal picture.

Adjustment

Page 17

-17-

■ Circuit Block Diagram

Analog PC

K1501

D-SUB

R

G

B

IC1504

3

AMP

IC1506

3

IC1505

3

K1505

R

1

G

1

K8L

K8R

IC701

LVDS

Interface

K8L

PDP

Module

Page 18

-18-

■ Power Supply Lines

■ Power Supply Lines

■ Power Source of IC (Main Board)

AC IN

POWER

Fuse

F601/2

Line Filter

LF601/2/3

POWER ON/OFF

K6A

P9

MAIN

POWER

MODULE

PDP

MODULE

OPTION

SLOT

(INTERFACE

BOARD)

K6Q

D26

AC

P6

K8L

T651

DC

5

2

Photo

Coupler

PDP

Switching

Transformer

1

3

PC651

D8

D3

11

10

1

11

D654

K8Q

RELAY

K30W

D659

IC651

Switching

Regulator

SS34

MODULE

Audio AMP

IC1602

IC1603

IC1604

PF-2

25,26,30

Q601

IC4109

L4111

IC4102

-5V_AD1

K16P

1

27V_Audio 12V_Audio

K16D

1

13V_Power 5V_Digital

D603

K8L

93, 137

6, 50, 94, 138

42

PF-4

5, 49

5V_Standby

IC1652

PANEL_FAIL

6

IC751

PDP

ON/OFF

IC101

19

9V_Analog

3.3V_AD

5V_AD

4

5

Q803

Q804

PF-4

PF-3

IC5009

IC5008

IC5107

IC5106

D4101

IC4108

-5V_AD2

5V_Standby

Q651RL651

IC801

Sub CPU

Panel

78

Fail

86

PDP GO

85

Power

Fail 4

Power

84

Fail 3

IC8071

IC8073

IC8072

2.5V_Matrix

3.3V_Matrix

2.5V_Matrix2

3.3V_Matrix2

D4102 D4103

K6C

1

8

Power

ON/OFF

VCC

T-Sensor-1

T-Sensor-2

Power

Fail 1

Power

Fail 2

3.3V_AP

3.3V_PIX

2.5V_PIX

CONTROL

A1902A

RC Pre-AMP

1

5V_Standby

K16C

8

49

16, 62, 99

92

93

82

Q801

Q802

83

PF-2

D5004

D5001

D5102

D5101

MAIN

3

3.3V_Standby

5V_SYNC

T-SENSOR-1

T-SENSOR-2

PF-1

1.5V_PIX

1.5V_PIX_P

D8072

D8076

D8071

D5002

D5003

D5104

D5103

5V_Standby

3

K19J

3

K18J

IC1651

D8073

D8074

D8077

D1711

K8F

K8R

K8N

K8M

MEMBRANE SW

K11F

44

5V_Standby

IC1101

JACK-A

K1015

18

18

5V_Standby

IC1509

-5V_D-SUB

K18N

4

4

5V_Standby

2

2

T-SENSOR-1

K18M

5

5

5V_Standby

2

2

T-SENSOR-2

5

K1104

5

JACK-B

16

8

8

16

5

2

SENSOR-A

1

IC1891

2

Temperature

Sensor

SENSOR-B

1

IC1881

2

Temperature

Sensor

IC1501

IC1502

IC1510

IC1503

IC1504

IC1505

IC1506

5V_Standby

IC1651

3.3V_Standby

D1711

5V_SYNC

27V_Audio 12V_Audio

13V_Power

8

IC1851

FAN Control

16, 62 99

IC801

Sub CPU

Reg

IC171213IC17131IC1714

Sync SEP Sync SW Sync SEP

IC1602

Reg

IC1603

Reg

Q601

IC1604

Reg

D1851

IC753

IC802

20

1

IC803

Reset

5

IC3104

9V_Analog

5V_Digital

IC5008

IC5009

IC5106

IC5107

IC8073

IC8072

IC8071

5

8

IC80616IC8075IC8402

IC804

EEPROM

IC1881

IC17168IC1717

20, 26,

IC101

30

Audio AMP

16

IC031

Audio Control

16

IC131

Audio SW

3.3V_Matrix

2.5V_Matrix

3.3V_Matrix2

2.5V_Matrix2

2.5V_PIX

1.5V_PIX_P

1

3.3V_PIX

3.3V_AP

1.5V_PIX

D1882

8

L4111

IC4109

Reg

IC5001

Matrix_1

IC1711

5

5V_AD

IC5101

Matrix_2

IC3001

Pixel Works

D1884 D1883 D1101

16

Reg

Reg

Reg

Reg

Reg

Reg

Reg

16

IC842114IC1941

IC176116IC1771

Sync SW Video SW

2

3.3V_AD

IC50025IC50031IC50048IC500614IC500714IC8101/2/3

5

IC5104

1,9,26,34

IC701

LVDS

IC8001

I/O

IC8422

IC752

IC4108

Reg

IC4102

Reg

IC4101

AD Converter

Reset

IC51081IC5102

Reset

16

73

4,16

14

5

14

2

8

IC18821IC751

20

-5V_AD2

-5V_AD1

14

IC3151

IC3152

IC3153

IC3154

IC5103

IC3101

IC3102

IC3103

Reset

2

2

8

14

14

8

IC4107

IC4104

IC4106

20

8

1

33,11

37

IC3141

Flash ROM

IC3142

20

IC3002

20

IC3003

7,18,31,42

SRAM

Page 19

-19-

■ Power Fail Circuit

Sub CPU (IC801) is programmed that the set goes to standby mode when there is circuit fail

as below. (Refer to "Power Supply Lines: P18)

1. Power Fail 1 : Detected the low voltage fail in Main board. (From 1.5V to 5V)

2. Power Fail 2 : Detected the High voltage fail in Main board. (13V)

3. Power Fail 3 : Detected the fail of Audio AMP IC (IC101).

4. Power Fail 4 : Detected the voltage fail of Interface Board (Option).

5. Temperature Fail : Detected the fail of Temperature Sensor IC (IC1881/1891).

6. Panel Fail (ALARM) : Detected the fail of PDP Module.

Note: In case of Panel Fail (ALARM), the set does not go to standby mode. (Only "PDP_GO" line is off.)

IC801

P FAIL 1

P FAIL 2

P FAIL 3

P FAIL 4

TEM. FAIL 1

TEM. FAIL 2

PANEL FAIL

POWER

ON/OFF

82

83

84

85

92

93

79

49

Low Voltage (1.5V - 5V) Fail Detect

(High: Normal, Low: Fail)

High Voltage (13V) Fail Detect

(High: Normal, Low: Fail)

Sound AMP. Fail Detect (To IC101 19 )

(Low: Normal, High: Fail)

(Option) Interface Board Voltage Fail Detect

(High: Normal, Low: Fail)

Temperature Fail Detect (To IC1891 2 )

Temperature Fail Detect (To IC1881 2 )

Panel Module Fail Detect

(High: Normal, Low: Fail)

Standby ON/OFF

(High: ON, Low: OFF)

PDP GO

86

PDP Module ON/OFF

(High: ON, Low: OFF)

Page 20

-20-

Power Fail Circuit

When operating the Power Fail Circuit, On-Screen-Display message or LED flashing time is

shown as below.

On-Screen-Display Message

1. TEMPERATURE FAIL

When the internal temperature exceeds normal ( approximately more than 80 degrees ), below message is

displayed for 10 seconds and the Plasma monitor will be turned off automatically.

LED Flashing

1. PANEL & TEMPERATURE FAIL: The color of LED is ‘RED ’.

2. POWER FAIL 1& 2: The color of LED is ‘GREEN ’.

3. POWER FAIL 3& 4: The color of LED is ‘YELLOW’.

Warning!

Internal temperature is too high.

Times of flashing Fail Name

1 Power Fail 1

2 Power Fail 2

3 Power Fail 1 & 2

Note:

1. In case of overlapped fail, 1 to 3 is repeated in turn.

2. If power fail is detected 3 times in 15 minutes, the monitor will stop operating.

Note:If pull off the AC cord, the information of these fails will be disappeared.

Times of flashing Fail Name

1 Panel Fail

2 Temperature Fail

3 Panel & Temperature Fail

Times of flashing Fail Name

1 Power Fail 3

2 Power Fail 4

3 Power Fail 3 & 4

Page 21

-21-

Power Fail Circuit

When finishing the repair or stopping Power Fail, can be checked the history of the past fails.

To see the history

1. Enter the service mode. (Refer to "Adjustment" P9 - P10.)

2. Check the Item No.241 or No.242 of Service Adjustment Data Table. (Refer to P15.)

1. History of Power Fail (Item No. 241)

Fail Name Data

No Fail 00h(0)

Power Fail 1 01h(1)

Power Fail 2 02h(2)

Power Fail 3 04h(4)

Power Fail 4 08h(8)

Panel Fail (ALARM) 10h(16)

Temperature Fail 20h(32)

2. History of Panel Fail (Item No. 242)

Fail Name Data

No Panel Fail 00h(0)

Voltage Fail (5V) 01h(1)

Voltage Fail (3V) 02h(2)

Panel Driver Fail 04h(4)

Note: If counted the overlapped fail, the sum of

each data is displayed.

For example:

Power Fail 2 & Panel Fail (ALARM)

02h + 10h = 12h(18)

Note: If counted the overlapped fail, the sum of

each data is displayed.

For example:

Voltage Fail (5V) & Panel Driver Fail

01h + 04h = 05h(5)

Attention: After finishing the service, their data should be reset to "00h(0)".

Page 22

-22-

■ Troubleshooting

No Power

Refer to Schematic Diagram or Power Supply Line, find out the part of trouble.

Before opening Cabinet Back, check the AC cord and power source.

Is LED flashed?

No

Ye s

Is

the voltage of

all lines in Power Unit

supplied?

Ye s

(or the voltage of some

lines is not supplied.)

After few seconds,

the set is switched off.

Check 'Fail' Circuit to refer service

manual 'Power Fail Circuit'.

No

(All 0V)

Is

fuse (F601/602)

in Power Board

broken?

No

Ye s

Check D659 or IC651 in

Power Board.

Check VA601 in Power

Board.

Main Power Module is

broken.

Check '5V_Standby' line

from Power Board to Main

Board.

Check PTH651 in Power

Board.

Check arround Sub CPU

(IC801) in Main Board.

Main Power Module is

broken.

Page 23

-23-

● System Control (Sub-CPU : IC801)

■ Control Port Functions

1 P96/ANEX1/SOUT4 RTC_DATAOUT O For real time clock

2 P95/ANEX0/CLK4 RTC_CLK O For real time clock

3 P94/DA1/TB4IN FAN-CTRL1 O Fan control 1 D/A

4 P93/DA0/TB3IN FAN-CTRL2 O Fan control 2 D/A

5 P92/TB2IN/SOUT3 Not used (Output: Low)

6 P91/TB1IN/SIN3 HS_DET I (Analog)PC-HSYNC IN DPMS input

7 P90/TB0IN/CLK3 Not used (Output: Low)

8 BYTE

9 CNVss CNVSS For writing

10 P87/XCIN Not used (Output: Low)

11 P86/XCOUT Not used (Output: Low)

12 RESET CPURST IC reset

13 XOUT

14 VSS

15 XIN

16 VCC

17 P85/NMI

18 P84/INT2 RC I RC input RC input

19 P83/INT1 Not used (Output: Low)

20 P82/INT0 VS_DET I (Analog)PC-VSYNC IN DPMS input

21 P81/TA4IN/U Not used (Output: Low)

22 P80/TA4OUT/U Not used (Output: Low)

23 P77/TA3IN Not used (Output: Low)

24 P76/TA3OUT Not used (Output: Low)

25 P75/TA2IN/W Not used (Output: Low)

26 P74/TA2OUT/W Not used (Output: Low)

27 P73/CTS2/RTS2/TA1IN/V Not used (Output: Low)

28 P72/CLK2/TA1OUT/V Not used (Output: Low)

29 P71/RxD2/SCL/TA0IN/TB5IN RXD2 I UART for option board Not used (Output: Low)

30 P70/TXD2/SDA/TA0OUT TXD2 O UART for option board Not used (Output: Low)

31 P67/TXD1 UARTTX O UART for PIX TX

32 P66/RxD1 UARTRX I UART for PIX RX

33 P65/CLK1 SCLCK I For writing Output: Low

34 P64/CTS1/RTS1/CLKS1 BUSY I For writing Output: Low

35 P63/TXD0 RS232C_RX O Control for RS232C RX

36 P62/RxD0 RS232C_TX I Control for RS233C TX

37 P61/CLK0 Not used (Output: Low)

38 P60/CTS0/RTS0 Not used (Output: Low)

39 P57/RDY/CLKOUT Not used (Output: Low)

40 P56/ALE Not used (Output: Low)

41 P55/HOLD EPM For writing Input

42 P54/HLDA DVI HOT DVI HOT High:Permisson

43 P53/BCLK Not used (Output: Low)

44 P52/RD Not used (Output: Low)

45 P51/WRH/BHE Not used (Output: Low)

46 P50/WRL/WR CE For writing Not used (Output: Low)

47 P47/CS3 Not used (Output: Low)

48 P46/CS2 RTC_CE For real time clock High:Communication

49 P45/CS1 STB O Power ON/OFF High:ON, Low:OFF

50 P44/CS0 AMP-MUTE1 O Low:Mute

51 P43/A19 RS232C_A O Mode SW for RS232C 51Pin /52Pin:

H/H:Multi-monitor,

52 P42/A18 RS232C_B O Mode SW for RS233C H/L:Inter-communication,

L/H:Through, L/L:Not used

53 P41/A17 Not used (Output: Low)

54 P40/A16 Not used (Output: Low)

55 P37/A15 SCL EEPROM

56 P36/A14 SDA EEPROM

57 P35/A13 Not used (Output: Low)

58 P34/A12 SCDT_ST1 I Low:No signal

59 P33/A11 Not used (Output: Low)

60 P32/A10 L-RED O High:ON, LowOFF

Pin NO. Pin Name Signal Name I/O Note Data

Page 24

-24-

Control Port Functions

61 P31/A9 L-GREEN O High:ON, LowOFF

62 VCC

63 P30/A8(/-/D7) Not used (Output: Low)

64 Vss

65 P27/A7(/D7/D6) Not used (Output: Low)

66 P26/A6(/D6/D5) Not used (Output: Low)

67 P25/A5(/D5/D4) Not used (Output: Low)

68 P24/A4(/D4/D3) Input

69 P23/A3(/D3/D2) Input

70 P22/A2(/D2/D1) Input

71 P21/A1(/D1/D0) Not used (Output: Low)

72 P20/A0(/D0/-) RESET_SW I Externai reset SW (Input) Low:Reset

73 P17/D15/INT5 FCOM O For real time clock Low:Fixed

74 P16/D14/INT4 AIRQ I For real time clock Not used (Input)

75 P15/D13/INT3 YIRQ I For real time clock

76 P14/D12 Not used (Output: Low)

77 P13/D11 FAN-LOCK1 I Fan Lock Input High:Normal, Low:Locked

78 P12/D10 PANEL-LED I Panel LED (Fail Detection)

79 P11/D9 ALARM I Panel Fail High:Normal, Low:Fail

80 P10/D8 PW_RST O PIX reset (Output) High:Reset

81 P07/D7 LINE OFF I Power OFF Detection Low:AC OFF

82 P06/D6 P-FAIL1 I 1.5V,2.5V,3.3V,5V High:Normal, Low:Fail

83 P05/D5 P-FAIL2 I 9V,12,13V High:Normal, Low:Fail

84 P04/D4 P-FAIL3 I For Audio AMP IC High:Fail, Low:Normal

85 P03/D3 P-FAIL4 I For Option Board (Slot) High:Normal, Low:Fail

86 P02/D2 PDPGO_5 O Panel ON/OFF High:ON, Low:OFF

87 P01/D1 PWRSW I Power SW

88 P00/D0 FAN-LOCK2 I Fan Lock Input High:Normal, Low:Locked

89 P107/AN7/KI3 Not used (Output: Low)

90 P106/AN6/KI2 Not used (Output: Low)

91 P105/AN5/KI1 Not used (Output: Low)

92 P104/AN4/KI0 T-SENSOR1 I Temp-Sensor (Analog input) A/D

93 P103/AN3 T-SENSOR2 I Temp-Sensor (Analog input) A/D

94 P102/AN2 Not used (Output: Low)

95 P101/AN1 KEY-IN I Key Input A/D

96 AVSS Not used (Output: Low)

97 P100/AN0 Not used (Output: Low)

98 VREF Not used (Output: Low)

99 AVcc Not used (Output: Low)

100 P97/ADTRG/SIN4 RTC_DATA I For real time clock

Pin NO. Pin Name Signal Name I/O Note Data

Page 25

-25-

■ Pin Description of Diode, Transistor and IC

AA

C

CBE

B2

K

C

BE

B1

C1

K

B1

A

E

C

C1

C2

E

K

B

C

E

A

E

C

C

E

B

C

E

B

B

B

E

C2

A

KK

C1

C2

B1 B2

E

B2

B2

B1

K

A

E1

C1

C2

E2

K

A

Index

Index

1

2

N

4

5

6

3

2

1

Index

Page 26

-26-

■ Parts List

MECHANICAL PARTS

1 610 305 4827 ASSY,CABINET BACK-J3TF

2 610 305 2373 CABINET FRONT-J3TF

(PDP-42WV1 / PDP-42WV1A)

610 308 6705 CABINET FRONT-J3TG

(PDP-42WV1S / PDP-42WV1AS)

3 610 306 3508 COVER-J3TF

4 610 308 6378 COVER SHEET-J3TF

5 610 305 4353 HANDLE L-J3TF

6 610 305 4360 HANDLE R-J3TF

7 610 305 7422 DEC SHEET-J3TF

8 610 305 7439 DEC SHEET R-J3TF

9 610 305 7446 DEC SHEET AC IN-J3TF

10 610 305 2427 DEC INLAY-J3TF

11 610 305 2410 DEC IND-J3TF

ACCESSORY

645 059 8050 ASSY,REMOCON JXMZA

610 306 2532 RC-BATTERY LID-CXPH

645 051 2322 RC CABLE,FXAF

645 023 4958 CORE,CLAMP

645 054 1162 CORD,POWER-3.0MK (US)

645 054 1155 CORD,POWER-3.0MK (EU, ASIA)

645 054 1148 CORD,POWER-3.138MK (UK)

OWNERS MANUAL

610 305 7934 OWNERS MANUAL-J3TF (English)

610 305 7941 OWNERS MANUAL-J3TF-D (Germany)

610 305 7958 OWNERS MANUAL-J3TF-F (French)

610 305 7965 OWNERS MANUAL-J3TF-I (Italian)

610 305 7972 OWNERS MANUAL-J3TF-E (Spanish)

!!!

Fig. No. Part No. Description Part No. Description

Button (Membrane SW)

See Electric Parts.

1

2

3

4

7

8

9

6

5

11

10

Page 27

-27-

Electrical Parts List

Product safety should be considered when a component replacement is made in any area of a PDP monior.

Components indicated by a mark in this parts list and the circuit diagram show components whose value have

special significance to product safety. It is particularly recommended that only parts specified on the following parts

list be used for components replacement pointed out by the mark.

!

● Read Description in the parts list

Read description in the Capacitor and Resistor as follows:

CAPACITOR

CERAMIC 100P K 50V

Rated Voltage

Tolerance Symbols:

Less than 10pF

A : Not specified B : ±0.1pF C : ±0.25pF

D : ±0.5pF E : +0 -1pF F : ±1PF

G : ±2pF H : +0.1 -0pF L : +0 -0.1pF

R : ±0.25 -0pF S : +0-0.25pF

More than 10pF

A : Not specified B : ±0.1% C : ±0.25%

D : ±0.5% F : ±1% G : ±2%

H : ±3% J : ±5% K : ±10%

L : ±15% M : ±20% N : ±30%

P : +100-0% Q : +30-10% T : +50-10%

U : +75-10% V : +20-10% W : +100-10%

X : +40-20% Y : +150-10%Z : +80-20%

Rated value: P=pico farad, U=micro farad

Material:

CERAMIC...........Ceramic

MT-PAPER.........Metallized Paper

POLYESTER......Polyester

MT-POLYEST.....Metallized Polyester

POLYPRO..........Polypropylene

MT-POLYPRO....Metallized Polypropylene

COMPO FILM.....Composite film

MT-COMPO........Metallized Composite

STYRENE...........Styrene

TA-SOLID...........Tantalum Oxide Solid Electrolytic

AL-SOLID...........Aluminium Solid Electrolytic

ELECT................Aluminum Foil Electrolytic

NP-ELECT..........Non-polarised Electrolytic

OS-SOLID..........Aluminium Solid with Organic Semiconductive Electrolytic

POS-SOLID........Polymerized Organic Semiconductive

DL-ELECT..........Double Layered Electrolytic

PPS-FILM...........Polyphenylene Sulfide Film

MT-PPS-FILM.....Metalized Polyphenylene Sulfide Film

MT-PEN-FILM.....Metalized Polyethylenenaphthalate Film

CAPACITOR.......Other

RESISTOR

CARBON 4.7K J A 1/4W

Performance Symbols:

A: General B: Non flammable Z: Low noise

Other: Temperature coefficient

T: ±10ppm/°C U: ±25ppm/°C C: ±50ppm/°C

D: ±100ppm/°C E: ±200ppm/°C F: ±250ppm/°C

G: ±350ppm/°C H: ±1000ppm/°C±10%W: ±1200ppm/°C±10%

Y: ±1400ppm/°C±10%J: ±2000ppm/°C±10% K: ±2400ppm/°C±10%

L: ±2700ppm/°C±10%M: ±3000ppm/°C±10%N: ±3300ppm/°C±10%

P: ±3600ppm/°C±10%Q: ±3900ppm/°C±10%R: ±4200ppm/°C±10%

S: ±4300ppm/°C±10%V: ±4500ppm/°C±10% X: ±8000ppm/°C±10%

Tolerance Symbols:

A: ±0.05% B: ±0.1% C:±0.25% D: ±0.5%

F: ±1% G: ±2% J:±5% K: ±10%

M: ±20% P: +5-15%Z: 0 ohm

Rated value, ohms:

Material:

CARBON...........Carbon

MT-FILM............Metal Film

OXIDE-MT.........Oxide Metal Film

SOLID................Composition

MT-GLAZE.........Metal Glaze

WIRE WOUND...Wire Wound

CERAMIC RES..Ceramic

FUSIBLE RES....Fusible

RESISTOR ........Other

K: 1,000, M: 1,000,000

Rated Wattage

Page 28

Electrical Parts List

-28-

MISCELLANEOUS

EL901 645 059 6131 PDP MODULE

(For PDP-42WV1 / PDP-42WV1S)

EL901 645 059 5424 PDP MODULE

(For PDP-42WV1A / PDP-42WV1AS)

EL902 645 059 6117 OPTICAL FILTER

FN901 645 057 8649 MOTOR,FAN DC 1.8W

FN903 645 062 2458 MOTOR,FAN DC 0.744W

M901 610 305 6487 BUTTON-42-J3TF (MENBRANE SW)

(For PDP-42WV1 / PDP-42WV1A)

M901 610 308 1120 BUTTON-42-J3TA (MENBRANE SW)

(For PDP-42WV1S / PDP-42WV1AS)

SPL 645 061 8086 SPEAKER TERMINAL,BOARD

SPR 645 061 8086 SPEAKER TERMINAL,BOARD

W7V-D1 610 305 9235 CORD 21P 1.25MM(LVDS CABLE)

610 305 0775 ASSY,PWB,MAIN-J3TF 1AA0B10N04000

TRANSISTOR

Q101 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q131 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q132 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q133 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q134 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q1601 405 151 2000 TR FSS134-TL

Q1711 405 134 5905 TR 2SA1037AK-T146-R

405 147 2205 TR 2SA1037AK-S-T146

405 002 0308 TR 2SA1037K T146 R

405 002 0407 TR 2SA1037K T146 S

405 002 6706 TR 2SA1179-M6-TB

405 002 6904 TR 2SA1179-M7-TB

405 163 1503 TR 2SA1179N-M6-TB

405 163 2708 TR 2SA1179N-M7-TB

405 173 9605 TR 2SA1235A1E

405 173 9704 TR 2SA1235A1F

Q1712 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q1713 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q1714 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q1715 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q1716 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q1717 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q1771 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q1772 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q1773 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q1774 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

!

!

!

!

Key No. Part No. Description Key No. Part No. Description

Page 29

-29-

Electrical Parts List

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q1851 405 148 2907 TR 2SC5103 TL P

405 148 3003 TR 2SC5103 TL Q

Q1853 405 148 2907 TR 2SC5103 TL P

405 148 3003 TR 2SC5103 TL Q

Q1854 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q1855 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q1931 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q1932 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q3101 405 045 8705 TR 2SK536-TB

Q3102 405 045 8705 TR 2SK536-TB

Q4101 405 079 1505 TR 2SC4269-4-TB

Q4102 405 079 1505 TR 2SC4269-4-TB

Q4103 405 079 1505 TR 2SC4269-4-TB

Q751 405 045 8705 TR 2SK536-TB

Q752 405 045 8705 TR 2SK536-TB

Q753 405 045 8705 TR 2SK536-TB

Q801 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q802 405 134 5905 TR 2SA1037AK-T146-R

405 147 2205 TR 2SA1037AK-S-T146

405 002 0308 TR 2SA1037K T146 R

405 002 0407 TR 2SA1037K T146 S

405 002 6706 TR 2SA1179-M6-TB

405 002 6904 TR 2SA1179-M7-TB

405 163 1503 TR 2SA1179N-M6-TB

405 163 2708 TR 2SA1179N-M7-TB

405 173 9605 TR 2SA1235A1E

405 173 9704 TR 2SA1235A1F

Q803 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

Q804 405 134 5905 TR 2SA1037AK-T146-R

405 147 2205 TR 2SA1037AK-S-T146

405 002 0308 TR 2SA1037K T146 R

405 002 0407 TR 2SA1037K T146 S

405 002 6706 TR 2SA1179-M6-TB

405 002 6904 TR 2SA1179-M7-TB

405 163 1503 TR 2SA1179N-M6-TB

405 163 2708 TR 2SA1179N-M7-TB

405 173 9605 TR 2SA1235A1E

405 173 9704 TR 2SA1235A1F

Q891 405 014 4509 TR 2SC2412K T146 R

405 014 4608 TR 2SC2412K T146 S

405 015 8704 TR 2SC2812-L6-TB

405 015 8902 TR 2SC2812-L7-TB

405 163 1602 TR 2SC2812N-L6-TB0

405 163 1701 TR 2SC2812N-L7-TB0

405 173 9803 TR 2SC3928A1R

405 173 9902 TR 2SC3928A1S

INTEGRATED CIRCUIT

IC031 409 526 7409 IC NJW1138M

IC101 409 539 8004 IC TA2024

IC131 409 438 5500 IC TC4052BFT

IC1602 409 550 1404 IC PQ1CY1032ZP

IC1603 409 533 3302 IC PQ1CZ41H2ZP

IC1604 409 531 6206 IC FA7701V-TE1

IC1651 409 416 6406 IC BA033FP-E2

IC1711 409 461 7304 IC AD8057ART

IC1712 409 441 8406 IC LA7217M-T-TRM

IC1713 409 484 2003 IC BA7078AF-E2

IC1714 409 438 5500 IC TC4052BFT

IC1716 409 428 8405 IC TC7WT125FU-TE12L

IC1717 409 428 8405 IC TC7WT125FU-TE12L

IC1761 410 358 1503 IC TC74HC4053AFT(EL)

IC1771 409 501 0906 IC BA7657F

IC1851 409 039 6609 IC NJM2904-T2

IC1881 409 431 7808 IC RTC-4574JE

IC1882 409 496 9601 IC PST600IM

IC1941 409 428 8405 IC TC7WT125FU-TE12L

IC3001 409 547 6306 IC PW181-10V

IC3002 410 346 8804 IC TC74LCX574FT

IC3003 410 346 8804 IC TC74LCX574FT

IC307A 410 354 3808 IC MBM29LV800TA-90PFTN

IC3101 410 362 6501 IC TC74LCX541FT

IC3102 409 533 6006 IC 24LC32AT-I/SN

IC3103 409 480 1307 IC PST573IM

IC3104 409 458 2305 IC TC7SZ32FU-TE85L

IC3141 410 497 9200 IC MBM29LV800TA90NC205A

IC3142 410 397 0406 IC IC61LV6416-15T

IC3151 409 536 9301 IC CD4051BPW

409 439 5509 IC TC4051BFT

IC3152 409 428 7101 IC AV9155C

IC3153 409 487 5704 IC TC7SZ125FU

IC3154 409 501 9107 IC ICS512MT

IC4101 410 353 1805 IC AD9884AKS-140

IC4102 409 448 5903 IC BD6111FV-E2

IC4104 409 461 7304 IC AD8057ART

IC4106 409 461 7304 IC AD8057ART

IC4107 409 461 7304 IC AD8057ART

IC4108 409 448 5903 IC BD6111FV-E2

IC4109 409 416 6406 IC BA033FP-E2

IC5001 409 528 6608 IC LC749400W

IC5002 409 462 2308 IC TC7SZ04FU-TE852

IC5003 409 496 9601 IC PST600IM

IC5004 409 439 8906 IC TC7WH125FU

IC5006 410 348 7409 IC TC74LCX125FT(EL)

IC5007 410 348 7409 IC TC74LCX125FT(EL)

IC5008 409 416 6406 IC BA033FP-E2

IC5009 409 499 1701 IC PQ025EZ01ZP

409 461 7700 IC PQ2TZ15

IC5101 409 528 6608 IC LC749400W

Key No. Part No. Description Key No. Part No. Description

Page 30

Electrical Parts List

-30-

IC5102 410 348 7409 IC TC74LCX125FT(EL)

IC5103 410 348 7409 IC TC74LCX125FT(EL)

IC5104 409 462 2308 IC TC7SZ04FU-TE852

IC5106 409 416 6406 IC BA033FP-E2

IC5107 409 499 1701 IC PQ025EZ01ZP

409 461 7700 IC PQ2TZ15

IC5108 409 496 9601 IC PST600IM

IC701 410 423 7201 IC THC63LVDM83R

IC751 409 438 5609 IC TC74ACT08FT

IC752 409 432 9108 IC TC74LCX08FT-(EL)

IC753 410 482 1202 IC TC74LCX573FT

IC8001 409 533 4804 IC TE7780

IC8002 409 462 2308 IC TC7SZ04FU-TE852

IC801 410 497 9408 IC M30624FGAFP-C207B

IC801A 409 536 3804 IC M30624FGAFP

IC802 409 325 4203 IC PST600DMT

IC803 409 152 5404 IC TC7S08F-TE85L

IC804 409 392 7503 IC 24LC08BT/SN

IC806 410 358 1503 IC TC74HC4053AFT(EL)

IC807 409 155 8006 IC TC7S04F-TE85L

IC8071 409 546 9803 IC PQ015EZ01ZP

IC8072 409 499 1701 IC PQ025EZ01ZP

409 461 7700 IC PQ2TZ15

IC8073 409 416 6406 IC BA033FP-E2

IC8101 410 321 8300 IC TC74VCX16244FT

IC8102 410 321 8300 IC TC74VCX16244FT

IC8103 410 321 8300 IC TC74VCX16244FT

IC8402 410 358 1503 IC TC74HC4053AFT(EL)

IC8421 409 438 5609 IC TC74ACT08FT

IC8422 409 432 9108 IC TC74LCX08FT-(EL)

CAPACITOR

C009 403 267 0606 NP-ELECT 4.7U M 16V

C010 403 267 0606 NP-ELECT 4.7U M 16V

C031 403 164 0204 CERAMIC 0.1U Z 25V

C032 403 377 1500 ELECT 1000U M 10V

C033 403 338 2300 ELECT 4.7U M 35V

C034 403 338 2300 ELECT 4.7U M 35V

C035 403 338 2300 ELECT 4.7U M 35V

C036 403 338 2300 ELECT 4.7U M 35V

C037 403 342 3300 CERAMIC 0.1U K 25V

C038 403 338 2300 ELECT 4.7U M 35V

C039 403 338 2300 ELECT 4.7U M 35V

C040 403 342 3300 CERAMIC 0.1U K 25V

C041 403 342 3300 CERAMIC 0.1U K 25V

C042 403 342 3300 CERAMIC 0.1U K 25V

C043 403 155 2309 CERAMIC 4700P K 50V

C044 403 155 2309 CERAMIC 4700P K 50V

C045 403 267 0606 NP-ELECT 4.7U M 16V

C046 403 267 0606 NP-ELECT 4.7U M 16V

C047 403 267 0606 NP-ELECT 4.7U M 16V

C048 403 267 0606 NP-ELECT 4.7U M 16V

C101 403 342 3300 CERAMIC 0.1U K 25V

C102 403 345 6605 CERAMIC 1U M 10V

C104 403 155 2200 CERAMIC 3300P K 50V

C105 403 346 8509 ELECT 680U M 16V

C107 403 348 5803 CERAMIC 0.47U K 10V

C108 403 348 5803 CERAMIC 0.47U K 10V

C109 403 325 6304 CERAMIC 0.22U K 10V

C110 403 321 7404 ELECT 100U M 16V

C111 403 325 6304 CERAMIC 0.22U K 10V

C112 403 164 0204 CERAMIC 0.1U Z 25V

C114 403 345 6605 CERAMIC 1U M 10V

C115 403 164 0204 CERAMIC 0.1U Z 25V

C116 403 348 5803 CERAMIC 0.47U K 10V

C117 403 348 5803 CERAMIC 0.47U K 10V

C119 403 345 6605 CERAMIC 1U M 10V

C120 403 155 2200 CERAMIC 3300P K 50V

C121 403 164 0204 CERAMIC 0.1U Z 25V

C122 403 348 5803 CERAMIC 0.47U K 10V

C123 403 348 5803 CERAMIC 0.47U K 10V

C124 403 325 6304 CERAMIC 0.22U K 10V

C125 403 325 6304 CERAMIC 0.22U K 10V

C126 403 164 0204 CERAMIC 0.1U Z 25V

C127 403 348 5803 CERAMIC 0.47U K 10V

C128 403 348 5803 CERAMIC 0.47U K 10V

C129 403 164 0204 CERAMIC 0.1U Z 25V

C130 403 164 0204 CERAMIC 0.1U Z 25V

C131 403 342 3300 CERAMIC 0.1U K 25V

C132 403 345 6605 CERAMIC 1U M 10V

C133 403 164 0204 CERAMIC 0.1U Z 25V

C134 401 105 7909 MT-GLAZE 0.000 ZA 1/16W

C135 401 105 7909 MT-GLAZE 0.000 ZA 1/16W

C136 403 304 2105 ELECT 47U M 6.3V

C137 403 149 9208 CERAMIC 0.01U Z 50V

C1601 403 149 9208 CERAMIC 0.01U Z 50V

C1608 403 378 3008 ELECT 330U M 35V

C1609 403 378 3008 ELECT 330U M 35V

C1611 403 164 0204 CERAMIC 0.1U Z 25V

C1612 403 343 3408 ELECT 10U M 25V

C1613 403 224 7006 CERAMIC 0.047U Z 50V

C1614 403 378 3008 ELECT 330U M 35V

C1615 403 343 4900 ELECT 470U M 25V

C1621 403 286 8201 ELECT 1000U M 6.3V

C1627 403 164 0204 CERAMIC 0.1U Z 25V

C1636 403 378 3008 ELECT 330U M 35V

C1637 403 164 0204 CERAMIC 0.1U Z 25V

C1638 403 378 2209 ELECT 470U M 25V

C1641 403 378 2209 ELECT 470U M 25V

C1642 403 378 2209 ELECT 470U M 25V

C1643 403 208 0702 TA-SOLID 4.7U M 16V

C1644 403 164 0204 CERAMIC 0.1U Z 25V

C1646 403 113 3805 CERAMIC 1000P K 50V

C1647 403 377 1500 ELECT 1000U M 10V

C1648 403 164 0204 CERAMIC 0.1U Z 25V

C1651 403 164 0204 CERAMIC 0.1U Z 25V

C1652 403 334 8603 ELECT 220U M 6.3V

C1653 403 334 8603 ELECT 220U M 6.3V

C1654 403 164 0204 CERAMIC 0.1U Z 25V

C1711 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C1712 403 164 0204 CERAMIC 0.1U Z 25V

C1713 403 334 8603 ELECT 220U M 6.3V

C1715 403 266 8207 NP-ELECT 10U M 16V

C1716 403 304 2105 ELECT 47U M 6.3V

C1718 403 164 0204 CERAMIC 0.1U Z 25V

C1719 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C1720 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C1721 403 345 6605 CERAMIC 1U M 10V

C1722 403 215 2201 CERAMIC 0.01U K 50V

C1723 403 334 8603 ELECT 220U M 6.3V

C1724 403 237 8700 CERAMIC 0.056U Z 50V

C1725 403 267 0606 NP-ELECT 4.7U M 16V

C1726 403 205 2808 CERAMIC 0.047U K 25V

C1727 403 314 5905 CERAMIC 0.47U K 16V

C1728 403 345 6605 CERAMIC 1U M 10V

C1729 403 323 8805 CERAMIC 2.2U Z 16V

403 255 7907 CERAMIC 2.2U Z 16V

C1730 403 345 6605 CERAMIC 1U M 10V

C1731 403 157 6909 CERAMIC 820P K 50V

C1732 403 224 6603 CERAMIC 0.022U Z 50V

C1733 403 157 3601 CERAMIC 100P J 50V

C1734 403 164 0204 CERAMIC 0.1U Z 25V

C1735 403 334 8603 ELECT 220U M 6.3V

C1736 403 164 0204 CERAMIC 0.1U Z 25V

C1737 403 164 0204 CERAMIC 0.1U Z 25V

C1740 403 149 9208 CERAMIC 0.01U Z 50V

C1741 403 164 0204 CERAMIC 0.1U Z 25V

C1742 403 164 0204 CERAMIC 0.1U Z 25V

C1752 403 149 9208 CERAMIC 0.01U Z 50V

C1754 403 149 9208 CERAMIC 0.01U Z 50V

C1756 403 149 9208 CERAMIC 0.01U Z 50V

C1758 403 149 9208 CERAMIC 0.01U Z 50V

Key No. Part No. Description Key No. Part No. Description

Page 31

-31-

Electrical Parts List

C1760 403 149 9208 CERAMIC 0.01U Z 50V

C1762 403 149 9208 CERAMIC 0.01U Z 50V

C1763 403 164 0204 CERAMIC 0.1U Z 25V

C1764 403 286 8201 ELECT 1000U M 6.3V

C1765 403 149 9208 CERAMIC 0.01U Z 50V

C1771 403 282 1206 NP-ELECT 22U M 16V

C1772 403 282 1206 NP-ELECT 22U M 16V

C1773 403 282 1206 NP-ELECT 22U M 16V

C1774 403 282 1206 NP-ELECT 22U M 16V

C1776 403 282 1206 NP-ELECT 22U M 16V

C1777 403 282 1206 NP-ELECT 22U M 16V

C1781 403 153 9300 CERAMIC 82P J 50V

C1782 403 153 9300 CERAMIC 82P J 50V

C1783 403 153 9300 CERAMIC 82P J 50V

C1851 403 343 3408 ELECT 10U M 25V

C1852 403 164 0204 CERAMIC 0.1U Z 25V

C1853 403 149 9208 CERAMIC 0.01U Z 50V

C1855 403 149 9208 CERAMIC 0.01U Z 50V

C1856 403 321 7503 ELECT 220U M 16V

C1858 403 321 7503 ELECT 220U M 16V

C1881 403 343 3408 ELECT 10U M 25V

C1882 403 164 0204 CERAMIC 0.1U Z 25V

C1885 403 164 0204 CERAMIC 0.1U Z 25V

C1887 403 164 0204 CERAMIC 0.1U Z 25V

C1932 403 343 3408 ELECT 10U M 25V

C1941 403 343 3408 ELECT 10U M 25V

C1942 403 164 0204 CERAMIC 0.1U Z 25V

C3001 403 157 2604 CERAMIC 30P J 50V

C3002 403 145 9905 CERAMIC 22P J 50V

C3003 403 164 0204 CERAMIC 0.1U Z 25V

C3004 403 164 0204 CERAMIC 0.1U Z 25V

C3005 403 164 0204 CERAMIC 0.1U Z 25V

C3006 403 164 0204 CERAMIC 0.1U Z 25V

C3007 403 164 0204 CERAMIC 0.1U Z 25V

C3008 403 164 0204 CERAMIC 0.1U Z 25V

C3009 403 164 0204 CERAMIC 0.1U Z 25V

C3010 403 164 0204 CERAMIC 0.1U Z 25V

C3011 403 164 0204 CERAMIC 0.1U Z 25V

C3012 403 334 8603 ELECT 220U M 6.3V

C3013 403 164 0204 CERAMIC 0.1U Z 25V

C3014 403 164 0204 CERAMIC 0.1U Z 25V

C3015 403 164 0204 CERAMIC 0.1U Z 25V

C3016 403 164 0204 CERAMIC 0.1U Z 25V

C3017 403 164 0204 CERAMIC 0.1U Z 25V

C3018 403 164 0204 CERAMIC 0.1U Z 25V

C3019 403 164 0204 CERAMIC 0.1U Z 25V

C3020 403 164 0204 CERAMIC 0.1U Z 25V

C3021 403 164 0204 CERAMIC 0.1U Z 25V

C3022 403 164 0204 CERAMIC 0.1U Z 25V

C3023 403 164 0204 CERAMIC 0.1U Z 25V

C3024 403 164 0204 CERAMIC 0.1U Z 25V

C3025 403 164 0204 CERAMIC 0.1U Z 25V

C3026 403 164 0204 CERAMIC 0.1U Z 25V

C3027 403 164 0204 CERAMIC 0.1U Z 25V

C3028 403 334 8603 ELECT 220U M 6.3V

C3029 403 164 0204 CERAMIC 0.1U Z 25V

C3030 403 164 0204 CERAMIC 0.1U Z 25V

C3031 403 164 0204 CERAMIC 0.1U Z 25V

C3032 403 164 0204 CERAMIC 0.1U Z 25V

C3033 403 164 0204 CERAMIC 0.1U Z 25V

C3034 403 334 8603 ELECT 220U M 6.3V

C3035 403 164 0204 CERAMIC 0.1U Z 25V

C3036 403 164 0204 CERAMIC 0.1U Z 25V

C3037 403 164 0204 CERAMIC 0.1U Z 25V

C3038 403 164 0204 CERAMIC 0.1U Z 25V

C3101 403 164 0204 CERAMIC 0.1U Z 25V

C3102 403 164 0204 CERAMIC 0.1U Z 25V

C3103 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C3104 403 343 3408 ELECT 10U M 25V

C3105 403 164 0204 CERAMIC 0.1U Z 25V

C3106 403 164 0204 CERAMIC 0.1U Z 25V

C3141 403 334 8603 ELECT 220U M 6.3V

C3142 403 330 7709 ELECT 47U M 25V

C3143 403 164 0204 CERAMIC 0.1U Z 25V

C3144 403 164 0204 CERAMIC 0.1U Z 25V

C3151 403 157 2505 CERAMIC 27P J 50V

C3155 403 164 0204 CERAMIC 0.1U Z 25V

C3156 403 164 0204 CERAMIC 0.1U Z 25V

C3157 403 334 8603 ELECT 220U M 6.3V

C3158 403 164 0204 CERAMIC 0.1U Z 25V

C3159 403 164 0204 CERAMIC 0.1U Z 25V

C3163 403 164 0204 CERAMIC 0.1U Z 25V

C3164 403 164 0204 CERAMIC 0.1U Z 25V

C3166 403 164 0204 CERAMIC 0.1U Z 25V

C3167 403 164 0204 CERAMIC 0.1U Z 25V

C4101 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C4102 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C4103 403 164 0204 CERAMIC 0.1U Z 25V

C4105 403 345 6605 CERAMIC 1U M 10V

C4106 403 164 0204 CERAMIC 0.1U Z 25V

C4108 403 345 6605 CERAMIC 1U M 10V

C4109 403 164 0204 CERAMIC 0.1U Z 25V

C4111 403 345 6605 CERAMIC 1U M 10V

C4112 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C4113 403 334 8603 ELECT 220U M 6.3V

C4114 403 334 8603 ELECT 220U M 6.3V

C4115 403 315 6802 CERAMIC 4.7U Z 16V

C4116 403 334 8603 ELECT 220U M 6.3V

C4117 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C4118 403 164 0204 CERAMIC 0.1U Z 25V

C4119 403 164 0204 CERAMIC 0.1U Z 25V

C4120 403 321 7404 ELECT 100U M 16V

C4121 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C4122 403 334 8603 ELECT 220U M 6.3V

C4123 403 164 0204 CERAMIC 0.1U Z 25V

C4124 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C4125 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C4126 403 334 8603 ELECT 220U M 6.3V

C4127 403 164 0204 CERAMIC 0.1U Z 25V

C4128 403 304 2105 ELECT 47U M 6.3V

C4129 403 157 3106 CERAMIC 56P J 50V

C4130 403 157 3106 CERAMIC 56P J 50V

C4131 403 157 3106 CERAMIC 56P J 50V

C4132 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C4133 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C4134 403 315 6802 CERAMIC 4.7U Z 16V

C4135 403 334 8603 ELECT 220U M 6.3V

C4136 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C4137 403 164 0204 CERAMIC 0.1U Z 25V

C4138 403 334 8603 ELECT 220U M 6.3V

C4139 401 105 7909 MT-GLAZE 0.000 ZA 1/16W

C4140 401 105 7909 MT-GLAZE 0.000 ZA 1/16W

C4141 401 105 7909 MT-GLAZE 0.000 ZA 1/16W

C4142 403 334 8603 ELECT 220U M 6.3V

C4143 403 157 3601 CERAMIC 100P J 50V

C4144 403 164 0204 CERAMIC 0.1U Z 25V

Key No. Part No. Description Key No. Part No. Description

Page 32

Electrical Parts List

-32-

C4145 403 157 3601 CERAMIC 100P J 50V

C4146 403 157 3601 CERAMIC 100P J 50V

C4147 403 164 0204 CERAMIC 0.1U Z 25V

C4148 403 164 0204 CERAMIC 0.1U Z 25V

C4149 403 164 0204 CERAMIC 0.1U Z 25V

C4150 403 164 0204 CERAMIC 0.1U Z 25V

C4151 403 164 0204 CERAMIC 0.1U Z 25V

C4152 403 343 3408 ELECT 10U M 25V

C4153 403 164 0204 CERAMIC 0.1U Z 25V

C4154 403 343 3408 ELECT 10U M 25V

C4155 403 164 0204 CERAMIC 0.1U Z 25V

C4157 403 298 9609 CERAMIC 0.1U K 16V

C4158 403 215 2201 CERAMIC 0.01U K 50V

C4159 403 164 0204 CERAMIC 0.1U Z 25V

C4160 403 164 0204 CERAMIC 0.1U Z 25V

C4161 403 298 9609 CERAMIC 0.1U K 16V

C4162 403 298 9609 CERAMIC 0.1U K 16V

C4163 403 164 0204 CERAMIC 0.1U Z 25V

C4164 403 164 0204 CERAMIC 0.1U Z 25V

C4165 403 164 0204 CERAMIC 0.1U Z 25V

C4166 403 164 0204 CERAMIC 0.1U Z 25V

C4167 403 164 0204 CERAMIC 0.1U Z 25V

C4168 403 164 0204 CERAMIC 0.1U Z 25V

C4169 403 164 0204 CERAMIC 0.1U Z 25V

C5001 403 334 8603 ELECT 220U M 6.3V

C5002 403 164 0204 CERAMIC 0.1U Z 25V

C5003 403 164 0204 CERAMIC 0.1U Z 25V

C5004 403 164 0204 CERAMIC 0.1U Z 25V

C5005 403 164 0204 CERAMIC 0.1U Z 25V

C5006 403 164 0204 CERAMIC 0.1U Z 25V

C5007 403 164 0204 CERAMIC 0.1U Z 25V

C5008 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C5009 403 164 0204 CERAMIC 0.1U Z 25V

C5011 403 157 3601 CERAMIC 100P J 50V

C5012 403 164 0204 CERAMIC 0.1U Z 25V

C5013 403 164 0204 CERAMIC 0.1U Z 25V

C5014 403 164 0204 CERAMIC 0.1U Z 25V

C5015 403 164 0204 CERAMIC 0.1U Z 25V

C5016 403 164 0204 CERAMIC 0.1U Z 25V

C5017 403 164 0204 CERAMIC 0.1U Z 25V

C5018 403 164 0204 CERAMIC 0.1U Z 25V

C5019 403 164 0204 CERAMIC 0.1U Z 25V

C5020 403 334 8603 ELECT 220U M 6.3V

C5021 403 334 8603 ELECT 220U M 6.3V

C5022 403 334 8603 ELECT 220U M 6.3V

C5023 403 334 8603 ELECT 220U M 6.3V

C5024 403 164 0204 CERAMIC 0.1U Z 25V

C5025 403 164 0204 CERAMIC 0.1U Z 25V

C5099 403 164 0204 CERAMIC 0.1U Z 25V

C5101 403 164 0204 CERAMIC 0.1U Z 25V

C5102 403 164 0204 CERAMIC 0.1U Z 25V

C5103 403 334 8603 ELECT 220U M 6.3V

C5104 403 164 0204 CERAMIC 0.1U Z 25V

C5105 403 164 0204 CERAMIC 0.1U Z 25V

C5106 403 164 0204 CERAMIC 0.1U Z 25V

C5107 403 164 0204 CERAMIC 0.1U Z 25V

C5108 403 164 0204 CERAMIC 0.1U Z 25V

C5109 403 164 0204 CERAMIC 0.1U Z 25V

C5110 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C5111 403 164 0204 CERAMIC 0.1U Z 25V

C5113 403 157 3601 CERAMIC 100P J 50V

C5114 403 164 0204 CERAMIC 0.1U Z 25V

C5115 403 164 0204 CERAMIC 0.1U Z 25V

C5116 403 164 0204 CERAMIC 0.1U Z 25V

C5117 403 164 0204 CERAMIC 0.1U Z 25V

C5118 403 334 8603 ELECT 220U M 6.3V

C5119 403 164 0204 CERAMIC 0.1U Z 25V

C5120 403 334 8603 ELECT 220U M 6.3V

C5121 403 334 8603 ELECT 220U M 6.3V

C5122 403 164 0204 CERAMIC 0.1U Z 25V

C5123 403 334 8603 ELECT 220U M 6.3V

C5124 403 164 0204 CERAMIC 0.1U Z 25V

C701 403 149 9208 CERAMIC 0.01U Z 50V

C702 403 164 0204 CERAMIC 0.1U Z 25V

C703 403 321 7404 ELECT 100U M 16V

C704 403 164 0204 CERAMIC 0.1U Z 25V

C705 403 149 9208 CERAMIC 0.01U Z 50V

C706 403 164 0204 CERAMIC 0.1U Z 25V

C707 403 149 9208 CERAMIC 0.01U Z 50V

C708 403 149 9208 CERAMIC 0.01U Z 50V

C709 403 164 0204 CERAMIC 0.1U Z 25V

C710 403 164 0204 CERAMIC 0.1U Z 25V

C712 403 164 0204 CERAMIC 0.1U Z 25V

C713 403 321 7404 ELECT 100U M 16V

C714 403 321 7404 ELECT 100U M 16V

C751 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C752 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C753 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C8001 403 164 0204 CERAMIC 0.1U Z 25V

C8003 403 164 0204 CERAMIC 0.1U Z 25V

C8004 403 164 0204 CERAMIC 0.1U Z 25V

C8005 403 334 8603 ELECT 220U M 6.3V

C8006 403 164 0204 CERAMIC 0.1U Z 25V

C8007 403 164 0204 CERAMIC 0.1U Z 25V

C8008 403 145 9905 CERAMIC 22P J 50V

C8009 403 139 7108 CERAMIC 12P J 50V

C801 403 113 4109 CERAMIC 2200P K 50V

C802 403 321 7404 ELECT 100U M 16V

C803 403 149 9208 CERAMIC 0.01U Z 50V

C804 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C805 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C806 403 164 0204 CERAMIC 0.1U Z 25V

C807 403 283 6309 CERAMIC 1U Z 10V

403 309 1400 CERAMIC 1U Z 10V

403 336 5600 CERAMIC 1U Z 10V

C8071 403 164 0204 CERAMIC 0.1U Z 25V

C8072 403 334 8603 ELECT 220U M 6.3V

C8073 403 164 0204 CERAMIC 0.1U Z 25V

C8074 403 164 0204 CERAMIC 0.1U Z 25V

C8075 403 334 8603 ELECT 220U M 6.3V

C8076 403 334 8603 ELECT 220U M 6.3V

C8077 403 334 8603 ELECT 220U M 6.3V

C8078 403 164 0204 CERAMIC 0.1U Z 25V

C8079 403 334 8603 ELECT 220U M 6.3V

C808 403 149 9208 CERAMIC 0.01U Z 50V

C8080 403 334 8603 ELECT 220U M 6.3V

C8081 403 164 0204 CERAMIC 0.1U Z 25V

C8082 403 164 0204 CERAMIC 0.1U Z 25V

C8083 403 334 8603 ELECT 220U M 6.3V

C8084 403 334 8603 ELECT 220U M 6.3V

C8085 403 334 8603 ELECT 220U M 6.3V

C8086 403 334 8603 ELECT 220U M 6.3V

C8087 403 334 8603 ELECT 220U M 6.3V

C8088 403 164 0204 CERAMIC 0.1U Z 25V

C8089 403 164 0204 CERAMIC 0.1U Z 25V

C809 403 157 1607 CERAMIC 6P D 50V

C8090 403 164 0204 CERAMIC 0.1U Z 25V

C8091 403 164 0204 CERAMIC 0.1U Z 25V

C8092 403 164 0204 CERAMIC 0.1U Z 25V

C810 403 157 1607 CERAMIC 6P D 50V