Page 1

V

INSTRUCTION MANUAL

MDF-U32

Ultra-Low Temperature Freezer

Page 2

Note:

1. No part of this manual may be reproduced in any form without the expressed written

permission of SANYO.

2. The contents of this manual are subject to change without notice.

3. Please contact SANYO if any point in this manual is unclear or if there are any

inaccuracies.

SANYO Electric Biomedical Co., Ltd. All rights reserved. Printed in Japan.

Page 3

CONTENTS

PRECAUTIONS FOR SAFE OPERATION P. 2

CAUTIONS FOR USAGE P. 6

ENVIRONMENTAL CONDITIONS P. 7

FREEZER COMPONENTS P. 8

Control panel and keypad P.10

INSTALLATION

Installation site P.11

Installation P.12

OPTIONAL COMPONENTS

Temperature recorder P.13

Back-up system P.14

Inventory rack P.15

START-UP OF UNIT P.16

TEMPERATURE SETTING

Chamber temperature P.17

Key lock function P.17

Alarm temperature setting P.18

ALARMS & SAFETY FUNCTIONS P.19

SETTING OF ALARM RESUME TIME P.20

REMOTE ALARM TERMINAL P.21

MONITOR OF FREEZER STATUS P.22

CHANGE OF COMPRESSOR DELAY TIME P.23

ROUTINE MAINTENANCE

Cleaning of cabinet P.24

Cleaning of condenser filter P.24

Defrosting of inside wall P.25

TROUBLESHOOTING P.26

DISPOSAL OF UNIT P.26

RECYLCE OF RECHARGEABLE BATTERY P.27

SPECIFICATIONS P.28

PERFORMANCE P.28

SAFETY CHECK SHEET P.29

1

Page 4

PRECAUTIONS FOR SAFE OPERATION

It is imperative that the user complies with this manual as it contains

important safety advice.

Items and procedures are described so that you can use this unit correctly and safely.

If the precautions advised are followed, this will prevent possible injury to the user and

any other person.

Precautions are illustrated in the following way:

WARNING

Failure to observe WARNING signs could result in a hazard to personnel

possibly resulting in serious injury or death.

CAUTION

Failure to observe CAUTION signs could result in injury to personnel and

damage to the unit and associated property.

Symbol shows;

this symbol means caution.

this symbol means an action is prohibited.

this symbol means an instruction must be followed.

Be sure to keep this manual in a place accessible to users of this unit.

< Label on the unit >

This mark is labeled on the cover in which the electrical components of high voltage are

enclosed to prevent the electric shock.

The cover should be removed by a qualified engineer or a service personnel only.

WARNING

As with any equipment that uses CO

equipment. It is important that you assess the work site to ensure there is suitable and sufficient

ventilation. If restricted ventilation is suspected, then other methods of ensuring a safe environment must

be considered. These may include atmosphere monitoring and warning devices.

gas, there is a likelihood of oxygen depletion in the vicinity of the

2

2

Page 5

PRECAUTIONS FOR SAFE OPERATION

Do not use the unit outdoors. Current leakage or electric shock may result if the unit is exposed to

rain water.

Only qualified engineers or service personnel should install the unit. The installation by

unqualified personnel may cause electric shock or fire.

Install the unit on a sturdy floor. If the floor is not strong enough or the installation site is not

adequate, this may result in injury from the unit falling or tipping over.

Never install the unit in a humid place or a place where it is likely to be splashed by water.

Deterioration of the insulation may result which could cause current leakage or electric shock.

Never install the unit in a flammable or volatile location. This may cause explosion or fire.

Never install the unit where acid or corrosive gases are present as current leakage or electric

shock may result due to corrosion.

Use a dedicated power source as indicated on the rating label attached to the unit.

Connect the power supply plug to the power source firmly. Improper insertion may cause a heat

or ignition.

Use a power supply outlet with ground (earth) to prevent electric shock. If the power supply

outlet is not grounded, it will be necessary to install a ground by qualified engineers.

Never ground the unit through a gas pipe, water main, telephone line or lightning rod. Such

grounding may cause electric shock in the case of an incomplete circuit.

Never store volatile or flammable substances in this unit if the container cannot be sealed. This

may cause explosion or fire.

Never store corrosive substances in this unit if the container cannot be sealed. This may lead to

damage to the inner components or electric parts.

Do not insert metal objects such as a pin or a wire into any vent, gap or any outlet for inner air

circulation. This may cause electric shock or injury by accidental contact with moving parts.

Use this unit in safe area when treating the poison, harmful or radiate articles. Improper use

may cause bad effect on your health or environment.

Disconnect the power supply to the unit prior to any repair or maintenance of the unit in order to

prevent electric shock or injury.

WARNING

3

Page 6

PRECAUTIONS FOR SAFE OPERATION

Ensure you do not inhale or consume medication or aerosols from around the unit at the time of

maintenance. These may be harmful to your health.

Never splash water directly onto the unit as this may cause electric shock or short circuit.

Never disassemble, repair, or modify the unit yourself. Any such work carried out by an

unauthorized person may result in fire or injury due to a malfunction.

Disconnect the power supply plug if there is something wrong with the unit. Continued

abnormal operation may cause electric shock or fire.

If the unit is to be stored unused in an unsupervised area for an extended period, ensure that

children do not have access and that doors cannot be closed completely.

The disposal of the unit should be accomplished by appropriate personnel. Remove doors to

prevent accidents such as suffocation.

Ventilate the room air when using the carbon dioxide gas for the back-up system. The CO

density level in the air could rise and may be harmful to humans.

Prepare a safety check sheet when you request any repair or maintenance for the safety of service

personnel.

Select a level and sturdy floor for installation. This precaution will prevent the unit from tipping.

Improper installation may result in water spillage or injury from the unit tipping over.

Connect the unit to a power source as indicated on the rating label attached to the unit. Use

of any other voltage or frequency other than that on the rating label may cause fire or electric shock.

Never bind, process, or step on the power supply cord, or never damage or break the power

supply plug. Do not use the supply plug if its cord is loose. This may cause fire or electric

shock.

When removing the plug from the power supply outlet, grip the power supply plug, not the cord.

Pulling the cord may result in electric shock or fire by short circuit.

Do not touch any electrical parts such as the power supply plug or any switches with a wet hand.

This may cause electric shock.

WARNING

CAUTION

2

4

Page 7

PRECAUTIONS FOR SAFE OPERATION

Check the setting when starting up of operation after power failure or turning off of power

switch. The stored items may be damaged due to the change of setting.

Do not put a container with water or heavy articles on the unit. It may cause injury if the articles

fall. Current leakage or electric shock may be resulted form the deterioration of insulation by spilled

water.

Do not climb onto the unit or do not put articles on the unit. This may cause injury by tipping or

damage to the unit.

Always hold the handle when closing the door. This will reduce the likelihood of a trapped finger.

Do not put glass bottles or cans into the compartment since they may be broken by frozen

contents and cause injury.

Do not touch the stored items with bare hand. Handing frozen contents or the inside walls with

naked hand may cause frostbite.

Do not lean on the door. This may cause injury if the unit tips over or door is broken.

Put on gloves at the time of maintenance to prevent injury by the edge or corner of the

components.

Check the filter mentioned in this manual and clean it as necessary. A dusty filter may cause

temperature rise or failure.

Do not touch the condenser directly when the filter is removed for cleaning. This may cause injury

by hot surface.

Disconnect the power supply plug before moving the unit. Take care not to damage the power

cord. A damaged cord may cause electric shock or fire.

Be careful not to tip over the unit during movement to prevent damage or injury.

Disconnect the power plug when the unit is not used for long periods. Keeping the connection may

cause electric shock, current leakage, or fire due to the deterioration of insulation.

Do not put the packing plastic bag within reach of children as suffocation may result.

CAUTION

5

Page 8

CAUTIONS FOR USAGE

1. When the first start-up or start-up after no use of long period, the warning device may not operate,

because its Ni-MH battery has completely discharged. This does not denote a malfunction. In this

case, continue to operate the unit for about 3 hours, then push the test switch to check if the warning

device operates. To fully recharge the completely discharged battery, the unit has to be operated for

about 2 days.

2. In the case of high ambient temperature, the cabinet front may heat up after the freezer starts to

operate first. However, this does not denote a malf unction. It is due to the hot gas piped around the

unit frame to prevent condensation around the cabinet.

3. Cool down the freezer chamber sufficiently before storing materials and put the materials in a small

batch to reduce the temperature rise.

4. The digital thermometer of this ultra-low temperature freezer is designed to display the temperature of

the center part of the freezing compartment. The thermometer sometimes displays a temperature a little

bit higher than the actual temperature of the center part depending on the amount or arrangement of

stored items.

5. An access port to take out the measuring cable in the case is provided on the back wall and right

bottom of the freezer. Be sure to replace the cap and thermal insulation after taking out of the cable, or

the chamber temperature cannot complete down, and frost may accumulate outside the port

surroundings.

6. Always open and close the door gently. Rough operation may lead fall down of stocked items,

incomplete closing, or damage of door gasket.

7. Check and rectify the problem as soon as possible when the alarm lamp is light and buzzer is activated.

Refer to table 5 on page 19 for the alarm.

8. Do not use brushes, acids, thinners, powdered soap or hot water for cleaning the freezer. Polishing

powders or hot water can deteriorate the painted surfaces or cause deformation, discoloration or

degeneration of plastic or rubber components. Be especially careful not to wipe plastic or rubber parts

with volatile solvents such as benzine. Wipe off a diluted neutral dishwashing detergent completely with

a wet cloth when it is used.

9. The frost will be built up on the chamber wall and inner door during operation. Use a scraper provided

with the freezer or equivalent tool to remove the frost. The inner door is hard to be opened when a large

amount of frost is built up on it. In this case, remove the frost by detaching the inner door as shown in

page 25.

10. There are pipelines for cooling behind the walls. Do not defrost inside walls using a knife, ice pick,

or screw driver. Be careful not to damage the walls or to make a hole on the walls as this could cause a

failure of the freezer. Also, take care not to drop a heavy item or anything with sharp edge on the

bottom of the chamber.

11. Because of a large freezer, the following facilities are needed; a dedicated power outlet of more than

15A capacity, a motor breaker of more than 15A or a general-purpose breaker of more than 30A. Do not

use a branched socket for power source as it may cause unstable voltage and result in a failure of the

unit. Always use a dedicated power outlet. For details, consult a Sanyo sales representative or an

electrician.

6

Page 9

ENVIRONMENTAL CONDITIONS

This equipment is designed to be safe at least under the following conditions (based on the IEC-1010-1):

1. Indoor use;

2. Altitude up to 2000 m;

3. Ambient temperature 5

4. Maximum relative humidity 80% for temperature up to 31

humidity at 40

5. Mains supply voltage fluctuations not to exceed ±10% of the nominal voltage;

6. Other supply voltage fluctuations as stated by the manufacturer;

7. Transient overvoltages according to Installation Categories (Overvoltage Categories) II; For mains

supply the minimum and normal category is II;

8. Pollution degree 2 in accordance with IEC 664.

o

C;

o

C to 40oC

o

C decreasing linearly to 50% relative

7

Page 10

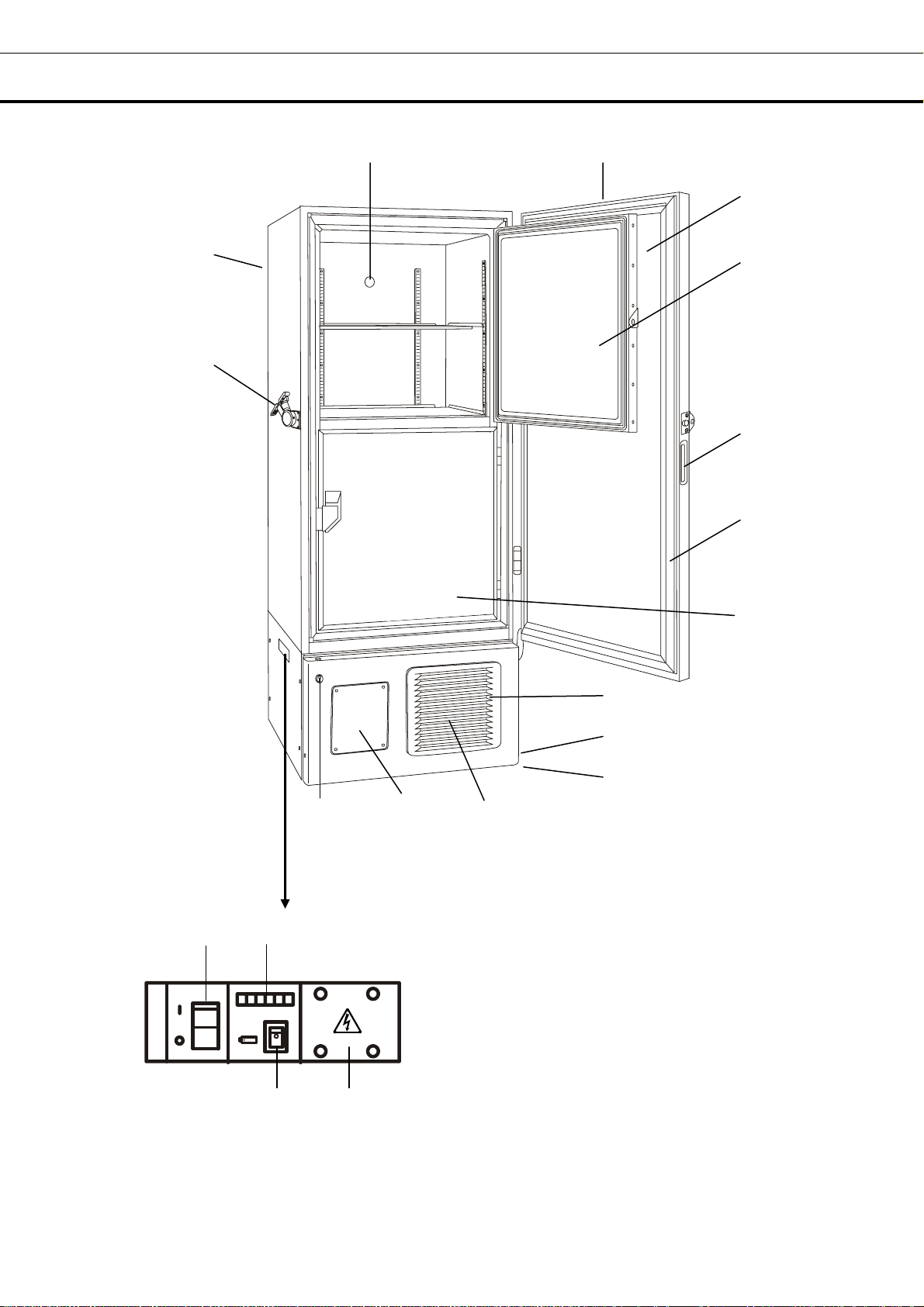

FREEZER COMPONENTS

11

3

13

7

17

5

14

15(inside)

18 16

8

1

6

2

4

5(inside)

12

10

9

8

Page 11

FREEZER COMPONENTS

1. Outer door: To open the door, grip the handle. On closing, lock the door latch completely.

2. Handle: Always grip this handle to open and close the outer door.

3. Door latch: Always lock the latch when the outer door is closed.

4. Magnetic door gasket: This provides a tight door seal and prevents cold air leak. Keep clean.

5. Access port (rear and bottom): This is used for leading a cable and sensor of a measuring

equipment, or nozzle of back-up system to chamber.

6. Inner door: The operation of the inner door should be quick to minimize the temperature rise in

chamber. Lock the door latch completely when the door is closed. The door is removable for cleaning

or defrosting. See page 25 “Routine maintenance”.

7. Lock: Turn clockwise to 180

8. Control panel (on the upper front of the door): Used for temperature setting and indication of

operating status is displayed on the panel. See page 10 for details.

9. Caster: 4 casters are provided to facilitate moving of the cabinet. For the installation, adjust the

leveling foot so that the front 2 casters cannot contact with the floor.

10. Leveling foot: The height of the freezer can be adjusted by this screw type foot. Keep the unit in

level at the installation.

11. Fixture (on back side): 2 fixtures serve as spacers between the cabinet and wall and also serve as

hooks to fix the unit. See page 12 “Installation”.

12. Air intake vent (grille): Do not block this vent to keep the proper cooling performance.

13. Power switch: This is for turning ON/OFF the power to the unit. ON – “I” OFF – “○”

14. Space for temperature recorder: An automatic temperature recorder (optional component) can be

attached here. See page 13 “Temperature recorder”.

15. Condenser filter (behind the grille): This filter prevents the dust from accumulating on the

condenser. The dusty filter may cause failure of refrigerating device. Clean the filter once a month.

See page 24 “Routine maintenance” for the cleaning.

16. Battery switch: This is a switch for a battery for power failure alarm. Normally, turn on this switch.

Be sure to turn off this switch if the freezer is not in operating for the long period.

17. Remote alarm terminal: This is used to notice an alarm condition of the unit to remote location.

Refer to page 21 “Remote alarm terminal”.

18. Space for optional component:

o

with a key and the outer door is securely locked.

9

Page 12

FREEZER COMPONENTS

A

Control panel and keypad

ULTRA LOW

1. Buzzer stop key (BUZZER): To silence the audible alarm under alarm condition, press this key.

The buzzer during alarm test cannot be silenced by this key.

2. Set key (SET): Temperature setting mode is led by pressing this key and the changeable digit is

flashed. By pressing this key again, the setting is memorized. The set mode returns to the

temperature display mode automatically when 90 seconds has passed without any key operation. Refer

to page 17 for details.

3. Digit shift key ( ): Pressing this key in the setting mode causes the changeable digit to shift. Key

lock is available by pressing this key for more than 5 seconds in the temperature display mode. Refer to

page 17 for details.

4. Numerical value shift key ( ): Pressing this key in the setting mode causes the numerical value to

shift. “ON-OFF” of key lock can be selected by pressing this key in the key lock mode. By pressing this

key for more than 5 seconds in the temperature display mode leads setting mode for alarm temperature

and alarm resume time. Refer to page 18 and 20 for details respectively.

5. Digital temperature indicator: This indicator shows the present chamber temperature or set

temperature.

6. Alarm lamp (ALARM): This lamp is flashed during alarm condition.

7. Alarm test key (ALARM TEST): To check the alarm system. Pressing this key with the battery

switch ON gets the alarm lamp to flash, the remote alarm to operate, and the buzzer to sound.

8. Door check lamp (DOOR): This lamp lights when the door is open.

9. Filter check lamp (FILTER): This lamp lights when the excessive dust is accumulated on the

condenser filter. When this lamp lights, clean the condenser filter following the procedure on page 24.

10. Battery check lamp (BATTERY): This lamp flickers to recommend the battery replacement. For

the replacement, consult Sanyo sales representative or agent.

11. Status monitor lamp (STATUS): This lamp lights when environmental condition or status gets

worse or the unit is out of normal operation.

12. Status key (STATUS): By pressing this key in the event of the status monitor lamp ON, the status

code is displayed on the temperature indicator. This key is not effective when the freezer is running

normally. See page 22 for details.

BUZZER

1

ALARM

TEST

TEMPERATURE

7 12 2 3

5 1011 9 68

STATUS SET

BATTERY

STATUS

FILTER

LARM

DOOR

4

10

Page 13

INSTALLATION

Installation site

To operate this unit properly and to obtain maximum performance, install the unit in a location with the

following conditions:

1. A location not subjected to direct sunlight

Installation in a location subjected to direct sunlight may lead to inadequate cooling.

2. A location with adequate ventilation

Leave at least 10 cm around the unit for ventilation. Poor ventilation will result in a reduction of the

refrigeration capacity.

3. A location away from heat generating sources

Avoid installing the unit near heat-emitting appliances such as gas ranges or stoves. Heat can cause

inefficient refrigeration.

4. A location with a sturdy and level floor

WARNING

Install the unit on a sturdy floor. If the floor is not strong enough or the installation site is not

adequate, this may result in injury from the unit falling or tipping over.

Select a level and sturdy floor for installation. This precaution will prevent the unit from tipping.

Improper installation may result in water spillage or injury from the unit tipping over.

5. A location not prone to high humidity

WARNING

Do not use the unit outdoors. Current leakage or electric shock may result if the unit is exposed to

rain water.

Never install the unit in a humid place or a place where it is likely to be splashed by water.

Deterioration of the insulation may result which could cause current leakage or electric shock.

6. A location without flammable or corrosive gas

WARNING

Never install the unit in a flammable or volatile location. This may cause explosion or fire.

Never install the unit where acid or corrosive gases are present as current leakage or electric shock

may result due to corrosion.

11

Page 14

INSTALLATION

Installation

1. Remove the packaging materials and tapes

Remove all transportation packaging materials and tapes. Open the doors and ventilate the unit. If the

outside panels are dirty, clean them with a diluted neutral dishwashing detergent. (Undiluted detergent

can damage the plastic components. For the dilution, refer to the instruction of the detergent.) After

the cleaning with the diluted detergent, always wipe it off with a wet cloth. Then wipe off the panels with

a dry cloth.

2. Adjust the leveling foot

Extend the leveling feet by rotating them

counterclockwise to contact them to the floor.

Ensure the unit is level.

3. Fix the unit

Two fixtures are attached to the rear of the frame.

Fix the frame to the wall with these fixtures and rope

or chain.

4. Ground (earth)

Leveling foot

Fixture

WARNING

Use a power supply outlet with ground (earth) to prevent electric shock. If the power supply outlet is

not grounded, it is necessary to install a ground by qualified engineers.

Never ground the unit through a gas pipe, water main, telephone line or lightning rod. Such

grounding may cause electric shock in the case of an incomplete circuit.

12

Page 15

OPTIONAL COMPONENTS

Temperature recorder

An automatic temperature recorders is available for this freezer as the optional component. The type of

the recorder is MTR-G85.

Following shows the attachment procedure.

1. Remove four screws on the front panel and take it off.

By removing four screws, take off the left side panel.

Then take off the cover for the recorder mounting space

by removing four screws. (Fig. 1)

2. As shown in the Fig. 2, insert the temperature

recorder to the mounting space and fix it to the back

side of the front panel by using the recorder fixture

enclosed with the recorder.

3. Take off the recorder sensor cover in the chamber

(bottom left side) by removing two screws. Then

remove the rubber cap and insulation covering the

sensor port. (Fig. 3)

4. As shown in the Fig. 4, pass the recorder sensor

through the sensor guide pipe from the front to the back.

The sensor guide pipe is provided on the upper left side

of the base compartment.

5. Take out the recorder sensor from the guide pipe at

the back side and pass the sensor to the chamber

through the access port. (Fig. 5)

6. Attach the recorder sensor on the sensor cover with

the enclosed clips. Seal the sensor port with a silicon

and replace the recorder sensor cover. Fix the cover

to the inside wall. (Fig. 6)

7. Remove the connector cover. Connect the recorder

connector at the end of the power cord with the white

connector on the left of the base compartment. Bind

the extra lead wire of the sensor with a nylon clip on the

back of the recorder. (Fig. 7)

8. Replace the left side panel and front panel and fix

them with screws.

connector

Fig. 2

Fig. 3

Fig. 4

Fig. 1

Sensor guide pipe

Fig. 5

Fig. 6

Fig. 7

13

Page 16

OPTIONAL COMPONENTS

Back-up system

WARNING

As with any equipment that uses CO

of the equipment. It is important that you assess the work site to endure there is suitable and

sufficient ventilation. If restricted ventilation is suspected, then other methods of ensuring a

safe environment must be considered. These may include atmosphere monitoring and warning

devices.

This freezer can be provided with a back-up system (CVK-UB2) which is available as an optional

component. For the installation, refer to the instruction manual enclosed with the system.

1. Switch of back-up system (BACKUP)

When turning on the system, the lamp is brightened.

This means that the system is ready. To stop the

operation of the system, turn off this switch.

2. Test switch (TEST)

This switch is for checking the operation of back-up

system. Pressing this switch is resulted in the release

of liquid carbon dioxide without system operation.

3. Temperature setting knob (TEMP. SET)

With this knob, set the temperature at which the system

is operated. The effective set temperature range is

between -50

o

C and -70oC.

gas, there is a likelihood of oxygen depletion in the vicinity

2

1

2

3

14

Page 17

OPTIONAL COMPONENTS

Inventory rack

The optional inventory rack is useful to store the precious materials in the chamber effectively. When

the rack is used, it is necessary to adjust the height of the shelves. Set the shelf support as shown in

the figure below.

Shelf stopper

IR-216U

IR-220U

Shelf support

No. 7 under first

screw from the top

No. 1 under forth

screw from the top

No. 1 under second

screw from the bottom

15

Page 18

START-UP OF UNIT

Follow the procedures for the initial and consequent operations of the unit.

1. Connect the power cord to the dedicated outlet having appropriate rating with the chamber empty, and

turn on the power switch on the freezer.

2. Turn off the switch of the back-up system (optional component) if it is installed.

3. Check that the battery switch is ON.

4. The audible alarm may activated. In this case, press the buzzer stop key (BUZZER) to silence the

alarm.

5. Set the desired chamber temperature. See page 17 for the temperature setting.

6. Check that the chamber temperature reaches the desired temperature.

7. Turn on the switch of back-up system (optional component) if it is installed.

8. Make sure that the alarm lamp lights and the buzzer sounds by pressing the alarm test key.

9. After confirming the above, you can put articles into the freezer chamber in a small batch to prevent the

temperature rise.

16

Page 19

TEMPERATURE SETTING

Chamber temperature

Table 1 shows the basic procedure for setting the chamber temperature. Perform key operations in the

sequence indicated in the table. The example in the table is based on the assumption that the desired

temperature is -75

Note: The unit is set at the factory that the chamber temperature -80

Table 1. Basic operation sequence (Example: Chamber temperature -75oC)

Description of operation Key operated Indication after operation

Turn the power switch ON.

1

2 Press SET key. SET

Set to -75 with the numerical value

3

shift key and digit shift key.

4 Press SET key.

Note:

• The temperature set mode returns to the temperature display mode automatically when 90 seconds has

passed without any key operation.

• Although the value of the chamber temperature setting can range from -50

temperature when there is no load is -85

o

C.

----

The current chamber temperature is

displayed.

The second digit is flashed.

SET

o

C when the ambient temperature is 30oC.

When pressed, the figure of settable

digit changes.

When pressed, the settable digit

is shifted.

Set temperature is memorized and the

current chamber temperature is

displayed.

o

C.

o

C to -90oC, the guaranteed

Key lock function

This unit is provided with the key lock function. When the key lock is ON, change of temperature setting

through the key pad is not available. The key lock is set in OFF at the factory.

Display Mode Function

L 0 Key lock is OFF Enable to change of temperature setting

L 1 Key lock is ON Disable to change of temperature setting

Table 2. Procedure for key lock setting (change from key lock OFF to key lock ON)

Description of operation Key operated Indication after operation

1 ----

2 Press digit shift key for 5 seconds.

Press numerical value shift key

3

and scroll the figure to 1.

4 Press SET key. SET

The current chamber temperature is

displayed.

The first digit is flashed.

When pressed, the figure of settable

digit changes.

The key lock is set to ON.

The current chamber temperature is

displayed.

17

Page 20

TEMPERATURE SETTING

Alarm temperature setting

This unit is provided with the high and low temperature alarm and the temperature at which the alarm is

activated is changeable.

The following procedure shows the setting of alarm temperature according to the condition below:

High temperature alarm: activates at the temperature 5

Low temperature alarm: activates at the temperature 5

Note:

The alarm temperature is set at the factory 10

o

C higher and lower than the set temperature.

The available range of alarm temperature is between 5

temperature.

Table 3. Procedure for setting high temperature alarm

Description of operation Key operated Indication after operation

1 ----

Press numerical value shift key for

2

about 5 seconds.

Press numerical value shift key

3

and scroll the figure to 1.

The first digit is flashed.

4 Press SET key. SET The first digit is flashed.

Scroll the figure to 005 by using

5

digit shift key and numerical value

shift key

6 Press SET key. SET

Table 4. Procedure for setting low temperature alarm

Description of operation Key operated Indication after operation

1 ----

Press numerical value shift key for

2

about 5 seconds.

Press numerical value shift key

3

and scroll the figure to 2..

The first digit is flashed.

4 Press SET key. SET The first digit is flashed.

Scroll the figure to -05 by using

5

digit shift key and numerical value

shift key

6 Press SET key. SET

o

C higher than the set temperature

o

C lower than the set temperature

o

C and 20oC higher or lower than the set

The current chamber temperature is

displayed.

The first digit is flashed.

When pressed, the figure of settable

digit changes.

When pressed, the changeable digit

moves.

Alarm temperature is memorized and

the current chamber temperature is

displayed.

The current chamber temperature is

displayed.

The first digit is flashed.

When pressed, the figure of settable

digit changes.

When pressed, the changeable digit

moves.

Alarm temperature is memorized and

the current chamber temperature is

displayed.

18

Page 21

ALARMS & SAFETY FUNCTIONS

This unit has the alarms and safety functions shown in Table 5, and also self diagnostic functions.

Table 5. Alarms and safety functions

Alarm & Safety Situation Indication Buzzer Safety operation

High temperature

alarm

Low temperature

alarm

Power failure alarm

Filter check When the condenser filter is clogged. Filter check lamp lights. ----- ----Battery check

Auto-return

Key lock When the key lock is “ON”. ----- -----

Sensor abnormality

Battery switch

check

Note:

• When the operation is started in high ambient temperature, the filter check lamp is sometimes flashed.

In this case, the lamp is off automatically when the chamber temperature is getting lower.

• The freezer resumes the operation after power failure with the temperature setting before power failure

as the chamber temperature setting and alarm temperature setting are memorized in the volatile memory.

• The chamber temperature is displayed for 5 seconds by pressing BUZZER key during power failure

alarm. Then the buzzer is silenced. The ALARM lamp keeps flashing.

If the chamber temperature is higher

than the temperature at which the

high temperature alarm is activated.

If the chamber temperature is lower

than the temperature at which the

low temperature alarm is activated.

When the power to the unit is

disconnected.

When about 2.8 years has passed with

power switch ON.

When there is no key pressing in

each setting mode for 90 seconds.

If the thermal sensor is disconnected.

If the thermal sensor is short-circuited.

If the cascade sensor is disconnected.

If the cascade sensor is short circuited.

If the filter sensor is disconnected.

If the filter sensor is short-circuited.

If the ambient temperature sensor is

disconnected.

If the ambient temperature sensor is

short-circuited.

When the battery switch is OFF during

alarm test.

ALARM lamp is flashed.

Temperature indicator is

flashed.

ALARM lamp is flashed. Intermittent tone Remote alarm.

Battery check lamp lights. ----- ----Chamber temperature is

displayed.

ALARM lamp is flashed.

E01 and chamber temp. are

displayed alternately.

ALARM lamp is flashed.

E02 and chamber temp. are

displayed alternately.

ALARM lamp is flashed.

E03 and chamber temp. are

displayed alternately.

ALARM lamp is flashed.

E04 and chamber temp. are

displayed alternately.

ALARM lamp is flashed.

E05 and chamber temp. are

displayed alternately.

ALARM lamp is flashed.

E06 and chamber temp. are

displayed alternately.

ALARM lamp is flashed.

E07 and chamber temp. are

displayed alternately.

ALARM lamp is flashed.

E08 and chamber temp. are

displayed alternately.

ALARM lamp is flashed.

E09 is flashed.

Intermittent tone with

15 minutes delay.

Intermittent tone

Intermittent tone

Intermittent tone

Intermittent tone

Intermittent tone Remote alarm.

Intermittent tone Remote alarm.

Intermittent tone Remote alarm.

Intermittent tone Remote alarm.

Remote alarm with 15

minutes delay.

-----

----- -----

Finishing of each

setting mode.

Change of setting is

disable.

Remote alarm.

Unit keeps continuous

running.

Remote alarm.

Unit keeps continuous

running.

Remote alarm.

Unit keeps running.

Remote alarm.

Unit keeps running.

19

Page 22

SETTING OF ALARM RESUME TIME

The alarm buzzer is silenced by pressing BUZZER key on the control panel during alarm condition (The

remote alarm is not silenced).

The buzzer will be activated again after certain suspension if the alarm condition is continued. The

suspension time can be set by following the procedure shown in the Table 6 below.

The example in the table is based on the assumption that the desired duration is 20 minutes.

Note: The duration is set in 30 minutes at the factory.

Table 6. Setting procedure for alarm resuming time (change from 30 minutes to 20 minutes)

Description of operation Key operated Indication after operation

1 ----

2 Press digit shift key for 5 seconds.

Set the figure to F25 with the digit

3

shift key and numerical value shift

key.

4 Press SET key. SET

Set the figure to 020 with the

5

numerical value shift key.

6 Press SET key. SET

• The settable alarm resume time is 10, 20, 30, 40, 50, or 60 minutes (The setting is 010, 020, 030, 040,

050, or 060). The buzzer would not reset if the reset time is set in 000.

• It is recommended to set the alarm resume time when the freezer is not under alarm condition. The

setting during alarm condition is effective on the next alarm condition.

• The setting cannot be changed during power failure.

• The remote alarm during power failure or buzzer and remote alarm during alarm test cannot be

silenced.

• The set mode returns to the temperature display mode automatically when 90 seconds has passed

without any key operation. In this case, any setting before pressing SET key is not memorized.

When pressed, the figure of settable

The current chamber temperature is

displayed.

The first digit is flashed.

The settable digit is shifted.

digit changes.

The current reset time is displayed.

The middle digit is flashed.

When pressed, the figure of settable

digit changes.

The setting is memorized and

the current chamber temperature is

displayed.

20

Page 23

REMOTE ALARM TERMINAL

The terminal of the remote alarm is installed at the lower left side of the unit. The alarm is outputted

from this terminal. Contact capacity is DC 30V, 2 A.

Contact output:

between COM. and N.O. between COM. and N.C.

At normal Open Close

At abnormal Close Open

Note:

The alarm is actuated when the power cord is disconnected from the outlet or the power switch is OFF.

REMOTE ALARM

N.O. COM N.C.

MAX DC30V 2A

21

Page 24

MONITOR OF FREEZER STATUS

The freezer has a function to monitor the running status of the unit as shown in table 7 below. This is to

notice the running status getting worse (not failure).

1. The STATUS lamp is lit when one of the running status shown in table 7 is detected.

2. The S code (--X, X: 1 to 3) is displayed on the temperature indicator by pressing STATUS key when

the STATUS lamp is lit.

3. Pressing the STATUS key again causes current chamber temperature display on the temperature

indicator. (The indication returns to the chamber temperature display automatically when no key is

operated for 90 seconds.)

Table 7. Monitor of running status

Kind of

function

Notice of

abnormal

ambient

temperature

Notice of low

voltage

Notice of

overload

condition

Note:

• The S code displayed on the temperature indicator is changed every a few seconds if two or three

status shown in the above table are detected at the same time. (--1 ⇒ --2 ⇒ --3 ⇒ --1 repeated)

• The monitoring function has no buzzer operation and no safety operation.

• In the case of multiple indication of S code, follow the remedy for each status.

When the ambient

temp. is over about

35

about 0

When the power

source voltage is

less than about 97V

when the rated

voltage is 115V or

less than about 195V

when the rated

voltage is between

220 and 240V.

When the running

rate of refrigerating

Circuit is more than

usual.

Status Indication

STATUS lamp

o

C or lower than

o

C.

lights.

“--1” is displayed.

STATUS lamp

lights.

“--2” is displayed.

STATUS lamp

lights.

“--3” is displayed.

If this status

continues

Decrease of cooling

performance or

durability of

refrigerating circuit.

Abnormal heat at

power supply outlet

or degrade of

starting performance

of refrigerating

circuit

Decrease of cooling

performance or

durability of

refrigerating circuit.

Remedy

Recheck of

air-conditioning of

installed site.

Use of dedicated

power source.

1. This is likely

happened when

large amount of

materials are stored.

2. Check of ambient

temp., voltage, and

sealing of

outer/inner door.

22

Page 25

CHANGE OF COMPRESSOR DELAY TIME

The delay time of high and low stage side compressor can be changed to reduce the load on the power

line and to facilitate the start-up (reset) of the freezer after power failure.

The example in the table is based on the assumption that the delay time is changed to 4 minutes.

(The delay time is set in 2 minutes at the factory.)

Note:

• The delay time should be same for high stage side and low stage side compressors.

• The setting range for delay time is between 2 and 15 minutes. The cool down of chamber temperature

may be slow when the setting of delay time is over 5 minutes, depending on the installation environment.

There is no need changing the delay time when the capacity of power source is enough.

Table 8. Changing procedure for delay time (change from 2 minutes to 4 minutes)

Description of operation Key operated Indication after operation

1 ----

Press numerical value shift key for

2

5 seconds.

Set the figure to F05 with the

3

numerical value shift key.

When pressed, the figure of settable

4 Press SET key. SET

Set the figure to 004 with the

5

numerical value shift key.

The current chamber temperature is

displayed.

The first digit is flashed.

digit changes.

The current delay time is displayed.

The first digit is flashed.

When pressed, the figure of the first

digit changes.

The delay time is memorized and

6 Press SET key. SET

the current chamber temperature is

displayed.

• The compressor starts to operate with the delay time set by the above procedure at the time of power

on or after power failure. For the low stage side compressor, however, its start up may be behind the

delay time because the compressor is affected by the chamber temperature and temperature of cascade

condenser installed in the freezer.

23

Page 26

ROUTINE MAINTENANCE

WARNING

Always disconnect the power supply to the unit prior to any repair or maintenance of the unit in

order to prevent electric shock or injury.

Ensure you do not inhale or consume medication or aerosols from around the unit at the time of

maintenance. These may be harmful to your health.

Cleaning of cabinet

• Clean the unit once a month. Regular cleaning keeps the unit looking new.

• Use a dry cloth to wipe off small amounts of dirt on the outside and inside of the unit and all accessories.

If the outside panels are dirty, clean them with a diluted neutral dishwashing detergent. (Undiluted

detergent can damage the plastic components. For the dilution, refer to the instruction of the detergent.)

After the cleaning with the diluted detergent, always wipe it off with a wet cloth. Then wipe off the

cabinet or accessories with a dry cloth.

• Never pour water onto or into the unit. Doing so can damage the electric insulation and cause failure.

• The compressor and other mechanical parts are completely sealed. This unit requires absolutely no

lubrication.

• Check the back-up system by pressing TEST switch once a month if it is installed.

• Remove the frost or ice on the chamber wall and clean the condenser filter once a month.

Cleaning of condenser filter

This unit is provided with the filter check lamp on the control panel. Clean the filter when this lamp lights.

Clean the filter once a month even if the check lamp is not on since a clogged filter may cause shorter

compressor life as well as the poor cooling.

Clean the filter by the procedure below.

1. Open the grille by pulling it to you as shown in the

figure.

2. Take out the condenser filter.

3. Wash the filter with water.

4. Replace the filter and the grille.

5. Check that the filter check lamp is off in the event the

check lamp was ON.

WARNING

Do not touch the condenser directly when the filter is removed for cleaning. This may cause injury by

hot surface.

24

Page 27

ROUTINE MAINTENANCE

Defrosting of inside wall

The frost is built at the upper portion of the chamber and inner door. The excessive frost possibly make

some gap between the cabinet and door gasket, which may cause poor cooling. Remove the frost on

the inner door with a scraper enclosed with the unit. Following shows the procedure for removing the

chamber frost.

Note: For removing the frost, do not use a tool with sharp edge such as a knife or a screw driver.

1. Turn off the back-up system if applicable.

2. Take out and transfer all the contents to another freezer or a container which is refrigerated by liquid

carbon dioxide or dry ice.

3. Turn off the power switch of the freezer.

4. Open the outer door and inner door. Remove the

inner door by lifting up as shown in the figure.

5. Leave the freezer as it is.

6. The water accumulated on the bottom of the

chamber should be wiped up with a dry cloth.

7. After cleaning the chamber and inner door, replace

the inner door and start up the unit according to the

procedure on page 16.

8. Put back the articles into the sufficiently cooled

freezer compartment.

9. Turn on the back-up system if it is provided.

25

Page 28

TROUBLESHOOTING

If the unit malfunctions, check out the following before calling for service.

The chamber is not cooled at all

1. The circuit breaker of power source is active.

2. The voltage is too low. (The status code “--2” is displayed. See page 22.) In this case, call an

electrician.

3. The power switch is not ON.

4. The large amount of articles (load) is stored in the chamber at one time. (The status code “--3” is

displayed. See page 22.)

The cooling is poor

1. The ambient temperature is too high. (The status code “--1” is displayed. See page 22.)

2. The latch of inner door is not closed completely. The outer door is not closed firmly.

(The frost or ice between the cabinet and door gasket possibly prevents door seal.)

3. The air intake vent is blocked.

4. The condenser filter is clogged. Always clean the filter when the filter check lamp is lit.

5. The set temperature is not inputted properly.

6. The freezer is not away from the direct sunlight.

7. There is any heating source near the freezer.

8. A rubber cap and insulation for the access port are not set correctly.

9. You put too many unfrozen articles into the freezer compartment.

Alarm test key cannot actuate the alarm

The alarm is activated only when the power switch is ON.

1. The nickel-metal-hydride battery has been discharged entirely. In this case, operate the freezer for

about 3 hours and depress the alarm test key again. Entirely discharged cell requires about 2 days’

operation of the freezer.

2. When only the buzzer or only the alarm is actuated by the alarm test key, the unactuated part is out of

order, and must be replaced.

Noise

1. The freezer is not installed on the sturdy floor.

2. The freezer is not leveled with the leveling feet.

3. There is anything touching the frame.

4. The freezer is in the status immediately after start up.

The unit sometimes causes a noise when the chamber temperature is high due to the large load. The

noise gets less and less accompanying with the cooling of the chamber.

Back-up test switch does not operate normally (if the back-up system is provided)

1. The liquid carbon dioxide tank is empty.

2. The valve of the carbon dioxide tank is not opened.

3. The ambient temperature is too high. In this case, move the tank to a cool location.

Inquire at liquid carbon dioxide suppliers about its installation, removal, adjustment, and examination.

DISPOSAL OF UNIT

WARNING

If the unit is to be stored unused in an unsupervised area for an extended period ensure that children

do not have access and doors cannot be closed completely.

The disposal of the unit should be accomplished by appropriate personnel. Always remove

doors to prevent accidents such as suffocation.

26

Page 29

RECYCLE OF RECHARGEABLE BATTERY

g p

The unit contains a rechargeable battery. The battery is recyclable. At the end

of it’s useful life, check with you local solid officials option or proper disposal.

1. Location of a nickel-metal-hydride battery

This unit is provided a nickel-metal-hydride battery for the power failure warning device. The battery is

located in the electrical box inside the cover on the lower left side. (Fig. 1)

The high voltage components are enclosed in the electrical box. The cover should be removed

by a qualified engineer or a service personnel only to prevent the electric shock..

2. Removal of nickel-metal-hydride battery

1) Turn off the power switch and disconnect the power supply plug.

2) As shown in the Fig. 2, remove 7 screws fixing the side cover with a screw driver and remove the side

cover..

3) Remove 4 screws fixing the electrical box cover with a screw driver. (Fig. 3)

4) Disconnect the battery connector and remove 2 screws fixing the battery mounting plate. (Fig. 4)

5) Take out the battery.

6) Follow the procedure for recycling or proper disposal.

Electrical box

Electrical box cover

Fig. 1 Fig. 2

Fig. 3 Fig. 4

Side cover

Battery

mountin

late

27

Page 30

SPECIFICATIONS

Name Ultra-Low Temperature Freezer

Model MDF-U32V

External dimensions W670 x D875 x H1860 (mm)

Internal dimensions W490 x D600 x H1140 (mm)

Effective capacity 333 L

Exterior Acrylic finish baked on zinc galvanized steel

Interior Acrylic finish baked on zinc galvanized steel

Outer door Acrylic finish baked on zinc galvanized steel

Inner door ABS resin panel with stainless frame, 2 doors

Shelf Stainless steel, 3 shelves (adjustable)

Access port 17 mm diameter, 2 locations (back, bottom left corner)

Insulation Vacuum insulation panel + Rigid polyurethane foamed-in place (CFC-FREE)

Compressor Hermetic type, Output; 400 W (high stage side), 600W (low stage side)

Evaporator Tube on sheet type

Condenser Fin and tube type (high stage side), Shell and tube type (low stage side)

Refrigerant R-407D (high stage side), R-508 (low stage side)

Temperature controller Microcomputer control system

Temperature display Digital display

Thermal sensor

Alarm High temp. alarm, Low temp. alarm, Power failure alarm

Remote alarm contact Allowable contact capacity: DC 30V, 2A

Battery Nickel-metal-hydride battery, DC6V, 1100mAh, Auto-recharge

Accessories 1 set of key, 1 scraper

Weight 258 kg

Optional component Inventory rack (IR-216U, IR-220U)

Note:

• Design or specifications will be subject to change without notice.

• The battery for power failure alarm is an article for consumption. It is recommended that the battery will be

replaced about every 3 years. Contact Sanyo sales agency at the time of replacement of the battery for recycling.

W464 x D535 (mm), Load; 50 kg/shelf

Platinum resistance (Pt 1000Ω)

Door alarm, Filter check, Battery alarm

3 drawers for lower compartment (MDF-30R)

Automatic temperature recorder (MTR-G85)

Back-up system (CVK-UB2): LCO

2

PERFORMANCE

Cooling performance -86oC at the center of the chamber (ambient temperature; 30oC, no load)

Temperature control range -50oC to -86oC (ambient temperature; 30oC, no load)

Power source 115V, 60Hz 220V, 50Hz 220V, 60Hz 230V, 50Hz 240V, 50Hz

Rated power consumption 780 W 680 W 730 W 670 W 705 W

Noise level 49 dB [A] (background noise; 20 dB)

Maximum pressure 1.9 MPa

Note : The unit with CE mark complies with EC directives 89/336/EEC, 93/68/EEC and 73/23/EEC

28

Page 31

CAUTION

Please fill in this form before servicing.

Hand over this form to the service engineer to keep for his and your safety.

Safety check sheet

1. Refrigerator contents :

Risk of infection:

Risk of toxicity:

Risk from radioactive sources:

(List all potentially hazardous materials that have been stored in this unit.)

Notes :

2.

Contamination of the unit

Unit interior

No contamination

Decontaminated

Contaminated

Others:

3. Instructions for safe repair/maintenance of the unit

a) The unit is safe to work on

b) There is some danger (see below)

Procedure to be adhered to in order to reduce safety risk indicated in b) below.

Date :

Signature :

Address, Division :

Telephone :

□Yes □No

□Yes □No

□Yes □No

□Yes □No

□Yes □No

□Yes □No

□Yes □No

□Yes □No

□Yes □No

□Yes □No

Product name: Model: Serial number: Date of installation:

Ultra-low temperature MDF-U32V

reezer

f

Please decontaminate the unit yourself before calling the service engineer.

29

Page 32

7FB6P10134200

Recycled paper

SANYO Electric Biomedical Co., Ltd.

5-5, Keihan-Hondori 2-Chome

Moriguchi City, Osaka 570-8677 Japan

Printed in Japan

Loading...

Loading...