Page 1

FILE NO.

Service Manual

CONTENTS

CD Portable Radio

Cassette Recorder

MCD-ZX700F

PRODUCT CODE No.

164 081 00

(XE)

Specification ..................................................................... 1

Laser beam safety precaution .......................................... 1

Tuner Adjustment ............................................................. 2

Tape Deck Adjustment ..................................................... 3

IC Block Diagram & Description ....................................... 3,7

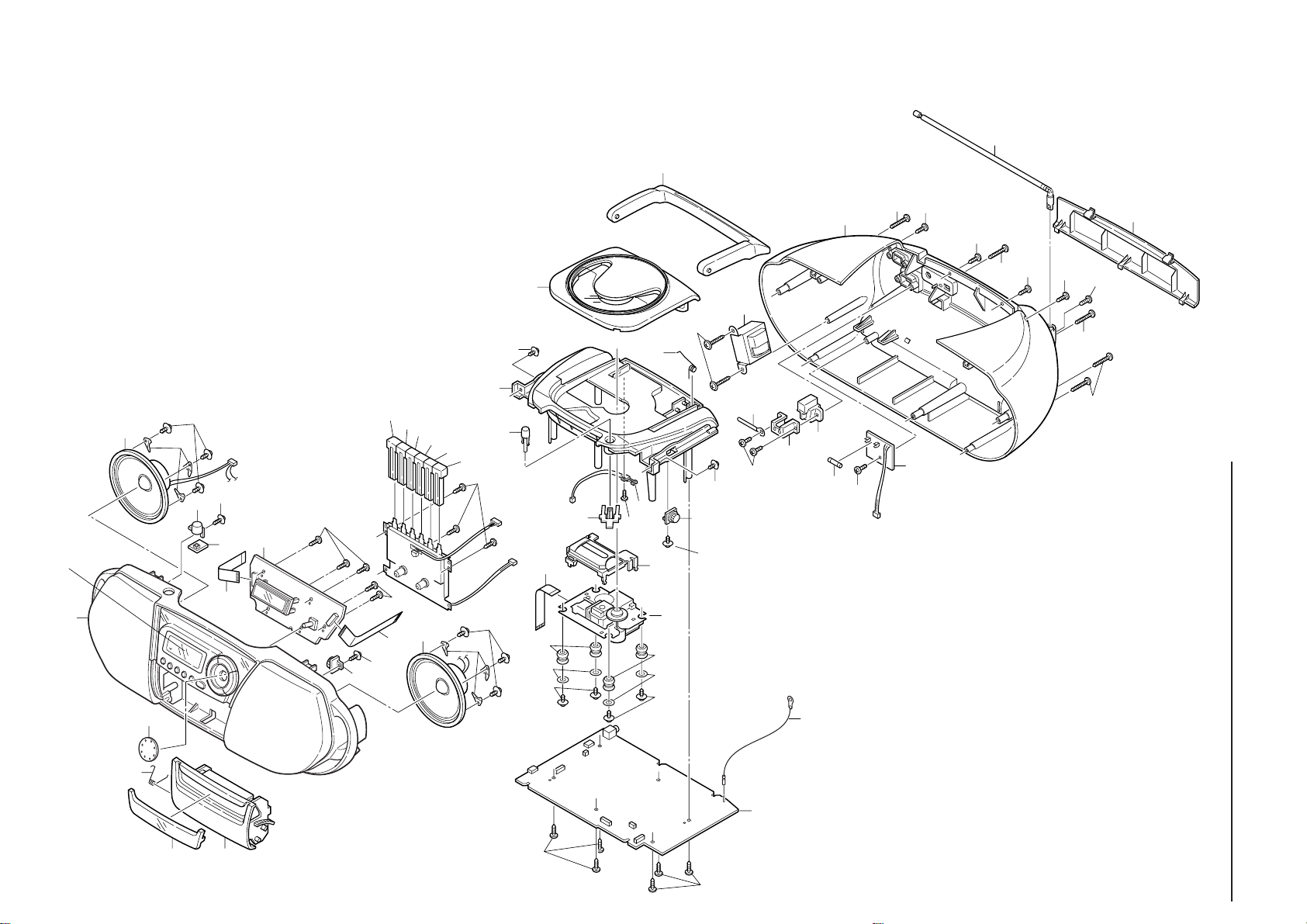

Exploded View (Cabinet & Chassis) ................................ 4

Parts List .......................................................................... 5

Exploded View & Parts List(Tape Deck) ......................... 7

Wiring Connection ............................................................ 11

Schematic Diagram (Micom) ............................................ 12

Schematic Diagram (CD) ................................................. 14

Schematic Diagram (Radio) .............................................16

Schematic Diagram (Audio) ............................................. 18

Wiring Diagram (CD Main/Amp/Tu) ............................... 20

Wiring Diagram (Rectifier, Display, Power) .................... 21

REFERENCE No. SM5810290

Page 2

This file was downloaded and provided FREE OF CHARGE

from the ManualDirectory community.

You can find many free to download Service Manuals & Schematics at

http://www.manualdirectory.co.uk

Page 3

SPECIFICATIONS

CD CHANGER SECTION

Channels .....................................2-channel stereo

Sampling frequency .................... 44.1 kHz

Pick-up ........................................ semiconductor laser

Laser output ................................ 0.6 mW (Continuous wave max.)

Wave length ................................ 790 nm

Wow and Flutter ..........................Below measurable limits

Radio

Reception frequency

FM ...........................................87.5 - 108 MHz (500 kHz step)

AM ........................................... 522 - 1,710 kHz (9 kHz step)

CASSETTE DECK

Track system ............................... 4 - track, 2 - channel stereo

Erasing system ........................... Magnet erase

Tape speed ................................. 4.75 cm/sec

Frequency response ................... 80 - 12,000 Hz

Fast forward and Rewind time .... Approx. 110 sec. (C - 60)

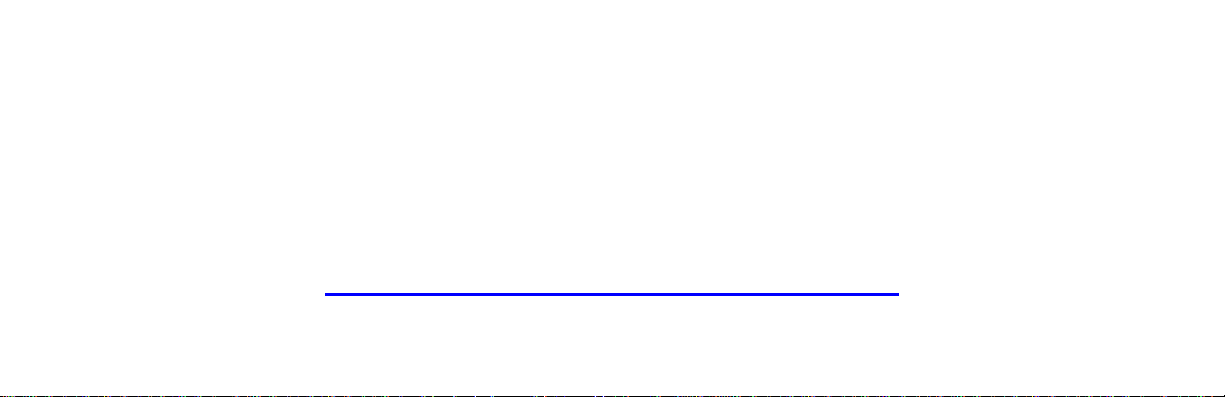

LASER BEAM SAFETY PRECAUTION

• Pickup that emits a laser beam is used on this CD section.

GENERAL SECTION

Output power ..............................3 W/ch (DC max.)

Speaker ....................................... 10 cm X 2

Terminal ...................................... PHONE : 32

Power source .............................. AC : 110 - 120/220 - 240 V , 50/60 Hz

.................................................... DC : 12V, 8 "R20/D" batteries

Dimensions ................................. Approx. 480(W) x 167(H) x 258(D)

mm

Weight (approx.) .........................3.0 kg (without batteries)

Specifications subject to change without notice.

CAUTION :

USE OF CONTROLS OR ADJUSTMENTS OR

PERFORMANCE OF PROCEDURES OTHER

THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

LASER OUTPUT................ 0.6 mW Max. (CW)

WAVE LENGTH ................. 790 nm

CAUTION – INVISIBLE LASER RADIATION WHEN OPEN AND

INTERLOCKS DEFEATED. AVOID EXPOSURE TO BEAM.

ADVARSEL – USYNLIG LASER STRÅLING VED ÅBNING, NÅR

SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION, UNDGÅ UDS ÆTTELSE

FOR STRÅLING.

VARNING – OSYNLIG LASER STRÅLNING NÄR DENNA DEL ÄR ÖPPNAD

OCH SPÄRR ÄR URKOPPLAD. STRÅLEN ÄR FARLIG.

VORSICHT – UNSICHTBARE LASERSTRAHLUNG TRITT AUS, WENN

DECKEL GEÖFFNET UND WENN SICHERHEITSVERRIEGELUNG

ÜBERBRÜCKT IST. NICHT, DEM STRAHL AUSSETZEN.

VARO – AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA

NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

- 1 -

Page 4

TP4

TP3

TP7

CT102

T101

L102

TP1

L101

TP2

TP6 CT101

TP5

TP8

TP9

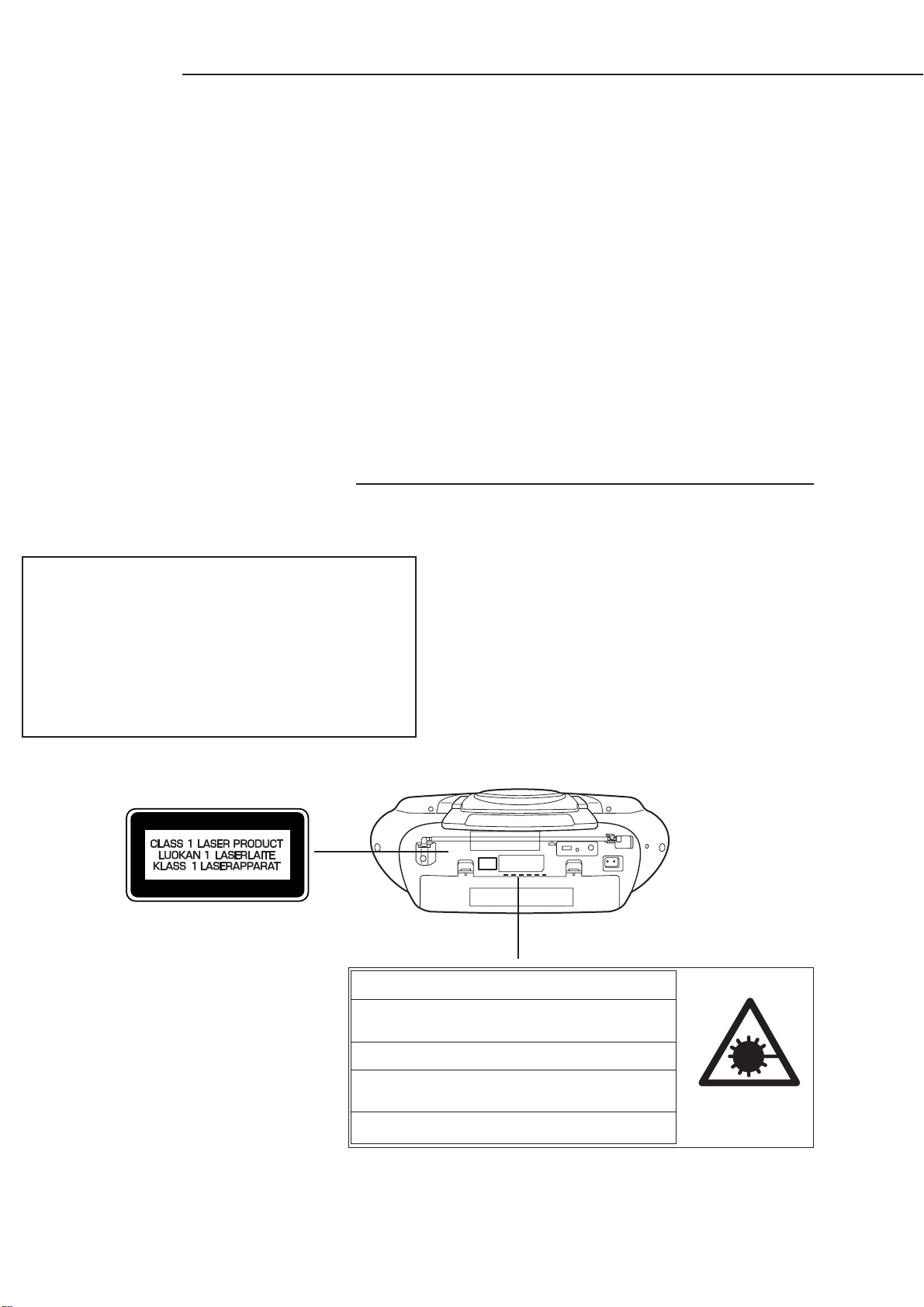

TUNER ADJUSTMENTS

t

• Use a plastic screw driver for adjustments.

• Adjust the intermediate frequency of AM and FM to the frequency of ceramic filter.

• Set of unit

Supply voltage : DC 12V

Speaker : 32

Function switch : RADIO

PARTS LOCATION

1. AM ADJUSTMENT

Step Adjusting Tuning Adjust- VTVM

Input Connection Output Connection

Circuit Frequency Instrument Input Instrument Output ment Oscilloscope

1IF 999 KHz AM sweep Loop ANT. VTVM Speaker T103 Max.

(450 KHz) generator oscilloscope

2 Tuning 522 KHz --- --- Digital TP7(H) T101 1.5V±0.05V

3 coverage 1611 KHz --- --- voltmeter TP2(E) --- 7.4V±0.1V

4 Tracking 603 KHz AM signal Loop ANT. VTVM Speaker AM COIL Max.

5 1404 KHz generator oscilloscope CT102

1. FM ADJUSTMENT BAND SELECT SWITCH : FM FM Dummy Antenna:75Ω unbalance

Step Adjusting Tuning Adjust- VTVM

Input Connection Output Connection

Circuit Frequency Instrument Input Instrument Output ment Oscilloscope

1IF98.0MHz FM sweep TP3(H) VTVM TP5(H) --- Non Adjustmen

10.7NHz generator TP4(E) oscilloscope TP4(E)

2 Tuning 87.5Hz --- --- Digital TP6(H) L102 2.0V±0.1V

3 coverage 108.0MHz --- --- voltmeter TP2(E) --- 7.2V±0.1V

4 Tracking 90.0.MHz FM signal TP1(H) VTVM TP8(H) L101 Max.

5 106.0MHz generator TP2(E) oscilloscope TP9(E) CT103

This is a basic adjustment.

- 2 -

Page 5

TAPE DECK ADJUSTMENTS

1. HEAD REPLACEMENT

• After replacement, demagnetize the heads by using a degausser.

• Be sure to clean the heads before attempting to make any adjustments.

• All wiring should be returned to the original position after work is completed.

2. HEAD AZIMUTH ADJUSTMENT

(1) Load the test tape(VTT-703, etc., 10 kHz) for azimuth

adjustment.

(2) Press the PLAY button.

(3) Use a cross-tip screwdriver to turn the screw for azimuth

adjustment so that the left and right output are maximized.

(4) Press the STOP button.

(5) After completion of the adjustment, use thread lock(TB-1401B)

to secure the azimuth-adjustment screw.

3. AC BIAS FREQUENCY ADJUSTMENT

(1) Connect counter to T201(BS).

(2) R/P switch in recording state.

(3) Adjustment T801 a plastic screw , AC bias frequency : 80 kHz.

4. MOTOR SPEED ADJUSTMENT

(1) Insert the test tape(TCC-119, etc., 3,000 Hz).

(2) Press the PLAY button.

(3) Use a flat-tip screwdriver to turn the SVR(located inside the

rear of the motor) to adjust SVR so that the frequency counter

become 3,000 Hz.

5. CHECKING THE MECHANISM TORQUES AND TENSION

• Clean the head, capstan and pinch roller before making any measurement.

Measurement Take-up torque Back tension Tape tension

Cassette for PLAY : TW-211A PLAY : TW-2111A Drive-power cassete

measurement F.FW/REW : TW-2231 TW-2412

PLAY 30 - 60 gr.cm 2.0 - 4.5 gr.cm 60 gr or more.

F.FWD 55 - 120 gr.cm. ----- -----

REW 55 - 120 gr.cm. ----- -----

This is a basic adjustment.

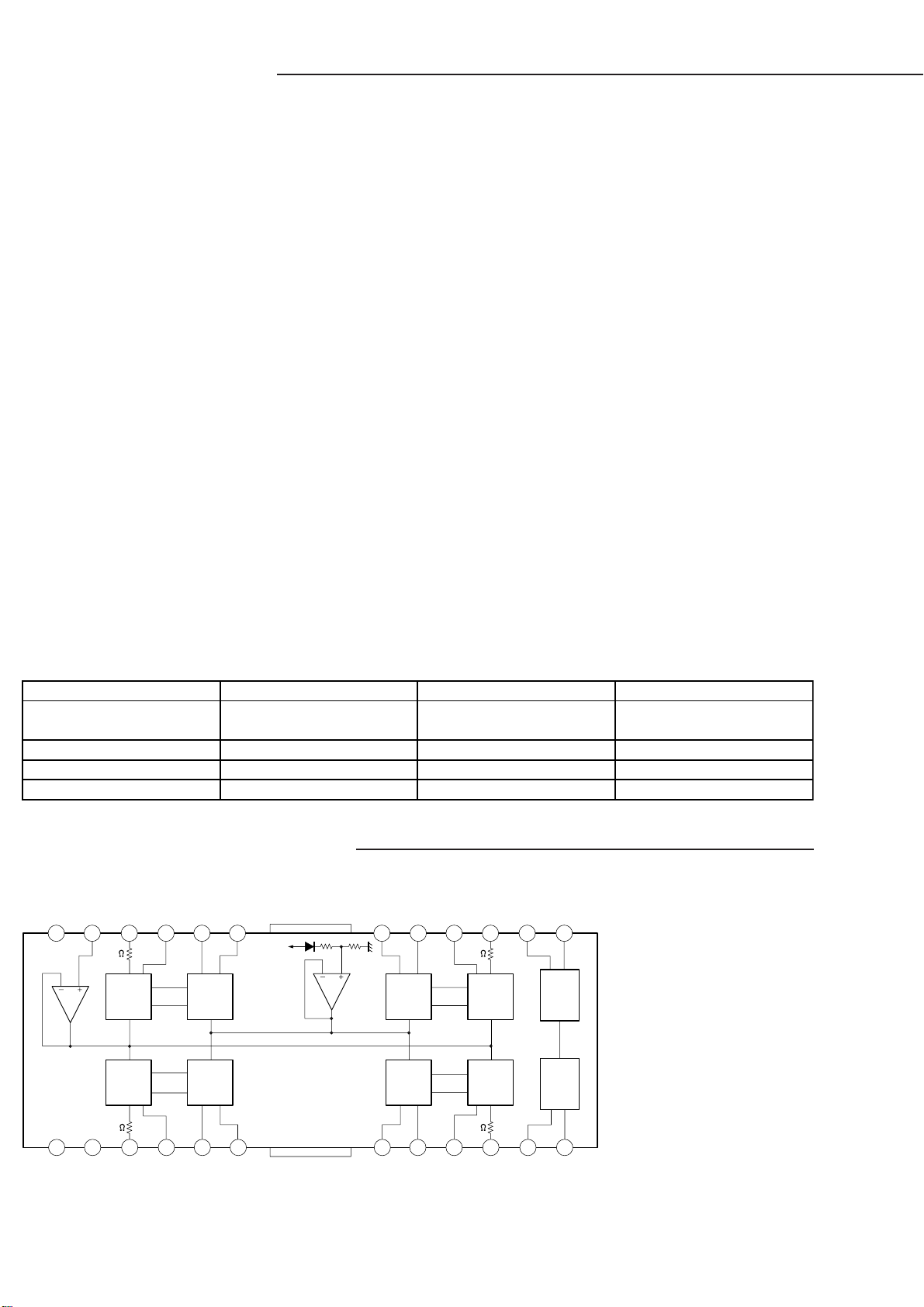

IC BLOCK DIAGRAM & DESCRIPTION

IC903 LA6541D(CD Driver)

Vcc Vref VIN4 VG4 Vo8 Vo7 GND Vo6 Vo5 VG3 VIN3 CD RES

11k

Level

Sift

Level

Sift

BTL

Driver

BTL

Driver

Vcc

BTL

Driver

BTL

Driver

11k

Level

Sift

Level

Sift

131415161718192021222324

RESET

Regulator

11k11k

123456 789

Vcc Mute VIN1 VG1 Vo1 Vo2 GND Vo3 Vo4 VG2 VIN2 Reg OUT Reg IN

10 11 12

- 3 -

Page 6

12

3

7

8

Y01

Y01

Y02

Y04

Y05

Y09

Y09

Y14

Y16

Y17

Y15

Y18

Y18

Y18

60

Y20

Y20

Y18

Y21

Y18

Y18

Y10

Y11

Y11

Y12

Y13

Y13

Y12

Y03

Y03

8

9

51

51

52

53

71

72

15

14

17

18

19

21

23

27

28

29

31

74

56

73

32

33

58

59

57

34

38

32

30

54

55

26

16

11

4

39

40

Y06

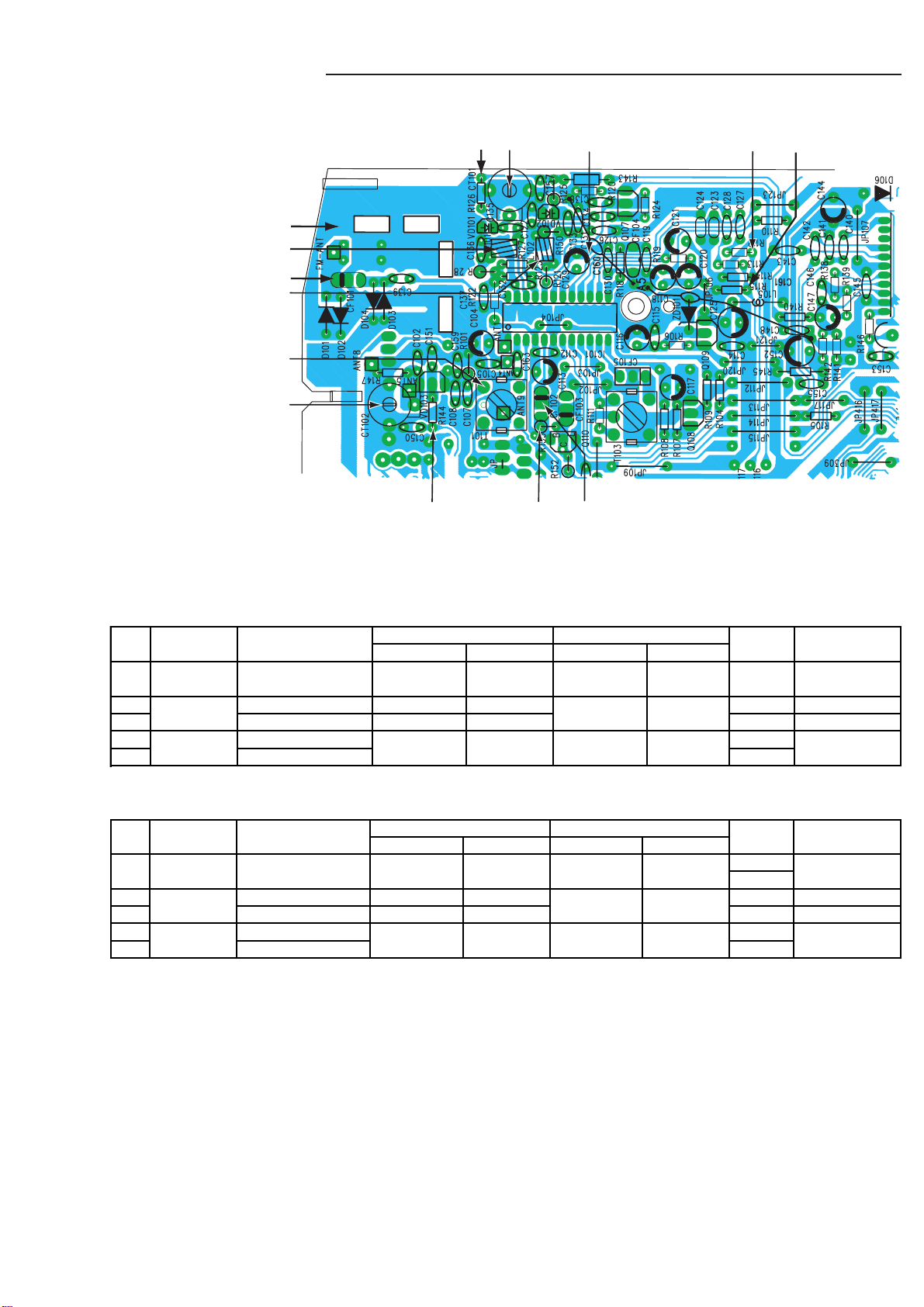

EXPLODED VIEW(CABINET & CHASSIS)

- 4 -

Page 7

PARTS LIST

PRODUCT SAFETY NOTICE

EACH PRECAUTION IN THIS MANUAL SHOULD BE FOLLOWED DURING SERVICING. COMPONENTS IDENTIFIED WITH

!!

!

THE IEC SYMBOL

CAN OF SPECIAL SIGNIFICANCE. WHEN REPLACING A COMPONENT IDENTIFIED , USE ONLY THE REPLACEMENT

PARTS DESIGNATED, OR PARTS WITH THE SAME RATINGS OF RESISTANCE, WATTAGE OR VOLTAGE THAT ARE

DESIGNATED IN THE PARTS LIST IN THIS MANUAL. LEAKAGE-CURRENT OR RESISTANCE MEASUREMENTS MUST

BE MADE TO DETERMINE THAT EXPOSED PARTS ARE ACCEPTABLY INSULATED FROM THE SUPPLY CIRCUIT

BEFORE RETURNING THE PRODUCT TO THE CUSTOMER.

CAUTION : Regular type resistors and capacitors are not listed. To know those values, refer to the schematic diagram.

IN THE PARTS LIST AND THE SCHEMATIC DIAGRAM DESIGNATE COMPONENTS IN WHICH SAFETY

Regular type resistors are less than 1/4W carbon type and 0 ohm chip resistors.

Regular type capacitors are less than 50V and less than 1000µF of Ceramic type and Electrolytic type.

PACKING & ACCESSORIES

REF.NO. PART NO. DESCRIPTION

645 055 7705 INSTRUCTION MANUAL

645 027 2073 POLY BAG,PWR CORD

645 044 1943 POLY BAG,I/B

645 035 1334 POLY BAG PE 18 X 24,UNIT

645 055 7804 POLY FOAM,2 PCS LEFT&RIGHT

645 055 7927 CARTON CASE

645 023 3463 POWER CORD,VDE APP

645 055 6760 REMOTE CTL,RC24-102000-070

CABINET & CHASSIS

REF.NO. PART NO. DESCRIPTION

1 645 055 7620 CASS DOOR LENS

2 645 055 6746 ASSY CASS LID

3 645 055 7798 CASS DOOR SPRING

4 645 055 7484 KNOB ROTARY,VOL

7 645 055 6708 ASSY CABINET

8 645 033 0360 SPK CLIP

9 645 055 7613 KNOB POWER CTL

11 645 033 4252 ASSY,GEAR CASS DOOR

14 645 055 7354 KNOB CASS PAUSE

15 645 055 7361 KNOB CASS STOP/EJECT

16 645 055 7378 KNOB CASS FFWD

17 645 055 7385 KNOB CASS REWIND

18 645 055 7392 KNOB CASS PLAY

19 645 055 7408 KNOB CASS RECORD

21 645 055 7347 HANDLE

23 645 055 6739 ASSY CD LID

26 645 042 0351 CD DOOR SPRING

27 645 055 7552 CD TRAY,TOP PANEL

28 645 055 7576 KNOB CD DOOR,OPEN

29 645 055 7545 CD DOOR LOCK

30 645 042 9378 ASSY GEAR CD DOOR

31 645 042 0375 CD MECHA COVER

32 645 033 3446 RUBBER SILICON

33 645 033 0391 AC SKT COVER

34 645 055 6692 ASSY CABINET REAR

38 645 055 7477 BATTERY LID

39 645 055 7651 FRONT CAB LENS

40 645 054 0776 CD DECK MECHANISM,13933162

FIXING PARTS

REF.NO. PART NO. DESCRIPTION

Y01 645 027 1168 SCR 3X8,SPK

Y02 645 023 6624 SCREW ST 3X10,POWER KNOB

Y03 645 023 6617 SCREW ST 3X10,CD CTL BD

Y04 645 027 1168 SCR 3X8,CASS DOOR GEAR

Y05 645 023 6617 SCREW ST 3X10,CASS DECK

Y06 645 027 1168 SCR 3X8,CD DOOR GEAR

Y10 645 033 4276 SCR 2X6,CD MICRO SW

Y11 645 027 1373 WASHER METAL

Y12 645 033 0247 SCR 2.6X8,CD DECK

Y13 645 023 6594 SCREW ST 3X8,MAIN BD

Y14 645 027 1182 SCR 3X20,X’FORMER

Y15 645 027 1328 SOLDERING SLUG

Y16 645 027 1144 SCR 2.8X12,AC SOCKET

Y17 645 023 6594 SCREW ST 3X8,RECTIFIER BD

Y18 645 027 1199 SCR 3X30,F CAB TO R CAB

REF.NO. PART NO. DESCRIPTION

Y20 645 023 6648 SCREW ST 3X12,

CD TRAY TO F CAB

Y21 645 027 1236 SCR 3X8,RADIO ANT

ELECTRICAL-PARTS

REF.NO. PART NO. DESCRIPTION

51 645 055 6777 SPK 4, SPK

52 645 055 7231 13P FFC CABLE,TO CTL BD CN702

53 645 055 7248 15P FFC CABLE,TO CTL BD CN701

54 645 043 9780 LEAF SW,CD LID SW

55 645 055 7255 16P FFC CABLE,TO CD DECK

56 645 042 0184 HSG 1PIN,FM ANT

57 645 041 9881 PWR TRANS,V3023FS

58 645 032 9760 AC SOCKET S-1-1225,VDE

59 645 055 7149 FUSE GLASS TUBE,FS1101

60 645 041 9928 ROD ANTENNA,2 SECTION

POWER P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

71 614 324 1850 ASSY,PWB POWER(Only initial)

SW711 645 042 0023 SW TACT,POWER ON /OFF

DISPLAY P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

72 614 324 1843 ASSY,PWB DISPLAY(Only initial)

C0709 645 055 6784 GOLD CAP DX-5R5H104

CN701 645 033 3675 FFC HEADER 15PINS

CN702 645 034 8440 FFC HEADER 13PINS

D0701 645 055 6821 DIODE 1N4148

D0703 645 055 6821 DIODE 1N4148

D0708 645 055 6821 DIODE 1N4148

D0709 645 055 6821 DIODE 1N4148

D0710 645 055 6821 DIODE 1N4148

D0711 645 055 6821 DIODE 1N4148

D0713 645 055 6821 DIODE 1N4148

D0715 645 055 6821 DIODE 1N4148

D0716 645 055 6821 DIODE 1N4148

D0717 645 055 6821 DIODE 1N4148

D0720 645 055 6821 DIODE 1N4148

D0721 645 055 6821 DIODE 1N4148

D0722 645 055 6821 DIODE 1N4148

D0726 645 055 6821 DIODE 1N4148

D0727 645 055 6821 DIODE 1N4148

D0729 645 055 6821 DIODE 1N4148

ED701 645 054 0615 LED ROUND TYPE,LED701

IC701 645 055 7040 IC LC587008 1P08

IC702 645 055 6951 IC PST600C

IC703 645 055 6968 IC PST600L

IR701 645 033 3477 DIODE RPM-6938-V4

L0701 645 034 6729 INDUCTOR 100UH

L0702 645 034 6729 INDUCTOR 100UH

LD701 645 055 7071 LCD DISPLAY,LCD701

Q0702 645 055 6890 TR 2SC3400AC

Q0703 645 055 6852 TR DTA114TS

Q0705 645 055 6890 TR 2SC3400AC

Q0706 645 055 6890 TR 2SC3400AC

Q0708 645 055 6890 TR 2SC3400AC

Q0709 645 032 9890 TR KTC-9015C

Q0710 645 055 6890 TR 2SC3400AC

- 5 -

Page 8

PARTS LIST

REF.NO. PART NO. DESCRIPTION

Q0711 645 032 9890 TR KTC-9015C

Q0712 645 055 6890 TR 2SC3400AC

SW701 645 042 0023 SW TACT,TAPE

SW702 645 042 0023 SW TACT,TUN / BAND

SW703 645 042 0023 SW TACT,FM MODE/RANDOM

SW704 645 042 0023 SW TACT,PERSET/REPEAT

SW705 645 042 0023 SW TACT,MEMORY

SW706 645 042 0023 SW TACT,BASS

SW707 645 042 0023 SW TACT,STOP

SW708 645 042 0023 SW TACT,B-SKIP

SW709 645 042 0023 SW TACT,CD /PLAY

SW710 645 042 0023 SW TACT,F-SKIP

VR701 645 055 7309 ROTARY ENCODER

X0701 645 055 7101 RESONATOR 4MHZ

X0702 645 055 7125 CRYSTAL

645 055 7521 DISPLAY BKT

645 055 7538 LED BKT

CD MAIN/AMP/TU P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

73 614 324 1836 ASSY,PWB CD MAIN/AMP/TU

(Only initial)

C0108 645 055 6791 POLY CAP 390PF

C0123 403 057 7501 POLYESTER 0.012U K 50V

C0124 403 057 7501 POLYESTER 0.012U K 50V

C0206 403 056 7908 POLYESTER 1000P K 50V

C0207 403 056 7908 POLYESTER 1000P K 50V

C0212 403 060 8205 POLYESTER 0.033U K 50V

C0213 403 060 8205 POLYESTER 0.033U K 50V

C0218 403 056 7908 POLYESTER 1000P K 50V

C0219 403 056 7908 POLYESTER 1000P K 50V

C0311 403 057 2803 POLYESTER 0.1U K 50V

C0312 403 057 2803 POLYESTER 0.1U K 50V

C0513 403 060 0506 POLYESTER 2700P K 50V

C0514 403 060 0506 POLYESTER 2700P K 50V

C0801 403 059 5901 POLYESTER 0.022U K 50V

C0802 403 057 0403 POLYESTER 0.01U K 50V

C0804 403 059 3600 POLYESTER 2200P K 50V

C0901 403 057 2803 POLYESTER 0.1U K 50V

C0902 403 060 8205 POLYESTER 0.033U K 50V

C0905 403 060 6102 POLYESTER 3300P K 50V

C0906 403 062 0306 POLYESTER 0.047U K 50V

C0907 403 058 5209 POLYESTER 0.15U K 50V

C0910 403 056 7908 POLYESTER 1000P K 50V

C0911 403 057 2803 POLYESTER 0.1U K 50V

C0912 403 058 3205 POLYESTER 0.015U K 50V

C0913 403 058 9900 POLYESTER 0.018U K 50V

C0920 403 059 3600 POLYESTER 2200P K 50V

C0923 403 060 8205 POLYESTER 0.033U K 50V

C0944 403 057 2803 POLYESTER 0.1U K 50V

C0970 403 058 5209 POLYESTER 0.15U K 50V

CF101 645 055 6937 BAND PASS FILTER

CF102 645 055 6913 CERAMIC FILTER

CF103 645 055 6913 CERAMIC FILTER

CF104 645 055 6906 CERAMIC FILTER

CF105 645 055 6920 CERAMIC FILTER

CN101 645 042 0177 FFC HEADER 15PINS

CN201 645 055 7170 5P HEADER

CN301 645 027 3803 WAFER 4P

CN401 645 027 3803 WAFER 4P

CN403 645 032 9982 HEADER 3PINS

CN901 645 055 7163 16P FFC HEADER

CN903 645 034 6781 FFC HEADER 13PINS

CN904 645 034 6798 HEADER 2PINS

CT101 645 023 6310 TRIMMER 10PF

CT102 645 023 6310 TRIMMER 10PF

D0101 645 055 6821 DIODE 1N4148

D0102 645 055 6821 DIODE 1N4148

D0103 645 055 6821 DIODE 1N4148

D0104 645 055 6821 DIODE 1N4148

D0105 645 055 6821 DIODE 1N4148

D0106 645 055 6821 DIODE 1N4148

D0301 645 055 6821 DIODE 1N4148

D0302 645 055 6821 DIODE 1N4148

REF.NO. PART NO. DESCRIPTION

D0303 645 023 6112 RECTIFIER 1N-4001

D0304 645 055 6821 DIODE 1N4148

D0305 645 055 6821 DIODE 1N4148

D0306 645 055 6821 DIODE 1N4148

D0307 645 055 6821 DIODE 1N4148

D0308 645 055 6821 DIODE 1N4148

D0309 645 055 6821 DIODE 1N4148

D0310 645 055 6821 DIODE 1N4148

D0311 645 055 6821 DIODE 1N4148

D0312 645 055 6821 DIODE 1N4148

D0313 645 055 6821 DIODE 1N4148

D0402 645 055 6821 DIODE 1N4148

D0901 645 055 6821 DIODE 1N4148

D0902 645 055 6821 DIODE 1N4148

IC101 645 055 6975 IC LA1823ESIA

IC102 645 055 7019 IC LC72131

IC201 645 055 6999 IC TA8142AP

IC301 645 032 9920 IC LA-4227

IC401 645 055 6982 IC KIA7808P

IC402 645 055 7033 IC S81256SGYX

IC501 645 055 7026 IC LC75342

IC901 645 055 7002 IC LA9241M

IC902 645 033 4740 IC LC78622E

IC903 645 033 4702 IC LA6541D

JK301 645 033 3743 EARPHONE JACK

L0101 645 049 9913 FM COIL 4.5T

L0102 645 027 0345 VHF COIL

L0105 645 027 0352 CHOKE COIL 100UH

L0301 645 044 1721 FERRITE BEAD

L0302 645 044 1721 FERRITE BEAD

L0303 645 044 1721 FERRITE BEAD

L0501 645 034 7177 INDUCTOR 1000UH

L0901 645 042 0108 CHOKE COIL 26UH

Q0107 645 034 6866 TR 2SC2839E

Q0108 645 034 7078 TR 2SC3330U

Q0109 645 027 0420 TR 8050C

Q0110 645 055 6876 TR 9018F

Q0301 645 033 3538 TR 2SD1936S AC

Q0302 645 033 3538 TR 2SD1936S AC

Q0303 645 023 6129 TR 9014C

Q0304 645 023 6129 TR 9014C

Q0305 645 023 6129 TR 9014C

Q0401 645 055 6883 TR KSA928A

Q0402 645 023 6129 TR 9014C

Q0403 645 055 6869 TR 8550B C

Q0404 645 023 6129 TR 9014C

Q0405 645 027 0420 TR 8050C

Q0407 645 055 6869 TR 8550B C

Q0408 645 023 6129 TR 9014C

Q0409 645 027 0420 TR 8050C

Q0801 645 027 0420 TR 8050C

Q0803 645 023 6129 TR 9014C

Q0901 645 033 3538 TR 2SD1936S AC

Q0902 645 033 3538 TR 2SD1936S AC

Q0903 645 033 3538 TR 2SD1936S AC

Q0904 645 033 3538 TR 2SD1936S AC

Q0905 645 033 3521 TR 2SA1317S AC

Q0907 645 033 3514 TR 2SB764D

Q0908 645 041 9959 TR 2SA1346AC

Q0909 645 033 3538 TR 2SD1936S AC

Q0910 645 033 3538 TR 2SD1936S AC

R0329 402 071 1304 FUSIBLE RES 2.2 JA 1/4W

SW100 645 055 7064 SW TACT,RESET

SW201 645 023 6327 SW RECORDING PS62D01-S,SH

T0101 645 055 6944 IFT,OSC 1A612R

T0103 645 033 3866 AM COIL,IF 2070

T0801 645 027 0307 BIAS COIL,IFT 3630

VD101 645 055 6807 DIODE SVC201

VD102 645 055 6807 DIODE SVC201

VD103 645 055 6814 DIODE SVC348

X0101 645 055 7118 CRYSTAL

X0901 645 052 4837 RESONATOR 16.934MHZ

ZD101 645 055 6838 ZENER 5.6V

ZD401 645 055 6845 ZENER 13V

- 6 -

Page 9

PARTS LIST

REF.NO. PART NO. DESCRIPTION

645 051 6474 FERRITE BEAD,

PRI OF X’FORMER TO AC SK

645 055 7095 FERRITE BEAD,CN401 TO CN1101

645 055 7200 HSG 4P,CN401 TO CN1101

645 042 0184 HSG 1PIN,FM ANT

645 042 0337 HEAT SINK

645 055 6685 ASSY BAR ANT

EXPLODED VIEW & PARTS LIST(TAPE DECK)

TM01

TM03

TM02

RECTIFIER P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

74 614 324 1867 ASSY,PWB RECTIFIER(Only initial)

D1101 645 023 6112 RECTIFIER 1N-4001

D1102 645 023 6112 RECTIFIER 1N-4001

D1103 645 023 6112 RECTIFIER 1N-4001

D1104 645 023 6112 RECTIFIER 1N-4001

D1105 645 055 6821 DIODE 1N4148

F1101 645 055 7149 FUSE GLASS TUBE,FS1101

645 035 0511 FUSE HOLDER MW1010K

645 042 0320 HEAT SINK

645 027 1397 NUT,HEAT SINK

TAPE DECK MECHANISM PARTS LIST

REF.NO. PART NO. DESCRIPTION

645 050 1814 CASS DECK MECHANISM

TM01 645 018 0637 R/P HEAD

TM02 645 050 1401 PINCH ROLLER

TM03 645 030 6839 E HEAD

TM04 645 050 1395 RF BELT

TM05 645 050 1784 MAIN BELT

TM06 645 050 2101 ASSY,MOTOR

TM04

TM05

TM06

IC BLOCK DIAGRAM & DESCRIPTION

IC101 LC72131(PLL)

IC402 S-81256G(Voltage Regulator)

IN

V

V

OUT

23

REFERENCE

GND

VOLTAGE

1

- 7 -

Page 10

IC BLOCK DIAGRAM & DESCRIPTION

IC902 LC78622E(Degital Signal Processor)

DEFI

EFMIN

FSEQ

CLV+

CLV-

V/P

PW

SBCK

SBSY

SFSY

WRQ

SQOUT

CQCK

COIN

RWC

1

10

22

12

13

14

49

51

47

50

63

CS

53

55

57

56

54

EFMO VVDDVVSSPDO ISET FR PCK TAI

9

Slice level

Control

Syncrnous Detect

EFM Demodulation

CLV

Digital Servo

Subcode Dxract

QCRC

COM

Inter Fase

Servo Commander

4

6

VCO Clock Oscillator

& Clock Control

General Ports

357 2

TEST2 TEST4

TST11

TEST1 TEST3 TEST5

21

59 64 11 32 33 62

2K,8bit

RAM

C1 C2 Error Detect &

Correct Control Flag

X’tal Root

Timing Generator

VDDV

SS

23

8

RAM Address

Generatorl

Interpolalation Mute

Billingual

Digital Attenuator

Quadruple Over Sampling

Digital Filter

1bit DAC

L.P.F

Digital Out

C2F

30

31

DOUT

(NC)

34

15 16 17 20 19 58 18 24 25 26 27 28 29 48 60 61 46 52 45 44 43 39 41 42 40 37 35 38 36

IC301 LA4227(Power Amp)

THERMAL

SHUT DOWN

PROTECTION

BS2 NF2

BS1

101112

3

Ch1

Ch2

-

+

+

-

VCC

STANDBY

1

STANDBY

OUT1

SW

2

OUT2

RV

DD

SS

MUTER

RCHO

RESJP+JP-TOFFTESHFL

CONT2

CONT4

CONT3

CONT1

TGL

4.2M16MEFLGEMPHCONT5

XV

SS

XOUT

RV

XV

DD

XINFSX

DD

MUTELLCHO

LV

LV

SS

IC501 LC75342(2 Band Equalizer)

NF1

9

4

PRE GND

IN1

BIAS

CIRCUIT

5

IN2 DC

(FILTER)

78

L4

11

L3

12

L2

13

L1

14

NC

15

NC

6

16

R1

17

R2

18

R3

19

R4

20

LSELO LIN LTRE LBASS1 LBASS2 LOUT

10 9 7 6 58

CONTROL

CIRCUIT

LOGIC

CIRCUIT

CONTROL

CIRCUIT

LVre f

CCB

INTERFACE

RVref

4

TEST

3

SS

V

2

CE

1

DI

30

CL

29

DD

V

28

Vref

27

NC

- 8 -

21 22 24 25 2623

RSELO RIN RTRE RBASS1 RBASS2 ROUT

Page 11

IC BLOCK DIAGRAM & DESCRIPTION

i

s

u

u

o

n

IC902 LC78622E(Degital Signal Processor)

Terminal

No.

Terminal

symbols

1 DEFI I

2 TAI I Input terminal for test. Pull-down resistor incorporated. Make sure to ground.

3 PDO OOutput terminal for phase-comparator for external VCO control.

4 VVSS - For PLL Ground terminal for internal VCO. Make sure to ground.

5ISET AI Resistive connection terminal for current regulation of PDO output.

6 VVDD - Power terminal for internal VCO.

7FRAI For VCO frequency range control.

8 VSS -

9 EFMO O Output terminal for EFM signals.

10 EFMIN I Input terminal for EFM signals.

11 TEST2 I

12 CLV+ O

13 CLV- O

14 V/*P O

15 HFL I

16 TEST2 I

17 TOFF O

18 TGL O

19 JP+ O

20 JP- O

21 PCK O

22 FSEQ O

23 VDD -

24 CONT1 I/O

25 CONT2 I/O

26 CONT3 I/O

27 CONT4 I/O

28 CONT5 I/O

EMPH/

29

CONT6

30 C2F O

31 DOUT O

32 TEST3 I

33 TEST4 I

34 PCCL I

MUTEL/C

35

ONT7

36 LVDD -

37 LCHO O

38 LVSS -

39 RVSS -

40 RCHO O

41 RVDD -

MUTER/C

42

ONT8

I/O

Input terminal for defect detection signals (DEF). (Ground when not used.)

Ground terminal for digital signals. Make sure to ground.

For slice level

control

Input terminal for test. Pull-down resistor incorporated. Make sure to ground.

Output for disk motor control. 3 values can be output by a command.

Output terminal for automatic switching monitor between rough servo and phase control. (Rough servo on "H"positi

phase servo on "L".

Input terminal for track detection signals. Schmitt input.

Input terminal for tracking error signals. Schmitt input.

Output terminal for tracking-off.

Output terminal for tracking gain switching. "L" position increases gain.

Output for track jump control. 3 values can be output by a command.

Terminal for clock monitor for EFM data reproduction. 4.3218 MHz when phase locked.

Output terminal for synchronizing signal detection. "H" position when the synchronizing signals detected in EFM sig

match with the synchronizing signals generated internally.

Power terminal for digital signals.

Generalized I/O terminal 1

Generalized I/O terminal 2

Generalized I/O terminal 3

Generalized I/O terminal 4

Generalized I/O terminal 5

Terminal for de-emphasis monitor. De-emphais disk is being reproduced while in the "H" position. Or generalized O

O

terminal 6.

Output terminal for C2 flag.

Output terminal for digital OUT. (EIAJ format)

Input terminal for test. Pull-down resistor incorporated. Make sure to ground.

Input terminal for test. Pull-down resistor incorporated. Make sure to ground.

Generalized I/O terminal for command identification. Pull-down resistor incorporated. When used as the same funct

as LC78622E, open circuit or ground. ("H" position: enables only generalized I/O command to be controlled. "L" po

enables all the commands to be controlled.)

O

L channel

1-bit DAC

R channel

1-bit DAC

O

Mute output terminal for L channel. Or generalized output terminal 7.

Power terminal for L channel.

Output terminal for L channel.

Ground terminal for L channel. Make sure to ground.

Ground terminal for R channel. Make sure to ground.

Output terminal for R channel.

Power terminal for R channel.

Mute output terminal for R channel. Or generalized output terminal 8.

Controlled by a serial data command from micro-computer. When not used, either

as input terminal and then ground or use as output terminal and then open circuit.

DESCRIPTION

- 9 -

Page 12

IC BLOCK DIAGRAM & DESCRIPTION

IC902 LC78622E(Degital Signal Processor)

Terminal

No.

Terminal

symbols

43 XVDD

44 XOUT

45 XIN

46 XVSS

47 SBSY

48 EFLG

49 PW

50 SFSY

51 SBCK

52 FSX

53 WRQ

54 RWC

55 SQOUT

56 COIN

57 *CQCK I

58 *RES

59 TST11

60 16M

61 4.2M

62 TEST5

63 *CS

64 TEST1

I/O

-

Power terminal for crystal oscillator

O

Joining terminal for crystal resonator (16.9344 MHz)

I

-

Ground terminal for crystal oscillator. Make sure to ground.

O

Output terminal for synchronizing signals of sub-code clock.

O

Monitor terminal for 1 bit or 2 bit error correction

O

Output terminal for sub-code P, Q, R, S, T, U or W.

O

Output terminal for synchronizing signals of sub-code frame. When sub-code is stood by, falls.

I

Input terminal for clock to read out sub-code. Schmitt input (when not used, make sure to ground.)

O

Output terminal for synchronizing signal (7.35 kHz) which is divided from crystal oscillator.

O

Output terminal for Q output standby of sub-code.

I

Input terminal for read/write control. Schmitt input.

O

Output terminal for Q output of sub-code.

I

Input terminal for command from micro-computer.

DESCRIPTION

Input terminal either for clock to take in command input or for clock to take out sub-code from SQOUT. Schmitt inpu

I

Input terminal for reseting this LSI. Switches to "L" position for a moment at power-on.

O

Output terminal for test. Make sure to open circuit. (Normally "L" output)

O

Output terminal of 16.9344 MHz

O

Output terminal of 4.2336 MHz

I

Input terminal for test. Pull-down resistor incorporated. Make sure to ground.

I

Input terminal for chip selecting. Pull-down resistor incorporated. Make sure to ground when not controlled.

I

Input terminal for test. No pull-down resistor. Make sure to ground.

Note: Each power terminal (VDD, VVDD, LVDD, RVDD and XVDD) must be supplyed with the same voltage.

IC901 LA9241M(Servo Signal Processor)

FSS

DRF CE

Vcc1 LDS LDD BH1 PH1 LF2 VR REF1 Vcc2

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

FE-FE

AGND

SP

REF

MICOM

INTER FACE

SPINDLE SERVO

APC

FIN2

1

2

FIN1

I/V

3

E

4

F

5

TB

6

TE-

7

TE

8

TESI

9

SCI

10

TH

11

TA

12

TD-

13

TD

14

JP

15

TO

16

FD

BAL

TE

T.SERVO & T.LOGICK

RF DET

VCA

VCA

F.SERVO & F.LOGICK

FA-FAFD-

DAT CL CLK DEF

SLED SERVO

SLC

RF Amp

48

NC

TBC

47

46

FSC

DGND

45

SLI

44

43

SLC

RFS-

42

RFSM

41

CV+

40

CV-

39

SLOF

38

HFL

37

TES

36

TOFF

35

TGL

34

33

JP+

32313029282726252423222120191817

JP-SL+SL-SLDSLEQSPDSP-SPGSPI

- 10 -

Page 13

WIRING CONNECTION

AC IN

BROWN

CD SWITCH

P. T

YELLOW

YELLOW

AC1

AC2

ORANGE

BROWN

DC+12V

DC+

FS1101

T1.6A L

250V

DC-12V

RECTIFIER

P. W. B

CN401

RED

CN1101

(3P)

(3P)

JK301

BATTERY

DC12V

CN902

(6P)

BLACK

PICKUP

(16P)

(6P)

CD MECHANISM

FM ROD

ANT.

CN702

(13P)

P701

BLACKRED

CN703

(2P)

WHITE

P702

POWER

P. W. B

DISPLAY P.W.B

BLACK

CN301

(4P)

CN904

(2P)

CN903

(13P)

CN901

(16P)

YELLOW

CN701

(15P)

BLACK

CD MAIN AMP/TU P.W.B

CN403

CN201

(5P)

(3P)

CN101

(15P)

TAPE DECK

MECHANISUM

R/P HEAD

MOTOR

SWITCH

ORANGE

RED

L-CH SPEAKER R-CH SPEAKER

- 11 -

M

BLACK

RED

Page 14

SCHEMATIC DIAGRAM(DISPLAY)

This is a basic schematic diagram.

- 13 -- 12 -

Page 15

SCHEMATIC DIAGRAM(CD)

This is a basic schematic diagram.

- 15 -- 14 -

Page 16

SCHEMATIC DIAGRAM(TUNER)

This is a basic schematic diagram.

- 17 -- 16 -

Page 17

SCHEMATIC DIAGRAM(MAIN)

This is a basic schematic diagram.

PRODUCT SAFETY NOTICE

Each precaution in this manual should be followed during servicing. Components identified with the IEC symbol

in the parts list and the schematic diagram designated components in which safety can be of special significance.

!!

!

When replacing a component identified by

same ratings of resistance, wattage or voltage that are designated in the parts list in this manual. Leakagecurrent or resistance measurements must be made to determine that exposed parts are acceptably insulated

from the supply circuit before returning the product to the customer.

!!

!

, use only the replacement parts designated, or parts with the

- 19 -- 18 -

Page 18

WIRING DIAGRAM (CD MAIN/AMP/TU)

CD MAIN/AMP/TU

- 20 -

Page 19

WIRING DIAGRAM RECTIFIER , DISPLAY , POWER)

DISPLAY

POWER

May./ '02 BB Printed in Japan

RECTIFIER

SANYO Technosound Co., Ltd.

Osaka, Japan

- 21 -

Loading...

Loading...