Page 1

SERVICE MANUAL

32D1850A/3MT56T2

1. Caution…………………………………………………………………………

2. specification……………………………………………………………………

3. Alignment Procedure…………………………………………………………

4.Scheme Diagram ……………………………………………………………

5. Troubleshooting………………………………………………………………

6. Explode drawing................................................................................................

This manual is the latest at the time of printing, and does not

include the modification which may be made after the printing, by

the constant improvement of product

Page 2

RISK OF

ELECTRIC

SHOCK DO

NOT

OPEN.

SCHNEIDER ELECTRONICS GMBH-GERMANY

1. CAUTION

CAUTION:

Use of controls, adjustments or procedures other than those specified herein may result in

hazardous radiation exposure.

CA UTION : TO RE DUCE THE RIS K OF

CA U T IO N

RISK

SHOCK

The lighting flash with arrowhead symbol, with an equilateral triangle is intended to

alert the user to the presence of uninsulated voltage within the product s

enclosure that may be of sufficient magnitude to constitute a risk of electric shock to

the person.

The exclamation point within an equilateral triangle is intended to alert the user to the

presence of important operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

ELECTRI

NOT

OPEN.

ELECTR ICAL SH OCK, DO NOT REMOVE

COVER (OR BACK). NO USER SERVICEABLE

PAR TS INS IDE . RE FER SER VIC ING TO

QUALIFIE D SERVIC E PERS ONNEL .

dangerous

WARNING: TO REDUCE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT

EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

2

Page 3

SCHNEIDER ELECTRONICS GMBH-GERMANY

IMPORTANT SAFETY INSTRUCTIONS

CAUTION:

Read all of these instructions. Sa ve these instructions for later use . Follo w all Warnings and

Instructions marked on the audio equipment.

1. Read Instructions-All the safety and operating instructionsshouldbe read before the productis operated.

2. Retain Instructions- The safety and operating instructions should be retained for future reference.

3. Heed Warnings- All warnings on the product and in the operating instructions should be adhered to.

4. Follow Instructions- All operating and use instructions should be followed.

FOR YOUR PERSONAL SAFETY

1. When the power cord or plugis damaged or frayed, unplug this television set from the wall outlet and refer servicing to

qualified service personnel.

2. Do not overload wall outlets and extension cords as this can result in fire or electric shock.

3. Do not allow anything to rest on or roll over the power cord, and do not place the TV where power cord is subject to

traffic or abuse. This may result in a shock or fire hazard.

4. Do not attempt to service this television set yourself as opening or removing covers may expose you to dangerous

voltage or other hazards. Refer all servicing to qualified service personnel.

5. Never push objects of any kind into this television set through cabinet slots as they may touch dangerous voltage

points or short out parts that could result in a fire or electric shock. Never spill liquid of any kind on the television set.

6. If the television set has been dropped or the cabinet has been damaged, unplug this television set from the wall outlet

and refer servicing to qualified service personnel.

7. If liquid has been spilled into the television set, unplug this television set from the wall outlet and refer servicing to

qualified service personnel.

8. Do not subject your television set to impact of any kind. Be particularly careful not to damage the picture tube surface.

9. Unplug this television set from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use a

damp cloth for cleaning.

10.1. Do not place this television set on an unstable cart, stand, or table. The television set may fall, causing serious injury

to a child or an adult, and serious damage to the appliance. Use only with a car t or stand recommended by the

manufacturer, or sold with the television set. Wall or shelf mounting should follow the manufacturer s instructions, and

should use a mounting kit approved by the manufacturer.

10.2. An appliance and cart combination should be moved with care. Quick stops, excessive force, and uneven surfaces

may cause the appliance and cart combination to overturn.

3

3

Page 4

SCHNEIDER ELECTRONICS GMBH-GERMANY

PROTECTION AND LOCATION OF YOUR SET

11. Do not use this television set near water ... for example, near a bathtub, washbowl, kitchen sink, or laundry tub, in a

wet basement, or near a swimming pool, etc.

Never expose the set to rain or water. If the set has been exposed to rain or water, unplug the set from the wall

outlet and refer servicing to qualified service personnel.

12. Choose a place where light (artificial or sunlight) does not shine directly on the screen.

13. Avoid dusty places, since piling up of dust inside TV chassis may cause failure of the set when high humidity persists.

14. The set has slots, or openings in the cabinet for ventilation purposes, to provide reliable operation of the receiver, to

protect it from overheating. These openings must not be blocked or covered.

Never cover the slots or openings with cloth or other material.

Never block the bottom ventilation slots of the set by placing it on a bed, sofa, rug, etc.

Never place the set near or over a radiator or heat register.

Never place the set in enclosure, unless proper ventilation is provided.

a built-in

PROTECTION AND LOCATION OF YOUR SET

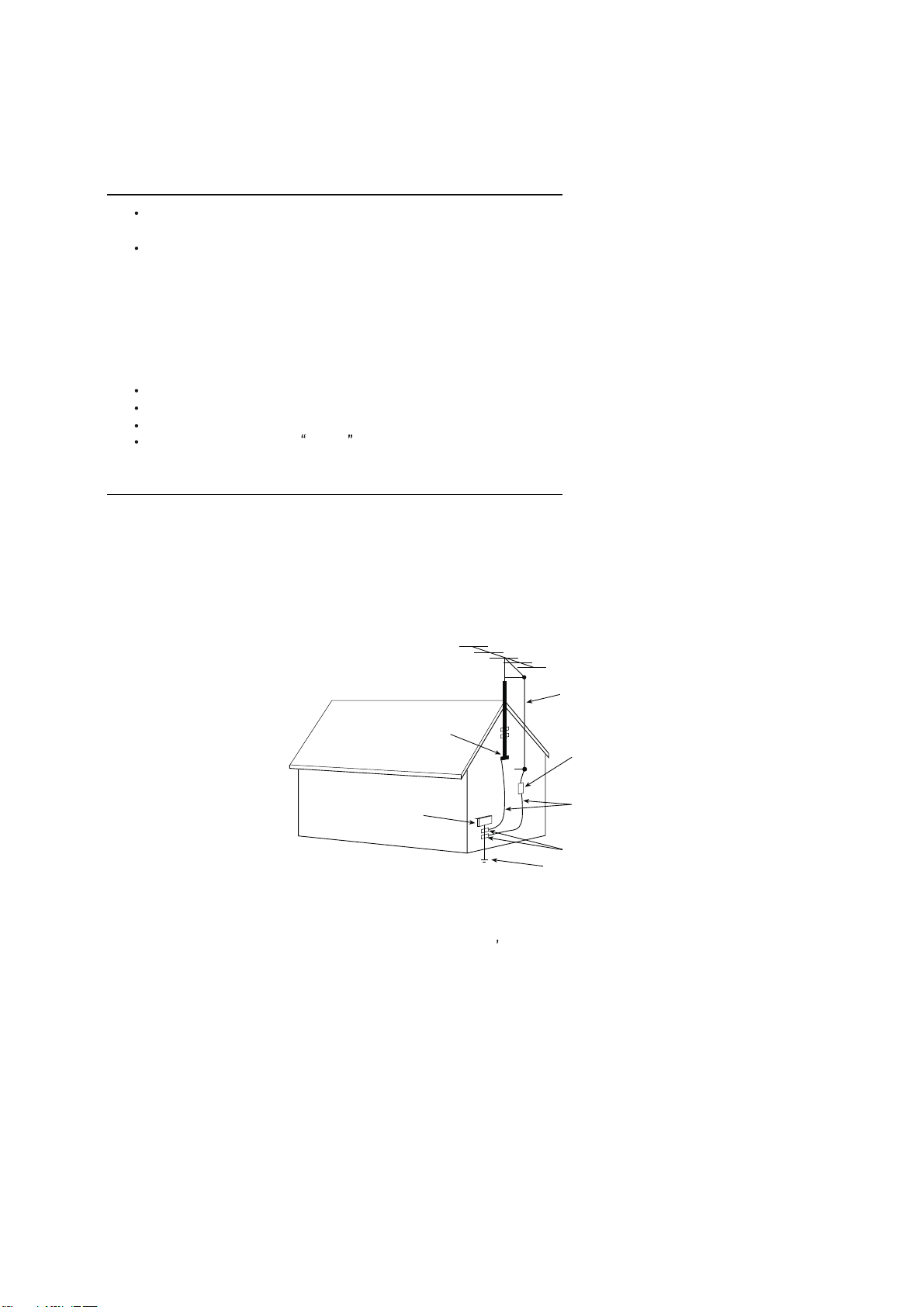

15.1. If an outside antenna is connected to the television set, be sure the antenna system is grounded so as to provide some

protection against voltage surges and built up static charges, Section 810 of the National Electrical Code, NFPA No.

70-1975, provides information with respect to proper grounding of the mast and supportingstructure, grounding of the

lead-in wire to an antenna discharge unit, size of grounding conductors, location of antenna discharge unit, connection

to grounding electrode, and requirements for the grounding electrode.

EXAMPLE OF ANTENNA GROUNDING AS PER NATIONAL ELECTRICAL CODE INSTRUCTIONS

EXAMPLE OF ANTENNA GROUNDING AS PER

NATIONAL ELECTRICAL CODE

ANTENNA

LEAD- IN WIRE

GROUND CLAMP

ELECTRIC SERVICE

EQUIPMENT

NEC-NATIONAL ELECTRICAL CODE

ANTENNA DISCHARGE

UNIT (NEC SECTION

810-20)

GROUNDING

CONDUCTORS

(NECSECTION 810-21)

GROUND CLAMPS

POWER SER VICE GROUNDING

ELECTRODE SYSTEM

(NEC ART 250. PART H)

15.2. Note to CATV system installer : (Only for the television set with CATV reception)

This reminder is provided to call the CATV system attention to Ar ticle 820-40 of the NEC that provides

installer s

guidelines for proper grounding and, in particular, specifies that the cable ground shall be connected to the grounding

system of the building, as close to the point of cable entry as practical.

16. An outside antenna system should not be located in the vicinity of overhead power lines or other electric lights or power

circuits, or where it can fall into such power lines or circuits. When installing an outside antenna system, extreme care

should be taken to keep from touching such power lines or circuits as contact with them might be fatal.

17. For added protection for this television set during a lightning storm, or when it is left unattended and unused for long

periods of time, unplug it from the wall outlet and disconnect the antenna. This will prevent damage due to lightning

and power-line surges.

4

4

Page 5

SCHNEIDER ELECTRONICS GMBH-GERMANY

OPERATION OF YOUR SET

18.

This television set should be operated only from the type of power source indicated on the marking label.If you are not

sure of the type of power supply at your home, consult your television dealer or local power company. For television

sets designed to operate from battery power, refer to the operating instructions.

19. If the television set does not operate normally by following the operating instructions, unplug this television set from the

wall outlet and refer servicingto qualifiedservice person nel. Adjust only those controls that are covered in the operating

instructions as improper adjustment of other controls may result in damage and will often require extensive work by a

qualified technician to restore the television set to normal operation.

20. When going on a holiday : If your television set is to remain unused for a period of time, for instance, when you go on

a holiday, turn the television set and unplug the television set from the wall outlet.

off

IF THE SET DOES NOT OPERATE PROPERLY

21. If you are unable to restorenormal operation by followingthe detailedprocedurein your operatinginstructions,

do not attempt any further adjustment. Unplug the set and call your dealer or service technician.

22. Whenever the television set is damaged or fails, or a distinct change in performance indicates a need for

service, unplug the set and have it checked by a professional service technician.

23. It is normal for some TV sets to make occasional snapping or popping sounds, particularly when being

turned on or off. If the snapping or popping is continuous or frequent, unplug the set and consult your

dealer or service technician.

FOR SERVICE AND MODIFICATION

24. Do not use attachments not recommendedby the television set manufacturer as they may cause hazards.

25. When replacement parts are required,be sure the service technicianhas used replacementparts specified

by the manufacturer that have the same characteristics as the original part. Unauthorized substitutions

may result in fire, electric shock, or other hazards.

26. Upon completion of any service or repairs to the television set, ask the service technician to perform

routine safety checks to determine that the television is in safe operating condition.

5

5

Page 6

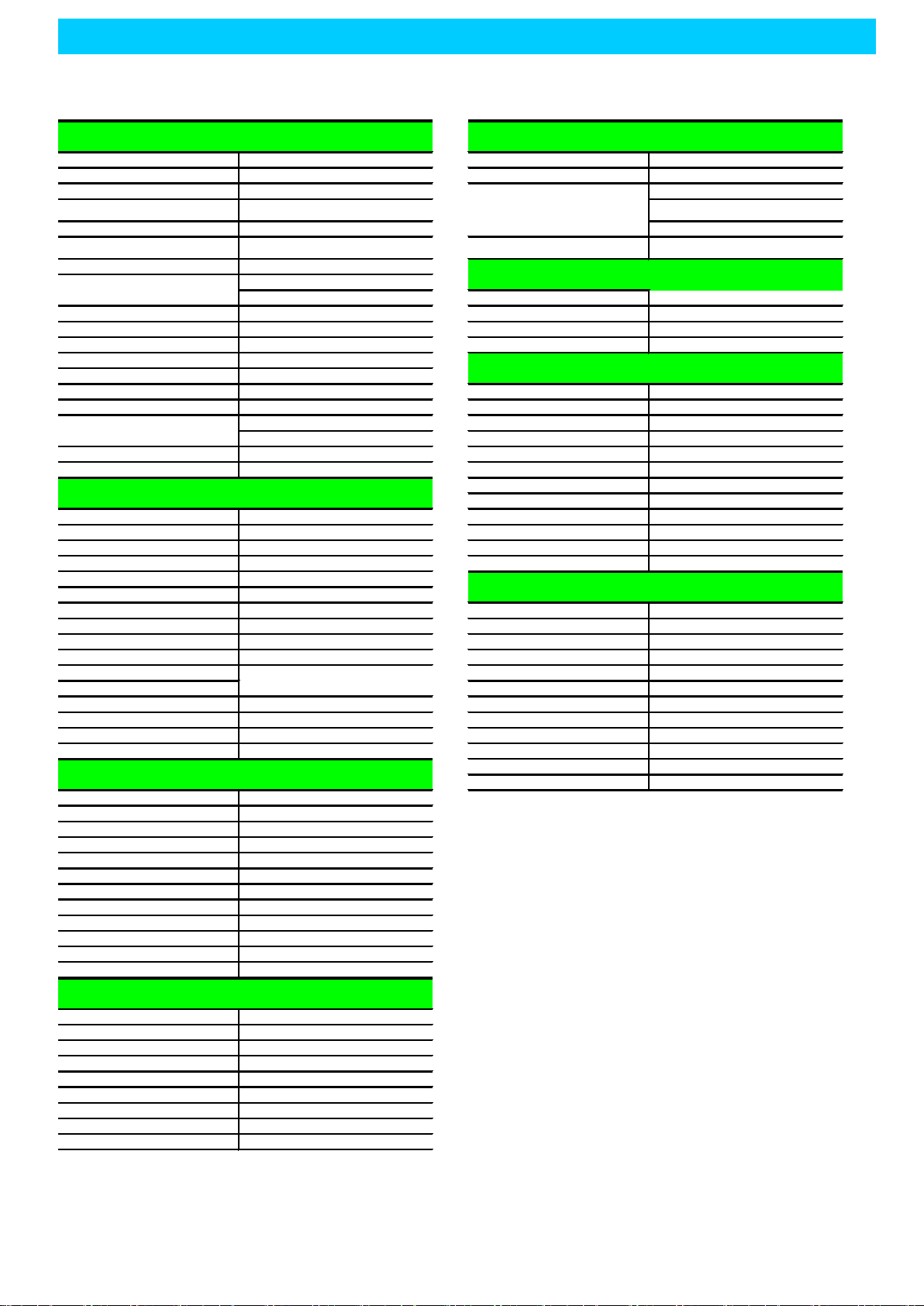

HDMI Video Format Up to 1080P

30,000hrs

PRODUCT SPECIFICATION RELEASE

Model: 32D1800/MT5655-LA(5 in 1 PCB)

Version:01 Issued On: 2016-08-10

Basic Information Media Format

Product Type

Chassis

CPU

GPU

OS Linux

Memory 1G DDR +4G EMMC File

OSD Language English/Spanish/Portuguese

TV System

AV System

TV Channels (Air)

TV Channels (Cable) 1~135

Power Supply

Power Consumption(TV On)

Power Consumption(Standby)

Certification

Internet Link

Wake-on-LAN Yes Display Resolution 1366×768

Basic Function

Auto Source --- Viewing Angle (H/V) 176°/176°

EPG

Subtitle/Closed Caption Yes Color 16.7M (8 bit)

Parental Control

Sleep Timer Yes

System Update Yes

Hotel Mode

Input Method Virtual keyboard USB 2

MHL --- AV in 1

Lightsensor --- YPbPr in No

GINGA Yes

HDMI HDMI with CEC、MHL2.0 、 ARC VGA in No

Picture

DCC(Dynamic Contrast Control) Yes

Backlight Adjustable Yes (0~100)

Color Temperature Normal/Cold/Warm

Picture Mode Vivid, Normal, Mild, User

Picture Size Auto、16:9、4:3、Just Scan

Picture enhancement technology On/Off

LCD Smart TV

3MT56B2SA.01

Quad core CPU ARM CA7,920MHz

---

ATV: NTSC-M, PAL-M/N

DTV: ISDB-T

PAL,NTSC

ATV:2~69, DTV:7~69

AC 110V-240V 50/60Hz

45W

≤0.5W

CB

Wired Network Default Aspect Ratio 16:9

Built in wireless(802.11 b/g/n 2x2)

Yes(at DTV)

Yes (at DTV)

Music

Picture

Video

Signal Format Capability

Component Video Format --DVI Video Format Up to XGA for HDMI-PC

PC Compatibility ---

Panel Specification

Backlight Unit

Panel supplier CSOT

Panel Size (inch) 32"

Brightness (cd/m2)(typ.) 220(typ.)

Contrast Ratio 3000:1

Response Time (G to G) 6.5ms

Life Time(Typ.) >

Refresh Rate 60Hz

Terminals

---

--- VGA audio in No

--- RJ45 1

--- SPDIF out 1

--- Earphone out No

HDMI 3

AUDIO out 1(R/L)

MHL share with HDMI

RF Input(2-F Type) 1

MP3, AC3, AAC,WMA

JPEG, PNG, BMP

MPEG2, MPEG4, H.264,H.265,WMV

---

LED

Sound

Speakers Integrated speakers (Bottom side)

Audio Power Output (THD=7%) 2×5W

Auto Volume Yes

Sound Mode Standard/Movie/Music/Clear voice/Personal

Sound Control

Frequency range Equalizer

Balance

Page 7

Essential Accessories (Default)

Pre-Installed Application List

NetFlix

Youtube

Golive3.0

Browser

Crackle

icflix

Foxxum

Deezer

Dailymotion

Others

Wireless Display

File Share

Yes

Yes

Yes

Yes

Yes

No

Yes

Yes

Yes

WeatherNation(Argentina&Mexico)

Babbidiboo(Brazil),Hellokids(others)

Yes

Yes

Operation Manual English (Default)

Remote Control

Base Stand

AC power cord 1 pcs

RC311

Integrated Packaging

Optional Accessories

Wall Mount WMB333

WI-FI

Batteries 2 pcs

---

Mechanical Key Specification

Diagonal size(cm) 80

Slim Edge Design---Up(mm) 14.6

Slim Edge Design---Bottom(mm) 20.6

Slim Edge Design---L&R(mm) 14.6

Carton Dimensions LxWxH(mm)

Container Loading---20 feet(pcs)

Container Loading---40 feet(pcs)

Container Loading--40 feet High (pcs) 1210 Net Weight Without Stand (Kg) 4.2

VESA Mounting Dimensions LxH(mm)

830 × 137 × 524

476

968

100×100

L1(mm)

W1(mm)

H1(mm)

L2(mm)

W2(mm)

H2(mm)

Net Weight With Stand(Kg)

Gross Weight With Packaging(Kg)

733.4

90.1

433.5

620

177

480.2

4.3

5.7

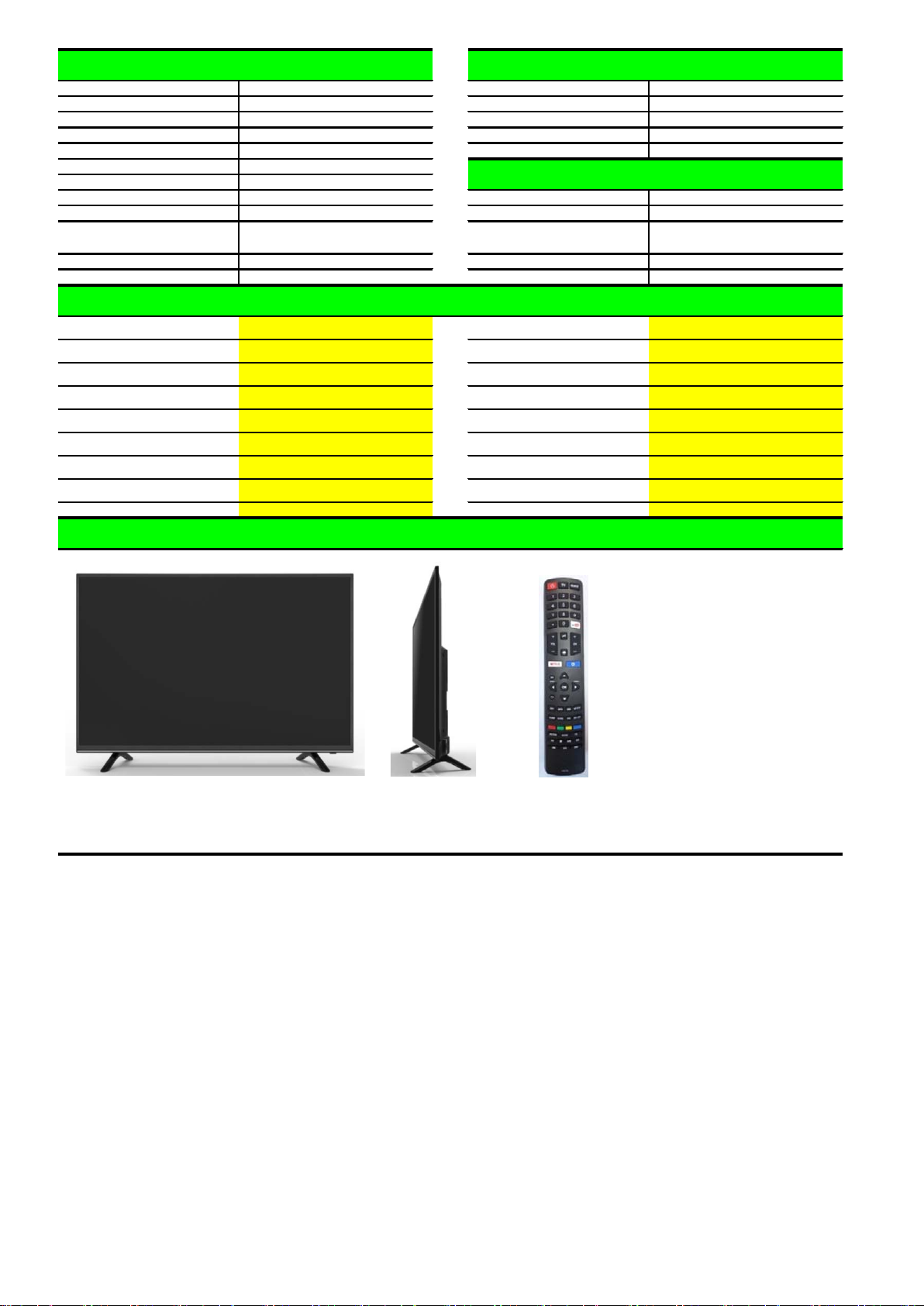

Mechanical ID Picture

Design and specifications are subject to change without notice!

Drafted by: Approved by:

Page 8

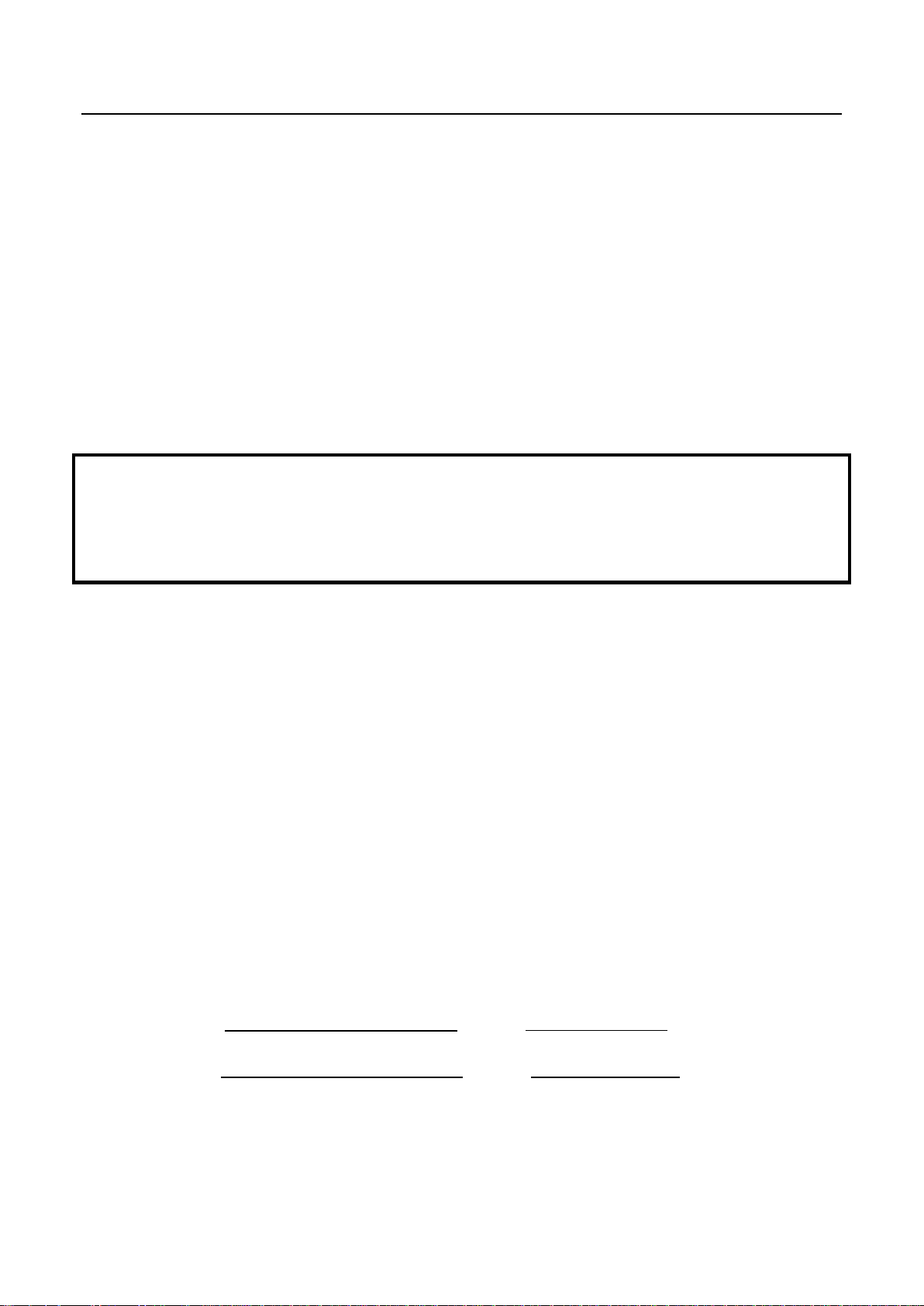

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

Factory Test & Alignment Specification V1.0

----MT56-AP

PREPARED BY : FENG LIU DATE : 2015-02-13

APPROVED BY: DATE :

1

Page 9

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

Content

1. General Description .............................................................................................................................. 3

2. Factory Menu ......................................................................................................................................... 5

2.1 Accessing Way ................................................................................................................................... 5

2.2 Factory Menu ...................................................................................................................................... 6

2.3 White Balance Menu .......................................................................................................................... 7

3. Design Menu .......................................................................................................................................... 7

3.1 Accessing Way ................................................................................................................................... 8

3.2 Design Menu ....................................................................................................................................... 8

3.3 Other Menu ......................................................................................................................................... 9

3.4 Service Menu ...................................................................................................................................... 9

3.5 Param Setting Menu ........................................................................................................................ 10

4. Test & Alignment ................................................................................................................................. 11

4.1 Pre-Conditions and Power Supply Check .................................................................................... 11

4.2 Project ID Modification .................................................................................................................... 11

4.3 Function Test .................................................................................................................................... 12

4.4 LAN/WLAN Test ............................................................................................................................... 13

4.5 SHOP INIT ........................................................................................................................................ 13

Appendix ...................................................................................................................................................... 14

Appendix 1: Warm-up Test .................................................................................................................... 14

Appendix 2: Software Upgrade ............................................................................................................. 15

Appendix 3: Network Connection ......................................................................................................... 17

Appendix 4: White Balance (WB) Adjustment .................................................................................... 18

2

Page 10

Class

Item

MT56-AP

Input

&

Output

RF Input

(PAL/DVB/DVB-T2)

CABLE&ANTENNA

HDMI

(480i/p, 576i/p, 720p up to 1080i/p, with

HDCP)

HDMI*3

VGA

1

VGA Audio

Shares audio sockets with Audio Input

Component Audio Input

RCA*2 (L+R)

AV Input

RCA*1

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

1. General Description

The information contained in this document is proprietary to TCL SZ FPD lab and shall

not be disclosed by the recipient to the third person without the written permission of

the team leader or GM of R&D.

MT56-AP chassis are designed for Asia & Pacific (AP) market Ready for Smart TV. It

features by its high integration, easy debugging (ADC adjustment free) as well as

convenience in terms of maintenance. Fast software upgrade through USB disk

facilitates both manufacture and after-sale service. Meantime, a variety of functions

involved in Factory Main Menu can not only bring benefits for production, but also

satisfy various demands of customers.

Note: Factory Main Menu (FMM) is divided into Factory menu and Design menu. Factory

Menu covers all indispensable functions during manufacture such as White Balance

Adjustment, SHOP etc., while Design Menu includes Service Menu, Hotel Menu, Param

Setting, Other Setting etc. Some settings like Param Setting and Other Setting is exclusively

used by R&D engineer, anyone else shouldn’t change the settings in the menu. When you

wish to learn the product information like project ID, project name, Hardware, software

version, release date, you can access to Service Menu. In addition, in Hotel Menu, we also

provide a great deal of useful functions for specific applications in hotel.

The main chip is from REALTEK and supports below features matrix:

3

Page 11

Input

&

Output

Audio Out

RCA*2

USB

(Video, audio and picture)

USB2.0*2

MHL

Shares with HDMI 1

PCMCIA

1

SPDIF output

RCA*1

NETWORK

RJ45 Socket

Functions

Internet

WIFI

Others

Serial connector

Multiplexing VGA

IC Details

&

Position

Main program

UF01

(Support online upgrade)

Mboot

UF01

(Support online upgrade)

EEPROM

U702

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

Note:

The software boot for U702 can be programed by Flash Tool.exe.

Every set has its unique HDCP key which is purchased from suppliers or HDCP

certification authority. Please check HDCP function in the process of production.

Once in a while, the software of main board may be upgraded. Please pay attention to

use the latest software before production.

4

Page 12

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

2. Factory Menu

Factory Menu is mainly used for factory production and satisfies various demands of customers. It covers

all indispensable functions during manufacture such as Warm up, White Balance, Shop, NVM Reset,

Power on mode, USB Clone etc.

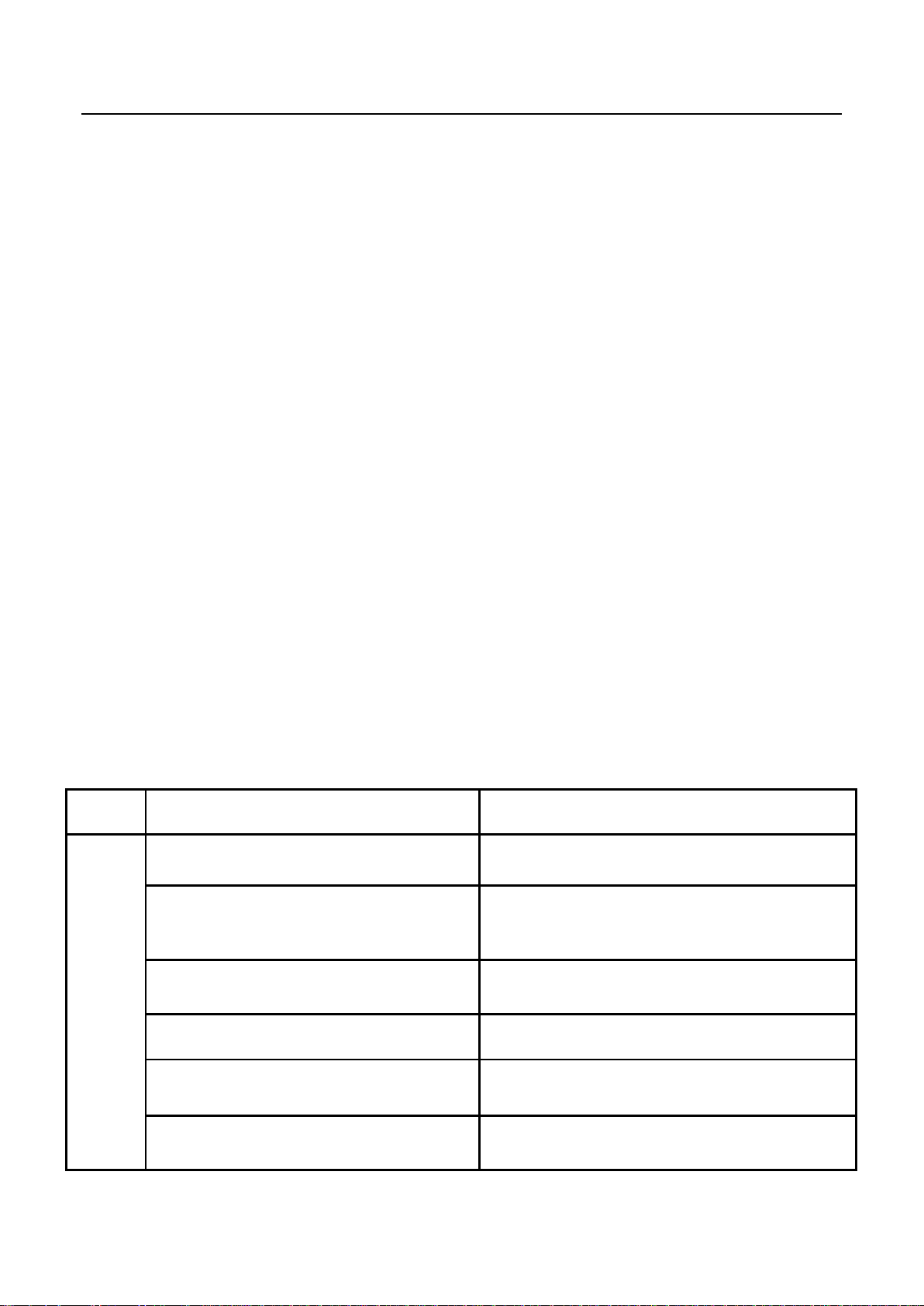

2.1 Accessing Way

a. When the Factory hotkey item of Factory Menu is disabled (OFF), press Menu button of remote

control, then select Settings/Picture, make sure the cursor stop on Contrast item submenu. Finally,

press 9, 7, 3, 5 consecutively.

b. When the Factory hotkey item of Factory Menu is enabled (ON, you can see the flashing Factory

Captions Info on the lower left corner), press Back button of remote control.

Press RCU “OK” key to enter the submenu.

Press RCU “Right” or “Left” key to change the values.

Press RCU “Right” or “Left” key run the function.

Press RCU “Back” or “Menu” key exit the Factory menu.

Factory Captions Info:

While “FactoryKey” is enabled, there is some toggled display information relative to MV, SV, ID, MID, to

facilitate 100% quick screening without accessing to whatever else menu:

P (Production/Factory mode flag)

MV (Mboot SW Version)

SV (Main SW Version)

ID (Project ID)

MEMC

5

Page 13

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

Factory Menu

Name

Default

Description

Factory hotkey

OFF

Factory Menu shortcut button switch

The item must be disabled (OFF) after production

Warm up

OFF

Aging mode, mainly used for factory aging.

Press “Menu” key on keyboard to exit the burning mode.

See Appendix 1 “Warm-up Test”

White Balance

..

White Balance Adjustment ( see details below)

Shop

>

It is crucial that the function is executed after production aim to clear information

of production process, ensure user cannot access to Factory Menu after

executing the item.

NVM Reset

>

Restore default value except White Balance, ADC data.

Power On Mode

STANDBY

ON: the set will power on after switching on power.

STANDBY: the set will remain standby status after switching on power.

LAST: the set will turn to the status in which it lies when last switching off.

If without requirement from certain customer, by default, the Setting should be

STANDBY

USB Clone

..

Select to choose the things you want to clone.

Preset Factory

Channel

..

Preset the channel table of factory. To preset the channel table of certain factory,

first, choose the corresponding factory name. Then press OK button of remote

control and wait OK is displayed on the screen.

DeviceID test

DO

Test device ID.

Other

Project Information

ADC

..

Analog To Digital Converter

SW NO.

device info

Version information of Main Software

Project Name

device info

Product model

Date

device info

Release date and time of main software

MID

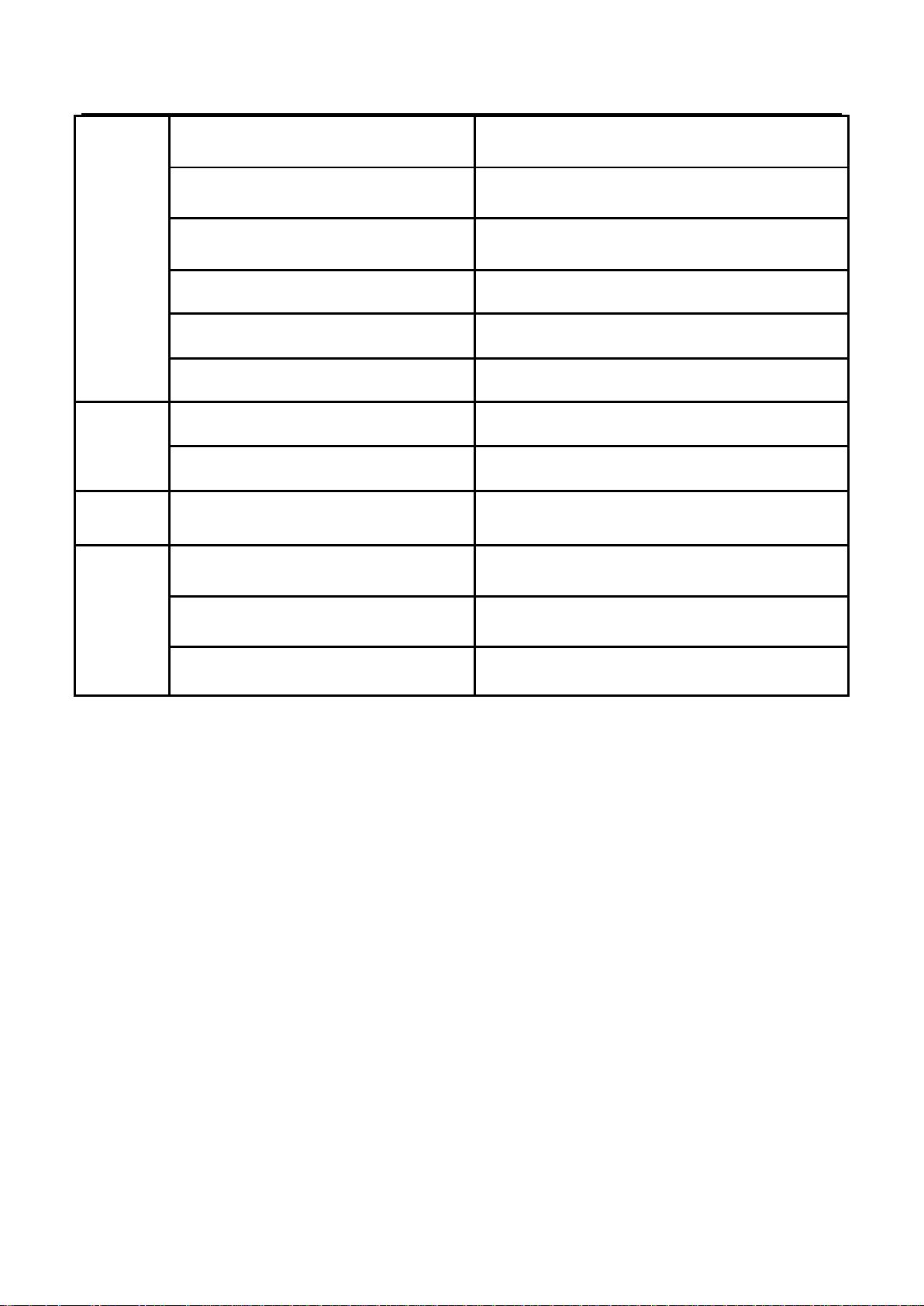

2.2 Factory Menu

6

Page 14

White Balance

Name

Default

Description

Source

ATV

Press RCU left/right key to change the TV source.

Color

normal

Select color temperature you intend to adjust Three groups of color

temperature: normal, Cold, Warm are available.

R gain

0-255

Gain of R channel ( cannot be changed after auto calibration)

G gain

0-255

Gain of G channel ( cannot be changed after auto calibration)

B gain

0-255

Gain of B channel ( cannot be changed after auto calibration)

R offset

128

Disabled, keep the default value

G offset

128

Disabled, keep the default value

B offset

128

Disabled, keep the default value

White Balance

init

>

White Balance Initalization. Before WB adjustment, this item should be

executed.

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

2.3 White Balance Menu

Press the button on remote control to select certain item and OK to adjust White Balance.

3. Design Menu

Design Menu includes Factory Menu, other,

Service Menu, Param Setting, Hotel Menu.

Some settings like Param Setting and Other

Menu is exclusively used by R&D engineer,

anyone else shouldn’t change the settings in the

menu. When you wish to learn the product

information like project ID, project name, chassis

name, software version, release date, you can

access to Service Menu. In addition, in Hotel

Menu, we also provide a great deal of useful

functions for specific applications in hotel.

7

Page 15

Design Menu

Name

Default

Description

Design Mode

hotkey

OFF

Design Menu shortcut button switch

The item must be disabled (OFF) after production

Factory menu

..

Access to Factory Menu

Other

..

The item includes a number of functions offering convenience for R&D engineer

to solve problems.

Service menu

..

Provide many useful information for after-sale service

Please reference to SERVICE MENU submenu

Param setting

..

Include sound setting,picture setting, SSC, DBC, CI Card, Overscan, WIFI

CHECK and USB FILE. Please reference to PARAM SETTING submenu.

Hotel menu

..

Include special functions which bring benefits to hotel management. The item is

accessible only when Hotel Service On/Off item is enabled (ON).

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

3.1 Accessing Way

a. When the Design mode hotkey item is disabled(OFF), press Menu button of remote

control, then select Settings/ Picture, make sure the cursor stop on Contrast item

submenu, press 1, 9, 5, 0 consecutively.

b. When the Design mode hotkey item of Design Menu is enabled (ON, you can see the

flashing Factory Captions Info on the lower left corner), press Back button of remote

control.

Press RCU OK key to enter the submenu.

Press RCU Right/Left key to change the values.

Press RCU Right/Left key run the function.

Press RCU Back/Menu key exit the Factory menu.

Design Captions Information is the same to Factory Captions Info.

3.2 Design Menu

8

Page 16

Other Menu

Name

Default

Description

TestPattern

>

Switch the TV source into test pattern, and restarting TV is the only way to excit.

UartEnable

OFF

The switch of VGA serial port information.

The item must be disabled (OFF) after production.

DeviceID

..

Show the device id of TV.

MAC

..

Show the MAC address of TV.

HuanID

..

Show the Huan id of TV.

ClientType

..

Show the Client type information.

Service Menu

Name

Default

Description

Project ID

1

Select project parameters, depending on the BOM description.

Hardware

MT5655

mainboard Chassis

Software

V8-MT56551-LF1V003

version number of Main Software

Bootloader

XXX

version number of bootcore

USB Update

..

Update the software by USB disk,

detailed description see Appendix 2 “Software Update”

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

3.3 Other Menu

The Other Menu contains some TV basic information, with which we can check the TV setting before

production.

3.4 Service Menu

Service Menu contains some basic information of the device, such as Project ID, Hardware, Software

version, USB Update etc. This menu is especially useful for after-sale service.

9

Page 17

Param setting Menu

Name

Default

Description

Sound Setting

..

Set sound mode, balance, sound scene, etc.

Picture Curve

..

Exclusively used by R&D

Picture Setting

..

Set picture mode, brightness, contrast, backlight, etc.

SSC Adjust

..

Spread Spectrum clocking.

Exclusively used by R&D.

DBC

..

Dynamic Backlight Control.

Exclusively used by R&D.

CI Card

ON

Common interface Card switch.

WIFI CHEAK

..

Check the WIFI link

USB FILE

..

Access the USB file

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

3.5 Param Setting Menu

Param Setting menu contains Sound Setting, Picture Curve, Picture Setting, SSC, DBC, CI Card,

Overscan, WIFI CHECK and USB FILE. But it is exclusively used by R&D engineer, anyone else shouldn’t

change the settings in the menu.

10

Page 18

Position

Value

Test Point

P103

12V±10%

12V

LDH1

5V±5%

+5V

P103

3.3V ±1%

3V3SB

UD33

3.3V ±1%

3V3

LDJ1

1.5V ±1%

DDR_1V5

LDB0

1.2V±1%

CORE_1V2

UD18

1.8V ±1%

1V8

UT2

3.3V ±1%

TUNER_VCC

U201

3.3V ±1%

3V3_DEMO

L201

1.1V ±1%

NC

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

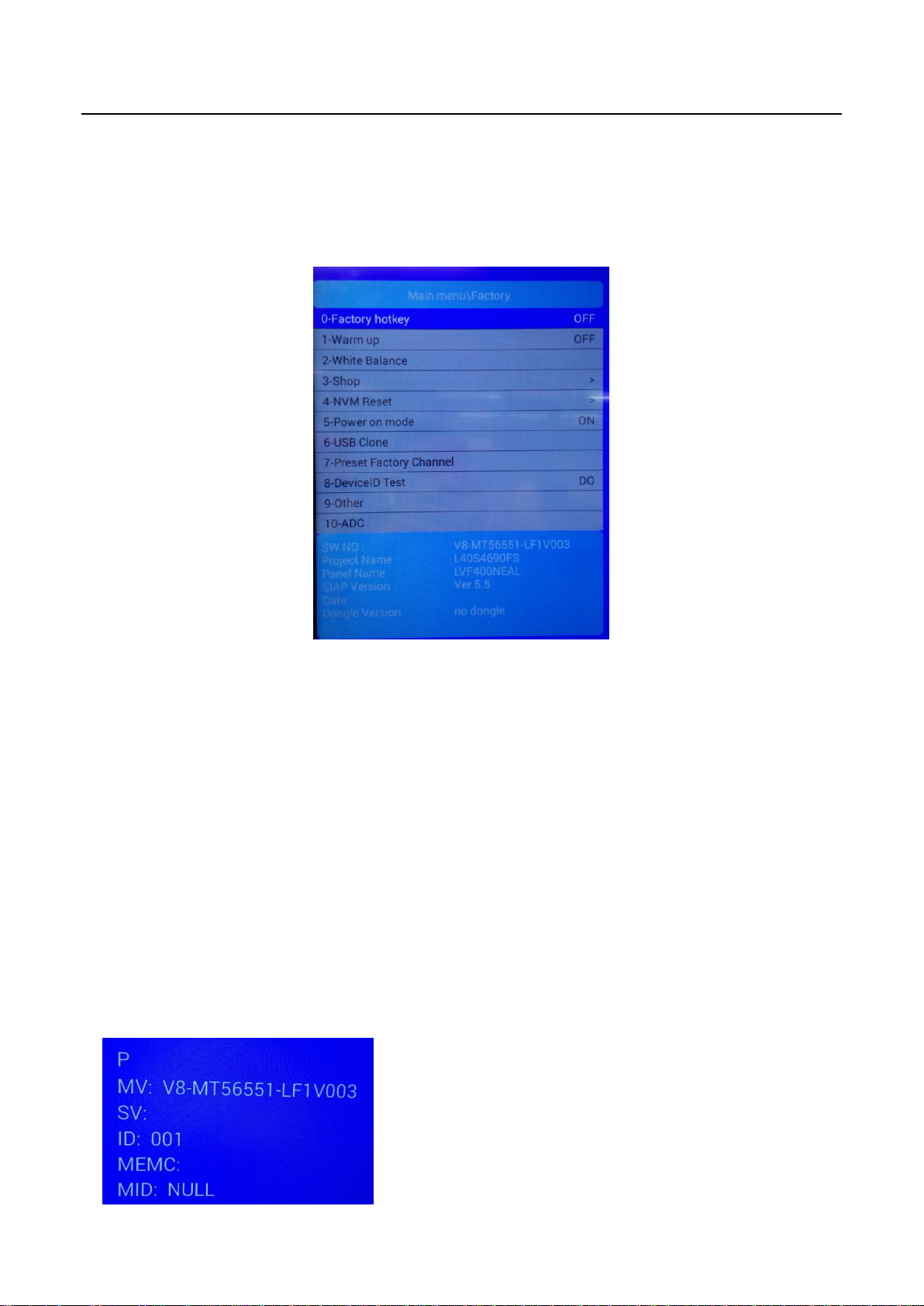

4. Test & Alignment

According to the requirement of order, we suggest take the below steps to finish the appropriate settings.

Note:

All tests and measurements mentioned hereafter have to be carried out at a normal mains voltage

(100 ~ 240 VAC)

All voltages have to be measured with respect to ground, unless otherwise stated

All final tests have to be done on a complete set including LCD panel in a room with temperature of

25+/-7°C

The Picture Performance assessment such as White Balance (luminance and colour temperature)

has to be performed into subdued lighted room after at least 60min of warm-up in order to avoid any

temperature drift influence (colorimetry vs time).

4.1 Pre-Conditions and Power Supply Check

Before power-on, please check the board according to the relevant block diagram and circuit diagram,

make sure that no serious issue or mistake can destroy the board. For example, the output of DC/DC and

LDO should not be shorted to ground.

Supply a suited voltage and power-on, then check the voltage according to the relevant block diagram,

circuit diagram and voltage spec, the error should be less than 5%, for example, the voltage for main chip

(+3V3, +2.5V, VDDC1V15, 1V5_DDR, etc.), the voltage for TUNER (TU_3V3), the voltage for amplifier

(AMP_VCC), etc.

4.2 Project ID Modification

There are different ID stored in the EMMC depending on different Panels settings and Model features, but

there’s only one key branching Project ID able to ensure normal display. And when you power on the TV

set, you should make sure the Project ID is accord with the BOM description. If not, you need to modify

11

Page 19

MODEL

ProjectID

Panel Name

L40S4690FS

001

LVF400NEAL

Source

Test Signal

Test Pattern

RF Input

(PAL/DVB/DVB-T2)

RF cable

Factory signal

AV

(CVBS)

Chroma/Fluke generator

PAL Half Color & Gray bars

VGA

Chroma/QuantumData

generator

1024x768@60Hz

Half Color & Gray bars

HDMI

(Video & Audio)

DVD with HDMI compliancy

Movie 720p@60Hz

LAN

(RJ45)

Ethernet

Any network

Audio OUT

RF signal

Suitable channel

USB

Video/MP3/Image

Home/Media/

SPDIF

DOSS

Audio output

PCMCIA

TV source

Suitbale PCMCIA Card

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

the ID. There are two methods to modify the ID:

Change Project ID in Design Menu

In case of “Design mode hotkey” is enabled, press “Back” button to enter Design Menu. To modify

Project ID, you need to go through “Service menuProject ID”, then press Left or Right key to

select suitable ID (Project name is dynamically refreshed). Finally restart the TV set.

In case of “Design mode hotkey” is unabled, you can enter the Design Menu easily with reference

to 3.1 Design Menu.

Change Project ID with RCU

Press “062598”+”Menu”+”XXX” (XXX represents project ID you’d like to switch to) in the remote

control and wait about half minutes, When the set restart automatically, you have successfully

changed project ID.

Here below is none exhaustive ProjectID table for reference:

4.3 Function Test

Once the Project ID is correct and the TV display normally, plug all external generator devices to relevant

inputs/outputs below according to their respective test patterns format and check picture content and

sound quality accordingly:

12

Page 20

Device ID

User ID

2bbf5dec37068855003ef54b9e27f3be68118899

3546187

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

4.4 LAN/WLAN Test

MAC Address Upgrade

Upgrading MAC address needs to use the tool in factory and through serial command. The specific

method is according to the operation of the factory guidance.

DeviceID (DID) and UserID (UID)

Purpose is to allow Other Network Download (OND) and further specific services over dedicated portal

based on AP. For such, specific DID (32 bytes) and UID (8 bytes) needs to be paired and overwritten into

memory for internal client encryption,as below:

Those DID/UID codes can only be set using UART commands following enclosed SIACP requirements

(rev. v3.9).

LAN Test

A rough LAN test can be done by connecting Ethernet to TV’s RJ45 and check that IP, subnet mask, DNS

addresses, which are visible on “HomeSettingsNetworkEthernet settingsIP settings” (ensure

that “Internet Connection” is Enabled at first). More in-depth test can be performed faster using suitable

UART/IR commands following SIACP requirements. SW will internally manage Network ID (NID) flag

controlling all MAC/DID/UID integrity to facilitate PA screening further.

See Appendix 3 “Network Connection”

4.5 SHOP INIT

At final process stage, it’s necessary to perform Shop init before any packing to leave Factory mode and

restore User default presets according to the requirement of order.

This function is accessible by selecting “Factory MenuShop”, then pressing RCU “Right ”or” Left” key.

Other faster methods are available on above enclosed SIACP requirements (rev. v3.9).

13

Page 21

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

Appendix

Appendix 1: Warm-up Test

Following TCL standard and practices, it’s required minimum 15min of Warm-Up that can be considered

as Burn-In. Additional aging for White Balance alignment is no more necessary due to consistent picture

performance with cloning usage. This function is accessible by selecting “Factory menu Warm up”,

pressing RCU “Right” or ”Left” key to set it ON, and then it enter in Warm up mode. Press “Menu” key on

keyboard to exit the burning mode. Other faster methods are available on above enclosed SIACP

requirements (rev. v3.9).

14

Page 22

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

Appendix 2: Software Upgrade

How to upgrade Mboot

Connect the computer and mainboard VGA port by a serial port tool.

Serial connector definition: VGA/P303: Pin4: RXD VGA Pin11:TXD

Open MTK “Mboot” software programming tool “Flash Tool”, and set serial port.

Import the mboot file, as below.

power on the TV, then Click Upgrade key and you will see the below message.

15

Page 23

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

How to upgrade FLASH Software

1. USB Upgrade

Download the update file (generally named V8-MT56551-LF1VXXX.pkg) to the root directory of your

USB device, and make sure there’s no other bin file named analogously. Then insert the USB device

to USB interface of TV set.

Power on the TV set, Press and hold on the menu key of key board at the same time. If the TV is

updating, you’ll see the below screen:

Upgrade process takes about 3~5 minutes.

After updating, the TV set will reset automatically.

2. Online Upgrade

Download the bin zip file “V8-MT56551-LF1VXXX.Zip” to the root directory of your USB device, and

do not change the file name. Then insert the USB device to USB interface of TV set.

Press RCU Menu/Settings/Picture/Contrast/1,9,5,0/Service menu/USB Update /Main

Upgrade/Local Update . If the upgrade file is found, TV will give a message that it verifying. TV

displays a warning message, it means selecting “confirm” to continue or “cancel” to exit. During

updating, do not power off the TV set.

After updating, the TV set will reset automatically.

16

Page 24

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

Appendix 3: Network Connection

You can set up your TV so that it can access the Internet through your local area network (LAN) using a

wired or wireless connection.

Connect to a wired network

Attach the TV set to your LAN using cable in three ways:

Connecting the LAN port on the TV to an external modem using a Cat 5 cable.

Connecting the LAN port on the TV to an IP Sharer which is connected to an external modem. Use

Cat 5 cable for the connection.

Depending on how your network is configured, you may be able to attach the TV to your LAN by

connecting the LAN port on your TV directly to a network wall outlet using a network cable. Note that

the wall outlet is attached to a modem or router anywhere in your house.

Select Home→ Settings→ Network → Ethernet Settings→IP Settings, then the TV will obtain IP

address Automatic configuration. In addition, you can set the IP address and password manually.

Connecting to a wireless network

To connect the TV set to your network wirelessly, you need a wireless router or modem and a Wireless

LAN Adapter.

If the TV set is equiped with an internal WiFi module, select Home→ Settings→ Network→ Wireless

Settings, then turn on Wireless Switch, select a wireless network and press OK to connect.

If you want to connect the TV set to a wireless network by a Wireless High Gain USB Adapter (USB

dongle), select Home→ Settings→ Network→ Wireless Settings, then turn on Wireless Switch and

External WiFi, and select a wireless network and press OK to connect.

17

Page 25

Product

type

Color

temperature

state

Color

temperature

chromaticity coordinate

tolerance

(X,Y)

X

Y

LCD

cold

13000K

0.270

0.270

±0.015

normal

10000K

0.280

0.290

warm

7500K

0.300

0.305

source

HDMI

VGA

AV/ATV

CMP

Timing value

69

14

38

79

Pattern value

103

103

103

103

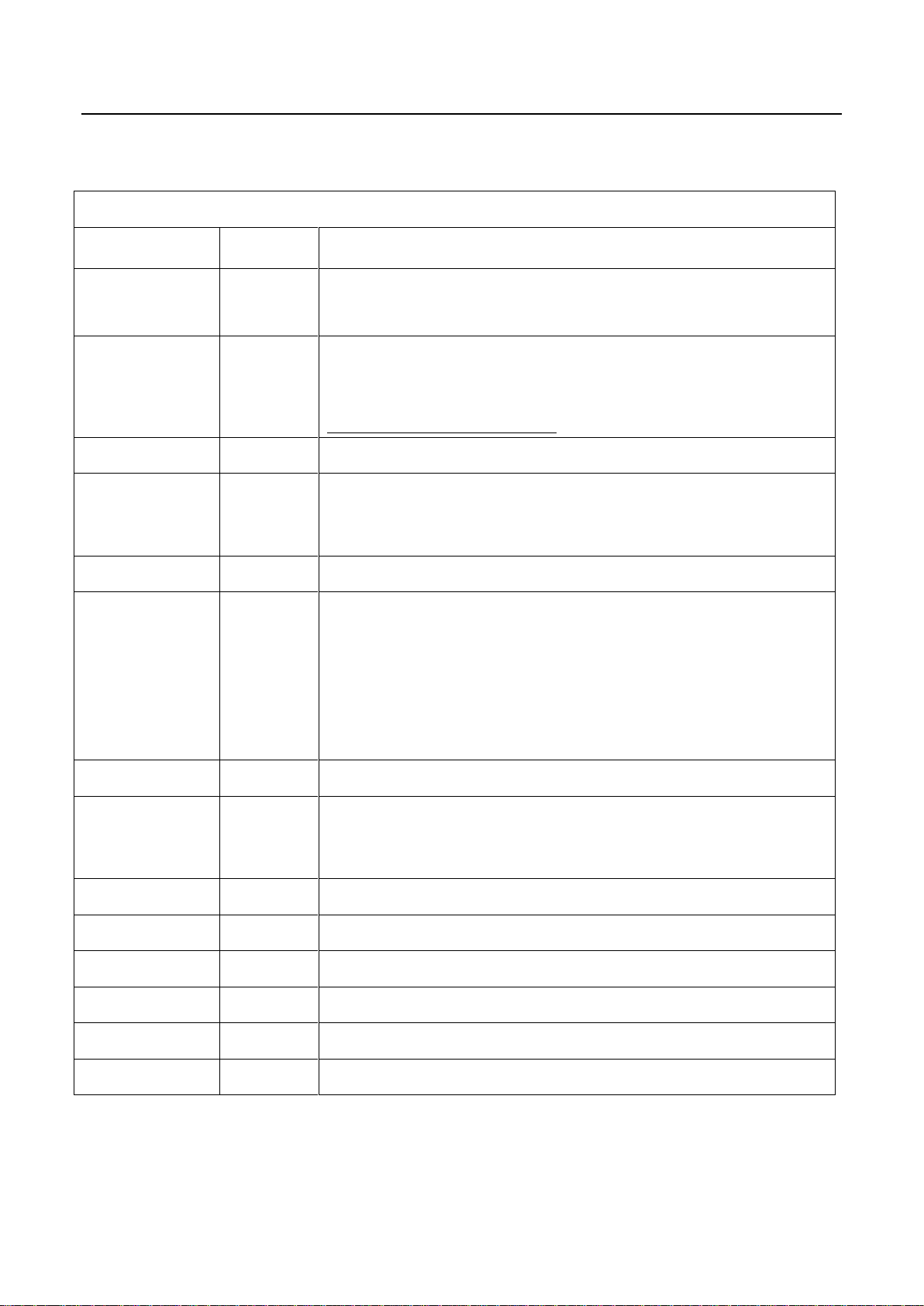

Factory Test & Alignment Specification For MT56-AP Series (V1.0)

Appendix 4: White Balance (WB) Adjustment

The White Balance generally is customized by PQ engineer, and uploaded to the PDM system, anyone

else shouldn’t change the value in the menu. If it is necessary to adjust, the following content can offer

some reference, but the process of adjusting White Balance is out of the range of this file. Please refer to

the relevant technical file of HuiZhou factory of TCL.

Calibration of Color Temperature

According to TCL standards, the color temperature and white reference coordinates of LCD like the

following table: (This standard is based on CA-310 color temperature meter)

White balance adjustment takes the Normal color temperature of HDMI channel as the reference.

Warm and Cold tone is relative to Normal mode. The adjustable gain range is 0~255.

The Normal color temperature of other channel is relative to the Normal mode of HDMI channel. The

adjustable gain range is also 0~255.

The manual adjustment is according to the regulation above. Additionally, when manually adjust, it

needs to do White Balance init first.

Take signal generator 22293 as an example, the timing value and pattern value of each source show in

the following table:

Note: 1) The input signal is 80% white when the pattern value of 22293 is 103.

2) The adjustment of White Balance should fulfill TCL matching specification.

18

Page 26

Trouble shooting diagram

Terms:

IR: Infrared Receiver

RC: Remote Control

IR logic: IR blink with RC action

LVDS: Low Voltage Differential Signal, output from processor and input for panel

O/C: Open Cell, panel with source board

BL: Back Light, light source for panel module

LB: LED (Light Emitting Diode) Bar, light source for BL module

VBL: Voltage for Back Light (before Boost)

VLED: Voltage for LED (after Boost)

OVP: Over Voltage Protection

OSD: On Screen Display

AMP: Amplifier

Page 27

1.No power

No power LED, RC or Key can not turn on TV. Power LED no light/no change.

Page 28

2.No Display / Black Panel

Back light is OK, sound is OK, but no picture.

Page 29

3.No back light

Power LED logic OK, sound OK, but no picture(Different from No Display).

Page 30

4.No sound

One or all signal source without sound.

Page 31

5.Signal source no function

One or several source no function.

Page 32

6.Abnormal Display

OSD NG or picture NG.

Page 33

8 7 6 5

8 7 6 5

4 3 2 1

4 3 2 1

MTK

MAIN POWER

12V

F

F

R203

3V3SB

L=>POWER_ON

H=>POWER_OFF

POWER_ON_OUT

(5)

R201

10K

E

E

BL_ON

T

BL_ON

(5)

BL_ON_OUT

GND

R205

220R

R204

10K

12_24_DETECT

10K

R200

10K

BT3906

Must controlled by PWM

A_DIMING

(5)

R206

10K

Q200

B

GND

GND

3V3SB

E

C

GND

(5)

T

POWER_ON

POWER_ON

R202

10K

12V

12V

16V

GND

PDIM

T

T

PDIM

C001

470U

C002

0.01U

R208

220R

L002

220R

T

P_GND

DIM_OUT

GND

R209

10K

12V_M

(5)

POWER_ON

POWER_ON

21

3

DDB1

BAT54C

NC

RDB8

RDB8

RDB8

RDB8

3K3

3K3

3K3

3K3

CDBC RDB0

CDBC

CDBC

CDBC RDB0

0.1U

0.1U

0.1U

0.1U

RDB9

RDB9

RDB9

RDB9

47K

47K

47K

47K

12V_M

12V_M

GND

GND

Connector

D

D

P899

IR_GND

IR_3V3

T

T

IR1

1

IR2

2

3

IR4

4

KEY

5

GND

C910

0.01U

L900

220R

LED_OUT

C911

220P

3V3SB

T

IR

R900

T

10K

3V3SB

IR_IN

LED_OUT

C912

470P

C913

0.1U

R903

470R

R902

1K

KEY Connector

(5)

(5)

12V

(Vin=5V-22V)

CDB0

CDB0

CDB0

CDB0

10U

10U

10U

10U

GND

GND

GND

GND

CDB2

CDB2

CDB2

CDB1

CDB1

CDB1

CDB1

10U 0.1U

10U 0.1U

10U 0.1U

10U

CDB2

0.1U

(Vin=4.5V-18V)

RESET_CON

RDB6

RDB6

RDB6

RDB6

8K2

8K2

8K2

8K2

NC

RDB0

RDB0

100K

100K

100K

100K

1

VIN

15

SW3

2

PGND

CDH1

10U

RDB1

RDB1

RDB1

91K

91K

91K

91K

14

3

CDH2

10U 0.1U

BAS316

13612

EN

AGND

UDB0

MP8765

PG

NC1

4

RDBA

NC/

GND

DDH1

Vref=0.6V

GND

GND

11

FB

NC2

5

0R

CDH3

CDB4

1U

10

VCC

MODE

7

GND

RDH2

22K

BST

SW2

SW4

SW1

VOUT

CDB3

CDB3

CDB3

CDB3

0.1U

0.1U

0.1U

0.1U

120K

RDH1

CDB5

CDB5

CDB5

CDB5

0.22U

0.22U

0.22U

0.22U

9

16

8

GND

RDB5

RDB5

RDB5

RDB5

4R7

4R7

4R7

4R7

CDH4

0.1U

RDB2

RDB2

RDB2RDB1

RDB2

100K

100K

100K

100K

NC/

220P

220P

220P

220P

RDB7

RDB7

RDB7

RDB7

NC/

GND

GND

Fixed Fsw=500KHZ

Fixed OCP=8.5A

GND

RDB4

RDB4

RDB4

RDB4

1M

1M

1M

1M

CDBB

CDBB

CDBB

10R

10R

10R

10R

CDH5

2U2

LDB0

LDB0

LDB0

LDB0

1UH

1UH

1UH

1UH

UDH1 TPS56528

1

EN

2

VFB

3

VREG5

4

PG

Fsw=650KHz

RDB3

470R

CDB6

CDB6

CDB6

CDB6

220P

220P

220P

220P

VBST

CDB7

CDB7

CDB7

CDB7

22U

22U

22U

22U

VIN

SW

GND

8

7

6

5

CDB8

CDB8

CDB8

CDB8

22U

22U

22U

22U

GND

GND

GND

0.1UCDH6

220P

CDH7

GND

NC

RDH3

6R8

NC

LDH1

4.7UH

Vref=0.6V

12V TO 1V2

CDB9

CDB9

CDB9

CDB9

22U

22U

22U

CDBD

CDBD

22U

22U

22U

22U

max5A

CDBA

CDBACDBD

CDBACDBD

CDBA

0.1U

0.1U

0.1U

0.1U

CORE_1V2

CORE_1V2

CORE_1V2

CORE_1V2

RDH4

33K

RDH5

3K6

RDH6

820R

12V TO 5V

GND

CDH8

22P

NC/

CDH9 CDH10

10U

Z1

T

CDH11

10U 10U

+5V

+5V

GND

CDH12

10U

@max5A

CDH13

0.1U

POWER_ON

RDH9

RDH7

10K

LDO 5V TO 3V3

4

4

4

4

4

UD33

UD33

UD33

UD33

AS1117-3.3

AS1117-3.3

AS1117-3.3

AS1117-3.3

5V 3V3

C122 C123

C122

C122

10U

10U

10U

VIN

3

3

3

3

C123

C123

0.1U

0.1U 10U

0.1U

GND

OUT

2

2

2

2

GND

3V3

3V3

3V3

3V3

GND/ADJ

1

1

1

GNDGND

T

C124

C124

10U

10U

47K

Q212

PMV65XP

S

RDH8

C

B

E

GND

D

G

CDH14

0.1U

10K

Q213

BT3904

5V

F

F

E

E

D

D

C

C

GND

KEY_GND

L902

600R

1

KEY

2

3

4

P900

B

B

For new power supply

KEY

T

T

GND

GND

3V3SB

R930

4.7K

D900

PESD5V0S1BL

NC

R941

F900 C914

GND

22K

12

0.1U

GND

GND

Delete R932 when the I/O(KEY_IN) support 3.3V

*

KEY_IN

Without via on net KEY_IN

The distance between different net via>2mm

R942

150K

(5)

12V TO 3V3SB

SY8291,2015-04-23

L050

GND

GND

GND

GND

D050

D050

D050

D050

SR34

SR34

SR34

L050

L050

3.3UH

3.3UH

3.3UH

R050

300K

C054

1000P

GND

GND

GND

GND

C055

22U

6

6

6

LX

LX

LX

LX

12V_M

A

A

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

(Vin=5V-40V)

C050

2.2U 2.2U

GND

GND

GND

GND

C051

C052

0.1U

GND

GND

GND

R058

0R

R059

180K/NC

5

5

5

IN

IN

IN

IN

4

4

4

EN

EN

EN

EN

AN_SY8291

AN_SY8291

FSW=800KHz

U002

U002

U002

BS

BS

BS

BS

GND

GND

GND

GND

FB

FB

FB

FB

1

1

1

2

2

2

3

3

3

GND

GND

GND

GND

GND

GND

GND

C053

0.1U

0.6V

R051

R051

R051

30K

30K

30K

R052

R052

36K

36K

GND

GND

GND

GND

3V3SB

3V3SB

3V3SB

C056

22U

T

T

T

T

GND

GND

GND

GND

C057

0.1U

3V3SB

3V3SB

3V3SB

max:1.2A

3V3SB

RDJ1

10K

STR

5

5

5V

(Vin=2.5V-6V)

Index-Lab

Index-Lab

RDJ2

0R

RDJ3

NC

0R

CDJ1

10U

...

...

...

...

...

...

...

...

Last saved :

Last saved :

GND

DD-MM

DD-MM

DD-MM

DD-MM

DD-MM

DD-MM

DD-MM

DD-MM

DATE

DATE

CDJ2

0.1U

C

C

DDR 1V5

STR

Vref=0.6V

RDJ7

33K

RDJ8

33K

GND

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

DESCRIPTION Last modifNAME

DESCRIPTION Last modifNAME

RDJ4

10K

RDJ5

NC

100K

UDJ1

RT8096A

4678

4678

LX

GND

EN

VIN

4

FB

5

22/08/2016:14:46

22/08/2016:14:46

CDJ3

0.1U

LDJ1

2.2UH

3

2

1

GND

CDJ4

22P

GND

...

...

...

...

...

...

...

...

RDJ6

100K

CDJ5

22U

SBU :

SBU :

TCLNO:

TCLNO:

.............

.............

CDJ6

22U

DDR_1V5

T

DDR_1V5

...........

...........

@max1A

ON:

ON:

BY:

BY:

CDJ7

0.1U

GND

DESIGNATION

DESIGNATION

3 2 1

3 2 1

LDO 3V3 TO 1V8

4

4

4

4

4

4

UD18

UD18

UD18

3V3

3V3

3V3

DRAWN

DRAWN

UD18

AS1117-1.8

AS1117-1.8

AS1117-1.8

AS1117-1.8

C125 C126

C125

10U

10U

TCL Thomson Electronics Ltd.

TCL Thomson Electronics Ltd.

B Building, TCL Tower, Nanhai Road

B Building, TCL Tower, Nanhai Road

Nanshan District, Shenzhen, Guangdong

Nanshan District, Shenzhen, Guangdong

Tel +86-755-3331xxxx Fax +86-755-3331xxxx

Tel +86-755-3331xxxx Fax +86-755-3331xxxx

VIN

VIN

3

3

3

3

C126

0.1U

0.1U

GND

GND

CHECKED

CHECKED

ON:

ON:

BY:

BY:

1V8

1V8

1V8

1V8

OUT

OUT

GND/ADJ

GND/ADJ

1

2

1

2

2

1

2

1

GNDGND

GND

DD-MM-YY

DD-MM-YY

......

......

T

T

10U

10U

C127

C127

C127

1V8

1V8

PAGE:

PAGE:

OF :

OF :

B

B

A

A

FORMAT DIN A2

FORMAT DIN A2

Page 34

8 7 6 5

4 3 2 1

F

RT201

100K

22U

1V1_DEMO

T

CT209

0.1U

GND

DEMO_1V2

@max1A

NOTE: All the test points should be out of TUN2.

(Vin=2.7V-7)

5V

CT204

RF_SW

T

IF-AN

11

IF-AP

10

NC3

9

NC2

8

NC1

VCC

SDA

SCL

GND

RF_SW

7

6

TUNER_VCC

5

4

3

GND

2

RF_SW

1

IF_AGC_D

E

CT1000.022U

TUN2

TUN1_GND

TUN1_VCC

T

T

T

CT10110U

GNDGNDGND

IF_AGC_D1

CT10322P

CT102

6800P

GNDGND

T

CT104

22P

GND

TU_SDA1

TU_SCL1

T

CT10522P

NC/

NC/

GND

TUNER_FAT-

TUNER_FAT+

AGC

SDA_DEMO

SCL_DEMO

CT10622P

10U

GND

CT205

0.1U

GND

Vref=0.6V

RT202

120K

RT203

30K

UT202

RT8096A

VIN

4

GND

LX

3

2

LT201

2.2UH

CT206

RT205

150K

CT207

22U

CT208

22P

FB

5

EN

1

GND

4

4

DEMO_1V2

TUNER_VCC

TUNER_VCC

UT33

CW1117-3.3

VIN

3

5V

CT11

CT7

10U

3V3

Close to Tuner

D

RT100

33R

10KRT101

Close to U001

RT103

33R

SW_RFRF_SW

(5)

0.1U

OUT

2

GND

TUNER_3V3

T

GND/ADJ

1

GNDGND GND

TUNER_VCC

CT12

10U

TUNER_VCC

LT3

120R

LT4

120R

LT2

120R

C300

10U

C302

10U

CT16

0.1U

C301

2U2

C303

2U2

CT17

0.1U

GND

0.1U

CT24

0.1U

CT18

0.1U

GND

DCORE_1V2

CT19

0.1U

GND

VDD33_VIO

CT23CT20

0.1U

VDD_VANA

F

E

D

RT102

NC/

10K

RT30 RT31

4K7

RT32

100R/NC

100R/NC

RT33

DCORE_1V2

GND

1

MP_A

2

MP_B

3

GPIO_0

4

DISEQC_CMD

5

DISEQC_IN

6

DISEQC_OUT

7

VDD_VCORE

8

GND1

9

VDD_VIO1

10

SCL_HOST

11

12

TS_VAL

4K7

GND

484746454443424140

NC

GND5

TC_ADC_P

TC_ADC_N

SCL_MAST

SDA_MAST

CLK_IN_OUT

VDD_VCORE3

TS_SYNC

TS_CLK

TS_DATA0/TS_SER

TS_DATA1

TS_DATA2

TS_DATA3

TS_DATA4

VDD_VCORE1

20

19

18

17

16

15

14

13

DCORE_1V2

GND

TUNER_IFN1

TUNER_IFP1

38

37

39

S_ADC_IN

S_ADC_QP

S_ADC_QN

XTAL_I/CLK_IN

VDD_VCORE2

TS_ERR/GPIO_1SDA_HOST

GND2

VDD_VIO2

TS_DATA5

24

23

22

21

VDD33_VIO

VDD_VANA

GND

S_ADC_IP

VDD_VANA

GND4

ADDR

XTAL_O

RESETB

MP_D

MP_C

GND3

TS_DATA7

TS_DATA6

CT46 0.1U

36

35

34

ADDR

33

32

31

30

29

DCORE_1V2

28

27

26

25

GND

0.1UCT45

TUNER_IFN

TUNER_IFP

RT61

220K

NC

ADDR

0R

RT62

TUNER_VCC

0.1U

GND

GND

RT42

4K7

CT29

XT16M

16M

RT43

220R

10P

CT21

10P

CT22

DEMOD_RST

C

GND

B

CT300

22P

SYS_SCL1

SYS_SDA1

CT301

AGC

CT25

0.1U

RT34

1K

GND

DEMOD_TSVAL

DEMOD_TSSYNC

DEMOD_TSCLK

DEMOD_TSDATA

CT28

0.1U

10P

CT41

GND

10PCT43

10P

CT42

RT35

10K

CT44 10P

close to CT33,CT34

I2C ADDR

READ:C9

WRITE:C8

MP_B

T

DIF_AGC

GND

22R

22R

22R

22R

SYS_SCL1

SYS_SDA1

RT38

RT39

RT40

RT41

GND

SDA_DEMO

SCL_DEMO

DCORE_1V2

VDD33_VIO

100R

100R

RT36

RT37

D_TSVAL

D_TSSYNC

D_TSCLK

D_TSDATA

UT3

SI2183

GND

3V3

TUNER_SCL

TUNER_SDA

AGC

TUNER_VCC

T

AGC

RT7

1K

CT10

TUNER_VCC

C

CT15

10U

6800P

GND

Close to SOC

RT26

10K

CT31

0.047U

GND

GND

NEAR THE SHIELD OUTLINE

IF_P

TUNER_FAT+

TUNER_FAT-

GND2

AGC

TUNER_FAT+

TUNER_FAT-

TUNER_VCC

B

6 12

IF_AGC

5

IF_P

4

IF_N

3

VCC

2

GND1

1

NC

GND

GND6

SCL

SDA

GND5

GND4

GND3

SCL_DEMO

11

SDA_DEMO

10

9

8

7

GND

SDA_DEMO

SCL_DEMO

SDA

SCL

T

T

TUN1

IF_N

T

T

CT8

10P

CT9

10P

RT21

RT22

GND

CLOSE TO RT32,RT33

220R

220R

RT60

10K

NC

IF_AGC

TUNER_IFP

TUNER_IFN

CT13

NC

10P

(5)

Close to MTK SOC

GND

CT14

10P

NC

RT18

0R

RT19

0R

GND

GND

NC/

RT20

CT27

NC/

CT26

680R

22P

22P

CT40 0.1U

0.1U

CT39

IFP

SOC OPTION

IFN

RT18/RT19/RT20 decided by the MTK SOC

100R

RT300

100R

RT301

IFN

IFP

(5)

22P

GND

(5)

CT34

22P

RT16

33R

RT15

33R

A

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

GND

CT33

22P

TUNER_VCC

RT11

RT10

4K7

4K7

Or connect to the nearest 3V3

SYS_SCL1

SYS_SDA1

(5)

(5)

SBU :

TCLNO:

Index-Lab

DATE

DESCRIPTION Last modifNAME

Last saved :

5

4678

.............

TCL Thomson Electronics Singapore Pte. Ltd.

8 Jurong Hall Road #28-01/06

The JTC Summit SINGAPORE 609434

DESIGNATION

DRAWN

DESIGNATION

3 2 1

ON:

BY:

Tel (65) 63092900 Fax (65) 63092999

CHECKED

PAGE:

ON:

BY:

OF :

A

FORMAT DIN A2

Page 35

8 7 6 5 4 3 2 1

F

KIR

KLED

K3V3

KGND

T

TT T

E

VS

HS75438

KIR1

OUT

GND2

GND1

12

DGND

DK1

PESD5V0S1BL

CK1

10U

RK1

100R

DGND

RK5

4K7

NC

K3V3SB

KLED_IN

KEYIN

1

2

3

4

5

PK1

D

27K

QK1

BT3906

E

B

C

RK2

10K

CK2

0.1U

RK4

1

F

E

D

RK3

1K

12

PESD5V0S1BL

C

DK2

DK3

DGND

DGND

NC/

B

K1

3

4 2

SPDIF

SPDIF

T

R325

220R

C322

220P

Close to IC

C323 0.1U

SPDIF_OUT

C

B

BLACK

P304

SPDIF_GND

3

2

1

T

SPDIF

NC/

F312

1

D304

PESD5V0S1BL

2

GND

R324

120R

A

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

A

45678

123

FORMAT DIN A3

Page 36

12 11 10 9 8 7 6 5 4 3 2 1

INTERNET

H

USB3.0 Port

U403

U403

U403

RT9711A

RT9711A

RT9711A

5

5 1

5

VIN

4

4

EN/EN# NC

VOUT

GND

(5)

(5)

470U

USB2_DM

16V

1

1

2

2

2

34

3

3

USB2_DP

GND

R928

4K7

UART_RX

NC/

GND

+5V

USB_EN

UART_TX

C925

3P3

C416

C416

C416

10U

10U

100

R997

GND

R424

R424

R424

10K

10K

10K

GND

R998

10K

3V3SB

3V3SB

R917

4K7

G

C924

3P3

NC/

When use ESD Device, must delete 3.3pF on USB data line

F

GND

10U

C417

USB_5V

R929

R940 2R2

2R2

C922

3P3

NC/

C418

NC/

GND

C923

3P3

GND

0.1U

C419

GNDU

USB

U2_DM

T

U2_DP

U2_DM

U2_DM

USB2_D-

T

F907 F908

GND

T

UART_RX

U2_DP

D426

D426

D426

2 1

2 1

PESD5V0S1BL

PESD5V0S1BL

PESD5V0S1BL

D428

D428

D428

2 1

2 1

PESD5V0S1BL

PESD5V0S1BL

PESD5V0S1BL

T

UART_TXUSB_5V

TT

UART_RX

UART_TX

NC/

12

NC/

12

R923

470R

R922

470R

GND

GND

10

11

9

1

8

2

7

3

6

4

5

P906

MNT-HOLE1

MNT-HOLE2

USB1_DM

USB1_DP

U1_DP

U1_DM

R999

2R2

2R2

R996

D499

PESD5V0S1BL

D498

PESD5V0S1BL

NC

T

USB_5V

12

12

USB1_D+

GND

T

U1_DM

U1_DP

GND

USB1_D-

Must be differential 100ohm

• WIFI

2R2

R407

TXVP

R408

13-ESD3V9-X4B45P

R412 2R2

RXVP

RXVN

2R2

R420

P999

1

VCC

2

DNEG

3

DPOS

4

GND

5

MNT-GND1

6

MNT-GND2

2R2

D401

D401

D401

RXP

RXN

TXP

TXNTXVN

D402

10

9

8

GND

7

65

C404

C404

C405

C405

0.01U 0.1U

GND GND

0.1U

C402

C402

0.1U

C403

0.01U

GND

1

2

3

4

NC/

ESD

13-ESD6V0-A4B0P6

4

312

2

4

3

1

2

4

7

6 5

7

6 5

7

6 5

1

3

9108

9108

8

9

10

U401

1

2

3

4

5

6

7

TS8121CLF

16

16

TX1P

15

15

TX1N

14

14

13

13

12

12

RX1P

11

11

10

RX1N

98

R401

75R 75R

R403

75R

P401

C406

GND

11

12

10

1

2

3

4

5

6

7

8

9

R402

R404

75R

1000P

TXC

TXC

RXC

RXC

TX1P

TX1N

TX1N

RX1P

RX1P

TXC

TXC

RX1N

RX1N

RXC

RXC

WAKE-ON-LAN

USB0_DM

USB0_DP

TP

TP

T

TN

TN

TN

T

RP

RP

RP

T

TC

TC

TC

T

RN

RN

T

RC

RC

RC

T

WIFI_ON

RESET_CON

BAS316

D434

D433

BAS316

100R

R933

3V3SB

0.01U

GND

R931 2R2

R932 2R2

R444

4K7

C453

+5V

C929

3P3

NC/

R445

470R

C730

3P3

NC/

GND

WIFI_SW

+5V

T

C731

0.01U

GND

Z2

T T

C732

0.1U

+5V

Z3

RST

GND

GND

IR2

GND

D-

D+

RST

WAKE_1

WGND

WIFI_PWR

T

T

D-

D+

WAKE_1

GND

KEY

IR4

IR1

GND

P402

6

5

4

3

2

1

12

11

10

P406

9

8

7

6

5

4

3

2

1

H

G

F

GND

GND

GND

HDMI/MHL Prot1

E

5V

3

R416

10K

MHL_SENSE

12

12

12

12

H1_HPD

12

R478

R478

R478

20K

20K

20K

5V

21

H1_SCL

H1_SCL

H1_SDA

H1_SDA

H1_SCL

H1_SDA

VBUS

B

C

E

GND

Q412

BT3904

B

B

B

GND

VBUS

VBUS

D410

BAT54C

R415

4K7

D

H1_SCL_IN

(5)

H1_SDA_IN

(5)

R417

100R

R418

100R

D414

PESD5V0S1BL

D405

PESD5V0S1BL

D403

C

PESD5V0S1BL

D404

PESD5V0S1BL

D412

PESD5V0S1BL

GND

MHL_SENSE

B

3V3SB

3V3SB

3V3SB

3V3SB

3V3SB

R481

300K

R479

R479

R479

47K

47K

47K

H1_RX2+ H2_RX2+

(5)

(5)

(5)

C

C

C

E

E

E

(5)

(5)

(5)

(5)

Q413

Q413

Q413

BT3904

BT3904

BT3904

MHL_SENSE

MHL_SENSE

H1_RX2-

H1_RX1+

H1_RX1MHL+/H1_RX0+

MHL-/H1_RX0-

H1_CLK+

(5)

H1_CLK-

H1_CLK-

(5)

R476

R476

R476

10K

10K

10K

S

G

D

3

1

VBUS

VBUS

Q414

MV65XP

2

R480

820R

4R7

100R

4R7

4R7

4R7

4R7

4R7

4R7

4R7

4R7

4R7

4R7

4R7

D413

BAT54A

R499

33R

H1_RX2+_IN

H1_RX2+_IN

R484

R413

H1_RX2-_IN

H1_RX2-_IN

R485

R485

R486

R486

R419

R419

MHL+/H1_RX0+_IN

MHL+/H1_RX0+_IN

R487

R487

MHL-/H1_RX0-_IN

MHL-/H1_RX0-_IN

R488

H1_CLK+_IN

H1_CLK+_IN

R489

R490

H1_CLK-_IN

H1_CLK-_IN

MHL_PWR_EN

H1_HPD

H1_RX1+_IN

H1_RX1+_IN

H1_RX1-_IN

H1_RX1-_IN

+5V

+5V

R482

100R

GND

GND

GND

1

2

3

4

13-ESD6V0-A4B0P6

1

2

3

4

ESDD420

13-ESD6V0-A4B0P6

C445

C467

0.1U

10U

GND

R483

300K

C446

0.047U

GND

10

9

8

7

65

ESDD419

10

9

8

7

65

H_CEC

VBUS

H1_HPD

5 1

EN/EN# OC

G524

GND

U404

OUTIN

GND

GND

H1_SCL

H1_SDA

2

34

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

C448

0.1U

P404

GND1

RX1+

RX1-

GND3

RXC+

RXC-

NC2

DDCDA

VCC

C447

10U

GND

RX2+

RX2-

GND2

RX0+

RX0-

GND4

NC1

DDCCLK

GND5

HPD

VBUS

GND

HDMI Port2

P405

R450

330R

NC/

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

GND

GND

GND

GND

C411

R451

82R

NC

H_CEC

H1_ARC

H2_SCL

H2_SCL

H2_SDA

H2_SDA

H2_5V

H2_HPD

1U

NC/

RX2+

GND1

RX2-

RX1+

GND2

RX1-

RX0+

GND3

RX0-

RXC+

GND4

RXC-

NC1

NC2

DDCCLK

DDCDA

GND5

VCC

HPD

H1_ARC_OUT

5V

5V

GND

GND

GND

GND

R446

47K

NC/

R447

47K

NC/

1

2

3

GND

4

1

2

3

4

13-ESD6V0-A4B0P6

R452

47K

R453 47K

H1_ARC

H1_ARC

ESDD421

13-ESD6V0-A4B0P6

10

9

8

7

65

ESDD422

R459

R460

H_CEC

10

9

8

7

65

100R

100R

GND

GND

GND

H2_RXC+_IN

H2_RXC+_IN

H2_RXC-_IN

H2_RXC-_IN

H2_SCL_IN

H2_SDA_IN

3V3SB

H2_RX2+_IN

H2_RX2+_IN

H2_RX2-_IN

H2_RX1+_IN

H2_RX1-_IN

H2_RX0+_IN

H2_RX0+_IN

H2_RX0-_IN

H2_RX0-_IN

LL4148

D429

R468

27K

100R

4R7

4R7

(5)

(5)

R469

4R7

4R7

4R7

4R7

4R7

4R7

H2_CLK+

R497

R498

HDMI_CEC

R491

R492

R493

R494

R495

R496

H2_CLK-

3V3SB

3V3SB

3V3SB

3V3SB

H2_RX2-

H2_RX1+

H2_RX1-

H2_RX0+

H2_RX0-

(5)

(5)

R475

R475

R475

47K

47K

47K

GND

(5)

(5)

(5)

(5)

(5)

(5)

D406

PESD5V0S1BL

D407

PESD5V0S1BL

D408

PESD5V0S1BL

D409

PESD5V0S1BL

D411

PESD5V0S1BL

D430

PESD5V0S1BL

(5)

C

C

C

Q410

Q410

Q410

B

B

B

BT3904

BT3904

BT3904

E

E

E

GND

H2_SCL

H2_SCL

12

H2_SDA

12

H2_5V

H2_5V

12

H2_HPD

12

H_CEC

12

/NC

H1_ARC

12

R471

47K

R472

R472

R472

910R

910R

910R

HDMI2_HPD

B

B

B

C

C

C

E

E

E

GND

H2_5V

H2_5V

Q411

Q411

Q411

BT3904

BT3904

BT3904

R473

R473

R473

75R

75R

75R

R474

R474

100K

100K

H2_HPD

H2_HPD

HDMI Port3

P407

3V3SB

3V3SB

3V3SB

3V3SB

3V3SB

10

11

12

13

14

15

16

17

18

19

1

2

3

4

5

6

7

8

9

R439

R439

R439

47K

47K

47K

H3_HPD

GND

H_CEC

B

B

B

RX2+

GND1

RX2-

RX1+

GND2

RX1-

RX0+

GND3

RX0-

RXC+

GND4

RXC-

NC1

NC2

DDCCLK

DDCDA

GND5

VCC

HPD

When AC power OFF and HDMI sourc is plugged in, HPD is Low

H3_SCL

H3_SDA

H3_SDA

H3_5V

H3_5V

(5)

C

C

C

BT3904

BT3904

BT3904

E

E

E

GND

GND

R440

R440

R440

47K

47K

47K

HDMI3_HPD

HDMI3_HPD

Q415

Q415

Q415

R441

R441

R441

910R

910R

910R

B

B

B

GND

GND

GND

1

2

3

4

ESDD423

13-ESD6V0-A4B0P6

1

2

3

4

ESDD424

13-ESD6V0-A4B0P6

R435

R435

R435

47K

47K

47K

47KR436

H3_5V

H3_5V

R442

R442

R442

75R

75R

75R

C

C

C

Q416

Q416

Q416

BT3904

BT3904

BT3904

E

E

E

GND

R443

R443

R443

100K

100K

100K

10

9

8

7

65

R437

R438

H3_HPD

H3_HPD

10

9

8

7

65

100R

100R

GND

H3_SCL_IN

H3_SDA_IN

GND

GND

H3_RX2-_IN

H3_RX1+_IN

H3_RX1-_IN

H3_RX0+_IN

H3_RX0-_IN

H3_RXC+_IN

H3_RXC+_IN

H3_RXC-_IN

H3_RXC-_IN

(5)

(5)

GND

4R7

4R7

4R7

4R7

4R7

4R7

4R7

4R7

H3_RX2+

H3_RX2+

R427

H3_RX2-

H3_RX2-

R428

H3_RX1+

H3_RX1+

R429

H3_RX1-

H3_RX1-

R430

H3_RX0+

H3_RX0+

R431

H3_RX0-

H3_RX0-

R432

H3_CLK+

H3_CLK+

R433

H3_CLK-

H3_CLK-

R434

D415

D415

D415

2 1

2 1

PESD5V0S1BL

PESD5V0S1BL

PESD5V0S1BL

D416

D416

D416

2 1

PESD5V0S1BL

PESD5V0S1BL

PESD5V0S1BL

D417

PESD5V0S1BL

D418

PESD5V0S1BL

12

12

12

12

12

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

H3_SCL

H3_SCL

H3_SDA

H3_5V

H3_5V

H3_HPD

H3_HPD

E

D

C

When Power on or Standby and HDMI source is plugged in, HPD is High

H1_HPD_CBUS

H1_HPD_CBUS

GND

For MTK5507, reading EDID when HPD is High

A

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

...

...

...

...

Index-Lab

Last saved :

DD-MM

DD-MM

DD-MM

DD-MM

When AC power OFF and HDMI sourc is plugged in, HPD is Low

When Power on or Standby and HDMI source is plugged in, HPD is High

For MTK5507, reading EDID when HPD is High

...

...

...

...

...

...

...

...

NAME Last modifDESCRIPTIONDATE

22/08/2016:15:33

...

...

...

...

SBU :

TCLNO:

.............

DESIGNATION