Page 1

HPC model Service Manual

Factory Model : 17”19”LCD MONITOR(DVI)

TABLE OF CONTENTS

I. SAFETY PRECAUTIONS

II.PRODUCT SAFETY NOTICE

III.SERVICE NOTES

V. SERVICE TOOL & EQUIPMENT REQUIRED

VI. SPECIFICATIONS

VII.LCD MONITOR BLOCK DIAGRAM

VIII.TROUBLE SHOOTING FLOW CHART

IX . LCD MONITOR ADJUSTMENT

X. USER SAFETY NOTICE

electronic(shenzhen)co.,LTD

HPC

January 2007

1

Page 2

I.SAFETY PRECAUTIONS

This monitor is manufactured and tested on a ground principle that a user's safety comes first. However, improper

use or installation may cause damage to the monitor as well as to the user. Carefully go over the following

WARNINGS before installing and keep this guide handy.

WARNINGS:

1. This monitor should be operated only at the correct power sources indicated on the label on the rear end of the

monitor. If you're unsure of the power supply in your residence, consult your local dealer or power company.

2. Use only the special power adapter that comes with this monitor for power input.

3. Do not try to repair the monitor yourself, as it contains no user-serviceable parts. Only a qualified technician

should repair this monitor.

4.Do not remove the monitor cabinet. There are high-voltage parts inside that may cause electric shock to human

bodies, even when the power cord is unplugged.

5.Stop using the monitor if the cabinet is damaged. Have it checked by a service technician.

6 Put your monitor only in a clean, dry environment. If it gets wet, unplug the power cable immediately and consult

your service technician.

7. Always unplug the monitor before cleaning it. Clean the cabinet with a clean, dry cloth. Apply non-ammonia

based cleaner onto the cloth, not directly onto the glass screen.

8.Do not place heavy objects on the monitor or power cord.

II. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety visual inspections and the protection

afforded by them cannot necessarily be obtained by using replacement components rated for higher voltages,

wattage, etc. Before replacing any of these components read the parts list in this manual carefully. The use of

substitute replacement parts that do not have the same safety characteristics as specified in the parts list may

create shock, fire, or other hazards.

III.SERVICE NOTES

1. When replacing parts or circuit boards, clamp the lead wires around terminals before soldering.

2. When replacing a high wattage resistor (more than 1W of metal oxide film resistor) in circuit board, keep the

resistor about 5mm away from circuit board.

3. Keep wires away from high voltage, high temperature components and sharp edges.

4. Keep wires in their original position so as to reduce interference.

5. Usage of this product please refers to also user's manual.

V. SERVICE TOOL & EQUIPMENT REQUIRED

1. SIGNAL GENERATOR OR PC

2. SCREW DRIVER

3. IRON

4. ABSORBER

5. SOLDER

VI.SPECIFICATIONS

5.1 PRODUCT SPECIFICATIONS

LCD panel 17’’/19" TFT

Power management Energy Star compliant VESA

DPMS compatible

Displayable Resolution 1024 x 1280 75Hz (max.)

2

Page 3

Pixel Dimension 0.264 (V) x 0.264 (H) mm /0.296(H) / 0.296(V) mm

LCD Display Color 8bit

Viewing Angle Horizontal: ± 80

Contrast Ratio 500 : 1

Brightness 300 cd/m2

Response Time 12ms

Active Display Area 337.920 (H) x 270.336(V) /376.32mm x 301.056mm

Temperature Operating 0°C ~ +35°C

Storage -20°C ~ +60°C

Compliance CE, FCC ,CB,CCC

Power Input Voltage AC 110-240V

Consumption 40w(max)

Audio 2w(L) + 1(R)

5.2 SUPPORTING TIMING CHART(timing chart)

o

H Vertical: ±80o V

MODE

L

support frequency

H-

ynnc (

KHZ)

bandwidt

h ( MHZ

)

Signal polarity

H V

1 VGA 640 X 480 60Hz 31.47 25.175 - +

2 VESA 640 X480 72Hz 37.86 31.5 - +

3 VESA 640 X 480 75Hz 37.5 31.5 - +

4 VGA 720 X 400 70HZ 31.47 28.322 - +

5 VESA 800 X 600 60Hz 37.88 40 + +

6 VESA 800 X 600 72Hz 48.08 50 + +

7 VESA 800 X 600 75Hz 46.88 49.5 + +

8 MAC 832 X 624 75Hz 49.72 57.28 - +

9 VESA 1024 X 768

48.36 65 - -

60Hz

10 VESA 1024 X 768

56.48 75 - -

70Hz

11 VESA 1024 X 768

60.02 78.75 + +

75Hz

12 MAC1152X 870 75Hz 68.68 100 - 13 VESA1280X1024

60 108 + +

60Hz

14 VESA1280 X 1024

80 135 + +

75Hz

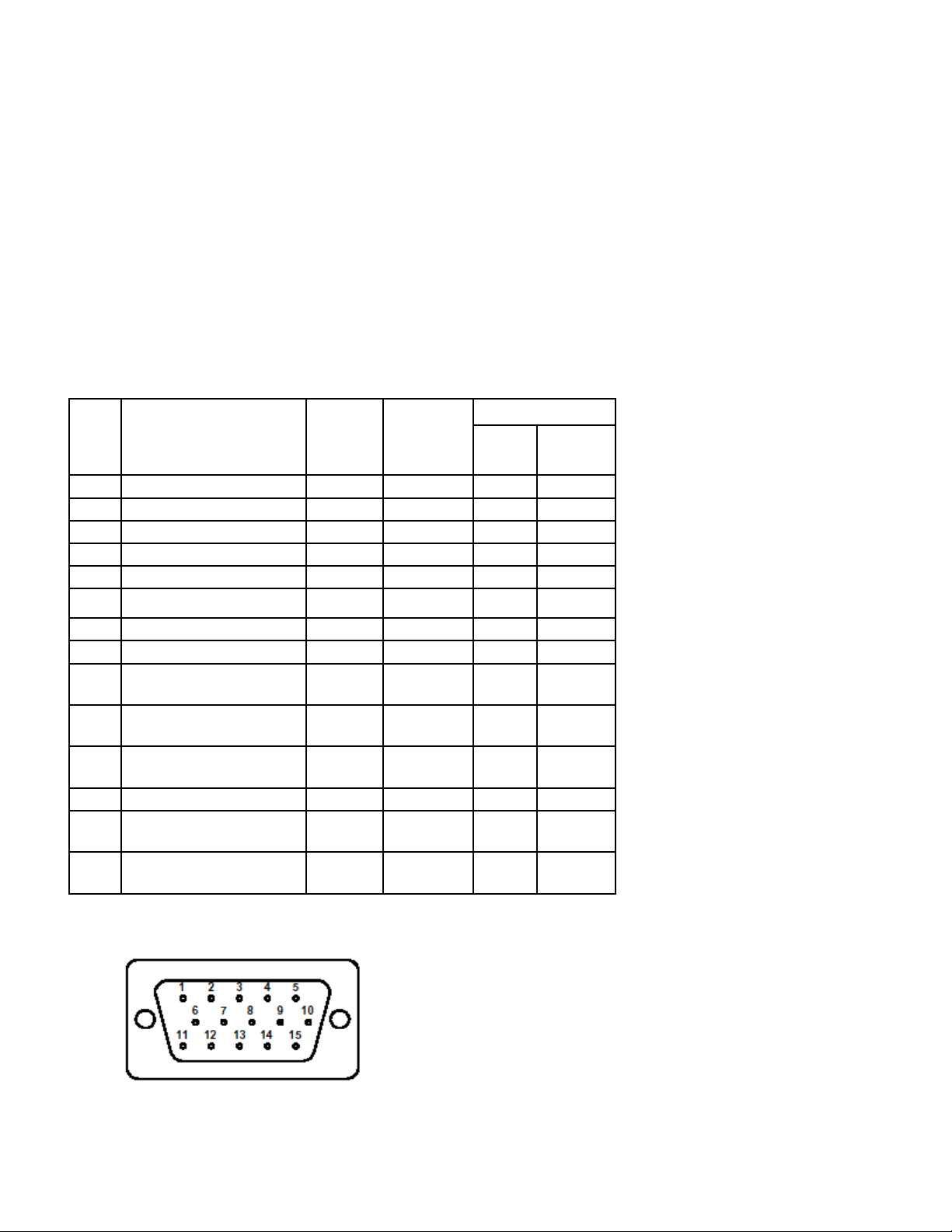

5.3 Pin - Assignment of 15-pin D-sub:

CONNECTOR SIGNAL DESCRIPTION

3

Page 4

1.RED 2.GREEN 3.BLUE 4.NC 5.GND

6.GND 7.GND 8.GND 9. NC 10.GND

11.NC 12.SDA 13.H.hync 14.V.hync 15.SCL

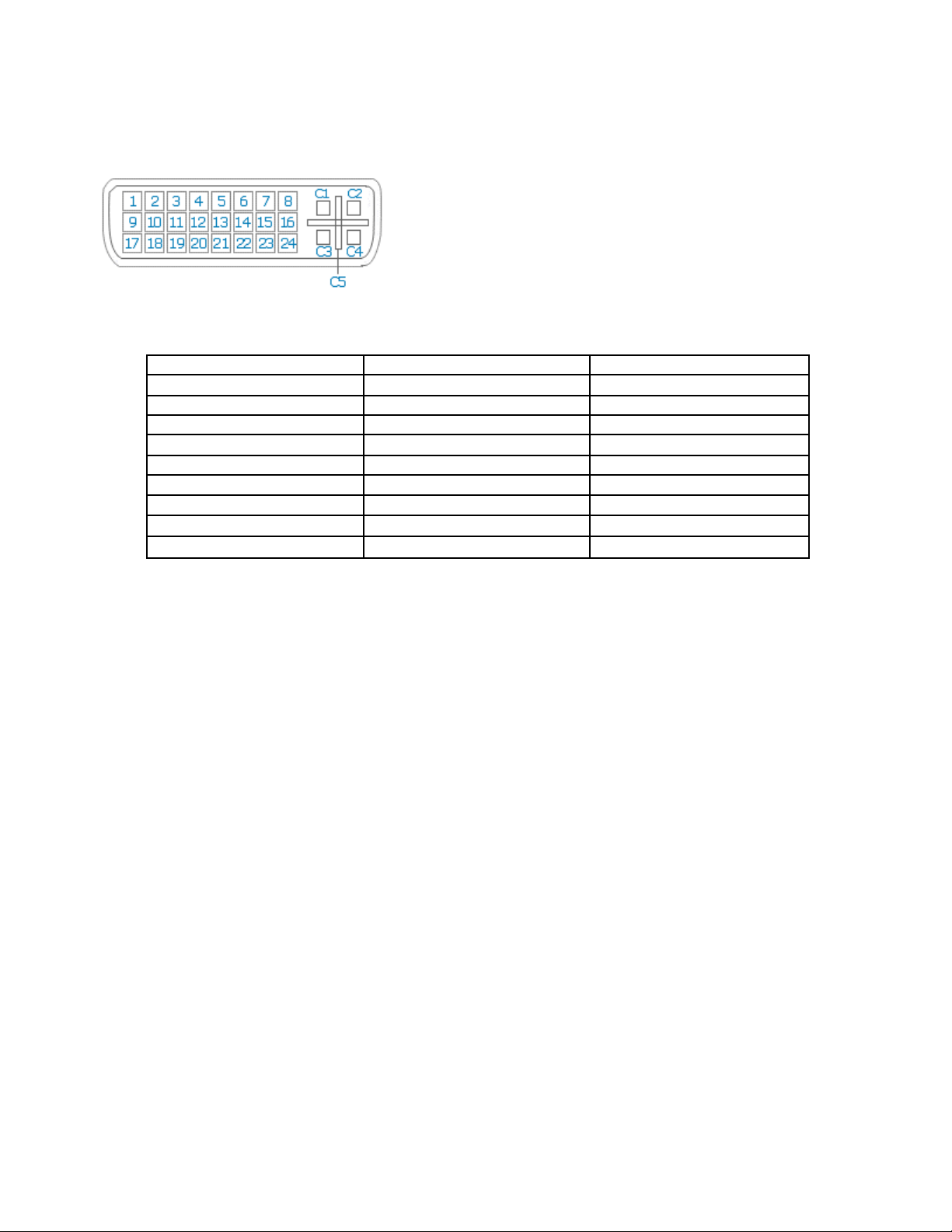

Pin - Assignment of DVI:

1. TMDS Data 2- 9. TMDS Data 1- 17. TMDS Data 0-

2. TMDS Data 2+ 10. TMDS Data 1+ 18. TMDS Data 0+

3. TMDS Data 2/4 shield 11. TMDS Data 1/3 shield 19. TMDS Data 0/5 shield

4. TMDS Data 4- 12. TMDS Data 3- 20. TMDS Data 5-

5. TMDS Data 4+ 13. TMDS Data 3+ 21. TMDS Data 5+

6. DDC Clock 14. +5V Power 22. Clock shield

7. DDC Data 15. GND 23. Clock +

8. Analog Vertical Sync 16. Hot Plug Detect 24. Clock C1.NC C2.NC C3.NC

C4.NC C5.NC

VII: BLOCK DIAGRAM

4

Page 5

VIII:TROUBLE SHOOTING FLOW CHART

Check on/Off

Replacing AC Power

Check

Check Y1

Check U2 on

3.3V

others.

OK

ok

7.1 No power.

Check peripheral

electrocircuit

Replacing

Panel

NG

OK

Check component on inverter

board.

NG

Replacing inverter

Cn6 pin1 12V

OK

OK

OK

Replacing RTD2525or

NG

NG

NG

Check U6 mcu

touch area.

Check power supply

Check electrocircuit

5

Page 6

7.2 No display

Checkcn1

Check Pcsignaland

NG

NG

7.3 loss color .

Check cn10 5V For panel

OK

Check cn7 connectoru

OK

OK

Replacing scaler IC

Checkcn6 pin1 12v

NG

Rework the connecter

NG

Check circuitry

7.4 NO AUDIO

Check R/G/B signal input

Check .signal wave

OK

NG

Rework cn10 to panel

connector

Check PC signal R/G/B

6

Page 7

Open volume in

OSD,

NG

OK

Check 12V on

U8

pin15/pin16,and

5.5v on pin14/17

Replacin

g

Check CN12

connector

OK

NG

Check pc audio

input

ok

NG

Replacing

TDA7496L

OK

IX.Adjustment

8.1 Adjustment Conditions and Precautions:

1.1.. Power supply voltage:

AC 110/120V± 10% 60 Hz± 5%, AC 220/240V± 10% 50 Hz ± 5%.

1.2 Warm up time:

The display must be power ON for at least 30 minutes at full white pattern before starting alignments. This is

especially critical in color temperature and white balance adjustments.

1.3signal input

reference the front detail specifications and timing table.

8.2Adjustment procedure

2.1. Timing : 1280x1024@75Hz.

2.2 Pattern : Full white.

2.3 Set Chroma Color analyzer at the center of screen and along a perpendicular to the screen at 20cm from the

display.

2.4. Under the normal display model ,press “Down” to close your monitor, then press Up to open it ,monitor will be

into

7

Page 8

factory preset mode, and pull out signal cable, will be BURN in mode.

2.5 .Select “9300” menu, adjust “red” until x=281±30, adjust “blue” until y=311±30. Then exit “9300” menu.

2.6 Select “6500” menu, adjust “red” until x=313±30, adjust “blue” until y=329±30. Then exit “6500” menu.

2.7 DC ON/OFF again, monitor will be exit factory mode menu.

2.8.On the OSD menu, color temperature set to 6500.

2.9. Change each mode on the timing table in turns and execute the “Auto Adjust ” function, then all the data of the

each mode will be auto saved after finish the “Auto Adjust “ function.

X. Notice

9.1 I feel very thankful for buying our LCD products,and you can regard our repairing rules as your reference ;if

we have

changed our repairing rules ,you will not be told again .Also, the eaxt repairing regulations should be in accordance

with the

attched materials (include the product spcfication and use regulation)

9.2 The monitor has no any repairing material ,if you want to get service,please get in touch with local

agent, or dail our free telephone: 800-830-7242

9.3 The ultimate explanation right of the repairing spcefication should be owed by the R&D Center of Hui

Pu Electronics (Shen Zhen) Co.Ltd .

HPC electronic(shenzhen)co.,LTD

January 2007

8

Page 9

5

12VCC

4

3

2

1

12VCC 4

C1

+

470uF/16V

BACKLIGHT_PW_5N

BRIGHTNESS

R3 4K7

C9

1uF

R7

4K7

Q3

MMBT3904

2 3

EC8.0-3.0

5DVCC2,3,4

MMBT3904

+5V

+5V

5DVCC

R1

5DVCC

C6

100nF

1

MMBT3904

R5 4K7

220

5V => 3.3V

Q2

2 3

R4

C14

1uF

R8

100

1K

Q1

1

2 3

RTD_VBRI 3

U4

1

2

3 6

4

CEM9435

SOIC08P-4MM

R2

BACKLIGHT_PW 2

4K7

PANELVCC

PANELVCC

8

7

5

C15

22uF/16V

EC5.0-2.0

PANELVCC 3

C16

100nF

C4

470uF/16V

EC8.0-3.0

C5

100nF

5DVCC2,3,4

5DVCC2,3,4

L1 BEAD/40R

C7

+

NC

C10

+

22uF/16V

EC5.0-2.0

C12

+

22uF/16V

EC5.0-2.0

L0805

TO263-TO223

U1 ATC1084_3Y3

3

VIN

VOUT

GND

1

U2 AMC1117-3.3V

3

VIN

VOUT

GND

1

U3 AMC1117-2.5V

3

VIN

VOUT

GND

1

C2

47uF/16V

EC5.0-2.0

2

2

2

C3

100nF

3DVCC

C8

+

22uF/16V

EC5.0-2.0

RTD_3DVCC

RTD_3DVCC

C11

+

22uF/16V

EC5.0-2.0

2.5DVCC

C13

+

22uF/16V

EC5.0-2.0

5DVCC 2,3,4

MCU_VCC

3DVCC 2

MCU and PANEL

DGND 2,3,4

RTD_3DVCC 3

2.5DVCC 3

RTD 2.5DVCC

Fullerton Technology(HongKong) LTD.

Room 1001 Block West,Shopping Plaza,No 123 Shengnan RD east Shengzhen China

Fullerton_SZ

Thursday, March 10, 2005

4

3

01.POWER

Size

CAGE Code

B

<Cage Code>

Scale

2

DWG NO

RTD2523 for HPC

Sheet

14

1

Rev

A

of

1

D D

JP1

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

1*8P_2.0mm_HEADER

DIP08PM-2.0-V

8

C C

3DVCC 5DVCC

3DVCC2

1*3P_2.54mm_Jumper

B B

PANEL_PW 0: PANEL_VCC ON

PANEL_PW 1: PANEL_VCC OFF

R9 4K7

PANEL_PW332

A A

5

JP2

123

123

1

R6

47K

1

Q4

MMBT3904

2 3

Page 10

5

Bus_Power3

WinBond

123

VGA5V3

5DVCC1,3,4

678

RP3

NC/4K7X4

4 5

D D

MCU_VCC

R21

C C

R25 0/NC

4K7

AUDIO_PWM3,4

CONNECTED3

Hot_Plug3

DDC2_SCL3

DDC2_SDA3

7496MUTE4

B B

DDC_SDA3

DDC_SCL3

RS232 and ISP

For Debug

1

A A

16

JP4

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

1*9P_2.0mm_HEADER

DIP09PM-2.0-V

GREEN_LED

RED_LED

R28 0

R26 0

14

R29 100

GLED

R31 100

RLED

JP3

1

2

3

4

1*4P_2.0mm_HEADER

C23

100nF

KEYPAD CONNECTOR

5

1

2

3

4

C24

100nF

21

BAT54C

3

SOT-23

123

MCU_VCC

RXD

100nF

4

D1

678

C25

4

3

5DVCC 5DVCC

Support PC99

D2

1N4148

3DVCC1

3DVCC

L3 BEAD/40R

L0603

+

RP4

4K7X4

4 5

C26

100nF

R22

4K7

C27

100nF

R23

4K7

RESET3

IR_RECEIVER

TXD

RXD

POWER_KEY

LED_G

LED_O

DOWN_KEY

UP_KEY

AUTO_KEY

MENU_KEY

HLIGHT_KEY

C28

100nF

R12

4K7

C18

10uF/16V

EC4.0-2.0

R24

10K

Q5

MMBT3906

2 3

1

R15 4K7

21

D3

BAT54C

3

SOT-23

2

P5.0/DA0

3

P5.1/DA1

4

P5.2/DA2

5

P5.3/DA3

6

P5.4/DA4

7

P5.5/DA5

8

HSCL2/P5.6

9

HSDA2/P5.7

14

P3.2/INT0

15

P3.3/INT1

16

P3.4/T0

17

P3.5/T1

18

P7.6/CLKO

19

P7.7

13

HDA1/TX/P3.1

11

HCL1/RX/P3.0

U6

MTV512

DGND1,3,4

SOT-23

Q6

MMBT3906

2 3

SOT-23

1

MCU_VCC

RST

10

RST

1 2

R30 1M

C21

22pF

44

VCC

MTV512

XTAL2

20

Y1

24MHz

C22

22pF

L2

BEAD/40R

L0603

C19

100nF

43424140393837

P1.0

XTAL1

21

P1.1

P1.2

VSS

22

R13 1K

C20

+

22uF/16V

EC5.0-2.0

P1.3

P1.4

P1.5

P6.7

P6.6/CLK0

P6.5

P6.4

P6.3/AD3

P6.2/AD2

P6.1/AD1

P6.0/AD0

VSYNC

NC

12

R10

330

LED_G

Q7

1

MMBT3904

2 3

678

RP2

4K7X4

123

4 5

36

P1.6

P1.7

1

NC

33

NC

31

30

29

28

27

26

25

24

32

NC

35

R27

10K

Fullerton_SZ

Friday, March 11, 2005

3

C

12

B

RED_LEDGREEN_LED

123

MCU_VCC

123

2

1

3

E

R14

1K

IICSDA

IICSCL

678

RP1

4K7X4

4 5

678

RP5

4K7X4

4 5

R11

330

1

MMBT3904

2 3

IICSDA

IICSCL

RTD_SDO/SDI

RTD_SCLK

IICSCL

IICSDA

PANEL_PW33

BACKLIGHT_PW

MCU_VCC

678

RP6

123

4 5

LED_O

Q8

R17 100

R16 100

4K7X4

MCU_VCC

DGND1,3,4

RTD_SDO/SDI 3

RTD_SCLK 3

RTD_SCSB 3

RTD_RESET 3

IICSCL

IICSDA

PANEL_PW33 1

BACKLIGHT_PW 1

HLIGHT_KEY

MENU_KEY

AUTO_KEY

UP_KEY

DOWN_KEY

POWER_KEY

8

5

6

4

U5

5DVCC

SDA

SCL

GND

X24C16

TEST

Fullerton Technology(HongKong) LTD.

Room 1001 Block West,Shopping Plaza,No 123 Shengnan RD east Shengzhen China

02.MCU/MTV512M64 or STK6011

Size

CAGE Code

B

<Cage Code>

Scale

2

DWG NO

RTD2523 for HPC

Sheet

1

7

3

A2

2

A1

1

A0

24

of

R18

0

C17

100nF

R19

NC/47K

Rev

A

Page 11

5

JP5

D D

SHELL1

DATA2-

DATA2+

DATA2/4 SHLD

DATA4-

DATA4+

DDC CLK

DDC DATA

A-VSHNC

DATA1-

DATA1+

DATA1/3 SHLD

DATA3-

DATA3+

H-PLUG-DET

DATA0-

DATA0+

DATA0/5 SHLD

DATA5-

DATA5+

CLK-SHLD

CLK+

A-RED

A-GREEN

A-BLUE

A-HSYNC

A-GND

SHEL12

25

RX2N

1

RX2P

2

3

4

5

DDC2_SCL

6

DDC2_SDA

7

8

RX1N

9

RX1P

10

11

12

13

14

+5v

15

GND

16

RX0N

17

RX0P

18

19

20

21

22

RXCP

23

RXCN

24

CLK-

C1

C2

C3

C4

C5

26

R33 0/500

R38 100

R34 100

R35

1K

Bus_Power 2

Hot_Plug 2

RTD_3DVCC1

R36

R39 NC

4K7

DVI24+5P

<PCB Footprint>

TMDS_AVCC

3

1%

3

1

D6

BAV99

R52

1%

75

2

R54 100

R55 100

R57

2K

R40 NC

L8 BEAD/40R

L0603

L9 BEAD/40R

L0603

L10 BEAD/40R

L0603

AVS

C71

10pF

R41

4K7

C56 10pF

R45 1M

C59 10pF

C63 10pF

C72

22pF

RTD_3DVCC

RTD_3DVCC1

C51

22uF/16V

EC5.0-2.0

RTD_3DVCC1

AHS

AVS

ADC_VCC ADC_VCCADC_VCC

1

2

1

2

D4

BAV99

3

C C

B B

BIN GINRIN

DDCSCL

DDC_SCL

VSYNC_IN SOG

HSYNC_IN

RTD_3DVCC RTD_3DVCC

2

DGND

3

1

BAV99

VSIN

HSIN

DDCSDA

D7

15

14

13

12

NC

11

2

JP7

VGA_CON15

1

D8

BAV99

3

L12 BEAD/40R L0603

1 2

1 2

L13 BEAD/40R L0603

BAV99

3

DGND

5

DGND

10

NC

4

NC

9

VGA_B+

3

VGA_B-

8

VGA_G+

2

VGA_G-

7

VGA_R+

1

VGA_R-

6

D5

2

A AA

CONNECTED 2

VGA5V 2

BIN

GIN

RIN

R50

1%

75

A

1

VGAHS

VGAVS

R56

2K

R51

75

DGND 1,2,4

5DVCC

D9 1N4148

1 2

5DVCC1,2,4 VGA5V 2

U8

1

TEST

VDD

2

NC

VCLK

3

WP

SCL

4 5

VSS SDA

24LC21

SOIC08P-4MM

A A

8

7

6

D10 1N4148

R66 100

R67 100

R68 100

1

12

12

C73

100nF

JP9

1*12P_2.0mm_HEADER

DIP12PM-2.0-V

5

R64

10K

DDC_SCL

DDC_SDA

12

11

10

9

8

7

6

5

4

3

2

1

5DVCC

D11 1N4148

5DVCC1,2,4

R65

10K

AVS

DDC_SCL 2

DDC_SDA 2

12

VSYNC_IN

11

HSYNC_IN

10

9

8

7

6

5

4

3

2

1

RIN

GIN

BIN

DDC_SDA

DDC_SCL

A

1 2

U9

1

TEST

2

NC

VCLK

3

WP

4 5

VSS SDA

24LC21

SOIC08P-4MM

4

RTD_3DVCC

3DVCC1

PLL_GND

RTD_3DVCC

L7 BEAD/80R

+

R43 100

R44 100

R46 100

R47 100

R48 100

R49 100

R53 100

L6 BEAD/80R

L0805

22uF/16V

EC5.0-2.0

L0805

22uF/16V

EC5.0-2.0

C55 47nF

C57 47nF

C58 47nF

C60 47nF

C61 47nF

C62 47nF

C64 47nF

RTD_3DVCC

C65

22uF/16V

EC5.0-2.0

TMDS_AVCC

C49

+

R3PVCC

C46

+

PLL_GND

Near to Chip

+

B+

B-

G+

G-

R+

R-

AHS

AVS

L11 BEAD/80R

L0805

C52

100nF

AHS

AVS

22uF/16V

EC5.0-2.0

PLL_GND

C47

100nF

RX2P

RX2N

RX1P

RX1N

RX0P

RX0N

RXCP

RXCN

C53

100nF

C66

USE COPPER

1.如果Reset要用RTD2523 R78=0 ,

R81=NC(C10、R25 )

2.如果Reset要用uP

R81=100(C10

8

VDD

7

R71 100

6

SCL

R72 100

4

可不上 。

来发,

、

R25 )

一定要上 。

D12 1N4148

12

C74

100nF

来发,

R78=NC ,

R69

10K

DDC2_SCL

DDC2_SDA

Bus_Power 2

R70

10K

C43

22pF

C44

22pF

R42 1K

C54

100nF

ADC_VCC

+

A

DDC2_SDA2

DDC2_SCL 2

DDC2_SDA 2

L4 BEAD/80R

L0805

R32

24.576MHz

1M

C48

100nF

C50

100nF

B+

BSOG

G+

GR+

R-DDC_SDA

C67

100nF

RTD_SCLK2

RTD_SDO/SDI2

RTD_SCSB2

RTD_RESET2

DDC_SDA2

DDC_SCL2

DDC2_SCL2

C29

22uF/16V

EC5.0-2.0

Y2

C68

100nF

RESET2

R3DVCC

+

U6

4

DPLL_VDD

5

APLL_VDD

3

DPLL_GND

8

APLL_GND

6

PLL_TEST1

7

PLL_TEST2

14

RX2P

15

RX2N

17

RX1P

18

RX1N

20

RX0P

21

RX0N

23

RXCP

24

RXCN

9

TMDS_TST/PWM1

12

EXT_RES

11

TMDS_VDD

13

TMDS_VDD

19

TMDS_VDD

26

TMDS_VDD

10

TMDS_GND

16

TMDS_GND

22

TMDS_GND

25

TMDS_GND

30

B+

31

B-

33

SOG/ADC_TEST

34

G+

35

G-

37

R+

42

AHS

43

AVS

C69

100nF

C30

100nF

XO

XI

ADC_VDD

ADC_VDD

29

36

C70

100nF

R58 NC/0

R59 0/NC

DDC_SDA

DDC_SCL

DDC2_SDA

DDC2_SCL

3

C33

C31

C32

C34

100nF

100nF

100nF

100nF

1

2

109

120

72

57

96

84

XI

XO

48

3.3V Ground

3.3V Ground

3.3V Ground

3.3V Ground

3.3V Ground

3.3V Ground

3.3V Ground

3.3V POWER 2.5V POWER

TMDS

RTD2523

PQFP128P-14X20MM

ADC

MCU

SDIO[0]

SCLK

SCSB

TCON[2]/SDIO[3]/PWM2

TCON[3]/SDIO2]

TCON[4]/SDIO[1]

5450111

515253

100R61

100R60

100R62

100R63

3

RESET#

56

ADC_GND

ADC_GNDR-ADC_VDD

ADC_GND

ADC_REFIO

ADC_GND

40

2738413928

32

C35

100nF

121

3.3V Power

C36

100nF

83

95

110

3.3V Power

3.3V Power

DDC2B

DDCSDA

DDCSCL

47

125

46

71

58

3.3V Power

3.3V Power

3.3V Power

DDCSCL2

DDCSDA2

126

49

98

127

2.5V Power

3.3V Power

Video Input

TCON Output

TCON[11]/V[0]/ARED0

TCON[10]/V[1]/BRED1

114

115

116

C37

100nF

128

69

2.5V Power

2.5V Power

2.5V Power

TCON[7]/V[4]/AGRN0

TCON[9]/V[2]/BRED0

TCON[8]/V[3]/AGRN1

TCON[6]/V[5]/DHS

118

117

119

122

C38

100nF

97

444570

2.5V Ground

2.5V Ground

2.5V Ground

TCON[0]/VCLK/DCLK

TCON[1]/V[7]/DENA

TCON[5]/V[6]/DVS

124

123

C39

C40

100nF

100nF

2.5V Ground

AR1P/TCON[0]/NC/ARED3

AR2N/TCON[1]/NC/ARED4

AR2P/TCON[5]/NC/ARED5

AR3N/TCON[6]/NC/ARED6

AR3P/TCON[7]/NC/ARED7

AG1N/TCON[8]/NC/AGRN2

AG1P/TCON[9]/NC/AGRN3

AG2N/TCON[10]/NC/AGRN4

AG2P/TCON[11]/NC/AGRN5

RSDS OUTPUT

LVDS Output

C41

+

22uF/16V

EC5.0-2.0

U7

TCON[12]/COUT/PWM2

PWM0/REFCLK

TCON[13]/COUT/PWM2

AR1N/NC/NC/ARED2

BG3N/NC/BGRN6

BG3P/NC/BGRN7

BCLKN/NC/BGRN0

BCLKP/NC/BGRN1

BB1N/NC/BBLU2

BB1P/NC/BBLU3

BB2N/NC/BBLU4

BB2P/NC/BBLU5

BB3N/NC/BBLU6

BB3P/NC/BBLU7

AG3N/TEAN/AGRN6

AG3P/TEAP/AGRN7

ACLKN/TEBN/ABLU0

ACLKP/TEBP/ABLU1

AB1N/TECN/ABLU2

AB1P/TECP/ABLU3

AB2N/TECLKN/ABLU4

AB2P/TECLKP//ABLU5

AB3N/TEDN/ABLU6

AB3P/TEDP/ABLU7

BR1N/TOAN/BRED2

BR1P/TOAP/BRED3

BR2N/TOBN/BRED4

BR2P/TOBP/BRED5

BR3N/TOCN/BRED6

BR3P/TOCP/BRED7

BG1N/TOCLKN/BGRN2

BG1P/TOCLKP/BGRN3

BG2N/TODN/BGRN4

BG2P/TODP/BGRN5

L5 BEAD/80R

L0805

113

112

55

108

107

106

105

104

103

102

101

100

99

68

67

66

65

64

63

62

61

60

59

94

93

92

91

90

89

88

87

86

85

82

81

80

79

78

77

76

75

74

73

AG3_N

AG3_P

ACLK_N

ACLK_P

AB1_N

AB1_P

AB2_N

AB2_P

AB3_N

AB3_P

BR1_N

BR1_P

BR2_N

BR2_P

BR3_N

BR3_P

BG1_N

BG1_P

BG2_N

BG2_P

2

2.5DVCCR2.5DVCC

C42

+

22uF/16V

EC5.0-2.0

2

2.5DVCC 1

RTD_VBRI

NC/0R37

RTD_PWM2

RP7 22_4

4 5

3 6

2 7

1 8

RP8 22_4

4 5

3 6

2 7

1 8

RP9 22_4

4 5

3 6

2 7

1 8

RP10 22_4

4 5

3 6

2 7

1 8

RP11 22_4

4 5

3 6

2 7

1 8

ABLU6_AB3N_E3ABLU7_AB3P_E3+

BRED2_BR1N_O0BRED3_BR1P_O0+

BRED4_BR2N_O1BRED5_BR2P_O1+

BRED6_BR3N_O2BRED7_BR3P_O2+

BGRN2_BG1N_OKBGRN3_BG1P_OK+

BGRN4_BG2N_O3BGRN5_BG2P_O3+

FULLERTON SZ

Friday, March 11, 2005

1

PANELVCC

PANELVCC1

RTD_VBRI 1

RTD_PWM2 2,4

AGRN6_AG3N_E0AGRN7_AG3P_E0+

ABLU0_ACLKN_E1ABLU1_ACLKP_E1+

ABLU2_AB1N_E2ABLU3_AB1P_E2+

ABLU4_AB2N_EKABLU5_AB2P_EK+

PANELVCC1

ABLU1_ACLKP_E1+

ABLU3_AB1P_E2+

ABLU5_AB2P_EK+

ABLU7_AB3P_E3+

BRED3_BR1P_O0+ BRED2_BR1N_O0BRED5_BR2P_O1+

BRED7_BR3P_O2+ BRED6_BR3N_O2-

BGRN3_BG1P_OK+ BGRN2_BG1N_OKBGRN5_BG2P_O3+

PANELVCC

BGRN5_BG2P_O3+

BGRN4_BG2N_O3BGRN3_BG1P_OK+

BGRN2_BG1N_OKBRED7_BR3P_O2+

BRED6_BR3N_O2-

BRED5_BR2P_O1+

BRED4_BR2N_O1-

BRED3_BR1P_O0+

BRED2_BR1N_O0ABLU7_AB3P_E3+

ABLU6_AB3N_E3ABLU5_AB2P_EK+

ABLU4_AB2N_EK-

ABLU3_AB1P_E2+

ABLU2_AB1N_E2ABLU1_ACLKP_E1+

ABLU0_ACLKN_E1AGRN7_AG3P_E0+

AGRN6_AG3N_E0-

JP8

DIP15X2PM-2.0-V

<PCB Footprint>

2

1

Fullerton Technology(HongKong) LTD.

Room 1001 Block West,Shopping Plaza,No 123 Shengnan RD east Shengzhen China

Pitch is 2.0mm

03.SCALER/RTD2023

Size

Custom

Scale

CAGE Code

<Cage Code>

DWG NO

RTD2523 for HPC

1

JP6

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

FPC-1.0MM-30P

<PCB Footprint>

12

34

56

78

910

1112

1314

1516

1718

1920

2122

2324

2526

2728

2930

Sheet

AGRN6_AG3N_E0-AGRN7_AG3P_E0+

ABLU0_ACLKN_E1ABLU2_AB1N_E2-

ABLU4_AB2N_EKABLU6_AB3N_E3-

BRED4_BR2N_O1-

BGRN4_BG2N_O3-

30

29

Rev

of

34

A

Page 12

5

4

3

2

1

12VCC

D D

R73

4K7

1

AUDIO_L_IN

AUDIO_R_IN

5DVCC

R75 100

3

Q9

MMBT3904

2

JP10

C C

PHONE_STEREO

PHONEJACK

1

2

3

4

5

C81

100pF

L16 BEAD/40R

L17 BEAD/40R

C82

100pF

L0805

L0805

AUDIO_PWM2,3

RTD_PWM22,3

C83

103

C77 0.47uF

C80 0.47uF

C84

103

R76 200K

C86

47uF/16V

EC5.0-2.0

12VCC1

DGND1,2,3

VO1

BEAD/40R

L0805

BEAD/40R

L0805

AMP_GND

C87

100nF

L14

L15

12V_AMP

Near to Chip TDA7496L

AMP_GND

1

2

3

4

5

6

7

8

9

10

C85

470uF/16V

EC8.0-3.0

C75

+

470uF/16V

EC8.0-3.0

GND

GND

GND

INL

VAROUT_L

VOLUME

VAROUT_R

N.C.

INR

SVR

TDA7496L

C76

100nF

U10

OUTL

OUTR

MUTE

GND

GND

GND

GND

STBY

20

19

18

17

16

Vn

15

Vn

14

13

12

11

AMP_GND

C78 470uF/16V

EC8.0-3.0

C79

470uF/16V

EC8.0-3.0

AMP_OUT_L+

AMP_OUT_R+

AMP_GND

5DVCC

JP11

4

4

3

3

2

2

1

1

1*4P_2.0mm_HEADER

DIP04PM-2.0-V

5DVCC 1,2,3

7496_MUTE

Q10

MMBT3906

SOT-23

R74

4K7

High>3.5V

R77

4K7

7496MUTE 2

AMP_GND

TDA7496L PIN11 is High,then Stand_by on

B B

TDA7496L PIN12 is High,then MUTE on

Fullerton Technology(HongKong) LTD.

Room 1001 Block West,Shopping Plaza,No 123 Shengnan RD east Shengzhen China

A A

04.AUDIO/TDA7496L

FULLERTON SZ

Size

CAGE Code

B

<Cage Code>

Thursday, March 10, 2005

5

4

3

Scale

2

DWG NO

RTD2523 for HPC

Sheet

44

1

Rev

A

of

Loading...

Loading...