Page 1

FILE NO

SERVICE MANUAL

LCD TV

LCD-

PRODUCT CODE No.: 113026104

CHASSIS NO. :

P42410-00

P42410-01

P42410-02

DP42410

SSB42TTZA1I (SET)

SSB42TTZA2I (SKD)

SSB42TTZA3I (SKD-old bezel)

REFERENCE No.:SM0945007-00

Page 2

CONTENTS

1. Safety precautions .................................................................................................

2. Alignment instructions and method of software upgrading.....................................

3. Working principle analysis of the unit ...................................................................

4. Block diagram ......................................................................................................

5. IC block diagram..................................................................................................

6. Wiring diagram ...................................................................................................

7. Troubleshooting guide..........................................................................................

8. Schematic diagram ..............................................................................................

APPENDIX-A: Assembly list

APPENDIX-B: Exploded View

Removing or Installing the Stand

3

5

15

16

18

20

22

27

Page 3

Attention:

please read the following points carefully.

Safety precautions

This service manual is only for service personnel to take reference with. Before

servicing

1. Instructions

Be sure to switch off the power supply before

inserting/plugging in connection wire Anti static measures to be taken (throughout the entire production

process!):

a) Do not touch here and there by hand at will;

b) Be sure to use anti static electric iron;

c) It’s a must for the welder to wear anti static gloves.

Please refer to the detailed list before replacing components that have special safety requirements.

Do not change the specs and type at will.

replacing or welding any components or

2. Points for attention in servicing of LCD

2.1 Screens are different from one model to another and therefore not interchangeable. Be sure to

Use the screen of the original model for replacement.

2.2 The operation voltage of LCD screen is

protecting yourself and the machine when testing the system in the course of normal operation or

right after the power is switched off. Please do not touch the circuit or the metal part of the module

high voltage. Be

sure to take proper measures in

That is in operation mode. Relevant operation is possible only one minute after the power is switched

off.

2.3 Do not use any adapter that is not identical with the TV set. Otherwise it will cause fire or damage

to the set.

2.4 Never operate the set or do any installation work in bad environment such as wet bathroom,

laundry, kitchen, or nearby fire source, heating equipment and devices or exposure to sunlight etc.

Otherwise bad effect will result.

2.5 If any foreign substance such as water, liquid, metal slices or other matters happens to fall into the

module, be sure to cut the power off immediately and do not move anything on the module lest it should

cause fire or electric shock due to contact with the high voltage or short circuit.

2.6 Should there be smoke, abnormal smell or sound from the module, please shut the power off at

once. Likewise, if the screen is not working after the power is on or in the course of operation, the

power must be cut off immediately and no more operation is allowed under the same condition.

2.7 Do not pull out or plug in the connection wire when the module is in operation or just after the

power is off because in this case relatively high voltage still remains in the capacitor of the driving

circuit. Please wait at least one minute before the pulling out or plugging in the connection wire.

2.8 When operating or installing LCD please don’t subject the LCD components to bending, twisting or

extrusion, collision lest mishap should result.

2.9 As most of the circuitry in LCD TV set is composed of CMOS integrated circuits, it’s necessary to

pay attention to anti statics. Before servicing LCD TV make sure to take anti static measure and

ensure full grounding for all the parts that have to be grounded.

2.10 There are lots of connection wires between parts behind the LCD screen. When servicing or

moving the set please take care not to touch or scratch them. Once they are damaged the screen

would be unable to work and no way to get it repaired.

If the connection wires, connections or components fixed by the thermo tropic glue need to disengage

when service, please soak the thermo tropic glue into the alcohol and then pull them out in case of

damage.

3

Page 4

2.11 Special care must be taken in transporting or handling it. Exquisite shock vibration may lead to

breakage of screen glass or damage to driving circuit. Therefore it must be packed in a strong case

before the transportation or handling.

2.12 For the storage make sure to put it in a place where the environment can be controlled so as to

prevent the temperature and humidity from exceeding the limits as specified in the manual. For

prolonged storage, it is necessary to house it in an anti-moisture bag and put them altogether in one

place. The ambient conditions are tabulated as follows:

Temperature

Scope for operation

5

~+ 35

oC

Humidity

2.13 Display of a fixed picture for a long time may result in appearance of picture residue on the

screen, as commonly called “ghost shadow”. The extent of the residual picture varies with the maker

of LCD screen. This phenomenon doesn’t represent failure. This “ghost shadow” may remain

in the picture for a period of time (several minutes). But when operating it please avoid displaying still

picture in high brightness for a long time.

Scope for storage

Scope for operation

Scope for storage

0 ~

+ 40oC

0% ~

90

0% ~ 90%

%

3. Points for attention during installation

3.1 The front panel of LCD screen is of glass. When installing it please make sure to put it in place.

3.2 For service or installation it’s necessary to use specified screw lest it should damage the screen.

3.3 Be sure to take anti dust measures. Any foreign substance that happens to fall down between the

screen and the glass will affect the receiving and viewing effect

3.4 When dismantling or mounting the protective partition plate that is used for anti vibration and

insulation please take care to keep it in intactness so as to avoid hidden trouble.

3.5 Be sure to protect the cabinet from damage or scratch during service, dismantling or mounting.

4

Page 5

2. Alignment instructions

2.1. Test equipment

VG-848 (Video, YPbPr and VGA signal generator)

VG-849 (

Video, YPbPr, VGA and

HDMI signal generator)

FLUKE 54200(TV signal generator)

CA210

(white balancer)

2.2. Power test

Connect main board, power board and IR board according the wiring diagram, connect

the power and press power key(Remote controller or Keypad) button to turn on the TV.

a) Test the pin voltage of P802/power board , the data is shown in table1:

Table1

voltage data of P802

P802 Pin1,2

Voltage

GND 22.8-25.2V

Pin3,4 Pin5,6,7

GND 11.4-12.6V 4.75-5.25V

For42”

Pin8,9 Pin10,11,12

On:2V-5.5V

Off: 0-0.5V

b) Test the pin voltage of P803/power board, the data is shown in table2:

Table2 voltage data of P803

P803 Pin1,2,3,4,5 Pin6,7,8,9,10

Voltage

22.8-25.2V GND NC 2V-5V 2.5-5V PWM NC

For42”

Pin11 Pin12 Pin13 Pin14

Pin13 Pin14 Pin15 Pin16

<0.6V

2.5-5V

PWM

2-5V

5

Page 6

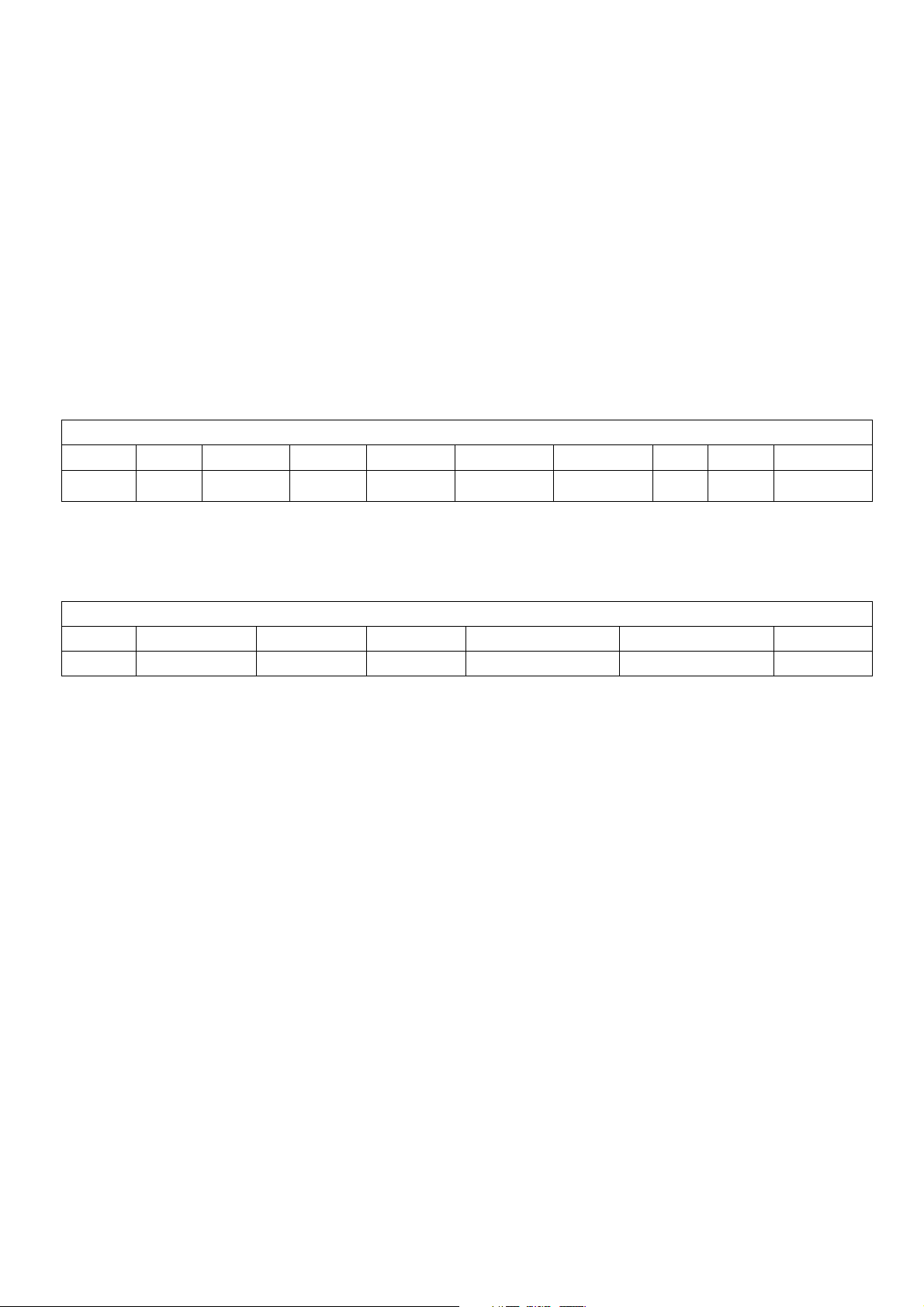

2.3. Alignment flow-chart

The alignment flow-chart is shown as fig-1

Connect to the center signal source and check each

Function of TV (station leaking, analog control, etc.)

Check the output of earphone and speaker.

Check if DDC, HDCP KEY, FLASH are written

Combined test for general assembly

White balance adjustment

Input AV/SVIDEO signal and check the function

Input HD signal and check the function of YPbPr

Input VGA signal and check if the display is normal, check

the function (analog control), horizontal/vertical center, etc.

Input HDMI signal and check if the display is normal, check

the function (analog control), horizontal/vertical center, etc.

Preset ex-factory

Check the accessories and packing

Fig-1 adjustment flow-chart

6

Page 7

2.4. Adjustment instruction

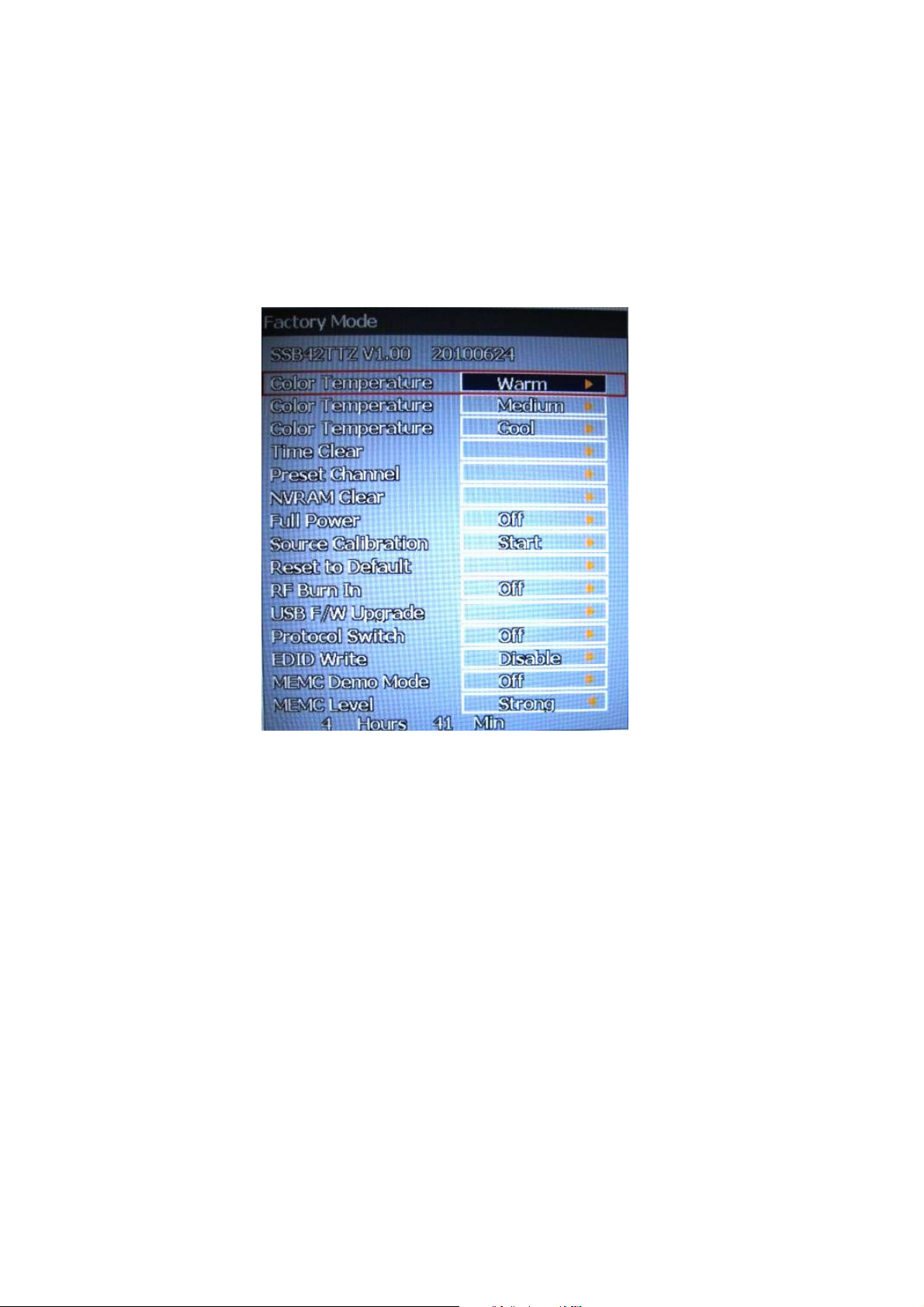

At any input source then press the remote controller buttons “<”, “EXIT” and “>” to enter factory mode.

During Factory menu, if “MENU” or “EXIT” key is pushed, system will exit factory mode.

2.4-1. Source Calibration

4-1.1. Set the TV input source to YPbPr; ASTRO-859 signal setting to PG2 program number 933(1080i).

(PG2 mode Timing 933 and Pattern 924 100% Color Bar.)

4-1.2. Entering into factory Mode: Press up or down key of remote control to select “Auto Calibration”, Press

「OK」 key to start.

-> Source calibration performed automatically when finished that will show OK.

7

Page 8

4-1.3. Change input source to PC.

Change Astro-859 Timing to No.953 (640x480@60Hz) and pattern on 953(8step V-grayscale).

Repeat step 4-1.2 to do source calibration,

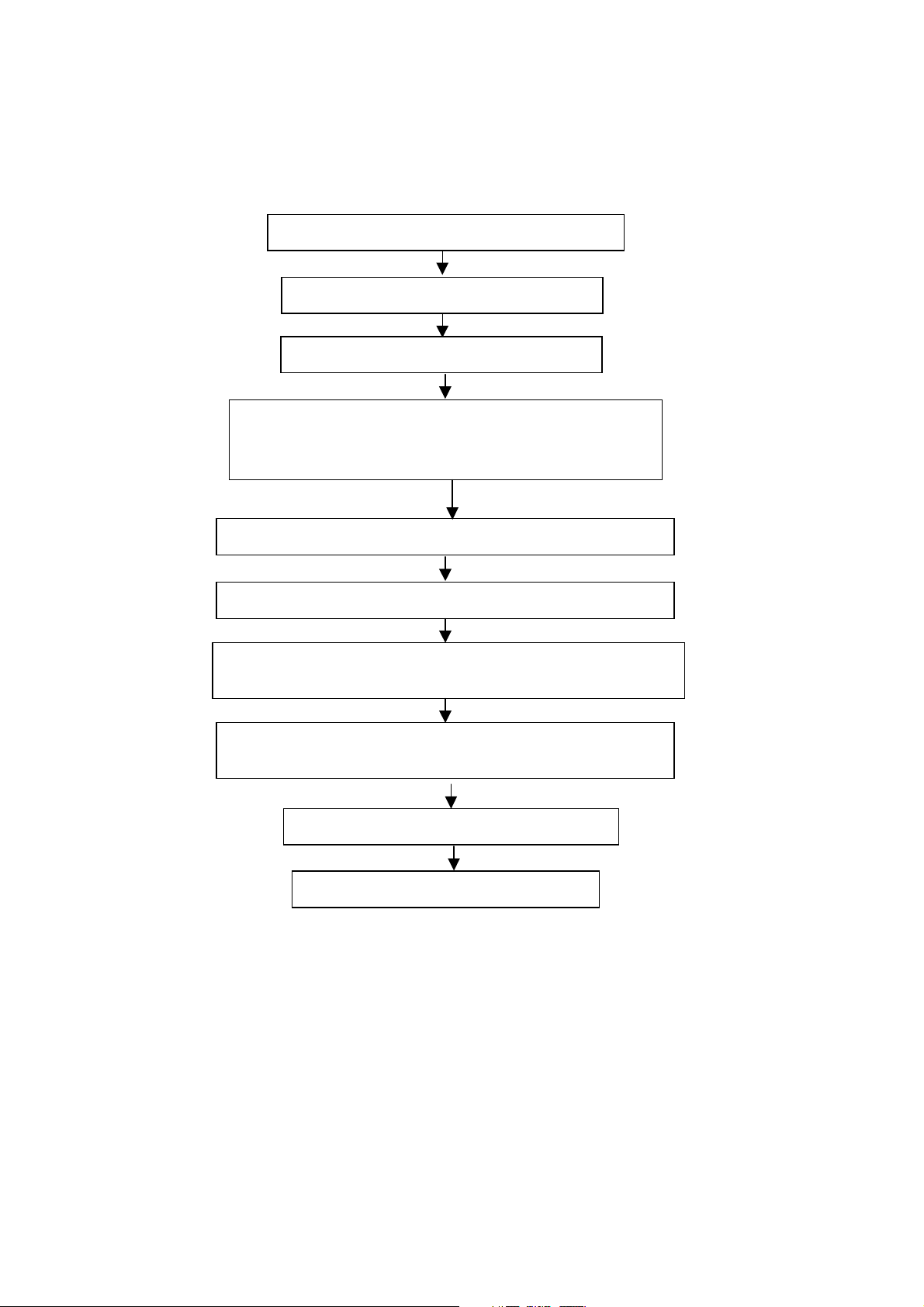

2.4-2. Color Temperature Adjustment & Check

4-2.1. Set input source.

Set the signal generator Astro-859 timing to PG2-924 on Video & YPbPr, PG2-860 on HDMI, and PG2-963

on PC. Pattern sets 956 on all of the source.

Then press Astro-859 “FORMAT” key and key, then adjust RGB value to R:204, G:204, B:204

8

Page 9

4-2.2. In factory mode OSD menu, select “Color Temperature” item, press “OK” key to enter the item.

R, G, B drive values are set for Warm, Medium, and Cool independently.

4-2.3. Set Color Temperature for “Warm”, “Medium” and “Cool” with following spec table.

Color temperature(for 42")

Color Temp. Cool Medium Warm

x 0.267

y 0.271

Tolerance ± 0.01

0.281

0.288

± 0.01

If the x and y value are larger than specification,

Decrease Red drive from default value.

Increase Blue drive from default value.

If the x or y or both x and y value is/are smaller than specification.

Decrease Blue drive from default value

According to a x and y value, please following adjustment of 1 or 2.

1 If x value is higher than spec

Decrease Red drive from default value.

2 If y value is higher than spec,

Increase Blue drive from default value

4-2.4 Exit Factory Mode:

After finishing adjusting color temperature, press [MENU] or [EXIT] to exit factory mode.

0.301

0.310

± 0.01

9

Page 10

2.5. Items of Factory menu

Vendor may customize design and add adjustment items Factory menu as far as all required items are

included.

Press up and down key can move high light item from Color Temperature Warn -> Color Temperature

Medium -> Color Temperature Cool ->Preset Channel-> Source Calibration -> Reset to Default.

The NVRAM Clear and Reset to Default items will have a check dialog “YES” and “NO” to do or not.

Push “Enter” key can select high light item function. (Press left and right can adjust value)

Display model name, firmware version and released date on top.

10

Page 11

5-1) Color Temperature for Warm

Press up or down key can select high light item function.

Press enter key to enter the item.

Following data for color temp shall be edited manually.

-R, G, B data for each preset.

-Press “Up” or “Down” key to select “R”, “G”, “B” item

-Press “Left” or “Right” key to set the “R”, “G”, “B” value.

-Press “MENU” or “EXIT” item to exit to factory mode

5-2) Color Temperature for Medium

Press up or down key can select high light item function.

Press enter key to enter the item.

Following data for color temp shall be edited manually.

-R, G, B data for each preset.

-Press “Up” or “Down” key to select “R”, “G”, “B” item

-Press “Left” or “Right” key to set the “R”, “G”, “B” value.

-Press “MENU” or “EXIT” item to exit to factory mode

5-3) Color Temperature for Cool

Press up or down key can select high light item function.

Press enter key to enter the item.

Following data for color temp shall be edited manually.

-R, G, B data for each preset.

-Press “Up” or “Down” key to select “R”, “G”, “B” item

-Press “Left” or “Right” key to set the “R”, “G”, “B” value.

-Press “MENU” or “EXIT” item to exit to factory mode

5-4) Time Clear

Press up or down key can select high light item function.

Press “Left” & “Right” key to select the item.

The timer on bottom is to record power on time for panel life.

It was set one time on production only.

5-5) Preset Channel

This is for factory to do some tests.

5-6) NVRAM Clear

Initialize program’s default values to NVRAM for following adjustment items accuracy.

In factory mode it is the first and important step to make sure all values are default value and correct.

- Reset settings: Channel table, Mode table (H/V Position, Clock, Phase), Source dependent setting

(Contrast, Brightness etc.), Common setting (Volume, Language etc.), Parental Control (Rating,

Password etc), Closed Caption.

To avoid a mistake initial process after factory setting is done. This item will have a check dialog to do the

initial or not.

NOTICE:

After this item is processed, the DUT needs to be powered off then AC powered off.

5-7) Full Power

This is for power consumption testing.

To measure the maximum power consumption of TV set, we adjust the value of following items to maximum.

11

Page 12

- Video: Contrast maximum value, Brightness maximum value, Backlight maximum value.

- Audio: Volume maximum value.

Press right key to turn on Full Power and OSD stay display until press enter key to recover from Full Power.

5-8) Source Calibration

Auto Calibration (gain/offset) must be adjusted color by firmware automatic adjustment in PC, and

Video3(Component) input source.

This item will have a result dialog “OK” or “NG”.

5-9) Reset to Default

This function is same as “NVRAM Clear”, but it will power off automatically after processing this function.

5-10) RF Burn In

Use “snow” pattern for burn in. Selected items are “On” and “Off”.

While turn on burn in mode, firmware will automatically turn off “Auto power off” function.

If there is no power supply suddenly, firmware will re-enter burn in mode automatically

when power supply is back.

Pressed the “Power” key, firmware will automatically turn off burn in mode.

- Burn in mode: Source is “TV”, Input Configuration is “Antenna” and channel is NTSC channel 2.

5-11) USB F/W Upgrade

The function is using USB device to upgrade firmware via USB port.

Copy the firmware file to USB device root path.

Execute this function to update firmware, the following OSD will display.

Note: After finishing updated, the system will reboot automatically

5-12) Protocol Switch

This is for debugging only. It is no use for service.

5-13) EDID Write

This is for writing EDID on the VGA source.

12

Page 13

5-14) MEMC Demo Mode

To separate screen into two parts that left side is 60Hz and right side is 120Hz for display.

5-15) MEMC Level

Changing MEMC level to Weak, Medium or Strong.

2.6. Performance check

No

Signal

name

Table4

Signal mode

Resolution

YPbPr

frequency(Hz)

signal format

Vertical

Horizontal

frequency

(KHz) (MHz)

Dot clock

frequency

Remarks

6-1 TV function

Connect RF to the center signal source, enter Channel menu → Channel Scan, check if there are channels be

skipped, check if the picture and speaker are normal.

6-2 AV/S-Video terminals

Input AV/S-Video signal, check if the picture and sound are normal.

6-3 YPbPr/YCbCr terminal

Input YPbPr signal (VG-859 signal generator), separately input the YUV signals listed in table4 and check if

the display and sound are normal at any situation (power on, channel switch and format convert, etc.)

1

2

3 720P/60

4 1080i/60 1920x1080 60 33.75 74.25

480i 720x480 59.94 15.73 27

480P 720x480 59.94 31.47 27

1280x720 60 45 74.25

6-4

PC(

VGA) terminal

Input

PC(V

GA) signal (VG-859 signal generator), separately input the signals listed in table5 and check the

display and sound. If the image is deflection of the Horizontal and Vertical, select Menu->PC->Auto Adjust to

perform auto-correct.

Signal mode

No

Signal

name

1

VGA 640 x 480

2 SVGA 800 x 600

3

XGA 1024 x 768

Resolution

Table5

PC

signal format

Horizontal

frequency

Vertical

frequency(Hz)

59.941 31.469 25.175

60.317 37.879 40

60.004 48.363 65

(KHz) (MHz)

Dot clock

frequency

Remarks

4

W-XGA

5

6 SXGA 1280 x 1024

1280 x 768

1360 x 768

59.87 47.776 79.5

60.015 47.712 85.5

60.02 63.981 108

13

Page 14

6-5 HDMI terminal

Input HDMI signal (VG-859 signal generator), separately input the signals listed in table6 and check the display

and sound (32KHz, 44.1KHz, 48KHz) at any situation (power on, channel switch and format convert, etc.)

Table6

HDMI

signal format

No

1

2

3

Signal mode

Signal

name

VGA 640 x 480 59.94 31.469 25.175

SVGA 800 x 600 60.317 37.879 40

XGA 1024 x 768 60.004 48.363 65

Resolution Vertical frequency(Hz) (KHz) (MHz)

Horizontal

frequency

Dot clock

frequency

Remarks

4

W-XGA

5

6

SXGA 1280 x 1024

7

8

9 720P/60

10 1080i/60 1920x1080 60 33.75 74.25

11 1080p/60 1920x1080 60 67.5 148.5

12 1080p/24 1920x1080 24 27 74.25

480i 720x480 59.94 15.734 27

480P 720x480 59.94 31.5 27.03

1280 x 768 59.87 47.776 79.5

1360 x 768 60.015 47.712 85.5

60.02 63.981 108

1280x720 60 45 74.25

6-6 other functions check

a) Check the turn on/turn off timer, sleep timer, picture/sound mode, OSD, stereo and analog TV Close Caption, V-

Chip, etc.

14

Page 15

3. Working principle analysis of the unit

1. NTSC/ATSC signal flow:

Antenna reception NTSC/ATSC signal will be send to tuner U32,

demodulating and output

These

differential IF+ IF- signal

interlace and scaler, then output LVDS level drive for panel display.

The

differential signals

amplifying, bass adjusting and volume control, the sound signal will

I2 S s i g na l b y

scaler

2. AV/S-VIDEO signal flow

S-VIDEO & Video path AV signal switch

differential IF+ IF- signal .

will send to the master control IC U1 to video/MPEGII decode, de-

will be fed into U1 to demodulate audio signals , after demodulating, pre-

I C

and sent to digital amplifier U5 amplifying,

by menu “Inpput list”

t h e n T u n e r w il l b e

b e t r a ns f or m i nt o d ig i t a l

then output to speaker.

via terminal socket, the signal and

the Video2 path AV signal will be fed to U1 to perform video decode, de-interlace and scaler, then

output LVDS drive level for panel display.

Audio signal from AV

the sound signal will be

amplifying,

output to speaker.

3. PC/YPrPb signal flow

terminal

via matched resistance is fed to U1 to bass adjust and volume control,

transfered into digital I2S signal by scaler IC

and sent to digital amplifier U5

PC and the Video2 path YPbPr signal are via terminal sent to U1 A/D conversion, output R/G/B of

24 bit to back end module to digital decode, image scale, then send to LVDS level drive for panel

display.

Sound signal of PC/YPrPb

te r m i n a l

via matched resistance

an d

sent to U1 to bass adjust and

volume control, the sound signal will be transform into digital I2S signal by scaler IC and sent to digital

amplifier U5 amplifying,

4. HDMI signal flow

HDMI video signal via terminal sent to

level for panel display. HDMI audio signal via decoder built-in terminal sent to

to bass adjust and volume control, the sound signal will

scaler IC and sent to digital amplifier

then output to speaker.

U1

U5

amplifying,

to digital decode, image scale, then output LVDS drive

U1 is

be

transform into digital I2S signal by

fed to back end

then output to speaker.

5. MEDIA signal flow

The JPEG file via USB terminal send to U1 to MPEG decode , image scale , then output LVDS

drive level for panel display .

15

Page 16

4. Block diagram-SANYO 42” ATSC model System Diagram

IR / LED Board

Light Sensor

42" MEMC

Main Board

HDMI 2

HDMI 1

Flash

MXIC

MX25L3205DM2I

PC

PC audio

DDRII 512M

Samsung

K4T51163QG-HCF7

DTV system IC

RENESAS

DTV-C7

R8J66977BG

S_Video

Composite

Y

Component

PrPb

Panel out

LVDS out

Audio I2S output

Digital audio out

(Coaxial)

Audio

AMP

ST

STA335W

DRV602PW

audio Line Out

IF +/-

R_out

L-out

DTVA50CVH1019B

ANT / CABLE

Tuner

Samsung

Side

HDMI

USB

Keypad

16

Page 17

Block diagram-POWER-42”

17

Page 18

5.IC block diagram

5-1. Renesas R8J66975-RFJZ , R8J66977BG-RFJZ

Model - SubModel Surround Maximum panel size Number of HDMI ports

R8J66975BG-RFJZ Simple surround WSXGA+

(1680 x 1050)

R8J66977BG-RFJZ Simple surround FullHD

(1920 x 1080)

Features

Main CPU

32bit RISC Super-H architecture SH3 CPU core

Demodulator

ATSC A/53 compliant 8VSB receiver /w QAM.

IF AGC control interface x1ch

System decoder (Stream demultiplexer)

Video and audio ES stream filtering x1

Section filtering: max. 32 PIDs

MPEG video decoder

Single ISO-13818-2 MP@ML or MP@HL support

Supports decoding of all ATSC-compliant formats

JPEG decoder

Decode Base-line JPEG file

2D Graphics

CEA-608/CEA-708-B closed caption support

Display processor, Video input/output

Full 10bit processing

MPEG Noise Filter (De-blocking/De-ringing)

Over Drive (Panel resolution : up to WXGA)

Inputs : CVBS x3, Y/C x2, YPbPr x2, RGB x1, HDMI x3

Outputs : 10-bit dual LVDS

Audio decoder, Audio input/output

ATSC A/52 Clear QAM compliant audio decoding support

Sound Demodulator

Inputs : SIF x1, Stereo x6

Outputs : PCM (I2S) x2, S/PDIF x1, Stereo x1

Peripheral interfaces

UART x1, Legacy serial interface x2, USB High Speed x1

General purpose I/Os

Memory interfaces

Serial Flash

16b width DDR2 800Mbps(5-5-5) SDRAM x 1

Power, clock and package

1.26(±0.06)V, 1.82(±0.08)V, 3.3(±0.15)V

25MHz X’tal

376pin PBGA

3

3

18

Page 19

5-2. Block diagram

19

Page 20

42” Block

20

Page 21

Wiring Connection

1

2

3

4

5

6

7

8

1

9

2

10

3

11

4

12

5

6

14

VTV-L42601 VTV-L42601 VTV-L42601 VTV-L42601 Power/B

CN1 CN3 CN15 CN2 P802

1 GND 1 LED Mute 1 VDD 21 GND 1 SPK_OUTR+ 1 GND

2 GND 2 LED Green 2 VDD 22 GND 2 SPK_OUTR- 2 GND

3 24V 3 LED Red 3 VDD 23 Panel SEL 3 SPK_OUTL- 3 24V

4 24V 4 GND 4 VDD 24 GND 4 SPK_OUTL+ 4 24V

5 GND 5 IR SENS 5 LV0OUT4M 25 LV1OUT4M 5 GND

6 GND 6 3.3V 6 LV0OUT4P 26 LV1OUT4P 6 GND

7 GND 7 Light Sensor 7 LV0OUT3M 27 LV1CKOM 7 GND

8 12V 8 5V 8 LV0OUT3P 28 LV1CKOP

9 12V 9 LV0OUT2M 29 LV1OUT3M

10 5V 10 LV0OUT2P 30 LV1OUT3P

11 5V 11 GND 31 LV1OUT2M

12 5V 12 GND 32 LV1OUT2P

13 Power ON 13 LV0CKOM 33 LV1OUT1M

14 AC OFF Detect 14 LV0CKOP 34 LV1OUT1P

15 BACKLIGHT_ADJ 15 GND 35 LV1OUT0M 15 BL_ADJ

CN16 8 12V

MEMC SEL 0 9 12V

SIDA1 10 5V

MEMC SEL 1 11 5V

SICL1 12 5V

FR Select 13 Power ON 13 BL_ADJ

GND 14 ACD

P803

24V

24V

24V

24V

24V

GND

GND

GND

GND

GND

NC

BL_EN

NC

16 BACKLIGHT_EN 16 GND 36 LV1OUT0P 16 BL_EN

17 LV0OUT1M 37 GND

18 LV0OUT1P 38 DCR EN

19 LV0OUT0M 39 BACKLIGHT_ADJ

20 LV0OUT0P 40 DCR ADJ

21

Page 22

7. Trouble Shooting

7-1. Fault clearance

22

Page 23

7-2. Troubleshooting guide

The flow chart shown below will help you to troubleshoot your Televison set with it doesn’t display

normally. Each procedure offers a simple way to check for system errors. Before starting, ensure

that there is a signal in and that the Televison is turned on.

7.2-1 Power LED no light

Change to new power board.

P /N : P K101V2010I (SSB42T)

23

Page 24

7.2-2 Has audio but no video out

Change to new power board.

P /N : P K101V2010I

(

SSB42T)

24

Page 25

7.2-3 Has video but no audio out

Have a video but no

sound

Check volume or

Mute

OK

Check Input

source

OK

Check speaker Change speaker

OK

MUTE

NG

NG

Cancel mute function

Or adjust volume up

Change source device

Change main pcb

25

Page 26

Change to new power board.

P /N : P K101V2010I (SSB42T)

26

Page 27

8.SCHEMATIC DIAGRAM

ELECTRON-42"

Page 28

5

Sheet Index

Page 03 - System Power

4

3

2

MAIN PCB1

MAIN PCB1

1

FW1

FW1

FIRMWARE

FIRMWARE

FW STC40T REV1.0

FW STC40T REV1.0

Page 04 - C7 & MCU / Key

D D

Page 05 - C7 & Tuner Input

EMIcover1

EMIcover1

Page 06 - C7 & Video Input

Page 07 - C7 & VGA Input

Page 08 - C7 & HDMI Input

Page 09- C7 & Audio Input

Page 10 - C7 & Debug IO / FLASH ROM

EMIcover-C7

EMIcover-C7

Page 11- C7 & Power

Page 12 - C7 & DDRII-800

Page 13 - C7 & LVDS Output

Page 14 - C7 & Audio Out

C C

Page 15 - Audio Amplifier

VTV-L40601 REV:0A

VTV-L40601 REV:0A

Notice

1. All Res. is 0603.

2. All Cap. is 0402 (<=0.47uF), 0603 (<=1uF), 0805 (<=10uF).

0402

NPO 5pF/50V, 10pF/50V, 22pF/50V, 27pF/50V, 33pF/50V, 36pF/50V, 47pF/50V, 220pF/50V

X7R 100pF/25V, 470pF/25V, 1000pF/25V, 2200pF/25V, 3300pF/25V, 0.01uF/25V, 0.01uF/50V, 0.022uF/25V

X5R 1uF/10V

Y5V 0.1uF/25V, 0.33uF/10V, 0.47uF/10V

B B

0603

Y5V 0.1uF/50V, 0.47uF/25V, 1uF/16V

X5R 10uF/6.3V

0805

X5R 4.7uF/16V

Y5V 0.47uF/50V, 0.68uF/50V, 1uF/50V, 3.3uF/10V, 10uF/10V

1206

Y5V 4.7uF/35V

1210

Y5V 10uF/35V

A A

3. The mark "#" to indicate that Part disuse.

Renesas Scaler

5

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

Title

Title

Title

SCHEMATIC,M/B VTV-L42601,SSB42T

SCHEMATIC,M/B VTV-L42601,SSB42T

SCHEMATIC,M/B VTV-L42601,SSB42T

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

A4

A4

A4

Date: Sheet of

Friday, June 04, 2010

Date: Sheet of

Friday, June 04, 2010

Date: Sheet of

4

3

Friday, June 04, 2010

2

401C2K

401C2K

401C2K

2 15

2 15

2 15

1

1A

1A

1A

Page 29

5

R7 0R7 0

12

C49

C49

10uF/10V/0805/NC

10uF/10V/0805/NC

C0805D

C0805D

GND

G

GND

C330

C330

10uF/10V/0805

10uF/10V/0805

P5V

P5V

update for AC off

screen garbage

20100526

R368

R368

1K/0402

1K/0402

CE

R369 100/1% /0402R369 100/1% /0402

B

Q45

Q45

MMBT3904L

MMBT3904L

R20 30K/1%/04 02R20 30K/1% /0402

1 2

R4

2.2KR42.2K

47K

47K

B

47K

47K

12

0.1uF/50V/NC

0.1uF/50V/NC

GND

R297 10K/0402R297 10K/0 402

1 2

12

C69

C69

1uF/16V

1uF/16V

C0603D

C0603D

GND GND

Power Module Input

CN1

CN1

JWT A2001W V2-16P

JWT A2001W V2-16P

1

2

3

4

5

6

7

8

9

10

D D

11

12

13

14

15

16

GND

C C

Standby Power

P5V

FB10

FB10

KHB0603N121SA

KHB0603N121SA

C329

C329

10uF/10V/0805

10uF/10V/0805

B B

L1 B201212K800TM

L1 B201212K800TM

L0805D

L0805D

P24V P_DA MP

1 2

L2 B201212K800TM/NC

L2 B201212K800TM/NC

L0805D

L0805D

1 2

POWER_O N2

PG

BKLT_EN

12

R9

10K/0402R910K/0402

GND

RTX update for power

shut down issue 20091231

R221 10K/ 1%/NCR221 1 0K/1%/NC

C318

C318

0.1uF/10V/0402

0.1uF/10V/0402

GND

R308

R308

10K/1%

10K/1%

U43

U43

GND

G9141T11U

G9141T11U

3

/SHDN

OUT

1

IN

SET

GND

2

GND G ND

P_DAMP

P12V

P5V

POWER_O N2 4

12

R10

R10

100K/0402

100K/0402

GND

P5V

R367

R367

560

560

D

C425

C425

10uF/10V/0805

10uF/10V/0805

S

GNDGND

Q44

Q44

MMBT3409L(2N7002E)

MMBT3409L(2N7002E)

3.3V_STB

5

R242

R242

4

RTX update for power

shut down issue 20091231

C197

C197

23.2K/1%

23.2K/1%

R307

R307

0.1uF/10V/0402

0.1uF/10V/0402

10K/1%

10K/1%

POWER_O N1

POWER_O N14

Frank update for DC

power on fail issue

20100202

LCD PANEL POWER MosFET

GND

5

12

R193KR19

3K

GND

12

C66

C66

10uF/10V/0805

10uF/10V/0805

C0805D

C0805D

P5VP12V

12

1 2

R39

R39

24K

24K

12

R18

R18

0/1206/NC

0/1206/NC

R1206D

R1206D

12

C75

C75

1uF/16V/NC

1uF/16V/NC

C0603D

C0603D

B

GND

R280R28

0

1 2

CE

MMBT3904LQ2MMBT3904L

U7

APM4461U7APM4461

1

8

S1

D4

2

7

S2

D3

3

6

S3

D2

5

G4D1

12

R22

R22

1K/1206

1K/1206

R1206D

12

GND

Q2

R1206D

GND

C70

C70

1uF/16V/NC

1uF/16V/NC

C0603D

C0603D

Vds = -24V

Vgs = -2.5V/-4.5V/-10V

Id = -2A/-4A/-7A

(APM4461)

1 2

12

R17

R17

0/1206

0/1206

R1206D

R1206D

+

+

GND

A A

PANEL_VEN

PANEL_VEN4

C65

C65

C58

C58

0.1uF/50V

0.1uF/50V

SE100uF/16V

SE100uF/16V

RTX update for panel

sequence 20100226

R25 22KR25 22 K

1 2

12

R26

R26

5.6K

5.6K

GND

3.3V_STB

R13

R13

22K

22K

ACOFF_DET

Q38

Q38

PDTC114ET

PDTC114ET

E C

GND

R8 0R8 0

1 2

1K/1%/0402/NC

1K/1%/0402/NC

R36 1K/1%/0402/NCR 36 1K/1%/0402/NC

C72

C72

MMBT3904L/NC

MMBT3904L/NC

R370

R370

10K/0402/NC

10K/0402/NC

GND

Q48

Q48

APM2301AAC

APM2301AAC

G

CE

Q3

B

MMBT3904LQ3MMBT3904L

L14 B201212K800TM

L14 B201212K800TM

L0805D

L0805D

COLLECTOR

DTC124EK

SOT-23B

BASE

4

D9

1N4148D91N4148

1 2

BKLT_EN

3.3VD

R35

R35

12

Q46

Q46

GND

BACKLIGHT_EN 4

L17

L17

B201212K800TM

B201212K800TM

L0805D

L0805D

1 2

DS

VDD_LCD

12

C57

C57

0.1uF/50V

0.1uF/50V

GND

EMITTER

4

ACOFF_DET 4

update for power team

standby 5V hold time

20100526

3.3V_STB

R330

R330

10K/1%/NC

10K/1%/NC

1 2

R32

R32

CE

1K/1%/NC

1K/1%/NC

B

1 2

12

GND

12

C71

C71

10uF/10V/0805

10uF/10V/0805

C0805D

C0805D

GND GND GND

VDD_LCD

R11 0R11 0

1 2

R12 0/NCR12 0/NC

1 2

C67

C67

100pF/25V/0402/NC

100pF/25V/0402/NC

12

C78

C78

10nF/25V/0402

10nF/25V/0402

RTX update for DC

power on fail

20100225

BACKLIGHT_ADJ 4,13

DCR_ADJ 13

3.3VD

12

C86

C86

0.1uF/10V/0402

0.1uF/10V/0402

3

DC - DC FROM VCC TO 1.25V(2A)

P5V

KHB0805W121S A_6A

KHB0805W121S A_6A

FB68

5V -> 1.8V

P5V

+

+

5V -> 3.3V

POWER_O N14

C196

C196

SE100uF/16V

SE100uF/16V

FB68

10uF/10V/0805

10uF/10V/0805

3.3VA

3.3VD

12

C50

C50

0.1uF/10V/0402

0.1uF/10V/0402

GND

C372

C372

POWER_O N1

3

GND GND

R45 10K/1%0402/NCR45 10K/1%0402/NC

R24 10K/1%0402R24 10K/1%0402

P5V

1 2

1 2

20K/1%/0402/NC

20K/1%/0402/NC

1 2

1.25VD

R18210R182

C379

C379

0.1uF/10V/0402

0.1uF/10V/0402

C378

C378

0.1uF/10V/0402

0.1uF/10V/0402

R40

R40

1 2

GND

R15 10K/0402R 15 10K/0402

C41

C41

1uF/16V

1uF/16V

C0603D

C0603D

GND GND

12

C74

C74

1uF/16V

1uF/16V

C0603D

C0603D

GND

R93 9.09K/1%/0402R93 9.09K/1 %/0402

1 2

R95

R95

9.09K/1%/0402

9.09K/1%/0402

1 2

GND

12

GND

R94 9.09K/1%/0 402R94 9.09K/1%/0402

1.25VD

GND

10

GND

12

C43

C43

0.1uF/10V/0402

0.1uF/10V/0402

GND

APM2301AAC

APM2301AAC

R296 10K/0402R296 10K/0402

1 2

B

12

12

R96

R96

10K/NC

10K/NC

C73

C73

C0603D

C0603D

1uF/16V

1uF/16V

1 2

R97

R97

9.09K/1%/0402

9.09K/1%/0402

1 2

10uF/16V/0805

10uF/16V/0805

GND

12

12

R98

R98

10K/NC

10K/NC

8

1

5

G

CE

5

6

7

8

C192

C192

1uF/16V

1uF/16V

C0603D

C0603D

Q47

Q47

C434

C434

U2

G5694U2G5694

VIN

LX

VCC

FB

EN

REF

PGND

GND

THEM_PAD

6

3

9

GND GND

P5V_SW

DS

C32

C32

+

+

SE100uF/16V

SE100uF/16V

GND

Q1

MMBT3904LQ1MMBT3904L

U6

G9731F11UU6G9731F11U

VO

VIN

VO

VPP

ADJ

POK

GND

VEN

ThPad

9

GND

U8

G9731F11UU8G9731F11U

5

VIN

6

VPP

7

POK

8

VEN

ThPad

9

12

GND

C317

C317

1uF/16V

1uF/16V

C0603D

C0603D

GND

C413

C413

0.1uF/50V

0.1uF/50V

GND

FOR TUNER

L28 2.2uH /3.8AL28 2.2uH /3.8A

7

C347 47pF /50V/0402C347 47pF/50V/04 02

4

R355 9.09K/1%R355 9.09K/1%

2

R354 16K/1 %R354 16K/1%

C191

C191

0.1uF/10V/0402

0.1uF/10V/0402

Vout=0.8Vx (1+R1/R2)

U3 G1117-3.3V-252U3 G1117-3.3V-252

3

Vin

12

C34

C34

0.1uF/10V/0402

0.1uF/10V/0402

GND

4

3

R100

R100

2

12.7K/1%

12.7K/1%

1

1 2

R101

R101

10K/1%

10K/1%

1 2

GND

4

VO

3

VO

2

ADJ

1

GND

U31

U31

SSD9117-5.0V-252

SSD9117-5.0V-252

VIN3VOUT

ADJ / GND

1

10uF/10V/0805

10uF/10V/0805

1 2

1 2

GND

2

C436

C436

2

1.25VD

C356

C356

PVM330uF/6V

PVM330uF/6V

GND GND

2

Vout

C35

C35

+

+

ADJ/GND

SE100uF/16V

1

GND

1.8A

+

+

GND GND GND

R106

R106

12.7K/1%

12.7K/1%

R103

R103

10K/1%

10K/1%

SE100uF/16V

GND

Frank update for video source

horizontal and water wave nois e

issue 20100401

12

C51

C60

C60

SE100uF/16V

SE100uF/16V

5VSW

1 2

C415

C415

0.1uF/10V/0402

0.1uF/10V/0402

C51

10nF/25V/0402

10nF/25V/0402

12

10nF/25V/0402

10nF/25V/0402

L71 B20 1212K800TM

L71 B20 1212K800TM

L0805D

L0805D

C52

C52

PVM330uF/16V

PVM330uF/16V

1.8D

+

+

GND GND GND

2

12

C36

C36

10nF/25V/0402

10nF/25V/0402

GND

12

B201212K800TM/NC

B201212K800TM/NC

C59

C59

C53

C53

0.1uF/10V/0402

0.1uF/10V/0402

L0805D

L0805D

12

5VSW_CP12V

12

C37

C37

0.1uF/10V/0402

0.1uF/10V/0402

GND

L68

L68

1 2

1 2

C61

C61

0.1uF/10V/0402

0.1uF/10V/0402

L7 B201212K800TM

L7 B201212K800TM

L0805D

L0805D

1 2

12

L69

L69

B201212K800TM/NC

B201212K800TM/NC

L0805D

L0805D

L13 B20 1212K800TM

L13 B20 1212K800TM

L0805D

L0805D

1 2

L67 B201212K800TM

L67 B201212K800TM

L0805D

L0805D

1 2

L15 B20 1212K800TM

L15 B20 1212K800TM

L0805D

L0805D

1

12

C38

C38

10uF/10V/0805

10uF/10V/0805

C0805D

C0805D

recover as a bead

20100401

12

C62

C62

10uF/10V/0805

10uF/10V/0805

C0805D

C0805D

Title

Title

Title

Size Document Num ber Rev

Size Document Num ber Rev

Size Document Num ber Rev

A2

A2

A2

Date: Sheet of

Date: Sheet of

Date: Sheet of

3.3VA

12

C39

C39

10nF/25V/0402

10nF/25V/0402

GND GNDGND

12

GND GND GN DGND

12

C186

C186

10uF/10V/0805

10uF/10V/0805

C0805D

C0805D

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

SCHEMATIC,M/B VTV-L42601,SSB42T

SCHEMATIC,M/B VTV-L42601,SSB42T

SCHEMATIC,M/B VTV-L42601,SSB42T

Friday, June 04, 2010

Friday, June 04, 2010

Friday, June 04, 2010

C54

C54

10uF/10V/0805

10uF/10V/0805

C0805D

C0805D

12

C376

C376

10nF/25V/0402

10nF/25V/0402

12

C63

C63

10nF/25V/0402

10nF/25V/0402

12

1.8VIF

1.8VD

401C2K

401C2K

401C2K

1

1.8VA

C55

C55

10nF/25V/0402

10nF/25V/0402

GNDGNDGND

12

C40

C40

0.1uF/10V/0402

0.1uF/10V/0402

12

C346

C346

0.1uF/10V/0402

0.1uF/10V/0402

GNDGNDGND

12

C64

C64

0.1uF/10V/0402

0.1uF/10V/0402

3.3VA

12

C56

C56

0.1uF/10V/0402

0.1uF/10V/0402

3 15

3 15

3 15

1.8VA

1.8VIF

1.8VD

1A

1A

1A

Page 30

5

3.3V_STB

PANEL_SEL

DAMP_RESETN

3.3V_STB

R31

R31

R30

R30

10K/0402

10K/0402

56K/0402

56K/0402

R0402D

R0402D

R0402D

R0402D

1 2

1 2

3.3V_STB

12

R41

R41

10K/0402

10K/0402

R0402D

R0402D

12

R315

R315

10K/0402

10K/0402

12

R42

R42

10K/0402

10K/0402

12

GND

C7 MCU

RTX update for DC

power on fail

20100130

MEMC_SEL_113

FR_SELECT13

D D

C C

B B

Check

DAMP_RESETN15

PANEL_SEL13

PC_HSYNC7

PC_VSYNC7

ACOFF_DET3

POWER_O N23

CUT_LEAK11

POWER_O N13

HDMI_CEC_C78

HDMI_HPD08

HDMI_HPD18

HDMI_HPD28

Keypad

R56 11K/1%R56 11K/1%

1 2

SW PUSH /4P/90D/1.3MM

SW PUSH /4P/90D/1.3MM

2

3

GND

GND

SW1

SW1

4

1

MENU VOL+VOL- CH+INPUT/EXIT CH- POWER

R57 6.19K/1%R57 6.19K/ 1%

1 2

SW PUSH /4P/90D/1.3MM

SW PUSH /4P/90D/1.3MM

2

3

GND

GND

SW2

SW2

4

1

3.6K/1%

3.6K/1%

R58

R58

1 2

SW PUSH /4P/90D/1.3MM

SW PUSH /4P/90D/1.3MM

2

3

GND

GND

SW3

SW3

4

1

R59 2.7K/1%R59 2.7K/1%

1 2

SW PUSH /4P/90D/1.3MM

SW PUSH /4P/90D/1.3MM

2

3

GND

GND

SW4

SW4

4

1

4

12

R37

R37

10K/0402

10K/0402

GND

KEY_POWER

PC_HSYNC

PC_VSYNC

ACOFF_DET

CUT_LEAK

POWER_O N1

HDMI_CEC_C7

IR_SENS

LED_COLOR

LED_R

HDMI_HPD0

HDMI_HPD1

HDMI_HPD2

R43

R43

1K/0402

1K/0402

update for LED

abnormal during

initial 20100112

GND

R60 1.8K/1%R60 1.8K/1%

1 2

SW PUSH /4P/90D/1.3MM

SW PUSH /4P/90D/1.3MM

2

3

GND

GND

SW5

SW5

4

1

U1A

U1A

R8J66977BG

R8J66977BG

BGA1090-1

BGA1090-1

W20

GPIO0

Y22

GPIO1

U19

GPIO2

V20

GPIO3

W21

GPIO4

W22

GPIO5

V21

GPIO6

M21

GPY05

M19

GPY06

N21

GPY07

L21

GPY08

L19

GPY09

L22

GPY10

K20

GPY11

K22

GPY12

K21

GPY13

L20

GPY14

K19

GPY15

J20

GPY16

J19

GPY17

J22

GPY18

P18

MODE0

1 2

R61 1.33K/1%R61 1.33K/ 1%

SW PUSH /4P/90D/1.3MM

SW PUSH /4P/90D/1.3MM

2

3

GND

GND

SW6

SW6

4

1

SCIRXD0

SCITXD0

SCIF0CSIO0

SCIF0CSIO0

SMDATA

SCISCK1

SCITXD1

SCIRXD1

SCIF1 CASIF

SCIF1 CASIF

MCU ADC

MCU ADC

BLC

BLC

12

R52

R52

10K/0402

10K/0402

KEY_IN0 KEY_POWER

SCLK0

STXD0

SRXD0

SMCLK

SMRST

MADIN0

MADIN1

MADIN2

MADIN3

MADIN4

MADIN5

MADIN6

MADIN7

QBLCA

QBLCB

W18

Y10

AB10

AA10

AA19

AB19

AA18

Y19

AA20

AB20

H19

G21

G20

H21

G22

H22

H20

J21

W17

Y17

PC_DET

BACKLIGHT_EN

PANEL_VEN

DAMP_PDN

INT_LINE

EDID_WPC

KEY_IN0POWER_O N2

Light_Sensor

LINE_MUTE

BACKLIGHT_ADJ

12

R376

R376

10K/0402

10K/0402

PWM_LED

12

R319

R319

10K/0402

10K/0402

GND

3.3V_STB3.3V_STB

SW PUSH /4P/90D/1.3MM

SW PUSH /4P/90D/1.3MM

2

3

GND

GND

SW7

SW7

4

1

AV1_S_DET

AB22

SCISCK0

AB21

12

R377

R377

10K/0402

10K/0402

R44 0/0402R44 0/0402

BACKLIGHT_ADJ 3,13

12

R53

R53

10K/0402

10K/0402

3

3.3V_STB

12

R318 10K/0402R318 10K/0402

R314 10K/0402/NCR314 10K/0402/NC

R316 10K/0402/NCR316 10K/0402/NC

12

12

AV1_S_DET 6MEMC_SEL_013

PC_DET 7

R38 0/0402R38 0/0402

12

BACKLIGHT_EN 3

DCR_EN 13

PANEL_VEN 3

DAMP_PDN 15

INT_LINE 15

EDID_WP 7

2

reserve for DCR

function 20100106

1

update for write protect 20091 211

12

12

R378

R378

10K/0402

10K/0402

12

R329

R329

10K/0402

10K/0402

12

R379

R379

10K/0402

10K/0402

12

12

R380

R380

R375

R375

10K/0402/NC

10K/0402/NC

1K/0402

1K/0402

RTX update for leakage

voltage 20100119

GND

LED_GREEN_C 7

12

R320

R320

1K/0402

1K/0402

update for LED

abnormal during

initial 20100112

GND

1206L035-CF21206L035-C

W/O LED Effect model--->8 pin connector

W/LED Effect model--->12pin connector

CN3

CN3

JWT A2001W V2-12P

JWT A2001W V2-12P

1

2

3

4

5

6

7

8

9

10

11

12

GND

100pF/25V/0402

100pF/25V/0402

L39 KHB06 03Q300SAL39 KHB0603Q300SA

1 2

PWM_LED

LED_color

C386

C386

100pF/25V/0402

100pF/25V/0402

TP22TP22

TP21TP21

LED_MUTE 3

LINE_MUTE 14

TP34TP34

IR & LED Connector

Light sensor Connector

P5V

12

L64

L64

B201212K800TM

B201212K800TM

L0805D

L0805D

R62

R62

18K/1%/0402

18K/1%/0402

12

F2

EZJZ1V80010D8EZJZ1V80010

D8

C388

100pF/25V/0402

C388

100pF/25V/0402

C385

C385

3.3V_STB

F3

F3

1206L035-C/NC

1206L035-C/NC

LED_GREEN_C 7

LED_R

IR_SENS

1 2

R102

R102

10K/1%

10K/1%

EZJZ1V80010

EZJZ1V80010

EZJZ1V80010

EZJZ1V80010

EZJZ1V80010

R63 30K/1%/040 2R63 30K/1%/0402

D13

D13

100pF/25V/0402

100pF/25V/0402

C387

100pF/25V/0402

C387

100pF/25V/0402

1 2

EZJZ1V80010

EZJZ1V80010

D16

D16

C335

C335

100pF/25V/0402

100pF/25V/0402

EZJZ1V80010

D17

D17

D18

D18

C336

C336

C339

100pF/25V/0402

C339

100pF/25V/0402

LED_MUTE 3

12

C348

C348

4.7uF/6.3V

4.7uF/6.3V

C0603D

C0603D

Light_Sensor

12

R105

R105

39K/1%

39K/1%

GND

GND GND

A A

5

4

3

GND

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

Title

Title

Title

SCHEMATIC,M/B VTV-L42601,SSB42T

SCHEMATIC,M/B VTV-L42601,SSB42T

SCHEMATIC,M/B VTV-L42601,SSB42T

Size Document Num ber Rev

Size Document Num ber Rev

Size Document Num ber Rev

A2

A2

A2

Date: Sheet of

Friday, June 04, 2010

Date: Sheet of

Friday, June 04, 2010

Date: Sheet of

2

Friday, June 04, 2010

401C2K

401C2K

401C2K

1

4 15

4 15

4 15

1A

1A

1A

Page 31

TUNER & C7

5

4

Default Setting Samsung tuner

3

close to Tuner

5VSW

12

R67

R67

4.7K/0402

4.7K/0402

2

12

R65

R65

4.7K/0402

4.7K/0402

1

D D

SAMSUNG

U32

U32

DTVA50C VH1019B

DTVA50C VH1019B

1

1-NC

2

2-B+

3

3-NC

22

22

13-IF MOINTOR

21

21

C C

U10 ENV56 U03D8F

U10 ENV56 U03D8F

15

GND

16

GND

GND

17

GND

18

GND

B B

17171818191920

20

GND

RF AGC Monitor

BT Monitor

IF Monitor

Panasonic

ENV56U03D8F

Panasonic

ENV56U03D8F

Panasonic Samsung

R76

R75

C97

C102

L23

L26

C697

C696

L24

A A

C100

L3,L4 0 ohm

4

4-NC

5

5-GND

6

10-NC

11-SCL

12-SDA

14-IFAGC

15-IF2

16-IF1

SCL

SDA

IF AGC

IFD-out1

IFD-out2

NC

NC

6-NC

7-NC

8-NC

9-NC

+B

7

8

9

10

11

12

13

14

15

16

1

2

3

5

6

9

10

R77

R77

11

1K/1%/040 2/NC

1K/1%/040 2/NC

12

13

14

R74

R74

1K/1%/040 2/NC

1K/1%/040 2/NC

GND

12

12

0 ohm

0 ohm 75 ohm

10nF

10nF

0.22uH

0.22uH

NC

NC

0.1uH

120pF

0.27uH-->0ohm

IF+

IF-

75 ohm

47pF

47pF

0.27uH

0.27uH

NC

NC

0.27uH

39pF

close to Tuner

B201212 K800TM

B201212 K800TM

5VSW

12

L27

L27

B201212 K800TM

B201212 K800TM

L0805D

L0805D

C109 10uF/10V/0805C109 10uF/10V/0805

12

C108 0.1uF/10V/0402C108 0.1uF/10V/0402

1 2

L12

L12

L0805D

L0805D

1 2

1 2

TUN_SCL

TUN_SDA

close to tuner

R76 75R76 75

1 2

GND

R75 75R75 75

1 2

L16

L16

B201212 K800TM

B201212 K800TM

L0805D

L0805D

close to Tuner and Guard GND

R73 0/0 402R73 0/0 402

1 2

12

C95

C95

0.1uF/10V /0402/NC

0.1uF/10V /0402/NC

GND

close to C7

C97

C97

47pF/50V /0402

47pF/50V /0402

1 2

1 2

L23

L23

FLMA-201 209-R27KT

FLMA-201 209-R27KT

L24

L24

TDK MLF1 608DR27K

TDK MLF1 608DR27K

L26

L26

FLMA-201 209-R27KT

FLMA-201 209-R27KT

1 2

1 2

C102

C102

47pF/50V /0402

47pF/50V /0402

12

C697

C697

15pF/50V /0402/NC

15pF/50V /0402/NC

GND

22pF/50V /0402

22pF/50V /0402

update for ATV disorderly

20100417

12

12

C100

C100

39pF/50V /0402

39pF/50V /0402

12

C696

C696

15pF/50V /0402/NC

15pF/50V /0402/NC

R68

R68

100/1%/04 02

100/1%/04 02

1 2

12

C90

C90

GND

close to c7 and Guard GND

R71 1K/1 %/0402R71 1K/1%/04 02

1 2

12

C92

C92

0.33uF/10 V/0402

0.33uF/10 V/0402

GND GND

L3

0/0805L30/0805

1 2

1 2

L4

0/0805L40/0805

R69

R69

100/1%/04 02

100/1%/04 02

1 2

12

C91

C91

22pF/50V /0402

22pF/50V /0402

GND

12

1 2

C3 33 pF/50V/NCC3 33 pF/50V/NC

C4 33 pF/50V/NCC4 33 pF/50V/NC

1 2

R72 1K /1%/0402R72 1K/1%/0 402

1 2

C93

C93

0.1uF/10V /0402

0.1uF/10V /0402

GND

R352 10K/1%/0 402R352 10K/1%/0 402

1 2

R347 10K/040 2R34 7 10K/040 2

1 2

GND

12

C104

C104

0.1uF/10V /0402

0.1uF/10V /0402

GND GND

PCB Name-Rev : VTV-L40602-0A

U1B

U1B

R8J66977BG

R8J66977BG

BGA1090 -1

BGA1090 -1

K3

SICL0

K2

SIDA0

J1

IFAGC

L4

RFAGC

K1

SANT

E3

SIFIN

F2

IFINP

F1

IFINM

E2

VRPIF

12

C105

C105

E1

VRMIF

0.1uF/10V /0402

0.1uF/10V /0402

IIC0

IIC0

VSB

VSB

VSB / SIF ADC

VSB / SIF ADC

C3,C4 NC 33pF-->NC

Title

Title

Title

SCHEMAT IC,M/B VTV-L42601,SS B42T

SCHEMAT IC,M/B VTV-L42601,SS B42T

SCHEMAT IC,M/B VTV-L42601,SS B42T

Size Document N umber Rev

Size Document N umber Rev

Size Document N umber Rev

A3

A3

A3

401C2K

401C2K

401C2K

Date: Sheet of

Date: Sheet of

Date: Sheet of

5

4

3

2

5 15Saturday, June 19, 2 010

5 15Saturday, June 19, 2 010

5 15Saturday, June 19, 2 010

1

1A

1A

1A

Page 32

5

4

3

2

1

5VSW_C

CE

Q14

Q14

MMBT3904L

MMBT3904L

12

R110

R110

390

390

GND

SPDIF 14

L80 KHB0603 Q300SA

L80 KHB0603 Q300SA

1 2

12

C296

C296

L0603D

L0603D

470pF/50V/NC

470pF/50V/NC

L81 KHB0603 Q300SA

L81 KHB0603 Q300SA

1 2

12

L0603D

L0603D

C297

C297

470pF/50V/NC

470pF/50V/NC

12

C137

C137

0.1uF/10V/0402

0.1uF/10V/0402

GND

AV3_Y AV3_R_IN

AV3 (YPbPr Input)

LINEOUT_L 14

C327

C327

C328

C328

GND

GND

12

R309

R309

470K

470K

12

R310

R310

470K

470K

LINEOUT_R 14

19" 26" NC

12

470pF/50V/NC

470pF/50V/NC

12

470pF/50V/NC

470pF/50V/NC

12

R104

R104

33K

L38

L38

KHB0603Q300SA

KHB0603Q300SA

AV3_Y_IN

1 2

C143

D D

C C

AV3_PB_IN AV3_Y_IN

AV3_PR_IN

AV3_L_IN

AV3_R_IN

B B

C143

10pF/25V/0402

10pF/25V/0402

IO5

IO5

2x4_COMPO-AUDIO_SW_OUT

2x4_COMPO-AUDIO_SW_OUT

T5

Pb

S5

G

T6

Pr

S6

G

T7

L

S7

G

B8

SW

T8

R

S8

G

12

GND GND

Y

G

SPDIF

G

L

G

R

G

1 2

12

10uF/10V/0805

10uF/10V/0805

R108

R108

75/1%

75/1%

T1

S1

T2

S2

T3

S3

T4

S4

C142

C142

33K

B

12

R109

R109

39K

39K

GND

GNDGND

AV2 (CVBS Input)

L79 KHB0603 Q300SAL 79 KHB0603Q300SA

AV2_R_IN AV2_AR

1 2

12

C325

C325

470pF/50V/NC

IO4

IO4

FRON-AV-KYOYAKU

FRON-AV-KYOYAKU

R

R

B1

CVBS

CVBS

T1

L

L

B2

T2

B3

T3

S1

S2

S3

A A

GND

470pF/50V/NC

GND GND

L72 KHB0603 Q300SAL 72 KHB0603Q300SA

AV2_L_IN AV2_AL

1 2

12

C323

C323

470pF/50V/NC

470pF/50V/NC

GND GND

FB24

FB24

KSI06033R3KA

KSI06033R3KA

R311

R311

75/1%

75/1%

Check

12

C324

C324

470pF/50V/NC

470pF/50V/NC

12

C322

C322

470pF/50V/NC

470pF/50V/NC

AV2_AR 9

AV2_AL 9

AV2_CVBS

19" 26" NC

L40 KHB0603 Q300SAL 40 KHB0603Q300SA

AV3_PB_IN AV3_PB

1 2

10pF/25V/0402

10pF/25V/0402

L42 KHB0603 Q300SAL 42 KHB0603Q300SA

1 2

10pF/25V/0402

10pF/25V/0402

GND

19" 26" NC

12

C159

C159

12

C173

C173

GND

IO6

IO6

CVBS

CVBS

Audio L

Audio L

Audio R

Audio R

JALCO / AV SV-IN_V

JALCO / AV SV-IN_V

GND

S_SWS_GND

S_SWS_GND

TOP_C

TOP_C

TOP_Y

TOP_Y

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

12

R115

R115

75/1%

75/1%

GNDGND

12

R125

R125

75/1%

75/1%

R337 1K/1%R337 1K/1%

GND

AV3_PR

AV1_S_DET 4

FB26 KSI06033R3KAFB26 KSI06033R3KA

FB27 KSI06033R3KAFB27 KSI06033R3KA

R335 75/1%R33 5 75 /1%

R336 75/1%R33 6 75 /1%

FB25

FB25

KSI06033R3KA

KSI06033R3KA

R334 75/1%R33 4 75 /1%

L66 KHB0603 Q300SAL 66 KHB0603Q300SA

AV1_L_IN

GND

1 2

12

C320

C320

470pF/50V/NC

470pF/50V/NC

GND GND

L70 KHB0603 Q300SAL 70 KHB0603Q300SA

AV1_R_IN AV1_AR

1 2

12

C312

C312

470pF/50V/NC

470pF/50V/NC

GND GND

AV3_L_IN

L43 KHB0603 Q300SAL 43 KHB0603Q300SA

1 2

12

C176

C176

470pF/50V/NC

470pF/50V/NC

L45 KHB0603 Q300SAL 45 KHB0603Q300SA

1 2

12

C180

C180

470pF/50V/NC

470pF/50V/NC

GND GND

AV1_C

AV1_Y

AV1_CVBS

AV1_AL

12

C319

C319

470pF/50V/NC

470pF/50V/NC

12

C311

C311

470pF/50V/NC

470pF/50V/NC

12

GNDGND

12

AV3_AL

C177

C177

470pF/50V/NC

470pF/50V/NC

AV3_ARAV3_PR_IN

C181

C181

470pF/50V/NC

470pF/50V/NC

AV1_AL 9

AV1_AR 9

AV3_AL 9

AV3_AR 9

12

0.1uF/10V/0402

0.1uF/10V/0402

GND

12

C162

C162

C163

C163

0.1uF/10V/0402

0.1uF/10V/0402

3.3VA_VP

CLOSE TO C7

12

C164

C164

0.1uF/10V/0402

0.1uF/10V/0402

1 2

C175 0.1uF /10V/0402C175 0.1uF/10V/0 402

AV3_Y

AV3_PB

AV3_PR

AV1_Y

AV1_C

AV1_CVBS

AV2_CVBS

12

C165

C165

0.1uF/10V/0402

0.1uF/10V/0402

1.8VA_AVD

C146 0.1uF/10V/0402C146 0.1uF/10V/0 402

1 2

C141 0.1uF/10V/0402C141 0.1uF/10V/0 402

1 2

C144 0.1uF/10V/0402C144 0.1uF/10V/0 402

1 2

C145 0.1uF/10V/0402C145 0.1uF/10V/0 402

1 2

C156 0.1uF/25V/0402C156 0.1uF/25V/0 402

1 2

C157 0.1uF/25V/0402C157 0.1uF/25V/0 402

1 2

C153 0.1uF/10V/0402C153 0.1uF/10V/0 402

1 2

C154 0.1uF/10V/0402C154 0.1uF/10V/0 402

1 2

C316 0.1uF/10V/0402C316 0.1uF/10V/0 402

1 2

12

C166

C166

0.1uF/10V/0402

0.1uF/10V/0402

R124 6.8K/1%/0 402R124 6.8K/1%/0 402

1 2

R128 1K/1%/040 2R128 1K/1%/0 402

1 2

C167

C167

C169

C169

1 2

1 2

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

0.1uF/10V/0402

12

C174

C174

0.1uF/10V/0402

0.1uF/10V/0402

GND

VIDEO C7

U1C

U1C

R8J66977BG

R8J66977BG

BGA1090-1

BGA1090-1

A15

SSIN1

C12

VIN2A

A7

VIN2B

B8

VIN2C

C14

SSIN2

A11

VIN3A

B12

VIN1B

D8

VIN3C

A8

VIN4A

B7

VIN4B

A12

VIN1A

C9

VIN7A

A10

VIN5A

C7

VIN5B

B6

VIN8A

A6

VRP

B10

VRM

B13

VREFA

B11

VREFB

A9

VREFC

A14

SSIN3

A13

YIN

B9

YOUT

D11

REXT

H4

LPF

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

Title

Title

Title

SCHEMATIC,M/B VTV-L42601,SSB42T

SCHEMATIC,M/B VTV-L42601,SSB42T

SCHEMATIC,M/B VTV-L42601,SSB42T

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

Custom

Custom

Custom

Date: Sheet of

Friday, June 04, 2010

Date: Sheet of

Friday, June 04, 2010

Date: Sheet of

5

4

3

2

Friday, June 04, 2010

401C2K

401C2K

401C2K

6 15

6 15

1

6 15

1A

1A

1A

Page 33

5

VGA INPUT INTER FANCE

IO11

IO11

DSUB15P -CONTECK

VGA_SDA

VGA_SCL

DSUB15P -CONTECK

11

12

13

14

15

16

17

GND

CAB_P

HSYNC

D D

C C

B B

VSYNC

PC-RED

1

6

PC-GREEN

2

7

3

8

D-RS232-R X

4

5VA_VGA

9

D-RS232-T X

5

10

GND

5VA_VGA

P5V

P5V

12

R152

R152

47K/0402

47K/0402

12

R155

R155

47K/0402

47K/0402

R137 100/NCR137 100/NC

1 2

L47 0L47 0

1 2

L48 0L48 0

1 2

L50 0L50 0

1 2

Q19

Q19

FDV301N

FDV301N

G

12

R157

R157

10K/0402

10K/0402

GND

FDV301N

FDV301N

G

12

R159

R159

10K/0402

10K/0402

GND

4

PC_DET

12

R145

R145

75/1%

75/1%

3.3V_STB

12

DS

R154 1K/1%/0402R154 1K/1%/0402

1 2

3.3V_STB

12

Q20

Q20

DS

R158 1K/1%/0402R158 1K/1%/0402

1 2

PC_DET 4

12

R146

R146

75/1%

75/1%

R153

R153

47K/0402

47K/0402

RS232-RX

CAB_P

R156

R156

47K/0402

47K/0402

RS232-TX

CAB_P

12

R147

R147

75/1%

75/1%

GNDGNDGND

RS232-RX 10

RS232-TX 10

R140 0R140 0

1 2

R141 0R141 0

1 2

R143 0R143 0

1 2

C184 10nF/25V/0402C184 10nF/25V/0402

1 2

C185 10nF/25V/0402C185 10nF/25V/0402

1 2

C188 10nF/25V/0402C188 10nF/25V/0402

1 2

RED+

GREEN+PC-BLUE

BLUE+

3

V-SYAC & H-SYNC BUFFER

HSYNC

VSYNC

L49

L49

KHB0603 Q300SA

KHB0603 Q300SA

1 2

L51

L51

KHB0603 Q300SA

KHB0603 Q300SA

1 2

D-SUB C7

HSYNC+

VSYNC+

GREEN+

BLUE+

RED+

12

C189

C189

47pF/50V /0402

47pF/50V /0402

GND GND

3.3V_STB

12

C190

C190

47pF/50V /0402

47pF/50V /0402

GNDGND

U1D

U1D

R8J66977BG

R8J66977BG

BGA1090 -1

BGA1090 -1

B14

HSIN

B15

VSIN

C11

VIN6A

C8

VIN3B

D9

VIN1C

3.3V_STB

R162 10K/0402R162 10K/0402

1 2

1 2

12

R142

R142

R144

R144

2.2K

2.2K

R163 10K/0402R163 10K/0402

1 2

1 2

12

R148 22/1%/0402R1 48 22/1%/040 2

R150

R150

2.2K

2.2K

2

22/1%/040 2

22/1%/040 2

GND

GND

U25

U25

74LVC1G 126

74LVC1G 126

1

OE

2

A

GND3Y

SOT-353

SOT-353

U26

U26

74LVC1G 126

74LVC1G 126

1

OE

2

A

GND3Y

SOT-353

SOT-353

1

3.3V_STB

C187 0.1uF/10V/0402C187 0.1uF/10V/0402

R138 1K/1%/0402R138 1K/1%/0402

1 2

R139 1K/1%/0402R139 1K/1%/0402

1 2

3.3V_STB

C310 0.1uF/10V/0402C310 0.1uF/10V/0402

R149 1K/1%/0402R149 1K/1%/0402

1 2

R151 1K/1%/0402R151 1K/1%/0402

1 2

1 2

1 2

GND

HSYNC+

PC_HSYNC

GND

VSYNC+

PC_VSYNC

PC_HSYNC 4

5

74LVC1G17

SOT-353

241

3

PC_VSYNC 4

5

Vcc

4

5

Vcc

4

PC Audio in

IO18

IO18

PHONEJA CK-JALCO

PHONEJA CK-JALCO

GND

GND

2

R

R

1

L

L

3

A A

GND

L52 KHB06 03Q300SAL52 KHB06 03Q300SA

1 2

12

C193

C193

470pF/50 V/NC

470pF/50 V/NC

GND GND

L53 KHB06 03Q300SAL53 KHB06 03Q300SA

1 2

12

C198

C198

470pF/50 V/NC

470pF/50 V/NC

GND GND

5

12

C194

C194

470pF/50 V/NC

470pF/50 V/NC

12

C199

C199

470pF/50 V/NC

470pF/50 V/NC

AV5_AR

AV5_AL

AV5_AR 9

AV5_AL 9

4

EDID - D sub

D6 BA T54CD6 B AT54C

3

12

C195

C195

0.1uF/10V /0402

0.1uF/10V /0402

1

2

3

4

U13 IS24C 02BU13 IS24C02 B

GND

A0

A1

A2

GND

2

1

3

reserve for ESD 20100203

5VA_VGA

VCC

WP

SCL

SDA

P5V

GND

12

R164

R164

4.7K/1%

4.7K/1%

8

7

6

5

12

C68

C68

10uF/10V /0805/NC

10uF/10V /0805/NC

C0805D

C0805D

12

12

R243

R243

4.7K/1%

4.7K/1%

R167

R167

4.7K/1%

4.7K/1%

D7 1N 4148D7 1N4148

1 2

R168 100R168 1 00

1 2

R172 100R172 1 00

1 2

1 CA1

BAT54C

BAV99L

3 CC

2

2 CA2

EDID_W P

VGA_SCL

VGA_SDA

EDID_W P 4

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

Title

Title

Title

SCHEMATIC,M/B VTV-L42601,SSB42T

SCHEMATIC,M/B VTV-L42601,SSB42T

SCHEMATIC,M/B VTV-L42601,SSB42T

Size Document N umber Rev

Size Document N umber Rev

Size Document N umber Rev

A3

A3

A3

Date: Sheet of

Friday, June 04, 201 0

Date: Sheet of

Friday, June 04, 201 0

Date: Sheet of

Friday, June 04, 201 0

401C2K

401C2K

401C2K

1

7 15

7 15

7 15

1A

1A

1A

Page 34

5

HDMI INPUT

IO19

IO19

NIKTTECH/H DMI_SMD_V

NIKTTECH/H DMI_SMD_V

HPD

5V

GND

SDA

SCL

D D

(RSD)

CEC

CLK-

CLKShield

CLK+

D0-

D0Shield

D0+

D1-

D1Shield

D1+

D2-

D2Shield

D2+

G120G221G322G4

23

GND

IO20

IO20

NIKTTECH/H DMI_SMD_V

NIKTTECH/H DMI_SMD_V

C C

HPD

5V

GND

SDA

SCL

(RSD)

CEC

CLK-

CLKShield

CLK+

D0-

D0Shield

D0+

D1-

D1Shield

D1+

D2-

D2Shield

D2+

G120G221G322G4

B B

23

GND

IO21

IO21

HDMI_CONN_R F

HDMI_CONN_R F

HPD

5V

GND

SDA

SCL

(RSD)

CEC

CLK-

CLKShield

CLK+

D0-

D0Shield

D0+

D1-

A A

D1Shield

D1+

D2-

D2Shield

D2+

G120G221G322G4

23

GND

improve HDMI pre-test ,

HPD impedance

R169 0R169 0

1 2

19

18

1 2

R173 10R 173 10

17

16

15

14

R179 0R179 0

1 2

13

12

11

10

9

8

7

6

5

4

3

2

1

GND

improve HDMI pre-test ,

HPD impedance

R170 0R170 0

19

1 2

18

1 2

R180 10R 180 10

17

16

15

14

R200 0R200 0

13

1 2

12

11

10

9

8

7

6

5

4

3

2

1

GND

improve HDMI pre-test ,

HPD impedance

R171 0R171 0

1 2

19

18

1 2

R209 10R 209 10

17

16

15

14

R216 0R216 0

1 2

13

12

11

10

9

8

7

6

5

4

3

2

1

GND

5

HPD0

5VD_HDMI0

CH0_SDA

CH0_SCL

HDMI_CEC

CH0_CLK-

CH0_CLK+

CH0_D0-

CH0_D0+

CH0_D1-

CH0_D1+

CH0_D2-

CH0_D2+

HPD1

5VD_HDMI1

CH1_SDA

CH1_SCL

HDMI_CEC

CH1_CLK-

CH1_CLK+

CH1_D0-

CH1_D0+

CH1_D1-

CH1_D1+

CH1_D2-

CH1_D2+

HPD2

5VD_HDMI2

CH2_SDA

CH2_SCL

HDMI_CEC

CH2_CLK-

CH2_CLK+

CH2_D0-

CH2_D0+

CH2_D1-

CH2_D1+

CH2_D2-

CH2_D2+

R174 1K/1%/0402R174 1K/1%/0402

1 2

G

12

R181

R181

10K/0402

10K/0402

GND GND

R176 1K/1%/0402R176 1K/1%/0402

1 2

G

12

R196

R196

10K/0402

10K/0402

GND GND

R205 1K/1%/0402R205 1K/1%/0402

1 2

G

12

R212

R212

10K/0402

10K/0402

GND GND

GND

3.3VA_HDMI

D

S

12

R183

R183

10K/0402

10K/0402

GND

3.3VA_HDMI

D

S

12

R184

R184

10K/0402

10K/0402

GND

3.3VA_HDMI

D

S

12

R211

R211

10K/0402

10K/0402

E C

Q25

Q25

2N7002E

2N7002E

E C

Q31

Q31

2N7002E

2N7002E

E C

Q36

Q36

2N7002E

2N7002E

22K

22K

22K

22K

PDTC124ET

PDTC124ET

22K

22K

22K

22K

PDTC124ET

PDTC124ET

22K

22K

22K

22K

PDTC124ET

PDTC124ET

update for HPD should

not work while AC off

R178

R178

20100226

12K

12K

1 2

B

Q24

Q24

PWR0

B

Q28

Q28

PWR1

B

Q35

Q35

PWR2

HDMI_HPD0

47K/0402

47K/0402

CH0_SCL

CH0_SDA

update for HPD should

not work while AC off

R189

R189

20100226

12K

12K

1 2

HDMI_HPD1

47K/0402

47K/0402

CH1_SCL

CH1_SDA

update for HPD should

not work while AC off

R207

R207

20100226

12K

12K

1 2

HDMI_HPD2

47K/0402

47K/0402

CH2_SCL

CH2_SDA

5VD_HDMI0

12

R185

R185

HDMI_HPD1 4

5VD_HDMI1

12

R192

R192

5VD_HDMI2

12

R206

R206

4

HDMI_HPD0 4

12

R186

R186

4.7K/0402

4.7K/0402

12

R195

R195

4.7K/0402

4.7K/0402

R197 0R197 0

1 2

R202 0R202 0

1 2

HDMI_HPD2 4

12

R210

R210

4.7K/0402

4.7K/0402

R214 0R214 0

1 2

R213 0R213 0

1 2

4

3.3V_STB

Q27

G

FDV301N

D S

D S

3.3V_STB

D S

3.3V_STB

D S

3.3V_STB

D S

3.3V_STB

D S

3.3V_STB

G

G

G

G

G

FDV301N

Q29

Q29

FDV301N

FDV301N

Q32

Q32

FDV301N

FDV301N

Q30

Q30

FDV301N

FDV301N

Q39

Q39

FDV301N

FDV301N

Q34

Q34

FDV301N

FDV301N

R193 0R193 0

1 2

R201 0R201 0

1 2

improve HDMI pre-test ,

I2C capacitance 20100225

improve HDMI pre-test ,

I2C capacitance 20100225

improve HDMI pre-test ,

I2C capacitance 20100225

3

19" 26" NC

3.3V_STB

R190

R190

R187

R187

4.7K/1%

4.7K/1% R218

4.7K/1%

3.3V_STB

4.7K/1%Q27

R194

R194

4.7K/1%

4.7K/1%

CH0_SCL_C7

CH0_SDA_C7

R198

R198

4.7K/1%

4.7K/1%

CH1_SCL_C7

CH1_SDA_C7

improve HDMI pre-test , CEC

line-capacitance ; CTS 1.3

19" 26" NC

3.3V_STB

R215

R215

R208

R208

4.7K/1%

4.7K/1%

4.7K/1%

4.7K/1%

CH2_SCL_C7

CH2_SDA_C7

3

C7 HDMI

CH2_D0+

CH2_D0-

CH2_D1+

CH2_D1-

CH2_D2+

CH2_D2-

CH2_CLK+

CH2_CLK-

CH2_SDA_C7

CH2_SCL_C7

PWR2

CH0_D0+

CH0_D0-

CH0_D1+

CH0_D1-

CH0_D2+

CH0_D2-

CH0_CLK+

CH0_CLK-

CH0_SDA_C7

CH0_SCL_C7

PWR0

3.3V_STB 3.3V_STB 3.3V_STB

12

R218

27K

27K

13

13

D14

D14

BAT54

BAT54

HDMI_CEC

A19

B19

A18

B18

A17

B17

A20

B20

C17

D17

C18

A21

A22

D19

D20

C19

C20

B21

B22

C16

A16

C15

U1E

U1E

R8J66977BG

R8J66977BG

BGA1090-1

BGA1090-1

RX02P

RX02M

RX12P

RX12M

RX22P

RX22M

RXC2P

RXC2M

DDC2_SDA

DDC2_SCL

PWR2

RX00P

RX00M

RX10P

RX10M

RX20P

RX20M

RXC0P

RXC0M

DDC0_SDA

DDC0_SCL

PWR0

D S

2

Q40

Q40

G

NTR4003NT1G /NC

NTR4003NT1G /NC

HDMI CH2

HDMI CH2

HDMI CH0

HDMI CH0

2

HDMI CH1

HDMI CH1

RX01P

RX01M

RX11P

RX11M

RX21P

RX21M

RXC1P

RXC1M

DDC1_SDA

DDC1_SCL

PWR1

1

12

R203

R203

27K/NC

27K/NC

HDMI_CEC_C7 4

CH1_D0+

E19

CH1_D0-

E20

CH1_D1+

D21

CH1_D1-

D22

CH1_D2+

C21

CH1_D2-

C22

CH1_CLK+

F19

CH1_CLK-

F20

CH1_SDA_C7

D16

CH1_SCL_C7

D15

PWR1

B16

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

Title

Title