Page 1

Ordering number: EN5631

LC86P5032

CMOS LSI

LC86P5032

8-Bit Single-Chip Microcontroller

Overview

The LC86P5032 microcontroller, a new addition to the

LC865000 series, is a 8-bit single chip CMOS microcontroller

with one-time PROM.

This microcontroller has the same function and pin assignment

as for the LC865000 series mask ROM version, and a 32K-byte

PROM.

The same DIP/QFP packages as for the LC865000 series are

available for shipment. It is suitable for setting up the first

release, for prototyping and developing and testing applications.

Features

(1) Option switching using PROM data

The optional functions of the LC865000 series can be

specified using PROM data.

The functions of the trial products can be evaluated using a

mass production board.

(2) Internal one-time PROM capacity : 32768 bytes

(3) Internal RAM capacity : 512 bytes

Mask ROM version PROM capacity RAM capacity

LC865032 32512 bytes 512 bytes

LC865028 28672 bytes 512 bytes

LC865024 24576 bytes 512 bytes

LC865020 20480 bytes 384 bytes

LC865016 16384 bytes 384 bytes

LC865012 12288 bytes 384 bytes

LC865008 8192 bytes 384 bytes

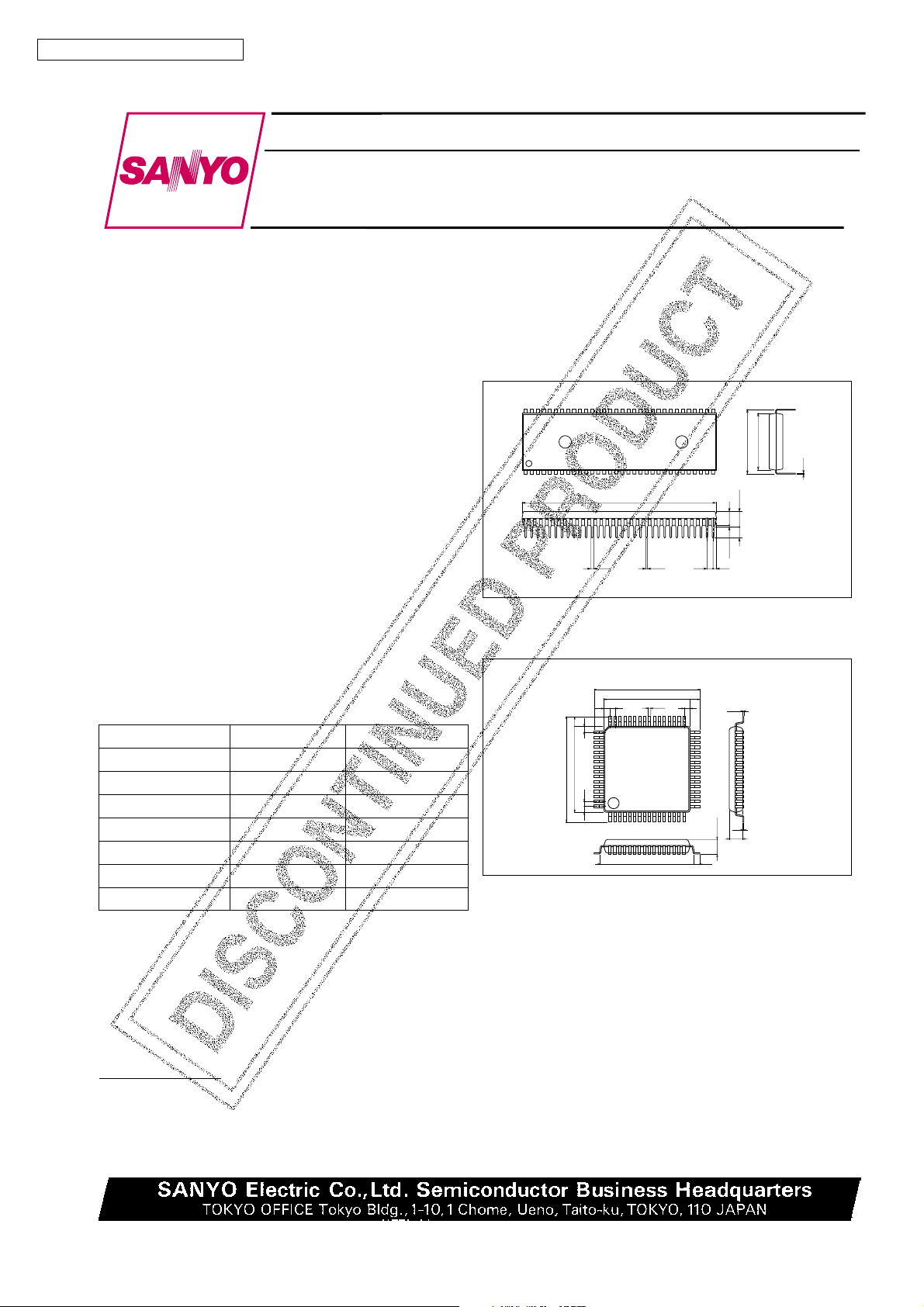

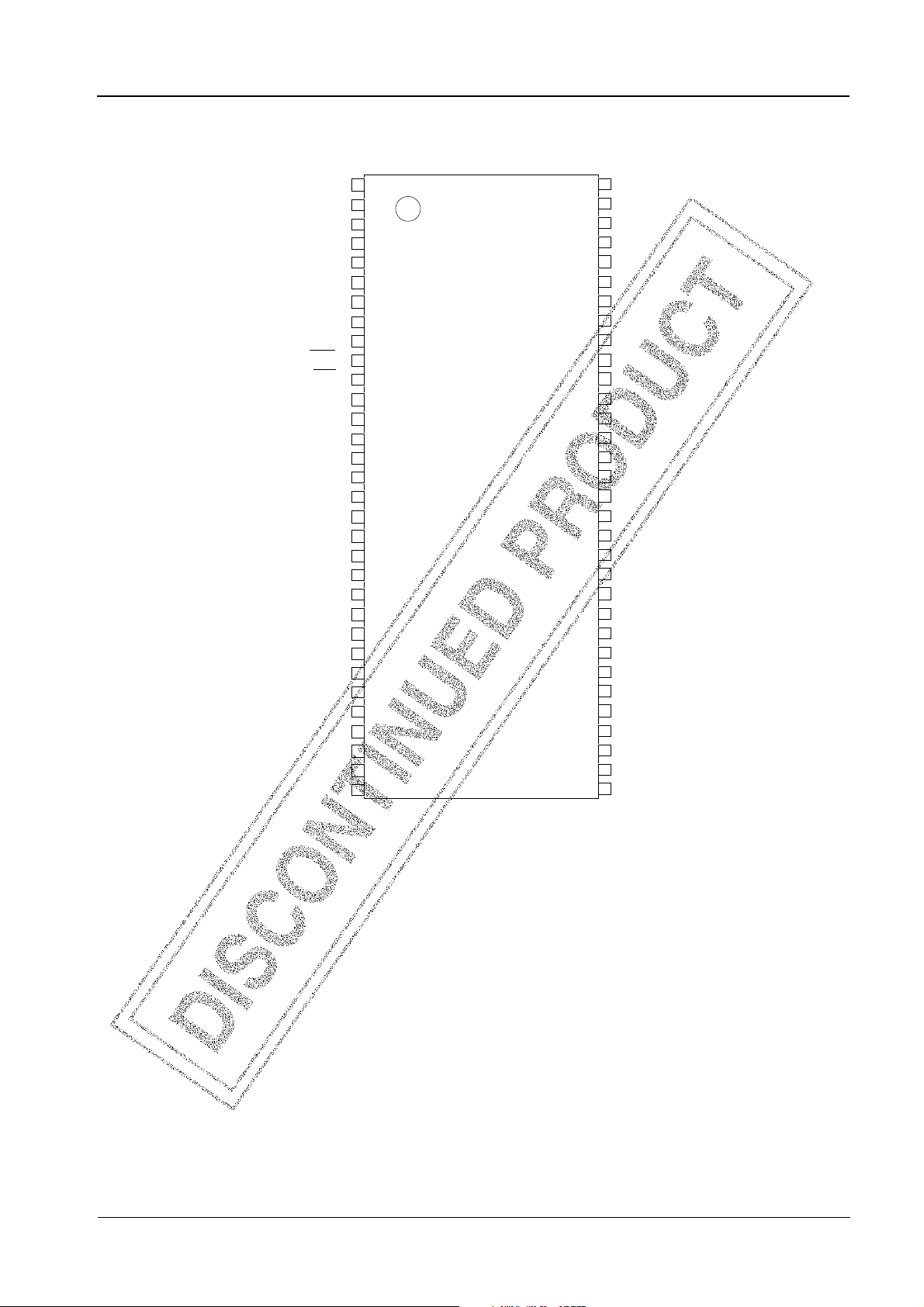

Package Dimensions

unit : mm

3071-DIP64S

[LC86P5032]

57.2

0.95 0.48 1.78 1.01

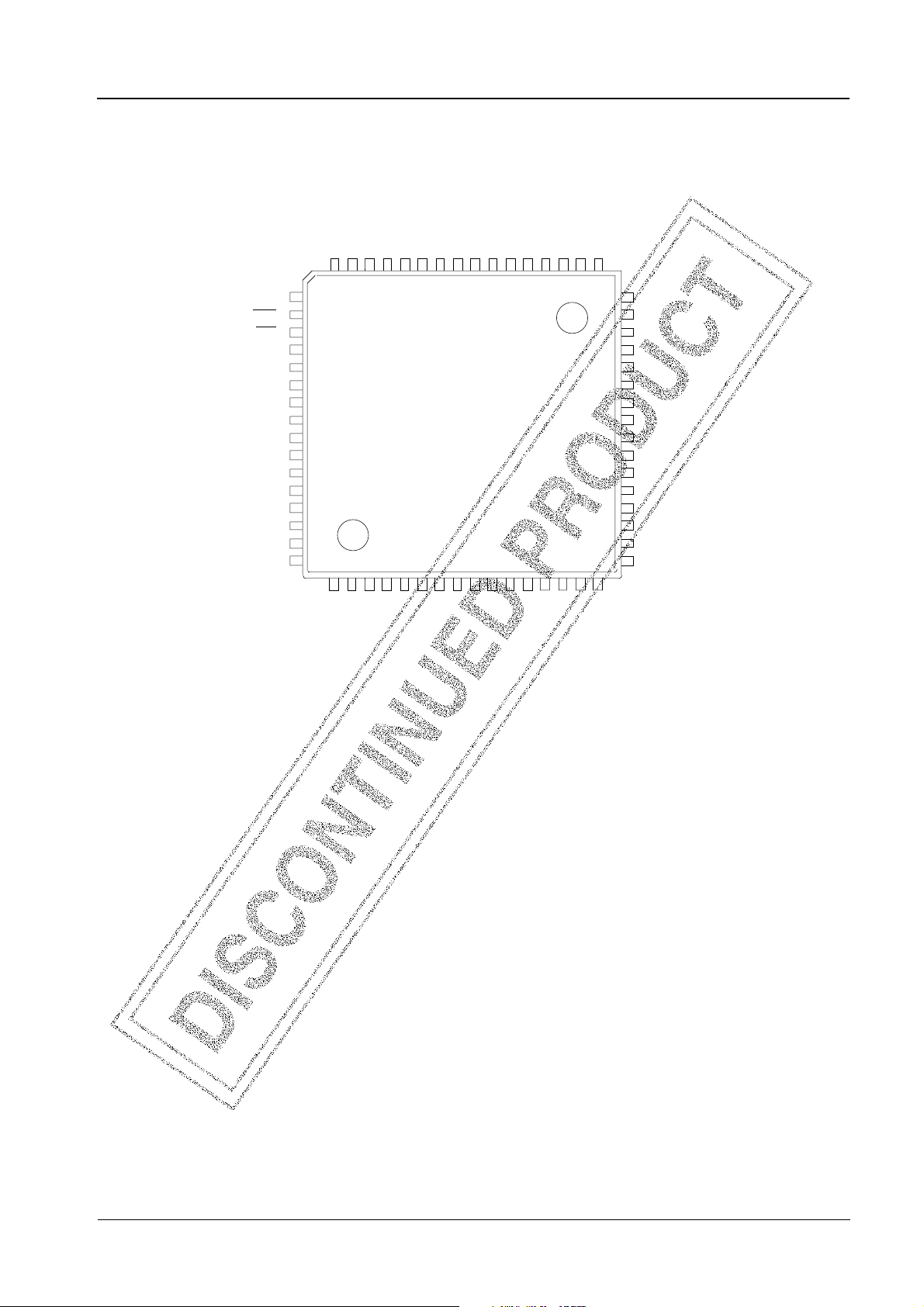

unit : mm

3159-QFP64E

[LC86P5032]

17.2

14.0

0.8

0.35

33

1

16

15.6

17.2

1.6

14.0

1.0

0.8

1.0

1.0

48

49

64

3364

19.5

321

5.0max

4.00.51min

3.2

SANYO : DIP52S

1.6

1.0

0.15

32

17

0.1

3.0max

2.7

0.8

SANYO : QFP64E

16.8

0.25

(4) Operating supply voltage : 4.5 to 6.0 V

(5) Instruction cycle time : 0.98 to 400 µs

(6) Operating temperature range : –30°C to +70°C

(7) Pins and package compatible with the mask ROM version

(8) Applicable mask version : LC865032/LC865028/LC865024/LC865020/LC865016/LC865012, LC865008

(9) Factory shipment : DIP-64S

QFP-64E

Programming service

We offer various services at nominal charges. These include ROM writing, ROM reading, and package stamping and screening.

Contact our local representatives for further information.

SANYO Electric Co., Ltd. Semiconductor LSI Div. Microcomputer Development Dep.

O3097HA (II)

No. 5631-1/22

Page 2

LC86P5032

Usage Notes

When using, please take note of the following.

(1) Differences between the LC86P5032 and the LC865000 series

Item LC86P5032 LC865032/28/24/20/16/12/08

Port status at reset Please refer to "Port status at reset" on the next page.

Operation after releasing reset The option is specified by degrees within 3 ms

after applying a 'H' level to the reset pin.

The program located at 00H is executed.

Operating voltage range 4.5 to 6.0 V 2.7 to 6.0 V

(V

)

DD

Total output current

[ ∑I

(1) ]

OAH

[ ∑I

(1) ]

OAH

Current drain Refer to 'Electrical Characteristics' on the semiconductor news.

[ I

(1)]

DDOP

[ I

(2)]

DDOP

[ I

(3)]

DDOP

[ I

(4)]

DDOP

• LC86P5032 Options

The program located at 00H is executed

immediately after applying a 'H' level to the

reset pin.

Option Pins, Circuits Option Settings

Configuration of input/output ports Port 0 1. Input : No pull-up MOS transistor

(Can be specified for Output : N-channel open drain

each bit.) 2. Input : Pull-up MOS transistor

Output : CMOS

Ports 1, 2 1. Input : No programmable pull-up MOS transistor

(Can be specified for Output : N-channel open drain

each bit.) 2. Input : Programmable pull-up MOS transistor

Output : CMOS

Ports 3, 4, 5 1. Input : No programmable pull-up MOS transistor

(Can be specified for Output : N-channel open drain

each bit.) 2. Input : Programmable pull-up MOS transistor

Output : CMOS

Port 7 pull-up MOS transistor Port 7 1. Pull-up MOS transistor not provided

(Can be specified for 2. Pull-up MOS transistor provided

each bit.) *P74 has no pull-up resistor option.

The port operation related to the option is different at reset. Please refer to the next table.

No. 5631-2/22

Page 3

LC86P5032

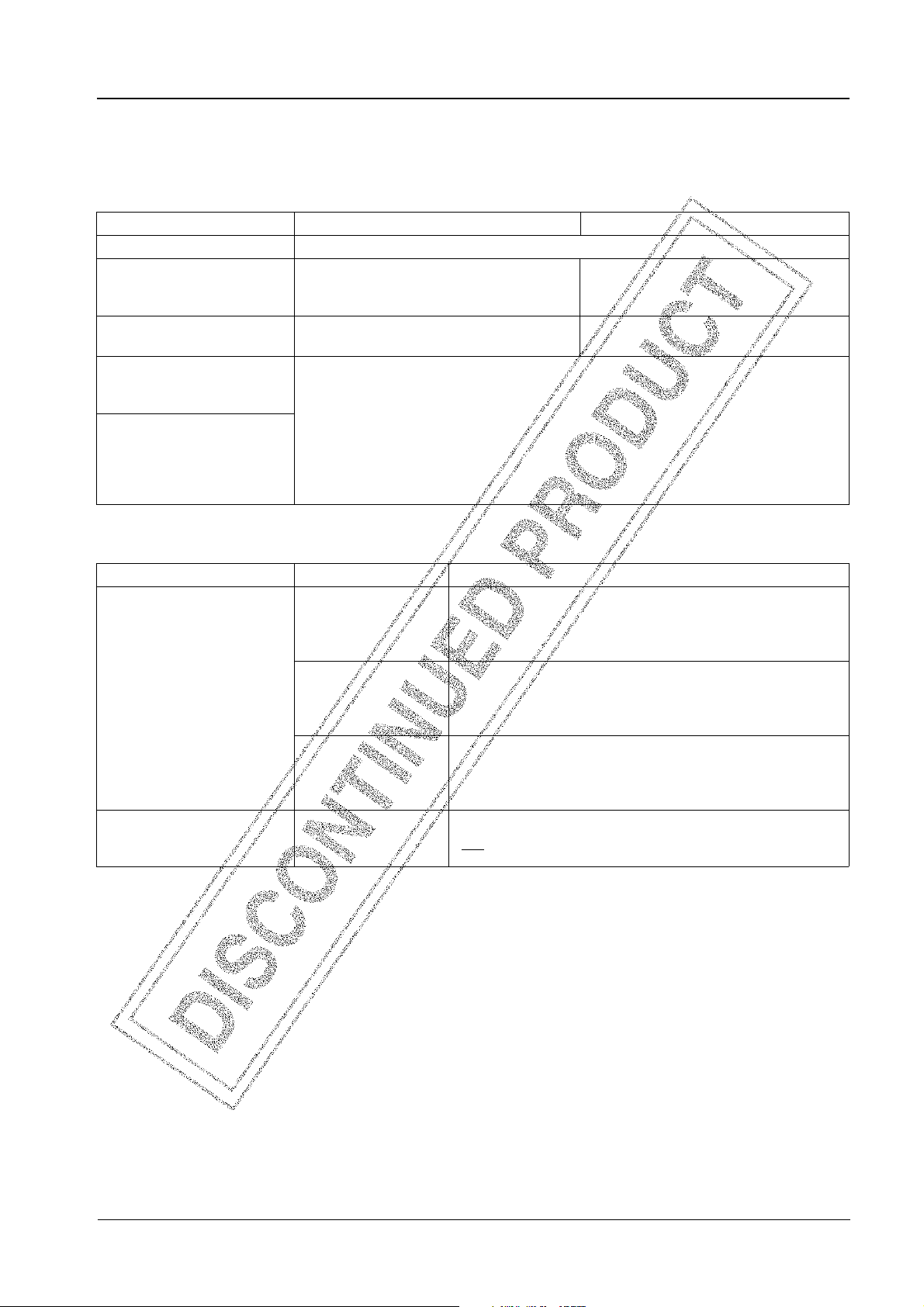

• Port configuration at reset

Pin Option settings LC86P5032 LC865032/28/24/20/16/12/08

P0 Input : No pull-up MOS transistor (Same as for the mask version) Input mode without pull-up MOS

Output : N-channel open drain transistor (Output is OFF)

Input : Pull-up MOS transistor Input mode Input mode with pull-up MOS

Output : CMOS • The Pull-up MOS transistor is not transistor (Output is OFF)

present during reset or several hundred

microseconds after releasing reset.

After that, the pull-up MOS transistor

is present. (Output is OFF)

P1,

Input : Programmable pull-up MOS transistor

P2 Output : N-channel open drain transistor (Output is OFF)

Input : Programmable pull-up MOS transistor

Output : CMOS transistor (Output is OFF)

P3, Input : Non-Programmable pull-up (Same as for the mask version) Input mode without pull-up MOS

P4, MOS transistor transistor (Output is OFF)

P5 Output : N-channel open drain

Input : Programmable pull-up MOS (Same as for the mask version) Input mode without pull-up MOS

transistor transistor (Output is OFF)

Output : CMOS

P7 Pull-up MOS transistor not provided (Same as for the mask version)

Pull-up MOS transistor provided Input mode Input mode with pull-up MOS

(Same as for the mask version) Input mode without pull-up MOS

(Same as for the mask version) Input mode without pull-up MOS

Input mode without pull-up MOS transistor

• The pull-up MOS transistor is not transistor

present during reset or several hundred

microseconds after releasing reset.

After that, the pull-up MOS transistor

is present.

(2) Option

The LC86P5032 uses 256 bytes addressed 7F00H to 7FFFH in program memory as option data area. This area does not affect the

execution of the program but means that the LC865032 program memory is 32512 bytes addressed 0000H to 7EFFH.

The option data is written using the option specifying program "SU865000. EXE". The option data is linked to the program area by

linkage loader "L865000. EXE".

(3) ROM space

7FFFH

7F00H

Option data

area 256 bytes

Option

Data Area

Option

Data Area

Option

Data Area

Option

Data Area

Option

Data Area

Option

Data Area

7EFFH

6FFFH

5FFFH

4FFFH

3FFFH

32K 28K 24K 20K 16K 12K 8K

0FFFH

LC865032 LC865028 LC865024 LC865020 LC865016 LC865012 LC865008

No. 5631-3/22

Page 4

LC86P5032

(4) Ordering information

1.When ordering identical mask ROM and PROM devices simultaneously.

Provide an EPROM containing the target memory contents together with separate order forms for each of the mask

ROM and PROM versions.

2.When ordering a PROM device.

Provide an EPROM containing the target memory contents together with an order form.

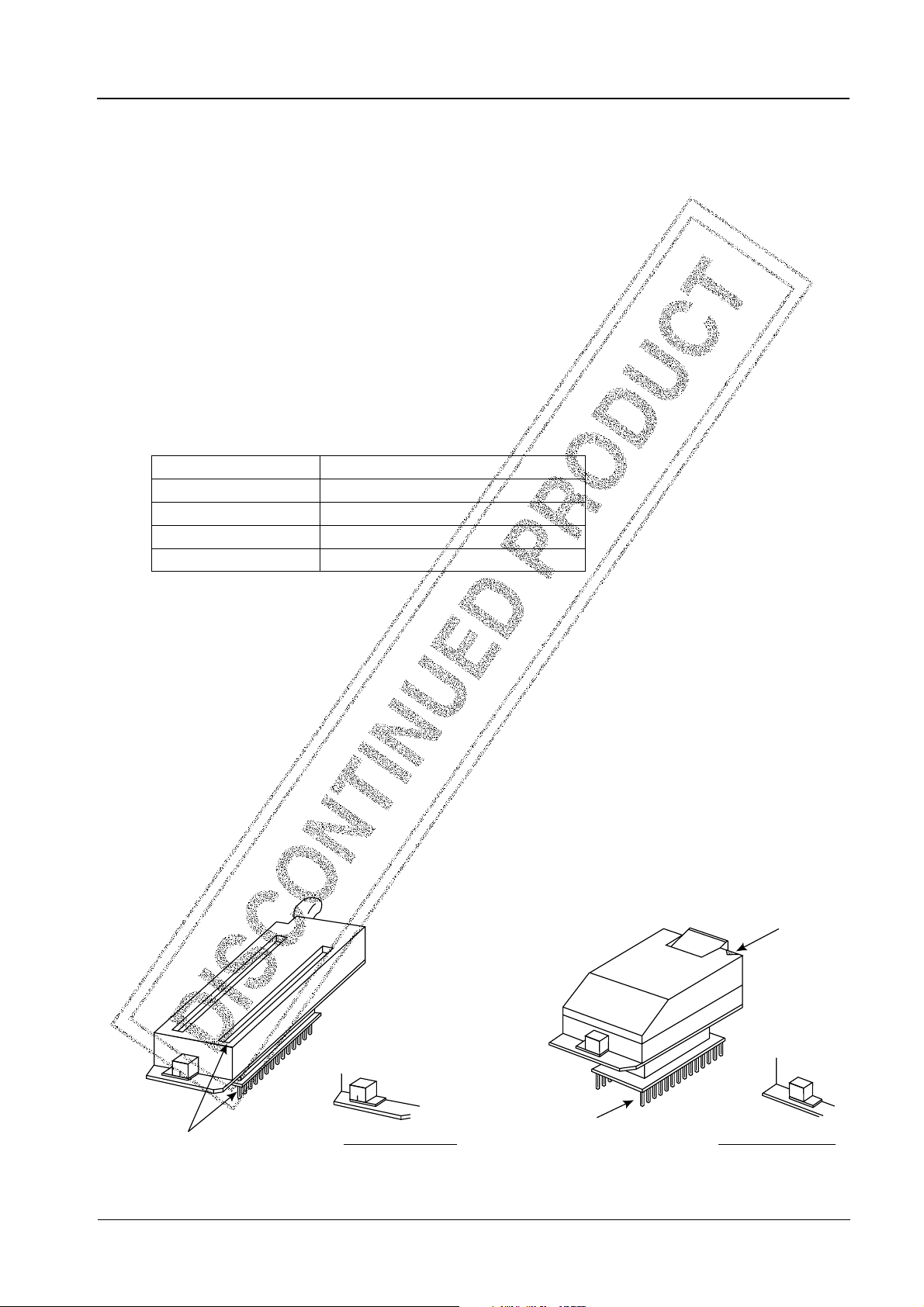

How to Use

(1) Specification of options

Programming data for the LC86P5032’s EPROM is required.

The debugged evaluation file (EVA file) must be converted to an INTEL-HEX formatted file (HEX file) with file converter

program EVA2HEX.EXE. The HEX file is used as the programming data for the LC86P5032.

(2) How to program the EPROM

The LC86P5032 can be programmed by an EPROM programmer with attachments W86EP5032D and W86EP5032Q.

• Recommended EPROM programmer

Supplier EPROM programmer

Advantest R4945, R4944, R4943

Andou AF-9704

AVAL PKW-1100, PKW-3000

Minato Electronics MODEL 1890A

• "27512 (Vp-p = 12.5 V) Intel high-speed programming" mode available. The address must be set to "0000H to 7FFFH"

and the jumper (DASEC) must be set 'OFF' at programming.

(3) How to use the data security function

"Data security" is a function to prevent EPROM data from being read.

Instructions on using the data security function:

1. Set the jumper of attachment 'ON'.

2. Attempt to program the EPROM. The EPROM programmer will display an error. The error indication is a result of

normal activity of the data security feature. This is not a problem with the EPROM programmer chip.

Notes

• The data security function is not carried out when the data of all addresses contain 'FF' at step 2 above.

• Data security cannot be executed when the sequential operation "BLANK=>PROGRAM=>VERIFY" is used at step 2 above.

• Set the jumper 'OFF' after execution of data security.

Pin 1 mark

OFF

O

OFF

Pin 1

ON

O

F

F

O

N

Data security OFF Data security OFF

Pin 1

N

OFF

ON

W86EP5032D W86EP5032Q

No. 5631-4/22

Page 5

Pin Assignment

LC86P5032

P10/SO0

P11/SI0/SB0

P12/SCK0

P13/SO1

P14/SI1/SB1

P15/SCK1

P16/BUZ

P17/PWM

TEST1

RES

XT1/P74

XT2

V

VSS

SS

CF1

CF2

V

DD

VDD

P80/AN0

P81/AN1

P82/AN2

P83/AN3

P84/AN4

P85/AN5

P86/AN6

P87/AN7

P70/INT0

P71/INT1

P72/INT2/T0IN

P73/INT3/T0IN

P30

P31

P32

P33

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

1

2

3

4

5

6

7

8

9

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

P07

P06

P05

P04

P03

P02

P01

P00

P27

P26

P25

P24

P23

P22

P21

P20

VDDV

PP

VDDVPP

V

SS

VSS

P51

P50

P47

P46

P45

P44

P43

P42

P41

P40

P37

P36

P35

P34

Top view

SANYO : DIP64S

No. 5631-5/22

Page 6

0

Pin Assignment

LC86P5032

TEST1

RES

XT1/P74

XT2

V

SS

VSS

CF1

CF2

V

DD

VDD

P80/AN0

P81/AN1

P82/AN2

P83/AN3

P84/AN4

P85/AN5

P86/AN6

P87/AN7

64

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

P16/BUZ

P15/SCK1

P17/PWM

47

46

123

P70/INT0

P71/INT1

P72/INT2/T0IN

P13/SO1

P11/SI0/SB

P12/SCK0

P14/SI1/SB1

43

P31

41

42

789

P32

44

45

456

P30

P73/INT3/T0IN

P10/SO0

P06

P07

40

39

P34

P35

P33

P05

P04

37

38

101112

P36

P03

36

131415

P40

P37

P02

35

P41

P01

34

P42

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

P00

33

P43

32

16

P27

P26

P25

P24

P23

P22

P21

P20

VDDV

PP

VDDVPP

VSS

V

SS

P51

P50

P47

P46

P45

P44

Top view

SANYO : QFP64E

No. 5631-6/22

Page 7

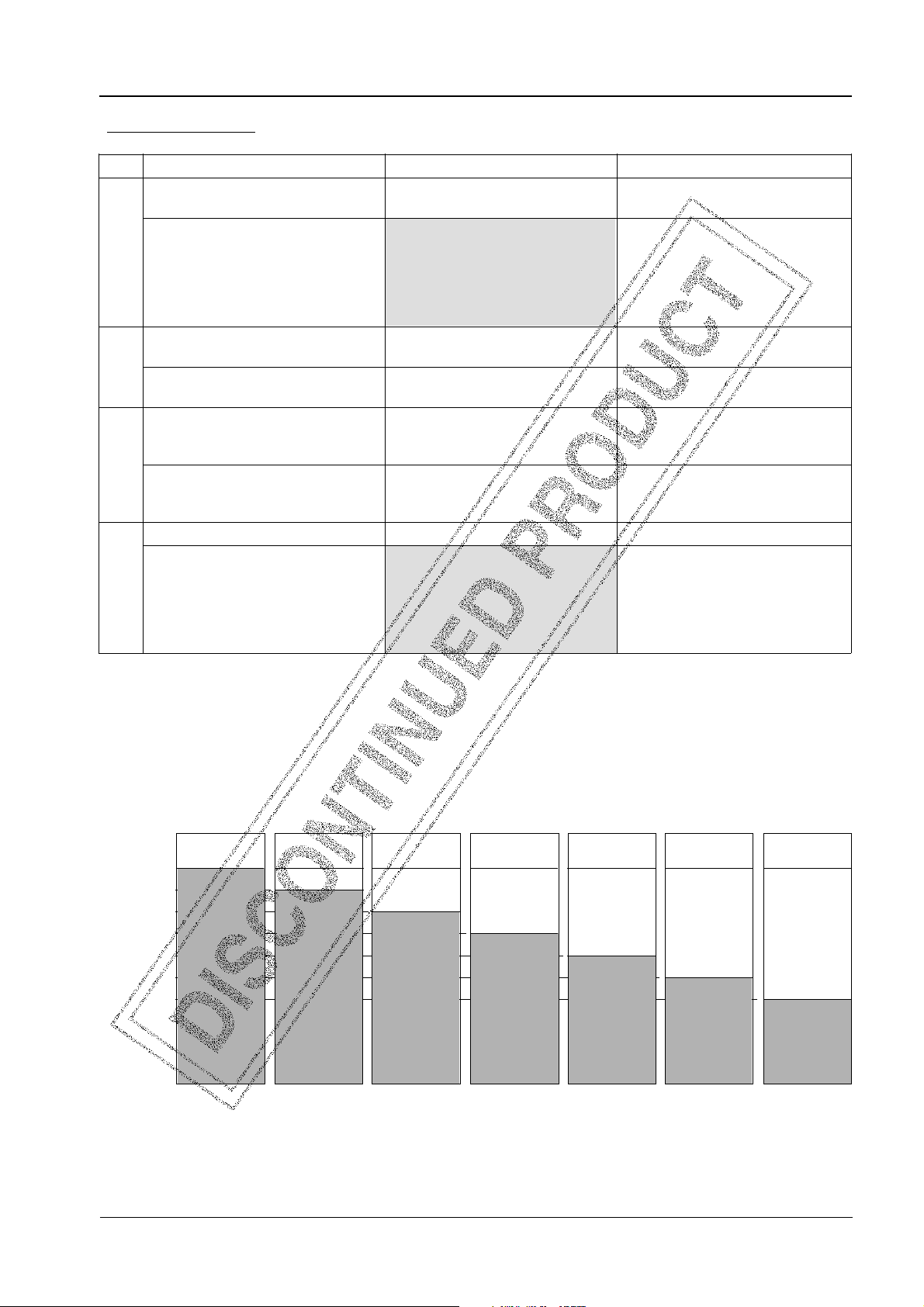

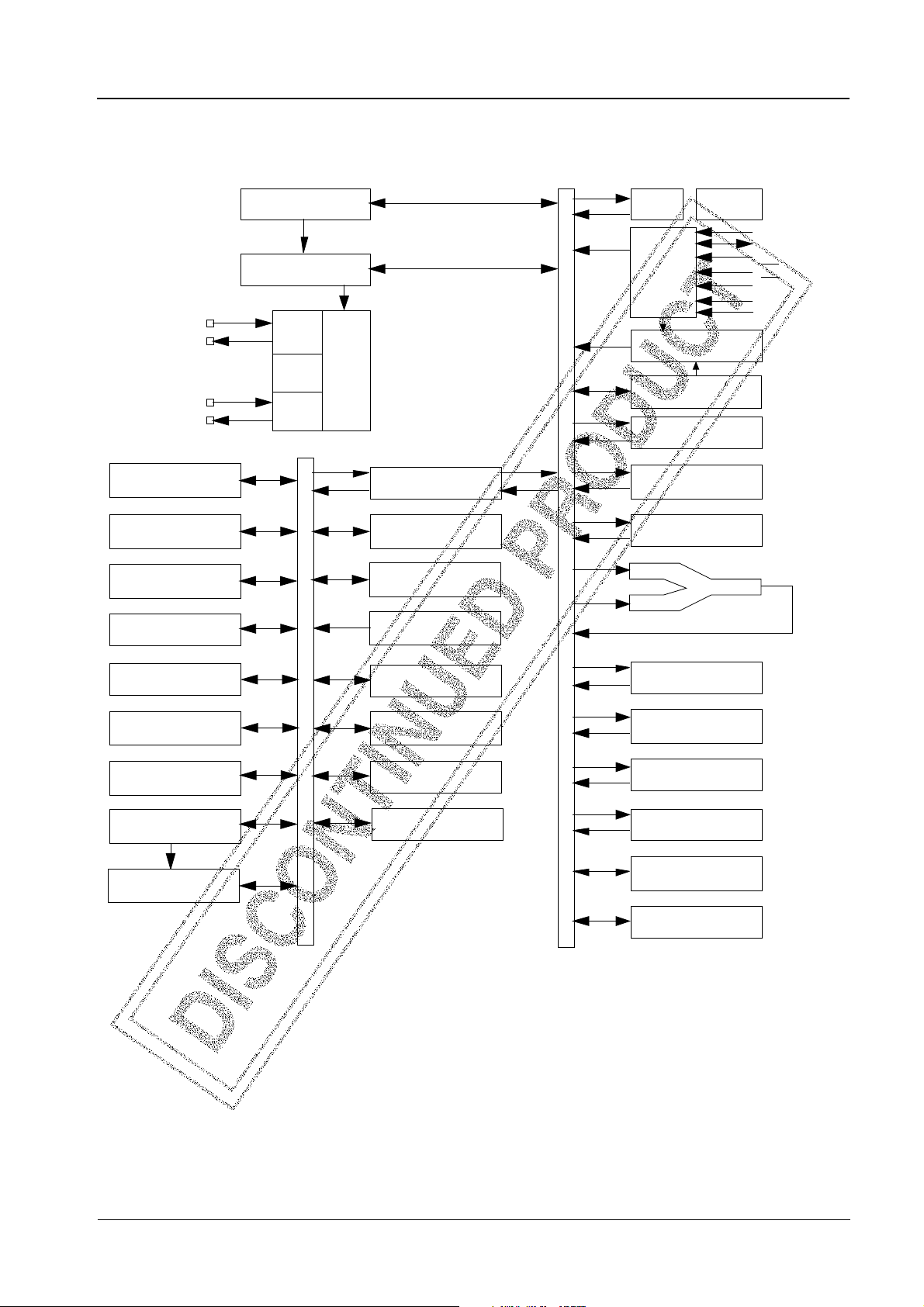

System Block Diagram

LC86P5032

Base timer

SIO 0

SIO 1

Timer 0

Interrupt control

Standby control

CF

RC

X tal

Colck

generator

Bus interface

Port 1

Port 7

Port 8

IR PLA

PROM

control

PROM(32KB)

PC

ACC

B register

C register

ALU

A16 to A0

D7 to D0

TA

CE

OE

DASEC

DD VPP

V

Timer 1

ADC

INT0 to INT3

Noise rejection filter

Real-time

service

XRAM

128 bytes

Port 2

Port 3

Port 4

Port 5

PSW

RAR

RAM

Stack

pointer

Port 0

Watchdog timer

No. 5631-7/22

Page 8

LC86P5032

LC86P5032 Pin Description

Pin name I/O Function description Option Function in PROM mode

V

SS

V

DD

VDDV

PP

PORT0 I/O • 8-bit input/output port • Pull-up resistor :

P00 to P07 • Input for port 0 interrupt Present/Not present

PORT1 I/O • 8-bit input/output port Output form : CMOS/ Data input/output

P10 to P17 • Data direction can be specified for each bit. N-channel open drain • D0 to D7

PORT2 I/O • 8-bit input/output port Output form : CMOS/

P20 to P27 • Data direction can be specified for each bit. N-channel open drain

PORT3 I/O • 8-bit input/output port Output form : CMOS/ Address input

P30 to P37 • Data direction can be specified for each bit. N-channel open drain • A7 to A0

PORT4 I/O • 8-bit input/output port Output form : CMOS/ Address input

P40 to P47 • Data direction can be specified for each bit. N-channel open drain • A14 to A8 (*5)

PORT5 I/O • 2-bit input/output port. Output form : CMOS/

P50 to P51 • Data direction can be specified for each bit. N-channel open drain

PORT7 • 5-bit input port Pullup resistor :

P70 I/O P70 : INT0 input/HOLD release/N-channel (P70, 71, 72, 73) Input of PROM control signal

P71 to P74 I P71 : INT 1 input/HOLD release. resistor. • OE (*2)

Power supply pin(–)

Power supply pin(+)

Power supply pin(+) Power for programming

• Input/output in nibble units

• Input for HOLD release • Output form : CMOS/

N-channel open drain.

• Other pin functions

P10 : SIO0 data output

P11 : SIO0 data input/bus input/output

P12 : SIO0 clock input/output

P13 : SIO1 data output

P14 : SIO1 data input/ bus input/output

P15 : SIO1 clock input/output

P16 : Buzzer output

P17 : Timer 1 output (PWM output)

• 15 V withstand at N-ch open-drain output

• 15 V withstand at N-ch open-drain output • P47 : TA (*4)

• 15 V withstand at N-ch open-drain output

• Other pin functions Present/Not present

Tr. output for watchdog timer. * P74 has no pull-up • DASEC (*1)

P72 : INT 2 input/timer 0 event input. • CE (*3)

P73 : INT 3 input with noise filter/timer 0

event input.

P74 : Input pin XT1 for 32.768 kHz crystal

oscillation

• Interrupt received format, vector address.

Rising Falling Rising High Low Vector

& level level

falling

INT0 Enable Enable Disable Enable Enable 03H

INT1 Enable Enable Disable Enable Enable 0BH

INT2 Enable Enable Enable Disable Disable 13H

INT3 Enable Enable Enable Disable Disable 1BH

No. 5631-8/22

Page 9

LC86P5032

Pin name I/O Function description Option Function in PROM mode

PORT8 I • 8-bit input port

P80 to P87 • Other functions

AD input port (8 port pins)

RES I Reset pin

TEST1 O Test pin

Should be left open.

XT1/P74 I • Input pin for 32.768 kHz crystal oscillation

• Other function : Input port P74

When not used, connect to V

XT2 O Output pin for 32.768 kHz crystal oscillation

When not used, should be left open.

CF1 I Input pin for ceramic resonator oscillation

CF2 O Output pin for ceramic resonator oscillation

• All port options can be specified in bit units.

*1 Memory select input for data security

*2 Output enable input

*3 Chip enable input

*4 TA ➝ PROM control signal input

*5 A14 ➝ Address input

DD

.

• Connect as shown in the following figure to reduce noise into V

Short-circuit the V

Short-circuit the V

pin to the VDDVPP pin.

DD

pin to the VSS pin.

SS

Power

supply

DD

pin.

V

DD

VDDV

V

SS

PP

LSI

V

SS

No. 5631-9/22

Page 10

LC86P5032

1. Absolute Maximum Ratings at Ta = 25°C, VSS = 0 V

Parameter Symbol Pins Conditions Ratings Unit

VDD[V] min typ max

Supply voltage VDD max VDD, VDDV

PP

Input voltage VI(1) • Ports 71, 72, 73, 74 –0.3 VDD+0.3

• Port 8

• RES

Input/output VIO(1) • Ports 0, 1, 2 –0.3 VDD+0.3

voltage • Ports 3, 4, 5 of

CMOS output

Highlevel

output

current

Peak

output

current

Total

VIO(2) •

I

(1) Ports 0, 1, 2, 3, 4, 5 • CMOS output –4mA

OPH

∑I

(1) Ports 0, 1, 2 Total of all pins –25

OAH

Ports 3, 4, 5 of opendrain output

output

Lowlevel

output

current

current

Peak

output

current

Total

output

current

∑I

(2) Ports 3, 4, 5 Total of all pins –20

OAH

I

(1) Ports 0, 1, 2, 3, 4, 5 At each pin 20

OPL

I

(2) Port 70 At each pin 15

OPL

∑I

(1) Ports 0, 1, 70 Total of all pins 40

OAL

∑I

(2) Port 2 Total of all pins 40

OAL

∑I

(3) Ports 3, 4, 5 Total of all pins 80

OAL

Power dissipation Pd max(1) DIP64S Ta = –30°C+70°C 720 mW

(max.)

Pd max(2) QFP64E Ta = –30°C+70°C 420

Operating Topr –30 70 °C

temperature range

Storage Tstg –65 150

temperature range

VDD = VDDV

• At each pin

PP

–0.3 +7.0 V

–0.3 15

No. 5631-10/22

Page 11

LC86P5032

2. Recommended Operating Range at Ta = –30°C to +70°C, VSS = 0 V

Parameter Symbol Pins Conditions Ratings Unit

VDD[V] min typ max

Operating voltage VDD(1) V

DD

range tCYC ≤ 400 µs

HOLD voltage V

HD

V

DD

Input high VIH(1) Port 0 (Schmitt) Output disabled 4.5 to 6.0 0.4V

voltage +0.9

VIH(2) • Ports 1, 2 Output disabled 4.5 to 6.0 0.75V

• Ports 72, 73

(Schmitt)

VIH(3) • Port 70 Output N-channel 4.5 to 6.0 0.75V

Port input/interrupt. transistor OFF

• Port 71

• RES (Schmitt)

VIH(4) Port 70 Output N-channel 4.5 to 6.0 0.9V

Watchdog timer transistor OFF

VIH(5) • Port 74 Output N-channel 4.5 to 6.0 0.75V

• Port 8 transistor OFF

VIH(6) Ports 3, 4, 5 of Output disabled 4.5 to 6.0 0.75V

CMOS output

(Schmitt)

VIH(7) Ports 3, 4, 5 of open Output disabled 4.5 to 6.0 0.75V

drain output

(Schmitt)

Input low VIL(1) Port 0 (Schmitt) Output disabled 4.5 to 6.0 V

voltage

V

(2) • Ports 1, 2, 3, 4, 5 Output disabled 4.5 to 6.0 V

IL

• Ports 72,73

(Schmitt)

VIL(3) • Port 70 N-channel transistor 4.5 to 6.0 V

Port input/interrupt. OFF

• Port 71

• RES (Schmitt)

VIL(4) Port 70 N-channel transistor 4.5 to 6.0 V

Watchdog timer OFF –1.0

VIL(5) • Port 74 N-channel transistor 4.5 to 6.0 V

• Port 8 OFF

Operation cycle tCYC 4.5 to 6.0 0.98 400 µs

time

0.98 µs ≤ tCYC 4.5 6.0 V

RAM and registers 2.0 6.0

retain their pre-HOLD

mode values.

V

13.5

0.2V

0.25V

0.25V

0.8V

0.25V

V

DD

DD

V

DD

V

DD

V

DD

V

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

SS

SS

SS

SS

SS

No. 5631-11/22

Page 12

LC86P5032

Parameter Symbol Pins Conditions Ratings Unit

VDD[V] min typ max

Oscillation FmCF(1) CF1, CF2 • 12 MHz (ceramic 4.5 to 6.0 11.76 12 12.24 MHz

frequency range resonator oscillation).

(Note 1) • Refer to Figure 1.

FmCF(2) CF1, CF2 • 3 MHz (ceramic 4.5 to 6.0 2.94 3 3.06

resonator oscillation).

• Refer to Figure 1.

FmRC RC oscillation 4.5 to 6.0 0.4 0.8 2.0

FsXtal XT1, XT2 • 32.768 kHz (crystal 4.5 to 6.0 32.768 kHz

oscillation).

• Refer to Figure 2.

Oscillation stable tmsCF(1) CF1, CF2 • 12 MHz (ceramic 4.5 to 6.0 0.03 0.5 ms

time period resonator oscillation).

(Note 1) • Refer to Figure 3.

tmsCF(2) CF1, CF2 • 3 MHz (ceramic 4.5 to 6.0 0.2 2

resonator oscillation).

• Refer to Figure 3.

tssXtal XT1, XT2 • 32.768 kHz (crystal 4.5 to 6.0 1 1.5 s

oscillation).

• Refer to Figure 3.

(Note 1) The oscillation constants are shown on Table 1 and Table 2.

No. 5631-12/22

Page 13

LC86P5032

3. Electrical Characteristics at Ta= –30°C to +70°C , VSS = 0 V

Parameter Symbol Pins Conditions Ratings Unit

VDD [V] min typ max

Input high

current

Input low

current

Output high

voltage

Output low

voltage

Pull-up MOS

transistor resistance

Hysteresis

voltage

Pin capacitance

IIH(1) 4.5 to 6.0 5 µA

•Ports 3, 4, 5 at

open-drain output

IIH(2) 4.5 to 6.0 1

•Port 0 without

pull-up MOS

transistor

•Ports 1, 2, 3, 4, 5

IIH(3) 4.5 to 6.0 1

•Ports 70, 71, 72, 73

without pull-up

MOS transistor

•Port 8

IIH(4) 4.5 to 6.0 1

IIL(1) 4.5 to 6.0 –1

•RES

•Ports 1, 2, 3, 4, 5

•Port 0 without

pull-up MOS

transistor

IIL(2) 4.5 to 6.0 –1

•Ports 70, 71, 72, 73

without pull-up

MOS transistor

•Port 8

IIL(3) 4.5 to 6.0 –1

VOH(1) 4.5 to 6.0 VDD–1V

•RES

•Ports 0, 1, 2, 3, 4, 5

at CMOS output

VOH(2) 4.5 to 6.0 VDD–0.5

VOL(1) 4.5 to 6.0 1.5

Ports 0, 1, 2, 3, 4, 5

VOL(2) 4.5 to 6.0 0.4

VOL(3) 4.5 to 6.0 0.4

Port 70

VOL(4) 4.5 to 6.0 0.4

Rpu 4.5 to 6.0 15 40 70 kΩ

•Ports 0, 1, 2, 3, 4, 5

•Ports 70, 71, 72, 73

V

HIS

•Ports 0, 1, 2, 3, 4, 5

•Ports 70, 71, 72, 73

•RES

CP 4.5 to 6.0 10 pF

All pins

•Output disabled

= 13.5 V

•V

IN

(including off-state leak

current of output transistor)

•Output disabled

•Pull-up MOS transistor

OFF. VIN = V

DD

(including off-state leak

current of output transistor)

VIN = V

DD

VIN = V

DD

•Output disabled

•Pull-up MOS transistor

OFF. V

IN

= V

SS

(including off-state leak

current of output transistor)

VIN = V

SS

VIN = V

SS

IOH = –1.0 mA

I

= –0.1 mA

OH

I

= 10 mA

OL

I

= 1.6 mA

OL

I

= 1 mA

OL

IOL = 0.5 mA

V

= 0.9 V

OH

DD

Output disable

•f = 1 MHz

•Unmeasured input

pins are set to

V

level.

SS

•Ta = 25°C

4.5 to 6.0 0.1V

DD

V

No. 5631-13/22

Page 14

LC86P5032

4. Serial Input/Output Characteristics at Ta = –30°C to +70°C , VSS = 0 V

Parameter Symbol Pins Conditions Ratings Unit

VDD [V] min typ max

Cycle

Low-

level

pulse

width

Input clock

Highlevel

pulse

width

Cycle

Serial clock

Lowlevel

pulse

width

Output clock

Highlevel

pulse

width

Data setup

time

Data hold

time

Serial input

Output delay

time

(Serial clock

is extrnal

clock.)

tCKCY(1) SCK0, SCK1 4.5 to 6.0 2 tCYC

tCKL(1) 4.5 to 6.0 1

tCKH(1) 4.5 to 6.0 1

tCKCY(2) SCK0, SCK1 4.5 to 6.0 2

tCKL(2) 4.5 to 6.0 1/2tCKYC

tCKH(2) 4.5 to 6.0 1/2tCKYC

tICK • SI0, SI1 4.5 to 6.0 0.1 µs

• SB0, SB1

tCKI 4.5 to 6.0 0.1

tCKO(1) • SO0, SO1 4.5 to 6.0 7/12tCYC

• SB0, SB1 +0.2

Refer to Figure 5.

• Use pullup resistor

(1 kΩ) when set to

open-drain output.

• Refer to Figure 5.

• Data set-up to

SCK0, 1

• Data hold from

SCK0, 1

• Refer to Figure 5.

• Use a pullup resistor

(1 kΩ) when set to

open-drain output.

Output delay

Serial output

time

(Serial clock

is internal

clock.)

tCKO(2) 4.5 to 6.0 1/3tCYC

• Data hold from

SCK0, 1

• Refer to Figure 5.

+0.2

No. 5631-14/22

Page 15

LC86P5032

5. Pulse Input Conditions at Ta = –30°C to +70°C, VSS = 0 V

Parameter Symbol Pins Conditions Ratings Unit

VDD [V] min typ max

High/low-level tPIH(1) • INT0, INT1 4.5 to 6.0 1 tCYC

pulse width tPIL(1) • INT2/T0IN

• INT3

tPIH(2) INT3 4.5 to 6.0 2

tPIL(2) (The noise rejection

clock selected to 1/1.)

tPIH(3) INT3 4.5 to 6.0 32

tPIL(3) (The noise rejection

clock selected to

1/16.)

tPIL(4) RES 4.5 to 6.0 200 µs

6. A/D Converter Characteristics at Ta = –30°C to +70°C, VSS = 0 V

Parameter Symbol Pins Conditions Ratings Unit

Resolution

Absolute

precision (Note 2)

Conversion

time

Analog input

voltage range

Analog port

input current

N 8 bit

ET 4.5 to 6.0 ±1/5 LSB

tCAD 4.5 to 6.0 15.68 65.28 µs

V

I

AINH

I

AINL

AIN

AN0 to AN7

• Interrupt acceptable

• Timer 0 pulse

countable

• Interrupt acceptable

• Timer 0 pulse

countable

• Interrupt acceptable

• Timer 0 pulse

countable

Reset acceptable

A/D conversion

time = 16 × tCYC

(ADCR2 = 0)

(Note 3)

A/D conversion

time = 32 × tCYC

(ADCR2 = 1)

(Note 3)

= V

V

AIN

DD

V

= V

AIN

SS

VDD [V] min typ max

(tCYC = (tCYC =

0.98 µs) 4.08 µs)

31.36 130.56

(tCYC = (tCYC =

0.98 µs) 4.08 µs)

4.5 to 5.5 V

SS

V

DD

4.5 to 5.5 +1 µA

4.5 to 5.5 –1

V

(Note 2) Quantizing error (±1/2 LSB) is ignored.

(Note 3) The conversion time is the period from execution of the instruction to start conversion to the completion of shifting the

A/D converted value to the register.

No. 5631-15/22

Page 16

LC86P5032

7. Current Drain Characteristics at Ta = –30°C to +70°C , VSS = 0 V

Parameter Symbol Pins Conditions Ratings Unit

VDD [V] min typ max

Current drain

during basic

operation

(Note 4)

I

DDOP

(1) V

DD

• FmCF = 12 MHz for

4.5 to 6.0 13 26 mA

ceramic resonator

oscillation.

• FsXtal = 32.768 kHz for

crystal oscillator.

• System clock :

CF oscillator.

• Internal RC oscillator

stopped.

I

(2) 4.5 to 6.0 7 14

DDOP

• FmCF = 3 MHz for

ceramic resonator

oscillation.

• FsXtal = 32.768 kHz for

crystal oscillator.

• System clock :

CF oscillator.

• Internal RC oscillator

stopped.

I

(3) 4.5 to 6.0 4 10

DDOP

• FmCF = 0 Hz

(when oscillator stops).

• FsXtal = 32.768 kHz for

crystal oscillator.

• System clock :

RC oscillator.

I

(4) 4.5 to 6.0 4 8

DDOP

• FmCF = 0 Hz

(when oscillator stops).

• FsXtal = 32.768 kHz for

crystal oscillator.

• System clock :

crystal oscillator.

• Internal RC oscillator

stopped.

No. 5631-16/22

Page 17

LC86P5032

Parameter Symbol Pins Conditions Ratings Unit

VDD [V] min typ max

Current drain at

HALT mode

(Note 4)

Current drain at

HOLD mode

(Note 4)

I

DDHALT

(1) V

DD

• HALT mode

4.5 to 6.0 5 10 mA

• FmCF = 12 MHz for

ceramic resonator

oscillation.

• FsXtal = 32.768 kHz for

crystal oscillator.

• System clock :

CF oscillator.

• Internal RC oscillator

stopped.

I

(2) 4.5 to 6.0 2.2 4.6

DDHALT

• HALT mode

• FmCF = 3 MHz for

ceramic resonator

oscillation.

• FsXtal = 32.768 kHz for

crystal oscillator.

• System clock :

CF oscillator.

• Internal RC oscillator

stopped.

I

(3) 4.5 to 6.0 550 1100 µA

DDHALT

• HALT mode

• FmCF = 0 Hz

(when oscillator stops).

• FsXtal = 32.768 kHz for

crystal oscillator.

• System clock :

RC oscillator

I

(4) 4.5 to 6.0 25 100

DDHALT

• HALT mode

• FmCF = 0 Hz

(when oscillator stops).

• FsXtal = 32.768 kHz for

crystal oscillator.

• System clock :

crystal oscillator.

• Internal RC oscillator

stopped.

I

(1) V

DDHOLD

I

(2) 2.5 to 4.5 0.02 20

DDHOLD

DD

HOLD mode

4.5 to 6.0 0.05 30

(Note 4) The currents of output transistors and pull-up transistors are ignored.

No. 5631-17/22

Page 18

LC86P5032

Table 1. Ceramic Resonator Oscillation Guaranteed Constants (Main clock)

Oscillation type Supplier Oscillator C1 C2

12 MHz ceramic resonator Murata CSA12.0MTZ 33 pF 33 pF

oscillation CST12.0MTW on chip

Kyocera KBR-12.0M 33 pF 33 pF

3 MHz ceramic resonator Murata CSA3.00MG040 100 pF 100 pF

oscillation CST3.00MGW040 on chip

Kyocera KBR-3.0MS 47 pF 47 pF

• For both C1 and C2, the K rank (±10%) and SL characteristics must be used.

Table 2. Crystal Oscillaion Guaranteed Constants (Sub-clock)

Oscillation type Supplier Oscillator C3 C4

32.768 kHz crystal oscillation Kyocera KF-38G-13P0200 18 pF 18 pF

• For both C3 and C4, the J rank (±5%) and CH characteristics must be used.

(If high precision is not necessary, use K rank (±10%) and SL characteristics.)

Notes • Since the circuit pattern affects the oscillation frequency, place the oscillation-related parts as close to the oscillation pins

as possible with the shortest possible pattern length.

• If you use other oscillators herein, we provide no guarantee for the characteristics.

CF1

C1

Figure 1 Ceramic Resonator Oscillation Figure 2 Crystal Oscillation

CF

Main-clock circuit Sub-clock circuit

CF2

C2

XT1

C3 C4

X tal

XT2

No. 5631-18/22

Page 19

Power supply

LC86P5032

V

DD

VDD lower limit

0V

RES

Internal RC

resonator

oscillation

CF1, CF2

XT1, XT2

Operation mode

HOLD release signal

Internal RC

resonator

oscillation

CF1, CF2

Reset time

t

msCF

t

ssXtal

Unfixed

Reset

Instruction execution mode

<Reset time and oscillation stable time.>

Valid

t

msCF

XT1, XT2

Operation mode

RES

t

ssXtal

HOLD

Instruction execution mode

<HOLD release signal and oscillation stable time.>

Figure 3 Oscillation Stable Time

VDD

V

DD

R

RES

R

RES

C

C

RES

RES

The values of C

such that reset time is at least 200 µs, measured from

(Note) Fix the value of C

the moment the power exceeds the V

is sure to reset untill 200µs, after

RES

and R

Power supply has been over inferior

limit of supply voltage.

should be determined

RES

RES

, R

lower limit.

DD

RES

that

Figure 4 Reset Circuit

No. 5631-19/22

Page 20

LC86P5032

0.5VDD

0.5 V

< AC timing point >

DD

SCK0

SCK1

SI0

SI1

SO0,SO1

SB0,SB1

t

CKCY

t

CKL

t

t

ICK

t

CKO

< Timing >

Figure 5 Serial Input/Output Test Conditions

CKI

t

CKH

VDD

1kΩ

50pF

< Test load >

t

PIL

Figure 6 Pulse Input Timing Conditions

t

PIH

No. 5631-20/22

Page 21

LC86P5032

Usage Notes

• The construction of the one-time programmable microcontroller with a blank built-in PROM makes it impossible for Sanyo

to completely factory-test it before shipping. To prove reliability of the programmed devices, the screening procedure

shown in the following figure should always be followed.

• It is not possible to perform a writing test on the blank PROM. 100% yield, therefore, cannot be guaranteed.

• Ensure dry packaging

The environment must be held at a temparature of 30°C or less and a humidity level of 70% or less.

• After opening the packing

The preparation procedures shown in the following figure should always be followed prior to mounting the packages on the

substrate. After opening the packing, a controlled environment must be maintained until soldering.

The environment must be held at a temperature of 30°C or less and a humidity level of 70% or less. Please solder within 96

hours.

a. Shipping with a blank PROM (Data to be programmed by customer)

DIP

Programming and

verifying

Recommended process of screening

Heat-soak

150 ± 5°C, 24 Hr

+1

–0

Program reading test

Mounting

QFP

Programming and

verifying

Recommended process of screening

Heat-soak

150 ± 5°C, 24 Hr

+1

–0

Program reading test

Mounting

b. Shipping with programmed PROM (Data programmed by Sanyo)

Mounting

QFPDIP

Mounting

No. 5631-21/22

Page 22

LC86P5032

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft’s

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges, or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer’s

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer’s products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

semiconductor products fail with some probability. It is possible that these probabilistic failures could

give rise to accidents or events that could endanger human lives, that could give rise to smoke or fire,

or that could cause damage to other property. When designing equipment, adopt safety measures so

that these kinds of accidents or events cannot occur. Such measures include but are not limited to protective

circuits and error prevention circuits for safe design, redundant design, and structural design.

In the event that any or all SANYO products(including technical data,services) described or

contained herein are controlled under any of applicable local export control laws and regulations,

such products must not be exported without obtaining the export license from the authorities

concerned in accordance with the above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or any information storage or retrieval system,

or otherwise, without the prior written permission of SANYO Electric Co. , Ltd.

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the “Delivery Specification”

for the SANYO product that you intend to use.

Information (including circuit diagrams and circuit parameters) herein is for example only ; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but

no guarantees are made or implied regarding its use or any infringements of intellectual property rights

or other rights of third parties.

This catalog provides information as of October, 1997. Specifications and information herein are subject to change without notice.

No. 5631-22/22

Loading...

Loading...