Page 1

Ordering number : EN4882

N1594TH (OT) B8-1395 No. 4882-1/24

Overview

The LC7868KE is a CMOS LSI that implements the

signal processing and servo control required by compact

disk players, laser disks, CD-V, CD-I and related

products. The LC7868KE provides several types of signal

processing to reduce the cost of CD player units, including

demodulation of the optical pickup EFM signal, deinterleaving and error detection and correction. It also

processes a rich set of servo system commands sent from

the control microprocessor. It can directly interface to the

dedicated serial inputs provided by the Sanyo LC78815

and LC78816 D/A converters.

Functions

• Input signal processing: The LC7868KE takes an HF

signal as input, digitizes (slices) that signal at a precise

level, converts that signal to an EFM signal, and

generates a PLL clock with an average frequency of

4.3218 MHz by comparing the phases of that signal and

a VCO output.

• Precise reference clock and necessary internal timing

generation using an external 16.9344 MHz crystal

oscillator

• Disk motor speed control using a frame phase difference

signal generated from the playback clock and the

reference clock

• Frame synchronization signal detection, protection and

interpolation to assure stable data readout

• EFM signal demodulation and conversion to 8-bit

symbol data

• Subcode data separation from the EFM demodulated

signal and output of that data to an external

microprocessor

• Subcode Q signal output to a microprocessor over the

serial interface after performing a CRC error check (An

LSB first output format can be selected.)

• Demodulated EFM signal buffering in internal RAM to

handle up to ±4 frames of disk rotational jitter

• Demodulated EFM signal reordering in the prescribed

order for data unscrambling and de-interleaving

• Error detection, correction, and flag processing (error

correction scheme: dual C1 plus dual C2 correction)

• The LC7868KE sets the C2 flags based on the C1 flags

and a C2 check, and then performs signal interpolation

or previous value hold depending on the C2 flags. The

interpolation circuit uses a quadruple interpolation

scheme. The output value is locked at zero when four or

more consecutive C2 flags occur.

• Support for command input from a control

microprocessor: commands include track jump, focus

start, disk motor start/stop, muting on/off and track

count (8-bit serial input)

• Built-in digital output circuits.

• Arbitrary track counting to support high-speed data

access

• Zero cross muting

• D/A converter input signal outputs with output data

continuity improved by 4× oversampling and digital

filtering

• Supports most D/A converters

• Built-in digital de-emphasis

• Built-in digital level and peak meter functions

• Support for bilingual applications

Features

• 64-pin QIP (miniature, reduced space package)

• Silicon gate CMOS process (low power)

• Single 5 V power supply (for application in portable end

products)

• Provision of a DEMO pin eases the manufacturing

processes associated with adjustment steps.

LC7868KE

SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquarters

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

Digital Signal Processor for

Compact Disc Players

CMOS LSI

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft’s

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges, or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

Page 2

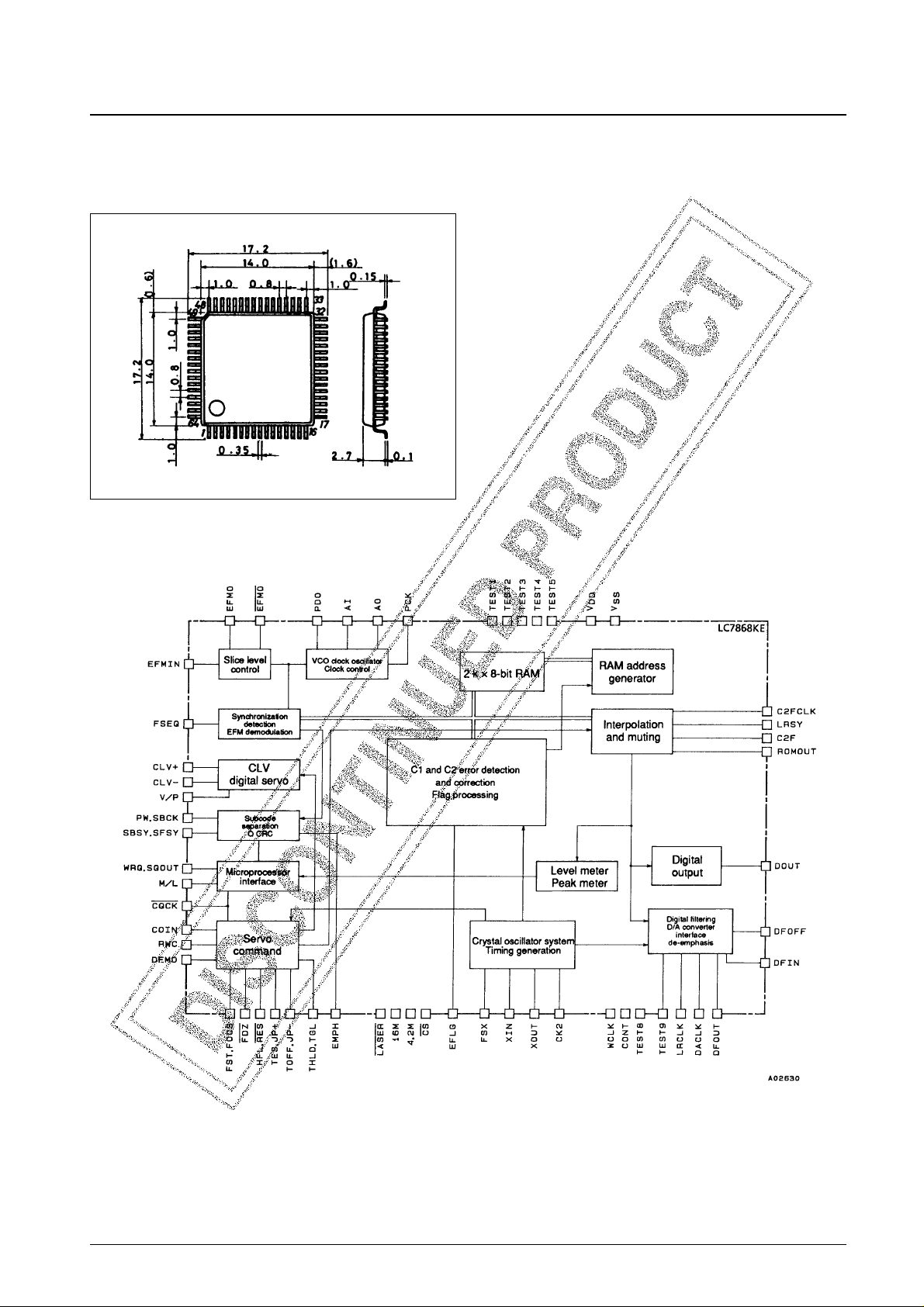

Equivalent Circuit Block Diagram

No. 4882-2/24

LC7868KE

Package Dimensions

unit: mm

3159-QFP64E

SANYO: QFP64E

[LC7868KE]

Page 3

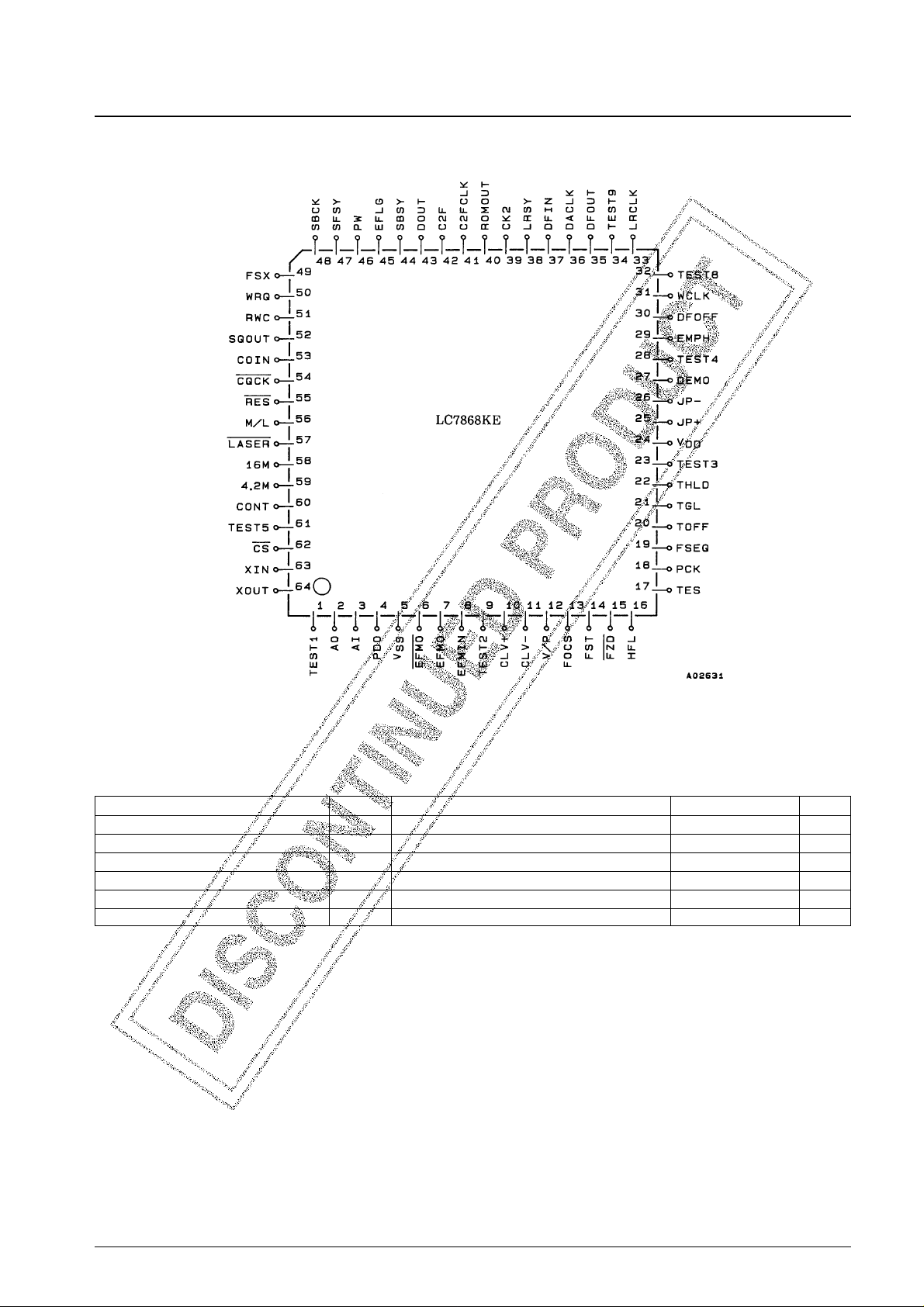

Pin Assignment

Specifications

Absolute Maximum Ratings at Ta = 25°C, VSS= 0 V

No. 4882-3/24

LC7868KE

Parameter Symbol Conditions Ratings Unit

Maximum supply voltage V

DD

max VSS– 0.3 to +7.0 V

Maximum input voltage V

IN

max VSS– 0.3 to VDD+ 0.3 V

Maximum output voltage V

OUT

max VSS– 0.3 to VDD+ 0.3 V

Allowable power dissipation Pd max 300 mW

Operating temperature Topr –30 to +75 °C

Storage temperature Tstg –40 to +125 °C

Top view

Page 4

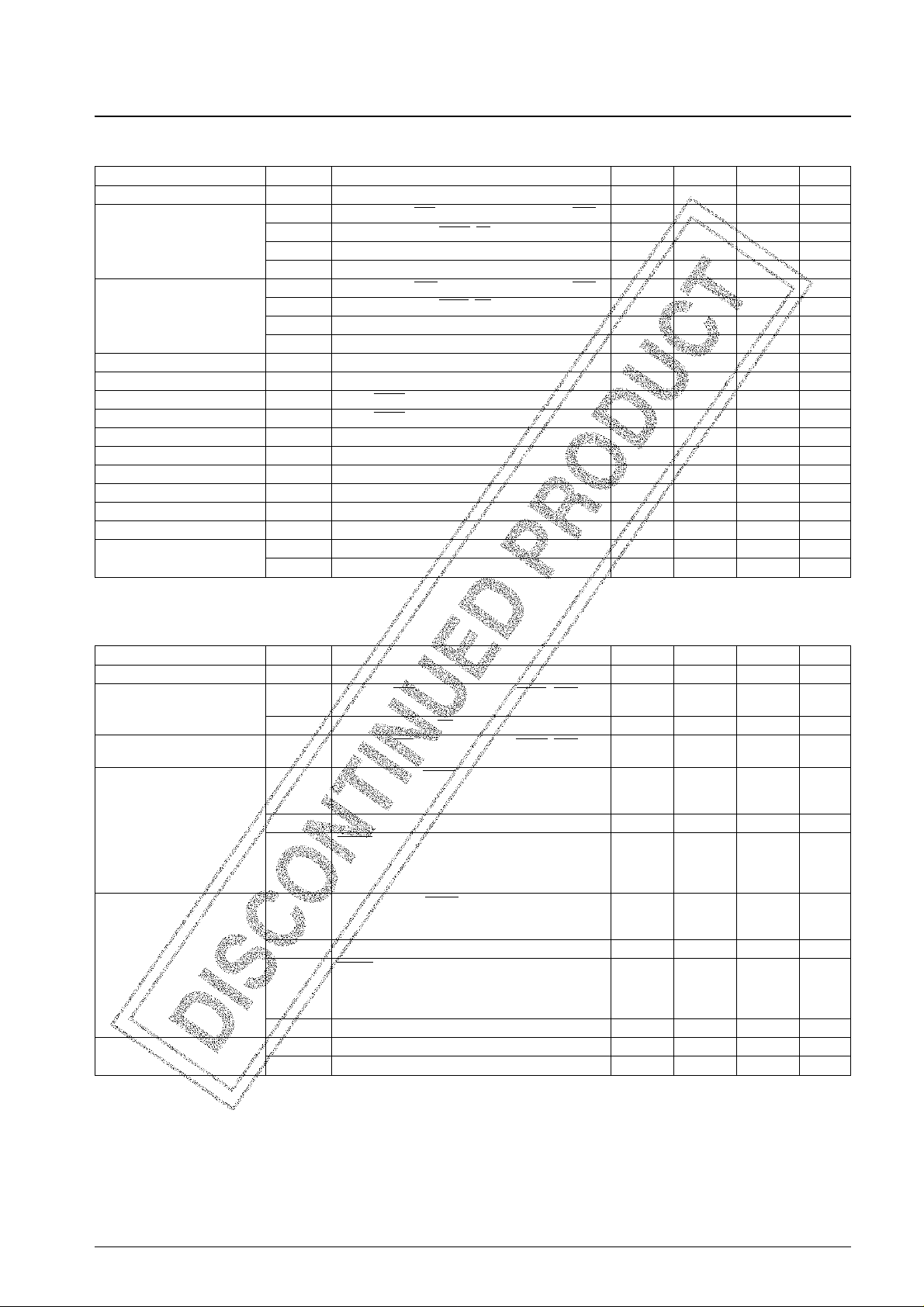

Allowable Operating Ranges at Ta = 25°C, VSS= 0 V

Electrical Characteristics at Ta = 25°C, V

SS

= 0 V, VDD= 5 V

No. 4882-4/24

LC7868KE

Parameter Symbol Conditions min typ max Unit

Supply voltage V

DD

V

DD

4.5 5.5 V

V

IH

(1) TEST1 to 5, AI, FZD, HFL, DEMO, DFOFF, M/L, RES 0.7 V

DD

V

DD

V

Input high level voltage

V

IH

(2) SBCK, RWC, COIN, CQCK, CS 2.2 V

DD

V

V

IH

(3) EFMIN 0.6 V

DD

V

DD

V

V

IH

(4) TES 0.8 V

DD

V

DD

V

V

IL

(1) TEST1 to 5, AI, FZD, HFL, DEMO, DFOFF, M/L, RES V

SS

0.3 V

DD

V

Input low level voltage

V

IL

(2) SBCK, RWC, COIN, CQCK, CS V

SS

0.8 V

V

IL

(3) EFMIN V

SS

0.4 V

DD

V

V

IL

(4) TES V

SS

0.2 V

DD

V

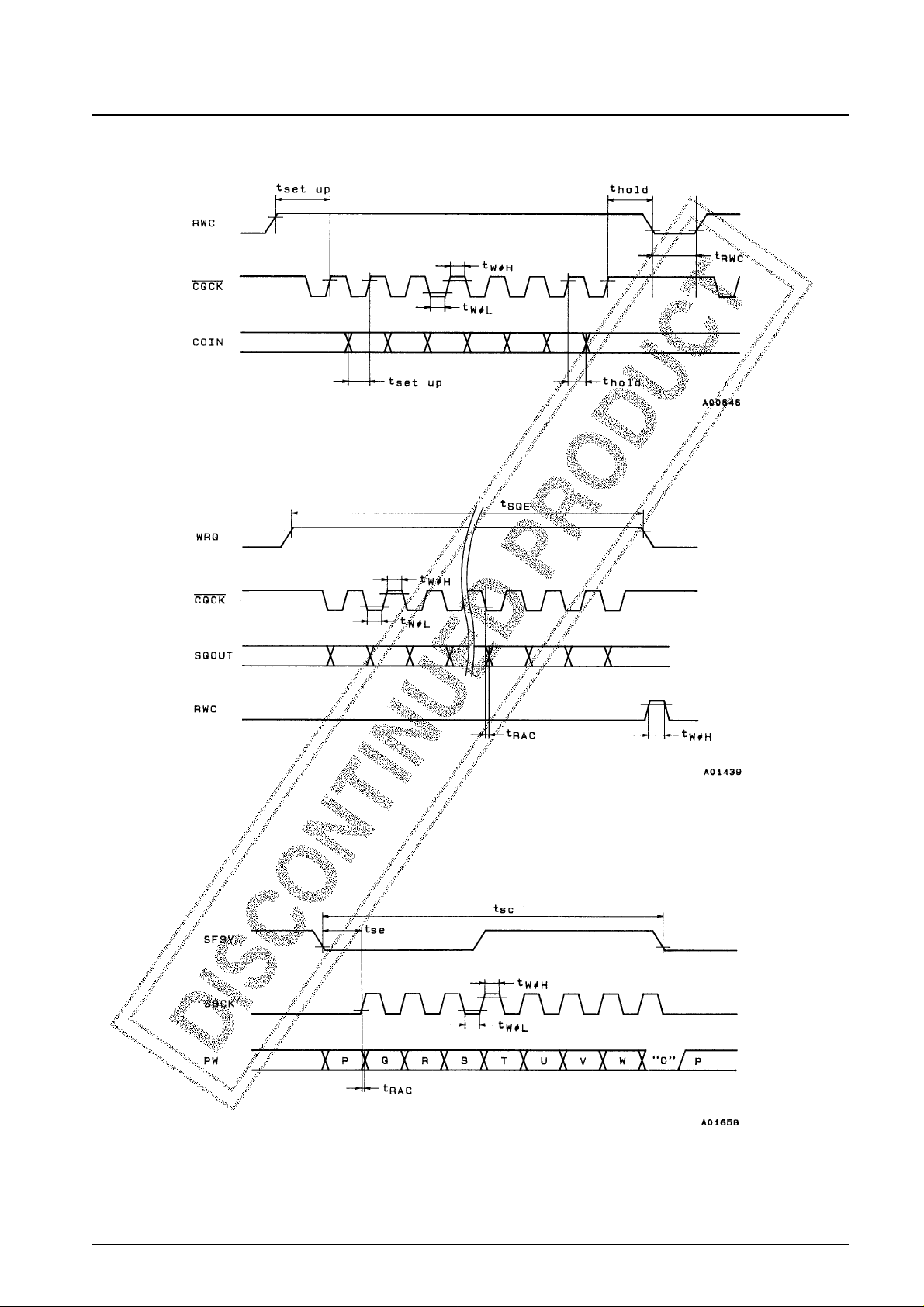

Data setup time t

setup

COIN, RWC: Figure 1 400 ns

Data hold time t

hold

RWC: Figure 1 400 ns

High level clock pulse width t

WøH

SBCK, CQCK: Figures 1, 2 and 3 400 ns

Low level clock pulse width t

WøL

SBCK, CQCK: Figures 1, 2 and 3 400 ns

Data read access time t

RAC

Figures 2 and 3 0 400 ns

Command transfer time t

RWC

RWC: Figure 1 1000 ns

Subcode Q read enable time t

SQE

Figure 2, with no RWC signal 11.2 ms

Subcode read cycle t sc Figure 3 136 µs

Subcode read enable time t se Figure 3 400 ns

Crystal oscillator frequency fX’tal XIN, XOUT 16.9344 MHz

Operating frequency range

fop (1) AI 2.0 20 MHz

fop (2) EFMIN: V

IN

≥ 1 Vp-p 10 MHz

Parameter Symbol Conditions min typ max Unit

Supply current I

DD

17 30 mA

I

IH

(1)

AI, EFMIN, FZD, TES, SBCK, COIN, CQCK, RES,

5µA

Input high level current

HFL, RWC, M/L: V

IN

= V

DD

IIH(2) TEST1 to 5, DEMO, CS: VIN= VDD= 5.5 V 25 75 µA

Input low level current I

IL

(1)

AI, EFMIN, FZD, TES, SBCK, COIN, CQCK, RES,

–5µA

HFL, RWC, M/L: V

IN

= V

SS

AO, PDO,EFMO, EFMO, CLV+, CLV–, FOCS, FSEQ,

V

OH

(1) PCK, TOFF, TGL, THLD, JP+, JP–, EMPH, EFLG, VDD– 1V

FSX, V/P: I

OH

= –1 mA

Output high level voltage

V

OH

(2) DOUT: IOH= –12 mA VDD– 0.5 V

LASER, SQOUT, 16M, 4.2M, CONT, LRCLK, WRQ,

V

OH

(3)

C2F, DACLK, SFSY, LRSY, SBSY, CK2, PW, ROMOUT,

VDD– 1V

C2FCLK, DFOUT, TEST9, TEST8, WCLK, DFIN:

I

OH

= –0.5 mA

AO, PDO, EFMO, EFMO, CLV

+

, CLV–, FOCS, FSEQ,

V

OL

(1) PCK, TOFF, TGL, THLD, JP+, JP–, EMPH, EFLG, 1 V

FSX, V/P: I

OL

= 1 mA

V

OL

(2) DOUT: IOL= 12 mA 0.5 V

Output low level voltage LASER, SQOUT, 16M, 4.2M, CONT, LRCLK, WRQ,

V

OL

(3)

C2F, DACLK, SFSY, LRSY, SBSY, CK2, PW, ROMOUT,

0.4 V

C2FCLK, DFOUT, TEST9, TEST8, WCLK, DFIN:

I

OL

= 2 mA

V

OL

(4) FST: IOL= 5 mA 0.75 V

Output off leakage current

I

OFF

(1) PDO, FST: VOH= V

DD

5µA

I

OFF

(2) PDO, FST: VOL= V

SS

–5µA

Page 5

Wave Form

Figure 1 Command Input

Figure 2 Subcode Q Output

Figure 3 Subcode Output

No. 4882-5/24

LC7868KE

Page 6

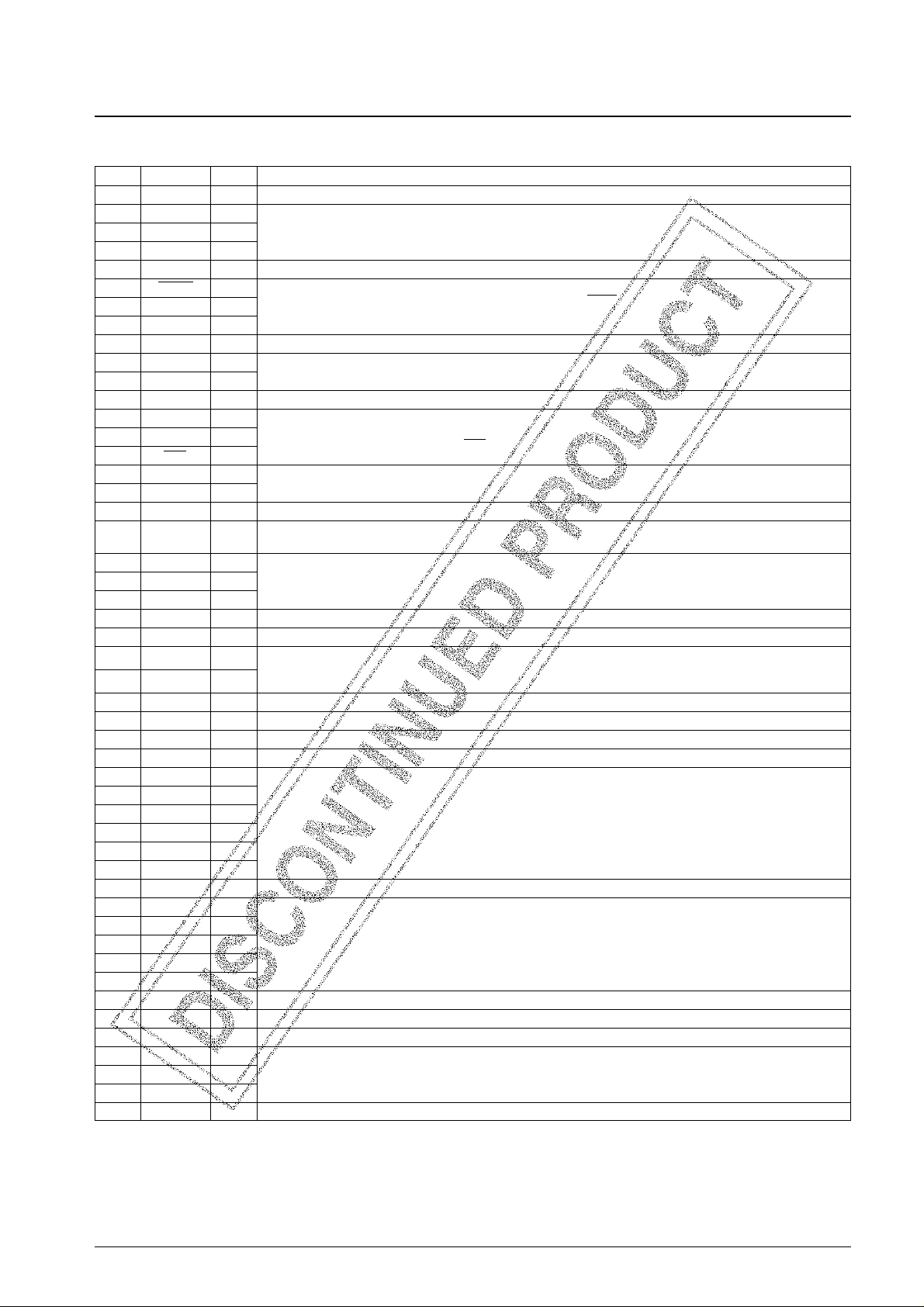

Pin Functions

No. 4882-6/24

LC7868KE

No. Name I/O Description

1 TEST1 I LSI test pin. Normally left open.

2AO O

3AI I

4 PDO O

5V

SS

— GND

6 EFMO O

7 EFMO O

8 EFMIN I

9 TEST2 I LSI test pin. Normally left open.

10 CLV

+

O

Disk motor control output.

11 CLV

–

O

Three-state output is also possible when specified by microprocessor command.

12 V/P O Outputs a high level during CLV rough servo and a low level during phase control.

13 FOCS O

14 FST O

15 FZD I

16 HFL I

17 TES I

18 PCK O PCK is the 4.3218 MHz monitor pin.

19 FSEQ O

FSEQ outputs a high level when the synchronization (positive FS) detected from the EFM signal matches the counter

synchronization (interpolation FS). (The output is latched for a single frame.)

20 TOFF O

21 TGL O

22 THLD O

23 TEST3 I LSI test pin. Normally left open.

24 V

DD

— +5 V

25 JP

+

O

26 JP

–

O

27 DEMO I Sound output function for end product adjustment manufacturing steps.

28 TEST4 I LSI test pin. Normally left open.

29 EMPH O De-emphasis is required when high.

30 DFOFF I Digital filter on/off switch. Filtering is turned off on a high level input.

31 WCLK O

32 TEST8 O

33 LRCLK O

34 TEST9 O

35 DFOUT O

36 DACLK O

37 DFIN O LSI test pin. Normally left open.

38 LRSY O

39 CK2 O

40 ROMOUT O CD-ROM application output signals

41 C2FCLK O

42 C2F O

43 DOUT O Digital output

44 SBSY O Subcode block synchronization signal

45 EFLG O C1, C2, single and double error correction monitor pin

46 PW O

47 SFSY O

48 SBCK I

49 FSX O 7.35 kHz synchronization signal output

Inputs for the LA9210 internal VCO output. (8.6436 MHz)

Set up PDO so that the frequency increases when the EFM signal and the phase output are positive.

Supply an HF signal with a 1 to 2 Vp-p level to EFMIN. EFMO and EFMO output EFM signals with opposite phases

that passed through an amplitude limiter circuit. These are used for slice level control.

FOCS outputs a high level when the focus servo is off. The lens is lowered by FST, and when FOCS is high the lens is

raised gradually. FOCS is reset when an FZD input occurs. These are used for focus pull-in.

The LC7868KE outputs a kick pulse from JP

+

and JP–in response to a track jump command. A track jump of the

specified number of tracks (1, 2, 4, 16, 32, 64, and 128) is performed.

The LC7868KE outputs a kick pulse from JP

+

and JP–in response to a track jump command. A track jump of the

specified number of tracks (1, 2, 4, 16, 32, 64, and 128) is performed.

The LC7868KE outputs a kick pulse from JP

+

and JP–in response to a track jump command. A track jump of the

specified number of tracks (1, 2, 4, 16, 32, 64, and 128) is performed.

Three-state output is also possible when specified by microprocessor command.

Outputs for an external D/A converter. These include a latch signal, an L/R switching signal, and a sample and hold

signal.

SFSY is the subcode frame synchronization signal. The P, Q, R, S, T, U, V and W subcodes can be read out by

applying 8 clock cycles to SBCK.

Continued on next page.

Page 7

Continued from preceding page.

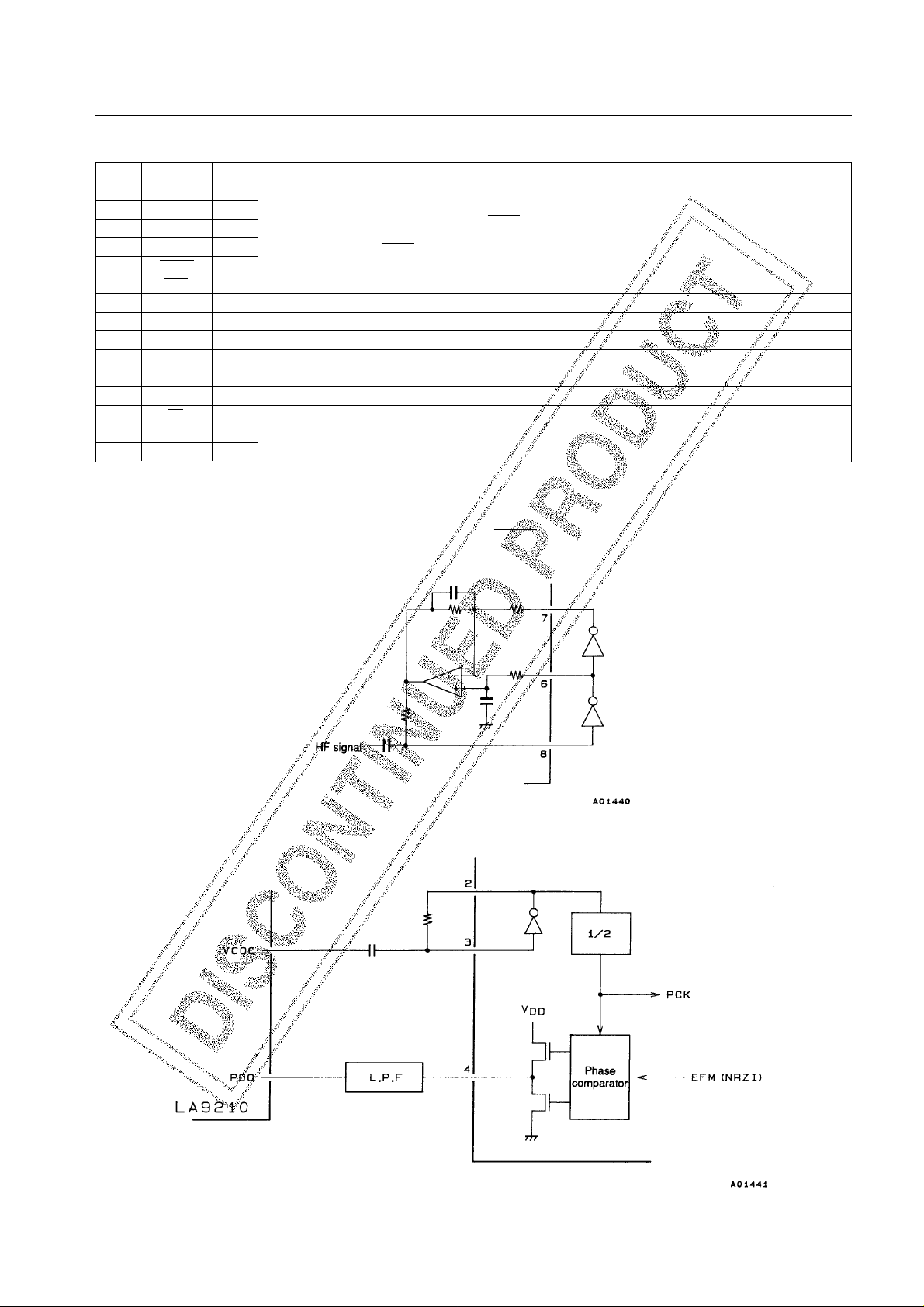

Pin Applications

1. HF signal input circuit; Pin 8: EFMIN, pin 7: EFMO, pin 6: EFMO

An EFM signal (NRZ) with an optimal slice level can be acquired by inputting the HF signal to EFMIN.

2. PLL clock generation circuit; Pin 4: PDO, Pin 3: AI, Pin 2: AO

A VCO can be constructed by combining the LC7868KE with the Sanyo LA9210. The PDO pin swings in the

positive direction when the VCO phase lags.

No. 4882-7/24

LC7868KE

No. Name I/O Description

50 WRQ O

51 RWC I

52 SQOUT O

53 COIN I

54 CQCK I

55 RES I This pin must be set low briefly after power is first applied.

56 M/L I Similar to pins number 50, 51, 52, 53 and 54 described above.

57 LASER O Output pin controllable by serial data sent from the microprocessor.

58 16M O 16.9344 MHz output pin

59 4.2M O 4.2336 MHz output pin

60 CONT O Output pin controllable by serial data sent from the microprocessor.

61 TEST5 I LSI test pin. Normally left open.

62 CS I Chip select pin. The LC7868KE becomes active when this pin is low. (A pull-down resistor is built-in.)

63 X

IN

I

Connections for a 16.9344 MHz crystal oscillator

64 X

OUT

O

WRQ goes high when the subcode Q data passes the CRC check. An external controller can read out data from

SQOUT by monitoring this pin and applying a CQCK signal. Set M/L to low when data is required LSB first.

The control microprocessor can send commands to the LC7868KE by setting RWC high and then sending command

data synchronized with CQCK.

Page 8

3. 1/2 VCO; Pin 18: PCK

PCK is a monitor pin that outputs an average frequency of 4.3218 MHz, which is the VCO frequency divided by two.

4. Synchronization detection monitor; Pin 19: FSEQ

Pin 19 goes high when the frame synchronization (a positive polarity synchronization signal) from the EFM signal

read in by PCK and the timing generated by the counter (the interpolation synchronization signal) agree. This pin is a

synchronization detection monitor. (It is held high for a single frame.)

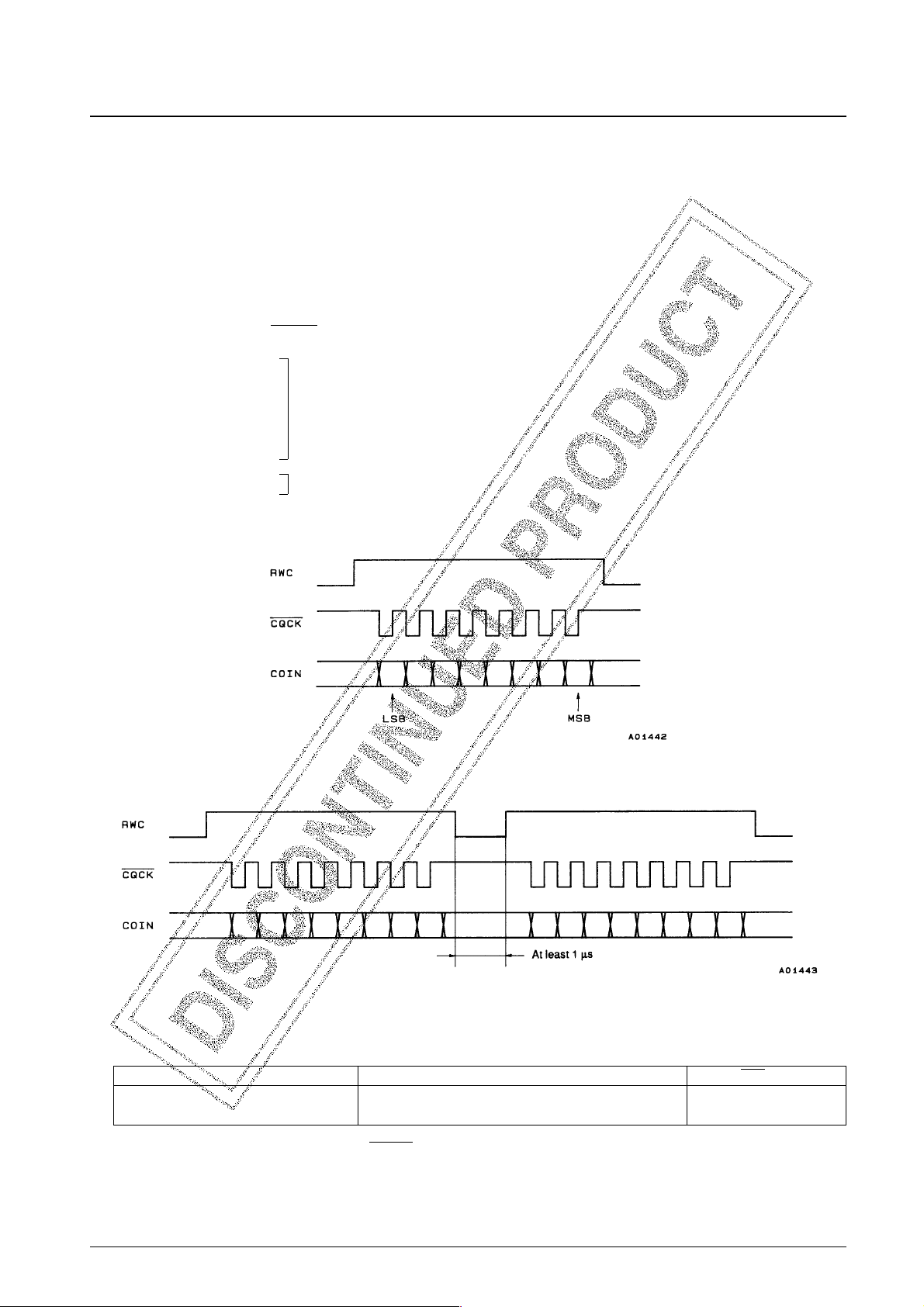

5. Servo command function; Pin 51: RWC, pin 53: COIN, pin 54: CQCK, pin 62: CS

Commands are input to the LC7868KE by setting RWC high and sending commands to the COIN pin in

synchronization with the CQCK clock.

Focus start

Track jump

Mute control 1-byte commands

Disc motor control

Other control commands

Track count 2-byte command

• One-byte commands

• Two-byte commands

Command execution starts on the falling edge of the RWC signal.

• Command noise exclusion

This command allows the noise on the CQCK clock signal to be excluded.

No. 4882-8/24

LC7868KE

MSB LSB Command RES = low

11101111 COMMAND INPUT NOISE EXCLUSION MODE

11101110 RESET NOISE EXCLUSION MODE

○

Page 9

6. Focus servo circuit; Pin 13: FOCS, pin 14: FST, pin 15: FZD, pin 57: LASER

• Laser control

• Focus start

When a focus start instruction (either FOCUS START #1 or FOCUS START #2) is input as a servo command,

first the charge on capacitor C1 is discharged by FST and the objective lens is lowered. Next, the capacitor is

charged by FOCS, and the lens is slowly raised. FZD falls when the lens reaches the focus point. When this signal

is received, FOCS is reset and the focus servo turns on. After sending the command, the microprocessor should

check the in-focus detection signal (the LA9210 DRF signal) to confirm focus before proceeding to the next part of

the program. If focus is not achieved by the time C1 is fully charged, the microprocessor should issue another

focus command and iterate the focus servo operation.

Note: 1. Values in parentheses are for the LASER START #2 command. The only difference is in the FST low period.

2. VAn FZD falling edge will not be accepted during the period that FST is low.

3. After issuing a focus start command, initialization will be performed if RWC is set high. Therefore, do not issue the next command during

focus start until the focus coil drive S curve has completed.

4. When focus cannot be achieved (i.e., when FZD does not go low) the FOCS signal will remain in the high state, so the microprocessor

should initialize the system by issuing a NOTHING command.

5. When the RESET pin is set low, the LASER pin is set high directly.

6. Focus start using the DEMO coil executes a mode #1 focus start.

No. 4882-9/24

LC7868KE

MSB LSB Command RES = low

00001000 FOCUS START #1

10100010 FOCUS START #2

00001010 LASER ON

10001010 LASER OFF ○

00000000 NOTHING

Page 10

7. CLV servo circuit; Pin 10: CLV+, pin 11: CLV–, pin 12: V/P

The CLV

+

pin provides the signal that accelerates the disk in the forward direction and the CLV–pin provides the

signal that decelerates the disk. Commands from the control microprocessor select one of four modes; accelerate,

decelerate, CLV and stop. The table below lists the CLV+and CLV–outputs in each of these modes.

Note: CLV servo control commands can set the TOFF pin low only in CLV mode. That pin will be at the high level

at all other times.

• CLV mode

In CLV mode the LC7868KE detects the disk speed from the HF signal and provides proper linear speed using

several different control schemes by switching the DSP internal modes. The PWM period is 7.35 kHz, the 1/64

duty period is 1.114s, and V/P outputs a high level during rough servo and a low level during phase control.

No. 4882-10/24

LC7868KE

MSB LSB Command RES = low

00000100 DISC MOTOR START (accelerate)

00000101 DISC MOTOR CLV (CLV)

00000110 DISC MOTOR BRAKE (decelerate)

00000111 DISC MOTOR STOP (stop)

○

Mode CLV

+

CLV

–

Accelerate High Low

Decelerate Low High

CLV **

Stop Low Low

Internal mode CLV

+

CLV

–

V/P

Rough servo (velocity too low) High Low High

Rough servo (velocity too high) Low High High

Phase control (PCK locked) PWM PWM Low

Page 11

• Rough servo gain switching

For 8 cm disks, the rough servo mode CLV control gain can be set about 8.5 dB lower than the gain used for 12 cm

disks.

• Phase control gain switching

The phase control gain can be changed by changing the divisor used by the dividers in the stage immediately

preceding the phase comparator.

• CLV three state output

The CLV three state output command allows the CLV to be controlled by a single pin.

No. 4882-11/24

LC7868KE

MSB LSB Command RES = low

10110001 CLV PHASE COMPARATOR DIVISOR: 1/2

10110010 CLV PHASE COMPARATOR DIVISOR: 1/4

10110011 CLV PHASE COMPARATOR DIVISOR: 1/8

1011000 NO CLV PHASE COMPARATOR DIVISOR USED

○

MSB LSB Command RES = low

10110100 CLV THREE STATE OUTPUT

10110101

CLV TWO STATE OUTPUT

○

(the scheme used by previous products)

MSB LSB Command RES = low

10101000 DISC 8 SET

10101001 DISC 12 SET

○

Page 12

• Internal brake modes

— Issuing the internal brake on (C5H) command sets the LC7868KE to internal brake mode. In this mode, the

disk deceleration state can be monitored from the WRQ pin when a brake command (06H) is executed.

— In this mode the disk deceleration state is determined by counting the EFM signal in a single frame to

determine the density, and when the EFM signal count falls under four, the CLV

–

pin is dropped to low. At the

same time the WRQ signal, which functions as a brake completion monitor, goes high. In internal brake

continuous mode, the CLV–pin high level output braking operation continues even after the WRQ brake

completion monitor goes high.

Note that if errors occur in deceleration state determination due to noise in the EFM signal, the problem can be

rectified by changing the EFM signal count from four to eight with the internal brake control command (A3H).

— In TOFF output disabled mode the TOFF pin is held low during internal brake operations.

Note: 1. If focus is lost during the execution of an internal brake command, the pickup must be re-focussed

and then the internal brake command can be reissued.

2. Since incorrect deceleration state determination is possible depending on the EFM signal playback

state (e.g., disk defects, access in progress), we recommend using these functions in combination

with a microprocessor.

8. Track jump circuit; Pin 16: HFL, pin 17: TES, pin 20: TOFF, pin 21: TGL, pin 22: THLD, pin 25: JP

+

, pin 26: JP

–

• The LC7868KE supports the two track jump commands listed below.

The earlier track count function uses the TES signal directly as the internal track counter clock.

To reduce counting errors resulting from noise on the rising and falling edges of the TES signal, the new track

count function prevents noise induced errors by using the combination of the TES and HFL signals, and

implements a more reliable track count function. However, dirt and scratches on the disk can result in HFL signal

dropouts that may result in missing track count pulses. Thus care is required when using this function.

No. 4882-12/24

LC7868KE

MSB LSB Command RES = low

11000101 INTERNAL BRAKE ON

11000100 INTERNAL BRAKE OFF

○

10100011 INTERNAL BRAKE CONT

11001011 INTERNAL BRAKE CONTINUOUS MODE

11001010 RESET CONTINUOUS MODE

○

11001101 TOFF OUTPUT DISABLED MODE

11001100 RESET TOFF OUTPUT DISABLED MODE

○

MSB LSB Command RES = low

00100010 NEW TRACK COUNT (using the TES/HFL combination)

○

00100011 EARLIER TRACK COUNT (directly counts the TES signal)

Page 13

• Track jump commands

When the LC7868KE receives a track jump instruction as a servo command, it first generates accelerating pulses

(period a) and next generates deceleration pulses (period b).

The passage of the braking period (period c) completes the specified jump. During the braking period, the

LC7868KE detects the beam slip direction from the TES and HFL inputs. TOFF is used to cut the components in

the TE signal that aggravate slip. The jump destination track is captured by increasing the servo gain with TGL. In

THLD period TOFF output mode the TOFF signal is held high during the period when THLD is high.

Note: Of the modes related to disk motor control, the TOFF pin only goes low in CLV mode, and will be high

during start, stop, and brake operations. Note that the TOFF pin can be turned on and off independently by

microprocessor issued commands. However, this function is only valid when disk motor control is in CLV

mode. The table lists the relationships between accelerating pulses, deceleration pulses and the braking

period.

No. 4882-13/24

LC7868KE

MSB LSB Command RES = low

10100000 OLD TRACK JUMP

○

10100001 NEW TRACK JUMP

00010001 1 TRACK JUMP IN #1

00010010 1 TRACK JUMP IN #2

00110001 1 TRACK JUMP IN #3

01010010 1 TRACK JUMP IN #4

00010000 2 TRACK JUMP IN

00010011 4TRACK JUMP IN

00010100 16TRACK JUMP IN

00110000 32TRACK JUMP IN

00010101 64TRACK JUMP IN

00010111 128TRACK JUMP IN

00011001 1 TRACK JUMP OUT #1

00011010 1 TRACK JUMP OUT #2

00111001 1 TRACK JUMP OUT #3

01011010 1 TRACK JUMP OUT #4

00011000 2TRACK JUMP OUT

00011011 4TRACK JUMP OUT

00011100 16TRACK JUMP OUT

00111000 32TRACK JUMP OUT

00011101 64TRACK JUMP OUT

00011111 128TRACK JUMP OUT

00010110 256TRACK CHECK

00001111 TOFF

10001111 TON

○

10001100 TRACK JUMP BRAKE

00100001 THLD PERIOD TOFF OUTPUT MODE

00100000 RESET THLD PERIOD TOFF OUTPUT MODE

○

Page 14

• Track jump modes

The table lists the relationships between acceleration pulse output, deceleration pulse output, and the braking

period.

Note: 1. As indicated in the table, actuator signals are not output during the 256 TRACK CHECK function. This is a mode in which the TES signal is

counted in the tracking loop off state. Therefore, feed motor forwarding is required.

2. The servo command register is automatically reset after the track jump sequence (a, b, c) completes.

3. If another track jump command is issued during a track jump operation, the content of that new command will be executed starting immediately.

No. 4882-14/24

LC7868KE

Standard track jump mode New track jump mode

Command

abcabc

1 TRACK JUMP IN (OUT) #1 233 µs 233 µs 60 ms 233 µs 233 µs 60 ms

1 TRACK JUMP IN (OUT) #2 0.5-track jump 233 µs 60 ms 0.5-track jump a period 60 ms

1 TRACK JUMP IN (OUT) #3 0.5-track jump 233 µs Does not occur 0.5-track jump a period Does not occur

1 TRACK JUMP IN (OUT) #4 0.5-track jump 233 µs

60 ms, TOFF = low

0.5-track jump a period

60 ms, TOFF = low

during the c period during the c period

2 TRACK JUMP IN (OUT) None None None 1-track jump a period Does not occur

4 TRACK JUMP IN (OUT) 2-track jump 466 µs 60 ms 2-track jump a period 60 ms

16 TRACK JUMP IN (OUT) 9-track jump 7-track jump 60 ms 9-track jump a period 60 ms

32 TRACK JUMP IN (OUT) 18-track jump 14-track jump 60 ms 18-track jump 14-track jump 60 ms

64 TRACK JUMP IN (OUT) 36-track jump 28-track jump 60 ms 36-track jump 28-track jump 60 ms

128 TRACK JUMP IN (OUT) 72-track jump 56-track jump 60 ms 72-track jump 56-track jump 60 ms

TOFF goes high after 256 tracks are TOFF goes high after 256 tracks are

256 TRACK CHECK jumped. The a and b pulses are not 60 ms jumped. The a and b pulses are not 60 ms

output. output.

TRACK JUMP BRAKE There are no a and b periods. 60ms There are no a and b periods. 60 ms

Page 15

• JP three state output

The JP three state output allows the track jump operation to be controlled from a single pin.

• Track check mode

The LC7868KE will count the specified number of tracks when the microprocessor sends an arbitrary binary value

in the range 16 to 254 after issuing either a track count in or a track count out command.

Note: 1. Once the desired track count has been input in binary, the track count operation is started by the fall of RWC.

2. During a track count operation the TOFF pin goes high and the tracking loop is turned off. Therefore, feed motor forwarding is required.

3. When a track count in/out command is issued the function of the WRQ signal switches from the normal mode subcode Q standby monitor

function to a track count monitor function. This signal goes high when the track count is half completed, and goes low when the count finishes.

The control microprocessor should monitor this signal for a low level to determine when the track count completes.

4. If a two-byte reset command is not issued, the track count operation will be repeated. That is, to skip over 20,000 tracks, issue a track count

200 command once, and then count the WRQ signal 100 times.

5. After performing a track count operation, use the brake command to have the pickup lock onto the track.

No. 4882-15/24

LC7868KE

MSB LSB Command RES = low

10110110 JP THREE STATE OUTPUT

10110111 JP TWO STATE OUTPUT (earlier scheme)

○

MSB LSB Command RES = low

11110000 TRACK COUNT IN

11111000 TRACK COUNT OUT

11111111 TWO BYTE COMMAND RESET

○

Page 16

9. Error flag output; Pin 45: EFLG, pin 49: FSX

The FSX signal is generated by dividing the crystal oscillator clock, and is a 7.35 kHz frame synchronization signal.

The error correction state for each frame is output from EFLG. The playback OK/NG state can be easily determined

from the extent of the high level that appears here.

10. Subcode P, Q, and R to W output circuit; Pin 46: PW, pin 44: SBSY, pin 47: SFSY, pin 48: SBCK

PW is the subcode signal output pin, and all the codes, P, Q, and R to W can be read out by sending eight clocks to

the SBCK pin within 136 µs after the fall of SFSY. The signal that appears on the PW pin changes on the falling

edge of SBCK. If a clock is not applied to SBCK, the P code will be output from PW. SFSY is a signal that is output

for each subcode frame cycle, and the falling edge of this signal indicates standby for the output of the subcode

symbol (P to W). Subcode data P is output on the fall of this signal.

SBSY is a signal output for each subcode block. This signal goes high for the S0 and S1 synchronization signals. The

fall of this signal indicates the end of the subcode synchronization signals and the start of the data in the subcode

block. (EIAJ format)

11. Subcode Q output circuit; Pin 50: WRQ, pin 51: RWC, pin 52: SQOUT, pin 54: CQCK, pin 56: M/L, pin 62: CS

Subcode Q can be read from the SQOUT pin by applying a clock to the CQCK pin.

No. 4882-16/24

LC7868KE

MSB LSB Command RES = low

00001001 ADDRESS FREE

10001001 ADDRESS 1

○

Page 17

Of the eight bits in the subcode, the Q signal is used for song (track) access and display. The WRQ will be high only

if the data passed the CRC error check and the subcode Q format internal address is 1*. The control microprocessor

can read out data from SQOUT in the order shown below by detecting this high level and applying CQCK. When

CQCK is applied the DSP disables register update internally. The microprocessor should give update permission by

setting RWC high briefly after reading has completed. WRQ will fall to low at this time. Since WRQ falls to low

11.2 ms after going high, CQCK must be applied during the high period. Data can be read out in an LSB first format

if the M/L pin is set low, and in an MSB first format if that pin is set low.

Note: * That state will be ignored if an address free command is sent. This is provided to handle CDV applications.

Note: 1. Normally, the WRQ pin indicates the subcode Q standby state. However, it is used for a different monitoring purpose in track count mode.

(See the item on track counting for details.)

2. The LC7868KE becomes active when the CS pin is low, and data is output from the SQOUT pin. When the CS pin is high, the SQOUT pin

goes to the high impedance state.

12. Level meter (LVM) data and peak meter (PKM) data readout

No. 4882-17/24

LC7868KE

MSB LSB Command RES = low

00101011 PKM SET (LVM Reset)

00101100 LVM SET(PKM Reset)

○

00101101 PKM MASK SET

00101110 PKM MASK RESET

○

Page 18

• Level meter (LVM)

— The LVM set (2CH) command sets the LC7868KE to LVM mode.

— LVM data is a 16-bit word in which the MSB indicates the L/R polarity and the low order 15 bits are absolute

value data. A one in the MSB indicates left channel data and a zero indicates right channel data.

— LVM data is appended after the 80 bits of SubQ data, and can be read out by applying 96 clock cycles to the

CQCK pin. Each time LVM data is read out the left/right channel state is inverted. Data is held independently

for both the left and right channels. In particular, the largest value that occurs between readouts for each

channel is held.

• Peak meter (PKM)

— The PKM set (2BH) command sets the LC7868KE to PKM mode.

— PKM data is a 16-bit word in which the MSB is always zero and the low order 15 bits are absolute value data.

This functions detects the maximum value that occurs in the data, whichever channel that value occurs in.

— PKM data is read out in the same manner as LVM data. However, data is not updated as a result of the readout

operation.

— PKM mode SubQ data absolute time is computed by holding the absolute time (ATIME) detected after the

maximum value occurred and sending that value. (Normal operation uses relative time.)

— It is possible to set the LC7868KE to ignore values larger than the already recorded value by issuing the PKM

mask set command, even in PLM mode. This function is cleared by issuing a PLM mask reset command. (This

is used in PK search in a memory track.)

13. Mute control circuit

An attenuation of 12 dB (MUTE –12 dB) or full muting (MUTE ∞ dB) can be applied by issuing the appropriate

command from the table. Since zero cross muting is used, there is no noise associated with this function. Zero cross

is defined for this function as the top seven bits being all ones or all zeros.

14. Bilingual function

• Following a reset or when a stereo (28H) command has been issued, the left and right channel data is output to the

left and right channels respectively.

• When an Lch set (29H) command is issued, the left and right channels both output the left channel data.

• When an Rch set (2AH) command is issued, the left and right channels both output the right channel data.

15. De-emphasis on/off; Pin 29: EMPH

The preemphasis on/off bit in subcode Q control information is output from the EMPH pin. De-emphasis should be

performed when this signal is high.

The LC7868KE includes a digital de-emphasis circuit in its digital filter block. The internal digital de-emphasis

circuit is turned on following a reset. An external de-emphasis circuit can be used by issuing the DEP OFF command

listed in the table.

No. 4882-18/24

LC7868KE

MSB LSB Command RES = low

00000001 MUTE: 0 dB

00000010 MUTE: –12 dB

00000011 MUTE: ∞ dB

○

MSB LSB Command RES = low

00101000 STO CONT

○

00101001 Lch CONT

00101010 Rch CONT

MSB LSB Command RES = low

01101001 DEP OFF

Page 19

16. D/A converter interface; Pin 30: DFOFF, pin 31: WCLK (TEST7) pin 32: TEST (SYSCLK), pin 33: LRRLK, pin

34: DFOUT (DATAR), pin 35: DFOUT (DATAR), pin 36: DACLK

Data for the D/A converter is output MSB first from DFOUT synchronized with the falling edge of DACLK.CONT

and CD-ROM XA reset

When a CD-ROM XA command is issued, data that is neither interpolated nor muted will be output from the

DFOUT and DOUT pins. (This command is used for CD-ROM XA application.) The CD-ROM XA reset command

also functions as a pin 60 CONT reset, so caution is required.

17. CD-ROM outputs; Pin 39: CK2, pin 37: LRSY, pin 40: ROMOUT, pin 42: C2F, pin 41: C2FCLK

Data is output MSB first from the ROMOUT pin in synchronization with the LRSY signal. This data is appropriate

for input to a CD-ROM LSI, since it is not interpolated, previous value held, or processed by the digital filter circuits.

CK2 is a 2.1168 MHz clock, and data is output on the CK2 rising edge. C2F is the flag information for data in 8-bit

units. C2FCLK is the synchronization signal for that flag.

No. 4882-19/24

LC7868KE

MSB LSB Command RES = low

01100010 DF FORM IIS

01100011 DF FORM LC78815

○

01101000 DF FORM B.B

10001000 CD-ROM XA

10001011 CONT AND CD-ROM XA RESET

○

Page 20

LC7868KE - LC89510 interface

18. Digital output circuit; Pin 43: DOUT

This is an output pin for use with a digital audio interface. Data is output in the EIAJ format. This signal has been

processed by the interpolation and muting circuits. This pin has a built-in driver circuit and can directly drive a

transformer.

• The DOUT pin can be locked at the low level by issuing a DOUT OFF command.

• The UBIT information in the DOUT data can be locked at zero by issuing a UBIT OFF command.

19. CONT pin: Pin 60: CONT

The CONT pin goes high when a CONT SET command is issued.

20. Crystal clock oscillator; Pin 63: XIN, pin 64: XOUT

The clock that is used as the time base is generated by connecting a

16.9344 MHz crystal oscillator between these pins. This oscillator

can be turned on and off under command control.

The OSC OFF command turns off both the VCO and crystal

oscillators. The table lists the relationships between the crystal and

VCO oscillators.

No. 4882-20/24

LC7868KE

MSB LSB Command RES = low

01000010 DOUT ON ○

01000011 DOUT OFF

01000000 UBIT ON ○

01000001 UBIT OFF

MSB LSB Command RES = low

10001110 OSC ON ○

10001101 OSC OFF

01100000 VCO 8M ○

01100001 VCO 16M

MSB LSB Command RES = low

00001110 CONT SET Low

10001011 CONT AND CD-ROM XA RESET ○

External

X’tal VCO

16.9344 MHz 8.6436 MHz 17.2872 MHz

Command VCO 8M VCO 8M VCO 16M

Page 21

Recommended crystal clock oscillator component values

21. 4.2M and 16M pins; Pin 59: 4.2M, pin 58: 16M

The 16.9344 MHz external crystal oscillator 16.9344 MHz buffer output signal is output from the 16M pin. That

frequency divided by four (a 4.2336 MHz frequency) is output from the 4.2M pin. When the oscillator is turned off

both these pins will be fixed at either high or low.

22. Reset circuit; Pin 55: RES

When power is first applied, this pin should be briefly set low and then set high. This will set the muting to –∞ dB

and stop the disk motor.

Setting the RES pin low sets the LC7868KE to the settings enclosed in boxes in the table.

23. Adjustment process sound output function; Pin 27: DEMO

No. 4882-21/24

LC7868KE

Manufacturer Oscillator Cin/Cout

CSA-309

5 pF to 10 pF

CITIZEN WATCH CO., LTD. HC-49/U-S

(Cin = Cout)

(16.9344 MHz)

Constant linear velocity servo START BRAKE CLV

Muting control 0 dB –12 dB

Q subcode address conditions Address free

Laser control ON (low) (high)

CONT High

OSC OFF

Track jump mode New

Track count mode Standard

New

Standard

ON

Low

OFF

Address 1

∞

STOP

Page 22

By setting this pin high, muting can be set to 0 dB, the disk motor can be set to CLV, and a focus start operation can

be performed, even without issuing any commands from the control microprocessor. Also, since the LASER pin

becomes active, if the mechanism and servo systems are complete, an EFM signal can be acquired with only this

equipment, and an audio signal can be produced without the presence of a microprocessor.

24. Other pins; Pin 1: TEST1, pin 9: TEST2, pin 23: TEST3, pin 28: TEST4, pin 61: TEST5, pin 37: DFIN

These pins are used for testing the LSI’s internal circuits. Since the pins TEST1 to TEST5 have built-in pull-down

resistors, they can be left open in normal operation.

Circuit Block Operating Descriptions

1. RAM address control

The LC7868KE incorporates an 8-bit × 2 k-word RAM on chip. This RAM is used as a buffer memory, and has an

EFM demodulated data jitter handling capacity of ±4 frames. The LC7868KE continuously checks the remaining

buffer capacity and controls the data write address to fall in the center of the buffer capacity by making fine

adjustments to the PCK side of the CLV servo circuit and the frequency divisor. If the ±4 frame buffer capacity is

exceeded, the LC7868KE forcibly sets the write address to the ±0 position. However, since the errors that occur due

to this operation cannot be handled with error flag processing, the IC applies muting to the output for a 128 frame

period.

2. C1 and C2 error correction

The EFM demodulated data is written to internal RAM to compensate for jitter, and the LC7868KE performs the

following processing with a constant timing based on the crystal oscillator clock. First, the LC7868KE performs C1

error checking and correction in the C1 block, determines the C1 flags, and writes the C1 flag register. Next, the

LC7868KE performs C2 error checking and correction in the C2 block, determines the C2 flags, and writes data to

internal RAM.

Note: 1. If the positions of the errors determined by the C2 check agree with the those specified by the C1 flags, the correction is performed and the

flags are cleared. However, if the number of C1 flags is 7 or higher, C2 correction may fail. In this case correction is not performed and the C1

flags are taken as the C2 flags without change. Error correction is not possible if one error position agrees and the other does not.

Furthermore, if the number of C1 flags is 5 or under, the C1 check result can be seen as unreliable. Accordingly, the flags will be set in this

case. Cases where the number of C1 flags is 6 or more are handled in the same way, and the C1 flags are taken as the C2 flags without

change. When there is not even one agreement between the error positions, error correction is, of course, impossible. Here, if the number of

C1 flags was 2 or under, data that was seen as correct after C1 correction is now seen as incorrect data. The flags are set in this case. The

other C1 flags are taken as the C2 flags without change.

2. When data is determined to have three or more errors and be uncorrectable, correction is, of course, impossible. Here, if the number of C1

flags was 2 or under, data that was seen as correct after C1 correction is now seen as incorrect data. The flags are set in this case. The other

C1 flags are taken as the C2 flags without change.

No. 4882-22/24

LC7868KE

C1 flag Error correction and flag processing

No errors No correction required · Flag reset

1 error Correction · Flag reset

2 errors Correction · Flag set

3 errors or more Correction not possible · Flag set

Position Division ratio or processing

–4 or less Force to ±0

–3 589

–2 589 Increase ratio

–1 589

±0 588 Standard ratio

+1 587

+2 587 Decrease ratio

+3 587

+4 or more Force to ±0

C2 flag Error correction and flag processing

No errors No correction required · Flag reset

1 error Correction · Flag reset

2 errors Depends on C1

*1

3 errors or more Depends on C1

*2

Page 23

Differences between the LC7868E and the LC7868KE

1. New functions

• CLV phase comparator divisor function (divisors of 2, 4, and 8)

• CLV three state output

• JP three state output

2. New commands

• Command input

• CLV servo

• Track jump

• Internal brake mode

3. Changed specification

• The “c” periods (braking periods) during track jump operations have all been changed from 24 ms to 60 ms.

No. 4882-23/24

LC7868KE

MSB LSB Command RES = low Function

11101111 COMMAND INPUT NOISE EXCLUSION MODE Excludes noise from the CQCK signal.

11101110

RESET NOISE EXCLUSION MODE

○

(earlier product scheme)

MSB LSB Command RES = low Function

11001011 INTERNAL BRAKE CONTINUOUS MODE

11001010

RESET CONTINUOUS MODE

○

(earlier product scheme)

11001101 TOFF OUTPUT DISABLED MODE

11001100

RESET TOFF OUTPUT DISABLED MODE

○

(earlier product scheme)

MSB LSB Command RES = low Function

10110001 CLV PHASE COMPARATOR DIVISOR: 1/2

10110010 CLV PHASE COMPARATOR DIVISOR: 1/4

10110011 CLV PHASE COMPARATOR DIVISOR: 1/8

10110000

NO CLV PHASE COMPARATOR DIVISOR USED

○

(earlier product scheme)

10110100 CLV THREE STATE OUTPUT MODE

10110101

RESET THREE STATE OUTPUT MODE

○

(earlier product scheme)

The earlier product compared the phase for

each 7.35 kHz cycle. A new frequency

divisor function has been added.

CLV servo can be controlled from a single

pin since a three state output function has

been added to the CLV

+

pin (and to the

CLV

–

pin as well).

MSB LSB Command RES = low Function

10110110 JP THREE STATE OUTPUT

10110111

RESET THREE STATE OUTPUT MODE

○

(earlier product scheme)

01010010 1 TRACK JUMP IN #4

01011010 1 TRACK JUMP OUT #4

00100001 THLD PERIOD TOFF OUTPUT MODE

00100000 RESET THLD PERIOD TOFF OUTPUT MODE

○

The track jump function can be controlled

from a single pin since a three state output

function has been added to the JP

+

pin (and

to the JP

–

pin as well).

TOFF is set low during the track jump “c”

period.

TOFF is set high during the track jump THLD

period.

TOFF is set high during the track jump THLD

period.The LC7868KE remains in continuous

brake operation mode even after WRQ goes

high.

TOFF goes low during internal brake

operation.

Page 24

No. 4882-24/24

LC7868KE

This catalog provides information as of August, 1998. Specifications and information herein are subject to

change without notice.

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer’s

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer’s products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

semiconductor products fail with some probability. It is possible that these probabilistic failures could

give rise to accidents or events that could endanger human lives, that could give rise to smoke or fire,

or that could cause damage to other property. When designing equipment, adopt safety measures so

that these kinds of accidents or events cannot occur. Such measures include but are not limited to protective

circuits and error prevention circuits for safe design, redundant design, and structural design.

In the event that any and all SANYO products described or contained herein fall under strategic

products (including services) controlled under the Foreign Exchange and Foreign Trade Control Law of

Japan, such products must not be exported without obtaining export license from the Ministry of

International Trade and Industry in accordance with the above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or any information storage or retrieval system,

or otherwise, without the prior written permission of SANYO Electric Co., Ltd.

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the “Delivery Specification”

for the SANYO product that you intend to use.

Information (including circuit diagrams and circuit parameters) herein is for example only; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but

no guarantees are made or implied regarding its use or any infringements of intellectual property rights

or other rights of third parties.

Loading...

Loading...