Page 1

Overview

The LC78626KE is a monolithic compact disk player

signal processing and servo control CMOS IC equipped

with an internal anti-shock control function. Designed for

total functionality including support for EFM-PLL, and

one-bit D/A converter, and containing analog low-pass

filter, the LC78626KE provides optimal cost-performance

for low-end CD players that provide anti-shock systems

by eliminating as many unnecessary features as possible.

The basic functions provided by this IC include

modulation of the EFM signal from the optical pick-up,

deinterleaving, detection and correction of signal errors,

prevention of a maximum of approximately 38 seconds of

skipping, signal processing such as digital filtering (which

is useful in reducing the cost of the player), and processing

of a variety of servo-related commands from the

microprocessor. The LC78626KE is an improved version

of the LC78626E. It provides 8× oversampling digital

filters and supports up to 16M of DRAM.

Functions

• When an HF signal is input, it is sliced to precise levels

and converted to an EFM signal. The phase is compared

with the internal VCO and a PLL clock is reproduced at

an average frequency of 4.3218 MHz.

• Precise timing for a variety of required internal timing

needs (including the generation of the reference clock) is

produced by the attachment of an external 16.9344 MHz

crystal oscillator.

• The speed of revolution of the disk motor is controlled

by the frame phase difference signal generated by the

playback clock and the reference clock.

• The frame synchronizing signal is detected, stored, and

interpolated to insure stable data read back.

• The EFM signal is demodulated and converted to 8-bit

symbolic data.

• The demodulated EFM signal is divided into subcodes

and output to the external microprocessor. (Three

general I/O ports are shared [exclusively] for this

purpose.)

• After the subcode Q signal passes the CRC check, it is

output to the microprocessor through a serial

transmission (LSB first).

• The demodulated EFM signal is buffered in the internal

RAM, which is able to absorb ±4 frame’s worth of jitter

resulting from variations in the disk rotation speed.

• The demodulated EFM signal is unscrambled to a

specific sequence, and deinterleaving is performed.

Package Dimensions

unit: mm

3151-QFP100E

21.6

0.8

3.0max

1.6

17.2

0.825

130

31

50

51

80

81

1.6

0.575

0.575

0.15

2.7

15.6

0.3

20.0

23.2

14.0

0.65

0.825

100

0.8

0.65

0.1

CMOS IC

21099RM(OT) No. 5995-1/34

SANYO: QFP100E (QIP100E)

[LC78626KE]

SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquarters

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-0005 JAPAN

DSP for Compact Disk Players

LC78626KE

Ordering number : EN5995

Continued on next page.

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft’s

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges, or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

Page 2

No. 5995-2/34

LC78626KE

Continued from preceding page.

• Error detection and correction is performed, as is a flag

process. (C1: two error/C2: two error correction

method.)

• The C2 flag is set after referencing the C1 flag and the

results of the C2 check, where the signal from the C2

flag is interpolated or held at its previous level. The

interpolation circuit uses double interpolation. When

there are two or more C2 flags in a row, the previous

value is held.

• Command (such as track jump, start focus, disk motor

start/stop, muting on/off, track count, etc.) is are

executed after they are entered from the microprocessor.

(An 8-bit serial input is used.)

• The digital output is equipped internally.

• High speed access is supported through discretionary

track counting.

• Using the 8× oversampling digital filter, D/A converter

signals with improved continuity of output data are

produced.

• A ∆∑-type D/A converter using a 3-order noise shaper is

equipped internally. (An analog low-pass filter is

equipped internally.)

• Internal digital attenuator (8-bit-α; 239 steps.)

• Internal digital deemphasis

• Uses 0 cross mute.

• Bilingual compatibility

• General I/O ports: 4. (Three of these are shared,

exclusively, with the subcode output function.)

• Up to 38 seconds of skip prevention (when using 16M

of DRAM) through 5-bit ADPCM compression/

expansion processing. 1M/4M/4M × 2/16Μ bits DRAM

can be selected.

• Memory overflow detection output

• Free memory output

Features

• 100-pin QIP

• A single 3.2 V power supply

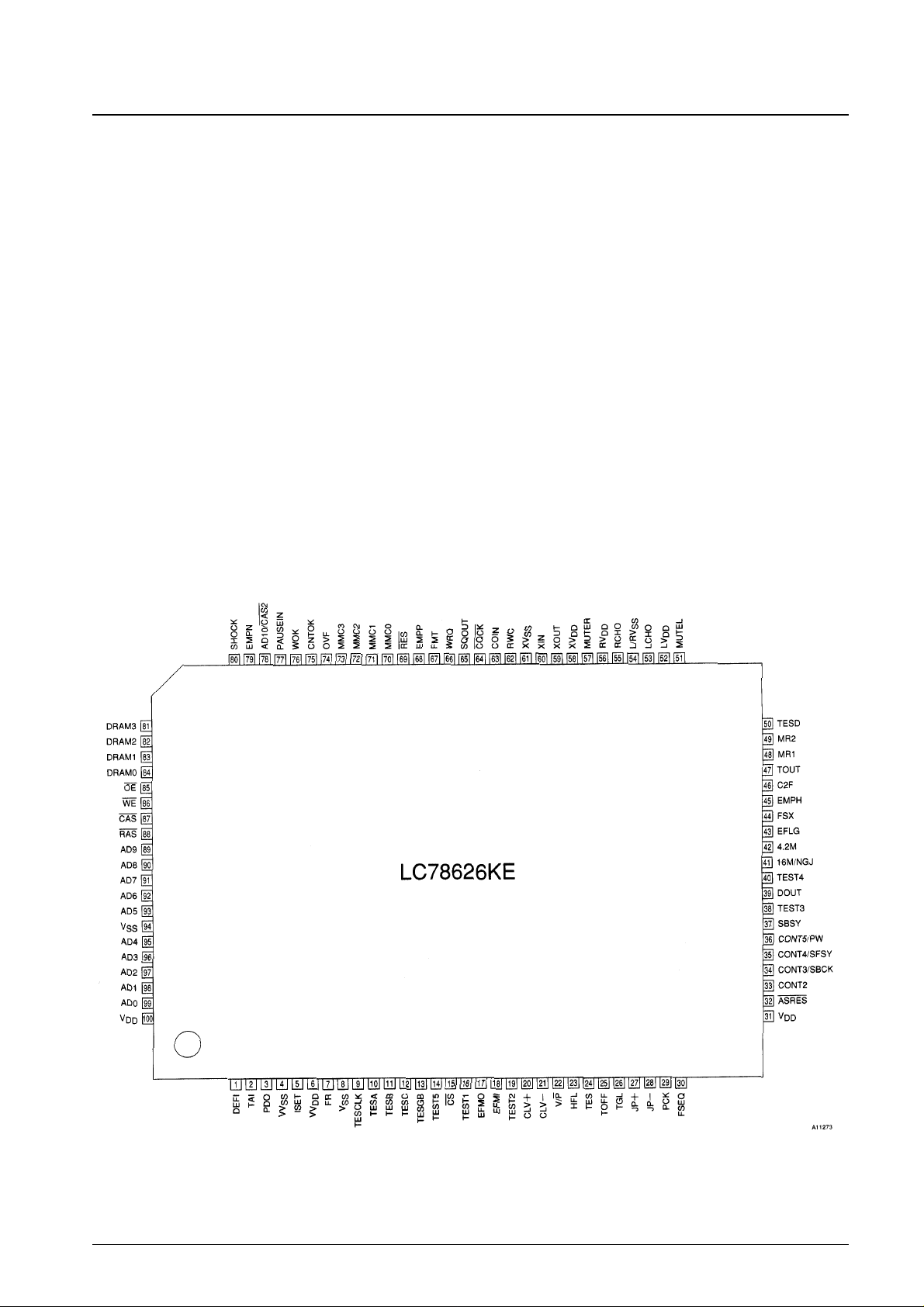

Pin Assignment

Top view

Page 3

Equivalent Circuit Block Diagram

No. 5995-3/34

LC78626KE

Digital out

RAM address

generator

Interpolation mute

Shock

detector

Contact

detector

ADPCM

encoder

Data width

changer

2K × 8-bit RAM

Digital

attenuator

4 × oversampling digital filter

C1, C2 error detection and

correction flag process

VCO clock production

clock control

Slice level control

Sync detect

EFM

demodulation

CLV digital servo

Subcode partition

QCRC

Microprocessor

interface

Servo commands

General ports

Disable

Crystal oscillator-system

timing generator

One-bit DAC

Low-pass

filter

ADPCM

decoder

DRAM control

Overflow process

initiation control

Page 4

No. 5995-4/34

LC78626KE

Parameter Symbol Conditions Ratings Unit

Maximum power supply voltage V

DD

max VSS– 0.3 to VSS+ 4.0 V

Input voltage V

IN

VSS– 0.3 to VDD+ 0.3 V

Output voltage V

OUT

VSS– 0.3 to VDD+ 0.3 V

Allowable power dissipation Pd max 400 mW

Operating temperature range Topr –20 to +75 °C

Storage temperature range Tstg –40 to +125 °C

Specifications

Absolute Maximum Ratings at Ta = 25°C, VSS= 0V

Parameter Symbol Conditions

Ratings

Unit

min typ max

V

DD

1

V

DD

, XVDD, LVDD, RVDD, VVDD:

3.0 3.6 V

Power supply voltage

ATT/DF/DAC to the normal speed

V

DD

2

V

DD

, XVDD, LVDD, RVDD, VVDD:

3.6 3.6 V

All functions guaranteed to 2× speed

V

IH

1

I/O and input pins with the exception of

0.7 V

DD

V

DD

V

Input high-level voltage

EFMI and DRAM0 to DRAM3

V

IH

2 EFMI 0.6 V

DD

V

DD

V

V

IH

3 DRAM0 to DRAM3 0.45 V

DD

V

DD

V

V

IL

1

I/O and input pins with the exception of

0 0.3 V

DD

V

Input low-level voltage

EFMI and DRAM0 to DRAM3

V

IL

2 EFMI 0 0.4 V

DD

V

V

IL

2 DRAM0 to DRAM3 0 0.2 V

DD

V

Data setup time t

SU

COIN, RWC: Figure 1 400 ns

Data hold time t

HD

COIN, RWC: Figure 1 400 ns

High level clock pulse width t

WH

SBCK, CQCK: Figures 1 to 3 400 ns

Low level clock pulse width t

WL

SBCK, CQCK: Figures 1 to 3 400 ns

Data read access time t

RAC

SQOUT, PW: Figures 2 and 3 0 400 ns

Command transfer time t

RWC

RWC: Figure 1 1000 ns

Subcode Q read enable time t

SQE

WRQ: Figure 2, no RWC signal 11.2 ms

Subcode ready cycle time t

SC

SFSY: Figure 3 136 µs

Subcode read enable time t

SE

SFSY: Figure 3 400 ns

Port input data setup time t

CSU

CONT2 to CONT5, RWC: Figure 4 400 ns

Port input data hold time t

CHD

CONT2 to CONT5, RWC: Figure 4 400 ns

Port input clock setup time t

RCQ

RWC, CQCK: Figure 4 100 ns

Port output data delay time t

CDD

CONT2 to CONT5, RWC: Figure 5 1200 ns

Input level

V

IN

1 EFMI: slice level control, VDD= 3.0 V 0.8 Vp-p

V

IN

2 XIN: C coupling input 1.0 Vp-p

Range of operating frequencies f

OP

EFMI 10 MHz

Crystal oscillator frequency f

X

XIN, XOUT 16.9344 MHz

Allowable Operating Range at Ta = 25°C, VSS= 0V

Parameter Symbol Conditions

Ratings

Unit

min typ max

Current drain I

DD

VDD, XVDD, LVDD, RVDD, VVDD:

14 20 mA

V

DD

= 3.0 to 3.4 V with normal playback

DEFI, EFMI, HFL, TES, RWC, COIN, CQCK,

I

IH

1

FMT, MR1, MR2, RES, TESD, WOK,

5 µA

PAUSE IN, SHOCK, TESCLK, TESA, TESB,

Input high-level current

TESC, TESGB, TEST1: V

IN

= V

DD

IIH2

TAI, TEST2 to TEST5, CS

15 55 µA

V

IN

= VDD= 3.6 V

Electrical Characteristics at Ta = 25°C, VDD= 3.2 V, VSS= 0V

Continued on next page.

Page 5

No. 5995-5/34

LC78626KE

Continued from preceding page.

Parameter Symbol Conditions

Ratings

Unit

min typ max

DEFI, EFMI, HFL, TES, RWC, COIN, CQCK,

FMT, MR1, MR2, RES, TESD, WOK,

Input low-level current I

IL

PAUSE IN, SHOCK, TESCLK, TESA, TESB, –5 µA

TESC, TESGB, TAI, TEST1 to TEST5, CS :

V

IN

= 0 V

EFMO, CLV

+

, CLV–, V/P, TOFF, TGL, JP+,

V

OH

1 JP–, PCK, FSEQ, EFLG, FSX, EMPH : 2.56 V

I

OH

= –1 mA

CONT2 to CONT5, SBSY, MUTEL, MUTER,

Output high-level current

VOH2 C2F, WRQ, SQOUT, 16M/NGJ, 4.2M, EMPP, 2.56 V

OVF, CNTOK, NGJ : I

OH

= –0.5 mA

V

OH

3 DOUT : IOH= –12 mA 2.72 V

V

OH

4

OE, WE, CAS, RAS, AD10/CAS2, AD9 to AD0,

2.56 V

DRAM3 to DRAM0 : I

OH

= –0.5 mA

V

OH

5 MMC0 to MMC3 : IOH= –2 mA 2.24 V

V

OL

1

EFMO, CLV

+

, CLV–, V/P, TOFF, JP+, JP–,

0.64 V

PCK, FSEQ, EFLG, FSX, EMPH : I

OL

= 1 mA

CONT2 to CONT5, SBSY, MUTEL, MUTER,

V

OL

2 C2F, WRQ, SQOUT, 16M/NGJ, 4.2M, EMPP, 0.32 V

Output low-level current

OVF, CNTOK : I

OL

= 2 mA

V

OL

3 DOUT : IOL= 12 mA 0.48 V

V

OL

4

OE, WE, CAS, RAS, AD10/CAS2, AD9 to AD0,

0.44 V

DRAM3 to DRAM0 : I

OL

= 0.5 mA

V

OL

5 MMC0 to MMC3 : IOL= 2 mA 0.96 V

PDO, CLV

+

, CLV–, JP+, JP–,

I

OFF

1 CONT2 to CONT5, DRAM0 to DRAM3, 5 µA

Output off leakage current

ASRES : V

OUT

= V

DD

PDO, CLV+, CLV–, JP+, JP–,

I

OFF

2 CONT2 to CONT5, DRAM0 to DRAM3, –5 µA

ASRES : V

OUT

= 0 V

Charge pump output current

I

PDOH

PDO : R

ISET

= 68 kΩ 30 42 54 µA

I

PDOL

PDO : R

ISET

= 68 kΩ –54 –42 –30 µA

Parameter Symbol Conditions

Ratings

Unit

min typ max

Total harmonic distortion rate TRD+N

LCHO, RCHO; 1 kHz: Uses the 0 dB data

0.035 0.038 %

input and the 20 kHz-LPF (in the AD725D)

LCHO, RCHO; 1 kHz: Uses the –60 dB data

Dynamic range DR input, the 20 kHz-LPF (in the AD725D), and 81 84 dB

the A filter

LCHO, RCHO; 1 kHz: Uses the 0 dB data

Signal to noise ratio S/N input, the 20 kHz-LPF (in the AD725D), and 87 92 dB

the A filter

Cross talk CT

LCHO, RCHO; 1 kHz: Uses the 0 dB data

79 82 dB

input and the 20 kHz-LPF (in the AD725D)

One-bit D/A Converter Analog Characteristics at

Ta = 25°C, VDD= LVDD= RVDD= 3.2 V, VSS= L/RVSS= 0 V

Note: Measured with the normal-speed playback mode in the Sanyo one-bit D/A converter block reference digital attenuator circuit.

Page 6

Figure 1 Command Input

Figure 2 Subcode Q Output

Figure 3 Subcode Output

No. 5995-6/34

LC78626KE

Page 7

No. 5995-7/34

LC78626KE

Figure 4 General Port Input Timing

Figure 5 General Port Output Timing

Page 8

No. 5995-8/34

LC78626KE

Description of Pins

Pin Pin

I/O Function

Output pin states

No. Name

during reset

1 DEFI I Defect detection signal (DEF) input. When not used, must be connected to 0 V. —

2 TAI I Test input. Equipped with internal pull-down resistor. Must be connected to 0V. —

3 PDO O Internal VCO control phase comparator output —

4 VV

SS

P

For the PLL

Internal VCO ground. Must be connected to 0 V. —

5 ISET AI PDO output current adjustment resistor connection —

6 VV

DD

P Internal VCO power supply —

7 FR AI VCO frequency range adjustment —

8 V

SS

P Digital system ground. Must be connected to 0 V. —

9 TESCLK I Test clock input. Must be connected to V

DD

. —

10 TESA I Test operation mode control input. Must be connected to V

DD

. —

11 TESB I Test operation mode control input. Must be connected to V

DD

. —

12 TESC I Test operation mode control input. Must be connected to V

DD

. —

13 TESGB I Test operation mode control input. Must be connected to V

DD

. —

14 TEST5 I Test input. Equipped with internal pull-down resistor. Must be connected to 0 V. —

15 CS I Chip select input. Equipped with internal pull-down resistor. When not controlled, must be connected to 0 V. —

16 TEST1 I Test input. Must be connected to 0 V. —

17 EFMO O For slice EFM signal output Undefined

18 EFMI I level control EFM signal input —

19 TEST2 I Test input. Equipped with internal pull-down resistor. Must be connected to 0 V. —

20 CLV

+

O

Disk motor control output. Can have a 3-state output depending on the command.

Low-level output

21 CLV

–

O

22 V/P O

Low-level output

23 HFL I Track detect signal input. Schmidt input. —

24 TES I Tracking error signal input. Schmidt input. —

25 TOFF O Tracking off output

High-level output

26 TGL O Tracking gain switch output. Gain is increased with low level. Undefined

27 JP

+

O

Track jump control output. Can be 3-state output depending on the command.

Low-level output

28 JP

–

O

29 PCK O EFM data playback clock monitor. 4.3218 MHz during phase lock.

Low-level output

30 FSEQ O Undefined

31 V

DD

P Digital system power supply —

32 ASRES I(I/O) Input mode

33 CONT2 I/O Input mode

Continued on next page.

Rough servo/phase control automatic switching monitor output. If a high level then rough servo mode.

If a low level then phase control mode.

Sync signal detect output. A high level when the sync signal detected from the EFM signal matches the

internally generated sync signal.

Reset signal input for initializing only the anti-shock control part (i.e. excluding the DSP part). Resets when

this pin is low level, and release the reset when this pin is high level. Tie this pin to the low level (i.e.,

connected to 0 V) if when using software control on the anti-shock part alone through the anti-shock part

only reset disable/release command ($F4) or the anti-shock only reset enable/inrush command ($F5).

Note: This pin is assigned as the least significant bit of the general I/O port however, use as a general I/O

pin is disabled. When the port I/O set command ($DB) is executed, the least significant bit is always “0,” and

the output driver is not turned ON.

General I/O pin 2. This controls the commands from the microcontroller. When not used, either set this as

an input port and connect to 0 V, or set this as an output port and leave it open.

Page 9

No. 5995-9/34

LC78626KE

Continued from preceding page.

Pin Pin

I/O Description

Output pin states

No. Name

during reset

34

CONT3/SBCK

I/O Input mode

35

CONT4/SFSY

I/O Input mode

36

CONT5/PW

I/O Input mode

37 SBSY O Subcode block sync signal output Undefined

38 TEST3 I Test input. Equipped with an internal pull-down resistor. Must be connected to 0 V. —

39 DOUT O Digital output. EIAJ format. Undefined

40 TEST4 I Test input. Equipped with an internal pull-down resistor. Must be connected to 0 V. —

41 16M/NGJ O Clock output

42 4.2M O 4.2336 MHz output Clock output

43 EFLG O C1, C2, one error, two error error correction monitor output Undefined

44 FSX O 7.35 kHz sync signal output (frequency divided from the crystal oscillator). Undefined

45 EMPH O Deemphasis monitor output. When high level, a deemphasis disk is being played back.

Low-level output

46 C2F O C2 flag output Undefined

47 TOUT O Test output. Under normal operation, this should be left open. Undefined

48 MR1 I

DRAM switch: high : 1M, low : 4M

—

49 MR2 I

1 M: high, low 4 M: low, low 16 M: low, high 4 M X 2: high, high (MR1, MR2)

50 TESD I Test input. Must be connected to 0V. —

51 MUTESL O L channel mute output

High-level output

52 LV

DD

P L channel power supply —

53 LCHO AO L channel output —

54 L/RV

SS

P

For the one-bit D/A

L/R channel ground. Must be connected to 0 V. —

55 RCHO AO

converter

R channel output —

56 RV

DD

P R channel power supply —

57 MUTER O R channel mute output

High-level output

58 XV

DD

P Crystal oscillator power supply —

59 XOUT O

16.9344 MHz crystal oscillator connection

—

60 XIN I

61 XV

SS

P Crystal oscillator ground. Must be connected to 0 V. —

62 RWC I Read/write control input. Schmidt input. —

63 COIN I Microcontroller command input —

64 CQCK I Input pin for the command input latch clock and the subcode readout clock. Schmitt input. —

65 SQOUT O Subcode Q output Undefined

66 WRQ O Subcode Q output standby output Undefined

67 FMT I Operating mode switch: high: shock proof, low: through. —

68 EMPP O DRAM empty (an RZP pulse is output when the DRAM is empty).

Low-level output

69 RES I External reset input: low reset (all internal blocks are reinitialized). —

Continued on next page.

General I/O pin 3. This controls the commands from the microcontroller. This pin is shared exclusively with

the subcode read clock input (SBCK). When not used, either set this as an input port and connect to 0 V, or

set this as an output port and leave it open.

General I/O pin 4. This controls the commands from the microcontroller. This pin is shared exclusively with

the subcode frame sync signal output (SFSY). When not used, either set this as an input port and connect

to 0 V, or set this as an output port and leave it open.

General I/O pin 5. This controls the commands from the microcontroller. This pin is shared, exclusively, with

the subcode P, Q, R, S, T, U, V, W output (PW). When not used, either set this as an input port and connect

to 0 V, or set this as an output port and leave it open.

Shared function pin that functions either as the 16.9344 MHz output (16M) or as the C2 flag data continuity check

start signal (detection start is indicated by a low to high transition). Controlled by microcontroller commands.

Page 10

No. 5995-10/34

LC78626KE

Continued from preceding page.

Pin Pin

I/O Description

Output pin states

No. Name

during reset

70 MMC0 O Remaining DRAM output

Low-level output

71 MMC1 O Remaining DRAM output

Low-level output

72 MMC2 O Remaining DRAM output

Low-level output

73 MMC3 O Remaining DRAM output

Low-level output

74 OVF O DRAM write terminated. (An RZP pulse is output when there is an overflow or a shock.)

Low-level output

75 CNTOK O Data contact point detection complete signal: low→ high: detection complete. (DRAM write start).

High-level output

76 WOK I DRAM write enable signal input: high: write enable. —

77 PAUSE IN I Pause signal input: high: pause. —

78

AD10/CAS2

O Undefined

79 EMPN O Remaining DRAM alarm output: low: memory low.

Low-level output

80 SHOCK I C2F shock detect pause signal input: low: pause shock detection. —

81 DRAM3 I/O DRAM data bus Input mode

82 DRAM2 I/O DRAM data bus Input mode

83 DRAM1 I/O DRAM data bus Input mode

84 DRAM0 I/O DRAM data bus Input mode

85 OE O DRAM control signal

Low-level output

86 WE O DRAM control signal

High-level output

87 CAS O DRAM control signal Undefined

88 RAS O DRAM control signal Undefined

89 AD9 O DRAM address bus

Low-level output

90 AD8 O DRAM address bus

Low-level output

91 AD7 O DRAM address bus

Low-level output

92 AD6 O DRAM address bus

Low-level output

93 AD5 O DRAM address bus

Low-level output

94 V

SS

P Digital system ground. Must be connected to 0 V. —

95 AD4 O DRAM address bus

Low-level output

96 AD3 O DRAM address bus

Low-level output

97 AD2 O DRAM address bus

Low-level output

98 AD1 O DRAM address bus Undefined

99 AD0 O DRAM address bus Undefined

100 V

DD

P Digital system power supply —

Shared function pin that functions either as a 16M DRAM address output (AD10) or as a DRAM control

signal (CAS2) used when 8M of DRAM (two 4M DRAM chips) is used. The function is switched by the

DRAM selection pins MR1 and MR2.

Page 11

Pin Applications

The HF Signal Input Circuit Pin 18: EFMI, Pin 17: EFMO, Pin 1: DEFI, and Pin 20: CLV

+

When an HF signal is input to the EFMI, an EFM signal (NRZ),

sliced at the optimal levels, is obtained.

As a countermeasure against defects, when the DEFI pin (Pin 1)

is high, the slice level control output EFMO pin (Pin 17) goes to

a high impedance state, and the slice level is held. However, this

is only enabled when the CLV is in phase-control mode, or in

other words, when the V/P pin (Pin 22) is low. This can be

structured from a combination with the DEF pin of LA9230/

40/50 series ICs.

* When the EFMI and CLV+signal lines are close to each other

then the error rate due to unnecessary radiation may increase.

It is recommended that these two lines be separated by a

ground line or by a VDDline as a shield line.

The PLL Clock Playback Circuit Pin 3: PDO, Pin 5: ISET and Pin 7: FR

The VCO circuit is equipped internally, and the PLL circuit is

structured using external resistors and external capacitors. The

ISET is the reference current for the charge pump. The PDO is

the loop filter for the VCO circuit, and the FR is the resistor that

determines the frequency range of the VCO.

Reference Values

R1 = 68 kΩ C1 = 0.1 µF (standard speed)

C1 = 0.047 µF (2× speed)

R2 = 680 Ω C2 = 0.1 µF

R3 = 1.2 kΩ

* It is recommended that a carbon coated resistor with a

tolerance of ±5.0% be used for R3.

The VCO Monitor Pin 29: PCK

This is the monitor pin with an average frequency of 4.3218 MHz, which is a 1/2 frequency division from VCO.

The Sync Detect Monitor Pin 30: FSEQ

The EFM signal goes high when the frame sync signal (the true sync signal) from the PCK matches the timing (the

interpolated sync signal) generated by the counter. This serves as the sync detect monitor (holding the high level over a

single frame).

No. 5995-11/34

LC78626KE

HF Signal

Frequency

and phase

comparator

Charge pump

Page 12

The Servo Command Functions Pin 62: RWC, Pin 63: COIN, Pin 64: CQCK

Various commands can be executed by setting RWC to high and by inputting the command from COIN synchronized

with the CQCK clock. The commands are executed beginning with the falling edge of RWC.

Focus start

Track jump

Mute control Single-byte commands

Disk motor control

Other control

Track check Two-byte command (two sets of RWC)

Digital attenuator

Two-byte commands (once set of RWC)

General port I/O settings

• Single-byte commands

• Two-byte commands (RWC 2 set: for the track count)

• Two-byte commands (RWC 1 set: digital attenuation and setting the general I/O port)

• Eliminating command noise

This command makes it possible to reduce the noise that is mixed into the CQCK clock. This is effective for noise of

less than 500 ns; however, the CQCK timing must be set to have 1 µs or more for tWL, tWH, and tSU.

No. 5995-12/34

LC78626KE

Code COMMAND RES = low

$EF Command input noise reduction mode

$EE Resets the command input noise reduction mode

●●

Command ($F0, $F8)

Data ($08 to $FE), command ($FF)

At least 1 µs

Data Commands ($81 to $87, $DB, $DC)

Page 13

The CLV Servo Circuit Pin 20: CLV+, Pin 21: CLV-, Pin 22: V/P

CLV+is the signal for accelerating the disk in the forward direction, while CLV–is the signal for decelerating the disk.

Depending on the commands from the microcontroller, one of the following four modes is selected: Accelerate,

decelerate, CLV, or stop. The CLV+and CLV–outputs for each mode are as shown in the table below.

* The CLV servo control command is such that the TOFF pin is low only when the CLV mode is in effect, and it is high

otherwise. The TOFF pin control by the command is only active when the CLV mode is in effect.

• CLV mode

In the CLV mode the rotation of the disk is detected from the HF signal, and a precise linear speed of rotation is

derived by exerting the respective forms on control when the internal modes of the DSP change. The PWM frequency

is 7.35 kHz. The V/P has a high output when the internal mode is the rough servo, and a low output when the internal

mode is phase control.

• Switching the rough servo gain

When the internal mode is the rough servo, the CLV control gain for the 8 cm disk can be reduced by 8.5 dB from the

level for the 12 cm disk.

No. 5995-13/34

LC78626KE

Code COMMAND RES = low

$04 DISC MOTOR START (Accelerate)

$05 DISC MOTOR CLV (CLV)

$06 DISC MOTOR BRAKE (Decelerate)

$07 DISC MOTOR STOP (Stop) ●●

MODE CLV

+

CLV

–

Accelerate High Low

Decelerate Low High

CLV Pulse output Pulse output

Stop Low Low

Internal mode CLV

+

CLV

–

V/P

Rough servo (when the rotational speed is determined to be low) High Low High

Rough servo (when the rotational speed is determined to be high) Low High High

Phase control (when the PCK clock is running) PWM PWM Low

Code COMMAND RES = low

$A8 DISC 8 cm Set

$A9 DISC 12 cm Set ●●

Page 14

• Switching the phase control gain

By changing the frequency division value of the first-stage frequency divider of the phase comparator it is possible to

change the phase control gain.

• CLV 3-state output

The CLV 3-state output command makes it possible to control the CLV with a single pin. However, because this will

cause the spindle gain to fall by 6 dB, it will be necessary to increase the gain on the servo side.

No. 5995-14/34

LC78626KE

Code COMMAND RES = low

$B1 CLV phase comparator 1/2 frequency division

$B2 CLV phase comparator 1/4 frequency division

$B3 CLV phase comparator 1/8 frequency division

$B0 CLV phase comparator, no frequency division ●●

Code COMMAND RES = low

$B4 CLV 3-state output

$B5 CLV 2-state output (traditional method) ●●

Phase

comparator

2-state output

3-state output

Acceleration

Deceleration

High impedance output

Page 15

• Internal brake mode

* The internal brake mode is turned on by inputting the internal brake on command ($C5). When in this mode, when

the brake command ($06) is executed it becomes possible to monitor the state of deceleration of the disk using the

WRQ pin.

* In this mode, the status of deceleration of the disk is determined by counting the density of the EFM signals in a

single frame, and the CLV–is low if the number of EFM signals is 4 or less. At the same time, the WRQ signal is

put to high as the break complete monitor. The microcontroller issues the STOP command if it senses that the

WRQ signal is high, and thus brings the disk to a complete stop. In the internal break continuous mode the CLV–=

high brake operation continues even when the break complete monitor WRQ goes high.

When noise in the EFM signal causes the deceleration status to be judged incorrectly, it may be advisable to use the

internal break control command ($A3) to change the EFM signal count from 4 to 8.

* In the TOFF output inhibited mode ($CD), TOFF is low while the internal break is in operation. Its use is

recommended because it is effective in preventing incorrect detection at the mirrored surface of the disk.

* When there is a loss of focus during the execution of an internal break command it will be necessary to reissue the

internal brake command after the focus has been reestablished.

* Because there is a risk that the EFM signal will be discerned incorrectly depending on the playback status

(scratched disks, access processes, etc.), use in conjunction with the microcontroller is recommended.

* When the internal brake mode is in effect, then it is possible to monitor the disk deceleration status at the WRQ Pin

by executing the DISC MTR BRAKE command ($06) in this DSP. However, if another command is executed

while this command is in process, then the command will be aborted. When you wish to prevent the function from

being aborted, then, after issuing the DISC MTR BRAKE command ($06), do not issue any other commands until

a high WRQ signal is detected and the DISC MTR STOP command ($07) is issued.

The Track Jump Circuit Pin 23: HFL, Pin 24: TES, Pin 25: TOFF, Pin 26: TGL, Pin 27: JP+, Pin 28: JP

–

• Types of track counters

The following two track count modes have been provided.

The conventional track counter uses the TES signal itself as the internal track counter clock. In the new track count

method, however, the TES signal is combined with the HFL signal to reduce the amount of noise, producing a more

accurate track count through reducing the number of miscounts due to noise in the rising edge and falling edge of the

TES signal. However, when the HFL signal is absent because of dust, scratches, etc., there is the danger that there

will be no track count pulse, and thus caution is required when using this method.

No. 5995-15/34

LC78626KE

Code COMMAND RES = low

$C5 Internal Break ON

$C4 Internal Break OFF ●●

$A3 Internal brake control

$CB Internal brake continuous mode

$CA Internal brake continuous mode reset ●●

$CD Internal brake TON mode

$CC Internal brake TON mode reset ●●

Code COMMAND RES = low

$22 The new track count (a combination of TES and HFL) ●●

$23 The conventional track count (direct count of the TES signal)

EFM signal

$06 command

Page 16

• The TJ command

When the track jump command is input to the servo command an acceleration pulse is generated (period a), following

which a deceleration pulse is generated (period b), after which the specific jump is completed after the brake period

(period c) elapses. In this break period the beam slip direction is detected through the TES and HFL inputs, and the

segment of the TES signal that propagates the internal slip is cut by TOFF. Moreover, by increasing the servo gain

using TGL, it is possible to lock onto the track that is the jump destination. In the JP pulse interval TOFF output

mode, TOFF is high during the interval when the JP pulse is generated.

* The TOFF pin is only low when the CLV mode is active when related to the disk control mode, and this terminal is

high during start, stop, and break control. Moreover, the TOFF pin can be turned on and off independently using

commands. However, the disk motor control is only enabled when the CLV mode is active.

No. 5995-16/34

LC78626KE

Code COMMAND RES = low

$A0 The conventional track jump ●●

$A1 The new track jump

$11 1 TRACK JUMP IN #1

$12 1 TRACK JUMP IN #2

$31 1 TRACk JUMP IN #3

$52 1 TRACK JUMP IN #4

$10 2 TRACK JUMP IN

$13 4 TRACK JUMP IN

$14 16 TRACK JUMP IN

$30 32 TRACK JUMP IN

#15 64 TRACK JUMP IN

$17 128 TRACK JUMP IN

$19 1 TRACK JUMP OUT #1

$1A 1 TRACK JUMP OUT #2

$39 1 TRACK JUMP OUT #3

$5A 1 TRACK JUMP OUT #4

$18 2 TRACK JUMP OUT

$1B 4 TRACK JUMP OUT

$1C 16 TRACK JUMP OUT

$38 32 TRACK JUMP OUT

$1D 64 TRACK JUMP OUT

$1F 128 TRACK JUMP OUT

$16 256 TRACK CHECK

$0F TOFF

$8F TON ●●

$8C TRACK JUMP BRAKE

$21 JP pulse period TOFF output mode

$20 JP pulse period TOFF output mode reset ●●

(Brake period)

(JP pulse period)

Page 17

• TJ mode

The relationships between the acceleration pulse, deceleration pulse, and brake interval are as shown in the table

below.

* The 256 TRACK CHECK does not produce an actuator drive signal as shown in the table above, rather because the

mode is such that the TES signal is counted when the tracking loop is off, it is necessary to provide a feed to the feed

motor.

* When the track jump sequence (a, b, c) is completed, the servo command register is reset automatically.

* When a new command has been input when the track jump is in process, that command is executed at that instant.

* In the 1 TRACK JUMP #3 command there is no brake period (period c), but rather caution is warranted because it is

necessary to generate the brake mode using an external circuit.

* Although in the 2TRACK JUMP IN (OUT) of the new track jump mode the brake period (period c) did not exist for

the LC78620E/21E/25E ICs, in this IC period C has been changed to 60 ms.

No. 5995-17/34

LC78626KE

Command

When in the conventional track jump mode When in the new track jump mode

a b c a b c

1 TRACK JUMP IN (OUT) #1 233 µs 233 µs 60 ms Same as in the conventional mode

1 TRACK JUMP IN (OUT) #2

0.5 TRACK

233 µs 60 ms

0.5 TRACK The same

60 ms

JUMP period JUMP period as for a

1 TRACK JUMP IN (OUT) #3

0.5 TRACK

233 µs

This period 0.5 TRACK The same This period

JUMP period does not exist JUMP period as for a does not exist

1 TRACK JUMP IN (OUT) #4

0.5 TRACK

233 µs

60 ms TOFF =“L” 0.5 TRACK The same 60 ms TOFF =“L”

JUMP period during period C JUMP period as for a during period C

2 TRACK JUMP IN (OUT) None

1 TRACK The same

60 ms

JUMP period as for a

4 TRACK JUMP IN (OUT)

2 TRACK

466 µs 60 ms

2 TRACK The same

60 ms

JUMP period JUMP period as for a

16 TRACK JUMP IN (OUT)

9 TRACK 7 TRACK

60 ms

9 TRACK The same

60 ms

JUMP period JUMP period JUMP period as for a

32 TRACK JUMP IN (OUT)

18 TRACK 14 TRACK

60 ms Same as in the conventional mode

JUMP period JUMP period

64 TRACK JUMP IN (OUT)

36 TRACK 28 TRACK

60 ms Same as in the conventional mode

JUMP period JUMP period

128 TRACK JUMP IN (OUT)

72 TRACK 56 TRACK

60 ms Same as in the conventional mode

JUMP period JUMP period

TOFF is high during the period over

256 TRACK JUMP IN (OUT) which 256 tracks elapse and pulses a 60 ms Same as in the conventional mode

and b are not produced

TRACK JUMP BRAKE There is no a or b period 60 ms Same as in the conventional mode

Slip detector

High during the brake interval

Page 18

The THLD signal is generated on the LA9230M, 9240M, 9250M Series side, and causes the tracking error signal to

be held during the JP pulse period.

* The tracking brake

The relationship between the TES, HFL, and TOFF signals during the track jump period c is as shown below. The

TOFF signal is generated from the HFL signal with the changing edge of the TES signal. The high of the HFL signal

is for the mirrored area, while the low is for the pitted area. As the beam sweeps from the mirrored surface to the

pitted area, TOFF becomes high, and as the beam sweeps from the pitted area to the mirrored surface, TOFF is made

low in the gain-enhanced state (TGL low), and the brake is applied.

• JP 3-state Output

Using the JP 3-state command, the track jump can be controlled with a single pin, however, the gain must be

increased on the servo side because the kick gain will decrease by 6 dB.

• Track check mode

After the track check IN or track check OUT command has been entered, then when a discretionary number between

8 and 254 is entered as binary data, a track count of the specified number + 1 will be performed.

No. 5995-18/34

LC78626KE

Code COMMAND RES = low

$B6 JP 3-state output

$B7 JP 2-state output (conventional method) ●●

Code COMMAND RES = low

$F0 Track check IN

$F8 Track check OUT

$FF Two byte command reset ●●

TES (when moving towards the outside)

TES (when moving towards the inside)

HFL

TOFF output

2-state output

3-state output

High impedance output

The number of desired track checks = the number of track checks input + 1

Command

Track check

Track check

In/Out command

Binary input of the desired

number of tracks +1

Double byte

command reset

Rising edge at the

number of tracks/2

Goes low when the track

check is complete.

Brake command

Page 19

* When the desired number of tracks is entered as a binary number, the track check operation begins with the falling

edge of the RWC.

* During the track check the TOFF pin becomes high and the tracking loop turns off, and thus there is the need to

provide a feed to the feed motor.

* When the track check In/Out commands are entered, the WRQ signal changes from the subcode Q standby monitor

that it is during normal times to become the track check monitor. This signal becomes high when half of the number

of tracks have been checked, and becomes low when the check is complete. The microcontroller sees that the WRQ

signal has become low and determines that the check has been completed.

* If the two-byte reset command is not entered, the track check operation begins again. In other words, if you wished to

advance 20,000 tracks, then a single 201 track check code would be sent and then when 100 cycles of the WRQ have

been counted, then there have been 20,000 track checks.

* When the track check is performed, the brake command is used to lock the pickup to a track.

The Error Flag Output Pin 43: EFLG, Pin 44: FSX

The FSX is the 7.35 kHz frame sync signal that is created by frequency dividing the crystal clock. For each frame, the

error correction status is output to EFLG. It is easy to tell the quality of the playback by the number of high pulses that

appear in the EFLG signal.

The Subcode P, Q and R to W Output Circuits

Pin 34: SBCK, Pin 35: SFSY/CONT4, Pin 36: PW/CONT5, Pin 37: SBSY

PW is the subcode signal output pin. (Note: Pin 35 and Pin 36 are, respectively, a general I/O pin and an exclusively

shared pin, and the selection of the pin depends on commands from the micro controller. See the item “General I/O

Ports” on page 24.) By applying 8 clocks to SBCK within 136 µs of the falling edge of SFSY, it is possible to read all

codes until P, Q, and R to W. The signal that appears at the PW pin changes with the rising edge of SBCK. When no

clock is applied to SBCK, the “P” code is output to PW. SFSY is a signal that is output for each subcode frame, and the

falling edge of this signal indicates that the subcode symbol (P to W) output is in standby. The subcode data P is output at

the falling edge of this signal.

SBSY is a signal output for each subcode block. This signal becomes high during sync signals S0 and S1, and its falling

edge indicates the end of the subcode sync signal and the beginning of the data in subcode block (in EIAJ format).

No. 5995-19/34

LC78626KE

1 correction

2 correction

Correction

function

No errors

Page 20

The Subcode Q Output Circuit Pin 66: WRQ, Pin 62: RWC, Pin 65: SQOUT, Pin 64: CQCK, Pin 15 CS

It is possible to read the subcode Q from the SQOUT pin by inputting a clock into the CQCK pin. Of the 8-bit subcodes,

the “Q” signal is useful in accessing musical selections, in displays, etc. WRQ is only high when the CRC has been

passed and the address in the subcode Q format is “1.” (See Note 1.) When the microcontroller detects this high level, it

can transmit a CQCK signal to read the data from SQOUT in the order shown below. When the CQCK transmission

begins, data changes in the internal registers of the DSP are inhibited. Once the microcontroller has completed its read,

RWC temporarily goes high, enabling data updating. At this time, WRQ goes low. Because WRQ goes low after being

high for 11.2 ms, the CQCK input starts during the interval when WRQ is high. The data can be read beginning with the

least significant bit.

Note 1: This conditions is ignored if an address-free command is sent (corresponding to the CDV).

The items within the parentheses are for the read-in area.

* The WRQ pin normally indicates the subcode Q standby; however, when in the track counter mode and when there is

an internal bake, it becomes a different monitor. (See the track count and internal brake items.)

* This IC becomes active when the CS pin is low, and the subcode Q data is output from the SQOUT pin. When the CS

pin is high, the SQOUT pin enters a high impedance state.

No. 5995-20/34

LC78626KE

Code COMMAND RES = low

$09 ADDRESS FREE

$89 ADDRESS 1 ●●

CONT ADR

TNO

INDEX (POINT)

MIN

SEC

FRAME

ZERO

AMIN (PMIN)

ASEC (PSEC)

AFRAME (PFRAME)

Sub Q data

Page 21

Bilingual Function

* At reset or when a stereo command ($28) has been entered, Lch and Rch are output, respectively, to Lch and Rch.

* When the Lch set command ($29) is entered, the Lch data is output to both Lch and Rch.

* When the Rch set command ($2A) is entered, the Rch data is output to both Lch and Rch.

Deemphasis Pin 45: EMPH

Of the subcode Q control data, the pre-emphasis on/off bit is output from the EMPH pin. When this pin is high, the

deemphasis circuit within this IC is activated, and the D/A converter output are de-emphasized.

Digital Attenuator

It is possible to apply digital attenuation to the audio data by setting the RWC high and inputting from the COIN a two

byte command synchronized with the CQCK clock.

After reset, the attenuation level is set to “MUTE” (the attenuation coefficient is 00H, where MUTE = –∞), and thus it is

necessary to directly set the attenuation coefficient EEH using the direct set (ATT DATA SET) command in order to

produce a sound. The attenuation level can be set to a range from 00H to EEH (239 different levels) by the

microcontroller commands.

This two byte command is different from the two byte commands used in track counting in that RWC only needs to be

set once, and it is not necessary to reset the two byte command either. (See the two byte command RWC1 set on page

13.)

After inputting the target attenuation level in terms of 00H to EEH, then if the attenuate step-up/step-down commands are

transmitted, the system steps closer to the target with the corresponding step size of 4, 8, or 16, synchronized with the

rising edge of LRSY. However, when the ATT DATA SET command has been used, then the target value is set directly.

When new data is entered during the transition, then the target value is approached from whatever value is in effect at

that time. Caution is required when using the step-up/step-down commands at this time.

No. 5995-21/34

LC78626KE

Code COMMAND RES = low

$28 STO CONT ●●

$29 Lch CONT

$2A Rch CONT

Code COMMAND RES = low

$81 ATT DATA SET DATA 00H Set

$82 ATT 4STEP UP (MUTE –∞ dB)

$83 ATT 4STEP DOWN

$84 ATT 8STEP UP

$85 ATT 8STEP DOWN

$86 ATT 16STEP UP

$87 ATT 16STEP DOWN

Command

Attenuation data 00H to EEH

Attenuate set command

Page 22

ATT DATA

The audio output level = 20 log ————— [dB]

100H

Because, for example, the time that it would take to increase the attenuation level from “00H” to “EEH” using the 4 stepup command would be as calculated below, this amount of time must be left before entering the next attenuation level

command:

238 level × 4 step-up

————————— ≈ 21.6 ms (approx.)

44.1 kHz (LRSY)

* In order to prevent noise due to arithmetic overflow in the one-bit D/A converter, settings greater than EEH are

prohibited.

Mute Output Pin 51: MUTEL, Pin 57: MUTER

When the Mute control (MUTE –∞ dB: $03) is exerted, and once the data for each channel has been continuously at “0”

for a specified amount of time, then this output goes high. Afterwards, when data is again entered, this output

immediately goes low.

C2 Flag Output Pin 46: C2F

C2F is an 8-bit unit flag that indicates the data error status.

Digital OUT Output Circuit Pin 39: DOUT

This is the digital audio interface output pin. Its output is in EIAJ format. This signal is interpolated, and the signal is

output through the MUTE circuit. Because this output pin is equipped with an internal driver, it can drive a transformer

directly.

* The digital OUT pin can be fixed low by inputting the DOUT OFF command.

* Of the DOUT data, the UBIT data can be fixed at low by entering the UBIT OFF command.

* By entering the CDROM-XA command, the DOUT pin can be switched to CD-ROM data that is not subjected to

interpolation or to mute control. (When this is done, the audio output is put into mute mode.) The ROMXA-RST

command returns the DOUT pin to the audio data output mode which is subject to interpolation and mute control.

(When this is done, the audio output mute is released.)

Mute Control Circuit

The sound level can be muted (MUTE –∞ dB) by the entry of the commands above. Because zero cross mute is used,

there is little noise during this operation. The zero cross determination is made in the range where the most significant 7

bits are all “1” or all “0.” Because the MUTE–12 dB command ($02) that was found in the LC78620E and 78621E has

been deleted, the digital attenuator is used and ATT DATA = 60 ($3C) is set.

No. 5995-22/34

LC78626KE

Code COMMAND RES = low

$42 DOUT ON ●●

$43 DOUT OFF

$40 UBIT ON ●●

$41 UBIT OFF

$88 CDROM-XA

$8B ROMXA-RST ●●

Code COMMAND RES = low

$01 MUTE 0 dB

$03 MUTE –∞ dB ●●

44.1 kHz (normal speed), 88.2 kHz (double speed)

Start

Stop

Page 23

Interpolation Circuit

If, when the error correction circuit cannot correct an error, the erroneous audio data is output without any correction, the

result would be excessive noise. In order to reduce this noise, the erroneous data is replaced with a linear approximation

based on the correct data on either side of the incorrect data. When there are two or more C2 flags, the previous data level

is held. However, when new data is output after two or more continuous flags, then a linear approximation is made based

on the correct data and the held value that is two points earlier and the middle point is replaced with this linear

approximation.

General I/O Ports Pin 33: CONT2, Pin 34: CONT3, Pin 35: CONT4/SFSY, Pin 36: CONT5/PW

The four signal lines, CONT2 to CONT5, have I/O ports. These lines are all input terminals at the time of reset. Unused

ports must either be connected to ground or set as output ports. Moreover, pins 35 and 36 are pins that are shared

(exclusively) as, respectively, the subcode frame sync signal output pin (SFSY) and the subcode output pin (PW). The

selection of the function of these pins is done by commands from the microcontroller.

Note that pin 34 functions as either the subcode readout clock input pin (SBCK) or as CONT3. When this pin is used as

SBCK, the CONT3 input pin mode (output disabled) must be selected.

The port data is read out sequentially from CONT2, CONT3, CONT4, and CONT5 with the falling edge of the CQCK

from the SQOUT pin when there is a port read command. The command uses a single-byte command format.

* When a command is applied to this DSP during a track check, track jump, or internal MTR brake operation, then the

DSP will terminate those operations. If you do not wish to terminate these operations, do not apply unnecessary

commands (including general port operation commands) during track check, track jump, or internal MTR brake

operations.

These ports can each be set individual as control output ports by the port I/O set command. The ports are selected by the

lower four bits of a single byte. Starting with the least significant bit, these four bits of this single byte data correspond to

CONT2, CONT3, CONT4, and CONT5. The command uses a two-byte command format (RWC1 set).

* Although the ASRES pin is allocated as the lowest-order bit of the general-purpose I/O port, it may not be used as a

general-purpose I/O port. Applications must set the lowest-order bit in the command code to 0 when setting up the

I/O port I/O direction with a PORT I/O SET command ($DBXX). Note that the system goes to this state after a reset.

No. 5995-23/34

LC78626KE

Code COMMAND RES = low

$DD PORT READ

$DB PORT I/O SET PORT I SET

$DC PORT OUTPUT

Code COMMAND RES = low

$F6 SFSY, PW output enabled

$F7 SFSY, PW output disabled ●●

* When there is an error in one place

Correct data

Flagged data

Interpolated data

Held at the previous value

* When there are continuous errors (three errors in this example).

A11301

A11300

Page 24

dn = 1: Set CONTn to be an output pin

dn = 0: Set CONTn to be an input pin

Where n = 2 to 5

The ports that are set to output pins then they can independently output either high or low levels. The lower four bits (bits

2 to 5) of the single byte of data correspond to the respective ports. Starting with the second bit from the LSB end of this

single byte of data, the bits correspond to CONT2, CONT3, CONT4, and CONT5. The command uses a two-byte

command format (RWC1 set).

dn = 1: Outputs a high level from the CONTn that is set to being an output

dn = 0: Outputs a low level from the CONTn that is set to being an output

Clock Oscillator Pin 60: XIN, Pin 59: XOUT

By connecting a 16.9344 MHz oscillator to these pins a clock is generated that serves as the time base.

The OSC OFF command is a command to stop the oscillation of the oscillator and the VCO oscillation. Moreover,

depending on the command, double speed playback is also possible.

* When structuring a double speed playback system, connect a 16.9344 MHz oscillator between the XIN (Pin 60) and

the XOUT (Pin 59), and set the playback speed using the double speed playback command.

* Recommended crystal/ceramic oscillator constants.

The load capacitance Cin and Cout will have different requirements depending on the actual print circuit board used, and

thus it is necessary to perform verification testing on the use print circuit board. Consult the oscillator manufacturer.

16M and 4.2M Pins Pin 41: 16M, Pin 42: 4.2M

When using double speed/normal speed playback mode, a 16.9344 MHz signal will be output from the 16M/NGJ pin

after the external crystal oscillator 16.9344 MHz. A 4.2336 MHz will be output constantly from the 4.2M pin, forming a

LA9230/40 Series LSI system clock. When OSC is off, both terminals are constantly either high or low.

16M/NGJ pin output switching command

No. 5995-24/34

LC78626KE

Single-byte data + $DB PORT I/O SET

Single-byte data + $DC PORT OUTPUT

Code COMMAND RES = low

$8E OSC ON ●●

$8D OSC OFF

$CE XTAL 16M ●●

$C2 Normal speed playback ●●

$C1 Double speed playback

Manufacturer Product No.

Load capacitance Dumping resistance

Cin = C out Rd

CITIZEN WATCH CO., LTD.

CSA-309 (16.9344 MHz) 6 pF to 10 pF (±10%) 0Ω

(Crystal Oscillator)

TDK, Ltd. FCR 16.93M2G (16.93 MHz) 15 pF (±10%) 100Ω (±10%)

(Ceramic oscillator) FCR 16.93MCG (16.93 MHz) 30 pF (Internal type) 47Ω (±10%)

Oscillator

(C1)

(C2)

Code COMMAND RES = low

$F3 16M FUNCTION ON ●●

$F2 NGJ FUNCTION ON

Page 25

Reset Circuit Pin 69: RES

When the power supply is turned on, first set this pin low and then set it to high. The muting is set to –∞dB and the disk

motor is set to stop.

When the RES pin is low, then the statuses found in the boxes above are set directly.

Other Pins Pin 2: TAI, Pin 16: TEST1, Pin 19: TEST2, Pin 38: TEST3, Pin 40: TEST4, Pin 14: TEST5

These are pins for testing the circuits within the IC. While TAI and TEST2 to TEST5 are equipped with internal pulldown resistors, for safety reasons, they should be connected to 0 V.

Explanation of the Block Functions

* RAM address control

This IC contains 8 bits × 2K words on on-board RAM, and, depending on the address control, the EFM modulation

data jitter absorption capability can have ±4 frames as the buffer memory capacity. Moreover, normally this buffer

margin is checked, and by precisely controlling the CLV servo circuit PCK-side frequency ratio it is possible to

control the data write address so that it will be centered on the size of the buffer. Also, when the ±4 frame buffer

capacity is exceeded, the write address can be forced to ±0, and because the resulting errors cannot be subjected to

flag processing, the mute is applied for a 128 frame period.

No. 5995-25/34

LC78626KE

CLV servo relationship START STOP BRAKE CLV

Muting control 0 dB –∞

Subcode Q address parameter Address1 Address Free

Track jump mode Conventional New

Track count mode Conventional New

Digital attenuator DATA0 DATA 00H to EEH

OSC ON OFF

Playback speed Normal speed Double speed

Digital filter normal speed ON OFF

Position Frequency divider ratio or process

–4 or lower Forces transition to ±0

–3 589

–2 589 Forward frequency division

–1 589

±0 588 Standard frequency division

+1 587

+2 587 Backwards frequency division

+3 587

+4 or greater Forces transition to ±0

Page 26

* C1 and C2 corrections

Data that has been EFM modulated is written to the internal RAM, the jitters are absorbed, and then, the following

processes are performed with uniform timing through the crystal oscillator clock. First, there is error checking and

correction as the C1 block, the C1 flag is determined and written to the C1 flag register. Next, error checking and

corrections are performed as the C2 block, and the C2 flag is determined and written to the internal RAM.

Notes:1. If the error position determined by the C2 check matches the C1 flag, then the error correction is performed and the flag is reset. However, when

there are seven or more C1 flags, then there would be the risk of an erroneous correction, and thus no correction is performed and the C1 flags

become C2 flags. When one of the error positions match, but another error position does not match, then no correction can be performed. Moreover,

when there are five or less C1 flags, then the C1 check is thought to be somewhat dubious, and thus the flag is set. When there are six or more, the

error correction is not possible and they are handled together, so the C1 flags become C2 flags as they are. When none or the error positions match,

naturally error correction cannot be performed, and when the number of C1 flags is two or less, then there may be errors even in the data that was

deemed OK by the C1 check, and thus the flag is set. In other cases, the C1 flags are used as C2 flags as they are.

2. When it is determined that error correction is not possible because there are three or more errors, then naturally error correction cannot be

performed and when the number of C1 flags is two or less, even the data that was deemed as OK in the C1 check may contain errors, and thus the

flags are set. In other cases, the C1 flags are used as C2 flags directly.

Anti-shock Function Pin 67: FMT, Pin 48: MR1, Pin 49: MR2, Pin 76: WOK, Pin 75: CNTOK, Pin 74: OVF, Pin 46:

C2F, Pin 66: WRQ, Pin 65: SQOUT

The anti-shock function of this IC reads data from the disk at double speed and stores it in the external DRAM. By

replaying that data that was stored when an external shock has caused the data acquisition to be defective, it is possible to

avoid defective playback due to external shocks. The anti-shock mode is set by placing the FMT pin high. When the data

is stored in external DRAM, the 16-bit data is compressed to 5 bits using ADPCM. Depending on the DRAM capacity

(1M/4M/8M/16M bits) the time that can be stored will be approximately 2.4 seconds (1M), approximately 9.5 seconds

(4M), approximately 19 seconds (8M), or approximately 38 seconds (16M). Depending on the type of DRAM, the MR1

/MR2 might have to be set. (See the table.) When in the anti-shock mode, the double speed data is written to the external

DRAM and then read at normal speed (1× speed) for playback, and thus the external DRAM will eventually become full.

When this happens, this IC stops writing to the DRAM and places the OVF pin high. The microcontroller monitors the

OVF and when the microcontroller senses that the OVF signal has gone high, it places the WOK pin low and in order to

find the point at which the writing was terminated (called the “L” point below) the system must perform a track jump.

The microcontroller has already determined through its monitoring of the frame number in the subcode Q the location of

the L point. The frame number at the point when the OVF pin becomes high track jumps to the location, and the L point

is sought by placing the WOK pin high that many frames earlier. When this IC finds the L point, the CNTOK pin is put

high, and the DRAM data write process begins again. Furthermore, sometimes the L point cannot be found, such as when

there is an external shock during the L point search. If the CNTOK pin has not become high even if the L point frame

number has been passed (by three or more frames), then it is determined that the L point was not found. When this

happens, a track jump is performed again, and the L point search begins again. When the search is performed again, the

track jump is performed with the WOK pin high. This IC determines whether or not there has been an external shock

through the use of the C2F flag. When the C2F flag becomes high then the OVF pin becomes high just as if the DRAM

was full, and writing to the DRAM is terminated. In this case, the microcontroller should perform the same process as if

the DRAM had become full.

No. 5995-26/34

LC78626KE

C1 check Correction and flag process

No error Correction not required/flag is reset

1 error Correction performed/flag is reset

2 errors Correction is performed and flag is set

3 or more errors Correction is not possible and flag is set

C2 check Correction and flag process

No error Correction not required/flag is reset

1 error Correction performed/flag is reset

2 errors See the C1 flag. (* 1)

3 or more errors See the C1 flag. (* 2)

Setting pins

Pin

MR2

High Low

High

8M-bit DRAM 1M-bit DRAM

MR1

((1M × 4bits) × 2) (256k × 4bits)

Low

16M-bit DRAM 4M-bit DRAM

(4M × 4bits) (1M × 4bits)

Page 27

A Schematic of the timing of the various signals during the anti-shock operations are shown in the figure below.

Anti-shock Independent Reset

It is possible to initialize only the anti-shock controller part (excluding the DSP part) by setting the ASRES pin to low.

The reset is released by setting this pin high. Furthermore, when controlling the independent reset using commands, the

ASRES pin must be tied low (connected to 0 V).

No. 5995-27/34

LC78626KE

Code COMMAND RES = low

$F4 Independent reset disable (release)

$F5 Independent reset enable/inrush ●●

Beginning of L point search

L point is found. Beginning of writing to the DRAM

L point because of shock

Track jump

L point because the DRAM is full

Track jump

Pin High Low

FMT Anti-shock mode: ON Anti-shock mode: OFF

A11304

Page 28

Table of Commands

Commands with blank columns: Commands that can not be used. Commands with asterisk marks: Commands that

are latched (i.e. mode set commands).

Commands marked with @ signs: Commands that are shared with the ASP (LA9240M, etc.). Commands in

parentheses: Commands that are exclusive for the ASP (reference).

Commands marked with % signs: Commands changed or added from the LC78622E.

In the DISC MTR BRAKE command ($06) function, when the internal brake on mode is on, the function that puts the

WRQ pin high is not latched. For details, see “Internal brake mode” on page 16.

No. 5995-28/34

LC78626KE

$00 (ADJ. RESET) $20 * TJ-time TOFF “L” $40 * UBIT ON $60

$01 * MUTE 0 dB $21 * TJ-time TOFF “H” $41 * UBIT OFF $61

$02 $22 * New Track Count $42 * DOUT ON $62

$03 * MUTE –∞dB $23 * Old Track Count $43 * DOUT OFF $63

$04 * DISC MTR START $24 $44 $64

$05 * DISC MTR CLV $25 $45 $65

$06 * DISC MTR BRAKE $26 $46 $66

$07 * DISC MTR STOP $27 $47 $67

$08 @ FOCUS START #1 $28 * STO CONT $48 $68

$09 * ADDRESS FREE $29 * LCH CONT $49 $69

$0A $2A * RCH CONT $4A $6A

$0B $2B $4B $6B

$0C $2C $4C $6C

$0D $2D $4D $6D

$0E $2E $4E $6E * DF normal speed “OFF”

$0F * TRACKING OFF $2F $4F $6F * %DF normal speed “ON”

$10 2TJ IN $30 32TJ IN $50 $70

$11 1TJ IN #1 $31 1TJ IN #3 $51 $71

$12 1TJ IN #2 $32 $52 1TJ IN #4 $72

$13 4TJ IN $33 $53 $73

$14 16TJ IN $34 $54 $74

$15 64TJ IN $35 $55 $75

$16 256TC $36 $56 $76

$17 128TJ IN $37 $57 $77

$18 2TJ OUT $38 32TJ OUT $58 $78

$19 1TJ OUT #1 $39 1TJ OUT #3 $59 $79

$1A 1TJ OUT #2 $3A $5A 1TJ OUT #4 $7A

$1B 4TJ OUT $3B $5B $7B

$1C 16TJ OUT $3C $5C $7C

$1D 64TJ OUT $3D $5D $7D

$1E $3E $5E $7E

$1F 128TJ OUT $3F $5F $7F

Page 29

No. 5995-29/34

LC78626KE

Commands with blank columns: Commands that can not be used.Commands with asterisk marks: Commands that are

latched (i.e. mode set commands).

Commands marked with @ signs: Commands that are shared with the ASP (LA9240M, etc.). Commands in parentheses:

Commands that are exclusive for the ASP (reference).

Commands marked with % signs: Commands changed or added from the LC78622E.

After the PLL DIV (the 1/2 frequency divider for the PLL part) is reset, then this turns off. (the opposite of the

LC78622E). However, the functions of the commands ($AC, $AD) are the same as for the LC78622E.

$80 $A0 * Old Track Jump $C0 $E0

$81 * ATT DATA SET $A1 * New Track Jump $C1 * Double speed playback $E1

$82 * ATT 4STP UP $A2 FOCUS START #2 $C2 * Normal speed playback $E2

$83 * ATT 4STP DOWN $A3 * Internal Brake CONT $C3 $E3

$84 * ATT 8STP UP $A4 $C4 * Internal BRAKE OFF $E4

$85 * ATT 16STP DOWN $A5 $C5 * Internal BRAKE ON $E5

$86 * ATT16STP UP $A6 $C6 $E6

$87 * ATT 16STP DOWN $A7 $C7 $E7

$88 * CDROMXA $A8 * DISC 8 cm SET $C8 $E8

$89 * ADDRESS 1 $A9 * DISC 12 cm SET $C9 $E9

$8A $AA $CA * Internal BRK-DMC “L” $EA

$8B * ROMXA RST $AB $CB * Internal BRK-DMC “H” $EB

$8C TRACK JMP BRAKE $AC * PLL DIV OFF $CC * Internal BRK-time TOFF $EC

$8D * OSC OFF $AD * PLL DIV ON $CD * Internal BRK-time TON $ED

$8E * OSC ON $AE $CE * X’tal 16M $EE * Command noise OFF

$8F * TRACKING ON $AF $CF $EF * Command noise ON

$90 (* F.OFF.ADJ.START) $B0 *

CLV PH1 frequency divider mode

$D0 $F0 *

@ TRACK CHECK (2BYTE DETECT)

$91 (* F.OFF.ADJ.OFF) $B1 *

CLV PH2 frequency divider mode

$D1 $F1

$92 (* T.OFF.ADJ.START) $B2 *

CLV PH4 frequency divider mode

$D2 $F2

$93 (* T.OFF.ADJ.OFF) $B3 *

CLV PH8 frequency divider mode

$D3 $F3

$94 (* LASER ON) $B4 * CLV 3-state output ON $D4 $F4

*

% Anti-shock part independent

reset disable/release

$95 (* LSR.OFF/F.SV.ON) $B5 * CLV 3-state output OFF $D5 $F5

*

% Anti-shock part independent

reset enable/inrush

$96 (* LSR OFF/F.SV.OFF) $B6 * JP 3-state output ON $D6 $F6 * % PW output enable

$97 (* SP.8 cm) $B7 * JP 3-state output OFF $D7 $F7 * % PW output disable

$98 (* SP.12 cm) $B8 $D8 $F8 *

@ TRACK CHECK OUT (2BYTE DETECT)

$99 (* SP.OFF) $B9 $D9 $F9

$9A (* SLED ON) $BA $DA $FA

$9B (* SLED OFF) $BB $DB * PORT OP.ED SET $FB

$9C (* EF.BAL.START) $BC $DC * PORT DATA SET $FC

$9D (* T.SERVO OFF) $BD $DD PORT READ $FD

$9E (* T.SERVO ON) $BE $DE $FE @ NOTHING

$9F $BF $DF $FF * @ 2BYTE CMD RESET

Page 30

Sample Application Circuit

No. 5995-30/34

LC78626KE

Page 31

Notes on Application Design

While it goes without saying that to achieve system reliability the absolute maximum ratings and allowable operating

conditions specified for this IC must be strictly adhered to, adequate consideration must also be given to the operating

environmental conditions, such as ambient temperature and static electricity, and to the mounting conditions used.

This section presents items that require special care during application design and IC mounting.

Handling of Unused Pins

• If unused input pins on this IC are left in the open state during IC operation, there are times when the IC may enter an

unstable state. Always follow all the directions for handling unused pins included in the documentation for this IC.

Also, do not connect any output pins to power supply, ground, or any other output lines.

• All general-purpose I/O ports must either be set to the output state and set to output a low level in software, or must be

left in the input state and pulled up or pulled down to a fixed input level.

Latch-up Prevention

• Due to the structure of this IC, all supply voltage pins must be supplied with the same potential.

— Also supply the same potential to the servo system ASP. The slice level control circuit is shared with this IC, and

application of the same potential is necessary. Also, the same potential must be supplied to all supply voltage pins

on the ASP IC.

• Do not allow the pin voltages on any of the input or output pins to exceed VDDor to fall lower than VSS. The timing of

signal application requires special care at power on to assure that this condition is met.

• Do not allow overvoltages or abnormal noise to be applied to this IC.

• In general, latch-up can be prevented by tying any unused pins to either VDDor VSS. However, be sure to follow any

special instructions provided with this IC for unused pin handling.

• Do not short the outputs.

continued on next page.

No. 5995-31/34

LC78626KE

Comparison of CD-DSP Functions

Model

LC78621E LC78625E LC78630E LC78624E

LC78626KE LC78622E

Function (LC78626E) (LC78622NE)

EFM-PLL Internal VCO Internal VCO Internal VCO Internal VCO Internal VCO Internal VCO

FR = 1.2kΩ FR = 1.2kΩ FR = 1.2kΩ FR = 1.2kΩ FR = 1.2kΩ (5.1kΩ) FR = 1.2kΩ

RAM 16k 16k 18k 16k 16k 16k

Replay speed 2× 2× 4× 2× 2× 2×

Digital out ●● ●● ●● ●● ●● ●●

Interpolation 4 4 2 2 2 2

Zero cross mute

●● ●● ●● ●● ●● ●●

–12dB, –∞ –12dB, –∞ –∞ –∞ –∞ –∞

Level meter peak search ●● ●● × × × ×

Bilingual ●● ●● ●● × ●● ●●

Digital attenuator ●● ●● ●● × ●● ●●

Digital filter 8fs 8fs 2fs × 8fs (4fs) 4fs (8fs)

Digital Deemphasis ●● ●● ●● × ●● ●●

General Ports

Output 2 2 2 × × × (3)

I/O × (4) 2 + (4) 5 1 + (3) 5

VCD compatible × ●● ●● × × ×

Anti-shock I/F ●● ●● ●● × Not necessary ×

Anti-shock controller × × × × ●● * ×

CD text × × × ●● × ×

CD-ROM I/F ●● ●● ●● × × ×

One-bit D/A converter ●● ●● × × ●● ●●

L.P.F × × × × ●● ●●

Power supply voltage 3.6 to 5.5 V 3.0 to 5.5 V 3.6 to 5.5 V 3.0 to 5.5 V

3.0 to 3.6 V (3.0 to 5.5 V)

3.0 to 5.5 V

Package QFP80E QFP80E QFP80E QFP64E QFP100E QFP64E

*Notes: 16M DRAM max

(4M DRAM max)

Page 32

No. 5995-32/34

LC78626KE

Interface

When the inputs and outputs of devices of different types are connected, incorrect operation may occur due to

discrepancies between the input VIL/VIHand output VOL/VOHvalues. Insert level shifters between devices that have

different supply voltages to prevent device destruction in systems that use dual power-supply systems.

Load Capacitance and Output Current

• When a load with a large capacitance is connected, since a load short lasts for an extended period, fused output lines

can be caused. Also, high charge and discharge currents can result in noise which can degrade end product performance

or result in incorrect operation. Always use the recommended load capacitances.

• Large output sink or source currents can also cause the same types of problems described in the previous item. Use the

recommended currents, while taking the maximum allowable power dissipation into account.

Notes on Power Application and Reset

• There are points that require care that are related to power application, the period during which a reset is applied, and

the period after a reset is cleared. Refer to the specific notes provided in the specification sheets for the individual

products, and design end products with these points in mind.

• The pin output states, the pin I/O settings, the contents of registers, and other aspects of this IC are not guaranteed

when power is first applied. Aspects that are defined by the reset operation or by settings are only guaranteed once the

reset or setting has been performed. Applications that use this IC should apply a reset immediately after power is

applied. Pin states and register values that are undefined may differ between samples, and may change between lots

over time. Applications should not depend on undefined states and values.

• The general-purpose I/O ports are set to the input state during a reset. For pins that must be fixed at high or low due to

fail-safe design considerations, pulling up to VDDor pulling down to VSSthrough an individual resistor can be an

effective design.

• When the 4.2MHz output is used as the microcontroller master clock, the reset circuit will be shared with the

microcontroller. Since the microcontroller will not be reset unless a clock signal is applied, do not control the reset

input to this IC from a microcontroller output port. If this IC has not been reset, the 4.2-MHz output is not guaranteed,

and the microcontroller may not be reset. This can result in incorrect application system operation.

Notes on Thermal Design

The failure rate of semiconductor devices is significantly accelerated by increases in ambient temperature and power

dissipation. To assure high reliability, designs must include adequate margins to take possible changes in ambient

conditions into account.

Notes on Printed Circuit Board Patterns

• If possible, the influence of common impedances should be reduced by separating the VDDand ground lines for each

system.

• The VDDand ground lines should be as wide and as short as possible to lower their high-frequency impedance. Ideally,

decoupling capacitors (0.01 to 1 µ F) should be inserted between each VDDand ground pair. These capacitors should be

located extremely close to their corresponding power supply system pins. Additionally, it is appropriate to insert a

capacitor of about 100 to 220 µ F between VDDand ground as a low-frequency filter. However, note that using

excessively large capacitors here can result in latch-up.

— In servo systems, the V

REF

lines should be handled in the same manner as the VCCand ground lines. Driver ground

lines should be particularly wide, and the recommended driver pattern should be used direct under the power

devices taking heat radiation effect into consideration.

— If a current output type pickup is used, locate the optical sensor connector and the ASP RF input as close together

as possible. If a voltage output type pickup is used, locate the I/V conversion resistor as close to the ASP RF input

side as possible.

• EFM signal lines should be kept as short as possible, and either adjacent lines should be avoided or VDDor ground

shield lines should be run between adjacent EFM signal lines.

Since the slice level controller output (EFMO) and the ASP clock output (4.2MHz) lines can easily disrupt EFM signal

Continued from preceding page.

Continued on next page.

Page 33

No. 5995-33/34

LC78626KE

lines, resistors connected to output pins should be located extremely close to the pin. Note that the smaller these

resistors, the larger the amount of spurious radiation emitted. Inversely, the output level may be adversely influenced if

the resistors are made too large. Design the 4.2MHz output according to the ASP input level requirements. (Design

center: 1 V p-p)

• Noise on the microcontroller interface signal lines can result in incorrect operation. While the best method for reducing

noise depends on the application itself, in general, the interface lines should be made as short as possible and

inductances and capacitances minimized. However, designs must also take crosstalk into account.

If long interface lines must be used, or if noise is a problem, inserting a noise exclusion circuit may be effective.

Design noise filters with the interface timing taken into account. Issuing the command noise reduction command [$EF]

may also be effective.

• Cover the area around the crystal oscillator element with the ground pattern.

Notes on Software Design

• Always follow the recommendations for software design provided in the IC documentation and do not use any

techniques specifically forbidden.

• If the digital outputs are used, issue a UBIT OFF [$41] command to this IC during initialization. UBIT ON [$40]

should only be used during playback to prevent DIR unlock and incorrect subcode recognition.

• During initialization, after clearing an IC reset, and after turning this IC's oscillator on, issue a 2-byte reset command

[$FF] to the LA9230M Series or LA9240M Series ASP to set up the ASP command register.