Sanyo DVD-SL22, DVD-SL25 Schematic

FILE NO.

Service Manual

PICTURE

z /ON

OPEN/CLOSE

LAST MEMO

MODE

PROGRAM

REPEAT A-B REPEAT

/RANDOM

ANGLE

ZOOM ANGLE

ON SCREEN

REPLAY

SUBTITLE

SETUP MENU

CHANGE

4

SUBTITLE

ON/OFF

ENT

b5a

AUDIO RETURN

TOP MENU

FWD SLOWREV SLOW

PAUSE/STEP

NEXTPREV

PLAY

REV FWD

CLEAR

123C

0

456

SEARCH

MODE

789

REMOTE CONTROLLER RB-SL22

(For UK) (For XE)

SURROUND

ON SCREEN

SUBTITLE

CHANGE

SUBTITLE

ON/OFF

AUDIO RETURN

REV FWD

PICTURE

LAST MEMO

MODE

PROGRAM

REPEAT A-B REPEAT

/RANDOM

ZOOM ANGLE

SETUP MENU

ENT

TOP MENU

PAUSE/STEP

PLAY

123C

456

789

REMOTE CONTROLLER RB-SL25

DVD Player

DVD-SL22 (UK)

(XE)

DVD-SL25 (UK)

(XE)

OPEN/CLOSE

ANGLE

REPLAY

FWD SLOWREV SLOW

NEXTPREV

CLEAR

0

SEARCH

MODE

(DVD-SL22)

(DVD-SL25)

CONTENTS

Specification.....................................................................1

Laser Beam Safety Precaution ........................................1

DVD Mechanism Replacement ........................................ 2

Mechanism Replacement ................................................ 3

Trouble Shooting..............................................................5

Service Mode ................................................................... 7

How to Load Software for MAIN P.W.Board .................... 10

Exploded View (Cabinet & Chassis) ................................11

Parts List .......................................................................... 12

Exploded View (DVD Mechanism) ................................... 15

Parts List .......................................................................... 15

PRODUCT CODE No.

137 118 07 (SL22/UK)

137 118 10 (SL22/XE)

137 118 02 (SL25/UK)

137 118 03 (SL25/XE)

Wiring Connection...........................................................16

FL Display Description ..................................................... 17

IC Block Diagram & Description.......................................18

Block Diagram..................................................................32

Schematic Diagram (DVD)...............................................34

Schematic Diagram (MPEG and FRONT) .......................36

Wiring Diagram (MAIN P.W.BOARD Parts side) ...........38

Wiring Diagram (MAIN P.W.BOARD Pattern side) ........ 40

Schematic Diagram (SCART & POWER SUPPLY) ......... 42

Wiring Diagram (POWER SUPPLY & FRONT,

SCART, MECHA-SW

and MECHA-IF)...................................43

REFERENCE No.

SM5810374

SPECIFICATIONS

Playback system:

DVD-Video, CD

Playback standard:

PAL or NTSC

Laser:

Semiconductor laser, wavelength: 650/790 nm

Laser output (Continuous wave max.):

1 mW (DVD)

0.5 mW (CD)

Frequency range (digital audio):

4 Hz to 44 kHz (DVD fs: 96 kHz)

Signal to noise ratio:

More than 105 dB

Harmonic distortion (digital audio):

0.003 %

Wow and flutter:

Below measurable level

Outputs:

DIGITAL OUT:

Foroptical lead

AV EURO CONNECTOR:

For Euro-AV/SCART lead

VIDEO OUT:

1.0 Vp-p (75 Ω)

AUDIO OUT:

L: 2 V rms

R: 2 V rms

Power requirements:

AC 230 V, 50 Hz

Power consumption:

11 W

Less than 2 W (standby mode)

Dimensions:

360(W) x 55(H) x 250(D) mm

Weight:

1.95 kg

This is a basic specifications.

Specifications subject to change without notice.

LASER BEAM SAFETY PRECAUTION

• Pick-up that emits a laser beam is used in this CD player section.

CAUTION :

USE OF CONTROLS OR ADJUSTMENTS

OR PERFORMANCE OF PROCEDURES

OTHER THAN THOSE SPECIFIED HEREIN

MAY RESULT IN HAZARDOUS RADIATION

EXPOSURE

LASER OUTPUT..........0.6 mW Max. (CW)

WAVELENGTH ............. 790 nm

CAUTION – INVISIBLE LASER RADIATION WHEN OPEN AND

INTERLOCKS DEFEATED. AVOID EXPOSURE TO BEAM.

ADVARSEL – USYNLIG LASER STRÅLING VED ÅBNING, NÅR

SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION, UNDGÅ UDS ÆTTELSE

FOR STRÅLING.

VARNING – OSYNLIG LASER STRÅLNING NÄR DENNA DEL ÄR ÖPPNAD

OCH SPÄRR ÄR URKOPPLAD. STRÅLEN ÄR FARLIG.

VORSICHT – UNSICHTBARE LASERSTRAHLUNG TRITT AUS, WENN

DECKEL GEÖFFNET UND WENN SICHERHEITSVERRIEGELUNG

ÜBERBRÜCKT IST. NICHT, DEM STRAHL AUSSETZEN.

VARO – AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA

NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE. ÄLÄ KATSO SÄ

R L

AUDIO OUT

VIDEO OUT

OPT.

DIGITAL

OUT

TEESEEN.

AV EURO CONNECTOR

(RGB OUT)

- 1 -

DVD MECHANISM REPLACEMENT

1. Cautionary instructions in handling the assy.

(Safety instructions)

Optical pickup

The laser beam used in the pickup is classified as "class 2".

Exposing your eyes or skin to the beam is harmful. Take care

not to do so.

(Caution against static electricity and leakage voltage)

Ground securely the work tables, tools, fixtures, soldering irons

(including those made of ceramic) and measuring instruments

used in the production lines and inspection departments that

handle loaders. The workers shall also be grounded.

(Cautionary instructions in handling)

Do not touch the object lens when handling a loader, or the lens

will be stained, resulting in inadequate playability.

There is no power supply protection circuit provided for this

product or adjustment/inspection device. Short-circuiting may lead

to fire or damage.

Take care so as to protect from exposure to water, the entry of

metallic pieces or dew condensation.

In particular, a strong magnet adjacent to the pickup will not only

get inoperative but can damage the pickup if a small metallic

piece, such as a screw or swarm, enters.

The loader edge can cause injury if inadvertently handled.

Do not touch a rotating disk, or injury may result.

Do not connect or disconnect roughly by an excessively strong

force, or a broken wire or bad contact may result.

Semiconductors are connected. Do not touch connector terminals

directly.

If the worker is grounded, there is nothing to worry about static

electricity, but the rust on the connector terminal surface caused

by the touch may result in bad contact.

(Caution)

Before disconnecting FFC

cable, make it "SHORT" as

shown left.

After connecting FFC

cable,make it "OPEN" as

shownleft.

(Power source)

The power source need be good in quality (free from

instantaneous interruptions or noises).

A low quality power source may well cause malfunction.

(OPEN)(SHORT)

This product is a precision device. Handle carefully.

A shock or dropping will cause misalignment or destruction. If it

should occur, refer to clause 2.

This product is so designed as to endure an initial shock

equivalent to a drop from a height of approx. 90 cm under the

packed condition.

After the initial shock, the resistivity will still remain at a level of

50 to 60 G, but the mechanical robustness will weaken.

Do not place in a dusty location.

The entry and deposition of dirt into or on the pickup lens or

moving section will cause malfunction or degradation.

(Connectors)

Do not connect or disconnect while power is on.

Connecting or disconnecting signal wires or the main power cord

when the power is on may destruct the unit or fixture.

When connecting, push all the way in securely.

An insufficient insertion may cause a bad contact, leading to an

erroneous operation.

(Storage)

Do not place or store in a dusty place or a place where dew

condensation is possible.

The entry and deposition of dirt or dust into or on the pickup lens

or moving section will cause malfunction or degradation.

Also, dew condensation causes rust; the rust penetrate into the

precision part of a pickup, causing malfunction, or degrading the

optical quality of the internal lens and reflector, which also leads

to malfunction.

- 2 -

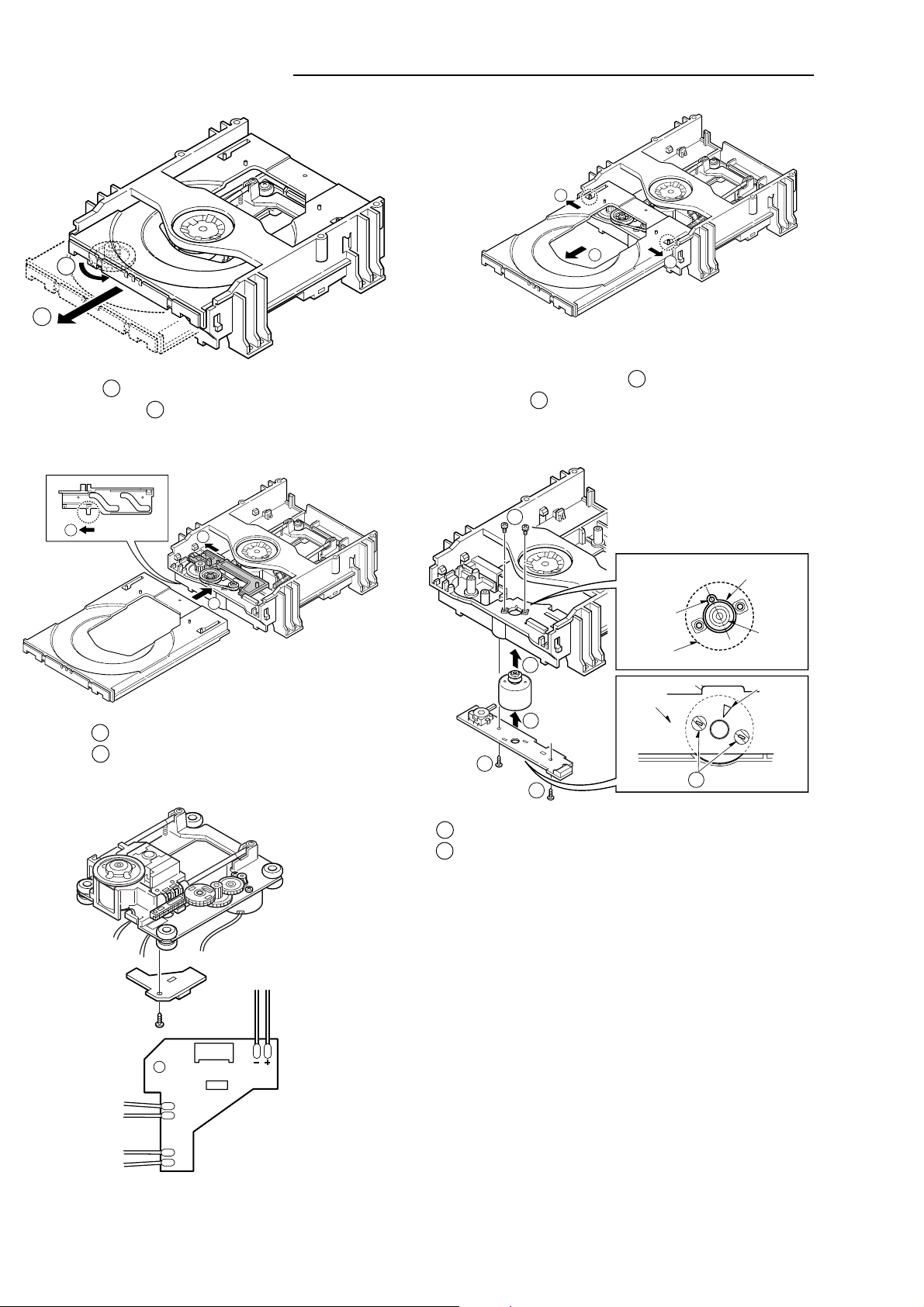

MECHANISM REPLACEMENT

1. How to remove the tray.

1

1

2

Rotate the 1 gear.

Move forward the 2 tray.

2. How to insert the tray.

1

Move the 1 slide to the left end.

Insert the 2 tray.

1

2

3. How to install the IF P.W.B.

2

1

Move both the right and left 1 tray pins to the ends

Remove the 2 tray.

4. How to install the motor.

2

ROUND

HOLE

1

3

4

4

MOTOR

MECHA

P.W.B

SOLDERING

5

SHASSIS

HOLE

PULLEY

TRIANGLE

MARK

WHITE

ORANGE

BLACK

RED

GND

LMT SW

SP1SP1+

CN002

BLACK

SLED2

SLED1

1 Adjust the motor terminal to boss in the chassis.

3 Adjust the round hole of the motor to the triangle mark of

P.W.B,and solder it.

RED

- 3 -

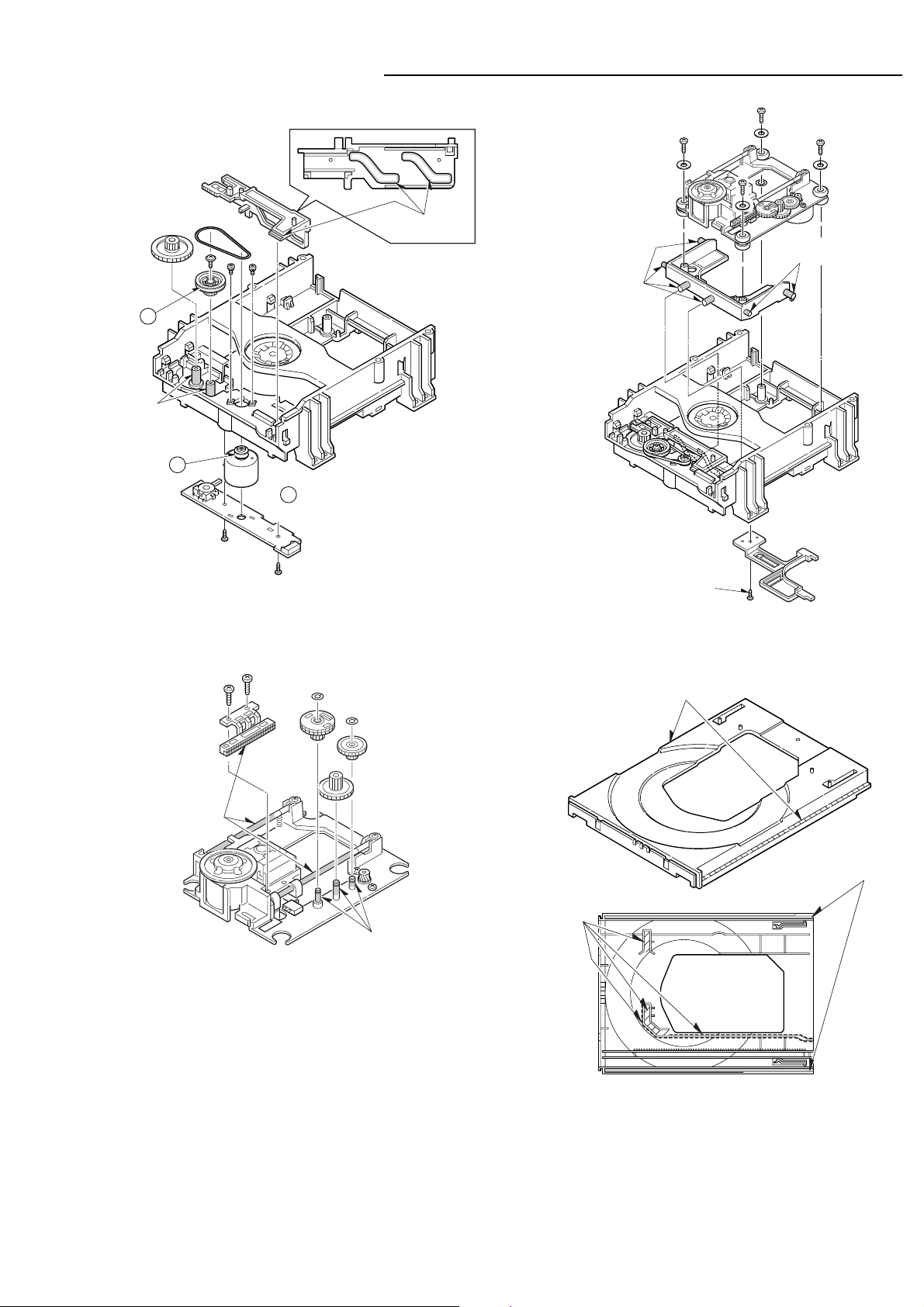

MECHANISM REPLACEMENT

5. Base mechanism mounting parts.

A

GREASE

EM-30LG

A

A

: Clean the groove by alcohol well.

GREASE

EM-30LG

GREASE

EM-30LG

GREASE

EM-30LG

6. Base mechanism parts.

GREASE

EM-30LG

GREASE

EM-30LG

Do not remove the pick-up from base mechanism because of

adjustment difficulty.

Apply screw lock

7. Tray parts.

GREASE

CDF-409

GREASE

CDF-409

GREASE

CDF-409

- 4 -

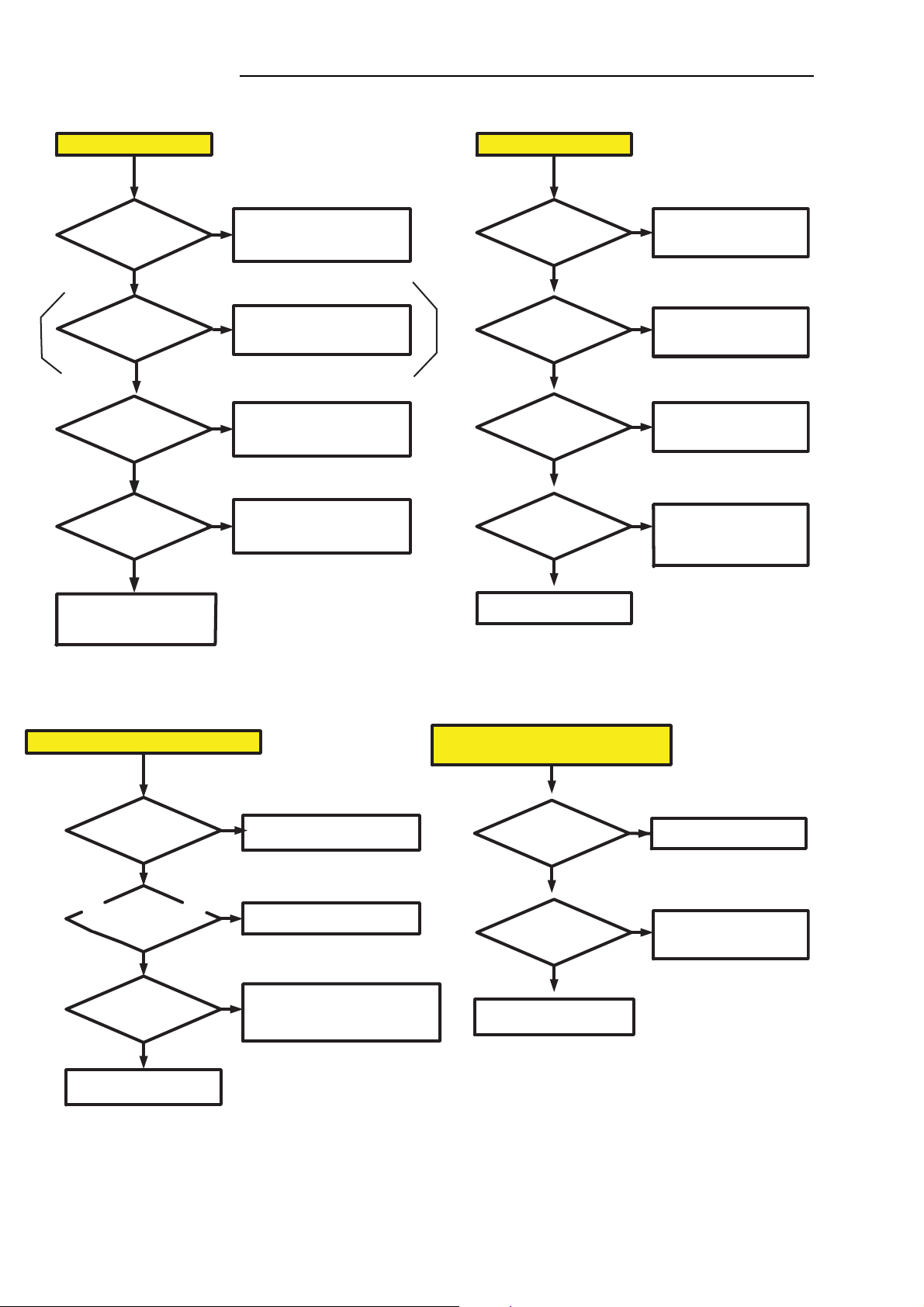

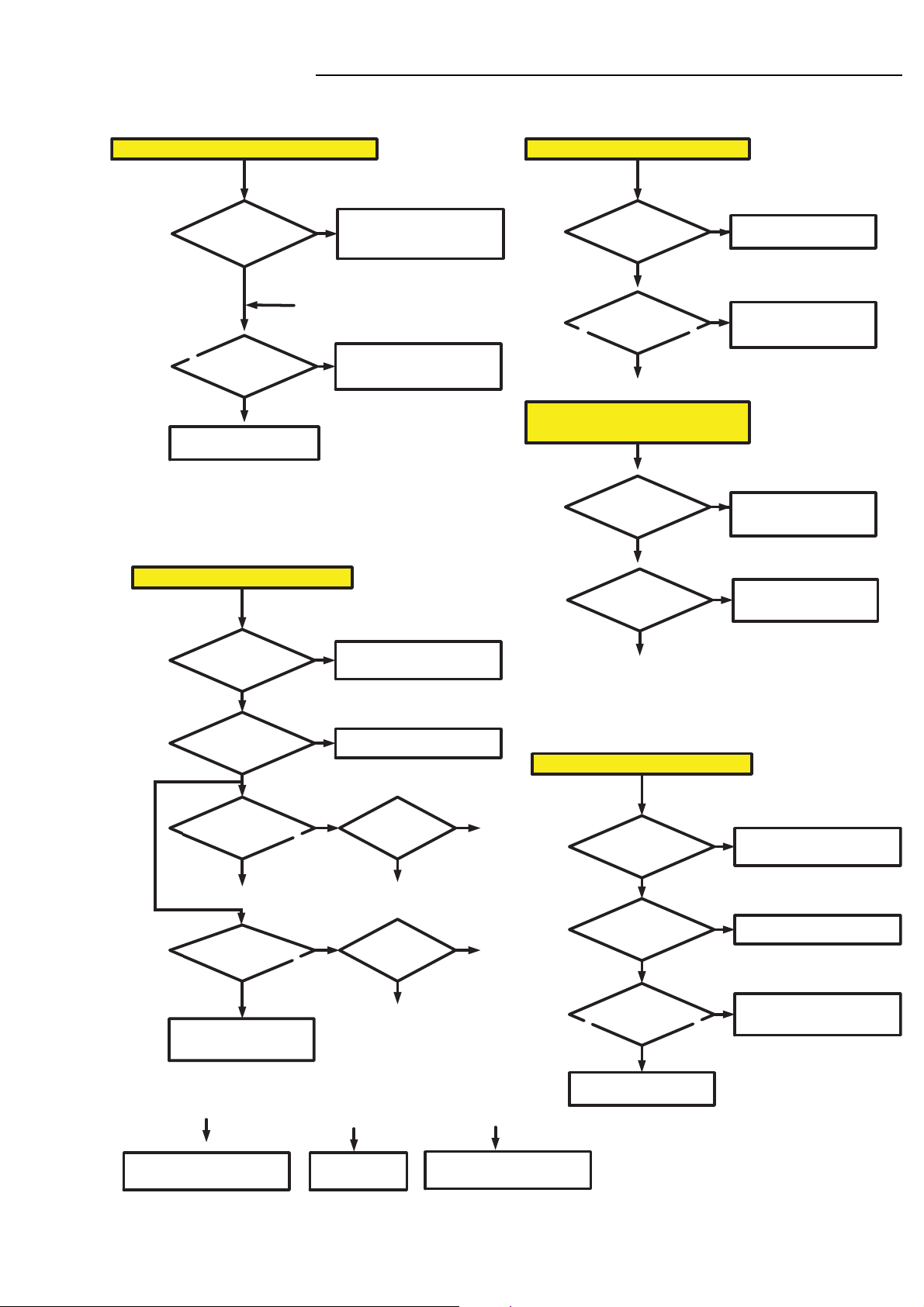

TROUBLE SHOOTING

POW ER DO ES NO

XE, UK only

T

TU

Is thevOltageat

pin3and 5 of CN

about5.6V

?

Y

ag

the volt

Is

of IC852

e

about

at pin

5.0V

Y

ag

Is the volt

of IC851

at pin

e

ab

out 3.3V?

Y

Is the voltageat pin

of IC850 about 1. 8V?

Y

RN

ON

N

81

1

Check IC483 and peri

pheralcircui

t.

DOESNOT LI

the volt

Is

pi n1 and 2 of FL 831

about-28V

GHT

DI

SPLA

Y

ag

e

at

?

N

eck FL2 lineof

Ch

PO

RBLOC

WE

K.

Y

N

3

?

Ch

eck

IC852 and peri

ph

eralcirc

uit.

pi n31and 32 of FL

Is th e volt

about-25V

ag

e

?

N

at

831

Check FL1 line of

BLOC

POWE

K.

R

Y

831

N

831

Check IC and

pheral ci

peri

rc

uit.

N

3

CheckIC851 and peri

circuit.

ph

eral

Is the voltageat

pin6and 24 of IC

about5V

?

Y

N

4

Check IC850 and peri

eral circui

ph

t.

Is thevoltag

at pi

n

15

about-30V

of IC

?

N

e

831

Check -30V line of

WERBLOCK.

PO

ex. PRAM open ?

Y

Check IC800, IC818, IC822

and peripheral circuite.e

LOADER DOES

Is

an

Isthe

NOT ACCEPT OPEN/C

the voltage at pi

of IC160 about

d14

Y

lose connection

andCN

to

LOADER.

16

CN160

N

en

Wh

ACIN,

ERMOTOR turn

LOAD

plac e FL or

Re

LOSE

N

n

3

?

9V

Check 9V li

POWERBLOC

ne

of

K.

NO

CO

LOR

COM

PLAYBACK PI

POSITEVI

PICTURE mode

BLACKand

IC

831 831

CTUR

DEOOU

is

WH

E?

IT

OF

E

T

Y

Change PICTUR

STANDA

E

RD .

mo

de to

N

at

Y

Ch

each other connectionto

2

eck

LOAD

ER

.

X8230 osc is

27

.000

MH

N

z?

CheckX8

and peripher

230

circui

al

t.

Y

Y

ec

Ch

kOPENorSHORTat pin 29, 26,27

an

?

d

24, 32

of IC80

0.

Check IC800 or

change IC80

0.

eck IC800 and

Ch

circ

uit.

N

pheral

pe

ri

- 5 -

TROUBLE SHOOTING

NO PLAYBACKPICTURE OFCOMPOSITEVIDEOOU

Y

e

Is ther

DEO signal

VI

at pin 170 of IC800.

Check composite signal line

(DAC_D line) and S8400 around.

N

A

ere

Is

th

wa

ve

from pin

rm

to pi

fo

n

23 ofIC800?

9

Y

Check IC800 or

change IC800.

DIGITALAUDIO OUT ON PLAYBACK

NO

N

CheckIC130 and peripheralcircuit.

T

NO PLAYBACKPICTUREOFS-VIDEOOUT

N

SelectS-VIDEOside.S8400 is S-VIDEOside?

Y

ere

Is

VIDEOsignal at

th

pin169 and 170 of IC80

Y

0?

Check DAC_A, DAC_D signal line

and S8400 around.

N

A

AYBACKPICURE OF COMPONENT

NOPL

VIDEO(UK,XE:RGB)

S8400 is

VIDEOside

(UK,XE:RGB)

there

Is

VIDE

pin 170,169 and173 of

CO

MPONEN

Osignal at

0?

IC80

OUT

N

T

?

ct

Sele

COMPONENT

(UK,XE:RGB)

si

de

.

Y

Y

Check DAC_A, DAC_B, DAC_C

signal line and S8400 around.

When CD

Is there wa

pi

n

veform

of IC859?

4

N

the volt

Is

of IC859 about 3. 3V?

age

at pi n

Y

When DVD

there waveform at

Is

pi

n

3and 16of IC80

N

D

e

veform at

ther

wa

Is

n

pi

and16 of

1

N

eck SPDIF CD signal line of

Ch

IC130 and peripheral

t.

circui

B

IC80

DI

A

OOUT

N

ON PLAY

at

BACK

Y

eck IC872,Q8720,Q8820and

Ch

peripheral ci

rcui

t.

Y

at

5

9?

CheckCN871(Optical modul)

and peripher

N

Check IC851 and peripheral ci

Y

al

circuit.

Pin 6 of IC859

is LO

W?

t.

rcui

AL

AN

NO

OG AU

Y

C

there AUDIO signal

Is

pin8and11of IC871?

N

B

Y

9?

Pin 6 of IC859

is HIGH

?

Y

C

Is there waveform at pi

1,2 and3of IC871?

N

N

n

CheckIC800 and peripheral circuit.

Y

N

Is there waveform at pi n

B

20,19, 18 and 4 of IC87

N

1?

Check IC800, IC820 and periph

ci

t.

rcui

eral

Y

Check IC871 or

change IC871.

C

D

Check SPDIF SEL (IC800 pin177 )

signal line

ange IC859.

Ch

Check IC800 pin181 and peripheral

circuit.

- 6 -

POWER

OPEN/CLOSE

STOP

PREV

NEXT

PLAY

SERVICE MODE

A. Market / Region Setup

In the initial condition for this model, Market and Region

information are undefined.

In the following cases, be sure to set up Market/Region.

1. When updating the system using CD-R

(Part code : 0PRADD7118--A).

2. When replacing a DVD substrate.

While Market/Region information are undefined, the message

"Region Undefined" is displayed on the screen.

NOTE: Even if the condition is not under 1 or 2 above, if the

message "Region Undefined" is displayed, be sure to set up

Market/Region.

B. How to enter Service Mode.

You can enter Service Mode in any one of the following ways (1 to 3).

1. Using the buttons on the main unit

Immediately (within one second) after pushing both STOP and POWER buttons simultaneously, push PREV button.

OPEN/CLOSE

2. Pushing the covered key located beneath Book Mark key on RB 1500 or REM-S1500.

3. Simultaneously pushing both Shift key and ON SCREEN key on

RB-SL30K.

PREV

NEXT

PLAY

STOP

POWER

- 7 -

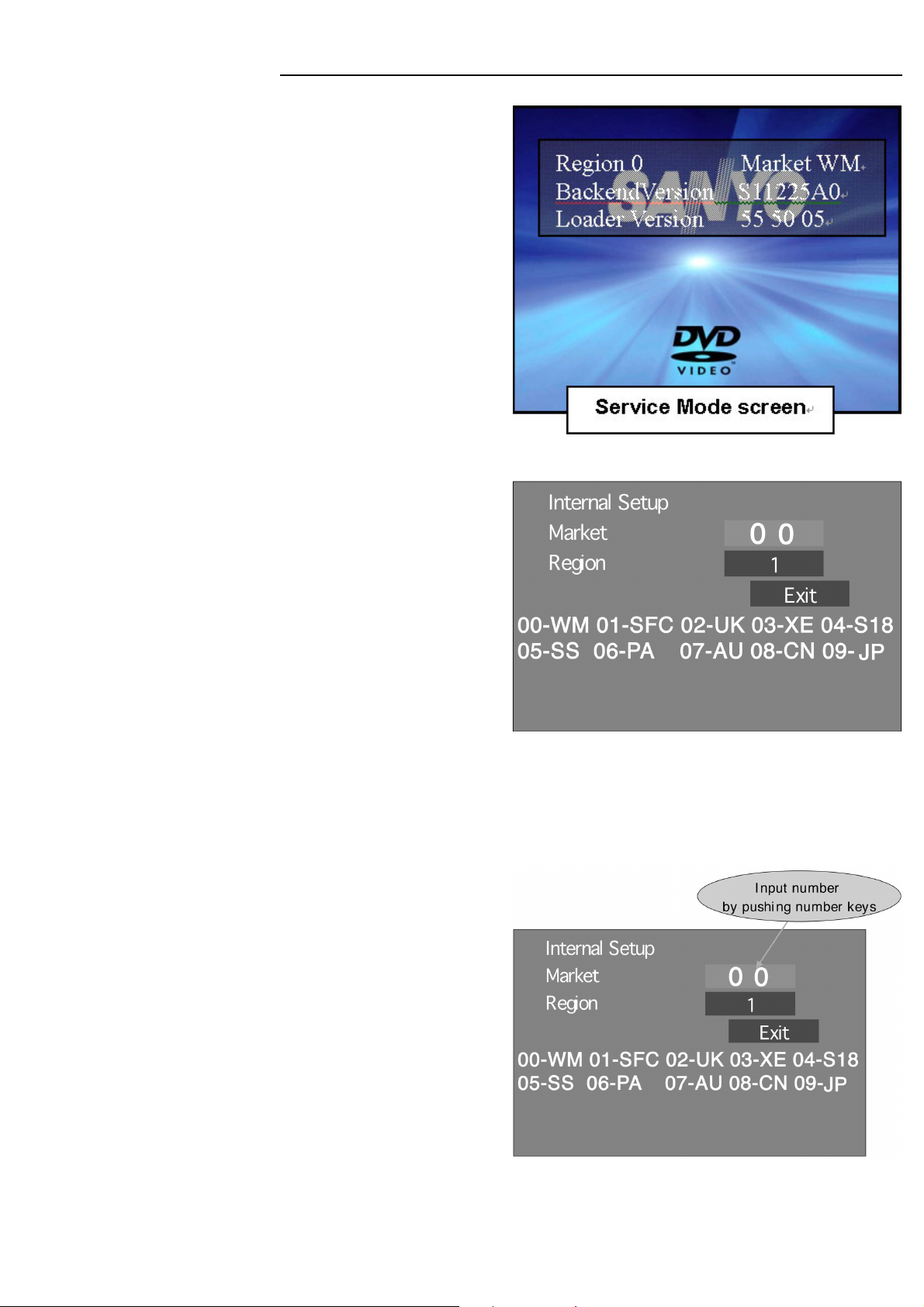

SERVICE MODE

C. Setup Procedures

1. Displaying SERVICE MODE screen

Display Service Mode screen following the instructions "How to

enter Service Mode" above.

2. Displaying Internal Setup screen

Push NEXT button within three seconds after operating the

Service Mode display.

On the Internal Setup screen shown on the right, set up Market

and Region.

Market/Rejion setup table.

3. Setting Market code

3.1. While a highlighted indicator is displayed on the right side

of the Market denotation, push numeric buttons on the

remote controller. Be sure to input by double figures.

For example,in WM, input 0,0,

When you push wrong number , push CLEAR button.

(The indicator reset to "00")

3.2. Specify the code of the model in accordance with the

Market/Region Setup Table above.

3.3 Once the desired code is displayed, push p button to move

the highlighted indicator to the Region input area.

- 8 -

SERVICE MODE

4. Setting REGION code

4.1 While a highlighted indicator is displayed on the right side

of the Region denotation, push ENT, -> and <- each button

on the remote controller. With each push the indicator will

advance as shown below.

1 <-> 2 <-> 3 <-> 4 <-> 5 <-> 6

4.2 Specify the number of the model in accordance with the

Market/Region Setup Table above.

4.3 Once the desired number is displayed, push p button to

move the highlighted indicator to Exit area.

5. Saving settings

5.1 Make sure that the Market and Region settings are properly

set.

(If any of the settings are incorrect, you can make a change

by moving the indicator using o button, and following

procedures 3 and 4 above. )

5.2 After ensuring that the settings are all correct, push ENT

button while the indicator is on Exit area. The settings are

now saved.

6. Finishing settings

6.1 After a few seconds, the Internal Setup screen disappears,

and then the Service Mode screen is displayed again for

three seconds as shown on the right.

You should check the settings.

Backend version

S 11225 A 0

Brand (S : SANYO , F : FISHER)

Version ( 2 0 0 1 . 12 . 25)

Sub Version (A,B,......Z)

Region ( 0 : Region undefined

1 ~ 6 : Region defined )

Loader version 55 50 05

6.2 Power OFF.

- 9 -

SERVICE MODE

D. IMPORTANT NOTE

1. Once the "Market/Region" settings are written into EEPROM (IC801) on the DVD substrate, they cannot be reset.

(However, updating the system using CD-R enables you to make new settings.)

2. While the Internal Setup screen is displayed, pushing the Power button enables you to terminate the operations without

making any settings.

HOW TO LOAD SOFTWARE FOR MAIN P.W.BOARD

1. Power on, then open tray.

2. It take on CD-ROM for UPDATE software to the tray, and tray close.

3. Display " UP DATE" in the FL display.

4. For the time being, tray open and FL display remain "UP DATE".

5. When software loading finished, "UP DATE"on the FL display disappears.

6. Next, set up market code and region code by "SERVICE MODE"

CD-ROM part code is "0PRADD7118--A".

CAUTION : After an MAIN P.W. board assy(614 326 4323) or IC assy (410 464 8601) exchange should carry out loarding of

the software by the newest CD-R,and should check operation.

- 10 -

EXPLODED VIEW (CABINET & CHASSIS)

Y03

Y03

5

Y03

2

Y02

3

1

4

Y01

Y01

73

Y06

Y04

Y06

Y06

Y04

Y02

Y03

71

Y03

6

Y05

7

Y08

Y07

Y07

53

52

51

8

54

72

55(XE)

55(UK)

Y09

9

56

Y08

- 11 -

Loading...

Loading...