Page 1

DS19390

Model:

COLOR TELEVISION

AS

FILE NO.

G6VTM, PRODUCT CODE 111340680

REFERENCE No. SS510026-10

Notice

CORRECTION

SERVICE FLASH

PRODUCTION CHANGE

ADD INFORMATION

Please add this notice to the Service Manual listed below.

REVISION 10

Category:

U.S.A. / CANADA

Destination:

APRIL / 17 / 2001

Date:

19390-10

Effective from: Chassis No.

SS510026-08

REF: No.

NOTE: Match the Chassis No. on the unit’s back cover with the Chassis No. in the Service Manual.

If the Service Manual Chassis No. does not match the unit’s, additional Service Literature is

required. This chassis is similar to Chassis No. 19390-08. Only the Difference Service

Information is given in this manual. For detailed Service Information, refer to the Original Service

Manual and Notices for Chassis No. 19390-08 used in Model DS19390 (SS510026-08).

INITIAL BUS DATA SETUP

Note: When IC802 (EEPROM) is replaced, the Service Menu No. 003 HP (H Phase), No. 007 VLN (V Linearity), No. 010 VSC (V S-

Correction), No. 021 SBI (Sub-Bias), No. 023 POS (Pre/Over-Shoot), No. 028 PRE (Pre-Shoot Width), No. 037 AF (AutoFlesh),

No. 041 RYA (R-Y/B-Y Angle) and No. 055 STI (Sub-Tint) should be set up for proper TV operation before attempting the

service adjustments.

1. Disconnect the AC power cord (AC 120V line).

2. While pressing the MENU key, reconnect the AC power cord. The Service Menu display will now appear.

2a. Select No. 003 HP (H Phase) with ▲ or ▼ key. Adjust the data with + or – key for 9.

3. Select No. 007 VLN (V Linearity) with ▲ or ▼ key. Adjust the data with + or – key for 16.

4. Select No. 010 VSC (V S-Correction) with ▲ or ▼ key. Adjust the data with + or – key for 10.

5. Select No. 021 SBI (Sub-Bias) with ▲ or ▼ key. Adjust the data with + or – key for 60.

6. Select No. 023 POS (Pre/Over-Shoot) with ▲ or ▼ key. Adjust the data with + or – key for 1.

7. Select No. 028 PRE (Pre-Shoot Width) with ▲ or ▼ key. Adjust the data with + or – key for 3.

8. Select No. 037 AF (AutoFlesh) with ▲ or ▼ key. Adjust the data with + or – key for 1.

9. Select No. 041 RYA(R-Y/B-Y Angle) with ▲ or ▼ key. Adjust the data with + or – key for 2.

10. Select No. 055 STI (Sub-Tint) with ▲ or ▼ key. Adjust the data with + or – key for 20.

11. Press the MENU key to turn off the Service Menu display.

1. IN THE SERVICE ADJUSTMENTS LIST

PAGE 3

Page 2

1. IN THE SERVICE ADJUSTMENTS LIST (Continued)

PAGE 4

— 2 —

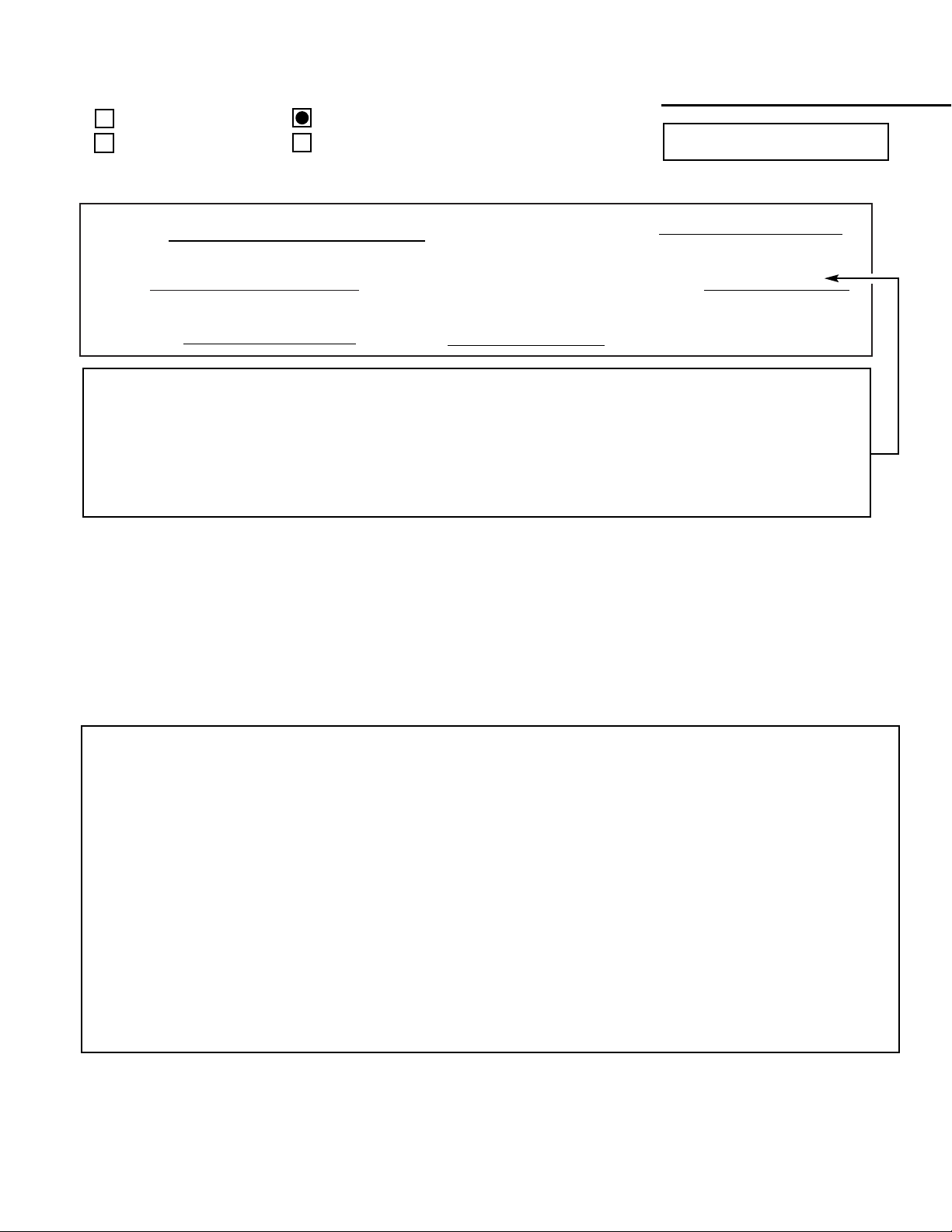

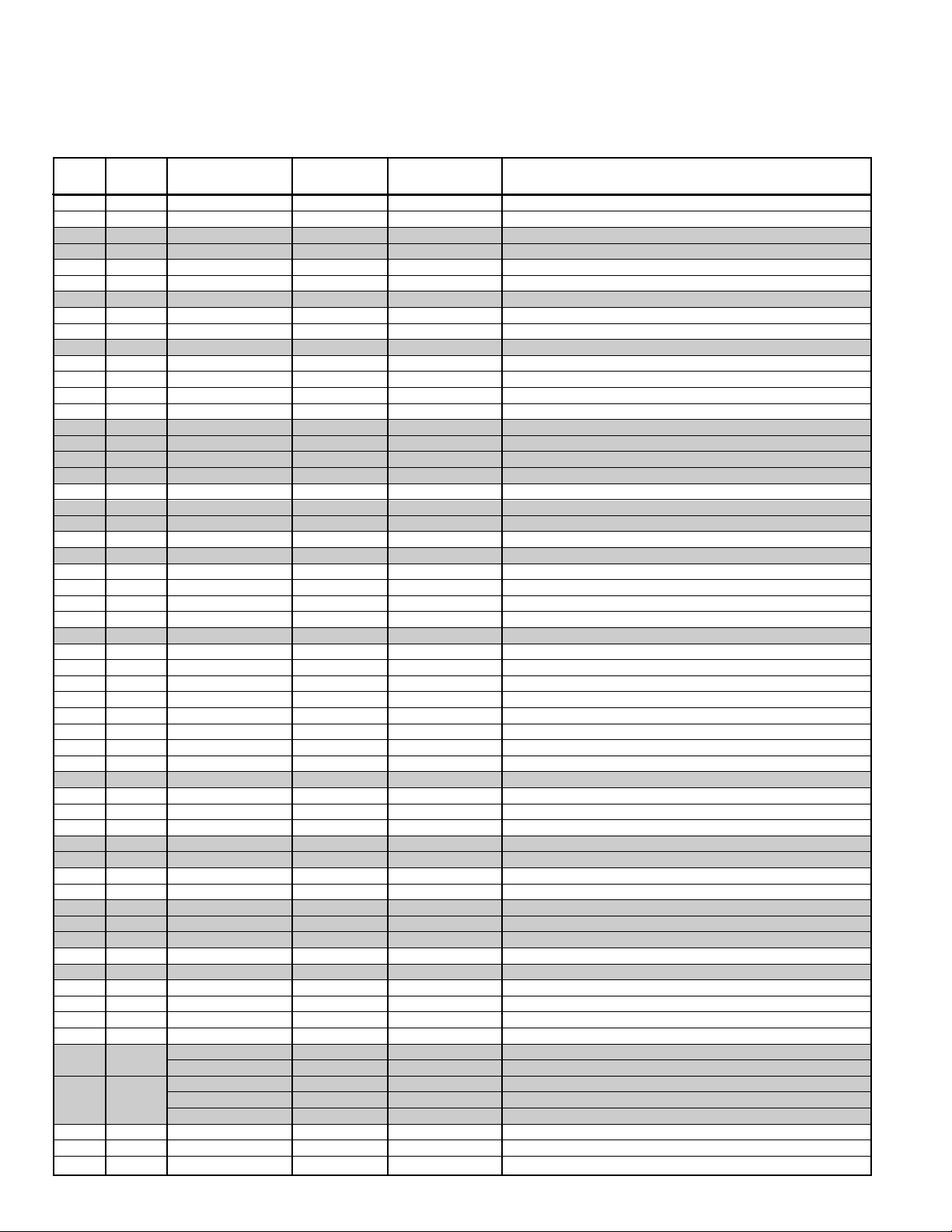

Table 1. ON-SCREEN SERVICE MENU

When IC802 (EEPROM) is replaced, check the bus data to confirm they are the same as below. The shaded menu should be checked

and be set up or readjusted according to the procedures described in the following pages. Initial Setup Data marked with an * should

be changed from Initial Reference Data. (See page 3 for Initial Bus Data Setup.)

No. TITLE

INITIAL REFERENCE INITIAL SETUP

RANGE OF DATA FUNCTION

DATA DATA

001 HFR 30 30 0~63 Align Horizontal Frequency

002 AFC 0 0 0, 1 Select Horizontal First Loop Gain & H-Sync Gating On/Off

003 HP 13 9* 0~31 Align Sync to Flyback Phase (Horizontal Phase)

004 VS 50 50 0~127 Align Vertical Amplitude (Vertical Size)

005 VPO 5 5 0~63 Align Vertical DC Bias (Vertical Position)

006 VSP 0 0 0, 1 Select Vertical Sync Separation Sensitivity

007 VLN 19 16* 0~31 Align Vertical Linearity

008 CRS 0 0 0~3 Service Test Mode (Normal/Black/White/Cross)

009 GRY 1 1 0, 1 OSD Gray Tone Enable

010 VSC 8 10* 0~31 Align Vertical S-Correction

011 HBR 3 3 0~7 H-Blanking Control for Right Side Edge on Screen

012 HBL 4 4 0~7 H-Blanking Control for Left Side Edge on Screen

013 CDM 0 0 0, 1 Select Count Down Mode

014 VC 7 7 0~7 Align Vertical Size Compensation

015 RB 0 0 0~255 Align Red OUT DC Level (Red Bias)

016 GB 0 0 0~255 Align Green OUT DC Level (Green Bias)

017 BB 0 0 0~255 Align Blue OUT DC Level (Blue Bias)

018 RD 64 64 0~127 Align Red OUT AC Level (Red Drive)

019 GD 8 8 0~15 Align Green OUT AC Level (Green Drive)

020 BD 64 64 0~127 Align Blue OUT AC Level (Blue Drive)

021 SBI 64 60* 0~127 Align Common RGB DC Level (Sub-Bias)

022 OSD 2 2 0~3 Align OSD AC Level

023 POS 0 1* 0, 1 Select Control for Pre/Over-Shoot Adjustment

024 FLS 1 1 0~7 Select Y/C Filter Mode

025 CKO 3 3 0~7 Select Color Killer Operational Point

026 GYA 0 0 0, 1 Select G-Y Angle

027 CRG 2 2 0~3 Select Coring Gain (w/Defeat)

028 PRE 1 3* 0~3 Select Pre-Shoot Width

029 WP 1 1 0~3 Select White Peak Limitter Operating Point

030 FSW 0 0 0, 1 Enable RGB Blanking or FBP

031 VBL 0 0 0, 1 Select Vertical Blanking Period

032 BSG 1 1 0~3 Select Black Stretch Gain

033 BSS 1 1 0~3 Select Black Stretch Start Point (w/Defeat)

034 DCR 1 1 0~3 Select Luma DC Restoration

035 YGM 1 1 0~3 Select Y Gamma Start Point

036 CBP 0 0 0, 1 Select Chroma BPF Bypass

037 AF 0 1* 0, 1 Enable AutoFlesh Function

038 BAT 4 4 0~7 Align Brightness ABL Threshold

039 MSD 0 0 0, 1 Disable Brightness Mid Stop

040 ABL 0 0 0, 1 Disable Brightness ABL

041 RYA 4 2* 0~15 R-Y/B-Y Angle

042 RAD 15 15 0~63 Align RF AGC Threshold (RF-AGC Delay)

043 IAS 0 0 0, 1 Disable IF and RF AGC (IF AGC Switch)

044 FMM 0 0 0, 1 Disable FM Outputs (FM Mute)

045 FL 15 15 0~31 Align WBA Output Level (FM Level)

046 VL 4 4 0~7 Align IF Video Level

053 SB 32 32 0~63 Align Sub-Brightness

054 SCO 10 10 0~31 Align Sub-Color

055 STI 22 20* 0~31 Align Sub-Tint

056 SSH 18 18 0~15 Align Sub-Sharpness

057 OPT 0 0 0~255 Option (Program Codes) (See Note 1 page 5.)

059 HR 13 13 0~31 Align OSD H-Position

062 SBO 5 5 0~255 Sub-Bright Offset

072 DRV

0~127 Red Drive Adjustment (See Note 2 page 5.)

0~127 Blue Drive Adjustment (See Note 2 page 5.)

– 0 0 0~255 Red Bias Adjustment (See Note 3 page 5.)

073 – 0 0 0~255 Green Bias Adjustment (See Note 3 page 5.)

– 0 0 0~255 Blue Bias Adjustment (See Note 3 page 5.)

074 R00 0 0 0~255 N/A

↓↓ ↓ ↓ ↓ ↓

146 R48 0 0 0~255 N/A

Page 3

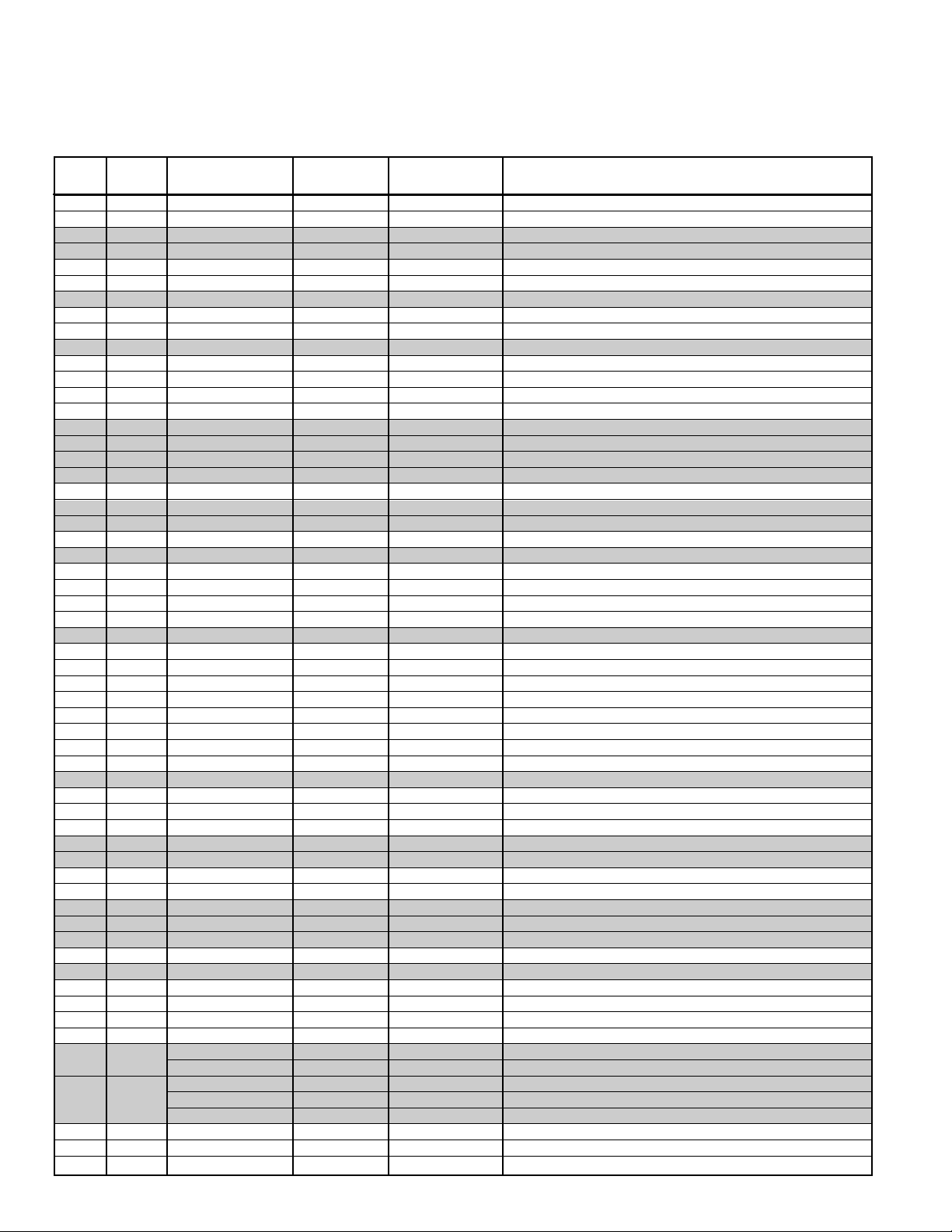

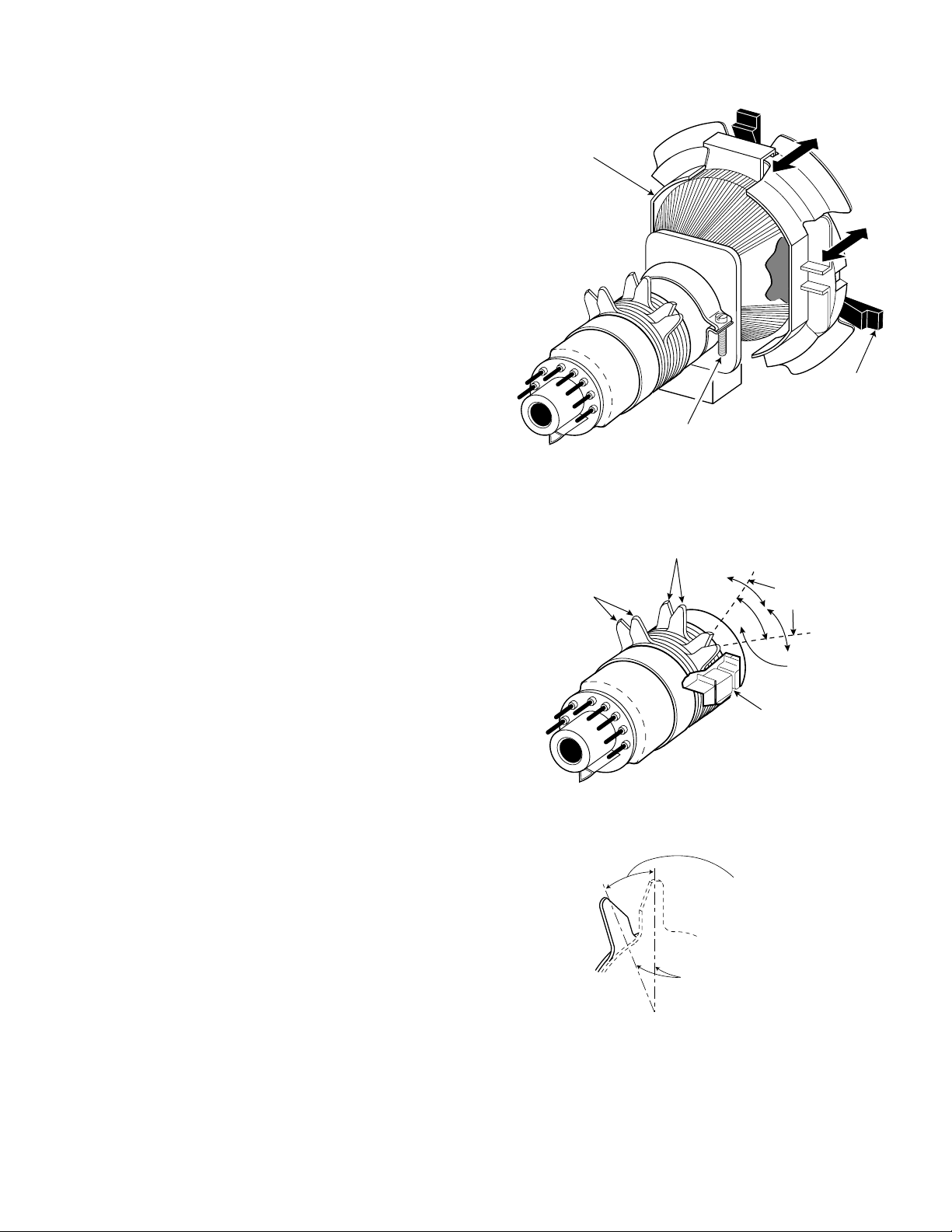

Figure 1. Deflection Yoke Movement

Figure 2. Purity and Convergence Magnets

Figure 3. Adjusting Magnet

2. IN THE PURITY AND CONVERGENCE ADJUSTMENTS LIST

PAGE 8

— 3 —

PURITY ADJUSTMENT

1. When replacing picture tube or deflection yoke, mount

deflection yoke and purity-convergence magnets assembly

properly. See Figure 1. Position the picture tube facing east

or west. Demagnetize the picture tube and receiver using

an external degaussing coil. Set receiver to Service Menu

No. 073 (no vertical sweep) while degaussing.

2. Place the yoke on tube neck fully against glass.

2a.Place the CPM on the tube neck aligning the center of

the purity magnet tabs (2 pole) over center of Focus

Gap (G3 & G4). See Figure 2.

3. Connect a color bar generator to the antenna terminal.

Switch the generator to a white field. Move yoke backward

on the neck until a uniform white field is obtained.

4. Allow 30 minutes warm up on a blank white field (high intensity grayscale).

Note: If white field cannot be obtained, check Grayscale

Adjustments on page 6.

5. Set the picture controls to the Auto levels. Select a green

raster, either with the signal generator or by adjusting the

bias controls. If a signal generator is used for this step, Skip

to Step 10. If the bias controls will be used, go to step 6.

6. Adjust Service Menu No. 015 RB (R-Bias), No. 016 GB (GBias), and No. 017 BB (B-Bias) data to 0 each.

7. Select Service Menu No. 073 (no vertical sweep).

8. Adjust the screen control counterclockwise until the

horizontal scan lines is no longer visible.

9. Select Service Menu No. 016 GB (G-Bias) and raise the

data to produce green raster. If retrace lines appear,

reduce screen control slightly.

10.Pull yoke back on the tube neck to obtain three-color raster

(blue, green and red).

11. Adjust the angle between the two purity magnet tabs to

center the vertical green belt in the picture tube. Do not

rotate tabs. See Figure 3.

12.Slowly slide the deflection yoke forward until a uniform

green screen is obtained.

13.Check the purity of the red and blue screens for uniformity.

Turn off other colors to check (use bias controls) or use

generator. If necessary, readjust the yoke position until all

screens are pure.

14.If bias controls and screen control were used to set purity,

reset Grayscale and Brightness Level. Refer to Grayscale

Adjustment on page 6 and Brightness Level Adjustment on

page 7.

15.Confirm that the yoke is not tilted. Tighten the yoke

mounting screw. Adjust convergence next.

DEFLECTION YOKE

SIX-POLE

MAGNET TABS

DEFLECTION YOKE

MOUNTING SCREW

PURITY

MAGNET

TABS

FOUR-POLE

MAGNET TABS

4

3

1

2

ANGLE OF MAGNET TABS

ANGLE

OF TABS

FOCUS GAP

(G3-G4)

RUBBER

WEDGE

MAGNET TABS

Page 4

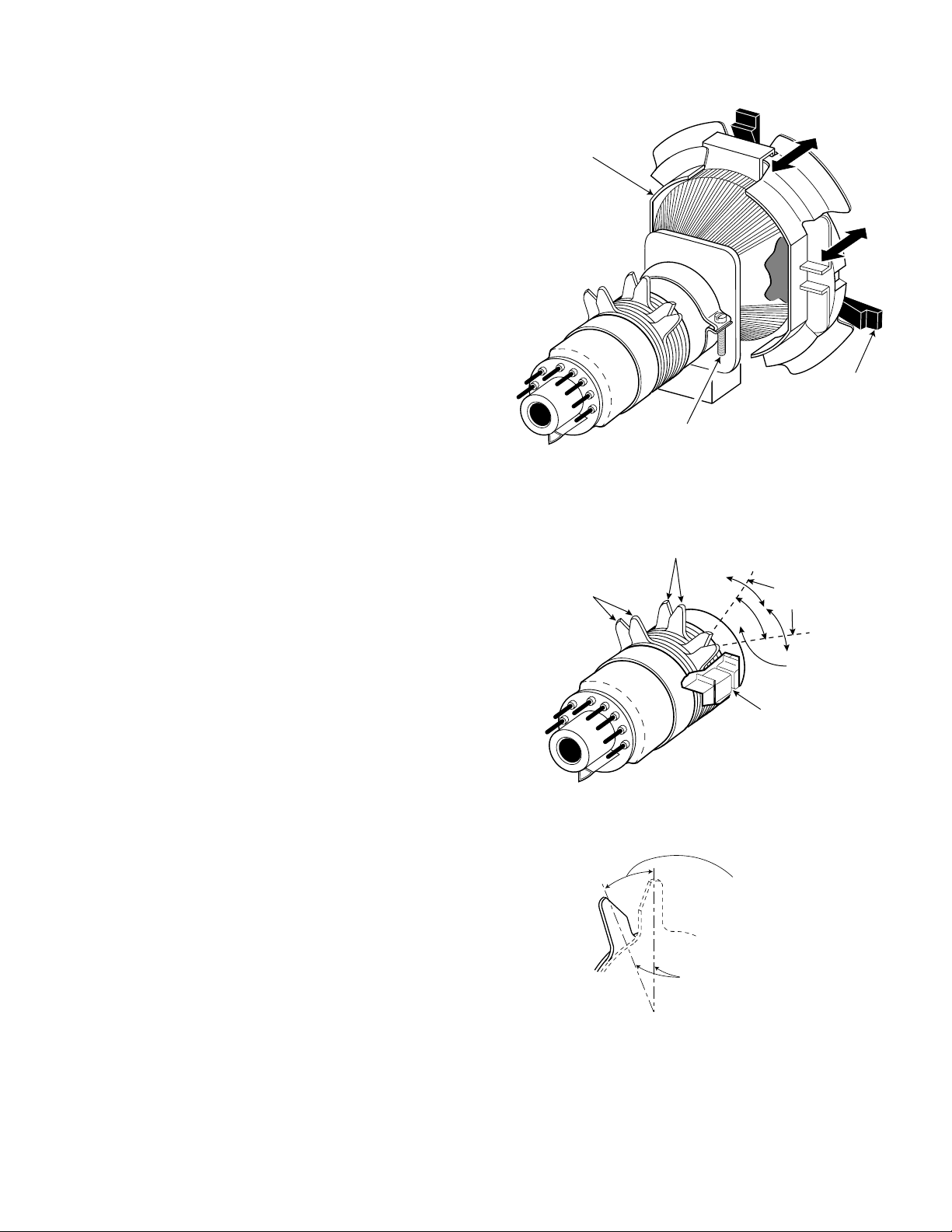

Page &

Section

Schematic

Location

Part No. Description Q’ty

Interchange-

ability

Old

403 353 4303 MT-POLYPRO 7100P H 1.5K

1NO

404 077 4303 MT-POLYPRO 7100P H 1.5K

★

C411 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

403 343 7901 MT-POLYPRO 7200P H 1.5K

1NO

404 077 4402 MT-POLYPRO 7200P H 1.5K

Old 645 044 9123 COIL, DEGAUSSING 1 NO

★

L901 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 645 044 9130 COIL, DEGAUSSING 1 NO

Old

610 238 2846 DEFLECTION YOKE

1NO

610 238 2853 DEFLECTION YOKE

★

L902 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

645 028 5943 YOKE, DEFLECTION

New 645 029 0893 YOKE, DEFLECTION 1 NO

645 042 7718 YOKE, DEFLECTION

Old 401 064 5701 OXIDE-MT 1.8 JA 2W 1 NO

★

R497 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 068 1600 OXIDE-MT 4.7 JA 2W 1 NO

Old 401 027 5007 CARBON 68 JA 1/6W 1 NO

R506 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 024 6700 CARBON 100 JA 1/6W 1 NO

402 055 3201 WIRE WOUND 1 KA WA 6W

Old 402 055 3300 WIRE WOUND 1 KA ZA 6W 1 NO

402 072 2706 WIRE WOUND 1 KA 5W

★

R601 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

402 057 8006 WIRE WOUND 3.3 KA ZA 6W

New 402 058 4403 WIRE WOUND 3.3 KA WA 6W 1 NO

402 075 4707 WIRE WOUND 3.3 KA 5W

Old

402 057 1304

WIRE WOUND 120 JA 15W

1NO

402 083 5208

WIRE WOUND 120 JA 15W

★R608

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

402 056 5204

WIRE WOUND 140 JA 15W

1NO

402 083 5307

WIRE WOUND 140 JA 15W

R714,

Old 401 255 9006 MT-GLAZE 82 JA1/10W 2 NO

R724

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New NOT USED NO

R718,

Old NOT USED NO

R728

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 255 9006 MT-GLAZE 82 JA1/10W 2 NO

Old 610 289 2741 ASSY, PWB, MAIN 1 NO

A100 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 291 1671 ASSY, PWB, MAIN 1 NO

Old 610 289 2758 ASSY, PWB, SOCKET 1 NO

A700 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 291 1688 ASSY, PWB, SOCKET 1 NO

Old 645 025 6103 SOCKET, CRT 8P 1 NO

★

K701 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New NOT USED NO

Old NOT USED NO

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

★K701A 645 026 1992 SOCKET, CRT 8P

New 645 036 4143 SOCKET, CRT 8P 1 NO

645 036 4150 SOCKET, CRT 8P

413 007 6201 CRT A48AAB37X

Old 413 007 7901 CRT A48AAB37X 1 NO

★Q901

414 009 2703 CRT A48AGD12X

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 414 009 8101 CRT A48JLL40X 1 NO

414 010 3003 CRT A48JLL40X(P)

Old NOT USED NO

Q901C - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 217 7787 CG PURITY MAGNET 1 NO

Page 13,

Chassis

Electrical

Parts List

3. IN THE CHASSIS ELECTRICAL PARTS LIST

The reason for change.

A : Misprint B : Quality Reliability C : Standardization D : Design

E : Add as a possible sub F : Schematic location change G : Purchasing Request

Reason

Page 16,

Chassis

Electrical

Parts List

Page 17,

Chassis

Electrical

Parts List

Page 14,

Chassis

Electrical

Parts List

Printed in U.S.A.

April / 2001 / 2200 SMC

For parts or service contact

SANYO Fisher Service Corporation

21605 Plummer Street,

Chatsworth, CA 91311 (U.S.A.)

300 Applewood Crescent,

Concord, Ontario L4K 5C7 (CANADA)

Page 5

DS19390

Model:

COLOR TELEVISION

AS

FILE NO.

G6VSM, PRODUCT CODE 111340680

REFERENCE No. SS510026-09

Notice

CORRECTION

SERVICE FLASH

PRODUCTION CHANGE

ADD INFORMATION

Please add this notice to the Service Manual listed below.

REVISION 9

Category:

U.S.A. / CANADA

Destination:

APRIL / 17 / 2001

Date:

19390-09

Effective from: Chassis No.

SS510026-08

REF: No.

NOTE: Match the Chassis No. on the unit’s back cover with the Chassis No. in the Service Manual.

If the Service Manual Chassis No. does not match the unit’s, additional Service Literature is

required. This chassis is similar to Chassis No. 19390-08. Only the Difference Service

Information is given in this manual. For detailed Service Information, refer to the Original Service

Manual and Notices for Chassis No. 19390-08 used in Model DS19390 (SS510026-08).

INITIAL BUS DATA SETUP

Note: When IC802 (EEPROM) is replaced, the Service Menu No. 003 HP (H Phase), No. 007 VLN (V Linearity), No. 010 VSC (V S-

Correction), No. 021 SBI (Sub-Bias), No. 023 POS (Pre/Over-Shoot), No. 028 PRE (Pre-Shoot Width), No. 037 AF (AutoFlesh),

No. 041 RYA (R-Y/B-Y Angle) and No. 055 STI (Sub-Tint) should be set up for proper TV operation before attempting the

service adjustments.

1. Disconnect the AC power cord (AC 120V line).

2. While pressing the MENU key, reconnect the AC power cord. The Service Menu display will now appear.

2a. Select No. 003 HP (H Phase) with ▲ or ▼ key. Adjust the data with + or – key for 9.

3. Select No. 007 VLN (V Linearity) with ▲ or ▼ key. Adjust the data with + or – key for 16.

4. Select No. 010 VSC (V S-Correction) with ▲ or ▼ key. Adjust the data with + or – key for 10.

5. Select No. 021 SBI (Sub-Bias) with ▲ or ▼ key. Adjust the data with + or – key for 60.

6. Select No. 023 POS (Pre/Over-Shoot) with ▲ or ▼ key. Adjust the data with + or – key for 1.

7. Select No. 028 PRE (Pre-Shoot Width) with ▲ or ▼ key. Adjust the data with + or – key for 3.

8. Select No. 037 AF (AutoFlesh) with ▲ or ▼ key. Adjust the data with + or – key for 1.

9. Select No. 041 RYA(R-Y/B-Y Angle) with ▲ or ▼ key. Adjust the data with + or – key for 2.

10. Select No. 055 STI (Sub-Tint) with ▲ or ▼ key. Adjust the data with + or – key for 20.

11. Press the MENU key to turn off the Service Menu display.

1. IN THE SERVICE ADJUSTMENTS LIST

PAGE 3

Page 6

1. IN THE SERVICE ADJUSTMENTS LIST (Continued)

PAGE 4

— 2 —

Table 1. ON-SCREEN SERVICE MENU

When IC802 (EEPROM) is replaced, check the bus data to confirm they are the same as below. The shaded menu should be checked

and be set up or readjusted according to the procedures described in the following pages. Initial Setup Data marked with an * should

be changed from Initial Reference Data. (See page 3 for Initial Bus Data Setup.)

No. TITLE

INITIAL REFERENCE INITIAL SETUP

RANGE OF DATA FUNCTION

DATA DATA

001 HFR 30 30 0~63 Align Horizontal Frequency

002 AFC 0 0 0, 1 Select Horizontal First Loop Gain & H-Sync Gating On/Off

003 HP 13 9* 0~31 Align Sync to Flyback Phase (Horizontal Phase)

004 VS 50 50 0~127 Align Vertical Amplitude (Vertical Size)

005 VPO 5 5 0~63 Align Vertical DC Bias (Vertical Position)

006 VSP 0 0 0, 1 Select Vertical Sync Separation Sensitivity

007 VLN 19 16* 0~31 Align Vertical Linearity

008 CRS 0 0 0~3 Service Test Mode (Normal/Black/White/Cross)

009 GRY 1 1 0, 1 OSD Gray Tone Enable

010 VSC 8 10* 0~31 Align Vertical S-Correction

011 HBR 3 3 0~7 H-Blanking Control for Right Side Edge on Screen

012 HBL 4 4 0~7 H-Blanking Control for Left Side Edge on Screen

013 CDM 0 0 0, 1 Select Count Down Mode

014 VC 7 7 0~7 Align Vertical Size Compensation

015 RB 0 0 0~255 Align Red OUT DC Level (Red Bias)

016 GB 0 0 0~255 Align Green OUT DC Level (Green Bias)

017 BB 0 0 0~255 Align Blue OUT DC Level (Blue Bias)

018 RD 64 64 0~127 Align Red OUT AC Level (Red Drive)

019 GD 8 8 0~15 Align Green OUT AC Level (Green Drive)

020 BD 64 64 0~127 Align Blue OUT AC Level (Blue Drive)

021 SBI 64 60* 0~127 Align Common RGB DC Level (Sub-Bias)

022 OSD 2 2 0~3 Align OSD AC Level

023 POS 0 1* 0, 1 Select Control for Pre/Over-Shoot Adjustment

024 FLS 1 1 0~7 Select Y/C Filter Mode

025 CKO 3 3 0~7 Select Color Killer Operational Point

026 GYA 0 0 0, 1 Select G-Y Angle

027 CRG 2 2 0~3 Select Coring Gain (w/Defeat)

028 PRE 1 3* 0~3 Select Pre-Shoot Width

029 WP 1 1 0~3 Select White Peak Limitter Operating Point

030 FSW 0 0 0, 1 Enable RGB Blanking or FBP

031 VBL 0 0 0, 1 Select Vertical Blanking Period

032 BSG 1 1 0~3 Select Black Stretch Gain

033 BSS 1 1 0~3 Select Black Stretch Start Point (w/Defeat)

034 DCR 1 1 0~3 Select Luma DC Restoration

035 YGM 1 1 0~3 Select Y Gamma Start Point

036 CBP 0 0 0, 1 Select Chroma BPF Bypass

037 AF 0 1* 0, 1 Enable AutoFlesh Function

038 BAT 4 4 0~7 Align Brightness ABL Threshold

039 MSD 0 0 0, 1 Disable Brightness Mid Stop

040 ABL 0 0 0, 1 Disable Brightness ABL

041 RYA 4 2* 0~15 R-Y/B-Y Angle

042 RAD 15 15 0~63 Align RF AGC Threshold (RF-AGC Delay)

043 IAS 0 0 0, 1 Disable IF and RF AGC (IF AGC Switch)

044 FMM 0 0 0, 1 Disable FM Outputs (FM Mute)

045 FL 15 15 0~31 Align WBA Output Level (FM Level)

046 VL 4 4 0~7 Align IF Video Level

053 SB 32 32 0~63 Align Sub-Brightness

054 SCO 10 10 0~31 Align Sub-Color

055 STI 22 20* 0~31 Align Sub-Tint

056 SSH 18 18 0~15 Align Sub-Sharpness

057 OPT 0 0 0~255 Option (Program Codes) (See Note 1 page 5.)

059 HR 13 13 0~31 Align OSD H-Position

062 SBO 5 5 0~255 Sub-Bright Offset

072 DRV

0~127 Red Drive Adjustment (See Note 2 page 5.)

0~127 Blue Drive Adjustment (See Note 2 page 5.)

– 0 0 0~255 Red Bias Adjustment (See Note 3 page 5.)

073 – 0 0 0~255 Green Bias Adjustment (See Note 3 page 5.)

– 0 0 0~255 Blue Bias Adjustment (See Note 3 page 5.)

074 R00 0 0 0~255 N/A

↓↓ ↓ ↓ ↓ ↓

146 R48 0 0 0~255 N/A

Page 7

Figure 1. Deflection Yoke Movement

Figure 2. Purity and Convergence Magnets

Figure 3. Adjusting Magnet

2. IN THE PURITY AND CONVERGENCE ADJUSTMENTS LIST

PAGE 8

— 3 —

PURITY ADJUSTMENT

1. When replacing picture tube or deflection yoke, mount

deflection yoke and purity-convergence magnets assembly

properly. See Figure 1. Position the picture tube facing east

or west. Demagnetize the picture tube and receiver using

an external degaussing coil. Set receiver to Service Menu

No. 073 (no vertical sweep) while degaussing.

2. Place the yoke on tube neck fully against glass.

2a.Place the CPM on the tube neck aligning the center of

the purity magnet tabs (2 pole) over center of Focus

Gap (G3 & G4). See Figure 2.

3. Connect a color bar generator to the antenna terminal.

Switch the generator to a white field. Move yoke backward

on the neck until a uniform white field is obtained.

4. Allow 30 minutes warm up on a blank white field (high intensity grayscale).

Note: If white field cannot be obtained, check Grayscale

Adjustments on page 6.

5. Set the picture controls to the Auto levels. Select a green

raster, either with the signal generator or by adjusting the

bias controls. If a signal generator is used for this step, Skip

to Step 10. If the bias controls will be used, go to step 6.

6. Adjust Service Menu No. 015 RB (R-Bias), No. 016 GB (GBias), and No. 017 BB (B-Bias) data to 0 each.

7. Select Service Menu No. 073 (no vertical sweep).

8. Adjust the screen control counterclockwise until the

horizontal scan lines is no longer visible.

9. Select Service Menu No. 016 GB (G-Bias) and raise the

data to produce green raster. If retrace lines appear,

reduce screen control slightly.

10.Pull yoke back on the tube neck to obtain three-color raster

(blue, green and red).

11. Adjust the angle between the two purity magnet tabs to

center the vertical green belt in the picture tube. Do not

rotate tabs. See Figure 3.

12.Slowly slide the deflection yoke forward until a uniform

green screen is obtained.

13.Check the purity of the red and blue screens for uniformity.

Turn off other colors to check (use bias controls) or use

generator. If necessary, readjust the yoke position until all

screens are pure.

14.If bias controls and screen control were used to set purity,

reset Grayscale and Brightness Level. Refer to Grayscale

Adjustment on page 6 and Brightness Level Adjustment on

page 7.

15.Confirm that the yoke is not tilted. Tighten the yoke

mounting screw. Adjust convergence next.

DEFLECTION YOKE

SIX-POLE

MAGNET TABS

DEFLECTION YOKE

MOUNTING SCREW

PURITY

MAGNET

TABS

FOUR-POLE

MAGNET TABS

4

3

1

2

ANGLE OF MAGNET TABS

ANGLE

OF TABS

FOCUS GAP

(G3-G4)

RUBBER

WEDGE

MAGNET TABS

Page 8

Printed in U.S.A.

Page &

Section

Schematic

Location

Part No.

Description

Q’ty

Interchange-

ability

Old

403 353 4303 MT-POLYPRO 7100P H 1.5K

1NO

404 077 4303 MT-POLYPRO 7100P H 1.5K

★

C411 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

403 343 8304 MT-POLYPRO 8000P H 1.5K

1NO

404 077 4709 MT-POLYPRO 8000P H 1.5K

Old

403 346 7304 MT-POLYPRO 0.36U J 250V

1NO

404 081 2906 MT-POLYPRO 0.36U M 200V

★C417

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

403 346 7007 MT-POLYPRO 0.24U J 250V

1NO

404 081 2500 MT-POLYPRO 0.24U M 200V

Old

610 238 2846 DEFLECTION YOKE

1NO

610 238 2853 DEFLECTION YOKE

★

L902 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 645 026 3927 YOKE, DEFLECTION 1 NO

Old 401 064 9907 OXIDE-MT 10K JA 2W 1 NO

★

R407 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 069 8202 OXIDE-MT 8.2K JA 2W 1 NO

Old 401 064 5701 OXIDE-MT 1.8 JA 2W 1 NO

★

R497 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 066 3002 OXIDE-MT 2.2 JA 2W 1 NO

402 055 3201 WIRE WOUND 1 KA WA 6W

Old 402 055 3300 WIRE WOUND 1 KA ZA 6W 1 NO

402 072 2706 WIRE WOUND 1 KA 5W

★

R601 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

402 057 8006 WIRE WOUND 3.3 KA ZA 6W

New 402 058 4403 WIRE WOUND 3.3 KA WA 6W 1 NO

402 075 4707 WIRE WOUND 3.3 KA 5W

Old

402 057 1304

WIRE WOUND 120 JA 15W

1NO

402 083 5208

WIRE WOUND 120 JA 15W

★R608

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

402 056 5204

WIRE WOUND 140 JA 15W

1NO

402 083 5307

WIRE WOUND 140 JA 15W

Old 610 289 2741 ASSY, PWB, MAIN 1 NO

A100 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 291 4948 ASSY, PWB, MAIN NO

Old 610 289 2758 ASSY, PWB, SOCKET 1 YES

A700 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

610 289 2758 ASSY, PWB, SOCKET

1 YES

610 291 4955

ASSY, PWB, SOCKET

413 007 6201 CRT A48AAB37X

Old 413 007 7901 CRT A48AAB37X 1 NO

414 009 2703 CRT A48AGD12X

★

Q901 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 414 009 3205 CRT A48KRD82X(DT) 1 NO

Old NOT USED NO

Q901C - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 217 7794 CG PURITY MAGNET 1 NO

Page 13,

Chassis

Electrical

Parts List

3. IN THE CHASSIS ELECTRICAL PARTS LIST

The reason for change.

A : Misprint B : Quality Reliability C : Standardization

D : Design E : Add as a possible sub F : Schematic location change

G : Purchasing Request

Reason

Page 15,

Chassis

Electrical

Parts List

Page 17,

Chassis

Electrical

Parts List

Page 14,

Chassis

Electrical

Parts List

April / 2001 / 2200 SMC

For parts or service contact

SANYO Fisher Service Corporation

21605 Plummer Street,

Chatsworth, CA 91311 (U.S.A.)

300 Applewood Crescent,

Concord, Ontario L4K 5C7 (CANADA)

Page 16,

Chassis

Electrical

Parts List

Page 9

AS

FILE NO.

SERVICE MANUAL

(SUPPLEMENT)

Remote Control Color

Television

DS19390 (U.S.A.)

(CANADA)

VERSION ADVANCE

Chassis No. 19390-08

NOTE: Match the Chassis No. on

the unit’s back cover with

the Chassis No. in the

Service Manual.

If the Original Version

Service Manual Chassis

No. does not match the

unit’s, additional Service

Literature is required. You

must refer to “Notices” to

the Original Service Manual

prior to servicing the unit.

G6VRM, PRODUCT CODE 111340680

REFERENCE No. SS510026-08

THIS CHASSIS IS SIMILAR TO MODEL AVM-1909S, CHASSIS NUMBER

G6V-1901S0. SERVICE INFORMATION GIVEN IN THIS MANUAL IS ONLY

THE DIFFERENCE INFORMATION FROM MODEL AVM-1901S, CHASSIS

NUMBER G6V-1901S0.

FOR ADDITIONAL SERVICE INFORMATION, REFER TO THE SERVICE

MANUAL FOR CHASSIS NUMBER G6V-1901S0 USED IN MODEL

AVM-1901S (SM5110190).

A

S

Page 10

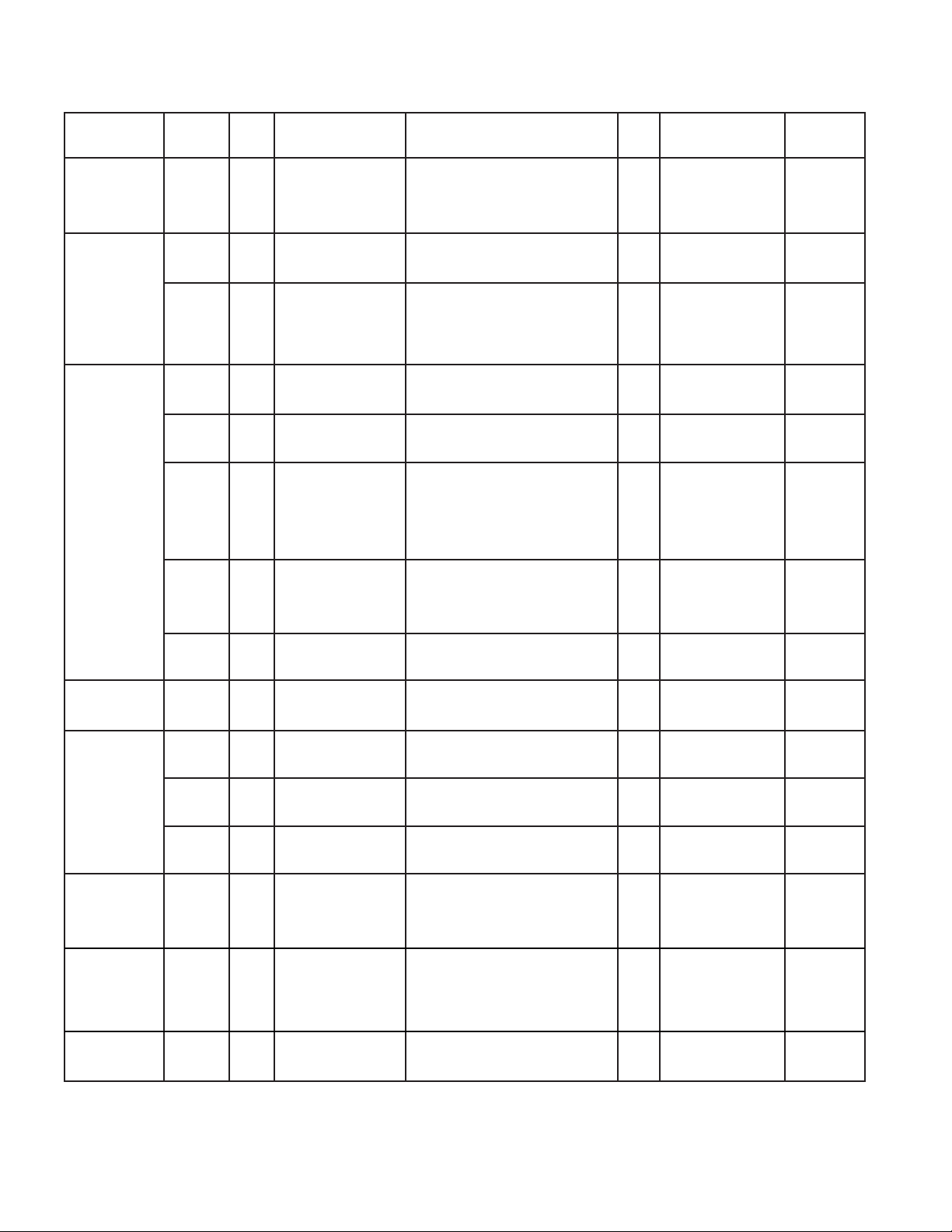

1 610 292 4701 CABINET FRONT 610 291 2166 CABINET FRONT

610 289 2888 OWNER’S MANUAL 610 292 9164 OWNER’S MANUAL

DIFFERENCES

MODEL DS19390 (Chassis No. 19390-08) SAME AS MODEL AVM-1901S

(Chassis No. G6V-1901S0) EXCEPT

:

1. IN THE CABINET / ACCESSORY PARTS LIST (PAGE 18)

MODEL AVM-1901S (Chassis No. G6V-1901S0)

MODEL DS19390 (Chassis No. 19390-08)

Part No. Description

KEY NO.

Part No. Description

A

S

7, 8

7, 8

7

6

7

2

1

3

5

4

Printed in U.S.A.

April / 2001 / 2200 SMC

For parts or service contact

SANYO Fisher Service Corporation

21605 Plummer Street,

Chatsworth, CA 91311 (U.S.A.)

300 Applewood Crescent,

Concord, Ontario L4K 5C7 (CANADA)

Page 11

DS19390

Model:

COLOR TELEVISION

AS

FILE NO.

G6VKM, PRODUCT CODE 111340680

REFERENCE No. SS510026-07

Notice

CORRECTION

SERVICE FLASH

PRODUCTION CHANGE

ADD INFORMATION

Please add this notice to the Service Manual listed below.

REVISION 7

Category:

U.S.A.

Destination:

JUNE / 5 / 2000

Date:

19390-07

Effective from: Chassis No.

SS510026-05

REF: No.

NOTE: Match the Chassis No. on the unit’s back cover with the Chassis No. in the Ser vice Manual.

If the Service Manual Chassis No. does not match the unit’s, additional Service Literature is

required. This chassis is similar to Chassis No. 19390-05. Only the Difference Service

Information is given in this manual.For detailed Service Information, ref er to the Original Service

Manual and Notices for Chassis No.19390-05 used in Model DS19390 (SS510026-05).

INITIAL BUS DATA SETUP

Note: When IC802 (EEPROM) is replaced, the Ser vice Menu No. 001 HP (H Phase), No. 013 TDS (Trap & D SW), No. 024 AG

(AFC Gain), No.026 SCO (Sub-Color), No.027 STI (Sub-Tint), and No. 031 HR (OSD Display H-Position) should be set up for

proper TV operation before attempting the service adjustments.

1. Disconnect the AC power cord (AC 120V line).

2. While pressing the MENU key, reconnect the AC power cord.The Service Menu display will now appear.

3. Select No. 001 HP (H Phase) with ▲ or ▼ key. Adjust the data with + or – key for 14.

4. Select No. 013 TDS (Trap & D SW) with ▲ or ▼ key. Adjust the data with + or – key for 1.

5. Select No. 024 AG (AFC Gain), with ▲ or ▼ key. Adjust the data with + or – key for 0.

6. Select No. 026 SCO (Sub Color) with ▲ or ▼ key. Adjust the data with + or – key for 7.

7. Select No. 027 STI (Sub Tint) with ▲ or ▼ key. Adjust the data with + or – key for 20.

8. Select No. 031 HR (OSD Display H-Position) with ▲ or ▼ key. Adjust the data with + or – key for 28.

9. Press the MENU key to turn off the Service Menu display.

1. IN THE SERVICE ADJUSTMENTS LIST

PAGE 3

Page 12

1. IN THE SERVICE ADJUSTMENTS LIST (Continued)

PAGE 4

Table 1. ON-SCREEN SERVICE MENU

When IC802 (EEPROM) is replaced, check the bus data to confirm they are the same as belo w.The shaded menu should be checked

and be set up or readjusted according to the procedures described in the following pages.Initial Setup Data marked with an * should

be changed from Initial Reference Data. (See page 3 for Initial Bus Data Setup.)

No. TITLE

INITIAL REFERENCE INITIAL SETUP

RANGE OF DAT A FUNCTION

DATA DATA

001 HP 15 14* 0~31 Horizontal Phase (Horizontal Centering)

002 IAS 0 0 0, 1 IF AGC Switch 0: TV (Normal) 1: AV (IF Gain Minimum)

003 RAD 25 25 0~63 RF AGC Delay

004 PT 64 64 0~127 PLL Tuning

005 ADA 31 31 0~63 APC Detect Adjust

006 CD 0 0 0, 1 C-Diff

007 VS 32 32 0~63 Vertical Size

008 RB 0 0 0~255 Red Bias

009 GB 0 0 0~255 Green Bias

010 BB 0 0 0~255 Blue Bias

011 RD 60 60 0~127 Red Drive

012 BD 60 60 0~127 Blue Drive

013 TDS 0 1* 0, 1 Trap & D (B.P.F.) Switch 0: OFF 1: ON

014 AF 0 0 0, 1 Auto Flesh 0: OFF 1: ON

015 BS 0 0 0, 1 Black Stretch 1: OFF 0: ON

016 VL 4 4 0~7 Video Level

017 FL 15 15 0~31 FM Level

018 NIS 1 1 0, 1 N/I Switch (Black Noise Inverter) 1: OFF 0: ON

019 ABL 1 1 0,1 ABL Defeat 0: OFF 1: ON

020 WP 1 1 0,1 White Peak Limiter 1: OFF 0: ON

021 GD 7 7 0~15 Green Drive Reduction

022 VC 0 0 0~7 Ver t. Comp

023 VD 32 32 0~63 Vert.DC

024 AG 3 0* 0~3 AFC Gain 00: Auto 01: High Gain 10: Low Gain 11: Non-Gate

025 SB 32 32 0~63 Sub-Brightness

026 SCO 10 7* 0~31 Sub-Color

027 STI 14 20* 0~31 Sub-Tint

028 SSH 8 8 0~15 Sub-Shar pness

029 OPT 0 0 0~255 Option 1 (

See Note 1 page 5.

)

030 OP2 0 0 0~255 Option 2 (

See Note 2 page 5.

)

031 HR 24 28* 0~63 H-Position (OSD H-Position)

032 INP N/A N/A N/A N/A

033 STE N/A N/A N/A N/A

034 FIL N/A N/A N/A N/A

035 LSP N/A N/A N/A N/A

036 HSP N/A N/A N/A N/A

037 SPV N/A N/A N/A N/A

038 PCO N/A N/A N/A N/A

039 PTI N/A N/A N/A N/A

040 SBO 0 0 0~255 Sub Bright Offset

041 DRV

0~127 Red drive Adjustment (

See Note 3 page 5.

)

0~127 Blue Drive Adjustment (

See Note 3 page 5.

)

– 0 0 0~255 Red Bias Adjustment (

See Note 4 page 5.

)

042 – 0 0 0~255 Green Bias Adjustment (

See Note 4 page 5.

)

– 0 0 0~255 Blue Bias Adjustment (

See Note 4 page 5.

)

043 T00 0 0 0~255 N/A

↓↓ ↓ ↓ ↓ ↓

115 T48 0 0 0~255 N/A

1. IN THE SERVICE ADJUSTMENTS LIST (Continued)

PAGE 6

VERTICAL CENTERING ADJUSTMENT

1. Tune receiver to an active channel.

2. Ch eck that picture is in the ver tical center of TV screen. If picture center is too low, connect resistor R513 (470 ohm, 1W). If picture

center is too high, connect resistor R512 (470 ohm, 1W).

— 2 —

Page 13

PURITY ADJUSTMENT

1. When replacing picture tube or deflection yoke, mount

deflection yoke and purity-convergence magnets assembly

properly. See Figure 1. Position the picture tube facing east

or west. Demagnetize the picture tube and receiver using

an external degaussing coil. Set receiver to Service Menu

No.042 (no vertical sweep) while degaussing.

2. Place the yoke on tube neck fully against glass.

2A.Place the CPM on the tube neck aligning the center of

the purity magnet tabs (2 pole) over center of Focus

Gap (G3 & G4). See Figure 2.

3. Connect a color bar generator to the antenna terminal.

Switch the generator to a white field. Move yoke backward

on the neck until a uniform white field is obtained.

4. Allow 30 minutes w arm up on a blank white field (high intensity grayscale).

Note: If white field cannot be obtained, check Grayscale

Adjustments on page 6.

5. Set the picture controls to the Auto levels. Select a green

raster, either with the signal generator or by adjusting the

bias controls. If a signal generator is used for this step, Skip

to Step 10. If the bias controls will be used, go to step 6.

6. Adjust Service Menu No.008 RB (R-Bias), No. 009 GB (GBias), and No.010 BB (B-Bias) data to 0 each.

7. Select Service Menu No.042 (no vertical sweep).

8. Adjust the screen control counterclockwise until the

horizontal scan lines is no longer visible.

9. Select Service Menu No. 009 GB (G-Bias) and raise the

data to produce green raster. If retrace lines appear, reduce

screen control slightly.

10. Pull yoke back on the tube neck to obtain three-color raster

(blue, green and red).

11. Adjust the angle between the two purity magnet tabs to

center the vertical green belt in the picture tube. Do not

rotate tabs. See Figure 3.

12. Slowly slide the deflection yoke forward until a uniform

green screen is obtained.

13. Check the purity of the red and blue screens for uniformity.

Turn off other colors to check (use bias controls) or use

generator. If necessary, readjust the yoke position until all

screens are pure.

14. If bias controls and screen control were used to set purity,

reset Grayscale and Brightness Level. Refer to Grayscale

Adjustment on page 6 and Brightness Level Adjustment on

page 7.

15. Confirm that the yoke is not tilted. Tighten the yoke

mounting screw. Adjust convergence next.

RUBBER

WEDGE

DEFLECTION YOKE

DEFLECTION YOKE

MOUNTING SCREW

Figure 1. Deflection Yoke Movement

SIX-POLE

MAGNET TABS

FOUR-POLE

MAGNET TABS

ANGLE

OF TABS

PURITY

MAGNET

TABS

4

3

2

1

FOCUS GAP

(G3-G4)

Figure 2. Purity and Convergence Magnets

MAGNET TABS

ANGLE OF MAGNET TABS

Figure 3. Adjusting Magnet

2. IN THE PURITY AND CONVERGENCE ADJUSTMENTS LIST

PAGE 10

— 3 —

Page 14

Page &

Section

Schematic

Location

Part No.

Description

Q’ty

Interchange-

ability

Old

403 353 4303 MT-POLYPRO 7100P H 1.5K

1NO

404 077 4303 MT-POLYPRO 7100P H 1.5K

★

C411 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

403 343 7901 MT-POLYPRO 7200P H 1.5K

1NO

404 077 4402 MT-POLYPRO 7200P H 1.5K

645 002 9103

COIL, DEGAUSSING

Old

645 022 8582

COIL, DEGAUSSING 1 NO

645 027 9379 ASSY, COIL, DEGAUSSING

★

L901 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 645 031 6975 COIL, DEGAUSSING 1 NO

645 035 8814 ASSY, COIL, DEGAUSSING

Old

610 238 2846 DEFLECTION YOKE

1NO

610 238 2853 DEFLECTION YOKE

★

L902 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 645 028 5943 YOKE, DEFLECTION 1 NO

645 029 0893 YOKE, DEFLECTION

Old 401 286 5305 MT-FILM 2.4K FA 1/6W 1 NO

★

R421 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 053 0403 MT-FILM 2K FA 1/6W 1 NO

Old 401 064 5701 OXIDE-MT 1.8 JA 2W 1 NO

★

R497 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 068 1600 OXIDE-MT 4.7 JA 2W 1 NO

Old 401 027 5007 CARBON 68 JA 1/6W 1 NO

R506 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 024 6700 CARBON 100 JA 1/6W 1 NO

Old 401 008 7501 CARBON 2.2K JA 1/2W 1 NO

R513 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New NOT USED NO

402 055 3201 WIRE WOUND 1 KA WA 6W

Old 402 055 3300 WIRE WOUND 1 KA ZA 6W 1 NO

402 072 2706 WIRE WOUND 1 KA 5W

★

R601 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

402 057 8006 WIRE WOUND 3.3 KA ZA 6W

New 402 058 4403 WIRE WOUND 3.3 KA WA 6W 1 NO

402 075 4707 WIRE WOUND 3.3 KA 5W

Old

402 057 1304

WIRE WOUND 120 JA 15W

1NO

402 073 4105

WIRE WOUND 120 JA 15W

★R608

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

402 056 5204

WIRE WOUND 140 JA 15W

1NO

402 076 9800

WIRE WOUND 140 JA 15W

R714,

Old 401 039 0205 MT-GLAZE 82 JA 1/10W 2 NO

R724

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New NOT USED NO

R718,

Old NOT USED NO

R728

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 039 0205 MT-GLAZE 82 JA 1/10W 2 NO

Old 610 284 7338 ASSY, PWB, MAIN 1 NO

A100 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 284 7369 ASSY, PWB, MAIN 1 NO

Old 610 284 7345 ASSY, PWB, SOCKET 1 NO

A700 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 284 7376 ASSY, PWB, SOCKET 1 NO

Old 645 025 6103 SOCKET, CRT 8P 1 NO

★

K701 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New NOT USED NO

Page 14,

Chassis

Electrical

Parts List

3. IN THE CHASSIS ELECTRICAL PARTS LIST

The reason for change.

A : Misprint B : Quality Reliability C : Standardization

D : Design E : Add as a possible sub F : Schematic location change

G : Purchasing Request

Reason

Page 17,

Chassis

Electrical

Parts List

Page 19,

Chassis

Electrical

Parts List

Page 15,

Chassis

Electrical

Parts List

Page 18,

Chassis

Electrical

Parts List

— 4 —

Page 15

— 5 —

Page &

Section

Schematic

Location

Part No.

Description

Q’ty

Interchange-

ability

Old NOT USED NO

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

★K701A 645 026 1992 SOCKET, CRT 8P

New 645 036 4143 SOCKET, CRT 8P 1 NO

645 036 4150 SOCKET, CRT 8P

413 007 6201 CRT A48AAB37X

Old 413 007 7901 CRT A48AAB37X 1 NO

★Q901

414 009 2703 CRT A48AGD12X

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 414 009 8101 CRT A48JLL40X 1 NO

414 010 3003 CRT A48JLL40X(P)

Old NOT USED NO

Q901C - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 217 7787 CG PURITY MAGNET 1 NO

Page 19,

Chassis

Electrical

Parts List

3. IN THE CHASSIS ELECTRICAL PARTS LIST (Continued)

The reason for change.

A : Misprint B : Quality Reliability C : Standardization

D : Design E : Add as a possible sub F : Schematic location change

G : Purchasing Request

Reason

Page 16

Printed in U.S.A.

June / 2000 / 2200 SMC

For parts or service contact

SANYO Fisher Service Corporation

21605 Plummer Street,

Chatsworth, CA 91311 (U.S.A.)

300 Applewood Crescent,

Concord, Ontario L4K 5C7 (CANADA)

Page 17

DS19390

Model:

COLOR TELEVISION

AS

FILE NO.

G6VJM, PRODUCT CODE 111340680

REFERENCE No. SS510026-06

Notice

CORRECTION

SERVICE FLASH

PRODUCTION CHANGE

ADD INFORMATION

Please add this notice to the Service Manual listed below.

REVISION 6

Category:

U.S.A.

Destination:

APRIL / 24 / 2000

Date:

19390-06

Effective from: Chassis No.

SS510026-05

REF: No. -

NOTE: Match the Chassis No. on the unit’s back cover with the Chassis No. in the Service Manual.

If the Service Manual Chassis No. does not match the unit’s, additional Service Literature is

required. This chassis is similar to Chassis No. 19390-05. Only the Difference Service

Information is given in this manual. For detailed Service Information, refer to the Original Service

Manual and Notices for Chassis No. 19390-05 used in Model DS19390 (SS510026-05).

INITIAL BUS DATA SETUP

Note: When IC802 (EEPROM) is replaced, the Service Menu No. 001 HP (H Phase), No. 013 TDS (Trap & D SW), No. 024 AG

(AFC Gain), No. 026 SCO (Sub-Color), No. 027 STI (Sub-Tint), and No. 031 HR (OSD Display H-Position) should be set up for

proper TV operation before attempting the service adjustments.

1. Disconnect the AC power cord (AC 120V line).

2. While pressing the MENU key, reconnect the AC power cord. The Service Menu display will now appear.

3. Select No. 001 HP (H Phase) with ▲ or ▼ key. Adjust the data with + or – key for 14.

4. Select No. 013 TDS (Trap & D SW) with ▲ or ▼ key. Adjust the data with + or – key for 1.

5. Select No. 024 AG (AFC Gain), with ▲ or ▼ key. Adjust the data with + or – key for 0.

6. Select No. 026 SCO (Sub Color) with ▲ or ▼ key. Adjust the data with + or – key for 7.

7. Select No. 027 STI (Sub Tint) with ▲ or ▼ key. Adjust the data with + or – key for 20.

8. Select No. 031 HR (OSD Display H-Position) with ▲ or ▼ key. Adjust the data with + or – key for 28.

9. Press the MENU key to turn off the Service Menu display.

1. IN THE SERVICE ADJUSTMENTS LIST

PAGE 3

Page 18

1. IN THE SERVICE ADJUSTMENTS LIST (Continued)

PAGE 4

Table 1. ON-SCREEN SERVICE MENU

When IC802 (EEPROM) is replaced, check the bus data to confirm they are the same as below. The shaded menu should be checked

and be set up or readjusted according to the procedures described in the following pages. Initial Setup Data marked with an * should

be changed from Initial Reference Data. (See page 3 for Initial Bus Data Setup.)

No. TITLE

INITIAL REFERENCE INITIAL SETUP

RANGE OF DATA FUNCTION

DATA DATA

001 HP 15 14* 0~31 Horizontal Phase (Horizontal Centering)

002 IAS 0 0 0, 1 IF AGC Switch 0: TV (Normal) 1: AV (IF Gain Minimum)

003 RAD 25 25 0~63 RF AGC Delay

004 PT 64 64 0~127 PLL Tuning

005 ADA 31 31 0~63 APC Detect Adjust

006 CD 0 0 0, 1 C-Diff

007 VS 32 32 0~63 Vertical Size

008 RB 0 0 0~255 Red Bias

009 GB 0 0 0~255 Green Bias

010 BB 0 0 0~255 Blue Bias

011 RD 60 60 0~127 Red Drive

012 BD 60 60 0~127 Blue Drive

013 TDS 0 1* 0, 1 Trap & D (B.P.F.) Switch

0: OFF 1: ON

014 AF 0 0 0, 1 Auto Flesh 0: OFF 1: ON

015 BS 0 0 0, 1 Black Stretch 1: OFF 0: ON

016 VL 4 4 0~7 Video Level

017 FL 15 15 0~31 FM Level

018 NIS 1 1 0, 1 N/I Switch (Black Noise Inverter) 1: OFF 0: ON

019 ABL 1 1 0,1 ABL Defeat

0: OFF 1: ON

020 WP 1 1 0,1 White Peak Limiter 1: OFF 0: ON

021 GD 7 7 0~15 Green Drive Reduction

022 VC 0 0 0~7 Vert. Comp

023 VD 32 32 0~63 Vert. DC

024 AG 3 0* 0~3 AFC Gain 00: Auto 01: High Gain 10: Low Gain 11: Non-Gate

025 SB 32 32 0~63 Sub-Brightness

026 SCO 10 7* 0~31 Sub-Color

027 STI 14 20* 0~31 Sub-Tint

028 SSH 8 8 0~15 Sub-Sharpness

029 OPT 0 0 0~255 Option 1 (See Note 1 page 5.)

030 OP2 0 0 0~255 Option 2 (See Note 2 page 5.)

031 HR 24 28* 0~63 H-Position (OSD H-Position)

032 INP N/A N/A N/A N/A

033 STE N/A N/A N/A N/A

034 FIL N/A N/A N/A N/A

035 LSP N/A N/A N/A N/A

036 HSP N/A N/A N/A N/A

037 SPV N/A N/A N/A N/A

038 PCO N/A N/A N/A N/A

039 PTI N/A N/A N/A N/A

040 SBO 0 0 0~255 Sub Bright Offset

041 DRV

0~127 Red drive Adjustment (See Note 3 page 5.)

0~127 Blue Drive Adjustment (See Note 3 page 5.)

–0 00~255 Red Bias Adjustment (See Note 4 page 5.)

042 – 0 0 0~255 Green Bias Adjustment (See Note 4 page 5.)

–0 00~255 Blue Bias Adjustment (See Note 4 page 5.)

043 T00 0 0 0~255 N/A

↓↓ ↓ ↓ ↓ ↓

115 T48 0 0 0~255 N/A

1. IN THE SERVICE ADJUSTMENTS LIST (Continued)

PAGE 6

VERTICAL CENTERING ADJUSTMENT

1. Tune receiver to an active channel.

2. Check that picture is in the vertical center of TV screen. If picture center is too low, connect resistor R513 (470 ohm, 1W). If picture

center is too high, connect resistor R512 (470 ohm, 1W).

— 2 —

Page 19

PURITY ADJUSTMENT

1. When replacing picture tube or deflection yoke, mount

deflection yoke and purity-convergence magnets assembly

properly. See Figure 1. Position the picture tube facing east

or west. Demagnetize the picture tube and receiver using

an external degaussing coil. Set receiver to Service Menu

No. 042 (no vertical sweep) while degaussing.

2. Place the yoke on tube neck fully against glass.

2A. Place the CPM on the tube neck aligning the center of

the purity magnet tabs (2 pole) over center of Focus

Gap (G3 & G4). See Figure 2.

3. Connect a color bar generator to the antenna terminal.

Switch the generator to a white field. Move yoke backward

on the neck until a uniform white field is obtained.

4. Allow 30 minutes warm up on a blank white field (high intensity grayscale).

Note: If white field cannot be obtained, check Grayscale

Adjustments on page 6.

5. Set the picture controls to the Auto levels. Select a green

raster, either with the signal generator or by adjusting the

bias controls. If a signal generator is used for this step, Skip

to Step 10. If the bias controls will be used, go to step 6.

6. Adjust Service Menu No. 008 RB (R-Bias), No. 009 GB (GBias), and No. 010 BB (B-Bias) data to 0 each.

7. Select Service Menu No. 042 (no vertical sweep).

8. Adjust the screen control counterclockwise until the

horizontal scan lines is no longer visible.

9. Select Service Menu No. 009 GB (G-Bias) and raise the

data to produce green raster. If retrace lines appear,

reduce screen control slightly.

10. Pull yoke back on the tube neck to obtain three-color raster

(blue, green and red).

11. Adjust the angle between the two purity magnet tabs to

center the vertical green belt in the picture tube. Do not

rotate tabs. See Figure 3.

12. Slowly slide the deflection yoke forward until a uniform

green screen is obtained.

13. Check the purity of the red and blue screens for uniformity.

Turn off other colors to check (use bias controls) or use

generator. If necessary, readjust the yoke position until all

screens are pure.

14. If bias controls and screen control were used to set purity,

reset Grayscale and Brightness Level. Refer to Grayscale

Adjustment on page 6 and Brightness Level Adjustment on

page 7.

15. Confirm that the yoke is not tilted. Tighten the yoke

mounting screw. Adjust convergence next.

Figure 1. Deflection Yoke Movement

Figure 2. Purity and Convergence Magnets

Figure 3. Adjusting Magnet

2. IN THE PURITY AND CONVERGENCE ADJUSTMENTS LIST (Continued)

PAGE 10

— 3 —

DEFLECTION YOKE

DEFLECTION YOKE

MOUNTING SCREW

SIX-POLE

MAGNET TABS

4

3

PURITY

MAGNET

TABS

FOUR-POLE

MAGNET TABS

1

2

FOCUS GAP

(G3-G4)

ANGLE OF MAGNET TABS

RUBBER

WEDGE

ANGLE

OF TABS

MAGNET TABS

Page 20

April / 2000 / 2000 SMC

Printed in U.S.A.

Page &

Section

Schematic

Location

Part No.

Description

Q’ty

Interchange-

ability

Old

403 353 4303 MT-POLYPRO 7100P H 1.5K

1NO

404 077 4303 MT-POLYPRO 7100P H 1.5K

★

C411 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

403 343 8304 MT-POLYPRO 8000P H 1.5K

1NO

404 077 4709 MT-POLYPRO 8000P H 1.5K

Old

403 346 7304 MT-POLYPRO 0.36U J 250V

1NO

404 081 2906 MT-POLYPRO 0.36U M 200V

★C417

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

403 346 7027 MT-POLYPRO 0.24U J 250V

1NO

404 081 2500 MT-POLYPRO 0.24U M 200V

Old

610 238 2846 DEFLECTION YOKE

1NO

610 238 2853 DEFLECTION YOKE

★

L902 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 645 026 3927 YOKE, DEFLECTION 1 NO

Old 401 064 9907 OXIDE-MT 10K JA 2W 1 NO

★

R407 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 069 8202 OXIDE-MT 8.2K JA 2W 1 NO

Old 401 064 5701 OXIDE-MT 1.8 JA 2W 1 NO

★

R497 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 066 3002 OXIDE-MT 2.2 JA 2W 1 NO

Old 401 026 9907 CARBON 4.7K JA 1/6W 1 NO

R504 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 401 027 2600 CARBON 5.6K JA 1/6W 1 NO

Old 401 008 7501 CARBON 2.2K JA 1/2W 1 NO

R513 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New NOT USED NO

402 055 3201 WIRE WOUND 1 KA WA 6W

Old 402 055 3300 WIRE WOUND 1 KA ZA 6W 1 NO

402 072 2706 WIRE WOUND 1 KA 5W

★

R601 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

402 057 8006 WIRE WOUND 3.3 KA ZA 6W

New 402 058 4403 WIRE WOUND 3.3 KA WA 6W 1 NO

402 075 4707 WIRE WOUND 3.3 KA 5W

Old

402 057 1304

WIRE WOUND 120 JA 15W

1NO

402 073 4105

WIRE WOUND 120 JA 15W

★R608

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New

402 056 5204

WIRE WOUND 140 JA 15W

1NO

402 076 9800

WIRE WOUND 140 JA 15W

Old 610 284 7338 ASSY, PWB, MAIN 1 NO

A100 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 281 6839 ASSY, PWB, MAIN NO

413 007 6201 CRT A48AAB37X

Old 413 007 7901 CRT A48AAB37X 1 NO

414 009 2703 CRT A48AGD12X

★

Q901 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 414 009 3205 CRT A48KRD82X(DT) 1 NO

Old NOT USED NO

Q901C - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D

New 610 217 7794 CG PURITY MAGNET 1 NO

Page 14,

Chassis

Electrical

Parts List

3. IN THE CHASSIS ELECTRICAL PARTS LIST

The reason for change.

A: Misprint B : Quality Reliability C : Standardization

D : Design E : Add as a possible sub F : Schematic location change

G : Purchasing Request

Reason

Page 17,

Chassis

Electrical

Parts List

Page 19,

Chassis

Electrical

Parts List

Page 15,

Chassis

Electrical

Parts List

Page 18,

Chassis

Electrical

Parts List

For parts or service contact

SANYO Fisher Service Corporation

21605 Plummer Street,

Chatsworth, CA 91311

Page 21

AS

FILE NO.

SERVICE MANUAL

(SUPPLEMENT)

Remote Control Color

Television

DS19390 (U.S.A.)

VERSION ADVANCE

Chassis No. 19390-05

NOTE: Match the Chassis No. on

the unit’s back cover with

the Chassis No. in the

Service Manual.

If the Original Version

Service Manual Chassis

No. does not match the

unit’s, additional Service

Literature is required. You

must refer to “Notices” to

the Original Service Manual

prior to servicing the unit.

G6VHM, PRODUCT CODE 111340680

REFERENCE No. SS510026-05

THIS CHASSIS IS SIMILAR TO MODEL AVM-1909S, CHASSIS NUMBER

G6E-1909S2. SERVICE INFORMATION GIVEN IN THIS MANUAL IS ONLY

THE DIFFERENCE INFORMATION FROM MODEL AVM-1909S, CHASSIS

NUMBER G6E-1909S2. FOR ADDITIONAL SERVICE INFORMATION,

REFER TO THE SERVICE MANUAL FOR CHASSIS NUMBER G6E1909S2 USED IN MODEL AVM-1909S (SM510237-02).

A

S

Page 22

1 610 277 3866 CABINET FRONT

610 274 8130 CABINET FRONT

610 275 1871 CABINET FRONT

3 610 276 6486 DEC SHEET 610 275 1901 DEC SHEET

4 610 275 1857 BUTTON UNITED 610 275 1864 BUTTON UNITED

6 610 277 3897 CABINET BACK

610 274 9922 CABINET BACK

610 275 1895 CABINET BACK

610 282 3219 OWNER’S MANUAL 610 282 3202 OWNER’S MANUAL

DIFFERENCES

Model DS19390 (Chassis No. 19390-05) Same as model AVM-1909S

(Chassis No. G6E-1909S2) Except:

1. IN THE CABINET / ACCESSORY PARTS LIST

MODEL AVM-1909S (Chassis No. G6E-1909S2)

MODEL DS19390 (Chassis No. 19390-05)

Part No. Description

KEY NO.

Part No. Description

A

S

7, 8

7, 8

7

6

7

2

1

3

5

4

April / 2000 / 2000 SMC Printed in U.S.A.

For parts or service contact

SANYO Fisher Service Corporation

21605 Plummer Street,

Chatsworth, CA 91311

Loading...

Loading...