Page 1

Direct Current

Motors and Drives

1/50 - 500 Hp

Page 2

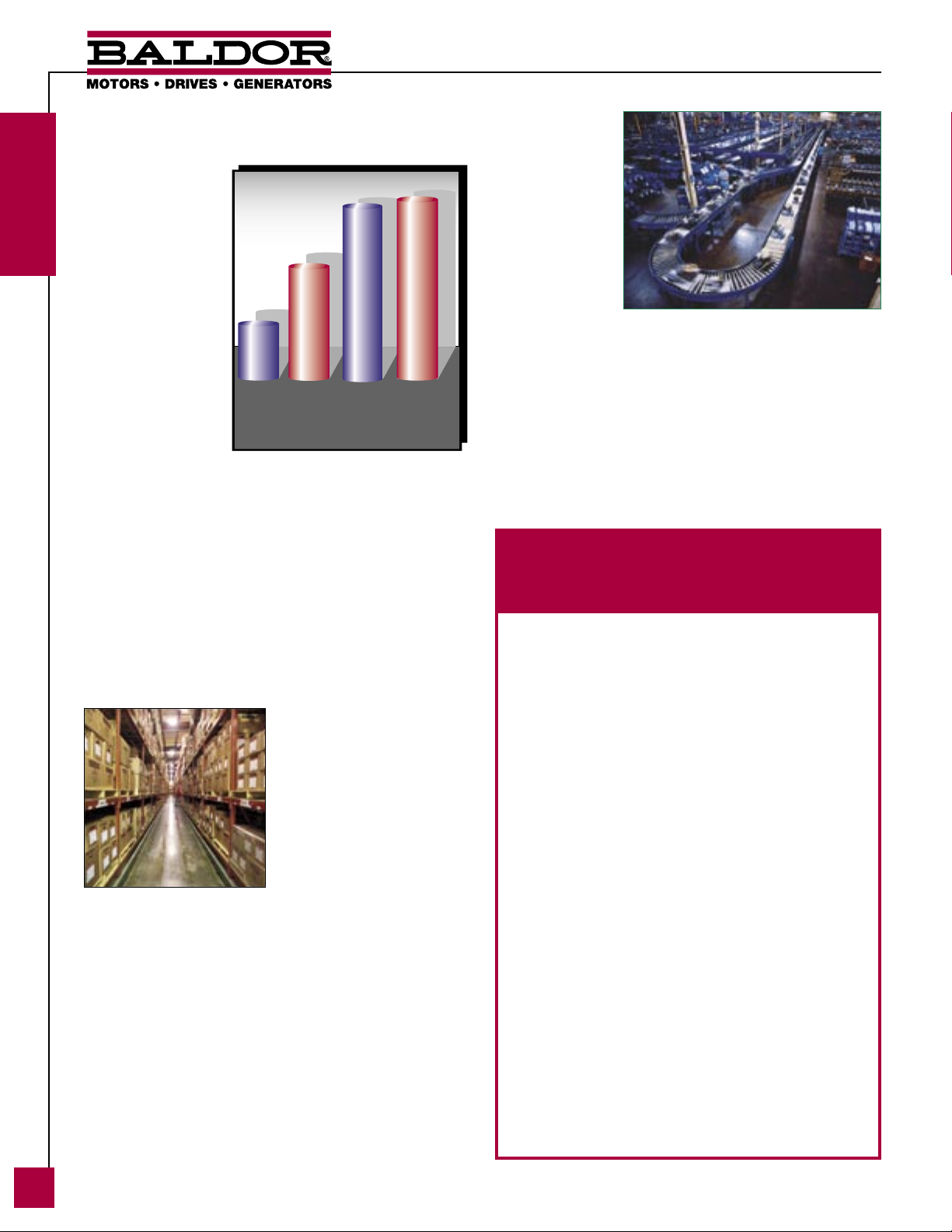

Why Baldor?

1985

20%

1990

2000

50%

90%

2003

94%

For over 85

years, Baldor has

strived to provide

customers with

the best value and

reliability in industrial

electric motors.

That dedication

shows in customer

preference for

Baldor motors.

To be considered

as the most

preferred...

Baldor offers

the industry’s

broadest line of

stock products. Save valuable time with just one call to

Baldor. We offer more than 7,000 stock motors, drives

and gearboxes.

Customer

Preference

Percentage of research studies in which

Baldor was chosen most preferred.

Industry’s

shortest lead

times/Flexible

manufacturing.

Baldor has

the industry’s

shortest lead

times on custom

motors – just

ten working

days. Our unique

FLEX FLOW

manufacturing process lets us produce any order in any

quantity, quickly and efficiently.

Industry’s best information. Only Baldor offers

customers so many choices for product information with

a wide variety of catalogs and product brochures,

a CD-ROM electronic catalog, the Baldor Web site

(www.baldor.com), or you may talk to a Baldor

customer service person or “ask the engineer” at

www.BaldorProSpec.com.

Energy-efficiency leader. We began lowering the

energy consumption of our motors in the 1920s, long

before others were even talking about it. Today, our

expansive line of Super-E® NEMA Premium® efficient

motors ranges from 1 through 1250 hp. Baldor’s

Super-E line offers customers the highest overall

efficiency levels in the industry.

Baldor products are

available at more

locations than any other

brand. Our 35 district

offices across North

America offer immediate

availability of Baldor

products to thousands of

distributors.

Continuous innovation to improve reliability.

Baldor leads the motor industry in applying new

technologies and materials to improve motor reliability.

Baldor was the first to introduce ISR® (Inverter Spike

Resistant®) magnet wire on our AC motors, which is up

to 100 times more resistant to voltage spikes. Baldor was

first to use Exxon’s Polyrex® EM grease, which protects

motor bearings better, providing improved lubrication

life, greater shear stability, and superior resistance to

washout, rust and corrosion.

Table of Contents

Page

DC Motor and Control Applications 1

Matched Performance 1

Typical Frame Sizes for PMDC Motors 2

SCR-Rated PMDC Motors 4

Baldor DC Motor Construction 6

Subfractional Hp PMDC

Motors and Gearmotors 7

Wound Field DC Motors 8

Integral Hp Wound Field DC Motors 10

Low Voltage DC Motors 11

DC Power Motors 11

Lifiting Magnet and DC Generators 11

DC SCR Controls 12

Tachometers 13

www.baldor.com

Page 3

DC Motors & Controls

0 200 400 800600 1000 1200 1400 1600 1800 2000

0

1

2

3

4

5

TORQUE (ft-lbs)

SPEED (rpm)

0

.4

.8

1.6

2.0

HORSEPOWER

1.2

Base

Speed

Intermittent Safe Operating Area

HP

Continuous Operating Area

for many different

applications

Baldor offers the widest variety of DC Motors. From

1/50 to 500 horsepower, our rugged industrial designs

may be used to power everything from a medical

blood centrifuge to the printing press for your Sunday

newspaper.

SCR-rated DC motors are available from stock in

permanent magnet designs through 5 horsepower.

Wound field designs are stocked through 500 HP. DC

motors with special features are available from stock for

special applications:

• Explosion-proof for hazardous locations

• Washdown Enclosures for food processing

• Metric mounting for replacement of motors built

to IEC standards

• Permanent magnet motors with a built-in

precision DC tachometer

• Right angle and parallel shaft gear motors

• 115 and 230 volt power motors built to IEEE 45

and USCG 259 standards for shipboard use

Custom motors are available

with special voltages, base

speeds, mountings and

other options. With Baldor,

building a custom motor to

the specifications you require

can eliminate assembly time,

adapters, repainting and other

costly operations. You buy only

what you require, and we deliver when

you need it.

Matched Performance™

We know how our DC motors and controls perform

when used together. This assured performance gives you

the Matched Performance™ that you need. The wide

range of SCR controls we offer assures that we have the

correct control for most applications. Let Baldor take the

guesswork out of matching motors and controls.

Baldor offers a wide range of DC motors with up to 500 Hp

available from stock.

www.baldor.com

Performance Specifications

BC140 Control and CDP3455 Motor 1HP

Input Voltage: 230V AC

50/60 Hz

1 Phase

Base Speed: 1750 RPM

Operating Speed Range: 0-2000 RPM

Constant Torque Speed Range: 90-1750 RPM

Constant Horsepower Speed Range: 1750-2000

RPM

Speed Regulation Std. Feedback Type: Armature

1% of Base

Speed

Opt. Feedback Type: Tachometer

1% of Set

Speed

Motor Cooling: TEFC

1

Page 4

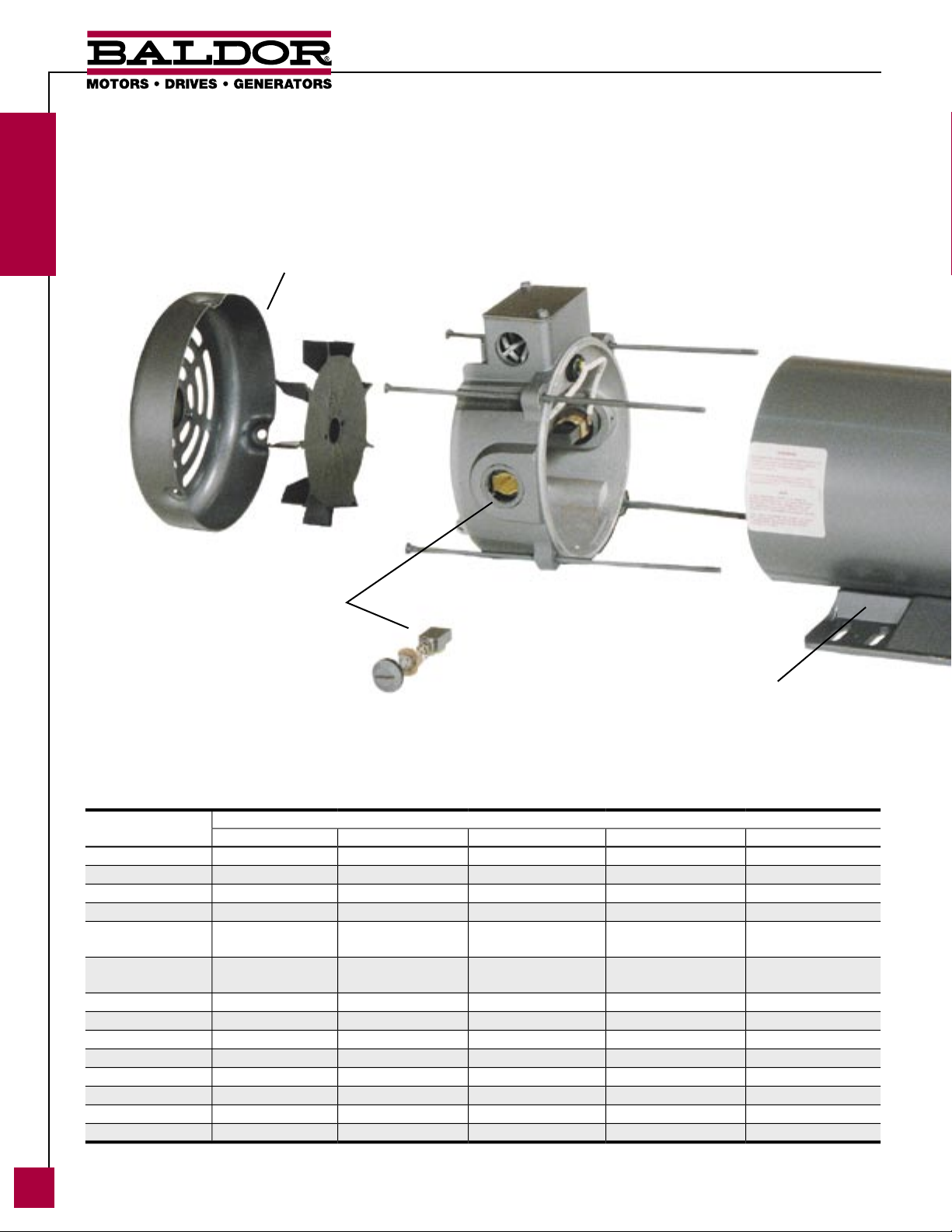

Baldor Permanent Magnet DC Motor

At the heart of our DC motor lineup are the many sizes of our versatile permanent magnet DC motors. These range in

output from 1/50 hp to the industry’s only 5 horsepower. Ruggedness, dependability and ease of use are the reasons

that Baldor PMDC motors are specified by more customers than any other.

Tach adaptable with optional tach

mounting kit (except explosion proof)

Long life brushes, constant force

springs on 42 and 180 frame

body sizes (33P & 36P).

Heavy duty steel frames with

removable mounting bases (36P

and explosion proof welded-on).

Typical Frame Sizes for Permanent Magnet DC Motors

Hp

1/50 ABP-0 ABP-0 ABP-0 ABP-0

1/25 ABP-0 ABP-0 ABP-0 ABP-0

1/10 42C, 48C or 56C 42C, 48C or 56C 42C, 48C or 56C 42C, 48C or 56C

1/8 56C 42C, 48C or 56C 42C, 48C or 56C 42C, 48C or 56C 42C, 48C or 56C

1/6 56C

1/4 56C 56C

1/3 56C 56C 56C 56C

1/2 56C 56C 56C 56C

3/4 143-5TC 56C 56C 56C

1 143-5TC 56C 56C 56C

1-1/2 182-4TC 143-5TC 143-5TC 143-5TC

2 182-4TC 143-5TC 143-5TC 182-4TC

3 182-4TC 182-4TC 182-4TC 182-4TC

5 1810ATC 182-4TC 182-4TC

Ratings 2 HP and above designed for 180 Volts only.

ABP = Non NEMA Foot Mount

1150 1750 2500 3500 5000

42C, 48C

56C

Base Speed

42C or 48C

56C

42C or 48C

56C

42C or 48C

56C

42C or 48C

56C

42C, 48C or 56C

42C, 48C or 56C

2

www.baldor.com

Page 5

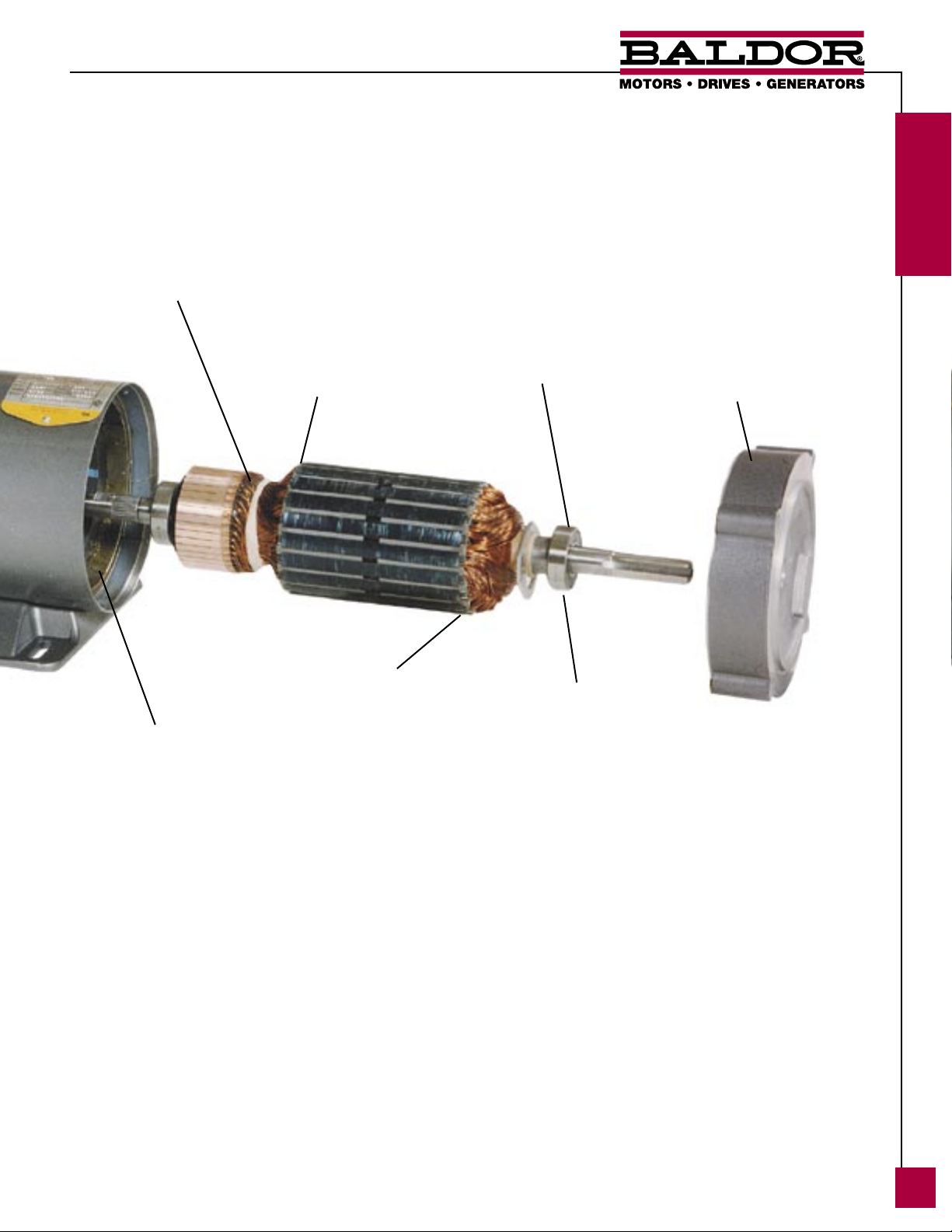

Armature connections fused

to commutator for reliability

and low resistance.

Class H+ moisture resistant

magnet wire operated at a Class

F rise for long insulation life.

Dynamic balanced armature for

smooth operation.

Highest quality oriented ceramic ferrite

magnets for increased motor efficiency.

Drive end bearing locked

in place allowing vertical

mounting or axial shaft

loads.

Double seal ball bearings

with moisture resistant

grease for long life.

Die cast alloy endplates

with steel bearing inserts.

www.baldor.com

3

Page 6

SCR - Rated Permanent

Magnet DC Motors

Baldor chooses to make a wide variety of SCR-Rated PMDC motors, each specifically designed to a horsepower

range. This optimizes the motor’s commutator, brushes and inertia to assure the best performance possible. We

further modify these designs for specific applications, washdown, explosion proof, metric mountings and integral DC

tachometer. Only Baldor offers the choice of such a wide range of DC motors from stock, so you can be assured of

having the best motor for your application.

TEFC

1/8 - 5 HP

90 or 180 Volt Armature

42 - 1810AT Frame

Metric Face or Flange

.15 - 3.7 kW, 1/5 - 5 HP

180 Volt Armature

IEC D63D - D112D

TENV

1/8 - 1 HP

90 or 180 Volt Armature

48 - 145TC Frame

Washdown Duty

Washdown White Design 1/4 - 5 HP

Paint-Free Design 1/4 - 1 HP

48 - 1810AT Frame

Integral DC Tach

Explosion Proof

1/4 - 1-1/2 HP

90 or 180 Volt Armature

56 - 145TC Frame

4

www.baldor.com

Integral 50 V/1000 RPM DC Tachometer

90 or 180 Volt Armature

48 - 1810AT Frame

1/4 - 5 HP

Page 7

Performance Data

TENV & TEFC PMDC Motors*

HP RPM

1/4 1750 56C TENV CDP3310 90 2.5 0.75

1/4 1750 56C TENV CDP3306 180 1.3 0.75

1/3 1750 56C TENV CDP3320 90 3.2 1.0

1/3 1750 56C TENV CDP3316 180 1.6 1.0

1/2 1750 56C TENV CDP3330 90 4.8 1.5

1/2 1750 56C TENV CDP3326 180 2.5 1.5

1/2 2500 56C TENV CDP3335 90 5.0 1.05

3/4 1750 56C TEFC CDP3440 90 7.6 2.25

3/4 1750 56C TEFC CDP3436 180 3.7 2.25

3/4 2500 56C TEFC CDP3443 90 7.5 1.58

1 1750 56C TEFC CDP3445 90 10.0 3.0

1 1750 56C TEFC CDP3455 180 5.0 3.0

1 2500 56C TEFC CDP3450 90 9.7 2.1

1 2500 56C TEFC CDP3460 180 4.9 2.1

1-1/2 1750 145TC TEFC CDP3575 180 7.7 4.5

1-1/2 2500 145TC TEFC CDP3580 180 7.0 3.15

2 1750 145TC TEFC CDP3585 180 9.6 6.0

2 2500 145TC TEFC CDP3590 180 10.0 4.2

3 1750 184TC TEFC CDP3603 180 14.0 9.0

3 1750 182C TEFC CDP3604 180 14.0 9.0

5 1750 1810ATC TEFC CDP3605 180 24.5 15.0

NEMA

Frame

Enclosure

Explosion Proof PMDC Motors

1/4 1750 56C TEFC CDPX3410 90 2.7 0.75

1/4 1750 56C TEFC CDPX3406 180 1.3 0.75

1/3 1750 56C TEFC CDPX3420 90 3.6 1.0

1/3 1750 56C TEFC CDPX3416 180 1.7 1.0

1/2 1750 56C TEFC CDPX3430 90 5.2 1.5

1/2 1750 56C TEFC CDPX3426 180 2.5 1.5

3/4 1750 56C TEFC CDPX3440 90 7.0 2.25

3/4 1750 56C TEFC CDPX3436 180 3.5 2.25

1 1750 56C TEFC CDPX3545 90 9.6 3.0

1 1750 56C TEFC CDPX3555 180 4.9 3.0

1-1/2 1750 145TC TEFC CDPX3575 180 7.1 4.5

IEC Metric Frame PMDC Motors**

.15-.20 1800 D63D TENV VP7424D 180 1.1 .60

.18-.25 1750 D71D TENV VP3311D 180 1.3 .75

.25-.33 1750 D71D TENV VP3316D 180 1.6 1.0

.37-.5 1750 D71D TENV VP3326D 180 2.5 1.5

.37-.5 3000 D71D TEFC VP3428D 180 2.5 0.9

.57-.75 1750 D80D TEFC VP3436D 180 3.7 2.25

.57-.75 3000 D80D TEFC VP3439D 180 3.6 1.31

.75-1.0 1750 D80D TEFC VP3455D 180 5.0 3.0

.75-1.0 3000 D80D TEFC VP3458D 180 5.1 1.75

1.1-1.5 1750 D90D TEFC VP3575D 180 7.7 4.5

1.1-1.5 3000 D90D TEFC VP3468D 180 7.7 2.63

1.5-2.0 1750 D90D TEFC VP3585D 180 9.6 6.0

1.5-2.0 3000 D90D TEFC VP3588D 180 10.0 3.5

2.2-3.0 1750 D112D TEFC VP3603D 180 14.0 9.0

3.7-5.0 1750 D112D TEFC VP3605D 180 24.5 15.0

NOTE: * Additional motors are available with washdown enclosures and with integral DC tachometers – same performance data.

** Additional motors are available with B14 face

Catalog

Number

Arm

Volts

Full Load

Amps

Rated Torq.

lb-ft

www.baldor.com

5

Page 8

Baldor DC Motor Construction

Baldor’s broad liine of DC motors continues to lead the industry with choices of permanent magnet or wound field

designs. Many different configurations are available from stock or Baldor can design and build a motor to meet exact

application requirements with our short leadtime.

DC Motor Construction Features

Clarksville Westville Charlotte

Features

HP Range 1/50 - 1/4 1/8 - 5 1 - 500

Class F insulation

1.0 Service factor

Long life brush system

Precision turned commutator with fused armature connections S S S

Permanent magent designs

Wound field designs S S

Operation above base speed with field weakening

2 electrical pole designs

4 electrical pole designs 360 frame - up

Overload thermostat

Mechanical Features

NEMA Frame sizes 42 - 56 48 - 1810AT 182 - 5010AT

IEC Frame Sizes

TENV and TEFC enclosures

DPFG - open enclosures O O S

DPBV - drip proof - blower cooled enclosures

Washdown and paint free washdown models

Explosion proof enclosure

MSHA - Mine Safety and Health Administration models

Integral DC tachometer models S

Tach adaptable

Steel Band - Die cast aluminum endplates, steel fan cover

Heavy rolled steel frame - cast iron endplates & fan cover

Die cast aluminum conduit box

Cast Iron conduit box

Double sealed ball bearings S S S

Hardware - cad plated

Motor unfiltered vibration at rated voltage & frequency < 0.15 in/sec velocity

Motor unfiltered vibration at rated voltage & frequency < 0.08 in/sec velocity

Non-sparking exteral cooling fan

Limited Warranty 18 months 18 months 18 months

Note: Contact your Baldor District Office for certified data, dimensions and features of a specific motor.

S S S

S S S

S S S

S S

S

S S 180 - 320 frame

O S-stock motors

63 71 - 112 132 - 250

S S S

S

S

S

O O

O S S

S S

S

S S

S

S S S

S S S

O O O

S S

6

www.baldor.com

Page 9

Subfractional Hp Permanent Magnet

DC Motors and Gearmotors

In addition to our larger DC motors, Baldor has a complete line of subfractional permanent magnet DC motors – alone

or with either right angle or parallel shaft gear reduction. Both in SCR-Rated and low voltage designs.

A wide variety of styles and mounting configurations of right angle gearmotors cover the range from 1/50 to 1/2

horsepower. Sealed gearbox housings with lifetime lubrication allow mounting in any position*. Their compact design

and broad selection of speeds make these units ideal for direct coupling to the load. In many cases, additional

equipment such as chain and sprockets can be eliminated. These units are well suited for all types of conveyorized

equipment, mixers, feeders, gate and door operators and many other applications.

Standardized mountings and optional bases make parallel shaft gearmotors ideal for original equipment as well as

replacement applications. These compact efficient gearmotors provide high output torque in a small package. They

are well suited to many applications such as all kinds of conveyorized equipment, food processing, printing and

packaging machines.

Subfractional HP Motors

1/100 - 1/4 HP

Parallel Shaft Gearmotors Output

Torques to 400 lb-in

NOTE: * Vertical motor below gearhead is not recommended. Avoiding this position will provide greater protection against oil leakage back into the motor.

Contact Baldor is this position cannot be avoided.

Right Angle Gearmotors Output

Torques to 250 lb-in

Low Voltage

1/50 - 1/4 HP

www.baldor.com

7

Page 10

Baldor’s Family of Wound Field DC Motors

Baldor also makes a wide variety of wound field SCR-Rated DC motors. These range from a 48 frame 1/8 HP motor

to a large 5010AT 500 HP size. We know that some customers still prefer the reliable Baldor wound field motors that

have been available for over 75 years. Baldor continues to expand our product range so we can be your primary

supplier of DC motors and drives.

Low voltage Baldor wound field motors are available with either a series or compound wound field. Special designs

are available for traction applications or hydraulic pumps. Power motors are designed for operation from a generator

or batteries.

TEFC 1/8-75 HP, TEAO 5-100 HP

TEUC 15-500 HP

180 Volt Armature – 100/200 Volt Field

240 or 500 Volt Armature – 150/300 Volt Field

Explosion Proof

1/2 - 3 HP

180 Volt Armature

100/200 Volt Field

DPFG-Drip Proof Fully Guarded

1-400 HP DPBV-Drip Proof

Blower Vented 1-500 HP

Textile Applications

DPFG-Drip Proof Fully Guarded

240A/240F 1-300 HP

Metric Face or Flan

.09 - 370 kW, 1/8 - 500 HP

Choice of Voltages to

Meet Most Applications

ge

8

www.baldor.com

Page 11

Performance Data

TENV & TEFC Shunt Wound DC Motors

HP RPM

1/4 1750 56C TEFC CD3425 90 100/ 50 3.0 0.3/0.6 0.75

1750 56C TEFC CD3433 90 100/ 50 3.4 0.4/0.8 1.0

1/3 1750 56C TEFC CD3434 180 200/100 1.9 0.21/0.42 1.0

1750 56C TEFC CD5333 90 100/ 50 3.7 0.5/1.0 1.0

1750 56C TEFC CD3450 90 100/ 50 5.2 0.5/1.0 1.5

1/2 1750 56C TEFC CD3451 180 200/100 2.6 0.25/0.5 1.5

1750 56C TEFC CD5350 90 100/ 50 5.0 0.44/0.88 1.5

1750 56C TEFC CD3475 90 100/ 50 7.8 0.6/1.2 2.25

3/4 1750 56C TEFC CD3476 180 200/100 3.9 0.3/0.6 2.25

1750 56C TEFC CD5375 90 100/ 50 8.0 0.6/1.2 2.25

1750 56C TEFC CD5319 90 100/ 50 10.0 0.6/1.2 3.0

1

1-1/2 1750 184C TEFC CD6215 180 200/100 7.5 0.25/0.5 4.5

2

3

5

7-1/2 1750 256UC TEFC CD9175 240 300/150 27.0 0.7/1.4 22.5

10 1750 256UC TEFC CD9110 240 300/150 35.0 0.65/1.3 30.0

1750 56C TEFC CD5318 180 200/100 5.0 0.3/0.6 3.0

1750 184C TEFC CD6219 90 100/ 50 9.6 0.55/1.1 3.0

1750 184C TEFC CD6218 180 200/100 5.0 0.25/0.5 3.0

1750 184C TEFC CD6202 180 200/100 9.5 0.4/0.8 6.0

1750 213C TEFC CD7502 180 200/100 10.0 0.3/0.6 6.0

1750 184TC TEFC CD6203 180 200/100 14.7 0.6/1.2 9.0

1750 215C TEFC CD7503 180 200/100 14.5 0.4/0.8 9.0

1750 215C TEFC CD7505 240 300/150 17.5 0.2/0.4 15.0

1750 256UC TEFC CD9105 180 200/100 23.0 1.0/2.0 15.0

NEMA

Frame

Enclosure

Explosion Proof Wound Field Motors

1/2 1750 182CZ TEFC CDX1850 90 100/50 4.9 0.55/1.1 1.5

3/4 1750 182CZ TEFC CDX1875 90 100/50 7.0 0.55/1.1 2.25

1

1-1/2 1750 184C TEFC CDX7150 180 200/100 7.5 0.25/0.5 4.5

2 1750 184C TEFC CDX7200 180 200/100 9.5 0.4/0.8 6.0

3 1750 215CY TEFC CDX7513 180 200/100 14.5 0.4/0.8 9.0

1750 182CZ TEFC CDX2001 180 200/100 5.0 0.25/0.5 3.0

1750 182C TEFC CDX7100 180 200/100 5.0 0.25/0.5 3.0

Catalog

Number

Arm / Fld Volts

F.L. Amerage

Arm / Fld Hi/Lo

Rated Torq.

lb-ft

www.baldor.com

9

Page 12

Baldor’s Extensive Line of Integral Hp

Wound Field DC Motors

DC motors continue to be an important product at Baldor. Our extensive stock of Integral HP ratings allows you to get

the motor required from our inventory. If the motor isn’t available from stock, our new large DC motor plant has the

capability to build it with the industry’s shortest lead times.

The following chart shows Baldor’s Integral Hp manufacturing capabilities.

Integral Hp Custom Motor Capabilities

DPFG and DPBV Enclosure, 500V Armature (240 volt available), Typical

Frame Sizes

HP

1

1.5

2 L186AT L186AT L186AT L182AT L182AT

3

5

7.5 368AT 366AT 328AT 288AT 259AT 2110AT 218AT L186AT L186AT

10 407AT 366AT 328AT 328AT 288AT 258AT 219AT 218AT 1810AT

15 409AT 407AT 368AT 365AT 328AT 288AT 258AT 219AT 218AT

20

25 508AT 409AT

30 506AT 506AT 407AT

40 508AT 504AT 504AT

50 508AT

60

75

100

125

150

200

250

300

400

500

NOTES: 1 240 Volt Armature Only

2 Blower Required (DPBV)

Totally Enclosed designs also available.

300 400 500 650 850 1150 1750 2500 3500

1 288AT 1 259AT 1 2110AT 1

328AT

1 328AT 1 288AT 1 259AT 1

365AT

2 368AT2 366AT2

407AT

2 366AT2

368AT

2

506AT

2 506AT2

506AT

2 506AT2 506AT2 504AT2 407AT2 368AT2

508AT

2 5010AT2 508AT2 506AT2 409AT2 407AT2

5011AT

2 508AT2 506AT2

5010AT

2 508AT2 506AT2 506AT2

5010AT

506AT 409AT

506AT 504AT

2 508AT2 506AT2 506AT2 409AT2 409AT2

5011AT

2 5011AT2 5010AT2 506AT2 504AT2

5012AT

366AT 328AT 328AT 259AT 2110AT 219AT

366AT

368AT

5011AT

BASE SPEED

1 L182AT 1 L182AT 1 L182AT 12 L182AT 12

L186AT

1 L186AT 1 L182AT 1 L182AT 1 L182AT 1

L186AT

218AT L186AT L186AT L186AT L182AT

2110AT 219AT L186AT L186AT L186AT

366AT 328AT 288AT 258AT 258AT

2

2 366AT2 365AT2

2 5010AT2

366AT

368AT2 366AT2

368AT2

506AT

2 5010AT2 508AT2

5012AT

328AT2

368AT 366AT 328AT

409AT2 368AT2 368AT2 366AT2

506AT

508AT

5011AT

288AT 259AT 259AT

328AT

328AT 288AT

366AT 329AT

368AT

407AT2 407AT2 366AT 2

506AT2

2 5010AT 2

287AT2

366AT2 366AT2

288AT2

328AT2

328AT2

288AT

10

www.baldor.com

Page 13

Low Voltage DC Motors – 12-72 VDC

More and more vehicles are being powered from batteries. Baldor is a long-time supplier of energy efficient DC

motors for electric vehicles.

Wound Field Motors

1/50 - 8 HP

DC Power Motors

Some applications require a DC motor to operate from a NEMA Type A power supply, a DC generator or back-up

battery system. For these jobs, Baldor makes a lineup of DC Power Motors for either a 115 or 230 volts DC. These

motors are typically compound wound, but are available in shunt or series construction. Some ratings are also

available as permanent magnet.

DC Power Motors

1/50 - 500 HP

Lifting Magnet and DC Generators

Baldor’s rugged industrial DC motors are used as the basis for our 230V DC lifting magnet generators. This provides

a heavy duty generator with cast iron endplates and a thick steel housing. Oversized brushes and commutators,

sealed ball bearings and corrosion-resistant epoxy paint ensure long life and minimum service requirements. These

generators are self-excited and have a drooping voltage characteristic. These are stocked with choice of base

mounting or base with C-face in 5-40 kW ratings. Larger custom ratings are also available.

DC Generators are available using our rugged Integral HP DC Motor frames. These can be designed with either

external or self-excited fields. Standard output voltages are 120 or 250 DC, other voltages are available.

5 - 40 kW

www.baldor.com

3/4 - 200 kW

11

Page 14

DC SCR Controls

Standard SCR

and Line Regen Controls

Baldor now offers a wide range of SCR controls to meet most

applications. Both standard and line regenerative designs are available.

Our line of single phase input controls are available for chassis mounting

or with NEMA 1 or NEMA 4X enclosures. Baldor’s controls for three

phase input are available as standard or line regen designs with common

keypad language and set up like our Inverters and Vector controls.

When you specify a Baldor SCR control along with your DC motor, you

are assured of Matched Performance™. We know what performance you

will get with the combination of our motor and control.

Accessory boards are also available to customize the control to meet

your particular application requirements. This may range from following

a process signal, leader/follower applications, serial interfaces and many

more.

Tachometer Selection Guide

XPY

DC

DC

Output

Volt.

V/1000

RPM

50

60

100

200

50

60

100

50

100

50

100

200

50

100

200

7

19

31.5

38

50

22.5

45

90

Ripple

Max.

Speed

5000

4166

2500

1250

5000

4166

2500

5000

2500

5000

2500

1250

5000

2500

1250

6000

6000

4000

4000

4000

5000

5000

3600

Max.

Temp.

RMS

Ripple

Current

400 mA

200 mA

0.5%

200 ma

100 mA

0.35

100 mA

0.35

0.5%

0.5%

1.5% 50 mA 2% 33 65 0.02 No

NA NA 18 40 0.03 No

Max

-

50 mA

50 mA

50 mA

1.0 A

0.5 A

-

2.0 A

1.0 A

-

Reversing

Error

2% 52 40 0.022 No

1% 33 65 0.045 No

1% 33 65 0.045 No

2% 48 65 0.012 Yes

2% 48 65 0.012 Yes

Cycles

Per

Rev.

Amb.

Temp

°C

Catalog

Number

PTG50XP

PTG60XP-M

PTG100XP

CUSTOM

PTG50XPS

PTG60XPS-M

PRG100XPS

PTGWD50XPS

PTGWD100XPS

PFTG4250XC

PTFG42100X

CUSTOM

PFTG4650XC

PFTG46100X

CUSTOM

BTG1000 30-AFL-0 50 5000 8.0% - 2% 24 40 0.2

PTG1024LD DPY 1024PPR 5000

PTG50NC

PTG4590AC

Baldor

Tach

Type

XPY-II

XPY-II

XC42

XC46

Pancake

Pancake

Approx.

Coefficient

%Volt/°C

Temp.

Compen.

Enclos.

TENV

IP54

TENV

IP54

TENV

IP65

TENV

IP54

TENV

IP54

TENV

IP54

TENV

IP54

TENV

IP54

TENV

IP54

Housing

Material

Aluminum

& Steel

Cast Iron 19 0.54

Cast Iron 19 0.54

Cast Iron

& Steel

Cast Iron

& Steel

Aluminum 6

Aluminum 1

Aluminum

& Steel

Aluminum

& Steel

Weight

Lbs.

5 0.93

25 6.47

35 9.90

3 0.33

4 1.65

Inertia

(lb-in2)

12

www.baldor.com

Page 15

Tachometers

Baldor offers a wide range of tachometers to meet almost any application that you may have. DC, AC and Digital

Encoder-based tachs are available either as stand-alone products or mounted to permanent magnet or wound field

motors.

Baldor tachometers are used in elevators, plastic extruders, printing presses, antenna drives and many other diverse

applications.

Our most popular XPY DC tach is available with PY or metric flange or foot mounting, in standard TENV or washdown

enclosures; all from stock.

Our newest PY style DC tach, the XPYII, is shorter in length, but full-featured in performance. Its rugged cast iron

housing is suited for mill applications and has better electrical shielding. The output signal has very low ripple current.

We even have a version that uses a metric mounting flange and can be made with either IP54 or IP65 enclosure.

XC tachs are used when a rugged DC tach is required. Many mill applications utilize these tachs because of their

voltage stability with temperature extremes, excellent output signal and cast iron construction.

DC XPY Tach

Flange and Foot mount

Pancake tachs with either DC, AC or Digital outputs are available for applications where space is at a premium.

Encoder-based digital tachs are available with a standard PY mounting flange for applications where new digital SCR

controls are used. These easily mount to existing PY mounting adapters.

Our BTG1000 provides a 50 volt/1000 RPM DC output. This low cost tach provides basic speed indication.

Modular DC tachs are also available for OEMs that can mount them as an integral part of their products.

AC, DC or Digital

Pancake Tach

DC XPII Tach

DPY

DC XC Tach

BTG1000

DC Tach

www.baldor.com

13

Page 16

Contact your nearest Baldor District Office at these

World Wide locations or visit www.baldor.com

UNITED STATES

ARIZONA

PHOENIX

4211 S 43RD PLACE

PHOENIX, AZ 85040

PHONE: 602-470-0407

FAX: 602-470-0464

CALIFORNIA

LOS ANGELES

6480 FLOTILLA

COMMERCE, CA 90040

PHONE: 323-724-6771

FAX: 323-721-5859

HAYWARD

21056 FORBES STREET

HAYWARD, CA 94545

PHONE: 510-785-9900

FAX: 510-785-9910

COLORADO

DENVER

2520 W BARBERRY PLACE

DENVER, CO 80204

PHONE: 303-623-0127

FAX: 303-595-3772

CONNECTICUT

WALLINGFORD

65 SOUTH TURNPIKE ROAD

WALLINGFORD, CT 06492

PHONE: 203-269-1354

FAX: 203-269-5485

FLORIDA

TAMPA/PUERTO RICO/

VIRGIN ISLANDS

3906 EAST 11TH AVENUE

TAMPA, FL 33605

PHONE: 813-248-5078

FAX: 813-247-2984

GEORGIA

ATLANTA

62 TECHNOLOGY DR.

ALPHARETTA, GA 30005

PHONE: 770-772-7000

FAX: 770-772-7200

ILLINOIS

CHICAGO

1601 FRONTENAC ROAD

NAPERVILLE, IL 60563

PHONE: 630-848-5100

FAX: 630-848-5110

INDIANA

INDIANAPOLIS

5525 W. MINNESOTA STREET

INDIANAPOLIS, IN 46241

PHONE: 317-246-5100

FAX: 317-246-5110

800-428-4141

IOWA

DES MOINES

1800 DIXON STREET, SUITE C

DES MOINES, IA 50316

PHONE: 515-263-6929

FAX: 515-2

MARYLAND

BALTIMORE

6660 SANTA BARBARA RD.

SUITE 22-24

ELKRIDGE, MD 21075

PHONE: 410-579-2135

FAX: 410-579-2677

MASSACHUSETTS

BOSTON

6 PULLMAN STREET

WORCESTER, MA 01606

PHONE: 508-854-0708

FAX: 508-854-0291

MICHIGAN

DETROIT

33782 STERLING PONDS BLVD.

STERLING HEIGHTS, MI 48312

PHONE: 586-978-9800

FAX: 586-978-9969

GRAND RAPIDS

668 3 MILE ROAD NW

GRAND RAPIDS, MI 49504

PHONE: 616-785-1784

FAX: 616-785-1788

MINNESOTA

MINNEAPOLIS

21080 134TH AVE. NORTH

ROGERS, MN 55374

PHONE: 763-428-3633

FAX: 763-428-4551

MISSOURI

ST LOUIS

422 INDUSTRIAL DRIVE

MARYLAND HEIGHTS, MO 63043

PHONE: 314-298-1800

FAX: 314-298-7660

KANSAS CITY

915 N W PLATTE VALLEY DR

RIVERSIDE, MO 64150

PHONE: 816-587-0272

FAX: 816-587-3735

NEW YORK

AUBURN

ONE ELLIS DRIVE

AUBURN, NY 13021

PHONE: 315-255-3403

FAX: 315-253-9923

63-6515

NORTH CAROLINA

GREENSBORO

1220 ROTHERWOOD ROAD

GREENSBORO, NC 27406

P O BOX 16500

GREENSBORO, NC 27416

PHONE: 336-272-6104

FAX: 336-273-6628

OHIO

CINCINNATI

2929 CRESCENTVILLE ROAD

WEST CHESTER, OH 45069

PHONE: 513-771-2600

FAX: 513-772-2219

CLEVELAND

8929 FREEWAY DRIVE

MACEDONIA, OH 44056

PHONE: 330-468-4777

FAX: 330-468-4778

OKLAHOMA

TULSA

2 EAST DAWES

BIXBY, OK 74008

PHONE: 918-366-9320

FAX: 918-366-9338

OREGON

PORTLAND

20393 SW AVERY COURT

TUALATIN, OR 97062

PHONE: 503-691-9010

FAX: 503-691-9012

PENNSYLVANIA

PHILADELPHIA

1035 THOMAS BUSCH

MEMORIAL HIGHWAY

PENNSAUKEN, NJ 08110

PHONE: 856-661-1442

FAX: 856-663-6363

PITTSBURGH

616H BEATTY ROAD

MONROEVILLE, PA 15146

PHONE: 412-380-7244

FAX: 412-380-7250

TENNESSEE

MEMPHIS

4000 WINCHESTER ROAD

MEMPHIS, TN 38118

PHONE: 901-365-2020

FAX: 901-365-3914

TEXAS

HOUSTON

4647 PINE TIMBERS

SUITE # 135

HOUSTON, TX 77041

PHONE: 713-895-7062

FAX: 713-690-4540

DALLAS

3040 QUEBEC

DALLAS, TX 75247

PHONE: 214-634-7271

FAX: 214-634-8874

UTAH

SALT LAKE CITY

2230 SOUTH MAIN STREET

SALT LAKE CITY, UT 84115

PHONE: 801-832-0127

FAX: 801-832-8911

WISCONSIN

MILWAUKEE

2725 SOUTH 163RD STREET

NEW BERLIN, WI 53151

PHONE: 262-784-5940

FAX: 262-784-1215

INTERNATIONAL SALES

FORT SMITH, AR

P.O. BOX 2400

FORT SMITH, AR 72902

PHONE: 479-646-4711

FAX: 479-648-5895

CANADA

EDMONTON, ALBERTA

4053-92 STREET

EDMONTON, ALBERTA T6E 6R8

PHONE: 780-434-4900

FAX: 780-438-2600

OAKVILLE, ONTARIO

2750 COVENTRY ROAD

OAKVILLE, ONTARIO L6H 6R1

PHONE: 905-829-3301

FAX: 905-829-3302

MONTREAL, QUEBEC

1844 WILLIAM STREET

MONTREAL, QUEBEC H3J 1R5

PHONE: 514-933-2711

FAX: 514-933-8639

VANCOUVER,

BRITISH COLUMBIA

1538 KEBET WAY

PORT COQUITLAM, BC V3C 5M5

PHONE 604-421-2822

FAX: 604-421-3113

WINNIPEG, MANITOBA

54 PRINCESS STREET

WINNIPEG, MANITOBA R3B 1K2

PHONE: 204-942-5205

FAX: 204-956-4251

AUSTRALIA

UNIT 3, 6 STANTON ROAD

SEVEN HILLS, NSW 2147,

AUSTRALIA

PHONE: (61) (2) 9674 5455

FAX: (61) (2) 9674 2495

UNIT 8, 5 KELLETTS ROAD

ROWVILLE, VICTORIA, 3178

AUSTRALIA

PHONE: (61) (3) 9753 4355

FAX: (61) (3) 9753 4366

IAMÉRICA DEL SUR

APTDO. 9109 0818 ZONA 6

BETHANIA,

CIUDAD DE PANAMÁ, PANAMÁ

PHONE: +507 261-5347

FAX: +507 261-5355

CENTRO AMÉRICA Y CARIBE

RESIDENCIAL PINARES DE SUIZA

POL. 15 #44,

NVA. SAN SALVADOR, EL SALVADOR

PHONE: +503 2288-1519

FAX: +503 2288-1518

CHINA

SHANGHAI JIAHUA BUSINESS CENTER

ROOM NO. A-8421

808 HONG QIAO ROAD

SHANGHAI 200030

PHONE: 86-21-64473060

FAX: 86-21-64078620

GERMANY

DIESELSTRASSE 22

D-85551 KIRCHHEIM

MUNICH, GERMANY

PHONE: (49) (89) 90508 - 0

FAX: (49) (89) 90508 - 492

INDIA

14, COMMERCE AVENUE

MAHAGANESH COLO

PAUD ROAD

PUNE - 411 038

MAHARASHTRA, INDIA

PHONE: 91 20 25 45 95 31/32

FAX: 91 20 24 55 95 30

NY

ITALY

BALDOR ASR AG

SUCCURSALE DI MENDRISIO

VIA BORROMINI, 20A

CH-6850 MENDRISIO

SWITZERLAND

PHONE: 41 91 640 9952

FAX: 41 91 630 2633

JAPAN

DIA BLDG 802,

2-21-1 TSURUYA-CHO,

KANAGAWA-KU

YOKOHAMA, 221-0835, JAPAN

PHONE: 81-45-412-4506

FAX: 81-45-412-4507

KOREA

ROOM 208-37

INCHEON INDUSTRIAL GOODS

CIRCULATING CENTER

SONGHYEON 3-DONG, DONG-GU

INCHEON. KOREA, 401-705

PHONE: 82 32 588 3253

FAX: 82 32 588 3254

MÉXICO

KM. 2.0 BLVD. AL AEROPUERTO

LEÓN 37545, GUANAJUATO,

MÉXICO

PHONE: 52 477 761 2030

FAX: 52 477 761 2010

MIDDLE EAST & NORTH AFRICA

VSE INTERNATIONAL CORP.

3233 NORTH ARLINGTON HEIGHTS

SUITE 100W

ARLINGTON HEIGHTS, IL 60004

PHONE: 847 590 5547

SINGAPORE

51 KAKI BUKIT ROAD 2

K B WAREHOUSE COMPLEX

SINGAPORE 417863

PHONE: (65) 6 744 2572

FAX: (65) 6 747 1708

SWITZERLAND

POSTFACH 73

SCHUTZENSTRASSE 59

CH-8245 FEUERTHALEN

SWITZERLAND

PHONE: (41) (52) 6474700

FAX: (41) (52) 6592394

TAIWAN

4F, NO. 25, SEC. 1,

TUNHUA S ROAD,

TAIPEI 10557, TAIWAN, R.O.C.

PHONE: (886-2) 2577-4352

(886-2) 2577-4157

FAX:

UNITED KINGDOM

6 BRISTOL DISTRIBUTION PARK

HAWKLEY DRIVE

BRISTOL BS32 0BF U.K.

PHONE: 44 1454 850000

FAX: 44 1454 859001

© Baldor Electric Company

BR600

Baldor Electric Company

P.O. Box 2400

Fort Smith, AR 72902-2400 U.S.A

Ph (479) 646-4711 • Fax (479) 648-5792

International Fax (479) 648-5895

www.baldor.com

Printed in U.S.A.

7/05 PROG 20,000

Loading...

Loading...