Page 1

SERVICE MANUAL

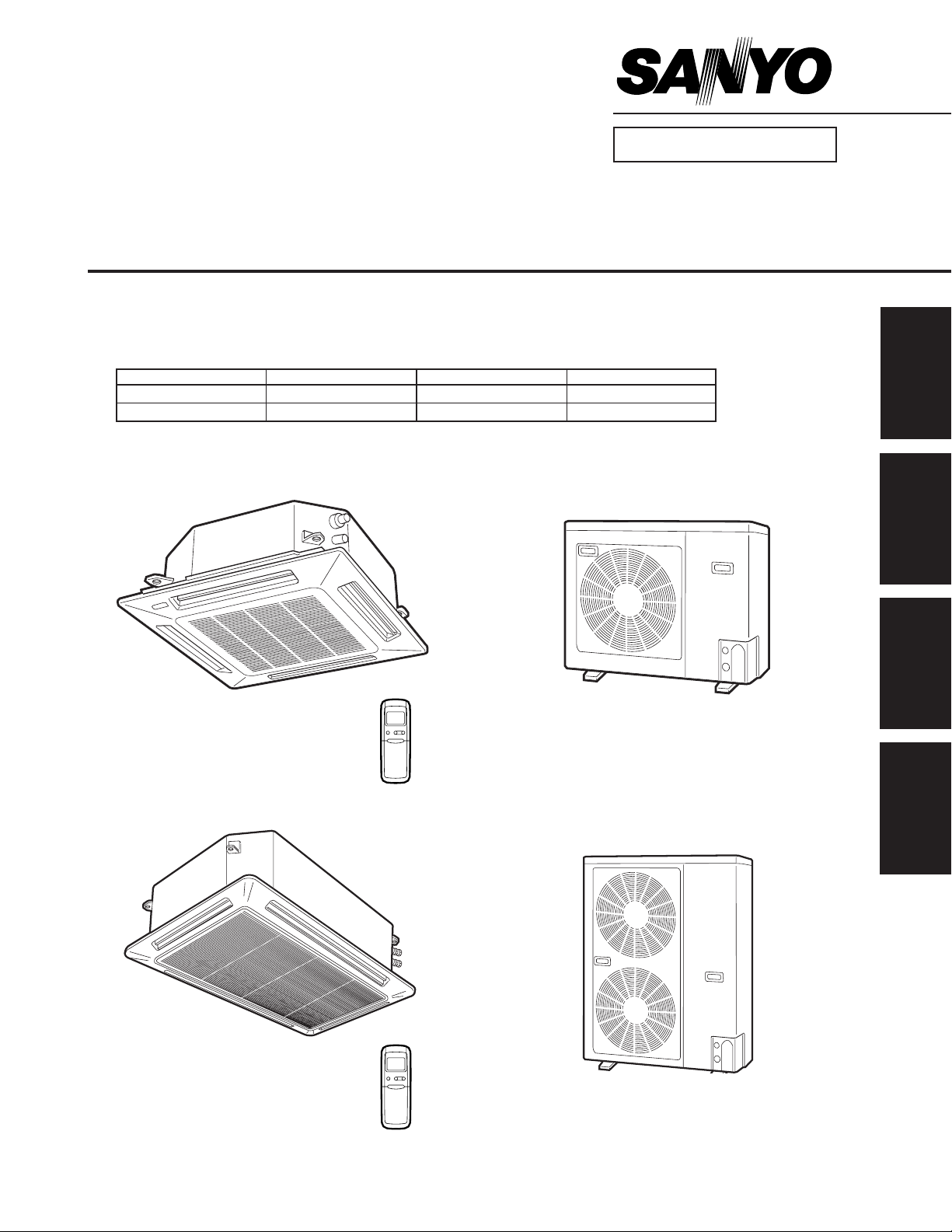

XHS2432 / CH2432

XHS3632 / CH3632

SPLIT SYSTEM AIR CONDITIONER

FILE NO.

Section

INDOOR MODEL No. PRODUCT CODE No. OUTDOOR MODEL No. PRODUCT CODE No.

XHS2432 854 013 40 CH2432 854 013 42

XHS3632 854 015 45 CH3632 854 014 57

Indoor Unit Outdoor Unit

XHS2432 CH2432

1

2

3

4

XHS3632 CH3632

85464849176000 REFERENCE NO. SM830076

Page 2

Important

Please Read Before Starting

This air conditioning system meets strict safety and operating

standards. As the installer or service person, it is an important

part of your job to install or service the system so it operates

safely and efficiently.

For safe installation and trouble-free operation, you must :

ⓦ Carefully read this instruction booklet before beginning.

ⓦ Follow each installation or repair step exactly as shown.

ⓦ Observe all local, state, and national electrical codes.

ⓦ Pay close attention to all warning and caution notices

given in this manual.

This symbol refers to a hazard or

unsafe practice which can result in

severe personal injury or death.

This symbol refers to a hazard or

CAUTION

unsafe practice which can result in

personal injury or product or

property damage.

If Necessary, Get Help

These instructions are all you need for most installation sites

and maintenance conditions. If you require help for a special

problem, contact our sales/service outlet or your certified dealer

for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for improper

installation or maintenance service, including failure to follow

the instructions in this document.

SPECIAL PRECAUTIONS

When Wiring

……………………………………………………………………

ELECTRICAL SHOCK CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH. ONLY A

QUALIFIED, EXPERIENCED ELECTRICIAN

SHOULD ATTEMPT TO WIRE THIS SYSTEM.

• Do not supply power to the unit until all wiring and tubing are

completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this system.

Carefully refer to the wiring diagram and these instructions

when wiring. Improper connections and inadequate grounding can cause accidental injury or death.

• Ground the unit following local electrical codes.

• Connect all wiring tightly. Loose wiring may cause overheating at connection points and a possible fire hazard.

When Transporting

……………………………………………………………………

Be careful when picking up and moving the indoor and outdoor

units. Get a partner to help, and bend your knees when lifting to

reduce strain on your back. Sharp edges or thin aluminum fins

on the air conditioner can cut your fingers.

When Installing

……………………………………………………………………

…In a Room

Properly insulate any tubing run inside a room to prevent

“sweating” that can cause dripping and water damage to walls

and floors.

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide a

solid, level foundation for the outdoor unit. This prevents water

damage and abnormal vibration.

…In an area with High Winds

Securely anchor the outdoor unit down with bolts and a metal

frame. Provide a suitable air baffle.

…In a Snowy Area (for Heat Pump-type Sys-tems)

Install the outdoor unit on a raised platform that is higher than

drifting snow. Provide snow vents.

When Connecting Refrigerant Tubing

……………………………………………………………………

• Ventilate the room well, in the event that refrigerant gas

leaks during the installation. Be careful not to allow contact

of the refrigerant gas with a flame as this will cause the

generation of poisonous gas.

• Keep all tubing runs as short as possible.

• Use the flare method for connecting tubing.

• Apply refrigerant lubricant to the matching surfaces of the

flare and union tubes before connecting them, then tighten

the nut with a torque wrench for a leak-free connection.

• Check carefully for leaks before starting the test run.

NOTE

Depending on the system type, liquid and gas lines may be

either narrow or wide. Therefore, to avoid confusion the

refrigerant tubing for your particular model is specified as either

“narrow” or “wide” rather than as “liquid” or “gas”.

When Servicing

……………………………………………………………………

• Turn the power OFF at the main power box (mains) before

opening the unit to check or repair electrical parts and

wiring.

• Keep your fingers and clothing away from any moving parts.

• Clean up the site when installation is finished. Check that no

metal scraps or bits of wiring have been left inside the unit.

CAUTION

• Ventilate any enclosed areas when installing or testing the

refrigeration system. Contact of refrigerant gas with fire or

heat can produce poisonous gas.

• Confirm after installation that no refrigerant gas is leaking. If

the gas comes in contact with a burning stove, gas water

heater, electric room heater or other heat source, it can

cause the generation of poisonous gas.

– 2 –

SM830076

Page 3

WHO SHOULD USE THIS MANUAL

This service manual is made to assist the service technician apply his knowledge and training

to this model air conditioner. This manual is written both for experienced service persons

and those who are new to air conditioning service. To help those with less experience or

who are new to this kind of unit we have included more explanations of basic procedures in

simple language than is usual in some service manuals. The experienced technician will of

course find he knows many of these things already and can go directly to the procedures and

information he needs; the less experienced technician will better understand what to do even

before he arrives on the job, and therefore be better able to work by himself as well as assist

the more experienced technician.

TABLE OF CONTENTS

1. SPECIFICATIONS.........................................................................................................6

1-1 Unit Specifications ................................................................................................7

1-2 Major Component Specifications ........................................................................11

(A)Indoor Unit .....................................................................................................11

(B)Outdoor Unit ..................................................................................................13

1-3 Other Component Specifications ........................................................................15

(A)Indoor Unit .....................................................................................................15

(B)Outdoor Unit ..................................................................................................17

1-4 Dimensional Data................................................................................................19

(A)Indoor Unit .....................................................................................................19

(B)Outdoor Unit ..................................................................................................21

1-5 Refrigerant Flow Diagram ...................................................................................23

1-6 Operating Range.................................................................................................23

2. PROCESSES AND FUNCTIONS ................................................................................25

2-1 Room Temperature Control ................................................................................26

(A)Cooling ..........................................................................................................26

(B)Heating ..........................................................................................................27

2-2 Cold Draft Prevention (Heating Cycle) ................................................................28

2-3 Automatic Fan Speed (Indoor Unit).....................................................................29

(A)Cooling ..........................................................................................................29

(B)Heating ..........................................................................................................29

2-4 Outdoor Fan Speed Control................................................................................30

(A)Cooling ..........................................................................................................30

(B)Heating ..........................................................................................................30

2-5 Freeze Prevention (Cooling) ...............................................................................31

2-6 Condensing Temperature Control (Cooling) ...................................................... 32

2-7 Overload Protection (Heating).............................................................................33

2-8 Discharge Temperature Control (Cooling and Heating)..................................... 34

– 3 –

SM830076

Page 4

2-9 Auto. Mode for Automatic Heating/Cooling Switching........................................ 35

2-10 Defrosting Control, Outdoor Heat Exchanger Coil (Heating).............................. 37

2-11 4-Way Valve, Solenoid Control ...........................................................................38

(A)Normal Control Mode ....................................................................................38

(B)AUTO Control Mode ......................................................................................39

2-12 Automatic Restart after Power Interruption ........................................................ 39

2-13 Electronic Expansion Valve ................................................................................40

2-14 Compressor Discharge Gas Temperature ......................................................... 40

(A)Cooling ..........................................................................................................40

(B)Heating (Except During Defrosting)...............................................................40

2-15 Compressor Current Detection Circuit ................................................................41

2-16 Electronic Expansion Valve Control ....................................................................42

2-17 Voltage Detection Control ...................................................................................43

3. ELECTRICAL DATA....................................................................................................45

3-1 Indoor Unit (Electric Wiring Diagram, Schematic Diagram) ............................... 46

3-2 Outdoor Unit (Electric Wiring Diagram, Schematic Diagram)............................. 48

4. SERVICE PROCEDURES ...........................................................................................53

4-1 Troubleshooting ..................................................................................................54

4-2 Checking the Electrical Components ..................................................................87

– 4 –

SM830076

Page 5

Introduction:

Read Me First!

This manual will help you understand and service the air conditioner. To help you find the information you need,

we have divided it into 5 main sections. Each section is divided into chapters with charts, tables and explanations to help you find and repair problems.

❑ Section 1: Specifications, tells you about the physical and electrical make up of the unit, as well

as its heating and cooling capacities. Look in this section to find the correct values for

components and functions.

❑ Section 2: Processes and Functions, explains each different part of the cooling and heating

cycle, and how each control function reacts to changing conditions to keep the room at the set

temperature range.

❑ Section 3: Electrical Data, which has fold-out schematic and wiring diagrams so you can find

the parts you need to check when something is wrong, and see how they should be connected.

❑ Section 4: Service Procedures, has two main parts, a

specific component to replace or adjust, and a chapter with specific procedures and values to

guide you in checking the electrical components in the unit.

WHAT IS IN THIS MANUAL

diagnostic

chapter to help you find the

HOW TO USE THIS MANUAL

You can use this manual both as a reference to find specific information about the capacity, functions and

construction of this unit, and as a source of information to help you set up and maintain the unit.

When this unit is not working properly, and the cause is not known, you can use the procedures in

Section 3: Servicing Procedures to find the problem, fix it, and restore the unit to its proper functioning.

This air conditioner has many helpful self diagnostic features to help you identify problem areas quickly.

So you will be ready when a problem happens, we suggest you look this manual over and become familiar with it

by following these steps:

1. Look at the TABLE OF CONTENTS to get an idea of what is in this manual and where to find it.

2. Look at the chapter about TROUBLE SHOOTING, so you are familiar with the way the flow

charts work. They are designed to guide you quickly through the possible causes for each kind of

problem that is likely to happen to the Unit. Particularly read the introduction to this section, and

the parts about the self-diagnosis and error codes which show on the display.

3. Look at the chapter about CHECKING ELECTRICAL COMPONENTS. You already know

about most of these procedures. This chapter gives you the specific values and methods for

these components. If you don’t know some of these procedures, you can easily learn them here.

4. Read the Instruction Manual! The Instruction Manual is included here because it helps you help

the user to set the temperature controls properly and know how to take care of any simple

problems that may happen, as well as know when to call for service. The Instruction Manual also

has illustrations, care, and installation information not found in the rest of the service manual. It is

short, and if you read it carefully, you will be able to answer the customers questions easily, and

also know the most efficient ways for setting times and temperatures.

Please use this manual to make your work easier, keep the air conditioner functioning well, and keep your

customers satisfied.

– 5 –

SM830076

Page 6

1. SPECIFICATIONS

1-1 Unit Specifications ...........................................................................................7

1-2 Major Component Specifications .................................................................. 11

(A)Indoor Unit ................................................................................................ 11

(B)Outdoor Unit .............................................................................................13

1-3 Other Component Specifications .................................................................. 15

(A)Indoor Unit ................................................................................................ 15

(B)Outdoor Unit .............................................................................................17

1-4 Dimensional Data...........................................................................................19

(A)Indoor Unit ................................................................................................ 19

(B)Outdoor Unit .............................................................................................21

1-5 Refrigerant Flow Diagram ............................................................................. 23

1-6 Operating Range............................................................................................23

1

– 6 –

SM830076

Page 7

1. Specifications

1-1 Unit Specifications

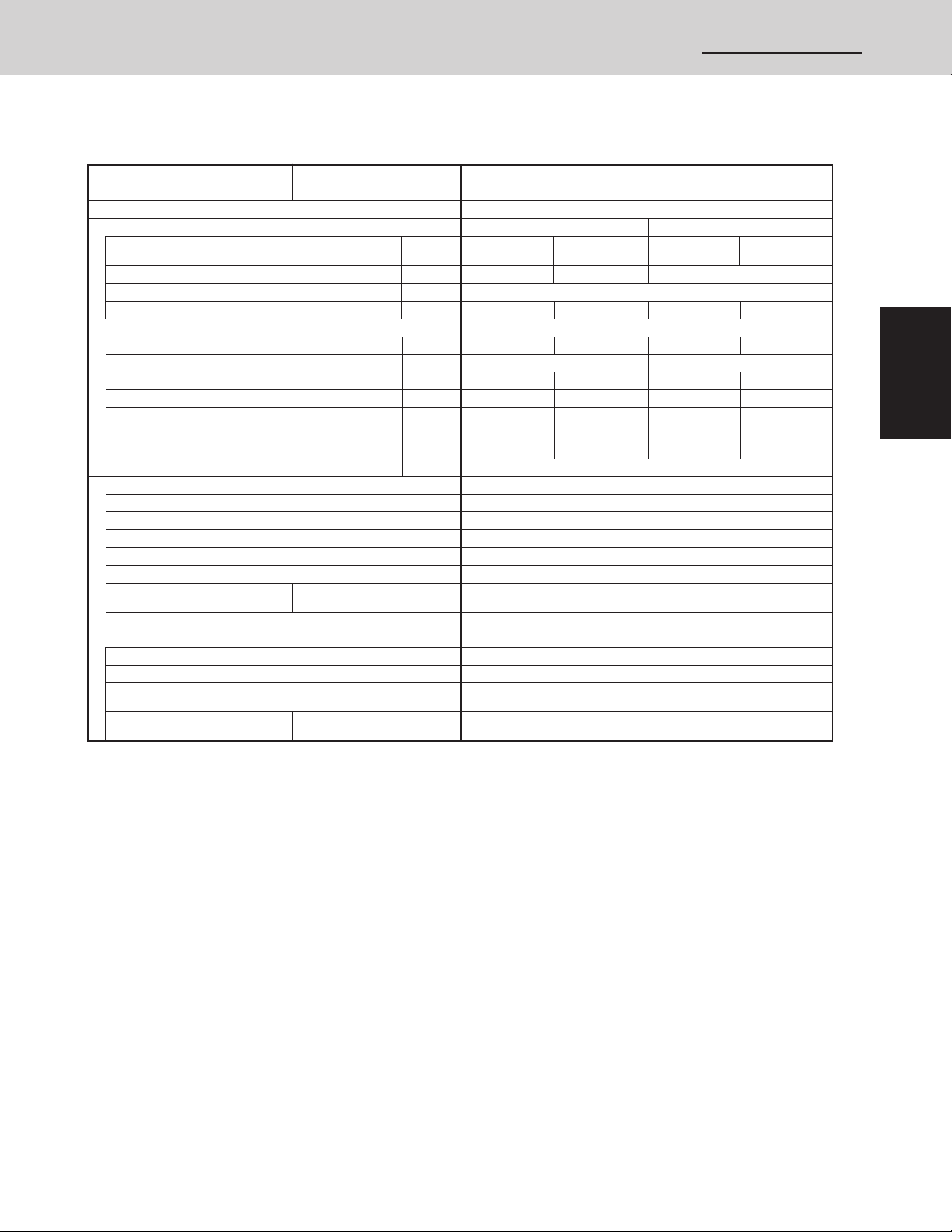

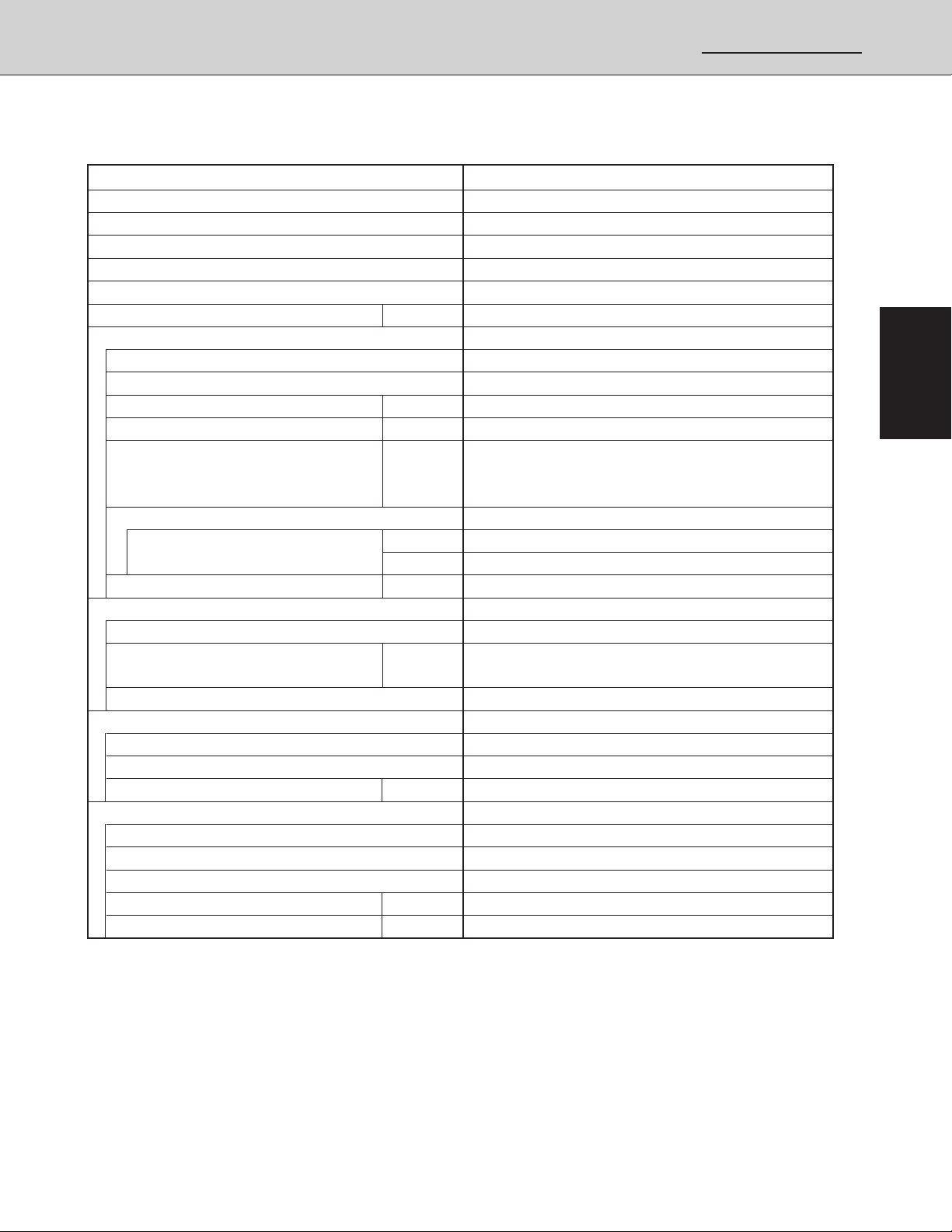

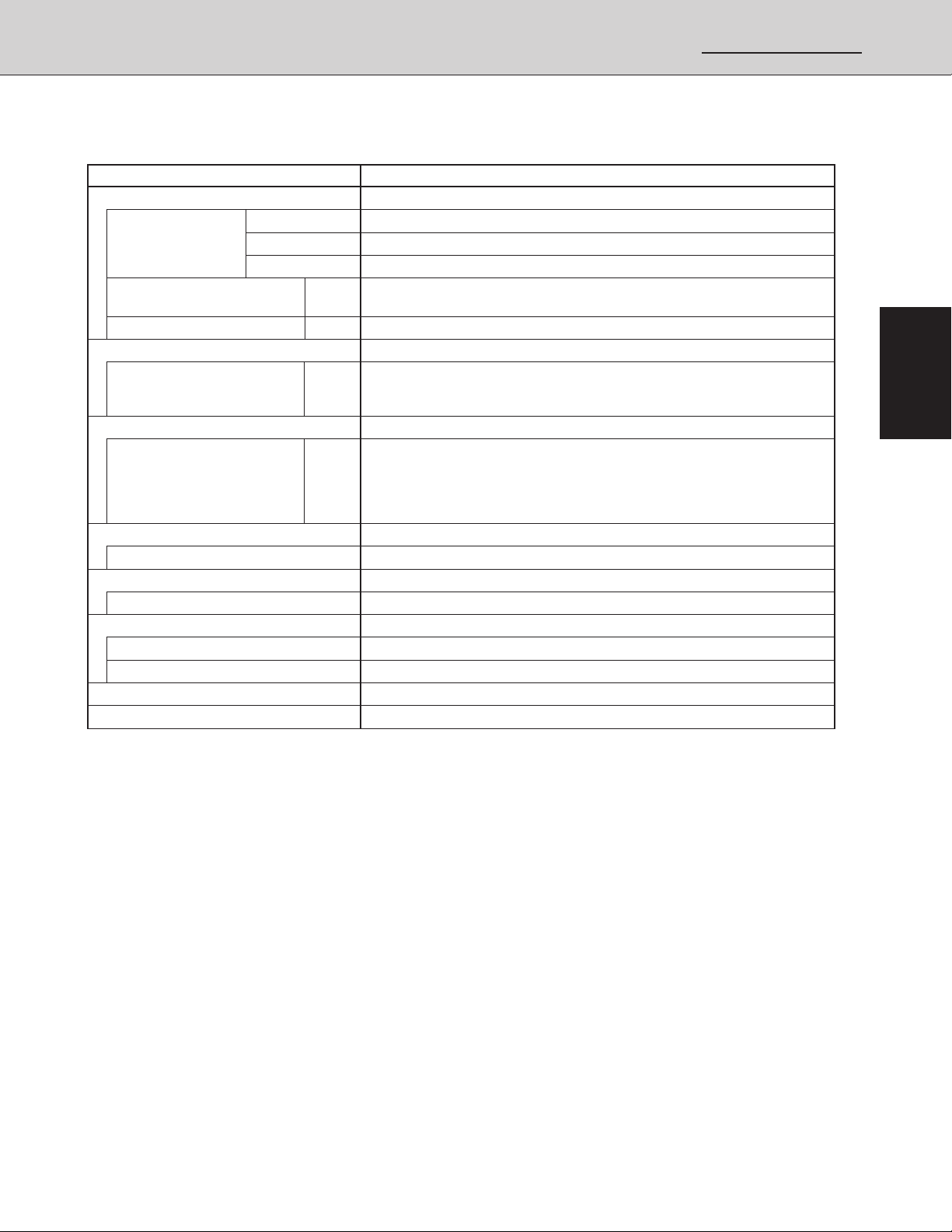

MODEL No. Indoor Unit XHS2432

Outdoor Unit CH2432

POWER SOURCE 230 - 208 V / 1 Phase / 60 Hz

PERFORMANCE Cooling Heating

Capacity* BTU / h 24,000 23,400 25,000 24,300

Moisture removal (High) Pints / h 8.6 8.4 —

Air circulation (Hi)

S.E.E.R. (H.S.P.F.)

ELECTRICAL RATINGS

Voltage rating VAC 230 208 230 208

Available voltage range VAC 187 - 253 187 - 253

Running amperes A 11.2 11.6 11.7 12.3

Max. running amperes A — — — —

Power input* W 2,450 2,350 2,500 2,450

Buck-up heater kW — — — —

Maximum fuse size A 30

FEATURES

Controls Microprocessor

Fan speeds Indoor / Outdoor 3 and Automatic control / 2 (Auto)

Timer ON / OFF 24-hours & Program

Air deflection Horizontal / Vertical — / Automatic

Air filter Washable, easy access, long life fiter (2,500 hr)

Operation sound Indoor dB - A 37 / 35 / 31

Hi / Me / Lo Outdoor - Hi dB - A 53

Refrigerant control Electronic Refrigerant Control Valve

REFRIGERANT PIPING

Limit of piping length ft. (m) 165 (50)

Limit of piping length at shipment ft. (m) 100 (30)

Limit of elevation difference ft. (m) Outdoor unit is higher than indoor unit: 165 (50)

between the two units Outdoor unit is lower than indoor unit: 100 (30)

Refrigerant piping Narrow pipe in. (mm) 1 / 4 (6.35)

Flare type Wide pipe in. (mm) 3 / 4 (19.05)

(17°F)** 16,400 15,800

cu.ft. / min.

BTU / Wh

(17°F)** 2,150 2,020

10.0 10.2 (7.0) (7.0)

540 / 510

1

2

3

– 7 –

4

SM830076

Page 8

1

2

1. Specifications

1-1 Unit Specifications

DIMENSIONS & WEIGHT Indoor unit Outdoor unit

Unit dimensions Height in. (mm) 9-27/32 (250) 28-30/32 (735)

Width in. (mm) 29-29/32 (760) 37 (940)

Depth in. (mm) 29-29/32 (760) 13-12/32 (340)

Net weight lbs. (kg) 49 (22) 157 (71)

Indoor grille dimensions Height in. (mm) 3-1/16 (78)

PNR-XHS2432 Width in. (mm) 33-27/32 (860)

Depth in. (mm) 33-27/32 (860)

Net weight lbs. (kg) 11 (5)

Indoor / Outdoor unit Height in. (mm) 11-6/32 (284) 32-17/32 (826)

Package dimensions Width in. (mm) 32-14/32 (824) 40 (1,016)

Depth in. (mm) 32-25/32 (833) 16-12/32 (416)

Shipping weight lbs. (kg) 60 (27) 170 (77)

Shipping volume cu.ft. (m3) 6.9 (0.195) 12.3 (0.349)

Indoor grille Height in. (mm) 4-3/32 (104)

Package dimensions Width in. (mm) 38-2/32 (967)

PNR-XHS2432 Depth in. (mm) 39-11/32 (999)

Shipping weight lbs. (kg) 18 (8)

Shipping volume cu.ft. (m3) 3.5 (0.100)

Cooling :

Rating conditions (*) : Room temperature 80 °F DB / 67 °F WB, Ambient temperature 95 °F DB / 75 °F WB

Heating :

Rating conditions (*) : Room temperature 70 °F DB / 60 °F WB, Ambient temperature 47 °F DB / 43 °F WB

Low temp conditions (**): Room temperature 70 °F DB / 60 °F WB, Ambient temperature 17 °F DB / 15 °F WB

DATA SUBJECT TO CHANGE WITHOUT NOTICE

3

4

– 8 –

SM830076

Page 9

1. Specifications

1-1 Unit Specifications

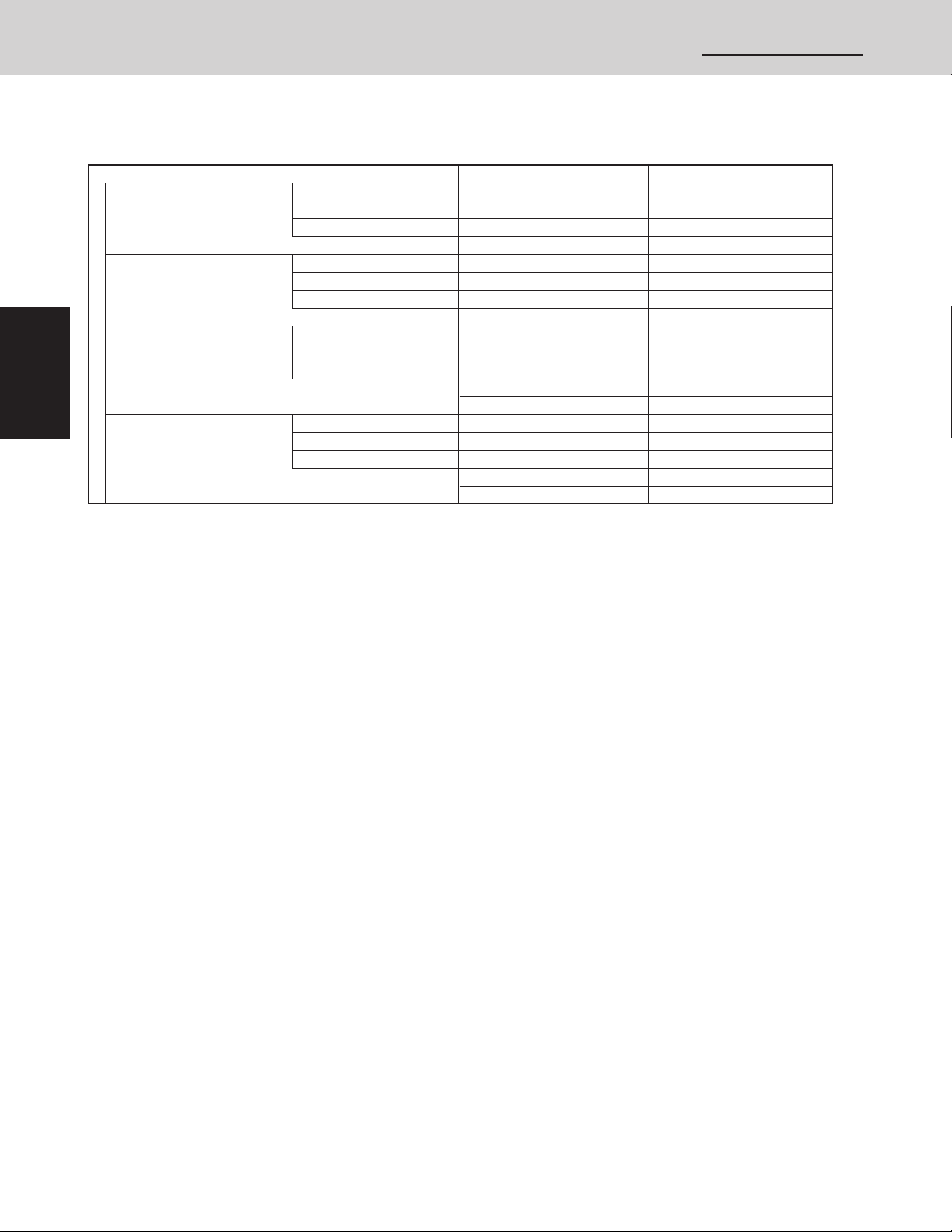

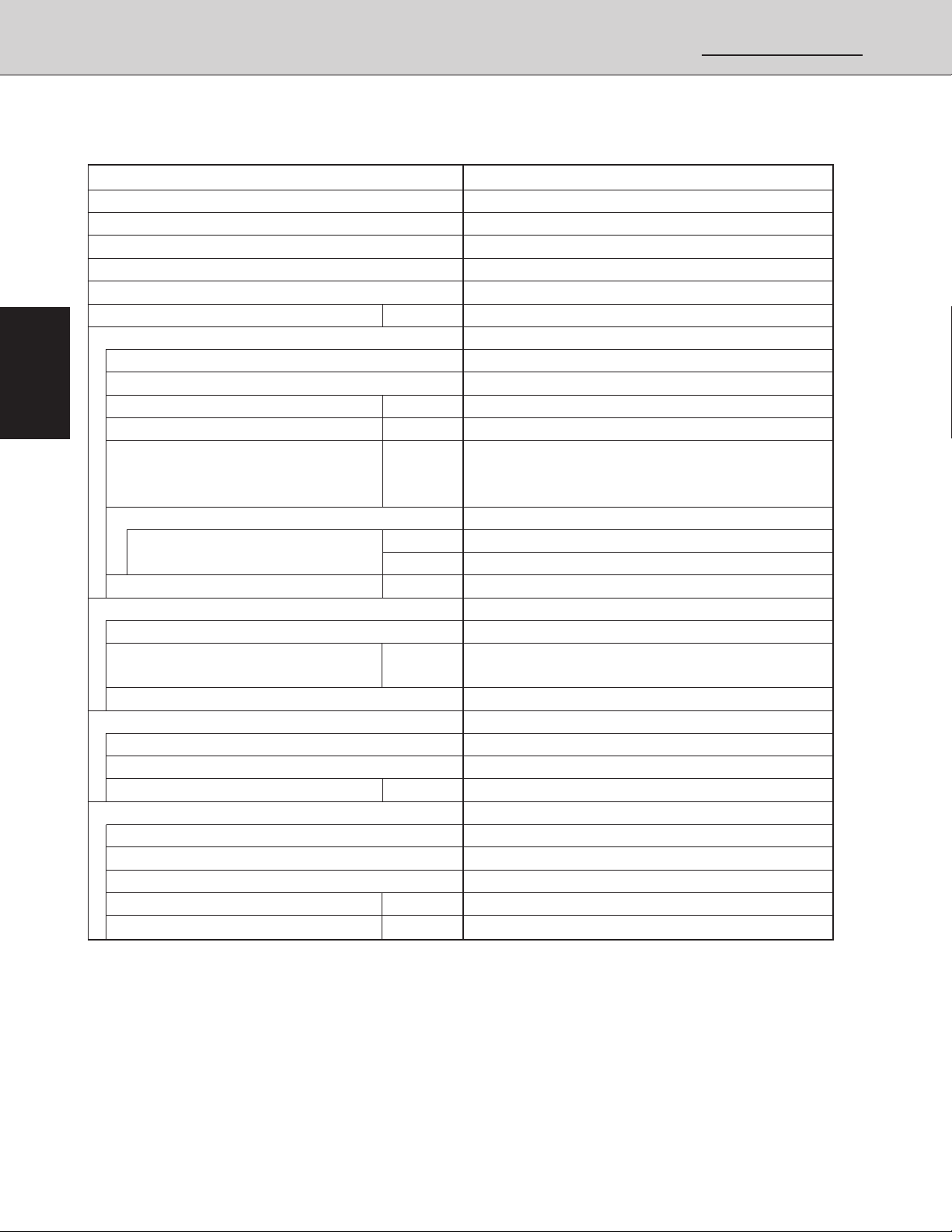

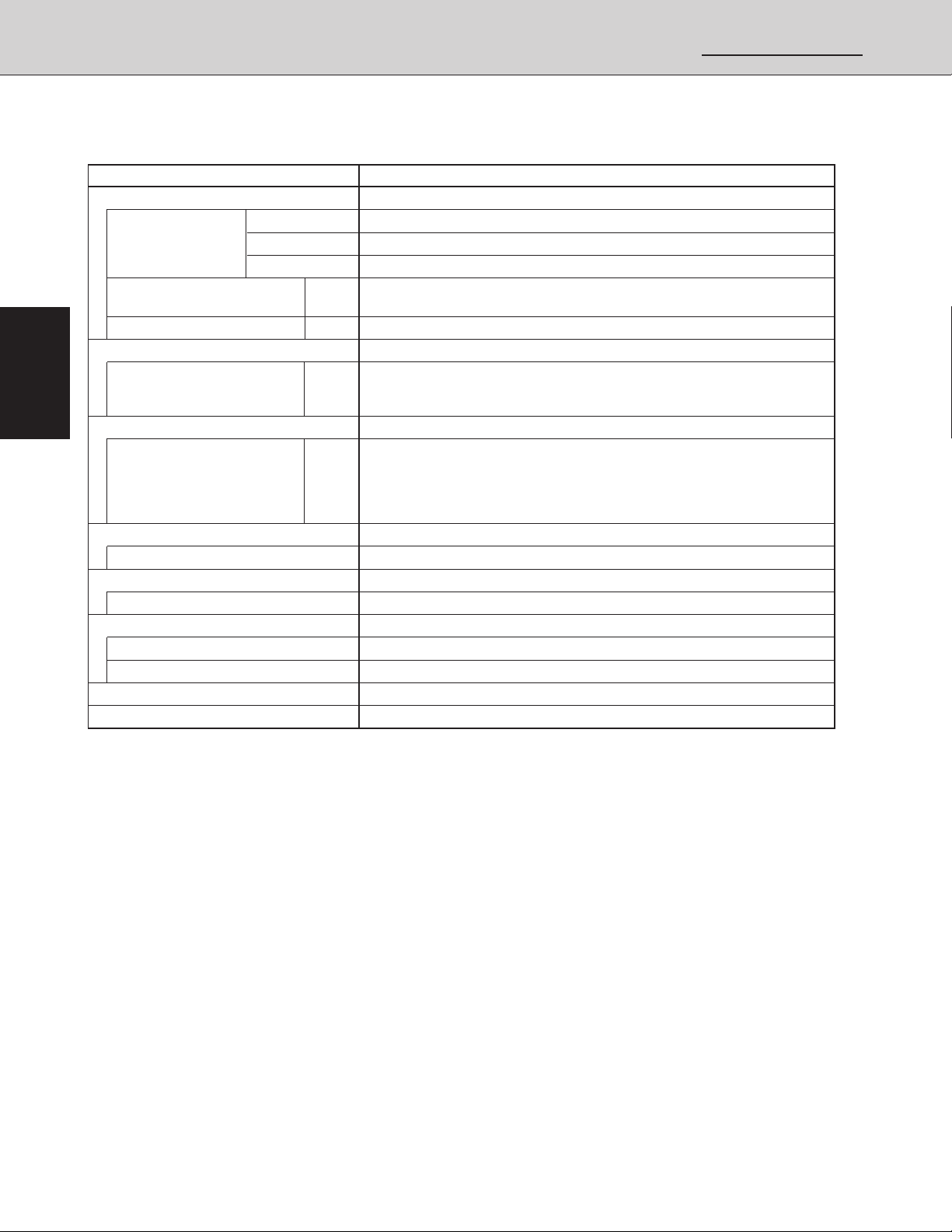

MODEL No. Indoor Unit XHS3632

Outdoor Unit CH3632

POWER SOURCE 230 - 208 VAC / 1 Phase / 60 Hz

PERFORMANCE Cooling Heating

Capacity* BTU / h 34,500 33,500 37,500 36,500

Moisture removal (High) Pints / h 11.1 11.1 —

Air circulation (Hi)

S.E.E.R. (H.S.P.F.)

ELECTRICAL RATINGS

Voltage rating VAC 230 208 230 208

Available voltage range VAC 187 - 253 187 - 253

Running amperes A 15.4 15.8 18.2 19.3

Max. running amperes A — — — —

Power input* W 3,350 3,200 3,850 3,750

Buck-up heater kW — — — —

Maximum fuse size A 30

FEATURES

Controls Microprocessor

Fan speeds Indoor / Outdoor 3 and Automatic control / 2 (Auto)

Timer ON / OFF 24-hours & Program

Air deflection Horizontal / Vertical — / Automatic

Air filter Washable, easy access, long life fiter (2,500 hr)

Operation sound Indoor dB - A 43 / 40 / 36

Hi / Me / Lo Outdoor - Hi dB - A 56

Refrigerant control Electronic Refrigerant Control Valve

REFRIGERANT PIPING

Limit of piping length ft. (m) 165 (50)

Limit of piping length at shipment ft. (m) 100 (30)

Limit of elevation difference ft. (m) Outdoor unit is higher than indoor unit: 165 (50)

between the two units Outdoor unit is lower than indoor unit: 100 (30)

Refrigerant piping Narrow pipe in. (mm) 3 / 8 (9.52)

Flare type Wide pipe in. (mm) 3 / 4 (19.05)

(17°F)** 25,000 23,500

cu.ft. / min.

BTU / Wh

(17°F)** 3,150 2,950

10.7 11.0 (7.0) (7.0)

980 / 880

1

2

3

– 9 –

4

SM830076

Page 10

1

2

1. Specifications

1-1 Unit Specifications

DIMENSIONS & WEIGHT Indoor unit Outdoor unit

Unit dimensions Height in. (mm) 11-1/32 (280) 48-20/32 (1,235)

Width in. (mm) 41-11/32 (1,050) 37 (940)

Depth in. (mm) 29-29/32 (760) 13-12/32 (340)

Net weight lbs. (kg) 60 (27) 203 (92)

Indoor grille dimensions Height in. (mm) 3-1/6 (78)

PNR-XHS3632 Width in. (mm) 33-27/32 (1,150)

Depth in. (mm) 33-27/32 (860)

Net weight lbs. (kg) 15 (7)

Indoor / Outdoor unit Height in. (mm) 12-14/32 (316) 52-7/32 (1,326)

Package dimensions Width in. (mm) 43-27/32 (1,114) 40 (1,016)

Depth in. (mm) 32-25/32 (833) 16-12/32 (416)

Shipping weight lbs. (kg) 71 (32) 227 (103)

Shipping volume cu.ft. (m3) 10.3 (0.293) 19.8 (0.56)

Indoor grille Height in. (mm) 4-3/32 (104)

Package dimensions Width in. (mm) 49-16/32 (1,257)

PNR-XHS3632 Depth in. (mm) 39-11/32 (999)

Shipping weight lbs. (kg) 29 (13)

Shipping volume cu.ft. (m3) 4.6 (0.131)

Cooling :

Rating conditions (*) : Room temperature 80 °F DB / 67 °F WB, Ambient temperature 95 °F DB / 75 °F WB

Heating :

Rating conditions (*) : Room temperature 70 °F DB / 60 °F WB, Ambient temperature 47 °F DB / 43 °F WB

Low temp conditions (**): Room temperature 70 °F DB / 60 °F WB, Ambient temperature 17 °F DB / 15 °F WB

DATA SUBJECT TO CHANGE WITHOUT NOTICE

3

4

– 10 –

SM830076

Page 11

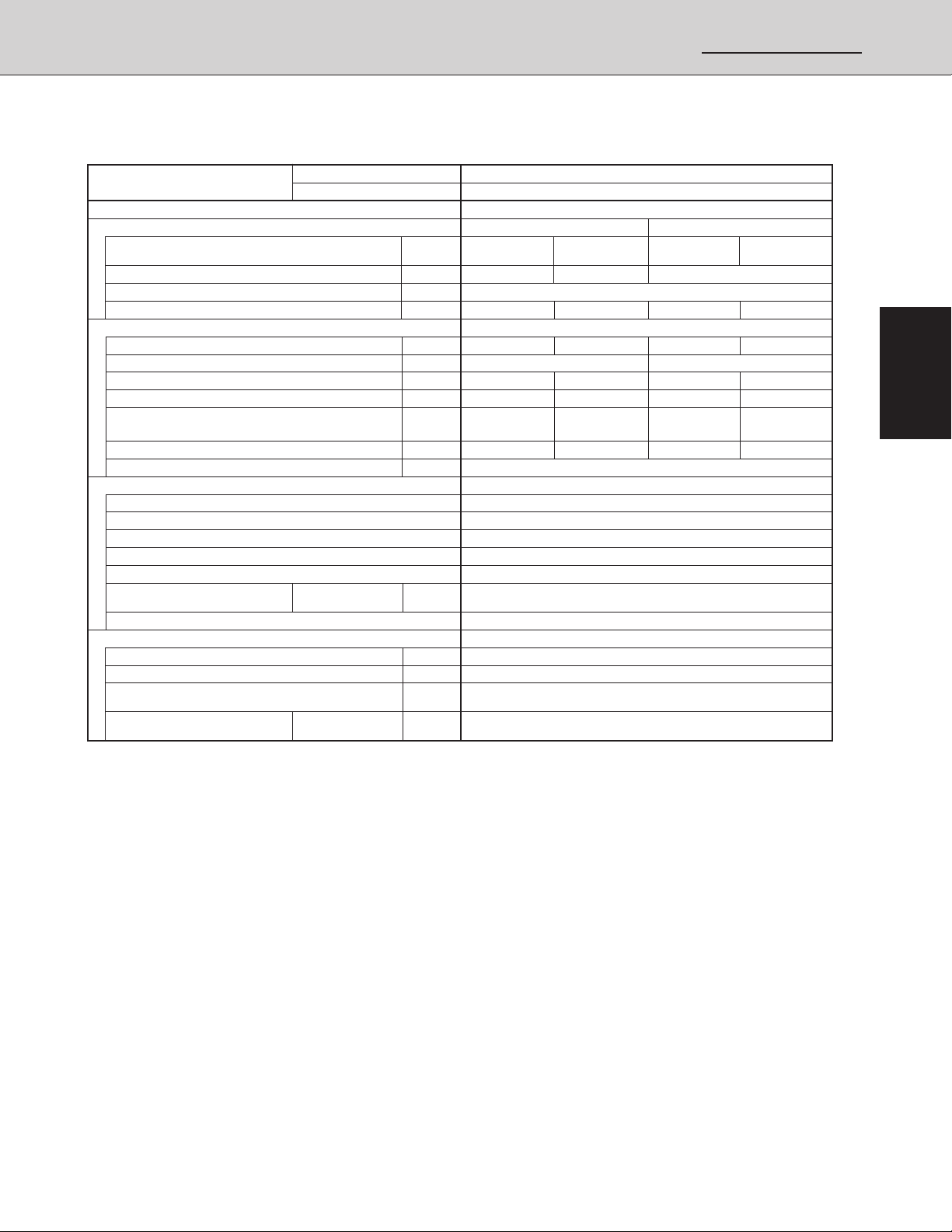

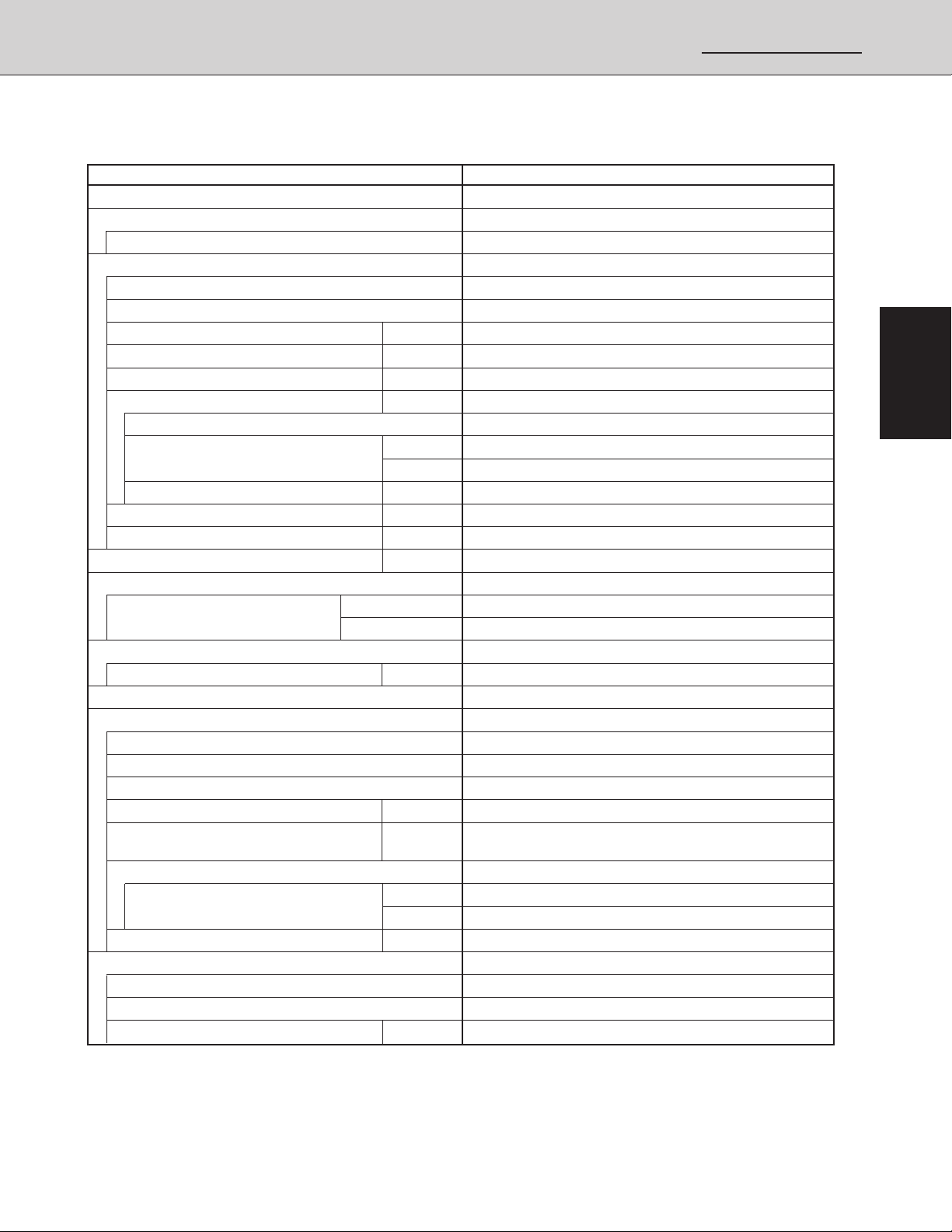

1. Specifications

1-2 Major Component Specifications

(A) Indoor Unit

MODEL No. XHS2432

Source 230 - 208 VAC / 1 phase / 60 Hz

Remote controller (Accessory) RCS - 5HPS4U

Controller P. C. B Ass'y CR - THS2432

Control circuit fuse 250 VAC, 3 A

Controller Ass'y CR - 3XHS

Fan (Number … diameter) in. (mm) Turbo (1…19-9/32 (490))

Fan motor

Model SFG6X - 41A5P

Source 230 - 208 V / 1 phase / 60 Hz

No. of pole … r.p.m. (230 V, High) rpm 6 … 451

Nominal output W 40

Coil resistance Ω BRW - WHT : 114.0 , ORG - YEL : 66.4

(Ambient temperature 68 °F) WHT - VLT : 23.9 , WHT - PNK : 77.4

VLT - ORG : 12.4 , YEL - BLK : 82.1

Safety device

Operating temperature Open °F266± 14.4

Close °F 174.2 ± 27

Run capacitor VAC, µF 440 V , 4 µF

Electronic expansion valve

Coil DKV - MOZS582E0

Coil resistance (at 20°C) Ω ORG - GRY : 46 , YEL - GRY : 46

RED - GRY : 46 , BLK - GRY : 46

Valve body IKV - 24D12

Heat exchanger

Coil Aluminum plate fin / Copper tube

Rows … Fins per inch 2 … 14.9

Face area ft.

Panel

Model No. PNR - XHS2432

Indicator Lamp Ass'y IND - 3THS

Auto louver motor MT8 - 3C

Auto louver motor … Rated V, W, rpm 240 VAC , 3 W , 3 rpm

Coil resistance (Ambient temperature 77 °F) Ω 16.430 Ω ± 8 %

2

(m2) 3.18 (0.295)

DATA SUBJECT TO CHANGE WITHOUT NOTICE

1

2

3

4

– 11 –

SM830076

Page 12

1

2

3

4

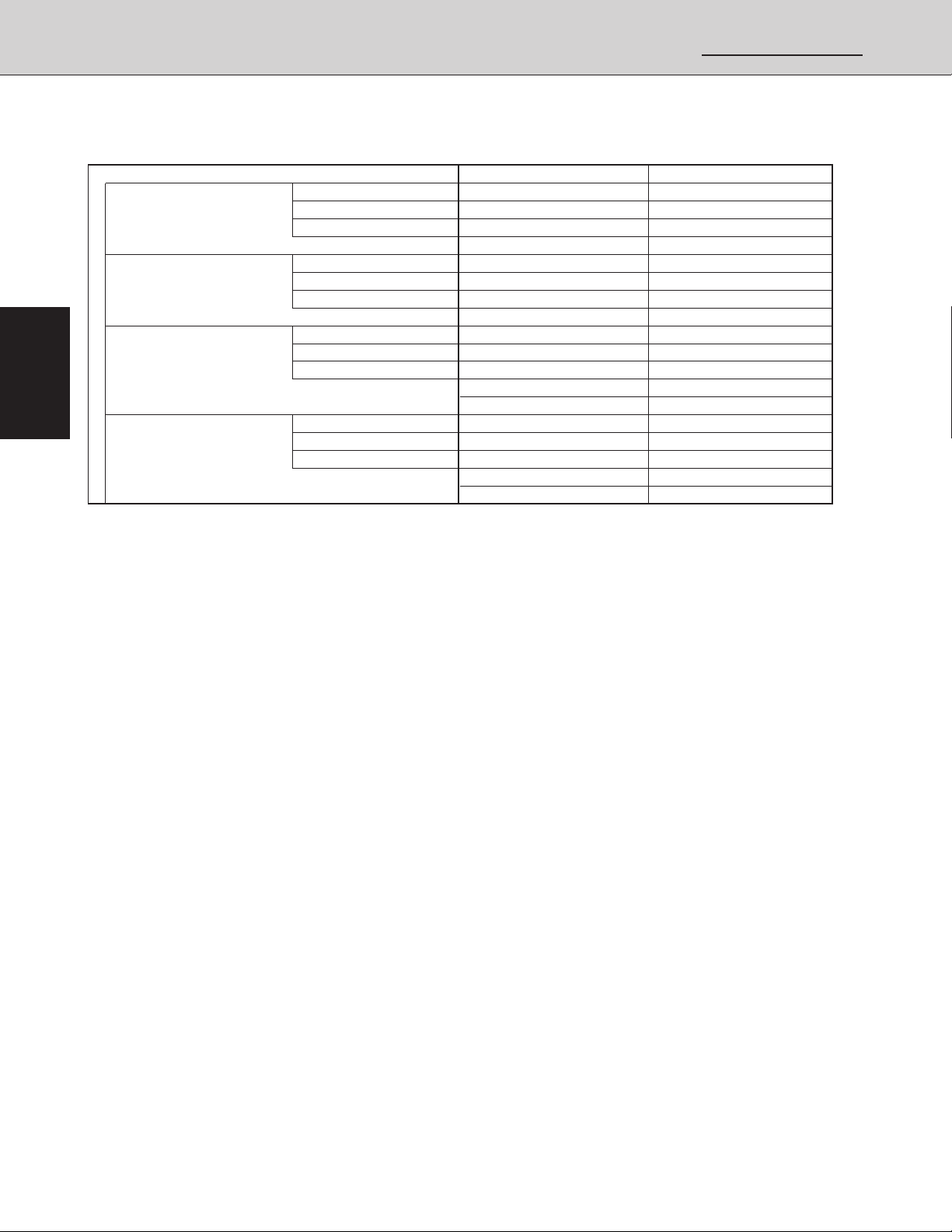

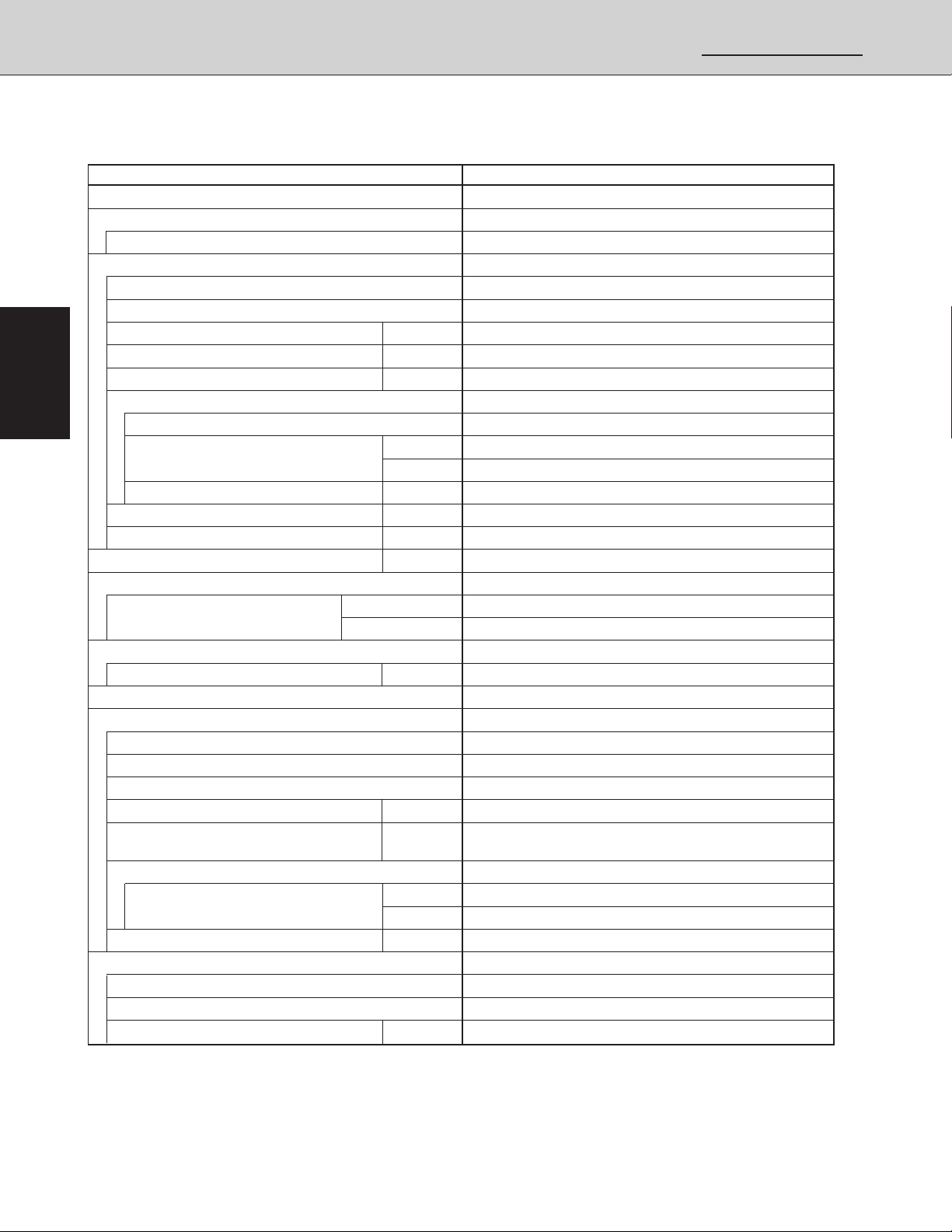

1. Specifications

1-2 Major Component Specifications

(A) Indoor Unit

MODEL No. XHS3632

Source 230 - 208 VAC / 1 phase / 60 Hz

Remote controller (Accessory) RCS - 5HPS4U

Controller P. C. B Ass'y CR - THS2432

Control circuit fuse 250 VAC, 3 A

Controller Ass'y CR - 3XHS

Fan (Number … diameter) in. (mm) Turbo (1…19-9/32 (490))

Fan motor

Model SFG6X - 61A3P

Source 230 - 208 V / 1 phase / 60 Hz

No. of pole … r.p.m. (230 V, High) rpm 6 … 560

Nominal output W 60

Coil resistance Ω BRW - WHT : 71.1 , ORG - YEL : 22.7

(Ambient temperature 68 °F) WHT - VLT : 8.7 , VLT - PNK : 43.2

VLT - ORG : 13.3 , YEL - BLK : 54.32

Safety device

Operating temperature Open °F266± 14.4

Close °F 174.2 ± 27

Run capacitor VAC, µF 440 V , 6 µF

Electronic expansion valve

Coil EKV - MOZS584E0

Coil resistance (at 20°C) Ω ORG - GRY : 46 , YEL - GRY : 46

RED - GRY : 46 , BLK - GRY : 46

Valve body HKV - 30D16

Heat exchanger

Coil Aluminum plate fin / Copper tube

Rows … Fins per inch 2 … 14.9

Face area ft.

Panel

Model No. PNR - XHS3632

Indicator Lamp Ass'y IND - 3THS

Auto louver motor MT8 - 3C

Auto louver motor … Rated V, W, rpm 240 VAC , 3 W , 3 rpm

Coil resistance (Ambient temperature 77 °F) Ω 16.430 Ω ± 8 %

2

(m2) 5.17 (0.48)

DATA SUBJECT TO CHANGE WITHOUT NOTICE

– 12 –

SM830076

Page 13

1-2 Major Component Specifications

(B) Outdoor Unit

MODEL No. CH2432

Source 230 - 208 VAC / 1 phase / 60 Hz

Controller P.C.B. Ass'y CR - CH2432 (Microprocessor)

Control circuit fuse 250 VAC, 3 A

Compressor Rotary (Hermetic)

Model C - 2R160H6T

Source 230 - 208 VAC / 1 phase / 60 Hz

Nominal output W 1,700

Compressor oil cc 800

Coil resistance (Ambient temperature 77 °F) Ω C – R : 0.885 , C – S : 1.773

Safety device Internal type

Overload relay models —

Operating temperature Open °F 297 ± 9

Close °F 198 ± 20

Operating ampere (at 77 °F) A —

Run capacitor VAC, µF 400 VAC, 40 µF

Crank case heater VAC, W 230 VAC, 30 W

Refrigerant amount charged at shipment lbs. (kg) R22 : 6.17 (2.8)

High pressure switch ACB-1UB11

Set pressure OFF lb/in2(kg/cm2) 426.6 (30 )

ON lb/in2(kg/cm2) 341.3 ± 28.44 (24 ± 2.0)

Fan Propeller

Number...diameter in. (mm) 1 ... 18 - 3/32 (460)

Fan speeds 2 (AUTO)

Fan motor

Model KFC6T - 91D6P

Source 230 - 208 VAC / 1 phase / 60 Hz

No. of pole ..... rpm (230 V, High) 6 ... 879

Nominal output W 110

Coil resistance Ω BRN – WHT : 67.14 , VLT – YEL : 11.42

(Ambient temperature 68 °F) WHT – VLT : 64.85 , YEL – PNK : 10.60

Safety device Internal type

Operating temperature Open °F 248 ± 9

Close °F 171 ± 27

Run capacitor VAC, µF 440 VAC, 4 µF

Heat exchange

Coil Aluminum plate fin / Copper tube

Rows ..... Fins per inch 2 ... 14.1

Face area ft.

2

(m2) 6.78 (0.63)

+ 28.44

+ 7.11

DATA SUBJECT TO CHANGE WITHOUT NOTICE

+ 2.0

+ 0.5

1. Specifications

1

2

3

4

– 13 –

SM830076

Page 14

1

2

3

4

1-2 Major Component Specifications

(B) Outdoor Unit

MODEL No. CH3632

Source 230 - 208 VAC / 1 phase / 60 Hz

Controller P.C.B. Ass'y CR - CH2432 (Microprocessor)

Control circuit fuse 250 V, 3 A

Compressor Rotary (Hermetic)

Model C - R221H6R

Source 230 - 208 VAC / 1 phase / 60 Hz

Nominal output W 2,200

Compressor oil cc 1,500

Coil resistance (Ambient temperature 77 °F) Ω C – R : 0.549 , C – S : 1.525

Safety device Internal type

Overload relay models —

Operating temperature Open °F 320 ± 9

Close °F 189 ± 20

Operating ampere (at 77 °F) A —

Run capacitor VAC, µF 400 VAC, 40 µF

Crank case heater VAC, W 230 VAC, 30 W

Refrigerant amount charged at shipment lbs. (kg) R22 : 8.82 (4.0)

High pressure switch ACB-1UB11

Set pressure OFF lb/in2(kg/cm2) 426.6 (30 )

ON lb/in2(kg/cm2) 341.3 ± 28.44 (24 ± 2.0)

Fan Propeller

Number...diameter in. (mm) 2 ... 18 - 3/32 (460)

Fan speeds 2 (AUTO)

Fan motor

Model KFC6T - 91D6P × 2

Source 230 - 208 V / 1 phase / 60 Hz

No. of pole ..... rpm (230 V, High) 6 ... 879

Nominal output W 110 × 2

Coil resistance Ω BRN – WHT : 67.14 , VLT – YEL : 11.42

(Ambient temperature 68 °F) WHT – VLT : 64.85 , YEL – PNK : 10.60

Safety device Internal type

Operating temperature Open °F 248 ± 9

Close °F 171 ± 27

Run capacitor VAC, µF 440 VAC, 4 µF × 2

Heat exchange

Coil Aluminum plate fin / Copper tube

Rows ..... Fins per inch 2 ... 14.1

Face area ft.

2

(m2) 11.63 (1.08)

+ 28.44

+ 7.11

DATA SUBJECT TO CHANGE WITHOUT NOTICE

+ 2.0

+ 0.5

1. Specifications

– 14 –

SM830076

Page 15

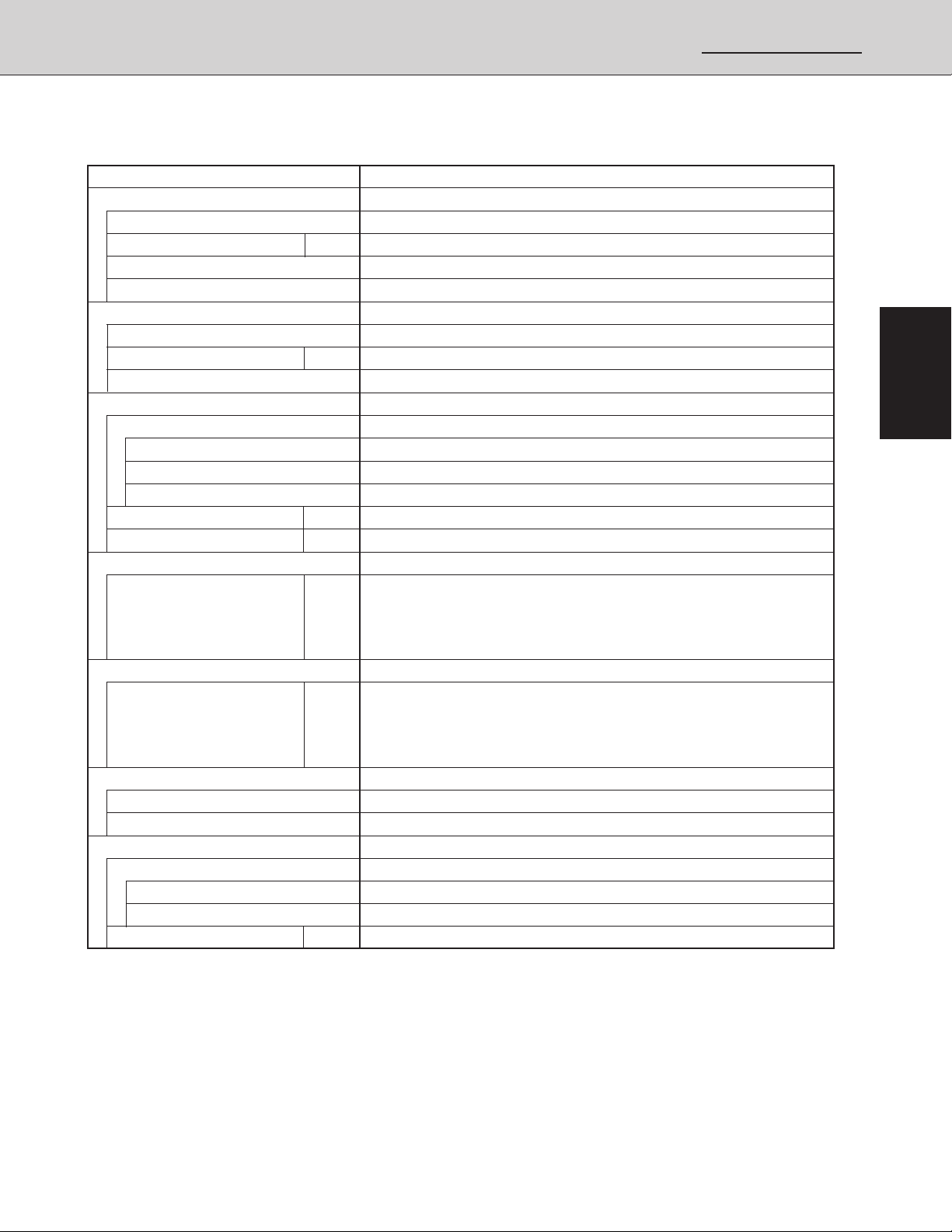

1. Specifications

1-3 Other Component Specifications

(A) Indoor Unit

MODEL No. XHS2432

Power Transformer ATR – II174B

Rated Primary 220 VAC, 60 Hz

Secondary 14.8 VAC 0.55 mA, 14.8 VAC 0.6 mA

Capacity —

Coil resistance

(Ambient temprature 77 °F)

Thermistor cut off temperature °F277

Thermistor (Coil sensor) : TH2, 3 PBC - 41E - S26

Coil resistance kΩ 14 °F : 23.7 , 41 °F : 12.1

Thermistor (Room sensor) : TH1 KTEC - 35 - S6

Coil resistance kΩ 32 °F : 16.5 , 104 °F : 2.7

Drain pump WP20SL - 21

Rated 230 / 208 VAC, 12.5 W

Float switch FS - 0218 - 102

MAX Rated (Contact rated) 50 W, DC 5V, 0.1 mA

Solenoid control valve or coil

Solenoid control valve IKV - 24D12

Solenoid coil DKV - MOZS582E0

Indicator Lamp Ass'y IND - 3THS

Synchronized Motor MT8 - 3C

Ω WHT - WHT : 101 , BRN - BRN : 0.42

23 °F : 18.8 , 50 °F : 9.7

32 °F : 15.0 , 59 °F : 8.0

41 °F : 12.8 , 113 °F : 2.2

50 °F : 10.0 , 122 °F : 1.8

68 °F : 6.3 , 131 °F : 1.5

86 °F : 4.0 ,

1

2

3

– 15 –

4

SM830076

Page 16

1

2

3

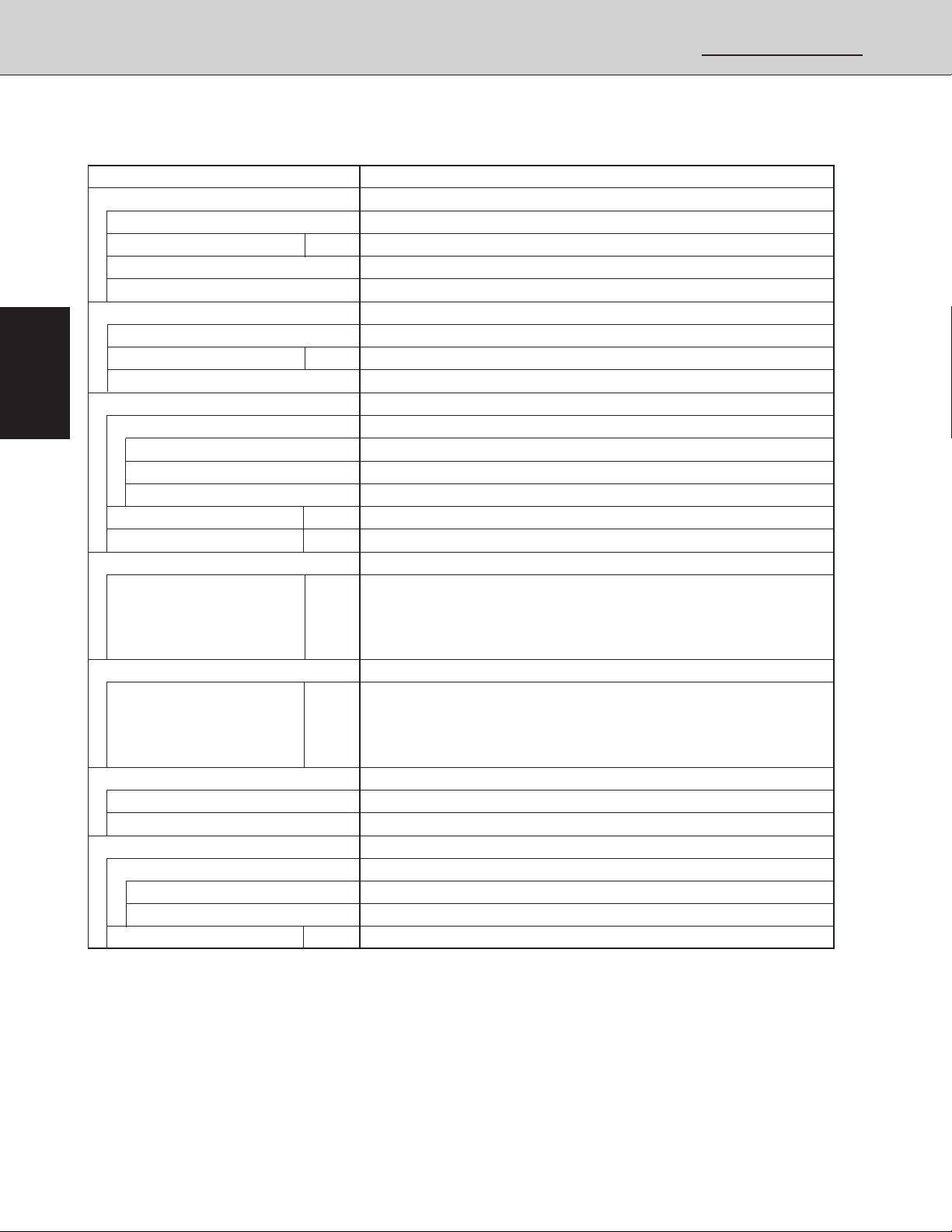

1. Specifications

1-3 Other Component Specifications

(A) Indoor Unit

MODEL No. XHS3632

Power Transformer ATR – II174B

Rated Primary 220 VAC, 60 Hz

Secondary 14.8 VAC 0.55 mA, 14.8 VAC 0.6 mA

Capacity —

Coil resistance

(Ambient temprature 77 °F)

Thermistor cut off temperature °F277

Thermistor (Coil sensor) : TH2, 3 PBC - 41E - S36

Coil resistance kΩ 14 °F : 23.7 , 41 °F : 12.1

Thermistor (Room sensor) : TH1 KTEC - 35 - S6

Coil resistance kΩ 32 °F : 16.5 , 104 °F : 2.7

Drain pump WP20SL - 21

Rated 230 / 208 VAC, 12.5 W

Float switch FS - 0218 - 103

MAX Rated (Contact rated) 50 W, DC 5V, 0.1 mA

Solenoid control valve or coil

Solenoid control valve HKV - 30D16

Solenoid coil EKV - MOZS728E0

Indicator Lamp Ass'y IND - 3THS

Synchronized Motor MT8 - 3C

Ω WHT - WHT : 101 , BRN - BRN : 0.42

23 °F : 18.8 , 50 °F : 9.7

32 °F : 15.0 , 59 °F : 8.0

41 °F : 12.8 , 113 °F : 2.2

50 °F : 10.0 , 122 °F : 1.8

68 °F : 6.3 , 131 °F : 1.5

86 °F : 4.0 ,

DATA SUBJECT TO CHANGE WITHOUT NOTICE

4

– 16 –

SM830076

Page 17

1. Specifications

1-3 Other Component Specifications

(B) Outdoor Unit

MODEL No. CH2432

Compressor Motor Magnetic Contactor FMCA - 1UL

Coil rated 240 VAC, 60 Hz

Coil resistance (at 77 °F) Ω 580 ± 15 %

Contact rated (Main) 230 VAC, 20 A

Contact rated (Auxiliary) 230 VAC, 3 A

Power Relay HH62S

Coil rated 240 VAC, 60 Hz

Coil resistance (at 77 °F) kΩ 17.2

Contact rated 220 VAC, 5 A

Power Transformer ATR - I65C

Rated

Primary 220 VAC, 60 Hz

Secondary 14 V, 0.4 A

Capacity 5.6 VA

Coil resistance (at 73 °F ) Ω WHT – WHT : 395.5 , BRN – BRN : 2.19

Thermal cut off temperature °F266

Thermistor (Coil sensor) : TH6, 7

Coil resistance kΩ 14 °F : 23.7 , 50 °F : 9.7

Thermistor (Comp. discharge gas sensor) : TH8

Coil resistance kΩ 140 °F : 13.8 , 194 °F : 5.1

Solenoid control valve or coil

Solenoid control valve V 389100

Solenoid coil LB 59005

Thermistor (PTC) TDK – 101YV

Rated

Max. voltage 400 VAC

Max. ampere 11.5 A

Resistance (at 77 °F) Ω 100 %

PBC - 41E - S4 , PBC - 41E - S26

23 °F : 18.8 , 68 °F : 6.5

32 °F : 15.0 , 86 °F : 4.4

41 °F : 12.1 , 104 °F : 3.1

113 °F : 2.6

PTC - 51H - S1

158 °F : 9.7 , 212 °F : 3.8

167 °F : 8.2 , 230 °F : 2.8

176 °F : 7.0 , 248 °F : 2.2

185 °F : 5.9 , 266 °F : 1.7

+ 30

– 20

DATA SUBJECT TO CHANGE WITHOUT NOTICE

1

2

3

4

– 17 –

SM830076

Page 18

1

2

3

4

1. Specifications

1-3 Other Component Specifications

(B) Outdoor Unit

MODEL No. CH3632

Compressor Motor Magnetic Contactor FMCA - 1SUL

Coil rated 240 VAC, 60 Hz

Coil resistance (at 68 °F) Ω 588 ± 10 %

Contact rated (Main) 240 VAC, 26 A

Contact rated (Auxiliary) 240 VAC, 3 A

Power Relay HH62S

Coil rated 240 VAC, 60 Hz

Coil resistance (at 77 °F) kΩ 17.2

Contact rated 220 VAC, 5 A

Power Transformer ATR - I65C

Rated

Primary 220 VAC, 60 Hz

Secondary 14 V, 0.4 A

Capacity 5.6 VA

Coil resistance (at 73 °F ) Ω WHT – WHT : 395.5 , BRN – BRN : 2.19

Thermal cut off temperature °F266

Thermistor (Coil sensor) : TH6, 7

Coil resistance kΩ 14 °F : 23.7 , 50 °F : 9.7

Thermistor (Comp. discharge gas sensor) : TH8

Coil resistance kΩ 140 °F : 13.8 , 194 °F : 5.1

Solenoid control valve or coil

Solenoid control valve V 389100

Solenoid coil LB 59005

Thermistor (PTC) TDK – 101YV

Rated

Max. voltage 400 VAC

Max. ampere 11.5 A

Resistance (at 77 °F) Ω 100 %

PBC - 41E - S4 , PBC - 41E - S36

23 °F : 18.8 , 68 °F : 6.5

32 °F : 15.0 , 86 °F : 4.4

41 °F : 12.1 , 104 °F : 3.1

113 °F : 2.6

PTC - 51H - S1

158 °F : 9.7 , 212 °F : 3.8

167 °F : 8.2 , 230 °F : 2.8

176 °F : 7.0 , 248 °F : 2.2

185 °F : 5.9 , 266 °F : 1.7

+ 30

– 20

DATA SUBJECT TO CHANGE WITHOUT NOTICE

– 18 –

SM830076

Page 19

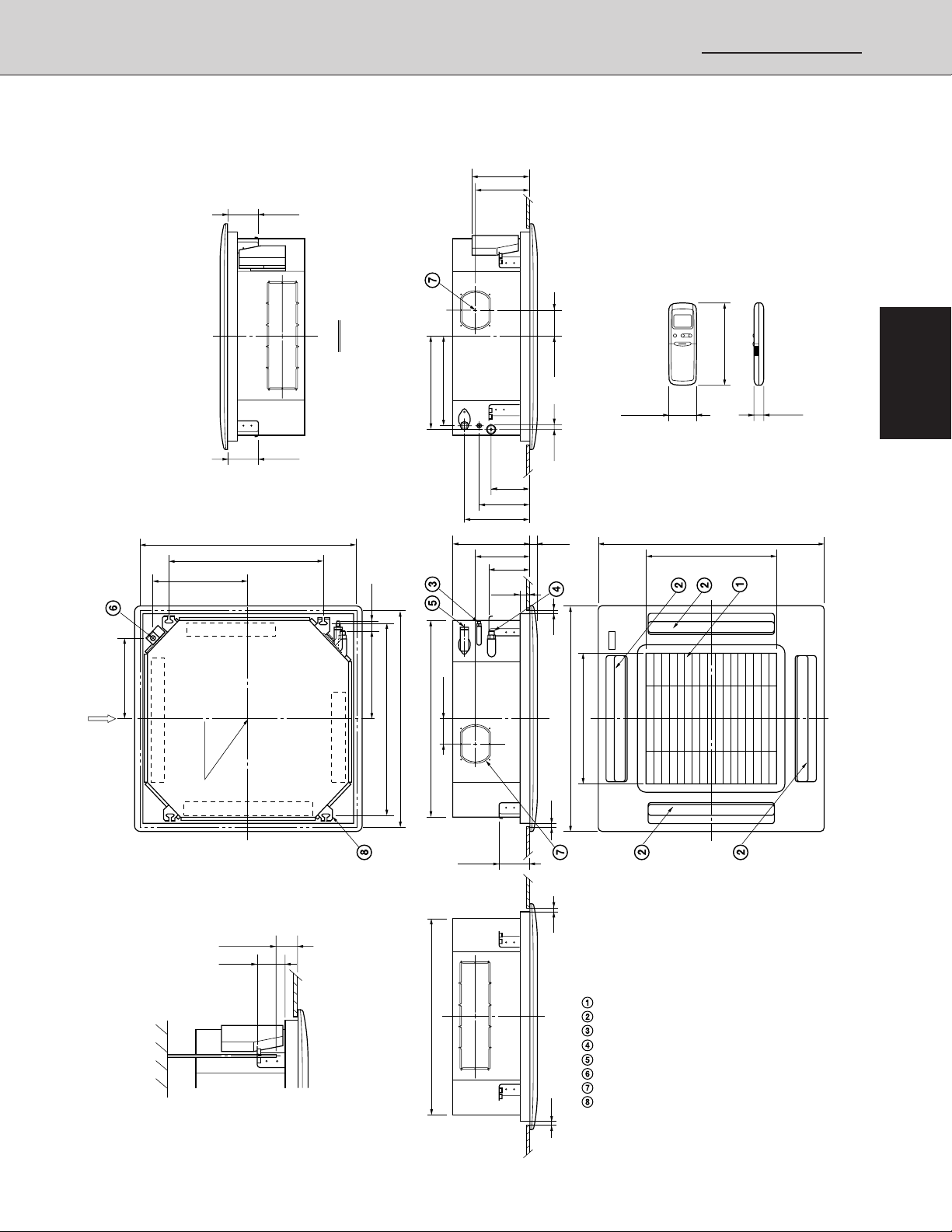

1-4 Dimensional Data

(A) Indoor Unit: XHS2432

4-29/32

1. Specifications

8-21/32

8-1/16

• Remote controller (Accessory)

X-view

14

13-3/8

4-29/32

5-29/32

7-7/8

10-1/32

32-9/32 (Ceiling opening)

23-7/32 (Suspention bolt pitch)

14

12

X

Grille center

13-2/4 1-3/8

32-9/32 (Ceiling opening)

28-3/4(Suspention bolt pitch)

11-23/32 1-3/16

8-1/16

6-1/2

1-7/8

3-15/16

29-29/32

3-15/16

19/32

1/2

1/2

33-27/32

19-11/16

2-13/32 23/32

33-27/32

19-11/16

6-25/32

1

2

3

4

Min. 2-3/8

3-1/32

4-29/32

29-29/32

– 19 –

1/2

1/2

Dimension : inch

Air intake

Air outlet

Narrow tube (1/4")

Wide tube (3/4")

Drain connection

Power line (conduit size : 1/2")

For discharge duct

Suspention bolt mounting

1024_X_S

SM830076

Page 20

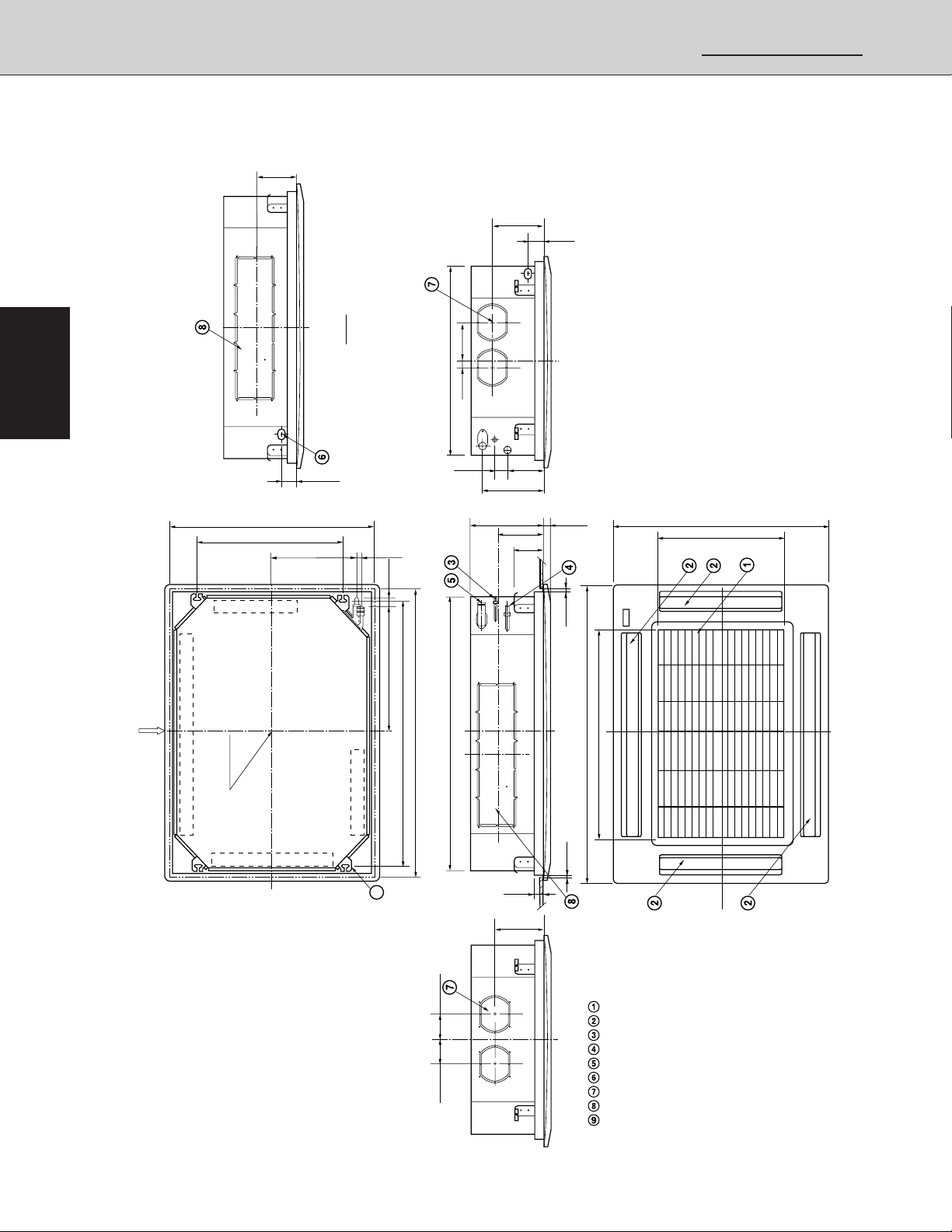

1-4 Dimensional Data

(A) Indoor Unit: XHS3632

8-19/32

1. Specifications

1

2

3

2-13/32

32-9/32 (Ceiling opening)

23-7/32 (Suspention bolt pitch)

13-15/32 19/32

X-view

19-9/32 1-9/16

5-23/321-3/8

29-29/32

2-3/4

8-9/32

6-1/2

11-7/32

12-29/32

8-19/32

4-29/32

2-3/8

1-3/16

15/32

33-27/32

19-11/16

4

Panel center

41-11/32

43-11/16 (Ceiling opening)

40-5/32 (Suspention bolt pitch)

9

3-15/16 3-15/16

1-7/8

8-9/32

45-9/32

31-3/32

15/32

Dimension : inch

Air intake grille

Air outlet

Refrigerant liquid line (ø3/8")

Refrigerant gas line (ø3/4")

Drain connection

Power supply entry

For discharge duct

Humidifier (option) mounting hole

Suspension bolt mounting

1346_X_S

– 20 –

SM830076

Page 21

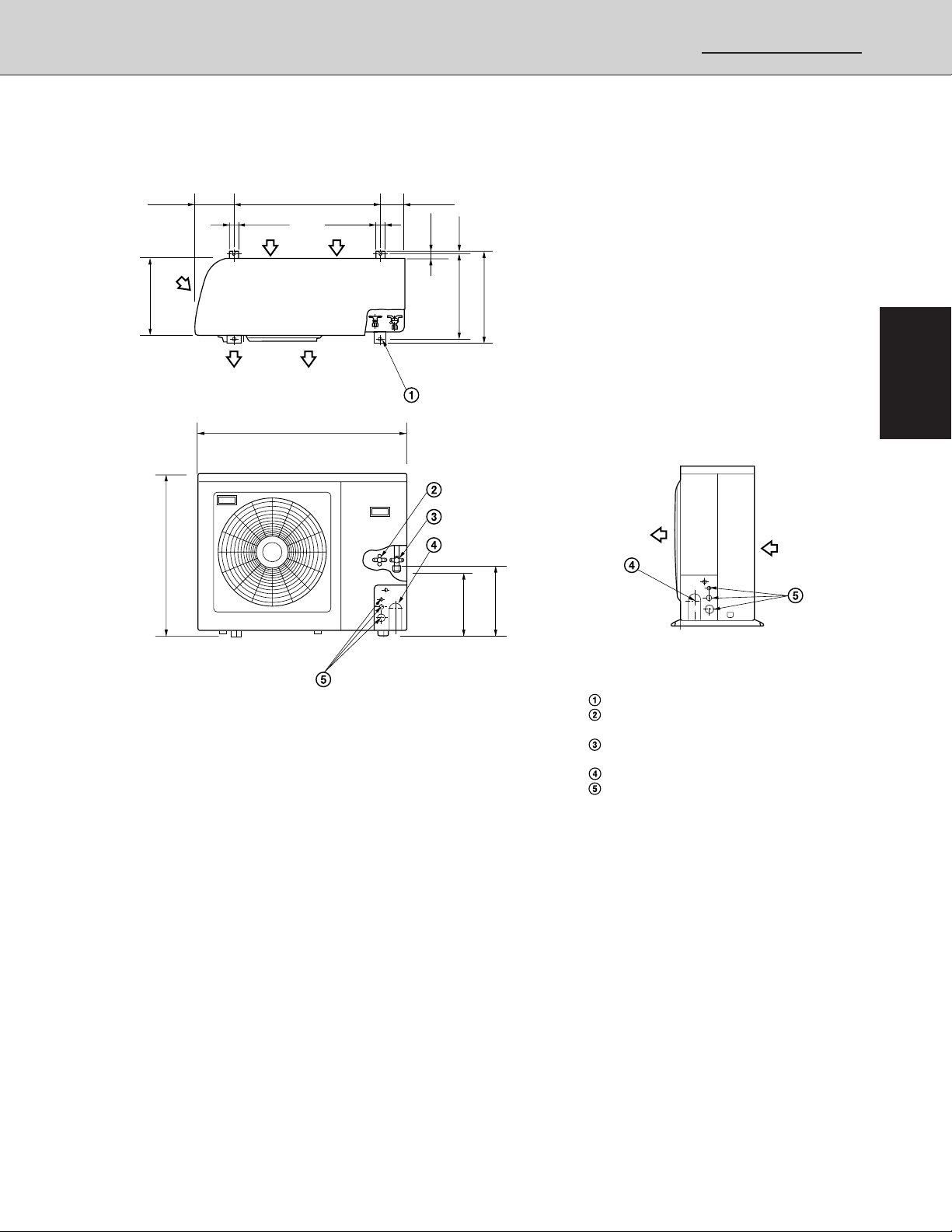

1-4 Dimensional Data

(B) Outdoor Unit: CH2432

1-31/32

1. Specifications

4-21/64266-11/16

1-31/32

1-3/16

13-3/8

28-15/16

37

14-31/32 13/32

11

15-3/4

12-1/16

Dimension : inch

Hole for anchor bolt (4-ø1/2)

Refrigerant tube joint (narrow tube)

Flare connection 1/4 in (6.35 mm)

Refrigerant tube joint (wide tube)

Flare connection 3/4 in (19.05 mm)

Refrigerant tubing inlet

Power supply inlet

1131_THS_I

1

2

3

4

– 21 –

SM830076

Page 22

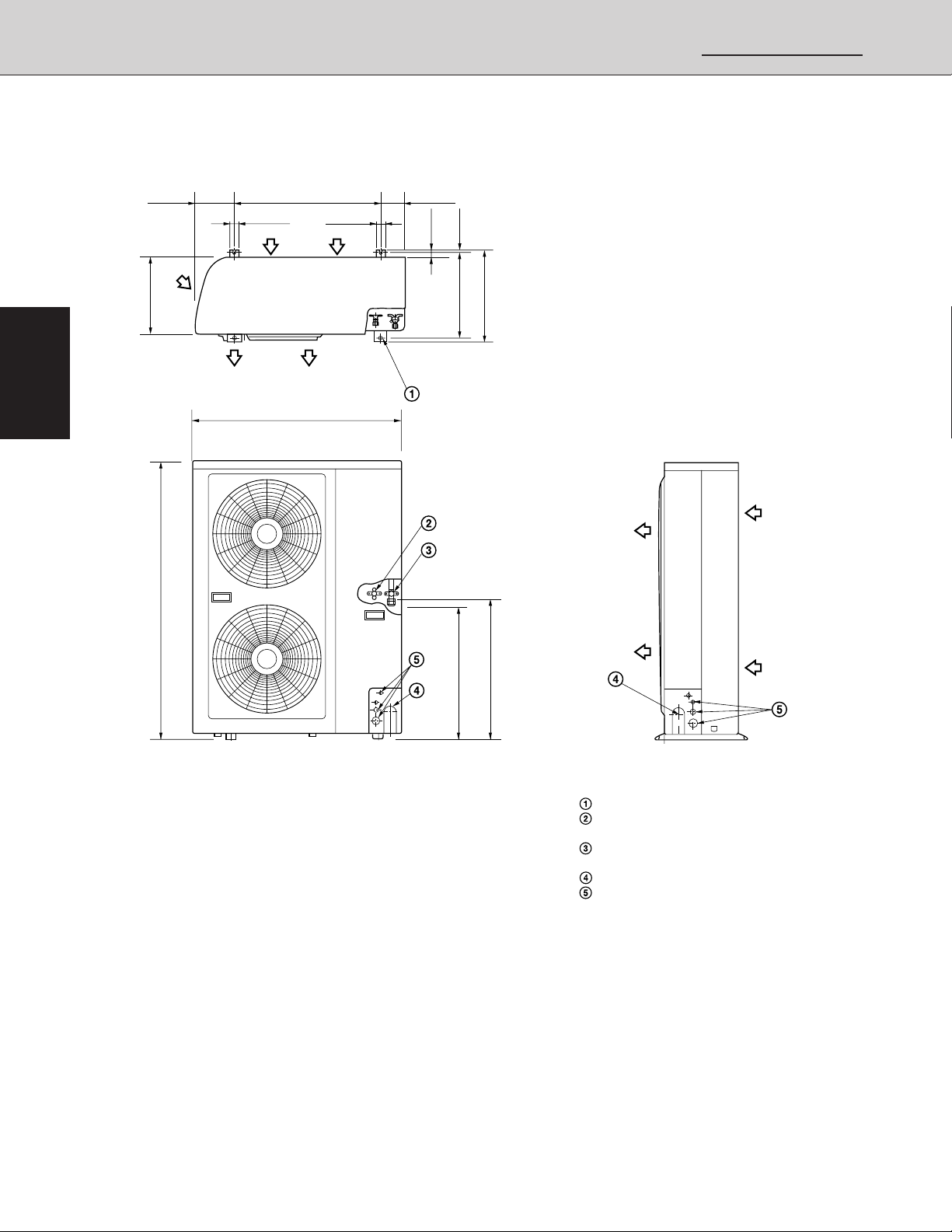

1-4 Dimensional Data

(B) Outdoor Unit: CH3632

1-31/32 1-31/32

1. Specifications

4-21/64266-11/16

1-3/16

1

2

3

13-3/8

48-5/8

37

15-3/4

14-31/32 13/32

22-27/32

23-29/32

4

– 22 –

Dimension : inch

Hole for anchor bolt (4-ø13)

Refrigerant tube joint (narrow tube)

Flare connection 3/8 in (9.52 mm)

Refrigerant tube joint (wide tube)

Flare connection 3/4 in (19.05 mm)

Refrigerant tubing inlet

Power supply inlet

1581_C_S

SM830076

Page 23

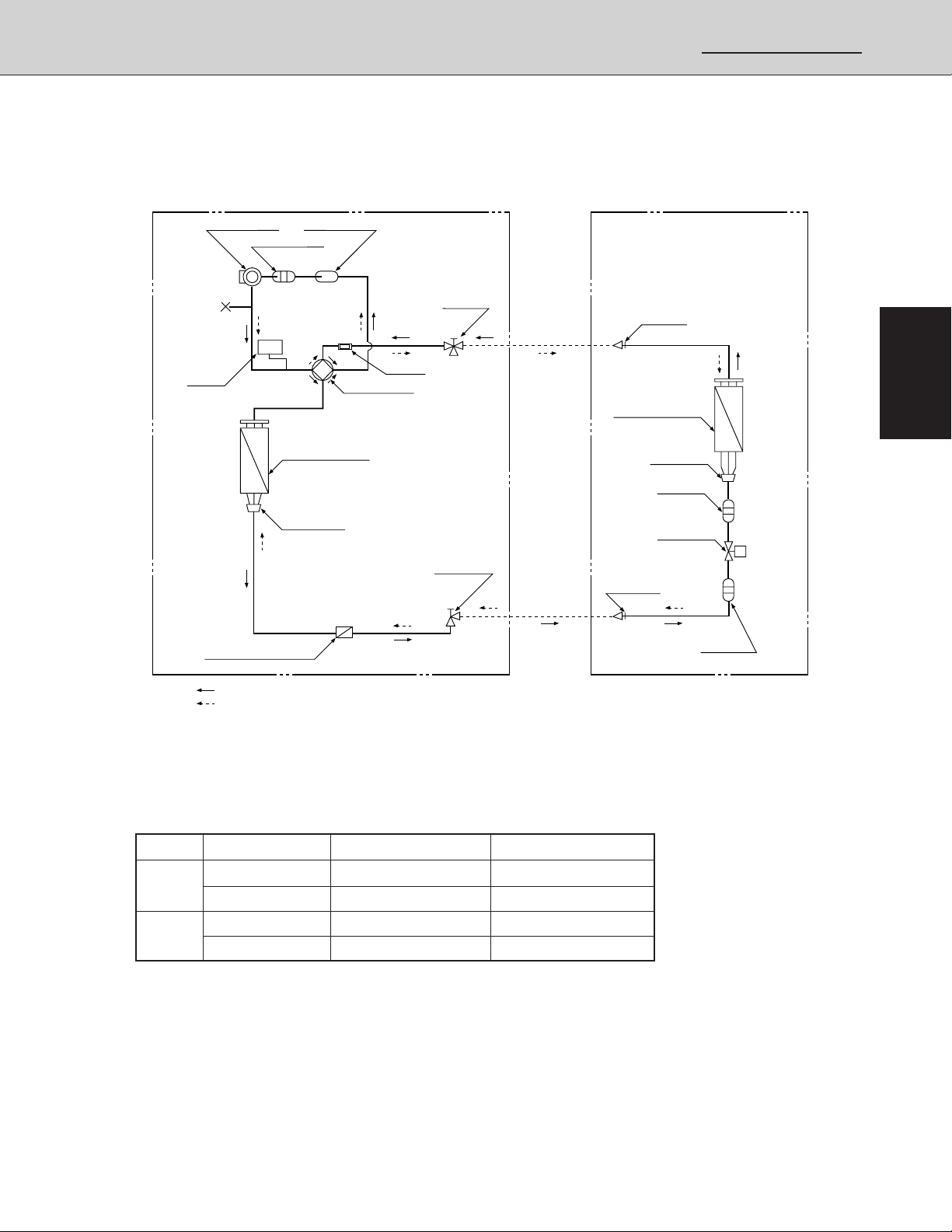

1-5 Refrigerant Flow Diagram

Outdoor Unit: CH2432 Indoor Unit: XHS2432

1. Specifications

Compressor

Accumulator

High

pressure

switch

Sub-heat exchanger

HP

EC

P

Cooling Cycle

Heating Cycle

Accumulator

4-way valve

Heat exchanger

Distributor

Muffler

Gas line

service

valve

Liquid line

service

valve

O.D.

3/4"

(19.05mm)

O.D.

1/4"

(6.35mm)

Gas line

nipple

Heat exchanger

Distributor

Strainer

Electronic

ref.control

valve

Liquid line

nipple

1

EC

P

2

M

Strainer

3

1132_THS_I

1-6 Operating Range

Temperature Indoor Air Intake Outdoor Air Intake

Cooling

Heating

Maximum 95 °F DB, 71 °F WB 115 °F DB

Minimum 67 °F DB, 57 °F WB 23 °F DB

Maximum 80 °F DB, 67 °F WB 75 °F DB, 65 °F WB

Minimum -DB / -WB 17 °F DB / 15 °F WB

4

SM830076

– 23 –

Page 24

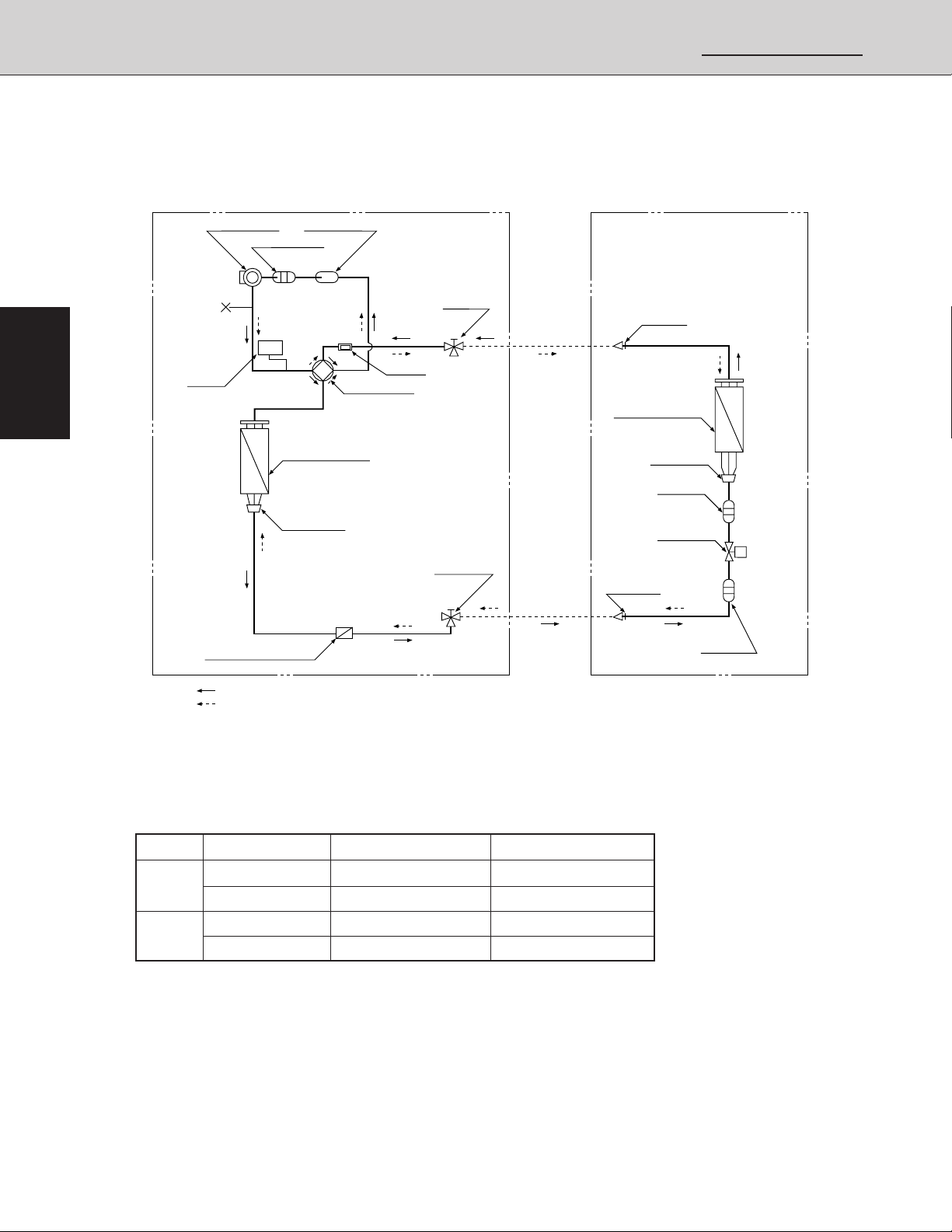

1-5 Refrigerant Flow Diagram

Outdoor Unit: CH3632 Indoor Unit: XHS3632

1. Specifications

1

2

3

Compressor

Accumulator

High

pressure

switch

Sub-heat exchanger

HP

EC

P

Cooling Cycle

Heating Cycle

Accumulator

4-way valve

Heat exchanger

Distributor

Muffler

Gas line

service

valve

Liquid line

service

valve

O.D.

3/4"

(19.05mm)

O.D.

3/8"

(9.52mm)

Gas line

nipple

Heat exchanger

Distributor

Strainer

Electronic

ref.control

valve

Liquid line

nipple

EC

P

M

Strainer

1398_THS_I

4

1-6 Operating Range

Temperature Indoor Air Intake Outdoor Air Intake

Cooling

Heating

Maximum 95 °F DB, 71 °F WB 115 °F DB

Minimum 67 °F DB, 57 °F WB 23 °F DB

Maximum 80 °F DB, 67 °F WB 75 °F DB, 65 °F WB

Minimum -DB / -WB 17 °F DB / 15 °F WB

– 24 –

SM830076

Page 25

2. Processes and functions

1. Specifications

2. PROCESSES AND FUNCTIONS

2-1 Room Temperature Control .......................................................................... 26

(A)Cooling .....................................................................................................26

(B)Heating .....................................................................................................27

2-2 Cold Draft Prevention (Heating Cycle) .......................................................... 28

2-3 Automatic Fan Speed (Indoor Unit)............................................................... 29

(A)Cooling .....................................................................................................29

(B)Heating .....................................................................................................29

2-4 Outdoor Fan Speed Control.......................................................................... 30

(A)Cooling .....................................................................................................30

(B)Heating .....................................................................................................30

2-5 Freeze Prevention (Cooling) ......................................................................... 31

2-6 Condensing Temperature Control (Cooling) ................................................. 32

2-7 Overload Protection (Heating)....................................................................... 33

2-8 Discharge Temperature Control (Cooling and Heating)................................ 34

2-9 Auto. Mode for Automatic Heating/Cooling Switching................................... 35

2-10 Defrosting Control, Outdoor Heat Exchanger Coil (Heating)......................... 37

2-11 4-Way Valve, Solenoid Control ..................................................................... 38

(A)Normal Control Mode ...............................................................................38

(B)AUTO Control Mode .................................................................................39

2-12 Automatic Restart after Power Interruption ................................................... 39

2-13 Electronic Expansion Valve .......................................................................... 40

2-14 Compressor Discharge Gas Temperature .................................................... 40

(A)Cooling .....................................................................................................40

(B)Heating (Except During Defrosting) ......................................................... 40

2-15 Compressor Current Detection Circuit .......................................................... 41

2-16 Electronic Expansion Valve Control .............................................................. 42

2-17 Voltage Detection Control ............................................................................. 43

Section

1

2

3

4

– 25 –

SM830076

Page 26

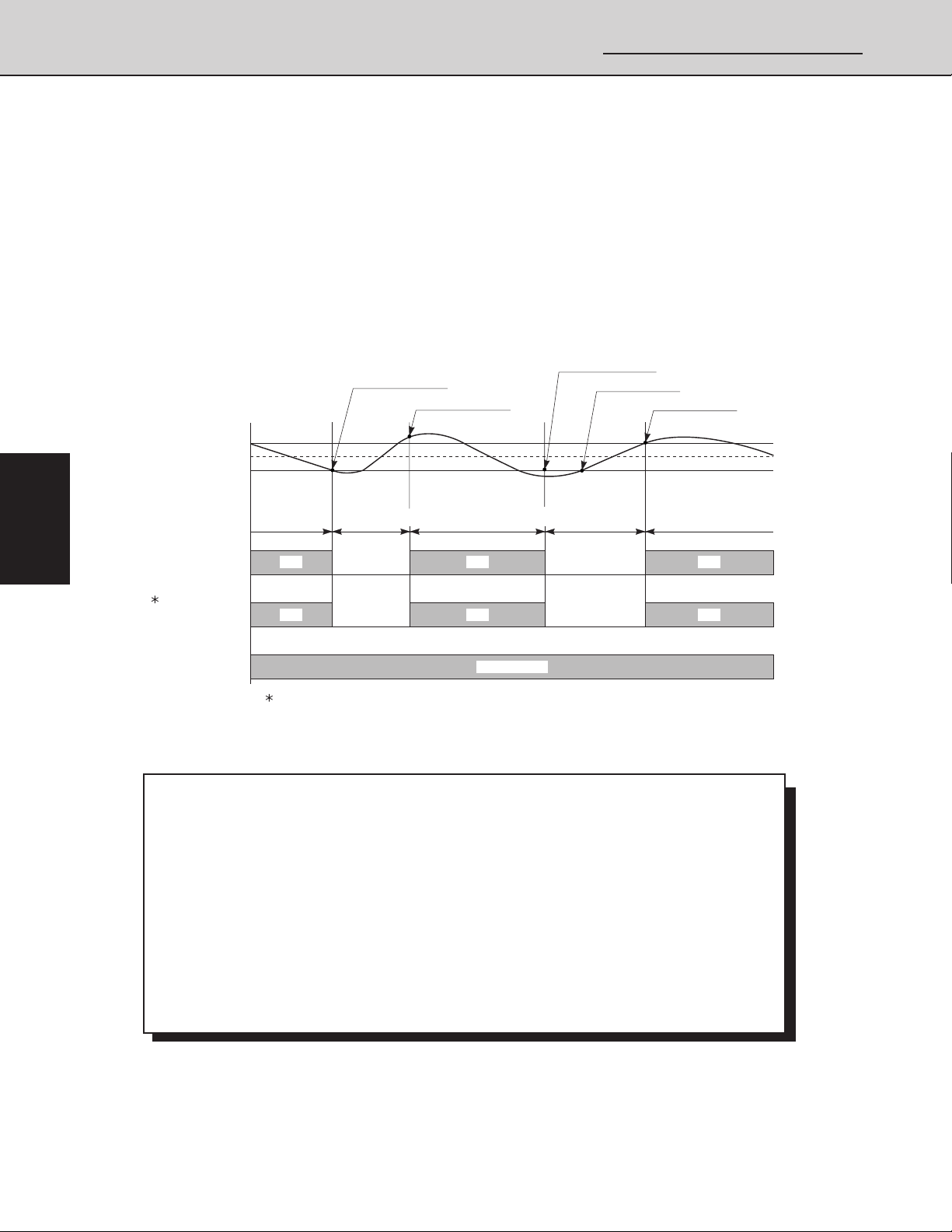

Section

1

2. Processes and functions

2-1 Room Temperature Control

The Unit adjusts room temperature by turning the outdoor unit’s compressor ON and OFF.

This process is controlled by the thermostat located in the remote control unit.

The figures on this and the next pages show how each part of the system performs when the

room temperature changes and the thermostat activates the compressor to start (thermo ON)

or stop (thermo OFF). Fig. 1 shows about the cooling cycle, and Fig. 2 shows about the

heating cycle.

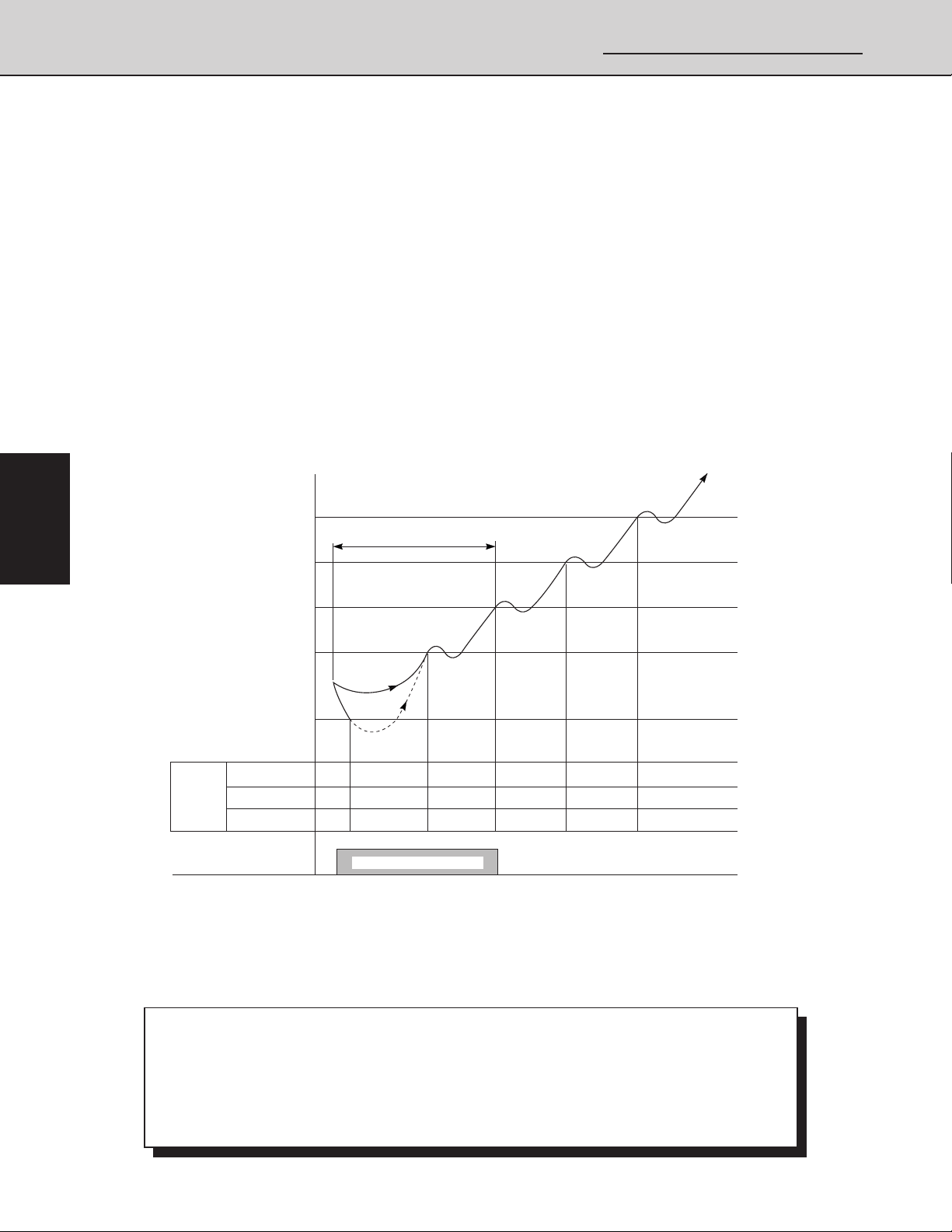

(A) Cooling

THERMO. OFF

(THERMO. ON)

(THERMO. OFF)

ROOM TEMP.

THERMO. ON

2

3

4

BODY SENSOR

SET TEMP

COMPRESSOR

OUTDOOR FAN

T+2 °F

. T °F

T–2 °F

1

(H OR M)

INDOOR FAN

MORE THAN

5 MINUTES

ON ON ON

ON ON ON

1. Refer to 2-4 Outdoor Fan Speed Control

3 MINUTES

OFF OFF

OFF OFF

5 MINUTES

SET SPEED

MORE THAN

3 MINUTES

MORE THAN

5 MINUTES

Fig. 1

Chart Summary and Explanations

❑ Once the compressor starts, it keeps running for 5 minutes.

❑ Once the compressor stops, it will not start running again for 3 minutes.

❑ If you change the operation mode (HEAT, COOL, or FAN) during the cooling cycle, the

control circuit stops the compressor for 3 minutes.

❑ For 5 minutes after the compressor is first turned on, and for 3 minutes after it is turned off,

the compressor is not controlled by the room sensor.

❑ Thermo ON: When room temperature rises 2°F (4°F when set on body sensor) above

the set temperature T˚, (T˚+2°F or T˚+4°F when set on body sensor):

Compressor ➞ ON

❑ Thermo OFF: When the room temperature is –2°F below the set temperature T˚:

Compressor ➞ OFF

1133_THS_I

– 26 –

SM830076

Page 27

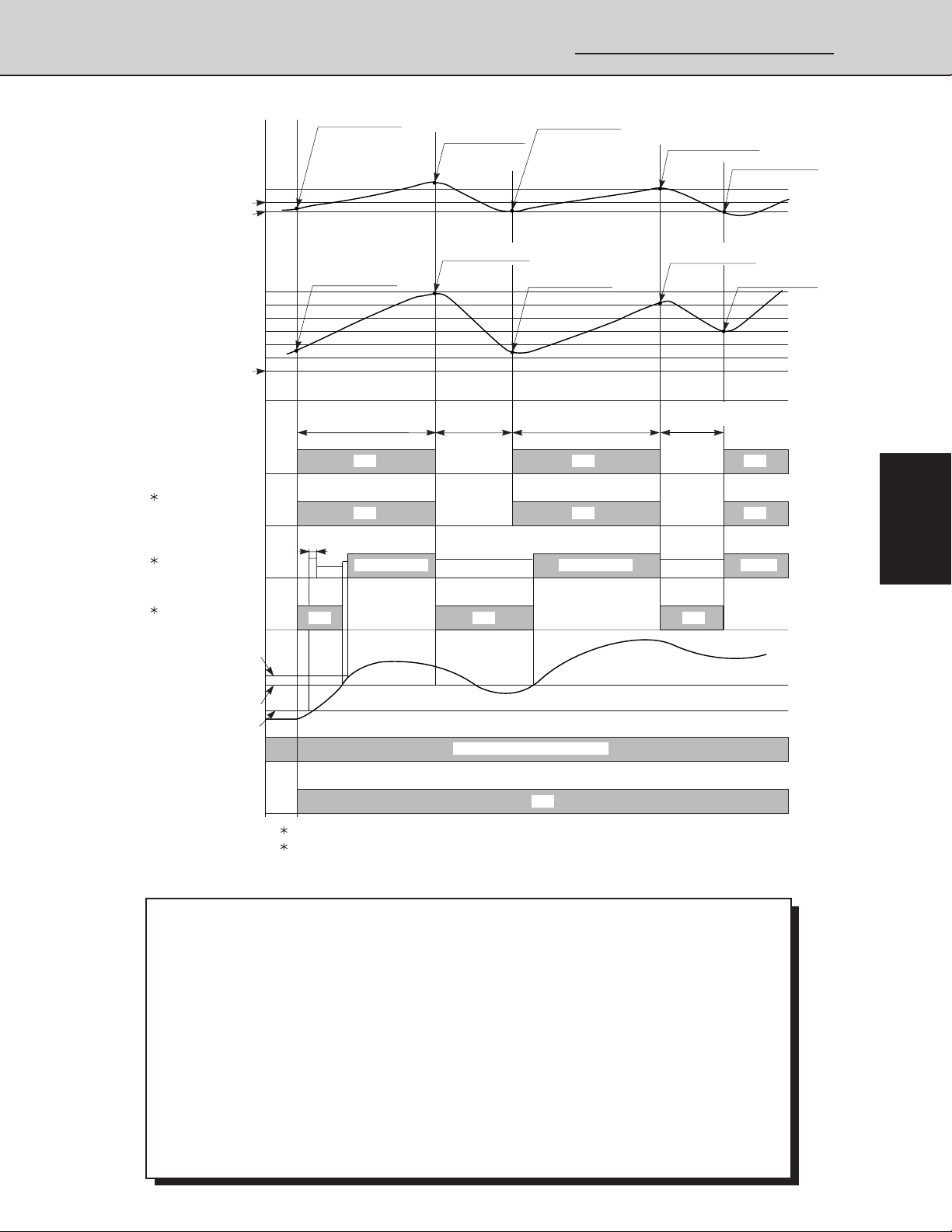

2. Processes and functions

1. Specifications

(B) Heating

REMOTE CONTROL

SENSOR

(Only for wireless

remote controller)

SETTING TEMP.

BODY SENSOR

SET TEMP.+7°F SHIFT

COMPRESSOR

1

OUTDOOR FAN

(H OR M)

2

INDOOR FAN

SET. +2°F

SET. –2°F

+2°F

–2°F

SET TEMP.

OFF

THERMO. ON

THERMO. ON

ONOFF

3 SECONDS

LL

LL

THERMO. OFF

THERMO. OFF

3 MINUTES

OFF

LL

THERMO. ON

THERMO. OFF

THERMO. OFF

MORE THAN

5 MINUTES5 MINUTES

ON OFF ONOFFOFF ON

ON OFF ON

SET SPEEDSET SPEED

MORE THAN

3 MINUTES

LL

THERMO. ON

THERMO. ONTHERMO. ON

Section

1

2

SET SPEED

2

STANDBY

INDOOR HEAT

EXCH.

COIL

TEMP.

E2

SOLENOID

COIL (4-WAY)

TEMP.

OPERATION

BUTTON

(88°F)

81°F

77°F

OFF

ON ON ON

OFF

1. Refer to 2-4 Outdoor Fan Speed Control

2. Refer to 2-2 Cold Draft Prevention (Heating)

OFF OFF

ON (REVERSING CYCLE)

ON

Chart Summary and Explanations

❑ Once the compressor starts, it keeps running for 5 minutes.

❑ Once the compressor stops, it will not start running again for 3 minutes.

❑ If you change the operation mode (HEAT, COOL or FAN) during the heating cycle, the

control circuit stops the compressor for 3 minutes.

❑ For 5 minutes after the compressor is first turned on, and for 3 minutes after it is turned off,

the compressor is not controlled by the room sensor.

When set on remote control sensor

Thermo ON: When room temperature is –2°F below the set temperature T˚.

Compressor ➞ ON

Thermo OFF: When the room temperature is 2°F above the set temperature T˚, (T˚+2°F)

Compressor ➞ OFF

When set on body sensor

NOTE: In case of Body sensor, operating temperature is shifted to setting temperature +7°F.

OFF

3

4

1134_THS_I

Fig. 2

– 27 –

SM830076

Page 28

2. Processes and functions

2-2 Cold Draft Prevention (Heating Cycle)

The cold draft prevention function controls indoor fan speed so a strong draft of cold air will

not blow out before the indoor heat exchange coils have warmed up.

❑ STANDBY shows on the remote controller when the indoor fan speed is LL (very

low) or OFF. This condition occurs in the following 3 cases:

• During Thermo OFF (refer to 2-1 B). Room Temperature Control, Heating)

Section

1

2

3

• During the defrosting operation (refer to 2-10 Defrosting Control, Heating)

• Until either the coil temperature E2 reaches 81°F or when a maximum of 6 minutes

has past.

❑ The indoor fan motor operates in L instead of LL for 3 seconds as it starts to give

the fan an initial boost.

92

MAX. 6 MINUTES

INDOOR UNIT

COIL TEMP.

E2 (°F)

88

81

77

50

4

SET

FAN

SPEED

❑ The main idea of this chart is to show that the indoor fan speed increases and gets closer to

❑ The indoor unit’s coil temperature is taken from sensor E2 located in the middle of the indoor

❑ The dotted line shows that the indoor fan motor is OFF. When the temperature at sensor E2

AUTO OR H

“STANDBY”

INDICATOR

the set fan speed as the coil temperature E2 rises.

heat exchange coil.

falls below 50°F, the indoor fan motor stops running.

LL LL/OFF LL L M H

M

LL LL/OFF LL L M M

L LL LL/OFF LL L L L

“STANDBY” APPEARS

LL= Very low speed

L= Low speed

Chart Summary and Explanations

– 28 –

M= Medium speed

H= High speed

1135_THS_I

Fig. 3

SM830076

Page 29

2. Processes and functions

1. Specifications

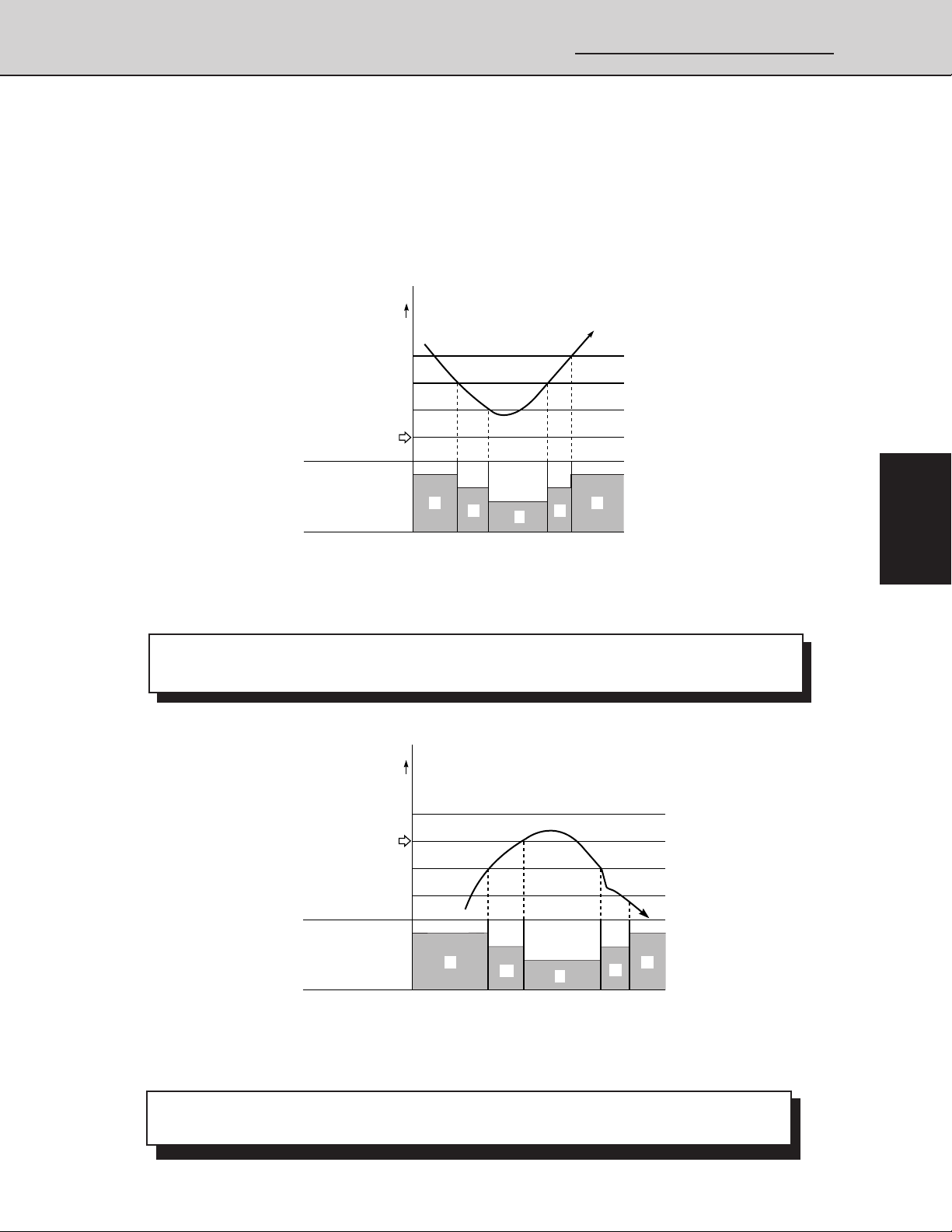

2-3 Automatic Fan Speed (Indoor Unit)

By pressing the FAN SPEED button on the remote controller, the fan speed can be set at

one of four steps: AUTO., HI., MED., or LO. When set at AUTO. the indoor unit fan speed

will be automatically adjusted to the room temperature as the two charts shown below.

(A) Cooling

❑ When the fan speed changes, it keeps the speed step for at least 3 minutes, even if the

(B) Heating

ROOM TEMP.

(deg)

+3

+2

+1

SET TEMP.

INDOOR FAN

SPEED

HM: High

: MiddleLLL

: Low

: Very low

H

MM

L

Chart Explanations and notes

temperature changes to another speed step during the time.

Section

1

H

2

0433_M_S

Fig. 4

3

ROOM TEMP.

(deg)

SET TEMP.

–2

–4

INDOOR FAN

SPEED H

HM: High

: MiddleLLL

: Low

: Very low

M

L

H

M

0434_M_S

Chart Explanations and notes

❑ When the fan speed changes, it keeps the speed step for at least 1 minute, even if the

temperature changes to another speed step during the time.

– 29 –

4

Fig. 5

SM830076

Page 30

2. Processes and functions

2-4 Outdoor Fan Speed Control

To optimize the performance of air conditioner, the outdoor fan speed is selected

automatically according to the outdoor temperature.

❑ Note that in both Cooling and Heating modes, the fan comes on at first at high

speed (H mode) for 5 seconds. Since outdoor conditions sometimes make it

difficult for the fan to start, this sudden surge of power may be necessary.

Section

1

2

3

❑ The outdoor fan operates in H mode for 3 minutes after the compressor stops

(excluding defrosting operation period).

❑ Charts below show how the outdoor fan speed changes with the change in

outdoor temperature.

(A) Cooling

Outdoor unit coil Outdoor fan

temperature [C2] motor (FMo)

or more 77°F H

less than 77°F M

77

OUTDOOR TEMPERATURE (°F)

H

M

Fig. 6

4

(B) Heating

Outdoor coil Outdoor fan

temperature [C2] motor (FMo)

or more 57°F M

less than 57°F H

M

57

H

OUTDOOR TEMPERATURE (°F)

Fig. 7

SM830076

– 30 –

Page 31

2. Processes and functions

1. Specifications

2-5 Freeze Prevention (Cooling)

Freeze Prevention keeps the indoor heat exchange coil from freezing. Freezing reduces the

efficiency of the unit, and frost buildup on the coil blocks cool air circulation from the indoor

unit's fan.

MIN. VALUE OF

EITHER E1 OR E2

INDOOR UNIT

TEMP.

ELECTRONIC REF.

CONTROL

VALVE SIGNAL

COMPRESSOR

(°F)

34

32

31

30

OPEN

CONTINUOUS

DETECTION

FOR 2 MINUTES

OPEN

ON ON

MINIMUM 3

MINUTES

Fig. 8

1138_THS_I

Note: Freeze prevention is controlled by the temperature at the indoor heat

exchanger coil as sensed by either sensor E1 (located at the entrance

of the coil) or sensor E2 (located on the middle of the coil). Freeze

prevention cycle is controlled by the lower temperature sensed at either

of the two sensors.

Chart Explanations and notes

Section

1

2

3

4

❑ This chart shows when the electronic refrigerant control valve opens to regulate the

temperature of the indoor unit coil to prevent freezing.

❑ If the refrigerant control is not effective and the temperature continues to drop and stays

below 30°F for 2 minutes continuously, the control circuit stops the compressor. The

compressor does not start again until the temperature rises above 34°F.

The compressor stops for 3 minutes minimum.

– 31 –

SM830076

Page 32

Section

I

1

2. Processes and functions

2-6 Condensing Temperature Control (Cooling)

Condensing temperature is controlled by the outdoor heat exchanger coil temperature as

sensed by sensor C2.

140

OUTDOOR UNIT

COIL TEMP. C2

(°F)

131

2

3

4

OUTDOOR FAN

SPEED

ELECTRONIC REF.

CONTROL VALVE

❑ This chart shows how the outdoor fan speed and the electronic refrigerant control valve

react to coil temperature to control condensing temperature.

❑ Sensor C2 is located in the middle of the outdoor unit heat exchange coil.

❑ When C2 rises above 140°F the electronic refrigerant control valve opens at 50 steps/30

seconds, and the outdoor fan speed is forced to change to high (H) until C2 falls below

131°F.

H, M H, M

Chart Explanations and notes

FORCED

H

OPEN

1139_THS_

Fig. 9

– 32 –

SM830076

Page 33

2-7 Overload Protection (Heating)

This function prevents the air conditioner from overloading.

(°F)

147

144

2. Processes and functions

1. Specifications

INDOOR UNIT COIL

TEMP. (E2)

ELECTRONIC REF.

CONTROL VALVE

OUTDOOR FM

140

138

131

127

OVERLOAD

PROTECTION OVERLOAD PROTECTION

OPEN

H OR M H OR MH M

OPEN

START UP

COMPENSATION

OFF

FUZZY CONTROLFUZZY CONTROL

Chart Explanations and notes

❑ This chart shows how the outdoor fan speed and the electronic refrigerant control valve

react to coil temperature to keep the indoor heat exchanger coil from overloading.

❑ When sensor E2 rises above 140°F the electronic refrigerant control valve opens at 50

steps/30 seconds until E2 falls below 138°F.

❑ Sensor E2 is located in the middle of the indoor unit heat exchange unit.

❑ When sensor E2 rises above 144°F, the control circuit stops the outdoor fan motor till the

temp. drops to 131°F

❑ Fuzzy control controls the electronic refrigerant control valve.

Fig. 10

Section

1

2

1140_THS_I

3

4

– 33 –

SM830076

Page 34

2. Processes and functions

2-8 Discharge Temperature Control (Cooling and Heating)

This function prevents the compressor motor from burnout by overheating.

239

221

203

Section

1

2

3

4

200

DISCHARGE GAS

TEMP. (°F)

OUTDOOR

FAN SPEED

COMPRESSOR

ELECTRONIC REF.

CONTROL VALVE

(DISCHARGE TEMP.)

194

185

H OR M

M

ON

H OR M

OPENOPEN

TRIP IS OPERATED.

Chart Summary and Explanations

❑ Discharge temperature is sensed by TH8 (discharge gas sensor).

❑ When the temperature rises above 203°F the electronic refrigerant control valve opens at

50 steps/30 seconds until the temperature falls below 200°F.

❑ During HEATING operation, when the temperature rises above 221°F, the control circuit

stops the outdoor fan motor until the temperature falls below 194°F. Please note that this

control does not function during COOLING operation.

❑ For both COOLING and HEATING modes, if the temperature reaches 239°F the operation

shuts down and alarm P3 appears on the remote controller.

❑ The outdoor fan speed is controlled on discharge temp. at heating mode.

1141_THS_I

Fig. 11

– 34 –

SM830076

Page 35

2. Processes and functions

1. Specifications

2-9 Auto. Mode for Automatic Heating/Cooling Switching

❑ When the AUTO mode is selected, the microprocessor calculates the difference

between the set temperature and the room temperature, and automatically switches

to the COOLING or HEATING mode to maintain the desired temperature.

Room temp. ] Set temp. ➔ COOLING

Room temp. < Set temp. ➔ HEATING

This means that if the room temperature is higher or equal to the set temperature,

COOLING operation starts. If the room temperature is lower than the set

temperature, HEATING operation starts.

A

COOLING SELECTION TEMP.

SHIFT SET TEMP.

+5 deg

+4 deg

Section

1

REMOTE CONTROLLED

SET TEMP.

SHIFT SET TEMP.

–4 deg

HEATING SELECTION TEMP.

–6 deg

B

C

HEATING COOLING HEATING

2

3

1142_THS_I

Fig. 12

4

– 35 –

SM830076

Page 36

Section

1

2

2. Processes and functions

Chart summary and Explanations

❑ This chart shows how the Operation Mode (COOLING or HEATING) is determined by the

microprocessor taking the room temperature into consideration. It also shows the

temperature points at which the cooling or heating mode is switched, when the AUTO mode

is selected.

❑ After operation starts, the set temperature shifts automatically by +4 deg. at cooling and

by -4 deg. at heating. For example, if cooling is selected, the set temperature changes from

68°F to 72°F.

(The display of the remote controller remains 68°F.)

❑ The change of the operation mode (heating to cooling, cooling to heating) by the change of

the room temperature during the operation is as follows.

Heating to Cooling; Room temp. ≥ Shifted temp +1.0 deg.

Cooling to Heating; Room temp. ≤ Shifted temp -2.0deg.

For example, if the room temperature rises above 73°F (=72+1) during the cooling

operation at the room temperature 68°F set by the remote controller, the operation changes

to cooling. When the room temperature lowers below 63°F (=65-2) thereafter, the operation

changes to heating again.

❑ In heating operation, using the body sensor, room temperature control is designed so that

room air temp. is sensed as 8 deg. lower than suctioned air at indoor unit taking into

account of the temperature gap between upper part and lower part of the room.

❑ Within 10 minutes after the compressor turns OFF, the operation does not change to

cooling (heating), even when the room temperature changes from C to A (A to C).

❑ When switching from cooling (heating) to heating (cooling), the actuation of the 4 way valve

will delay about 30-50 seconds after the compressor turns ON.

3

4

– 36 –

SM830076

Page 37

2. Processes and functions

1. Specifications

2-10 Defrosting Control, Outdoor Heat Exchanger Coil (Heating)

When the outdoor temperature is low, frost may form on the outdoor heat exchanger coil.

When this occurred, the defrosting system operates. The microprocessor in the outdoor unit

monitors the relationship between the temperature of the outdoor heat exchanger coil and the

outdoor temperature so it can defrost when necessary.

Flow of Defrosting

Heating operation

No counting time for detecting

frost : 15 minutes

Detecting the frost

Stand by time for defros:

25 minutes

Defrosting

Release of defrosting

Time Chart for Defrosting

OUTDOOR COIL

TEMP. C1 (°F)

Y

“RELEASE OF

DEFROSTING”

RANGE

50

OUTDOOR AIR TEMP.

7.3 50

27

18

The area below the heavy line

is the frost detection area.

–4

Either continuous 8 minutes or cumulative 60 minutes

are required to detect frost in the “Frosting” range.

Refer to time chart.

*Minimum continuous operating time by defrosting is 48 minutes (= 15 + 8 + 25).

Occurs either when the temperature of C1 (the outdoor

heat exchanger coil) has reached 50°F or above,

or when the maximum defrosting time (9 minutes)

has elapsed.

MAX. 9 MINUTES 1 MINUTE1 MINUTE

(°F)

X

Section

1

2

3

1143_THS_I

Fig. 13

COMPRESSOR

SOLENOID COIL

(4 WAY VALVE)

OUTDOOR FAN

(H OR L)

INDOOR FAN

(SET SPEED)

“STANDBY”

INDICATOR

❑ During the defrost cycle, STANDBY appears on the remote controller.

❑ *......Cold Draft Prevention may operate occasionally

ON

ON

ON

“STANDBY” APPEARS

Defrosting

Start

ON ON

OFF OR LL

Release of

Defrosting

– 37 –

OFF

OR LL

ON

ON

0442_M_S

4

Fig. 14

SM830076

Page 38

Section

1

2. Processes and functions

2-11 4-Way Valve, Solenoid Control

The basic function of the 4-way valve is to direct the refrigerant in the correct direction

according to the Operation Mode (COOLING or HEATING) selected.

The following two charts show conditions of the controls and functions listed in the left hand

column when the solenoid is ON or OFF. Chart (A) on this page shows the relationships when

the temperature control is in NORMAL mode, and Chart (B) on the next page shows the

relationships when the remote controller is set to AUTO mode.

(A) Normal Control Mode

2

3

4

POWER SOURCE

OPERATION

BUTTON

MODE

BUTTON

COMPRESSOR

SOLENOID COIL

(4-WAY VALVE)

COOL

HEAT

OFF

OFF

HEAT

2

3 MINUTES

TURN OFF

ON ON ON

OFF

1. . . More than 5 minutes 2. . . More than 3 minutes

ON

TURN ON

ON

COOL

THERMO OFF

OFF

ONON

THERMO

ON

1 111

HEAT

THERMO OFF

OFFOFFOFF

22

ON

THERMO

ON

ON

0443_M_S

Fig. 15

Chart Summary and Explanations

❑ For the first 3 minutes after power is applied, the 4–way valve remains OFF and the

compressor will not operate, even if the ON button is pushed.

❑ If the 4–way valve is turned OFF with the compressor operating, the air conditioner

operates in COOLING mode. See Table below.

❑ If the 4–way valve is turned ON with the compressor operating, the air conditioner operates

in HEATING mode. See Table below.

Operation Mode

COOLING OFF

HEATING ON

4-way valve

solenoid

Compressor

ON

– 38 –

SM830076

Page 39

(B) AUTO Control Mode

2. Processes and functions

1. Specifications

ON

ON

MORE THAN 10 MINUTES

(THERMO. OFF)

COOL

OFFOFF

MORE THAN

30 – 50 SECONDS

OFF

HEAT

THERMO. OFF

THERMO. ON

MORE THAN

3 MINUTES

ON

0445_M_S

OPERATION

BUTTON

AUTO

MODE

CONTROL HEAT

COMPRESSOR

SOLENOID COIL

(4-WAY VALVE)

COOL

OFFPOWER SOURCE

MORE THAN 10 MINUTES

3 MINUTES

OFF OFF

OFF

ON ON ON ON

30 – 50 SECONDS

(THERMO. OFF)

HEAT

MORE THAN

ON

Fig. 16

When the Compressor has stopped while in AUTO mode, the 4-way valve switches on

(heating) or off (cooling) within 1 minute according to the following conditions:

Section

1

2

3

Compressor has stopped

under the operation of

“AUTO mode” condition.

4-way valve delays its

switching for 30 – 50 seconds

after compressor has been

turned ON.

0446_M_S

2-12 Automatic Restart after Power Interruption

This air conditionner has a power failure recovery function.

4

Fig. 17

– 39 –

SM830076

Page 40

2-13 Electronic Expansion Valve

❑ This valve allows very precise and smooth control of the amount of refrigerant flow in the

system. Since the valve is operated by a step motor, the control circuits can open or

close it in very exact amounts, so the degree of heating or cooling can be changed by

just a little, or changed very quickly or slowly.

(Completely close …… 0 step)

(Full open ................480 step)

2. Processes and functions

Section

1

2

3

4

Model

24 type 100 step 120 step 480 step

36 type 90 step 90 step 480 step

Heating Cooling

Min. open

Max. open

❑ Fuzzy Control

Fuzzy Control is a controlling system to control electronic refrigerant control valve using

fuzzy logic. It regulates the functions of heating and cooling, as well as some of the

processes inside the unit, by taking account of many different conditions of temperature,

fan speed, etc. These control circuits work automatically to send just the right amount of

refrigerant through the Electronic Refrigerant Control Valve.

2-14 Compressor Discharge Gas Temperature

(A) Cooling

Indoor temp. (°F) 68 – 77 79 – 82 84 – 90

Outdoor temp. (°F) 55 or below 57 – 61 81 – 95 97 – 109

Compressor discharge

gas temp. (°F)

104 – 176 104 – 194 140 – 212 158 – 221

(B) Heating (Except During Defrosting)

Indoor temp. (°F) 64 – 70 72 – 77 79 – 86

Outdoor temp. (°F)

Compressor discharge

gas temp. (°F)

❑ Operate the unit at least 30 minutes to stabilize the discharge temperature.

❑ The above discharge temperature was measured with a 15m tubing length.

The temperature may vary with tubing length.

32 or below

104 – 176122 – 194122 – 194122 – 212140 – 221 122 – 194 140 – 212 158 – 221

34 – 50

32 or below

– 40 –

34 – 50 52 – 70

32 or below

34 – 50 52 – 70

SM830076

Page 41

2. Processes and functions

1. Specifications

2-15 Compressor Current Detection Circuit

❑ The Compressor Current Detection Circuit detects the compressor current and,

depending on the current range, can stop the compressor motor so it will not be

damaged by overcurrent.

❑ Overcurrent can be caused by several factors, particularly mechanical seizing of the

compressor or liquid backflow. Either of these conditions can hold the compressor

to run, and thus drawing so much current that the motor can burn out.

Comp. Amps.(A)

Locked Comp. Cut-off Range

Is 1.4

+

Is 1.17

+

Is

Rated Current

value

Overload Protection Range

Normal Operation Range

0447_M_S

Section

1

Fig. 18

Outdoor Model

CH2432 17.1 20.0 23.9

CH3632 27.5 32.0 38.5

❑ Overload Protection

• When the detected current is 1.17 – 1.4 times greater than the rated current value (Is) and continues

for 30 seconds, both compressor and outdoor fan stop (Thermostat OFF).

• After 3-minute pause, if the air conditioner is ready for Thermostat ON, it starts again. However, if the

condition mentioned above repeats twice within 30 minutes, the remote controller displays the alarm

message H01, compressor overload.

❑ Locked Compressor Cut-off

• When the detected current is 1.4 times greater than the rated current value (ls) and continues for 2

seconds, both compressor and outdoor fan stop (Thermostat OFF).

• After 3-minute pause, if the air conditioner is ready for Thermostat ON, it starts again. However, if the

condition mentioned above repeats twice, the remote controller displays the alarm message H02,

compressor locked.

❑ Failure of Compressor Current Detection

• When the Compressor Current Detection Circuit fails to detect the compressor current within 2

seconds after compressor starts, both compressor and outdoor fan stop (Thermostat OFF).

• After 3-minute pause, if the air conditioner is ready for Thermostat ON, it starts again. However, when

the circuit fails to detect the current twice in a row, the remote controller displays alarm message H03,

Failure of compressor Current Detection.

Rated Current Value Overload Protection Locked Compressor Cut-off

ls (A) ls x 1.17 (A) Is x 1.4 (A)

Chart Summary and Explanations

2

3

4

– 41 –

SM830076

Page 42

2. Processes and functions

2-16 Electronic Expansion Valve Control

The circulation volume of the refrigerant is controlled by a pulse type electronic control valve.

When the power is switched ON, the opening degree of the electronic control valve is

controlled between 90 and 480 steps after setting the initial step at the time when the

thermostat is ON.

Contents and Order of control

Section

1

2

3

4

Cooling

Start

Discharge gas temperature control

Outdoor unit coil temperature control

Freeze prevention control

Refrigerant flow distribution control

Discharge gas target temperature

control (Fuzzy control)

*

Repeat control in accordance with the priority order.

*

Discharge gas temperature control

High load prevention control

Refrigerant flow distribution control

Discharge gas target temperature

control (Fuzzy control)

Heating

Start

Heating start up control

*

0451_M_S

Even though the operation is performed every 30 seconds, the control of discharge gas

temperature, high load prevention, outdoor unit coil temperature and freeze prevention

activates when it occurs.

(1) Refrigerant flow distribution control

At the control of flexible combination (a plural number of indoor units are set), the opening

degree of the electronic control valve is controlled by the indoor unit coil temperature.

Cooling: indoor unit coil E2 temperature (located at the middle of coil)

Heating: indoor unit coil E1 temperature (located at the outlet of coil)

(2) Fuzzy control (optimal refrigerant flow rate control)

By outputting the fuzzy estimation result corresponding to the fuzzy input variables (the indoor

unit coil temp., the deviation between the actual discharge gas temp. and the target discharge

gas temperature calculated from the outdoor unit coil temperature and the change thereof),

the electronic refrigerant valve is controlled so that the unit can perform its maximum ability in

accordance with the indoor and outdoor temperature conditions at the operation.

– 42 –

SM830076

Page 43

2. Processes and functions

2-17 Voltage Detection Control

When the power voltage falls below 160 V or rises above 260 V, operation lamp and stand-by

lamp flash alternately to protect the compressor and electrical components.

1. Specifications

Section

1

2

3

4

– 43 –

SM830076

Page 44

Section

1

2. Processes and functions

2

3

4

– 44 –

SM830076

Page 45

3. Electrical data

3. ELECTRICAL DATA

3-1 Indoor Unit (Electric Wiring Diagram, Schematic Diagram) ............................... 46

3-2 Outdoor Unit (Electric Wiring Diagram, Schematic Diagram)............................. 48

Section

1

2

3

4

– 45 –

SM830076

Page 46

3-1 Indoor Unit

11

1 XHS2432, XHS3632

11

3. Electrical data

Section

1

2

3

4

ORG

Connector

GRN/YEL

BLK

LM

Earth

Terminal

49FI

GRN/YEL

FMI

RC1

Earth

• Electric Wiring Diagram

Control

Line

Terminal

GRY

IND

GRY

GRY

WHT

VLT

ORG

YEL

BLK

BRN

PNK

G

2 U1 U2

Power

Line

To Outdoor Unit

1

3P(WHT)

123

123

P

S

61

61

Connector

S

P

Connector

9P(WHT)

23456789

123456789

1

S

P

PNK

BRN

BRN

6P(WHT)

CONT

GRN/YEL

BLK

GRY

RED

BRN

VLT

ORG

YEL

BLK

BLU

PNK

WHT

RED

Earth

Terminal

BLK

WHT

RED

YEL

PNL

(GRN)

212121

(BLK)

Coil E2

(GRN)

(RED)

Coil E1

GLM

12VSGCD

2143

31 31

49FI(GRY)

HH

5713 231231

31

COM(YEL) HLLL

SG 12V G

21

SG1 SG2

31

N

R

(YEL)

WL(BLU)

FMI(WHT)

RC(BLU)

SG1(BLU)

SUP(BLK)

Room Temp

43

21

SEC(WHT)

31

N

Controller (CR-THS2432)

R

PRY(WHT)

453

21

T6 (WHT)DP (BLU)FS (RED)E

31

31

BLK

BLK

BLK

BLK

BLK

BLK

BRN

BRN

RED

RED

WHT

WHT

GRY

BLK

YEL

RED

ORG

BLK

BLK

BLK

BLK

DP

GRN/YEL

TR1

MOV

FS

Earth

TH1 TH2 TH3

GRN/YEL

Terminal

Earth

Terminal

W 854-2-5268-772-00-0 (XHS)

Terminal

Plate(4P)

– 46 –

SM830076

Page 47

3-1 Indoor Unit

11

1 XHS2432, XHS3632

11

4P-1

4P-2

N COM

F1(3A)

1

R

1X

3X 3X

LL L HHH COM

LL L HHHHT

FMI

RC1

F2(3A)

3. Electrical data

• Schematic Diagram

CR-THS2432

Controller

CD

CONT

3X

RY2

2X

RY1

49FI

1

SG WL

2

12V

3

G

4

1

2

SEC

3

4

1

PRY

3

3

1X

LM

DP

DC12V

SG1

12VRC

PNL

SG1

SG2

SG

T6

FS

G

1

2

3

1

2

3

4

5

1

2

3

1

3

Room Thermistor

1

2

Indoor Coil

1

2

Indoor Coil

1

2

1

2

4P-U24P-

To Outdoor Unit

MOV

U1

TH1

E1

TH2

E2

TH3

Section

1

FS

2

3

49FI

1

2X

21

RY2

DP

11357

6 7543

8

49FI

9

RY1

LM

1

DP

333

1

1

LM

2

3

1

IND

6

TR1

Symbols Description

FMI

49FI

RC1

F1,2

DP

LM

TR1

1X-3X

RY1-RY2

MOV

FS

Indoor Fan Motor

Indoor Motor Thermal Protector

Running Capacitor

Fuse

Drain Pump

Auto Louver Motor

Power Transformer

Auxiliary Relay

Auxiliary Relay

Motor Operated Valve

Float Switch

Symbols Description

TH1

TH2

TH3

CR-THS2432

CONT

IND

Room Thermistor

Thermistor (Indoor Coil E1)

Thermistor (Indoor Coil E2)

Indoor Controller

Controller

Indicator Lamp Assy

Terminal Plate

Connector

Terminal

S 854-2-5268-772-00-0 (XHS)

4

– 47 –

SM830076

Page 48

Section

1

3-2 Outdoor Unit

11

1 CH2432

11

TH6

BLK

1

C1

BLK

2

(BLK)

TH7

BLK

1

C2

BLK

2

(RED)

TH8

WHT

WHT

2

1

Discharge

Gas (GRN)

21

SEC

2P

(WHT)

13

PRY

3P(WHT)

31

63PH

3P(RED)

31

20S

3P(YEL)