Page 1

AS

FILE NO.

SERVICE MANUAL Remote Control Color

Television

AVM-1901S (U.S.A.)

(CANADA)

ORIGINAL VERSION

Chassis No. G6V-1901S0

NOTE: Match the Chassis No. on

the unit’s back cover with

the Chassis No. in the

Service Manual.

If the Original Version

Service Manual Chassis

No. does not match the

unit’s, additional Service

Literature is required. You

must refer to “Notices” to the

Original Service Manual

prior to servicing the unit.

Contents

Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . 2

Service Adjustments. . . . . . . . . . . . . . . . . . . 3 - 7

Purity and Convergence Adjustments . . . . . 8 - 9

Service Hints . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Mechanical Disassemblies. . . . . . . . . . . . . . . . 11

Chassis Electrical Parts List. . . . . . . . . . . 12 - 17

Cabinet Parts List . . . . . . . . . . . . . . . . . . . . . . 18

Component and Test Point Locations. . . . 19 - 21

Schematic Diagrams . . . . . . . . . . . . . . . . 25 - 32

Block Diagram . . . . . . . . . . . . . . . . . . . . . 26 - 27

Voltage Charts . . . . . . . . . . . . . . . . . . . . . 26 - 27

Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Specifications

Power Rating . . . . . . . . . . . . . . . . . . . . . . 120V, 60Hz

68W (Avg), 1.4A(Max)

Antenna Input Impedance . . . . . . . . . . . . . . . . . . 75Ω

UHF/VHF/CATV

Receiving Channel. . . . . . . . . . . . . . . . . 2 - 13 (VHF),

14 - 69 (UHF),

01, 14-94, 95-125 (CATV)

Remote Ready . . . . . . . . . . . 23 Key Remote Control

Sound Output . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 W

Intermediate Frequency

Picture IF Carrier . . . . . . . . . . . . . . . . . . 45.75MHz

Sound IF Carrier. . . . . . . . . . . . . . . . . . . 41.25MHz

Color Sub Carrier . . . . . . . . . . . . . . . . . . 42.17MHz

Picture Tube . . . . . . . . . . . A48AAB37X/A48AGD12X

Semiconductors

Integrated Circuits. . . . . . . . . . . . . . . . . . . . . . . . . 7

Transistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Except within Tuner and RC Pre-Amp.

Cabinet Dimensions

Width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 488mm

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 452mm

Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 467mm

REFERENCE No.

SM5110190

AVM-1901S, G6VMM, PRODUCT CODE 111340691

A

S

Page 2

— 2 —

SAFETY PRECAUTIONS

WARNING: The chassis of this receiver has a floating ground

with the potential of one half the AC line voltage in respect to

earth ground. Service should not be attempted by anyone not

familiar with the precautions necessary when working on this

type of equipment.

The following precautions must be observed:

1. An isolation transformer must be connected in the power line

between the receiver and the AC line before any service is

performed on the receiver.

2. Comply with all caution and safety-related notes provided on

the side of the cabinet, inside the cabinet, on the chassis, and

the picture tube.

3. When replacing a chassis in the cabinet, always be certain

that all the protective devices are installed properly, such as

control knobs, adjustment covers, shields and barriers.

DO NOT OPERATE THIS TELEVISION RECEIVER

WITHOUT THE PROTECTIVE SHIELD IN POSITION AND

PROPERLY SECURED.

4. Before replacing the back cover of the set, thoroughly inspect

the inside of the cabinet to see that no stray parts or tools

have been left inside.

Before returning any television to the customer, the

service technician must perform the following safety checks

to be sure that the unit is completely safe to operate without

danger of electrical shock.

ANTENNA COLD CHECK

Remove AC plug from the 120 VAC outlet and place a jumper

across the two blades. Connect one lead of an ohmmeter to the

jumpered AC plug, and touch the other lead to each exposed

antenna terminal (UHF and VHF antenna terminals). The resistance must measure between 1M ohm and 5.2M ohm. Any

resistance value below or above this range indicates an abnormality which requires corrective action.

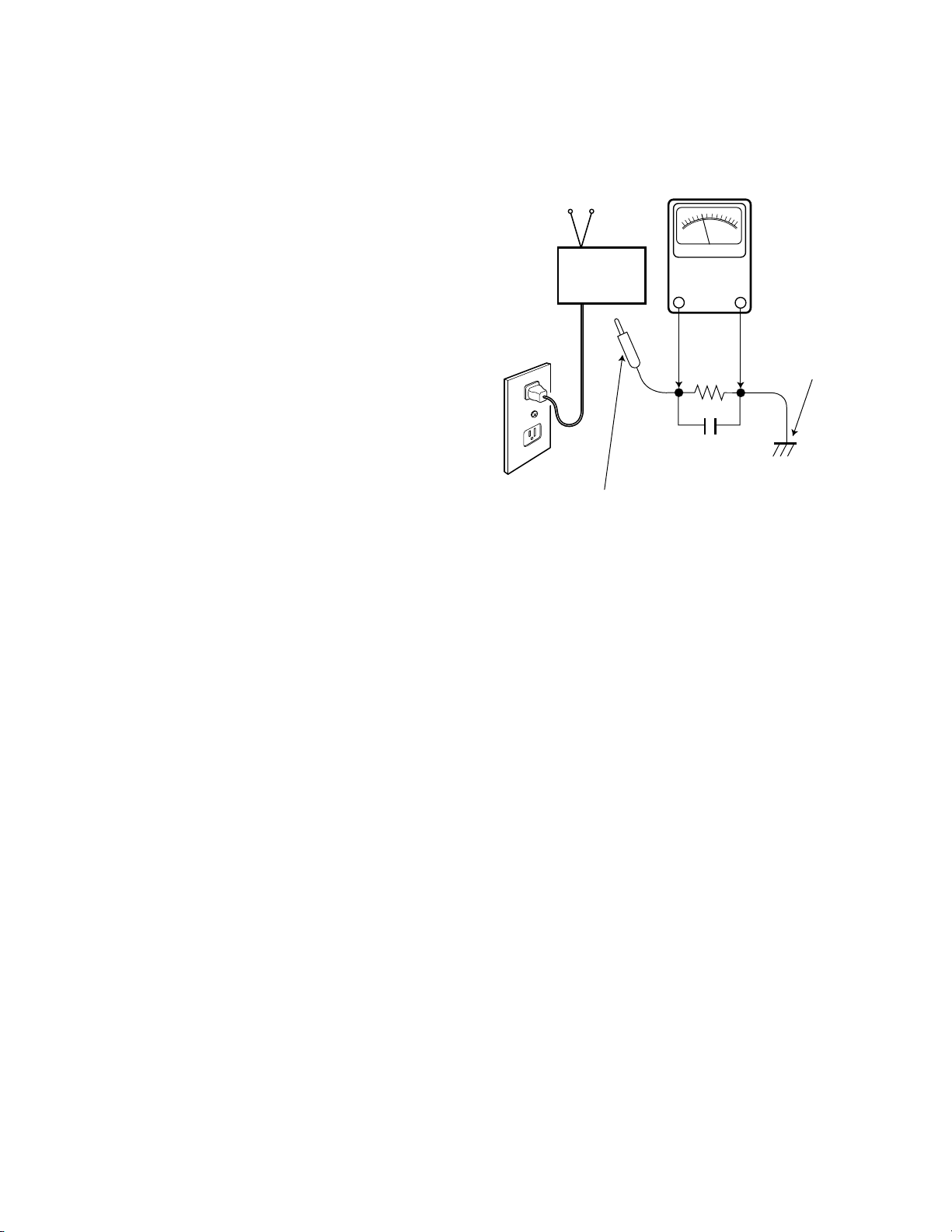

LEAKAGE CURRENT CHECK

Plug the AC line cord directly into a 120 VAC outlet. (Do not use

an isolation transformer for this check.) Use an AC voltmeter,

that has 5000 ohms per volt or more sensitivity. Connect a 1500

ohm 10 watt resistor, paralleled by a 0.15 µF 150 VAC capacitor,

between a known good earth ground (water pipe, conduit, etc.)

and all exposed metal parts of the cabinet (antennas, handle

bracket, metal cabinet, screw heads, metal overlays, control

shafts, etc.). Measure the AC voltage across the 1500 ohm

resistor. The AC voltage should not exceed 750 mV. A reading

exceeding 750 mV indicates that a dangerous potential exists.

The fault must be located and corrected. Repeat the above test

with the receiver power plug reversed.

NEVER RETURN A RECEIVER TO THE CUSTOMER

WITHOUT TAKING THE NECESSARY CORRECTIVE

ACTION.

X-RADIATION PRECAUTION

The primary source of X-RADIATION in solid-state receivers is the

picture tube. The picture tube is specially constructed to limit X-Ray

emission. For continued X-RADIATION protection, the replacement

tube must be the same type as the original (including the suffix letter in the part numbers). Excessive high voltage may produce

potentially hazardous X-RADIATION. To avoid such hazards, the

high voltage must be maintained within specific limits. Refer to the XRADIATION WARNING NOTE on the CHASSIS SCHEMATIC in

this service manual for specific high voltage limits. If the high voltage exceeds specified limits, check the components specified on

the chassis schematic diagram and take the necessary corrective

action. Carefully follow the instructions for the +B Voltage Check

and the High Voltage Check to maintain the high voltage within the

specified limits.

HIGH VOLTAGE HOLD-DOWN TEST

To prevent X-RADIATION from the picture tube due to excessive

high voltage, a HOLD-DOWN circuit is provided in the high voltage circuit. Every time the receiver is serviced, the high voltage

HOLD-DOWN circuit must be tested for proper operation. Refer

to the HIGH VOLTAGE HOLD-DOWN TEST in service adjustments.

PRODUCT SAFETY NOTICE

When replacing components in a receiver, always keep in mind

the necessary product safety precautions. Pay special attention

to the replacement of components marked with a star (★) in the

parts list and in the schematic diagrams. To ensure safe product

operation, it is necessary to replace those components with the

exact same PA RTS.

SAFETY INSTRUCTIONS

READING SHOULD NOT EXCEED 750 mV.

AC VOLTMETER

(5000 ohms per volt or more sensitivity)

TELEVISION

RECEIVER

Good earth ground

such as a water pipe,

conduit, etc.

AC OUTLET

1500 ohm

10 watt

0.15 µF 150V AC

To be touched to all of exposed metal parts.

Voltmeter Hook-up for Leakage Current Check.

Page 3

GENERAL

This set has an On-screen Service Menu system included in the CPU that allows remote operation for most of the service adjustments.

ON-SCREEN SERVICE MENU SYSTEM

1. Enter the Service Menu:

• While pressing the MENU key, reconnect the AC power cord. The Service Menu Display will now appear. (See Figure 1 below.)

2. Service Adjustments:

• Press the ▲or ▼ key to select the desired service menu you want to adjust. (See page 4 for On-screen Service Menu.)

• Use the + or – key to adjust the data.

3. Exit from the Service Menu:

• Press the MENU key to turn off the Service Menu display.

SERVICE ADJUSTMENTS

— 3 —

IC802 (EEPROM) REPLACEMENT

When IC802 (EEPROM) is replaced, IC801 (CPU) will automatically write the initial reference data into IC802 for basic TV operation. However, the bus data should be checked and some bus data should be set up before attempting the service adjustments.

(See pages 4 – 5 for detailed information.)

INITIAL BUS DATA SETUP

Note: When IC802 (EEPROM) is replaced, the Service Menu No. 007 VLN (V Linearity), No. 010 VSC (V S-Correction), No. 021 SBI

(Sub-Bias), No. 023 POS (Pre/Over-Shoot), No. 028 PRE (Pre-Shoot Width), No. 037 AF (AutoFlesh), No. 041 RYA (R-Y/B-Y

Angle) and No. 055 STI (Sub-Tint) should be set up for proper TV operation before attempting the service adjustments.

1. Disconnect the AC power cord (AC 120V line).

2. While pressing the MENU key, reconnect the AC power cord. The Service Menu display will now appear.

3. Select No. 007 VLN (V Linearity) with ▲ or ▼ key. Adjust the data with + or – key for 16.

4. Select No. 010 VSC (V S-Correction) with ▲ or ▼ key. Adjust the data with + or – key for 7.

5. Select No. 021 SBI (Sub-Bias) with ▲ or ▼ key. Adjust the data with + or – key for 60.

6. Select No. 023 POS (Pre/Over-Shoot) with ▲ or ▼ key. Adjust the data with + or – key for 1.

7. Select No. 028 PRE (Pre-Shoot Width) with ▲ or ▼ key. Adjust the data with + or – key for 3.

8. Select No. 037 AF (AutoFlesh) with ▲ or ▼ key. Adjust the data with + or – key for 1.

9. Select No. 041 RYA (R-Y/B-YAngle) with ▲ or ▼ key. Adjust the data with + or – key for 2.

10. Select No. 055 STI (Sub-Tint) with ▲ or ▼ key. Adjust the data with + or – key for 18.

11. Press the MENU key to turn off the Service Menu display.

No. Data

XXX XXX XXX XXXXXXXX

DECIMAL DATA

(ZERO SUPPRESSED)

Figure 1. Service Menu Display

No. 001-046, 053-057, 59, 63, 74-146

TITLE

BINARY DATA

(8 bit)

No. Data

72 DRV R XXX B XXX

No. 072

TITLE

OR

DECIMAL DATA

(ZERO SUPPRESSED)

DECIMAL DATA

(ZERO SUPPRESSED)

Page 4

— 4 —

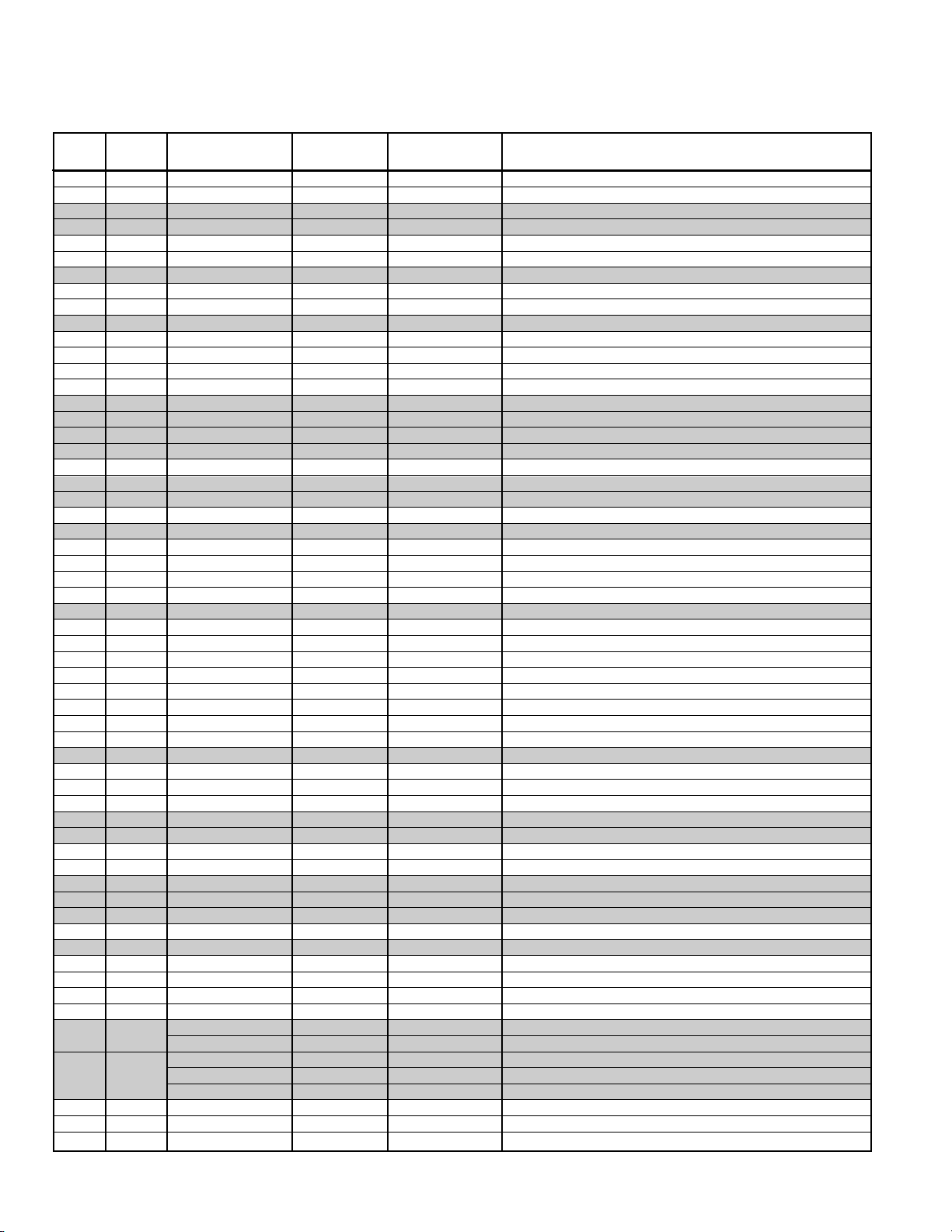

Table 1. ON-SCREEN SERVICE MENU

When IC802 (EEPROM) is replaced, check the bus data to confirm they are the same as below. The shaded menu should be checked

and be set up or readjusted according to the procedures described in the following pages. Initial Setup Data marked with an * should

be changed from Initial Reference Data. (See page 3 for Initial Bus Data Setup.)

No. TITLE

INITIAL REFERENCE INITIAL SETUP

RANGE OF DATA FUNCTION

DATA DATA

001 HFR 30 30 0~63 Align Horizontal Frequency

002 AFC 0 0 0, 1 Select Horizontal First Loop Gain & H-Sync Gating On/Off

003 HP 13 13 0~31 Align Sync to Flyback Phase (Horizontal Phase)

004 VS 50 50 0~127 Align Vertical Amplitude (Vertical Size)

005 VPO 5 5 0~63 Align Vertical DC Bias (Vertical Position)

006 VSP 0 0 0, 1 Select Vertical Sync Separation Sensitivity

007 VLN 19 16* 0~31 Align Vertical Linearity

008 CRS 0 0 0~3 Service Test Mode (Normal/Black/White/Cross)

009 GRY 1 1 0, 1 OSD Gray Tone Enable

010 VSC 8 7* 0~31 Align Vertical S-Correction

011 HBR 3 3 0~7 H-Blanking Control for Right Side Edge on Screen

012 HBL 4 4 0~7 H-Blanking Control for Left Side Edge on Screen

013 CDM 0 0 0, 1 Select Count Down Mode

014 VC 7 7 0~7 Align Vertical Size Compensation

015 RB 0 0 0~255 Align Red OUT DC Level (Red Bias)

016 GB 0 0 0~255 Align Green OUT DC Level (Green Bias)

017 BB 0 0 0~255 Align Blue OUT DC Level (Blue Bias)

018 RD 64 64 0~127 Align Red OUT AC Level (Red Drive)

019 GD 8 8 0~15 Align Green OUT AC Level (Green Drive)

020 BD 64 64 0~127 Align Blue OUT AC Level (Blue Drive)

021 SBI 64 60* 0~127 Align Common RGB DC Level (Sub-Bias)

022 OSD 2 2 0~3 Align OSD AC Level

023 POS 0 1* 0, 1 Select Control for Pre/Over-Shoot Adjustment

024 FLS 1 1 0~7 Select Y/C Filter Mode

025 CKO 3 3 0~7 Select Color Killer Operational Point

026 GYA 0 0 0, 1 Select G-Y Angle

027 CRG 2 2 0~3 Select Coring Gain (w/Defeat)

028 PRE 1 3* 0~3 Select Pre-Shoot Width

029 WP 1 1 0~3 Select White Peak Limitter Operating Point

030 FSW 0 0 0, 1 Enable RGB Blanking or FBP

031 VBL 0 0 0, 1 Select Vertical Blanking Period

032 BSG 1 1 0~3 Select Black Stretch Gain

033 BSS 1 1 0~3 Select Black Stretch Start Point (w/Defeat)

034 DCR 1 1 0~3 Select Luma DC Restoration

035 YGM 1 1 0~3 Select Y Gamma Start Point

036 CBP 0 0 0, 1 Select Chroma BPF Bypass

037 AF 0 1* 0, 1 Enable AutoFlesh Function

038 BAT 4 4 0~7 Align Brightness ABL Threshold

039 MSD 0 0 0, 1 Disable Brightness Mid Stop

040 ABL 0 0 0, 1 Disable Brightness ABL

041 RYA 4 2* 0~15 R-Y/B-YAngle

042 RAD 15 15 0~63 Align RF AGC Threshold (RF-AGC Delay)

043 IAS 0 0 0, 1 Disable IF and RF AGC (IF AGC Switch)

044 FMM 0 0 0, 1 Disable FM Outputs (FM Mute)

045 FL 15 15 0~31 Align WBA Output Level (FM Level)

046 VL 4 4 0~7 Align IF Video Level

053 SB 32 32 0~63 Align Sub-Brightness

054 SCO 10 10 0~31 Align Sub-Color

055 STI 22 18* 0~31 Align Sub-Tint

056 SSH 18 18 0~15 Align Sub-Sharpness

057 OPT 0 0 0~255 Option (Program Codes) (See Note 1 page 5.)

059 HR 13 13 0~31 Align OSD H-Position

063 SBO 5 5 0~255 Sub-Bright Offset

072 DRV

0~127 Red Drive Adjustment (See Note 2 page 5.)

0~127 Blue Drive Adjustment (See Note 2 page 5.)

– 0 0 0~255 Red Bias Adjustment (See Note 3 page 5.)

073 – 0 0 0~255 Green Bias Adjustment (See Note 3 page 5.)

– 0 0 0~255 Blue Bias Adjustment (See Note 3 page 5.)

074 R00 0 0 0~255 N/A

↓↓ ↓ ↓ ↓ ↓

146 R48 0 0 0~255 N/A

Page 5

SERVICE ADJUSTMENTS (Continued)

— 5 —

PROGRAM CODES

The microprocessor used in this model is a multi-purpose type

and is used in several different models. To ensure proper

operation and the correct features for your particular model, the

Program Codes must be correct.

Note 1. Option Data 1 (No. 057 OPT) should be decimal 0

(00000000 binary). See page 3 INITIAL DATA SETUP for set

up procedure. If this program code is wrong the TV will not

operate properly.

Note 2. Red/Blue Drive Adjustments in Service Menu No.

072 DRV: Adjust Red and Blue Drive Levels alternately with 1,

3, 7, and 9 keys on the remote control. (See figure 2.) The Drive

Level adjustment data will be written in the Service Menu No.

018 and 020 automatically.

1

2

3

4 5 6

7 98

RB(–)

RB(+)

BB(–)

BB(+)

(N/A)

GB(–)

(N/A)

GB(+)

(N/A)

FOR RED BIAS ADJUSTMENT

FOR BLUE BIAS ADJUSTMENT

FOR GREEN BIAS ADJUSTMENT

Figure 2.

Figure 3.

1

2

3

4 5 6

7 98

RD(–)

RD(+)

BD(–)

BD(+)

(N/A)

(N/A)

(N/A)

(N/A)

(N/A)

FOR RED DRIVE ADJUSTMENT

FOR BLUE DRIVE ADJUSTMENT

BIT FUNCTION

DATA

01

0 TV/HOTEL TV HOTEL

1 NOT USED N/A

2 NOT USED N/A

3 NOT USED N/A

4 NOT USED N/A

5 NOT USED N/A

6 NOT USED N/A

7 NOT USED N/A

Note 3. Red/Green/Blue Bias Adjustments in Service Menu

No. 073: Adjust each Bias Level with 1, 3, 4, 6, 7, or 9 key on

the remote control. (See figure 3.) The Bias Level adjustment

data will be written in the Service Menu No. 015 ~ 017

automatically.

Page 6

SERVICE ADJUSTMENTS (Continued)

— 6 —

ANTENNA CONNECTIONS

This receiver is designed for UHF/VHF reception. A 75 ohm

terminal is provided for UHF and VHF receptions. When

connecting a CATV antenna system, connect the 75 ohm

coaxial cable directly to the 75 ohm terminal. For 300 ohm VHF

antenna, use an adapter (not included with the TV set).

CIRCUIT PROTECTION

Fuse F601 (4A) is included in the AC line. This fuse must be

replaced with the proper fuse (see Parts List).

+B VOLTAGE CHECK

Connect Voltmeter + lead to TJ1 135V and – lead to ground

(TE7). Connect receiver to AC 120V line. Tune receiver to an

active channel. Set the picture controls to the Auto levels.

Voltage must measure between +133.0V and 136.1V. If the

voltage is out of this range, the power circuit must be checked.

No +B adjustment is provided on this chassis.

HORIZONT AL CENTERING ADJUSTMENT

1. Tune receiver to an active channel.

2. Check that picture is in the horizontal center of TV screen.

If picture is not centered horizontally, perform steps 3 ~ 6.

3.Turn off the receiver and disconnect the AC power cord

(120V AC line).

4. While pressing the MENU key, reconnect the AC power cord.

The Service Menu display will now appear.

5. Select No. 003 HP (Horizontal Phase) with ▲ or ▼ key.

6. Adjust the data with + or – key for proper horizontal center.

To turn off the Service Menu display, press the MENU key.

VERTICAL SIZE ADJUSTMENT

1. Tune receiver to an active channel.

2. Check the vertical size of the picture. If the vertical size is too

large or small, perform steps 3 ~ 6.

3.Turn off the receiver and disconnect the AC power cord

(120V AC line).

4. While pressing the MENU key, reconnect the AC power cord.

The Service Menu display will now appear.

5. Select No. 004 VS (Vertical Size) with ▲ or ▼ key.

6. Adjust the data with + or – key for full scan. To turn off the

Service Menu display, press the MENU key.

VERTICAL CENTERING ADJUSTMENT

1. Tune receiver to an active channel.

2. Che ck that picture is in the vertical center of TV screen. If picture center is too low, replace resistor R513 (2.2K ohm, 1/2W)

with 470 ohm, 1W resistor. If picture center is too high, connect

resistor R512 (470 ohm, 1W).

GRA YSCALE ADJUSTMENT

1. Set the picture controls to the Auto levels.

2. Turn off the receiver and disconnect the AC power cord

(120V AC line).

3. While pressing the MENU key, reconnect the AC power

cord. The Service Menu display will now appear.

4. Select No. 015 RB (Red Bias), No. 016 GB (Green Bias),

and No. 017 BB (Blue Bias) with ▲ or ▼ key and set each

data to 0 with + or – key.

5. Select No. 018 RD (Red Drive) and No. 020 BD (Blue Drive)

with ▲or ▼ key and set each data to 64 with + or – key .

6. Set No. 019 GD (Green Drive) data to 8, No. 053 SB (SubBrightness) data to 32, No. 054 SCO (Sub-Color) data to

10, No. 055 STI (Sub-Tint) to 18 and No. 056 SSH (SubSharpness) data to 18 with ▲ or ▼, and + or – keys.

7. T urn Screen Control (T402) to minimum (fully counterclockwise).

8. Select the Service Menu No. 073 (Bias Adjustments) with ▲

or ▼ key.

9. Advance Screen Control (T402) clockwise to obtain just

visible one color line. If line does not appear, place this

control to maximum (fully clockwise).

10. Raise each Bias Level with 3, 6, and 9 keys to obtain just

visible white line. (See Figure 4 below.)

11. Select the Service Menu No. 072 DRV (Drive Adjustments)with

▲ or ▼ key.

12. Adjust Red and Blue Drive Levels alternately with 1, 3, 7, or

9 key to produce normal black and white picture in highlight

areas. (See figure 5 below.)

13. Check for proper grayscale at all brightness levels.

To turn off the Service Menu display, press the MENU key.

Note: If Grayscale Adjustment is made after picture tube

replacement, check Brightness Level Adjustment.

FOCUS ADJUSTMENT

Adjust focus control (T402) for well defined scanning lines.

CAUTION

FOR CONTINUED PROTECTION AGAINST A RISK

OF FIRE, REPLACE ONLY WITH THE SAME TYPE

4A, 125V FUSE.

ATTENTION : POUR MAINTENIR LA PROTECTION

CONTRE LES RISQUES D’ INCENDIE UTILISER UN

FUSIBLE DE RECHANGE DE MEME TYPE 4A, 125V

.

1

2

3

4 5 6

7 98

RB(–)

RB(+)

BB(–)

BB(+)

(N/A)

GB(–)

(N/A)

GB(+)

(N/A)

FOR RED BIAS ADJUSTMENT

FOR BLUE BIAS ADJUSTMENT

FOR GREEN BIAS ADJUSTMENT

Figure 4. Remote Control Number keys’ function in Service

Menu No. 073

1

2

3

4 5 6

7 98

RD(–)

RD(+)

BD(–)

BD(+)

(N/A)

(N/A)

(N/A)

(N/A)

(N/A)

Figure 5. Remote Control Number keys’ function in

Service Menu No. 072 DRV

FOR RED DRIVE ADJUSTMENT

FOR BLUE DRIVE ADJUSTMENT

4A 125V

Page 7

— 7 —

VCO ADJUSTMENT

Note: VCO must be adjusted after IC101 (Signal Processor),

IC802 (EEPROM) or T151 (PLL VCO Coil) is replaced.

1. Connect digital voltmeter + lead to IC101 pin 58 (C153 (+))

on main board and – lead to main board ground.

2. T une receiver to an active channel. Set the picture controls

to Auto levels.

3. Confirm voltmeter reading of 3.6 ± 0.2 VDC.

4. If the voltage is out of this range, adjust PLL VCO Coil

(T151) for 3.6 ± 0.2 VDC.

5. Disconnect voltmeter from chassis.

RF-AGC ADJUSTMENT

1. Tune receiver to strongest VHF station in your area.

2. Set contrast and brightness controls for maximum.

3. Turn off the receiver and disconnect the AC power cord

(120V AC line).

4. While pressing the MENU key, reconnect the AC power

cord. The Service Menu display will now appear.

5. Select No. 042 RAD (RF-AGC Delay) with ▲ or ▼ key.

6. Adjust the data with + or – key in the direction which

causes snow to appear; then in the opposite direction until

the snow just disappears.

7. To turn off the Service Menu display, press the MENU key.

VIDEO LEVEL ADJUSTMENT

1. Connect a color-bar generator to the antenna terminal.

Switch the generator to a white field (100 IRE).

2. Set the picture controls to the Auto levels.

3. Turn off the receiver and disconnect the AC power cord

(120V AC line).

4. Connect oscilloscope + lead to terminal TP16 (C211(–)) on

main board and – lead to main board ground.

5. While pressing the MENU key, reconnect the AC power

cord. The Service Menu display will now appear.

6. Confirm voltage reading of 1.0 ± 0.1 Vp-p. If voltage is

within this range, Skip to Step 9. If voltage is out of this

range, go to step 7.

7. Select No. 046 VL(IF Video Level) with ▲ or ▼ key.

8. Adjust the data with + or – key for 1.0 ± 0.1 Vp-p at TP16.

To turn off the Service Menu display, press the MENU key.

9. Disconnect oscilloscope from chassis.

BRIGHTNESS LEVEL ADJUSTMENT

Note: Grayscale, RF-AGC, Video Level and High Voltage Check

must be adjusted before attempting Brightness Level

Adjustment.

1. Connect a color-bar generator to the antenna terminals.

2. Switch the generator to the crosshatch pattern.

3. Set the picture controls to the Auto levels.

4. Turn off the receiver and disconnect the AC power cord

(120V AC line).

5. Connect voltmeter (high impedance) + lead to terminal

TP51 and – lead to terminal TP50 on main board. Set

voltmeter for 1.5V ~ 3V range.

6. While pressing the MENU key, reconnect the AC power

cord. The Service Menu display will now appear.

7. Select No. 053 SB (Sub-Brightness) with ▲ or ▼ key.

8. Adjust the data with + or – key for 730 mVDC.

9. Press the MENU key to turn off the Service Menu display.

10. Check brightness level on every active channel, readjust

(repeat steps 5 ~ 9) if necessary.

Note: Do not set to excessive brightness level, otherwise the

contrast level will be suppressed.

HIGH VOLTAGE CHECK

Note: +B (+135V) Voltage Check and Grayscale Adjustment

must be completed before attempting High Voltage Check.

1. Connect high voltage voltmeter negative lead to ground,

and connect + lead to anode of picture tube.

2. Tune receiver to an active channel and confirm TV is

operating properly.

3. Eliminate the beam current by adjusting the contrast and

brightness controls to minimum.

4. Confirm high voltage is within 25.0 KV and 27.0 KV. If reading is not within range, check horizontal circuit.

No high-voltage adjustment is provided on this chassis.

HIGH VOLTAGE HOLD-DOWN TEST

Every time the receiver is serviced, the HIGH VOLTAGE

HOLD-DOWN circuit must be tested for proper operation by

following these steps:

1. Connect receiver to 120V AC line. Tune receiver to active

channel. Set the picture controls to the Auto levels.

2. Check that the voltage measured between TP7 and TE7

(ground side) is within 16.5 VDC to 21 VDC. If the voltage

is out of this range, the Hold-Down Circuit must be checked.

3. Connect a DC Voltage supply to TP7 and TE7 through a

100 ohm 1/4W resistor. Adjust the DC voltage to 23 VDC.

The receiver should shutdown, losing raster and sound.

Then the receiver should turn off automatically. This reaction indicates that the Hold-Down circuit is functioning

properly. If the receiver does not shutdown, a malfunction

is indicated and its cause must be found and corrected.

4. To obtain picture again, remove the DC Supply and wait a

few minutes. Now turn on the receiver.

FM LEVEL ADJUSTMENT

1. Select a channel with audio of 1 KHz 100% modulation. Set

the picture controls to the Auto levels.

2. Turn off the receiver and disconnect the AC power cord

(120V AC line).

3. Connect oscilloscope + lead to terminal TP21 (IC101 pin

75) on main board and – lead to main board ground.

4. While pressing the MENU key, reconnect the AC power

cord. The Service Menu display will now appear.

5. Confirm voltage reading of 1.5 ± 0.2 Vp-p. If voltage is

within this range, Skip to Step 8. If voltage is out of this

range, go to step 6.

6. Select No. 045 FL(FM Level) with ▲ or ▼ key.

7. Adjust the data with + or – key for 1.5 ± 0.2 Vp-p at TP21.

To turn off the Service Menu display, press the MENU key.

8. Disconnect oscilloscope from chassis.

Page 8

— 8 —

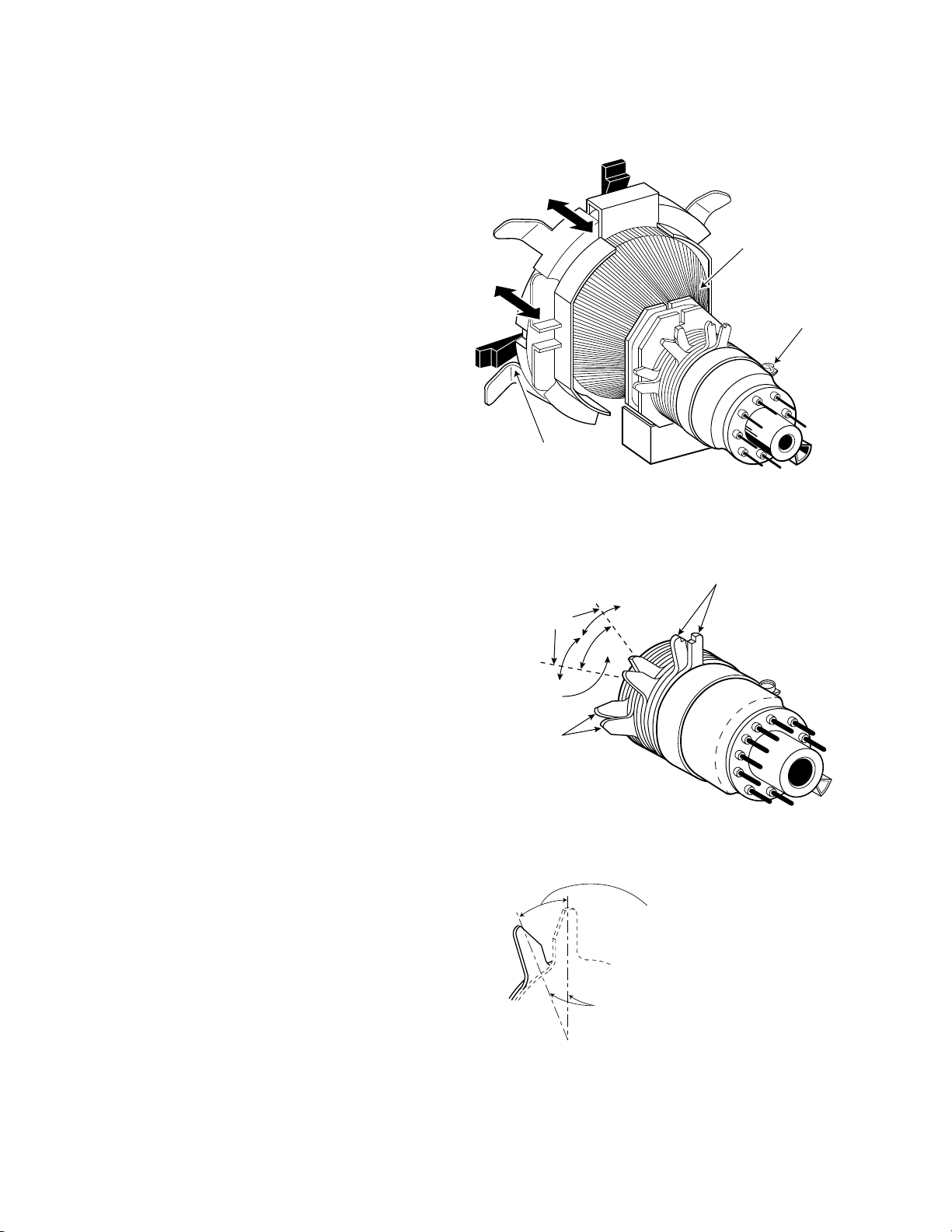

PURITY AND CONVERGENCE ADJUSTMENTS

PURITY ADJUSTMENT

1. When replacing picture tube or deflection yoke, mount

deflection yoke and purity-convergence magnets assembly

properly. See Figure 1. Position the picture tube facing east

or west. Demagnetize the picture tube and receiver using

an external degaussing coil. Set receiver to Service Menu

No. 073 (no vertical sweep) while degaussing.

2. Place the yoke on tube neck fully against glass.

3. Connect a color bar generator to the antenna terminal.

Switch the generator to a white field. Move yoke backward

on the neck until a uniform white field is obtained.

4. Allow 30 minutes warm up on a blank white field (high

intensity grayscale).

Note: If white field cannot be obtained, check Grayscale

Adjustments on page 6.

5. Set the picture controls to the Auto levels. Select a green

raster, either with the signal generator or by adjusting the

bias controls. If a signal generator is used for this step, Skip

to Step 10. If the bias controls will be used, go to step 6.

6. Adjust Service Menu No. 015 RB (R-Bias), No. 016 GB (GBias), and No. 017 BB (B-Bias) data to 0 each.

7. Select Service Menu No. 073 (no vertical sweep).

8. Adjust the screen control counterclockwise until the

horizontal scan lines is no longer visible.

9. Select Service Menu No. 016 GB (G-Bias) and raise the

data to produce green raster. If retrace lines appear,

reduce screen control slightly.

10. Pull yoke back on the tube neck to obtain three-color raster

(blue, green and red).

11. Adjust the angle between the two purity magnet tabs to

center the vertical green belt in the picture tube. Do not

rotate tabs. See Figure 3.

12. Slowly slide the deflection yoke forward until a uniform

green screen is obtained.

13. Check the purity of the red and blue screens for uniformity.

Turn off other colors to check (use bias controls) or use

generator. If necessary, readjust the yoke position until all

screens are pure.

14. If bias controls and screen control were used to set purity,

reset Grayscale and Brightness Level. Refer to Grayscale

Adjustment on page 6 and Brightness Level Adjustment on

page 7.

15. Confirm that the yoke is not tilted. Tighten the yoke

mounting screw. Adjust convergence next.

CAUTION: Purity and Convergence adjustments have been made at the factory. Readjustments should be made

only after the picture tube or deflection yoke is replaced. Follow the steps below for the necessary readjustments.

Figure 1. Deflection Yoke Movement

Figure 2. Purity and Convergence Magnets

Figure 3. Adjusting Magnet

RUBBER

WEDGE

FOUR-POLE

MAGNET TABS

1

2

ANGLE

OF TABS

PURITY

MAGNET

TABS

DEFLECTION YOKE

SIX-POLE

MAGNET TABS

4

3

DEFLECTION YOKE

MOUNTING SCREW

ANGLE OF MAGNET TABS

MAGNET TABS

Page 9

CONVERGENCE ADJUSTMENT

CENTER CONVERGENCE ADJUSTMENT

1. Connect a crosshatch generator to antenna terminals.

2. Set Contrast control to low level to eliminate Blooming.

Reduce Brightness level to obtain black background if

necessary.

3. Adjust the angle between the four-pole magnet tabs 1 and 2

(Figure 2), and superimpose the red and blue vertical lines

in the center area of the picture screen. See Figure 4.

4. Keeping the tabs at the same angle, rotate them together to

superimpose the blue and red horizontal lines in the center

area of the picture screen. See Figure 4.

5. Adjust the six-pole magnet tabs 3 and 4 so the converged

red/blue line is superimposed on the green line. This is the

same procedure used in Steps 3 and 4. See Figure 5.

OUTER AREA CONVERGENCE ADJUSTMENT

The outer area convergence is performed by positioning of the

yoke as follows:

1. Move the top of the yoke toward or away from the picture

tube. This movement will affect the vertical lines at the top

and bottom and the horizontal lines at the sides.

See Figure 6.

2. Check that splits at 12 O’Clock and 6 O’Clock positions are

minimized, adjust yoke for best compromise. Secure with

wedge at 12 O’Clock position. See Figure 1.

3. Move the side of the yoke toward or away from the picture

tube to converge the horizontal lines at the top and bottom

and the vertical lines at the sides. See Figure 7.

4. Check that splits at 12 O’Clock and 6 O’Clock are

minimized, adjust yoke for best compromise. Secure yoke

position with the side wedges. See Figure 1.

Note: When reusing the rubber wedges, apply a small

amount of silicone rubber adhesive or hot melt to each

of the wedges.

— 9 —

Figure 4. Blue an Red Line Movement Figure 6. Top of Yoke Movement

Figure 5. Blue/Red and Green Line Movement Figure 7. Side of Yoke Movement

BLUE

GREEN

BLUE

RED

BLUE

RED

Adjust four-pole tabs angle to

superimpose blue and red vertical

line.

Adjust four-pole tabs together

to superimpose red and blue

horizontal line.

Line movement when adjusting

top of yoke in and out.

BLUE

BLUE / RED

GREEN

BLUE

GREEN

RED

GREEN

RED

GREEN

RED

BLUE

GREEN

RED

BLUE

GREEN

Adjust six-pole tabs angle to

superimpose red / blue and

green vertical line.

Adjust six-pole tabs together

to superimpose red / blue and

green horizontal line.

Line movement when adjusting

side of yoke in and out.

RED

Page 10

— 10 —

SERVICE HINTS

POWER FAILURE DETECTOR

This set is equipped with a Power Failure Detector function included in the CPU which checks for an abnormal condition in the

chassis power supplies, including the power supply derived from the Horizontal Output Transformer.

If, while the power is on, a failure is caused by any of the following which results in a low voltage supply, the CPU will turn the set off

in 1.5 seconds to prevent unnecessary damage:

•

Failure within the power supply circuits.

•

A short circuit in the load side from the supply.

•

Stoppage of the Horizontal Output Oscillator caused by the X-Radiation protection Hold-Down Circuit.

If, while the power is off, the power is switched on and any of these failures remains uncorrected, the CPU will shut off the power

within 3 seconds.

Check the following if the set is turned off by the power failure detector.

1. Disconnect the AC power cord (120V AC line) for at least 10 seconds.

2. Connect a DC Voltmeter to the following TEST POINTS.

3. Press the power key and check for the proper voltage supplies.

4. If any of these voltages is low, the power failure detector should turn the set off within 3 seconds.

5. Check all circuits listed above.

Note: This set is equipped with a Power Surge Protection feature included in the CPU. If power failure occurs three times within 15

minutes, the CPU will automatically stop functioning to help prevent secondary damage. (TV will not turn on by pressing the

power key.) To reset the operating programs within the CPU, disconnect the AC power cord for at least 10 seconds.

TJ5 9V

TJ6 5V

D429 Cathode 10V

D802 Cathode 15V

Page 11

MECHANICAL DISASSEMBLIES

CABINET BACK REMOVAL

1. Refer to Figure 1, remove 4 screws.

2. Pull off cabinet back and remove.

— 11 —

CHASSIS REMOVAL

1. Remove cabinet back.

2. Discharge the picture tube anode (2nd anode lead) to the

dag coating (picture tube grounding lead).

3. Disconnect Degaussing coil socket (KD), Picture tube socket, Deflection yoke connector (KX), Speaker connector

(KSP), picture tube ground leads, and 2nd anode lead.

4. Remove chassis completely by sliding it straight back.

PICTURE TUBE REMOVAL

CAUTION: Do not disturb the deflection yoke or magnet

assembly on the picture tube neck. Care must be taken to

keep these assemblies intact, unless picture tube is being

replaced. Discharge the picture tube to the coating before

handling the tube.

1. Remove chassis, referring to Chassis Removal instructions.

2. Place cabinet’s front face down on a soft surface.

3. Remove the screw on each corner of the picture tube and

GENTLYlift the picture tube out of the cabinet.

4. Install a replacement picture tube in reverse order. Properly

install the degaussing coil and picture tube grounding lead on

the picture tube. See Figure 2.

Note: If Picture T ube is being replaced, mount the Degaussing Coil

properly on the tube. See Figure 2.

Figure 2. Picture Tube Removal

Figure 1. Cabinet Back Removal

TO PICTURE TUBE

SOCKET BOARD

GROUND

TO MAIN BOARD

GROUND

DEGAUSSING

COIL SOCKET

DEGAUSSING

COIL

PICTURE-TUBE

GROUNDING LEAD

DEGAUSSING

COIL HOLDER

DEGAUSSING

COIL HOLDER

Page 12

— 12 —

CHASSIS ELECTRICAL PARTS LIST

CAPACITORS

NOTES:

Read description of the Capacitor as follows:

(Example)

CERAMIC 100P K 50V

Rated Voltage

Tolerance Symbols:

less than 10PF

A . .Not specified

B . .±0.1PF C . .±0.25PF

D . .±0.5PF F . .±1PF

G . .±2PF R . .+0.25 - 0PF

S . .+0 - 0.25PF E . .+0 - 1PF

more than 10PF

A . .Not specified

B . .±0.1% C . .±0.25%

D . .±0.5% F . .±1%

G . .±2% H . .±3%

J . .±5% K . .±10%

L . .±15% M . .±20%

N . .±30% P . .+100 - 0%

Q . .+30 - 10% T . .+50 - 10%

U . .+75 - 10% V . .+20 - 10%

W .+100 - 10% X . .+40 - 20%

Y . .+150 - 10% Z . .+80 - 20%

Rated Value: P...Pico Farad U...Micro Farad

Material:

CERAMIC . . . . . .Ceramic

MT-PAPER . . . . .Metalized Paper

POLYESTER . . .Polyester

MT-POLYEST . . .Metalized Polyester

POLYPRO . . . . .Polypropylene

MT-POLYPRO . .Metalized Polypropylene

COMPO-FILM . .Composite Film

MT-COMPO . . . .Metalized Composite

STYRENE . . . . .Styrene

TA-SOLID . . . . . .Tantalum Solid

AL-SOLID . . . . . .Aluminum Solid

ELECT . . . . . . . .Electrolytic

NP-ELECT . . . . .Non-Polarized Electrolytic

OS-SOLID . . . . .Aluminum Solid with Organic

Semiconductive Electrolytic

C001 403 047 8402 ELECT 0.1U M 50V

C002 403 224 5804 CERAMIC 2200P K 50V

C004 403 039 6508 ELECT 100U M 10V

C006 403 044 1703 ELECT 470U M 16V

C007 403 067 5603 MT-COMPO 0.1U J 50V

403 166 6808 MT-POLYEST 0.1U J 63V

C008 403 043 6006 ELECT 330U M 16V

C101 403 038 6301 ELECT 220U M 6.3V

C103 403 224 6108 CERAMIC 0.01U K 50V

C106 403 050 6600 ELECT 3.3U M 50V

C131 403 049 0008 ELECT 1U M 50V

C132 403 224 6108 CERAMIC 0.01U K 50V

C133 403 224 6108 CERAMIC 0.01U K 50V

C134 403 224 5705 CERAMIC 1000P K 50V

C137 403 364 7508 CERAMIC 10P J 50V

C141 403 224 6108 CERAMIC 0.01U K 50V

C142 403 343 4603 CERAMIC 0.022U K 50V

C143 403 224 6108 CERAMIC 0.01U K 50V

C146 403 224 6108 CERAMIC 0.01U K 50V

C147 403 038 1603 ELECT 100U M 6.3V

C151 403 048 6308 ELECT 0.47U M 50V

C153 403 048 6308 ELECT 0.47U M 50V

C161 403 357 9601 CERAMIC 0.1U Z 50V

C211 403 051 0607 ELECT 4.7U M 50V

C212 403 049 9803 ELECT 2.2U M 50V

C221 403 224 6108 CERAMIC 0.01U K 50V

C252 403 062 0504 POLYESTER 0.047U K 50V

403 312 2203 POLYESTER 0.047U K 50V

C253 403 048 6308 ELECT 0.47U M 50V

C256 403 049 0008 ELECT 1U M 50V

C257 403 224 6108 CERAMIC 0.01U K 50V

C258 403 043 9106 ELECT 47U M 16V

C272 403 050 6600 ELECT 3.3U M 50V

C284 403 041 8804 ELECT 10U M 16V

C285 403 224 6108 CERAMIC 0.01U K 50V

C401 403 043 0202 ELECT 220U M 16V

CAUTION: To Protect against electrical shock and for continued product safety, refer to SAFETY PRECAUTIONS,

X-RADIATION PRECAUTIONS, HIGH VOLTAGE HOLD-DOWN TEST, and PRODUCT SAFETY NOTICE on Page 2.

Notes: Parts having Location Number are located on the following boards.

Numbers under 700 Series . . . . . . . . . . . . . . . . . . . . . .On the Main Board.

Numbers 700 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . .On the Picture Tube Socket Board.

Numbers 800 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . .On the Main Board

Numbers 900 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . .Out of Board.

Numbers 1900 series . . . . . . . . . . . . . . . . . . . . . . . . . . .On the Main Board

PRODUCT SAFETY NOTICE

PRODUCT SAFETY SHOULD BE CONSIDERED WHEN A REPLACEMENT IS MADE IN ANY AREA OF A RECEIVER.

COMPONENTS INDICATED BY A STAR (★) IN THIS PARTS LIST AND THE SCHEMATIC DIAGRAM DESIGNATE

COMPONENTS IN WHICH SAFETY CAN BE OF SPECIAL SIGNIFICANCE. IT IS PARTICULARLY RECOMMENDED

THAT ONLY PARTS DESIGNATED ON THE FOLLOWING PARTS LIST BE USED FOR COMPONENT REPLACEMENT

DESIGNATED BY A STAR. NO DEVIATIONS FROM RESISTANCE, WATTAGE, AND VOLTAGE RATINGS MAY BE

MADE FOR REPLACEMENT ITEMS DESIGNATED BY A STAR.

Schematic

Location

Part No.

Description

Schematic

Location

Part No.

Description

Note: Schematic part location numbers may not always match with the part descriptions.

The part descriptions are correct and should be used.

Page 13

— 13 —

C402 403 224 6108 CERAMIC 0.01U K 50V

C403 403 063 0206 POLYESTER 6800P K 50V

403 312 2807 POLYESTER 6800P K 50V

C405 403 086 2607 NP-ELECT 1U M 50V

C406 403 076 0200 CERAMIC 220P K 500V

C407 403 076 3607 CERAMIC 470P K 500V

C408 403 076 3102 CERAMIC 3900P K 500V

★C411 403 353 4303 MT-POLYPRO 7100P H 1.5K

404 077 4303 MT-POLYPRO 7100P H 1.5K

★C417 403 346 7304 MT-POLYPRO 0.36U J 250V

404 081 2906 MT-POLYPRO 0.36U M 200V

C421 403 038 6301 ELECT 220U M 6.3V

C426 403 224 6108 CERAMIC 0.01U K 50V

C441 403 224 6108 CERAMIC 0.01U K 50V

C482 403 115 0802 ELECT 22U M 100V

C483 404 069 2102 ELECT 47U M 160V

C484 403 051 0607 ELECT 4.7U M 50V

C487 403 054 1502 ELECT 470U M 35V

C489 403 044 1703 ELECT 470U M 16V

C491 403 041 8804 ELECT 10U M 16V

C493 404 056 5307 NP-ELECT 2.2U M 100V

C496 403 044 1703 ELECT 470U M 16V

C497 403 038 1603 ELECT 100U M 6.3V

C498 403 043 9106 ELECT 47U M 16V

C501 403 049 4204 ELECT 10U M 50V

C502 403 053 2104 ELECT 220U M 35V

C503 403 044 6609 ELECT 10U M 25V

C504 403 042 4805 ELECT 1000U M 16V

C505 403 067 7805 MT-COMPO 0.47U J 50V

403 166 7706 MT-POLYEST 0.47U J 63V

C506 403 059 0104 POLYESTER 0.018U K 50V

403 312 0100 POLYESTER 0.018U K 50V

C508 403 028 1705 CERAMIC 56P J 50V

C509 403 067 7805 MT-COMPO 0.47U J 50V

403 166 7706 MT-POLYEST 0.47U J 63V

C511 403 063 2309 POLYESTER 0.068U K 50V

403 312 3002 POLYESTER 0.068U K 50V

C516 403 049 0008 ELECT 1U M 50V

★C601 404 066 1702 MT-POLYEST 0.1U M 275V

404 071 2107 MT-POLYEST 0.1U K 250V

★C604 403 075 7101 CERAMIC 1000P K 500V

★C605 403 075 7101 CERAMIC 1000P K 500V

C606 404 049 4706 ELECT 330U M 200V

404 085 9000 ELECT 330U M 200V

C607 403 103 0005 ELECT 4.7U M 160V

C621 403 075 7101 CERAMIC 1000P K 500V

C622 403 047 5005 ELECT 470U M 25V

C623 403 039 3507 ELECT 470U M 6.3V

C701 403 224 5705 CERAMIC 1000P K 50V

C711 403 357 9403 CERAMIC 820P J 50V

C721 403 357 9403 CERAMIC 820P J 50V

★C742 403 077 2807 CERAMIC 1000P Z 2K

C801 403 224 6108 CERAMIC 0.01U K 50V

C806 403 039 3507 ELECT 470U M 6.3V

C807 403 234 9809 CERAMIC 18P J 50V

C808 403 234 9809 CERAMIC 18P J 50V

C811 403 235 0607 CERAMIC 100P J 50V

C812 403 235 0607 CERAMIC 100P J 50V

C822 403 041 8804 ELECT 10U M 16V

C831 403 049 0008 ELECT 1U M 50V

C834 403 224 6108 CERAMIC 0.01U K 50V

C841 403 224 6108 CERAMIC 0.01U K 50V

C842 403 224 6108 CERAMIC 0.01U K 50V

C843 403 224 6108 CERAMIC 0.01U K 50V

C862 403 224 6108 CERAMIC 0.01U K 50V

C891 403 086 2607 NP-ELECT 1U M 50V

C892 403 224 5705 CERAMIC 1000P K 50V

C894 403 323 3602 CERAMIC 0.047U K 50V

C896 403 049 9803 ELECT 2.2U M 50V

C1902 403 038 1603 ELECT 100U M 6.3V

DIODES

D101 407 056 2307 ZENER DIODE RD36EB1 (36V)

407 100 0204 ZENER DIODE MTZJ36A (36V)

D351 407 056 8002 ZENER DIODE RD5.1EB2 (5.1V)

407 063 8606 ZENER DIODE MTZJ5.1A (5.1V)

D409 407 007 6606 DIODE ES1

407 124 5506 DIODE RMPG06G

407 124 6404 DIODE ERA18-04

★D421 407 158 1307 ZENER DIODE HZ11B2L (11V)

★D422 407 158 1307 ZENER DIODE HZ11B2L (11V)

D428 407 054 4808 ZENER DIODE RD13EB3 (13V)

407 099 3309 ZENER DIODE MTZJ13C (13V)

D429 407 013 4306 DIODE 1S2076A

407 013 7109 DIODE 1S2473

408 008 2406 DIODE 1N4148

D481 407 007 6606 DIODE ES1

407 124 5506 DIODE RMPG06G

407 124 6404 DIODE ERA18-04

D482 407 011 4407 DIODE TVR1G

D483 407 007 6606 DIODE ES1

407 124 5506 DIODE RMPG06G

407 124 6404 DIODE ERA18-04

D484 407 006 4108 DIODE ERB44-04

407 007 7603 DIODE EU2

D486 407 006 4108 DIODE ERB44-04

407 007 7603 DIODE EU2

D487 407 005 8602 DIODE ERA15-02

407 011 3004 DIODE S5277B

407 088 6502 DIODE MPG06D

408 009 9404 DIODE 1N4002ID

D490 407 057 0104 ZENER DIODE RD5.6EB3 (5.6V)

407 063 8903 ZENER DIODE MTZJ5.6C (5.6V)

D496 407 013 4306 DIODE 1S2076A

407 013 7109 DIODE 1S2473

408 008 2406 DIODE 1N4148

D501 407 005 8602 DIODE ERA15-02

407 011 3004 DIODE S5277B

407 088 6502 DIODE MPG06D

408 009 9404 DIODE 1N4002ID

★D602 407 005 7605 DIODE EM2B

407 013 3200 DIODE 1S1887A

408 008 8606 DIODE GP15G

★D603 407 005 7605 DIODE EM2B

407 013 3200 DIODE 1S1887A

408 008 8606 DIODE GP15G

Schematic

Location

Part No.

Description

Schematic

Location

Part No.

Description

Page 14

— 14 —

★D604 407 005 7605 DIODE EM2B

407 013 3200 DIODE 1S1887A

408 008 8606 DIODE GP15G

★D605 407 005 7605 DIODE EM2B

407 013 3200 DIODE 1S1887A

408 008 8606 DIODE GP15G

D621 407 005 8602 DIODE ERA15-02

407 011 3004 DIODE S5277B

407 088 6502 DIODE MPG06D

408 009 9404 DIODE 1N4002ID

D622 407 013 4306 DIODE 1S2076A

407 013 7109 DIODE 1S2473

408 008 2406 DIODE 1N4148

D623 407 056 8002 ZENER DIODE RD5.1EB2 (5.1V)

407 056 8200 ZENER DIODE RD5.1EB3 (5.1V)

407 063 8606 ZENER DIODE MTZJ5.1A (5.1V)

407 099 5204 ZENER DIODE MTZJ5.1B (5.1V)

D801 407 013 4306 DIODE 1S2076A

407 013 7109 DIODE 1S2473

408 008 2406 DIODE 1N4148

D802 407 013 4306 DIODE 1S2076A

407 013 7109 DIODE 1S2473

408 008 2406 DIODE 1N4148

D831 407 222 5903 ZD UDZS3.6B-TE-17 (3.6V)

D834 407 057 6304 ZENER DIODE RD7.5EB1 (7.5V)

407 057 6403 ZENER DIODE RD7.5EB2 (7.5V)

407 063 9207 ZENER DIODE MTZJ7.5B (7.5V)

407 099 5808 ZENER DIODE MTZJ7.5A (7.5V)

D836 407 149 0807 DIODE 1SS355-TE-17

D843 407 149 0807 DIODE 1SS355-TE-17

INTEGRATED CIRCUITS

IC001 409 343 0409 IC TDA7231A

★IC101 409 491 4809 IC LA76834NM-TBM

IC481 409 366 7904 IC UPC78M09AHF

409 367 2809 IC BA178M09T

409 370 0007 IC MC78M09CT

409 377 5401 IC L78M09CV

★IC501 409 340 1805 IC LA7840

★IC601 409 047 8602 IC STR30135

IC801 410 388 1900 IC LC863428V-5V67-TLM

IC802 409 333 3700 IC 24LC02B/P

409 376 1503 IC ST24C02B6

409 440 8902 IC M24C02-BN6

409 495 6908 IC CAT24WC02P

409 497 0706 IC S524C20D21-DCB0

COILS

★LF601 610 031 5938 LINE FILTER

610 031 6089 LINE FILTER

610 031 6096 LINE FILTER

610 031 6119 LINE FILTER

610 031 6126 LINE FILTER

610 223 1212 LINE FILTER

610 290 3027 LINE FILTER

L164 645 003 9713 INDUCTOR,15U K

645 016 2657 INDUCTOR,15U K

L401 645 017 7682 INDUCTOR,5.6U,FILTER

L402 610 031 9998 PIPE CORE

L403 610 031 9998 PIPE CORE

L801 645 008 2894 INDUCTOR,5.6U K

645 016 3104 INDUCTOR,5.6U K

L821 645 008 2894 INDUCTOR,5.6U K

645 016 3104 INDUCTOR,5.6U K

★L901 645 044 9123 ASSY,COIL,DEGAUSSING

★L902 610 238 2846 DEFLECTION YOKE

610 238 2853 DEFLECTION YOKE

TRANSISTORS

Q401 405 029 6901 TR 2SC2228-E

405 040 5600 TR 2SC2228-D

405 040 6102 TR 2SC2228M

★Q402 405 157 1304 TR 2SD2634-YB

Q490 405 023 5009 TR 2SD400-E-MP

405 023 5306 TR 2SD400-F-MP

Q621 405 011 8401 TR 2SC1740S-Q

405 011 8500 TR 2SC1740S-R

405 011 8609 TR 2SC1740S-S

405 012 2002 TR 2SC1815-GR

405 012 2101 TR 2SC1815-O

405 012 2309 TR 2SC1815-Y

405 020 7501 TR 2SC945A-PA

405 020 7709 TR 2SC945A-QA

405 020 7907 TR 2SC945A-RA

405 151 8705 TR 2SC536NG-NPA

405 157 0505 TR 2SC536NF-NPA

Q622 405 011 8401 TR 2SC1740S-Q

405 011 8500 TR 2SC1740S-R

405 011 8609 TR 2SC1740S-S

405 012 2002 TR 2SC1815-GR

405 012 2101 TR 2SC1815-O

405 012 2309 TR 2SC1815-Y

405 020 7501 TR 2SC945A-PA

405 020 7709 TR 2SC945A-QA

405 020 7907 TR 2SC945A-RA

405 151 8705 TR 2SC536NG-NPA

405 157 0505 TR 2SC536NF-NPA

Q623 405 001 7407 TR 2SA1015-O(SAN)

405 001 7605 TR 2SA1015-Y(SAN)

405 004 3109 TR 2SA564A-Q(CU)

405 004 3208 TR 2SA564A-R(CU)

405 006 1707 TR 2SA933S-Q

405 006 1806 TR 2SA933S-R

405 151 3304 TR 2SA608NF-NPA

406 000 6804 TR 2SA1015-GR(SAN)

Q701 405 041 6507 TR 2SC2621-D-RA

405 041 6705 TR 2SC2621-E-RA

405 066 4304 TR 2SC2621-C-RA

405 066 9903 TR 2SC2688(1)-K

405 067 0008 TR 2SC2688(1)-L

405 067 0107 TR 2SC2688(1)-M

406 000 3605 TR 2SC3620(LB-SAN-1)

Schematic

Location

Part No.

Description

Schematic

Location

Part No.

Description

Page 15

— 15 —

Q711 405 041 6507 TR 2SC2621-D-RA

405 041 6705 TR 2SC2621-E-RA

405 066 4304 TR 2SC2621-C-RA

405 066 9903 TR 2SC2688(1)-K

405 067 0008 TR 2SC2688(1)-L

405 067 0107 TR 2SC2688(1)-M

406 000 3605 TR 2SC3620(LB-SAN-1)

Q721 405 041 6507 TR 2SC2621-D-RA

405 041 6705 TR 2SC2621-E-RA

405 066 4304 TR 2SC2621-C-RA

405 066 9903 TR 2SC2688(1)-K

405 067 0008 TR 2SC2688(1)-L

405 067 0107 TR 2SC2688(1)-M

406 000 3605 TR 2SC3620(LB-SAN-1)

Q831 405 002 0308 TR 2SA1037K T146 R

405 002 0407 TR 2SA1037K T146 S

405 002 6706 TR 2SA1179-M6-TB

405 002 6904 TR 2SA1179-M7-TB

405 134 5905 TR 2SA1037AK-T146-R

405 147 2205 TR 2SA1037AK-S-T146

405 163 1503 TR 2SA1179N-M6-TB

405 163 2708 TR 2SA1179N-M7-TB

C136 401 150 6001 MT-GLAZE 0.000 ZA 1/10W

J001 401 150 6001 MT-GLAZE 0.000 ZA 1/10W

J131 401 150 6001 MT-GLAZE 0.000 ZA 1/10W

J202 401 150 6001 MT-GLAZE 0.000 ZA 1/10W

J256 401 150 6001 MT-GLAZE 0.000 ZA 1/10W

J257 401 150 6001 MT-GLAZE 0.000 ZA 1/10W

J286 401 150 6001 MT-GLAZE 0.000 ZA 1/10W

J291 401 150 6001 MT-GLAZE 0.000 ZA 1/10W

J404 401 150 6001 MT-GLAZE 0.000 ZA 1/10W

J622 401 150 6001 MT-GLAZE 0.000 ZA 1/10W

J806 401 150 6001 MT-GLAZE 0.000 ZA 1/10W

J821 401 150 6001 MT-GLAZE 0.000 ZA 1/10W

R001 401 256 3607 MT-GLAZE 15K JA 1/10W

R002 401 256 7308 MT-GLAZE 6.8K JA 1/10W

R004 401 025 5405 CARBON 2.2 JA 1/6W

R106 401 009 7005 CARBON 33K JA 1/2W

R131 401 256 6004 MT-GLAZE 27K JA 1/10W

R132 401 024 6700 CARBON 100 JA 1/6W

R133 401 255 6401 MT-GLAZE 3K JA 1/10W

R142 401 026 4605 CARBON 33K JA 1/6W

R143 401 150 6209 MT-GLAZE 1K JA 1/10W

R151 401 152 3206 MT-GLAZE 330 JA 1/10W

R161 401 150 5806 MT-GLAZE 100K JA 1/10W

R162 401 150 5806 MT-GLAZE 100K JA 1/10W

R163 401 255 8702 MT-GLAZE 22 JA 1/10W

R164 401 150 6209 MT-GLAZE 1K JA 1/10W

R165 401 162 2701 MT-GLAZE 180 JA 1/10W

R166 401 256 7506 MT-GLAZE 390 JA 1/10W

R211 401 256 7100 MT-GLAZE 680K JA 1/10W

R212 401 256 7100 MT-GLAZE 680K JA 1/10W

R251 401 162 3005 MT-GLAZE 22K JA 1/10W

R252 401 162 3005 MT-GLAZE 22K JA 1/10W

R272 401 027 5502 CARBON 6.8K JA 1/6W

R273 401 150 5905 MT-GLAZE 10K JA 1/10W

R276 401 256 0408 MT-GLAZE 12K JA 1/10W

R281 401 150 5905 MT-GLAZE 10K JA 1/10W

R284 401 256 5601 MT-GLAZE 47 JA 1/10W

R286 401 162 2701 MT-GLAZE 180 JA 1/10W

R287 401 162 2701 MT-GLAZE 180 JA 1/10W

R288 401 162 2701 MT-GLAZE 180 JA 1/10W

R301 401 150 5905 MT-GLAZE 10K JA 1/10W

R353 401 024 7400 CARBON 10K JA 1/6W

R400 401 024 6700 CARBON 100 JA 1/6W

★R401 401 066 1404 OXIDE-MT 1.8K JA 2W

★R402 401 065 7704 OXIDE-MT 1.5K JA 2W

★R403 401 065 7704 OXIDE-MT 1.5K JA 2W

R404 401 025 7409 CARBON 220 JA 1/6W

R405 401 162 4101 MT-GLAZE 5.6K JA 1/10W

R406 401 017 1804 CARBON 2.7K JA 1/4W

★R407 401 064 9907 OXIDE-MT 10K JA 2W

★R408 401 068 3703 OXIDE-MT 470 JA 2W

★R411A 401 066 3705 OXIDE-MT 2.7 JA 2W

R416 401 026 9303 CARBON 47 JA 1/6W

★R421 401 286 5305 MT-FILM 2.4K FA 1/6W

★R422 401 052 6802 MT-FILM 10K FA 1/6W

★R423 401 053 2605 MT-FILM 3.3K FA 1/6W

R426 401 027 5205 CARBON 680 JA 1/6W

R428 401 024 9701 CARBON 12K JA 1/6W

R441 401 150 6209 MT-GLAZE 1K JA 1/10W

R442 401 150 5905 MT-GLAZE 10K JA 1/10W

R443 401 150 5905 MT-GLAZE 10K JA 1/10W

R444 401 150 5905 MT-GLAZE 10K JA 1/10W

R449 401 265 1700 MT-GLAZE 4.7K FA 1/10W

★R481 401 011 1206 CARBON 68 JB 1/2W

Schematic

Location

Part No.

Description

Schematic

Location

Part No.

Description

RESISTORS

NOTES:

Read description of the Resistor as follows:

(Example)

CARBON 4.7K J A 1/4W

Rated Wattage

Performance Symbols:

A..General B...Non-flammable

Z...Low noise

Other...Temperature coefficient

Tolerance Symbols:

A...0.05%B...0.1% C...0.25%

D...0.5% F...1% G...2%

J...5% K...10% M...20%

P...+5 -15%

Rated Value, ohms:

K...1,000 M...1,000,000

Material:

CARBON . . . . . . . .Carbon

MT-FILM . . . . . . . .Metal Film

OXIDE-MT . . . . . . .Oxide Metal Film

SOLID . . . . . . . . . .Composition

MT-GLAZE . . . . . .Metal Glaze

WIRE WOUND . . .Wire Wound

CERAMIC RES . . .Ceramic

FUSIBLE RES . . . .Fusible

Page 16

— 16 —

★R482 401 011 9004 CARBON 1 JB 1/4W

★R483 401 006 7701 CARBON 1 JB 1/2W

★R484 401 059 9608 OXIDE-MT 2.2 JA 1W

R485 401 025 4606 CARBON 18K JA 1/6W

★R486 401 066 9103 OXIDE-MT 27 JA 2W

★R487 401 008 3800 CARBON 2.2 JB 1/2W

R488 401 008 9901 CARBON 27 JA 1/2W

★R489 401 065 9609 OXIDE-MT 18 JA 2W

R490 401 026 6609 CARBON 390 JA 1/6W

R491 401 024 7004 CARBON 1K JA 1/6W

R492 401 156 8504 MT-FILM 33K FA 1/6W

R493 401 018 5801 CARBON 330K JA 1/4W

R495 401 011 1107 CARBON 68 JA 1/2W

R496 401 011 1107 CARBON 68 JA 1/2W

★R497 401 064 5701 OXIDE-MT 1.8 JA 2W

R499 401 008 9901 CARBON 27 JA 1/2W

R503 401 026 7002 CARBON 3.9K JA 1/6W

R504 401 026 9907 CARBON 4.7K JA 1/6W

R505 401 006 8401 CARBON 1.5 JA 1/2W

R506 401 027 5007 CARBON 68 JA 1/6W

R507 401 006 8807 CARBON 1.8 JA 1/2W

R508 401 027 5502 CARBON 6.8K JA 1/6W

R509 401 027 5502 CARBON 6.8K JA 1/6W

★R511 401 060 7402 OXIDE-MT 270 JA 1W

R513 401 008 7501 CARBON 2.2K JA 1/2W

R517 401 025 4606 CARBON 18K JA 1/6W

R518 401 025 4606 CARBON 18K JA 1/6W

★R601 402 055 3201 WIRE WOUND 1 KA WA 6W

402 055 3300 WIRE WOUND 1 KA ZA 6W

402 072 2706 WIRE WOUND 1 KA 5W

R602 402 078 5008 CARBON 1M JA 1/2W

R604 401 012 7009 CARBON 10K JA 1/4W

R605 401 016 5803 CARBON 220K JA 1/4W

★R606 401 010 2600 CARBON 47 JB 1/2W

★R607 401 068 6209 OXIDE-MT 5.6 JA 2W

★R608 402 057 1304 WIRE WOUND 120 JA 15W

402 083 5208 WIRE WOUND 120 JA 15W

R620 401 007 7601 CARBON 150 JA 1/2W

★R621 402 078 6203 WIRE WOUND 820 KA 6W

★R622 401 067 0000 OXIDE-MT 270 JA 2W

R623 401 150 6100 MT-GLAZE 2.2K JA 1/10W

R624 401 008 0908 CARBON 180 JA 1/2W

R625 401 162 4101 MT-GLAZE 5.6K JA 1/10W

R626 401 150 6209 MT-GLAZE 1K JA 1/10W

R627 401 162 3708 MT-GLAZE 4.7K JA 1/10W

R628 401 150 6100 MT-GLAZE 2.2K JA 1/10W

R629 401 150 6100 MT-GLAZE 2.2K JA 1/10W

R701 401 025 3807 CARBON 180 JA 1/6W

R703 401 256 0309 MT-GLAZE 820 JA 1/10W

R704 401 255 9006 MT-GLAZE 82 JA 1/10W

R706 401 009 1508 CARBON 2.7K JA 1/2W

★R707 401 058 9807 OXIDE-MT 12K JA 1W

R711 401 025 3807 CARBON 180 JA 1/6W

R713 401 256 0309 MT-GLAZE 820 JA 1/10W

R714 401 255 9006 MT-GLAZE 82 JA 1/10W

R716 401 009 1508 CARBON 2.7K JA 1/2W

★R717 401 058 9807 OXIDE-MT 12K JA 1W

R721 401 025 3807 CARBON 180 JA 1/6W

R723 401 027 8305 CARBON 820 JA 1/6W

R724 401 255 9006 MT-GLAZE 82 JA 1/10W

R726 401 009 1508 CARBON 2.7K JA 1/2W

★R727 401 058 9807 OXIDE-MT 12K JA 1W

R801 401 256 5809 MT-GLAZE 270K JA 1/10W

R803 401 255 6500 MT-GLAZE 100 JA 1/10W

R804 401 255 6500 MT-GLAZE 100 JA 1/10W

R806 401 162 3708 MT-GLAZE 4.7K JA 1/10W

R807 401 150 5905 MT-GLAZE 10K JA 1/10W

R808 401 150 5905 MT-GLAZE 10K JA 1/10W

R809 401 162 3708 MT-GLAZE 4.7K JA 1/10W

R823 401 024 6700 CARBON 100 JA 1/6W

R829 401 024 6700 CARBON 100 JA 1/6W

R831 401 150 5905 MT-GLAZE 10K JA 1/10W

R832 401 150 5905 MT-GLAZE 10K JA 1/10W

R833 401 152 3206 MT-GLAZE 330 JA 1/10W

R834 401 150 5806 MT-GLAZE 100K JA 1/10W

R837 401 024 7400 CARBON 10K JA 1/6W

R842 401 256 0309 MT-GLAZE 820 JA 1/10W

R843 401 256 0309 MT-GLAZE 820 JA 1/10W

R844 401 256 0309 MT-GLAZE 820 JA 1/10W

R846 401 150 6209 MT-GLAZE 1K JA 1/10W

R847 401 162 4101 MT-GLAZE 5.6K JA 1/10W

R848 401 162 4101 MT-GLAZE 5.6K JA 1/10W

R849 401 027 2600 CARBON 5.6K JA 1/6W

R851 401 256 5908 MT-GLAZE 2.7K JA 1/10W

R852 401 256 1702 MT-GLAZE 33K JA 1/10W

R856 401 024 6700 CARBON 100 JA 1/6W

R857 401 024 6700 CARBON 100 JA 1/6W

R862 401 255 6500 MT-GLAZE 100 JA 1/10W

R863 401 150 6001 MT-GLAZE 0.000 ZA 1/10W

R864 401 256 0200 MT-GLAZE 120K JA 1/10W

R865 401 024 7004 CARBON 1K JA 1/6W

R881 401 255 6500 MT-GLAZE 100 JA 1/10W

R882 401 255 6500 MT-GLAZE 100 JA 1/10W

R883 401 255 6500 MT-GLAZE 100 JA 1/10W

R884 401 255 6500 MT-GLAZE 100 JA 1/10W

R886 401 150 5905 MT-GLAZE 10K JA 1/10W

R892 401 162 2909 MT-GLAZE 220 JA 1/10W

R893 401 255 6500 MT-GLAZE 100 JA 1/10W

R894 401 255 6005 MT-GLAZE 1M JA 1/10W

R897 401 026 9600 CARBON 470 JA 1/6W

R898 401 162 3609 MT-GLAZE 470 JA 1/10W

R899 401 162 3807 MT-GLAZE 470K JA 1/10W

R1901 401 150 5905 MT-GLAZE 10K JA 1/10W

R1902 401 150 6209 MT-GLAZE 1K JA 1/10W

R1903 401 162 2800 MT-GLAZE 1.8K JA 1/10W

R1904 401 150 6100 MT-GLAZE 2.2K JA 1/10W

R1905 401 256 7605 MT-GLAZE 3.9K JA 1/10W

R1906 401 162 4101 MT-GLAZE 5.6K JA 1/10W

R1907 401 256 0408 MT-GLAZE 12K JA 1/10W

R1909 401 255 6500 MT-GLAZE 100 JA 1/10W

SWITCHES

SW1901 645 006 9673 SWITCH,PUSH 1P-1T (POWER)

SW1902 645 006 9673 SWITCH,PUSH 1P-1T (VOL.+)

SW1903 645 006 9673 SWITCH,PUSH 1P-1T (VOL.–)

SW1904 645 006 9673 SWITCH,PUSH 1P-1T (CH.

▲)

Schematic

Location

Part No.

Description

Schematic

Location

Part No.

Description

Page 17

— 17 —

SW1905 645 006 9673 SWITCH,PUSH 1P-1T (CH.▼)

SW1906 645 006 9673 SWITCH,PUSH 1P-1T (MENU)

TRANSFORMERS

T151 645 047 8680 TRANS,OSC 45.75MHZ

T401 610 000 7901 DRIVE TRANS

610 000 7918 DRIVE TRANS

645 047 2015 DRIVE TRANS

★T402 645 043 3825 TRANS,FLYBACK

FILTERS/CRYSTALS

X141A 421 008 9008 SAW F TSF5235P

X161 610 015 3059 TRAP,CERAMIC 4.5MHZ

645 041 1618 TRAP CERAMIC 4.5MHZ

X251 610 012 0655 CRYSTAL OSCILLATOR

610 204 4195 CRYSTAL OSCILLATOR

610 245 9746 CRYSTAL OSCILLATOR

X801 645 004 1938 OSC,CRYSTAL 32.768KHZ

645 004 1945 OSC,CRYSTAL 32.768KHZ

MISCELLANEOUS

A100 610 289 2741 ASSY,PWB,MAIN

★A101 645 038 5827 TUNER,U/V

645 042 1976 TUNER,U/V

★A102 645 044 2513 BLOCK,SPECIAL(ANT)

645 045 1171 BLOCK,SPECIAL(ANT)

A700 610 289 2758 ASSY,PWB,SOCKET

A1901 645 041 1519 UNIT,REMOCON RECEIVER

645 044 0519 UNIT,REMOCON RECEIVER

★F601 423 007 1601 FUSE 125V 4A

423 007 1809 FUSE 125V 4A

423 018 8101 FUSE 125V 4A

F601A 645 000 5077 HOLDER,FUSE

645 016 0479 HOLDER,FUSE

F601B 645 000 5077 HOLDER,FUSE

645 016 0479 HOLDER,FUSE

★K701 645 025 6103 SOCKET,CRT 8P

★PS601 408 041 8205 THERMISTOR PTH451A3R0Q11

★Q901 413 007 6201 CRT A48AAB37X

413 007 7901 CRT A48AAB37X

414 009 2703 CRT A48AGD12X

Q901A1 610 117 0154 DY SPACER

610 117 7924 DY SPACER

Q901A2 610 117 0154 DY SPACER

610 117 7924 DY SPACER

Q901A3 610 117 0154 DY SPACER

610 117 7924 DY SPACER

★RL601 645 000 4155 RELAY

645 011 2713 RELAY

645 015 8629 RELAY

645 024 7767 RELAY

645 024 7828 RELAY

SP901 645 028 0870 SPEAKER,8

★W601 645 030 5276 CORD,POWER-2.0MK

★W902 610 240 8775 (USA) GND CONNECTOR

610 252 5625 ASSY,WIRE GND CONNECTOR

610 287 6574 ASSY,WIRE GND CONNECTOR

Schematic

Location

Part No.

Description

Schematic

Location

Part No.

Description

Page 18

CABINET PARTS LIST

— 18 —

1 610 292 4701 CABINET FRONT

2 610 236 9267 SANYO BADGE

3 610 275 1901 DEC SHEET

4 610 275 1864 BUTTON UNITED

411 078 1101 SCREW 4X14

OR 412 036 1805 SCREW 4X14

5 610 267 0851 CAP RC

6 610 291 2203 CABINET BACK

411 078 1101 SCREW 4X14 (4 USED)

OR 412 036 1805 SCREW 4X14 (4 USED)

7 412 000 7604 CRT MTG SCREW 5X30 (4 USED)

8 610 102 7151 DC HOLDER (2 USED)

411 078 1101 SCREW 4X14 (2 USED FOR MTG SP)

OR 412 036 1805 SCREW 4X14 (2 USED FOR MTG SP)

645 044 3176 ASSY,RC TRANSMITTER

OR 645 044 3213 ASSY,RC TRANSMITTER

610 290 1221 RC-BATTERY COVER

OR 610 290 1283 RC-BATTERY COVER

610 289 2888 OWNER'S MANUAL

CABINET PARTS LIST

KEY NO. PARTS NO. DESCRIPTION

ACCESSORY PARTS LIST

KEY NO. PARTS NO. DESCRIPTION

7, 8

7, 8

7

6

7

2

1

3

5

4

A

S

Page 19

— 19 —

COMPONENT AND TESTPOINT LOCATIONS

MAIN BOARD - Parts Side

CAUTION

FOR CONTINUED PROTECTION AGAINST A RISK OF FIRE,

REPLACE ONLY WITH THE SAME TYPE 4A, 125V FUSE.

ATTENTION : POUR MAINTENIR LA PROTECTION CONTRE

LES RISQUES D’ INCENDIE UTILISER UN FUSIBLE DE

RECHANGE DE MEME TYPE 4A, 125V

.

4A 125V

Page 20

— 20 —

MAIN BOARD - Foil Side

Page 21

— 21 —

PICTURE TUBE SOCKET BOARD - Parts Side

PICTURE TUBE SOCKET BOARD - Foil Side

Page 22

NOTES

Page 23

NOTES

Page 24

April / 2001 / 2770 SMC Printed in U.S.A.

For parts or service contact

SANYO Fisher Service Corporation

21605 Plummer Street,

Chatsworth, CA 91311 (U.S.A.)

300 Applewood Crescent,

Concord, Ontario L4K 5C7 (CANADA)

Page 25

— 25 — — 26 — — 28 —— 27 —

IC802

EEPROM

RC IN

KEY IN

IIC SCL

IIC SDA

28

12

2

1

3

4

6

7

BUS SDA

BUS SCL

CF1

CF2

X141A

SAW

FILTER

5

6

15

OSD (R)

OSD (G)

OSD (B)

AFT S- CU RV E

11

12

13

14

8

19

20

21

22

10

AGC

IF

A101

UHF/VHF TUNER

WITH PLL

& BAND SW

Q621

RELAY

DRIVE

POWER

ON/OFF

D602~D605

FULL WAVE

RECTIFIER

LF601

LINE

FILTER

F601

AC

FUSE

C601

AC120V

60Hz

13

ANT.

OSD

SW

BPA

COLOR

DEMOD.

HORIZ.

DRIVER

SYNC

SEP.

VIDEO

DET.

FM

DET.

73

69

56

54

26

30

40

17

18

19

4.5MHz

SOUND

TRAP

VIDEO & SIF

INT. VIDEO

H.V.

FOCUS

SCREEN

HEATER

LOW +B

Q401

HORIZ.

DRIVE

Q402

HORIZ.

OUTPUT

HOLD DOWN

DETECT.

H-PULSE

B

G

R

Q701 B OUT

Q711 G OUT

Q721 R OUT

L902

DEFLECTION

YOKE

V

H

Q901

PIX TUBE

IC101

SIGNAL PROCESS

IC801

CPU

WITH

CAPTION

DECODER

H

V

HOLD DOWN

5

2

BEAM

VOLTAGE

DETECT.

ACL

11

ABL-IN

ABL

L901

DEGAUSSING

COIL

Q622/Q623

5V REG.

25

POWER FAIL

Q831

RESET

+5V

ALWAYS

COMPOSITE VIDEO

D428

(13V)

R428

D486

D429

AUDIO +B

4 2

+9V

IC001

AUDIO

AMP.

SP901

SPEAKER

D482

PS601

POSISTOR

C807

RL601

ON/OFF

RELAY

SW1901~SW1906

CONTROL KEYS

A1901

RC PRE-AMP

IC501

VERT.

OUTPUT

T402

HORIZ.

OUTPUT

TRANS.

BLOCK DIAGRAM

OSD (BLK)

RESET

C831R831

+

ANODE LEAK

DETECT.

T401

H-DRIVE

TRANS.

IC601

POWER

REG.

C808

RF AGC

9

77

49

RF AGC

BUS

INTERFACE

SDA

SCL

9

10

CONT

BRITE

DC

REST

BLACK

STRETCH

DELAY

LINE

15

ABL

Q490

5V REG.

9

8

D801

D496

D802

L164

X161

X801

33

+135V

+5V

ALWAYS

7

/

IC481

9V REG.

D484

52

AFC

(15V)

(10V)

A102

ANTENNA

SHIELD BLOCK

6

3

VERT. + B

4A 125V

CAUTION

FOR CONTINUED PROTECTION AGAINST A RISK

OF FIRE, R EPLA CE ON LY W ITH T HE SAM E T YPE

4A, 125V FUSE.

4A 125V

ATTENTION : POUR M AIN TE NIR L A PR OTECT ION

CONTRE LES RISQUES D'INCENDIE UTILISER UN

FUSIBLE DE RECHANGE DE MEME TYPE 4A, 125V.

R801

to A101

MB/PB

+5V

B8

L801

R851

R852

78/79

VIF

BPF

C137

33

BPF

C

Y

RGB

MATRIX

18

17

37

36

H-SYNC

V-SYNC

DRIVE/

CUT-OFF

67

H-SYNC

V-SYNC

VIDEO

AMP.

(5V)

(9V)

MODEL AVM-1901S Chassis No. G6V-1901S0

SCHEMATIC DIAGRAMS

NOTES ON SCHEMATIC DIAGRAM

1. All resistance values in ohms K=1,000 M=1,000,000.

2. Unless otherwise noted on schematic, all capacitor values less than 1 are expressed in µF (Micro Farad), and the

values more than 1 are in pF.

3. Unless otherwise noted on schematic, voltage reading taken with VOM from point indicated to chassis ground.

Voltage reading taken using of fset color bar-signal on VHF channel 5, all controls at normal. Line voltage at 120 volts.

Some voltages may vary with signal strength.

4. Waveforms were taken with offset color-bar signal and controls adjusted for normal picture. Waveforms marked with

an ✽ may vary with signal strength.

5. Symbol indicates a fusible resistor, which protects the circuit from possible short circuits.

PRODUCT SAFETY NOTICE

THE COMPONENTS DESIGNATED BY A STAR (★) ON THIS SCHEMATIC DIAGRAM DESIGNATE COMPONENTS

WHOSE VALUES ARE OF SPECIAL SIGNIFICANCE TO PRODUCT SAFETY. SHOULD ANY COMPONENT

DESIGNATED BY A STAR NEED TO BE REPLACED, USE ONLY THE PART DESIGNATED IN THE PARTS LIST. DO

NOT DEVIATE FROM THE RESISTANCE, WATTAGE AND VOLTAGE RATINGS SHOWN.

SERVICE NOTES:

1. When replacing parts on circuit boards, clamp the lead wires to terminals before soldering.

2. When replacing high wattage resistors on circuit board, keep the resistor body 10 mm (3/8”) from circuit board.

3. Keep wires away from high voltage and high temperature components.

X-RADIATION WARNING NOTE

THIS TV CONTAINS CRITICAL PARTS TO PROTECT AGAINST X-RADIATION. NORMAL 2ND ANODE VOLTAGE IS

26.0KV AT ZERO BEAM CURRENT AT 120 VOLTS AC LINE, AND MUST NOT EXCEED 27.0KV UNDER ANY

OPERATING CONDITION. SEE HIGH VOLTAGE CHECK ON PAGE 7.

WAVEFORMS

Note: Voltages were measured with offset color-bar signal and controls adjusted for normal picture.

CAPACITOR AND RESISTOR CODE CHART

CAPACITOR (Example)

500 C K 1500 B D ........................... ±0.5pF

T ............................ +50% –10%

J ............................ ±5%

K ........................... ±10%

M ........................... ±20%

N ........................... ±30%

Characteristics P ...........................

+100% –0%

Value code Z ........................... +80%

–20%

Tolerance code C ........................... ±0.25pF

Material code C ........................... Ceramic

Voltage rating E ........................... Electrolytic

F ........................... Polyester

N ........................... Polypropylene

T ............................ Tantalum

K ........................... Ceramic

H ........................... MT-Composite

P ........................... NP. Electrolytic

M ........................... MT-Polypropylene

RESISTOR (Example)

6 Y K 4.7 D ........................... ±0.5%

F ........................... ±1%

G ........................... ±2%

J ............................ ±5%

Value code K ........................... ±10%

Tolerance code M ........................... ±20%

Material code F ............................ Fusible

Wattage rating N ........................... Metalized Carbon

S ........................... Oxide Metalized

Y ........................... Wire Wound

C ........................... Solid

D ........................... Carbon Film

W .......................... Wire Wound

VOLTAGE CHARTS

Device/Pin # Volts/Mode

IC001-1 14.8

IC001-2 7.3

IC001-3 0.5

IC001-4 0

IC001-5 GND

IC001-6 GND

IC001-7 GND

IC001-8 GND

IC101-1 GND

IC101-2 GND

IC101-3 GND

IC101-4 GND

IC101-5 GND

IC101-6 5.2

IC101-7 2.1

IC101-8 0.4

IC101-9 4.3

IC101-10 4.3

IC101-11 4.2

IC101-12 1.5

IC101-13 1.5

IC101-14 1.5

IC101-15 0

IC101-16 8.2

IC101-17 2.2

IC101-18 2.1

IC101-19 2.2

IC101-20 GND

IC101-21 GND

IC101-22 GND

IC101-23 GND

IC101-24 GND

IC101-25 N.C.

IC101-26 2.2

IC101-27 2.6

IC101-28 5.2

IC101-29 2.7

IC101-30 0.6

IC101-31 GND

IC101-32 4.9

IC101-33 1.1

IC101-34 1.7

IC101-35 4.9

IC101-36 5.2

IC101-37 4.2

IC101-38 4.7

IC101-39 GND

IC101-40 0

IC101-41 GND

IC101-42 GND

IC101-43 GND

IC101-44 2.2

IC101-45 3.6

Note: Voltages were measured with offset color-bar signal and controls adjusted for normal picture.

Device/Pin # Volts/Mode

IC101-46 N.C.

IC101-47 2.9

IC101-48 0

IC101-49 1.9

IC101-50 GND

IC101-51 GND

IC101-52 2.7

IC101-53 5.2

IC101-54 2.7

IC101-55 2.6

IC101-56 2.2

IC101-57 GND

IC101-58 3.4

IC101-59 4.5

IC101-60 4.5

IC101-61 GND

IC101-62 GND

IC101-63 GND

IC101-64 GND

IC101-65 2.4

IC101-66 N.C.

IC101-67 2.0

IC101-68 2.4

IC101-69 3.2

IC101-70 GND

IC101-71 GND

IC101-72 GND

IC101-73 2.3

IC101-74 GND

IC101-75 2.2

IC101-76 2.5

IC101-77 2.1

IC101-78 2.9

IC101-79 2.9

IC101-80 GND

IC481-1 (IN) 13.9

IC481-2 GND

IC481-3 (OUT) 9.1

IC501-1 GND

IC501-2 10.1

IC501-3 27.5

IC501-4 2.6

IC501-5 2.6

IC501-6 27.1

IC501-7 1.0

IC601-1 GND

IC601-2 136.0

IC601-3 159.3

IC601-4 135.1

IC601-5 N.C.

IC801-1 4.9

IC801-2 4.9

IC801-3 4.3

Device/Pin # Volts/Mode

IC801-4 4.3

IC801-5 GND

IC801-6 1.8

IC801-7 2.7

IC801-8 4.9

IC801-9 2.1

IC801-10 0.8

IC801-11 3.4

IC801-12 0

IC801-13 4.9

IC801-14 2.5

IC801-15 2.5

IC801-16 4.5

IC801-17 5.2

IC801-18 4.2

IC801-19 0

IC801-20 0

IC801-21 0

IC801-22 0

IC801-23 N.C.

IC801-24 N.C.

IC801-25 4.9

IC801-26 GND

IC801-27 GND

IC801-28 4.7

IC801-29 GND

IC801-30 GND

IC801-31 GND

IC801-32 GND

IC801-33

POWER ON: POWER OFF:

4.5 0

IC801-34 GND

IC801-35 4.9

IC801-36 4.9

IC802-1 GND

IC802-2 GND

IC802-3 GND

IC802-4 GND

IC802-5 4.9

IC802-6 4.9

IC802-7 GND

IC802-8 4.9

Q401-B 0.3

Q401-C 45.6

Q401-E GND

Q402-B 0.7

Q402-C N/A

Q402-E 0.7

Q490-B 5.9

Q490-C 7.2

Q490-E 5.2

Q621-B

POWER ON: POWER OFF:

0.7 0

Device/Pin # Volts/Mode

Q621-C

POWER ON: POWER OFF:

0 16.8

Q621-E GND

Q622-B

POWER ON: POWER OFF:

5.0 5.8

Q622-C

POWER ON: POWER OFF:

18.4 5.8

Q622-E

POWER ON: POWER OFF:

4.9 5.0

Q623-B

POWER ON: POWER OFF:

4.3 16.8

Q623-C

POWER ON: POWER OFF:

4.9 5.0

Q623-E

POWER ON: POWER OFF:

5.1 17.6

Q701-B 2.2

Q701-C 145.9

Q701-E 2.1

Q711-B 2.1

Q711-C 153.6

Q711-E 2.0

Q721-B 2.1

Q721-C 156.7

Q721-E 2.0

Q831-B 4.3

Q831-C 4.9

Q831-E 4.9

Connector KS - 1 pin (TP36)

(R-Output)

2.9V HORIZ.

2

IC501

pin

(Vertical Output)

52.5V VERT.

Connector KS -

2

(G-Output)

2.5V HORIZ.

5

IC501pin

(Inverting Input)

0.26V VERT.

pin

Connector KS - 3 pin (TP35)

(B-Output)

3.1V HORIZ.

Q401-Base

(Horizontal Drive)

0.7V HORIZ.

C211- – lead (TP16)

(Horizontal Output)

(Video Input)

0.6V HORIZ.

Q402-Base

6.0V HORIZ.

INTEGRATED CIRCUITS

TOP VIEW

MARK

1

COUNT TERMINALS IN

ARROW DIRECTION

SIDE VIEW

1

1

1

PHOTO COUPLERS

TOP VIEW

C

1 1

1

1

1

3

2

3

2

1

IN

(1)

GND

(2)

OUT

(3)

E

C

TOP VIEW

TRANSISTORS

B

B

B

C

EC

E

E

E

C

B

B

B ... BASE

C ... COLLECTOR

E ... EMITTER

C

E

E

C

B

CHIP TRANSISTORS

C

B ... BASE

C ... COLLECTOR

E ... EMITTER

B

E

B

EC

B

B

E

C

CHIP RESISTORS

TOP VIEW

123

DIODES

AK

A

AK

A

K

INFRARED EMITTING

A....ANODE

K....CATHODE

3

12 x 10 = 12K ohm

K

K

K

A

A

9

T402

pin

(Heater)

1

5

11

27.5V HORIZ.

Page 26

MODEL AVM-1901S Chassis No. G6V-1901S0

SM

5110190

— 29 —

— 30 — — 31 — — 32 —

SP901

A10B13400

KTP

KT1P

KT2P

KT3P

KT4P

KT5P

KSP

J10EA030J

1

3

KT1P/.../KT5P

J30B0250N:

J30B0250N:

J30B0250N:

J30B0250N:

J30B0250N:

J30B1380N

J30B1380N

J30B1380N

J30B1380N

J30B1380N

C884

X

<ALWAYS 5V>

<POWER FAIL>

X

C806

6.3EM

470

D883D884

L821

L2B9

5R6KN:

L2E1

5R6KN

X

C821

A1901

U20B32400:

U20B35900

123

R881

R882

R883

R884

X

X

D882

D881

C883

X

R809

1/10GJ

4.7KC

R806

1/10GJ

4.7KC

5.0V

5.0V

B8

B8

L801

L2B9

5R6KN:

L2E1

C801

5R6KN

KK

0.01

LZB

5.0V

5.0V

B7

B7

C822

X

16EM

10

C809

X

C1902

6.3EM

100

C802

X

D802

R

C008

16EM

330

R1909

1/10GJ

100C

D1902

X

1/10GJ100C

1/10GJ100C

1/10GJ100C

1/10GJ100C

IC801

QXXAVB754P

C811 C812

CJ

100CL

R808

1/10GJ

10KC

VDD

EEPROM

IC802

24LC02B/P:

CAT24WC02P:

M24C02-BN6:

S524C20D21:

ST24C02B6

1234

HJ0.1:

63GJ0.1V

STATUS

IIC

SDA

123456789101112 13 14 15 16 17 18

R807

1/10GJ

10KC

5678

SCL

SDAVSS

C003

X

1234

C006

16EM

470

C007

R004

2.2

C004

10EM

100

X

R1907

R1908

1/10GJ

CH -

MENU