Page 1

AVL262

1 682 345 88:

SM0915043

Page 2

CONTENTS

Safety precautions………………………………………………………………………..…

Alignment instructions …………………………….…….…………………………………

Method of software upgrading……………………………………………………………..

Working principle analysis of the unit……………………………….………….………….

Block diagram…………………………………..………………………………….…………

IC block diagram………………………………………………………………………..……

Wiring diagram …………………………………………………………………………….

Troubleshooting guide ………………………………………………………………..……

Schematic diagram…………………………………………………………………………

APPENDIX-A: Main Assembly

APPENDIX-B: Exploded View

Removing or Installing the Stand

Wall mounting instructions

1

3

6

12

13

14

18

19

24

Page 3

Attention: This service manual is only for service personnel to take reference with. Before

servicing please read the following points carefully.

Safety precautions

1. Instructions

Be sure to switch off the power supply before replacing or welding any components or

inserting/plugging in connection wire Anti static measures to be taken (throughout the entire

production process!):

a) Do not touch here and there by hand at will;

b) Be sure to use anti static electric iron;

c) It’s a must for the welder to wear anti static gloves.

Please refer to the detailed list before replacing components that have special safety requirements.

Do not change the specs and type at will.

2. Points for attention in servicing of LCD

2.1 Screens are different from one model to another and therefore not interchangeable. Be sure to

use the screen of the original model for replacement.

2.2 The operation voltage of LCD screen is 700-825V. Be sure to take proper measures in

protecting yourself and the machine when testing the system in the course of normal operation or

right after the power is switched off. Please do not touch the circuit or the metal part of the module

that is in operation mode. Relevant operation is possible only one minute after the power is

switched off.

2.3 Do not use any adapter that is not identical with the TV set. Otherwise it will cause fire or

damage to the set.

2.4 Never operate the set or do any installation work in bad environment such as wet bathroom,

laundry, kitchen, or nearby fire source, heating equipment and devices or exposure to sunlight etc.

Otherwise bad effect will result.

2.5 If any foreign substance such as water, liquid, metal slices or other matters happens to fall into

the module, be sure to cut the power off immediately and do not move anything on the module lest it

should cause fire or electric shock due to contact with the high voltage or short circuit.

2.6 Should there be smoke, abnormal smell or sound from the module, please shut the power off at

once. Likewise, if the screen is not working after the power is on or in the course of operation, the

power must be cut off immediately and no more operation is allowed under the same condition.

2.7 Do not pull out or plug in the connection wire when the module is in operation or just after the

power is off because in this case relatively high voltage still remains in the capacitor of the driving

circuit. Please wait at least one minute before the pulling out or plugging in the connection wire.

2.8 When operating or installing LCD please don’t subject the LCD components to bending, twisting

or extrusion, collision lest mishap should result.

2.9 As most of the circuitry in LCD TV set is composed of CMOS integrated circuits, it’s necessary

to pay attention to anti static. Before servicing LCD TV make sure to take anti static measure and

ensure full grounding for all the parts that have to be grounded.

2.10 There are lots of connection wires between parts behind the LCD screen. When servicing or

moving the set please take care not to touch or scratch them. Once they are damaged the screen

1

Page 4

would be unable to work and no way to get it repaired.

If the connection wires, connectors or components fixed by the thermotropic glue need to disengage

when service, please soak the thermotropic glue into the alcohol and then pull them out in case of

damage.

2.11 Special care must be taken in transporting or handling it. Exquisite shock vibration may lead to

breakage of screen glass or damage to driving circuit. Therefore it must be packed in a strong case

before the transportation or handling.

2.12 For the storage make sure to put it in a place where the environment can be controlled so as to

prevent the temperature and humidity from exceeding the limits as specified in the manual. For

prolonged storage, it is necessary to house it in an anti-moisture bag and put them altogether in one

place. The ambient conditions are tabulated as follows:

Temperature Scope for operation 0 ~ +50 oC

Scope for storage -20 ~ +60 oC

Humidity Scope for operation 20% ~ 85%

Scope for storage 10% ~ 90%

2.13 Display of a fixed picture for a long time may result in appearance of picture residue on the

screen, as commonly called “ghost shadow”. The extent of the residual picture varies with the

maker of LCD screen. This phenomenon doesn’t represent failure. This “ghost shadow” may remain

in the picture for a period of time (several minutes). But when operating it please avoid displaying

still picture in high brightness for a long time.

3. Points for attention during installation

3.1 The front panel of LCD screen is of glass. When installing it please make sure to put it in place.

3.2 For service or installation it’s necessary to use specified screw lest it should damage the screen.

3.3 Be sure to take anti dust measures. Any foreign substance that happens to fall down between

the screen and the glass will affect the receiving and viewing effect

3.4 When dismantling or mounting the protective partition plate that is used for anti vibration and

insulation please take care to keep it in intactness so as to avoid hidden trouble.

3.5 Be sure to protect the cabinet from damage or scratch during service, dismantling or mounting.

2

Page 5

Alignment instructions

1. Test equipment

PM5518 (video signal generator)

VG-848 (VGA and HDMI signal generator)

CA210 (color analyzer)

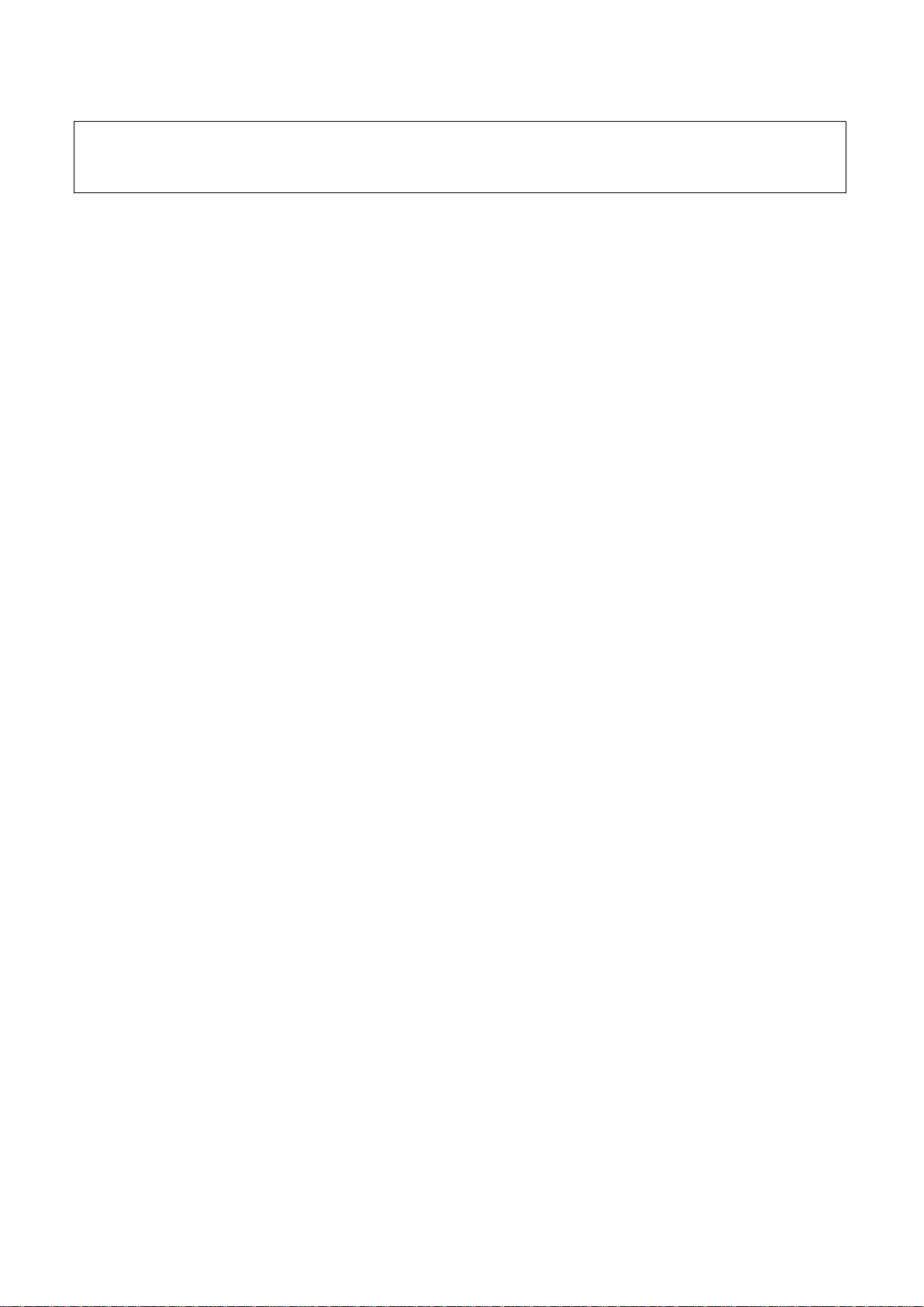

2 Alignment flow-chart

The alignment flow-chart is shown as fig-1

Check DDC, HDCP KEY, FLASH and POWER control IC

Factory initialization setup

IF channel AFT voltage of TV and AGC voltage

ADC correction of VGA, YPbPr

White balance adjustment

Fig-1 adjustment flow-chart

3 Unit adjustments

Connect all the boards according to wiring diagram, connect with power and observe the display.

Method for entering factory menu: press “INPUT”, “2”, “5”, ”8” and “0” in turn to enter factory

menu; press “CH+” and “CH-” to select adjustment items and press “VOL+” and “VOL-” to adjust

value items, press “MENU” continuously to exit.

Method for software upgrading: enter factory menu and select “OPTION”, set ISP to 1 or insert

jump wire J201, then you can upgrade the software on line. After upgrade, it needs to set ISP back

to 0 or pull out jump wire J201. After software upgrade finish, please turn off the TV and then turn on,

enter the factory menu and initialize the EEPROM (EEPROM-MEMORAY RECALL).

3.1 Initialization

The items are only for some units which have special demands. They do not need to be adjusted for

normal units.

Enter factory menu, select “OPTION” and “HOTEL OPTION” sub-menu, adjustment of items to see

table1.

Performance check

Preset ex-factory

3

Page 6

Table1 sub-menu adjustment

Items Preset Introduce

HOTEL 0 1: HOTEL OPTION of factory menu is optional

0: HOTEL OPTION of factory menu is not optional

LOGO 1 1: display LOGO in no signal or turn on

0: no LOGO display

ADC PRESCALE 00A adjust according the power consumption

SIF PRESCALE 001 adjust according the power consumption

BACK LIGHT 100 Adjust according the screen

ALL COLOR 1 1: white balance of each channel auto offset based on the HDMI white

balance

0: white balance of each channel adjust the offset base separately

NO STANDY 11 01: turn on 00: memory function of turn on 10: standby

INIT VOLUME 0-100 Volume when turn on

INIT CHANNEL 1-200 Channel when turn on

INIT SRC Program source Input Source when turn on

EEPROM-MEMORAY

RECALL

> EEPROM Initialization (operate when EEPROM data chaos)

3.2 Adjustment for AFT and AGC of IF channel in TV

3.2.1 IF AFT adjustment

Turn on the TV then enter the factory menu, set IF VCO to 1, disconnect J601, adjust L610 to value

2.5V of TP603 (A face), then solder J601.

3.2.2 IF AGC adjustment

Input 172.25MHz RF signal of 60dB to RF terminal, adjust RP601 to value 3.3V of TP601 (A face)

and there should be no obvious snowy picture. Increase the TV signal to 90dBV and it should be no

obvious noisy.

3.3 White balance adjustment

3.3.1 HDMI white balance adjustment

a. Input VG-848 signal to HDMI: TIMING854(800*600/60Hz) 8 level gray scale of PAT920,

adjust the balance with CA210.

b. Enter COLOR TEMP sub menu and select color temperature of standard (1000K), the value

of coordinate is commend.

c. Fixed B OFF, adjust R OFF, G OFF to let the color coordinate of the second level be

(280,290) (CPT panel) and the brightness be 2-10nit or so; Fixed B GAIN, adjust R GAIN, G GAIN

to let the color coordinate of the seventh level be (280,290) (CPT panel). Repeat adjust R OFF, G

OFF, R GAIN and G GAIN, until the color coordinate of the two level gray scale be (280,290) (CPT

panel).

3.3.2 VGA/YPbPr/ AV white balance check and correct

a. Connect VG-848 signal of VGA to VGA terminal and input TIMING854(800*600/60HZ)

PATTERN921(16 gray levels), enter ADC ADJ sub menu, select AUTOTUNE and wait for OK

display. Input PAT920(8 gray levels), check if the white balance is normal, if not, set ALL COLOR to

0 and fine adjust according the method of 3.2.2.

b. connect VG-848 YPbPr signal to YPbPr terminal and input TIMING972(1080I/60Hz) PAT908

4

Page 7

color bar(include back/white bars), enter submenu of ADC ADJ, select AUTOTUNE and wait for OK

display. Input PAT920(8 gray levels), check if the white balance is normal, if not, set ALL COLOR to

0 and fine adjust according the method of 3.2.2

c. Input AV signal(PM5518, 8 gray levels, PAL for Chinese and NTSC for America) to VIDEO 1

terminal, check if the white balance is normal, if not, set ALL COLOR to 0 and fine adjust according

the method of 3.2.2.

Note: it can’t set back to 1 once ALL COLOR changes to 0.

4 Performance check

4.1 TV function

Enter searching menu → auto search, connect RF-TV terminal with central signal source and check

if the picture is normal, if there are channels be skipped. Check CCD and V-CHIP for America.

4.2 AV/S, YPbPr terminals

Input AV/S, YPbPr / YCbCr HD signal, check if it is normal.

4.3 VGA terminal

Insert VGA terminal, input VGA format signal of 640X480@60 Hz and check if the display is normal.

4.4 HDMI terminal

Insert HDMI terminal, input 640X480@60Hz signal, check if the display is normal. Check HDCP

function.

4.5 check sound channel

Check the speaker and earphone of each channel.

4.6 RS232 terminal

Insert the earphone wire to COM port, check the long-distance control function with special test

software.

4.7 other function check

Check the turn on/turn off timer, asleep timer, picture/sound mode, OSD, freeze/mute, stereo/SAP,

magic picture, ect.

4.8 presetting before ex-factory

Item Setting Item Setting Item Setting

PICTURE MODE NAUTRAL

SOUND MODE NEWS

NR LOW HALFTONE 50 ANTENNA CATV

ZOOM FULL DURATION 15 Turn off channel TV

4.9 software instruction

No. Code Model Function

N303 5272404002 AT24C04IV-10SU-2.7 HDCP Yes FSX.2A3360-034

OSD English

VGA/HDMI color

temperature

Flash write

before paste

STANDARD

Method

N305 5272540003 EN25F40 Flash Yes FSX.2A3360-062

N202 5272402002 AT24C02BN10SU-1.8 VGA EDID Yes FSX.2A3360-030

N501 5272404002 AT24C02BN10SU-1.8 HDMI EDID Yes FSX.2A3360-030

N502 5272404002 AT24C02BN10SU-1.8 HDMI EDID Yes FSX.2A3360-030

N503 5272404002

N601 5270008001 ATMEGA8L-8AI Power control Yes FSX.2A3360-061

AT24C02BN10SU-1.8

HDMI EDID Yes FSX.2A3360-030

5

Page 8

Method of software upgrading

1. The tools and software demanded

1) Please confirm that PC has the software of ISP_TOOL and install the parallel interface drive

program Port95nt.

2) ISP_TOOL icon is bellow:

3) One serial cable (25 pins) and one VGA cable (15 pins), the parallel cable connects the PC and

the upgrade instrument, the VGA cable connects the TV and the upgrade instrument.

2. The steps for upgrading software

1) Please confirm that the connection wires and the upgrade instrument are connected well before

the software written and then power on the TV.

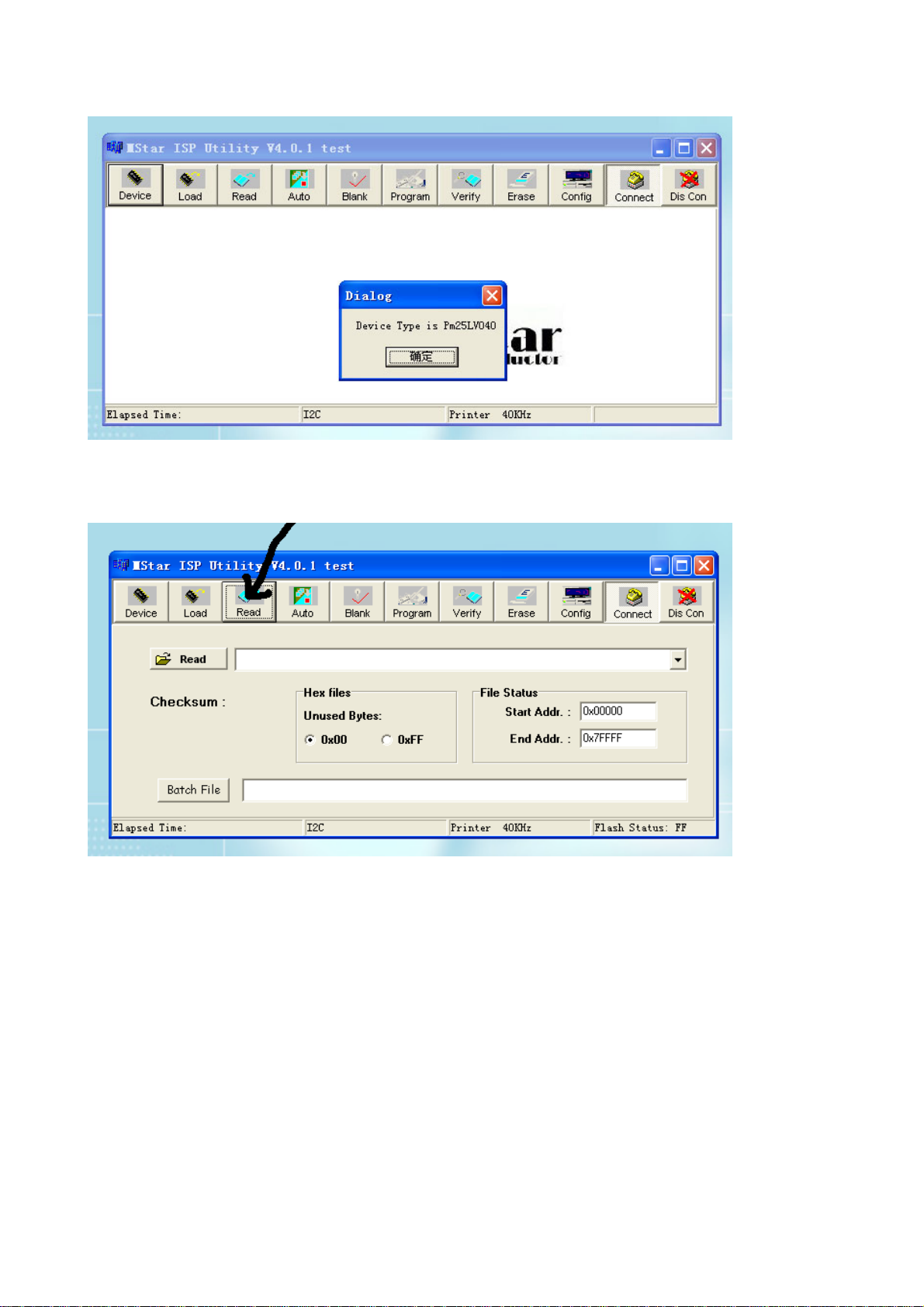

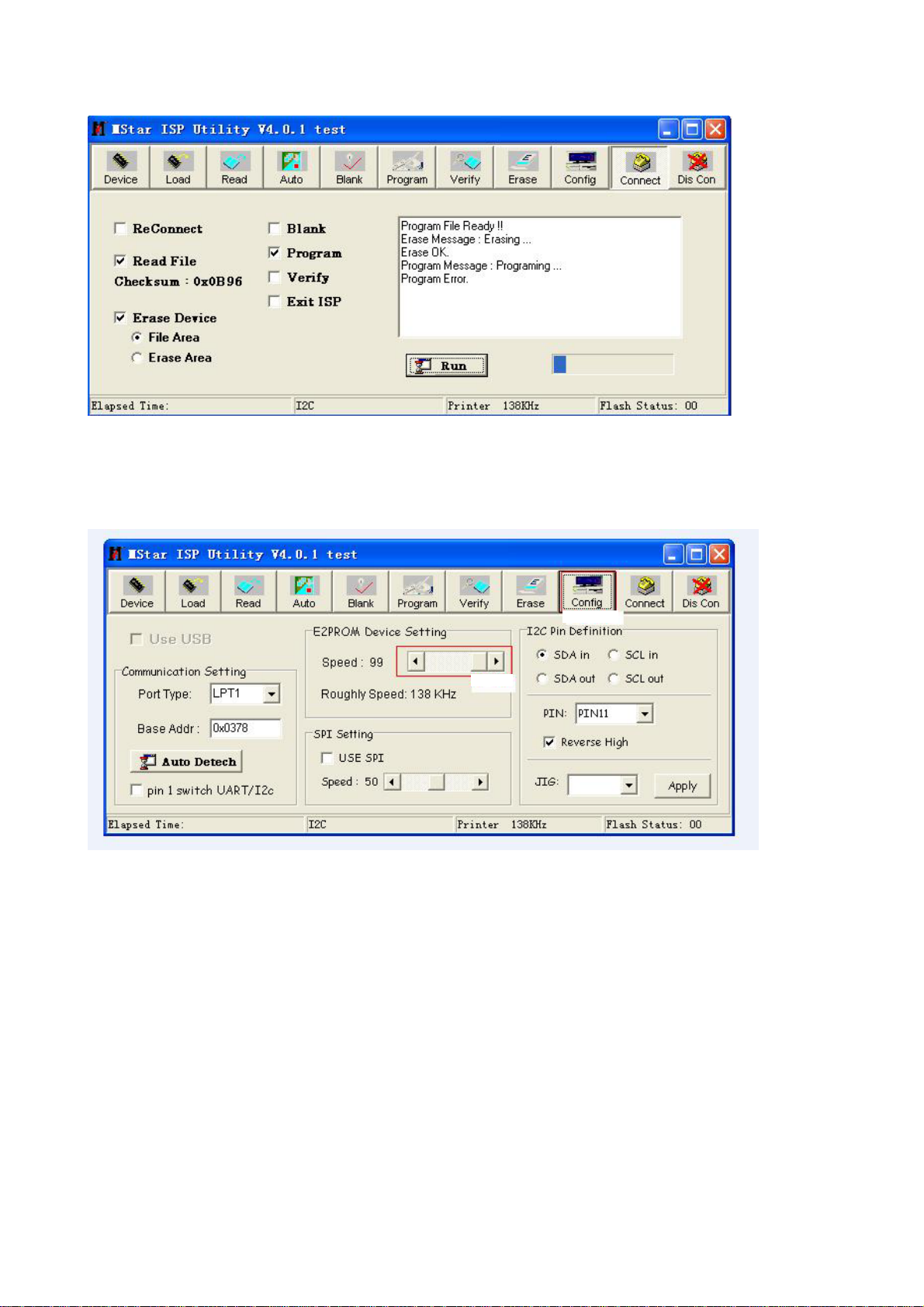

2) Double click the icon ISP_TOOL to open it:

3) Press “Connect“ to connect TV, if the connection is done successfully as shown below, then

press “enter”.

6

Page 9

Note: if it appears error, check the connection wires and check if ISP item of the factory menu is set

to 1, if not, please set it to 1.

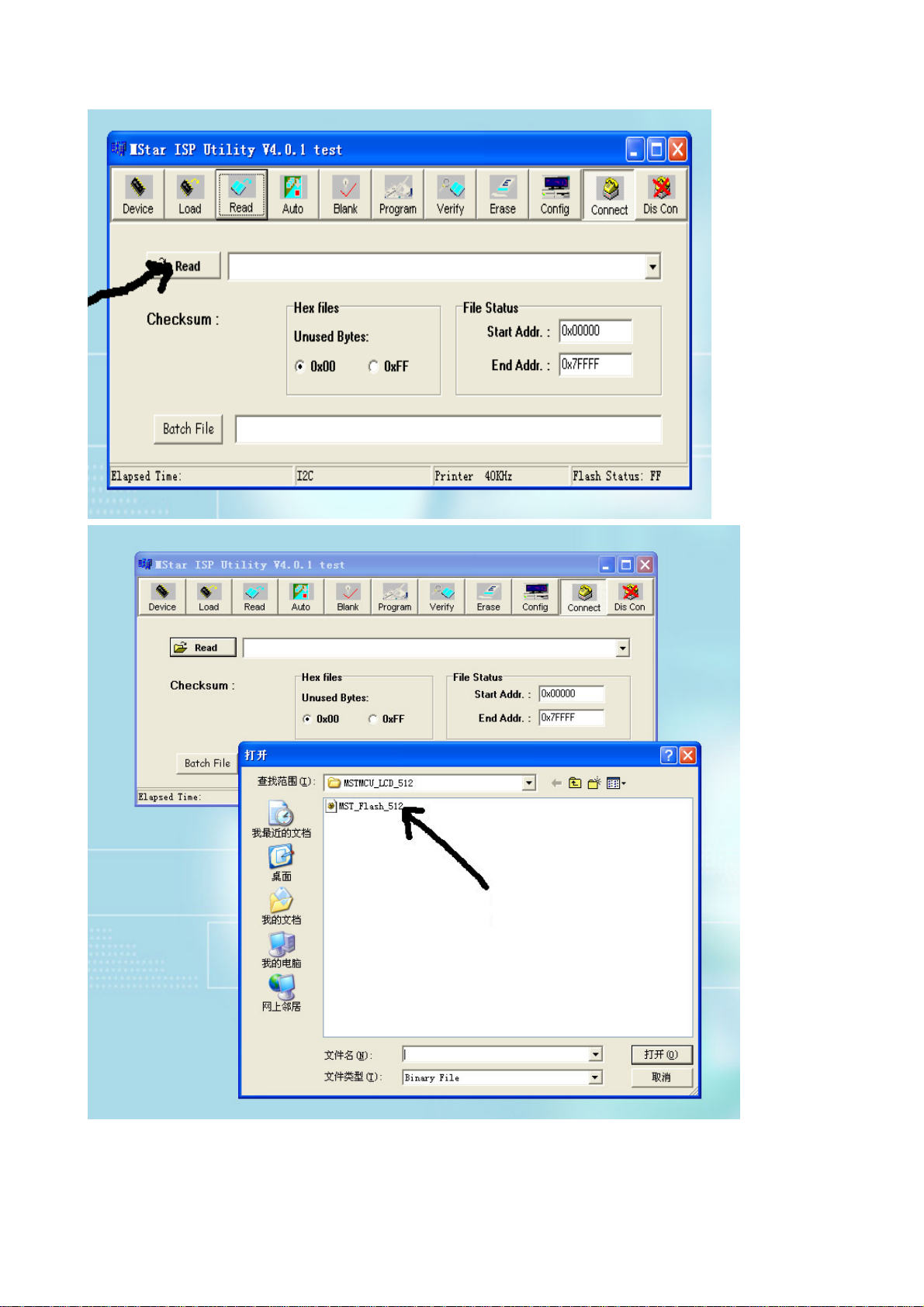

4) After connection is done, it needs to read the Binary document. Press “Read” as shown below:

5) Search the document needed to write in the “Read” check box.

7

Page 10

Select

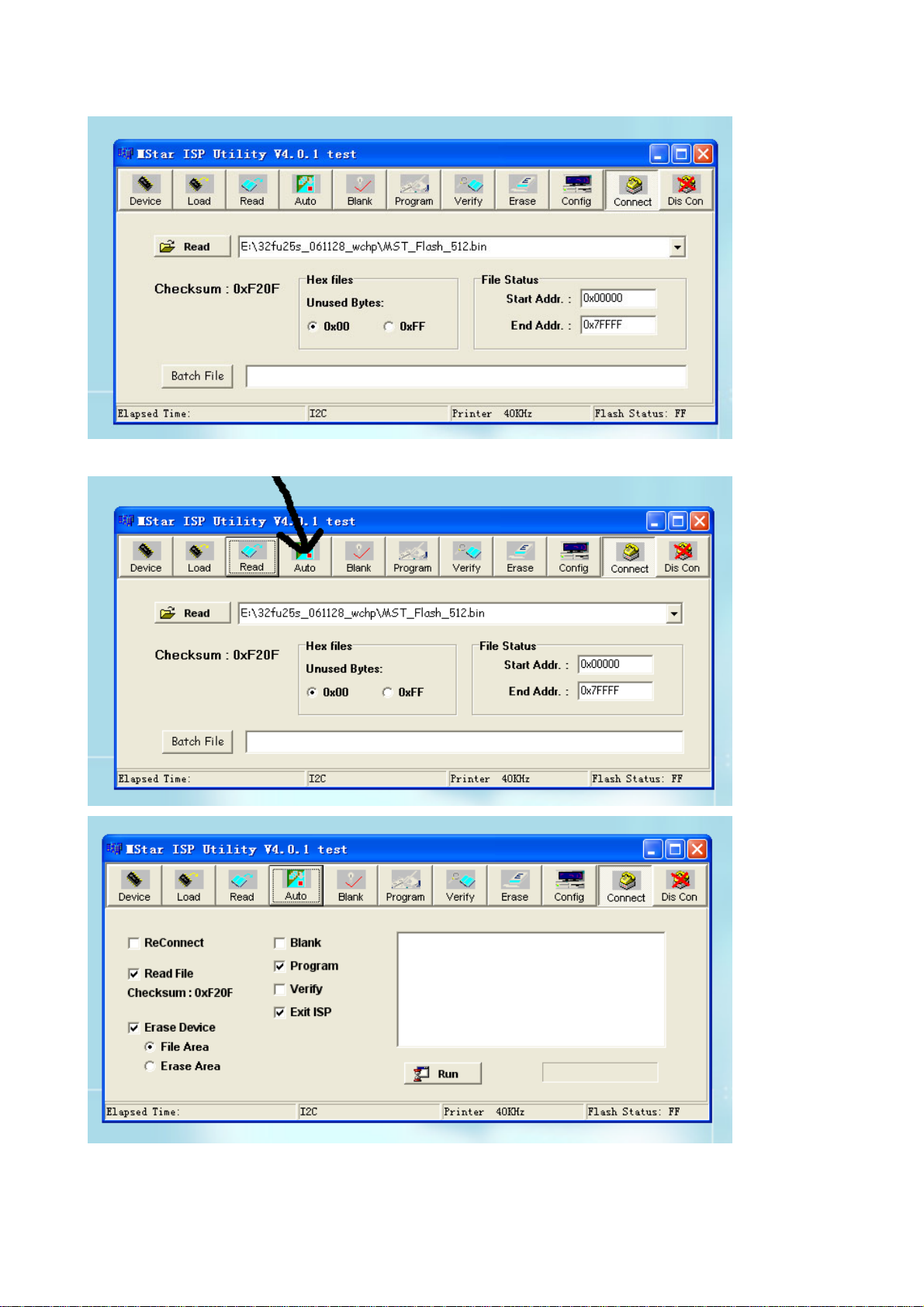

6) Select the document then the window will appear as shown below:

8

Page 11

7) Press “Auto” to select the writing function.

Select the items shown in the picture above:

(a) Read File

9

Page 12

(b) Program

(c) Exit ISP

(d) Erase Device

(e) File Area

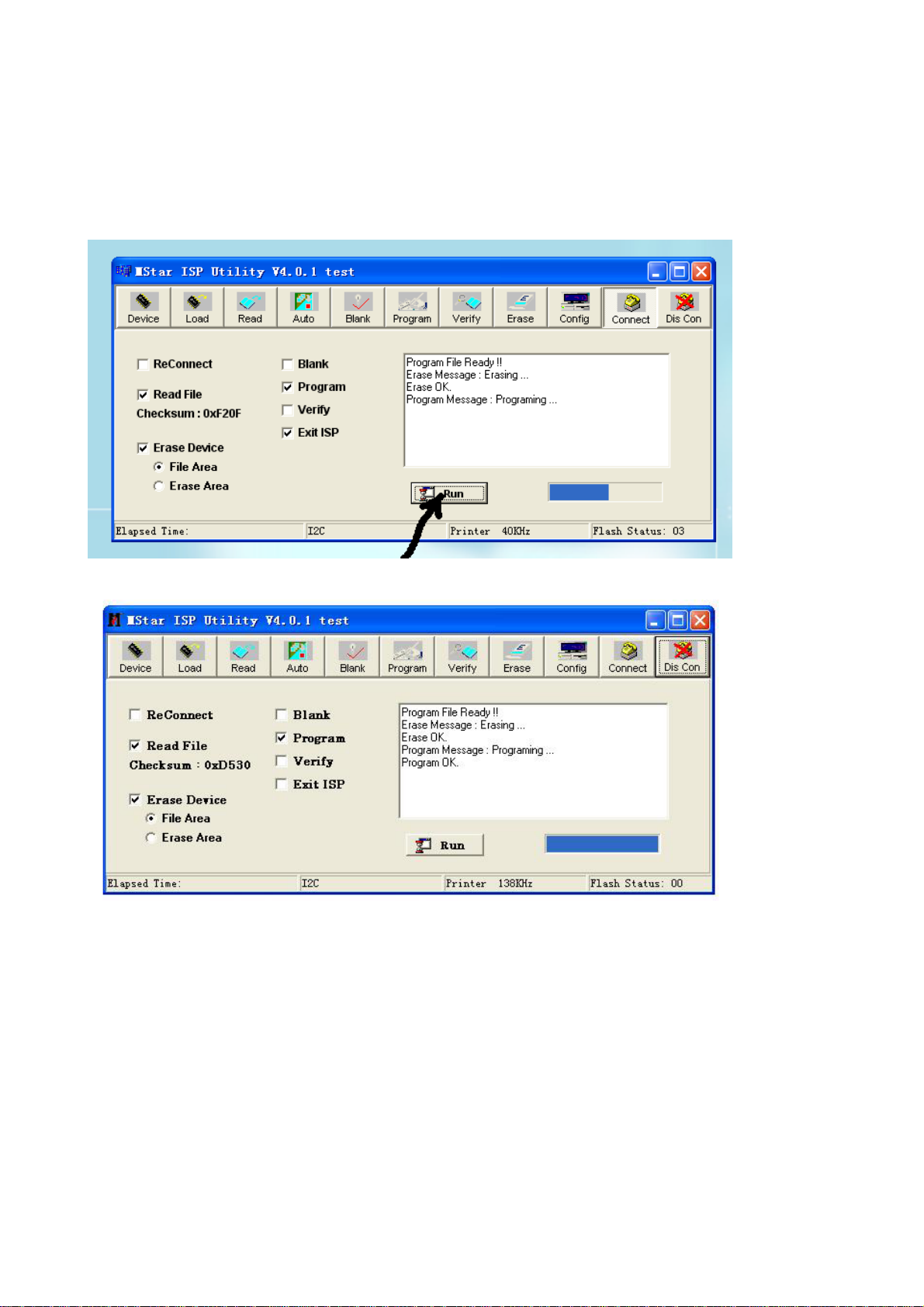

8) Press “Run” to begin the writing program, wait till the blue bar is complete.

After writing, it will display OK:

If there is error appeared (shown as below), press “Run” again to rewrite the program till it is

success.

10

Page 13

Note1: keep the connection well and don’t cut off the power during the writing process.

Note2: the writing speed can be adjusted as shown below. Select “Config” then adjust Speed BAR,

the value is bigger the speed is faster. But it is easier to appear error when increase the speed, so it

need to select a suitable speed according the PC.

Step 1

Step 2

11

Page 14

Working principle analysis of the unit

The RF signal received by antenna will be sent to tuner TUNER601, then IF signal will be

obtained through high amplified, mixed frequency. After pre-intermediate amplified by V602, it will

be sent to acoustic surface-wave Z602 to do IF filter and get better IF characteristics, then it will be

sent to N602 (R2S40401) to do intermediate amplification, phase-lock loop VCO and synchronous

wave detection to get the composite video signal TV-CVBS; after pre-intermediate amplification IF

will also be sent to acoustic surface-wave Z601 to do filter at the same time, the it will be sent to

N602 to do intermediate amplification and output the second sound intermediate frequency signal

TV-SIF.

The TV-CVBS and TV-SIF signal will be sent to main IC N304 (MST9U89). Video signal of AV1,

AV2, S-VIDEO, YPbPr1 and YPbPr2 will also be sent to MST9U89, their audio signal via audio

switch N207 (HEF4052BT) selection to MST9U89 (AV1 and S-VIDEO share the same audio jacks).

HDMI1, HDMI2 and HDMI3 via HDMI switch N504 (TMDS351) selection, then sent to MST9U89

together with VGA.

The main IC N304(MST9U89) is a high performance and fully integrated IC, which can realize

HDMI interface processing, video decoding, video switch selection, A/D and D/A conversion,

interlace/de-interlace processing, modes conversion, OSD and low-voltage differential output, ect.

And it also has functions of audio selection, processing and MCU.

The video signal via MST9U89 processing, output 4 pairs differential signal and 1 pair clock

signal for LCD panel display.

The audio signal via MST9U89 processing, it will be sent to N206 (BH3547F) amplifying to

earphone. The audio signal will also sent to sound amplifier N203 (TPA3120) amplifying to speaker.

12

Page 15

Block diagram

KEY

P A N E L

I/O port

Power

manage Meg8

DDR

Serial flash

Speaker

D class

amplifier

TPA3120

Earphone

MST9U89CL

HDCP

KEY

Earphone

amplifier

BH3547

EEPROM

HDMI 1

AV 1

HDMI switch

HDMI 2

VGA&L/R

YPrPb1 &L/R

HDMI 3

YPrPb2 &L/R

AV 2

S-VIEDO

R2S10401

TUNER

AV-OUT

13

Page 16

IC block diagram

1. MST9U89BL

The MST9U89BL is a high performance and fully integrated IC for multi-function LCD monitor/TV

with resolutions up to full HD (1920x1080). It is configured with an integrated triple-ADC/PLL, an

integrated DVI/HDCP/HDMI receiver, a multi-standard TV video and audio decoder, two video

de-interlacers, two scaling engines, the MStarACE-3 color engine, an on-screen display controller,

an 8-bit MCU and a built-in output panel interface. By use of external frame buffer, PIP/POP is

provided for multimedia applications Furthermore, 3-D video decoding and processing are fulfilled

for high-quality TV applications. To further reduce system costs, the MST9U89BL also integrates

intelligent power management control capability for green-mode requirements and spread-spectrum

support for EMI management.

14

Page 17

2. R2S10401SP

R2S10404SP is a semiconductor integrated circuit consisting of PLL split-carrier VIF/SIF signal

processing system compliant with PAL.

15

Page 18

3. TPA3120D2

The TPA3120D2 is a 20-W (per channel) efficient, Class-D audio power amplifier for driving stereo

single ended speakers or mono bridge tied load. The TPA3120D2 can drive stereo speakers as low

as 4Ω. The efficiency of the TPA3120D2 eliminates the need for an external heat sink when playing

music.

The gain of the amplifier is controlled by two gain select pins. The gain selections are 20, 26, 32, 36

dB.

The outputs are fully protected against shorts from GND to ROUT or LOUT and output-to-output

shorts with an auto recovery feature.

16

Page 19

17

Page 20

Wiring diagram

main board

power board

connection board

18

Page 21

Trouble shooting

1. Fault clearance

Before servicing please check to find the possible causes of the troubles according to the table

below.

1.1 Antenna (signal):

Picture is out of focus or jumping Bad status in signal receiving

Poor signal

Check if there are failures with the electrical connector or

the antenna.

Check if the antenna is properly connected.

Fringe in picture Check if the antenna is correctly oriented.

Maybe there is electric wave reflected from hilltop or

building.

Picture is interfered by stripe shaped

bright spots

There appear streaks or light color

on the screen

1.2 TV set:

Symptoms Possible cause

Unable to switch the power on Check to see if the power plug has been inserted properly

No picture and sound Check to see if the power supply of liquid crystal TV has

Deterioration of color phase or color

tone

Screen position or size is not proper Check is the screen position and size is correctly set up.

Picture is twisted and deformed Check to see if the picture-frame ratio is properly set up.

Picture color changed or colorless Check the “Component” or “RGB” settings of the liquid

Possibly due to interference from automobile, train, high

voltage transmission line, neon lamp etc.

Maybe there is interference between antenna and power

supply line. Please try to separate them in a longer

distance.

Maybe the shielded-layer of signal wire is not connected

properly to the connector.

Check if interfered by other equipment and if interfered

possibly by the equipment like transmitting antenna,

non-professional radio station and cellular phone.

into the socket.

been switched on. (As can be indicated by the red LED at

the front of the TV set)

See if it’s receiving the signal that is transmitted from other

source than the station

Check if it’s connected to the wrong terminal or if the input

mode is correct.

Check if the signal cable connection between video

frequency source and the liquid crystal TV set is correct.

Check if all the picture setups have been corrected.

crystal TV set and make proper adjustment according to the

19

Page 22

signal types.

Picture too bright and there is

distortion in the brightest area

Picture is whitish or too bright in the

darkest area of the picture

No picture or signal produced from

the displayer if “XXX in search”

appears.

There appears an indication -

“outside the receivable scope)

Remote control cannot work

properly

No picture and sound, but only

hash.

Blur picture Check if the antenna cable is correctly connected.

No sound Check if the “mute” audio frequency setting is selected.

When playing VHS picture search

tape, there are lines at the top or

bottom of the picture.

Check if the contrast setting is too high.

Possibly the output quality of DVD broadcaster is set too

high.

It maybe also due to improper terminal connection of the

video frequency signal in a certain position of the system.

Check if the setting for the brightness is too high

Possibly the brightness grade of DVD player (broadcaster)

is set too high.

Check if the cable is disconnected.

Check if it’s connected to the proper terminal or if the input

mode is correct.

Check if the TV set can receive input signal. The signal is

not correctly identified and VGA format is beyond the

specified scope.

Check if the batteries are installed in the reverse order.

Check if the battery is effective.

Check the distance or angle from the monitor.

Check if there is any obstruct between the remote control

and the TV set.

Check if the remote control signal- receiving window is

exposed to strong fluorescence.

Check if the antenna cable is correctly connected, or if it

has received the video signal correctly.

Of if it has received the right video signal.

Check if the sound volume is set to minimum.

Make sure the earphone is not connected.

Check if the cable connection is loose.

When being played or in pause VHS picture search tape

sometimes can’t provide stable picture, which may lead to

incorrect display of the liquid crystal TV, In this case please

press “auto” key on the remote control so as to enable the

liquid crystal TV set to recheck the signal and then to

display correct picture signal

20

Page 23

2. Troubleshooting guide

f

n

f

f

p

n

2.1. The panel doesn’t light

Connect the power, check i

the red indicator is light i

STANDBY?

no

Check if X403 PIN9 (5V) o

main board is normal?

no

Check STANDBY circuit o

ower supply board

no

Replace N304

yes

Press POWER button on the

unit or remote sensor control

and check the indicator.

blue

Check if the PIN3 of X401 on

main board is high-level?

yes

Check back light board

no

Replace N601

red

Check if the PIN11 of X403 i

main board is low-level (less

than 0.8V)?

yes

Check power

supply board

21

Page 24

2.2. Have back light, but no picture

y

p

d

t

R

p

Check if the unit button

and remote control

operation?

yes

Does display OSD

menu in screen when

ress menu button?

no

no

Replace

main board

no

Enter factory-menu,

initialization EEPROM,

then turn off the TV,

turn on again, displa

icture?

Adjust main boar

again

yes

yes

yes

yes

Check if the all channels

have no signal?

no

HDMI/VGA/YPRPB

Which channel is

no signal?

TV

Check if the outpu

signal of TUNE

(pin11) is normal?

no

Replace TUNER

Replace

main board

22

Page 25

2.3. Have picture, but no sound

n

d

t

p

d

p

k

Check if X203 on mai

board has signal output?

no yes

Check if the relevant pins of the

sound amplifier have square

wave output?

no yes

Check the

back-circuit of the

sound amplifier

Check if the soun

amplifier has signal inpu

through R201, R202?

Check if N304 has

signal input?

no yes

Check the peripheral

circuit, crystal an

ower supply of N304.

The speaker has problem.

yesno

Check the peripheral circuit,

ower supply and MUTE of the

sound amplifier.

Follow the sound signal

input channel and chec

each level circuit

23

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

27" backlight

Page 34

27" power

Page 35

Page 36

APPENDIX-A: Main assembly (AVL262)

Name No. Main components and its No.

Main board XI6HK0140110 N304 MST9U89 (5270989003)

N602 R2S10401 (5271040101)

N203 TPA3120 (5273120001)

AV board XI6HK0144610

IR board

Key board XI6HU0310510

Backlight board XI6HU0121410

T-CON board XI6HU0122610

Power board XI6HU0122010

Remote control XI6010Y05601 RC-Y56-0A

Panel

XI6LW0310910

XI5203265502 V260B1-L02

Page 37

APPENDIX-B: Exploded view (AVL262)

5

6

1

2

3

4

9

8

7

10

11

12

Part list

No. Description

Front cabinet

1

T-CON board

2

3

Panel

Backlight board

4

Power board

5

6

Main board

Keyboard

7

8

Back cabinet

9

Stand

10

11

12

Speaker

AV board

IR board

Page 38

Mechanical Replacement Parts List (AVL262 ver. 1.0)

Ref. No. Part No. Description Q’TY Remarks

1 XI5QX32W213A Front cabinet 1

2 XI6HU0122610 T-CON board 1

3 XI5203265502 Panel 1 V260B1-L02

4 XI6HU0121410 Backlight board 1

5 XI6HU0122010 Power board 1

6 XI6HK0140110 Main board

7 XI6HU0310510 Keyboard 1

8 XI5HX32WI02A Back cabinet 1

9 XI6151078800 Stand 1

10 XI6170699060 Speaker 1

11 XI6HK0144610 AV board 1

12 XI6LW0310910 IR board 1

13 XI5944033600 User manual 1

14 XI6010Y05601 Remote control 1 RC-Y56-0A

Note:

Only the parts in above list are used for repairing.

Other parts except the above parts can't be supplied.

Page 39

Removing or Installing the Stand

Cautions:

1. Carefully handle the unit during setup and consult authorized service personnel to ensure successful

installation.

2. Before performing work spread cushioning over the base area to lay the Display on. This will prevent it from

being damaged.

3. Disconnect the AC power cord firstly.

To remove the stand: (if wall mounting)

1.Lay your TV flat (screen down) on a table or bench. Make sure that you put down a soft cushion or cloth so that your TV

is not scratched.

2.Loosen the eight M4 screws on the Stand to remove the Stand. (Please keep these screws for future use if you want

to install the stand again.)

Remove eight screws

To install the stand

1.Lay your TV flat (screen down) on a table or bench. Make sure that you put down a soft cushion or cloth so that your TV

is not scratched.

2. Align the locator holes in the stand with the locators on the TV back, and then align the holes in the stand column with the

holes in the TV back, and then secure the stand to the TV with eight M4 screws.

a ot r

oc

L

le

t

a or ho

c

Lo

Use eight M4 screws to

secure the stand to the TV

3.Place your TV upright.

Note

! Do not remove the stand from the TV unless using an optional bracket to mount it.

! The appearance of the unit may differ from the actual one.

Page 40

WALL MOUNTING INSTRUCTIONS

Safety Precautions:

1. Be sure to ask an authorized service personnel to carry out setup.

2. Thoroughly read this instruction before setup and follow the steps below precisely.

3.The wall to be mounted should be made from solid materials. Only use accessories supplied by the manufacturer.

4.Very carefully handle the unit during setup. We are not liable for any damage or injury caused by mishandling or improper installation.

5.Be sure to place the unit on a stable and soft platform which is strong enough to support the unit.

6.Do not uplift the speaker when moving the display. The appearance of the unit may different from the actual ones.

7.Design and specifications are subject to change without notice.

8. Retain these instructions for future reference.

Note: All the wall mounting parts are optional and may be unavailable in your model.

Below we will show you how to mount the Display on the wall using our company’s wall mounting components.

11

Take out these parts from the box.

Wall Mounting

Component

(including bracket

and connector)

Expansion Bolt

Wood Screw

M4 Screw

Fig. 1

Fully insert the two insertions on the wall mounting connector into the

44

locating grooves on the wall mounting bracket from top to bottom end.

22

Screw 4pcs expansion bolts to fix

the wall mounting bracket on the

wall.

Wall

Wall Mounting Bracket

Fig. 2a

If your wall is a wooden structure, please

fix the wall mounting bracket on the wall

with 8 pcs wood screws.

Wall

Wall Mounting Bracket

Fig. 2b

55

Use screwdriver to revolve the Clasper to the Positioner

following the direction of the arrow.

33

Use the 4pcs M4 screws to fix the wall

mounting connector to the rear of the

display unit.

Wall Mounting Connector

Fig. 3

Clasper

Positioner

Fig. 4

Fig. 5

Page 41

SEP/2008

Loading...

Loading...