(

90478

)

Safe Handling of R/C System and Precautions

To use your purchased R/C System properly and safely, please read this instruction carefully and make sure to follow the precautions. Improper use of the product

or negligence of following safety precautions can cause trouble to others or harm

to the user.

■ For safety, please make sure to follow each of the precautions below.

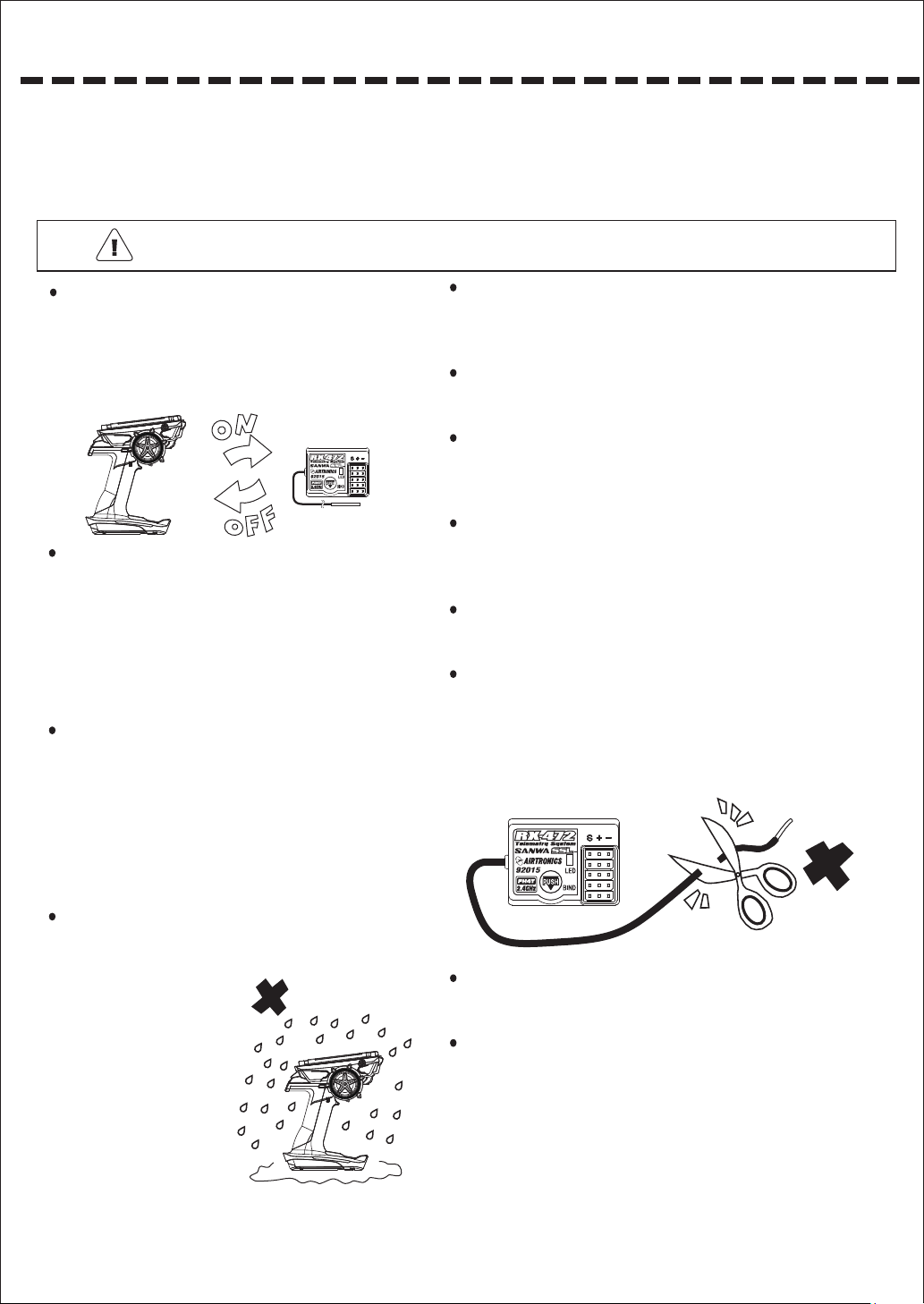

Warning Precautions for Installation and Operation

When turning the power switch of R/C System on,

please turn on in order of ① Transmitter → ② Receiver.

And when turning the power switch off,please do so in

order of ① Receiver →②Transmitter.

☆

If you reverse the order of the switches, it

causessudden high rotation of the engine and

the motor and it’s extremely dangerous.

Please use electrical noise countermeasure on the

body of your car.

☆

If metals rub against each other, it causes electrical

noise which may lead to abnormal performance.

Please be sure that all screws and nuts are not loose.

☆

Nitro or gas engine and electric motor can cause

noise also. Please use a noise countermeasure

such as a plug with resistor or noise killer

condenser.

Please make sure to run a performance check

(signalreception test) of R/C System before

operation. When it moves abnormally or it doesn’t

move, please don’t operate. Even if the test result

on a desk is normal,please be cautious when

operating for the first time especially, since the

radio wave arrival distance varies depending on

the installation method of the receiver, how the

antenna is set, the direction of the transmitter

antenna is facing and geography.

Never operate on a rainy day.

☆

The interior of the transmitter is built with

sensitive electronic parts. If water runs

on the surface of the case

and enters inside, it can

cause abnormal

performance or

malfunction and it can be

dangerous.

If the receiver or a servo

☆

sinks in the water,

immediately collect it and

dry the interior. When the

interior is dry,please

submit it to the Sanwa

Service for inspection even if it performs normally.

The receiver is a precise instrument. Please do not add a strong

impact or vibration.

☆

Use a thick sponge to prevent vibrations.

Install the receiver as far as possible from the speed controller,

motor and the battery.

When installing the receiver on a metallic chassis or a carbon

chassis, use three layers of double adhesive tape pieces to

keep the receiver from touching the chassis.

When there is a radio disturbance, change the installation

location of the receiver or change from a vertical placement to a

horizontal placement or vice versa.

Don't place a motor cord or a battery cord close to the receiver

since it can cause abnormal performance.

Keep the antenna of the receiver out as much as possible. And

keep it straight and stretched. Don't cut the extra length of the

line or bend it.

☆

It’s dangerous when the antenna is short since the range of

travelling becomes narrow.

☆

Never cut the antenna.

Don't place the antenna close to a motor cord or a battery cord.

Using a conductive piano wire on a metallic chassis or carbon

chassis can cause abnormal performance from electrical noise.

Don’t place a piano wire close to the chassis.

1

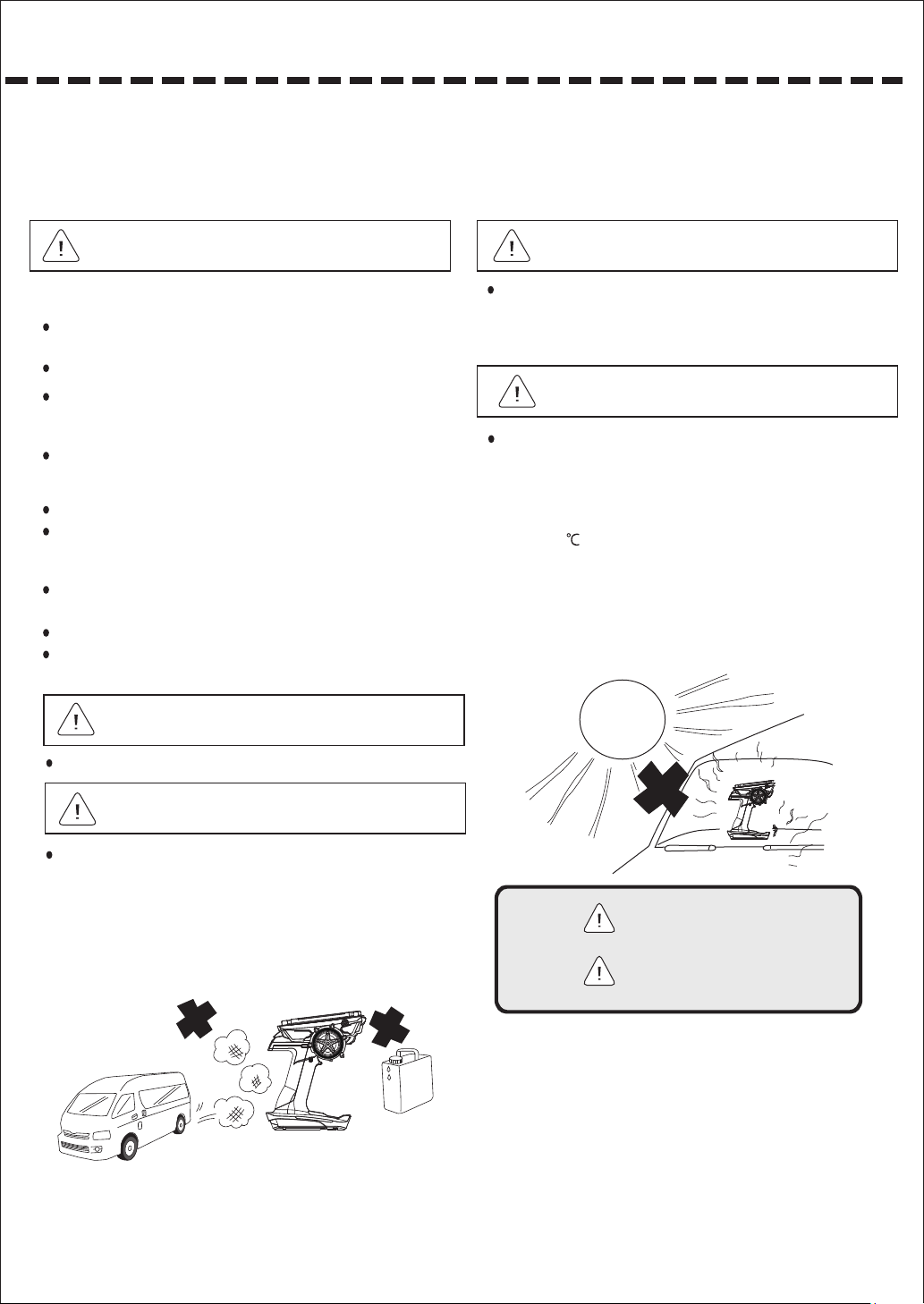

Warning Precaution For Operating RC Car

Note About Handling the Transmitter

When operating an RC car, please make sure to follow the

following notes and avoid giving trouble to others.

Maintain the body of the car (boat) in a perfect condition

and check the safety.

Do not operate an RC car in a crowd or on a public road.

Make sure to disconnect the connector of the power

battery and remove the power battery from the car after

operation.

When operating simultaneously with other RC users, make

sure to have a control staff and follow the instruction of the

control staff.

Try not to interfere with other people’s operation.

Be sure to apply for a radio control insurance. For

application to apply a radio control insurance, inquire a

radio control operator registration agency.

Be sure to install a “muffler (sound absorber)” with a

silencing effect on an engine car.

Don't start engine early in the morning.

Please make sure to clean the location used for operation

before you leave.

Note About Operation

Don't use this RC system for other than model use.

Don't hit, drop or subject to strong impact.Touching the

transmitter, receiver, servos or FET speed controller with a

hand stained with tire traction agent can cause malfunction

or deforming the case.

Note Storage Location

Don't store the product in the following locations:

☆

Extremely hot or cold place.

☆

Place exposed to the direct sunlight for long hours.

☆

Especially if the product is left in a closed car with a direct

sunlight hitting, the temperature inside the car can rise

above 80 depending on the season. It can cause

deforming or malfunction.

☆

Place with high humidity and poor ventilation

☆

Place with vibrations

☆

Place with dust, steam or heat

☆

Place that is blown with engine exhaust gas or a place

close to a fuel can

Note Daily Maintenance

When exhaust gas or fuel of the engine is on the product,

wipe with a soft dry cloth. When the product is heavily

stained, soak a soft clean cloth with water or neutral

detergent, squeeze tightly and wipe with it. Don't use

thinner, benzene, alcohol, motor cleaner or brake cleaner

since they can damage the surface finishing and alter the

quality.

What each

marks

indicate

Warning

Note

Precautions you must

follow to avoid accidents

or injury

Precautions you must

follow to avoid malfunctions

2

Safe Handling of R/C System and Precautions

Note Precautions to Use the Product Safely

● 2.4 GHz frequency band is not only used for radio control. This frequency band is shared with ISM

(Industry, Science and Medical) band. It can be affected by microwave ovens, wireless LAN, digital

cordless telephones, audio equipment, Bluetooth of game machines or cell phones and short-range

communication such as VICS. Also, be cautious about being affected by amateur radio and premises

radio stations for moving body identification since this frequency band is used for them as well.

When a harmful radio frequency interference is done to an existing radio station, stop the transmission

of the radio frequency immediately and take a measure to avoid the interference.

● For RC circuit, minimize the use of equipment that can affect 2.4 GHz systems and make sure to

check the safety beforehand. Also, follow the instruction of the facility manager.

● When operating the models behind a building or a steel tower, blocking the direction of radio wave

transmission can cause reduction of operation response or loss of control. Always operate within the

range you can visually check.

● Don't grab the transmitter antenna. Doing so can be dangerous since it can weaken the radio signal

output and narrow the range of operation.

● Don't attach any metal parts around the antenna of the transmitter.

● If you have the transmitter’s antenna extremely close to a servo or speed controller other than the

receiver, it can cause malfunction but it is an influence of a strong high frequency output and it is not

abnormal.

● The receiver is a precise instrument. Don’t subject it to strong impact or vibrations. Use a thick

sponge to prevent vibrations.

● Keep the antenna wire of the receiver out as much as possible. And keep it straight and stretched.

Don't cut the extra length of the antenna line or bend it.

● Don't place the antenna wire of the receiver close to a electrical noise source like a motor wire or a

battery wire.

● When installing the receiver on a metallic chassis or a carbon chassis, use layers of double adhesive tape pieces to keep the receiver from touching the chassis as much as possible.

3

INDEX

■ Layout and Specification of the Set・・・・・・・・・・・・・・・・・・・・・・・・・・・・5

● Layout of the Set (5)

● Specification of the Set (5)

■ Before start using・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・6 - 8

● Adjusting tension of the steering and throttle (6)

● Adjusting the adjustable trigger (7)

● About the power source, output format and Bind (8)

■ About connecting and installing the receiver・・・・・・・・・・・・・・・・・・・・9-10

● About the receiver, handling the antenna,built-in antenna receiver (9)

● About connection setup (10)

■ Names of each part of the transmitter・・・・・・・・・・・・・・・・・・・・・・・・・11-12

■ How to use each feature・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・13-60

● About Key Operation (13)

● About Power On Alarm (13)

● About the Display Panel (14)

● About the Menu Structure (15)

● About Short Cut Menu (16-18)

• Direct Model Select (16)

• Quick Setup (17-18)

● Setting [SETTING] (19-32)

• Dual Rates (D/R] (19)

• Speed [SPEED](20)

• Curve [CURVE] (21-24)

• Fail Safe [F/S] (25)

• Base [BASE] (25-28)

• Reverse [REV] (26)

• Sub Trim [SUB-T] (26)

• End Point Adjustment [EPA] (27-28)

• Trim [TRIM] (29-30)

• Anti-Lock Brake [ALB] (31)

• Offset [OFFSET] (32)

• Throttle Type [TH TYPE] (32)

● AUX [AUX] (33-36)

• Step AUX [STEP AUX] (33)

• Point AUX [POINT AUX](33)

• 4 Wheel Steering [4WS] (34)

• Motor On Axle [MOA] (34)

• AUX Mixing [AUX-MIX] (35)

• Code AUX [CODE AUX] (36)

● Timer [TIMER] (37-39)

• Setup [SETUP] (37,38)

• Lap Timer [LAP TIMER] (38)

• Interval Timer [INT TIMER](39)

• Down Timer [DOWN TIMER] (39)

● Telemetry [TELEMETRY] (40-44)

• LOG [LOG DATA] (40)

• Telemetry Setting [TELEMETRY SETTING] (43)

• Graph Setting [GRAPH SETTING](44)

• Telemetry Switch [TELEMETRY SWICH](44)

● Model [MODEL] (45-48)

• Model Select [MODEL SELECT] (45)

• Model Name [MODEL NAME](46)

• Model Copy [MODEL COPY] (47)

• Model Clear [MODEL CLEAR] (48)

● System [SYSTEM] (49-60)

• Bind [BIND] (49-50)

• Key Assign Switch [KEY ASSIGN SW](51)

• Key Assign Trim [KEY ASSIGN TRIM] (52)

• Custom List [CUSTOM-LIST] (53)

• AUX TYPE [AUX TYPE] (54)

• Racing Mode [RACING MODE] (55)

• Battery [BATTERY] (56)

• Buzzer [BUZZER] (56)

• LCD [LCD] (57)

• LED [LED] (57)

• Clock [Clock] (58)

• Setup [SETUP] (58)

• Calibration [CALIBRATION] (59)

• Firmware [Firmware] (60)

■Key Assign Features Overview・・・・・・・・・・・・・・・・・・・・61

■ About handling the sensor ・・・・・・・・・・・・・・・・・・・・・・・62

■Index・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・63

■At a time like this・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・64

■Service and Support 65

■FCC Compliance Statement

・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

66

4

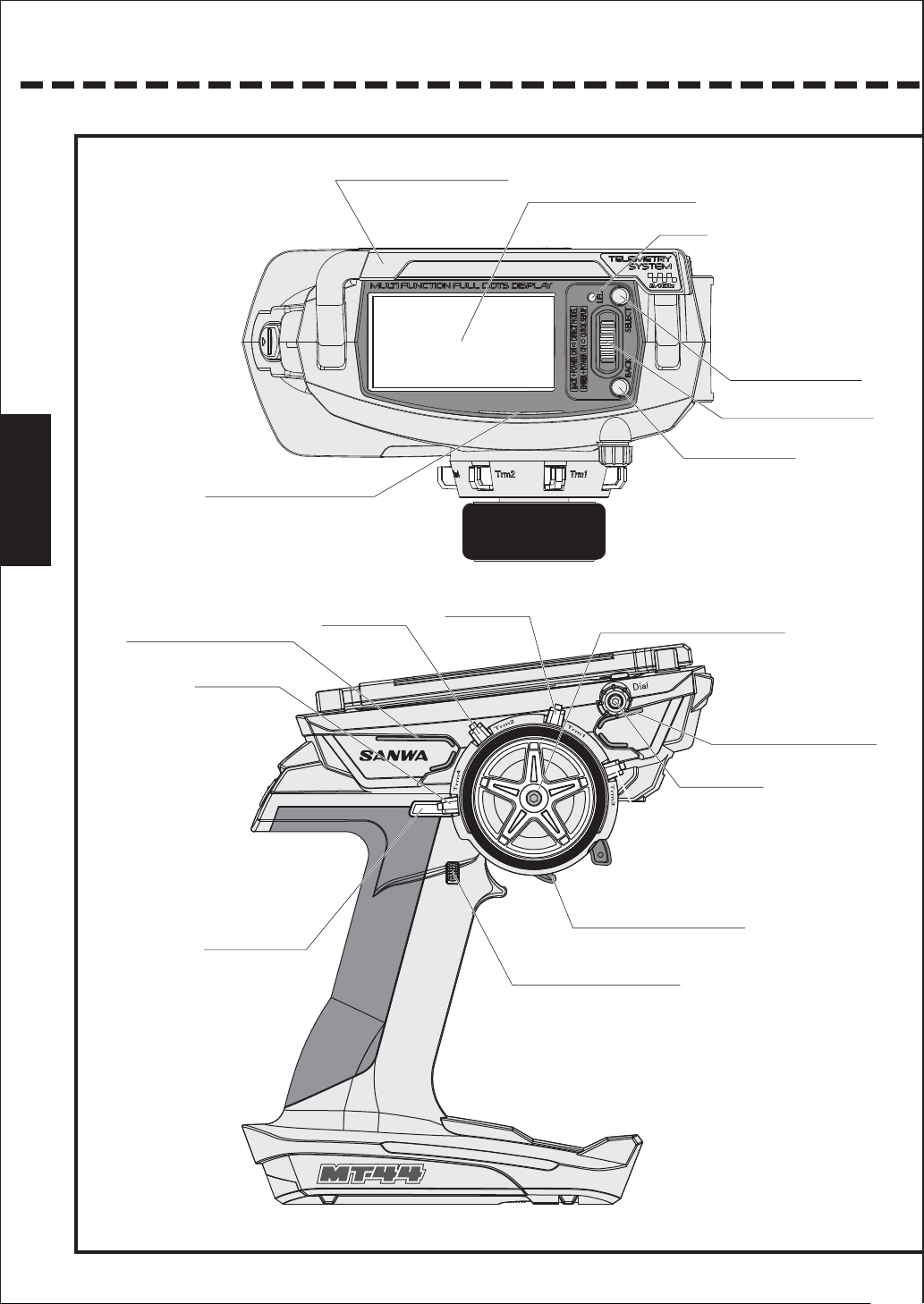

Names of each part of the transmitter

Carrying handle

(Movable)

Names of each part of the

transmitter

送

信

機

各

部

の

名

称

Function LED

Display Panel

LED

*LED will be on when

Telemetry is ON and

Receiver Battery is OFF.

LED will be flashing

while Telemetry alram

is active.

Back Button

Select Button

Multi-Selector

X illumination

Trim 4

(TRM 4)

Switch 2

(SW 2)

Trim 2

(TRM 2)

Trim 1

(TRM 1)

Steering Wheel

X illumination

Dial

Trim 3

(TRM 3)

Throttle Trigger

Push Switch 1

(SW1)

11

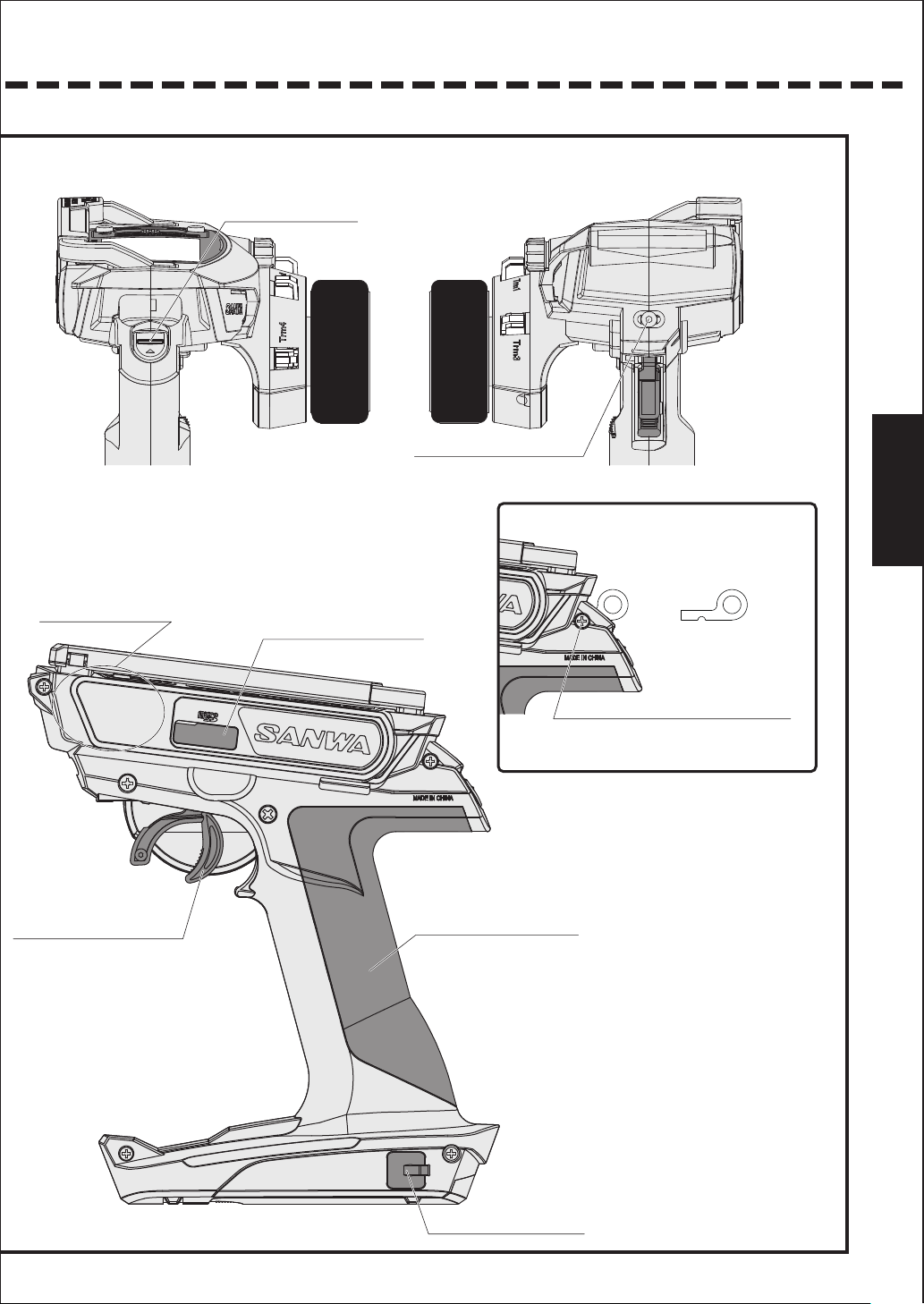

Power Switch

Trigger Position

Adjusting Screw

When using the Strap Hook

Names of each part of the

transmitter

送

信

機

各

部

の

名

称

Antenna interior

Throttle Trigger

Micro SD cover

Strap Hook

Remove the screw, attach the hook

and tighten the screw.

*Make sure that the hook is facing the right direction.

Grip

(Normal/Small)

Connector Cover

12

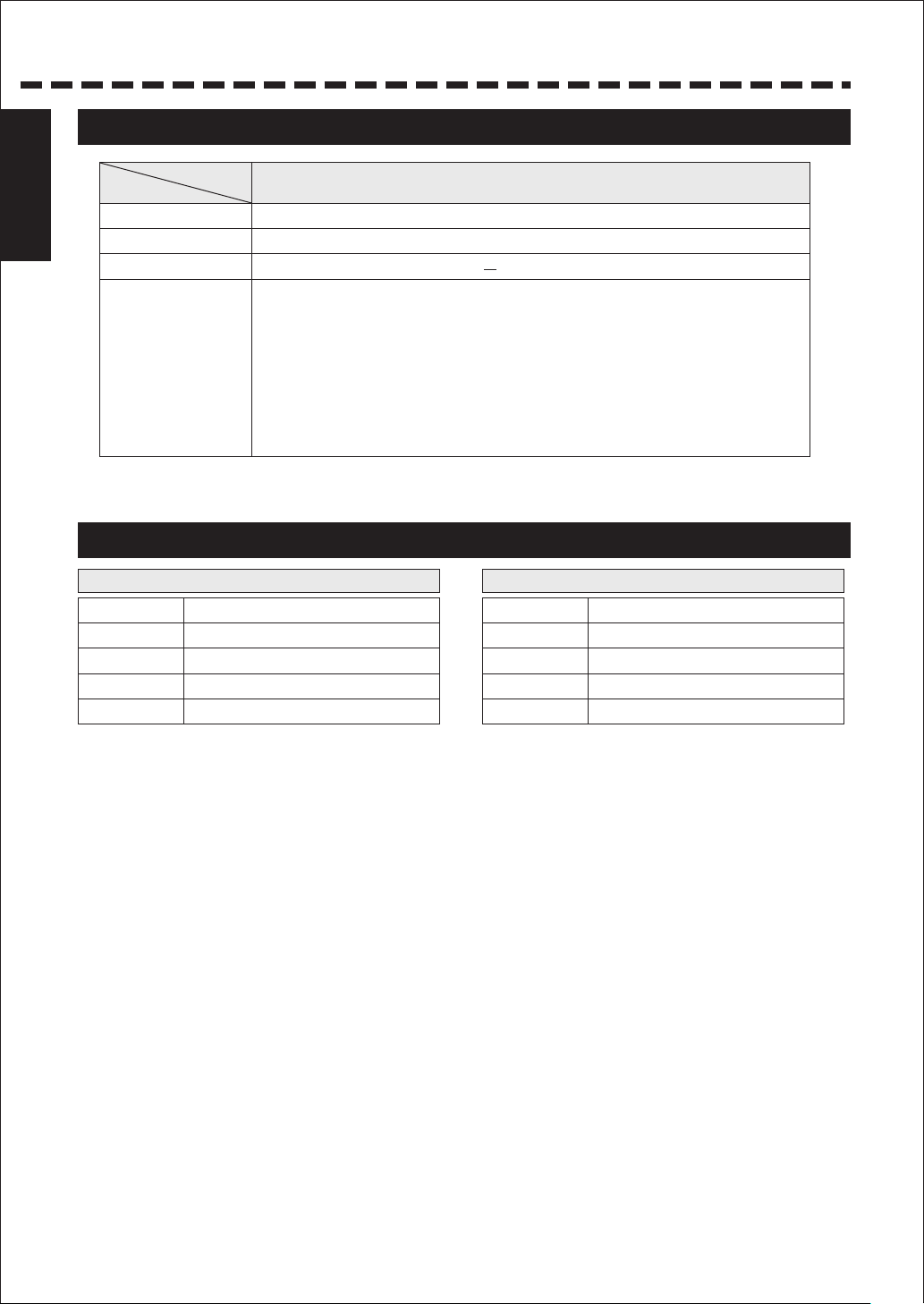

Structure and the Standard of the Set

Structure and the

Standard of the Set

Structure of the Set

RX-482 PC (Primary Component)

Transmitter

Receiver

Servos

Accessories

Set Specification

<A>Transmitter

Product No.

Output Display

Modulation Method

Power Source

Weight

*Be careful with the input voltage. If voltage above

allowable voltage is inputted, the transmitter will be

damaged.

TX-471

Analog/Digital display (Power Source Volt age Dis play )

2.4GHz Spectrum Spread System

Size AAA batteries x 3 (Corresponding voltage: DC 2.7 ~ 5.0 V)

371g

TX-471

RX-482

Strap Hook x 1

Trigger Angle Spacer x 1

Brake Trigger +1/+2 x each 1

Grip Pad S size x 1

Receiver Dust Cover x 1

Switch Harness x 1

Instruction Manual x1

●Please check what’s included before your use.

<B>Receiver

Item

Modulation Method

Size

Power Source

Weight

RX-482

2.4GHz Spectrum Spread System

18.2x24.4x27.1mm

DC3.7~7.4V

7.1g

5

Before using

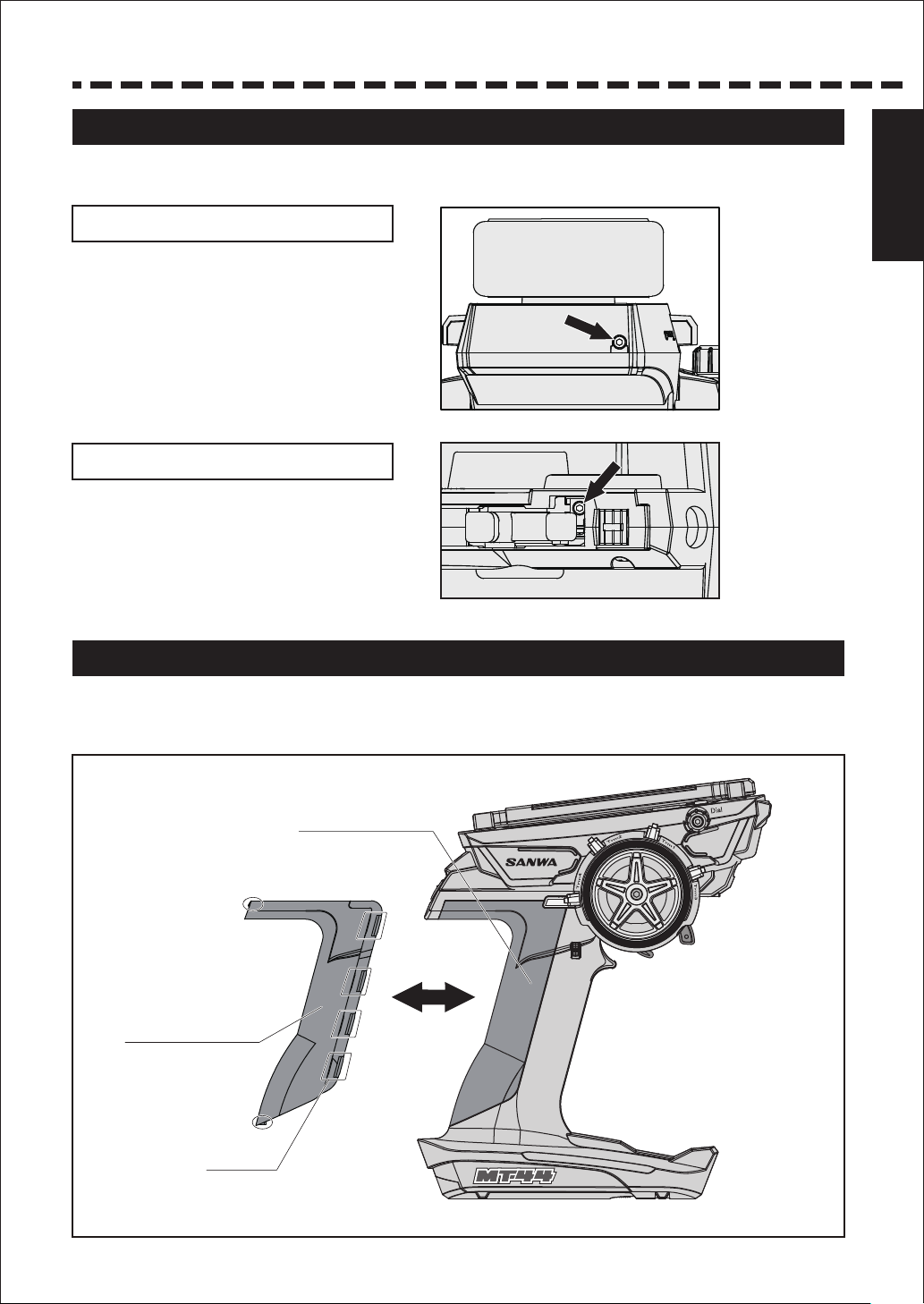

Adjusting the steering and throttle tension

With MT-44, the user can easily adjust the tension of the steering/throttle trigger to match operation of

the steering/throttle to the user’s preference.

Adjusting the steering tension

By inserting a hexagon wrench driver

(1.5mm) to the place where the arrow is

pointing at in the illustration on the right and

turning, you can adjust the tension of the

steering spring.

*The spring tension is the softest at the time

when the product is shipped out from the

factory. As you tighten with a hexagon

wrench driver (1.5mm), the spring tension

will be hardened.

Adjusting TH trigger tension

By inserting a hexagon wrench driver

(1.5mm) to the place where the arrow is

pointing at in the illustration on the right and

turning, you can adjust the tension of the

throttle spring.

Structure and the

Standard of the Set

Adjusting the grip pad

The user can choose a grip pad from two types of normal/small to suit the size of the user’s hand.

(The normal size is installed at the factory.)

Do not pull forcefully because it’s locked to the grip of the receiver with tabs of the grip pad (at 11 locations).

Grip Pad

(Normal)

Grip Pad

(Small)

Tabs

(11 locations)

6

Before using

Before using

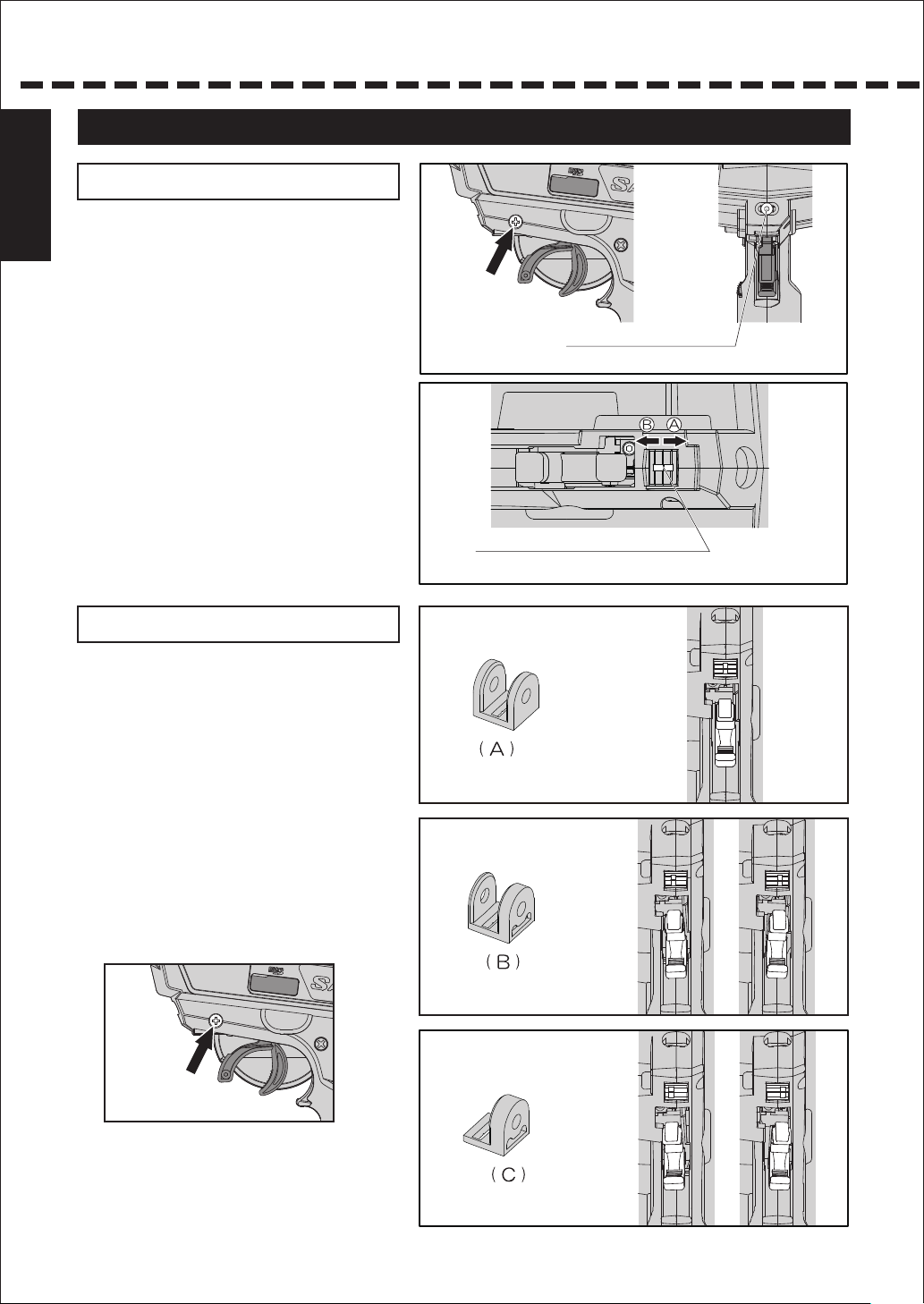

Adjusting the full adjustable trigger

Adjusting the trigger position

Loosen the fixing screws of the trigger on the back of the

transmitter. Then, adjust the adjusting screw of the trigger

position on the back of the transmitter to set the trigger at the

position of your preference. When you turn the adjusting

screw of the trigger position clockwise, the trigger position

Fixing screw of the trigger

gauge moves to the direction A. By turning it counter

clockwise, the trigger position gauge moves to the direction B.

*The range of the trigger movement is 5mm. If you turn the

screw forcefully beyond the range, it can cause malfunction.

Once you set the trigger position, tighten the fixing screw and

adjusting the trigger is done.

*Be careful with the direction of turning the screw because

the trigger position is set at the furthest point of the A side at

the factory.

Adjusting the trigger angle

By switching the angle spacer A/B/C, it is possible to adjust

the angle of the throttle trigger to five steps.

Adjusting screw

for the trigger position

Trigger position gauge

Adjustable range: approximately 5mm

Angle spacer

1) Remove the fixing screw of the trigger on the back of the

transmitter.

2) Adjust the angle by changing the direction of the angle

spacer to have an angle easy to operate.

3) Once the trigger angle is set, fix the fixing screw of the

trigger on the back of the transmitter.

Fixing screw of the trigger

Installed at the factory

Angle spacer

Angle spacer

7

Adjustment of Brake Trigger

You can adjust trigger position according to your fingers by

replacing brake trigger included. Standard Size, +1 Size,

and +2 Sice is included.

1) Remove the brake trigger fixing screw.

2) Select Brake Trigger according to your fingers.

3) Fix the brake trigger by the screw.

BRAKE TRIGGER

FIXING SCREW

BRAKE TRIGGER

( +1 )

( +2 )

Before using

3) Fix the bakre trigger by the screw.

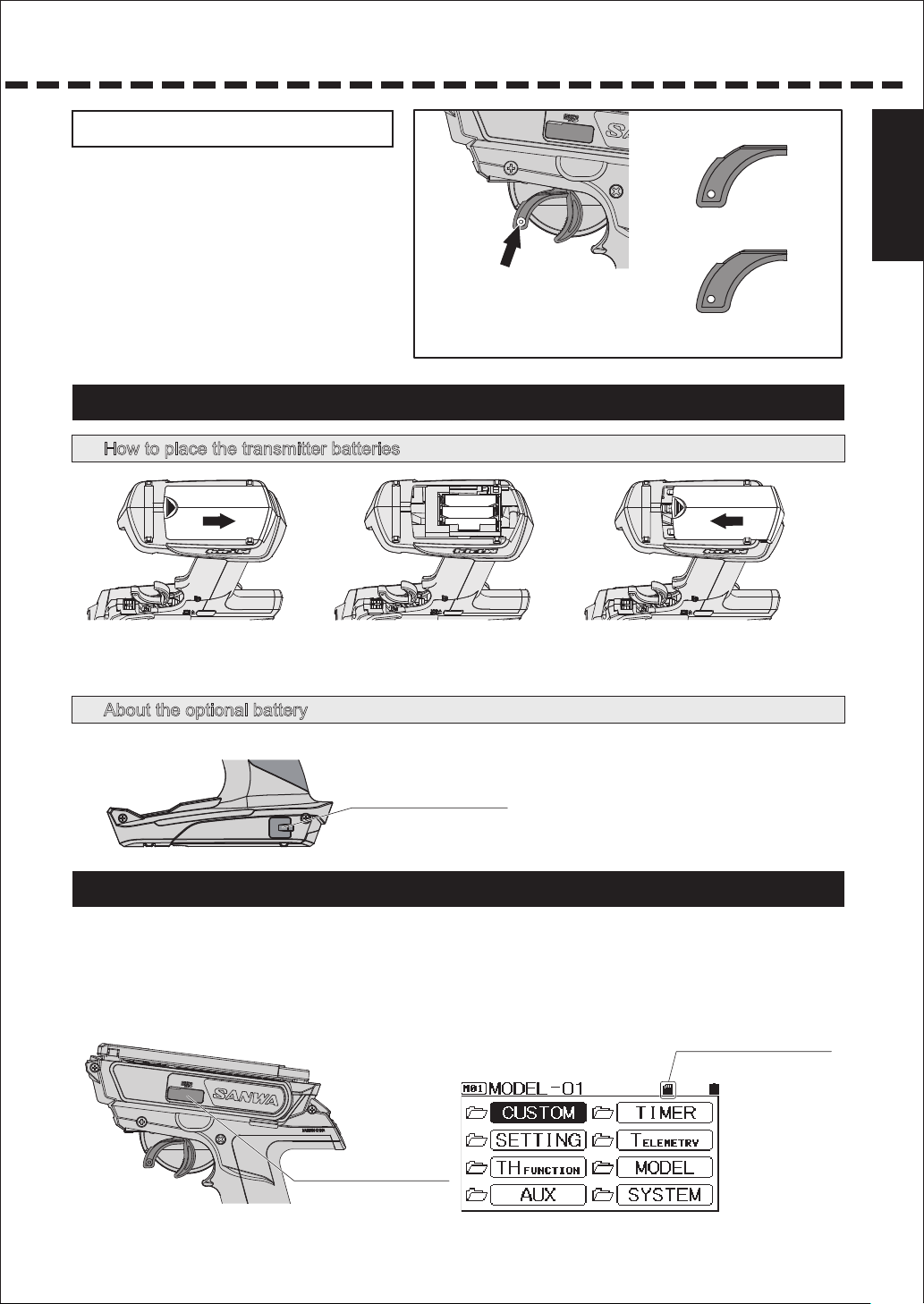

About the power source

How to place the transmitter batteries

Open the battery compartment cover by sliding the

①

cover to the direction of the arrow while pressing it

lightly.

Place 3 size AAA batteries. Make sure to

observe correct polarities.

③②

Align the convex part of the battery compartment cover and the

groove of the battery compartment, slide the cover to the

direction of the arrow and close tightly.

About the optional battery

●When using an optional battery, you can access to the charging port on the side of the battery from the connector cover.

Connector Cover

About Micro SD Card

MT-44 is compatible to Micro SD Cards. By using a Micro SD Card, it is possible to save model data and telemetry data.

●

Also, it is possible to do firmware update using a Micro SD Card when a firmware update of MT-44 is released.

After inseting micro SD card into MT-44, the file mnamed “MT-44” is made and the folder named “MODEL” is made.

●

The model data is saved in the folder.

If the log data is exported, the folder named “Log” is made and the data named “csv” is saved in the folder.

When micro SD card is inserted,

this mark will be on.

Micro SD Cover

8

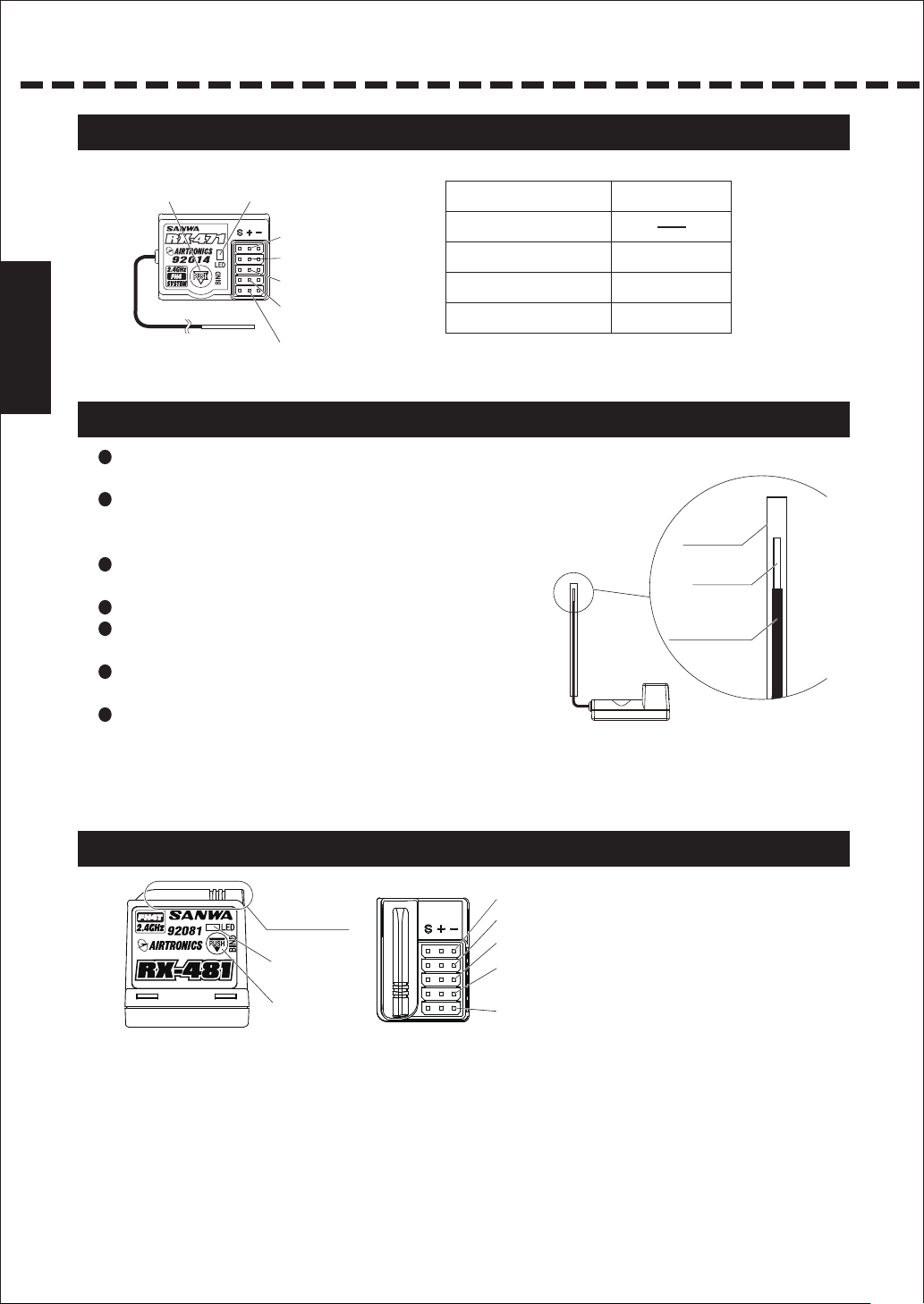

About connection and installation of the receiver

About the receiver

●RX-471(Example)

BIND Button

About connection and

installation of the receiver

LED

BATT

CH4:4ch

CH3:3ch

CH2: Throttle

(FET Speed Controller)

CH1: Steering

Condition of the Receiver LED

When receiving a signal

When it cannot receive a signal

while setting up BIND

Battery Fail Safe Operation is launched

After Battery Fail Safe Operation is launched,

it becomes unable to receive a signal.

Blue light is on

Blue light flashes.

Blue light flashes rapidly.

Blue and Red lights are on.

Red light is on.

About handling the Antenna

Reception distance may vary depending on the location where the receiver and

the antenna are installed.

To protect the reception part (3 cm from the top) of the antenna, make sure to

place the antenna in the antenna pipe as shown in the right illustration so that

the top of the antenna is not exposed outside of the antenna pipe.

Don’t bend the antenna reception part or the antenna coaxial cable because

breaking can occur inside.

Don’t pull the coaxial cable forcefully. It may damage the receiver interior.

Install the antenna on an RC car so that the antenna reception part is in as high

place as possible.

Don’t cut or bind the antenna reception part or the antenna coaxial cable since

the receiver sensitivity might decrease.

Keep the receiver antenna away from the motor and the FET Speed Controller

(including cables) and raise it straight.

Antenna Pipe

Antenna Reception part

Antenna coaxial cable

About built-in antenna receiver

BATT

Antenna Reception part

LED

BIND Button

●

Reception distance may vary depending on the location where the Antenn Reception part is installed.

●

Install the antenna so that the antenna reception part in the above illustration is as high as possible.

9

CH4:4ch

CH3:3ch

CH2:Throttle

(FET Speed Controller)

CH1: Steering

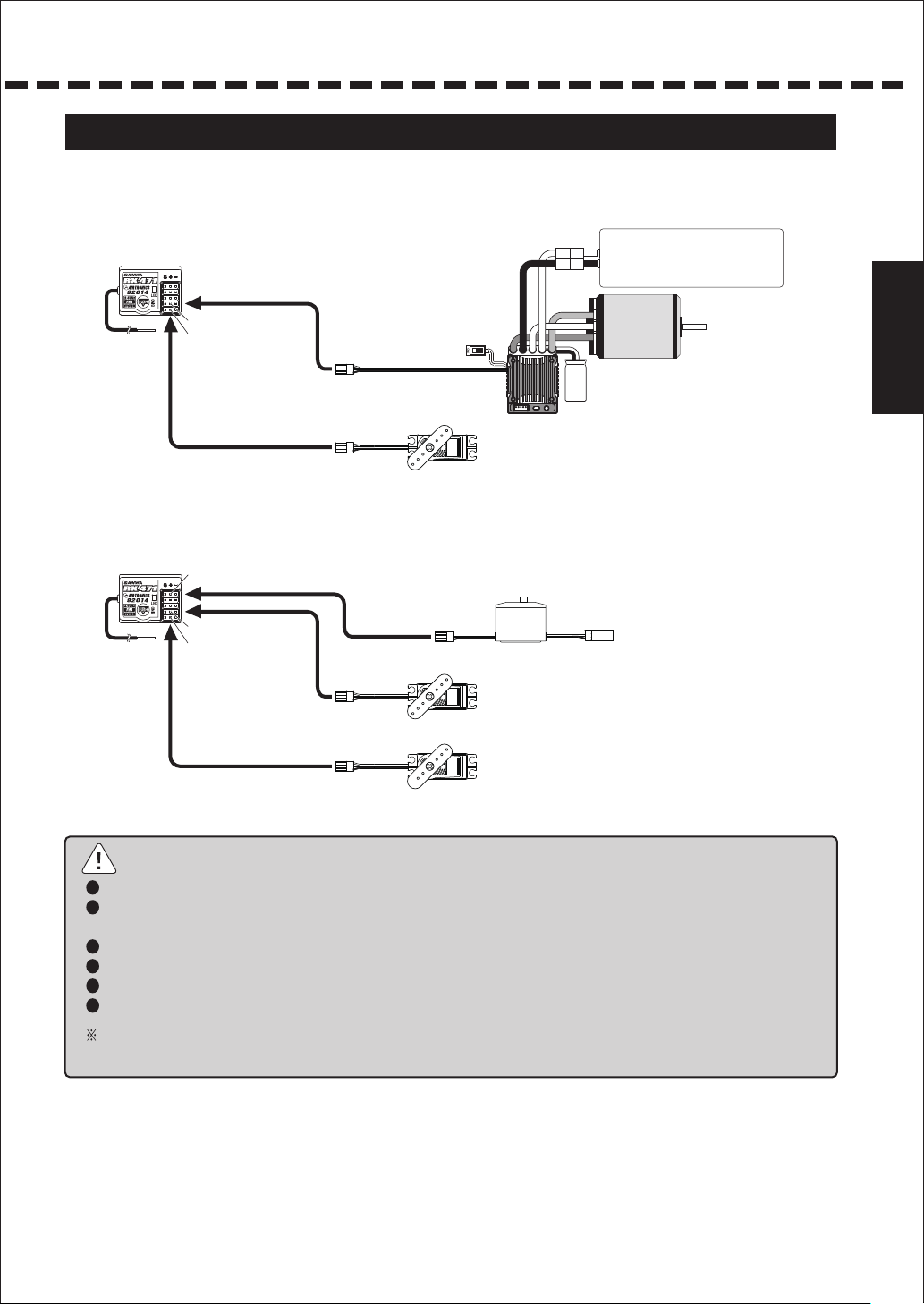

About connection setup

● Connect the receiver and servos as shown in the illustration below.

・Connection example when used on an EP car

Connecting to CH2

CH2

CH1

Connecting to CH1

Servos

• Connection example when used on a GP (engine) car

BATT

Connection to BATT

Connecting to CH2

CH2

CH1

(Steering)

(Throttle)

Power battery

Motor

FET Speed Controller

Connection to the receiver battery

About connection and

installation of the receiver

Servos

Connecting to CH1

(Steering)

Note

If the connector is disconnected due to a vibration during operation, it can cause runaway. Connect the connector of the receiver, servos and switches securely.

Because the receiver is susceptible to vibration, impact and water, make sure to take measures for vibration-proof and waterproof. Negligence of taking these

measures can cause runaway.

When installing the receiver, keep the receiver away from a carbon chassis and metallic chassis.

If metal parts installed on an RC car touch each other, it can cause noise that affects reception performance and it can cause runaway.

Make sure to install a noise killer condenser on the brush motor for electric RC cars. Without a noise killer condenser, it can cause noise and runaway.

For R/C System parts such as the transmitter, receiver, servos, FET Speed Controller and transmitter battery, use genuine SANWA products.

When combining products other than genuine SANWA products, modifying, adjusting or exchanging parts is done at a place other than SANWA, we do not take

any responsibility.

10

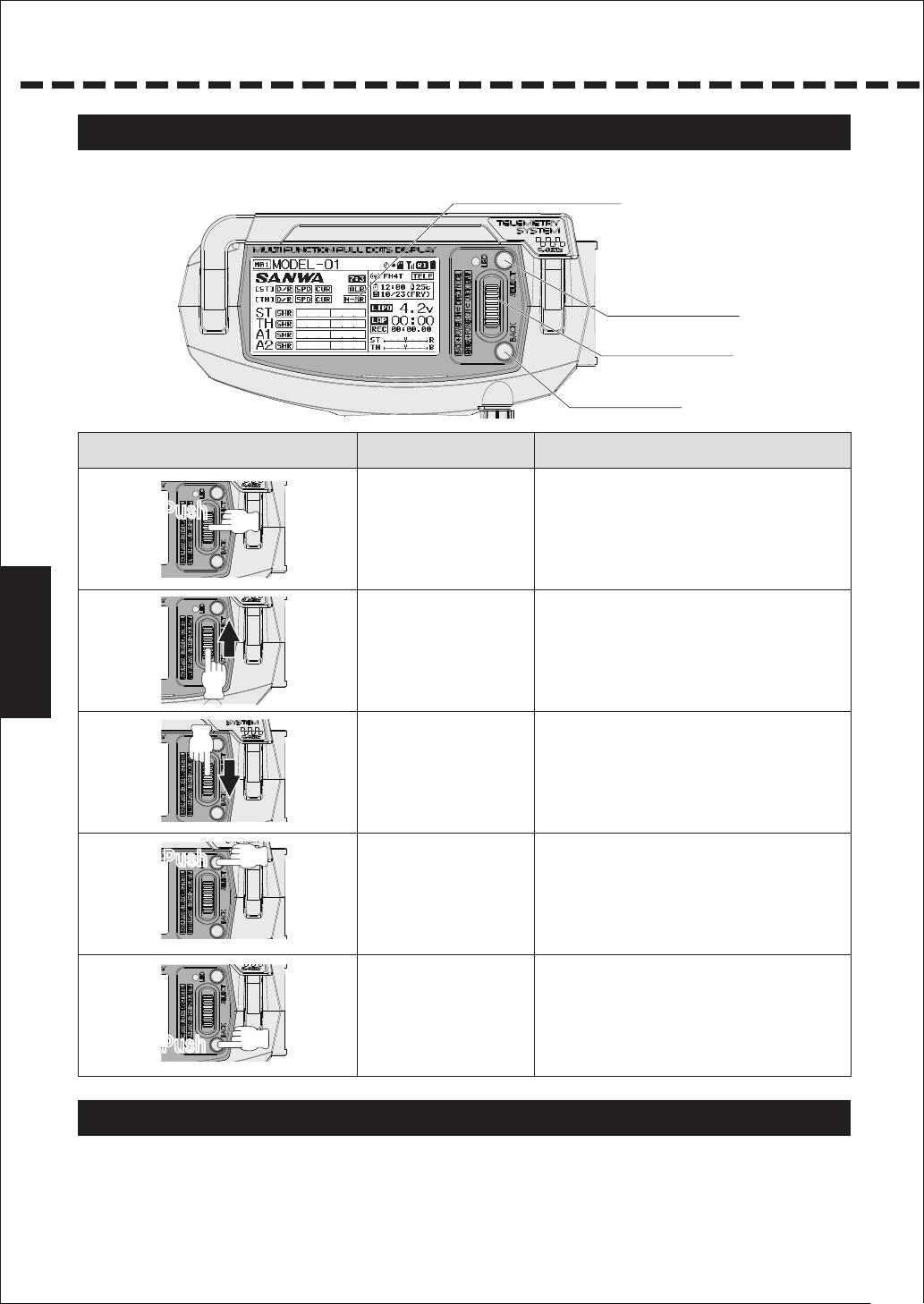

Usage of each feature

Push

About Key operation

●

The user can set up and make a calling easily with the Multi-Selector and Select button/Back button.

Key operation PerformanceNames

Display Panel

Select Button

Multi-Selector

Back Button

Enter

Push

Usage of each feature

Multi-Selector Up ● The cursor moves upward.

Multi-Selector Down

Push

Select ● Selects a channel or feature.

Back/Cancel ● Goes back to one step before.

● Moves to the setup screen from the top screen.

● Selects a feature and item to set.

● By long pressing the button, the setting goes back

to default.

● The set value increases.

● Moves the cursor downward.

● The set value decreases.

● Cancels the setting.

13

About Power On Alarm

● MT-44 displays “No Operation” with a warning alarm after 10 minutes of no operation of the steering

wheeel, throttle trigger and switches. Alarm is turned off, if the steering wheel, throttle trigger or a switch

is operated. In case you do not use them, turn the power switch off.

About the Display Panel

● Each feature of MT-44 allows you to directly select a feature with the Multi-Selector.

● You can set up each channel feature separately.

● As you turn the power switch on, the top screen launches after the boost screen

is displayed(when the boot setting is on).

When changing each setting, select the menu by operating the Multi-Selector.

Name

Model Number

Top Screen

Effect Indicator

Telemetry Screen

Each Telemetry

data

Micro SD card

Log

Timer

As you move up/down with the Multi-Selector,

it becomes a toggle between Top Screen/Telemetry Screen.

Telemetry

Racing Mode

Battery Indicator

Clock

If effect or function is active,

icon will be displayed.

Timer

Log Timer

Trim

By connecting each sensor to RX461

or RX462, using combination of

RX461/RX462 and SUPER VORTEX

or SV-PLUS series, and turning the

Telemetry feature on, data is sent to

the transmitter and it is displayed

on the Telemetry Screen.

Usage of each feature

Menu Window

•Select the Menu

(Screen example)

*Enter operation from

the Top Screen

14

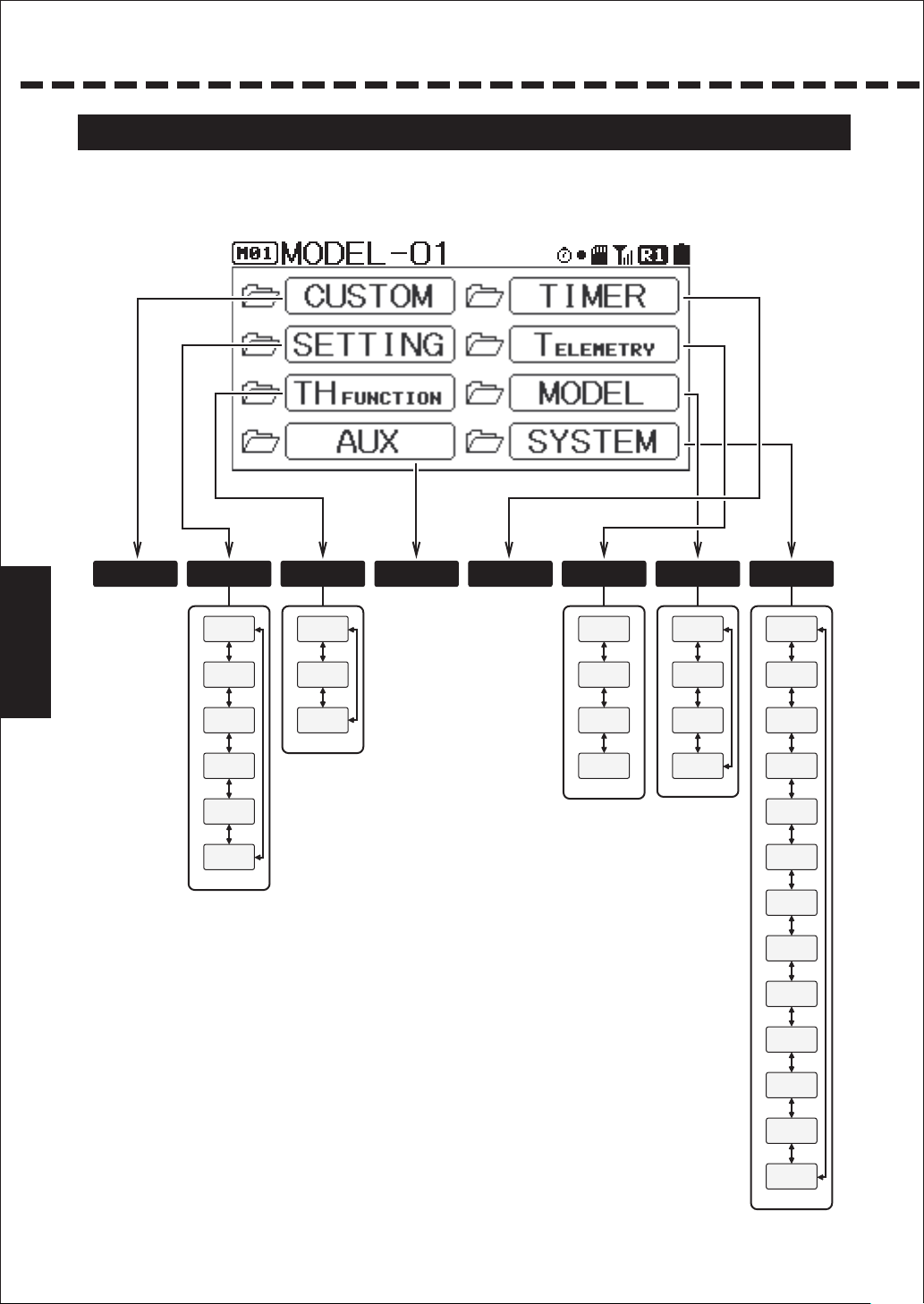

Usage of each feature

About the Menu structure

● The user can set up features and do model memory call easily by using each key.

● The Menu consists of Setting, AUX, Model, Timer, Telemetry and System Menu, and related features

are included in each menu.

Usage of each feature

CUSTOM

(P.53)

Custom Menu

It is set with the

Custom List within

the System.

SETTING

D/R

(P.19)

SPEED

(P.20)

CURVE

(P.21~24)

TH-FUNCTION

ALB

(P.31)

OFFSET

(P.32)

TH TYPE

(P.32)

F/S

(P.25)

BASE

(P.25~28)

TRIM

(P.29、30)

AUX

(P.33~36)

Set up all items

of the accessory

channels of

3ch/4ch.

TIMER

(P.37~39)

Various timer

setups and lap

display menu.

TELEMETRY

LOG DATA

(P.40)

TELEMETRY SETTING

(P.43)

GRAPH SETTING

(P.44)

TELEMETRY SWITCH

(P.44)

MODEL

SELECT

(P.45)

NAME

(P.46)

COPY

(P.47)

CLEAR

(P.48)

SYSTEM

BIND

(P.49、50)

KEY ASSIGN

(P.51、52)

CUSTOM-LIST

(P.53)

AUX TYPE

(P.54)

R-MODE

(P.55)

BATTERY

(P.56)

BUZZER

(P.56)

LCD

(P.57)

LED

(P.57)

CLOCK

(P.58)

SETUP

(P.58)

CALIBRATION

(P.59)

FIRMWARE

(P.60)

15

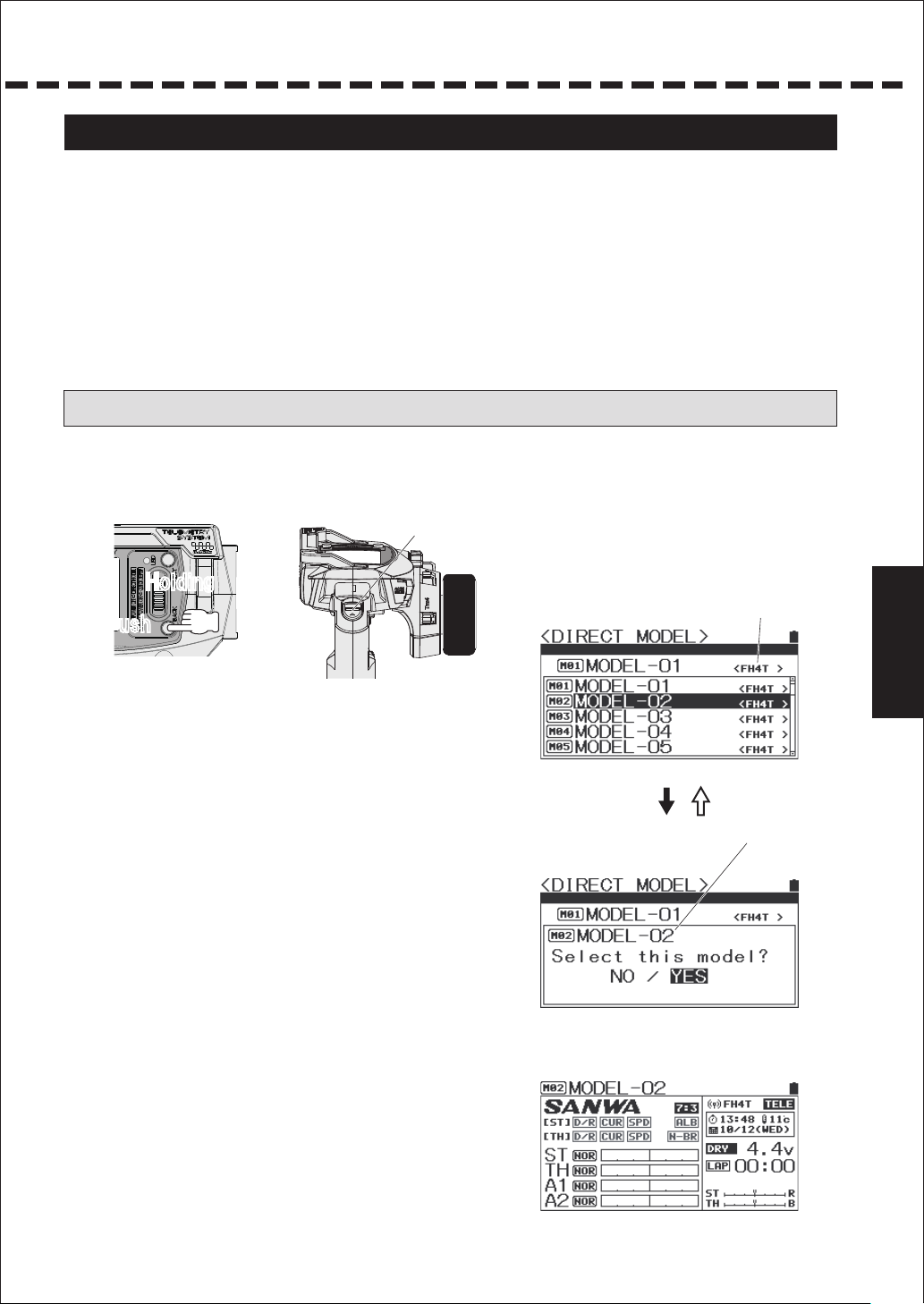

About Short Cut Menu

MT-44 has a feature of Short Cut Menu that is launched as the user performs key operation

when operating the power switch.

If you turn the power switch on while pressing the Back Button, it becomes the Direct Model

Select and if you turn the power switch on while doing Enter operation, the Quick Setup

feature launches.

Direct Model Select is a feature for quickly selecting a model to run and Quick Setup is a

feature for various setup with easy operation when setting up a new RC car.

Quick Setup feature is set in the following order using the Enter operation after launching.

Selecting Model → Selecting Type → Initializing Model → Selecting RF Modes → Selecting

Response Mode → BIND → Setting Base

Direct Model Select < DIRECT MODE >

Direct Model Select

1) Turn the power switch on while pressing the Back button.

Power Switch

ON

HoldingHolding

Push

2) Selecting Model

Select a Model you wish to call with Multi-Selector.

Selection range: M01 ~ M20

3) Move the cursor to the Model you wish to call and

do Enter operation. A message is displayed on the

screen. Select a Model following the display.

⇒

①

MODEL Selection Screen

RF MODE display

ENTER BACK

Model to be changed

②

Confirmation Screen

NO →

Back to

YES→ Change Model and move to the top.

①

to is displayed.

Usage of each feature

16

Usage of each feature

About Short Cut Menu

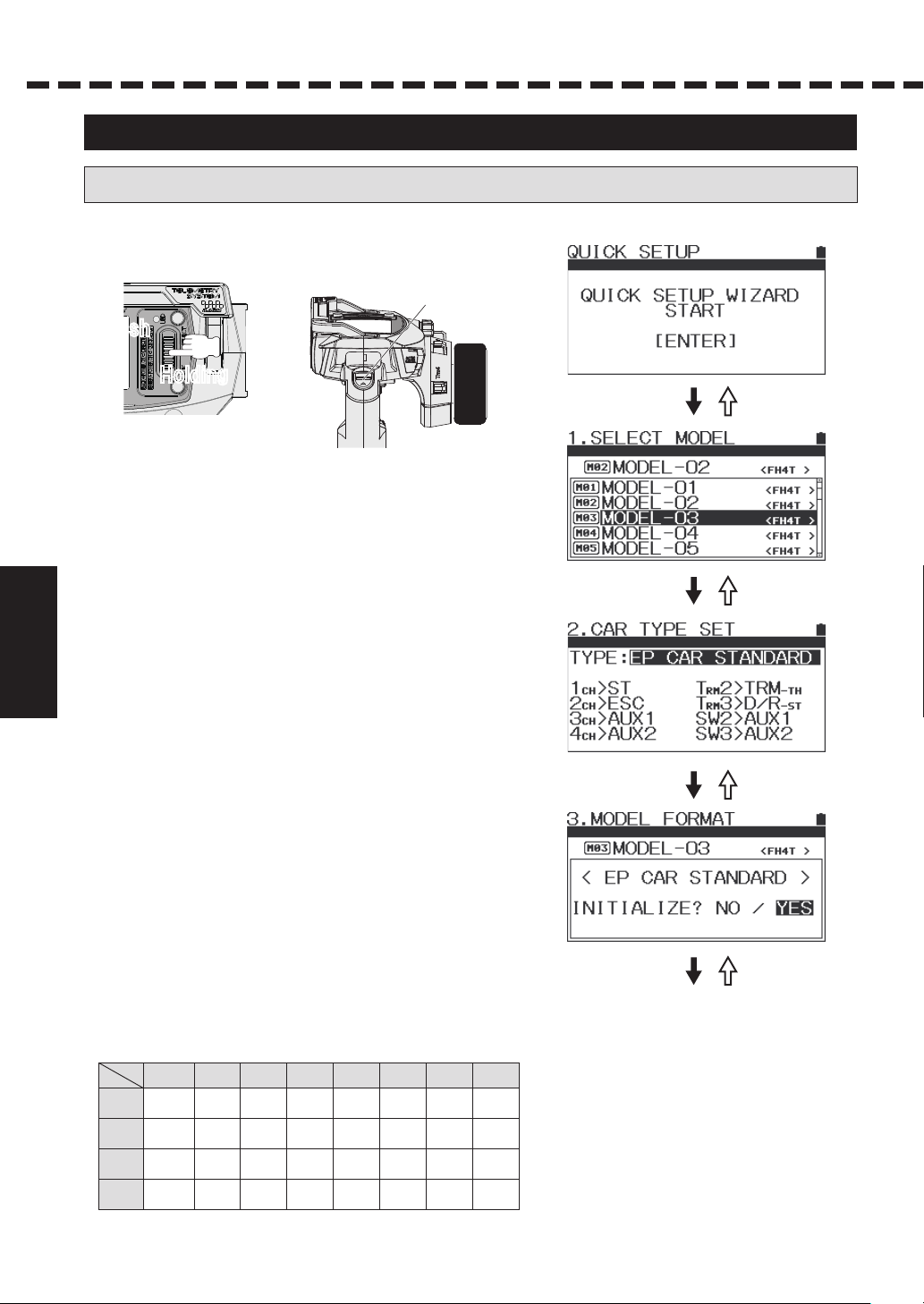

Quick Setup <QUICK SETUP WIZARD>

● Quick Setup

1) Turn the power switch on while doing Enter operation

Power Switch

ON

Push

⇒

Holding

2) Quick Setup screen is displayed.

As you do Enter operation, Quick Setup Wizard is

launched.

ENTER BACK

Usage of each feature

3) When the screen is changed to Model selection screen,

ENTER BACK

select a Model to set up by using Multi-Selector.

When a Model to set is selected, set with Enter operation.

4) When the screen is changed to Car Type selection

screen, select a Car Type using Multi-Selector.

When a Car Type is selected, set with Enter operation.

Setting up Type

○ Setting range: EP CAR STANDARD

ENTER BACK

EP CAR (LED UNIT)

EP CAR (SVZ)

EP CAR (SVD)

GP CAR STANDARD

1/5 GP CAR DUAL BR1

1/5 GP CAR DUAL BR2

CRAWLER 4WS/MOA

○ Default: EP CAR STANDARD

ENTER BACK

*Channel operation of each type will be as follows.

Channel operation specifications for each Type

CH

CH1

CH2

CH3

CH4

TYPE

EP CAR

EP CAR

STANDARD

STEERING

ESC

AUX1

AUX2

EP CAR

(LED UNIT)

(SVZ)

STEERING STEERING STEERING STEEIRING

ESC ESC ESC

LED-ST

CODE1

CODE2

EP CAR

(SVD)

CODE1

CODE2

GP CAR

STANDARD

THROTTLE

/BRAKE

AUX1

AUX2

1/5 GP

DUAL BR1

STEERING

1

THROTTLE

/BRAKE R

STEERING

2

BRAKE FLED-TH

1/5 GP

DUAL BR2

STEERING

THROTTLE

BRAKE

R

BRAKE

F

CRAWLER

4WS/MOA

STEERING

F

ESC

F

STEERING

R

ESC

R

17

*Select a type to be used according to an RC.

5) When deciding the car type using Enter,

the screen changes to Initialization (Model Initialization) screen.

Do initialization following the message.

ENTER BACK

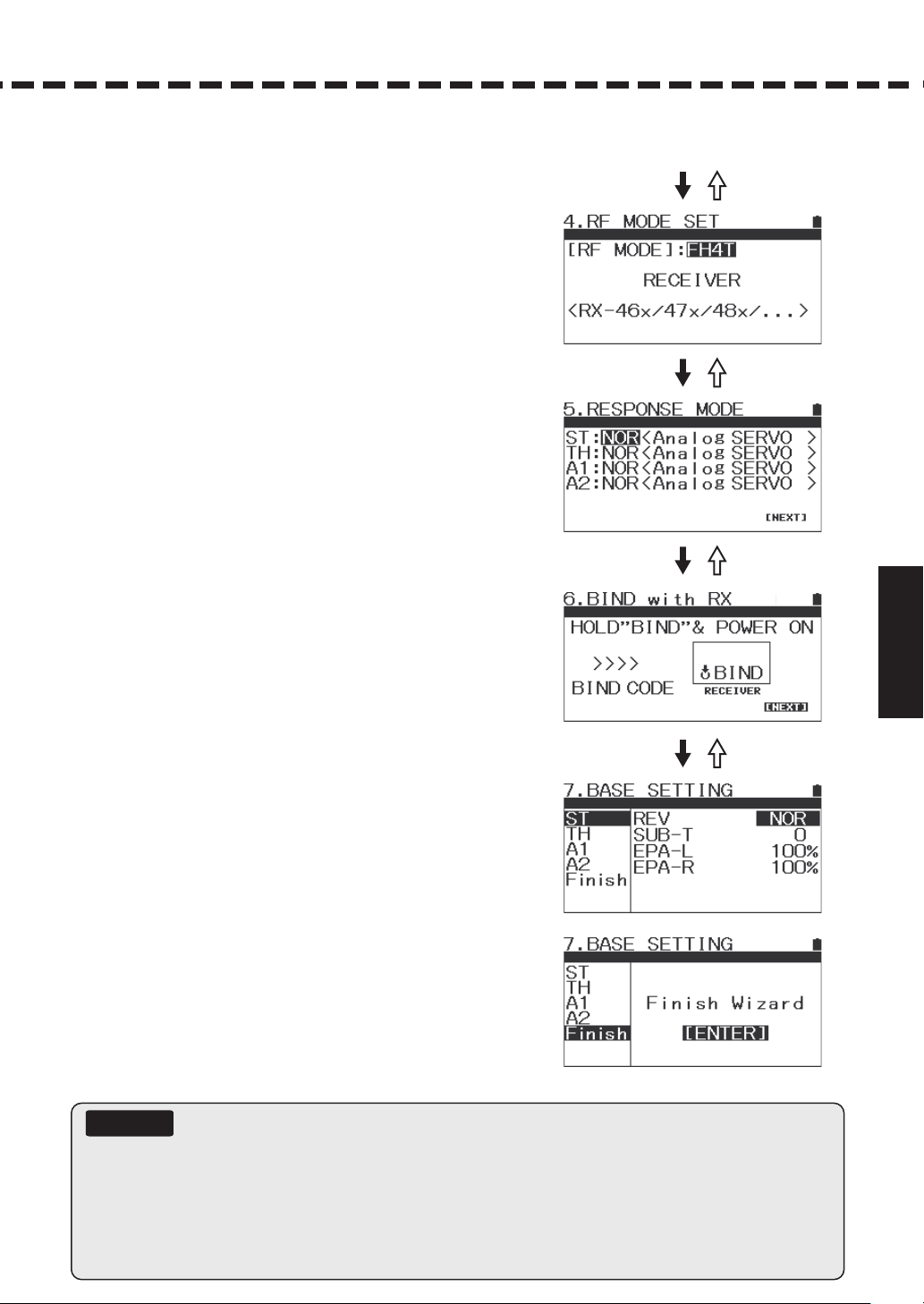

6) When initializing (Initializing Model) is completed, the scr

changes to RF Mode Selection Screen. Set RF Mode by using

Up key/Down key and finalize with th水Enter key for the

receiver to be used.

○ Setting range: FH4T/FH3

○ Default: FH4T

・Compatible Receivers:

FH4T: RX-482, RX-481, RX-472, RX-471,

7) Once RF Mode for the receiver is determined, the screen

changes to the Response Mode screen.

Set Response Mode according to the servos and the equipmen

to be used.

Set with Up key/Down key and finalize with the Enter key.

○ Setting range: NOR (Normal/Analog Servos)

SHR (High Response/Digital Servos)

SSR (Super Response/SRG Servos)

○ Default: NOR (Normal/Analog Servos)

RX-47T, RX-462, RX-461,

SV-Plus Series

FH3: RX-451R, RX-451, RX-381, RX-380

een

ENTER BACK

ENTER BACK

t

Usage of each feature

ENTER BACK

8) When Response Mode setting is completed,

the screen changes to BIND Set up Screen.

Follow the screen message and start Binding.

9) When Binding (BIND) is done, the screen changes to

the Base Set Up screen. Complete setting for each channel

(refer to P. 25-28).

10) When Base setting is done, Set Up Wizard will end.

If you press the Enter button, the screen changes to the

Top screen.

Important

● Please note that the analog servos do not work in SHR/SSR modes. If you mistakenly use the analog servos in SHR/SSR mdoes,

it does not work normally and the servos will be broken. Never use analog servos in SHR/SSR modes.

For digital servos (SRG, ERB, ERS Series and Digital ERG Series), either NOR or SHR mode works.

● SSR mode works only for SRG Servos, SUPER VORTEX/SV-PLUS series, HV-12, STOCK SPECIAL and HV-01.

● MT-44 will not be SSR mode by using RX-451R to BIND with SHR display. It works as the display shows.

● With SHR/SSR mode, BL-RACER, BL-FORCE, F2000, F2200. F3000 F3300, SBL-01 02 and 03CL do not work.

Make sure to use them in NOR mode.

● SV-08, HV-10, HV-12 and F2500 work in NOR/SHR modes.

18

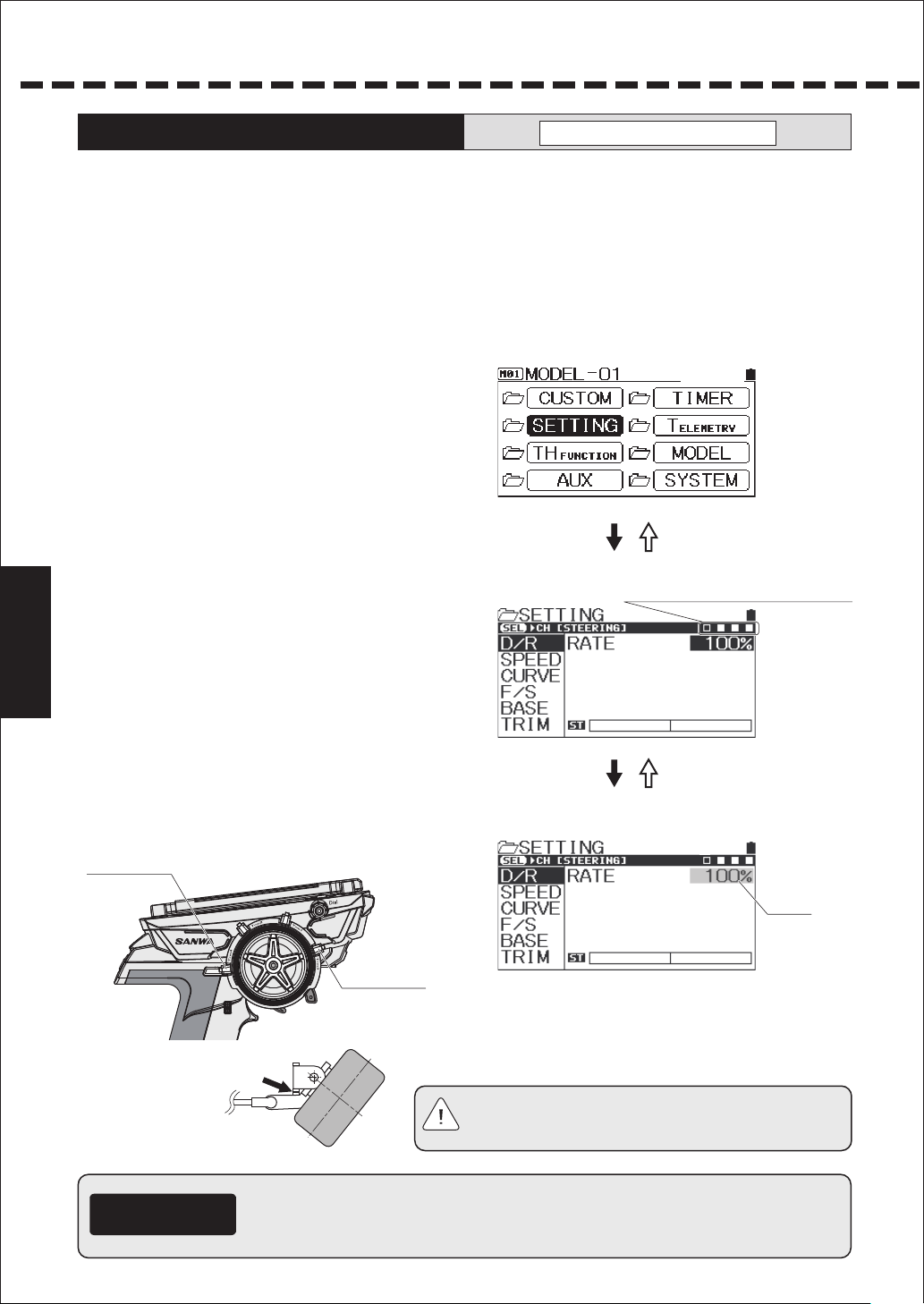

Usage of each feature

Dual Rates [D/R]

● You can adjust rudder angle when operating the steering wheel and throttle trigger to their peak.

To correspond to the RC car or road condition, adjust the rudder angle as you operate.

*You can adjust steering for both right and left at the same time and throttle separately for high

and brake sides. You can also adjust the brake side more precisely than adjusting with EPA.

● Donʼt increase the setting rate of dual rates (D/R) from the condition in which the linkage locks

by operating the steering wheel and throttle trigger.

● You can also adjust more precisely by adjusting dual rates of the throttle side.

*When AUX1/AUX2 are set to CODE5/CODE10, setting change of D/R will not be reflected

to the performance.

1) Select features [ST/TH (H, L)/AUX1/AUX2)

to adjust with the Select key.

2) Determine the feature to adjust with the Enter key

and adjust the setting rate with the multi-select key.

3) Adjust the valus of DUAL RATE by multi-selector.

Usage of each feature

4) During operation, the steering dual rates can be

adjusted with Trim 3, brake dual rates can be

adjusted with Trim 4. Itʼs possible to assign other

features to Trim 3 and Trim 4 with the key assign trim

feature (P. 52).

SETTING

ENTER BACK

DUAL RATE SETTING SCREEN

Select Channel by Multi-selector button.

*When cancelling a selected feature,

operate the Back button.

○ Setting range: ST/TH-H/AUX1/AUX2:0%~100%

TH-L:0%~120%

○ Default: ST/TH/AUX1/AUX2:100%

Trim 4

Trim 3

*Make sure that the servos do

not lock to make clicking

sound! Note)

The same for throttle.

Supplement

● Adjust the end point of the steering/throttle linkage before

adjusting dual rates (P. 27, 28).

ENTER BACK

Steering Dual Rates Selection Screen

Note

● If the linkage is locked for a long period,

it can cause the servo motor breakage.

Flashing

19

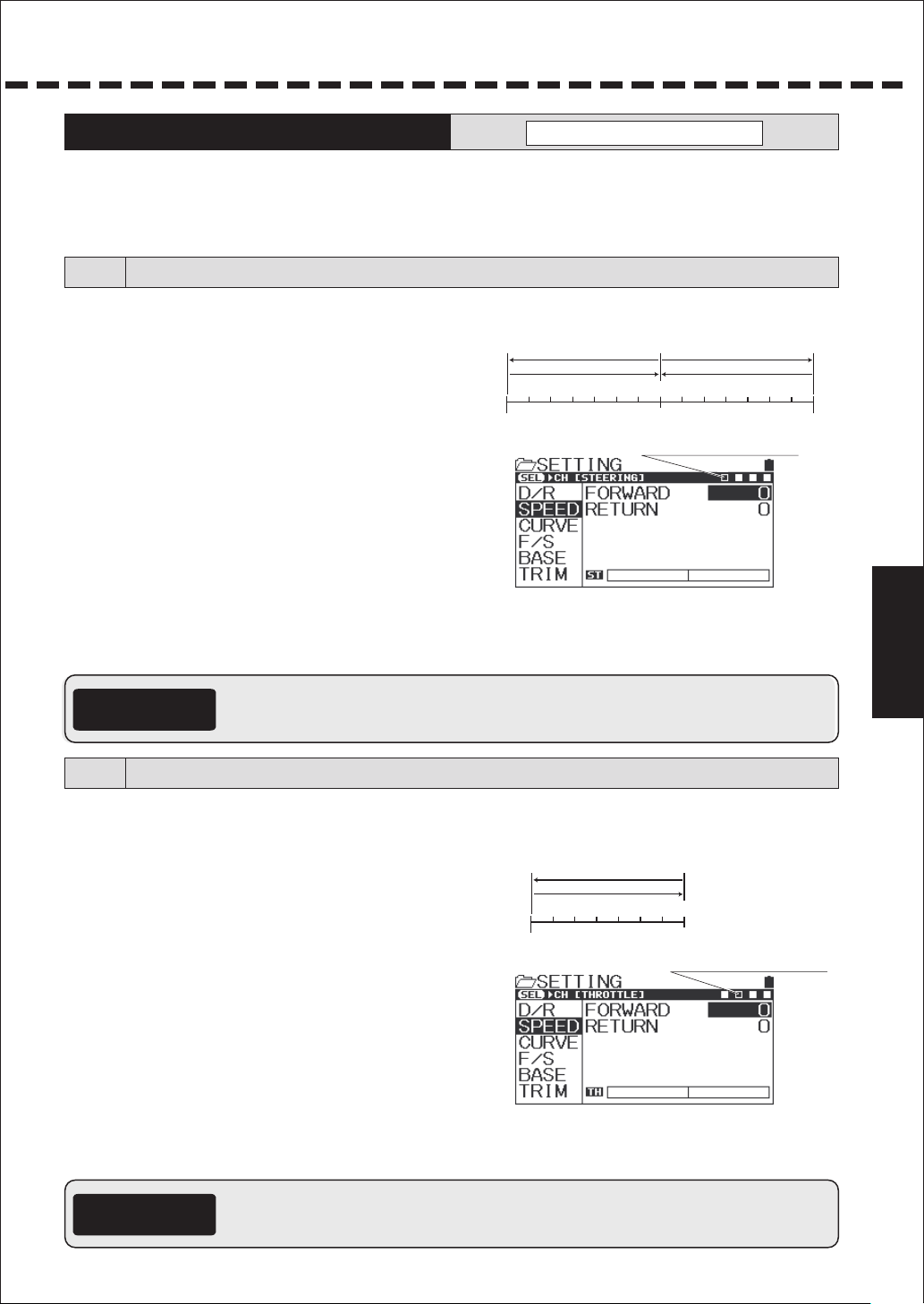

SPEED

●

Features to control the speed of the servos used for steering and throttle. By setting, the RC car is not affected even

SETTING

when doing a sudden operation. On the steering side, smooth corner work becomes possible and on the throttle side,

stable rising from a corner by throttle work with saved power.

* When setting AUX TYPE to [CODE5/CODE10], adjusting the speed feature of the AUX channel does not affect the performance.

* When setting the speed of the AUX channel, do so using steering/throttle as a reference.

[ST] Steering Speed

●A feature to delay the speed of the steering servos against the steering operation. You can set speed for steering

forward and returning individually. For steering operation slower than setting, the speed feature does not work.

1) Select [ST (Steering)] with Up key/Down key.

2) Setting on the forward side [FORWARD]

Select [FORWARD] with the Enter key and adjust the

setting value with Up key/Down key.

*When cancelling a selected feature, use the Back key.

L

End

FORWARD

RETURN

N

Neutral

Choose [ST] by selector button.

○ Setting range: 0~-100

○ Default: 0

3) Setting on the Return side (RETURN]

Select [RETURN] with the Enter key and adjust the setting value with Up key/Down key.

○ Setting range: 0~-100

○ Default: 0

*Adjust during actual operation. When not using the features or when a setting value cannot be determined even after

adjustment, set the value to 0% (linear).

FORWARD

RETURN

R

End

Usage of each feature

●For driving an RC car, steering operation that suits the movement of the RC car is important and excessive operation

Supplement

is not recommended. Steering speed can minimize unnecessary operation and enables smooth cornering.

●When steering speed and steering curve are combined, the effect is doubled.

[TH] Throttle Speed

●

A feature to slow down the performance speed of the throttle se rvos and delay the response of the speed controller against thr ottle

operation. You can set speed for entering throttle (Forward) and returning (Return) individually. The speed feature does not work with

throttle operation slower than the setting. *Setting is only for High side and Brake side cannot be set.

1) Select [TH (Throttle)] with Up key/Down key.

2) Setting on the forward side [FORWARD]

Select [FORWARD] with the Enter key and adjust the

setting value with Up key/Down key.

*When cancelling a selected feature, use the Back key.

H

End

○ Setting range: 0~-100

○ Default: 0

3) Setting on the Return side (RETURN)

Select [RETURN] with the Enter key and adjust the setting

value with Up key/Down key.

○ Setting range: 0~-100

○ Default: 0

*Adjust during actual operation. When not using the features or when a setting value cannot be determined

even after adjustment, set the value to 0% (linear).

● For driving an RC car, throttle operation that suits the movement of the RC car is important and excessive operation

Supplement

is not recommended. Throttle speed can minimize unnecessary operation and enables smooth performance.

● When throttle speed and throttle curve are combined, the effect is doubled.

FORWARD

RETURN

N

Neutral

Choose [TH] by selector button.

20

Usage of each feature

Curve [CURVE]

●Features to change the operating quantity of the servos again st operation of the steering

wheel/throttle trigger. When the setting value is on the plus (+) side, it responds quickly,

when on the minus side (-), it responds mildly.

● You can select a curving movement exponential (EXP) and a linear movement adjustable rate control (ARC).

* When setting AUX TYPE to [CODE], adjusting the curve feature of the AUX channel does not affect

the performance. When setting curve for the AUX channel, do so using steering/

・Exponential (EXP)

Quick

Servo Operating Quantity

Normal

Mild

Steering Wheel L End Operating Quantity

Throttle Trigger H End Operating Quantity

Usage of each feature

・Adjustable Rate Control (ARC)

You can change the position where operation is changeable by adjusting the setting of POINT.

Quick

Normal

Neutral Position

Servo Operating Quantity

Servo Operating Quantity

Steering Wheel R End Operating Quantity

Throttle Trigger B End Operating Quantity

Servo Operating Quantity

Setting/SETTING

Quick

Normal

Quick

throttle as a reference.

Mild

POINT

Normal

Mild

Steering Wheel L End Operating Quantity

Throttle Trigger H End Operating Quantity

Neutral Position

Steering Wheel R End Operating Quantity

Throttle Trigger B End Operating Quantity

Mild

[ST] Steering Exponential

●

You can change the steering feature from Mild to Linear to Quick. In general, if you find your RC car oversteering,

change the setting to the minus side and if you find under steering, change to the plus side.

Steering Exponential is a simultaneous setting for L and R.

1) Select ST with the Select button and

set CURVE TYPE of ST to [EXP] with the multi-selector.

2) Adjust the setting value with the multi-selector.

○Setting range: -100%~100%

○Default: 0%

*When cancelling a selected feature, use the Back button.

Stee ring

Operatio n Position

21

[TH] Throttle Exponential

●

You can change the throttle feature from Mild to Linear and to Quick. In general, when operating

on a slippery road or if you find over powering, change the

operating on a high-grip road or if you find lack of power i

You can set the High side and the brake side separately.

*Selection of the High side and the brake side is done

by trigger operation.

1) Select TH with the Select button and set

CURVE TYPE of TH to [EXP] with the multi-selector.

2) Adjust the setting value with the multi-selector.

setting to the minus side and when

n the power unit, change to the plus side.

Select H/B by trigger operation.

○Setting range: -100%~100%

○Default: 0%

[AUX1]

●You can change the operation feature of AUX1 from Mild to Linear to Quick.

You can set the High end and the Low end separately.

*When setting AUX1 to [CODE5/CODE10] in AUX TYPE,

changing the setting does not affect the performance.

1) Select AUX1 with the Select button and

set CURVE TYPE of AUX1 to [EXP] with the

multi-selector.

2) Adjust the setting value with the multi-selector.

○Setting range: -100%~100%

○Default: 0%

[AUX2]

●You can change the operation feature of AUX2 from Mild to Linear and to Quick.

You can set the High end and the Low end separately.

*When setting AUX2 to [CODE5/CODE10] in AUX TYPE,

changing the setting does not affect the performance.

AUX1 • Exponential

AUX2 • Exponential

Throttle Operation Position

Usage of each feature

1) Select AUX2 with the Select button and set

CURVE TYPE of AUX2 to [EXP] with the multi-selector.

2) Adjust the setting value with the multi-selector.

○Setting range: -100%~100%

○Default: 0%

22

Usage of each feature

CURVE

SETTING

[ST] Steering Adjustable Rate Control

●

You can change the steering feature from Mild to Linear and to Quick. In general, if you find your RC car

oversteering, change the setting to the minus side and if you find understeering, change to the plus side.

Steering Adjustable Rate Control is a simultaneous setting for L and R.

1) Select ST with the Select button and set CURVE TYPE of ST to

2) Setting Rate [RATE]

Select [RATE] with the multi-selector and

adjust the setting value.

○Setting range: -100%~100%

○Default: 0%

3) Setting Point [POINT]

Select [POINT] with the multi-selector and

adjust the setting value.

Usage of each feature

○Setting range: 5%~95%

○Default: 0%

* When cancelling a selected feature, use the Back button.

Steering Operation Position

[ARC] with the multi-selector.

[TH] Throttle Adjustable Rate Control

●

You can change the throttle feature from Mild to Linear and to Quick. In general, when operating

on a slippery road or if you find over powering, change the setting to the minus side and when

operating on a high-grip road or if you find lack of power in the power unit, change to the plus side.

You can set the High side and the brake side separately.

*Selection of the High side and the brake side is done by trigger operation.

1) Select TH with the Select button and set

CURVE TYPE of TH to [ARC] with the multi-selector.

2) Setting Rate [RATE]

Select [RATE] with the multi-selector and adjust

the setting value.

○Setting range: -100%~100%

○Default: 0%

3) Setting Point [POINT]

Select [POINT] with the multi-selector and adjust the setting value.

○Setting range: 5%~95%

○Default 50%

Select H/B by trigger operation.

Point Setting Position

23

* When cancelling a selected feature, use the Back button.

[AUX1]

●You can change the AUX1 performance feature from Mild to Linear and to Quick.

You can set the High side and the Low side separately.

*When setting AUX1 to [CODE5/CODE10] in AUX TYPE,

changing the setting does not affect the performance.

1) Select AUX1 with the Select button and set

CURVE TYPE of AUX1 to [ARC] with the multi-selector.

2) Setting Rate [RATE]

Select [RATE] with the multi-selector and

adjust the setting value.

AUX1 Adjustable Rate Control

○Setting range: -100%~100%

○Default: 0%

3) Setting Point [POINT]

Select [POINT] with the multi-selector and adjust the setting value.

○Setting range: 5%~95%

○Default: 0%

*When cancelling a selected feature, use the Back button.

[AUX2]

●You can change the operation feature of AUX2 from Mild to Linear and to Quick.

You can set the High side and the Low side separately.

*When setting AUX2 to [CODE5/CODE10] in AUX TYPE,

changing the setting does not affect the performance.

1) Select AUX2 with the Select button and set

CURVE TYPE of AUX2 to [ARC] with the multi-selector.

2) Setting Rate [RATE]

Select [RATE] with the multi-selector and

adjust the setting value.

AUX2 Adjustable Rate Control

Point Setting Position

Usage of each feature

○Setting range: -100%~100%

○Default: 0%

3) Setting Point [POINT]

Select [POINT] with the multi-selector and adjust the setting value.

○Setting range: 5%~95%

○Default: 0%

*When cancelling a selected feature, use the Back button.

Point Setting Position

24

Usage of each feature

Fail Safe [F/S]

●Fail Safe Operation is a feature to keep the servos in a predetermined position for each channel in the event

that the receiver cannot receive a signal from the transmit ter. A feature to keep the servos in a predetermined

position for the servo of the throttle channel (2ch) in the event that the battery voltage on the receiver side of

an engine RC car goes below the set voltage is Battery Fail Safe Operation.

●Battery Fail Safe Operation cannot be set when the throttle channel (2ch) is set to FREE/HOLD (*Battery Fail

Safe Operation works only for the throttle channel).

*Donʼt use Battery Fail Safe Operation feature for electric RC cars.

1)Select F/S with the multi-selector and select a channel to s et

fail safe operation (ST/TH/AUX1/AUX2) with the select butt on.

2)Enter the set channel and operate the multi-selector.

The fail safe mode setting changes in order of FREE -> FS

->HOLD.

○Setting range: FREE/FS(100%~-100%)/HOLD

○Default: FREE

*About each mode

FREE (Free Mode): When thre receiver cannot receive the signal from the transmitter,

the signal output to the servo stops and the servo will be free.

FS (Fail Safe Mode):When the receiver cannot receive the signal from the transmitter,

the servo will be held in the set position.

Usage of each feature

HOLD(Hold Mode): The last postion before the signal from the transmitter to the receiver is lost will be held.

When the receiver can receive the signal from the receiver again, each mode of FREE/HOLD/FS

・

is automatically released.

3)Setting the Fail Safe (FS)

Move to the position where the Fail Safe Operation is used . When the position is determined,

long press the Enter key to set the position when the Fail Safe Operation works.

SETTING

Setting F/S

For safety reason, we recommend setting the throttle channel on the brake side when setting the Fail Safe.

*

4)Setting the Battery Fail Safe Operation

After setting the throttle channel position, move the cursor to [B-F/S] to set the voltage.

○Setting range: ・For FH3: OFF, 3.5v ~ 5.0v (*Not compatible with Li-Po Battery)

v4.7 ~ v5.3 ,FFO :4HF roF・

*The Battery Fail Safe Operation is a feature to activate

Fail Safe Operation when the receiver battery voltage rises

up to the set voltage on a GP car.

Don't use the Battery Fail Safe feature on electric RC cars.

5)Checking the Fail Safe Operation

Turn off the power of the receiver while the Fail Safe Operation

is set and check if the servo moves to the position where the

Fail Safe Operation is set.

BATT-F/S Setting

F/S Setting Position

Setting F/S

●About the Fail Safe Operation

Important

When the Fail Safe feature is on, check the setting of the Fail Safe before operating.

Don't change the setting of the Fail Safe during operation.

25

BASE

●

Base [BASE] is a feature to integrate features of the Reversethat determines the direction of the servo of each channel

SETTING

and the speed controller according to a specific RC car, the Sub Trim that adjusts the neutral position and the End Point

Adjustment [EPA] that sets the operating quantity into one feature (Base) to allow you to make a setting all at once.

Reverse [REV]

●

This is used when operation and the movement of the servo are reversed while operating Steering/Throttle/AUX1/AUX2.

1)Select BASE with the multi-selector and select a channel to set

(ST/TH/AUX1/AUX2) with the select button.

2)Enter with the channel to be set and use the multi-selector.

The Reverse setting will be changed.

When cancelling a selected feature, use the Back key.

*

○

Setting range: NOR/REV

○

Default: NOR

Setting REV

Sub Trim [SUB-T]

●

Using the Sub Trim feature, correct the neutral (center) of Steering/Throttle/AUX1/AUX2 so that Trim can be

used in the center position. When installing a servo on to an RC car, center the servo with Sub Trim first before

adjusting End Point Adjustment.

1)Before using, center (0) each main trim.

2)Select SUB-T with the multi-selector and select a channel

(ST/TH/AUX1/AUX2) to adjust Sub Trim with the select button.

Usage of each feature

3)Determine by Enter operation in the channel to set.

4)Install the servo horn (servo savor horn) as close to centered as possible.

*

For installation position of the servo horn,

follow the instruction on the car body side.

5)Use the multi-selector to adjust the center.

Trim 2

○Setting range: L150~R150(ST)

H150~B150(TH)

H150~L150(

AUX1、AUX2

)

○Default: 0

Note:

●

When installing the servo horn onto your servo, fix the servo h orn as close to the

center as possible and center it with Sub Trim. If Sub Trim and the transmitter

main trim are off to one side, it causes dead band (the range the servo does not

move) to the steering wheel and the throttle trigger.

●

Important

○Center Trim (Main Trim)

Even if you move the neutral position

with Trim, the end of the operation

angle does not move.

About Trim and Sub Trim

Trim is a feature for adjusting the neutral (center) position of the servo. When your model does not run straight after installing the steering servo onto

the model, Trim adjusts the main trim of the steering. Also, the neutral position of the carburetor on RC cars needs neutral adjustment of the throttle

servo along with linkage adjustment after installing the se rvo. Neutral position adjustment is necessary not only after in stalling the servo but for

changes that happen during running such as tire wears and chassis twist. MT-S Trim features two types of Trim including Center Trim that adjusts only

the neutral position without changing the end of the operat ing angle and Parallel Trim that moves the end of the operating angle and the neutral

position simultaneously. Sub Trim that adjusts the neutral (center) position before fixing the servo horn is Parallel Trim and the main trim is Center Trim.

○Parallel Trim (Sub Trim)

When you move the neutral position with Trim,

the end of the operation angle also moves.

When Sub Trim is adjusted after linkage is

completed, readjustment of End Point

Adjustment (EPA) will be necessary.

Adjusting the center position

Setting SUB-T

Trim 1

90°

26

Usage of each feature

BASE

●

Base [BASE] is a feature to integrate features of Sub Trim that adjusts the direction of the servo of each channel

SETTING

and the speed controller according to a specific RC car and the End Point Adjustment [EPA] that sets the

operating quantity into one feature (Base) to allow you to make a setting all at once.

End Point Adjustment [EPA]

●

You can adjust left and right operating quantity of the steering servo when operating the steering wheel/throttle

trigger and operating quantity of the high side and the brake side of the throttle servo, and the servo operating

quantity of AUX1, AUX2 (3ch, 4ch).

[ST-EPA] Steering End Point Adjustment

●Due to linkage, suspension balance and the difference of the ti re diameter, left and right cornering radius

can be different. In case of this, this feature adjusts the servo operating quantity of left and right so that left

and right cornering radius can be the same.

1) Before adjusting Steering End Point Adjustment (ST-EPA), make a neutral adjustment of the servo (P.26).

• Neutral adjustment is to align the center position with Sub Trim by turning the power on and installing

the servo horn in the approximate center position.

2) Select either of [EPA-L/EPA-R] with the multi-selector and

determine with the Enter.

Usage of each feature

3) Adjust the operating quantity with the multi-selector.

*When the cursor is on either of EPA-L/EPA-R,

it is also possible to move the cursor

by steering operation.

○Setting range: L/R 0~150%

○Default: L/R 100%

*Make sure the servos do not

lock to make clicking sound!

If the linkage is locked for a long period,

it can cause the servo breakage.

Note

Choose [ST] by select button.

[TH-EPA] Throttle End Point Adjustment

●It adjusts the High Point of FET Speed Controller, Brake Point, carburetor of engine cars and the brake

operating quantity.

1) For an engine car, make a neutral adjustment of the servo (P.16) before adjusting the Throttle End Point Adjustment

(TH-EPA),

• Neutral adjustment is to align the center position with Sub Trim by turning the power on and installing

the servo horn in the approximate center position.

2) Select [TH/Throttle] with the Select button.

3) Select either of [EPA-H/EPA-B] with the multi-selector and

determine with the Enter.

4) Adjust the operating quantity with the multi-selector.

When adjusting FET Speed Controller, normally set both the high

side and the brake side to 100% and set neutral, high point and

brake point on the FET Speed Controller side (Setting method is

different depending on the FET Speed Controller).

* When the cursor is on either of EPA-H/EPA-B, it is also possible to

move the cursor by trigger operation.

○Setting range: H/B 0~150%

○Default: H/B 100%

27

*Make sure the servos

do not lock to make

clicking sound!

Choose [TH] by select button.

●

When EPA setting value is too large on

the fully open side of the carburetor and

Note

the brake side for throttle linkage,

the servo is locked and it can cause the

motor malfunction and runaway.

[AUX1-EPA]

●You can use AUX1 for functions of accessories and adjust the maximum steering angle (operating quantity)

with EPA. Since you can set H/L separately, precise adjustment is possible.

*When setting AUX1 to [CODE5/CODE10] in AUX TYPE, the operation will not be refected even by adjusting EPA.

1) Before adjusting AUX1 End Point Adjustment (AUX1-EPA), make a neutral adjustment of the servo (P. 26).

• Neutral adjustment is to align the center position with Sub Trim by turning the power on and installing the servo

horn in the approximate center position.

2) Select [AUX1] with the Select button. Select either of [EPA- H/EPA-L]

with the multi-selector and determine with the Enter.

3) Adjust the operating quantity with the multi-selector.

○Setting range: H/L 0~150%

○Default: H/L 100%

AUX1 End Point Adjustment

Choose [AUX1] by select button.

[AUX2-EPA]

●You can use AUX2 for functions of accessories and adjust the maximum steering angle (operating quantity)

with EPA. Since you can set H/L separately, precise adjustment is possible.

*When setting AUX2 to [CODE5/CODE10] in AUX TYPE, the operation will not be reflected even by adjusting EPA.

1) Before adjusting AUX2 End Point Adjustment (AUX2-EPA), make a neutral adjustment of the servo (P. 26).

• Neutral adjustment is to align the center position with Sub Trim by turning the power on and installing the servo

horn in the approximate center position.

2) Select [AUX2] with the Select button. Select either of [EPA-H/EPA-L]

with the multi-selector and determine with the Enter.

3) Adjust the operating quantity with the multi-selector.

○Setting range: H/L 0~150%

○Default: H/L 100%

AUX2 End Point Adjustment

Choose [AUX2] by select button.

Usage of each feature

28

Usage of each feature

TRIM

● For Trim, you can adjust Trim for each channel and set the Trim action (center/parallel).

TRIM

●Correct neutral (center) of each channel (ST/TH/AUX1/AUX2) with Trim.

●As default, steering is set for Trim 1 (TRM1), and throttle for Trim 2 (TRM2).

1) Select a channel (ST/TH/AUX1/AUX2) for adjusting

Trim with the Select button.

2) Determine with Enter operation and adjust with the

multi-selector.

○Setting range: ST:L100~R100

TH:H100~B100

AUX1:H100~L100

AUX2:H100~L100

○Default: ST:0

TH:0

AUX1:0

AUX2:0

*Make an adjustment with TRM1 (ST) and TRM2 (TH)

Usage of each feature

during operation. You can change the Trim lever position

with the Key Assignments Trim feature (P. 52).

Important

●About Trim

Trim is a feature to adjust the neutral (center) position of the servos.

After installing the steering servo onto a car, you can adjust with Trim when the car does not move straightly.

Neutral position adjustment is necessary not only after installing the servo but for changes that happen during

running such as tire wears and chassis twist.

●Itʼs Sub Trim that adjusts het center position when adjusting linkage (P. 26)

SETTING

Selecting a channel with the Select button

Trim 2

(TRM 2)

Trim 1

(TRM 1)

29

●

If Trim and Sub Trim are off to one side, it causes dead band (the range the servo does not move) to the steering wheel and the

throttle trigger. When installing the servo horn, fix the servo horn as close to the center as possible and center it with Sub Trim.

Note

TRIM TYPE

●You can set Trim performance of each channel to Center Trim (CENT) and Parallel (PARA).

●As default, steering is set for Trim 1 (TRM1), and throttle for Trim 2 (TRM2).

1) Select a channel (ST/TH/AUX1/AUX2) to set with the Select button.

2) Determine with Enter operation and adjust with the multi-selector.

○Setting range: CENT (Center Trim)/PARA (Parallel Trim)

○Default: CENT (Center Trim)

Important

●About Center Trim and Parallel Trim

There are two types of Trim including Center Trim that adjusts only the neutral position without changing the end of the operating

angle and Parallel Trim that moves the end of the operating angle and the neutral position simultaneously. Sub Trim that adjusts

the neutral (center) position before fixing the servo horn is Parallel Trim and the main trim has options of Center Trim and Parallel Trim.

You can select according to your purpose.

○Center Trim

Even if you move the neutral

position with Trim, the end of the

operation angle does not move.

○Parallel Trim

When you move the neutral position with Trim,

the end of the operation angle also moves.

When Sub Trim is adjusted after linkage is completed,

readjustment of End Point Adjustment (EPA) will be

necessary.

Selecting a channel with the Select button

CONVERT

●A feature to convert Trim that has been adjusted in each channel to Sub Trim and EPA and to correct Trim

to center. Depending on a setting, there is a case you cannot convert.

1) Select a channel (ST/TH/AUX1/AUX2) to convert with

the Select button.

2) Once a channel to set is determined, launch the convert

feature with Enter operation.

3) For example, if the converting feature is used when Steering

Trim is [L20] and each [EPA] is 100%, the flow will be as shown

in right illustration. Trim will be centered [0] and the portion

of the Trim movement will be converted to Sub Trim and EPA.

*Conversion can be set in each channel.

ENTER BACK

ENTER

Usage of each feature

⇒

Conversion is completed.

30

Usage of each feature

THROTTLE FUNCTION /TH-FUNCTION

●The throttle function allows you to adjust the setting values of ALB (Anti-Lock Brake), OFFSET and TH TYPE

(throttle type) of the throttle channel.

Anti-Lock Brake[ALB]

● Anti-Lock Brake enables stable braking on a low grip road.

● Because of the stable braking, you can trace cornering lines as intended.

1) Select the throttle function with the multi-selector and determine

with the Enter operation.

2) When selecting [ALB] with the multi-selector and determining with

the Enter, the menu changes to ALB setup menu.

3) Setting Stroke (STROKE)

Set Stroke of ALB with the multi-selector.

Stroke is the width of repeated actions at the time of bra king.

,

○Setting range OFF

○Default OFF *OFF ALB does not work when it is off.

4) Setting Point (POINT)

Set Point of ALB with the multi-selector.

Point is the position where ALB starts acting when operating the

brake.

Usage of each feature

○Setting range: 5%~100%

○Default: 80%

5) Setting Lag (LAG)

Set Lag of ALB with the multi-selector.

Lag is a setting of time lag from the time when operating to the

point to the time when ALB starts acting.

○Setting range: 0.00s~1.00s

○Default: 0.00s

6)Setting Cycle (CYCLE)

Set a cycle of ALB with the multi-selector.

Cycle is a frequency setting of repeated actions for braking.

○Setting range: 0.01s~1.00s

○Default: 0.08s

* When Anti-Lock Brake is working, X illumination and

Function LED flash.

0~100%

THROTTLE FUNCTION/TH-FUNCTION

ENTER BACK

ENTER BACK

Set each Parameter.

31

Lag

Point

Full Brake

Position of the Point

Neutral

*ALB is activated when operating from the

point position to full brake.

Neutral

Servo action

Brake operation

Cycle

Stroke

Supplement

●

Activate the brake rather strongly not to the extent that the t ires of your RC car lose their grips

(not to slip) and adjust so that Anti-Lock Brake is activated just before the tires are locked and slide.

●

If you set ALB using a speed controller with a back on an RC car, you may not able to operate back

movement. When using a back movement, turn ALB off.

OFFSET

THROTTLE FUNCTION/TH-FUNCTION

● By moving the position of the throttle neutral at the time of starting an engine RC car engine,

it improves the start-up performance of the engine.

You can fix at a position where idling speed is increased so that the engine will not stop during refueling your engine RC car.

●

● By operating the switch that has been set, you can stop the engine of your RC boat.

● You can use various power sources with Offset feature.

● ON/OFF of the Offset feature is not assigned to the switch and keys at the factory.

When using, assign the features with key assignment (P. 51, 52)

OFFSET Position

When setting plus

1) Select the throttle function with the multi-selector and

determine with the Enter operation.

2) Select [OFFSET] with the multi-selector and determine with Enter.

It will change to OFFSET Setting menu.

3) Setting Offset [OFFSET]

Set ON/OFF of the Offset feature with the multi-selector.

○Setting range: ON/OFF

○Default: OFF

4) Setting Type [TYPE]

Set Type of the Offset with the multi-selector.

○Setting range: I-UP (Idle Up)/N-BR (Neutral Brake)

○Default: I-UP

OFFSET Position

Neutral position

when setting plus

Servo operating quantity

Trigger Control Input

Neutral position

for Normal

OFFSET Position Neutral position

when setting minus

OFFSET Position

when setting minus

5) Setting Point [POINT]

Set Point of the Offset with the multi-selector.

○Setting range: H100%~B100%

○Default: 0%

ENTER BACK

6) Setting Beep [BEEP]

Set Alarm (Beep) that goes off when the Offset is activated.

○Setting range: ON/OFF

○Default: OFF

When the Offset feature is working, X illumination and Function

*

LED flash.

Usage of each feature

THROTTLE TYPE[TH TYPE]

THROTTLE FUNCTION/TH-FUNCTION

●You can move the neutrals position of the throttle and set the operating ratio of the forward side and the brake

(backward) side to either 7:3 or 5:5.

*Set the throttle type according to the speed controller to be used.

1) Select the throttle function with the multi-selector and determine

with the Enter operation.

2) Select [TH TYPE] with the multi-selector and determine with Enter.

3) Setting the Throttle Type

Set the Throttle Type with the multi-selector.

○Setting range: F7:B3 / F5:B5

○Default: F7:B3

ENTER BACK

*When changing TH TYPE, the screen changes to the confirmation

screen and a message is displayed. Operate following the message.

32

Usage of each feature

AUX

●

AUX is a feature to set the performance of AUX1 and AUX2 (3ch, 4ch). You can choose from STEP AUX (STEP),

POINT AUX (POINT), 4WS (4-Wheel Steering: Coordinate Phase, Opposite Phase). MOA (Motor On Axle), AUX-MIX

(AUX Mixing: ST à AUX/TH-AUX) and CODE5/CODE10 (Code Communication).

*Setting of AUX TYPE is done in the System Menu. Make a setting according to the purpose of the use.

STEP AUX

● Setting Step AUX allows you to set the operating quantity by operating assigned Trim or a switch.

● By factory default, the AUX feature is set to the Step AUX.

1) Select [AUX] with the multi-selector and define with the Enter

operation.

2) Setting Step AUX (STEP AUX)

Determine [CH] to activate with the Select button and set the

position of the motion with the multi-selector.

*Operating quantity can be set with EPA

(End Point Adjustment, P.27, 28).

*Assign the features to Trim and Dial with Key

Usage of each feature

Assignments according to the used method.

Motion Position Display

AUX

ENTER BACK

Secreting a Channel with the Select Button

POINT AUX

●By setting Point AUX and assigning the movement of AUX1/AUX2 (3ch, 4ch) to the switch and Trim, you can

move the servo to the set Point.

The Point that moved can be set with EPA (End Point Adjustment).

Adjust the Point position according to the usage.

Amount of Points will be 2 ~ 6 points and can be set with AUX TYPE.

*

1) Select [AUX] with the multi-selector and set with AUX TYPE.

2) Setting Point AUX (POINT AUX)

Determine [CH] to activate with the Select button and set

the Point of the motion with the multi-selector.

*Set to [POINT AUX] with (AUX TYPE) of (SYSTEM) according to

the usage.

*Assign the features to Dial and Trim with Key Assignments to

operate or operate with the multi-selector.

33

AUX

ENTER BACK

4-Wheel Steering

AUX

●With the operation of assigned Trim or Switch, control the motion of the 4 Wheel Steering.

1) Select [AUX] with the multi-selector and define with the Enter operation.

2) Setting Operating Mode

Set the Operating Mode of 4WS with the multi-selector.

Set the Operating Mode according to the usage.

* When using during operation, assign the feature of the

Operating Mode to Trim or the switch.

Steering the Motion Image

F-ST

ENTER BACK

<L Side Operation> <Neutral> <R Side Operation>

REV

<L Side Operation> <Neutral> <R Side Operation>

NOR

<L Side Operation> <Neutral> <R Side Operation>

R-ST

<L Side Operation> <Neutral> <R Side Operation>

Motor On Axle [MOA] (Front-Rear Wheel Separate Drive)

AUX

Servo Motor

Switching the Operation Mode

●By setting Motor On Axle (MOA], you can adjust the drive ratio of front and rear wheels of a front-rear dual

motor car.

1) Select [AUX] with the multi-selector and define with the Enter

operation.

Usage of each feature

2) Setting Operating Mode

Set the Operating Mode of MOA with the multi-selector.

*Adjust Step setting to change the drive distribution of front- rear

with [MODE] of [AUX TYPE] of [SYSTEM].

*When using, assign the features to Dial or Trim or operate with

the multi-selector.

*Connect the speed controller for controlling the rear motor to

the channel (AUX1/AUX2) that is set to MOA.

MOA Motion Image

Front Drive

Rear Drive

By changing the ratio, you can adjust the gear ratio of front-rear.

Front Drive

Rear Drive

Front Drive

Rear Drive

ENTER BACK

Servo Motor

Front-rear drive ratio

34

Usage of each feature

AUX

●

AUX is a feature to set the performance of AUX1 and AUX2 (3ch, 4ch). You can choose from STEP AUX (STEP),

POINT AUX (POINT), 4WS (4-Wheel Steering: Coordinate Phase, Opposite Phase), MOA (Motor On Axle),

AUX-MIX (AUX Mixing: ST-AUX/TH-AUX) and CODE5/CODE10 (Code Communication).

*Setting of AUX TYPE is done in the System Menu. Make a setting according to the purpose of the use.

AUX MIXING[AUX-MIX]

●Setting AUX Mixing allows you to mix from the steering to AUX and from the throttle to AUX.

*Set AUX TYPE and MODE for operation to use for [AUX TYPE] of [ SYSTEM].

●At factory, the AUX feature is set to Step AUX.

1) Select [AUX] with the multi-selector and define with the Enter

operation.

2) Setting Mixing Rate

Set the Mixing Rate with the multi-selector.

○Setting range: 0~100%

○Default: 100%

* Set to [AUX MIX] with [AUX TYPE] of [SYSTEM] and set the

Usage of each feature

Mixing performance with [MODE] according to the usage.

Assign the features of the Mixing Rate to Trim or the switch

*

with Key Assignments, or operate with the multi-selector.

AUX

ENTER BACK

Servo Monitor

Setting Mixing Rate

35

CODE AUX

●

Code AUX (CODE AUX) is a feature to perform code communication by assigning a setting value to each code

AUX

of CODE5 and CODE10 (CODE5/5 code, CODE10/10 code). It is an extension feature to change the setting of

speed controller (SUPER VORTEX series and SV-PLUS series) and the Gyro System (SGS-01C/SGS-01D)

that are compatible to CODE AUX.

●You can set 2 types of Code AUX1 and CODE AUX2.

*Setting of CODE is done by setting [TYPE] of [SYSTEM] menu. By setting [MODE], the display is changed

according to each equipment. When setting [MODE] to [USER], each code display allows the user to set.

*When using an AUX channel as CODE AUX, make sure to set the response mode of A1/A2 that are set for

BIND to [SHR] (See P.49, 50).

When using CODE AUX, do not connect the servo to CH3 and CH4 of

*

the receiver to be used.

*When using, assign the features to Dial or Trim with the Key assignments or operate with the multi-selector.

1) Select [AUX] with the multi-selector and define with the

Enter operation.

2) Setting Code AUX

Select [CODE AUX] to change setting and adjust the setting

value with the multi-selector.

○Setting range: -100~100%

○Default: 0%

*When AUX TYPE is set to CODE5/CODE10, the following is

displayed according to the setting of CODE AUX in the servo

monitor display of the top screen.

AUX TYPE = When setting is CODE AUX, bar display

CODE1 Parameter

CODE4 Parameter

CODE3 Parameter

CODE6 Parameter

+100 -1000

CODE5 Parameter

CODE9 Parameter

CODE7 Parameter

CODE8 Parameter

CODE2 Parameter

CODE10 Parameter

ENTER BACK

When TYPE setting is [CODE10]

and MODE setting is [SV-STK]

When MODE setting is [USER]

When TYPE setting is [CODE5]

and MODE setting is [SVZ]

Usage of each feature

When MODE setting is [USER]

36

Usage of each feature

TIMER

● It has three timer features including Lap Timer, Interval Timer and Down Timer.

●

When selecting a timer and operate the Select button, you can toggle between the timer screen and the setting screen.

* When a timer is activated, X Illumination and Function LED flash.

● You can check the lap time measured on the LAP TIMER screen.

● When Enter is being operated while Lap Timer is activated/not activated,

the screen is changed to the Lap Time display.

You can check each lap time with the multi-selector.

ENTER

BACK

⇔

Select Button

<LAP TIMER Screen>

Usage of each feature

SETUP

● Make all settings of the timers with the Setup Menu.

1) Setting TYPE

Select [TYPE] with the multi-selector to do setting.

○Setting range: LAP/INT/DOWN

○Default: LAP

• LAP: Possible to measure and record each lap up to 999 laps

(for all models)

• INT: The timer is activated at the set time.

• DOWN: It can be a guideline for calculating running time and

the fuel cost of a GP car.

2) Setting GOAL TIME

By setting a goal time, the Alarm is activated.

<SETUP Screen>

TIMER

ENTER BACK

37

○Setting range: 00: 00 ~ 99: 59 (00: 01 unit)

○Default: 5: 00

3) Setting INTERVAL

The Alarm is activated at the set time (It tells you the lap time).

○Setting range: 00: 00 ~ 99: 59 (00: 01 unit)

○Default: 01: 00

4) Setting LAP NAVI

It activates the alarm at the set time at the time of running and

uses it as a guideline for the goal time.

〇Setting range: 00:00.01s~99:59.99

〇Default:

*LAP NAVI will not start at 00 : 00. 00.

--:--.--

⇒

Select Button

5) Setting START

Set the Timer Start from the Trigger Interlock/Switch/Random.

○Setting range: TRIGGER/SW/RANDOM

○Default: TRIGGER

6) Setting DATA-LOG

It sets Telemetry Data Log (record) along with the timer.

○Setting range: OFF/ON

○Default: OFF

Function LED

X Illumination

*Log starts along with the timer feature.

LAP TIMER

● You can measure and record each lap up to 999 laps (works for all models).

● Pre Alarm (PRE-ALM) is installed and the alarm goes off before the goal.

1) Select [TIMER] with the multi-selector and determine with the

Enter operation.

2) Starting the Timer

As a default, the timer switch is set to SW1. By holding S W1,

the timer becomes a standby state for starting and by either

pressing SW1 again or operating the throttle trigger,

measuring starts.

3) Every time you operate SW1, lap time is measured.

The switch does not work for 3 seconds after operating SW1.

4) Completing measuring

By holding SW1, measuring will be completed.

*You can check the measured lap time on the LAP TIMER screen.

When Enter is being operated while the lap timer is activa ted/

stopped on the LAP TIMER screen, the screen is changed to the

lap time display. You can check each lap time with the multi selector operation (not possible on the SETUP screen).

*When turning the power switch off while the timer is activated,

the timer will be reset.

*When the timer is set to SW1/SW2, the timer will be in the standby

mode by holding the switch even on a screen other than the

setting screen.

SWITCH1

LED flashes while the timer is activated.

TIMER

ENTER BACK

ENTER BACK

Usage of each feature

38

Usage of each feature

Interval Timer [INT TIMER]

●It activates the alarm at the time set at the beginning of

running and uses it as the guideline for the goal time.

1) Select [TIMER] with the multi-selector and determine with the

Enter operation.

2) Setting the Type [TYPE]

Operate the Select button and select [INT] with [TYPE].

3) Setting Interval (INTERVAL)