SanRex Power Supply for Metal Surface Treatment User Manual

LEADING THE NEW POWER ELECTRONICS

▲ ▲

Power Supply for Metal Surface Treatment

SANSHA ELECTRIC MFG. CO., LTD.

Power Supply for Met

经济性。 尤其是电镀以先进的加工技术在表面处理技术中占有着非常重 要的角色。

=

实际使用。

Diversified surface treatment technology

As for the surface treatment technology, the usage and function are extending to the function platings of a decoration, rust prevention, and electronic parts more and more now. As for this surface treatment technology, high accuracy or more, the high quality, and the economy are strongly demanded by such an average. Especially, galvanization bears an important role by the function with excellent the processing technology.

Process of metal-surface treatment

Metal surface treatment or plating involves a complicated process of pre-treatment, various plating processes, and post-treat- ment that are considered as the treatment of base materials, in addition to other processes depending on each material and finishing method.

Today, however, stricter quality, improvement in energy efficiency, and process rationalization are required in plating, no matter how complicated and advanced the process is.

Our new power supply units are one way of comprehensively resolving such issues.

The new systems are capable of quickly and efficiently adjusting optimal electric current required for various kinds of plating, thus improving plating quality as well as responding to the needs of the energy saving era.

These new systems greatly reduce noise and pollution as well.

Reformation of surface treatment power supply

As the technologies of the surface treatment industry quickly advance, a technology revolution is required in power supply systems. Power electronics technologies (semiconductor elements for power supply, conversion technology, and control technology) that support the technology revolution have been advancing every day. In particular, the development of higher frequency wavelength technology for power supplies completely changed the concept of conventional power supply for plating. This resulted in commercialization of the inverter power supply and pulse power supply systems.

In the future, SanRex will strive for better precision and higher efficiency, along with development of smaller and lighter devices, as well as improved energy efficiency and quality through centralized management of automated plating lines based on micro controller technology.

1

Technology based on more than half a century of development

SanRex is developing power supply units for metal surface treatment that keep up with the rapidly diversifying needs of the electronics industry.

al Surface Treatment

………… /

Reliability improvement & speed up and formation film of productivity. A wavy control that suits a new process is materialized. The challenge of the road to the process with an infinite possibility is supported.

A lineup for the inverter power supply with the latest digital control & an efficient electric power semiconductor.

Design based on in depth knowledge of the locus of metal surface processing ensures stable performance over the long term.

因此可以在短时间内实现高信赖度的系统构筑。

We mounted the interface in accordance with an international standard. Therefore the system construction of high reliability will be achieved in a short time.

■ Image |

|

Ethernet |

|||||||||

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PLC |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Operation PC |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

Open field network |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DC AUTO |

MRT MRT-HPR |

|

|

|

|

Printer |

|

Heater |

Pump |

Sensor |

|

|

Conveyer |

|

|

|

Others |

SanRex DeviceNetPLC RS232C

In the product of SanRex, the open network communication such as DeviceNet began to appear in the industry and was installed. It is possible to connect by this function the personal computer, the control equipment such as PLC, and between, and the match with mechanism is also easy. Troublesome program development and a special substrate by special communications such as the current remote controls and RS232C are unnecessary.

(There is something that it is not possible to correspond with a part of model. )

2

Power Supply for Metal Su

|

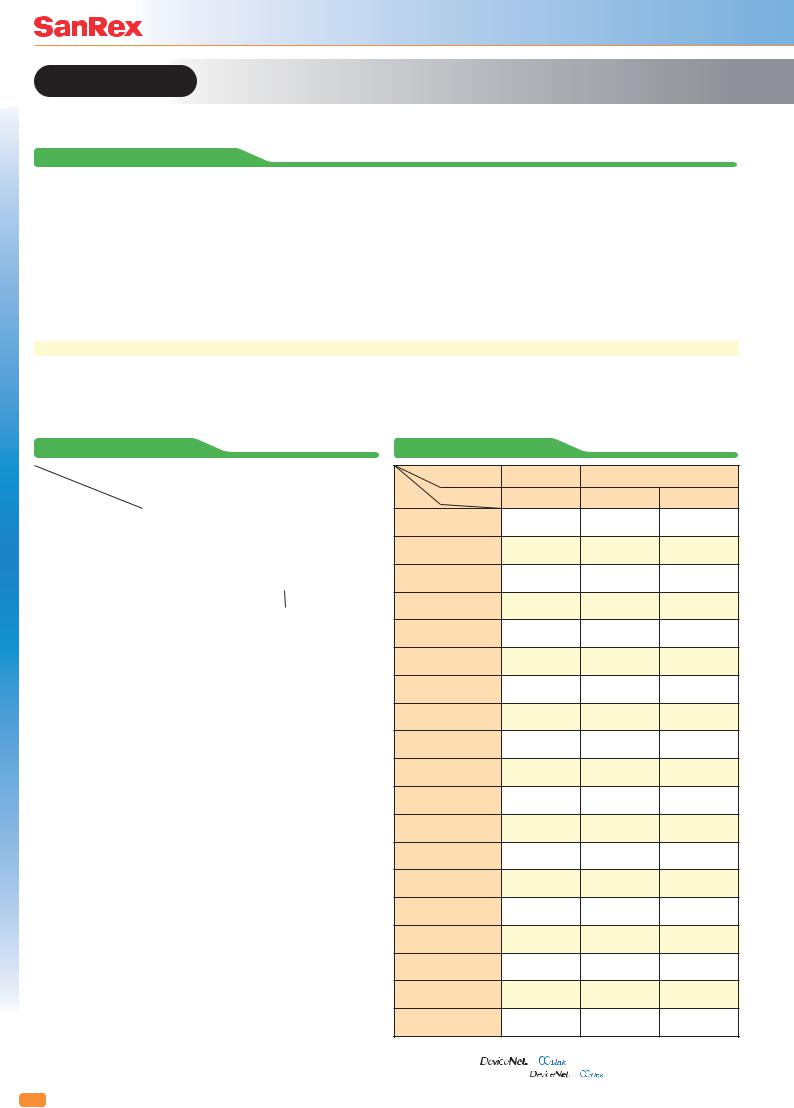

A variety of models available in series |

|

10A 15000A

It is eight kinds from for the lab of 10A in output current to a large capacity of 15,000A or less in output current.

40 |

200 300 |

500 |

800 |

1,500 |

3,000 |

5,000 |

15,000 |

|||||||||||

30V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20V |

|

|

H K |

|

|

|

|

|

MRT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15V |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MRS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

10V |

|

|

|

|

|

|

|

|

|

MRS-PR |

|

|

|

|

|

|||

|

|

|

|

MRT-HPR |

|

|

|

|

|

|

|

|

|

|

|

8V |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6V |

|

|

|

|

|

|

|

SMR |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4V |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

10A |

100A |

|

|

1,000A |

|

|

|

10,000A |

||||||||

|

Improved environmental durability |

间稳定运行。

The interior is duct structure. Only heat sink is air-cooled. Electronic components are protected against influence from environment in order to maintain stable characteristics for along time.

|

Fan with a long service life and easy replacement |

Fan motion is varied by operating and there by fan has longer life (mechanically) and reduced noise. In case of defect, fan is easily replaced.

3

rface Treatment

|

Selectable output waveform mode |

|

Products Lineup

|

HK series |

5 8 |

|

|

|

|

|

DC AUTO |

|

|

|

|

MRT |

9 10 |

|

|

series

SMART

Mini-Rex

|

|

|

|

GOLDWAVE (Free waveform) mode |

|

|

||||||||||||

|

If dedicated software (option) is used, op- |

|

|

|||||||||||||||

5-150Hz 6.7ms-200ms |

eration with any waveform output be- |

|

|

|||||||||||||||

comes possible. |

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||

• 1 cycle : 5 - 150Hz (6.7 - 200ms) |

|

|

||||||||||||||||

64 |

|

|

|

• Waveform setting : input by spread sheet software |

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

• 1 cycle resolution : 64 points in one cycle |

|

|

|||||||

|

|

|

|

|

|

High-speeding of output pulse current |

|

|

||||||||||

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

● |

●DC high-speed pulse control |

|

|

|||||||||||||

|

|

● |

●Positive-Reverse high-speed pulse control |

|

|

|||||||||||||

|

|

● |

●Reversible high-speed switching |

|

|

|||||||||||||

|

Normal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MRT- |

HPR WAVEFORM of MRT-HPR |

|

|

|

|

|

||||||||||

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

5% |

|

|

|

|

|

|

|

|

0 |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

Idle period |

0 |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

Reverse |

Ripple current |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

content rate 5% |

|

|

|

|

|

|

|

50 |

μs |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

Rise time 50+s |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

The newly developed high-speed switch- |

|

|

|||||||||||||||

( ) 50μs TYP |

ing circuit has realized high speeding of |

|

|

|||||||||||||||

|

|

|

|

50+ sec or less of output current polarity |

|

|

||||||||||||

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

switching time (rise and fall time). |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

Through-hole |

|

|

|

Via-hole |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

Excess plating |

|

|

|||||||||||

|

|

|

|

|

|

Plating areas |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Conventional plating |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

by DC power |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Uniform plating

MRT-HPR

Plating by MRT-HPR

MRT |

11 12 |

-HPR |

|

series |

|

|

M Power |

|

|

|

|

MRS |

13 14 |

series |

|

|

SUPER |

|

MINI-REX |

|

|

|

|

MRS |

15 16 |

- PR |

|

series |

|

|

SUPER |

|

MINI-REX |

|

|

|

|

SMR |

17 18 |

series |

|

|

SMART |

|

Mini-Rex |

|

|

|

|

MED |

19 20 |

|

|

series |

|

|

SUPER |

|

MINI-REX |

|

|

|

|

|

21 22 |

|

|

|

|

4

DC AUTO HK series

Superior model with sophisticated functions and environmental durability

Remote control pendant (Option)

HKD

TYPE

HKE

TYPE

1. : 1ms

这一专用的控制盒也可以用于HKE

Remote control pendant is easily operated by a jog dial. An exclusive-use remote control pendant is provided also for HKE type.

Features

Pulse mode operation with minimum 1msec pulsation

2. |

|

GOLDWAVE (Free wave form) mode |

3. |

RS-485 |

High speed communication (RS-485) |

4. |

/ |

Current integration function |

5. |

|

Operation pattern memorizing |

Easy setup with jog dial

移动下一位数值设定。

Adjust |

Set up |

Push

The jog dial is used for output current and voltage setup. One dial is capable of digit-by-digit numerical value setup and moving through values, which allows easy setup.

Diagnose defects with abnormality indicator and alarm

/

Individual indication of problems allows for easy analysis. Buzzer and abnormal output signal notify of defects. Continuous operation mode is also available in case of output defects.

Pilling up is allowed

2

( )

Example

Units can be piled up to 2 stacks. *For more stacks piling, we provide

exclusive-use rack as an option.

5

Power Supply for Metal Surface Treatment

Power source for metal plating of small capacity

|

|

|

Selectable output waveform mode |

||||||||

|

|

|

|

|

|||||||

|

|

|

|

|

A. |

|

|

|

A. GOLDWAVE (Free waveform) mode |

||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

If dedicated software (option) is used, operation with any waveform out- |

||||

|

|

|

|

|

5-150HZ 6.7ms-200ms |

|

put becomes possible. |

|

|||

A. |

|

|

|

• 1 cycle : 5 - 150Hz (6.7 - 200ms) |

|||||||

|

|

• Waveform setting : input by spread sheet software |

|||||||||

|

64 |

|

|||||||||

GOLDWAVE mode |

|

|

• 1 cycle resolution : 64 points in one cycle |

||||||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B. |

|

|

|

B. Chopper (pulse) mode |

||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

1ms |

|

• Minimum 1msec pulsation output is possible. |

||||

|

|

|

|

|

|

|

• Suitable for plating precious ornament and/or lead free soldered |

||||

|

|

|

|

|

|

|

components. |

|

|||

B. |

|

|

|

||||||||

|

|

|

|

|

|

• Synchronized operation of multi-units is possible. |

|||||

Chopper (Pulse) mode |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

C. |

|

|

|

C. Single phase full wave mode |

||

|

|

|

|

|

|

|

|

||||

C. |

|

|

|

Suitable for silver plating. |

|

||||||

Single phase full wave mode |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

High speed communication |

|

|||||

|

|

|

|

|

|

|

|||||

RS-485 38,400bps. |

|

RS-485 communication port is equipped. Maximum communication |

|||||||||

|

|

|

|

|

|

|

|

|

|

speed is 38,400bps. |

|

|

Open Field Network Applicability (Option) |

||||||||||

|

|

|

|||||||||

|

With open field network, it can be controlled by simple program on |

||||||||||

|

|

|

|

sequencer side. It can be applied to most of mainstream open field |

|||||||

|

|

|

networks in the world. |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

/ |

Current integration function |

|

|||||||||

|

|

|

|||||||||

8 |

8-digit ampere-hour meter is built in for controlling plating thickness. |

||||||||||

|

|

|

|

Current integrated value in each pattern of operation can be shown as |

|||||||

|

|

|

ampere-second, ampere-minute or ampere-hour. |

||||||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

|

|

|

|

Function |

||

|

|

|

|

|

|

|

Preset |

|

|

4 |

Set by jog dial, 4 digit display |

|

Individual |

|

|

Counter |

|

|

4 |

4 digit display |

|||

|

|

Setting & Display |

|

|

1 9999AS/ 1 9999AM |

|

|||||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

1 9999AH ( ) |

(selectable) |

||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Preset |

|

|

8 |

Set by jog dial, 8 digit display |

|

Total |

|

|

Counter |

|

|

8 |

8 digit display |

|||

|

|

|

|

|

|

|

Display |

|

|

1 99999999AH |

|

最多可存储99

Energization Timer

Energization time can be controlled by a timer for controlling plating thickness.

Operation pattern memorizing

A.Memorized operation

Memorized operation function workable at any set values is provided. 99 patterns of operation parameters can be memorized.

B.Patterned operation

Continuous operation at different parameters memorized in memorized operation.

|

Item |

Function |

|

|

|

|

|

|

|

|

1 CV 8.0V 150AM 2 CC 150A |

( ) |

|

99 |

|

Memory (Parameters setting) |

|

99 patterns |

With operation mode select key, parameters can be set. |

|

|

|

Memory 1: CV: 8.0V, preset 150AM Memory 2: CC: 150A |

|

|

|

As shown above, different parameters are memorized individually and integrated into any |

|

|

|

operation conditions by one-touch operation. |

6

DC AUTO HK series

|

|

Common specification |

|

|

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|||

|

|

Control method |

|

PWM PWM control switching method |

||||

|

|

|

|

|

100/200V |

( ) |

|

/ / |

|

|

|

|

Single phase |

(Changeover) |

|

/ / V |

|

|

|

|

|

|

|

|||

|

|

|

Voltage |

200V |

( ) |

|

/ / V |

|

|

|

|

|

|||||

|

|

|

|

|

|

(Exclusive use) |

|

|

|

|

|

3-phase |

200/400V |

( ) |

|

/ / / |

|

Input |

|

|

|

(Changeover) |

|

/ / V |

||

|

|

|

Frequency |

50/60Hz |

|

|

|

|

|

|

|

Voltage range |

±10% |

|

|

|

|

|

|

|

Control |

|

|

Constant current or constant voltage |

||

|

|

|

Adjustable range |

0~ |

0 - Rated value (Current, Voltage) |

|||

|

|

|

Precision |

|

|

|

|

|

|

|

Input voltage fluctuation |

±0.5% |

|

Rated value ±0.5% within |

|

||

Output |

|

|

|

|||||

|

|

|

Load fluctuation |

±0.5% 10~100% |

Rated value ±0.5% within (output voltage 10 - 100%) |

|||

|

|

|

Ripple |

RMS 1% ( , ) |

RMS 1% or below (of rated value at rated input/output) |

|||

|

|

|

|

|

|

|

|

|

Input voltage is automatically recognized and changed by one touch operation.

|

|

|

|

Product List |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

4V |

8V |

|

12V |

|

15V |

20V |

||||

|

Output Voltage |

|

|

|

|

|

|

||||||

|

|

Product made |

Standard |

Product made |

|

Standard |

Product made |

||||||

Output Current |

|

to order |

Product |

|

to order |

|

Product |

to order |

|||||

|

|

input |

|

100/200V |

|

|

|

|

|||||

|

|

Single phase |

|

(Changeover ) |

|

|

|||||||

A |

kVA |

input kVA |

0.10 |

0.18 |

|

0.26 |

|

|

0.33 |

0.43 |

|||

|

Outer |

|

|

|

A A type |

|

|

|

|||||

|

|

|

|

|

|

|

|||||||

|

case 1 |

|

|

|

|

|

|

||||||

|

|

Cooling |

|

|

Natural cooling |

|

|

||||||

|

|

method |

|

|

|

|

|

|

|

|

|

|

|

|

|

input |

100/200V |

|

|

|

200V( ) |

||||||

|

|

|

Single phase 200V |

||||||||||

|

|

|

Single phase |

(Changeover ) |

|

|

(Exclusive use) |

||||||

A |

kVA |

input kVA |

0.19 |

0.36 |

|

0.51 |

|

|

0.63 |

0.83 |

|||

|

Outer |

|

|

|

A A type |

|

|

|

|||||

|

|

|

|

|

|

|

|||||||

|

case 1 |

|

|

|

|

|

|

||||||

|

|

Cooling |

|

Natural cooling |

|

|

|

||||||

|

|

method |

|

|

|

|

|

|

|

|

|

|

Forced air cooling |

|

|

input |

100/200V |

|

|

|

|

200V( ) |

|||||

|

|

Single phase |

(Changeover ) |

|

|

|

Single phase (Exclusive use) |

||||||

A |

kVA |

input kVA |

0.28 |

0.53 |

|

0.75 |

|

|

0.93 |

1.23 |

|||

|

Outer |

|

|

|

A A type |

|

|

|

|||||

|

|

|

|

|

|

|

|||||||

|

case 1 |

|

|

|

|

|

|

||||||

|

|

Cooling |

Natural cooling |

|

|

Forced air cooling |

|||||||

|

|

method |

|

|

|

|

|

|

|

|

|

|

|

|

|

input |

|

200V( ) Single phase (Exclusive use) |

|

||||||||

A |

kVA |

input kVA |

0.45 |

0.84 |

|

1.22 |

|

|

1.52 |

2.01 |

|||

|

Outer |

|

|

|

A A type |

|

|

|

|||||

|

|

|

|

|

|

|

|||||||

|

case 1 |

|

|

|

|

|

|

||||||

|

|

Cooling |

|

|

Forced air cooling |

|

|

||||||

|

|

method |

|

|

|

|

|

|

|

|

|

|

|

|

|

input |

200V( ) |

|

|

200/400V |

|

||||||

|

Single phase (Exclusive use) |

|

Three phase |

(Changeover ) |

|||||||||

A |

kVA |

input kVA |

0.88 |

1.69 |

|

2.41 |

|

|

3.05 |

3.48 |

|||

|

Outer |

A A type |

|

|

|

|

|

|

B B type |

|

|||

|

|

|

|

|

|

|

|

||||||

|

case 1 |

|

|

|

|

|

|

|

|||||

|

|

Cooling |

|

|

Forced air cooling |

|

|

||||||

|

|

method |

|

|

|

|

|

|

|

|

|

|

|

|

|

input |

|

|

200/400V |

|

|

|

|||||

|

|

|

Three phase |

|

(Changeover ) |

|

|

||||||

A |

kVA |

input kVA |

1.14 |

2.20 |

|

3.17 |

|

|

3.92 |

5.16 |

|||

|

Outer |

|

|

B B type |

|

|

|

|

|

C C type |

|||

|

|

|

|

|

|

|

|

||||||

|

case 1 |

|

|

|

|

|

|

|

|||||

|

|

Cooling |

|

|

Forced air cooling |

|

|

||||||

|

|

method |

|

|

|

|

|

|

|

|

|

|

|

|

|

input |

|

|

200/400V |

|

|

|

|||||

|

|

|

Three phase |

|

(Changeover ) |

|

|

||||||

A |

kVA |

input kVA |

1.48 |

2.86 |

|

4.18 |

|

|

5.16 |

6.80 |

|||

|

Outer |

|

|

B B type |

|

|

|

|

|

C C type |

|||

|

|

|

|

|

|

|

|

||||||

|

case 1 |

|

|

|

|

|

|

|

|||||

|

|

Cooling |

|

|

Forced air cooling |

|

|

||||||

|

|

method |

|

|

|

|

|

|

|

|

|

|

|

|

|

input |

|

200/400V |

|

|

|

|

|||||

|

|

Three phase |

|

(Changeover ) |

|

||||||||

A |

kVA |

input kVA |

2.22 |

4.29 |

|

6.18 |

|

|

7.74 |

|

|||

|

Outer |

|

|

C C type |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|||||

|

case 1 |

|

|

|

|

|

|

|

|

||||

|

|

Cooling |

|

Forced air cooling |

|

|

|

||||||

|

|

method |

|

|

|

|

|

|

|

|

|

|

|

As for dimensions of outer case, see "external dimensions diagram".

Input voltage is automatically recognized and changed by one touch operation.

|

|

|

|

Functions |

|

|

|

|

|

|

|

||

|

|

HKD |

|

HKE |

|

|

|

Model |

|

|

|||

|

|

10 300A |

|

20 300A |

10A |

|

Function Output current |

|

|||||

|

|

|

|

|||

/ |

|

● |

|

● |

|

|

Panel start/stop |

|

|

|

|||

|

|

|

|

|

|

|

/ |

|

|

● |

|

● |

● |

External start/stop |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

● |

|

● |

● |

Output adjustment |

|

|

||||

|

|

|

|

|

||

CC/CV |

|

|

● |

|

● |

● |

CC/CV selection |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

● |

|

|

|

Output waveform selection |

|

|||||

|

|

|

|

|||

|

|

|

● |

|

● |

● |

Digital voltmeter |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

● |

|

● |

● |

Digital ammeter |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

● |

|

|

|

Preset counter |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

● |

|

|

|

Total counter |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

○ |

|

● |

|

External command |

|

|

||||

|

|

|

|

|

||

|

|

○ |

|

● |

|

|

Output current monitor |

|

|

||||

|

|

|

|

|

||

|

|

○ |

|

● |

|

|

Output voltage monitor |

|

|

||||

|

|

|

|

|

||

|

|

|

○ |

|

● |

|

Abnormal output |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

○ |

|

|

|

Open field network |

|

|

||||

|

|

|

|

|||

RS-485 |

|

|

● |

|

|

|

RS-485 communication |

|

|

||||

|

|

|

|

|

||

|

|

|

○ |

|

○ |

|

Remote control |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

● |

|

● |

|

Soft start |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

○ |

|

○ |

|

Crossover control |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

● |

|

○ |

|

Initial current setting |

|

|

||||

|

|

|

|

|

||

● Standard |

○ Option |

Not available |

|

|||

" |

|

" " |

" |

|

||

We provide dedicated PCBs for " |

" " |

" respectively. |

|

|||

7

Loading...

Loading...