Page 1

VAC

C1

C

6

R

1

D

1

BR

1

R2

C2

T1

D

P

PC1

C3

R

OCP

C

Y

C5

1 2 3 4

D/ST D/STBRNC

S/OCP FB/OLP

GND

VCC

8 7

5

STR-A6000

U1

D2

C4

R

C

R

B

R

A

D51

C51

R51

R52

U51

R54

R56

C52

S

PC1

R53

R55

L51

C53

VOUT

(+)

TC_STR-A6000_1_R1

(-)

Products

P

(Adapter)

P

(Open frame)

AC230V

~265V

AC230V

~265V

f

OSC(AVG)

= 67 kHz

f

OSC(AVG)

= 100 kHz

Off-Line PWM Controllers with Integrated Power MOSFET

STR-A6000 Series Data Sheet

General Descriptions

The STR-A6000 series are power ICs for switching

power supplies, incorporating a MOSFET and a current

Package

DIP8

mode PWM controller IC.

The low standby power is accomplished by the

automatic switching between the PWM operation in

normal operation and the burst-oscillation under light

load conditions. The product achieves high

cost-performance power supply systems with few

external components.

Not to Scale

Lineup

Features

• Current Mode Type PWM Control

• Brown-In and Brown-Out function

• Auto Standby Function

No Load Power Consumption < 25mW

• Operation Mode

Normal Operation ----------------------------- PWM Mode

Standby ---------------------------- Burst Oscillation Mode

• Random Swit ching Functi on

• Slope Compensation Function

• Leading Edge Blanking Function

• Bias Assist Function

• Audible Noise Suppression function during Standby

mode

• Protections

・Overcurrent Protection (OCP)*; Pulse-by-Pulse,

built-in compensation circuit to minimize OCP point

variation on AC input vol tage

・Overload Protection (OLP); auto-restart

・Overvoltage Protection (OVP); latched shutdown

・Thermal Shutdown Protection (TSD); latched shutdown

*STR-A60××H D has two types OCP

Typical Application Circuit

• Electrical Characteristics

V

(min.) f

DSS

STR-A605×M 650 V

STR-A607×M 800 V

STR-A605×H 650 V

STR-A606×H 700 V

STR-A606×HD 700 V 100 kHz

*STR-A60××HD has two types OCP

• MOSFET ON Resistance and Output Power, P

OUT

R

Products

STR-A6051M 3.95 Ω 18.5 W 14 W 31 W 21 W

STR-A6052M 2.8 Ω 22 W 17.5W 35 W 24.5 W

STR-A6053M 1.9 Ω 26 W 21W 40 W 28 W

STR-A6079M 19.2 Ω 8 W 6 W 13 W 9 W

STR-A6059H

STR-A6069HD

STR-A6061H

STR-A6061HD

STR-A6062H

STR-A6062HD

STR-A6063HD 2.3 Ω 25 W 20 W 40 W 28 W

* The output power is actual continues power that is measured at

50 °C ambient. The peak output power can be 120 to 140 % of the

value stat ed here. Core size, ON Duty, and thermal design affect

the output power. It may be less than the value stated here.

DS(ON)

(max.)

AC85

6Ω 17 W 11 W 30 W 19.5 W STR-A6069H

3.95Ω 20.5 W 15 W 35 W 23.5 W

2.8 Ω 23 W 18 W 38 W 26.5 W

Applications

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 1

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

• Low power AC/DC adapter

• White goods

• Auxiliary power supply

• OA, AV and industrial equipment

OSC(AVG)

67 kHz

100 kHz

OUT

OUT

*

AC85

Page 2

STR-A6000 Series

Contents

General Descriptions ------------------------------------------------------------------------------------------ 1

1. Absolute Maximum Ratings --------------------------------------------------------------------------- 3

2. Electrical Characteristics ------------------------------------------------------------------------------ 4

3. Performance Curves ------------------------------------------------------------------------------------ 6

3.1 Derating Curves ------------------------------------------------------------------------------- 6

3.2 Ambient Temperature versus Power Dissipation Curve ------------------------------ 6

3.3 MOSFET Safe Operating Area Curves --------------------------------------------------- 7

3.4 Transient Thermal Resistance Curves ---------------------------------------------------- 9

4. Functional Block Diagram --------------------------------------------------------------------------- 11

5. Pin Configuration De finitions ----------------------------------------------------------------------- 11

6. Typical Application Circuit -------------------------------------------------------------------------- 12

7. Package Outline ---------------------------------------------------------------------------------------- 13

8. Marking Diagram -------------------------------------------------------------------------------------- 13

9. Operational Description ------------------------------------------------------------------------------ 14

9.1 Startup Operation --------------------------------------------------------------------------- 14

9.2 Undervoltage Lockout (UVLO)----------------------------------------------------------- 15

9.3 Bias Assist Function ------------------------------------------------------------------------- 15

9.4 Constant Output Volt age Control -------------------------------------------------------- 15

9.5 Leading Edge Blanking Function -------------------------------------------------------- 16

9.6 Random Switching Function -------------------------------------------------------------- 16

9.7 Automatic Standby M ode Function ----------------------------------------------------- 16

9.8 Brown-In and Br own-Out Function ----------------------------------------------------- 17

9.8.1 DC Line Detection ------------------------------------------------------------------------ 17

9.8.2 AC Line Detection ------------------------------------------------------------------------ 18

9.9 Overcurrent Protection Function (OCP) ----------------------------------------------- 19

9.10 Overload Protection Function (OLP)---------------------------------------------------- 20

9.11 Overvoltage Protection (OVP) ------------------------------------------------------------ 20

9.12 Thermal Shutdown Function (TSD) ----------------------------------------------------- 20

10. Design Notes -------------------------------------------------------------------------------------------- 21

10.1 External Components----------------------------------------------------------------------- 21

10.2 PCB Trace Layout and Component Placement --------------------------------------- 22

11. Pattern Layout Example ----------------------------------------------------------------------------- 24

12. Reference Design of Power Supply ----------------------------------------------------------------- 25

Important Notes ---------------------------------------------------------------------------------------------- 27

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 2

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Page 3

STR-A6000 Series

A6059H / 69H

/ 69HD

A6051M / 61H

/ 61HD

A6052M / 62H

/ 62HD

A6059H / 69H

/ 69HD

MOSFET Power

Dissipation

Control Part Power

Dissipation

Operating Ambient

Temperature

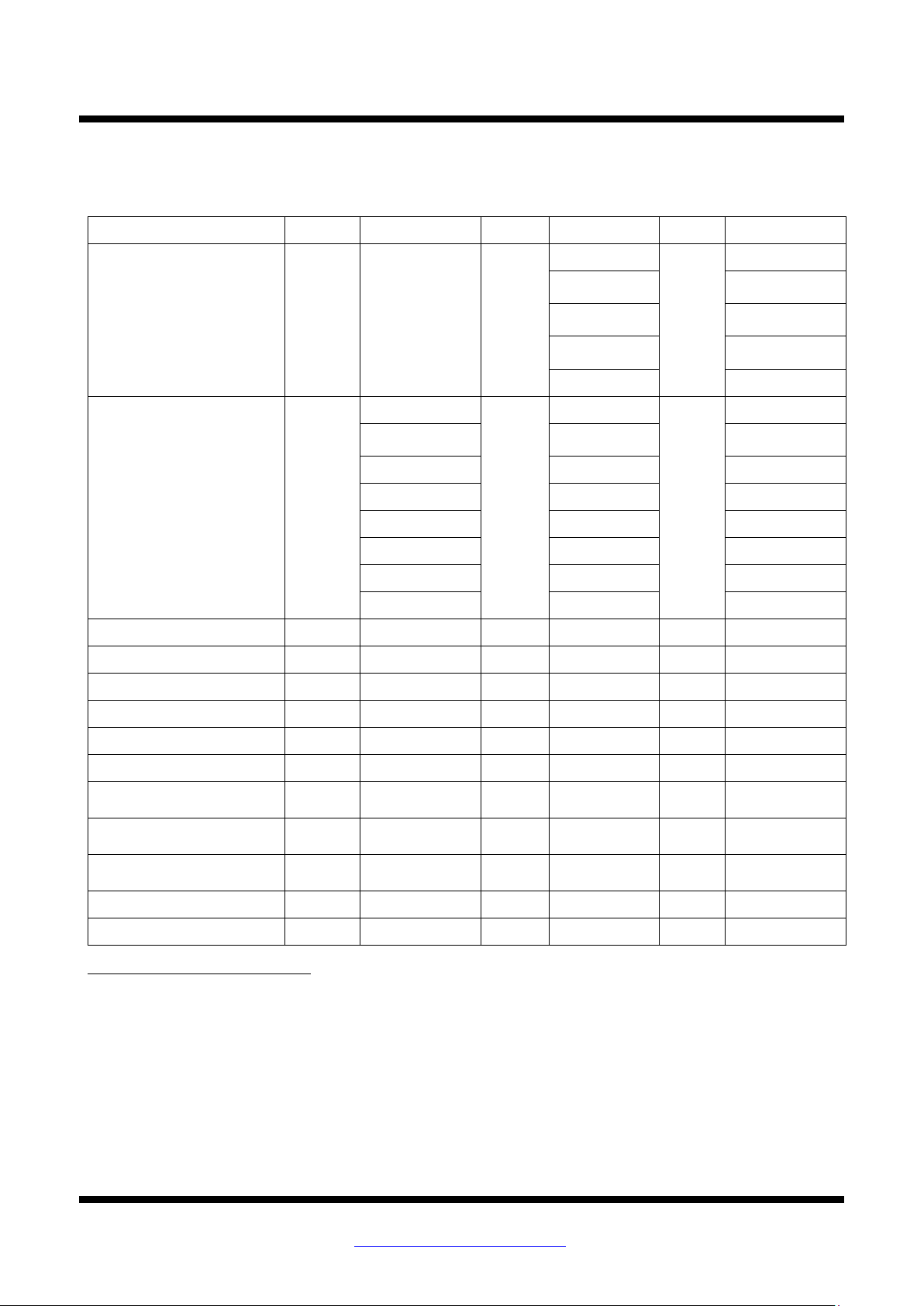

1. Absolute Maximum Ratings

Current polarities are defined as follo ws: current going into the IC (sinking) is po sitive current (+) ; and current coming

out of the IC (sourcing) is negative current (−).

Unless otherwise specified, T

Parameter

= 25 °C, 7 pin = 8 pin.

A

Symbol Test Conditions Pins Rating Units Remarks

1.2

1.8

Drain Peak Current

(1)

I

Single pulse 8 – 1

DPEAK

2.5

A

3.0

4.0

I

Avalanche Energy

S/OCP Pin Voltage

(2)(3)

=1.2A

LPEAK

I

=1.8A

LPEAK

I

=2A

LPEAK

I

=2A

LPEAK

I

LPEAK

I

LPEAK

I

LPEAK

I

LPEAK

=2.2A

=2.3A

=2.5A

=2.7A

8 – 1

1 − 3 −2 to 6 V

V

EAS

S/OCP

7

24

46

47

56

62

72

86

mJ

BR Pin Voltage VBR 2 − 3 −0.3 to 7 V

BR Pin Sink Curr ent IBR 2 − 3 1.0 mA

A6079M

A6053M / 63HD

A6079M

A6061H / 61HD

A6051M

A6062H / 62HD

A6052M

A6063HD

A6053M

FB/OLP Pin Voltage

FB/OLP Pin S ink Current

VCC Pin Voltage

(4)

VFB 4 − 3 −0.3 to 14 V

IFB 4 − 3 1.0 mA

VCC 5 − 3 32 V

PD1

(5)

8 – 1 1.35 W

PD2 5 – 3 1.2 W

(6)

Storage Temperature T

TOP — −20 to 125 °C

— −40 to 125 °C

stg

Channel Temperature Tch — 150 °C

(1)

Refer to 3.3 MOSFET Safe Operating Area Curves

(2)

Refer to Figure 3-2 Aval anche Energy Derating Coe fficient Curve

(3)

Single pulse, V

(4)

Refer to Figure 3-3 Ambient temperature versus power dissipation curve

(5)

When embedding this hybrid IC onto the printed circuit board (cupper area in a 15 mm × 15 mm)

(6)

The recommended internal frame temperature, TF, is 115°C (max.)

= 99 V, L = 20 mH

DD

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 3

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Page 4

STR-A6000 Series

Test

Conditions

Startup Circuit Operation

Voltage

= 13.5 V

Startup Cur rent Biasin g

Threshold Voltage

I

OCP Threshold Voltage at

Zero ON Duty

OCP Threshold Voltage at

36% ON Duty

OCP Threshold Voltage in

Leading Edge Blanking Time

FB/OLP pin Oscillation Stop

Threshold Voltage

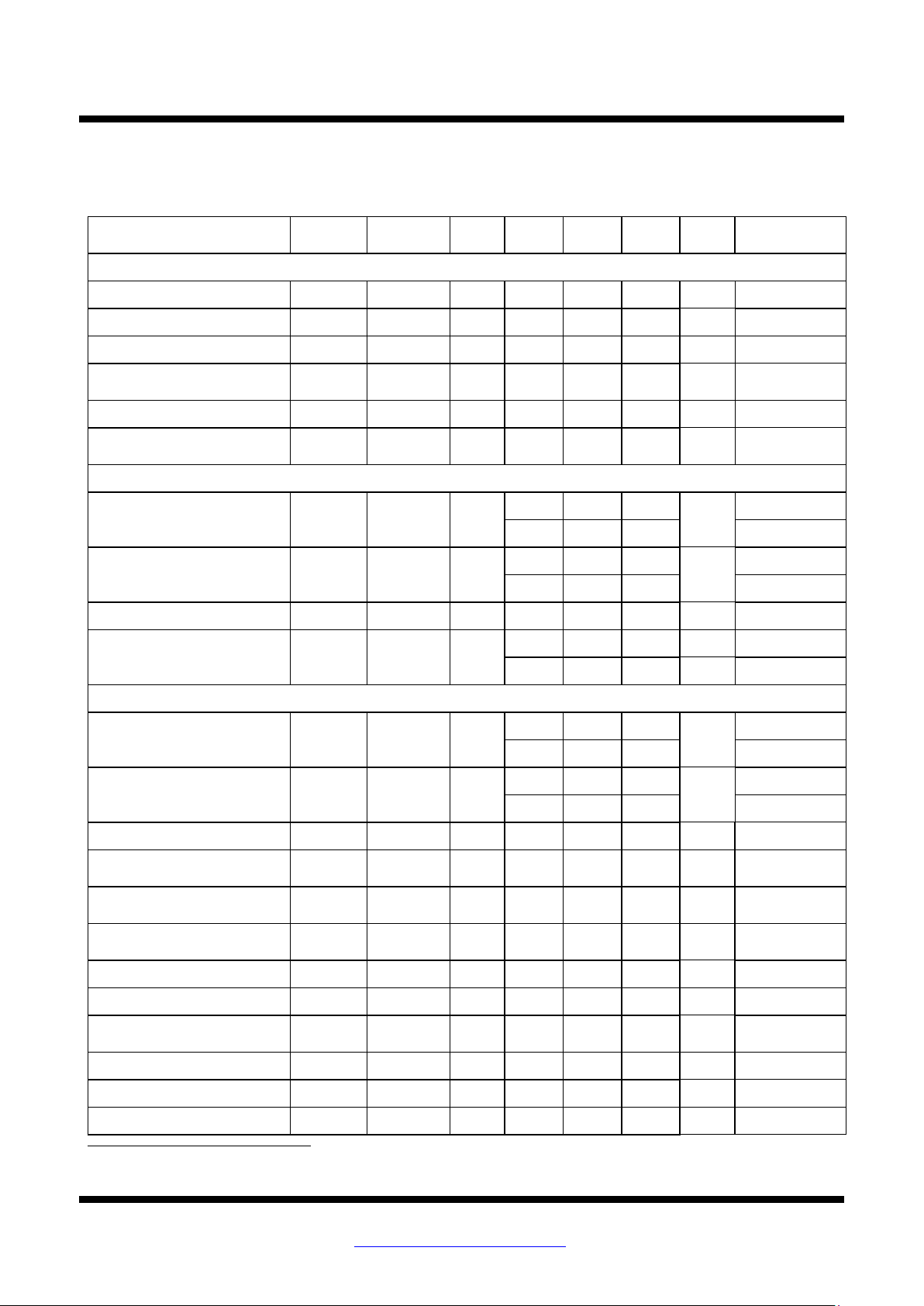

2. Electrical Characteristics

Current polarities are defined as follows: current going into the IC (sinking) is positive current (+); and current

coming out of the IC (sourcing) is negative current (−).

Unless otherwise specified, T

Parameter Symbol

= 25 °C, VCC = 18 V, 7 pin = 8 pin.

A

Pins Min. Typ. Max. Units Remarks

Power Supply Start up Operation

Operation Start Voltage V

Operation Stop Voltage

(1)

V

Circuit Current in Operation I

V

Startup Cur rent I

STARTUP

V

Normal Operation

Average Switching

Frequency

f

OSC(AVG)

Switching Frequency

Modulation Deviation

Maximum ON Duty D

Minimum O N Time t

ON(MIN)

Protection Function

CC(ON)

CC(OFF)

CC(ON)

ST(ON)

CC(BIAS)

V

V

= − 100 µA

CC

CC

CC

= 12 V

5 − 3 13.8 15.3 16.8 V

5 − 3 7.3 8.1 8.9 V

5 − 3 — — 2.5 mA

8 − 3 — 38 — V

5 − 3 − 3.7 − 2.5 − 1.5 mA

5 − 3 8.5 9.5 10.5 V

60 67 74

8 − 3

kHz

90 100 110

— 5 —

Δf 8 − 3

kHz

— 8 —

MAX

8 − 3 77 83 89 %

— 540 — ns

8 − 3

— 470 —

A60××M

A60××H / HD

A60××M

A60××H / HD

A60××M

A60××H / HD

Leading Edge Blanking Time tBW

OCP Compensation

Coefficient

OCP Compensation ON Duty

DPC

D

V

V

V

OCP(LEB)

Maximum Feedback Current I

Minimum Feedback Current I

FB(MAX)

FB(MIN)

V

OLP Threshold Voltage V

OLP Operation Current I

CC(OLP)

OLP Delay Time t

(1)

V

CC(BIAS)

> V

CC(OFF)

always.

—

— 280 —

— 20 —

— 340 —

—

— 33 —

DPC

OCP(L)

OCP(H)

V

= 32 V

CC

— — 36 — %

1 − 3 0.70 0.78 0.86 V

1 − 3 0.81 0.9 0.99 V

1 − 3 1.32 1.55 1.78 V

V

= 12 V

CC

V

= 12 V

CC

4 − 3 − 340 − 230 − 150 µA

4 − 3 − 30 − 15 − 7 µA

4 − 3 0.85 0.95 1.05 V

4 − 3 7.3 8.1 8.9 V

5 − 3 − 300 600 µA

— 54 68 82 ms

FB(STB)

FB(OLP)

OLP

A60××M

ns

A60××H / HD

A60××M

mV/μs

A60××H / HD

A60××HD

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 4

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

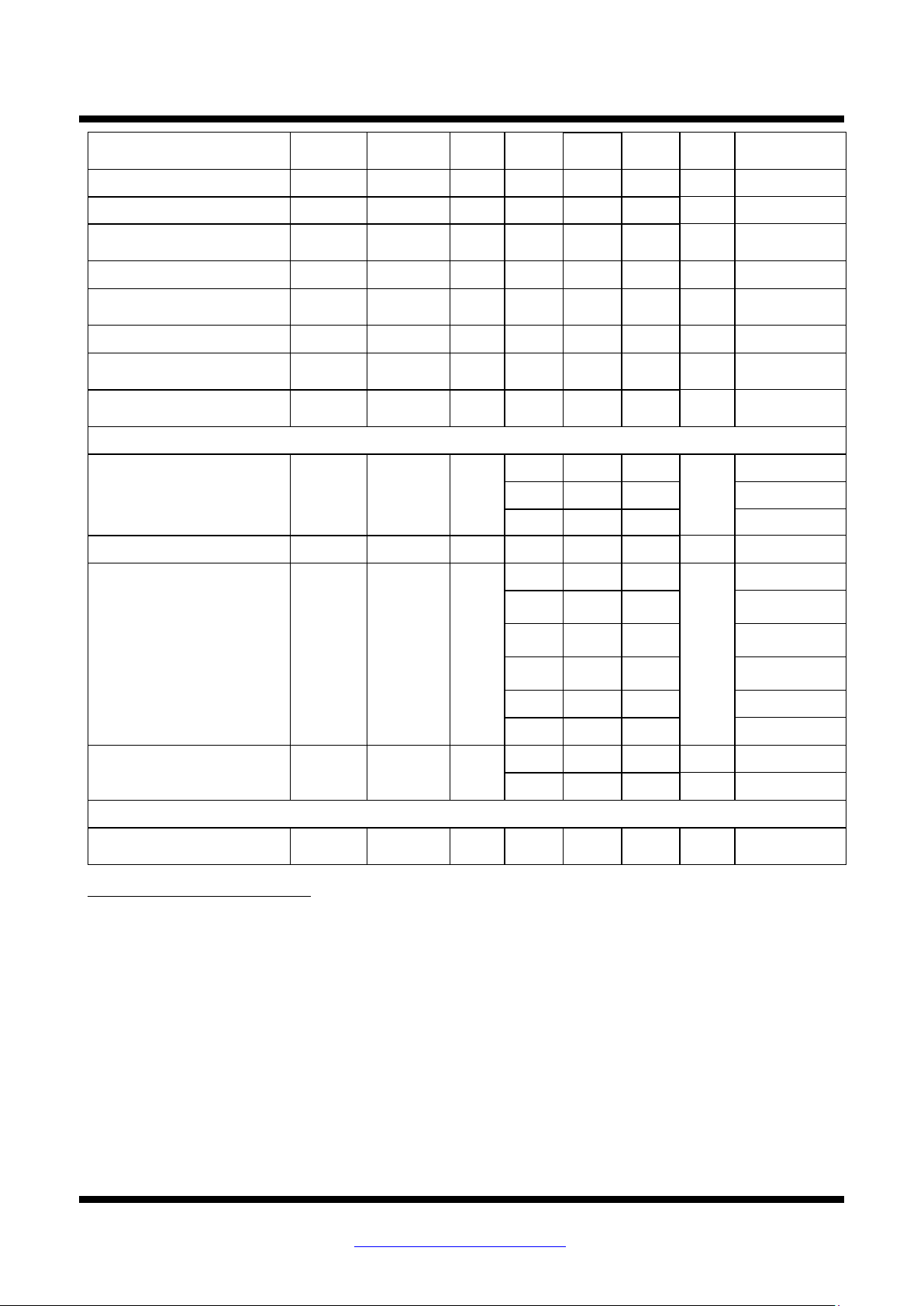

Page 5

STR-A6000 Series

Test

Conditions

Brown-Out Threshold

Voltage

BR Function Disabling

Threshold

Latch Circuits Holding

Current

Thermal Sh ut down Operat ing

Temperature

A6059H / 69H

/ 69HD

A6051M / 61H

/ 61HD

A6052M / 62H

/ 62HD

Channel to Case Thermal

Resistance

Parameter Symbol

FB/OLP Pin Clamp Voltage V

FB(CLAMP)

Brown-In Threshold V oltage V

V

BR Pin Clamp Voltage V

BR(CLAMP)

V

OVP Threshold Voltage V

(2)

I

CC(LATCH)

MOSFET

Drain-to-Source Breakdown

Voltage

Drain Leakage Current I

Pins Min. Typ. Max. Units Remarks

4 − 3 11 12.8 14 V

V

BR(IN)

BR(OUT)

BR(DIS)

CC(OVP)

T

— 135 — — °C

j(TSD)

= 32 V

CC

V

= 32 V

CC

V

= 32 V

CC

V

= 32 V

CC

V

= 9.5 V

CC

2 − 3 5.2 5.6 6 V

2 − 3 4.45 4.8 5.15 V

2 − 3 6 6.4 7 V

2 − 3 0.3 0.48 0.7 V

5 − 3 26 29 32 V

5 − 3 — 700 — μA

650 — —

8 – 1

V

DSS

700 — —

800 — — A607×

8 – 1 — — 300 μA

DSS

— — 19.2

V

A605×

A606×

A6079M

— — 6

On Resistance

R

DS(ON)

I

= 0.4A

DS

8 − 1

— — 3.95

Ω

— — 2.8

A6063HD

A6053M

A6053M

Switching Time

Thermal Resistance

(3)

— — 2.3

— — 1.9

— — 250 ns

tf 8 – 1

— — 400 ns

θ

ch-C

— — — 22 °C/W

(2)

A latch circuit is a circuit operated with Overvoltage Protection function (OVP) and/or Thermal Shutdown function

(TSD) in operation.

(3)

θ

is thermal resistance between channel and case. Case temperature (TC) is measured at the center of the case top

ch-C

surface.

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 5

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Page 6

STR-A6000 Series

Safe Operating Area

Temperature Derating Coefficient (%)

1.35W

3. Performance Curves

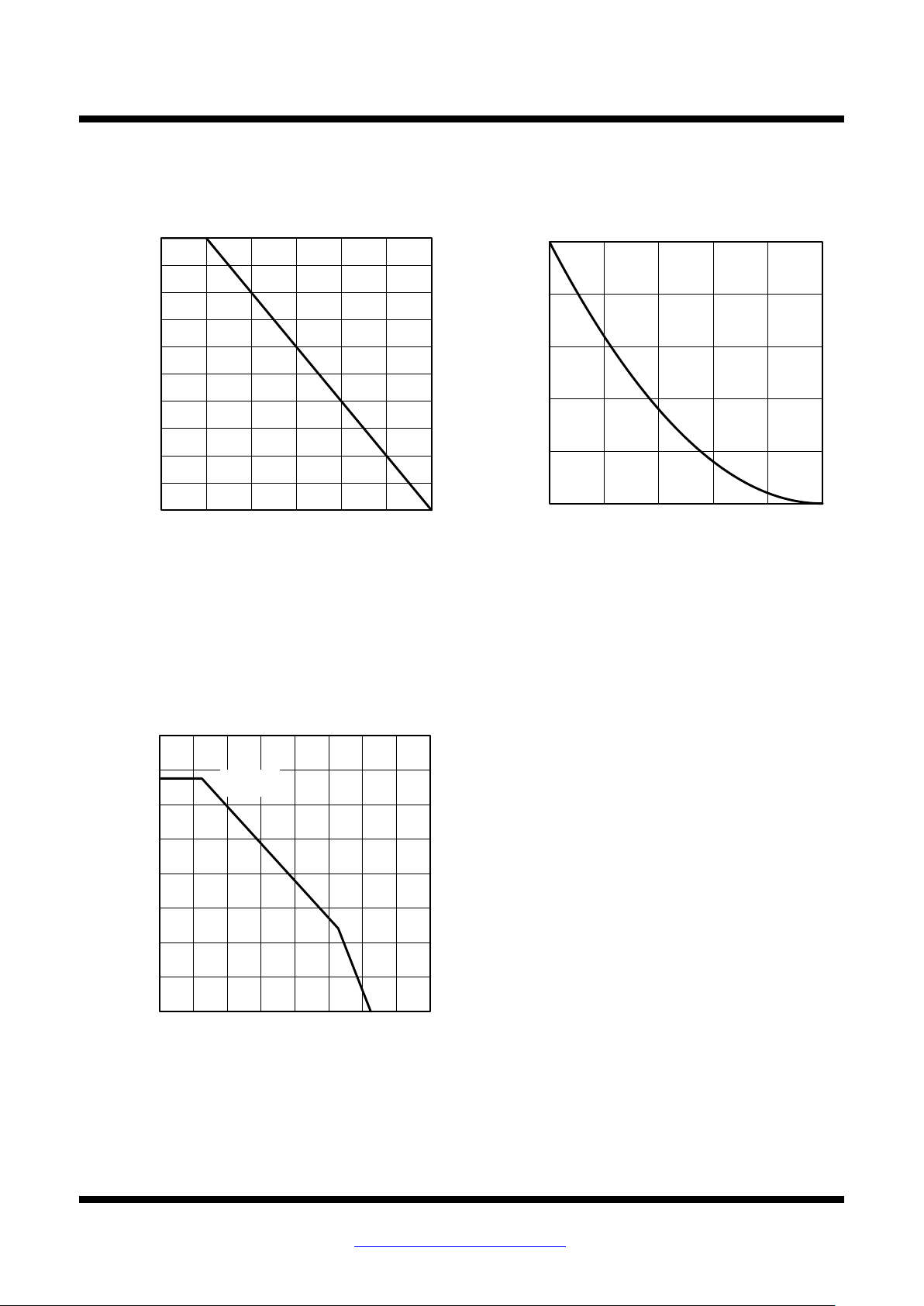

3.1 Derating Curves

100

80

60

40

20

0

0 25 50 75 100 125 150

Channel Temperature, Tch (°C)

Figure 3-1. SOA Temperature Derating Coefficient

Curve

100

80

60

40

20

Temperature Derating Coefficient (%)

AS

0

E

Figure 3-2. Avalanche Energy Derating Coefficient

25 50 75 100 125 150

Channel Temperature, Tch (°C)

Curve

3.2 Ambient Temperature versus Power Dissipation Curve

1.6

1.4

1.2

(W)

1

D1

0.8

0.6

0.4

Power Dissipation, P

0.2

0

0 20 40 60 80 100 120 140 160

Ambient Temperature, TA(°C )

Figure 3-3. Ambient Temperature Versus Power

Dissipation Curve

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 6

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Page 7

STR-A6000 Series

• STR-A6051M

• STR-A6052M

• STR-A6053M

• STR-A6079M

10

Drain Current, I

Drain-to-Source Voltage (V)

0.1ms

1ms

0.1ms

1ms

0.1ms

1ms

0.1ms

1ms

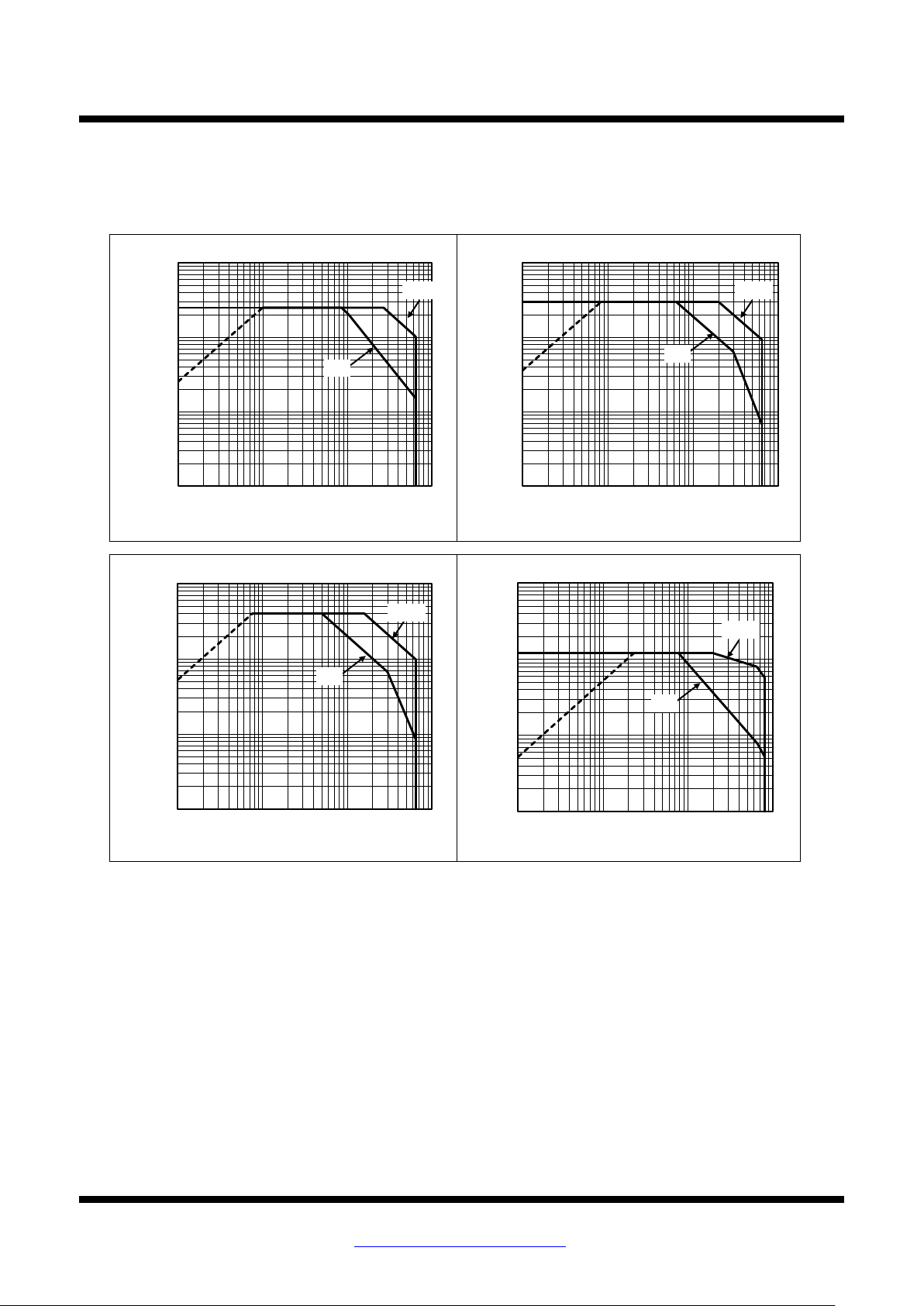

3.3 MOSFET Safe Operating Area Curves

When the IC is used, the safe operating area curve should be multiplied by the temperature derating coefficient

derived from Figure 3-1. The broken line in the safe operating area curve is the drain current curve limited by

on-resistance.

Unless otherwise specified, T

= 25 °C, Single pulse.

A

10

1

(A)

D

0.1

0.01

1 10 100 1000

10

1

(A)

D

0.1

Drain Current, I

1

(A)

D

0.1

Drain Current, I

0.01

1 10 100 1000

Drain-to-Source Voltage (V)

10

1

(A)

D

0.1

Drain Current, I

0.01

1 10 100 1000

Drain-to-Source Voltage (V)

0.01

1 10 100 1000

Drain-to-Source Voltage (V)

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 7

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Page 8

STR-A6000 Series

• STR-A6059H

• STR-A6061H / 61HD

• STR-A6062H / 62HD

• STR-A6063HD

• STR-A6069H / 69HD

10

Drain Current, I

0.1ms

1ms

0.1ms

1ms

0.1ms

1ms

0.1ms

1ms

Drain Current, I

D

(A)

Drain-to-Source Voltage (V)

10

1

(A)

D

0.1

0.01

1 10 100 1000

Drain-to-Source Voltage (V)

10

1

(A)

D

0.1

Drain Current, I

1

(A)

D

0.1

Drain Current, I

0.01

1 10 100 1000

Drain-to-Source Voltage (V)

0.01

1 10 100 1000

Drain-to-Source Voltage (V)

10

1

(A)

D

0.1

Drain Current, I

0.01

1 10 100 1000

Drain-to-Source Voltage (V)

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 8

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Page 9

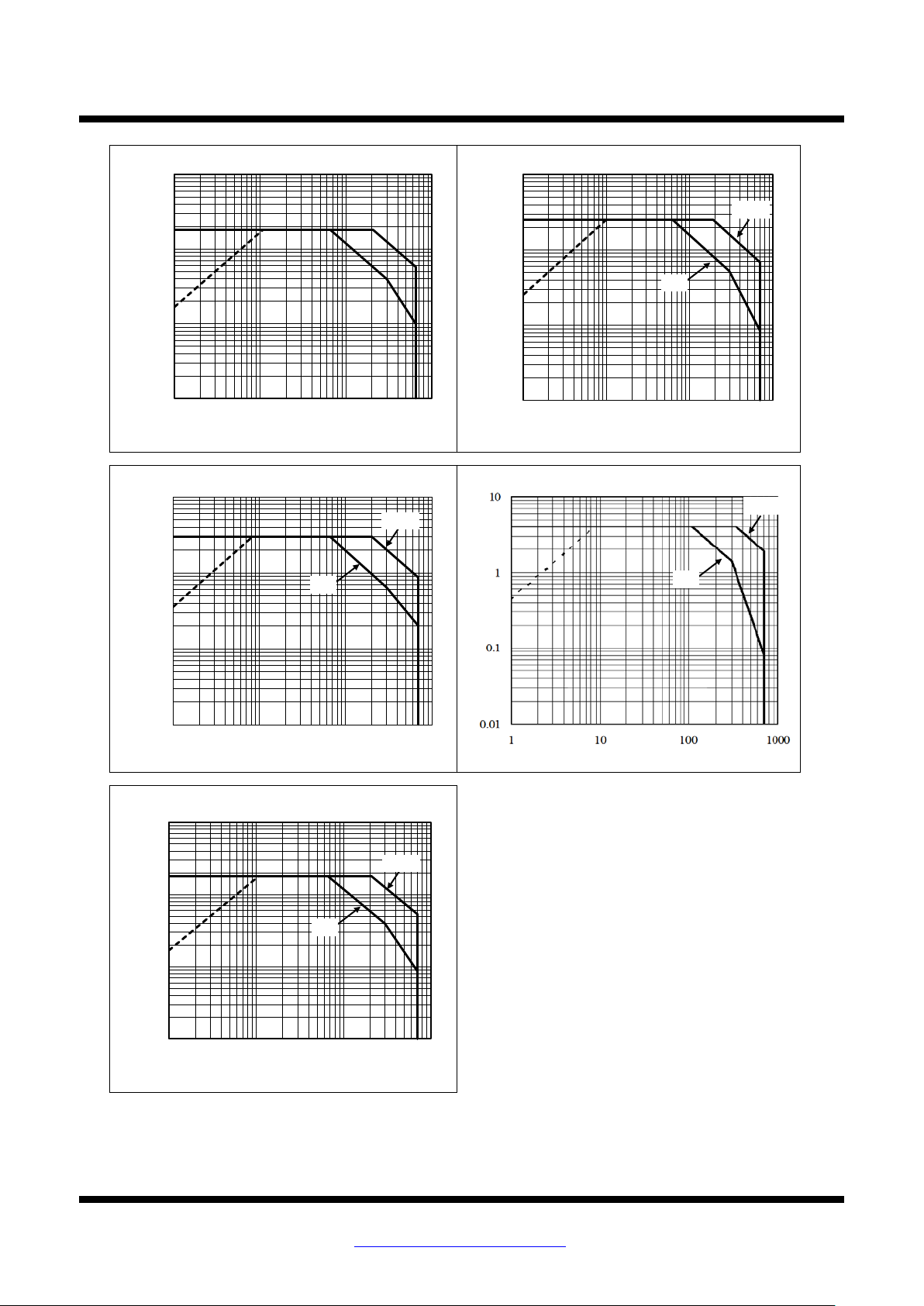

STR-A6000 Series

• STR-A6051M / 61H / 61HD

• STR-A6052M / 62H / 62HD

• STR-A6053M

Transient Thermal Resistance,

Time (s )

1µ 10µ 100µ 1m 10m 100m

1µ 10µ 100µ 1m 10m 100m

1µ 10µ 100µ 1m 10m 100m

10

Transient Thermal Resistance,

3.4 Transient Thermal Resistance Curves

10

1

0.1

θch-c (°C/W)

0.01

1

0.1

θch-c (°C/W)

0.01

10

1

0.1

θch-c (°C/W)

Transient Thermal Resistance,

0.01

Time (s)

Time (s )

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 9

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Page 10

STR-A6000 Series

• STR-A6059M / 69H / 69HD

• STR-A6079M

• STR-A6063HD

10

Transient Thermal Resistance

Time (s )

100n 1µ 10µ 100µ 1m 10m 100m

1µ 10µ 100µ 1m 10m 100m

1µ 10µ 100µ 1m 10m 100m

10

Transient Thermal Resistance

1

0.1

θch-c (°C/W)

0.01

10

1

0.1

θch-c (°C/W)

0.01

Transient Thermal Resistance

1

0.1

θch-c (°C/W)

0.01

0.001

Time (s )

Time (s)

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 10

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Page 11

STR-A6000 Series

UVLO

OVP

TSD

REG

Brown-in

Brown-out

PWM OSC

OLP

Feedback

control

Slope

compensation

LEB

Drain peak current

compensation

OCP

Startup

DRV

VREG

6.4V

12.8V

7V VCC

VCC

BR

FB/OLP

D/ST

S/OCP

GND

7,8

1

3

4

2

5

SRQ

BD_STR-A6000_R1

1

5

6

7

8

4

3

2

S/OCP

BR

GND

FB/OLP

VCC

D/ST

D/ST

MOSFET source and overcurrent protection

(OCP) signal input

Constant voltage control signal input and over

load protection (OLP) signal input

Power supply voltage input for control part and

overvoltage protection (OVP) signal input

4. Functional Block Diagram

5. Pin Configuration Definitions

Pin Name Descriptions

1 S/OCP

2 BR Brown-In and Brown-Out d e te c tion voltage input

3 GND Ground

4 FB /OLP

5 VCC

6 − (Pin removed)

7

8

D/ST MOSFET drain and startup current input

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 11

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Page 12

STR-A6000 Series

VAC

C1

C6

R1

D1

BR1

R2

C2

T1

D

P

PC1

C3

R

OCP

C

Y

CRD clamp snubber

C5

C(RC)

damper snubber

1 2 3 4

D/ST D/STBRNC

S/OCP FB/OLP

GND

VCC

8 7

5

STR-A6000

U1

D2

C4

R

C

R

B

R

A

D51

C51

R51

R52

U51

R54

R56

C52

S

PC1

R53

R55

L51

C53

VOUT

(+)

TC_STR-A6000_2_R1

(-)

VAC

C1

C6

R1

D1

BR1

R2

C2

T1

D

P

PC1

C3

R

OCP

C

Y

CRD clamp snubber

C5

C(RC)

damper snubber

1 2 3 4

D/ST D/STBRNC

S/OCP FB/OLP

GND

VCC

8 7

5

STR-A6000

U1

D2

D51

C51

R51

R52

U51

R54

R56

C52

S

PC1

R53

R55

L51

C53

VOUT

TC_STR-A6000_3_R1

(+)

(-)

6. Typical Application Circuit

The following drawings show circuits enabled and disabled the Brown-In/Brown-Out f unct i o n.

The PCB traces D/ST pins should be as wide as possible, in order to enhance thermal dissipation.

In applications having a power supply specified such that D/ST pin has large transient surge voltages, a clamp

snubber circuit of a capacitor-resistor-diode (CRD) combination should be added on the primary winding P, or a

damper snubber circuit of a capacitor (C) or a resistor-capacitor (RC) combination should be added between the D/ST

pin and the S/OCP pin.

Figure 6-1. Typical Application Circuit (enabled Brown-In/Brown-Out function, DC line detection)

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 12

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Figure 6-2. Typical Application Circuit (disabled Brown-In/Brown-Out function)

Page 13

STR-A6000 Series

1

8

Part Nu mber

A 6 0 × × ×

S K Y M D

Control Number

STR-A60××M

STR-A60××H

Lot Numbe r:

Y is the last digi t of the year of manufactu re (0 to 9)

M is the m onth of the ye a r (1 to 9, O, N, or D)

D is a period of da ys:

1: the first 10 days of the month (1st to 10th)

2: the second 10 days of the month (11th to 20th)

3: the last 10–11 days of the m onth (21st to 31st)

1

8

A 6 0 × × H

S K Y M D D

STR-A60××HD

Part Nu mber

Control Number

Lot Numbe r:

Y is the last digi t of the year of manufactu re (0 to 9)

M is the m onth of the ye a r (1 to 9, O, N, or D)

D is a period of da ys:

1: the first 10 days of the month (1st to 10th)

2: the second 10 days of the month (11th to 20th)

3: the last 10–11 days of the m onth (21st to 31st)

7. Package Outline

• DIP8 (The following show a representative type of DIP8.)

NOTES:

1) dimensions in millimeters

2) Pb-free (RoHS compliant)

8. Marking Diagram

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 13

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Page 14

STR-A6000 Series

.)(minV

V.)(max

V

)

OVP(CC

CC)BIAS

(CC

<<

<<

CC

V

STRATUP

)INT(CC)ON(CC

START

I

VV

×C2

t

-

=

VAC

C

1

D

2

R2

C2

T1

D

P

BR1

VCC

GND

D/ST

7, 8

3

5

U1

V

D

BR

2

V

CC

(ON)

VCC pin

voltage

Drain current

,

I

D

t

START

V

CC(

ON)

VCC pin

voltage

Drain current,

I

D

t

START

BR pin

voltage

V

BR(IN)

V

CC(OFF)

9. Operational Description

All of the parameter values used in these descriptions

are typical values, unless they are specified as minimum

or maximum.

Current polarities are defined as follows: current

going into the IC (sinking) is positive current (+); and

current coming out of the IC (sourcing) is negative

current (−).

9.1 Startup Operation

Figure 9-1 shows the circuit around IC. Figure 9-2

shows the start up operation.

The IC incorporates the startup circuit. T he circuit is

connected to D/ST pin. When D/ST pin voltage reaches

to Startup Circuit Operatio n Voltage V

startup circuit starts operation.

During the startup process, the constant current,

I

VCC pin voltage increases to V

= − 2.5 mA, charges C2 at VCC pin. When

STARTUP

CC(ON)

control circuit starts operation.

During the IC operation, the voltage rectified the

auxiliary wi nding voltage , V

, of Figure 9-1 becomes a

D

power source to the VCC pin. After switching ope ration

begins, the startup circuit turn s off automatically so that

its current consumption becomes zero.

The approxi mate val ue of a uxili ar y windin g volt age i s

about 15 V to 20 V, taking ac count of t he wind ing t urns

of D winding so that VCC pin voltage becomes

Equation (1) within the spec ifica tion of i nput a nd out put

voltage variation of power supply.

= 38 V, the

ST(ON)

= 15.3 V, the

With Brown-I n / Brown-Out function

When BR pin vo ltage is mor e than V

and less than V

= 5.6 V, the Bias Assist Functio n

BR(IN)

BR(DIS)

= 0.48 V

(refer to Section 9.3) is disabled. Thus, VCC pin

voltage repeats increasing to V

V

becomes V

( shown in Figure 9-3). When BR pi n voltage

CC(OFF)

or more, the IC starts switching

BR(IN)

and decreasing to

CC(ON)

operation.

Figure 9-1. VCC Pin Peripheral Circuit

(Without Brown-In / Brown-Out)

(1)

⇒10.5 (V)

26 (V)

Figure 9-2. Startup Operation

The oscillation start timing of IC depends on

(Without Brown-In / Brown-Out)

Brown-In / Brown-Out function (refer to Section 9.8).

Without Brown-In / Brown-Out function (BR pin

voltage is V

When VCC pin voltage increases to V

= 0.48 V or less)

BR(DIS)

CC(ON)

, the IC

starts switching operation, As shown in Figure 9-2.

The startup time of IC is determined by C2 capacitor

value. The approximate startup time t

START

(shown i n

Figure 9-2) is calcula te d as follows:

(2)

where,

t

V

START

CC(INT)

: Startup time of IC (s)

: Initial voltage on VCC pin (V)

Figure 9-3. Startup Operation

(With Brown-In / Brown-Out)

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 14

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Page 15

STR-A6000 Series

Circuit current, I

CC

I

CC

(

ON

)

V

CC

(

OFF

)

V

CC(ON

)

VCC pin

voltage

StartStop

IC starts operation

VCC pin

voltage

V

CC(

ON)

V

CC(BIAS

)

V

CC(OFF

)

Startup failure

Startup success

Target operating

voltage

Time

Bias assist period

Increase with rising of

output voltage

PC1

C3

R

OCP

1 3 4

S/OCP

FB/OLP

GND

U1

I

FB

V

ROCP

V

SC

FB Comparator

Drain current

,

I

D

+

-

Voltage on both

sides of R

OCP

V

ROCP

Target voltage including

Slope Compensation

9.2 Undervoltage Lockout (UVLO)

Figure 9-4 shows the rela tionship of VCC pin voltage

and circuit current I

to V

= 8.1 V, the control circuit stops operation by

CC(OFF)

. When VCC pin voltage decreases

CC

UVLO (Undervoltage Lockout) circuit, and reverts to

the state before startup.

Figure 9-4. Relationship between

VCC Pin Volta ge and I

CC

9.3 Bias Assist Function

Figure 9-5 shows VCC pin voltage behavior during

the startup period.

After VCC pin voltage increases to V

at startup, the IC starts the operation. Then circuit

current increases and VCC pin voltage decreases. At the

same time, the a u xili ary winding vol ta ge V

proportion to output voltage. These are all balanced to

produce VCC pin voltage.

= 15.3 V

CC(ON)

increase s i n

D

pin voltage decreases to the startup current threshold

biasing voltage, V

= 9.5 V. While the Bias Assist

CC(BIAS)

function is activated, any decrease of the VCC pin

voltage is counteracted by providing the startup current,

I

, from the startup circuit. Thus, the VCC pin

STARTUP

voltage is kept almost constan t.

By the Bias Assist function, the value of C2 is

allowed to be small and the startup ti me beco mes shorter.

Also, because the increase of VCC pin voltage becomes

faster when the output runs with excess voltage, the

response time of the OVP function becomes shorter.

It is necessary to check and adjust the startup process

based on actual operation in the application, so that poor

starting conditions may be avoid e d.

9.4 Constant Output Voltage Control

The IC achieves the constant voltage control of the

power suppl y output by usin g the current-mode control

method, which enhances the response speed and

provides the stable operation.

The FB/OLP pin voltage is internally added the slo pe

compensation at the feedback control (refer to Section 4

Functional Block Dia gram), a nd the tar get volta ge, V

is generated. The IC compares the voltage, V

ROCP

current detection resistor with the target volta ge, V

the internal FB comparator, and controls the peak value

of V

so that it gets close to VSC, as sho wn in Figure

ROCP

9-6 and Figure 9-7.

SC

, of a

, by

SC

,

Figure 9-6. FB/OLP Pin Peripheral Circuit

Figure 9-5. VCC Pin Voltage during Startup Period

The surge voltage is induced at output winding at

turning off a power MOSFET. When the output load is

light at startup, the surge voltage causes the unexpected

feedback control. This results the lowering of the output

power and VC C pi n vol ta ge. When t he V CC p in vo lta ge

decreases to V

operation and a startup failure occurs. In order to prevent

this, the Bias Assi st function i s activate d when the VCC

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 15

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

CC(OFF)

= 8.1 V, the IC stops switching

Figure 9-7. Drain Current, I

Operation in Steady Operation

, and FB Comparator

D

Page 16

STR-A6000 Series

t

ON1

Target voltage

wi t hout slope c ompensation

t

ON2

T T T

Normal

operation

Standby

operation

Normal

operation

Burst oscillation

Output current,

I

OUT

Drain current,

I

D

Below several kHz

• Light load conditions

When load conditions become lighter, the output

voltage, V

, increases. Thus, the feedback current

OUT

from the error amplifier on the secondary-side also

increases. The feedback current is sunk at the FB/OLP

pin, transferred through a photo-coupler, PC1, and the

FB/OLP pin voltage decreases. Thus, V

and the peak value of V

and the peak drain current of I

is contro lled to be low,

ROCP

decreases.

D

decreases,

SC

This control prevents the output voltage from

increasing.

• Heavy load conditions

When load conditions become greater, the IC

performs the inverse operation to that described above.

Thus, V

increases and the peak drain current of ID

SC

increases.

This control prevents the output voltage from

decreasing.

In the current mode control method, when the drain

current waveform becomes trapezoidal in continuous

operating mode, even if the peak current level set by the

target voltage is constant, the on-time fluctuates based

on the initial value of the drain current.

This result s in the on-time fluctua ting in multiples of

the funda mental op erat ing fr eque ncy as shown i n Figure

9-8. This is called the subharmonics phenomenon.

In order to avoid this, the IC incorporates the Slope

Compensation function. Because the target voltage is

added a down-slope compensation signal, which reduces

the peak drain current as the on-duty gets wider relative

to the FB/OLP pin signal to compensate V

, the

SC

subharmonics phenomenon is suppressed.

Even if subharmonic oscillations occur when the IC

has some excess supply being out of feedback control,

such as during startup and load shorted, this does not

affect performance of normal operation.

for the constant voltage control of o utput.

In peak-current-mode control method, there is a case

that the power MOSFET turns off due to unexpected

response of FB comparator or overcurrent protection

circuit (OCP) to the steep s urge current in tur ning on a

power MOSFET.

In order to p revent this response to the surge voltag e

in turning-on the power MOSFET, the Leading Edge

Blanking, t

and STR-A60××HD for 280 ns) is built-in. During t

(STR-A60××H for 340 ns, STR-A60××H

BW

BW

,

the OCP thre shold voltage be comes about 1.7 V whic h

is higher than the normal OCP threshold voltage (refer

to Section 9.9).

9.6 Random Switching Function

The IC modulates its switching frequency randomly

by superp osing the mod ulati ng freq uenc y on f

OSC(AVG)

in

normal operation. This function reduces the conduction

noise compared to others without this function, and

simplifies noise filtering of the input lines of power

supply.

9.7 Automatic Standby Mode Function

Automatic standby mode is activated automatically

when the drain current, I

conditions, at which I

maximum drain current (it is in the OCP state). The

operation mode becomes burst oscillation, as shown in

Figure 9-9. Burst oscillation mode reduces switching

losses and improves power supply efficiency because of

periodic non-switching intervals.

, reduces under light load

D

i s less tha n 15 % to 20 % of the

D

Figure 9-9. Auto Standby Mode Timing

Figure 9-8. Drain Current, I

in Subharmonic Oscillation

, Waveform

D

Generally, to improve efficiency under light load

conditions, the frequenc y of the burst oscillation mode

becomes just a few kilohertz. Because the IC suppresses

the peak dra i n c ur r ent well during b urs t oscillation mode,

audible noises can be reduced.

9.5 Leading Edge Blanking Function

The IC uses the peak-current-mode control method

If the VCC pin voltage decreases to V

during the transition to the burst oscillation mode, the

Bias Assist function is activated and stabilizes the

CC(BIAS)

= 9.5 V

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 16

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Page 17

STR-A6000 Series

BR Pi n Voltage

V

BR(IN)

V

BR(OUT)

t

OLP

Dr a i n C ur r e n t,

I

D

V

DC

U1

BR

2

C4

R

C

GND

3

R

B

R

A

V

AC

BR1

C1

Standby mode operation, because I

STARTUP

is provided to

the VCC pin so that the VCC pin voltage does not

decrease to V

CC(OFF)

.

However, if the Bias Assist function is always

activated during steady-state operation including

standby mode, the power loss increases. Therefore, the

VCC pin voltage should be more than V

CC(BIAS)

, for

example, by adjusting the turns ratio of the auxiliary

winding and secondary winding and/or reducing the

value of R2 in Figure 10-2 (refer to Section 10.1

Peripheral Components for a detail of R2).

9.8 Brown-In and Brown-Out Function

This function stops switching operation when it

detects low input line voltage, and thus prevents

excessive input current and overheating.

This function turns on and off switching operation

according t o the BR pin vol tage detectin g the AC input

voltage. When BR pin voltage becomes more than

V

and the drai n currnet.

pin voltage is V

voltage decreases from steady-state and the BR pin

voltage falls to V

Delay Time, t

operation. When the AC input vo ltage incr eases and the

BR pin voltage reaches V

operating state that the VCC pin voltage is V

more, the IC starts switching ope ration.

unnecessary, connect the BR pin trace to the GND pin

trace so that the BR pin voltage is V

= 0.48 V, this function is activated.

BR(DIS)

Figure 9-10 sho ws waveforms of t he BR pin voltage

Even if the IC is in the operating state that the VCC

or more, when the AC input

CC(OFF)

= 4.8 V or less for the OLP

BR(OUT)

= 68 ms, the IC stops switching

OLP

= 5.6 V or more in the

BR(IN)

CC(OFF)

or

In case the Brown-In and Brown-Out function is

or less.

BR(DIS)

becomes t

= 68 ms or more, the IC stops switching

OLP

operation.

● STR-A60××HD:

When the BR pin voltage falls to V

less for t

= 68 ms, the IC stops switching operation.

OLP

BR(OUT)

= 4.8 V or

There are two types of detection method as follows:

9.8.1 DC Line Detection

Figure 9-11 shows BR pin peripheral circuit of DC

line detection. There is a ripple voltage o n C1 occurring

at a half period of AC cycle. In order to detect each peak

of the ripple voltage, the time constant of R

should be shorter than a half period of AC cycle.

Since the cycle of the ripple voltage is shorter than

, the switching operation does not s top when only the

t

OLP

bottom part of the ripple voltage becomes lower than

BR(OUT)

.

V

Thus it minimizes the influence of load conditions on

the voltage detection.

Figure 9-11. DC Line Detection

The components around BR pin:

and C4

C

・ R

and RB are a few megohms. Because of high

A

voltage applied and high resistance, it is

recommended to select a resistor designed against

electromigration or use a combination of resistors

in series for that to reduce each applied voltage,

according t o the requirement of the application.

is a few hundred kilohms

・ R

Figure 9-10. BR Pin Voltage and Drain Current

Waveforms

C

・ C4 is 470 pF to 2200 pF for high frequency noise

reduction

Neglecting the effect of both input resistance and

During burst oscillation mode, this funct ion operates

as follows:

● STR-A60××M and STR-A60××H:

This function is disabled during switching operation

stop period in burst oscillation mode. When the BR

pin voltage falls to V

or less in burs t oscillation

BR(OUT)

forward voltage of rectifier diode, the reference value of

C1 voltage when Brown-In and Bro wn-Out function is

activated is calculated as follows:

mode and the sum of switching operation period

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 17

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Page 18

STR-A6000 Series

+

+×=

C

BA

)TH(BR)OP(DC

R

RR

1VV

Value

(Typ.)

)OP(DCRMS

)OP(AC

V

2

1

V ×=

V

DC

U1

BR

2

C

4

R

C

GND

3

R

B

R

A

V

AC

BR1

C1

VCC

3

R

S

+

+××

π

=

C

BA

)TH

(

BRRMS

)OP

(

AC

R

RR

1V

2

V

(3)

where,

: C1 voltage when Brown-In and

V

DC(OP)

Brown-Out function is activated

: Any one of threshold voltage of BR pin

V

BR(TH)

(see Table 9-1)

Table 9-1. BR Pin Threshold Voltage

Parameter Symbol

Brown-In Threshold V oltage V

Brown-Out Threshold Voltage V

V

can be expressed as the effective value of AC

DC(OP)

BR(IN)

BR(OUT)

5.6 V

4.8 V

input voltage us in g Eq uat ion (4).

R

, RB, RC and C4 should be selected based on actual

A

(4)

operation in the application.

9.8.2 AC Line Detection

Figure 9-12 shows BR pin peripheral circuit of AC

line detection. In order to detec t the AC input voltage ,

the time constant of R

period of AC cycle. Thus the response of BR pin

detection becomes slow compared with the DC line

detection.

This method detects the AC input voltage, and thus it

minimizes the influence from load conditions. Also, this

method is free of influence from C1 charging and

discharging time, the latch mode can be released

quickly*

and C4 should be longer than the

C

* High-Speed Latch Release

When Overvoltage Protection function (OVP) or

Thermal Shutdown function (TSD) are activated,

the IC stops switching operation in latch mode.

Releasing the latch mode is done by decreasing the

VCC pin voltage below V

the BR pin voltage below V

or by decreasing

CC(OFF)

.

BR(OUT)

In case of the DC line detection or without

Brown-in / Brown-Out function, the release time

depends on discharge time of C1 and takes longer

time until VCC pin voltage decreases to release

voltage.

In case of the AC line detection, BR pin voltage is

decreased quickly when AC input volt age, V

AC

, is

turned off, and thus the latch mode is quickly

released.

The components around BR pin:

・ R

and RB are a few megohms. Because of high

A

voltage applied and high resistance, it is

recommended to select a resistor designed against

electromigration or use a combination of resistors

in series for that to reduce each applied voltage,

according t o the requirement of the application.

is a few hundred kilohms

・ R

C

・ R

must be adjusted so that the BR pin voltage is

S

more than V

voltage is V

CC(OFF)

= 0.48 V when the VCC pin

BR(DIS)

= 8.1 V

・ C4 is 0.22 μF to 1 μF for averaging AC input

voltage and high frequenc y no ise red uct io n.

Neglecting the effect of input resistance is zero, the

reference effective value of AC input voltage when

Brown-In and Brown-Out function is activated is

calculated as follows:

(5)

where,

V

AC(OP)RMS

:The effective value of AC input voltage

when Brown-In a nd B ro wn-Out function

is activated

:Any one of threshold voltage of B R pin

V

BR(TH)

(see Table 9-1)

, RB, RC and C4 should be selected based on actual

R

A

operation in the application.

Figure 9-12. AC Line Detection

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 18

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Page 19

STR-A6000 Series

Surge pulse voltage width at turning on

t

BW

V

OCP

’

V

OCP(LEB)

(STR-A60××HD)

C1

T1

D51

R

OCP

U1

C51

C(RC)

Damper snubber

7,8

D/ST

S/OCP

1

C(RC)

Damper snubber

ON Duty (%)

D

DPC

V

OCP(L)

0

D

MAX

100

V

OCP(H)

0.5

1.0

50

OCP Threshold Voltage after

compensation, V

OCP

'

ONTime

DPCV

'V

)L(OCP

OCP

×+

=

)AVG(OSC

)

L(OCP

f

ONDuty

DPC

V ×+=

9.9 Overcurrent Protection Function

(OCP)

Overcurrent Protection Function (OCP) detects each

drain peak current level of a power MOSFET on

pulse-by-pulse basis, and limits the output power when

the current level reaches to OCP threshold voltage.

During Leading Edge Blanking Time, the operation of

OCP is different depending on the products as follows.

● STR-A60××HD:

During Leading Edge Blanking Time, the OCP

threshold voltage becomes V

is higher than the normal OCP threshold voltage as

shown in Figure 9-13. Changing to this threshold

voltage prevents the IC from respondi ng to the surge

voltage in turning-on the power MOSFET. This

function operates as protection at the condition such

as output windings shorted or unusual withstand

voltage of secondary-side rectifier diodes.

● STR-A60××M and STR-A60××H:

OCP is disabled during Leading Edge Blanking Time.

When power MOSFET turns on, the surge voltage

width of S/OCP pin should be less than t

Figure 9-13. In order to pr event surge voltage, pay extra

attention to R

trace layout (refer to Section 10.2).

OCP

In addition, if a C (RC) damper snubber of Figure

9-14 is used, reduce the capacitor value of damper

snubber.

= 1.55 V which

OCP(LEB)

, as sho wn in

BW

Figure 9-14. Damper Snubber

< Input Compensatio n Function >

ICs with PWM co ntr o l usual l y ha ve s o me pr o p aga tio n

delay time. The steeper the slope of the actual drain

current at a high AC input voltage is, the larger the

detection voltage of actual drain peak current is,

compared to V

. Thus, the peak current has some

OCP

variation depending on the AC input voltage in OCP

state. In order to reduce the variation of peak current in

OCP state, the IC incorporates a built-in Input

Compensatio n f unc t io n.

The Input Compensation Function is the function of

correction of OCP threshold voltage depending with AC

input voltage , as shown in Figure 9-15. When AC input

voltage is lo w (ON Duty is broad), the OCP threshold

voltage is controlled to become high. The difference of

peak drain current become small compared with the case

where the AC i np ut volt age is hi gh (O N D uty is na rr ow) .

The compensation signal depends on ON Duty. The

relation between the ON Duty and the OCP threshold

voltage after compensation V

' is expressed as

OCP

Equation (6). When ON Duty is broade r than 36 %, the

' becomes a constant value V

V

OCP

OCP(H)

= 0.9 V

Figure 9-13. S/OCP Pin Voltage

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 19

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Figure 9-15. Relationship between ON Duty and Drain

Current Limit after Compensation

(6)

where,

: OCP Thre shold Voltage at Zero ON Duty

V

OCP(L)

DPC: OCP Compensat i on Coefficient

ONTime: On-time of power MOSFET

ONDuty: On duty of power MOSFET

f

OSC(AVG)

: Average PWM Switching Frequency

Page 20

STR-A6000 Series

PC1

C3

4

FB

/OLP

U1

VCC

5

GND

3

D2

R2

C2

D

VCC pin voltage

FB/OLP pin voltage

Drain current,

I

D

V

CC(OFF)

V

FB(OLP)

t

OLP

V

CC(ON)

Non-switching interval

t

OLP

×=

)NORMAL(CC

)NORMAL(OUT

OUT(OVP)

V

V

V

9.10 Overload Protection Function (OLP)

Figure 9-16 shows the FB/OLP pin peripheral circ uit,

and Figure 9-17 shows each waveform for OLP

operation. When the pea k drain current of I

by OCP operation, the output voltage, V

and the feedback current from the secondary

photo-coupler becomes zero. Thus, the feedback current,

, charges C3 connected to the FB/OLP pin and the

I

FB

FB/OLP pin voltage increases. When the FB/OLP pin

voltage increases to V

OLP delay time, t

= 68 ms or more, the OLP function

OLP

= 8.1 V or more for the

FB(OLP)

is activated, the IC stops switching o peration.

During OLP operation, Bias Assist Function is

disabled. Thus, VCC pin voltage decreases to V

the control circuit stops operation. After that, the IC

reverts to the initial state by UVLO cir cuit, and the IC

starts operation when VCC pin voltage increases to

by startup current. Thus the intermittent

V

CC(ON)

operation by UVLO is repeated in OLP state.

This intermittent op eration reduces the stress of parts

such as power MOSFET and secondary side rectifier

diode. In addition, this operation reduces power

consumption because the switching period in this

intermittent operation is short co mpared with oscillation

stop period. When the abnormal condition is removed,

the IC returns to normal operatio n automatically.

is limited

D

, decreases

OUT

CC(OFF)

,

9.11 Overvoltage Protection (OVP)

When a voltage between VCC pin and GND pin

increases to V

activated, the IC stops switching operation at the latched

state. In order to keep the latched state, when VCC pin

voltage decreases to V

activated and VCC pin voltage is kept to over the

CC(OFF)

.

V

Releasing the latched state is done by turning off the

input voltage and by dropping the VCC pin voltage

below V

V

BR(OUT)

CC(OFF)

.

In case the VCC pin voltage is provided by using

auxiliary winding of transformer, the overvoltage

conditions such as output voltage d etection circuit open

can be detected because the VCC pin voltage is

proportional to output voltage. The approxima te val ue o f

output volt age V

by using Equation (7).

where,

V

OUT(NORMAL)

V

CC(NORMAL)

: VCC pin voltage in normal operation

= 29 V or more, OVP function i s

CC(OVP)

, the bias assist function is

CC(BIAS)

, or by dropping the BR pin voltage below

OUT(OVP)

in OVP condition is calculated

29 (V)

(7)

: Output voltage in normal o peration

9.12 Thermal Shutdown Function (TSD)

When the temperature of control circuit increases to

= 135 °C (min.) or more, Thermal Shutdown

T

j(TSD)

function (TSD) is activated, the IC stops switching

operation at the latched state. In order to keep the

latched state, when VCC pin voltage decreases to

V

pin voltage is kept to over the V

Figure 9-16. FB/OLP Pin Peripheral Circuit

Releasing the latched state is done by turning off the

input voltage and by dropping the VCC pin voltage

below V

V

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 20

Figure 9-17. OLP Operational Waveforms

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

, the bias assist functio n is activated and VCC

CC(BIAS)

BR(OUT)

, or by dropping the BR pin voltage below

CC(OFF)

.

CC(OFF)

.

Page 21

STR-A6000 Series

VAC

C1

C6

R1

D1

BR1

R2

C2

T1

D

P

PC1

C3

R

OCP

CRD clamp snubber

C5

1 2 3 4

D/ST D/STBRNC

S/OCP FB/OLP

GND

VCC

8 7

5

U1

D2

C4

R

C

R

B

R

A

C(RC) damper snubber

Without R

2

With R

2

VCC pin voltage

Output current, I

OUT

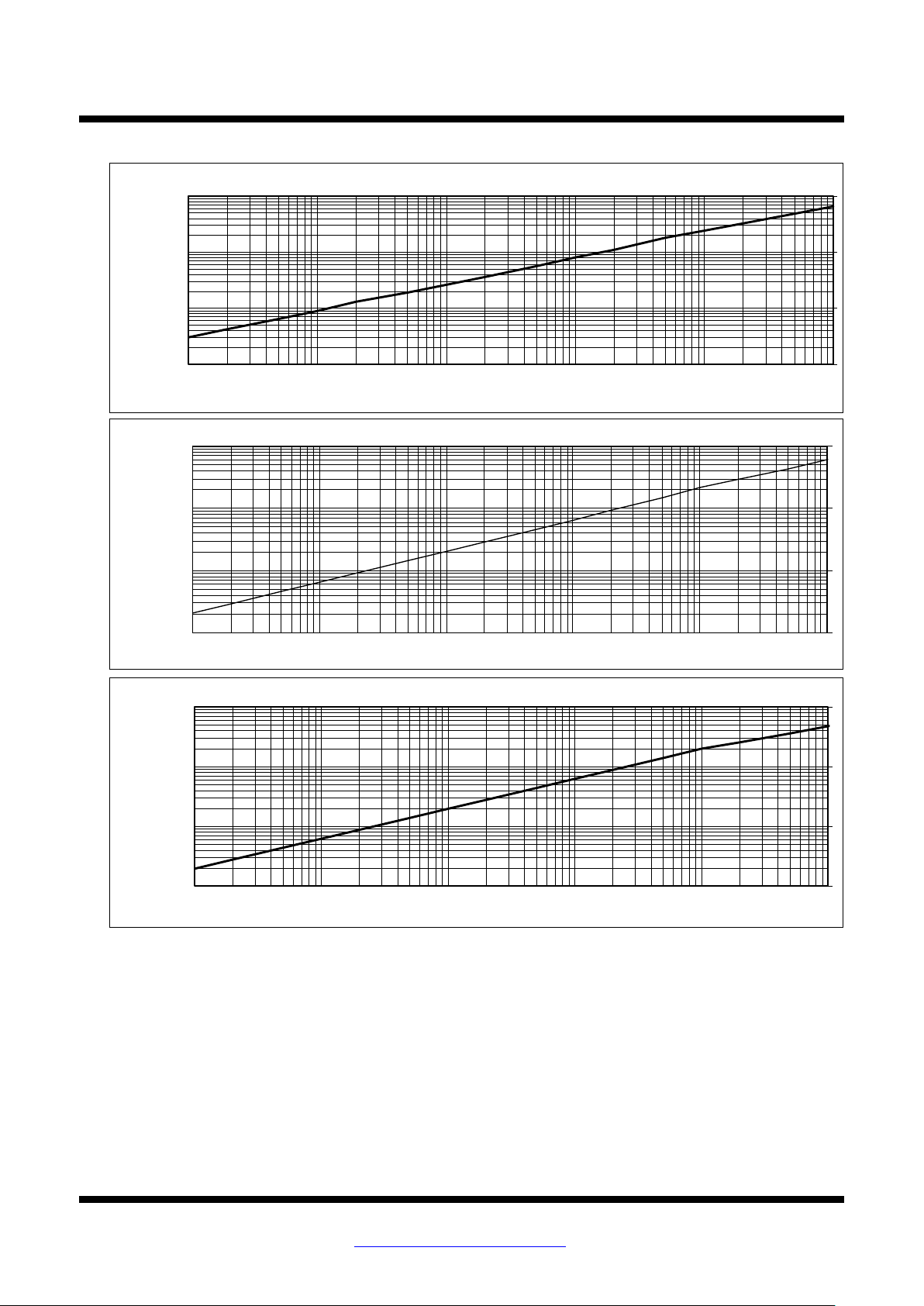

10. Design Notes

10.1 External Components

Take care to use properly rated, including derating as

necessary and proper type of components.

Figure 10-1. The IC Peripheral Circuit

• Input and Output Electrolytic Capacitor

Apply proper derating to ripple current, voltage, and

temperature rise. Use of high ripple current and low

impedance types, designed for switch mode power

supplies, is recommended.

• FB/OLP Pin Peripheral Circuit

C3 is for high frequency noise reduction and phase

compensation, and should be connected close to these

pins. The value of C3 is recommended to be about

2200 pF to 0.01µF, and should be selected based on

actual operation in the application.

• VCC Pin Peripheral Circuit

The value of C2 in Figure 10-1 is generally

recommended to be 10µ to 47μF (refer to Section 9.1

Startup Operation, because the startup time is

determined by the value of C2).

In actual power supply circuits, there are cases in

which the V CC p in vo lta ge fluc tua tes i n pr opo rti on to

the output current, I

(see Figure 10-2), and the

OUT

Overvoltage Protection function (OVP) on the VCC

pin may be activated. This happens because C2 is

charged to a peak voltage on the auxiliary winding D,

which is caused by the transie nt surge voltage c o upl ed

fro m the pri mary winding wh en the power MOSFET

turns off.

For alleviating C2 peak charging, it is effective to add

some value R2, of several tenths of ohms to several

ohms, in series with D2 (see Figure 10-1). The

optimal value of R2 should be determined using a

transformer matching what will be used in the actual

application, because the variation of the auxiliary

winding voltage is affected by the transformer

structural design.

• S/OCP Pin Peripheral Circuit

• BR pin peripheral circuit

Because R

voltage and are high resistance, t he following should be

considered according to the requirement of the

application:

See the section 9.8 about the AC input voltage

detection function and the components around BR pin.

When the detection resistor (R

decreased and the C4 value is increased to prevent

unstable operation resulting from noise at the BR pin,

pay attention to the low efficiency and the slow

response of BR pin.

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 21

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

In Figure 10-1, R

is the resistor for the current

OCP

detection. A high frequency switching current flows

to R

, and may cause poor operation if a high

OCP

inductance resistor is used. Choose a low inductance

and high surge-tolerant type.

a nd RB (see Figure 10-1) are app lied high

A

▫ Select a resistor designed against electromigration,

or

▫ Use a combination of resistors in series for that to

reduce each applied voltage

, RB, RC) value is

A

Figure 10-2. Variation of VCC Pin Volta ge and Power

• Snubber Circuit

In case the surge voltage of V

is large, the circuit

DS

should be added as follows (see Figure 10-1);

・ A clamp snubber circuit of a capacitor-resistor-

diode (CRD) combination should be added on the

primary wi nding P.

・ A damper snubber circuit of a capacitor (C) or a

resistor-capacitor (RC) combination should be

added between the D/ST pin and the S/OCP pin.

In case the damper snubber circuit is added, this

components should be connected near D/ST pin

and S/OCP pin.

Page 22

STR-A6000 Series

D

51

C51

R51

R52

U51

R54

R56

C52

S

PC1

R53

R55

L51

C53

VOUT

(-)

T1

(+)

Margin tape

Margin tape

Margin tape

Margin tape

P

1 S1 P2 S2

D

P1 S

1 D S

2 S1 P2

Winding structural example

(a)

Winding structural example (b

)

Bobbin Bobbin

• Peripheral circuit of secondary side shunt regulator

Figure 10-3 shows the secondary side dete c tion circuit

with the sta ndard shunt regulator IC (U51).

C52 and R53 are for phase compensation. The value

of C52 and R53 are recommended to be around

0.047μF to 0.47μF and 4.7 kΩ to 470 kΩ, respectively.

They should be selected based on actual operation in

the application.

Figure 10-3. Peripheral Circuit of Secondary Side

Shunt Regulator (U51)

▫ The coupling of the winding P and the secondary

output winding S should be maximized to reduce the

leakage inductance.

▫ The coupling of the winding D and the winding S

should be maximized.

▫ The coupling of the winding D and the winding P

should be minimized.

In the case of multi-output power supply, the

coupling of the secondary-side stabilized output

winding, S1, and the others (S2, S3…) should be

maximized to improve the line-regulation of those

outputs.

Figure 10-4 shows the winding st ructural e xamples

of two outputs.

Winding structural example (a):

S1 is sandwiched between P1 and P2 to

maximize the coupling of them for surge

reduction of P1 and P2.

D is placed far from P1 and P2 to minimize the

coupling to the primary for the surge reduction of

D.

Winding structural example (b )

P1 and P2 are placed close to S1 to maximize the

coupling of S1 for surge reduction of P1 and P2.

D and S2 are sandwiched by S1 to maximize the

coupling of D and S1, and that of S1 and S2.

This structure reduces the surge of D, and

improves the line-regulation of outputs.

• Transformer

Apply proper design margin to core temperature rise

by core loss and copper loss.

Because the switching currents contain high

frequency currents, the skin effect may become a

consideration.

Choose a s uitable wire gauge in considerati on of the

RMS current and a current density of 4 to 6 A/mm

If measures to further reduce temperature are still

necessary, the following should be considered to

increase the total surface area of the wiring:

▫ Increase the number of wires in parallel.

▫ Use litz wires.

▫ Thicken the wire gauge.

In the following cases, the surge of VCC pin

voltage bec omes high.

▫ The surge voltage of primary main winding, P, is

▫ The winding structure of auxiliary winding, D, is

When the surge voltage of winding D is hi gh, the

VCC pin voltage increases and the Overvoltage

Protection function (OVP) may be activated. In

transformer design, the following should be

considered;

2

.

high (low output voltage and high output current

power supply designs)

susceptible to the noise of winding P.

Figure 10-4. Winding Structural Examples

10.2 PCB Trace Layout and Component

Placement

Since the PCB circuit trace design and the component

layout significantly affects operation, EMI noise, and

power dissipation, the high frequency PCB trace should

be low impedance with small loop and wide t race.

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 22

Page 23

STR-A6000 Series

C1

C6

R1

D1

D2

R2

C2

T1

C51

D

P

S

PC1

C3

R

OCP

C5

1 2 3 4

D/ST

BR

NC

S/OCP FB/OLP

GND

8 7

5

STR-A6000

U1

A

D

ST

C

Y

D51

D/ST VCC

R

C

R

A

R

B

C4

(1)Main trace should be wide

trace and small loop

(6)Main trace of secondary side should

be wide trace and small loop

(2) Control GND trace should be connected at a

single point as close to the R

OCP

as possible

(3) Loop of the power

supply should be small

(4)R

OCP

should be as close to S/OCP pin as

possible.

(7)Trace of D/ST pin should be

wide for heat release

(5)The components connected to

the IC should be as close to the

IC as possible, and should be

connected as short as possible

In additi o n, the ground traces affect radia ted EMI noi se,

and wide, short traces should be taken into account.

Figure 10-5 shows the circuit design example.

(1) Main Circuit Trace Layout

This is the ma in trace co ntaining s witching c urrents,

and thus it should be as wide trace and small loop as

possible.

If C1 and the IC are distant from each other, placing

a capacitor such as film capacitor (about 0.1 μF and

with prope r voltage rating) clo se to the transformer

or the IC is recommended to reduce impedance of

the high frequency current loop.

(4) R

(5) Peripheral components of the IC

Trace Layout

OCP

should be placed as close as possible to the

R

OCP

S/OCP pin. The connection between the power

ground of the main trace and the I C ground should

be at a single po int ground (poi nt A in Figure 10-5)

which is close to the base of R

OCP

.

The components for control connected to the IC

should be placed as close as possible to the IC, and

should be connected as short as possible to the each

pin.

(2) Control Ground Trace Layout

Since the operation of IC may be affected from the

large current of the main trace that flows in control

ground trace, the control ground trace should be

separated from main trace and connected at a single

point ground ing o f poi nt A in Figure 10-5 as close to

the R

pin as possible.

OCP

(3) VCC Trace Layout

This is the trace for supplying power to the IC, and

thus it should be as small loop as possible . If C2 and

the IC are distant from each other, placing a

capacitor such as film capacitor C

(about 0.1 μF to

f

1.0 μF) close to the VCC pin and the GND pin is

recommended.

(6) Secondary Rectifier Smoothing Circuit Trace

Layout:

This is the trace of the rectifier smoothing loop,

carrying t he switchin g current, and thus it should b e

as wide trace and small loop as possible. If this trace

is thin and long, inductance result ing from the loop

may increase surge voltage at turning off the po wer

MOSFET. Proper rectifier smoothing trace layout

helps to increase margin against the power MOSFET

breakdown voltage, and reduces stress on the clamp

snubber circuit and losses in it.

(7) Thermal Considerations

Because the power MOSFET has a positive thermal

coefficient of R

, consider it in thermal design.

DS(ON)

Since the copper area under the IC and the D/ST pin

trace act as a heatsink, its traces should be as wide as

possible.

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 23

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Figure 10-5. Peripheral Circuit Example Around the IC

Page 24

STR-A6000 Series

3

CN1

C3

T1

D51

R52

U51

D1

P1

S1

PC1

4

L51

L2

C52

R53

C4

F1

1

3

C1

TH1

L1

NC

1 2 4

D/ST D/ST

BR

S/OCP FB/OLP

VCC

8 7

5

STR-A6000

U1

GND

3

1

2

OUT2(+)

C5

C7

C6

C8

C10

C11

D2

D3

D4

D1

D7

D8

R3

R4

R1

R5

R7

R6

D52

C51 C53

C55

R51

R54

R55

R56

R57

R58

R59

R60

R61

JW51 JW52

JW2

JW3

CP1

C54

C57

CN51

C2

C9

JW4

OUT2(-)

OUT1(+)

OUT1(-)

1

2

OUT3(+)

D21

C21

R21

OUT3(-)

IN OUT

GND

1

2

3

U21

C22

D2

1

2

OUT4(+)

D31

C31

R31

OUT4(-)

C32

JW31

JW21

CN21

CN31

R2

L52

C56

C12

C13

JW6

JW7

JW8

JW9

JW10

JW11

JW53

JW54

11. Pattern Layout Example

The following show the PCB pattern layout example and the schematic of circuit using STR-A6000 series.

The above circuit symbols correspond to these of Figure 11-1.Only the parts in the schematic are used. Other parts

in PCB are leaved open.

Figure 11-1. PCB Circuit Trace Layout Example

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 24

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Figure 11-2. Circuit Schematic for PCB Circuit Trace Layout

Page 25

STR-A6000 Series

IC

STR-A6059H

Input volt a ge

AC85V to AC265V

Maximum output power

7.5W

Output voltage

5V

Output current

1.5A (max.)

3

C3

T1

D51

R52

U51

D

P1

S2

PC1

4

L51

L2

C52

R53

C2

F1

1

3

C1

TH1

L1

R1

NC

1 2 4

D/ST D/ST

BRS/OCP FB/OLP

VCC

8 7

5

STR-A6000

U1

GND

3

5V/1.5A

C4

C6

C7

C5

C8

C9

D2

D5

D6

R2

R3

R4

R7

R8

R9

C51

C53

R51

R54

R55

R56

R57

PC1

C55

S1

D1

D3

D4

TC_STR-A6000_4_R1

VOUT(+)

VOUT(-)

Recommended

Sanken Parts

Recommended

Sanken Parts

(3)

(2)

L2

(2)

Inductor

470μH R8

(3)

General

2.2MΩ

TH1

(2)

NTC thermistor

Short R9

(3)

General

2.2MΩ

D1 General

600V, 1A

EM01A

PC1 Photo-coupler

PC123 or equiv

D2 General

600V, 1A

EM01A

U1 IC

STR-A6059H

See

the specification

D5 Fast recovery

1000V, 0.5A

EG01C

D51 Schottky

90V, 4A

FMB-G19L

D6 Fast recovery

200V, 1A

AL01Z

C51 Electrolytic

680μF, 10V

C1

(2)

Film, X2

0.047μF, 275V

C52

(2)

Ceramic

0.1μF, 50V

C2 Electrolytic

10μF, 400V

C53 Electrolytic

330µF, 10V

C3 Electrolytic

10μF, 400V

C55

(2)

Ceramic

1000pF, 1kV

C4 Ceramic

1000pF, 630V

R51 General

220Ω

C6

(2)

Ceramic

0.01μF

R53

(2)

General

22kΩ C7

(2)

Ceramic

1000pF

R54 General, 1%

Short

C8

(2)

Ceramic

Open R55 General, 1%

10kΩ C9 Ceramic, Y1

2200pF, 250V

R56 General, 1%

10kΩ

R1

(2)

General

Open R57 General

Open

V

=2.5V

TL431 or equiv

12. Reference Design of Power Supply

As an example , the follo wing sho w the power s upply specification, the circuit schematic, the bill of materials, and

the transformer specification.

Power Supply Specification

Circuit Schematic

Bill of Materials

Symbol Part Type Ratings

F1 Fuse AC250V, 3A R4

L1

D3 General 600V, 1A EM01A T1 Transformer

D4 General 600V, 1A EM01A L51 Inductor 5μH

C5 Electrolytic 22μF, 50V R52 General 1.5kΩ

R2

R3 General 1.5Ω, 1/2W

(1)

Unless otherwise specified, the volt age rating of capacitor is 50 V or less and the power rating of resistor is 1/8 W or less.

(2)

It is necessary to be adjusted based on actual operation in the application.

(3)

Resistors applied high DC voltage and of high resistance are recommended to select resistors desig ned against elec tromigration or use

combinations of resist o rs in series for th at to reduce each applied voltage, according to the requir ement of the application.

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 25

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

(1)

Symbol Part Type Ratings

Metal oxide 330kΩ, 1W

CM inductor 3.3mH R7 General 330kΩ

-

REF

(2)

General 4.7Ω U51 Shunt regulator

(1)

Page 26

STR-A6000 Series

Winding

Symbol

Number of Turns (T)

Wire Diameter (mm)

Construction

Two-layer,

solenoid winding

Single-layer,

solenoid winding

Single-layer,

solenoid winding

Single-layer,

solenoid winding

Bobbin

D

S1

P1

V

DC

D/ST

VCC

GND

VOUT(+)

5V

S2

S1

D

P1

S2

: Start at this pin

Cross-section view

VOUT(-)

Transformer Specification

▫ Primary Inductance, L

▫ Core Size :EI-16

▫ Al-value :132 nH/N

▫ Winding Specification

Primary Winding P1 73 2UEW-φ0.18

Auxiliary Winding D 17 2UEW-φ0.18×2

Output Winding 1 S1 6 TEX-φ0.3×2

Output Winding 2 S2 6 TEX-φ0.3×2

:704 μH

P

2

(Center gap of about 0.26 mm)

STR-A6000-DSJ Rev.4.4 SANKEN ELECTRIC CO., LTD. 26

Mar. 13, 2015 http://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2008

Page 27

STR-A6000 Series

Important Notes

● All data, illustrations, graphs, tables and any other information included in this document as to Sanken’s products listed herein (the

“Sanken Products”) are current as of the date this document is issued. All contents in this document are subject to any change

without notice due to improvement of the Sanken Products, etc. Please make sure to confirm with a Sanken sales represent ative

that the contents set forth in this document reflect the latest revisions before use.

● The Sanken Products are intended for use as components of general purpose electronic equipment or apparatus (such as home

appliances, office equipment, telecommunication equipment, measuring equipment, etc.). Prior to use of the Sanken Products,

please put your signature, or affix your name and seal, on the specification documents of the Sanken Products and return them to

Sanken. When considering use of the Sanken Products for any applications that require higher reliability (such as transportation

equipment and its control systems, traffic signal control systems or equipment, disaster/crime alarm systems, various safety

devices, etc.), you must contact a Sanken sales representative to discuss the suitability of such use and put your signature, or affix

your name and seal, on the specification documents of the Sanken Products and return them to Sanken, prior to the use of the

Sanken Products. The Sanken Products are not intended for use in any applications that require extremely high reliability such as:

aerospace equipment; nuclear power control systems; and medical equipment or systems, whose failure or malfunction may result

in death or serious injury to people, i.e., medical devices in Class III or a higher class as defined by relevant laws of Japan

(collectively, the “Specific Applications”). Sanken assumes no liability or responsibility whatsoever for any and all damages and

losses that may be suffered by you, users or any third party, resulting from the use of the Sanken Products in the Specific

Applications or in manner not in compliance with the instructions set forth herein.

● In the event of using the Sanken Products by either (i) combining other products or materials therewith or (ii) physically,

chemically or otherwise pro cessing or treating the same, you must duly consider all possible risks that may result from all such

uses in advance and proceed therewith at your own responsibility.

● Although Sanken is making efforts to enhance the quality and reliability of its products, it is impossible to completely avoid the

occurrence of any failure or defect in semiconductor products at a certain rate. You must take, at your own responsibility,

preventative measures incl uding using a sufficient safety design and confirming safety of any equipment or systems in/for which

the Sanken Products are used, upon due consideration of a failure occurrence rate or der ating, etc., in ord er not to cause any human

injury or death, fire accident or social harm which may result from any failure or malfunction of the Sanken Products. Please refer

to the relevant specification documents and Sanken’s official website in relation to derating.

● No anti-radioactive ray design has been adopted for the Sanken Products.

● No contents in this document can be transcribed or copied without Sanken’s prior written consent.

● The circuit constant, operation examples, circui t examples, pat tern la yout examples, d esign examples, recommended examples, all

information and evaluation results based thereo n, etc., described in this document are presented for the sole purpose of reference of

use of the Sanken Products and Sanken assumes no responsibility whatsoever for any and all damages and losses th at may be

suffered by you, users or any third party, or any possible infringement of any and all property rights including intellectual property

rights and any other rights of you, users or any third party, resulting from the foregoing.

● All technical information described in this document (the “Technical Information”) is presented for the sole purpose of reference

of use of the Sanken Products and no license, express, implied or otherwise, is granted hereby under any intellectual property

rights or any other rights of Sanken.

● Unless otherwise agr eed in writi ng between Sanken an d you, Sanken makes no warranty of any kind, whether express or implied,

including, without limitation, any warranty (i) as to the quality or performance of the Sanken Products (such as implied warranty