Sanken SAMCO-NS Series, NS-4A003-B, NS-4A017-B, NS-4A004-B, NS-4A006-B Instruction Manual

...

Compact Vector Control Inverter

VVVF Inverter

SAMCO-NS series

Instruction Manual (

Simple Version

)

SANKEN ELECTRIC. CO., LTD.

Warning Notification

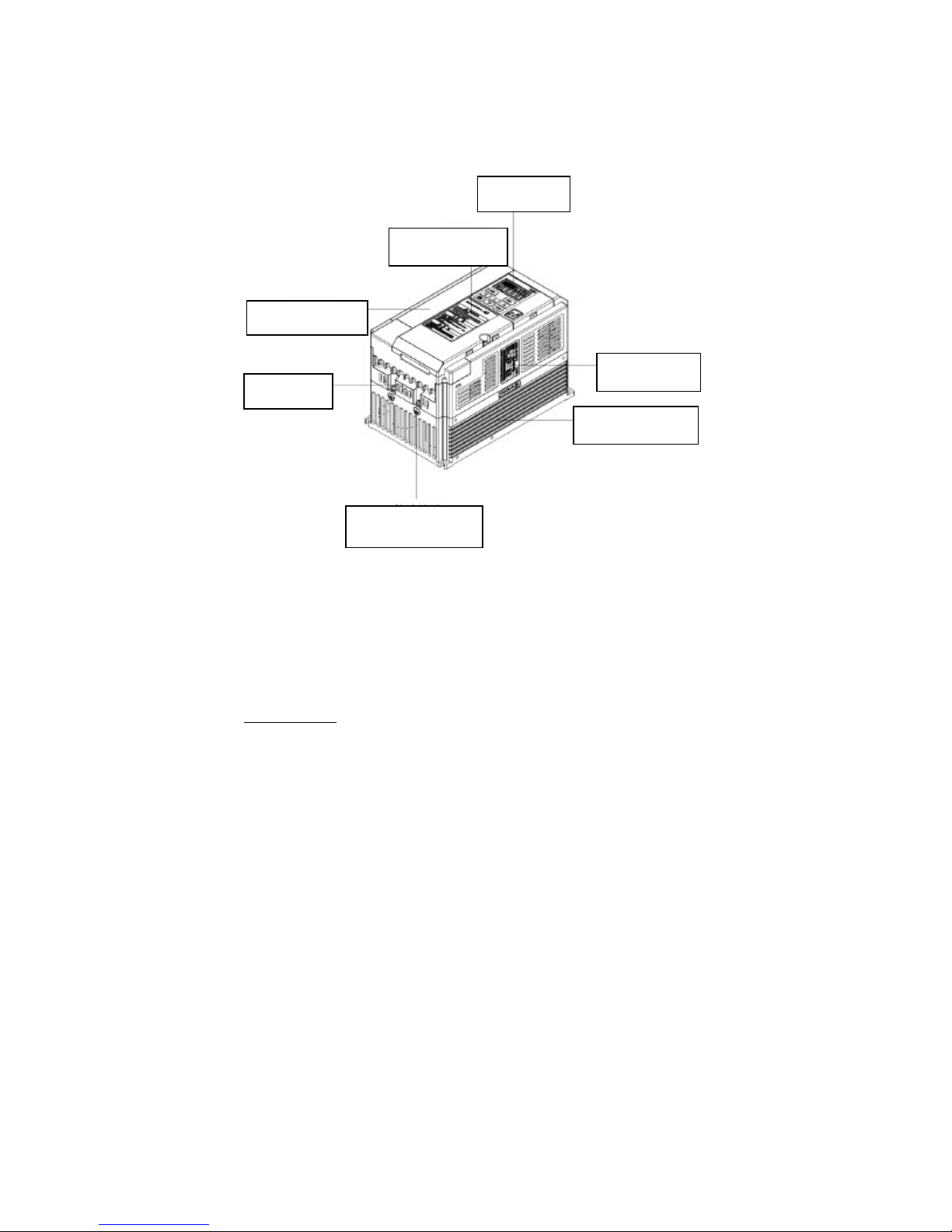

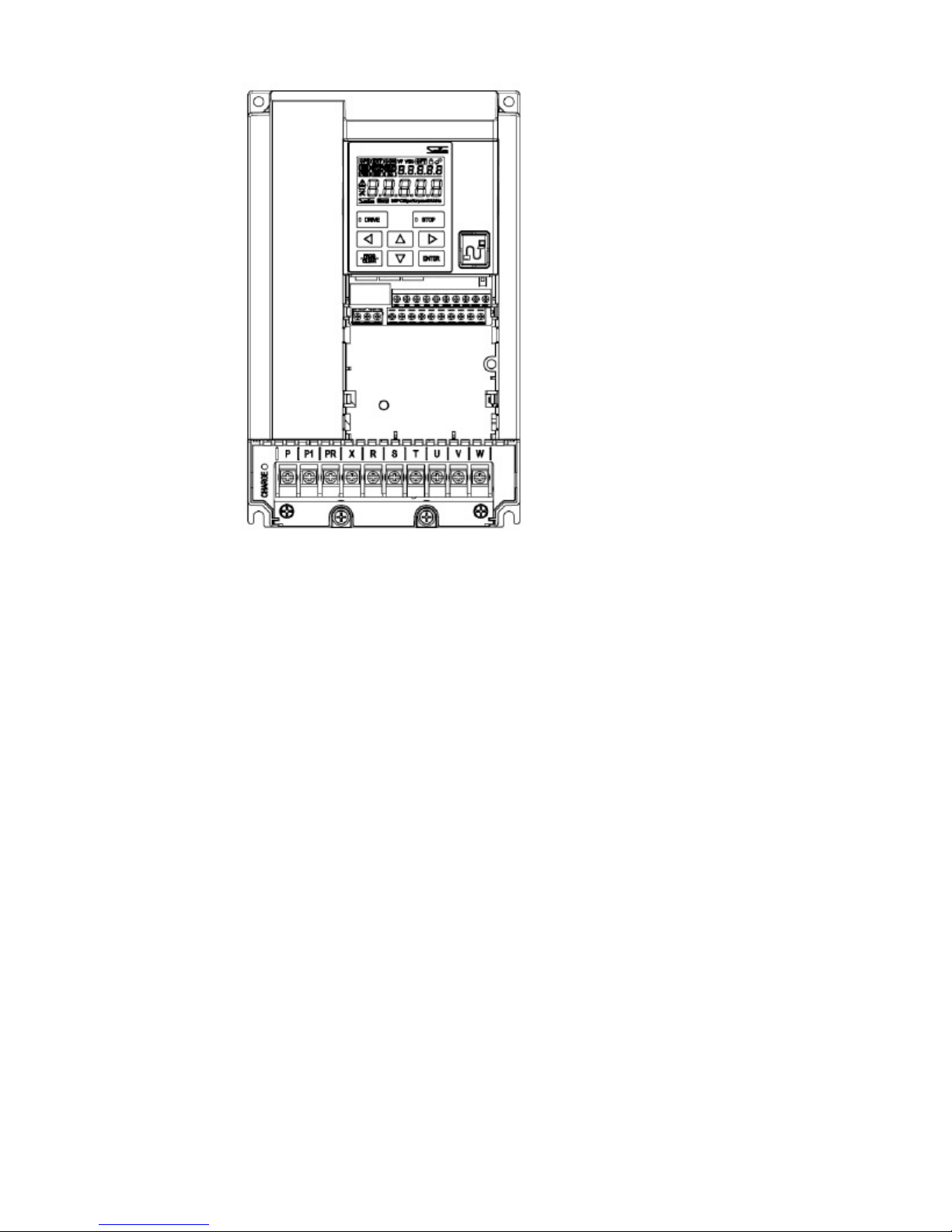

Plastic outlook frame

Terminal block

Grounding terminal

Checking the product and precautions on use

Checking the product

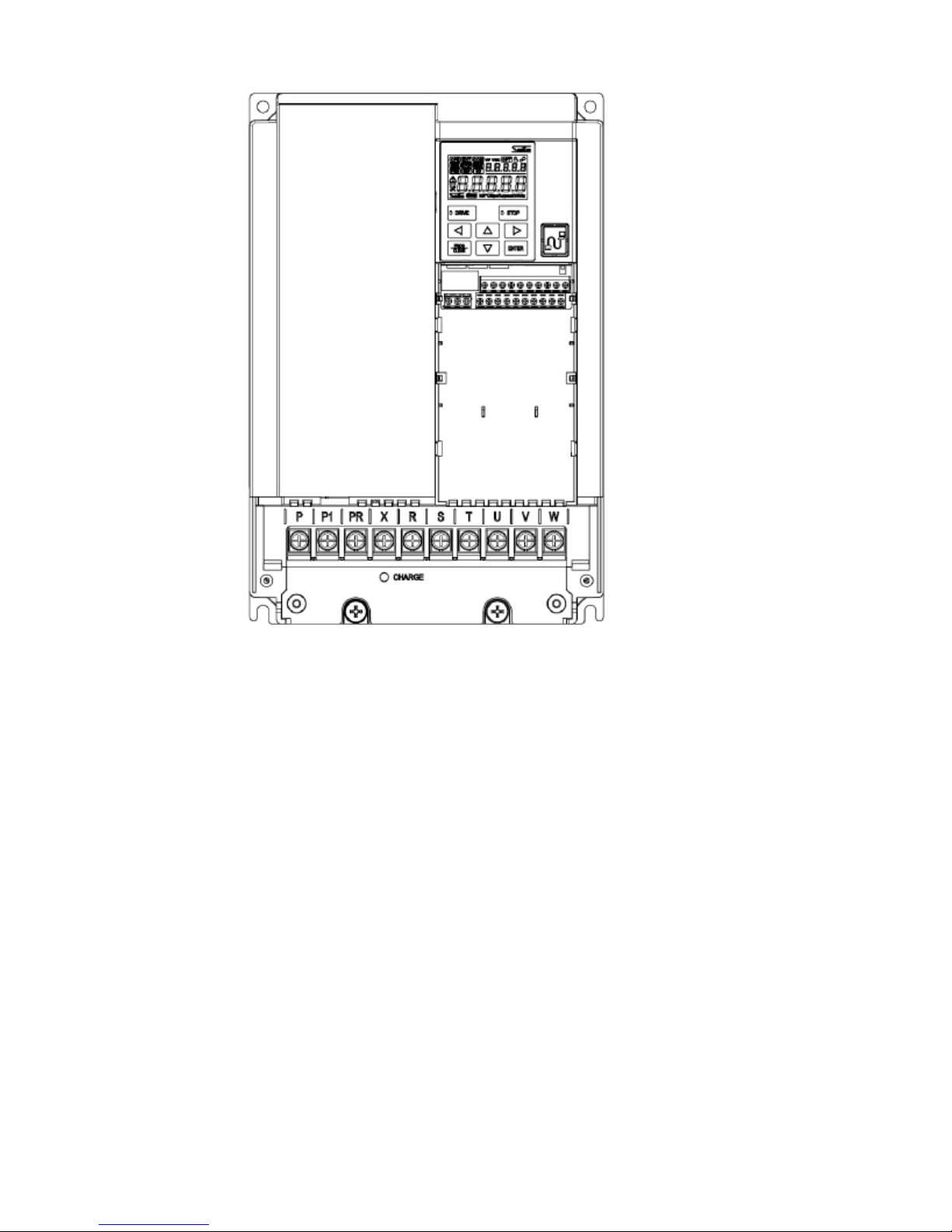

■ Product body:

NS Vector Control Inverter Body (For example: NS-4A017-B):

LCD Display

-1-

Rating nameplate

Radiator structure

Rated Current

Load Mode

The contents of the model

Series Name

Vo ltage Class

3Ø-400V

Rating nameplate

Internal Code

B: 120% 1 Min.

A017: 17A

Capacity: 7.5KW

-2-

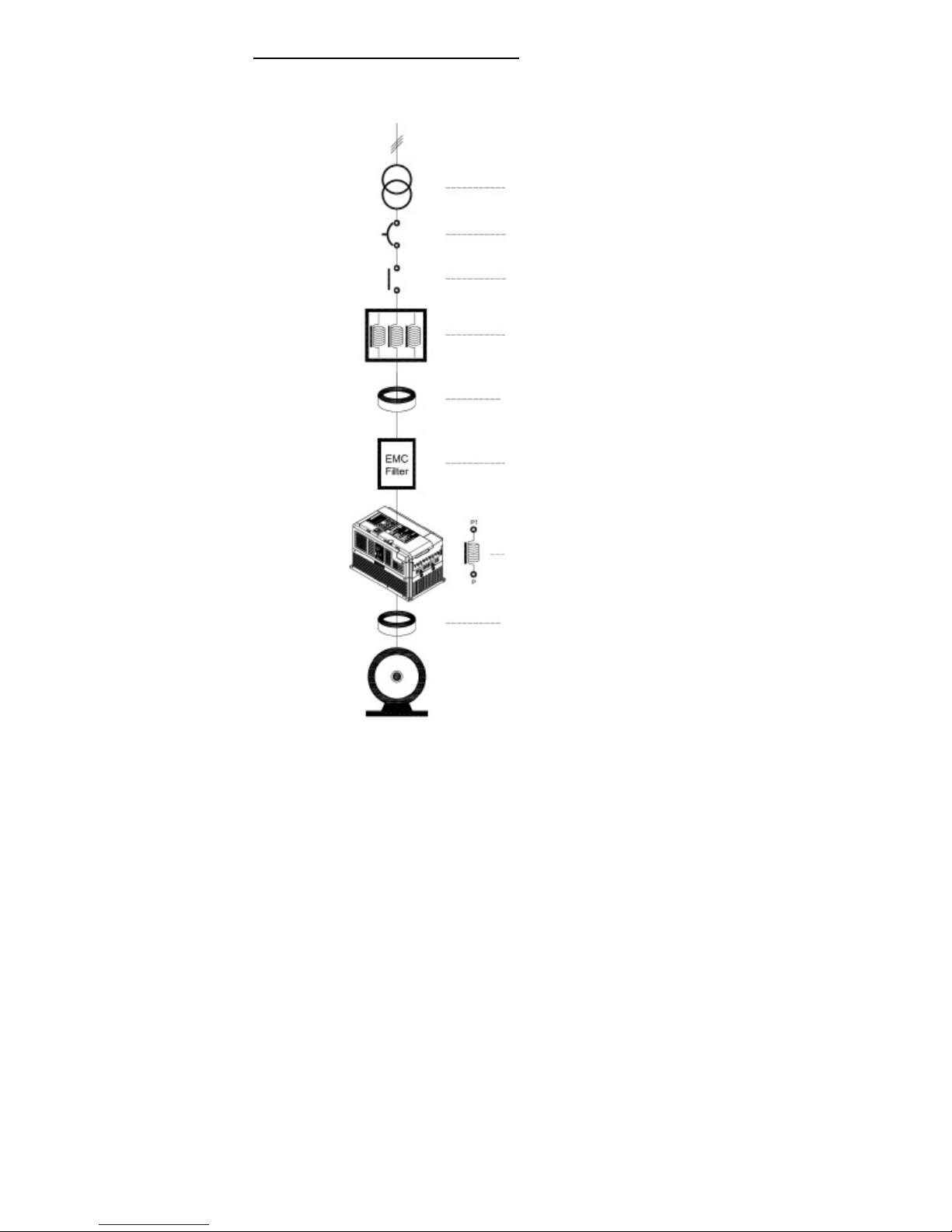

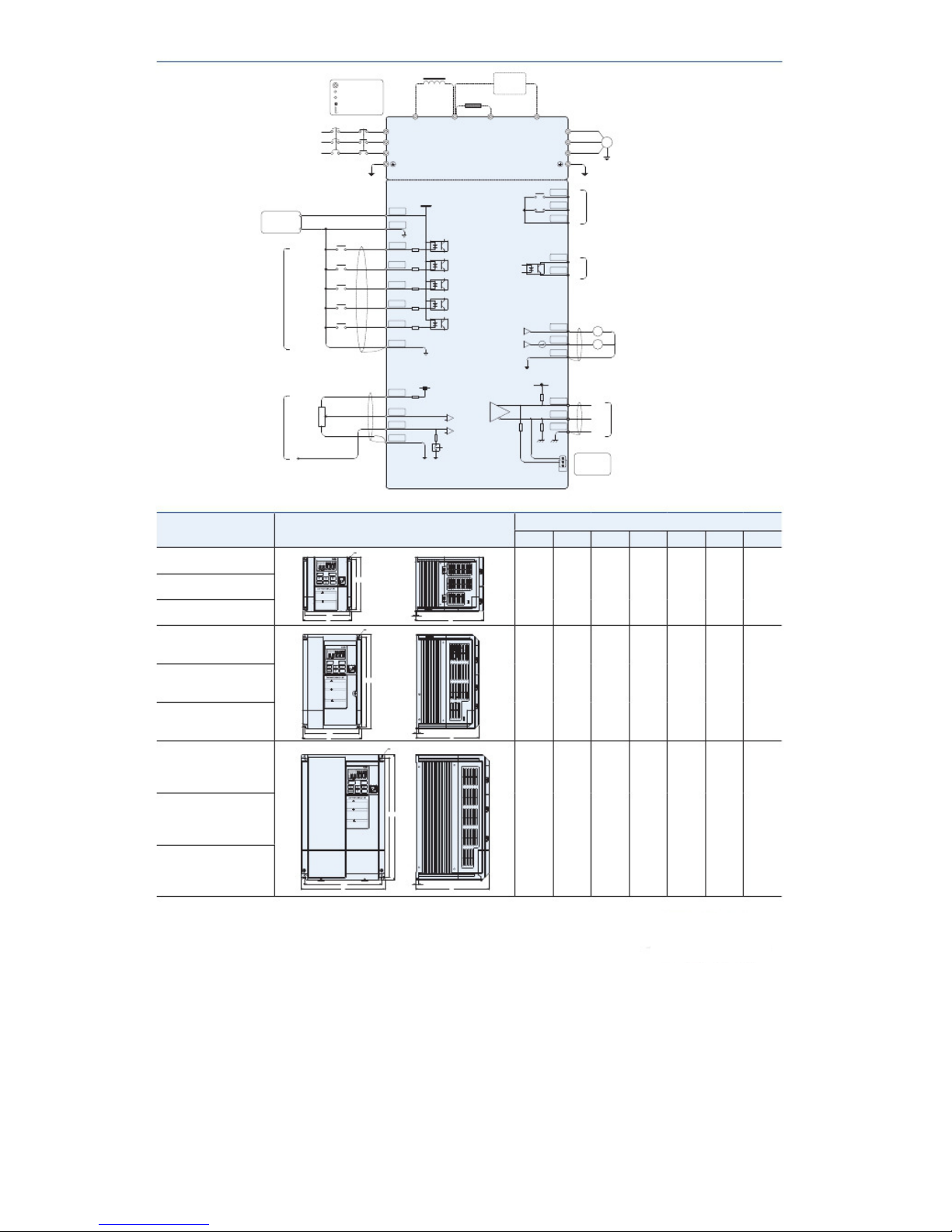

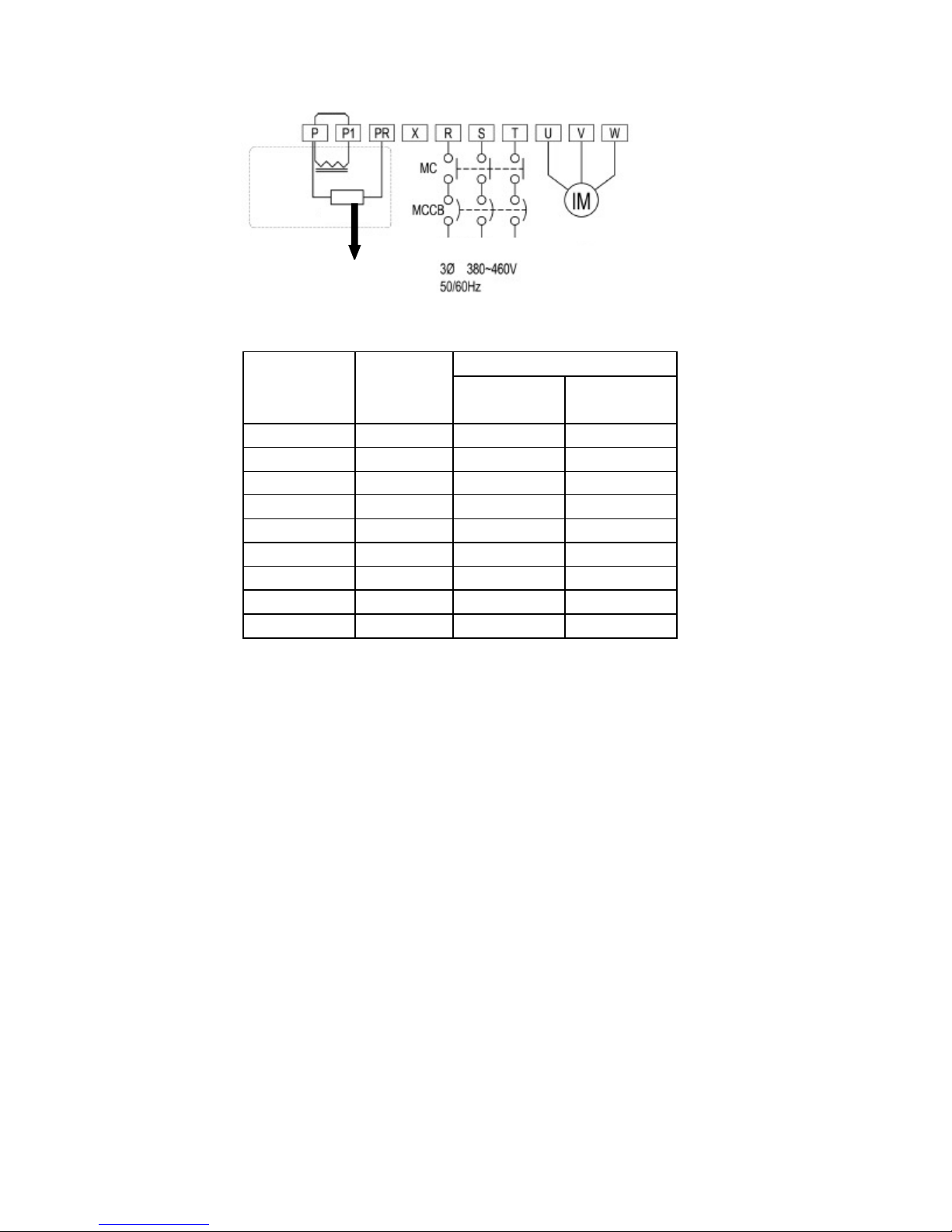

Connection with peripheral device

Draft for the connection with peripheral device

Power Supply

Input power supply transformer

Wiring circuit breaker

Or

Leakage circuit breaker

Electromagnetic contactor

AC reactor

Zero-phase reactor

Radio noise filter

/noise filter

DC reactor

Zero-phase reactor

-3-

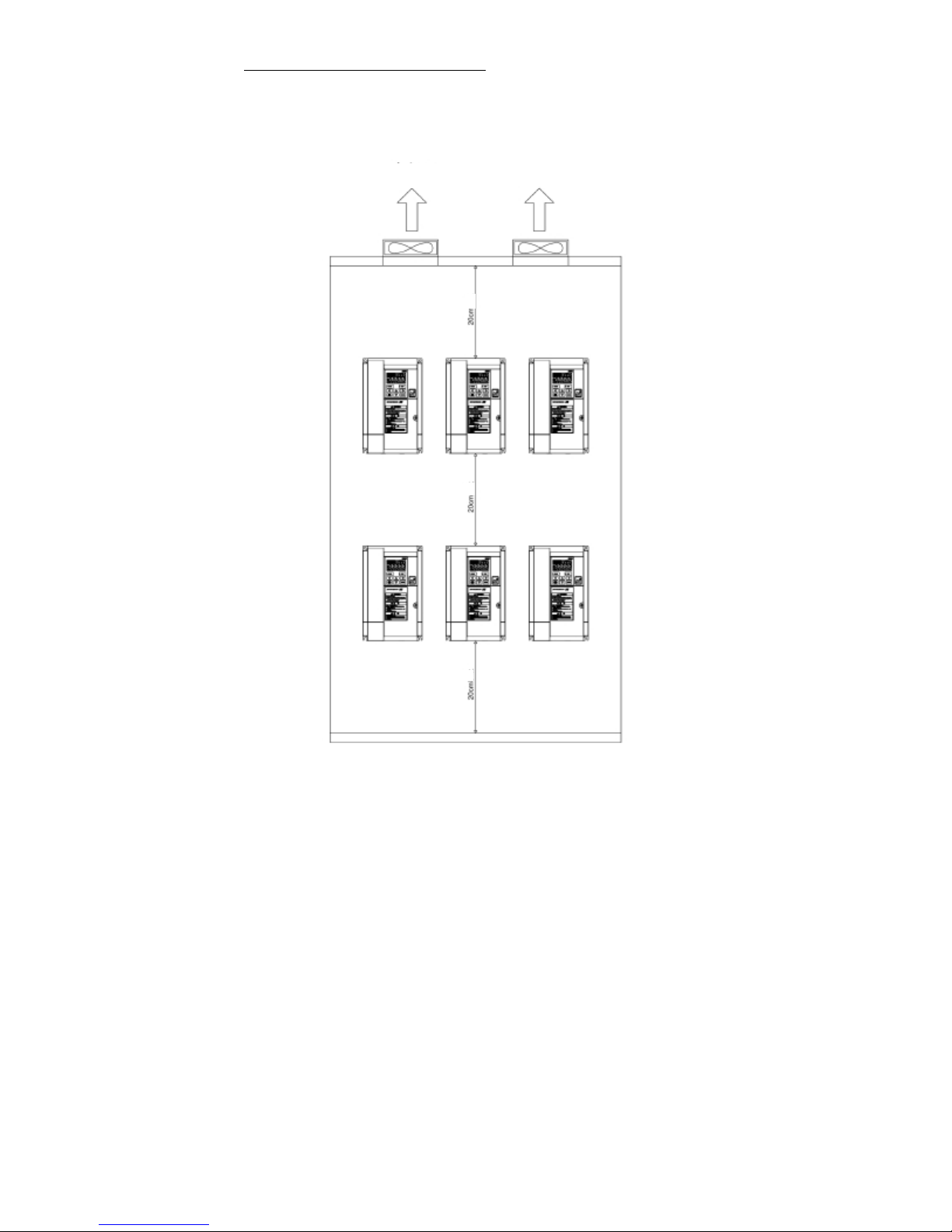

■ Installation in the side of left / right :

Pls. assure the space is above 5cm, whatever is between the inside of cabinet and the

outlook frame of Inverter, or between Inverter’s outlook frame while installed in the side of left/right

Or could be caused of not enough of heat dissipation for Inverter.

-4-

■ Installation more layers in the side of up /down:

Pls. assure the distance is above 20cm, whatever is between the inside of cabinent and the outlook frame of Inverter,

or between the Inverter’s outlook frame, and ensure the ventilation and cooling for each Inverter, or will be caused of

being not enough of heat dissipation.

Cooling Air

Cooling Air

-5-

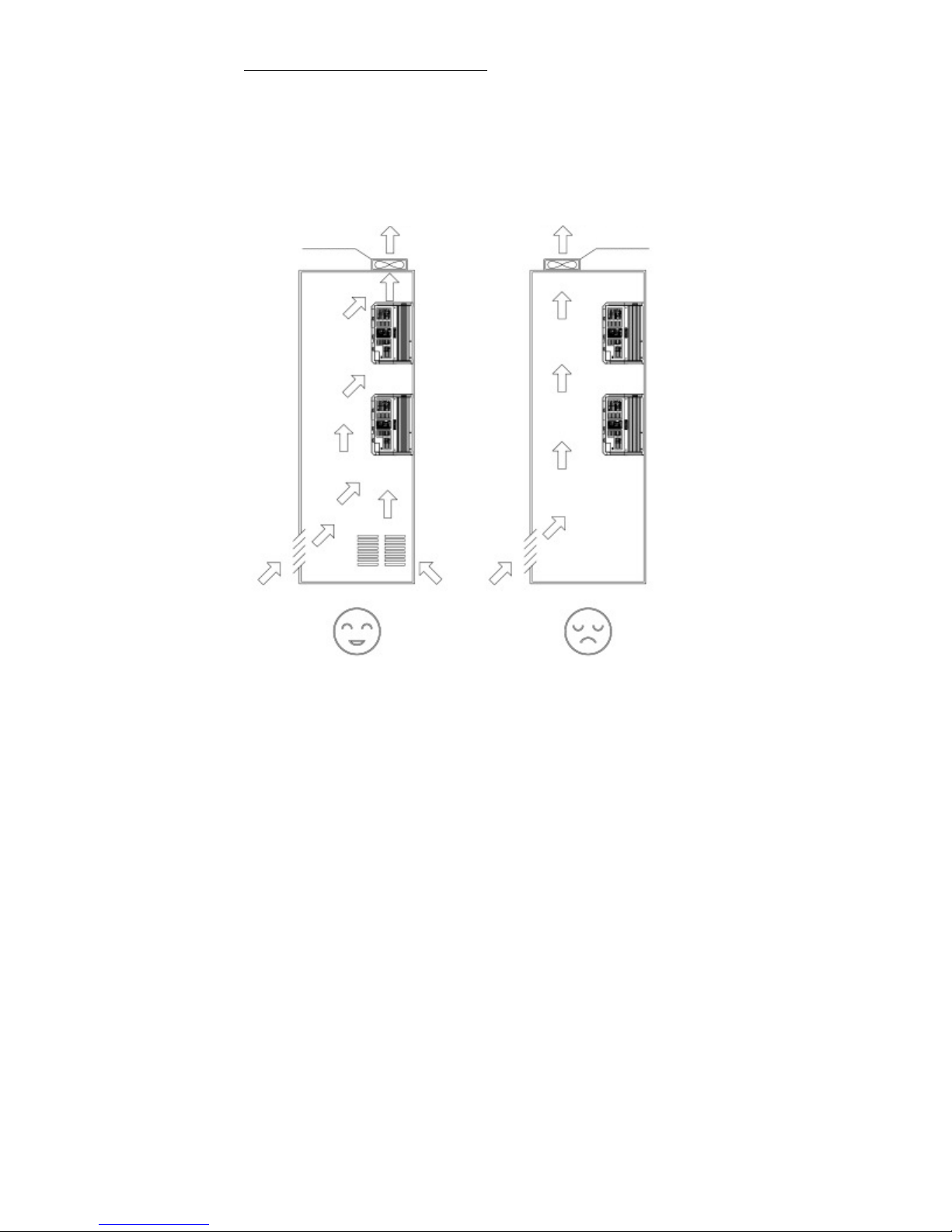

V

entilation Fan

■ Installment site for ventilation fan in the cabinent:

■ Notification:

◆ When several inverters are set in a control cabinet, be sure to local the ventiliation fans properly

to allow free aire circulation.

◆ Ensure the air in the outside of cabinent flow to the Inverter’s heat dissipation route, take those heat from the

Inverter in operation away in efficient.

◆ If the ventiliation fans are located properly, t he ambient termperature will rise and affect the cooling of the Inverter.

Ven tilation Fan

Cooling Air

Cooling Air

(Correct) (Incorrect)

-6-

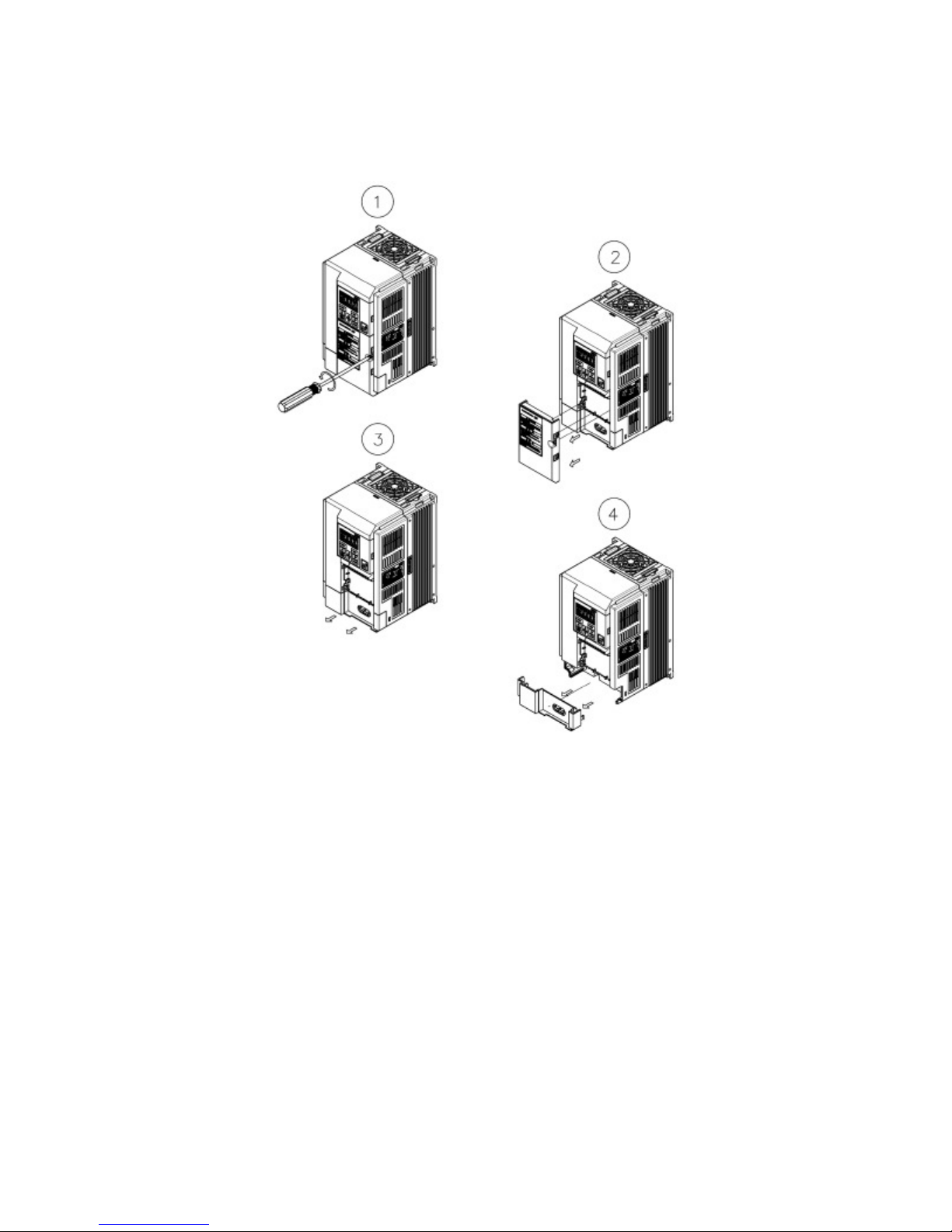

Removal and Installation of the front cover

(1)Removal of front cover (Lower)

Unscrew the M4 screws, dismantle as the below Pic.

◆

Pls. carry out this work during the main circuit wiring、control circuit wiring.

-7-

(2)Changed fan

Carry out this work only under changing fan.

(3)Installation

On installation, carrry out this work as the reverse procedures.

-8-

电位器

>5kΩ

JP2

CLEAR

ENTE R

for

10

open

after

while

CLEAR

ENTE R

取付け、運転の前に必ず取扱説明書を読み、

そ

の指示に従うこと。

通電中及び電源遮断後10分以内

はカバーを開け

ないこと。

for

10

open

after

while

CLEAR

ENTE R

取付け、運転の前に必ず取扱説明書を読み、

そ

の指示に従うこと。

通電中及び電源遮断後10分以内

はカバーを開け

ないこと。

for

10

open

after

while

Terminal Connection Draft

Terminal in Main circuit

Input terminal

Output terminal

Communication terminal

Isolation cable

DC reactor (optional selection)

Brake Unit

(Optional)

Braking Resistor (Optional Selection)

P1 P PR X

Input Power

3Ø 380~460V

50/60Hz

MCC B

MC

R

S

T

Main Circuit

U

V

W

IM

3 phase inductive motor

User load

Load Current<150mA

24V

DCM

Digital Power

24V

FA

FB

FC

Relay contact output

Contact capacity:250V,0.3A

Factory preset:Breakdow display

Code No.:F1513

FR

RR

2DF

3DF

MBS

DI1

DI2

DI3

DI4

DI5

DCM

Control Circuit

DO1

DOE

Vout

V

Iout

Open collector output

Allowed loading:48V,50mA

Factory preset:Display in operation

Code No.:F1509

0 ~ 10V Voltage output

4 ~ 20mA Current output

Digital signal on ground

Frequency setting power 12V

ACM

Analog signal

5V

Only for potentiometer

V+

0~5V,0~10V voltage

0.3W

0~10Vvoltage or 4~20mA current

VRF

V/ I

ACM

F1002=9 Current Mode

Analog signal on ground

Terminal resistor

5G

TRA

TRB

SG

ON

OFF

Terminal Resistor

Switching

RS485 communication port

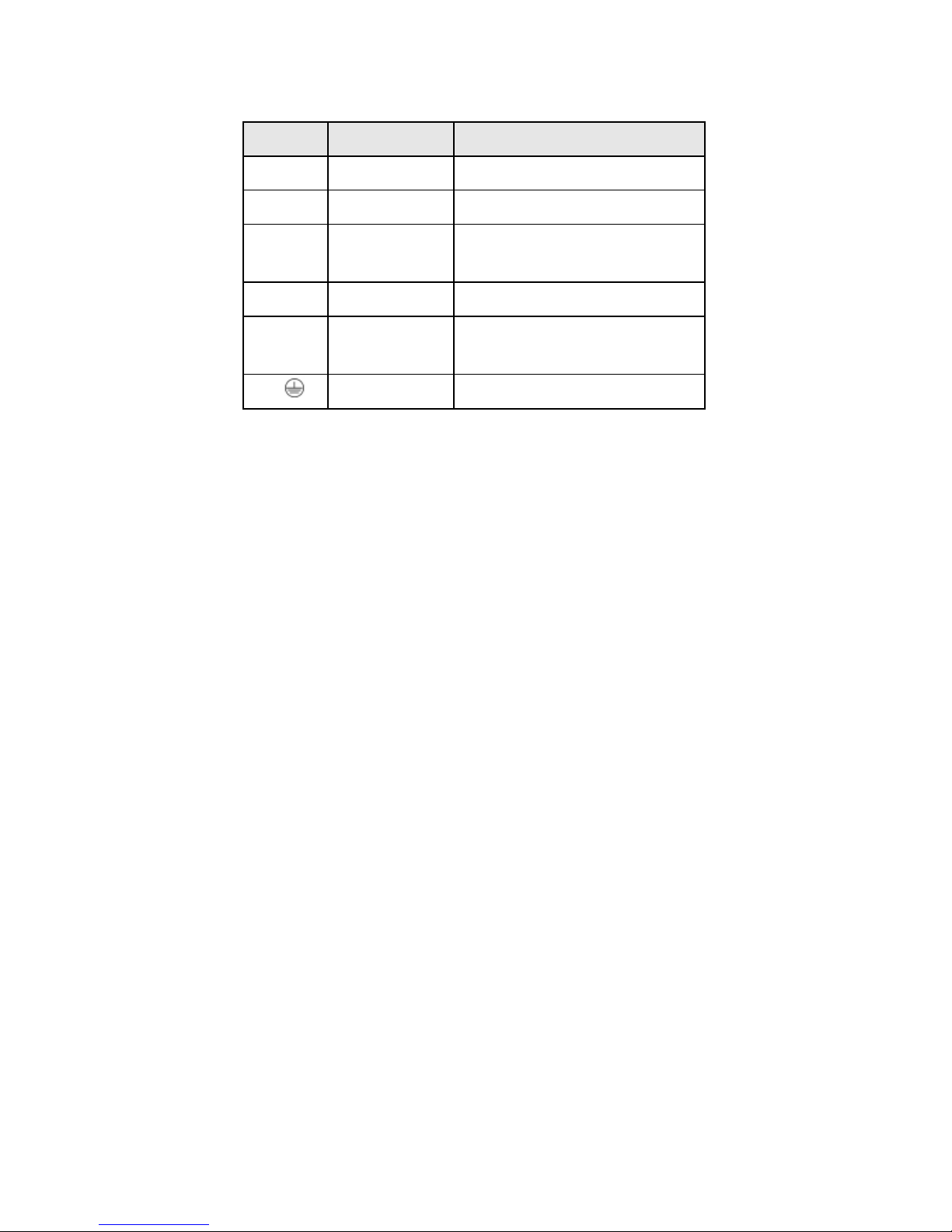

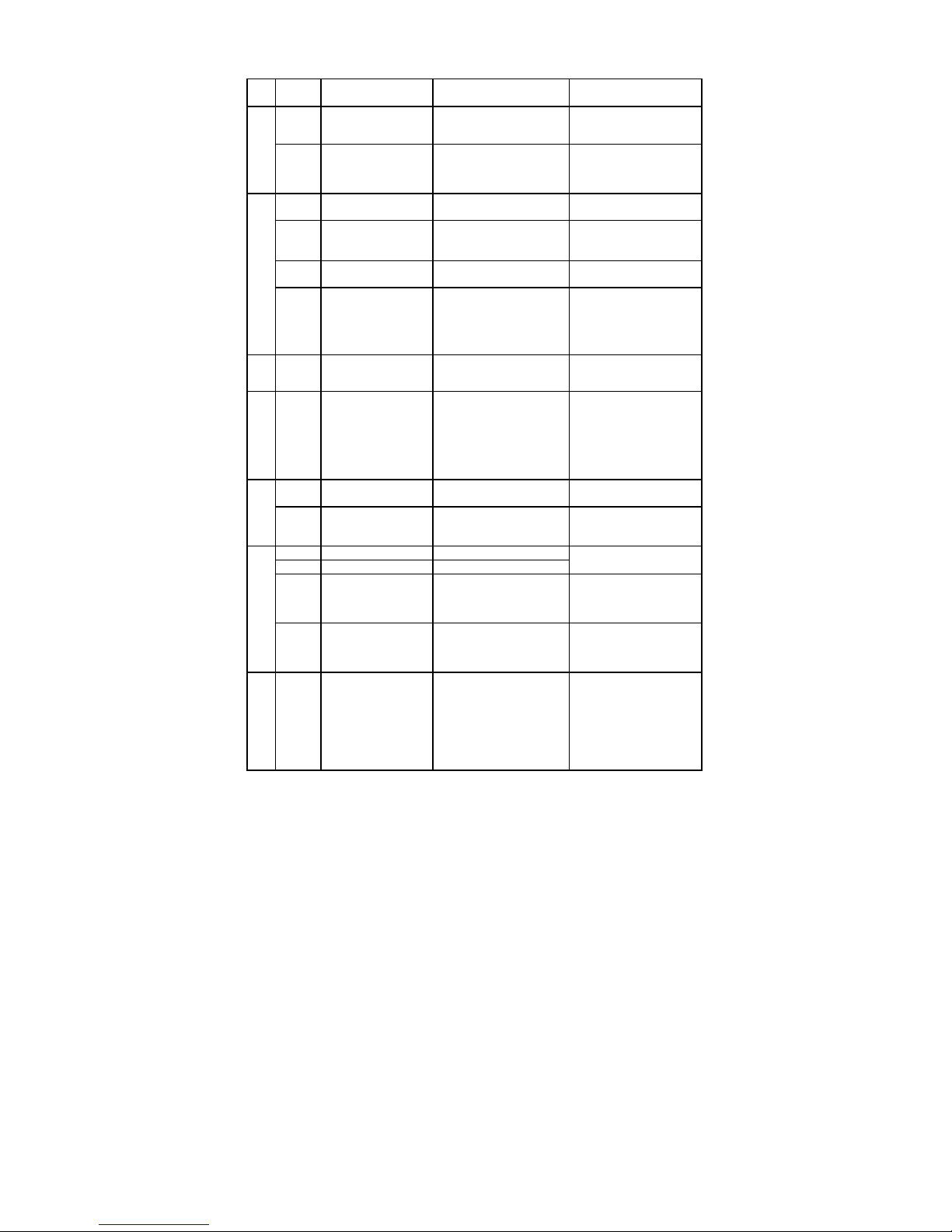

Outlook dimensions

Mode No. Outlook Frame

Dimension

H H1 W W1 D

d

t

NS-4A003-B

Ød

Easyk W ° C Mp a % r p m skVAH z

NS-4A004-B

DRIV E

STOP

PROG

WARNING

■

Riskofelectricshock.

●Readthemanualb eforein stallationand operation .

●Do

not

minutes

this

cover

isolating

power.

isappliedor

●Ensure

properearthconnection.

H1H

130

121

115

106

166

4.5

5

危险

NS-4A006-B

■有可能引起受伤,触电。

●安装运行前请务必阅读操作说明书并遵照其指示。

●通电时及切断电源10分钟内 请不要打开前面盖板。

●请正确接地。

W1

W

t

D

Ød

NS-4A009-B

Easyk W ° C Mp a % r p m skVAH z

DRIV E STOP

PROG

NS-4A013-B

WARNING

■

Riskofelectricshock.

●Readthemanual

befo r ei ns t al l ati o n

and

oper a ti on.

●Do

not

minutes

this

cover

isolating

power.

isappliedor

●Ensure

properearthconnection.

危険

■けが、感電のおそれあり。

●

●

●確実に接地を行うこと。

H1H

225

214

140

129

150

5.5

6

危险

■有可能引起受伤,触电。

●安装运行前请务必阅读操作说明书并遵照其指示。

●通电时及切断电源10分钟 内请不要打开前面盖板。

●请正确接地。

NS-4A017-B

W1

W

t

D

Ød

NS-4A024-B

Easyk W ° C Mp a % r p m skVAH z

DRIV E STOP

PROG

NS-4A032-B

WARNING

■

Riskofelectricshock.

●Readthemanualb eforein stallationand operation .

●Do

not

minutes

this

cover

isolating

power.

isappliedor

●Ensure

properearthconnection.

危険

■けが、感電のおそれあり。

●

●

●確実に接地を行うこと。

危险

■有可能引起受伤,触电。

●安装运行前请务必阅读操作说明书并遵照其指示。

●通电时及切断电源10分钟 内请不要打开前面盖板。

●请正确接地。

H1H

300

285

200

185

175

6.5

6

NS-4A038-B

-9-

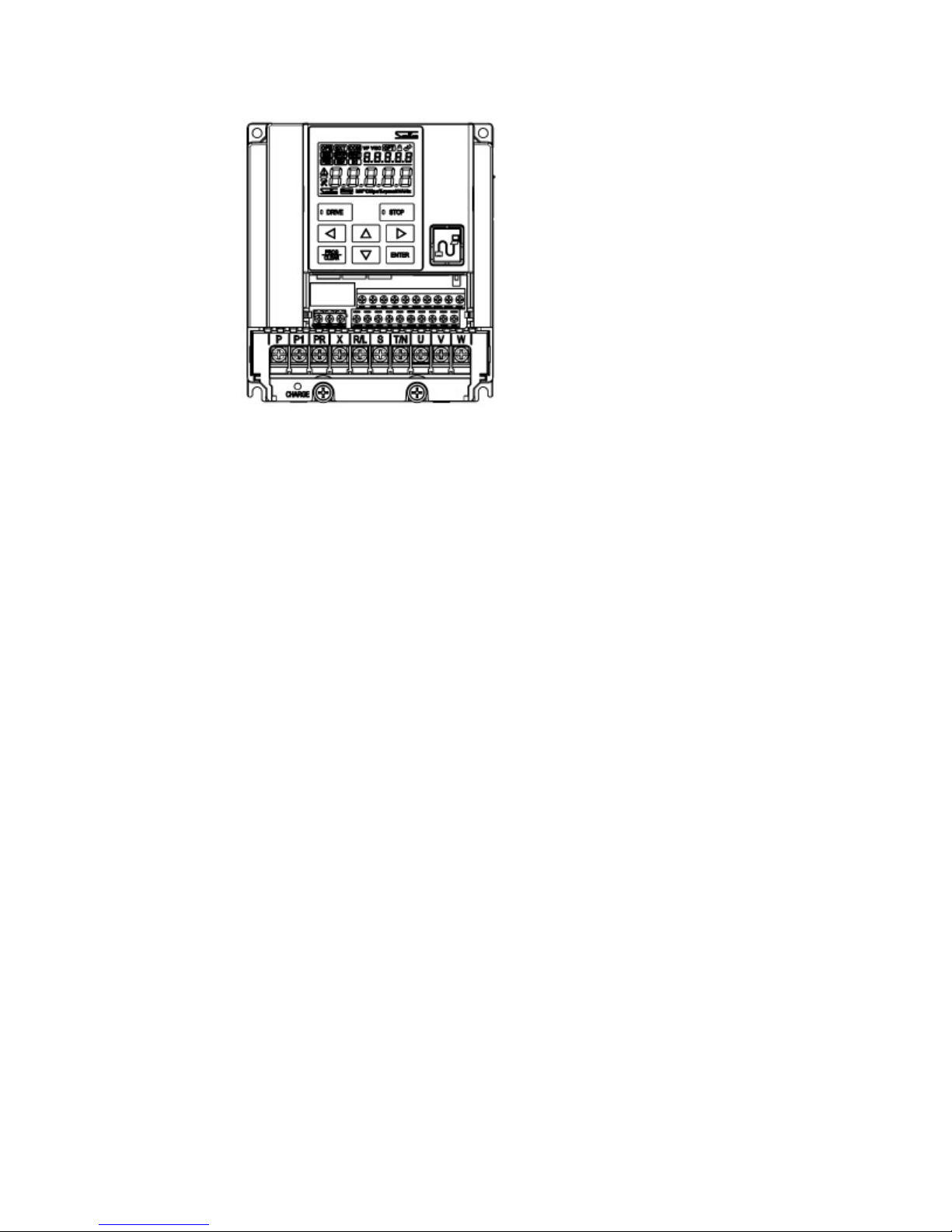

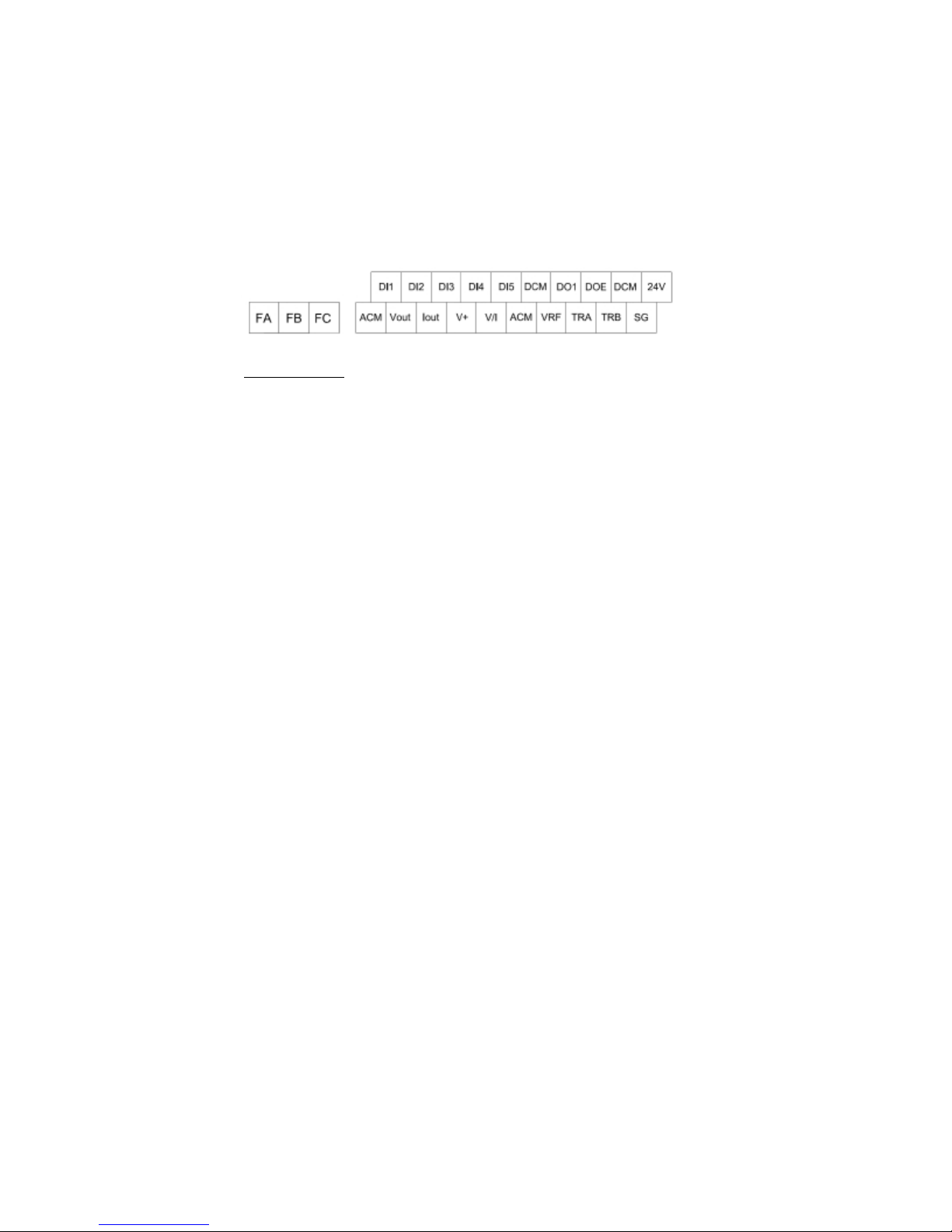

Multi

-

functions terminal

Frequency setting terminal

Relay

-9-

Description of Main Circuit Terminals

*1

When connecting the reactor, pls. remove the jumper

P1 and P

Composition of Main Circuit Terminals

Terminal Symbol

R,S,T Input Power Terminals Terminals connected to 3 phase commercial power supply

U,V,W Inverter output terminals Terminals connected to 3 phase induction motor

P,P1 DC reactor connection

P,PR

P,X

Brak Resistor connection

termials

DC side voltage terminals

Name Description

Terminals connected to DC reactor *1

Terminals

Terminals connected to brake resistor between P-PR

Ground Terminal Terminal for grounding of inverter casing

Terminals connected to brake unit

P is DC positive,X is DC negatitive

-10-

Distribution Terminal For Main Circuit

1.NS-4A003-B、NS-4A004-B、NS-4A006-B

-11-

2.NS-4A009-B、NS-4A013-B、NS-4A017-B

-12-

3.NS-4A024-B、NS-4A032-B、NS-4A038-B

-13-

(Leakage circuit brakerer)

DC

Optional Accessory

Braking Resistor

Power Supply

Motor

Main circuit terminal connection draft

Shorten Plate

Reactor

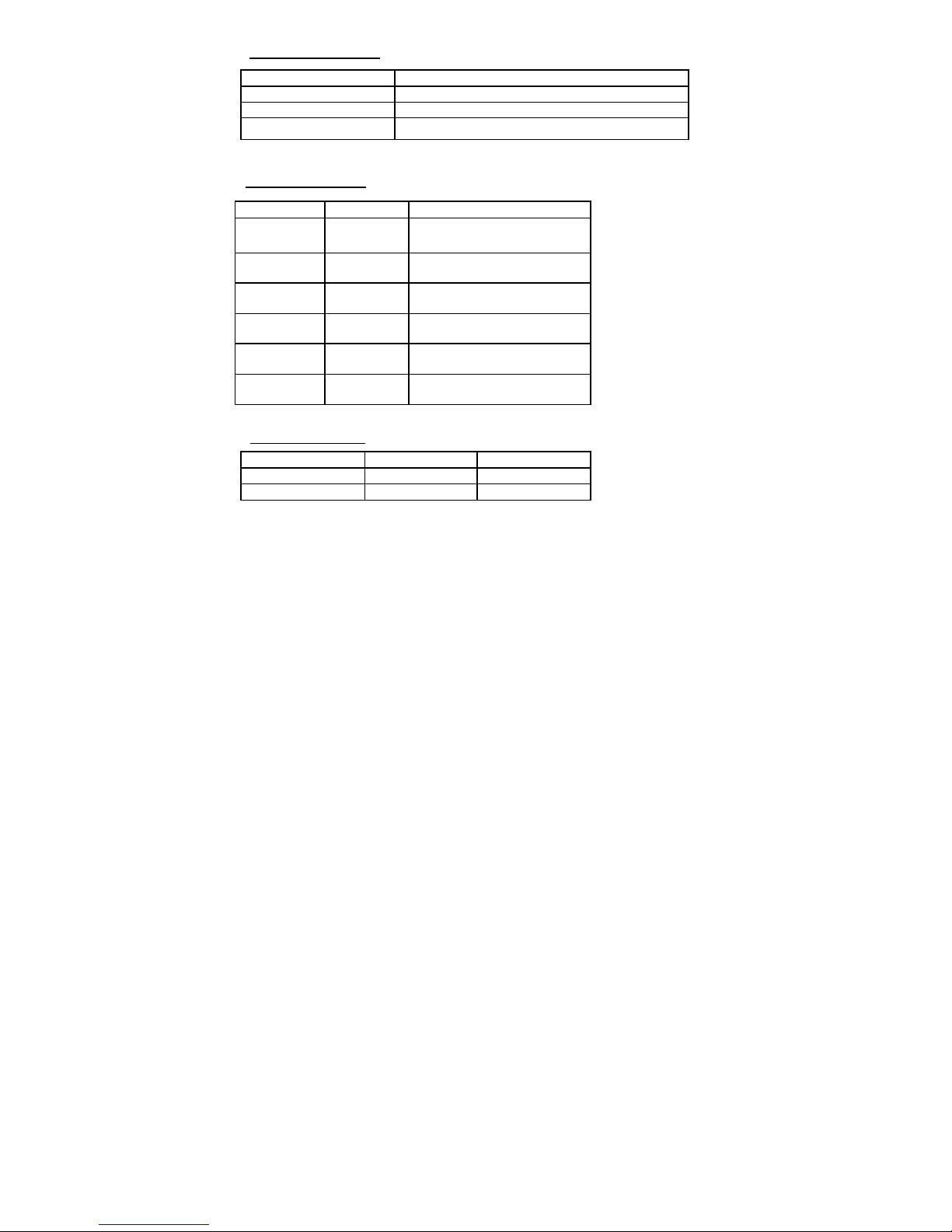

◎ Capacities of MCCB and MC and wire size

MCCB

Model No.

[A]

NS-4A003-B 5 7 20

NS-4A004-B 5 7 20

NS-4A006-B 15 7 20

NS-4A009-B 20 7 20

NS-4A013-B 30 7 20

NS-4A017-B 30 17 32

NS-4A024-B 50 25 50

NS-4A032-B 60 25 50

NS-4A038-B 70 32 60

MC(Electromagnetic contactor)

Rated Current

[A]

-14-

Rated making current

[A]

Recommend Wire Size

Note 1: The value for wires in the main circuit are for

600V

IV

PVC-insulated wires (

60 ) When the ℃

diameter

Main Circuit

Recommended wire size[mm ]

Input Wire R、S、T

NS-4A003-B 2.0 (2.0) 2.0 (2.0) 2.0 (2.0) 5.5

NS-4A004-B

NS-4A006-B

NS-4A009-B

2.0 (2.0) 2.0 (2.0) 2.0 (2.0) 5.5

2.0 (2.0) 2.0 (2.0) 2.0 (2.0) 5.5

2.0 (2.0) 2.0 (2.0) 2.0 (2.0) 5.5

P、P1

PR、X

2

U、V、W

Grounding wire

Tightening

Screw

Torque

N·m

M4 1.2 5.5

Max.

Wire size

2

mm

NS-4A013-B

NS-4A017-B

NS-4A024-B

3.5 (2.0) 3.5 (2.0) 2.0 (2.0) 5.5

5.5 (2.0) 5.5 (2.0) 3.5 (2.0) 5.5

5.5 (2.0) 5.5 (2.0) 5.5 (2.0) 5.5

NS-4A032-B

NS-4A038-B

8.0 (3.5) 8.0 (3.5) 8.0 (3.5) 14

14 (5.5) 14 (5.5) 8.0 (3.5) 14

M5 2.0 14

inverter ambient temperature is 40℃

The value in( )are for

Note 2: The maximum wire size indicates the maximum wire cross-sectional are that can be used with

the terminal block

600V bridged-polyethylened insulated wires(90℃)

-15-

※

1

The above brake resistor is selected by the max. use rate

10%ED.

Model No.

NS-4A003-B 700Ω or above

NS-4A004-B 700Ω or above

NS-4A006-B 320Ω or above

NS-4A009-B 160Ω or above

NS-4A013-B 120Ω or above

NS-4A017-B 80Ω or above

NS-4A024-B 60Ω or above

NS-4A032-B 40Ω or above

NS-4A038-B 40Ω or above

External brake resistor(Recommend) External brake resistor (limit value)

Resistor value Capacity

100W

100W

200W

400W

600W

800W

1000W

1500W

1500W

※ 1

Resistor value Capacity

420Ω or above

420Ω or above

190Ω or above

130Ω or above

80Ω or above

52Ω or above

38Ω or above

32Ω or above

32Ω or above

-16-

300W

300W

300W

500W

800W

1100W

1500W

1800W

1800W

※ 1

Recommend wire size

:

0.75[

mm

2

Composition of Control Circuit Terminals

Wire size

Terminal screw diameter:M3

]

Tightening torque:0.5[N•m]

The arrangement of control circuit terminals is as shown in the following

■ Most Attention:

▲ Don’t input stronger voltage to the control terminal! Or control board burnt

▲ Pls. move the control calbe far away to power cable in avoid of intevenue or noise.

-17-

Function of control circuit terminals

nput and

power supply

5mA

Power supply for customer

Max. allowable output current

tion through

selected on site for Inverter side

whethe connected

Type Terminal

Symbol

Multi function input

DCM

DI1

~

DI5

ACM

+V

Analog value input

VRF

V/I

Power

Supply

24V 24V client’s power supply DC24V

Multifunctional output

DO1

DOE

Analog value output

Vout

Iout

Communication terminals

TRA

TRB

SG

JP2 Terminal resistor switching

Contact output

FA

FB

FC

Terminal Name

Digital signal common

terminals

Multi-Functional input

terminals

Analog signal common

terminals

Frequency setting power

supply

Analog voltage input

terminal

Analog voltage or input

Current terminal

Multifunctional collector

output terminals

0~10V voltage output

terminal

4~20mA current output

terminal

RS485 communication sending/receiving (+) RS485“+” signal

RS485 communication sending/receiving (-)

RS485 common

communication terminals

selected

Abnormal alarm signal

Output and multifunctional

Contact output

Function Description

Common terminals for digital i

output signals and 24V

Signals valid while the short

-circuited between DIX and

DCM

Common terminals for analog

Input and output

Connected to a potentiometer

of 5kΩ,0.3W or above

Setting frequency through input

voltage

This way of current/voltage

switching independely

Sending signals for func

selected fuction code.

voltage output for setting

internal signal

Current output for setting

Internal signal

RS485“-” signal

SG terminal for connected

communicated equipment while

RS485 on communication

The selection of

100Ω terminal resistor

The default of that terminal is

Inverter warning and stop contact

output signal, which is selected the

others function through setting

function code of F1513、F1504

Rated Specification

Total current consumed:

100mA or less

Input resistor:about 6.6kΩ

When short-circuited:about 3~

Total current consumed:100mA or less

DC 10~12V

※ it can not be connnected to any

Element other than the potentiometer

Input resistor:about 34kΩ

Max. alllowed voltage:DC12V

Vo ltage input is the same spec. as

VRF current input resisto: about

250Ω, Max.allowed current:30mA

for DC 24V 150mA

Open collector output

Allowable loading: DC48V

、50mA

0~10V

4~20mA

Communication speed:1200-57600bps

Total Length:500m

※

Communication equipment side

Single-end earthed

OFF Resistor Open

ON Resistor Connection

Contact capacity: AC250V/0.3A

The selection of warning contact

Normal:FA-FC opened

Abnormal:FA-FC closed

-18-

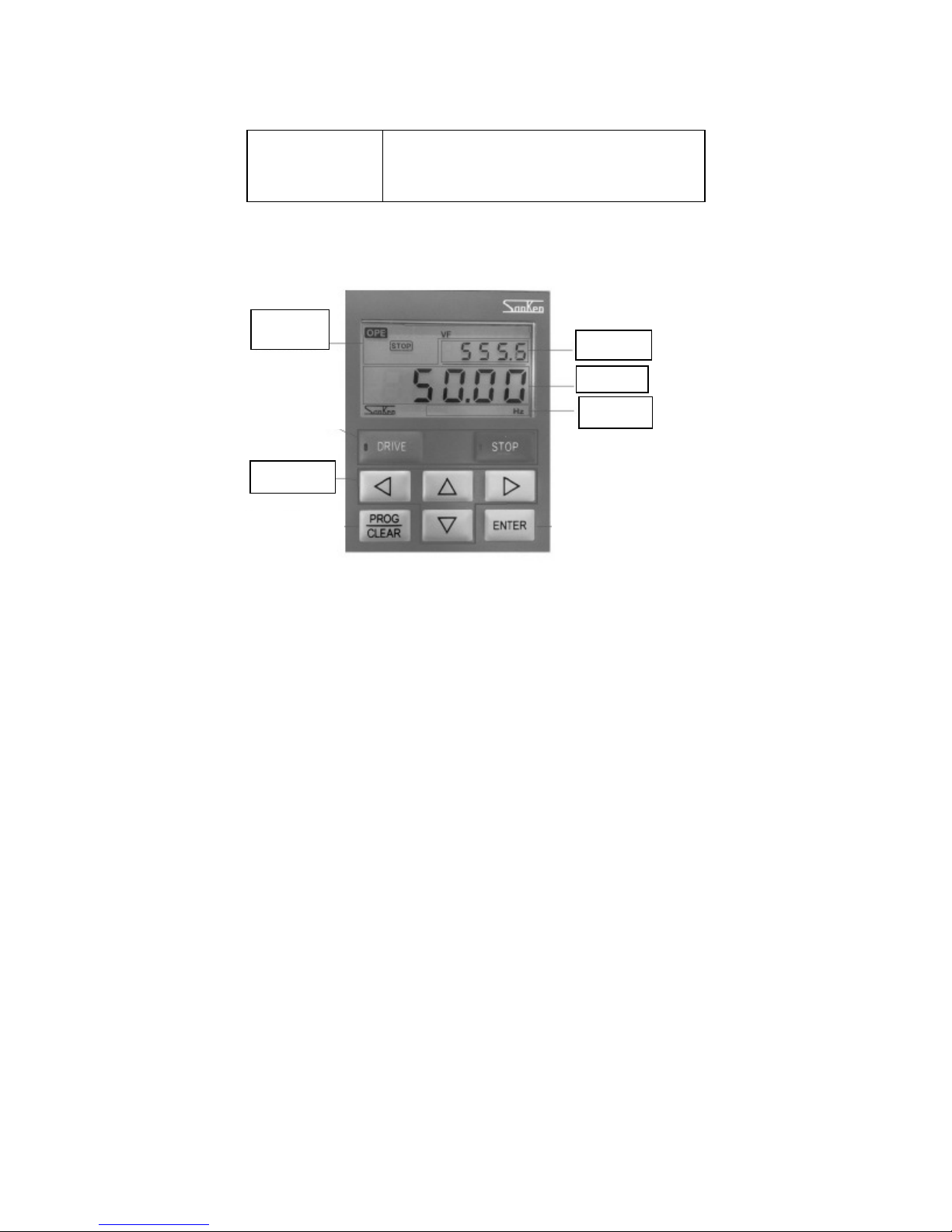

LCD Operation Panel

Information

Status Display

Name and Function for each part of panel

Inverter status during operation /stop

<Frequency> <Output Current> <Roatation Speed> <load factor>

<Output Voltage> <Pressure Value>

Inverter Condition

Direction Key

Sec ond ary sc ree n

Primary screen

Units

Description:

Primary Screen 5 digit 7 segment LCD : Shown the following data through changing Left/Right direction key or

parameters setting, “Current operation frequency、Output current、RPM、Load factor、Output voltage、Voltage value、

Set value and warning content”.

Secondary Screen 5 digit 7 seg ment LCD: Shown t he data of “Current output voltage、DC Voltage、Active power、Apparent

power、Radiator temperature and the others content” by setting parameters.

“Units” is only for primary screen, mainly display “Frequency(Hz)、Output current(A)、Speed roation(Rpm)、Load factor(%)、

Output voltage(V)、Pressure value(MPa)”.

-19-

List of each status description

Function Code Display Code No. and data

F1001, and

Operation panel display mode:

Prmary screen and Secondary screen classified by【Status Display】and【Function Code Display】

two Modes, and switched that through【PROG】Key

For example: Push【PR/CL】Key, secondary screen shown

Primary screen show the value of F1001

Push【ENTER】Key, Primary screen flashing, and revise

data through【∧ 】、【∨ 】、【<】、【>】

Push【ENTER】Key, parameters setting successfully

Status display mode for Inverter statis monitor、Alarm display、Output frequency setting and run/ stop

Inverter and so on.

5-3-1 Version Display

Turn on the power supply in a while, Primary monitor show the Inverter Version.

Such as: VER 1.00 as the below:

U0100

LCD Inverter Status Information

Display content Description

Operation panel control

External terminal control

Remote communication control

Operation

Stop

Standby

Forward

Reverse

DC braking

Inverter status mode

Display Inverter status.

Display Inverter each status in operation and stop.

Display Content Description

V/f control mode

Vector control mode

Operational parts

Parameters locked

Communication

Inverter alarm

Inverter brake-down

-20-

表

5-4

转速显示内容

Speed display content

Operation mode display

Action status

Stop

Operation

Fault

Operation lamp “off”, Stop lamp “on”

Operation lamp “on”, Stop lamp “off”

Operation lamp “flashing”, Stop lamp “flashing”

Display content

Monitor mode display

Display content

Frequency Hz

Output current A Output Current

Rotation speed rpm Speed

Load factor % Load factor

Unit

7-Segments LCD display

On operation:That is output frequency

At stop: That is setting frequency

Output Voltage V Output voltage

Pressure MPa Pressure feedback

Motor control mode

V/f control mode

Sensorless vector control Mode

Operation

Motor synchronized speed

Motor estimated speed Set speed

Stop

Set speed

During Inverter status monitor display, press【<】key or 【>】key one times, switching the display content

on the primary screen at one times, the display content on primary screen can also be switched by the function

code. As for the details, pls. referring the function code: F2303.

When the alrarm is stopped, alarm type will be shown on the primary screen.

※ During alarm display, even press【<】Key or 【>】Key, it can’t be switched the display on primary screen.

※ It can be switched to the function code display mode through press【PROG】key during alarm display.

-21-

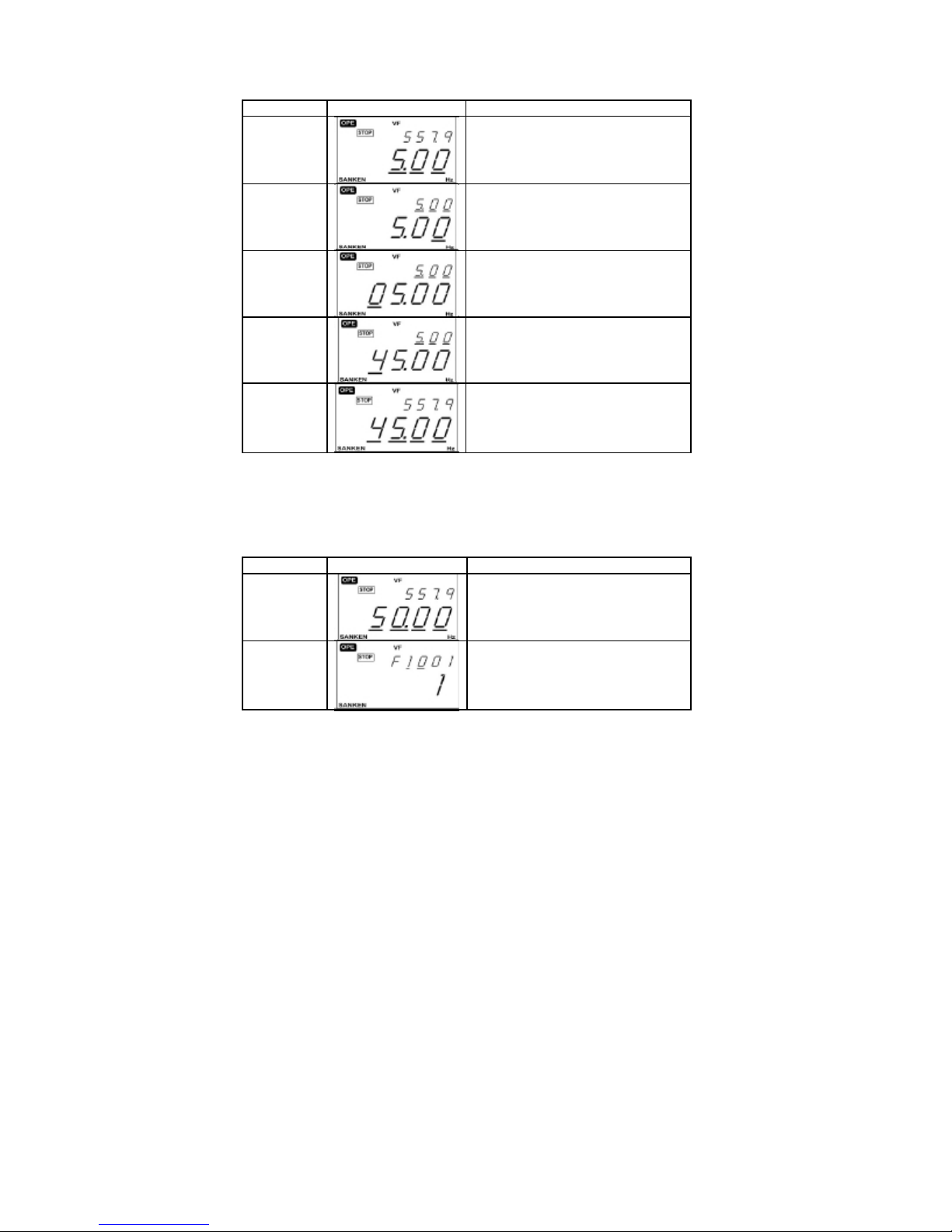

For Example

:

From

5Hz to 45Hz

For example: set

F1414=10

inished, and then back

g,

During status monitor display, frequency setting as the below method whatever is on operation or at stop

Operation

Display

Description

Status monitor display(Frequency display)

【ENTER】

Input value display the last right digit.

(Revise the value while this digit flashing)

※( 1)

【<】*3

【∧ 】*4

【ENTER】

Press 【<】key one time, flahsing position will move to

the left on one digit.

Press【<】key 3 times,ten digits flashing.

(※1)

Press【∧】key every one time, value added 1

Press【∨】key every one time, value minus 1

Press【∧】key 4 times, ten digits value will be changed

to “4”

Press【ENTER】, frequency setting f

to the status monitor interface.

※ 1 While no needing the frequency setting,press【PR/CL】key return to status monitor display Mode.

Basic operation

Function code setting

Normal operation used for the changing the value of function code.

Operation Display

【PR/CL】

Description

Status monitor display(frequency display)

Press【PR/CL】key show function code input

interface.

Second display parameters number10 flashin

and the value could be revised.

-22-

※

1 When no needing to set the new value, return to parameter number setting interface through

【∧ 】*4

【>】

【∧ 】*13

【ENTER】

【∧ 】*9

【ENTER】

【PROG】Key.Parameter numble in the second monitor flashing.

Confirmation

Some function codes need to re-confirm for the prevent of wrong operation which could be caused

of data re-written.

For example:set F1001=10

Press【∧】key, changing number to 14, second display

parameters number 14 flashing, may be revised again.

Press【>】key switch to parameters number revised

mode, second display parameters number 01 flashing,

the value could be revised

Press【∧】Key, parameters number revise to 14,

Seondary monitor parameters number 14 flashing,

may be revised.

Press【ENTER】Key, switch to parameters modify mode,

primary monitior F1414 value 1 flashing,

may be amended.

Press【∧】key, revised the parameters value to

10, primary monitor F1414 revised value 10 flashing,

and can be amended.

Press【ENTER】key, confirm the changing value,

secondary monitor parameter number 14 flashing,

may be modified. Parameter value revised finished.

.

Operation Display

【PR/CL】

Description

Status monitor display(Frequency display)

Press【PR/CL】key show display function code input

interface, secondary monitor paramerter no: 10 flashing,

may be ameneded.

-23-

※

1

ready

flashing, press

【

PROG/

CLEAR

】

key return to function code selection interface

while

alue

key, primary monitor show the setting value, secondary

【ENTER】

【∧ 】

【ENTER】

【∧ 】

【PR/CL】

found out some wrong on operation, and interrupt the action of input.

※ 2

Press【PROG/ CLEAR】key could also return to status monitor display mode interface.

Primary monitor parameter value 1 flashing, that is

meaning to be revised the current value.

Press 【∧ 】key, to change the revised v

to 10

Press 【ENTER】

monitor show flashing, remind to the final

confirmation for the setting value.(※1)

Press【∧】again, new setting confirmed, and display

return to the function code selection interface. (※2)

Press【PROG】key,return to status monitor

display interface.

5-5 Special Functions

5-5-1 Changed code display function

Due to the data in the current function code is different with the factory presets and user’s initial

value, therefore, it displays the function code for which data values have changed.

This is an effective function for finding out the difference between the current function code and

factory presets or user’s initial value.

Repair and maintenance functions such as confirmation of codes etc, can be easily executed.

-24-

For example:

D

isplay the disfference with the factory pr

eset

-25-

】

key, starting to search thee function code, that

】

Operation Display

【ENTER】

【∧ 】/【∨

Or digit keyboard

(Optional selection)

【ENTER】

Searching Ending

【∧ 】/【∨

Or

Or

【PR/CL】

Description

Select function code F1602

(Changed code display function)

Press【ENTER】Key, entered into the

parameters setting condition.

Press【∧】/【∨】or digit keyboard, select 1.

F1602=1 , this will compare the factory presets with

current function code data.

Press【ENTER】

which is the value changed compared with the factory

presets.

Primary monitor 7 segments display F

Searching ending, secondary monitor display the

changed code, and flashing.

No changed code found, secondary monitor display

on flashing, primary monitor show the current value for

related parameter.

Browse the page of different parameter code

and its current value through【∧】/【∨】key.

Press【PR/CL】Key, back to the selection

of function code interface.

ind

in flashing.

End

Alarm status confirmation

Alarm status confirmation is the function shown the Inverter status in case of a Alarm.

It could be confirmed for alarm status during the latest 5 times through function code F1806~F1810

New alarm happened, the easliest alarm will be deleted. That is latest alarm in F1806, and the earliest

one in F1810.

For example: While the latest alarm occurs, the confirmation for Inverter’s status.

Operation Display

Or

【ENTER】 Or

【∧ 】/【∨ 】

【PR/CL】

Or

Description

Select function code F1806

(Alarm status confirmation)

Press【ENTER】,alarm name in1

Monitor show the current display alarm name If

the alarm isn’t recorded, display

Alarm saving, press【∧ 】/【∨ 】, switching the

shown content. Secondary monitor display the name

(※ 1), primary monitor show the

value during alarm happened (※ 2)

Press 【PR/CL】Key,which is back to the

selection of function code

st

Monitor . 2

nd

Function code F1805=9 is set. all alarm record will be deleted. At this moment, the data records in

F1806 t~ F1810 will be erased.

-26-

※

2 The value displayed is the status before the occurrence of an alarm. Therefore, if an alarm is caused by transient over

-

current, over

※ 1:Display name as below:

Display Content

Alarm Name -

Output Frequency Hz

Output current A

Output Voltage V

Dc Voltage V

Output Power kW

Radiator Temperature ℃

Unit

voltage he stored value is the differ ent from the current value、voltage value on the alar m.

Monitor display list

Monitor Display

The Data is on flashing during initialization.

During initialization of user data, the data is displayed flashing.

The data is on flashing on the confirmation of user data.

Display shown that needs to reconfirm the operation by function code.

During search of the function code, of which user data is discrepant from

the default settings, the display is on flashing status.

The display is flashing during the trasfer of host function code data to the

operation panel.

During the trasfer of the operation panel function code to host, it is displayed flashing.

It is displayed flashing, while the desired data can’t be found through the function code

search and alarm history record.

Indicates auto turning.

Description

-27-

Function code are functionally classified into “function blocks”

Function Code

Representation and Description of Function Code

By changing the function code, Inverter action can be changed

Function

Basic operation function

F10xx~F13xx

Inpu/output-related function

F14xx~F15xx

System-related functions

F16xx~F18xx

Special function

F19xx~F20xx

Scheduled opertion functions

F21xx~Fxx

Display function F23xx F23xx LCD display function

PID fucntion

F30xx~F33xx

Water supply fu nction F34xx F34xx Water supply fu nction

Communication functions

F40xx~F41xx

Motor parameter F5xxx F5xxx Motor parameter

Vector Co ntrol F60xx F60xx Vect or Control Function

Function Block

F10xx

F11xx

F12xx

F13xx

F14xx Input function

F15xx Output function

F16xx System function

F17xx Protective function

F18xx Information function

F19xx Energy-saving function

F20xx V∕f characteristics

F21xx Multi-speed function

Fxx Scheduled operation function

F30xx Basic PID1 Function

F31xx Basic PID2 Function

F32xx Combined function of PID1,PID2

F33xx PID control parameter reading

F40xx Serial communication functions

F41xx MODBUS communication function

Function Block Name

Basic function

Starting• Braking function

Display function

Auxiliary functions

-28-

ol)

1

1

1

Function Code List

Basic Operation Function F10xx~F13xx

Runing Function F10xx~F13xx

Code Function Name Data Content

1001 Motor control mode

selection

1:V∕f Control Mode

2:Speed Control(Speed sensorless vector contr

3:Speed Control(Speedy sensor vector control)

10:Auto tuning mode 1

11:Auto tuning mode 2

40:V•f separation control

Setting

resolution

1

Factory

preset

1st Speed frequency

1002

Setting selection

1003 V∕f patten selection

1004 Torque boost

1005 Base Voltage

1006 Base Frequency 0.1~600Hz

1:Operation Panel

2:External analog VRF voltage(0~5V)

3:External analog VRF voltage(0~10V

or potentiometer)

4:External analog V/I Voltage(0~5V)

5:External analog V/I voltage(0~10V

or potentiometer)

9:External analog V/I current(4~20mA)

11: External analog VRF voltage+V/I voltage

14: External analog VRF voltage-V/I voltage

15: External analog V/I voltage-VRF voltage

18: External analog VRF voltage+V/I current

19: External analog VRF voltage-V/I current

20: External analog V/I current-VRF voltage

21: Terminal block stepping

22: Communication

25: Pulse Train Input

26: External analog VRF forward /reverse r un

operation(0~10V、5V reference)

27: External analog V/I forward/ reverse run

operation(0~10V、5V reference)

1:Linear patten

2:Square-law decreasing patten (weak)

3:Square-law decreasing patten (strong)

0~20%(Maximum voltage ratio)

400V series 0:No AVR

50~460V

-29-

1

1

0.1%

1V

0.01Hz

※ 1

※ 1

※ 1

60

1

5

1% 50

1% 50

shaped acceleration

1% 0

1% 50

1% 50

1% 0

Code Function Name Data Content

1007 Upper frequency limit 5~600Hz

1008 Lower frequency limit 0.05~200Hz

1009 Carrier frequency

adjustment

1010 Acceleration/

Deceleration Curve

Reference frequency

1011

for acceleration

/deceleration

1012 1st acceleration time 0~6500 sec.

1013 2nd acceleration time 0~6500 sec.

1014 3rd acceleration time 0~6500 sec.

1015 4th acceleration time 0~6500 sec.

1016 1st deceleration time 0~6500 sec.

1017 2nd deceleration time 0~6500 sec.

1018 3rd deceleration time 0~6500 sec.

1019 4th deceleration time 0~6500 sec.

1020 JOG acc./dec.time 0~20 sec.

1021 JOG frequency 0~60Hz

1022 1st start of S-shaped

Acceleration

1023 1st end of S-shaped

Acceleration

1024 Gradient of middle of

1st S-

1025 1st start of S-shaped

Deceleration

1026 1st end of S-shaped

Deceleration

1027 Gradient of middle of

1st S-shaped

Deceleration

5~130

1:Random Soft Carrier Mode 1

2:Random Soft Carrier Mode 2

3:Random Soft Carrier Mode 3

4:Random Soft Carrier Mode 4

1:Linear

2:S-shaped

3:Reduction of acceleration/deceleration

1~120Hz

0~200%

0~200%

0~100%

0~200%

0~200%

0~100%

-30-

Setting

resolution

0.01Hz

0.01Hz

1

1

0.01Hz

0.1 sec.

0.1 sec.

0.1 sec.

0.1 sec.

0.1 sec.

0.1 sec.

0.1 sec.

0.1 sec.

0.1 sec.

0.01Hz

Factory

preset

0.05

※ 1

※ 1

※ 2—1

※ 2—2

※ 2—3

※ 2—4

※ 2—5

※ 2—6

※ 2—7

※ 2—8

0.1

1% 50

1% 50

1% 0

1% 50

1% 50

1% 0

1

0

1

1

Code

1028 2nd Start of S-shaped

1029 2nd End of S-shaped

1030 Gradient of middle of 2nd

1031 2nd Start of S-shaped

1032 2nd End of S-shaped

1033 Gradient of middle of

1034

1035

1036

1037 Terminal block stepping

1038 Terminal block stepping

1101 Operation command selection

Function Name

Acceleration

Acceleration

2nd S-shaped acc.

Deceleration

Deceleration

2nd S-shaped dec.

1st speed frequency selection A

1st speed frequency selection B

1st speedy frequency selection C

Frequency varied

Frequency clear

Data Content

0~200%

0~200%

0~100%

0~200%

0~200%

0~100%

1: Operation Panel

2: External analog VRF voltage(0~5V)

3: External analog VRF Voltage(0~10V

or potentiometer)

4: External analog V/I voltage(0~5V)

5: External analog V/I voltage(0~10V

or potentiometer)

9: External analog V/I current(4~20mA)

21: Terminal block stepping

22: Communication

25: Pulse train input

26: External analog VRF forward/reverse run

(0~10V 5V Reference)

27: External analog V/I forward/reverse run

(0~10V 5V Reference)

0.1~10Hz/sec

0:Clear No(Frequency Maintain)

1:Power OFF clear

2:Stop Clear

1:Operation Panel

2:External Terminal

3:Communication

4: External Terminal (Three Wired)

Setting

resolution

1

0.1Hz 2.5

1

1

Factory

preset

1

1

1102 Starting Method

1:Starting frequency

2:Flying Start

3:Starting frequency after DC braking

-31-

1

1

0

0

0

5

0

1

1

1

1 5

Duty cycle of brake resistor

Discharge resistor on signal

1

Code Function Name

1103 Starting frequency

1104 Operation start frequency 0~20Hz

1105 Start delay time

1106 Start standby time

1107 Start standby frequency 0.05~60Hz

1108 Restart after momentary

Power failure

1109 Direction of rotation of

Motor

1110 Direction of rotation of

Motor (Setting through

Operation panel)

1111 Braking method

1112 DC braking start frequency

Data Content

0.05~60Hz

0~5 sec.

0~120 sec.

0: Do not start

1: Restart

2: Compensation for momentary power failure

1:Forward and reverse run

2:Forward run only

3:Reverse run only

1:Forward

2:Reverse

1: Deceleration to stop

2: Deceleration to stop + DC braking

3: Free run stop

4: Deceleration to stop + continuously DC braking

0.05~20Hz

1113 DC braking time

1114 DC braking force

1115

1116

Output time

1117 Parameters setting

Continuously DC braking

1~25 Sec.

1~10

0: No brake resistor

2~25%ED

98: No discharge resistor protection

(with discharge)

99: External brake unit

0.01~10.00 sec.

0:Braking invalid

1:Braking Valid

2:Valid for braking time

-32-

Setting

resolution

0.01Hz

0.01Hz

0.1sec.

0.1sec.

0.01Hz

1

1

1

1

0.01Hz

0.1 Sec. 2

1%ED

0.01sec. 0.1

1

Factory

preset

0.5

※ 1

1

2

2

2

1 5

1 5

1 1

1

Code Function Name

1118 DC braking start

Frequency on stop

1119 DC braking time

T1

1120 DC braking time

T2

1121 DC braking time

T3

1122 DC braking force F1

1123 DC braking force F2

1124 Overexcited deceleration

Rate

1201 Monitor display selection

(Optional Parts)

Data Content

0.05~60Hz

0.1~6500.0 sec.

0.1~6500.0 sec.

0.1~6500.0 sec.

1~10

1~10

0.01~4.00

1:Frequency [Hz]

2:Output Current [A]

3:Speed of rotation [rpm].

4:Load factor [%]

5:Pressure[MPa]

6:No unit display

-33-

Setting

resolution

0.01Hz

0.1sec.

0.1sec.

0.1sec.

1

Factory

preset

3

0

1 ※

Code Function Name

1202 State display selection

Data Content

1:No units(Multiple of F1203 )

2:Output voltage [V]

3:Dc voltage [V]

4:Active power [kW]

5:Apparent power [kVA].

6:Radiator Temperature [℃]

7:Command Speed [rpm]

8:PID1 feedback value [Hz]

9:PID2 feedback value [Hz]

10:VRF analog input value [Hz]

11:V/I analog input value [Hz]

14:Partial excitation current [A]

15:Partial torque current [A]

17:Setting pressure[MPa]

18:Command pressure[MPa]

19:Pressure feedback[MPa]

20:Regular pump switching calculating time

29:Command frequency [Hz]

35:Detect speed of rotation[rpm]

44:Target frequency[Hz]

45:Output frequency[Hz]

Setting

resolution

1

Factory

preset

1203 Multiple for no unit

display

1301 1st jump bottom frequency

0~100 times

(multiple of output frequency)

0~600 [Hz]

1302 1st jump top frequency

0~600 [Hz]

1303 2nd jump bottom frequency

0~600 [Hz]

1304 2nd jump top frequency

0~600 [Hz]

1305 3rd jump bottom frequency

0~600 [Hz]

1306 3rd jump top frequency

0~600 [Hz]

1307 Auto alarm recovery

1308 Instability elmination 0~20

0:No Auto reset function

1:Auto reset function

0.01 times 1

0.01 [Hz] 0

0.01 [Hz] 0

0.01 [Hz] 0

0.01 [Hz] 0

0.01 [Hz] 0

0.01 [Hz] 0

1

-34-

mode

1: Continuous Operation

0

0

1

2

Code Function Name

Operation direction

1309

Switching in v/f control

Data Content

0: Start from the direction opposite to current

directiorn after a stop

Setting

resolution

1

Factory

preset

1315 Shotest operation time

function

1316 2nd upper frequency

1317 3rd upper frequency

1318 Cooling fan ON/OFF

control

1319 Functions corresponding

to high altitude areas

1320 Rating Selection

0~99.99 sec.

5~600Hz [Hz]

5~600Hz [Hz]

0:0N/OFF control

1:Normally ON

1:1000m or below

2:1000m~1500m or below

3:1500m~2000m or below

4:2000m~2500m or below

5:2500m~3000m

1:A Mode(Heavy Loading)150% 1 min.

2:B Mode(Light loading)120% 1 min.

-35-

0.01 sec. 0

0.01 [Hz] 60

0.01 [Hz] 60

1

1

1

Function Code List

-

Input/Output Functions

F14xx

~

F16xx

0

60

0

60

1 10

1 10

1 0

0

1

1

Input/Output Functions F14xx~F16xx

Code Function Name

1401 Bias frequency

(VRF)

1402 Gain frequency

(VRF)

1403 Bias frequency

(V/I)

1404 Gain frequency

(V/I)

1407 External analog input

Filter time

(VRF)

1408 External analog input

Filter time

(V/I)

1410 Set frequency gain

1411 Analog input switching

For set frequency gain

Data Content

0~±600 [Hz]

(Frequency at 0V )

0~±600 [Hz]

(frequency at 5V / 10V )

0~±600 [Hz]

(Frequency at 0V / 4mA )

0~±600 [Hz]

(frequency at5V or 10V or 20mA)

1~500(set value 1=10ms)

1~500(set value 1=10ms)

0~100

0: No analog input

1: External analog VRF voltage(0~5V)

2: External analog VRF voltage(0~10V

or potentiometer)

3: External analog V/I voltage(0~5V)

4: External analog V/I voltage(0~10V

or potentiometer)

8: External analog V/I current(4~20mA)

Setting

resolution

0.1 [Hz]

0.1 [Hz]

0.1 [Hz]

0.1 [Hz]

Factory

preset

1

1412 MBS terminal input

Method

1413 ES input signal

Functions

1:Level triggered

2:Edge triggered

1:Normally open

2:Normally close

1

1

-36-

DI1

1

Code Function Name Data Content

1414

Input terminal

1415

Definition

1416

Input terminal DI2

1417

Definition

1418

Input terminal DI3

Definition

Input terminal DI4

Definition

Input terminal DI5

Definition

0:Unused

2:RR,

4:3DF

6:ES,

8:AD2,

10:JOG,

12:9DF,

14:RR+JOG,

16:RR+AD2,

18:RR+AD3,

20:RR+2DF,

22:RR+3DF,

24:RR+2DF+3DF,

26:RR+AD2+2DF,

28:RR+AD2+3DF,

29:FR+AD2+2DF+3DF,

30:RR+AD2+2DF+3DF,

31:FR+AD3+2DF,

33:FR+AD3+3DF,

35:FR+AD3+2DF+3DF,

36:RR+AD3+2DF+3DF,

37:PTR,

40:HD,

46:CCL,

57:P0,

59:FR+RCCL,

65:RR+MBS,

68:2DF+AD3,

70:3DF+AD3,

75:3MAX,

77:PIDLCK,

79:Terminal selection for

continuous DC braking

84: S2,

86: PIDH,

88: PID1EX,

91: IHOLD,

109: RCCL,

115: 1DFB,

117: ROPE,

119: ROPE+RCOM,

121: 1DFB+RCOM,

130:RUN

131:STOP

135:FR/RR

136:R3W

137: ROPE+RCOM+R3W

138: Valid for high speed pulse

train

253~255: for factory

adjustment

1:FR,

3:2DF,

5:MBS,

7:RST,

9:AD3

11:5DF,

13:FR+JOG,

15:FR+AD2,

17:FR+AD3,

19:FR+2DF,

21:FR+3DF,

23:FR+2DF+3DF,

25:FR+AD2+2DF,

27:FR+AD2+3DF,

32:RR+AD3+2DF,

34:RR+AD3+3DF,

39:FR+5DF,

47:PC,

58:FR+CCL,

64:FR+MBS,

67:2DF+AD2,

69:3DF+AD2,

74:2MAX,

76:VFPID,

83:For factory

Adjustment

85:PIDL,

87:RPID1,

89:PID2EX,

92:ICLEAR

114:1DFA,

116 :

1DFA+1DFB,

118: RCOM,

120: 1DFA+ROPE,

122: 1DFA+1DFB

+ROPE+RCOM,

Setting

resolution

Factory

preset

1

-37-

10

Effective number of bits for

10

0

1

0

Code Function Name

1422 Reference frequency

for pulse input

1423

Effective number of bits

for VRF detection

1424

V/I detection

1501 Internal analog output

function 1

1502 Internal analog output

Coefficient 1

1503 Internal analog output

Bias 1

Data Content

1000~60000

7~10bit

7~10bit

0: No Function

1: Set frequency [Hz]

2: Output frequency [Hz]

3: PID1 feedback value [Hz]

4: PID2 feedback value [Hz]

5: Output current [A]

6: Output voltage [V]

7: DC voltage [V]

8: Radiator temperature [℃]

9: Load factor [%] (electric thermistor

integrated value)

10: Load factor [%](Ratio to rated current)

11: VRF analog input value [V]

12: V/I analog input value [V]

14: Speed [rpm]

15: Active power [kW]

16: Apparent power [kVA]

17: PID1 command value [Hz]

18: PID1 input deviation value [Hz]

19: PID2 command value [Hz]

20: PID2 input deviation value [Hz]

24: External PID1 output value [Hz]

25: External PID2 output value [Hz]

35: command frequency [Hz]

36: command torque [%]

0~20

0~±10.0V

-38-

Setting

resolution

1bit

1bit

0.01

0.1V

1Hz

Factory

preset

1000

1

0

1

0

10

0

Code Function Name Data Content

1504 Internal analog output

Function 2

1505 Internal analog output

coefficient 2

1506 Internal analog output

Bias 2

1507 Approach frequency 0~600Hz

Frequency matching range

1508

0:No function

1:Set frequency [Hz]

2:Output frequency [Hz]

3:PID1 feedback value [Hz]

4:PID2 feedback value [Hz]

5:Output current [A]

6:Output voltage [V]

7:DC voltage [V]

8:Radiator temperature [℃]

9: Load factor [%] (accumulated vale of electric

thermistor)

10: Load factor [%](Ratio to rated current)

11:VRF analog input value [V]

12:V/I analog input value [V]

14:Speed [rpm]

15:Active power [kW]

16:Apparent power [kVA]

17:PID1 command value [Hz]

18:PID1 input deviation value [Hz]

19:PID2 command value [Hz]

20:PID2 input deviation value [Hz]

24:External PID1 output value [Hz]

25:External PID2 output value [Hz]

35:Command frequency [Hz]

36:Command torque [%]

0~20

4~±20.0mA

0~10Hz

-39-

Setting

resolution

0.1mA

0.01Hz

0.01Hz

0.01

Factory

preset

1

Selection of output

1

Code Function Name Data Content

1509

terminal DO1

0: Unused

1: In operation 1

2: Undervoltage

3: End of simple scheduled operation

4: In operation 2

5: Frequency matching (1st speed frquency)

6: Frequency matching (1st ~16th speed frequency)

7: Frequency approach

8: Overload alarm level setting signal (the value of F1704 )

9: Electric thermistor pre-alarm signal(80% of electric

thermistor)

10:Radiator overheat pre-alarm signal

13:Excitiation and DC braking signals

14:Lower frequency limit matching signal

15:Upper frequency limit matching signal

18:FR signal 19:RR signal

20:2DF signal 21:3DF signal

22:5DF signal 23:9DF signal

24:AD2 signal 25:AD3 signal

26:JOG signal 27:MBS signal

28:ES signal 29:RST signal

32:Discharge resistor on signal

34:Frequency counter(output frequency)

35:Frequency counter(command frequency)

36:Overload alarm level setting signal (Including

Acceleration/Deceleration)

43:Low speed detection signal

47:Motor speed counter

48:Forward run detection signal

49:Reverse run detection signal

60:breakdown output

61:In forward run(only for three wired)

62:In reverse run(only for three wired)

Setting

resolution

1

Factory

preset

1512 Counter output

multiple

1~100 times

1 times 1

-40-

0

Code Function Name Data Content

1513 Relay contact output

Selection

0: Alarm contact

1: In operation 1

2: Undervoltage

3: End of simply scheduled operation

4: In operation 2

5: Frequency matching (1st speed frequency)

6: Frequency matching(1st ~16th speed frequency)

7: Frequency approach

8: Overload alarm level setting signal (the value of

F1704)

9: Electric thermitor pre-alarm signal(80% of electric

thermitor)

10:Radiator overheat pre-alarm signal

13:Excitation and DC braking signals

14:Lower frequency limit matching signal

15:Upper frequency limit matching signal

16:Servo on ready signal

17:Zero servo completion signal

18:FR signal 19:RR signal

20:2DF signal 21:3DF signal

22:5DF signal 23:9DF signal

24:AD2 signal 25:AD3 signal

26:JOG signal 27:MBS signal

28:ES signal 29:RST signal

32:Discharge resistor on signal

36:Overload alarm level setting signal (Including in

Acceleration/Deceleration)

43:Low speed detection signal

48:Forward run detection signal

49:Reverse run detection signal

Setting

resolution

1

Factory

preset

1518 Low speed matching

Level

1519 Low speed matching

Range

0~2000rpm

0~100rpm

1rpm 100

1rpm 10

-41-

Function Code List

– System

-

Related Functions

F16xx~F18xx

0

0

0

0

System-related Functions F16xx~F18xx

Code Function Name

1601 Copy Function

(Optional accessories)

Data content

0:No function

1: Transfer current code data to the operation panel

2: Transfer the contents stored by operation panel

to the inverter

(Excluding motor parameters measured)

3: Transfer the contents stored by operation panel

to the inverter

(Including motor parameters measured)

Setting

resolution

Factory

preset

1

1602

Changing code display

Function

1603 Function Lock

1604 Data initialization

1701 Output current limiting

Function

1702 Electric thermal setting

0:No Function

1:Display differences from factory preset

2:Display differences from user’s initial value

0:Code data changeable(No lock function)

1:Code data unchangable(except F1603)

2:Code data (except frequency setting-related)

unchangable(except F1603、F1021、

F2101~ F2116)

3:Code data unchangeable (excep F1603 and

function code using communication)

0:No function

1:Initialize factory presets

2:Invalid parameters by auto tuning

3:Initialize user’s data

99:set user’s initial value

A Mode 0:No function

50~200%

B Mode 0:No function

50~150%

0:No function

20~105%

-42-

1%

1%

1

1

1

150%

120%

100

0

1

0

Missing phase detection

3

1

Code Function name

1703 Output current limit

at constant speed

Data content

0: No function

1: Yes, V/f mode(Current acceleration/deceleration

time)

2: Yes, V/f mode( 1st acceleration/deceleration

time)

3: Yes, V/f mode(2nd acceleration/deceleration

time)

4: Yes, V/f mode (3rd acceleration/deceleration

time)

5: Yes, V/f mode (4th acceleration/deceleration

time)

6: Yes, V/f mode and speed vector control mode

(1st acceleration/deceleration time)

7: Yes, V/f mode and speed vector control mode

(2nd acceleration/deceleration time)

8: Yes, V/f mode and speed vector control mode

(3rd acceleration/deceleration time)

9: Yes, V/f mode and speed vector control mode

(4th acceleration/deceleration time)

Setting

resolution

1

Factory

preset

1704 Overload alarm level

Setting value

1705 Motor Type

1706

Function to switch “OV”

And “LV” alarms when

stopped

1707

Function

1708 Overvoltage stalling

prevention functions

1709 Feedback signal

disconnection detection

time

A Mode

20%~200%

B Mode

20%~150%

1:General-purpose motor

2:Exclusive motor for Inverter

0:“ov”enabled; “Lv”disabled when stopped

1:“ov”disabled; “Lv”enabled when stopped

2:“ov”disabled; “Lv”disabled when stopped

3:“ov”enabled; “Lv”enabled when stopped

0:No input phase loss, No output phase loss

1:Input phase loss, No output phase loss

2:No input phase loss, output phase loss

3:Input phase loss, output phase loss

0:No overvoltage stalling prevention functions

1:Overvolatage stalling prevention functions

0:Only warning

0.01~119.99 sec.

120:No disconnection detection

-43-

1%

1%

1

1

1

1

0.01sec. 5

150

120

0

0

Code Function Name

1710

Carrier frequency varied

by lowering temperature

(Active when only A

mode selected)

1801 Inverter host software

Version query

1802 Memory version query

Data content

0:Disabled

1:Enabled

Read only

Read only

Setting

resolution

Factory

preset

1

Version

Version

1803 Operation panel software

Version query

1804 Operation time display Read only

1805 Reading alarm data

1806

Alarm status confirmation 1 Read only

1807

Alarm status confirmation 2 Read only

1808

Alarm status confirmation 3 Read only

1809

Alarm status confirmation 4 Read only

1810

Alarm status confirmation 5 Read only

Read only

0:No function

1:Read start

9:Record erase

-44-

1 hr.

Version

---

1

---

---

---

---

---

---

---

---

---

---

Special Functions

F19xx~F20xx

0

1% 0

10

1

separation command

0

1V 0

1V 0

20

40

0

time constant

1 10

1

Special Functions F19xx~F20xx

Code Function Name

1901 Energy-saving mode

selection

1902

Simple energy-saving rate 0~50%

1903

Simple energy-saving time 0~65000 sec,

2001 V·f separation function

selection

2002 V·f

voltage

2003 Arbitrary V/f patten

Intermediate voltage 1

2004 Arbitrary V/f patten

Intermediate voltage 2

2005 Arbitrary V/f patten

Intermediate frequency 1

2006 Arbitrary V/f patten

Intermediate frequency 2

2007 Automatic torque boost

selection

Data Content

0:No function

1:Simple energy-saving mode(V/f mode)

2:Auto energy-saving mode

1:V·f proportional separation

2:Complete separation

0:No function (command given by VRF)

0.01~10.23V

0~460V

0~460V

0.05~600Hz

0.05~600Hz

0:No automatic torque boost

1:Vo ltage compensation function

2:Slip frequency compensation

Setting

resolution

0.01V

0.01Hz

0.01Hz

1

1sec.

1

1

Factory

preset

2008

2009

Slip compensation response

Slip compensation multiple

0~1000(set value 1=10ms)

0.01~2

-45-

0.01

Graph operation function

F21xx~Fxx

0

10

20

30

40

50

60

0

0

5

15

25

35

45

55

0

0

1

10

10

10

10

10

10

10

10

10

T10

10

10

Graph operation function F21xx~Fxx

Code Function Name Data Content

2101 1st frequency

2102 2nd frequency 0~600Hz

2103 3rd frequency 0~600Hz

2104 4th frequency 0~600Hz

2105 5th frequency 0~600Hz

2106 6th frequency 0~600Hz

2107 7th frequency 0~600Hz

2108 8th frequency 0~600Hz

2109 9th frequency 0~600Hz

2110 10th freuqency 0~600Hz

2111 11th frequency 0~600Hz

2112 12th frequency 0~600Hz

2113 13th frequency 0~600Hz

2114 14th frequency 0~600Hz

2115 15th frequency 0~600Hz

2116 16th frequency 0~600Hz

Selection of

2201

scheduled operation

Simple scheduled

2202

operation repetition

2203 Operation timer T1 0~65000 sec.

2204 Operation timer T2 0~65000 sec.

2205 Operation timer T3 0~65000 sec.

2206 Operation timer T4 0~65000 sec.

2207 Operation timer T5 0~65000 sec.

2208 Operation timer T6 0~65000 sec.

2209 Operation timer T7 0~65000 sec.

2210 Operation timer T8 0~65000 sec.

2211 Operation timer T9 0~65000 sec.

2212 Operation timer

2213 Opertion timer T11 0~65000 sec.

0~600Hz

0:Normal operation

1:Simple scheduled operation

2:Disturbed operation

0:Continuous

1~250:Repetition count

0~65000 sec.

-46-

Setting

resolution

0.01Hz

0.01Hz

0.01Hz

0.01Hz

0.01Hz

0.01Hz

0.01Hz

0.01Hz

0.01Hz

0.01Hz

0.01Hz

0.01Hz

0.01Hz

0.01Hz

0.01Hz

0.01Hz

1

1

1sec.

1sec.

1sec.

1sec.

1sec.

1sec.

1sec.

1sec.

1sec.

1sec.

1sec.

Factory

preset

-47-

10

10

10

10

10

1

1

11

11

in

T3

11

in T4

11

in T5

21

in T6

21

in T7

21

in T8

11

in T9

11

in

T10

11

Code Function Name

2214 Operation timerT12 0~65000 sec.

2215 Operation timerT13 0~65000 sec.

2216 Operation timerT14 0~65000 sec.

2217 Operation timerT15 0~65000 sec.

2218 Operation stop timer

T0

Midway stop

2219

deceleration time

Midway start

2220

acceleration time

Forward/reverse and

2221

Acceleration

/deceleration in T1

Forward/reverse and

2222

acceleration/deceleration

in T2

Forward/reverse and

2223

Acceleration/deceleration

Forward/reverse and

2224

Acceleration/deceleration

Forward/reverse and

2225

Acceleration/deceleration

Forward/reverse and

2226

Acceleration/deceleration

Forward/reverse and

2227

Acceleration/deceleration

Forward/reverse and

2228

Acceleration/deceleration

Forward/reverse and

2229

Acceleration/deceleration

Forward/reverse and

2230

Acceleration/deceleration

Data Content

0~65000 sec.

1:1st deceleration time(value of F1016 )

2:2nd deceleration time(value of F1017 )

3:3rd deceleration time(value of F1018)

4:4th deceleration time(value of F1019 )

1:1st acceleration time(value of F1012 )

2:2nd acceleration time(value of F1013)

3:3rd acceleration time(value of F1014)

4:4th acceleration time(value of F1015)

X Y

X…1: Forward

2: Reverse

Y…1~4: Acceleration/deceleration time

specified

Setting

resolution

1sec.

1sec.

1sec.

1sec.

1sec.

1

1

---

---

---

---

---

---

---

---

---

---

Factory

preset

in

T11

11

in T12

21

in

T13

21

in

T14

21

in

T15

21

0

1% 0

Code Function Name

Forward/reverse and

2231

Acceleration/deceleration

Forward/reverse and

2232

Acceleration/deceleration

Forward/reverse and

2233

Acceleration/deceleration

Forward/reverse and

2234

Acceleration/deceleration

Forward/reverse and

2235

Acceleration/deceleration

2236

Disturb modulation

analog input switching

Disturb modulation rate

2237

Data Content

0: No analog input

1: External analog VRF voltage(0~5V)

2: External analog VRF voltage(0~10V

or potentiometer)

3: External analog V/I voltage(0~5V)

4: External analog V/I voltage(0~10V

or potentiometer)

8: External analog V/I current(4~20mA)

0~50%

-48-

Setting

resolution

Factory

preset

---

---

---

---

---

1

Display Function

F23xx

1 8

1 1

Display Function F23xx

Code Function Name Data Content

LCD contrast adjustment

2301

2303 LCD ‘s 1st screen

display parameters

setting(1-5)

1~16

0:No display

1:Frequency[Hz]

2:Output current[A]

3:Speed[rpm]

4:Load factor[%]

5:Output voltage[V]

6:DC voltage[V]

7:Active power[kW]

8:Apparent power[kVA]

9:Radiator Temperature[℃]

10:Command speed[rpm]

11:PID1 feeback value[Hz]

12:PID2 feedback value[Hz]

13:VRF analog input value

14:V/I analog input value

17:Partial excitation current[A]

18:Partial torque current[A]

20:Set pressure[Mpa]

21:Command pressure[Mpa]

22:Feedback pressure[Mpa]

32:Command frequency[Hz]

33:Command torque[%]

42:Target frequency[Hz]

43:Output frequency[Hz]

99:Factory adjustment

Setting

resolution

Factory

preset

-49-

2

10

Code Function Name Data Content

2304 LCD ‘s 2nd screen

display parameters

setting

1:No unit(Multiple of F1203 )

2:Output voltage [V]

3:DC voltage[V]

4:Active power [kW]

5:Apparent power [kVA].

6:Radiator temperature [℃]

7:Command speed [rpm]

8:PID1 feedback value [Hz]

9:PID2 feedback value [Hz]

10:VRF analog input value [Hz]

11:V/I analog input value [Hz]

14:Partial execitation current [A]

15:Partial torque current [A]

17:Set pressure[MPa]

18:Command pressure[MPa]

19:Feedback pressure[MPa]

20:Regular pump to switch calculating time

29:Command frequency [Hz]

35:Detection speed [rpm]

44:Target frequency [Hz]

45:Output frequency [Hz]

Setting

resolution

Factory

preset

1

2306

LCD backlight out

time

0:off

1~600:the time until it goes off

999:Normally on

-50-

1min.

PID Function

F30xx~F33xx

command value input

1

0

judgement

1 10

PID Function F30xx~F33xx

Code Function Name

3001

PID1

switching

Data Content

1:Frequency

2:External analog VRF voltage(0~5V)

3:External analog VRF voltage(0~10V

or potentiometer)

4:External analog V/I voltage(0~5V)

5:External analog V/I voltage(0~10V

or potentiometer)

9:External analog V/I current(4~20mA)

11:Function code setting(F3017)

Setting

resolution

1

Factory

preset

3002

PID1 Feedback input

switching

3003

PID1 control proportion’

gain

3004

PID1 control integral time

3005

PID1 control differential

time

3006

PID1control integral separation

3007

PID1 feedbak signal

Input filter time constant

value

0: No input

1: External analog VRF voltage(0~5V)

2: External analog VRF voltage(0~10V

or potentiometer)

3: External analog V/I voltage(0~5V)

4: External analog V/I voltage(0~10V

or potentiometer)

8: External analog V/I current(4~20mA)

10: Communication mode

0~100

0.01~100 sec.

0~100 sec.

5~100%(upper frequency limit reference)

1~500(set value 1=10ms)

3008 Indirect PID1 input

reference

3009 PID1 deviation limit

value

3010 PID1 output limit value 0:No limit

5~100%(Target value reference)

0:No limit

1~100%(Upper freuqncy limit reference)

1~100%(Upper frequency limit reference)

1

0.01 0.1

0.01 sec. 1

0.01 sec. 0

0.1% 100

0.1% 20

0.1% 100

0.1% 100

-51-

1

1:

The positive or negative

deviation indicates the

d

ifferent

gain

1

1

1

0

0

0

Code Function Name

PID1 operation polarity

3011

switching

3012

PID1 gain polarity switching

3013 PID1 command value

gain

3014 PID1 feedback value

gain

3015

PID1 control proportional

gain( negative F3012=2)

3016

PID1 control integral time

(negative :F3012=2)

3017

PID1 control command value

3018

PID1 control feedback value

(communication function)

3019

Frequency corresponding to

PID1 control max. command

value

3101 PID2 command value

Input switching

Data Content

1:Command value-feedbakck value

2:Feedback value-command value

same gain

2: The positiveor negative deviation indicates the

0~50

0~50

0~100

0.01~100 sec.

0~6000

0~6000

0~600Hz

1: Frequency

2: External analog VRF voltage(0~5V)

3: External analog VRF voltage(0~10V

or potentiometer)

4: External analog V/I voltage(0~5V)

5: External analog V/I voltage(0~10V

or potentiometer)

9: External analog V/I current(4~20mA)

11: Function code setting(F3117)

Setting

resolution

1

1

0.01

0.01

0.01

0.01 sec. 0.1

0.1

0.1

0.01Hz 60

1

Factory

preset

0.1

-52-

0

Code Function Name Data Content

3102

PID2 Feedback input

switching

0:No input

1:External analog VRF voltage(0~5V)

2:External analog VRF voltage (0~10V

or potentiometer)

3:External analog V/I voltage(0~5V)

4:External analog V/I voltage (0~10V

or potentiometer)

8:External analog V/I current(4~20mA)

10:Communication mode

-53-

Setting

resolution

Factory

preset

1

Setting

resolution

Factory

preset

roportional

1

0

value

1 10

20

1

1:

The plus or minus de

viation indicates

the

different

gain

1

1

1

0

function

0

Code Function Name

3103 PID2 control p

gain

3104 PID2 control integral

Time

3105

PID2 control dividential

Time

PID2 control integral

3106

speparation judgement

3107

PID2 feedback signal

Input filter time constant

3108 Indirect PID2 input

Reference

3109

PID2 deviation limit value

3110 PID2 output limit value

3111 PID2 operation polarity

switching

3112 PID2 gain polarity

Switching

3113 PID2 command value

gain

3114 PID2 Feedback value

Gain

3115

PID2 control proportional

gain

(Negative :F3012=2)

3116

PID2 control integral time

(negative :F3012=2)

Data Content

0~100

0.01~100 sec.

0~100 sec.

5~100%(Upper frequency limit reference) 0.1%

1~500(set value 1=10ms)

5~100%(Target value reference)

0:No limit

1~100% (Upper frequency limit reference)

0:No limit

1~100% (Upper frequency limit reference)

1:command value-feedback value

2:feedback value-command value

same gain

2: The plus or minus deviation indicates the

0~50

0~50

0~100

0.01~100 sec.

0.01

0.01 sec.

0.01 sec.

0.1%

0.1%

0.1%

1

1

0.01

0.01

0.01

0.01sec.

0.1

100

100

100

0.1

0.1

3117 PID2 control command

Value

PID2 control feedback

3118

value(communication

)

0~6000

0~6000

0.1

0.1

-54-

60

1

1

)

20

2

0

0

1

0

1

1

1

Code Function Name

Frequency corresponding

3119

to PID2 control max.

command value

Data Content

0~600Hz

Setting

resolution

0.01Hz

Factory

preset

3123

PID start mode seleciton

3124 PID end mode selection

3125 PID end setting value 1~100%(upper frequency limit standard

3127

PID feedback signal

abnormal detection time

3201

PID control action selection

3203

External PID control

selection

3204 External PID operation

mode selection

3205

PID constitution selection

3206 Command value addition

Calculation PID control

gain

3207

PID1/PID2 switching time

1:Direct input mode

2:Condition input mode

1:Direct end mode

2:Condition end mode

0:Only warning

0.01~119.99 sec.

120:No abnormal detection

0:Open loop control

1:PID1 control

2:PID2 control

4:External terminal switching PID control

5:Timing switch PID control

0:No external PID control

1:PID1 external control

2:PID2 external control

4:PID1 and PID2 external control

1:Operation interlock with Inverter operation

2:PID output after power input

3:PID output controled by external terminals

0:without command value addition calculation

1:with command value addition calculation

0.01~100

0.1~6000 min.

1

1

0.1%

0.01 sec.

1

1

1

1

0.01

0.1 min.

0.1

3301 Reading PID1 command

Value

3302 Reading PID1 feedback

Value

Ready only

Ready only

---

---

-55-

1

1

1

feedback

1

1

1

Code Function Name

3303

Re adi ng PID1 in put

Deviation

3304 Reading PID1 output

Value

3305

Reading PID2 command

Va lue

3306 Reading PID2

Value

3307 Reading PID2 input

Deviation

3308 Reading PID2 output

Value

Data Content

Read only

Read only

Read only

Read only

Read only

Read only

-56-

Setting

resolution

Factory

preset

---

---

---

---

---

---

Water Supply Function

F34xx

0

5

1% 50

5

Pressure command

Pref

0

0

0

Upper pressure

value

limit Ph

1

Lower pressure value

limit PL

0

Water Supply Function F34xx

Code Function Name Data Content

Water supply mod e

3401

3402

3403

3404

Selection

Lower limit range

continued time T1

Sleep wake up ratio

K

Sleep wake up

Judgement time Tp

0:Water supply function disabled

1:Single Pump Mode

0.1~10 Min.

30~95%

0.1~10 min.

Setting

resolution

0.1min.

0.1min.

Factory

preset

1

3405

3406

3407

3408

3409

3410

3411

Analog feedback upper

pressure limit

Analog feedback lower

Pressure limit

The slip of pressure in

Acceleration

/Deceleration

Allowed deviation on

Motor switching

0~9.999MPa

0~±9.999MPa

0~±9.999MPa

0.001~9.999MPa

0~9.999MPa

0.001~9.999MPa

0.0-20.0%

-57-

0.001MPa

0.001MPa

0.001MPa

0.001MPa

0.001MPa

0.001MPa

0.1%

0.1

0.0

Communication Functions

F40xx~F41xx

1

1

Communication response

time

10

1

1

4

1

1

0

0

0

0

1

Communication Functions F40xx~F41xx

Code Function Name

4001 Message checksum 0:No

4003

Pull up/Down function

4004

4005 Serial communication

function

Data Content

1:Yes

0:No

1:Yes

10~6000ms

0:No function

1:Dedicated protocol communication function

2:ModBus communication function

Setting

resolution

1ms

Factory

preset

1

1

1

4006 Inverter No.

4007

Communication speed 1:1200bps

4008 Parity bit

4009 Stop bit

4010 End bit

4011 Inverter response to

specified commands

ModBus communication

4101

timeout setting

ModBus communication

4102

timeout action

Modbus register address

4103

switching

0~254;for Modbus only

(1~32;RS485 communication)

5:19200bps

2:2400bps

3:4800bps

4:9600bps

0:No

1:Odd

2:Even

1:1 bit

2:2 bits

0:CR+LF

1:CR

0:Sent

1:No sent(Error response sent)

2:No sent(No error response sent)

0:No function

0.01~600 sec.

0:Keep the status

1:Stop alarms

1:Register No. A

2:Register No. B

6:38400bps

7:57600bps

-58-

1

1

1

1

1

1

0.01 sec.

1

1

Motor Parameters

F5xxx

r

esolution

p

reset

0

2

Motor Parameters F5xxx

Code Function Name

5001 Motor poles voltage

capacity

5002 Motor current rating 0.1~999.9A

5003

Motor frequency rating

5004 Motor speed rating 0~24000 rpm

5005

Motor insulation type 1:Type A

Motor’s rated voltage

5006

during auto tuning of

parameters

5007

Rated motor slip ratio

Data Content

X Y ZZZ

X:Poles

Y:Rated Voltage

Z:Motor Capacity

About 30~110% of the Inverter current rating

10~600Hz

2:Type E

3:Type B

4:Type F

5:Type H

0:The voltage selected by F5001

100~460V

0~50%

The setting of motor

5008

parameters auto tunning

range

0:No range

50~300%

Setting

—

0.1A

1Hz

1rpm

1

1V

0.1%

0.1%

Factory

※

※

※

※

※ 1

200

1

1

1

1

5009

Motor stator resistance 55kW or below

5010

Motor rotator resistance

5011

Motor stator inductance

75kW or above

55kW or below

75kW or below

55kW or below

-59-

0.001 ~ 65

Ω

0.01~650m

Ω

0.001 ~ 65

Ω

0.01~650m

Ω

0.1 ~

6000mH

0.001Ω

0.01mΩ

0.001Ω

0.01mΩ

0.1mH

Motor’s mutual inductance

Motor’s moment of

inerita

1

5012

Motor rotator inductance

5013

5014

Motor excitation current 0.01~650A

5015

5016 Load’s inerita moment

ratio

75kW or above

55kW or below

75kW or above

55kW or below

75kW or above

2

0~65kgm

1~200 times

-60-

0.01 ~

600mH

0.1 ~

6000mH

0.01 ~

600mH

0.1 ~

6000mH

0.01 ~

600mH

0.01A

0.001kgm

0.01 times

0.01mH

0.1mH

0.01mH

0.1mH

0.01mH

※ 1

2

※ 1

Vector Control

F60xx

r

esolution

p

reset

0

0

1

Vector Control F60xx

Code Function Name Data Content

6001 Torque limiter

(Power running)

6002

Torque limiter analog

Input function

(Power running)

A Mode

B Mode

0:F6001

1:External analog VRF voltage(0~5V)

2:External analog VRF voltage(0~10V

or potentiometer)

3:External analog V/I voltage(0~5V)

4:External analog V/I voltage(0~10V

or potentiomenter)

8:External analog V/I current(4~20mA)

Setting

Factory

0~200% 0.1%

0~150% 0.1%

1

6003 Torque limiter

(Regeneration)

6004

Torque limiter analog

Input function

(Regeneration)

6005 Multiple for starting

excitation current

6006

Starting excitation

time

6007 Multiple for braking

excitation current

6008 Braking Excitation

time

6009 Current control gain

compensation

6010 Speed control ASR

Proportional gain

6011 Speed control ASR

Integral time

A Mode

B Mode

0:F6003

1:External analog VRF voltage(0~5V)

2:External analog VRF voltage(0~10V or

potentiometer)

3:External analog V/I voltage(0~5V)

4:External analog V/I voltage(0~10V or

potentiometer)

8:External V/I current(4~20mA)

0.1~2 times(for applicable motor)

0:No starting excitation

0.1~10 sec.

0.1~2 times(for applicable motor)

0:No braking excitation

0.1~10 sec.

0.5~1.5

0.01~150%

0~20 sec.

-61-

0~200% 0.1%

0~150%

1

0.01 times 1

0.1 sec.

0.01 times 1

0.1 sec.

0.01 1

0.01%

0.001 sec.

※ 1

※ 1

※ 1

Setting

r

esolution

Factory

p

reset

0

0

0

30

1

15

10

30

Code Function Name Data Content

6014

Motor virbration

reduction rate

Lower frequency limit

6015

for motor vibration

reduction function

Upper frequency limit

6016

For motor vibration

reduction

6017

Starting Tor que 0~100%

Starting torque

6018

Duration time

Va riable 2nd gain for

6019

Speed control

Frequency top of

6020

variable gain for speed

control

Frequency bottom of

6021

variable gain for speed

control

0:No Function

1:75%

2:50%

3:25%

0~240Hz

0~240Hz

0~6500 sec.

0:No variable gain function

0.01~150%

0~240Hz

0~240Hz

1

0.01Hz

0.01Hz

0.1%

0.1sec.

0.01%

0.01Hz

0.01Hz

-62-