Contents

APPLICATION GUIDE

Threading

Thread turning and thread milling

Introduction

1 Basics in threads

2 Applications

Threading methods

Thread turning vs thread milling

Thread Turning

Thread Milling

3 Products

Thread Turning

CoroThread® 266

CoroCut® XS

CoroTurn® XS

CoroCut® MB

T-Max Twin-Lock®

Extended offer

Thread Milling

CoroMill® 327

CoroMill® 328

CoroMill® Plura

Grade information

2

3

9

10

14

35

46

48

56

58

60

62

64

65

67

69

70

72

4 Troubleshooting

5 Technical reference

Cutting data

Programming

Thread turning infeed recommendations

External thread milling recommendations

Formulas

Inch/mm conversion table

76

86

92

96

112

114

118

ntr

oduction

Introduction

Modern threading tools can produce complex component features

with relative ease, but to gain consistent results there are a number of considerations to be made.

In this application guide, we show you how to achieve threading

success with Sandvik Coromant tools. Our aim is to help you to

choose the right tooling combinations to produce consistent, high

quality threads and guide you towards the most productive and

problem-free threading performance.

This guide also includes information on basic threading principles

- together with deeper application information, troubleshooting

advice and nally, a technical reference section to cover all of your

thread machining needs.

2

.

Basic in threads

1. Basics in threads

What is a thread?

Threads are classi ed according to the main functions they perform in a component.

Primary functions of a thread:

• To form a mechanical coupling

• To transmit motion by converting a rotational movement into a linear movement, and vice

versa.

• To obtain a mechanical advantage, by using a small force to

create a larger force.

Threads are also classi ed into various pro les or forms. The selection of these forms will

be in uenced by many other secondary, but still vital, functions.

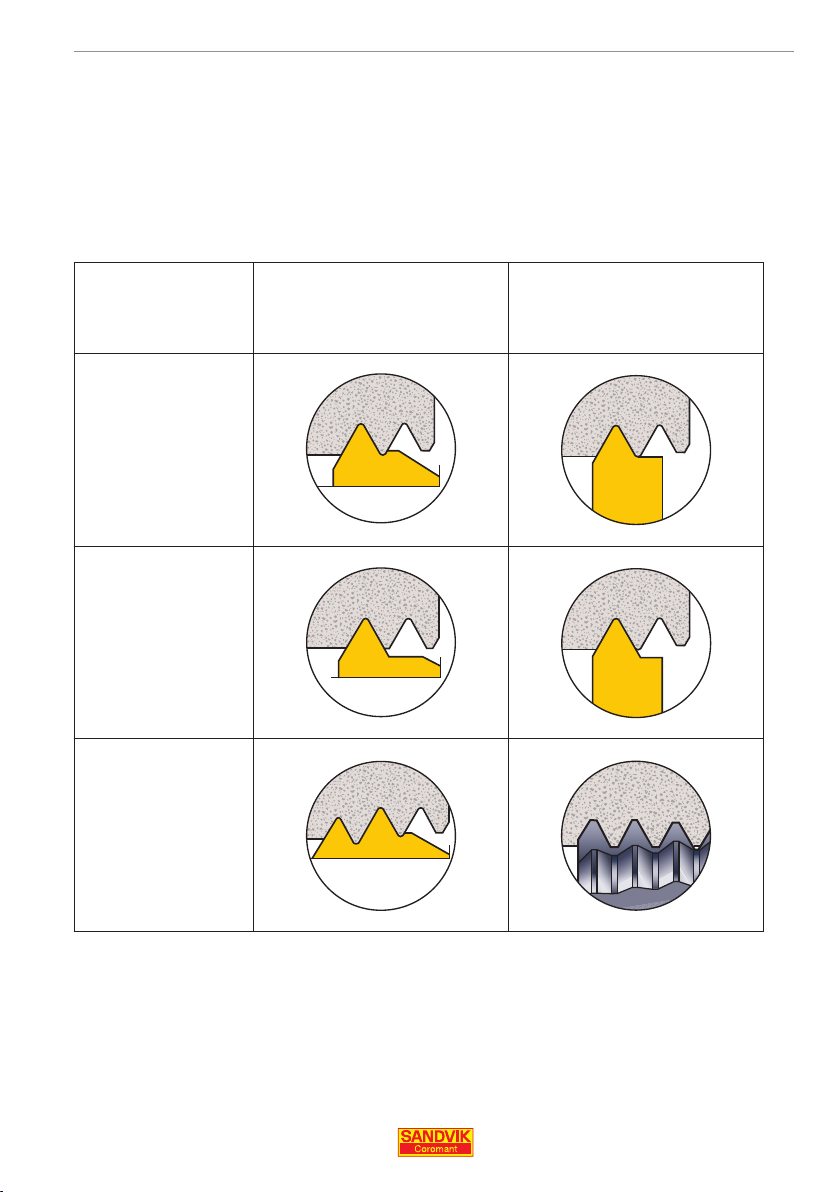

Thread forms

The thread pro le de nes the geometry of a thread and includes component diameters

(major, pitch and minor), the thread pro le angle, pitch and helix angle. The most common

thread forms or pro les produced today are shown below.

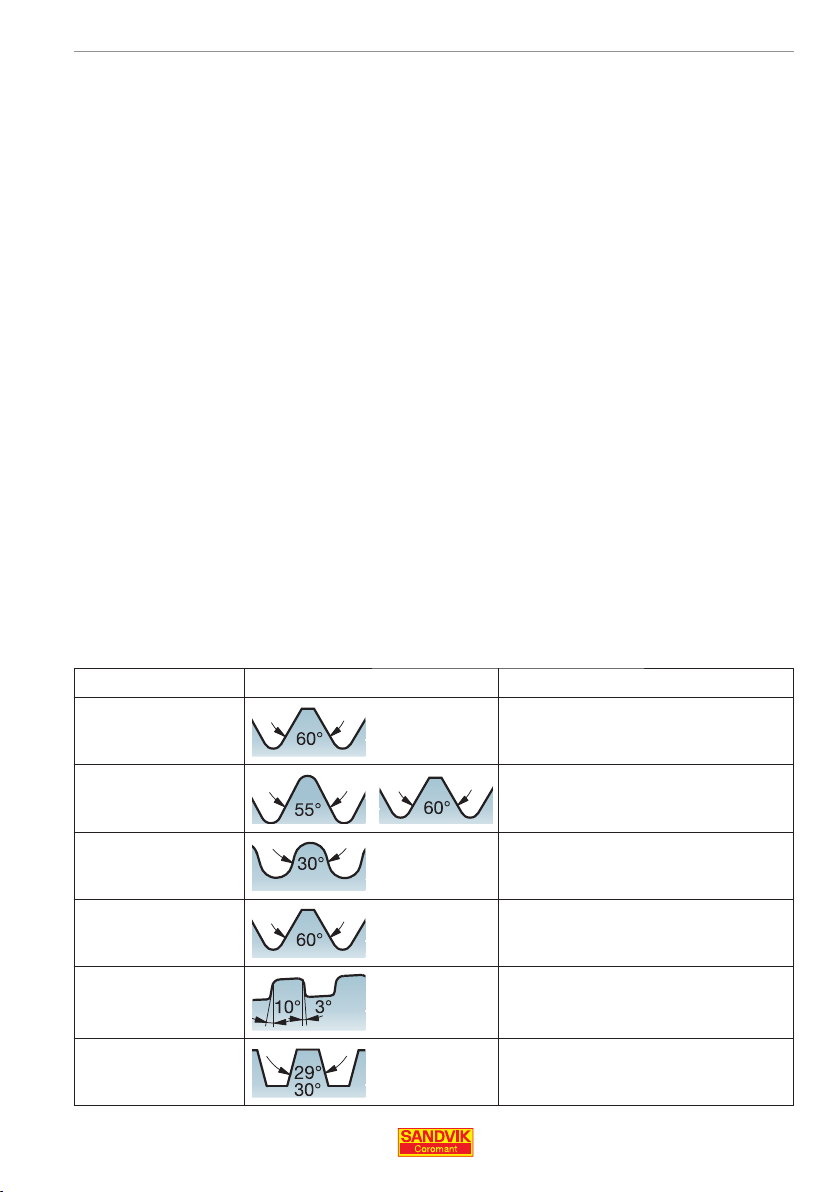

Application Thread form Thread type

Connecting

General usage

Pipe threads Whitworth, British Standard (BSPT),

Food and re Round DIN 405

Aerospace MJ, UNJ

Oil and gas API Rounded, API Buttress, VAM

Motion

General usage

ISO metric, American UN

American National, Pipe Threads,

NPT, NPTF

Trapezoidal, ACME, Stub ACME

3

.

Basic in threads

Threading terms and de nitions

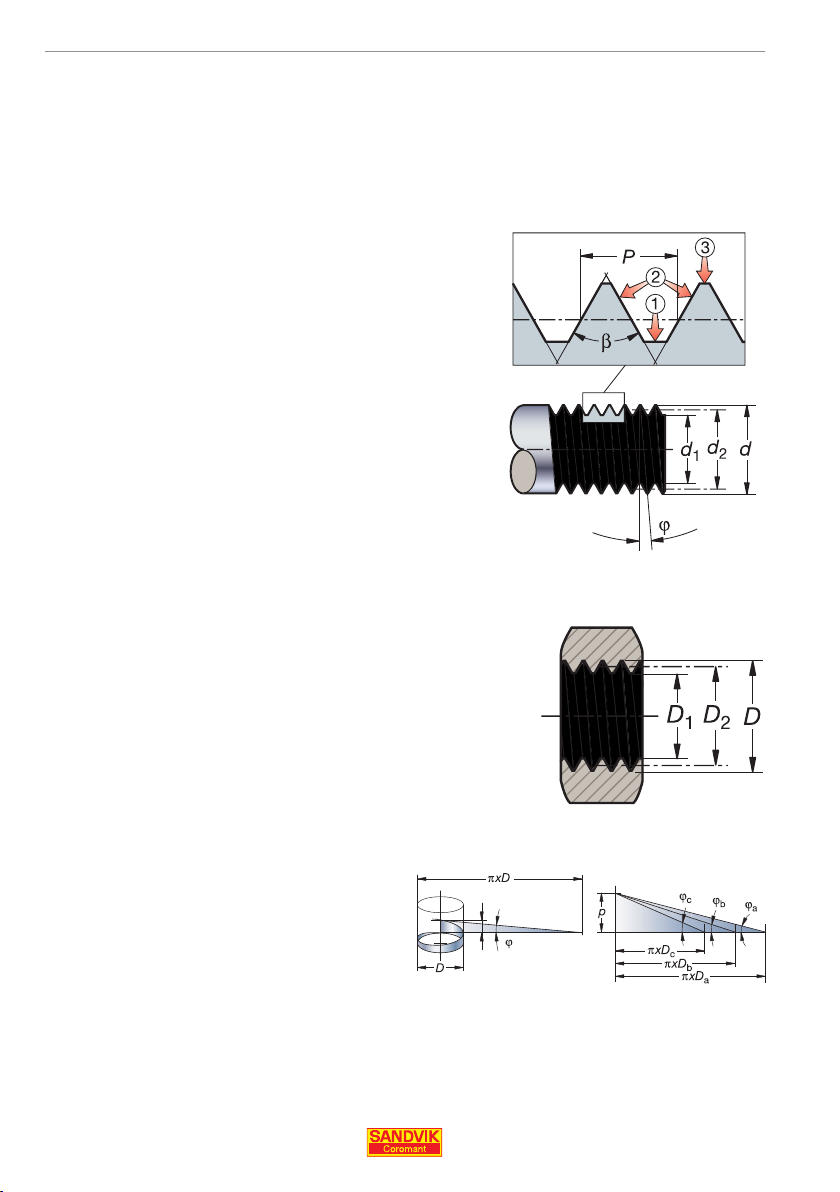

1. Root/bottom

The bottom surface joining the two adjacent anks of

the thread

2. Flank/side

The side of a thread surface connecting the crest and

the root

3. Crest/top

The top surface joining the two sides, or anks.

P = Pitch, mm or threads per inch (t.p.i.)

= The pro le angle

= The helix angle of the thread

d / D = The major diameter, external/internal

d

/ D1 = The minor diameter, external/internal

1

d

/ D2 = The pitch diameter, external/internal

2

Pitch diameter, d2 / D

2

This is the effective diameter of the screw

thread; approximately half way between the

major and minor diameters.

Helix angle

The helix angle ()is the geometrical shape

of the screw thread, it is based on the pitch

diameter of the thread (d

pitch (P) – the distance from one point on a

thread pro le to the corresponding point on

the next.

This measurement can be represented by

a triangle being unwound from the component.

4

, D2), and the

2

The same pitch on different diameters gives a different helix angle,

see example above.

ds

Thread designations

International standards

To ensure that the two (internal and external) halves of a threaded

joint t together properly to produce a connection capable of bearing a speci ed load, threads must maintain certain standards.

International standards for thread forms have therefore been established for all common thread types.

Below are examples of Metric, UN and Whitworth thread designations.

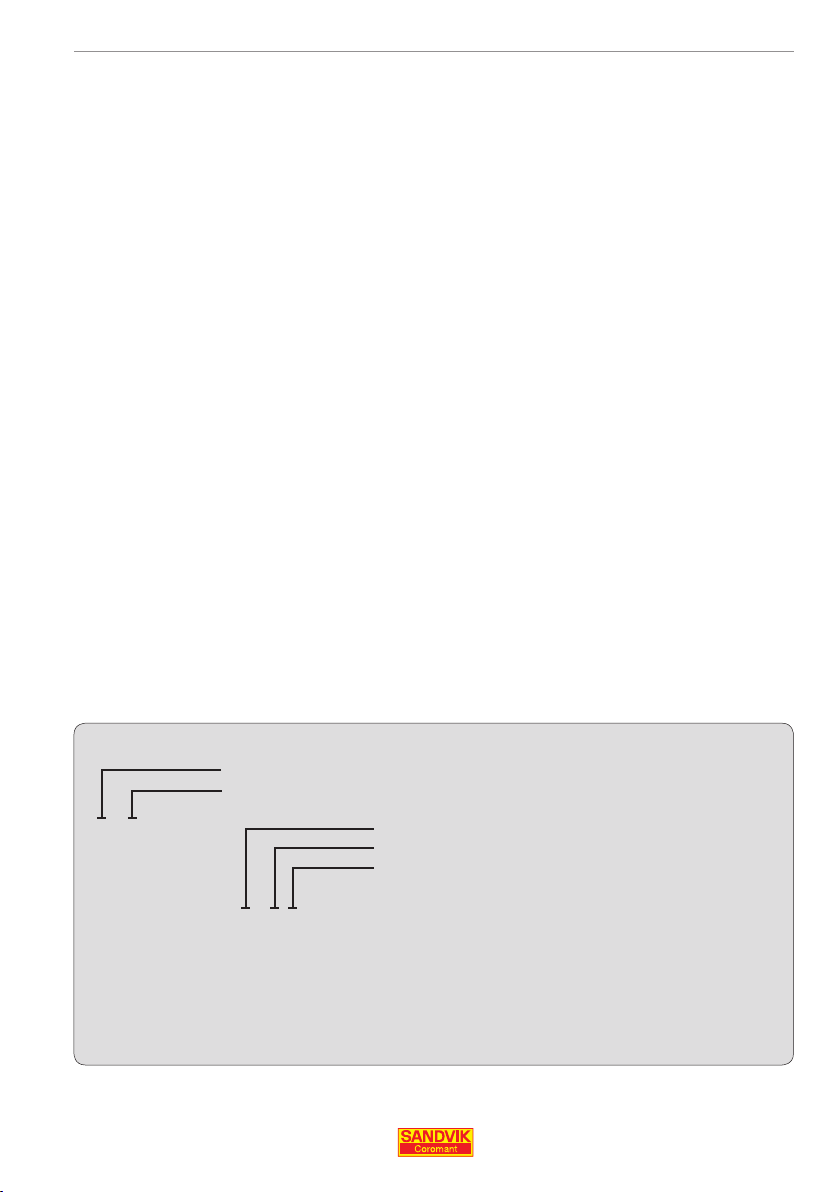

ISO metric thread designations

The complete thread designation is made up of values for the

thread form and the tolerance. The tolerance is indicated by a number for the tolerance grade, and letters for the tolerance position.

. Basic in threa

Examples:

M16 - 6h

Thread designation and nominal dimension

Tolerance class for pitch and crest position

Pitch

Tolerance class for pitch diameter

Tolerance class for crest diameter

M10 x 1.25 5g6g

A t between threaded parts is indicated by the internal thread tolerance class

followed by the external thread tolerance class, separated by an oblique stroke.

5

.

Basic in threads

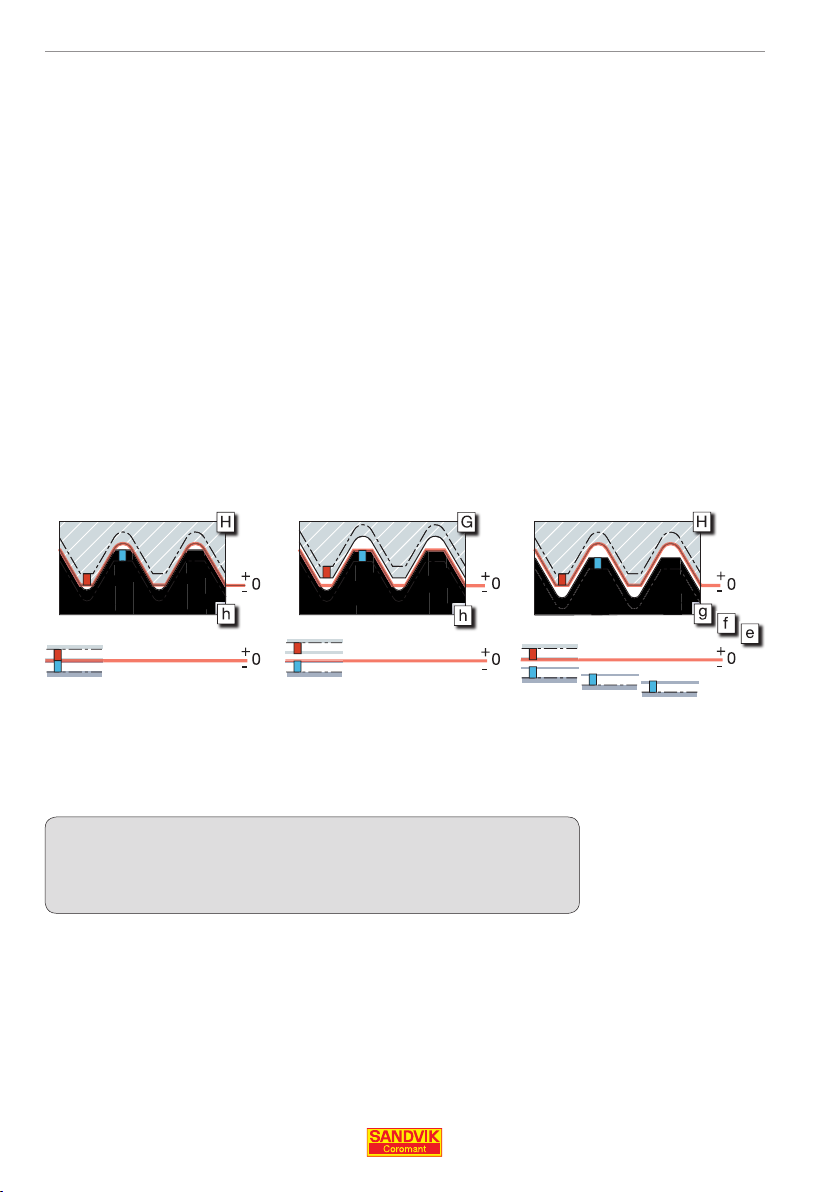

Tolerance positions

The tolerance position identi es the fundamental deviation and is

indicated with an upper-case letter for internal threads and a lower

case letter for external threads. A combination of tolerance grade and

position give the tolerance class. The values of the tolerance classes

are given in the standards for the different threading systems.

Tolerance positions

Internal threads H and G

External threads h, g, f and e

6

ds

ISO inch threads (UNC, UNF, UNEF, UN)

The UN system has three tolerance classes, ranging from 1

(course) to 3 ( ne). A typical UN thread is designated as follows:

¼” 20UNC – 2A

2A – Indicates a medium tolerance

UNC – Indicates a course pitch

20 – Pitch value: threads per inch (t.p.i.)

¼” – Major thread diameter

ISO - uni ed (UN):

. Basic in threa

Loose tolerance

Medium tolerance

Tight tolerance

Tolerance position

Types of UN thread

UNC thread diameter with course pitch

UNF thread diameter with ne pitch

UNEF thread diameter with extra- ne pitch

UN thread diameter with constant pitch

All of the above types of thread can be created using the UN insert

from Sandvik Coromant

The pitch value is indicated in t.p.i. (threads per inch).

To convert to metric, this should be divided by 25.4 using the

following equation:

1A 1B

2A 2B

3A 3B

20 t.p.i. 25.4/20 = 1.27 mm.

7

.

Basic in threads

Whitworth threads (G, R, BSW, BSF, BSPF)

Whitworth screw threads are now obsolete, but Whitworth pipe

threads are a recognized international standard. There are two

tolerance classes for external-, and one tolerance class for internal

Whitworth pipe threads.

Whitworth pipe thread designations

These threads are divided into 2 groups:

• Pressure-tight joints not made on the thread, ISO 228/1

• Pressure-tight joints made on the thread, ISO 7/1

Whitworth pipe threads:

BSW

BSF

BSP.F

Fine Only

Coarse

A

B

one

class

Tolerance position

Examples of Whitworth pipe thread designations:

Pressure tight joints not made on the thread:

ISO 228/1 G

= G 1 ½ A

(external)

= G 1 ½ (internal)

= parallel thread

= pipe diameter, not thread diameter

1 ½

A or B = external tolerance class only

Pressure tight joints made on the thread:

ISO 7/1 = R

7/1 = Rc 1 ½R

7/1 = R 1 ½R

Sandvik Coromant’s WH inserts are to be used for parallel threads.

The PT inserts are for the conical thread.

8

1 ½R

p

= parallel thread, internal

p

= conical thread, internal

c

= conical thread, external

s

2. Applications

Threading methods

Various methods and applications exist for generating screw

threads. The choice of application will be based on the time taken

to produce the thread and the level of thread precision required.

Different ways of making threads

. Application

Metal cutting

Within the metal cutting area, thread turning, thread milling and

thread tapping are common threading techniques using cemented

carbide cutting tools. The design of component and machine tool

are the main factors when deciding which technique to use, and

there are a number of important considerations to be made in order

to maximize success.

Molding

Rolling

Metal cutting threading methods

Thread millingThread turning Thread tapping Thread whirling

Grinding

9

. Application

s

Thread milling vs. thread turning

This application guide focuses on thread turning and thread milling

products and application techniques. Each technique has its own

advantages in certain situations.

Thread turning Thread milling

Thread turning

• Normally the most productive threading method

• Covers the largest number of thread pro les

• An easy and well known threading process

• Provides a better surface nish

• Can be used in deep holes with dampened bars

• Has dedicated thread programs in CNC machines

Thread milling

• Threading of non-rotating components

• Interrupted cuts offer good chip control in long-chipping materials

• Lower cutting forces make it possible to thread in long overhangs and thin-walled

components

• Threads close to a shoulder or bottom, no need for a relief groove

• Enables machining of large workpieces which cannot be easily mounted on a lathe

10

s

Insert types

Three main types of threading principle can be used to produce a

thread. The different technical and economic arguments for each

insert are the main guide in the choice of application.

Thread turning Thread milling

Full pro le

. Application

V-pro le

Multi-point

11

. Application

s

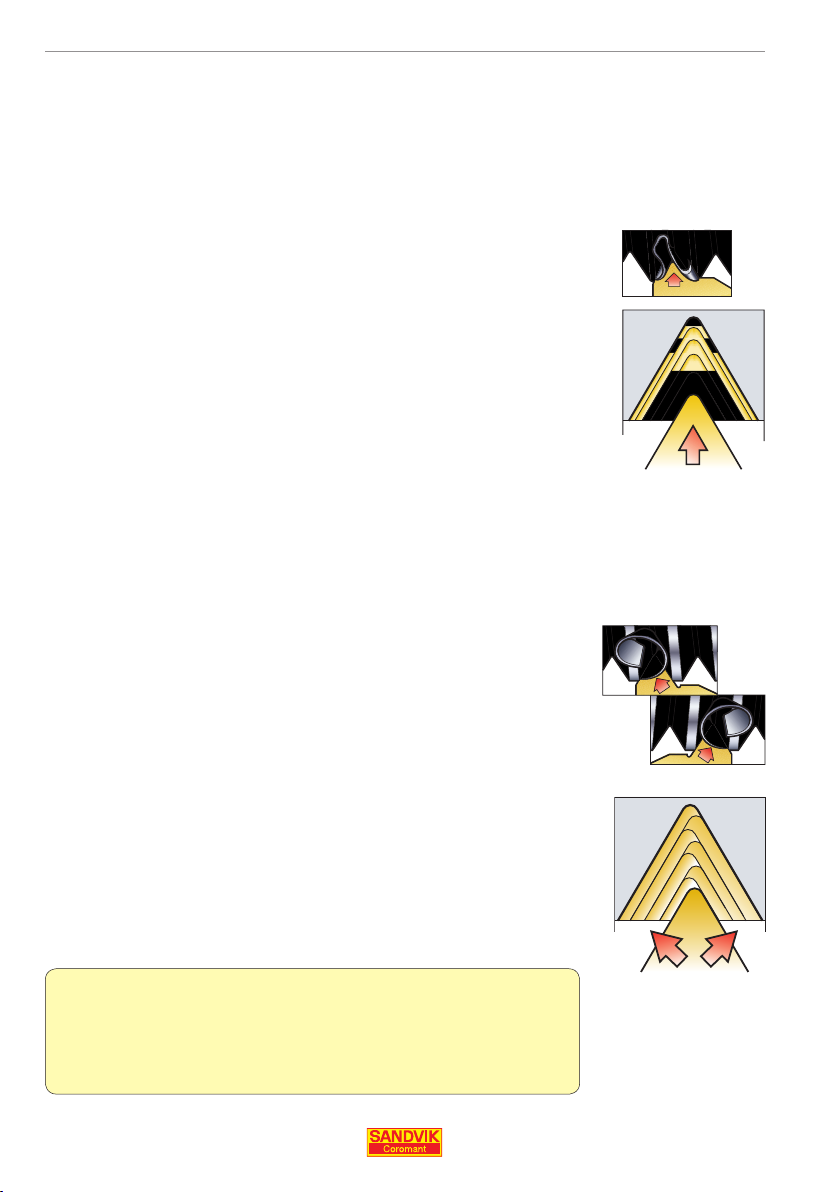

Full pro le inserts – rst choice for high quality

thread forms

The most common insert type, used to form a complete thread

pro le, including the crest.

• Ensures correct depth, bottom and top pro le for a stronger thread

• Extra stock should be 0.03 – 0.07 mm (0.001 – 0.003”)

• No deburring required after threading operation

• Fewer passes required compared to a V-pro le insert, due

to the larger nose radius

• Separate insert required for each pitch and pro le

• Productive threading performance

Extra stock should be left on the workpiece for topping the nish

diameter of the thread.

Quality

Extra stock

V-pro le inserts – threading with minimum tool

inventory

These inserts do not top the thread crests. Therefore, the outer

diameter for screws and inner diameter for nuts must be turned to

the right diameter prior to threading.

• Same insert can be used for a range of pitches - provided

that the thread pro le angle (60° or 55°) is the same

• Fewer inserts needed in stock

• The nose radii is designed to offer the smallest pitch,

which reduces tool life

12

Flexibility

s

Multi-point inserts – productive, economic

threading in mass production

Multi-point inserts are similar to full pro le-, but have more than

one insert point (two pointed inserts give double productivity, three

pointed insert give triple etc.) Stable conditions are needed due to

increased cutting forces as the cutting edge has a longer contact

length.

Considerations should be made for thread turning and thread milling:

. Application

Milling

• Completes the thread in one revolution, when using solid carbide

thread mills.

Turning

• Requires fewer passes, giving better tool life, productivity and

lower tool costs.

• Requires longer passes beyond the workpiece thread to accomodate the extra points.

Thread turning with multi-point inserts

requires longer passes beyond the

workpiece.

Productivity

13

. Applications – Thread turnin

g

Thread turning

Thread turning is the most common method of producing threads.

The many tooling systems offered by Sandvik Coromant cover

internal and external applications and make it possible to produce

threads of all sizes and pro les, across all segments of the

engineering industry.

Indexable-insert thread turning tools such as CoroThread 266 and

others offer high quality performance, providing dampening against

vibrations, security in small holes, and in the toughest materials.

14

. Applications – Thread turnin

g

Insert geometries

Selecting the correct insert geometry is important in threading,

especially in machines where there is limited supervision. Here,

geometry A offers consistent tool life and quality and is the rst

choice for most applications, while geometry F is sharper, reducing

cutting forces.

The chip-forming geometry C enables more continuous and unsupervised machining, free from sudden stoppages. This results in

predictable tool life, and more active machining time.

First choice

Geometry A

First choice

• First choice for most operations and materials

• Rounded cutting edge for

safe and consistent tool

life

• Good edge security

Geometry F

Sharp edge

• Sharp cutting edge

• Clean cuts in sticky or

work-hardening materials

• Low cutting forces and

good surface nish

• Reduced built-up edge

Geometry C

Chip-forming geometry

• Maximum chip control,

minimum supervision

required

• High security for all

threading, particularly

internal

• Optimized for low carbonand low-alloyed steels

• To be used with 1° modi ed ank infeed only

15

2. Applications – Thread turnin

g

Insert geometries

MC CMC Geometries

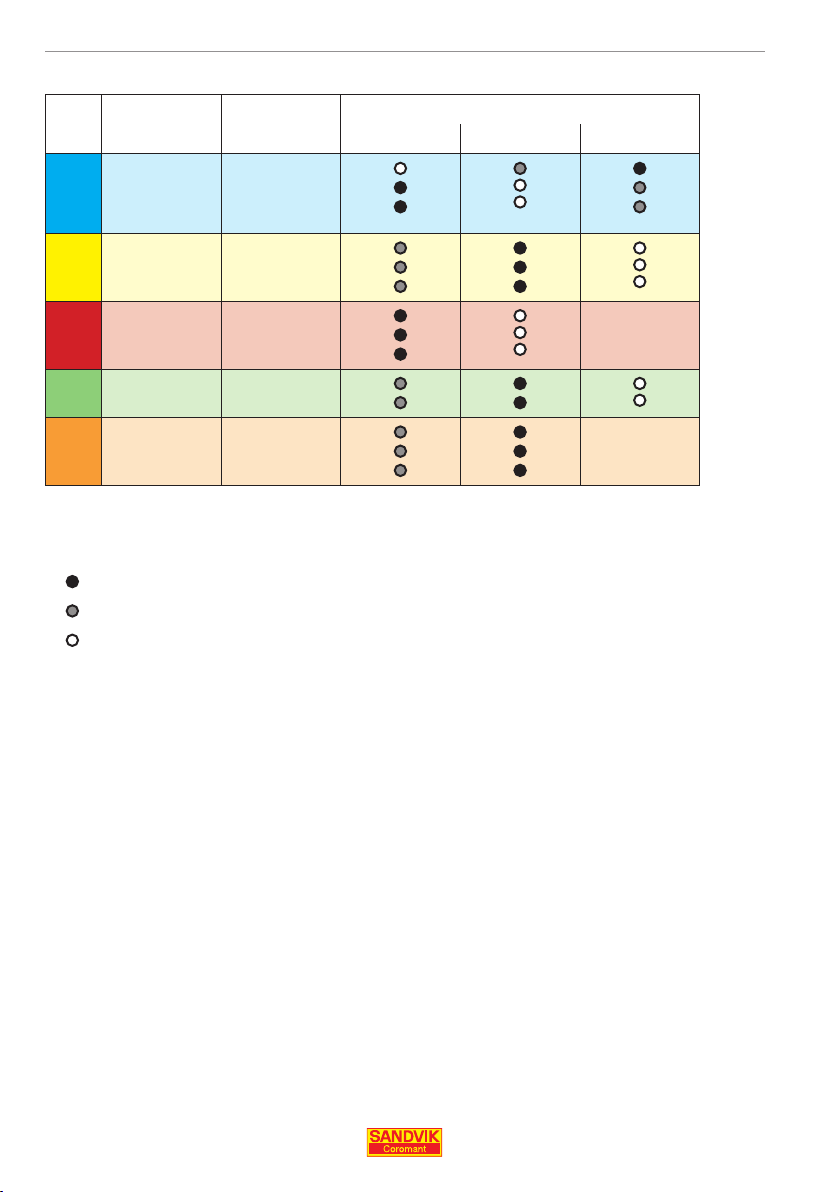

ISO No. No.

P1.1.Z.AN

P

P2.1.Z.AN

P2.5.Z.HT

P3.1.Z.HT

M5.0.Z.AN

M

M1.0.Z.AQ

M3.1.Z.AQ

K1.1.C.NS

K

K2.2.C.UT

K3.1.C.UT

N1.2.Z.UT

N

N3.2.C.UT

S1.0.U.AN

S

S2.0.Z.AG

S4.2.Z.AN

For ISO-H use CBN-insert, CB7015

First choice

Second choice

Alternative choice

01.1

02.1

02.2

03.21

05.11

05.21

05.51

07.2

08.2

09.1

30.11

33.2

20.11

20.22

23.21

AFC

16

. Applications – Thread turnin

g

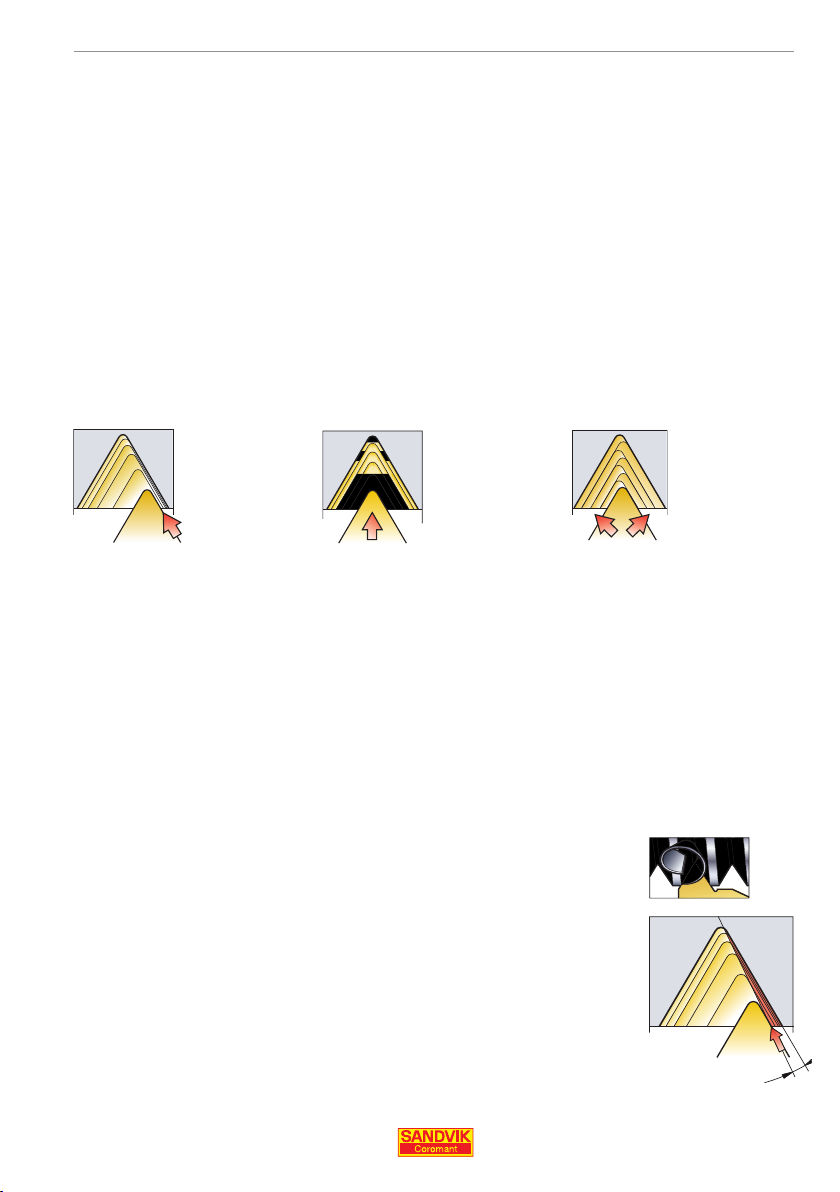

Infeed

Infeed method dictates how the insert is applied to the workpiece

to create the thread form. The three common infeed choices are

modi ed- ank-, radial-, and incremental infeed.

The infeed method used in threading will directly in uence:

• Chip control

• Thread quality

• Insert wear

• Tool life

Modi ed ank infeed Radial infeed Incremental infeed

Modi ed ank infeed

Has many advantages over radial infeed, and most CNC machines

are pre-programmed for this method which is modi ed (angled)

slightly to avoid the insert edge rubbing on the component surface.

• Recommended for all operations and insert types

• Chip is easier to form or guide, compared to radial infeed

• Chip is thicker but generated only on one side of the insert, making it easier to cut

• Fewer passes than for radial infeed, as less heat is transferred to

the insert

• Can be used on both anks of the thread (opposite anking) to

steer the chip in best direction

• For larger threads, and to eliminate vibration problems

• Use 3-5° infeed angle for A- and F-geometries

• An infeed angle of 1° should be used for C-geometry.

17

2. Applications – Thread turnin

g

Radial infeed

The most commonly-used infeed method and the only one possible

on many non-CNC lathes.

• Produces a stiff, V-shaped chip, which is dif cult to form

• Insert wear is even on both anks

• Suitable for ne pitches

• Insert tip is exposed to high temperatures, restricting the

possible infeed depth

• Risk of vibration and poor chip control in large pitches

Incremental infeed - for pitches larger than 5 mm (5 t.p.i.)

This infeed type is the rst choice for larger thread pro les.

• Even insert wear and long tool life

• A- and F-geometries should be used

• Special CNC machine programme is required

Very large thread pro les can be pre-machined with a turning

tool, nishing passes can be made with the threading tool

For more information see page 33 (Threading large pro les).

18

. Applications – Thread turnin

g

Successful chip control in thread turning

Threading can present problems in machines where there is limited

supervision. Chips can get trapped in chucks, often resulting in tool

damage and lost machining time.

To avoid these problems and achieve the best possible chip control,

use modi ed- ank infeed, together with a C-geometry (chip-control)

insert.

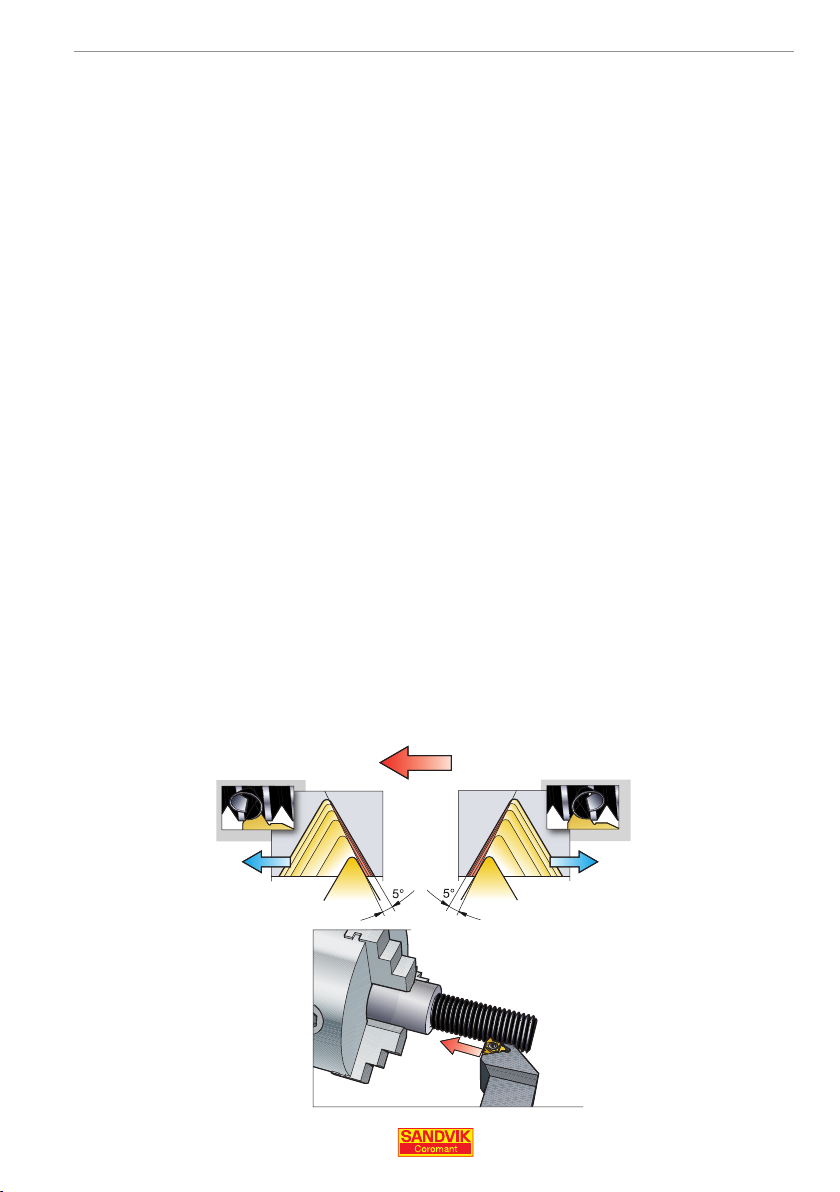

Opposite ank infeed

With this infeed type, the insert can cut using both anks (opposite

anking) meaning that the chip can be steered in the right direction.

This helps to ensure continuous, trouble-free machining, free from

unplanned stoppages.

Standard modi ed

ank infeed

Feed

direction

Chip direction Chip direction

Opposite

ank infeed

19

2. Applications – Thread turnin

g

Infeed depths per pass

Decreasing depth per pass (constant chip area)

• First choice, most common

• First pass is deepest

• More ‘balanced’ chip area

• Even load on insert

• Last pass 0.07 mm (.003 inch)

Constant depth per pass

• Each pass is of equal depth, regardless of number of passes

• More demanding on the insert

• Can improve chip control

• Increases the required number of passes

• Should not be used for pitches larger than 1.5 mm or 16 t.p.i.

• A less-productive method

First choice

Normal CNC lathes are equipped with dedicated threading cycles,

where pitch, thread depth and number of passes can be set in different ways – including the rst and last passes.

For the last pass, we strongly recommend against using a spring

pass (a cut without radial cutting depth). It is more bene cial to use

the recommended infeed cycles to ensure better thread quality and

longer insert tool life.

20

. Applications – Thread turnin

g

Number of passes and size of infeed per pass

The recommended depths of cut for the different passes are shown

in the table below.

• These are recommended as starting values - the most suitable

number of passes must be determined by trial and error.

• Infeeds of less than 0.05 mm (0.002 inch) should be avoided

• For Cubic Boron Nitride-tipped inserts, infeed should not exceed

0.10-0.12 mm (.004-.005 inch)

• For multi-point inserts, it is essential that the correct infeed recommendations are used

Infeed value recommendations

Number of infeeds and total depth of thread.

For tables and recommendations see chapter 5, Technical reference (page 96) or use the Sandvik Coromant threading calculator

for more values.

21

2. Applications – Thread turnin

g

Tool holder selection

The choice of tool holder used in a threading operation is in uenced by many factors:

• Component shape

• Tool availability

• Machine type and condition

• Chip control requirements

• Hand of thread

• Tool holder choice

Coromant Capto®

Quick change

coupling - for large,

internal threads

Boring bar - for

internal threading

coupling - for internal

and external threading

Drop head - for

external threading

QS shank tool - for external small part machining

in sliding head machines

22

Shank tool - for

external threading

Exchangable cutting

head - for internal and

external threading,

with anti-vibration

bars.

. Applications – Thread turnin

g

External thread turning

This is the most common thread turning method. It is often easier

and less demanding on the tool and there are a number of different

methods which can be used to achieve the desired results.

Upside-down tool holders

In many operations, it is bene cial to use a tool holder in an

upside-down position, to help remove chips more effectively.

Drop-head tool holders are specially developed for threading

upside-down and allow the correct centre height to be maintained,

without having to change the clamping in the turret.

Conventional tool holder

(right-hand)

Drop-head tool holder

(right-hand)

23

2. Applications – Thread turnin

g

Internal thread turning

Internal threading is more demanding than external threading, due

to the increased need to evacuate chips effectively.

Chip evacuation, especially in blind holes, is helped by using lefthand tools for right-hand threads and vice versa (pull-threading).

However, this also creates the greatest risk of insert movement.

Modi ed ank infeed should always be used to generate a spiral

chip, which is easy to guide towards the entry of the bore

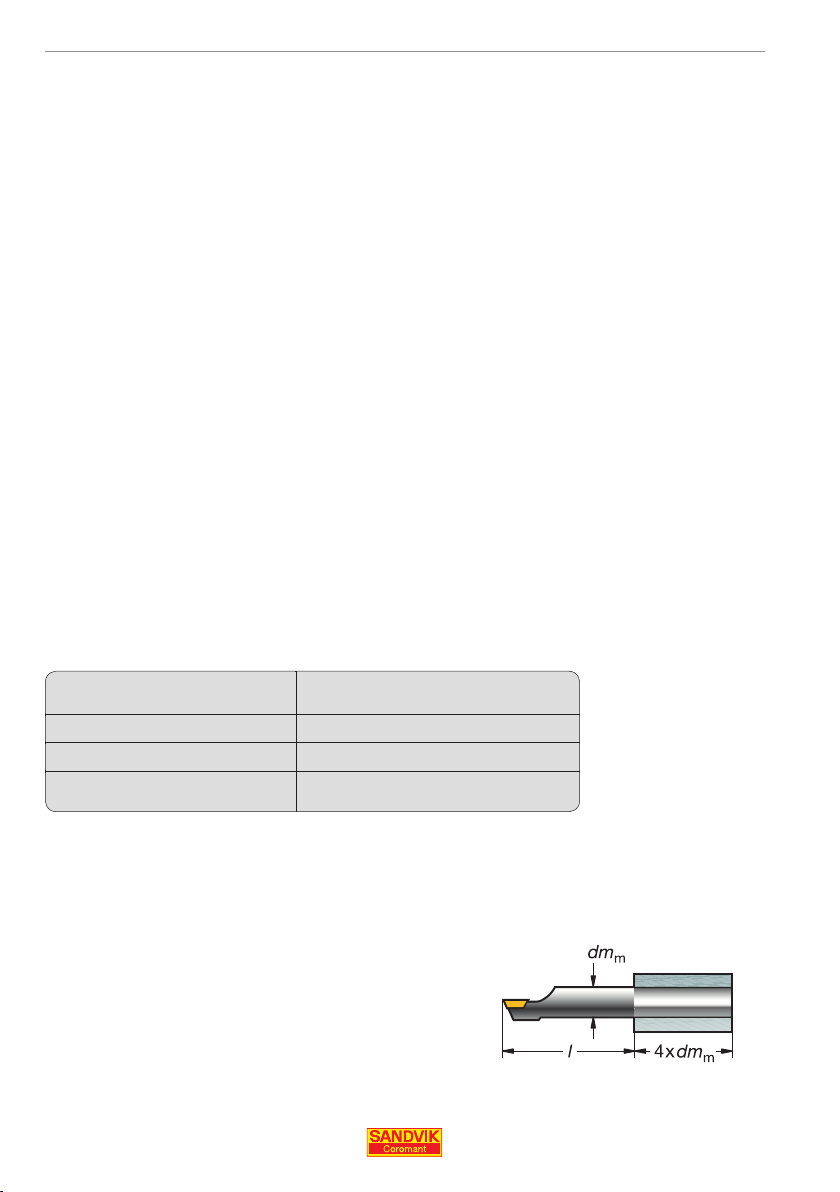

Boring bar selection also has a strong in uence on the effectiveness of internal threading. Three main bar types can be used for

internal threading, depending on the length of overhang and level of

stability required.

• Steel boring bars - maximum 2-3 x bore diameter overhang

• Steel dampened boring bars - maximum 5 x bore diameter overhang

• Carbide boring bars - maximum 5-7 x bore diameter overhang

Boring bar type Max. overhang

Steel

Steel dampened

Carbide

Boring bar de ection is in uenced by the boring bar material,

diameter, overhang and cutting forces. The recommended clamping

length in a boring bar holder with a sleeve is 4 x bar diameter dm

24

2-3 x dm

5 x dm

5-7 x dm

m

m

m

.

m

g

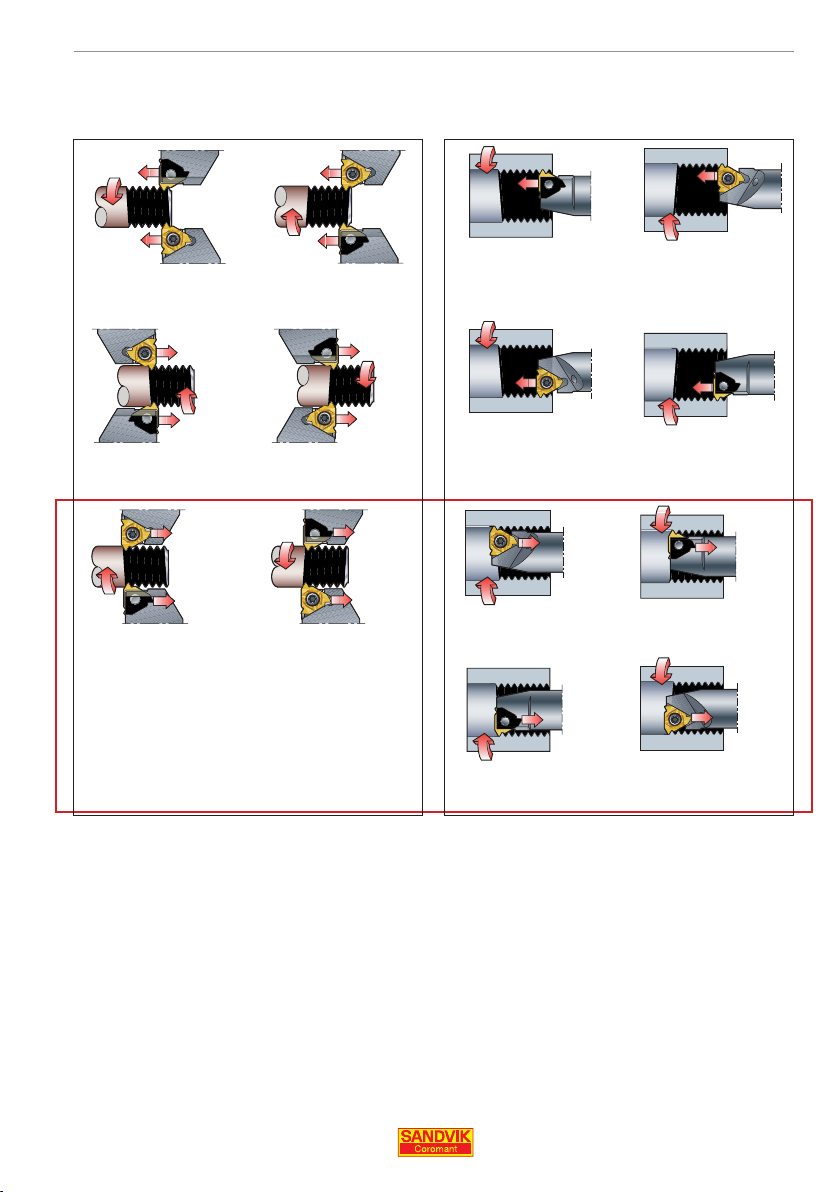

External Internal

Right hand

threads

Most

common

Left hand

threads

Right hand

threads

. Applications – Thread turnin

Left hand

threads

Right hand

tool/insert

Right hand

tool/insert

Left hand

tool/insert

Left hand

tool/insert

Left hand

tool/insert

Right hand

tool/insert

A negative shim must be used.

Right hand

tool/insert

Most common

Right hand

tool/insert

Left hand

tool/insert

Left hand

tool/insert

Left hand

tool/insert

Left hand

tool/insert

Right hand

tool/insert

Right hand

tool/insert

Thread turning methods

A thread can be produced in a number of ways. The spindle can rotate clockwise or

anticlockwise, with the tool fed towards or away from the chuck. The thread turning tool can

also be used in the normal- or upside-down position (the latter helps to remove chips).

Working away from the chuck

Using right-hand tools for left-hand threads (and vice-versa) enables cost savings through

tool inventory reduction (a negative shim must be used). Care must be taken due to the

risk of insert movement, particularly at the beginning of the thread.

25

2. Applications – Thread turnin

g

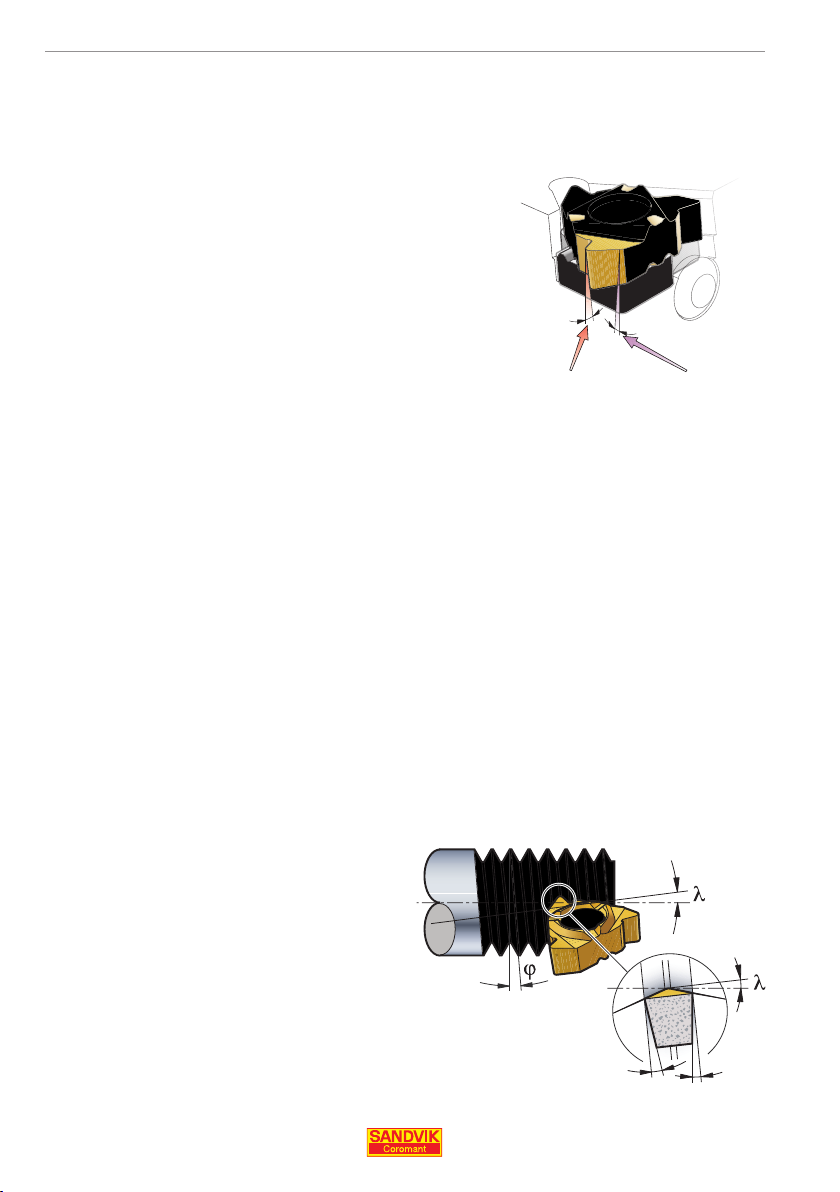

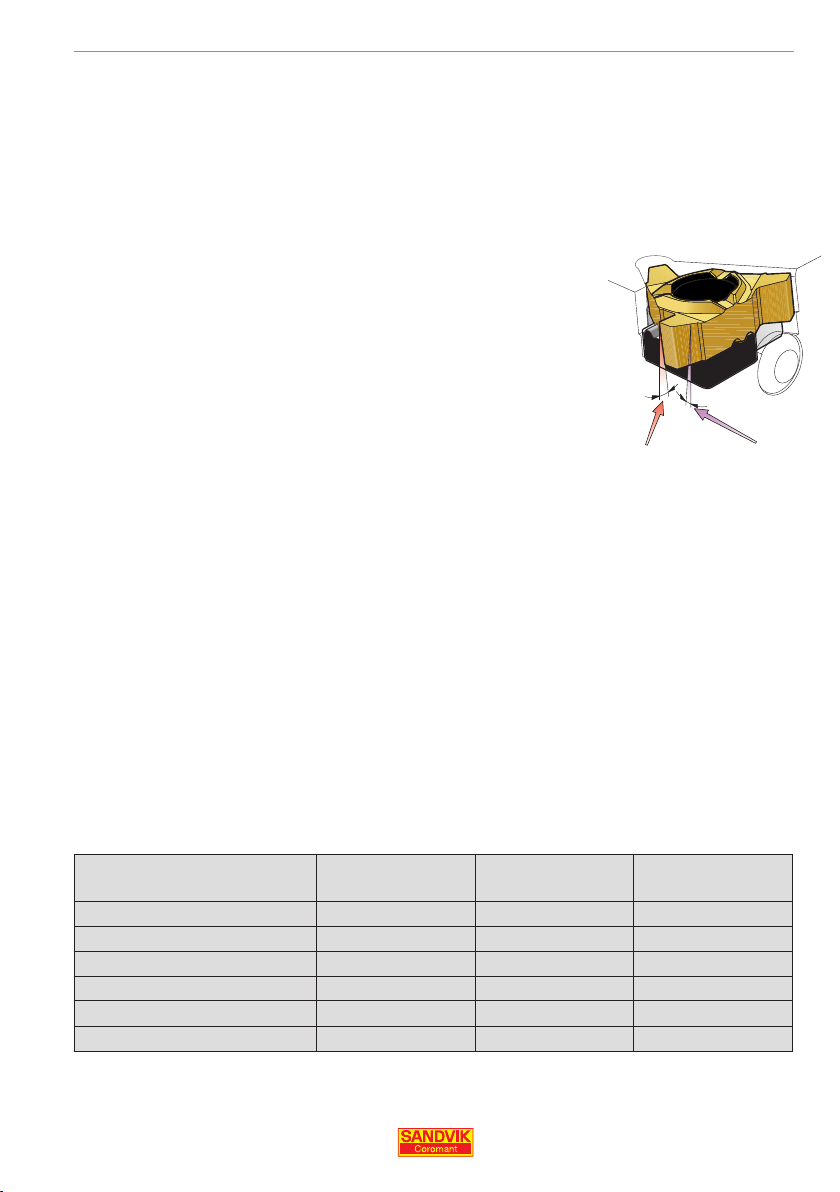

Insert clearance angles

Two types of angular clearance between the insert and thread are

necessary for precise, accurate threading. These are:

• Flank clearance

• Radial clearance

Radial clearance

Flank clearance

Cutting edge clearance between the sides of the insert and thread

ank is essential to ensure that tool wear develops evenly, to give

consistent, high quality threads. The insert should therefore be

tilted to gain maximum symmetrical clearance from the anks ( ank

clearance angle).

The tilt angle of the insert should be the same as the helix of the

thread, to ensure success.

Flank clearance

26

Flank

clearance

. Applications – Thread turnin

g

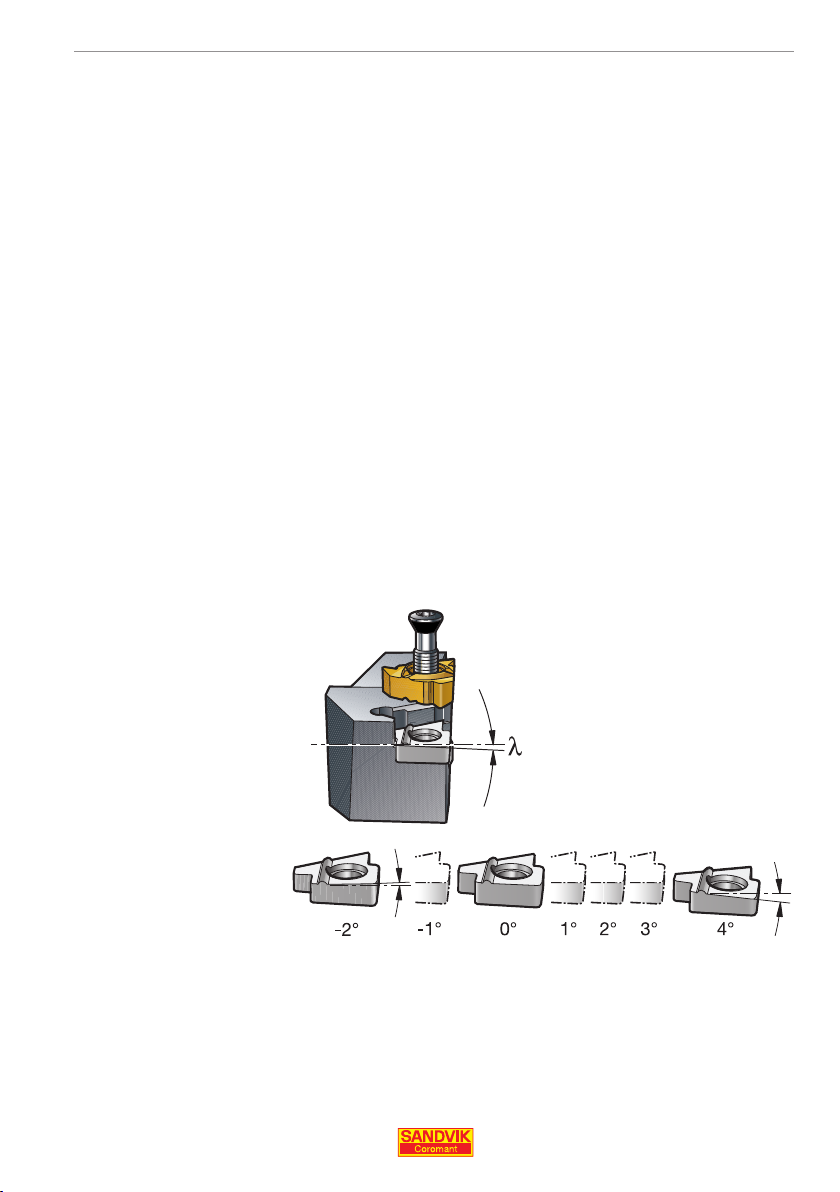

Selecting shims to tilt the insert for ank clearance

Insert shims are used to give different tilts to the insert, so that

the angle of insert inclination is the same as the helix of the

thread. See table opposite for methods of selecting the correct

insert shim.

• The standard shim in the holder is 1°, the most common angle of

inclination

• Shims are available in 1° steps, in the range -2° to 4°

• Negative-inclination shims are required when turning left-hand

threads with right-hand tools, and vice versa

= the angle of insert

inclination

The ank clearance angle of the insert is adjusted by changing

the shim under the insert in the tool holder. Standard tool holders have a 1° insert inclination angle.

27

m

π

2. Applications – Thread turnin

g

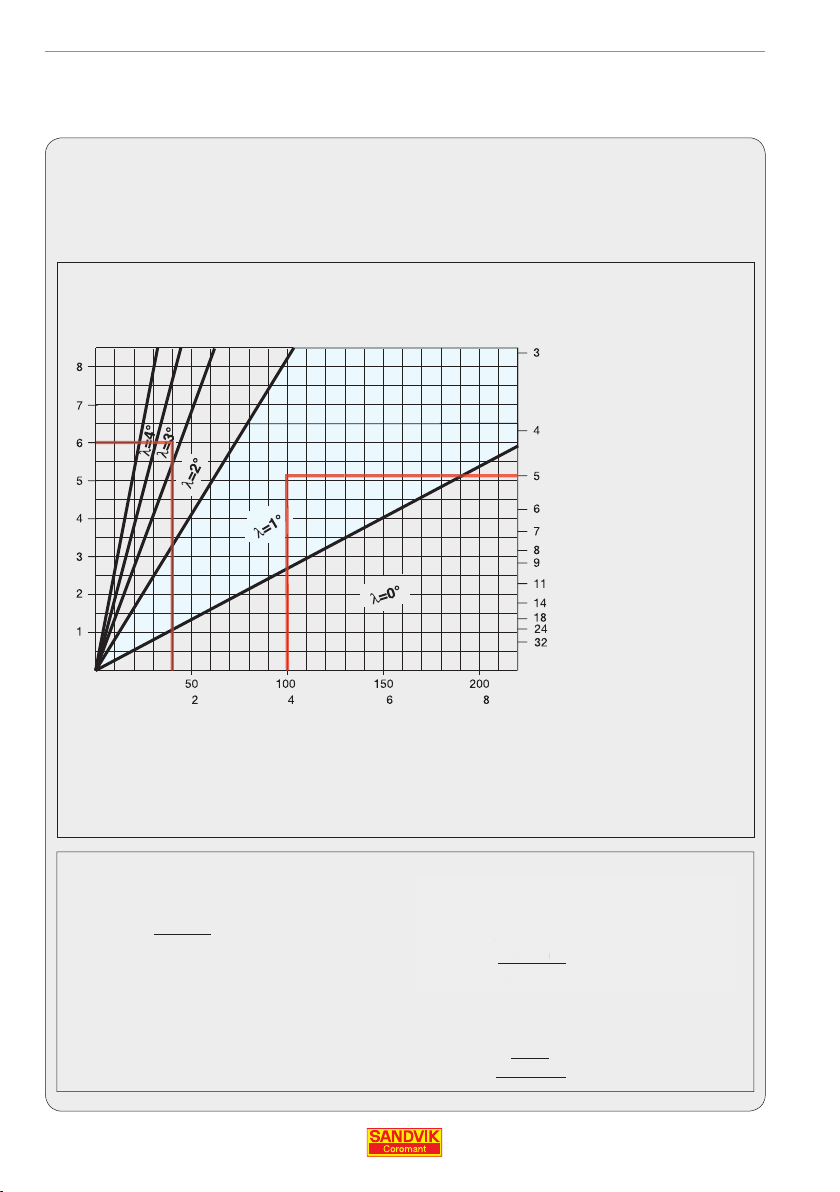

Methods for selecting the correct shim

Two alternative ways to select the correct shim:

A. Use the diagram, selecting shims.

B. Use the formula to calculate the helix angle to choose the corresponding shim.

Workpiece diameter and pitch in uence inclination angles

A.

Lead (Pitch) mm Threads/inch

Workpiece

diameter

For a pitch of 6 mm and a workpiece diameter of 40 mm, a 3° shim is

required. For a pitch of 5 threads per inch and a diameter of 4 inches, a

1° shim is required.

B.

P

=

tan

P

d

28

d2 x π

=

Pitch

=

Effective diameter of thread

2

=

P = 6 mm

d

= 40 mm

2

= arctan

P = 5 t.p.i.

= 4”

d

2

= arctan

mm

inch

6 mm

m

40 mm x π

mm x

1

5 t.p.i.

4” x π

= 2.7° use a 3° shim

= .91° use a 1° shim

g

Relationship between ank clearance, radial clearance and

thread pro le angle

The smaller the thread pro le and radial clearance angles, the

smaller the ank clearance angle (see table below for ank clearance values when the correct shim, equal to the helix angle, is

used).

Please note that as the pro le angle becomes smaller, it is more

important to choose the correct shim.

. Applications – Thread turnin

Threads with small pro le angles

ACME, Stub ACME, trapezoidal and rounded threads fall into this

category and put extra pressure on the cutting edge. To minimize

this pressure, choose the correct shim to tilt the insert.

Thread

Pro le

Metric, UN

Whitworth

Trapezoidal

ACME

Buttress

Angle Internal 15° External 10°

( ()()

Flank clearance Flank clearance

60° 7.6° 5°

55° 7.1° 4.7°

30° 4° 2.6°

29° 3.8° 2.5°

10° / 3° 2.7° / 0.8° 1.8° / 0.5°

Radial

clearance ()

Flank

clearance

29

2. Applications – Thread turnin

g

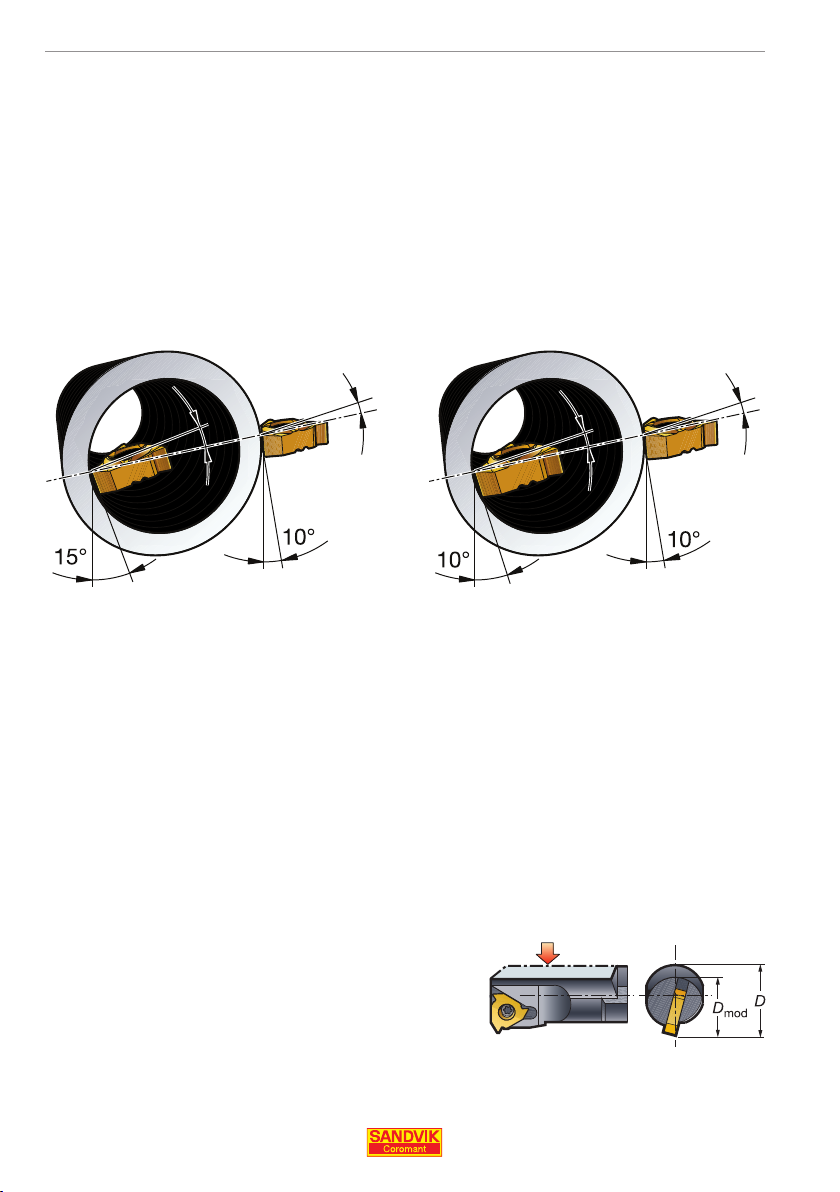

Radial clearance

To give adequate radial clearance, inserts are tilted in the tool

holder 10° or 15°.

It is important to use internal inserts with internal tool holders, and

vice-versa, to ensure that the correct thread form is achieved.

Insert sizes 11, 16 and 22 mm

Insert size 27 mm (5/8 inch)

(1/4, 3/8 and 1/2 inch)

Modi ed bars for small holes

Internal boring bars can be modi ed to t small holes and can be

used in place of special tools. These modi ed bars retain their

rigidity, as long as the recommended minimum dimension D

retained – see main catalogue for further information.

30

min

is

Loading...

Loading...