Sandvik Coromant Silent tools User Manual

How to reduce vibration

in metal cutting

Turning - Rotating

Introduction

Vibration in metal cutting is familiar to every machine tool operator. This

phenomena is recognised in operations such as internal turning, threading,

grooving, milling, boring and drilling, to which there are several reasons

why this problem occurs. Some are related to the machine tool itself, to the

clamping of the tool, the length and diameter of the tool holder and the

cutting data to be used. More of this will be discussed later.

There will be several different actions to consider when solving this pro-

blem. Reducing the process parameters is one such consideration, however,

this could have a negative effect on productivity. Our focus, therefore, will

be easy hands on recommendations for productive solutions and easy to

use products. This strategy will be emphasized throughout this guide

which will also contain useful information relating to the tool holder e.g.

clamping methods, extensions and the types of inserts that can be used.

Stretching beyond the normal limit of 4 x the L/D (Length by Dia-

meter) ratio is possible when using a Silent Tools tool holder.

Silent Tools is a Trade Mark for a family of tool holders for turning,

milling, boring and drilling with a damper inside to minimise the problems

with vibration. You will find more information about these damped adap-

tors in a separate chapter. Products with a similar function can be referred

to as tuned, damped or anti-vibration tools.

The aim, with this application on hand, is for you to have easy access to

information giving you productive solutions for eliminating vibrations in

your metal cutting process.

For further information and assistance, please contact your local

Sandvik Coromant representative.

Sandvik Coromant – How to reduce vibration in metal cutting

Sandvik Coromant – How to reduce vibration in metal cutting

Contents

Turning

Practical tips and hints on how to reduce vibrations ................ 02

Select your tool system ................................................................. 04

Turning: hands on information ....................................................07

Threading: hands on information ................................................12

Grooving: hands on information .................................................14

Holding the bar ..............................................................................17

Internal machining theory ............................................................19

Boring very deep holes ..................................................................21

Eliminating vibration with damped boring bars ........................24

Silent Tools

Productivity with slender tools ................................................... 25

Which products have Silent Tools ................................................26

Sandvik Coromant – How to reduce vibration in metal cutting

Milling

Practical tips and hints on how to reduce vibrations ................ 28

Select your tool system ..................................................................32

Main applications and milling concepts ......................................32

Operations – tool recommendations ...........................................37

Clamping ....................................................................................... 40

Hands on info .................................................................................43

Boring

Practical tips and hints how to reduce vibrations ..................... 48

Select your tool system ..................................................................51

Hands on info .................................................................................53

Silent Tools

Silent tools within milling ............................................................55

Sandvik Coromant – How to reduce vibration in metal cutting

Turning

Practical tips and hints

on how to reduce vibrations

Dimension and tolerance problems:

1. Choose a smaller nose radius.

2. Choose a more wear resistant grade.

3. If there is between 4 x D to 6 x D overhang choose a carbide bar.

4. If there is over 6 x D overhang, choose a Silent Tool.

Chip jamming:

1. Increase the coolant flow.

2. Change the insert geometry.

3. Reduce the cutting speed.

Sandvik Coromant – How to reduce vibration in metal cutting2

Bad surface finish:

1. Increase the coolant flow.

2. Choose an insert with a sharp cutting edge.

3. Check that all chips have been evacuated.

4. Choose a smaller nose radius than the depth of cut.

5. If there is between 4 x D to 6 x D overhang, choose a carbide bar.

6. If there is over 6 x D overhang, choose a Silent Tool.

Vibration:

1. Choose a smaller nose radius than the depth of cut

2. Choose a positive insert with open chip breaker.

3. Increase the feed.

4. If there is between 4 x D to 6 x D overhang, choose a carbide bar.

5. If there is over 6 x D overhang, choose a Silent Tool.

Sandvik Coromant – How to reduce vibration in metal cutting 3

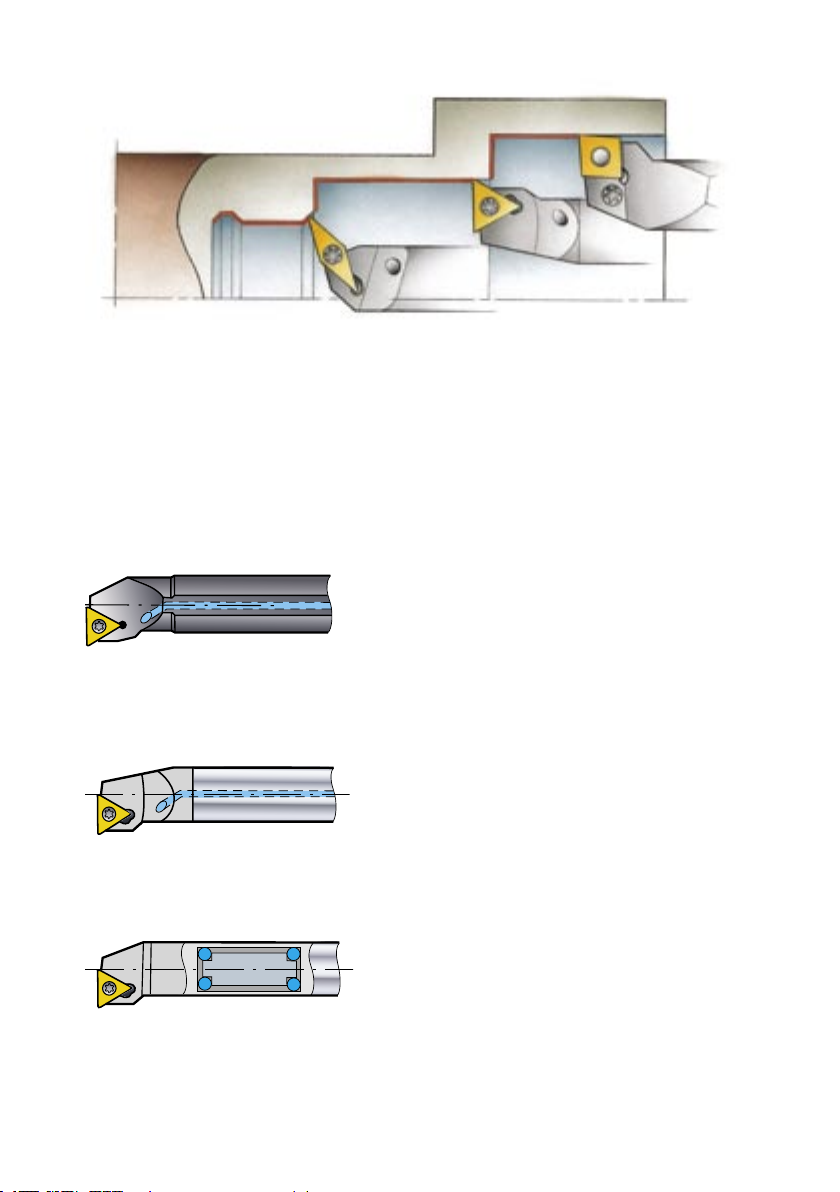

Select your tool system

One application within metal cutting that is very sensitive to vibration

is internal turning. The different tools for the applications have various

parameters that can be adjusted to suit the machine, the component and

the material.

In this chapter we will talk about the choice of tooling, various applications, how to minimise the risk of vibration and how to improve

productivity.

Choosing the correct tool for the application

Depending on the application and the component, it is important to choose

the tool that can give the highest output and security.

Depending on the component diameter there are three Sandvik Coromant

systems available to you.

CoroTurn RC with double-sided negative inserts for applications with

hole diameters from 20 mm. This system enables applications from finishing to roughing using modern grades and Wiper inserts for increased

productivity.

CoroTurn 107 single-sided inserts with seven degree relief angle are designed

for turning applications with hole diameters from 8 mm and applications

where copying is the main focus.

CoroTurn 111 is a system of inserts with eleven degree relief angle, designed

for hole diameters from 6.5 mm - 32 mm where the overhang is generally

longer and where there is a need for tools requiring lower cutting forces.

Sandvik Coromant – How to reduce vibration in metal cutting4

The boring bar families above include insert geometries that are designed

for specific applications, such as finish turning of steel materials, roughing

in stainless steel machining etc. This is needed to become more productive

at every application.

Solid steel bars

Recommended for overhangs up to 4 x bar diameter.

Carbide reinforced bars

Recommended for overhangs up to 6 x bar diameter.

Carbide reinforced and damped bars

Recommended for overhangs up to 10 x bar diameter.

Sandvik Coromant – How to reduce vibration in metal cutting 5

CoroTurn SL (type 570)

Modular system for various

operations – turning, grooving and

threading and holders, including solid

steel and Silent Tool holders. Also available are

cylindrical bars and Coromant Capto bars. This Coro-

Turn SL system of boring bars ranges from 16 mm to 100 mm

diameter, and all having the benefit of a quick change system.

CoroTurn, CoroCut and U-lock solid bars

Boring bar programme including Coromant

Capto steel bars and cylindrical bars with

both steel and carbide bar material. Turning

operations possible.

CoroCut MB

Boring bar programme includes steel and

carbide bars focusing on grooving operations but

also turning and threading operations are possible. Min hole diameter starts at 10 mm.

CoroTurn XS

For internal machining of small bores starting

with minimum hole diameter 1 mm. CoroTurn

XS enables turning, grooving and threading

operations all with one holing system.

Sandvik Coromant – How to reduce vibration in metal cutting6

ap<r

ε

ap=r

ε

ap>r

ε

∆

R

a

p

F

C

[N]

F

C

[N] FC [N]

a

p

a

p

a

p

r

ε

r

ε

r

ε

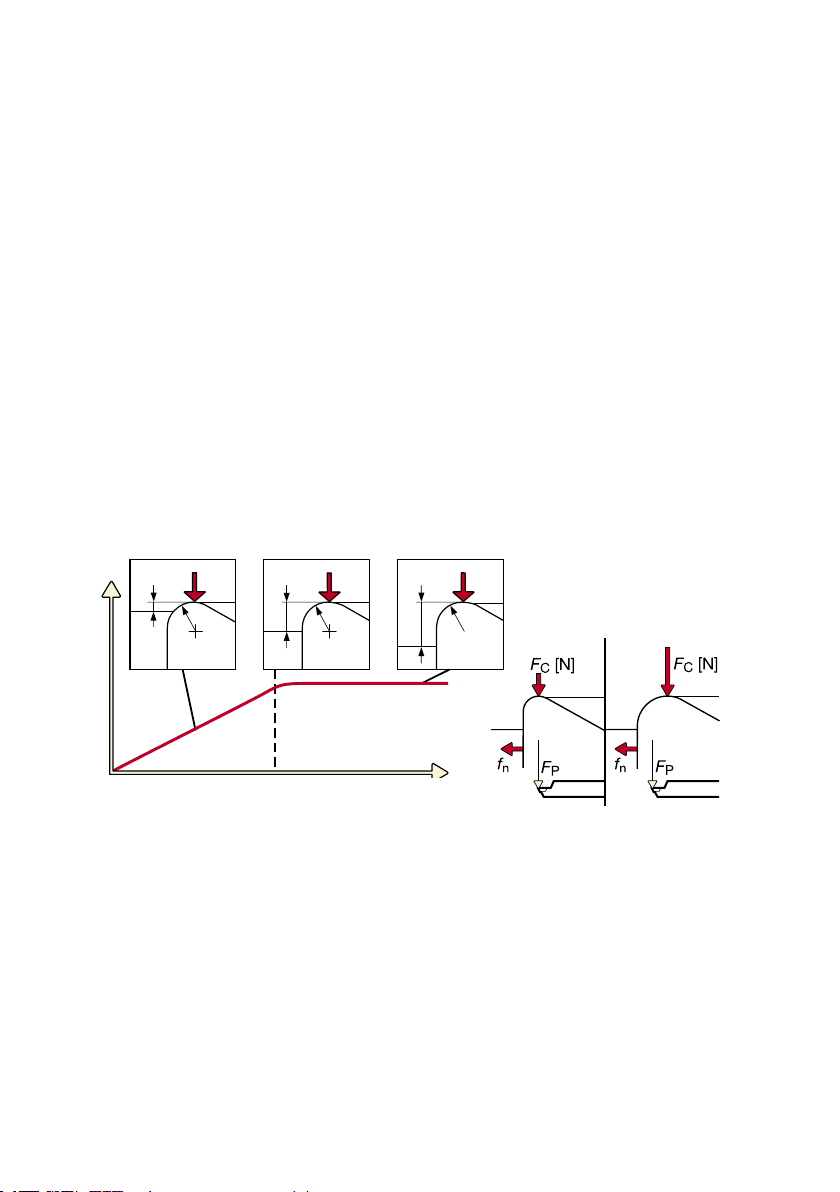

Turning

Choice of insert

Choosing the right insert can be enough to eliminate vibration and also

improve your manufacturing productivity.

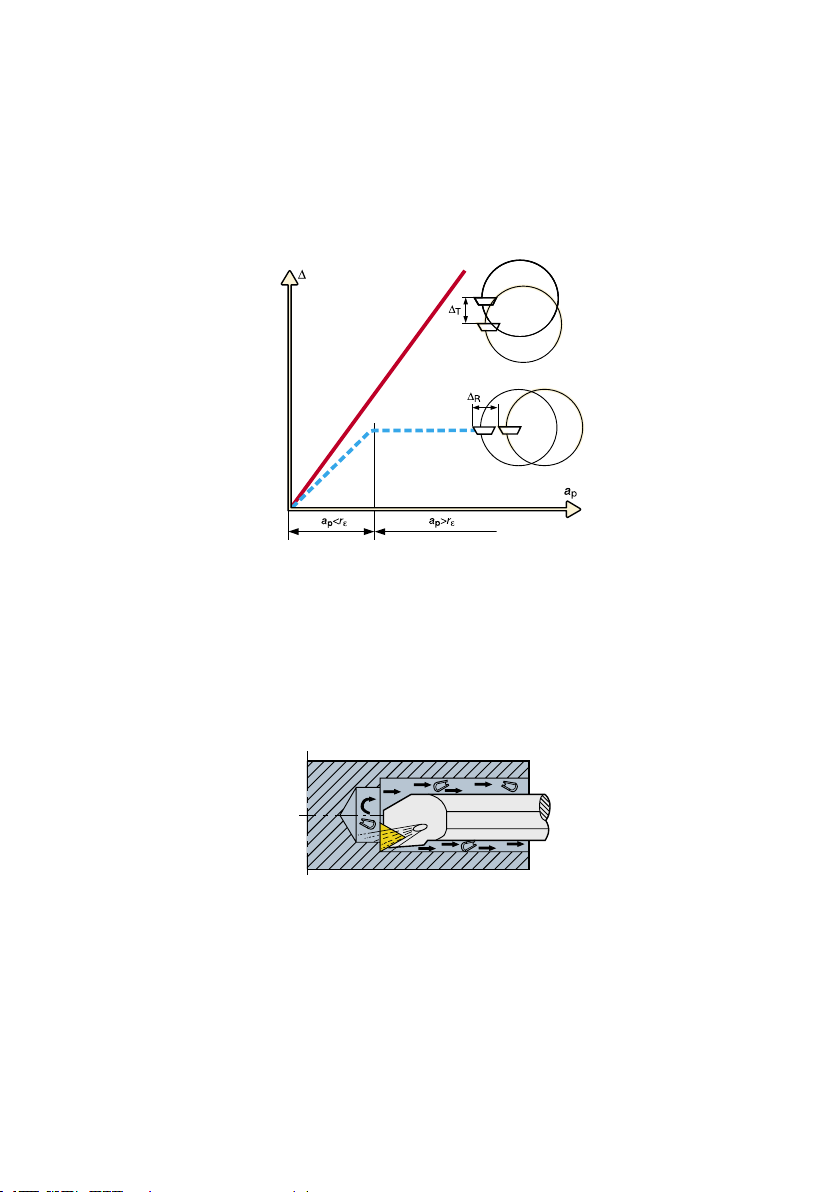

Nose radius:

It is important to choose a nose radius that is smaller than the cutting depth

as this has the same effect as choosing the correct entering angle. If the nose

radius is too large it will push the tool in the radial direction and affect the

dimensions of the component.

Wiper inserts act as a large nose radius and will generally need a bit more

care when applying to internal turning. To decrease the radial cutting forces

it is a normal requirement to increase the feed.

Practical hints:

Always choose a smaller nose radius than the cutting depth.

Sandvik Coromant – How to reduce vibration in metal cutting 7

Sandvik Coromant – How to reduce vibration in metal cutting8

Insert size:

It is important to choose an insert strong enough to withstand the

cutting forces but at the same time it must suit the component and its

application. Too large a cutting depth will lead to excessive cutting forces

and too small cutting depth will lead to increased friction between the

insert and component causing component dimension problems.

Cutting force is extremely important when using long overhangs.

Practical hints:

• Do not exceed 2/3 of the cutting edge length when turning as this will

result in too high cutting forces on the cutting edge.

Carbide grade:

Generally when turning small holes with small boring bars it is beneficial to use sharp inserts as this helps to cut the metal more smoothly.

Sharp inserts need suitable grades, and grades such as the GC1025 and

GC4015, have relatively thin coatings that will enhance the cutting action.

Choose a grade according to Sandvik Coromant’s CoroKey matrix.

Steel grades: 4000 series and

5000 series (Cermet inserts)

Stainless grades: 2000 series

Cast iron grades: 3000 series

All round grades: 1000 series

Steel Materials

Stainless Steel

Cast Iron

Non-ferrous

Super alloys

Hardened materials

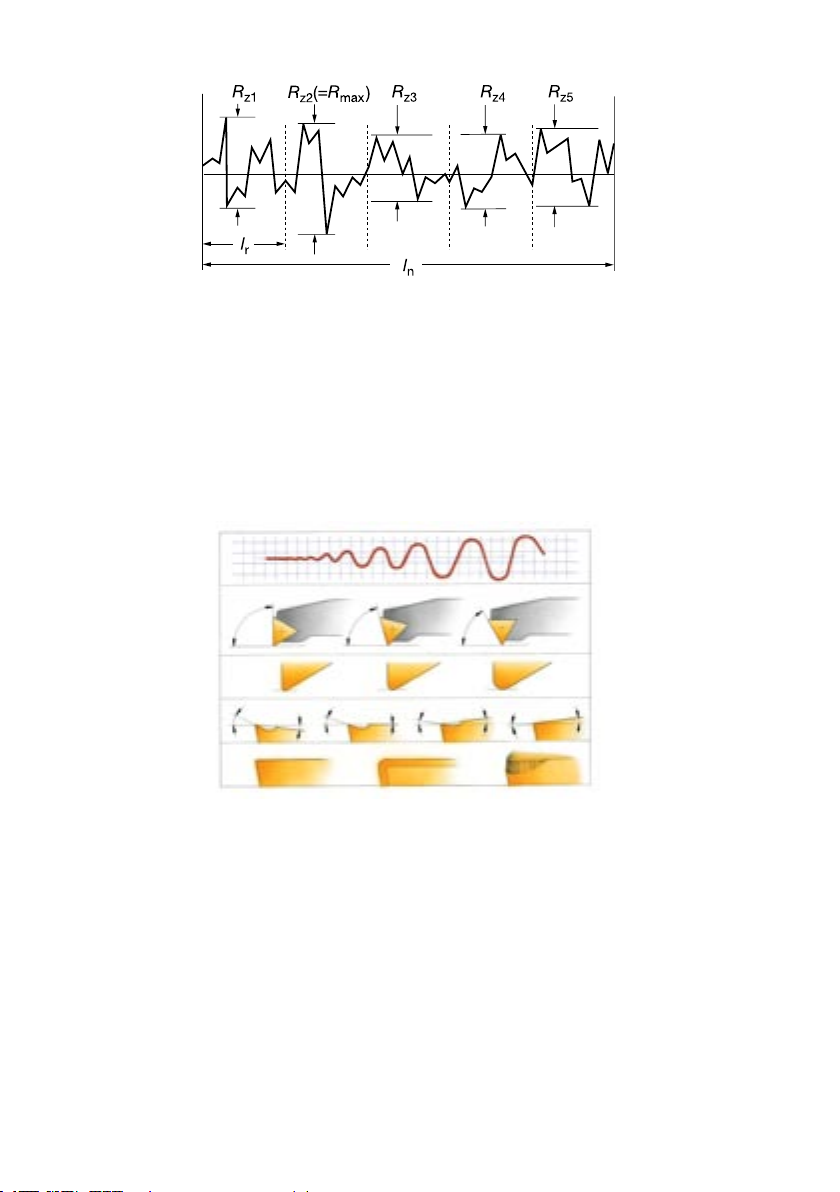

Geometries:

Sandvik Coromant geometries are designed and dedicated for each application area and component materials. Choose your geometry with the

application in mind, finishing-roughing, to give the best possible chip

breaking together with good machining results.

Examples of geometry:

- PF: Finshing of steel materials

- PM: Medium machining of steel materials

- PR: Roughing of steel materials

Practical hints:

• Choose an open chip breaker, medium chip breaker (PM), instead of

a finishing geometry as the finishing geometry can break the chips too

hard and lead to excessive cutting forces resulting in bad surface finish.

Insert style:

Depending on the operation – longitudinal turning or copying – the choice

of insert style affects the result of the machining process.

Practical hints:

• T-style inserts are first choice for internal longitudinal turning as this

style of insert uses an entering angle at 91 degrees. This helps to direct

the cutting forces correctly.

• D and V-style inserts both have good copying possibilities and small

insert point angles, which help to reduce the force variation.

Sandvik Coromant – How to reduce vibration in metal cutting 9

Tool overhangs:

Depending on the depth of the hole that needs to be turned, it is important

to choose the correct type of tool holder and tool holder material.

Boring bar materials:

As seen on the diagram the following boring bar materials can be selected to suit

the length to diameter ratio overhangs.

Steel boring bars: Up to 4 x D

Carbide boring bars: Up to 6 x D

Steel damped boring bars short design: Up to 7 x D Silent Tools

Steel damped boring bars long design: Up to 10 x D Silent Tools

Carbide reinforced damped boring bars: Up to 14 x D Silent Tools

All damped boring bars are called Silent Tools and consist of different

variations of tools, the most common being CoroTurn SL (570) system.

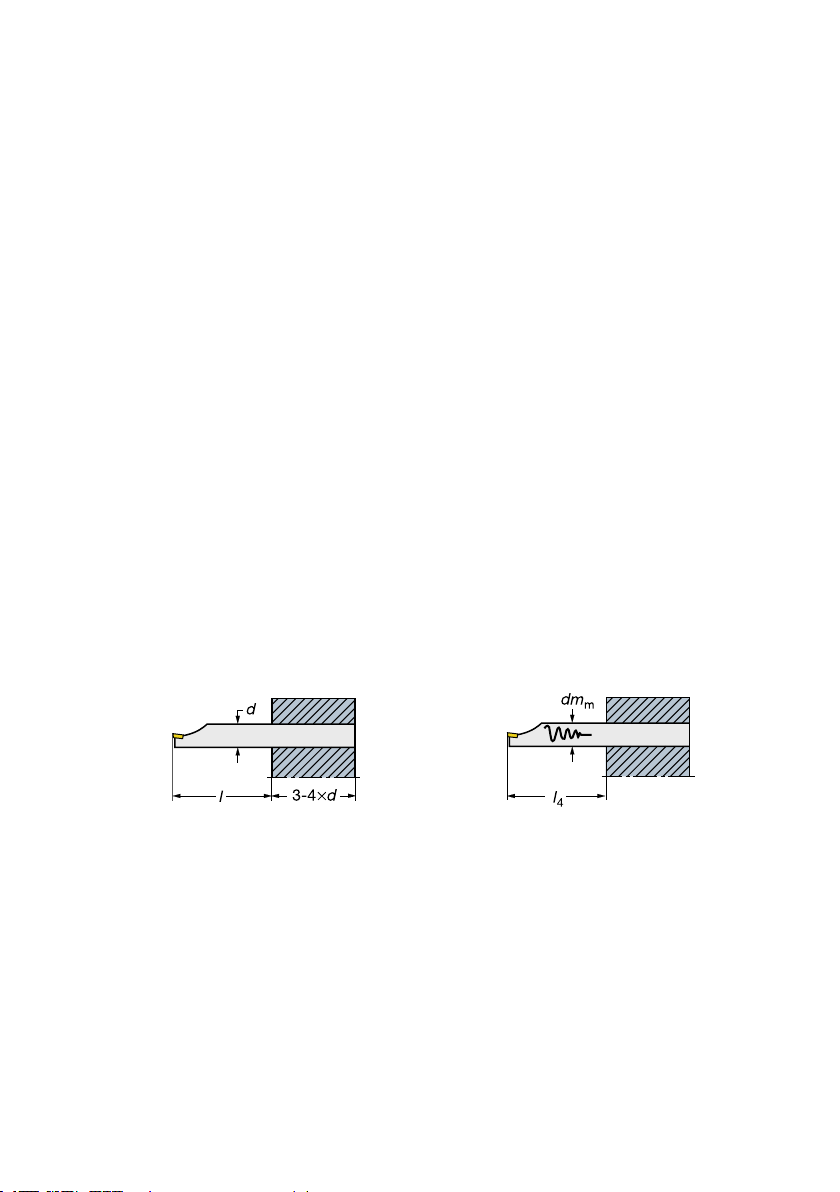

Solid bars

Smallest possible overhang.

Max recommended overhang for steel bars

4 x D (/)

Max recommended overhang for Carbide

bars 6 x D (/ )

Sandvik Coromant – How to reduce vibration in metal cutting10

Tuned damped bars

/4 = damped part.

Do not clamp on this area. This is indicated

on the boring bar.

Max recommended overhang for damped

bars, short design 7 x D and long design

10 x D.

Chip evacuation:

Chip evacuation during boring is critical to performance and the

security of the operation. Relatively short, spiral-shaped chips should be

aimed for with internal turning. These are easy to evacuate and do not

place such large stresses on the cutting edge when chipbreaking occurs.

Hard breaking of the chips, when very short chips are obtained, uses

more power and increases vibration. On the other hand, long chips make

chip evacuation more difficult and present a risk of swarf-clogging. It is

necessary, therefore, to choose an insert geometry which, together with

the chosen machining parameters, fulfil the requirements for good chip

control.

When internal turning is undertaken, the chip flow can be critical –

particularly when deep holes are being machined. The centrifugal force

presses the chips outwards which means, with internal turning, that the

chips remain in the workpiece. The remaining chips can be pressed into the

machined surface or get jammed and damage the tool. It is recommended,

therefore, that internal turning tools should have internal coolant supply.

The chips will then be flushed out of the hole effectively. Compressed air

can be used instead of cutting fluid and by way of through holes, allow the

chips to be blown through the spindle and collected in a container.

Chip evacuation is a critical factor for successful boring.

Sandvik Coromant – How to reduce vibration in metal cutting 11

Threading

Choosing the correct tool for the application

Choice of tooling family:

T-MAX U -Lock for threading hole diameters from 12 mm

CoroCut MB for threading hole diameters from 10 mm

CoroCut XS for threading hole diameters from 4 mm

Chip evacuation:

Chip evacuation is also very important when internal threading, parti-

cularly the feed direction which should be from inside out giving better

chip control. This, combined with a modified flank infeed, will produce

spiral chips which are then led out towards the mouth of the hole. Overhang, blind holes and material type are also of great importance when

internal threading and should be given due consideration.

The infeed per pass should not be more than 0.2 mm and never less than

0.06 mm. Never run a final pass without infeed, and it is important to have

a firm force on the bar to minimize vibrations.

Overhang:

Compared with turning, threading is limited to a certain overhang due

to the increased side (radial) forces. For overhangs beyond 2.5 x D it is

recommended to use Silent Tools holders or carbide reinforced shanks to

minimize vibration and thus increase productivity.

2 - 2.5 x D solid steel boring bars

3 - 5 x D Silent Tools boring bars

Sandvik Coromant – How to reduce vibration in metal cutting12

Rounded (ER treated) cutting edge

First choice in most operations and

materials

Example: R166.0G-16MM01–150

Geometry F

Sharp cutting edge

Reduced cutting forces and good

surface finishes

Example: R166.0G-16MM01F150

Geometry C

Chip breaking geometry

For maximum chip control and

minimum supervision

Example: R166.0G-16MM01C150

Inserts:

First choice is the all round geometry the GC 1020 for the ISO P, M and

K areas. F geometry with its sharp cutting edge is suitable for more tricky

materials and C geometry for reliable chip breakage.

Threading applications:

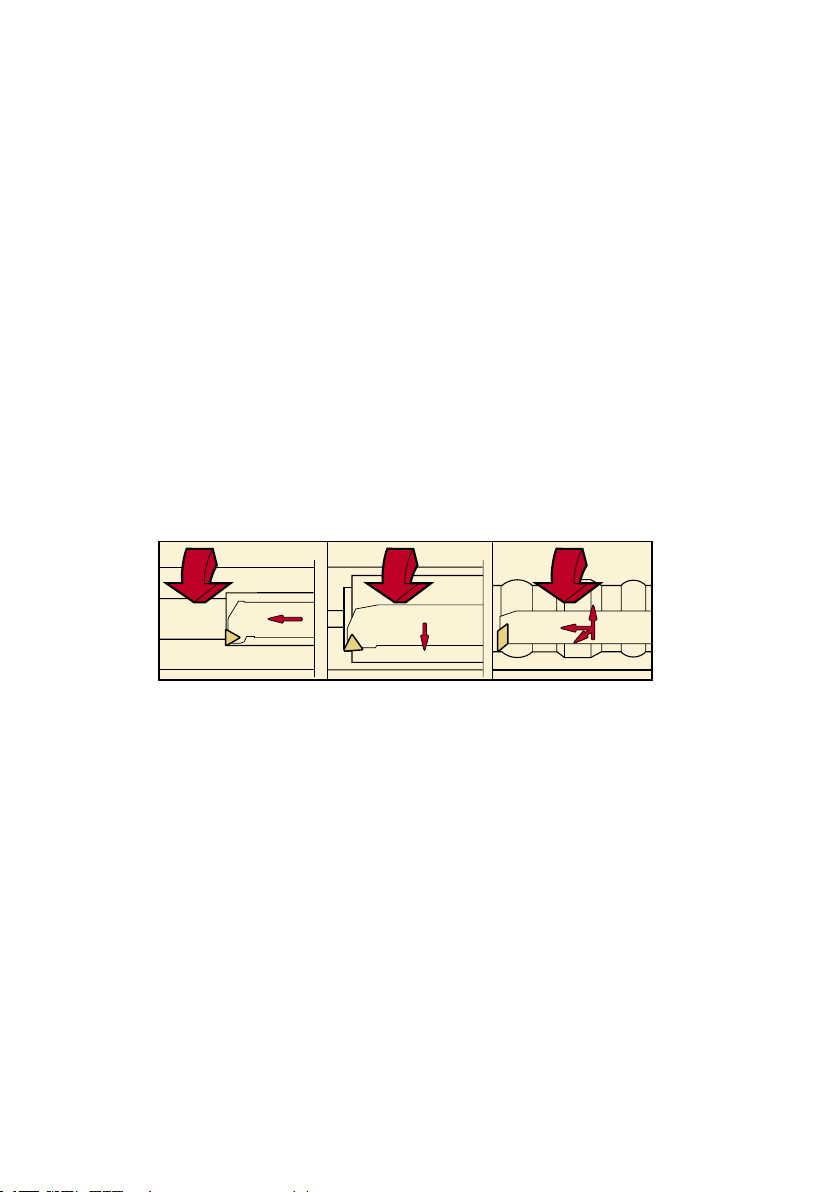

When threading it is possible to change the programme in order to minimize the risk of vibration. By modifying the flank infeed, the axial cutting

forces will increase, which will also reduce any vibration.

Sandvik Coromant – How to reduce vibration in metal cutting 13

Grooving

Choosing the correct tool for the application

Choice of tooling family:

CoroCut for grooving hole diameter from 25 mm

T-MAX Q -Cut for grooving hole diameter from 20 mm

CoroCut MB for grooving hole diameter from 10 mm

CoroTurn XS for grooving hole diameter from 4.2 mm

Chip evacuation:

To avoid chip jamming within grooving operations it is important to direct

the coolant into the groove and evacuate the chips. Chips in the groove

can cause insert breakage, bad surface finish or difficulties in keeping

tolerances. For this to be effective it is recommended to choose toolholders

or cutting heads with integrated coolant.

It is also possible to change the programming of the machine with micro

stops so that chip breaking can be achieved and the evacuation of chips is

made possible.

Overhang:

Compared with turning, grooving is limited to a certain overhang due to

the increased side (radial) forces. We recommend, therefore, you choose

Silent Tool holders or carbide reinforced so that the productivity can be

increased.

2 - 2.5 x D solid steel boring bars

3 - 5 x D Silent Tool boring bars

Sandvik Coromant – How to reduce vibration in metal cutting14

Loading...

Loading...