Sandvik Coromant Quick Change for CNC Lathes User Manual

USER AND BUYERS GUIDE

Quick Change for

CNC Lathes

Contents

Quick Change 3

Key benets 6

Increase machine utilization – Green Light Machining 6

Improved safety and ease of use for operator 9

Coromant Capto® Quick Change features 10

Increased metal cutting efciency with Coromant Capto® 18

Working with Quick change - planning to production 22

Machine options 24

Clamping unit styles and options 29

Driven tool holders 32

Accessories to be considered for Quick Change 34

2

Quick Change

Making all lathes more efcient

Using quick change will reduce the measuring, set up and tool change time

allowing extra metal cutting time for all these machines. Through coolant

delivery ensures that the full capabilities of the machine are harnessed

with optimized cutting units to deliver the coolant with maximum impact and

reduce setting.

Make sure the tooling is considered together with the machine investment

to ensure that the machine utilization and metal cutting efciency are

optimized.

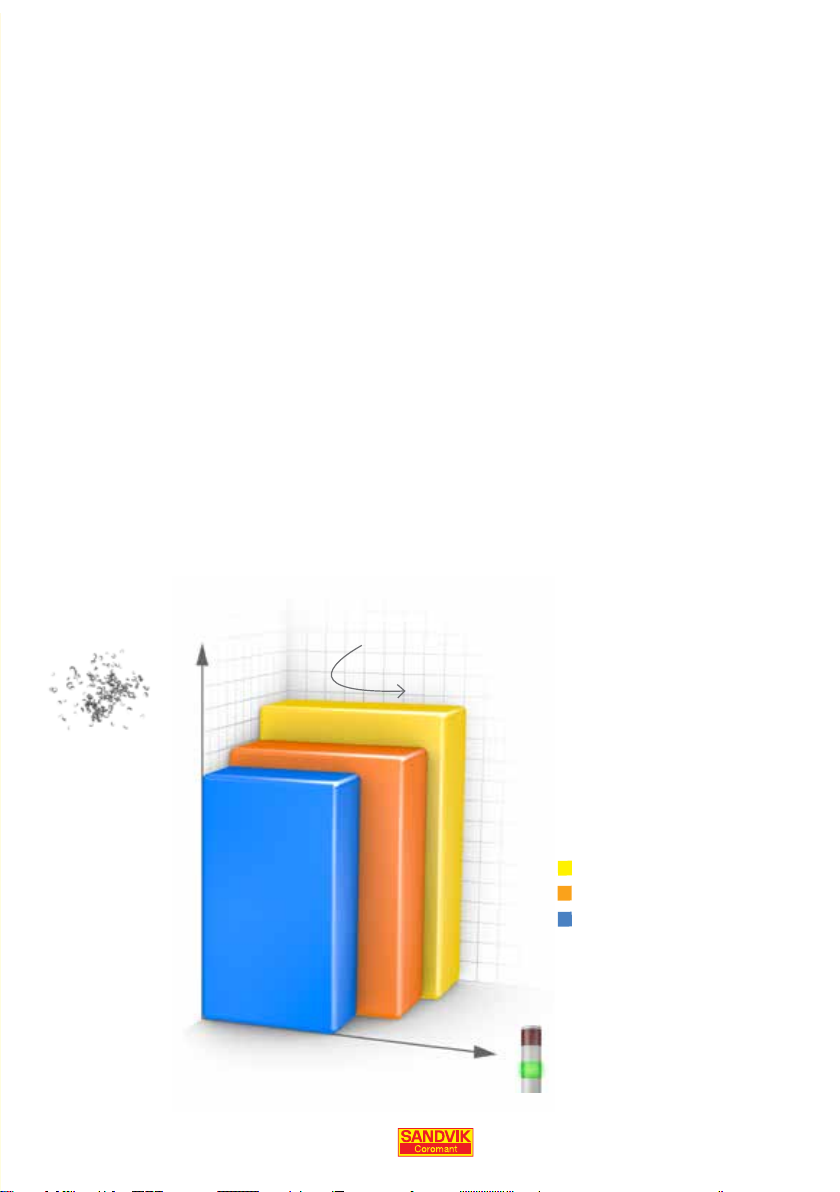

Metal cutting efciency

High pressure coolant!

High Pressure coolant

Quick change

Normal production

Machine utilization

3

Quick Change

Making all lathes more efcient

Turning Centers –

fast tool indexing but typically have a lower

utilization than machining centers due to

the tool change and setup time. Quick

change holders ensure the green light on

the machine is on for longer!

Machine options such as sub spindle,

Y-axis and half turret indexing allow for extra

tool positions to be added to each turret

position. This increases the number of tool

positions for sister tooling or reduced tool

changing.

Vertical Lathes –

widely available with automatic tool change.

For VTLs without ATC capability tool blocks

with quick change reduce the tool change

and set up time considerably. Dedicated

tool blocks with clamping unit sets built in

can be supplied with the machine or easily

retrotted onto existing machines.

4

Heavy duty & at bed lathes –

extremely high stability but slow tool indexing and changing with no

ATC. Shank tool holders are very heavy often needing a crane. Quick

change is widely used with VDI DIN 69881 (dovetail) holders on at

bed lathes or dedicated clamping unit blocks on heavy duty lathes.

With the limited number of tool positions quick change has a dramatic

effect on machine efciency.

5

Key benets -

Quick change versus shank and conventional ER

driven units

5-10 mins

Increase machine utilization –

Green Light Machining

1. Reduced batch change over time using tooling kits

Quicker tool changing

- External turning (5 to 10 mins)

this increases when using shank tools with high pressure

coolant.

- Internal turning (5 to 15 mins)

with boring bars it takes longer time than a shank tool with

center height and internal coolant setting.

- Driven tool holders (5 to 20 mins)

standard driven tools are either ER collets or face milling.

ER has a limited tool diameter allowing only end milling

(max dia 25 with ER40). This means either low productivity

or 2 separate driven units are needed which increases the

setting time and investment.

30 secs

6

2. Increased number of tool positions with double tool holders

When the machine has one or more of the following options:

- Y axis

- Half turret

- Sub spindle

Turning centers with driven tool holders often have limited space

- using double clamping units allows either sister tooling or

increased variety of tools thereby reducing tool change requirement for a wider range of components.

3. Reduced worn tool indexing time

- Driven tool holders

- Solid carbide (5 mins)

every time a solid carbide tool is changed the tool offset needs

to be re-calibrated.

- Indexible drill/mill (5 mins)

with multiple inserts to use sister tool and change the cutter off

line whilst the machine is running is much quicker.

30 secs

5-10 mins

- Static tool holders

- For single inserts with good accessibility it can go as quick to

change directly in the machine. However being able to remove

the tool ensures.

- Improved maintenance of the tool.

- Correct mounting.

- No stoppages due to visit to stores for spare parts (dropped

screw, broken shim).

7

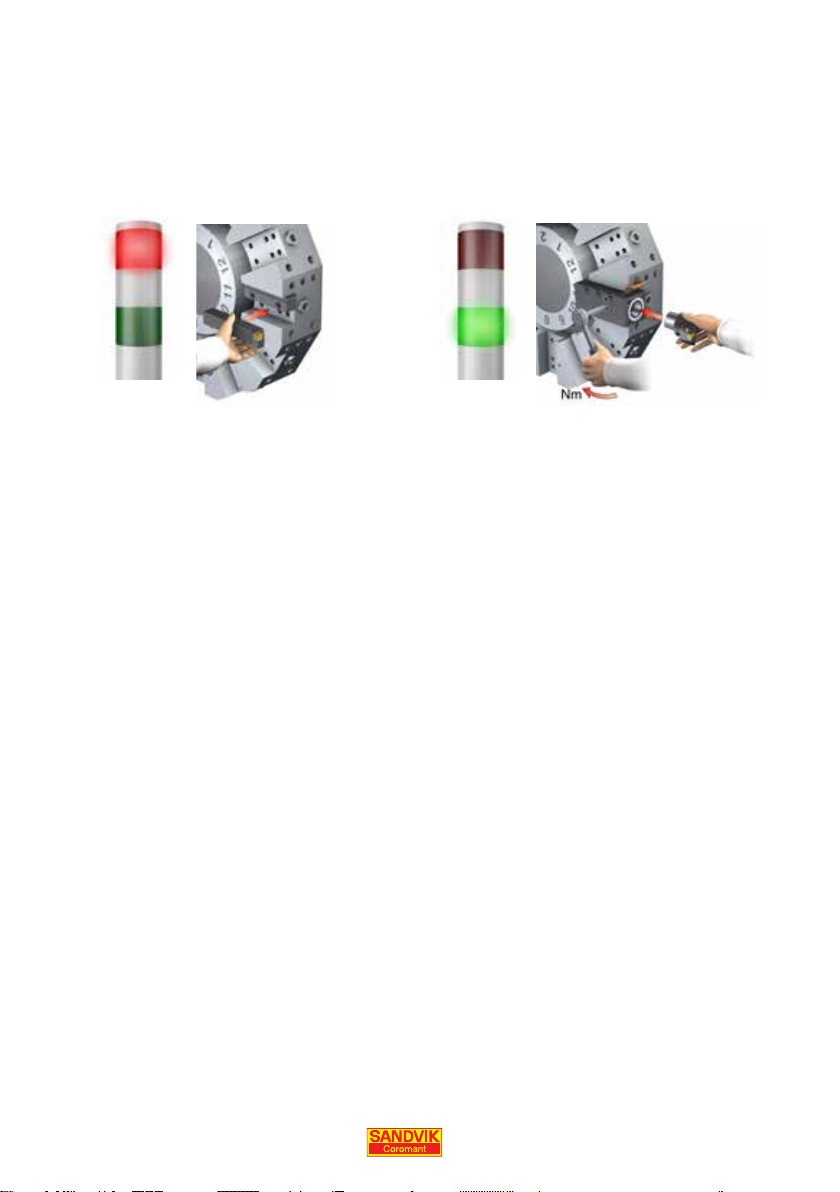

4. Eliminate coolant pipe setting

Varies from application to application but when operators are

setting the coolant pipe direction it normally takes 2 to 3

attempts to get it right – red light on!

Poor chip control often then knocks the pipe and so setting is

quite a regular occurrence.

5. Quicker production start up

By eliminating either ‘rst test component’ or ‘measuring cuts’

the production rate is increased and scrap reduced. The best

analogy is the pit stop in motor racing. Calculated through the

year if quick change was used the number of additional

components produced and reduced scrap rate is signicant.

First test component – higher volume production - The rst

component of every tool change is often scrapped and the tool

change time needs to be considered as:

- change tool (keep old offset)

- cut complete part

- measure nished component

- adjust offset

Measuring cuts – low/medium volume production – Taking a

measuring cut with backed off offset ensures that the

component is not scrapped but can take longer time. Tool

change time needs to be considered as:

- change tool

- back off offset

- cut

- measure

- adjust offset

8

Improved safety and ease of use for operator

Easy to use

- Change the insert outside the machine reducing accidents,

errors and searching for dropped parts

- Eliminate coolant setting with xed nozzle position

- Remove safety issues with changing ER driven tool holders

where 2 wrenches are sometimes called ‘knuckle busters’

- Offset dimensions in tool code – consistent for each size

- Only one version of coupling reducing errors (ISO 26623)

- Technical and user support

- CAD drawings (DXF) and 3D models (.stp) of clamping and

cutting units available on www.sandvik.coromant.com for

simulation

Versatility

- Modular solution makes it easy to build different tool

combinations

- Large program of tools – next day delivery

- Easy to standardize in all machine types

Ergonomic

- Light weight cutting units – especially in VTLs and heavy duty

lathes where large shank tools (5050, 8080) are extremely

heavy for handling which increases the tool change time

considerably

- Easy to handle and store either at the machine or centrally

9

Coromant Capto® Quick Change features

Coromant Capto was introduced in 1990 and since then there

have been no modications to the coupling design. In 2008 it

became an ISO standard and Coromant Capto could also be

described as the standard for quick change on turning centers

now.

The cutting tool program has expanded over the years as well

as one new size added in 2010 – C10 for really heavy duty

applications. Below are some of key benets of the system

which ensure that both your machine utilization and metal

cutting efciency are maximized.

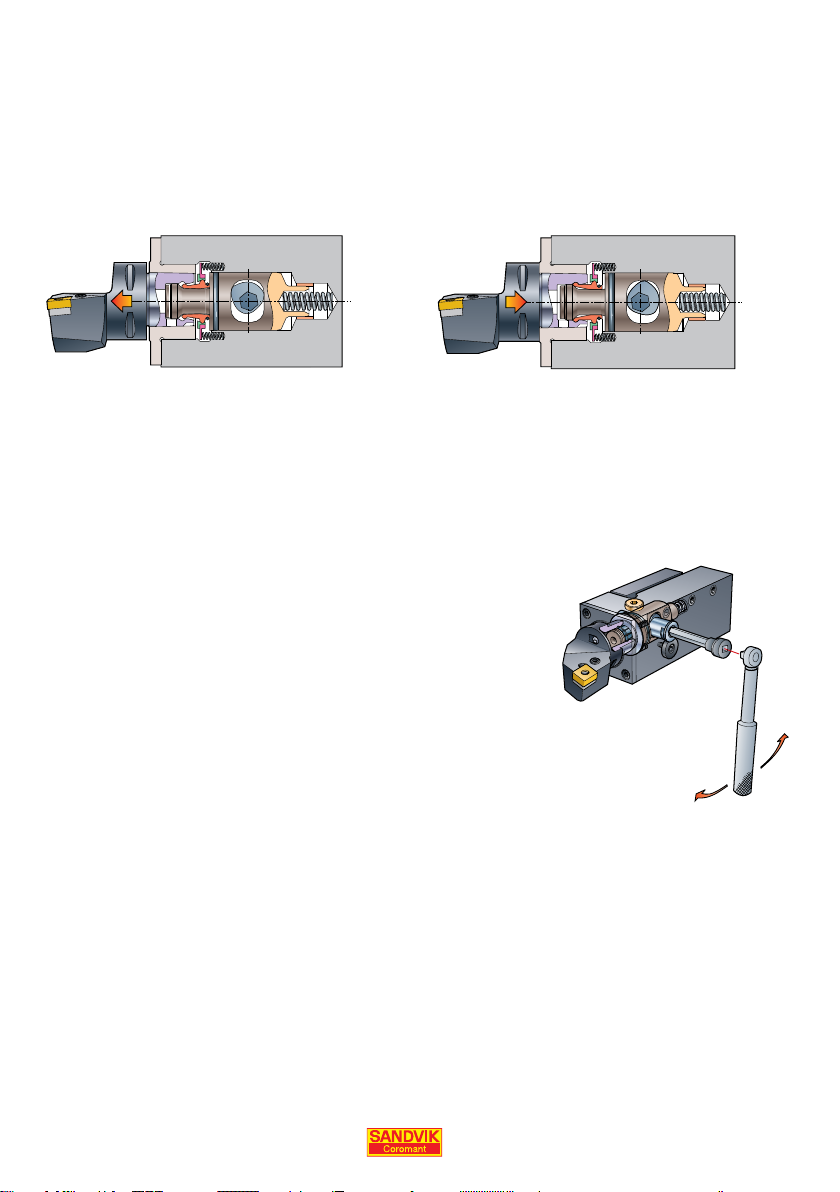

Segment clamping

The camshaft activated drawbar is used for both locking the

coupling, with segment clamping, and for pushing out the

cutting head. Only ½ a turn is needed to lock and unlock the

manual clamping unit. The camshaft has a self locking angle

and will not open during machining.

10

Repeatability

The high precision of the coupling and its self centering

design ensures a repeatable accuracy less than ±2 microns

in the x, y and z axes for one and the same cutting unit in

the same female receiver.

This allows pre-setting outside the machine for high batch

production or tool kits for batch change over. Both eliminate

measuring cuts allowing faster start up and reduced scrap

rates.

11

Increased stability

Stability is measured in terms of bending stiffness and torque transmission.

The key features providing the superior stability are:

Face and taper contact

- resisting bending moments and providing positional

accuracy.

Polygon coupling

- the large contact area transmits torque without any loose

parts such as pins or keys. The torque load is spread

symmetrically without peaks irrespective of direction

with the polygon shape self centering for accurate tip

seat center height.

High clamping force

- the segment clamping generates high clamping forces

ensuring a press fit and a two face contact resisting the

bending moment generated during cutting.

12

Loading...

Loading...