Sandvik Coromant Heat resistant super alloys User Manual

APPLICATION GUIDE

Heat resistant super alloys

High pressure coolant machining

for better productivity and results

More information

Useful information and application techniques can be found in our

catalogues, handbooks and application guides, such as PluraGuide.

CoroGuide web is an internet-based catalogue including a cutting

data module (also available on CD) where you can find cutting data

recommendations for your specific application.

Visit our websites for the latest news!

www.sandvik.coromant.com

www.aero-knowledge.com

Contents

Introduction 2

1. Heat resistant super alloys – HRSA 3

Alloy groups 4

Machinability/raw material

condition 5

Common component types 7

Coolant requirement 8

2. Turning of nickel-based materials 9

Machining stages 9

Typical wear mechanisms 11

Insert shape selection 13

Cutting tool materials 21

Ceramic insert grades 22

Carbide insert grades 26

SCL – predictive machining 28

Geometries and chip breaking 31

Recommended starting choices 34

Tailor Made 36

Engineered solutions 37

Component/feature solutions 42

3. Turning of cobalt-based materials 51

Process considerations 52

Typical wear recommendations 53

Insert shape selection 54

Optimized tools for internal machining 55

Recommended starting choices 57

Carbide insert grades 58

Engineered solution 58

Component/feature solutions 59

4. Milling 60

Production planning process 61

Typical components 61

Machining strategy 62

Cutter concept 64

Milling process with indexable inserts 65

Face milling with carbide inserts 68

End milling/90 degree approach 77

Ceramic milling 82

Solid carbide – CoroMill Plura in

HRSA machining 88

Exchangeable-head CoroMill 316

in HRSA machining 97

Component/feature based solutions 98

Recommended start cutting data 102

5. Hole making 104

Hole types and hole making methods 104

Tools for hole making 106

Circular ramping from solid 107

Circular interpolation of existing holes 108

Back chamfering/deburring 109

Thread milling 110

Recommended start cutting data 112

Component/feature solutions 114

6. Technical data 118

7. Material cross-reference list 120

Introduction

This application guide concentrates on optimizing machining of heat resistant super

alloys (HRSA).

For one of the most challenging material

groups to machine, optimized tools are naturally a prerequisite, but equally important

is how to apply them.

We will guide you through the most common materials and machining applications.

We aim to give you application and process

recommendations that will help you use our

products in the most productive manner

with maximum process reliability and component quality.

Our goal is to support customers with

complete tooling solutions that meet cost

reduction and quality improvment initiatives.

Productivity along with quality and reliability

are our focus. When we talk about productivity you will see that we measure this in

terms of cm3/min. It is important to understand the relationship between the combination of speed, feed and depth of cut and

not just cutting speed alone which is often

the most damaging parameter when considering tool life.

2

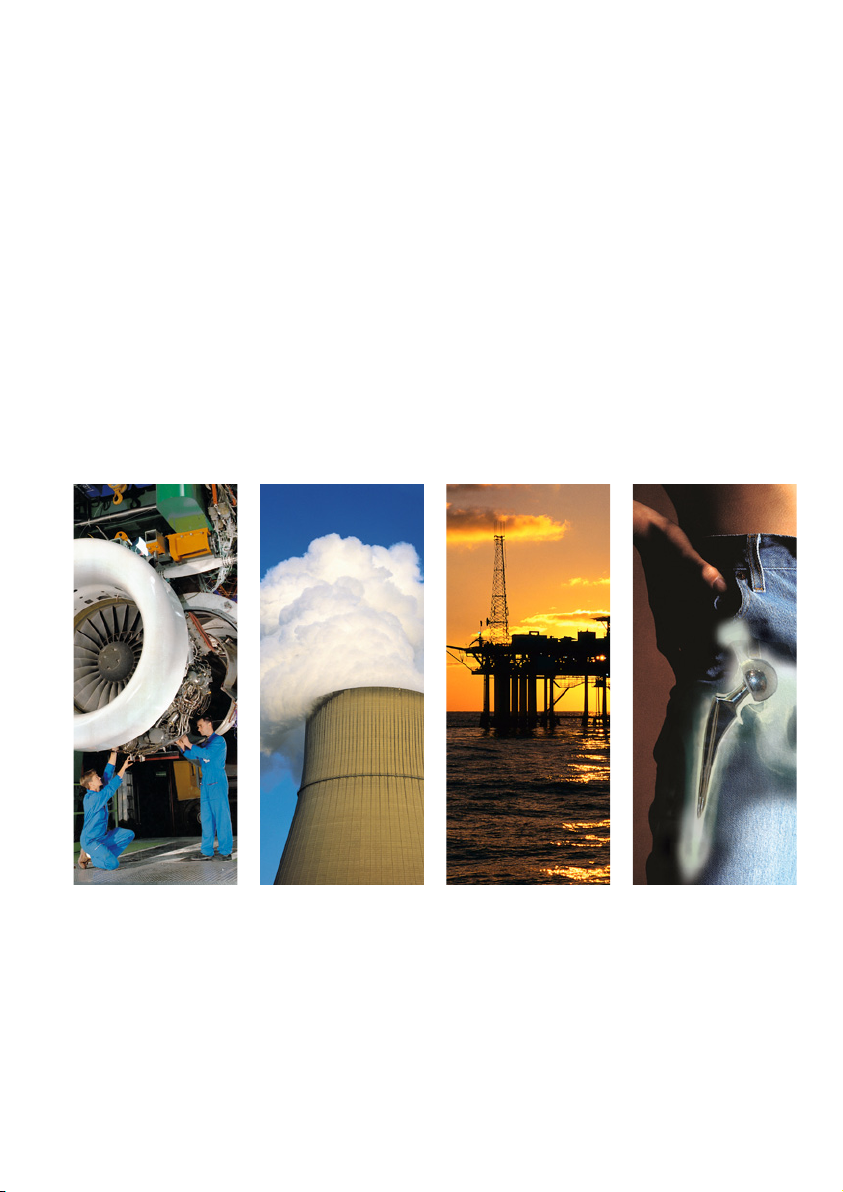

1. Heat resistant super alloys – HRSA

Heat resistant super alloys (HRSA) are a family of alloys utilised in

various industry segments:

Aerospace engine – combustion and turbine sections.

Stationary gas turbines – combustion and turbine sections.

Oil and gas – marine applications.

Medical – joint implants.

The properties which make them attractive are:

•Retension of strength and hardness at high temperatures.

•Corrosion resistance.

Aerospace engine Stationary gas tur-

bines

Oil and gas Medical

3

Alloy groups

HRSA materials fall into three groups:

nickel-based, iron-based and cobalt-based

alloys. The physical properties and machining behaviour of each varies considerably,

due both to the chemical nature of the alloy

and the precise metallurgical processing it

receives during manufacture. Whether the

metal is annealed or aged is particularly

influential on the subsequent machining

properties.

Nickel-based are the most widely used, and

currently constitute over 50% of the weight

of advanced aircraft engines. The trend is

that this will increase in new engines in the

future.

Common types include:

•Inconel 718, Waspaloy, Udimet 720

– precipitation hardened

•Inconel 625 – solution strengthened

(not hardenable)

Iron-based have been developed from

austenitic stainless steels. Some have very

low thermal expansion coefficients (such as

Incoloy 909) which make them especially

suited for shafts, rings, and casings.

However, they have the poorest hot strength

properties of the three groups.

Common types:

•Inconel 909

•A286

•Greek Ascoloy

Cobalt-based display superior hot corrosion

resistance at high temperatures compared

to nickel-based alloys. They are more expensive and also more difficult to machine due

to their great wearability.

The use in turbines is restricted to combustion parts in the hottest engine areas.

Their main use is seen in surgical implants,

which utilise their inherent corrosion resistance.

Common types:

•CoCr

•Haynes 25

•Stellite 31

The most common HRSA alloys (see page 120 for the complete list)

Material Hardness HB

Inconell 718

Inconell 706

Inconell 625

Hastelloy S

Hastelloy X 160

Nimonic PK33 350

Udimet 720

Waspaloy

Stellite 21 280 340

Stellite 31

Ann. Aged

285

200

4

Alloy

group

Nickel

Iron

Cobalt

Code

MC S2.0.Z.AN CMC 20.2 425

MC P5.0.Z.AN CMC 05.3 Greek Ascoloy 300

MC M1.0.Z.PH CMC 05.4 A286 300

MC S2.0.Z.AN CMC 20.21 Incoloy 909

MC S3.0.Z.AG CMC 20.3 Haynes 25

With such a wide spread of materials under the generic heading of HRSA the machining

behaviour can vary greatly even within the same alloy group. In fact the same material can

have numerous machining recommendations.

Heat generated during cutting

Hardness

HB

400

300

200

100

(tendency for plastic deformation)

Nimonic 1023

Inconel 718

Nimonic PK 33

Waspaloy

Nimonic 90

Nimonic 105

Nimonic 263

Inconel 625

Nimonic 75

17-4 PH

Jethete

M152

Austenitics

Stainless

Incoloy 901

Crucible

A286

Incoloy 901

Incoloy 800

Sanicro 30

Fe based alloys Ni based alloys

steels

10 20 30 40 50 60 70 80 90

Nimonic 80A

Weight %

Nickel & cobolt

= Stainless

steel

= Heat treated

(aged)

= Solution

treated

(annealed)

Tendency

for notch wear

Precipitation hard enable

alloys in annealed conditions

Machinability/raw material condition

Heat treatment

Annealing – heating to controlled temperature then cooling at

Solution treatment – heating followed by rapid cooling <30HRC

Ageing – slow cooling after solution treatment up to 48HRC

The state of heat treatment affects the

hardness of the component and hence the

wear mechanisms. The formation of the

chip is a good indicator of the hardness –

with hard materials it is easier to break the

chip.

Hardened materials have increased cutting temperatures and show a tendency to

notching of the cutting edge at the depth

controlled rate.

Softer materials machine similarly to the

stainless steel family.

Insert grades with greater toughness and

reduced hot hardness – resistance to high

temperatures – are required due to reduced

cutting temperatures and increased chip

hammering. Here, damage to areas outside

the actual cutting edge is caused by the

chip breaking against the insert.

of cut. The combination of a low entering

angle and a hard substrate with a coating

offering a heat barrier is required.

<30HRC

5

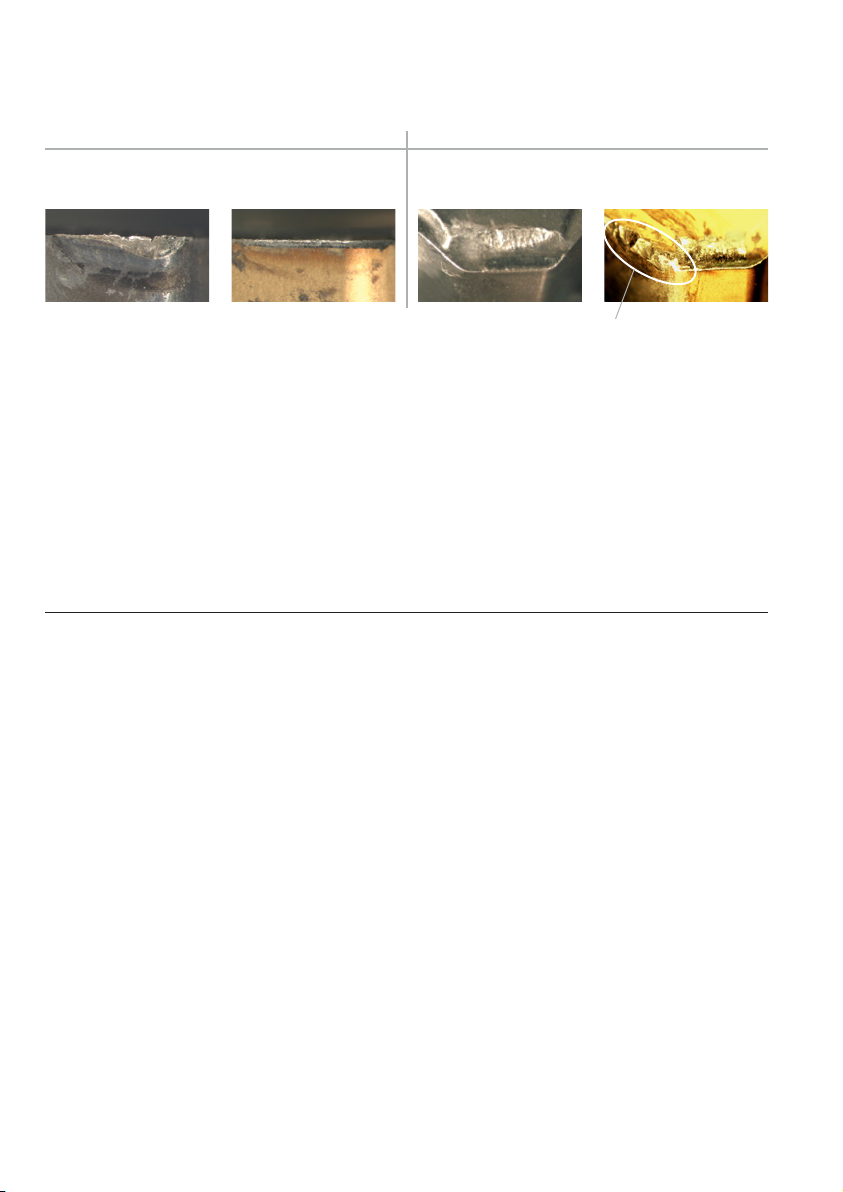

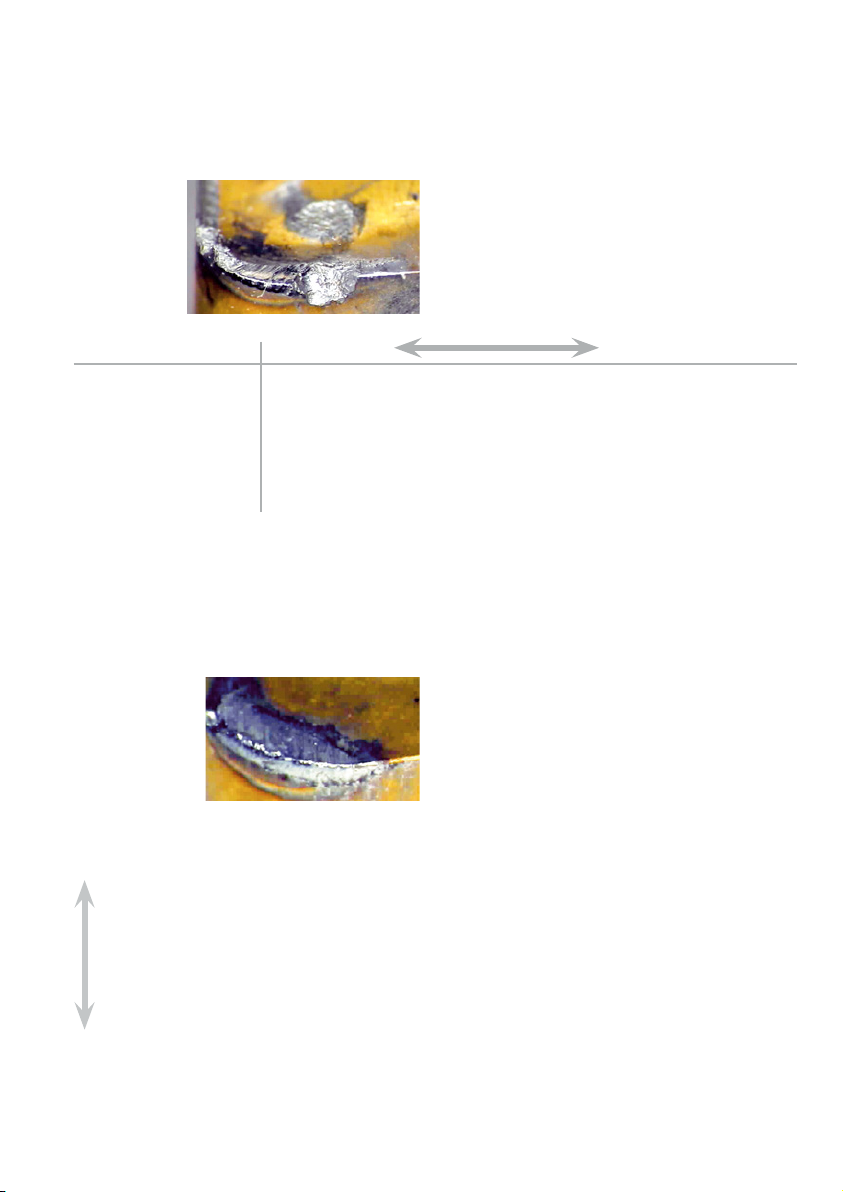

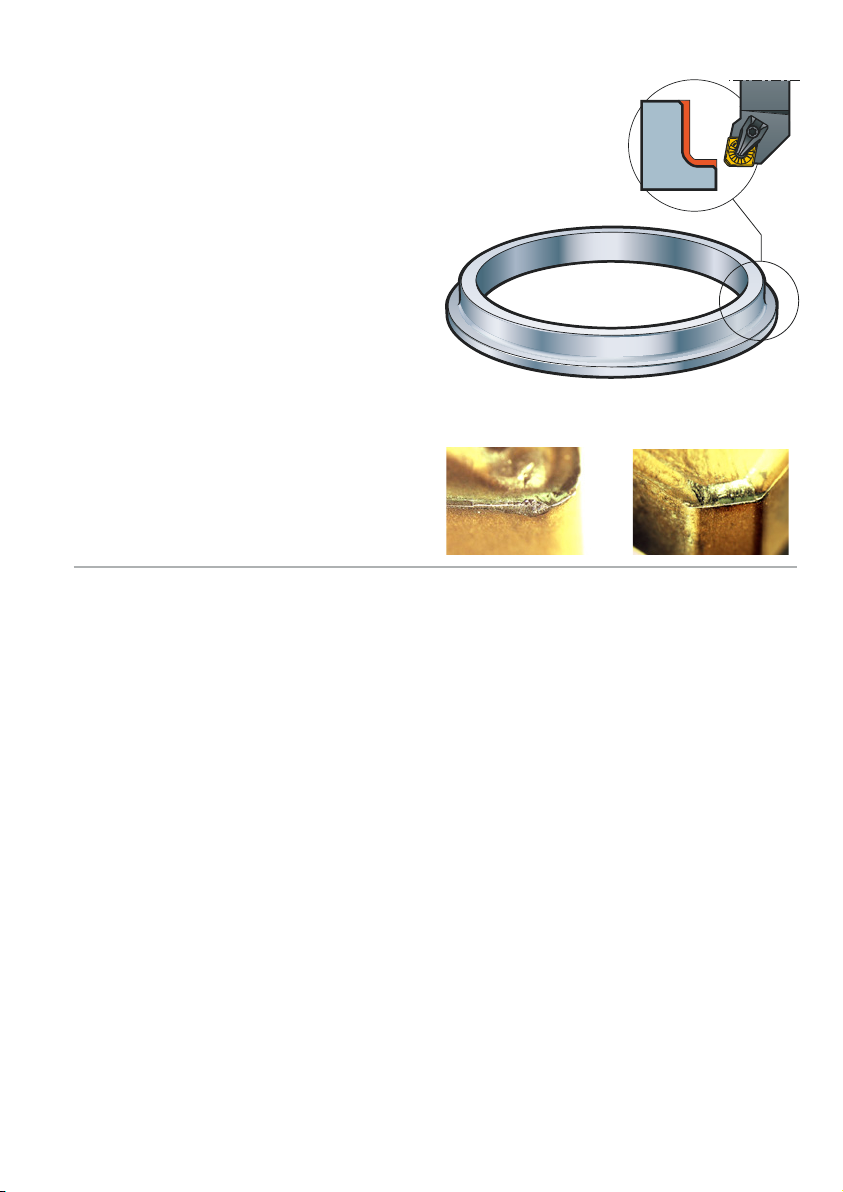

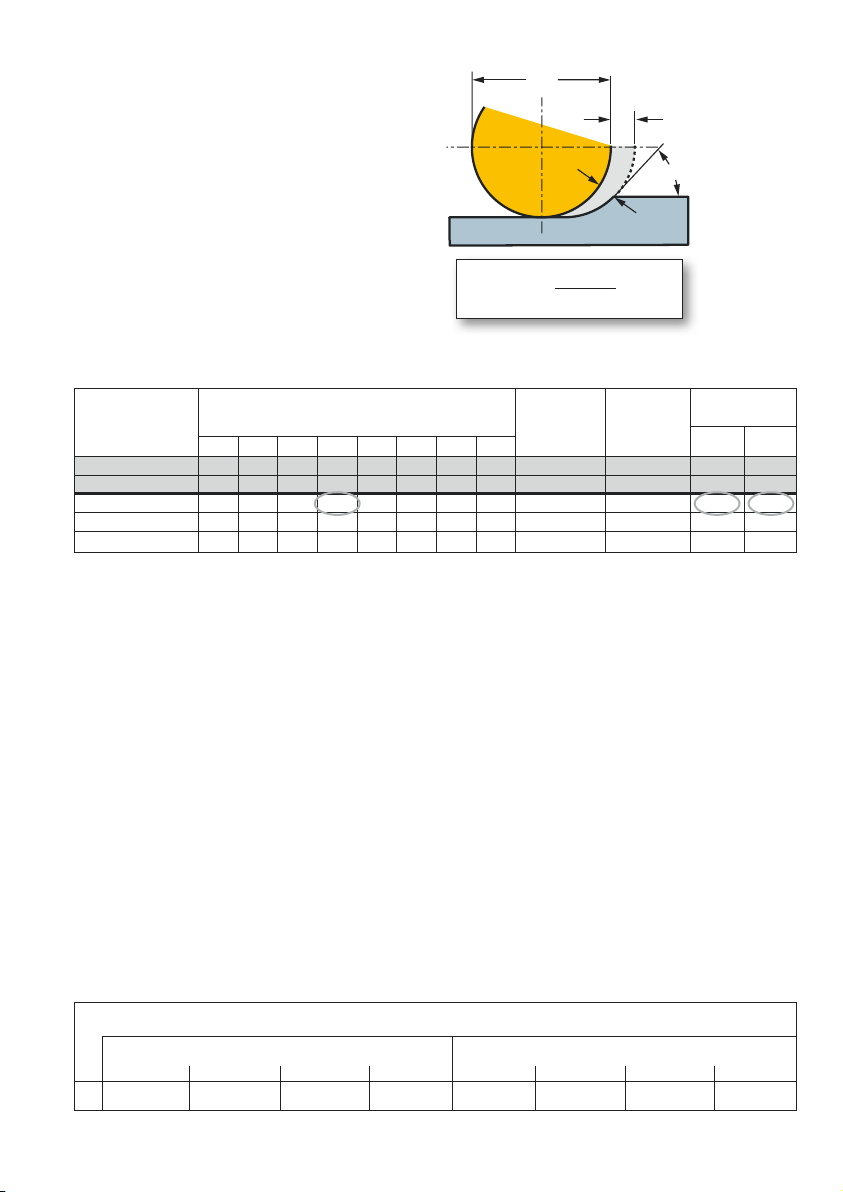

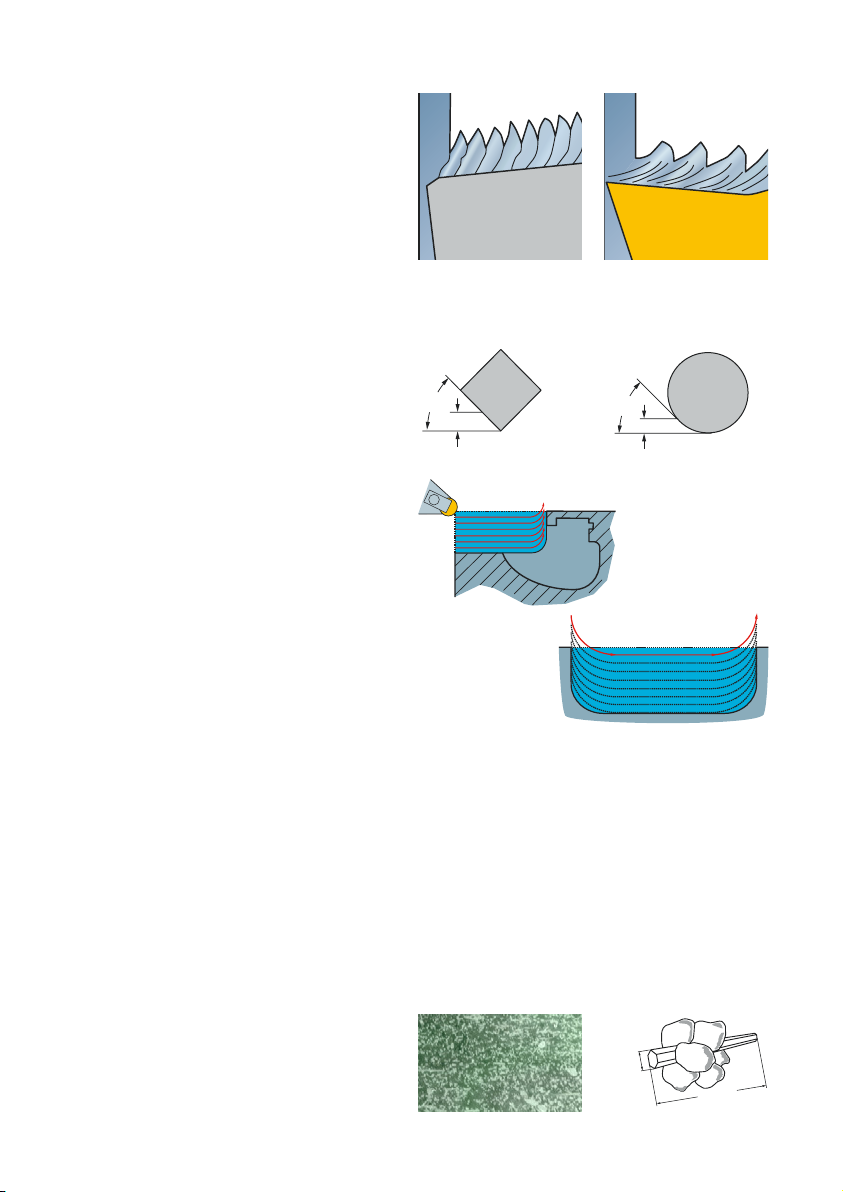

Comparison of wear depending upon

material hardness and insert grade

CNMX 1204A1-SM – vc 50 m/min, fn 0.25 mm/r, ap 1.5 mm

Hard material Soft material

GC1105 GC1105

S05F

Raw material production method

Depending upon the size, shape and

strength requirements of the component,

various production methods for the blank

material will be adopted.

The production method varies the machinability of the material and will change the

wear characteristics.

S05F

7 min6 min 12 min

Chip hammering

3.5 min

Material

Forging large

Casting complex shape poor

Bar stock <200 mm diameter good

Each of these raw material types directly

affects the alloy’s micro structure, and so

also affects the subsequent machining

behaviour:

Forged materials have a finer grain size

than in castings, which improves the

strength and grain flow of the component.

When machining forgings, reducing the

speed and increasing the feed generally

Components Advantage/suitability Machinability

high strength

low strength

availability/strength

most sensitive to notch wear and abrasive

wear. They can be easily identified due to

their visibly mottled surface (the ‘orange

peel’ effect).

Bar stock material is the easiest form of

raw material to deal with. Notching is not

so much of a problem, which allows harder

and more wear resistant insert grades to

be used than for forgings.

gives the maximum possible metal removal

rate with good tool life.

In castings the opposite applies, and applying low feeds (0.1 mm chip thickness) and

higher speeds can be beneficial. Castings

have poor machinability and tend to be

6

medium

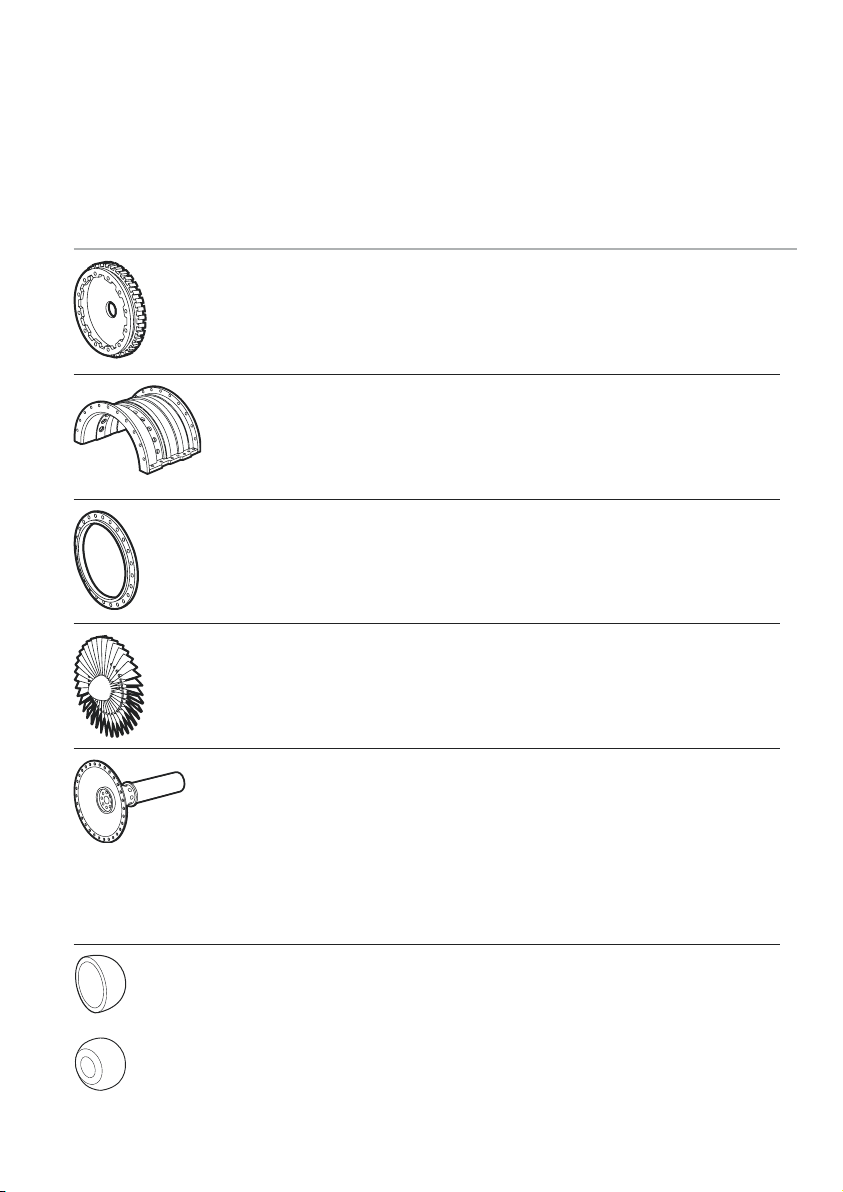

Common component types

Typical HRSA components, and an indication of the different machining methods involved

for each include:

Aerospace and gas turbine – nickel based

Component

Turning

Milling Drilling Others

Discs

Casings

Rings

Blades

Blisks

Impellers

Shafts

60% 10% 5% 25%

45% 40% 15%

95% 5%

10% 50% 40%

70% 5% 25%

Medical – CoCr

Component Turning

Cup

Head

90% 10%

90% 10%

Milling Drilling Others

7

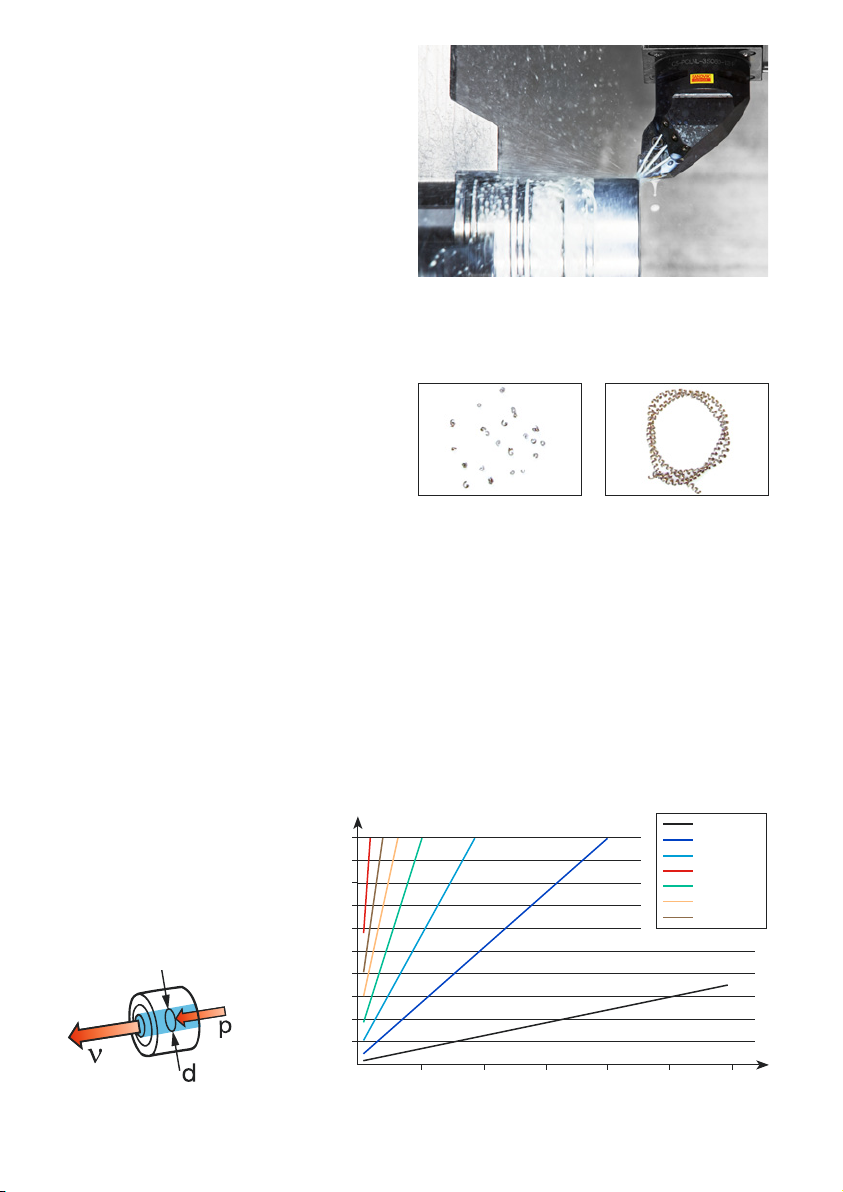

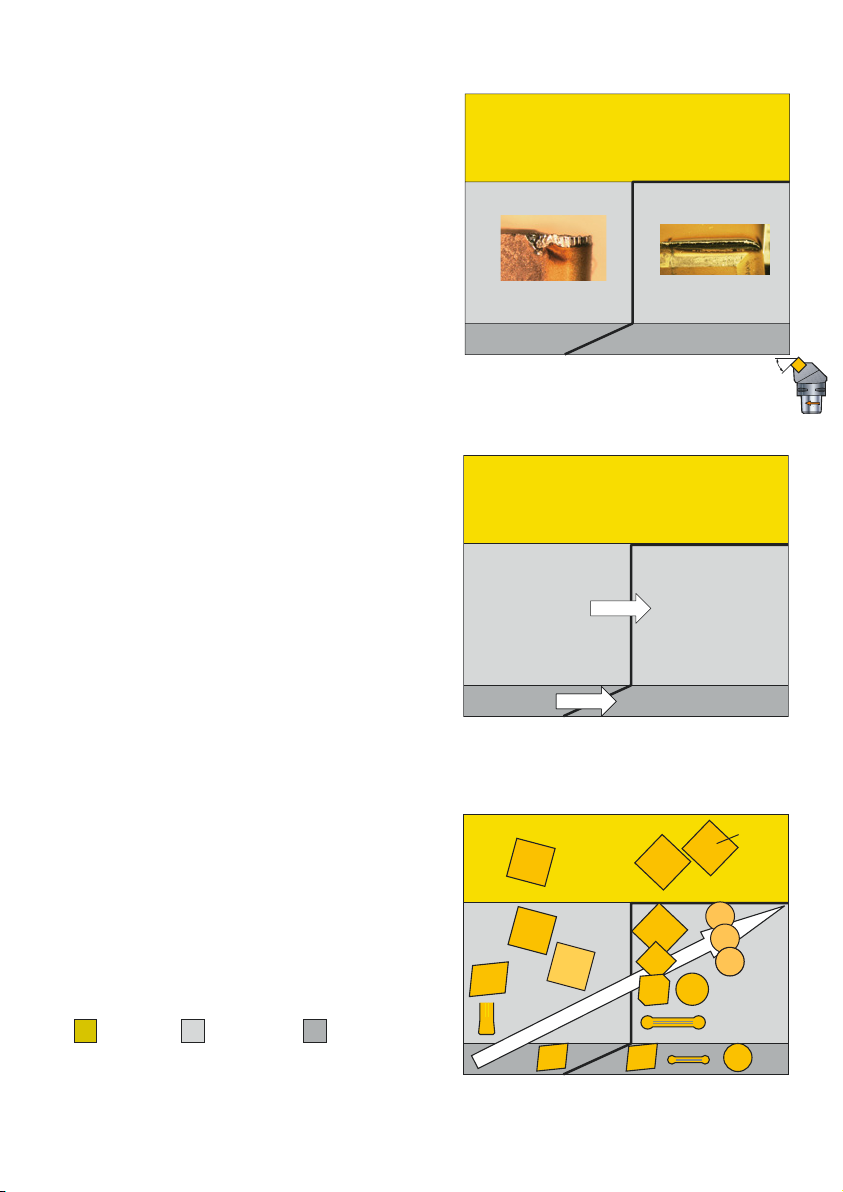

Coolant requirements

Coolant should be applied in all operations

excluding milling with ceramics. The volume

should be high and well directed.

High pressure coolant HPC (up to 80 bar)

shows positive results in terms of tool life

and consistency.

Dedicated HPC-tools with fixed nozzles give

parallel laminar jets of coolant with high

velocity accurately directed at the right zone

between insert and chip.

HPC improves the chip control

CNGG 120408-SGF

vc 65 m/min, ap 1.0 mm, fn 0.2 mm/r

Inconel 718

For milling and drilling, all tools with internal

coolant supply can benefit from HPC even if

tools prepared for nozzles give higher possibility to use smaller nozzle diameters for

high pressure.

• Turning,useatleast20l/minanda

basic pressure of 70 bar.

CoroTurn HP tool, 80 bar

Compared chips made with a CoroTurn HP tool versus a

conventional tool and standard coolant pressure.

Conventional tool

• Millinganddrilling,useatleast50l/min

to accomodate the extra nozzles on the

milling cutter and the largest drill diameters.

Flow required for specified nozzle diameter and 80 bar high pressure pump

The pressure (p) hitting the cutting

zone is dependent on the number

of nozzles, the nozzle diameter

(d) and the flow (ν) given from the

pump.

A higher flow rate is needed for

tools with many outlets or large

hole diameter for the coolant.

Flow, ν

litres/min

100

90

80

70

60

50

40

30

20

10

0

1 5 10 15 20 25 30

Nozzle diameter, d

∅ 0.5 mm

∅ 1.0 mm

∅ 1.5 mm

∅ 2.0 mm

∅ 2.5 mm

∅ 3.0 mm

∅ 3.5 mm

Number of nozzles

8

2. Turning of nickel-based materials

– aerospace engine and stationary gas turbines

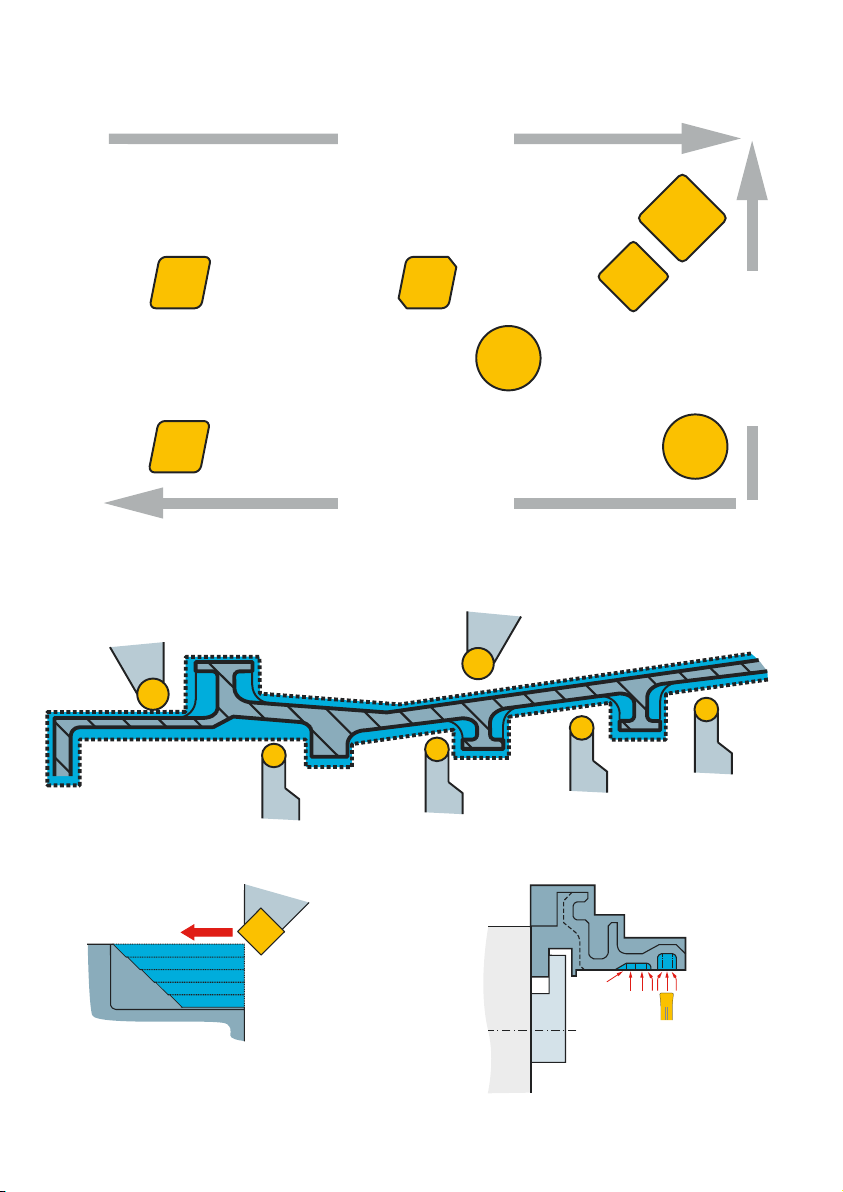

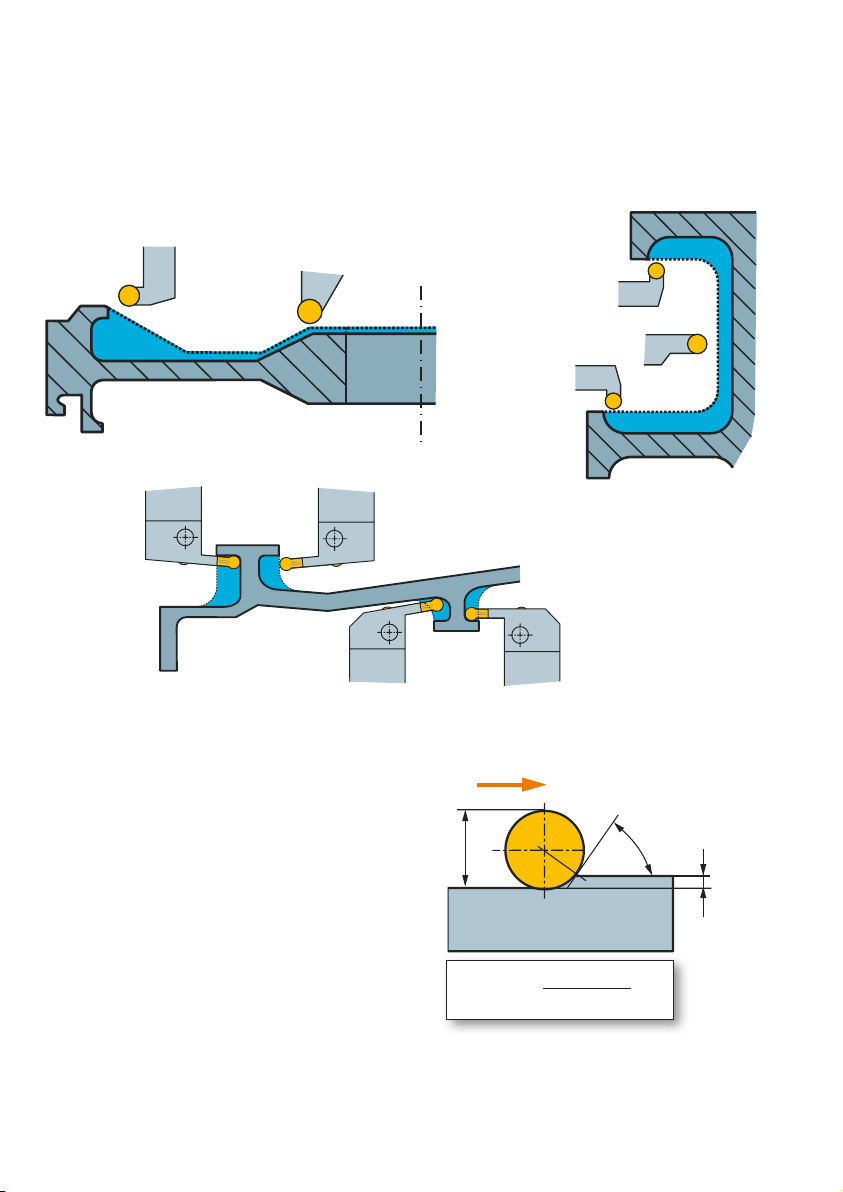

Classification of machining stages

The production cycle for the machining of a HRSA component can be broken into three distinct stages, each with specific demands on the tooling and the machined surface.

FSM – First stage machining – up to 10 mm depth of cut

The forged components often have rough,

uneven skin or scale. They are generally

machined in the soft condition (the hardness is typically 26 HRC) at the foundry

to the basic component shape. Coated

carbide grades are used at high feed rates,

large depths of cut and low speeds.

Ceramics may also be used with good

machine and forging conditions. Here the

main priorities are productivity and large

stock removal – in the total machining process, up to 80% of the original weight will

be machined away, and the bulk of it will be

removed during FSM.

The component shapes are simple and

standard general turning tool holders can

be used. Many critical parts have a ring

removed at this stage for material analysis.

CoroCut insert in geometry -TF and grade

GC1105 is outstanding for this operation.

Material to be

removed

9

ISM – Intermediate stage machining – 0.5 to 5 mm depth of cut

At this stage the material is mainly in the

final hard/aged condition, (the hardness is

typically 36 to 46 HRC) having undergone

some form of heat treatment after FSM.

The ISM process involves profiling of the

component with varying depths of cut at

moderate tolerances, where productivity is

important but insert security is equally vital.

In this area, ceramics offer the best productivity where stability allows. Due to the complex shape of the components, ISM may

involve a high degree of grooving/ recessing and profiling, which can require a large

amount of special tool holders.

LSM – Last stage machining – 0.2 to 1 mm depth of cut

LSM represents the least amount of material removal, but imposes the highest

demands on surface quality. For this critical

stage of production, the tools, tool paths

and cutting data are sometimes certified by

end producers of the aerospace engine.

These parts should be machined with

cemented carbide grades, to ensure a minimal deformation zone and correct residual

stresses in the finished component surface.

Material to be

removed

Material to be

removed

Factors which affect the residual stresses

most are:

Speed – not above 60 m/min for critical

parts.

Tool wear – maximum 0.2 mm. Use S05F

for best tool life.

10

Chip thickness (feed/radius combination)

– too low chip thickness (below 0.1 mm)

generates more heat and work-harden the

surface. For round inser ts and large radius

increase the feed. (see page 19).

Typical wear mechanisms

With carbide grades two wear mechanisms dominate – plastic deformation and notch wear.

It is important to identify which is the most prominent before selecting the correct grade

and strategy.

Notch wear on main cutting edge is a

mechanical wear which is concentrated at

the depth of cut. The extent of notch wear

is directly related to:

Least notch Most notch

Entering/lead angle

Depth of cut

Geometry

Material hardness

Material condition

Grade

Round inserts

Below nose radius

Positive

Soft condition

Bar stock

PVD fine grain carbide

(GC1115, GC1105)

Forged

CVD

(S05F)

C/DNMG 95 degree

Above nose radius

Negative

Hardened

Cast

Ceramic

(CC6060/CC6065/CC670)

Because of these factors, notching is the critical wear for ISM where the material is hard

and the depth of cut is relatively high. To reduce notching, use as small entering angle as

possible.

Plastic deformation (PD)/even flank wear

– as a result of combined high temperatures and high pressure on the cutting

edge. This wear is much more of a gradespecific issue than notch wear, which is

more application related. Good wear resistance and hot hardness will reduce the likeli-

Flank wear resistance

Hot hardness

Ceramic

Carbide

Bulk toughness

Turning Grooving

CC6060, CC6065

CC670 CC670

S05F

GC1105 GC1105

GC1115

H13A H13A

GC1125 GC1125

GC2025 GC2135

GC2035 GC1145

hood of plastic deformation.

In case of excessive flank wear, use a more

wear resistant grade or reduce the cutting

speed.

11

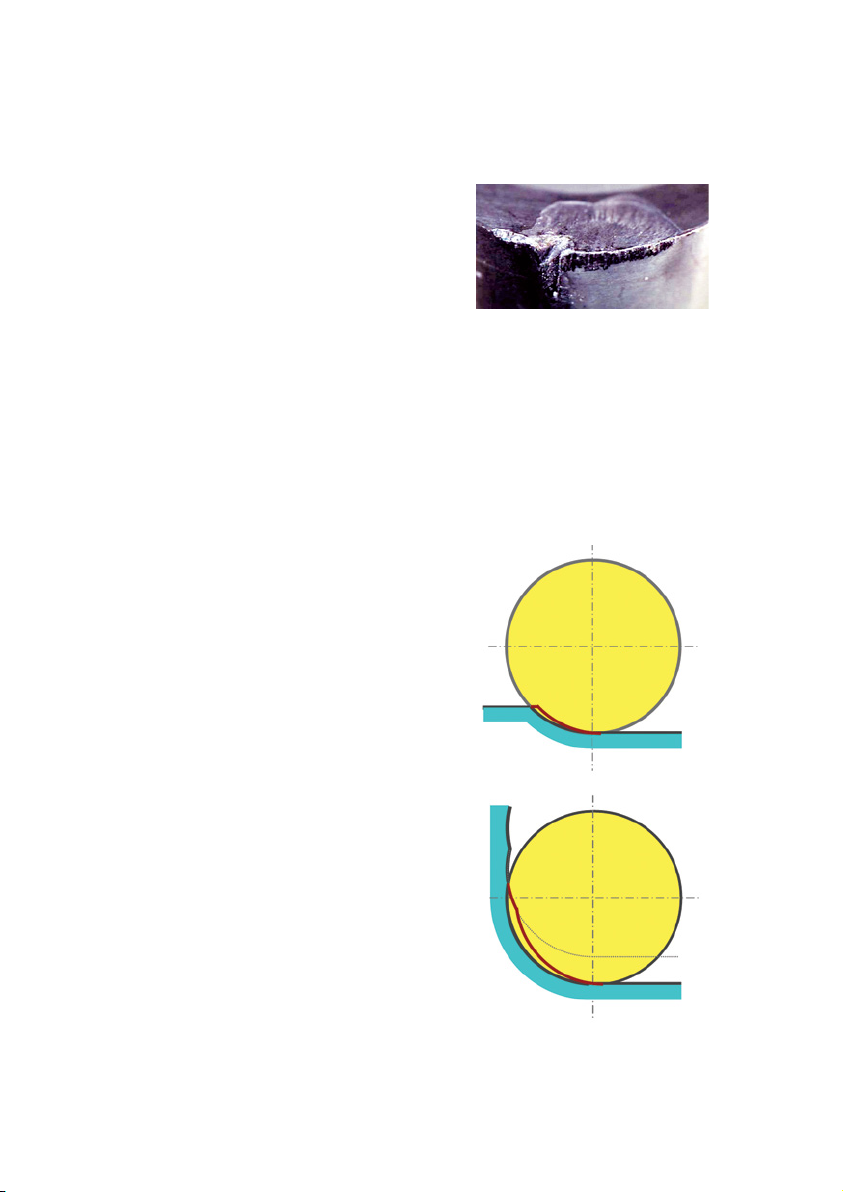

Top slice wear – this type of wear is common for ceramics in HRSA. Small slices of

the cutting tool material are lost around

the insert’s top face. When the flank of

the insert is worn, the workpiece pressure

against the periphery will be high enough

to break small slices away along the edge

line.

The recently sliced area will then form a

new sharp edge that again cuts well, and

the cutting process can continue under

these circumstances for a long time without

posing a threat to the overall quality, in less

sensitive roughing or semi-finishing operations.

In finishing operations, where surface quality and/or burr formation is important,

top slicing can be critical. This tendency

increases with high feed rates due to

increased radial pressure.

To reduce top slice

In stable conditions:

•Lower the cutting pressure by reducing

the chip area:

– feed rate

– depth of cut, a

– arc of engagement

•Use optimized programming techniques

•Use CC670 which is stronger due to

whisker reinforcement.

p

Small slices are lost around the

insert’s top face

In unstable conditions where top slice is

caused by vibrations:

•Reduce engagement angle with program-

ming techniques

•Use CC6065 rather than CC6060

12

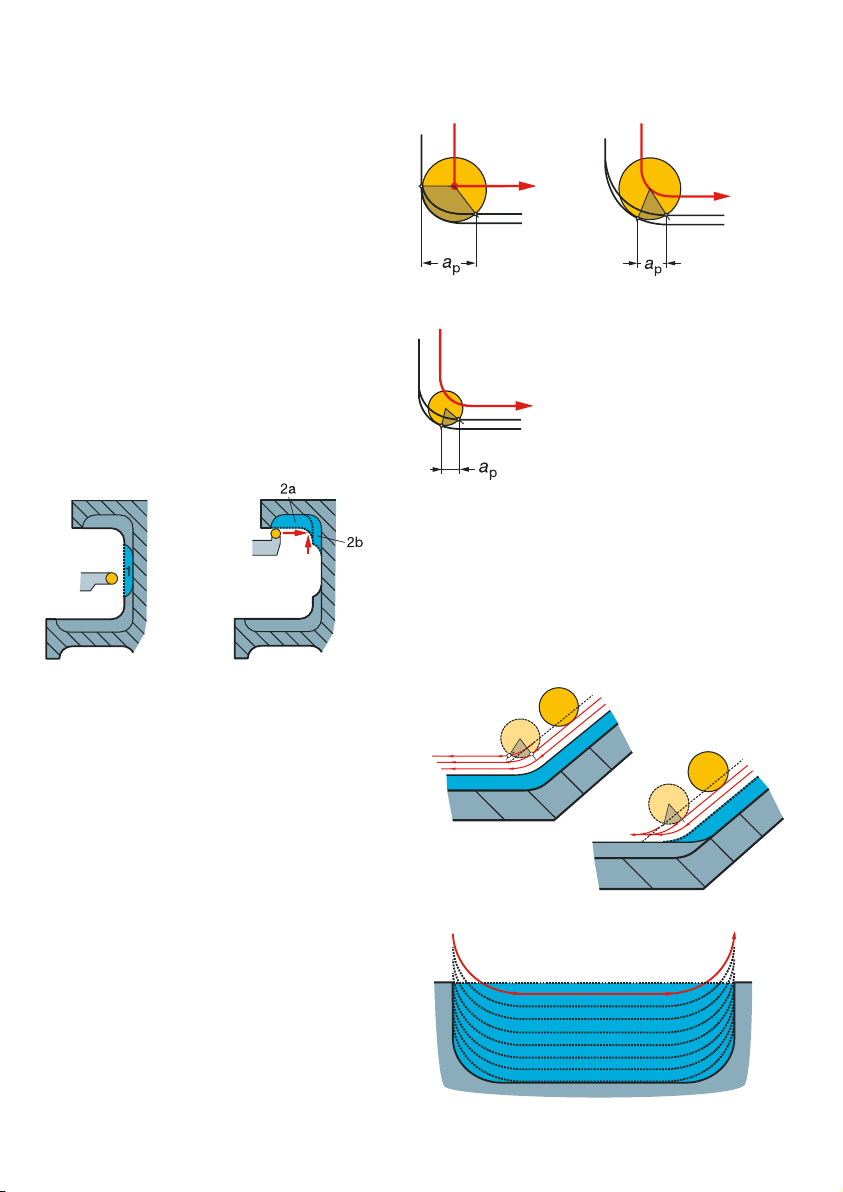

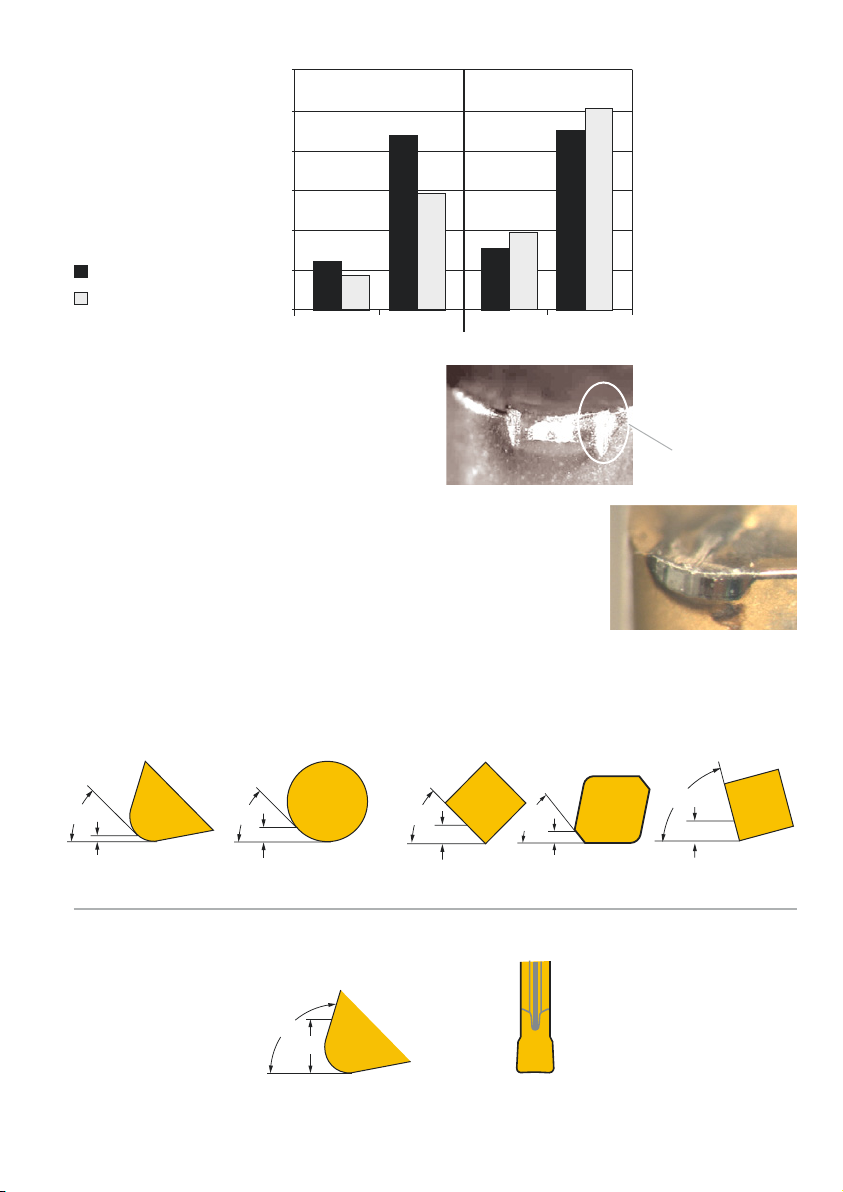

Insert shape selection

Entering angle – k

r

With a standard C/D/SNMG style insert

for roughing, the entering angle is constant

regardless of depth of cut.

CNMX

CNMG DNMG SNMG

Effect of entering angle

Notch wear on the inserts is the major

problem when machining HRSA. The worst

notching occurs when the depth of cut is

greater than the nose radius, and the entering angle is 90°. (The depth of cut is the

influencing factor – with a depth of cut

smaller than the nose radius, the effective

entering angle is reduced even when the

angle on the insert itself is 90°).

By following some general rules the wear

can be controlled allowing more productive

grades to be used.

•Use as small entering angle as possible

(max 60°, min 25°)

– eg. SNMG, CNMX where k

•Round inserts – use no greater entering

angle than 45° or 0.15 x diameter.

= 45°.

r

However, with round inserts the entering

angle varies from 0 to 90° depending upon

the ratio between depth of cut and diameter.

RCMT

h

ex

a

p

k

r

hex = fn x 0.71

hex = chip thickness

f

n

a

p

h

hex ≈ f

f

n

ex

n

•Ramping – program a varying depth of cut

into the cutting operation. This spreads

the notching over the whole cutting edge,

giving longer tool life and more predictable wear. This method is used predominantly with ceramics, and mainly with

round inserts.

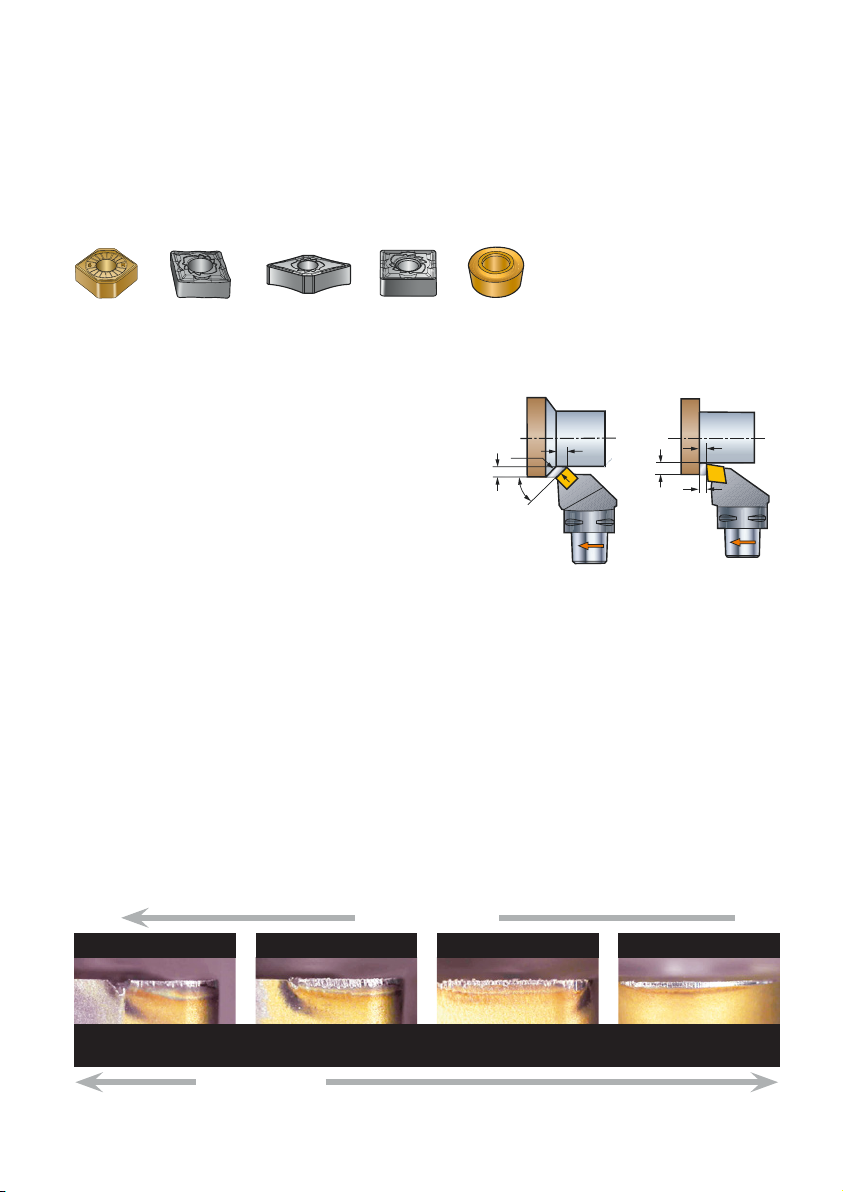

Effect of entering angle on wear mechanism

CNMG 95°

Material: Inconel 718 (46 HRC) – ap 2.0 mm, fn 0.25 mm/rev, vc 50 m/min – 5 min. time in cut

Notch No notch

SNMG 75°

Radial forces

SNMG 45°

HighLow

Round

13

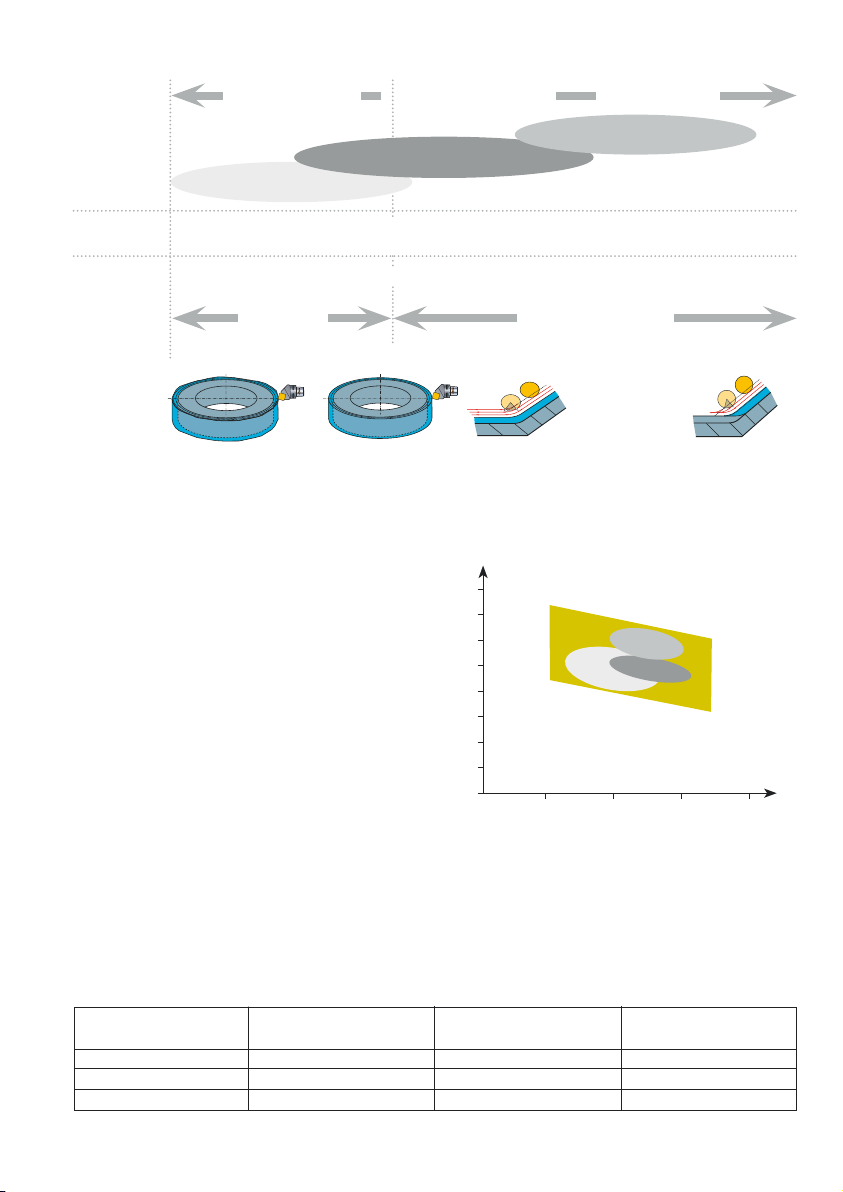

Selecting the right insert for the job

FSM

Best productivity

ISM

LSM

- to shoulder

- pocketing

Depth of cut

Thin walls

14

Xcel insert – high productive machining into a corner

Examples of machining

Casing

Ring

A tooling solution for semi-rough turning

into shoulders, combines a host of design

advantages combing the benefits of a

square and rhomboid insert into one single

tool:

•reduced notch wear and increased feeds

compared to rhombic inserts.

•reduced radial forces and constant chip

thickness compared to round inserts.

•greater accessibility in confined spaces

than square inserts, in addition to having

the ability to machine in two directions,

and provide a known offset point for precise positioning of the cutting edge.

C-style CNMX-SM S-style SNMG

Longer tool life, secure machining, and

increased cutting data – all the best possible advantages are available from a single

tool.

Two chamfer sizes are available, to suit

depths of cut up to 2.7 mm in intermediate

stage machining, ISM. They are offered in

several grades, all proven performers in ISO

S materials.

Insert code Max ap mm

CNMX 1204A1-SM 1.7

CNMX 1204A2-SM 2.7

Grade recommendations – first choice

<35 HRC S05F

>35 HRC GC1105

Titanium H13A

Iron based GC2015

15

The inserts fit into a standard CNMG holder

but require a new shim to accommodate

their design.

New shims

5322 234-07 for T-Max P lever design holders

5322 234-08 for CoroTurn RC holders

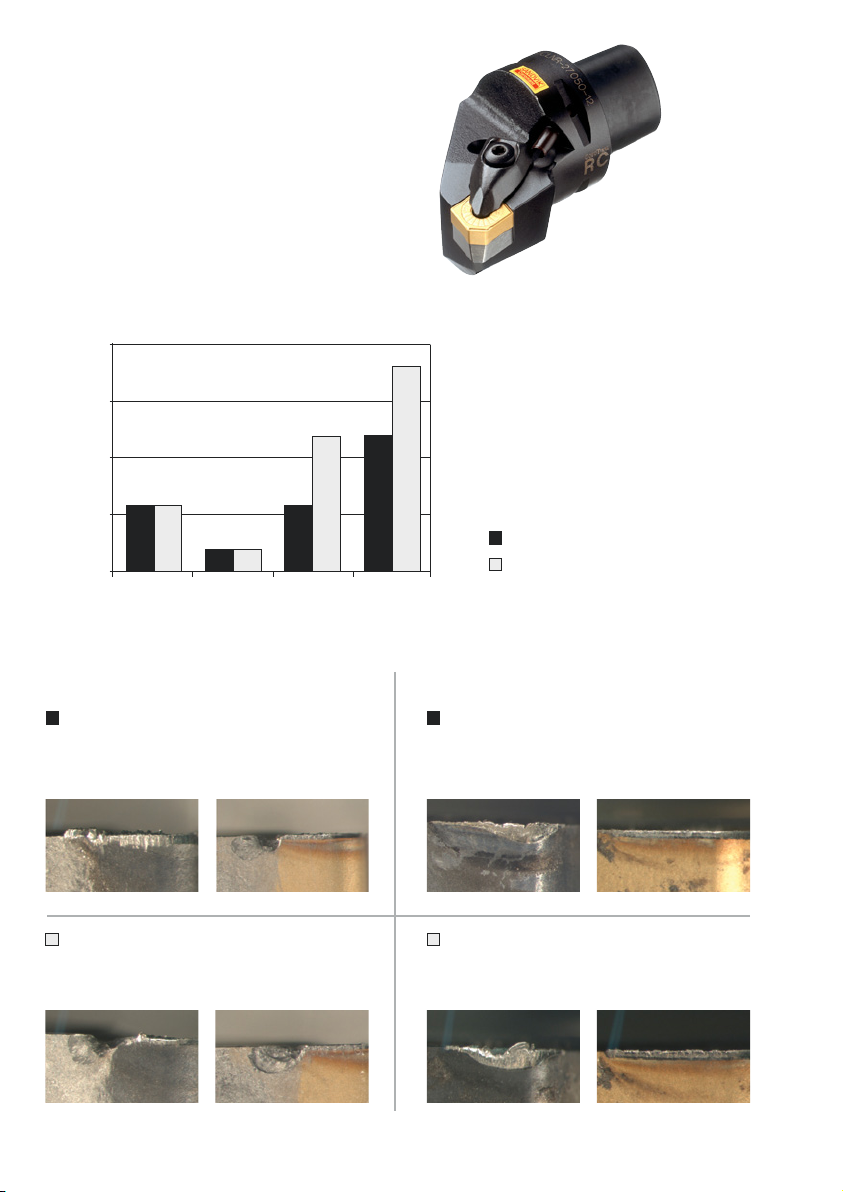

Tool life test – Inconel 718 (46 HRC) – ap 1.7 mm, fn 0.25 mm/r

20

H

min

15

10

A B

5

C D

0

CNMG GC1105 CNMG S05F CNMX GC1105 CNMX S05F

F G

E

CNMG

vc 50 m/min

GC1105

A C E

vc 40 m/min

GC1105

6 min 2 min

6 min 2 min 12 min 18 min

S05F

S05F

DB

CNMX

vc 50 m/min

GC1105

vc 40 m/min

GC1105

vc 50 m/min

vc 40 m/min

S05F

6 min 12 min

G

S05F

HF

16

Turning of heat resistant super alloys

Xcel allows productivity to be doubled in

nickel-based HRSA, through increased

cutting data and a longer-lasting tool life.

Data

Material: NIMONIC PE 16

Ring, diameter 650 mm

Cutting depth: 1.7 mm

Insert:

Feed:

Cutting speed:

Number of components/edge:

Competitor

Competitor

0.2 mm/r

32 m/min

1 piece

Result

Over 100 % productivity increase

Time in cut reduction: 8 min to 3.5 min

Xcel

CNMX 12 04 A2-SM

grade GC1005

0.3 mm/r

50 m/min

2 pieces

17

Round inserts and CoroCut®inserts with -RO geometry

Round inserts are the strongest inserts

available, and allow high productivity.

Typically aerospace components are large,

with large radii and blending profiles

designed to eliminate high stress points

allowing round inserts to be used.

Entering angle – k

r

The best performance is achieved when

the entering angle remains under 45°. This

gives a depth of cut of 0.15 x insert diameter (the maximum depth of cut should be

no greater than 0.25 x diameter).

For larger depths of cut than 25% of the

diameter, it is better to use square inserts

with a constant 45° entering angle.

18

k

iC

=

r

(0.5iC–ap)

0.5iC

cosk

r

a

p

Note: this principle also applies to standard

inserts when the depth of cut is less than

the nose radius.

Chip thickness

The chip thickness varies with round

inserts, and depends upon the entering

angle. With low ap/iC ratios, the feed can

be increased in order to raise the chip

thickness to a desired level.

Recommended chip thicknesses h

HRSA are:

Carbide 0.1 to 0.35 mm

Ceramic 0.08 to 0.15 mm

ex

for

fn =

iC

f

n

k

r

h

ex

h

ex

sink

r

Depth of cut to

diameter ratio

ap/iC

3 4 5 6 8 10 12 16

0.25 0.75 1 1.25 1.5 2 2.5 3 4 60° 1.16 0.12 0.41

0.2 0.6 0.8 1 1.2 1.6 2 2.4 3.2 53° 1.25 0.13 0.44

0.15 0.45 0.6 0.75 0.9 1.2 1.5 1.8 2.4 46° 1.4 0.14 0.49

0.1 0.3 0.4 0.5 0.6 0.8 1 1.2 1.6 37° 1.66 0.17 0.58

0.05 0.15 0.2 0.25 0.3 0.4 0.5 0.6 0.8 26° 2.3 0.23 0.81

Depth of cut for insert diameter, in mm

Entering

angle k

r

Feed modification

value

Feed min/max

mm/r

hex 0.1 mmhex 0.35

Example

6 mm diameter CoroCut RO insert.

Depth of cut 0.9 mm gives a maximum

entering angle k

= 46°.

r

To machine with:

Minimum 0.1 mm chip thickness the correct feed is 0.14 mm/r.

Maximum 0.35 mm chip thickness the

correct feed is 0.49 mm/r.

Surface finish

The surface finish generated has a direct

relationship to both the nose radius size

and the feed rate. To achieve a certain

surface finish, a small nose radius requires

a lower feed rate than a large nose radius

– which in practical terms means that small

nose radius inserts lead to lower productivity.

Therefore, for the highest productivity the

nose radius should be as large as possible

– the largest of all being round inserts.

mm

Maximum feed fn mm/r to achieve surface finish R

Nose radius size mm Insert diameter mm

0.4 0.8 1.2 1.6 8 10 12 16

f

0.17 0.22 0.27 0.32 0.5 0.57 0.62 0.7

n

8.0 – Ra 1.6 µm – N7

max

19

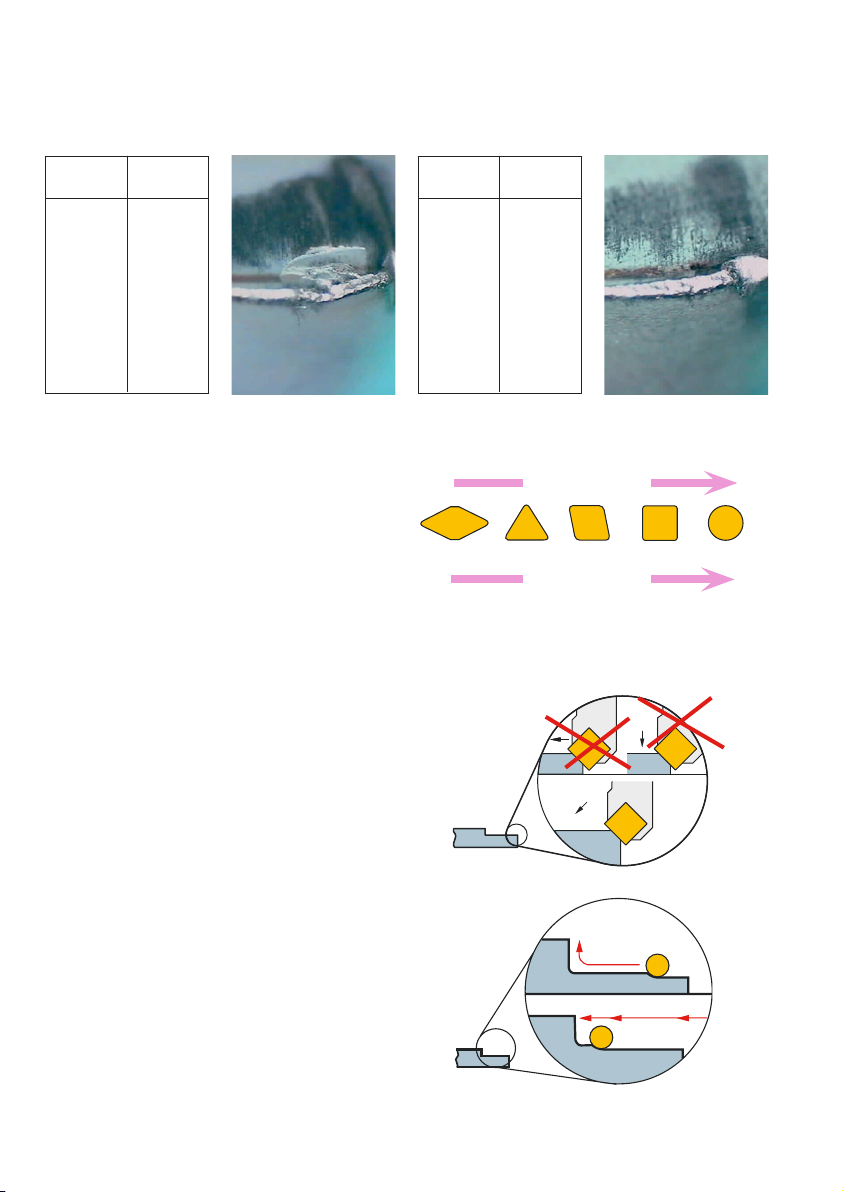

Application hints

‘Wrap-around’ is a problem which occurs

with round inserts when plunging or profiling into corners. Due to high angular

engagement creating high cutting pressures, the feed needs to be reduced. To

reduce this problem, optimized programming strategies together with smaller insert

radii should be used.

Recommendations

1) Never plunge straight into cut.

2) Roll in and out of cut.

3) Roughing – programmed radius same

size as insert diameter.

4) Finishing – insert diameter no greater

than 1.75 times programmed radius.

Insert too large

–

for radius

Insert decreased

+

for radius

The component feature to be machined

needs to be broken down into stages so

that a face and diameter are not machined

simultaneously as this will naturally

increase the depth of cut and cause ‘wraparound’

Radius increased

+

for insert

Programming recommendations

Because of the wrap around problem in the

radii, the feed needs to be reduced as the

size of cut increases. The larger the difference between the radius and the insert

diameter, the less the feed needs to be

reduced.

However a good starting point is to use

50% feed rolling into radius compared to

parallel cuts.

‘Trochoidal turning’

By breaking the part into manageable

pieces this method can be used for all profiling requirements. The direction of passes

can be alternated when using CoroCut and

RCGX inserts to best utilise the edge.

20

Face and

–

diameter

50% f

n máx

f

n max

Programmed radius = inser t diameter

+

50% f

Only

diameter

n max

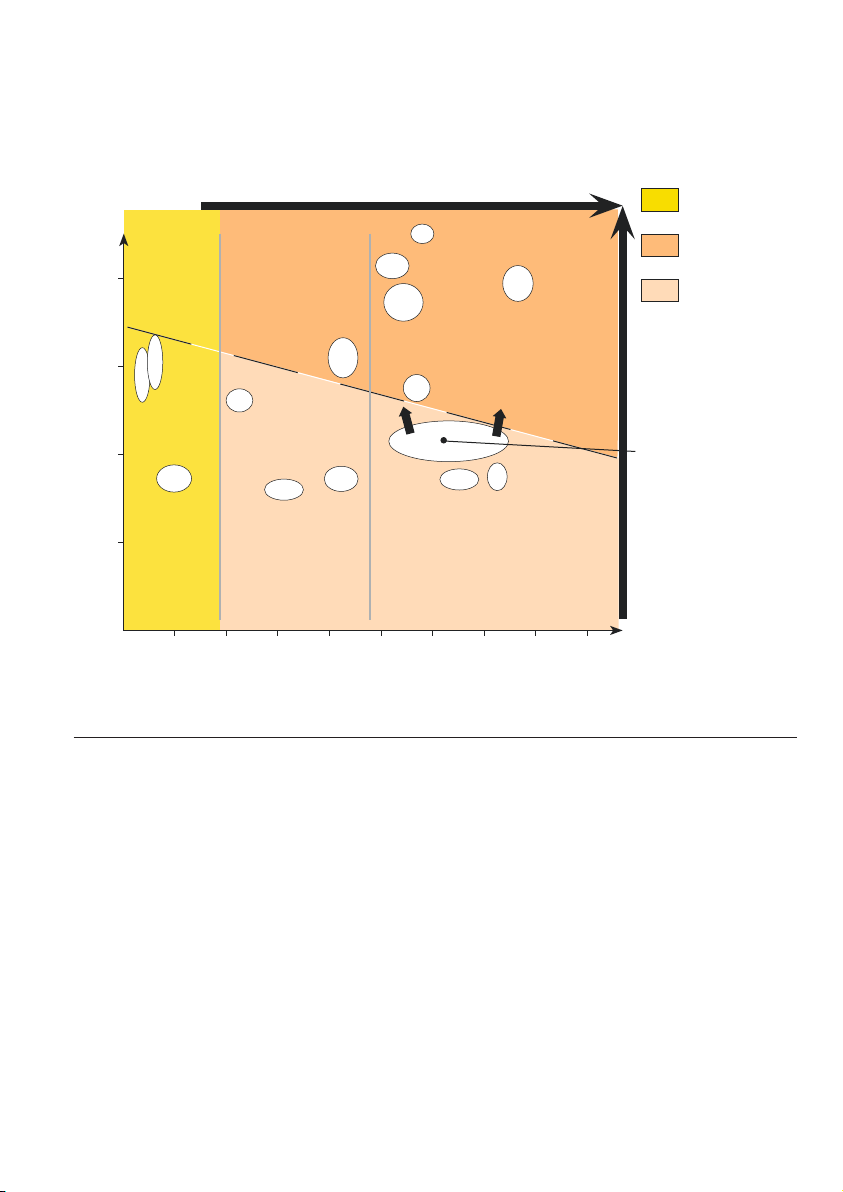

Cutting tool materials

Grade selection when machining HRSA

should not be considered in terms of finishing and roughing. Plastic deformation (PD)

is present in all operations, however the

formation of notch wear is driven by the

entering angle of the insert.

Wear mechanisms per area

Depth of cut (ap) mm

8

Toughness/PD – interrupted cut

PD demanding – continuous cut

5

In practice this means that the grade selection is optimized depending upon the shape

of the insert.

For an ‘all-round’ grade, working in all areas

GC1105 is the best choice.

The diagram shows the most productive

choice of grade relative to the insert shape.

0.5

PD and notch

demanding

PD demanding

90º 75º 60º 45º 30º 15º

Entering angle (k

Optimized grade per area

Depth of cut (ap) mm

8

GC2015 – interrupted cut

GC1105/ceramic – continuous cut

5

PD and notch

demanding

GC1105

GC1115

PD demanding

Ceramic

S05F

(GC1105)

(GC1125

intermittent)

0.5

GC1105 S05F (GC1105)

90º 75º 60º 45º 30º 15º

Entering angle (k

Optimized insert shape per area

Depth of cut (ap) mm

8

1115

1105

2015

intermittent

)

r

)

r

FSM

=

26 HRC

ISM

=

46 HRC

Notch = depth of cut notching

LSM

=

46 HRC

5

3

/min

S05F

S05F

S05F

S05F

S05F

0.5

1105

1105

Productivity –

1105

1115

Q

cm

90º 75º 60º 45º 30º 15º

Entering angle (k

6060

6065

670

S05F

r

21

)

Ceramic insert grades

Ceramic cutting materials offer excellent

productivity in roughing operations in FSM

and ISM. Their application differs greatly

compared to carbide due to their:

•High temperature resistance – allows

high cutting speed to be applied to produce a highly plasticised and sheared

chip.

•Low toughness – can lead to edge frittering, top slice and notch wear.

Both of these factors mean that for successful application the following rules need

to be applied:

• Optimizeenteringangleatabout45° to

reduce notch, round or square inserts

should be used.

• Maximumchipthickness–between

0.08 to 0.15 mm.

• Optimizedprogrammingtechniques

- to minimize notch on entry and long

passes.

- control the cutting arc of engagement in

corners.

Ceramics Carbide

45º

>45º

There are 2 types of ceramics developed

for use in HRSA:

•Sialon – (Silicon, Aluminium, Oxygen,

Nitrogen) – a mixture of silicon nitride and

aluminium oxide. It has the best chemical

stability resisting notch wear:

- CC6060 – optimized choice for long

cutting lengths in clean material and for

profiling/pocketing with optimized programming techniques.

- CC6065 – optimized for heavy roughing

applications, plunging and machining

direct into corner.

22

•Whiskered ceramic – to provide the

improved toughness and bulk strength

compared to the traditional ceramic,

fibres are included:

- CC670 – first choice for machining of

forged components with rough scale

and ovality.

0.5 mm

10–80 mm

Grade application areas

Bulk toughness

CC670

Notch wear

resistance

CC6060

CC6065

Programming

consideration

Material

consideration

Skin, scale, ovality High quality forging Pre-machined

First stage

machining

– 26 HRC

Programmed direct

into corner/plunging

Cutting parameters

The speed should be balanced to create

enough heat in the cutting zone to plasticise the chip but not too high to unbalance

the ceramic.

The feed should be selected to give a chip

thickness which is high enough to not workharden the material but not be too high to

cause edge frittering.

Higher feeds and depths of cut require a

reduction of the cutting speed.

These boundaries will change depending

upon the component material hardness and

grain size.

400

300

200

100

Programmed with roll-in,

roll-out of corner

Intermediate stage

machining – 46 HRC

v

c

Short tool life – too high

cutting temperature

material

CC6060

CC6065

CC670

Edge line frittering – too

Work hardening of

workpiece material

low cutting temperature

Top slice – high cutting

pressure

0

0.05 0.1 0.15 0.2

h

ex

Start cutting data recommendations (RNGN 12, RCGX 12) – Inconel 718 (38 to 46 HRC)

Grade Cutting speed, vc Cutting depth, a

CC670 200 to 300 m/min 2 mm 0.1 to 0.15 mm/r

CC6065 200 to 250 m/min 2 mm 0.15 to 0.2 mm/r

CC6060 250 to 300 m/min 2 to 3 mm 0.15 to 0.2 mm/r

p

Feed, f

n

23

Application hints for round inserts

Trouble shooting – wear mechanisms

Top slice

Notch wear

Reason Remedy

Too high

cutting

pressure

Reduce

feed

Reduce ap

on round

insert

Use

CC670

Application hints for ceramic inserts

Insert selection

•Wherepossibleuseroundorsquare

inserts with a small entering angle and

large nose radius.

•Alwaysusethestrongestinsertnose

angle.

•Thickinsertsgiveadditionalstrength.

Pre-chamfering

•Protectstheinser twhenitfirstenters

from initial chipping/notch formation.

•Toavoidnotchwearwhenchamfering,

use a direction feed at 90° to the produced chamfer.

Reason Remedy

Sensitive

cutting

tool material

Specific

to HRSA

Low High

Low

Careful

programming techniques

Reduce

entering

angle

Use

CC6060,

CC6065

Productivity

Radial forces

High

Turning to a shoulder either:

•Rolluptotheshoulderwitharadiusthe

size of the insert diameter to prevent

increased depth of cut.

•Reducefeedby50%(fn/2) when approch-

ing a shoulder due to the depth of cut

increasing.

24

fn/2 fn fn/2

Notch wear

Notch wear can be minimized with good

planning and some general advice:

•Useroundinser tswheneverpossible–

ensure the relationship between depth

of cut a

exceed 25%.

•Use45ºenteringanglewhendepthofcut

exceeds 25% of iC.

•“Rolloveraction”inprogrammingto

eliminate the need for pre-chamfering and

minimize the notch wear. There will be

one contact point where the insert hits

the hard scale/surface at the corner of

the component and one different point at

the ap line.

•Rampingensuresthatanydamageis

spread out along the cutting edge. The

depth of cut should be varied between

25% iC to 15% (do not ramp to zero).

and insert diameter does not

p

mm mm

6.35 0.9

9.52 1.4

12.70 1.9

19.06 2.8

25.40 3.8

•Multiplepasseswithvaryingap can be an

alternative.

•ForRCGX/RPGXinserts,programinboth

directions to utilise more edges on the

insert.

25

Carbide insert grades

GC1105

A TiAlN PVD coated fine-grain carbide with

good hot hardness and toughness properties. It is optimized for inserts with 95º

entering angle but is an all-round grade giving effective performance through FSM, ISM

and LSM areas.

The coating gives extremely good adhesion which is required for lower feeds and

depths of cut. SGF is a ground insert with

sharp edges, this combined with GC1105

is outstanding in extreme finishing on vibration sensitive components with low feeds.

GC1115

A micro-grained carbide providing security

in more edge toughness demanding operations, e.g. reduce problems with notch wear

or chip hammering.

The PVD coating contains TiAlN for edge

line toughness as well as an aluminium

chromium oxide providing resistance

against built-up formation and crater wear.

A good balance of toughness and wear

resistance makes GC1115 ideal also for

more unstable conditions.

S05F

A CVD coated fine grain carbide with excellent hot hardness properties. It is optimized for applications with a 45º approach

(square, round, CoroCut RO and finishing).

The CVD coating provides an excellent heat

barrier allowing greater productivity and tool

life through ISM and LSM.

It is a grade for optimizing productivity

which does not allow for applications with

entering angles over 75º due to poor notch

wear resistance.

When in need of more bulk

toughness or if an uncoated

grade is required.

H13A

26

When in need of a more secure

solution, in more edge toughness

demanding operations.

GC1105

S05F

GC1115

First choice

When in need of more heat

and wear resistance at entering angles less than 75°.

Surface finish

comparison

Surface roughness, Ra mm

3

2.5

2

1.5

1

S05F H13A

= New insert

= Worn insert

0.5

0

0.15 0.25 0.15 0.25

Feed, mm/r

Surface integrity tests have shown that

S05F, applied at vc 40 m/min, gives

extremely consistent deformation depth

and residual stress profiles, when comparing new and worn inserts. The dimensional

accuracy and lack of any coning/taper is

also seen to eliminate the need for re-cut-

CNMG 120408-23 H13A

Wear causing poor

surface with worn

insert.

ting or spring passes. Both of these are the

result of minimal wear on the trailing edge

compared to other grades.

CNMG 120408-SF S05F

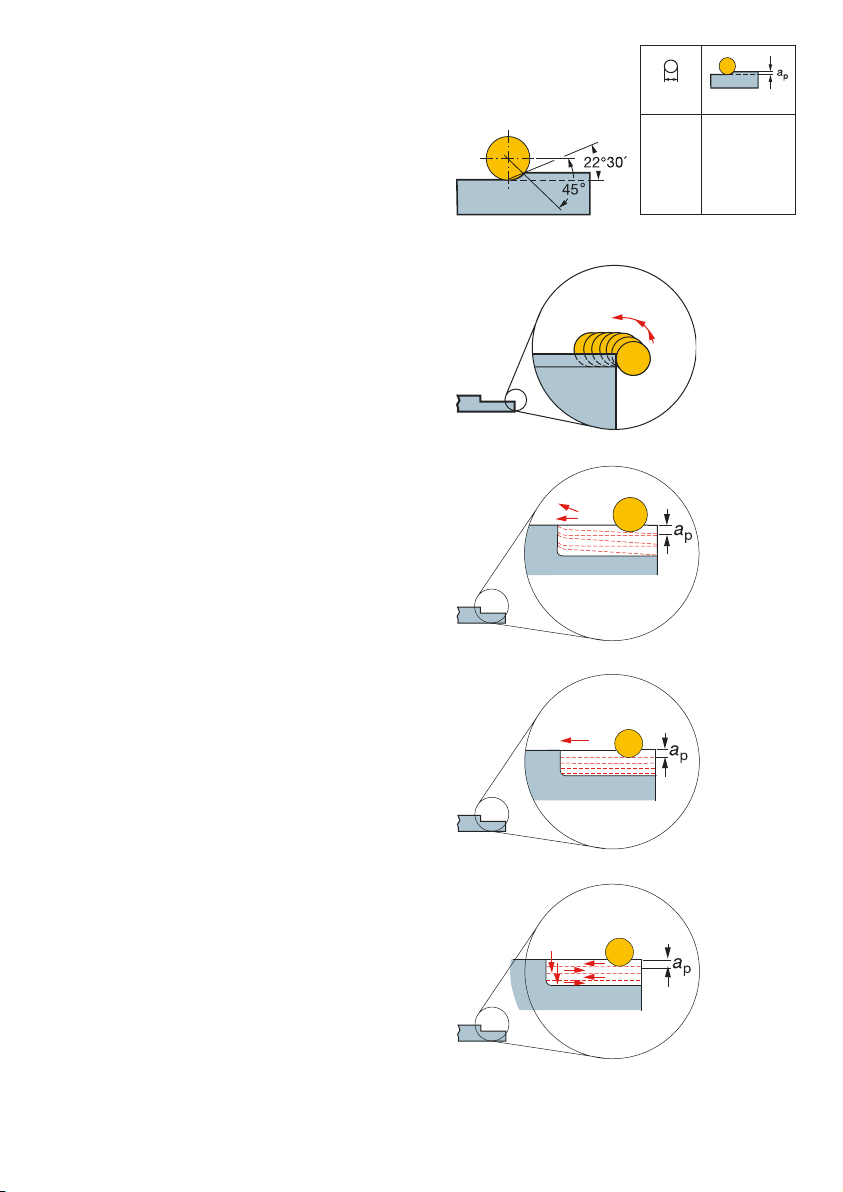

S05F applications – PD demanding

45º

a

p

CNMG/DNMG RCMX/RO SNMG/CNMX SNMG

45º

45º

a

p

a

p

45º

a

p

75º

a

p

GC1105 applications – notch demanding

95º

a

p

CNMG/DNMG TF/GF

27

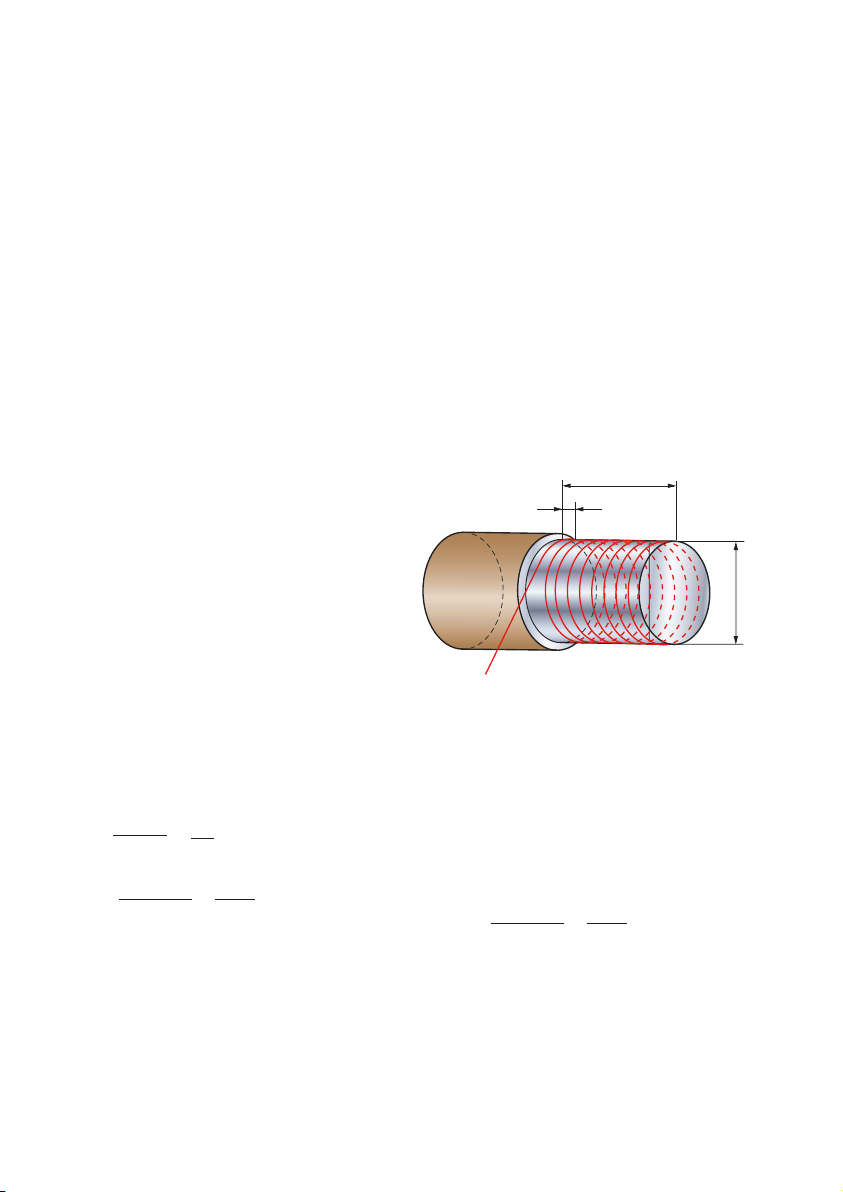

Spiral cutting length (SCL) – predictive machining

SCL was introduced by Sandvik Coromant

for the machining of HRSA due to the typically short tool life. One insert normally

machines one pass and is then indexed. It

is important to be able to predict for:

•Roughing–addingastopintheprogram

to change the insert

•Finishing–cuttingdatawhichensures

that the pass is completed with a predictable wear so as not to have to change

during the cut or recut the pass.

Application – process flow

Roughing

1) Select optimum inser t style to suit component/process.

2) Use optimized vc, ap and fn for that

insert shape/application and note SCL

capability eg CNMX 1204A1-SM S05F

vc 50 m/min, fn 0.35 mm, ap 1.7 mm.

3) Note SCL capability for that insert

SCL = 450 m, see page 30.

4) Calculate SCL for component feature

Dm1 = 450 mm, lm =150 mm.

D

x π

l

SCL =

1000

450 x 3.14

1000

m1

SCL =

5) Confirm calculated SCL with insert capabilities – program required number of

insert changes

eg. 606/450 – 2 edges required.

x

m

f

n

150

x

0.35

= 606 m

SCL is a method of calculating the length

of cut required for a particular feature and

then confirming with our specific recommendations to ensure a reliable process.

Each SCL graph is unique and only applicable for that insert, geometry, grade, depth

of cut and material. For finishing we give

you a range of cutting speeds to allow for

different length of cut requirements. For

roughing we have identified the optimum

parameters for each insert style and give

you one length.

l

m

f

n

D

m1

Finishing

1) Select optimum inser t style to suit component/process.

2) Use optimized ap for that insert shape/

application choose feed

eg. CNMG 120408-SF 1105 – fn 0.15

mm, ap 0.25 mm.

3) Calculate SCL for component feature

eg. Dia 450 mm, lm = 150 mm.

SCL =

450 x 3.14

1000

150

x

0.15

= 1414 m

4) Select cutting speed from:

CNMG 120408-SF 1105 ap 0.25, fn 0.15

mm’ diagram eg. vc = 50 m/min, see

page 30.

Note. How to calculate, see page 118-119.

28

Loading...

Loading...