Page 1

SERVICE & OPERATING MANUAL

SERVICE & OPERATING MANUAL

SERVICE & OPERATING MANUALSERVICE & OPERATING MANUAL

AIR OPERATED DOUBLE DIAPHRAGM PUMP

B25 & X25

B25 & X25

B25 & X25B25 & X25

Hygienic Series

Inc. Lube Free Models

This pump is Atex approved for use

in potentially explosive at mospheres

Group II category 2

Table of Contents

Service / Maintenance Log, Recycling 2

Dimensions 3

Performance Curve 3

Technical Data & Temperature limitations 4

Explanation of Pump Nomenclature 4

Principle of Pump Operation 5

Installation guide 5

Important Warnings & Safety Information 6

Troubleshooting 7

Grounding the Pump 7

Warranty 8

Service 8

Air Valve Overhaul 8

Wet-side Overhaul 8

Exhaust Safety 9

Parts List 10

Assembly Drawing 11

Declaration of Conformity 12

HG-CF-921 Rev. L - 28.07.05 Page 1

II 2 GD c

57470 31783

Page 2

Service / Maintenance Log

Date Details Completed

RECYCLING

Many components of BLAGDON ai r operated do uble diaphragm pumps are made of recyclable materials. W e encourage pum p

users to recycle worn out parts and pumps whenever possible, after any hazardous pumped fluids are thoroughly flushed.

Contact Information

Contact Phone / Fax No.

HG-CF-921 Rev. L - 28.07.05 Page 2

Page 3

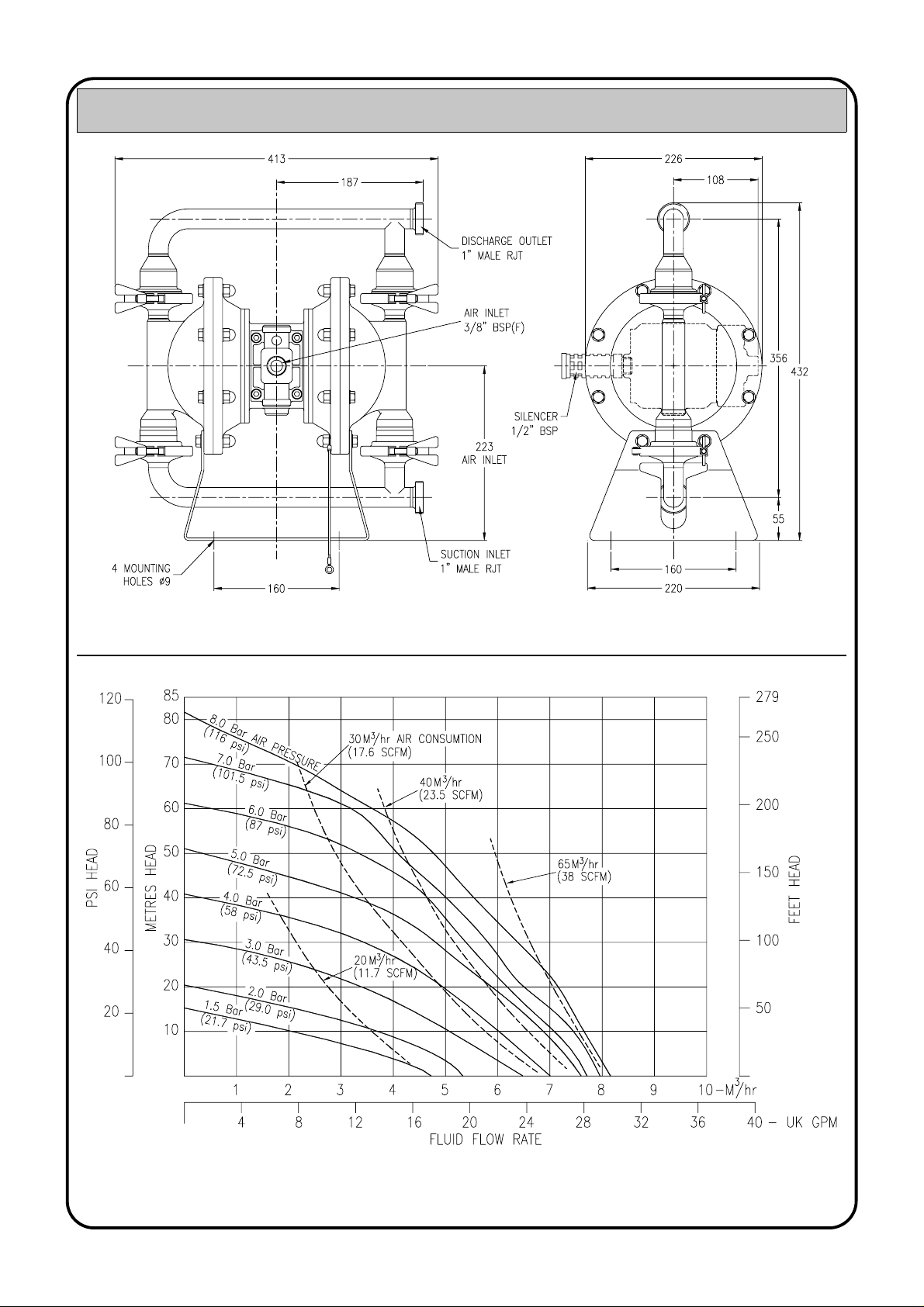

GA Drawing & Performance Curve

GA Drawing & Performance Curve

GA Drawing & Performance CurveGA Drawing & Performance Curve

General Assembly :- B25 / X25 Hygienic Models, all dimensions +/- 2mm

B25 / X25 Hygienic Performance Curve

Performance based on water at ambient temperature

HG-CF-921 Rev. L - 28.07.05 Page 3

Page 4

TECHNICAL DATA

FLUID CONNECTIONS CAPACITY MAX SOLIDS MAX DISCHARGE HEAD DISPLACEMENT/STROKE

1” RJT Male 0 - 136 Litres/Minute

(0 - 30 Gallons/Minute)

MAX. WORKING PRESSURE AIR INLET TEMPERATURE LIMITS PUMP WEIGHTS :-

8.6 Bar (125 psi) 3/8” BSP (F) Determined by Elastomers 21.5 Kg

5 MM

(3/16”)

88 Meters

(289 ft)

0.5 Litres

(0.11 UK Gallons)

Materials

EPDM - Shows very good water and chemical resistance. Has poor resistance to oils and solvents, but is fair on

ketones and alcohols.

Virgin PTFE - Chemically inert, virtually impervious. Very few chemicals are known to react chemically with

PTFE : molten alkali metals, turbulent liquid or gaseous fluorine and a few fluoro-chemicals such as chlorine

trifluoride or oxygen difluoride which readily liberate free fluorine at elevated temperatures.

• Gentle pumping action to avoid damage to food and

• Pressures to 8.6 bar.

beverage products.

• Capable of handling high viscosity & SG fluids.

• Range of RJT/DIN/FERRULE connections.

• Certified CIP cleanable.

• Self priming for emptying containers.

• EU Design approval

• Food grade elastomers – EPDM/PTFE

• 316L Stainless Steel

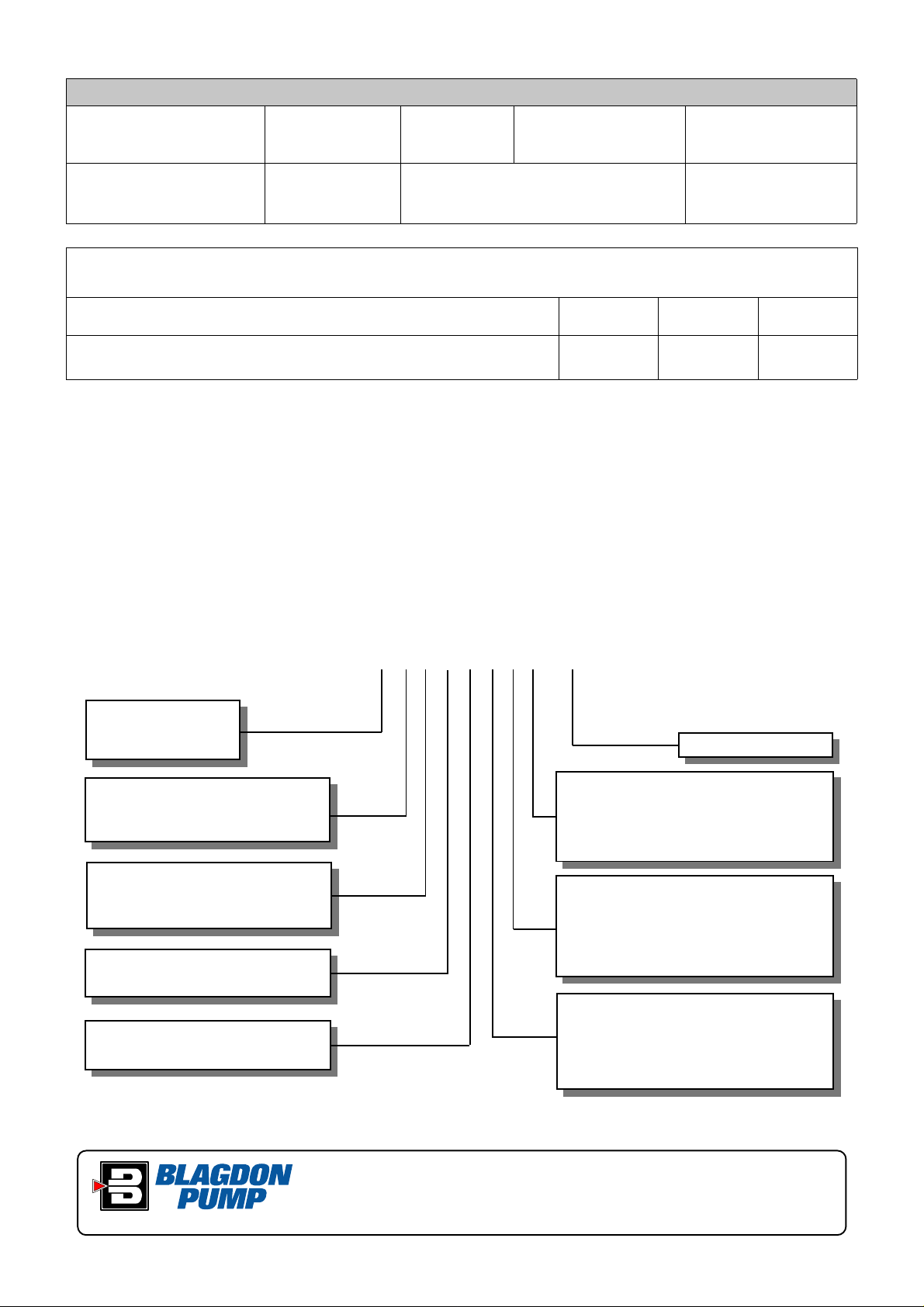

TYPICAL CODE = 25. Z F. B B. E E E - L F

Operating Temperatures

Maximum Minimum Optimum

212oF

o

100

356oF

o

180

C

C

-11oF

o

-24

32oF

o

C

0

C

50o to 212oF

o

to 100oC

10

50o to 212oF

o

to 100oC

10

MODEL

25 : STANDARD

X25 : ATEX CAT. 2

WETTED COMPONENTS

Z : 316L STAINLESS STEEL

(POLISHED)

NON - WETTED COMPONENTS

F : NICKEL PLATED ALUMINIUM

S: 316L STAINLESS STEEL

VALVE TYPE

B : BALL

SUCTION ORIENTATION

B : BOTTOM

This pump should be used in accordance with the requirements of the Health and Safety at Work Act 1974.

All business conducted subject to Blagdon Pump. Terms and Conditions of Sale, available on request.

LUBE FREE

VALVE SEATS

E : EPDM (FOOD GRADE)

S : STAINLESS STE EL

VALVE BALLS

E : FOOD GRADE EPDM

T : PTFE

S : 316 STAINLESS STEEL

DIAPHRAGMS

E : EPDM (FOOD GRADE)

O : ONE PIECE PTFE

IMPORTANT

LAMBERT ROAD,ARMSTRONG, WASHINGTON,

TYNE & WEAR NE37 1QP, ENGLAND.

TEL. : 0044 (0) 191 4177475

FAX. : 0044 (0) 191 4175435

Web Site : www.blagdonpump.com

E-Mail : sales@blagdonpump.com

HG-CF-921 Rev. L - 28.07.05 Page 4

Page 5

PRINCIPLE OF PUMP

OPERATION

This ball valve type diaphragm pump is

powered by compressed air and is a 1:1 ratio

design. The inner side of one diaphragm

chamber is alternately pressurised while

simultaneously exhausting the other inner

chamber. This causes the diaphragms, which are

connected by a common shaft secured by plates

to the centres of the diaphragms, to move in a

reciprocating action. (As one diaphragm

performs a discharge stroke the other diaphragm

is pulled to perform the suction stroke in the

opposite chamber.) Air pressure is applied over

the entire i nner surface of the di aphragm while

liquid is discharged from the opposite side of

the diaphragm. The diaphragm operates in a

balanced conditi on during the discharge stroke

which allows the pump to be operated at

discharge heads of over 200 feet (61 meters) of

water.

For maximum diaphragm life, keep the pump as

close to the liquid being pumped as possible.

Positive suction head in excess of 10 feet of

liquid (3.048 meters) may require a back

pressure regulating device to maximize

diaphragm life.

Alternate pressurising and exhausting of the

diaphragm chamber is performed by an

externally mou nted, pilot operated , 2 way type

distributi on valve. When th e spool shift s to one

end of the valve block body, inlet pressure is

applied to one chamber and the other diaphragm

chamber exha usts. When th e spool shift s to the

opposite end of the valve body, the pressure to

Lubricator

Filter/Regulater

Installation Guide

Fig. 1

the chambers is reversed. This alternating

movement of th e spool inside th e valve body is

controlled by a pilot air pressure signal held

against the diaphragm shaft, between seals in the

diaphragm shaft bushes. This signal is released,

triggering the movement of the spool, when pilot

holes in the diaphragm shaft align with the held

pilot signal, s ending the s ignal to exha ust , which

in-turn causes a pressure imbalance around the

spool, sendin g it to the op posit e end of th e valve

body. This simultaneously sends inlet pressure

to the opposite chamber.

The chambers are connect ed by manifolds with a

suction and discharge ball valve for each

chamber, maintaining flow in one direction

through the pump.

INSTALLATION

The typical installation shown in FIG. 1 is only a

guide to selecting and installing system

components. Your installation will depend on

the type of fluid being pumped and your

application needs. To reduce the risk of serious

bodily injury and damage to property, never use

fluids in this pump which are not compatible

with the wetted com ponents. Contact you r local

distributor or the manufacturer for system design

assistance & compatibility if necessary.

Mount the pump in an upri ght position. Failur e

to ensure an upright position may result in loss

of or poor priming characteristics. Ensure the

pump is securely mounted to avoid movement

and possible risk of bodily injury.

PRESSURE The pump delivers the same

pressure at the discharge outlet as the air

pressure applied at the air inlet (unless pump is

configured as a 2: 1 ra tio m o de l).

NOTE: Pressure Regulator (H) should be

installed where air supply could exceed 125

psi.

SAFETY

Your BLAGDON PUMP is a high

performance unit capable of achieving

high output s at high efficien cies. However, as

is common with pneumatic equipment, the

pump efficienc ies is reliant upon the air being

clean, dry and filtered. Failure to comply with

these requirements may lead to loss of

performance and reduced component life and in

extreme cases, permanent damage to the pump.

To avoid leaks, ensure that all fluid connections

are tight. The use of PTFE thread tape correc tly

applied should be used to ensure 100% leak

proof connections. Failure to ensure 100%

sealability of the suction connection could

adversely affect suction performance.

If you are pumping hazardous fluids, or

operating the pump in an enclosed area, it is

essential that the exhaust from the pump is

piped away to a safe location. When pumping

hazardous fluids the above instructions must be

adhered to in order to ensure safe operating

procedures. (Under certain operating

conditions the failure of internal components

can lead to the pumped fluid being exhausted

via the pump exh aust outlet).

WARNING

NEVER place your hands over or near the

pump suction inlet. Powerful suction could

cause serious bodily injury.

FLUSH THE PUMP This pump was

tested with water containing an oil-based rust

inhibitor. If thi s solution could c ontaminate or

react with the fluid you are pumping, flush the

pump thoroughly with a solvent/detergent to

clean internal components. The solvent/

detergent must be compatible with the pump

materials of con struct ion. Ca re shou ld b e taken

to flush the pump each time it is disassembled

for maintenance or repair.

CAUTION All BLAGDON PUMPS are

built lubricated with grease during assembly

and need no further lubrication. If the use of oil

cannot be avoided, this will not present any

problems. A light No. 2 class lithium grease is

recommended. Other grades may cause the Air

Logic System to op erate intermitt ently, thereby

causing a loss of ou tput and failu re to operate.

Other seals are available for “clean room”

conditions

If the pump accelerates or is running too fast

due to a lack of fluid, then stop it immediately

by shutting off the air supp ly. A dry pump will

accelerate to a high speed causing wear to

elastomers.

If the fluid you are pumping tend s to dry up or

set when it is no t moving, then flush th e pump

as often as necessary to prevent the fluid from

drying in the pump. Drain the pump thoroughly

before storing.

If feasible, invert pump to allow any fluid to

drain from the no n- r e turn valves

.

HG-CF-921 Rev. L - 28.07.05 Page 5

Page 6

Important Warnings and Safety Information

IMPORTANT

Read these safety warnings and instructions in this manual completely, before installation and start-up of the pump. It

is the responsibility of the purchaser to retain this manual for reference. This manual must be kept with, and supplied

with the pump at all times. Failure to comply with the recommendations stated in this manual will damage the pump,

and void factory warranty. These instructions are available if required, in the language or languages of the country or

countries in which the equipment is used. Please refer to the manufacturer for details.

IMPORTANT!

This pump is pr essuri zed i ntern ally wit h air pressu re du rin g ope ration . Al ways mak e certai n t hat all bol ting i s in good con ditio n and that

all of the correct bolting is reinstalled d uring assembly. End-user m ust ensure correct fitting of Inlet / Outlet con nections. Crossed

threads or over tightening of con nections will result in leaks. Quick action/release c onnections are not recommended. If thei r use is

unavoidable, the levers must be locked to avoid them being forced apart in a hazardous manner.

WARNING!

Before maintenanc e or repair, shu t off the compre ssed air line, bl eed the pre ssure, and dis connect the air l ine from the p ump. The discharge line may be press urized and must be ble d of its pre ssu re. E n d- use r m ust ensu re co rr ect r egulation of air supply pressure, as any

increase in air pressure results in a similar increase in product pressure if stalled-out.

WARNING!

Before doing any maintenance on the pump, be certain all pressure is completely vented from the pump, suction, discharge, piping, and

all other openings and connectio ns. Be certai n the air suppl y is locked o ut or made non- operational , so that it c annot be start ed while

work is being don e on the pump. B e cert ain that a pproved eye p rotection and prot ective cl othing ar e worn at all tim es in th e vicinit y of

the pump. Failure to follow these recommendations may result in serious injury or death.

WARNING!

Airborne particles and loud noise hazards. Wear ear and eye protection.

WARNING!

Take action to prevent st atic sparking. Fire or explosio n can result, especially when han dling flammable liquids. The pum p, piping,

valves, containers or other miscellaneous equipment must be grounded. Refer to exhaust safety instructions on page 9.

WARNING!

When used for toxic or ag gressive fluids, th e pump should al ways be flushed cl ean prior to disass embly. User mu st ensure chemic al

compatibility, and any pressure / temperature limits are not exceeded. These instructions include all the information for relevant

diaphragm temperature limits. Pump temperature range can also be found on data-plate attached to the pump.

If pump is not used f or m ore than 5 d ays, car e mu st be tak en whe n res tar ting . If in an y d oubt, remo ve p ump f rom li ne and fl ush wi th a

suitable cleaner. Solidified deposits within the pump may cause damage to the diaphragms.

CAUTION!

Before pump ope ration, inspect all gasketed fasteners for l ooseness caused b y gasket creep. Re-torqu e loose fasteners to prevent

leakage. Follow r ecommended torques stated in this manual. In cases of excess vibration, Blagdon recom mend fitting a Pulsation

Dampener to rem ove ef fects of pulse actions from p ump oper ation. Flexibl e connecti ons can be use d, but must b e kept t o a mi nimum

length necessary to avoid sharp flexing or straining movements

HG-CF-921 Rev. L - 28.07.05 Page 6

.

Page 7

TROUBLE SHOOTING GUIDE

NOTE :- Check all solutions before dismantling the pump.

PROBLEM CAUSE SOLUTION

Pump will not s tart Air valve assembly malfunction/Seizure

Erratic flow Diaphragm failure on one side.

Pump strokes but will not

discharge

Fluid discharged from air

exhaust

Intermitten t str oke rate Over lubrication

Obstructed fluid line.

Obstructed diaphragm chamber.

Diaphragm failure causing fluid & excessive air to be

expelled through the exhaust.

Diaphragm seal failure.

Air valve system malfunction.

Air connected to exhaust.

Valve ball not seating.

Suction leakage.

Diaphragm failure causing fluid & excessive air to be

expelled through the exhaust.

Diaphragm seal failure.

Air valve system malfunction.

Excessive suction lift.

Suction line leakage.

Valve ball not seating correctly or damaged.

Suction line or strainer clogged.

Diaphragm failure.

Diaphragm Failure.

Loose frontplate.

Diaphragm shaft seal failure.

Air valve system malfunction.

Valve ball not seating / partially obstructed.

Check carrier for freedom of movement. Clean, oil & replace.

Clean line or increase line size.

Remove obstruction.

Replace diaphragm.

Replace shaft seals.

Check all seals in valve chest assembly.

Re-connect to air inlet.

Replace diaphragm.

Check and remove obstruction.

Check and correct.

Replace diaphragm.

Replace shaft seals.

Check all seals in valve chest assembly.

Shorten suction line.

Check and correct.

Check and remove obstruction / replace.

Clear.

Replace diaphragm.

Replace diaphragm.

Re-Torque to manual specifications.

Shut-down pump. Remove air connection

into pump & introduce a small quantity of degreasing agent into air valve and replace

line. Run pump until clear.

Replace seals.

Check all seals in valve chest assembly.

Clear obstruction.

ATEX Certified units :- X25

These models are certified to :-

II 2 GD c

Non-electrical equipment for potentially explosive atmospheres,

: EN13463-1 : 2001

‘c’ - Internal control of production.

Grounding the pump :-

WARNING!

Take action to prevent static sparking. Fire or

explosion can result , especially when handling

flammable liquids. The pump, piping, valves,

containers or other miscellaneous equipment

must be grounded.

The Atex approved units are supplied with a natural earth ground

cable. This cable is 2 meters in length and permanently connected

through a nut and bolt at the inner cover casting. The other end is free

to connect to the nearest available suitable point to provide a natural

earth ground. This must be done to reduce the risk of electro-s tatic

sparking.

HG-CF-921 Rev. L - 28.07.05 Page 7

Page 8

IMPORTANT!

Read these instructions

completely, before

is the responsibility of the purchaser t o

retain this manual for reference.

Failure to comply with the

recommendations stated in this

manual will damage the pump, and

void factory warranty.

installation and start-up. It

SERVICE

The following sections give a general

overview on how to service all models of

BLAGDON Diaphragm Pumps. For

details on individual part numbers,

quantities, materials, etc., please consult

the parts list supplied with the pump.

NOTE : Before commencing any

service or maintenance work on the

pump, ensure that the air supply has

been disconnected o r isolated.

AIR VALVE SYSTEMS

PNEUMATIC TYPE Remove the 4

screws securing the valve block to the

valve chest, together with an y associated

gaskets or seals.

Remove slide valve plate & slide valve

from the valve block ass embly. Clean al l

parts thoroughly and inspect for

excessive wear, replacing where

necessary.

The slide valve and valve plate contact

faces should be flat and free from

scratches. A light polishing on a flat

surface with a fine abrasive paper will

remove most scratches.

If excessive wear is suspected in the

valve block bore or valve carrier, remove

the valve block plugs and withdraw the

valve carrier. Check valve block plug orings for wear or attack & replace where

required.

Clean the valve carrier & valve block

bore with white spirits to remove any oil

films.

NOTE : The nominal diametrica l

clearance between th e valve carrier and

the valve block bore should be 0.05 -

0.09mm. A clearance in excess of this

will cause the valve system to run

erratically.

Apply a light grease to the valve block

plug O-rings when re-assembling into the

valve block bore. Any damage to the Oring may cause the valve system to

malfunction.

Re-assemble the valve block assembly &

HG-CF-921 Rev. L - 28.07.05 Page 8

re-torque in accordance to the settings

shown in the parts list.

In the event of a complete air-side

overhaul, the pump should be disassembled down to the centre section

assembly as described later in the “WetSide Overhaul” section.

With the valve block assembly

dismantled, remove the inner covers

where appropriate.

A careful note of the position of all

related seals and gaskets should be made

to facilitate re-assembly.

Remove diaphragm shaft bushes, where

appropriate, and check all seal s and ‘O’

rings for wear or damage. If worn,

replace immediately.

NOTE:- The integrity of the diaphr agm

shaft seals is essential for the correct

functioning of all pneumatically

actuated valve systems.

Check the diaphragm shaft for e xcessive

wear as this will result in premature seal

failure. Replace as required. Lubri cate

all components and re-assemble as

detailed above, in reverse order. Ensure

the correct position of all components

detailed in all sectional assembly

drawings.

WET-SIDE OVERHAUL

REPLACING BALL VALVES

Remove discharge manifold from pump

assembly together with associated valve

balls, seats and ‘O’ rings.

NOTE :- The orientation of the val ve

seat relative to the valve ball should be

noted as incorrect positioning may

result in a performance loss.

Turn pump th rough 180

suction manifold. Clean and inspect the

components. Check for any wear or

damage and replace as required .

NOTE :- Ball or valve seat wear may

result in loss of performance and

suction lift.

Re-assemble the valve balls/seats and

ensure manifolds are adequ ately torqued

to the settings shown in the parts list.

REPLACING DIAPHRAGMS

Remove both suction and discharge

manifolds as detailed in the previous

section, removing all ball valves, seats

and ‘O’ rings.

Loosen and remove both outer covers

from the pump assembly. The

orientatio n of the covers should be noted

so as to facilitate re-assembly.

o

and remove the

Holding one of the frontplates in a vice,

(‘soft jaws’ should be fitted), or with an

adjustable spanner, loosen and remove

the frontplate from the opposite end.

Remove the diaphragm, backplate and

bumpstop from diaphragm shaft.

Carefully withdraw the diaphragm shaft

from the centre section and hold the free

end in a vice, holdin g between the flats

machined on the end. Loosen and

remove the frontplate and remove the

diaphragm together with backplate and

bumpstop (where fitted).

NOTE :- Care should be taken with all

plastic, coated and hygienic pumps, so

that the surface of the frontplate is not

damaged.

Thoroughly clean all parts and check for

wear, damage, swelling, cracking,

delamination and chemical attack.

Replace components where required.

NOTE :- Rubber diaphragms should be

replaced if they are worn to such an

extent that the fabric re-enforcing is

evident on the surface of the diaphragm.

For pumps fitted with PTFE diaphragms,

a light coating of grease should be

applied to the back-up diaphragm prior to

re-assembly.

Before re-assembly, it is advisable to

check the condition of the diaphragm

shaft seal/’O’ rings for wear or attack. If

either is evident, it is recommended that

they be replaced.

Assemble the diaphragms onto the shaft

in a reverse sequence to their removal.

Care should be taken as to the orientation

of the diaphragm relative to the front and

back plates. All diaphragms have “AIR

SIDE” moulded onto one side. The

backplate must be fitted adjacent to the

AIR SIDE of the diaphragm.

NOTE :- To achieve a leak free seal

around the clamp ba nds a plastic mallet

(A) should be used to gently tap the

clamp band into position, in a circular

manner. (Ref Fig. 2) The clamp (B)

should be tightened simultaneously

whilst using the mallet.

On all pumps fitted with stainless steel

fasteners, including clamp bands, it is

recommended that anti-seizure paste is

applied to the threads .

Bolted assemblies should be torqued to

the settings shown

in the parts list.

The manifolds

should be reassembled as

described in the

previous section.

Fig. 2

A

B

Page 9

EXHAUST SAFETY WHEN PUMPING HAZARDOUS LIQUIDS

WARNING!

In the event of diaphragm ruptu re, pum ped m ateri al m ay enter t he ai r end of t he pum p, and be disch arge d into the a tm osphere . If pum pi ng

a product which is hazardous or toxic, the air exhaust must be piped to an appropriate area for safe disposition.

Flooded Suction Installation

Suction Lift Installation

Submerged Installation

Exhaust Safety :-

When a diaphragm fails during operation, pumped liquid can enter and contaminate the air side of the pump. If diaphragm failure is not

severe, i.e. a small split or hole, then the pump can continue to run, with air being forced into the product being pumped. If however the

failure is more serious, then the pum p may stop, with fluid or fumes being expelled through the exhaust. Under these conditions it is

recommended that the exhaust is piped away to a safe area. In standard suction lift conditions this can simply be done by pi ping fr om t he

exhaust connection to a safe area. Multiple installations can be piped to a common connection, then to a safe area. In flooded suction

conditions the exhaust must be taken to a point higher than the fluid level to prevent any siphoni ng away. In submerged c onditions ens ure

exhaust is piped away above fluid level.

In all conditions ensure exhaust outlet is not expelling across a non-conductive surface. The exhaust must not be placed less than 100mm

from any non-conductive surface, as this may generate a propagating brush discharge resulting in a possible ignition sourc e.

HG-CF-921 Rev. L - 28.07.05 Page 9

Page 10

HG-CF-921 Rev. L - 28.07.05 Page 10

PARTS LIST

PARTS LIST - cont.

REF

No.

1 25-065 PUMP STAND

2 25-057 SUCTION MANIFOLD (see table for optional connections)

3 25-064 CLAMP BAND

4 SEE TABLE VALVE SEAT

5 SEE TABLE VALVE BALL

6 25-056 OUTER COVER

7 SA10403 FRONTPLATE ASSY

8 SEE TABLE DIAPHRAGM

9 25-058 DISCHARGE MANIFOLD (see table for optional connections)

10 1A259 BACKPLATE

11 1A009 BUMP STOP

12 25-059 INNER COVER

13 G242 O-RING

14 40-196 VALVE CHEST

15 25-060 DIAPHRAGM SHAFT

16 G367 O-RING

17 G245 O-RING

18 G189 O-RING

19 40-194 DIAPHRAGM SHAFT BUSH

20 G514 O-RING (See table for Lube Free Seal Option)

21 D310 SOCKET CAP SCREW

22 C173 SPRING WASHER

23 A040 BOLT

24 C044 WASHER

25 B469 NUT

26 A035 BOLT

27 G339 O-RING

28 D314 SOCKET CAP SCREW

29 G243 O-RING

30 40-204 GASKET

31 40-005 VALVE PLATE

32 40-004 SLIDE VALVE

33 H501 CIRCLIP

34 40-207 VALVE BLOCK PLUG

35 G512 O-RING

36 40-192 VALVE CARRIER

PART

NUMBER

DESCRIPTION

QTY

1

1

4

4

4

2

2

2

1

2

2

2

2

1

1

2

2

2

2

6

4

4

12

32

16

4

8

8

2

1

1

1

2

2

2

1

REF

No.

37 40-215 VALVE BLOCK

38 40-047 SILENCER (STANDARD MODELS ONLY)

39 G431 O-RING (USED WITH ST. STEEL SEATS ONLY)

38 1A377 SILENCER

40 SA10288 GROUNDING LEAD ASSY.

41 SP467 ATEX CAT.2 I/D TAG

42 SP473 TIE-LOK TIE

PART

NUMBER

THE FOLLOWING PARTS ARE USED ON ATEX CERTIFIED MODELS

DESCRIPTION

ELASTOMER TABLE

REF

No.

- These items are available in a recommended spares kit. Please refer to your local stockist / distributor for details.

- These items are available in a recommended spares kit - SA10415 - Air side Kit

Lube Free Air Side Kit :- SA10433

- These items are available as Sub-Assy. Spare :- SA10463

DESCRIPTION FOOD GRADE

4 VALVE SEAT 25-061 - 25-097 4

5 VALVE BALL 25-062 1A002 1A197 4

8 DIAPHRAGM 25-063 25-071 - 2

EPDM

PTFE STAINLESS

STEEL

QTY

LUBE FREE COMPONENTS

REF

No.

20 LUBE FREE SEAL (CENTRE SECTION) 25-072 6

CONNECTION

TYPE 1”

SUCTION MANIFOLD DISCHARGE MANIFOLD

DIN 25-112 25-113 1

FERRULE 25-115 25-116 1

IDF 25-067 1 25-068

DESCRIPTION PTFE QTY

OPTIONAL MANIFOLD PART NUMBERS

See distributors for details

QTY

NOTES

QTY

1

1

4

1

1

1

1

Page 11

HG-CF-921 Rev. L - 28.07.05 Page 11

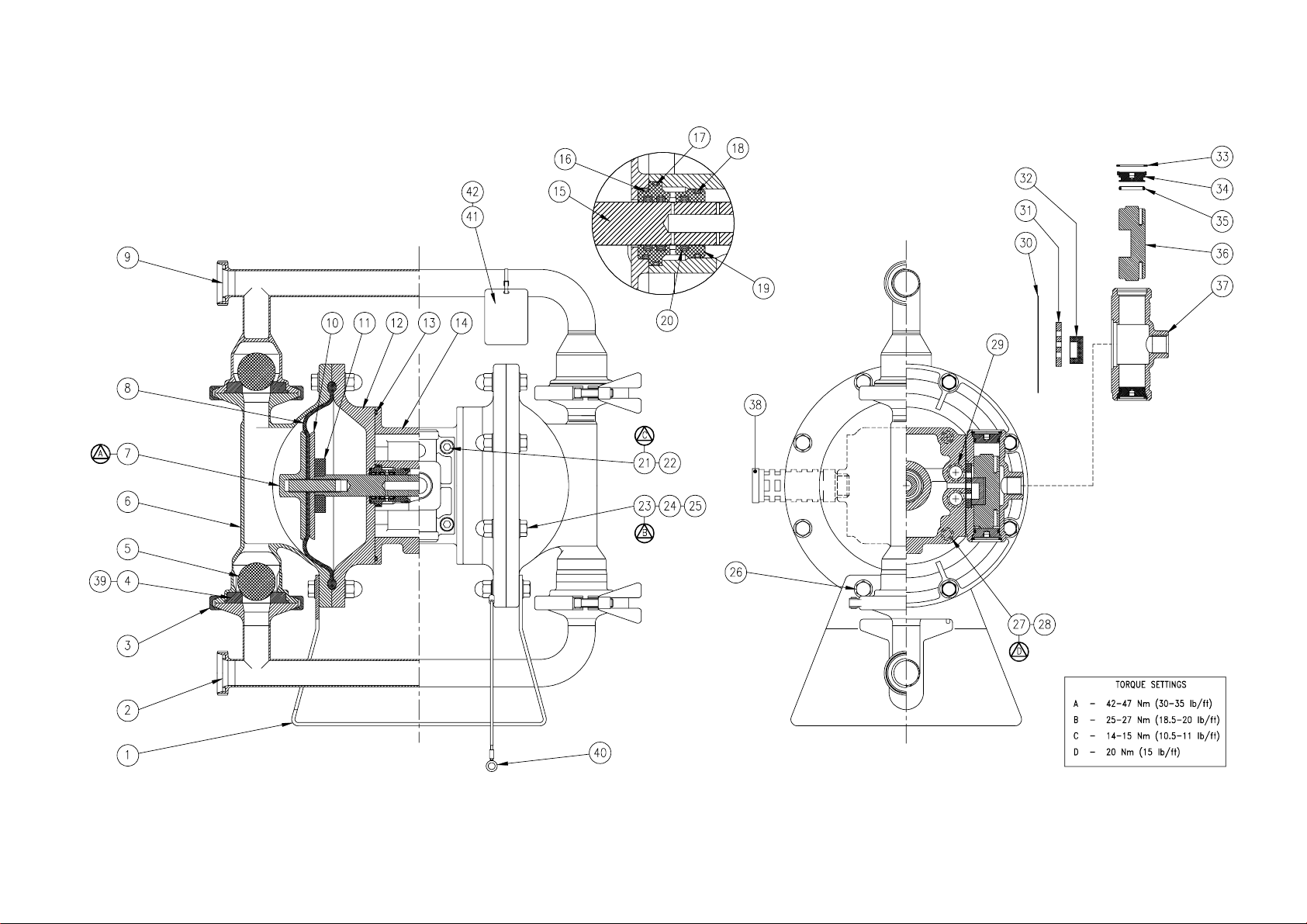

Sectional General Assembly :- B25 Hygienic Pump.

Refer to page 10, Parts List table for Item Ref. Nos.

Page 12

BLAGDON PUMP

A Unit of IDEX Corporation

Lambert Road, Armstrong,

Washington, Tyne & Wear.

NE37 1QP, England.

Tel. +44 (0) 191 4177475

Fax. +44 (0) 191 4175435

Jeff Sill,

General Manager

HG-CF-223 (REV 4)

HG-CF-921 Rev. L - 28.07.05 Page 12

Loading...

Loading...