Page 1

SERVICE AND OPERATING MANUAL

ELECTRO-PNEUMATIC SPEED

The Warren Rupp Electro-Pneumatic Speed Control System

can be used to control SandPiper® Pumps, as well as most other

air-operated, double diaphragm pumps on the market. The Warren

Rupp Speed Control offers several benefi ts:

· Easy to Install and Operate.

· Increases Flexibility of Entire System.

· Variable Flow Rate Control.

· NEMA 4X Rated Controls.

· Manual Mode

(On-Board, Single-Turn Potentiometer).

· Or Automatic Mode

(Optional 4-20mA Input Terminal).

· Operates on 110 OR 220 VAC Power.

CONTROL SYSTEM

· Rated for maximum inlet pressures of 125 psi.

PRINCIPLE OF

OPERATION

The Warren Rupp ElectroPneumatic Speed Control System is

comprised of three components that

operate with most diaphragm pumps

to optimize operational variable fl ow

rate demands.

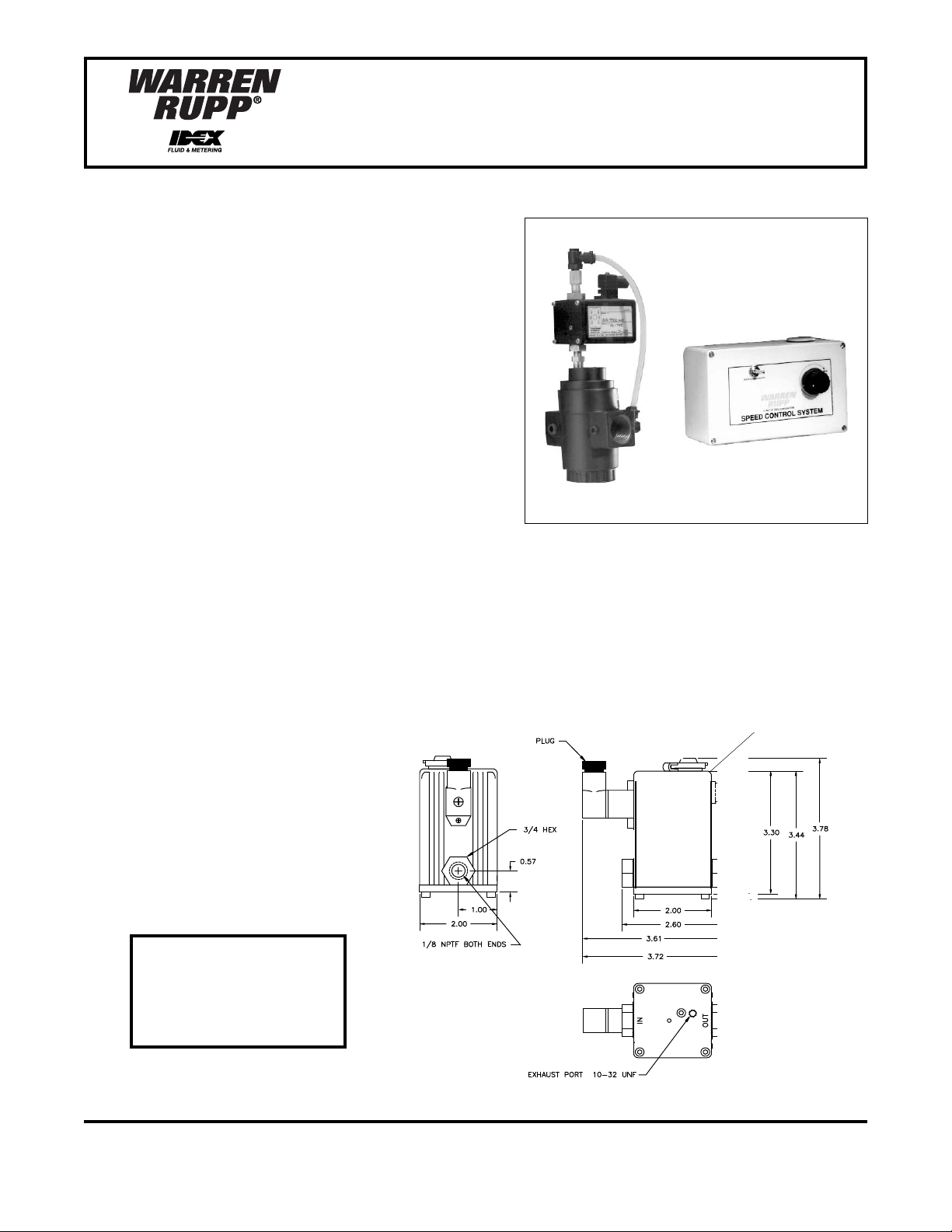

The fi rst component is an

electronically operated proportional

pilot valve that utilizes patented technology to provide extremely accurate

pneumatic control in a NEMA 4X

rated container. (See Figure 1.)

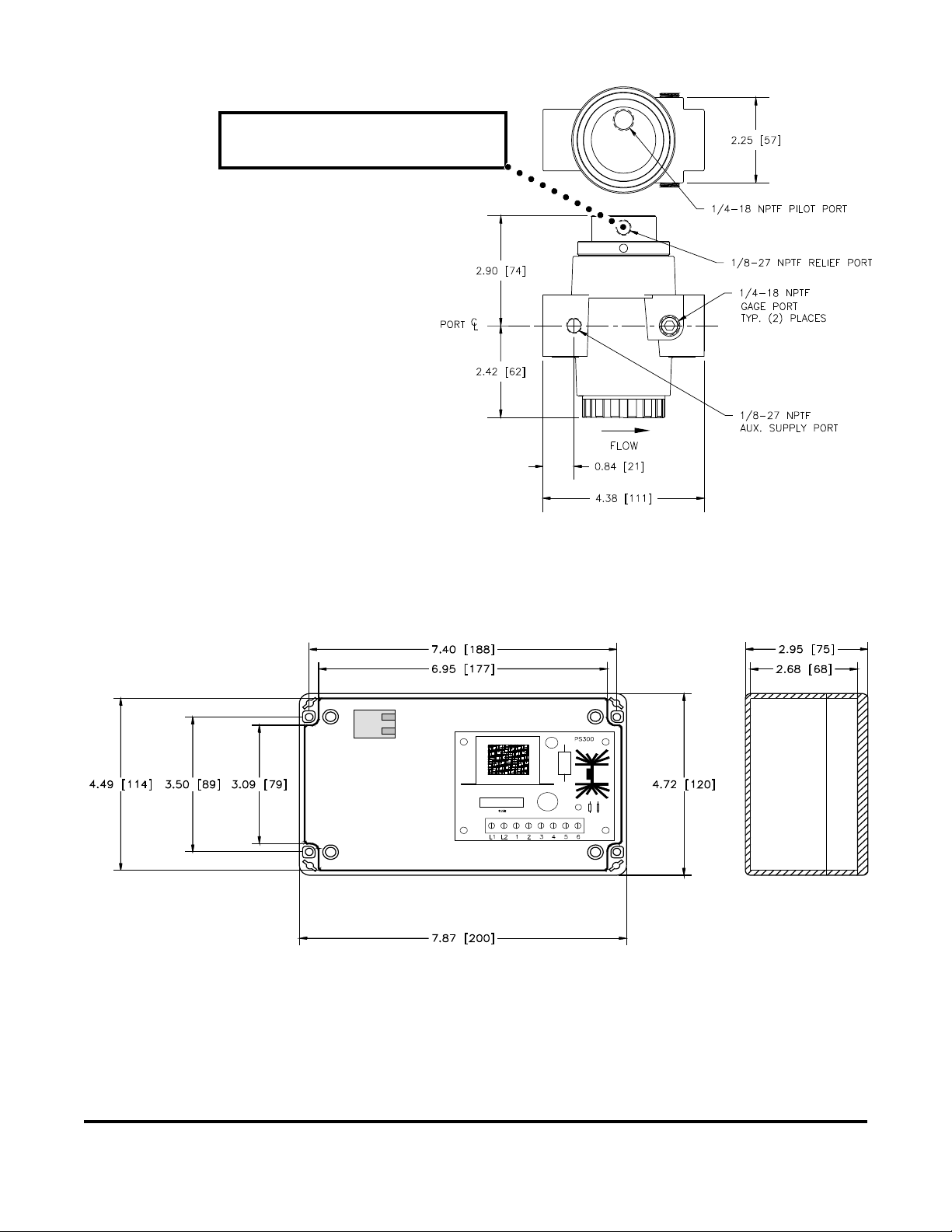

The second component is

a diaphragm, air-piloted pressure

regulator that offers higher fl ow rates

that translate into faster responses.

(See Figure 2.)

CAUTION!

Always disconnect

power before working

on units.

032-022-000 (110V)

032-023-000 (220V)

For ½ " through 4" Pumps

Pressure Regulator Port: 1"

Pilot Valve

Figure 1

WARREN RUPP, INC. • A Unit of IDEX Corporation • P.O. Box 1568 • Mansfi eld, OH 44901 USA • (419) 524-8388 Fax (419) 522- 7867

www.warrenrupp.com

spdctrol-rev0808

Speed Control Page 1

Page 2

NOTE! The plug must be removed from the

relief port before operation of the unit.

The third component is the NEMA 4X rated

enclosure housing the power supply necessary

for the proportional valve as well as a control

potentiometer for manual operation. A switch on

the enclosure allows the user to select between

manual control via the provided potentiometer or

a remote control from a user supplied source,

such as a process controller supplying a 4-20

mA signal. (See Figure 3.) A 25-foot length

of electrical cable to the proportional valve is

provided. (See Installation Guide.)

1" Port Model

Figure 3

Figure 2

WARREN RUPP, INC. • A Unit of IDEX Corporation • P.O. Box 1568 • Mansfi eld, OH 44901 USA • (419) 524-8388 Fax (419) 522- 7867

www.warrenrupp.com

spdctrol-rev0808

Speed Control Page 2

Page 3

INSTALLATION & CONNECTION

Mechanical Connections: Plumb the outlet of

the air piloted regulator (procedure explained earlier) to

the inlet of the diaphragm pump. Plumb the inlet of the

air piloted regulator to the supply air. Supply air must

be clean, dry compressed air, not to exceed 125 psi.

Mount the control box in desired location.

Electrical Connections: The Warren Rupp

Speed Control System 032-022-000 is shipped

standard, set up for 110V. Speed Control System

032-023-000 is shipped standard, set up for 220V.

The units are marked accordingly on the exterior and

interior of the Power Supply Module. Be certain you

have the correct unit before installing. Connect

the AC incoming power to terminal on Power Supply

marked L1 and L2.

DO NOT USE neutral (ground) wire.

If the Warren Rupp Speed Control is to be used

as a stand-alone control device (no remote controller

used to provide command signal) the switch on the

outside of the control box ("Manual/Automatic") should

remain in the Manual position. In this scenario, any

desired changes in pressure output of the valve are

made by simply adjusting the potentiometer knob on

the face of the control panel. Clockwise turning of the

potentiometer increases the pressure speed and output. Counter clockwise movement decreases speed

and output.

NOTE: Each input volt equals 12.5 psi output

pressure. For example, at 65 psi input, the potentiometer would operate between minimum and halfway to maximum on the dial to achieve maximum

performance of this unit. (See Fig. 6).

If a remote controller is used to provide a 4-20

mA command signal, locate the small circuit board on

the inside of the face plate of the control box. Connect

4-20 + to terminal marked S+. Connect 4-20 - to terminal

marked S-. (See Figure 5.) In this scenario, when the

switch on the outside of the control box marked Manual/

Automatic is in the Manual position, the command signal is from the potentiometer on the face of the control

panel. When the switch is in the Automatic position,

the command signal comes from the 4-20 mA control

signal supplied by the remote controller.

Front View of Power Supply Module

3 amp Fuse: Replacement Part 358-001-000

Rear View of Power Supply Module

PS-300

C

A

B

D

E

Figure 4

POTENTIOMETER

MANUAL CONTROL KNOB

F

Do not exceed 125 psi input

pressure.

This setting represents

maximum performance at

approximately 65 psi input

S-

S+

Figure 5

WARREN RUPP, INC. • A Unit of IDEX Corporation • P.O. Box 1568 • Mansfi eld, OH 44901 USA • (419) 524-8388 Fax (419) 522- 7867

pressure.

Operating range of this unit

at 65 psi input pressure.

Figure 6

Maximum

Minimum

www.warrenrupp.com

spdctrol-rev0808

Speed Control Page 3

Page 4

AUTOMATIC OPERATION

This unit can be set up in the Automatic Mode for process

control (see Fig.7). In the Automatic Mode, the speed controller

will accept 4-20mA input signal to adjust the speed to meet the

application requirements.

The box is punched and plugged with contacts provided,

to accept 20-24AWG, 2-conductor cord. The input signal to the

speed control is usually generated from a programmable or

process controller which manages the overall application. There

can be numerous sensing devices used to control application

requirements, feeding signals to the programmable or process

controller. This controller then provides a 4-20mA signal to the

Warren Rupp Speed Controller, increasing or decreasing the

speed to meet demands of the application.

AUTOMATIC INSTALLATION POSSIBILITIES

Proximity Switch

or

The sensing devices might include any of the following:

1. Pump shaft proximity switch for sensing pump

speed.

2. Pressure transmitter for sensing system pressure,

suction pressure, or discharge pressure.

3. Timer.

4. Level control sensing device.

5. Flow sensing device.

6. Temperature probe.

7. Ph sensor.

8. Weight scale.

This is a partial list of possible devices.

Pressure Transducer

or

Timer

or

Level Control

or

Flow Sensor

Process

Controller

Figure 7

4-20mA

signal

AUTO

MANUAL

Speed Controller

Pump

WARREN RUPP, INC. • A Unit of IDEX Corporation • P.O. Box 1568 • Mansfi eld, OH 44901 USA • (419) 524-8388 Fax (419) 522- 7867

www.warrenrupp.com

spdctrol-rev0808

Speed Control Page 4

Page 5

IMPORTANT

Consult and follow

all local codes

and requirements

when installing this unit.

Installation Guide

NEMA 4X control box houses 110 or 220

A

VAC power supply; manual potentiometer;

and manual/automatic switch. In manual

mode, the on-board potentiometer is utilized.

In automatic mode, a remote connection

must be in place.

Part No. 032.022.000 - 110V

Part No. 032.023.000 - 220V

Power cord from control box to Electro-

B

pneumatic controller is supplied by the

manufacturer in 25' (7.62m) length. Cord is

22 AWG, 6 conductor.

For automatic mode, an optional 4-20mA

C

input signal connects here. Hole is punched

and drilled. The end-user provides remote

controller and 20-24 AWG, 2 conductor cord.

WARREN RUPP, INC. • A Unit of IDEX Corporation • P.O. Box 1568 • Mansfi eld, OH 44901 USA • (419) 524-8388 Fax (419) 522- 7867

www.warrenrupp.com

spdctrol-rev0808

Electro-pneumatic control unit. Output

D

pressure is proportional to incoming

command signal. Maximum input pressure

is 125 psi.

Diaphragm type, air-piloted pressure

E

regulator, with 1" (25.4mm) port.

Power source. 110 or 220 VAC. End-user

F

supplies 16-18 AWG, 2 conductor power

cord.

40 micron fi ltration is recommended.

G

Speed Control Page 5

Loading...

Loading...