Page 1

MonoLaserPrinter

XpressM262x/M282xSeries

MANUAL

SERVICE

MonoLaserPrinter

1.Precautions

2.ProductSpecicationsandDescription

3.DisassemblyandReassembly

4.Troubleshooting

5.SystemDiagrams

6.SchematicDiagrams

Contents

RefertotheservicemanualintheGSPN(seetherearcover)formoreinformation.

Page 2

Contents

Contents

1.Precautions......................................................................................................................................1−1

1.1.Safetywarning........................................................................................................................1−1

1.2.Cautionforsafety....................................................................................................................1−2

1.2.1.Toxicmaterial.............................................................................................................1−2

1.2.2.Electricshockandresafetyprecautions.........................................................................1−2

1.2.3.Handlingprecautions...................................................................................................1−4

1.2.4.AssemblyandDisassemblyprecautions...........................................................................1−4

1.2.5.Disregardingthiswarningmaycausebodilyinjury............................................................1−5

1.3.CautionforDataLoss...............................................................................................................1−6

1.4.ESDprecautions......................................................................................................................1−7

2.ProductSpecicationsandDescription..................................................................................................2−1

2.1.ProductSpecications..............................................................................................................2−1

2.1.1.ProductOverview........................................................................................................2−1

2.1.2.Specications.............................................................................................................2−2

2.1.2.1.GeneralPrintEngine......................................................................................2−2

2.1.2.2.ControllerandSoftware..................................................................................2−2

2.1.2.3.PaperHandling.............................................................................................2−4

2.1.2.4.Consumables................................................................................................2−4

2.1.2.5.ReliabilityandService...................................................................................2−5

2.1.2.6.Environment................................................................................................2−5

2.1.2.7.Options.......................................................................................................2−6

2.1.2.8.Maintenanceparts.........................................................................................2−6

2.1.3.ModelComparisonTable..............................................................................................2−7

2.2.SystemOverview.....................................................................................................................2−8

2.2.1.FrontView.................................................................................................................2−8

2.2.2.RearView..................................................................................................................2−9

2.2.3.PaperPath..................................................................................................................2−10

2.2.4.SystemLayout............................................................................................................2−11

2.2.4.1.FeedingPart.................................................................................................2−12

2.2.4.2.TransferRoller.............................................................................................2−13

2.2.4.3.DriveUnit...................................................................................................2−13

2.2.4.4.Fuser..........................................................................................................2−14

2.2.4.5.LSU(LaserScannerUnit)...............................................................................2−15

2.2.4.6.TonerSystem...............................................................................................2−16

2.2.5.Hardwareconguration................................................................................................2−17

2.2.5.1.Mainboard..................................................................................................2−18

2.2.5.2.OPEboard...................................................................................................2−20

2.2.5.3.WirelessLANboard......................................................................................2−21

iCopyright©1995-2013SAMSUNG.Allrightsreserved.

Page 3

Contents

2.2.5.4.JointPBA....................................................................................................2−22

2.2.5.5.ElectricalPartsLocation.................................................................................2−23

2.2.5.6.SMPSBoard................................................................................................2−26

2.2.5.7.HVPSBoard................................................................................................2−28

2.2.6.EngineF/WControlAlgorithm......................................................................................2−29

2.2.6.1.Feeding.......................................................................................................2−29

2.2.6.2.Transfer.......................................................................................................2−29

2.2.6.3.Fusing.........................................................................................................2−30

2.2.6.4.LSU............................................................................................................2−30

2.2.7.SoftwareDescriptions..................................................................................................2−31

2.2.7.1.Softwaresystemoverview..............................................................................2−31

2.2.7.2.Architecture.................................................................................................2−31

2.2.7.3.DataandControlFlow...................................................................................2−32

3.DisassemblyandReassembly..............................................................................................................3−1

3.1.Precautionswhenreplacingparts................................................................................................3−1

3.1.1.Precautionswhenassemblinganddisassembling...............................................................3−1

3.1.2.PrecautionswhenhandlingPBA.....................................................................................3−1

3.1.3.ReleasingPlasticLatches..............................................................................................3−2

3.2.Screwsusedintheprinter..........................................................................................................3−3

3.3.ReplacingtheMainSVCparts...................................................................................................3−4

3.3.1.SideCover.................................................................................................................3−4

3.3.2.RearCover.................................................................................................................3−5

3.3.3.FrontCover................................................................................................................3−6

3.3.4.TopCover..................................................................................................................3−7

3.3.5.MainBoard................................................................................................................3−7

3.3.6.SMPS........................................................................................................................3−8

3.3.7.HVPS........................................................................................................................3−8

3.3.8.Bin-FullSensor...........................................................................................................3−9

3.3.9.MainDriveunit...........................................................................................................3−9

3.3.10.PickupandRegiClutch...............................................................................................3−10

3.3.11.PickupandForwardroller............................................................................................3−10

3.3.12.RetardRoller..............................................................................................................3−11

3.3.13.DuplexUnit...............................................................................................................3−12

3.3.14.TransferRoller............................................................................................................3−13

3.3.15.LSU..........................................................................................................................3−13

3.3.16.FuserUnit..................................................................................................................3−14

3.3.17.ExitSensor.................................................................................................................3−14

3.3.18.FeedandRegisensorPBA............................................................................................3−15

3.3.19.OPEPBA..................................................................................................................3−16

3.3.20.WirelessLANPBA......................................................................................................3−16

Copyright©1995-2013SAMSUNG.Allrightsreserved.ii

Page 4

Contents

3.3.21.Motor........................................................................................................................3−17

4.Troubleshooting................................................................................................................................4−1

4.1.AlignmentandAdjustments.......................................................................................................4−1

4.1.1.ControlPanel..............................................................................................................4−1

4.1.2.UnderstandingthestatusLED........................................................................................4−3

4.1.3.JamRemoval..............................................................................................................4−4

4.1.4.Periodicdefectiveimage...............................................................................................4−10

4.1.5.Usefulmanagementtools..............................................................................................4−11

4.1.5.1.UsingSamsungEasyPrinterManager(WindowsandMacintoshonly)....................4−11

4.1.5.2.UsingSamsungPrinterStatus(Windowsonly)...................................................4−13

4.1.5.3.UsingSmartPanel(Linuxonly).......................................................................4−14

4.1.6.UpdatingFirmware......................................................................................................4−15

4.1.6.1.UpdatethermwarebyusingtheUSBport........................................................4−15

4.1.6.2.Updatethermwarebyusingthenetwork..........................................................4−15

4.1.7.EDCprogram.............................................................................................................4−18

4.2.Troubleshooting......................................................................................................................4−20

4.2.1.Procedureofcheckingthesymptoms...............................................................................4−20

4.2.1.1.BasicCheckList...........................................................................................4−21

4.3.ErrorCodeandTroubleshooting.................................................................................................4−22

4.4.Imagequalityproblem..............................................................................................................4−37

5.SystemDiagrams..............................................................................................................................5−1

5.1.BlockDiagram........................................................................................................................5−1

5.2.ConnectionDiagram.................................................................................................................5−2

6.SchematicDiagrams..........................................................................................................................6−1

6.1.ToolforTroubleshooting...........................................................................................................6−1

6.2.Glossary.................................................................................................................................6−2

6.3.TheSamplePatternfortheTest..................................................................................................6−8

6.4.Selectingalocation..................................................................................................................6−9

6.5.ModelNameandCode.............................................................................................................6−10

iiiCopyright©1995-2013SAMSUNG.Allrightsreserved.

Page 5

1.Precautions

Inordertopreventaccidentsanddamagestotheequipmentpleasereadtheprecautionslistedbelowcarefullybefore

servicingtheproductandfollowthemclosely .

1.1.Safetywarning

1)Onlytobeservicedbyafactorytrainedservicetechnician.

Highvoltagesandlasersinsidethisproductaredangerous.Thisproductshouldonlybeservicedbyafactorytrained

servicetechnician.

2)UseonlySamsungreplacementparts.

Therearenouserserviceablepartsinsidetheproduct.Donotmakeanyunauthorizedchangesoradditionstothe

productasthesecouldcausetheproducttomalfunctionsandcreateanelectricshocksorrehazards.

3)LaserSafetyStatement

TheprinteriscertiedintheU.S.toconformtotherequirementsofDHHS21CFR,chapter1SubchapterJfor

ClassI(1)laserproducts,andelsewhereiscertiedasaClassIlaserproductconformingtotherequirementsofIEC

60825-1.ClassIlaserproductsarenotconsideredtobehazardous.Thelasersystemandprinteraredesignedso

thereisneveranyhumanaccesstolaserradiationaboveaClassIlevelduringnormaloperation,usermaintenance

orprescribedservicecondition.

1.Precautions

•Wavelength:800nm

•Beamdivergence

-Paraller:11degrees

-Perpendicular:35degrees

•Maximumpowerofenergyoutput:12mW

WARNING

NeveroperateorservicetheproductwiththeprotectivecoverremovedfromLaser/Scannerassembly.Thereected

beam,althoughinvisible,candamageyoureyes.

Whenusingthisproduct,thesebasicsafetyprecautionsshouldalwaysbefollowedtoreduceriskofre,electricshock,

andpersonalinjury .

Copyright©1995-2013SAMSUNG.Allrightsreserved.1-1

Page 6

1.Precautions

1.2.Cautionforsafety

1.2.1.Toxicmaterial

Thisproductcontainstoxicmaterialsthatcouldcauseillnessifingested.

1)Pleasekeepimagingunitandtonercartridgeawayfromchildren.Thetonerpowdercontainedintheimagingunitand

tonercartridgemaybeharmful,andifswallowed,youshouldcontactadoctor.

1.2.2.Electricshockandresafetyprecautions

Failuretofollowthefollowinginstructionscouldcauseelectricshockorpotentiallycauseare.

1)Useonlythecorrectvoltage,failuretodosocoulddamagetheproductandpotentiallycauseareorelectricshock.

2)Useonlythepowercablesuppliedwiththeproduct.Useofanincorrectlyspeciedcablecouldcausethecableto

overheatandpotentiallycauseare.

3)Donotoverloadthepowersocket,thiscouldleadtooverheatingofthecablesinsidethewallandcouldleadtoare.

4)Donotallowwaterorotherliquidstospillintotheproduct,thiscancauseelectricshock.Donotallowpaperclips,pins

orotherforeignobjectstofallintotheproduct,thesecouldcauseashortcircuitleadingtoanelectricshockorrehazard.

5)Nevertouchtheplugsoneitherendofthepowercablewithwethands,thiscancauseelectricshock.Whenservicing

theproduct,removethepowerplugfromthewallsocket.

6)Usecautionwheninsertingorremovingthepowercord.Whenremovingthepowercord,gripitrmlyandpull.The

powercordmustbeinsertedcompletely,otherwiseapoorcontactcouldcauseoverheatingleadingtoare.

1-2Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 7

1.Precautions

7)Takecareofthepowercable.Donotallowittobecometwisted,bentsharplyaroundcornersorpowercablemaybe

damaged.Donotplaceobjectsontopofthepowercable.Ifthepowercableisdamageditcouldoverheatandcausea

re.Exposedcablescouldcauseanelectricshock.Replacethedamagedpowercableimmediately,donotreuseor

repairthedamagedcable.Somechemicalscanattackthecoatingonthepowercable,weakeningthecoverorexposing

cablescausingreandshockrisks.

8)Ensurethatthepowersocketsandplugsarenotcrackedorbrokeninanyway.Anysuchdefectsshouldberepaired

immediately.T akecarenottocutordamagethepowercableorplugswhenmovingthemachine.

9)Usecautionduringthunderorlightningstorms.Samsungrecommendsthatthismachinebedisconnectedfromthe

powersourcewhensuchweatherconditionsareexpected.Donottouchthemachineorthepowercordifitisstill

connectedtothewallsocketintheseweatherconditions.

10)A voiddampordustyareas,installtheproductinacleanwellventilatedlocation.Donotpositionthemachineneara

humidierorinfrontofanairconditioner.Moistureanddustbuiltupinsidethemachinecanleadtooverheatingand

causeareorcausepartstorust.

11)Donotpositiontheproductindirectsunlight.Thiswillcausethetemperatureinsidetheproducttorisepossiblyleading

totheproductfailingtoworkproperlyandinextremeconditionscouldleadtoare.

12)Donotinsertanymetalobjectsintothemachinethroughtheventilatorfanorotherpartofthecasing,itcouldmake

contactwithahighvoltageconductorinsidethemachineandcauseanelectricshock.

13)WhenreplacingtheSMPSboard,pleasewait5minutesafterunpluggingthepowercord,thenreplaceit.Y ou

cangetashockbytheelectricdischarge.

Copyright©1995-2013SAMSUNG.Allrightsreserved.1-3

Page 8

1.Precautions

1.2.3.Handlingprecautions

Thefollowinginstructionsareforyourownpersonalsafetytoavoidinjuryandsoasnottodamagetheproduct.

1)Ensuretheproductisinstalledonalevelsurface,capableofsupportingitsweight.Failuretodosocouldcause

theproducttotiporfall.

2)Theproductcontainsmanyrollers,gearsandfans.Takegreatcaretoensurethatyoudonotcatchyourngers,hairor

clothinginanyoftheserotatingdevices.

3)Donotplaceanysmallmetalobjects,containersofwater,chemicalsorotherliquidsclosetotheproductwhichifspilled

couldgetintothemachineandcausedamageorashockorrehazard.

4)Donotinstallthemachineinareaswithhighdustormoisturelevels,besideonopenwindoworclosetoahumidieror

heater.Damagecouldbecausedtotheproductinsuchareas.

5)Donotplacecandles,burningcigarettes,etcontheproduct,Thesecouldcauseare.

6)Ensurethatthemachineisinstalledandusedinproperareatomeetthetemperatureandhumidityspecications.

•IfthemachineisstoredatbelowzeroCelsiusforalongtime,donotusethemachineinstantlyaftermovement.It

canmalfunction.Takecareofthemachinestorage.IfthemachineisstoredatbelowzeroCelsiusforalongtime,

keepthemachineatroomtemperatureandinstallit.

1.2.4.AssemblyandDisassemblyprecautions

1)ReplacepartscarefullyandalwaysuseSamsungparts.T akecaretonotetheexactlocationofpartsandalsocable

routingbeforedismantlinganypartofthemachine.Ensureallpartsandcablesarereplacedcorrectly.Pleasecarryout

thefollowingproceduresbeforedismantlingtheproductorreplacinganyparts.

2)Ensurethatpowerisdisconnectedbeforeservicingorreplacinganyelectricalparts.

3)Disconnectinterfacecablesandpowercables.

4)Onlyuseapprovedspareparts.Ensurethatpartnumber,productname,anyvoltage,currentortemperaturerating

arecorrect.

5)Whenremovingorre-ttinganypartsdonotuseexcessiveforce,especiallywhenttingscrewsintoplastic.

6)Takecarenottodropanysmallpartsintothemachine.

7)HandlingoftheOPCDrum

•TheOPCDrumcanbeirreparablydamagedifitexposedtolight.T akecarenottoexposetheOPCDrumeither

todirectsunlightortouorescentorincandescentroomlighting.Exposureforaslittleas5minutescandamage

thesurfaceofthephotoconductivepropertiesandwillresultinprintqualitydegradation.Takeextracarewhen

servicingtheproduct.RemovetheOPCDrumandstoreitinablackbagorotherlightproofcontainer.Take

carewhenworkingwiththeCovers(especiallythetopcover)openaslightisadmittedtotheOPCareaandcan

damagetheOPCDrum.

•TakecarenottoscratchthegreensurfaceofOPCDrumUnit.IfthegreensurfaceoftheDrumCartridgeis

scratchedortouchedtheprintqualitywillbecompromised.

1-4Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 9

1.2.5.Disregardingthiswarningmaycausebodilyinjury

1)Becarefulwiththehightemperaturepart.

Thefuserunitworksatahightemperature.Usecautionwhenworkingontheprinter.W aitforthefuserunitto

cooldownbeforedisassembly.

2)Donotputngersorhairintotherotatingparts.

Whenoperatingaprinter,donotputhandorhairintotherotatingparts(Paperfeedingentrance,motor,fan,etc.).

Ifdo,youcangetharm.

1.Precautions

3)Whenyoumovetheprinter,usesafeliftingandhandlingtechniques.

Thisprinterisheavy .Usetheliftinghandleslocatedoneachsideofthemachine.Backinjurycouldbecausedif

youdonotliftcarefully.

4)Ensuretheprinterisinstalledsafely.

Ensuretheprinterisinstalledonalevelsurface,capableofsupportingitsweight.Failuretodosocouldcausethe

printertotiporfallpossiblycausingpersonalinjuryordamagingtheprinter.

5)Donotinstalltheprinteronaslopingorunstablesurface.Afterinstallation,doublecheckthattheprinterisstable.

Copyright©1995-2013SAMSUNG.Allrightsreserved.1-5

Page 10

1.Precautions

1.3.CautionforDataLoss

TopreventlossofcustomersdatatheSVCengineerprovidesend-userwithrelevantinformationinadvance.

1-6Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 11

1.Precautions

1.4.ESDprecautions

Certainsemiconductordevicescanbeeasilydamagedbystaticelectricity.Suchcomponentsarecommonlycalled

“ElectrostaticallySensitive(ES)Devices”orESDs.ExamplesoftypicalESDsare:integratedcircuits,someeldeffect

transistors,andsemiconductor“chip”components.Thetechniquesoutlinedbelowshouldbefollowedtohelpreducethe

incidenceofcomponentdamagecausedbystaticelectricity.

CAUTION

Besurenopowerisappliedtothechassisorcircuit,andobserveallothersafetyprecautions.

1)Immediatelybeforehandlingasemiconductorcomponentorsemiconductor-equippedassembly,drainoffany

electrostaticchargeonyourbodybytouchingaknownearthground.Alternatively,employacommerciallyavailable

wriststrapdevice,whichshouldberemovedforyourpersonalsafetyreasonspriortoapplyingpowertotheunit

undertest.

2)AfterremovinganelectricalassemblyequippedwithESDs,placetheassemblyonaconductivesurface,suchas

aluminumorcopperfoil,orconductivefoam,topreventelectrostaticchargebuildupinthevicinityoftheassembly.

3)UseonlyagroundedtipsolderingirontosolderordesolderESDs.

4)Useonlyan“anti-static”solderremovaldevice.Somesolderremovaldevicesnotclassiedas“anti-static”can

generateelectricalchargessufcienttodamageESDs.

5)DonotuseFreon-propelledchemicals.Whensprayed,thesecangenerateelectricalchargessufcienttodamageESDs.

6)DonotremoveareplacementESDfromitsprotectivepackaginguntilimmediatelybeforeinstallingit.Most

replacementESDsarepackagedwithallleadsshortedtogetherbyconductivefoam,aluminumfoil,oracomparable

conductivematerial.

7)ImmediatelybeforeremovingtheprotectiveshortingmaterialfromtheleadsofareplacementESD,touchtheprotective

materialtothechassisorcircuitassemblyintowhichthedevicewillbeinstalled.

8)MaintaincontinuouselectricalcontactbetweentheESDandtheassemblyintowhichitwillbeinstalled,until

completelypluggedorsolderedintothecircuit.

9)MinimizebodilymotionswhenhandlingunpackagedreplacementESDs.Normalmotions,suchasthebrushingtogether

ofclothingfabricandliftingone’sfootfromacarpetedoor,cangeneratestaticelectricitysufcienttodamageanESD.

Copyright©1995-2013SAMSUNG.Allrightsreserved.1-7

Page 12

2.ProductSpecicationsandDescription

2.ProductSpecicationsandDescription

2.1.ProductSpecications

2.1.1.ProductOverview

1)PrintingSpeed

•XpressM262xSeries:Upto26ppminA4(27ppminLetter)

•XpressM282xSeries:Upto28ppminA4(29ppminLetter)

2)PrintingResolution

•Upto1,200x1,200dpieffectiveoutput

3)Processor

•600MHz

4)PrinterLanguageEmulation

•SPL/PCL5e/PCL6

5)Memory

•DDR3128MB

6)Interface

•Hi-SpeedUSB2.0,Ethernet10/100BaseTXInterface

7)ControlPanel

•NoLCD,4keysand2LEDs

8)Tonercartridge

•Initial

-XpressM2620,M2820Series:1,500pages

-XpressM2625,M2825Series:1,200pages

•Standard/HighYield

XpressM2620,M2820Series:3,000pages

XpressM2x25Series:1,200pages/3,000pages

2-1Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 13

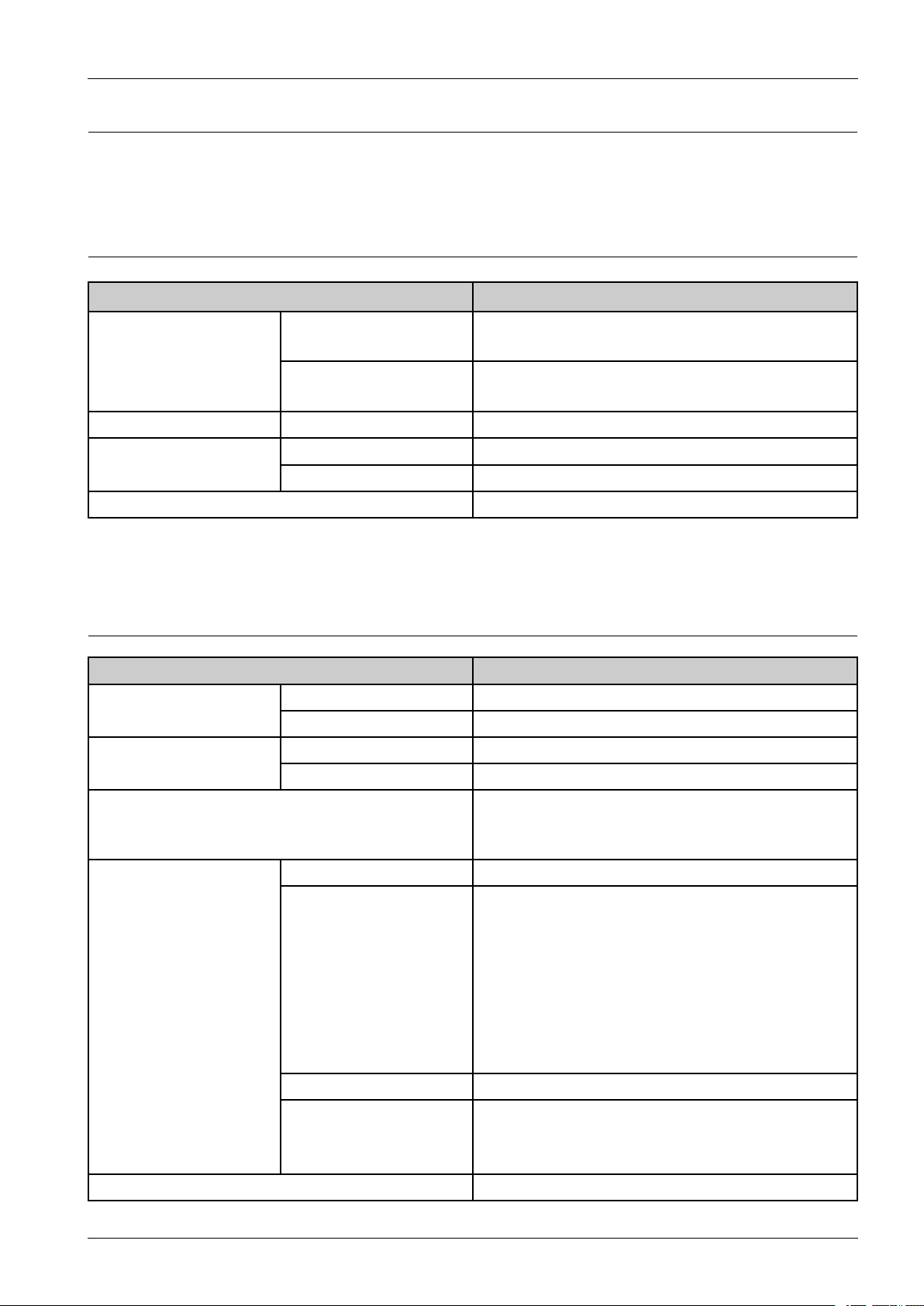

2.1.2.Specications

•ProductSpecicationsaresubjecttochangewithoutnotice.

2.1.2.1.GeneralPrintEngine

ItemSpecication

2.ProductSpecicationsandDescription

EngineSpeed

WarmuptimeFromSleepLessthan14seconds

FPOT

(1)‘D’Modelonly.

2.1.2.2.ControllerandSoftware

Processor

Memory

Simplex

Duplex(1)

FromReadyLessthan8.5seconds

FromSleepLessthan14seconds

ResolutionUpto1,200x1,200dpieffectiveoutput

ItemSpecication

CPU600MHz(Cortex-A5)

ImageProcessorReCP(RenderingEngineforCleanPage)

XpressM262xSeries:Upto26ppminA4(27ppminLetter)

XpressM282xSeries:Upto28ppminA4(29ppminLetter)

XpressM262xSeries:Upto13ppminA4(14ppminLetter)

XpressM282xSeries:Upto14ppminA4(15ppminLetter)

DDR3128MB

Notsupport

XpressM262x,M262xD:SPL

PrinterLanguage

WindowXP/2003Server/Vista/2008server/7/2008ServerR2/8

Linux

ClientOSSupport

MacOSX10.5~10.8

UNIX(1)

FontsPCL:95ScalableFonts(IncludeOCR-A/OCR-B)/1Bitmap

Copyright©1995-2013SAMSUNG.Allrightsreserved.2-2

XpressM262xND,M282xND/DWSeries:SPL/PCL5e/

PCL6

RedHatEnterpriseLinuxWS4,5,6(32/64bit)

Fedora5,6,7,8,9,10,11,12,13,14,15(32/64bit)

OpenSuSE10.2,10.3,11.0,11.1,11.2,11.3,11.4(32/64bit)

Mandriva2007,2008,2009,2009.1,2010(32/64bit)

Ubuntu6.06,6.10,7.04,7.10,8.04,8.10,9.04,9.10,10.04,

10.10,11.04(32/64bit)

SuSELinuxEnterpriseDesktop10,11(32/64bit)

Debian4.0,5.0,6.0(32/64bit)

SunSolaris9,10,11(x86,SP ARC)

HP-UX11.0,11iv1,11iv2,11iv3(P A-RISC,Itanium

IBMAIX5.1,5.2,5.3,5.4,6.1,.7.1(PowerPC)

Page 14

2.ProductSpecicationsandDescription

ItemSpecication

USBHighspeedUSB2.0

Interface

NetworkProtocol(2)

(1)XpressM282xModelonly

(2)Networksupportmodelonly

–XpressM2620ND,M282xND/DWSeries

(3)Wirelesssupportmodelonly

-XpressM282xDWSeries

USBHost(DirectUSB)Notsupport

WiredLAN(2)Ethernet10/100BaseTx

WirelessLAN(3)Wireless802.11b/g/n

TCP/IP

TCP/IPv4/v6/HTTP/SNMPv1/v2c/v3/SMTP/DNS/

WINS/DDNS/DHCP/BOOTP/AutoIP/StandardTCP/IP

Printing/LPR/WSDPrint/IPP/UPnP(SSDP)/Bonjour/

WSDDiscovery/SLP/SetIP/GoogleCloudPrint/WSD

Scan

Others

–IPPs/IPSec

2-3Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 15

2.1.2.3.PaperHandling

ItemSpecication

InputCapacityStandard250–sheetCassetteTray/1–sheetManualFeeder

2.ProductSpecicationsandDescription

PrintingSize

Standard

CassetteTray

ManualFeeder

OutputCapacity

Max.216x356mm(8.5"x14")*

Min.76x127mm(3"x5")*

Capacity250–sheet

MediaSizeA4,A5,A6,Letter,Legal,Executive,Folio,Ocio,ISOB5,JISB5

MediaTypesPlain,Thin,Thick,Cardstock,Recycled,Archive,Bond

MediaWeight60~163g/(16~43lb)*

Sensing

Capacity1–sheet

MediaSize

MediaTypes

MediaWeight60~220g/(16~58lb)*

SensingYes

FaceDown:150–sheet

Faceup:1–sheet

H/WInstallDetect:NoPaperEmpty:Y esPaperTypeDetect:NoPaperSize

Detect:No

A4,A5,A6,Letter,Legal,Executive,Folio,Ocio,ISOB5,JISB5,Envelope

(Monarch/No-10/DL/C5/C6),Custom76x127mm~216x356mm(3"x5"

~8.5"x14")

Plain,Thin,Thick,Thicker,Cardstock,Transparency ,Pre-Printed,Recycled,

Archive,Bond,Label,Envelope,ThickEnvelope,Cotton,Colored

2.1.2.4.Consumables

[SeparatedT onerSystem]

ModelItemAverageYield(1)PartCode

XpressM2625series

XpressM2825series

ImagingUnit9,000PagesML T -R116

[IntegratedT onerSystem]

ModelItemAverageYield(1)PartCode

XpressM2620series

XpressM2820series

(1)DeclaredyieldvalueinaccordancewithISO/IEC19752.

LaserTonerCartridge

InitialToner1,200Pages-

StandardT oner1,200PagesMLT -D116S TonerCartridge

HighYieldToner3,000PagesMLT-D116L

InitialToner1,500Pages-

StandardT oner--

HighYieldToner3,000PagesMLT-D115L

Copyright©1995-2013SAMSUNG.Allrightsreserved.2-4

Page 16

2.ProductSpecicationsandDescription

2.1.2.5.ReliabilityandService

2.1.2.6.Environment

ItemSpecication

Max.MonthlyDuty12,000pages

MPBF30,000pages

MTTRLessthan30min

ItemSpecication

PrintingSimplexLessthan50dBA

StandbyLessthan26dBA AcousticNoiseLevel

SleepLessthan26dBA

ReadyLessthan45W

NormaloperationLessthan400W

PowerConsumption

Certication

Dimension

(WxDxH)

Weight

Max/PeakLessthan450W

SleepLessthan0.9W

PowerOffLessthan0.2W

TECLessthan1.1kWh/week

TelecommunicationTBR-21,KC,Part68,ICCS03,NTC

SafetycUL,CB,KC,TUV -GS,PSB

EMC/EMIFCCPart15ClassB,ICES003,CE(EN),KCC

DocumentNo

SecurityNo

OthersNo

SET368x334.5x202mm(14.5"x13.2"x8.0")*

SETPacking452x418x330mm(17.8"x16.5"x13")*

Net(SETwithout

Consumables)

Net(SETwith

Consumables)

Gross(SETwith

Packing)

6.3kg(13.8lbs)

7.2kg(16.0lbs)

9.1kg(20.1lbs)

Consumable(without

Packing)

2-5Copyright©1995-2013SAMSUNG.Allrightsreserved.

TonerCatridge

ImagingUnit0.38kg(0.84lbs)

1.2K:0.50kg(1.10lbs)

3.0K:0.54kg(1.19lbs)

Page 17

2.ProductSpecicationsandDescription

2.1.2.7.Options

ItemSpecication

MemoryN/A

SecondCassetteN/A

HardDiskN/A

2.1.2.8.Maintenanceparts

ItemImagePartCodeLife

•220V

Fuser

•JC91–01034B

•110V

•JC91–01034A

100,000pages

TransferRollerJC66-01218A100,000pages

Pick-Up/Feed/

ForwardRollerAssy

RetardRollerJC90–01107B50,000pages

JC93–00405A50,000pages

Copyright©1995-2013SAMSUNG.Allrightsreserved.2-6

Page 18

2.ProductSpecicationsandDescription

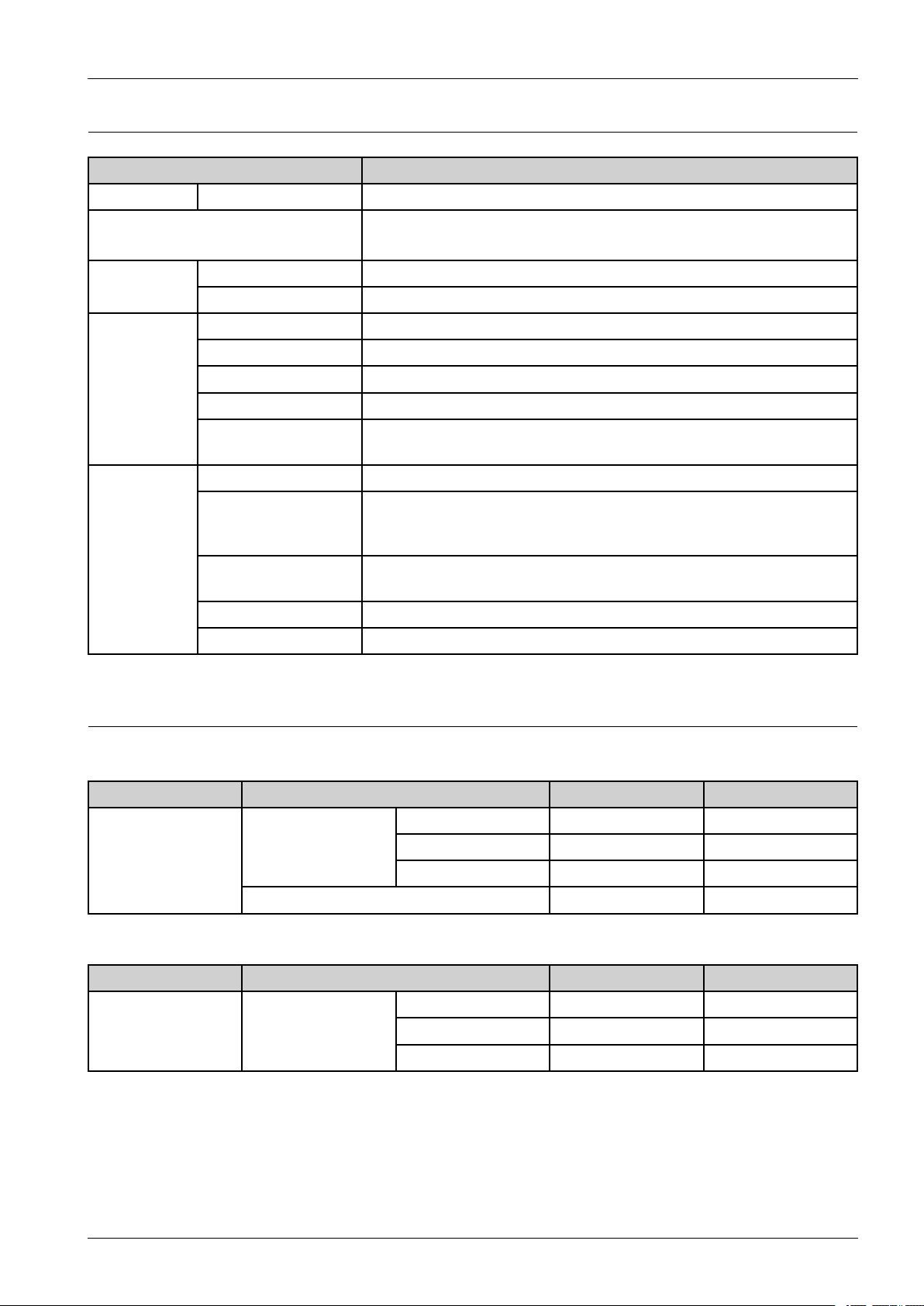

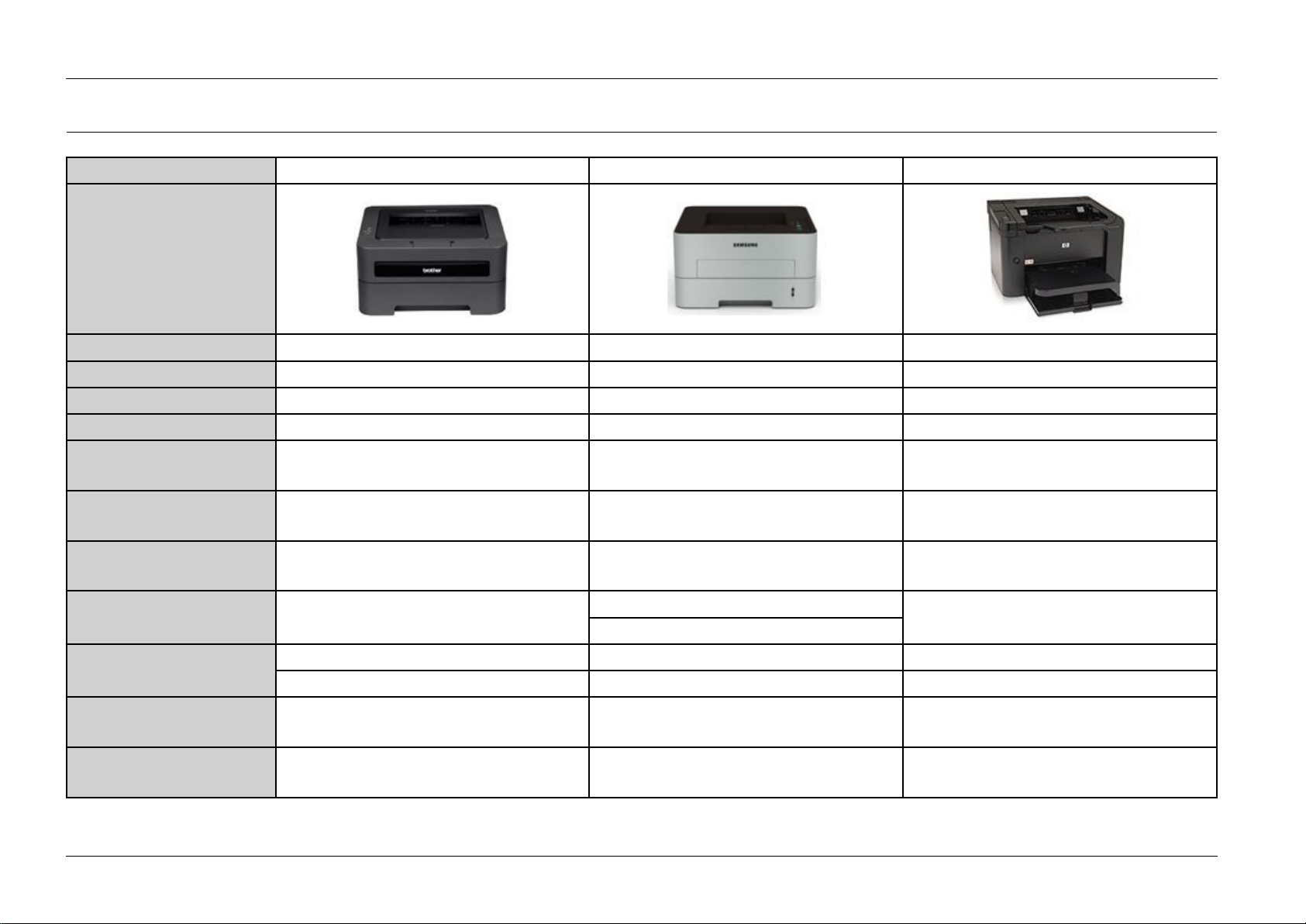

2.1.3.ModelComparisonTable

BrotherHL-2250DN(HL-2270DW)SamsungSL-M2825(0)ND(M2825DW)HPHPP1606dn

ProductImage

PrintingSpeed26/27ppmBlack(A4/Letter)28/29ppmBlack(A4/Letter)25/26ppmBlack(A4/Letter)

FirstTimetoPrintLessthan8.5sec.Lessthan8.5sec.Asfastas7sec(fromAuto-Off)

Memory(MB)32MBMemory128MBMemory32MB

CPU(Processor)Speed200MHz600MHz400MHz

PowerConsumption

(Sleep/Ready/Printing)

Noise

(Ready/Printing)

ProductSize

(WxDxH)

ProductWeight

(kg,lbs)

InitialConsumablesLifetime

SeparatedT ypeToner

(Standard/High)

UnitedTypeToner

(Standard/High)

2-7Copyright©1995-2013SAMSUNG.Allrightsreserved.

0.9W(SleepWLANOn:2.8W)/65W/495W1.2W/45W/400W

31dB/53dB26dB/50dBINA/53dB

368x360x183mm(14.5"x14.2"x7.2")368x334.5x201mm

7.17Kg(15.8lbs.):All-in-One

6.8Kg(15.4lbs.)

7.39Kg(16.3lbs.):Separate

TonerCartridge:700pagesTonerCartridge:1000pages

DrumUnit:12,000pagesDrumUnit:9,000pages

1.2K/2.6K1.0K/2.5K2.1K

1.5K/3.0K

0.4W(Manual-off),1.6W(Auto-off)/2.2W/

440W

378x284x246mm(15.24"x11.18"x9.69")

(Max.387x420x255mm)

7.0Kg(15.4lbs.)

Page 19

2.ProductSpecicationsandDescription

2.2.SystemOverview

Thischapterdescribesthefunctionsandoperatingprincipalofthemaincomponent.

2.2.1.FrontView

NOTE

•Thisillustrationmaydifferfromyourmachinedependingonitsmodel.

•Somefeaturesandoptionalgoodsmaynotbeavailabledependingonmodelorcountry.

1OutputTray

2ControlPanel

3FrontCover

4PaperLevelIndicator

5Tray1

6ManualFeeder

(1)XpressM2620,M2820Series

(2)XpressM2625,M2825Series

7PaperWidthGuides

8PaperWidthGuidesonaManualFeeder

9LaserT onerCartridge(1)

10TonerCartridge(2)

11ImagingUnit(2)

Copyright©1995-2013SAMSUNG.Allrightsreserved.2-8

Page 20

2.ProductSpecicationsandDescription

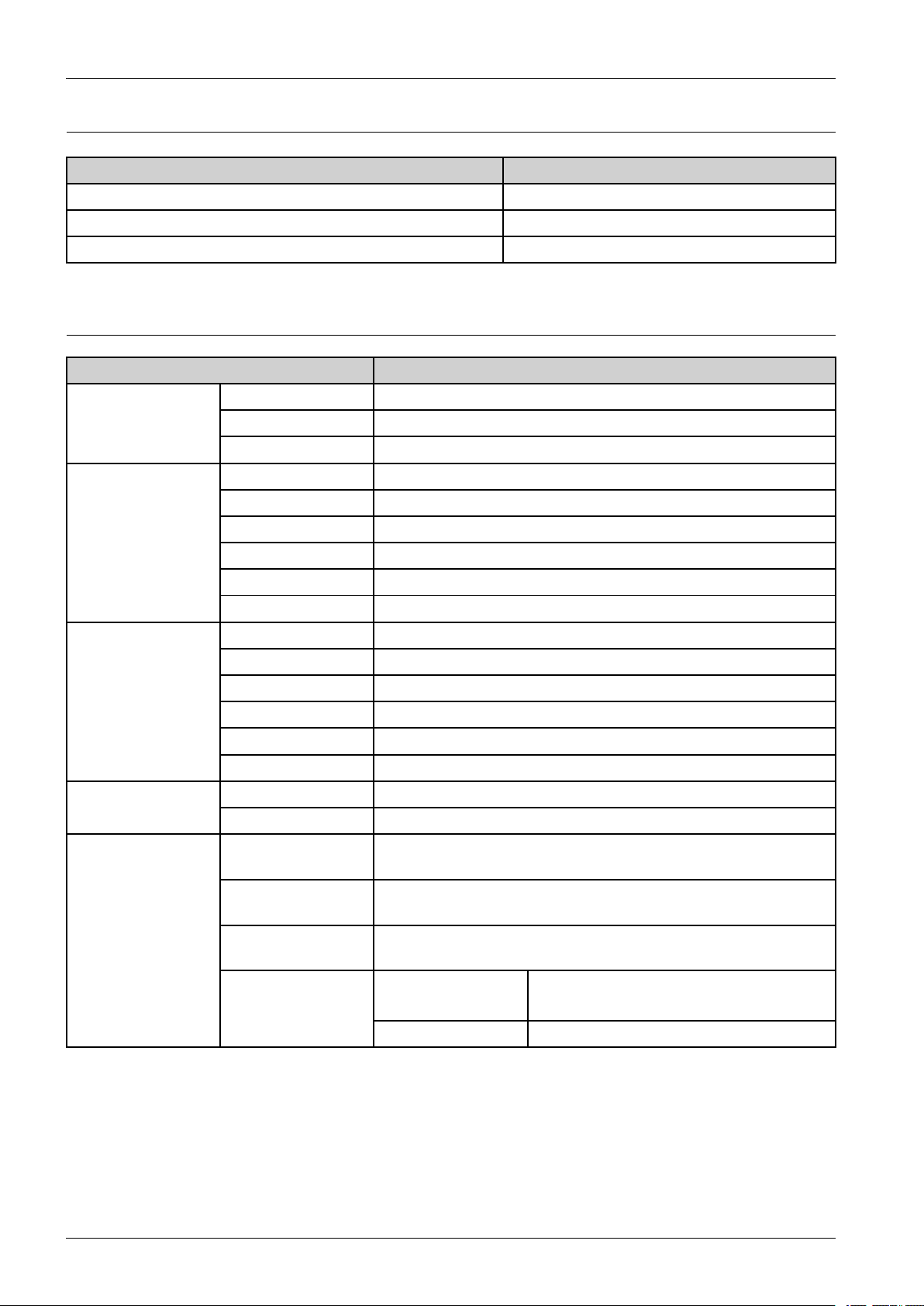

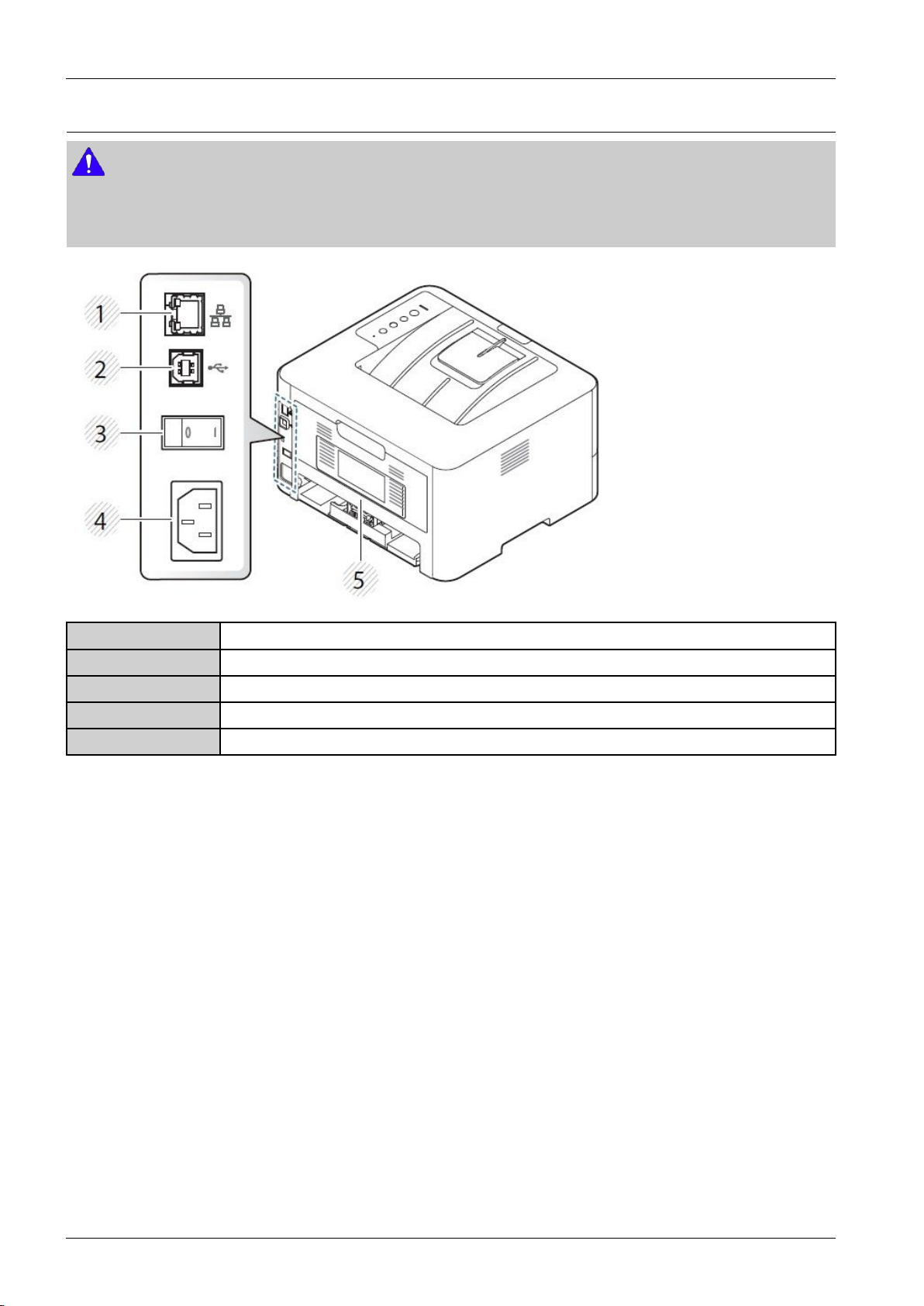

2.2.2.RearView

NOTE

•Thisillustrationmaydifferfromyourmachinedependingonitsmodel.

•Somefeaturesandoptionalgoodsmaynotbeavailabledependingonmodelorcountry.

1NetworkPort(1)

2USBPort

3PowerSwitch(2)

4PowerReceptacle

5RearCover

(1)Networkandwirelessmodelsonly

(2)PowerSwitchsupportmodelsonly.

2-9Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 21

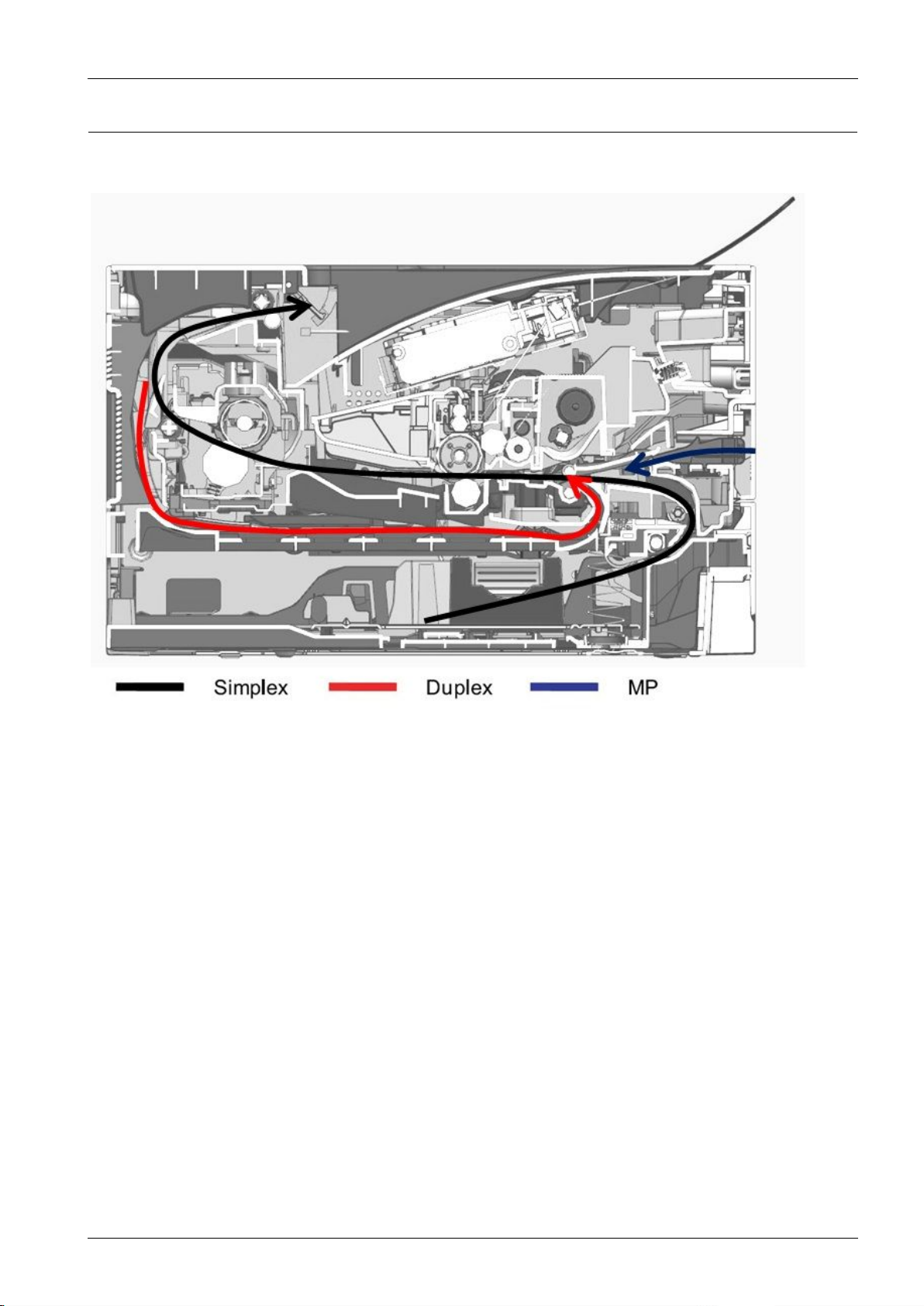

2.2.3.PaperPath

Thefollowingdiagramdisplaysthepaththepaperfollowsduringtheprintingprocess.

2.ProductSpecicationsandDescription

Copyright©1995-2013SAMSUNG.Allrightsreserved.2-10

Page 22

2.ProductSpecicationsandDescription

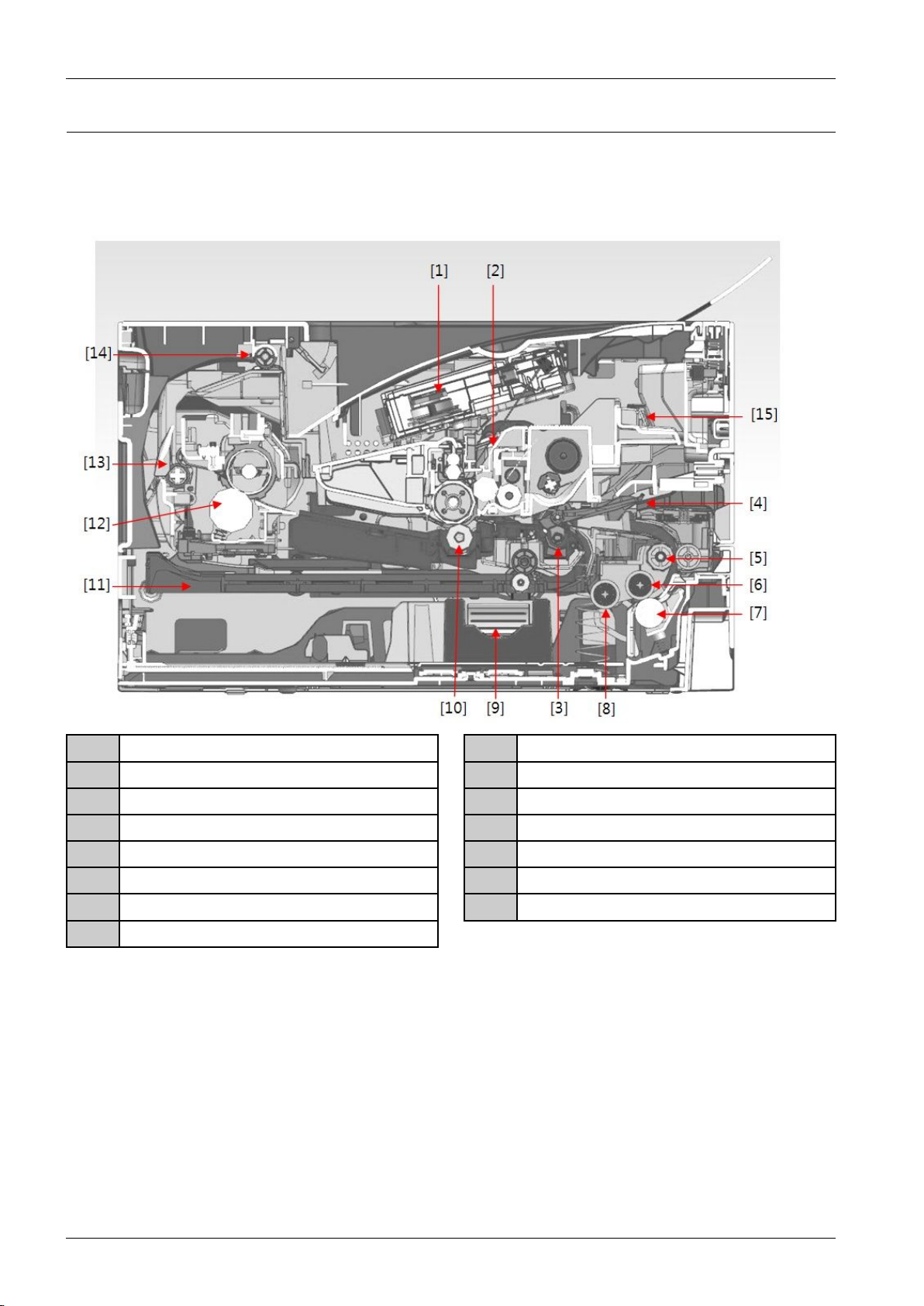

2.2.4.SystemLayout

ThismodelconsistsoftheEngineparts,HardwareandFirmware.Theenginepartsconsistsofthemechanicalparts

comprisingFrame,Duplex,Tonercartridge,Driveunit,Transferroller,Fuser,Cassette.TheHardwarepartconsistsofthe

maincontrolboard,powerboard,operationpanel,PCInterface.

1LSU

2TonerCartridge

3Regi.Roller

4MP

5FeedRoller

6ForwardRoller

7RetardRoller

8Pick-upRoller

(1)DuplexModelonly(XpressM2x2xD/ND/DW)

(2)TonerCartridgeSaperateModelonly(XpressM2x25/M2x26)

9Cassette

10TransferRoller

11DuplexUnit(1)

12FuserUnit

13ExitRoller1

14ExitRoller2

15TonerCartridgePressureUnit(2)

2-11Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 23

2.ProductSpecicationsandDescription

2.2.4.1.FeedingPart

Itconsistsofacassette,anMPtrayforsupplyingdifferenttypesofmedia(envelope,label,specialpaper)andparts

relatedtopapertransferring.

1)Cassette

Thecassettestoresthepaper(Capacity:250sheets(80g/paperstandard).Boththesideguideandtherearguidecanbe

adjustedforvarioustypesofpapersfromA6tolegalsizepaper.Ithasapaperexistencesensingfunction,paperarranging

function,varioussizepapersacceptingfunction.

2)Pick-Up/Forward/Retardroller

Whenpickuptakesplace,thepickuprollermovesdowntocomeintocontactwiththesurfaceofthepaper .Thepickuproller

movesdownwhenthepickupclutchisactivated.Theforwardrollerandtheretardrollerservetomakesurethatasingle

sheetofpaperismovedtothepaperpath,andthepaperismovedasfarastheregistrationrollerbytheworkofthefeedroller.

(A)Pick-upRoller

(B)RetardRoller

(C)ForwardRoller

Copyright©1995-2013SAMSUNG.Allrightsreserved.2-12

Page 24

2.ProductSpecicationsandDescription

3)Registrationroller

Itisusedasanantiskewdevice,andtosetupproperregistrationtimingwiththatofthetonedimageonthedrum.Italsois

usedforjamdetectiontoensurepaperhasleftthepapertray.

4)ManualFeeder

Themulti-purposetraycanholdspecialsizesandtypesofprintmaterial,suchaspostcards,notecards,andenvelopes.

2.2.4.2.TransferRoller

ThetransferrollerdeliversthetoneroftheOPCdrumtothepaper.

•LifeSpan:Printover100,000sheets(in15~30℃)

2.2.4.3.DriveUnit

Inthismodel,thedrivingdeviceconsistsofBLDCmotor,Regi./Pickupclutches,variousgearsforOPC,Fuser,Pickup,Feed,Regi,Exit.

2-13Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 25

2.ProductSpecicationsandDescription

2.2.4.4.Fuser

ThisunitconsistsofHeatRoller,aThermostat,andThermistors,etc.Itfusesthetonerthatwastransferredbythetransfer

rollerontothepaper,byapplyingpressureandhightemperaturetocompletefusingprocess.

1)Thermostat

Whenaheatlampisoverheated,aThermostatcutsoffthemainpowertopreventover-heating.

•ThermostatType:Non-ContacttypeThermostat

•ControlTemperature:195℃±5℃

2)Thermistor

Itisatemperaturedetectingsensor .

•TemperatureResistance:7(180℃)

3)Heatroller

Theheatrollertransferstheheatfromthelamptoapplyaheatonthepaper.

ThesurfaceofaheatrolleriscoatedwithTeon,sotonerdoesnotsticktothesurface.

4)Pressureroller

Apressurerollermountedunderaheatrollerismadeofasiliconresin,andthesurfacealsoiscoatedwithTeon.Whena

paperpassesbetweenaheatrollerandapressureroller,toneradherestothesurfaceofapaperandispermanentlyfused.

5)HalogenLamp

•V oltage:120V(115±5%)/220V:230±5%

•Capacity:850W att±42.5W

6)Itemsforsafety

Protectingdeviceforoverheating

•1stprotectiondevice:Hardwarecutsoffwhenoverheated

•2ndprotectiondevice:Softwarecutsoffwhenoverheated

•3rdprotectiondevice:Thermostatcutsoffmainpower.

Safetydevice

•Afuserpoweriscutoffwhenafrontcoverisopened

•Maintainatemperatureoffusercover’ssurfaceunder80℃foruser,andattachacautionlabelatwherecustomer

canseeeasilywhencustomeropenarearcover.

Copyright©1995-2013SAMSUNG.Allrightsreserved.2-14

Page 26

2.ProductSpecicationsandDescription

2.2.4.5.LSU(LaserScannerUnit)

ItisthecorepartoftheLBPwhichswitchesfromthevideodatareceivedtothecontrollertotheelectrostaticlatentimage

ontheOPCdrumbycontrollinglaserbeam,exposingOPCdrum,andturningprincipleofpolygonmirror.TheOPCdrumis

turnedwiththepaperfeedingspeed.TheHSYNCsignaliscreatedwhenthelaserbeamfromLSUreachestheendofthe

polygonmirror,andthesignalissenttothecontroller.ThecontrollerdetectstheHSYNCsignaltoadjusttheverticallineof

theimageonpaper.Inotherwords,aftertheHSYNCsignalisdetected,theimagedataissenttotheLSUtoadjusttheleft

marginonpaper.Theonesideofthepolygonmirrorisonelineforscanning.

2-15Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 27

2.ProductSpecicationsandDescription

2.2.4.6.TonerSystem

Byusingtheelectronicphotoprocess,itcreatesavisualimage.Inthetonercartridge,theOPCunitandthedeveloping

unitareinabody.TheOPCunithasOPCdrumandchargingroller,andthedevelopingunithastoner,supplyroller,

developingroller,andblade.

•DevelopingMethod:Nonmagnetic1elementcontactingmethod

•Toner:Nonmagnetic1elementshattertypetoner

•OPCCleaning:Collectthetonerbyusingcleaningblade

•Handlingofwastedtoner:Collectthewastedtonerinthecleaningframebyusingcleaningblade

•Classifyingdevicefortonercartridge:IDisclassiedbyCRUM.

[IntegratedTonerSystem]

ImageLayout

[SeparatedTonerSystem]

ImageLayout

Copyright©1995-2013SAMSUNG.Allrightsreserved.2-16

Page 28

2.ProductSpecicationsandDescription

2.2.5.Hardwareconguration

TheML-295xseriesElectricalCircuitSystemconsistsofthefollowing:

•Mainboard(Systemboard)

•OPEboard

•SMPSboard

•HVPSboard

DiagramoftheML-295xseriesElectricalCircuit

ML-295xserieshasasystemboardofintegratedenginecontrollerandvideocontroller.

Theenginecontrollercontrolsallmodulesrequiredtoprint,thatis,LSU,HVPS,SMPS,FAN,Fuser,etc.

ItcommunicateswiththevideocontrolblockinsideCPUforprinting.Andithastheinterfaceforallvideosyncsignal

toprintoutthevideodata.

ThevideocontrollerreceivesprintdatafromthehostthroughnetworkorUSBPort.Ittakesthisinformationandgenerates

printablevideobitmapdata.

Themainboardadoptsthe600MHzCPU,onboardDDR3memory(128MB)toperformprintingjobssuccessfully.

2-17Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 29

2.ProductSpecicationsandDescription

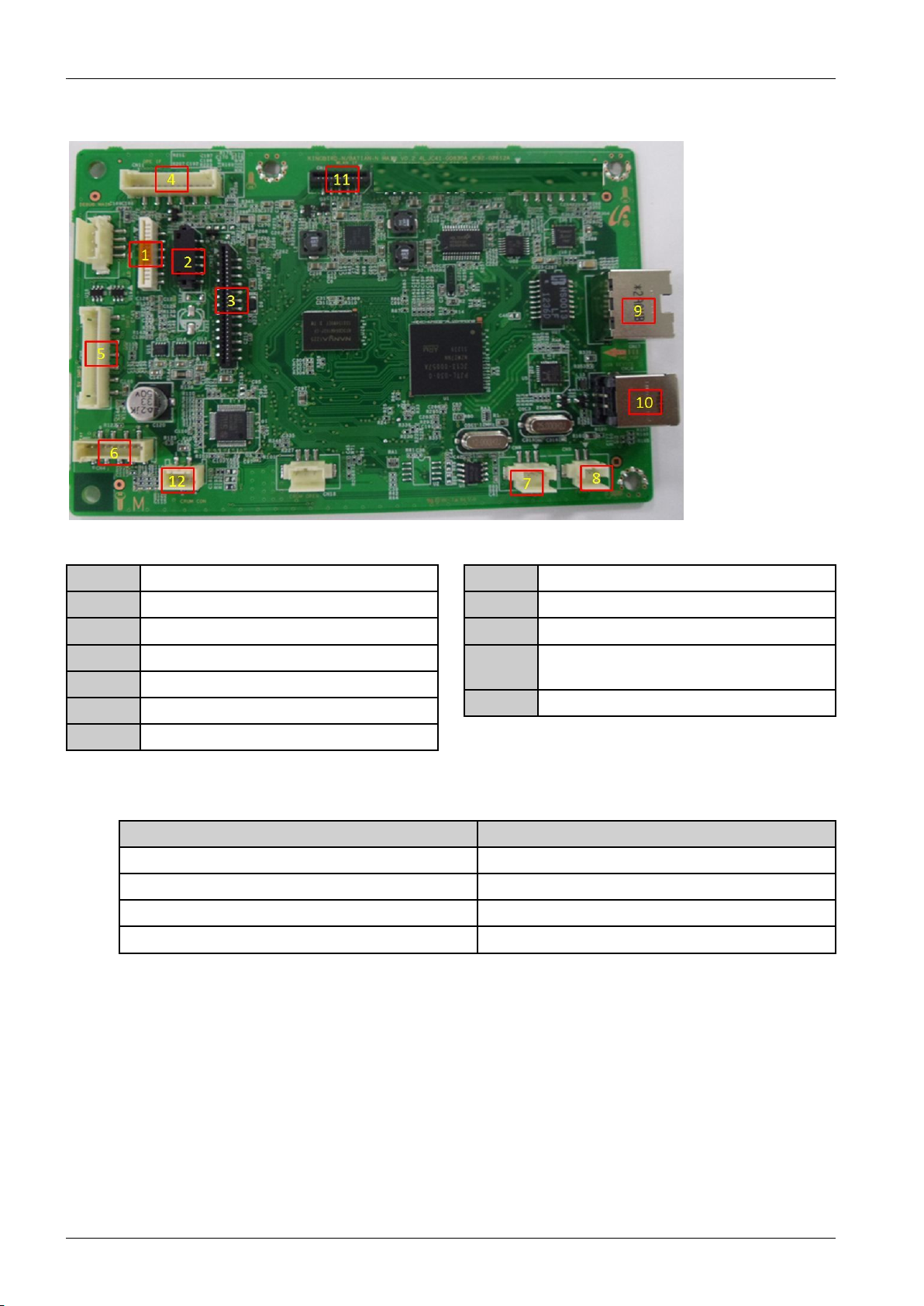

2.2.5.1.Mainboard

A1500chipisadoptedasthemainprocessor.Itsprocessspeedis600MHz.Itisintegratedenginecontrollerandvideo

controller.

DDR3128MBisadoptedforhighspeeddataprocessing.Boothas8MBSPI.

USBistheembeddedtypeandwirednetworksupports100Mfullduplex.

[Mainboarddiagram]

Copyright©1995-2013SAMSUNG.Allrightsreserved.2-18

Page 30

2.ProductSpecicationsandDescription

[Mainboardimage]

•Connection

1LSUVideoconnector

2LSUMotorconnector

3HVPSinterfaceconnector

4OPEconnector

5SMPSinterfaceconnector

6MainBLDCMotorconnector

7PaperExitsensorconnector

•Information

-PartCode:

-PBAname:PBA-MAIN

8Fuserthermistorinterfaceconnector

9Wirednetworkconnector

10USBdeviceconnector

11Wirelessmoduleinterfaceconnector(Wireless

modelonly)

12Cruminterfaceconnector(DependonModel)

ModelPartCode

XpressM262xJC92-02616B

XpressM262xNDJC92-02615B

XpressM282xNDJC92-02615D

XpressM282xDWJC92-02615F

2-19Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 31

2.ProductSpecicationsandDescription

2.2.5.2.OPEboard

TheOPEControlleriscomposedofanOPEMICOM(STM8SP103K3MAFTR),SatusLED,ModeLED,PowerLED,WPS

LED(ML-2955DWmodelonly).OPEcommunicateswithmaincontrollerviaUART .ThepowerLEDiscontrolled

bythemainboard.

[OPEboarddiagram]

[OPEboardimage]

•Information

-PartCode:JC92–02609A

-PBAname:PBAOPE

•Connection

1MAINPBAI/FHARNESS(JC39-01990A)

Copyright©1995-2013SAMSUNG.Allrightsreserved.2-20

Page 32

2.ProductSpecicationsandDescription

2.2.5.3.WirelessLANboard

TheWirelessLANModulesupports802.11b/g/n.ItcommunicateswithvideocontrollerviaSPI.(1)

[WLANboardimage]

•Information

-PartCode:JC92–02517A

-PBAname:PBA-WNPC

•Connection

1INTERF ACECONNECTORTOSYSTEMBOARD

(JC39-01984A,FFCCABLE-WLAN)

(1)Wirelesssupportmodelsonly.

–XpressM282xDW

2-21Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 33

2.2.5.4.JointPBA

TheJointPBAistheinterfaceconnectionboardforRegi.clutch,Pick-upclutch,Fan.

[JointPBAimage]

•Information

-PartCode:JC92–02406A

-PBAname:JOINTPBA

2.ProductSpecicationsandDescription

•Connection

1Regi.Clutch

2Pick-UpClutch

3HVPSI/F

4Fan

Copyright©1995-2013SAMSUNG.Allrightsreserved.2-22

Page 34

2.ProductSpecicationsandDescription

2.2.5.5.ElectricalPartsLocation

1)Sensors

Ref.DescriptionControllerFunction

S1Photointerrupter(Paperemptysensor)Paperemptysensor

S2Photointerrupter(exitSensor)Paperdetection

S3Photointerrupter(Binfullsensor)BINFULLdetection

S4Photointerrupter(Regisensor)Paperdetection

S5Photointerrupter(feedSensor)Paperdetection

S6SwitchFrontCover

MainBoard

Coveropendetection

2-23Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 35

2)Motor,Clutch

2.ProductSpecicationsandDescription

RefDescription

1Mainmotor

2Pickupclutch

3Registrationclutch

Copyright©1995-2013SAMSUNG.Allrightsreserved.2-24

Page 36

2.ProductSpecicationsandDescription

3)Board

RefDescriptionFunction

1HVPSHighV oltageGeneration

2SMPSConstantV oltageGeneration

3MainBoardMainController

4CrumBoard(1)TonerCartridgeCheck

5OPEBoardTonerstatusdisplay/MachineOperationforpower,cancel.

6WLANBoard(2)Wi-Fi

(1)TonerCartridgeSeparateModelonly(XpressM2x25/M2x26)

(2)Wi-FiReadyModelonly(XpressM2x2xDW)

2-25Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 37

2.ProductSpecicationsandDescription

2.2.5.6.SMPSBoard

TheSMPS(SwitchingModePowerSupply)BoardsupplieselectricpowertotheMainBoardandotherboardsthrougha

MainController.Thevoltageprovidedincludes+5V ,and+24Vfroma110V/220Vpowerinput.

[SMPSboardimage]

•Specication

GeneralInput/OutputVoltage

-AC110V(90V~135V)

-AC220V(180V~270V)

-InputCurrent:10.0A(110V)/8.0A(220V)

-OutputPower:58W

▪DC5V:10W

▪DC24V:48W

•Information

110V220V

PartCodeJC44–00206AJC44–00207A

PBAnameSMPSV1SMPSV2

•Connection

1AC_Inlet

2INPUT_ACSwitch

3FUSER_ACOutput

4OUTPUT_DC

Copyright©1995-2013SAMSUNG.Allrightsreserved.2-26

Page 38

2.ProductSpecicationsandDescription

•Input/Outputconnector

ACInputConnector(CON2)

PinAssignPinNoDescription

1AC_L

2AC_N

ACInputConnector(CON4)

PinAssignPinNoDescription

1AC_N

2AC_N

DCOutputConnector(CON3)

PinAssignPinNoDescriptionPinAssignPinNoDescription

1GNDGround85V+5VPower

2GNDGround95V+5VPower

3GNDGround10GNDGround

424V+24VPower1124V_OFFSleepmode

524V+24VPower12RELAYONFuserRelay

624V+24VPower1324V_FPhotoTriacBias

7GNDGround14FuseronFuserOn

ACOutputforHeaterController

ACInputSwitch

2-27Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 39

2.ProductSpecicationsandDescription

2.2.5.7.HVPSBoard

Thisboardgenerateshigh-voltagechannelswhichincludesMHV ,DEV ,BLADE,SUPPL Y ,THV .

[HVPSboardimage]

•Information

-PartCode:JC44–00205A

-PBAname:HVPS

•Connection

1Charger

2DEV

3SUP

4Blade

5THV

6HVPSI/F

7ClutchI/F

8OutbinFullI/F

9CrumI/F

10F ANSMPSI/F

11Regi,FeedsensorI/F

12EmptysensorI/F

Copyright©1995-2013SAMSUNG.Allrightsreserved.2-28

Page 40

2.ProductSpecicationsandDescription

2.2.6.EngineF/WControlAlgorithm

2.2.6.1.Feeding

Iffeedingfromacassette,thedriveofthepickuprolleriscontrolledbycontrollingthesolenoid.Theon/offofthe

solenoidiscontrolledbycontrollingthegeneraloutputportortheexternaloutputport.Whilepapermoves,occurrence

ofJamisjudgedasbelow.

ItemDescription

JAM0•Afterpickingup,papercannotbeenteredbecausetopaperisnotfed.

•Afterpickingup,paperenteredbutitcannotreachtothefeedsensorinpredeterminedperiodof

time.duetoslip,etc.

•Afterpickingup,ifthefeedsensorisnoton,re-pickup.Afterre-pickingup,ifthefeedsensoris

notonaftercertaintime,itisJAM0.

•Eventhoughthepaperreachestothefeedsensor,thefeedsensordoesn’tbeON.

JAM1•Aftertheleadingedgeofthepaperpassesthefeedsensor,thetrailingedgeofthepapercannotpass

thefeedsensorafterpredeterminedperiodoftime.

•Aftertheleadingedgeofthepaperpassesthefeedsensor,thepapercannotreachtheexitsensor

afterpredeterminedperiodoftime.

*Thepaperexistsbetweenthefeedsensorandtheexitsensor.

JAM2Afterthetrailingedgeofthepaperpassesthefeedsensor,thepapercannotpasstheexitsensorpredetermined

periodoftime.

2.2.6.2.Transfer

Thechargingvoltage,developingvoltageandthetransfervoltagearecontrolledbyPWM(PulseWidthModulation).The

eachoutputvoltageischangeableduetothePWMduty.Thetransfervoltageadmittedwhenthepaperpassesthetransfer

rollerisdecidedbyenvironmentconditions.Theresistancevalueofthetransferrollerischangedduetothesurrounding

environmentortheenvironmentoftheset,andthevoltagevalue,whichchangesduetotheenvironments,ischanged

throughADconverter.Thevoltagevalueforimpressingtothetransferrollerisdecidedbythechangedvalue.

2-29Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 41

2.ProductSpecicationsandDescription

2.2.6.3.Fusing

Thetemperaturechangeoftheheatroller’ssurfaceischangedtotheresistancevaluethroughtheuseofathermistor.

TheMainBoardusestheresistancevalueoftheThermistorandconvertsittoavoltagevaluethroughtheuseofanAD

converter,thetemperatureisdecidedbasedonthevoltagevalueread.TheACpoweriscontrolledbycomparingthetarget

temperaturetothevaluefromthethermistor.Ifthevaluefromthethermistorisoutofcontrollingrangewhilecontrollingthe

fusing,theerrorstatedinthebelowtableoccurs.

•OpenHeatError

Whentheengineoperatesthewarm-upprocess,ifthetemperatureofthexingunitisnothigherthanaspecied

temperature,theenginedenesOpenHeatError.Whenthiserrorisdetected,theenginestopsallfunctionsandkeeps

theerrorstate.Also,theengineinformstheerrorstatusofthemainsystem,soitcantakeappropriateaction;andthen

theerrormessageisdisplayedatLCDwindoworLEDinformingtheerrorstatusoftheuser.

•LowHeatError

Whentheengineisatstand-by,printingorwarm-upmode,ifthetemperatureofthexingunitislowerthanthe

speciedtemperatureateachstateandthelowertemperaturestateismaintainedduringthespeciedtime,theengine

denesLowHeatError.Whenthiserrorisdetected,theenginestopsallfunctionsandkeepsitattheerrorstate.Also,

theengineinformstheerrorstatusofthemainsystem,soitcantakeappropriateaction;andthentheerrormessage

isdisplayedatLCDwindoworLEDinformingtheerrorstatusoftheuser.

•OverHeatError

Foroverallenginestate,ifthetemperatureofthexingunitishigherthanthespeciedtemperatureandthetemperature

stateisdetectedforaspecicduration,thentheenginedenesOverHeatError.Whenthiserrorisdetected,theengine

stopsallfunctionsandkeepsitattheerrorstate.Also,theengineinformstheerrorstatusofthemainsystem,soit

cantakeappropriateaction;andthentheerrormessageisdisplayedatLCDwindoworLEDinformingtheerror

statusoftheuser.

2.2.6.4.LSU

LSUreceivestheimagedatafromPVCorHPVCandmakethelatentimageonOPCsurface.Itusesthesinglebeam,

LD.TheerrorsrelatedtoLSUareasfollows:

•ByLready

Whentheprintingisstarted,theenginedrivesthepolygonmotorofLSU.Afterthespeciedtimeiselapsed,ifthe

motorisnotinareadystatus,theenginedetectstheerrorthatthepolygonmotorisnotinareadystatus.Ifthiserror

happens,theenginestopsallfunctionsandkeepsitattheerrorstate.Also,theengineinformstheerrorstatusofthe

mainsystemandtheerrormessageisdisplayedatLCDwindowtoinformtheerrorstatusoftheuser.

•ByHsync

Whenthepolygonmotorisready,theLSUsendsoutthesignalcalledHsyncandusedtosynchronizewitheachimage

line.So,iftheenginedoesnotdetectconsecutivelythesignalforaxedtime,itdenestheHsyncError.Ifthiserror

happens,theenginestopsallfunctionsandkeepsitattheerrorstate.Also,theengineinformstheerrorstatusofthe

mainsystemandthentheerrormessageisdisplayedatLCDwindowtoinformtheerrorstatusoftheuser.LSUError

Recovery:IftheLReadyorHsyncerrorhappens,thepaperisexitedbeforetheerrorcodeisinitiated.Theenginemode

ischangedtorecoverymodeandtheengineinformsthemainsystemoftheenginemode.Andtheenginechecksthe

LSUerror.Iftheerrordoesn’thappen,theprintingjob.

Copyright©1995-2013SAMSUNG.Allrightsreserved.2-30

Page 42

2.ProductSpecicationsandDescription

P rin te r /MFP

HOS T

S o ftw a r e

Driv e r

Web -b as e d

App lic atio n

S ta n d -alo n e

App lic atio n

Fi rm wa re

App lic atio n

(Em ula tio n )

Kern e l

2.2.7.SoftwareDescriptions

2.2.7.1.Softwaresystemoverview

Thesoftwaresystemofthismodelisconstructedwith

•HostSoftwarepartthattheapplicationsoftwareoperatedinWindowandWebEnvironment

•FirmwarepartsthatisaEmbeddedsoftwarecontrolsprintingjob.

2.2.7.2.Architecture

HostSoftwareismadeupof

1)GraphicUserInterfaceoffersthevariouseditingfunctionstouserinHost.

2)DrivertranslatesthereceiveddocumenttoaPrintingCommandlanguagewhichprintercanunderstandandtransfers

datatospooler.

3)Stand-aloneApplicationoffersthevariousprintingapplicationsuchasEasyPrinterManager,PrinterStatusinWindow

system.

4)Web-based-ApplicationoffersthesamefunctionsasStand-aloneApplicationinW ebenvironment.

Firmwareismadeupof

1)Application(Emulation)thatisainterpretertranslatesdatareceivedfromHosttoaprintinglanguage(PCL,PS,GDI,

etc.)tobeabletomaketheusertotakesameoutputasoriginallyonewhatcomposedinHost.

2)KernelcontrolsandmanagethewholeprocedureincludingControlowandPrintingJobbeforetransferringtoEngine

system.

2-31Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 43

2.2.7.3.DataandControlFlow

Driv e r

- PC L3, PS 3

Web -ba s ed

- Do cum e nt Mana ge m ent

S ys tem

- Netwo rk Ad minist rat ion

- S tatus Mon ito r

- Re m o te Co ntro l Pane l

S ta nd -a lo n e

- P rinte r S etting Utility

- Netwo rk Ad minist rat ion

- S tatus Mon ito r

Q

Q

p

p

s

s

uu

N

N

p

p

o

o

jj

u

u

p

p

s

s

Netw o r k

Interfa c e

App licatio n

KERNE L

App licatio n

(Em ulat io n)

- P CL

- P S3

En gin e

US B

Ho s t Firmwa re

2.ProductSpecicationsandDescription

TheaboveBlockDiagramisexplainedthat:

HostSideismadeupof

1)DriverthatisWindowsapplicationsoftwaretranslateprinteddatatooneofprinterlanguageandcreatespoolerle.

2)Web-basedApplicationthatofferavariousprinteradditionalfunctions,managementofprintingjob,printer

administration,StatusmonitortomonitoringtheprinterstatusbyrealtimeinW eb,independentenvironmentonOS.

3)Stand-aloneApplicationthatisasimilarWindowsoftwareassameasabove2.

4)PortMonitorthatmanagesthenetworkcommunicationbetweenspoolerandNetworkInterfaceCard,orvarious

additionalapplicationandNetworkInterfaceCard,(thisis,atrst,makecommunicationlogicalport,managethedata,

transferthemfromspoolertonetworkport,andoffertheresultofprinting).

FirmwareSideismadeupof

1)NetworkInterfaceCardisthatrelaythecommunicationbetweenHostandkernelusingvariousnetworkprotocol.

2)Kernelisthatmanagestheowcontrolofemulationprocedure,receivingdatafromHostorNetworkcardandprinting

withengine&renderingjob.

3)Emulationisthatinterpretsthevariousoutputdatafromselectedemulation.

4)Engineisthatprintsrenderedbit-mapdatatopaperwithrequiredsizeandtypebyKernel.

Andthen,forJobSpoolingfunctionforMulti-User,Multi-PrintingthatisoccurredinNetworkprintingandvarious

additionalprintingfunctions,thisKernelusemax.10Queuingsystemsinamemory.

Copyright©1995-2013SAMSUNG.Allrightsreserved.2-32

Page 44

2.ProductSpecicationsandDescription

InPrinting,thetwoproceduresare

1)CaseofusingUSBPort

•AfteruserstarttoprintthewanteddocumenttoPCLstringorcompressedGDIbit-mapdata,theDrivertranslates

theallgraphicdataoftheclientPCandsenddatatohostspooler.Andthenthespoolersendsthedatastreamto

theprinterviaUSBport.

•KernelreceivesthisdatafromHost,andthenselectemulationttodataandstartselectedone.Afteremulationjob

end,Kernelsendstheoutputbit-mapdatatoEngineusingPrinterVideoController(byclocktypeforLSU).

•Engineprintthereceiveddatatorequiredpaperwiththesequentialdevelopingprocess.

2)CaseofusingNetworkInterfaceCard

•AfteruserstarttoprintthewanteddocumenttoPCLstringorcompressedGDIbit-mapdata,Drivertranslatethe

allgraphicdataofitandsenddatatohostspooler.

•Ifso,PortmonitormanagingnetworkportreceivesdatafromspoolerandsendsadatastreamtotheNetwork

InterfaceCard.

•NetworkinterfacecardreceivesitandsendtoKernelpart.

•KernelreceivesthisdatafromHost,andthenselectemulationttodataandstartselectedone.Afteremulationjob

end,Kernelsendstheoutputbit-mapdatatoEngineusingPrinterVideoController(byclocktypeforLSU).

•Engineprintthereceiveddatatorequiredpaperwiththesequentialdevelopingprocess.

2-33Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 45

3.DisassemblyandReassembly

3.DisassemblyandReassembly

3.1.Precautionswhenreplacingparts

3.1.1.Precautionswhenassemblinganddisassembling

•UseonlyapprovedSamsungspareparts.Ensurethatpartnumber,productname,anyvoltage,currentortemperature

ratingarecorrect.Failuretodosocouldresultindamagetothemachine,circuitoverload,reorelectricshock.

•Donotmakeanyunauthorizedchangesoradditionstotheprinter,thesecouldcausetheprintertomalfunctionand

createelectricshockorrehazards.

•Takecarewhendismantlingtheunittonotewhereeachscrewgoes.Thereare19differentscrews.Useofthewrong

screwcouldleadtosystemfailure,shortcircuitorelectricshock.

•DonotdisassembletheLSUunit.Onceitisdisassembleddustisadmittedtothemirrorchamberandwillseriously

degradeprintquality .Therearenoserviceablepartsinside.

•Regularlychecktheconditionofthepowercord,plugandsocket.Badcontactscouldleadtooverheatingandrfe.

Damagedcablescouldleadtoelectricshockorunitmalfunction.

3.1.2.PrecautionswhenhandlingPBA

StaticelectricitycandamageaPBA,alwaysusedapprovedanti-staticprecautionswhenhandlingorstoringaPBA.

•PrecautionswhenmovingandstoringPBA

1)PleasekeepPBAinaconductivecase,anti-staticbag,orwrappedinaluminumfoil.

2)DonotstoreaPBAwhereitisexposedtodirectsunlight.

•PrecautionswhenreplacingPBA

1)Disconnectpowerconnectorsrst,beforedisconnectingothercables.

2)Donottouchanysolderedconnections,connectorterminalsorotherelectronicpartswhenhandlinginsulatedparts.

•PrecautionswhencheckingPBA

1)BeforetouchingaPBA,pleasetouchothergroundedareasofthechassistodischargeanystaticelectricalcharge

onthebody.

2)TakecarenottotouchthePBAwithyourbarehandsormetalobjectsasyoucouldcreateashortcircuitorgetan

electricshock.TakeextracarewhenhandlingPBAswithmovingpartsttedsuchassensors,motorsorlampsas

theymaygethot.

3)Takecarewhentting,orremoving,screws.Lookoutforhiddenscrews.Alwaysensurethatthecorrectscrewis

usedandalwaysensurethatwhentoothedwashersareremovedtheyarerettedintheiroriginalpositions.

Copyright©1995-2013SAMSUNG.Allrightsreserved.3-1

Page 46

3.DisassemblyandReassembly

3.1.3.ReleasingPlasticLatches

Manyofthepartsareheldinplacewithplasticlatches.Thelatchesbreakeasily;releasethemcarefully.

Toremovesuchparts,pressthehookendofthelatchawayfromtheparttowhichitislatched.

3-2Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 47

3.DisassemblyandReassembly

3.2.Screwsusedintheprinter

Thescrewslistedinthetablebelowareusedinthisprinter.Pleaseensurethat,whenyoudisassembletheprinter,youkeep

anoteofwhichscrewisusedforwhichpartandthat,whenreassemblingtheprinter,thecorrectscrewsareusedinthe

appropriateplaces.

6003-000196SCREW-T APTYPE;PWH,+,B,M3,L10,NIPL T,SWRCH18A2

6003-000269SCREW-T APTYPE;BH,+,-,S,M3,L6,ZPC(WHT),SWRCH18A,-2

6003-000282

6003-000196SCREW-T APTYPE;PWH,+,B,M3,L10,NIPL T,SWRCH18A1

6003-000282

6003-000196SCREW-T APTYPE;PWH,+,B,M3,L10,NIPL T,SWRCH18A22

6003-000269

6003-000196SCREW-T APTYPE;PWH,+,B,M3,L10,NIPL T,SWRCH18A1

6003-000261

6003-000269SCREW-T APTYPE;BH,+,-,S,M3,L6,ZPC(WHT),SWRCH18A,-12

6003-000282

6003-000269SCREW-T APTYPE;BH,+,-,S,M3,L6,ZPC(WHT),SWRCH18A,-6

6003-000282

6003-000196FRAME-PAPER_PA THSCREW-T APTYPE;PWH,+,B,M3,L10,NIPLT,SWRCH18A9

6003-000196

6003-000282LSUSCREW -T APTYPE;BH,+,-,B,M3,L8,ZPC(BLK),SWRCH18A,-5

6003-000196COVER-TOPSCREW-T APTYPE;PWH,+,B,M3,L10,NIPL T,SWRCH18A4

6003-000196SCREW-T APTYPE;PWH,+,B,M3,L10,NIPL T,SWRCH18A1

6003-000269

FUSER

FUSER-UPPER

FRAMEMAIN

DUPLEX

FRAMEMAIN-LEFT

FRAME

MAIN-RIGHT

FRAME

BASE-PICKUP

MAINLINE

SCREW-T APTYPE;BH,+,-,B,M3,L8,ZPC(BLK),SWRCH18A,-2

SCREW-T APTYPE;BH,+,-,B,M3,L8,ZPC(BLK),SWRCH18A,-2

SCREW-T APTYPE;BH,+,-,S,M3,L6,ZPC(WHT),SWRCH18A,-26

SCREW-T APTYPE;BH,+,-,B,M3,L6,ZPC(WHT),SWRCH18A,-3

SCREW-T APTYPE;BH,+,-,B,M3,L8,ZPC(BLK),SWRCH18A,-1

SCREW-T APTYPE;BH,+,-,B,M3,L8,ZPC(BLK),SWRCH18A,-1

SCREW-T APTYPE;PWH,+,B,M3,L10,NIPLT,SWRCH18A2

SCREW-T APTYPE;BH,+,-,S,M3,L6,ZPC(WHT),SWRCH18A,-13

Copyright©1995-2013SAMSUNG.Allrightsreserved.3-3

Page 48

3.DisassemblyandReassembly

3.3.ReplacingtheMainSVCparts

3.3.1.SideCover

1.RemovetheCassettefromPrinter.

2.OpentheFront-Cover,thenpullouttheT onerCartridge.

3.RemovetheLeftCoverandRightCover.*Attentionto

thedirectionofthehooks

3-4Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 49

3.3.2.RearCover

3.DisassemblyandReassembly

1.RemovetheSideCovers.

(Referto3.3.1SideCover)

2.Turnthemachineback,thenremove4screwsofthe

backsideofthemachine.

3.OpentheLowerRearCover.

4.Remove2hooksateachsideoftheLowerRearcover.

5.Remove2screwoftheupperbacksideofthemachine,

thenpullofftheRearCover.

Copyright©1995-2013SAMSUNG.Allrightsreserved.3-5

Page 50

3.DisassemblyandReassembly

3.3.3.FrontCover

1.RemoveSideCoversandRearCover.

(Referto3.3.1SideCover)

(Referto3.3.2RearCover)

2.RemoveaHarnesscableatrightsideofthemachine.

3.RemoveahookatinsideoftheFrontCover.

4.RemovetheFrontCover.

3-6Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 51

3.3.4.TopCover

3.DisassemblyandReassembly

1.RemovetheSideCovers,theRearCover,andtheFront

Cover.

(Referto3.3.1SideCover)

(Referto3.3.2RearCover)

(Referto3.3.3FrontCover)

3.3.5.MainBoard

1.RemovetheRightCover.

(Referto3.3.1SideCover)

2.Removeallconnectorsontheboard.

2.Remove2screwsattheupperofthemachine.

3.RemovetheTopCovertoupward.

3.Remove4screwsontheboard

4.SeparatetheMainBoardfromthemachine.

Copyright©1995-2013SAMSUNG.Allrightsreserved.3-7

Page 52

3.DisassemblyandReassembly

3.3.6.SMPS

1.RemovetheRightCover

(Referto3.3.1SideCover)

2.Removeallconnectorsontheboard.

3.Remove6screwsontheboard.

3.3.7.HVPS

4.SeparatetheSMPSfromthemachine.

1.RemovetheRightCover

(Referto3.3.1SideCover)

2.Removeallconnectorsontheboard.

3.Remove6screwsontheboard.

4.SeparatetheHVPSfromthemachine.

3-8Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 53

3.3.8.Bin-FullSensor

3.DisassemblyandReassembly

1.Removetherightcover.

2.Removethemainboard.

3.Unplugthesensorconnector.

3.3.9.MainDriveunit

1.Removetheleftcover.

2.Remove5screws.

4.ReleasetheBin-Fullsensor.

3.Releasethemaindriveunitaftermovingtheholderto

theright.

Copyright©1995-2013SAMSUNG.Allrightsreserved.3-9

Page 54

3.DisassemblyandReassembly

Reg i. Clutc h

Pic k up Clutch

3.3.10.PickupandRegiClutch

1.Removetheleftcover.2.Removethewashersecuringtheclutch.Unplugthe

connectoronJointPBA.Andreleasetheclutch.

3.3.11.PickupandForwardroller

1.Removethebottombarafterremoving2screws.

2.Remove2screws.

3.Releasethepick-up/forwardrollerAssy.

3-10Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 55

3.3.12.RetardRoller

3.DisassemblyandReassembly

1.Removethecassette.

2.Opentheretardrollercover.

3.Releasetheretardrollerholder.Thenreleasetheretard

rollerformitsholder.

NOTE

Whenreassemblingtheretardrollerholder,placetwo

springsonthebottomhole.

Copyright©1995-2013SAMSUNG.Allrightsreserved.3-11

Page 56

3.DisassemblyandReassembly

3.3.13.DuplexUnit

1.Removethecassette,thenremove4screwsfromthe

RearCover .

2.OpentheRearCover.Releasethe2hingesattheeach

sideofthecover.Andthenremovetherearcover .

3.Standthemachine.Pushthegreenhandletorelease

theduplexunit.

4.Pulloffthehinge,thenremovetheDuplexUnitto

upward.

3-12Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 57

3.3.14.TransferRoller

1

2

1.Openthefrontcover.Removethetonercartridge.

2.Removetheholder.Thenremovethetransferroller.

3.DisassemblyandReassembly

3.3.15.LSU

1.Removethetopcover.2.Unplug2atcables.Remove3screws.Andrelease

theLSU.

Copyright©1995-2013SAMSUNG.Allrightsreserved.3-13

Page 58

3.DisassemblyandReassembly

3.3.16.FuserUnit

1.Removetherightandrearcover.

2.Unplug2connectors.(SMPSboardx1,Mainboard

x1)

3.3.17.ExitSensor

3.Removethefuserunitafterremoving4screws.

1.Removethefuserunit.2.Releasetheexitsensorafterunpluggingtheconnector.

3-14Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 59

3.3.18.FeedandRegisensorPBA

Ho o k

3.DisassemblyandReassembly

1.Removetheduplexunit.

2.Remove1screw.

3.Removethesensorcoverwhilepushingthehook.

4.RemovethesensorPBAafterunpluggingtheconnector.

Copyright©1995-2013SAMSUNG.Allrightsreserved.3-15

Page 60

3.DisassemblyandReassembly

3.3.19.OPEPBA

1.Removethetopcover.

2.Remove2screwsontheboard.

3.Removeaconnectorontheboard,thenseparatethe

boardfromthemachine.

3.3.20.WirelessLANPBA

1.Removetopcover.2.ReleasetheWLANPBA.

3-16Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 61

3.3.21.Motor

3.DisassemblyandReassembly

1.First,removeallcovers.

2.Seethebottomofthemachine.Remove2screws.And

removePLATE-BOTTOM.

3.RemovetheDuplexunitwhilepushinggreenbuttons.

5.RemoveGEAR-RDCNEXIT,GEAR-IDLEEXIT,

GEAR-EXT.

6.RemoveClutchesandGEAR-FEEDafterremoving

washerssecuringthem.

7.Turnthemachinetobackward.Removing10screws.

4.Remove1screw.RemovetheGROUND-SA W .And

unplugthemotorconnector.

Copyright©1995-2013SAMSUNG.Allrightsreserved.3-17

Page 62

4.Troubleshooting

4.Troubleshooting

4.1.AlignmentandAdjustments

Thischapterdescribesthemainfunctionsforservice,suchastheproductmaintenancemethod,thetestoutputrelatedto

maintenanceandrepair,Jamremovingmethod,andsoon.

Itincludesthecontentsofmanual.

4.1.1.ControlPanel

NOTE

Thiscontrolpanelmaydifferfromyourmachinedependingonitsmodel.Therearevarioustypesofcontrolpanels.

1

TonerLED

2

Eco

4-1Copyright©1995-2013SAMSUNG.Allrightsreserved.

Showsthestatusofthetoner .

EntersEcomodetoreducetonerconsumptionandpaperusage.

Page 63

4.Troubleshooting

3

•Infosheet(1):Printsademopageandnetworkcongurationreport.

•WPS(2):Conguresthewirelessnetworkconnectioneasilywithout

acomputer .

Demopage(1)

•Printscreen(3):PressthisbuttonandthegreenLEDwillstartblinking.

Ifyouwanttoprintonlytheactivescreen,releasethebuttonwhenthe

greenLEDstopsblinking.Ifyouwanttoprintthewholescreen,release

thebuttonwhileit’sblinking.

WPS(2)

Printscreen(3)

4

Cancel

NOTE

•PrintScreencanonlybeusedintheWindowsandMacoperatingsystems.

•YoucanonlyusethisfunctionwithUSBconnectedmachine.

•Whenprintingtheactivewindow/wholemonitorscreenusingtheprint

screenbutton,themachinemayusemoretonerdependingonwhatisbeing

printed.

•Youcanonlyusethisfunctionifthemachine’sEasyPrinterManager

programisinstalled.IfyouareaMacOSuser,youneedtoenableScreen

PrintSettingsfromtheEasyPrinterManagertousethePrintScreen

feature.

Stopsanoperationatanytimeandtherearemorefunctions.

•Cancelsthecurrentjob.

•Printsdemopage:Pressandholdthisbuttonforabout2secondsuntil

thestatusLEDblinksslowly ,andrelease.

•SuppliedInfo&EventLog:Pressandholdthisbuttonforabout6

secondsandrelease.

•Printscongurationreports/networkcongurationreports(4):Pressand

holdthisbuttonforabout4secondsuntilthestatusLEDblinksfast,

andrelease.

5

Power

6

StatusLED

(1)XpressM2x2xNDModelOnly

(2)XpressM282xDWModelOn;y

(3)XpressM262x,M262xDModelOnly

(4)NetworkandWirelessModelOnly

Youcanturnthepoweronandoffwiththisbutton.

Showsthestatusofyourmachine.

Copyright©1995-2013SAMSUNG.Allrightsreserved.4-2

Page 64

4.Troubleshooting

4.1.2.UnderstandingthestatusLED

ThecoloroftheLEDindicatesthemachine'scurrentstatus.

StatusLED

StatusDescription

OffThemachineisoff-line.

Themachineisinpowersavemode.

Status

LED

Green

Blinking•Whenthebacklightslowlyblinks,themachineisreceivingdatafromthe

computer.

•Whenthebacklightblinksrapidly,themachineisprintingdata.

OnThemachineison-lineandcanbeused.

Red

Orange

BlinkingAminorerrorhasoccurredandthemachineiswaitingfortheerrortobecleared.When

On•Thecoverisopened.Closethecover.

BlinkingUpgradingrmware.

OnApaperjamhasoccurred.

TonerLED/WPSLED

StatusDescription

Yellow

LED

theproblemiscleared,themachineresumes.

•Thereisnopaperinthetraywhenreceivingorprintingdata.Loadpaperin

thetray .

•Themachinehasstoppedduetoamajorerror.Rebootthepowerandtrythe

printingjobagain.Iftheproblempersists,pleasecallforservice.

•Animagingunithasalmostreacheditsestimatedcartridgelifea.Itis

recommendedtoreplacetheimagingunit.

BlinkingSmallamountoftonerisleftinthecartridge.Theestimatedcartridgelifeof

tonerisclose.Prepareanewcartridgeforreplacement.Y oumaytemporarily

increasetheprintingqualitybyredistributingthetoner.

OnAtonercartridgehasalmostreacheditsestimatedcartridgelife.Itis

recommendedtoreplacethetonercartridge.

OffAlltonercartridgesareatnormalcapacity .

Blue

WPSLED

Blue

PowerLED

Green

ECOLED

4-3Copyright©1995-2013SAMSUNG.Allrightsreserved.

BlinkingThemachineisconnectingtoawirelessnetwork.

OnThemachineisconnectedtoawirelessnetwork.

OffThemachineisdisconnectedfromawirelessnetwork.

OnThemachineisinpowersavemode.

OffThemachineisinreadymodeorthemachine’ spowerisoff.

OnEcomodeison.

OffEcomodeisoff.

Page 65

4.1.3.JamRemoval

4.Troubleshooting

Ifapaperjamoccurs,thestatusLEDonthecontrolpanel

lightsorange.Findandremovethejammedpaper.To

resumeprintingafterclearingpaperjams,youmustopen

andclosethefrontcover.

InTray

1)Openandclosethefrontcover.Thejammedpaperis

automaticallyejectedfromthemachine.Ifthepaper

doesnotexit,gotothenextstep.

2)Pullouttray.

NOTE

Toavoidtearingthepaper,pullthejammedpaperoutslowly

andgently.

4)Inserttraybackintothemachineuntilitsnapsinto

place.Printingautomaticallyresumes.

3)Removethejammedpaperbygentlypullingitstraight

out.

Ifthepaperdoesnotmovewhenyoupull,orifyou

donotseethepaperinthisarea,checkthefuserarea

aroundthetonercartridge.

Copyright©1995-2013SAMSUNG.Allrightsreserved.4-4

Page 66

4.Troubleshooting

Inthemanualfeeder

1)Ifthepaperisnotfeedingproperly ,pullthepaperout

ofthemachine.

2)Openandclosethemanualfeeder.

4-5Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 67

Insidethemachine

4.Troubleshooting

NOTE

*Thefuserareaishot.Takecarewhenremovingpaperfrom

themachine.

*Whenapaperjamoccurs,youhavetocheckthemodel

number.

XpressM2620/M2820Series

1)Openthefrontcover.

2)RemovetheT onerCartridge.

4)Closethejamguide.

5)Installthetonercartridge.

3)Pullthejamguides,thenremoveajammedpaper.

6)Closethefrontcoverandcheckprintingautomatically

resumes.

Copyright©1995-2013SAMSUNG.Allrightsreserved.4-6

Page 68

4.Troubleshooting

XpressM2625/M2825Series

1)Openthefrontcover,andthenremovetheToner

Cartridge.

2)RemovetheDrumUnit.

4)Closethejamguide.

5)InstalltheDrumUnit.

3)Pullthejamguides,thenremoveajammedpaper.

6)Closethefrontcoverandcheckprintingautomatically

resumes.

4-7Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 69

Inexitarea

4.Troubleshooting

1)Openandclosethefrontcover.Thejammedpaperis

automaticallyejectedfromthemachine.Ifyoudonot

seethejammedpaper,gotonextstep.

2)Gentlypullthepaperoutoftheoutputtray.

Ifyoudonotseethejammedpaperorifthereisany

resistancewhenyoupull,stopandgotothenextstep.

3)Opentherearcover.

5)RemovethejammedpaperintheExitUnit.

6)ClosetheFusercover.

4)OpentheFusercoverwithpushingtheeachsidelevers

(GreenColor)

7)ClosetheRearCoverandcheckprintingautomatically

resumes.

Copyright©1995-2013SAMSUNG.Allrightsreserved.4-8

Page 70

4.Troubleshooting

Intheduplexarea

1)RemovetheRearCover.

.

2)RemovethejammedpaperintheDuplexUnit.

3)ClosetheRearCoverandcheckprintingautomatically

resumes.

4-9Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 71

4.Troubleshooting

4.1.4.Periodicdefectiveimage

Ifanimagedefectsappearsatregularintervalsontheprinted-paper,itisduetoafaultyordamagedroller.Refertothetable

belowandchecktheconditionoftheappropriateroller.

RollerPeriod(mm)PhenomenonDefectivepart

1PressureRoller75.4mmBackground

2HeatRoller77.6mmBlackspotandimageghost

3ChargingRoller26.7mmBlackSpotandlineandperiodicband

4OPCDrum75.49mmWhiteandBlackSpots

5SupplyRoller63.22mmPeriodicBandbylittledifferenceofdensity

6DevelopingRoller36.75mmWhitespot,Horizontalblackband

7TransferRoller47.12mmGhost,DamagedimagebyabnormaltransferTransferroller

Fuser

TonerCartridge

Copyright©1995-2013SAMSUNG.Allrightsreserved.4-10

Page 72

4.Troubleshooting

4.1.5.Usefulmanagementtools

4.1.5.1.UsingSamsungEasyPrinterManager(WindowsandMacintoshonly)

NOTE

•Thisfeaturemaynotbeavailabledependingonmodeloroptionalgoods.

•AvailableforWindowsorMacintoshOSusersonly.

•ForWindows,InternetExplorer6.0orhigheristheminimumrequirementforSamsungEasyPrinterManager .

SamsungEasyPrinterManagerisanapplicationthatcombinesSamsungmachinesettingsintoonelocation.Samsung

EasyPrinterManagercombinesdevicesettingsaswellasprintingenvironments,settings/actionsandlaunching.Allof

thesefeaturesprovideagatewaytoconvenientlyuseyourSamsungmachine.SamsungEasyPrinterManagerprovidestwo

differentuserinterfacesfortheusertochoosefrom:thebasicuserinterfaceandtheadvanceduserinterface.Switching

betweenthetwointerfacesiseasy:justclickabutton.

UnderstandingSamsungEasyPrinterManager

Toopentheprogram:

•ForWindows,SelectStart>ProgramsorAllPrograms>SamsungPrinters>SamsungEasyPrinterManager>

SamsungEasyPrinterManager.

•ForMacintosh,OpentheApplicationsfolder>Samsungfolder>SamsungEasyPrinterManager.

TheSamsungEasyPrinterManagerinterfaceiscomprisedofvariousbasicsectionsasdescribedinthetablethatfollows:

NOTE

Thescreenshotmaydifferdependingonoperatingsystemyouareusing.

4-11Copyright©1995-2013SAMSUNG.Allrightsreserved.

Page 73

4.Troubleshooting

NoAreaDescription

1PrinterListTheprinterlistdisplaystheinstalledprintericonsonyourcomputer.

2PrinterInformationThisareagivesyougeneralinformationaboutyourmachine.Youcancheck

information,suchasthemachine’smodelname,IPaddress(orPortname),

andmachinestatus.

NOTE

Troubleshootingbutton:ThisbuttonopensTroubleshootingGuidewhenan

erroroccurs.Y oucandirectlyopenthenecessarysectionintheuser’sguide.

3ApplicationInformationIncludeslinksforchangingtotheadvancedsettings,preference,help,and

about.

4QuicklinksDisplaysQuicklinkstomachinespecicfunctions.Thissectionalsoincludes

linkstoapplicationsintheadvancedsettings.

5ContentsAreaDisplaysinformationabouttheselectedmachine,remainingtonerlevel,

andpaper.Theinformationwillvarybasedonthemachineselected.Some

machinesdonothavethisfeature.

6OrderSuppliesClickontheOrderbuttonfromthesupplyorderingwindow.Y oucanorder

replacementtonercartridge(s)fromonline.

Advancedsettingsuserinterfaceoverview

Theadvanceduserinterfaceisintendedtobeusedbythepersonresponsibleformanagingthenetworkandmachines.

•DeviceSettings

Youcancongurevariousmachinesettingssuchasmachinesetup,paper,layout,emulation,network,andprint

information.

•ScantoPCSettings

ThismenuincludessettingstocreateordeletescantoPCproles.

-ScanActivation:Determineswhetherornotscanningisenabledonthedevice.

-Prole:Displaysthescanningprolessavedontheselecteddevice.

-Basictab:Containssettingsrelatedgeneralscananddevicesettings.

-Imagetab:Containssettingsrelatedtoimagealtering.

•FaxtoPCsettings

Thismenuincludessettingsrelatedtothebasicfaxfunctionalityoftheselecteddevice.

-Disable:IfDisableisOn,incomingfaxeswillnotbereceivedonthisdevice.

-EnableFaxReceivingfromDevice:Enablesfaxingonthedeviceandallowmoreoptionstobeset.

•AlertSettings

Thisismenuincludessettingsrelatedtoerroralerting.

-PrinterAlert:Providessettingsrelatedtowhenalertswillbereceived.

-EmailAlert:Providesoptionsrelatingtoreceivingalertsviaemail.

-HistoryAlert:Providesahistoryofdeviceandtonerrelatedalerts.

•JobAccounting