Samsung WM1255AGS/XEN, WM1245A Service Manual

THE FEATURE OF PRODUCT

WM1255A

Manual

SERVICE

Refer to the service manual in the itself (http://itself.sec.samsung.co.kr/) for the more information.

BASIC MODEL

WM1245A

WM1255AGS/XEN

1. Silver Nano Sterilization,

Anti-bacteria

2. Premium Design

3. Wide Graphic Display

4. Direct Drive Motor

5. A Giant 10kg Capacity

6. 40cm Wide Porthole

7. Slanted Drum

8. Optimal Drying System

1. PRECAUTIONS

1-1. SAFETY PRECAUTIONS

1-2. PRECAUTIONS UPON INSTALLATION

2. THE FEATURE OF PRODUCT

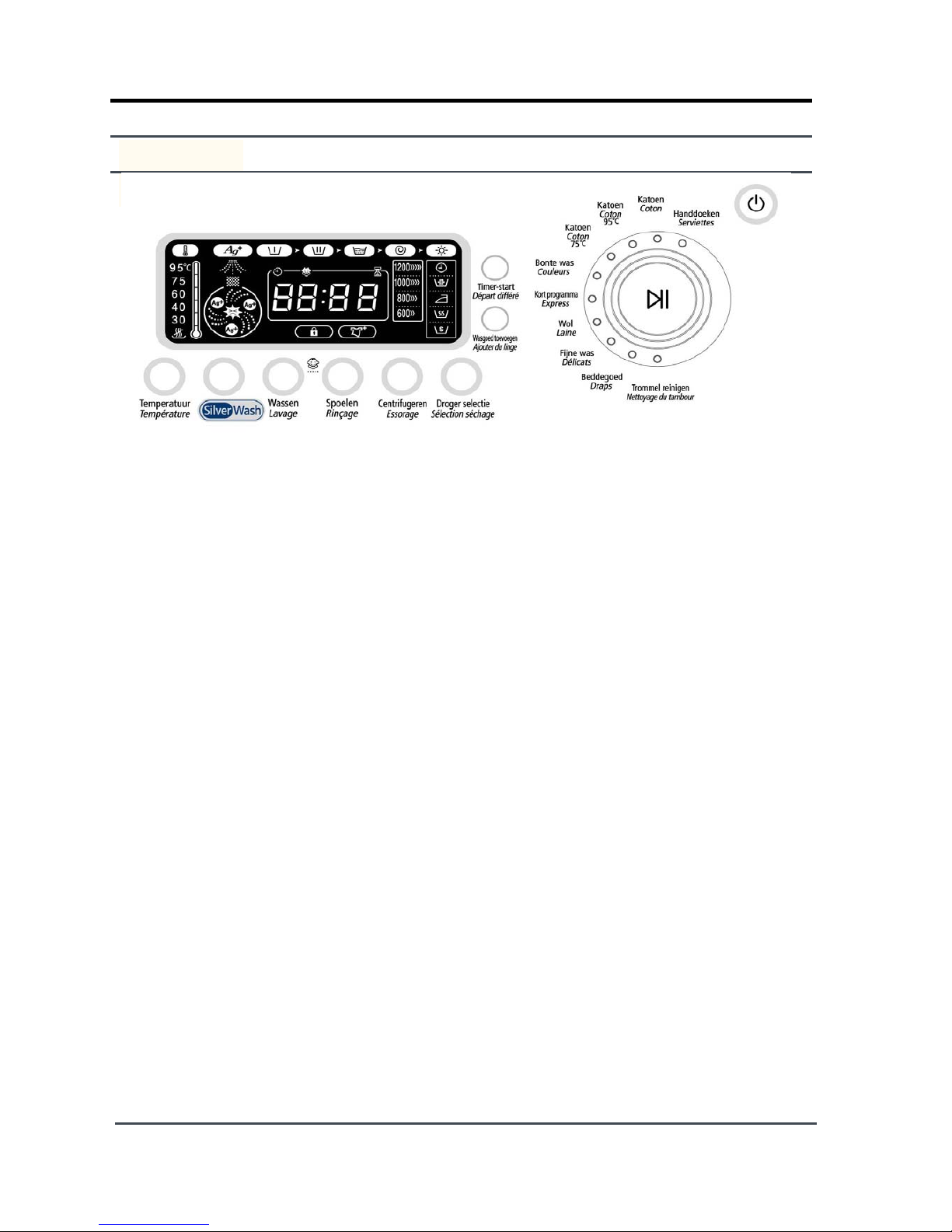

2-1. PART NAMES

2-2. SPECIFICATIONS

2-3. THE COMPARATIVE SPECIFICATIONS OF PRODUCT

2-4. THE COMPARATIVE SPECIFICATIONS OF PRODUCT

2-5. WM1255A FEATURES

3. PRODUCT SPECIFICATIONS

3-1. OVERVIEW OF THE CONTROL PANEL

4. ALIGNMENT AND ADJUSTMENTS

4-1. ERROR MODE

4-2. TROUBLESHOOTING (TEST MODE)

4-3. DETAILED EXAMINATION OF PROBLEMS

5. ASSEMBLY AND DISASSEMBLY

5-1. TOOLS FOR DISASSEMBLY AND ASSEMBLY

5-2. ASSEMBLY AND DISASSEMBLY

6. TROUBLE DIAGNOSIS

6-1. RELATED PARTS TO ERRORS FOR CHECKING

7. EXPLODED VIEWS AND PARTS LIST

7-1.

EXPLODED VIEW OF WHOLE PARTS

7-2.

EXPLODED VIEW OF DETERGENT TRAY/SUB PCB

7-3.

PARTS LIST OF DETERGENT TRAY/SUB PCB

7-4.

EXPLODED VIEW OF TUB/DAMPER/MAIN/MOTOR PCB

7-5. PARTS LIST OF TUB/DAMPER/MAIN/MOTOR PCB

7-6. EXPLODED VIEW OF FRAME FRONT/ASSY DOOR

7-7. PARTS LIST OF FRAME FRONT/ASSY DOOR

7-8. EXPLODED VIEW OF FRAME

7-9. PARTS LIST OF FRAME

7-10. Bolt & SCREW

2

1

6

7

8

13

20

23

25

26

38

41

27

40

5

9

42

43

44

45

46

47

48

49

CONTENTS

8. BLOCK DIAGRAM

9. THE ACTUAL PCB

9-1. THE ACTUAL MAIN PCB

9-2. THE ACTUAL SUB PCB

10. SCHEMATIC-DIAGRAM

11. PCB CIRCUIT DIAGRAM

11-1. PCB CIRCUIT DIAGRAM (Main)

11-2. CIRCUIT DIAGRAMS OF MAIN PARTS

11-3. MOTOR-DRIVING PART

11-4. DISPLAY PART

12. REFERENCE INFORMATION

12-1. MODEL NAME

12-2. TERMINOLOGY

12-3. FABRIC CARE CHART

12-4. ELECTRICAL WARNINGS

12-5. Q&A

51

52

53

56

62

62

63

60

59

55

54

57

58

CONTENTS

- 1 -

1. Ensure that users do not repair the product themselves.

▶

This may cause harm or shorten the lifetime of the product.

2. Ensure that the power plug is disconnected before performing A/S (especially A/S for electrical parts).

▶

Beware of electric shock

3. Ensure that users do not use several plugs for one outlet at the same time.

▶

This may cause fire from overheating.

4. Check for any marks of physical damage, fusion, cuts or fire damage at the power plug and the outlet.

▶

Repair or exchange it at once if there is some damage. (It could cause electric shock or fire)

5. Ensure that the product is properly earthed.

▶

If not, it may cause electric shocks through electrical leakage.

6. Do not use water directly on the main body when cleaning the product.

▶

This may cause electric shocks or fire, and shorten the lifetime of the product.

7. The line connection for the Harness may not be permeabled by water and must be secure while performing

the A/S.

▶

It should not be split or cut when a limited amount of force is applied.

8. Completely remove dust or foreign substances from any parts such as Housing, the line connection, the

contact point, etc. while performing the A/S.

▶

This will prevent in advance the danger of fire by Tracking, Short Circuits, etc.

9. Check for traces of water permeation of electrical parts and the Harness.

▶

If water has permeated any parts already, exchange the parts or completely remove the moisture.

10. Check the assembly condition of the parts after finishing the A/S.

▶

Maintain the same conditions as before the A/S.

11. When you pull out the power cord, be sure to hold the plug part when pulling the cord out.

▶

If the cord is damaged, it may cause electric shocks or fire.

12. Ensure that the power plug is removed from the outlet when the washing machine is not in use.

▶

Else it may cause electric shock or fire through lightning.

13. Do not use or preserve any kind of flammable spray or ignitable materials such as gasoline, thinner, alcohol,

etc. around the washing machine.

▶

Volatile materials may explode or ignite through electrical sparks.

14. Do not place a bowl filled with water or wet clothes on the washing machine.

▶

If the water spills, it may cause electric shock or fire, and shorten the lifetime of the product.

15. Do not install the washing machine in places exposed to snow or rain.

▶

This may cause electric shock or fire and shorten the lifetime of the product.

16. Do not press any operating buttons using sharp items such as pins, needles etc.

▶

This may cause electric shock or mechanical trouble.

17. Check if the product has been evenly and firmly installed on the ground.

▶

Too much vibration will shorten the lifetime of product.

18. Ensure that a connector is being used to connect a wire to another wire for a complete connection.

▶

If it is treated only with tape, it may cause fire by tracking.

19. If you have to turn the washing machine on its side when performing the A/S, ensure that it is placed down

gently on the ground with support

▶

If the washing machine is turned upside down, some of the parts may be damaged by the tub.

1. Precautions

1-1. Safety Precautions

- 2 -

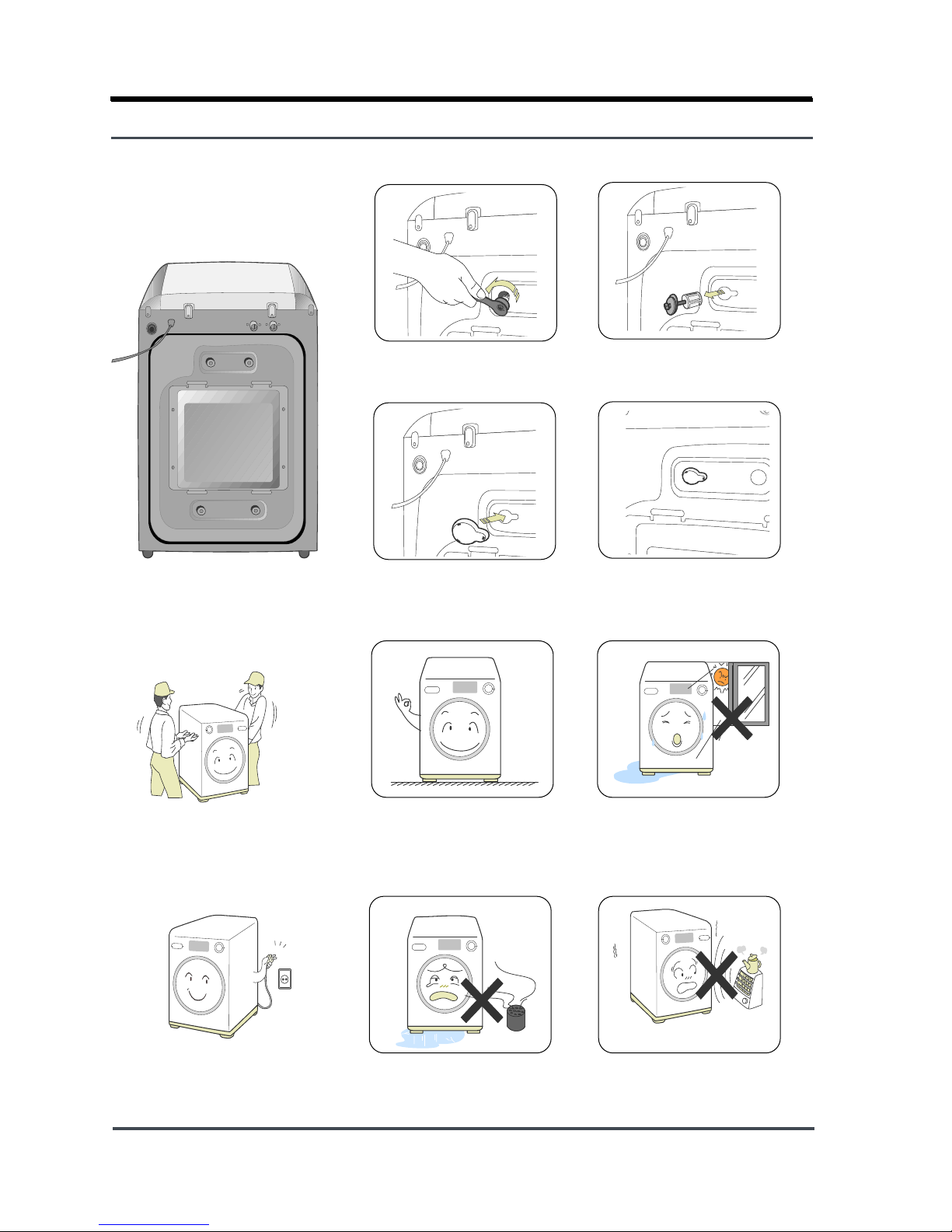

■

How to disassemble

the safety apparatus

1. Remove the screw of the safety

apparatus using a spanner.

2. Remove the safety apparatus from

the back of the main body.

3. Insert the stopper into

the groove for fixing the

safety appratus.

4. Insert 4 stoppers into each

groove for fixing the safety

appratus.

Install the product on a

solid and flat surface.

Avoid places with direct sunlight

and humidity for the installation. A

well-ventilated place is a good

position for installing the product.

Do not install the product at the

place where gas is emitted,

which will freeze the product in

winter season.

Avoid locations close to heat

sources such as a stove.

■

Safety Notes before

Installing

At least two people are needed

to unpack or move the product,

due to its weight.

Install the washig machine

where the power cord or

plug can be easily pulled out.

1-2.Precautions upon Installation

- 3 -

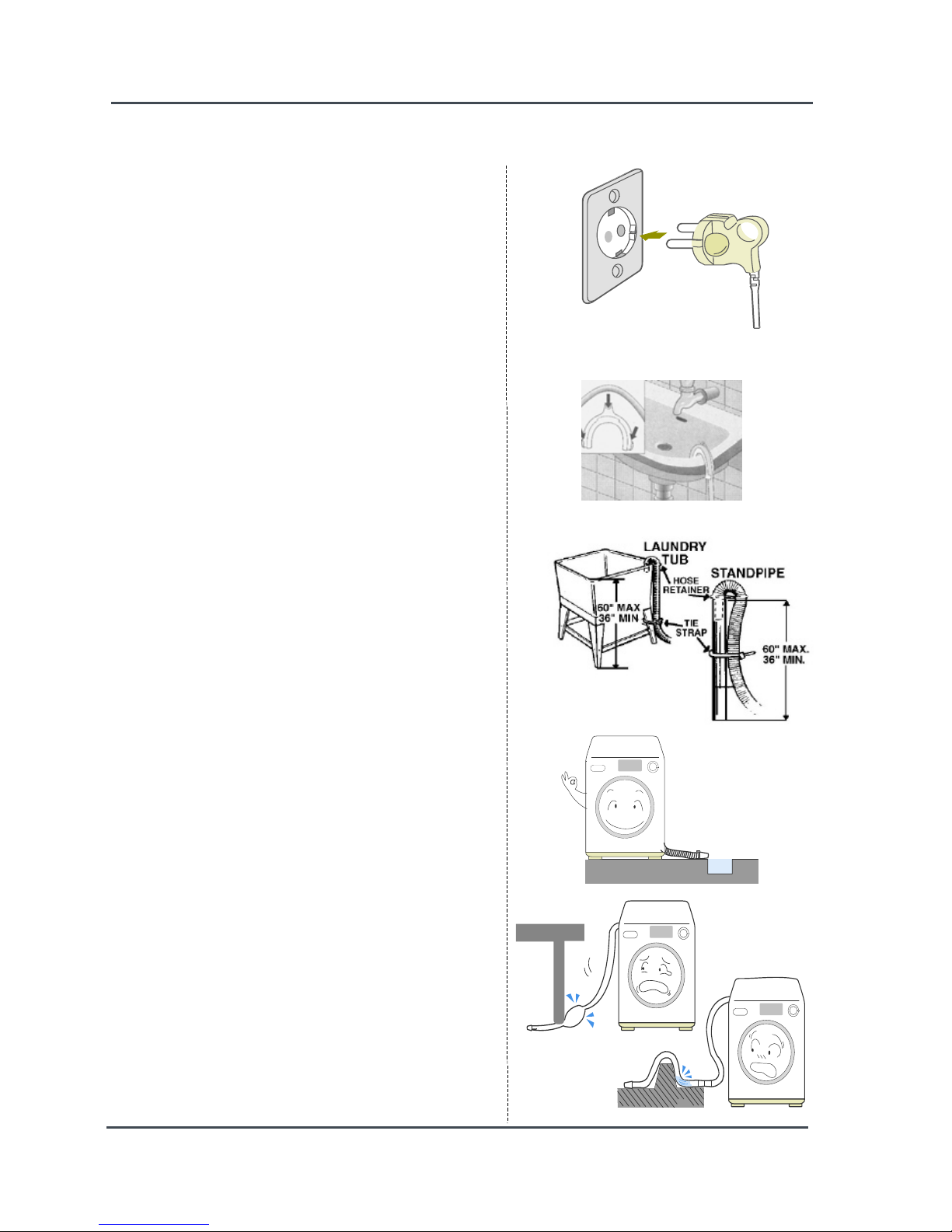

■ Grounding

※ Make sure to ground the unit to prevent

electric leakage or shock.

With a grounded receptacle

▶ It does not need an additional grounding.

■ Water Drainage

Note: Caution must always be exercised to

avoid collapsing or damaging the drain hose.

For best performance the drain hose should

not be restricted in any way, through elbows,

couplings or excessive lengths.

▶ Hook the drain hose over the Wash Basin or

Laundry Tub or plug the end of the drain hose

into the Standpipe

- The end of the drain hose must be passed

through the Hose Guide or secured as shown in

the picture to prevent it from popping up

during drainage of water.

- The outlet end of the drain hose must be at

least 60-90 cm above the base of the machine.

▶ Seal the drain pipe connections

- If not, it may cause water leakage.

▶ Prevent water from siphoning away

- If the end of the drain hose is put in water,

it could siphon away water during washing.

So, make sure that the end of the drain hose

is not put in water.

- 4 -

■

Installation Manner

1. Select an installation place in

advance.

▶

The distance between the washing

machineandthewallmustbeat

least 10cm.

2. Check the balance

▶

If you press down or shake any part of

the front, left or right side of the washing

machine and it still wobbles, adjust the

feet again until the machine is standing

solidly.

3. Adjust the height using the adjustable feet.

▶

The machine is in a

balanced state when all

four adjustable feet are

firnly on the ground and

there is no movement.

If uneven

▶

Adjust the lowest of the 4 adjustable feet while lifting the washing machine a little.

▶

Adjust the height by turning the nut to the left as in the figure.

(The adjustable foot will be lengthened.)

※

Caution

※

After adjusting the horizontal

balance, fix the nut tightly so

that it doesn't come loose

through vibration or noise.

▶

Tighten the nut after making

the adjustments.

- 5 -

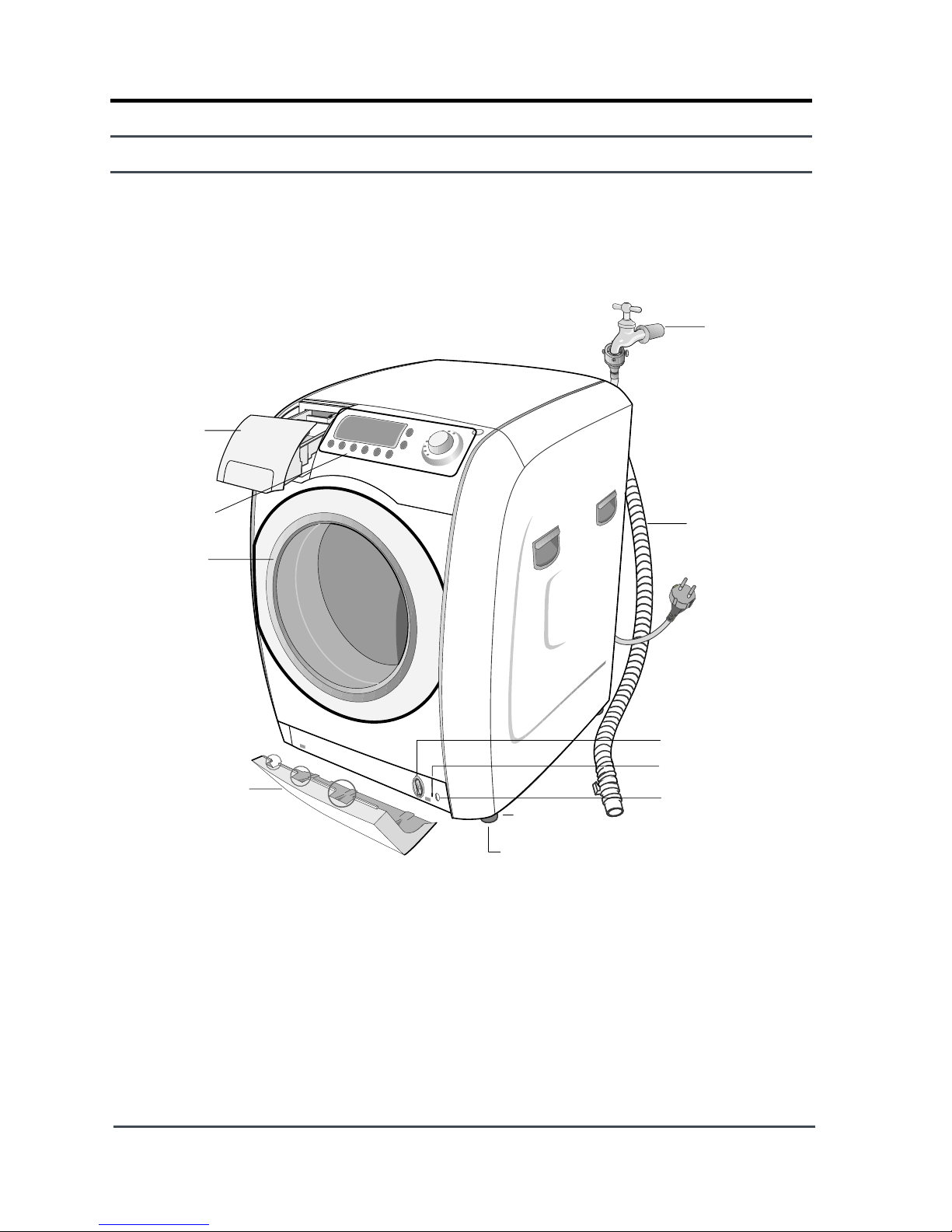

Cold Water

supply hose

Drain Hose

Door

Debris filter

Door release

Emergency drain

tube

Base cover

Adjustable feet

Control panel

Detergent

Drawer

2.

THE FEATURE OF PRODUCT

2-1.

Part Names

- 6 -

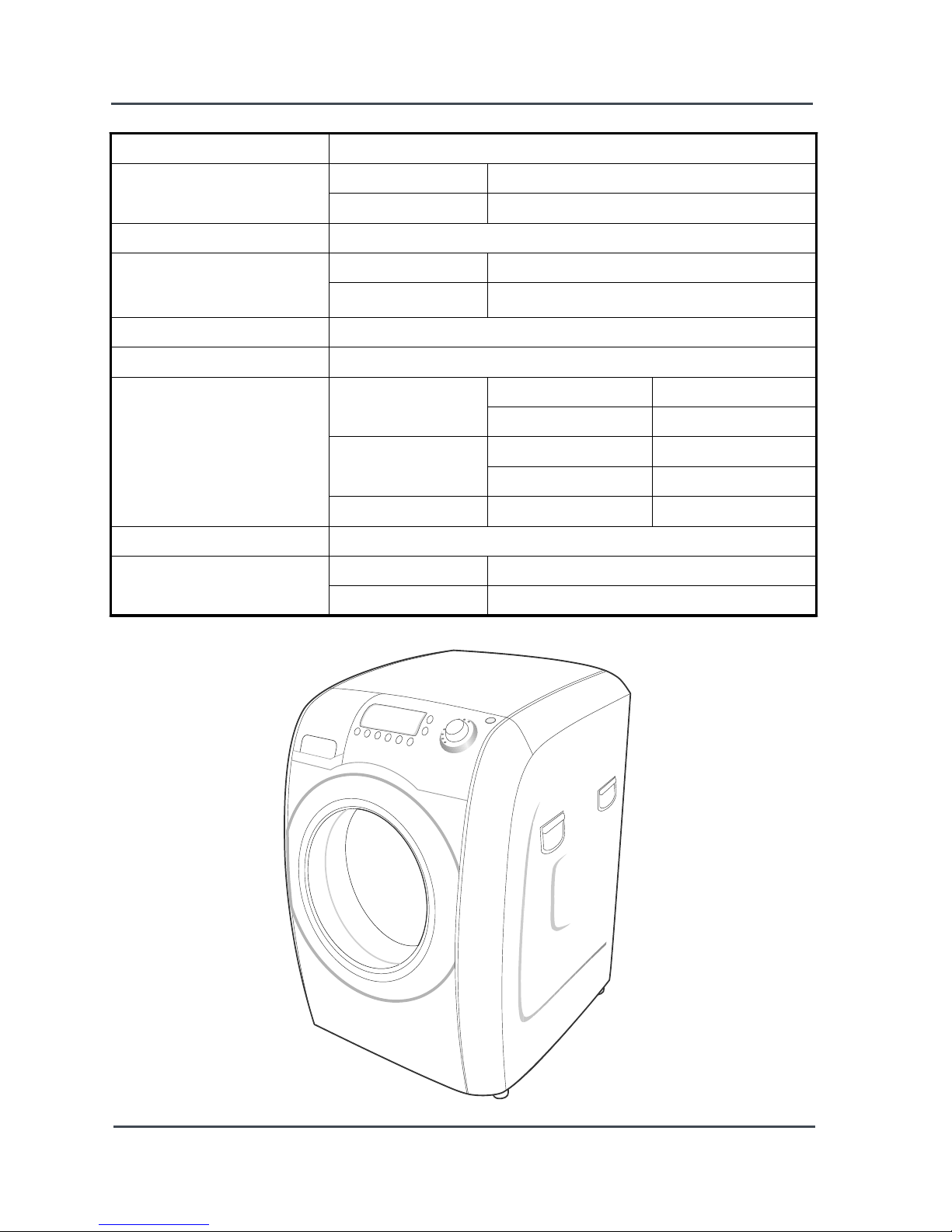

2-2. Specifications

WASH TYPE

FRONT LOADING TYPE

DIMENSION

NET W650mm X D774mm X H939mm

GROSS W727mm X D857mm X H1015mm

WATER PRESSURE

50 kPa ~ 780 kPa

WEIGHT

NET 92 kg

GROSS 99 kg

WASH&SPINCAPACITY

10.0 kg (DRY LAUNDRY)

DRY CAPACITY

6.0 kg

POWER CONSUMPTION

WASHING

220V 170W

240V 170W

WASHING and

HEATING

220V 2000W

240V 2400W

Drying 220V 2100W

WATER C ONSUMPTION

125ℓ(COTTON COURSE)

SPIN REVOLUTION

MODEL WM1255A

rpm 1200

- 7 -

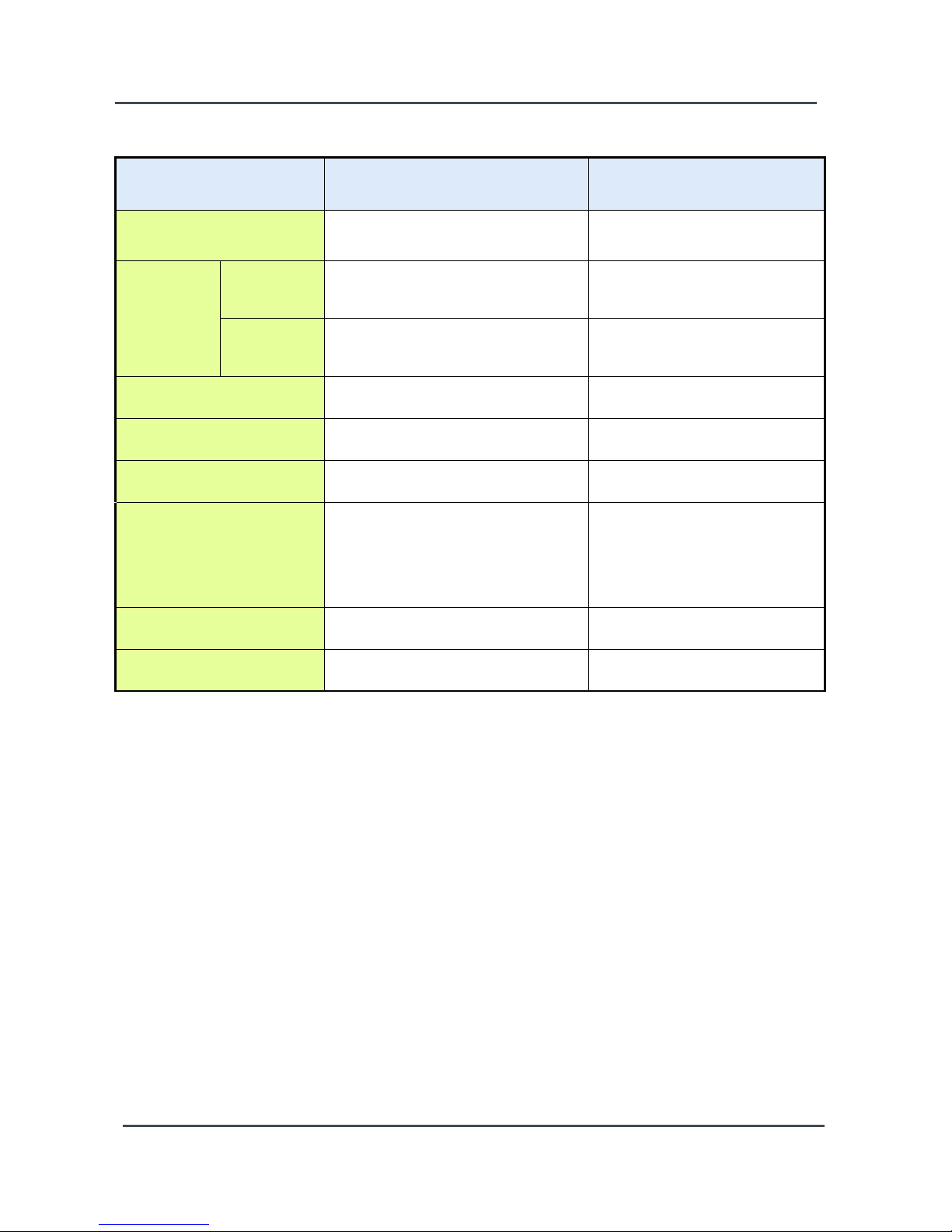

2-3. THE COMPARATIVE SPECIFICATIONS OF PRODUCT

Item 10.0kg Old (10.0kg)

Model Name

WM1255A WM1245A

Capacity

Washing

10.0kg 10.0kg

Drying

6.0kg 6.0kg

Drum Capacity

78

ℓ

78

ℓ

Washing Motor

DD INVERTER DD INVERTER

Heater (220V)

1900W 1900W

Supply/Drain

Cold water / Drain pump Cold water / Drain pump

Balancer

Weight Weight

SIZE(W*D*H)

650*774*939 650*774*939

- 8 -

2-4. THE COMPARATIVE SPECIFICATIONS OF PRODUCT

10.0kg

Model Name

WM1255A WM1245A

Function

AG+ WASH

OO

MEMORY

OO

Exterior Replacement Part

Name

Specifications

Design

Top Cover

SNOW-WHITE SNOW-WHITE

Panel-Control

SNOW-WHITE SNOW-WHITE

Panel-Drawer

SNOW-WHITE SNOW-WHITE

Cover Door

IMPERIAL-SILVER IMPERIAL-SILVER

Deco Top

IMPERIAL-SILVER IMPERIAL-SILVER

Deco Front

IMPERIAL-SILVER IMPERIAL-SILVER

Button-Push(F)

SNOW-WHITE SNOW-WHITE

AG+ KIT

Nomal Hard Water

Knob-Encoder

JOG-DIAL

Chrome Vapor

Disposition

Chrome Vapor

Disposition

Button-Encoder

SNOW-WHITE SNOW-WHITE

Button-Push(P)

SNOW-WHITE SNOW-WHITE

- 9 -

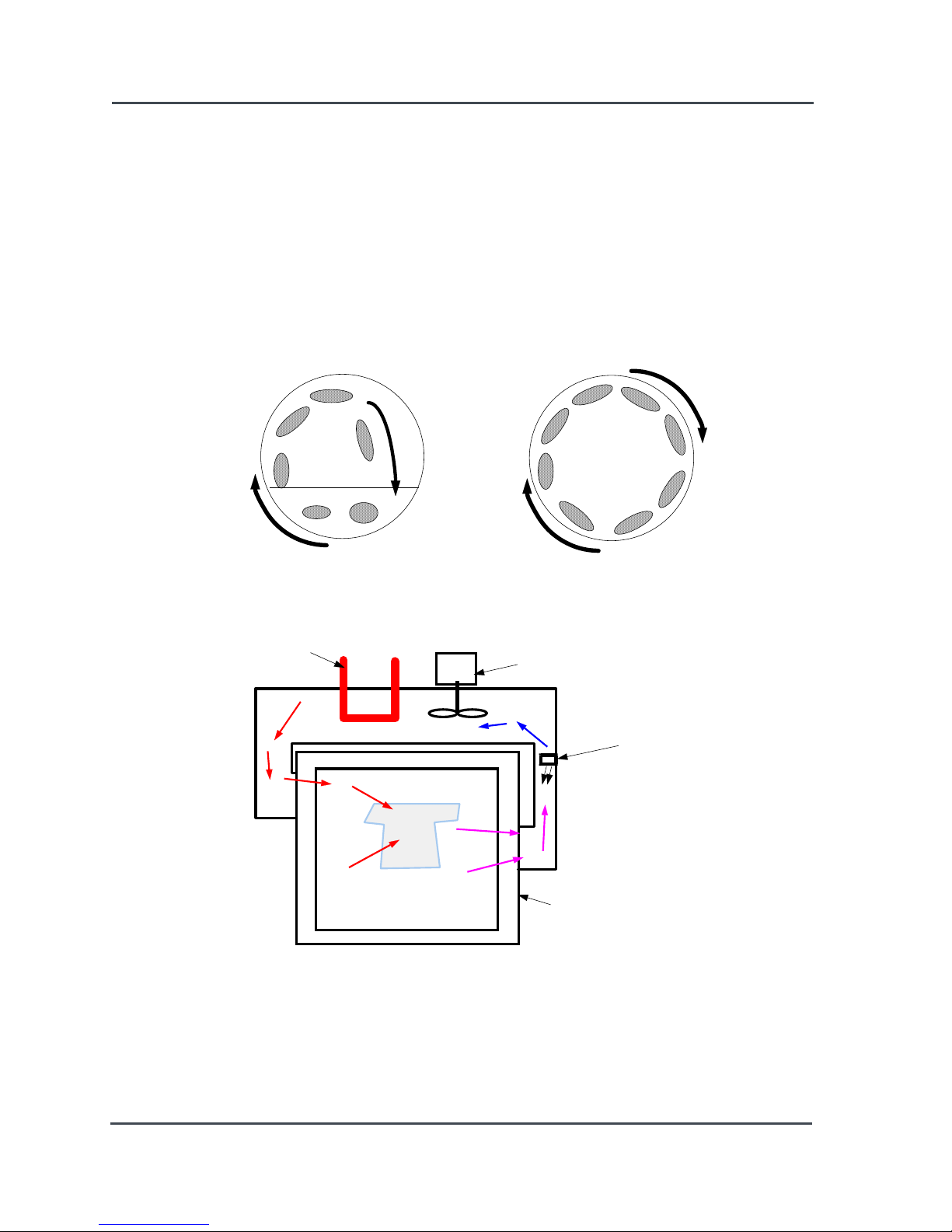

This washing machine performs the washing and dehydration functions by rotating its drum around a 10°

inclined axis of rotation to the horizontal axis.

1. Washing

The washing technique employed is to let the clothing fall from the top of the drum cycle.

2. Dehydration

The dehydration technique employed squeezes the water out using centrifugal force which pushes

the clothing out towards the wall of the drum through the high speed rotation of the drum.

(Max 1200 RPM)

3. Drying

Condensing System: This heats the internal and evaporates the moisture contained in the laundry

into steam and further uses the condenser to condense the steam before draining, resulting in a

temperature decrease inside the drum.

This is easy to install as this does not require a separate duct.

2-5. WM1255A Features

For Dehydration

rotating MAX 1200rpm

For Washing

rotating 40~50rpm

Drum

Tub

Heater

Fan Motor

Condensed

Water Nozzle

- 10 -

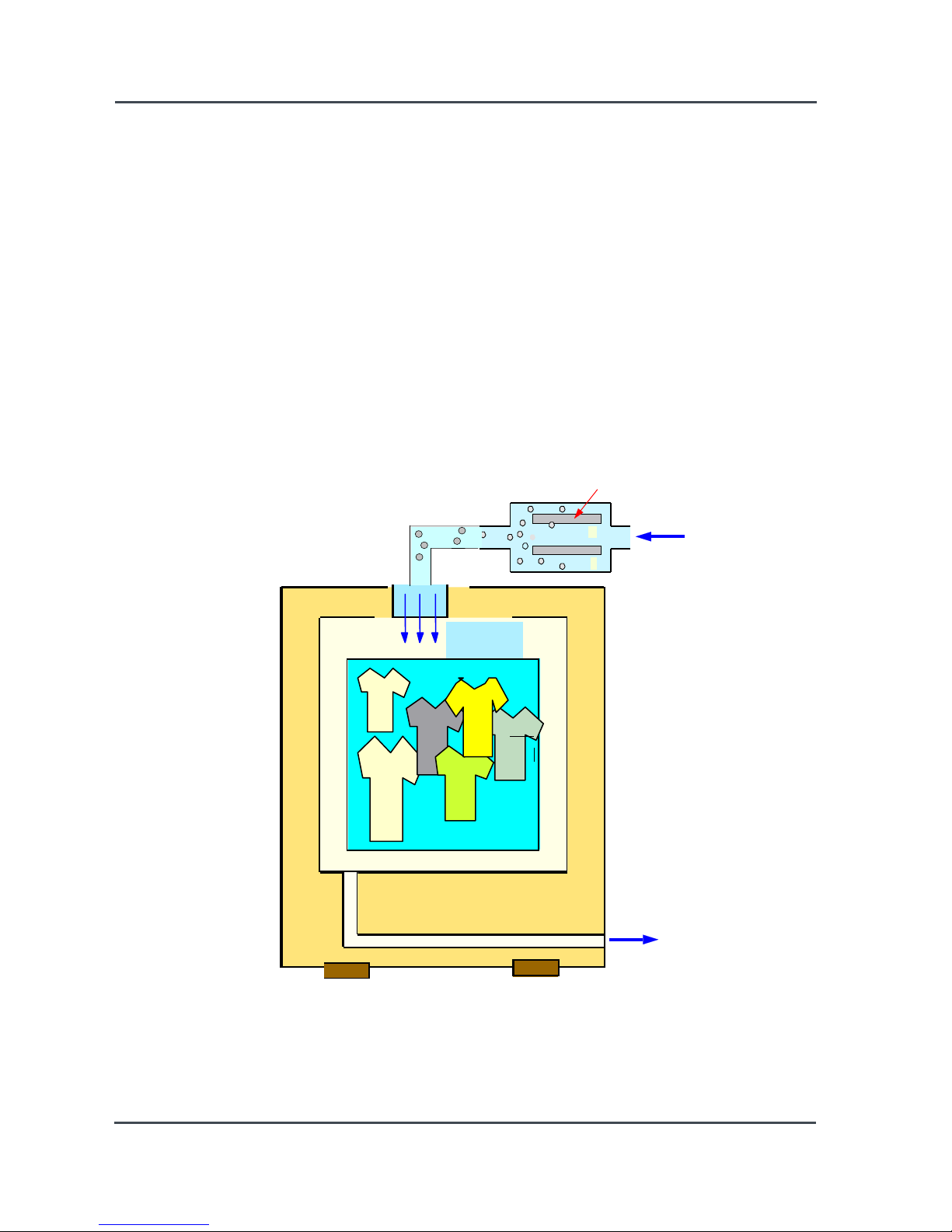

4. Silver-Nano System

1) Purpose

- Provides sterilization for the wash cycle using the combination of the silver ionized water and

the chemical detergent.

- Provides anti-bacteria feature to protect external bacteria from infiltrating into the laundry

by means of silver-nano coating.

- Prevents any harmful substances from growing in the tub (mold, various bacteria, bad smell,

etc)

2) Driving System

- Ag+ ionized water, generated by electrolysis, provides anti-bacteria coating and sterilization

for the laundry.

+

-

Ag+

Ag+

Ag+

Electrolysis

Ag+

Ag+

Ag+

Ag+

Ag+

Ag+

Ag+

Ag+

Ag+

Ag+

Ag+

Ag+ Ag+ Ag+

Ag+

Colloid

Ag+

Ag+

Ag+

Drainage

Water supply

Silver plate

- 11 -

5. Advantages of the WM1255A

(1)

Maximized Anti-bacteria and Sterilization - Introducing Silver Nano Technology

(2) Saves water (Washes with a smaller amount of water than 'normal' washing machines)

(3) Less wear and tear on clothing

(4) High-temperature washing (95℃-washing) available for sterilization/hygiene purposes.

(5) It is an energy saving model by employing a high-efficiency motor.

(6) Less noise and vibration due to the continual sensing of any Unbalance.

(7) The machine has a lighter weight due to the use of a liquid balance.

(8) 10kg super-slim size (650 mm)

(9) An increase in the washing/rinse efficiencyandadecreaseinthewashingtimerealizedby

employing a Water Turbine.

(10) Convenient handles intalled for wasy moving.

(11) Automatic power cut function (If a user doesn't press the START button within 10min of the

power being switched on, power is automatically cut off.)

(12) A self-examining function of any problems.

(13) The addition of clothing for different cycles is possible (the initial stage of the water supply,

the tub-temp low) after the begining of the wash.

(14) A noise-minimizing design for dehydration by employing a low-noise motor, a low-noise pump

andanoildamper.

(15) A Child Lock function (Safety Apparatus for protecting children)

(16) Shortens the drying time owing to the optimal drying system.

(17) Various drying courses (Normal, Sterilization, Low-temp)

(18) Automatically senses the amount of moisture to adjust the drying time.

(19) Uses the sterilization drying system for removing bacteria.

- 12 -

Samsung Electronics

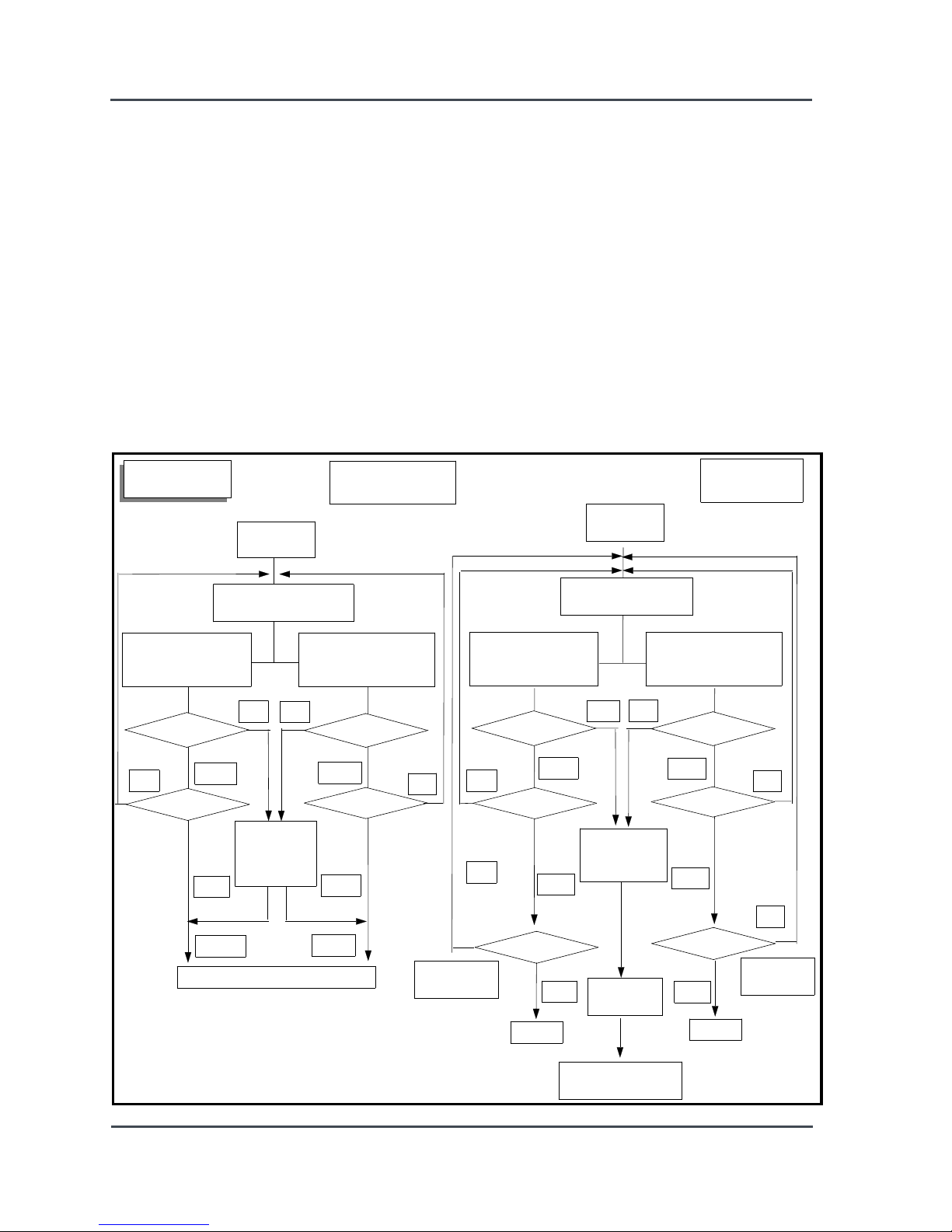

Reference 1. Un-Balance Sensing

The maximum rpm (600, 800, 1000, 1200rpm) for the main dehydration cycle is determined bythe

result of the Unbalance Sensing. And if the result of the Unbalance Sensing goes beyond the set

value, it performs a re-operation.

The restart of the operation begins from the clothes-untwisting cycle after pausing the Unbalance

Sensing.

For wash and rinse cycles (Unbalance Sensing)

If an Unbalance is sensed at a low speed, it performs the Unbalance Sensing a max. of 10 times.

And if sensed at a high speed, it does a max. of 5 times. If Unbalance is over the set value

thereafter, it performs the next cycle without performing dehydration.

For the final dehydration cycle (Unbalance Sensing)

If Unbalance is sensed at a low speed, it performs Unbalance Sensing a max. of 10 times. And if

sensed at a high speed, it does a max. of 5 times. If Unbalance is over the set value thereafter,

the water is supplied during the dehydration cycle to perform the cloth-untwisting cycle a max. of 3

times. However, in a case where 'Unbalances' exceed 3 times, an UE Error is displayed. If there

are no 'Unbalances' during the dehydration cycle, it directly performs dehydration regardless of the

intermediate stages such as dehydration during washing/rinse and final dehydration.

Restart of

Operation

For Final

Dehydration

Drain

Cycle

Cloth-untwisting

Cycle

Unbalance sensing

(low speed :85

~95rpm)

Retry

Simple

/Main

Dedydration

10times

YES

YES

Next Cycle

For

Washing/Rinse

Unbalance sensing

(low speed

:200~250rpm)

NO

NO

YES

Retry

5times

YES

YES

NO

YES

NO

Drain

Cycle

Cloth-untwisting

Cycle

Unbalance sensing

(low speed :85

~95rpm)

Retry

Simple

/Main

Dehydration

10times

YES

Unbalance sensing

(low speed

:200~250rpm)

NO

NO

YES

Retry

5times

YES

NO

YES

NO

Cloth-

untwisting

3times

3times

Error

Error

YES

YES

NO

NO

Re-supply

of Water

Re-supply

of Water

End of

Dehydration

- 13 -

At Stop / Acceleration

Unbalance

The centers of gravity for both

'Unbalance' and 'liquid balance' face

downward.

At constant speed

The centers of gravity for both 'Unbalance'

and 'liquid balance' at a speed faster than

the resonance point face in the opposite

direction, so that it functions in a way to

remove the unbalance.

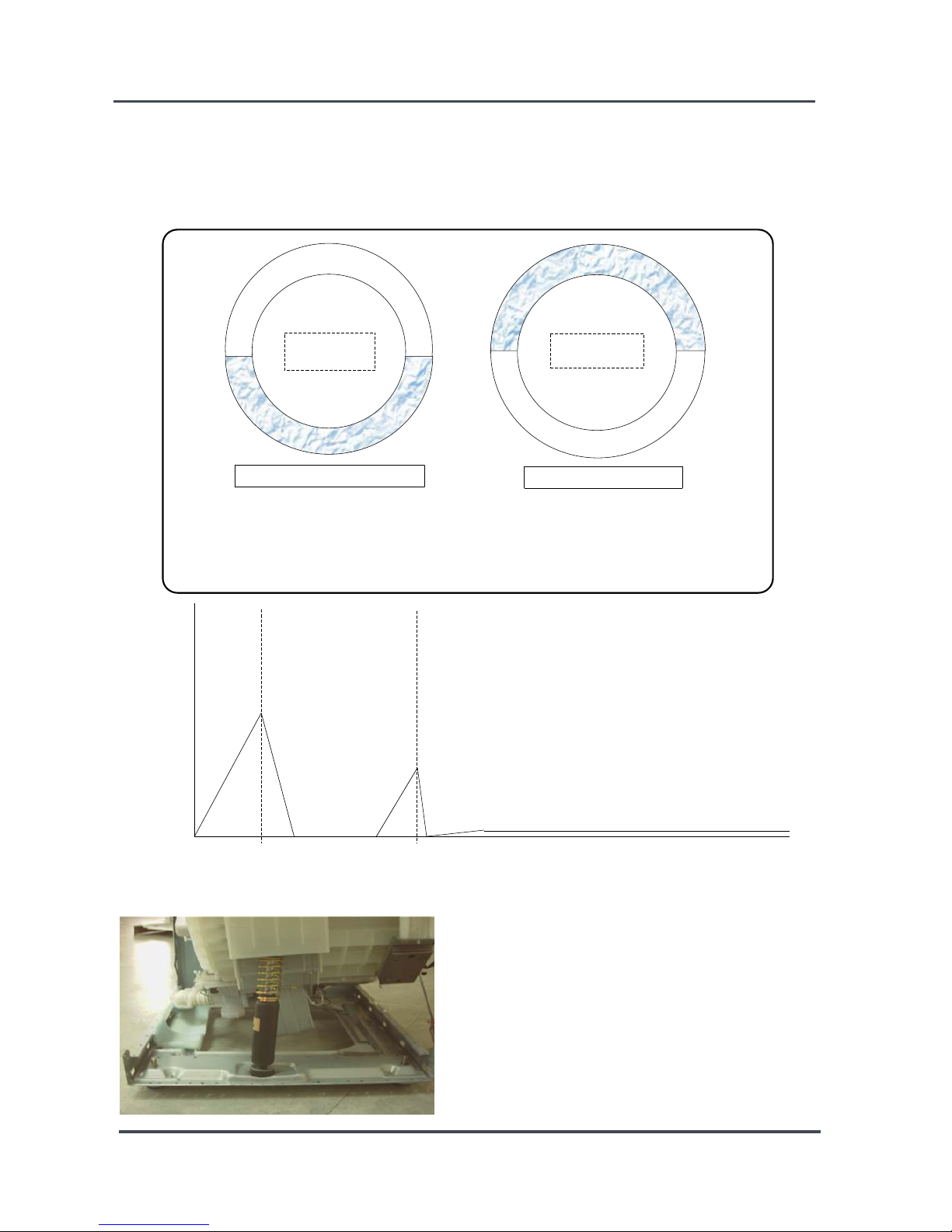

Reference 2. Liquid Balance

- Principle of Liquid Balance

The previous drum-type washing machines used to control 'Unbalances' on the principle of

weight so that the weight of the product was quite heavy, whereas this product decreases the

weight by employing a liquid balance..

Unbalance

언

발

란

스

의

크

기

속도

제1공진점

제 2 공진점

최종 탈수 속도 구간

(언발란스 < 500g)

Reference 3. Application of the oil damper

The application of the oil damper improves the

abrasion noise generated by the previous abrasion

damper, so that it decreases noise during

dehydration.

(A decrease of 5dB at maximum rpm of dehydration)

Volume

of

Unbalance

1st resonance

2nd resonance

period of final spinning speed

(Unbalance < 500g)

Speed

- 14 -

1. Cycle Display LED

●

It displays the present operating cycle and the setup cycle.

●

Pressing the Pause button displays the amount of cycles remaining.

2. Power Switch

●

This switches thepowerON/OFF.

3. Start Switch

●

This is used to Start/Pause the operation.

4. Jog Dial Switch

●

This selects one of the washing courses.

●

The order of the washing courses is as follows: Towel/Cotton/Cotton95℃/Cotton75℃/Coloureds

/Quick/Wool/Delicate/Bedding/Clean Tub.

5. Types of Functional Buttons

1) Temperature Setting Button

●

This sets the temperature of the wash.

●

However, there is a different temperature limit for each course.

●

The temperature can be selected in the successive order of

℃

(

Cold Water)→30

℃→40℃

→60℃→75℃→95℃

.

●

The selection of the temperature is only available for the Wash Cycle.

●

It is impossible to set the wash temperature during a wash.

●

If the wash temperature button is pressed during washing, the selected temperature is

displayed for 3 seconds.

●

If a temperature is selected, it switches the℃LED on.

2) Silver Wash Button

●

Silver Nano particles are supplied during the wash and rinse cycles.

●

The time consumed for the rinse cycle will be longer than for other courses.

●

You could not select the key after the start of any operation.

●

When you select the silver nano key in a single cycle mode, the cycle is set to the default

of the normal course and you can only select the silver nano key in wash or rinse cycles.

●

When the silver nano key is selected, the silver nano kit starts operating its anti-bacteria

function.

- Silver Sterilization: the silver nano kit starts operation in water supply for the washing

cycle or additional supply.

3-1. OVERVIEW OF THE CONTROL PANEL

3.

PRODUCT SPECIFICATIONS

- 15 -

- Silver Anti-bacteria: the silver nano kit starts operation in water supply for the last

rinse cycle.

●

When the silver nano key is selected, the last rinse time becomes longer than the others for

effective anti-bacteria feature.

●

When the silver nano key is selected, the silver nano LED turns on and when the wash or rinse

cycles are done, the LED turns off. And the LED blinks when the silver nano kit starts

operation or during the silver sterilization or anti-bacteria rinse cycles.

3) Wash Button

●

The user can select one in this order: Wash→Prewash→Wash Only

→

Prewash + Wash Only.

4) Rinse Button

●

The number of rinse times for each course can be selected in successive order

Number of Rinse Times→+3 times→+4 times→+5 times→6times→1time

ㆍㆍㆍ

.

The WASH and SPIN procedures will be deleted at this time. However, they are not

deleted if the Rinse Button is handled after the selection of Wash-Only or Spin-Only.

●

When the Rinse Button was selected, the number of rinse times can be selected from betwen

1 and 6 times for each course.

5) Spin Button

●

A rotation speed for the dehydration cycle can be selected in the following order:

800→1000→1200→600.

●

The WASH and RINSE procedures will be deleted at this time. However, they are not

deleted if the SPIN Button is selected after the selection of Wash-Only or SPIN-Only.

6) Drying Selector Button

●

The drying process is performed according to the steps below when the Drying button

is pressed.

- Standard → Sterilization → Easy Iron → Low temperature → Time setting (30min → 60min

→ 90min → 120min → 150min) → Cancel

●

The button does not perform a standalone cycle, but an additional course added to the

other cycles

●

When selecting Drying, the Drying icon is turned on and pressing it again turns it off.

●

This function cannot be selected after entering the drying cycle and is only changeable

when Paused. However, it cannot be selected in Pause mode when Drying for normal

courses has been selected.

●

It can only be selected in the Cotton, 95℃, 65℃, Coloureds, Quick or Dedicated Drying

courses

7) Delay Start Button

●

This button functions to reserve the end time of the function currently set. Set the

Delay Start time and press the START button to operate this function.

●

The Delay Start time can be selected in hourly units and in a 24 hour range.

●

It is impossible to change the Delay Start time and the course after the operation starts.

●

After selecting this function, the Delay Start LED stays ON for the whole duration time.

●

The Delay Start time decreases in hourly units.

8) Add Laundry Button

●

You can add laundry when a cycle or operation is in process or the door is closed under

conditions other than the door being unlocked and the temp. sensor of the fan housing

- 16 -

below 55℃.

- You cannot select the add laundry function during the Clean-tub course

●

When selecting the add laundry key, if the machine is already operating, the machine stops

temporarily.

●

When the add laundry key is pressed, the machine stops the drum rotating and drains the

water to below the door lock level.

Add Laundry

Pumping Rate

ON OFF

22 sec. 4 sec.

●

When the water level falls below the door-open level and the door is open, the add

laundry process is cancelled.

●

The add laundry LED turns on or off as below;

a. When the door is closed and the temp. sensor of the fan housing is below 70℃ and the water

is below 55℃, the add laundry LED turns on to inform you that the add laundry key can be

selected.

b. When the add laundry key is selected and the machine stops the drum rotating or drains

water, the add laundry LED blinks to inform you that it is in process.

c. When the door lock is off or the temperature is high, the add laundry LED turns off.

9) Start/Pause Button

This button enables the selection of one of two functions in the order of Pause→Start

→

Pause→Startㆍㆍ.

Door Unlock

Conditions

The water level is higher than 23.95kHz or the water temp is

below 55℃.

The temp. sensor of the fan housing is below 70℃.

The water level is below 22.90kHz (10Kg) or 22.60kHz (12Kg).

The drum has stopped rotating.

The door can be opened when all conditions above are satisfied.

- 17 -

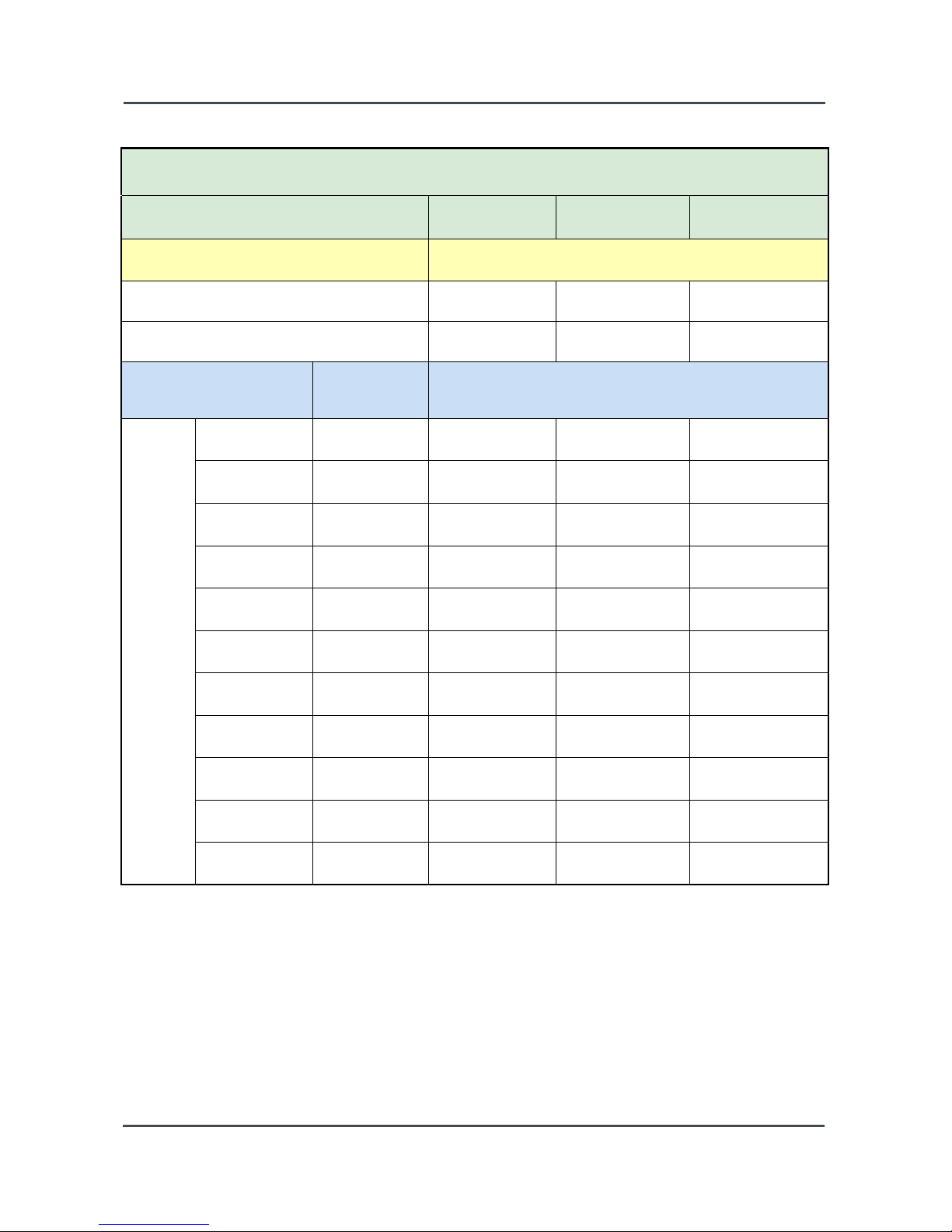

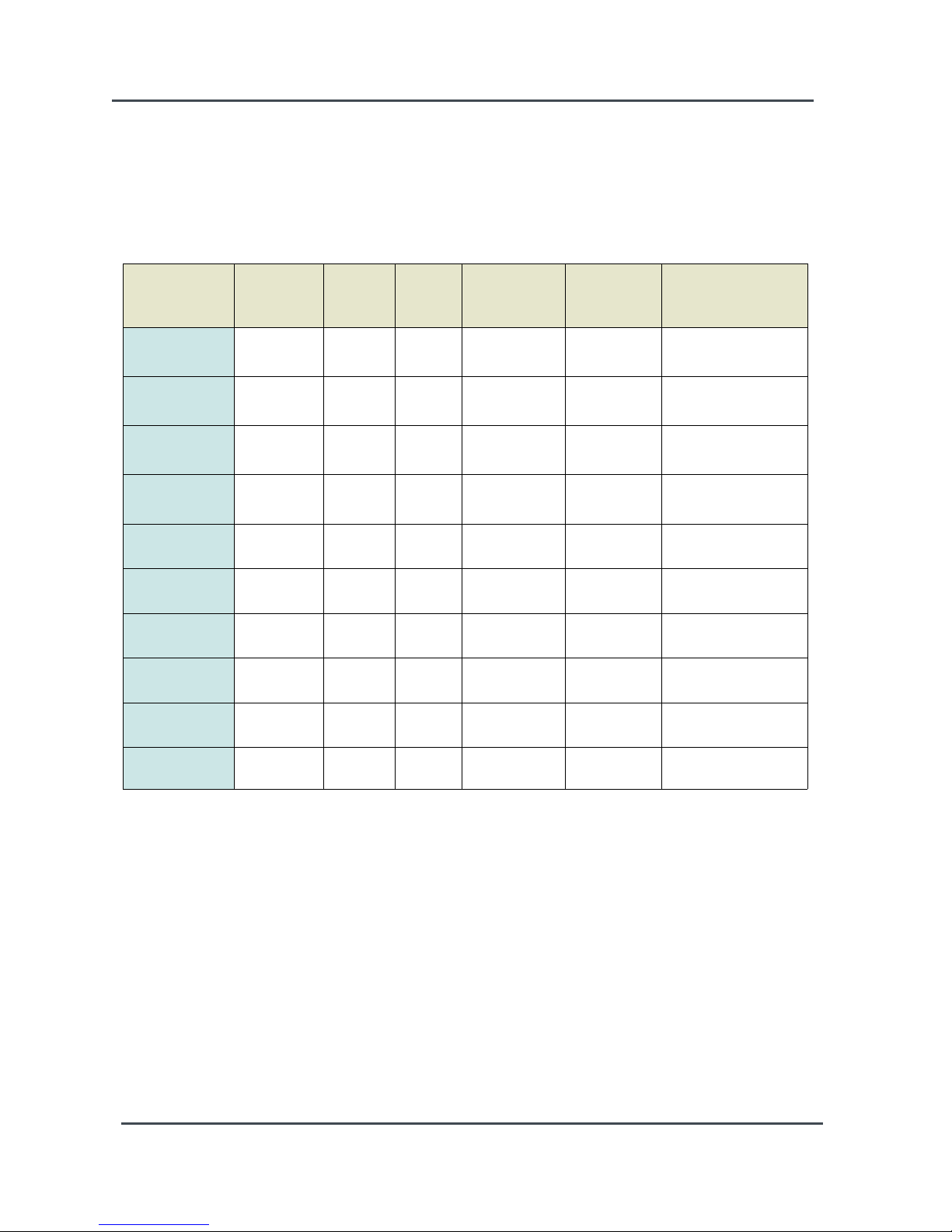

6. Program Chart

①

.Jog-dialSwitch

This switch enables the selection of a course in the following order: Towel↔Cotton

↔

Cotton 95

℃↔

Cotton 75

℃↔

Coloureds↔Quick↔Wool↔Delicate↔Bedding

↔

Clean Tub.

The initial default value at the time of switching the Power on is Cotton Course.

②

. The initial default values for each course:

☞

Main Dehydration (rpm) means the maximum rotation speed that can be operated in case of a

small Unbalance. If there is a large Unbalance, a lower speed will be automatically set.

③

. Every course is set up with Encorder S/W, and cycles can be changed manually before

pressing the Start Button.

④

. It is possible to change some of the cycles even after hitting the Start Button. (Example:

the Rinse and Spin information can be changed during a wash)

⑤

.Ifoneofthecoursesisselected,thatLEDwillstayON.Butifthecourseisoperating,its

LED repeatedly displays On/Off every 0.7 second.

⑥

. The Wool and Delicate courses cannot be changed once the Start Button is pressed.

⑦

.The95℃and 65℃courses cannot be changed once the heater starts.

Course Capacity

Default

Temp.

Rinse

Main

Dehydration

(rpm)

Preliminary

Washing

Temperature

selectable

Towel 5 kg 40

℃

3 times 600 Selectable

cold water,

40℃,95

℃

Cotton 10 kg 40

℃

3 times 800 Selectable

cold water,

30℃,40℃,60

℃

Cotton 95

℃

7kg 95

℃

3 times 800 Selectable 75℃,95

℃

Cotton 75

℃

7kg 75

℃

3 times 800 Selectable 60℃,75

℃

Coloureds 10 kg 40

℃

3 times 800 Selectable 40℃,60

℃

Quick 5 kg 40

℃

2times 800 -

cold water,30℃,

40

℃

Wool 4 Kg

(Cold

Water)

3times 600 -

cold water,30℃,

40

℃

Delicate 4 Kg

(Cold

Water)

3times 600 -

cold water,30℃,

40

℃

Bedding 5 kg

(Cold

Water)

3 times 800 Selectable

cold water,30℃,

40

℃

Clean Tub

--

2times

--40℃

- 18 -

7. Function Buttons

1) The Function Buttons have 75±16.7ms of the effective time of pressing.

2) If the press of a Function Button is sensed, a function button sound is heard.

3) If two or more buttons are pressed, the button pressed first will be selected.

(Except for special buttons (Power Button))

4) Cases where Function Buttons are not selectable:

①

. No buttons can be selected after pressing the Start command, except the Power Button,

the Start/Pause Button, and the Child Lock Button.

②

. The selection of the Wash Temperature is not accepted if a cold course was already

selected.

③

. In the case where an Error is generated, all buttons except the Power and Start buttons

cannot be selected.

④

. If the Child Lock function is set, only the Power and Child Lock Release buttons can be

selected.

⑤

. Completed cycles cannot be selected again.

8. Detailed Information for Each Cycle

1) Common Information for Every Cycle

①

. If each cycle is selected, it progresses in the following order:

(Prewash)→Wash→Spin→Rinse→Spin→Rinse

→

Spin→Rinse→Final Spin→End

②

. If the Start/Pause button is pressed during the operation of a cycle, it stops that cycle. One

more press of the button will re-start that cycle. (In this manner: Stop→Start→Stop

→ㆍㆍ

)

③

. During the pause the remaining time does not decrease and every steering part (Motor, Valve,

Heater, ect.) stays in the OFF condition.

④

. The LED display of each course and the cycle stays On at the time of selection, while it

refreshes every 0.7 second while operating. The LED of a finished cycle turns OFF.

⑤

. A buzzer will sound every time a cycle is set up.

⑥

. It is possible to change the course and cycle with the function buttons during the operation of

a course. (Except for the Lingerie and Wool Courses)

⑦

. If users swich on the Power, a melody plays once.

⑧

. It is not possible to select any button, except the Power Button, while the melody sounds.

⑨

. When the Power is switched On, the steering parts (Motor, Valve, Heater, etc.) are in an Off

conditionandtheCottonCourseisselectedasdefault.

2) Wash Cycle

The Wash Cycle performs the following operations: Water Supply/ Water Stirring/ Wetting/

Heating/ Washing/ Cooling/Drain.

( Wetting/Heating/Cooling cycles are performed only when the temperature is set to over 40℃.)

- 19 -

3) Water Supply Function

①

When selecting Wash

-. Water is supplied through cold water + hot water(option) valves to the frequency level of the

wash set up for each course.

(The hot-water valve does not operate when the temperature is set to below 60℃.)

If the wash temperature is set to over 40℃for each course, it supplies water to

the set-up level and performs a Wetting Cycle and then starts the Heating cycle.

-. When the water level decreases during the Wetting Cycle after the end of the water

supply, it supplies water using a supplementary water-supply function.

(Except for the Wool and Lingerie courses)

-. Conditions of the Hot-Water Supply (Option)

●

For a temperature setup of over 60℃the cold/hot water valves operate at the same time.

●

Both cold and hot water are used for steering the water level and as supplementary water.

4) Drying Function

① When the drying function starts, the heater, fan/M, drying water supply and drainage motor

perform their operations, running the washing motor using a stream of water.

② The drying cycle is processed in the order below:

- Detection of Drying Amount

- Primary Drying: Operates the 2000W heater (2 1000W heaters)

- Secondary Drying: Operates the 1000W heater

- Ventilation: When the drying cycle is done with dryness sensing, the washer turns off

the heater and only runs the fan motor, lowering the temperature inside the drum.

All cycles are completed when the temperature of the internal sensor (air sensing) is

below 70℃ (60℃ inside of the drum).

③ Dedicated Drying Course Algorithm

a. When selecting Dedicated Drying, the drying cycle starts to operate and completes

its operation once cooling has ended.

b. During the initial drying operation, if the water level goes over a certain level,

pre-heating is added before dehydrating. When selecting a drying time, the washer

enters the drying cycle directly without sensing the dry amount. When select a

drying option, drying is performed after twice sensing the dry amount.

c. If pre-heating is added to dehydrating, the display time increases by 17 minutes.

d. Selecting the Drying Time does not require detecting the drying amount while the

Drying Option does require detecting the amount twice when the remaining time is

displayed.

④ Algorithm when adding Drying to normal courses

a. The drying feature can be added to courses other than wool, lingerie, quilt and

drum washing.

b. When drying is added, the last dehydrating cycle is converted from normal to pre-heat.

When all normal cycles are done before the drying process starts, the washer senses

the drying amount to reset the drying time and displays the remaining time.

(For Drying added by the Drying Option)

- 20 -

5) SOFT KEEP

① When all cycles are done along with Drying, the END feature starts to operate. Once this is

completed, if you do not remove the laundry, the washer rotates the drum in reverse to avoid

wrinkles.

② The reverse-rotation continues up to 30 minutes after the completion of all cycles.

③ The SOFT KEEP time does not belong to the total washing time.

④ When all cycles are done, the END MELODY is performed and the door lock is switched off.

(However, the door stays locked while the tube is running)

⑤ When opening the door while rotating, all motor and display functions stop operating and

turn off.

⑥ While the Soft Keep feature runs after the washer performs all cycles and the first End

Melody function, the End Melody feature operates every ten minutes and the End message is

continually displayed.

⑦ The rotating direction of the motor is displayed in the same way as that of the drum while

the washer performs Soft Keep.

⑧ No operating keys are activated and even if pressed, they are automatically switched off

while in Soft Keep.

Loading...

Loading...