Page 1

Samsung Electronics 4-1

4. Disassembly and Reassembly

4-1 Cabinet and PCB

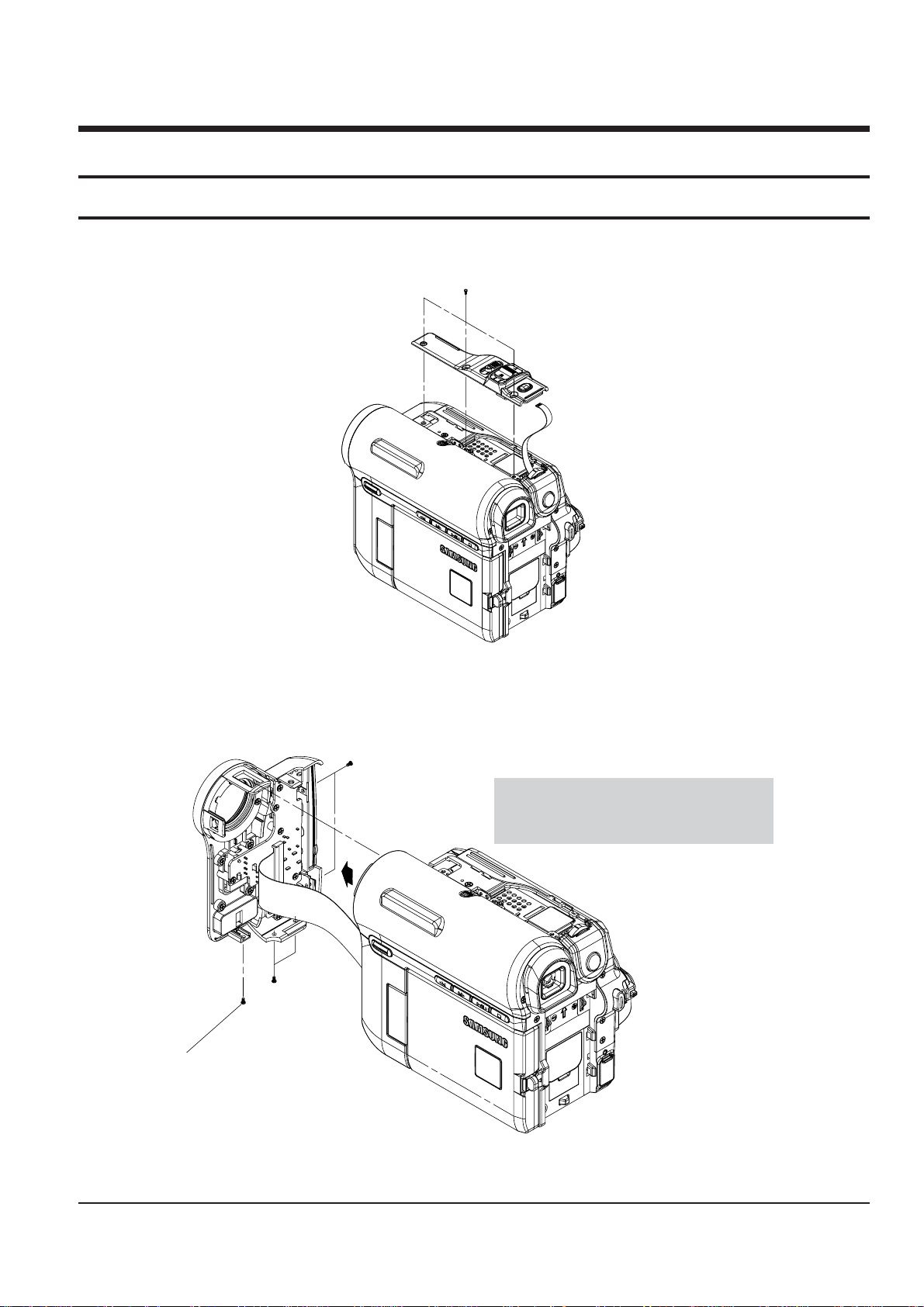

4-1-1 Ass’y Zoom Removal

ΠREMOVE 3 SCREWS

(M 1.7 X 4 BLK)

Fig. 4-1 Ass’y Zoom Removal

4-1-2 Ass’y Front Removal

Fig. 4-2 Ass’y Front Removal

ΠREMOVE 2 SCREWS

(M1.7 X 4 BLK)

´ REMOVE

2 SCREWS

(M1.7 X 4 BLK)

ˇ REMOVE 1 SCREW

(M1.7 X 5 WHT)

Caution : Please indicate that the connector

must be detached before separating

the Front Assembly

Page 2

4-2

Disassembly and Reassembly

Samsung Electronics

Fig. 4-4 Ass’y Left Removal

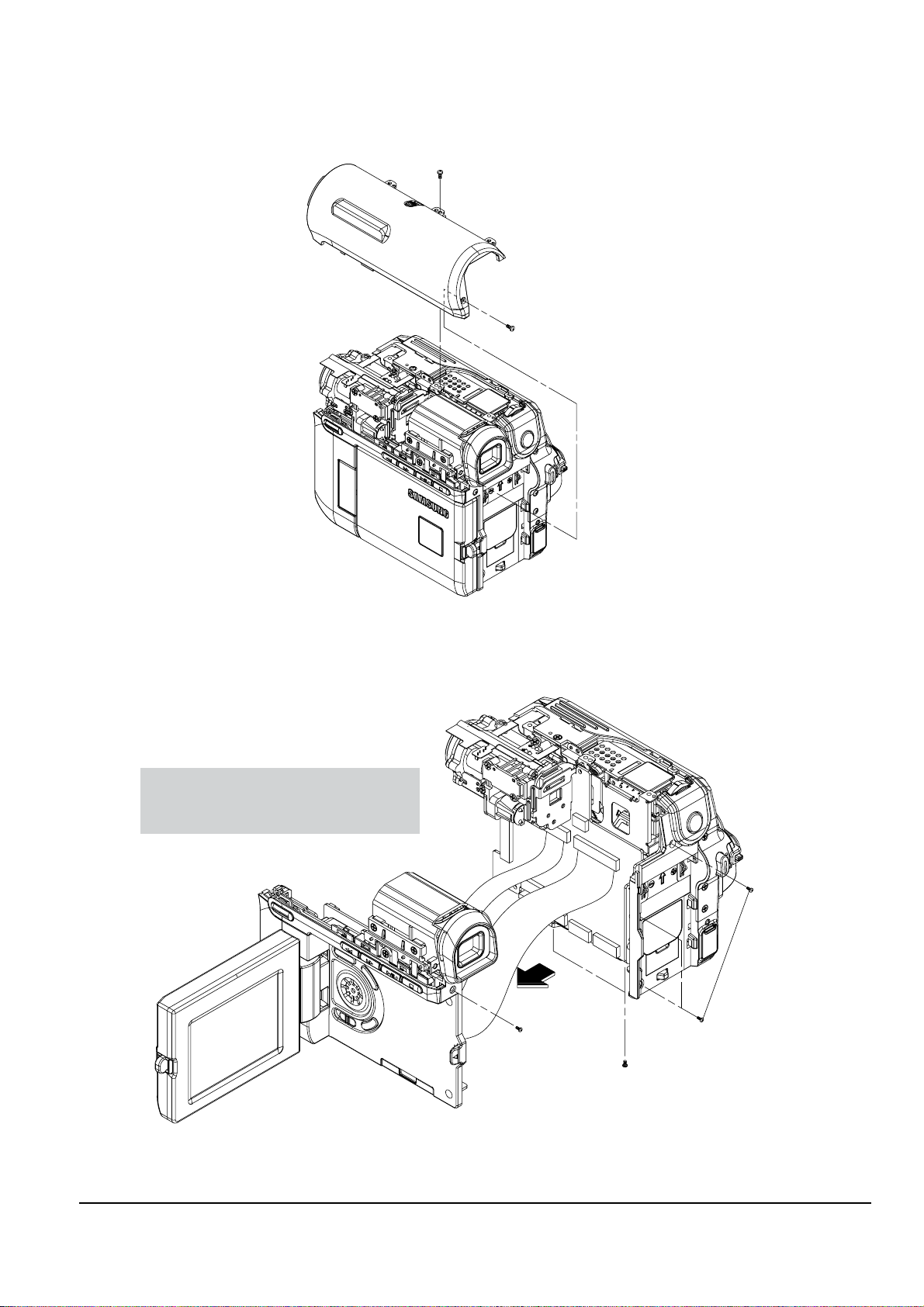

4-1-3 Ass’y Top Removal

ΠREMOVE 1 SCREW

(M1.7 X 4 BLK)

´ REMOVE 1 SCREW

(M1.7 X 5 WHT)

Fig. 4-3 Ass’y Top Removal

4-1-4 Ass’y Left Removal

ΠREMOVE 3 SCREWS

(M1.7 X 4 BLK)

´ REMOVE 2 SCREWS

(M1.7 X 4 BLK)

ˇ REMOVE 1 SCREW

(M1.7 X 5 WHT)

Caution : Please indicate that the connectors

must be detached before separating

the Left Assembly

Page 3

Disassembly and Reassembly

4-3Samsung Electronics

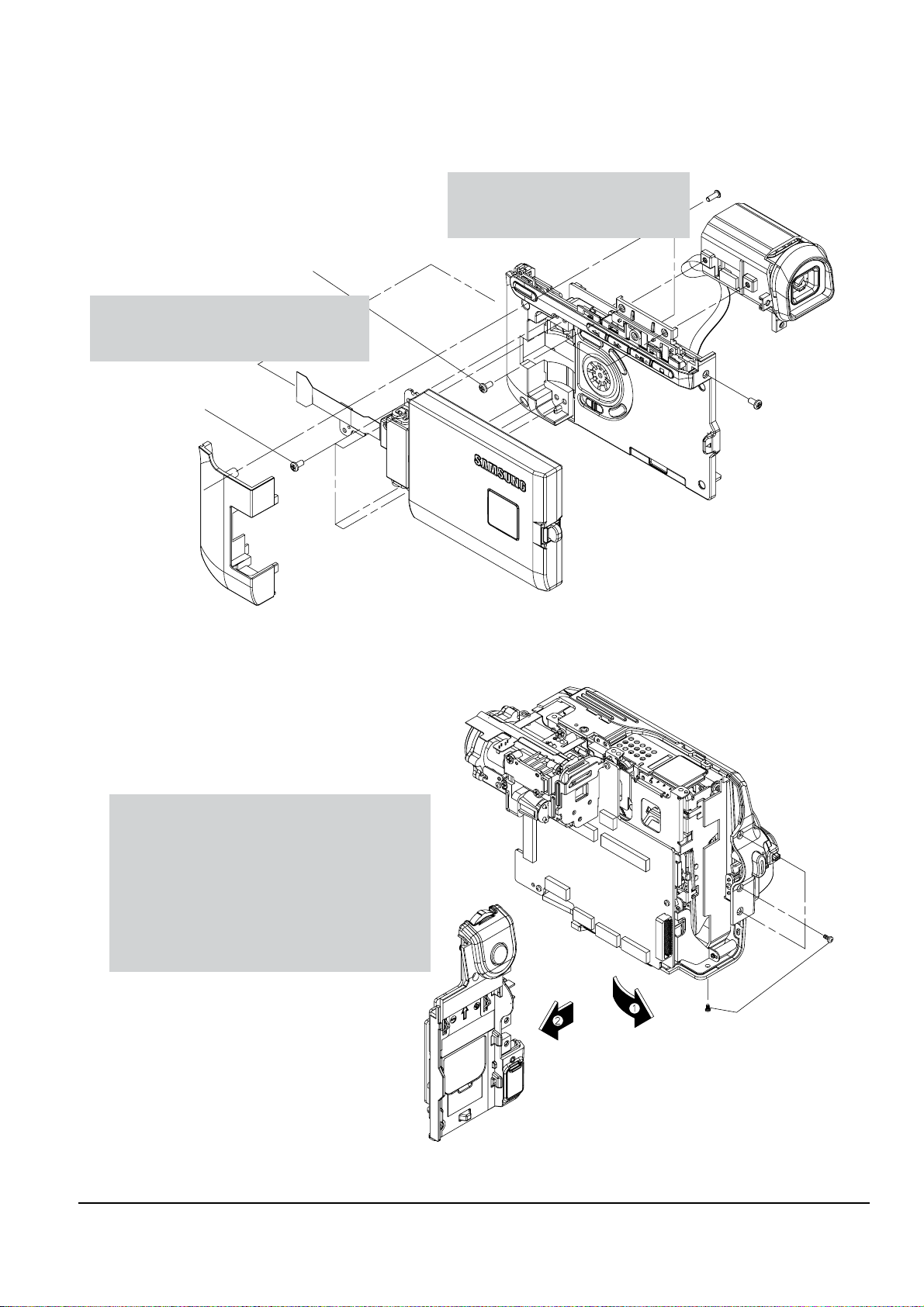

4-1-5 Ass’y LCD & EVF/CVF Removal

ΠREMOVE 3 SCREWS

(T1.7 X 4 BLK)

´ REMOVE 1 SCREW

(M1.7 X 5 WHT)

ˇ REMOVE 4 SCREWS

(T2 X 5 BLK)

¨ REMOVE 2 SCREWS

(M1.7 X 3 WHT)

Caution : Please indicate that there is a

connector on the View-Finder

that must be detached

Caution : Please indicate that this connector

must be detached before separating

the LCD Assembly

Fig. 4-5 Ass’y LCD & EVF/CVF Removal

4-1-6 Ass’y Rear Removal

Fig. 4-6 Ass’y Rear Removal

ΠREMOVE 4 SCREWS

(M1.7 X 4 BLK)

Caution : The Rear Assembly is connected to the

Main PCB. Pulling it to the left as

indicated in the illustraton can cause

the connector to break. This removal

instruction should indicate that the Rear

assembly should be pulled Forward first

in order to disconnect it from the Main PCB.

Then it can be pulled to the left

to separate it from the Main PCB

Page 4

4-4

Disassembly and Reassembly

Samsung Electronics

Fig. 4-8 Ass’y Right Removal

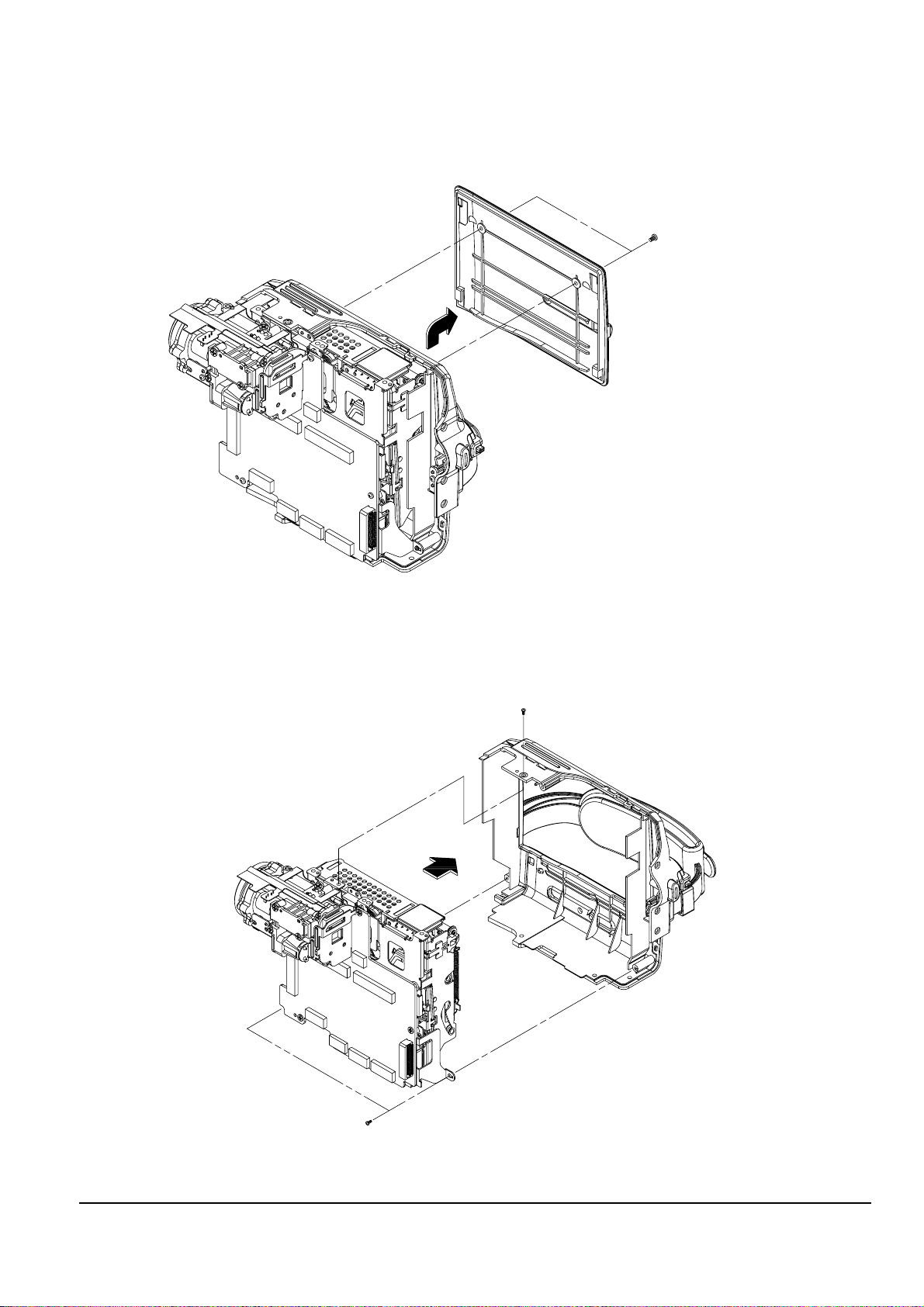

4-1-7 Ass’y Cover Housing Removal

Fig. 4-7 Ass’y Cover Housing Removal

ΠREMOVE 2 SCREWS

(M1.4 X 3 BLK)

4-1-8 Ass’y Right Removal

ΠREMOVE 2 SCREWS

(M1.7 X 4 BLK)

´ REMOVE 2 SCREWS

(T1.7 X 4 BLK)

Page 5

Disassembly and Reassembly

4-5Samsung Electronics

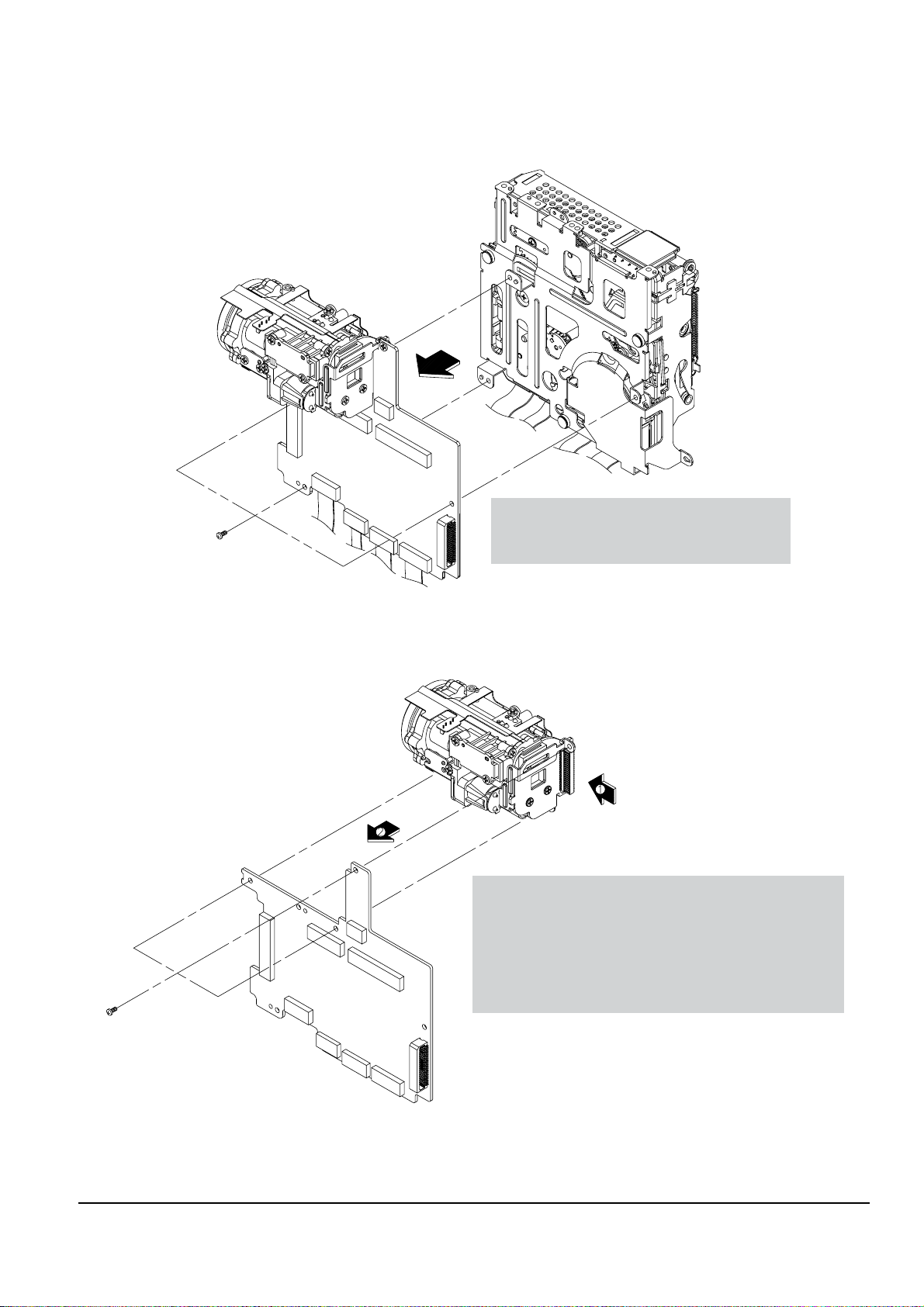

4-1-9 Ass’y Deck Removal

Fig. 4-9 Ass’y Deck Removal

ΠREMOVE 3 SCREWS

(M1.7 X 2.5 BLK)

Caution : Please indicate that these connectors

must be detached before separating

the Deck Assembly from the MAIN PCB.

4-1-10 Ass’y Main PCB Removal

Fig. 4-10 Ass’y Main PCB Removal

ΠREMOVE 3 SCREWS

(M1.7 X 2.5 BLK)

Caution : The Lens Assembly is connected to the Main PCB.

Pulling it to the left as indicated in the illustration

can cause the connector to break. This removal

instruction should indicate that the Lens assembly

should be pulled Forward first in order to disconnect

it from the Main PCB. Then it can be pulled to the

left to separate it from the Main PCB.

Page 6

4-6

Disassembly and Reassembly

Samsung Electronics

4-2-1 How to Load and Unload (Setting the Mechanical Modes)

1) Set the power-supply output to approximately 3V~5V, and connect it to the Motor Loading(= Loading Motor).

2) Choose the polarity depending on whether loading or unloading. (See Table 4-1)

3) Supply the voltage to the Motor Loading(= Loading Motor).

Fig. 4-11 Loading and Unloading

AB

Movement of Chassis

+

_

Unloading

_

+ Loading

<Table 4-1>

DC POWER SUPPLY

A

B

4-2 Deck

Page 7

Disassembly and Reassembly

4-7Samsung Electronics

4-2-2 Housing Ass’y

3

HOUSING LOCK L ´

ˇ HOUSING LOCK R

ΠLEVER LOCK

¨ LEVER HOUSING

ˆ SHAPE OF PIN

Ø CAM PART

∏ CAM PART

HOUSING ASS'Y ”

<DETAIL A>

"A"

Fig. 4-12 Housing Ass’y

4-2-2(a) Disassembly

1) Push the Lever(see arrow “A”, Detail A) turn the

Lever Lock Œ and open the Housing Ass’y ”.

2) Separate the Hook of Housing Lock L ´ and

Housing Lock R ˇ and then lift it.

3) Separate the Shape of Pin L and R ˆ from Cam

Parts Ø, ∏ of Main Chassis and then lift the

Housing Ass’y ”.

4-2-2(b) Reassembly

1) Mount the Shape of Pin L and R ˆ to Cam Parts Ø,

∏ of Main Chassis.

2) Mount Housing Lock L ´, R ˇ to right and left ,

and then locked.

Note : Do disassembly and reassembly in the

unloading mode.

Page 8

4-8

Disassembly and Reassembly

Samsung Electronics

4-2-3 Cover Reel Ass’y, Idler Ass’y

4-2-3(a) Disassembly

1) Lift the Cover Reel Ass’y Œ (See arrow “A”).

2) Then lift the Idler Ass’y ´.

4-2-3(b) Reassembly

1) Fit the Idler Ass’y ´ into the Pin.

2) Mount the Cover Reel Ass’y Œ to the Main Chassis

is groove in the oposite direction of arrow “A”.

"A"

2

ΠCOVER REEL ASS'Y

´ IDLER ASS'Y

Fig. 4-13 Cover Reel Ass’y, Idler Ass’y

Page 9

Disassembly and Reassembly

4-9Samsung Electronics

4-2-4 Reel Disk T, Brake T, Lever Eject

4-2-4(a) Disassembly

1) Lift up the Brake T ´.

2) Lift up the Reel Disk T Œ.

3) Separate the Lever Eject’s hook from the Main

Chassis, and then Lift up the Lever Eject ˇ.

Fig. 4-14 Reel Disk T, Brake T, Lever Eject

4-2-4(b) Reassembly

1) Insert the Lever Eject ˇ into the shape of pin ¨,

and then lock the Lever Eject’s hook Eliminate

this step.

2) Mount the Reel Disk T Œ to the pin Ø.

3) Insert the Brake T ´ into the shape of pin ˆ.

4

6

BRAKE T ´

ˇ LEVER EJECT

SHAPE OF PIN ˆ

Ø PIN

ΠREEL DISK T

¨ SHAPE OF PIN

Note 1 : When disassembling, take care not to deform

the part. Do not stain the post.

Page 10

4-10

Disassembly and Reassembly

Samsung Electronics

4-2-5 Arm Tension (=Tension Arm) Ass’y, Reel Disk S

4-2-5(a) Disassembly

1) Separate the Spring Tension (=Tension Spring)Œ

form Hook of Main Chassis.

2) Remove the Washer Slit ˇ, and then lift up the Arm

Tension (=Tension Arm) ¨.

3) Lift up the Reel Disk S ˆ.

Fig. 4-15 Arm Tension (=Tension Arm) Ass’y, Reel Disk S

4-2-5(b) Reassembly

1) Mount the Reel Disk S ˆ.

2) Push the Arm Tension (=Tension Arm) Ass’y ¨

in the direction “A”, and then insert into the Pin Ø.

3) Insert the Washer Slit ˇ, and then attach the Spring

Tension (=Tension Spring) Πto Main Chassis Hook

´ and Arm Tension Hook ∏.

4

"A"

3

SPRING TENSION (=TENSION SPRING) Œ

ARM TENSION (=TENSION ARM) HOOK ∏

PIN Ø

MAIN CHASSIS HOOK ´

¨ ARM TENSION (=TENSION ARM) ASS'Y

ˆ REEL DISK S

ˇ WASHER SLIT

Note 1 : When disassembling, take care not to deform

any part. Do not stain the post.

Note 1 : When reassembling or disassembling,

position of Spring Tension (=Tension

Spring) Πis same.

Note 2 : When inspecting the motion, Forward and

Reverse Tensions must be inspected.

Note 3 : When reassembling, confirm that the bending

of the Arm Tension (=Tension Arm) is

inserted into the Guide Cam.

Page 11

Disassembly and Reassembly

4-11Samsung Electronics

4-2-6 Drum

4-2-6(a) Disassembly

1) Remove 3 Screws Œ, and then remove the Spring

Plate ´.

2) Lift up the Drum ˇ.

7

5

4

2

1

Ø HEAD TIP

DRUM ˇ

¨ 1 BENDING

∏ PUTTING PLACE OF DRUM

ˆ 1 HOLE

´ SPRING PLATE

Π3 SCREWS

4-2-6(b) Reassembly

1) Mount and insert the Drum ˇ to the 1 Bending ¨

and 1 Hole ˆ.

2) Insert the Spring Plate ´, and then secure

3 Screws Œ.

Fig. 4-16 Drum

Note 1 : Do not touch the Head tip Ø when removing

or reassembling the Drum ˇ.

Note 2 : Do not touch the path post when removing or

reassembling

Page 12

4-12

Disassembly and Reassembly

Samsung Electronics

4-2-7 Loading Motor Ass’y, Pinch Review Ass’y

4-2-7(a) Disassembly

1) In unload mode, rotate the Pinch Review Ass’y Œ

in a clockwise direction and left up the

Pinch Review Ass’y Œ.

2) De-solder the 2 points.

3) Remove the 1 screw ˇ and separate the 1 hook of

Loading Motor Ass’y ¨.

4) Lift up the Loading Motor Ass’y ¨.

4-2-7(b) Reassembly

1) Lock the one hook of Loading Motor Ass’y ¨ and

secure one screw ˇ.

2) Re-solder the 2 wires.

(+ into red wire , - into blue wire)

3) In disassembling position, insert the Pinch Review

Ass’y Œ and rotate the Pinch Review Ass’y Œ in

unload position.

3

4

2

SOLDER POINTS

LOADING MOTOR ASS'Y ¨

ˇ 1 SCREW

ΠPINCH REVIEW ASS'Y

Fig. 4-17 Loading Motor Ass’y, Pinch Review Ass’y

Note : When disassembling and reassembling, be

careful not to touch the Pinch Roller

and the review post.

Page 13

Disassembly and Reassembly

4-13Samsung Electronics

4-2-8 Guide Roller S,T , Pole Base S,T , Gear Loading S,T Ass’y

4-2-8(a) Disassembly

1) Lift up the Pole Base S Œ(T ˇ) Ass’y form the link

of the Gear Loading S ´(T ¨) Ass’y.

2) Turn the S ˆ and T Ø Guide Rollers counter

clockwise to remove them.

3) Separate the hook of the Gear Loading S ´ and

lift down the Gear Loading S ´(T ¨) Ass’y.

6

2

3

GUIDE ROLLER S ˆ

ˇ POLE BASE T ASS'Y

POLE BASE S ASSY Œ

Ø GUIDE ROLLER T

GEAR LOADING S ASS'Y ´

∏ MAIN CHASSIS

¨ GEAR LOADING T ASS'Y

4-2-8(b) Reassembly

1) Turn the S ˆ and T Ø Guide Rollers clockwise and

reassemble.

2) Replace the S ´ and T ¨ Gear Loading assemblies.

3) Fit the Pole Base S Œ(T ˇ) Ass’y in the link of the

Gear Loading S ´(T ¨) Ass’y.

Fig. 4-18 Guide Roller S,T , Pole Base S,T , Gear Loading S,T Ass’y

Note1 : When disassembling and reassembling, be

careful not to touch the Guide

Roller S ˆ and T Ø.

Note2 : When disassemblig and reassembling the

Guide Roller S ˆ and T Ø, be careful not to

deform the Gear Loading S ´ and T ¨ Ass’y.

Note 1 : When reassembling, confirm the assemble

point.

Note 2 : Disassembly and reassembly is done in the

Unload mode.

Note 3 : After assembling, make sure that loading and

unloading work correctly by applying 3V~5V

to the Loading Motor.

Page 14

4-14

Disassembly and Reassembly

Samsung Electronics

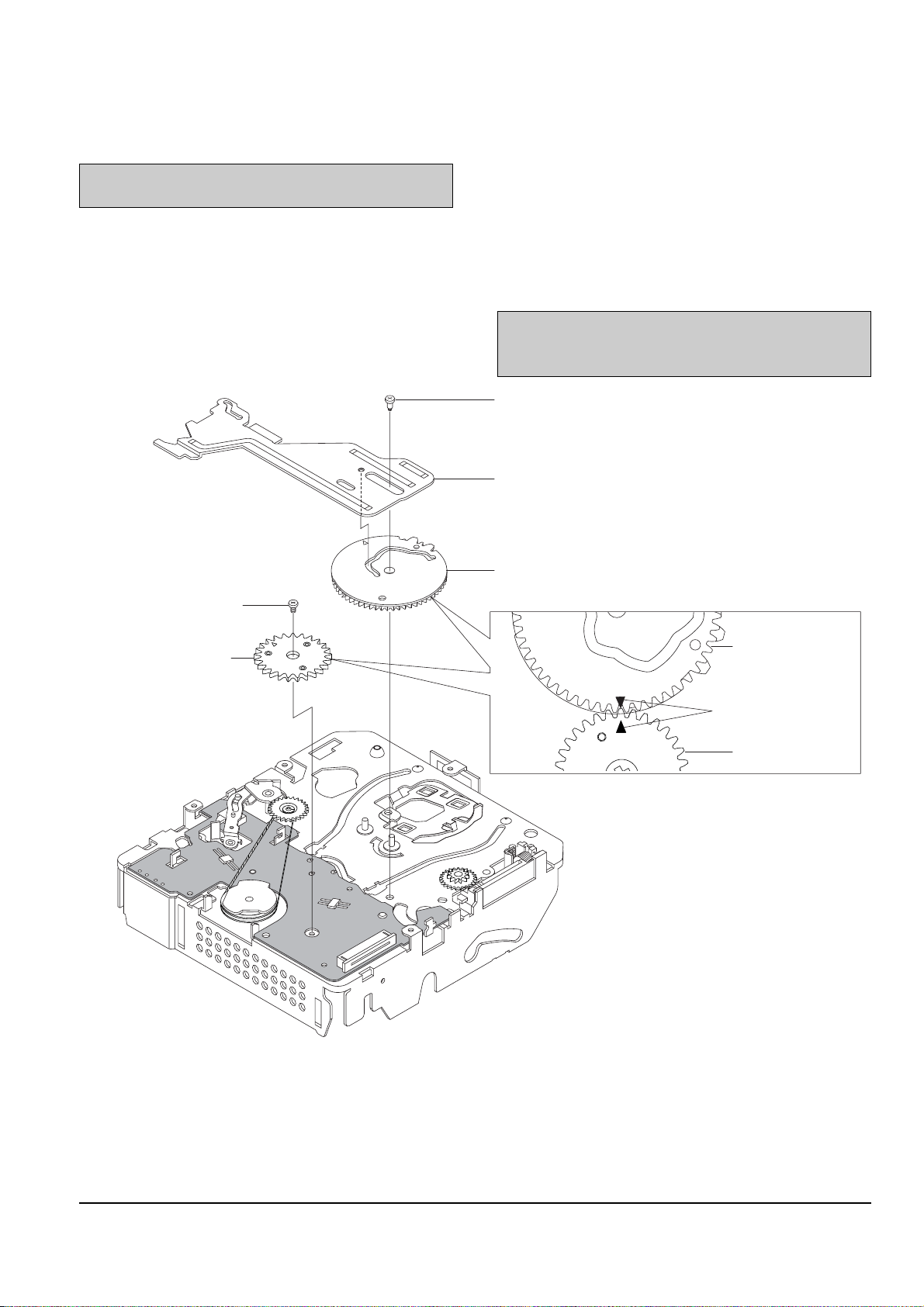

4-2-9 Slide Main, Gear Cam Main, Gear Mode Switch

4-2-9(a) Disassembly

1) Remove the 1 screw Œ and lift up the Slide Main ´.

2) Lift up the Gear Cam Main ˇ.

3) Remove the 1 screw ¨ and lift up the

Gear Mode Switch ˆ.

4-2-9(b) Reassembly

1) Mount the Gear Mode Switch ˆ and secure the

1 screw ¨.

2) After assemble and fit the Gear Cam Main ˇ,

Gear Mode Switch ˆ to assemble point.

3) Mount the Slide Main ´ and secure 1 screw Œ.

Π1 SCREW

´ SLIDE MAIN

ˇ GEAR CAM MAIN

1 SCREW ¨

GEAR MODE SWITCH ˆ

GEAR CAM MAIN

ASSEMBLE POINT

(TWO ARROWS)

GEAR MODE SWITCH

Fig. 4-19 Slide Main, Gear Cam Main, Gear Mode Switch

Note : Disassembly and reassembly must be done

with the Deck Assembly in the Unload mode.

Note : When reassembling, confirm that pin of Slide

Main ´ is inserted into the cam of

Gear Cam Main ˇ.

Page 15

Disassembly and Reassembly

4-15Samsung Electronics

4-2-10 Cover Capstan, Capstan Motor Ass’y

4-2-10(b) Reassembly

1) Mount the Capstan Motor Ass’y ¨ and secure the

2 Screws ˇ.

2) Lock the 2 hooks of Cover Capstan ´ and

1 Screw Œ.

Fig. 4-20 Cover Capstan, Capstan Motor Ass’y

2

3

4

1 SCREW Œ

´ COVER CAPSTAN

ˇ 2 SCREWS

¨ CAPSTAN MOTOR ASS'Y

4-2-10(a) Disassembly

1) Remove the 1 Screw Œ.

2) Separe 2 hooks of Cover Capstan ´ and then lift up

the Cover Capstan ´.

3) Remove the 2 Screws ˇ, and then lift up the

Capstan Motor Ass’y ¨.

Note : Be careful not to damage the gears during the

disassembly and reassembly process.

Page 16

4-16

Disassembly and Reassembly

Samsung Electronics

4-2-11 Belt Timing (Timing Belt), Gear Capstan, Gear Pulley, Lever Review

4-2-11(a) Disassembly

1) Lift up the Lever Review Œ.

2) Remove the Washer Slit ´ and lift up the

Gear Capstan ˇ.

3) Separate the Pulley Belt Timing (=Timing Belt) ¨

and lift down the Gear Pulley ˆ.

Fig. 4-21 Belt Timing (=Timing Belt), Gear Capstan, Gear Pulley, Lever Review

2

3

4

LEVER REVIEW Œ

GEAR PULLEY ˆ

´ WASHER SLIT

ˇ GEAR CAPSTAN

¨ PULLEY BELT TIMING (=TIMING BELT)

4-2-11(b) Reassembly

1) Mount the Gear Pulley ˆ and hang the Belt

Timing (=Timing Belt) ¨ on the Gear Pulley ˆ.

2) Hang the Pulley Belt Timing ¨ on the lower gear

of the Gear Capstan ˇ, and then mount the Gear

Capstan ˇ.

3) Insert the Washer Slit ´.

4) Mount the Lever Review Œ.

Loading...

Loading...