Page 1

LED TV

Chassis : U8KA

Model : UE40H5003AW

UE48H5003AW

SERVICE

LED TV Contents

1. Precautions

2. Product specications

3. Disassembly and Reassembly

4. Troubleshooting

5. Wiring Diagram

Manual

UE**H5003AW

Page 2

Contents

1. Precautions ...................................................................................................................1-1

1-1. Safety Precautions ..............................................................................................................1-1

1-1-1. Warnings ...................................................................................................................1-1

1-1-2. Servicing the LED TV ...............................................................................................1-1

1-1-3. Fire and Shock Hazard .............................................................................................1-1

1-1-4. Product Safety Notices ............................................................................................. 1-2

1-2. Servicing Precautions ..........................................................................................................1-3

1-2-1. General Servicing Precautions ................................................................................. 1-3

1-3. Static Electricity Precautions ...............................................................................................1-4

1-4. Installation Precautions .......................................................................................................1-5

2. Product Specications.................................................................................................2-1

2-1. Product information .............................................................................................................2-1

2-2. Product specication ...........................................................................................................2-2

2-2-1. Detailed Specications .............................................................................................2-2

2-2-2. Specications ...........................................................................................................2-6

2-2-3. Jack Differ ................................................................................................................. 2-7

2-3. Accessories ........................................................................................................................2-8

3. Disassembly and Reassembly ....................................................................................3-1

3-1. Disassembly and Reassembly ............................................................................................3-1

4. Troubleshooting ...........................................................................................................4-1

4-1. Troubleshooting ...................................................................................................................4-1

4-2. How to Check Fault Symptom .............................................................................................4-3

4-3. Factory Mode Adjustments ..................................................................................................4-5

4-3-1. Detail Factory Option ................................................................................................4-5

4-3-2. Entering Factory Mode .............................................................................................4-6

4-3-3. Factory Data .............................................................................................................4-7

4-4. White Balance ...................................................................................................................4-22

4-4-1. Calibration ..............................................................................................................4-22

4-4-2. Service Adjustment ................................................................................................. 4-22

4-4-3. Adjustment .............................................................................................................. 4-24

4-5.White Balance - Calibration ................................................................................................4-25

4-6. Software Upgrade ..............................................................................................................4-27

4-6-1. How to Check the Software Version .......................................................................4-27

4-6-2. How to Upgade Software and Micom ..................................................................... 4-29

4-7. Rear Cover Dimension ......................................................................................................4-31

5. Wiring Diagram .............................................................................................................5-1

5-1. Wiring Diagram ....................................................................................................................5-1

5-2. Connector ...........................................................................................................................5-2

5-3. Cables .................................................................................................................................5-5

Page 3

This Service Manual is a property of Samsung Electronics Co.,Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law.

© 2014 Samsung Electronics Co.,Ltd.

All rights reserved.

Printed in Korea

Page 4

1. Precautions

1. Precautions

1-1. Safety Precautions

Follow these safety, servicing and ESD precautions to prevent damage and to protect against potential hazards such as

electrical shock.

1-1-1. Warnings

For continued safety, do not attempt to modify the circuit board.

WARNING

1-1-2. Servicing the LED TV

When servicing the LED TV, Disconnect the AC line cord from the AC outlet.1.

It is essential that service technicians have an accurate voltage meter available at all times. Check the calibration of this 2.

meter periodically.

1-1-3. Fire and Shock Hazard

Before returning the monitor to the user, perform the following safety checks:

Inspect each lead dress to make certain that the leads are not pinched or that hardware is not lodged between the 1.

chassis and other metal parts in the monitor.

Inspect all protective devices such as nonmetallic control knobs, insulating materials, cabinet backs, adjustment and 2.

compartment covers or shields, isolation resistorcapacitor networks, mechanical insulators, etc.

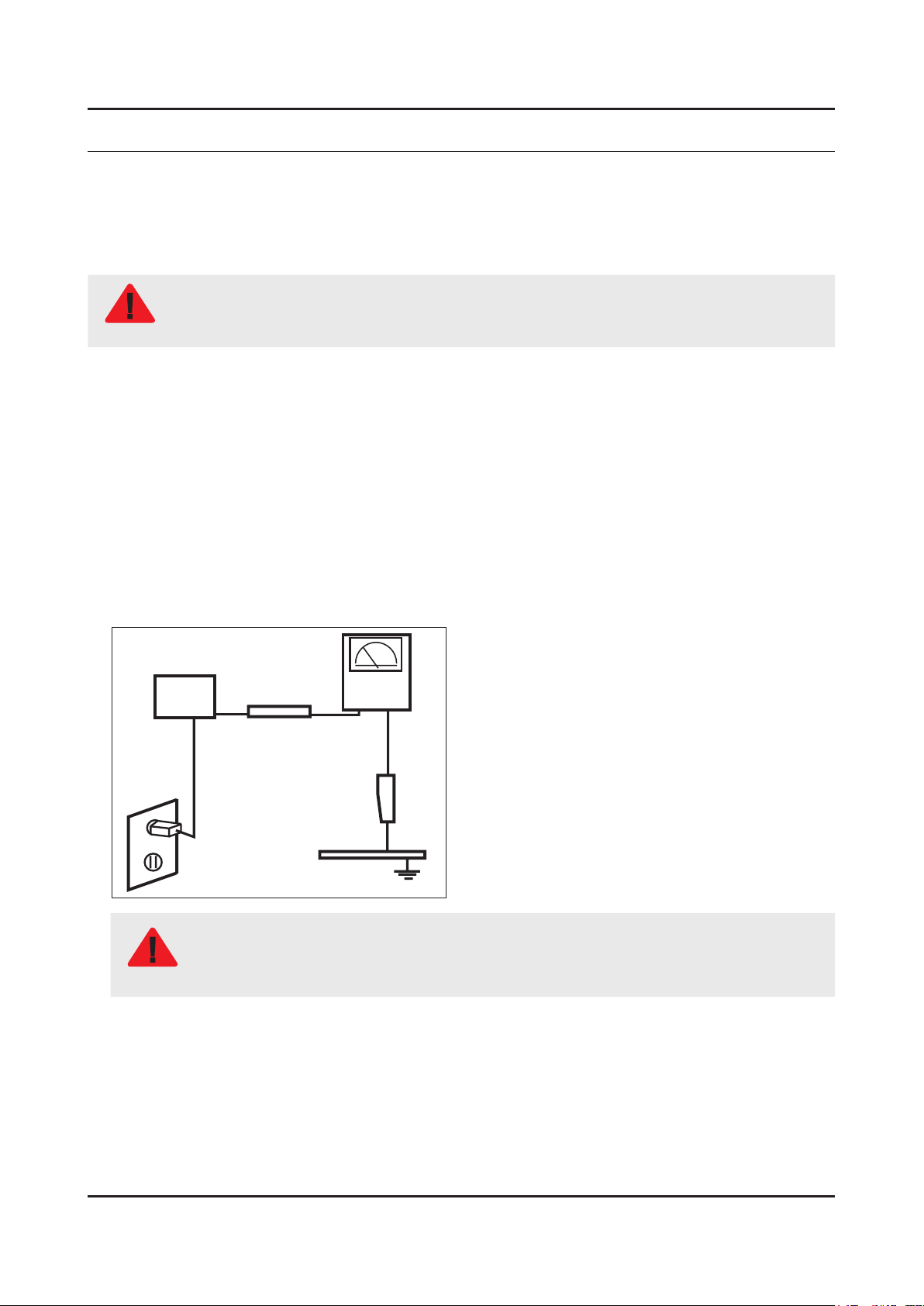

Leakage Current Hot Check:3.

Disconnect the AC power and DC power jack before servicing.

(READING SHOULD)

DEVICE

UNDER

TEST

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

NOT BE ABOVE 0.5mA

2-WIRE CORD

TEST ALL

EXPOSED METAL

SURFACES

LEAKAGE

CURRENT

TESTER

EARTH

GROUND

Do not use an isolation transformer during this test.

Use a leakage current tester or a metering system that complies with American National Standards

WARNING

Institute (ANSI C101.1, Leakage Current for Appliances), and Underwriters Laboratories (UL

Publication UL1410, 59.7).

With the unit completely reassembled, plug the AC line cord directly into a 120V AC outlet. With the unit’s AC switch rst 4.

in the ON position and then OFF, measure the current between a known earth ground (metal water pipe, conduit, etc.)

and all exposed metal parts, including: metal cabinets, screwheads and control shafts.

The current measured should not exceed 0.5 milliamp.

Reverse the power-plug prongs in the AC outlet and repeat the test.

1-1

Page 5

1-2

1. Precautions

1-1-4. Product Safety Notices

Some electrical and mechanical parts have special safetyrelated characteristics which are often not evident from visual

inspection. The protection they give may not be obtained by replacing them with components rated for higher voltage,

wattage, etc. Parts that have special safety characteristics are identied by

replacement that does not have the same safety characteristics as the recommended replacement part might create

shock, re and/or other hazards. Product safety is under review continuously and new instructions are issued whenever

appropriate.

on schematics and parts lists. A substitute

Page 6

1-3

1. Precautions

1-2. Servicing Precautions

An electrolytic capacitor installed with the wrong polarity might explode.

WARNING

Before servicing units covered by this service manual, read and follow the Safety Precautions section of

CAUTION

NOTE

1-2-1. General Servicing Precautions

Always unplug the unit’s AC power cord from the AC power source and disconnect the DC Power Jack before 1.

attempting to: (a) remove or reinstall any component or assembly, (b) disconnect PCB plugs or connectors, (c) connect

a test component in parallel with an electrolytic capacitor.

Some components are raised above the printed circuit board for safety. An insulation tube or tape is sometimes used. 2.

The internal wiring is sometimes clamped to prevent contact with thermally hot components. Reinstall all such elements

to their original position.

After servicing, always check that the screws, components and wiring have been correctly reinstalled. Make sure that 3.

the area around the serviced part has not been damaged.

Check the insulation between the blades of the AC plug and accessible conductive parts (examples: metal panels, input 4.

terminals and earphone jacks).

Insulation Checking Procedure: Disconnect the power cord from the AC source and turn the power switch ON. Connect 5.

an insulation resistance meter (500 V) to theblades of the AC plug. The insulation resistance between each blade of the

AC plug and accessible conductive parts (see above) should be greater than 1 megohm.

Always connect a test instrument’s ground lead to the instrument chassis ground before connecting the positive lead; 6.

always remove the instrument’s ground lead last.

this manual.

If unforeseen circumstances create conict between the following servicing precautions and any of the

safety precautions, always follow the safety precautions.

Page 7

1-4

1. Precautions

1-3. Static Electricity Precautions

Some semiconductor (solid state) devices can be easily damaged by static electricity. Such components are commonly

called Electrostatically Sensitive Devices (ESD). Examples of typical ESD are integrated circuits and some eld-effect

transistors. The following techniques will reduce the incidence of component damage caused by static electricity.

Immediately before handling any semiconductor components or assemblies, drain the electrostatic charge from your 1.

body by touching a known earth ground. Alternatively, wear a discharging wrist-strap device. To avoid a shock hazard,

be sure to remove the wrist strap before applying power to the monitor.

After removing an ESD-equipped assembly, place it on a conductive surface such as aluminum foil to prevent 2.

accumulation of an electrostatic charge.

Do not use freon-propelled chemicals. These can generate electrical charges sufcient to damage ESDs.3.

Use only a grounded-tip soldering iron to solder or desolder ESDs.4.

Use only an anti-static solder removal device. Some solder removal devices not classied as “anti-static” can generate 5.

electrical charges sufcient to damage ESDs.

Do not remove a replacement ESD from its protective package until you are ready to install it. Most replacement ESDs 6.

are packaged with leads that are electrically shorted together by conductive foam, aluminum foil or other conductive

materials.

Immediately before removing the protective material from the leads of a replacement ESD, touch the protective material 7.

to the chassis or circuit assembly into which the device will be installed.

Be sure no power is applied to the chassis or circuit and observe all other safety precautions.

CAUTION

Minimize body motions when handling unpackaged replacement ESDs. Motions such as brushing clothes together, or 8.

lifting your foot from a carpeted oor can generate enough static electricity to damage an ESD.

Page 8

1-5

1. Precautions

1-4. Installation Precautions

For safety reasons, more than a people are required for carrying the product.1.

Keep the power cord away from any heat emitting devices, as a melted covering may cause re or electric shock.2.

Do not place the product in areas with poor ventilation such as a bookshelf or closet. The increased internal temperature 3.

may cause re.

Bend the external antenna cable when connecting it to the product. This is a measure to protect it from being exposed 4.

to moisture. Otherwise, it may cause a re or electric shock.

Make sure to turn the power off and unplug the power cord from the outlet before repositioning the product. Also check 5.

the antenna cable or the external connectors if they are fully unplugged. Damage to the cord may cause re or electric

shock.

Keep the antenna far away from any high-voltage cables and install it rmly. Contact with the highvoltage cable or the 6.

antenna falling over may cause re or electric shock.

When installing the product, leave enough space (0.4m) between the product and the wall for ventilation purposes. 7.

A rise in temperature within the product may cause re.

If an equipment is provided with a replaceable battery, and if replacement by an incorrect type could result in an 8.

explosion (for example, with some lithium batteries), the following applies:

Risk of explosion if battery is replaced by an incorrect type dispose of used batteries according to •

the instructions.

Do not dispose of batteries in a re.•

Do not short circuit, disassemble or overheat the batteries.•

CAUTION

Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent •

type.

Do not be exposed to excessive heat such as sunshine, re or the like.•

Page 9

2. Product Specications

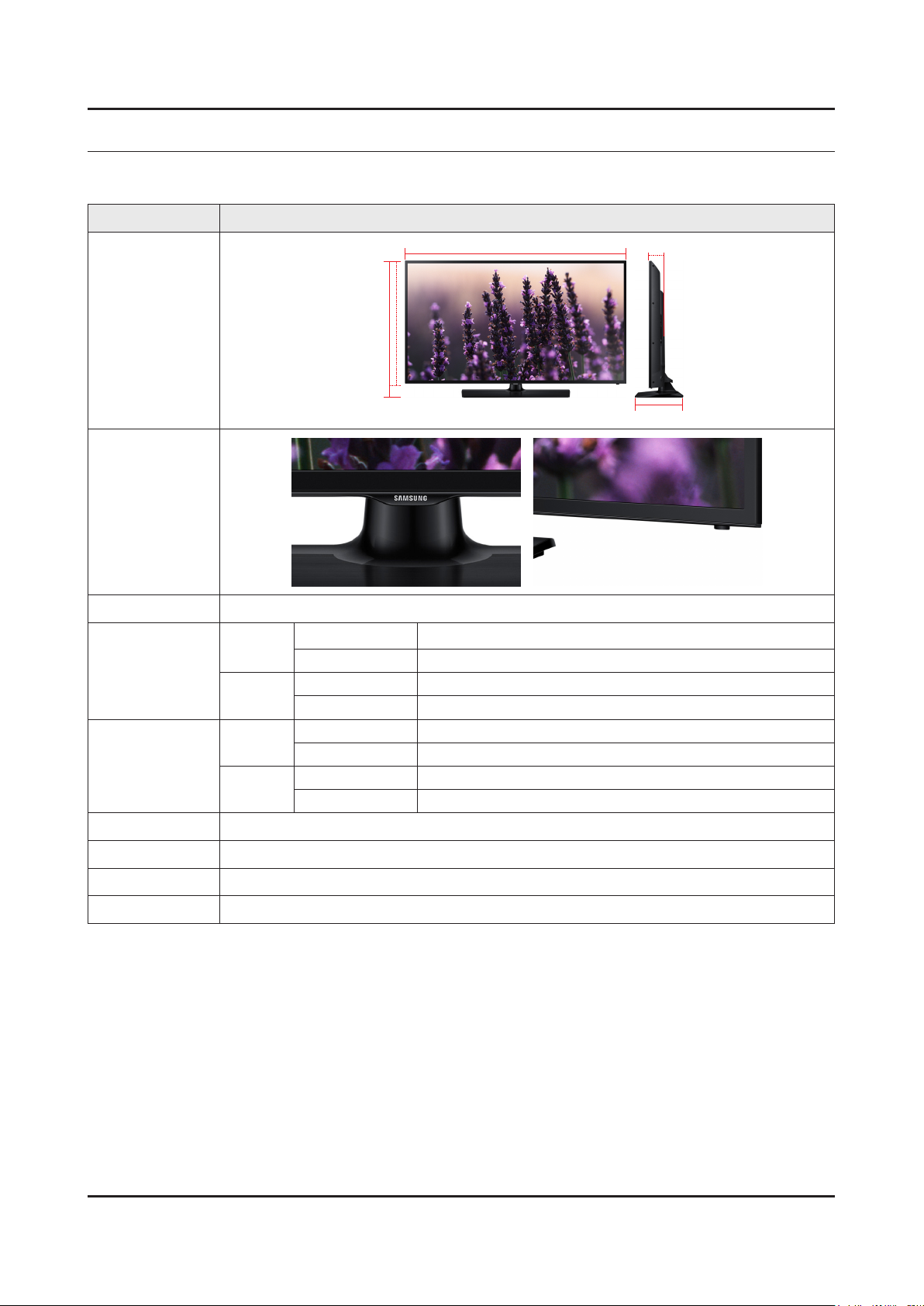

2-1. Product information

Model UE**H5003AW

2. Product specications

W

Front View

Detail View

Front Color Black (Panel)

Dimensions

40H500*

W x H x D

48H500*

40H500*

Weight

48H500*

Panel Type Slim LED

Set with Stand 905.2 x 562.3 x 196.4 mm / 35.6 x 22.1 x 7.7 inches

Set without Stand 905.2 x 525.4 x 91.1 mm / 35.6 x 20.7 x 3.6 inches

Set with Stand 1083.2 x 677.0 x 203.9 mm / 42.6 x 26.7 x 8.0 inches

Set without Stand 1083.2 x 637.8 x 90.9 mm / 42.6 x 25.1 x 3.6 inches

Set with Stand 7.1 kg / 15.7 lbs

Set without Stand 6.4 kg / 14.1 lbs

Set with Stand 9.8 kg / 21.6 lbs

Set without Stand 9.0 kg / 19.8 lbs

H

* W : Width H : High D : Depth

D

Flash Memory 128 Mbyte

DDR 256 Mbyte

Feature Media Play(Movie)

2-1

Page 10

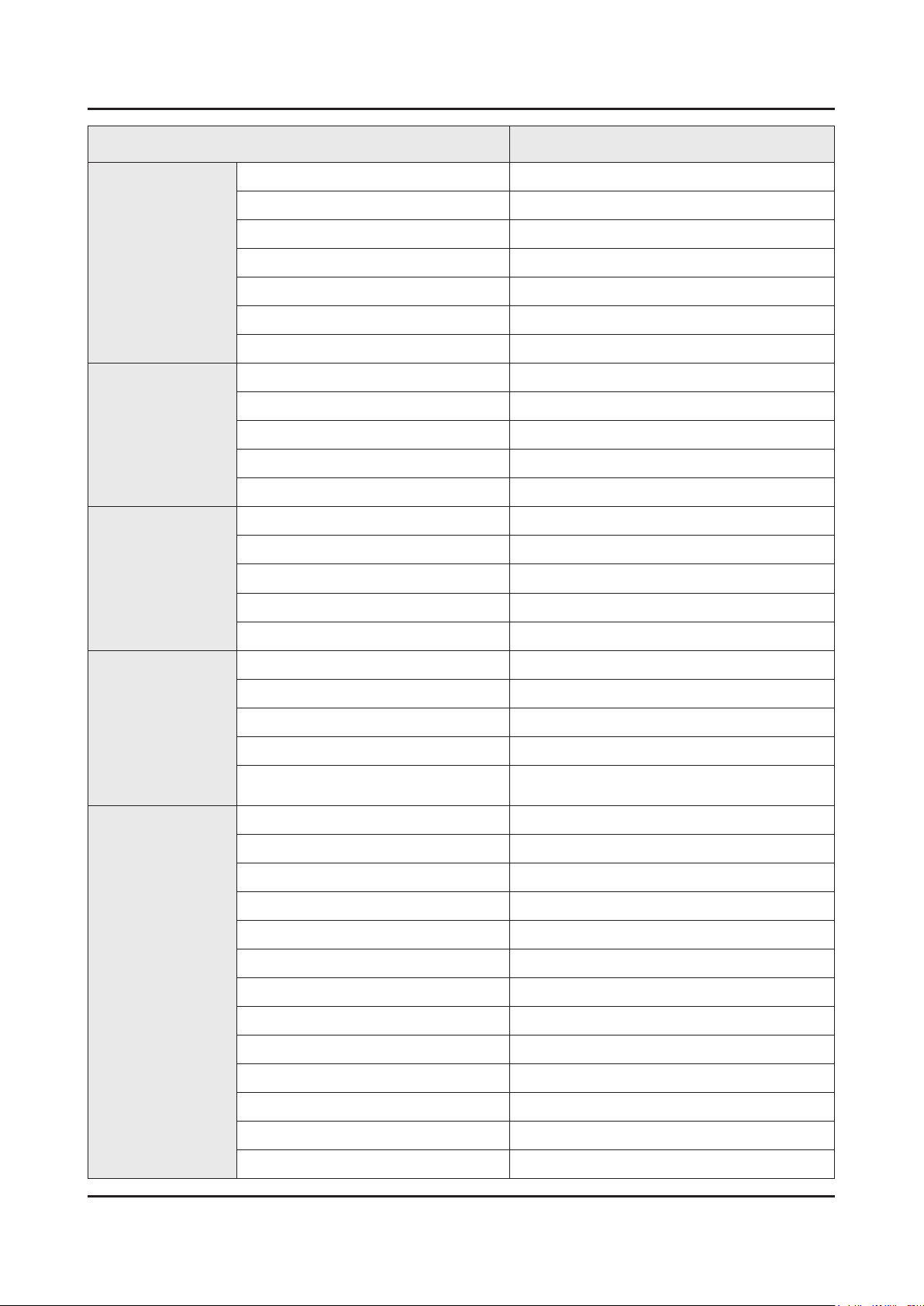

2-2

2. Product specications

2-2. Product specication

2-2-1. Detailed Specications

NOTE

Design and specications are subject to change without prior notice.

Item UE**H5003AWXTK

General Information

Display

Video

Audio

Product LED

Series 5

Country TURKEY

Screen Size 40"/48"

Resolution 1,920 x 1,080

Ultra Clear Panel N/A

Picture Engine HyperReal Engine

Clear Motion Rate 100

Micro Dimming N/A

Precision Black (Local Dimming) N/A

Wide Color Enhancer (Plus) Yes

Wide Color Gamut N/A

Color Accuracy N/A

Auto Depth Enhancer N/A

Film Mode Yes

Dolby MS10 / MS110 Dolby Digital Plus / Dolby Pulse

Smart TV

DTS Studio Sound / DNSe+ DTS Studio Sound

DTS Premium Sound / DTS Premium

Sound 5.1

3D Sound N/A

Auto Volume Leveler Yes

Sound Customizer N/A

Sound Output (RMS) 10Wx2

Speaker Type Down Firing + Full Range

Woofer N/A

HD Audio N/A

Smart Hub N/A

Samsung SMART TV N/A

On TV N/A

Movies & TV Shows N/A

Multimedia N/A

DTS Premium Sound 5.1

Page 11

2-3

2. Product specications

Item UE**H5003AWXTK

Smart TV

Smart Interaction

Smart Convergence

Apps N/A

Game N/A

Fitness N/A

Kids N/A

Multi-Screen (Dual / Quad Screen) N/A

Skype™ on Samsung TV N/A

Web Browser N/A

Voice Interaction N/A

Voice Control N/A

Camera Built-in N/A

Face recognition N/A

Motion control N/A

Contents Streaming N/A

Screen Mirroring N/A

Samsung SMART View N/A

Smart Home N/A

Tuner/Broadcasting

Connectivity

Easy Pin pairing N/A

Twin Tuner N/A

CI/CI+/2CI+ CI+ (1.3)

DTV Tuner DVB-TC

Analog Tuner Yes

MHP / MHEG / HbbTV / ACAP / GINGA /

OHTV

HDMI 2

USB 1

Component In (Y/Pb/Pr) No

Composite In (AV) No

Ethernet (LAN) N/A

Headphone No

Digital Audio Out (Optical) 1

RF In (Terrestrial / Cable input) 1

Ex-Link ( RS-232C ) No

IR Out N/A

No

CI Slot 1

Scart 1

MHL 3 N/A

Page 12

2-4

2. Product specications

Item UE**H5003AWXTK

Connectivity

Design

Additional Feature

One Connect (Jack) N/A

WiFi Direct N/A

Wireless LAN Adapter Support N/A

Wireless LAN Built-in N/A

Anynet+ (HDMI-CEC) N/A

Design High Glossy

Bezel Type NNB (12mm)

Front Color Black

Light Effect (Deco) N/A

Stand Type Square

Swivel (Left/Right) N/A

Samsung 3D N/A

3D Converter N/A

Instant On N/A

Quad Core+ N/A

Accessibility N/A

Auto Power Off Yes

Clock&On/Off Timer Yes

Sleep Timer Yes

BD Wise Plus N/A

Caption (Subtitle) Yes

Channel List USB-Clone Yes

ConnectShare™ (USB 2.0) Movie

Football Mode Basic

Embeded POP Yes

EPG Yes

PVR Ready N/A

Game Mode Yes

Multiroom Compatible N/A

OSD Language Local Language

Picture-In-Picture Yes

BT HID Built-in N/A

USB HID Support N/A

Smart Evolution Support N/A

TV SoundConnect N/A

Page 13

2-5

2. Product specications

Item UE**H5003AWXTK

Additional Feature

Eco Feature

Accessory

Teletext (TTXT) Yes

Time Shift N/A

Eco Sensor Yes

Energy Efciency Class A+ A++

Mercury Content 0.0mg

Lead Presence Yes

3D Active Glasses (Included) N/A

Remote Controller Model TM1240A

Batteries (for Remote Control) Yes

Samsung Smart Touch Control (Included) N/A

Ultra Slim Wall Mount Supported N/A

Mini Wall Mount Supported Yes

Vesa Wall Mount Supported Yes

Floor Stand Support N/A

TV Camera (Included) N/A

IR Extender Cable (Included) N/A

Wireless Keyboard (Included) N/A

Wireless LAN Adaptor (Included) N/A

User Manual Yes

E-Manual Yes

Power Cable Yes

Slim Gender Cable N/A

Page 14

2-6

2. Product specications

2-2-2. Specications

Feature

Brightness : 300 cd/m•

Dynamic Contrast Ratio : Mega DCR •

CMR : 100•

Specications

Model UE**H5003AW

Item Description

Screen Size (Diagonal) 40 inches 48 inches

LCD Panel FHD 60 Hz

Display Colors 16.7 M color

Display Resolution 1,920 x 1,080

Input Signal Analog 0.7 Vp-p ± 5% positive at 75Ω, internally terminated

Input Sync Signal H/V Separate, TTL, P. or N.

2

AC Power Voltage & Frequency AC220~240V 50/60Hz

Sound (Output) 20 W (10 W X 2)

Page 15

2-7

2. Product specications

2-2-3. Jack Differ

Region HDMI USB

EU&N.EU&Turkey 2

CIS&Africa 2 1 1 1

Australia, New Zealand,

Singapore&S.A.

Region HP Audio out Optical CI Scart

EU&N.EU&Turkey NO NO

CIS&Africa NO NO 1 1 NO

Australia, New Zealand,

Singapore&S.A.

2 1 1 1

NO NO 1 NO NO

1

Component In

(Y/Pb/Pr)

NO NO

1 1

Component In

(AV)

1

Page 16

2. Product specications

2-3. Accessories

NOTE

The items’ colors and shapes may vary depending on the model.•

Cables not included in the package contents can be purchased separately.•

The part code for some accessories may differ depending on your region.•

Product Code. No Product Code. No

Remote Control• AA59-00741A User Manual•

Batteries (AAA x 2)• 4301-000121

Power Cord• 3903-000849

Image Product Code. No

Holder-Wire Stand• BN61-08370A

Warranty Card (Not available •

in some locations)

BN68-06308S

BN68-06308X

BN68-02839P

2-8

Page 17

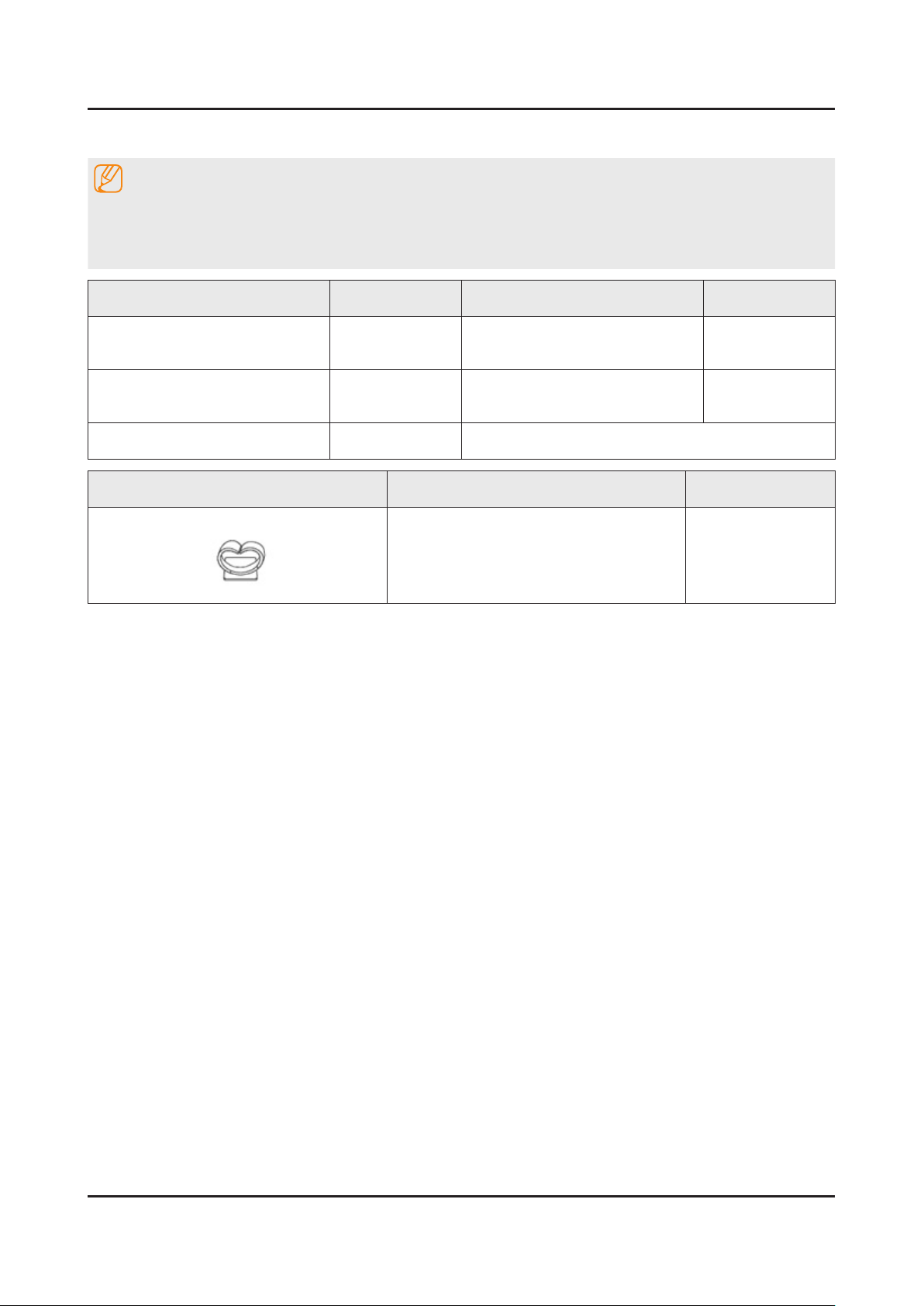

3. Disassembly and Reassemble

3. Disassembly and Reassembly

This section of the service manual describes the disassembly and reassembly procedures for the LED TV.

This LED TV contains electrostatically sensitive devices. Use caution when handling these components.

WARNING

3-1. Disassembly and Reassembly

Disconnect the LED TV from the power source before disassembly.1.

Follow these directions carefully; never use metal instruments to pry apart the cabinet.2.

CAUTION

Place TV face down on cushioned table.

If there is no additional coment, it is same for all inches.3.

Description Picture Description Screws

1

Remove 4 screws from the stand.

2

Remove stand.

3

6003-001782

3-1

Page 18

3-2

3. Disassembly and Reassemble

Description Picture Description Screws

Remove the screws of rear-cover.

4

Remove the rear-cover.

5

Remove the screws.

6

6003-001782

Remove the speakers and power cables.

7

6003-001856

6001-003016

Page 19

3-3

3. Disassembly and Reassemble

Description Picture Description Screws

Remove the LVDS Cable and Panel Drive

8

Cable.

Completed disassembly.

9

NOTE

Reassembly procedures are in the reverse order of disassembly procedures.

Page 20

4. Troubleshooting

4-1. Troubleshooting

Previous Check

Check the various cable connections rst.1.

Check to see if there is a burnt or damaged cable. -

Check to see if there is a disconnected or loose cable connection. -

Check to see if the cables are connected according to the connection diagram. -

Check the power input to the Main Board.2.

Main Ass’y

Power Cable

4. Troubleshooting

Power Ass’y

LVDS Cable

Speaker

Main Board Assy (CN202)

9 A13V 10 UNDER_DRIVER

7 A13V 8 PWM_DIM

5 A13V 6 SW_POWER_TO _SMPS

3 A13V 4 GND

1 GND 2 GND

Check the power in & output between SMPS & Main Board, Main Board & Panel, IP & Panel.3.

4-1

Page 21

4-2

4. Troubleshooting

How to know it is from Main Board or T-Con when some problems happen

No Picture : Backlight is on, but there is no picture and LED indicator in front of TV is blinking.1.

Check the LVDS Cable connection. If still problems, change the T-Con Board and then Main Board step by step. -

Picture distortion : Enter the service mode 2. ⇢ Choose ‘SVC’ ⇢ Check the ‘internal pattern.’

Enter ‘Service Mode.’ -

If you do not have Factory remote control•

Power OFF Info MENU Mute Power On

If you have Factory remote control•

INFO Factory

Choose ‘SVC.’3.

Choose ‘Test pattern.’4.

Select the each pattern and then check all pattern is ok or not.5.

Option

Control

Debug

SVC

ADC/WB

Advanced

Pattern Status is Change the Test Pattern is made by the NOVATEK IC

OK Main Board We guess front of NOVATEK IC has problem.

NG Panel and T-Con Board We guess back of NOVATEK IC has problem.

Test Pattern Pattern Sel

Page 22

4-2. How to Check Fault Symptom

4-3

4. Troubleshooting

Power cord on.

Yes

Diagnostics

Check ‘Stand-By A5.3V’

5.3V appear at BD210?

0V to A13V (CN202 #3)

Yes

Set On.

Yes

Check ‘SW_POWER’ more than 3.3V

appear at CN202(#6)

0V to 3.3V↑ (CN202 #6)

Yes

Check ‘Power of main IC(B1.15V)’ appear

at BD917

Check ‘Power of DDR IC(B1.5V)’ appear

at BD911

Yes

Check ‘Power of LVDS (13V)’

appear at TP-PANEL_VCC?

0V to 13V (TP-PANEL_VCC)

No

No

No

No

Cause : There did not supply the

power from SMPS.

Measure : Change 10p power cable

and SMPS.

Cause : Main IC(NT14L) did not

control the SW_Power.

Measure : Change the Main Assy.

Cause : There is problem at

DCDC(IC201)/LDO(IC204).

Measure : Change the Main Assy.

Cause : There is proble at FET(Q202_

NFRC) or Main IC(NT14L) did

not control the SW_PVCC.

Measure : Change the Main Assy.

Yes

Change the LVDS cable ?

No

Change the Panel.

Page 23

4-4

4. Troubleshooting

Location of Parts

Main Board_Front

C

B

A

Detail

BD917

CN202 #6

A

BD210

CN202 #3

C

BD911

(B1.5V)

B

(B1.15V)

Page 24

4-3. Factory Mode Adjustments

4-5

4. Troubleshooting

4-3-1. Detail Factory Option

NOTE

If you replace the main board with new one, please change the factory option as well.

The options you must change are "Type".

UE**H5003AWXTK

Model Name 40" 48"

Vendor SDC SDC

Panel

SMPS

MAIN ASSY

(depending on the country)

Byte Item

0 Factory Reset -

1 Type 40D6AF0S 48B6AF0S

2 SW Model UH5003

3 BOM Model 5003

4 Local Set depending on the country

5 Tuner

6 Ch Table NONE

Code BN95-01875A N95-01886A

Spec. CY-HH040BGNV1V/H CY-HH048BGEV1V/H

Vendor SEM SEM

Code BN44-00754A BN44-00757A

Spec. L40G0B_ESM L48G0B_ESM

Chassis Ass'y BN91-00962J BN91-00962K

PBA Ass'y code BN94-07155J BN94-07155K

DVB-TC

(depending on the country)

Page 25

4-6

4. Troubleshooting

4-3-2. Entering Factory Mode

To enter ‘Service Mode’ Press the remote -control keys in this sequence :

If you do not have Factory remote control•

Power OFF INFO MENU MUTE Power On

If you have Factory remote control•

INFO Factory

If you don’t have Factory remote control, can’t control some menus•

Initial SERVICE MODE DISPLAY State

Option

Control

Debug

SVC

ADC/WB

Advanced

T-NT14LDEUC-xxxx.x

T-NT14LDEUS-xxxx

E-Manual : NLDVBEUxH-xxxx

EDID SUCCESS

CALIB : AV/COMP/PC/HDMI/

Option : 40D6AF0S,EU_SPAIN,5003,NONE

DTP-SDAL-NT14L-xxxx

RFS:"NT14L xxxx" K/20xx-xx-xx

KERNEL:xxxx.xxxx,/Onboot: xxxx

TCON Version:----

NSP-DTVTD-xxxx

Model: UE40H5003

CIP FAIL

Factory Data Ver:xxx

EERC Version: xxx

NSP-BP-HAL-xxxx

NSP-AP-CNC-xxxx

NSP-AP-MM-xxxx

NSP-BP-MW-xxxx

NSP-BP-APP-xxxx

NSP-PNG-xx-xxxx

Date of purchase:-/-/----

Page 26

4-7

4. Troubleshooting

4-3-3. Factory Data

Note

Version of the software is written in 0002.•

Black• : I should not be possible to adjust or change that does not require a change item

Blue : Adjustment Services for the corresponding

Red : Items that are secured

Option

Factory Menu Name Data Range Remark Key

Factory Reset - -

Type 40D6AF0S

Local Set Local Set Select Local

SW Model UH5003 UH5003

BOM Model 5003 5003

TUNER S-TC Not Detected/S_TC/S-T2C/S_TCS2/S_

Ch Table NONE

MRT Option

Front Color U-S-C-MEGA

Lvds Format JEIDA

Language_Arabic EU

Region PANEURO

PnP Language ENG

WIFI REGION E A~Z/AA/AB

OTN Support OFF ON/OFF

MediaPlay DLNA …

TTX OFF ON/OFF

China HD OFF ON/OFF

NT Conversion OFF ON/OFF

Num of DTV 1 0~2

Num of AV 0 0~3

Num of COMP 0 0~3

T2CS2

Num of HDMI 2 0~4

Num of SCART 1 0~2

Num of USB Port 1 0~2

Num of RVU 0 0~1

Num Of Display 2 1~2

Num of IPTV 0 0~1

Num of RUI 0 0~1

Page 27

4-8

4. Troubleshooting

Factory Menu Name Data Range Remark Key

TOOLS Support 1849

LNA Support 0 0~1

24Px4 Support OFF ON/OFF

BD Wise Support OFF ON/OFF

Data Service Support OFF ON/OFF

PVR Support OFF ON/OFF

CI Support ON ON/OFF

OTA Support General General/OFF

LEDMotionPlus Support ON ON/OFF

Natural Mode Support OFF ON/OFF

Relax Mode Support OFF ON/OFF

HDMI/DVI SEL 2 1~4

Select LCD/PDP LCD LCD/PDP

Wall Mount 0 0~1

HV Flip OFF OFF/HV Flip/V Flip/H Flip

PVR RECORD NUM 0 0~2

Light Effect OFF ON/OFF

e-POP Default ON ON/OFF

CAMERA Support OFF ON/OFF

NETWORK Support Not Support Not Support/Cable/Ext-Wi/Int-Wi/

EcoSensor Support ON ON/OFF

3D Support OFF ON/OFF

BT Support OFF ON/OFF

BT ADDRESS Not Support Not Support

HP LINE Headphone Headphone/LineOut/NONE

Capture Recording Support OFF ON/OFF

JAVA Date Serivce Support OFF ON/OFF

ExtOnly-Wi/Error

Engineer option

Type Of PANEL KEY Horizontal Horizontal/Vertical/PDPVertical/

5 Way Function Key R_BOTTOM L_BOTTOM/R_BOTTOM/L_BACK/R_

PDPHorizon/None

BACK/4

Contents Bar 0 0~1

Cable Modulation …

Standby led on/off OFF ON/OFF

Recognition Support OFF ON/OFF

IF AGC 0 0~10

D AGC 0 0~10

Page 28

4-9

4. Troubleshooting

Factory Menu Name Data Range Remark Key

PH BW 3 0~10

FQ BW 3 0~10

PH RATE 4 0~10

PD EN 1 0~10

PEQ Inx 208

WF Scale

Num of Network Stream 0 0~1

DP V Size 1 0~1

Backend Device ECHO_FS NONE/ECHO_FP/ECHO_FS/PARMA

BT_AUDIO_ON_OFF OFF ON/OFF

Cong_AV_PATH

V_HDMI IDENT TYPE 2134

V_HDMI PATH TYPE BACD

V_EDID TYPE LCD_HD LCD_FHD/LCD_HD

V_ATV CVBS_PORT_2

V_AV1 AV_COMP_G1

V_AV2 CVBS_PORT_3

V_COMP1 ADC_PORT_1

V_COMP2 None

V_PC ADC_PORT_0

V_SCART1_CVBS CVBS_PORT_3

V_SCART1_RGB ADC_PORT_2

V_SCART2_CVBS None

V_SCART2_RGB None

A_ATV SIF

A_DTV DECODER

A_AV1 AUIN1

A_AV2 AUIN0

A_COMP1 AUIN1

A_COMP2 None

A_PC AUIN0

A_SCART1 AUIN0

A_SCART2 None

A_DVI None

A_HDMI None

A_Media DECODER

USING_PSI_UPDATE …

Fast Logo Delay 0 0~20

Page 29

4-10

4. Troubleshooting

Factory Menu Name Data Range Remark Key

Num Of PANEL KEY 6 0~20

Control

Factory Menu Name Data Range Remark Key

EDID

EDID ON/OFF ON ON/OFF

EDID WRITE ALL Success

EDID WRITE PC …

EDID WRITE HDMI Success

EDID WRITE HDMI1 …

EDID WRITE HDMI2 …

EDID WRITE HDMI3 …

EDID WRITE HDMI4 …

EDID Ver HDMI 1.3

EDID Port NONE

EDID WRITE DVI …

Sub Option

RS-232 Jack

Serial Log On/Off

Watchdog

Checksum

Fast Boot in Production

USB Serial

Eeprom Reset

EER Reset

NVR All Clear

ECO IC TYPE

Info Link Server Type

Info Link Country

TTX Group

Visual Test

MediaPlay DB

OPTION_SWU

OTN Server Type operating operating/development

OTN Test Server OFF ON/OFF

SWU Reset

SWU Duration OFF ON/OFF

Page 30

4-11

4. Troubleshooting

Factory Menu Name Data Range Remark Key

SWU Fail Test OFF ON/OFF

SWU_Diag_Code

OPTION_NUM

Num of ATV 1 0~2

Num of SVIDEO 0 0~3

Num of PC 0 0~1

Num of DVI 0 0~1

Num of OPTICAL Link 1 0~1

Num of MEDIA 1 0~1

Num of Tuner 1 0~1

Num of PVR RECORD 0 0~1

RF Remocon Support OFF ON/OFF

CDD mode …

DPMS Support OFF ON/OFF

Num of IPTV CIP 0 0~1

Num of CI 1 0~1

Num of DECODER 0 0~1

T-CON Device

BOARD CONTROL OFF ON/OFF

RM

Server Type Operating operating/development

RTS Mode 0 0~1

PSA

FKP Download1

FKP Download2

LMK threshold 0

Low threshold 0

High threshold 0

CSB ON ON/OFF

CLB ON ON/OFF

EEPG Enable OFF ON/OFF

FAnet Thread 2 ON/OFF

UNIQUE TRIPLET ON ON/OFF

ASIA PROMOTION OFF

PDP Option

HOTEL Option

Hospitality Mode OFF ON/OFF

Power On

Page 31

4-12

4. Troubleshooting

Factory Menu Name Data Range Remark Key

Menu OSD

Music Mode

External Source

Eco Solution

Cloning

Shop Option

Shop Mode OFF ON/OFF

Exhibition Mode OFF ON/OFF

3D Cube OFF ON/OFF

Asia Option

Sepco 120Hz OFF ON/OFF

Unbalance OFF ON/OFF

FMTransmitter Support OFF ON/OFF

FMTransmitter Carrier OFF ON/OFF

AF Level adjust 3 0~7

TX Power Level 0 0~3

Mono Last Memory OFF ON/OFF

H Shaking OFF ON/OFF

SOUND

High Devi OFF ON/OFF

Carrier_Mute OFF ON/OFF

Speaker Delay Normal 0

Wiselink Delay Menu 0

Pilot Level High Thld 0x13h

Pilot Level Low Thld 0x09h

Pilot_Phase_diff_on_THR OFF ON/OFF

FM Prescale 0x2Eh

AM Prescale 0x1Ch

NICAM Prescale 0x1Dh

Amp Model NTP7414

Amp Volume 0xcbh

Amp Scale 0x9ah

Amp Check Sum 0x1E6B4764

SubWoofer Support 0 0~7

Woofer Type 0 0~7

Woofer Volume 0xcbh

Woofer Scale 0x8ah

Woofer Check Sum NONE

Page 32

4-13

4. Troubleshooting

Factory Menu Name Data Range Remark Key

Woofer Local Check Sum NONE

Amp local Check Sum NONE

Speaker EQ ON ON/OFF

PEQ Test Ready Ready/Set1~Set5

Speaker cut-off Freq 5

SPDIF PCM Gain -9dB

FM M Prescale 0

BTSC Mono Prescale 0

BTSC stereo Prescale 0

SAP Prescale 0

A2 Ident High Thld 15

A2 Ident Low Thld 4

Carrier2 Amp High Thld 16

Carrier2 Amp Low Thld 14

Carrier2 SNR High THR 32

Carrier2 SNR Low THR 17

Audio-IP Test Ready Ready/Set1~Set9

SRS Tuning Parm 0

TruBass-CheckSum 0

Mic Scale 0

India Sound OFF ON/OFF

Wall Filter Type 0

SAP High Thld 9

SAP Low Thld 7

Bottom Checksum 0

Bottom Local CHeckSum 0

DEBUG

Factory Menu Name Data Range Remark Key

Spread spectrum

LVDS Spread ON ON/OFF

LVDS Period 40K 20K/30K/40K

LVDS Amplitude 1.0 0.0/0.5/1.0/1.5/2.0/2.5/3.0

DDR Spread ON ON/OFF

DDR Period 20K 20K/30K/40K

DDR Amplitude 1.0 0.0/0.5/1.0/1.5/2.0

FRC LVDS SSC ON/OFF ON ON/OFF

Page 33

4-14

4. Troubleshooting

Factory Menu Name Data Range Remark Key

FRC LVDS SSC MFR 1

FRC LVDS SSC MRR 10

FRC LVDS SSC Period 0

FRC LVDS SSC Modulation 1

FRC DDR SSC ON/OFF ON ON/OFF

FRC DDR SSC MFR 1

FRC DDR SSC MRR 10

FRC DDR SSC Period 1

FRC DDR SSC Modulation 1

DDR Margin

A CTRL_OFFSET_0_3 0 0~1

A CTRL_OFFSET_D 0 0~1

B CTRL_OFFSET_0_3 0 0~1

B CTRL_OFFSET_D 0 0~1

ND ADJ Support 0 0~1

MICOM POWER OFF 0 0~1

RF Mute Time 6ms 0ms~10ms

CI+1.3 0 0~1

FRC

FRC FDISPLAY ON/OFF OFF ON/OFF

PC Mode ON/OFF OFF ON/OFF

Home Panel FRC OFF ON/OFF

Tuner Margin 0 0~1

MPEG Margin 1000

H.264 Margin 8

CAM Wait Time 0

TS Clock delay 0

TCON_TEMP READ 0.00

TEMP LAST 60.00

DCC VERSION 0x0

DCC CHK SEL 0

DCC CHECK LOCAL 0x0

DCC CHECK TOTAL 0x0

MultiACC Checksum 0

IIC Bus Stop OFF ON/OFF

Tuner Status

DVB

SNR

0 0

Page 34

4-15

4. Troubleshooting

Factory Menu Name Data Range Remark Key

BER

Signal Strength

Bandwidth

Frequency

LNA Status

FFT

Modulation

Code Rate

GI

Hier Modulation

Frequency Offset

Timing Offset

AGC

UCB

PLL Type

DEMOD Type

TPS Lock

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

RS Lock

SSI

0 0

0 0

SQI 0 0

Firmware Version 0 0

ISDB-T

FFT Size_1 0 0

Guard Interval_1 0 0

Freq.Offset_1 0 0

SNR_1 0 0

IF AGC_1 0 0

TMCC Lock_1 0 0

TS Packet_1 0 0

Master Lock_1

A_Modulation_1

A_Code Rate_1

0 0

0 0

0 0

A_Timer InterLeave_1 0 0

A_Segments Num_1 0 0

A_BER_1 0 0

B_Modulation_1 0 0

B_Code Rate_1 0 0

Page 35

4-16

4. Troubleshooting

Factory Menu Name Data Range Remark Key

B_Timer InterLeave_1 0 0

B_Segments Num_1 0 0

B_BER_1 0 0

C_Modulation_1 0 0

C_Code Rate_1 0 0

C_Timer InterLeave_1 0 0

C_Segments Num_1 0 0

C_BER_1 0 0

SVC

Factory Menu Name Data Range Remark Key

Test Pattern

Pattern Sel RGB_RAMP

Logic Pattern Sel …

Logic Level Sel …

FRC Pre Test Pattern 0

FRC Post Test Pattern 0

SOC TCON Test Pattern 0 0~1

SOC TCON Pattern Level 0 0~1

SOC TCON FRC Pattern 0 0~1

HDMI WB Pattern 0 0~1

HDMI Pattern Sel 0 0~1

Panel Display Time 60Hr

SVC Info 0

Delete S/N Failure Failure/Success

Upgrade

T-CON Usb Download Failure Failure/Success

T-CON CheckSum N/A

Logic Usb D/L …

SUBMICOM UPGRADE Ready

BT UPGRADE

BT FREEPAIRING ON ON/OFF

Function Upgrade Failure Failure/Success

FRC3D FW Upgrade

Camera Upgrade 0 0~1

Mic Upgrade 0 0~1

Page 36

4-17

4. Troubleshooting

Factory Menu Name Data Range Remark Key

CPLD USB Download 0 0~1

JP MICOM UPGRADE Failure Failure/Success

DP MICOM UPGRADE Failure Failure/Success

Jump Upgrade Failure Failure/Success

MIC PROGRAM UPGRADE Failure Failure/Success

Smart Hub Reset 0

ER Count

WD Count 0

AR Count 0

WIFI ER Count 0

BT ER Count 1

HDMI Stable Cnt 1

Camera ER Count 0

Power Fail Error Count 0

LOG

Select Log Type MICOM

Log View 0

Delete Log

Debug Log Down

Self Diagnosis

Loop Back

LAN Test

AV Audio Test Failure Failure/Success

DVIN Audio Test Failure Failure/Success

CVBS Test Failure Failure/Success

COMP Test Failure Failure/Success

USB HUB Test

HDMI Test NG/NG/NG/NG

SCART Audio Test Failure Failure/Success

SCART CVBS Test Failure Failure/Success

SCART RGB Test Failure Failure/Success

PC Audio Test Failure

PC Self Test Failure

CPU Failure Failure/Success

DDR

FLASH

EEPROM

Page 37

4-18

4. Troubleshooting

Factory Menu Name Data Range Remark Key

X-TAL Failure Failure/Success

Tuner1

Sound AMP Failure Failure/Success

HDMI Switch IC Failure Failure/Success

USB HUB IC Failure Failure/Success

WIFI Failure

LVDS

T-CON/FRC

PCB Test Failure Failure/Success

MOIP 0

BT

EcoSensor

Voltage 0

Device Self Test 0

App Self Test

EXT Sound Inspection

Woofer Sound Inspection NONE

ATV CH Inspection Failure Failure/Success

DTV CH Inspection

Satellite CH Inspection

PDP Discharge Voltage

IREPF

OPTION_HDMI

DVI/HDMI SOUND Auto Auto/DVI

HDMI HOT PLUG Disable Disable/Enable

HOT PLUG SWITCHING Boot Boot/Source

HOT PLUG DURATION 200ms

CLK TERM DURATION 200ms

HDMI FLT CNT SIG 100ms

HDMI FLT CNT LOS 100ms

UNSTABLE BAN CNT 3500ms

HDMI ROBIN 1 0~1

HDMI Callback 0 0~1

HDMI CTS Thld 8 0~15

HDMI CTS Cnt1 1 0~15

HDMI EQ AUTO AUTO/Low/Middle/High/Strong

HDMi Write Type Combine Combine/Separate

Page 38

4-19

4. Troubleshooting

Factory Menu Name Data Range Remark Key

HDMI Switch NONE NONE/SIL9287/TMDS461

DVI SET TIME 300ms

HDMI Sync DE DE/HV

HDMI 3D DET 0 0~1

HOT PLUG OFF HOLD

TIME

DVB CI

TS Clock delay TC 0

TS Clock delay S 0

CI Control Buf ON ON

TS Clock delay CPU -1

CAL Data Backup_Copy …

CAL Data Restore_Copy …

Expert

N/D ADJ …

Source …

ATV IF AGC SPEED 0 0~16

Reset

EEPROM_Reset

Factory_Reset

Auto Power MEMORY MEMORY/ALWAYS ON/ALWAYS

0 0~1

OFF

ADC/WB

Factory Menu Name Data Range Remark Key

ADC

AV Calibration /

Comp Calibraion /

PC Calibration /

HDMI Calibration /

ADC Result

1st_Y_GH 0

1st_Y_GL 0

1st_Cb_BH 0

1st_Cb_BL 0

1st_Cr_RH 0

1st_Cr_RL 0

Page 39

4-20

4. Troubleshooting

Factory Menu Name Data Range Remark Key

2nd_R_L 134

2nd_G_L 134

2nd_B_L 134

2nd_R_H 49

2nd_G_H 49

2nd_B_H 49

White Balance

R-Offset 128

G-Offset 128

B-Offset 128

R-Gain 115

G-Gain 128

B-Gain 151

WB_W2_R_Offset 128

WB_W2_B_Offset 128

WB_W2_R_Gain 139

WB_W2_B_Gain 94

WB_N_R_Offset 128

WB_N_B_Offset 128

WB_N_R_Gain 131

WB_N_B_Gain 133

MGA

MAG On/Off OFF

R1_Gain 512

G1_Gain 512

B1_Gain 512

R2_Gain 512

G2_Gain 512

B2_Gain 512

R3_Gain 512

G3_Gain 512

B3_Gain 512

R4_Gain 512

G4_Gain 512

B4_Gain 512

R5_Gain 512

G5_Gain 512

Page 40

4-21

4. Troubleshooting

Factory Menu Name Data Range Remark Key

B5_Gain 512

R6_Gain 512

G6_Gain 512

B6_Gain 512

R7_Gain 512

G7_Gain 512

B7_Gain 512

R8_Gain 512

G8_Gain 512

B8_Gain 512

R9_Gain 512

G9_Gain 512

B9_Gain 512

R10_Gain 512

G10_Gain 512

B10_Gain 512

Advanced

Page 41

4-22

4. Troubleshooting

4-4. White Balance

4-4-1. Calibration

Into the Factory Mode.1.

Select 2. SVC Menu.

Select 3. ADC/WB menu.

Select 4. ADC menu.

Option

Control

Debug

SVC

ADC/WB

Advanced

4-4-2. Service Adjustment

ADC

AV Calibration

Comp Calibration

PC Calibration

HDMI Calibration

You must perform Calibration in the Lattice Pattern before adjusting the White Balance.

Color Calibration

Adjust Specication•

Source Setting Mode Pattern Use Equipment

HDMI 1280 x 720@60 Hz Pattern #24 (Chess Pattern) CA210 & Master MSPG925 Generator

(Chess Pattern)

Use other equipment only after comparing the result with that of the Master equipment. -

Input mode Calibration Pattern

CVBS IN (Model_#1) Perform in NTSC B&W Pattern #24 Lattice

Component IN (Model_#6) Perform in 720p B&W Pattern #24 Lattice

PC Analog IN (Model_#21) Perform in VESA XGA (1024x768) B&W Pattern #24 Lattice

HDMI IN Perform in 720p B&W Pattern #24 Lattice

Page 42

4-23

4. Troubleshooting

Method of Color Calibration (AV)

Apply the NTSC Lattice (N0. 3) pattern signal to the AV IN 1 port.1.

Press the Source key to switch to “AV1” mode.2.

Enter Service mode.3.

Select the “ADC” menu.4.

Select the “AV Calibration” menu.5.

In “AV Calibration Off” status, press the “► ” key to perform Calibration.6.

When Calibration is complete, it returns to the high-level menu.7.

You can see the change of the “AV Calibration” status from Failure to Success. 8.

Method of Color Calibration (Component)

Apply the 720p Lattice (N0. 6) pattern signal to the Component IN 1 port.1.

Press the Source key to switch to “Component1” mode.2.

Enter Service mode.3.

Select the “ADC” menu.4.

Select the “Comp Calibration” menu.5.

In “Comp Calibration Off” status, press the “ ►” key to perform Calibration.6.

When Calibration is complete, it returns to the high-level menu.7.

You can see the change of the “Comp Calibration” status from Failure to Success.8.

Method of Color Calibration (PC)

Apply the VESA XGA Lattice (N0. 21) pattern signal to the PC IN port.1.

Press the Source key to switch to “PC” mode.2.

Enter Service mode.3.

Select the “ADC” menu.4.

Select the “PC Calibration” menu.5.

In “PC Calibration Off” status, press the “ ►” key to perform Calibration.6.

When Calibration is complete, it returns to the high-level menu.7.

You can see the change of the “PC Calibration” status from Failure to Success.8.

Method of Color Calibration (HDMI)

Apply the 720p Lattice (N0. 6) pattern signal to the HDMI1/DVI IN port.1.

Press the Source key to switch to “HDMI1” mode.2.

Enter Service mode.3.

Select the “ADC” menu.4.

Select the “HDMI Calibration” menu.5.

In “HDMI Calibration Off” status, press the “►” key to perform Calibration.6.

When Calibration is complete, it returns to the high-level menu.7.

You can see the change of the “HDMI Calibration” status from Failure to Success.8.

Page 43

4-24

4. Troubleshooting

4-4-3. Adjustment

Into the Factory Mode.1.

Select 2. SVC Menu.

Select 3. ADC/WB menu.

Select 4. WB menu.

Option

Control

Debug

SVC

ADC/WB

Advanced

White Balance

(Low light)

Sub Bright

R offset

G offset

B offset

(High light)

Sub Contrast

R gain

G gain

B gain

Page 44

4-5.White Balance - Calibration

4-25

4. Troubleshooting

White Balance Manual adjustment

DEVICES PANEL-TYPE

CA-210

40D6AF0S

RGB Measurement

Levels

10 IRE 0x01 O

20 IRE 0x02 O

30 IRE 0x03 X

40 IRE 0x04 O

50 IRE 0x05 X

60 IRE 0x06 X

70 IRE 0x07 O

80 IRE 0x08 X

90 IRE 0x09 X

100 IRE 0x0A O

Code Check

Levels

10 IRE O 0.02 0.02 0.4

20 IRE O 0.02 0.02 0.4

30 IRE O 0.02 0.02 0.4

40 IRE O 0.02 0.02 0.4

50 IRE O 0.02 0.02 0.4

60 IRE O 0.02 0.02 NA

70 IRE O 0.02 0.02 NA

80 IRE O 0.02 0.02 NA

90 IRE O 0.02 0.02 NA

100 IRE O NA NA NA

Panel Inspection Spec.

Check x(±) y(±) Gamma(±)

Gray Check Adjust Spec(xyL) Adjust Target offset(xyL)

Levels

10 IRE 0x01 X 0.005 0.005 0.07 0 0 0

20 IRE 0x02 O 0.005 0.005 0.05 0 0 0

30 IRE 0x03 X 0.005 0.005 0.04 0 0 0

40 IRE 0x04 O 0.004 0.004 0.03 0 0 0

50 IRE 0x05 X 0.004 0.004 0.02 0 0 0

60 IRE 0x06 X 0.004 0.004 0.02 0 0 0

70 IRE 0x07 O 0.004 0.004 0.02 0 0 0

80 IRE 0x08 X 0.004 0.004 0.01 0 0 0

90 IRE 0x09 X 0.004 0.004 0.01 0 0 0

100 IRE 0x0A X NA NA NA NA NA NA

Code Check x(±) y(±) L(±) x(±) y(±) L(±)

Page 45

4-26

4. Troubleshooting

Target Gamma 2.30

Black

Target xy

x y

0.231 0.208

Option x

Auto 0.282

Contrast

300000

Color Tone Target Spec.

High x y

COOL

0.267 0.282

x(±) y(±)

0.004 0.004NORMAL 0.286 0.302

WARM2

Low x y x(±) y(±)

COOL NA NA

WARM2 NA NA

0.318 0.349

NA NANORMAL NA NA

y

0.299

Panel Spec. ±

Gamma 2.2 0.35

x

0.281 0.03

y 0.288 0.03

ACC x

ACC y x,y value 0.015

255 white 0.015

10IRE Gamma target

RetryCount

LFD Contrast

20~128

255

26~255

2.3

3

0

Page 46

4-27

4. Troubleshooting

4-6. Software Upgrade

Software Upgrade can be performed by downloading the. latest rmware from samsung.com to a USB memory device.

Current Version - The software already installed in the TV.•

Software is represented as ‘Year/Month/Day_Version’.

4-6-1. How to Check the Software Version

Use the Main Menu

Click the "MENU" key in remote controller.1.

Select "Support" menu.2.

Locate the menu cursor "Software Upgrade" menu.3.

Click the "INFO" key.4.

Check the Main SW and Micom version. -

Page 47

4-28

4. Troubleshooting

Use the Factory Mode

Option

Control

Debug

SVC

ADC/WB

Advanced

T-NT14LDEUC-xxxx.x

T-NT14LDEUS-xxxx

E-Manual : NLDVBEUxH-xxxx

EDID SUCCESS

CALIB : AV/COMP/PC/HDMI/

Option : 40D6AF0S,EU_SPAIN,5003,NONE

DTP-SDAL-NT14L-xxxx

RFS:"NT14L xxxx" K/20xx-xx-xx

KERNEL:xxxx.xxxx,/Onboot: xxxx

TCON Version:----

NSP-DTVTD-xxxx

Model: UE40H5003

CIP FAIL

Factory Data Ver:xxx

EERC Version: xxx

NSP-BP-HAL-xxxx

NSP-AP-CNC-xxxx

NSP-AP-MM-xxxx

NSP-BP-MW-xxxx

NSP-BP-APP-xxxx

NSP-PNG-xx-xxxx

Date of purchase:-/-/----

Page 48

4-29

4. Troubleshooting

4-6-2. How to Upgade Software and Micom

Insert a USB drive containing the rmware upgrade downloaded from samsung.com into the TV. Please be careful not

to disconnect the power or remove the USB drive while upgrades are being applied. The TV will turn off and turn on

automatically after completing the rmware upgrade. Please check the rmware version after the upgrades are complete

(the new version will have a higher number than the older version). When software is upgraded, video and audio

settings you have made will return to their default (factory) settings. We recommend you write down your settings before

beginning rmware update. After update is completed, restore your previous settings.

Main Software Upgrade

Store the sw program named "T-NT14LDEUC" in USB memory stick.1.

Connect the USB. -

Click the "MENU" key in Remote Controler.2.

Select "Support" menu.3.

Locate the menu cursor "Software Update" menu.

Locate the menu cursor "Update now" menu.4.

Page 49

4-30

4. Troubleshooting

Click the "ENTER" key.5.

Click the "ENTER" key.6.

Wait for upgrade complete.7.

Check the Software Version. -

Page 50

4-7. Rear Cover Dimension

4-31

4. Troubleshooting

F

D

E

A

B

C

Rear Cover Dimension 40" 48"

A 200

B

C

D

E

F

200 200

574.7 667.2

194.9 284.6

166.1 208.3

248.9 320.3

200

Page 51

Main Board

IP Board

PANEL

Speaker

CNL802

CNM803

Speaker

FUNCTION& IR

CN1

CN202

%0

CN302

%0A(*&

T-CON

0

0

5. Wiring Diagram

5. Wiring Diagram

5-1. Wiring Diagram

5-1

Page 52

5-2

5. Wiring Diagram

5-2. Connector

Main Board

8

9

10

3

6

7

2

1

5

4

1

CN1202_FHD (to Panel)

1 NC 16 EVEN_TX3+_LVDS

2 GND 17 EVEN_TX3-_LVDS

3 FRC_SDA 18 GND

4 PWM_DIM1_FRC 19

5 FRC_SCL 20

6 FRC_NRESET 21 GND

7 LVDS_FORMAT 22 EVEN_TX2+_LVDS

8 TCON_SDA 23 EVEN_TX2-_LVDS

9 TCON_WP 24 EVEN_TX1+_LVDS

10 NC 25 EVEN_TX1-_LVDS

11 UPDATE_CHECK 26 EVEN_TX0+_LVDS

12 TCON_SCL 27 EVEN_TX0-_LVDS

13 GND 28 GND

14 EVEN_TX4+_LVDS 29 ODD_TX4+_LVDS

15 EVEN_TX4-_LVDS 30 ODD_TX4-_LVDS

EVEN_TXCLK+_

LVDS

EVEN_TXCLK-_

LVDS

1

CN1202_HD (to Panel)

31 ODD_TX3+_LVDS 42 ODD_TX0-_LVDS

32 ODD_TX3-_LVDS 43 GND

33 GND 44 GND

ODD_TXCLK+_

34

35

36 GND 47 Panel_13V_PW

37 ODD_TX2+_LVDS 48 Panel_13V_PW

38 ODD_TX2-_LVDS 49 Panel_13V_PW

39 ODD_TX1+_LVDS 50 Panel_13V_PW

40 ODD_TX1-_LVDS 51 Panel_13V_PW

41 ODD_TX0+_LVDS

LVDS

ODD_TXCLK-_

LVDS

45 GND

46 NC

Page 53

5-3

5. Wiring Diagram

2

CN202 (to Power board)

1 GND 6

2 GND 7 A13V

3 A13V 8 PWM_DIM

4 GND 9 A13V

5 A13V 10 UNDER_DRIVER

3

CN402 (FUNCTION)

1 IR 5 MSDA

2 GND 6 KEY_INPUT1

3 A3.3V 7 KEY_INPUT2

4 MSCL 8 LED_STB

4

CN302 (SPEAKER)

1 R+ 3 L+

2 R- 4 L-

5

CN401_SC (SCART)

1 SC_SR_OUT 12 NC

2 SC_AV2_SR_IN 13 GND

3 SC_SL_OUT 14 GND

4 GND 15 SC_R

5 GND 16 SC_FB

6 SC_AV2_SL_IN 17 GND

7 SC_B 18 GND

8 IDENT_SC 19 SC_CVBS_OUT

9 GND 20 SC_AV2_CVBS_IN

10 NC 21 GND

11 SC_G

SW_POWER_TO

_SMPS

7

CN502_H2 (HDMI2)

1 HDMI2_RX2+ 11 GND

2 GND 12 HDMI2_RXCLK-

3 HDMI2_RX2- 13 CEC

4 HDMI2_RX1+ 14 NC

5 GND 15 HDMI_SCL

6 HDMI2_RX1- 16 HDMI_SDA

7 HDMI2_RX0+ 17 GND

8 GND 18 5V

9 HDMI2_RX0- 19 STB_CHECK

10 HDMI2_RXCLK+

8

CN1101 (USB1)

1 B5V_USB1 3 USB_DP

2 USB_DM 4 GND

9

OP301_OP (OPTICAL)

1 SPDIF_OUT 3 GND

2 B5V

6

CN501_H1 (HDMI1)

1 HDMI1_RX2+ 11 GND

2 GND 12 HDMI1_RXCLK-

3 HDMI1_RX2- 13 CEC

4 HDMI1_RX1+ 14 NC

5 GND 15 HDMI1_SCL

6 HDMI1_RX1- 16 HDMI1_SDA

7 HDMI1_RX0+ 17 GND

8 GND 18 HDMI1_5V

9 HDMI1_RX0- 19 STB_CHECK

10 HDMI1_RXCLK+

Page 54

5-4

5. Wiring Diagram

10

CN1301_CI (PCMCIA)

1 GND 35 GND

2 PCM_DATA[3] 36 PCM_CD1

3 PCM_DATA[4] 37 TSO_DATA[3]

4 PCM_DATA[5] 38 TSO_DATA[4]

5 PCM_DATA[6] 39 TSO_DATA[5]

6 PCM_DATA[7] 40 TSO_DATA[6]

7 PCM_CE1 41 TSO_DATA[7]

8 PCM_ADDR[10] 42 NC

9 PCM_OE 43 NC

10 PCM_ADDR[11] 44 PCM_IORD

11 PCM_ADDR[9] 45 PCM_IOWR

12 PCM_ADDR[8] 46 CH_START

13 PCM_ADDR[13] 47 CH_DATA[0]

14 PCM_ADDR[14] 48 CH_DATA[1]

15 PCM_WE 49 CH_DATA[2]

16 PCM_IRQA 50 CH_DATA[3]

17 VCC_CI_5V 51 VCC_CI_5V

18 VCC_CI_5V 52 VCC_CI_5V

19 CH_VALID 53 CH_DATA[4]

20 CH_CLK 54 CH_DATA[5]

21 PCM_ADDR[12] 55 CH_DATA[6]

22 PCM_ADDR[7] 56 CH_DATA[7]

23 PCM_ADDR[6] 57 TSO_CLK

24 PCM_ADDR[5] 58 PCM_RESET

25 PCM_ADDR[4] 59 PCM_WAIT

26 PCM_ADDR[3] 60 NC

27 PCM_ADDR[2] 61 PCM_REG

28 PCM_ADDR[1] 62 TSO_VALID

29 PCM_ADDR[0] 63 TSO_START

30 PCM_DATA[0] 64 TSO_DATA[0]

31 PCM_DATA[1] 65 TSO_DATA[1]

32 PCM_DATA[2] 66 TSO_DATA[2]

33 VCC_CI_5V 67 PCM_CD1

34 GND 68 GND

Page 55

5-5

5. Wiring Diagram

5-3. Cables

Use Model Function Cable Power Harness (PD - Main)

Code

No.

Image

UE40H5003

UE40H5004

UA40H5003

(AFRICA)

UA40H5003

(Emerging DTV)

UE48H5003

UE48H5004

UA48H5003

(AFRICA)

UA48H5003

(Emerging DTV)

BN39-01916A

BN39-01916B

BN39-01885S

BN39-01885S

BN39-01885W

BN39-01885D

BN39-01885D

BN39-01885S

Use Model LVDS CABLE (Main - panel)

Code

No.

UE40H5003

UE40H5004

UA40H5003

(AFRICA)

UA40H5003

(Emerging DTV

UE48H5003

UE48H5004

UA48H5003

(AFRICA)

UA48H5003

(Emerging DTV)

)

BN96-33236Q

BN96-33236Q

BN96-33236T

BN96-33236W

BN96-33236X

BN96-33236W

BN96-33236U

Image

Loading...

Loading...