ROOM AIR CONDITIONER

INDOOR UNIT

AD26B1C13

AD18B1C09

SERVICE

OUTDOOR UNIT

UD26B1C2

UD18B1C2

Manual

CONTENTSAIR CONDITIONER

1. Installation

2. Disassembly and Reassembly

3. Troubleshooting

4. Exploded Views and Parts List

5. Refrigerating Cycle Block Diagrams

6. Wiring Diagrams

E DB98-05645A(1)

7. Schematic Diagrams

1. Installation

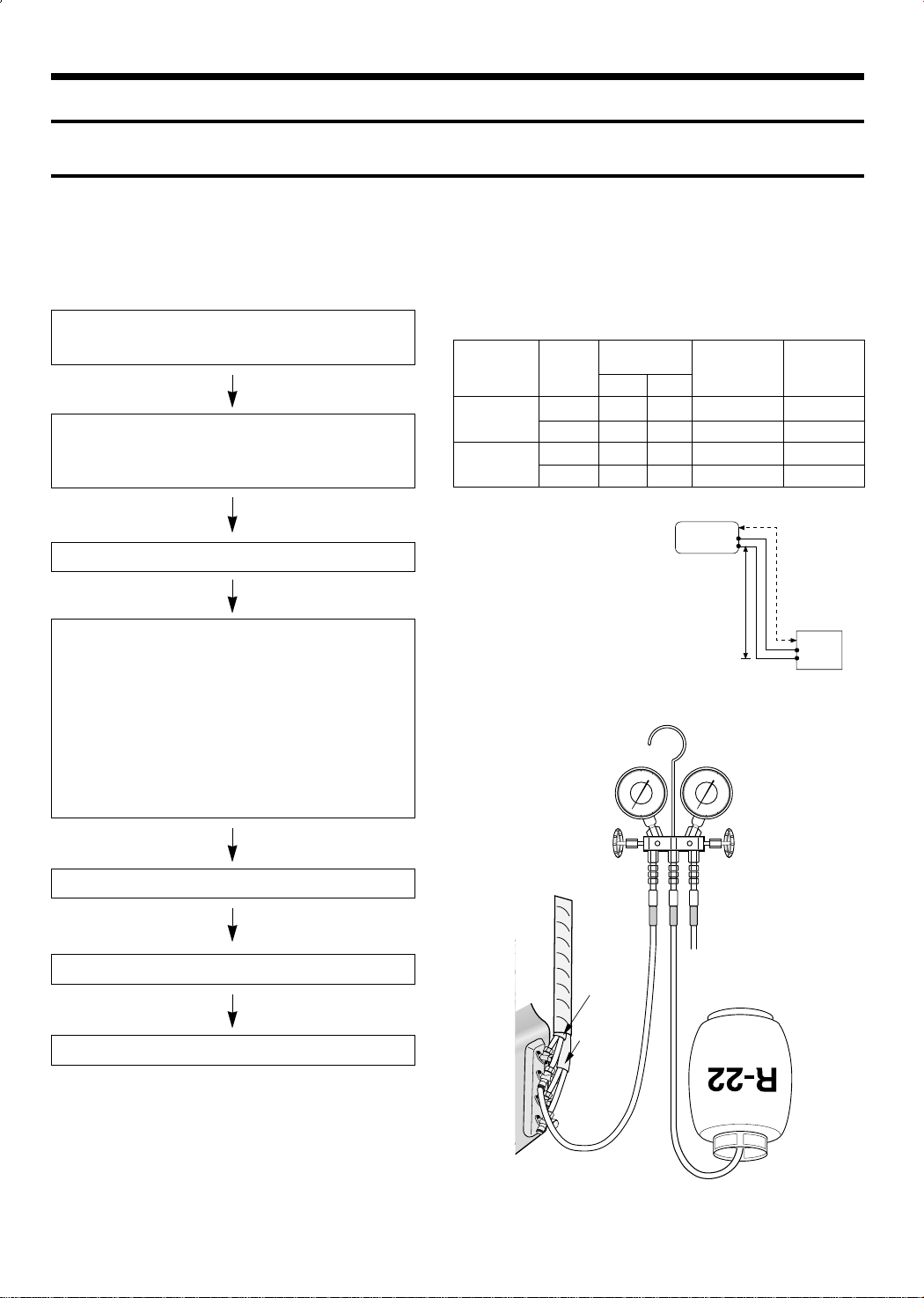

1-1 Refrigerant Refill Procedure

If connecting pipe of more than 5 metres is installed, additional refrigerant should be charged by extra

metre. You don’t have to charge additional refrigerant up to 5 metres of connecting pipe.

1. Remove the valve stem cap and service port of 3-way

valve.

2. Connect the charging hose of low pressure side of

Manifold gauge to the packed valve having a charging

port(1/2” Packed valve) as shown at the right figure.

3. Operate the unit at the cooling mode.

4. Slowly open the valve of the low pressure side of

Manifold gauge counterclockwise until the low pressure

of manifold gauge indicates 4.8 to 5.5 kg/cm

2

(68 a

78psi) at the high cool operation (1-unit operation) and

the standard temperature.

It is recommend that refrigerant should be slowly put in.

If the refrigerant is put in too quickly, compressor will be

damaged.

• Piping length and the height

Pipe Size

LIQUID GAS

AD26B1C13

AD18B1C09

Additional refrigerant charge

(R22,g)

• When length of the pipe is

over 5u by the unit, you

should charge

the refrigerant Formulas

A-UNIT : 20gx(La-5)/m

B-UNIT : 20gx(Lb-5)/m

(La:the length of A-unit’s

pipe Lb:the length of

B-unit’s pipe)

A-UNIT 1/4” 1/2” 15m(49ft 3in) 7m(23ft)

B-UNIT 1/4” 1/2” 15m(49ft 3in) 7m(23ft)

A-UNIT 1/4” 3/8” 15m(49ft 3in) 7m(23ft)

B-UNIT 1/4” 3/8” 15m(49ft 3in) 7m(23ft)

INDOOR UNIT

Max.piping

length

A

B

Max

height

B

A

OUTDOOR UNIT

5. Stop operation of the air conditioner.

6. Disconnect the charge hose of manifold gauge.

7. Close the cap of each valve.

INDOOR

A-UNIT

INDOOR

B-UNIT

1

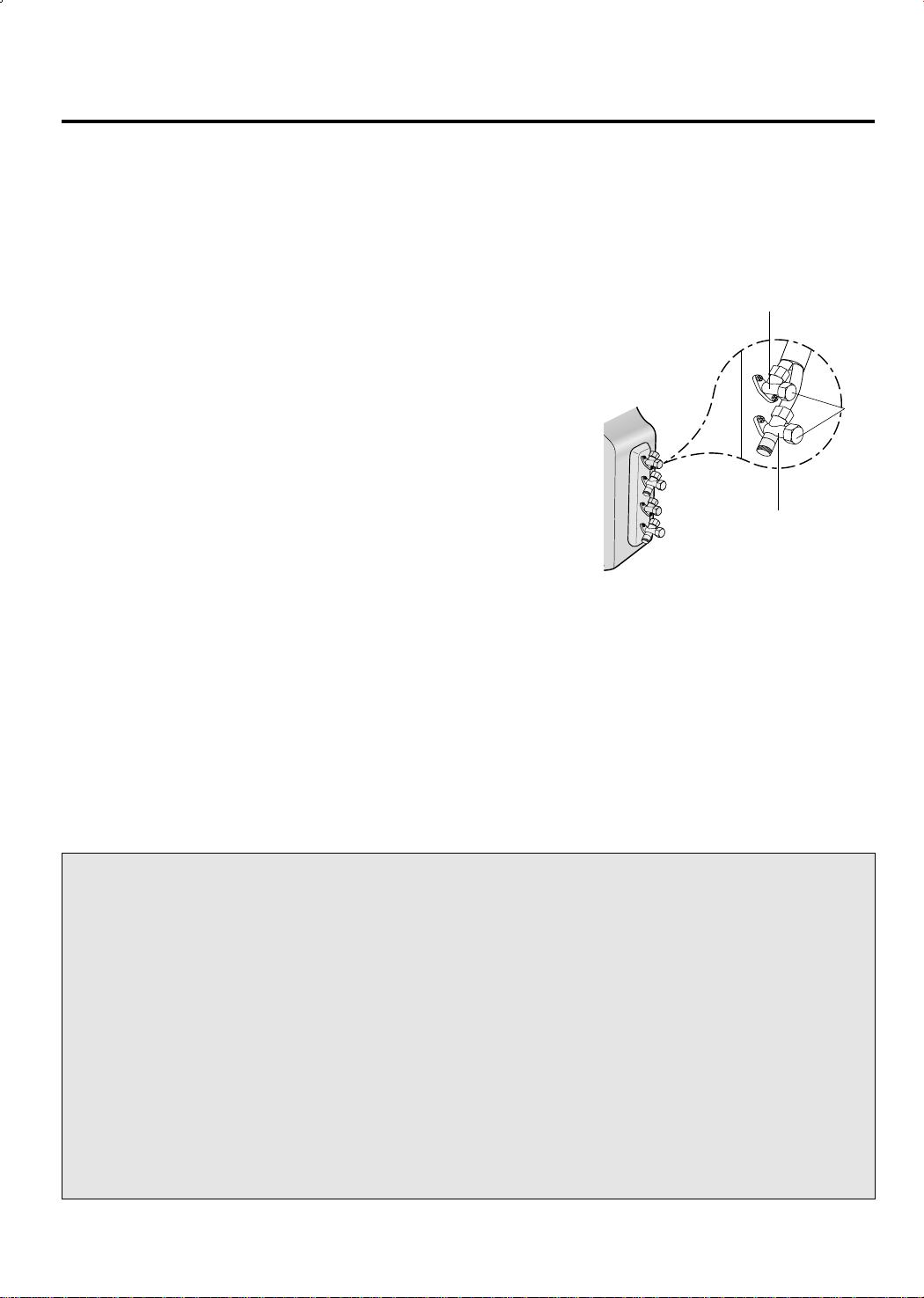

1-2 “Pump down” Procedure

1. Confirm that both the 2-way and 3-way valves are set to

the open position.

(1) Remove the valve stem caps.

(2) Be sure to use a hexagonal wrench to operate the Gas

side valve stems.

2. Operate the unit for 10 to 15 minutes.

3. Stop operation and wait for 3 minutes, then connect the

charge set to the service port of the 3-way valve.

(1) Connect the charge hose with the push pin to the ser-

vice port.

4. Air purging of the charge hose.

(1) Open the low-pressure valve on the charge set slightly

to air purge from the charge hose.

5. Set the liquid side 2-way valve to the closed position.

6. Operate the air conditioner at the cooling cycle and stop

operation immediately after setting the 3-way valve to the

closed position when the gauge indicates 0 kg/cm2G.

If the unit can not be operated at the Cooling Mode(weater

is rather cool), operate the unit at the Trubo Mode.

So that the unit can be operated.

7. Disconnect the charge set, and mount the both 3-way

valve’s stem nuts and the service port cap.

2-Way Valve

Cap

3-Way Valve

Relocation of the air conditioner

• Refer to this procedure when the unit is relocated.

1. Carry out the pump down procedure

(refer to the details of ‘pump down’).

2. Remove the power cord.

3. Disconnect the assembly cable from the

indoor and outdoor units.

4. Remove the flare nut connecting the indoor

unit and the pipe.

At this time, cover the pipe of the indoor

unit and the other pipe using a cap or vinyl

plug to avoid foreign material entering.

2

5. Disconnect the pipe connected to the outdoor unit.

At this time, cover the valve of the outdoor

unit and the other pipe using a cap or vinyl

plug to avoid foreign material entering.

6. Make sure you do not bend the connection

pipes in the middle and store together with

the cables.

7. Move the indoor and outdoor units to a new

location.

8. Remove the mounting plate for the indoor

unit and move it to a new location.

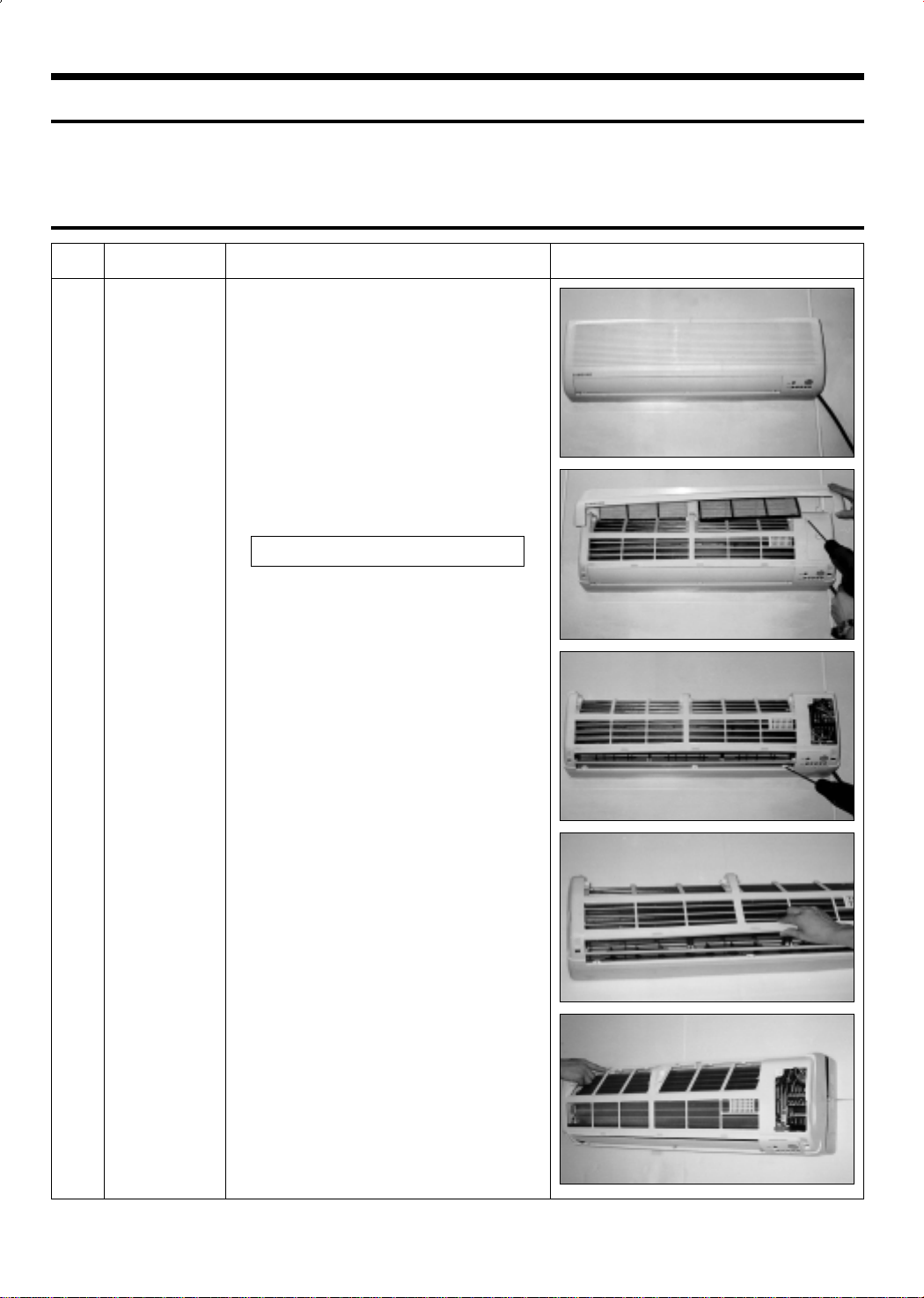

2. Disassembly and Reassembly

Stop operation of the air conditioner and remove the power cable before repairing the unit.

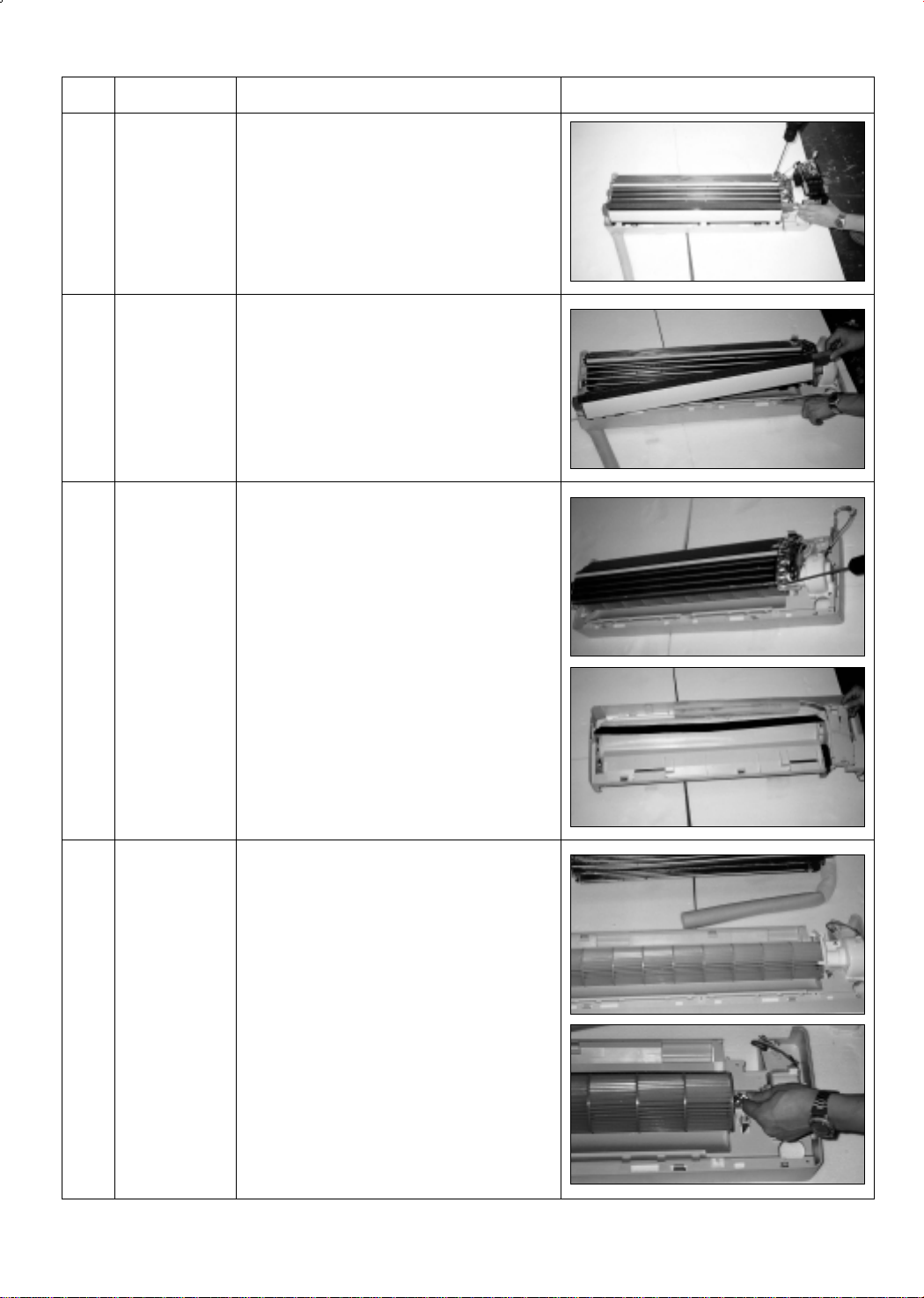

2-1 Indoor Unit

No Parts Procedure Remark

Front Grille1 1) Stop the air conditioner operation and block the

main power.

2) Separate tape of front panel upper.

3) Contract the second finger to the left, and right

handle and pull to open the inlet grille.

4) Take the left and right filter out.

*Taking off the deodorizing filter.

5) Loosen one of the right fixing screw and separate the terminal cover.

6) Loosen three fixing screws of front grille.

7) Pull the upper left and right of discharge softly

for the outside cover to be pulled out.

8) Pull softly the lower part of discharge and push

it up.

Caution;

Assemble the front panel and fix the

hooks of left and right.

3

No Parts Procedure Remark

2

3

4

Electrical Parts

(Main PCB)

Ass’y Tray Drain.

Heat Exchanger

1) Do “1”above.

2) Take all the connector of PCB upper side out.

(Inclusion Power cord)

3) Separate the outdoor unit connection wire from

the terminal block.

4) If pulling the Main PCB up. it will be taken out.

1) Do “1”, “2”, above.

Separate the drain hose from the extension

drain hose.

2) Pull tray drain out from the back body.

1) Do “1” and “2”, “3”, above.

2) Loosen two fixing earth screws of right side.

3) Separate the connection pipe.

4) Separate the holder pipe at the rearside.

5

Fan Motor and

Cross Fan

5) Loosen the three fixing screws of right and left

side.

6) Lifting the heat exchanger up a little to push the

up side for separation from the indoor unit.

1) Do “1”, “2”, ”3”, “4”, above.

2) Loosen the fixing two screws and separate the

motor holder.

3) Loosen the fixing screw of fan motor.

(By use of M3 wrench)

4) Separate the fan motor from the fan.

5) Separate the fan from the left holder bearing.

4

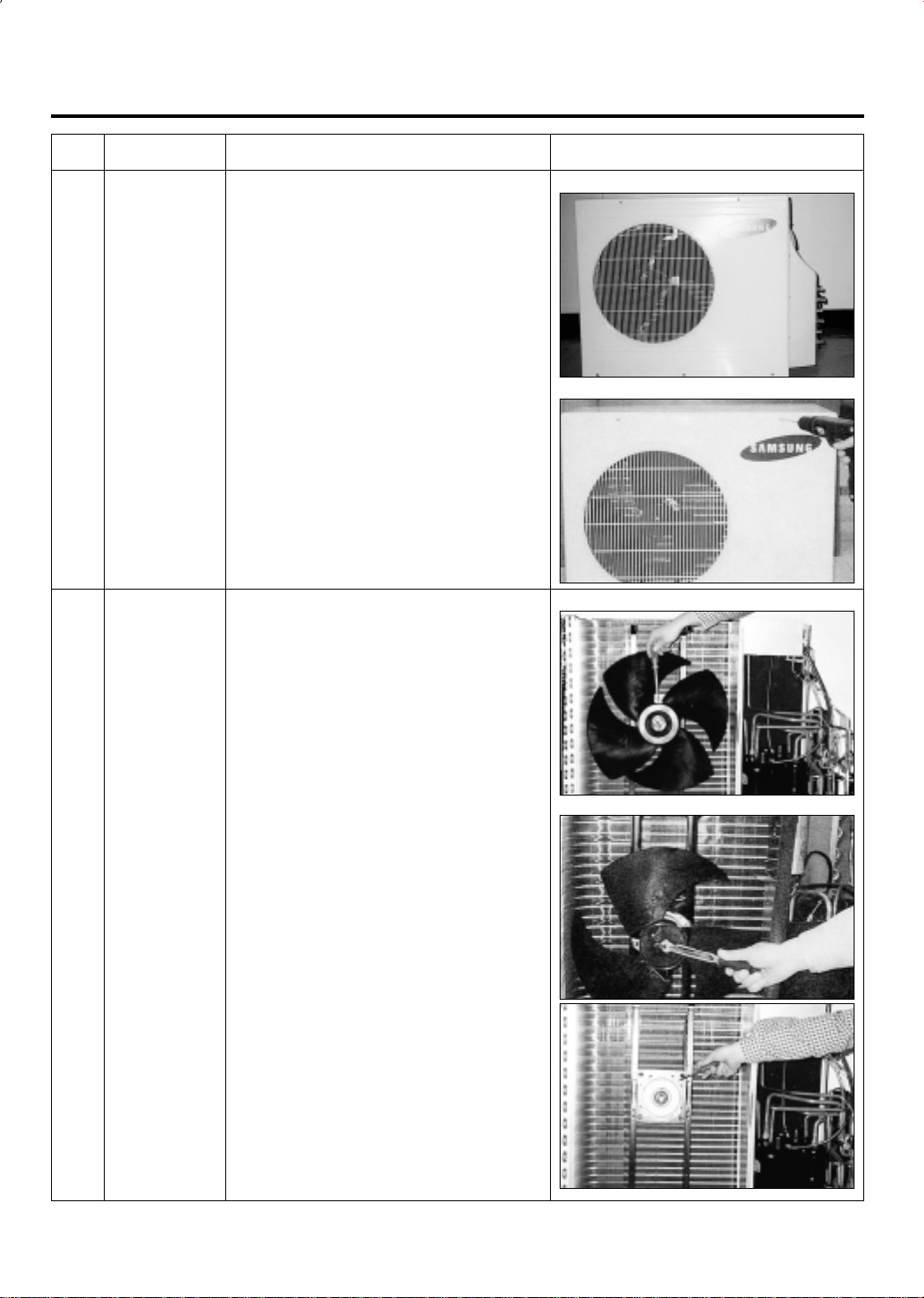

2-2 Outdoor Unit

No Parts Procedure Remark

1

2

Cabinet

Fan Motor

&

Propeller Fan

1) Turn off the unit and remove the power cable.

2) Remove the top cover.

3) Remove the control box cover.

4) Unplug the ass'y cable.

5) Remove the cabi-side.

6) Remove the cabi-front.

* When you assemble the parts, check if the

each parts and electric connectors are fixed

firmly.

1) Do Procedure “1” above.

2) Remove the nut flange.

(Turn to the right to remove as it is a left turned

screw)

3) Disassemble the propeller fan.

<UD26B1C2>

<UD18B1C2>

<UD26B1C2>

<UD18B1C2>

5

3. Troubleshooting

3-1 Items to be checked first

1) The input voltage should be rating voltage ±10% range.

The airconditioner may not operate properly if the voltage is out of this range.

2) Is the link cable linking the indoor unit and the outdoor unit linked properly?

The indoor unit and the outdoor unit shall be linked by 5 cables.

Check the terminals if the indoor unit and outdoor unit are properly linked by the same number

of cables. Otherwise the airconditioner may not operate properly.

3) When a problem occurs due to the contents illustrated in the table below it is a symptom not

related to the malfunction of the airconditioner.

NO Operation of air conditioner

1 The STD operation indication LED blinks when a

power plug of the indoor unit is plugged in for the first time.

2 In a COOL operation mode, the compressor does not

operate at a room temperature higher than the setting

temperature that the IN DOOR FAN should operate.

In a HEAT operation mode, the compressor does not

operate at a room temperature lower than the setting

temperature that indoor fan should operate.

3 Fan speed setting is not allowed in AUTO or DRY mode.

4 Compressor stops operation intermittently in DRY mode.

5 Compressor of the outdoor unit is operating although it is

turned off in a HEAT mode.

6 Timer LED only of the indoor unit lights up and the

air conditioner does not operate.

7 The compressor and indoor fan stop intermittently in HEAT

mode.

8 Indoor fan and outdoor fan stop operation intermittently in

a HEAT mode.

Explanation

It indicates power is on. The LED stops blinking if the operation

ON/OFF button on the remote control unit is pushed.

In happens after a delay of 3 minutes when the compressor is

reoperated. The same phenomenon occurs when a power is on.

As a phenomenon that the compressor is reoperated after a delay

of 3 minutes, the indoor fan is adjusted automatically with reference to a temperature of the air blew

The speed of the indoor fan is set to LL in DRY mode.

Fan speed is 5 steps is selected automatically in AUTO mode.

Compressor operation is controlled automatically in DRY mode

depending on the room temperature and humidity.

When the unit is turned off while de-ice is activated, the compressor continues operation for up to 9 minutes (maximum) until

the deice is completed.

Timer is being activated and the unit is in ready mode.

The unit operates normally if the timer operation is cancelled.

The compressor and indoor fan stop intermittently if room temperature exceeds a setting temperature in order to protect the compressor from overheated air in a HEAT mode.

The compressor operates in a reverse cycle to remove exterior ice

in a HEAT mode, and indoor fan and outdoor fan do not operate

intermittently for within 20% of the total heater operation

9 The compressor stops intermittently in a COOL mode or DRY

mode, and fan speed of the indoor unit decreases.

6

The compressor stops intermittently or the fan speed of the indoor

unit decreases to prevent inside/outside air frozen depending on

the inside/outside air temperature.

4) Indoor unit observes operation condition of the air conditioner, and displays self diagnosis details

on the display panel.

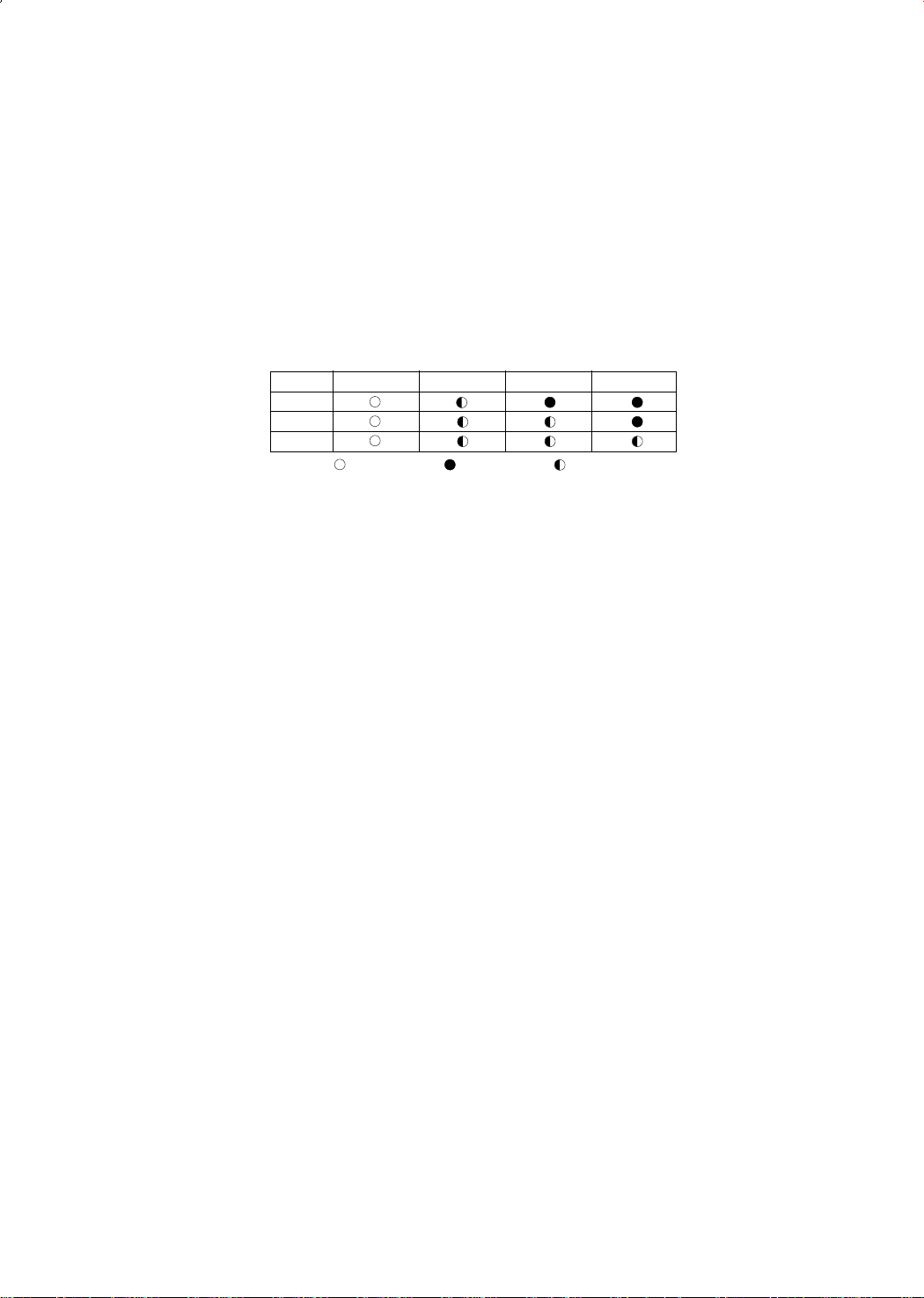

NO

Display

Standard Timer Nature Power

(GREEN)

1

2

3

4

5

6

7

X

(GREEN)

X

X

(GREEN)

(GREEN)

X

X

X

X

X

X

X

Self Diagnosis

Restore from power failure (input initial power)

X

Indoor unit Room sensor Error (open or short)

X

Indoor unit heat exchanger temperature sensor Error (open or short)

X

Indoor fan malfunctioning (for speed is below 450rpm)

X

In case that the communication between the indoor unit and outdoor unit is not made

X

for 60 seconds

Outdoor sensor Error (open or short)

- Outdoor sensor

X

- Pipe sensor A, B

The malfunction ot 4way valve in heat mode operation.

7

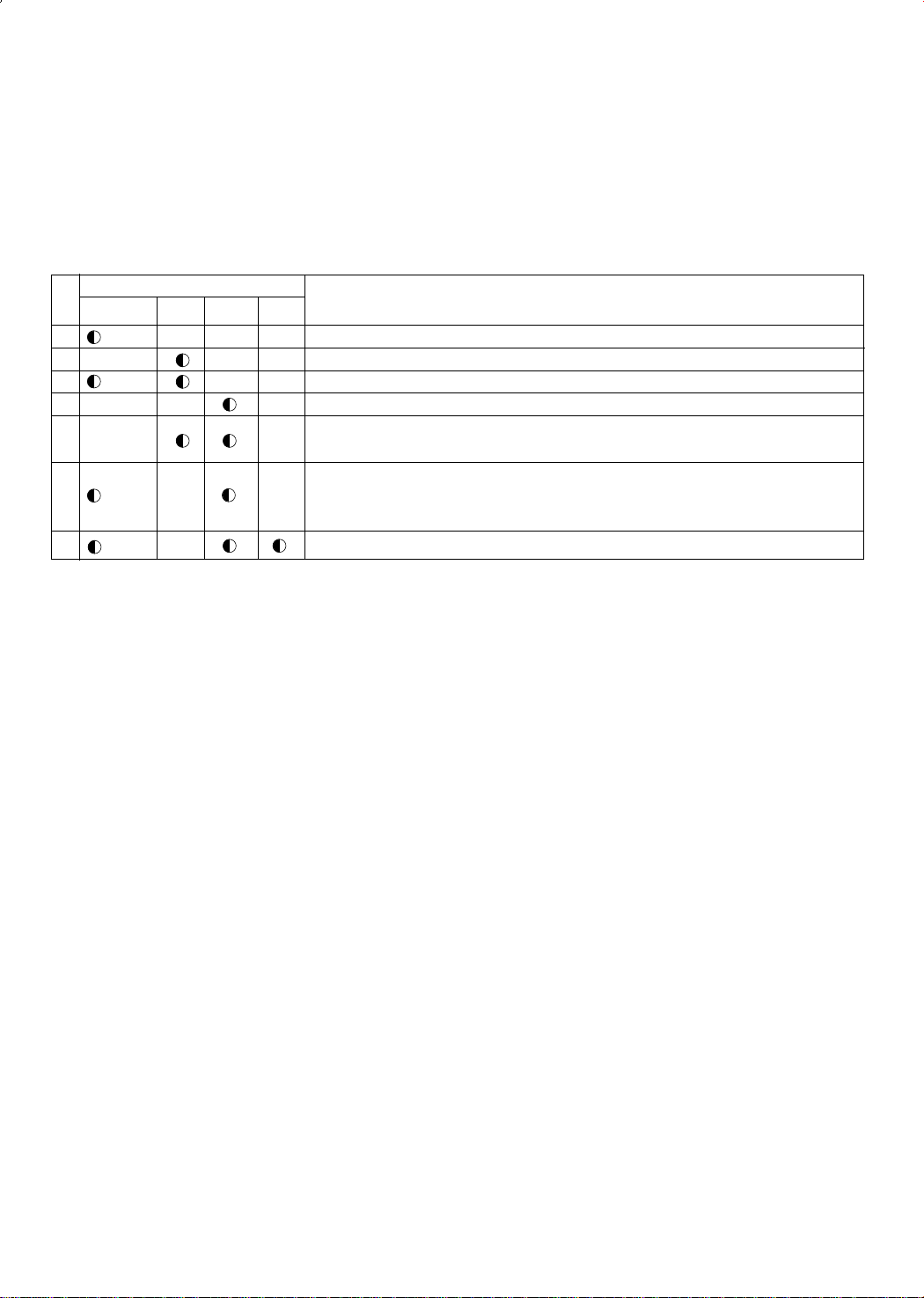

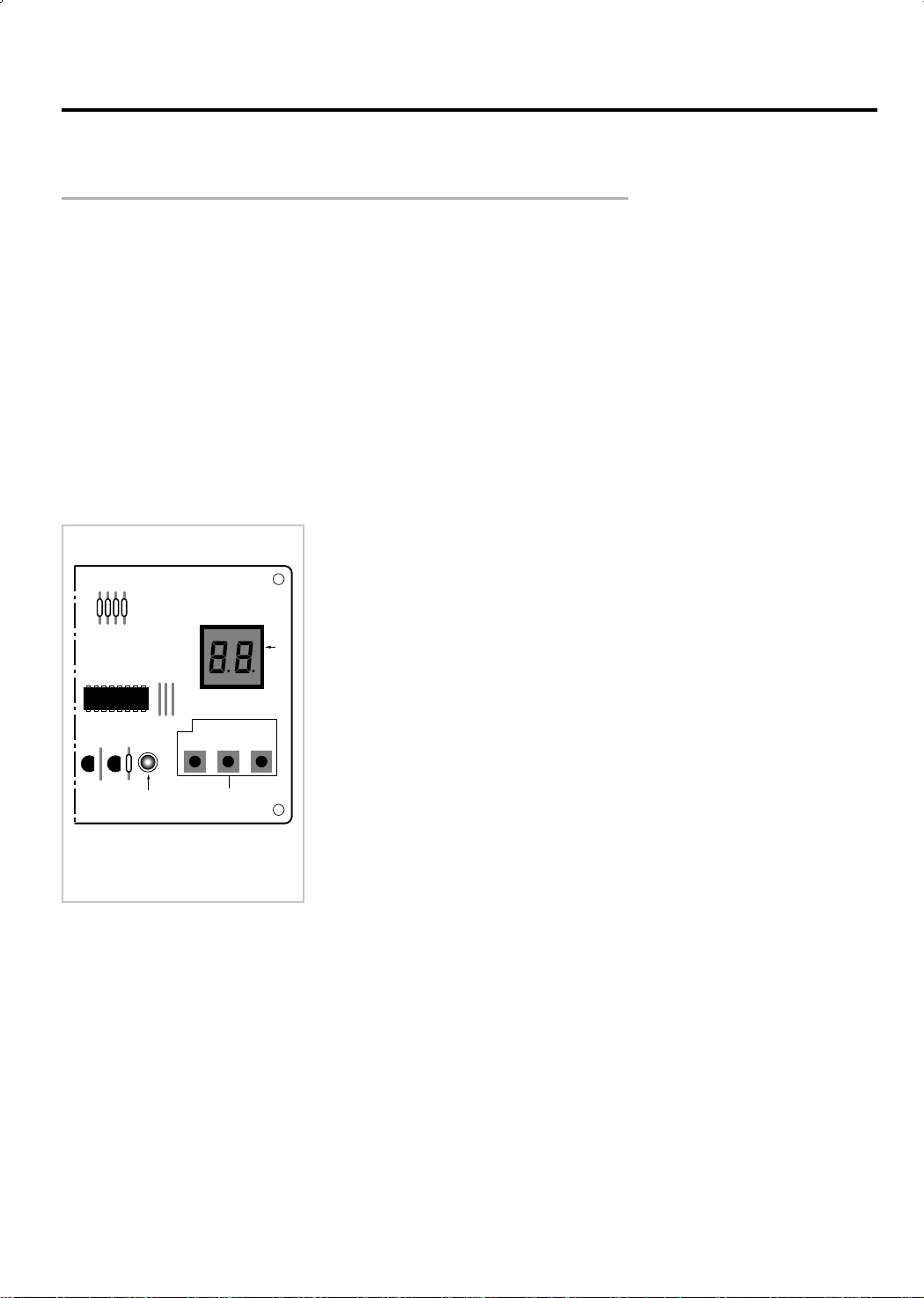

3-2 Checking and Testing Operations (Outdoor Unit)

C

a

b

TEST OPERATING

CB

A

To complete the installation, perform the following checks and tests to ensure that

the air conditioner is operating correctly.

1. Review all the following elements in the installation:

• Installation site strength

• Piping connection tightness to detect any gas leakages

• Connection wiring

• Heat-resistant insulation of the piping

• Drainage

• Earthing wire connection

• Correct operations (follow the steps below)

• Room select switch in the indoor unit

2. Apply the power to the outdoor unit.

- Check the fuse (250V~, 5A) : The fuse is open when the power line (L1, N2) is short.

OUTDOOR UNIT

A : PCB display

B : Red LED

C : PCB switch

3. Check the connection of PCB communication of outdoor unit.

(Check whether the red LED of outdoor unit PCB is flickering.)

• The communication lamp is flickering after the display of each

unit on the outdoor PCB display part. (every one second).

LED is not flikering, if the connection is bad or the room select

switch is located in the wrong position.

- LED lamp (red) flickering after display of A (0.5 sec)

- LED lamp (red) flickering after display of b (0.5 sec)

- LED lamp (red) flickering after display of C (0.5 sec)

Note : PCB switch “C” is used for triple split multi air conditioner.

Result : If all of three units display lamps are flickering, the connection

wires and the room option connections are good.

8

If the lamp is not flickering, check as follows:

A. Check the display part of indoor unit of each unit (A,B) after outdoor unit PCB switch S/W-Ais on.

A. Check the status of each unit indoor room select switch.

A. (Adjust the select switch suitable to the unit A, B.)

A. - A unit : STANDARD LED on, TIMER LED flickering

A. - B unit : STANDARD LED on, TIMER and NATURE LED flickering

A. - C unit : STANDARD LED on, TIMER and NATURE, POWER LED flickering (In case of triple

split multi air conditioner)

UNIT

STANDARD TIMER NATURE POWER

A

B

C

Lamp ON

Lamp OFF Lamp Flasher

4. Check the test operation status by pressing the PCB switch

4. S/W-A and S/W-B of outdoor unit.

4. • Check the operation status by pushing the switch one at time.

4. • Perform the test operation only for the unit selected last.

4. • Check the pipe pressure and the other operation status during the test operation.

4. • Check items when the error occurs during the test operation (each unit)

- Check there is enough refrigerant.

- Check pipe connections.

9

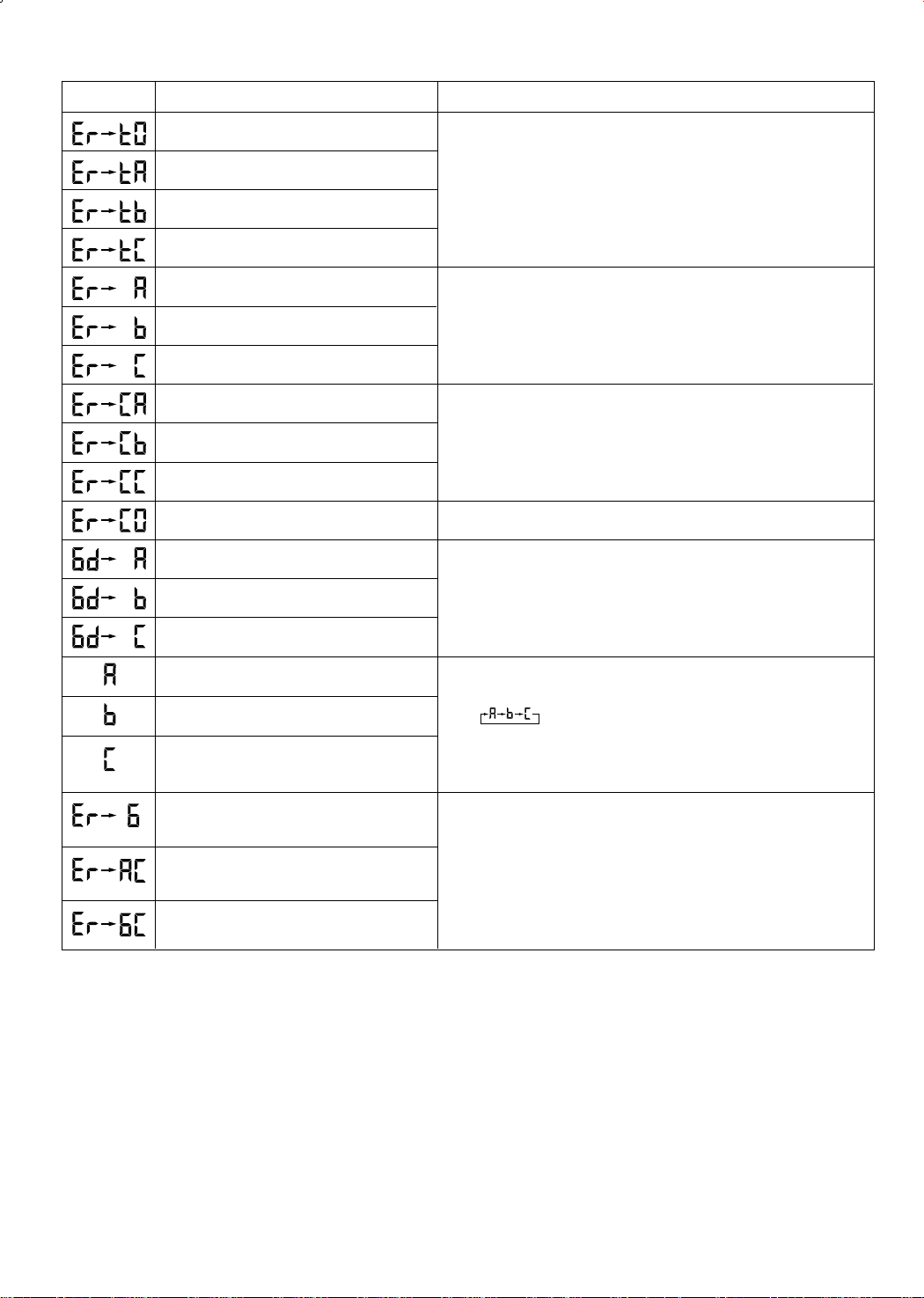

DISPLAY EXPLANATION

REMARK

Outdoor sensor error (Short/Open)

Outdoor A cond pipe sensor error (Short/Open)

Outdoor B cond pipe sensor error (Short/Open)

Outdoor C cond pipe sensor error (Short/Open)

A unit test operation error

B unit test operation error

C unit test operation error

A unit test communication error

B unit test communication error

C unit test communication error

A,B,C unit all communication error

A room test operation OK

B room test operation OK

Be sure to check after applying the power to the outdoor unit.

Display when the test operation finishes.

• When the pipe temperature difference of indoor unit

• (pipe temperature 4 minutes before - Actual pipe temperature)

• is less than 5˚C.

Be sure to check during the test operation.

Display of power application.

Display 4 minutes after the COMP is on.

C room test operation OK

Communication unit number display : A unit

Communication unit number display : B unit

Communication unit number display : C unit

(In case of triple split multi air conditioner)

Refrigerant leaks

High temperature of the A cond

High temperature of the B cond

•Normal operation

•Unit A,B and C are changed every one second.

•The communication lamp is flickering after display of each unit.

•(possibility to check the communication status)

•During the test operation the unit under test is on and off every 0.25s.

10

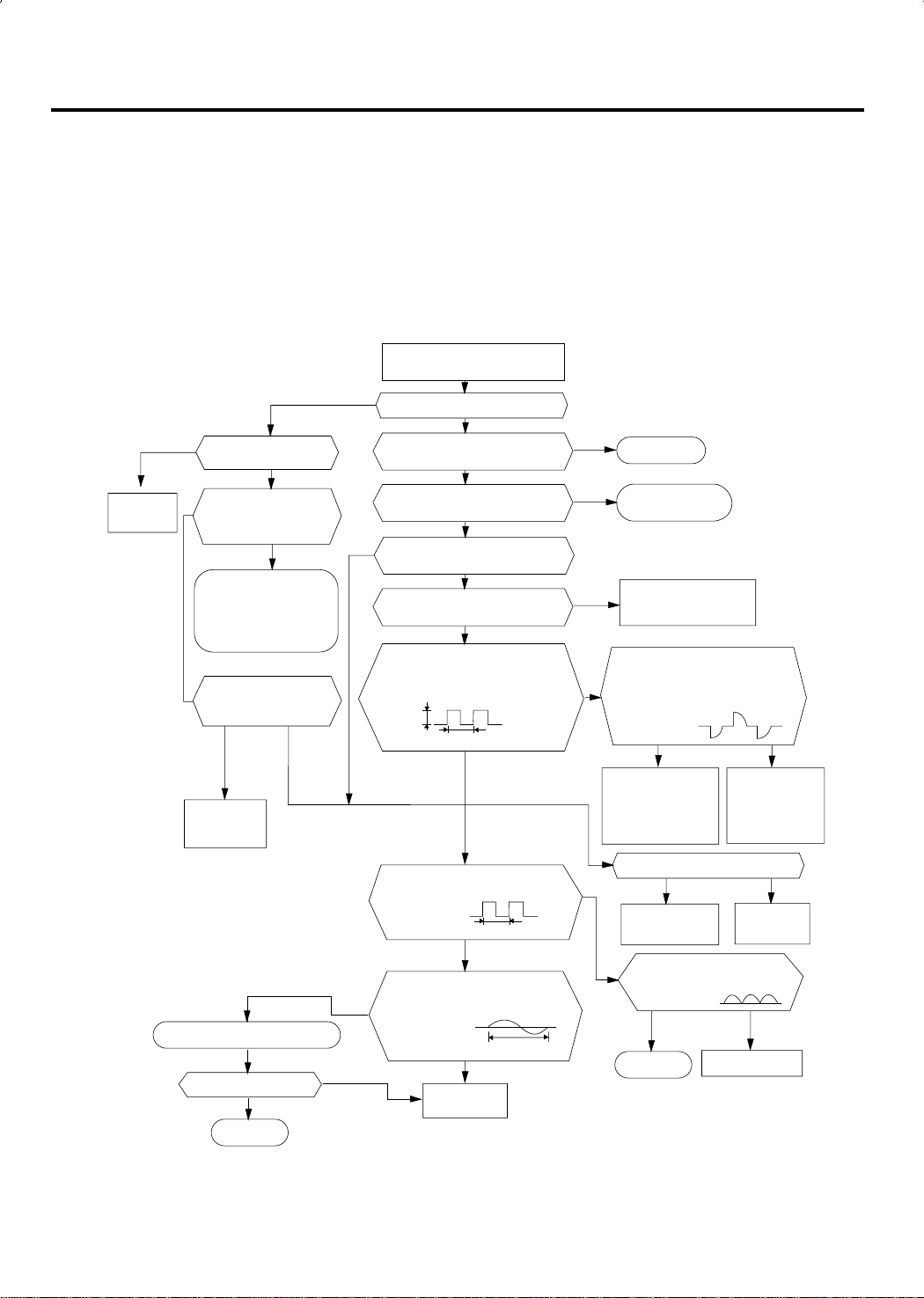

3-3 Fault Diagnosis by Symptom

3-3-1 No Power (completely dead)-Initial diagnosis

1) Checklist :

(1) Is input voltage normal?

(2) Is AC power linked correctly?

(3) Is output voltage of DC regulator IC KA7805 (IC02) normal? (4.5VDC-5.5VDC)

2) Troubleshooting procedure

Remove power cord and plug in

again in approx. 5 seconds

YES

Replace

PCB display

Is DC voltage of PCB

display normal?

NO

Is rating voltage ±10%

range applied to the

primary side (~,~)

of the “BD71”

NO

•Check linkage between

power cord and

terminal tap

•Check fuse

Is 14~18VAC appear in

the secondary side (+, -)

of “BD71”

NO

Replace

SMPS PARTS

Replace resonator (X301)

Is operation normal?

YES

YES

OK

NO

Is operation lamp blinking?

Does operation start when

run/stop button on the remote

controller unit pushed?

Is transmission display of the

remote controller unit blinking?

Is "beep"sound heard from the

NO

Is DC voltage of the PCB module

5VDC Is voltage of #60 (indoor fan)

DC5V

Is voltage at #52 terminal of the

Are voltage at #48 and #49 of the

NO

NO

main unit?

normal?

of the micom normal?

10ms

micom normal?

micom normal?

Replace micom

YES

NO

YES

YES

YES

NO

YES

YES

10ms

250ns

YES

NO

NO

YES

NO

Normal

Refer to remote control

unit fault diagnosis

Replace PCB module.

Is voltage at SS71(indoor fan)

Check connections

compressor 4-way

valve, outdoor fan and

indoor fan.

Is output voltage of ICO2 normal?

Check PCB pattern.

Replace main PCB.

Is voltage output terminal of

TLP180(PC02) normal?

YES

OK

DC12V

YES

Replace RY71,

RY73, RY72 and

YES

Replace ICO2

Replace TLP180(pc02)

NO

SS71

NO

NO

11

3-3-2 When the power voltage is not available

1) Inspection items

(1) Is the power voltage is normal? (The rating voltage ±10% range)

(2) Is the power cord is correctly connected and is the contact good?

(3) Does the sound “ting” come out with the operation lamp (green) flickering when the

power is applied?

If it is not flickering, do inspect and repair in accordance with the following inspection

sequence.

2) Inspection sequence

Is the operation lamp of

No trouble

(normal)

YES

indoor unit on when the

operation /stop button of

remote controller is

pressed?

NO

YES

Is the operation lamp flickering with the

Apply the power

sound of “ting”?

NO

Check of remote

controller

Normal

Is the communication

NO

YES

signal of remote

controller surely sent

and received ?

Is there no problem

between the connector of

Ass’y display PCB and the

receiving module?

Replace of

Ass'y display PCB

YES

NO

Is the outdoor power connected normally?

YES

Is the fuse (F701, 250V, 3.15A) of PCB open?

NO

Is the voltage at Socondary side of transformer

of PCB (TN71)? (AC15V~AC25V)

YES

Is the output voltage of voltage regulator

IC (KA 7812) DC 10V and 12V?

YES

Is the output voltage of electrostatic voltage

regulator IC (KA 7805) DC 4.5 V - 5.5 V?

YES

NO

YES

NO

NO

NO

Check of the installation

method and electrical circuit

Replace the fuse (250V, 3.15 A)

Transformer is out of

order - replace

Repair and replace the power

source rectifying diode (D101-

D105) and KA7812.

KA7805 is out of order - replace

12

Replace the main PCB of indoor unit

3-3-3 No Power (Outdoor unit)

1) Inspection items

(1) Á Is the power source normal (The rating Voltage ±10% range)?

(2) Is the outdoor power connected normally? ((1) of terminal : L, (2) of terminal : N,

(3) of terminal : communication) ?

(3) Check whether the display of outdoor PCB(SEG1) is shown in the order of A- B - C when the

power is applied.

If the display (SEG 1) is not shown the inspection and repair shall be performed in the sequence

of the following:

2) Inspection sequence

Normal of

outdoor PCB

Replace the

transformer

Measurement of resistance

NO NO

Assemble the transformer

YES YES

PCB and whether

the LED 1 is contin-

uously flickering.

NO

Replace the fuse

(F701) 250V 3.15A.

of power transformer

Are they as follows?

1st side 190 ~ 210Ω

2nd side 0.9 ~ 1.1Ω

YES

in the normal way.

Check the

communication of

Put the power off and put it on after

Is the display of PCB shown in the

Are the power cord ((1) L, (2) N) and

communication line (3) of outdoor terminal

Is the terminal of PCB terminal (RY71, 72, 73)

are assembled in the correct position?

YES

Insert the primary side of power transformer

in the terminal GT01 and then is the voltage

of secondary side normal? (AC 15V- AC 25V)

Is the fuse (F101, 250V 2 A) blown out?

Check whether the output voltage of

Check whether the output voltage of

5 seconds.

sequence of A-B-C?

NO

block connected correctly?

YES

YES

Is the fuse open? (F701)

NO

YES

NO

IC01 (KA 7812) is DC 12V.

YES

IC02 (KA 7805) is DC 5V.

YES

NO

YES

NO

NO

Reinstall the power cord and

communication line with the

reference of installation manual.

After watching the display of

NO

PCB board, assemble the

color and shape of housing

correctly as follows:

BLK

WHT

RED

Replace the fuse F101

(250V 2 A).

Check and Replace the rectifying

diode of power side

(D101 - D104) and KA 7812.

Replace the IC 02 (KA7805)

BLK

WHT

RED

Replace the outdoor unit Ass'y main PCB.

13

3-3-4 When the fan of indoor unit does not operate

1) Inspection items

(1) Is the power voltage normal?

(2) Is the connector of indoor fan with the good contact? (CN73)

(3) Is the soldering status of running condenser (CR71) with the good contact?

(4) Is connector of the Hall IC with the good contact (CN 43) ?

(5) Is the indoor fan rotating when it is under operation mode?

(6) Is the FAN LED (green) flickering when the indoor fan stalled (for more than 15 seconds) and

the trouble condition of speed detecting part?

Put the power off and put it on after 5 seconds.

YES

Error occurs after the

indoor unit fan motor is

rotating for 15 seconds?

(FAN Lamp flickering)

YES

Replacement of

indoor unit fan motor.

Is the operation lamp flickering for 3 minutes and

YES

If the operation /stop button of the remote controller

is pressed, is the operation lamp flickering and then is

the indoor fan rotating after 5~6 seconds?

YES

Is AC 120V and higher shown across the indoor fan

then put off?

YES

YES

connector (CN73) ?

NO

NO

NO

If the power is not available

(indoor unit), item no 3-3-1.

Replace of indoor unit PCB Ass'y.

NO

Is the type of MICOM (IC 04) Pin no.

63 old type ?

120Hz

YES

Is the pin no. 12 of IC 06 (KID 65003)

the old type?

120Hz

YES

Is the pin no 25 of MICOM

the old type?

Replace the indoor unit PCB Ass'y due to the

Micom defect.

NO

NO

Replace the IC 06 (KID 65003)

and SS71(G3MB202pl).

Replace Q401 (Ksc 945Y).

14

3-3-5 When the outdoor unit fan does not operate

1) Inspection items

(1) The outdoor unit fan motor operates only when the operating conditions are satisfied and is selected

by the RY74(LOW) and PY75(HI) to rotate.

(2) Is the power voltage normal?

(3) Is the contact of outdoor unit fan motor (CN 73) good?

(4) Is the winding resistance of outdoor unit fan motor 58Ω at Hi side and 143Ω at low side?

(5) The outdoor unit fan motor operates with Hi at over 28°C and low at below 26°C during the cooling

operation, and operates with Hi at below 14°C and low at over 15°C during the heating operation.

2) Inspection sequence

Apply the power to the outdoor unit and operate the indoor unit.

Is the indoor unit under operating conditions?

YES

Is it operating in the High speed?

NO

Is the voltage shown across the connector (1)↔(3) ((1)↔(5))

(the rating voltage ±10% range)?

NO

Is no. 11 ( 12) of IC 06 at low? (DC 0.7 V)

NO

Is pin no. 48(49) of IC 04 (MICOM) at High (DC 5 V)?

NO

Is the outdoor unit fan motor under the operating

conditions?

NO

Normal

NO

YES

YES

YES

YES

YES

Check the winding resistance of outdoor unit fan

Defect of IC 04(MICOM) - replace the IC 04

Normal (operation off)

Normal

motor winding resistance → Replace

Contact bad of RY 74(Low), RY 75(High)

→ Replace

Defect of IC06 output

→ Replace

or PCB ass’y

* Operating specification of the FAN of outdoor unit

(1) When the COMP is under the COMP ON condition during the cooling and heating operation,

Hi or LOW operation is selected according to the temperature condition of outdoor room.

(2) When A room and B room are mixed to operate , it is always under low operation.

(3) Perform the comp ON/OFF control in the dry mode.

(4) When it is under the operation of anti-freezing, overload protection, defrost operation, it may

be Low, high or Off.

(5) Hi = High speed, Low = Low speed

15

3-3-6 When the UP/DOWN Louver Moter Does Not Operate. (Initial Diagnosis)

1) Checklist :

(1) Is input voltage normal?

(2) Is the UP/DOWN louver motor properly connected with the connector (CN61)?

2) Troubleshooting procedure

Remove power cord and plug in again in approx. 5 seconds.

Is operating lamp blinking?

YES

Does operation start when swing button of

the remote control unit pushed?

NO

Voltage at pin #33 ~ #36 of micom (ICO4) change?(Squarewave)

YES

Volatge at pin #13, #14, #15, #16 of IC05 (KID65003)

change?(Squarewave)

YES

UP/DOWN louver motor is faulty.

YES

Check as in the procedure "No Power parts".

Refer to page 11.

YES

Normal

NO

Micom (IC04) is faulty.

NO

Driver IC05 (KID65003) is faulty.

16

3-3-7 If Operation By Remote Control Unit Is Impossible. (Initial Diagnosis)

1) Troubleshooting procedure

Remove power cord and plug in again approx. 5 Seconds

Is operation lamp blinking?

YES

“ “ sound heard from the indoor unit when ON/OFF

button on the remote control unit pushed?

NO

Voltage of battery less than 2.5V (Remote Control Unit)?

NO

LCD display status of REMOCON normal?

YES

Transmission display lamp ( ) blinking when

ON/OFF button on the remote control unit pushed?

YES

Voltage at PIN #30 of Remocon Micom change?

YES

Voltage at collecter of Q601 or Q602 change?

YES

NO

Check as in the procedure “NO Power parts”.

YES

YES

NO

NO

NO

NO

Q601(C4375Y) or Q602(C1623Y) is faulty.

Refer to page 11.

Normal

Replace battery.

LCD is faulty.

Replace button.

Micom is faulty.

IR LED(CL-1L5EU) is faulty.

Voltage at pin #26 of micom (IC04) change (INDOOR UNIT)?

YES

Micom (IC04) is faulty.

NO

Receiver module is faulty.

17

3-3-8 When the 4 way valve (A,B) is not operating

1) Inspection items

(1) Are the 4 way valve A and B under the operating conditions?

(When the COMP A (4 way valve A ) and COMP B (4 way valve B) are on during the

heating operating)

(2) Is the power voltage normal?

(3) Is the connecting of 4 way valve A (CN 75) and B (CN 76) good?

2) Inspection sequence

Put off the outdoor unit power and put it on again after 5 seconds.

Select the heating operation of A(B) room by the remote controller.

Has 3 minutes passed after selection of A(B) room heating?

YES

Is the 4 way valve A(B) on?

NO

Is the voltage shown across the 4 way valve A(B) connector

(CN 75, CN 76) ?

NO

Is the pin no 47(46) of IC 04 ( MICOM) at high (DC 5V) ?

NO

Is the 4 way valve A (B) under operating conditions?

NO

Normal

NO

YES

YES

YES

YES

Defect of IC 04(MICOM) - replace the IC 04

Keep 4 way valve off.

Normal

Defect of RY 76 (RY 77) contact and coil

→ Replace the Relay

Defect of IC 06 (IC 07 ) output → Replace

or PCB ass’y

*4 way valve operating conditions

(1) During the defrost control, put the 4 way valve A(B) off.

(2) During the heating operation put the 4 way valve A(B) on.

(3) The changeover of heating to cooling : put the 4 way valve off immediately (in case of B and C room).

(4) The changeover of cooling to heating : it is on after 170 seconds delay.

18

3-3-9 When the compressor does not operate

1) Inspection items

(1) Is the COMP A under the operating conditions? (cooling operating of A, B(C) room)

(2) Is the power voltage normal? (the rating voltage ±10% range)

(3) Are the connector connection of COMP A(RY 72, 73) and B(RY 71) good?

(4) The COMP A(B) is operated on and off in accordance with the operating conditions of indoor

unit of A (B. C) room.

2) Inspection sequence

Apply the outdoor power and operate the indoor unit A(B, C)

Is the comp A under the operating condition?

Has 3 minutes passed COMP A(B) after the power initial

Is the voltage (the rating voltage ±10% range) shown

across the terminal of Comp A(B) power applied?

Is the voltage of pin no. 14, 13( 15) at low

Is the voltage of pin no. 50, 51 (52) of IC 04 (micom) at

Is comp A (B ) under the operating condition?

in the cooling mode.

YES

and COMP on/off

YES

Is comp A (B) on?

NO

NO

(DC 0.7V)?

NO

high (DC 5V)?

NO

NO

*Refer to the power measuring terminal

NO

NO

YES

YES

YES

YES

YES

Normal (comp A (B) off)

Keep Comp A (B) off

Normal

Defect of comp A (B) and running condenser

→ Replace

Defect of Ry 72, 73 (Comp B) and Ry 71(comp A)

contact and coil → Replace

Defect of IC 06 output

→ Replace

Defect of Ic 04 (micom)

→ Replace

Normal (comp A (B ) off)

* Comp A (B ) operating conditions

(1) Comp A : Comp on /off control in accordance with the Aroom during the heating and cooling

indoor unit operation

(2) Comp B : Comp on /off control in accordance with the B(C) room during the heating and cooling

indoor unit operation

* Comp A(B ) power measuring terminal

(1) Comp A measuring ; RY 73 (4) ´ RY 72 (4)

(2) Comp B measuring ; RY 71 (4) ´ RY 72 (4)

(3) Power input ; RY 72 (3) ´ RY 73(3)

BLK

WHT

RED

RY72

(4)

(3)

RY71

(3)

RY73

(3)

BLK

(4)

WHT

(4)

RED

19

3-4 Set up the Model option

The Method for Setting up the model option with remocon

• It is necessary to set up option code after replacing the main-PCB as a service parts.

Make sure that you can set up the option of code the remote controller after you replace the main

PBA otherwise, the unit won’t be working properly and all LED lamps on display will be flickering.

Step 1 : Preparing the remocon to main PCB option set

st

1

Remove the battery from the remocon.

2ndPress the temperature raise/down button simultaneously

and insert the battery again.

3rdMake sure the remocon display shown as .

Step 2 : Second stage preparation of the remocon option set.

❈ Note ; In case the wrong letter has been selected, continue to press the button until the correct letter appears.

st

1

If the first stage number “ ” appears on the display, proceed to the second stage.

nd

2

Every time the ! and & button, “ ” and “ ” each continue to appear.

rd

3

Whenever pressing the @, #, $, %, ^, *, (, ), 1, 2 button, the number increase from

0~9(0123456789) and A, b, C, d, E, F each time.

! If the first number is , it is correct otherwise press until

appear.

@ When pressing the button ~ appear on the display,

select one of them.

20

# When pressing the button ~ appear on the display,

select one of them.

$ When pressing the button ~ appear on the display,

select one of them.

% When pressing the button ~ appear on the display,

select one of them.

^ When pressing the button ~ appear on the display,

select one of them.

! If the first number is , it is correct otherwise press until

appear.

@ When pressing the button ~ appear on the display,

select one of them.

# When pressing the button ~ appear on the display,

select one of them.

$ When pressing the button ~ appear on the display,

select one of them.

% When pressing the button ~ appear on the display,

select one of them.

^ When pressing the button ~ appear on the display,

select one of them.

Step 3 : Reconfirming option set after completion

(in case of ex. 000000-1700b7)

After pressing selector for the mode, the display shown as .

After pressing selector for the mode, the display shown as .

Step 4 : Pressing the ON/OFF button ( )

direction of remote controller for unit, the sound “Ding” or “Diriring” is heard and the first

LED lamp on the left side is flickering at the same time, then the input of option is completed. (If the diriring sound isn’t heard, try again pressing the ON/OFF button.)

Step 5 : Unit operation test-run

First, Remove the battery from the remote controller.

Second, Re-insert the battery into the remote controller.

Third, Press ON/OFF key with the direction of remote controller for set.

• Error Mode

st

1

If all lamps of indoor unit are flickering, Plug out and plug in again and pressing ON/OFF key to retry.

nd

2

If the unit is not working properly or all lamps are continuously flickering after setting the option code, see

if the correct option code is set up for it’s model.

When pressing the operation ON/OFF key with the

21

<Table of the option code>

MODEL

AD26B1C13

AD18B1C09

OPTION CODE

015773-100373

015223-10020C

22

MEMO

23

4. Exploded Views and Parts List

17

16

14

22

9

7

21

3

4

5

6

19

20

8

12

25

13-4

23

13-3

13-2

13

13-1

11

10

2

1

15

18-1

18-5

18-4

18

18-6

18-6-1

18-2

18-3

24

4-1 Indoor Unit

24

■

Parts List

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

13-1

13-2

13-3

13-3-1

13-3-2

13-4

14

15

16

17

18

18-1

18-2

18-3

18-4

18-5

18-6

18-6-1

19

20

21

22

23

24

25

CODE NO

DB64-00085A

DB63-00064B

DB95-00287K

DB63-00067A

DB92-00031L

DB67-00051A

DB67-00032A

DB63-00083A

DB94-00020A

DB60-20011A

DB31-00071B

DB32-00020A

DB93-01223A

DB93-00319B

DB65-00046A

DB93-00268A

2202-000780

DB32-00037A

DB39-00147A

DB94-00056E

DB94-00104A

DB61-00165A

DB70-00036A

DB94-00058F

DB94-00062E

DB66-00127B

DB66-00128A

DB66-00128B

DB63-00082A

DB95-20138A

DB31-10129A

DB61-40251A

DB67-60030A

DB96-01123K

DB96-01123J

DB94-40003A

DB93-00861B

DB70-00114A

DB63-00226A

Description

GRILLE AIR INLET

GUARD-AIR FILTER

FILTER CLEANER ASS´Y

COVER TEMINAL

ASS´Y PANEL

SPACER EVAP LOW

SPACER EVAP UP

COVER U BEND

ASS´Y FAN CROSS

BOLT SPECIAL

MOTOR FAN IN

THERMISTOR WIRE ASS´Y

ASS’Y CONTROL IN

ASS´Y PCB MAIN

TERMINAL BLOCK ASS´Y

ASS´Y PCB DISPLAY

C CERAMIC,MLC-AXIAL

MODULE REMOCON

CONNECT WIRE PCB

ASS´Y BACK BODY(RIGHT SIDE)

ASS´Y HOLDER MOTOR

HOLDER PIPE

PLATE HANGER

ASS´Y TRAY DRAIN(RIGHT SIDE)

ASS´Y DRAIN HOSE

BLADE H

BLADE V,A

BLADE V,B

SCREEN SAFETY WIRE

ASS´Y MOTOR STEPPING

MOTOR STEPPING; GSP 24RW

HOLDER SENSOR

SPRING SENSOR

ASS’Y CYCLE IN(EVAPORATOR)

ASS´Y BEARING

ASS´Y REMOCON

PLATE-KNOCKOUT

COVER TERMINAL BLOCK

Q’TY

AD18B1C09 AD26B1C13

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

6

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

6

1

1

1

1

1

1

1

1

1

1

REMARK

25

4-2 Outdoor Unit

12

15

8

17

3

4

5

7

6

9(9-1~9-2)

14(14-1~14-4)

2

1

10

13(13-1~13-6)

16(16-1~16-7)

11

4-2-1 UD26B1C2

26

■

Parts List

No.

CODE NO

Description Specification

Q’TY

REMARK

UD26B1C2

1

2

3

4

5

6

7

8

9

9-1

9-2

10

11

12

13

13-1

13-2

13-3

13-4

13-5

13-6

14

14-1

14-2

14-3

14-3-1

14-4

14-4-1

15

16

16-1

16-2

16-3

16-4

16-5

16-6

16-7

17

DB90-00075D

DB90-20207A

DB67-50067A

DB31-00095A

DB61-20093A

DB63-30027C

DB94-50041D

DB90-10574B

DB90-40120B

DB63-10434B

DB63-10433B

DB90-00742A

DB96-01356K

DB63-30110J

48D135IU1EL

DB60-30018A

DB60-30028A

DB63-10165D

DB63-20002A

DB73-00067A

DB35-00015H

DB99-00224A

DB99-00225A

DB99-00226A

DB99-00222A

DB95-00243C

DB99-00223A

DB95-00243D

DB32-00025B

DB93-01232A

2301-001379

2501-001237

DB26-10070A

DB61-00585A

DB61-00584A

DB65-40072F

PD-UD18B1-01

DB95-00329A

ASSY CABI FRONT

ASSY BASE OUT

FAN PROPELLER

MOTOR FAN

BASE MOTOR

GUARD COND

ASSY PARTITION

ASSY CABI SIDE

ASSY COVER

COVER

COVER CONTROL

ASSY CABI UPPER

ASSY COND-UNIT

SCREEN GUARD

ROTARY COMPRESSOR

NUT FLANGE

NUT WASHER

COVER TERMINAL

GASKET

GROMMET ISOLATOR

OLP

ASSY VALVE

ASSY VALVE CHECK A

ASSY VALVE CHECK B

ASSY VALVE 4WAYA

ASSY SOLENOIDE COIL

ASSY VALVE 4WAY B

ASSY SOLENOIDE COIL

THERMISTOR OUT ASS’Y

ASSY CONTROL OUT

C-OIL

C-OIL

TRANS POWER

CASE PCB

CASE CONTROL OUT

TERMINAL BLOCK

ASSY PCB PARTS

ASSY HEATER

ASS’Y

ASS’Y

AS+G/F20%, D495

OSM-738SRC

SGCC-M, T1.2

SC-90073T

ASS’Y

ASS’Y

ASS’Y

PP

PP

ASS’Y

UD26B1C2

P.E.H 100%

48D135IU1EL

PI0.8, M5

HEX, 2C, M8

PBT, 2.5

EPDM, T0.8

NR 40˚

RAC12074-9622

ASS’Y

ASS’Y

ASS’Y

ASS’Y

ASS’Y

ASS’Y

ASS’Y

103AT

ASS’Y

4uF, 450V

35uF, 450V

DC17, AC230, 600mA

ABS

SGCC-M, T0.8

ASS’Y

ASS’Y

ASS’Y

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

6

2

2

6

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

27

4-2-2 UD18B1C2

15

16(16-1~16-7)

13(13-1~13-6)

14(14-1~14-4)

9

3

1

10

4

6

5

7

8

2

11

17

12

28

■

Parts List

No.

CODE NO

Description Specification

Q’TY

REMARK

UD18B1C2

1

1-1

2

3

4

5

6

7

8

9

10

11

12

13

13-1

13-2

13-3

13-4

13-5

13-6

14

14-1

14-2

14-3

14-3-1

14-4

14-4-1

15

16

16-1

16-2

16-3

16-4

16-5

16-6

16-7

17

DB90-00734A

DB63-00320A

DB90-00733A

DB67-50063A

DB31-00001A

DB61-20008C

DB63-00343A

DB94-00180A

DB90-00737B

DB90-40176B

DB90-00742A

DB96-01717B

DB61-00821D

44B102IU2EL

DB60-30018A

DB60-30028A

DB63-10165D

DB63-20002A

DB73-00070A

DB35-00015C

DB99-00231A

DB99-00227A

DB99-00228A

DB94-00229A

DB95-00243A

DB99-00230A

DB95-00243B

DB32-00025A

DB93-01234A

2301-001370

2501-001235

DB26-10070A

DB61-00585A

DB61-00891A

DB65-40072F

PD-UD18B1-01

DB95-00329B

ASSY CABI FRONT

GUARD FAN

ASSY BASE OUT

FAN PROPELLER

MOTOR FAN

BASE MOTOR

GUARD COND

ASSY PARTITION

ASSY CABI SIDE RH

ASSY COVER CONTROL

ASSY CABI UPPER

ASSY COND-UNIT

GUIDE SCREEN

ROTARY COMPRESSOR

NUT FLANGE

NUT WASHER

COVER TERMINAL

GASKET

GROMMET ISOLATOR

OLP

ASSY VALVE

ASSY VALVE CHECK A

ASSY VALVE CHECK B

ASSY VALVE 4WAYA

ASSY SOLENOIDE COIL

ASSY VALVE 4WAY B

ASSY SOLENOIDE COIL

THERMISTOR OUT ASS’Y

ASSY CONTROL OUT

C-OIL

C-OIL

TRANS POWER

CASE PCB

CASE CONTROL OUT

TERMINAL BLOCK

ASSY PCB PARTS

ASSY HEATER

ASS’Y

SC-90073T

ASS’Y

AS+G/F20%, D405

IC-9630SLJ5A

SGCC-M,T1.2

SC-90073T

ASS’Y

ASS’Y

ASS’Y

ASS’Y

ASS’Y

P.E.H 100%

44B092JW1EL

PI0.8, M5

HEX, 2C, M8

PBT, 2.5

EPDM, T0.8

NR 35˚

RAC12067-9622

ASS’Y

ASS’Y

ASS’Y

ASS’Y

ASS’Y

ASS’Y

ASS’Y

103AT

ASS’Y

2.5uF, 450V

25uF, 450V

DC17, AC230, 600mA

ABS

SGCC-M, T0.8

ASS’Y

ASS’Y

ASS’Y

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

6

2

2

6

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

29

4-3 ASS’Y CONTROL IN (DB93-01223A)

■

Parts List

No

30

10

11

Description

1

2

3

4

5

6

7

8

9

HOLDER CONTROL

ASS’Y MAIN PCB

TERMINAL BLOCK ASSY

ASSY DISPLAY PCB

CONNECTOR WIRE PCB U/D

HOLDER CLAMP IN

SEAL CONTROL SIDE

SEAL H/CONTROL FRONT

SCREW MACHINE

LABEL

CORE

Specification

DB61-00160B

DB93-00319B

DB65-00046A

DB93-00268A

DB39-00147A

DB61-00219A

DB72-10191T

DB72-00127V

-

-

DB31-40005A

Remark

5. Refrigerating Cycle Block Diagram

INDOOR UNIT OUTDOOR UNIT

2Way valve

(A)

Cross fan

Heat

exchanger

(Evaporator)

T1

(B)

T2

Liquid side

Cross fan

Gas side

Capillary tube

Compressor-A

3Way valve

Check valve

Capillary tube

Propeller fan

Heat

exchanger

(Condenser)

Compressor-B

4Way valve

Refrigerating cycle temperature and pressure

STD Pressure Piping Temp.(°F) Temp. Condition (°F)

Operating Condition (psi)

T1 T2

3-WAY V/V DB WB DB WB

Standard 57-71 50-54 50-54 80 67 95 75

Cooling Max over load - 61-64 61-64 80 67 115 75

Low temp. - 34-39 34-39 67 57 67 57

Standard 242-284 90-97 140-158 70 60 47 43

Heating Max over load - 97-104 149-167 80 - 75 65

Deice - 82-90 104-113 70 60 35 33

Indoor Outdoor

31

6. Wiring Diagrams

6-1 Indoor Unit

32

6-2 Outdoor Unit

33

7. Schematic Diagrams

7-1 Indoor Unit

■ AS07A5(6)MA / AS09A5(6)MA

34 35

7-2 Outdoor Unit

■ AS07A5(6)MA / AS09A5(6)MA

3736

ELECTRONICS

Printed in Korea.

Loading...

Loading...