Samsung SN-S082D, TS-K632D Service Manual

The exterior design and some parts of the product may be changed without prior notification.

Service

Manual

DVD-W SLIM

DVD-W SLIM

Product Features

Product Features

READ

Contents

Contents

Chapter 1 Safety Precautions

Chapter 2 General Specifications and

Features

Chapter 3 Functional Description and

Installation

Chapter 4 Disassembly and Assembly

Chapter 5 Troubleshooting

Chapter 6 Block Diagram

Chapter 7 Schematic Drawings

1

1-1. Safety Precautions for Repairs

1. Safety Precautions

1) Since the equipment uses laser diode, ensure

that eyes and parts of the body do not come

near the laser diode while performing repair

service.

2) Do not disassemble pickup to repair. If the laser

diode is faulty, then replace the complete pickup

assembly.

3) Perform repair services away from electrical

equipments such as TV to avoid interference

from these equipments.

4) Ensure to unplug the power cord from the unit

before replacing any parts.

5) Ensure to insert the disc properly into the unit

before use.

6) Since this equipment cannot be used as a

standalone unit, it must be installed in a PC

(586 or higher) with appropriate device driver from

the floppy disk to verify proper operation.

7) This equipment has many parts with properties

related to safety. These parts are specifically

noted in the parts list and schematic drawings.

Ensure to replace these parts with new parts

that have the same specifications.

- Since the laser diode in the optical pickup

bundle can be easily damaged by the static

electricity in human body or clothing, use

the following grounding guidelines when

handling the bundle.

Wear a wrist strap with one end properly

grounded. The wrist strap discharges the static

electricity in human body.

Work on a conductive material such as copper

plate that is properly grounded.

Since the static electricity stored in clothing is

not easily discharged, ensure that clothing does

not make a contact with the pickup bundle.

1-2. Safety Precautions for Installations

A certain semiconductor components are highly

susceptible to damages caused by electrostatic

discharge (ESD).

Semiconductors components such integrated circuits,

field effect transistors, and other semiconductor

devices are examples of devices that are highly

sensitive to ESD.

Use the following guidelines to reduce the damages

caused by the ESD.

1) Before handling any semiconductor components

or parts that contains semiconductors,

immediately discharge all static electricity in the

body by making a contact with a grounded

metallic object. A commercially available wrist strap

may also be used.

The static electricity must be discharged to avoid

potential impact on the voltage during testing.

2) After removing ESD-sensitive components or

parts, place the items on a conductive surface

such as on a piece of aluminium to prevent

accumulation of charges and exposure to ESD.

3) Use properly grounded soldering iron to solder

or to de-solder ESD-sensitive components.

4) Only use anti-static soldering iron to de-solder

ESD-sensitive components.

Use of soldering irons not classified as “anti -static”

has enough electrostatic charges to cause damages

to the components.

5) Do not use chemical sprays such as Freon.

These chemicals have enough electrostatic

charges to cause damages to the ESD-sensitive

components.

6) Do not remove replacement parts from the

anti-static packaging until they are ready for

installation. [Most of the replacement parts are

packaged in conductive foam, aluminium, or

other conductive materials with all the leads

shorted together.]

7) Before removing the anti-static packing

materials for the new parts, make a contact with

the chassis or protective material for the circuits

to discharge the static charges.

8) Minimize body movement when handling

unprotected ESD-sensitive parts and

components. (The movement of body causes

build up of electrostatic charges from friction

between layers of clothing, and between the

shoes and the carpet which may cause damage

to the components.)

Caution: Ensure that the power does not get transferred to

the chassis or to the circuitry, and that all general

safety guidelines are followed.

2

1-3. Static Electricity, PL, and Voltage Safety Precautions

1) Read all safety and operational manuals before

operating the product.

2) Keep the safety and operational manuals for

future reference.

3) Follow all precautions and operational

instructions shown inside or on the outside of

the product.

4) Follow all operational and maintenance

precautions.

5) Unplug the power cord from the socket before

cleaning operation. Do not use liquid or aerosol

type of cleaners to clean the exterior cabinet.

Use a dry cloth only to clean the dust off the

cabinet.

6) Do not use any attachments not recommended

by the manufacturer. This may be unsafe and may

damage the product.

7) Do not use the product near water such as

bathtubs, washbasins, washing machines,

swimming pools, or lakes.

8) Never place the product on the bed, sofa,

radiator, or near any heat source.

9) Power: Only use the type described on the label.

Contact the dealer if the power type cannot

be identified. To operate the product using

batteries or other sources of power,

consult the operating manual.

10)Lightening: Unplug the power during lightening

and during a long period when the

product is not being used.

11) Electrical Overload: Do not plug excessive number of

power cords into the outlet

or extension outlet to prevent fire

hazard and electrical shock.

12) Never put any object or liquid in the product.

It may cause fire or electrical shock due to a

potential contact with the power supply and/or

short-circuit.

13) Replacement Parts: The service technician

must use a replacement part with

the same exact specification.

Use of replacement part with

incorrect specification may

result in fire, electrical shock,

and other safety hazards.

14) Safety Inspection: Always perform a safety

inspection after a service

and/or repairs.

Important Safety Precaution:

The product contains special components important for

safety.

These components are identified with in the schematic

drawings.

These components must be replaced with components with

the exact same specification to prevent electrical shock, fire,

and other hazards.

Do not modify any part of the original product design without

manufacturer

s permission.

Warning: A death or a serious injury may result if the

instructions are not followed properly.

Caution: Property damage may result if the instructions

are not followed properly.

Description of Warning / Caution

3

2. General Specifications and Features

2-1. General Specifications

2-2. Features

DC +5V, 1.5A

- Drive Type:

- Power Consumption:

Internal

- Interface: S-ATA

- Data Transfer Rate:

CD

DVD

Write (CD-R)

1,200KB/sec ( 8X), 2,400KB/sec (16X)

3,600KB/sec (24X), 4,800KB/sec (32X)

6,000KB/sec (40X), 7,200KB.sec (48X)

Write (CD- RW)

600KB/sec ( 4X), 1,500KB/sec (10X)

2,400KB/sec (16X), 3,600KB/sec (24X)

4,800KB/sec (32X),

Read (CD- ROM)

6,000KB/sec (Maximum: 40X)

7,200KB/sec (Maximum: 48X)

Read (DVD±R, DVD±RW) 10,800KB/sec(8X), 16,200KB/sec(12X)

Write

(DVD+R) 21,600 KB/sec(16X)

Write

(DVD-R) 21,600 KB/sec(16X)

Write

(DVD+RW,-RW) 10.800KB/sec(8X), 8,100KB/sec(6X)

Write

(DVD+R DUAL LAYER) 10,800KB/sec(8X)

Write

(DVD+R DUAL LAYER) 5,400KB/sec(4X)

Write (DVD-RAM )6,750MB/sec (FAT32)

- ACCESS TIME

- (CD-ROM) 1/3 Stroke: < 130ms

Full Stroke: <160ms

- (DVD-ROM) 1/3 Stroke: < 130ms

Full Stroke: <160ms

- Buffer Size: 2MB

- Error Rate: Mode 1:10-12

Mode 2: < 10-9

- Frequency Response: 20Hz~20KHz (Line out)

- Signal to Noise Ratio: 70dB (1KHz, Line out)

- Distortion: < 0.15% (1KHz)

- Channel Separation: Line out: 65dB (1KHz)

- Laser Type: Semiconductor Laser

- Audio Output: Line out : 0.7Vrms¡¾10% 47Kohm

- Dimensions:

128(W) X 12.7(H) X 127(D)

- Weight:

170g

3. Functional Description and Installation

4

3-1. Hardware Functional Description

Read

CD-ROM: CAV 24X Max.

CD-R: CAV 24X Max.

CD-RW: CAV 24X Max.

5

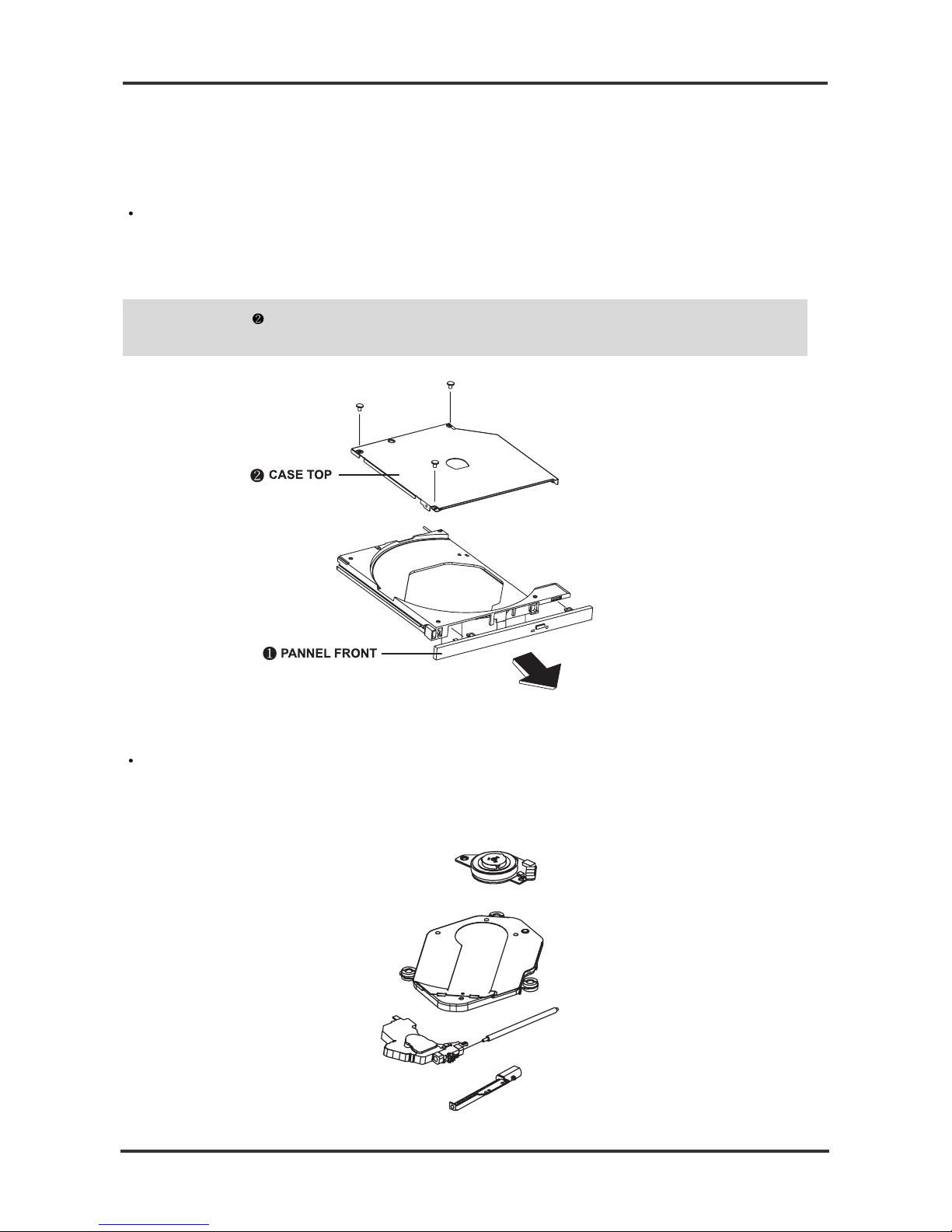

4-1. Disassembly

CASE-TOP and ASSY PANEL FRONT Disassembly

4-1-1. Exterior Components and PCB Disassembly

(a) Unscrew 3 Screws in the back by ejecting SET and pulling it forward.

(b) Detach CASE TOP by pushing back and lifting up.

(c) Detach COVER-DECK.

Note: If the tray does not open, then force the tray open manually by pushing the pin Clip 3

into the emergency hole on the unit.

ASSY-FEED ING Disassembly

(a) Detach FPC-SUB from MONITOR-SPINDLE, and FPC-PU,

FPC-MONITOR SPINDLE from MAIN-PCB.

(b) Detach ASSY-FEEDING from ASSY-TRAY.

4. Disassembly and Assembly

6

ASSY-SOLENOID Disassembly

(a) Unscrew 2 SCREWs in the bottom of ASSY TRAY.

(b) Detach GUIDE GROUND.

(c) Detach ASSY-SOLENOID from ASSY TRAY.

ASSY PCB MAIN Disassembly

(a) Unscrew 2 SCREWs in ASSY PCB MAIN.

(b) Detach FPC MAIN by turning over ASSY PCB MAIN.

(c) Detach ASSY PCB MAIN from ASSY TRAY.

Loading...

Loading...