Samsung SWF-P8IW Service Manual

WASHING MACHINE

SWF-P8IW/XEH

SWF-P10IW/XEH

SERVICE

Manual

WASHING MACHINE CONTENTS

1. SPECIFICATIONS

2. OVERVIEW OF THE WASHING MACHINE

3. OVERVIEW OF THE CONTROL PANEL

4. PROCESS TABLE

5. GENERAL REEOR FUNCTION

6. TROUBLE DIAGNOSIS

7. TEST MODE

8. DESIGNATION OF MAIN COMPONENTS

9. PCB SHEMATIC DIAGRAM

PCB CIRCUIT DIAGRAM

PCB PATTERN DIAGRAM

WIRING DIAGRAM

10.ASSEMBLE AND DISASSEMBLE

11.TOOLS FOR DISASSEMBLY AND ASSEMLY

12.EXPOLDED VIEW AND PARTS LIST

2 SAMSUNG ELECTRONICS CO., LTD

Caution for the safety during servicing

1. Do not allow the customer to repair the product.

☞ The person may be injured or the product life may be shortened.

2. Execute A/S after unplugging the power supply unit.

☞ Be care of the electric shock.

3. Do not plug several plugs in the same outlet.

☞ It may cause the fire due to overheat.

4. Check the damage, pressing or burning of the power plug or outlet.

☞ Replace it promptly if it has problem.(It may cause the electric shock or fire)

5. Do not clean the main body with the water.

☞ It may cause the electric shock and fire and shorten the product life)

6. The wiring of the harness shall be free from the moisture and tightened during serving.

☞ It shall not be deviated by certain impact.

7. Remove any dust or filth on the housing section,wiring section,connection section during servicing.

☞ Protect the cause of the fire such as the tracking,shortage and etc.

8. Check any mark of the moisture on the electrical parts, harness section and etc.

☞ Replace the parts or remove the moisture.

9. Check the assembly status of the parts after servicing.

☞ Maintain the status before servicing.

10. Pull out the power cord with holding the plug.

☞ Be care of the electric shock and fire when the cord is damaged.

11. Unplug the power plug from the outlet when the wash machine is not used.

☞ Be care of the electric shock and fire due to the strike of the lightening.

12. Do not use or store the spray or flammable materials(including gasoline,alcohol and etc.)

around the wash machine.

☞ Be care of the explosion or fire due to the electric spark.

13. Do not put the bowl of water or wet laundry on the wash machine.

☞ If the water is penetrated to the wash machine, this may cause the electric shock or fire.

14. Do not install the wash machine in the place where the snow or rain falls.

☞ It may cause the electric shock and fire and shorten the product life.

15. Do not push the control buttons with the awl,pin, or sharp materials.

☞ It may the electric shock and trouble.

16. Check the wash machine is leveled horizontally and installed properly on the floor.

☞ The vibration may shorten the product life.

17. Joint the wire by the connector correctly.

☞ When the wire is jointed by the tape, this may cause the fire due to the tracking.

18. When the wash machine is to be laid for the service, put the pad on the floor and lay the

product at side slowly.

☞ If the wash machine is laid front, the relay may be damaged by the tub.

19. When the wash-heater is replaced, check it is inserted in the bracket-heater and screw the nut.

☞ If the wash-heater is not inserted in the bracket-heater properly, this may cause the noise and

leakage since it is contacted to the drum.

!

1. Specifications

SAMSUNG ELECTRONICS CO., LTD 3

WASH TYPE FRONT LOADING TYPE

DIMENSION GROSS W 669mm X D 656mm X H 910mm

NET W 598mm X D 555mm X H 844mm

WATER PRESSURE 50 kPa ~ 800 kPa

WEIGHT GROSS 80 kg

NET 75 kg

WASHand SPIN CAPACITY 50 kg (DRY LAUNDRY)

POWER CONSUMPTION WASHING 220 V 180 W

240 V 180 W

WASHING and HEATING 220 V 2400 W

240 V 2800 W

SPIN MODEL SWF-P8 SWF-P10 SWF-P12

220 V 430 W 500 W 550 W

240 V 430 W 500 W 550 W

PUMPING 34 W

WATER CONSUMPTION 54 (STANDARD COURSE)

SPIN REVOLUTION MODEL SWF-P8 SWF-P10 SWF-P12

rpm 800 1000 1200

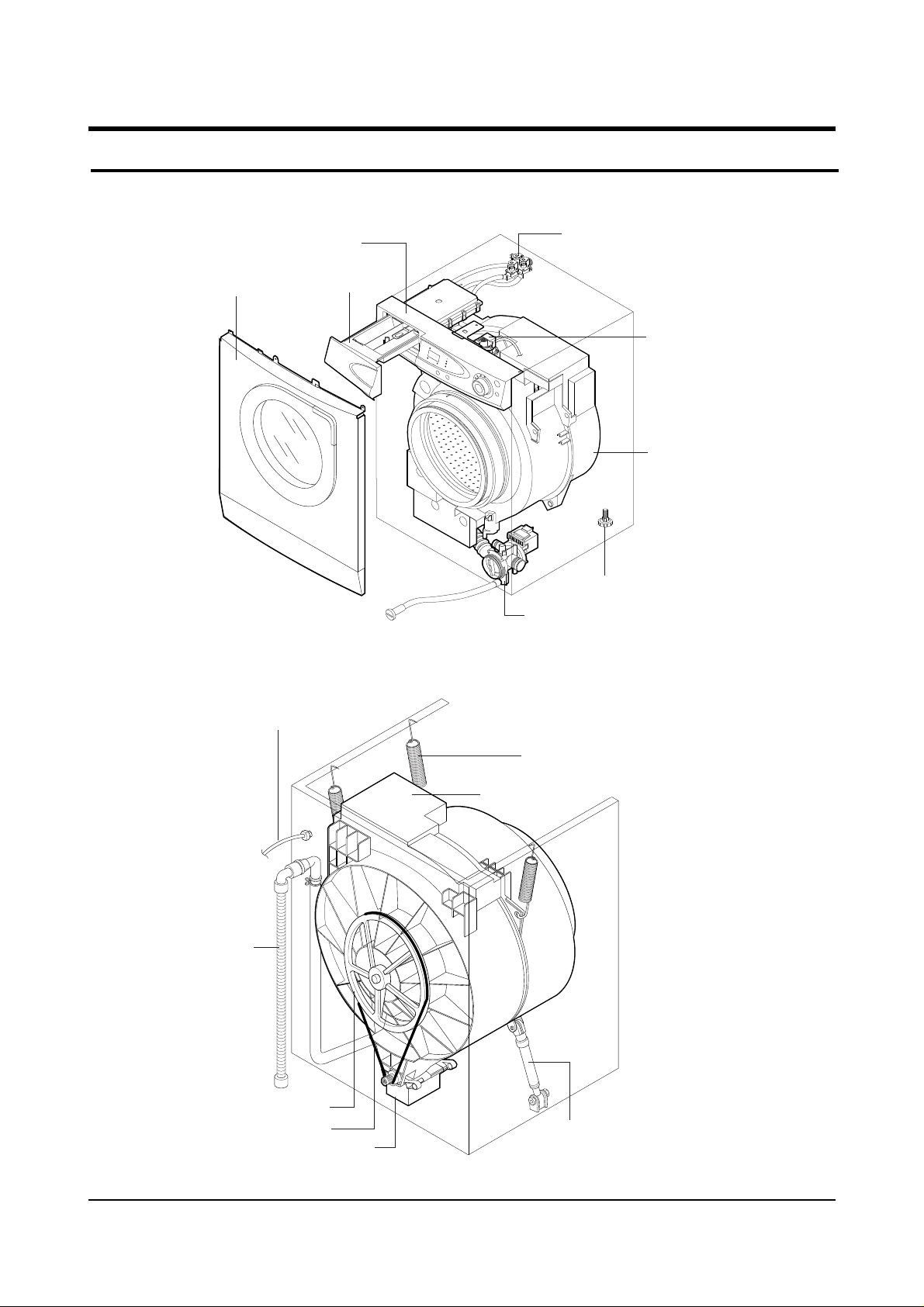

2. Overview of the Washing Machine

4 SAMSUNG ELECTRONICS CO., LTD

ASSY PUMP

TUB

WATER SUPPLY VALVE

SENSOR

PRESSURE

ASSY DOOR

ADJUSTABLE LEG

CONTROL-PANEL

DRAWER

DRAIN

HOSE

POWER CORD

BUFFER

SPRING

WEIGHT-BALANCE

SHOCK

ABSORBER

PULLEY

BELT

ASSY MOTOR

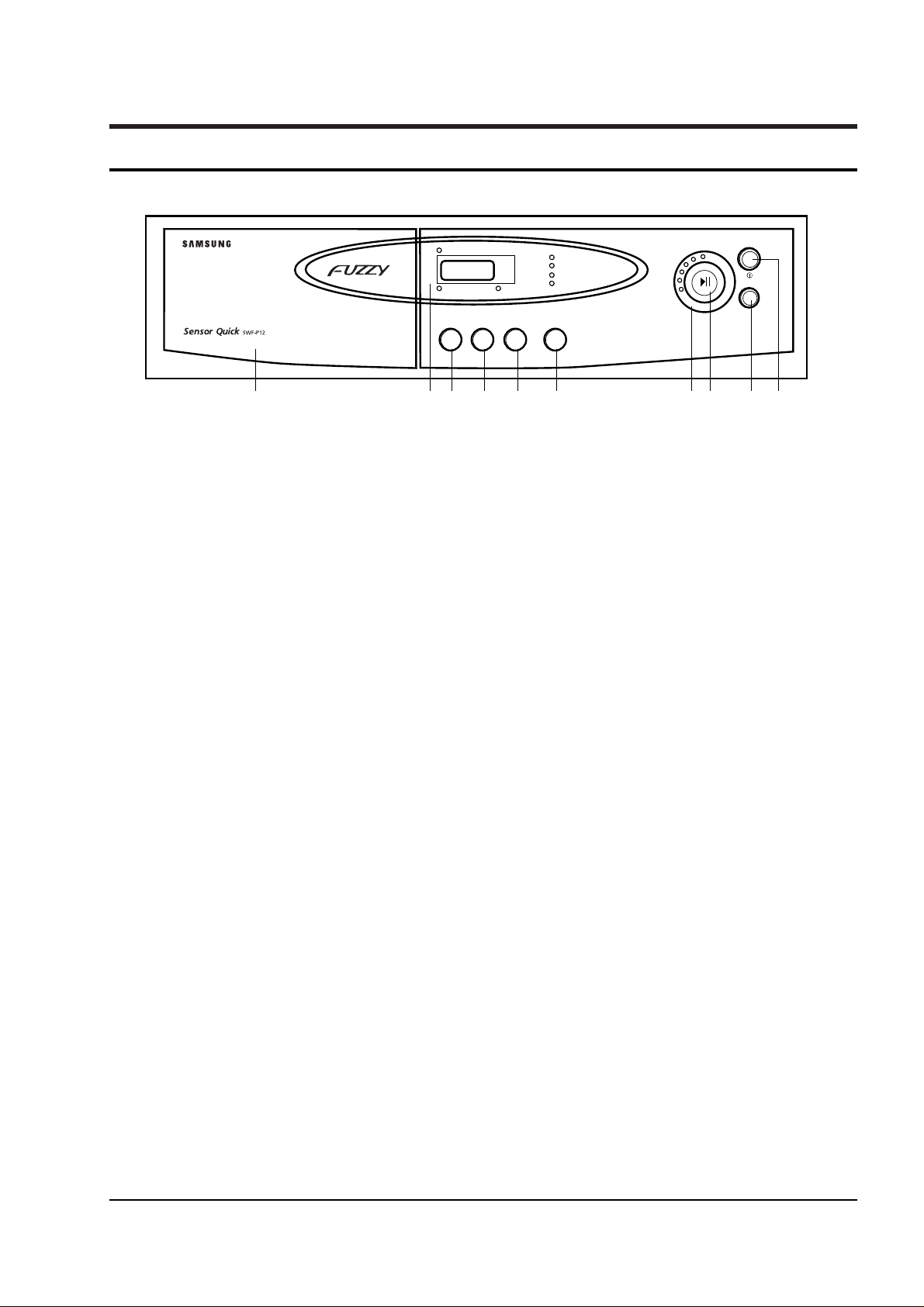

3. Overview of the control panel

SAMSUNG ELECTRONICS CO., LTD 5

1. Detergent dispenser

2. Display panel

Displays the remaining wash cycle time, error messages and cancel —.

3. Temperature selection button

Press the button repeatedly to cycle through the available water temperature options

(cold water, 30°C, 40°C, 60°C and 90°C).

4. Spin selection button

Press the button repeatedly to cycle through the available spin speed options

P12 : (400, 600, 800, 900, 1000, and 1200 rpms.),

P10 : (400, 600, 800, 900 and 1000rpms),

P8 : (400, 600 and 800 rpms).

5. Delay Start button

Press the button repeatedly to cycle through the available delayed start options

(from 1 hour to 24 hours in one hour increments).

6. Function button

Press the button repeatedly to cycle through the available partial wash options

(Prewash, Wash, Rinse, or Spin).

7. Fuzzy Control dial

Turn the dial to select one of the six available wash programs

(Eco, Speedy, Wool, Delicate, Synthetic or Cotton).

8. (Start/Pause) button

Press to pause and restart programs.

9. Door Open button

Press to open the washing machine door.

10. 1) (On/Off) button

Press once to turn the washing machine on, press again to turn the washing machine off. If the

washing machine power is left on for longer than 10minutes without any buttons being touched,

the power automatically turns off.

o

C

rpm

Min

Fuzzy control

Temp Spin Delay Start Function

Door open

Spin

Check

Remaining Time

Delay Start

Rinse

Wash

Pre-wash

Eco

Speedy

Wool

Delicate

Synthetic

Cotton

21 3 4 5 6 7 8 109

12:00

6 SAMSUNG ELECTRONICS CO., LTD

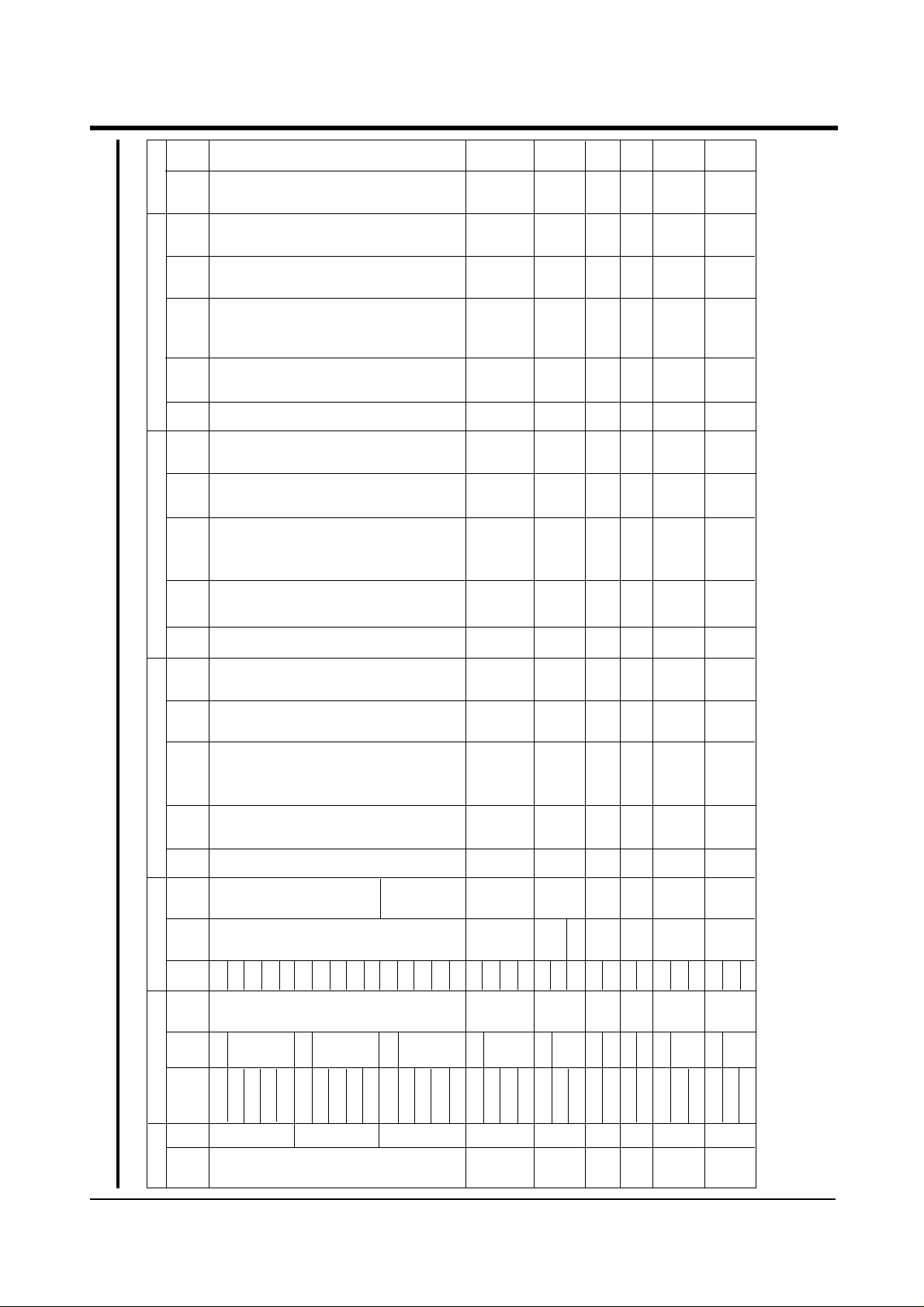

4. Process table

DIVISION WATER SUPPLY WASHING RINSING 1 RINSING 2 RINSING 3 SPINNING

COURSE LOAD WATER TEMP BOILING LAYER WASH WASHING REVERSE RINSE WATER INTERMEDIATE SPINNING REVERSE RINSE WATER INTERMEDIATE SPINNING REVERSE RINSE WATER INTERMEDIATE

(kg) SELECT SPINNING TIME WATER rpm TIME CURRENT SPINNING TIME rpm TIME CURRENT SPINNING TIME rpm TIME CURRENT SPINNING

CURRENT TIME TIME TIME

COLD WATER X 45min

30˚C 40min

1.5 40˚C 40min

60˚C O 30min

90˚C -

COLD WATER X 50min

30˚C 45min

COTTON 3.0 40˚C O 40 45min 9 / 6 4min 8 / 5 850 100sec 45 3min 8 / 5 850 100sec 45 3min 8 /5 850

60˚C 35min

90˚C -

COLD WATER X 55min

30˚C 50min

5.0 40˚C 50min 48

60˚C

O

40min

90˚C -

COLD WATER O 25min

30˚C 20min

SYNTHETIC

2.5

40˚C X

-

20min

7 / 8 40 3min 7 / 8 850 60sec 40 3min 7 / 8 850 60sec 40 3min 7 / 8 850

60˚C -

COLD WATER X 15min

DELICATE 2.0 30˚C 10min

6 / 7

30 2min 6 / 7 400 40sec 30 2min 6 / 7 - - 30 2min 6 / 7 -

40˚C

O -

10min 5 / 10

COLD WATER X 15min

WOOL 1.5

30˚C O

-

10min

3 / 12 25 2min 3 / 7 200 60sec 25 1min 3/ 7 - - 25 1min 3 / 7 -

COLD WATER X 20min

ECONOMY 1.5

30˚C O

-

15min

9 / 6 40 3min 9 /6 600 6sec 40 3min 9 / 6 600 60sec 40 - - -

COLD WATER X 15min

SPEEY 2.0 30˚C

O

- 10min 12 / 3 45 3min 10 / 5 850 60sec 45 2min 10 / 5 850 60sec 45 - - -

40˚C 10min

COLD WATER X 10min

PRE 5.0 30˚C

O

- 10min 9 / 6 40 - - - - - - - - - - - - -

40˚C 15min

SPINNING REVERSE SPINNING TIME

TIME rpm rpm

P12:1200

100sec 45 P10:1000 7’40’

P8:850

60sec 40 850 100sec

- 30 600 100sec

- 25 400 60sec

- - 850 150sec

- - P12,10:1000 150sec

P8:850

- - 850 100sec

5. General Error Function

SAMSUNG ELECTRONICS CO., LTD 7

•· When an error occurs, this function starts to keep generating error melody sounds and displays error

indicators as shown in the followings per corresponding error by blinking in 0.5sec interval until the error status

is completely cleared out. In this case, all the driving devices are turned off until the error is cleared out.

1. WATER SUPPLY ERROR

- Water Supply Error occurs when water level frequency does not show changes more than 50Hz or water

is not supplied up to the water level presetting for 20 min or more at the time of initial water supply, the

error status can be cleared by turning POWER S/W OFF and resuming the POWER ON initial status.

- Display shows ‘E1’.

2. WATER DRAIN ERROR

- In case the water level frequency is 25.3KHz or less in the initial phase of UNB-detecting cycle.

- Water Drain error can be cleared by turning POWER S/W OFF and resuming the POWER ON initial status.

- Display shows ‘E2’.

3. OVER-FLOW ERROR

- Over-Flow error occurs when the water level is in abnormal operation (OVER-FLOW: 22.40KHz/50ߧ or

more). It can be cleared by turning POWER S/W OFF. Water is drained prior to POWER S/W OFF and it

is forced to be drained for 2 min if a frequency of more than 25.24 KHz is detected.

- Display shows ‘E3’.

4. DOOR OPEN ERROR

- Door Open error can be cleared by closing the door.

- Display shows ‘door’.

5. UNBALANCE ERROR

- Unbalance error is cleared by POWER S/W OFF and by resuming the POWER ON initial status.

- Display shows ‘E4’.

6. WATER HEATER ERROR

- In case the water temperature varies by 40°C or more in 5 min, or by 2°C or less in 10 min after heating is started.

- It can be cleared by turning POWER S/W OFF.

- Display shows ‘E5,E6’.

7. ASS’Y PRESSURE S/W ERROR

* Generated Frequency Signal of WATER LEVEL(W/L) S/W (KHz)

- If the same signal as the above table is detected for more than 5 seconds, it is a PRESSURE S/W Error.

- When the error occurs, perform the time-drain for 3 min and then turn off the water drain pump. Then the

display shows ‘E7’ as a pressure s/w error indicator.

8. ABNORMAL WATER TEMPERATURE ERROR

- In case the water temperature is 60°C or more in the synthetic course, 50°C or more in the delicate

course, and 40°C or more in the wool course.

- At the time of initial water supply, if the water temperature is not appropriate, water starts to be drained

and it is forced to be drained for 2 min when the abnormal frequency of 25.24KHz is detected.

- Display shows ‘E8’.

- This error can be cleared by POWER S/W OFF.

Lvevl Low Level High Level

Abnormal W/L Frequency 30.00 KHz 15.00 KHz

Course Water Temp

Synthetic 60˚C or more

Delicate 50˚C or more

Wool 40˚C or more

8 SAMSUNG ELECTRONICS CO., LTD

6. Trouble Diagnosis

°· As the micom wash machine is configured of the complicate structure, there might be the service call.

Below information is prepared for exact trouble diagnosis and suitable repair guide.

1) As some electronic components are damaged by the charged static electricity from the resin part of wash

machine or the human body, prepare the human body earth or remove the potential difference of the

human body and wash machine by contacting the power supply plug when the work contacting to PCB is

executed.

2) Since AC220~240V is applied to the triac T1 and T2 on P.C.B, the electric shock may occur by touching

and be careful that the strong and weak electricity are mixed.

3) If the P.C.B assembly is out of order, do not replace the component on P.C.B except TACT switch since

the component is coated by the urethane.

4) As the P.C.B assembly is designed for no trouble, do not replace the P.C.B assembly by the wrong

diagnosis and follow the procedure of the trouble diagnosis when the micom is not operated normally.

5) As the parts on P.C.B are coated by the urethane, they can not be tested by the test bar of the meter.

Check the trouble by the test mode method according to the procedure.

Caution for the Repair and Replacement

Please follow below instruction for the trouble diagnosis and parts replacement.

POWER SUPPLY PLUG

Loading...

Loading...